Patents

Literature

1031 results about "Solution composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

: In chemistry, a solution is a special type of homogeneous mixture composed of two or more substances. The term aqueous solution is when one of the solvents is water.[1] In such a mixture, a solute is a substance dissolved in another substance, known as a solvent.

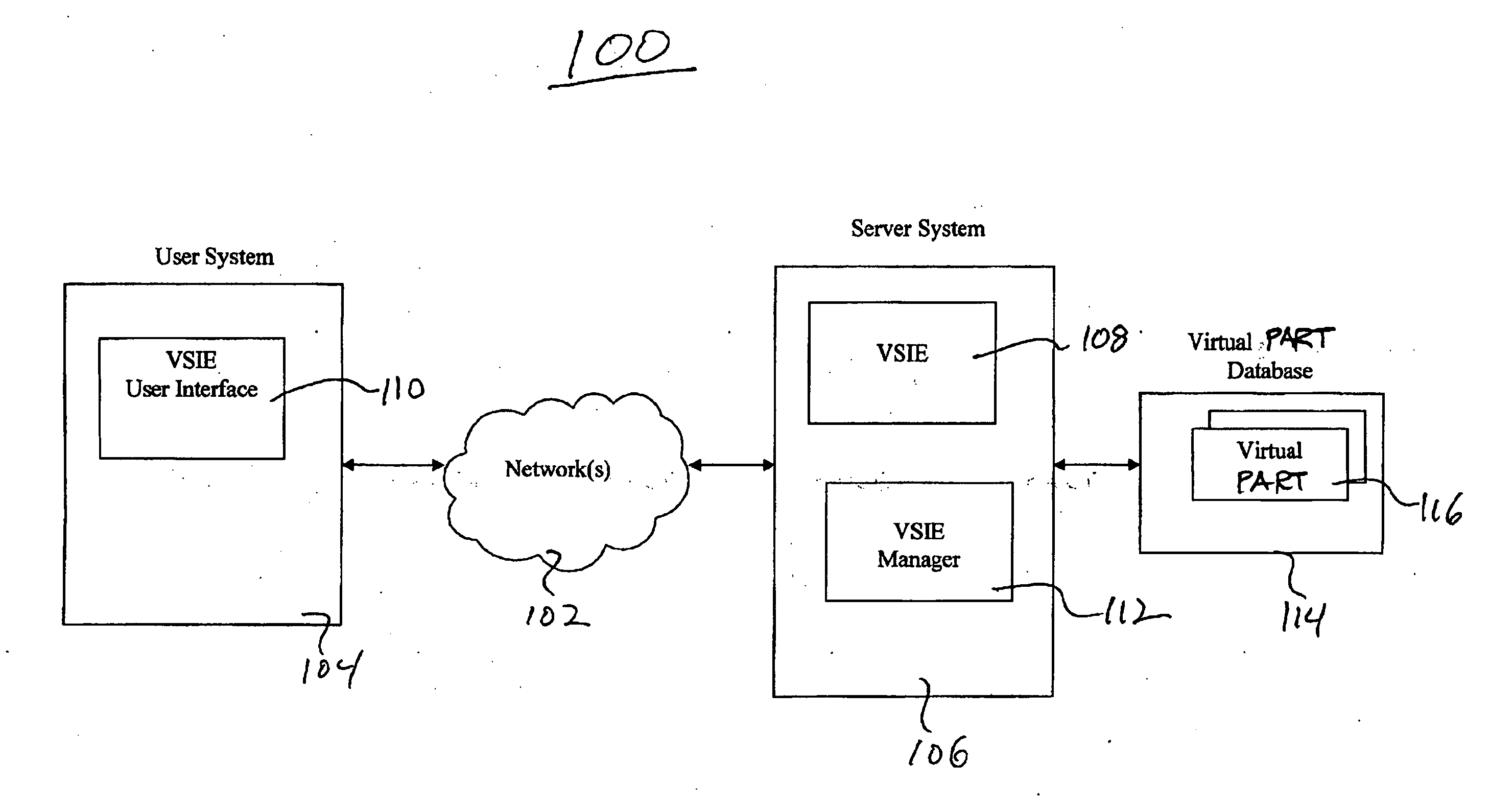

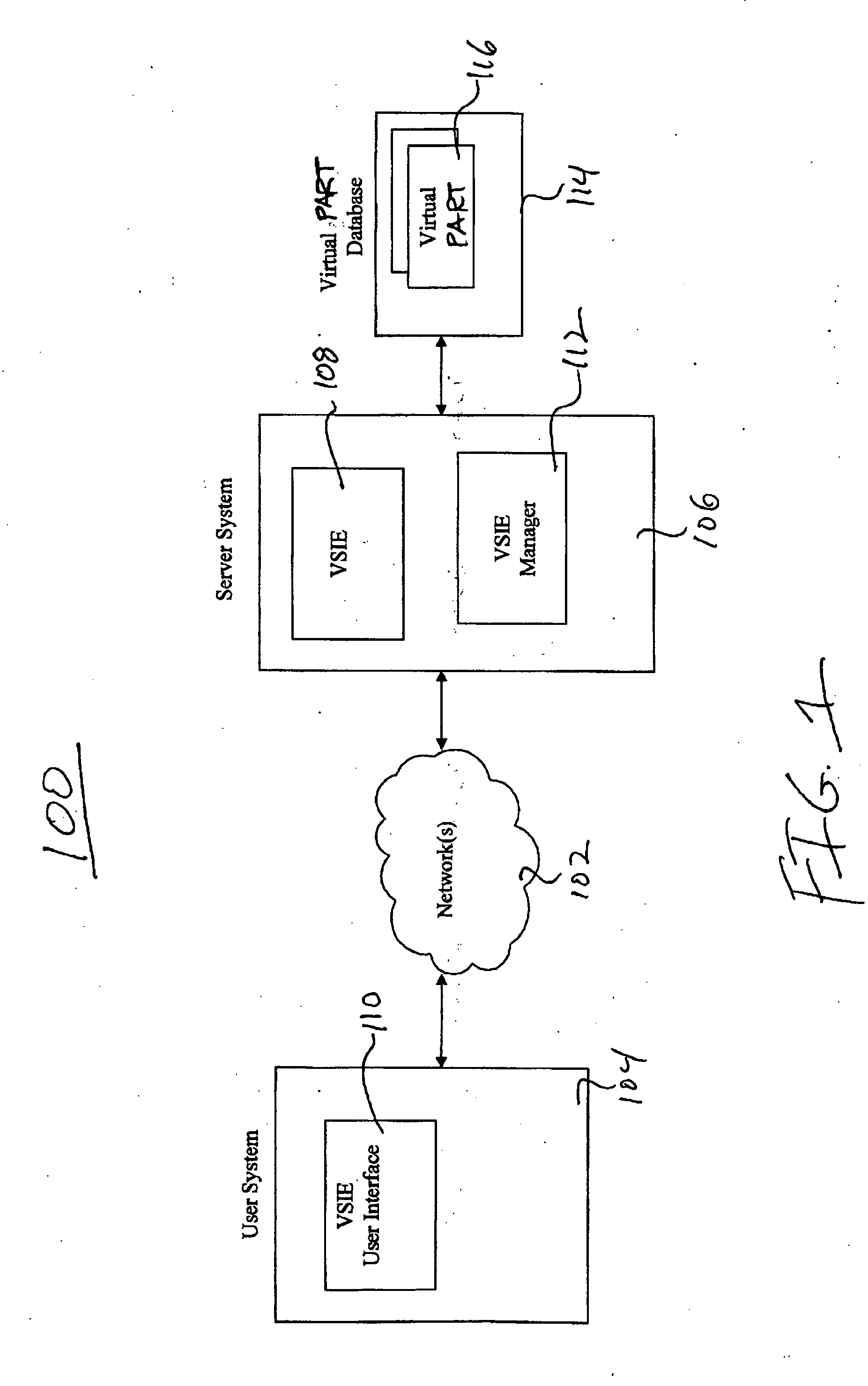

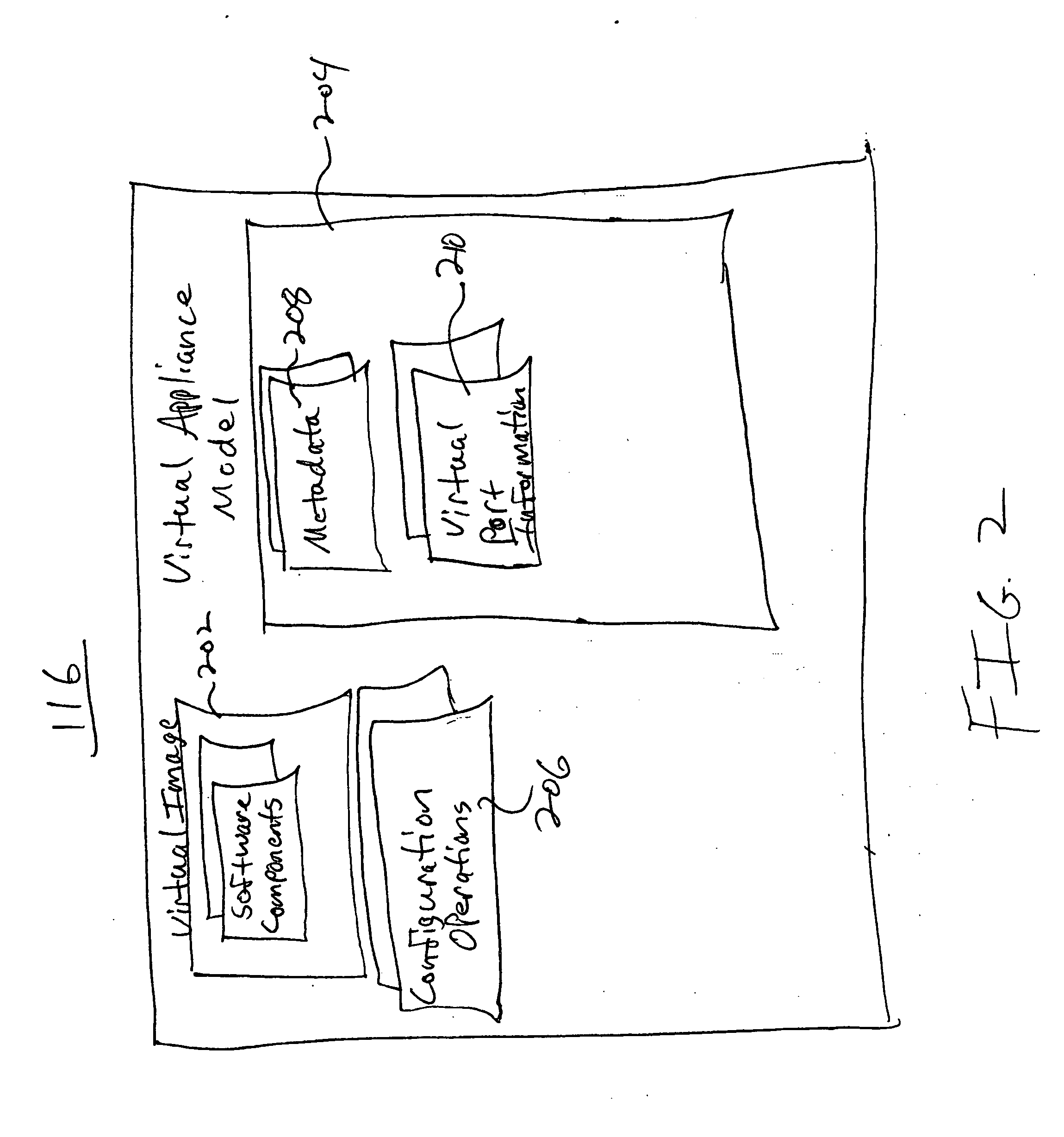

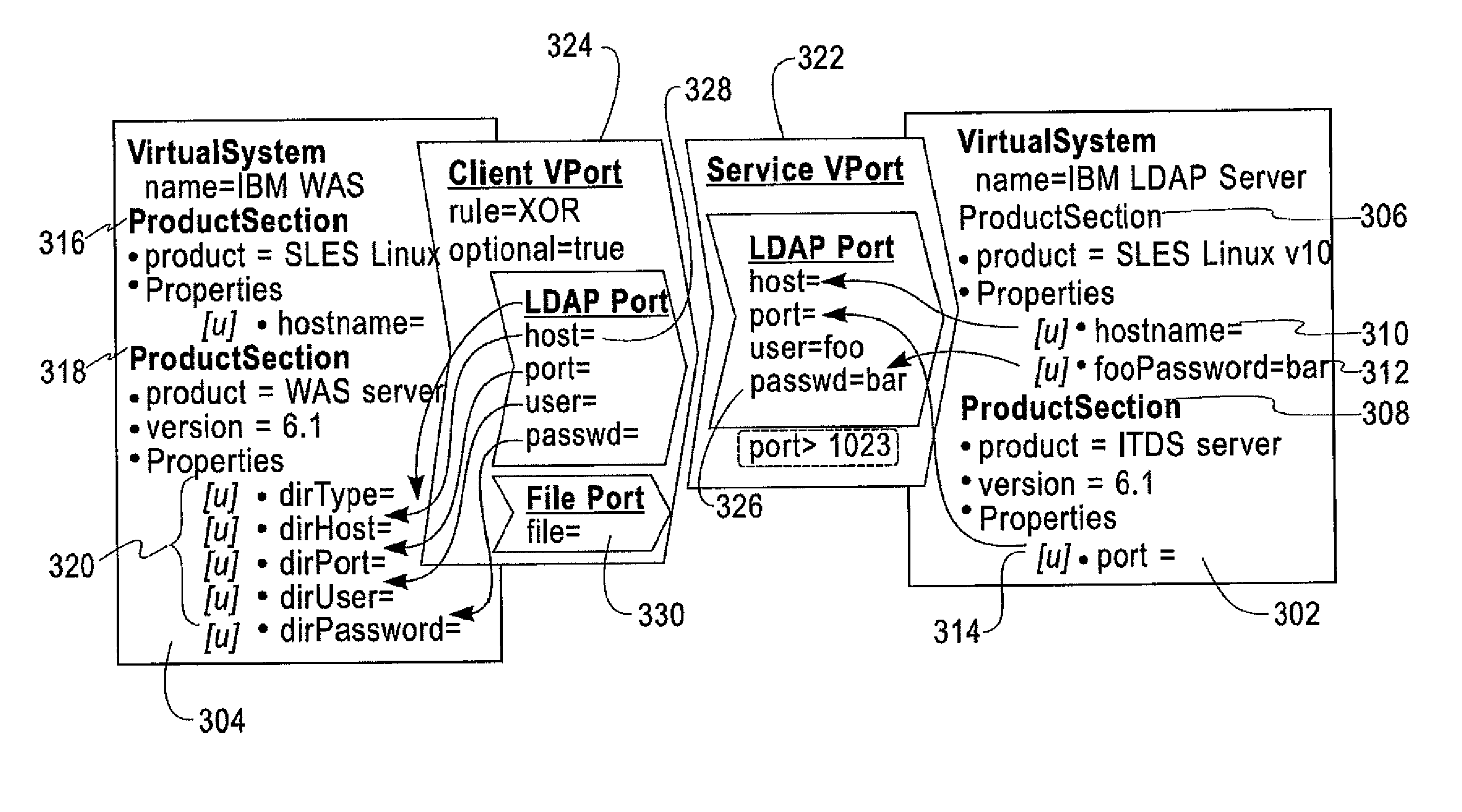

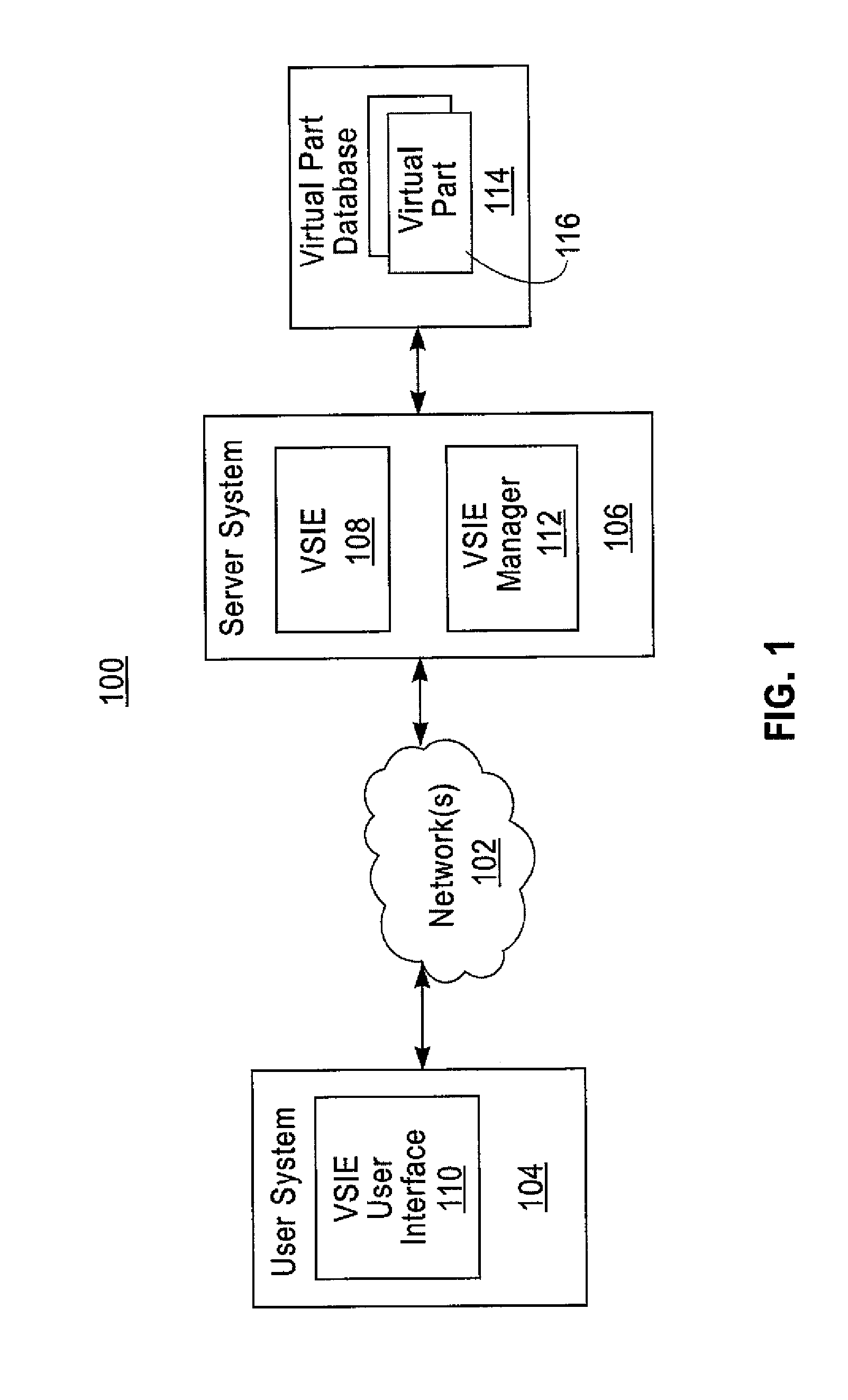

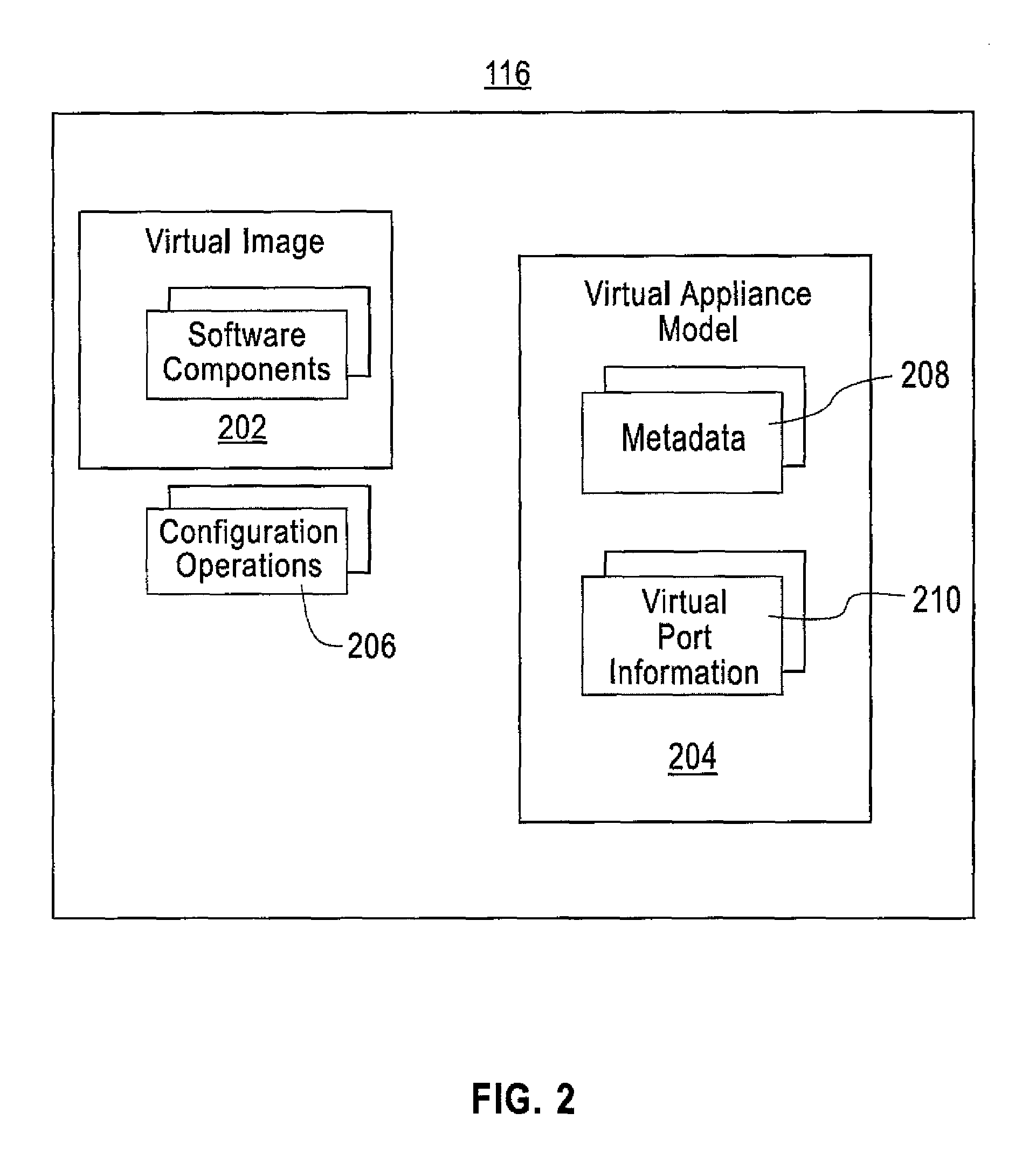

Virtual solution composition and deployment system and method

InactiveUS20100306772A1Multiprogramming arrangementsMultiple digital computer combinationsInformation processingInformation handling system

A method and information processing system are provided for creating a virtual part and for composing and deploying a virtual solution with one or more virtual parts. The virtual part includes: a virtual image including a set of compatible software components; a set of configurability points, each configurability point defining at least one parameter of the virtual part that is configurable; a set of virtual ports, wherein each virtual port indicates at least one of a set of virtual parts required by the virtual part and a set of virtual parts that are compatible with the virtual part; and a set of configuration scripts adapted to reconfigure the virtual image.

Owner:IBM CORP

Nasal delivery of cyclodextrin complexes of anti-inflammatory steroids

