Environment-friendly high-density solid-free weighting agent and preparation method

A high-density, solid-free technology, applied in the fields of drilling fluids and completion fluids, can solve problems such as poor stability against high temperature and high pressure, corrosion, and low density of completion fluids, and achieve low corrosion, good rheology, and moderate price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

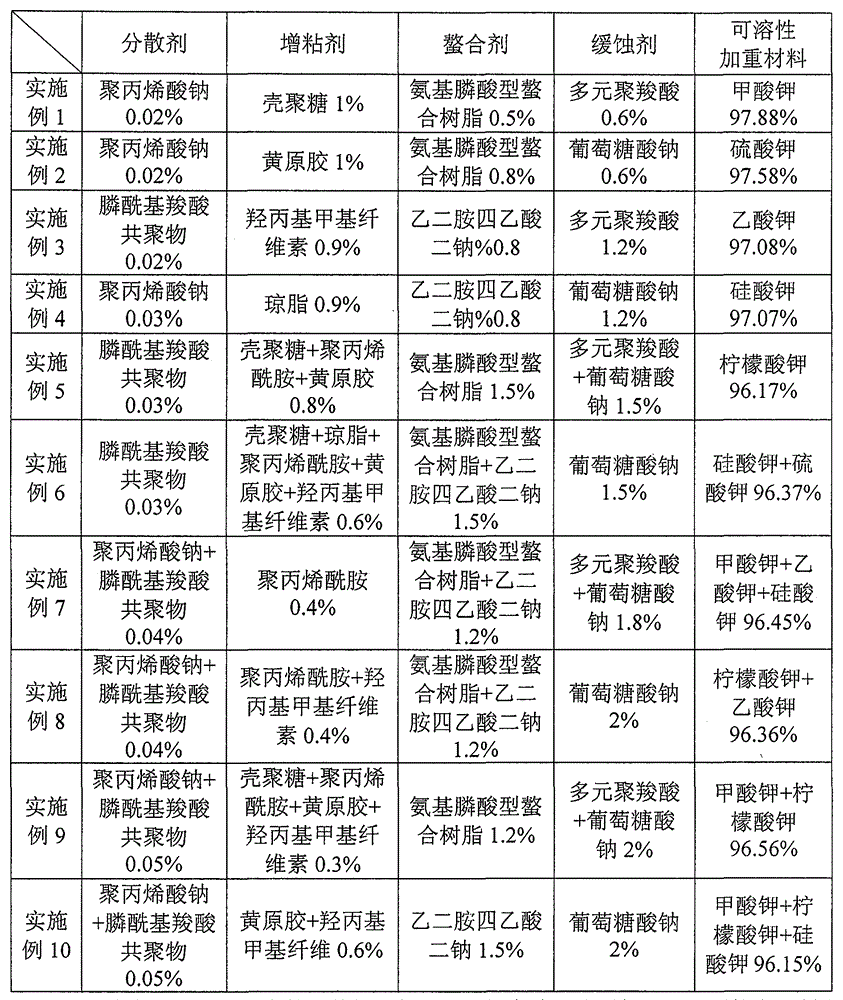

[0037] An environment-friendly high-density non-solid phase weighting agent, its components are proportioned as follows by weight fraction:

[0038] Dispersant: 0.02 to 0.05 parts;

[0039] Tackifier: 0.3 to 1 part;

[0040] Chelating agent: 0.5 to 1.2 parts;

[0041] Corrosion inhibitor: 0.6~2 parts;

[0042] Soluble Weighted Material: Balance.

[0043] Specifically, the dispersant is selected from one or both of sodium polyacrylate and phosphonocarboxylic acid copolymer.

[0044] Specifically, the thickener is selected from one or more of chitosan, agar, polyacrylamide, xanthan gum, and hydroxypropyl methylcellulose. Preferably, the thickener is one or both of xanthan gum and hydroxypropyl methylcellulose.

[0045] Specifically, the chelating agent is one or both of aminophosphonic acid chelating resin and disodium edetate.

[0046] Specifically, the corrosion inhibitor is one or both of polycarboxylic acid and sodium gluconate.

[0047] Specifically, the soluble weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com