Patents

Literature

45results about How to "High adhesive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot melt adhesive composition containing alpha-olefin/aromatic vinyl compound random copolymer

A hot melt adhesive composition exhibiting excellent adhesive strength and which is useful as an adhesive for styrene resins contains (B) tackifier and (C) ethylene / C3-C20 alpha-olefin / aromatic vinyl compound random copolymer and, in some embodiments also (A) base polymer, such as polyolefin, polar group-containing polymer and aromatic vinyl compound / conjugated diene copolymer. A low molecular weight polyolefin may also be included in all embodiments. The randon copolymer (C) may be prepared by polymerizing the alpha-olefin and aromatic vinyl compound in the presence of a metallocene containing catalyst. In addition to excellent adhesive strength the hot melt adhesives have improved workability.

Owner:MITSUI CHEM INC

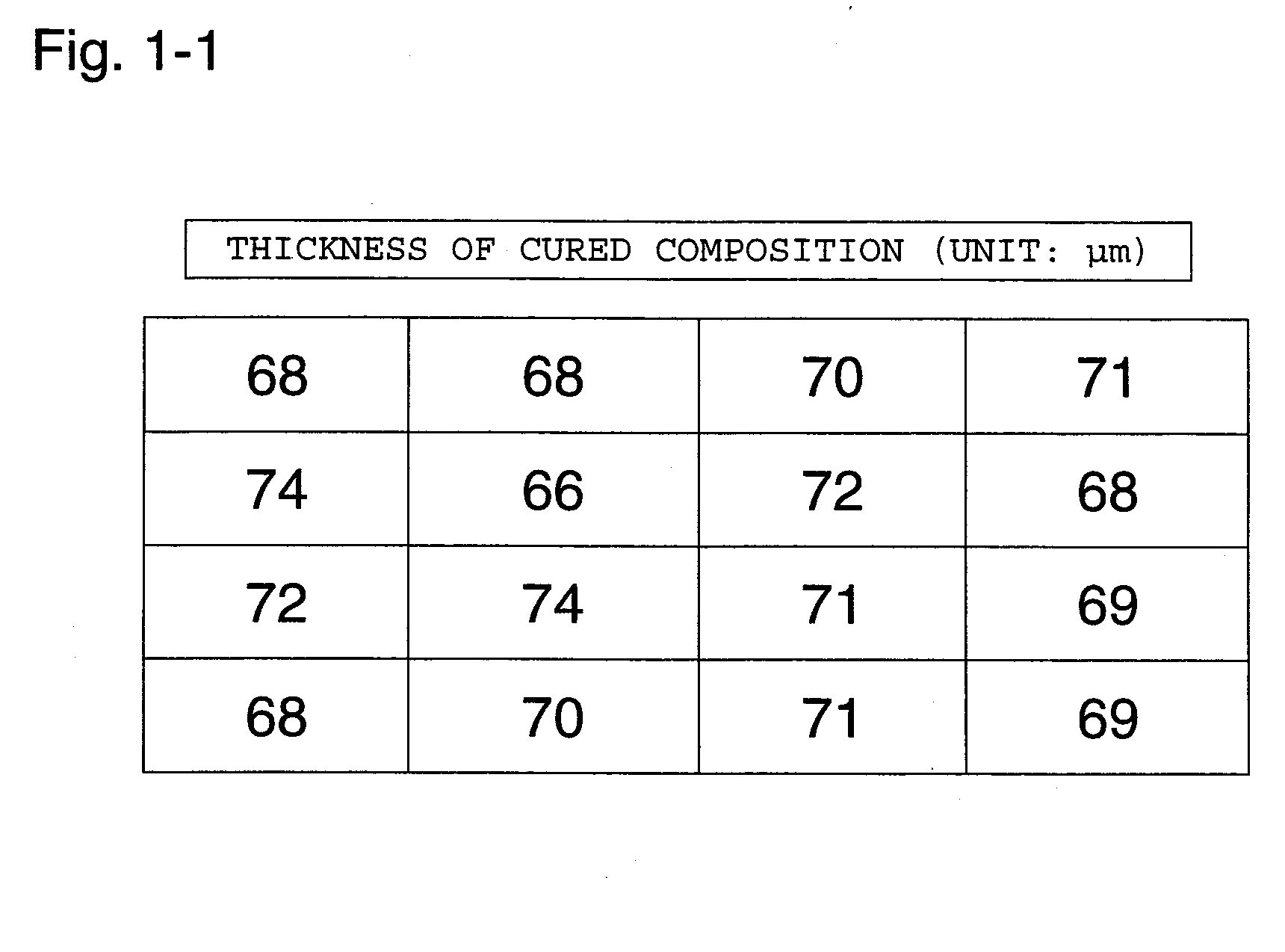

Curable composition and method for temporal fixation of structural member using the same

ActiveUS20100012263A1High adhesive strengthEasily obtainedLamination ancillary operationsPolyureas/polyurethane adhesivesSolventTemperature-responsive polymer

To provide a method for temporarily fixing an optical member for processing, and a curable composition useful for such a method.A curable composition comprising (A) a polyfunctional (meth)acrylate, (B) a monofunctional (meth)acrylate, (C) a photopolymerization initiator, and (D) a polar solvent. The curable composition may further contain (G) a temperature-responsive polymer and / or a copolymer of a temperature-responsive polymer, or (H) a granular material. The method for temporarily fixing a member, comprises temporarily fixing the member by means of such a curable composition, processing the temporarily fixed member, and immersing the processed member in warm water of from 30 to 90° C., thereby to remove a cured resin of the curable composition.

