Patents

Literature

46results about How to "Solve the problem of uneven spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

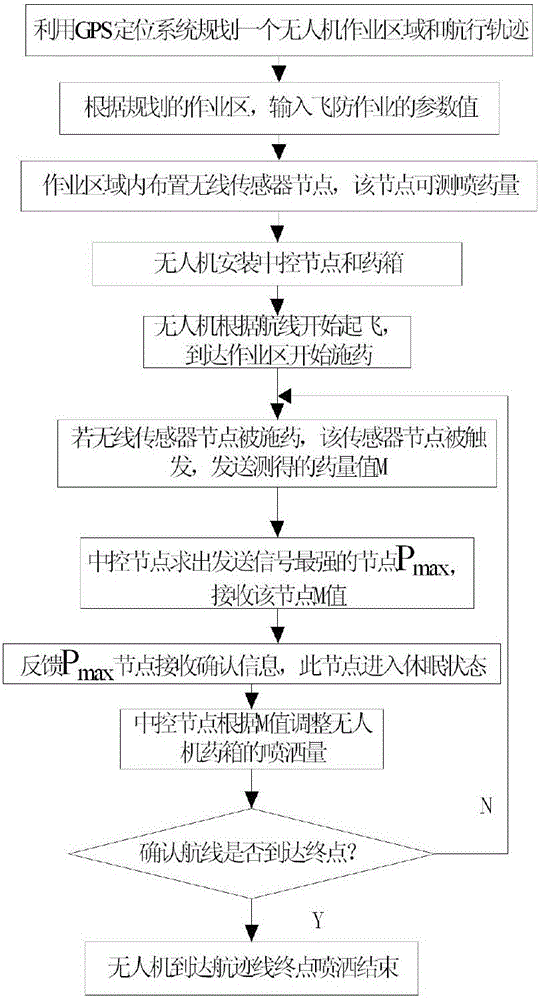

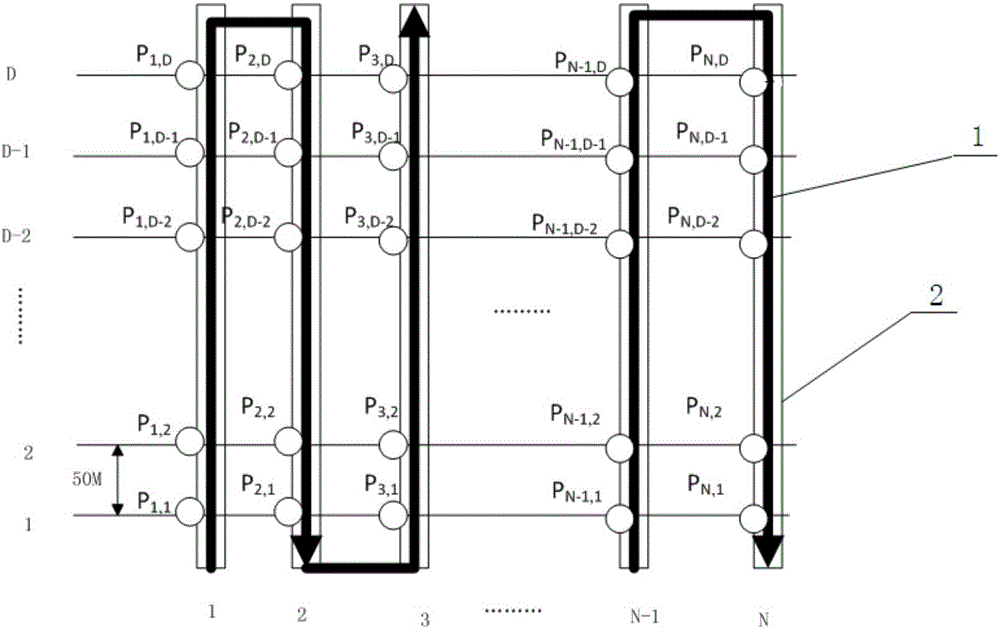

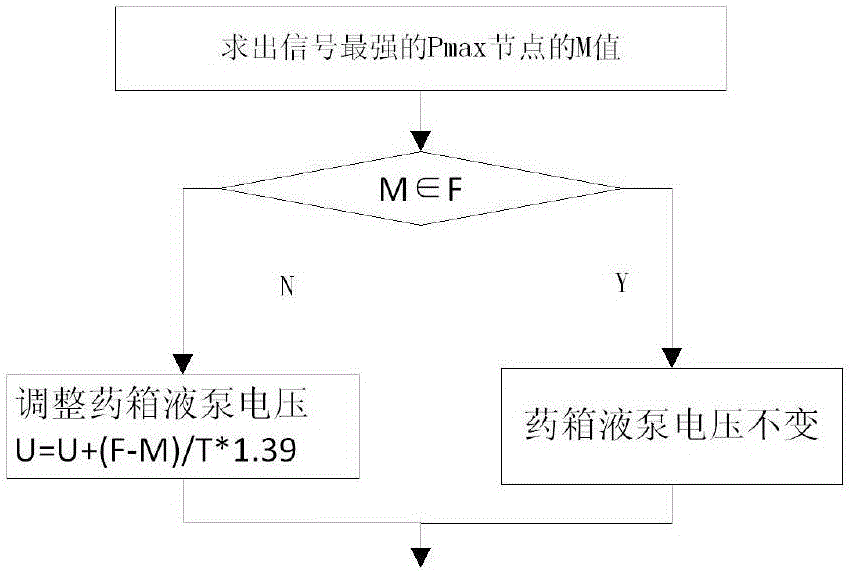

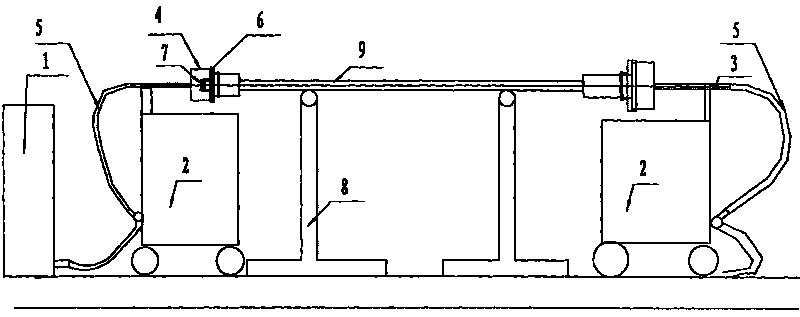

Self-adaption precise pesticide applying method of unmanned aerial vehicle

InactiveCN106200674AImprove autonomous flight capabilitiesSolve the problem of uneven sprayingPosition/course control in three dimensionsGps positioning systemUncrewed vehicle

The invention discloses a self-adaption precise pesticide applying method of an unmanned aerial vehicle, and belongs to the technical field of agricultural plant protection mechanical automation. The method comprises the following steps that a GPS is started, the area to which pesticide is about to be applied is divided into one or more rectangular areas through the system, and the unmanned aerial vehicle track line is planned according to the four-point positions of the rectangular areas; parameter values of flying protection work are input into the system, and the parameter values comprise the operation area, average flight speed and the pesticide applying standard range [F1, F2]; a wireless sensor node is arranged in the spraying operation area; a central control node in communication with the wireless sensor node is mounted on the unmanned aerial vehicle; the unmanned aerial vehicle is started, and the unmanned aerial vehicle carries out pesticide applying when flying to the starting point position in the four points of the rectangular areas according to the planned track line. By means of the self-adaption precise pesticide applying method, the autonomous flight capacity of the plant protection unmanned aerial vehicle in precise pesticide applying operation is improved, the problem of uneven spraying caused by objective factors of the plant protection unmanned aerial vehicle is solved, and the operation effect and operation yield of the plant protection unmanned aerial vehicle are guaranteed.

Owner:JILIN AGRICULTURAL UNIV

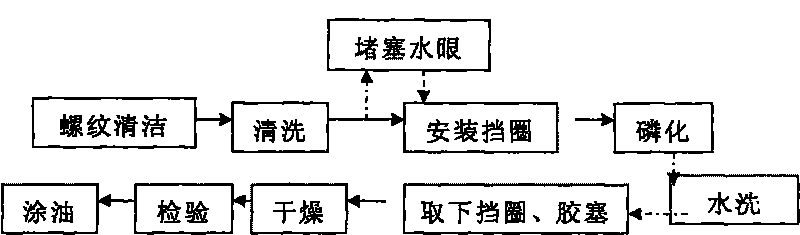

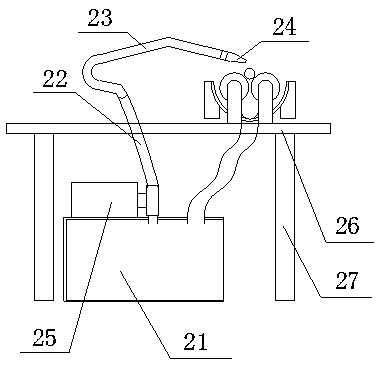

Closed circulating heating thermal phosphorization device and phosphorization method

InactiveCN101696497ASolve temperature problemsSolve the technical problem of uneven spraying of liquid medicineMetallic material coating processesClose contactPetroleum engineering

The invention discloses a closed circulating heating thermal phosphorization device and a phosphorization method, relating to the technical field of drilling tool thread phosphorization. The device comprises a fluid heater, a phosphorization pool, a heating controller, a spray head, a circulation pipeline, a rubber check ring and a rubber stopper, wherein the fluid heater and the phosphorization pool are connected through the circulation pipeline; the spray head is fixed above the phosphorization pool; a water outlet of the circulation pipeline is connected with the spray head; a drilling rod is supported by a pipe rack and arranged above the phosphorization pool; the rubber stopper is arranged in a water hole of the drilling rod; the rubber check ring is sleeved on a drilling rod joint, and the inner wall of the rubber check ring is in close contact with the outer wall of the spray head; threads extend into a cavity formed by the spray head and the rubber check ring; and the heating controller is connected with the fluid heater. The invention can control the temperature, the pressure and the flow to carry out semi-soaking type phosphorization on the threads so as to solve the technical problems of difficult temperature constancy and non-uniform medicine liquid spraying in thermal phosphorization.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

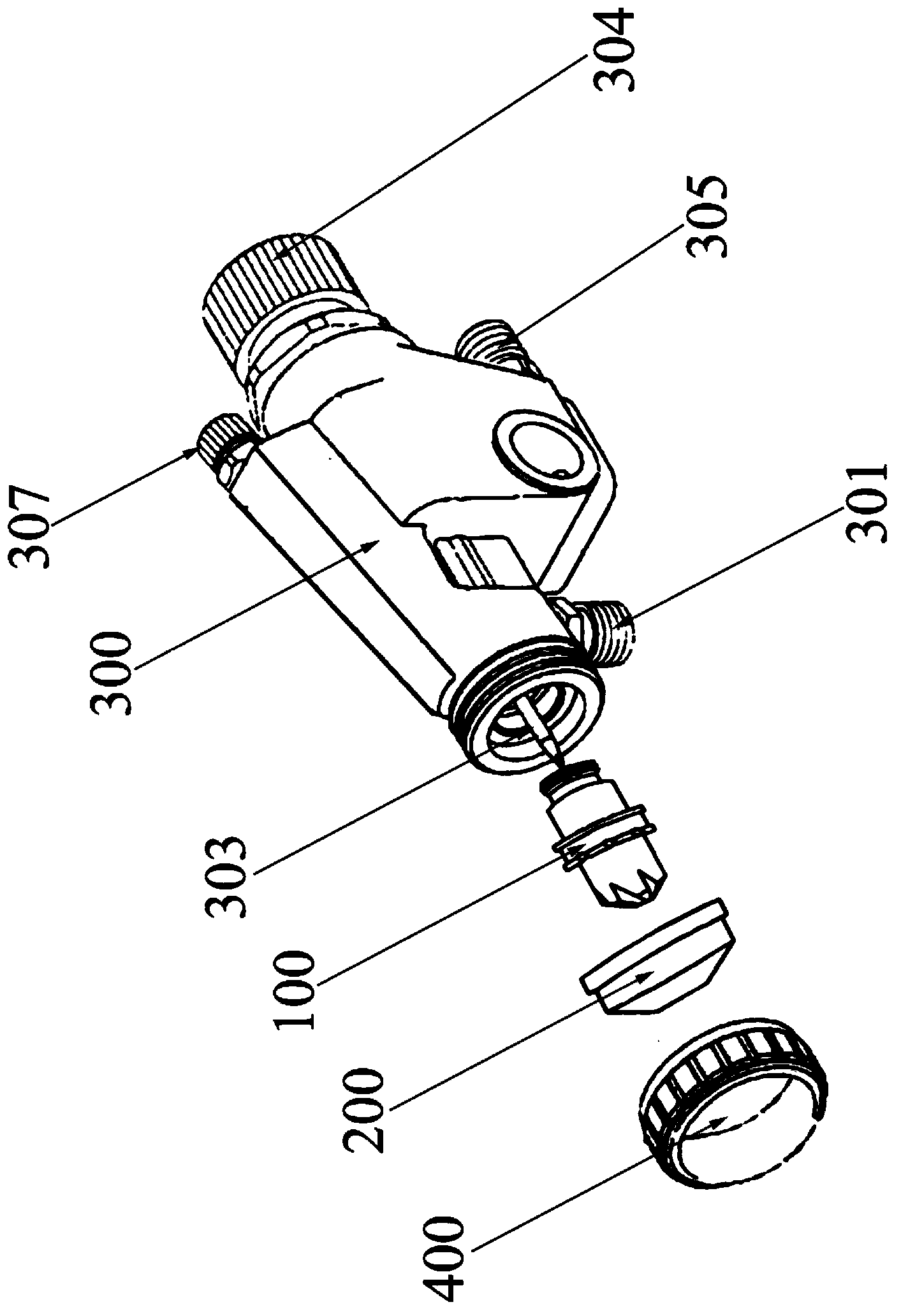

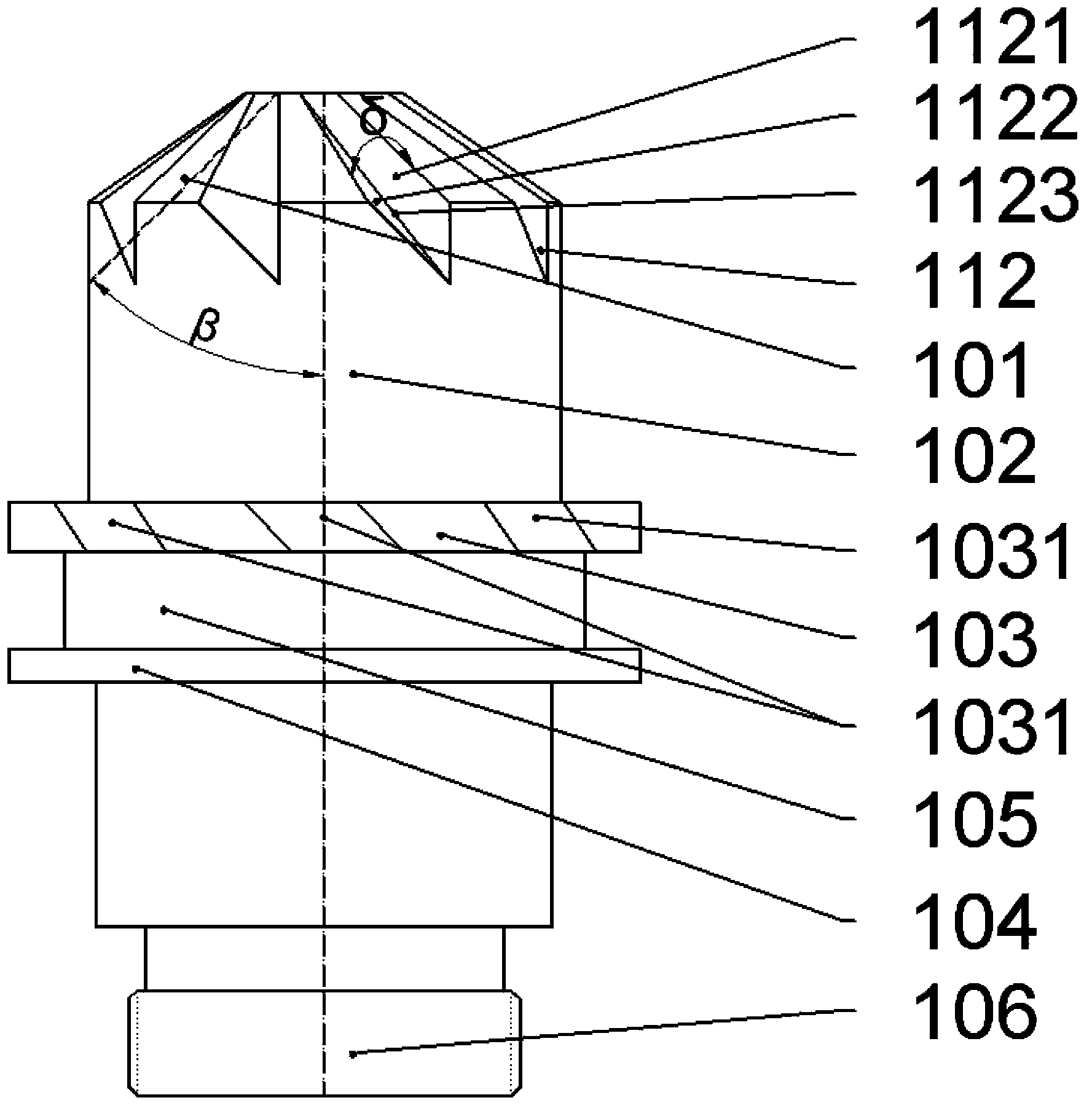

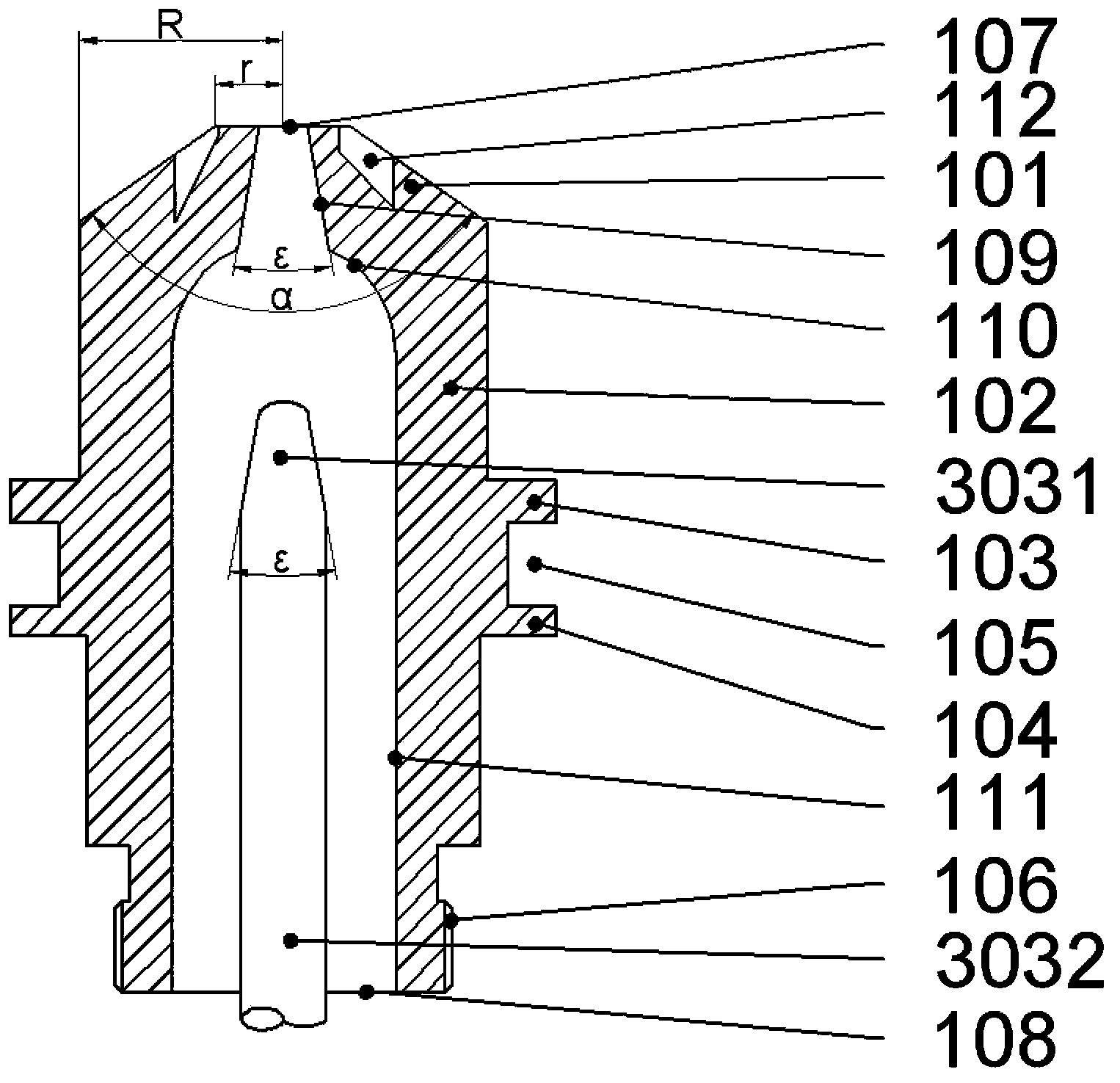

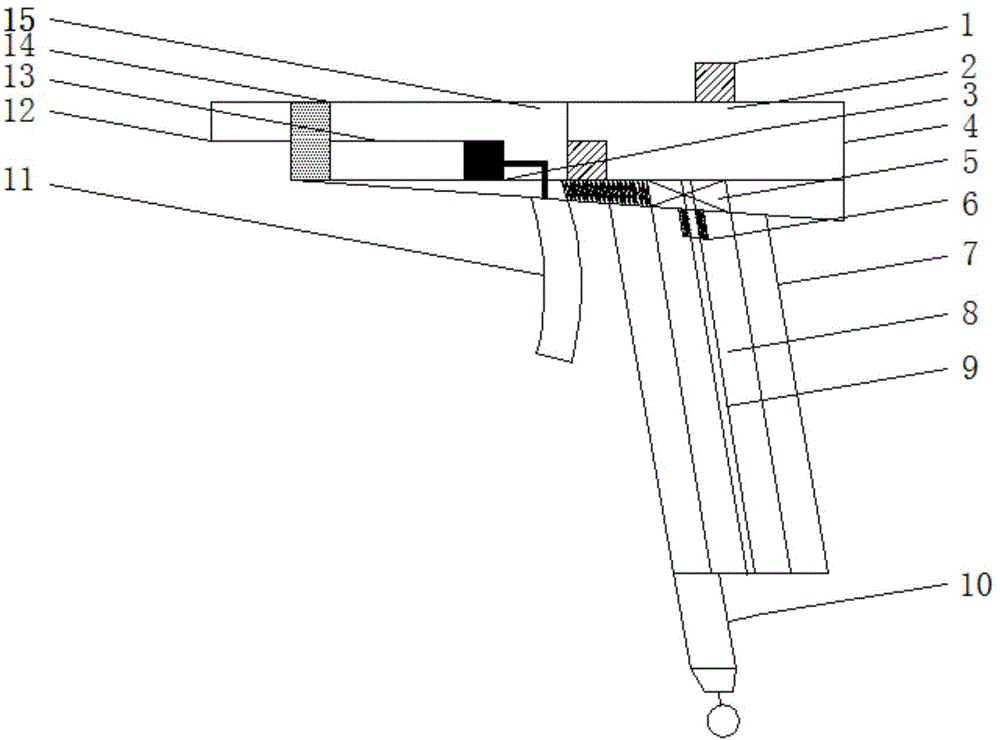

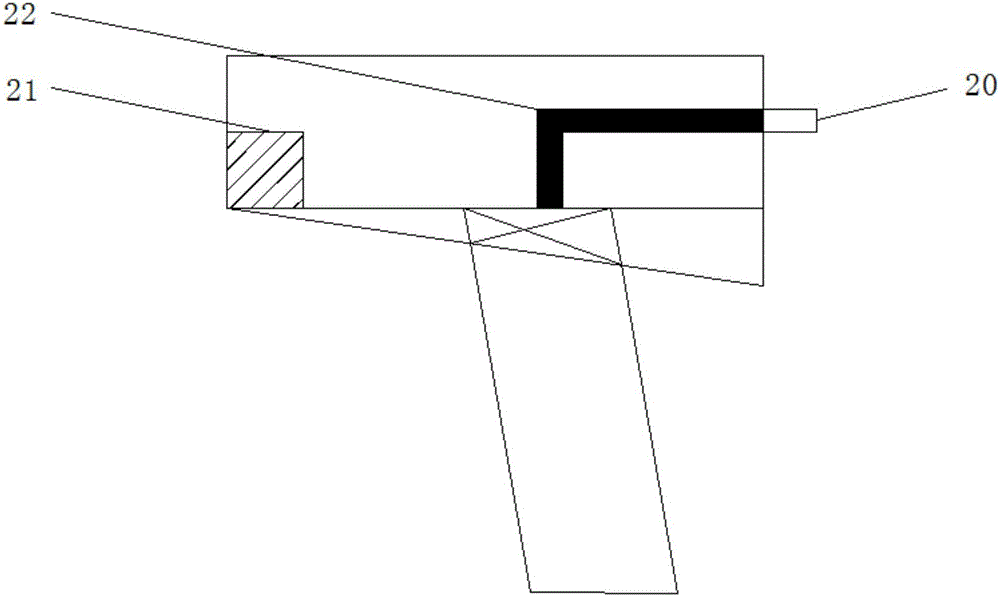

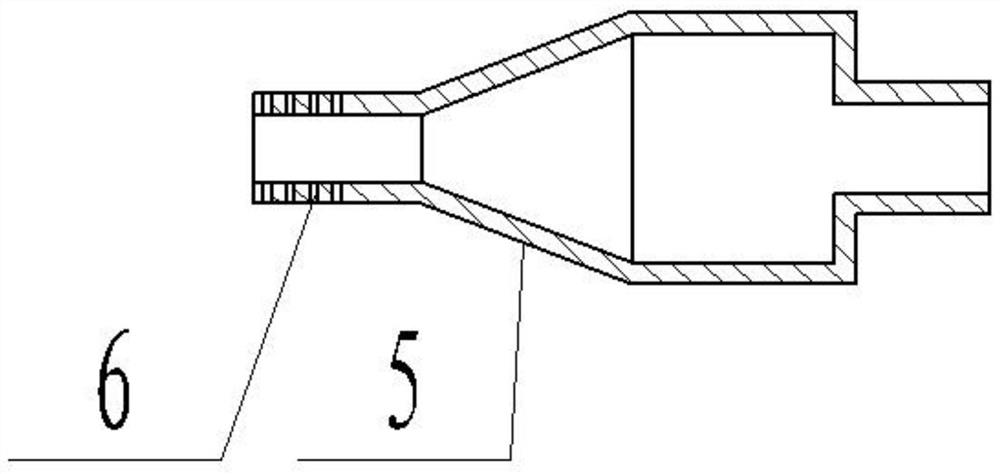

Nozzle component for viscous liquid and spray gun with nozzle component

The invention relates to mechanical devices for dispersing liquid, in particular to a nozzle component for viscous liquid and a spray gun with the nozzle component. The nozzle component is composed of a nozzle with a head portion in the shape of a circular truncated cone and an air cap, an air groove with a function of restraining the gas jet direction is formed on the side face of the head portion, an outlet section of an inner cavity of the air cap is provided with a beveled first inner wall coincident with the head portion in conical degree, the spray gun comprises a spray gun body with a gas inlet, a liquid inlet, a gun head and the nozzle component, and a gas outlet and a liquid outlet are arranged in the gun head. The nozzle component and the spray gun have the advantages that spray floating is reduced substantially, and liquid consumption is greatly reduced compared with conventional modes; service life of a container is prolonged, and operating cost and maintenance cost of enterprises are saved; the spray gun is large in spraying angle, can reach 120 degrees to great extent and is uniform in spraying; the problem that common nozzles are difficult to spray viscous media is solved; the liquid is sprayed out in a rotating mode, so that the problem of nonuniformity in spraying of inner walls of cup-shaped objects is solved.

