Fiber reinforced flexible aerogel composite material and preparation method thereof

A technology of flexible airgel and composite materials, which is applied in the field of fiber-reinforced flexible airgel composite materials and its preparation, which can solve the problems of limited use, low strength, and poor toughness, and achieve low equipment cost, low density, and porous small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

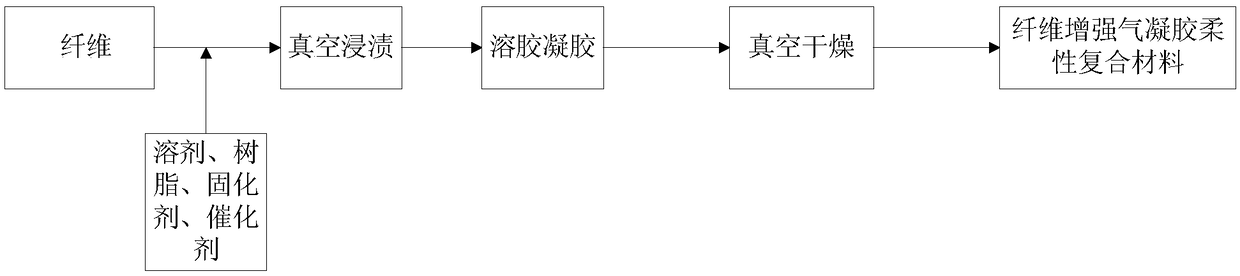

Method used

Image

Examples

Embodiment 1

[0043](1) Choose carbon fiber three-dimensional woven cloth as the reinforcement, and the fiber porosity is 80%; choose tert-butanol as the organic solvent, oxalic acid as the curing agent, sodium hydroxide as the catalyst, and polycyanonitrile as the matrix. Prepare 20wt% polycyanonitrile resin solution, add 5wt% curing agent and mix evenly, then add 1wt% catalyst to complete the organic solution preparation.

[0044] (2) After putting the carbon fiber three-dimensional woven cloth into the vacuum impregnation device, use the sealing material to seal the vacuum impregnation device completely, turn on the vacuum pump to vacuum, observe the gauge value of the vacuum pump, and ensure that the pressure in the vacuum impregnation container is 15kPa, and the vacuum time is 15 minutes. Turn off the vacuum pump and let stand for 20min.

[0045] (3) Keep the internal pressure of the vacuum impregnation device at 15kPa, and use a pressure difference of 15kPa to press the organic soluti...

Embodiment 2

[0050] (1) Choose carbon fiber needle felt as reinforcement, fiber porosity 90%; choose tert-butanol as solvent, oxalic acid as curing agent, sodium hydroxide as catalyst, and silicone rubber as matrix. Prepare a 15wt% silicone rubber resin solution, add 2.5wt% curing agent and mix evenly, then add 1.5wt% catalyst to complete the organic solution preparation.

[0051] (2) After putting the carbon fiber needle felt into the vacuum impregnation device, use the sealing material to seal the vacuum impregnation device completely, turn on the vacuum pump to evacuate, observe the gauge value of the vacuum pump, and ensure that the pressure in the vacuum impregnation container is 15kPa, and the vacuum time is 15 minutes. Turn off the vacuum pump and let stand for 20min.

[0052] (3) Keep the internal pressure of the vacuum impregnation device at 10kPa, and use a pressure difference of 10kPa to press the organic solution into the carbon fiber needle felt. When the organic solution comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com