Owner:DENKA CO LTD

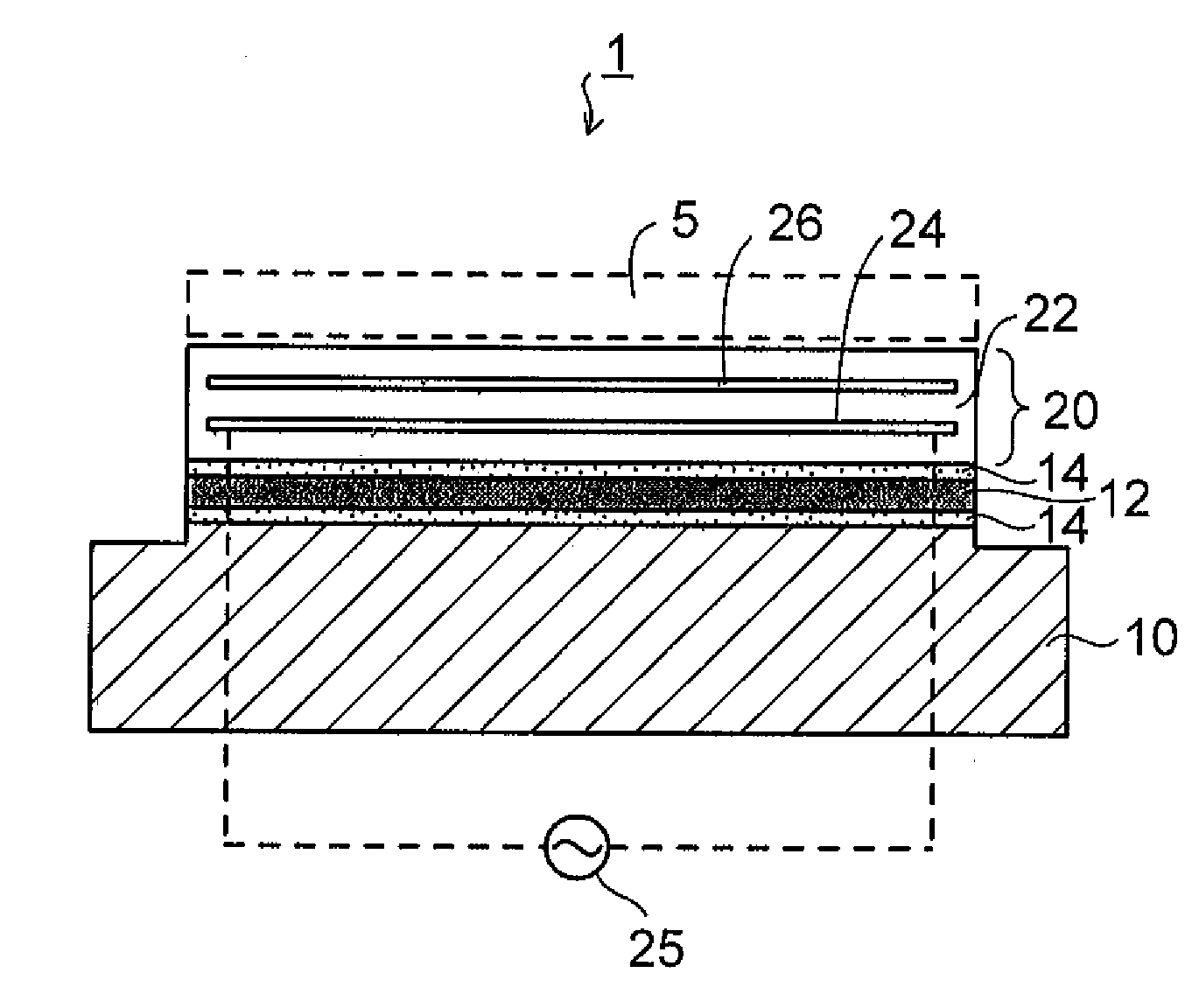

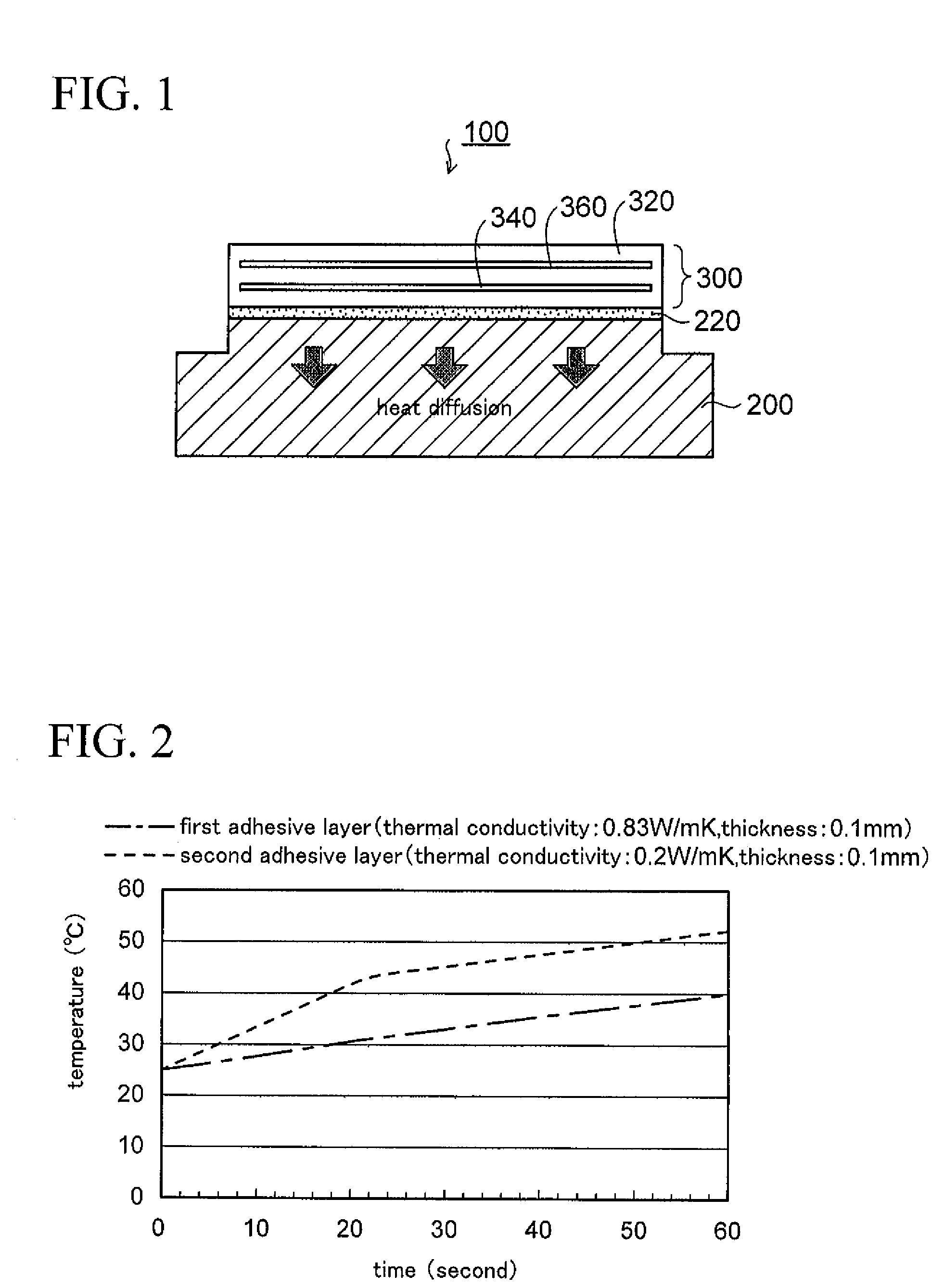

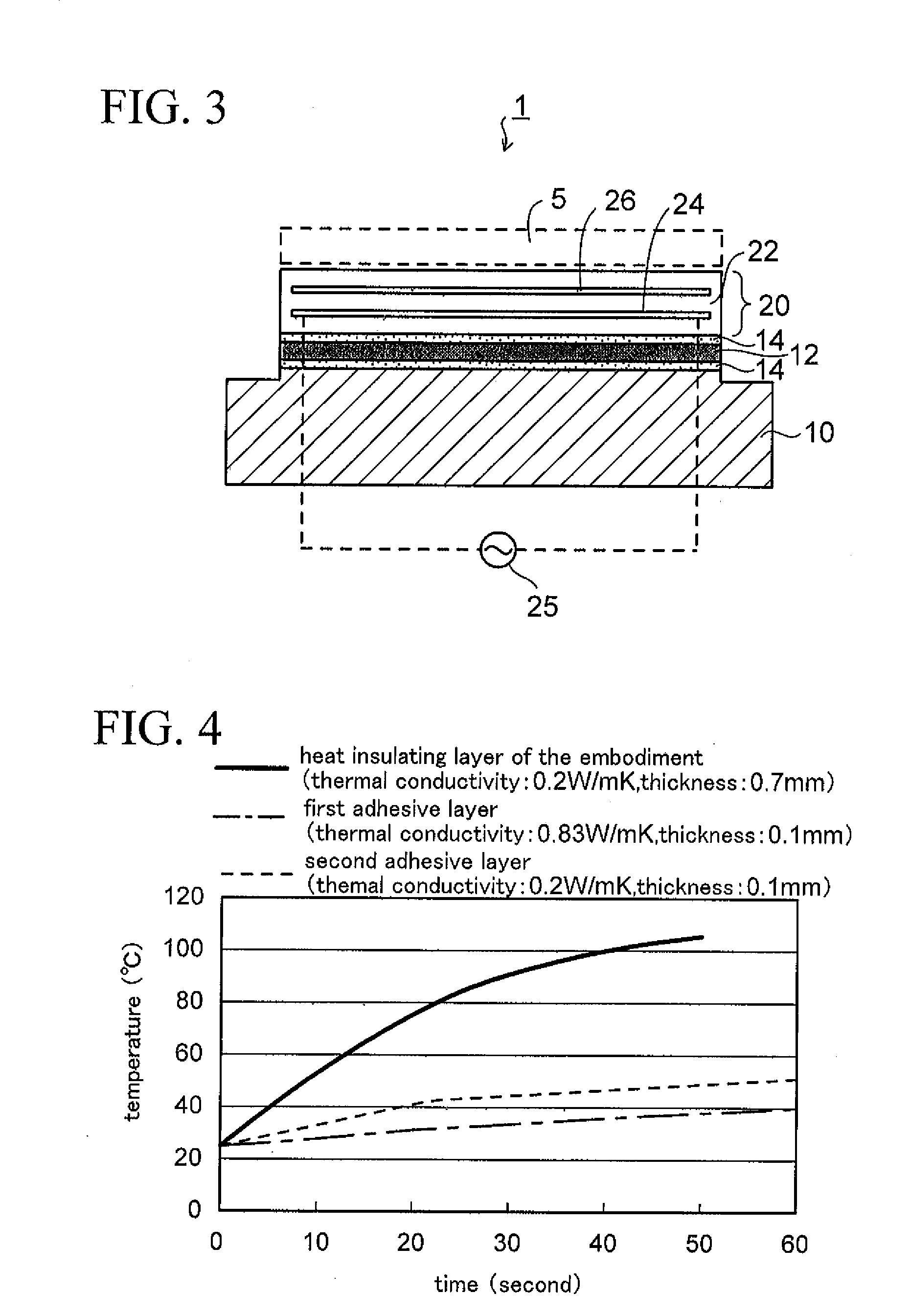

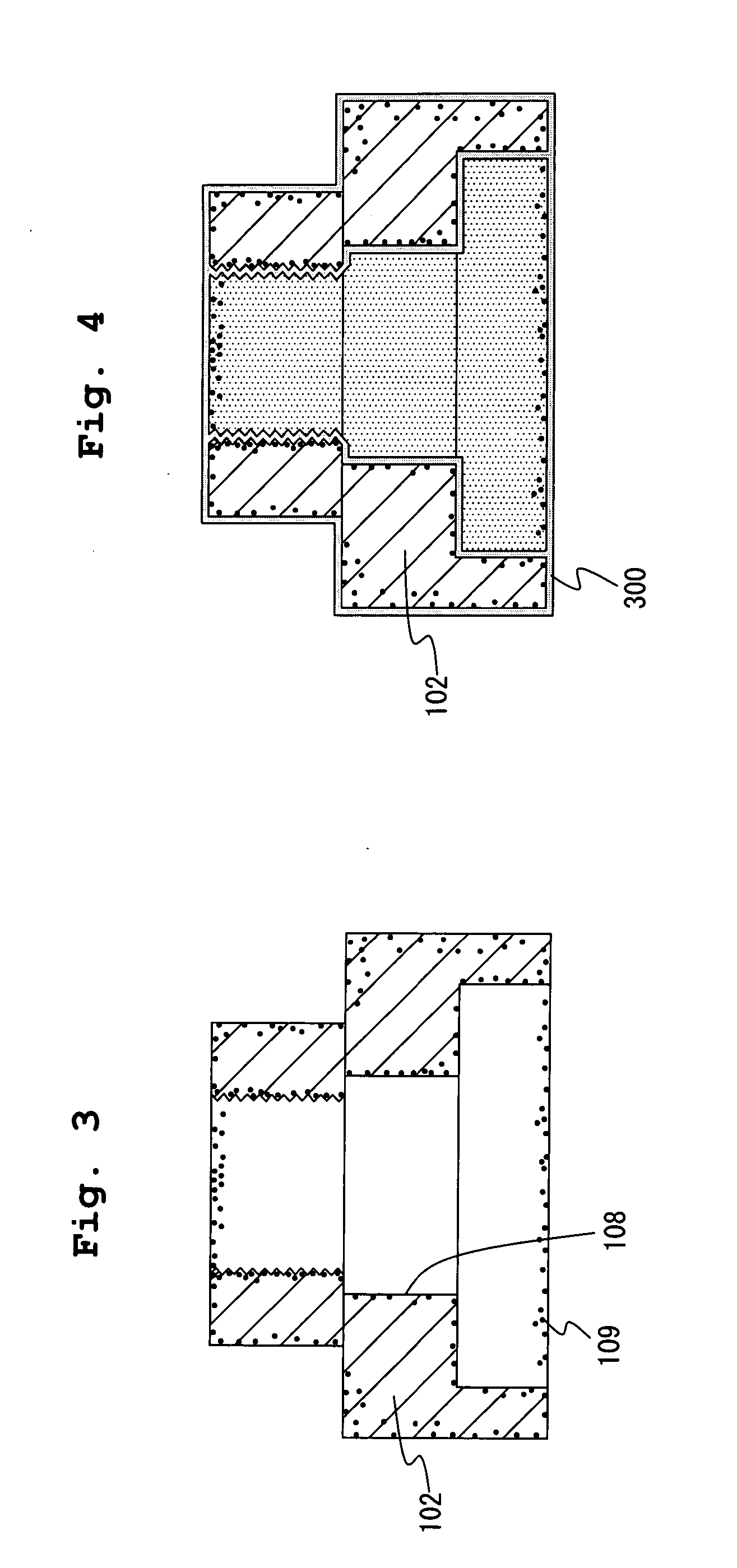

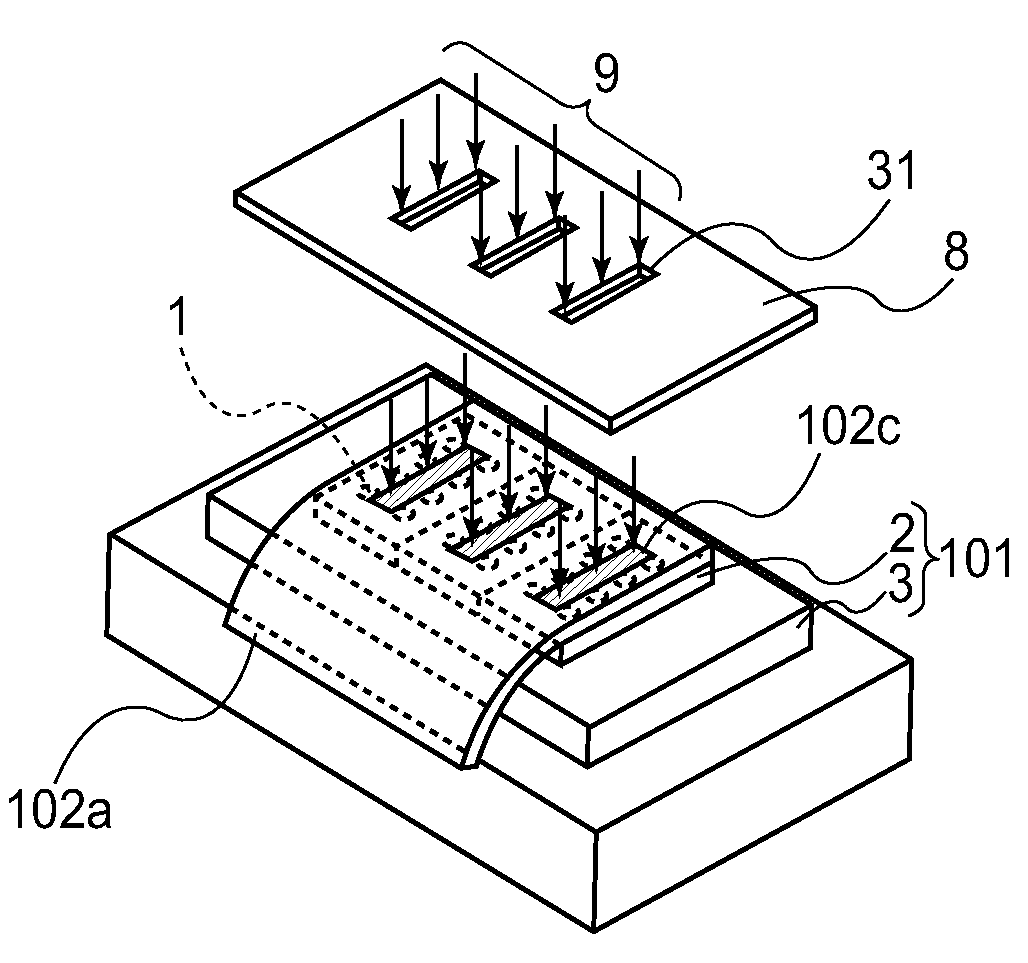

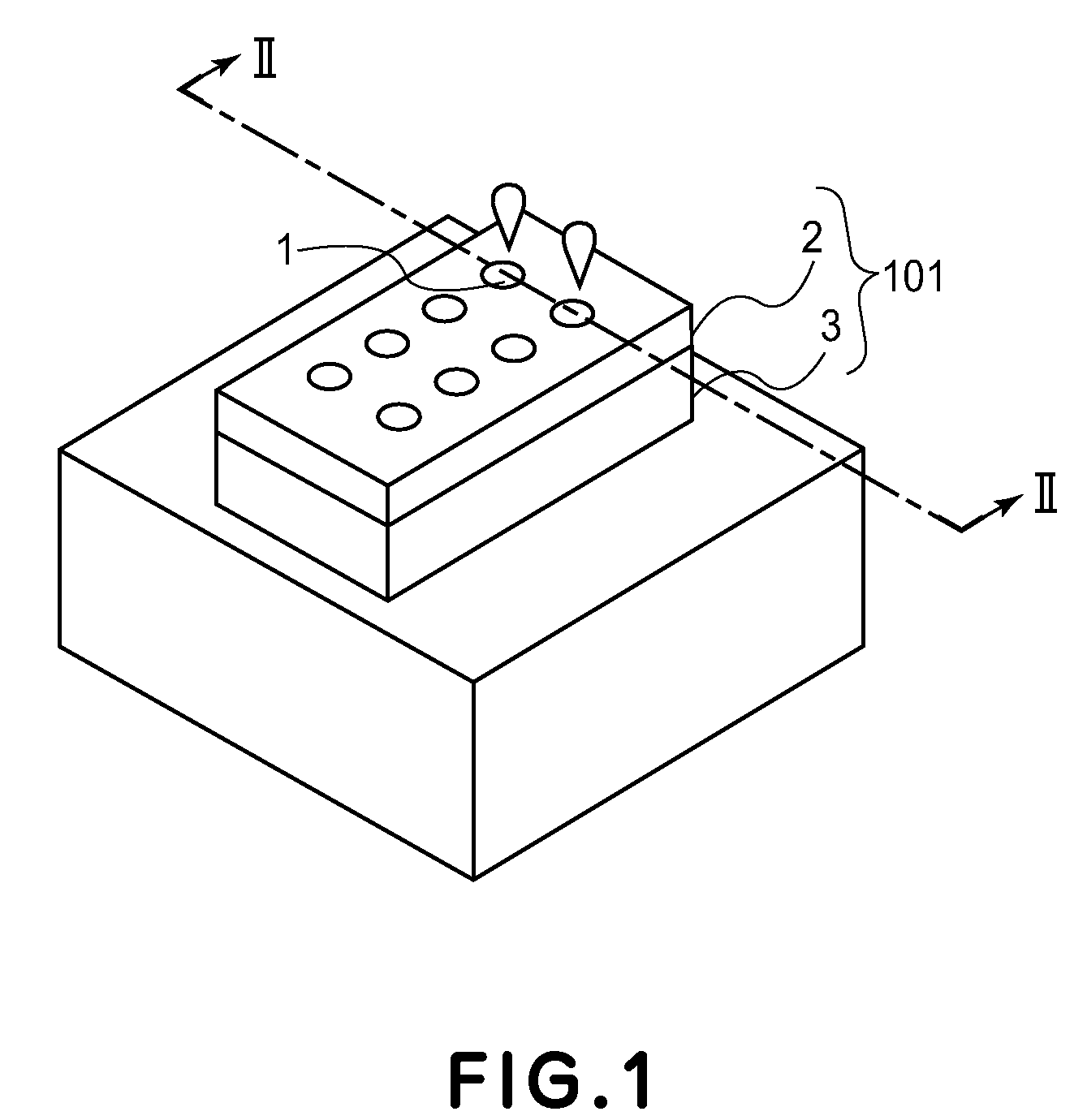

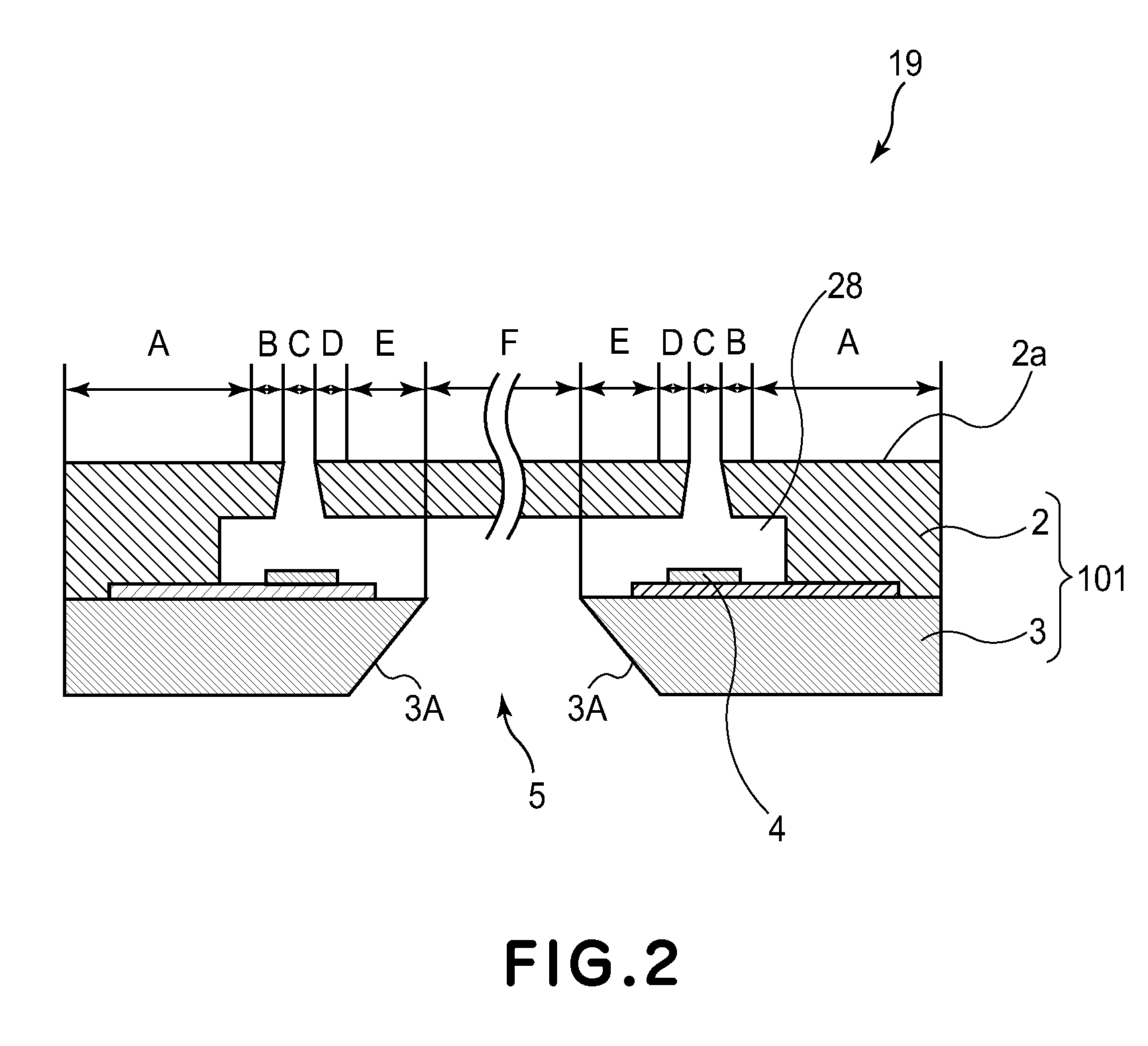

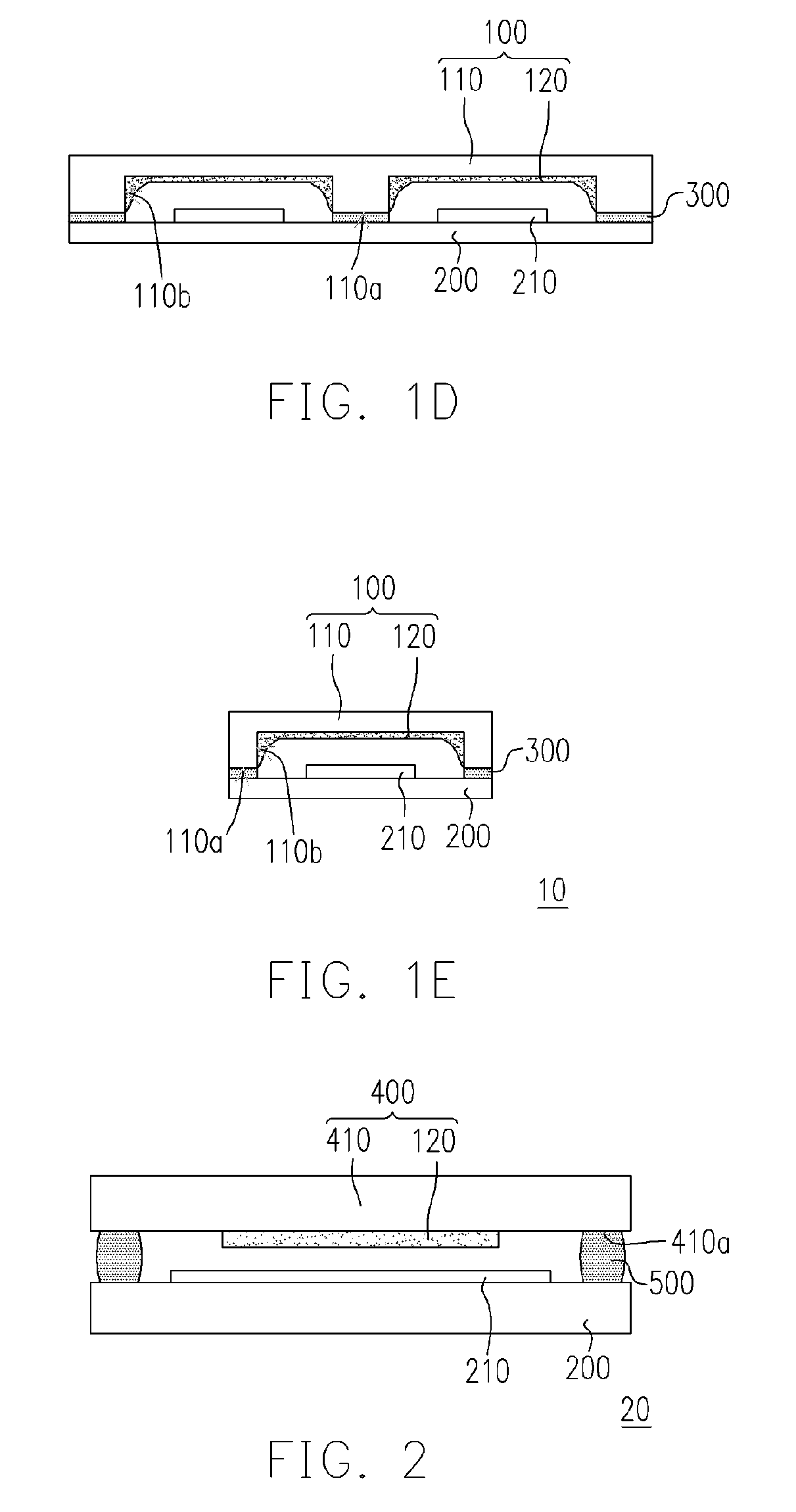

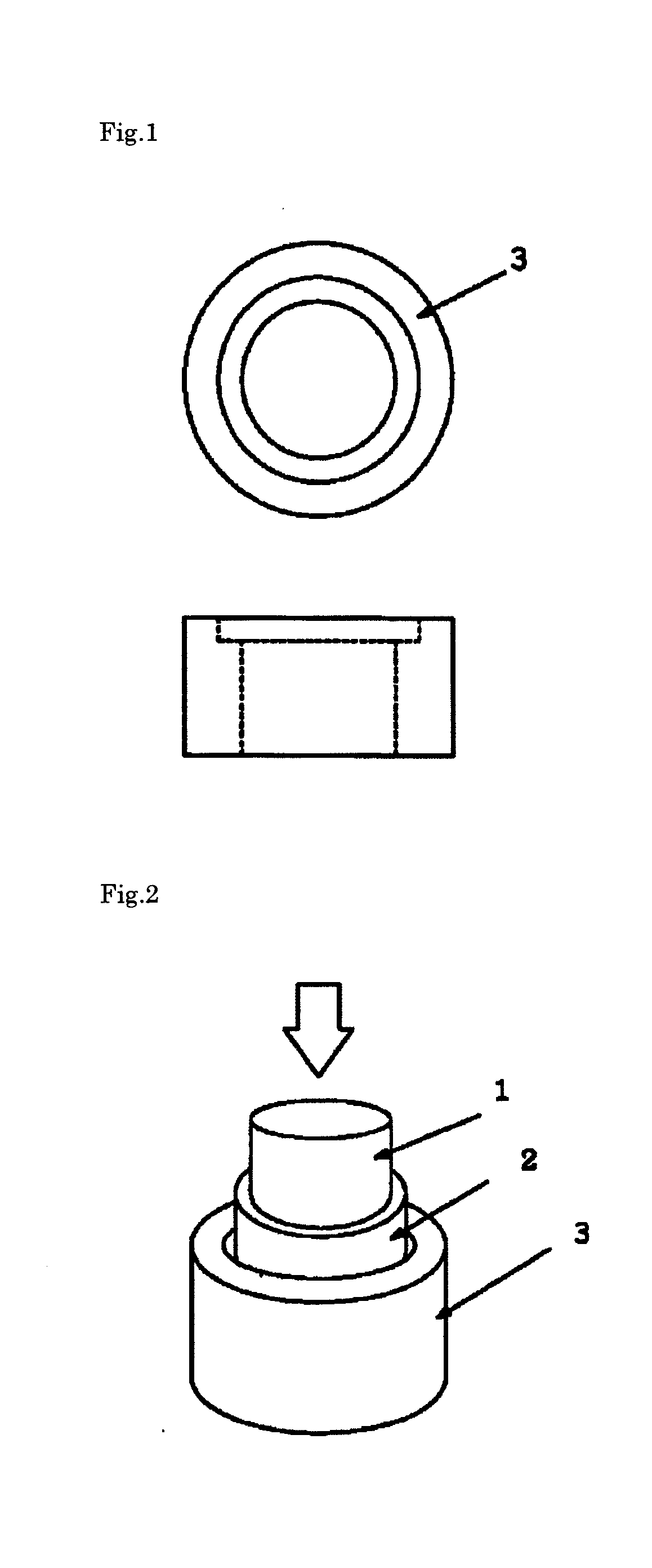

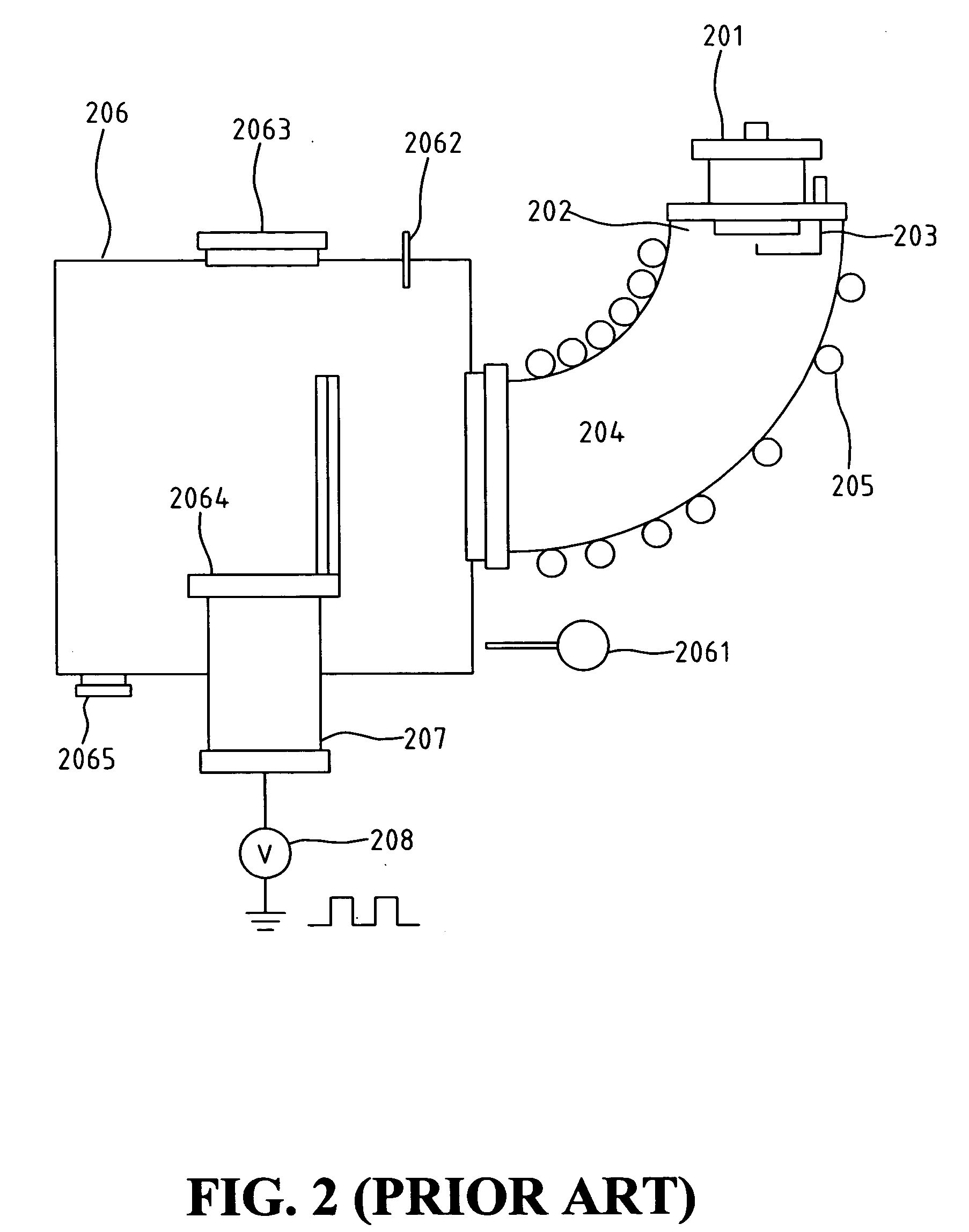

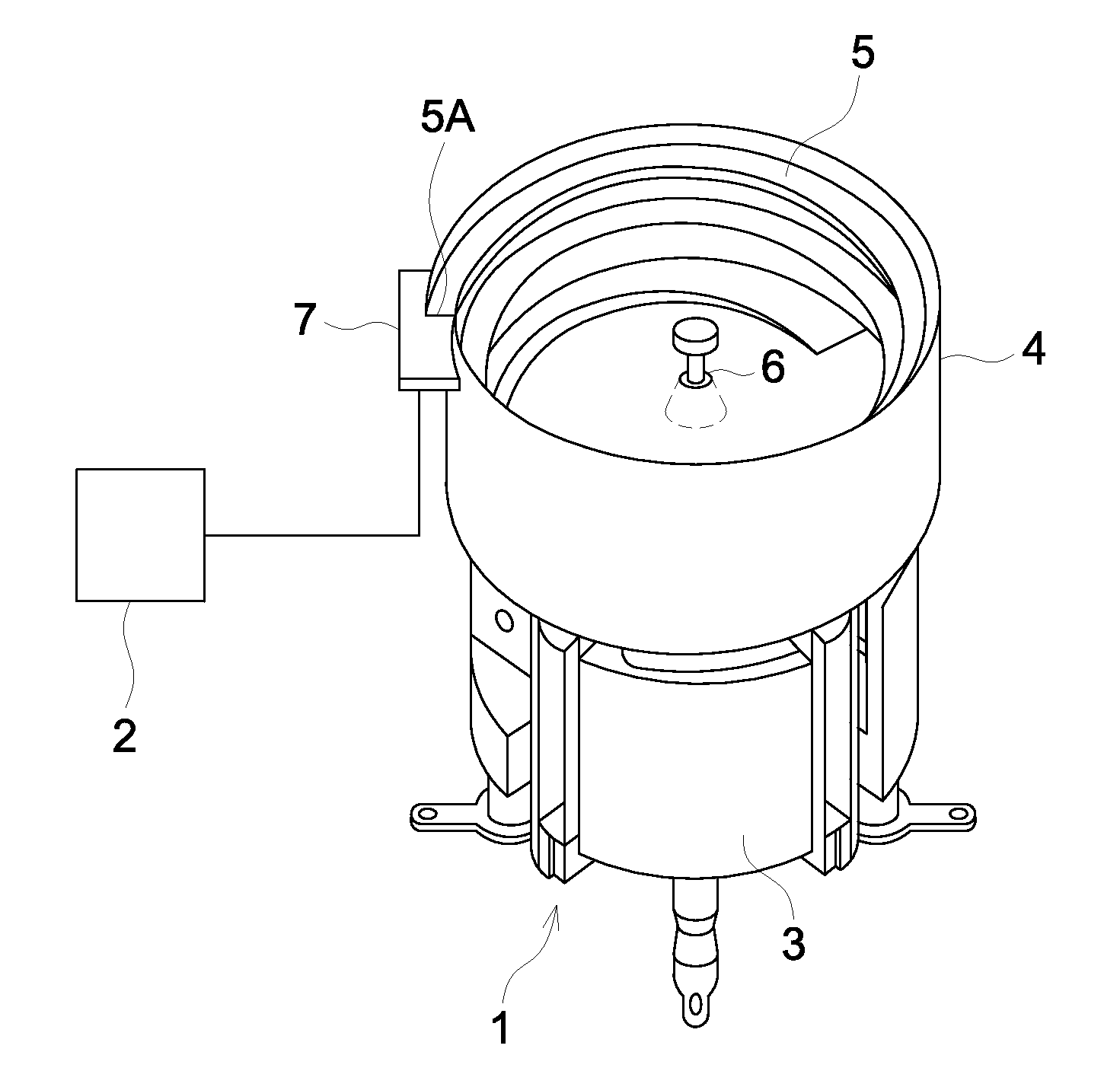

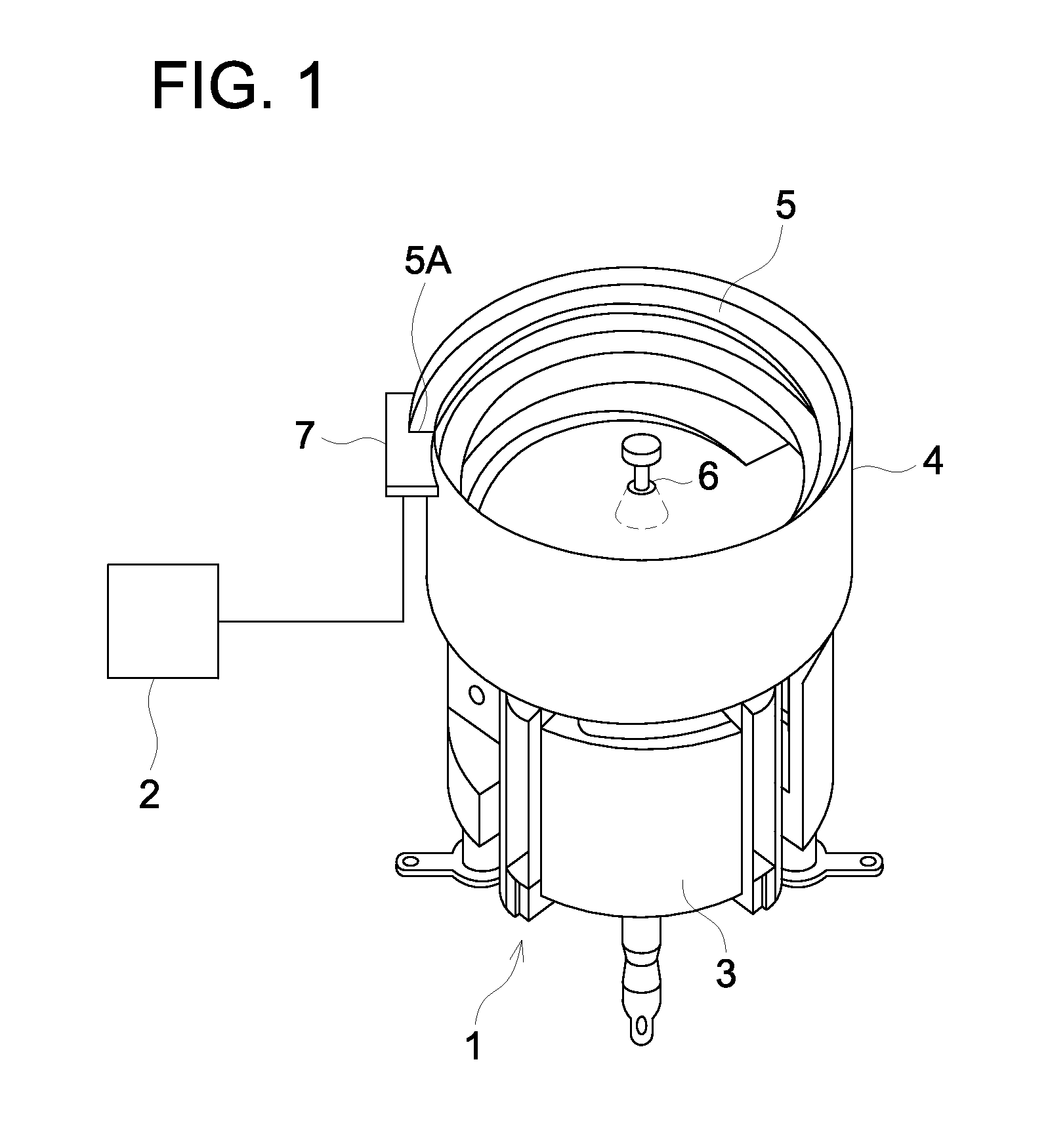

Electrostatic chuck

InactiveUS20090059461A1Adhesive strengthHigh adhesive strengthSemiconductor/solid-state device manufacturingElectrostatic holding devicesEngineeringElectrical and Electronics engineering

An electrostatic chuck of the invention includes a base portion; a heat insulating layer bonded onto the base portion; and a chuck function portion bonded on the heat insulating layer and composed by providing a heater electrode and an electrostatic chuck (ESC) electrode in a ceramic substrate portion. Adhesive layers are respectively provided on the both surface sides of the heat insulating layer. In the case where the base portion and the chuck function portion are bonded together with high adhesion strength, openings are formed in the heat insulating layer and are filled with the adhesive layers.

