Patents

Literature

107results about How to "Crystal dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

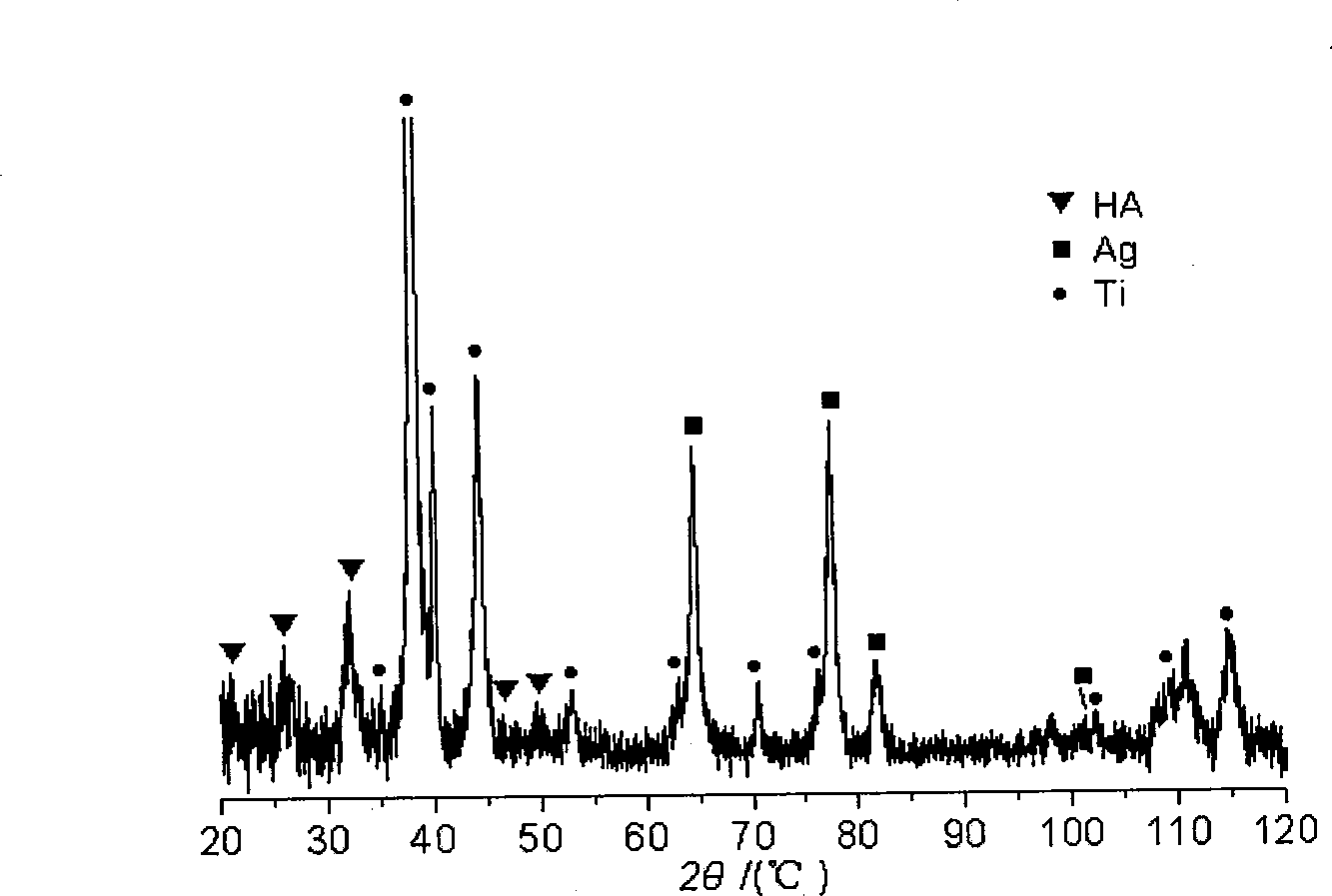

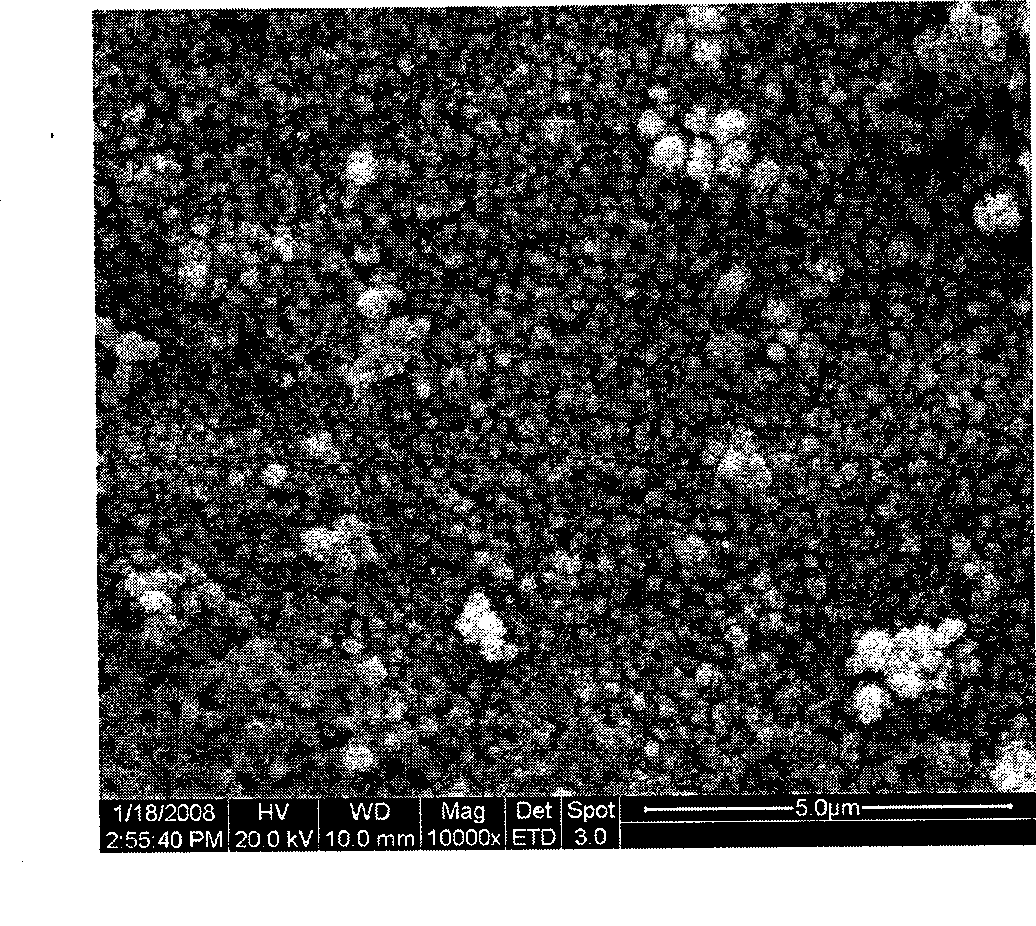

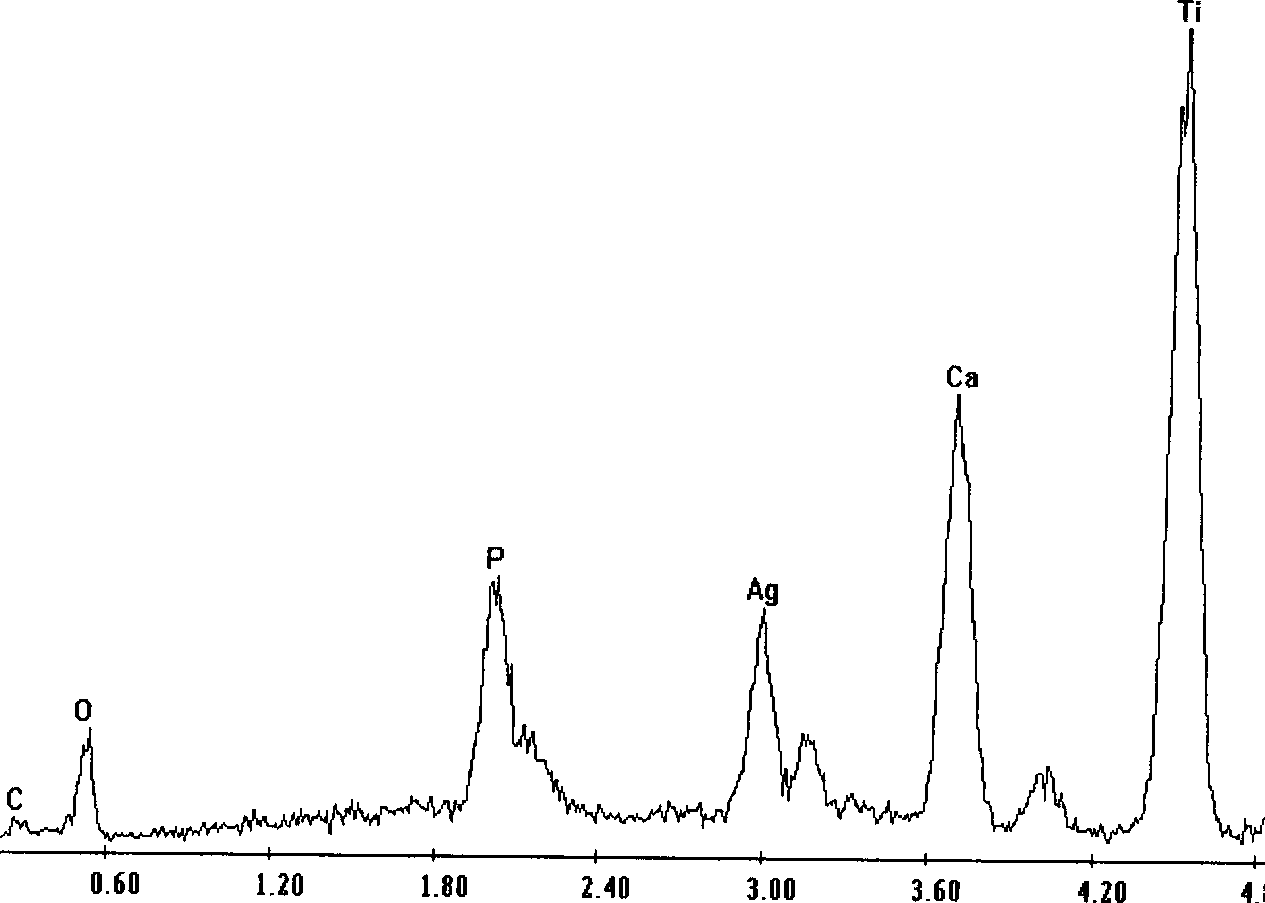

Method for preparing hydroxyapatite/nano silver antimicrobial composite coating by pulse electrochemical deposition

InactiveCN101485901AReduce concentration polarizationCrystal denseCoatingsProsthesisElectrolytic agentPhosphate

The invention discloses a method for preparing a hydroxyapatite / nano silver antibacterial composite coating through pulse electrochemical deposition, which comprises: using a calcium salt, phosphate, silver nitrate and a proper amount of coordination agent to prepare electrolyte with certain concentration and pH value, and performing electrodeposition in a electrolytic cell provided with a three-electrode system; taking a saturated calomel electrode as a reference electrode, a platinum sheet as a counter electrode and biological medical metal to be coated as a working electrode, wherein the pulse high electric potential is 0 volt, the pulse low electric potential is -2.0 volts, the pulse width is 100 seconds, and the deposition time is 2 hours; and depositing compositions in the coating on a base material in a mode of ions, uniformly dispersing nano silver generated during deposition in the composite coating, and finally preparing the hydroxyapatite / nano silver antibacterial compositecoating.

Owner:SOUTHWEST JIAOTONG UNIV

Multi-coordination-agent cyanide-free electrogilding liquid and electrogilding process

ActiveCN103741181AExcellent bath performanceGood coating performancePotassium hydroxidePotassium carbonate

The invention relates to multi-coordination-agent cyanide-free electrogilding liquid and an electrogilding process, which belong to the technical field of electrogilding. The electrogilding liquid is prepared from a main coordination agent, an auxiliary coordination agent, potassium hydroxide, potassium carbonate, goldpotassium chloride, combined additives and ultrapure water. The electrogilding process comprises the following steps: 1, preprocessing a substrate; 2, electroplating an intermediate nickel plating layer; 3, electrogilding, namely washing the substrate after electroplating the intermediate nickel plating layer with ultrapure water, directly feeding the substrate into a plating cell containing the multi-coordination-agent cyanide-free electrogilding liquid to be electrogilded, taking out a sample from the electrogilding liquid after the electrogilding, washing the surface of the sample by utilizing distilled water, and drying the sample through cold air. Double coordination agents are used as the coordination agents of gold ions in the electrogilding liquid, so that a cyanide-free electrogilding system which has high current efficiency, smoothness and compactness in plating layer crystallization, wide current density range, wide temperature requirement and capability of guaranteeing the golden bright appearance of the plating layer compared with those of a single coordination agent system is obtained.