Aqueous, anti-inflammatory steroid compositions in solution form suitable for nasal administration and having a reduced stinging sensation are provided as well as a method for treating inflammation of the nasal mucosa by intranasal administration of anti-inflammatory steroid compositions. These solution compositions may result in enhanced nasal bio-availability. The anti-inflammatory steroid composition suitable for intranasal administration includes an anti-inflammatory steroid in an amount of from about 0.0001% to about 2.0% (w / v); a cyclodextrin in an amount of from about 0.1% to about 20% (w / v); an alcohol co-solvent in an amount of from about 0.2% to about 35% (w / v); a crystallization inhibitor where required, an effective amount of an antimicrobial preservative; an effective amount of an antioxidant; an effective amount of a chelating agent; water; and a pH adjusting agent sufficient to adjust the pH of the composition to from about 4 to about 7.

Owner:QPHARMA

Virtual solution composition and deployment system and method

InactiveUS8281307B2Multiprogramming arrangementsMultiple digital computer combinationsInformation processingInformation handling system

Owner:INT BUSINESS MASCH CORP

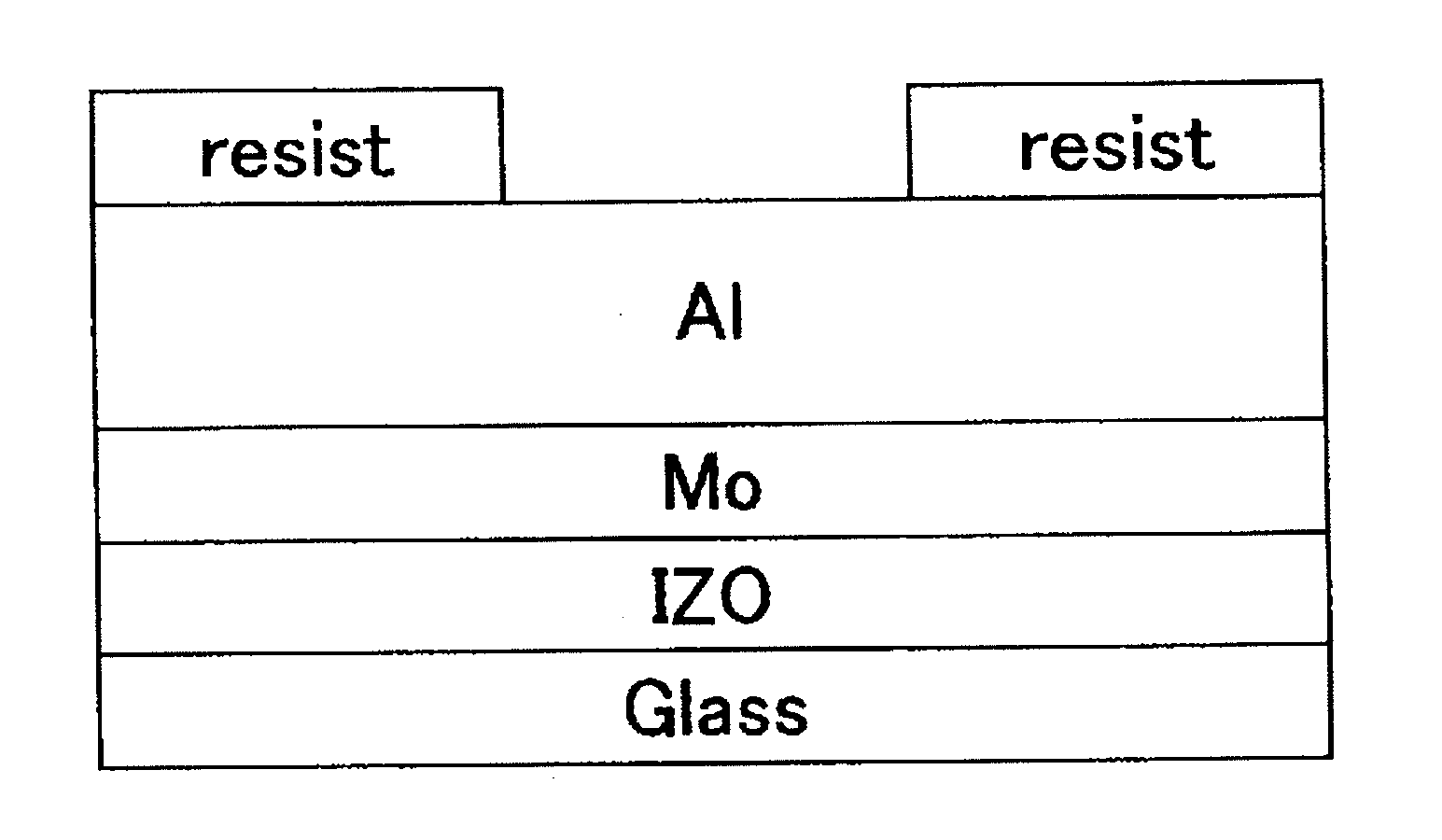

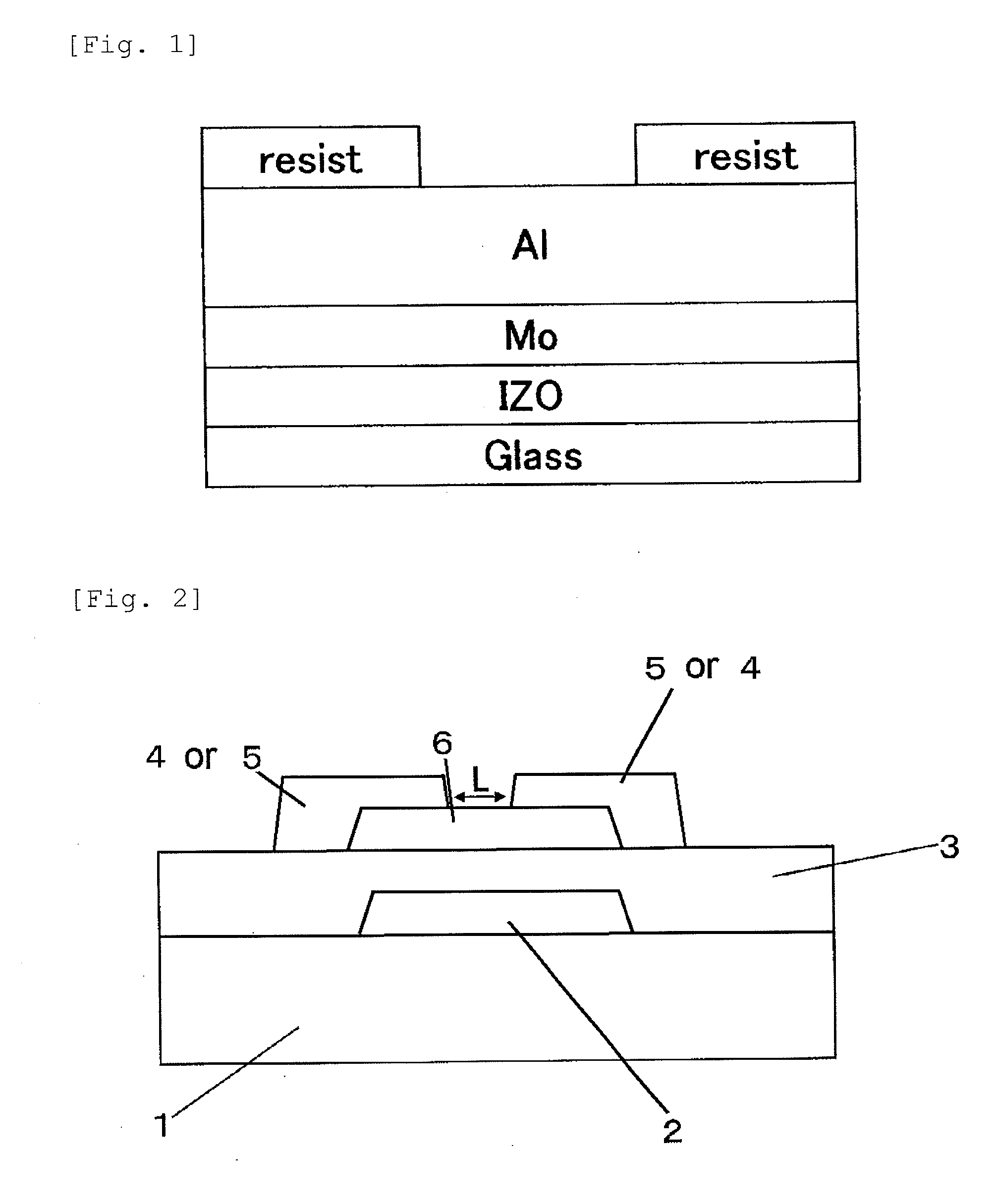

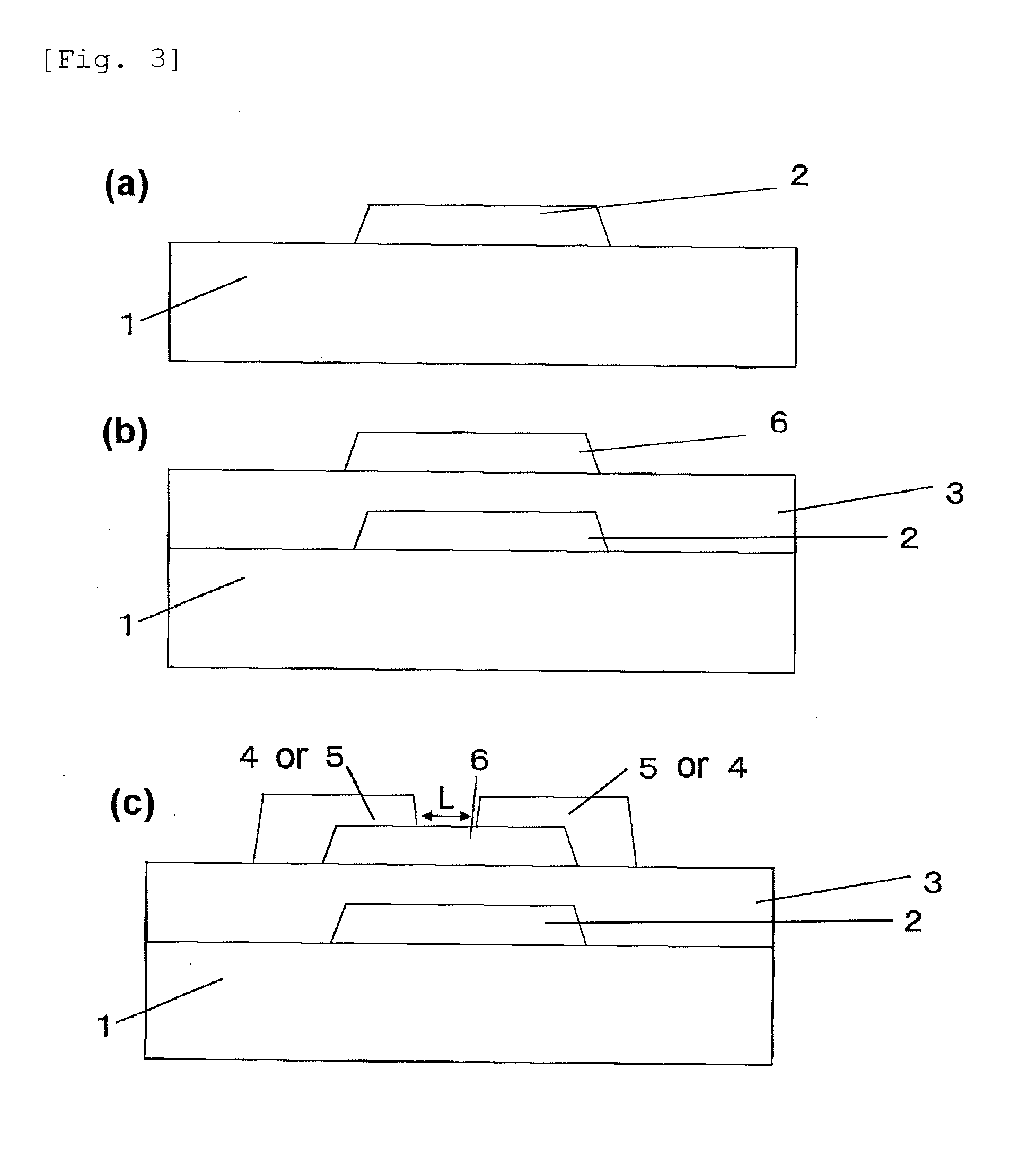

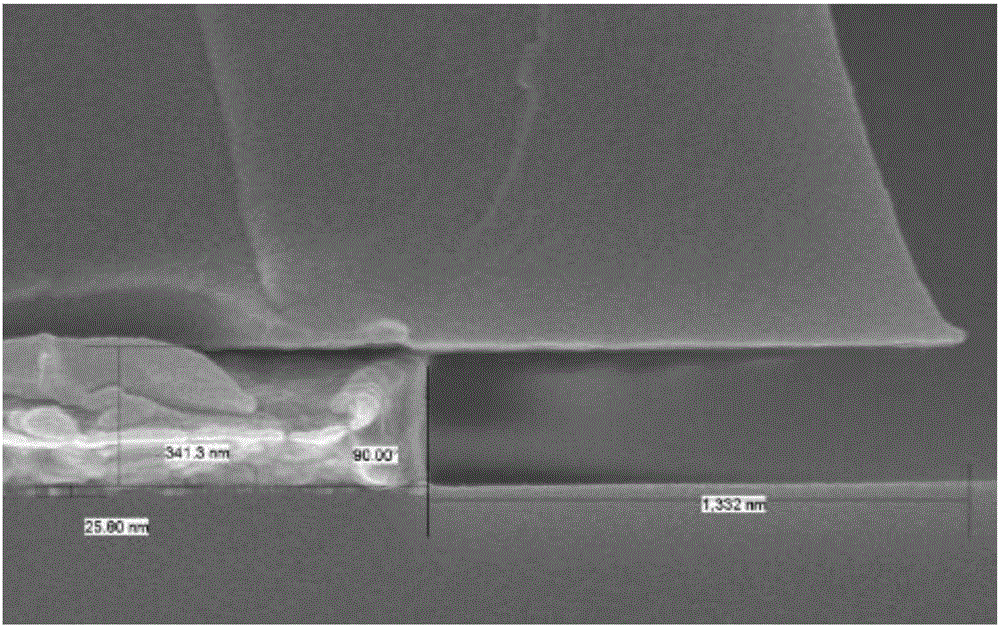

Etching solution composition

InactiveUS20100320457A1High selectivityImprove uniformity and stabilitySemiconductor/solid-state device manufacturingNon-linear opticsMetallurgyAlloy

Provided is an etching solution composition for selectively etching a metal film, which is composed of Al, Al alloy or the like and is arranged on an amorphous oxide film, from a laminated film including the metal film and an amorphous oxide film of various types. The etching solution composition is used for selectively etching the metal film from the laminated film which includes the amorphous oxide film and the metal film composed of Al, Al alloy, Cu, Cu alloy, Ag or Ag alloy, and is composed of an aqueous solution containing an alkali.

