Patents

Literature

162results about How to "Save running cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

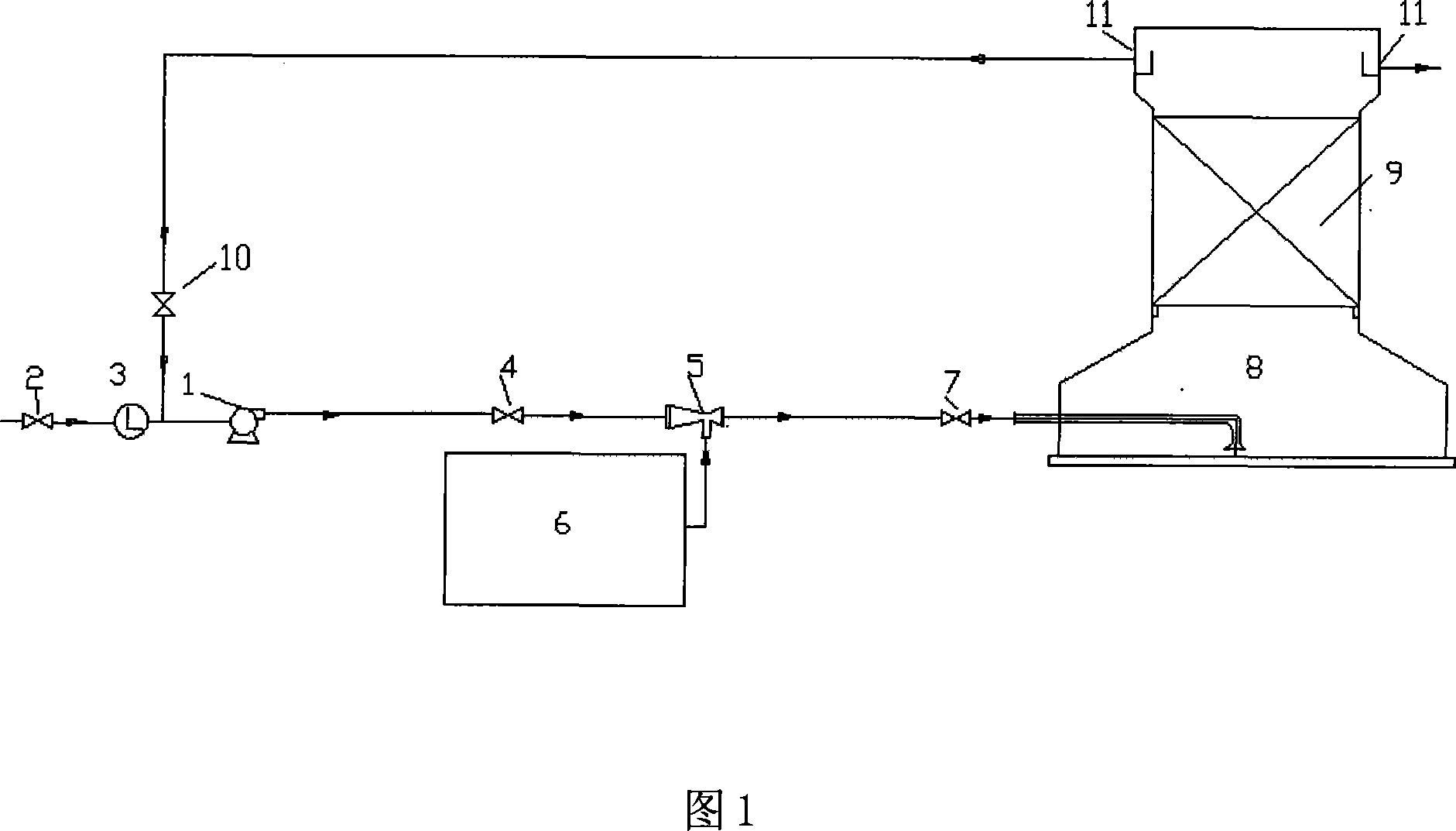

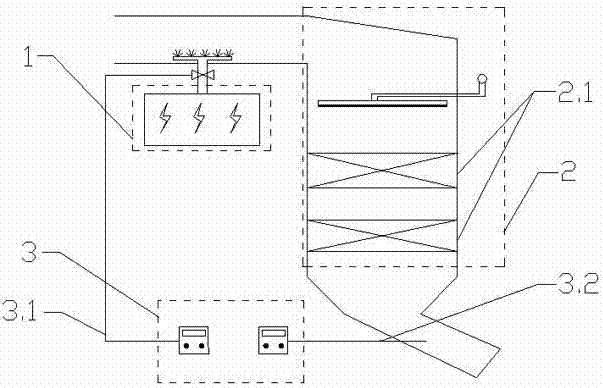

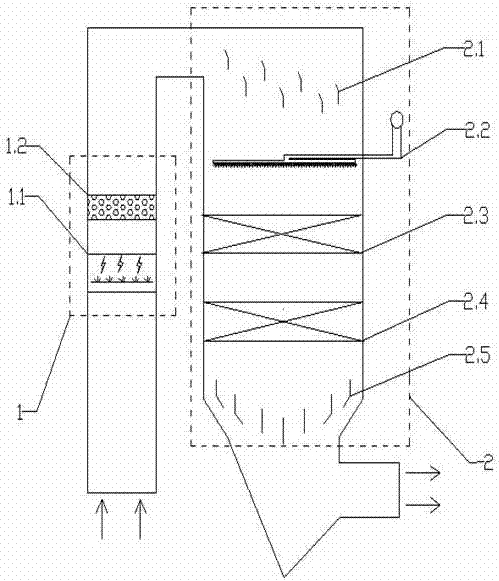

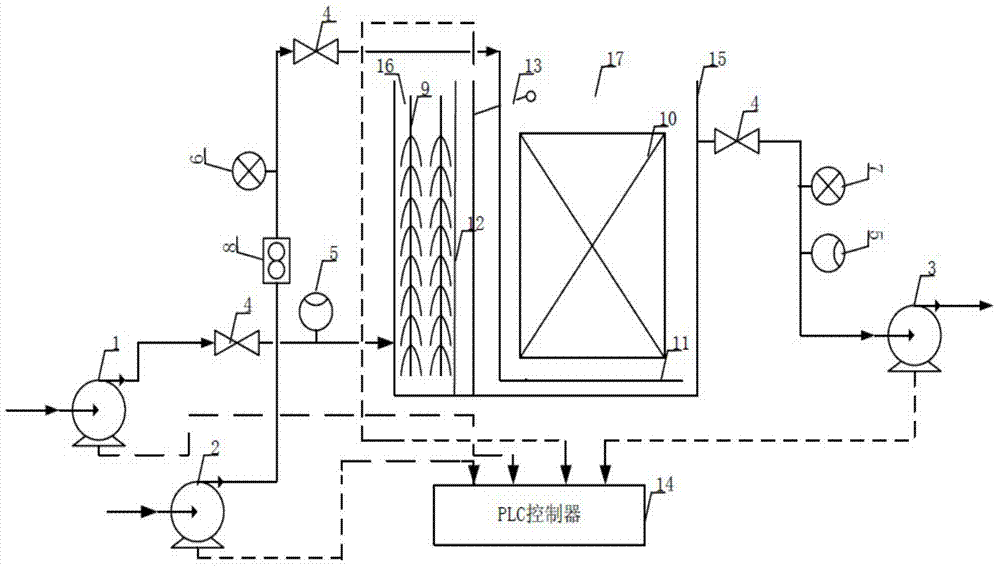

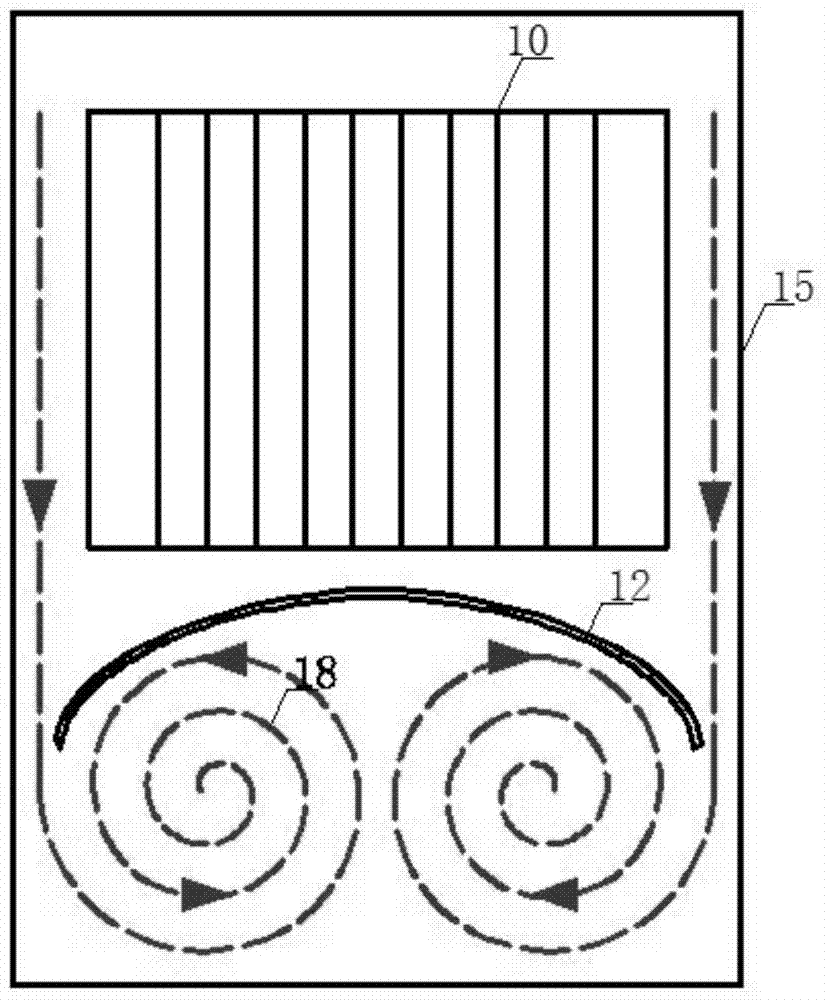

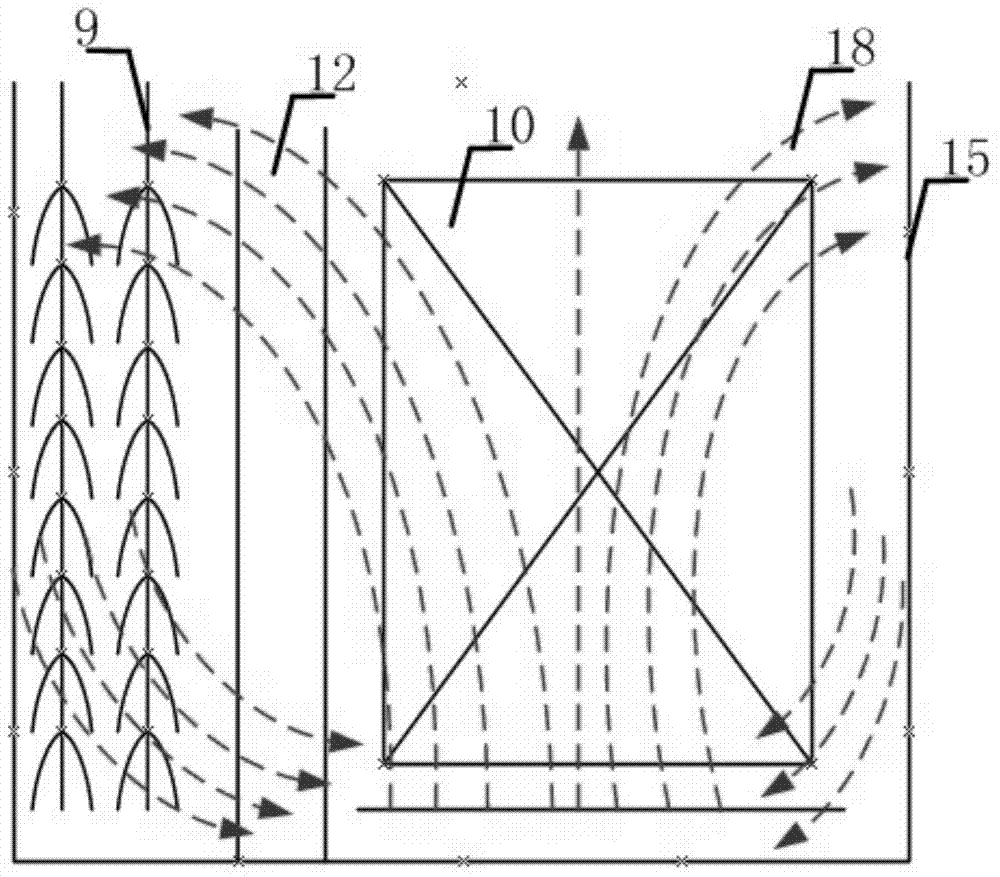

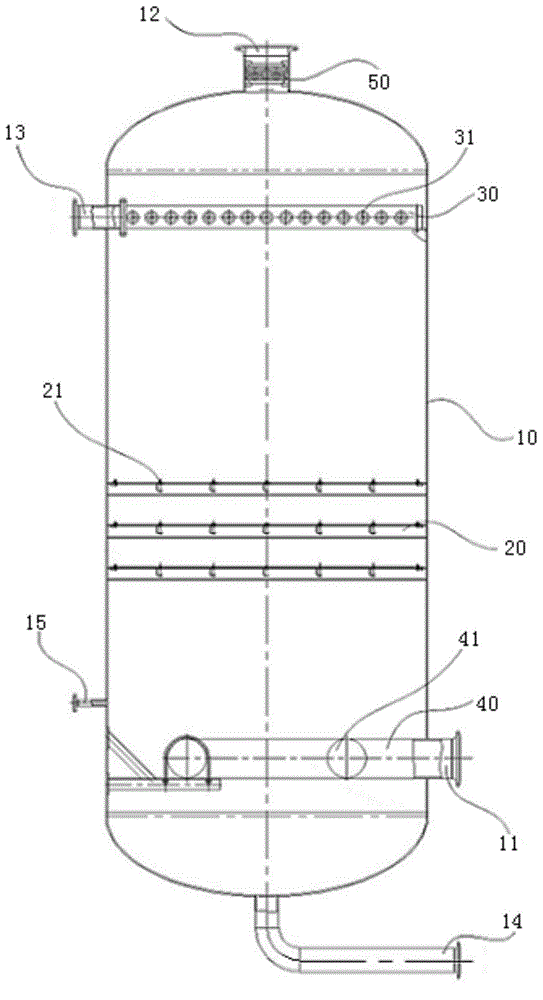

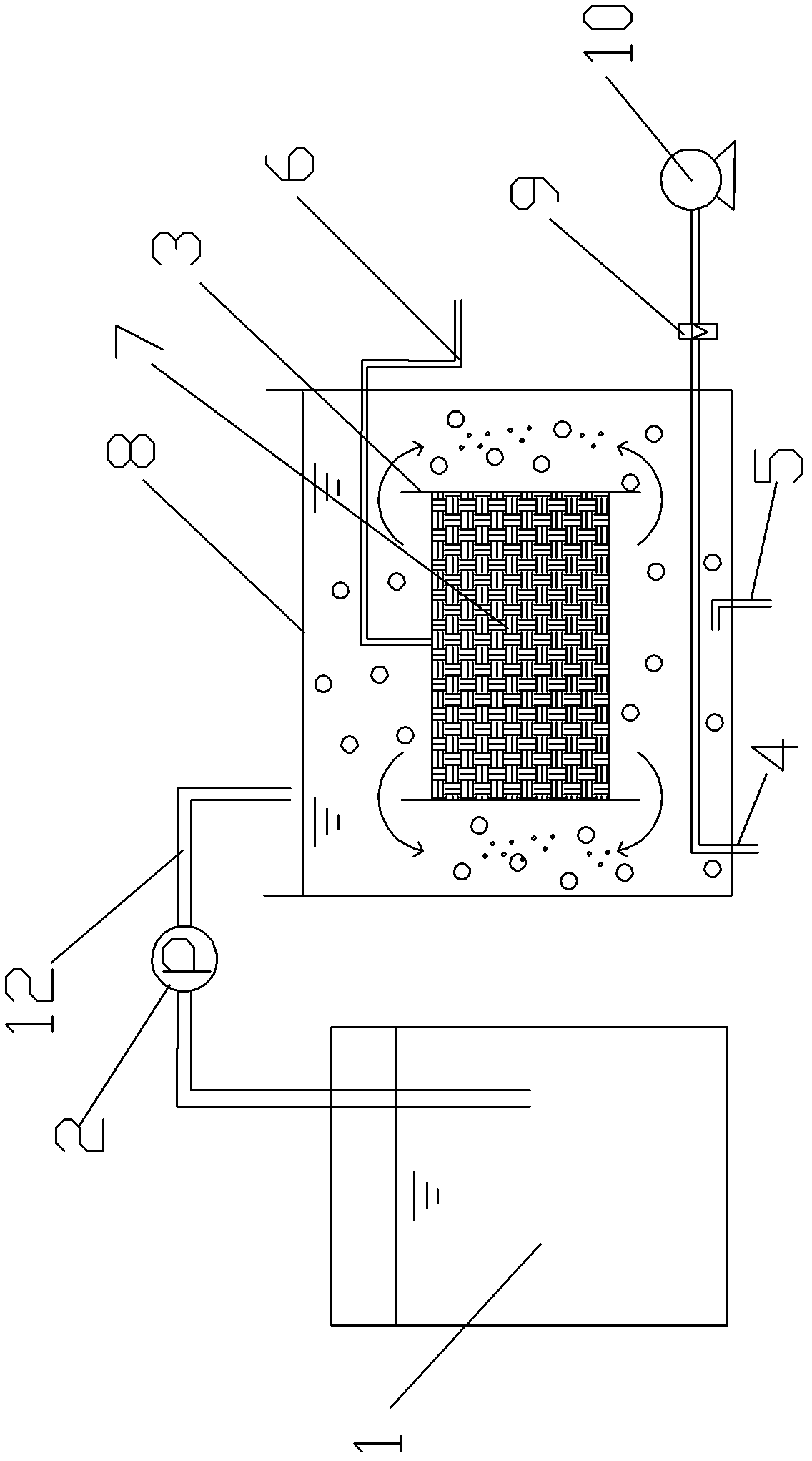

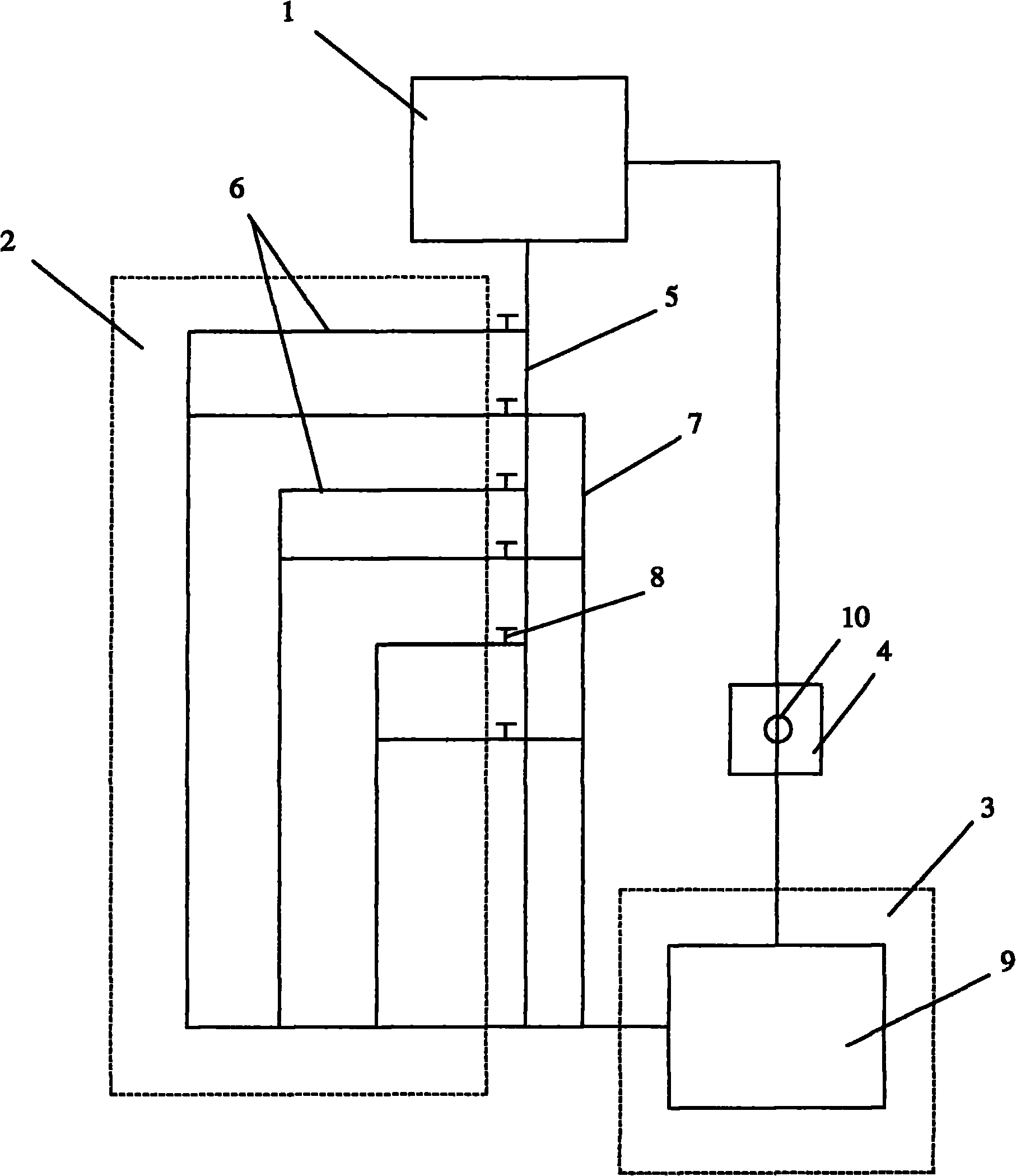

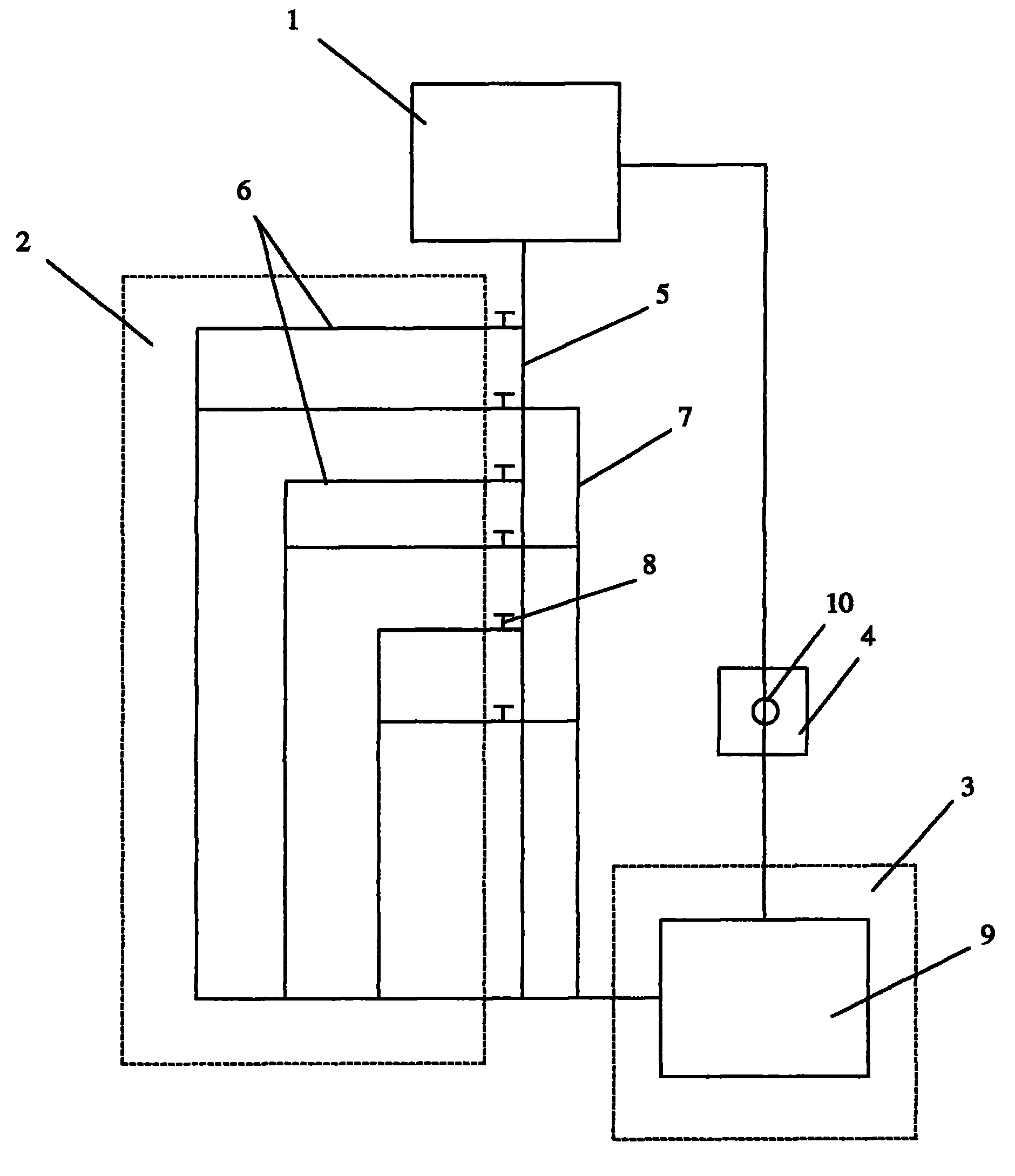

Integrated ozone and aeration biological filtering pool water treatment apparatus and method