Owner:HARBIN INST OF TECH

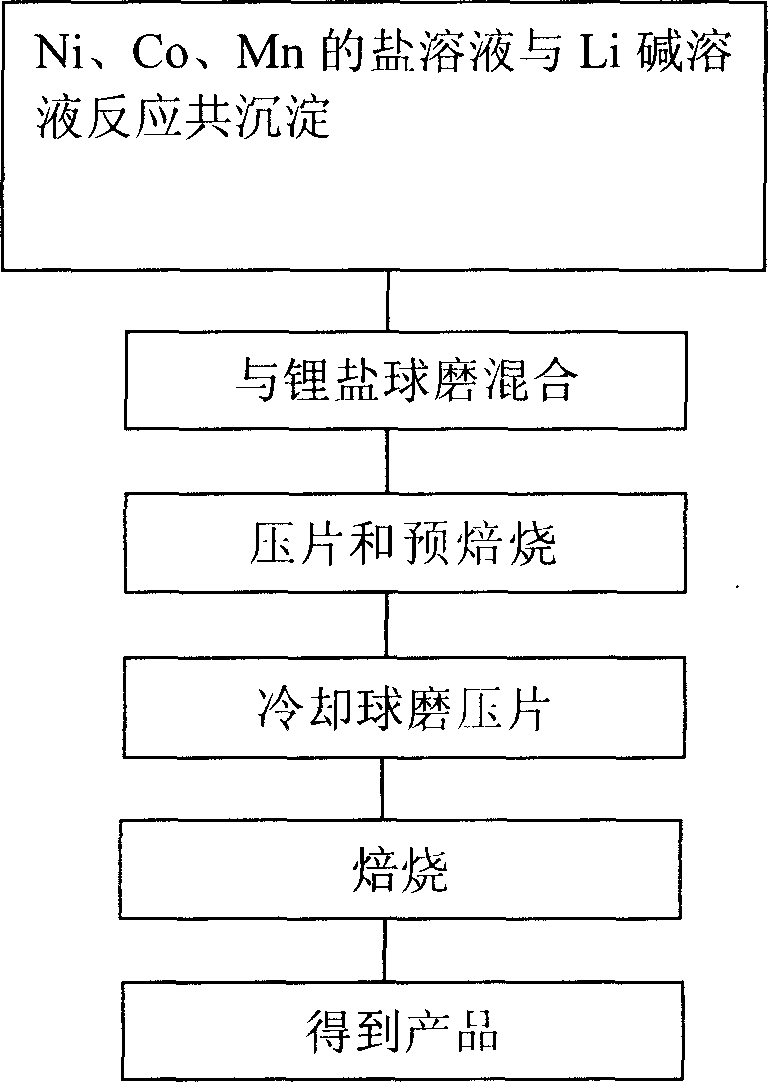

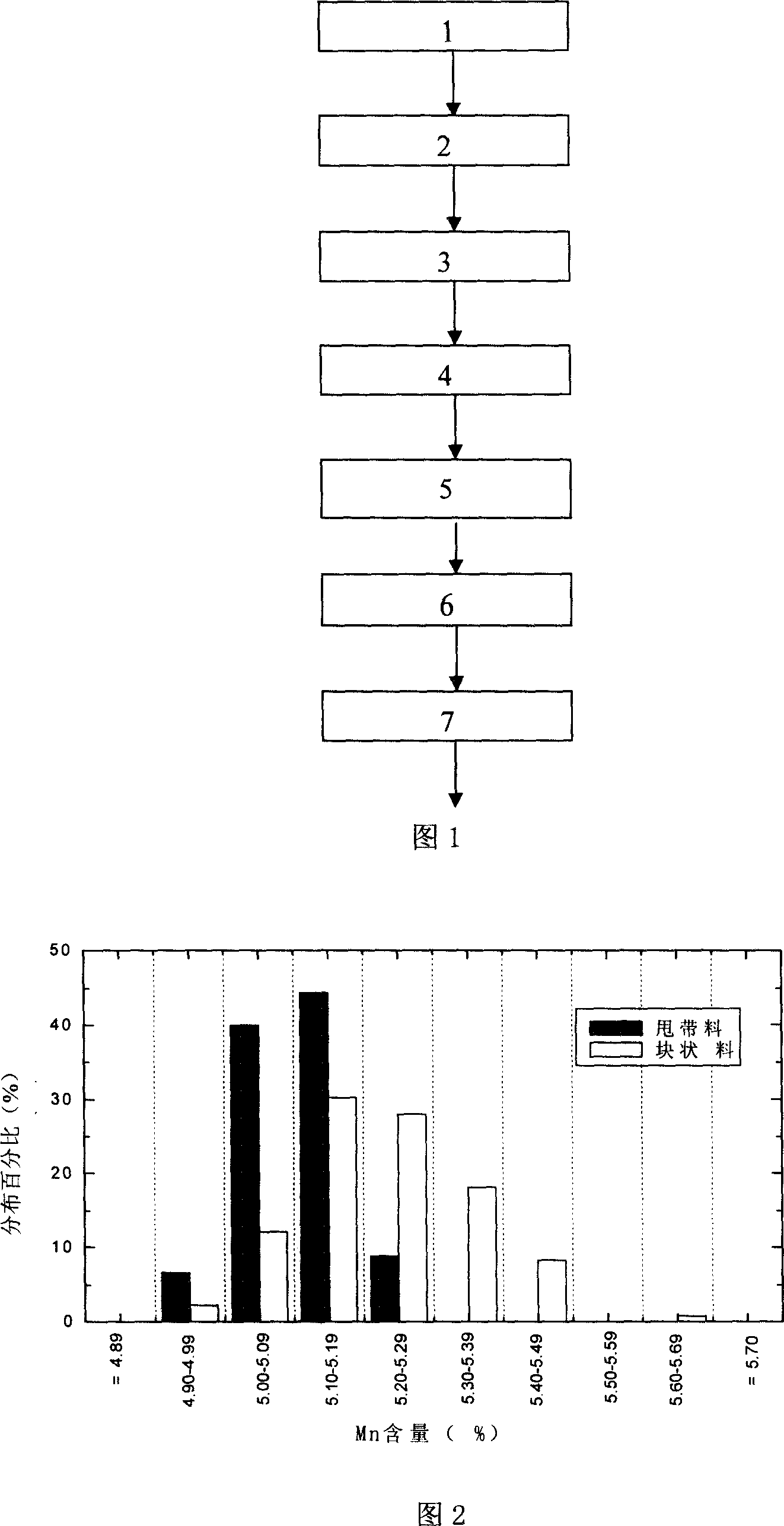

Lithium manganese cobalt nickle oxygen of manganese cobalt nickle triple lithium ionic cell positive material and its synthesizing method

InactiveCN101083321APrevent oxidationCrystal denseElectrode manufacturing processesLithium compoundsNickel saltManganese

The invention belongs to a manganese cobalt nickel three Yuan lithium ionization cell anode material, specifically relates to the lithium manganese cobalt nickel oxygen and its synthetic method. The high-capacity, the high safety performance of other battery positive electrode material is unable to compare with lithium manganese cobalt nickel oxygen, moreover low in price, the good compatibility with the electrolyte, the outstanding circulation performance, will certainly to thrust the market in the recent several years. The chemical formula of lithium manganese cobalt nickel oxygen is: The LiMn1 / 2Co1 / 4Ni1 / 4O2 crystal structure is a hexagonal system. The synthetic method of lithium manganese cobalt nickel oxygen is: (1) preparing the mix solution which is composed by the manganese salt, the cobalt blue, the nickel salt, under the agitation situation, joining the alloy salt brine, the complexing agent simultaneously in the reacting system according to the certain proportion distinction, simultaneously adjusts the join speed of alkali to maintain pH to be constant; After continuous feed certain times, filtrate and wash the precipitate to obtain the forerunner body. (2) Grinding and mixing lithium source element and forerunner body ball, after mixed evenly, compacting, roasting, and decomposing to obtain the lithium manganese cobalt nickel oxygen. Then cooling, grading, mixing to obtain the product.

Owner:湖南美特新材料科技有限公司

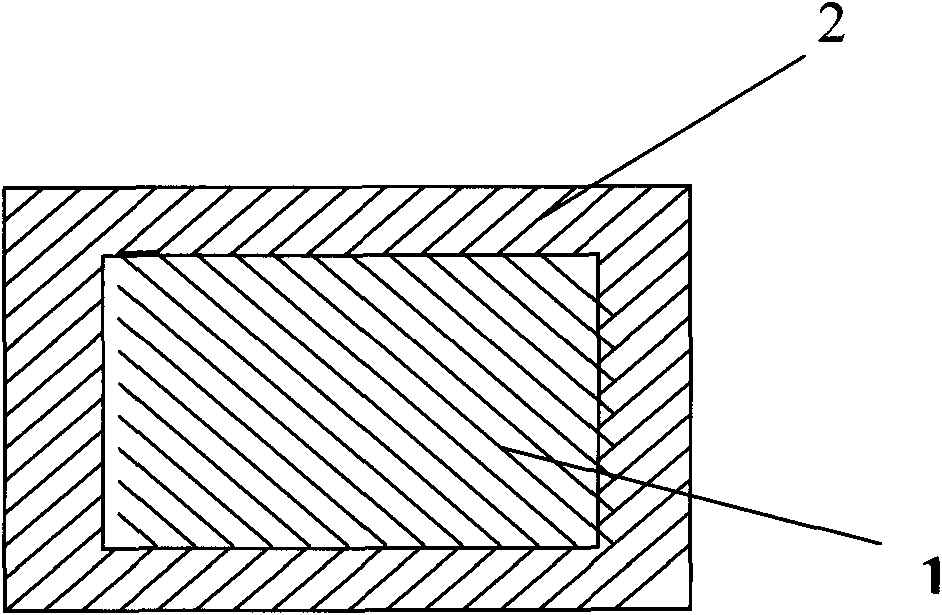

Porous, controllable and low-modulus bone defect repair bracket and preparation method thereof

ActiveCN103751840APromote ingrowthSolve the interface stress problemElectrolytic inorganic material coatingProsthesisApatiteRapid prototyping

The invention discloses a porous, controllable and low-modulus bone defect repair bracket which consists of a porous, controllable and low-modulus titanium alloy bracket and a biological activity coating on the surface of the titanium alloy bracket. The invention further discloses a preparation method of the bone defect bracket. The method comprises the steps that the low-modulus and porous titanium alloy bracket in a controllable internal microstructure is prepared by a quick forming technique; a uniform hydroxyapatite coating and a strontium doped hydroxyapatite coating are prepared on the surface of the bracket in the controllable microstructure; an electrolyte with certain concentration is prepared; a potential is controlled in an electrolytic bath of a three-electrode system; and pulse electrochemical deposition is performed. The elastic modulus of the prepared titanium alloy bracket is equivalent to that of a bone; the prepared hydroxyapatite coating or strontium doped hydroxyapatite coating is combined with a titanium alloy well; the concentration of strontium is controllable; and an implant provided with the biological activity coating can be used for a bone defect of a massive bearing part clinically.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

Production process of low-stress electroforming printing nickel screen

The invention relates to a production process of a low-stress printing nickel screen, which comprises the following steps of: (a) making a nickel screen die; (b) primarily coating the nickel screen; and (c) secondarily coating the nickel screen. The production process of the low-stress printing nickel screen is characterized in that a hard chromium layer is coated outside a bottom nickel layer of the die, electrolytes for coating nickel in the preparation of the die and the nickel screen are both nickel aminosulfonate with the concentration of 480-580 g / l and the working temperature of 43-47 DEG C, and vaseline with the concentration of 20 percent is adopted as a passivant for passivating the die. The nickel amino-sulfonate, instead of a traditional nickel sulfate, is used as the nickel-coating electrolyte, and the obtained nickel screen has low electric nickel layer stress and good toughness, elasticity and recovery. The original nickel sulfate electrolyte works at a temperature of 70 DEG C, but the nickel amino-sulfonate works at a temperature of 43-47 DEG C and saves electricity. Due to the hard chromium layer coated on the die, the wearing resistance of the die and the opening evenness of the nickel screen are improved. The die is passivated by the vaseline with the concentration of 20 percent so as to lessen the pollution and prolong the service life of the die.

Owner:金昌宇恒镍网股份有限公司

Lithium NCM (nickel cobalt manganese) material and preparation method thereof

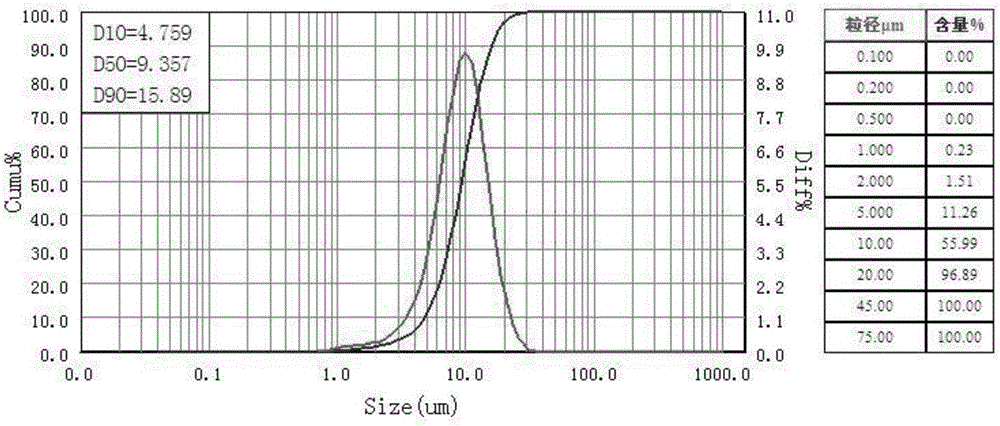

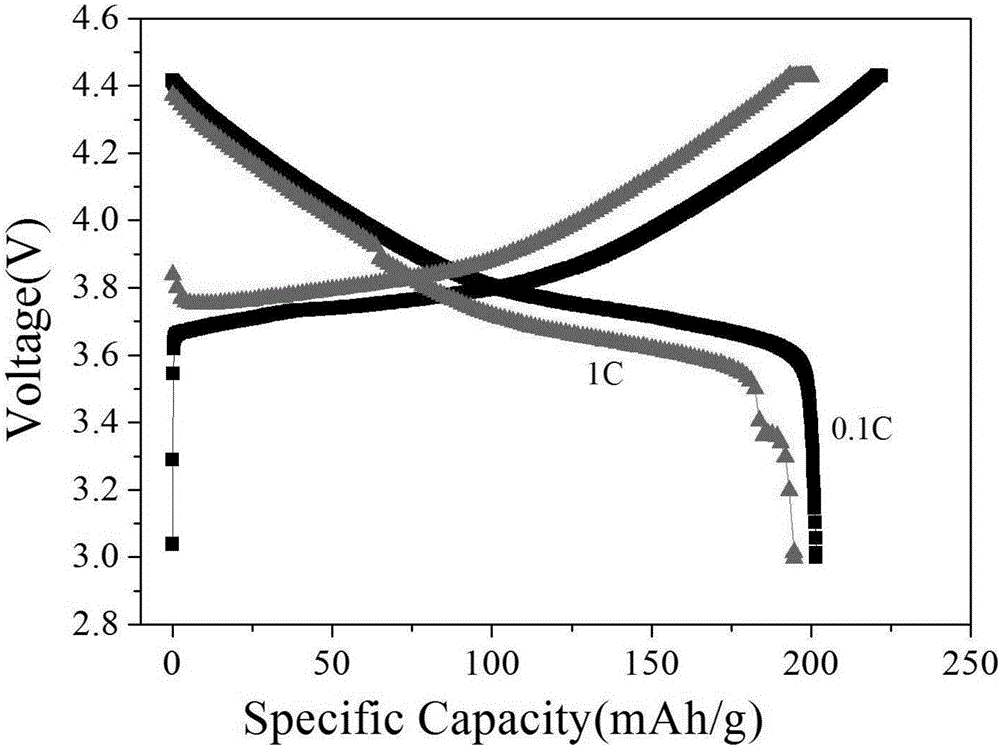

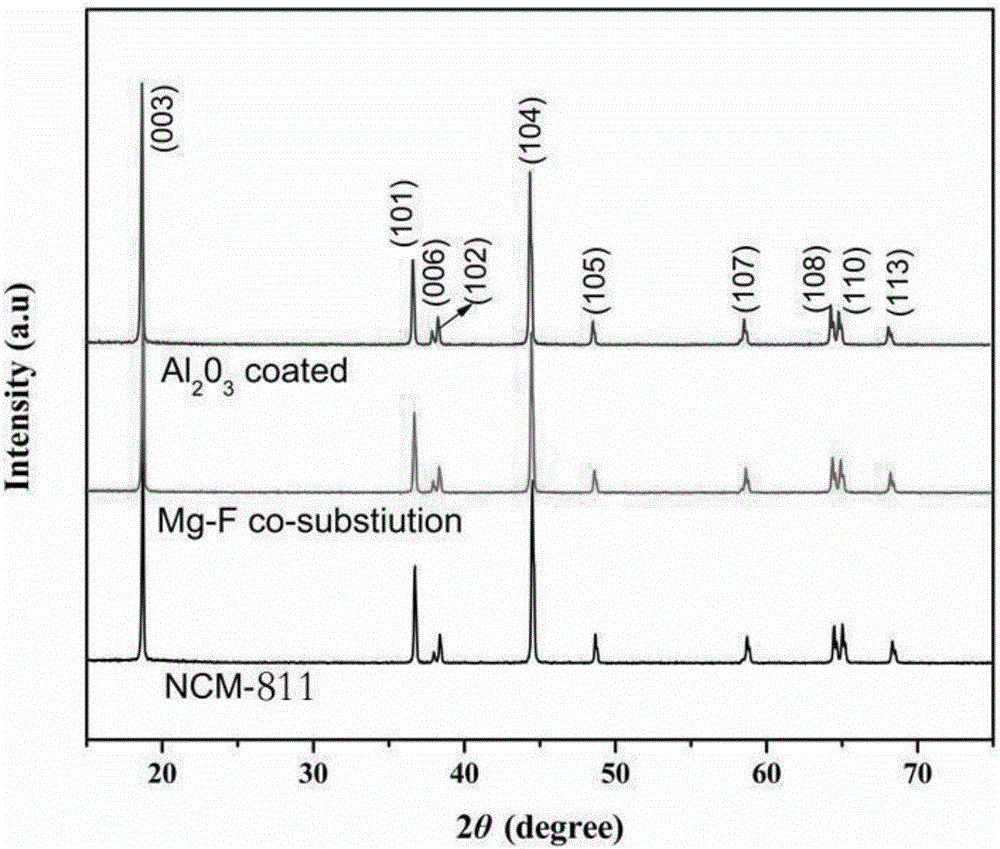

InactiveCN107180963AReduce solubilityChange the band structureCell electrodesSecondary cellsManganeseCobalt

