Patents

Literature

406results about How to "Realize green environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather resistant thick steel plate and manufacturing method thereof

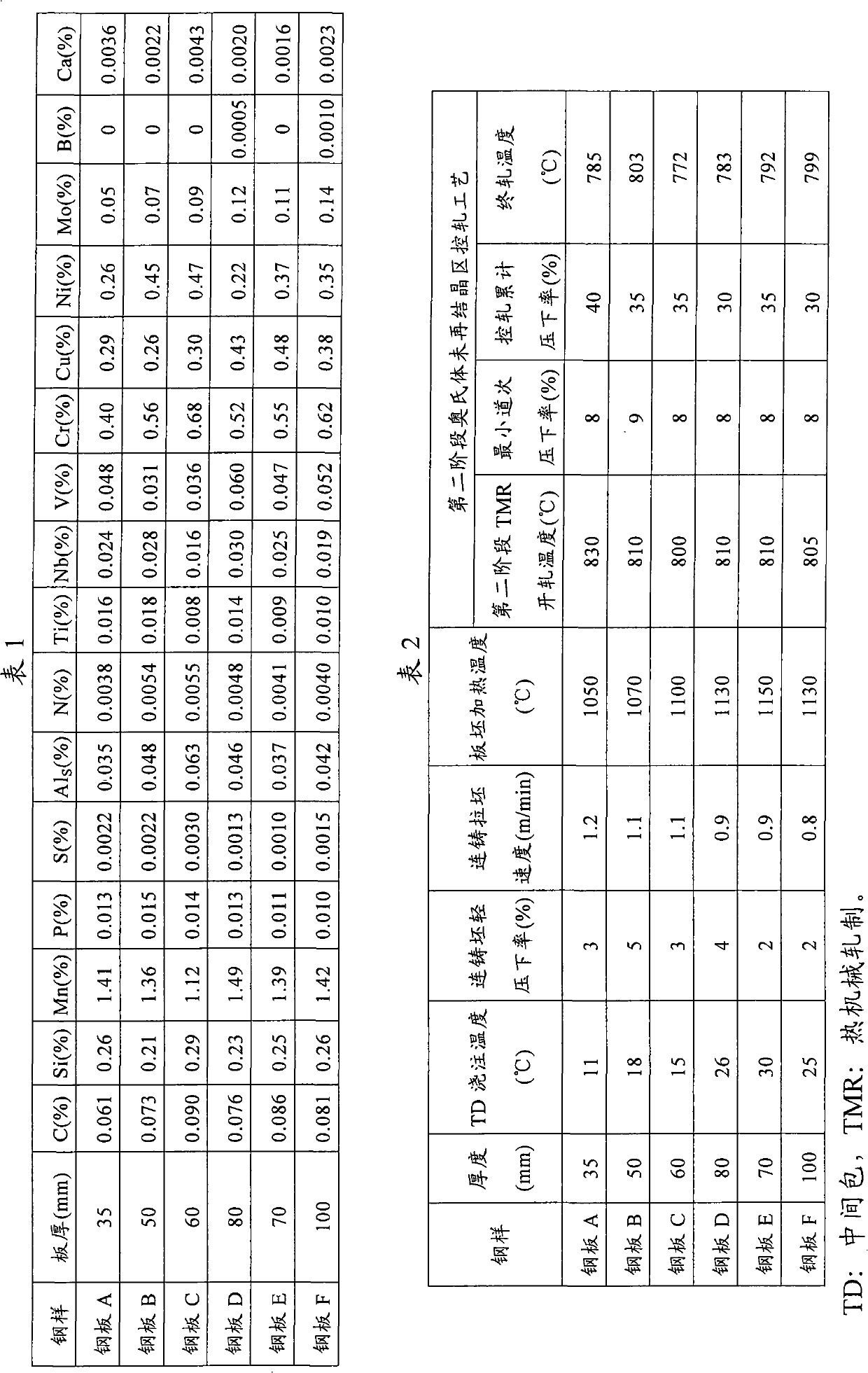

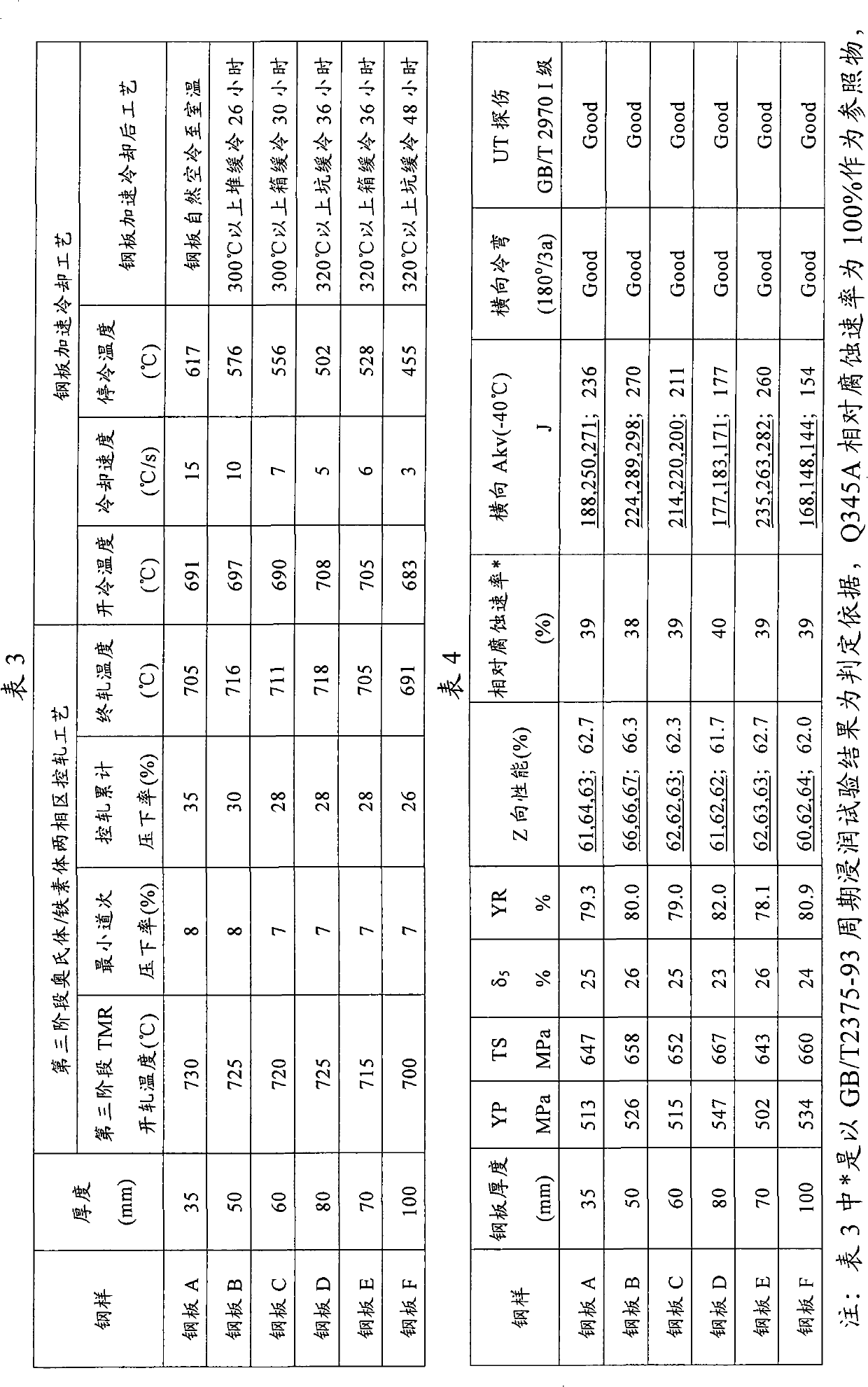

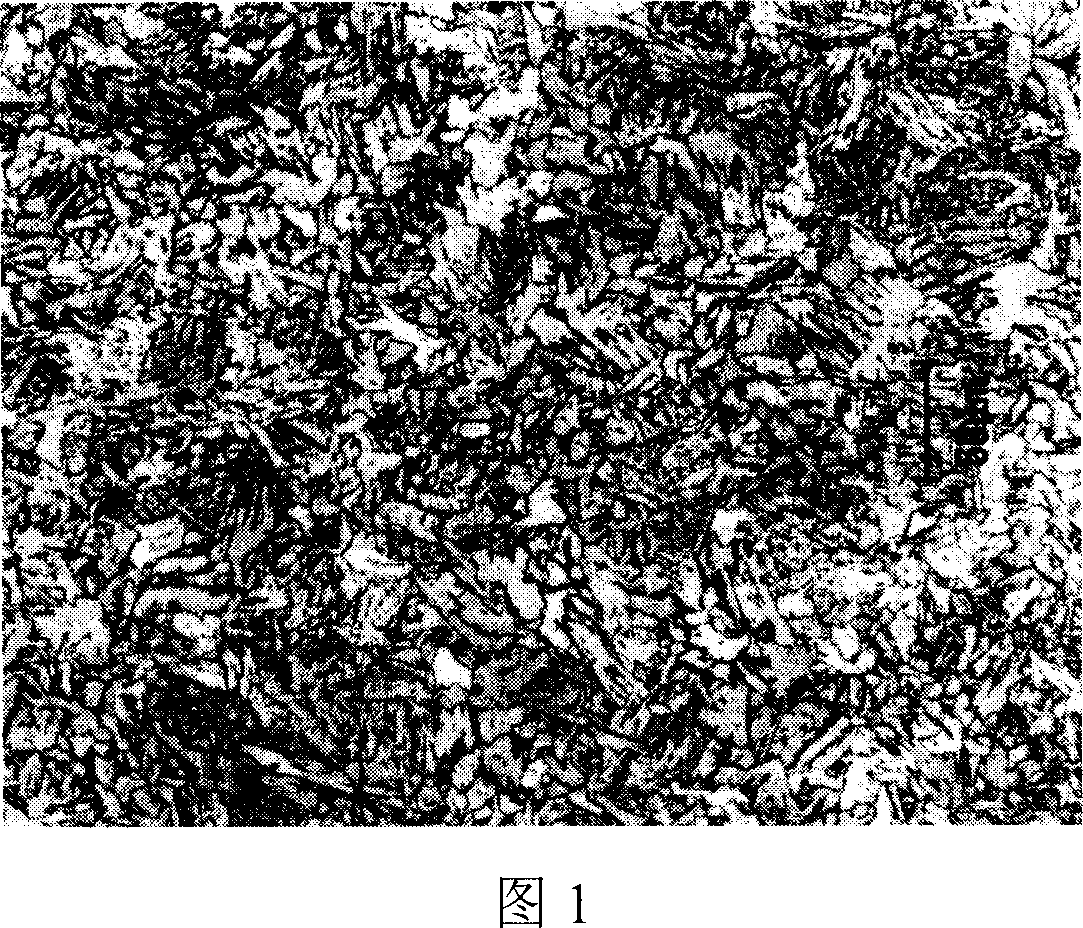

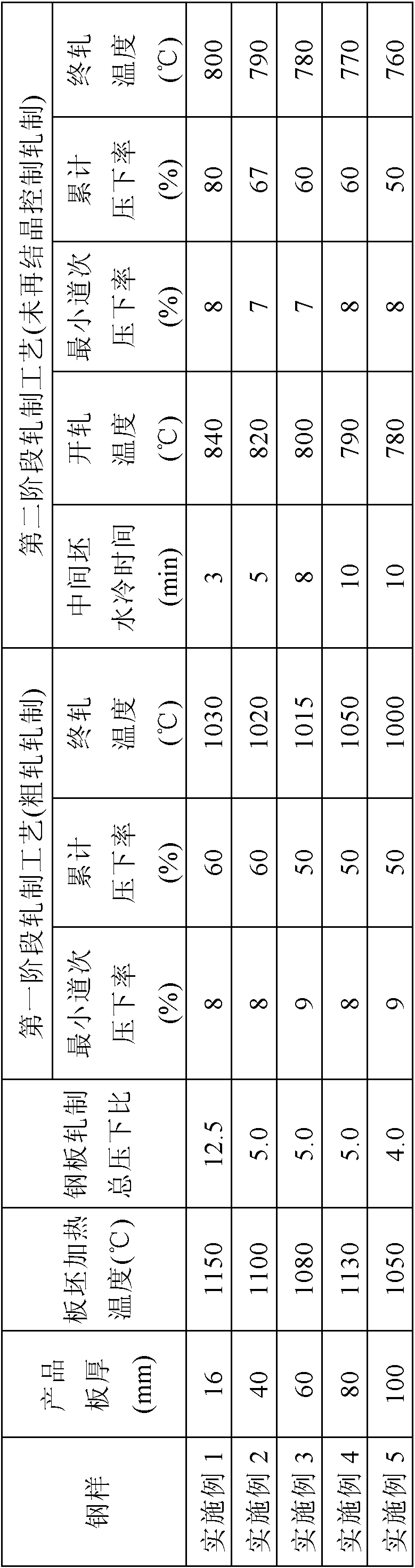

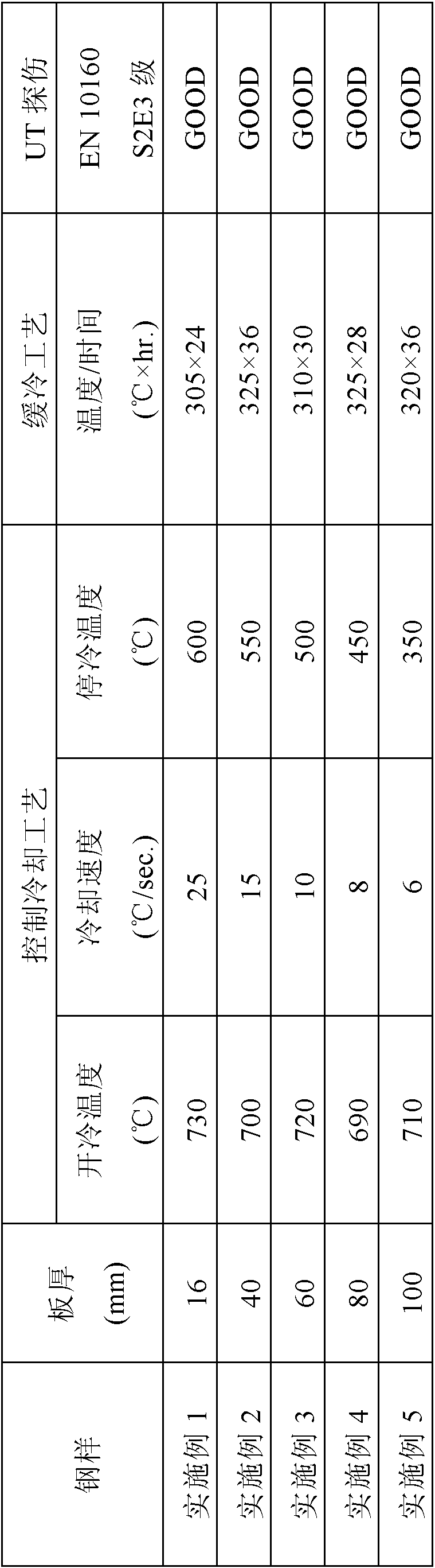

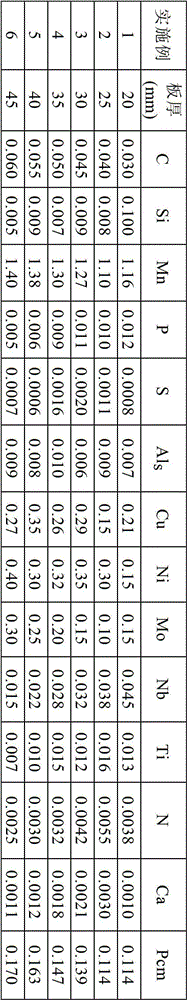

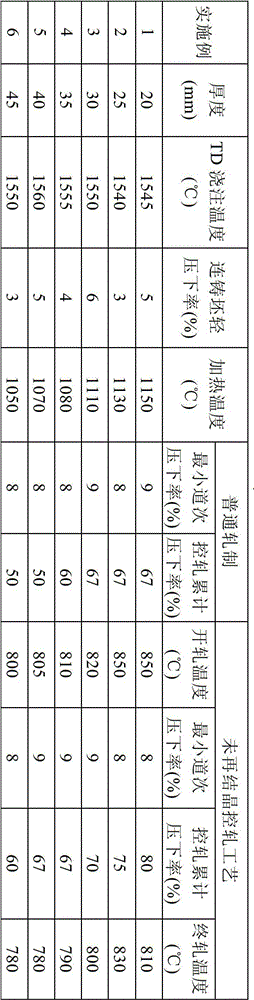

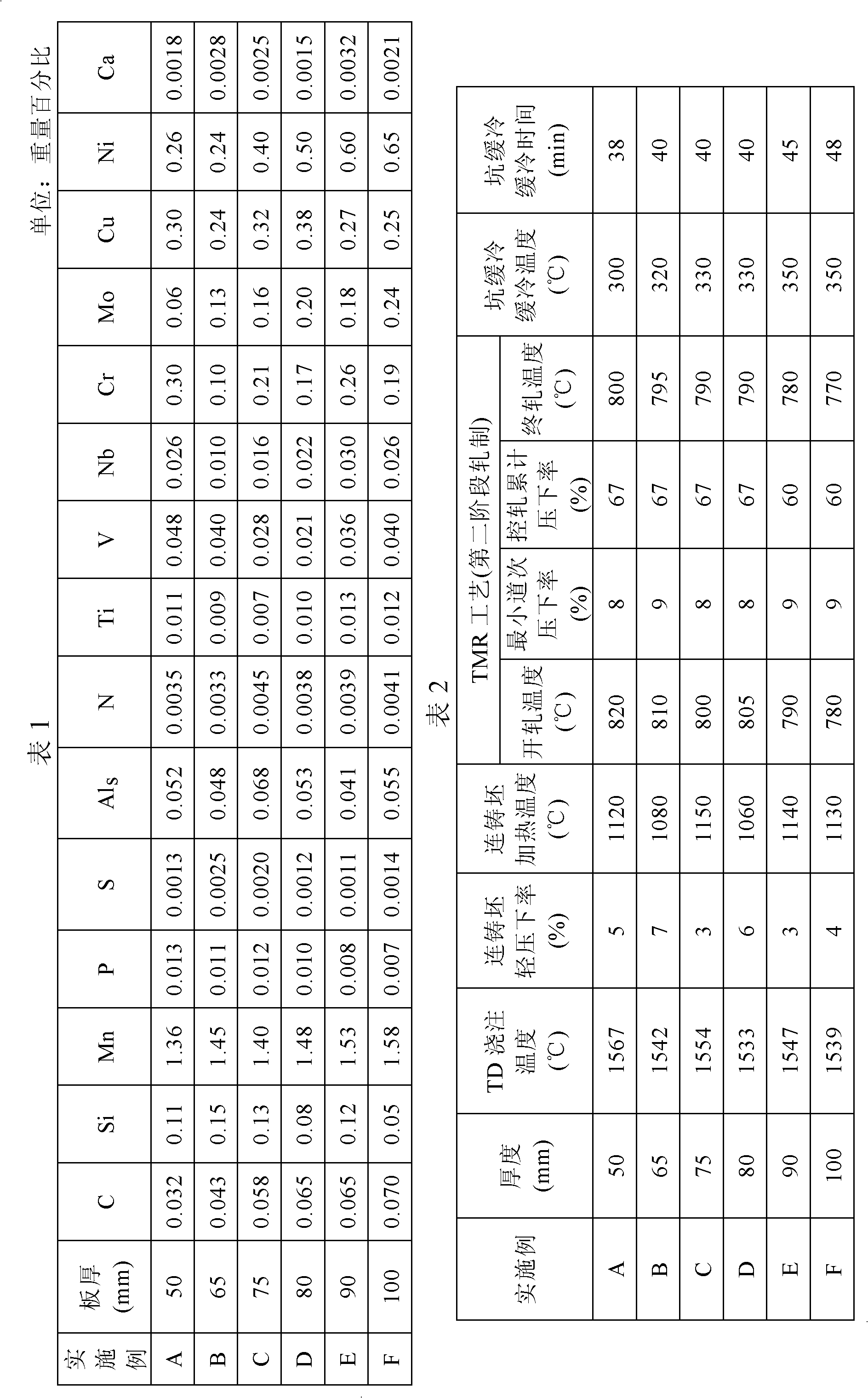

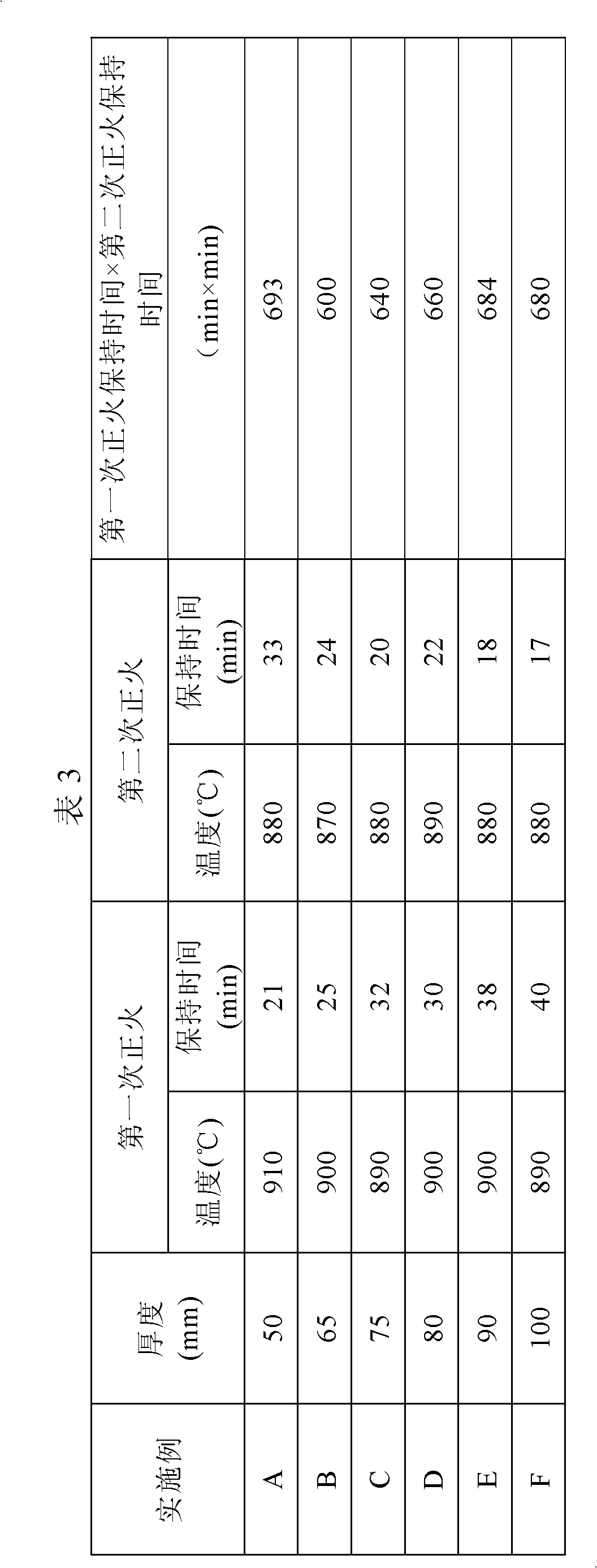

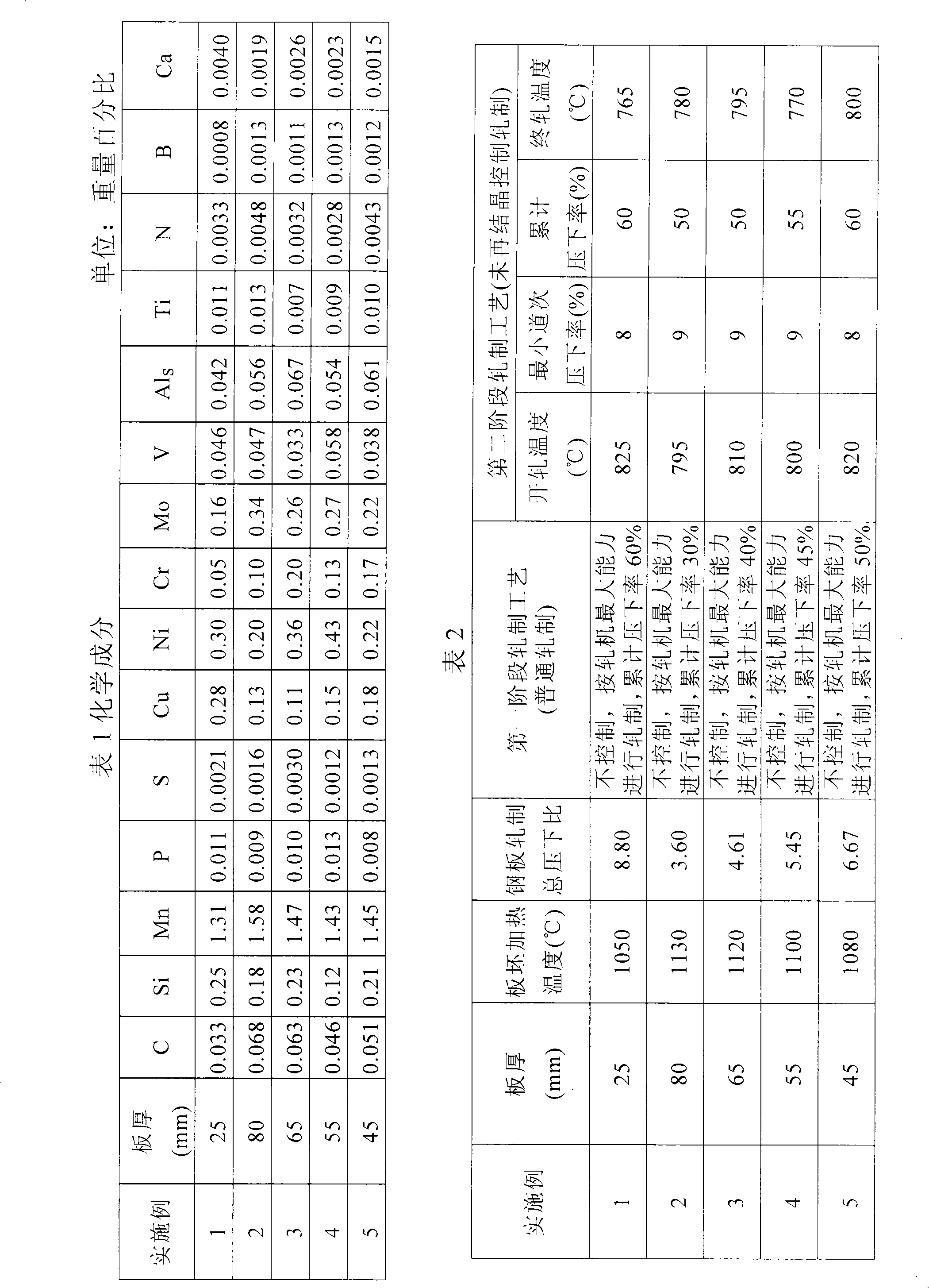

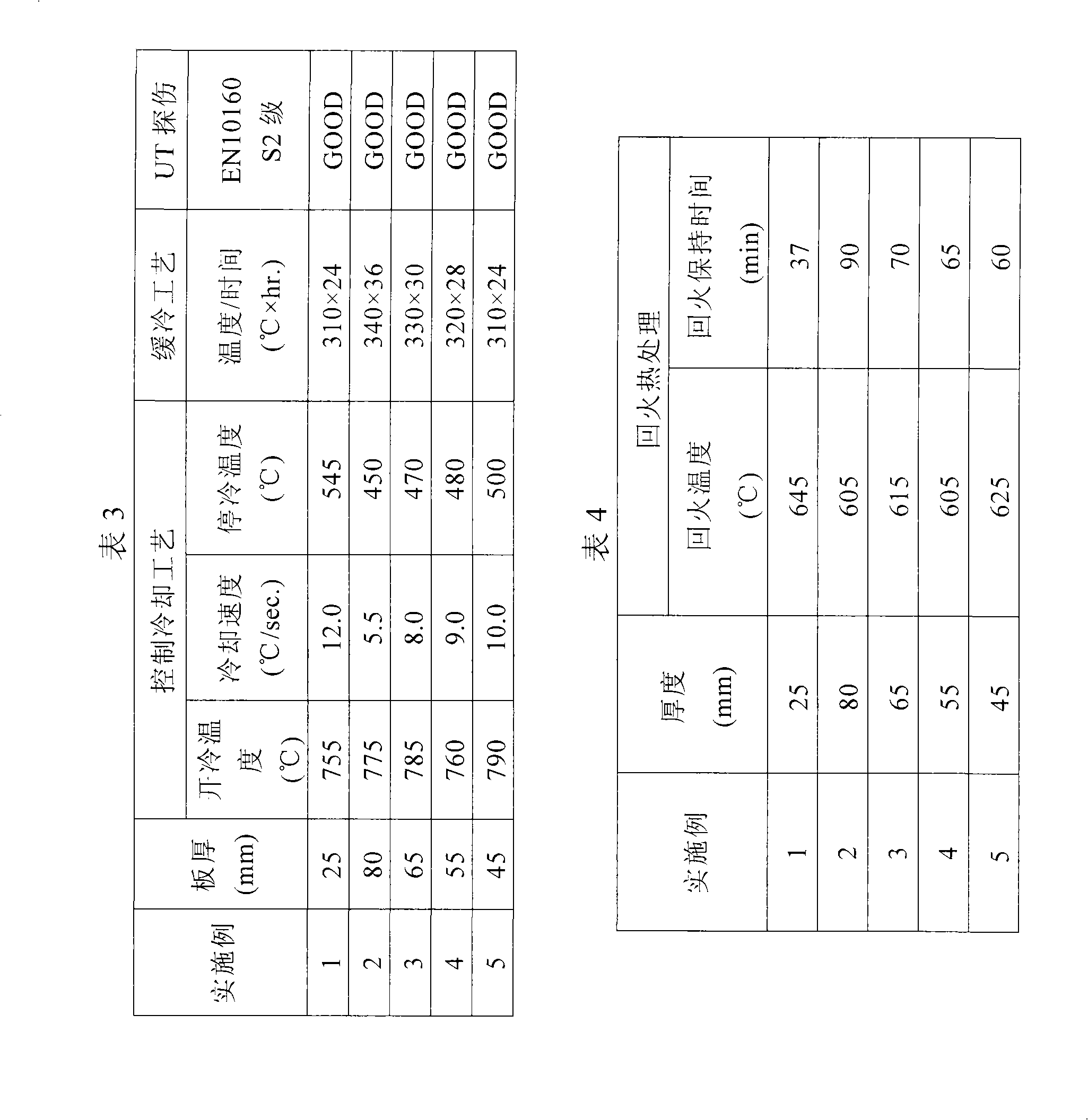

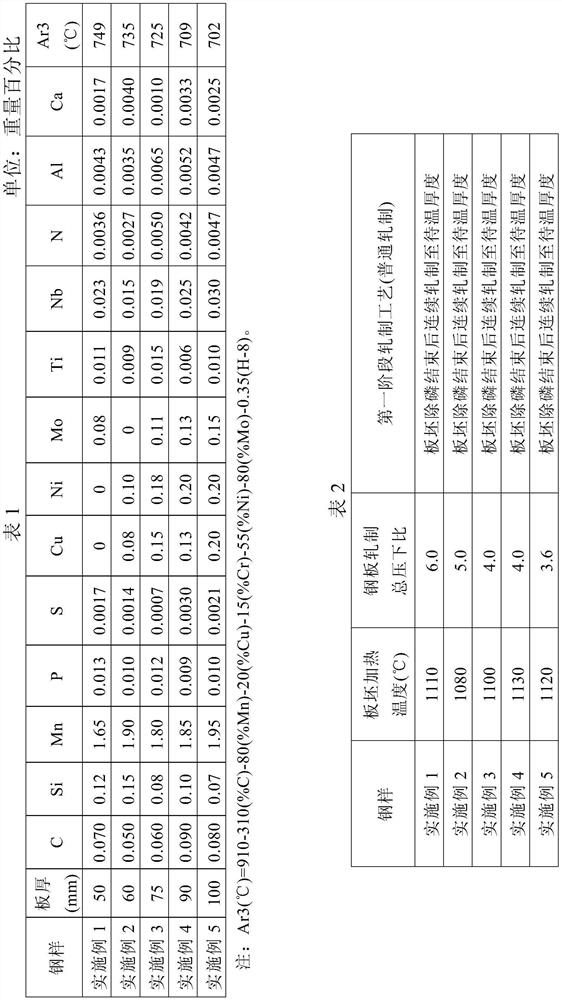

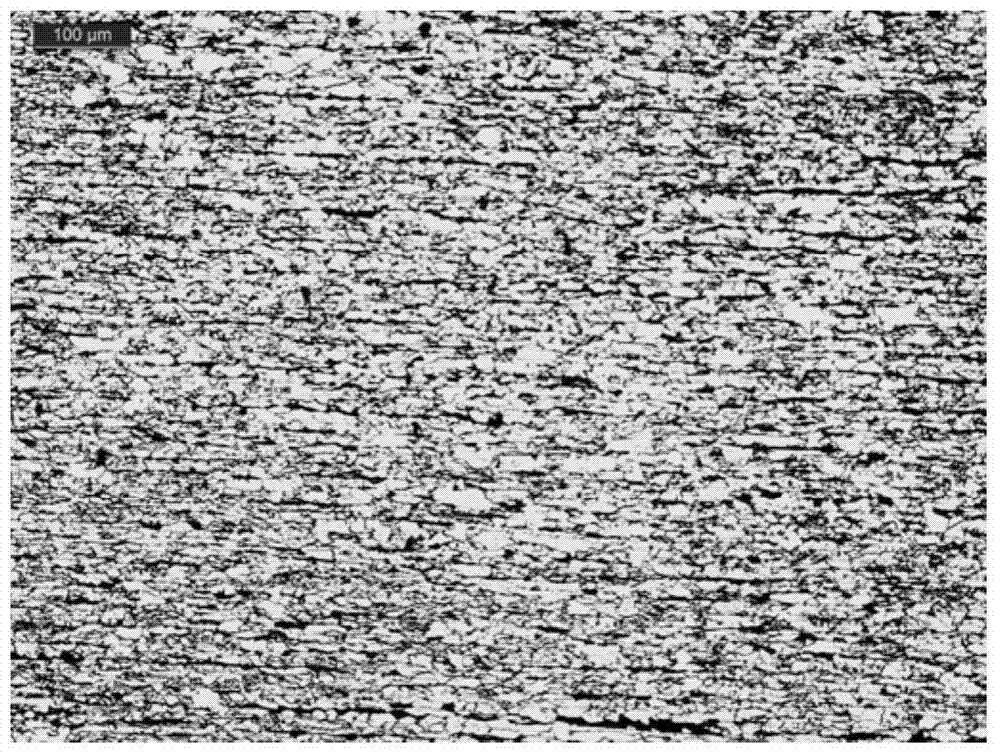

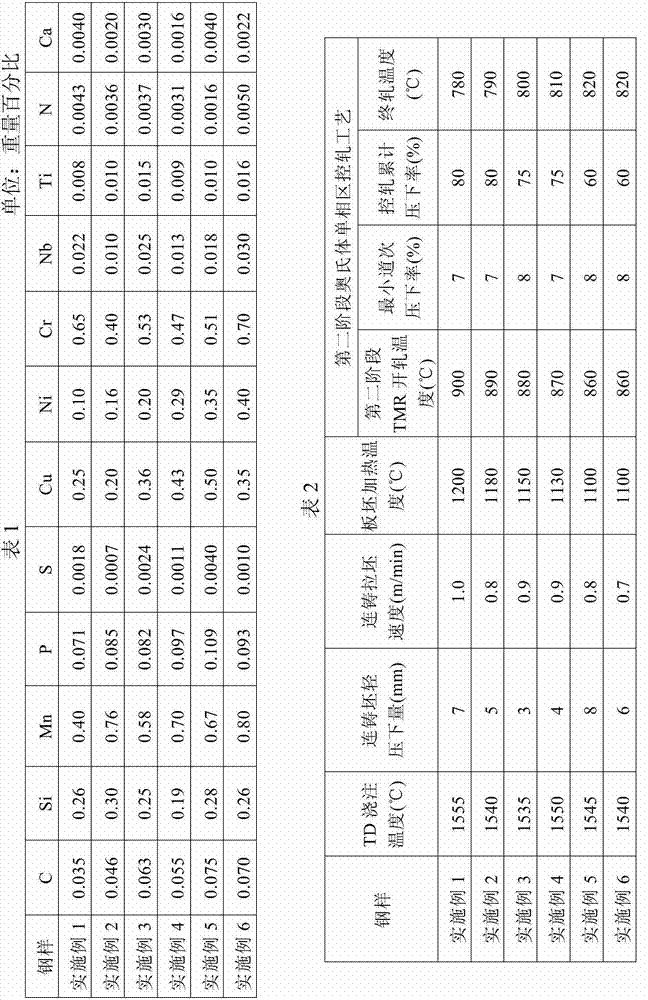

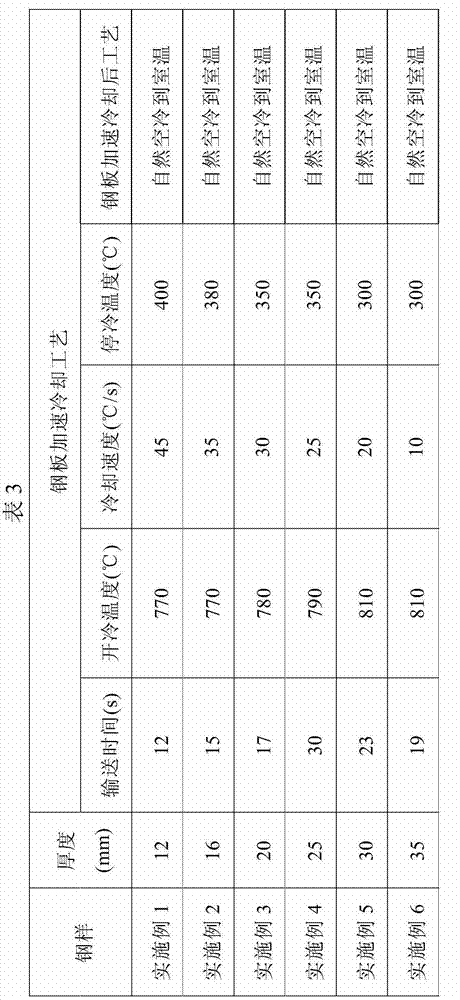

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate for low temperature use and capable of being welded in superhigh energy and its production process

