Closed circulating heating thermal phosphorization device and phosphorization method

A closed circulation and chemical device technology, which is applied in the coating process of metal materials, can solve the problems of constant temperature, uneven spraying of chemical solution, etc., and achieve short phosphating treatment time, good corrosion resistance, and good film formation. fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

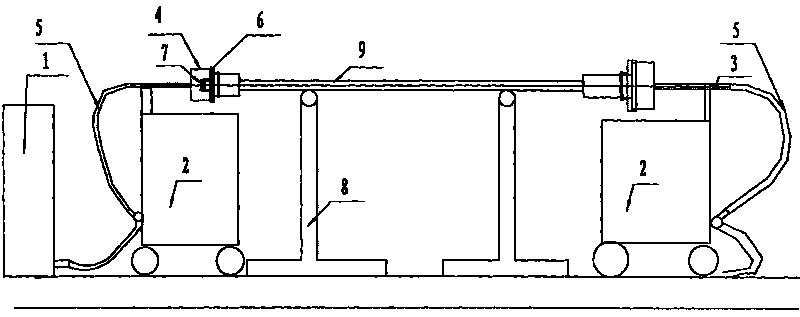

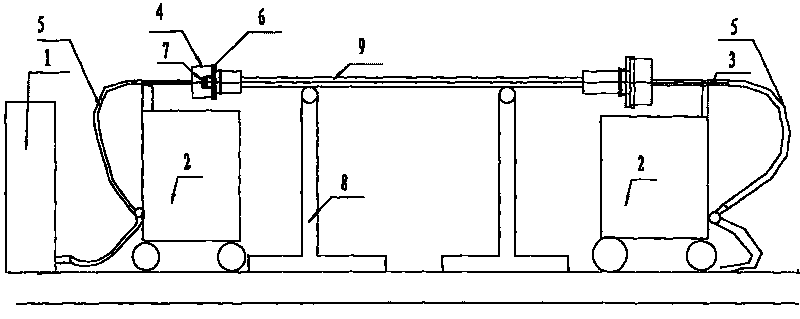

[0030] Refer to the attached figure 1 , the invention discloses a closed cycle heating thermal phosphating device, comprising a fluid heater 1, a phosphating tank 2, a heating controller, a nozzle 4, a circulation pipeline 5, a rubber retaining ring 6 and a rubber plug 7, the The fluid heater 1 and the phosphating tank 2 are connected through a circulation pipeline 5, the nozzle 4 is fixed above the phosphating tank 2, the water outlet of the circulation pipeline 5 is connected to the nozzle 4, and the drill pipe 9 is supported and set by the pipe frame 8 Above the phosphating tank 2, the rubber plug 7 is installed in the water hole of the drill pipe 9, the rubber retaining ring 6 is sleeved on the joint of the drill pipe 9, the inner wall of the rubber retaining ring 6 is in close contact with the outer wall of the nozzle 4, and the thread extends into the In the cavity formed by the spray head 4 and the rubber retaining ring 6 , the heating controller is connected with the f...

specific Embodiment approach

[0032] A preferred embodiment of the present invention is as follows:

[0033] Double-layer stainless steel phosphating tank 2, the interlayer is filled with insulation materials, and the bottom of the tank has a return pipe connection and a waste liquid discharge port. Both the fluid heater 1 and the circulation pipeline 5 are commercially available fluid heater 1 and circulation pipeline 5 with acid-resistant and high-temperature-resistant functions, which can heat the liquid medicine to 97 degrees Celsius within half an hour, and the medicine liquid passes through the circulation pipeline 5 It is used circularly between the fluid heater 1 and the phosphating tank 2. The heating controller adopts a commercially available heating controller, which is composed of an electric control cabinet and a temperature control system. The temperature control system can set the heating time and temperature. After the temperature reaches the setting, it will automatically stop heating. Whe...

Embodiment 3

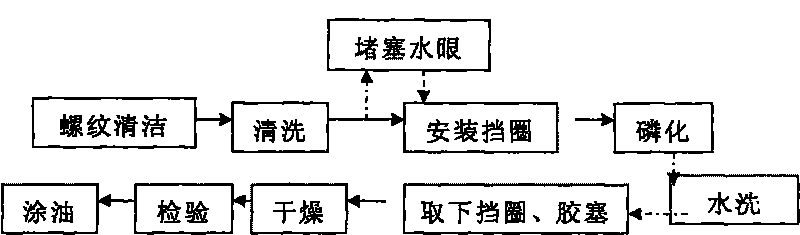

[0046] The concrete phosphating step of this method is as follows:

[0047] a. Set the rubber retaining ring 6 on one end of the drill pipe 9 to be phosphated, move the phosphating tank 2, and make the outer wall of the nozzle 4 above the phosphating tank 2 closely contact with the inner wall of the rubber retaining ring 6;

[0048] b. Open the 5 valves of the circulation pipeline, start the circulation pump in the circulation pipeline 5, and when the pressure rises to 0.8Mpa and the circulation is smooth, start the fluid heater 1, and when the fluid heater 1 turns the phosphating solution in the phosphating tank 2 When heating to 95°C, open the nozzle 4 valve, close the empty-load liquid return pipe valve in the small circulation pipeline 5, and carry out the phosphating operation, and the phosphating time is 10-20 minutes;

[0049] c. After the phosphating is completed, open the valve of the no-load liquid return pipe in the large circulation pipeline 5, close the valve of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com