Owner:康泽士上海洁净设备有限公司

Intelligent variable sprinkling control system adapting to driving speed and realization method thereof

ActiveCN107479369ASolve the problem of uneven sprayingReal-time adjustment of spraying amountFlow control using electric meansControllers with particular characteristicsPest controlElectric control

The invention discloses an intelligent variable sprinkling control system adapting to a driving speed and a realization method thereof; the intelligent variable sprinkling control system comprises a pressure sensor, an electric control unit, and a nozzle; one end of the pressure sensor is arranged in the front end of the nozzle, and the pressure sensor is used for sensing the sprinkling pressure in a sprinkling pipeline; the other end of the pressure sensor is connected with the electric control unit; the intelligent variable sprinkling control system can solve the problems that an artificial sprinkling amount adjusting mode is non-uniform in a sprinkling effect; the equipment is added with the intelligent control system so as to monitor the driving speed changes in real time and adjust the sprinkling amount in real time, thus ensuring the sprinkling accuracy and uniformity, preventing insect disease poor control effect or spray burn phenomenon, and effectively reducing operator labor intensity.

Owner:LOVOL HEAVY IND CO LTD

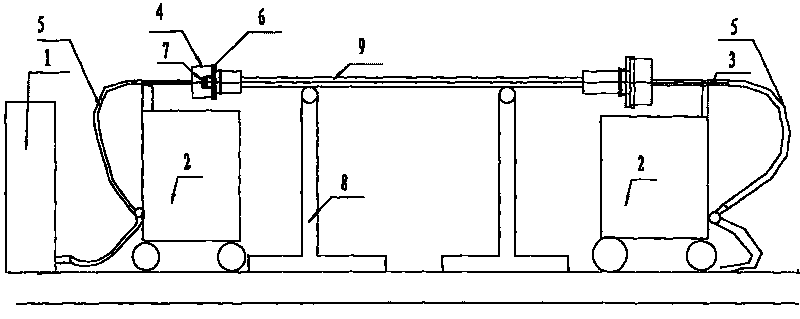

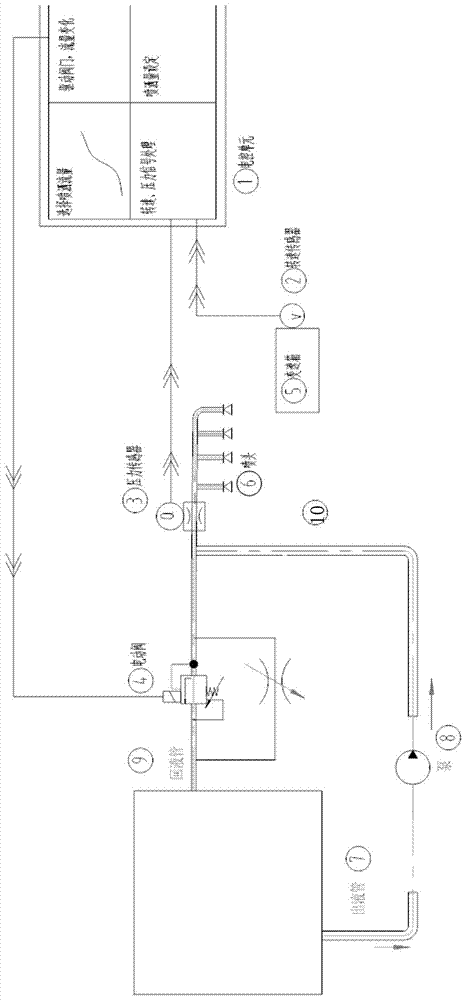

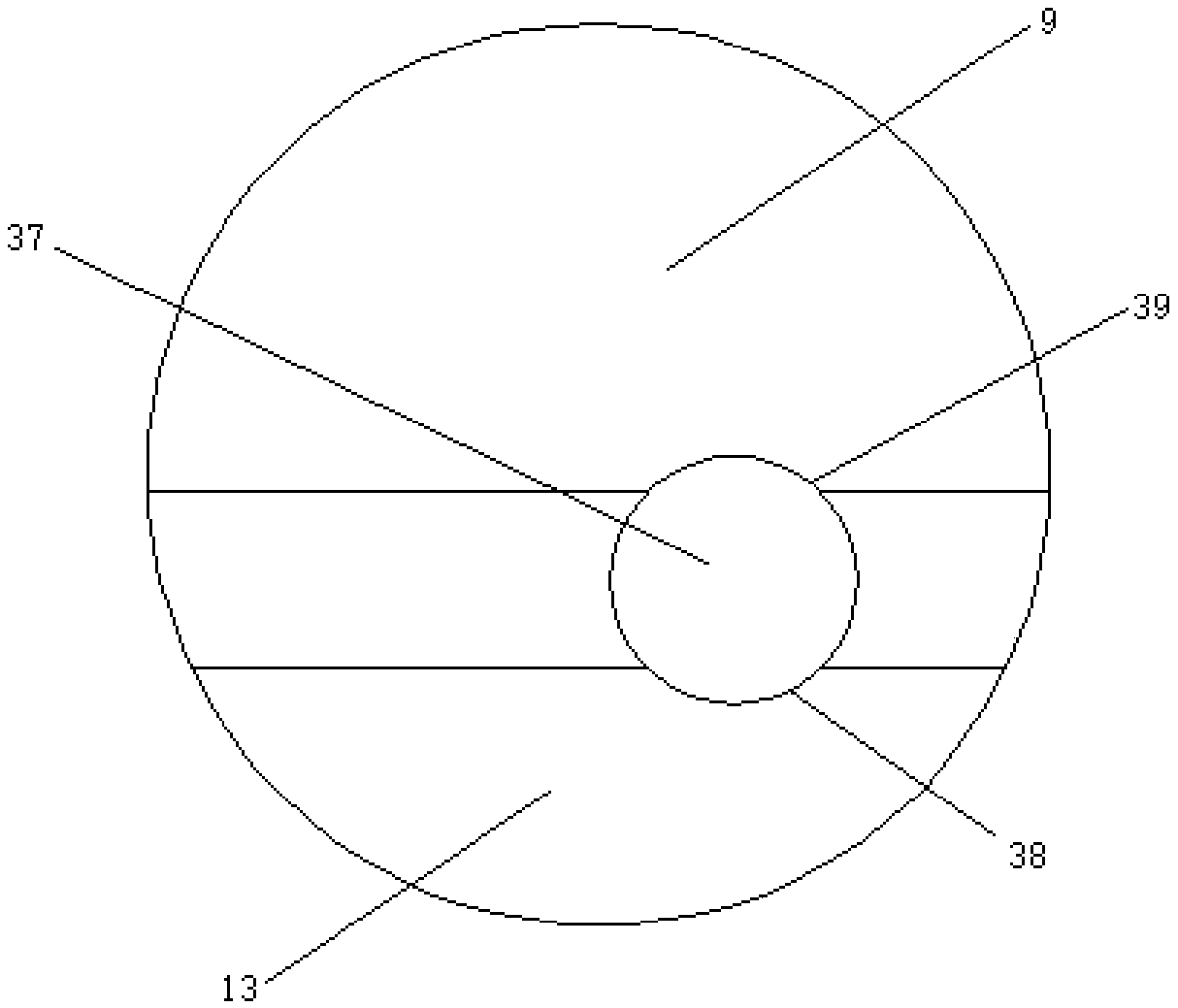

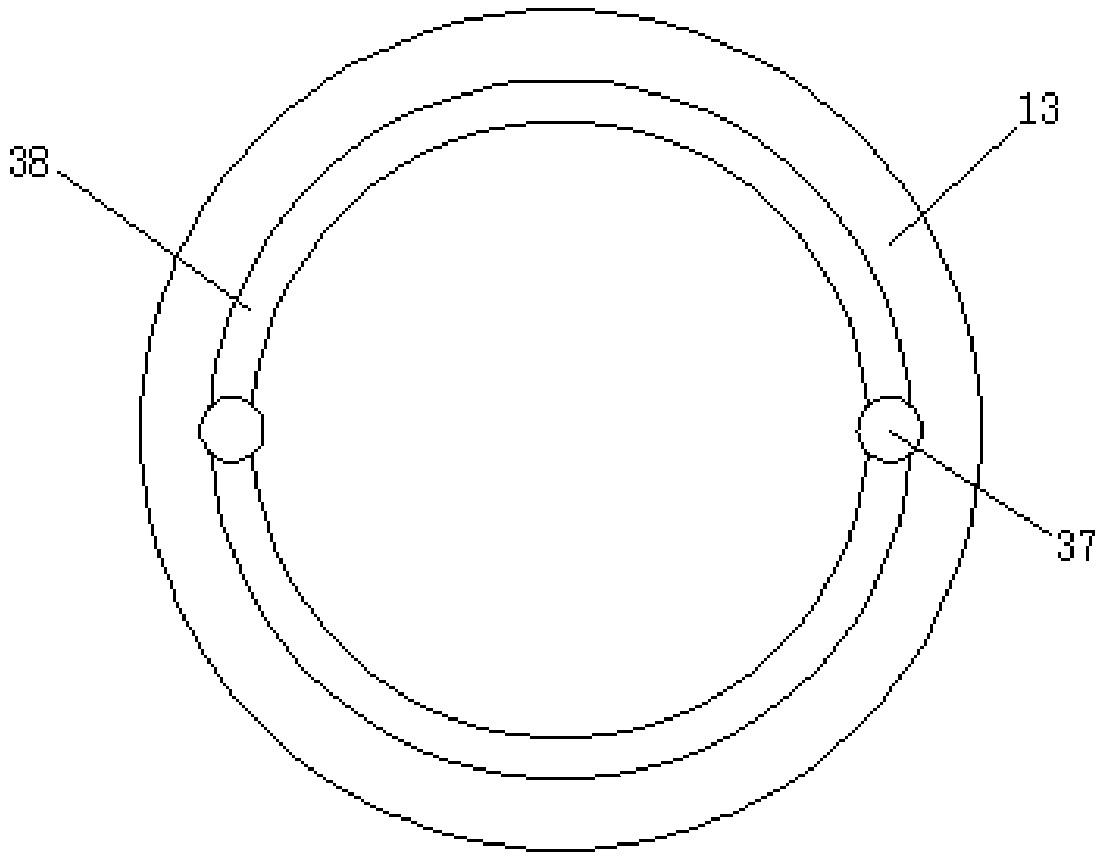

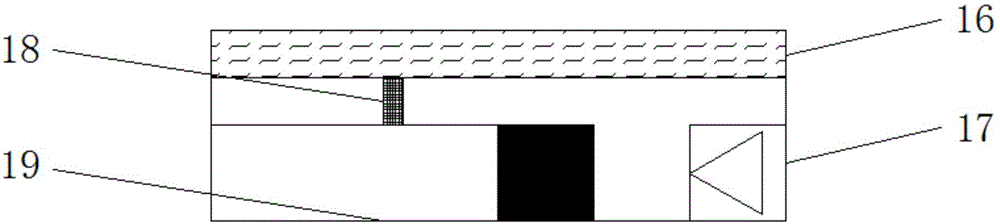

High-voltage electrostatic oiling system

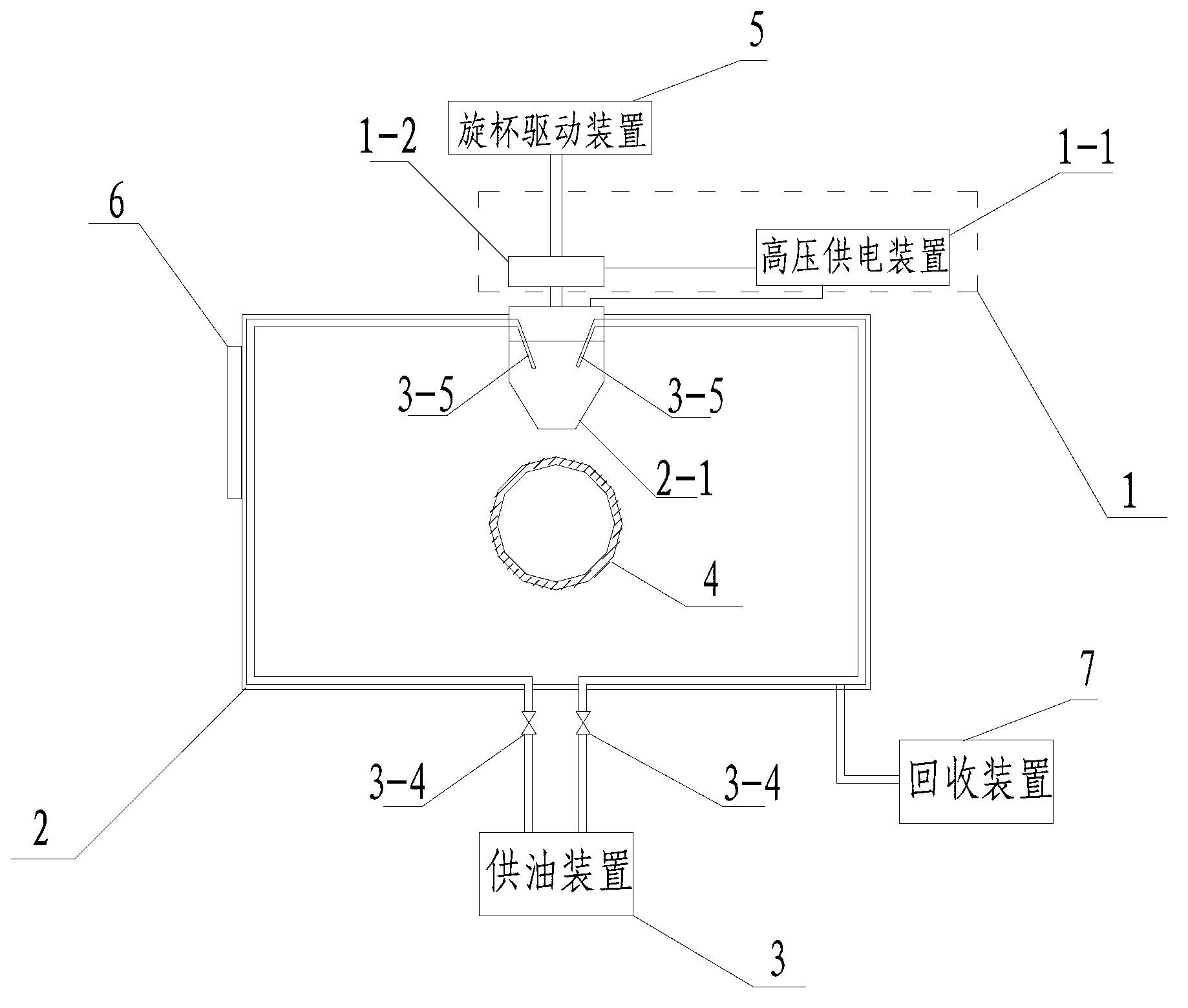

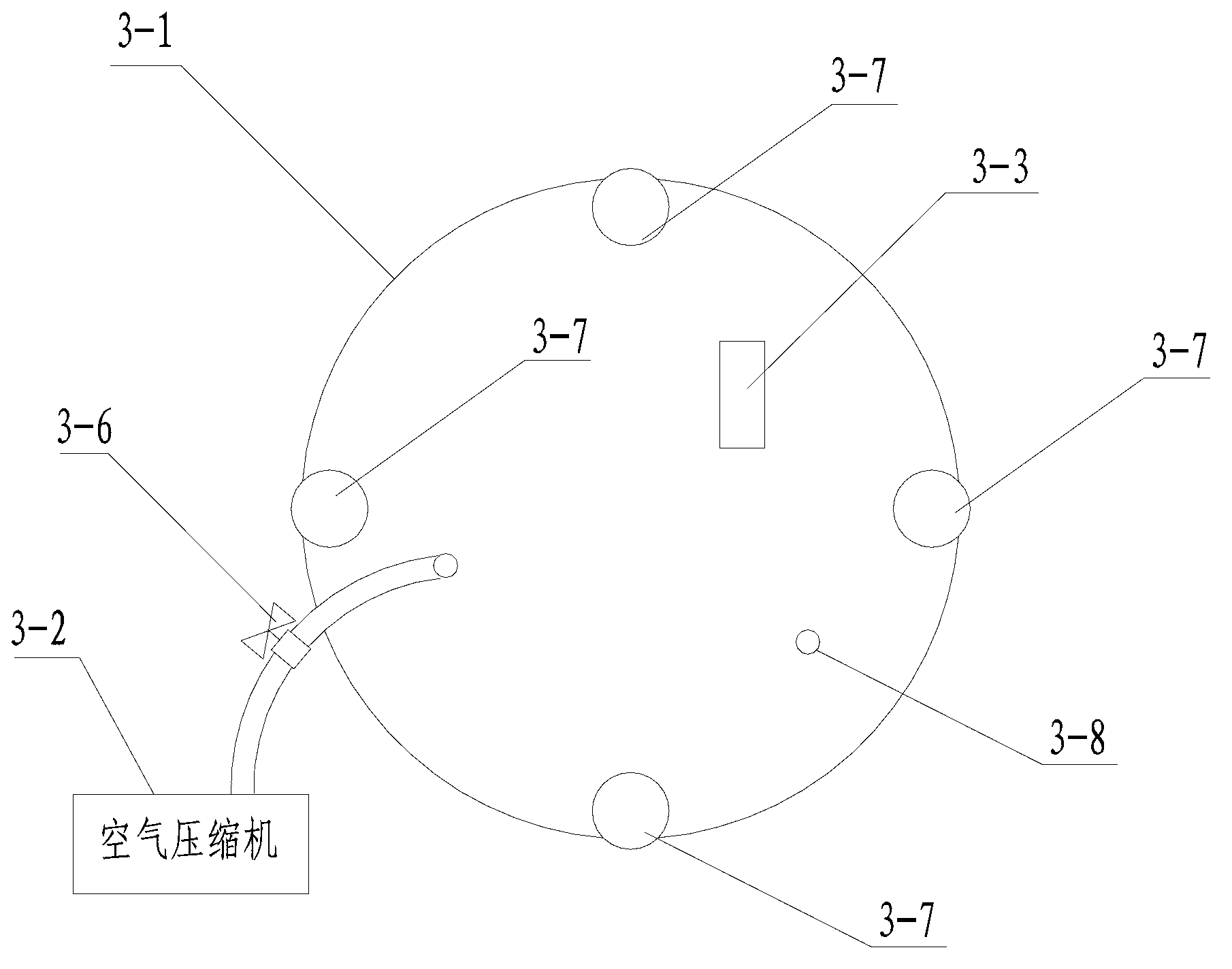

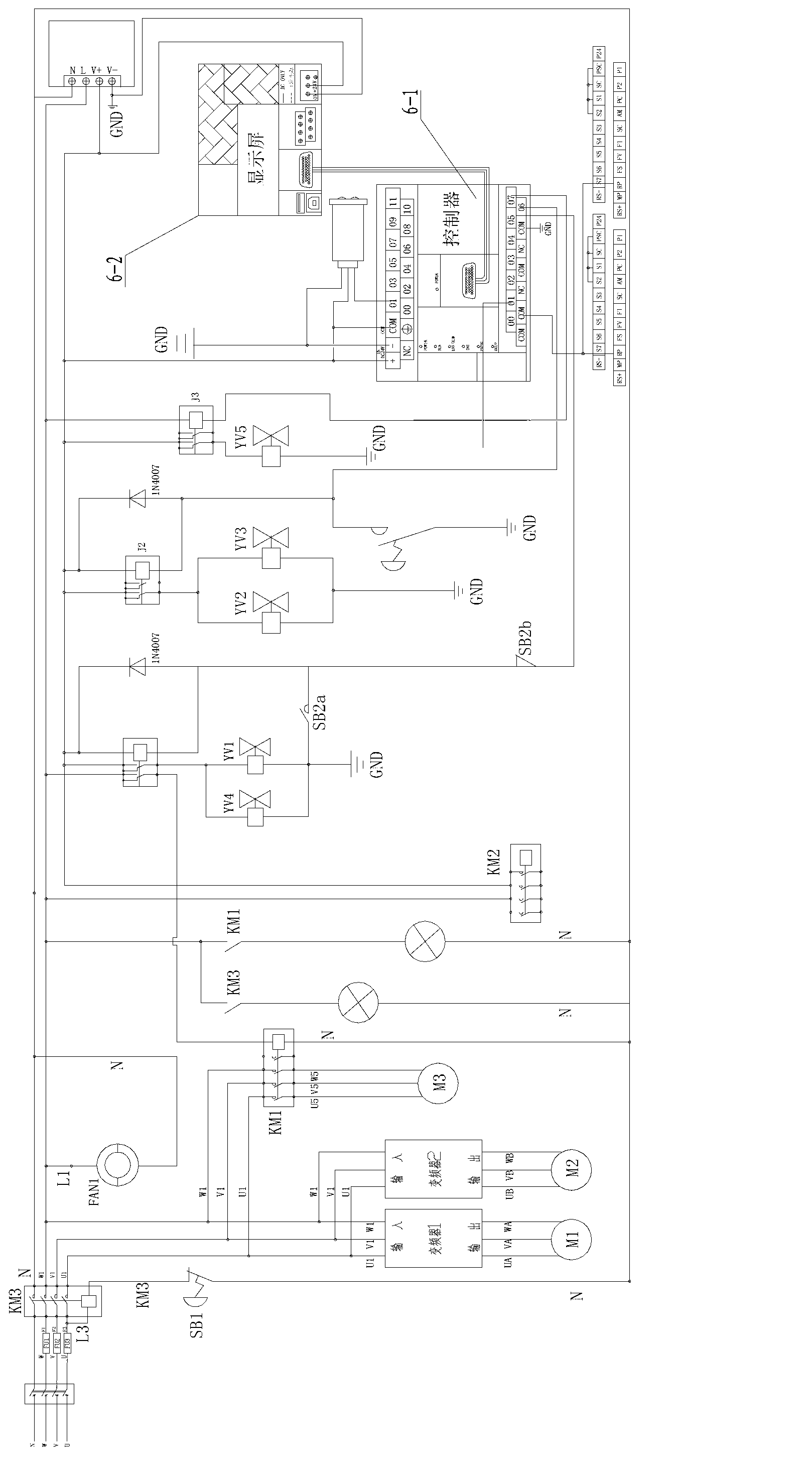

ActiveCN102935410ASolve the problem of uneven sprayingUniform coatingLiquid spraying plantsSpray coatingControl cell

A high-voltage electrostatic oiling system relates to spray coating devices used on production lines, and aims to solve the problems in the prior art that outer surfaces of steel belts, steel tubes and steel wires are not coated with paint uniformly, and the paint loss is large. The high-voltage electrostatic oiling system includes a high-voltage electrostatic generation device, an oiling box, an oil supply device, a workpiece conveying device, a rotary cup driving device, a control unit and a recovery device; the oiling box is provided with a box body, a through hole is formed at the center of the top of the box body, the rotary cup driving device is arranged above the through hole, a rotary cup is arranged in the through hole, a driving output end of the rotary cup driving device is communicated with a driving input end of the rotary cup, and a cup mouth of the rotary cup faces downward to an inner cavity of the oiling box; the oiling device comprises an oil barrel, an air compressor, a pressure gauge, an electromagnetic valve, two oil output valves and two oil nozzles; the control unit includes a controller and a display screen; and an input port of the recovery device is communicated with the inner cavity of the oiling box. The high-voltage electrostatic oiling system is suitable for oiling various production lines continuously.