Owner:IDEMITSU KOSAN CO LTD +1

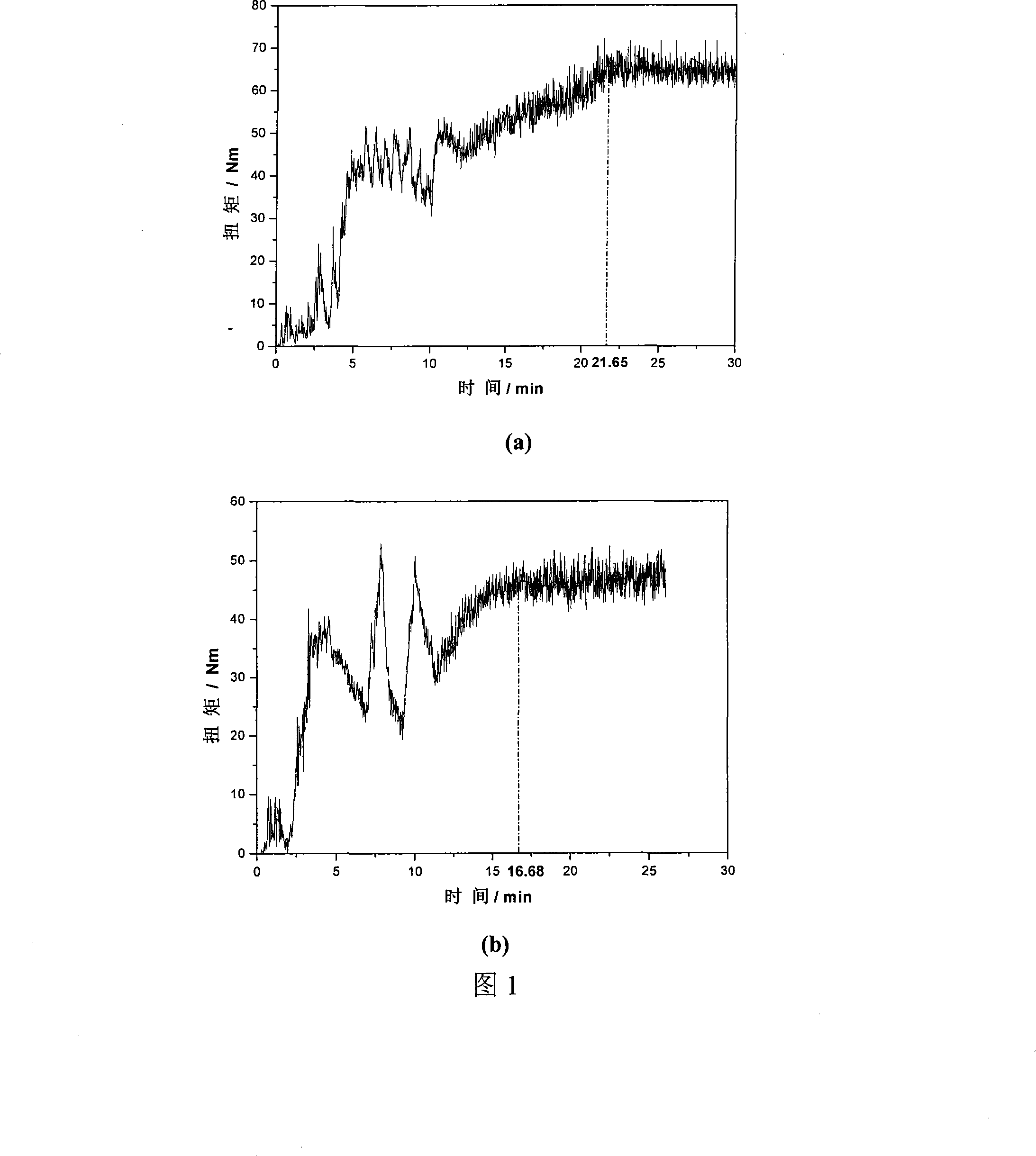

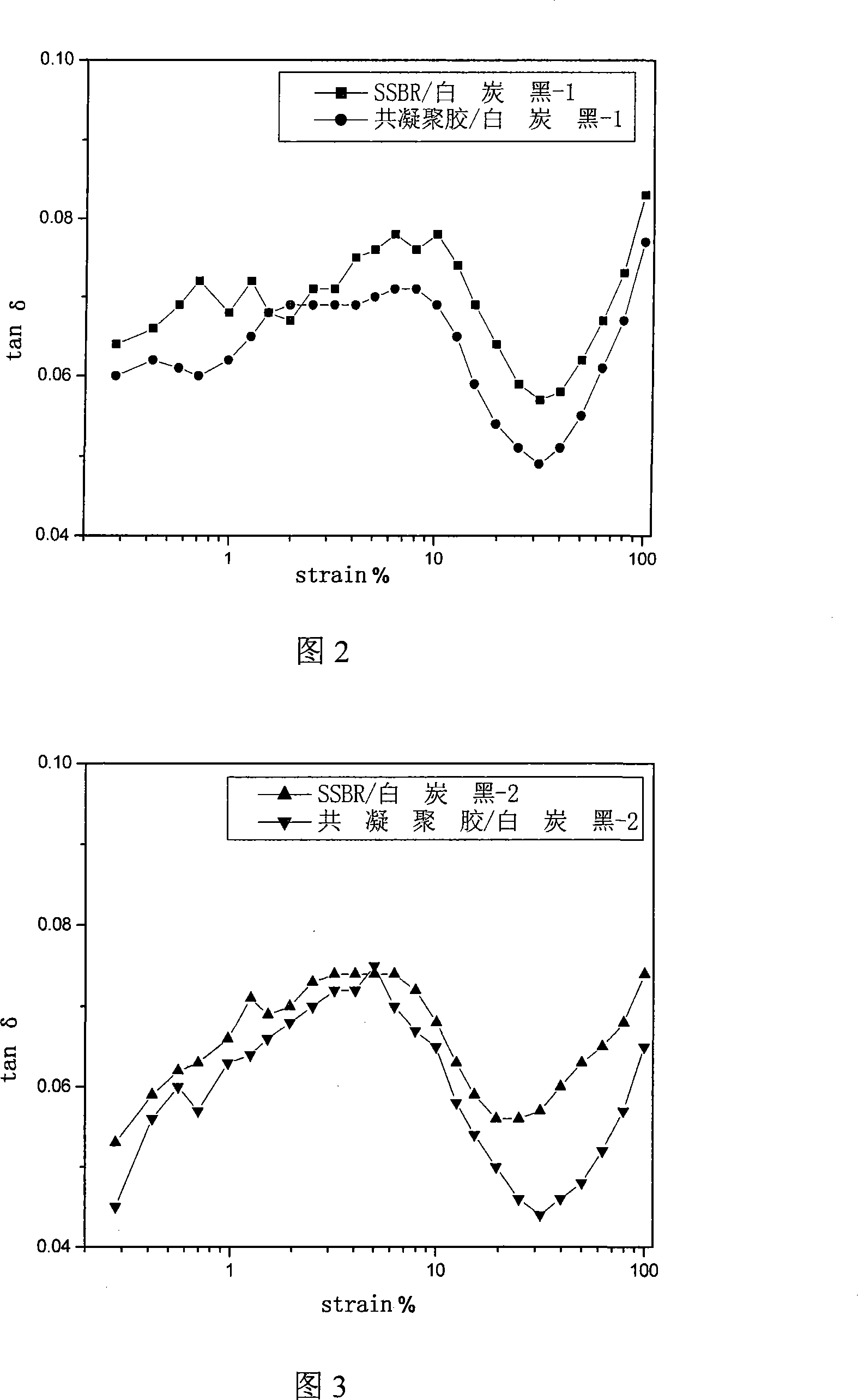

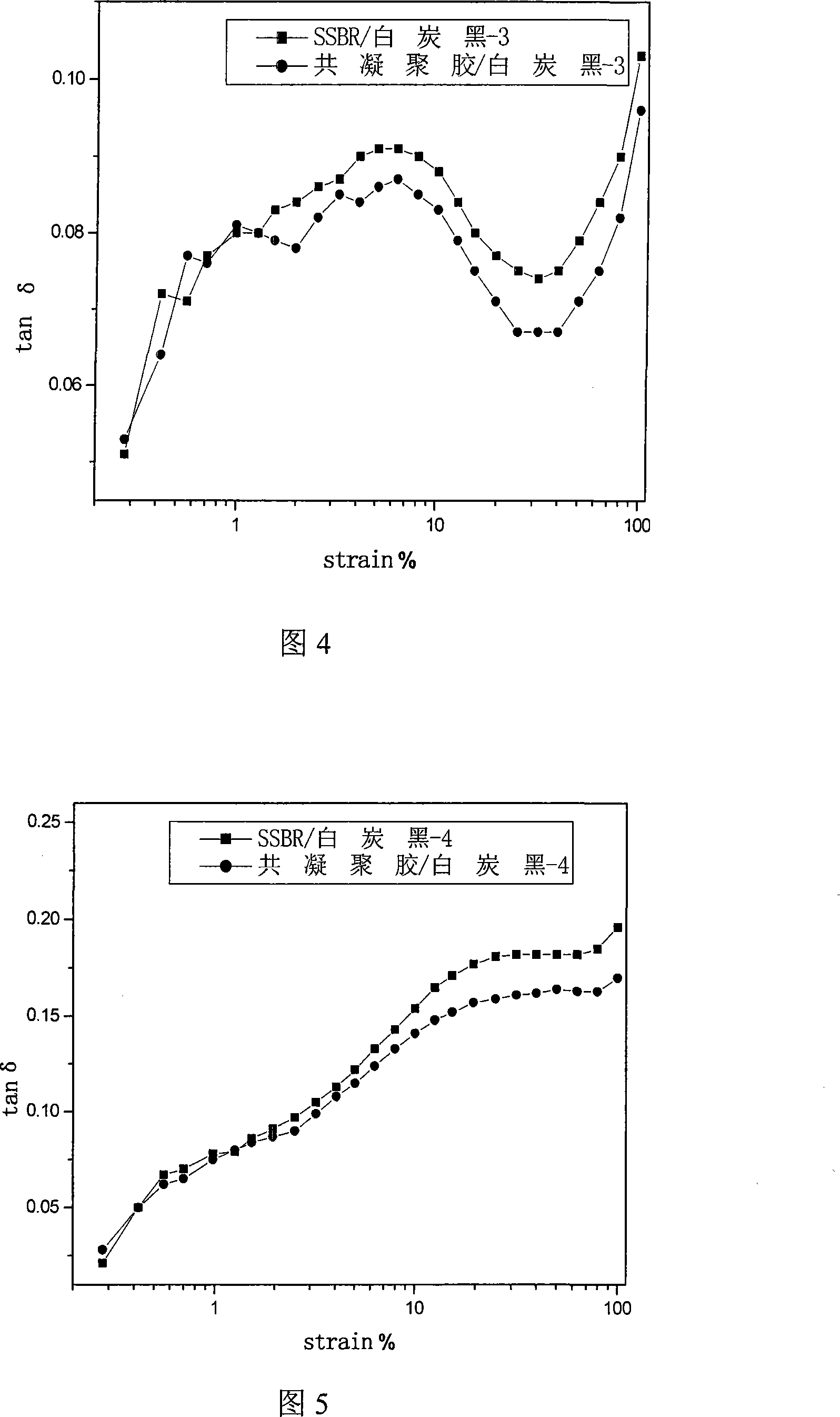

Process for producing white carbon black/solution polymerized butadiene styrene rubber nano-composite material

The invention relates to a method for preparing a white carbon black / solution-polymerized styrene-butadiene rubber nano composite material. In the invention, nano white carbon black powder and silane coupling agent are fully mixed and condensation reaction is carried out at high temperature, organic modified nano white carbon black powder is obtained and added into solution-polymerized styrene-butadiene; the mixture of the white carbon black powder and solution-polymerized styrene-butadiene is stirred and removes solvent and then dried, thus obtaining the silicon dioxide / solution-polymerized styrene-butadiene rubber nano composite material prepared by co-polymerization. The invention expands the range of methods for preparing the nano composite material with solution composition. The adopted method using the organically modified white carbon black is simple and easy for operation and the solution composite technique is fast and convenient with low cost. The prepared co-polymerized rubber can be taken as master batch and is added with the white carbon black or added with other fillings for preparing novel nano composite material. The physical and mechanical properties and dynamic mechanical property of the rubber prepared by the method are better than the properties of coordinative amount of filling prepared by mechanical mixing method and the composition speed of subsequent fillings of the rubber prepared by the method is faster than that prepared by the mechanical method.

Owner:BEIJING UNIV OF CHEM TECH

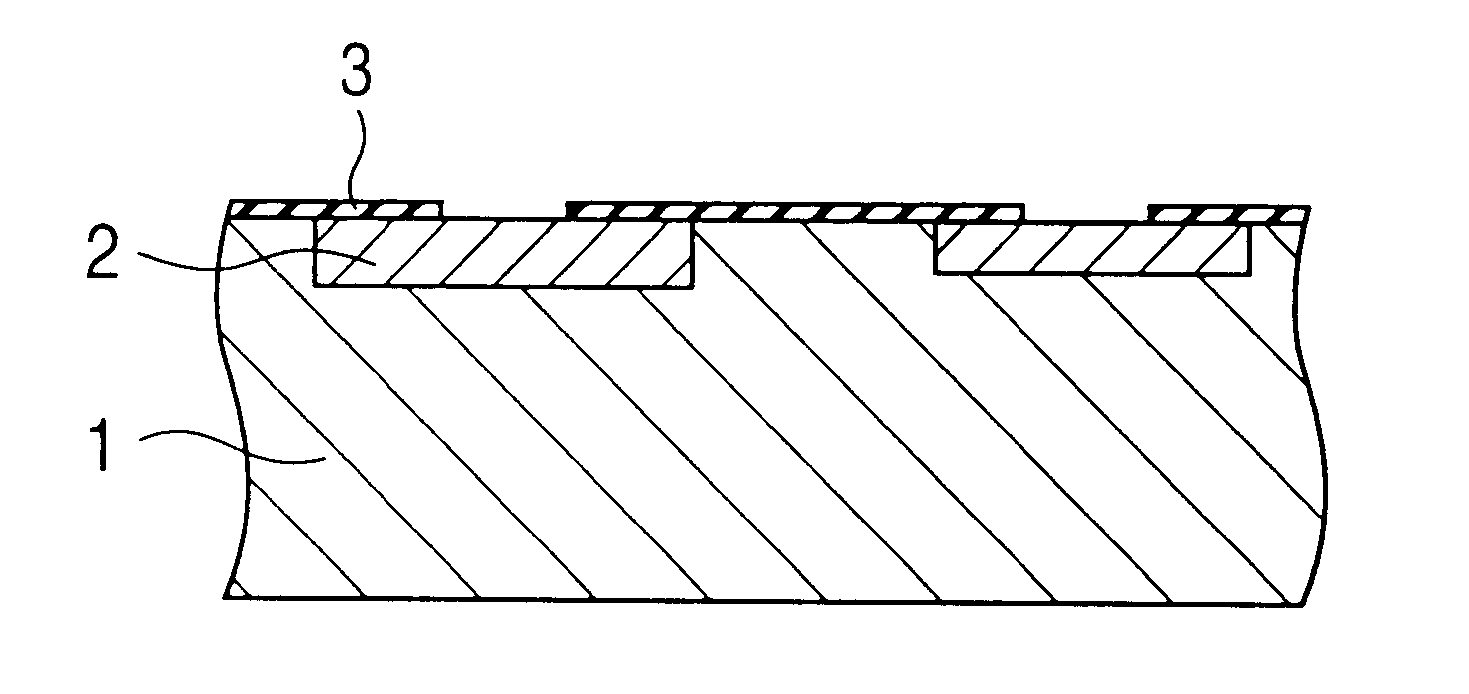

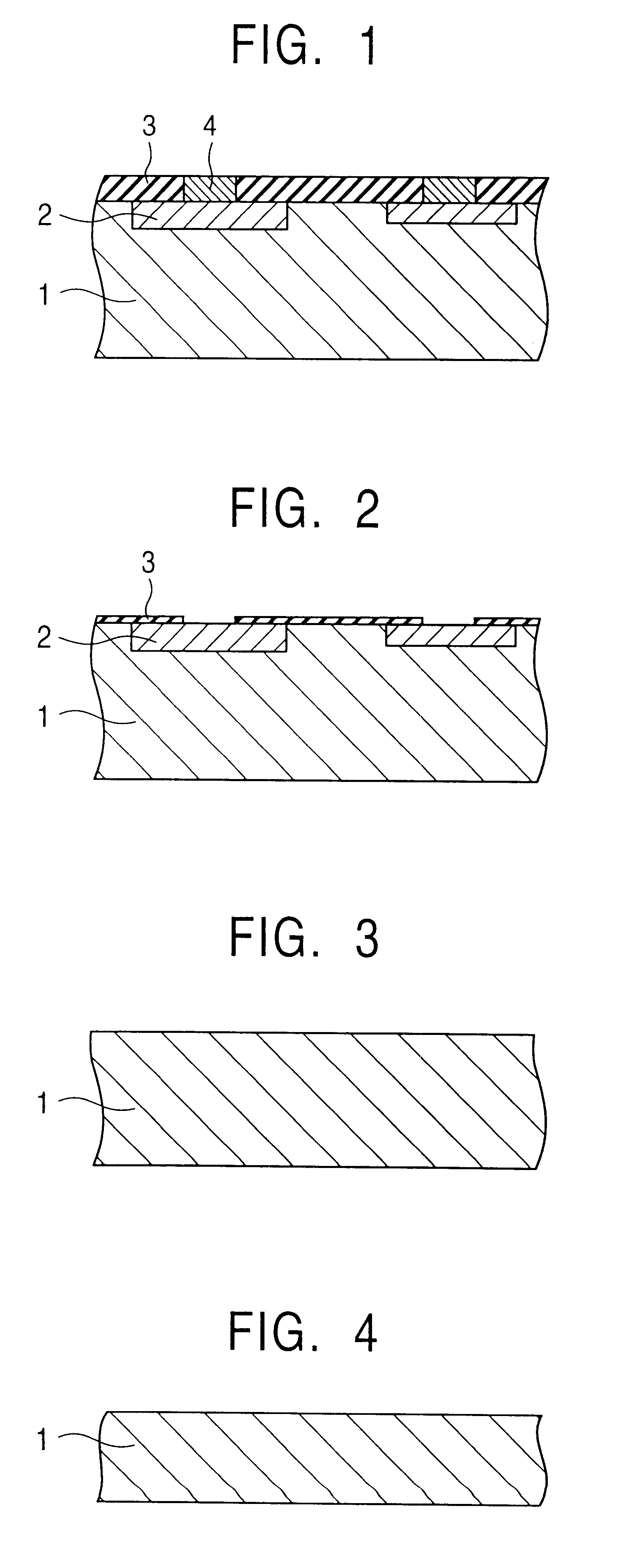

Method for reclaiming wafer substrate and polishing solution compositions therefor

InactiveUS6451696B1Extension of timeReduce thicknessSemiconductor/solid-state device manufacturingDielectric layerMetal

A method for reclaiming a wafer substrate material having a metallic film and a dielectric film includes a step for removing the entire metallic film and a part of the dielectric film with a chemical etching agent so as not to substantially dissolve the wafer substrate material itself, a step for removing the residual dielectric layer and the degenerated zone beneath the surface of the substrate by chemical-mechanical polishing, and a step for polishing at least one surface of the substrate.