The invention discloses a lithium NCM (nickel cobalt manganese) material. The lithium NCM material is prepared by doping Mg (magnesium), Al (aluminum) or Ti (titanium) and F (fluorine) into a 811 type lithium NCM cathode material. The lithium nickel manganese cobalt material has the advantages that by simultaneously doping Mg, Al or Ti and F into the 811 type NCM electrode material, the rate discharge property and specific capacity of the material are effectively improved; the corrosion of HF (hydrogen fluoride) to the material is effectively inhibited, the dissolving of Co is reduced, and the structure stability and thermal stability of the material are greatly improved.

Owner:四川新锂想能源科技有限责任公司

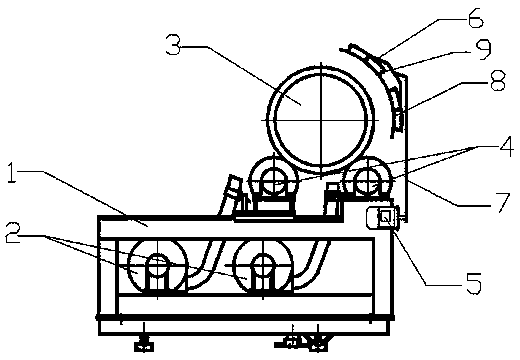

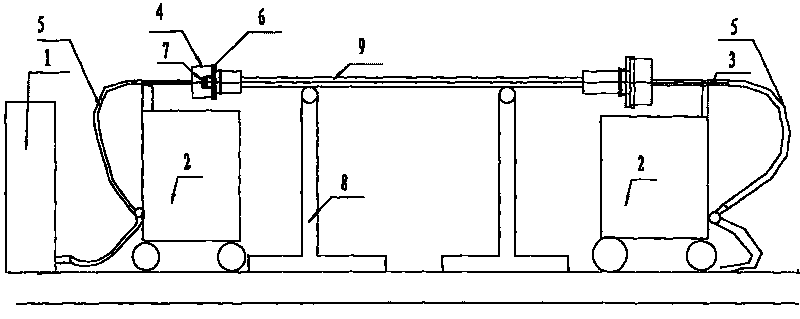

Production equipment and production technology for HDPE (high density polyethylene)spirally enwound structure-wall pipe (Krah pipe)

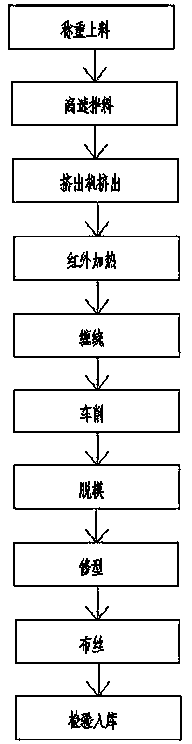

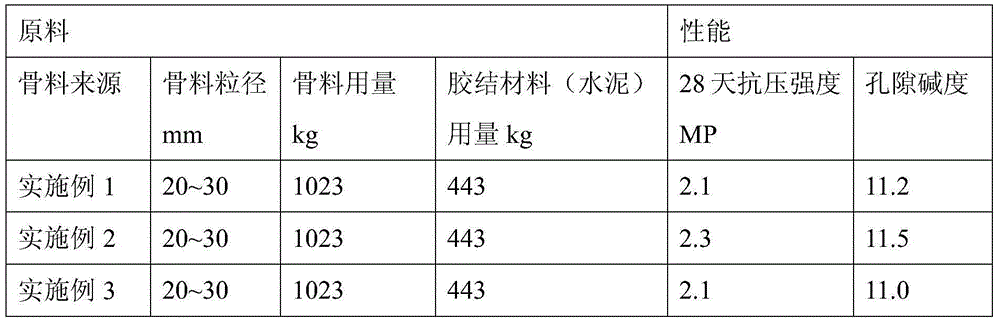

ActiveCN103963325AReduce manufacturing costImprove heating efficiencyTubular articlesElectric fusesProcess engineering

The invention discloses production equipment and a production technology for an HDPE (high density polyethylene) spirally enwound structure-wall pipe (Krah pipe).The equipment comprises a base trolley, cooling fans, a mold roller, rolling wheels, a servo motor, an infrared heating device and a rotating rod. The technology comprises material mixing, feeding, vacuum feeding, extrusion, enwinding, turning, demolding, modification, electric fuse distribution, inspection and storage. According to the production equipment and the production technology, infrared high-frequency heating is adopted, the heating efficiency is high, the cost is low, and the operation is simple and convenient; the ring stiffness is increased by above 30% due to addition of short-glass-fiber master batches; characteristics of HDPE are adopted, so that the comprehensive performance of the pipe is improved; the weld seam quality of the pipe is guaranteed, and the weld seam quality and the overall external pressure resistance of the pipe are also improved.

Owner:HUNAN QIANYUAN NEW MATERIAL

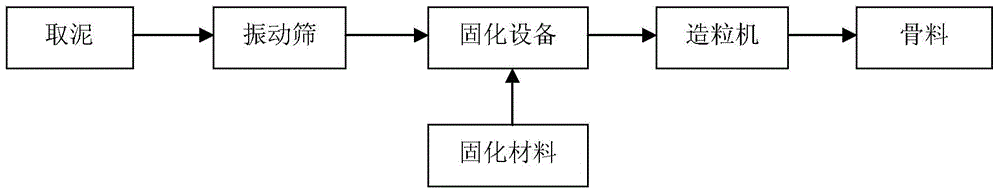

Curing sintering-free granulation method for sludge

The invention provides a curing sintering-free granulation method for sludge. The method comprises the following steps: filtering sludge with a vibrating filter sieve so as to separate solid waste like plants and pebble in the sludge; placing the sludge having undergone filtration into a curing apparatus, sprinkling a curing agent, adding fine aggregate and carrying out mixing; and subjecting the cured sludge to granulation with a granulator so as to obtain pebble or cobblestone-shaped aggregate. The invention further provides application of the pebble or cobblestone-shaped aggregate prepared by using the method in preparation of plant type porous concrete or other water constructions. The method uses industrial waste as a curing agent for immobilization of the sludge and has the advantages of simple process, high curing efficiency and achievement of the good effect of treatment of waste with waste.

Owner:祝建中

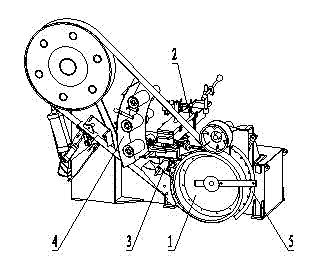

Manufacturing process and equipment for storage battery hauling net lead strip or net punching plate gate lead strip

ActiveCN102931416AReduce lead fume pollutionReduce lossElectrode carriers/collectorsMetal rolling arrangementsPunchingPollutant emissions

The invention discloses a manufacturing process for a storage battery hauling net lead strip or a punching net plate gate lead strip. The manufacturing process comprises the steps of melting electrolytic lead and adding alloy elements, conveying to the mixture to a continuous lead strip casting machine, and casting the mixture to a coarse alloy lead strip, then taking the coarse alloy lead strip as the raw materials and directly conducting cold rolling on the coarse alloy lead strip to be refined lead strip used for the hauling net or a punching net by the continuous lead strip casting machine. The manufacturing process comprises the steps of a. melting the electrolytic lead; b. conveying lead liquid; c. continuously casting to from the coarse alloy lead strip; d. continuously rolling to form the refined alloy lead strip; and e. rolling and storing. In addition, the invention also provides special manufacturing equipment. According to the manufacturing process and the manufacturing equipment, not only the discharging amount of pollutants such as lead fume can be obviously reduced, the energy consumption and the material loss also can be reduced, and the product quality and the production efficiency of the lead acid storage battery plate gate hauling net or the punching net lead strip can be improved.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

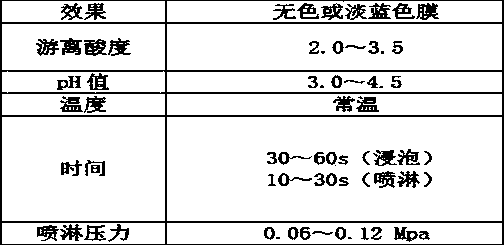

Chromium-free coating agent and preparation method thereof

ActiveCN103938199AImprove adhesionImprove corrosion resistanceMetallic material coating processesChromium freeZirconium oxychloride

The invention relates to the field of a metal surface treatment agent, and particularly relates to a chromium-free coating agent and a preparation method thereof. The chromium-free coating agent is prepared from the following raw materials by mass percent: 2-6% of hexafluorozirconic acid, 1.7-6.7% of composite silane coupling agent, 0.8-1.5% of zirconium oxychloride, 0.5-1% of citric acid and the balance of water. The chromium-free coating agent does not contain chromium ions, has the characteristics of being short in treatment time, less in sediments, compact in crystal, stable in bath solution, easy to manage and the like, and is especially applicable to surface treatment of aluminum and aluminum alloy before coating. A layer of colorless corrosion-resistant passivation layer can be formed on the aluminum surface in a spraying or soaking manner, so that the adhesive force between a coating and a matrix and the corrosion resistance of the matrix are greatly improved.

Owner:HUNAN JINYU CHEM

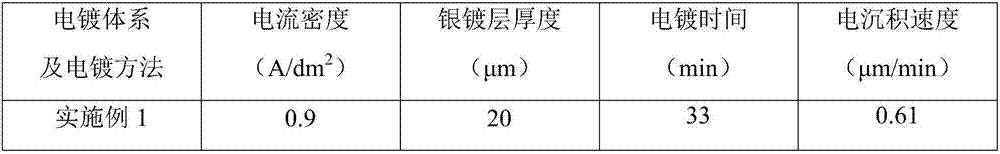

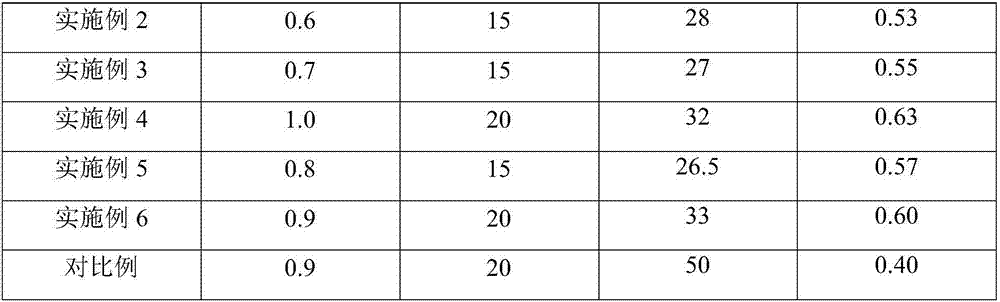

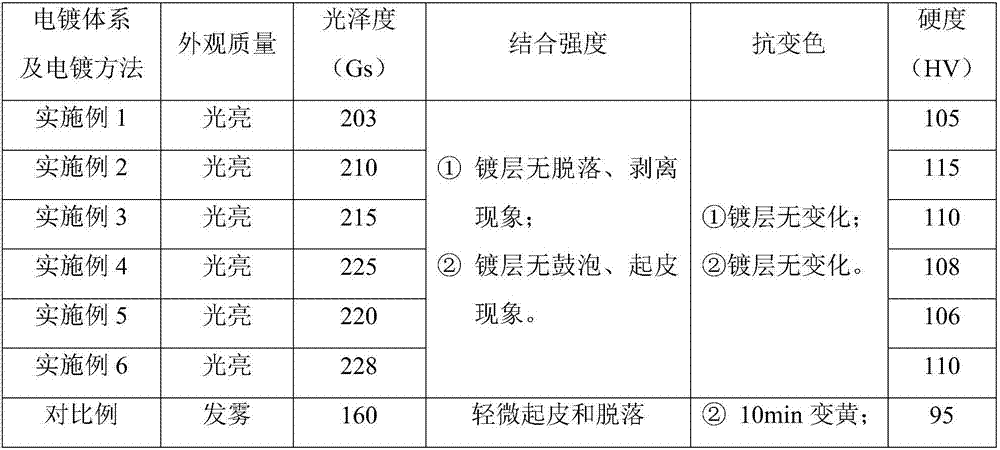

Alkaline cyanide-free silver plating electroplating liquid and silver plating method