ActiveCN101070216AEasy to handleReduce the difficulty of installation and constructionTreatment using aerobic processesMultistage water/sewage treatmentAeration systemBiological filter

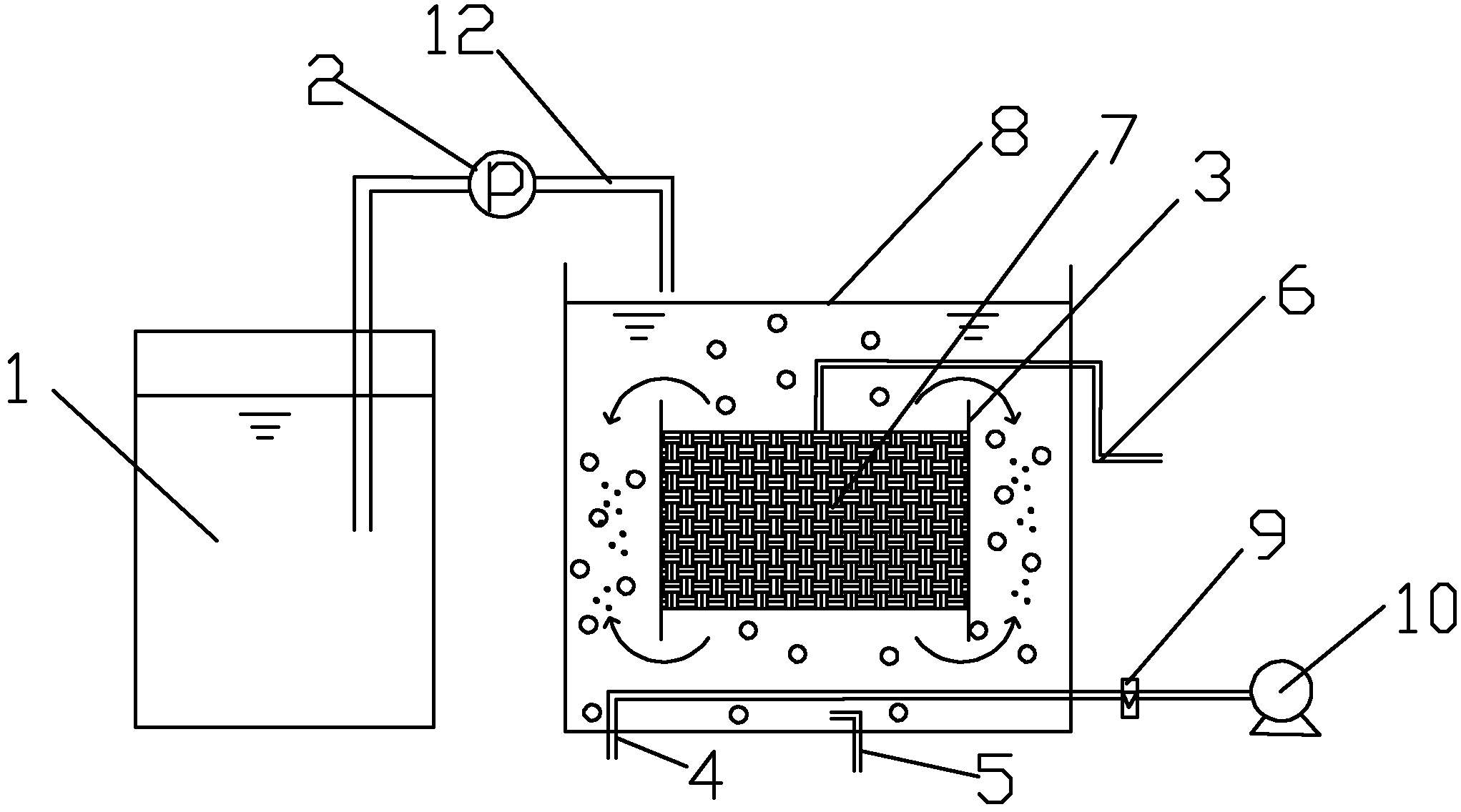

This invention relates to water disposal facility and means of integrated ozone and aerating biological filter. This aerating biological filter(9) is above ozone catalysis chamber(8), connects with ozone catalysis chamber(8) through the filter plate of biological filter(9); ozone catalysis chamber joints with Venturi tube(5), Venturi tube(5) respectively joints with ozone occurring system(6) and influent water pump(1); ozone occurring system(6) is a ozonizer that by silent discharge method translate oxygen of air into ozone. The water after pretreatment by ozone passes the filter plate of the aeration biological filter pool at the top of the ozone reaction chamber to enter the biological filter pool uniformly and stay for about 1 to 4 hours. This invention can advance aerating efficiency without fixing aerating system, and the flow between aerating biological filter and ozonization buffer pool cell is equilibrium, possess merits of high efficiency, low cost and so on.

Owner:SOUTH CHINA UNIV OF TECH

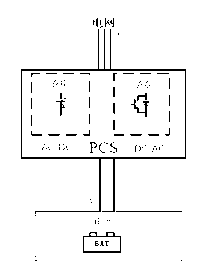

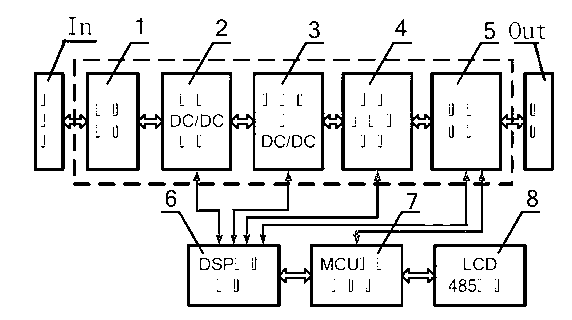

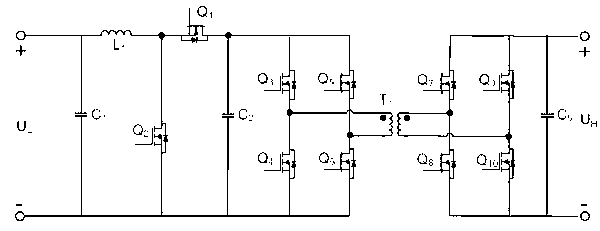

Charge-discharge two-way power converter for battery for electric car

InactiveCN102709994AHigh degree of intelligenceImprove conversion efficiencyBatteries circuit arrangementsApparatus with intermediate ac conversionThree levelAutomotive battery

A charge-discharge two-way power converter for a battery for an electric car adopts the structure that an input port (In) connected with a storage battery and an output port (Out) connected with a grid are mounted outside a main circuit; the main circuit is connected with a control circuit; the main circuit comprises a battery side filter circuit (1), a like-polarity bi-directional DC / DC converter (2), and a high-frequency isolation DC / DC circuit (3), a three-phase three-level circuit (4) and a grid side filter circuit (5) which are sequentially connected; and the control circuit comprises a DSP main controller (6), an MCU auxiliary controller (7) and an LCD or 485 communication circuit (8). According to the invention, the circuit adopts comparatively less elements, the intelligent degree is high, self detection and fault protection functions are provided, the equipment and operation costs are saved, the conversion efficiency is high, the working process is quick, stable, and controllable, the size is small, the dynamic property is good, and the purposes of environmental protection and energy conservation are achieved.

Owner:上海煦达新能源科技有限公司

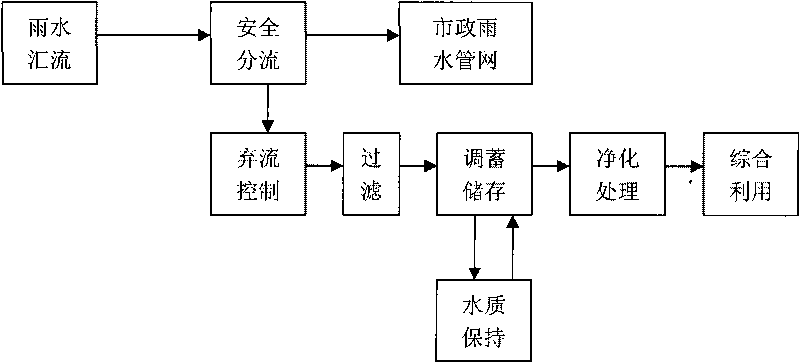

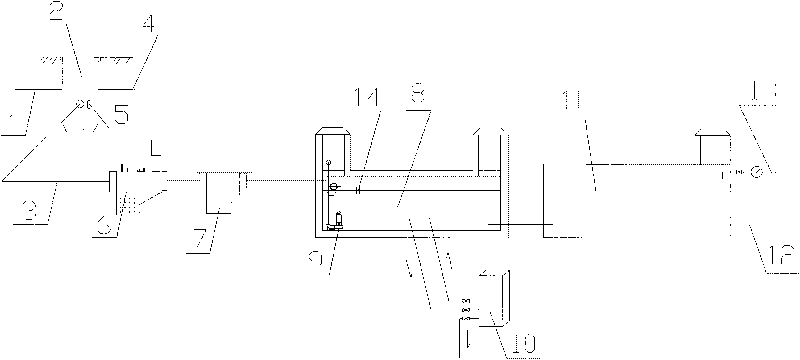

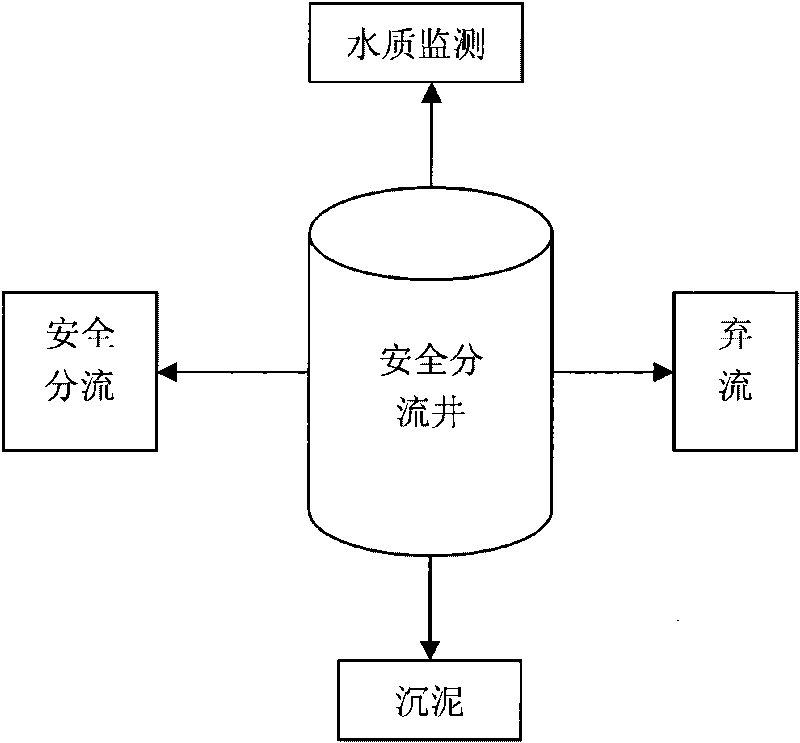

Rain and flood utilization system

InactiveCN101736774ADrainage safetyEnsure normal drainageGeneral water supply conservationSewage drainingEcological environmentFiltration

Owner:北京科净源科技股份有限公司

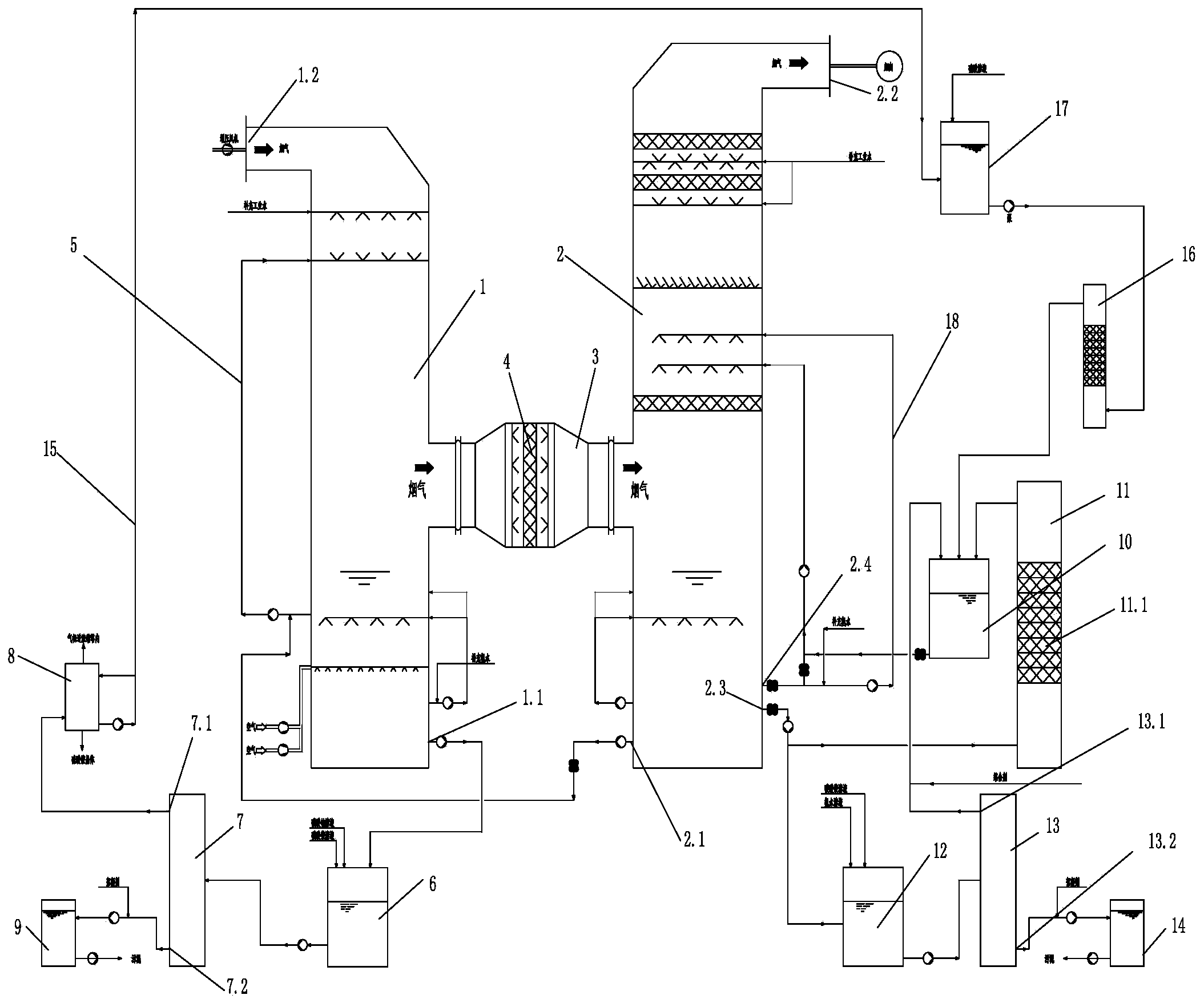

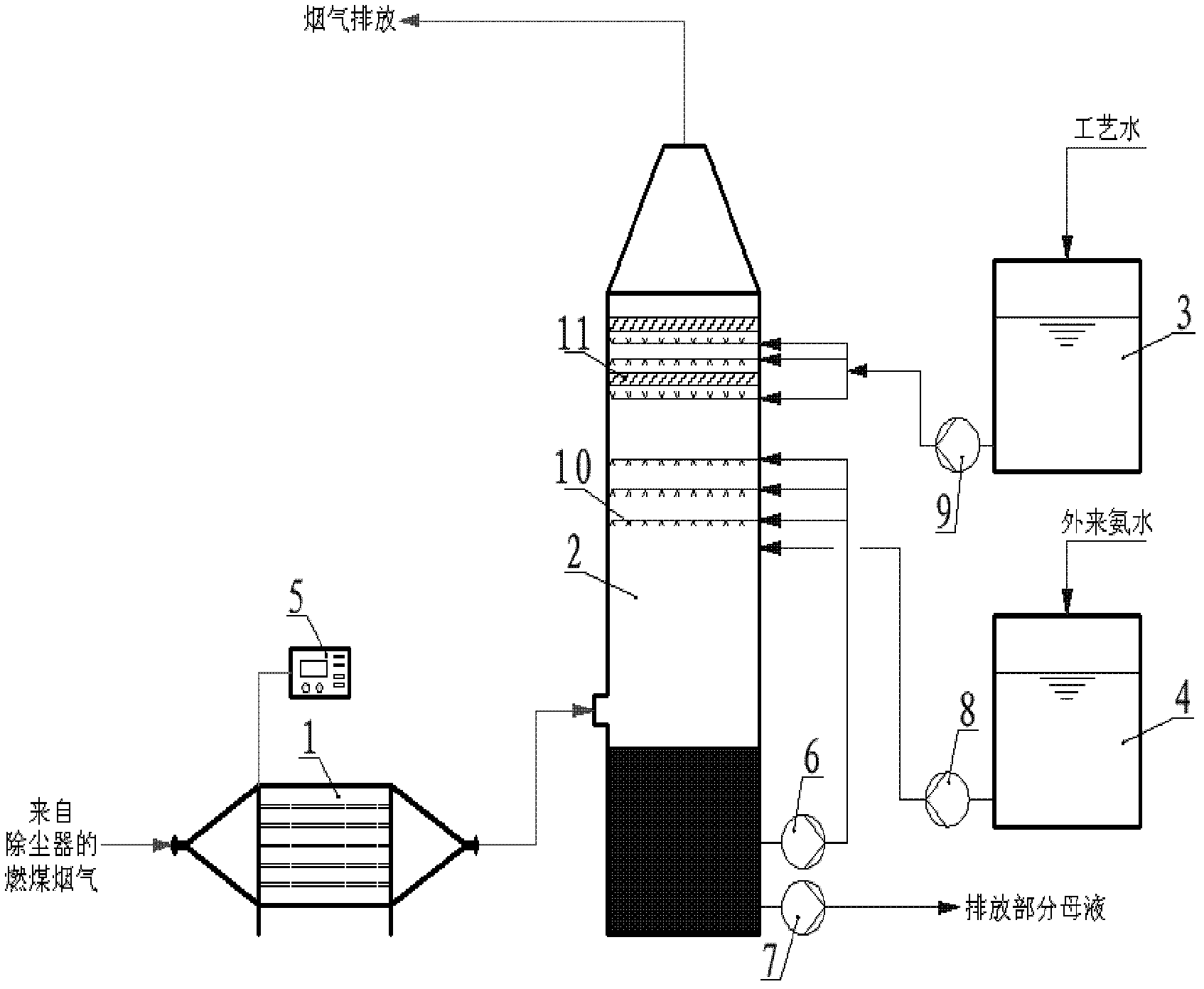

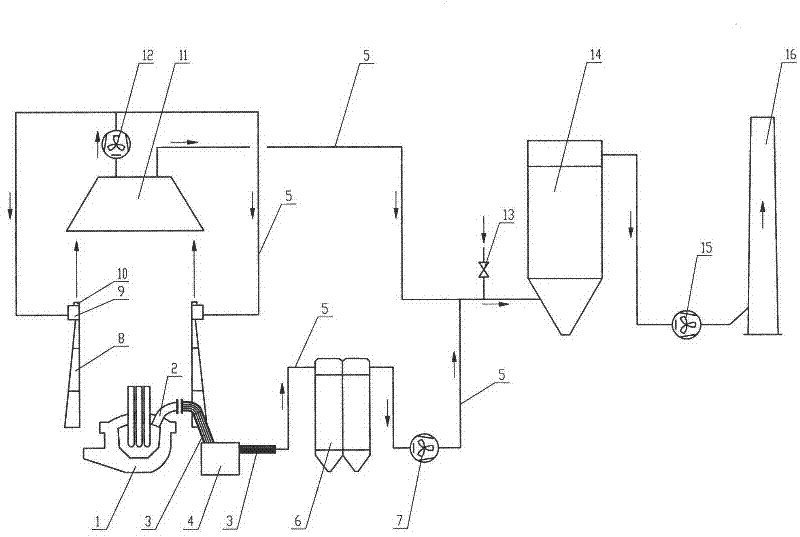

Synchronous denitration process based on wet ammonia process flue gas desulfurization

InactiveCN104226095ALow investment costLow running costDispersed particle separationAmmonium sulfatesSulfateFlue gas

The invention discloses a synchronous denitration process based on wet ammonia process flue gas desulfurization. The problems such as high operating cost and equipment investment cost, complex process and high energy consumption existing in an existing process are solved. According to the technical scheme, the process comprises the following steps: pressurizing flue gas, feeding the flue gas into a concentrating tower, allowing the flue gas to contact and react with a concentrated solution in the tower, feeding the flue gas out of the concentrating tower into an absorption tower to contact and react with absorption liquid in the tower, feeding a small amount of reacted concentrated solution at the bottom of the concentrating tower into an ammonium sulfate crystallization system, and adding a complexing agent EDTA-Fe (II) or adding EDTA-Na salt and ferrous sulfate according to a molar ratio of 1:1 into the absorption liquid in the absorption tower, so that the concentration of the EDTA-Fe (II &III) in the absorption liquid is 0.015-0.05mol / L; and feeding a small amount of absorption liquid in the absorption tower into the concentrating tower to be mixed with the concentrated solution. The synchronous denitration process disclosed by the invention has the advantages of simplicity, low operating cost and equipment investment, capacity of performing high-efficiency synchronous desulfurization and denitration and low energy consumption.

