Non-cyanide bright electroplated silver composite additive and application method thereof in non-cyanide silver electroplating system

A technology of bright electroplating and inorganic additives, which is applied in the field of electroplating silver, can solve the problems of easy failure when exposed to light, narrow current density range, and narrow temperature window, so as to expand the working current density range, realize green environmental protection, and increase the electrodeposition speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

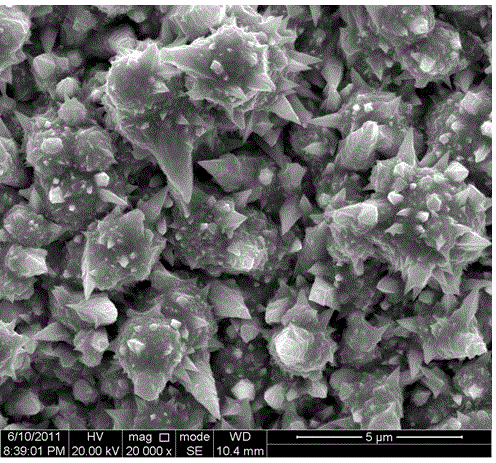

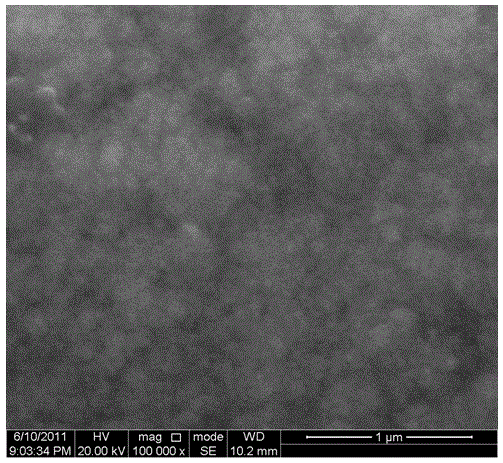

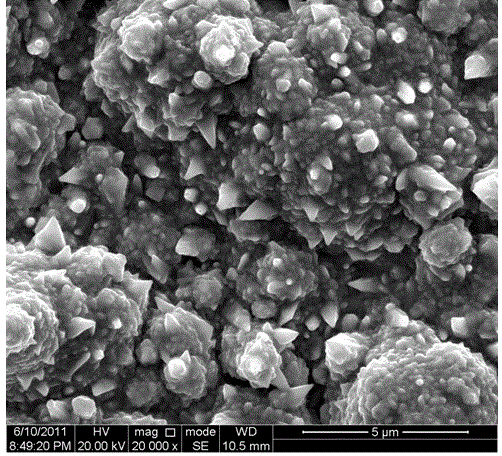

[0038] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the composition of the electroplating silver combination additive is as follows: polyethylene glycol 0.25g / L, 2,2-bipyridine 10g / L, polyethyleneimine 0.1g / L, tartaric acid 0.5g / L, barium nitrate 0.1g / L, lanthanum nitrate 0.05g / L, sodium selenite 1.25g / L to prepare cyanide-free electroplating silver plating combination additives, in the pre-plating silver process, in the plating The dosage of the additive in the liquid is 1~45ml / L. figure 1 It is the SEM picture of the electroplated silver coating without additives, figure 2 It is the SEM picture of the silver plating layer after adding the silver plating additive. Depend on figure 2 It can be seen that after electroplating with the additive provided in this embodiment, a silver plating layer with a macroscopic mirror gloss, uniform and flat appearance, uniform and dense microscopic crystals observed by SEM, no cracks, and...

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the silver electroplating composite additive is composed of: 5 g / L of succinimide, 1.5 g / L of 2-aminopyridine, and 3 g / L of uracil , sodium dodecylbenzene sulfonate 1g / L, potassium selenocyanate 1.0g / L, and copper manganate 0.1g / L are formulated as silver plating additives. L. After electroplating, a silver-plated layer with specular luster macroscopically, uniform and smooth appearance, uniform and dense microscopic crystals observed by SEM, no cracks, and excellent coating leveling ability observed by AFM is obtained.

specific Embodiment approach 4

[0040] Embodiment 4: The difference between this embodiment and Embodiment 2 is that the combined additive for electroplating silver is composed of: hypoxanthine 4.5g / L, piperonal 1.5g / L, thiourea 1.5g / L, hydroxyl Ethylethylenediaminetriacetic acid 3g / L, cadmium nitrate 0.5g / L, and sodium thiosulfate 0.25g / L were used to prepare the combined silver plating additives. The dosage of the additives in the high-speed silver plating process was 5~35ml / L. After electroplating, a silver-plated layer with specular luster macroscopically, uniform and smooth appearance, uniform and dense microscopic crystals observed by SEM, no cracks, and excellent coating leveling ability observed by AFM is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com