Owner:KOBE STEEL LTD

High pH antiperspirant compositions of enhanced efficacy

InactiveUS7087220B2Good curative effectIncrease valueCosmetic preparationsToilet preparationsIrritationStrontium

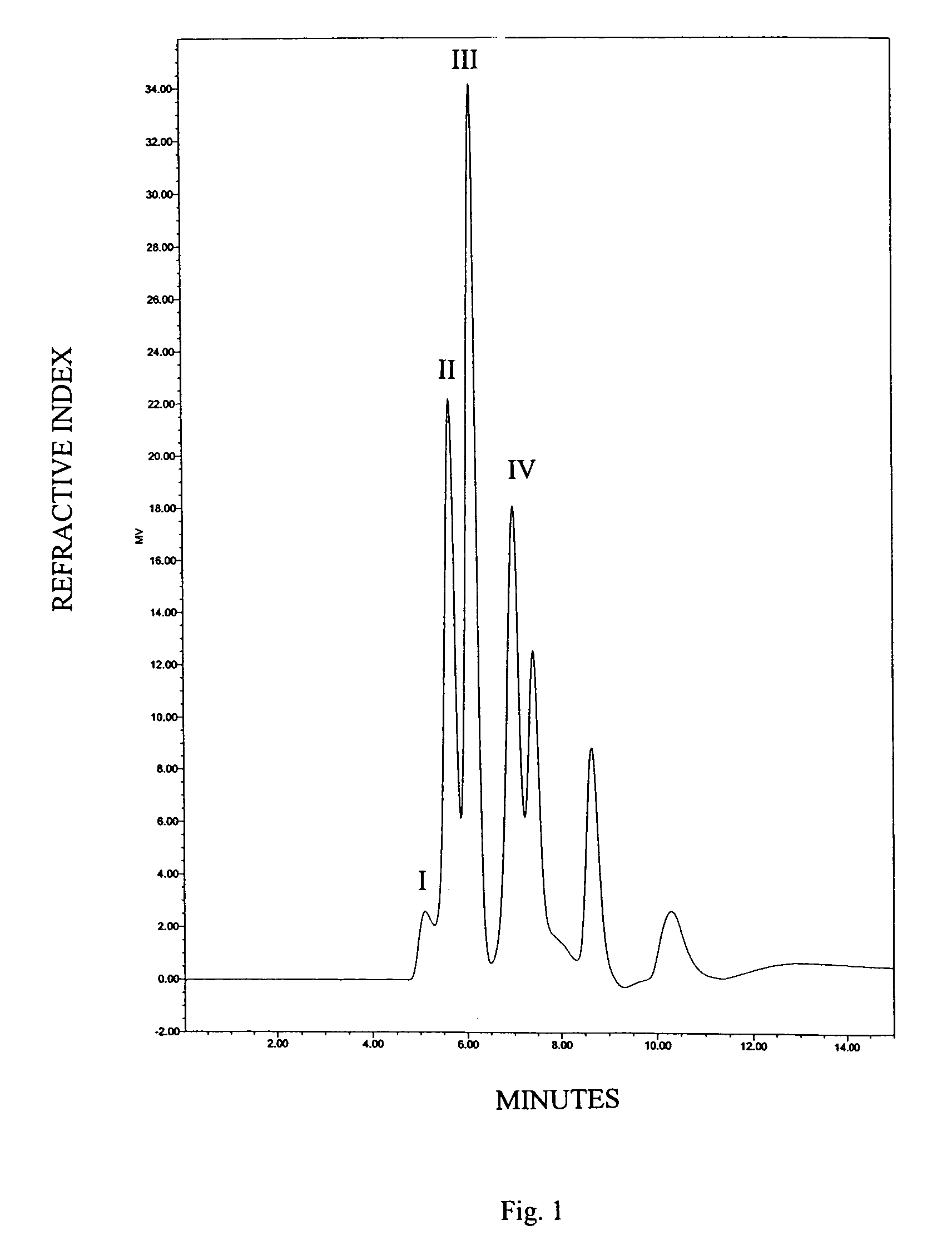

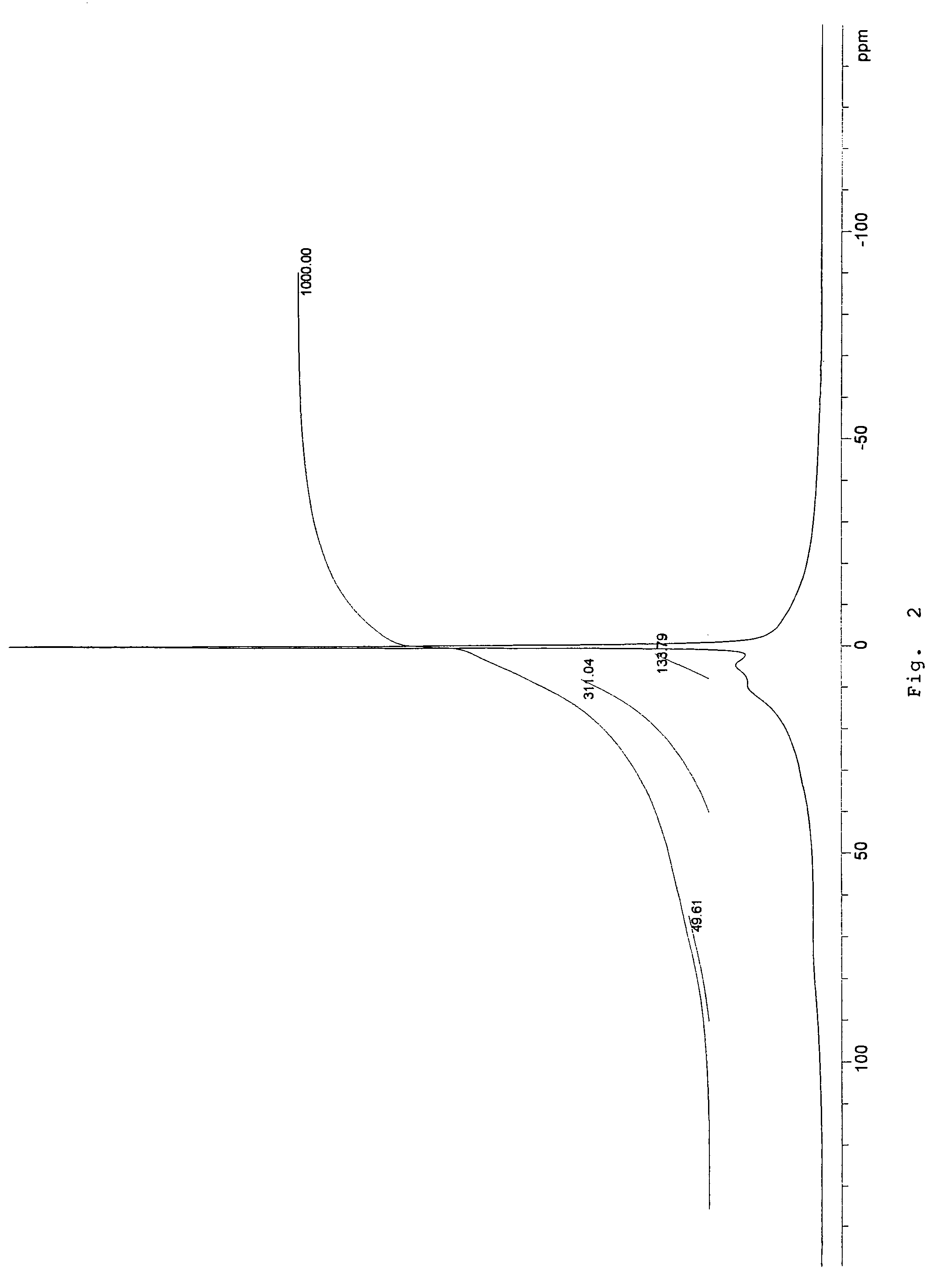

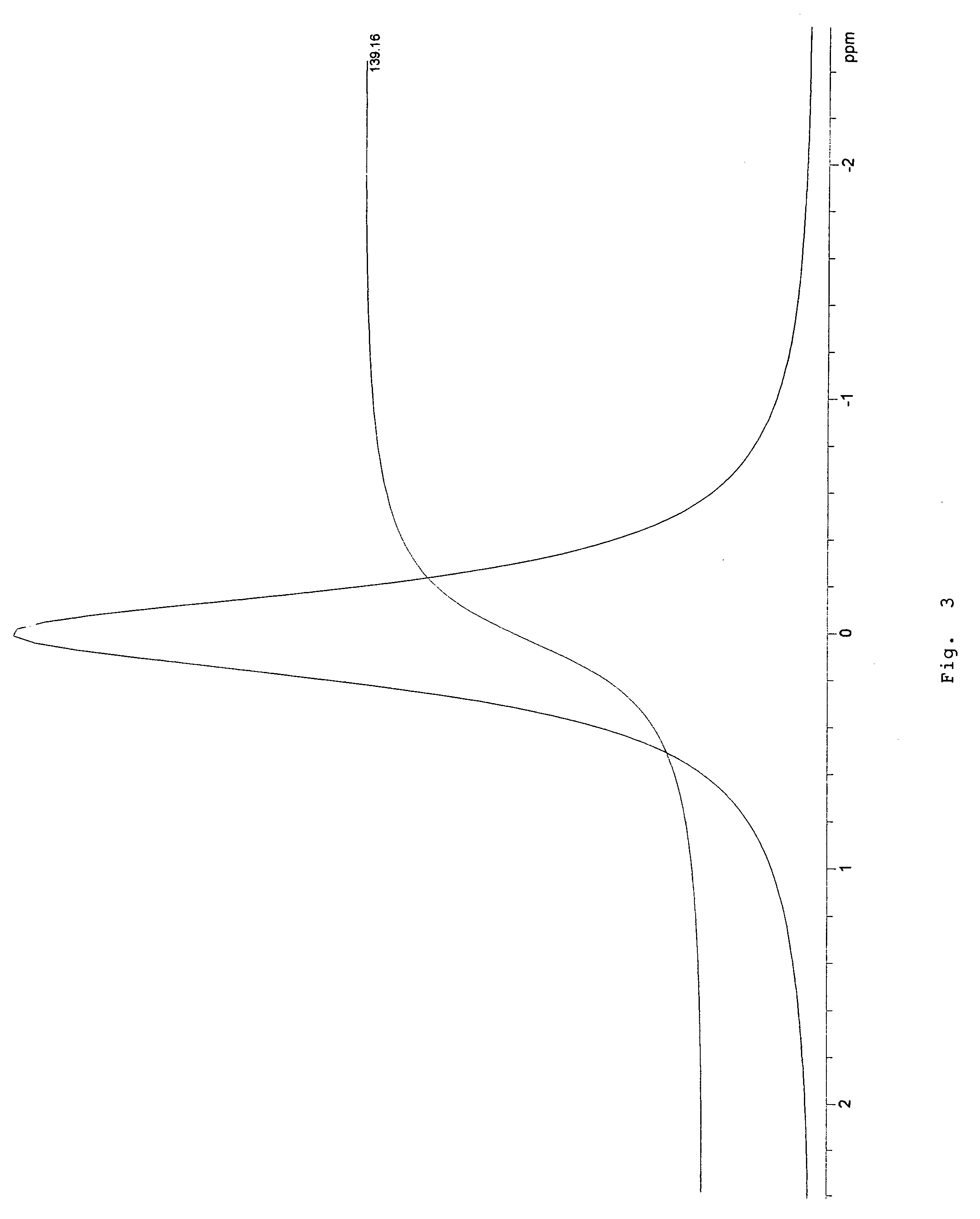

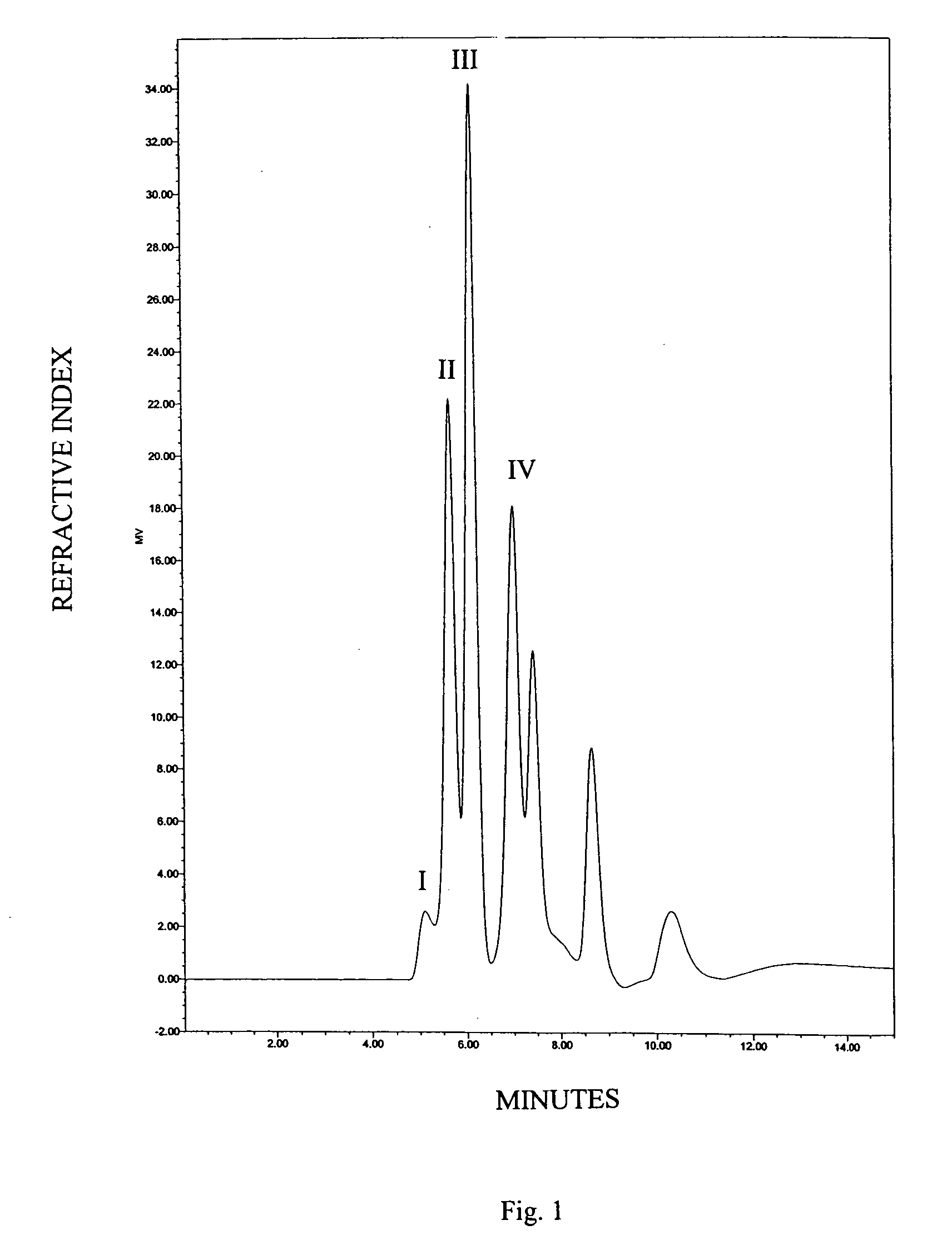

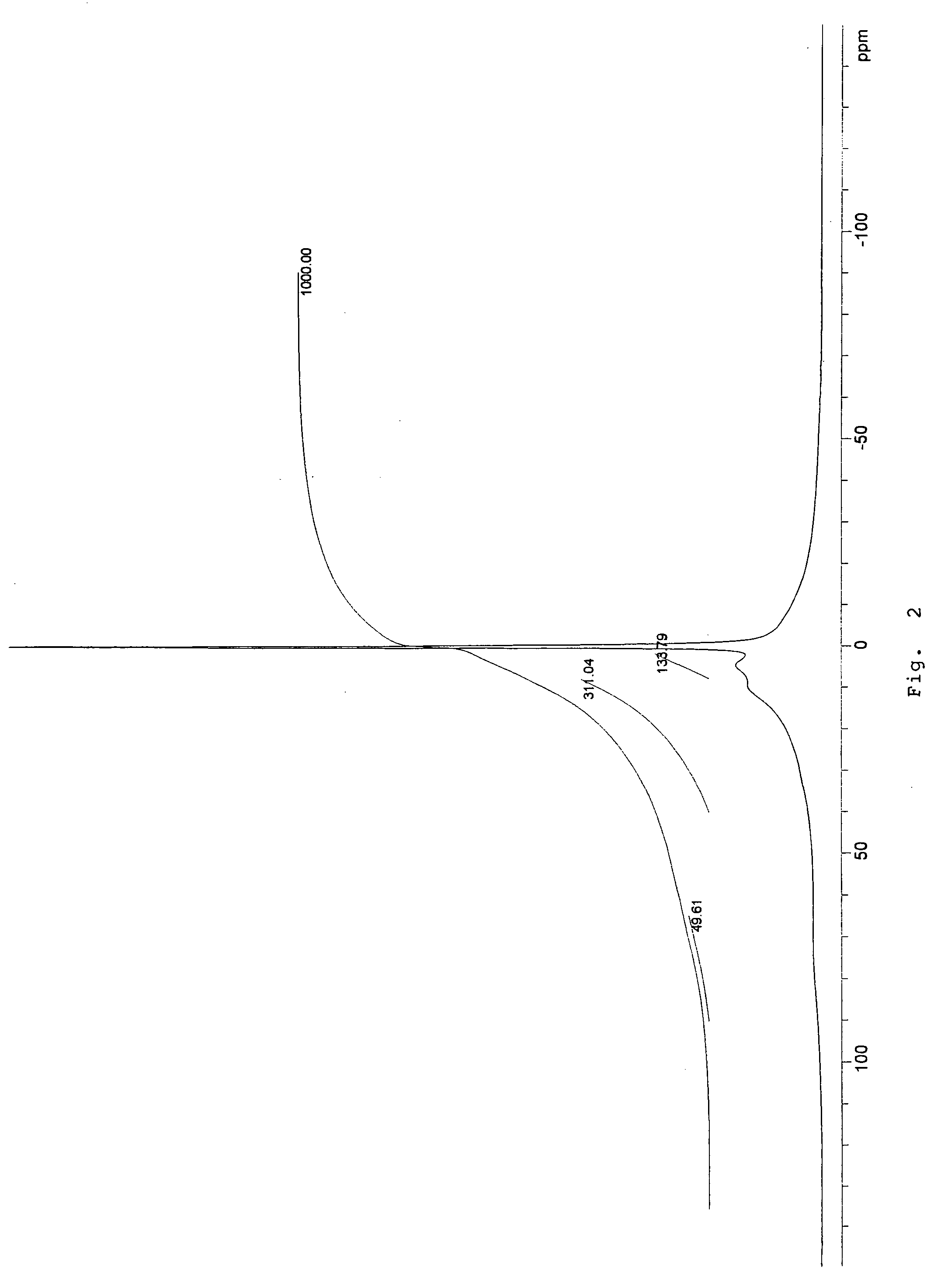

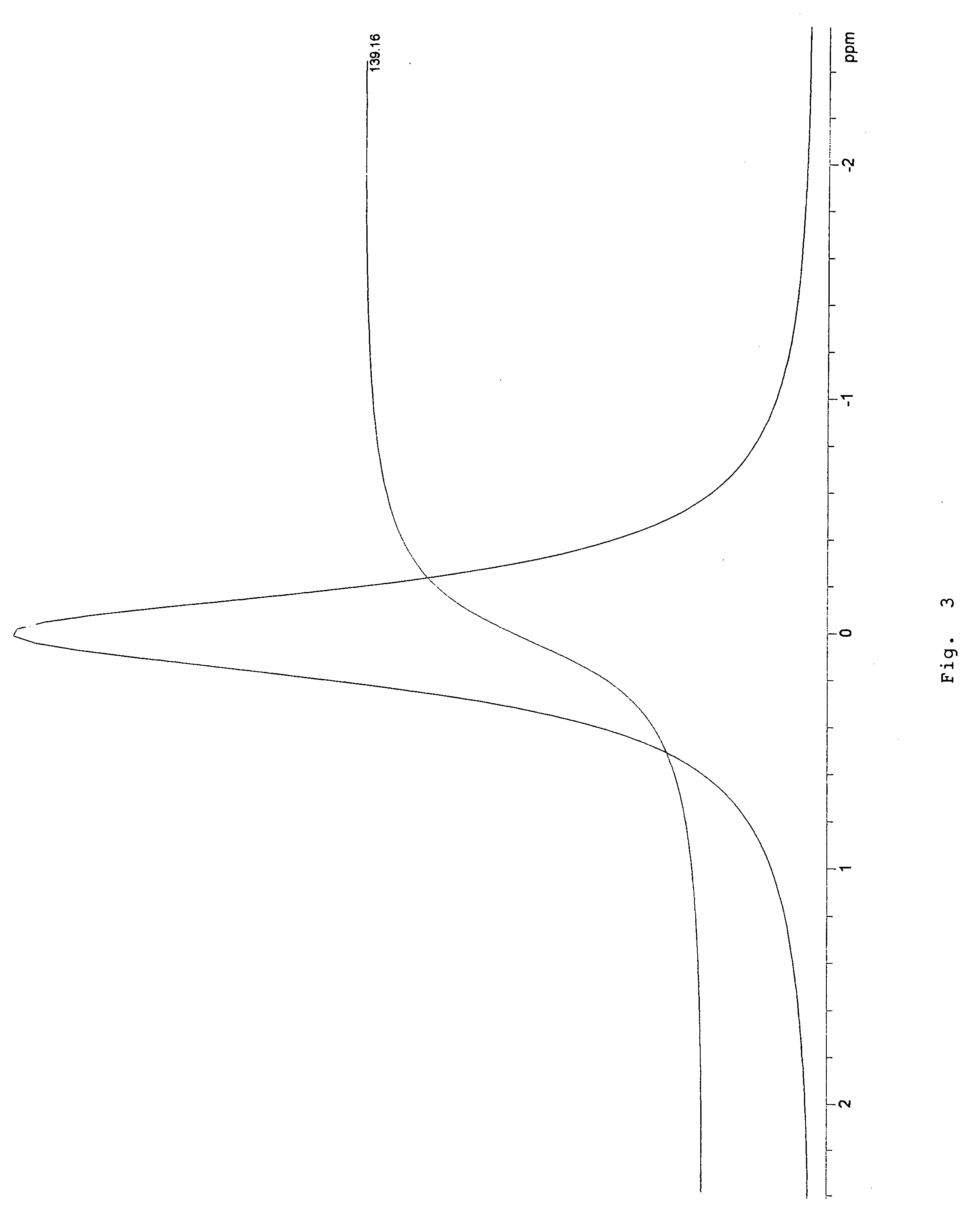

Aluminum and aluminum-zirconium antiperspirant compositions of enhanced efficacy and a pH value of at least 3.5 are provided that are made by reaction with insoluble, strongly alkaline strontium or calcium salts. The aluminum and aluminum-zirconium strontium or calcium compositions show high pH values with characteristic HPLC Band III to Band II ratios of at least 0.5. The basic aluminum halohydrate (or nitrate) solutions typically have aluminum to anion ratio of less that 1.9. The solution compositions are stable with respect to both HPLC Band III to Band II ratio and viscosity at concentrations of about 20% to about 40% by weight of anhydrous solid. The solid state compositions form hard sticks with low irritation, at low metal to chloride ratios of about 0.9 to about 1.2.

Owner:SUMMIT RES LAB

High pH antiperspirant compositions of enhanced efficacy

InactiveUS20050265939A1Good curative effectGreat enhanced efficacyCosmetic preparationsToilet preparationsAntiperspirantsIrritation

Aluminum and aluminum-zirconium antiperspirant compositions of enhanced efficacy and a pH value of at least 3.5 are provided that are made by reaction with insoluble, strongly alkaline strontium or calcium salts. The aluminum and aluminum-zirconium strontium or calcium compositions show high pH values with characteristic HPLC Band III to Band II ratios of at least 0.5. The basic aluminum halohydrate (or nitrate) solutions typically have aluminum to anion ratio of less that 1.9. The solution compositions are stable with respect to both HPLC Band III to Band II ratio and viscosity at concentrations of about 20% to about 40% by weight of anhydrous solid. The solid state compositions form hard sticks with low irritation, at low metal to chloride ratios of about 0.9 to about 1.2.

Owner:SUMMIT RES LAB