Owner:SHINKO ELECTRIC IND CO LTD

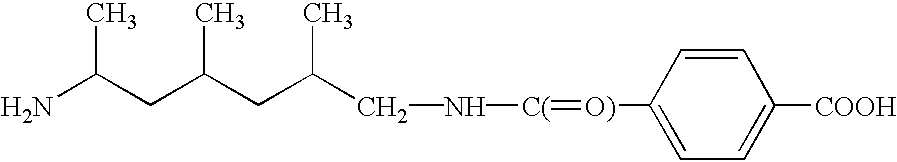

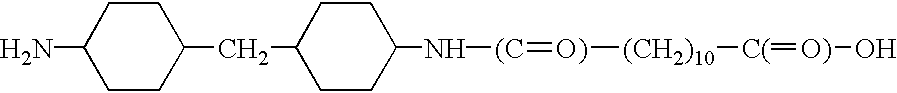

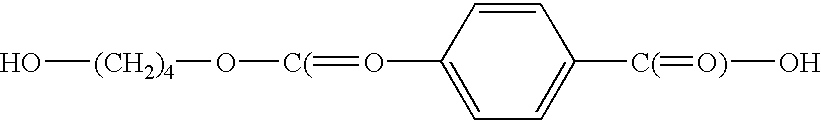

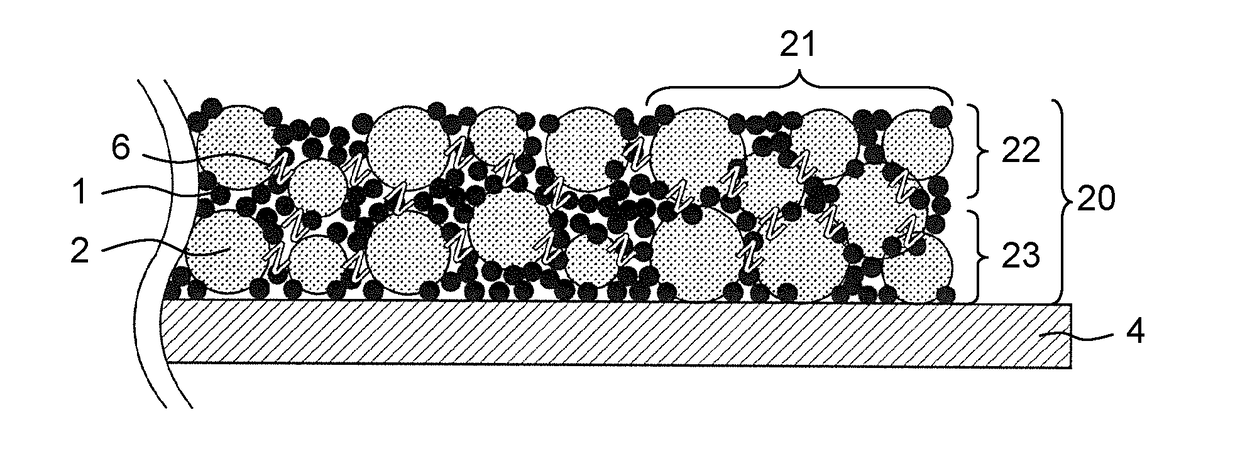

Binder for secondary battery exhibiting excellent adhesion force

ActiveUS20120183848A1Improved cycle propertyHigh adhesive strengthElectrode carriers/collectorsActive material electrodesMeth-Battery electrode

Provided is a binder for secondary battery electrodes comprising polymer particles obtained by polymerizing (a) a (meth)acrylic acid ester monomer; (b) at least one monomer selected from the group consisting of an acrylate monomer, a vinyl monomer and a nitrile monomer; and (c) a (meth)acrylamide monomer and an unsaturated monocarbonic acid monomer, with two or more cross-linking agents with different molecular weights. Based on the combination of specific components, the binder basically improves stability of an electrode in the process of fabricating the electrode, thus providing secondary batteries with superior cycle properties.

