Nozzle component for viscous liquid and spray gun with nozzle component

A spray head component and viscous liquid technology, which is applied in the direction of liquid spraying devices, spraying devices, etc., can solve the problems of multiple spraying and excessive spraying mist, and achieve the effects of reducing mist, uniform spraying, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

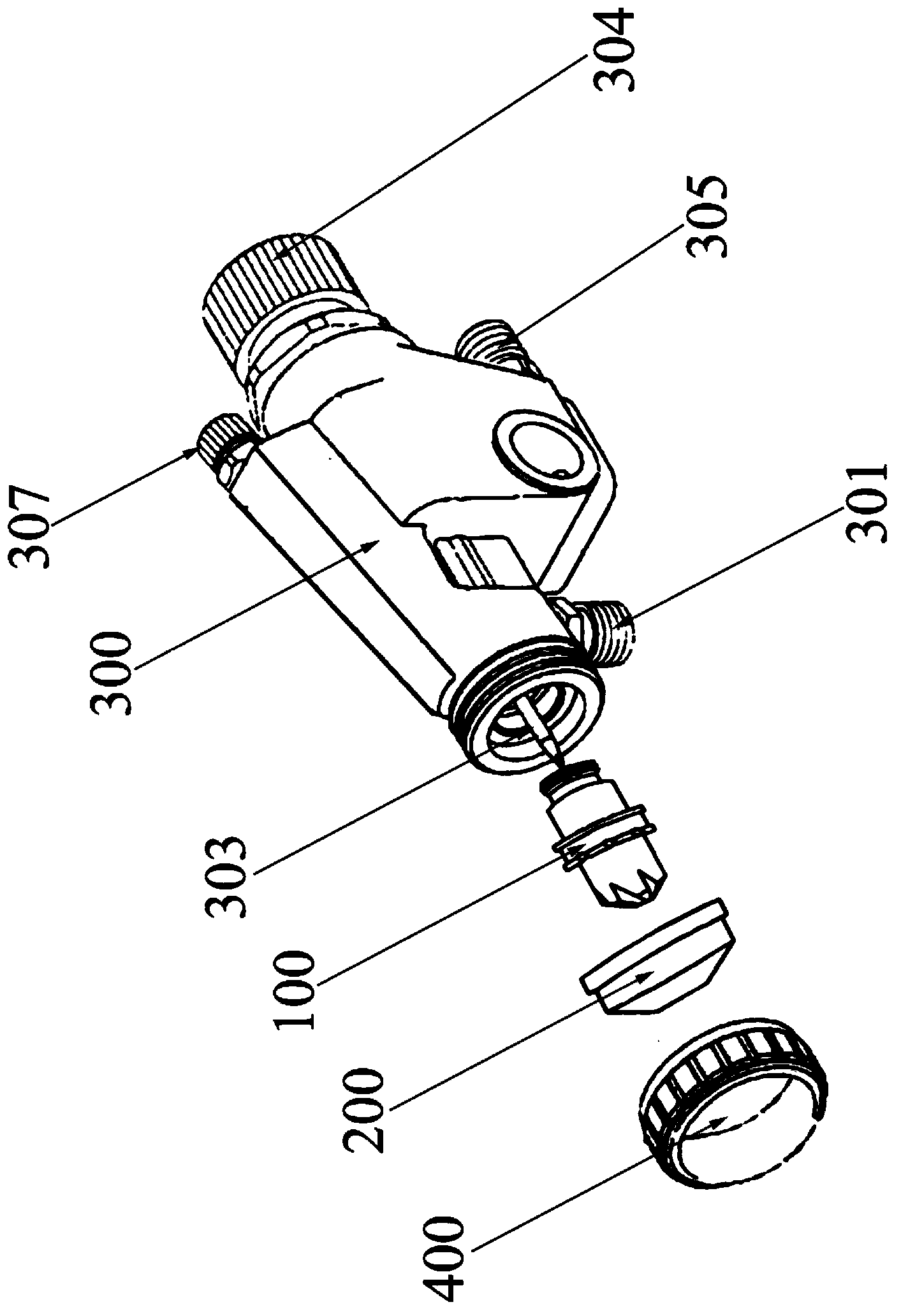

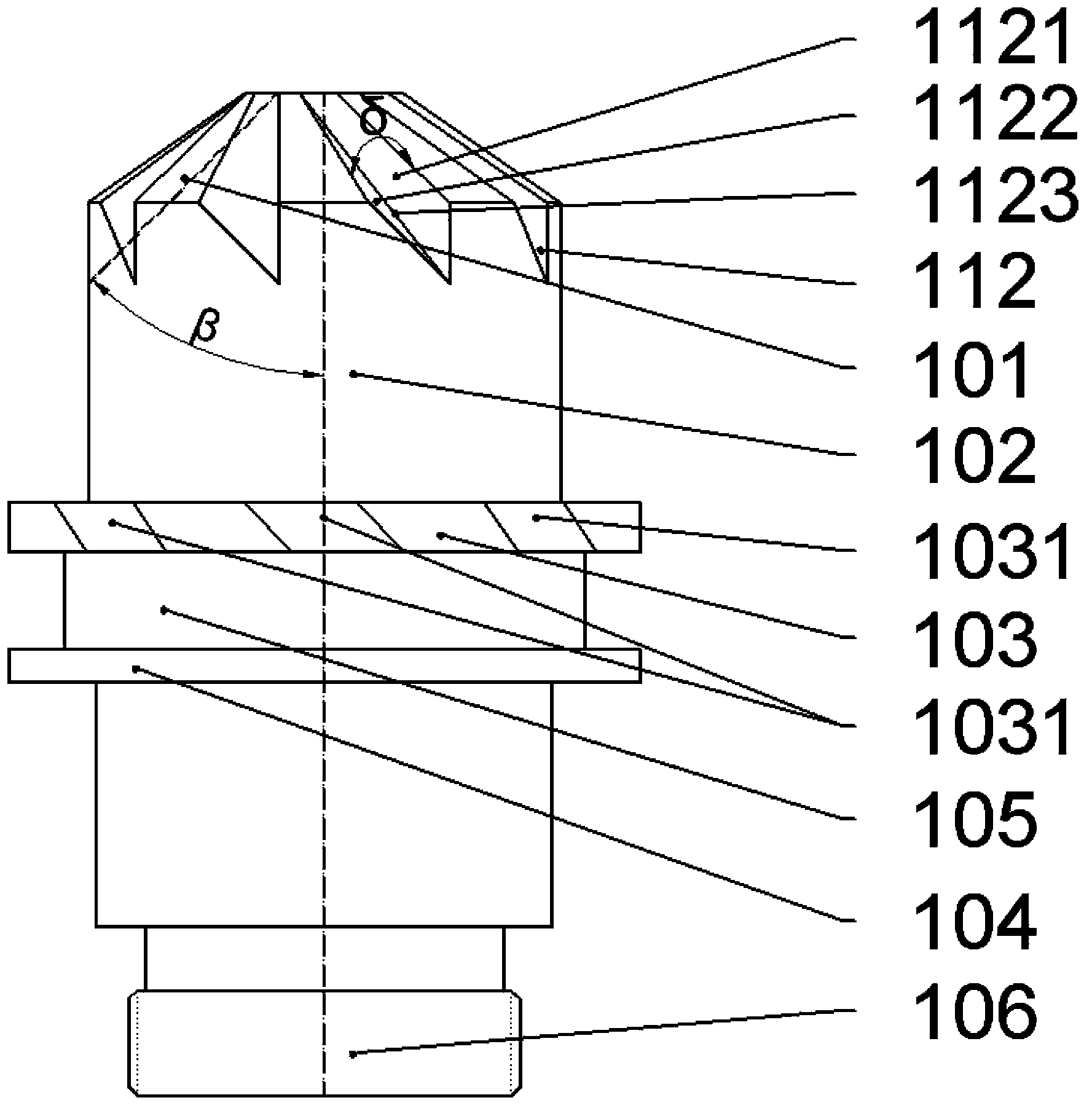