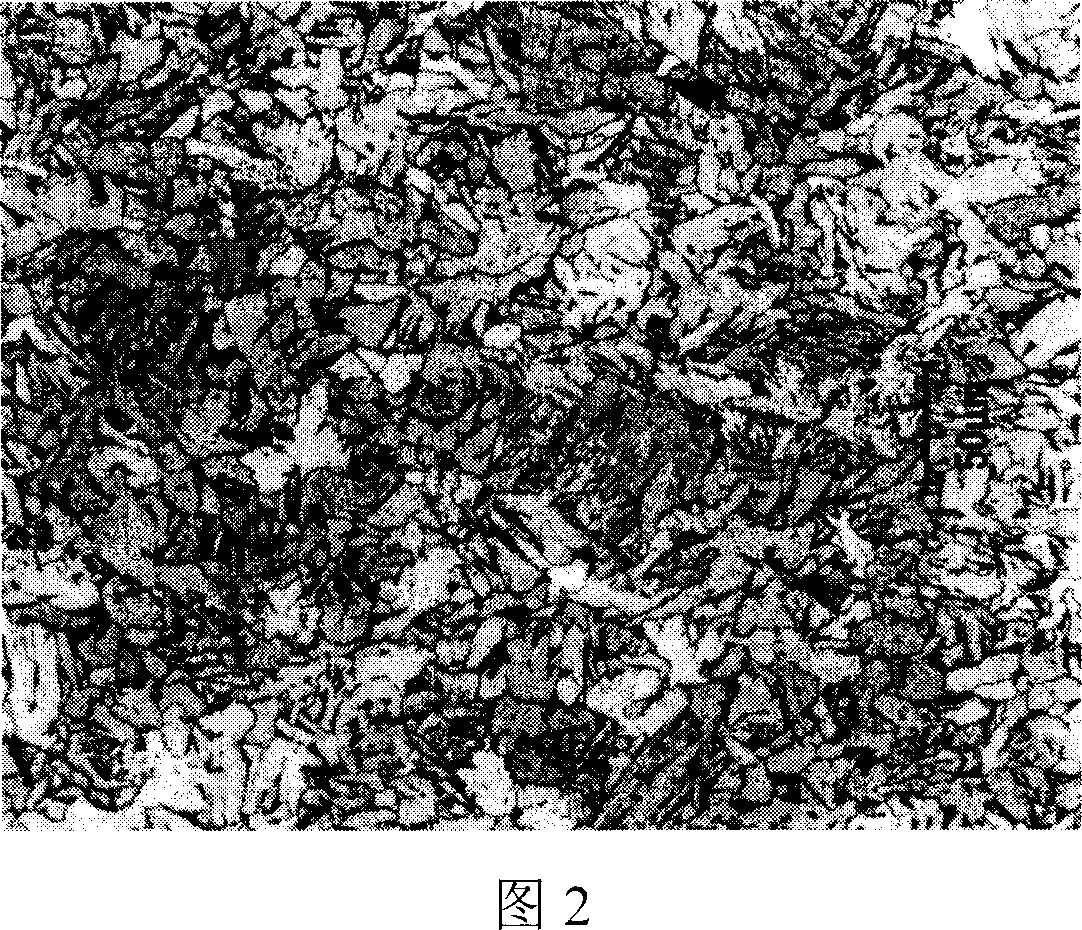

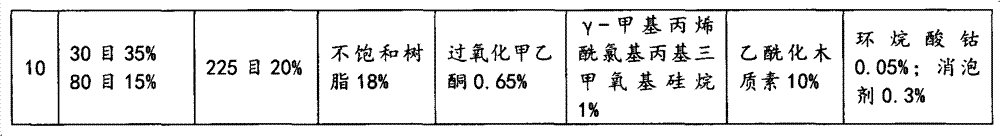

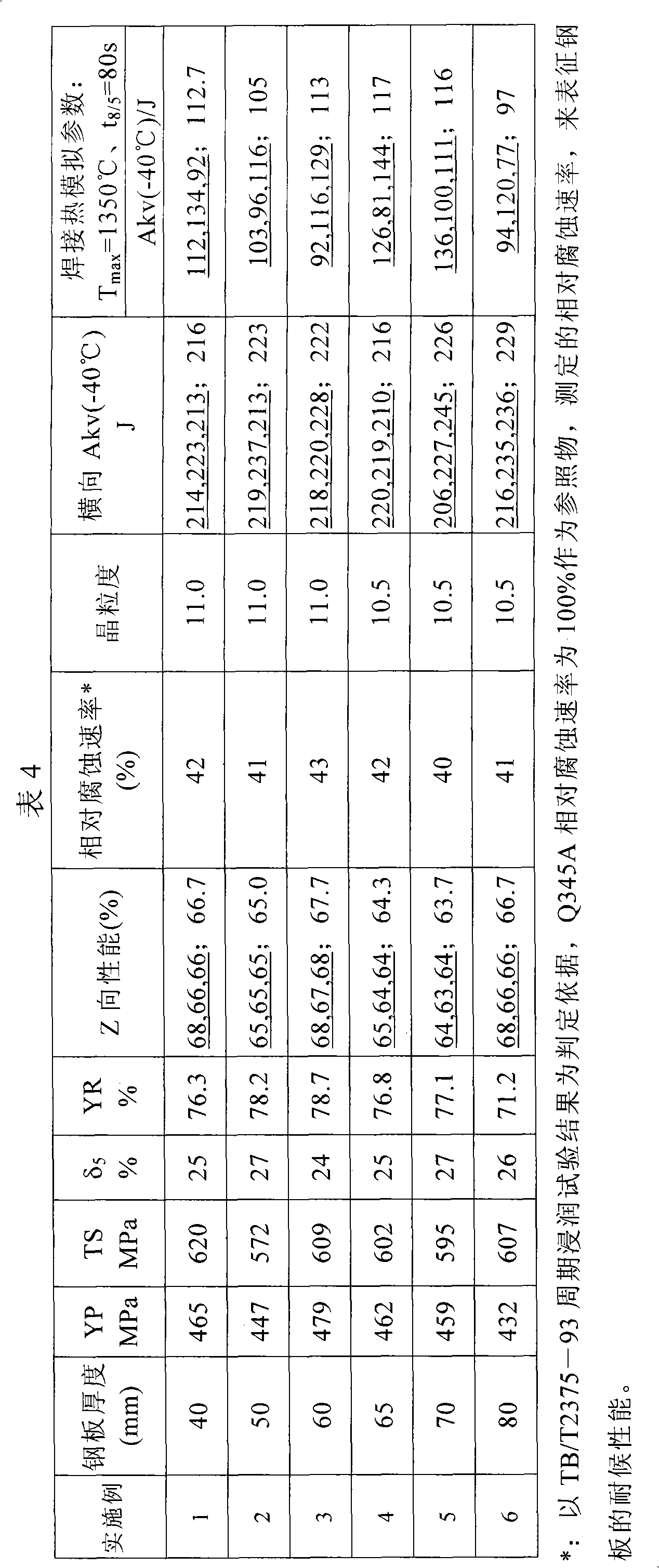

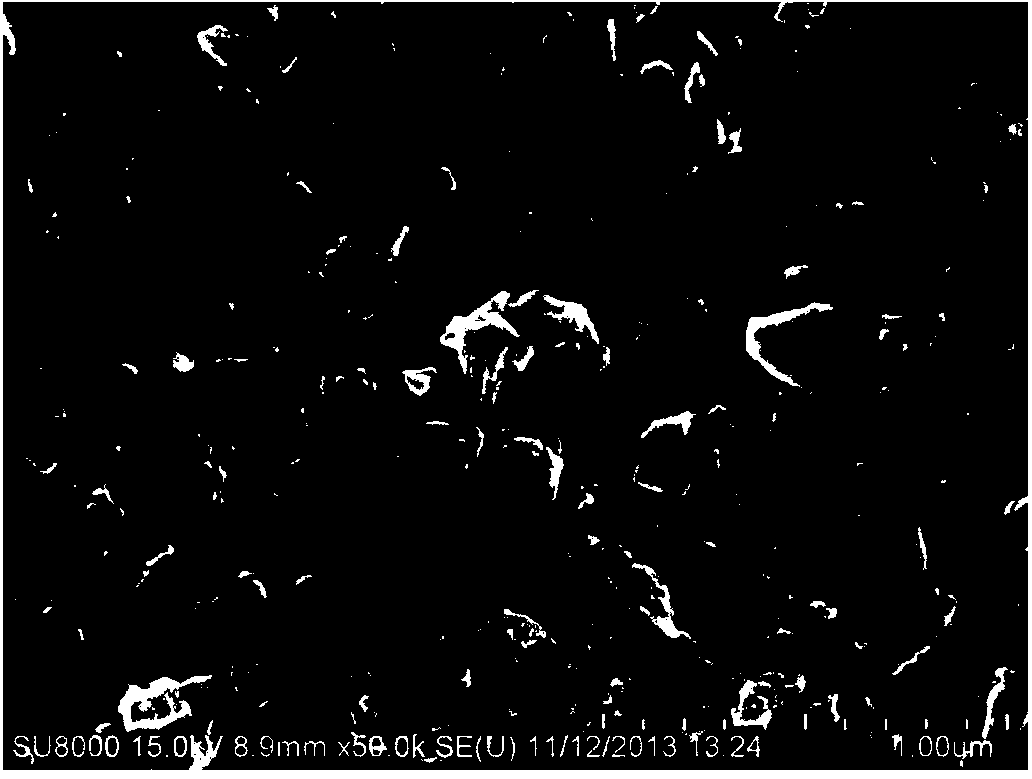

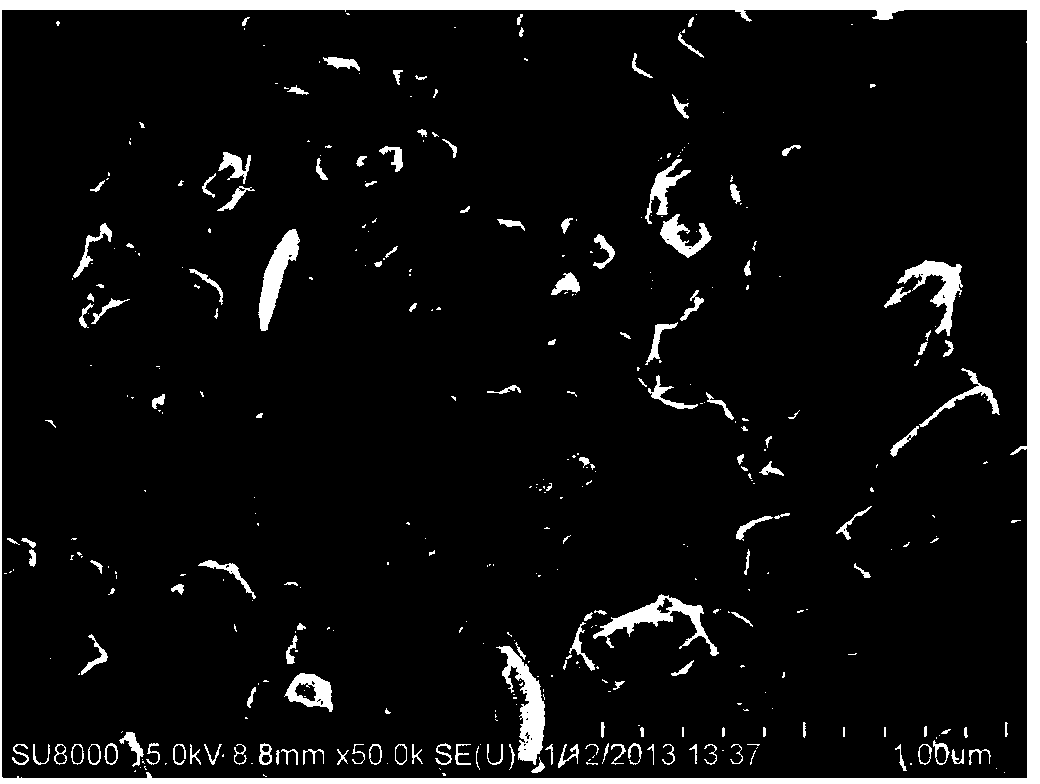

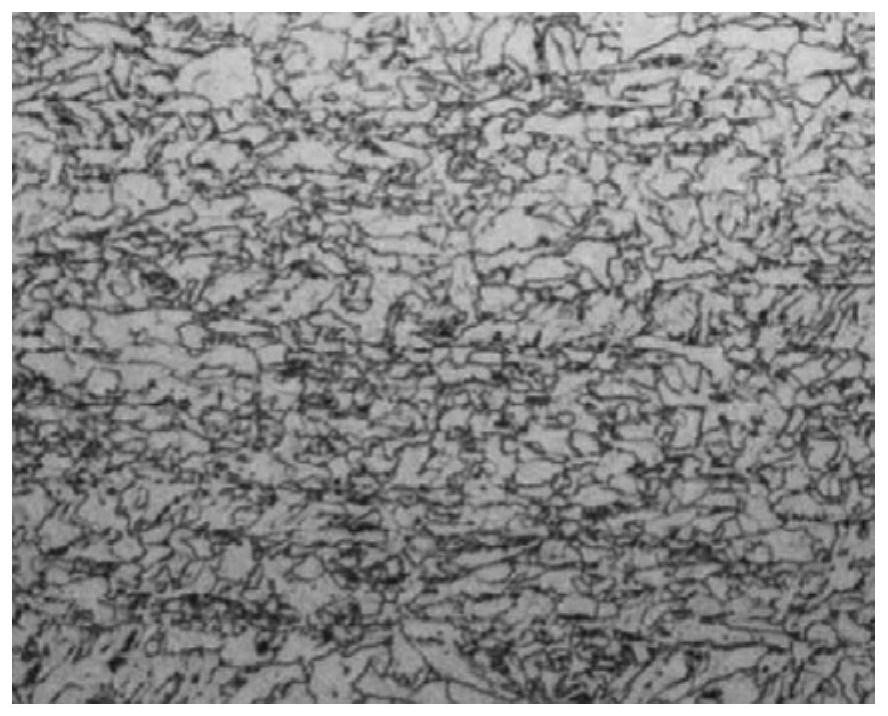

ActiveCN101045976AImprove low temperature toughnessHigh strengthTemperature control deviceHeat treatment process controlSteel platesCrystallite

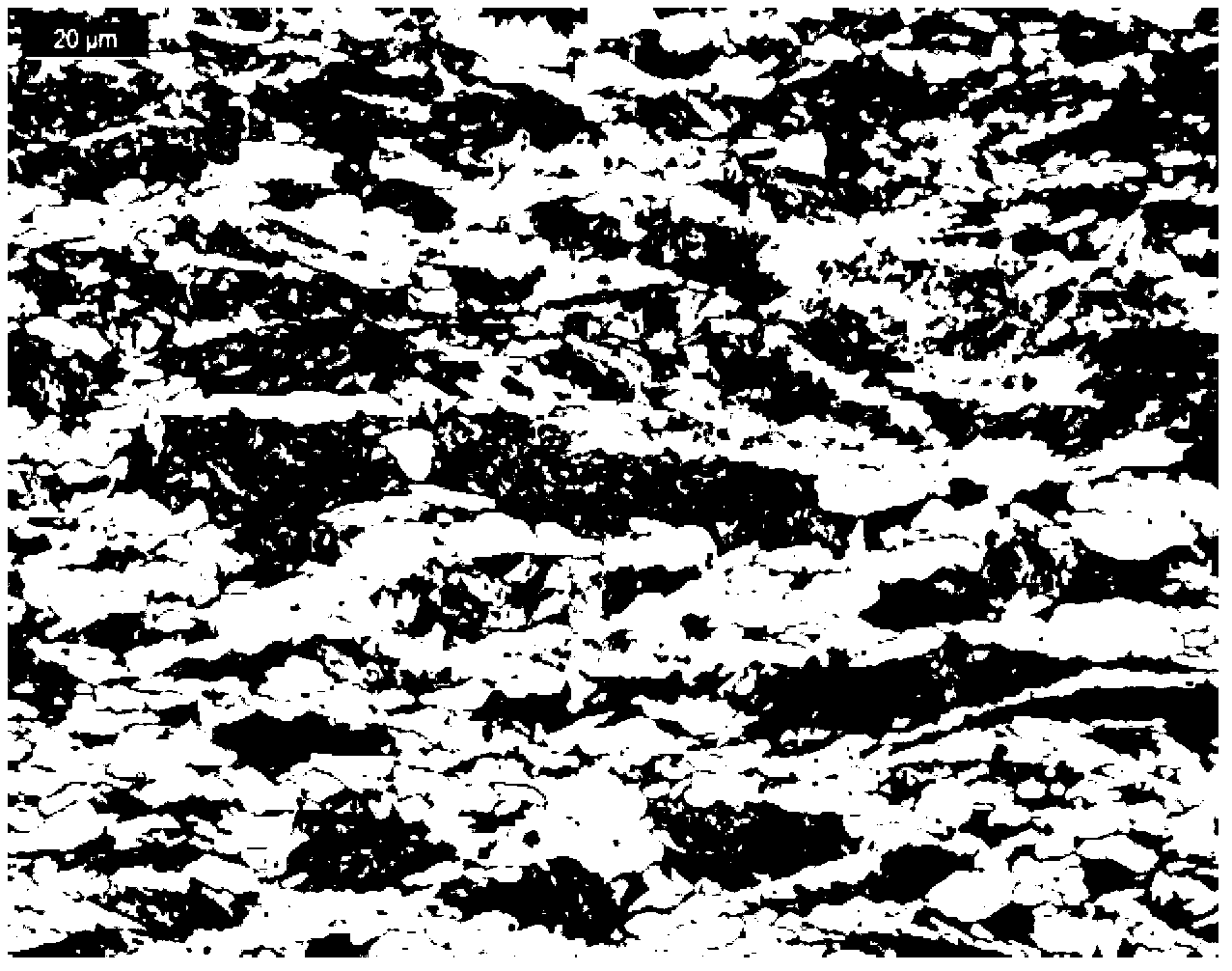

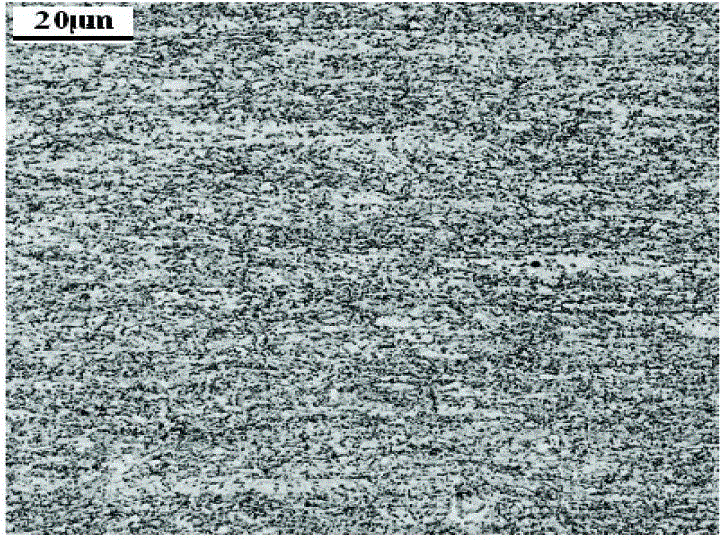

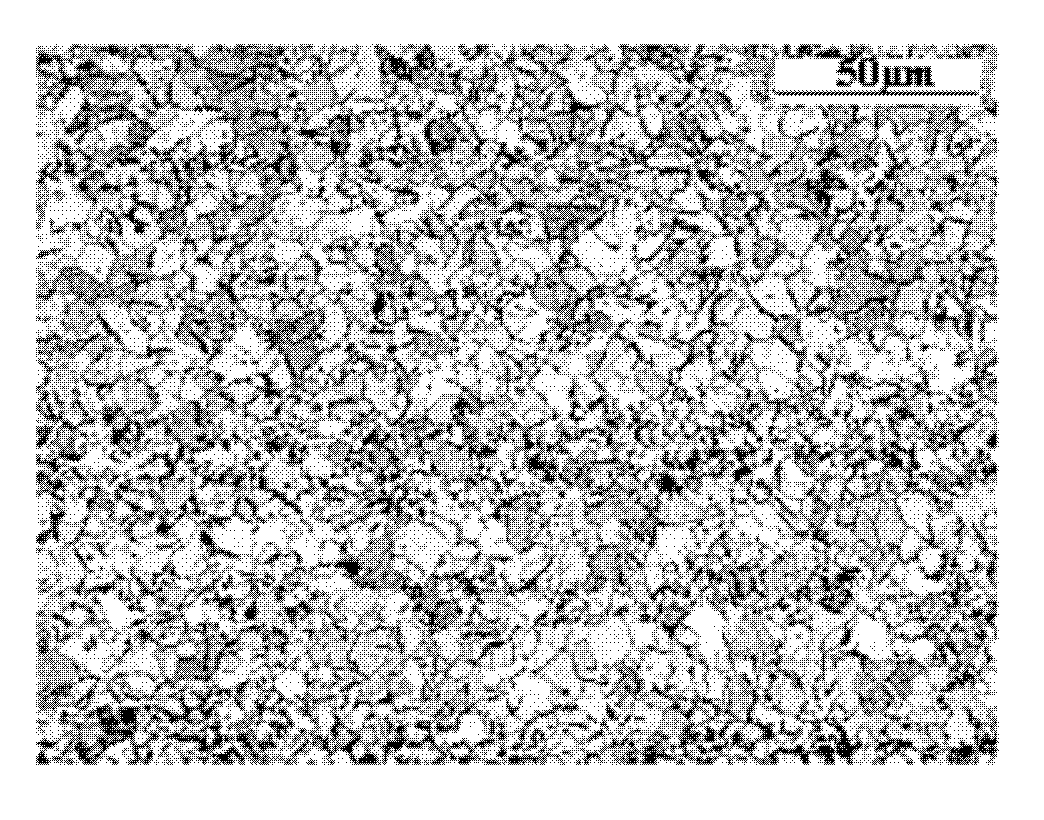

The thick steel plate for low temperature use and capable of being welded in superhigh energy has the material comprising C 0.030-0.050 wt%, Si not more than 0.2 wt%, Mn 1.50-1.80 wt%, P not more than 0.01 wt%, S not more than 0.002 wt%, Nb 0.010-0.020 wt%, Als 0.040-0.060 wt%, Ti 0.008-0.012 wt%, N not more than 0.0035 wt%, Ca 0.001-0.005 wt%, B 0.001-0.003 wt%, and Fe and inevitable impurity for the rest, with Pcm not more than 0.18 wt%. The present invention has low alloy steel as basis, properly raised Als content, C / Mn ratio of 0.020-0.050, Ti-B microalloying, Ca or REM treatment, Ti / N ratio of 3.0-3.5, optimized TMCP treatment, microscopic structure comprising small amount of ferrite and diffused bainite crystal of average crystal grain size below 15 micron, excellent mechanical performance and welding performance, and is especially suitable for being used as high strength ship deck, low temperature pressure container, offshore platform, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

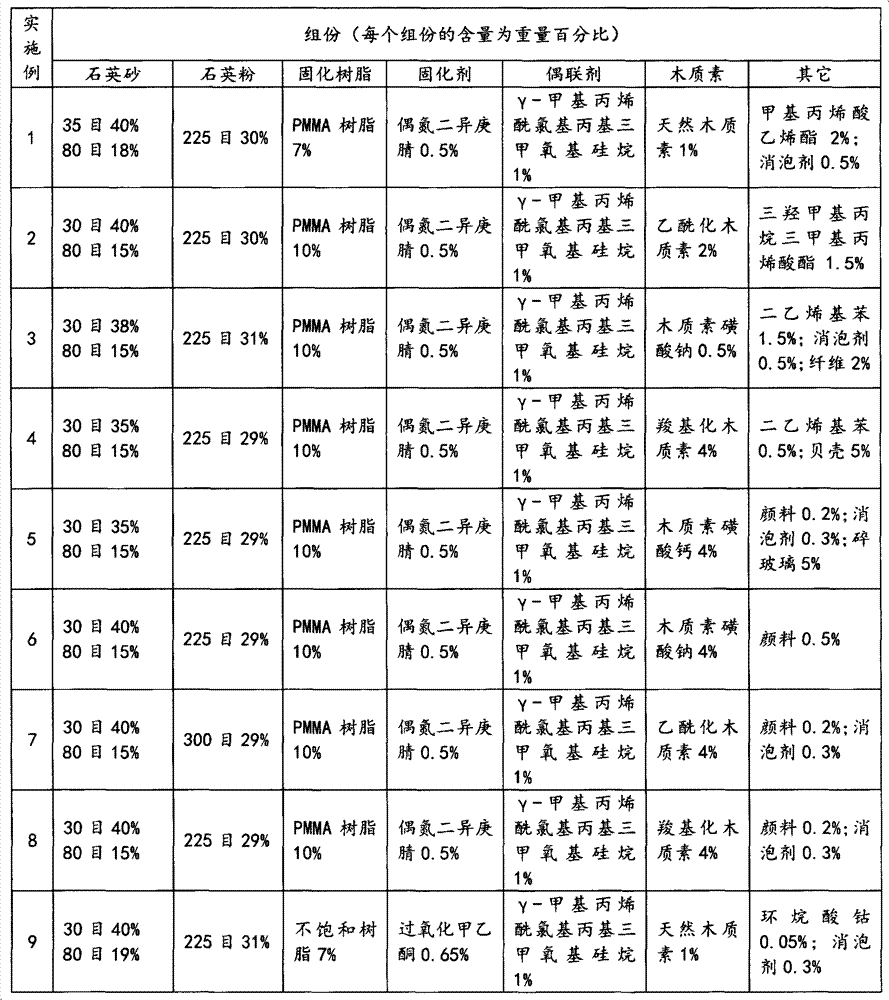

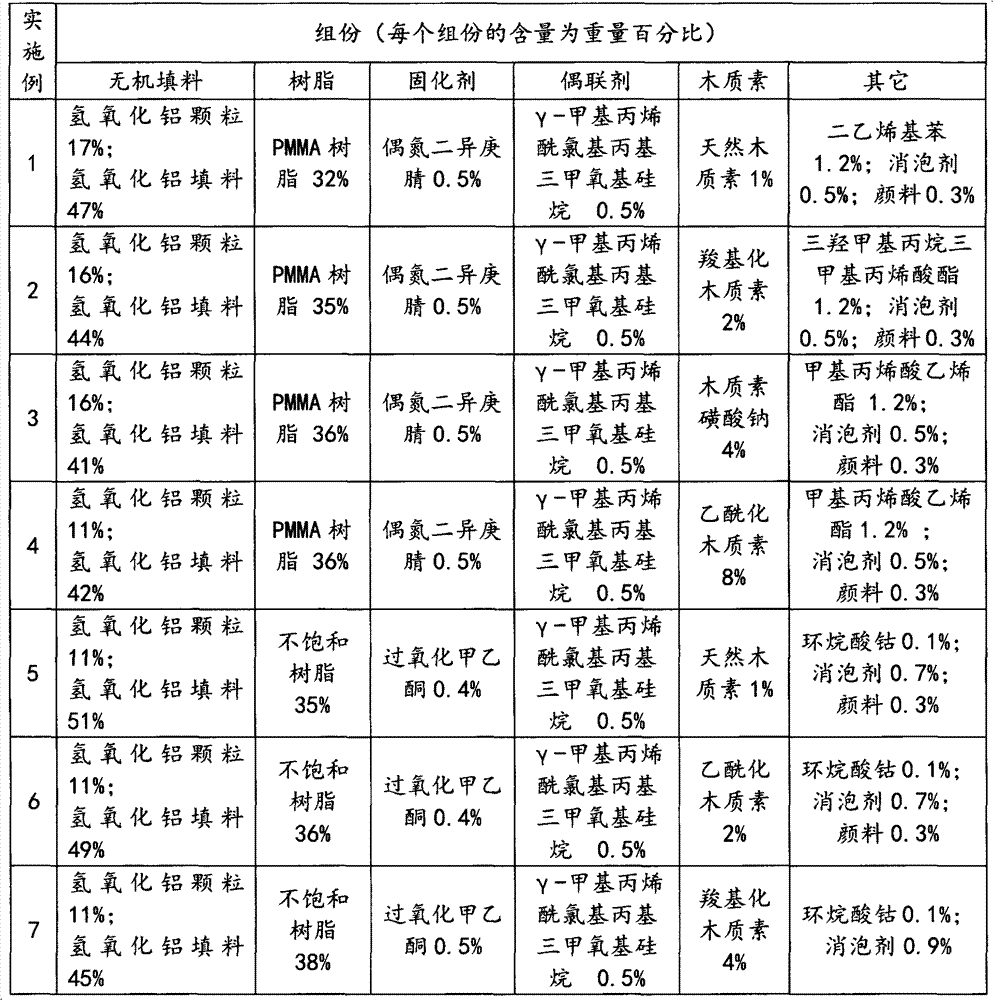

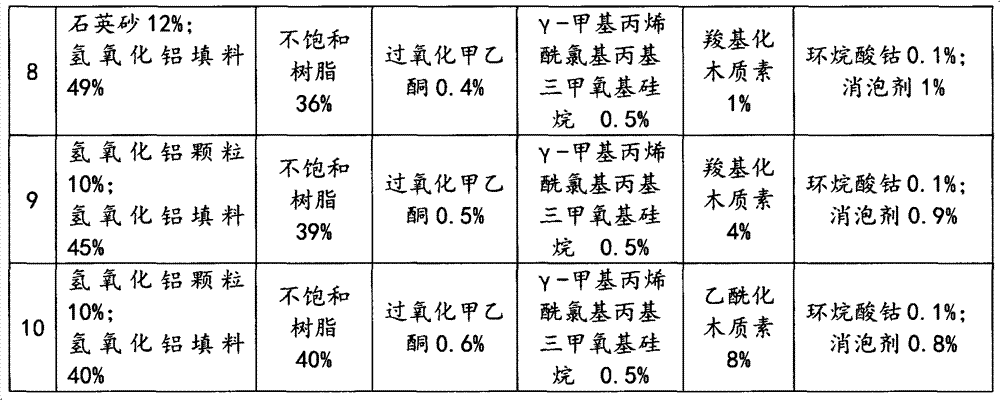

Bio-based artificial quartz stone and production process thereof

ActiveCN102898070AReduce environmental pollution problemsAchieve recyclingCeramic shaping apparatusWeather resistanceDefoaming Agents

A bio-based artificial quartz stone and a production process thereof are disclosed. The bio-based artificial quartz stone includes the following components by weight: 0-80% of quartz sand; 10-70% of quartz powder; 3-20% of curable resin; 0.05-3% of a curing agent; 0.01-40% of lignin; 0-5% of a crosslinking agent; 0.05-5% of a coupling agent; 0-1% of a promoter; 0-2% of a pigment; and 0-3% of a defoaming agent. According to the invention, the lignin is used in the artificial quartz, the environmental pollution of the lignin is reduced, the cost of the artificial quartz is reduced, and at the same time the weather resistance and light stability of the artificial quartz are improved, thus the artificial quartz has antibacterial ability, is green and environmental-friendly, and is suitable for using in building decoration of living environments.