Owner:LG CHEM LTD

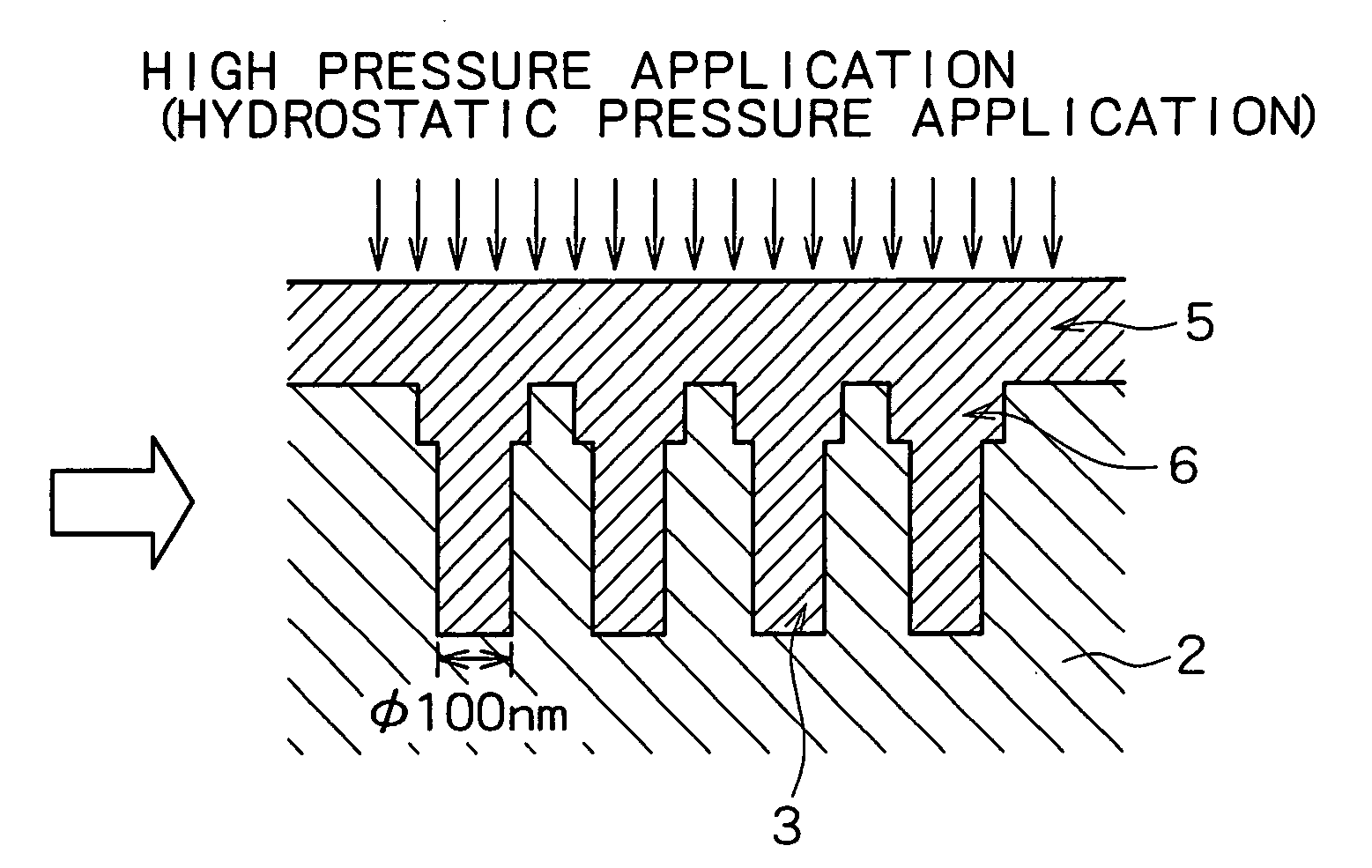

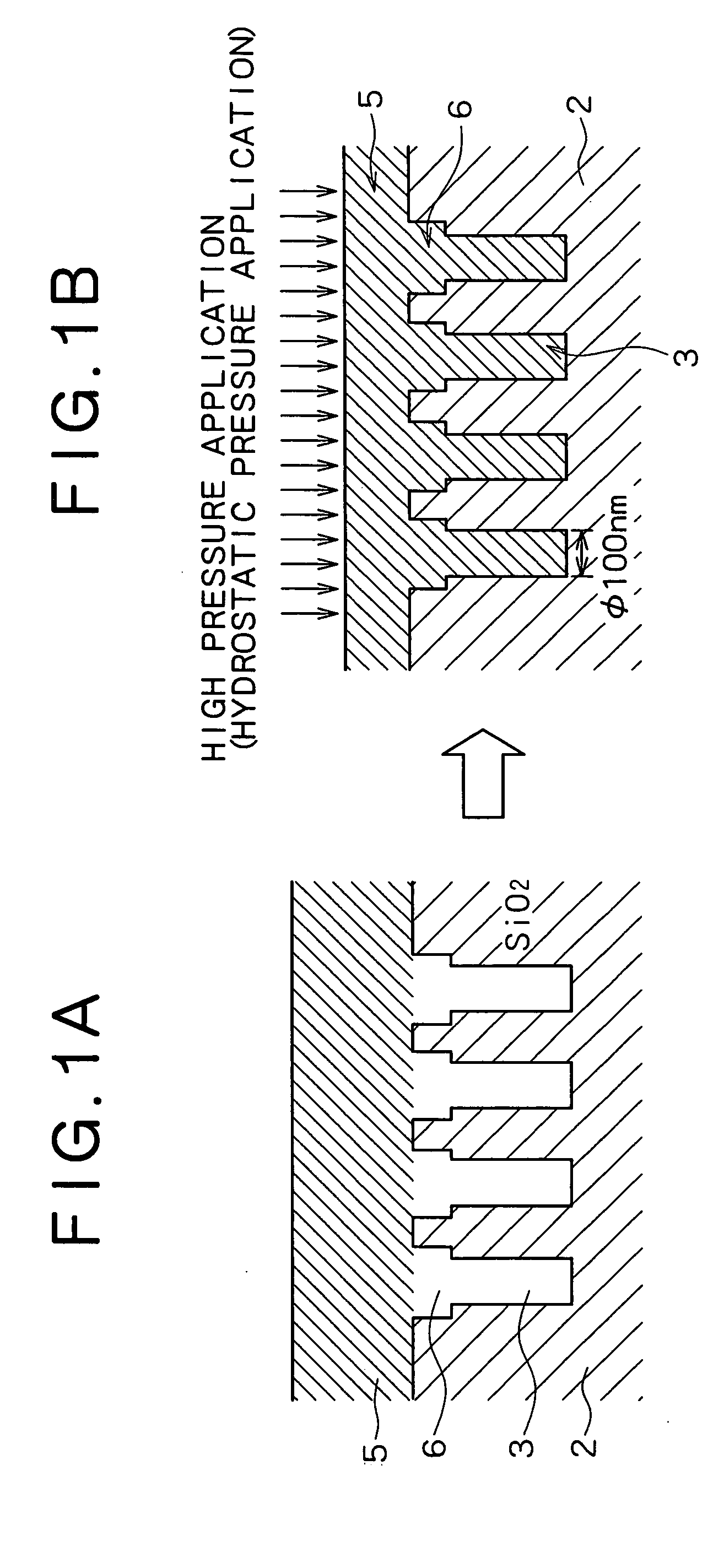

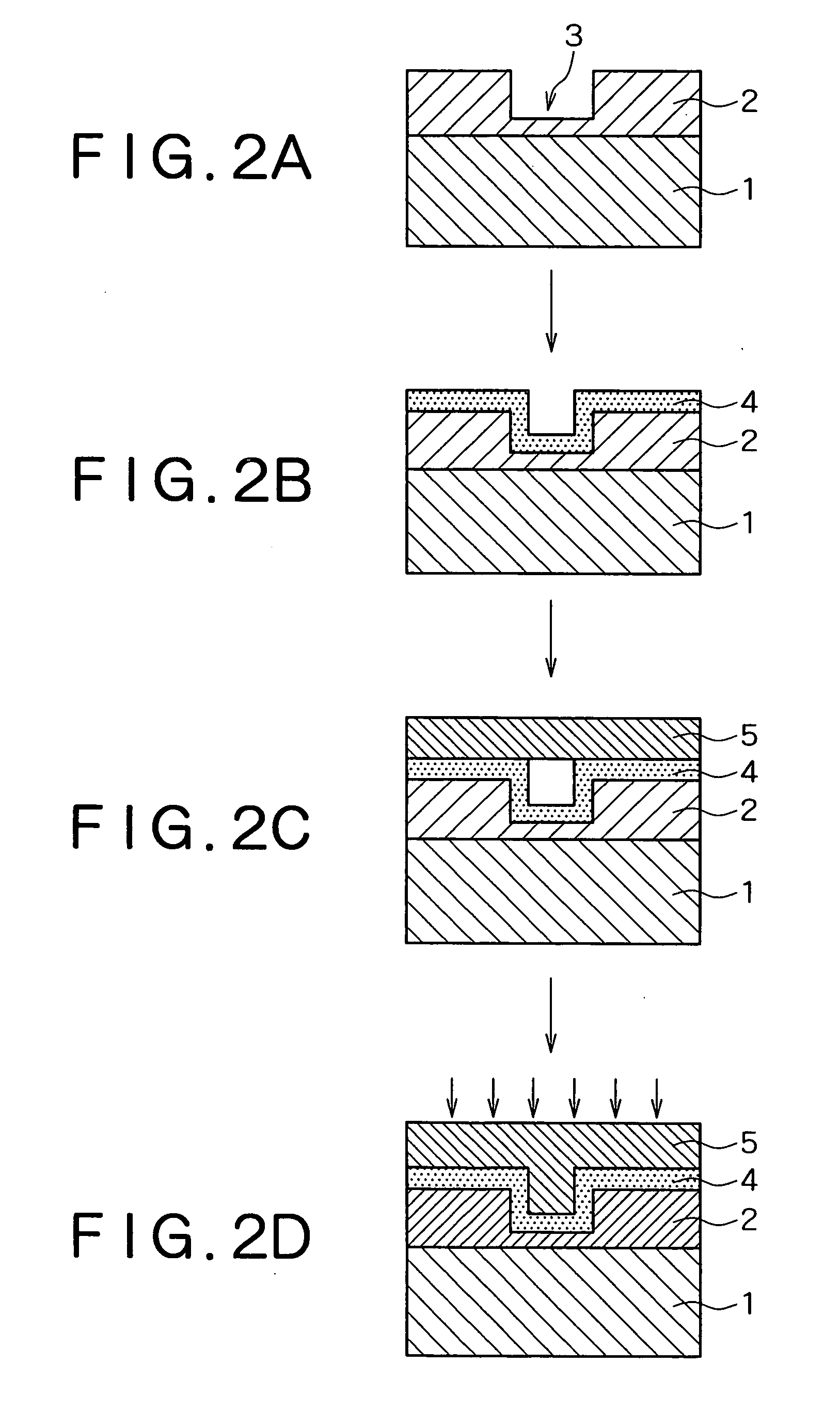

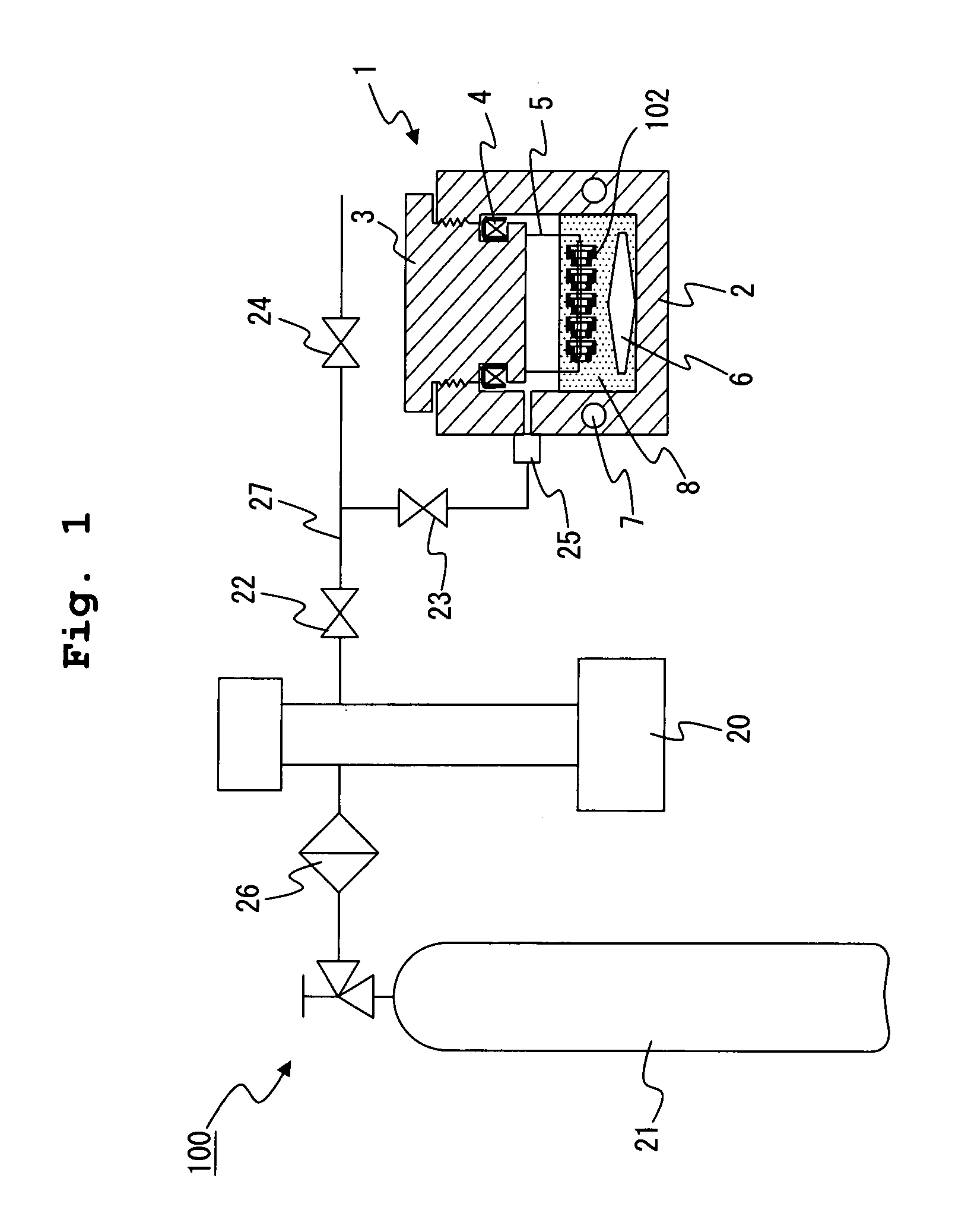

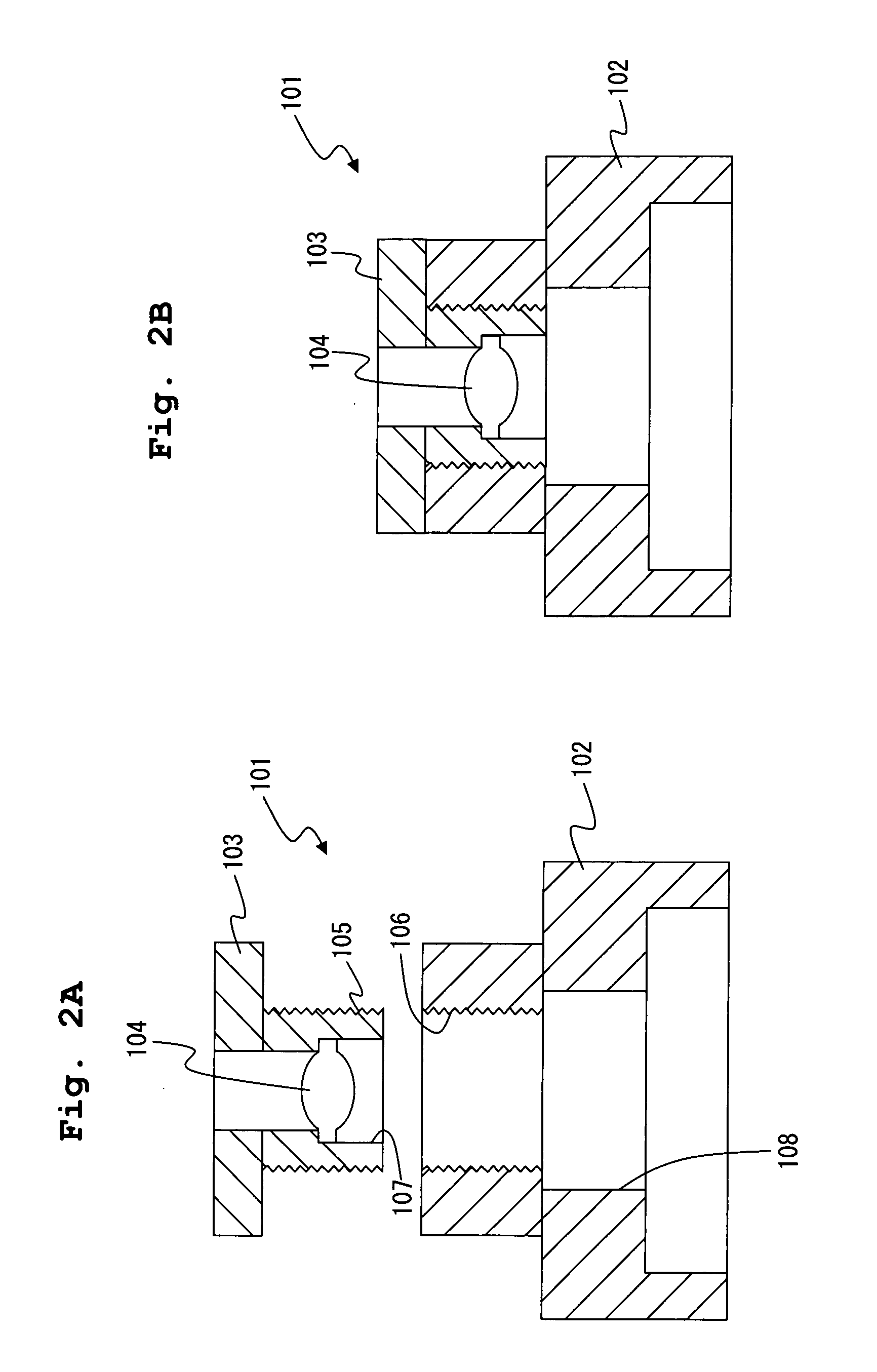

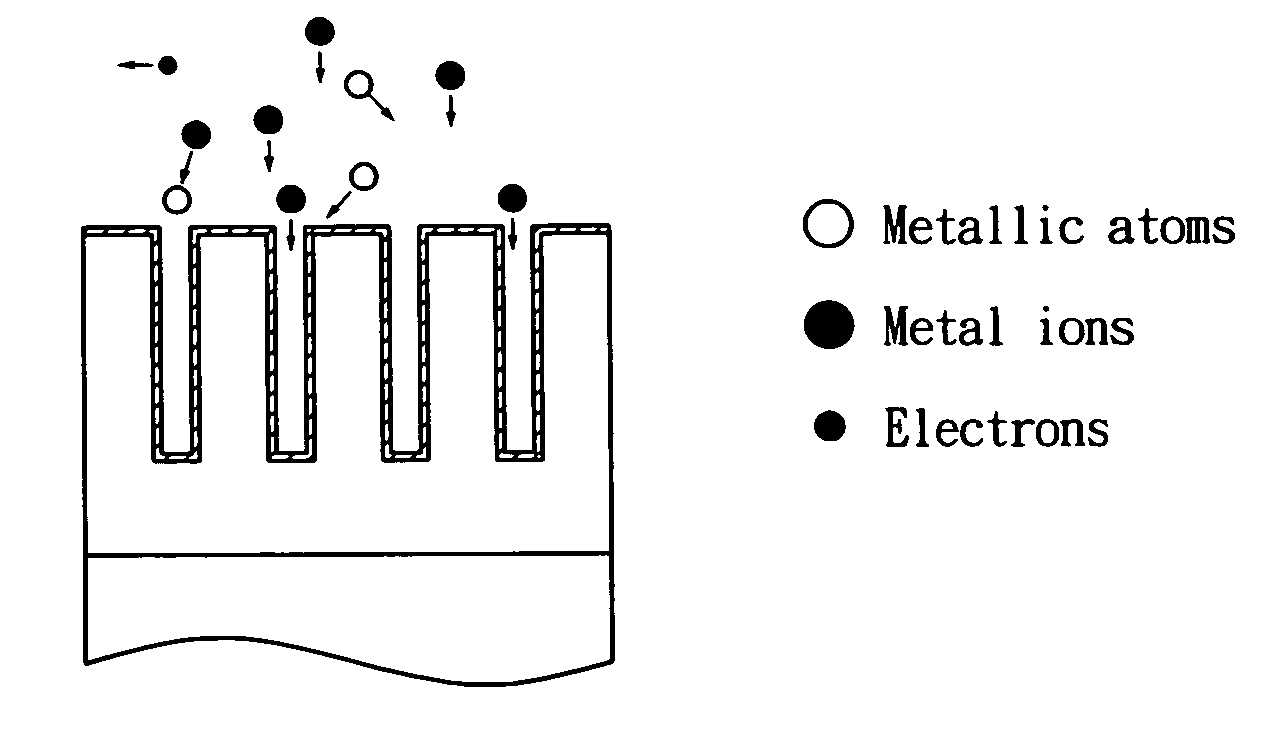

Method for fabricating copper-based interconnections for semiconductor device

InactiveUS20060019496A1Low electrical resistivityHigh adhesive strengthSemiconductor/solid-state device manufacturingHigh pressureCopper

Cu-based interconnections are fabricated in a semiconductor device by depositing a thin film of Cu or Cu alloy on a dielectric film by sputtering, the dielectric film having trenches and / or via holes at least one groove and being arranged on or above a substrate, and carrying out high temperature and high pressure treatment to thereby embed the Cu or Cu alloy into the trenches and / or via holes, in which the sputtering is carried out at a substrate temperature of −20° C. to 0° C. using, as a sputtering gas, a gaseous mixture containing hydrogen gas and an inert gas in a ratio in percentage of 5:95 to 20:80.

Owner:KOBE STEEL LTD

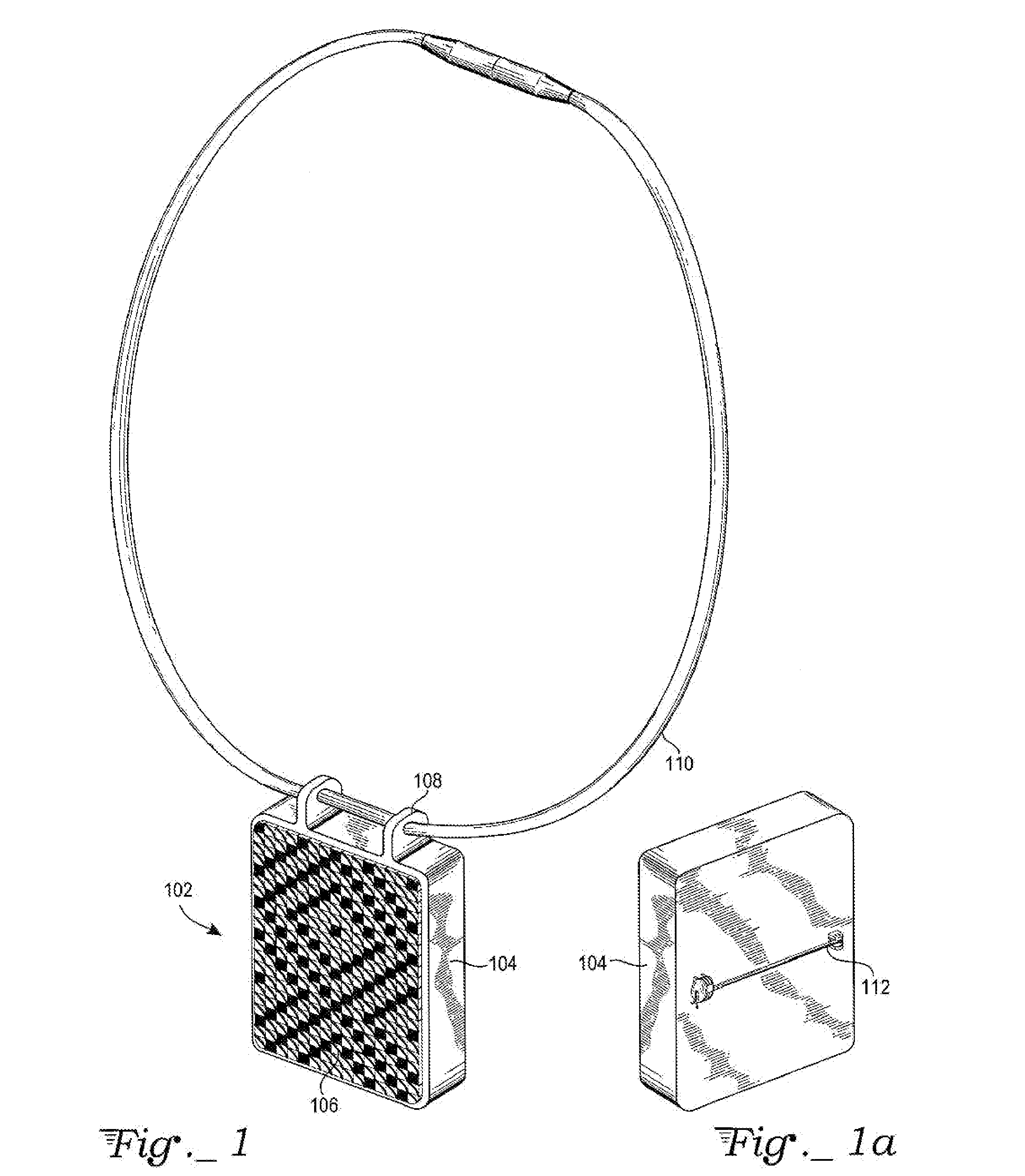

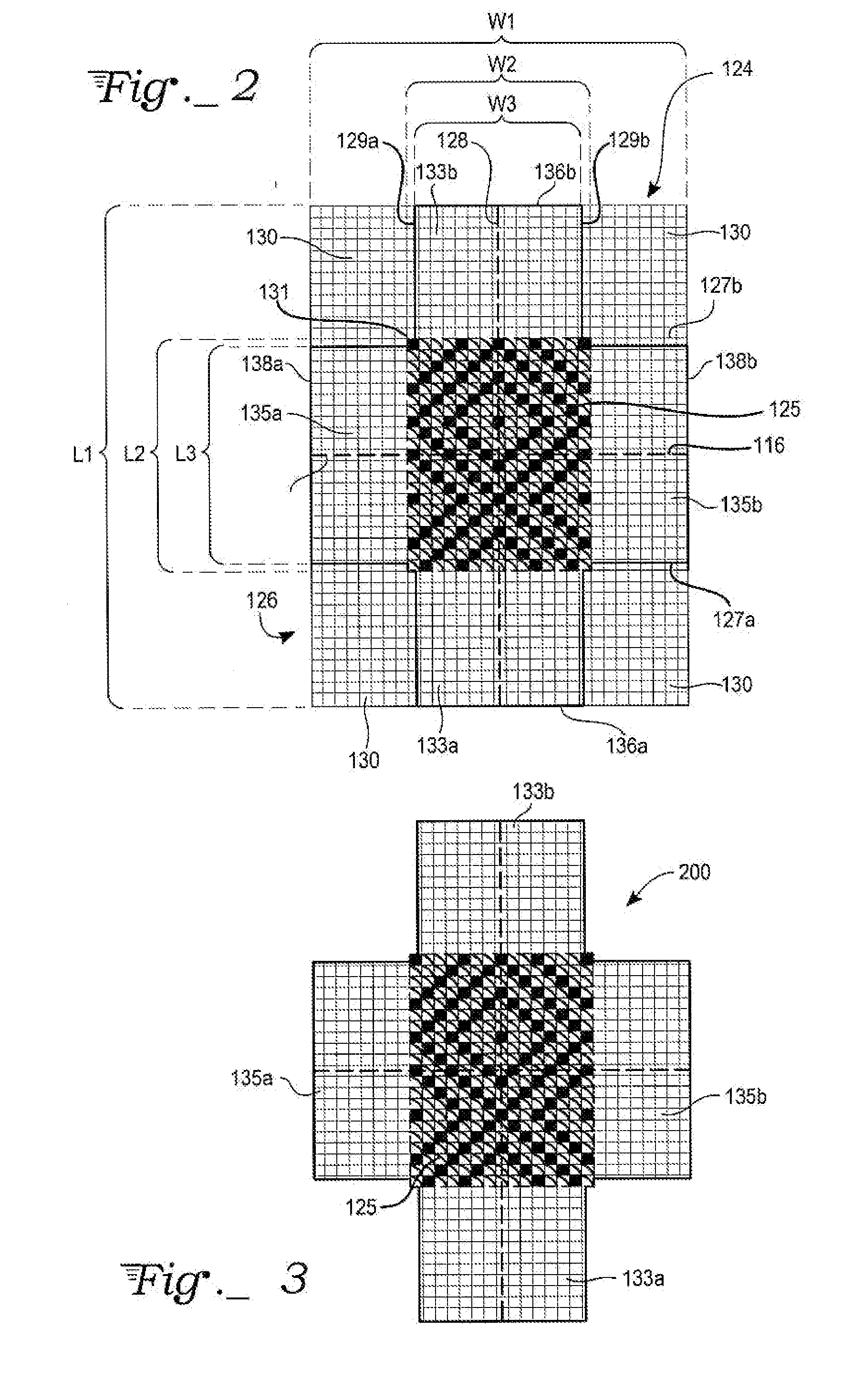

Fabric artwork with mounting assembly for nesting in frame

InactiveUS20080229641A1Avoid contactHigh adhesive strengthPicture framesBroochesMechanical engineering

Owner:SLAUTTERBACK FREDERICK A

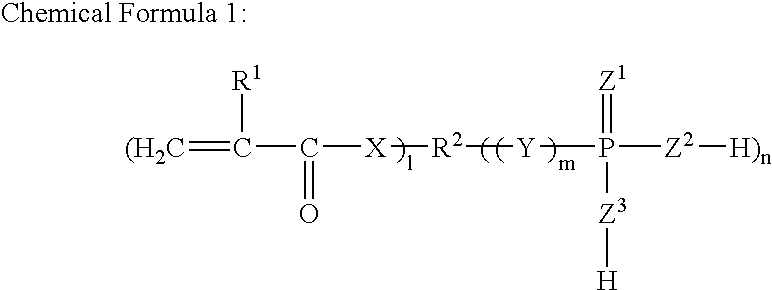

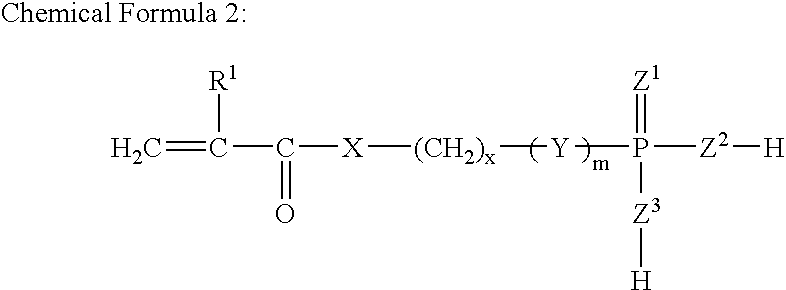

Adhesive composition and method for temporarily fixing member by using the same

ActiveUS20100000670A1High adhesive strengthPresent inventionLamination ancillary operationsSynthetic resin layered productsChemistryMeth-

To provide a method for temporarily fixing an optical member suitable for processing of optical members, and an adhesive composition useful for such a method.An adhesive composition comprising (A) a polyfunctional (meth)acrylate, (B) a monofunctional (meth)acrylate and (C) a photopolymerization initiator, wherein the glass transition temperature of a cured resin obtained from the adhesive composition is from −50° C. to 40° C. A method for temporary fixing a member, which comprises bonding and temporarily fixing the member by means of the above adhesive composition, processing the temporarily fixed member, and immersing the processed is member in warm water of at most 90° C., thereby to remove a cured resin of the adhesive composition from the member.

Owner:DENKA CO LTD

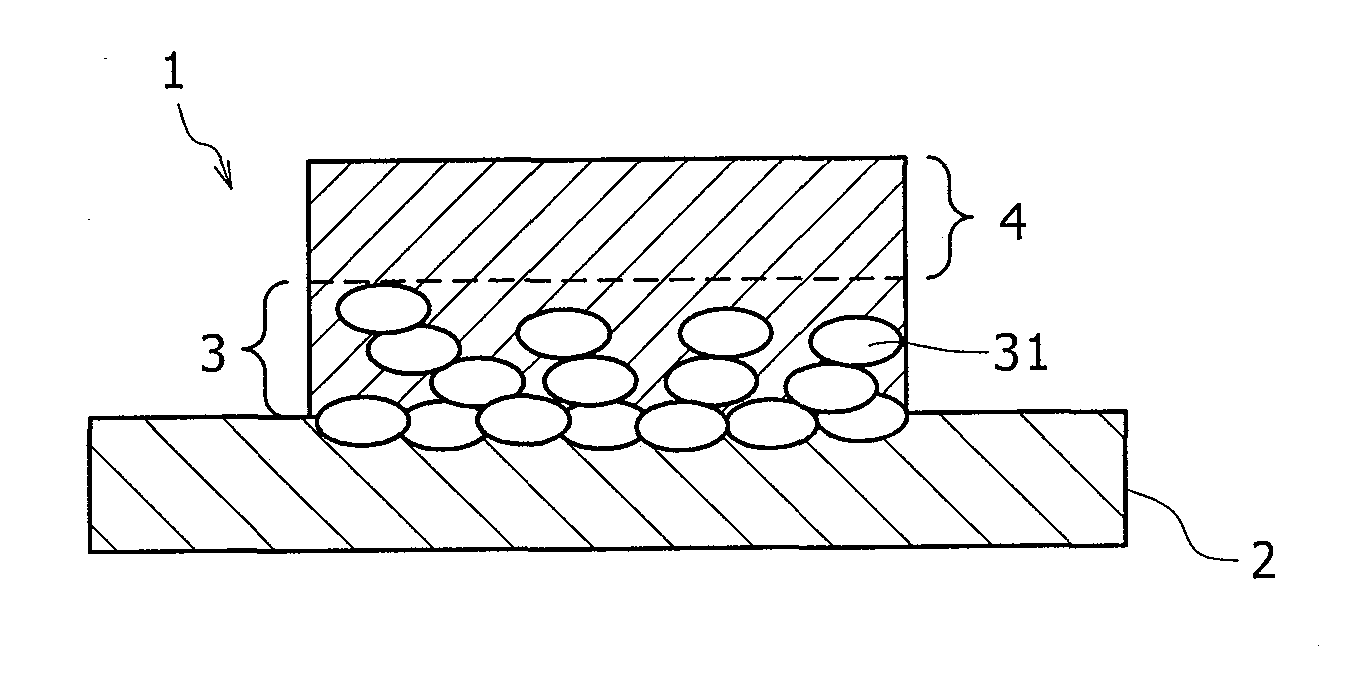

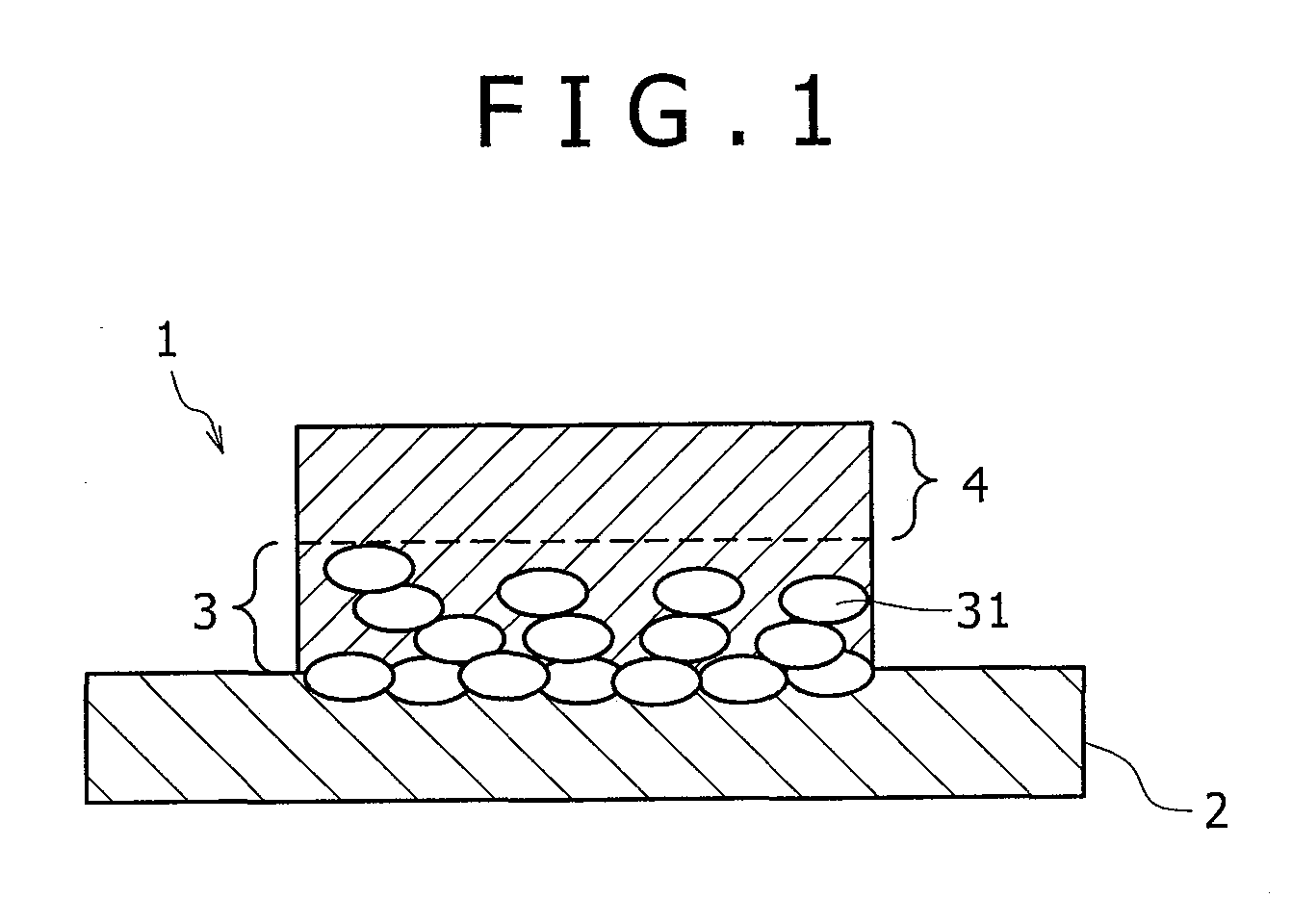

Method of manufacturing polymer member and polymer member

InactiveUS20070264451A1Low costHigh adhesive strengthEnvelopes/bags making machinerySynthetic resin layered productsElectroless platingCarbon dioxide

An electroless plating film with high adhesive strength is formed on surfaces of polymer substrates of various kinds, at low cost by providing a method of manufacturing a polymer member, including: preparing a polymer substrate having metallic fine particles impregnated on and inside a surface thereof; bringing pressurized carbon dioxide into contact with the polymer substrate to swell a surface area of the polymer substrate; and bringing an electroless plating solution containing pressurized carbon dioxide and being in a state causing a plating reaction, into contact with the polymer substrate while the surface area of the polymer substrate is swollen, to form a plating film on the polymer substrate.

Owner:HITACHT MAXELL LTD

Metal Bonding Member and Fabrication Method of the Same

InactiveUS20110244262A1High adhesive strengthPoor solder wettabilityPretreated surfacesMechanical vibrations separationMetal substrateMetallurgy

Provided are a metal bonding member having both a high adhesion strength and an excellent heat cycle reliability and a fabrication method of the same. A metal bonding member has a solder layer formed on at least a part of the surface of a metal substrate. The metal bonding member has an adhesion layer formed of metal particles having an excellent wettability with the solder layer in the interface between the solder layer and the metal substrate. The adhesion layer is partially buried in the metal substrate to form an anchor layer.