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

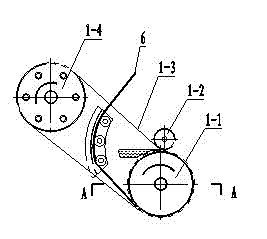

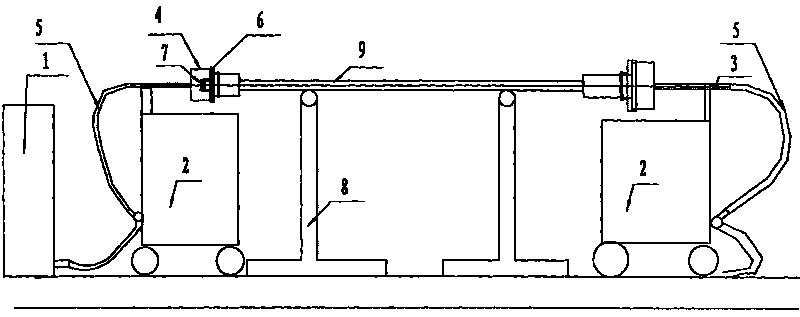

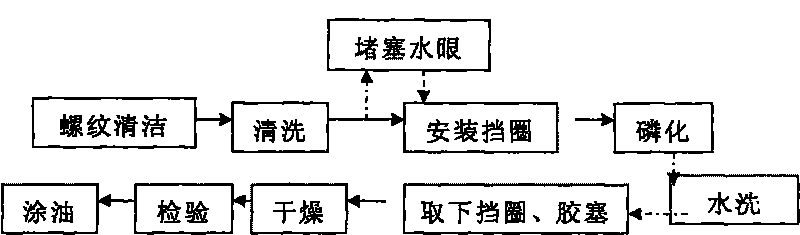

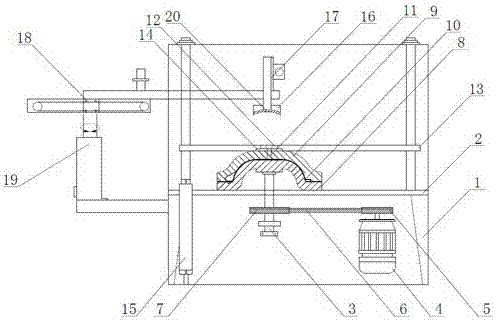

Closed circulating heating thermal phosphorization device and phosphorization method

InactiveCN101696497ASolve temperature problemsSolve the technical problem of uneven spraying of liquid medicineMetallic material coating processesClose contactPetroleum engineering

The invention discloses a closed circulating heating thermal phosphorization device and a phosphorization method, relating to the technical field of drilling tool thread phosphorization. The device comprises a fluid heater, a phosphorization pool, a heating controller, a spray head, a circulation pipeline, a rubber check ring and a rubber stopper, wherein the fluid heater and the phosphorization pool are connected through the circulation pipeline; the spray head is fixed above the phosphorization pool; a water outlet of the circulation pipeline is connected with the spray head; a drilling rod is supported by a pipe rack and arranged above the phosphorization pool; the rubber stopper is arranged in a water hole of the drilling rod; the rubber check ring is sleeved on a drilling rod joint, and the inner wall of the rubber check ring is in close contact with the outer wall of the spray head; threads extend into a cavity formed by the spray head and the rubber check ring; and the heating controller is connected with the fluid heater. The invention can control the temperature, the pressure and the flow to carry out semi-soaking type phosphorization on the threads so as to solve the technical problems of difficult temperature constancy and non-uniform medicine liquid spraying in thermal phosphorization.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

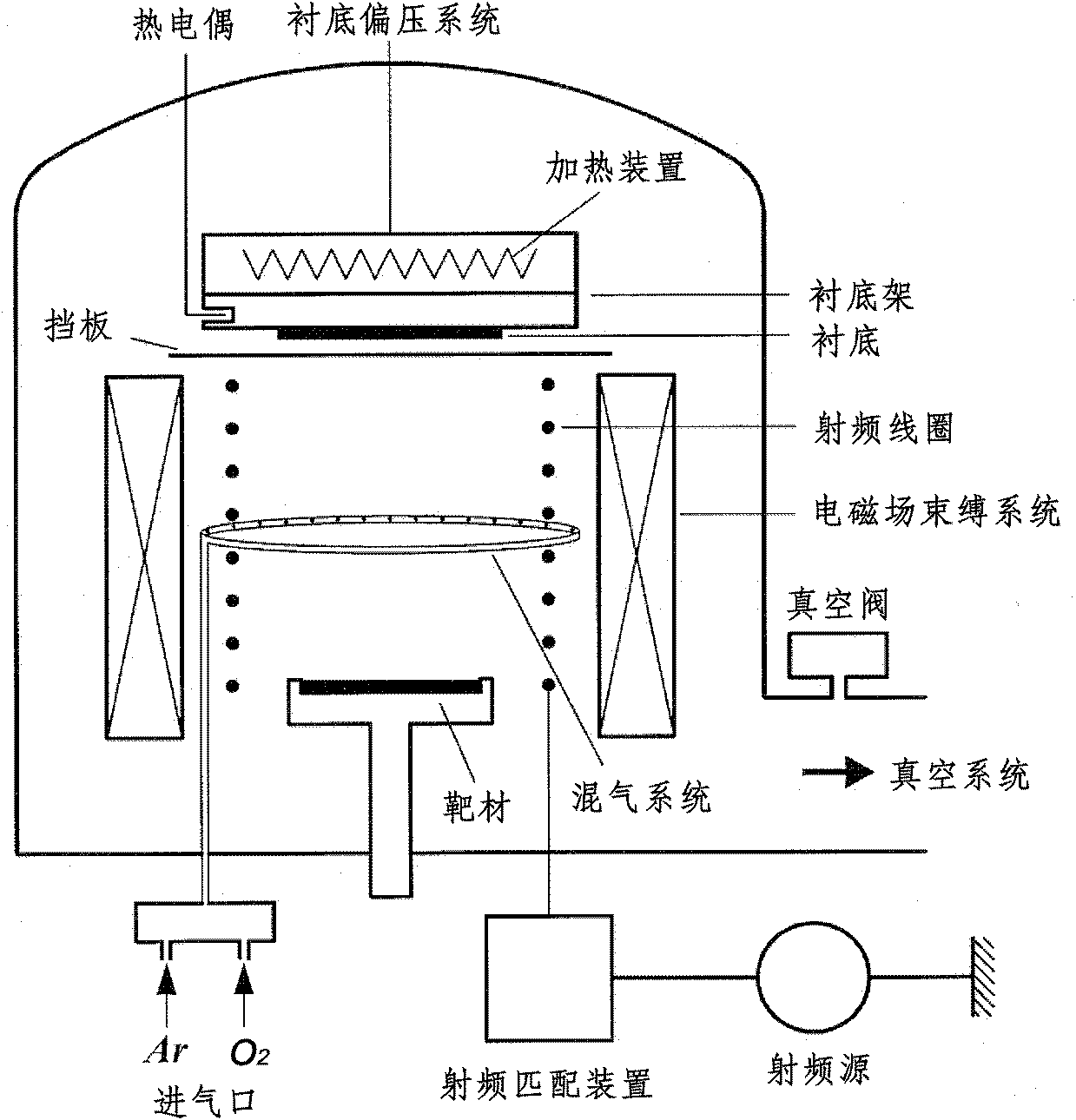

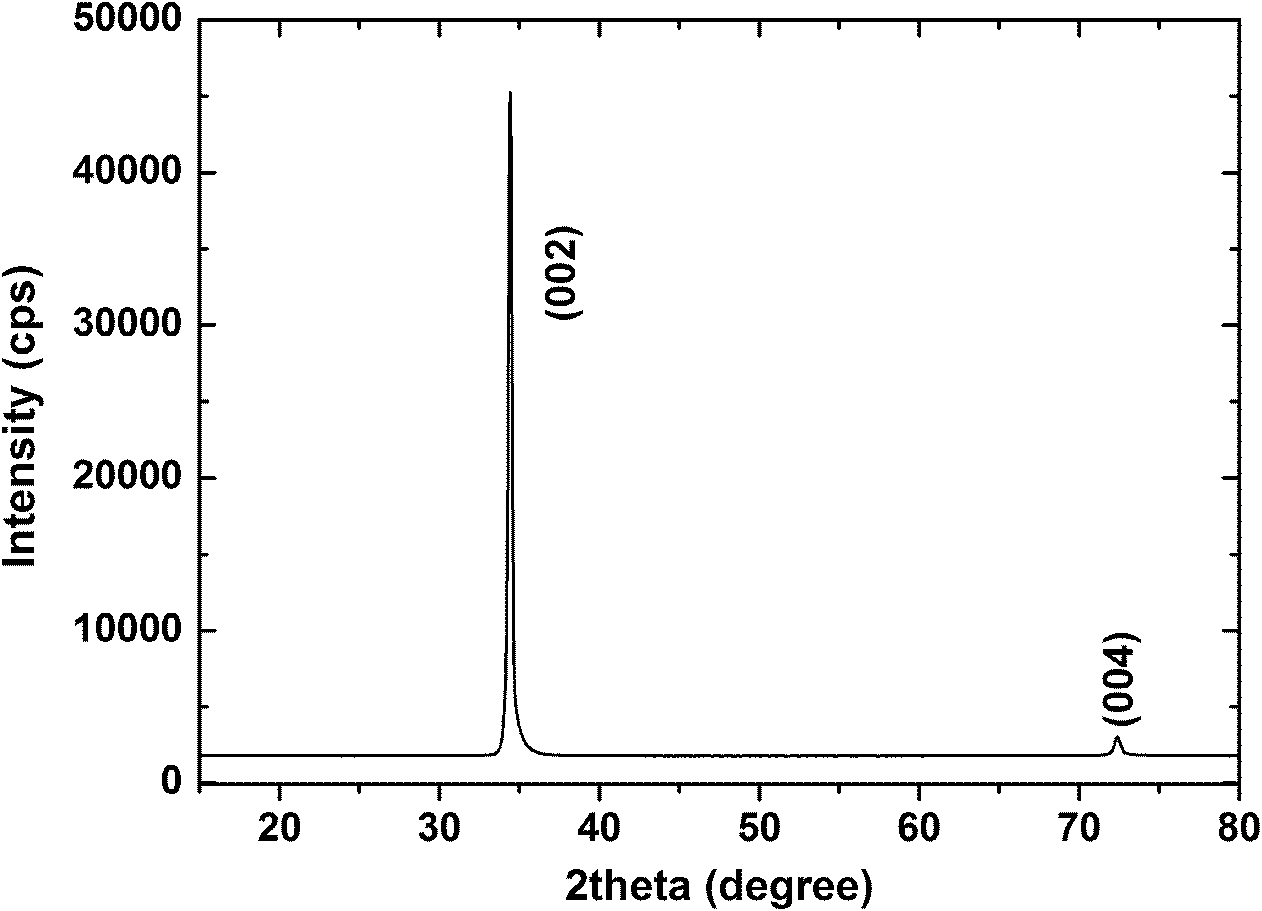

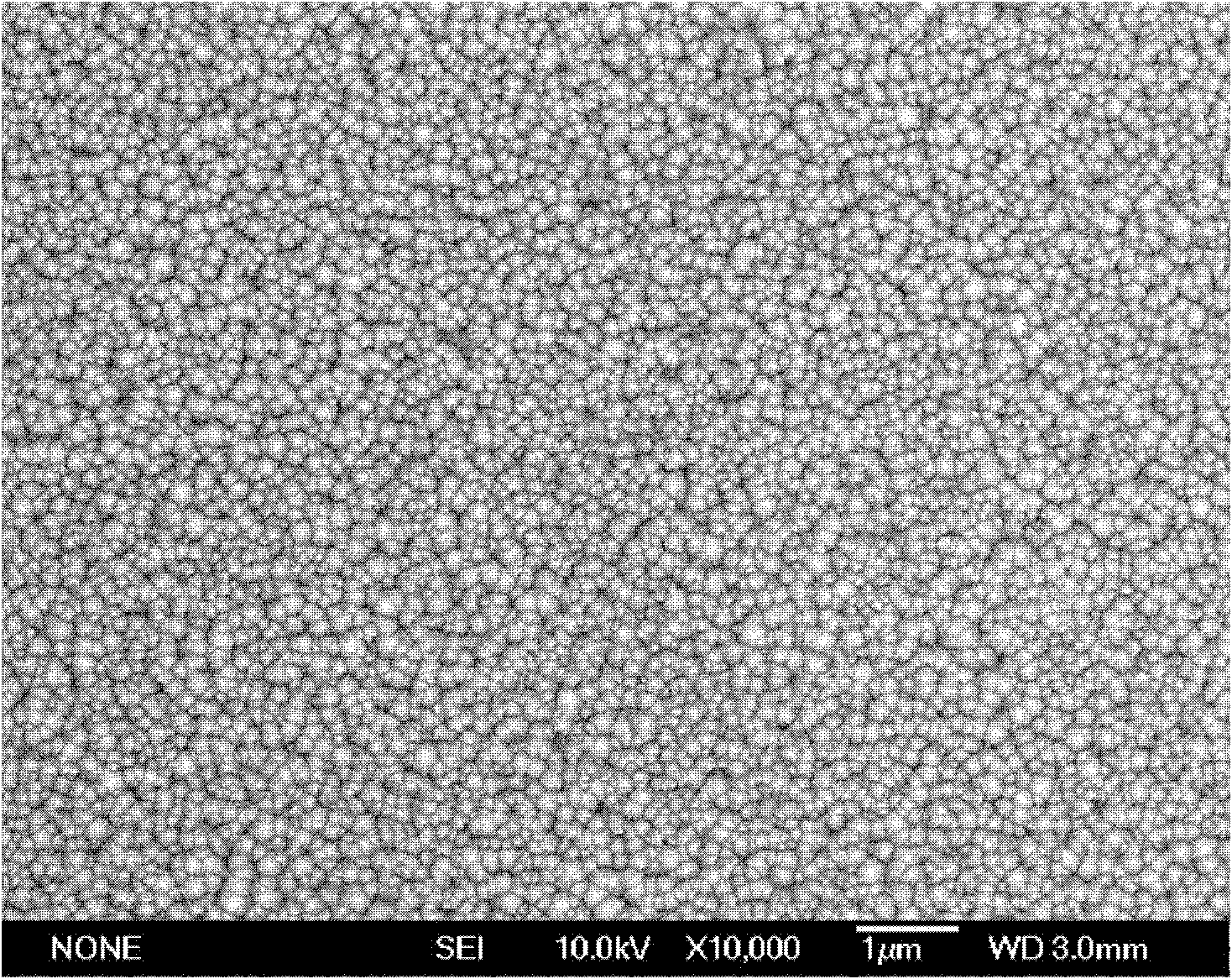

Preparation method of Al-doped zinc oxide transparent conductive thin film

ActiveCN102312201ALow growth temperatureImprove uniformityVacuum evaporation coatingSputtering coatingInductively coupled plasmaZinc

The invention belongs to the field of transparent conductive thin films, relates to a preparation method of an Al-doped ZnO transparent conductive thin film, and in particular relates to an inductively coupled plasma reinforced physical vapour deposition (ICP-PVD) method. The ICP-PVD method comprises the following steps of: firstly preparing a Zn1-xAlxO (x is more than or equal to 0.01 and is less than or equal to 0.05) target material; and placing a clean and dry substrate into an ICP-PVD system, and controlling all the technological parameters of the ICP-PVD system to carry out thin film deposition, so as to obtain the Al-doped ZnO transparent conductive thin film. The method provided by the invention adopts simple equipment, is easy to operate and can realize large-area and mass production of coating films. Compared with the traditional thin film equipment, the ICP-PVD system realizes constrain and acceleration effects on various charged particles in plasma, thus crystallization quality of the thin film and controllability of doping of a donor are improved, a ZnO thin film with low resistivity, high transmissivity and good repeatability and stability can be easily obtained, andthe thin film can be applied to photoelectronic devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Centrifugal casting machine of casting iron pan and centrifugal casting method thereof

InactiveCN107081414AHigh densityReduce consumption costFoundry mouldsFoundry coresMachineCentrifugal force

The invention discloses a centrifugal casting machine of a casting iron pan. The centrifugal casting machine comprises a rack. A lower bearing plate is horizontally arranged on the rack, a rotating shaft is vertically arranged on the lower bearing plate, and a power rotation-driving mechanism is arranged at a lower free end of the rotating shaft; a lower die is arranged at an upper free end of the rotating shaft, an upper die is arranged over the lower die in an on-off mode, and a centrifugal chamber is formed between the upper die and the lower die in a fastening mode; and a layer of high-temperature die coating layer is coated on the surface of the centrifugal chamber, a casting port communicating with the inner portion of the centrifugal chamber is formed in the upper die, the upper die is arranged on an upper bearing plate through a bearing, and the upper bearing plate is arranged on a lifting air cylinder. Centrifugal force enables specific pressure to increase sharply, and the functions that the density inside cast iron solution is increased, the crystal is compact, a fine grain layer is thickened, air holes inside the cast iron are decreased, and the surface quality is improved can be achieved easily; and the production period is shortened, the rate of finished products is improved, and the consumption of primary metal and the production cost of products are reduced.