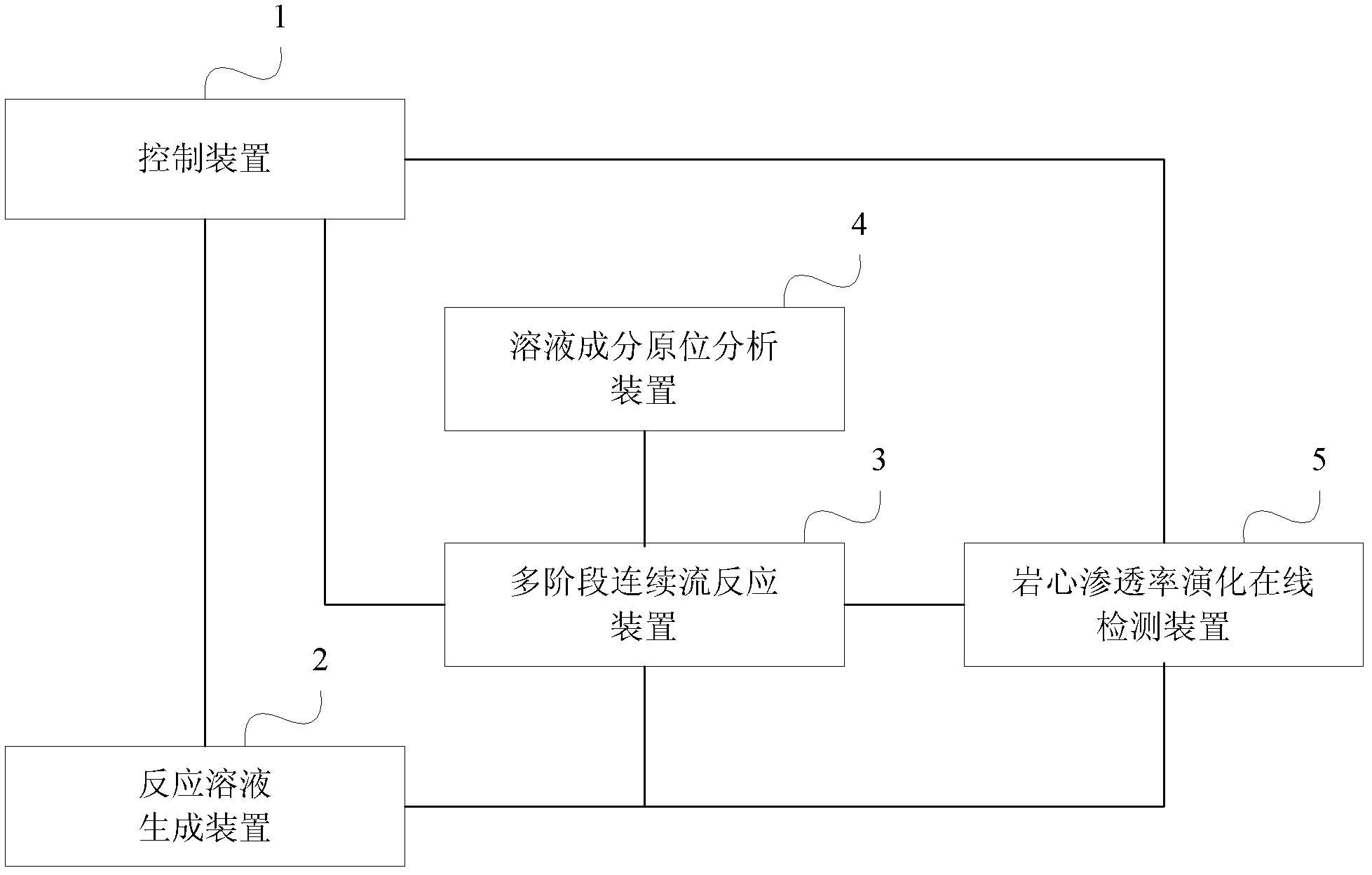

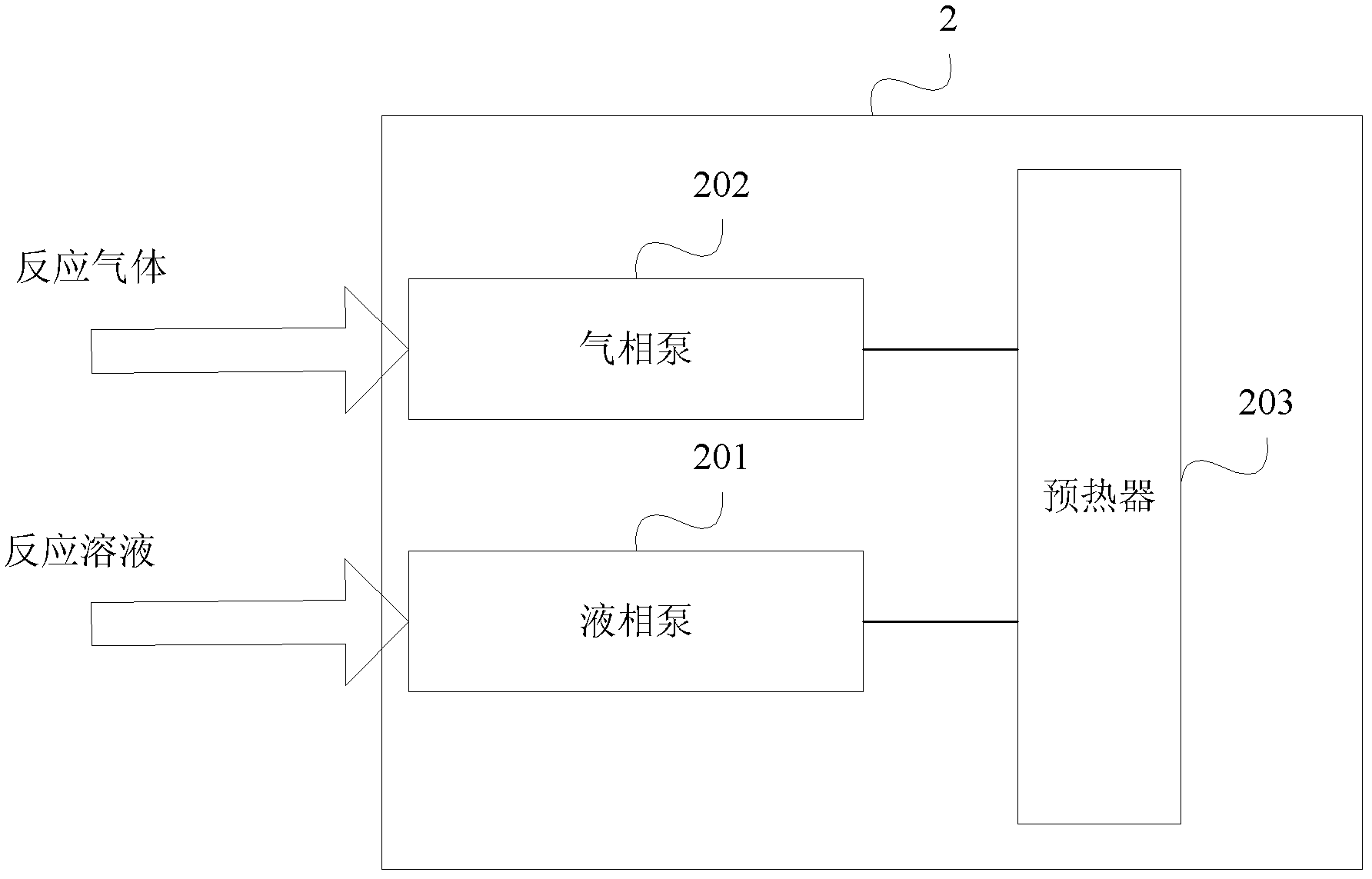

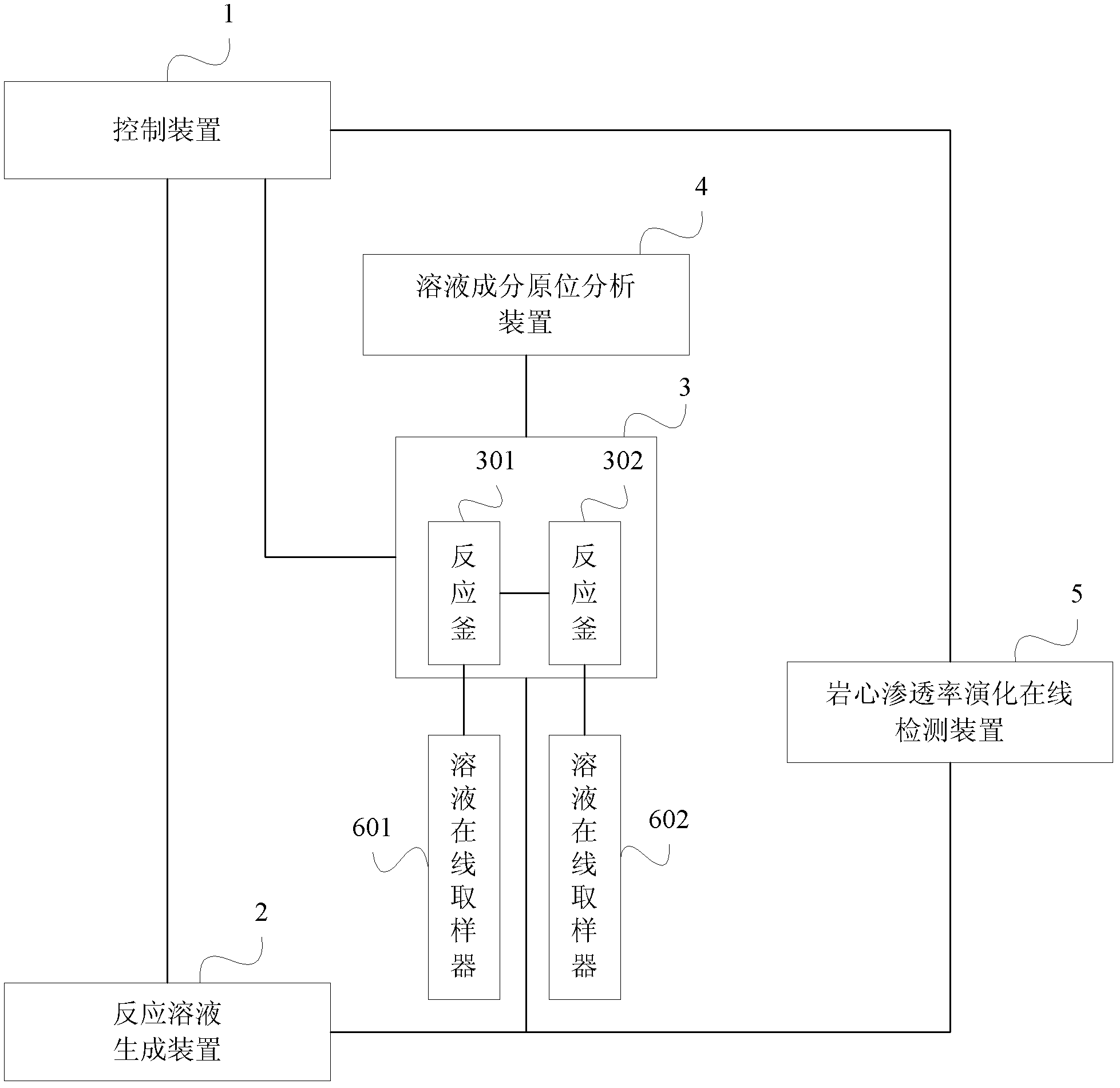

Diagenesis simulation experiment device

ActiveCN102435716AEffective simulationAchieve Retrofit EfficiencyEarth material testingColor/spectral properties measurementsEngineeringContinuous flow

The embodiment of the invention provides a diagenesis simulation experiment device, which contains a control device, a reaction solution supply device, a multistage continuous flow reaction device, a solution composition in situ analysis device and a core permeability evolution online detection device. The control device is respectively connected with the reaction solution supply device, the multistage continuous flow reaction device and the core permeability evolution online detection device. The reaction solution supply device is respectively connected with the multistage continuous flow reaction device and the core permeability evolution online detection device. The multistage continuous flow reaction device is connected with the solution composition in situ analysis device. The core permeability evolution online detection device is respectively connected with the multistage continuous flow reaction device and the reaction solution supply device. The diagenesis simulation experiment device provided by the invention can be used to finish more than two stages of water-rock reaction processes at different temperatures and pressures and under the condition of maintaining continuous flow of a fluid and realize continuous multistage water-rock reaction experimental simulation.

Owner:PETROCHINA CO LTD

Aqueous polyimide precursor solution composition and method for producing aqueous polyimide precursor solution composition

InactiveUS20130171520A1High environmental acceptabilityEasy to produceElectrolytic capacitorsHybrid capacitor electrodesSolubilitySolvent

A method for producing an aqueous polyimide precursor solution composition, including reacting a tetracarboxylic dianhydride and a diamine, which has a solubility in water at 25° C. of 0.1 g / L or more, in the presence of an imidazole, using water as a reaction solvent to provide an aqueous polyimide precursor solution composition.