Owner:SUZHOU TOPOLINE TECH

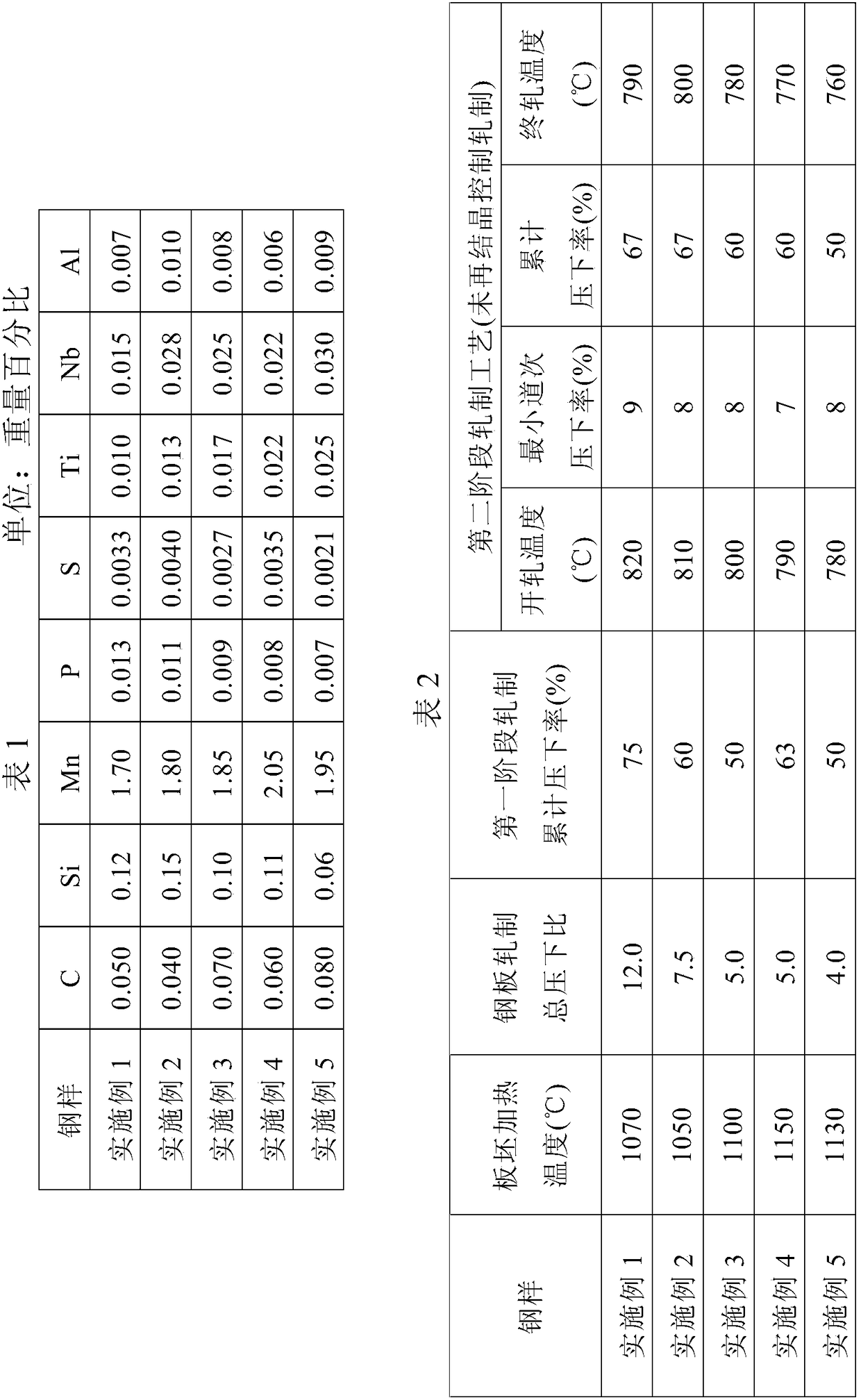

Steel used at lower temperature and method for manufacturing same

ActiveCN101545077AIncrease the content of acid-soluble AlsEliminate Recycling DifficultiesMetal rolling arrangementsSheet steelChemical composition

The invention discloses a steel used at a lower temperature and a method for manufacturing the same. The steel comprises the following chemical components by weight percentage: 0.060 to 0.090 percent of C, less than or equal to 0.20 percent of Si, 1.10 to 1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.040 to 0.070 percent of Als, 0.05 to 0.45 percent of Cu, 0.05 to 0.35 percent of Ni, 0.05 to 0.30 percent of Cr, 0.007 to 0.011 percent of Ti, 0.007 to 0.020 percent of Nb, less than or equal to 0.0040 percent of N, 0.001 to 0.011 percent of Ca, and the balance of Fe and inevitable impurities. The manufacturing process comprises of the steps: making the steel plate obtain excellent low-temperature toughness and making the steel plate bear the big line energy welding. The steel and the method can be widely applied to petroleum natural gas pipelines, low-temperature gas tank bodies LPG, low temperature steel plates of LNG.

