Patents

Literature

883 results about "Citrate potassium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium citrate (also known as tripotassium citrate) is a potassium salt of citric acid with the molecular formula K3C6H5O7. It is a white, hygroscopic crystalline powder. It is odorless with a saline taste.

Offset printing fountain solution composition containing composite buffer system

InactiveCN101758680AAdapt to the needs of actual printingGood buffer tolerancePrinting pre-treatmentSodium citrateCitric acid

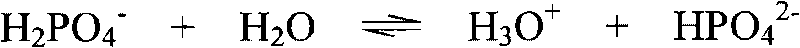

The invention relates to an offset printing fountain solution composition containing composite buffer system, which contains two buffer systems, wherein one of the buffer systems comprises citric acid and M2(I)HPO4, and in the molecular formula M2(I)HPO4, M is K plus, Na plus or NH4 plus ion; and the other buffer system comprises citric acid and potassium citrate, sodium citrate or ammonium citrate, components are as follows in percentage by weight: 1.0-10 percent of the citric acid, 1.0-10 percent of K2HPO4, Na2HPO4 or (NH4)2HPO4, 1.0-10 percent of the potassium citrate, the sodium citrate or the ammonium citrate, and the balance water. When 1 percent to 5 percent by weight of working solution prepared with the diluted fountain solution is used for printing, the change of pH value is less than 0.35, and when 1 percent to 2 percent of working solution is prepared, the change of pH value is less than 0.25. The ultrahigh buffering property of the fountain solution can significantly help to improve adaptability and tolerance during high-speed printing operation.

Owner:HUNAN NORMAL UNIVERSITY

Antimicrobial and odor adsorbing textile

The antimicrobial and odor adsorbing fabric substrate has a surface and at least a portion of the surface is coated with a finish. The finish contains a compound selected from the group consisting of silver particle-containing compounds, silver ion-containing compounds, silver ion-generating compounds, and any combinations thereof, a hyperbranched polyethyleneimine derivative, potassium citrate, inorganic chloride, a polyurethane binder, and a cross-linking agent. The silver-ion containing compound is selected from the group consisting of silver zirconium phosphate, silver zeolite, silver glass, and any mixtures thereof or a conductive silver containing nanoparticle. The hyperbranched polyethyleneimine derivative is of the formula:(R)x−h-PEI−(A)y where R is a non-hyperbranched hydrocarbon group and the hydrocarbon group has at least one linear portion. The linear portion has between 5 and 30 carbon atoms, x is a number from 1 to 10,000, h-PEI is a hyperbranched polyethyleneimine, A is an organic compound having from 1 to 4 carbon atoms, and y is a number from 0 to 500.

Owner:MILLIKEN & CO

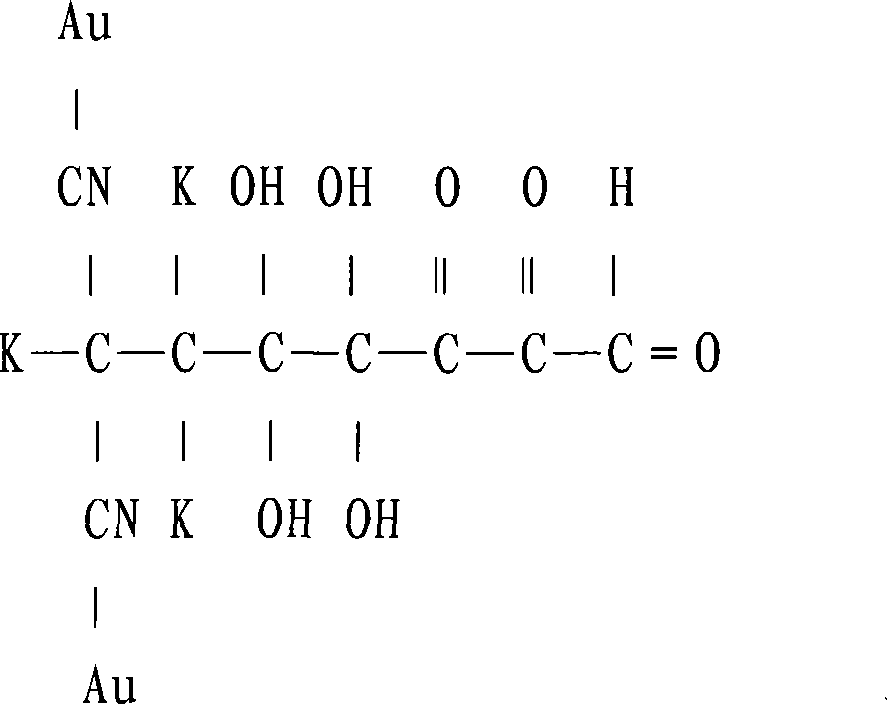

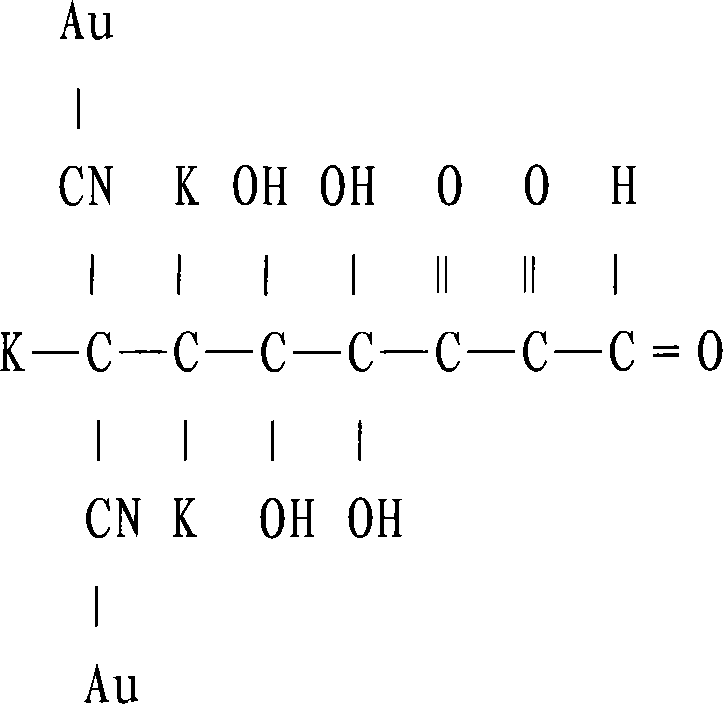

Gold potassium citrate for gold plating and preparation method thereof

InactiveCN101781784ALow toxicityPH value is stableLiquid/solution decomposition chemical coatingChemical compositionCITRATE ESTER

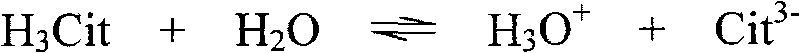

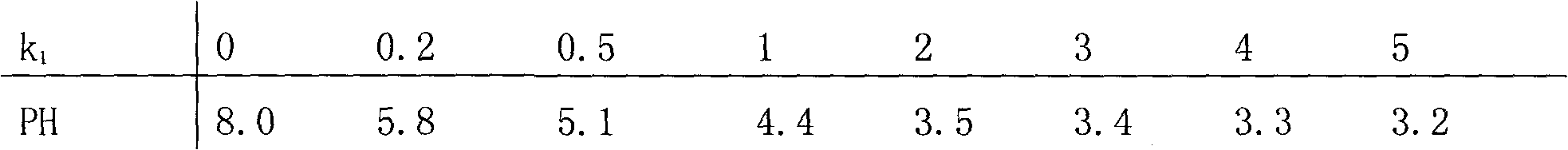

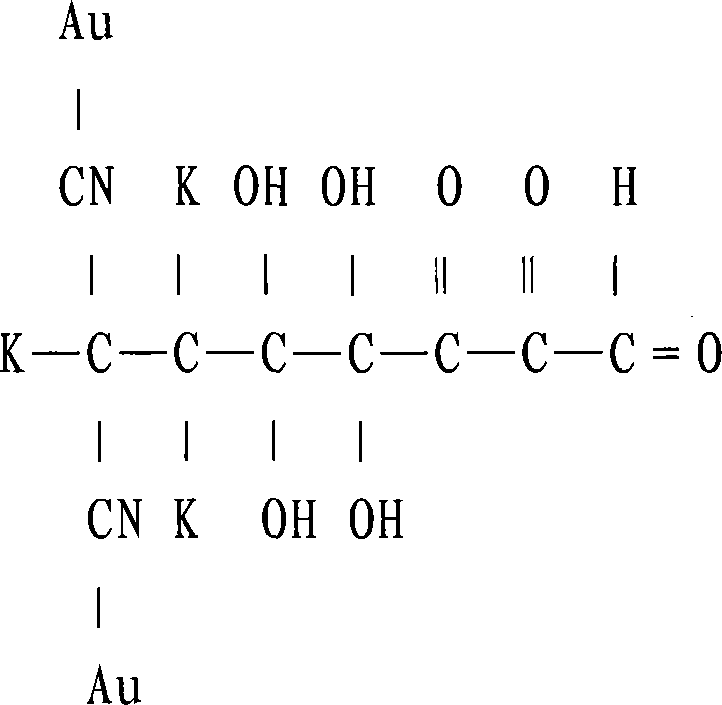

The invention relates to gold potassium citrate for gold plating and a preparation method thereof. The gold potassium citrate is used to substitute for gold potassium cyanide in acidic and neutral gold plating technology. The problem that the product coverage area is too wide when gold citrate is used in the gold plating technology is solved. The technical scheme is that the gold potassium citrate is the mixed crystal of gold potassium cyanide and citric acid potassium salt and the chemical composition of the gold potassium citrate is KAu (CN)2 (K3C6H5O7. k1C6H8O7) k2, wherein KAu (CN)2 is gold potassium cyanide, K3C6H5O7.k1C6H8O7 is citric acid potassium salt which is mixed by potassium citrate K3C6H5O7 and citric acid C6H8O7, k1 is the molar ratio of potassium citrate to citric acid, is more than or equal to zero and is less than or equal to three, and k2 is the molar ratio of citric acid potassium salt to gold potassium cyanide, is more than or equal to one point three and is less than five. The method is mainly suitable for the acidic and neutral gold plating technology.

Owner:张东山

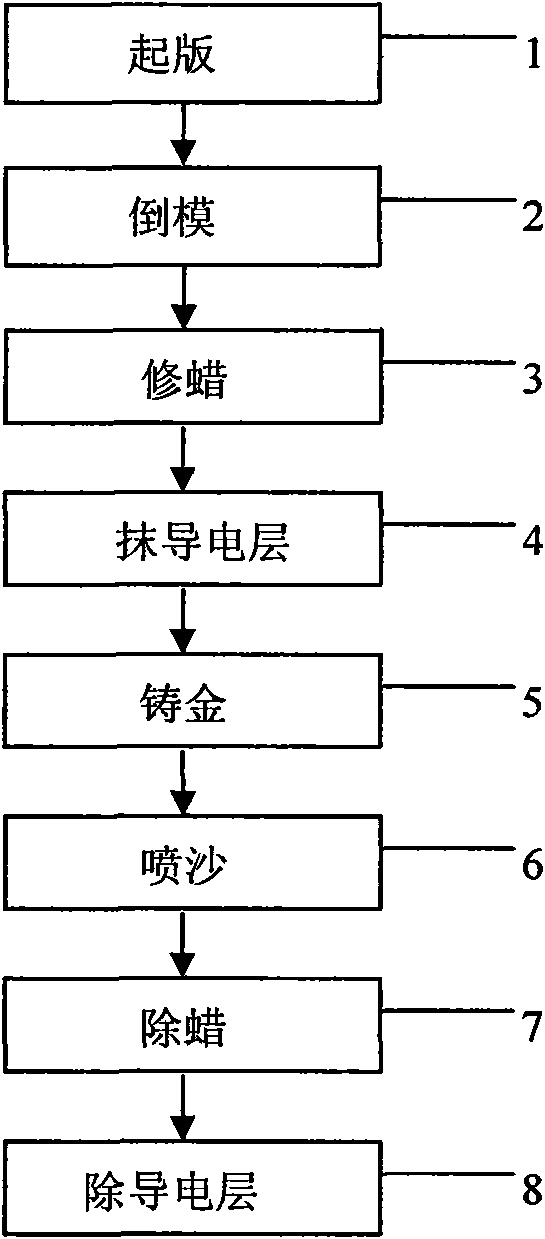

Method for electroforming hard gold product

InactiveCN101560676AIncrease in sizeHigh hardnessElectroforming processesChemical structurePotassium

The invention relates to a method for electroforming hard gold products. The method comprises the following steps: template picking, mould pouring, wax repairing and electric conducting layer coating are carried out to obtain a wax mould of a gold product to be processed, and a layer of electric conductive oil is coated on the surface of the wax mould; and a titanium net is taken as anode in the gold electroforming step, the wax mould coated with the electric conductive oil is put in an electrotyping bath as cathode, the electroforming solution is put in the electrotyping bath and includes sulfurous acid gold potassium, ammonium sulfite and potassium citrate, wherein the sulfurous acid gold potassium is combined with the ammonium sulfite, a trivalent gold ion is reduced into a univalent gold ion, the univalent gold ion generates close crystal grains, the close crystal grains are combined through the potassium citrate to form complexing gold through PH buffer solution, the gold is deposited on the wax mould to form a casting gold layer, and the half-finished product is prepared; and the wax film in the half-finished product and the electric conductive layer are removed in the wax removal step and the electric conductive layer removal step to obtain the finished product. The volume and the hardness of the gold product are changed by using the variation of the chemical structure of the gold ion, so that the hardness, the volume and the toughness of the gold product meet the standards simultaneously.