Owner:大庆北油工程技术服务有限公司

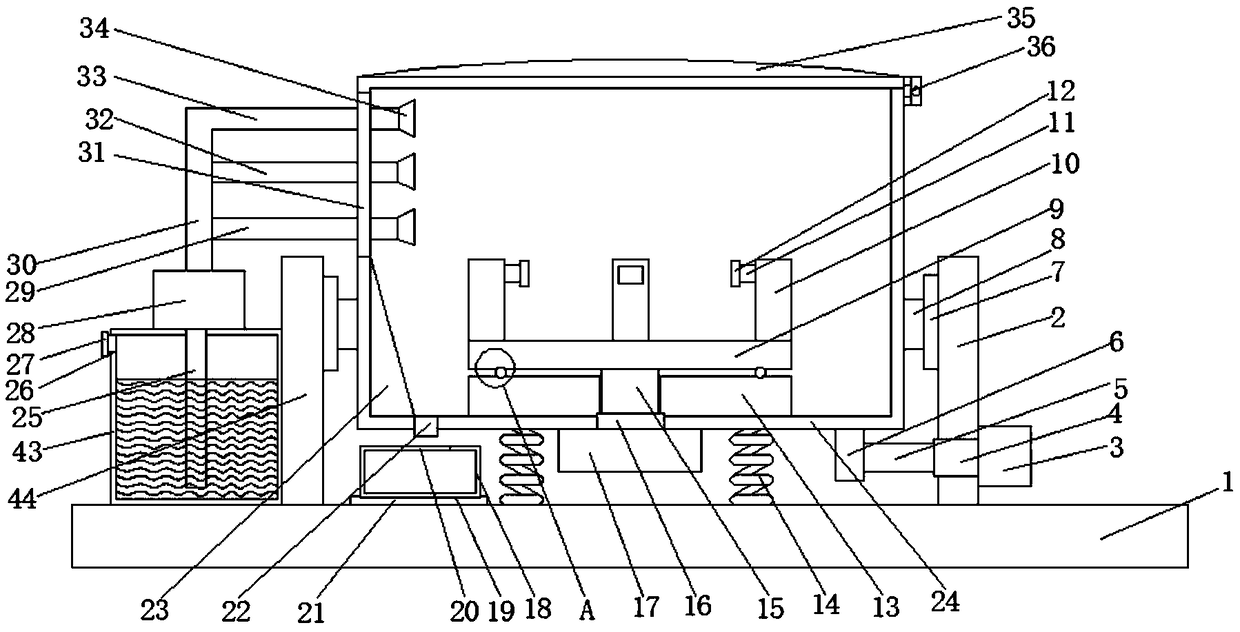

Centrifugal vibrating type multi-point-location daily ceramic glazing machine

The invention provides a centrifugal vibrating type multi-point-location daily ceramic glazing machine, and relates to the field of ceramic glazing. The centrifugal vibrating type multi-point-locationdaily ceramic glazing machine comprises a pedestal, wherein left and right sides of the top of the pedestal are separately connected with a second supporting plate and a first supporting plate; upperparts of opposite surfaces of the first supporting plate and the second supporting plate are connected with slide plates; and ends, away from the supporting plates, of the two slide plates are connected with slide rods. According to the centrifugal vibrating type multi-point-location daily ceramic glazing machine provided by the invention, a glaze pumping shaft is used for pumping glaze, and glaze is sprayed through a first branch tube, a second branch tube and a third branch tube; a first motor, a first rotary shaft, an eccentric wheel and a glazing box are connected, so that the glazing boxvibrates up and down; and a second motor, a second rotary shaft and a placing plate are connected, so that the placing plate rotates to generate centrifugal force, and therefore, ceramic glazing on the placing plate is more uniform and more convenient, and the inconvenient ceramic glazing problem and the uneven ceramic glazing problem are solved.

Owner:大埔县馨明园陶瓷有限公司

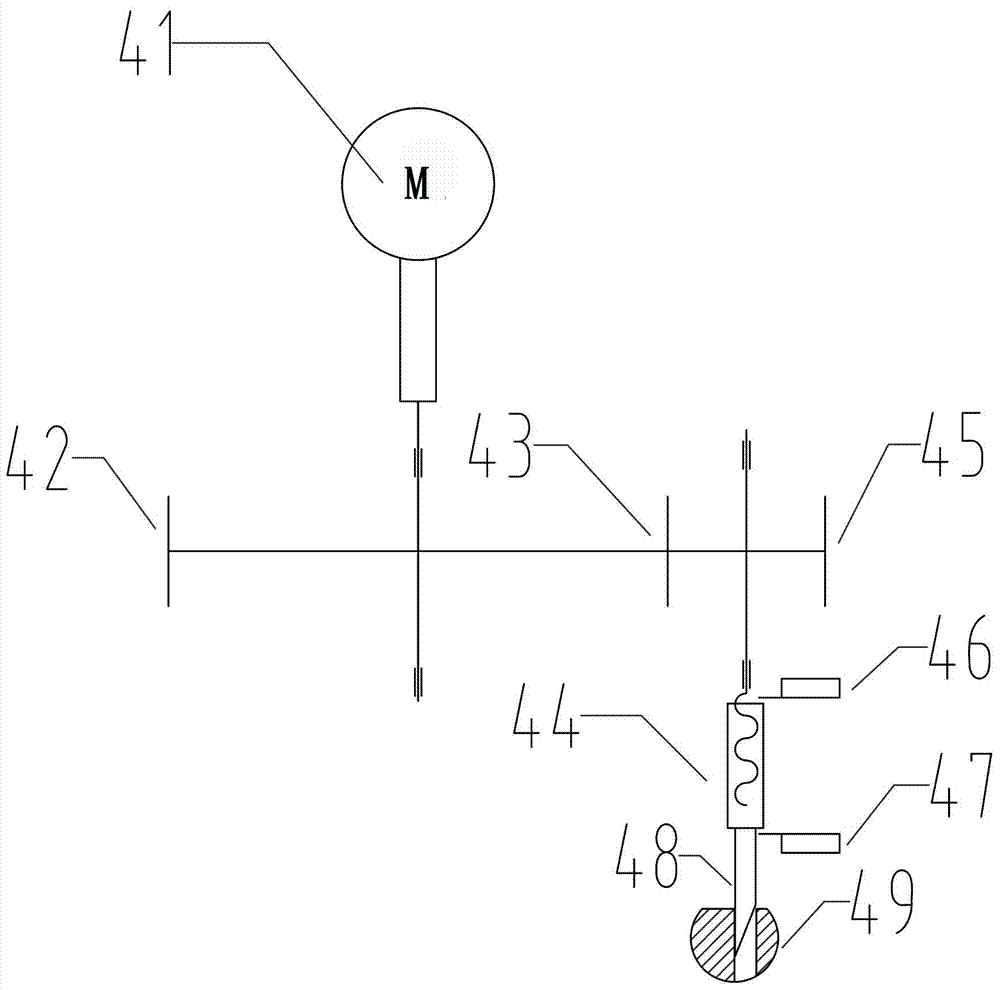

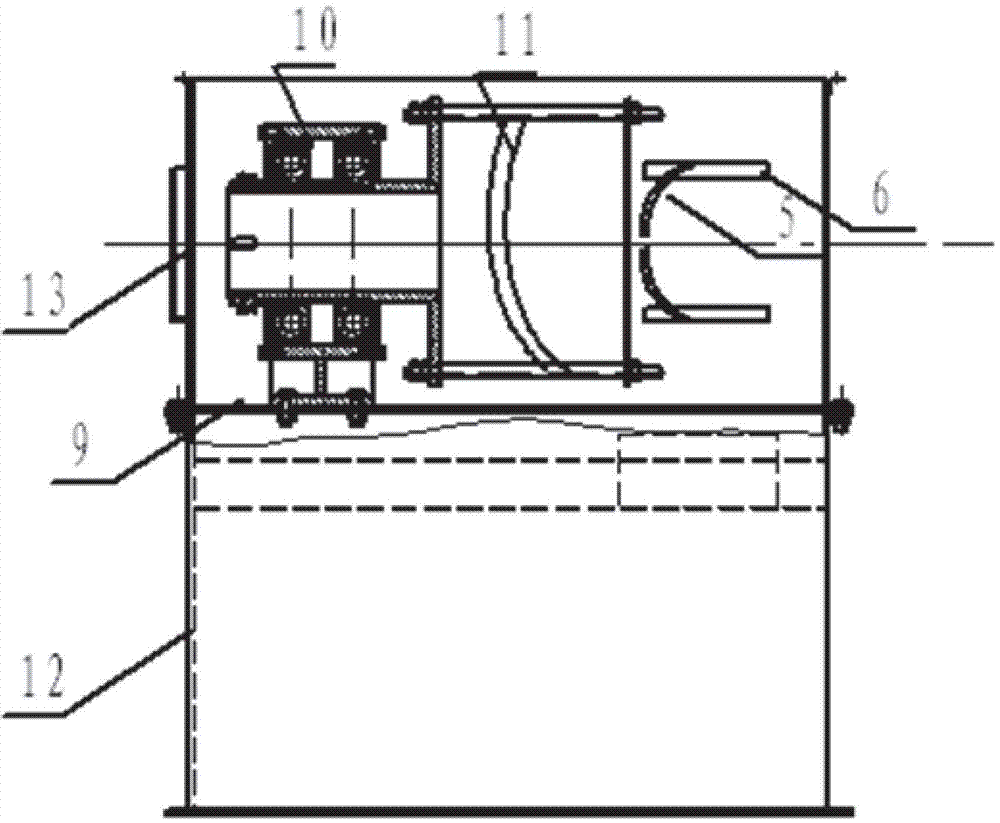

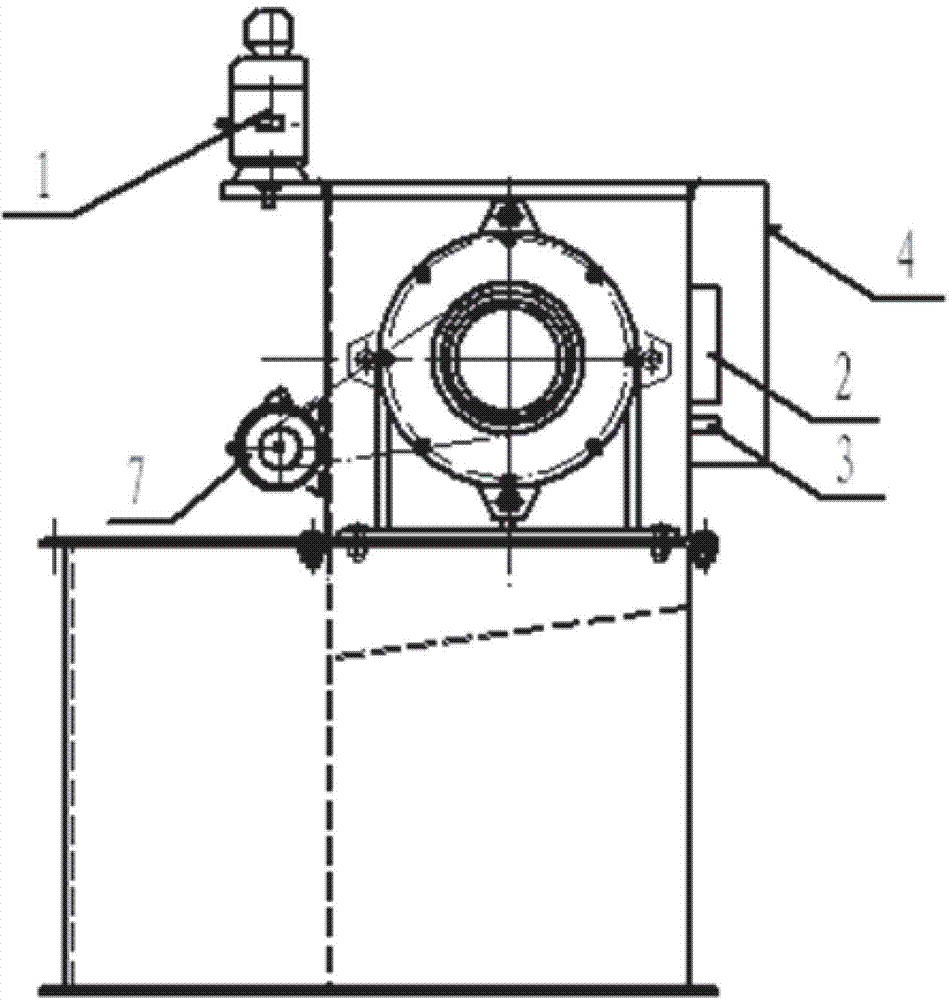

Adjustable scrapable high-voltage cable pitch coating device

ActiveCN102820107ASolve the problem of uneven sprayingSolve quality problemsCable/conductor manufactureFrequency changerLow speed

The invention discloses an adjustable scrapable high-voltage cable pitch coating device which comprises a sprayer (5) for painting pitch, a scraping belt (11) for performing scraped finishing on the surface of the cable painted with pitch, a variable frequency motor (1), a frequency converter (2), a programmable logic controller (3) and a potentiometer (4), wherein the potentiometer (4) presets analog quantity for flow of the pitch, signals of the potentiometer (4) are transmitted to the PLC (3) and then transmitted to the frequency converter (2) through digital operation of the PLC (3), the frequency converter (2) is provided with low-speed vectors for controlling actions of the variable frequency motor (1), and flow of a pitch pump is controlled by rotating speed of the variable frequency motor (1), so that the sprayer (5) is controlled to spray pitch with proper flow. The adjustable scrapable high-voltage cable pitch coating device effectively controls the flow of the pitch by adopting an electric automatic closed loop, solves the problem of even coating of the pitch and achieves stable coating during production of high-voltage cables.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

Spraying device for coating

The invention discloses a spraying device for a coating. The device comprises a base, wherein supporting columns are fixedly connected to the left and right sides of the top of the base; a first driven wheel is hinged to the top end of the supporting column on the right side of the top of the base; a motor is fixedly connected to the right side of the top of the base; a driving wheel is fixedly connected to the motor in a sleeving manner through a rotary shaft at one end of the motor; the driving wheel is in transmission connection to the first driven wheel through a first conveyor; a second driven wheel is hinged to the top end of the supporting column on the left side of the top of the base; and a second conveyor belt is in transmission connection to the surface of the second driven wheel. According to the spraying device for the coating, the coating on the surface of a coated product is brushed flatly uniformly by arranging an electric push rod and a brush plate, so that the problemthat the spraying device sprays the coating unevenly is solved. By arranging a material storage room, a first connecting pipe, a nozzle and a through hole, the coating can be more uniformly sprayed to the surface of the product, so that the spraying device sprays the coating more uniformly.

Owner:佘峰

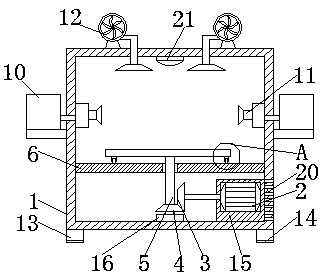

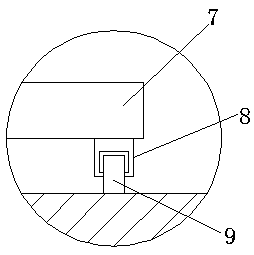

Uniform paint spraying device used for machining

InactiveCN109046859ASpray evenlySolve the problem of uneven sprayingSpray boothsEngineeringMachining

The invention discloses a uniform paint spraying device used for machining. The device comprises a box. A motor is arranged at the inner bottom of the box. An output shaft of the motor is fixedly connected with a first gear. The bottom of the first gear is engaged with a second gear. The interior of the second gear is fixedly connected with a rotary bar. The interior of the box is fixedly connected with a supporting plate. The top of the rotary bar penetrates through the supporting plate and is fixedly connected with an operating table. The two sides of the bottom of the operating table are fixedly connected with supports correspondingly. The bottoms of the supports are movably connected with vehicle wheels correspondingly. According to the uniform paint spraying device used for machining,by arranging the box, the motor, the first gear, the second gear, the rotary bar, the supporting plate, the operating table, the supports, the vehicle wheels, paint boxes, paint spraying machines andfans, the paint spraying device used for machining is made to have the advantage of uniform spraying, the working efficiency of the paint spraying device is improved, and meanwhile, the problem thata traditional paint spraying device used for machining is not uniform in spraying is solved.

Owner:ZHENGZHOU KANGXIAO TECH CO LTD

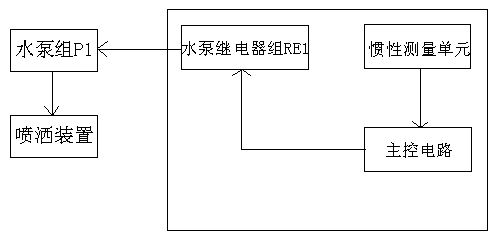

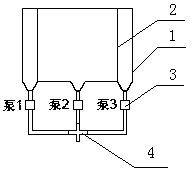

Intelligent sprinkling system and method based on plant-protecting unmanned aerial vehicle pressure-type spray heads

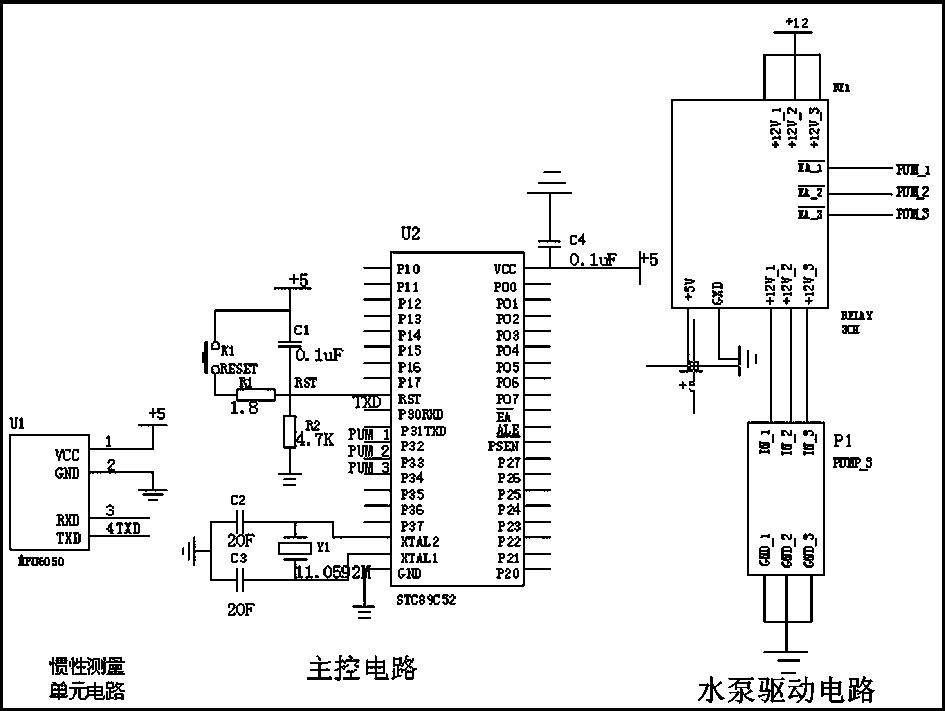

PendingCN108508809AOvercoming uneven sprayingSolve the problem of uneven sprayingProgramme controlComputer controlInertial measurement unitPesticide

The invention relates to an intelligent sprinkling system and method based on plant-protecting unmanned aerial vehicle pressure-type spray heads. The intelligent sprinkling system comprises a sprayingdevice and a control system. The spraying device consists of a pesticide tank, a water pump, a pesticide pipe and spraying heads. The control system consists of an inertial measurement unit, a mastercontrol circuit and a water pump driving circuit. The inertial measurement unit comprises an attitude sensor U1 for measuring the acceleration speed of a plant-protecting unmanned aerial vehicle, themaster control circuit comprises a master control chip U2, and the flight speed of the aerial vehicle is obtained by receiving the acceleration speed data of the attitude sensor U1 through time integration. The water pump driving circuit consists of a relay group RE1 and a water pump set. The intelligent sprinkling system and method based on plant-protecting unmanned aerial vehicle pressure-typespray heads achieves liquid pesticide concentration control by spraying different concentrations of pesticide at an acceleration stage, makes pesticide spraying uniform and improves the operating efficiency.

Owner:SHANXI AGRI UNIV

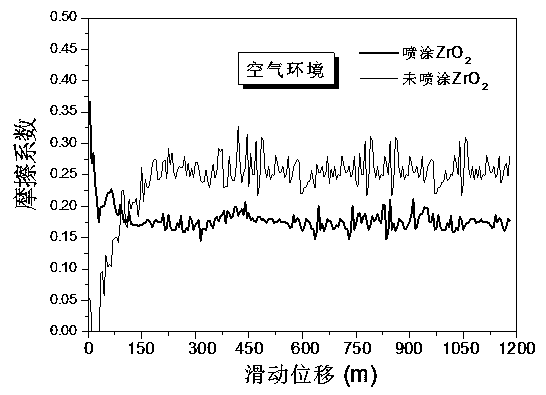

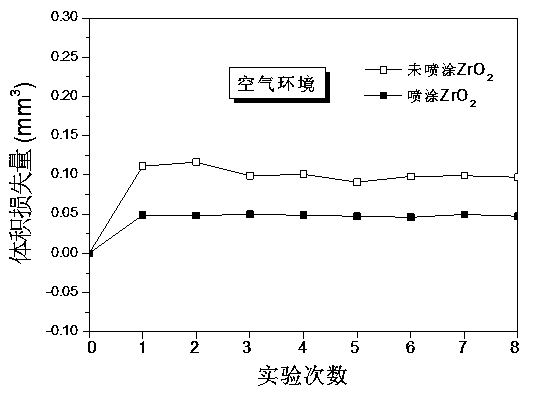

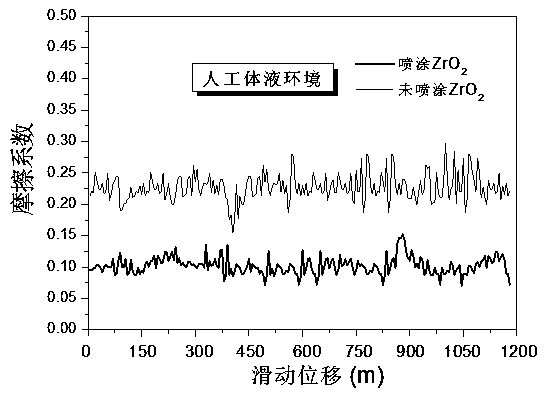

Technology method for improving surface abrasion resistance of laser additive manufacturing metal artificial knee joint

InactiveCN110923613AOvercome wear resistanceOvercome resilienceMolten spray coatingArticular surfacesSand blasting

The invention discloses a technology method for improving surface abrasion resistance of a laser additive manufacturing metal artificial knee joint, and belongs to the technical field of surface treatment. The technology method comprises the following steps that firstly, sand blasting treatment is conducted, sand blasting treatment is conducted on the surface of the artificial knee joint, and thesurface roughness reaches Ra3.2; secondly, preheating treatment is conducted, the artificial knee joint is heated to 40-50 DEG C, and nanometer zirconia powder is sprayed and heated to 40-50 DEG C; and thirdly, spraying is conducted, and zirconia ceramic powder is used for conducting plasma spraying on the sprayed surface. Nanometer zirconia particles are sprayed to the surface of the artificial knee joint, and inherent defects that a traditional knee joint is low in abrasion resistance, and full ceramic joint toughness is poor are overcome. A layer structure with anisotropism is formed on theceramic surface obtained after plasma spraying, the ceramic layer brittle fracture tendency can be greatly reduced through the structure, the structure and other structures are well matched after spraying, inherent forming and moving states of the knee joint cannot be influenced, the service life of the artificial knee joint is prolonged, and the pain of patients is reduced.