Owner:BAOSHAN IRON & STEEL CO LTD

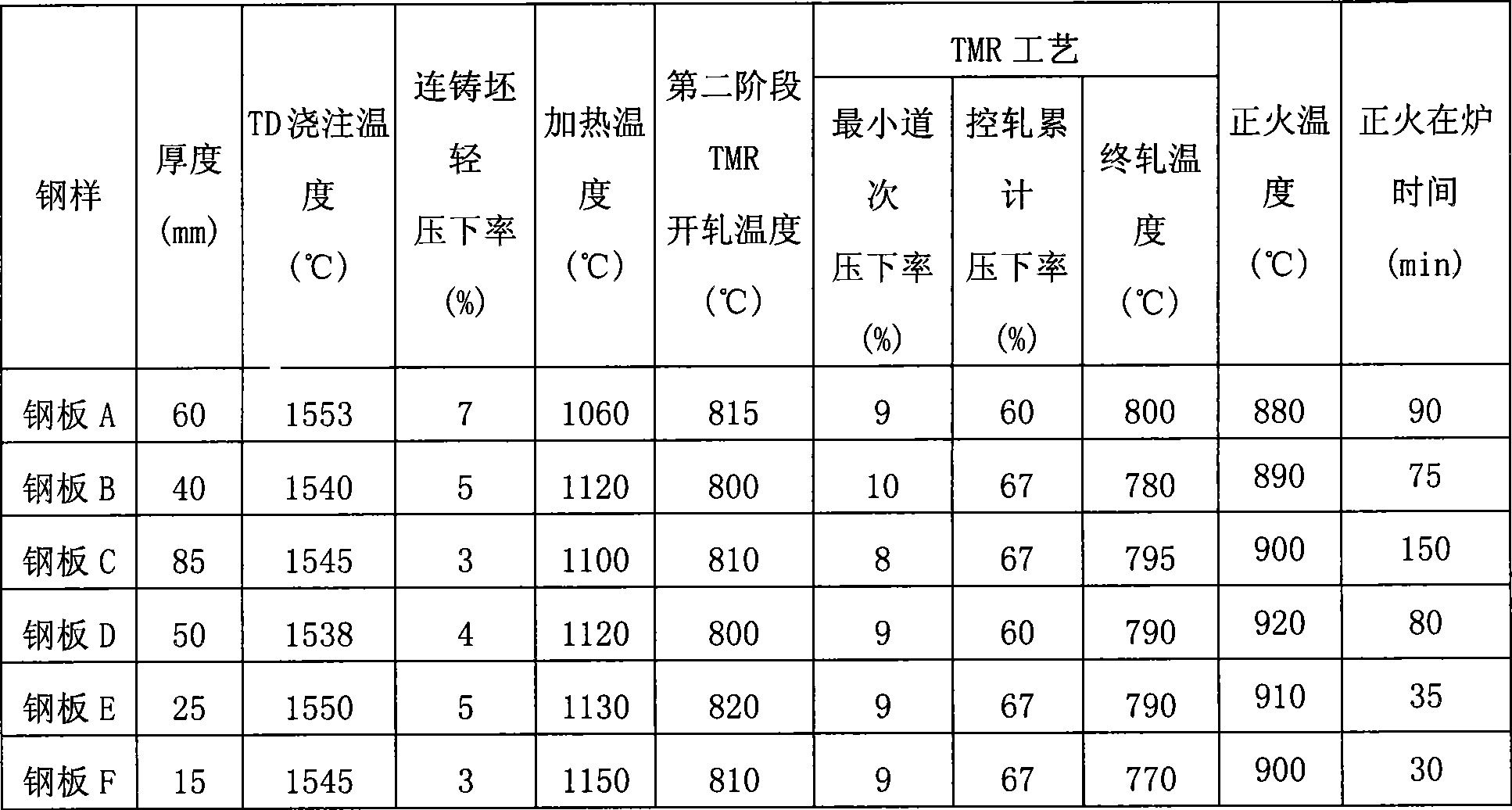

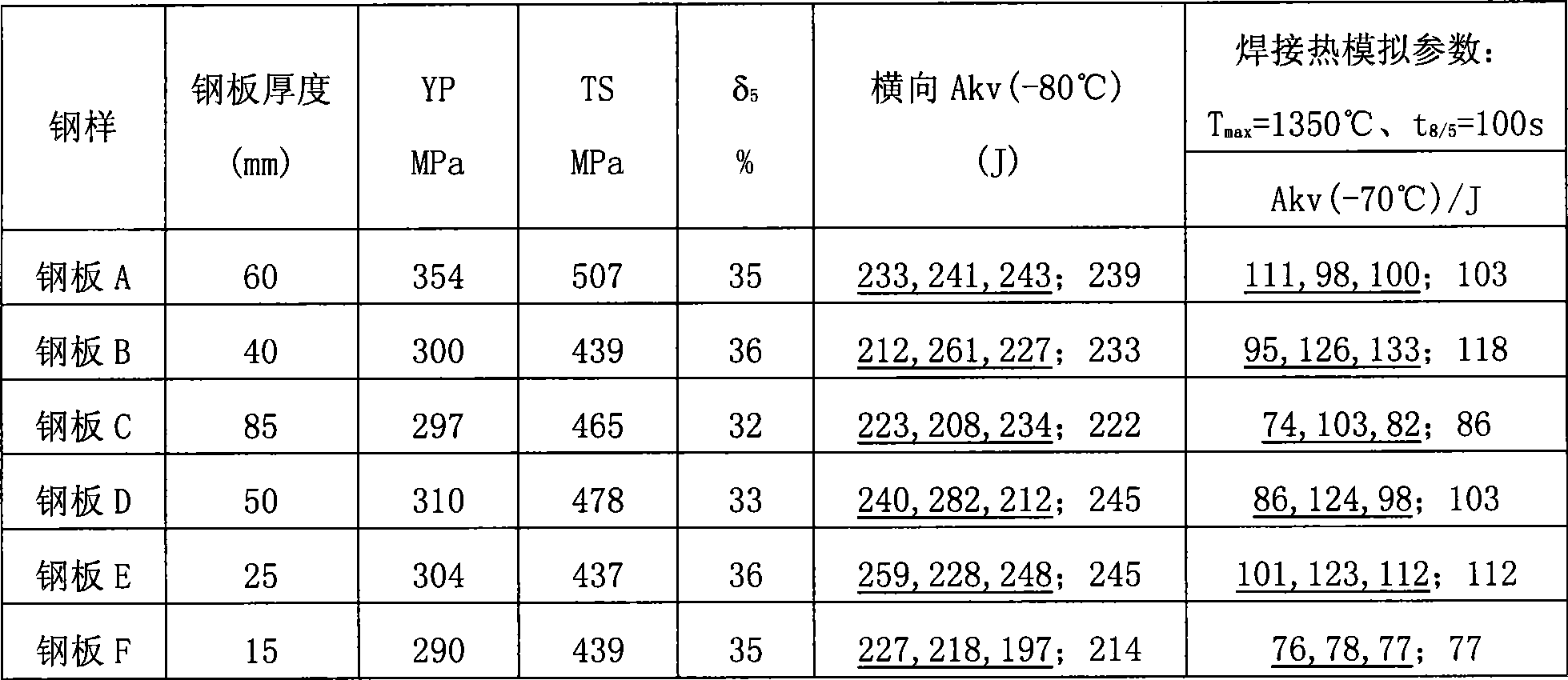

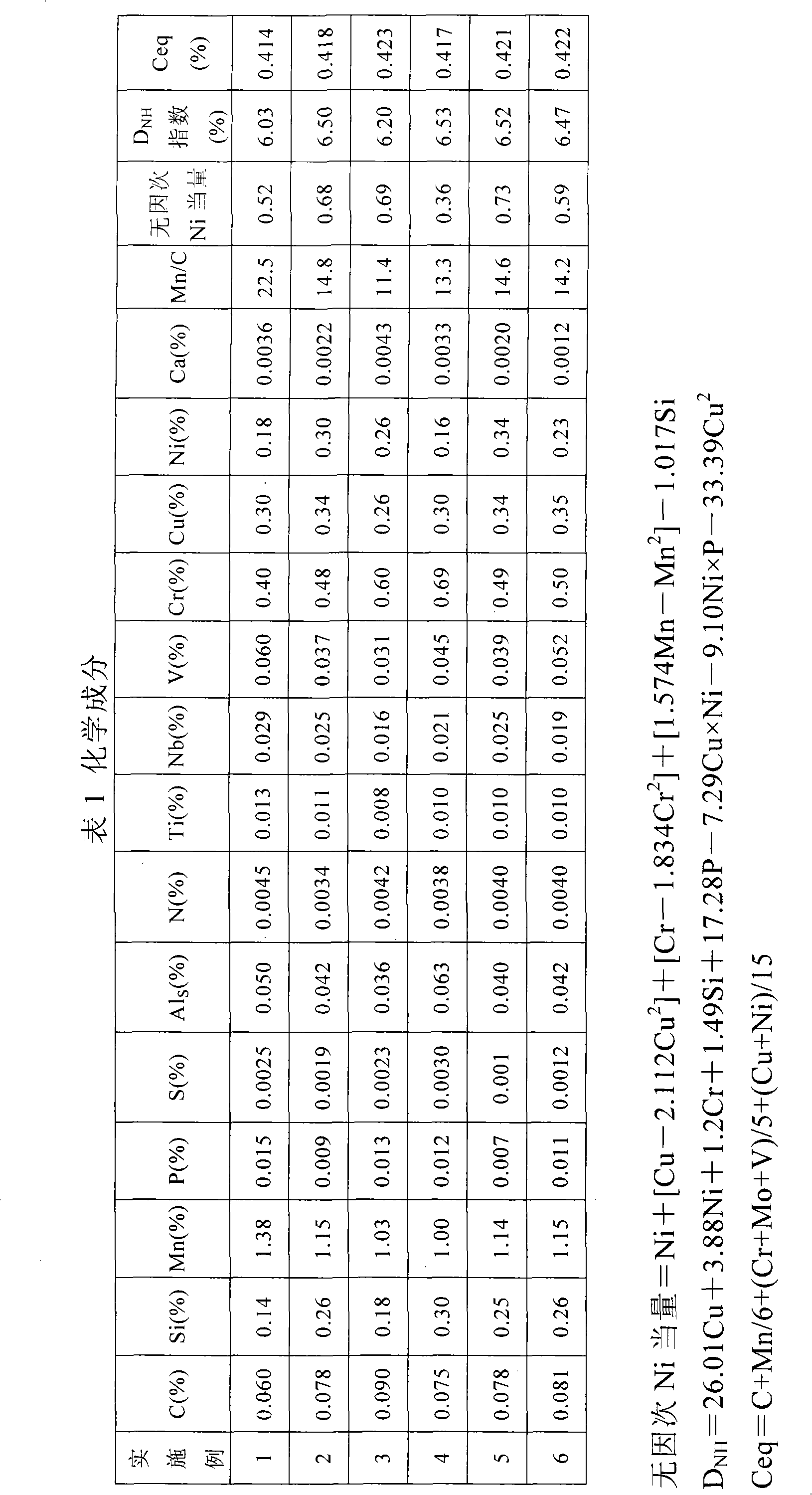

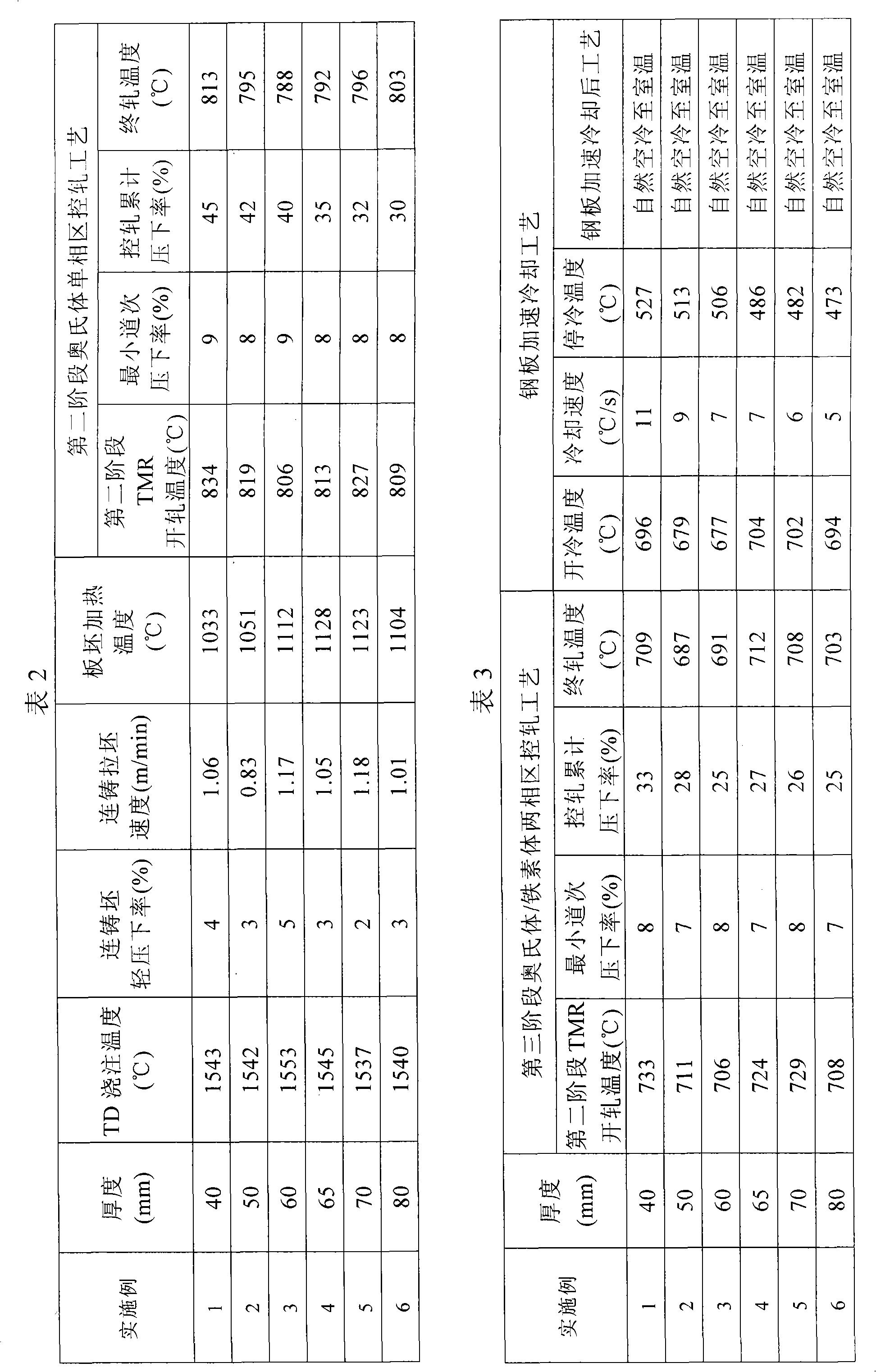

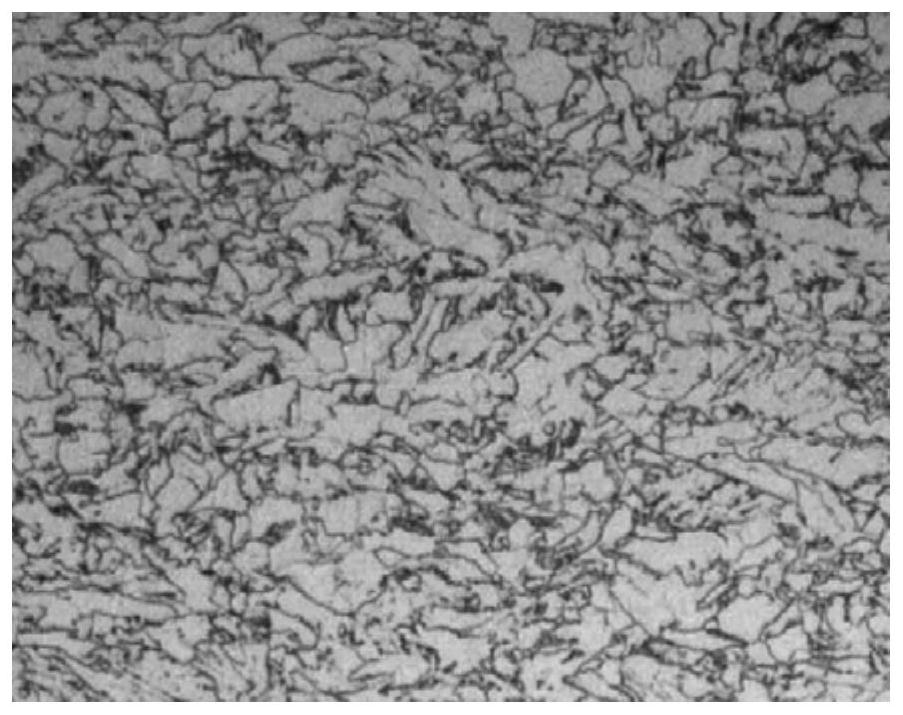

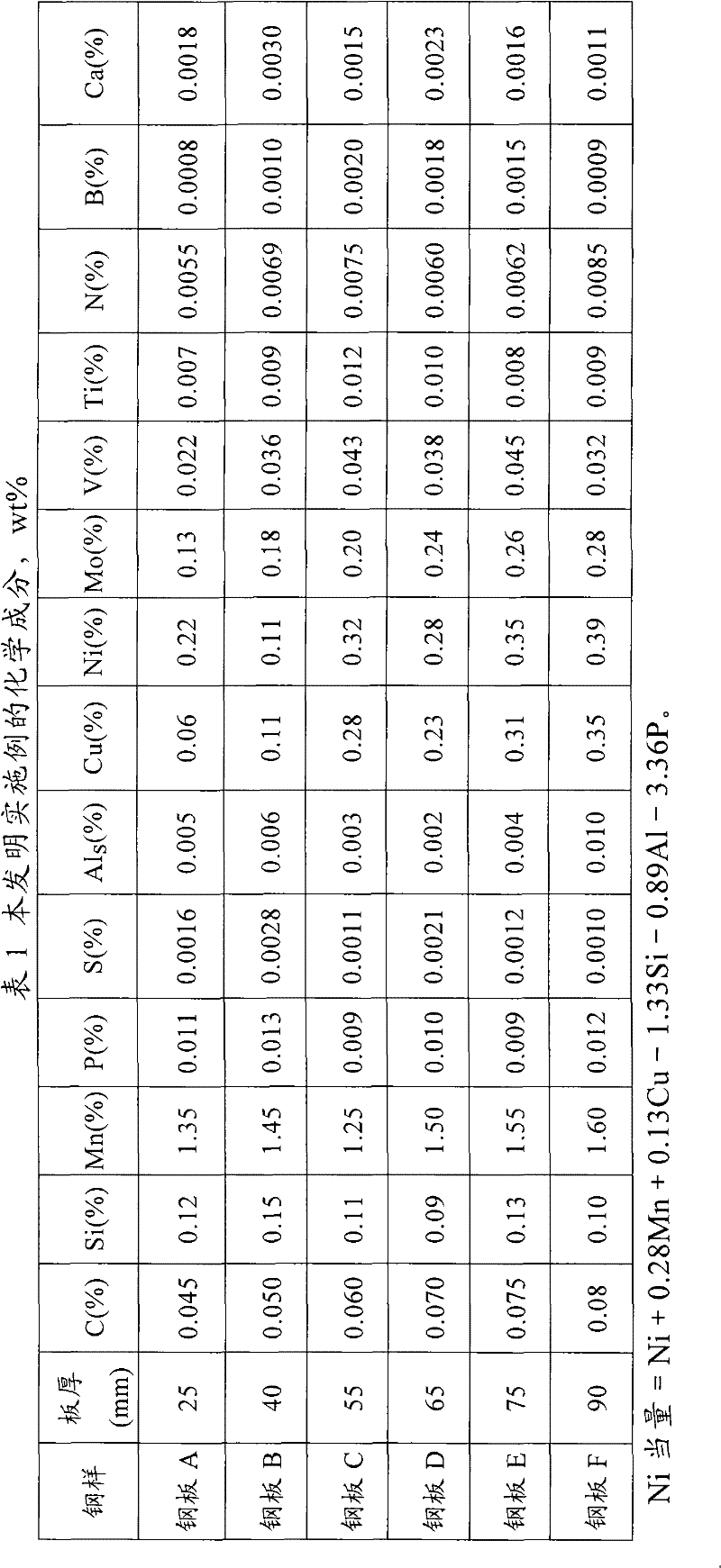

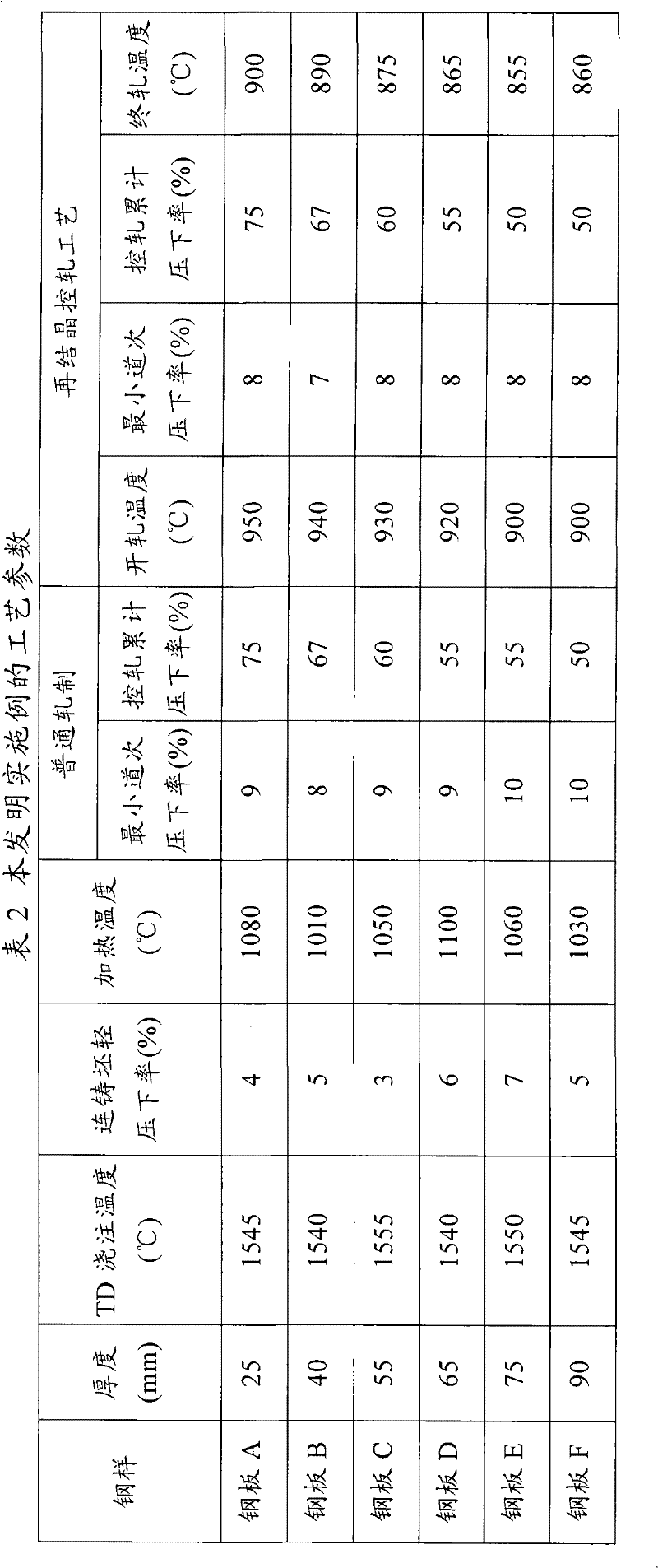

High-performance weather-proof building structural steel and manufacturing method thereof

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

Method for preparing nano copper conductive ink

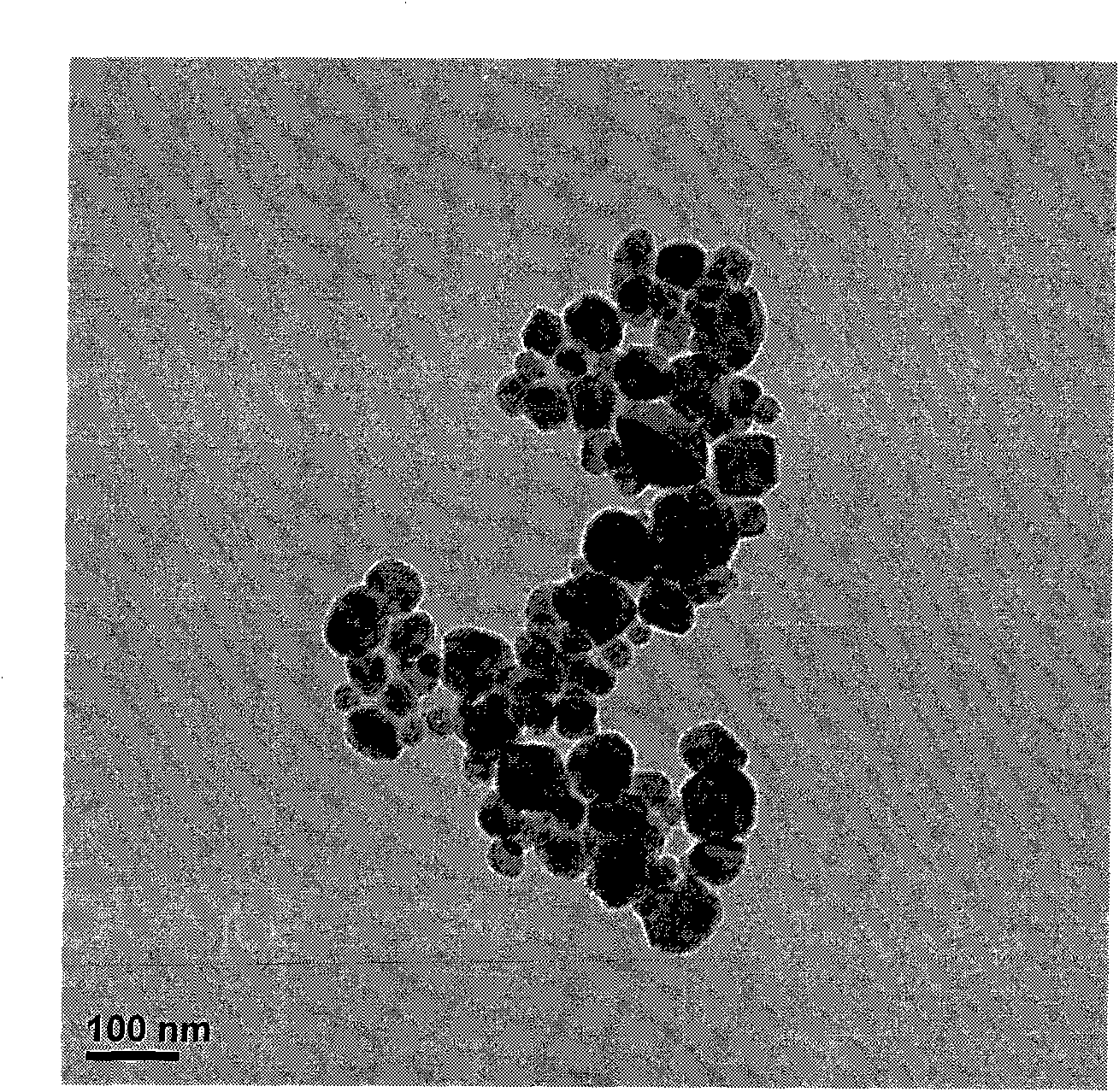

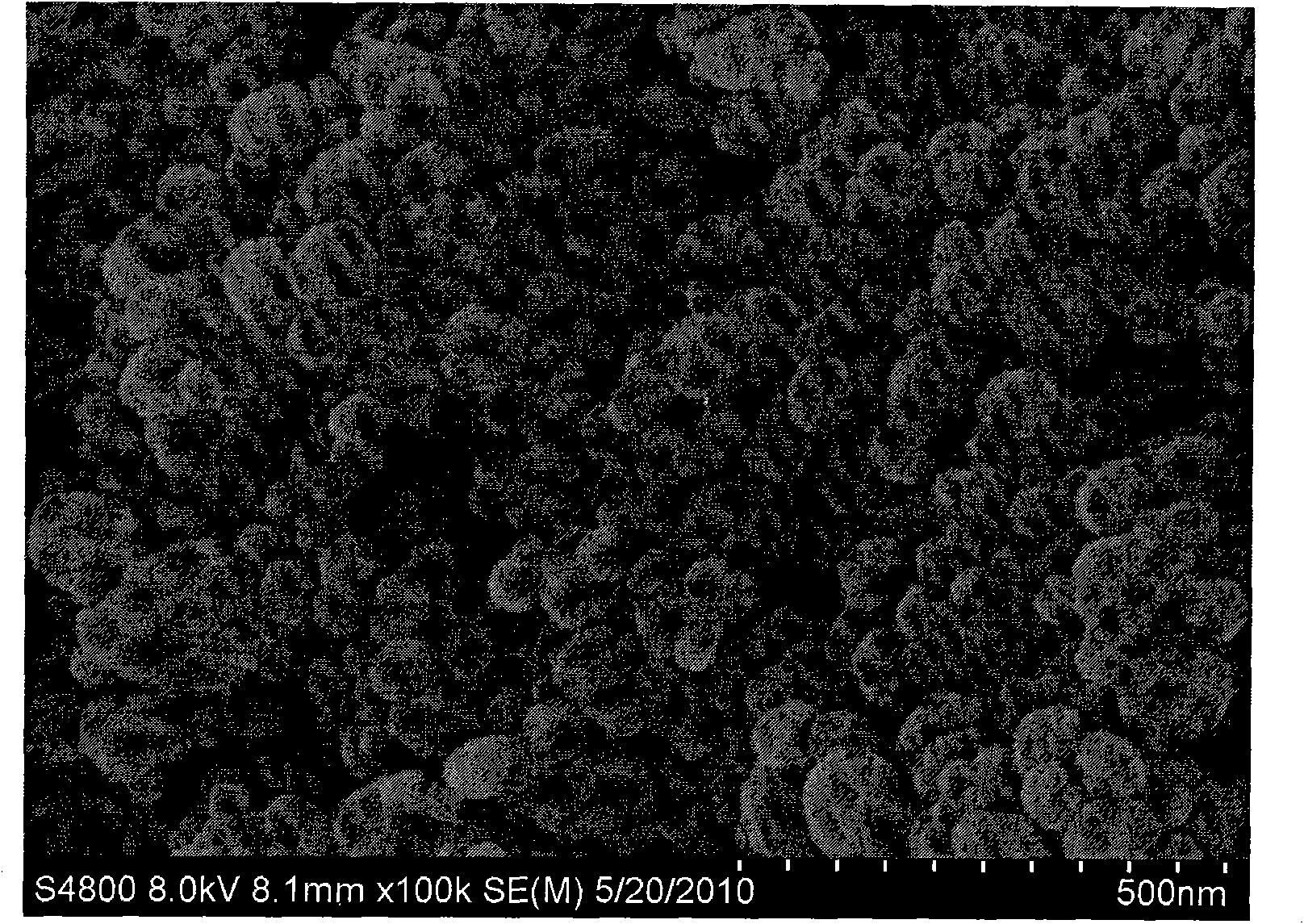

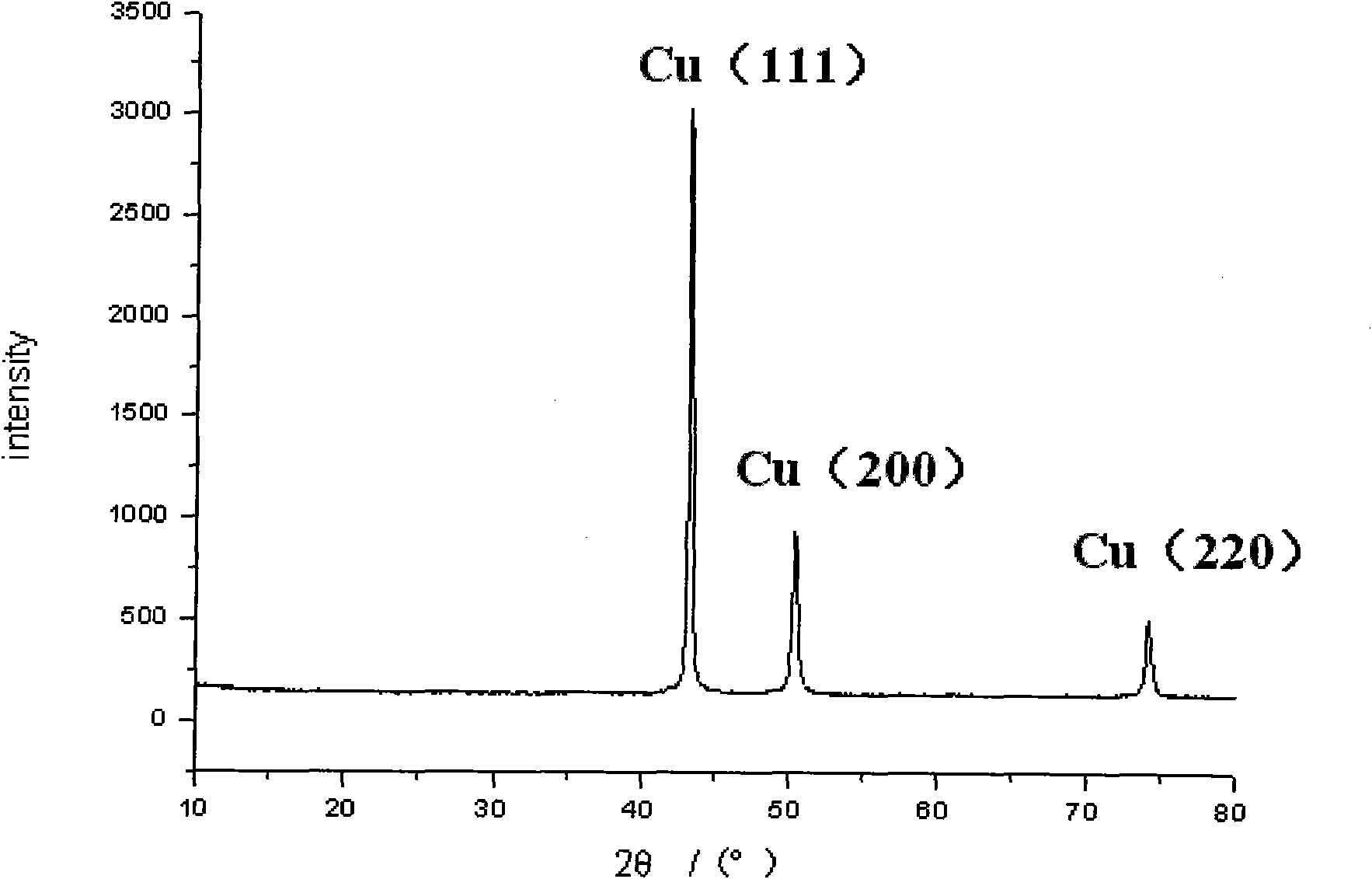

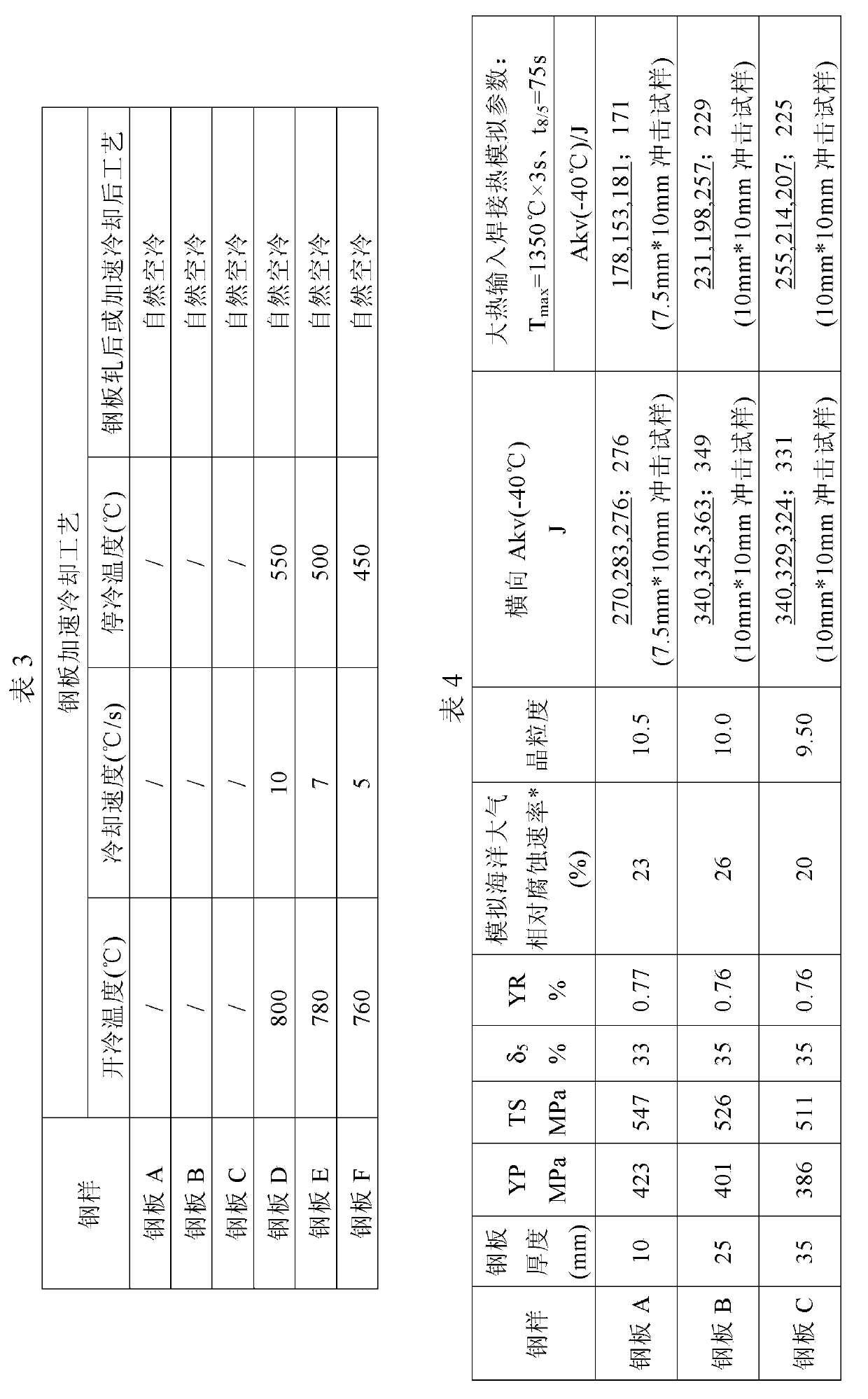

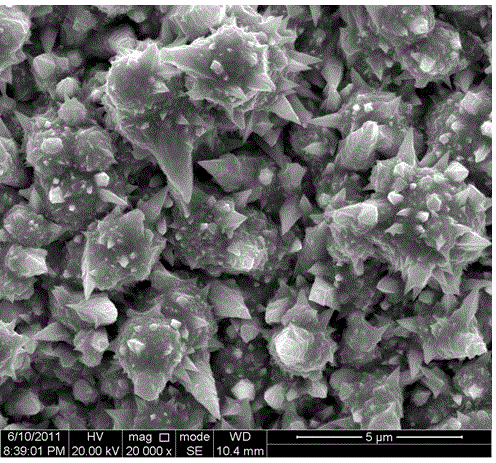

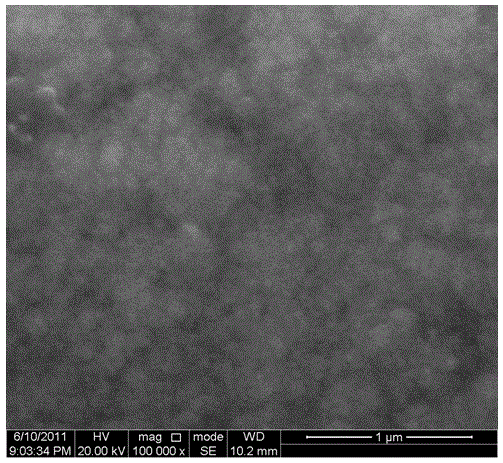

ActiveCN101880493AGood dispersionCharacteristic peaks are obviousInksNon-conductive material with dispersed conductive materialOrganic solventRoom temperature

The invention discloses a method for preparing nano copper conductive ink, which can be applied in the field of printing electronic technology, in particular ink jet printing technology. The preparation method comprises the following steps of: dissolving copper salt and protective agent into a solvent, heating and stirring the solution, adding a small amount of alkali solution to adjust the pH ofthe solution to between 7 and 10, dripping a reducing agent into the solution, continuously stirring the solution to react for 30 to 60 minutes, and then cooling the reaction solution to room temperature to obtain nano copper dispersion; performing centrifuging, washing and vacuum drying at room temperature on the nano copper dispersion to obtain nano copper granules; and dispersing the nano copper granules into an organic solvent, and ultrasonically treating the solution to obtain the nano copper conductive ink. The method solves the problems of complex preparation process and long preparation period in the prior art, has the advantages of simple and convenient operation, low production cost, short flow and no harmful waste generation, and realizes the goals of environmental protection and economy; and the prepared nano copper conductive ink has good dispersion property and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

HT550 steel plate with ultrahigh toughness and excellent weldability and manufacture method thereof

ActiveCN103320692AImprove performanceShorten the manufacturing cycleFurnace typesQuenching agentsSheet steelYield ratio

