Sludge treatment method and sludge treatment system

A technology of sludge treatment and treatment method, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. It can solve boiler tail corrosion, sludge conveying system blockage, sewage Solve the problems of limited amount of sludge treatment, achieve the effect of reducing sludge treatment costs, good social and economic benefits, and realizing harmlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

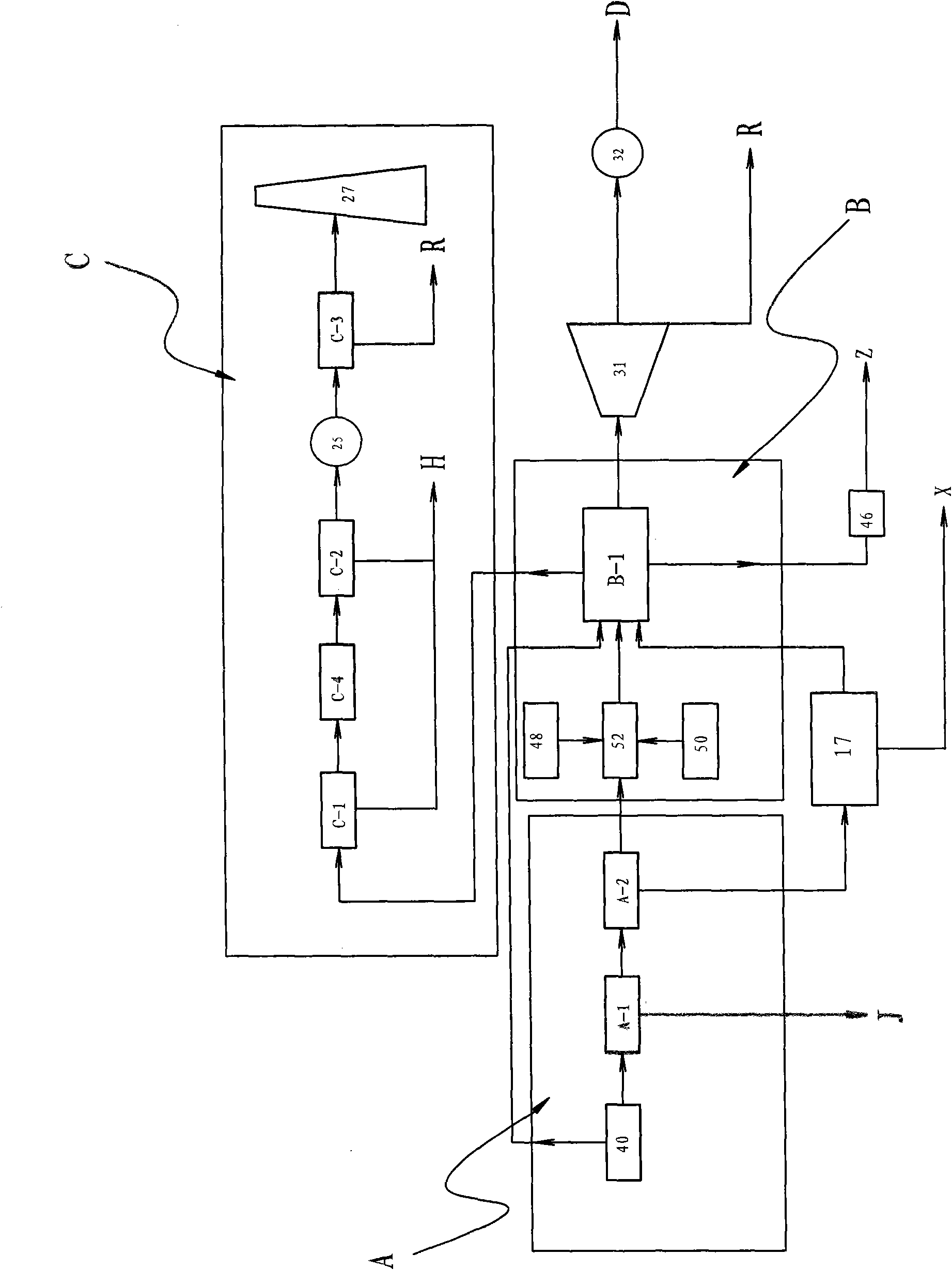

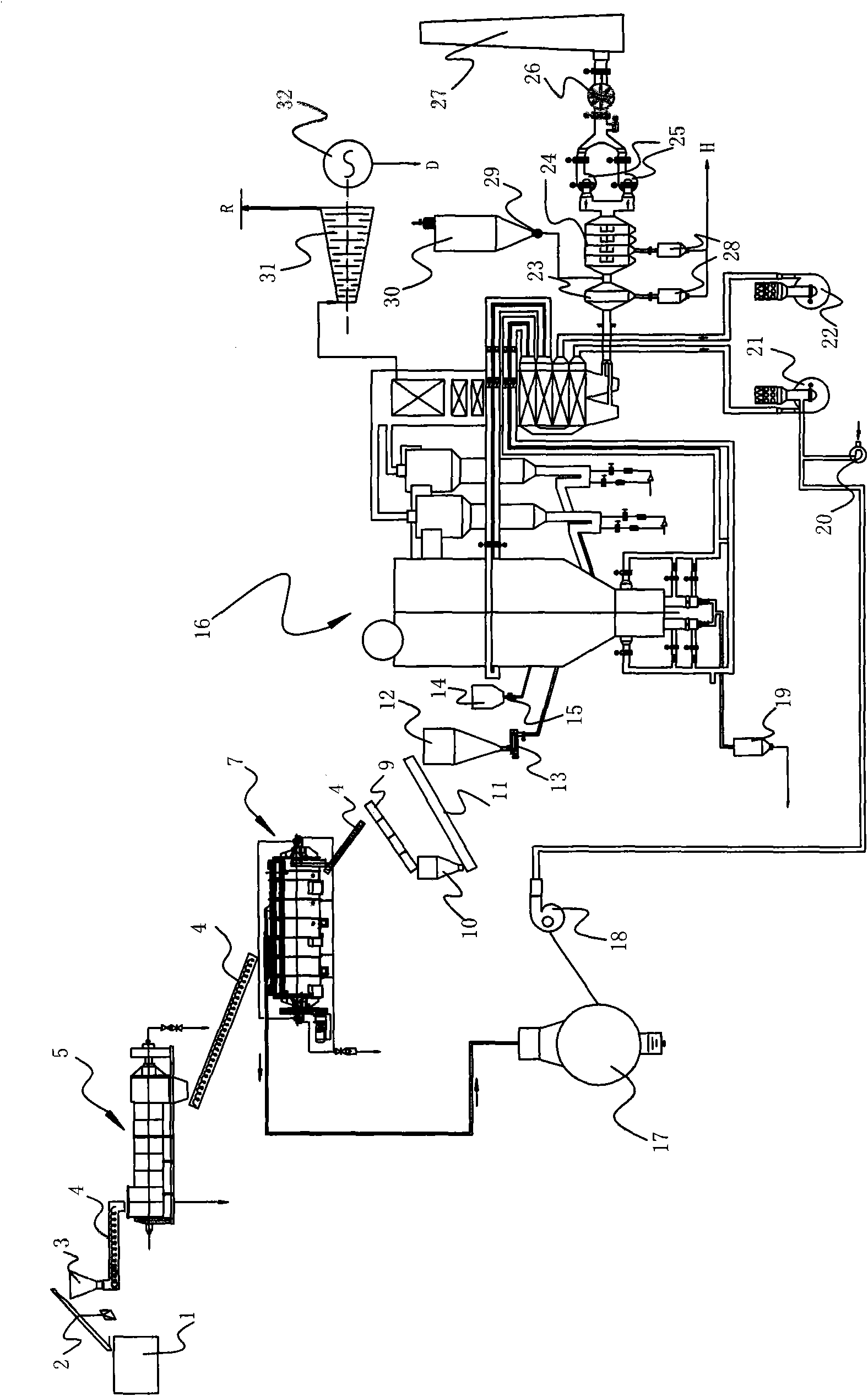

[0034] figure 1 An embodiment of the sludge treatment method according to the present invention is shown, wherein the embodiment includes:

[0035] - drying step A, wherein the wet sludge is dried by a drying device;

[0036] - Incineration step B, wherein the sludge dried in the drying step A is transported to an incinerator and mixed with a combustion aid for mixed incineration;

[0037] - Tail gas treatment step C, wherein the tail gas produced in the incineration step B is discharged after being purified.