Owner:HITACHI LTD

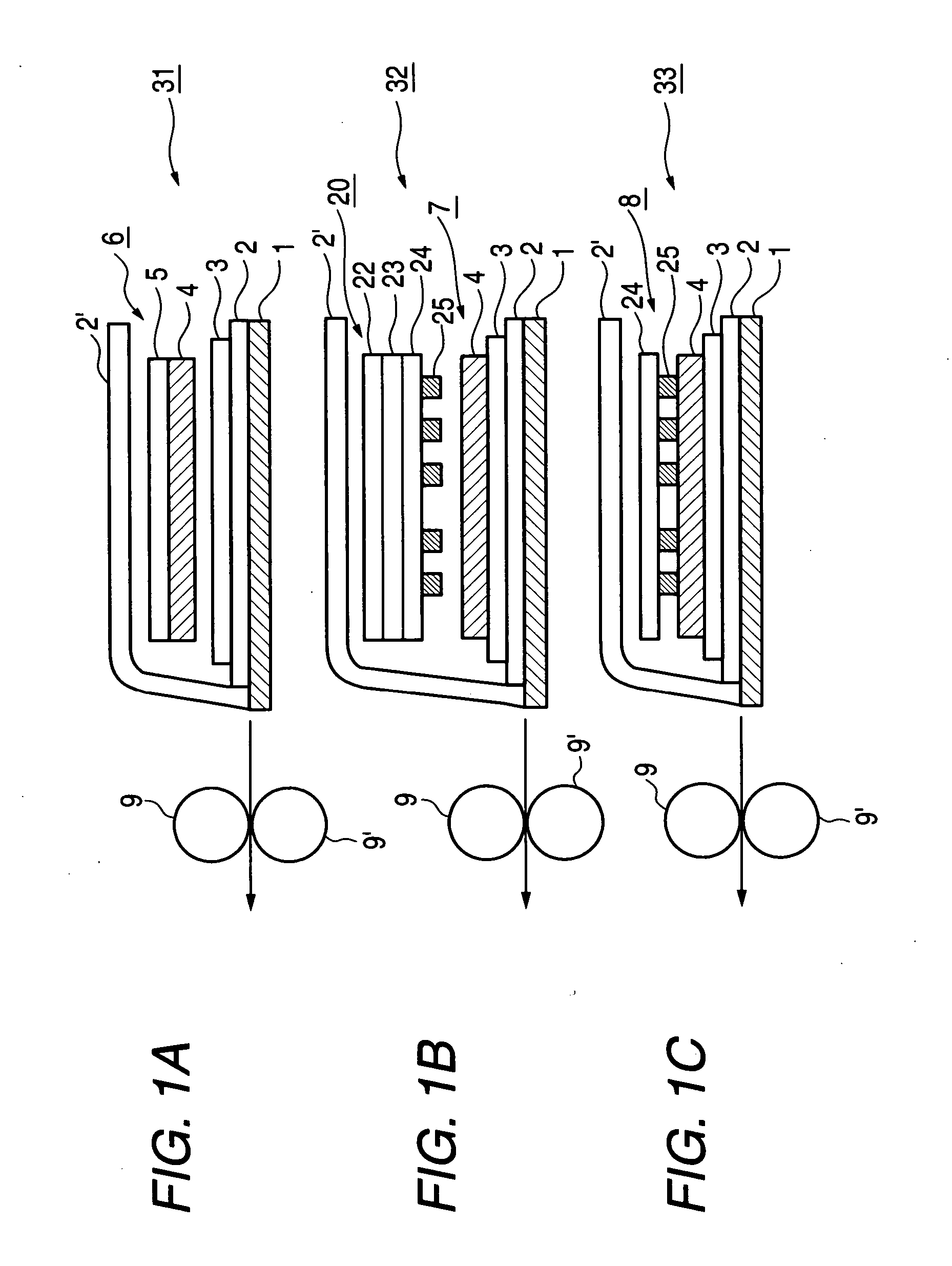

Liquid jetting head, method for changing protective tape in adhesive strength, and protective tape

InactiveUS20070263034A1Adhesive strength be lowerHigh adhesive strengthPrintingLiquid jetEngineering

A liquid ejecting head includes an ejection side surface; an ejection outlet, formed in the ejection side surface, for ejecting liquid; a protection tape pasted on the ejection side surface, wherein the protection tape is partly irradiated with ultraviolet radiation or infrared radiation after being pasted on the ejection side surface such that bonding strength is different depending on a position of the protection tape.

Owner:CANON KK

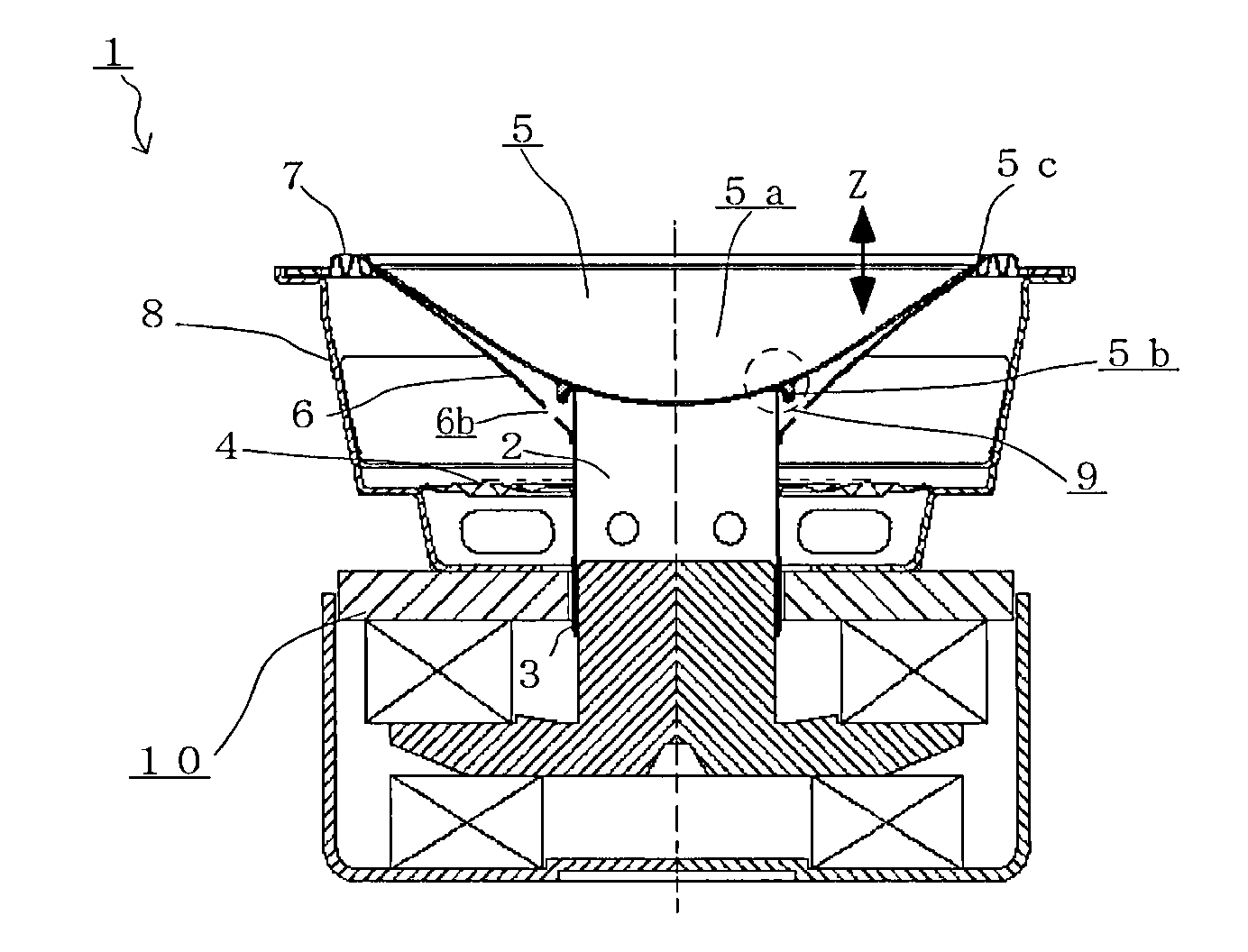

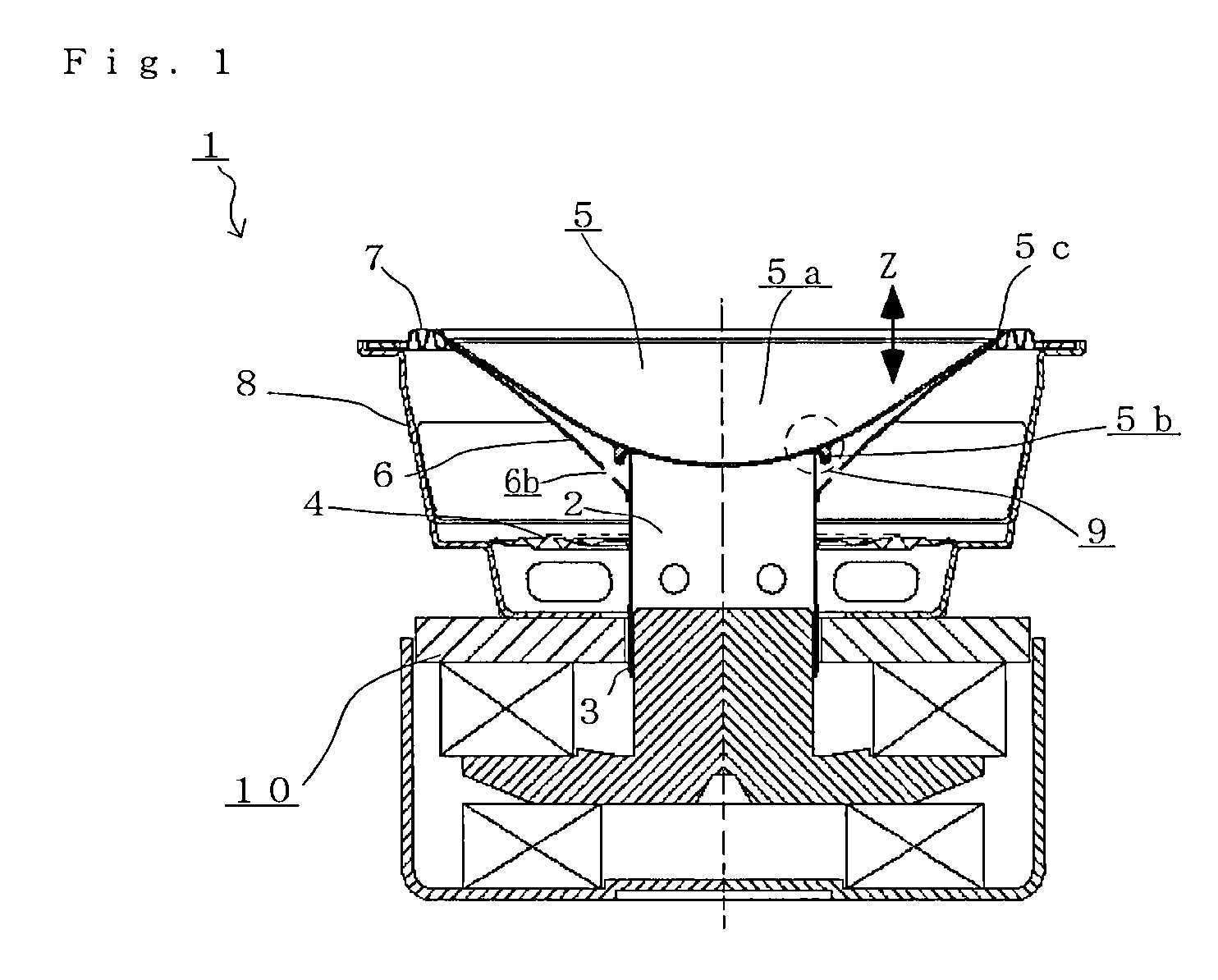

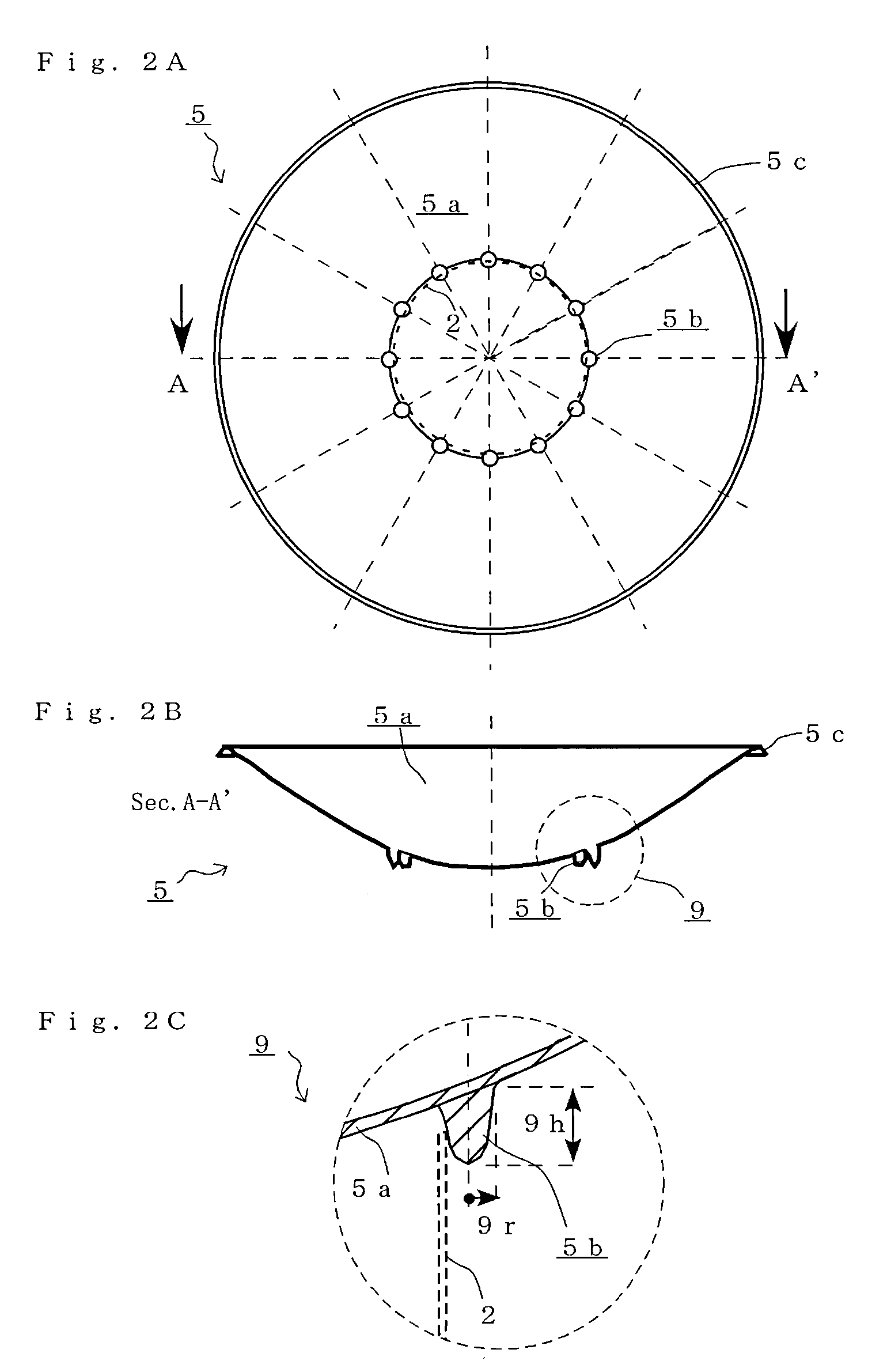

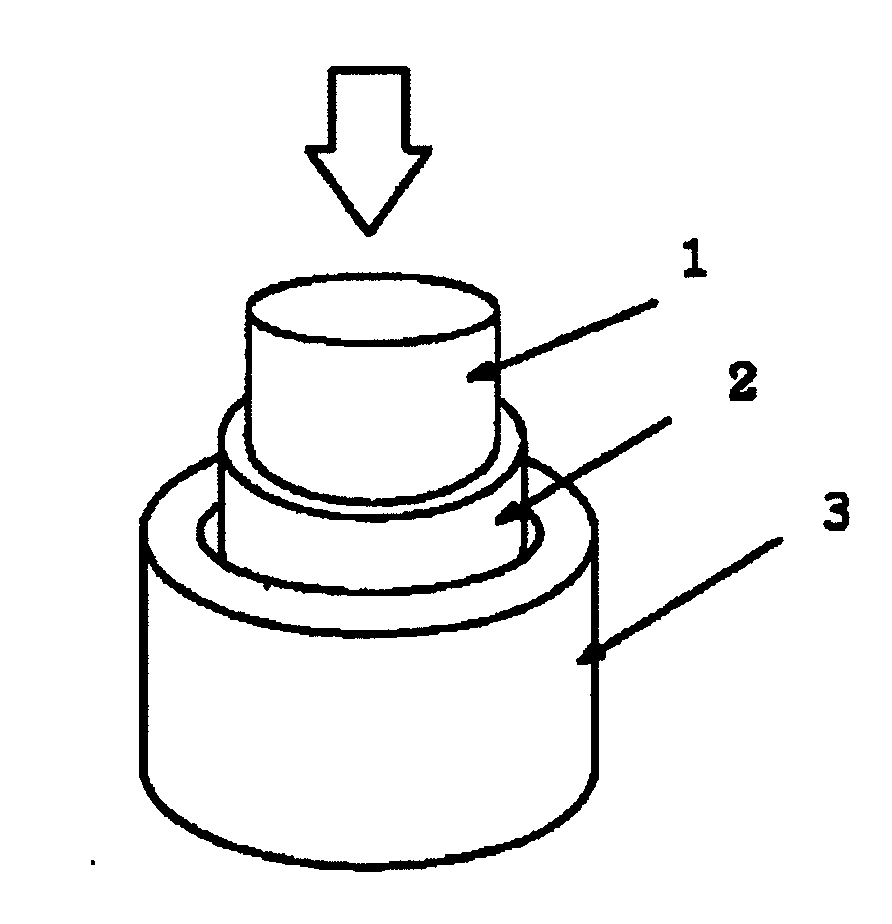

Loudspeaker

InactiveUS20090214075A1High adhesive strengthSmall peak dip in sound pressure frequency characteristicFibre diaphragmsTransducer detailsLoudspeakerEngineering

The loudspeaker includes a dome diaphragm that is made of a base material impregnated in a thermosetting resin; a cone diaphragm whose outer circumference side end portion is coupled with an outer circumference end portion of the dome diaphragm; and a voice coil having a bobbin whose one end is coupled to a back surface of the dome diaphragm, and whose outer curved surface is coupled with an inner circumference end portion of the cone diaphragm, wherein the dome diaphragm is provided with a plurality of cone-shaped projections that is formed by hardening the thermosetting resin, projecting from the back surface, and disposed in a circular pattern with a space between each other, the plurality of cone-shaped projections defining a coupling portion to which the one end of the bobbin is coupled.

Owner:ONKYO TECH KK

Redox Curing-Type Nonaqueous Curable Composition

ActiveUS20080081889A1High adhesive strengthSecuring timeSurgical adhesivesDentistry preparationsWater solubleWetting

A nonaqueous curable composition including a liquid radical polymeric monomer (a), an organic peroxide (b) and a powdered water-soluble reducing compound (c) with the powdered water-soluble reducing compound (c) dispersed in the liquid radical polymeric monomer (a) is provided.According to the nonaqueous curable composition of this invention, time necessary for adhesion can be secured, and high adhesive strength against a wetting material, and more particularly, a biological hard tissue such as a dentine can be attained, and thus, the present invention is extremely industrially valuable.