Owner:义乌市爱釜义自动化科技有限公司

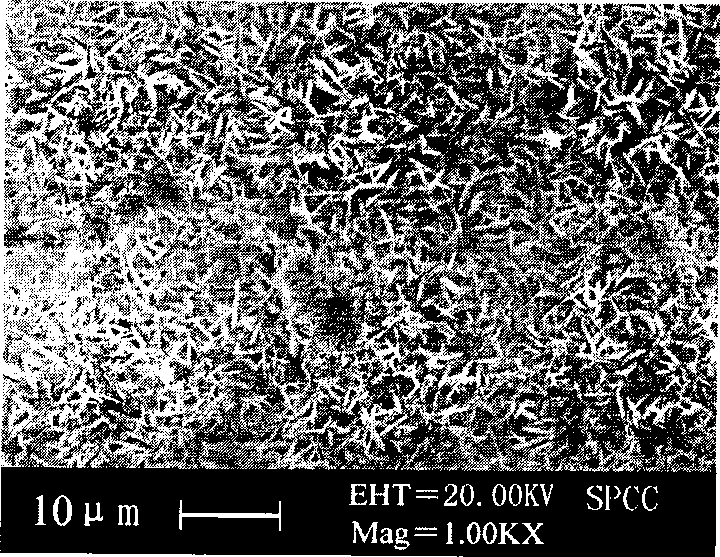

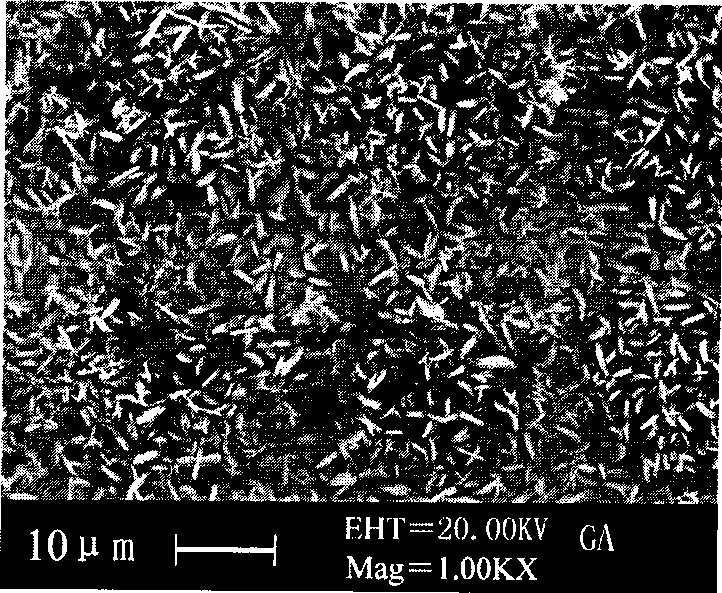

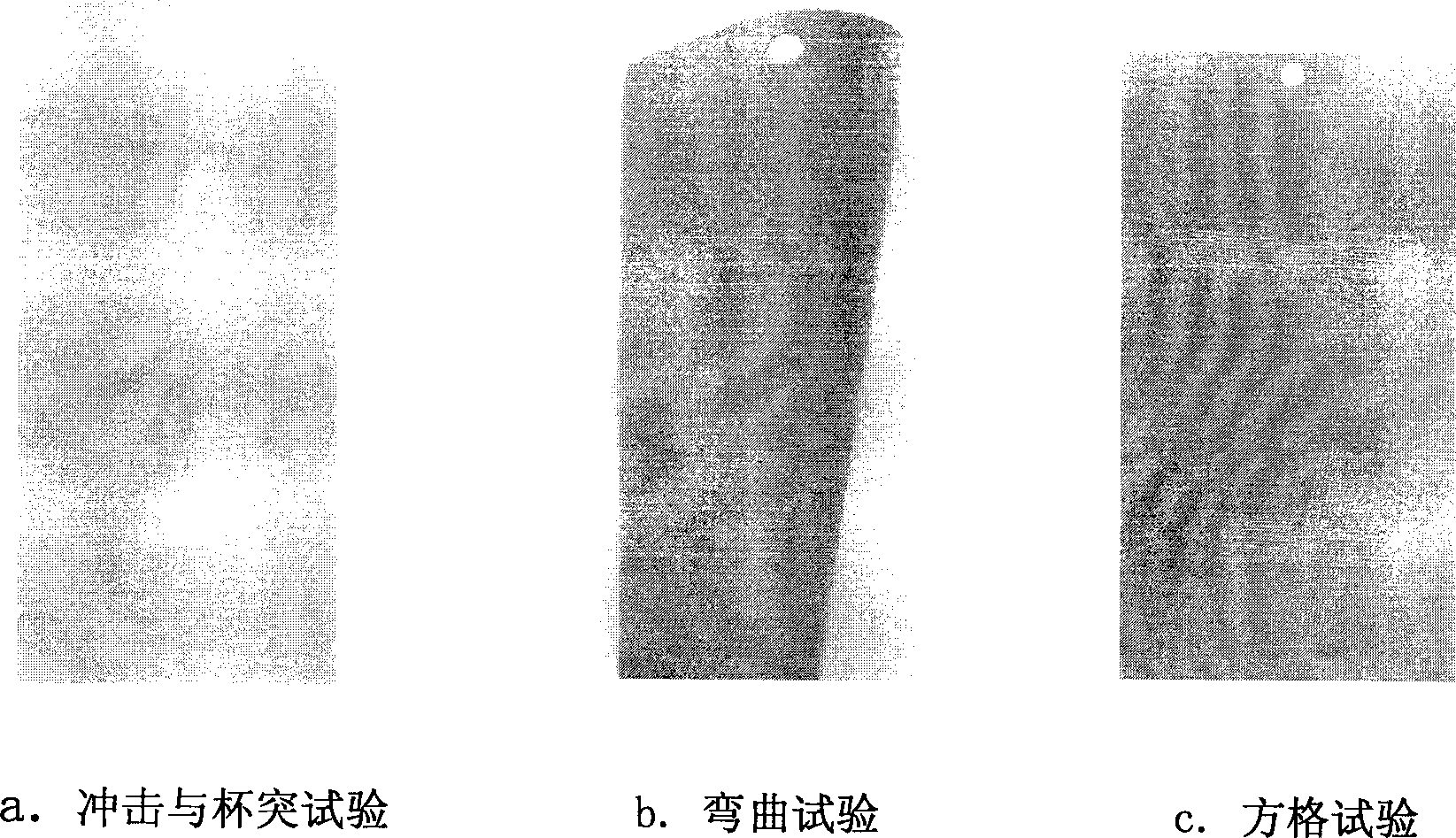

Non-nickle ion phosphating agent for steel plate processing

InactiveCN101386980AHigh speedCrystal denseMetallic material coating processesSalt spray testManganese

The invention provides a nickel ion-free phosphating agent for steel plate treatment. The nickel ion-free phosphating agent is characterized by comprising the following matters in percentage by weight: 30 to 50 percent of phosphoric acid, 2 to 5 percent of zinc oxide, 2 to 4 percent of manganese carbonate, 7 to 10 percent of magnesium nitrate, 0.8 to 1.2 percent of cobalt nitrate, 0.2 to 0.4 percent of sodium wolframate, 5 to 8 percent of sodium carbonate and the balance being water. The phosphating agent is used for treating a conversion coating, is quick in phosphating filming, dense in crystallization, good in matching with a cathodic electrophoretic coating, and can reach over 720 hours in a 5 percent of neutral salt spray test. The nickel ion-free phosphating agent is simple in processing, low in product cost and meets the requirement of environmental protection.

