Offset printing fountain solution composition containing composite buffer system

A technology of lithographic printing and composite buffering, which is applied in the field of lithographic printing fountain solution compositions containing a composite buffer system, and can solve problems such as poor adaptability of printing fountain solutions, deterioration of printing operation environment, and reduction of PS plate printing durability , to achieve the effect of improving the quality of printed products, storage resistance, and buffer tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

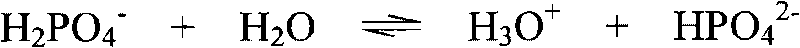

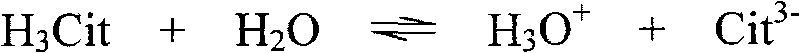

Method used

Image

Examples

Embodiment 1

[0044] Fountain solution ratio for lithographic printing: 4.0% citric acid, K 2 HPO 4 4.5%, potassium citrate 4.0%, carboxymethyl cellulose 1.0%, nonionic surfactant AEO-9 1.5%, bactericidal algaecide Kaisong 1.0%, and the rest is water. The original solution is stored for 1 year without precipitation, algae and mold growth.

[0045] Preparation of the working solution: take the stock solution of the dampening solution in Example 1 and dilute it 50 times with water to obtain a dampening working solution containing 2 wt% of the stock solution. The pH of the working solution is 5.15, and when the working solution is prepared at 1-2w%, the change of the pH value is 0.15.

Embodiment 2

[0047] Fountain solution ratio for lithographic printing: 1.3% citric acid, Na 2 HPO 4 2.2%, sodium citrate 1.0%, polyvinylpyrrolidone 1.0%, nonionic surfactant OP-10 1.0%, bactericidal algicide hydantoin 1.5%, and the rest is water. The original solution is stored for one and a half years without precipitation, algae and mold growth.

[0048] Preparation of the working solution: Take the stock solution of the dampening solution in Example 2 and dilute it 50 times with water to obtain a dampening working solution containing 2 wt% of the stock solution. The pH of the working solution is 5.23, and when the working solution is prepared at 1-2w%, the change of the pH value is 0.25.

Embodiment 3

[0050] Fountain solution ratio for lithographic printing: 8% citric acid, (NH 4 ) 2 HPO 4 6%, ammonium citrate 9%, polyvinyl alcohol (molecular weight 20000) 5%, non-ionic surfactant TX-10 2.5%, bactericidal algicide hydantoin 2.0%, and the rest is water stock solution stored for 2 years without precipitation, No algae and mold growth.

[0051] Preparation of the working solution: take the stock solution of the dampening solution in Example 3 and dilute it 50 times with water to obtain a dampening working solution containing 2 wt% of the stock solution. The pH of the working solution is 5.03, and when the working solution is prepared at 1-2w%, the change of the pH value is 0.12.

[0052] Relevant technical indicators of the dampening working solution prepared from the lithographic printing dampening solution of the present invention:

[0053] "Stock solution" in the table refers to the stock solution of dampening solution prepared according to the ratio of the components i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com