Owner:KURARAY NORITAKE DENTAL

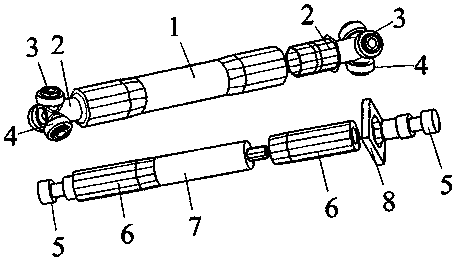

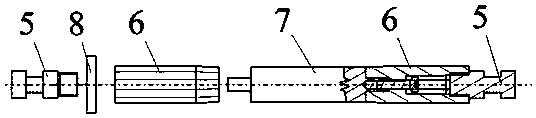

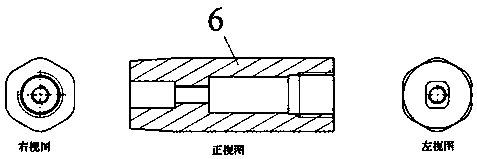

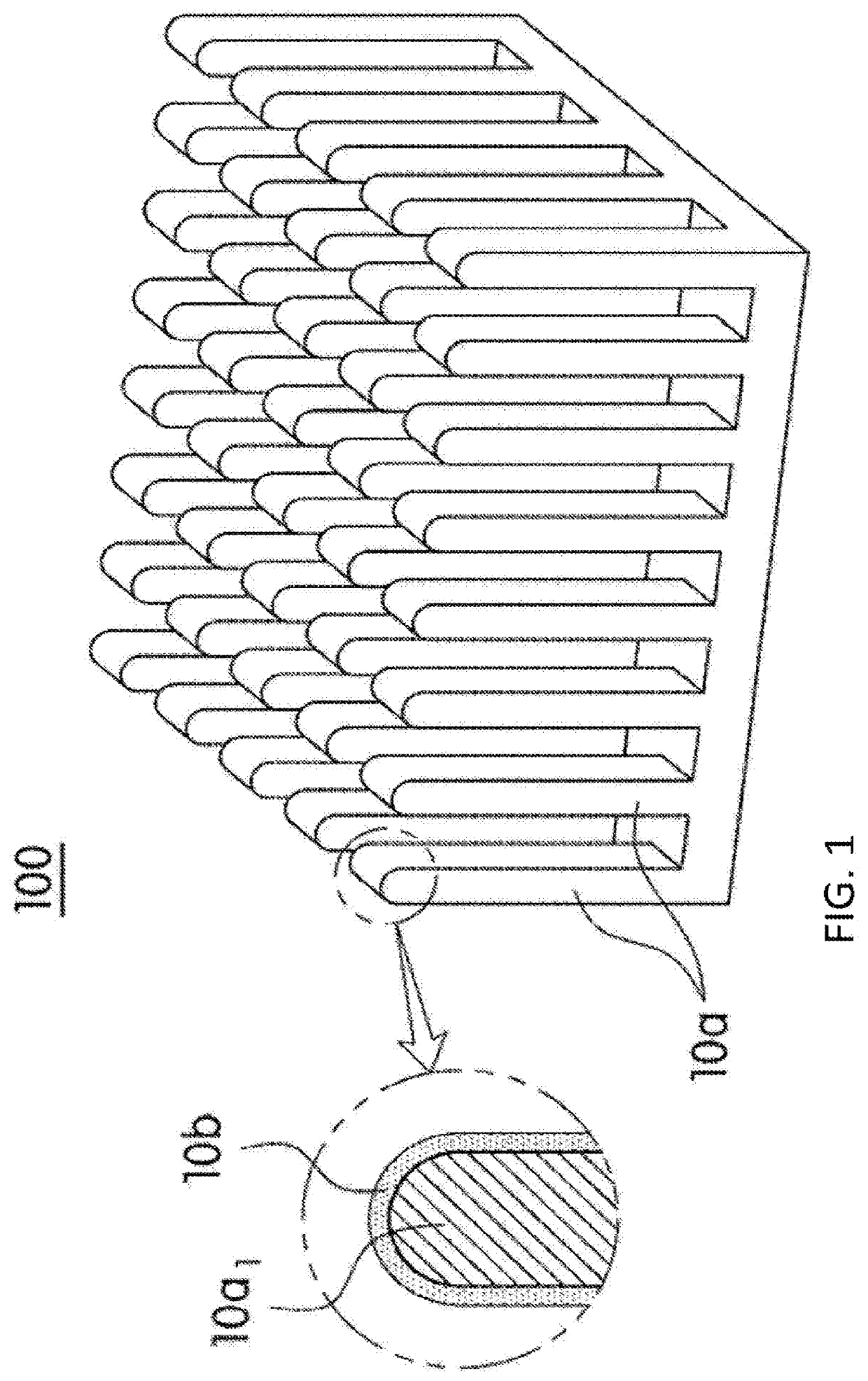

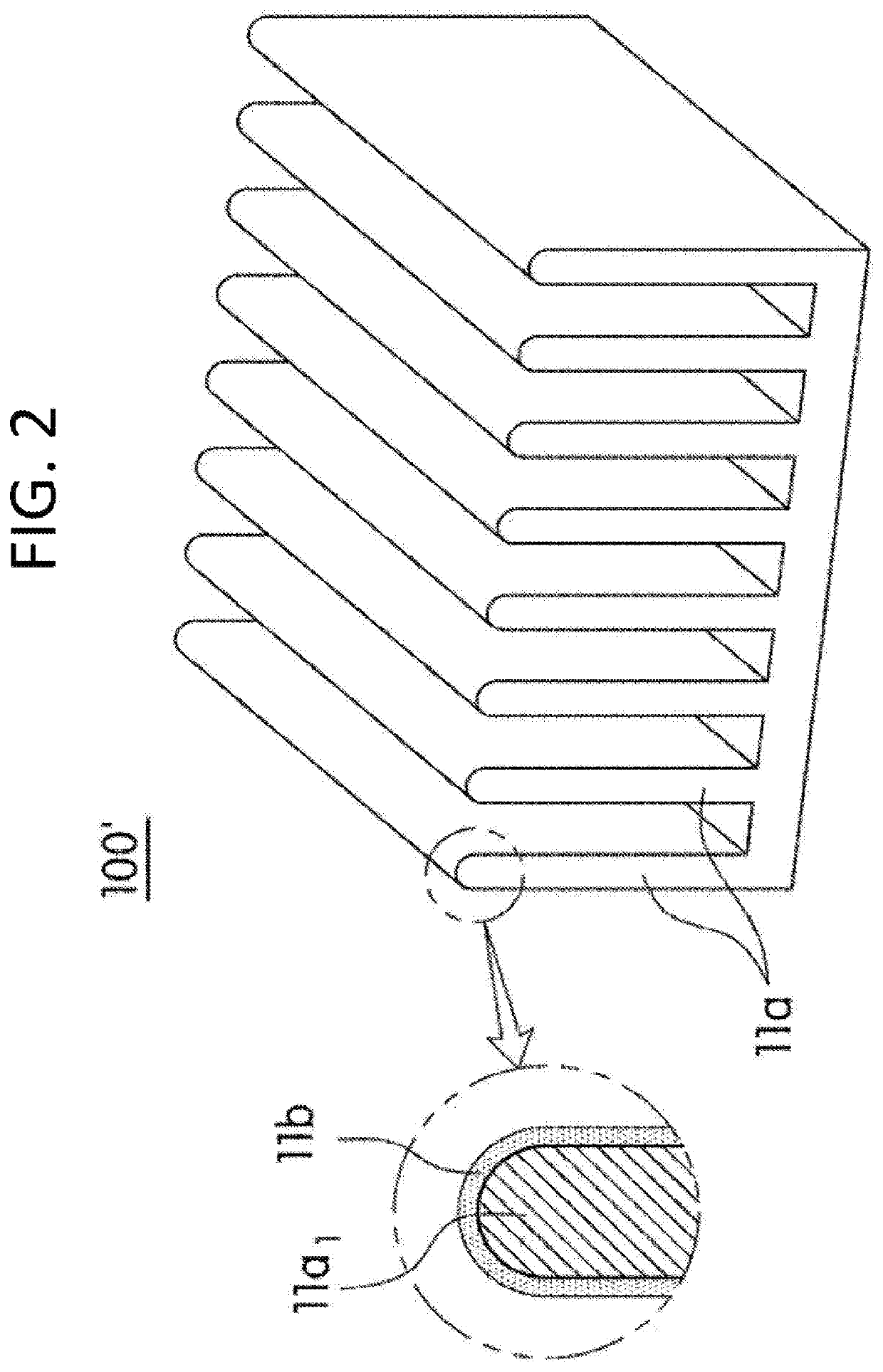

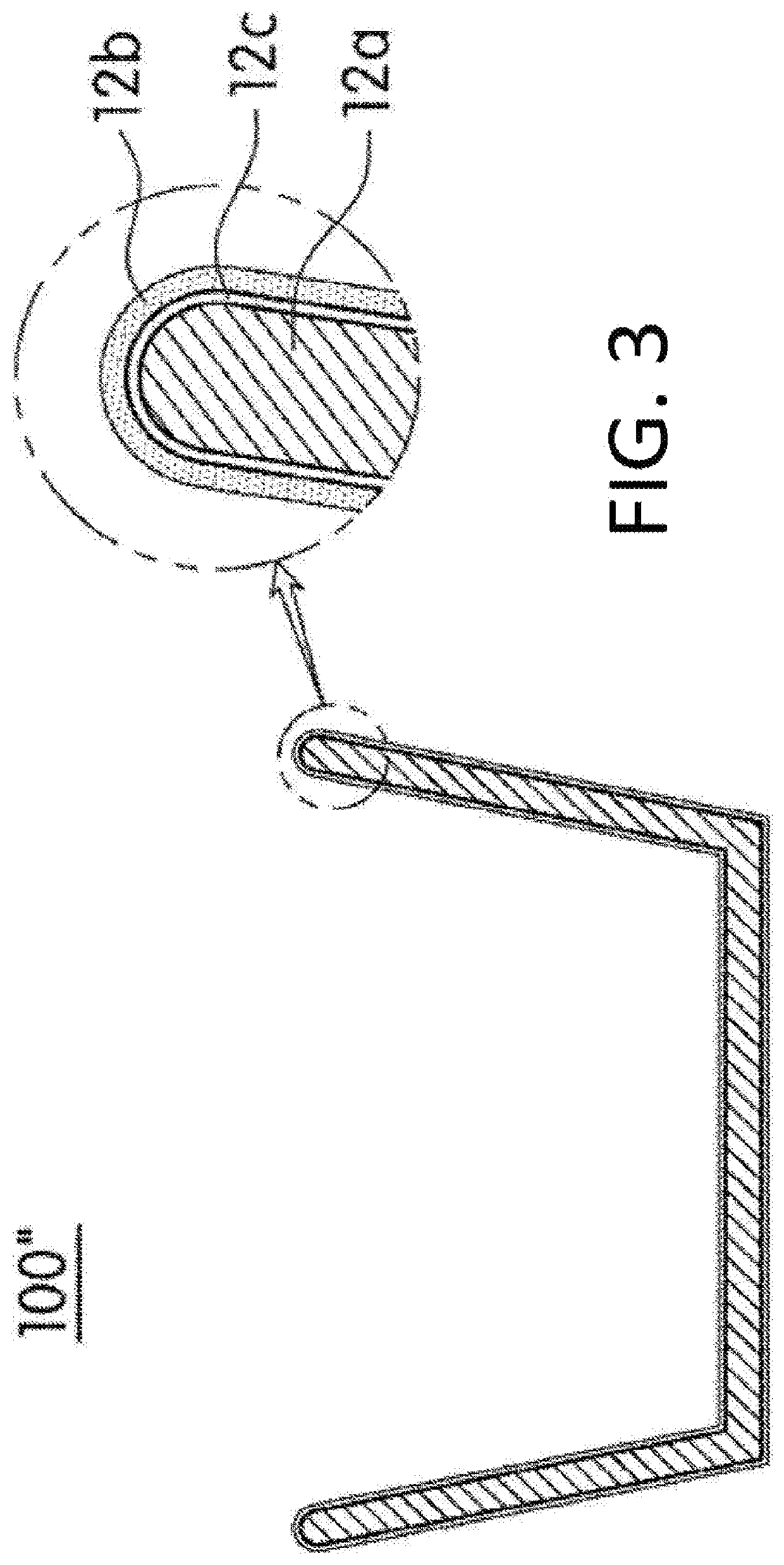

Carbon fiber winding paving variable cross-section adhesive transmission shaft and combined type mould thereof

PendingCN107605928AHigh adhesive strengthEasy to assemble and disassembleYielding couplingShaftsNeedle roller bearingEngineering

The invention relates to a carbon fiber winding paving variable cross-section adhesive transmission shaft and a combined type mould thereof. The carbon fiber transmission shaft comprises a carbon fiber tube 1, an integrated joint 2 and the combined type mould. The two ends of the carbon fiber tube 1 are bonded on the integrated joint 2, a three-ball pin column at the other end of the integrated joint 2 is matched with a needle bearing 3 and a ball ring 4 to form constant-speed universal connection, and the needle bearing is limited by a clamp spring. A clamp 5 is in a cylindrical shape, and the mold and machining equipment are connected by the clamp 5. The combined type mould comprises a mould body 6 with the two ends being hexagon-like cross sections (including a transition section) and amould body 7 with the middle being circular cross section, and the combined type mould is positioned and matched by a groove and a boss on the mould and then connected with the cylindrical clamp 5. Acenter hole of a square block 8 is used for assisting demoulding. According to the carbon fiber winding paving variable cross-section adhesive transmission shaft and the combined type mould thereof,the design is reasonable, assembly and disassembly of the mould are convenient, the paving scheme is flexible, the problem that demoulding is difficult is solved, the material performance is sufficiently utilized, the transmission shaft and the combined type mould can adapt to different machining equipment and working conditions, the feasibility and operability are high, the weight is lowered by about 53% compared with steel, the inertia is reduced, and energy is saved.

Owner:HARBIN INST OF TECH AT WEIHAI

Composite material and method for preparation thereof

InactiveUS20030118839A1High adhesive strengthBonded firmlySynthetic resin layered productsThin material handlingMolecular orbitalInteraction energy

A composite of a resin member bonded to a vulcanized rubber member is obtained with using a rubber member vulcanized with a radical-generating agent (e.g., an organic peroxide) and a thermoplastic resin having at least 2 atoms, on average, selected from H and S atom per molecule, each atom having not less than 0.006 of an orbital interaction energy coefficient S represented by the following formula (1): S=(CHOMO,n)2 / |Ec-EHOMO,n|+(CLUMO,n)2 / |Ec-ELUMO,n| (1) wherein Ec: an orbital energy (eV) of a radical, CHOMO,n: a molecular-orbital coefficient of a highest occupied molecular orbital (HOMO) of an n-th H or S atom constituting a basic unit of the resin, EHOMO,n: an orbital energy (eV) of the HOMO, CLUMO,n: a molecular-orbital coefficient of a lowest unoccupied molecular orbital (LUMO) of the n-th H or S atom constituting the basic unit of the resin, ELUMO,n: an orbital energy (eV) of the LUMO, and above all represent a value calculated by a semiempirical molecular orbital method MOPACPM3. The thermoplastic resin includes a polyamide, a polyester, a PPE, a POM, a PPS, a polyolefinic resins, and the unvulcanized rubber may comprise a vulcanization-activating having plural polymerizable unsaturated bonds. The invention gives the composite of the resin bonded directly to the rubber firmly without adhesives in wide combinations of the resin and the rubber.

Owner:DAICEL DEGUSSA

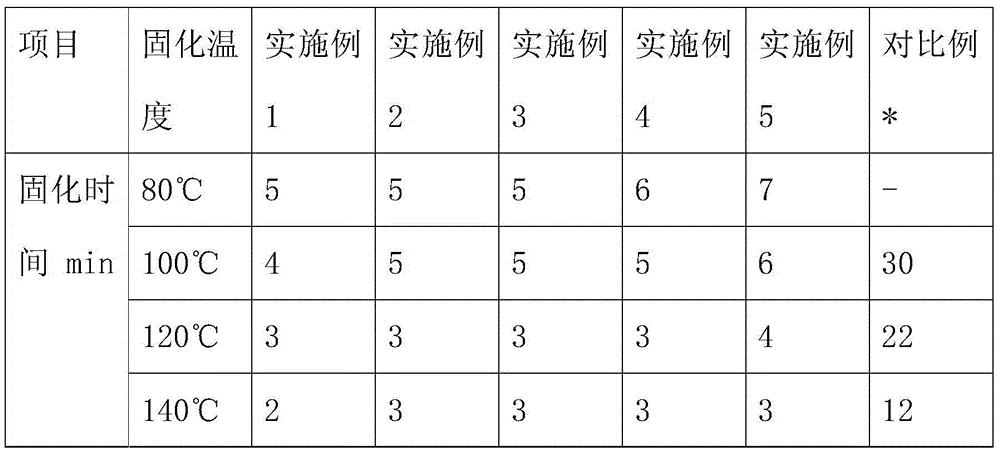

Production method for scientific and technological ecological impregnated paper

ActiveCN105220570AHigh adhesive strengthShort curing timeNon-fibrous pulp additionPaper coatingAdverse effectEngineering

The invention discloses a production method for scientific and technological ecological impregnated paper. The method is sequentially carried out according to the following steps: preparing urea-formaldehyde glue; preparing triamine glue; carrying out primary impregnation; carrying out primary drying; carrying out coating; carrying out secondary impregnation; carrying out secondary drying; carrying out tailoring; carrying out inspection; carrying out packaging; and putting the paper in storage. The scientific and technological ecological impregnated paper prepared by virtue of the method can fully replace wood veneer for veneer manufacture of an ecological board and eliminate adverse effect caused by wood veneer in a home decoration process, so that the integral quality level of the ecological board is improved. Compared with the impregnated paper prepared from urea-formaldehyde glue and triamine glue, the impregnated paper disclosed by the invention is high in impact resistance and wear resistance, low in content of free formaldehyde, smooth and uniform in distribution of glue, and can fully cover the texture of the board, so that the bottom exposing and carbonizing phenomena are eliminated, the yield of a product is improved and the service life of the product is prolonged.