Owner:武汉金凰珠宝股份有限公司

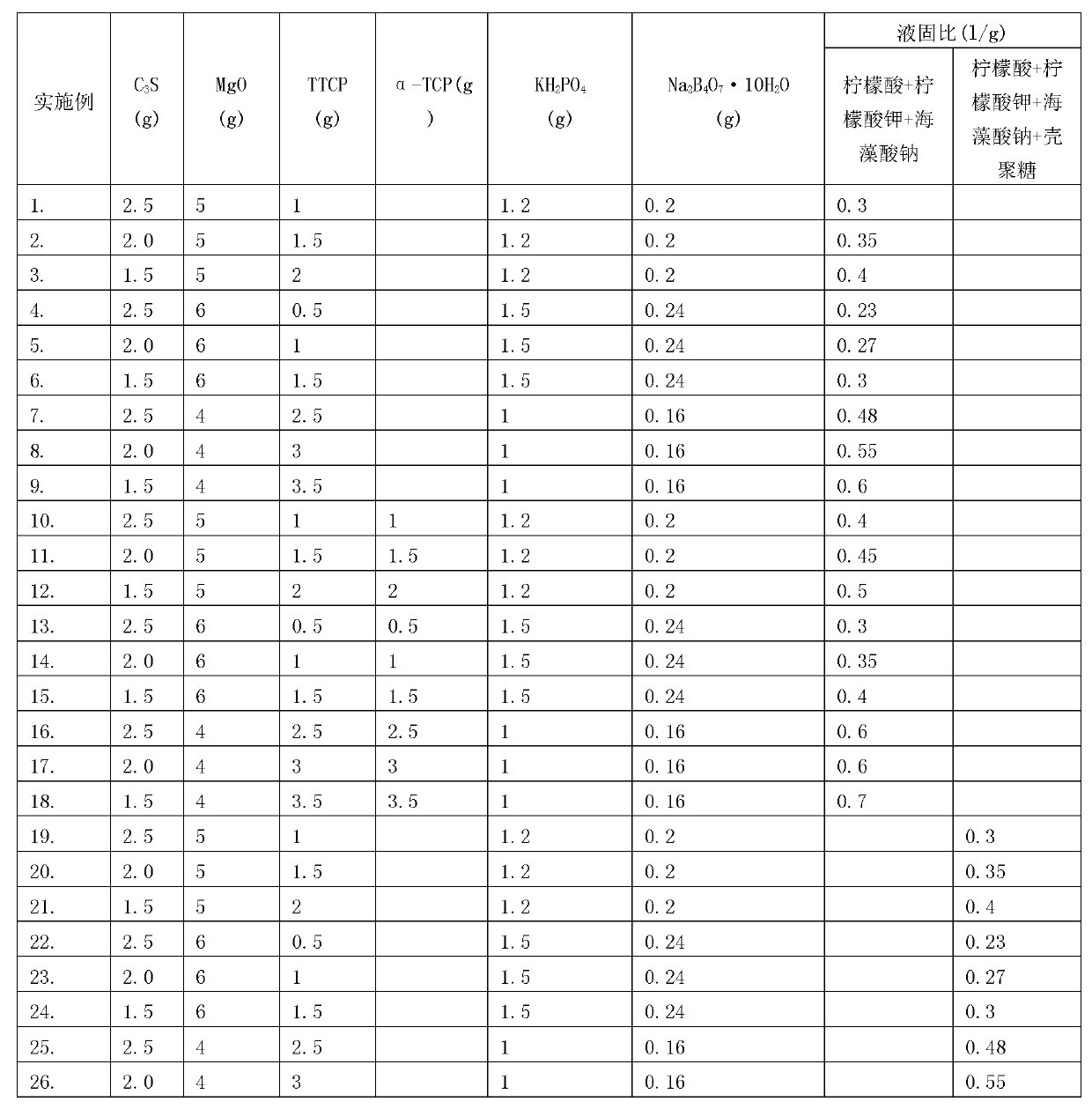

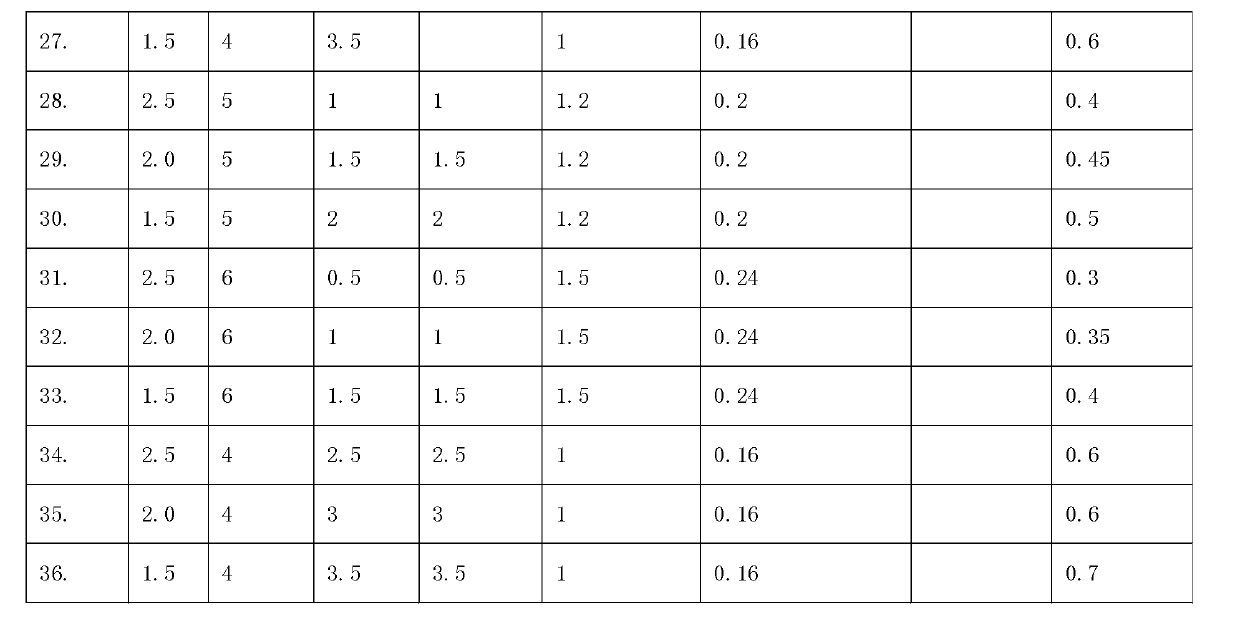

Self-setting composite bone repair material for human body hard tissue repair and application

The invention discloses a self-setting composite bone repair material for human body hard tissue repair and application. The self-setting composite bone repair material comprises solid-phase powder and a liquid phase, wherein the solid-phase powder contains 5-20% of tricalcium silicate, 30-70% of electric smelting magnesium oxide, 5-30% of calcium phosphate bone cement, 5-30% of potassium dihydrogen phosphate or ammonium dihydrogen phosphate, and retarder accounting for 2-10% of the weight of basic oxide, i.e. magnesium oxide; the liquid phase is selected from one or a mixture of more than one of deionized water, soluble phosphate, sodium alginate, citric acid, potassium citrate and chitosan; and the ratio of the liquid phase to the solid phase is 0.3-0.8ml / g, and the solid-phase powder and the liquid phase are uniformly blended. The bone cement material has good combination property; and as the initial setting time of the bone cement material is 3-20 minutes, the final settling time is 7-50 minutes, and the compressive strength is 10-50Mpa in 24 hours and 20-90Mpa in 72 hours, the bone cement material can meet the requirement of clinical application and is suitable for treating bone defect repair and osteoporosis and fixing and treating bone fractures in orthopedic departments, spine surgery, plastic surgery and stomatological departments.

Owner:HENAN POLYTECHNIC UNIV

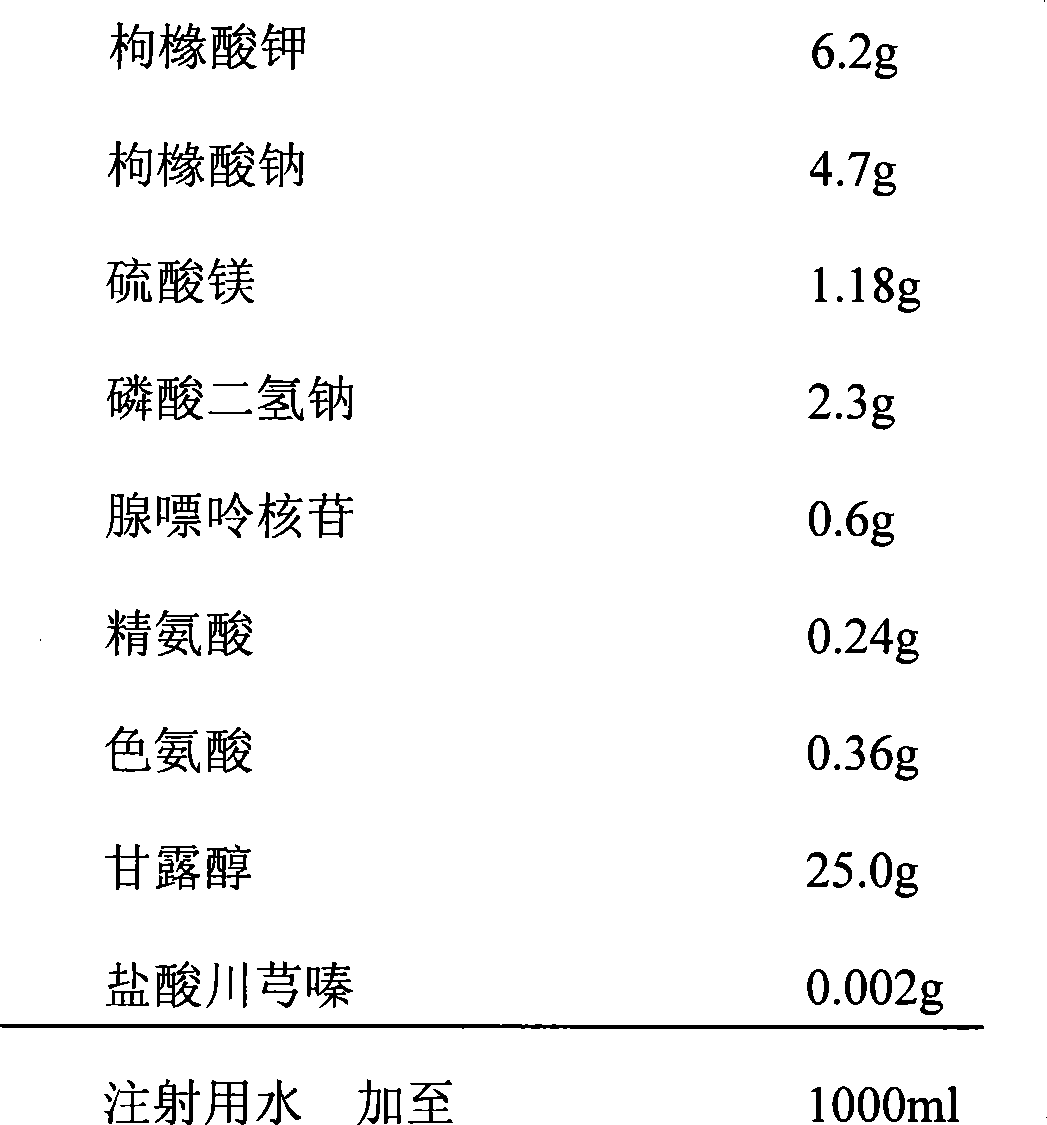

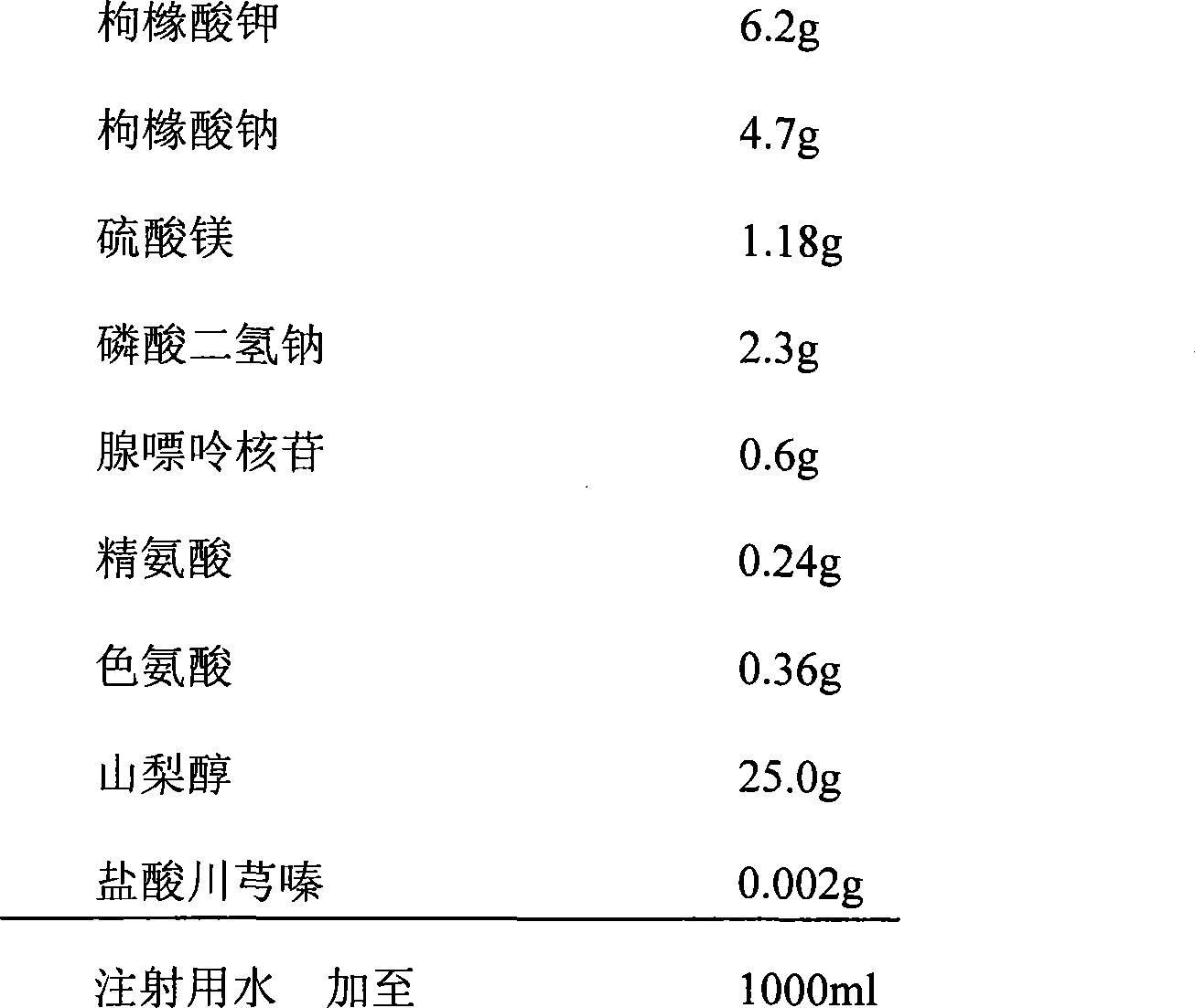

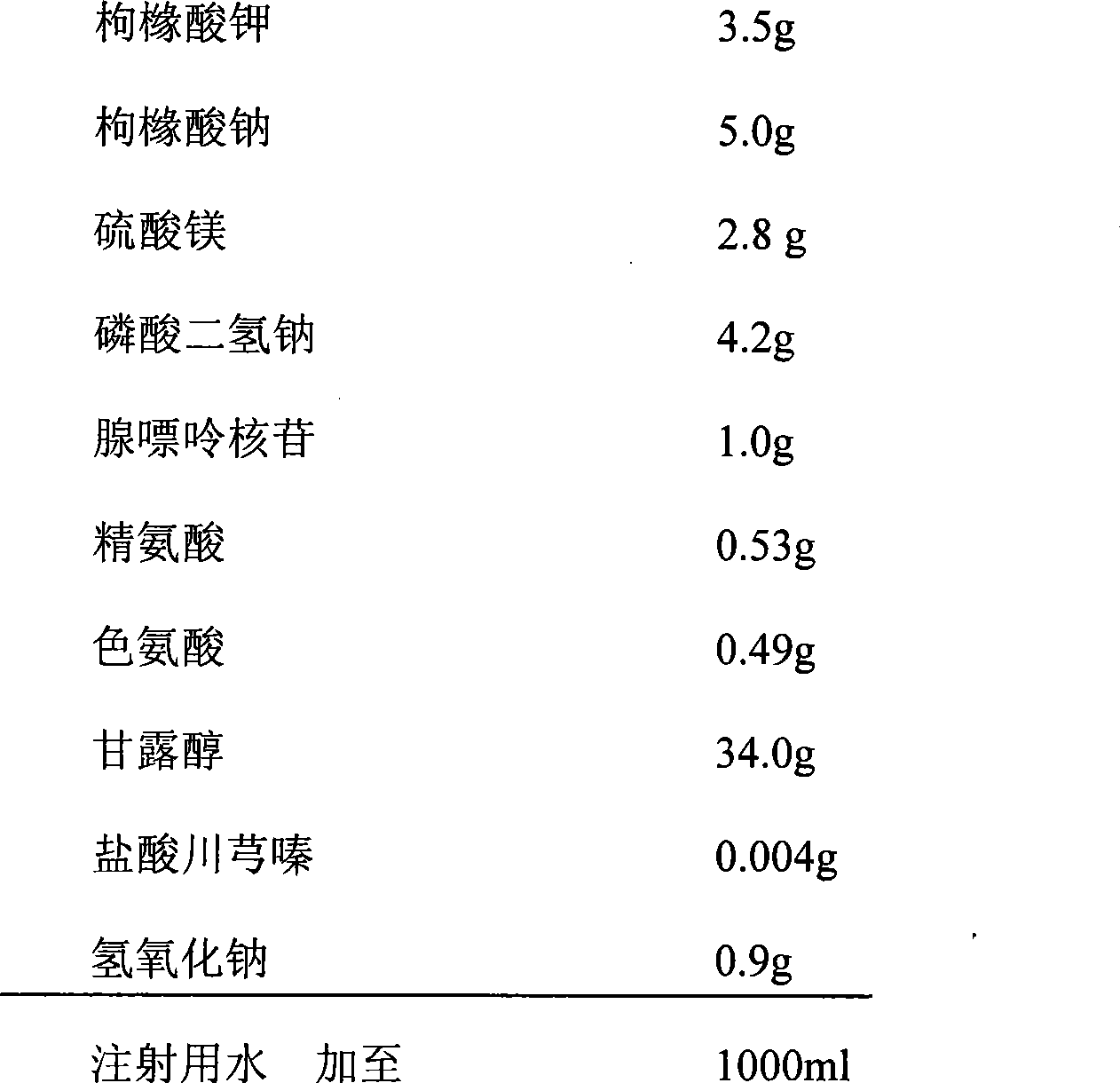

Organ preservative fluid and preparation method thereof

InactiveCN101496512AEffective preservationPrevent ischemia-reperfusion injuryDead animal preservationReperfusion injuryTetramethylpyrazine hydrochloride