Owner:SHANDONG UNIV OF TECH

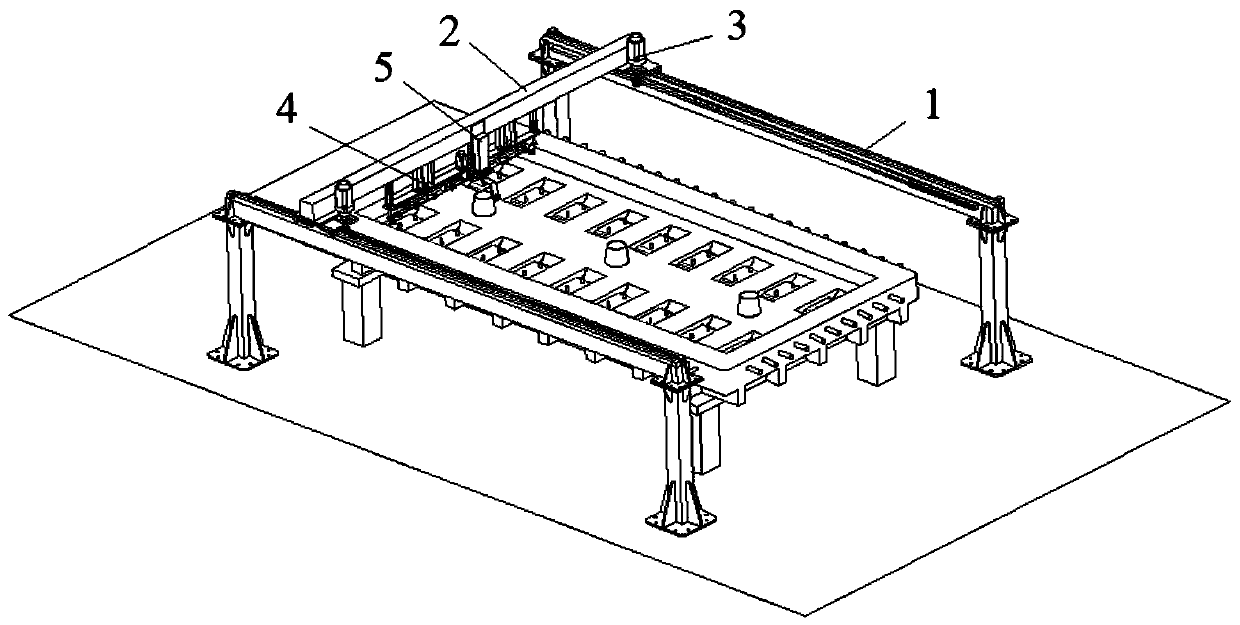

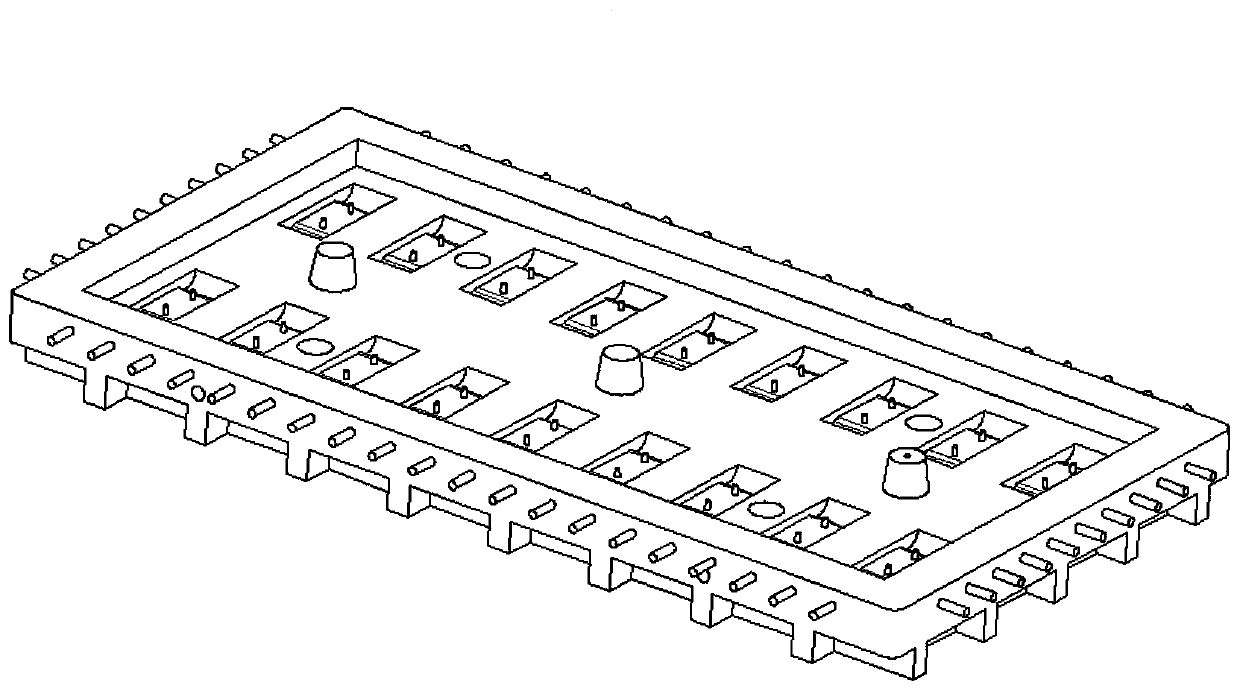

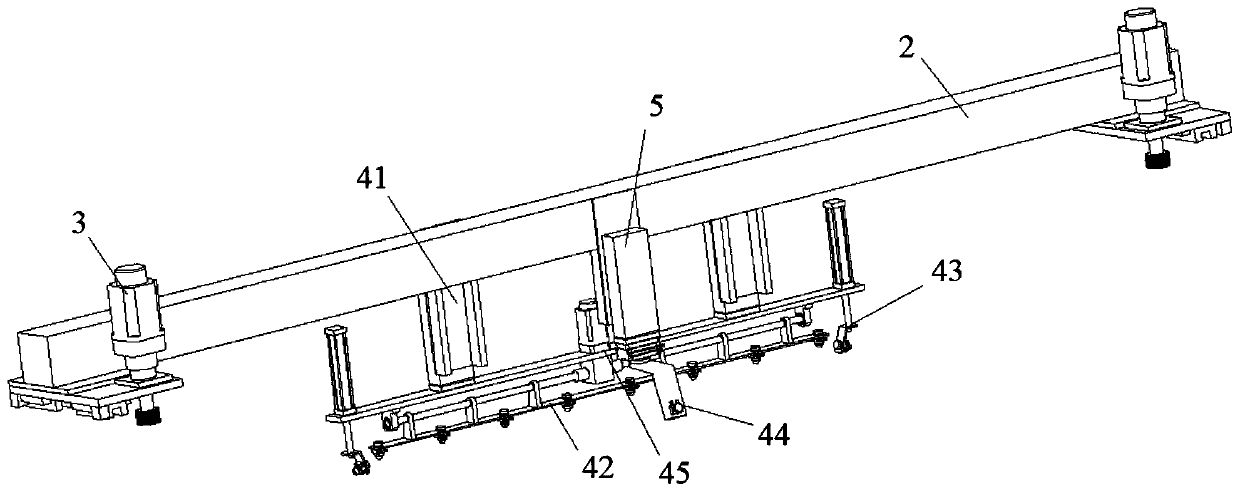

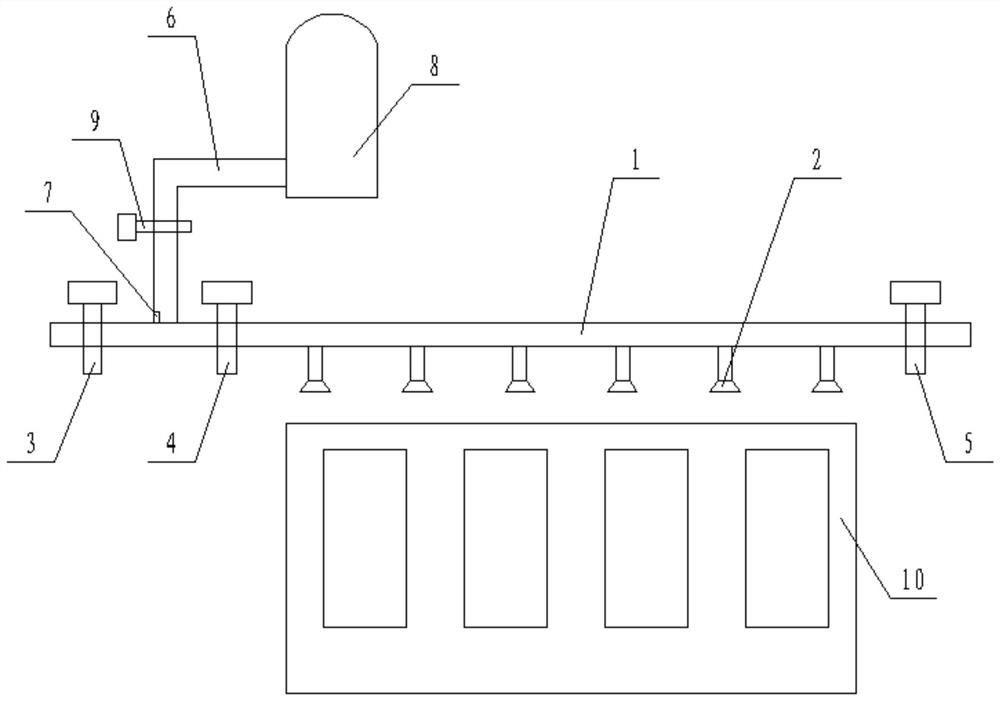

Spraying equipment for release agent for track board

The application provides spraying equipment for a release agent for a track board. The spraying equipment comprises guide rails, a movable cross beam and a spraying system arranged on the movable cross beam; the spraying system includes a lifting mechanism, a bottom face spraying mechanism, a side wall spraying mechanism, a middle spray nozzle and a rotating mechanism. In practical application, the bottom face spraying mechanism and the side wall spraying mechanism can be driven through the lifting mechanism to do vertical motion so as to spray the bottom face and the two longitudinal side walls of a mold, and then, the bottom face spraying mechanism is driven through the rotating mechanism to rotate, and thereby, a spraying direction is changed so as to spray the transversal side walls ofthe two ends of the mold; and still annular spraying is performed on a protrusion part in the mold through the middle spray nozzle. The spraying equipment can spray all parts of the mold, and makes all the parts uniform by controlling spraying time, and thereby, the problem of uneven spraying caused by a traditional release agent spraying method is solved.

Owner:北京好运达智创科技有限公司

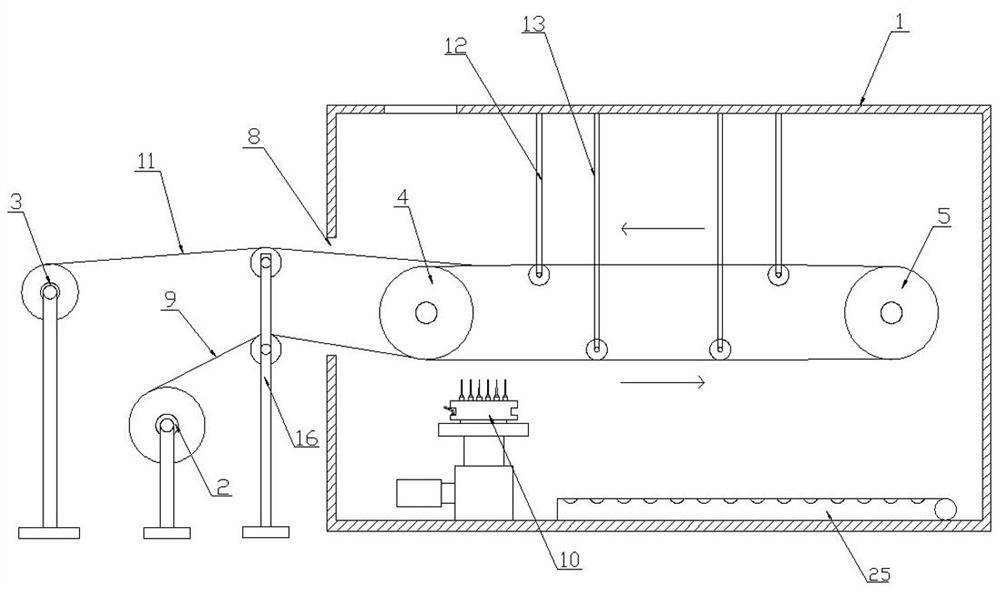

Matrix type multi-needle electrostatic spinning equipment

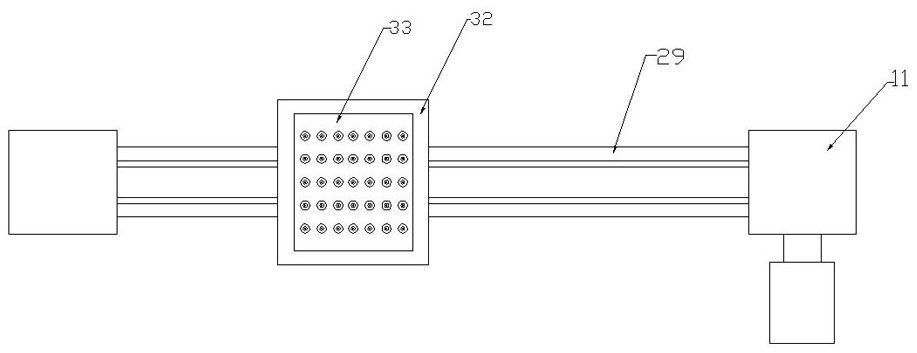

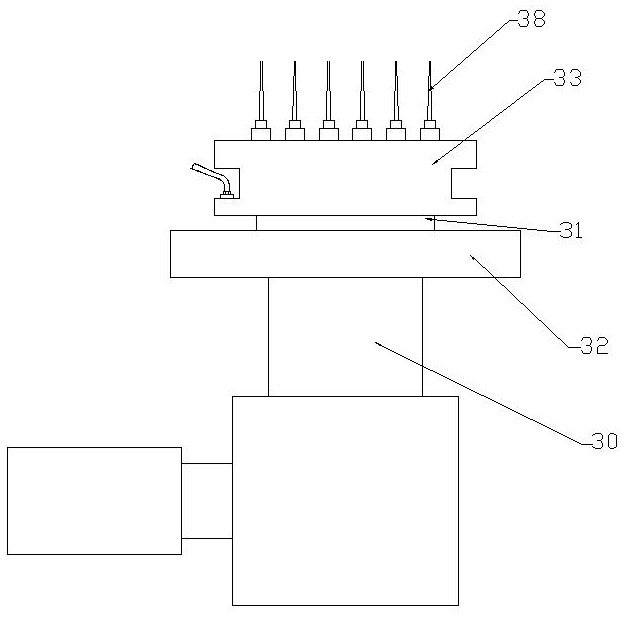

ActiveCN112301437ARealize continuous productionAchieve mass productionFilament/thread formingCoatingsSpinningNanofiber

The invention discloses matrix type multi-needle electrostatic spinning equipment which comprises an electrospinning chamber, a feeding mechanism and a collecting mechanism arranged outside one side of the electrospinning chamber, and a conveying mechanism and a spinning mechanism arranged in the electrospinning chamber, wherein the conveying mechanism comprises a driving roller, a driven roller and a steel belt arranged between the driving roller and the driven roller in a sleeving mode; a movable end of a non-woven fabric base material on a feeding roller penetrates through a material passing channel, then bypasses the driven roller along the lower surface of the steel belt, comes out of the upper part of the material passing channel and is wound on the collecting roller; and a spinningmechanism is arranged below the steel belt close to one side of the driving roller and is used for spraying an electrostatic spinning raw material on the surface of the non-woven fabric base materialto form a nanofiber membrane layer. The electrostatic spinning device integrates the functions of feeding, spinning, drying and collecting; the integrated large electrostatic spinning equipment capable of achieving continuous production is formed; the conveying mechanism of the equipment is more stable, spinning is more uniform, and the automation degree and the production efficiency are higher.

Owner:河南曼博睿新材料科技有限公司

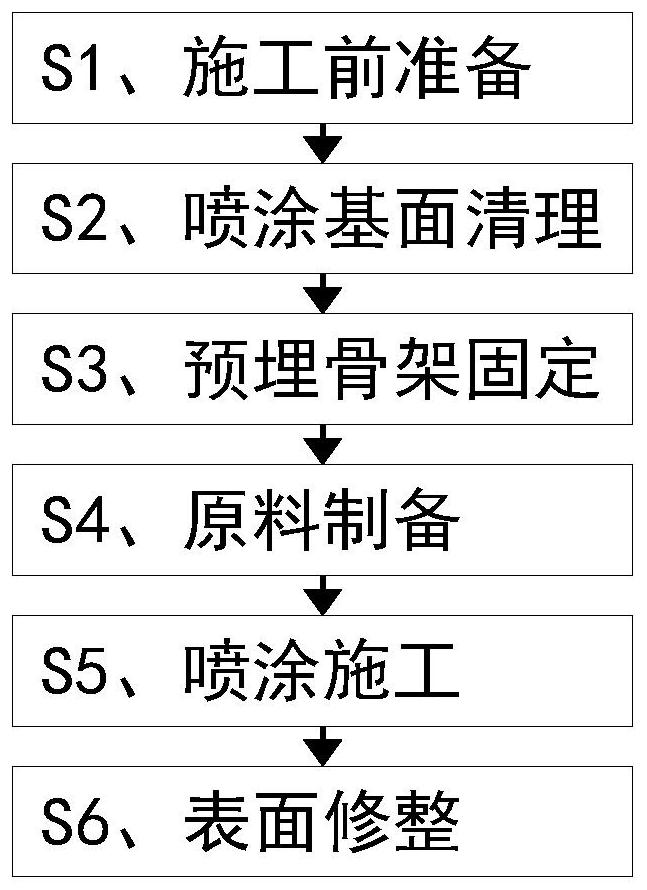

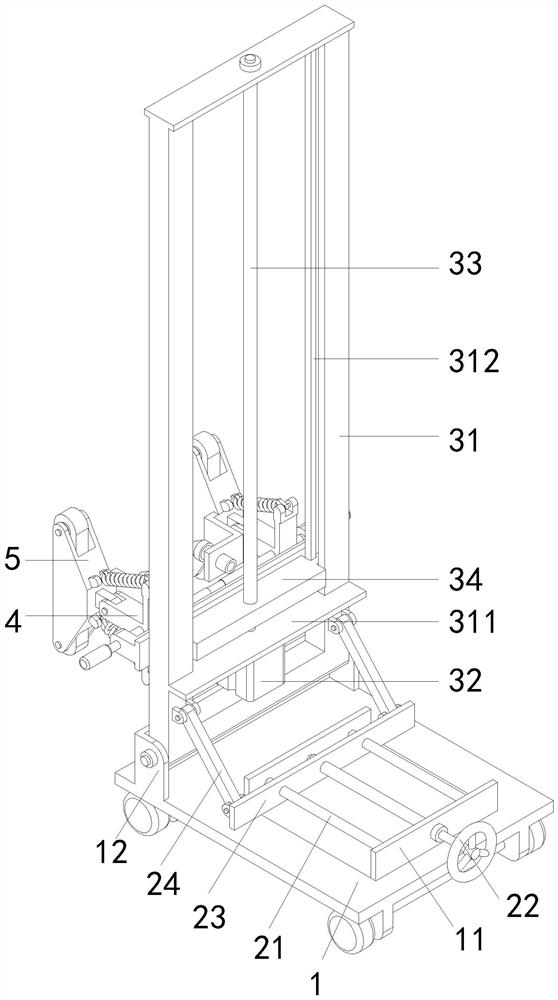

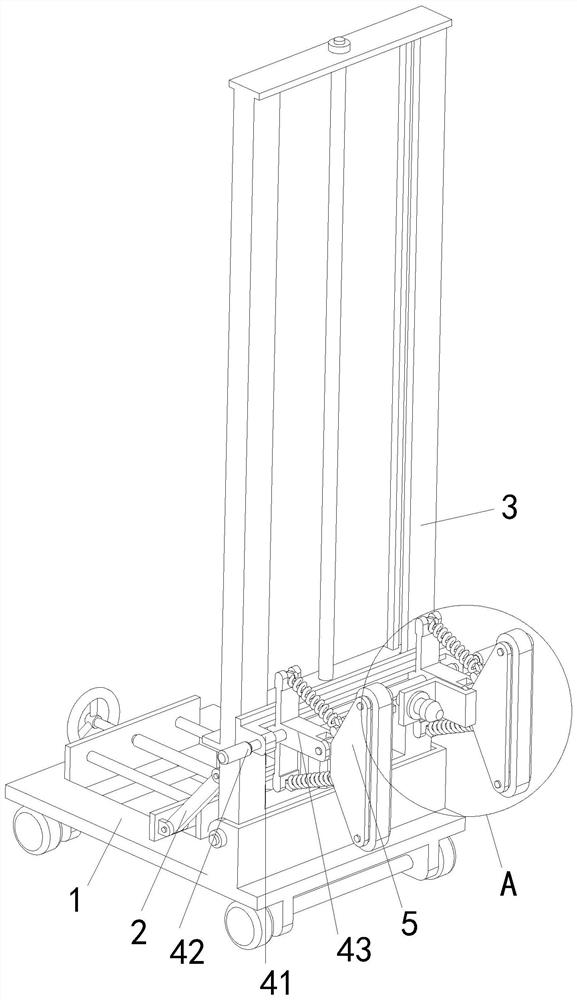

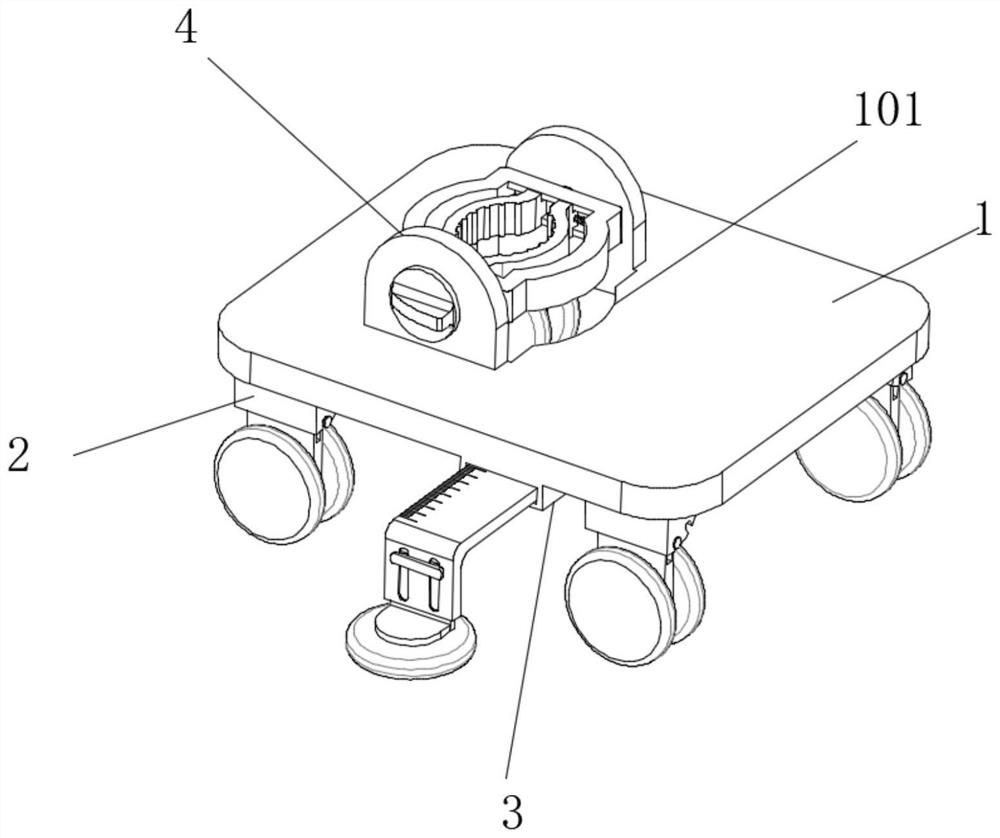

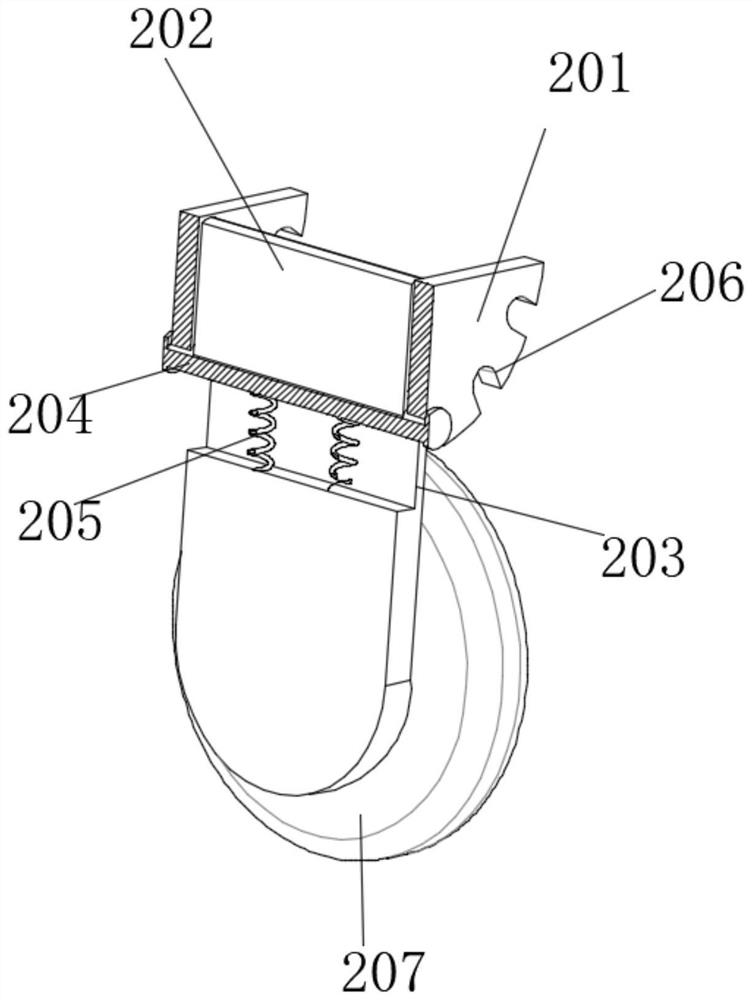

Building energy-saving reconstruction heat preservation outer wall building construction method

The invention relates to a building energy-saving reconstruction heat preservation outer wall building construction method, in particular to an inorganic fiber spraying heat preservation outer wall auxiliary spraying construction device. The device comprises a walking vehicle, an angle adjusting mechanism, a spraying walking mechanism, a distance adjusting mechanism, and a framework covering mechanism. By means of the inorganic fiber spraying heat preservation outer wall auxiliary spraying construction device, auxiliary construction can be carried out in cooperation with manpower in the inorganic fiber spraying process, so that the problems that later cleaning is inconvenient and the workload is increased due to the fact that inorganic fibers are bonded to an embedded framework are solved, the problem that spraying at the high position of a wall is inconvenient is solved, and the problems that spraying is uneven and materials are wasted due to the fact that the spraying distance is too long and spraying is too dispersed are solved.

Owner:青岛盈鑫建设集团有限公司

Automatic spraying device with uniform spraying

InactiveCN109332045ASolve the problem of uneven sprayingSpray evenlyLiquid spraying apparatusGear wheelElectric machinery

The invention discloses an automatic spraying device with uniform spraying. The automatic spraying device comprises a base, wherein supporting legs are fixedly connected to the bottom of the base; a shell is fixedly connected to the middle of the bottom of the base; a motor is fixedly connected to the right side of the bottom of an inner cavity of the shell; the output end of the motor is fixedlyconnected with a first gear; and the left side of the first gear is meshed with a second gear. By virtue of matched use of the base, the supporting legs, the shell, the motor, the first gear, the second gear, a placing plate, a support, rollers, an iron barrel body, a groove, a first water level sensor, a material discharging pipe, a first pipe sleeve, a box body, a controller, a first feeding pipe, a second pipe sleeve, an alarm module, a water pump, a spray head, a second feed pipe, a discharge pipe, a second water level sensor, a central processing unit and a power supply module, the problem that an existing automatic spraying device is uneven in spraying is solved; and the automatic spraying device has the advantages of being uniform in spraying and worthy of popularization.