Owner:DILONG NEW MATERIAL LINYI

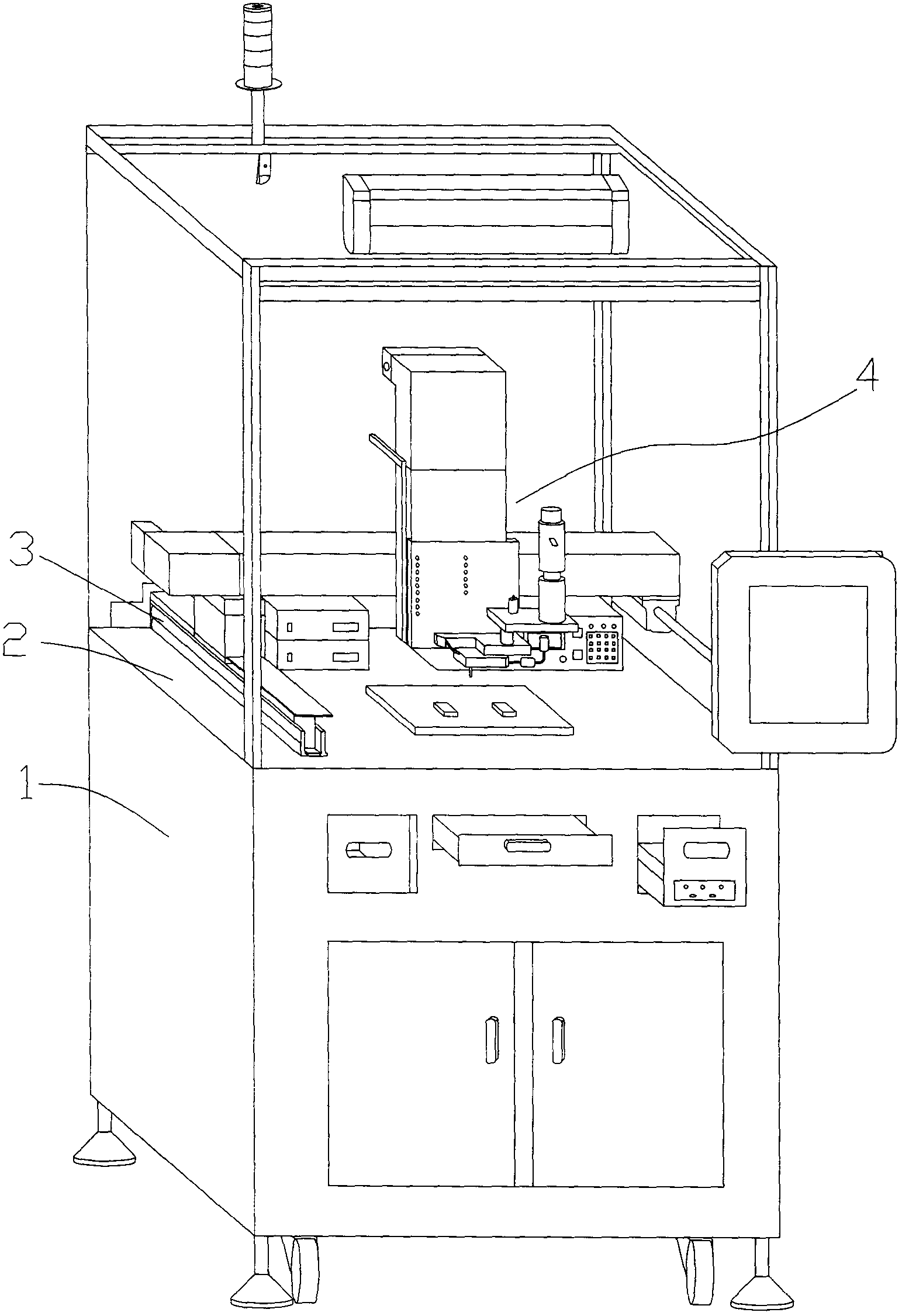

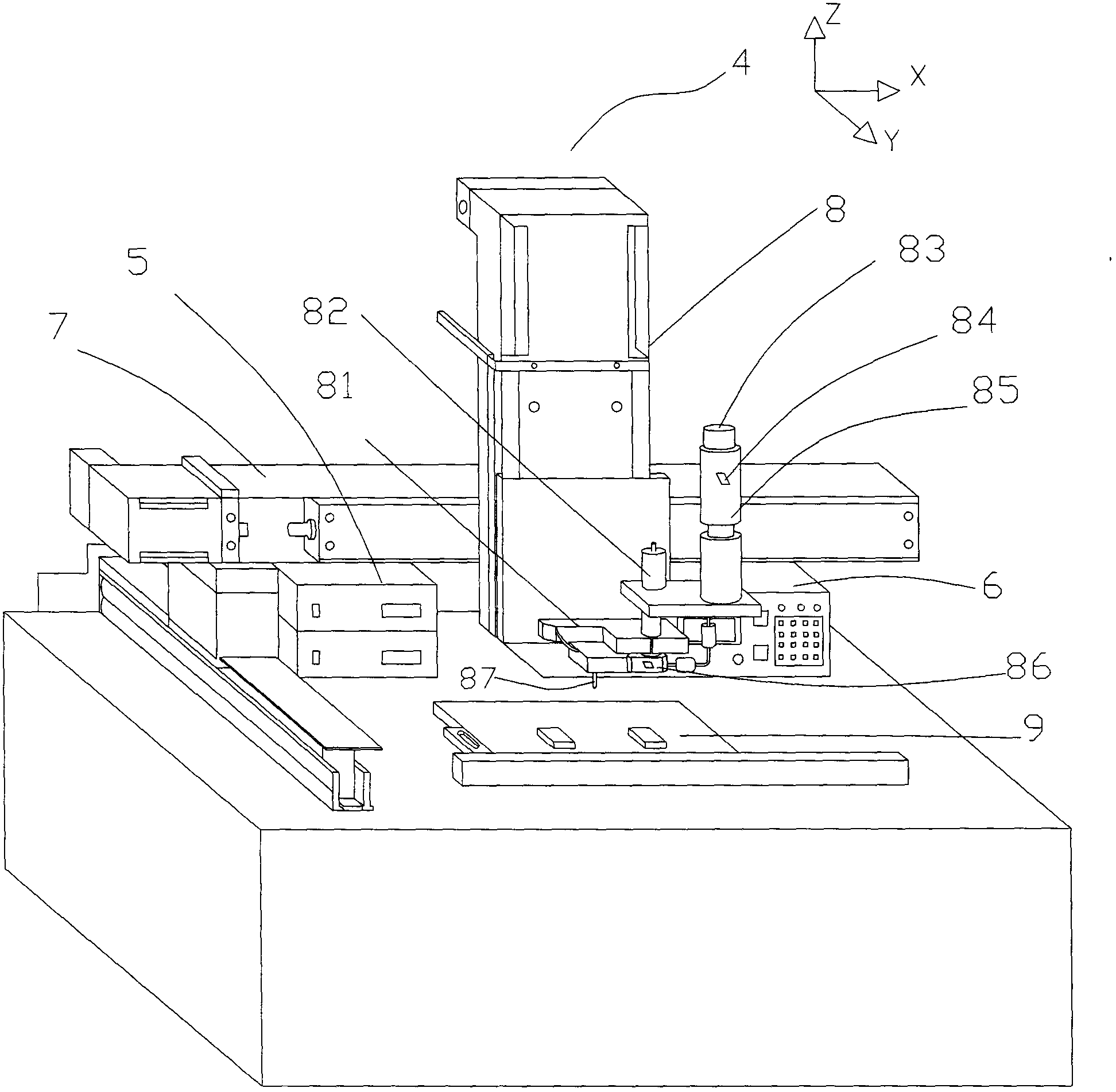

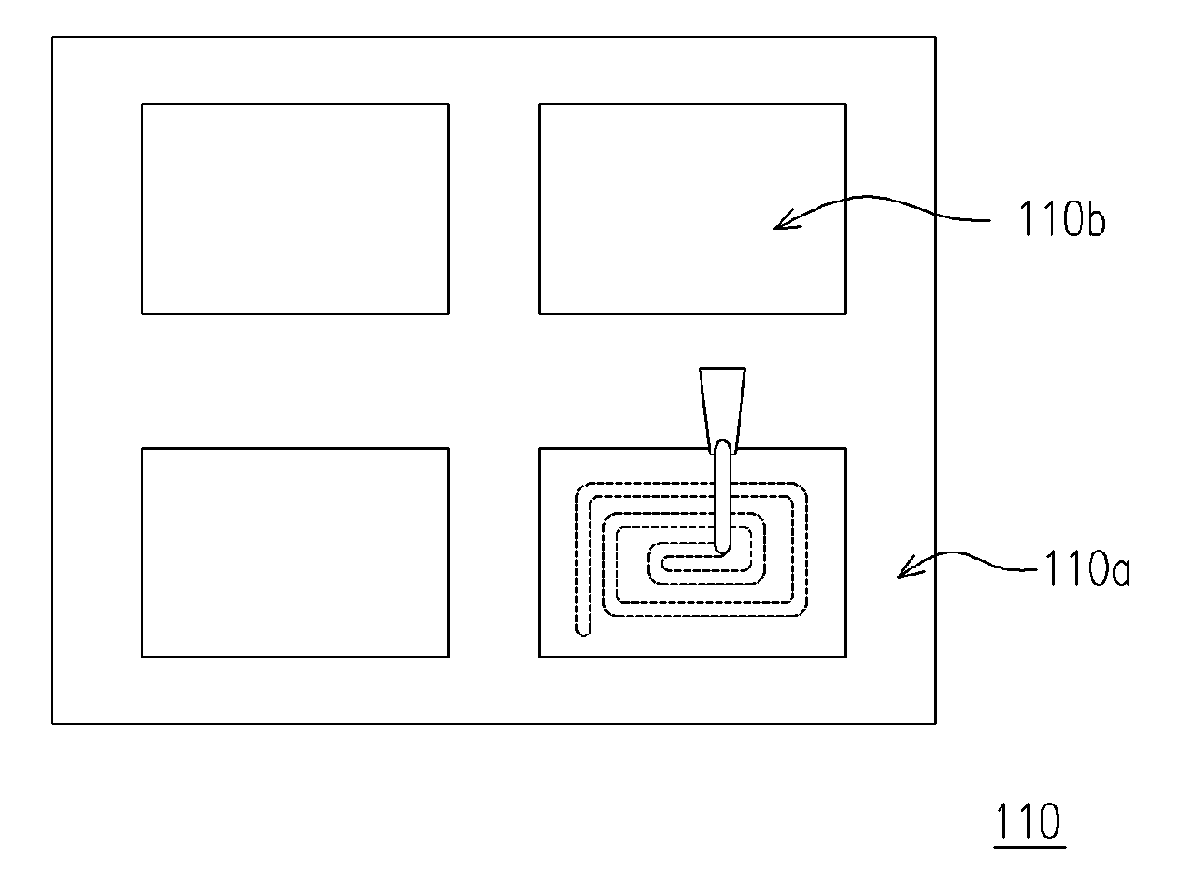

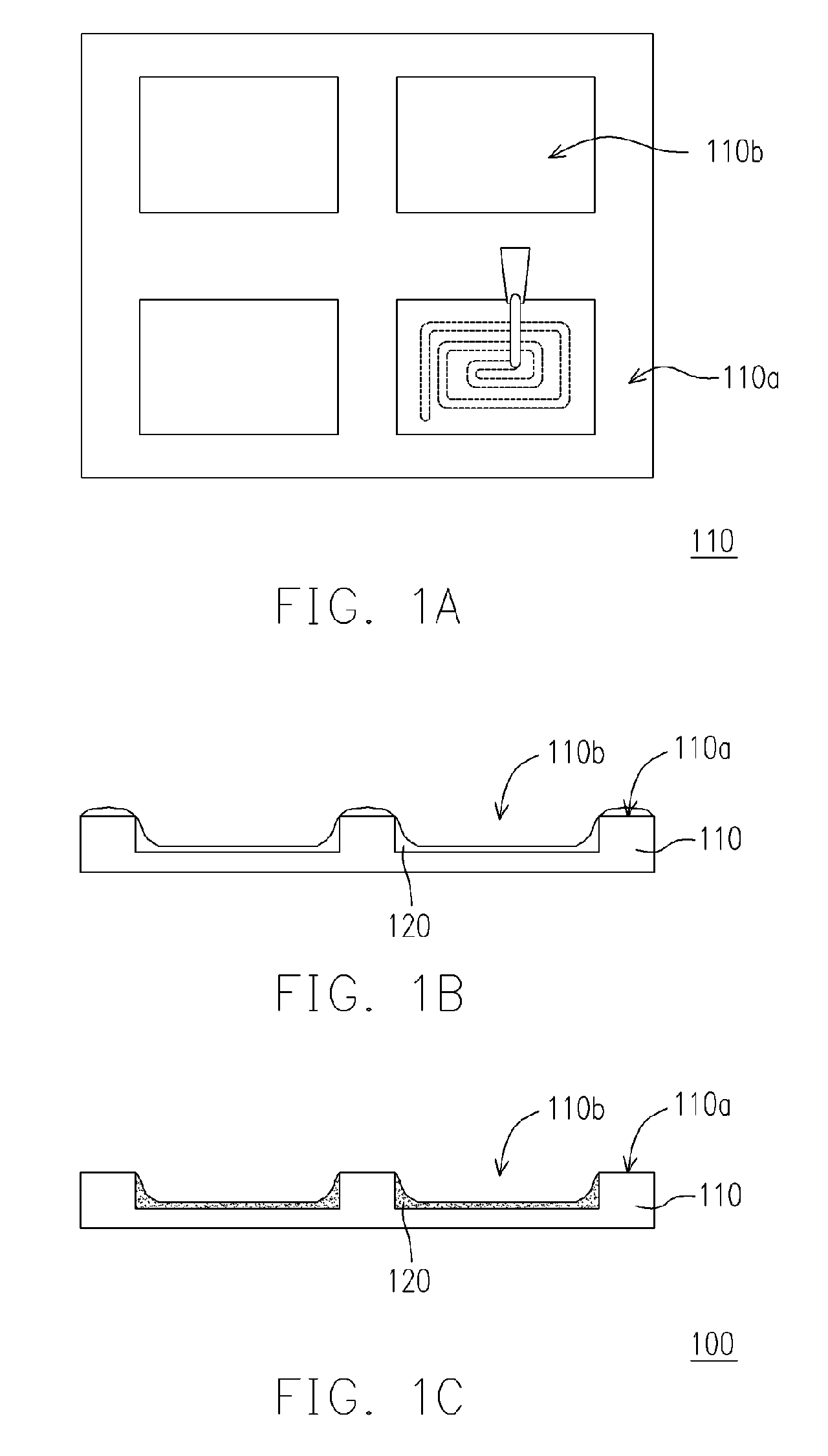

Glue coating machine and gluing method

InactiveCN103801484AHigh adhesive strengthImprove sealingLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses a glue coating machine which comprises a machine body, a Y-axis guide rail and a glue coating device, wherein the Y-axis guide rail is arranged on a machine table and extends along the Y-axis direction, the glue coating device is arranged on the machine table and consists of an X-axis guide rail extending along the X-axis direction, a Z-axis guide rail perpendicular to the X-axis direction and the Y-axis direction, a sliding seat, a screw valve embedded in the middle of the sliding seat, a clamp type glue bucket, a screw valve controller, a heater and a temperature controller; the invention further discloses a gluing method, which comprises the following steps: putting hot melt colloid into the clamp type glue bucket, heating through the heater to melt the hot melt colloid, controlling the temperature of the hot melt colloid to be unchanged through the temperature controller, regulating the screw valve through the screw valve controller to pressurize glue, controlling the motion trace of a needle head through the X-axis guide rail, the Y-axis guide rail and the Z-axis guide rail, and extruding the glue from the needle head to be evenly coated on the set trace. The glue coating machine can perform all-around automatic dispensing, and glue does not flow vertically and does not overflow, and is high in gluing strength and sealing property, so that the effects of being dustproof, antishock, waterproof and the like can be achieved, and the pass percentage of workpieces can be increased.

Owner:江苏盈盛复合材料有限公司

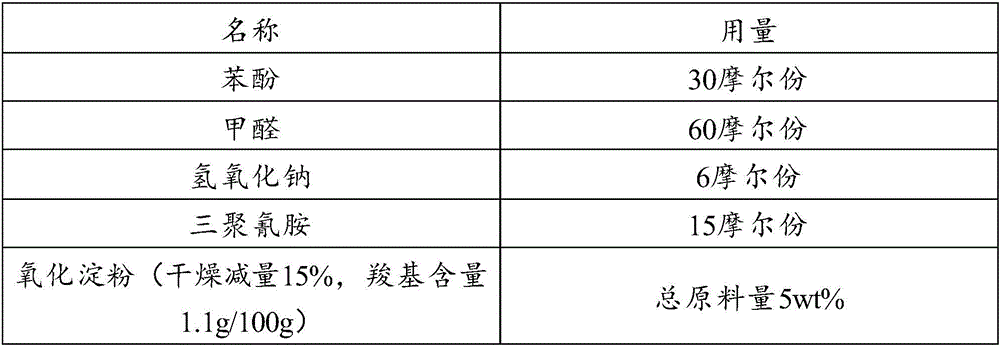

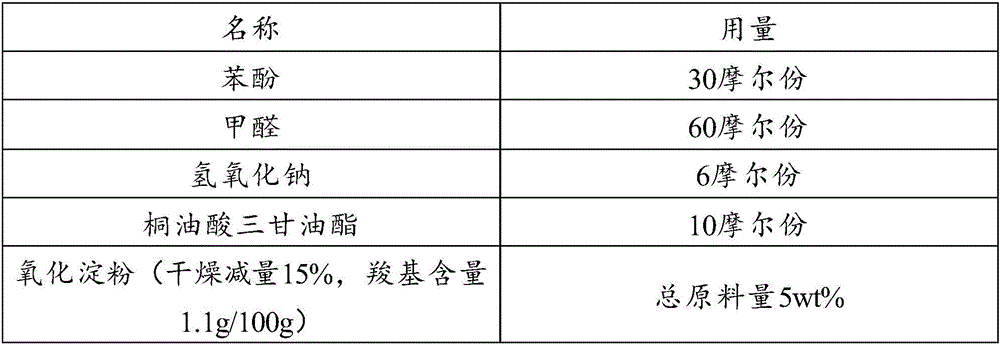

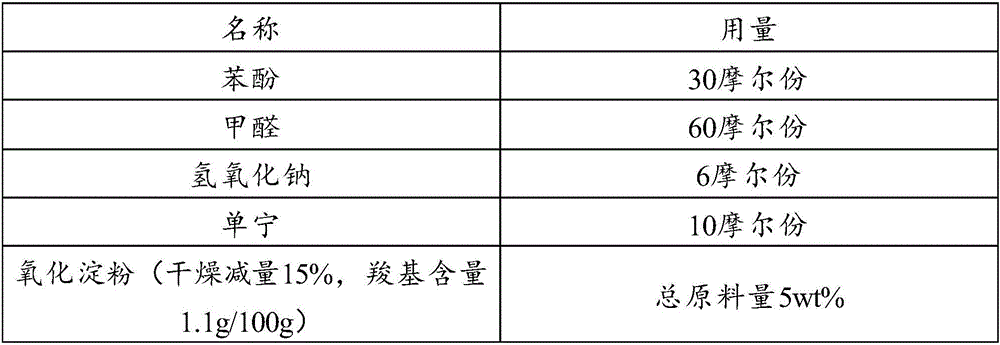

Modified phenolic resin adhesive

InactiveCN106750065AHigh adhesive strengthImprove adhesion strengthAldehyde/ketone condensation polymer adhesivesFree phenolAldehyde

The invention belongs to the field of phenolic resins and in particular relates to a modified phenolic resin adhesive. The modified phenolic resin adhesive is prepared by the method of heating phenol, formaldehyde, alkali and a modifying agent for reaction so as to obtain the modified phenolic resin adhesive, wherein the modifying agent contains multiple ones of cyanamide compound, eleostearate, oxidized starch and tannin. As multiple specific modifying agents are added in the preparation process of the phenolic resin adhesive, the modified phenolic resin adhesive has the advantages that the residue amounts of free phenol and aldehyde in the prepared adhesive can be obviously reduced and the adhesive strength of the adhesive can be obviously improved. The experiment result shows that the content of the free aldehyde in the modified phenolic resin adhesive is lower than 0.3 wt%, the content of the free phenol in the modified phenolic resin adhesive is lower than 4 wt% and the adhesive strength of the modified phenolic resin adhesive is higher than 3 MPa.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Organic electroluminescent device, cover plate of organic electroluminescent device, and method for fabricating cover plate

InactiveUS20070046198A1High adhesive strengthSuperior water absorptivityDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceEngineering

A method for fabricating a cover plate of an organic electroluminescent device comprising the following steps is provided. First, a substrate is provided, wherein the substrate has a bonding region. Then, a liquid-state desiccant layer is formed on the substrate, wherein the liquid-state desiccant layer is surrounded by the bonding region. Next, the liquid-state desiccant layer is cured to form a desiccant layer. Then, the bonding region of the substrate is cleaned. As mentioned above, the contaminants on the bonding region can be drastically reduced. Moreover, an organic electroluminescent device and a cover plate thereof are also provided.

Owner:CHUNGHWA PICTURE TUBES LTD

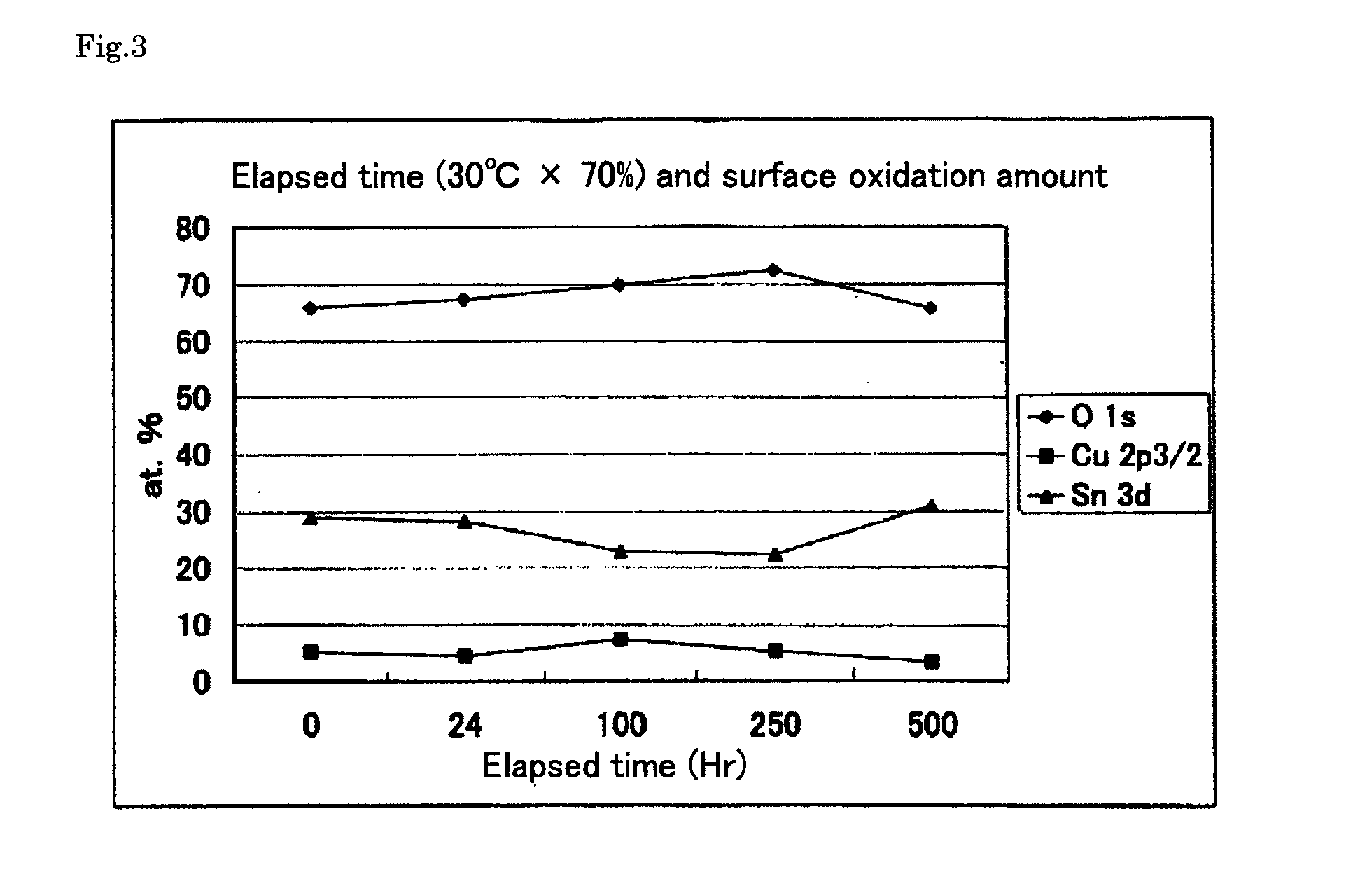

Rare earth metal-based permanent magnet

ActiveUS20110037549A1High adhesive strengthHigh bonding strengthPermanent magnetsMagnetic materialsMagnetSurface layer

An objective of the present invention is to provide a rare earth metal-based permanent magnet with improved adhesion properties. A rare earth metal-based permanent magnet of the present invention as a means for achieving the objective has a laminated plating film, and is characterized in that the plating film comprises as an outermost surface layer a SnCu alloy plating film having a film thickness in a range from 0.1 μm to 2 μm, the composition of the SnCu alloy plating film is 35 mass % or more but less than 55 mass % of Sn and the rest being Cu, and a base plating film having two or more layers including at least a Ni plating film and a Cu plating film which are formed as the lower layer under the SnCu alloy plating film, and among the base plating film, the Ni plating film is located just below the SnCu alloy plating film. A joined structure fabricated using the rare earth metal-based permanent magnet of the present invention exhibits favorable initial adhesion strength when combined with a silicone-based adhesive, and is less deteriorated in adhesion strength even after a moisture resistance test.

Owner:HITACHI METALS LTD

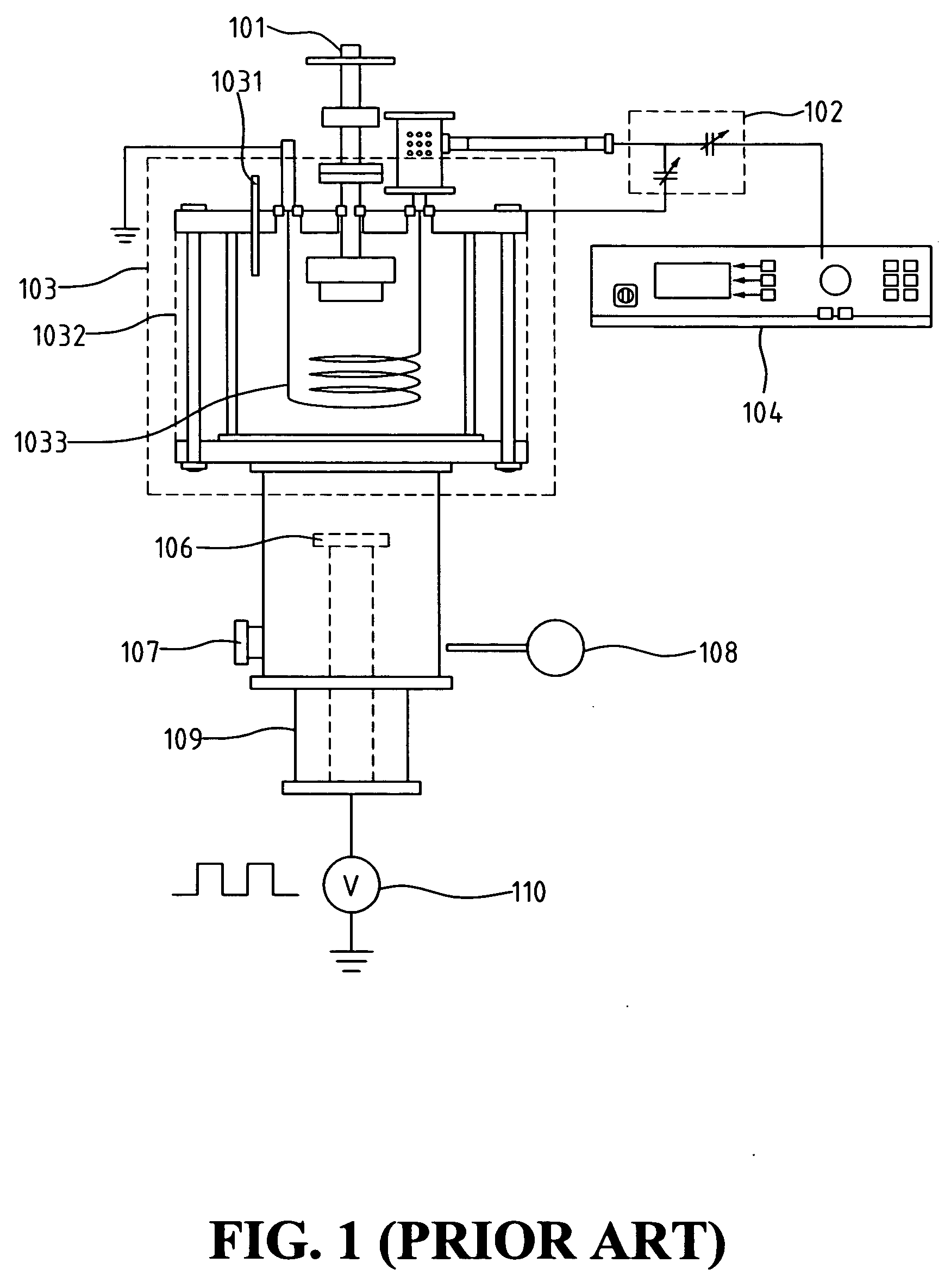

Method for the surface activation on the metalization of electronic devices

InactiveUS20060040065A1Good electricalHigh adhesive strengthElectric discharge tubesVacuum evaporation coatingChemistryElectroless plating

Owner:NATIONAL TSING HUA UNIVERSITY

Insulating heat dissipation coating composition and insulating heat dissipation unit formed using the same

PendingUS20200154608A1Good thermal conductivityHigh adhesive strengthEpoxy resin coatingsCooling/ventilation/heating modificationsThermal conductivityOrganic solvent

An insulating heat dissipation coating composition including a coating layer-forming component including a subject resin, and an insulating heat dissipation filler. Therefore, the coating composition may have excellent thermal conductivity and excellent thermal emissivity, and therefore an insulating heat dissipation coating layer which exhibits excellent heat dissipation performance and has insulating property may be formed. In addition, the heat dissipation coating layer formed thereby has a very excellent adhesive strength to a surface to be coated so as to significantly prevent peeling of the coating layer during use, and to maintain durability of the coating layer even against a physical or chemical stimulus such as external heat, organic solvent, moisture or shock, which is generated after the coating layer is formed.