[0038] Combine below figure 1 with 2 To illustrate in detail, at first, in the drying step A, the wet sludge 40 with a water content of 75% to 90% (weight ratio) stored in the wet sludge pool 1 is dried to reduce its water content to A safety threshold, for example around 42%. Wherein, the drying step further includes a deep dehydration step and a thermal drying step. in:

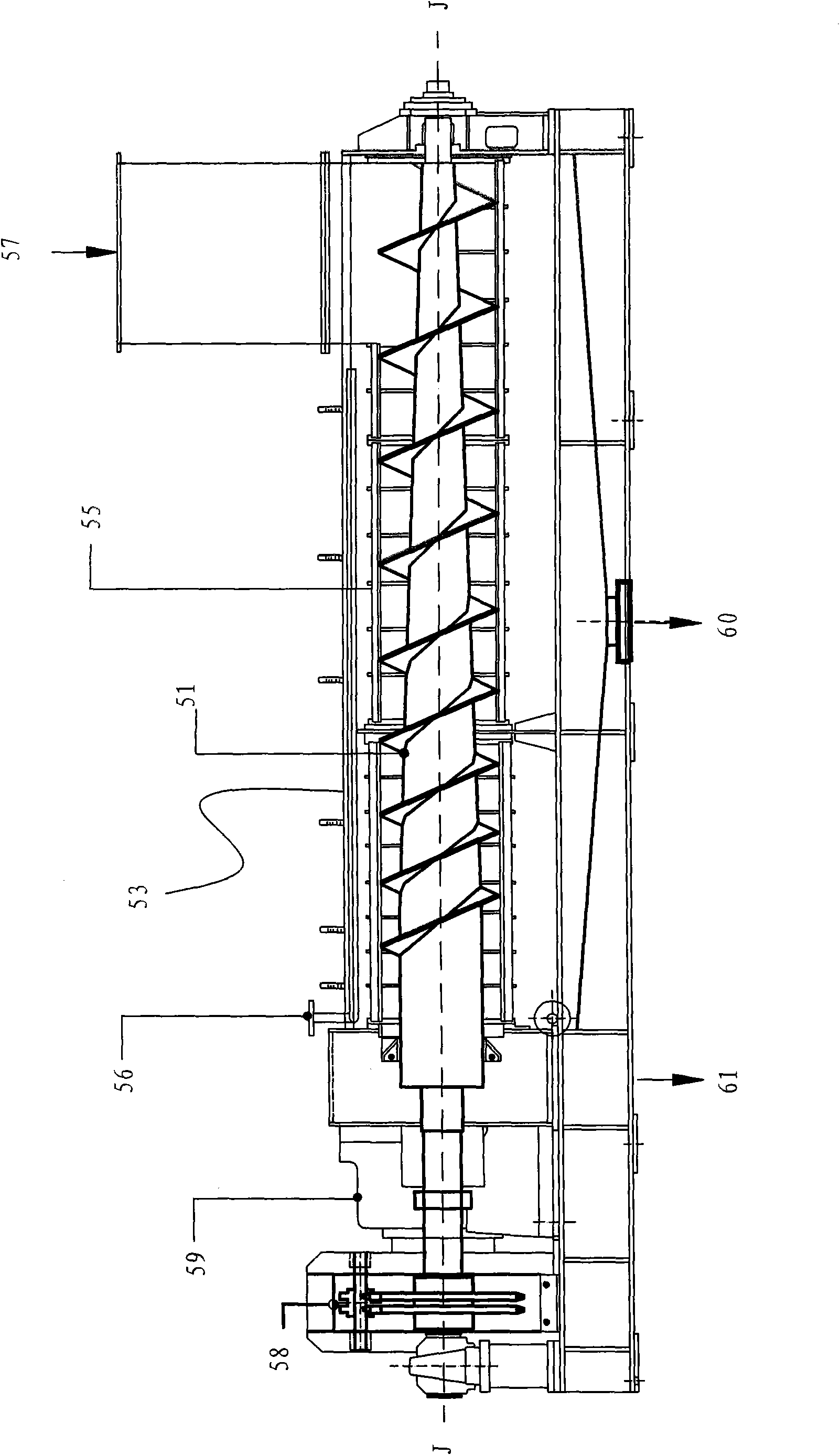

[0039] - First carry out the deep dehydration step A-1. In this step, first put the wet sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com