Owner:河南中恒网络科技有限公司

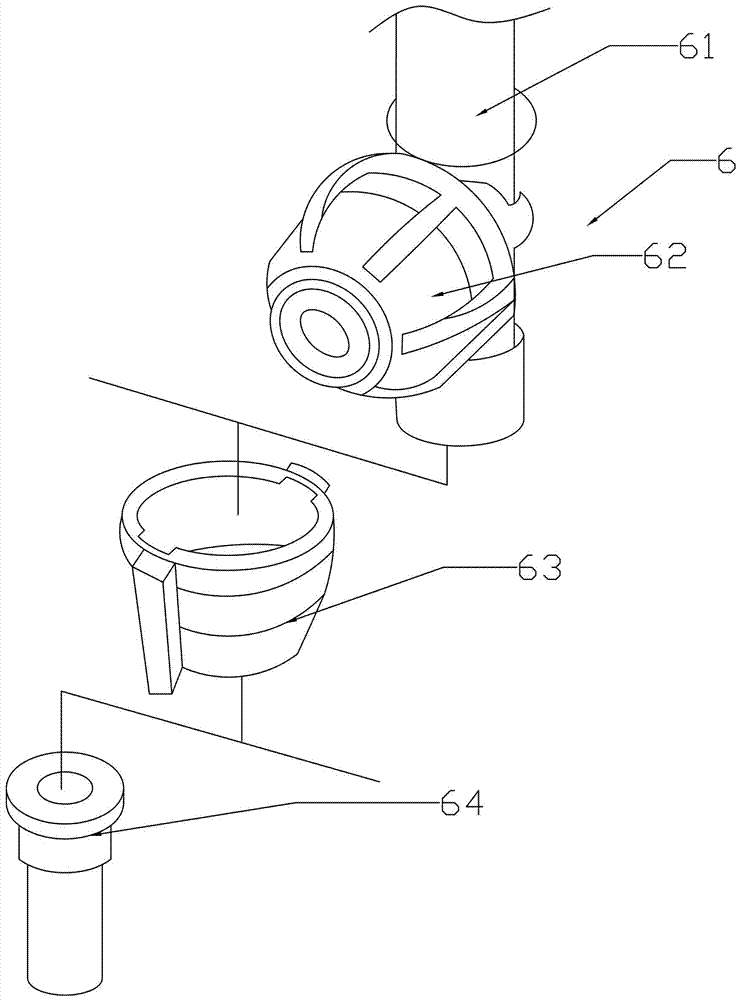

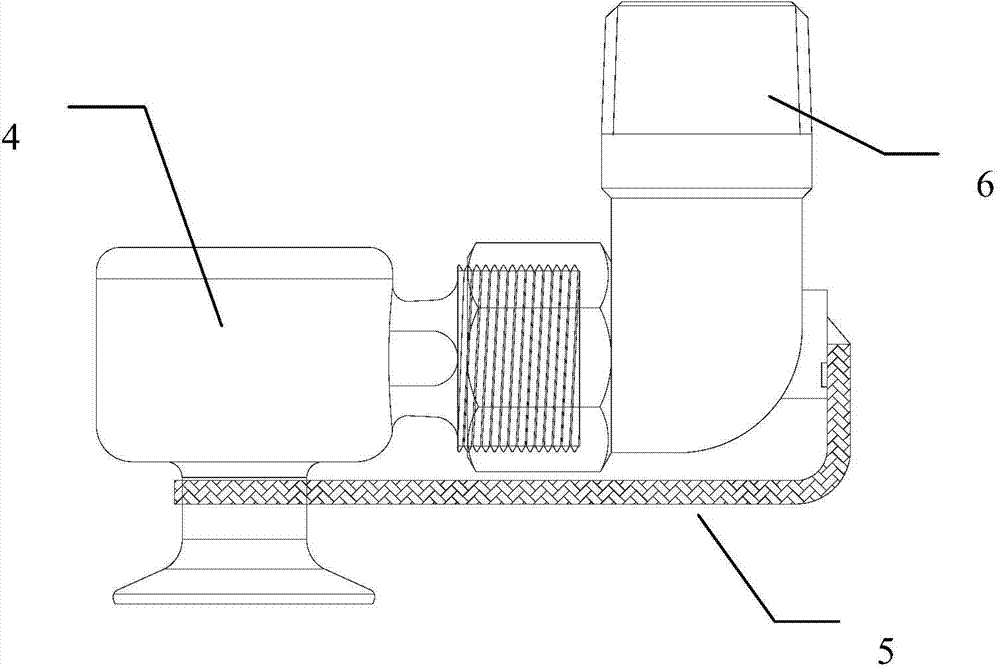

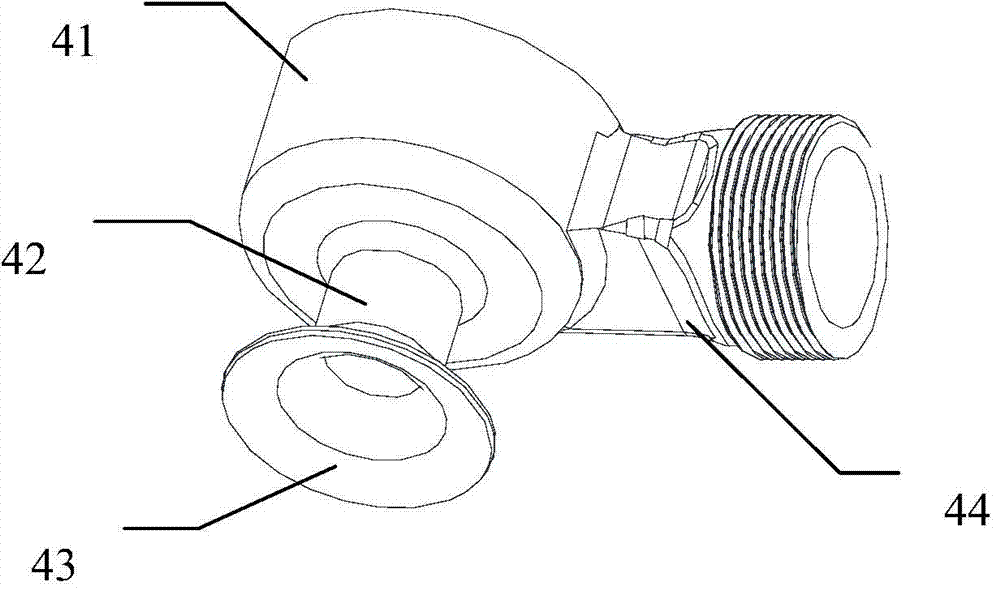

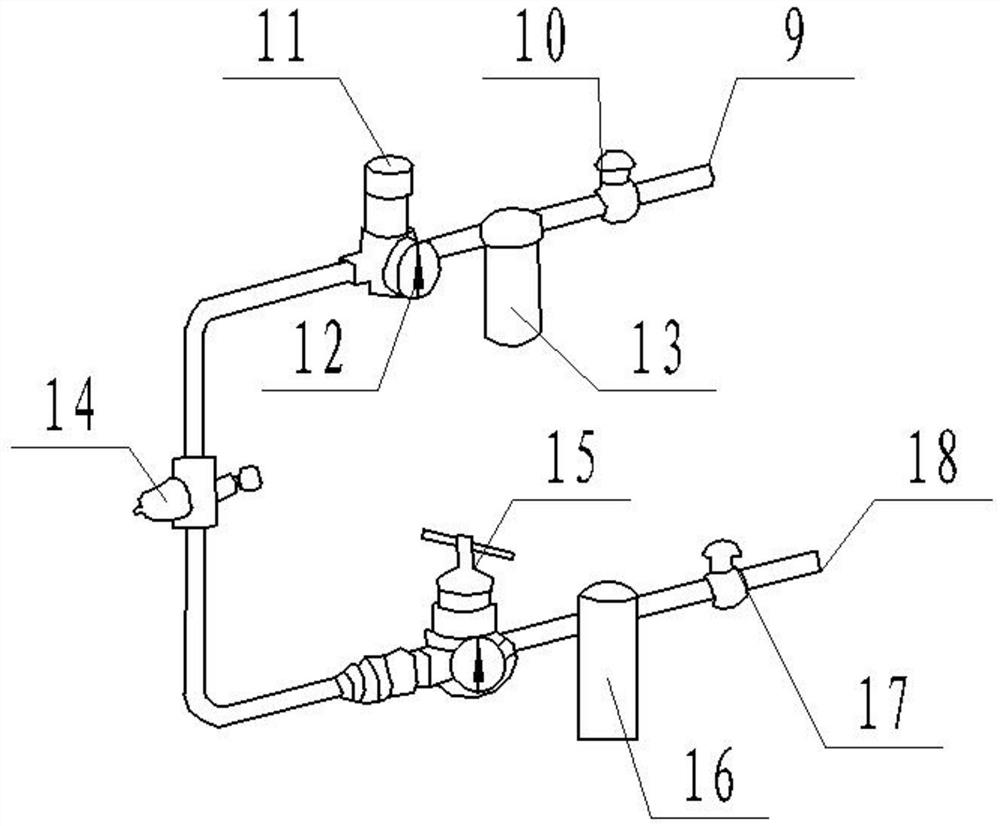

Sea water spraying system of sea water desalting device

InactiveCN103570089AStable structureImprove spray uniformityGeneral water supply conservationSeawater treatmentDesalinationSystem requirements

The invention provides a sea water spraying system of a sea water desalting device, which is arranged in an evaporator device of a sea water desalting system and comprises a supporting frame, a spraying pipe and more than one nozzle, wherein the spray pipe comprises a spraying main pipe and a spraying branch pipe; nozzle connection seats are uniformly arranged on the spraying branch pipes; the nozzle is connected on the corresponding nozzle connection seat and a tangential centrifugal nozzle; a nozzle adapter is arranged between the nozzle and the nozzle connection seat; and the nozzle adapter is respectively in threaded connection with the nozzle and the nozzle connection seat, and is fixed with thread sealant. According to the invention, the structure and performance of the novel spraying system meet the requirements of the sea water desalting device; and the nozzle is firm in structure and has favorable spraying uniformity, and the spray particle size conforms to MED system requirements, thereby being beneficial to improve outlet water quality of the system, heat transfer of the evaporator and stable operation of the system. Besides, the problem of nonuniform spraying is solved, and the sea water spraying system plays a significant role in ensuring safe operation of equipment and preventing formation of hard scales of a heat exchange pipe.

Owner:ZHONGHE SEAWATER DESALINATION ENG

Paint spraying gun of paint spraying equipment

InactiveCN106140522AReasonable structurePaint objects evenly and efficientlyLiquid spraying apparatusSpray nozzleWrench

The invention discloses a paint spraying gun of paint spraying equipment. The paint spraying gun comprises a gun body. A detachable oil spray nozzle is installed on one side of the gun body, and a filter net is fixed to one side of the interior of the gun body; an atomizer is fixedly installed on one side of the filter net, an oil storage bin is fixed to one side of the atomizer, and a water valve is installed at the upper end of the middle of the oil storage bin in an embedded manner; a wrench is installed at the lower end of the middle of the gun body, a spring is fixed to one side of the wrench, and the spring is installed in the gun body; a pressurizer is installed on one side of the spring and also installed in the gun body, the spring is also fixed to the lower end of the pressurizer, and the spring is installed outside an air supply tube; an oil conveying tube is installed outside the air supply tube, and the oil conveying tube wraps the spring and the air supply tube and is fixed to the lower end of the pressurizer; and the oil conveying tube, the spring and the air supply tube are all installed in a handle, and a cable connecting device is installed on the left side of the lower end of the handle in an embedded manner. According to the paint spraying gun, oil paint can be evenly brushed, meanwhile, materials are saved, and paint spraying quality is improved.

Owner:成都元始信息科技有限公司

Anti-seismic adjustable anti-corrosion steel structure support coating

ActiveCN114082569ASpray evenlySolve the problem of uneven sprayingSpraying apparatusEngineeringMechanical engineering

The invention discloses an anti-seismic adjustable anti-corrosion steel structure support coating, and relates to the technical field of coating equipment. A mounting plate is arranged, sliding assemblies are arranged at the four corners of the lower surface of the mounting plate, a guide assembly is fixedly connected to the middle of the lower surface of the mounting plate, and a spray gun clamping assembly is fixedly connected to the middle of the upper surface of the mounting plate; each sliding assembly comprises two symmetrically-distributed arc-shaped plates, the top ends of the inner sides of the arc-shaped plates are movably connected with movable plates through pin shafts, and the two sides of the inner sides of the movable plates are movably connected with rolling wheels through bearings. According to the device, the mounting plate, the sliding assembly, the guide assembly and the spray gun clamping assembly are arranged, the mounting plate is matched with the sliding assembly, so that the device can slide on the surface of the steel structure support; the guide assembly is arranged, the sliding track of the device is fixed, then paint can be evenly sprayed, and the spray gun clamping assembly can fix a spray gun to the device, so that the problem that a handheld spray gun is uneven in spraying is solved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

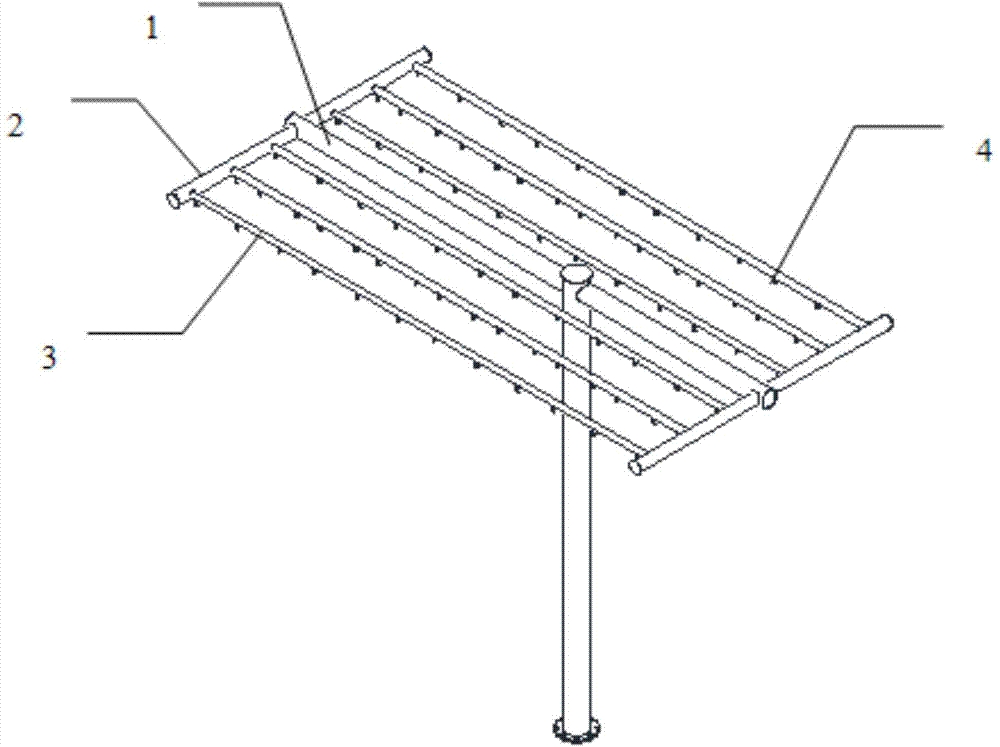

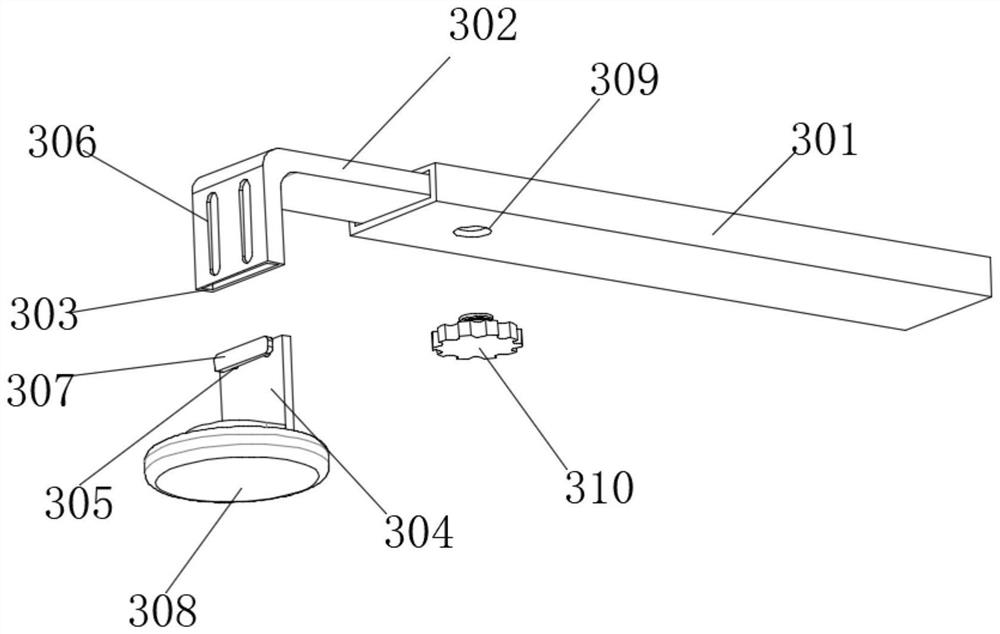

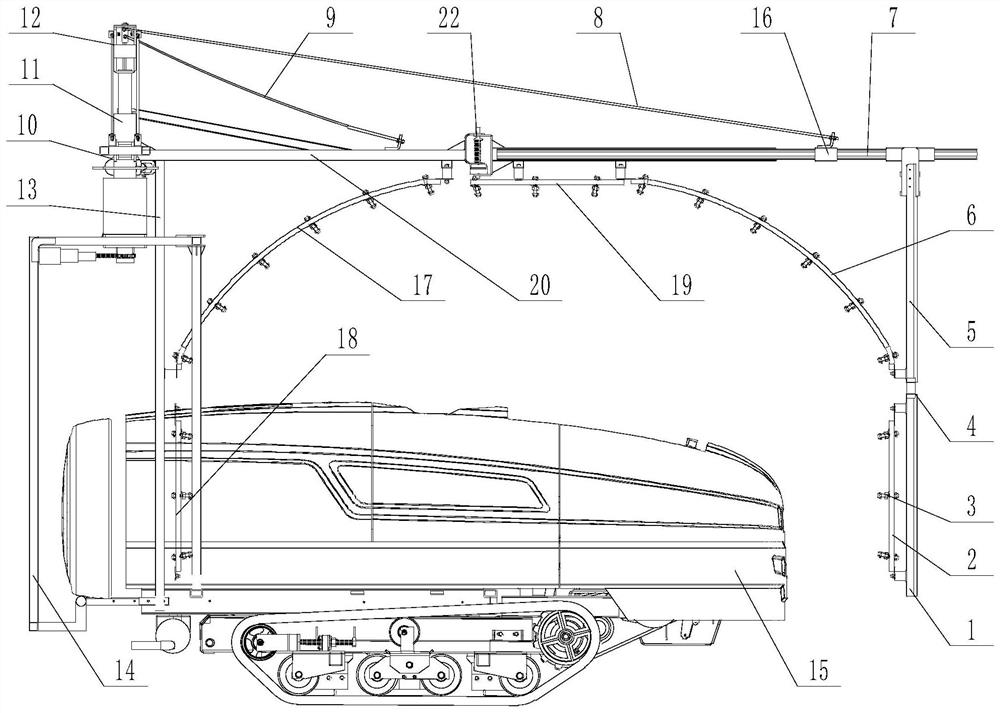

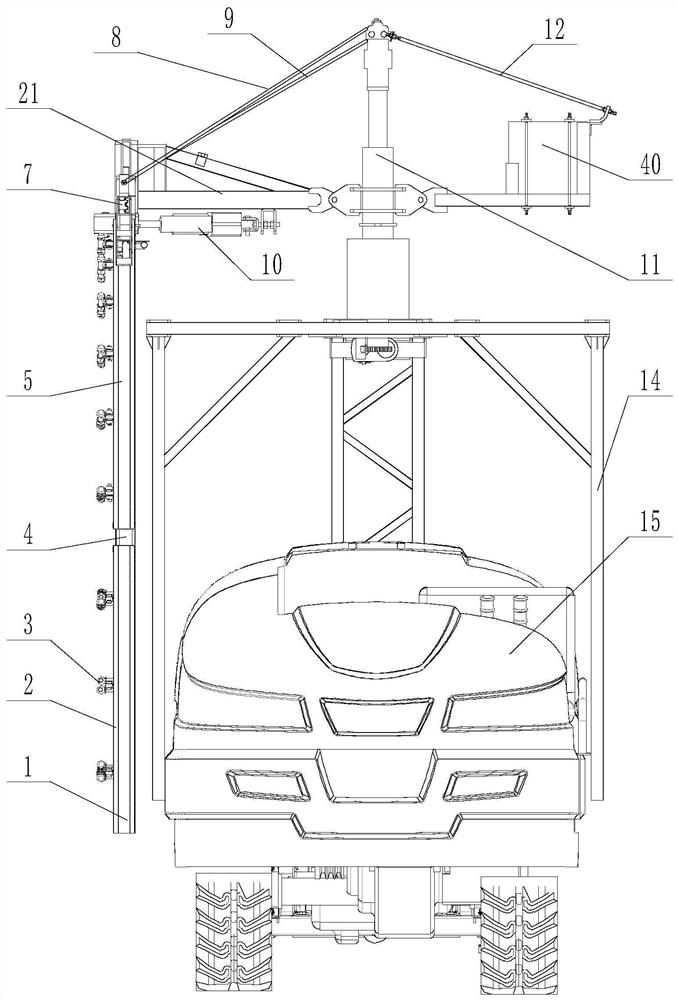

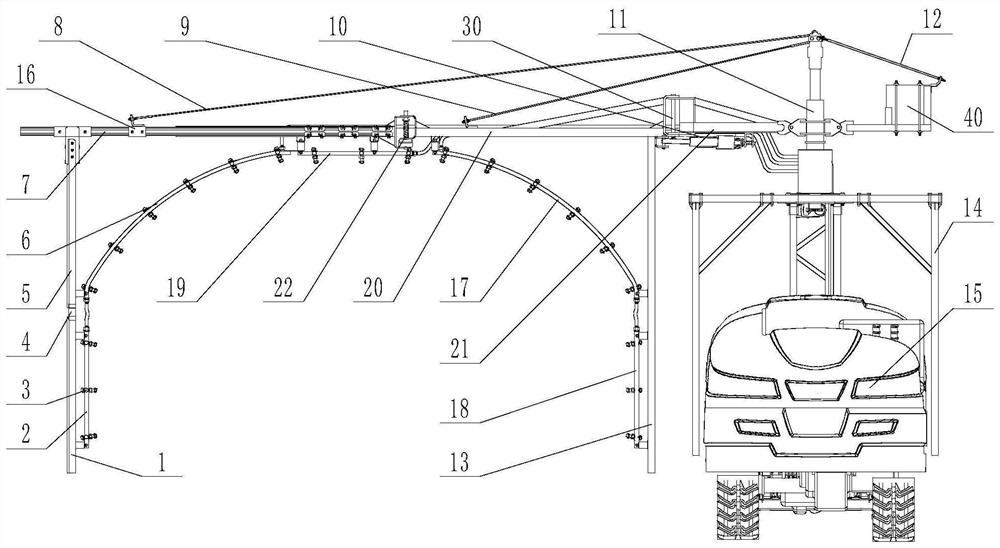

Gantry type orchard spraying mechanism

PendingCN112889782ASolve the problem of uneven sprayingAdapt to work modePlant protectionInsect catchers and killersAgricultural engineeringMechanical engineering

The invention discloses a gantry type orchard spraying mechanism, and belongs to the technical field of agricultural machinery. The gantry type orchard spraying mechanism overcomes the defect that in the prior art, a traditional orchard spraying mechanism is not suitable for terraced field spraying. The main body structure of the gantry type orchard spraying mechanism comprises a rack, wherein a rotating mechanism is arranged on the rack, a leveling mechanism and a spraying rod fixing arm are arranged on the rotating mechanism, the spraying rod fixing arm is connected with a spraying rod through a spraying rod connecting arm and a spraying rod anti-collision mechanism, and a spraying rod support mechanism is arranged at the lower end of the spraying rod connecting arm and the lower end of the spraying rod. The gantry type orchard spraying mechanism is mainly used for plant protection spraying operation of orchards.