Owner:SHENYANG PARKERIZING

Method for electroplating metals of tin and bismuth

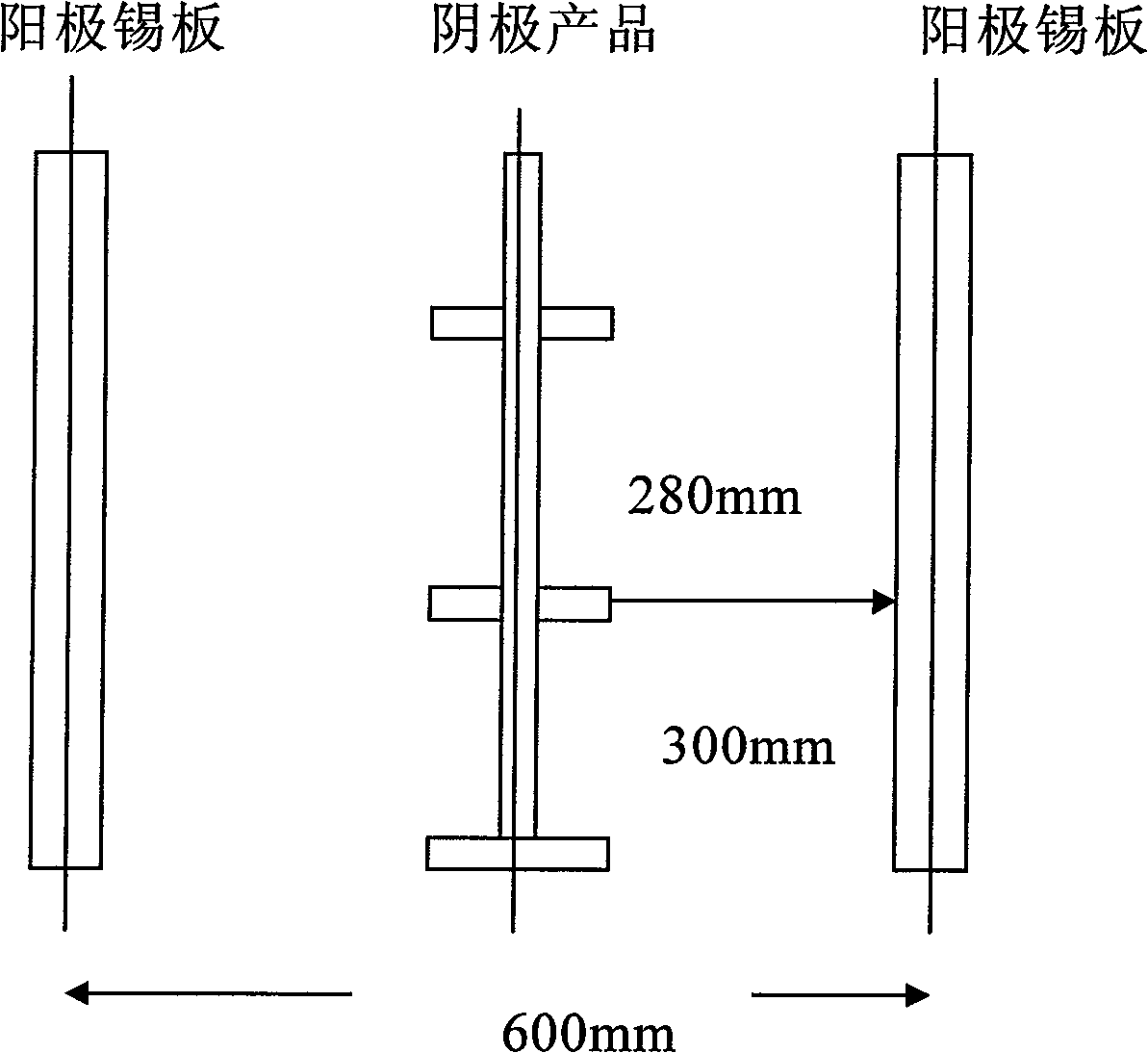

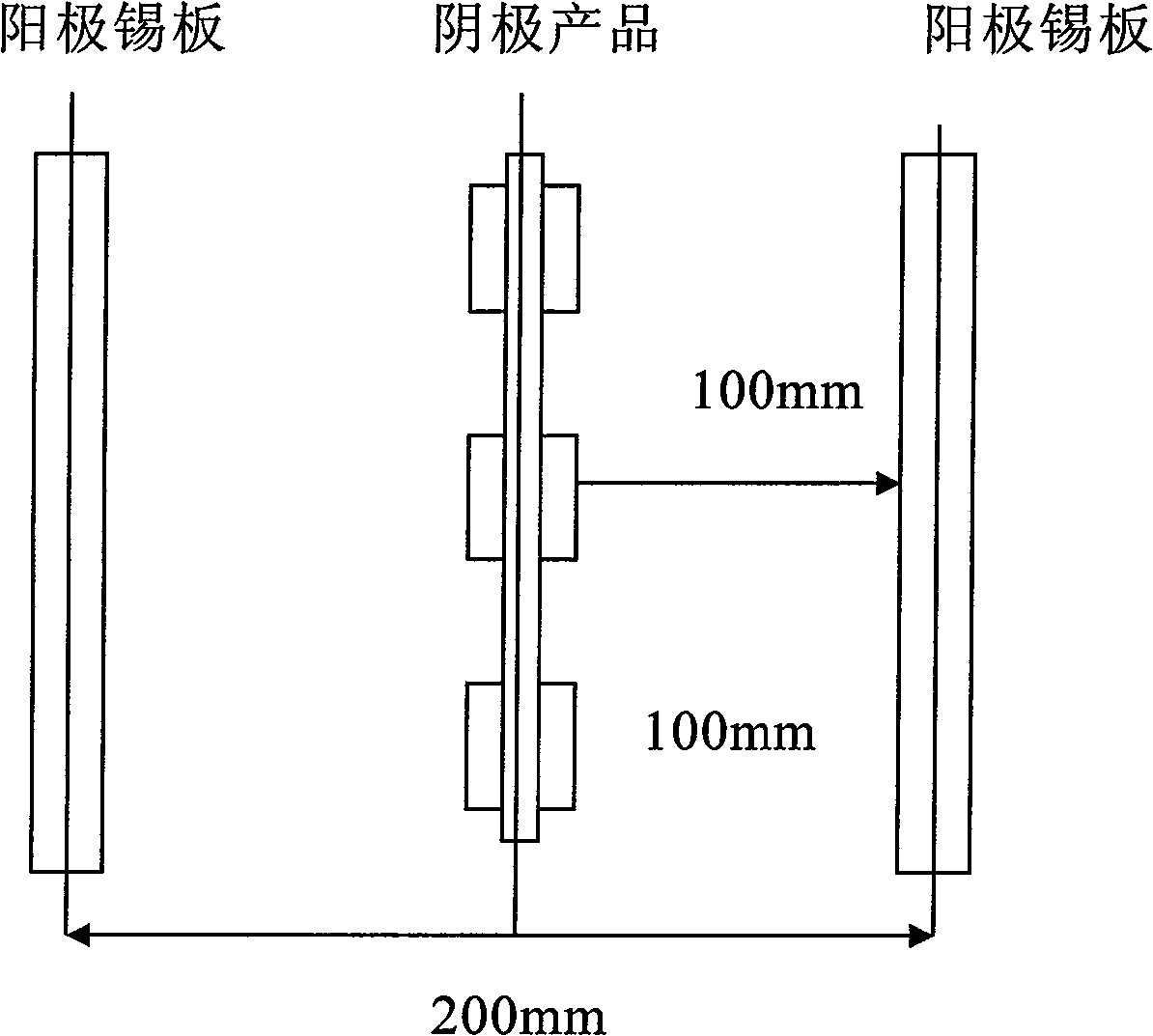

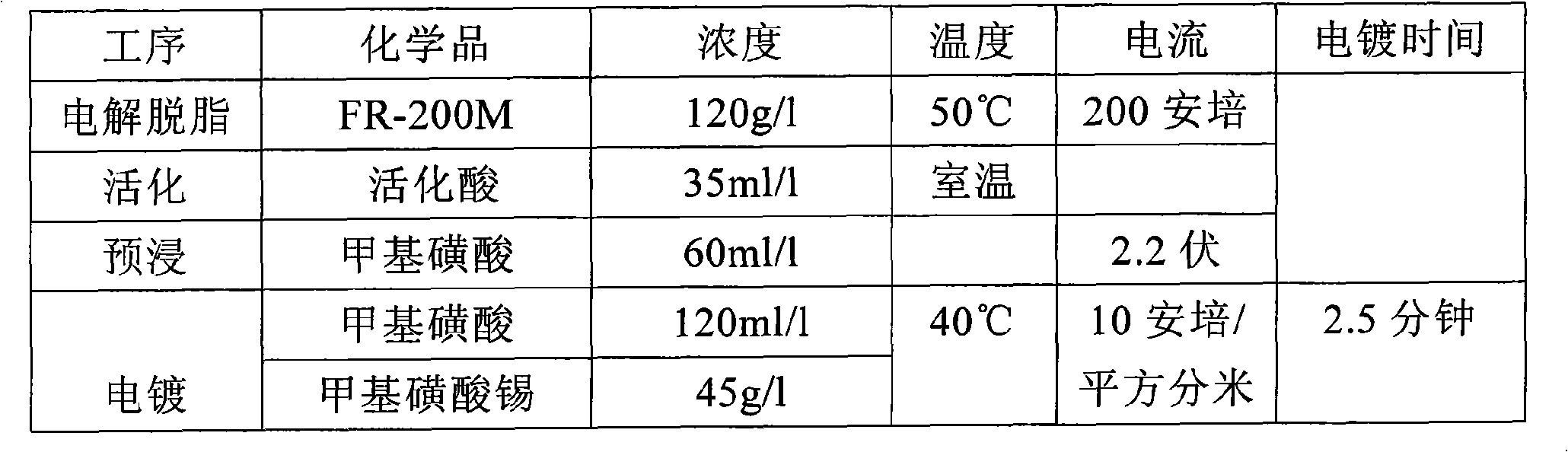

InactiveCN101538726AUniform thicknessEvenly distributed ingredientsSquare decimeterMethane sulfonate

The invention relates to a method for electroplating metals of tin and bismuth, which is characterized by comprising 40-80g / l of tin methane-sulfonate and 1-3g / l of bismuth methane-sulfonate in terms of volume mass ratio, and also comprising 100-280ml / l of methylsulfonic acid, 30-100ml / l of additive SNB31 produced by Dr. Ing Max Schlotter GmbH & Co. KG, 5-15ml / l of additive SNB14 produced by Dr. Ing Max Schlotter GmbH & Co. KG, and the balanced water in terms of volume ratio; and the electroplate liquid is used for electroplating for 1.5-2.5min with a current density of 10-20 ampere / square decimeter and at a temperature of 35-65 DEG C. The cathode plate of the plating tank containing the electroplate liquid is a conveying steel belt, and the distances between an electroplating part and two anode plates are the same. The tin and bismuth metal layers electroplated by the invention have uniform thickness and even distribution of bismuth, and tin and bismuth metal layers have good weldability.

Owner:WUXI WELNEW MICRO ELECTRONICS

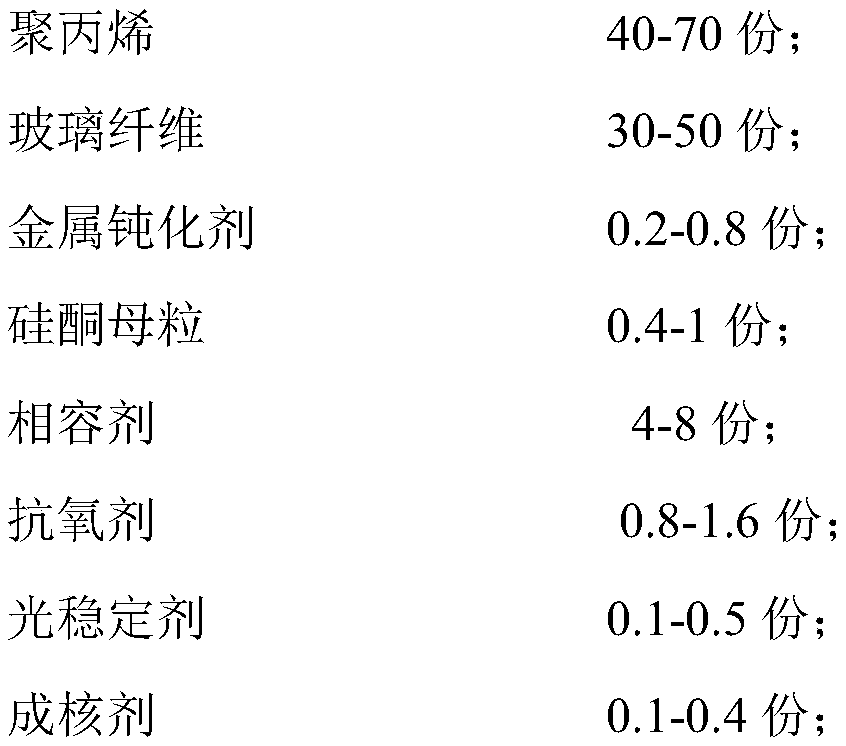

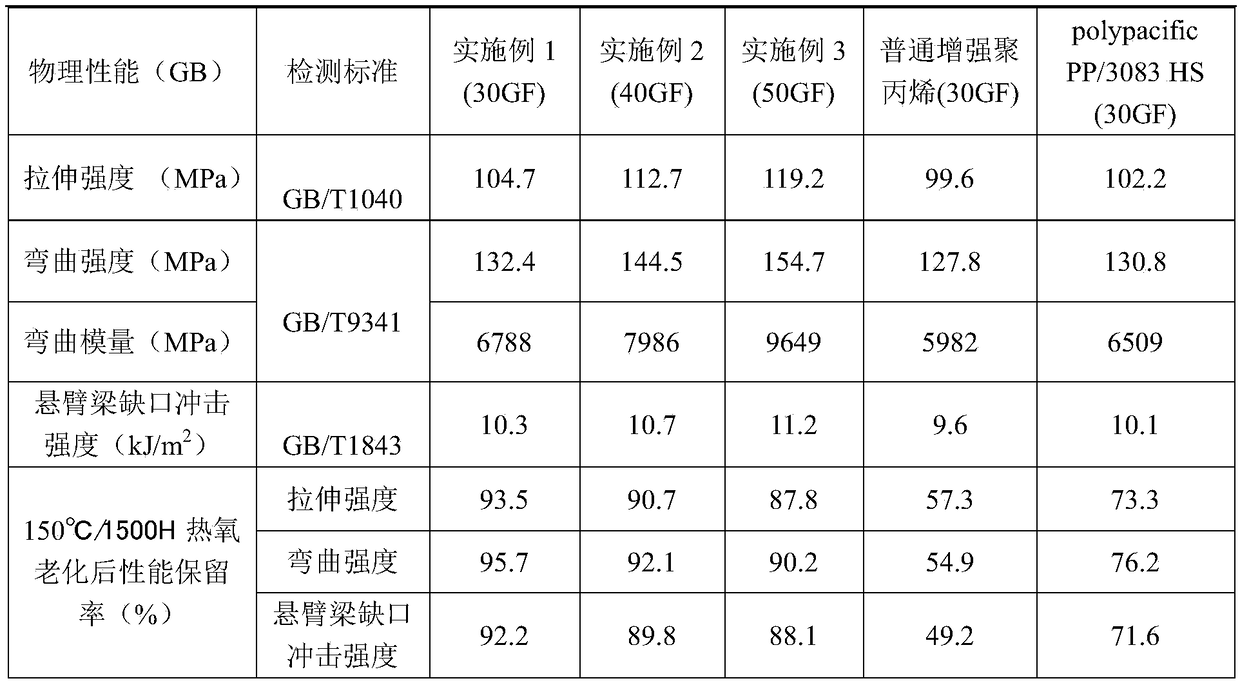

Thermo-oxidative aging resistant glass fiber reinforced polypropylene material and preparation method thereof

The invention discloses a thermo-oxidative aging resistant glass fiber reinforced polypropylene material and a preparation method thereof. The material is composed of the following components: polypropylene, glass fibers, a metal deactivator, a silicone master batch, a compatilizer, an antioxidant, a light stabilizer, a nucleating agent and a lubricating agent. By utilizing the synergistic thermo-oxidative aging resistance between functional additives, aging catalysis of metal ions on the material matrix can be inhibited by matching with the metal deactivator, so that the thermo-oxidative aging resistance of the metallic insert material is obviously improved; the prepared reinforced polypropylene has long-term thermo-oxidative aging resistance, and the performance retention rate is more than 85% after thermo-oxidative aging of 150DEG C per 1500 hours; the catalytic aging influence of the metal ions on the polymer matrix can be eliminated aiming at injection materials with metal inserts, and the problems that the application environments of reinforced polypropylene products in the fields of automobiles, household appliances and electronic materials are limited and the long-term service performance is greatly reduced are solved.

Owner:ORINKO NEW MATERIAL CO LTD

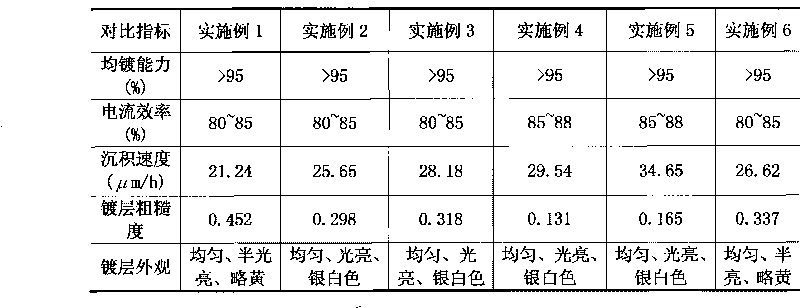

Double-pulse cyanide-free alkali silver electroplating method

The invention discloses components of double-pulse cyanide-free alkali silver electroplating solution and a process. Silver nitrate is used as a main salt, sodium thiosulfate and ammonium thiosulfate are used as complexing agents, sodium metabisulfite is used as an auxiliary complexing agent, sodium sulfate is used as a conductive salt, boric acid is used as a pH value adjustor, and gelatin is added into the plating solution. The operation conditions comprise that the pH value of the plating solution is 4.0 to 4.5, the temperature of the plating solution is 20 to 30 DEG C, and the mechanical stirring speed is 100 to 150rpm. A silver plating layer with fine and compact crystallization can be obtained by adopting double-pulse electroplating, controlling the duty ratio, average current density and working time of the positive and negative pulses and electroplating on pure copper or copper alloy without silver immersion plating pretreatment. The plating solution of the invention has the advantages of simple formulation, easy control, strong even plating and covering capabilities, and high batch production stability. The plating layer has fine and compact crystallization and good appearance luster, and has no peeling, shedding and stripping; and the technology can replace a cyanide silver electroplating process, and can be used as a surface electroplating process for jewelries, artware and parts of electronic products.

Owner:KUNMING UNIV OF SCI & TECH

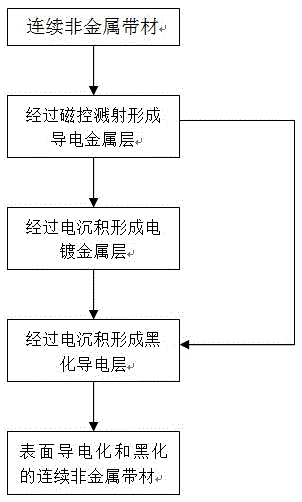

Conductive treatment and oxide treatment method for continuous non-metal strip

InactiveCN105648438AImprove conductivityImprove shielding effectMagnetic/electric field screeningFinal product manufactureMetal stripsElectromagnetic shielding

The invention discloses a conductive treatment and oxide treatment method for a continuous non-metal strip. Firstly, the surface of the continuous non-metal strip serving as a substrate is plated by metal, then an oxidized conductive layer is formed through electro-deposition, and the black continuous non-metal strip can be obtained. The strip has excellent conductivity, light absorption and extinction performance, heat absorption and cooling performance, friction resistance, corrosion resistance, electromagnetic shielding performance and wave-absorbing capacity, and has huge application value in the field of electromagnetic shielding and wave-absorbing materials.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

Casting process for cylinder sleeves

The invention discloses a casting process for cylinder sleeves. The process includes the steps: making a mould for the cylinder sleeves; making a mould joint with a side gate according to casting specifications to obtain a molding box of an external mould, a positioning core and a gate core; arranging a gate and a feed head on the mould; adding clay sand into the mould for clay sand molding, and matching 1.25-1.45% of furan resin and sulfonic acid accounting for 30-60% of the resin to serve as curing agents; patching the molded clay sand mould and brushing coating on the surface of the same; subjecting the clay sand mould to mould matching and mould assembling; pressing the clay sand mould; placing a pouring cup on the pouring gate of the mould and placing a feed head cup on the feed head; and pouring melted iron into a cavity of the clay sand mould by a crane ladle for casting. The casting process for the cylinder sleeves has the advantages of short period, high work efficiency, low cost and wide application range in mould manufacturing.