The invention relates to a preservation solution for organs, tissues or cells of human bodies or animals. The organ preservation solution comprises sodium citrate, potassium citrate, magnesium sulfate, sodium dihydrogen phosphate, sodium hydroxide, adenosine, arginine, tryptophan, mannitol, tetramethylpyrazine hydrochloride and other components. The organ preservation solution can be used for cooling, lavaging and preserving the organs of the human bodies or the animals, can effectively preserve human in vitro kidneys for 48 hours and animal in vitro kidneys for 72 hours, can prevent ischemia-reperfusion injury, and has great value for clinical application.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

Cigarette with dobble-layer of cigarette paper

The present invention discloses cigarette with tobacco encircled with two, one inner and one outer, layers of cigarette paper. The inner layer of cigarette paper contains inorganic stuffing 20-40 wt%, combustion assistant 6-10 wt% and essence 12-18 wt%; and the outer layer of cigarette paper contains inorganic stuffing 25-35 wt% and combustion assistant 5-10 wt%. The said inorganic stuffing is calcium carbonate, magnesium hydroxide, magnesia, trihydroxyl aluminum or their mixture; the combustion assistant is the mixture of potassium citrate and sodium citrate with weight ratio between potassium ion and sodium ion of 2-4; and the essence is one of menthyl palmitate, vanillin, menthyl carbonate and beta-carotene. The present invention can reduce the side flow fume of cigarette, lower tar and reduce fragrance loss.

Owner:YUNNAN RES INST OF TOBACCO SCI

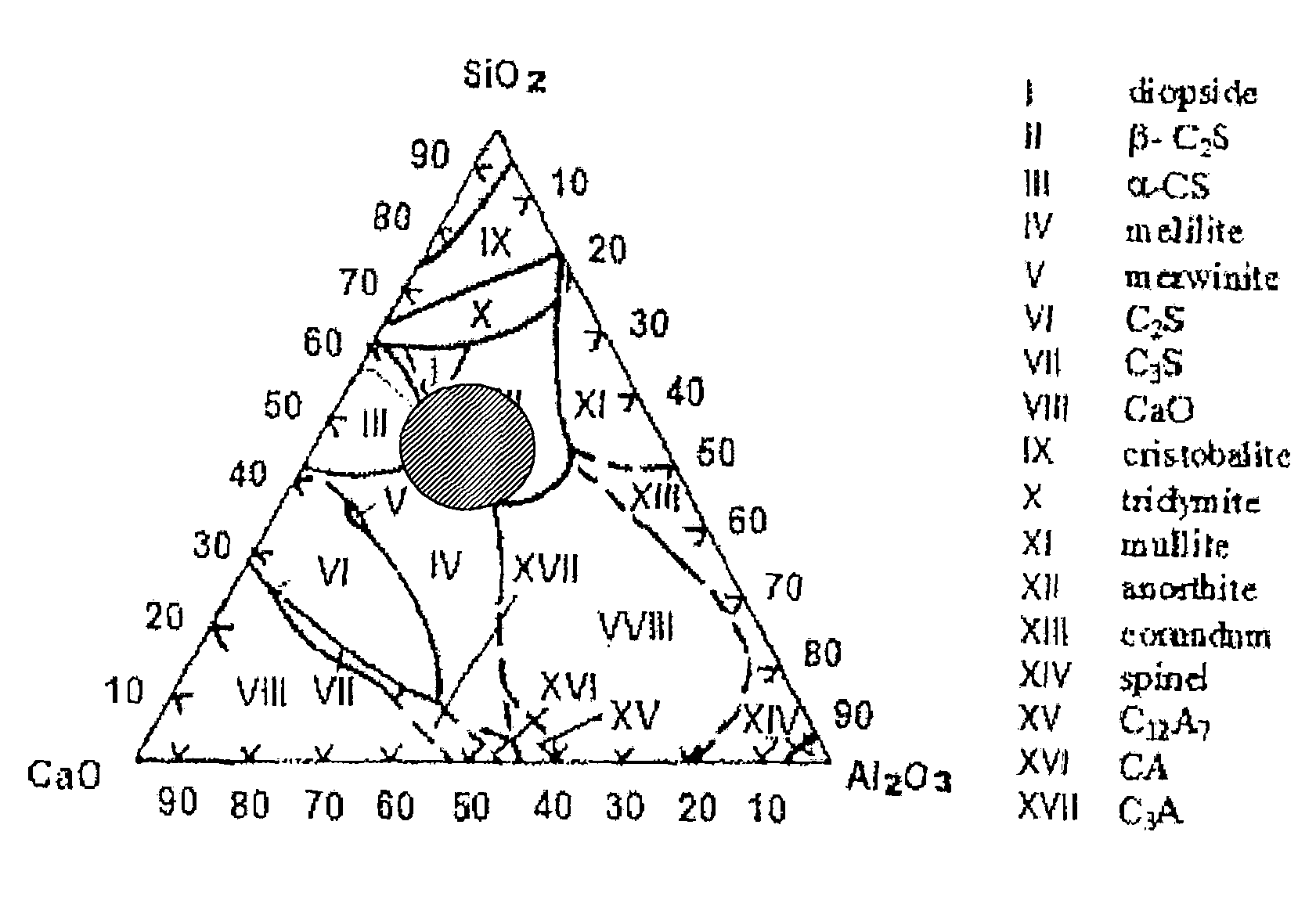

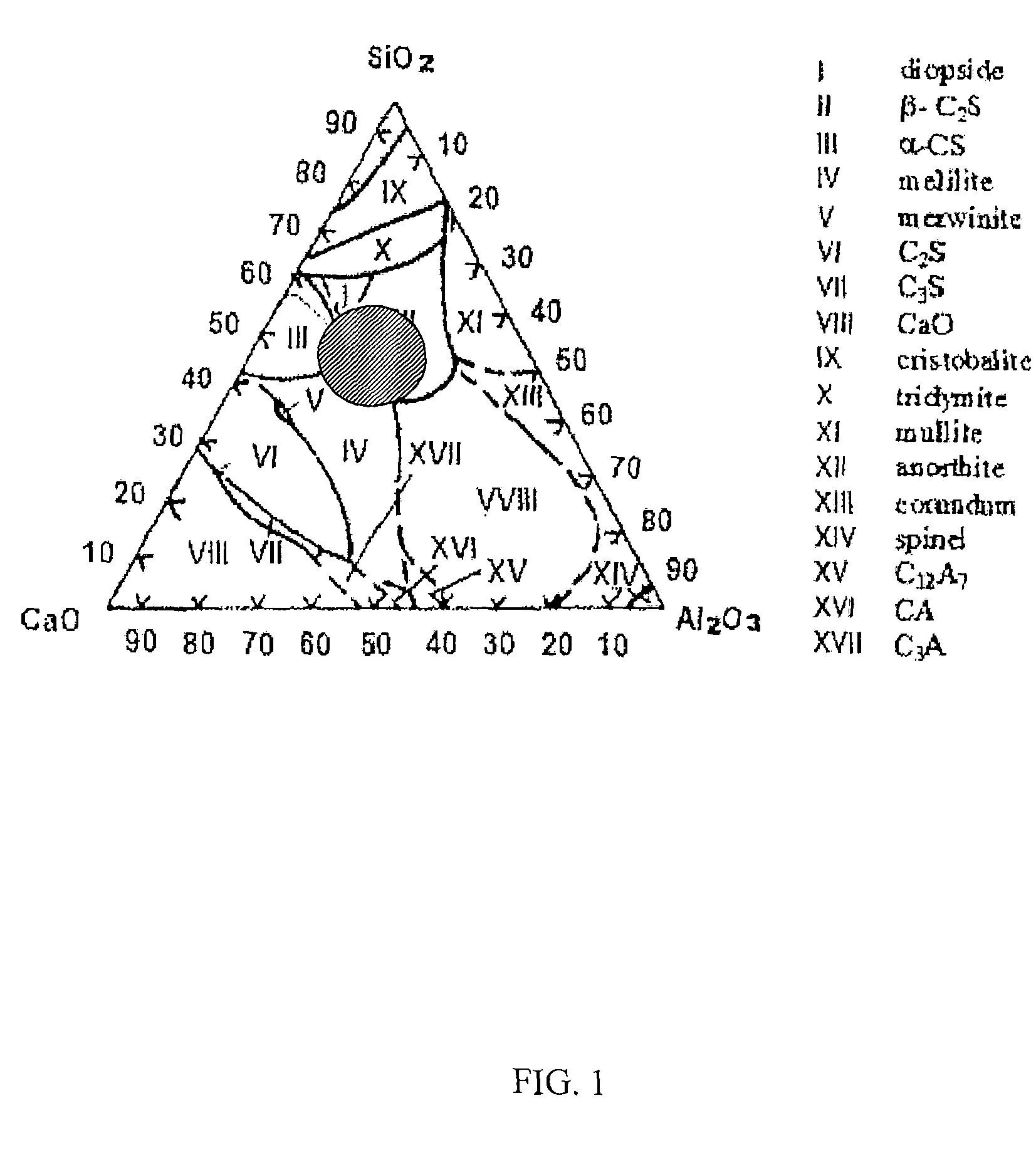

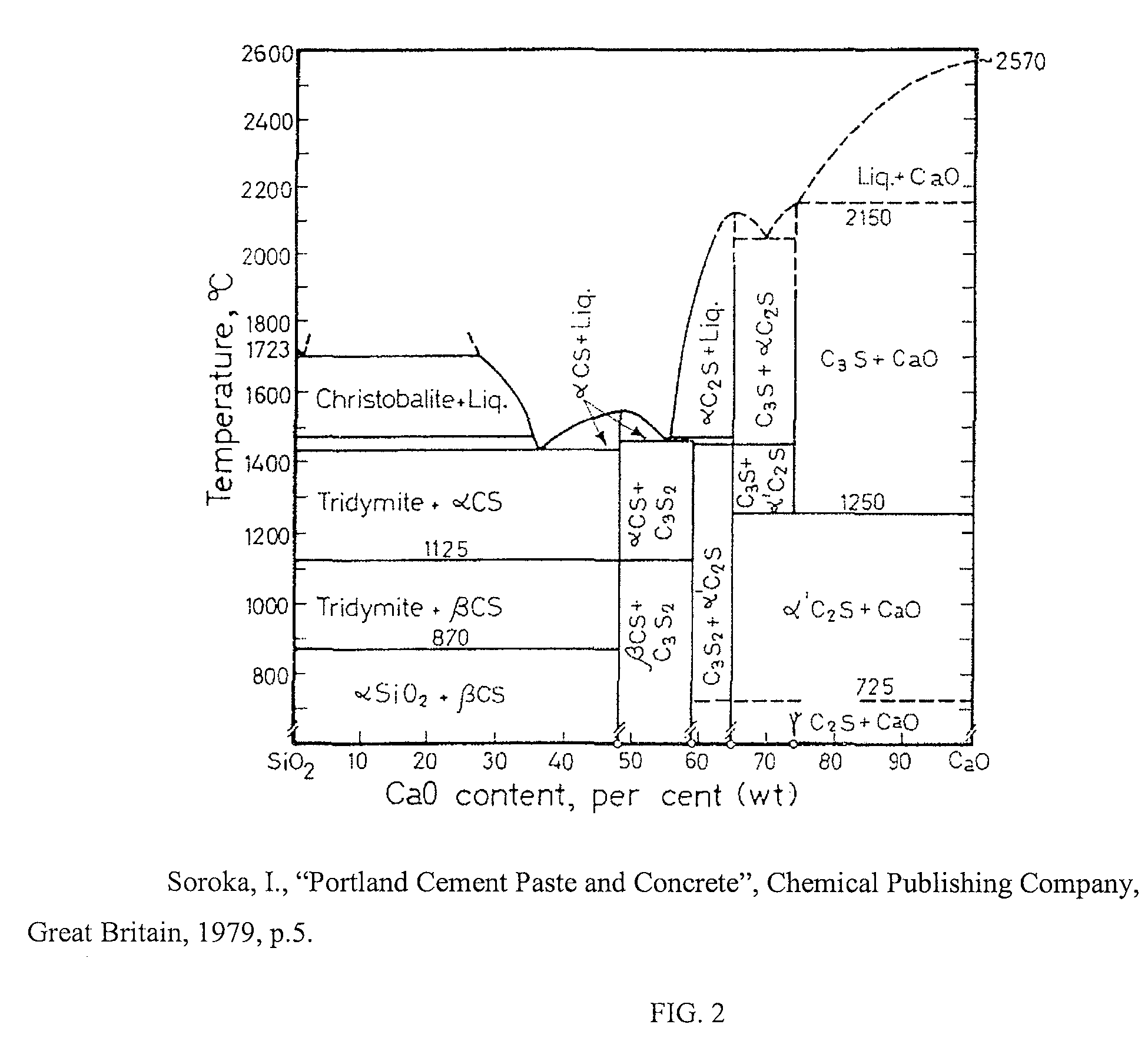

High strength cement, mortar and concrete including industrial by-products

Cementitious compositions in which the cementitious properties of fly-ash are carefully controlled. The cementitious compositions may be substantially free harsh acids and bases such as citric acids (≈pH 2.2) and alkali metal activators including alkali hydroxides (≈pH 12-14) and metal carbonates (≈pH 11.6). The use of these harsh chemicals creates acid base reactions during use of the products. Instead of these harsh chemicals, a citric salt, for example potassium citrate, may be used as a reaction accelerator. Boric compounds may be used as a retarder in the compositions.