Owner:UBE IND LTD

Novel cellular factor-containing solution compositions

InactiveUS20090054339A1Low variabilityLow production costAntibacterial agentsBiocideBiologySolution composition

Owner:STEMNION

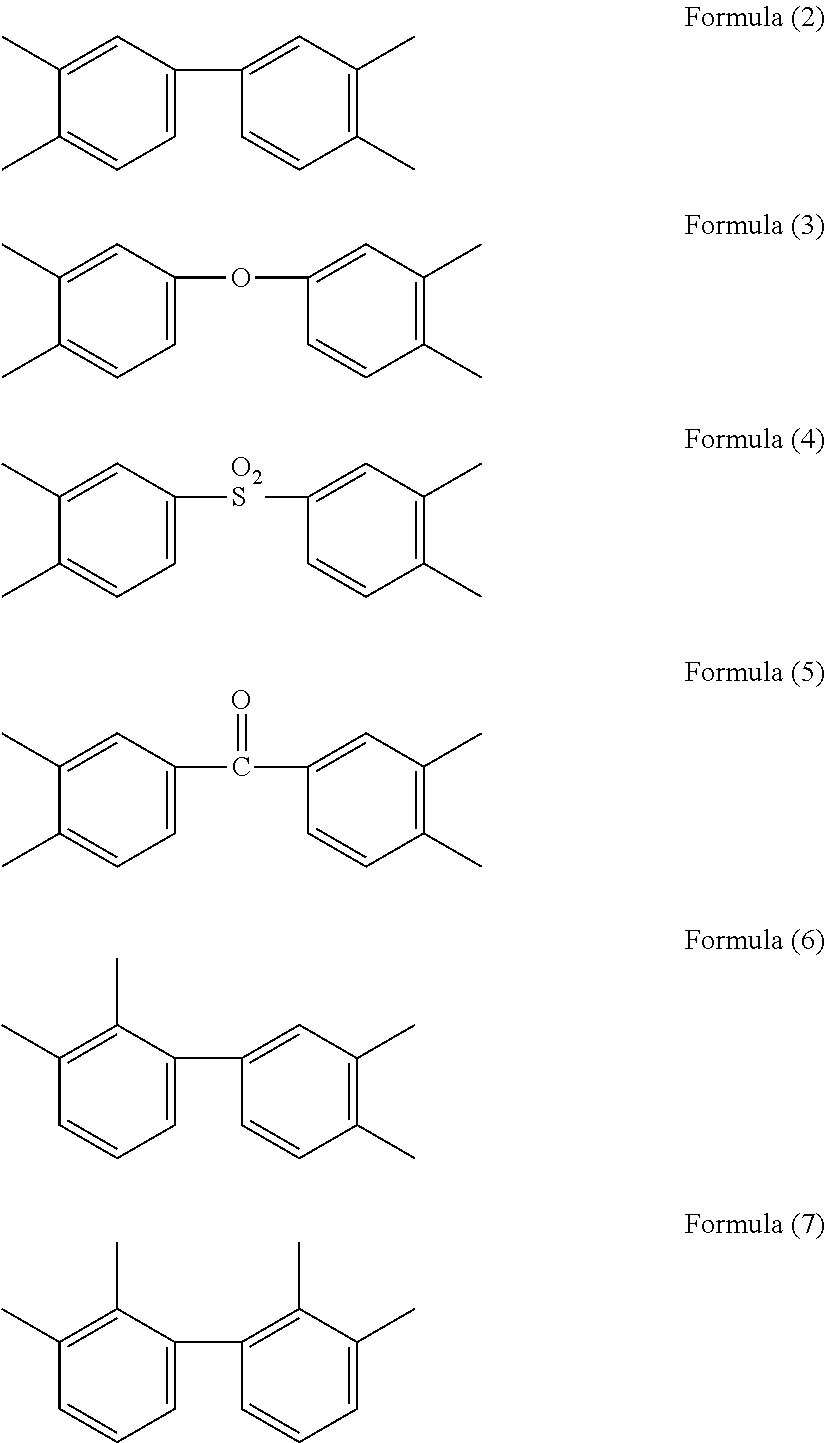

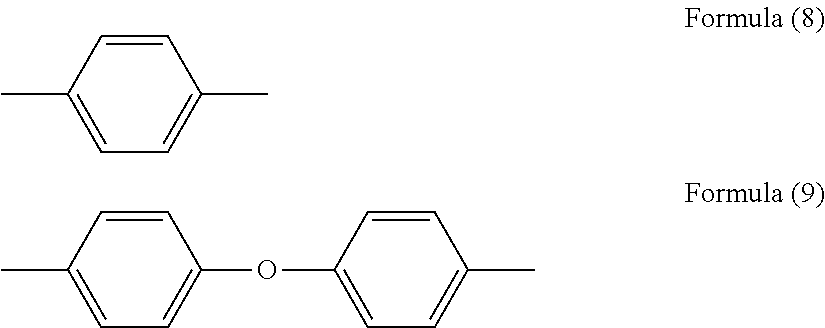

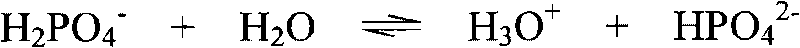

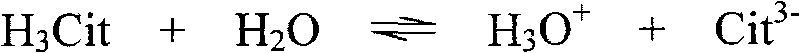

Offset printing fountain solution composition containing composite buffer system

InactiveCN101758680AAdapt to the needs of actual printingGood buffer tolerancePrinting pre-treatmentSodium citrateCitric acid

The invention relates to an offset printing fountain solution composition containing composite buffer system, which contains two buffer systems, wherein one of the buffer systems comprises citric acid and M2(I)HPO4, and in the molecular formula M2(I)HPO4, M is K plus, Na plus or NH4 plus ion; and the other buffer system comprises citric acid and potassium citrate, sodium citrate or ammonium citrate, components are as follows in percentage by weight: 1.0-10 percent of the citric acid, 1.0-10 percent of K2HPO4, Na2HPO4 or (NH4)2HPO4, 1.0-10 percent of the potassium citrate, the sodium citrate or the ammonium citrate, and the balance water. When 1 percent to 5 percent by weight of working solution prepared with the diluted fountain solution is used for printing, the change of pH value is less than 0.35, and when 1 percent to 2 percent of working solution is prepared, the change of pH value is less than 0.25. The ultrahigh buffering property of the fountain solution can significantly help to improve adaptability and tolerance during high-speed printing operation.

Owner:HUNAN NORMAL UNIVERSITY

Solution composition and method for electroless deposition of coatings free of alkali metals

InactiveUS6911067B2Low costImprove anti-corrosion performanceAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless depositionMaterials science

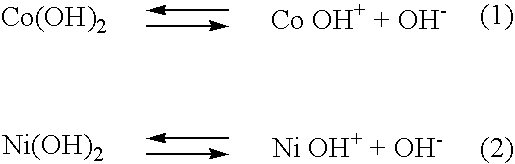

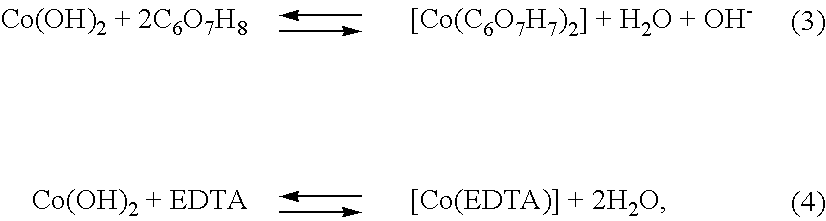

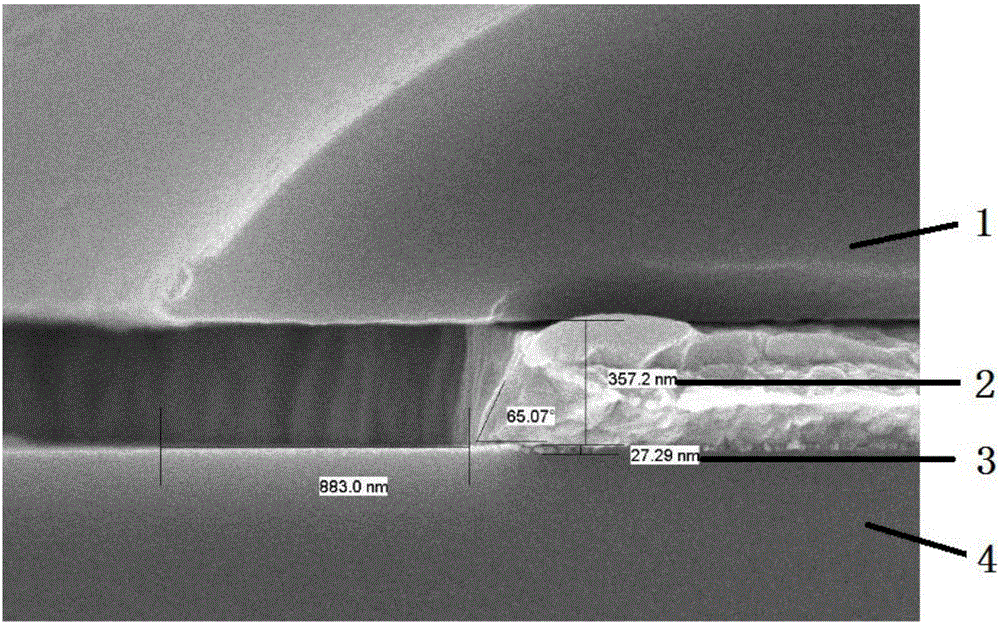

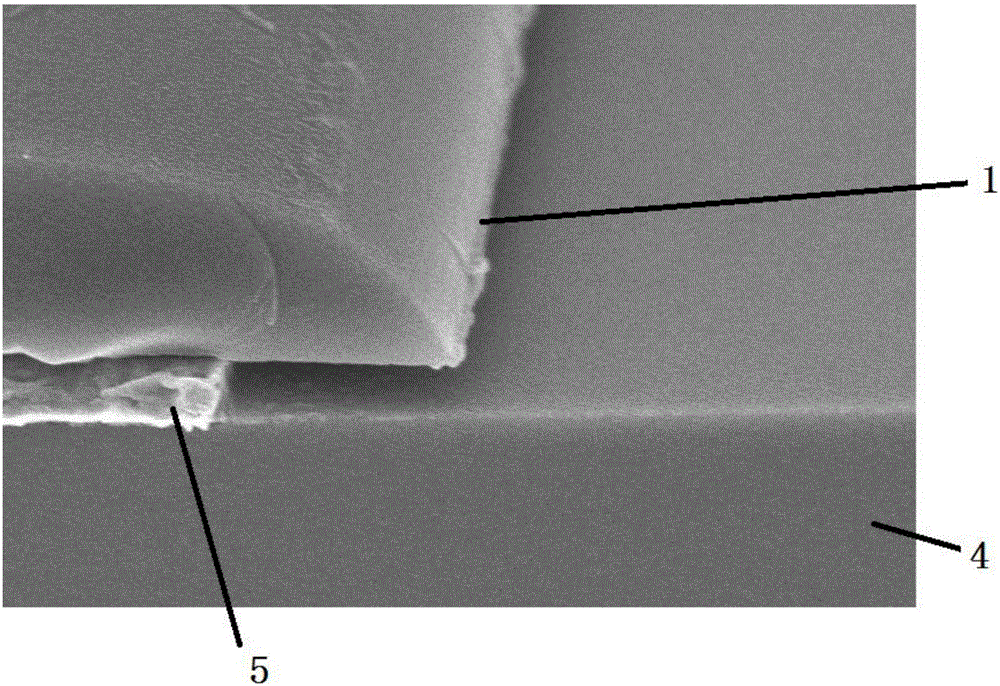

An electroless deposition solution of the invention for forming an alkali-metal-free coating on a substrate comprises a first-metal ion source for producing first-metal ions, a pH adjuster in the form of a hydroxide for adjusting the pH of the solution, a reducing agent, which reduces the first-metal ions into the first metal on the substrate, a complexing agent for keeping the first-metal ions in the solution, and a source of ions of a second element for generation of second-metal ions that improve the corrosion resistance of the aforementioned coating. The method of the invention consists of the following steps: preparing hydroxides of a metal such as Ni and Co by means of a complexing reaction, in which solutions of hydroxides of Ni and Co are obtained by displacing hydroxyl ions OH− beyond the external boundary of ligands of mono- or polydental complexants; preparing a complex composition based on a tungsten oxide WO3 or a phosphorous tungstic acid, such as H3[P(W3O10)4], as well as on the use of tungsten compounds for improving anti-corrosive properties of the deposited films; mixing the aforementioned solutions of salts of Co, Ni, or W and maintaining under a temperatures within the range of 20° C. to 100° C.; and carrying out deposition from the obtained mixed solution.

Owner:LAM RES CORP

Core/shell nano particle grinding agent polishing solution composition and method for preparing same

The present invention relates to one kind of core-shell type nanometer particle abrasive polishing liquid composition and its preparation process, and belongs to the field of surface polishing technology. The polishing liquid includes abrasive, oxidant and water, and features the abrasive is core-shell type nanometer composite particle abrasive, which has traditional abrasive, such as superfine alumina, silica, zirconia, cerium oxide, titania, ferric oxide, diamond or silicon nitride, as inner core, and hydrophilic segment polymer or compound containing organic functional group as shell. The polishing liquid is suitable for chemical and mechanical polishing of memory hard disc chip and aluminum magnetic disc, and has the advantages of reduced surface roughness and waviness, reduced surface mechanical damage and effective elimination of micro default.

Owner:SHANGHAI UNIV

Etching solution composition and metal film etching method using same

The invention relates to an etching solution composition, prepared from the following components: 4-25wt% of hydrogen peroxide, 0.01-10wt% of an etching inhibitor, 0.01-10wt% of a chelating agent, 0.01-3wt% of etching additives, 0.01-10wt% of a hydrogen peroxide stabilizer and the balance of water, wherein the total weight of the composition is 100%. The invention also provides a conductive metal film etching method. The method comprises the step of enabling the etching solution composition to be contacted with a conductive metal film, wherein an upper layer metal film is formed by at least one of aluminum, aluminum alloy, copper and copper alloy, and a lower layer metal film is formed by molybdenum and / or titanium.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

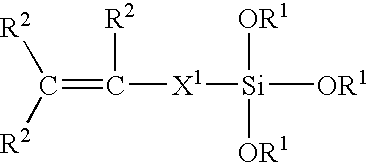

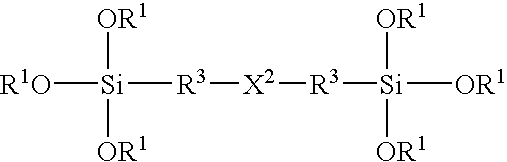

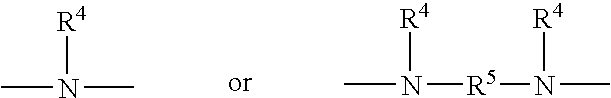

Silane coatings for metal

InactiveUS20050058843A1Improve corrosion resistanceAvoid corrosionLiquid surface applicatorsFibre treatmentSilyleneSilanes

Owner:UNIVERSITY OF CINCINNATI

Use of novel draw solutes and combinations thereof to improve performance of a forward osmosis system and process

This disclosure describes draw solution compositions for FO processes which increase the available membrane area for permeation and are also amenable to reconcentration with standard techniques, such as membrane filtration and evaporative technologies. The composition are comprised of a water soluble draw solute having surface active properties, i.e., a surfactant.

Owner:HYDRATION SYST

Nanocrystalline iridium series oxide coating electrode preparation method

The invention discloses a making method of nanocrystalline iridium-series oxide coating electrode in the electrochemical appliance technical domain, which comprises the following steps: predisposing base; proceeding mechanic disposal; deoiling through alkaline and acid; allocating the coating liquid; coating. The solution of IrO2-Ta2O5-MO2 coating is composed of 30-95% H2IrCl6 solution and TaCl5 solution with the molar rate of Ir and Ta at 7: 6 and 5-70% third element M chloride with Sn, Mn, Ti, Nb, Pb and Si, wherein the even size of IrO2 grain is 8-15nm, which stabilizes the electrode.

Owner:UNIV OF SCI & TECH BEIJING

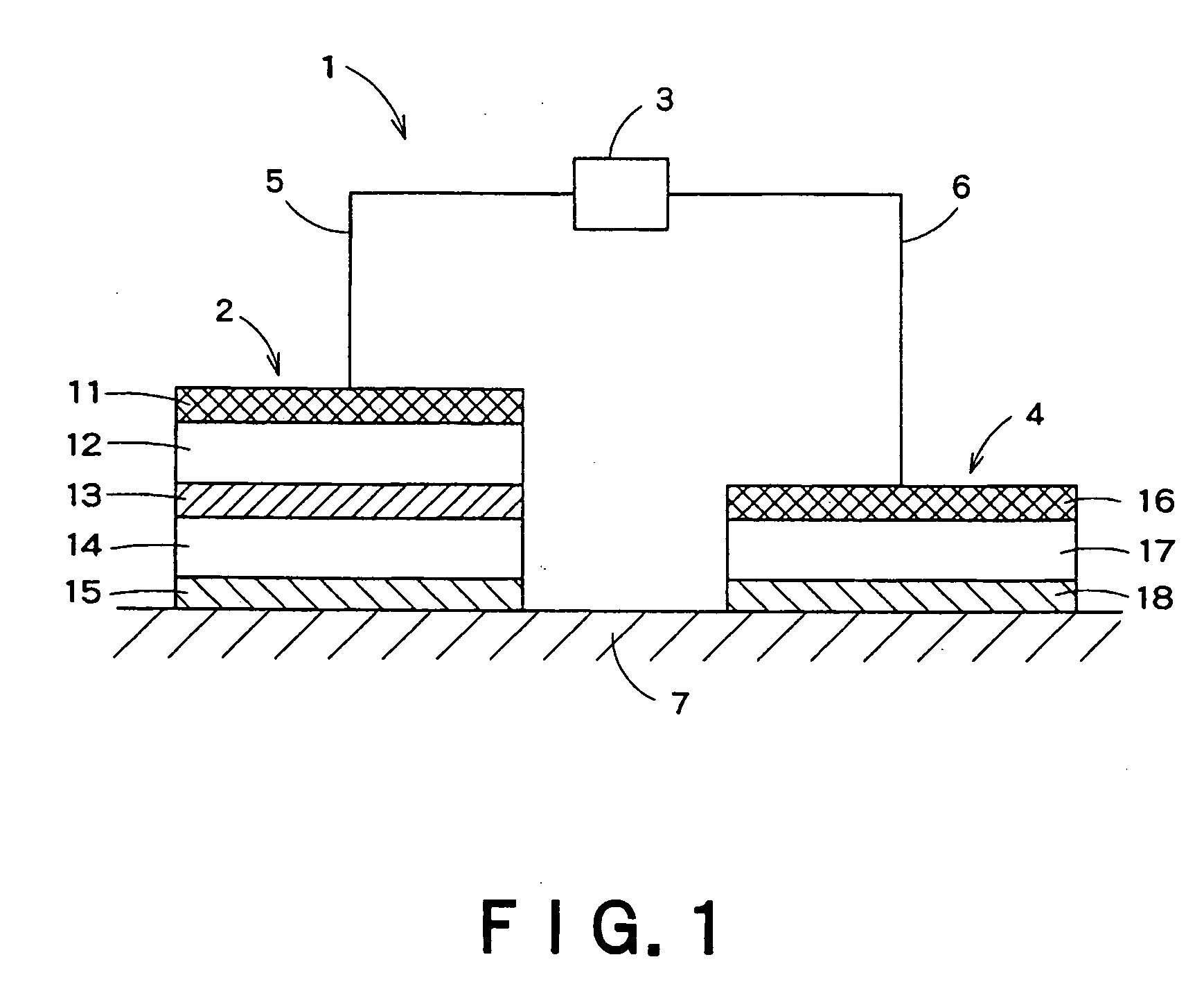

General purpose electrolyte solution composition for iontophoresis

A single electrolyte solution composition may be used in an anode side and in a cathode side of an iontophoresis device. The electrolyte solution may include a compound having an oxidation-reduction potential lower than that of water, the compound including, in combination, both a component that is likely to be relatively reduced and a component that is likely to be relatively oxidized.