Owner:WUHAN WUTUO TECH +2

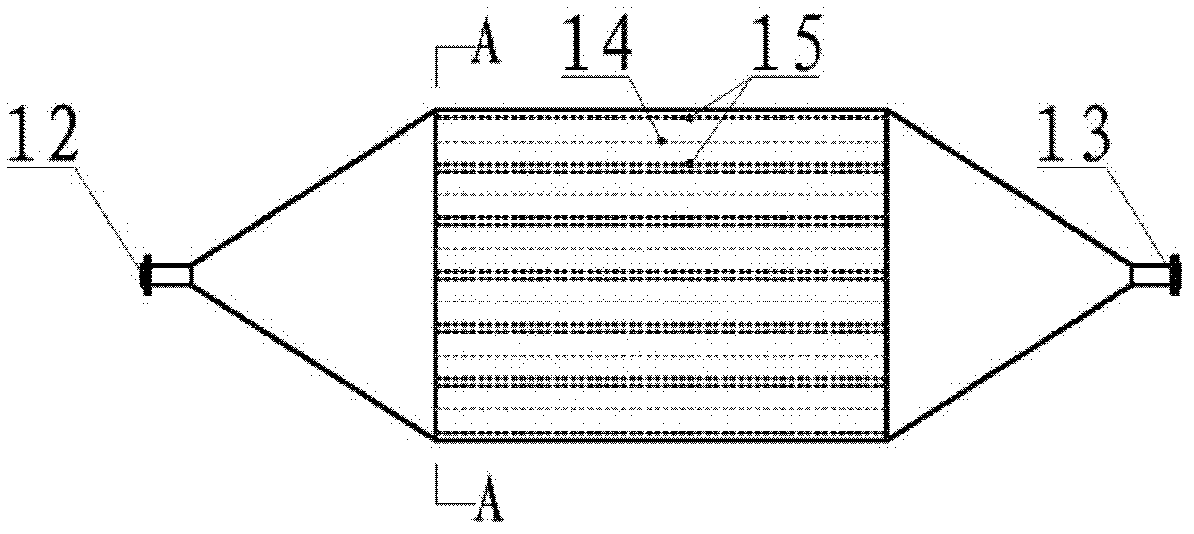

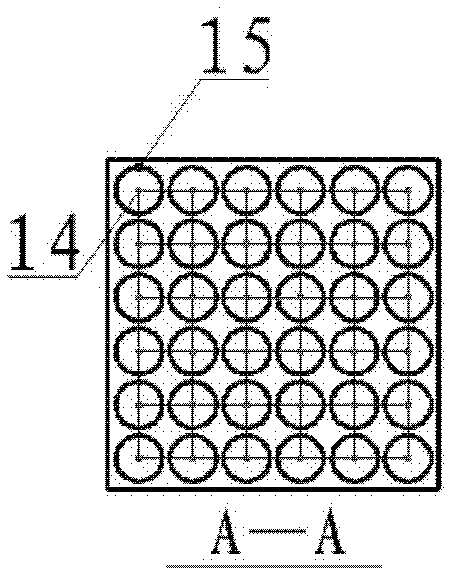

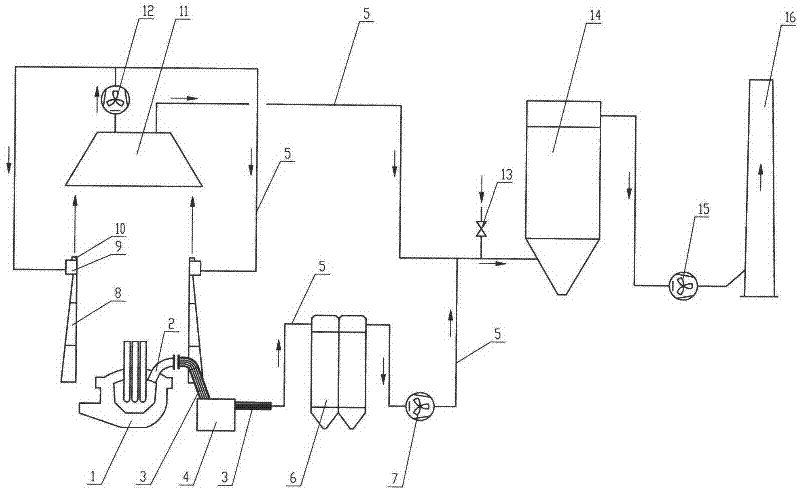

Coal-fired flue gas desulphurization denitration process and desulphurization denitration device thereof

InactiveCN102500207AImprove absorption rateHigh removal rateAmmonium nitratesDispersed particle separationLow temperature plasmaChemistry

The invention discloses a coal-fired flue gas simultaneous desulphurization denitration process by low temperature plasma oxidation combined with ammonia-method wet absorption; the process comprises two processes of low temperature plasma oxidation and ammonia-method wet absorption; coal-fired flue gas to be treated is firstly introduced into a low temperature plasma reactor through a flue, and thus 40%-50% of NO in the flue gas is oxidized into NO2; the conditioned flue gas is introduced into a simultaneous desulphurization denitration spray tower, and fully contacts ammonia water absorption liquid so as to remove SO2 and NOx in the flue gas and discharge the flue gas; the absorption liquid at the bottom of the simultaneous desulphurization denitration spray tower is delivered into a spray layer again for recycle through an absorption liquid circulating pump; ammonia water in an ammonia water groove is supplied continuously to the spray tower through an ammonia water pump; and a part of mother liquor is discharged through a mother liquor transfer pump. The process of the invention is applicable to the simultaneous desulphurization denitration treatment of coal-fired flue gas, and the device of the invention has the advantages of good pollutant removing effect, simple equipment, less land occupation, convenient operation, and convenience for management.

Owner:SOUTHEAST UNIV

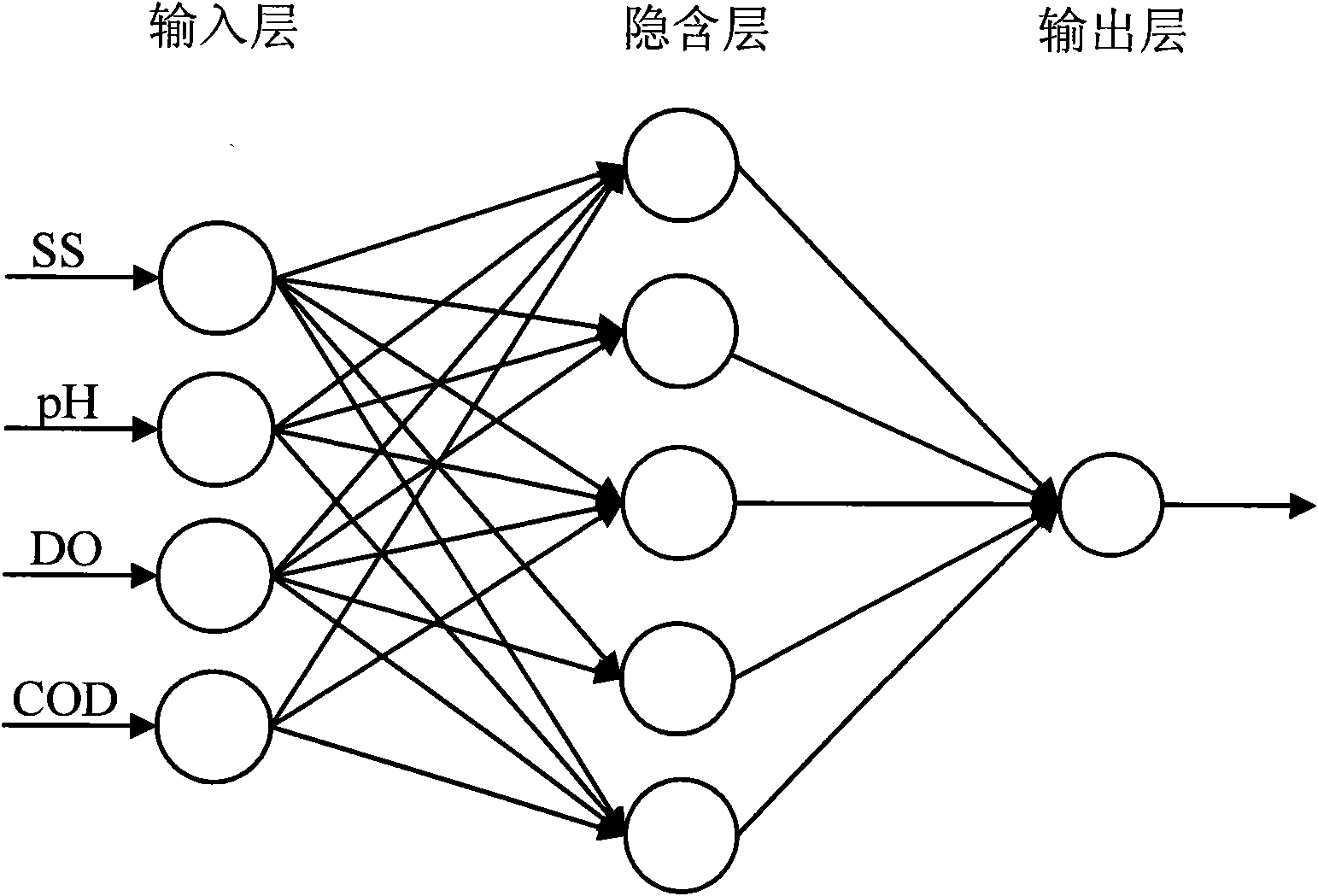

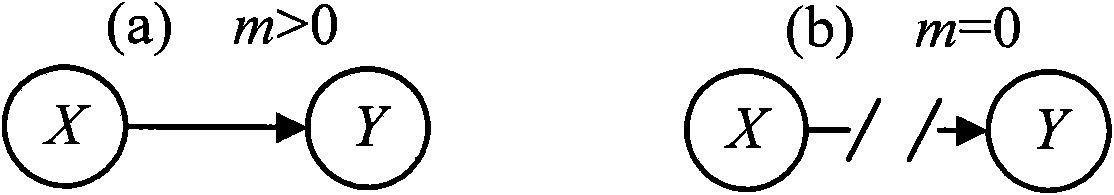

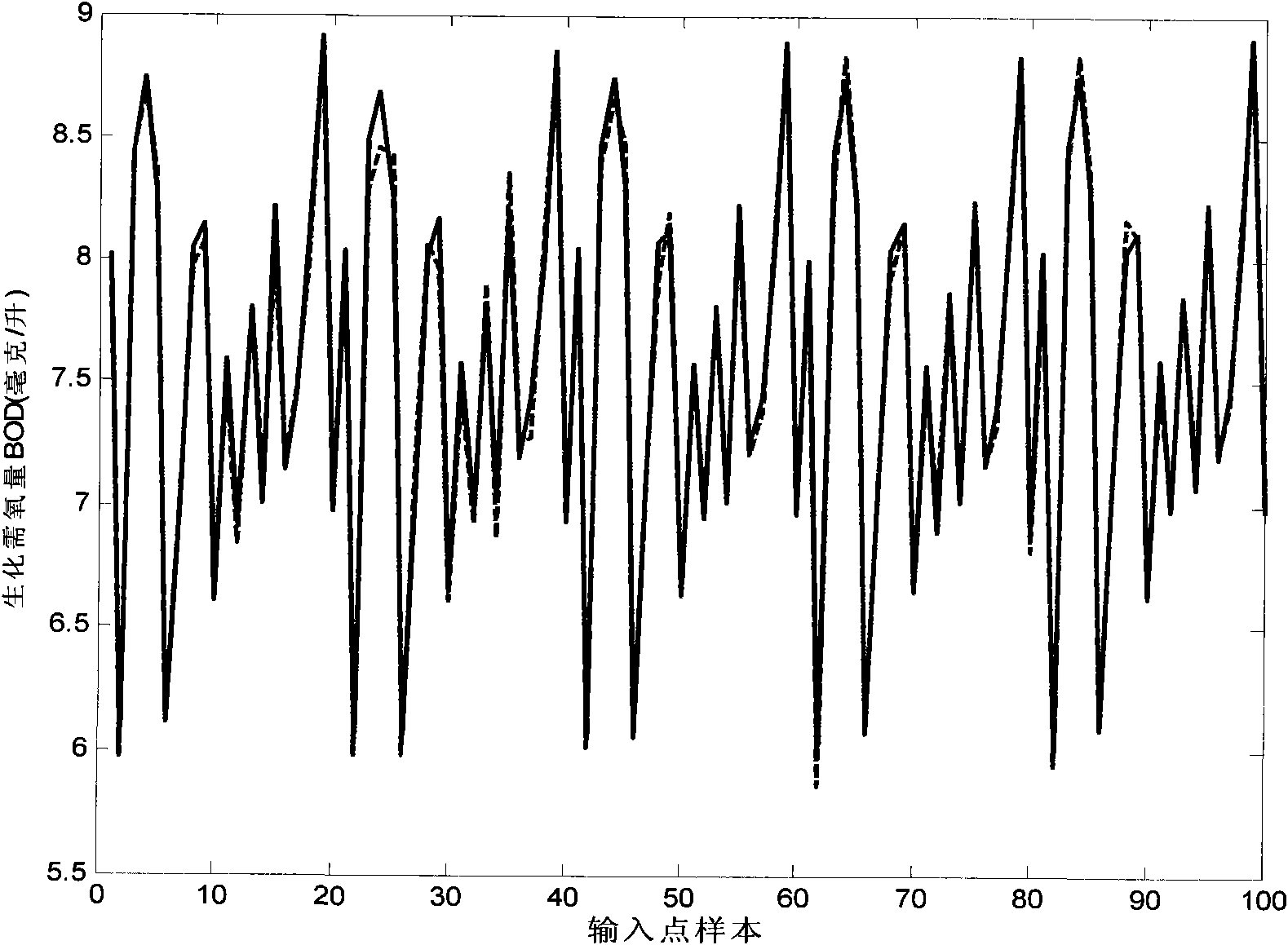

Biochemical oxygen demand BOD soft measurement method based on elastic radical basis function neural network

ActiveCN101957356AGuaranteed uptimeSave investment costBiological neural network modelsTesting waterMathematical modelWater quality

The invention discloses a biochemical oxygen demand BOD soft measurement method based on elastic radical basis function neural network, belonging to the technical field of detection. The sewage processing process has severe production condition and serious random disturbance, has the characteristics of strong nonlinearity, large time varying and serious lag and is hard to build a precise mathematical model by mechanism analysis. The invention utilizes the liveness function of an RBF neuron to judge the activeness of the neuron, and divides the neuron with strong activeness; then, joint strength between the hidden layer neuron and the output layer neuron of an RBF neuron network is analyzed by calculating a mutual information dependency function so as to revise the neural network structureaccording to the mutual information intensity; and finally, the parameter of the neural network is adjusted until the network structure satisfies the requirement on processing information. The invention improves the quality and the efficiency of sewage processing, lowers sewage processing cost and provides in-time water quality and relevant parameter monitoring for realizing closed loop control for the sewage processing process so as to accelerate sewage treatment plants to efficiently and stably operate.

Owner:BEIJING UNIV OF TECH

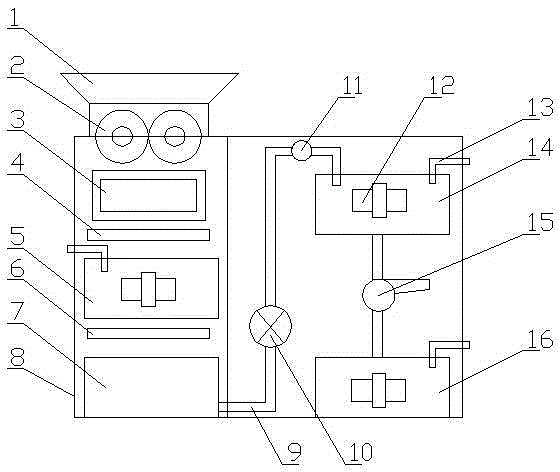

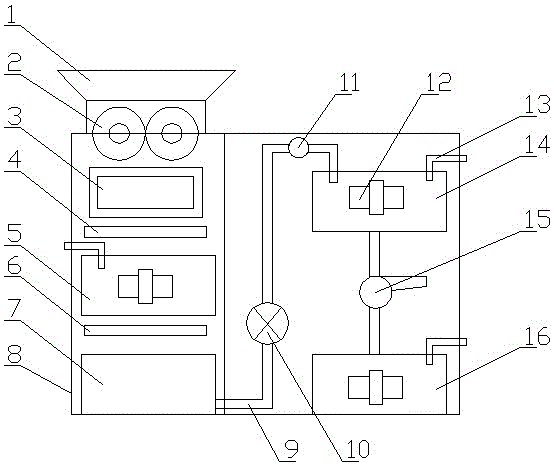

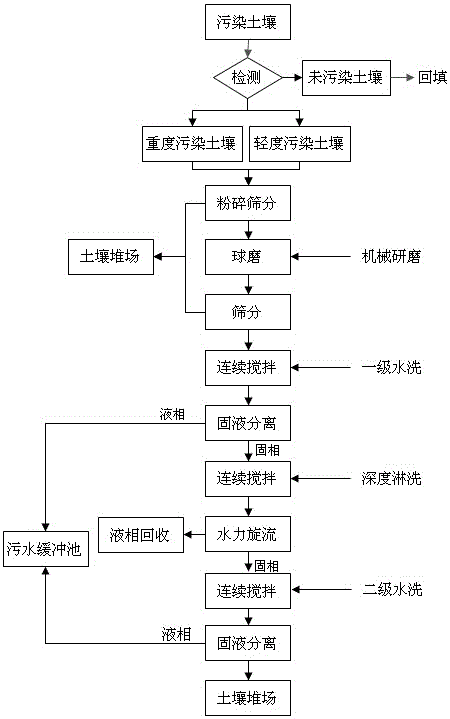

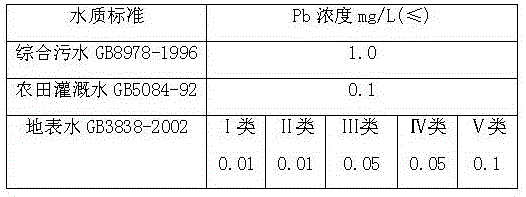

Heavy metal contaminated soil remediation equipment and remediation process thereof

ActiveCN105268737AOverall small sizeSmall footprintContaminated soil reclamationSoil scienceSoil remediation

The invention relates to heavy metal contaminated soil remediation equipment. The heavy metal contaminated soil remediation equipment comprises a machine frame, a feeding hopper, grinding rollers, a ball mill, a screen sieve, a first-level rinsing pool, a linear vibrating screen, a slurry buffer pool, a slurry pump, a centrifugal machine, a deep leaching pool, a belt filter press and a second-level rinsing pool. Contaminated soil is subjected to mechanical grinding, first-level rinsing, first-level solid-liquid separation, deep leaching, second-level rinsing and second-level solid-liquid separation to be remedied. The heavy metal contaminated soil remediation equipment is advanced in process, good in treatment effect, high in working efficiency and high in automation degree.

Owner:GUANGZHOU FIRST MUNICIPAL ENG CO LTD

MTP (methanol to propylene) device and novel separation process thereof

ActiveCN105503492AReduce lossLess solvent absorptionDistillation purification/separationHydrocarbon from oxygen organic compoundsGas phaseSolvent

The invention relates to an MTP (methanol to propylene) separation device and a novel separation process adopted by the MTP device. The novel separation process comprises the steps that quenched reaction gas is pressurized by a compressor and undergoes washing and alkali wash treatment on a third compression section, a gas phase at the outlet of a fourth compression section goes to a depropanizer and a liquid phase goes to a debutanizer, water phases of separating tanks among the sections of the compressor return to a quench tower, and a hydrocarbon phase is sent to a separating tank at the outlet of the fourth compression section after being pressurized; the materials ejected from the debutanizer go to the depropanizer and the materials discharged from tower reactors enter a dehexanizer; a deethanizer compressor is arranged between a deethanizer and an oil absorption tower, the oil absorption tower adopts recycle propane or C4 as an absorbing solvent, fuel gas excluding C2 is obtained at the tower tops, the materials discharged from the tower reactors go to a stripping tower to recover the propane or C4 solvent, and the materials ejected from the stripping tower go to an ethylene rectification tower, thus obtaining the byproduct ethylene. The novel separation process has the effects that the process flow can be effectively optimized; the energy consumption of systems, the pipeline corrosion and the cost of investment can be effectively reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

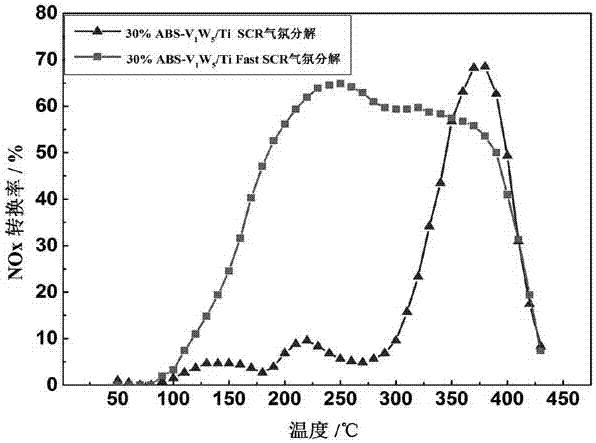

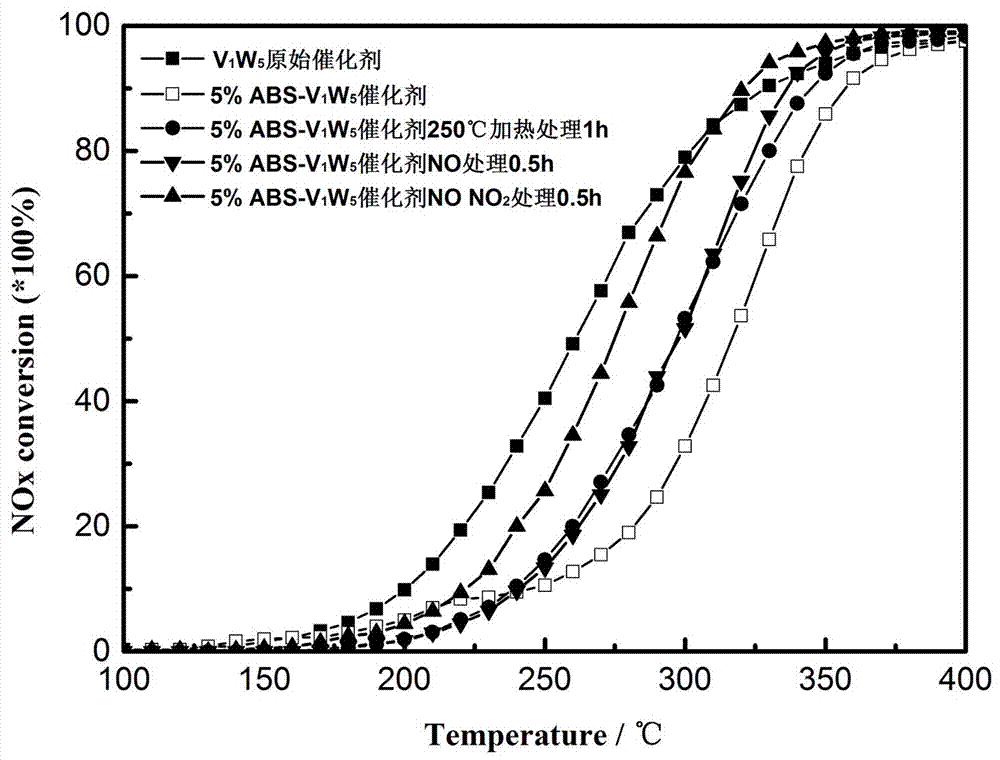

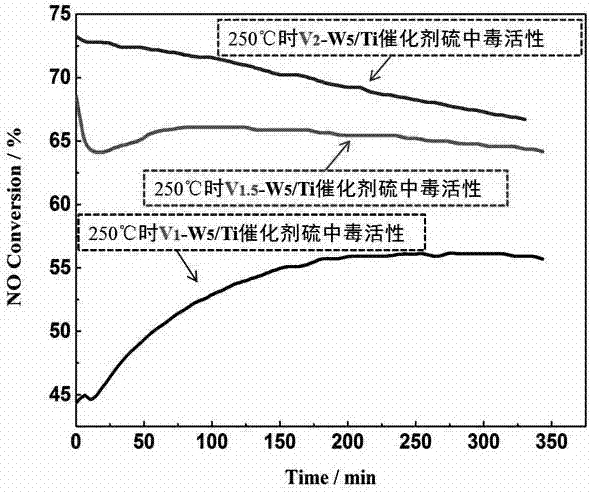

Method and device applied to in-situ regeneration of sulfur-poisoning SCR denitration catalyst

ActiveCN107376930AReduce catalytic activityLower decomposition temperatureGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention provides a method and a device applied to in-situ regeneration of a sulfur-poisoning SCR denitration catalyst. The method comprises the following steps: pre-oxidizing part of smoke before entering to an SCR denitration reactor when the SCR denitration catalyst is deactivated by sulfur poisoning, oxidizing part of NO in the smoke, then enabling the smoke to enter into the SCR denitration reactor, accelerating decomposition of ammonium sulfate on the surface of the catalyst, and carrying out regeneration process of the catalyst. The device applied to in-situ regeneration of the sulfur-poisoning SCR denitration catalyst comprises an ozone generator, an electromagnetic valve, an SCR denitration reactor and a smoke NOx component online monitor. The method and the device are capable of effectively decomposing ammonium sulfate deposited on the surface of the catalyst under the condition with temperature of 200-380 DEG C; the activity of the treated sulfur-poisoning catalyst is improved; the service life of the catalyst is prolonged; the replacement cost of the catalyst is reduced.