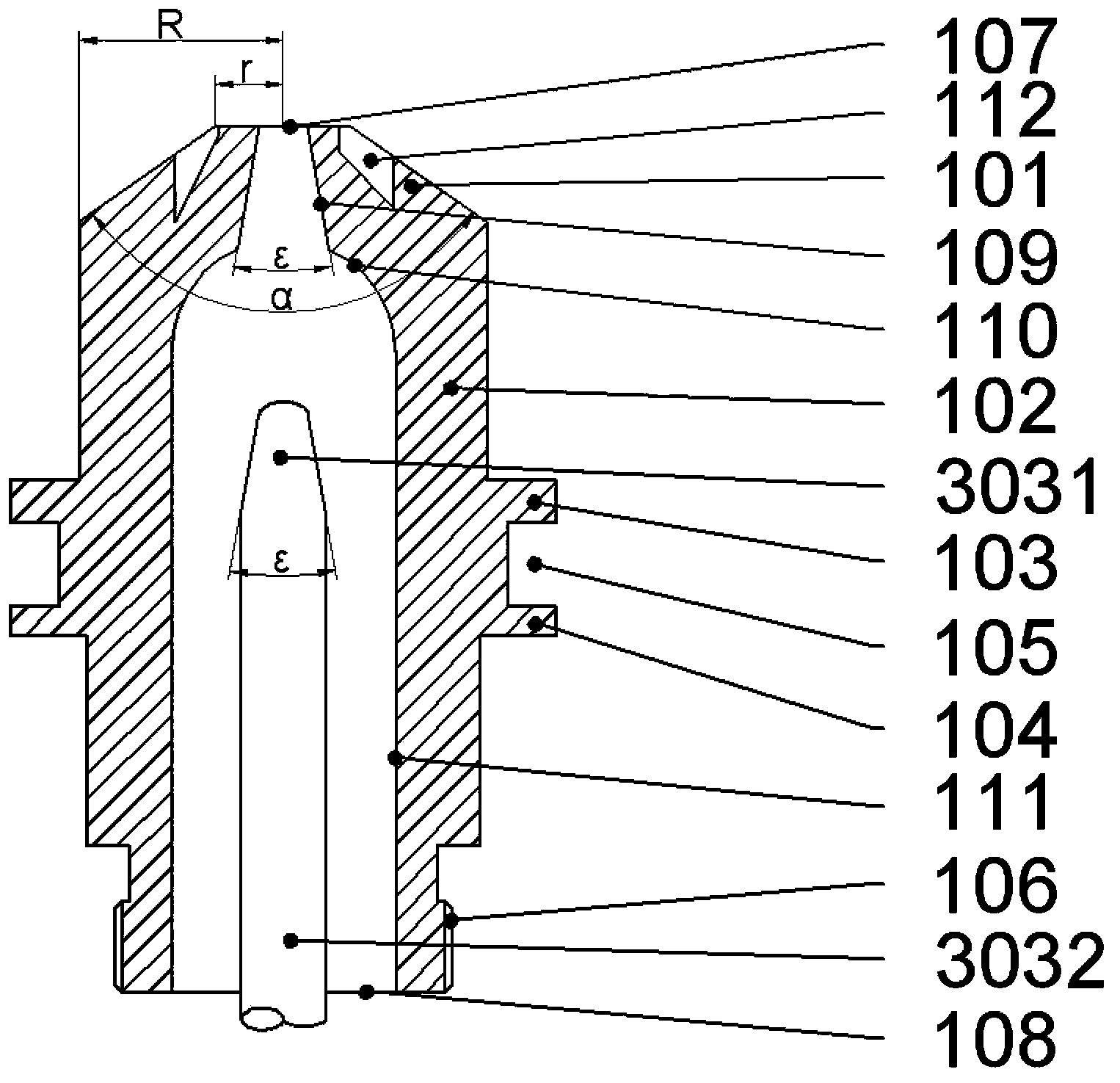

[0047] Such as Figure 1-8 As shown, the labels represent:

[0048] Nozzle 100, head 101, nozzle body 102, front flange 103, notch 1031, rear flange 104, first annular air groove 105, external thread 106, liquid injection port 107, liquid inlet 108, inner wall of round table 109, ball table Inner wall 110, cylindrical inner wall 111, air groove 112, first side wall 1121, second side wall 1122, groove bottom 1123;

[0049] Air cap 200, front opening 201, flange 202, sealing end surface 203, first inner wall 204, second inner wall 205, third inner wall 206;

[0050] Spray gun body 300, liquid inlet 301, liquid cavity 302, first needle valve 303, needle body 3031, needle head 3032, liquid adjustment knob 304, air inlet 305, air cavity 306, gas adjustment knob 307, first sealing end surface 308 , external thread 309, second se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com