Owner:BAOSHAN IRON & STEEL CO LTD

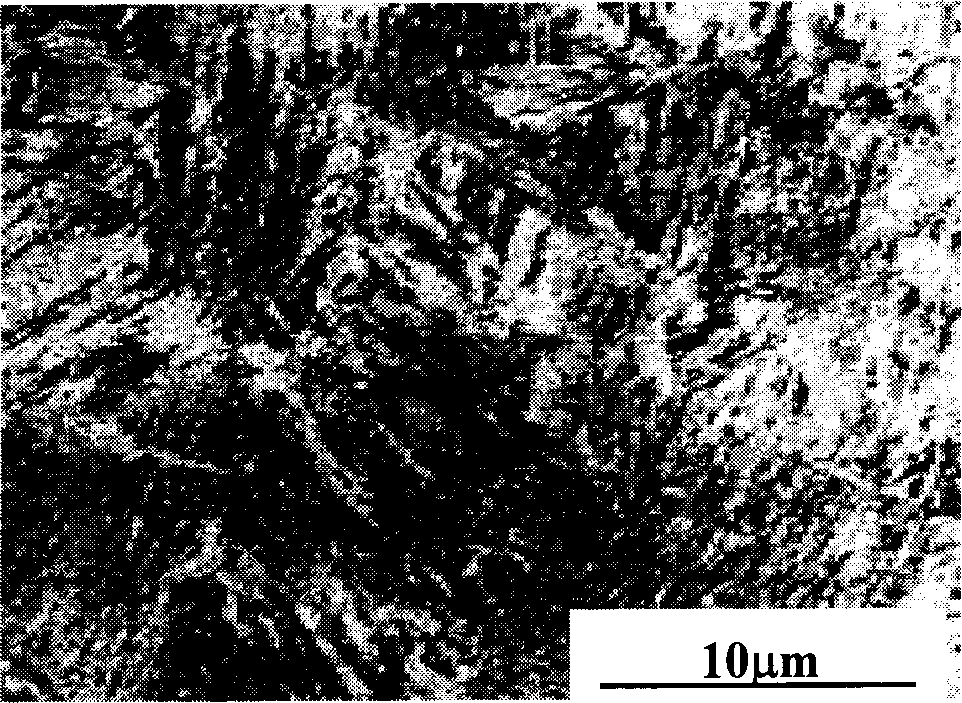

High-strength low-temperature steel with high hydrogen induced cracking (HIC) and sulfide stress corrosion cracking (SSC) resistance and manufacturing method thereof

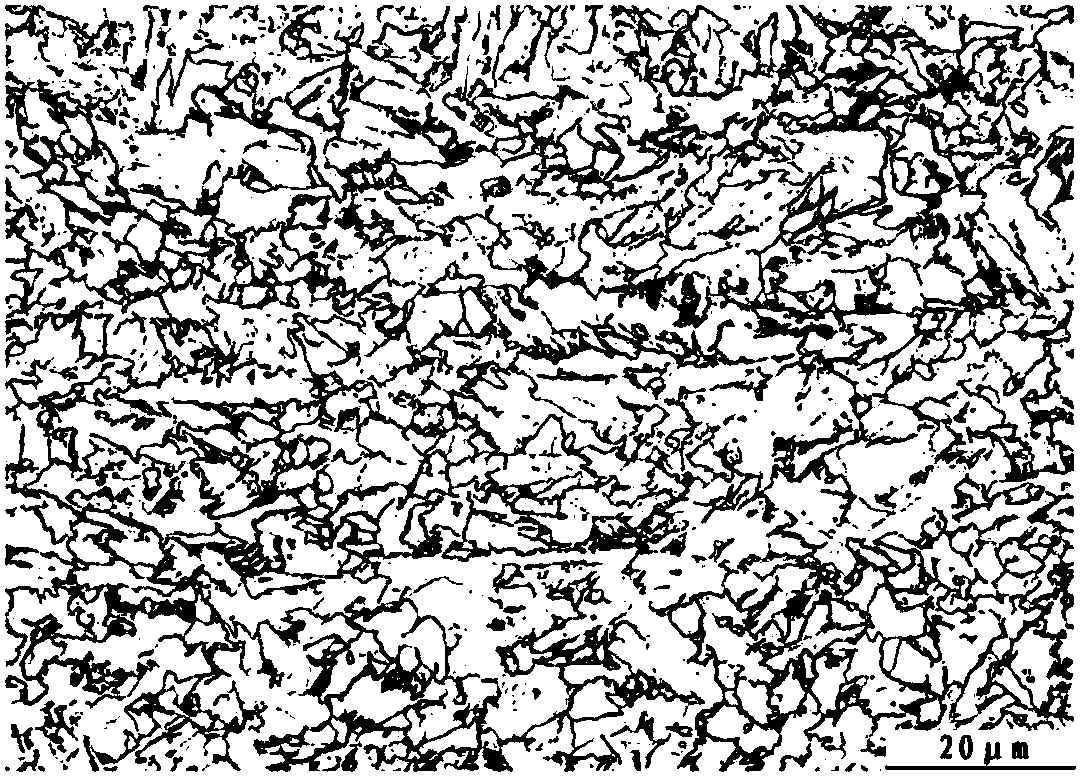

ActiveCN102719745AReduce consumptionReduce difficultyHeat treatment process controlStress corrosion crackingSteel tube

The invention relates to high-strength low-temperature steel with high hydrogen induced cracking (HIC) and sulfide stress corrosion cracking (SSC) resistance and a manufacturing method thereof. A low alloy steel component system with ultra-low C content, low Si content, medium Mn content, low Als content, low N content, a little alloyed Ni and Mo and trace Ti and Nb is adopted, Mn / C is more than or equal to 22, the segregation index 1.32 (percent C)*[(1.53 (percent Mn)+1.37 (percent Si)+1.15 (percent Mo)+1.06 (percent Cr)+(percent Cu)+0.86 (percent Ni)]*[(30 (percent P)+10 (percent S)] is less than or equal to 0.060, [(percent Si)+(percent Als)]*(percent C) is less than or equal to 0.0035, Pcm is less than or equal to 0.018 percent, Nib / Ti is 1.5 to 3.5, Ca treatment is performed, Ca / S is 0.80 to 3.00, the microstructure of a finished steel plate product consists of uniform and fine acicular ferrites and a few upper bainites by optimizing a thermal mechanical control processing (TMCP) technology, and the average particle size is less than 10mu m; and the characteristics of high strength, toughness and HIC and SSC resistance are achieved, high heat input welding can be performed, and the steel is particularly suitable for manufacturing a low temperature storage tank, a low temperature pressure steel pipe, an ocean platform in an ice sea area, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate capable of being welded under large heat input and method for manufacturing the same

ActiveCN1804093AUniform and excellent low temperature toughnessEnsure safetyManufacturing cost reductionMaterials science

The invention provides a thick steel plate for large-thread energy welding, wherein the constituents comprise (by weight percentage) C 0.010-0.020%, Si 0.10-0.30%, Mn 1.80-2.30%, P<=0.010%, S<=0.003%, Nb 0.015-0.030%, Al 0.025-0.050%, Ti 0.010-0.020%, N 0.003-0.006%, REM 0.001-0.005ppm, Mg 0.002-0.006%, B 10-35ppm, and balancing Fe.

Owner:BAOSHAN IRON & STEEL CO LTD

Polyacrylate hot-melt pressure sensitive adhesive for polyethylene protective film and preparation method thereof

InactiveCN102020956ARealize green environmental protectionFilm/foil adhesivesEster polymer adhesivesTectorial membraneFunctional monomer

The invention discloses polyacrylate hot-melt pressure sensitive adhesive for a polyethylene protective film and a preparation method thereof. The polyacrylate hot-melt pressure sensitive adhesive is prepared from polyacrylate hot-melt pressure sensitive adhesive emulsion by polymerization reaction and spray drying, wherein the polyacrylate hot-melt pressure sensitive adhesive emulsion comprises the following components in percentage by weight: 20-35% of soft monomer, 8-20% of hard monomer, 0.4-4% of functional monomer, 0.1-2% of emulsifier, 0.05-0.6% of initiator and 45-55% of deionized water. By using the polyacrylate hot-melt pressure sensitive adhesive disclosed by the invention, the polyethylene protective film with balanced initial viscous force, lasting viscous force, peel strength and cohesive force can be produced; and volatile organic compound is not discharged during the production and environmentally-friendly production of the polyethylene protective film can be realized.

Owner:GUANGDONG TAMAY NEW MATERIALS

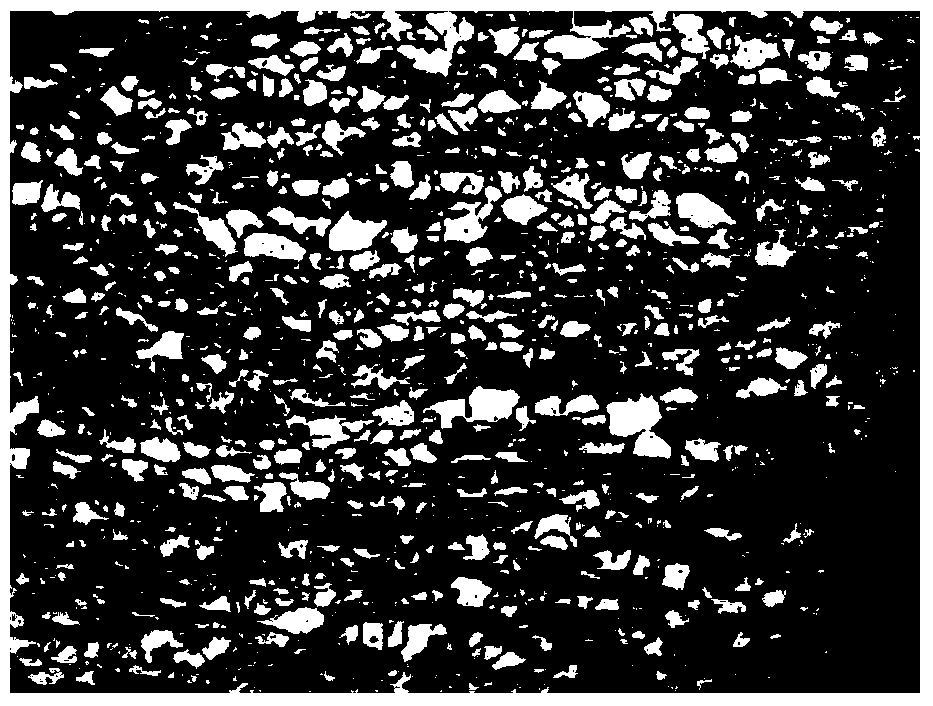

High tempering parameter PWHT embrittlement resistant, extra thick cryogenic steel plate and manufacture method thereof

ActiveCN102691007AIncrease the content of acid-soluble AlsExcellent anti-HICToughnessMaterials science

A high tempering parameter PWHT embrittlement resistant, extra thick cryogenic steel plate and a manufacture method thereof. The steel plate comprises, by weight, 0.030%-0.070% of C, Si no more than 0.15%, 1.30%-1.60% of Mn, P no more than 0.013%, S no more than 0.0025%, 0.040%-0.070% of Als, 0.10%-0.40% of Cu, 0.25-0.65% of Ni, 0.10%-0.30% of Cr, 0.05%-0.25% of Mo, 0.007%-0.013% of Ti, 0.010%-0.030% of Nb, 0.020%-0.050% of V, N no more than 0.0045%, 0.001%-0.004% of Ca, residual iron and unavoidable inclusions. According to optimized controlled rolling and two times of normalizing technology, the steel plate gains extremely high ultralow temperature toughness, excellent HIC / SCC resistance, weldability and bearing capacity of high heat input welding; and more importantly, the steel plate has excellent high tempering parameter PWHT embrittlement resistance characteristic, and is especially suitable for manufacture of large-scale LPG low temperature storage tank, low temperature storage tank for ship and ocean platform for ice ocean.

Owner:BAOSHAN IRON & STEEL CO LTD

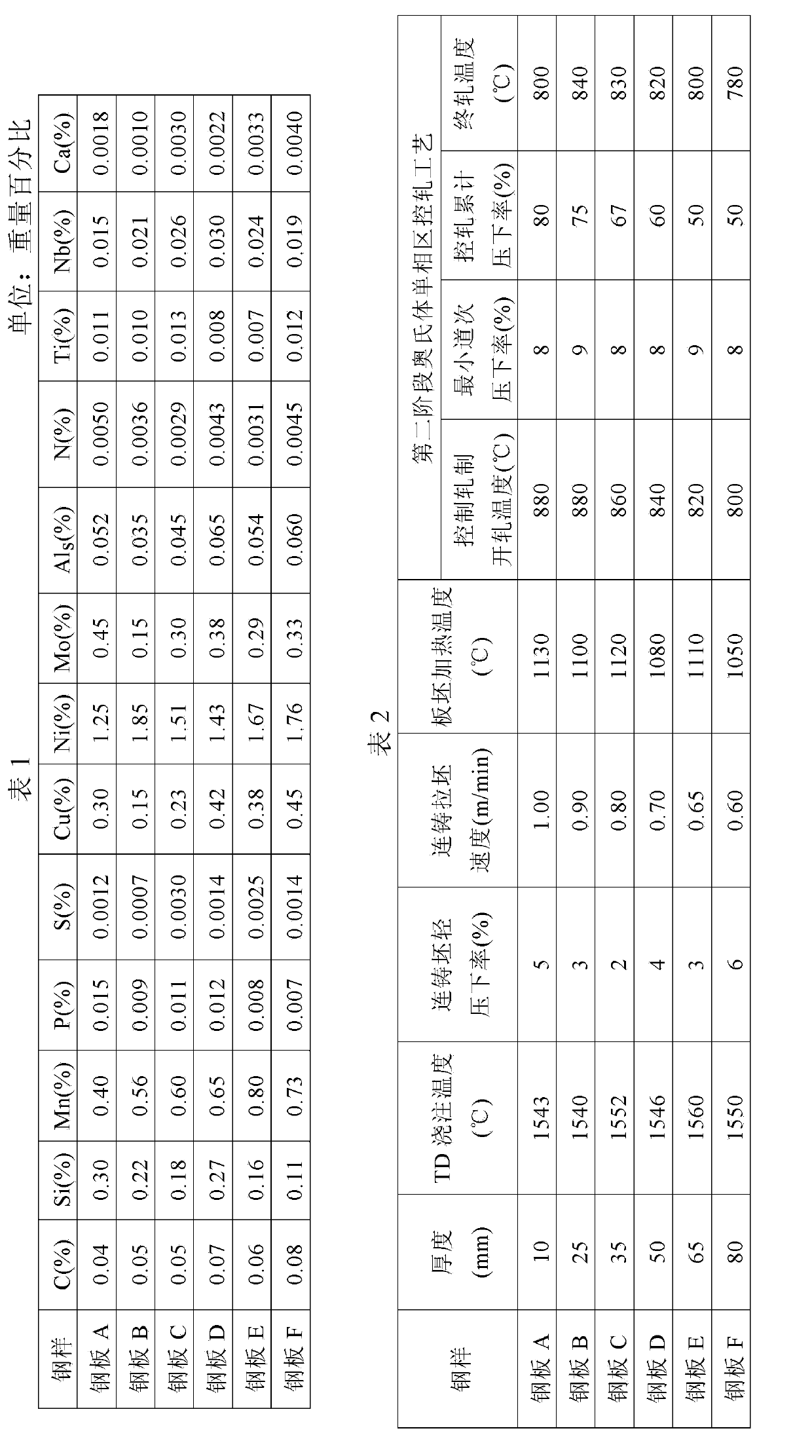

High-performance marine climate resistant steel plate and manufacturing method thereof

The invention relates to a high-performance marine climate resistant steel plate and a manufacturing method thereof. The high-performance marine climate resistant steel plate comprises the following components in percentage by weight: 0.040-0.080 percent of C, less than or equal to 0.30 percent of Si, 0.40-0.80 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.15-0.45 percent of Cu, 1.25-1.85 percent of Ni, 0.15-0.45 percent of Mo, 0.007-0.013 percent of Ti, 0.015-0.030 percent of Nb, 0.035-0.065 percent of Als, less than or equal to 0.0050 percent of N, 0.001-0.004 percent of Ca and the balance of Fe and inevitable impurities. According to the high-performance marine climate resistant steel plate and the manufacturing method thereof, a low-alloy weathering resistant steel system adopting ultralow C-low Mn-high Als-low N-(Cu and high Ni) alloying-Nb microalloying-ultramicro Ti treatment is used for controlling sea atmosphere corrosion resistant parameter Eta to be greater than or equal to 1.36, (%Ni)*(%Mo) to be greater than or equal to 0.27, Ceq to be less than or equal to 0.42 percent, Ca treatment and Ca / S to be 1.0-3.0 and Ca*S0.28 to be less than or equal to 1.0*10<-3>; the sea atmosphere corrosion resistant steel plate with excellent toughness, strong plasticity matching, low yield ratio, sea atmosphere corrosion resistant property and fatigue resistance is obtained by adopting TMCP, and the sea atmosphere corrosion resistant steel plate can be welded at high heat input.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-cyanide bright electroplated silver composite additive and application method thereof in non-cyanide silver electroplating system

The invention relates to a non-cyanide bright electroplated silver composite additive and an application method thereof in a non-cyanide silver electroplating system, and belongs to the technical field of silver electroplating. The electroplated silver composite additive is characterized in that the combination of an inorganic additive and an organic additive is adopted, so that the adding quantity of the additive is wide in range; the solution electroplating performance and the coating electroplating performance of the non-cyanide silver electroplating system are obviously improved due to the addition of the corresponding combined additive. The non-cyanide bright electroplated silver composite additive cannot be decomposed in storage and application processes because of having extremely high stability, and can be used for effectively accelerating the electrolytic deposition speed of a silver electroplating layer without influencing the current efficiency of a cathode at the same time. Thus, the density range of a permissible working current is effectively enlarged; the silver electroplating layer with excellent performance can be obtained; the non-cyanide silver electroplating system in which the additive is added is suitable for production requirements in different fields; the silver electroplating carried out by virtue of cyanides can be completely replaced with the non-cyanide silver electroplating system in the industrial production and the application field. As a result, the environmental friendliness of a silver electroplating process is realized.

Owner:HARBIN INST OF TECH

Multi-coordination-agent cyanide-free electrogilding liquid and electrogilding process

ActiveCN103741181AExcellent bath performanceGood coating performancePotassium hydroxidePotassium carbonate

The invention relates to multi-coordination-agent cyanide-free electrogilding liquid and an electrogilding process, which belong to the technical field of electrogilding. The electrogilding liquid is prepared from a main coordination agent, an auxiliary coordination agent, potassium hydroxide, potassium carbonate, goldpotassium chloride, combined additives and ultrapure water. The electrogilding process comprises the following steps: 1, preprocessing a substrate; 2, electroplating an intermediate nickel plating layer; 3, electrogilding, namely washing the substrate after electroplating the intermediate nickel plating layer with ultrapure water, directly feeding the substrate into a plating cell containing the multi-coordination-agent cyanide-free electrogilding liquid to be electrogilded, taking out a sample from the electrogilding liquid after the electrogilding, washing the surface of the sample by utilizing distilled water, and drying the sample through cold air. Double coordination agents are used as the coordination agents of gold ions in the electrogilding liquid, so that a cyanide-free electrogilding system which has high current efficiency, smoothness and compactness in plating layer crystallization, wide current density range, wide temperature requirement and capability of guaranteeing the golden bright appearance of the plating layer compared with those of a single coordination agent system is obtained.

Owner:HARBIN INST OF TECH

Steel plate HT690 capable of being subjected to high heat input welding and manufacturing method thereof

ActiveCN102041459AImprove performanceShorten the manufacturing cycleRoll force/gap control deviceTemperature control deviceWater pipeThermo mechanical

The invention relates to an HT690 steel plate capable of being subjected to high heat inputwelding and a manufacturing method thereof. A component system treated by low C-high Mn-(Nb+V+B) microalloying-ultramicro Ti is adopted, the acid-soluble Als content in steel is properly improved, the Als is not less than (Mn equivalent / C)*(Ntotal-0.292Ti), (Mn equivalent) / C is between 20 and 40, Pcm is not more than 0.205 percent, the Ti / N is between 2.0 and 4.0, (Cu+Ni+Mo+Cr) is alloyed and Ni / Cu is not less than 1.0, the Ca is treated and the Ca / S ratio is between 0.80 and 3.00 and the F*DI index is controlled to be not less than 0.80*finished steel plate thickness, a TMCP (Thermo-Mechanical Control Process) and a tempering process are optimized to ensure that the microscopic structure of a finished steel plate is fine tempering bainite, and the average crystal cluster size is below 25mum. The steel plate can bear high heat input welding at the same time of obtaining the properties of uniform and excellent obdurability and strong plasticity matching, is especially suitable for large steel structures of a hydroelectric pressure water pipe, a vortex, a sea platform and the like, and can realize low-cost and stable batch industrialized production.