Owner:TITI ELLEBEAU INC

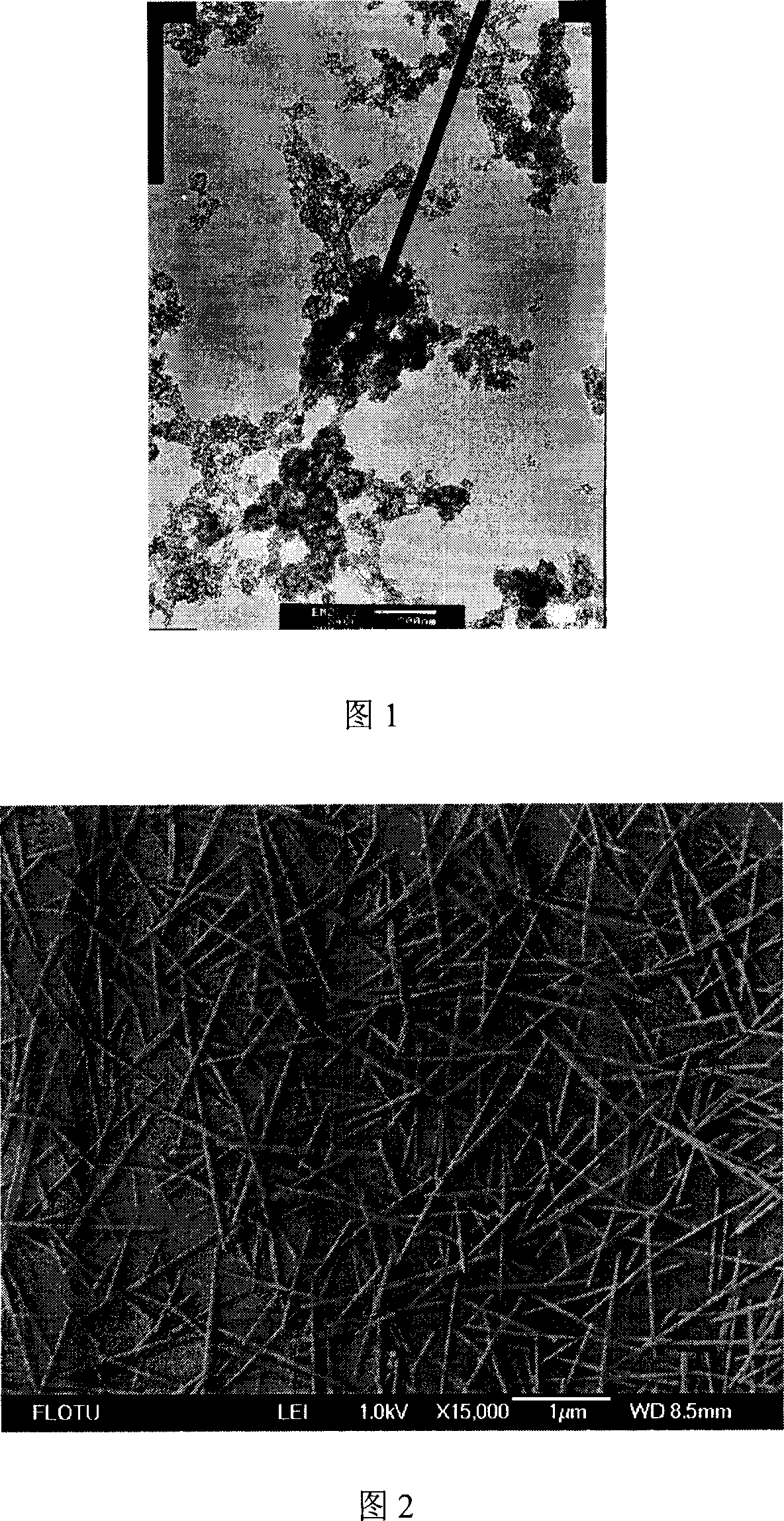

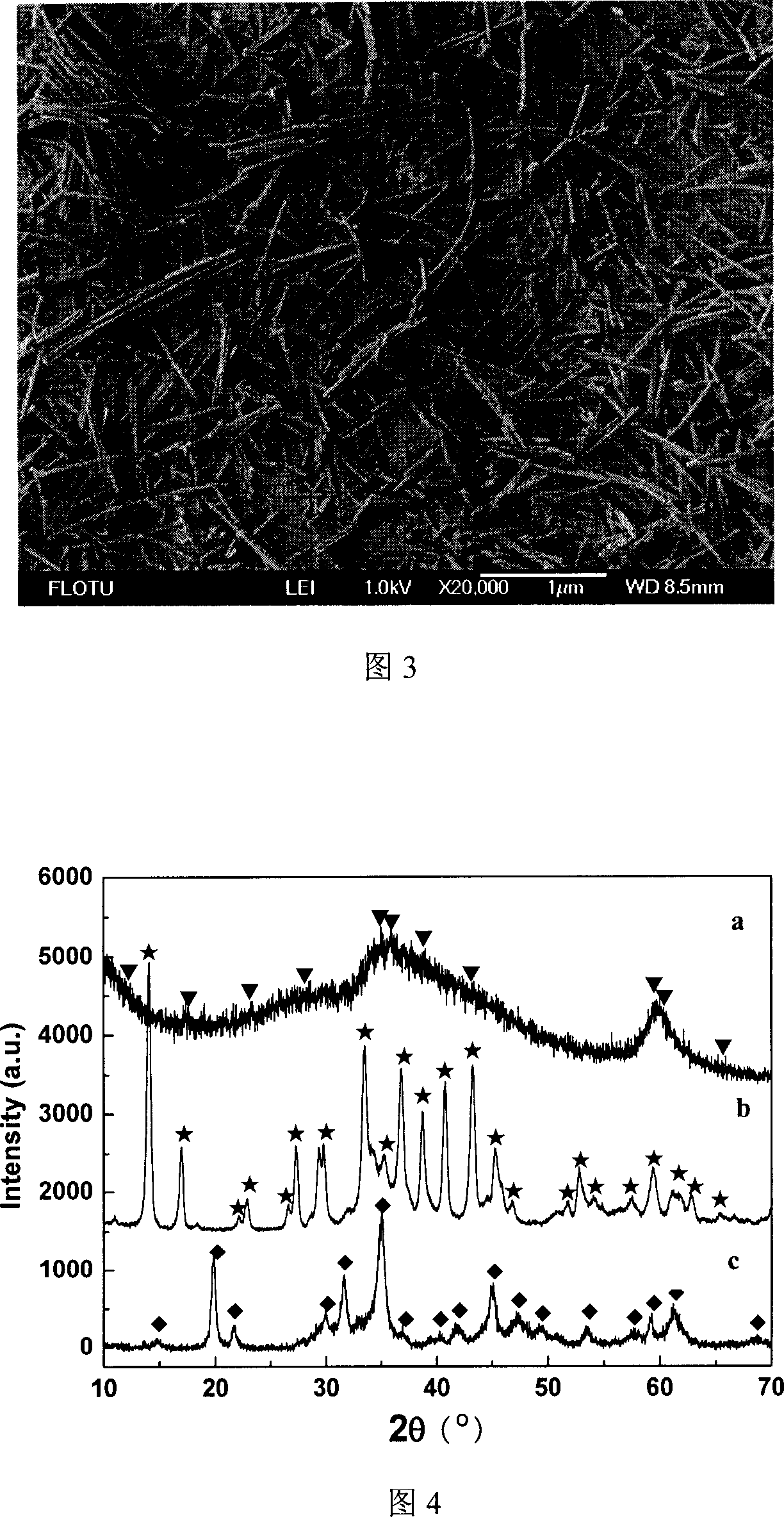

Magnesium borate whisker hydrothermal synthesis preparation method

InactiveCN1936104AStable structureSmall particle sizePolycrystalline material growthFrom normal temperature solutionsMagnesium saltWhiskers

The invention relates to a hydrothermal synthesis manufacturing method for magnesium borate crystal whisker that adopts inorganic magnesium salt, magnesium borate and inorganic alkali as main raw material, adding inorganic alkali into mixture solution of magnesium salt and borate at 10-90 degree centigrade, taking hydrothermal treatment to normal temperature product at 100-300 degree centigrade, realizing directional growth through controlling hydrothermal rocks constituents and technology condition to gain one dimension appearance feather alkali magnesium borate crystal whisker, washing, drying the hydrothermal product, and baking under the existence of crystallographic form transforming agent at 600-800 degree centigrade to realize structure reconstruction and phase converting to gain regular appearance and equal size magnesium borate crystal whisker. The invention has the advantages of simple technology, mild condition, cheap raw material, and easy to be manufactured.

Owner:TSINGHUA UNIV

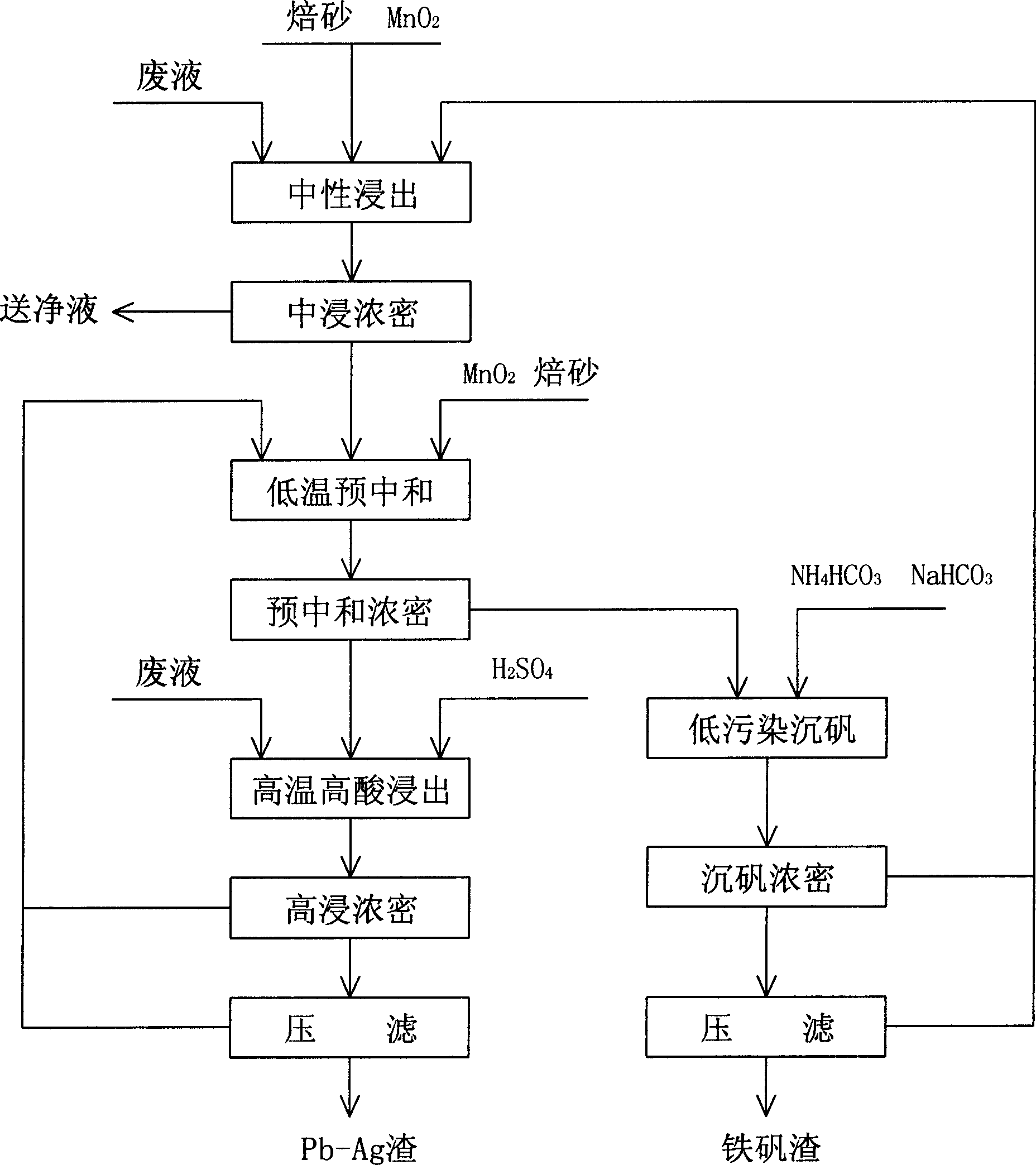

Low pollution vanadium settling iron-removing wet zinc smelting method

ActiveCN1900330AHigh recovery rateReduce consumptionProcess efficiency improvementAcid concentrationZinc smelting

The present invention discloses a kind of wet zinc smelting process, which includes four main technological steps of neutral leaching, low temperature pre-neutralizing, high temperature high acid concentration leaching, and low pollution vanadium settling and iron removing. Before low pollution vanadium settling and iron removing, the high temperature high acid concentration leaching step has iron leached at most, and the solution composition is regulated in the low temperature pre-neutralizing step for satisfactory iron removing effect during vanadium settling without need of adding neutralizing agent. The technological process is suitable for treating complicated zinc concentrate, and has raised metal recovering rate, strengthened impurity removing capacity, raised ultimate product quality, lowered material and power consumption and reduced pollution.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD +1