Owner:CHONGQING UNIV +1

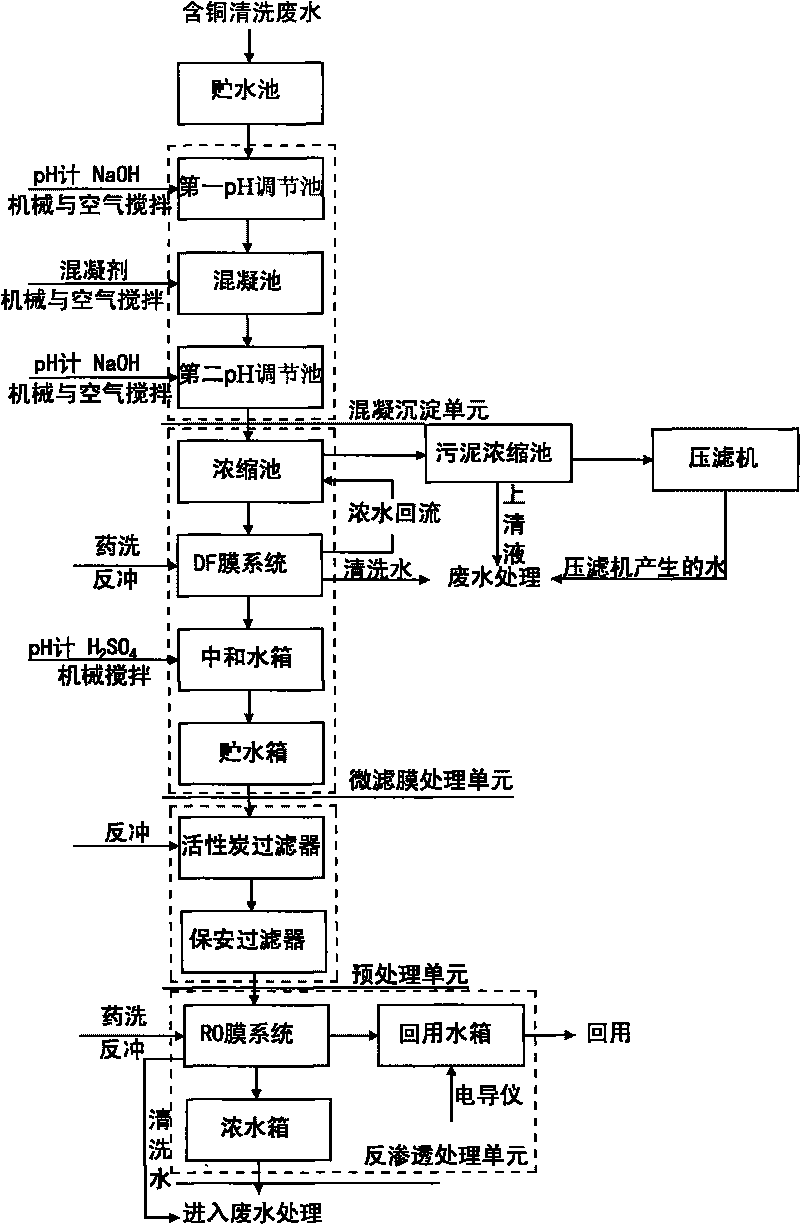

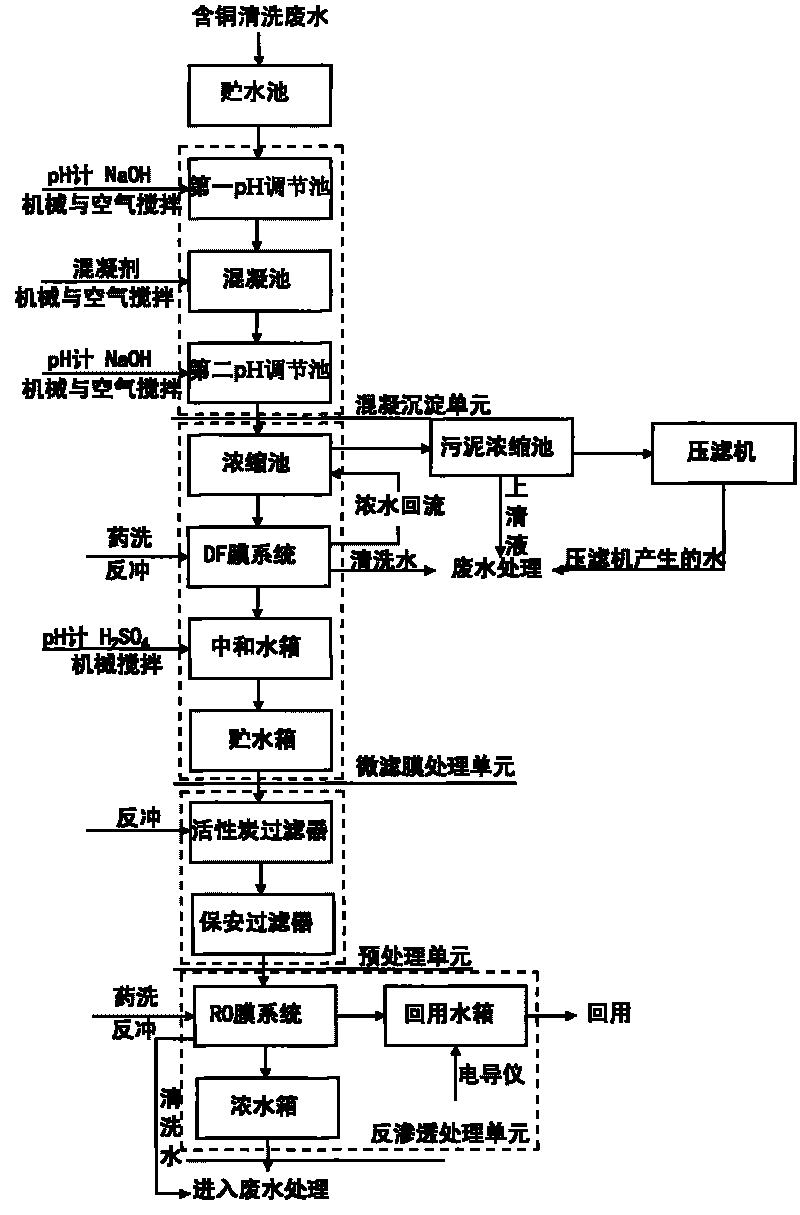

Electronic electroplating wastewater recycling advanced treatment technology

InactiveCN101734815AImprove coagulation and sedimentation effectAvoid easy cloggingWaste water treatment from metallurgical processMultistage water/sewage treatmentMembrane technologyReverse osmosis

The invention relates to an electronic electroplating wastewater recycling advanced treatment technology. The technology uses a large amount of rinse-wastewater with heavy metals in the production process of the electronic electroplating industry as the main object, adopts a combined technology of pH adjustment-microfiltration membrane treatment-pretreatment-reverse osmosis membrane treatment, is mainly characterized by the joint application of DF membrane technology and RO membrane technology and can achieve the aim of reusing wastewater and reducing the emission of heavy metals; and the reuse water reaches the production demand of process water, thus saving the fresh water consumption of the industry, effectively reducing the production cost of the industry, solving the pollution problem of heavy metals, increasing the clean production level of the electronic electroplating industry and having remarkable social environmental and economic benefits.

Owner:苏州市环境工程有限责任公司

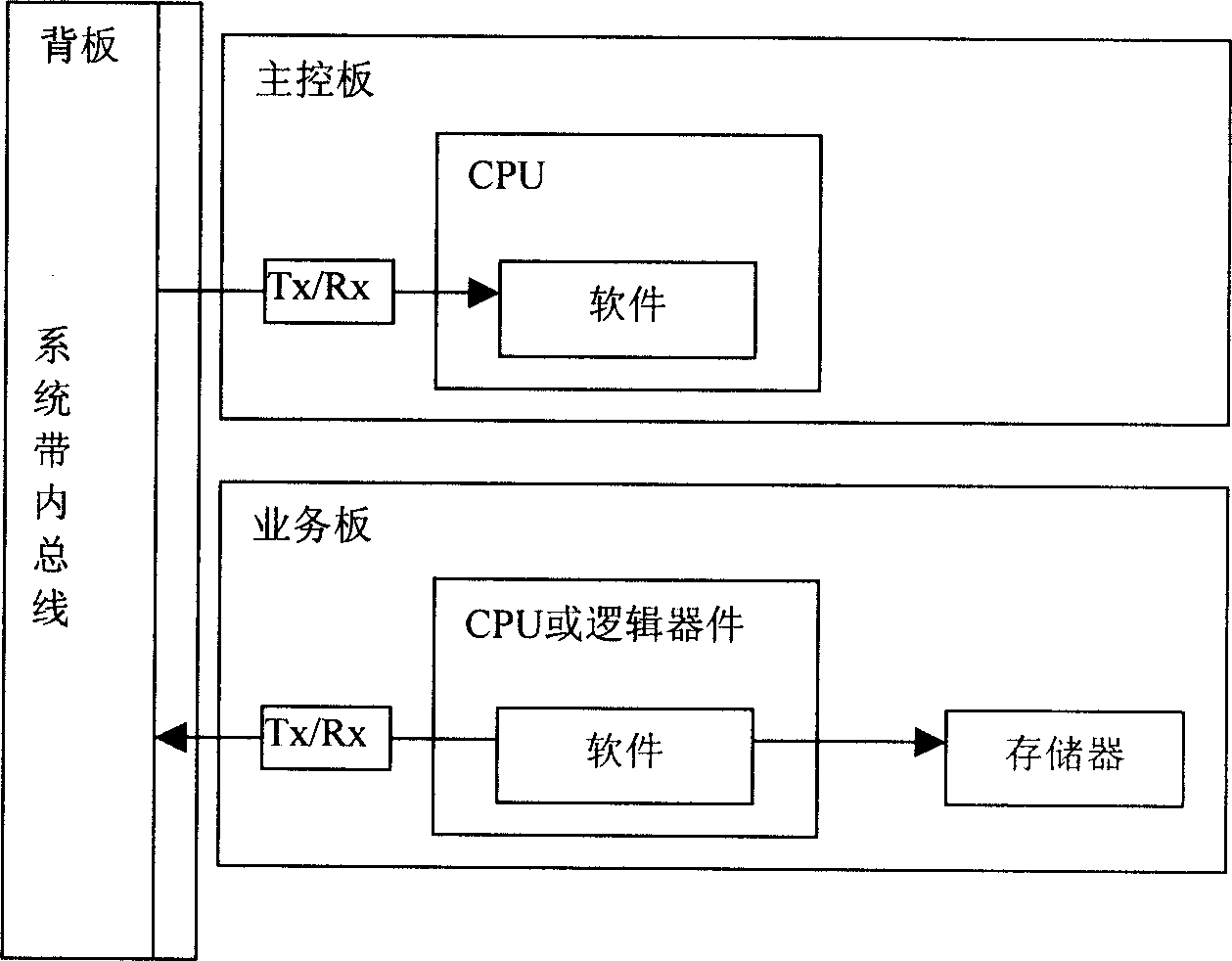

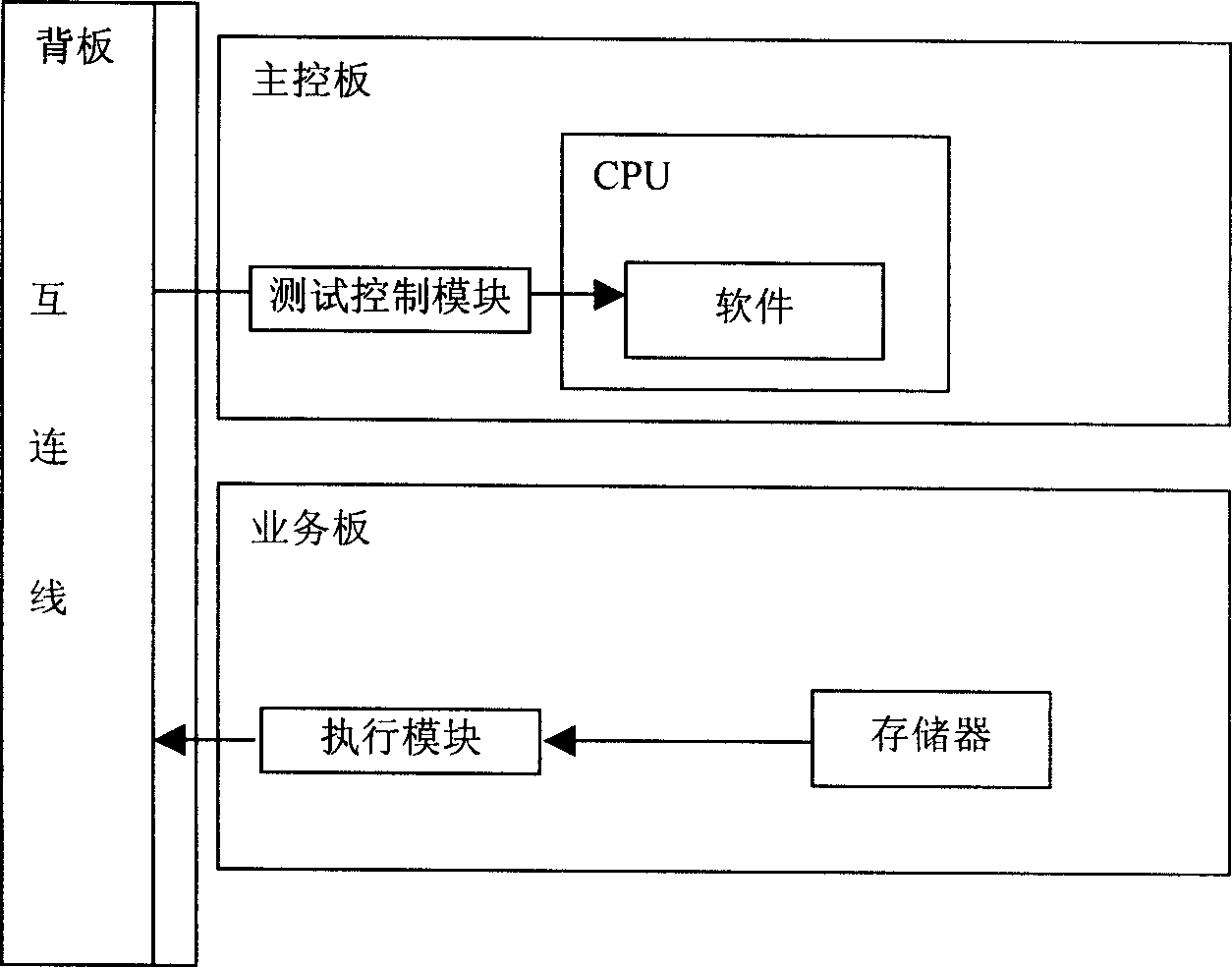

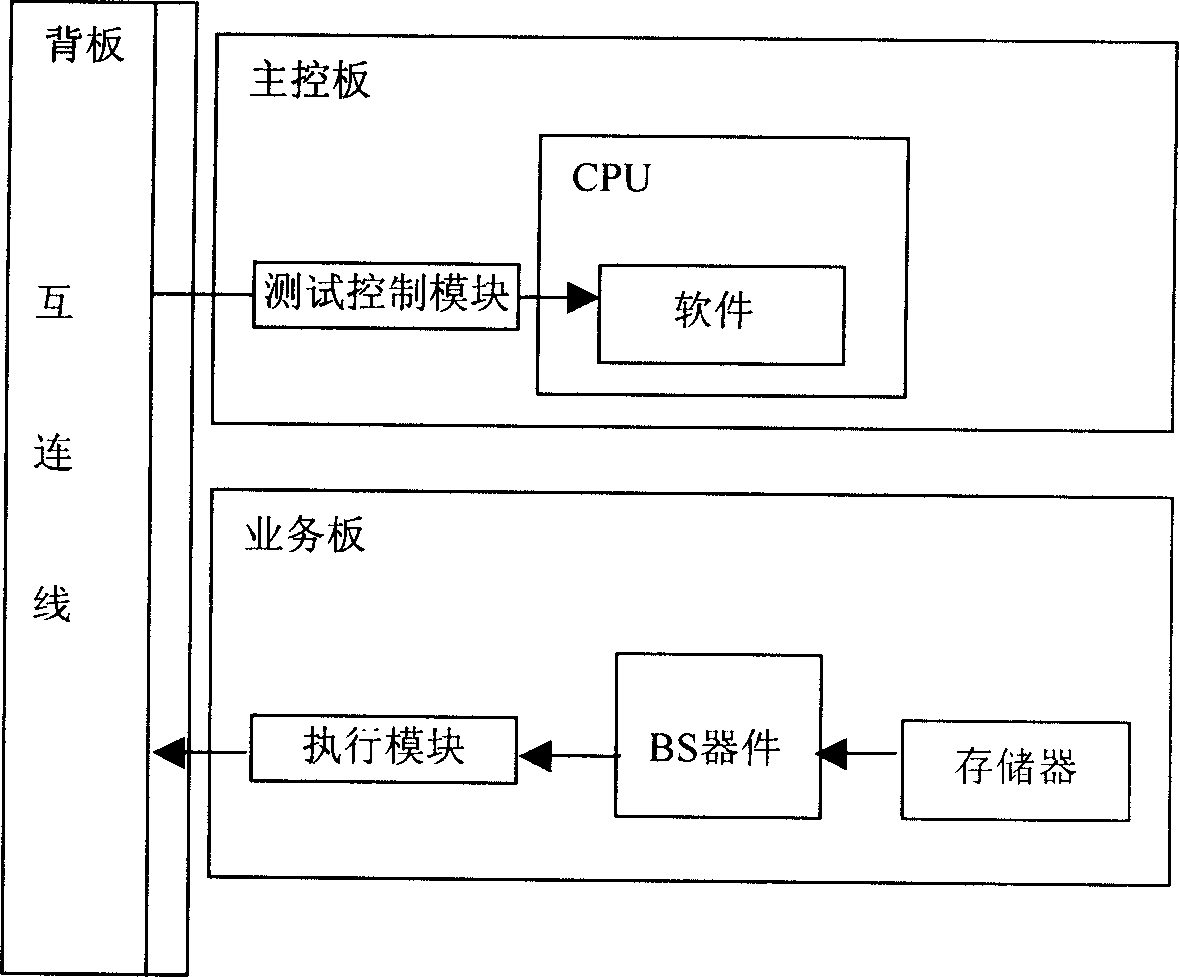

Single board read/writ system and method for information

InactiveCN1862512APrecise positioningFacilitate failure analysisMemory systemsInterconnectionEmbedded system

The present invention discloses a reading / writing system of single board information and method. The main control board of the invented system includes test control module, it is connected with CPU of main control board; the service board includes execution module connected with memory of the service board, said execution module is independent from CPU of service board or logic device; the described test control module is connected with the described execution module by means of interconnection line being in backboard. Besides, said invention also provides the concrete steps of implementing the invented method for reading / writing single board information.

Owner:HUAWEI TECH CO LTD

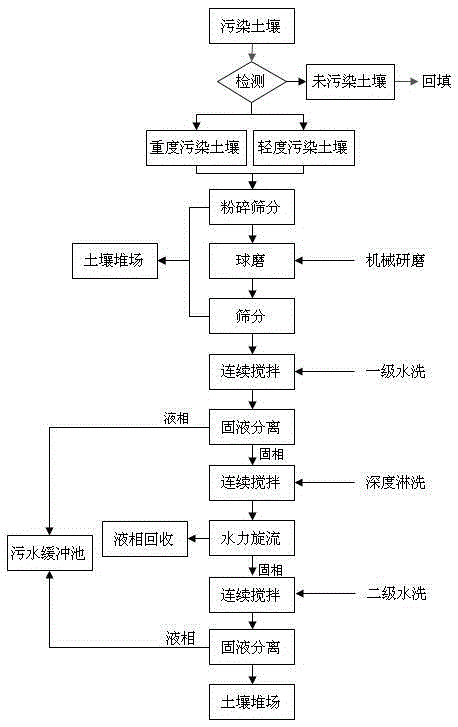

Treatment device for heavy metal polluted soil and treatment process thereof

InactiveCN106077060AOverall small sizeSmall footprintContaminated soil reclamationBelt filterElution

The invention relates to a treatment device for heavy metal polluted soil. The treatment device comprises a machine frame, a feeding hopper, crushing rollers, a ball grinder, a separation screen, a first-stage water washing pool, a linear vibration screen, a slurry buffering pool, a slurry pump, a centrifugal machine, a deep elution pool, a belt filter press and a second-stage water washing pool. The polluted soil is remedied through mechanical grinding, first-stage water washing, first-stage solid-liquid separation, deep elution, second-stage water washing and second-stage solid-liquid separation. The process is advanced, the treatment effect is good, the work efficiency is high, and the automation degree is high.

Owner:杰瑞环境工程技术有限公司

Efficient medium and low temperature sulfur-containing flue gas denitration device and method based on Fast SCR reaction

InactiveCN107051203AReduce heating linksAvoiding Sulfur Poisoning ProblemsDispersed particle separationFlue gasReaction temperature

The invention discloses an efficient medium and low temperature sulfur-containing flue gas denitration device and method based on Fast SCR reaction, and the sulfur-containing flue gas denitration device and method can be used in a utility boiler and flues on the tail portions of various industrial furnace. The sulfur-containing flue gas denitration device comprises an oxidization module used for oxidizing NO and an SCR reaction module used or denitration, part of NO in flue gas is converted into NO2 through the oxidization module and then enters the SCR reaction module, and pre-oxidized flue gas and sprayed NH3 are mixed and enter a selective catalytic reduction layer to conduct rapid SCR reaction. The catalytic reduction layer is made of a low-vanadium loaded vanadium, tungsten and titanium cellular catalyst, and the reaction temperature is 200-350 DEG C. The denitration system has efficient sulfur poisoning resistance and greatly promotes denitration efficiency of the flue gas low-temperature section, it is verified through experiments that under the low-temperature sulfur-containing flue gas atmosphere at the temperature of 250 DEG C, the system has the obvious denitration effect, and the efficiency can reach 90% or more and is kept stable.