Owner:SECURED NOTEHOLDERS LLC

Non-cyanide alkaline copper plating bath, preparation and use method thereof

The present invention is a new non-cyanide alkaline copper plating bath, preparation and use method thereof. In the copper plating bath, using copper sulfate or basic copper carbonate as main salt, using hydroxy-ethylidene diphosphonic acid as main complexant, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator; the operation conditions are: cathode current density is 0.5-3.0 A / dm [2], pH of plating bath controlled between 12 and 13, plating bath temperature is 50-70 DEG. Comparing with the prior known technology, the invention has following advantages or positive effects: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

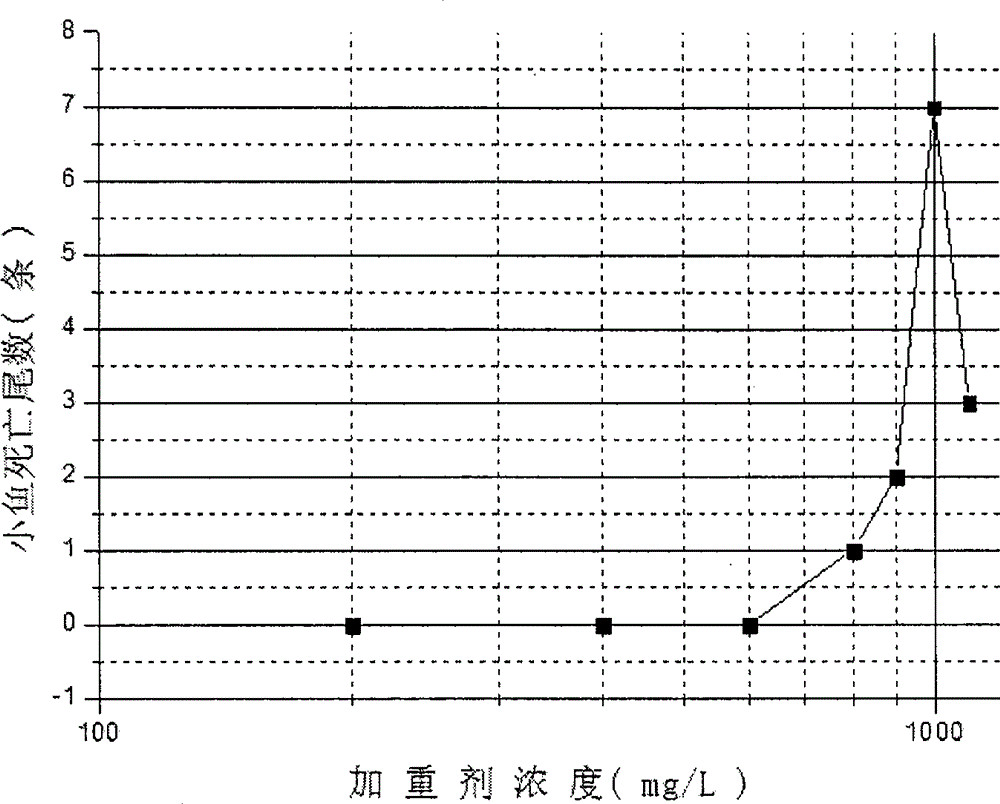

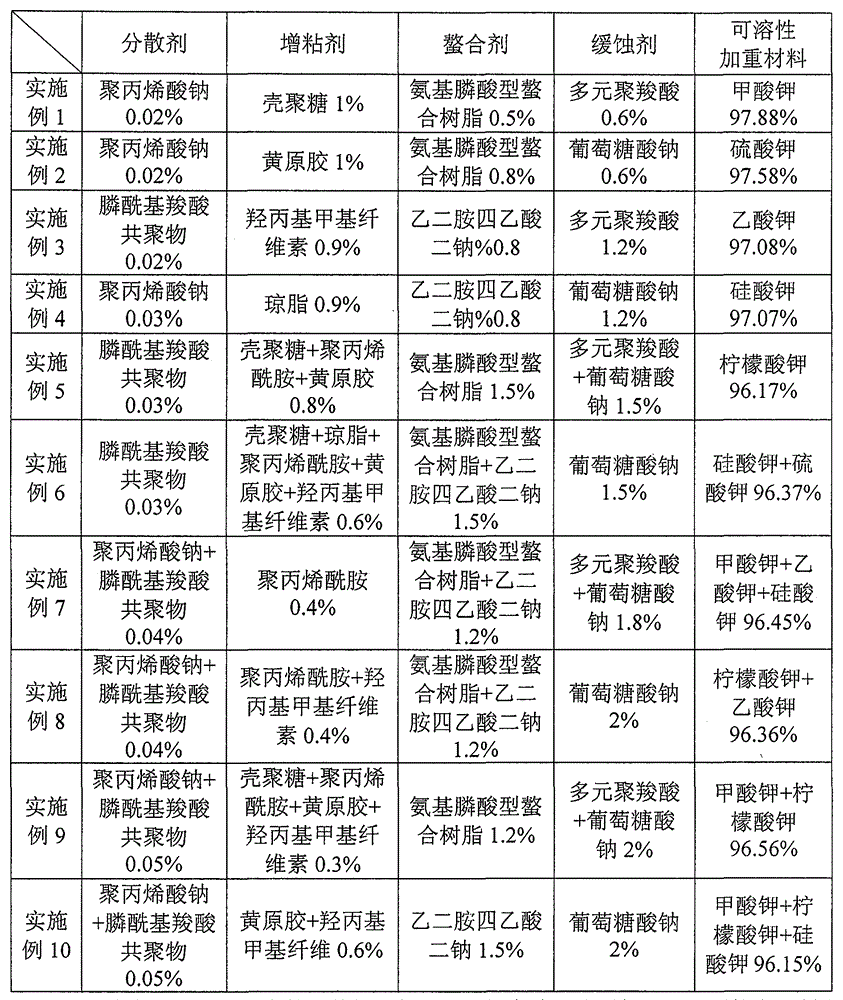

Environment-friendly high-density solid-free weighting agent and preparation method

ActiveCN104610937AWide range of densitiesReduce pollutionDrilling compositionCarboxylic acidPotassium formate

An environment-friendly high-density solid-free weighting agent comprises components in parts by weight as follows: 0.02-0.05 parts of a dispersant, 0.3-1 part of a tackifier, 0.5-1.2 parts of chelating agent, 0.6-2 parts of a corrosion inhibitor and the balance of soluble weighting materials, wherein the dispersant is one or two of sodium polyacrylate and copolymer of phosphono and carboxylic acid; the tackifier is one or more of chitosan, agar, polyacrylamide, xanthan gum and hydroxypropyl methyl cellulose; the chelating agent is one or two of aminophosphonic acid chelate resin and ethylenediamine tetraacetic acid disodium; the corrosion inhibitor is one or two of multiple polycarboxylate and sodium gluconate; the soluble weighting materials are one or more of potassium formate, potassium citrate, potassium acetate, potassium silicate and potassium sulfate. The process steps are as follows: the raw materials are taken in weight proportion, mixed and uniformly stirred; the raw materials are added to water and dissolved at the high temperature of 70-80 DEG C; a product is evaporated to dryness, and solid is obtained; the obtained solid is ground into powder, and the solid weighting agent is obtained.

Owner:成都西油华巍科技有限公司

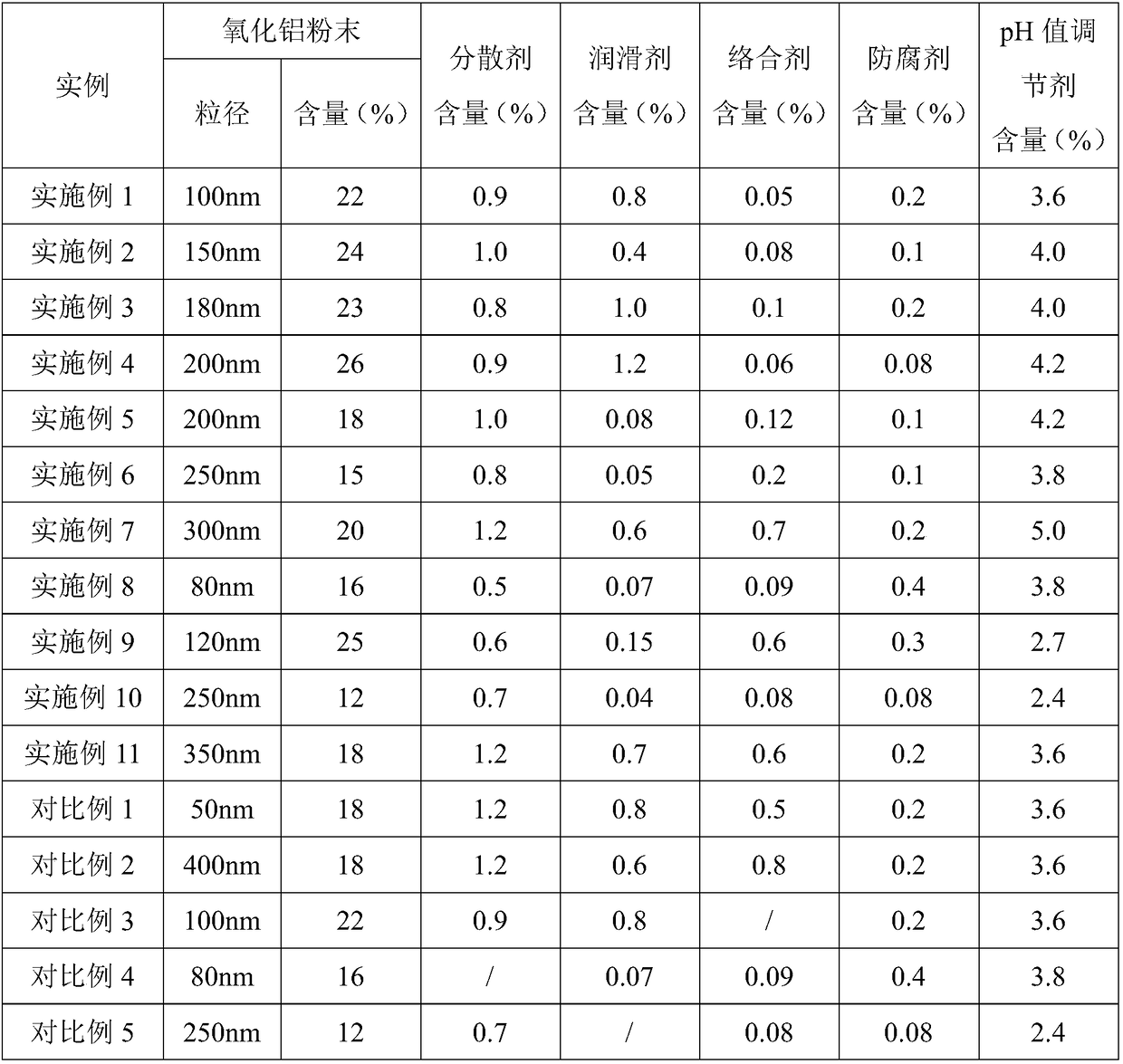

Aluminum oxide polishing solution used for polishing sapphire and preparation method thereof

ActiveCN108239484AEasy to prepareLow costPolishing compositions with abrasivesSodium lactateAlkylphenol

The invention provides aluminum oxide polishing solution used for polishing sapphire. The aluminum oxide polishing solution is aqueous solution comprising the following components: 12-26wt% of alpha-aluminum oxide powder with the particle size of 80-350nm, 0.5-1.2wt% of a dispersing agent, 0.04-1.2wt% of a lubricating agent, 0.05-0.7wt% of a complexing agent, 0.08-0.4wt% of a preservative and 2.4-5wt% of a pH value regulator, wherein the dispersing agent is one or more than one of poly vinyl alcohol, polyvinylpyrrolidone, alkylphenol polyoxyethylene and fatty alcohol polyoxyethylene ether, thelubricating agent is one or more than one of polyethylene glycol 400, polyethylene glycol 600 and glycerin, the complexing agent is one or more than one of sodium gluconate, sodium lactate and potassium citrate, and the preservative is one or more than one of benzotriazole, potassium borate and sodium borate. The polishing solution provided by the invention has high polishing efficiency in a sapphire processing process, lubricating effect is excellent, a processed product surface is good in quality, and the polishing solution is simple in preparation method, low in cost and beneficial to industrial popularization and application.

Owner:LENS TECH CHANGSHA

Weathering crust illuviation-type rare-earth ore leaching agent and method for extracting rare earths by using same

InactiveCN103484668AUse low concentrationReduce dosageProcess efficiency improvementRare earthCitrate salt

The invention provides a weathering crust illuviation-type rare-earth ore leaching agent and a method for extracting rare earths by using the same, particularly a leaching agent solution for weathering crust illuviation-type rare-earth ores. The active component is citrate, wherein the citrate is any one of ammonium citrate, sodium citrate, potassium citrate and magnesium citrate, or mixture of sodium citrate, potassium citrate and magnesium citrate. The method for extracting rare earths from weathering crust illuviation-type rare-earth ores comprises the following steps: leaching by using the citrate as the active component of the leaching agent to obtain a rare-earth leaching mother solution, removing impurities, and adding a precipitant to obtain a rare-earth enriched substance. In the weathering crust illuviation-type rare-earth extraction process, cation exchange interaction and anion (citrate ion) complex action exist, and the two actions can cooperate to enhance the rare-earth recovery rate and lower the concentration and consumption of the leaching agent.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

