Method for treating sludge through refluxing of acidified fermentation liquor and application of method

A technology of acidification fermentation and fermentation liquid, which is applied in the direction of biological sludge treatment, waste fuel, etc., can solve the problems of process pollution and energy consumption, save operation and investment costs, increase the amount of methane produced by digestion, and improve the efficiency of gas production by digestion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

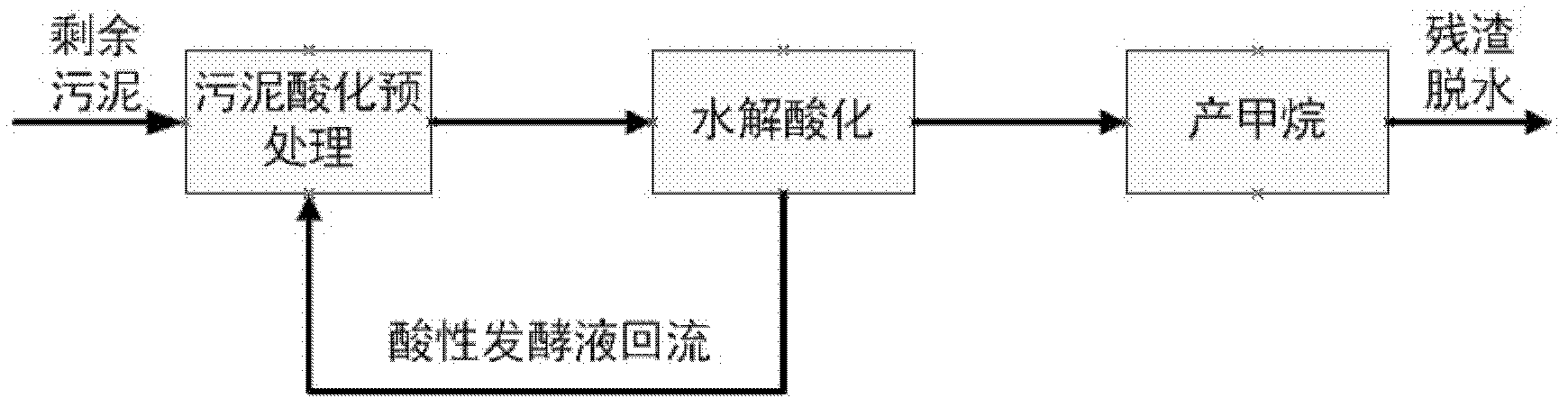

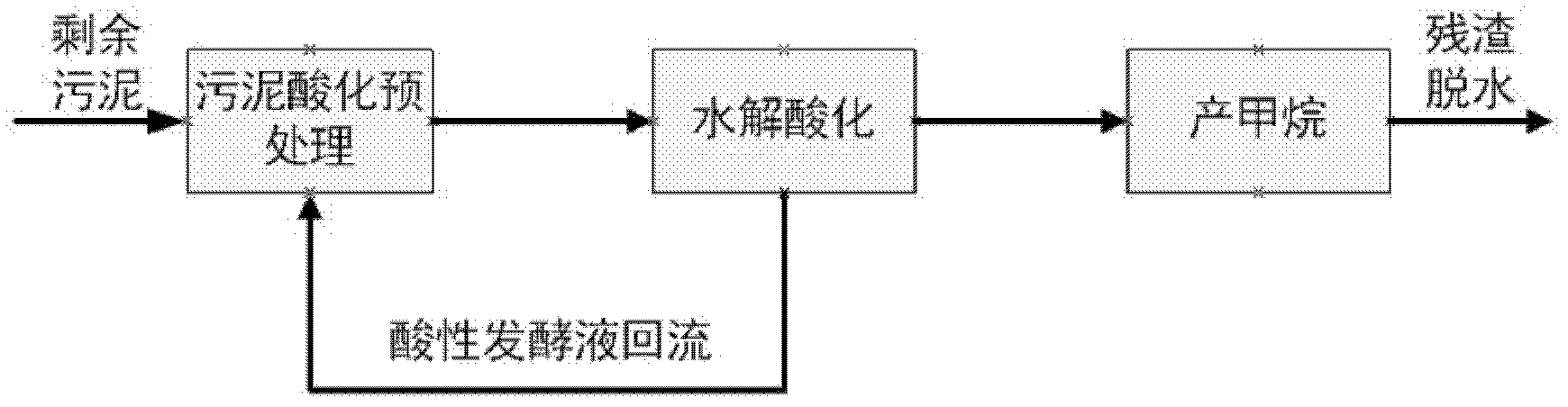

Method used

Image

Examples

Embodiment 1

[0016] The solid content of the sludge in the pretreatment tank is 2.6%, the reflux ratio of the fermentation broth is 65%, and the sludge is stirred to make it evenly mixed. The pretreatment time was 18h, and the TCOD in the sludge liquid phase increased by 1564mg / L after pretreatment. The sludge after acidification pretreatment enters the hydrolysis acidification tank through the sludge pump, the hydraulic retention time is 48h, and the pH value of the fermentation broth drops to 4.73. The sludge after hydrolysis and acidification enters the methanation pool through the sludge pump, the hydraulic retention time is 150h, the methane gas production is 334.2ml / g VS, and the gas production is increased by 46.2%.

Embodiment 2

[0018] The solid content of the sludge in the pretreatment tank is 2.9%, the reflux ratio of the fermentation broth is 80%, and the sludge is stirred to make it evenly mixed. The pretreatment time was 40h, and the TCOD in the sludge liquid phase increased by 2234mg / L after pretreatment. The sludge after acidification pretreatment enters the hydrolysis acidification tank through the sludge pump, the hydraulic retention time is 20h, and the pH value of the fermentation broth drops to 3.96. The hydrolyzed and acidified sludge enters the methanation tank through the sludge pump, the hydraulic retention time is 190h, the methane gas production is 363.4ml / g VS, and the gas production is increased by 58.9%.

Embodiment 3

[0020] The solid content of the sludge in the pretreatment tank is 3.5%, the reflux ratio of the fermentation broth is 96%, and the sludge is stirred to make it evenly mixed. The pretreatment time was 72h, and the TCOD in the sludge liquid phase increased by 2765mg / L after pretreatment. The sludge after acidification pretreatment enters the hydrolysis acidification tank through the sludge pump, the hydraulic retention time is 75h, and the pH value of the fermentation broth drops to 2.36. The hydrolyzed and acidified sludge enters the methanation tank through the sludge pump, the hydraulic retention time is 220h, the methane gas production is 403.8ml / g VS, and the gas production is increased by 76.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com