Owner:CHONGQING UNIV

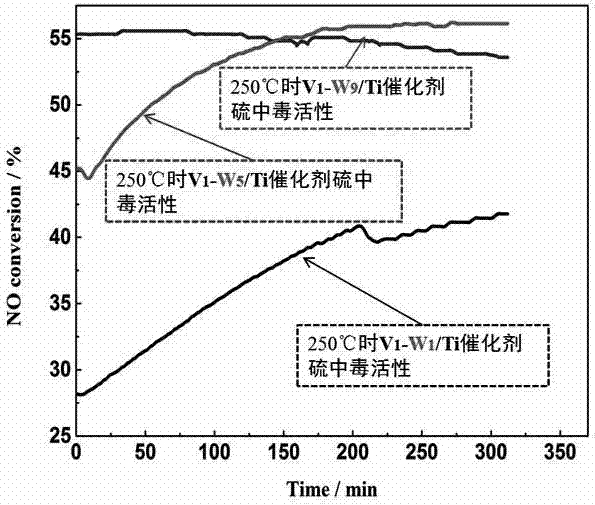

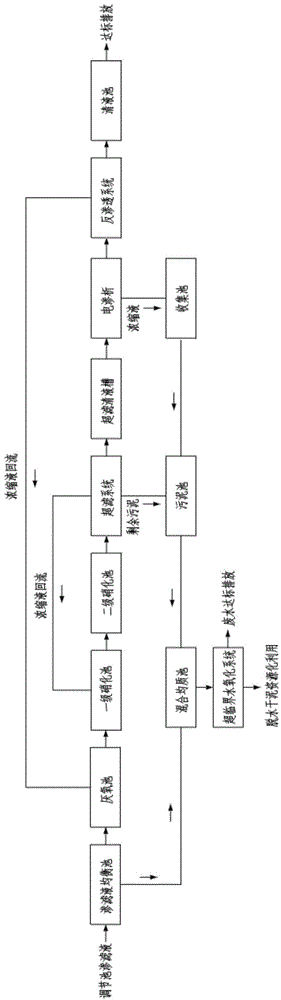

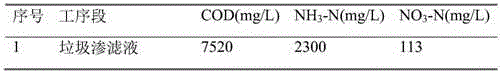

Treatment method of garbage leachate

ActiveCN104787982ADehydration lowers moisture contentAchieve reductionMultistage water/sewage treatmentFresh water organismUltrafiltration

The invention discloses a treatment method of garbage leachate. The treatment method comprises the following steps: leachate in a garbage regulation pool is introduced into a leachate equalization pool; one part of effluent in the leachate equalization pool flows through an anaerobic pool to degrade organic pollutants, then enters a primary nitrification pool and a secondary nitrification pool in sequence to degrade organic pollutants and nitrify ammonia, and then enter an ultrafiltration system to obtain an ultrafiltration concentrated solution; the ultrafiltration concentrated solution flows back to the primary nitrification pool; ultrafiltration freshwater enters an ultrafiltration clear liquid tank, is introduced into an electrodialysis system to concentrate inorganic salt, and then enters a reverse osmosis system; a reverse osmosis concentrate flows back to the anaerobic pool to further degrade organic pollutants, and the reverse osmosis freshwater is discharged in compliance with the standards; meanwhile, the other part of the effluent in the leachate equalization pool is fully mixed with sludge generated by the ultrafiltration system and concentrated solution generated by the electrodialysis system in a mixing and homogenizing pool, and then enters a supercritical water oxidation system; the effluent is discharged in compliance with the standards; the generated concentrated solution is subjected to resource utilization after centrifugal dewatering. The treatment method treats a waste with another waste, and realizes the reduction and recycling of sludge.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

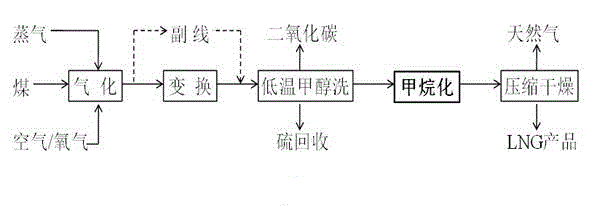

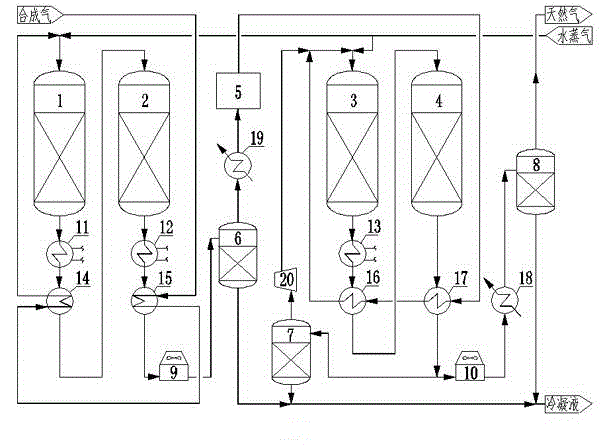

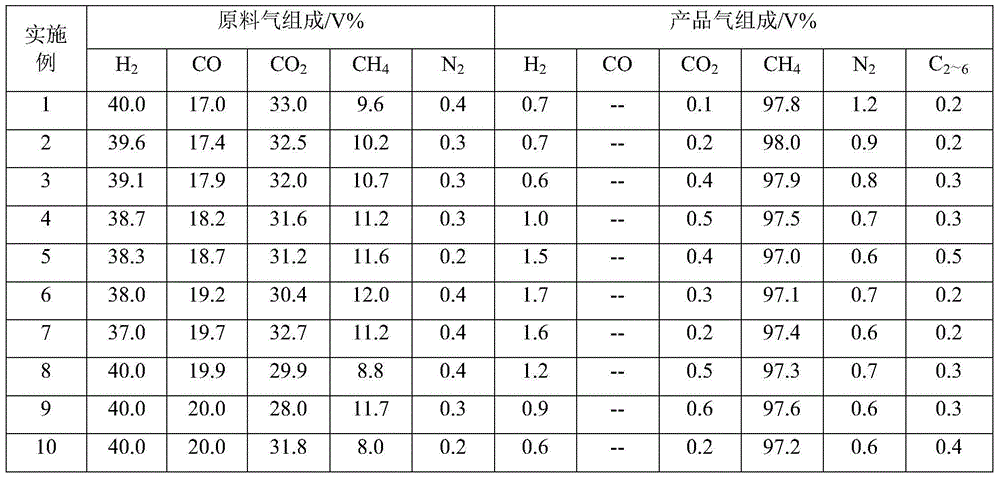

Process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas

ActiveCN104164262AWith characteristicsHave made significant progressGaseous fuelsMethanationWater vapor

The invention provides a process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas. The process is characterized in that the synthesis gas enters sulphur-tolerant methanation reactors I and II in sequence, and the mixed gas of the synthesis gas and water vapor enters a rectisol system so as to remove the impurities such as CO2, H2S and the like in the gas after undergoing sulphur-tolerant shift and sulphur-tolerant methanation reaction on a molybdenum-based bifunctional catalyst and then undergoes methanation reaction in methanation reactors I and II in sequence under the action of Ni-based methanation catalysts, thus obtaining the natural gas product. The process has the advantages of simple process flow, small equipment investment, low comprehensive energy consumption and excellent natural gas products.

Owner:SEDIN ENG +1

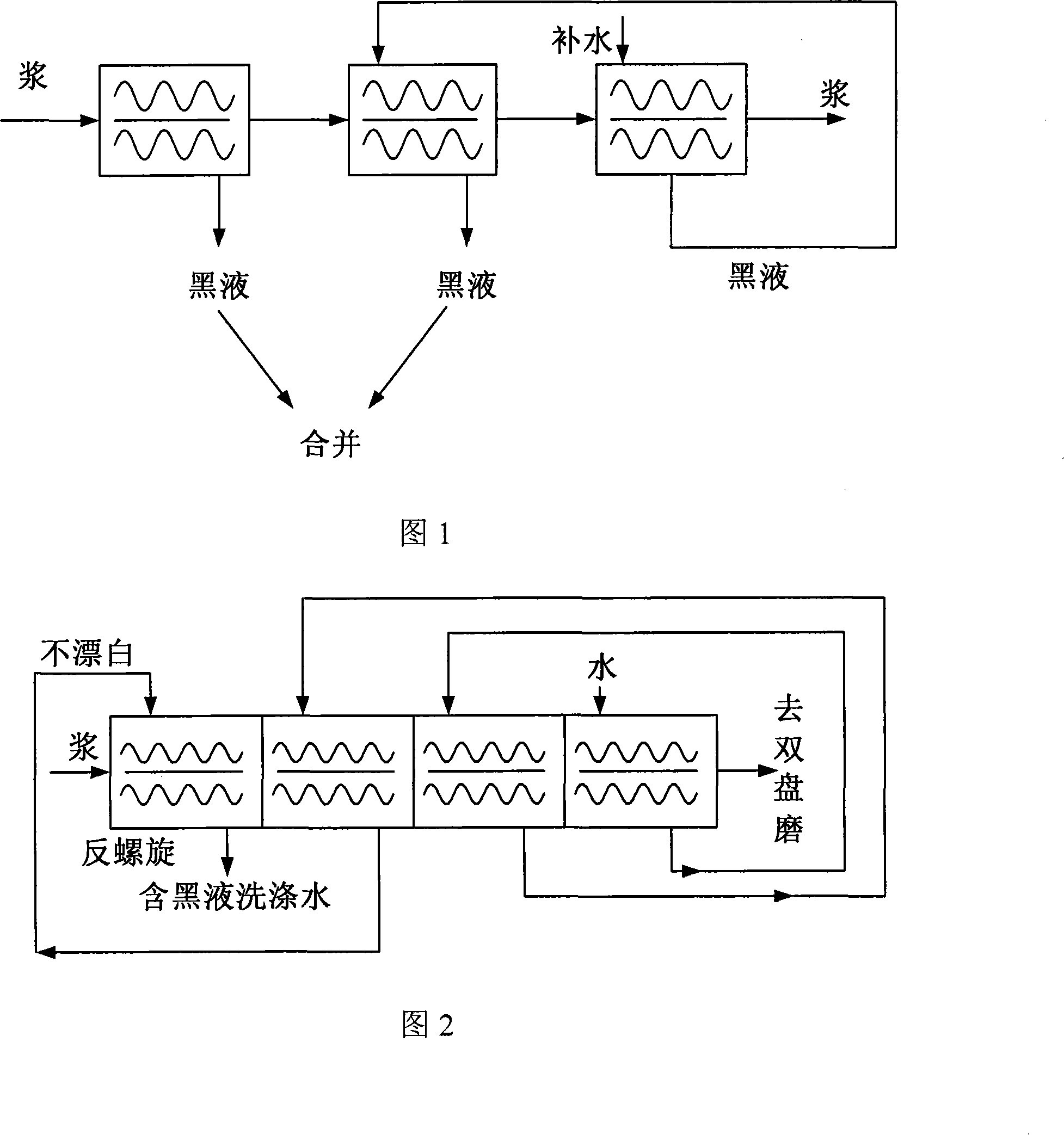

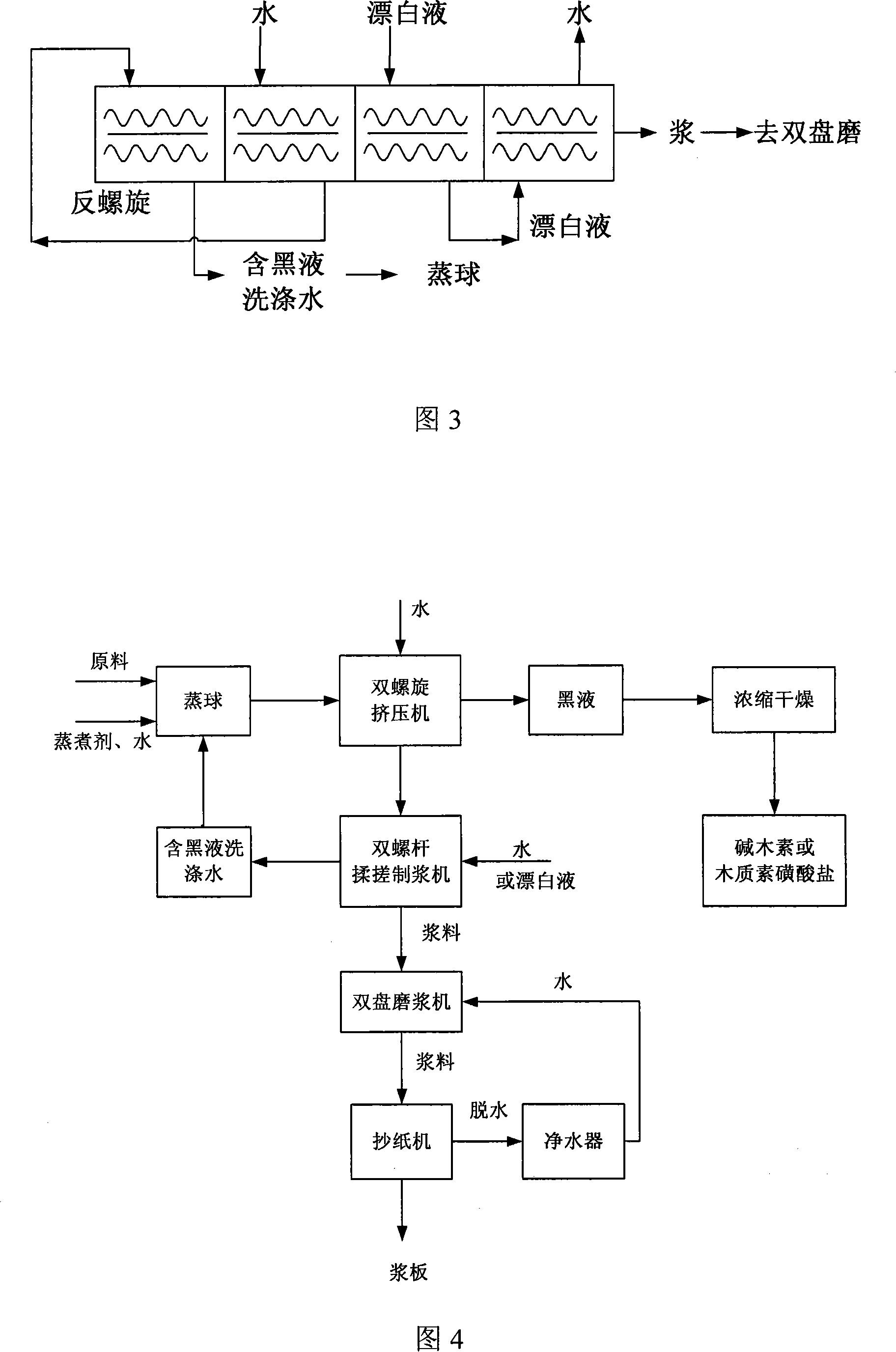

Pulping method with zero discharge of sewage water

InactiveCN101220565AHigh extraction rateLess investmentPulp liquor regenerationWashing/displacing pulp-treating liquorsPolyesterBlack liquor

The invention discloses a pulp making method for discharging sewage thoroughly which includes the following steps: pulping material, steam cooking agent and catalyst are mixed evenly and put into a spherical digester and the mixture is cooked by steam; the cooked material is squeezed by passing through a plurality of twin-screw extruders connected in series so as to extract black liquid and obtain the pulp material, and the black liquid obtained from the last twin-screw extruder is squeezed sequentially after returning to the former twin-screw extruder, while the black liquid obtained from a first and a second twin-screw extruders is merged straightly, and the merged black liquid is concentrated and dried to obtain alkali lignin and or lignosulfonate; the pulp material is delivered into a twin-screw rubbing and kneading pulper, the polyester washing is carried out in multiple-section series while the pulp is grinded, or the polyester washing is carried out in multiple-section series and bleached in multiple-section series, the washing water is returned to the washing process in the former section, and finally the residuary black liquid is obtained, that is the washing water coming from the first washing process; then, the residuary black liquid is returned to the pulping material or the spherical digester; the pulp material is refined in a dual-disk refining machine by adding water, then a pulp plate is made after the refined pulp material enters a paper machine. Meanwhile, the removed water circulates to the dual-disk refining machine or other processes needing the water by the pure water treatment.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Integrated MBR (Membrane Bio-Reactor)

InactiveCN103613195AReduce pollutionImprove pollutionTreatment with aerobic and anaerobic processesFiberCarbon fibers

The invention relates to the field of sewage reuse, and particularly relates to an integrated MBR (Membrane Bio-Reactor). The integrated MBR is divided into an anoxic area and an aerobic area by using a baffle structure, carbon fiber packing is hung in the anoxic area, and an aeration device and a membrane assembly are placed in the aerobic area; the volume ratio of the anoxic area to the aerobic area is 1:3. The integrated MBR has the characteristics that due to the adoption of an integrated reaction device, the mode of multi-section processing in a single biochemical environment is solved, and the land-occupied area is saved; according to the structure characteristics, sewage circularly flows between the anoxic area and the aerobic area under the action of aeration, and shows different water flow characteristics; the device can simultaneously and effectively perform nitrification and denitrification processes, so that the sludge return is saved, thereby reducing the capital expenditure and the operation cost, and under the condition that the overall sludge concentration is not changed, the sludge concentration of the anoxic area is increased, and the sludge concentration of the aerobic area is reduced, thereby effectively reducing the membrane pollution; a carbon source required by denitrification is supplemented in a mode of feeding water from the anoxic area, thereby saving the cost.

Owner:BEIJING UNIV OF CHEM TECH

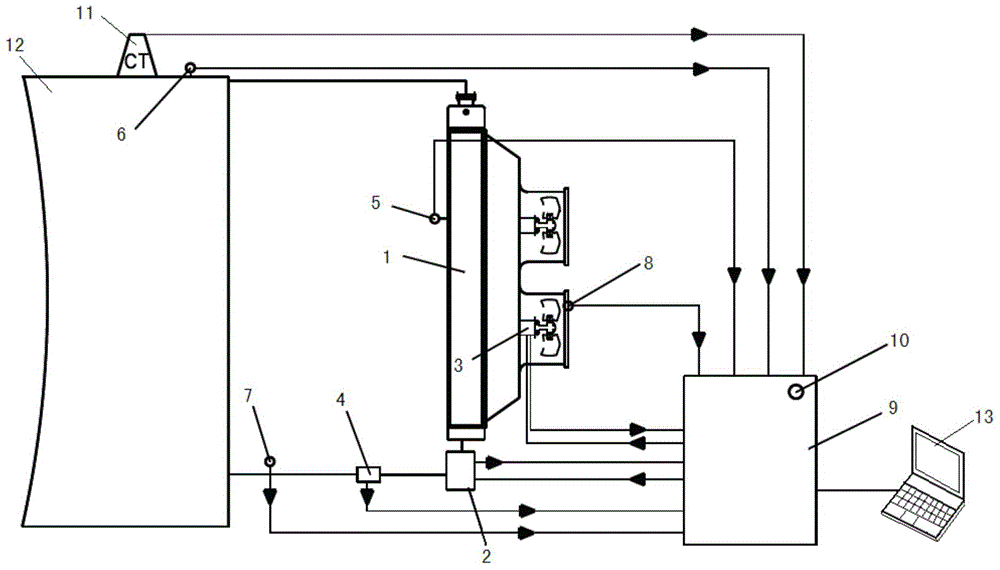

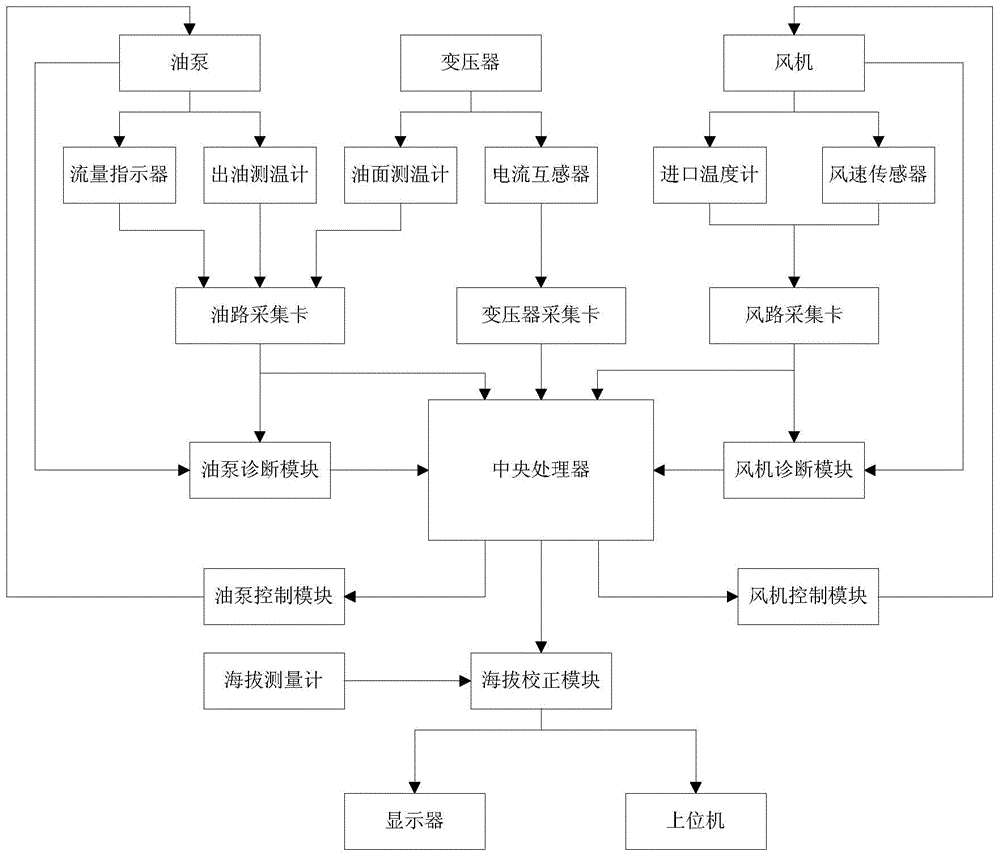

Intelligent cooler control system and method for transformer

ActiveCN104597934ASave running costSave maintenance costTemperature control using electric meansControl systemProcess engineering

The invention provides an intelligent cooler control system for a transformer. The intelligent cooler control system comprises a current transformer, an oil level temperature measuring meter, an oil outlet temperature measuring meter, a flow indicator, an inlet thermometer, a wind speed sensor and a control box, wherein the current transformer and the oil level temperature measuring meter are arranged on the transformer, the oil outlet temperature measuring meter and the flow indicator are arranged on an output pipeline of an oil pump which is arranged in a cooler, the inlet thermometer is arranged at the position of a fan inlet which is arranged in the cooler, the wind speed sensor is arranged at the position of a fan outlet which is arranged in the cooler, and the control box is provided with a control circuit. An intelligent cooler control method comprises step 1, initializing parameter settings and collecting control parameters; step 2, obtaining the actual cooling capacity of a cooling system and the actual losses of the transformer through calculation according to intrinsic parameters of the transformer and the collected control parameters; step 3, performing comparison on the actual cooling capacity Py of the cooler and the actual losses P of the transformer and controlling the oil pump of the cooler and or a fan according to a comparison result; step 4, repeating the step 2 and the step 3 according to the intrinsic parameters of the transformer and the timely-collected control parameters until the oil pump and the fan reach the operation state when Py is equal to P in the step 3.