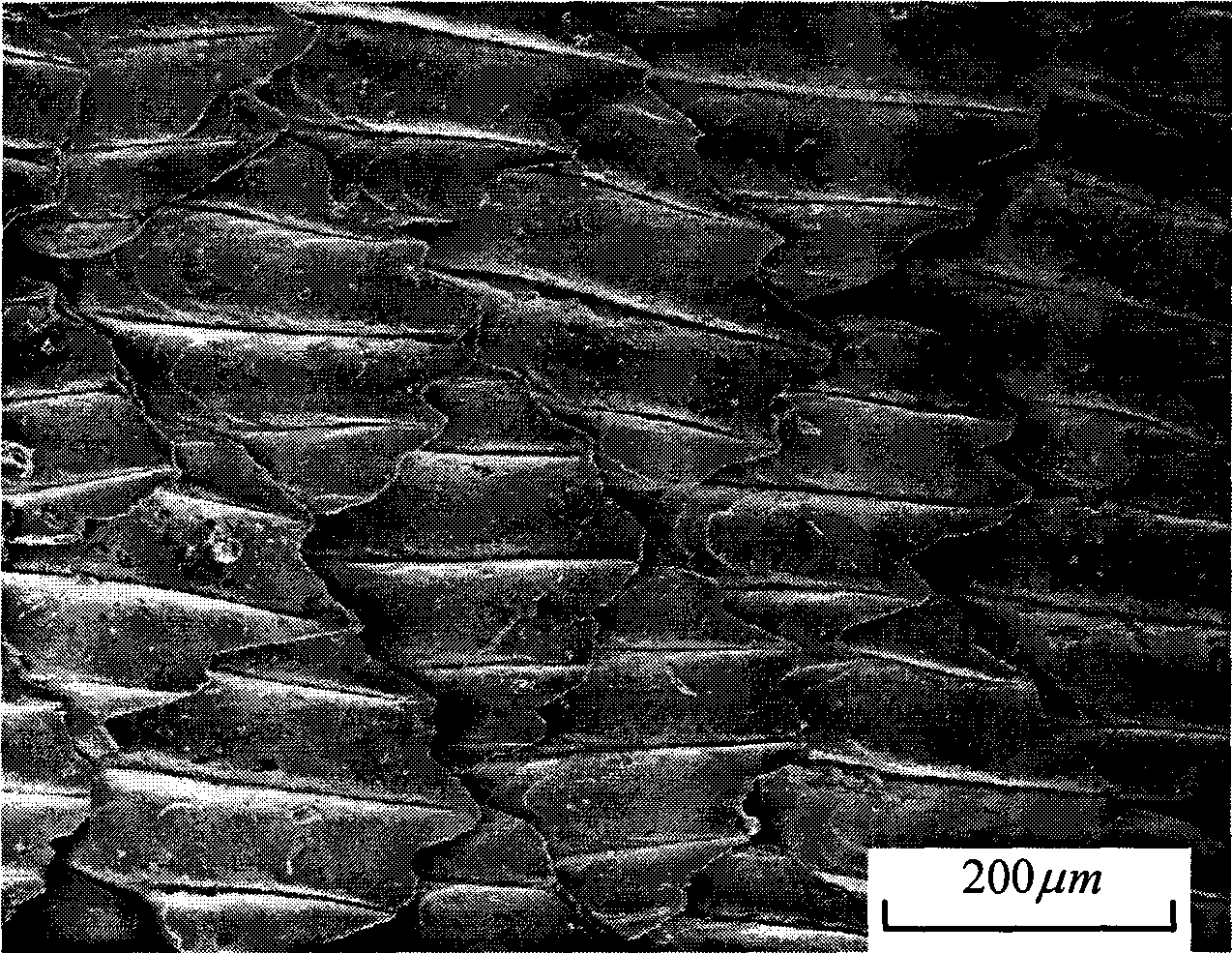

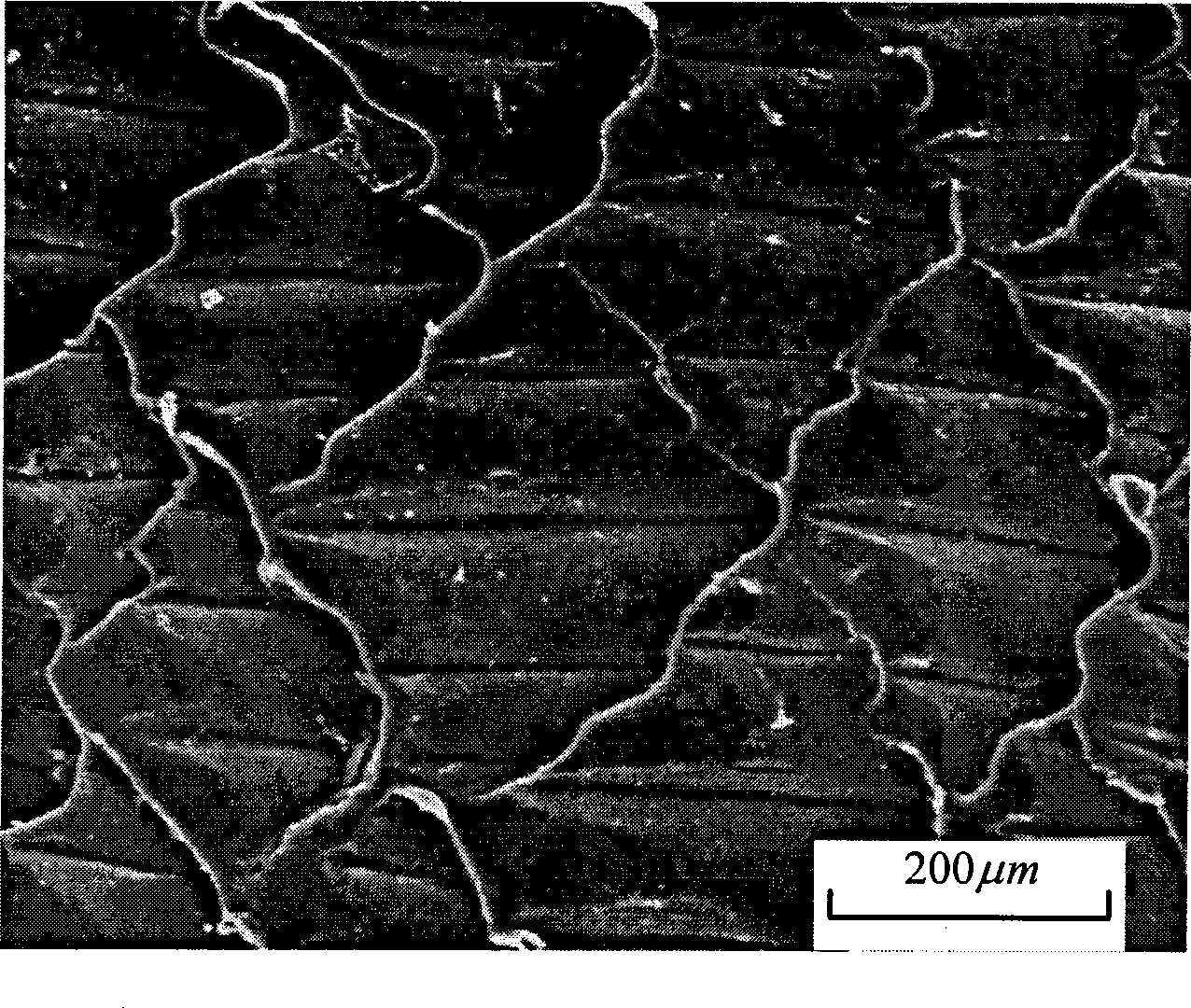

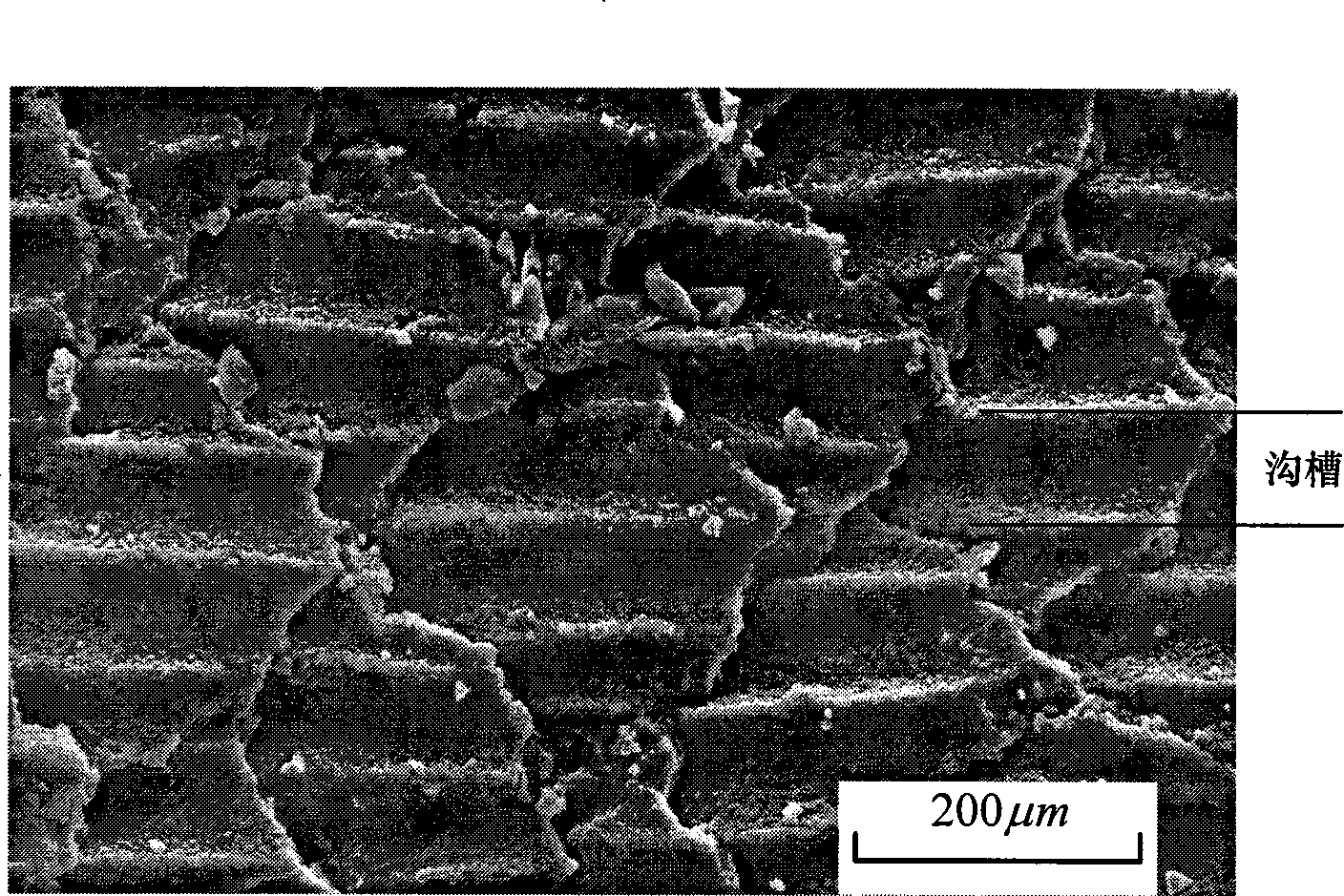

Shark intimating covering having self-lubricating groove and composite anti-drag function and manufacturing method thereof

The invention discloses an artificial shark skin with function of self-lubricating groove complex drag reduction. The artificial shark skin in a copying way is provided with micron-size grooves which have self-lubricating function. The artificial shark skin is made from waterborne epoxy resin and polyacrylamide aqueous solution, wherein 50-70g of the polyacrylamide aqueous solution is added to 10g of the waterborne epoxy resin; the waterborne epoxy resin consists of waterborne epoxy resin emulsion and waterborne epoxy resin curing agent and is a bi-component epoxy resin. The process for manufacturing the artificial shark skin fully proves that the drag reduction mechanism of the shark skin can be simulated from the two aspects of high-fidelity groove shape and self-lubricating mucus by the biological copy-forming technology, thus realizing double bionics of geometric attributes and interface attributes of low-resistance organism surface, which is to become the development trend of the bionic drag reduction surface manufacture technology in the future and has wide application prospect.

Owner:BEIHANG UNIV

Agricultural spray solution compositions and methods

InactiveUS20130079228A1Reduced characteristicsImprove biological activityBiocideLiquid surface applicatorsSolubilityReverse osmosis

An agrichemical is disclosed having increased bio-activity which is adapted for spray application in a form which offers reduced aerial drift and improved deposition on organisms, reduced agglomeration and gellation problems, is adapted for use with chemicals, pesticides and fertilizers and allows for lower agrichemical use rates. Various adjuvants and surfactants are combined with fertilizers or pesticides, such as herbicides fungicides and insecticides, to reduce application problems relating to droplet size, foaming, chemical stability, plant and area coverage, droplet drift, surface tension, suspension, incompatability, phytoxicity, solubility, volatilization and evaporation, while providing enhanced bio-efficacy and low aquatic toxicity. Purifying the agrichemical composition water source by any of various known processes such as oxidation, ultra-filtration, deionization, reverse osmosis or nanofiltration lowers or removes alkaline components, such as calcium, magnesium, iron, sodium, etc., and reduces water hardness, and further increases the agrichemical's bio-efficacy.

Owner:FREED BRIAN E

Hydrogenation catalyst steeping fluid composition and preparation method of hydrogenation catalyst

ActiveCN101462078AImprove hydrogenation activityHigh cracking activityCatalyst activation/preparationHydrocarbon oil crackingReaction temperatureFluid composition

The invention provides a hydrogenation catalyst soaking solution composition, which comprises a precursor of a hydrogenation active ingredient, a soaking additive and water, wherein the soaking additive has similar pKa value with that of the precursor of the hydrogenation active ingredient and comprises carbon-carbon double bond and / or carbon-carbon triple bond substances in molecular structure. The invention also provides a method for preparing a hydrogenation catalyst, which comprises: using the soaking solution to soak a catalyst carrier, and drying and roasting the catalyst carrier, wherein the soaking solution is the hydrogenation catalyst soaking solution composition. The hydrogenation catalyst prepared from the hydrogenation catalyst soaking solution composition has higher hydrogenation activity and higher cracking activity at the same reaction temperature compared with a hydrogenation catalyst prepared by the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stabilized ascorbic acid compositions and methods therefor

ActiveUS20050154054A1Improve stabilityImprove solubilityCosmetic preparationsBiocideSolubilityCaffeic acid

The present invention relates to ascorbic acid single-phase solution compositions that provide enhanced stability, enhanced solubility and an enhanced photoprotective effect as compared to prior compositions. The compositions comprise L-ascorbic acid; a cinnamic acid derivative such as p-coumaric acid, ferulic acid, caffeic acid, sinapinic acid, a derivative thereof, and a combination thereof; a solvent comprising a glycol ether and an alkanediol; and water; the composition having a pH of no more than about 3.5. The compositions may also comprise a form of Vitamin E and are useful for treatment of radical-induced damage to a subject, particularly the skin of a subject.

Owner:LOREAL USA CREATIVE INC

Ophthalmic solution

An improved ophthalmic composition comprising an anionic polymeric substance, such as Hyaluronic Acid and / or Carboxymethylcellulose, in combination with any of various cationic monomeric or dimeric antimicrobial agents, such as Cetylpyridinium Chloride and / or Alexidine Dihydrochloride, wherein said compositions provide additional comfort and biocompatibility with lenses without significantly affecting the antimicrobial efficacy of the antimicrobial agent and without therefore requiring a substantially increased concentration of the agent such as that could expose contact lens wearers to increased levels of the disinfecting agent. Solutions according to the present invention may be used for effective multipurpose contact lens disinfection compositions, lens packaging solution compositions, and / or eye drops such as rewetters and tears.

Owner:ABBOTT MEDICAL OPTICS INC

Chromium-free metal surface treatment agent

InactiveUS20050037227A1Improve adhesionAvoid performanceLiquid surface applicatorsSynthetic resin layered productsChromium freeSolvent

Provided is a chromium-free metal surface treatment agent excellent in rust inhibitive performance which can be used in a surface treatment of metal products, in particular, galvanized metal products. The metal surface treatment agent consists essentially of a siliceous binder solution comprising water and / or alcohol as a solvent, and the concentration of the silica component is 8 to 25% by weight. In particular, a metal surface treatment agent containing an alcoholic solution of alkoxysilane oligomer having a weight averaged molecular weight of 1000 to 10000, which is obtained by hydrolyzed condensation polymerization of alkoxysilane, can suppress the occurrence of white rusting for a long time. It is preferred that 3 to 25 parts by weight of a dispersed nano-sized titanium dioxide powder having an average primary particle size of not more than 70 nm, per 100 parts by weight of the silica component be suspended in the siliceous binder solution. The rust inhibitive performance of the metal surface treatment agent can be further improved by using an alcohol-soluble polyvinyl butyral resin and by adding a silane coupling agent having a vinyl or epoxy group as a functional group, in combination with a dispersed nano-sized powder of titanium dioxide.

Owner:HODEN SEIMITSU KAKO KENKYUSHO CO LTD

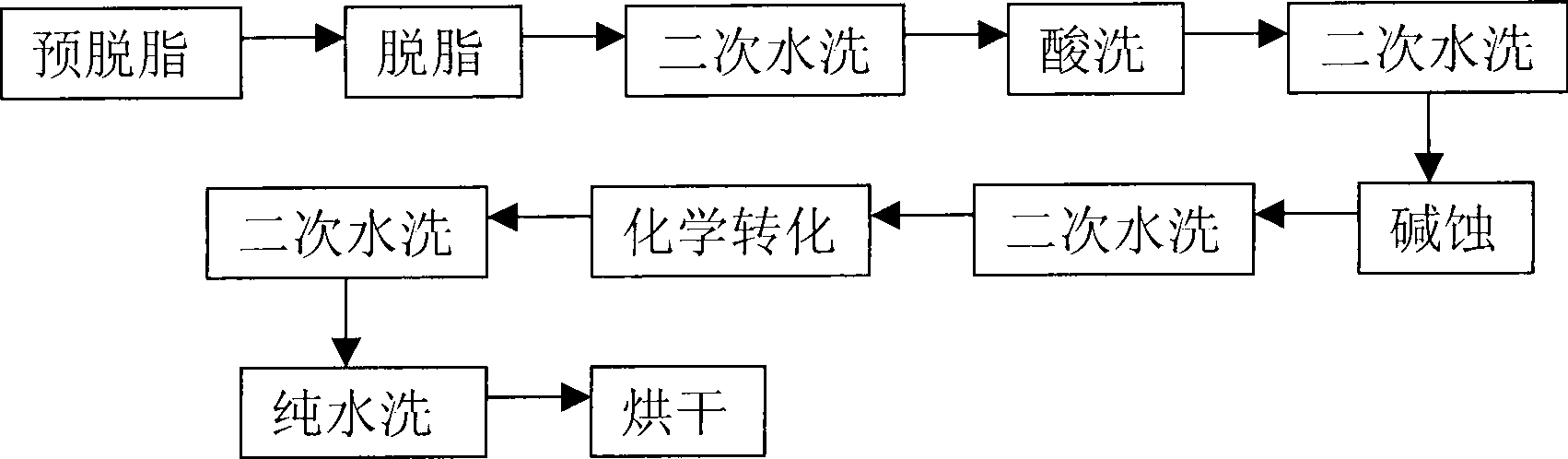

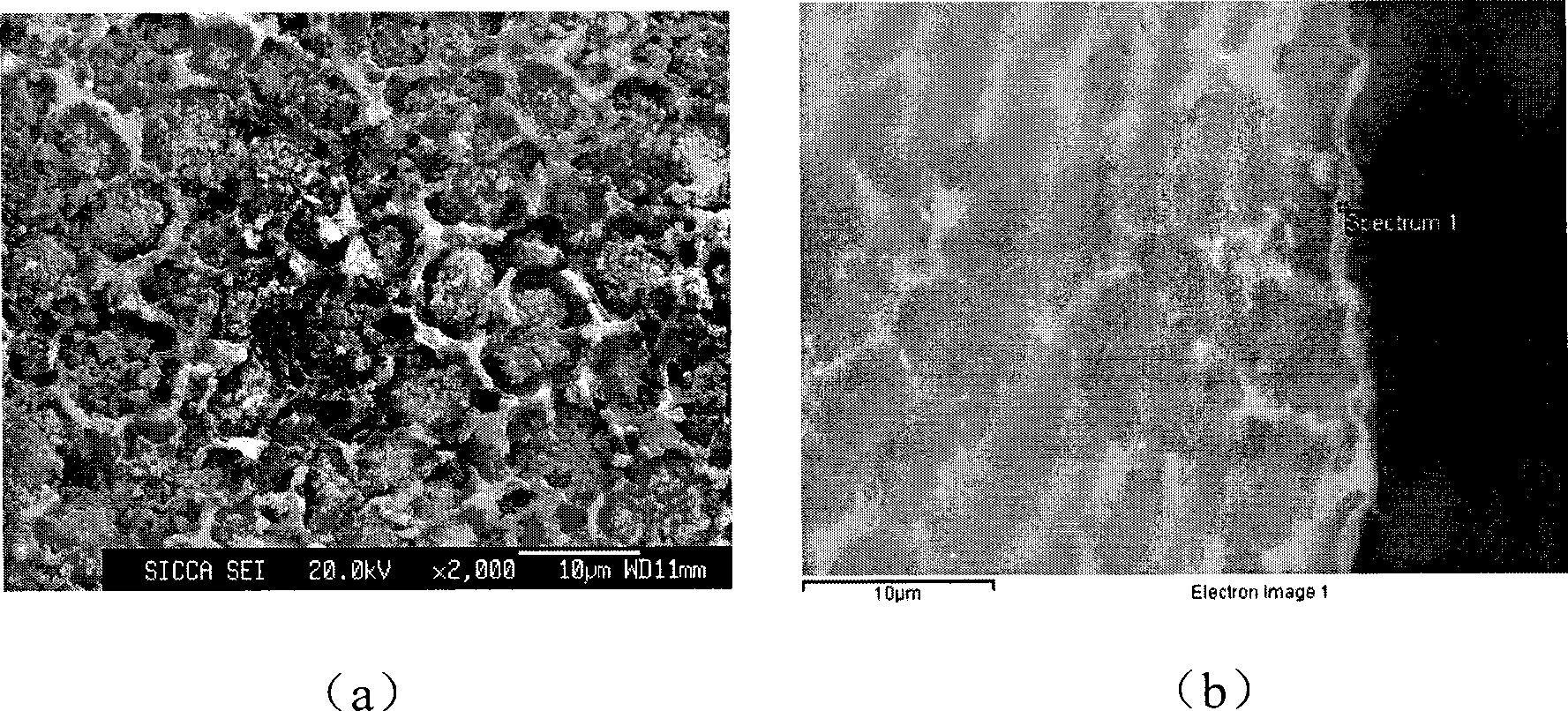

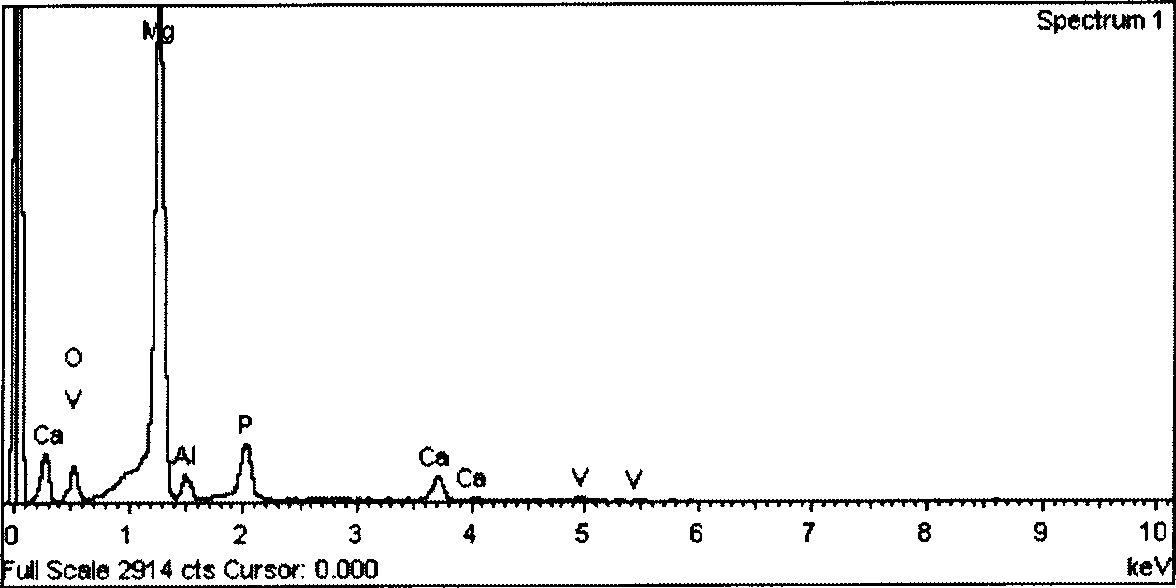

P-Ca-V composite phosphating solution on magnesium alloy surface and chemical conversion processing method

ActiveCN101418441AImprove corrosion resistanceLow resistivityMetallic material coating processesSalt spray testAcid washing

The invention relates to a composite phosphating solution of P-Ca-V on the surface of a magnesium alloy and a method for chemical conversion treatment. The solution is characterized in that each liter of the composite phosphating solution comprises the following compositions: 4 to 20 milliliters of 85 percent phosphoric acid of, 5 to 30 grams of sodium dihydrogen phosphate, 10 to 40 grams of calcium nitrate, 0.5 to 10 grams of benzene sulfonic acid sodium salt, 0.5 to 5 grams of ammonium metavanadate, and the balance being water. The method comprises the following steps: pre-degreasing, degreasing, secondary water washing, acid washing, secondary water washing, alkaline etching, secondary water washing, chemical transformation, secondary water washing, pure water washing, and drying. Taking an AZ91D magnesium alloy as an example, 48 hours after a corrosion resistance salt spray test after the treatment by the method of the invention, the corrosion area of the AZ91D magnesium alloy is less than 1 percent; the paint film adhesive force is at 0 level by a grid method and is obviously superior to the performance of a chromate conversion coating; and the formed chemical conversion coating does not contain crystal water. The composite phosphating solution has the synergistic reaction of Ca and V, as well as the functions of a corrosion inhibitor and a wetting agent of the benzene sulfonic acid sodium salt.

Owner:嘉兴中科亚美合金技术有限责任公司

Stabilized ascorbic acid compositions and methods therefor

ActiveUS7179841B2Improve stabilityImprove solubilityCosmetic preparationsBiocideCoumaric acidCaffeic acid

Owner:LOREAL USA CREATIVE INC

Novel composition for preparing polysaccharide fibers

This invention pertains to a novel solution composition useful for preparing fibers from poly(α(1→3) glucan). The fibers prepared according to the invention, have“cotton-like” properties, are useful in textile applications, and can be produced as continuous filaments on a year-round basis. The solution comprises a 5-20% solids concentration of poly(α(1→3) glucan) in an aqueous alkali metal hydroxide, in particular NaOH at concentration of 2 to 10 weight-%.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com