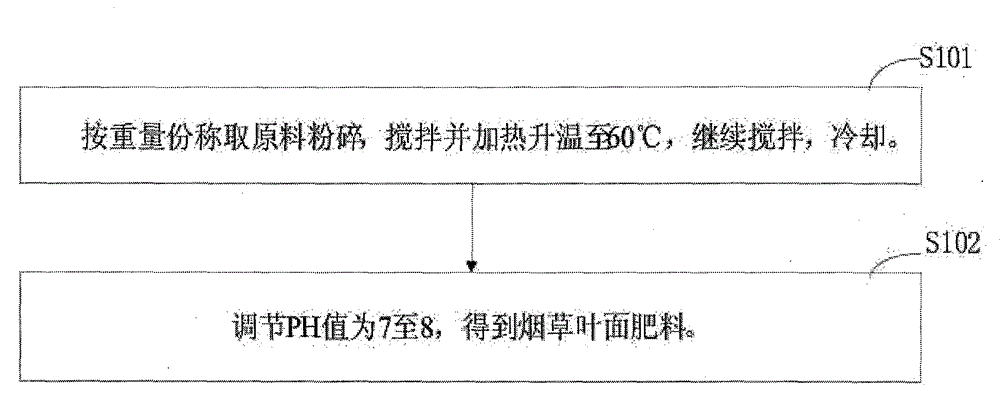

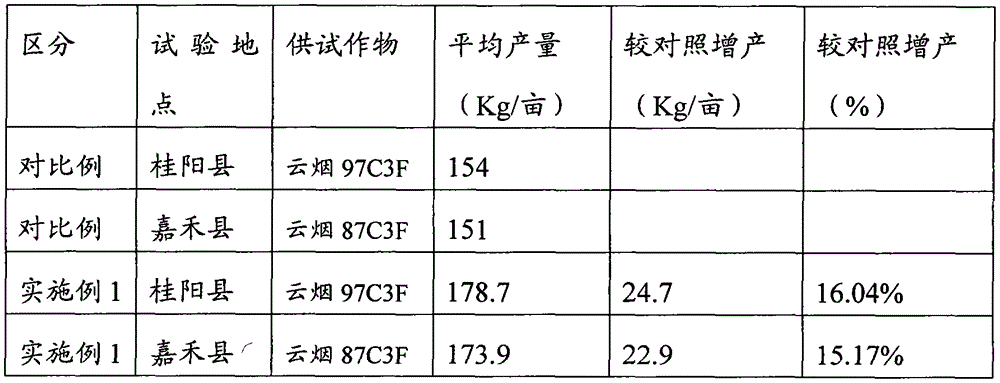

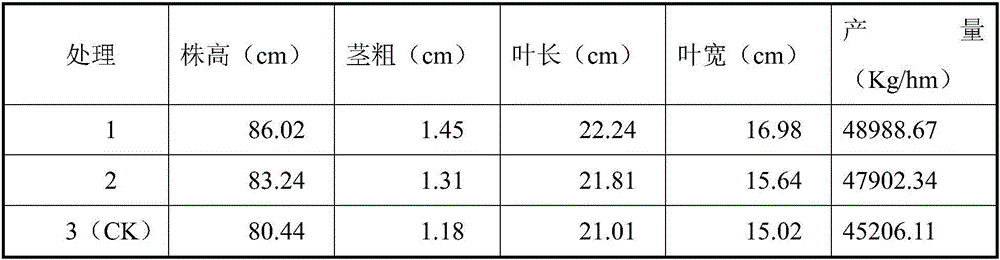

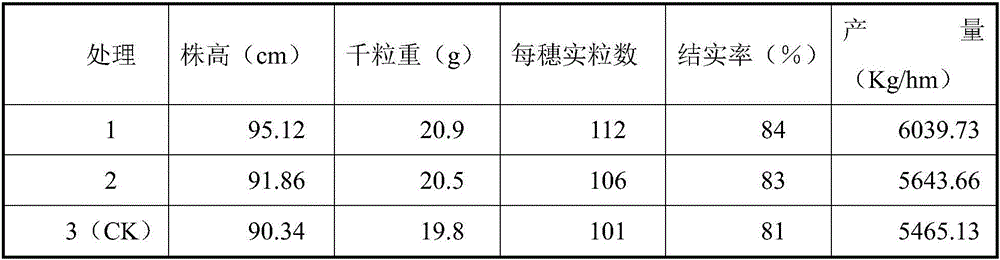

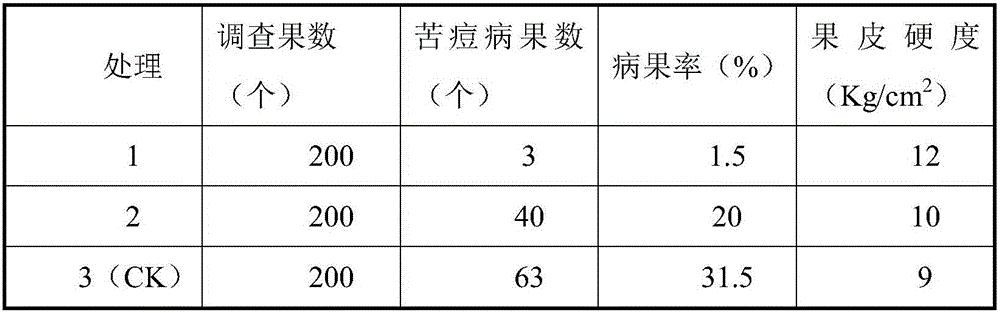

Tobacco foliar fertilizer and preparation method thereof

A tobacco foliar fertilizer and a preparation method thereof. The tobacco foliar fertilizer includes following components, by weight: 20-25 parts of potassium tripolyphosphate, 15-20 parts of potassium citrate, 3-6 parts of sargassum fermentation extract, 0.5-2 parts of glutathione, 0.5-2 parts of [beta]-deoxyglucose, 0.1-1 part of trans-abscisic acid, 0.5-1 part of xylooligosaccharide, 0.2-0.5 parts of salicylic acid, 1-3 parts of boric acid, 0.1-0.5 parts of ammonium molybdenate, 0.5-2 parts of EDTA-chelating zinc, 0.5-2 parts of EDTA-chelating magnesium, 0.3-2 parts of EDTA-chelating manganese, 0.3-1 part of EDTA-chelating copper, 0.5-1 part of alkyl polysaccharide glycoside and 31-56.2 parts of water. The tobacco foliar fertilizer is reasonable in combination and proportion, can promote growth of tobacco, can enhance the resistance capability on viruses, cold and dryness of tobacco, can increase yield, is green and environmental-friendly and can greatly improve quality of tobacco.

Owner:HUNAN AGRICULTURAL UNIV +5

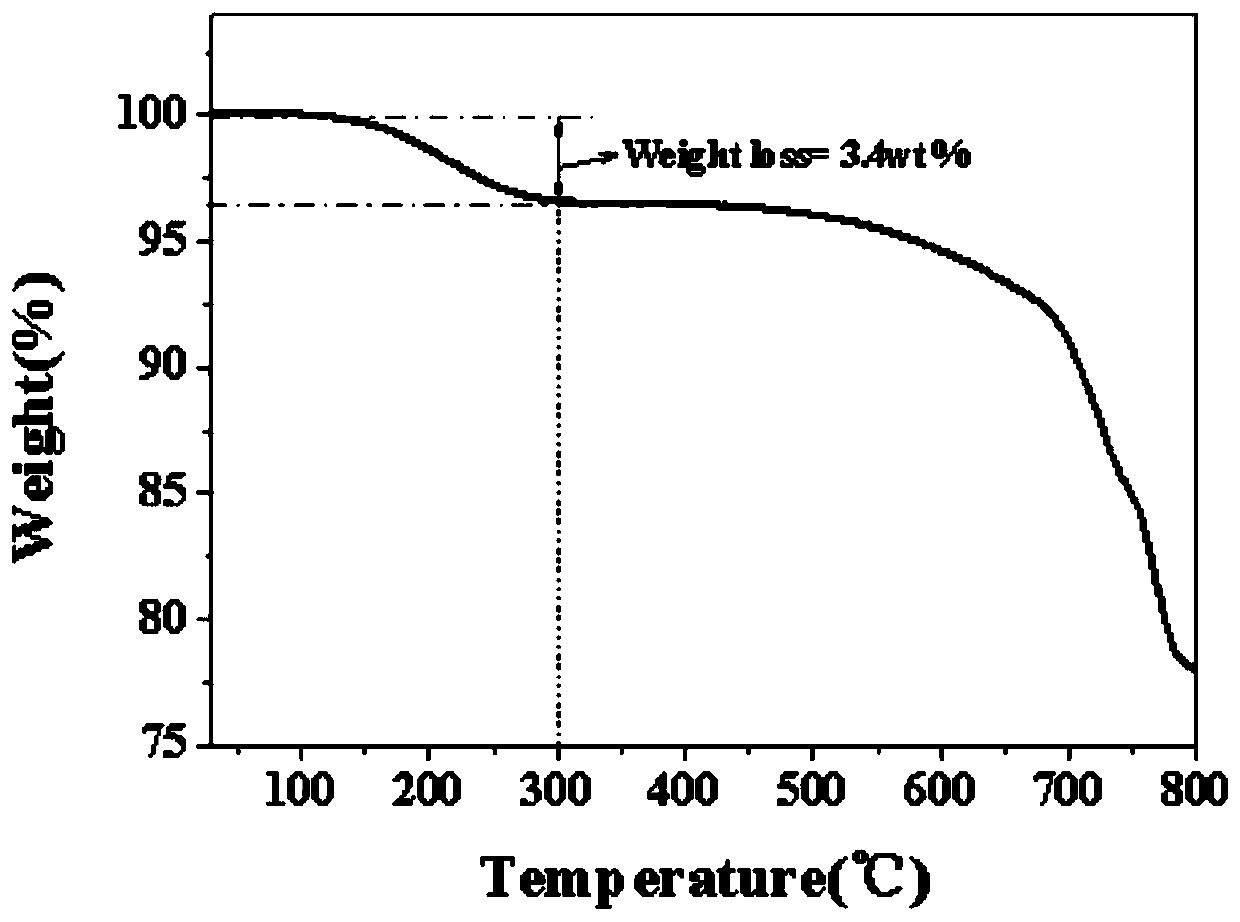

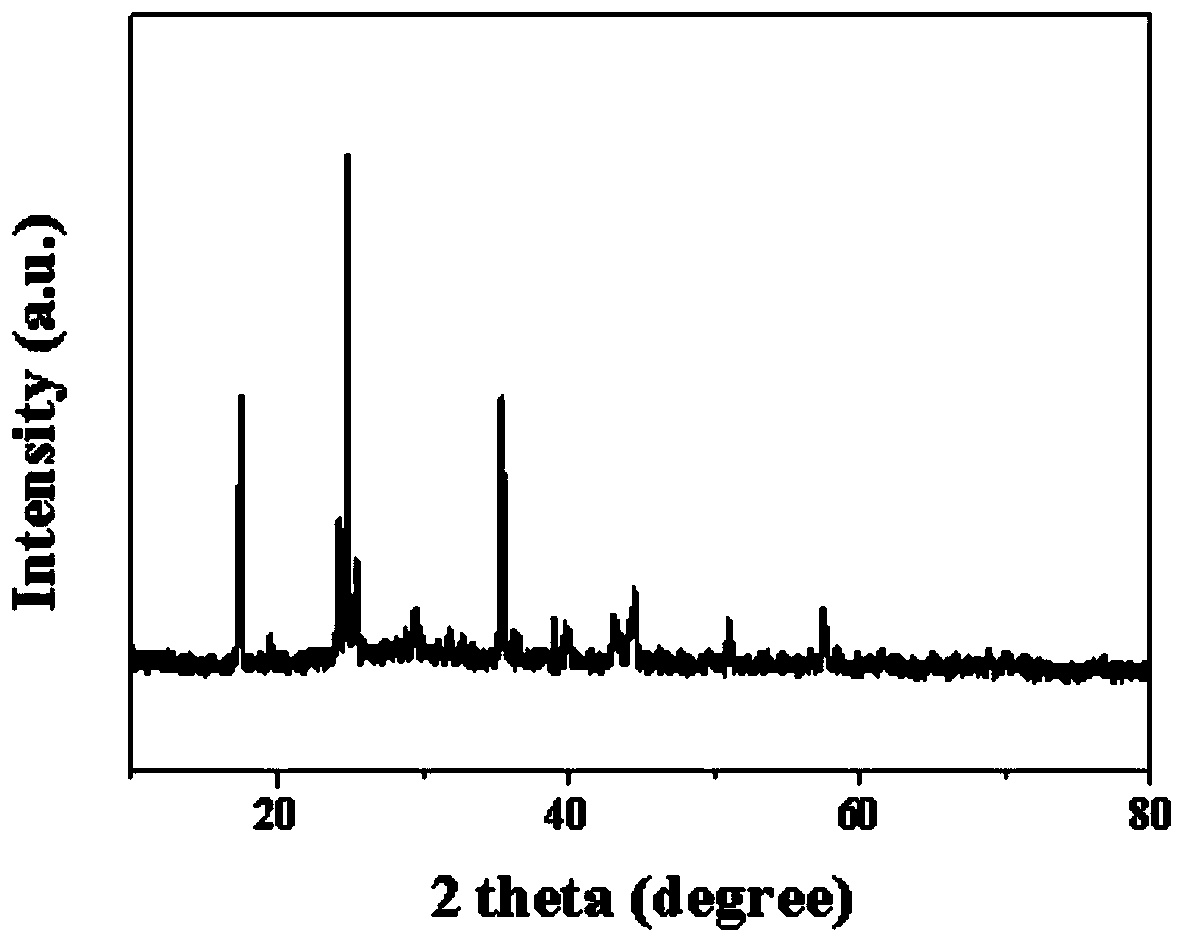

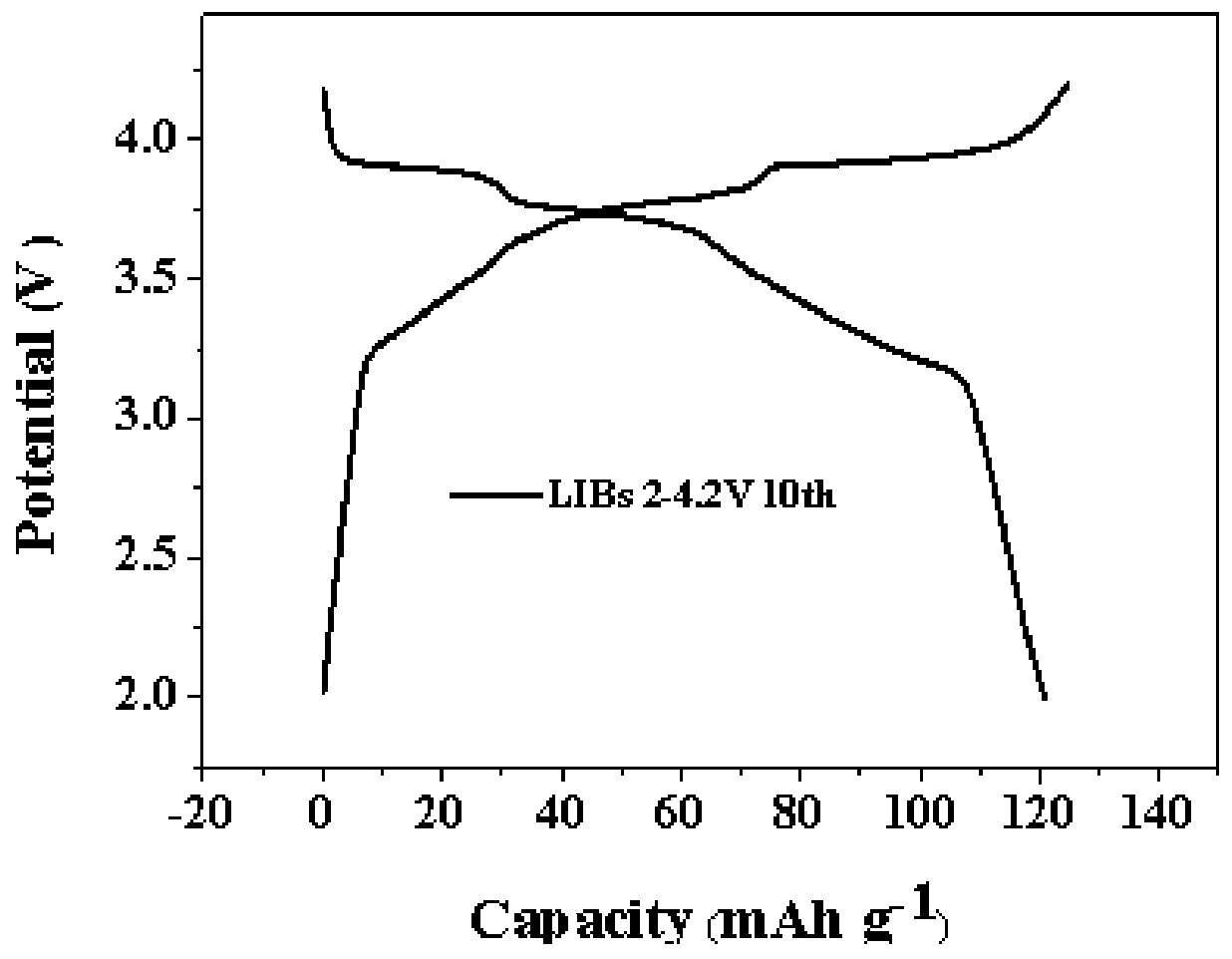

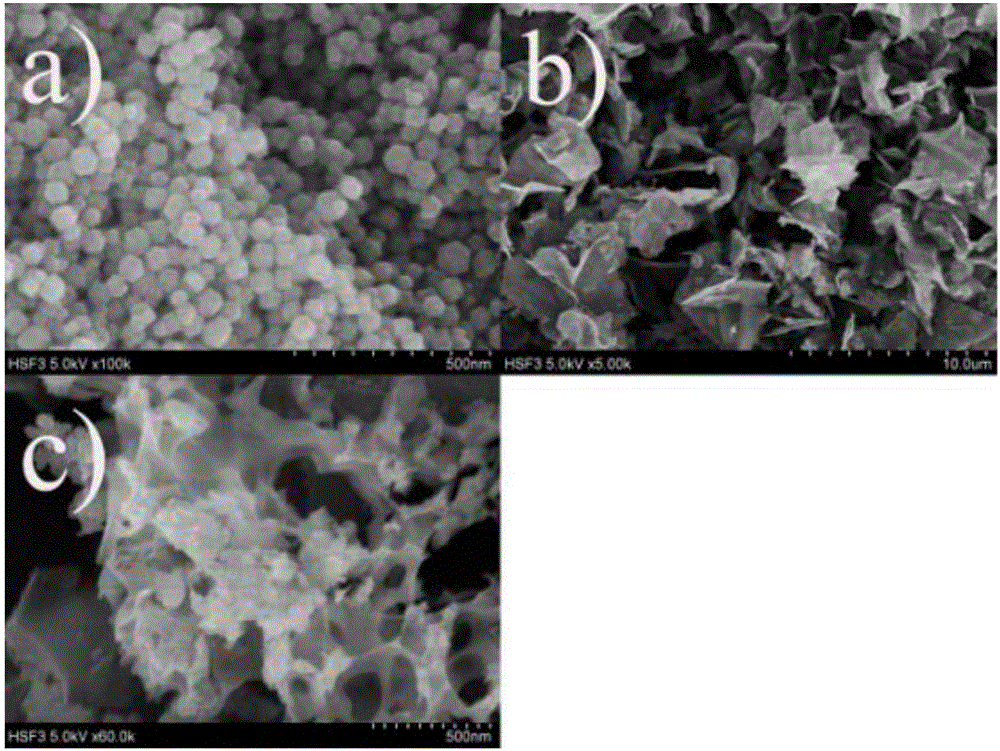

Prussian white analog cathode material and preparation method and application thereof

ActiveCN110002465AImprove crystal structureReduce defectsIron cyanidesSecondary cellsNew energyAqueous solution

The invention belongs to the field of new-energy batteries, and particularly relates to a Prussian white analog cathode material and a preparation method and application thereof. The preparation method of the Prussian white analog cathode material comprises the following steps: (1), acquiring an aqueous solution of K4Fe (CN)6, which is recorded as a solution A; (2), acquiring a mixed aqueous solution of a transition metal salt of Mn and potassium citrate, which is recorded as a solution B; and (3), dropwise adding the solution A into the solution B, continuing heating and stirring after completion of dropwise addition, aging for several hours, performing solid-liquid separation, collecting and washing a precipitate, and drying to obtain the Prussian white analog cathode material. The Prussian white analog cathode material adopts an open three-dimensional network frame structure, has a large gap position, and can guarantee free deintercalation of various ions such as Li<+>, Na<+> and K<+>.