Owner:BAOSHAN IRON & STEEL CO LTD

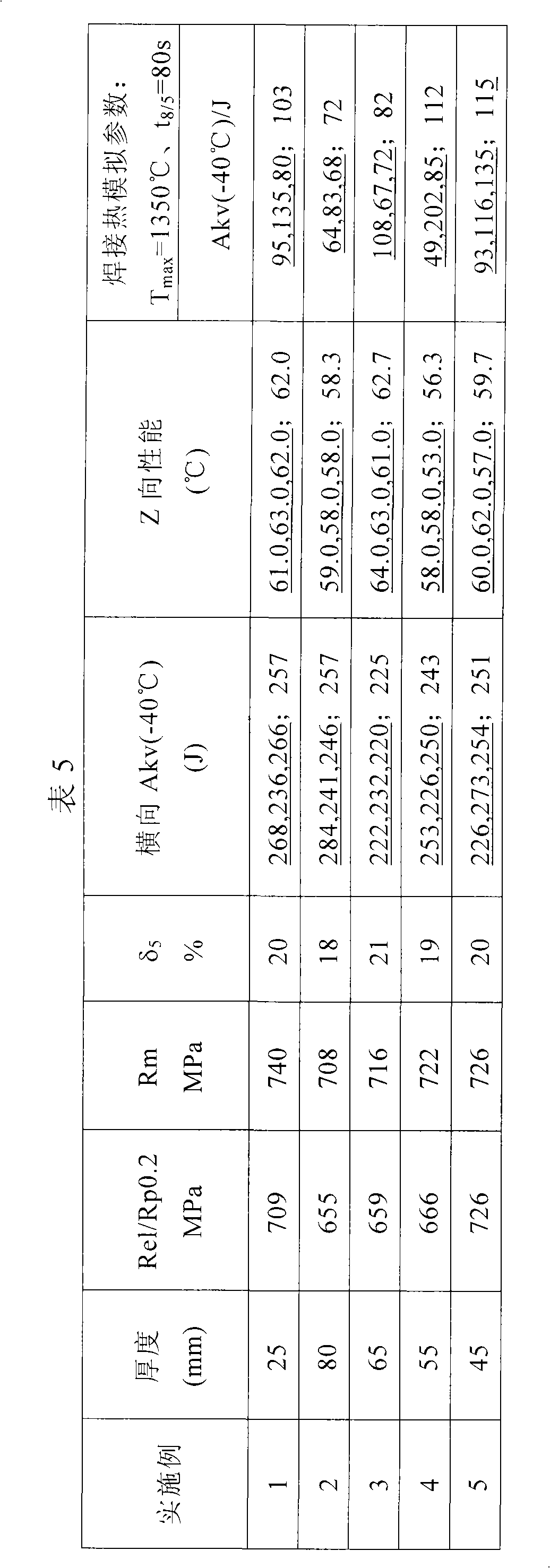

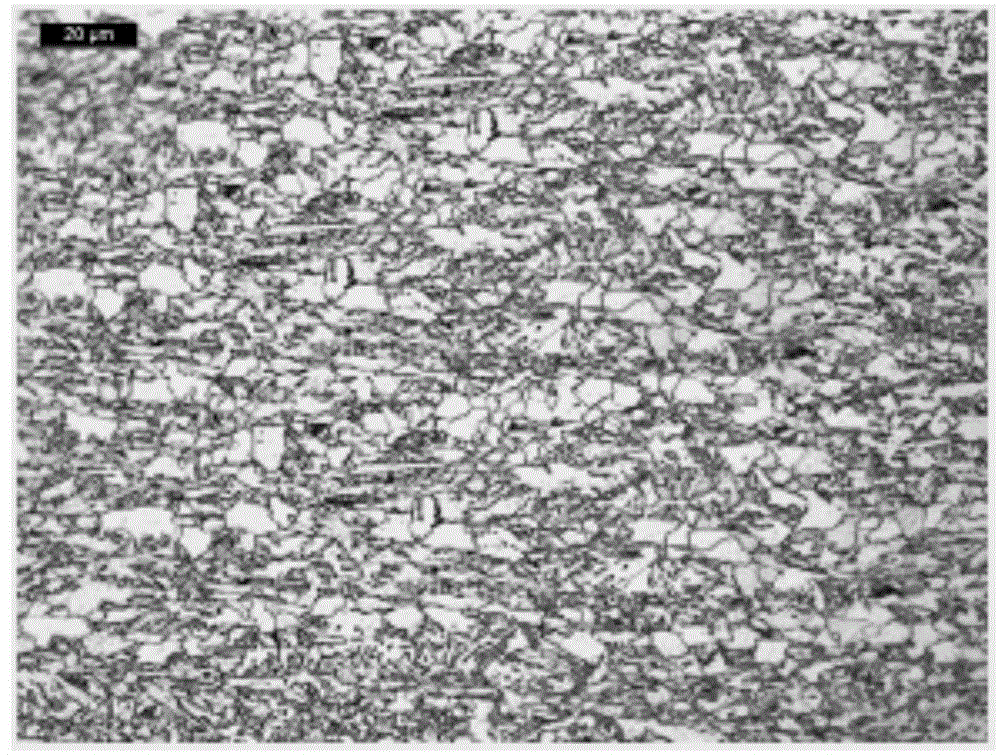

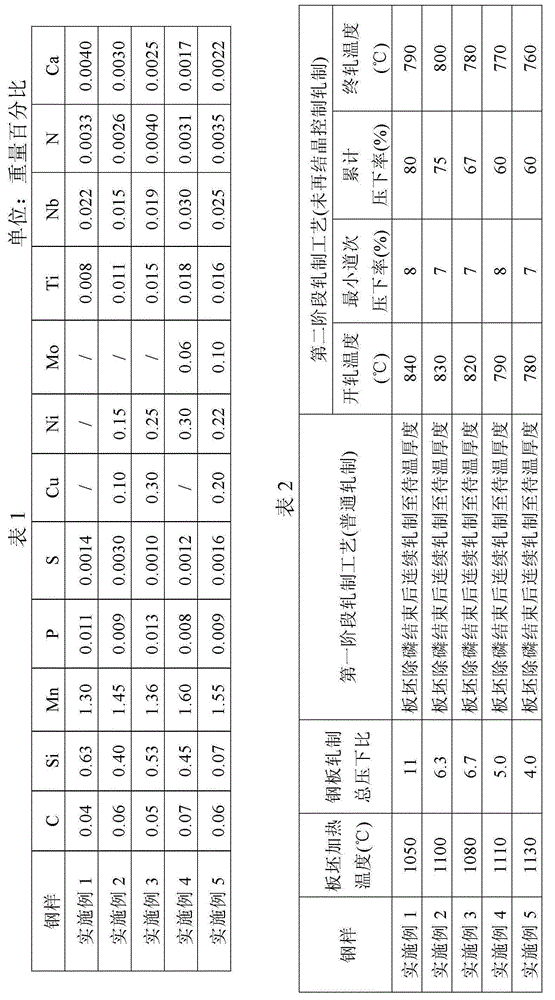

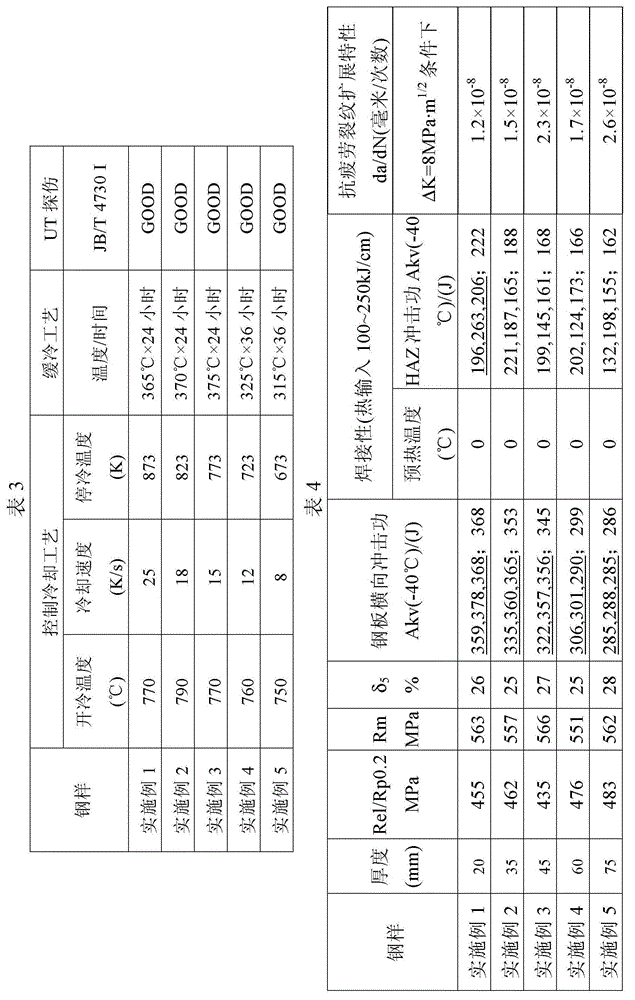

High-quality steel plate capable of resisting fatigue crack growth and manufacturing method thereof

ActiveCN104561796AShorten the manufacturing cycleIncrease added valueFurnace typesHeat treatment furnacesMetallurgyImpurity

The invention discloses a high-quality steel plate capable of resisting fatigue crack growth and a manufacturing method thereof. The high-quality steel plate comprises the following constituents in percentage by weight: 0.040-0.070% of C, 0.40-0.70% of Si, 1.30-1.60% of Mn, less than or equal to 0.013% of P, less than or equal to 0.003% of S, less than or equal to 0.30% of Cu, less than or equal to 0.30% of Ni, less than or equal to 0.10% of Mo, 0.008-0.018% of Ti, 0.015-0.030% of Nb, less than or equal to 0.0040% of N, 0.0010-0.0040% of Ca, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps: using the ultra-low carbon C-high Si-intermediate Mn-Nb system low alloy steel as a base, controlling [%C]*[%Si] to be 0.022-0.042 and {([%C]+3.33[%Nb])*[%Si]}*V cooling velocity / T cold shutdown to be from 1.15*10<-4> to 2.2*10<-3>, carrying out Ca treatment, enabling Ca / S to be equal to 1.0-3.0 and (%Ca)*(%S)<0.28> to be smaller than or equal to 1.0*10<-3>, optimizing the TMCP technology, enabling the finished product steel plate microscopic structure to become a ferrite and uniformly dispersed bainite dual-phase structure, and allowing the average grain size of the microscopic structure to be 10 microns below.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

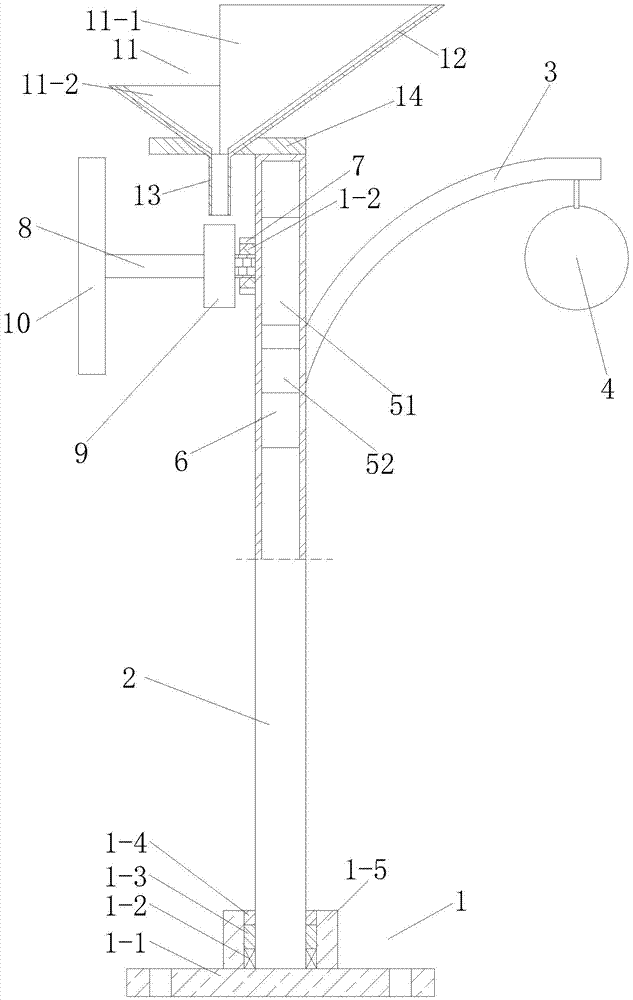

Photovoltaic solar energy, wind power and rainwater generating integrated generating set

InactiveCN105443318AIncrease profitEffective continuous lightingFinal product manufacturePV power plantsImpellerPhotovoltaic solar energy

The invention relates to the technical field of solar photovoltaic generating, in particular to a photovoltaic solar energy, wind power and rainwater generating integrated generating set. The integrated generating set comprises a bottom plate body, a wind energy collecting module, a rainwater energy collecting module and a solar energy collecting module. The wind energy collecting module comprises a bearing block and fan blades. The bearing block is connected with a rotating shaft through a bearing, and one end of the rotating shaft is fixedly connected with the fan blades. The rainwater energy collecting module comprises a hopper and an impeller, the impeller is fixedly arranged on a shaft body of the rotating shaft, and the hopper is fixedly arranged on the top of a lamp supporting pole through a hopper support. A photovoltaic solar panel is fixedly arranged on the inner surface of the hopper. The rotating shaft and the photovoltaic solar panel are connected with the generating set. By means of the integrated generating set, generating is carried out through the solar energy, the wind power and the rainwater, effective continuous lighting of a streetlamp is guaranteed, the conventional energy source is saved, and pollution is reduced. The integrated generating set has the advantages of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:苏州华安普电力科技股份有限公司

Method for dyeing cotton fabric with tea dye and finishing liquor used by method

InactiveCN103451963ARealize green environmental protectionHas antibacterial propertiesDyeing processVegetal fibresAcetic acid solutionClean water

The invention discloses a method for dyeing a cotton fabric with tea dye and finishing liquor used by the method. The method comprises the following process steps of (1) crushing tea leaves, and adding clean water to extract the tea dye; (2) preparing the finishing liquor from the following materials in parts by weight: 1-5 parts of chitosan powder, 20-25 parts of a glacial acetic acid solution with the concentration being 4%, and 1000 parts of water, namely firstly adding the glacial acetic acid solution with the concentration being 4% into the chitosan powder gradually, simultaneously stirring uniformly, adding water, and mixing uniformly to obtain the finishing liquor; (3) finishing the cotton fabric with the finishing liquor in an immersing and rolling method; and (4) dyeing the cotton fabric finished by the finishing liquor. The method disclosed by the invention has the advantages that not only can the dyeing depth and fastness of the dyed cotton fabric be improved, but also the antibacterial effect and the clean and environment-friendly effects can be achieved.

Owner:CHANGZHOU TEXTILE GARMENT INST

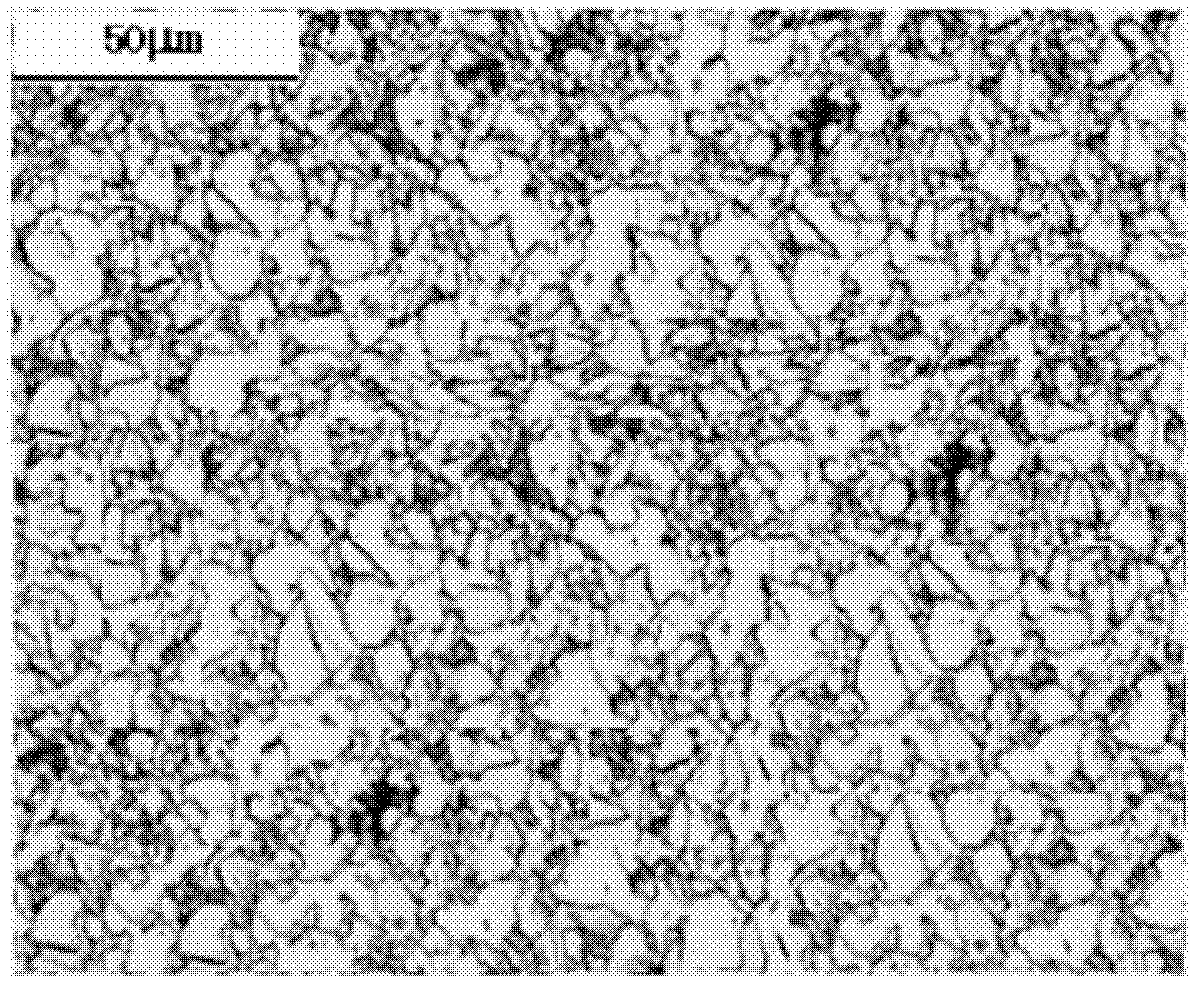

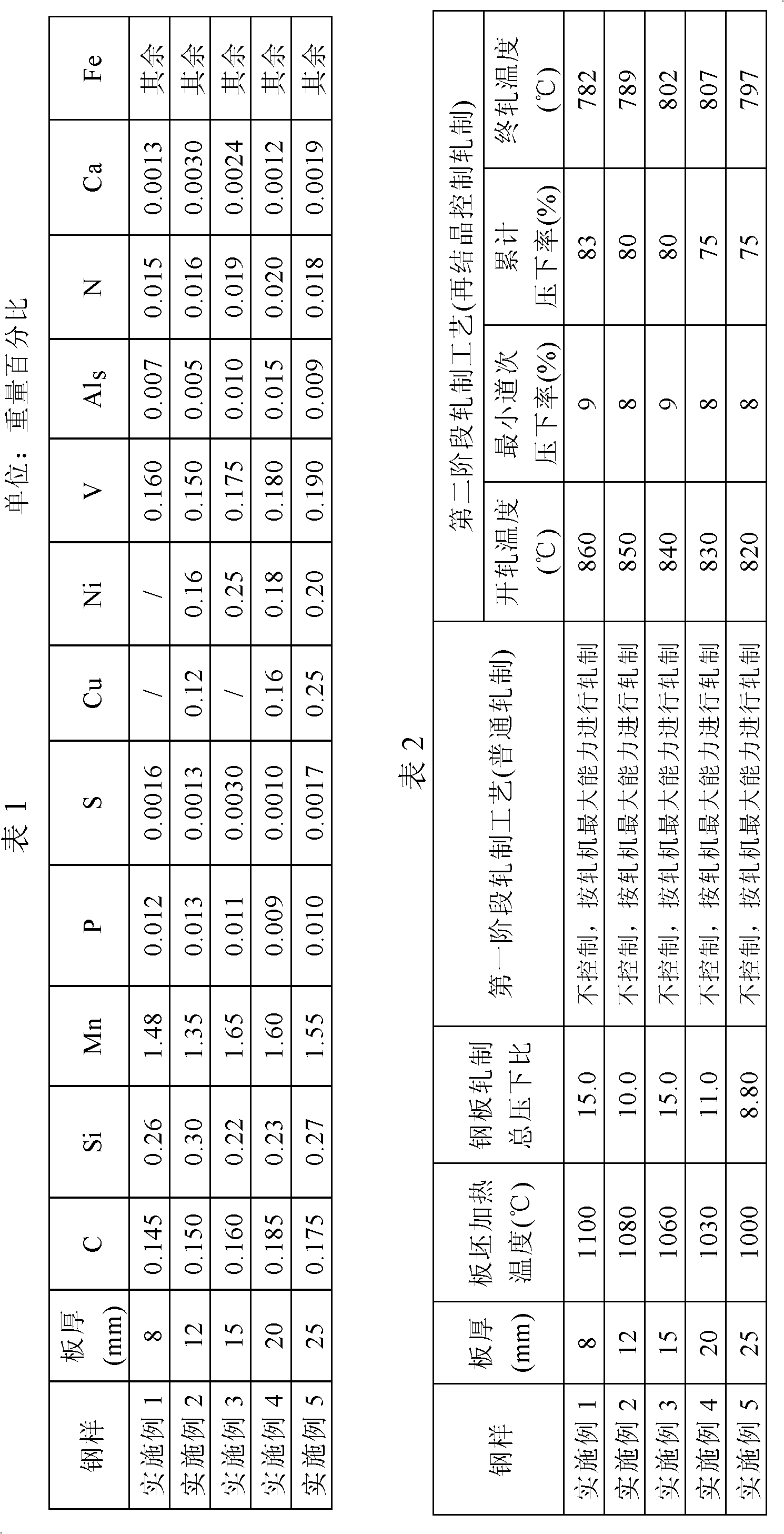

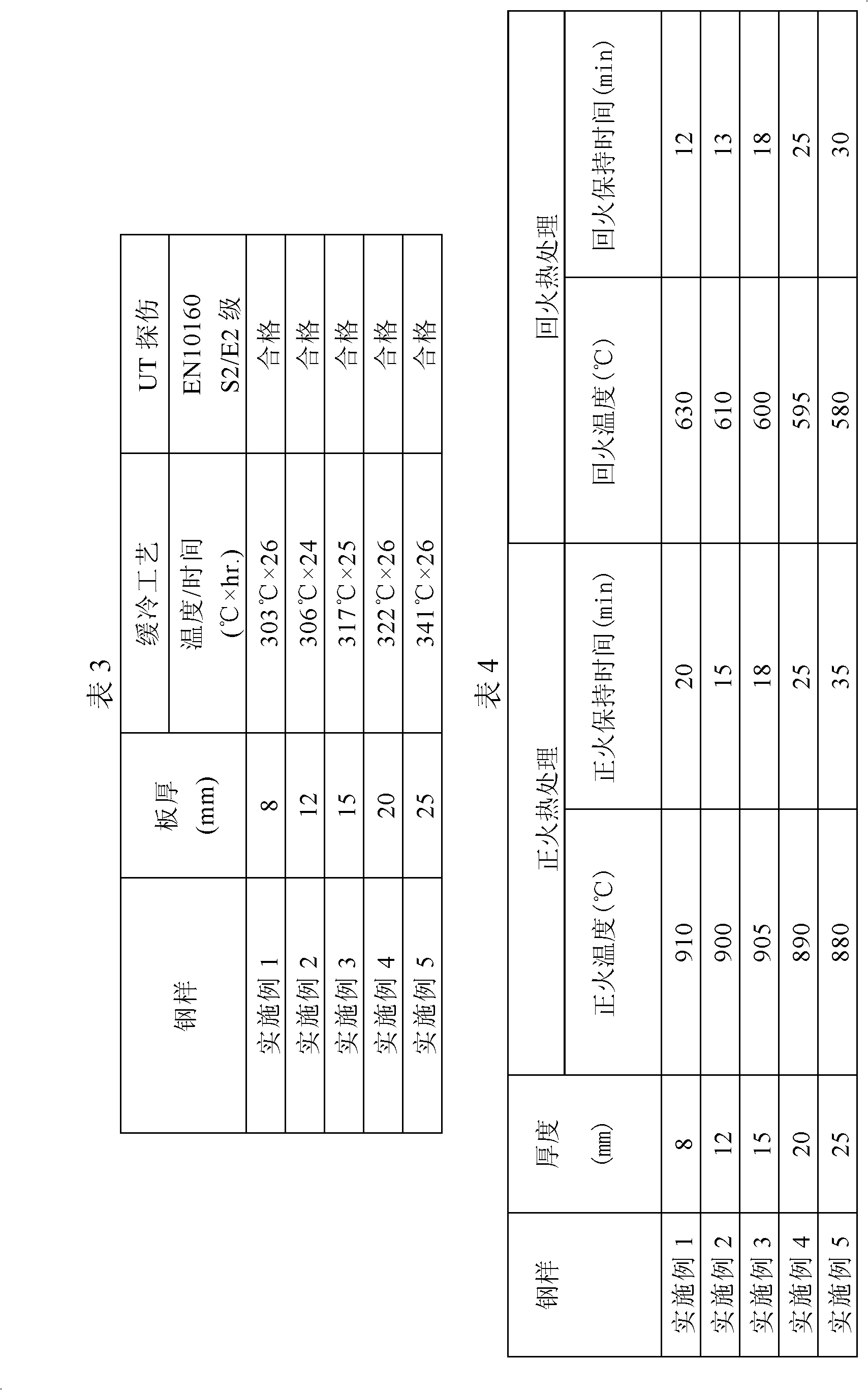

60kg-level low-cost and high-toughness steel plate and production method thereof

Disclosed are a 60kg-level low-cost and high-toughness steel plate and a production method thereof. The 60kg-level low-cost and high-toughness steel plate comprises, in weight percentage, 0.145%-0.185% of C, not less than 0.30% of Si, 1.35%-1.65% of Mn, not less than 0.013% of P, not less than 0.003% of S, not less than 0.25% of Cu, not less than 0.25% of Ni, 0.005%-0.015% of AlS, 0.150%-0.190% of V, 0.015%-0.020% of N, 0.001%-0.003% of Ca, and the balance of Fe and unavoidable impurities. Based on an alloyed component system of medium C, low Si, high Mn, ultralow AlA and high V with metallurgical technical control, RCR-NT (recrystallization controlled rolling-normalized tempering) processes are optimized, the microstructure of the finished steel plate includes even and small ferrite, pearlite and trace granular bainite, average grain size of the ferrite is smaller than 15 micrometers, even and fine match of high toughness and high plasticity is obtained, and the steel plate has extremely fine low-temperature toughness. The steel plate is especially applicable to large-sized steel structured containers, such as bearing components, petroleum storage tanks, mobile tankers and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Cyanide-free bright electrogilding additive and application thereof

The invention discloses a cyanide-free bright electrogilding additive and an application thereof, which belongs to the technical field of electrogilding. The electrogilding additive is prepared from additives and ultra-pure water, wherein the additives are organic additives or mixtures of inorganic additives and organic additives; the concentration of each component in the additive is 0.5-30g / L. The cyanide-free bright electrogilding additive disclosed by the invention has the functions of improving the brightness of a plated layer, refining crystal grains, stabilizing plating liquid and reducing surface tension. Therefore, the additive can be applied to electrogilding plating liquid, and the addition amount is 0.1-100mL / L. By adopting the additive disclosed by the invention, the properties of the plating liquid and the plating layer of a multi-coordination agent cyanide-free electrogilding system can be effectively improved, the plating liquid has no unstable situations of decomposition, precipitation and the like under long-time working condition, and an electrogilding layer which is golden and full bright macroscopically, uniform and compact in micro crystal, flat and crackless can be obtained under the electroplating condition.