Owner:CHINA XD ELECTRIC CO LTD

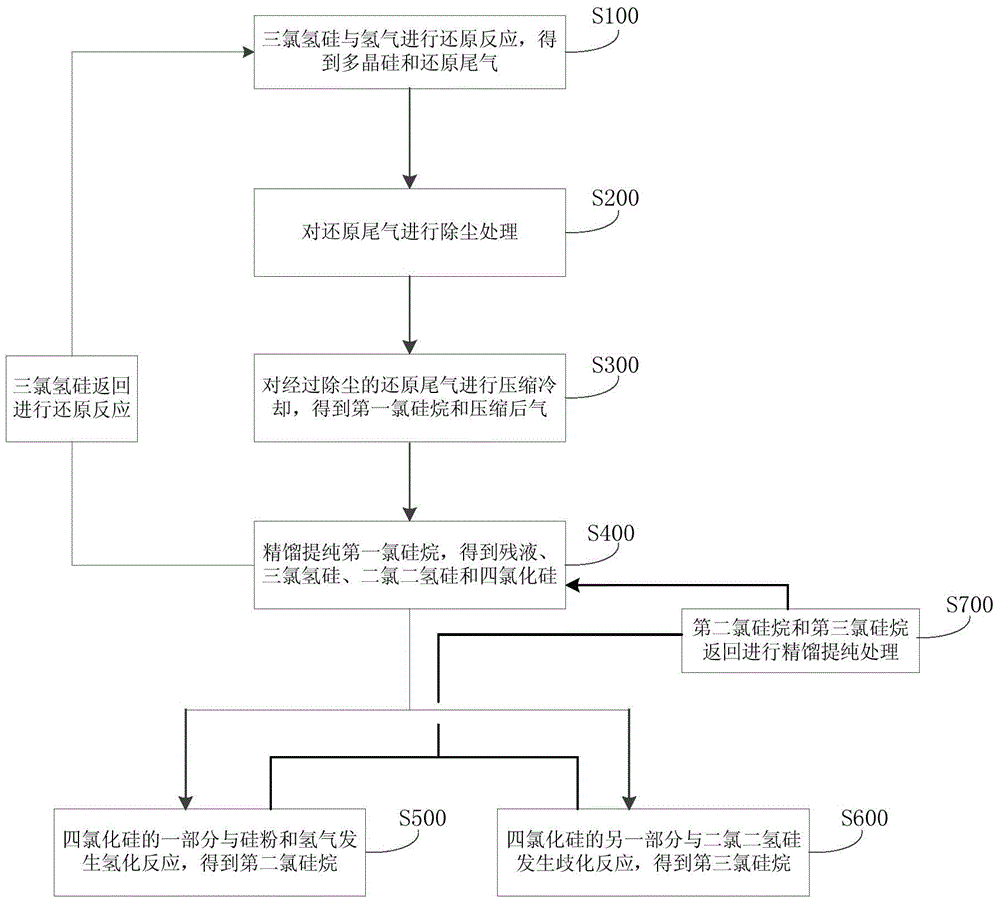

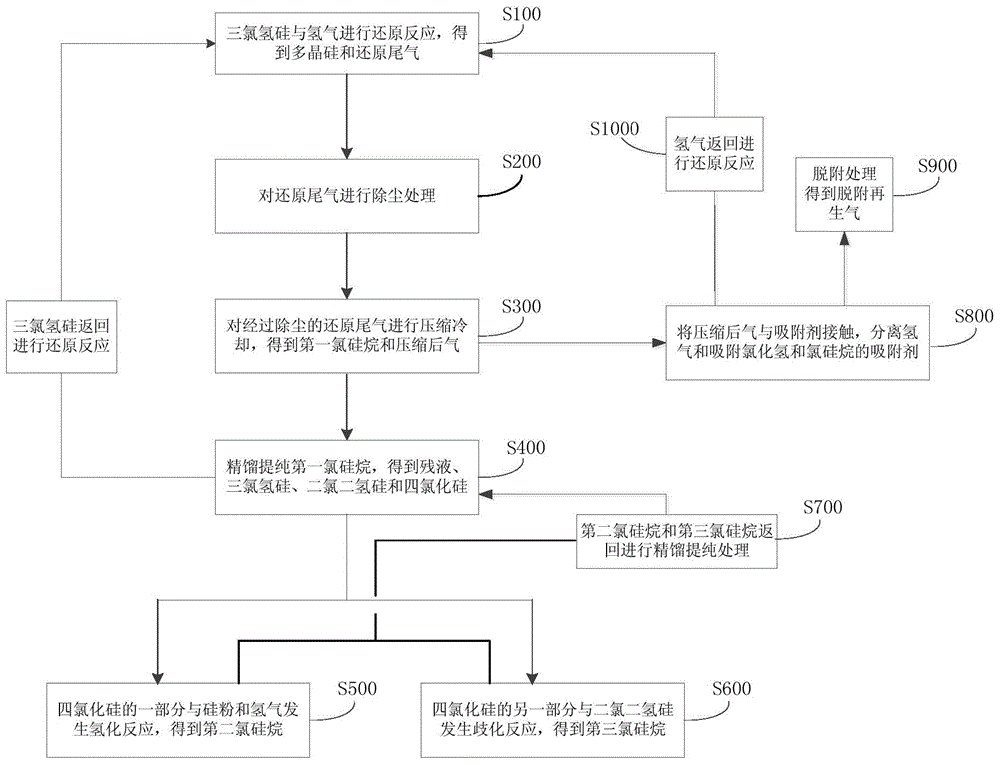

Method and system for cyclic utilization of materials during production of polycrystalline silicon

ActiveCN103553048AReduce manufacturing costEasy to handleChlorine/hydrogen-chlorideSilicaDistillationHydrogenation reaction

The invention discloses a method and system for cyclic utilization of materials during production of polycrystalline silicon. The method comprises the steps of (1) performing reduction reaction on trichlorosilane and hydrogen to obtain polycrystalline silicon and reduction tail gas; (2) performing dust removal treatment on the reduction tail gas to obtain reduction tail gas subjected to dust removal; (3) performing compression cooling treatment on the reduction tail gas subjected to dust removal so as to separate first chlorosilane and compressed gas from the reduction tail gas; (4) performing distillation and purification on first chlorosilane to obtain residual liquid, trichlorosilane, dichlorosilane and silicon tetrachloride; (5) returning trichlorosilane obtained in the step (4) to the step (1) to perform reduction reaction, and performing hydrogenation reaction between one part of silicon tetrachloride and silicon powder and hydrogen so as to obtain second chlorosilane; (6) performing reverse disproportionation reaction between one part of silicon tetrachloride and dichlorosilane so as to obtain third chlorosilane; (7) returning second chlorosilane and third chlorosilane to the step (4) to perform distillation and purification.

Owner:CHINA ENFI ENGINEERING CORPORATION

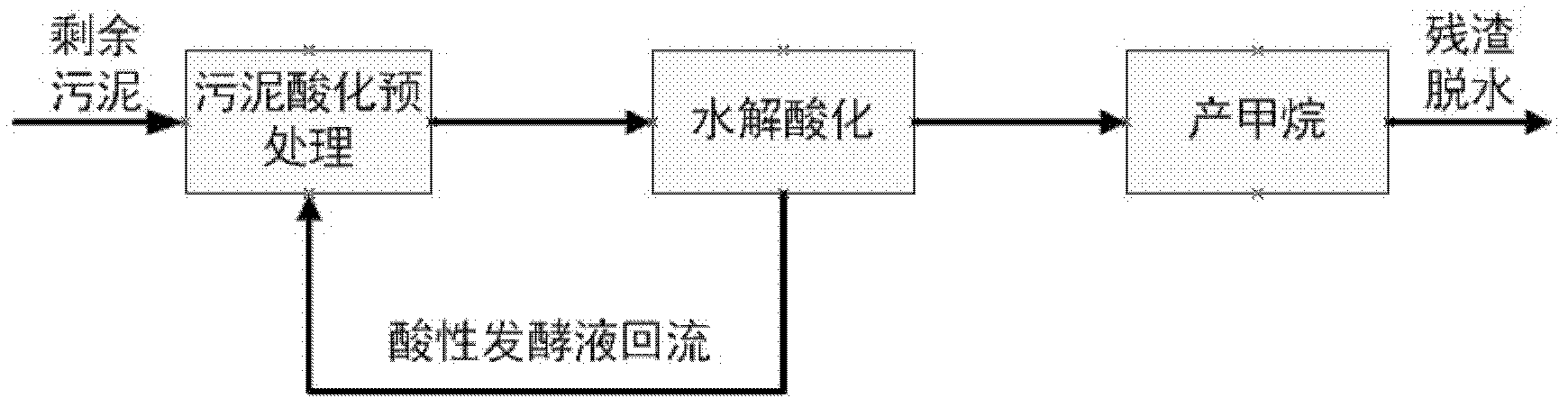

Method for treating sludge through refluxing of acidified fermentation liquor and application of method

InactiveCN102531311AIncrease productionReduce pretreatment costsWaste based fuelBiological sludge treatmentMethane productionPre treatment

The invention discloses a method for treating sludge through the refluxing of acidified fermentation liquor and application of the method. The method comprises the following steps of: performing hydrolytic acidification on the sludge, refluxing the acidified fermentation liquor of the sludge, performing acidification pretreatment on the sludge, and performing hydrolytic acidification fermentation on the pretreated sludge and producing methane by using a product. The sludge is subjected to acidification pretreatment by using the fermentation liquor of the sludge, so that the time required by anaerobic digestion is shortened, the gas yield is improved, and the operating cost is reduced.

Owner:TIANJIN UNIV

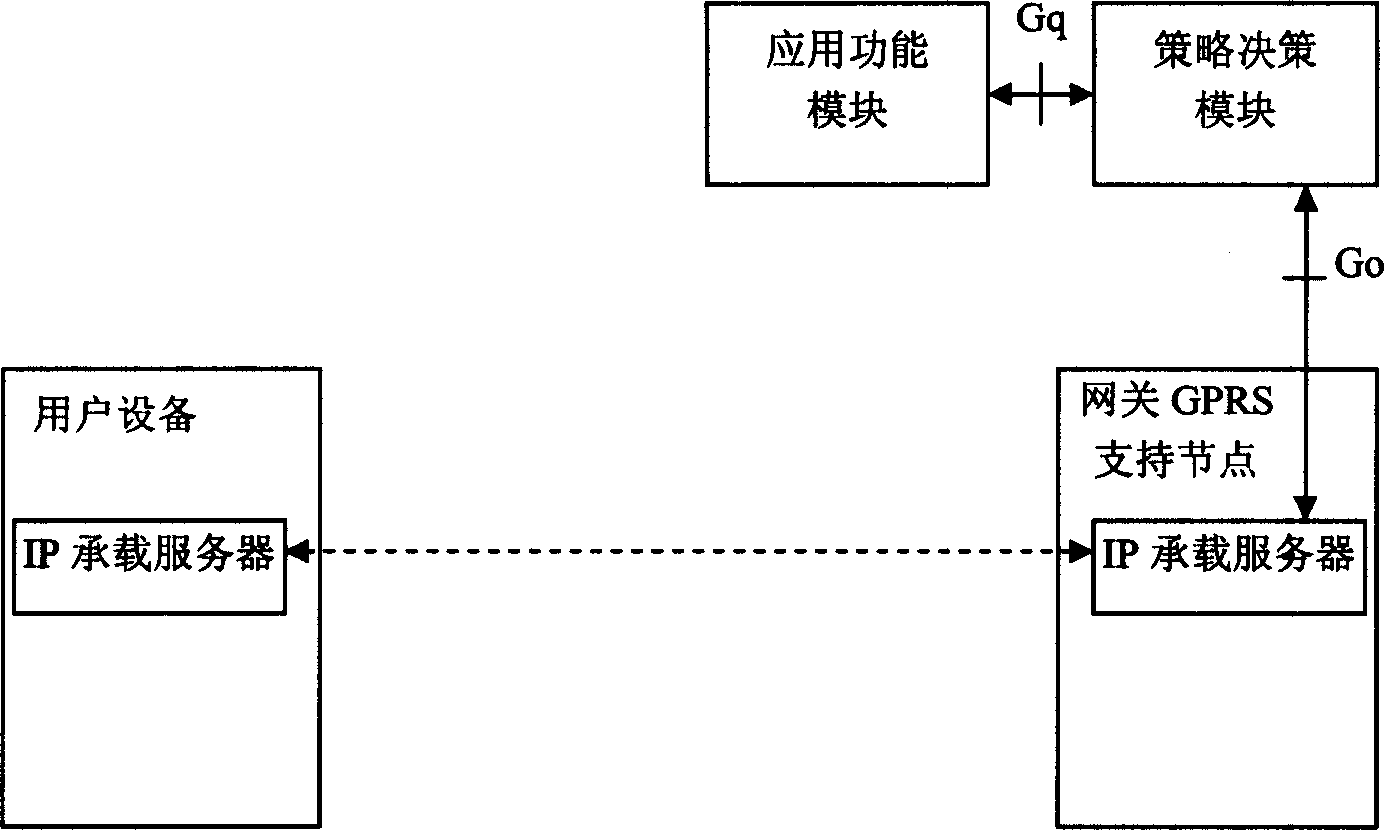

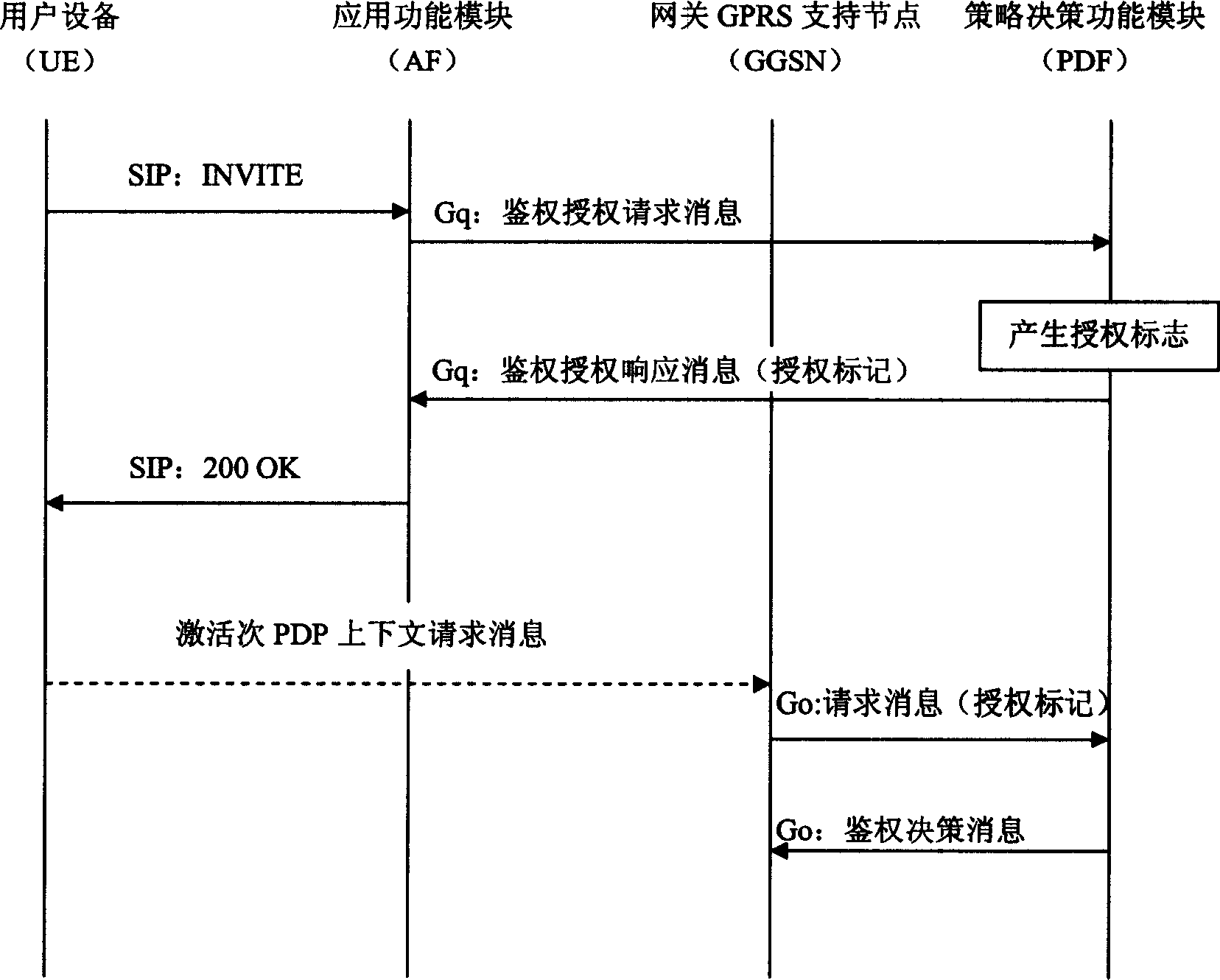

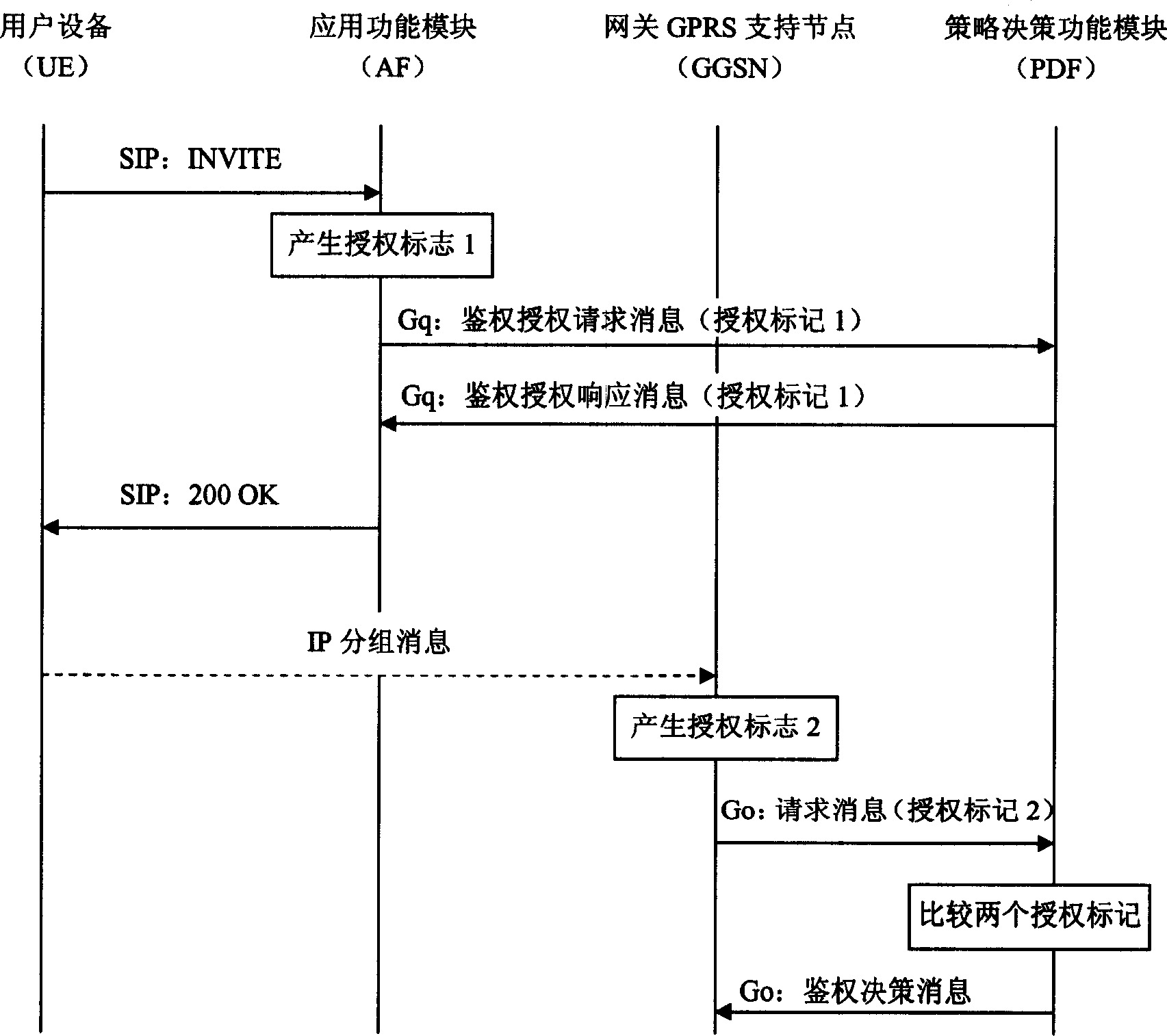

Method for controlling communication service quality using policy functional module

InactiveCN1829145AEasy to modifySave manufacturing costNetwork traffic/resource managementUser identity/authority verificationQuality of serviceControl communications

The present invention provides method using strategy decision making function module (PDF to control communication services quality. Said method is subscriber equipment (UE) transmitting service request messages to application function module (AF), application function module generating an authorizing sign (AT), through Gq interface transmitting AT carried authentication authorizing request message to PDF, PDF storing AT, and through Gq interface feeding back AT carried authentication authorizing response message to AF, UE transmitting a IP blocking message to gateway GPRS support node (GGSN), GGSN generating completely same AT with above-mentioned AT, through Go interface transmitting said AT carried request message to PDF, PDF comparing received two AT, if same then notifying GGSN said user authentication successfully, using said service required service quality. The present invention can realize PDF provided QoS control without PDP context.

Owner:SIEMENS CHINA

Integrated GAC (granular activated carbon)-DMBR (dynamic membrane bio-reactor) sewage treatment device and treatment process thereof

InactiveCN102249414AReduce pollutionExtended operating cycleTreatment using aerobic processesTreatment with aerobic and anaerobic processesSludgeSewage treatment

The invention discloses an integrated GAC (granular activated carbon)-DMBR (dynamic membrane bio-reactor) sewage treatment device which comprises a raw water tank and a reactor, wherein the reactor is connected with the raw water tank by a through pipe; a membrane-assembly mounting bracket is installed in the reactor, a membrane assembly is installed in the membrane-assembly mounting bracket, and the bottom of the reactor is provided with an aerator pipe and a sludge discharge pipe; the aerator pipe is fixedly connected with an aeration blower; and granular activated carbons are uniformly distributed in the reactor. The invention also discloses a treatment process for granular activated carbons. The device and process disclosed by the invention have the characteristics of slow membrane pollution, high treatment efficiency, long running period, easy cleaning and large membrane flux.

Owner:HUAQIAO UNIVERSITY

High-efficiency integral aerating device for sewage treatment

ActiveCN103332783AIncrease dissolved oxygenDissolved oxygen levelSustainable biological treatmentBiological water/sewage treatmentOxygenAir compressor