Owner:HUAZHONG UNIV OF SCI & TECH

Organic titanium-potassium fertilizer and preparation method thereof

The invention discloses organic titanium-potassium fertilizer and a preparation method thereof. The fertilizer is characterized in that the fertilizer takes water as solvent; and the compositions of the fertilizer in every liter of water are: 5 to 100g of organic chelated titanium, 75 to 200g of glucose, 600 to 800g of potassium citrate, 0 to 130g of borax or boric acid, 0 to 90g of humic acid or potassium humate, 0 to 60g of EDDHA chelating agent and 7 to 12g of auxiliary agent. The organic titanium-potassium fertilizer not only makes effective use of the prior fertilizer resources to change the status quo of constant high potassium fertilizer price in China, relieve contradictions between supply and demand and save resource, but also overcomes the differences between southern China and northern China in climate, soil, and the like, thereby playing a remarkable role in solving soil hardening, salinization and acidification. The fertilizer can also improve adverse circumstance resistance of crops, and is suitable for soil of various climates and various crops; moreover, the fertilizer better ensures yield increase of various crops and solves the problems of farmers such as low economic benefits, income increase, labor intensity reduction and the like; meanwhile, the fertilizer is propitious to advocate rational application of the fertilizer and improve the quality of farm products.

Owner:榆林好婆姨农业科技有限公司

Gold potassium lemon acid for gold plating and method for producing the same

ActiveCN101172946BReduce processing costsReduce pollutionCarboxylic acid salt preparationGold contentPotassium

The invention discloses citric acid gold potassium used for gold plating and the preparation method thereof. The molecular formular of the citric acid gold potassium is K3Au2C9H5O7N2. The method comprises the steps as follows: gold trichloride is dissolved in water of certain temperature, is concentrated and diluted under the temperature for multiple times, and is reacted with potassium citrate, ethylene diamine tetraacetic acid and malononitrile in a reactor under the certain temperature and the certain time to produce the organic gold salt which has low toxicity and contains no free cyanogen. When the product has the same gold content with the potassium gold cyanide, the total CN- is 5 to 6 percent, being 50 percent lower than that of the CN- in the potassium gold cyanide. The waste liquid after gold plating contains free the CN- in small amount. The invention reduces the cost of waste water treatment for the electroplating plants.

Owner:HENGSHENG TECH R&D CO LTD

Preparation method of sugar alcohol chelated medium trace element liquid fertilizer

PendingCN106242759AObvious yield increase effectPromote chelationCalcareous fertilisersMagnesium fertilisersSolubilityAlcohol sugars

The invention discloses a preparation method of a sugar alcohol chelated medium trace element liquid fertilizer, comprising the following steps: respectively using medium elements and trace elements in two reaction vessels to prepare mother liquor under different conditions and in presence of a chelating agent, mixing the two mother liquors and stirring, carrying out secondary chelating, and cooling to room temperature. The liquid fertilizer comprises the following substances (by weight): 3-10% of sugar alcohol, 0.5-3% of potassium citrate, 30-50% of calcium nitrate, 0-6% of calcium acetate, 0-8% of calcium citrate, 0-50% of magnesium nitrate, 2.5-5% of zinc nitrate, 1-3% of boric acid, 0.5-2% of organoboron, 0-2.5% of EDTA-Zn and the rest of water. The technology is simple. By the method of firstly respectively chelating and mixing medium trace elements for secondary chelating, better chelating degree can be achieved at low temperature. Meanwhile, the product has good solubility and meets requirements of sprinkling and dropping irrigation equipment. In addition, the sugar alcohol chelating technology is beneficial to crop absorption and utilization and can be widely promoted.

Owner:SINOCHEM YANTAI CROP NUTRITION

ZIF-8 pyrolysis porous carbon-graphene composite material, manufacturing method and application thereof

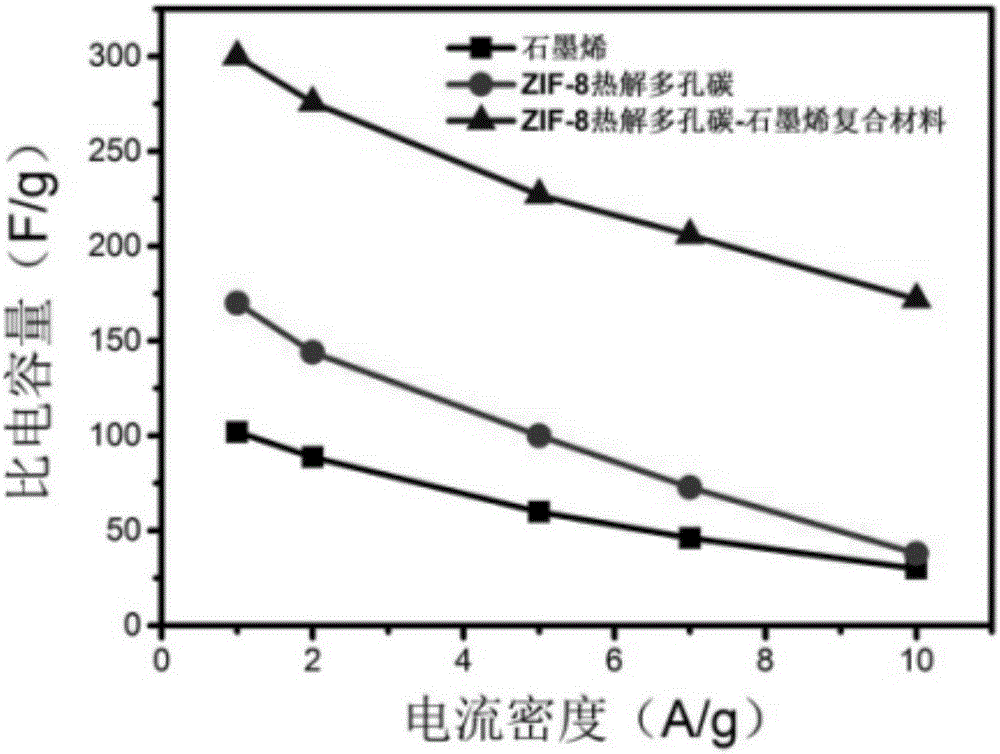

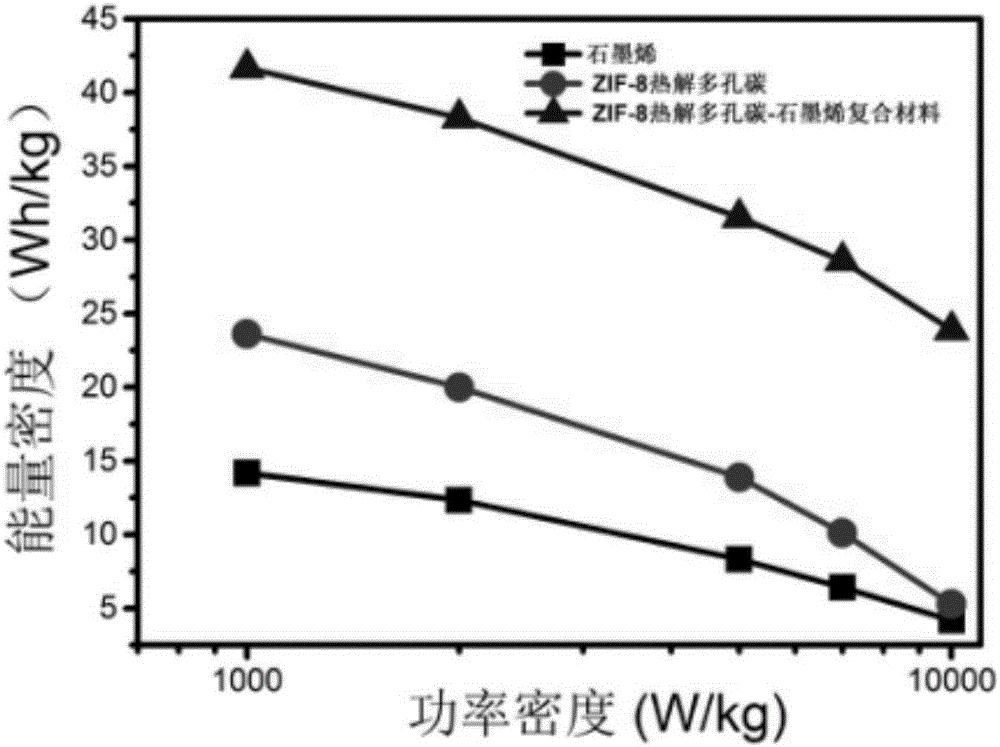

InactiveCN106783197AImprove performanceHigh specific capacityHybrid capacitor electrodesGrapheneCapacitancePorous carbon

The invention relates to a ZIF-8 pyrolysis porous carbon-graphene composite material, a manufacturing method and an application thereof. The structure of the composite material is characterized in that graphene is wrapped on a surface of ZIF-8 pyrolysis porous carbon. The manufacturing method comprises the following steps of mixing zinc nitrate hexahydrate and 2-methylimidazole and dissolving in a solvent; standing for 1-2hs and acquiring a milk-shape solution; centrifuging, washing, carrying out vacuum drying and acquiring ZIF-8 crystal; and mixing the ZIF-8 crystal and potassium citrate, grinding, carrying out high temperature carbonization and acid pickling, drying and acquiring the material. The manufacturing method is simple and cost is low. The acquired ZIF-8 pyrolysis porous carbon-graphene composite material possesses advantages that a chemical property is stable, a capacitive character is good, a specific surface area is high and so on. A hierarchical pore and a three-dimensional conducting framework are fully used to increase electrochemical performance. Under a 1A / g current density, a specific capacitance reaches 300F / g. The material is an ideal high performance electrode material of a super capacitor.

Owner:DONGHUA UNIV

Coal washing and desulfurizing agent composition and preparation method thereof

The invention relates to an adjuvant for coal washing and desulfurizing. The adjuvant is prepared from the following raw materials in parts by weight: 20-25 parts of sodium hypochlorite NaClO, 12-15 parts of ammonium persulfate (NH4)S2O8, 8-12 parts of sodium glycollate HOCH2COONa, 6-10 parts of sodium acetate CH3COONa, 7-12 parts of potassium citrate K3C6H5O7H2O, 5-9 parts of sodium gluconate, 5-9 parts of edetic acid, 7-12 parts of potassium permanganate KMnO4, 25-32 parts of methanol CH3OH, 22-30 parts of triethanolamine (HOCH2CH2)3N, 12-16 parts of sodium dichromate Na2Cr2O7, 3-5 parts of polyaluminum ferric chloride PAFC,1-2 parts of urea CON2H4, 1-2 parts of polyacrylamide PAM, 0.5-0.8 part of sodium dodecyl benzene sulfonate C18H29NaO3S, 0.2-0.4 part of dispersing agent JFC and 100-120 parts of water. The adjuvant disclosed by the invention is simple to use, stable in performance and free of large investment and transformation equipment; the removal rate of inorganic sulfur and organic sulfur is more than 70 percent; and the removal rate of nitric oxides is more than 70 percent.