Owner:HARBIN INST OF TECH

460MPa crack arresting steel plate with low cost and large heat input welding and manufacturing method thereof

The invention discloses a 460MPa crack arresting steel plate with low cost and large heat input welding and a manufacturing method thereof. The 460MPa crack arresting steel plate is prepared from thefollowing components in percentage by weight: 0.040% to 0.080% of C, less than or equal to 0.15% of Si, 1.70% to 2.05% of Mn, less than or equal to 0.013% of P, less than or equal to 0.0040% of S, 0.015% to 0.030% of Nb, 0.010% to 0.025% of Ti, less than or equal to 0. 010% of Al, and the balance of Fe and inevitable impurities. According to the invention, ultra-low carbon C, ultra-low Si, high Mn-Nb combined low alloy steel is taken as the basis, the (%Al) is less than or equal to 0.010%, micro Ti treatment is carried out, DI*T cold opening*Vc) / T stop cooling is more than or equal to 11.5 andless than or equal to 26.5, (%Mn)*Ceq is more than or equal to 0.55 and less than or equal to 0.85, TMCP process is optimized, the yield strength of the steel plate is more than or equal to 460MPa, the tensile strength is more than or equal to 550MPa, Charpy impact energy (Single value) at -40 DEG C is more than or equal to 100J, Kca at -10 DEG C) is more than or equal to 6,500N / mm<1.5>, and large heat input welding and ultra-low cost manufacturing can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-cost and high-crack-arrest extra-thick steel plate and manufacturing method thereof

ActiveCN111621694AHigh strengthImprove toughnessFurnace typesHeat treatment furnacesUltimate tensile strengthImpact energy

The invention discloses a low-cost and high-crack-arrest extra-thick steel plate and a manufacturing method thereof. The low-cost and high-crack-arrest extra-thick steel plate comprises the followingcomponents of, in percentage by weight, 0.050%-0.080% of C, less than or equal to 0.15% of Si, 1.65%-1.95% of Mn, less than or equal to 0.013% of P, less than or equal to 0.003% of S, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.15% of Mo, 0.006%-0.015% of Ti, 0.015%-0.030% of Nb, less than or equal to 0.0050% of N, 0.035%-0.065% of Al, 0.0010%-0.0040% of Ca and the balance Fe and inevitable impurities. According to the low-cost and high-crack-arrest extra-thick steel plate and the manufacturing method thereof, a component system of ultra-low C,low Si, high Mn, Nb microalloying and ultra-micro Ti treatment is adopted, the high-crack-arrest steel plate with excellent weldability is obtained through a TMCP process, wherein the yield strengthof the steel plate is larger than or equal to 460 MPa, the tensile strength of the steel plate is 570-720 MPa, Charpy impact energy (single value) at the temperature of 50 DEG C below zero is larger than or equal to 100 J, and the Kca (10 DEG C below zero) is larger than or equal to 8000 N / mm <3 / 2>.

Owner:BAOSHAN IRON & STEEL CO LTD

A quenched and tempered low temperature steel and its manufacturing method

ActiveCN102286692AImprove low temperature toughnessGood welding processTemperature control deviceChemical IngredientsQuenching

The invention relates to hardened and tempered low-temperature steel, which comprises the following chemical ingredients by weight percentage: 0.040 percent to 0.080 percent of C, at most 0.15 percent of Si, 1.20 percent to 1.60 percent of Mn, at most 0.015 percent of P, at most 0.003 percent of S, at most 0.010 percent of Als, 0.05 percent to 0.35 percent of Cu, 0.10 to 0.40 percent of Ni, 0.10 percent to 0.30 percent of Mo, 0.007 percent to 0.012 percent of Ti, 0.020 percent to 0.050 percent of V, 0.0055 percent to 0.0085 percent of N, 0.0008 percent to 0.0020 percent of B and 0.001 percentto 0.004 percent of Ca. In addition, the element contents meet the following relationship that: Mn / C is greater than or equal to 15 but smaller than or equal to 30; the equivalent weight of Ni is greater than or equal to 0.25 percent; Ti / N is between 1.0 and 2.0; B is greater than 0.714(N-0.292Ti-0.518Als); Ni / Cu is greater than or equal to 1.0; Ca / S is between 1.0 and 3.0, and in addition, the Ca(percentage)*S(percentage)0.28 is greater than or equal to 1.0*10<-4> but smaller than or equal to 1.5*10<-3>; and the rest are iron and unavoidable impurities. The steel is manufactured through combining processes of recrystallization control milling, on-line direct quenching, tempering heat treatment, the excellent low-temperature performance can be obtained, and in addition, a steel plate can bear large-line energy welding and is particularly suitable for being used for making liquefied petroleum gas (LPG) low-temperature storage tanks.

Owner:BAOSHAN IRON & STEEL CO LTD

Biobased artificial stone and production process thereof

A biobased artificial stone and a production process thereof are disclosed. The artificial stone includes the following components: inorganic filler, resin, a curing agent, an accelerating agent, a crosslinking agent, a coupling agent, an antifoaming agent, lignin and a pigment. The formula of the artificial stone includes by weight: 10-85% of the inorganic filler; 3-60% of the resin; 0.03-3% of the curing agent; 0-2% of the accelerating agent; 0.05-2% of the coupling agent; 0.05-5% of the crosslinking agent; 0-3% of the antifoaming agent; 0.01-40% of the lignin; and 0-2% of the pigment. According to the invention, the lignin is used in the artificial stone, the lignin is turned into wealth from waste, the environmental pollution of the lignin is reduced, the cost of the artificial stone is reduced, and at the same time the weather resistance and light stability of the artificial stone are improved, thus the artificial stone has antibacterial ability, is green and environmental-friendly, and is suitable for building decoration of living environments.

Owner:SUZHOU TOPOLINE TECH

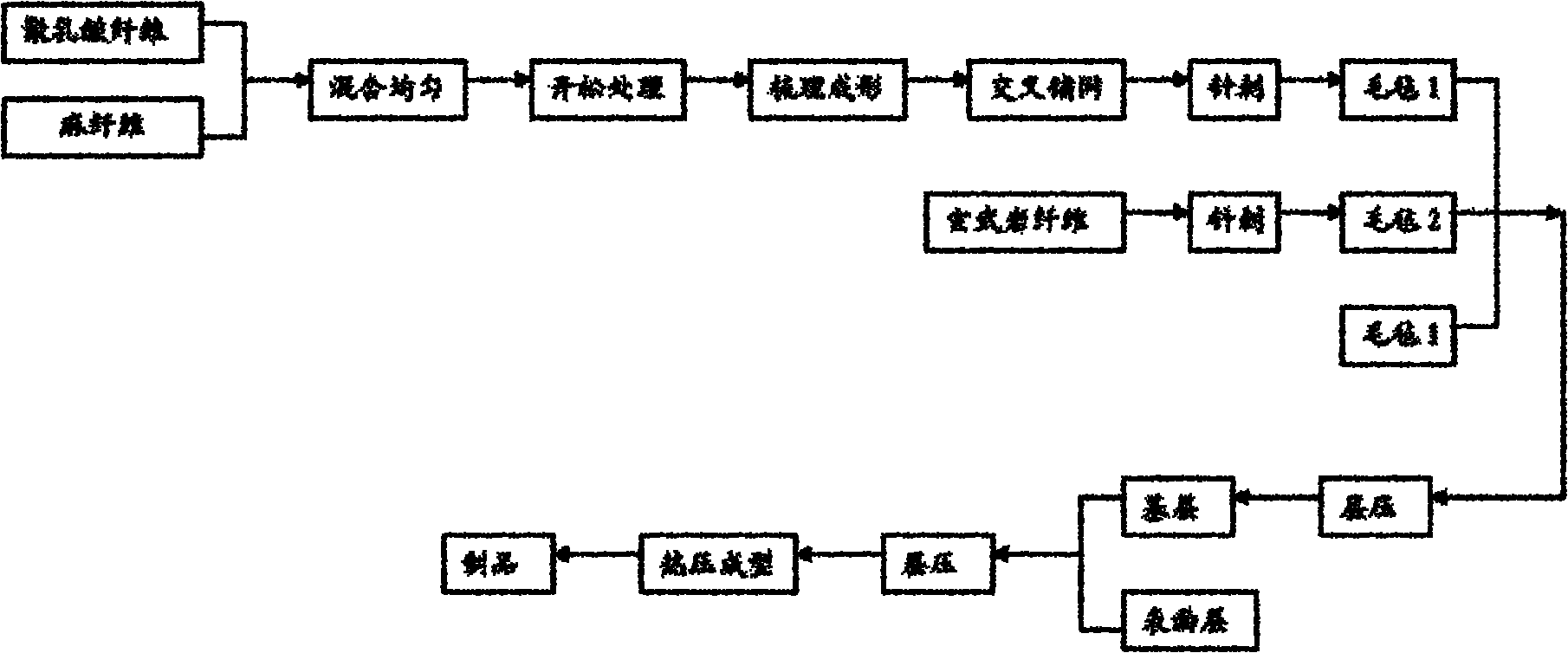

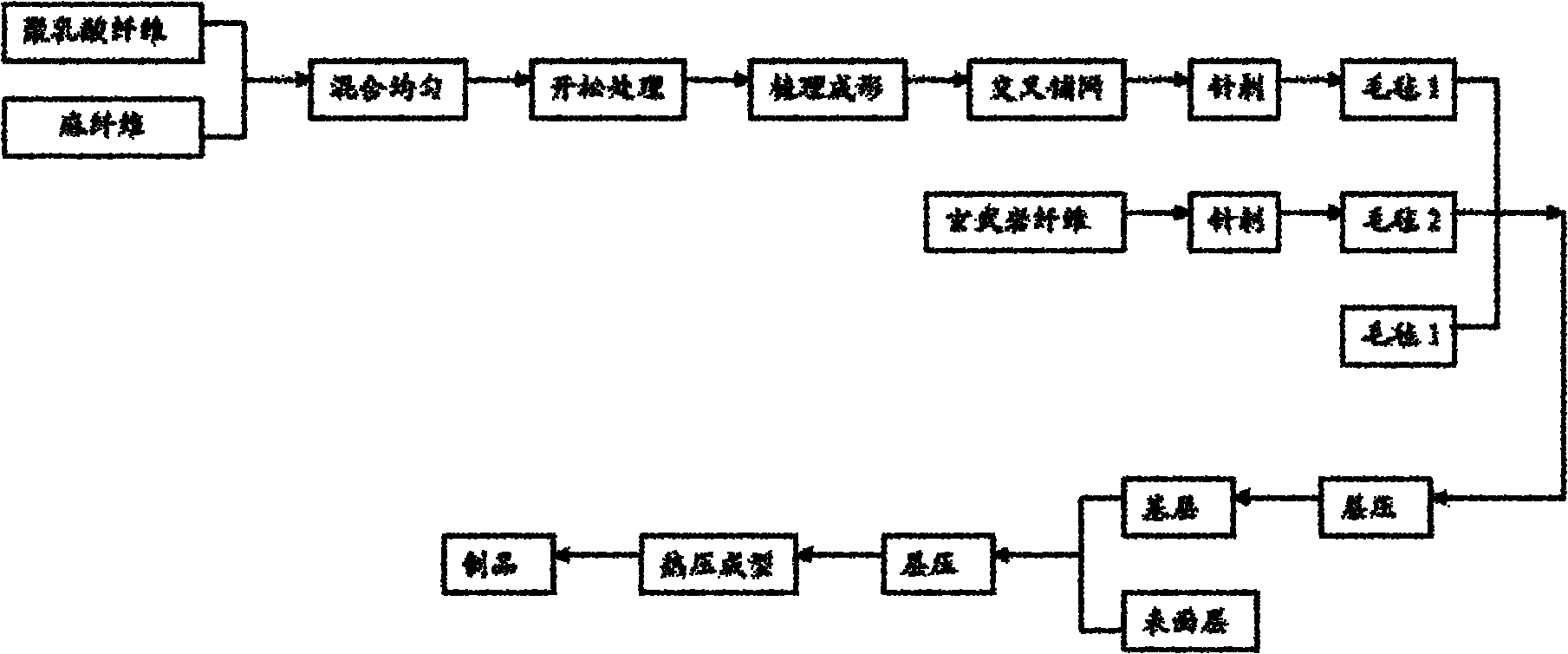

Composite fiber automobile interior board and production method thereof

InactiveCN102166842AImprove tensile propertiesGood filterability at high temperatureLaminationLamination apparatusSurface layerSisal fiber

The invention relates to a composite fiber automobile interior board and a production method thereof. The automobile interior board comprises a base layer and a non-woven or woven surface layer which is laminated on the at least one surface of the base layer, wherein the base layer consists of the following composite fibers: first fibers, namely polylactic acid fibers, second fibers, namely bastose selected from at least one of jute fibers, sisal fibers, ramie fibers, linen fibers, hemp fibers and kenaf fibers, and third fibers, namely basalt fibers in a weight percentage ratio of (20-70):(10-60):(10-60); and the surface layer consists of polylactic acid fibers. The composite fiber automobile interior board can be made into a three-dimensional deep drawing high-strength automobile interior board, and is safe, firm and environment-friendly when used as the base material of an automobile door inner board and a ceiling.

Owner:DALIAN UNIV OF TECH

Humic acid coated urea and production method thereof

InactiveCN104058898ARealize green environmental protectionIncrease profitAgriculture gas emission reductionFertilizer mixturesWater basedEmulsion

The invention provides multifunctional humic acid type coated urea and a production method thereof. The production method comprises the following step: by taking urea as an inner core, humic acid and derivatives thereof as a main coating material and carrier, and a water-based emulsion as viscose, adding corresponding functional components and various auxiliary materials, thus obtaining the multifunctional humic acid type coated urea. The multifunctional humic acid type coated urea has the functions of moisture retention, fertilizer maintenance, slow dissolution, slow release and the like, and the utilization ratio of the urea is improved more effectively; and since the coated urea is produced under the condition of normal temperature and pressure, the process is easy to operate and control and easy to realize continuous large-scale production.

Owner:YANSHAN UNIV

High-toughness and high-weather-resistance steel and manufacturing method thereof

The invention discloses high-toughness and high-weather-resistance steel and a manufacturing method thereof. The high-toughness and high-weather-resistance steel comprises the following components in percentage by weight: 0.035-0.075% of C, no more than 0.30% of Si, 0.40-0.80% of Mn, 0.07-0.11% of P, no more than 0.004% of S, 0.20-0.50% of Cu, 0.10-0.40% of Ni, 0.40-0.70% of Cr, 0.008-0.016% of Ti, 0.010-0.030% of Nb, no more than 0.0050% of N, 0.001%-0. 004% of Ca, and the balance of Fe and unavoidable impurities, wherein by taking a C-Mn-P component system with low C, low Mn and high P as a foundation and through the alloying of Cu, Ni and Cr, [%C] / [%P] is controlled to be not smaller than 0.49, [%Mn] / [%C] is controlled to be not smaller than 10, the weather resistance index DNH is controlled to be not smaller than 6.50%, [%C]*([%P]+2.5[%S]) is controlled to be not more than 0.0025, [%Ca] / [%S] is controlled to be equal to 1.0-3.0, ([%Cu]+0.36[%Ni]+0.27[%Cr])*[%P] is controlled to be not smaller than 0.030, [%Ca]*[%S]0.28 is controlled to be not more than 0.002, and a TMCP (ThermoMechanical Control Process) is adopted. Therefore, the high-toughness and high-weather-resistance steel has excellent low-temperature toughness, bending cold machining characteristic and high weather resistance, and is suitable to be used as a compartment body structure of a coating-free high-speed train.

Owner:BAOSHAN IRON & STEEL CO LTD

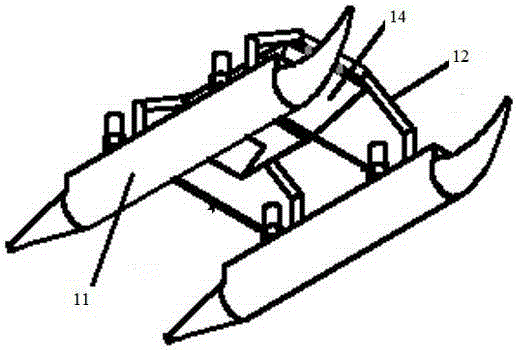

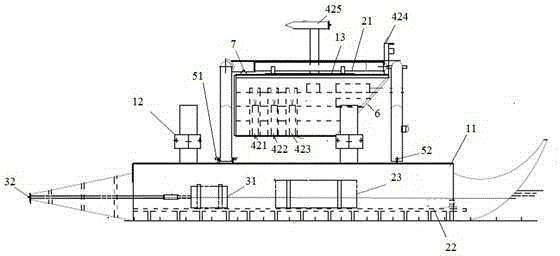

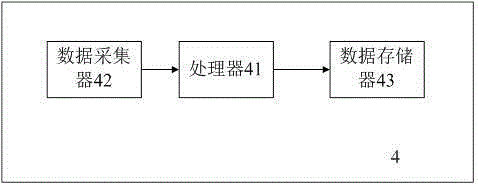

Small multifunctional solar twin-hull unmanned ship

InactiveCN105197180AGood stability and seakeepingEasy to assemble and disassemblePropulsion power plantsPropulsive elementsMarine engineeringOcean environment

The invention discloses a small multifunctional solar twin-hull unmanned ship. The small multifunctional solar twin-hull unmanned ship comprises an unmanned ship body, and the unmanned ship body comprises a pair of sheet bodies used for making the unmanned ship float on the water surface, a pair of connecting bridges, a backing plate, a main hull, an electric system, a propelling system and a control system. The connecting bridges are erected between the pair of sheet bodies, the backing plate is arranged between the pair of connecting bridges, and the backing plate and the pair of connecting bridges form a vertical structure. The main hull is arranged on the lower surface of the backing plate, and the electric system, the propelling system and the control system are arranged on the unmanned ship body. Corresponding ocean environment monitoring tasks can be completed, collected data can be transmitted back in time, and high efficiency, environmental friendliness and intelligence are integrated.

Owner:SHANGHAI MARITIME UNIVERSITY

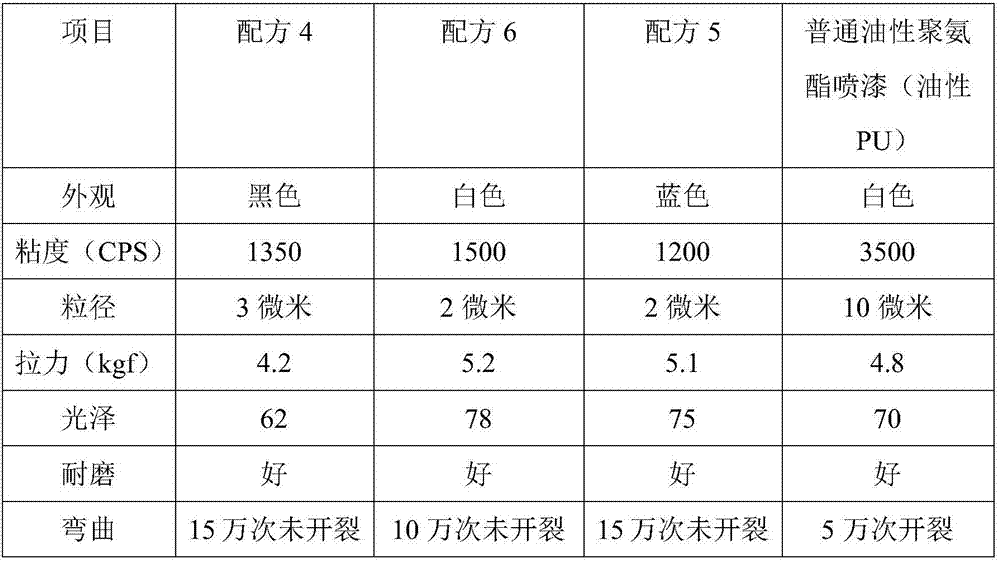

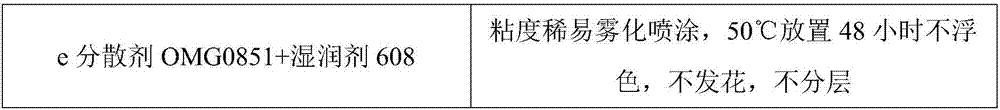

Waterborne polyurethane spray paint for fabric and shoe materials and preparation method of waterborne polyurethane spray paint

InactiveCN107418418AGood dispersionLow viscosityPolyurea/polyurethane coatingsEmulsion paintsDispersion stabilityBiological activation

The invention discloses waterborne polyurethane spray paint for fabric and shoe materials and a preparation method of the waterborne polyurethane spray paint. The waterborne polyurethane spray paint is prepared from components such as waterborne polyurethane, water, toner and auxiliaries. The spray paint is good in dispersion stability, high in dyeing degree, good in brilliance, easy to process, free of sagging, free of bubbles, good in levelling, physical property and activation property, easy for secondary processing and free of polishing, can be bent for 130 thousand times or more, and is especially suitable for materials such as the fabric and the shoe materials.

Owner:HUNAN XINLIHUA NANO TECH

Novel environment-friendly energy-saving wood-plastic composite board for truck carriages and preparation method of novel environment-friendly energy-saving wood-plastic composite board

The invention discloses a novel environment-friendly energy-saving wood-plastic composite board for truck carriages and a preparation method of the novel environment-friendly energy-saving wood-plastic composite board. The composite board is obtained by mixing wooden powder and HDPE (high-density polyethylene) resin with surface treating agent, processing auxiliaries, intensifier and compatilizer according to a certain proportion in a high-speed mixer by means of characteristics of high-polymer interface chemical principles and plastic filling modification, pelleting to obtain the composite board material through an extruder after mixing. The processed wood-plastic composite board material has the advantages of simple-substance materials including plastic, wood and metal and the like, can be used as bottom boards and retaining board of carriages of light trucks and van trucks and substitute for conventional wooden boards, bamboo plywood boards and steel boards, waterproof, mildew-proof and formaldehyde-free effect, improving grade of the trucks, environment friendliness and recycling of resources are realized.

Owner:ANHUI RED FOREST NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com