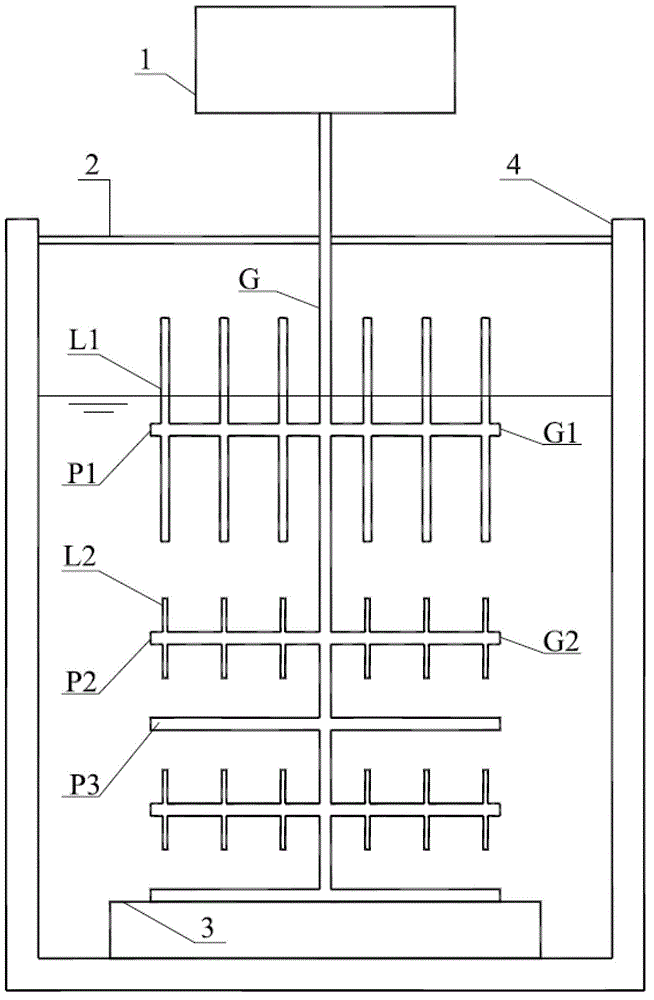

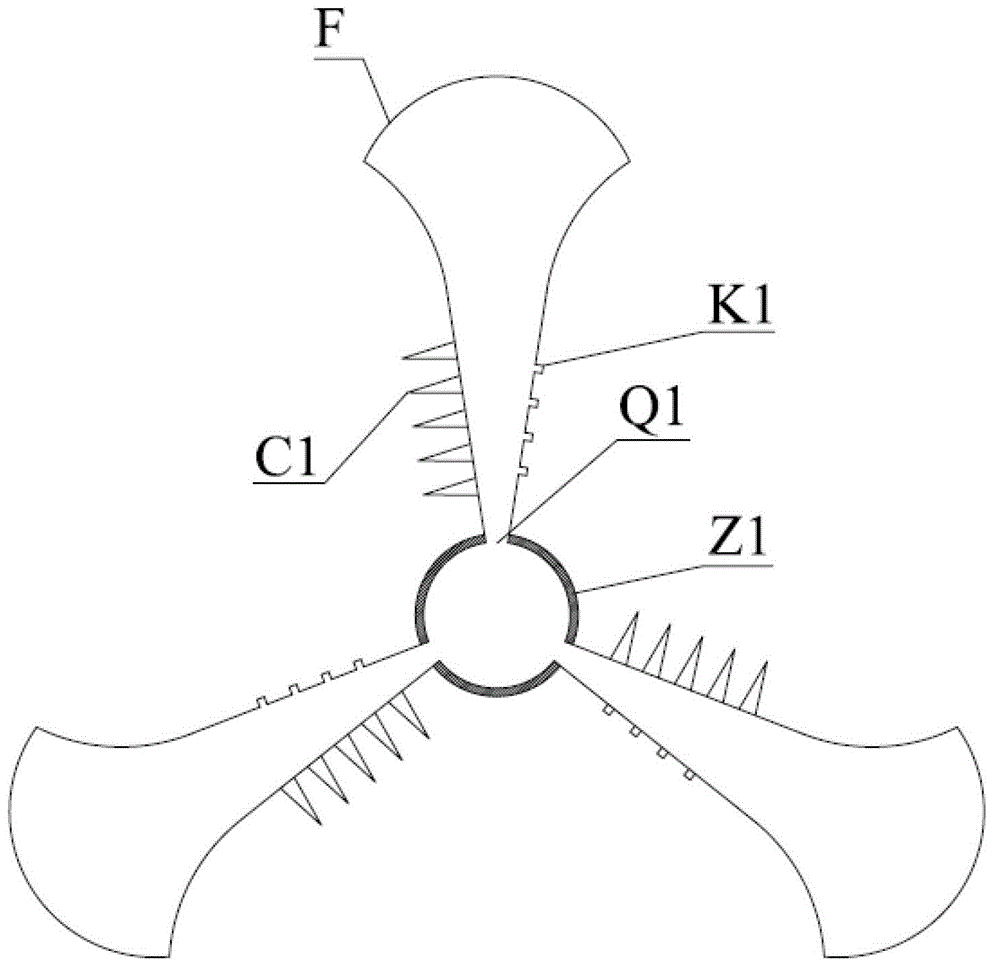

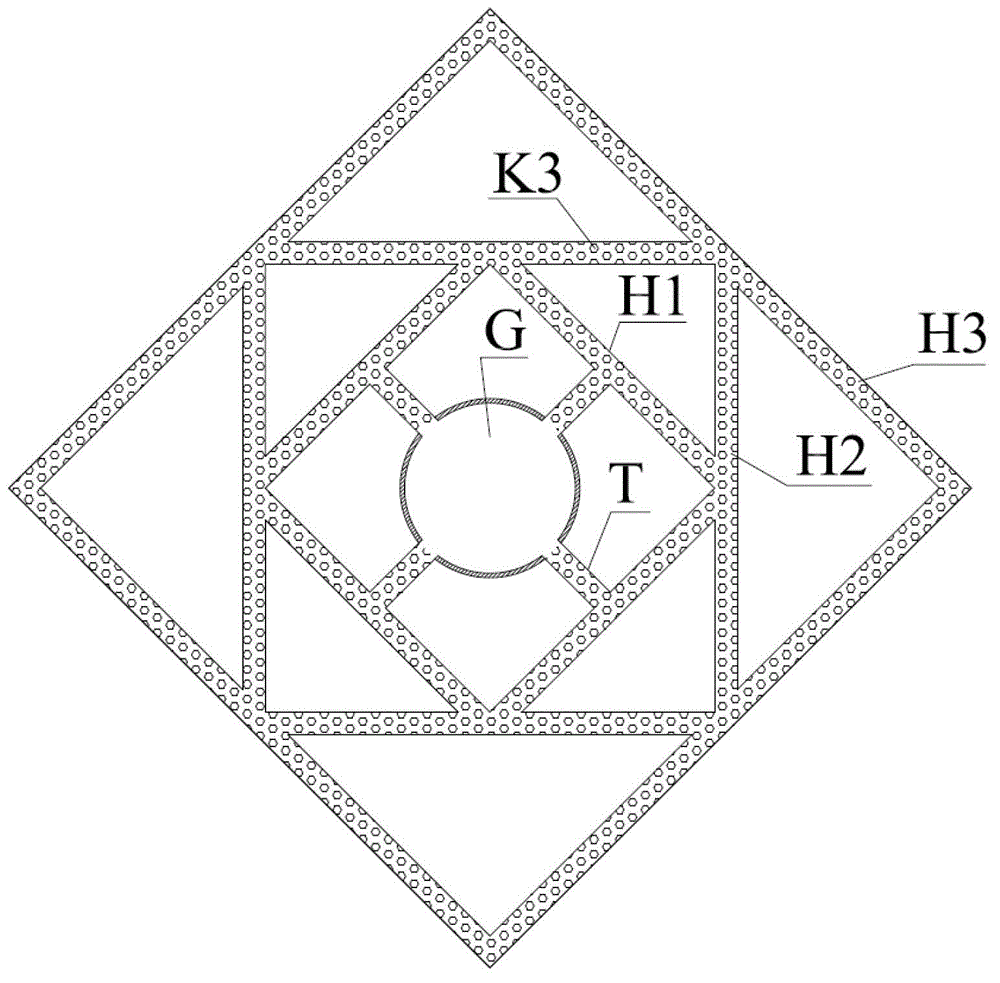

The invention relates to a high-efficiency integral aerating device for sewage treatment, belonging to the field of sewage treatment aerating equipment. The device is composed of an air compressor, a compressed air delivery pipe system, a water-surface water-jump aeration mechanism, an underwater blast aeration mechanism and an underwater stirring mechanism, wherein the water-surface water-jump aeration mechanism is aeration rotary-axe wheel rows which are communicated by connecting compressed air delivery branch pipes in series, and the aeration rotary-axe wheel rows are communicated with the upper parts of air delivery main pipes through the air delivery branch pipes and are arranged on the surface of a water body; the underwater blast aeration mechanism is microporous aeration circular pipes, and the microporous aeration circular pipes are communicated with the compressed air delivery main pipes through microporous radial-connecting pipes and are arranged in the water body; the stirring mechanism is stirring wheel rows which are communicated by connecting the compressed air delivery branch pipes in series, and the stirring wheel rows are communicated with the air delivery main pipes through the air delivery branch pipes and are arranged between the aeration rotary-axe wheel rows and the microporous aeration circular pipe groups and between upper and lower microporous aeration circular pipe groups respectively. A set of compressed air power source is adopted, dissolved oxygen in the water body is integrally, efficiently, synchronously increased and is quickly and uniformly distributed, and the aeration efficiency and the energy utilization rate are significantly increased.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

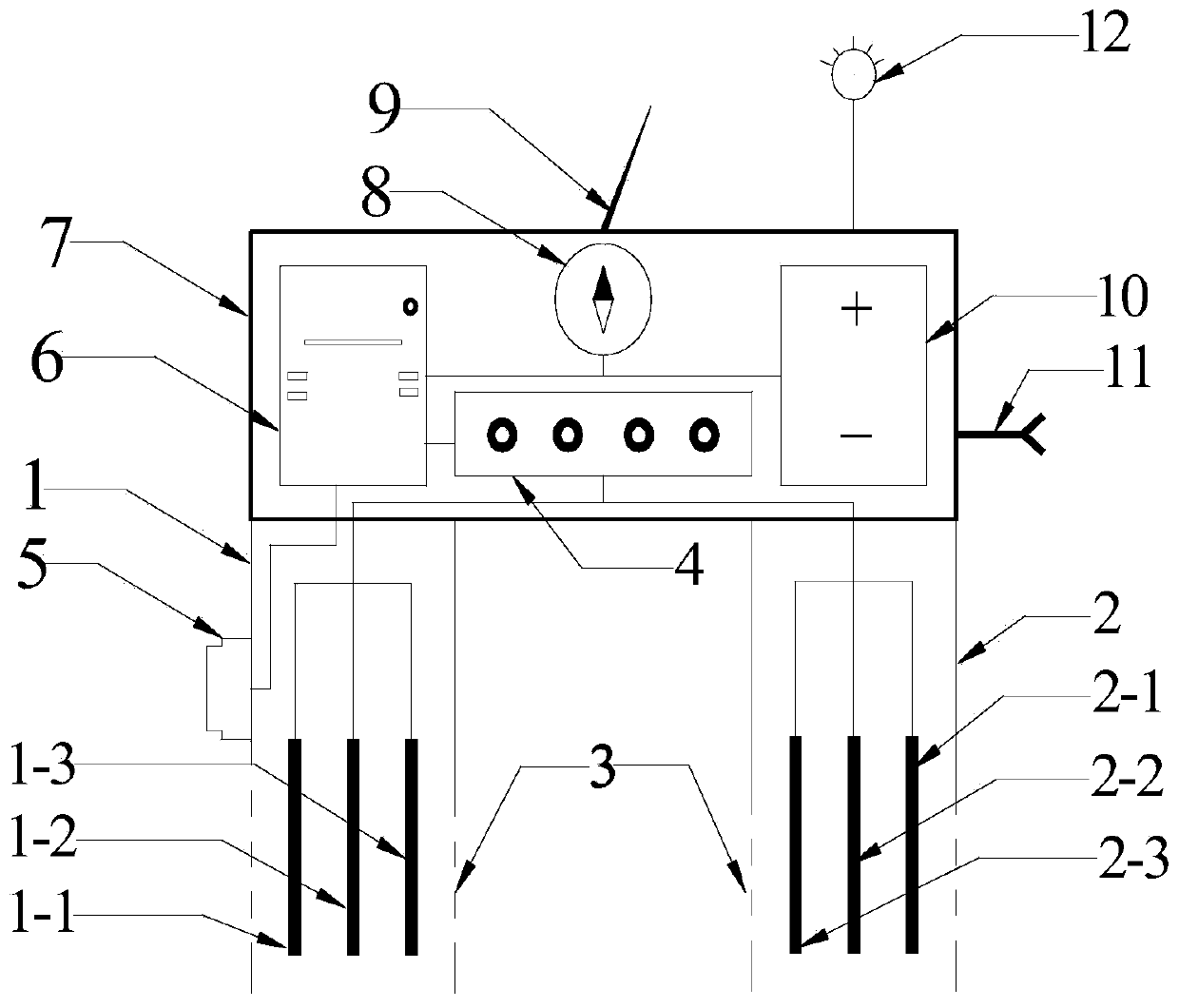

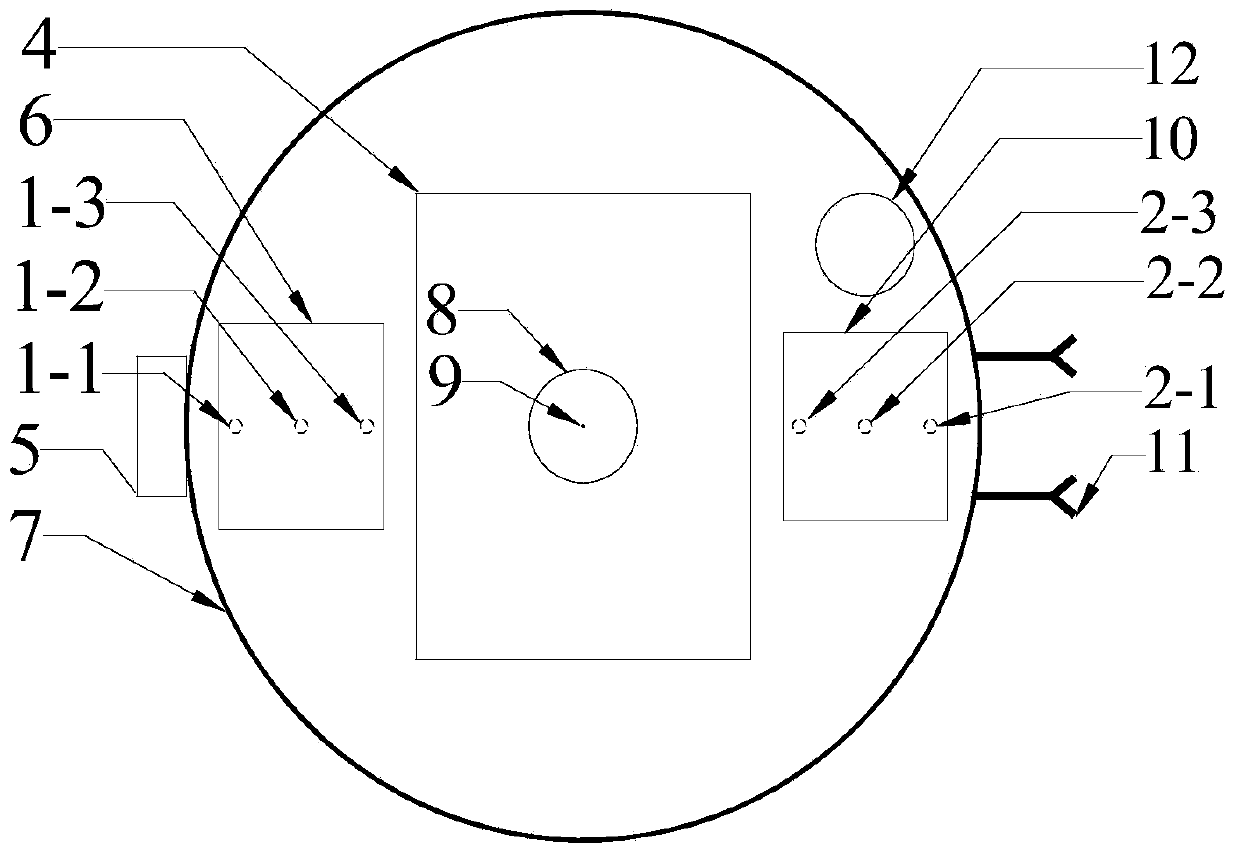

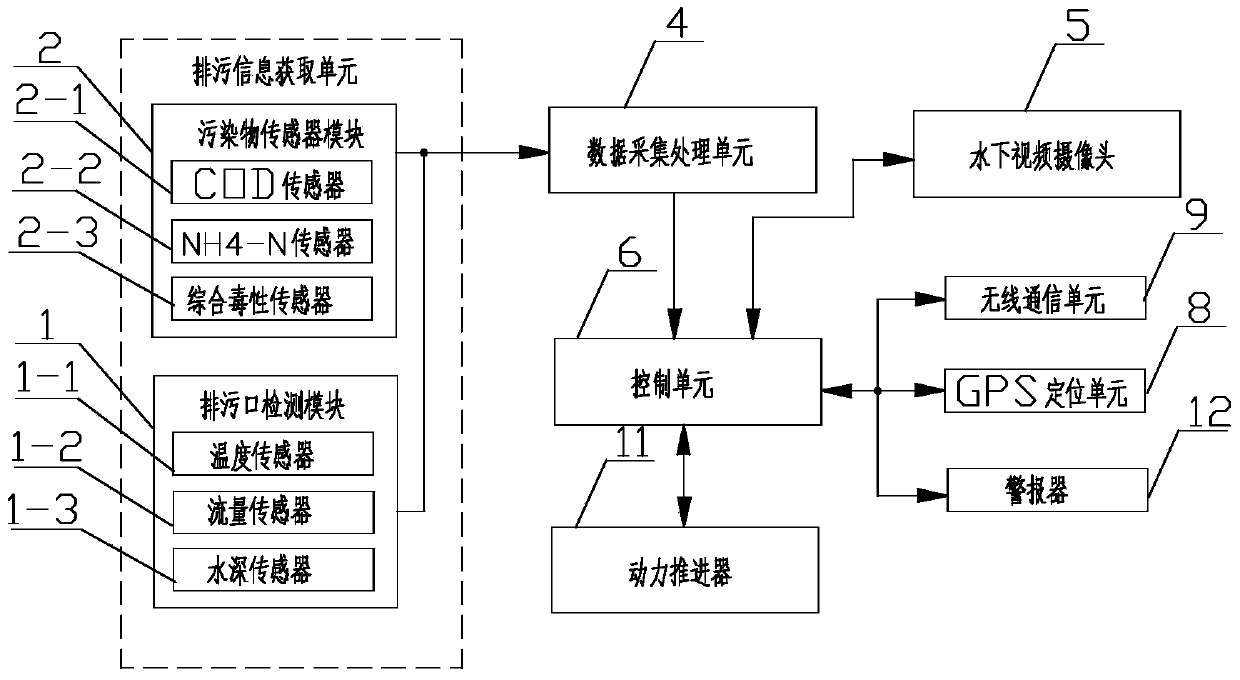

System and method for evidence obtaining in water body pollution-discharge cruise monitoring

ActiveCN104199406AHelp meet emission standardsHelp the situationProgramme total factory controlData acquisitionDischarge data

The invention discloses a system for evidence obtaining in water body pollution-discharge cruise monitoring. The system comprises a housing, as well as a pollution-discharge information obtaining unit, a data acquisition and processing unit, an underwater video camera, a control unit, a wireless communication unit and a power propeller which are installed on the housing, wherein the data acquisition and processing unit is used for calculating a pollutant concentration value or the standard-exceeding degree of a comprehensive toxicity index according to the water body pollution-discharge data obtained by the pollution-discharge information obtaining unit in real time, and sending to the control unit; the control unit is used for starting the underwater video camera to carry out pollution-discharge process shooting evidence obtaining while identifying that the concentration value of the pollutants discharged by a water area or the standard-exceeding degree of the comprehensive toxicity index achieves the maximum value. The system disclosed by the invention is capable of carrying out cruise monitoring on the hidden illegal pollutant discharge and sudden water pollution of various water bodies with a single pollutant discharge port or water intake port, realizing space-time continuous coverage monitoring for large-area water areas, a plurality of pollutant discharge ports and sudden water pollution through system marshalling, and avoiding the law enforcement supervision blind areas of water conservancy and environmental protection departments on water body hidden pollution and other illegal pollutant discharge behaviours.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Electric furnace smoke dedusting process capable of realizing refluxing of part of smoke

InactiveCN102506589AReduce the amount of smokeAvoid interferenceWaste heat treatmentBaghousePeak value

The invention relates to an electric furnace smoke dedusting process capable of realizing refluxing of part of smoke. A smoke refluxing branch system is additionally arranged on the traditional electric furnace smoke dedusting system, the smoke refluxing branch system comprises a roof cover, an air curtain fan, an air supply equalizer, a blow-off nozzle and pipelines, peak values of smoke which enters into equipment such as a bag-type dust collector, a dedusting fan and the like can be reduced, so that a dedusting system operates at low flow and low energy consumption, thus investment and operating cost can be reduced. Smoke produced during charging and tapping of an electric furnace is guided to the roof cover under the joint action of a guide plate and an air curtain and is captured by the roof cover, one part of the smoke is discharged from a roof cover direct discharge opening, enters into the bag-type dust collector by virtue of a pipeline to be filtered and the filtered smoke which reaches the standard is fed into a chimney by the dedusting fan to be discharged; and the other part of the smoke is discharged from a roof cover refluxing opening, is fed into the air supply equalizer by the air curtain fan by virtue of a pipeline and is blown out of the blow-off nozzle, and the smoke which is blown out directly returns to the roof cover. The smoke produced during the oxygen blowing and smelting of the electric furnace is dedusted according to the traditional process and is discharged after reaching the standard.

Owner:尹华勤

Constant temperature heating system of hothouse

ActiveCN101933447ASave electricitySave investment costClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention provides a constant temperature heating system of a hothouse, comprising a heat source used for preparing hot water and a pipeline used for transporting the hot water to the hothouse to carry out heating. The constant temperature heating system of the hothouse is characterized by also comprising one or a set of water towers, wherein the water towers are used for storing the prepared hot water and supplying pressure needed by water transportation, the pipeline is a parallel water supply pipeline and comprises a main water feeding pipe and a plurality of branch water feeding pipes, wherein the branch water feeding pipes are all communicated with the main water feeding pipe, hierarchically supply heating to a located shed area and sequentially supplement heating for the branch water feeding pipe at the front according to the sequence of from far to near.

