Device and method for realization of partially denitrified synchronous autotrophic nitrogen removal by sludge fermentation coupled denitrification

An autotrophic denitrification and denitrification technology, which is applied in the field of water treatment, can solve problems such as large impact, pipeline blockage, and increased process complexity, and achieve the effects of reducing impact, saving operating costs, and saving organic resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

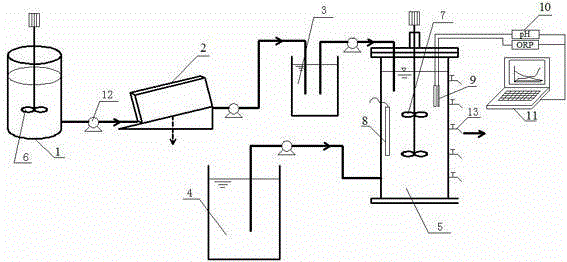

[0029] This method will be further explained in combination with specific drawings and experimental cases. The synchronous autotrophic denitrification device for partial denitrification realized by coupling denitrification with sludge fermentation includes a sludge hydrolysis acidification reaction vessel 1, a sludge dehydrator 2, and a fermentation liquid storage tank 3 , the raw water tank 4 and the partial denitrification synchronous autotrophic denitrification reactor 5, the bottom of the sludge hydrolysis acidification reaction vessel 1 is connected to the inlet of the sludge dehydrator 2 through a pipeline, and the outlet of the sludge dehydrator 2 is connected to the fermentation liquid storage tank through a pipeline 3. The fermentation liquid storage tank 3 is connected to the top part of the denitrification synchronous autotrophic denitrification reactor 5 through pipelines, and the raw water tank 4 is connected to the lower part of the denitrification synchronous auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com