Owner:SHANDONG YONGJIA POWER

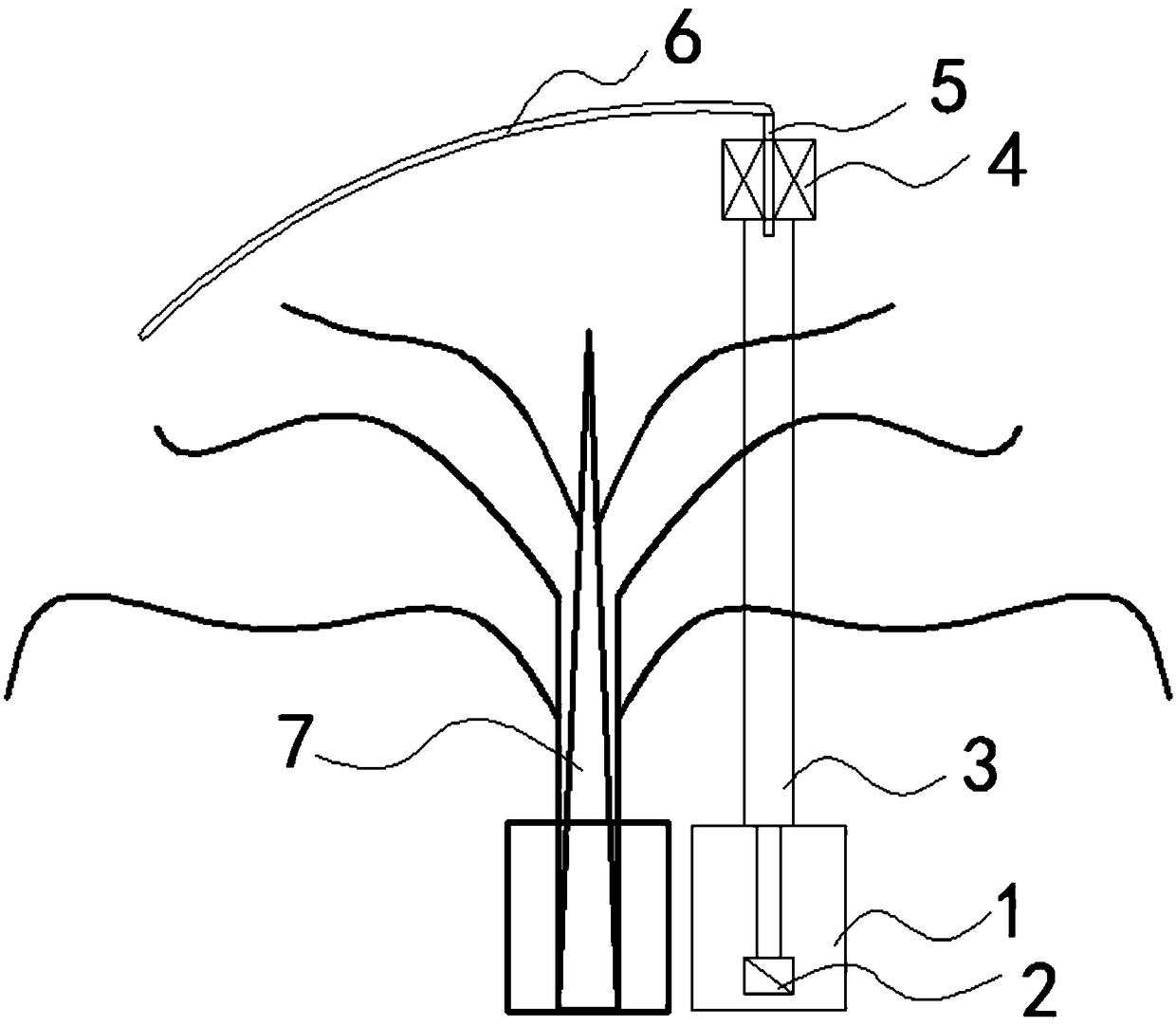

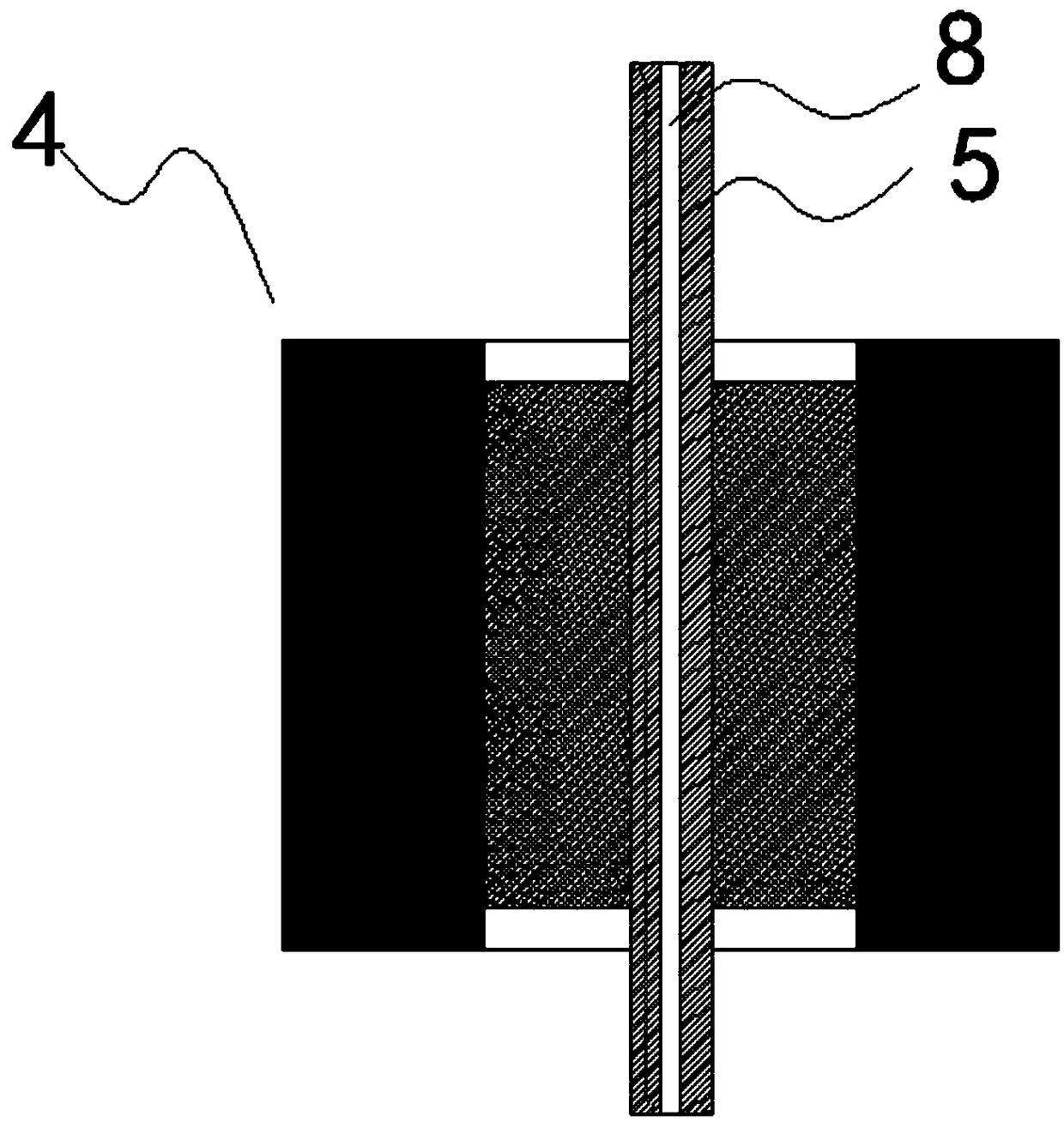

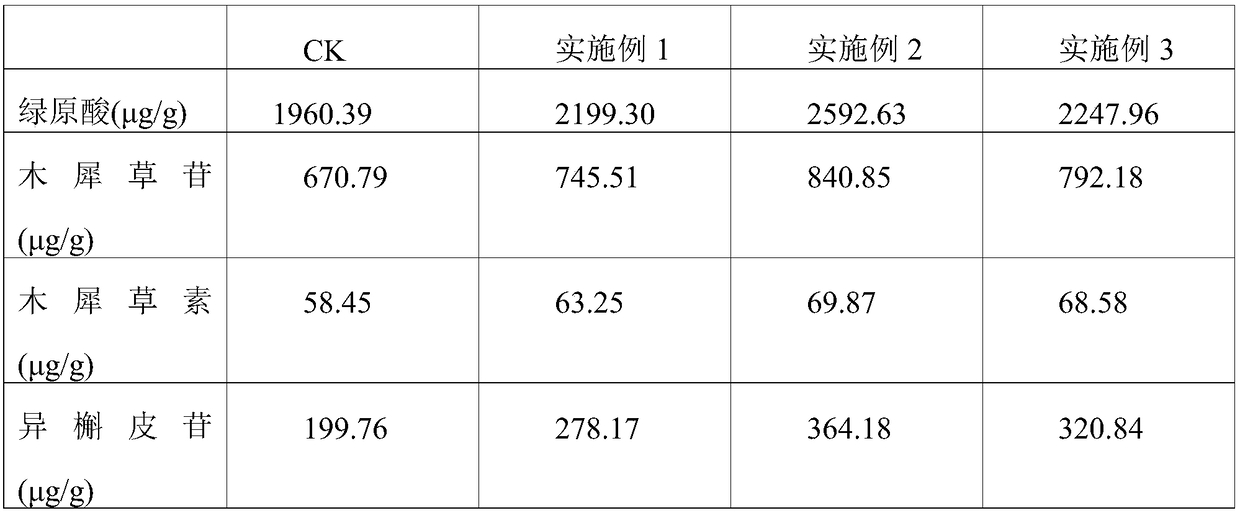

Planting method for improving quality of Lonicera japonica

ActiveCN108934678APromote photosynthesisPromote accumulationMovable spraying apparatusFertilising methodsActive componentBud

The invention discloses a planting method for improving the quality of Lonicera japonica. The planting method comprises the steps of: spraying gibberellin to Lonicera japonica plants when Lonicera japonica plants grow to an early stage of a first crop of young flowerbuds, wherein the mass concentration of the gibberellin is 200 mg*L<-1> to 400 mg*L<-1>. Specifically, the planting method includes:fertilizing the Lonicera japonica plants, conducting topdressing, and spraying gibberellin until harvest. By reasonable fertilization and topdressing, the method can further ensure sufficient nutrients for better photosynthesis of plants, increase accumulation of nutrients, promote flower bud differentiation of plants, and increase yield of Lonicera japonica. By applying the gibberellin solution to flower buds in the early stage of the first crop of flowerbuds, the method disclosed by the invention can increase the content of the active components of the Lonicera japonica, such as chlorogenicacid, luteoloside, luteolin and isoquercitrin.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

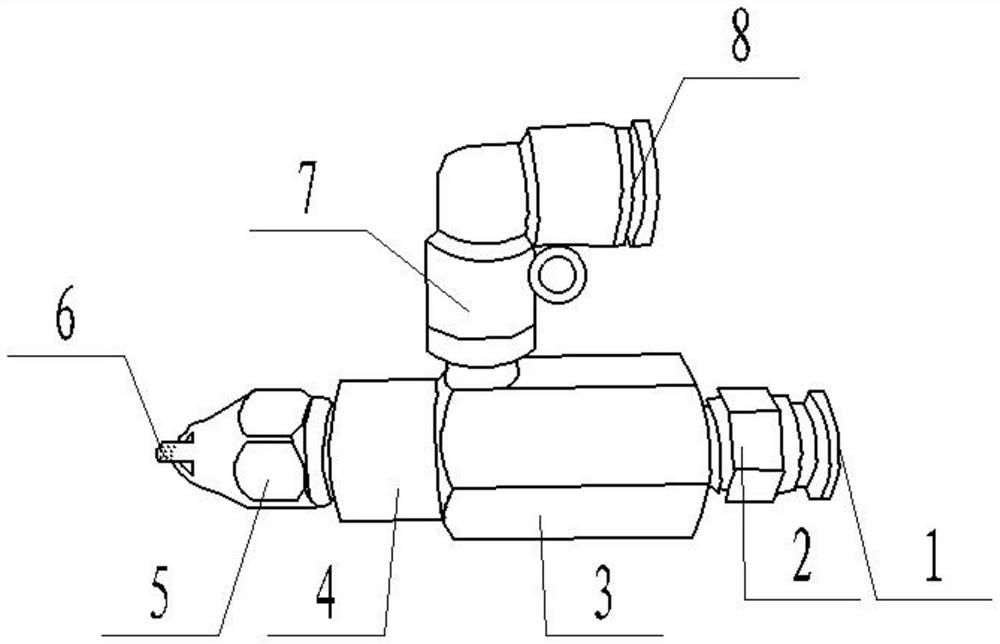

Mining dust removal spray head

InactiveCN112337668AWide range of useEasy to operateLiquid spraying apparatusAerosolizationStructural engineering

The invention discloses a mining dust removal spray head comprising an air inlet pipe connector, a locking nut, a spray head base body and a nozzle connecting sleeve, the locking nut is arranged at one end of the spray head base body, the air inlet pipe connector is arranged on one side of the locking nut, and the nozzle connecting sleeve is arranged at the other end of the spray head base body. An atomizing nozzle is arranged on the nozzle connecting sleeve, an atomizing hole is formed in the atomizing nozzle, a connecting bend is arranged above the spray head base body, a water inlet pipe connector is arranged at one end of the connecting bend, an air pressure regulating valve is arranged at the air inlet pipe connector, and a pressure gauge is arranged at the air pressure regulating valve. The dust removal spray head has the beneficial effects that the dust removal spray head adopts a pressure spraying mode, the water pressure is adjusted by changing the pressure of air, then the water spraying height is adjusted, impurities in the air and liquid can be filtered through a filter, the impurities are prevented from blocking the atomizing nozzle, and the service life of the dust removal spray head is effectively prolonged.