Owner:陆宝庆

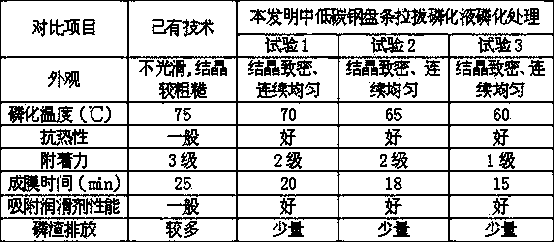

Phosphating solution for drawing of low-carbon and medium-carbon steel wire rod

InactiveCN103757620AReduce frictionExtended service lifeMetallic material coating processesPhosphateSlag

The invention discloses a phosphating solution for drawing of a low-carbon and medium-carbon steel wire rod. The phosphating solution comprises the following components: 11-23 g / L of zinc dihydrogen phosphate, 16-26 g / L of zinc nitrate, 4-6 g / L of a compound accelerant, 3-8 g / L of tartaric acid and the balance of water, wherein the compound accelerant is a mixture of sodium chlorate, sodium nitrite and potassium permanganate. A preparation method of the phosphating solution comprises the steps of charging, stirring, diluting to a constant volume and the like. The phosphating solution for drawing of the low-carbon and medium-carbon steel wire rod, provided by the invention, is applicable to a lubricant coating of the low-carbon and medium-carbon steel wire rod which is not drawn; a phosphating film formed through the processing of the phosphating solution for drawing of the low-carbon and medium-carbon steel wire rod has the advantages of compact film crystal, continuity, uniformity, capability of being adsorbed on a metal surface, good heat resistance viscidity, easiness in cleaning, rust protection, good combining capacity with a lubricant medium and the like; the phosphating solution is applicable to high speed drawing, and adopts a compound accelerant system of sodium chlorate, sodium nitrite and potassium permanganate, so that content of phosphorus slag of the processed solution is low, pollution is lowered, and the environmental performance is good.

Owner:BENGBU YUCHENG NEW MATERIAL TECH

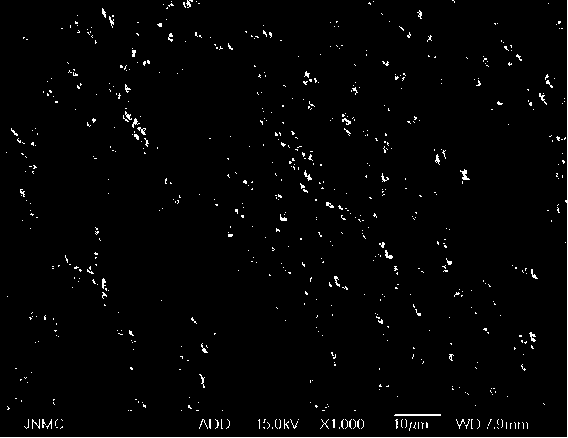

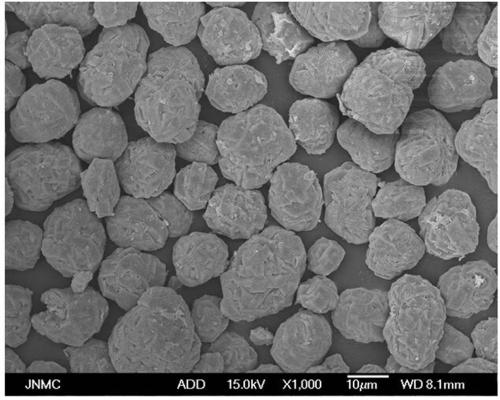

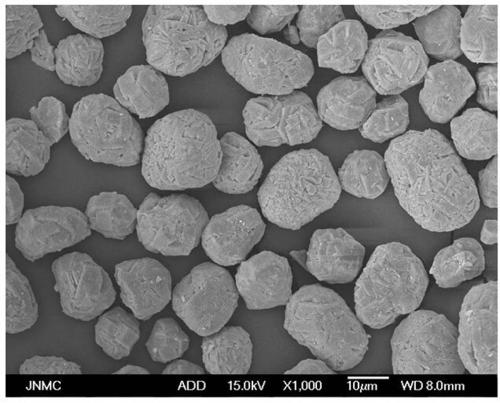

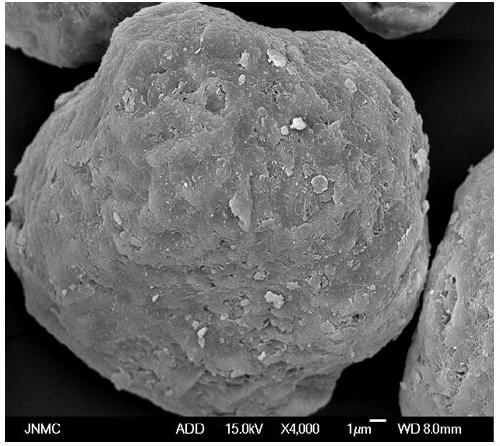

Preparation method of metal coated cobaltosic oxide

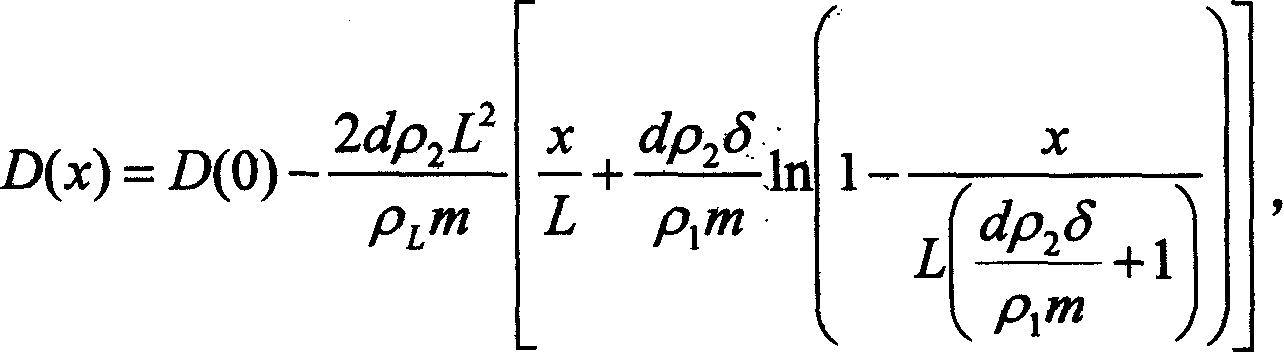

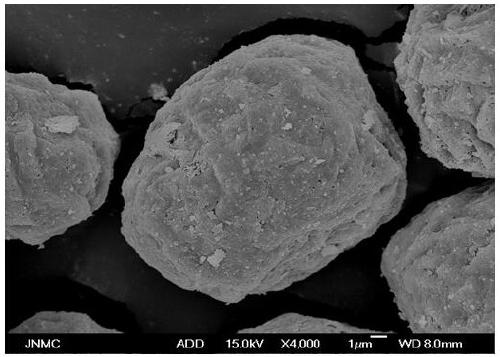

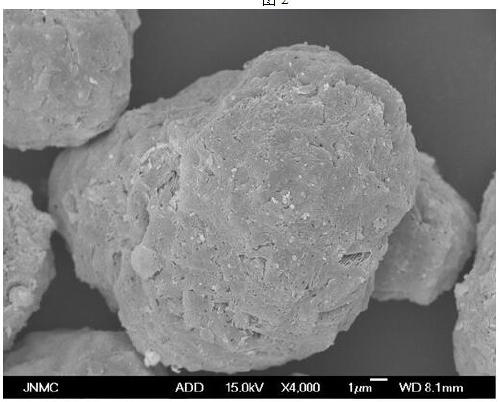

PendingCN110071275AIncrease the number of crystal nucleiGrowth inhibitionCell electrodesSecondary cellsCobalt hydroxideCobalt(II,III) oxide

The invention discloses a preparation method of metal coated cobaltosic oxide. The method provided by the invention comprises the steps of: increasing the concentration gradient of a cobalt solution added into a reaction kettle along with the extension of synthesis time, and simultaneously adjusting the solid-to-liquid ratio of slurry in the reaction kettle to synthesize dense cobalt hydroxide with the laser granularity D50 of 17-19 [mu]m by employing a wet method; and after the synthesis is finished, adding a metal solution and a precipitator solution into the reaction kettle in parallel flowto perform metal coating, and after the coating is finished, performing washing, drying and calcining for a synthesized product to obtain a metal-doped cobaltosic oxide product. The cobaltosic oxideproduct prepared by the method is uniform in doped element distribution and spherical or sphere-like in appearance.

Owner:JINCHUAN GROUP LIMITED +1

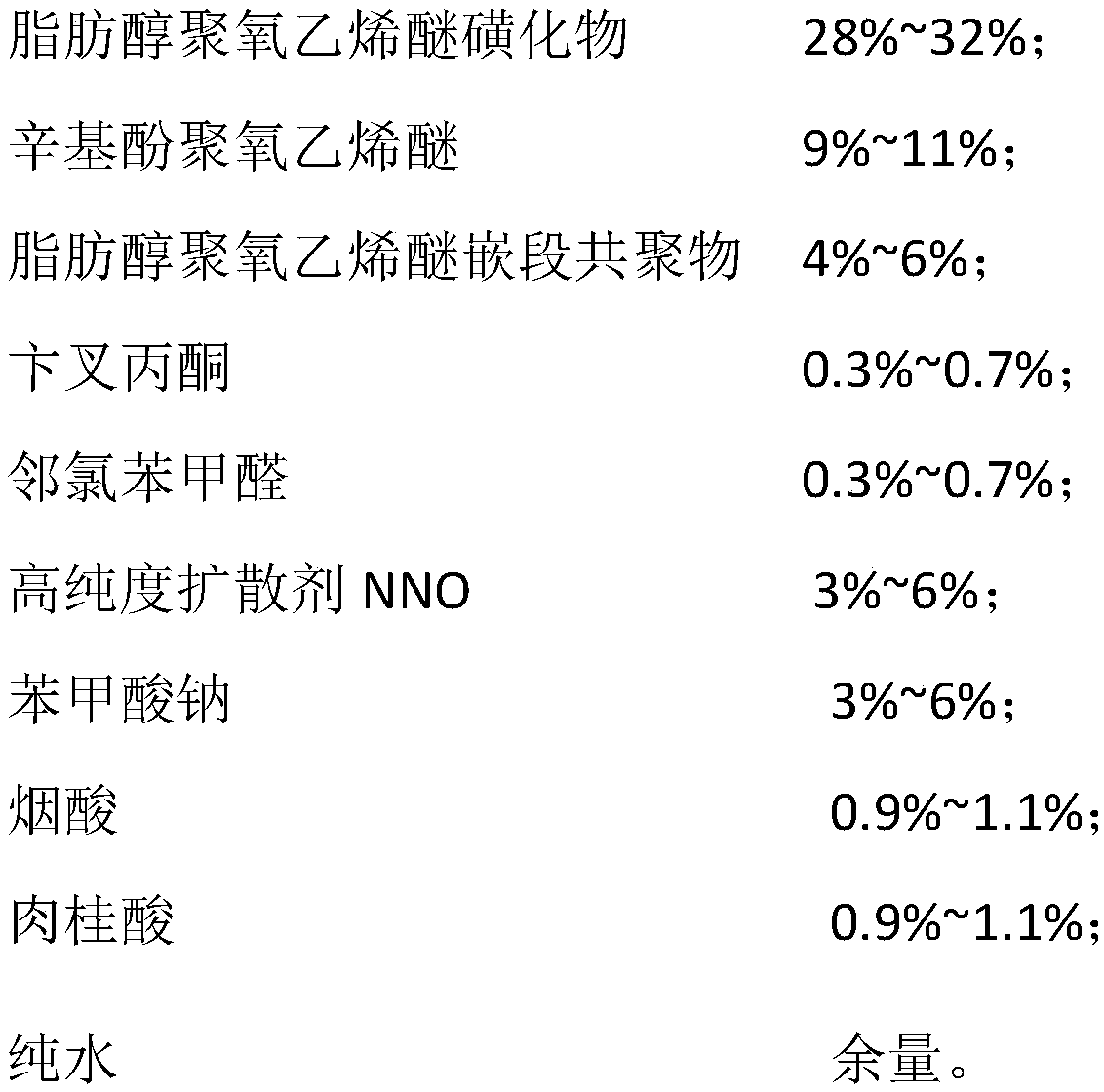

Novel acidic zinc-plating additive

The invention discloses a novel acidic zinc-plating additive. The additive comprises the following components of, in percentage by weight, 25%-35% of fatty alcohol-polyoxyethylene ether sulphonate, 8%-12% of octyl phenol polyoxyethylene ether; 3%-8% of fatty alcohol-polyoxyethylene ether block copolymer, 0.2%-0.8% of benzyl fork acetone, 0.2%-0.8% of o-chlorobenzaldehyde, 2%-7% of high-purity diffusant NNO, 2%-7% of sodium benzoate, 0.8%-1.2% of nicotinic acid, 0.8%-1.2% of cinnamic acid and the balance pure water. According to the additive, a zinc-plated layer with good brightness, leveling and ductility can be rapidly obtained in acid zinc-plating; the cloud point is high, the temperature resistance is good, the current efficiency is high, the light emitting speed is fast, throwing is good, the efficiency is high, and the zinc-plated layer is suitable for rolling plating and hanging plating; the zinc-plated layer is compact in crystallization, non-brittle of zinc and free of foaming,various blue-white and colorful passivation treatment can be easily accepted, and the corrosion-resistant performance is excellent; and the consumption of the additive is less in the plating liquid,supplement and maintenance are convenient, and the additive is economical and practical.