Owner:北京格瑞那环能技术有限责任公司

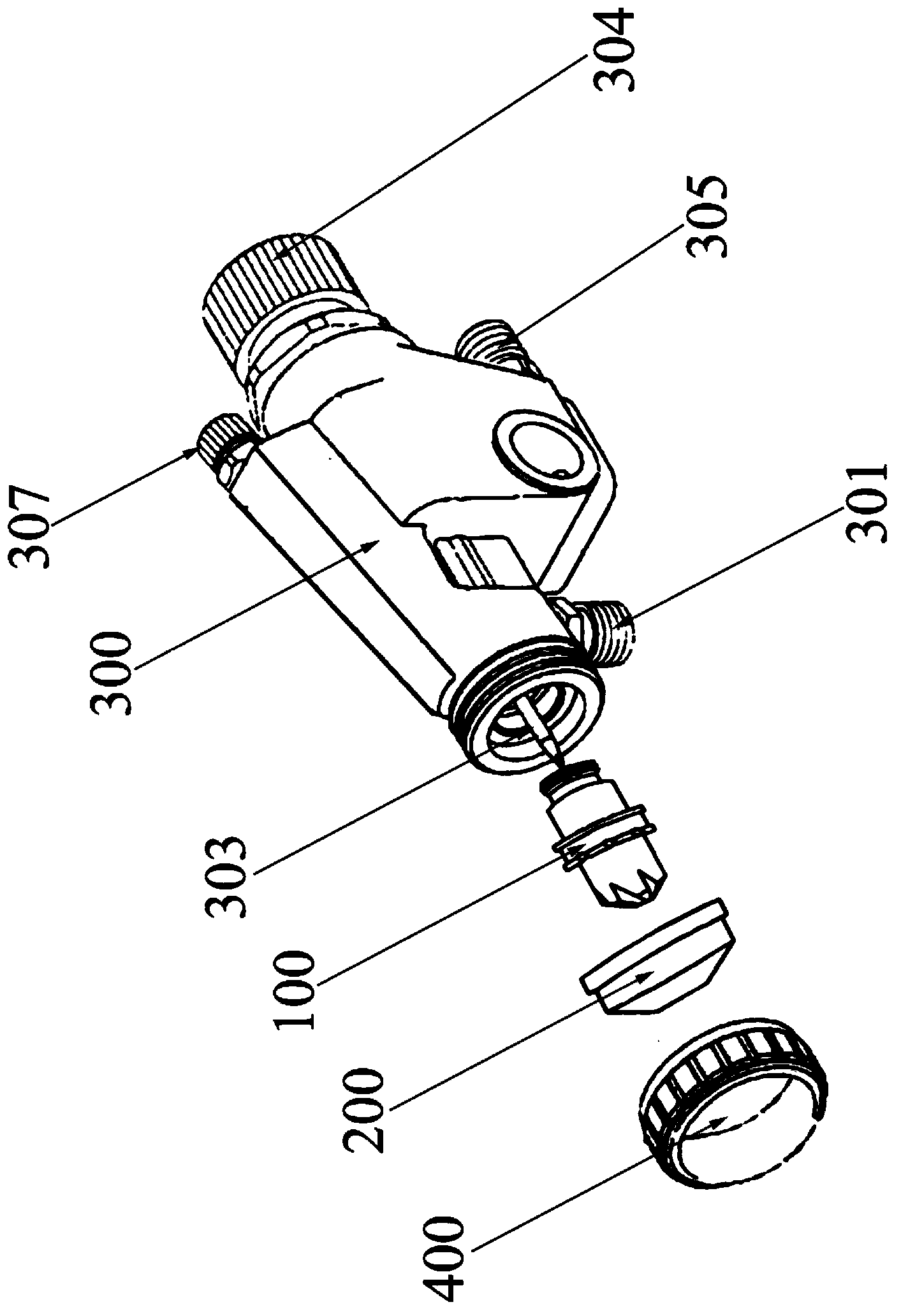

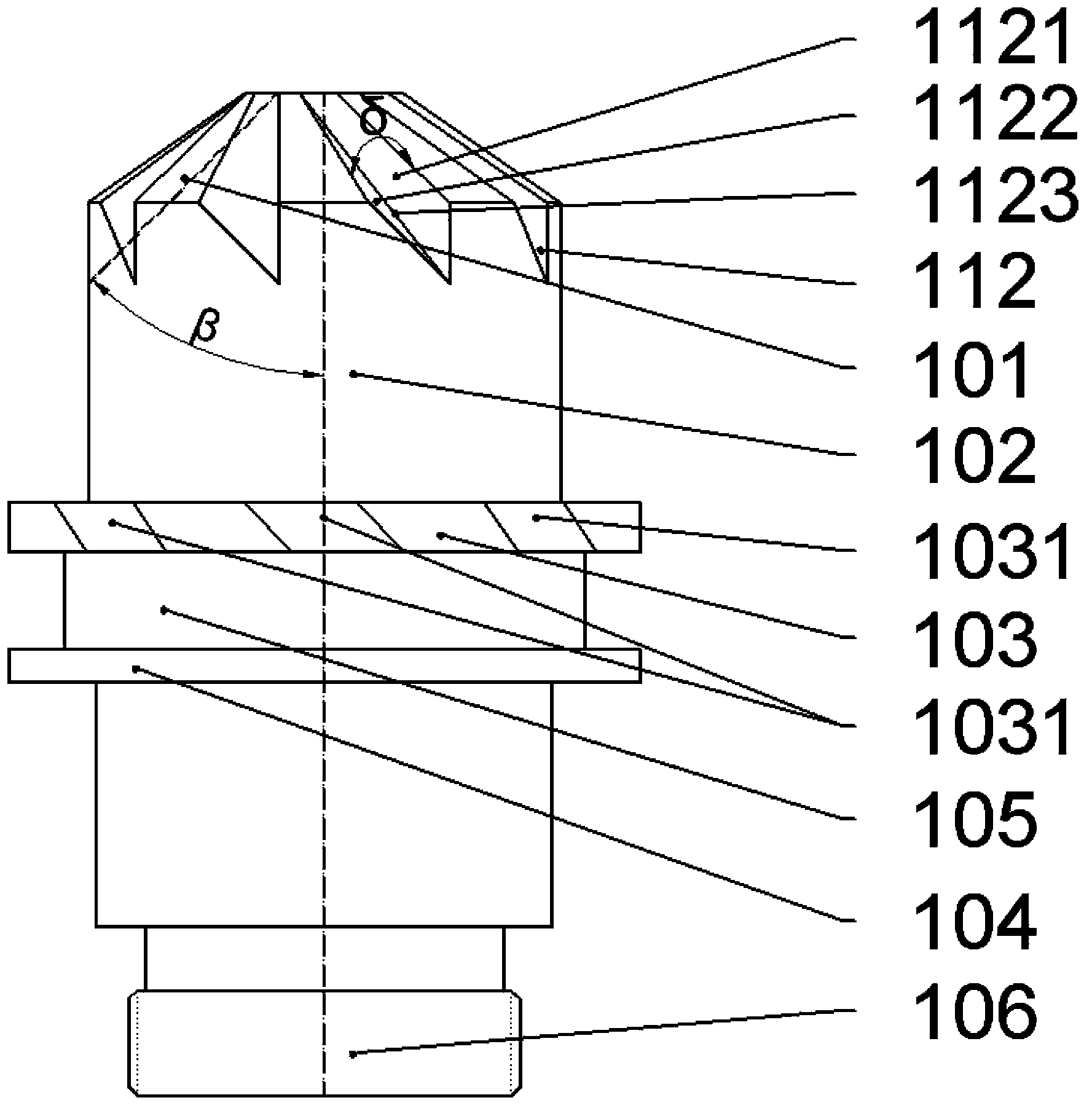

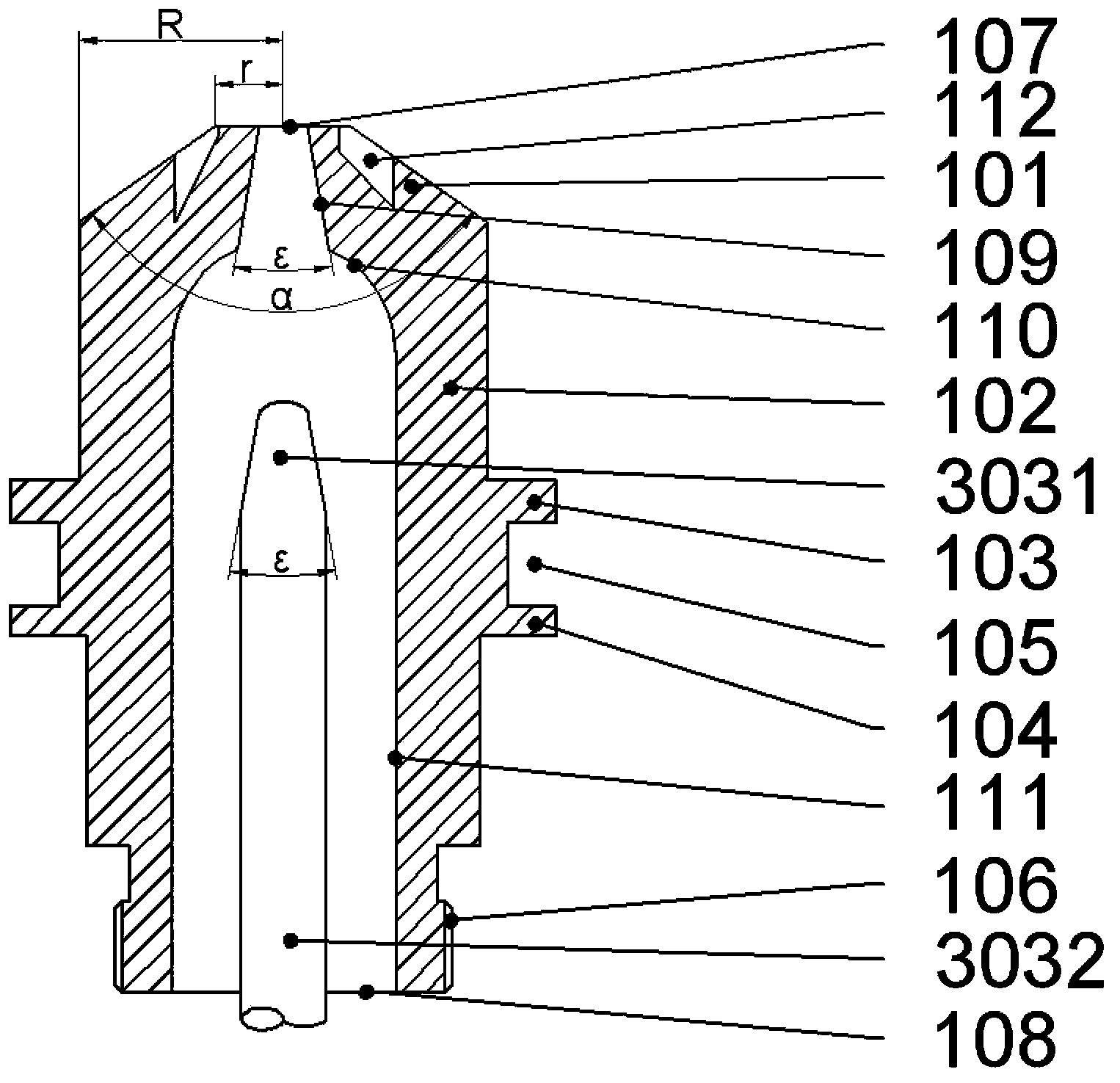

Nozzle component for viscous liquid and spray gun with nozzle component

The invention relates to mechanical devices for dispersing liquid, in particular to a nozzle component for viscous liquid and a spray gun with the nozzle component. The nozzle component is composed of a nozzle with a head portion in the shape of a circular truncated cone and an air cap, an air groove with a function of restraining the gas jet direction is formed on the side face of the head portion, an outlet section of an inner cavity of the air cap is provided with a beveled first inner wall coincident with the head portion in conical degree, the spray gun comprises a spray gun body with a gas inlet, a liquid inlet, a gun head and the nozzle component, and a gas outlet and a liquid outlet are arranged in the gun head. The nozzle component and the spray gun have the advantages that spray floating is reduced substantially, and liquid consumption is greatly reduced compared with conventional modes; service life of a container is prolonged, and operating cost and maintenance cost of enterprises are saved; the spray gun is large in spraying angle, can reach 120 degrees to great extent and is uniform in spraying; the problem that common nozzles are difficult to spray viscous media is solved; the liquid is sprayed out in a rotating mode, so that the problem of nonuniformity in spraying of inner walls of cup-shaped objects is solved.

Owner:康泽士上海洁净设备有限公司

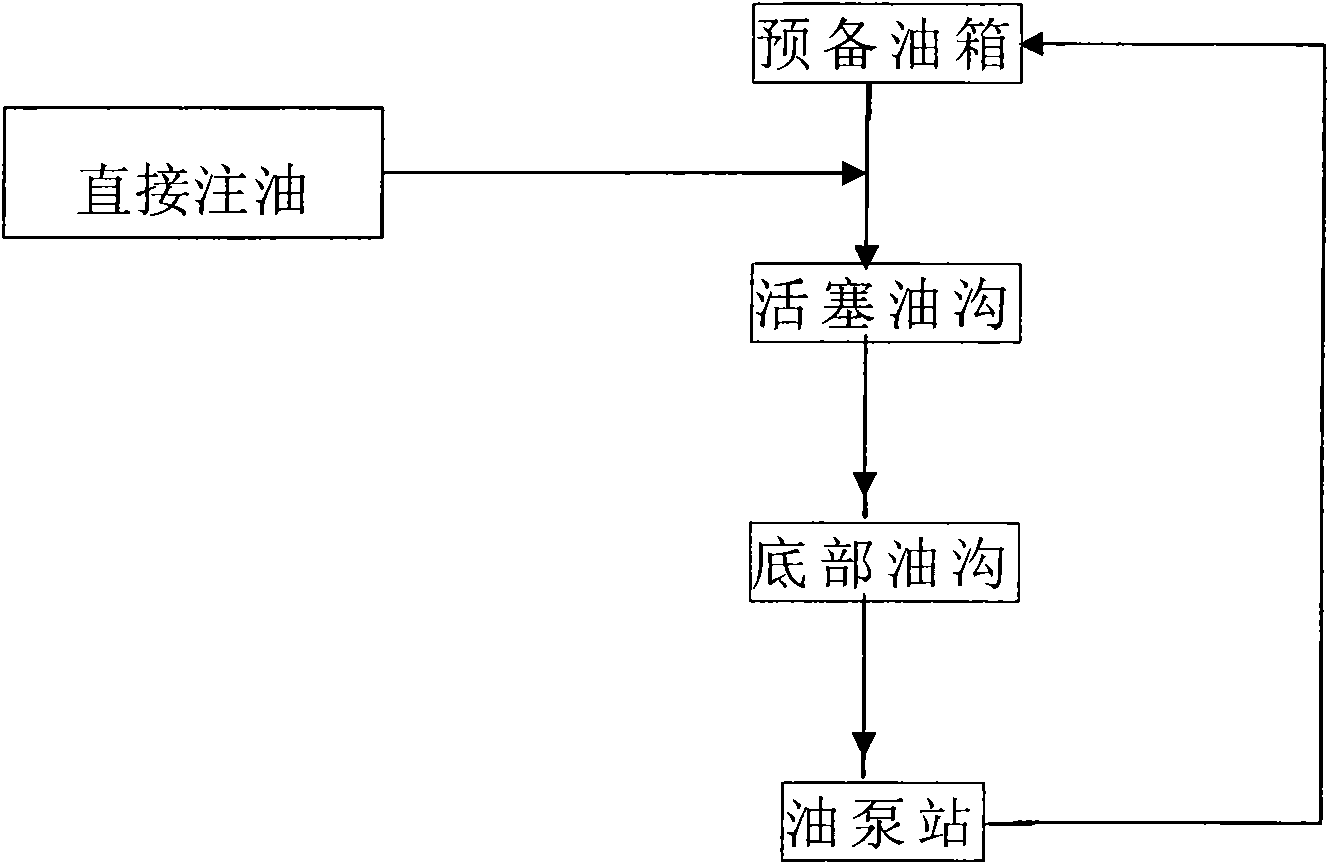

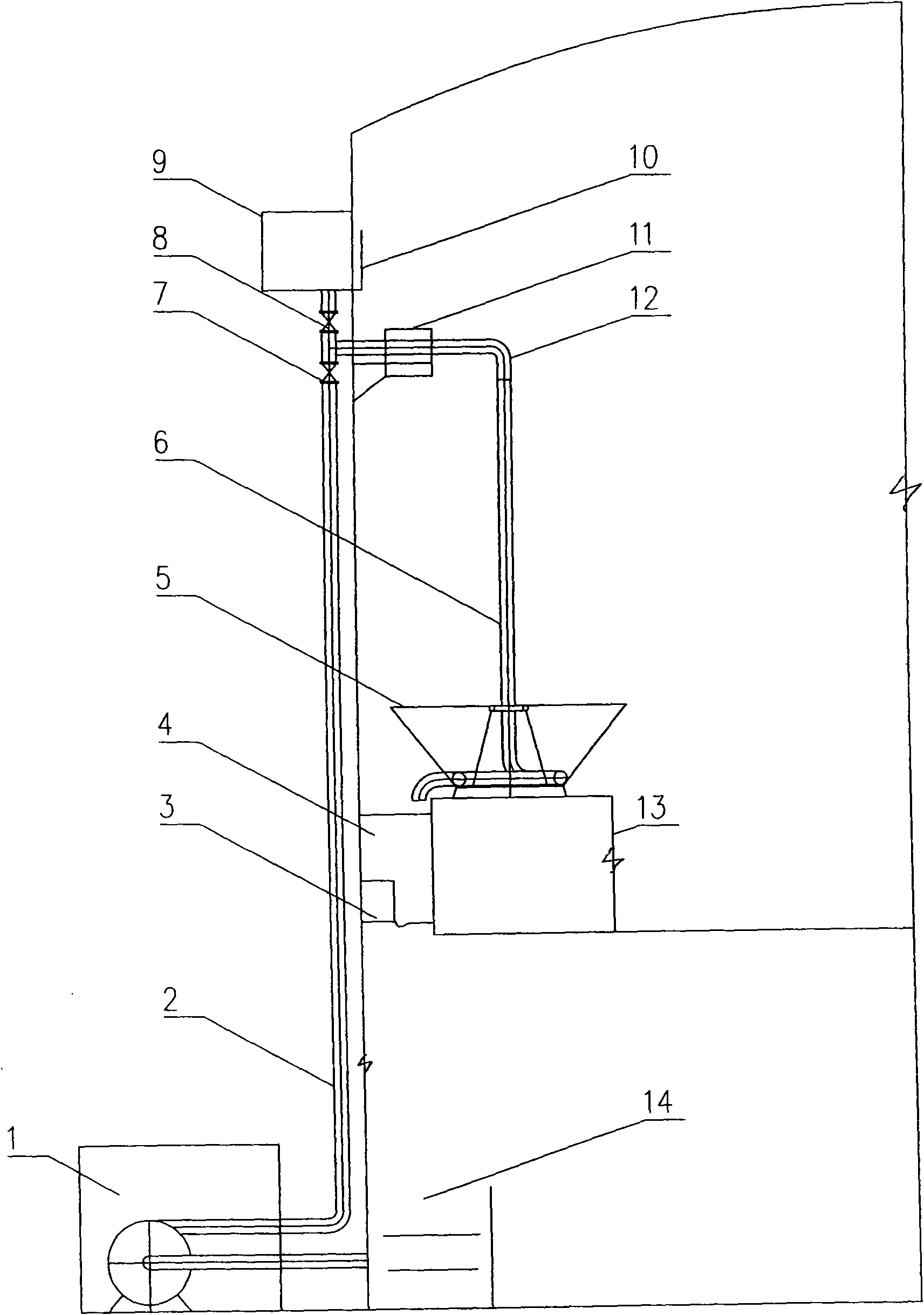

Dry type gas-holder seal oil cycling device

ActiveCN101644380APrevent splashReduce the number of unitsPipe supportsVariable capacity gas holdersPipe supportGas holder

The invention belongs to the technical field of general engineering, and in particular relates to a dry type gas-holder seal oil cycling device, which comprises an oil pump station and a seal oil overflow system, wherein a tee joint arranged between two valves of a seal oil ascension pipe is connected with an upper part fixed joint of an oil rubber hose; the upper part fixed joint is arranged on apipeline support frame; the oil rubber hose is placed in a spooler; the spooler is placed on a gas-holder piston annular beam; and an outlet of the oil rubber hose is in a piston oil gallery. The drytype gas-holder seal oil cycling device has remarkable effect, solves the problem of the splatter of seal oil in a gas holder through a cycling system, reduces the number of the oil pump station, saves the original cost and operating cost and improves safety, and can be widely applied to the dry type gas holder.

Owner:CISDI ENG CO LTD

Method for repairing steel rail with laser

ActiveCN101949116AImprove wear resistanceAccelerated corrosionRailway track constructionIron powderApplication areas

The invention provides a method for repairing a steel rail with laser, belonging to the semiconductor laser application field. The method is characterized in that the old steel rail with surface defects is rapidly and reliably repaired for reuse without impact on traffic order on the premise of not disassembling the steel rail. The method mainly comprises the following steps: pre-cleaning the steel rail, acquiring and analyzing as well as sorting steel rail information, repairing the steel rail by filling iron powder, performing metallurgical fusion with the laser, and polishing the repair of the rail. The device employed in the method has small volume and light weight, thus being capable of being integrated on a rail running locomotive or a car for daily maintenance or rescue and repair of the rail.

Owner:吉光半导体科技有限公司

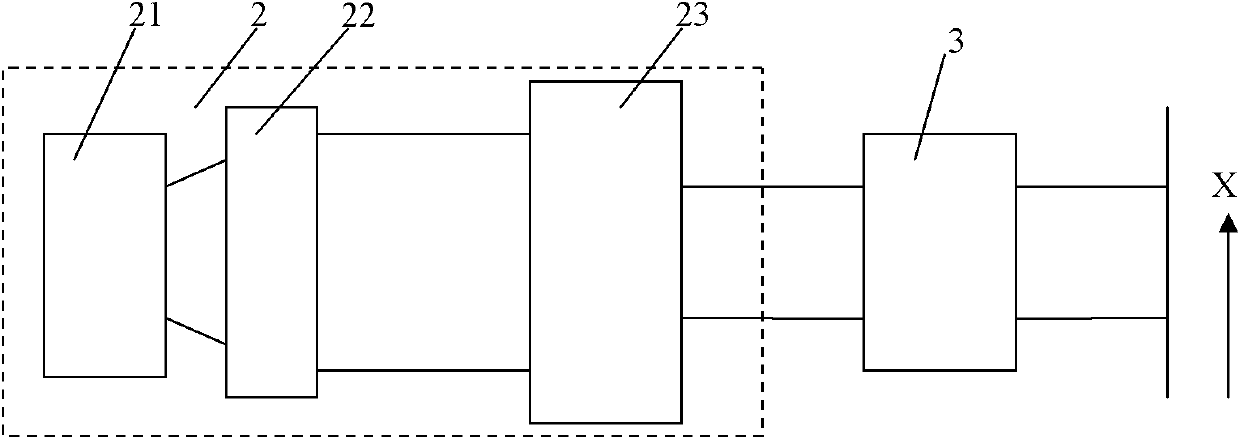

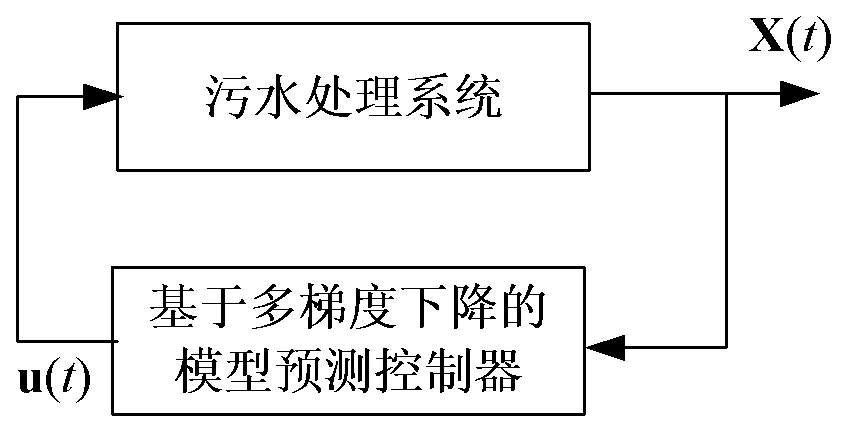

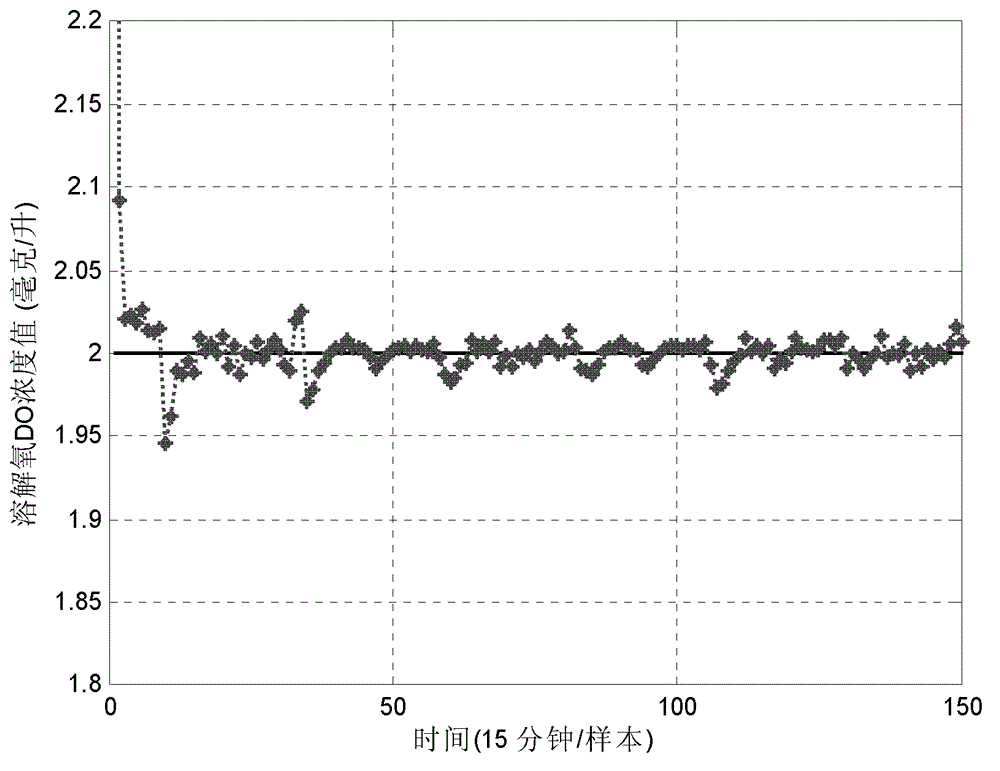

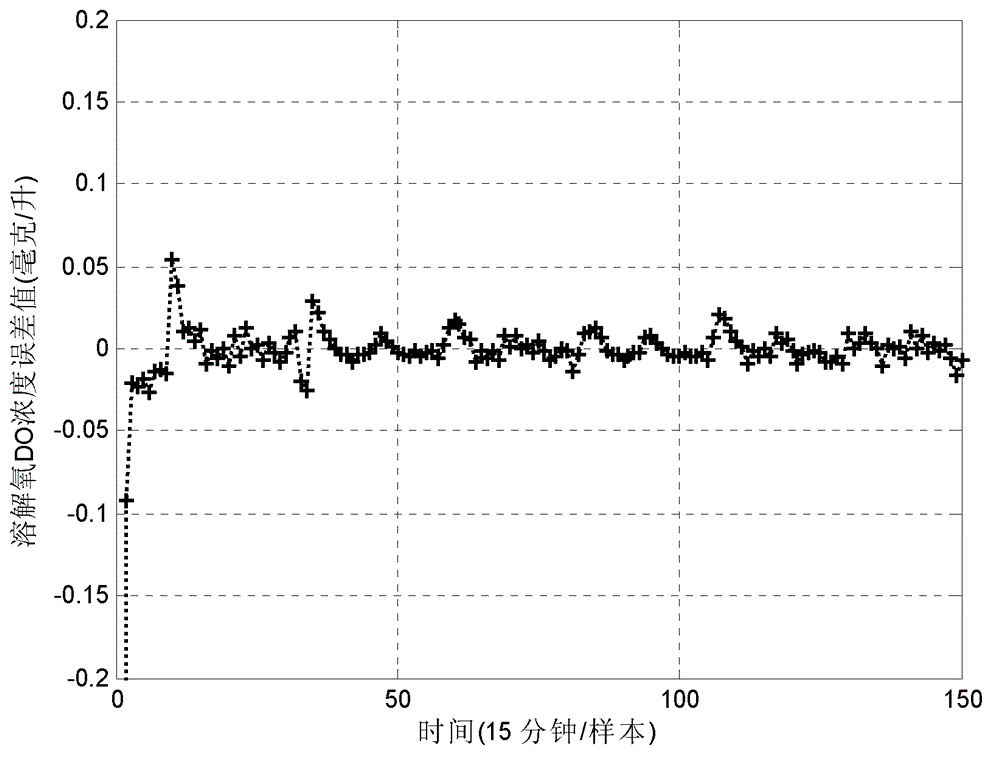

Sewage treatment process optimization control method based on multiple gradient descent

ActiveCN104360597AGuaranteed uptimeSave investment costSpecial data processing applicationsAdaptive controlProcess optimizationAeration rate

The invention provides a sewage treatment process optimization control method based on multiple gradient descent, focuses on the disadvantages that the linearity, coupling and uncertainty are high in the sewage treatment process and aims to control the concentrations of dissolved oxygen DO and nitrate nitrogen SNO simultaneously in the sewage treatment process. The control method includes establishing a multiple objective function of a control system, the multiple objective problem of the sewage treatment process is solved by the optimization method based on multiple gradient descent, and the purposes of controlling the concentrations of dissolved oxygen DO and nitrate nitrogen SNO by controlling the aeration rate and the internal recirculation flow after the optimization are achieved; the problem of the multiple objective problem of the sewage treatment process is solved, the control precision of the dissolved oxygen DO and nitrate nitrogen SNO in the sewage treatment process is improved, normal operation of the sewage treatment process is guaranteed, and the efficient and stable operation of a sewage treatment plant is guaranteed.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com