Owner:眭丽琼

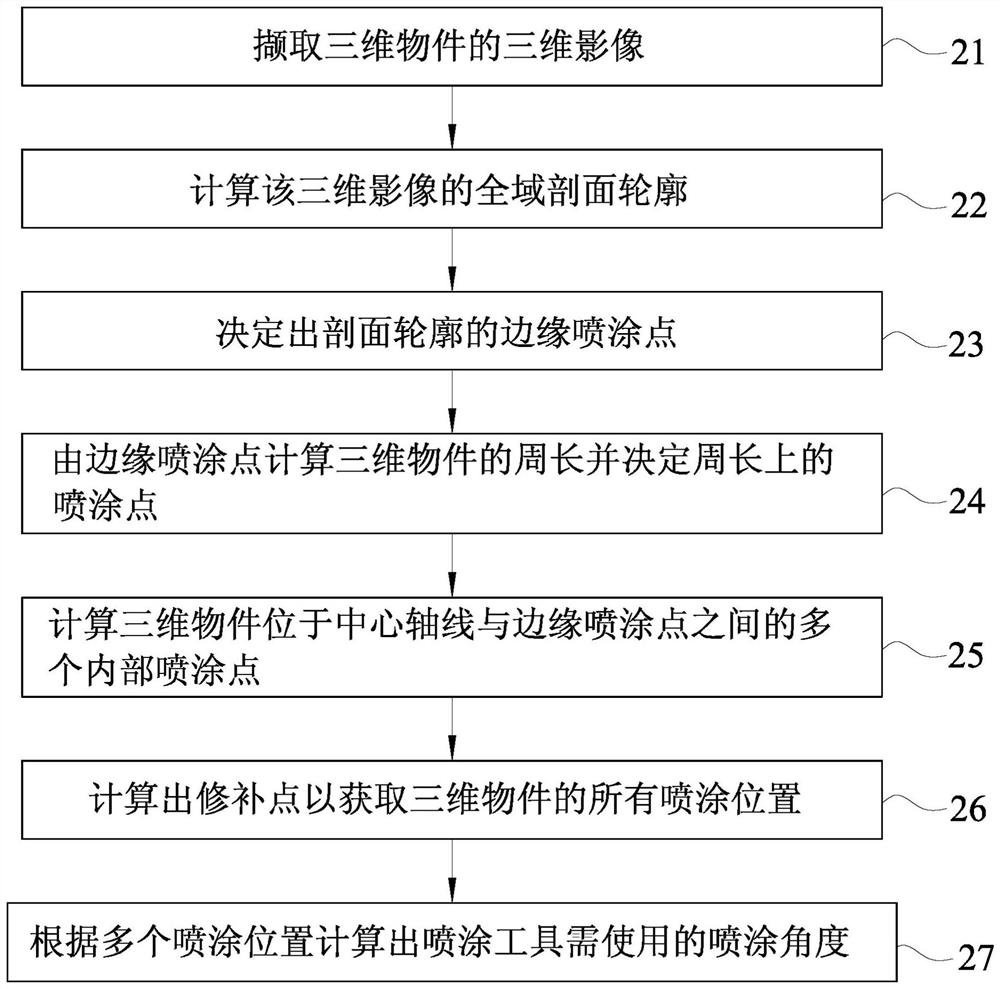

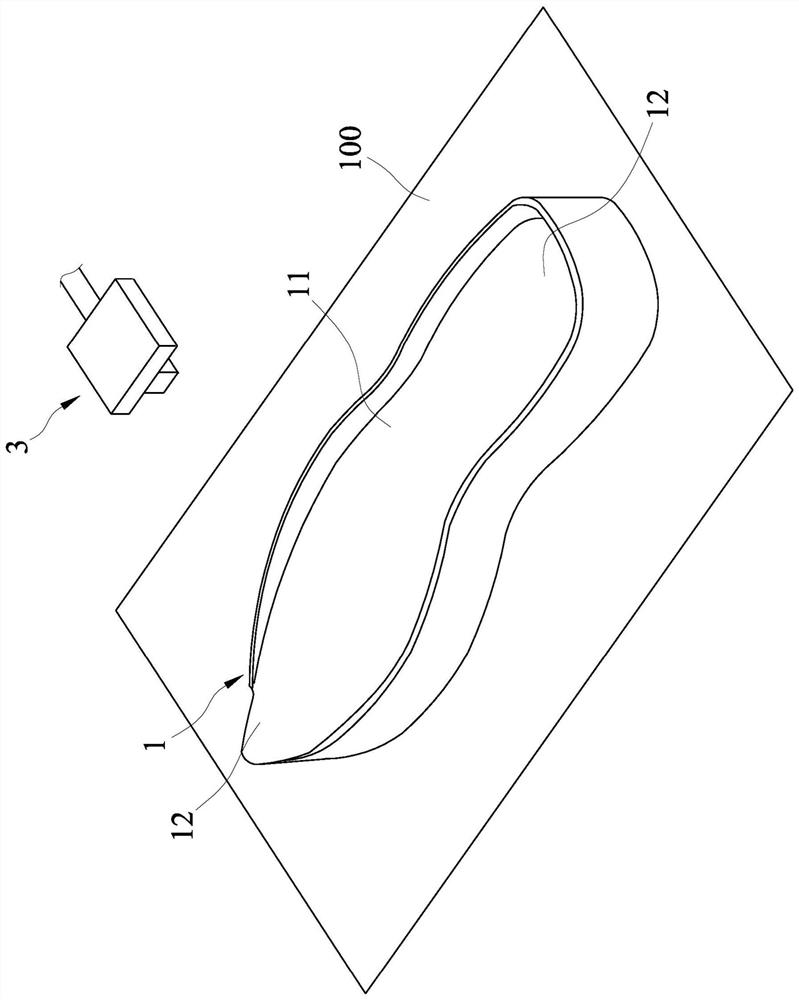

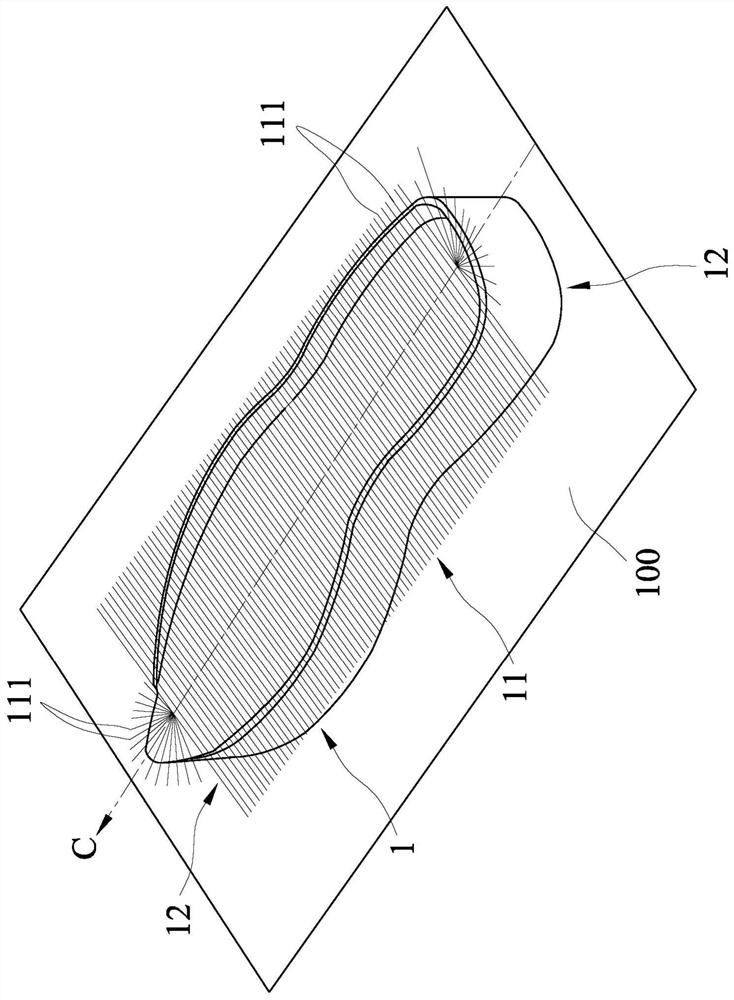

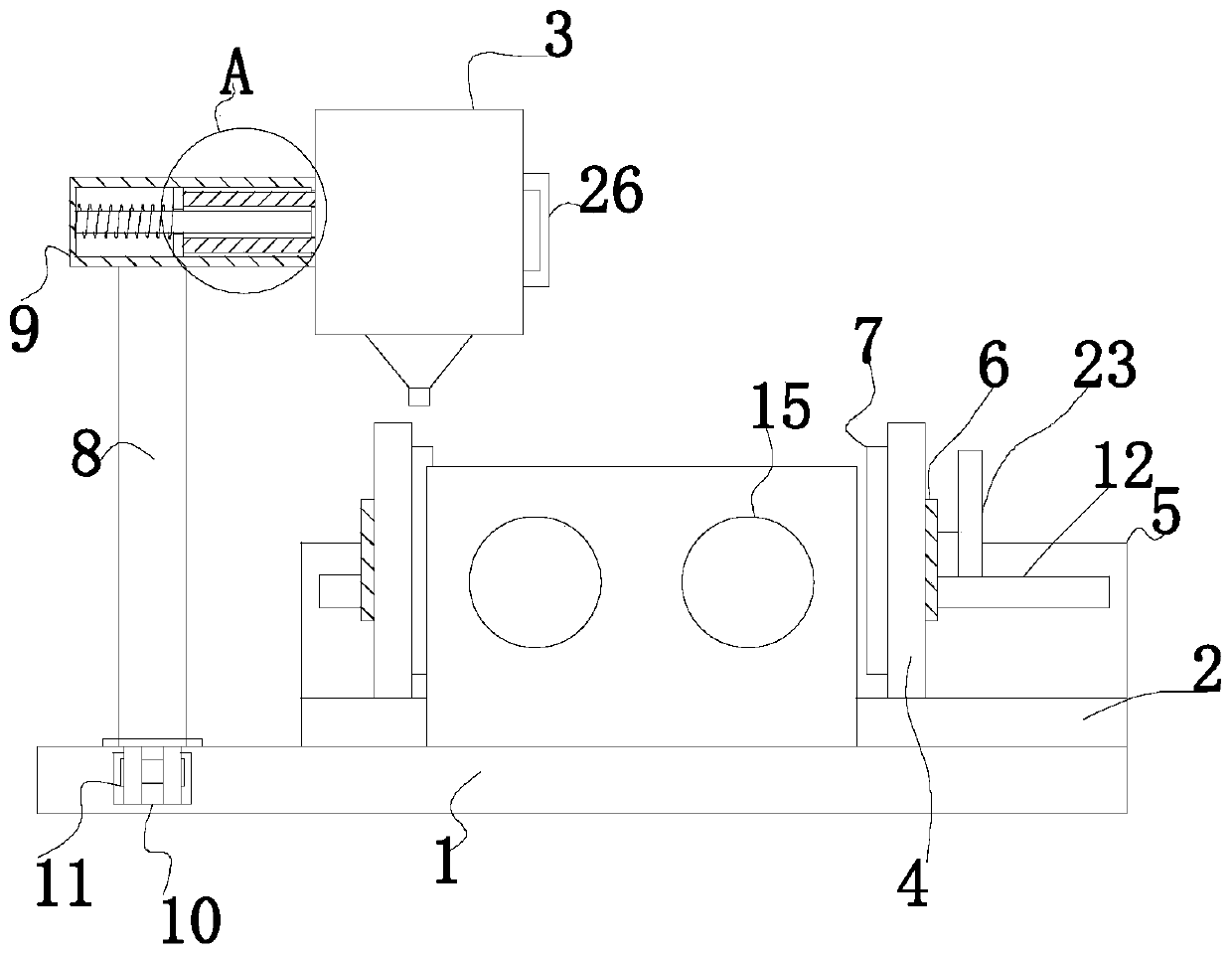

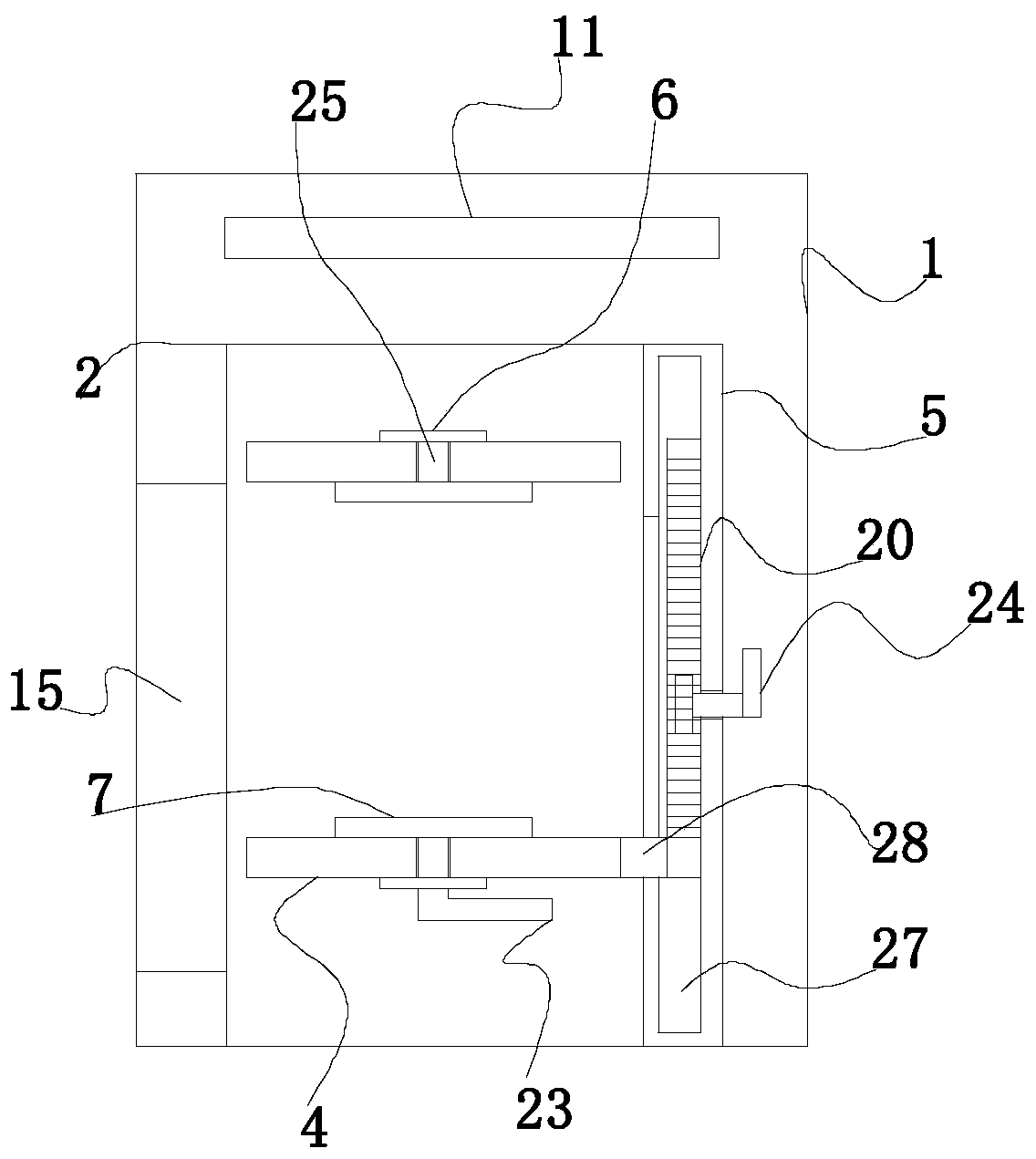

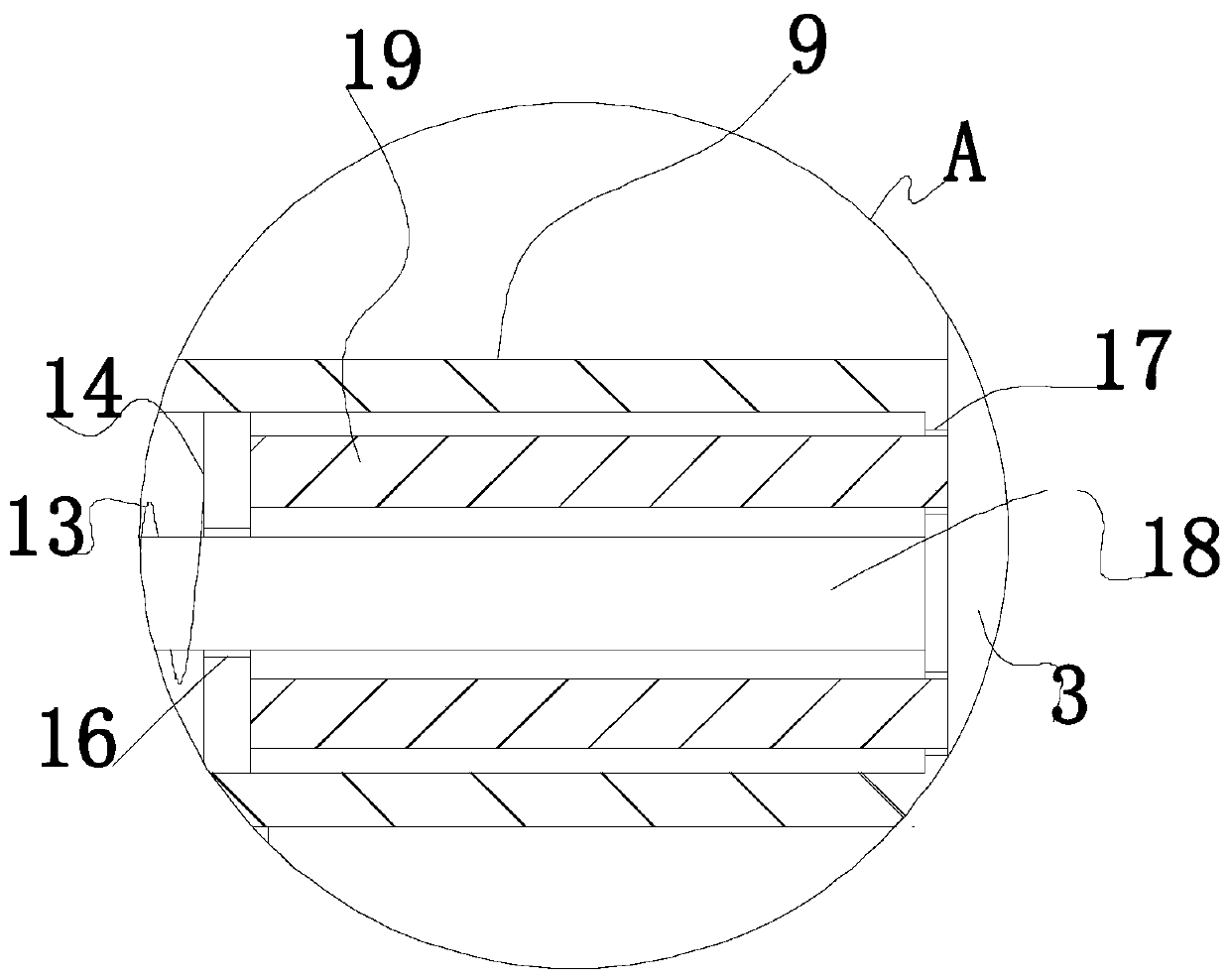

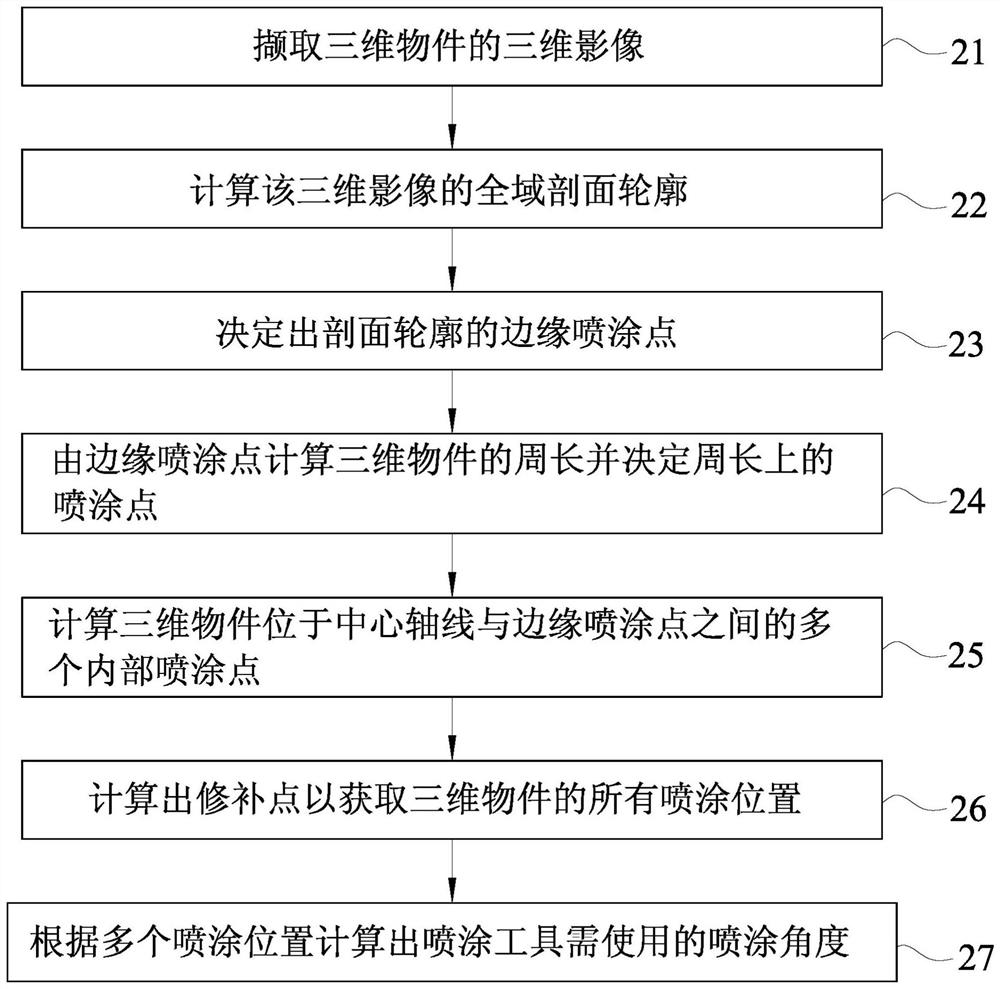

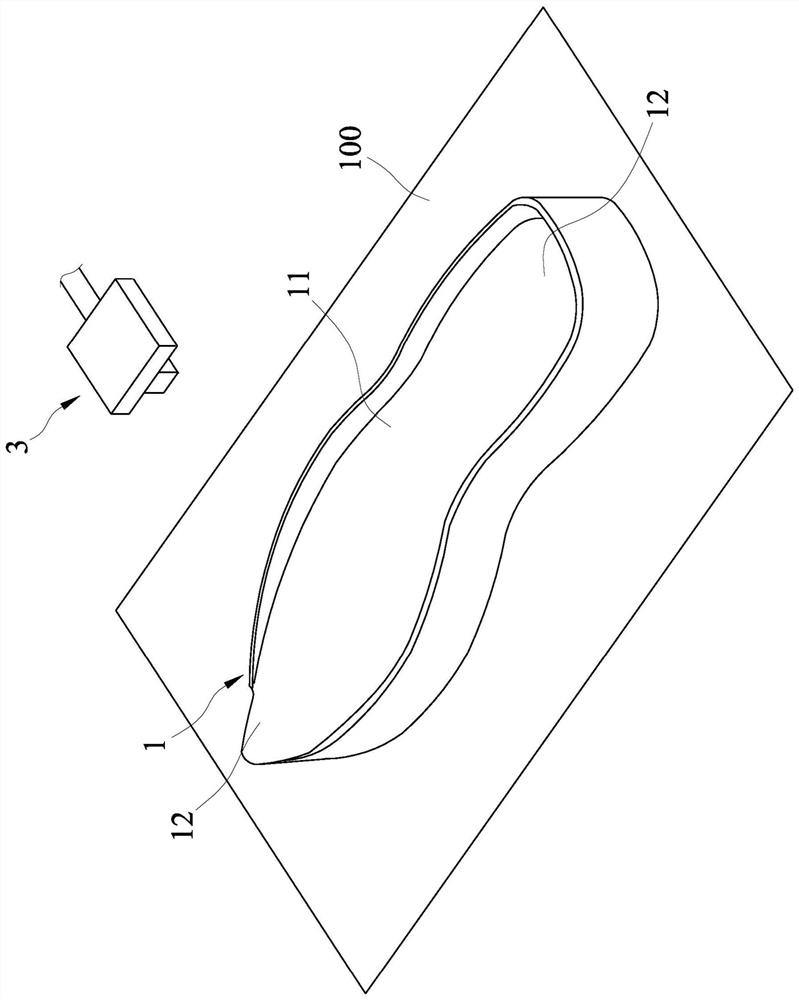

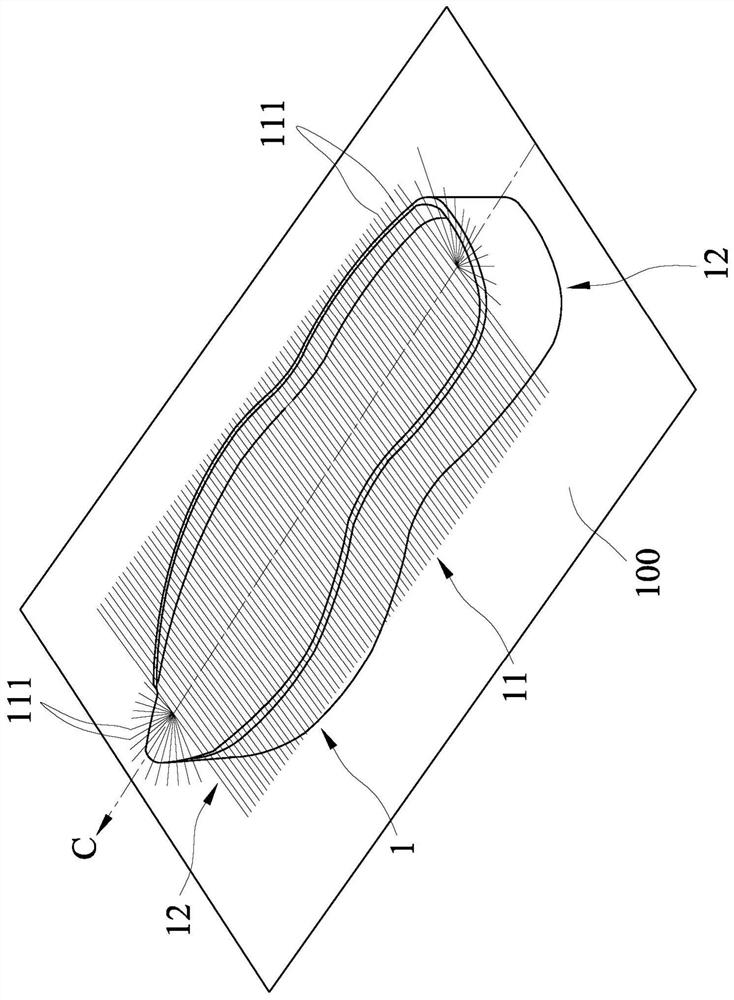

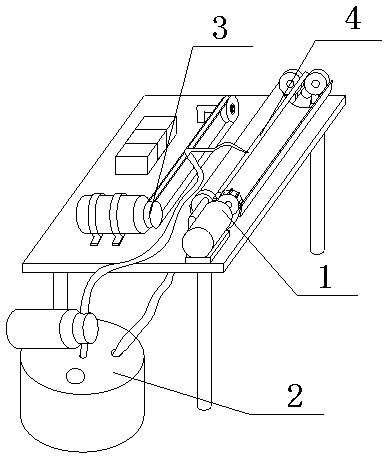

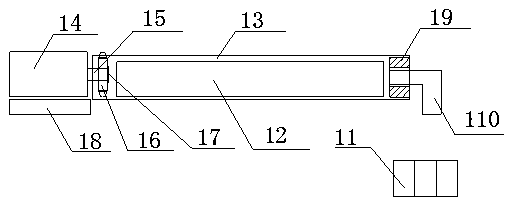

Spraying position calculating system

ActiveCN112189947ASmall sizeSolve the problem of uneven sprayingImage enhancementAdhesive processesEngineeringMechanical engineering

A spraying position calculating system is used for calculating the spraying position of a three-dimensional object so as to be used for spraying of a spraying tool with a spraying width, and comprisesa three-dimensional image capturing unit and a calculating unit. The three-dimensional image capturing unit is used for acquiring a three-dimensional image of the three-dimensional object, and the calculating unit is used for calculating a plurality of edge spraying points of the three-dimensional object according to the three-dimensional image and solving a plurality of internal spraying pointsfrom the edge spraying points to the surface of the three-dimensional object according to the spraying width.

Owner:ORISOL ASIA

Hardware part paint spraying device

InactiveCN111195575ASolve uneven sprayingSpeed up dryingPretreated surfacesCoatingsAir dryingSpray painting

The invention discloses a hardware part paint spraying device. The hardware part paint spraying device comprises an operation table, fixing plates, an adjusting plate, a supporting column and connecting plates, wherein the bottom end of the operation table is fixedly connected to the upper part of a base, the bottoms of the fixing plates are fixedly connected to the operation table, the fixing plates movably sleeve movable shafts, one ends of the movable shafts penetrate through the fixing plates and extend to be fixedly connected with clamping plates, the ends, deviating from the clamping plates, of the movable shafts are fixedly connected with limiting plates, a first sliding groove is formed in one end of the base, a sliding wheel is fixedly connected to the bottom end of the supportingcolumn, the supporting column is slidably connected into the first sliding groove through the sliding wheel, and a first connecting rod is fixedly connected to the inner wall of a hollow rod. According to the hardware part paint spraying device, the position between the two fixing plates can be adjusted through cooperation of a movable plate, a gear, the fixing plates, a movable block and the groove, paint spraying can be conducted on parts of different lengths, meanwhile, air drying of the sprayed parts can be accelerated by using a fan, and the problems that a device is inconvenient to adjust and slow in the air drying are solved.

Owner:田清

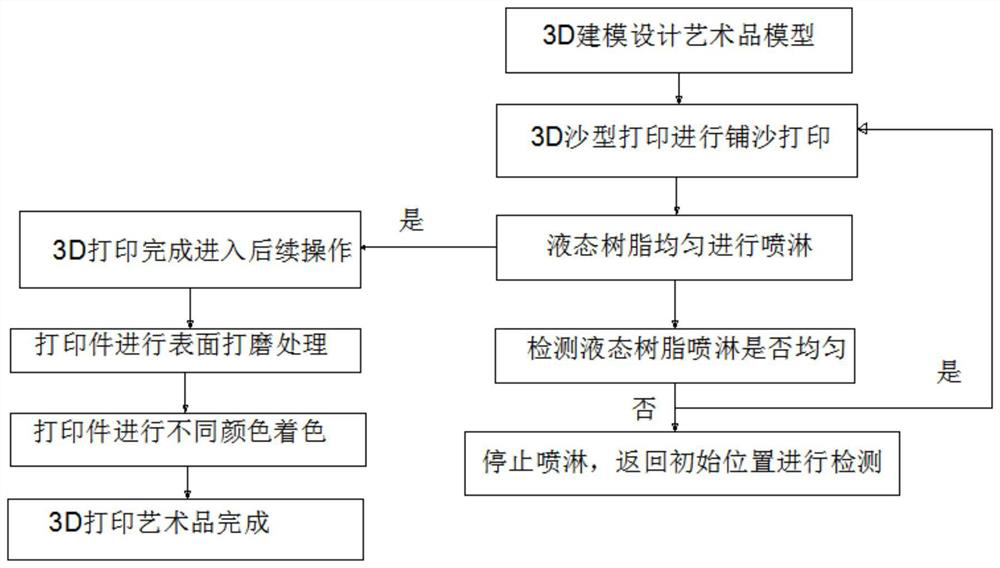

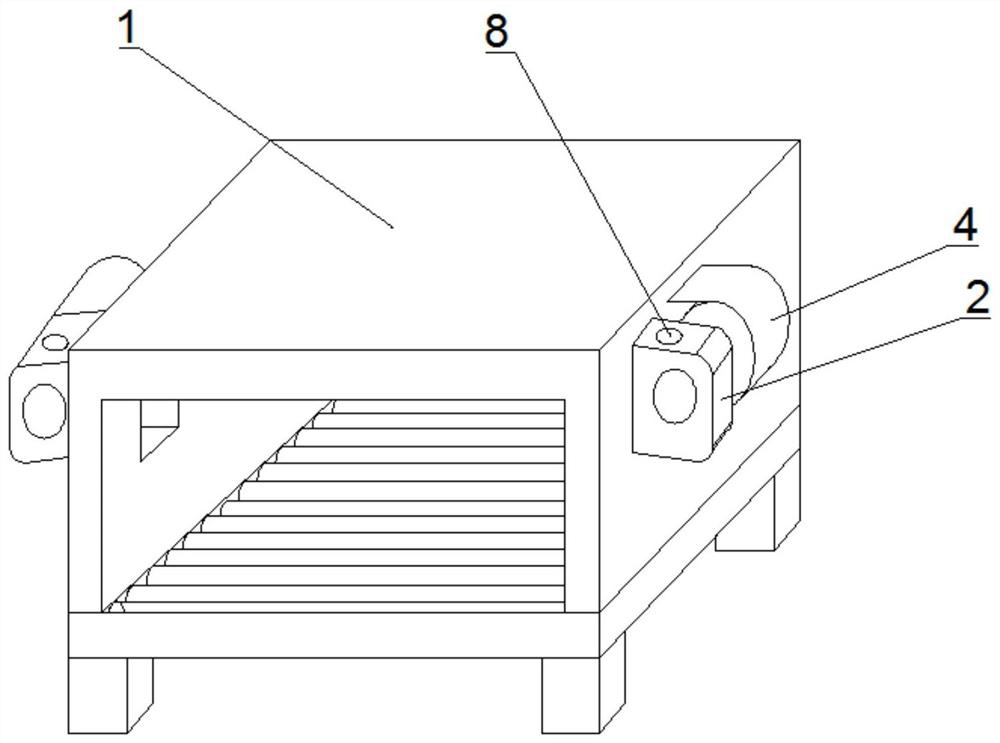

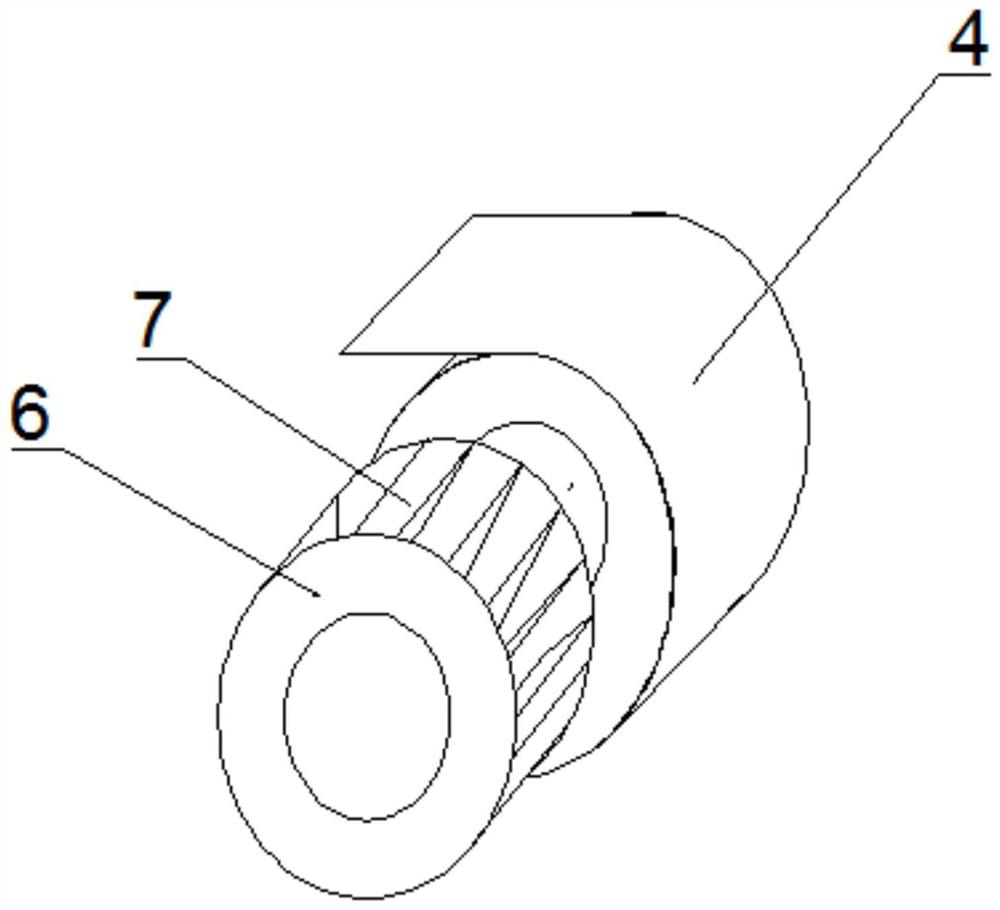

Artwork manufacturing method adopting 3D-printed sand mold

InactiveCN112808932AQuality improvementSolve the problem of uneven sprayingAdditive manufacturing apparatusMoulding toolsGraphicsLiquid resin

The invention discloses an artwork manufacturing method adopting a 3D-printed sand mold. The artwork manufacturing method comprises the following steps that S1, initial modeling of the artwork is completed through three-dimensional modeling, and a modeling drawing is printed through 3D printing equipment; S2, multi-layer sand laying operation is conducted according to a sand laying device of the 3D printing equipment, wherein the thickness of each layer of laid sand is controlled to range from 0.1 mm to 0.35 mm; S3, after sand laying is completed, liquid resin is evenly sprayed through spraying micropores of a spraying device; and S4, after the step S3 is completed, spraying position scanning detection is conducted through a detection device, and the cross section of the three-dimensional modeling drawing is compared with the drawing sprayed by the spraying device through scanning detection. By the adoption of the artwork manufacturing method adopting the 3D-printed sand mold, manufacturing of the complex sand mold artwork can be achieved without manual carving or molds, the manufacturing period is greatly shortened, the obtained sand mold artwork has high dimensional precision and surface smoothness, and can fully reflect the design level of a designer, and the artwork manufacturing method is very suitable for manufacturing various sand mold sculptures and artware.

Owner:无锡惠思特快速制造科技有限公司

Spraying position calculation system

ActiveCN112189947BSmall sizeSolve the problem of uneven sprayingImage enhancementAdhesive processesEngineeringMechanical engineering

A spraying position calculation system is used to calculate the spraying position of a three-dimensional object for spraying by a spraying tool with a spraying width. The spraying position calculation system includes a three-dimensional image capture unit and a calculation unit. The 3D image capturing unit is used to capture a 3D image of the 3D object, and the calculation unit is used to calculate a plurality of edge spraying points of the 3D object according to the 3D image, and according to the spray width from the A plurality of internal spraying points are obtained from the edge spraying points towards the surface of the three-dimensional object.

Owner:ORISOL ASIA

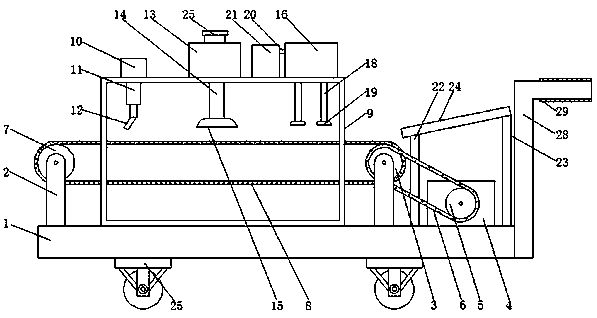

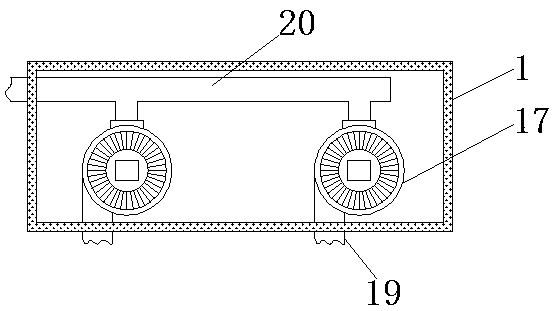

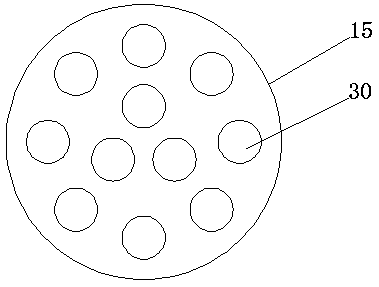

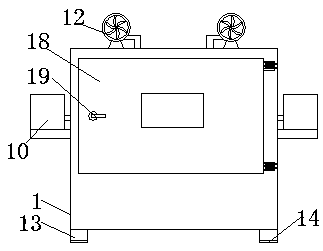

Direct spraying type automatic bean bar production equipment

InactiveCN108029782ASmooth rotationRealize the function of thermoformingCheese manufactureFood scienceDrive shaftElectric machine

The invention provides a direct spraying type automatic bean bar production equipment, which comprises a battery panel, an electric heating plate, a semicircular column, a No.1 motor, a transmission shaft, a straight gear, an end cover, a rectangular block, a No.1 bearing and a No.1 support rod. The No.1 motor is arranged on the upper end of a bearing plate; the transmission shaft is arranged on aNo.1 motor shaft; the straight gear is arranged on the transmission shaft; the end cover is arranged on the right end of the transmission shaft. According to the design, a heating forming function isrealized, a water tank is arranged on the lower end of the bearing plate, a water pipe is arranged on the upper end of the water tank, a flexible pipe is arranged on the upper end of the water pipe,and a water spraying nozzle is arranged on the right end of the flexible pipe, so that a water circulation function is realized; the direct spraying type automatic bean bar production equipment provided by the invention is novel in structure, convenient to operate, high in mechanization degree and high in practicability.