Owner:LANZHOU XINXING NEUTRAL CLEANING TECH

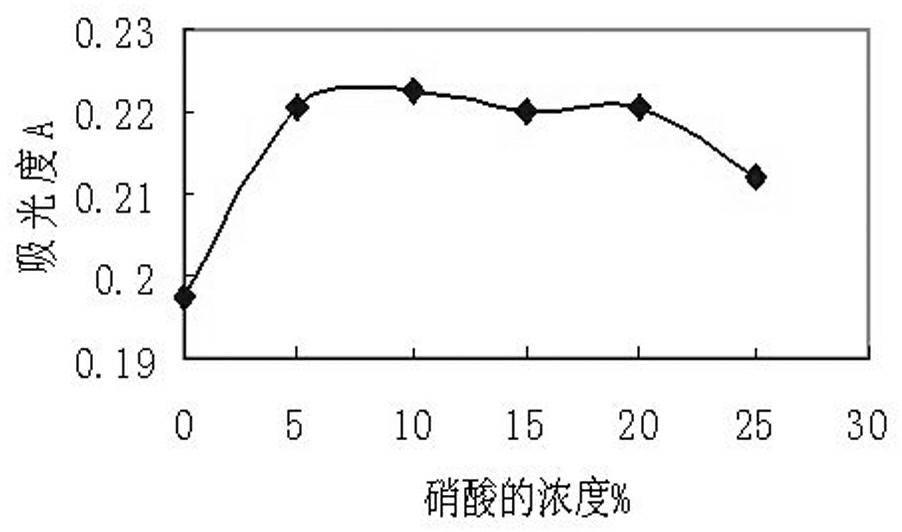

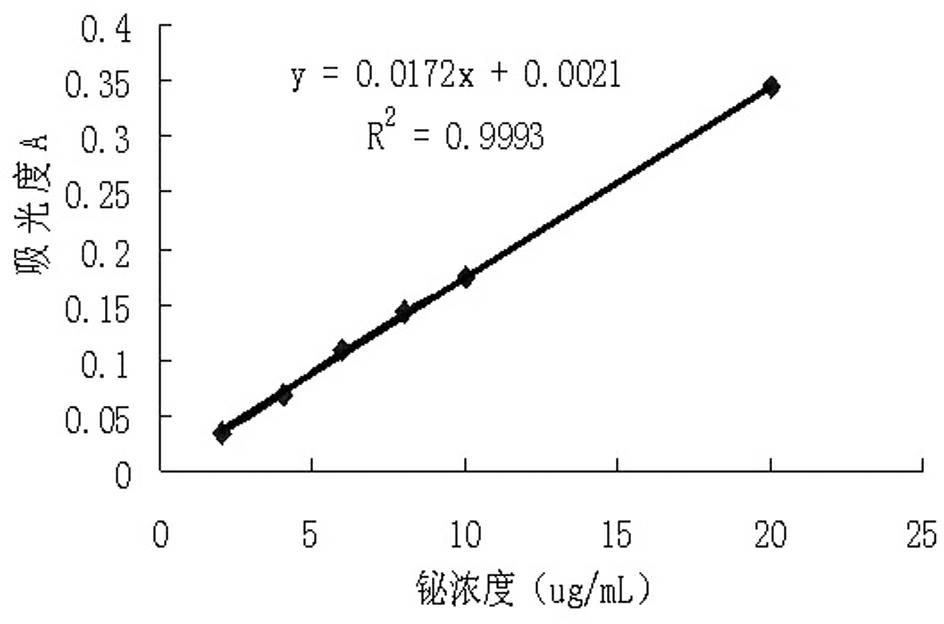

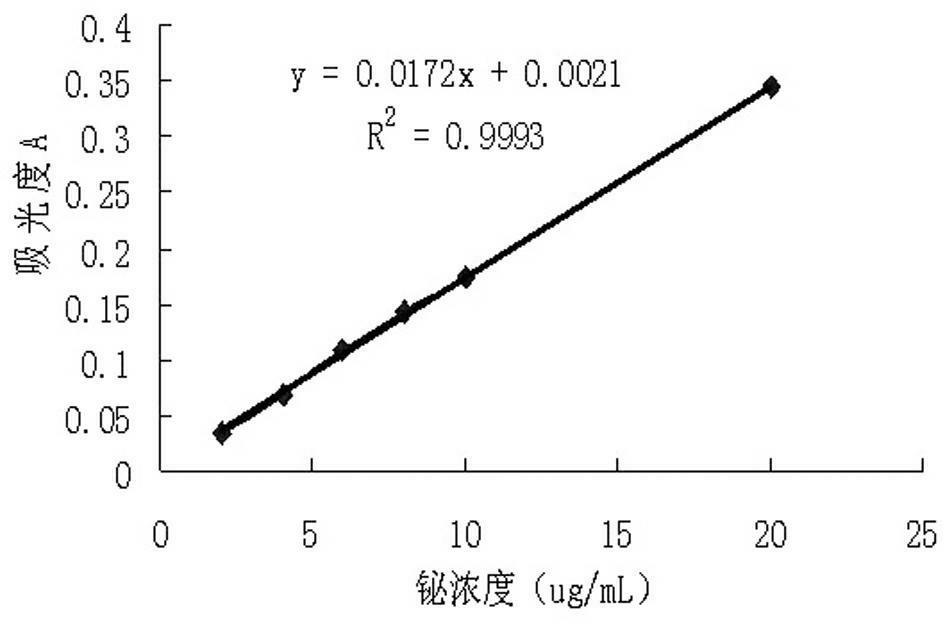

Method for detecting content of bismuth in bismuth potassium citrate medicament

InactiveCN102590123AReduce typesEasy to prepareColor/spectral properties measurementsBismuthCitrate potassium

The invention relates to a method for detecting the content of bismuth in a bismuth potassium citrate medicament. According to the method, a sample is dissolved with acid; and the content of the bismuth in the bismuth potassium citrate medicament is determined by adopting an air-acetylene flame atomic absorption spectrometry and a bismuth hollow cathode lamp according to the absorption of a bismuth element in the medicament for a bismuth characteristic line. The method for detecting the content of the bismuth in the bismuth potassium citrate medicament by adopting the atomic absorption spectrometry is free from troublesome pretreatment, fewer in reagent types, simple in solution preparation and simple and quick in operation; and in addition, the method has the advantages of favorable selectivity and reproducibility, high accuracy, consistent measuring result with that of an official method, satisfaction in result and practical value.

Owner:长治学院

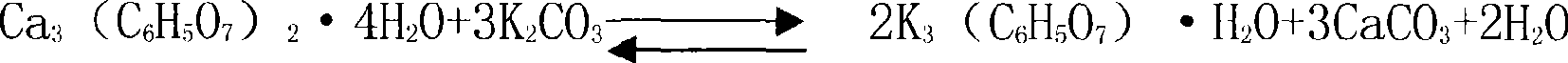

Double decomposition precipitation transformation production method of potassium citrate

InactiveCN101434970AProduct hygienic quality requirements qualifiedReduce consumptionMicroorganism based processesCarboxylic acid salt preparationDecompositionPotassium carbonate

The invention discloses a double decomposition precipitation conversion production method of potassium citrate, which is characterized by comprising the following steps: (1) citric acid filtrate is prepared; (2) calcium carbonate is added into the citric acid filtrate for conducting neutralization reaction so as to prepare solid calcium citrate; (3) the impurities are removed by washing; (4) double decomposition reaction is carried out on the washed calcium citrate and potassium carbonate, and then calcium carbonate and potassium citrate solution is generated; (5) by filtering separation, the calcium carbonate solid and the potassium citrate solution are obtained, later the calcium carbonate is returned to the step 2 for re-use; (6) decolorization is conducted; and (7) the potassium citrate solid is prepared. The invention only uses two types of raw materials of pharmaceutical-grade powdered activated carbon and food-grade potassium carbonate, thereby greatly reducing the type of raw materials, and simultaneously produces no solid and gas waste, and significantly simplifies the production process of the potassium citrate, lowers the production cost and improves the economic benefit.

Owner:LAIWU TAIHE BIOCHEM

Building interior wall special-purpose antibacterial mildew-resistant emulsion paint

The invention discloses building interior wall special-purpose antibacterial mildew-resistant emulsion paint. The building interior wall special-purpose antibacterial mildew-resistant emulsion paint comprises acrylic acid emulsion, polyurethane emulsion, bisphenol A epoxy resin, diphenylsilanediol, nanometer titanium dioxide, nanometer silica sol, nanometer zinc oxide, active carbon, tourmaline nanometer powder, dodecafluoroheptyl methacrylate, a film forming assistant, sorbitan monopalmitate, lauric acid, phenolic resin, N-phenyl-N'-cyclohexyl-p-phenylenediamine, potassium citrate, propyl p-hydroxybenzoate, succinic acid, sodium alginate, imidazolidone, chitosan, water and an assistant. The building interior wall special-purpose antibacterial mildew-resistant emulsion paint can form a fine paint film, has good antibiosis and mildew resistance and excellent water resistance and workability, has a refreshing smell and has strong adhesion to a base material.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Non-cyanide copper plating solution

Cyanogen-free preplated copper solution belongs to the technical field of surface treatment electroplating. The solution adopts a nontoxic organic phosphine compound to replace cyanide as a complexing agent for the preplated copper, and is particularly suitable for preplated copper used to electroplate steel, aluminum, magnesium, zinc, titanium and titanium alloy. The cyanogen-free preplated copper solution has the following main technical characteristic that the solution consists of (a) one sort of copper sulphate, basic cupric carbonate or copper nitrate with the volume concentration of between 30 and 60 g / L; (b) one sort or two sorts of compounds selected from methylene diphosphonic acid, 1-hydroxyethylidene 1.1 diphosphonic acid and 1-hydroxybutyleneidene 1.1 diphosphonic acid with the volume concentration of between 120 and 160 g / L; (c) one sort or two sorts of compounds selected from methylamino dimethylene diphosphonic acid, hexamethylene diamine tetramethylene phosphonic acid and ethylenediamine tetramethylene phosphonic acid with the volume concentration of between 2 and 5 g / L; (d) one sort of potassium citrate, amine citrate or seignette salt with the volume concentration of between 6 and 12 g / L, and (e) polyethyleneimine alkyl slat or aliphatic amine ethoxy sulfonated substance (AESS) with the volume concentration of between 0.02 and 0.05 g / L. The cyanogen-free preplated copper solution has the characteristics of stable service performance, simple solution compositions, convenient maintenance, high safety, environmental protection, reliable plating coat binding and the like.

Owner:江南工业集团有限公司

Gold potassium lemon acid for gold plating and method for producing the same

ActiveCN101172946AReduce processing costsReduce pollutionCarboxylic acid salt preparationGold contentPotassium

The invention discloses citric acid gold potassium used for gold plating and the preparation method thereof. The molecular formular of the citric acid gold potassium is K3Au2C9H5O7N2. The method comprises the steps as follows: gold trichloride is dissolved in water of certain temperature, is concentrated and diluted under the temperature for multiple times, and is reacted with potassium citrate, ethylene diamine tetraacetic acid and malononitrile in a reactor under the certain temperature and the certain time to produce the organic gold salt which has low toxicity and contains no free cyanogen. When the product has the same gold content with the potassium gold cyanide, the total CN- is 5 to 6 percent, being 50 percent lower than that of the CN- in the potassium gold cyanide. The waste liquid after gold plating contains free the CN- in small amount. The invention reduces the cost of waste water treatment for the electroplating plants.

Owner:HENGSHENG TECH R&D CO LTD

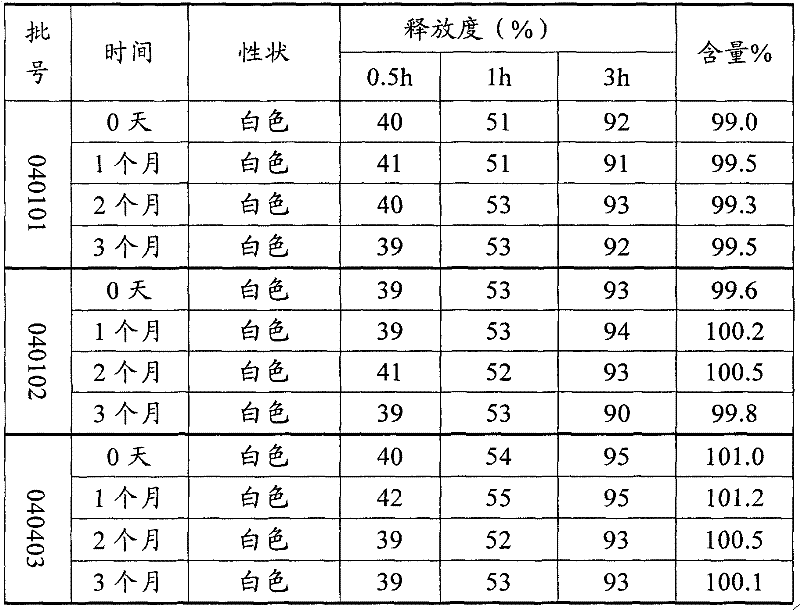

Potassium citrate sustained release tablet and preparation method thereof

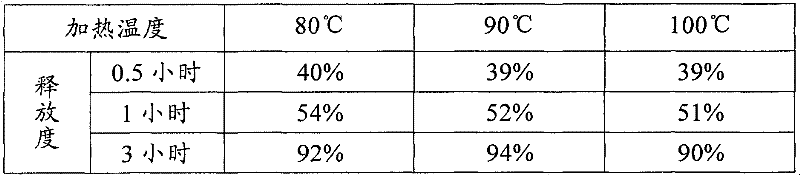

ActiveCN102240272A3 hours of increased releaseQuality improvementOrganic active ingredientsPharmaceutical delivery mechanismSustained Release TabletMedicine

The invention provides a potassium citrate sustained release tablet and a preparation method thereof. A weight ratio of potassium citrate to a waxy sustained release matrix is 10:0.7-1.1, preferably 10:0.83-1.0, and most preferably 10:1.0. The sustained release tablet allows the concentration of citric acid radical in urine to be effectively increased, the fluctuation of the concentration of citrate in the urine to be reduced, and a stable and high level of the citrate concentration to be kept. More importantly, the three-hour release rate, the tabletting performance and the moisture resistance of the sustained release tablet are further improved.

Owner:LIVZON GROUP LIVZON PHARMA FACTORY

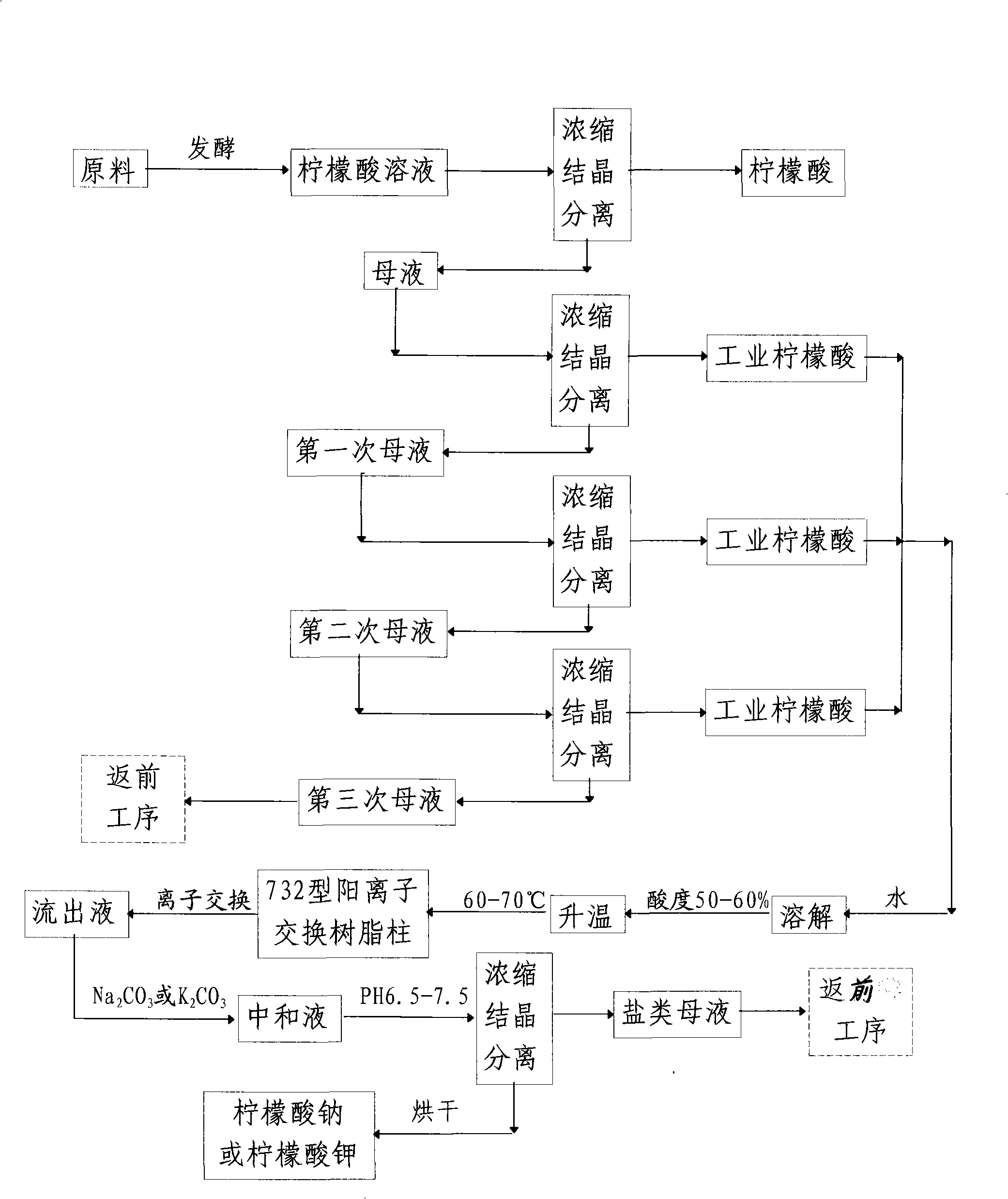

Process for preparing citrate salt from mother liquor for citric acid production

ActiveCN101407454ASave human effortSave moneyCarboxylic acid salt preparationFermentationCITRATE ESTERCitrate salt

The invention discloses a technique for preparing citrate by utilizing mother liquor produced by citric acid, which comprises the following steps: a. industrial citric acid is obtained by concentrating, crystallizing, and separating mother liquor after citric acid is purified; b. the mother liquor after industrial citric acid is separated is respectively concentrated, crystallized and separated again for a plurality of times until the concentration of Fe<+3> of the final mother liquor is bigger than 200ppm; K value of easily carbon compound is bigger than 2.0; the mother liquor is retreated in the former working procedure; c. industrial citric acid is treated with 732 type cation exchange resin column; the effluent liquid is neutralized with sodium carbonate or potassium carbonate to obtain sodium citrate or potassium citrate; the technique for preparing citrate by utilizing mother liquor produced by citric acid has the advantages that not only the mother liquor is treated well, but also impurities are removed in the processing procedure to get the citrate product, thus improving economic benefits of the whole enterprise.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

Hydrogen-enriched water powder solid beverage

InactiveCN107173657AExtended release timeGood synergyMetabolism disorderAlgae medical ingredientsHydrogenAdditive ingredient

The invention discloses a hydrogen-enriched water powder solid beverage. The hydrogen-enriched water powder solid beverage comprises the following ingredients in parts by weight: 80-90 parts of seaweed extracts or seaweed powder, 5-10 parts of resistance dextrin, 1-5 parts of maltodextrin, 1-5 parts of rice plumule extracts or rice plumule powder, 0.01-0.1 part of taurine, 0.01-0.1 part of vitamins, 0.01-0.1 part of potassium citrate, 0.4-0.8 part of sodium carbonate and 0.2-0.5 part of silicon dioxide.