Owner:宁波市鄞州艾博化工科技有限公司

Trivalent chromium electroplating solution and preparing method thereof

The invention relates to the field of environment-friendly electroplating hard chromium, in particular to a novel trivalent chromium electroplating solution and a preparing method thereof. The problem that existing hexavalent chromium ions greatly influence health and environment protection is solved. The electroplating solution includes 0.5 mol / L-1.0 mol / L of chromium chloride, 0.2 mol / L-0.5 mol / L of chromium sulfate, 1.5 mol / L-3.0 mol / L of a coordination agent, 0.1 mol / L-1.0 mol / L of a buffer agent, 0.5 mol / L-2.5 mol / L of conducting salt, 2 g / L-10 g / L of a wetting agent, 2 g / L-10 g / L of a dispersing agent and the balance water. By means of the novel trivalent chromium electroplating solution and the preparing method thereof, a blend system for different kinds of trivalent compounds of chromium is adopted, a special additive is used in the electroplating solution under a conventional electroplating device, the thickness of a chromium plating layer is effectively increased to 60 microns or above, crystals are compact, and the bonding force with a base body is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing hydrogen storing alloy powder

The invention relates to the making of stored hydrogen alloy powder. It is cheap, with great improvement in discharge capacity, recycling life and high power discharge feature. It pretreats the material with polishing and drying machines, smelting the material to form into alloy thin plate and annealing, powdering the alloy in inert atmosphere to get the alloy powder. It is easy to adjust the grain, suitable for big current discharge.

Owner:XTC HYDROGEN ENERGY SCI & TECH (XIAMEN) CO

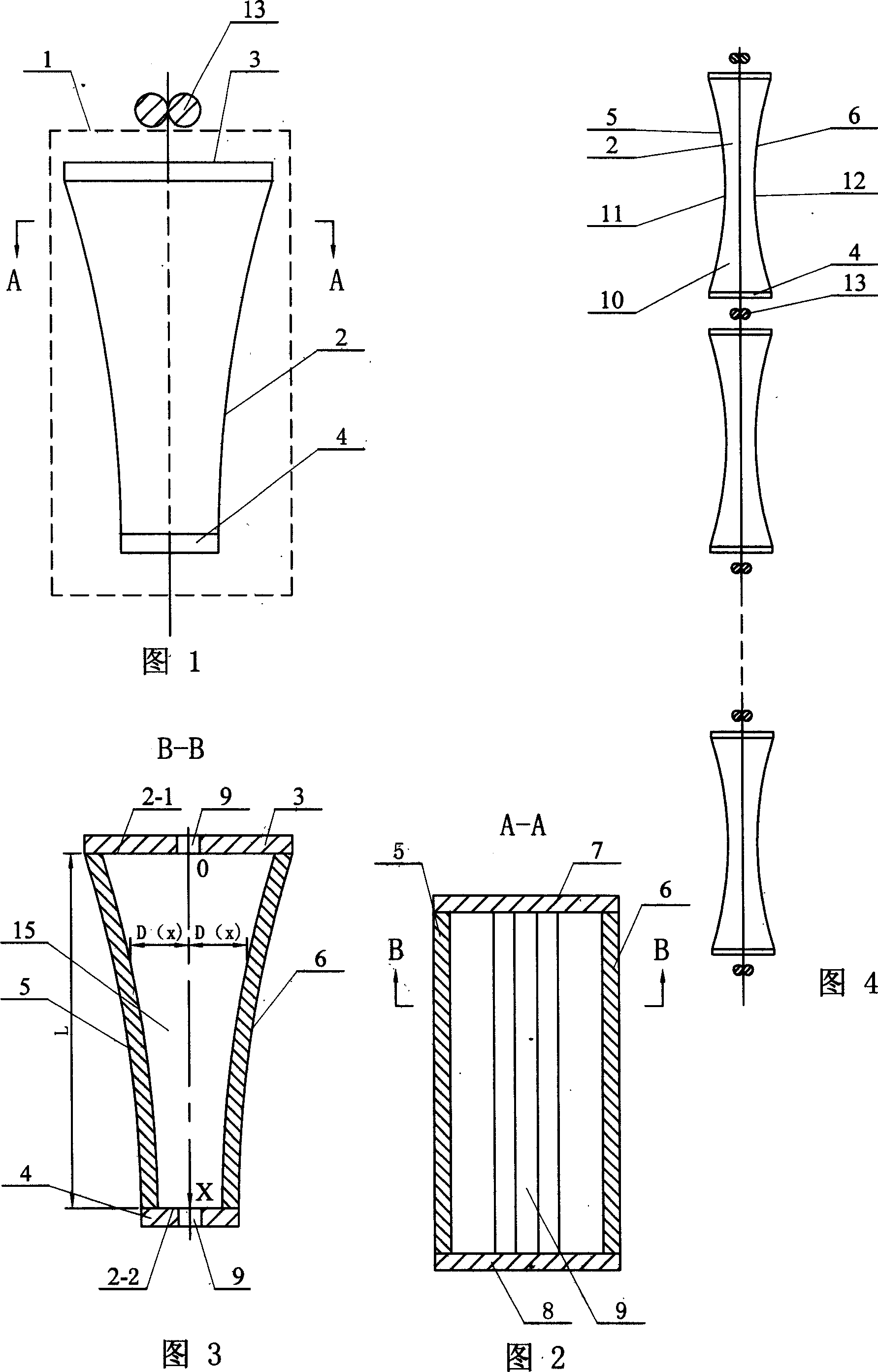

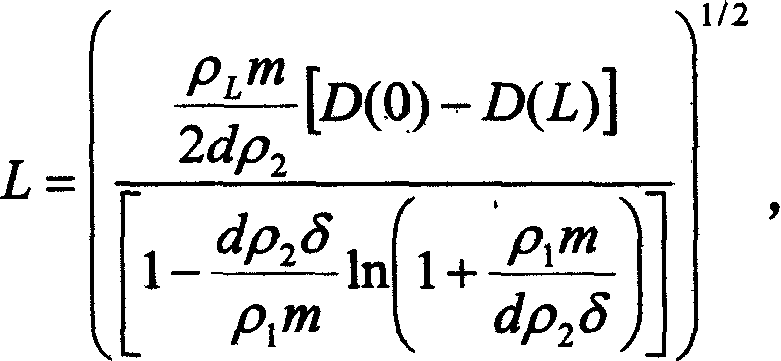

Anode unit for continuous electroplating of belt poor conductor

InactiveCN1637173AUniform distribution of current densityOptimal Current Density ControlElectrodesGalvanic anodeProduction line

The anode device for continuous electroplating of belt poor conductor consists of at least one anode unit. The anode unit consists of one through cavity, one upper insulating cover plate and one lower insulating cover plate. The through cavity is formed with the first anode plate, the first insulating baffle, the second anode plate and the second insulating baffle connected successively. The upper insulating cover plate is connected to the upper port of the through cavity, the lower insulating cover plate to the lower port, and both the upper insulating cover plate and the lower insulating cover plate have slot with symmetrical plane coinciding with that of the through cavity. The through cavity has flared longitudinal profile passing through two anode plates. Owing to the special shape of anode to control the current density for electrically depositing metal, the single electroplating bath may have maximum anode length, and the continuous electroplating production line may have least electroplating baths.

Owner:HARBIN INST OF TECH

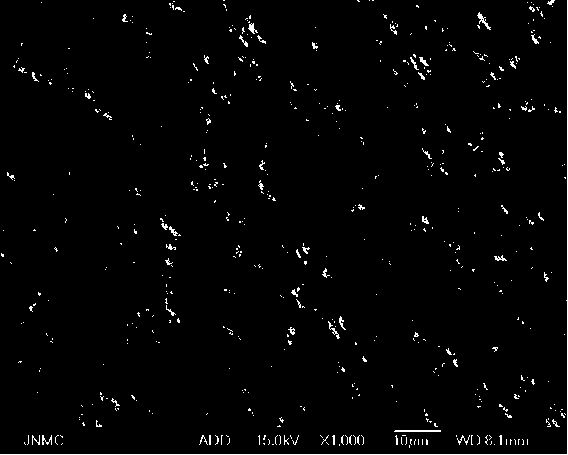

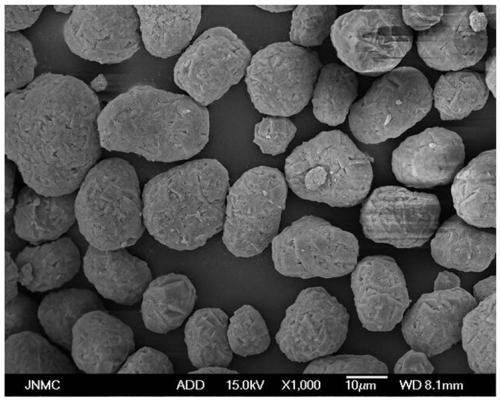

Preparation method of rare earth element-doped cobaltosic oxide

ActiveCN110002514ACrystal denseEvenly dispersedCobalt oxides/hydroxidesRare-earth elementLiquid ratio

The invention discloses a preparation method of rare earth element-doped cobaltosic oxide. The method comprises the following steps: rear earth element is added into a cobalt solution; with the extension of synthetic time, concentration gradient of the cobalt solution added to a reaction kettle increases or decreases; simultaneously, solid-to-liquid ratio of slurry in the reaction kettle is adjusted, and cobalt hydroxide with uniform doping is synthesized by a wet method; after the synthesis, the synthetic product is washed, dried and calcined to obtain a large granular or small granular rareearth element-doped cobaltosic oxide product.

Owner:JINCHUAN GROUP LIMITED +1

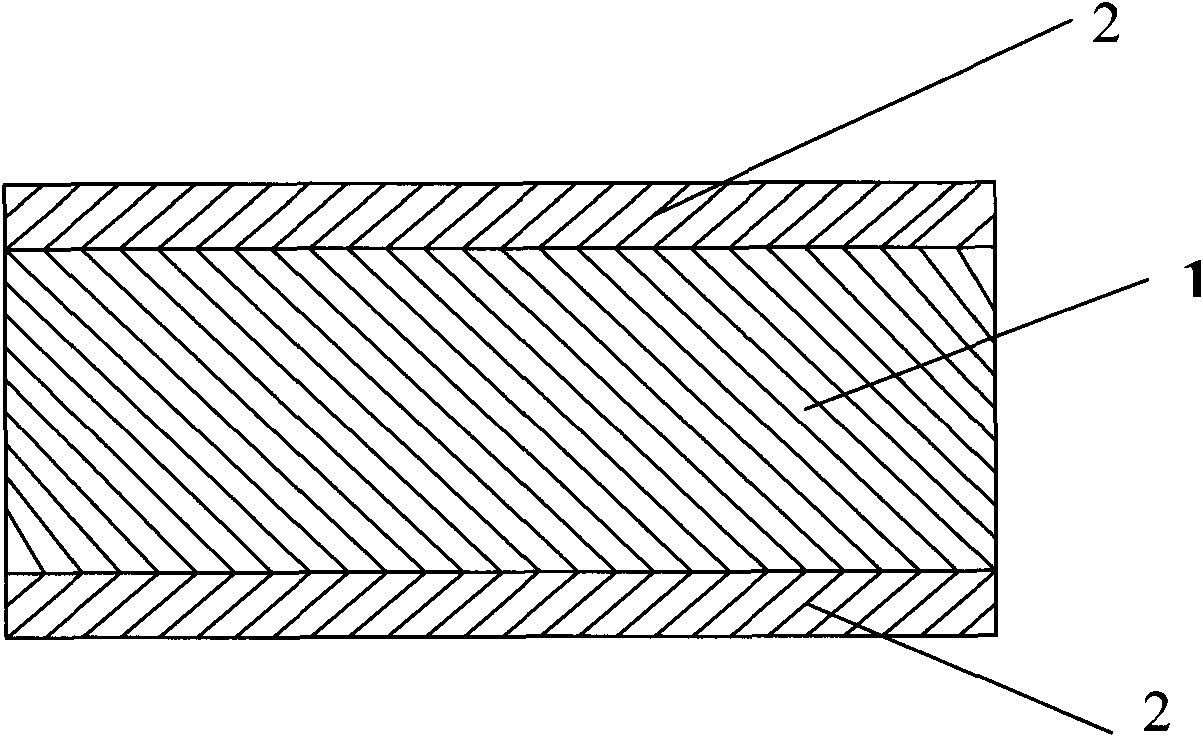

Conductive lead-free tin alloy -coated copper belt for solar photovoltaic cell

InactiveCN101789453AHarm reductionReduce pollutionMetal/alloy conductorsSemiconductor devicesAlloy coatingHuman health

The invention discloses a conductive lead-free tin alloy-coated copper belt for a solar photovoltaic cell. The conductive lead-free tin alloy-coated copper belt for the solar photovoltaic cell consists of a copper belt (1) and a tin alloy layer (2) coated outside the copper belt (1), and is characterized in that the tin alloy layer (2) comprises the following components in percentage by weight: 0.10 to 2.00 percent of Cu, 0.01 to 0.30 percent of Ti, 0.01 to 0.50 percent of Si, 0.05 to 0.8 percent of P, and the balance of Sn. The tin alloy coating of the lead-free tin alloy-coated copper belt of the invention contains no lead, so that the material reduces the damage to human health and the pollution to the environment in the production and application processes of the material, has remarkable environmental protection advantages, and adapts to international lead-free, environmental protection and green resource trend. The lead-free tin alloy-coated copper belt of the invention is mainly used as a conductive functional component material of the solar photovoltaic cell.

Owner:昆明三利特科技有限责任公司

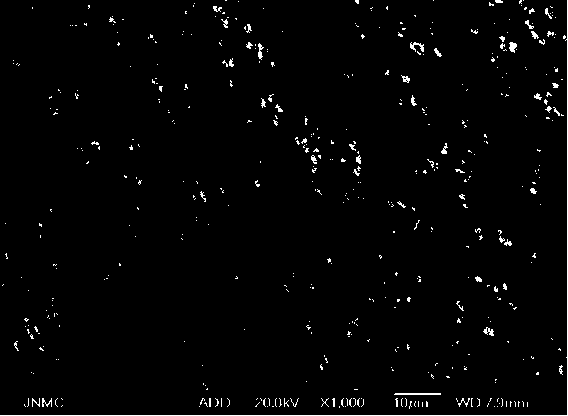

Preparation method of cobaltosic oxide

ActiveCN110002513AIncrease the number of spawnsCrystal denseCobalt oxides/hydroxidesCobalt(II,III) oxideGranularity

The invention discloses a preparation method of cobaltosic oxide. The method comprises the following steps: with the extension of the synthesis time, concentration gradient of a cobalt solution addedinto a reaction vessel increases or decreases, and solid-liquid ratio of slurry in the reaction vessel is adjusted, and dense cobalt hydroxide is synthesized by a wet method; after the synthesis, thesynthesis product is washed, dried and calcined to obtain a cobaltosic oxide product. By the process, spherical or spheroidal large-grained cobaltosic oxide product with laser particle size D10 being12-15 microns, D50 being 17-19 microns, D90 being 22-25 microns, tap density being greater than or equal to 2.4 g / cm<3> and specific surface area being 1.0-3.0 m<2> / g or spherical or spheroidal small-grained cobaltosic oxide product with laser particle size D10 being 1-3 microns, D50 being 3-5 microns, D90 being 7-10 microns, tap density being greater than or equal to 2.5 g / cm<3> and specific surface area being 1.0-3.0 m<2> / g can be prepared.

Owner:JINCHUAN GROUP LIMITED +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com