Owner:重庆柯颖宝科技有限公司

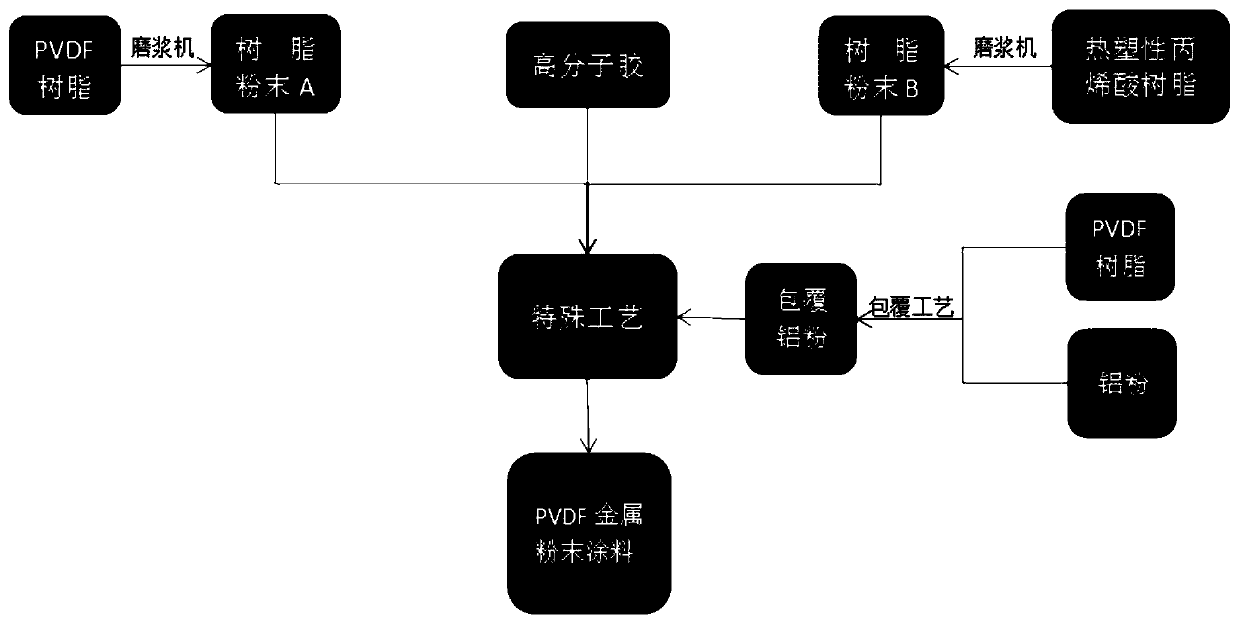

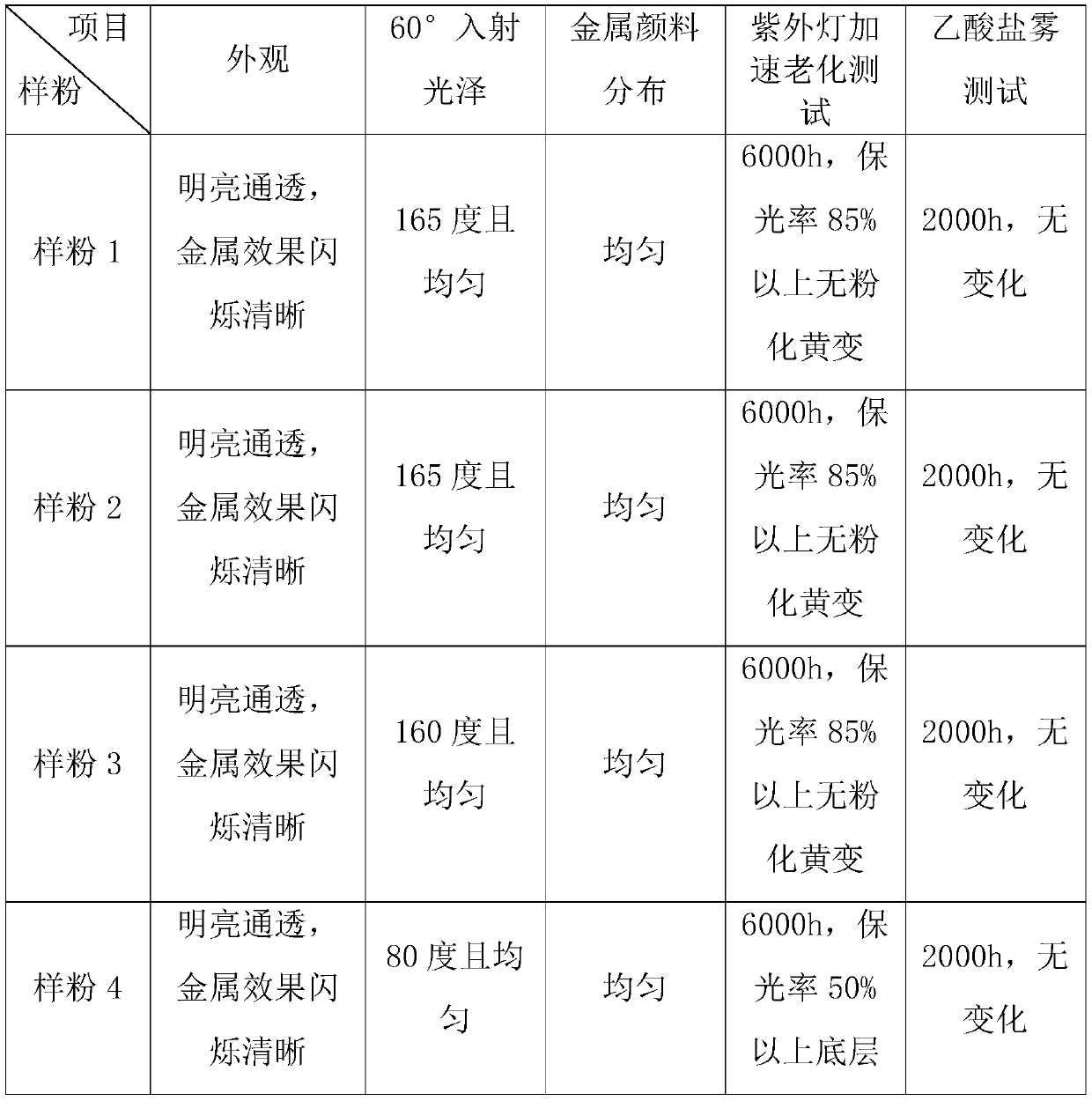

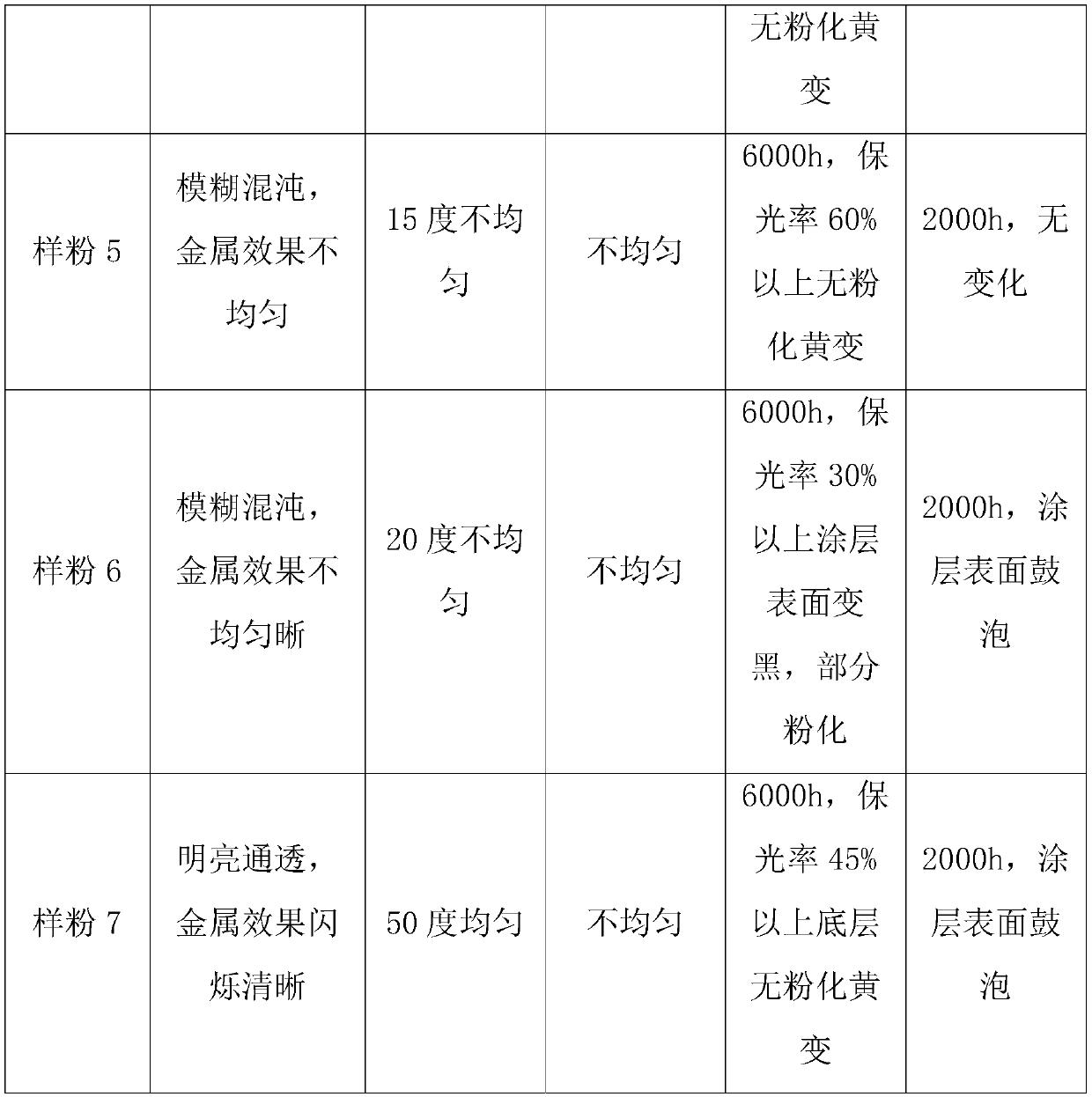

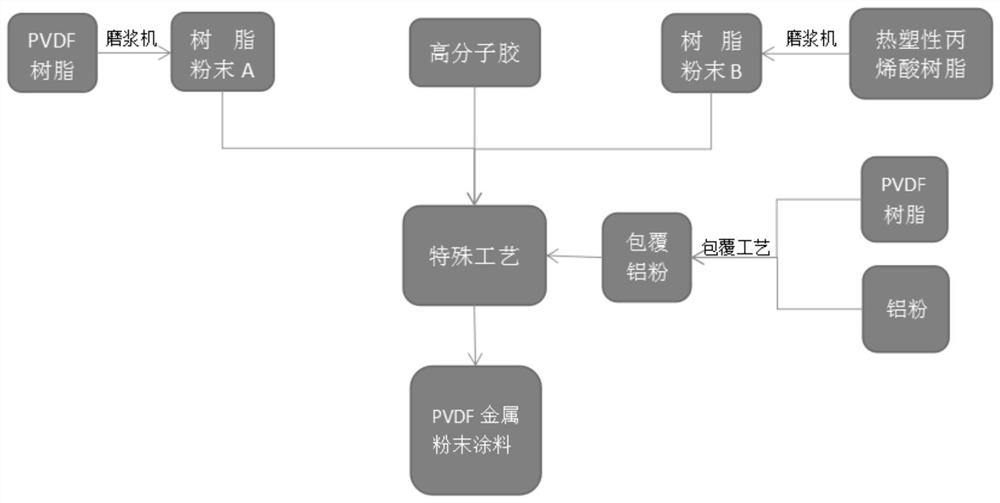

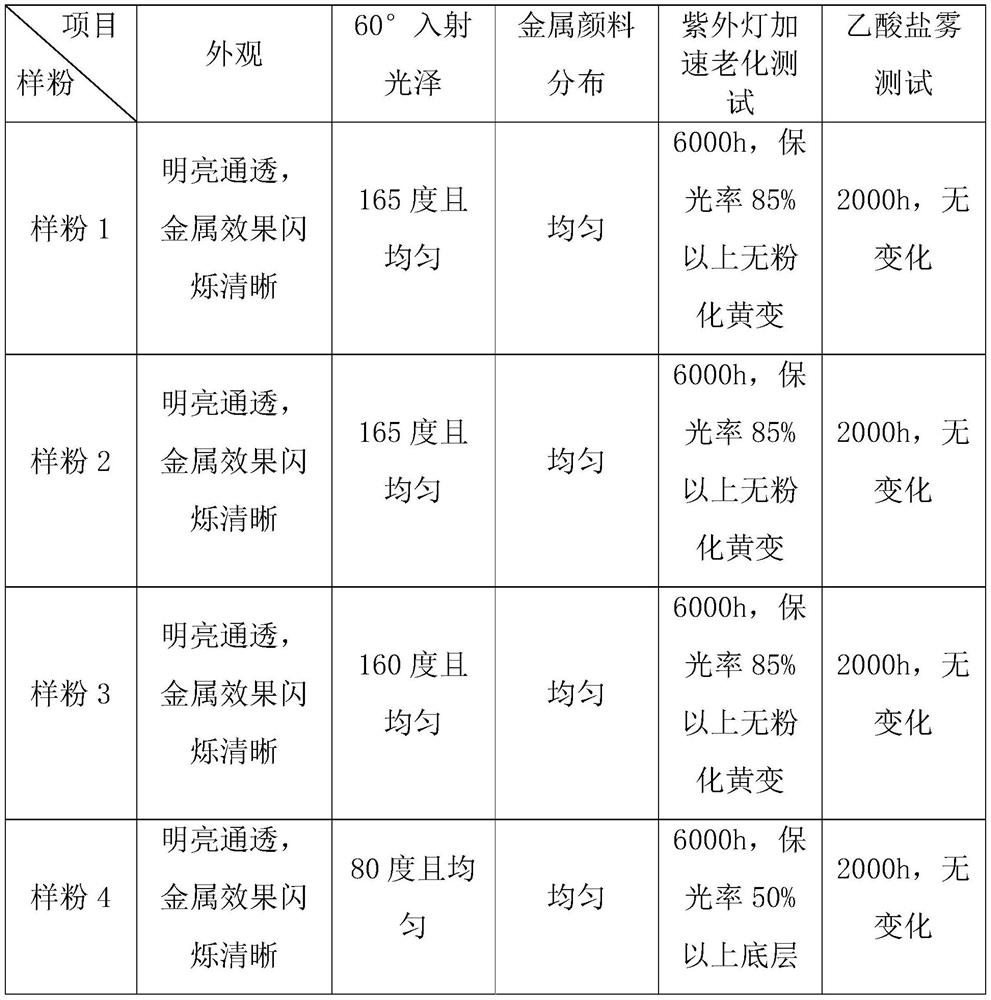

PVDF metal powder coating for metal surface, and preparation method thereof

The invention provides a PVDF metal powder coating for a metal surface, and a preparation method thereof. Thermoplastic acrylic resin and PVDF resin are ground through a pulping machine, and then aremixed with macromolecules and coated aluminum powder to prepare the powder coating, and the problem that in the electrostatic spraying process of the powder coating, spraying is not uniform due to theelectrification difference between the components is solved under the synergistic effect of the components; and a temperature control device is arranged in the pulping machine, so that excessive bonding in the powder grinding process is avoided, ground resin powder A and resin powder B are microscopically in an irregular fibrous shape, and the probability of mutual entanglement of the two resin powders in a reaction kettle is greatly increased. Besides, the PVDF resin is used for coating aluminum powder, and then the coated aluminum powder is added into the reaction kettle, so that the problem that the aluminum powder is oxidized or corroded when the powder coating forms a coating layer can be effectively solved, and the powder coating which is uniform in bonding, high in coating layer transparency and remarkable in metal effect is further obtained.

Owner:WESDON RIVER POWDER PAINT SCI RES CO LTD

A kind of PVDF metal powder coating for metal surface and preparation method thereof

The invention provides a PVDF metal powder coating for metal surfaces and a preparation method thereof. The thermoplastic acrylic resin and PVDF resin are ground by a refiner, and then mixed with a polymer and coated aluminum powder to prepare a powder coating. The synergy of the components Under the action of the powder coating, it can solve the problem of uneven spraying caused by the difference in chargeability between the components during the electrostatic spraying process; and a temperature control device is installed in the refiner to avoid excessive bonding of the powder during the grinding process, so that the grinding out The resin powder A and the resin powder B are microscopically irregular and fibrous, which greatly increases the probability of the two resin powders being entangled with each other in the reactor. In addition, the PVDF resin is used in the present invention to coat the aluminum powder and then add it to the reaction kettle, which can effectively solve the problem that the aluminum powder is oxidized or corroded when the powder coating is formed, and then obtain uniform bonding and excellent coating performance. Powder coating with high transparency and outstanding metallic effect.

Owner:WESDON RIVER POWDER PAINT SCI RES CO LTD

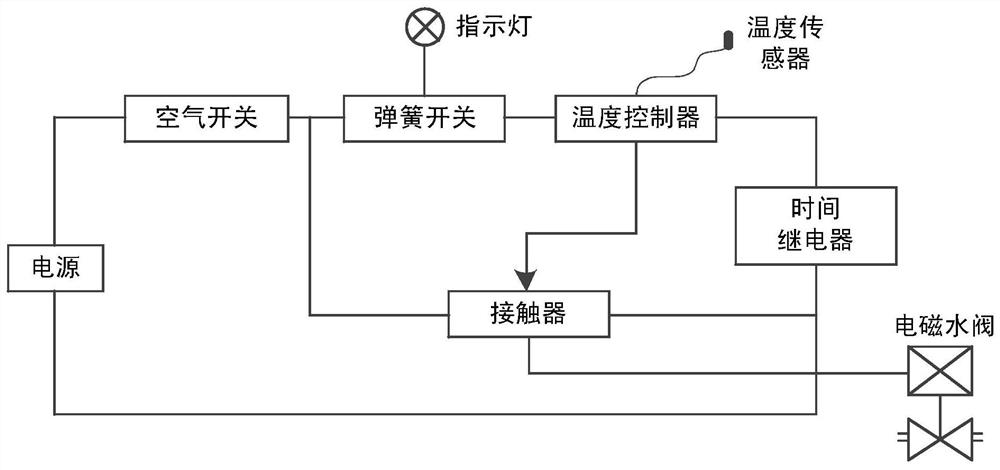

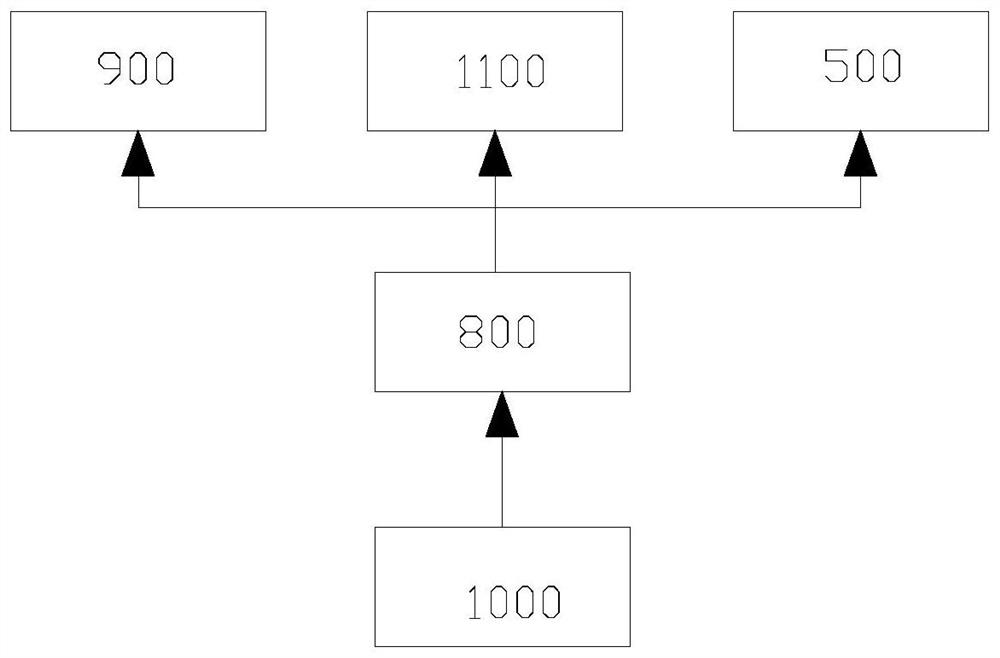

Non-contact transformer auxiliary automatic cooling system and method

ActiveCN110853889BReduce work intensityImprove work efficiencyTransformers/inductances coolingTemperature controlTransformer

Owner:MEISHAN POWER SUPPLY CO STATE GRID SICHUAN ELECTRIC POWER CO

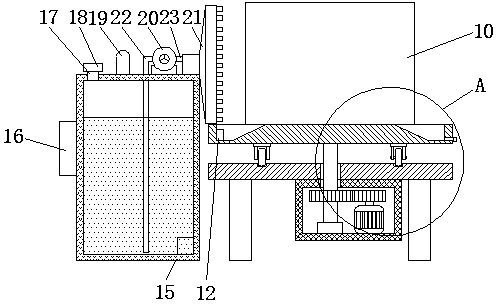

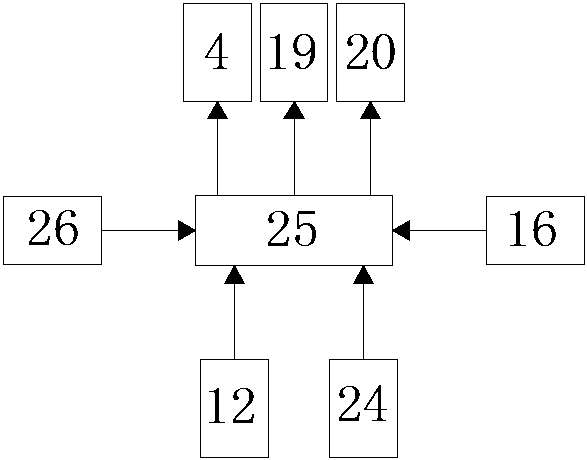

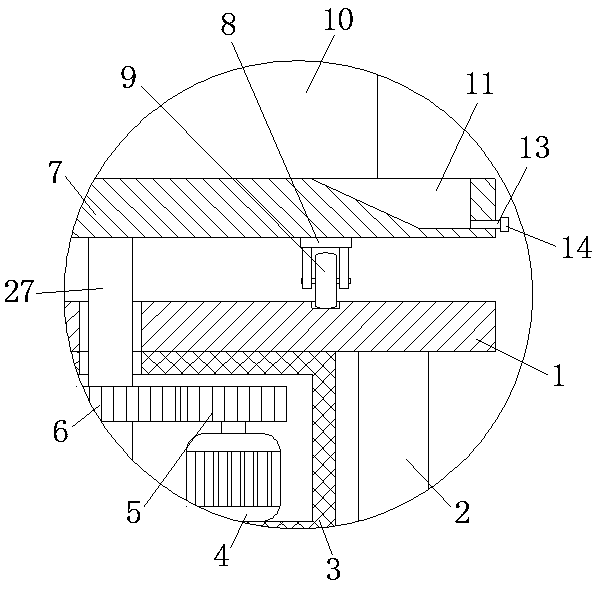

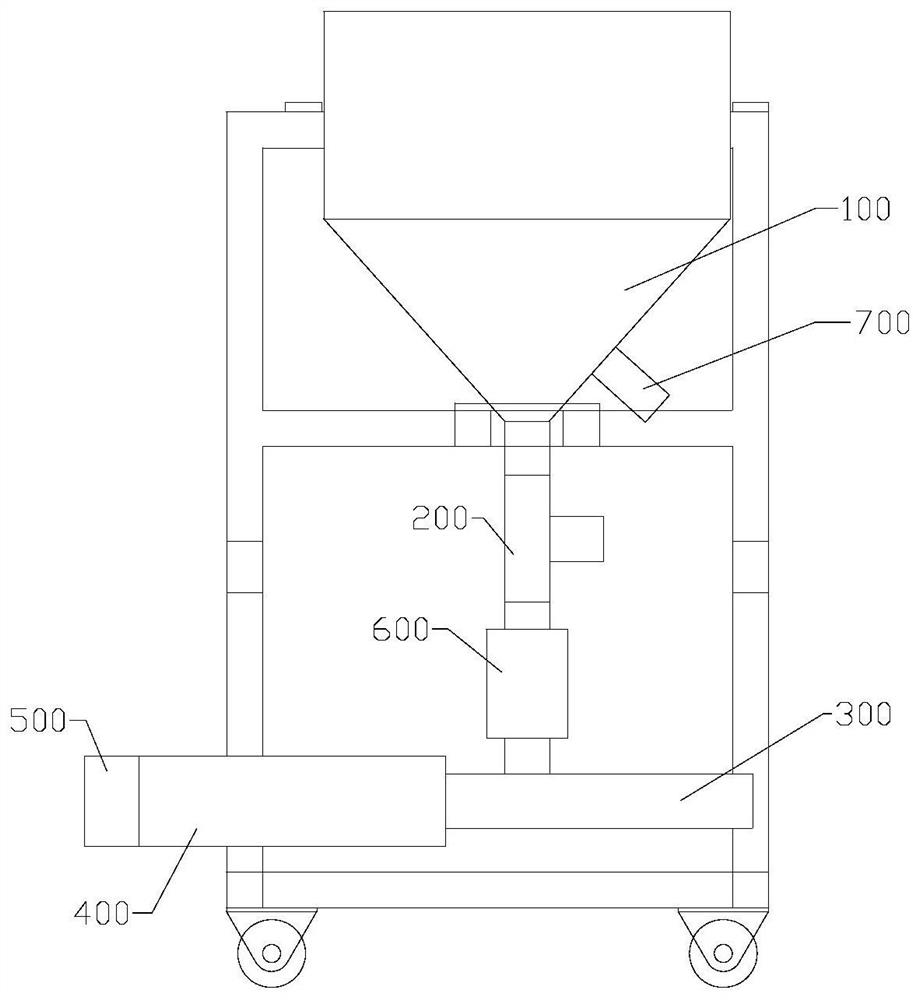

Glue supply system and spraying production equipment

InactiveCN113042248AEasy to controlSolve the problem of uneven sprayingSpraying apparatusControl cellEngineering

The invention discloses a glue supply system and spraying production equipment. The glue supply system comprises a glue supply unit and a control unit. The glue supply unit comprises a glue heating and stirring barrel, a glue inlet connecting pipe, a glue outlet pipe, a screw pump and a screw pump driving device. The control unit comprises a PLC, a first electromagnetic valve, a first pressure sensor and a second electromagnetic valve. The PLC is used for controlling the screw pump driving device to work. The PLC controls the first electromagnetic valve to be opened and closed. The first pressure sensor is arranged in the glue outlet pipe. The second electromagnetic valve is arranged at the joint of the glue outlet pipe and a glue gun. The first pressure sensor is arranged in the glue outlet pipe, and the PLC controls the opening and closing of the first electromagnetic valve and the second electromagnetic valve, so that the glue amount is controlled, the uniform glue outlet amount each time can be ensured, and the problem of non-uniform door plate spraying caused by the non-uniform glue outlet amount is solved.

Owner:佛山市信洛智能设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com