Owner:SHICHENG BIOLOGICAL ENG SHANGHAI CO LTD

Composition of materials and processes for making boroncitrates to create cements with field adjustable set times

A family of compounds has been developed containing a substantial quantity of boron in solution with other beneficial ingredients that has been heretofore unobtainable. These compounds are named and referred to herein as “Boroncitrates”. The individual Boroncitrates are: boron lithium citrate (BLiCit), boron potassium citrate (BKCit) and boron sodium citrate (BNaCit). These Boroncitrates can be used individually or in combination with one another. Alkali metals such as rubidium, cesium and francium could also be made into Boroncitrates; but, there is no advantage in using these very scarce and much more expensive alkali metals.Use of Boroncitrates provides a new and improved means for hydraulic cementitious compositions to take set faster or slower, as determined by the user and as the individual jobsite needs dictate; thereby providing the long-sought, unfulfilled flexibility required by today's rapidly expanding concrete industry. As discussed herein, the application and use of Boroncitrates can provide beneficial improvement in many hydraulic cement varieties, such as, but not limited to, Portland Cement, class C fly ash and blended hydraulic cements containing combinations of the above.

Owner:KIRKPATRICK WILLIAM D +1

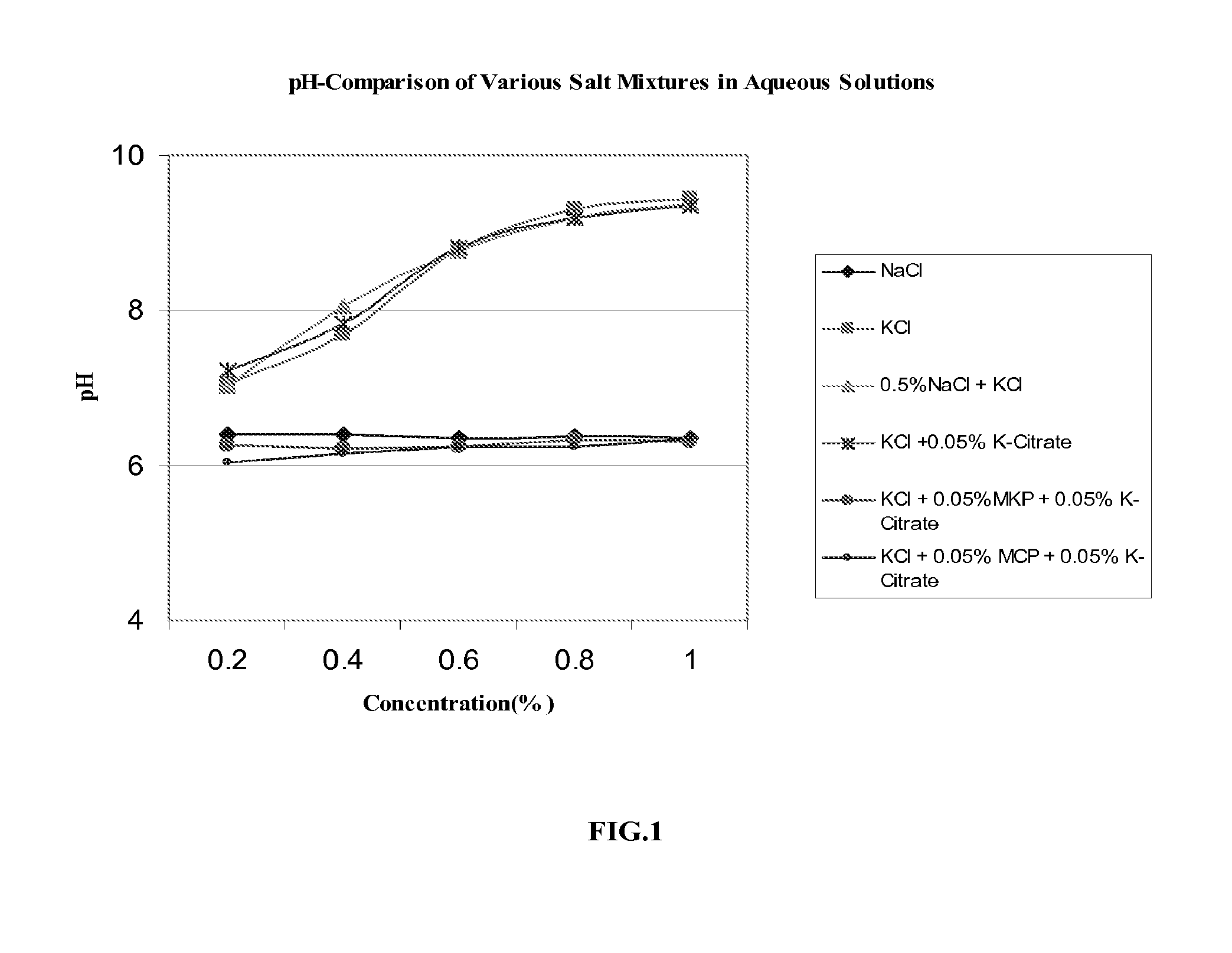

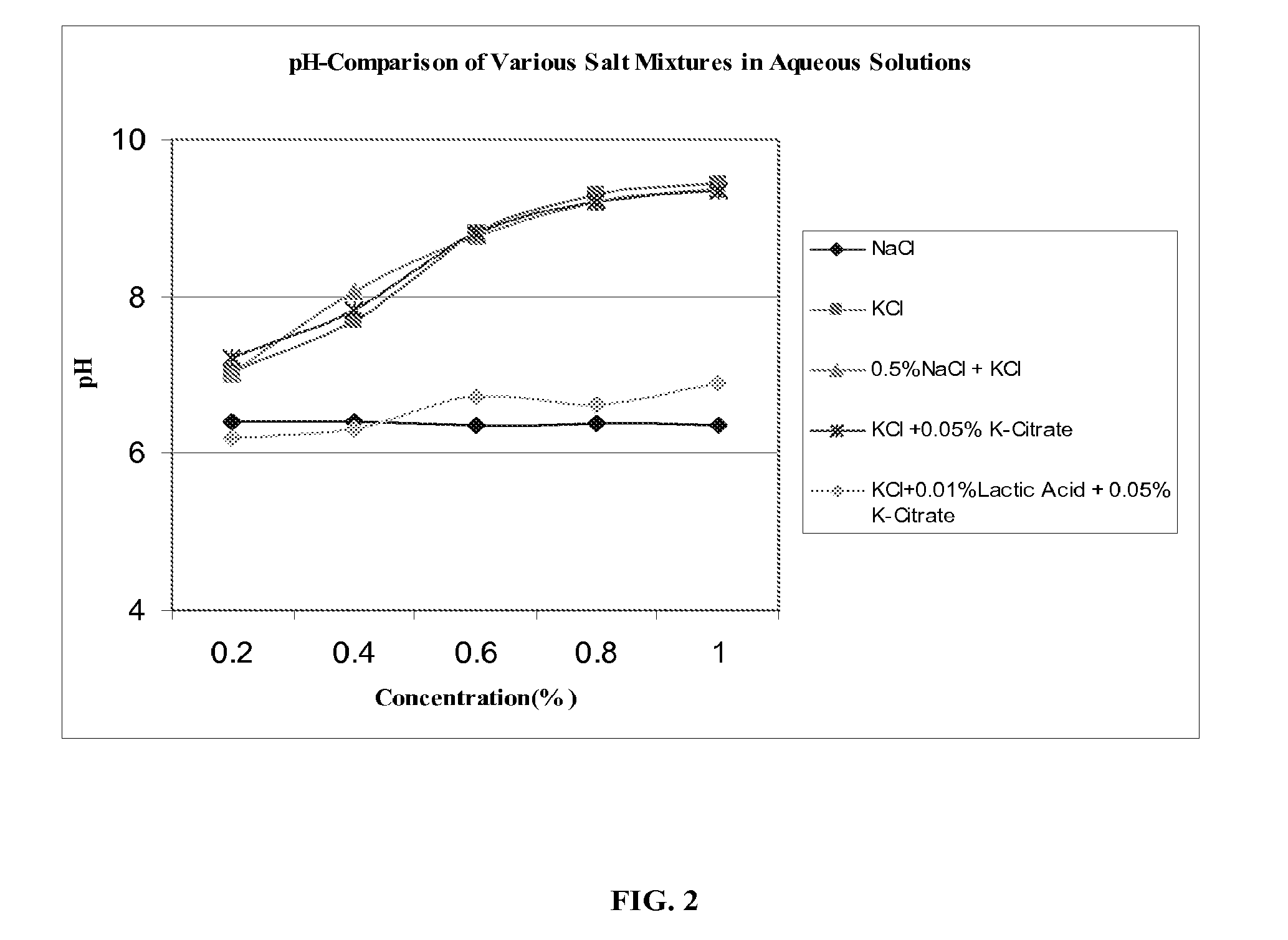

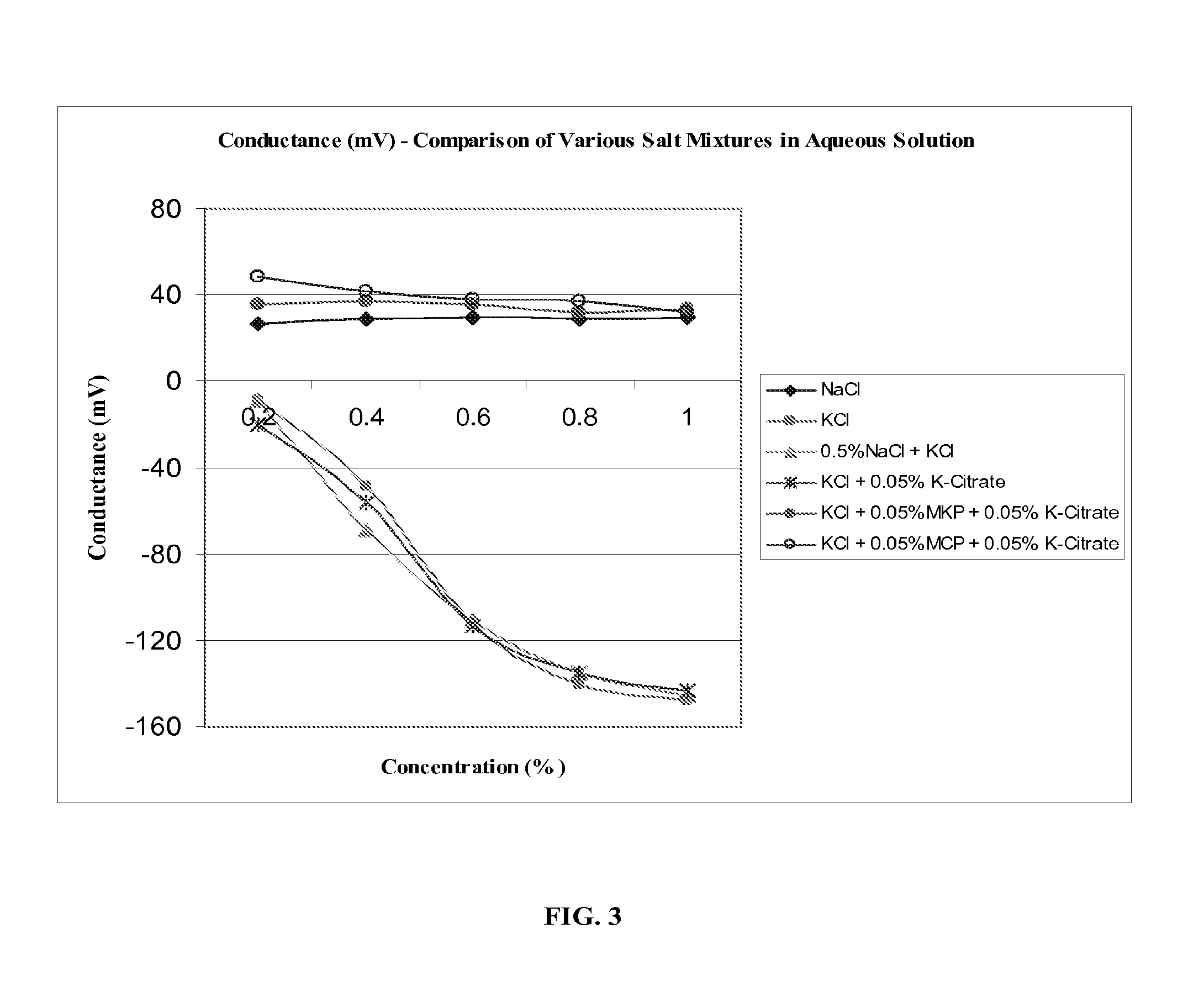

Methods and compositions for reducing sodium content in food products

InactiveUS20090196957A1Reduce sodiumEnhancing salt perceptionMilk preparationMeat/fish preservationOrganic acidMonopotassium phosphate

The invention provides compositions and methods for reformulating foodstuffs to reduce sodium content, while significantly enhancing salt perception and minimizing additional bitterness. In certain embodiments, the invention provides salt taste enhancing compositions including a blend of three potassium salts—namely, potassium chloride, monopotassium phosphate, and potassium citrate—which, when used in conjunction with sodium chloride, significantly enhances the salt perception in foods and beverages, while imparting no or limited bitter aftertaste. In other embodiments, the invention provides salt taste enhancing compositions including potassium chloride in combination with an organic acid and, optionally, an organic acid salt of potassium.

Owner:CAMPBELL SOUP COMPANY

Cigarette paper additive, preparation method and application thereof

InactiveCN101775759AImprove suction qualityEffective pH adjustmentSurface covering paperNon-fibrous pulp additionPotassiumTar

The invention discloses a cigarette paper additive, a preparation method and application thereof. The cigarette paper additive of the invention comprises the following ingredients in mass percent: 40 to 50 percent of potassium phosphate, 20 to 30 percent of potassium citrate, 20 percent of apple potassium, 10 percent of glucose and citric acid solution, wherein the citric acid solution is used for regulating the pH value of the accessory agent solution to the required range. The invention belongs to the improvement of the existing cigarette paper. When the cigarette paper adopting the cigarette paper additive of the invention is made into cigarette finished products, the pH value of the mainstream smoke can be regulated to a certain degree, the smoking quality of the cigarette can be effectively improved, and at the same time, the contents of the tar and the carbon monoxide in the mainstream smoke can be effectively reduced.

Owner:CHINA TOBACCO GUANGDONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com