Owner:AMOGREENTECH CO LTD

Process for producing hard-coated optical materials

InactiveUS20050227085A1High adhesive strengthSynthetic resin layered productsCoatingsChemistryOptical materials

Owner:MITSUBISHI GAS CHEM CO INC

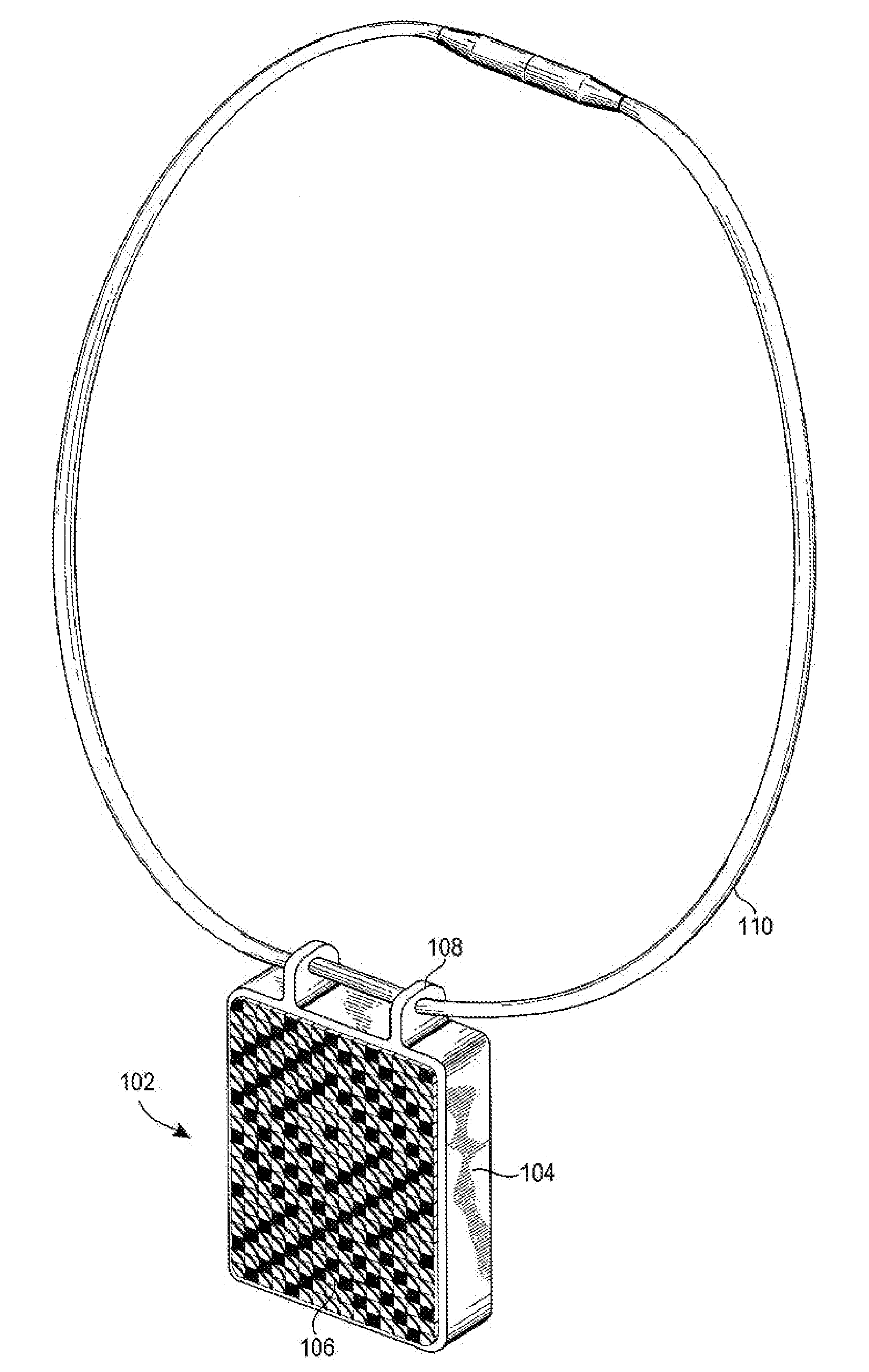

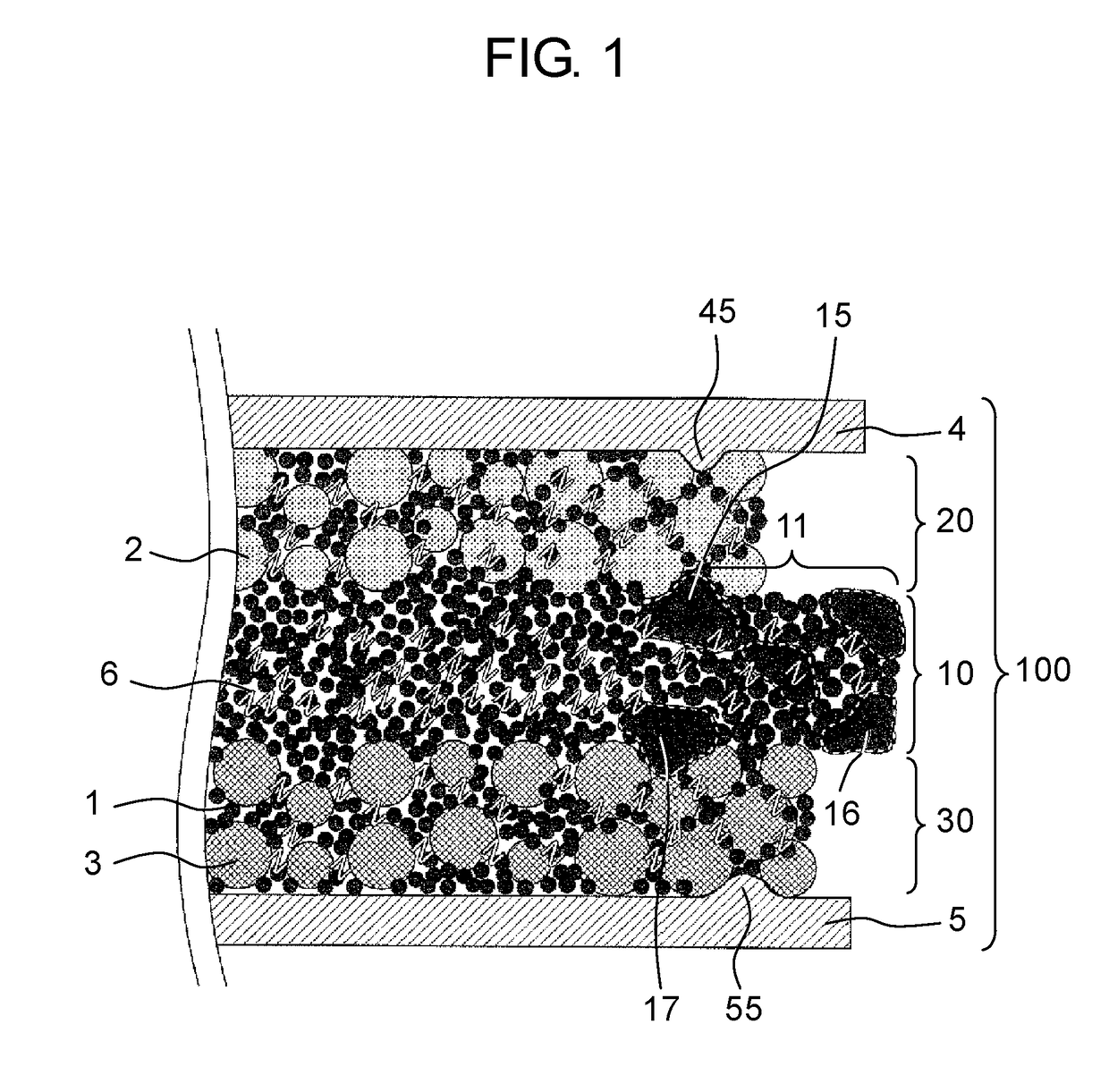

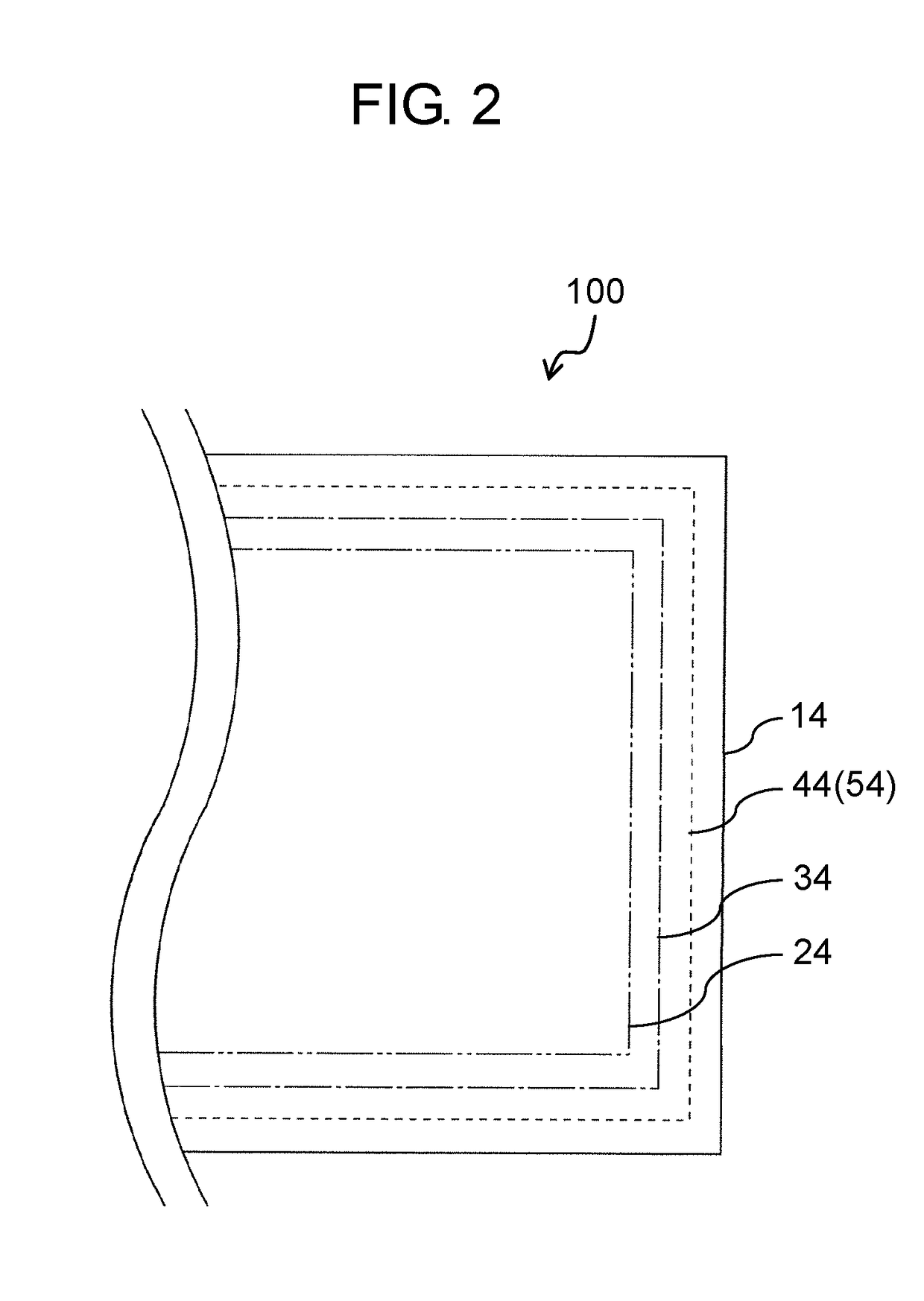

All-solid-state battery and manufacturing method

ActiveUS20180226652A1High adhesive strengthExcellent battery characteristicSolid electrolytesElectrode thermal treatmentIonCurrent collector

An all-solid-state battery includes a positive-electrode current collector, a positive electrode layer, a negative-electrode current collector, a negative electrode layer, and a solid electrolyte layer. The positive electrode layer is formed on the positive-electrode current collector and includes at least a positive-electrode active material. The negative electrode layer is formed on the negative-electrode current collector and includes at least a negative-electrode active material. The solid electrolyte layer is disposed between the positive electrode layer and the negative electrode layer and includes at least a solid electrolyte having ion conductivity. At least one member selected from the group consisting of the positive-electrode current collector, the positive electrode layer, the negative-electrode current collector, the negative electrode layer, and the solid electrolyte layer includes a heated region at an end portion of the at least one member.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

High-strength sealing glue for paper packaging box

InactiveCN102898982AHigh bonding strengthImprove permeabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesNon toxicityMass ratio

The invention discloses a high-strength sealing glue for a paper packaging box, which comprises the following components in parts by mass: 30-40 parts of binder, 40-50 parts of plasticizer, 10-20 parts of tackifier, 6-9 parts of wetting agent, 4-5 parts of associated monomer, an appropriate amount of emulsifier, an appropriate amount of preservative, an appropriate amount of initiator and an appropriate amount of deionized water. The binder is formed by compounding butyl acrylate and an EVA (Ethylene-vinyl acetate) emulsion, and two monomers of ethylene and vinyl acetate are subjected to an emulsion polymerization reaction to form a calibration emulsion with the solid content of 50%, i.e., the EVA emulation; and the binder comprises the following components by mass ratio: 50-80 parts of butyl acrylate and 50-20 parts of EVA emulsion. The high-strength sealing glue provided by the invention has the advantages of large early adhesive force, high bonding strength, strong permeability, environmental friendliness, non-volatilization, non-toxicity, tastelessness and the like for a non-polar hard sticky material, at the same time, the production process is simple, the production cost is low, raw materials are easily purchased, no three wastes are generated, no burning danger is generated, the development direction of a high molecular polymer is closely linked, and the urgent needs of the market are met.

Owner:蚌埠市比优特包装印务有限责任公司

Improved silane crosslinking cable

InactiveCN103489524AGood adhesionHigh adhesive strengthInsulated cablesPower cablesChemistryThermal contraction

The invention discloses an improved silane crosslinking cable. The improved silane crosslinking cable comprises a copper core, a silane crosslinking insulating layer and an ethylene-vinyl acetate thermal contraction layer, wherein the copper core is located at the center of the improved silane crosslinking cable, the silane crosslinking insulating layer is arranged on the outermost layer of the improved silane crosslinking cable in an extruded mode and is 2mm thick, and the ethylene-vinyl acetate thermal contraction layer is arranged between the copper core and the silane crosslinking insulating layer in a wrapped mode and is 0.1mm thick. The improved silane crosslinking cable effectively overcomes the shortcoming that the silane crosslinking insulating layer is poor in adhesive force and plays a role in reducing thermal contraction.

Owner:江苏鑫丰塑业有限公司

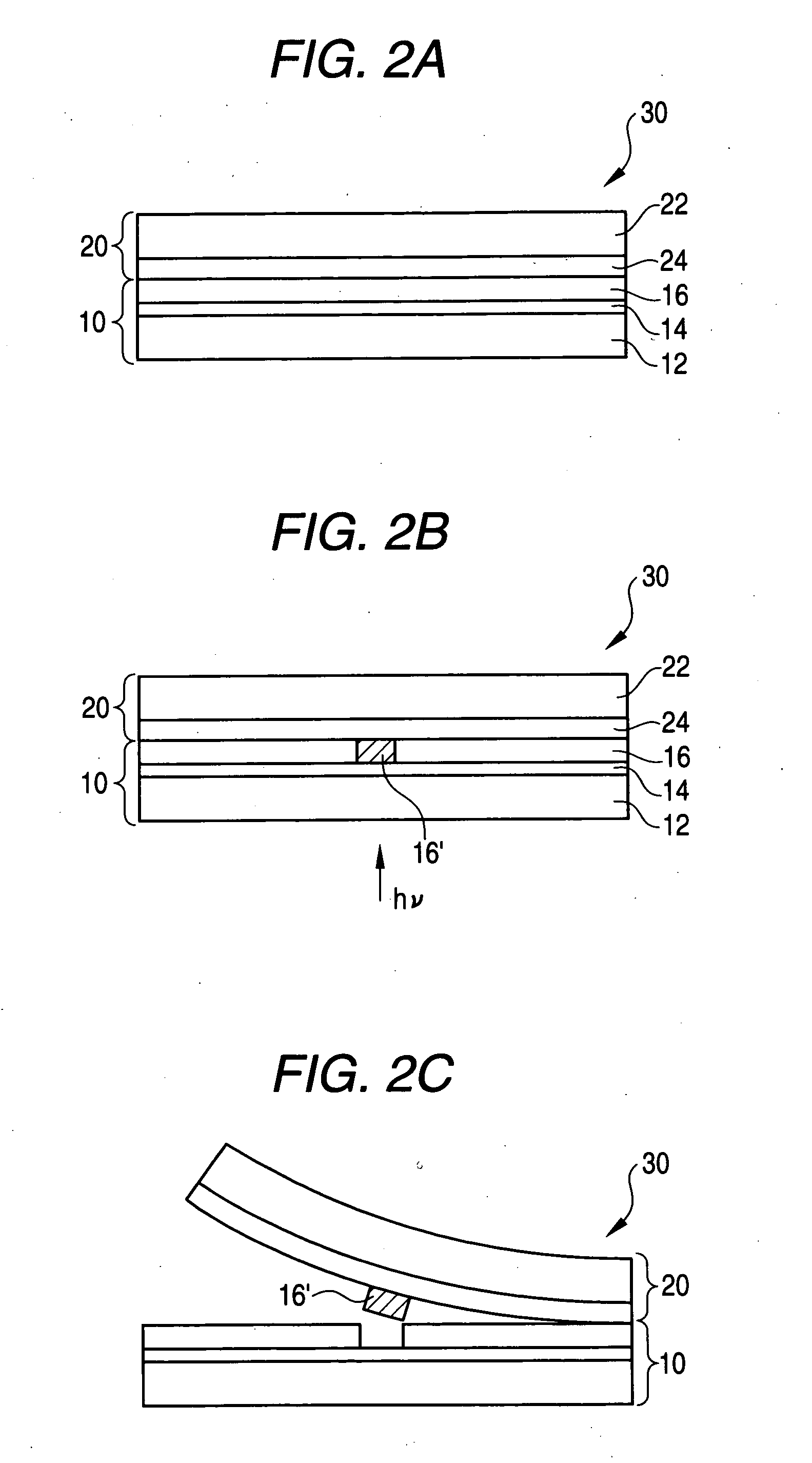

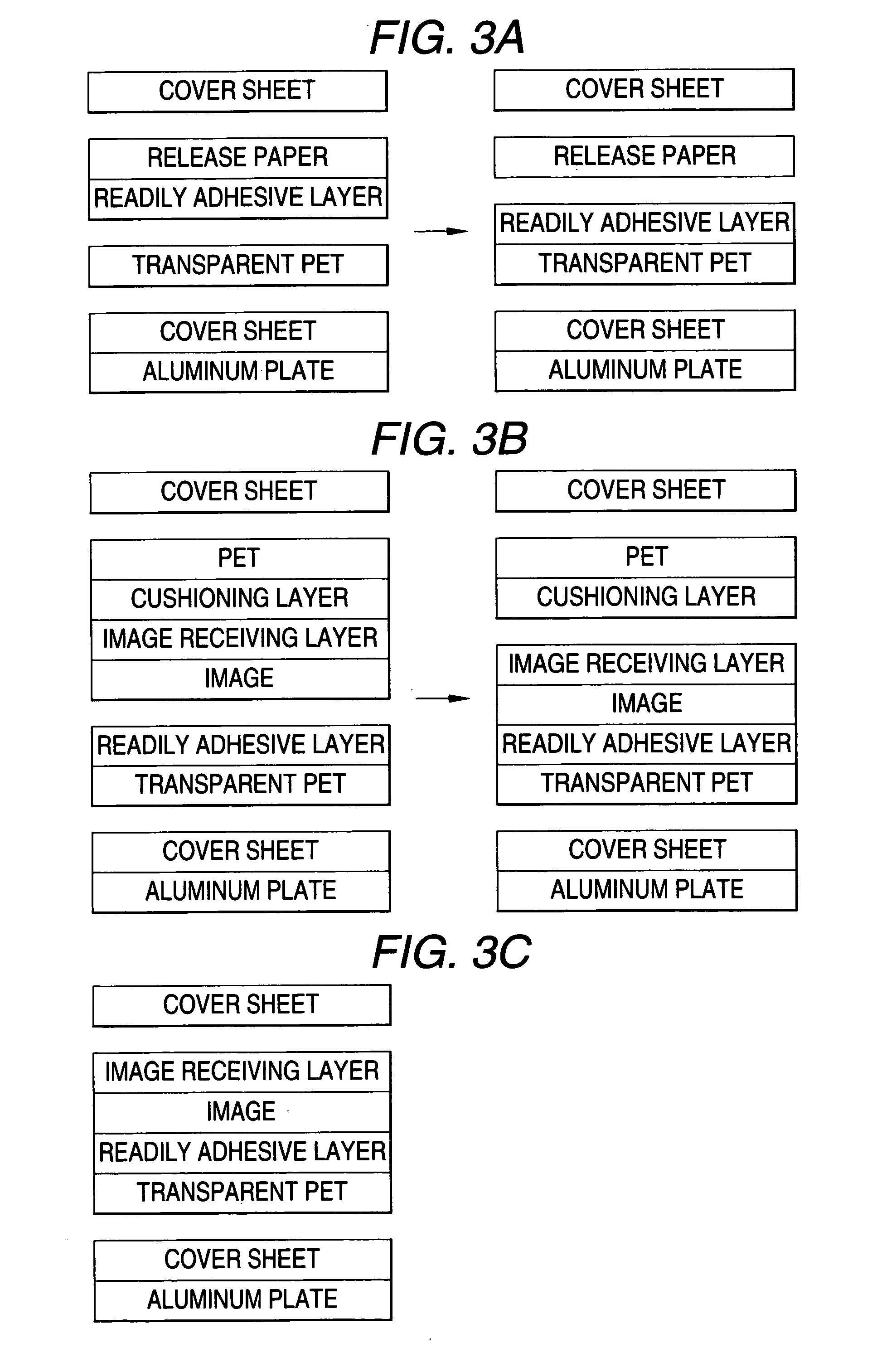

Image forming method and final medium to be transferred

InactiveUS20050227024A1High adhesive strengthHigh image qualityThermographyColour-separation/tonal-correctionImage transferImage formation

An image forming method comprises: keeping a face of a final medium to be transferred towards a face of an intermediate transfer medium, wherein the final medium to be transferred comprises a transparent support having a readily adhesive layer, and the intermediate transfer medium has an image recorded on an image receiving layer; transferring the image onto the readily adhesive layer, so as to form a transferred image; and subjecting a surface of the readily adhesive layer having the transferred image to a smoothening treatment. And a final medium to be transferred for the image forming method comprises: a transparent support; and a readily adhesive layer provided on a surface of the transparent support onto which an image is to be transferred, wherein the readily adhesive layer has a surface roughness of from 0.5 to 7 μm in terms of Rz.

Owner:FUJIFILM CORP +1

Fabric flocking adhesive with low-temperature cured capacity

ActiveCN105542689AHigh adhesive strengthGood washing resistanceMacromolecular adhesive additivesPolyether adhesivesButyl acrylateEmulsion

The invention discloses a fabric flocking adhesive with low-temperature cured capacity. The fabric flocking adhesive comprises raw materials in parts by weight as follows: 30-45 parts of an acrylic ester emulsion, 2-5 parts of phthalazinone polyarylether, 3-8 parts of acryloyl-beta-cyclodextrin ester, 0.5-2 parts of a compound cross-linking agent, 0.5-1 part of a cross-linking monomer initiator, 4-8 parts of a compound emulsifier and 30-50 parts of deionized water, wherein the acrylic emulsion is a mixture of methacrylic acid, methyl methacrylate, diethylene glycol dimethacrylate and butyl acrylate in the mass ratio being 10:(1-2):(1-4):(2-4). The fabric flocking adhesive capable of being cured at a low temperature has good flocking effect and broad application prospect.

Owner:SUZHOU FANGYOU NEW MATERIAL

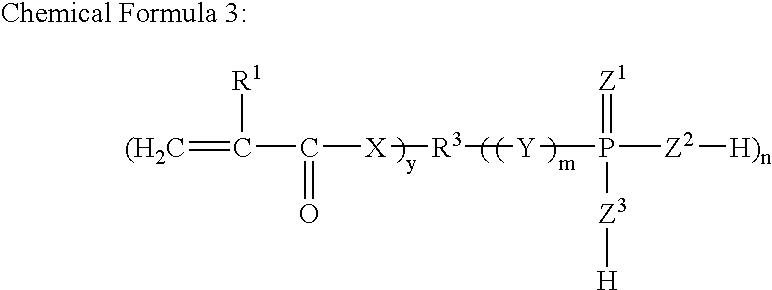

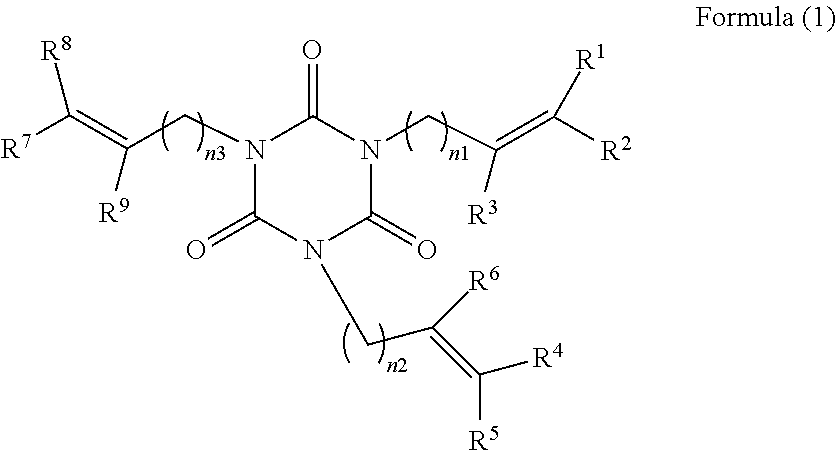

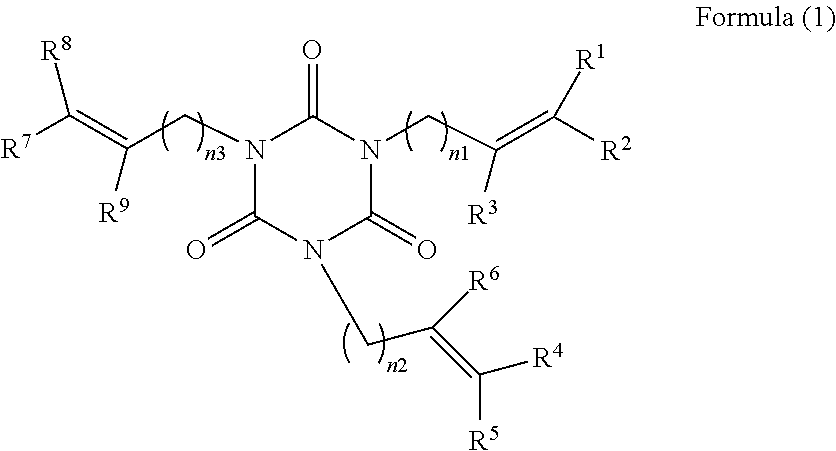

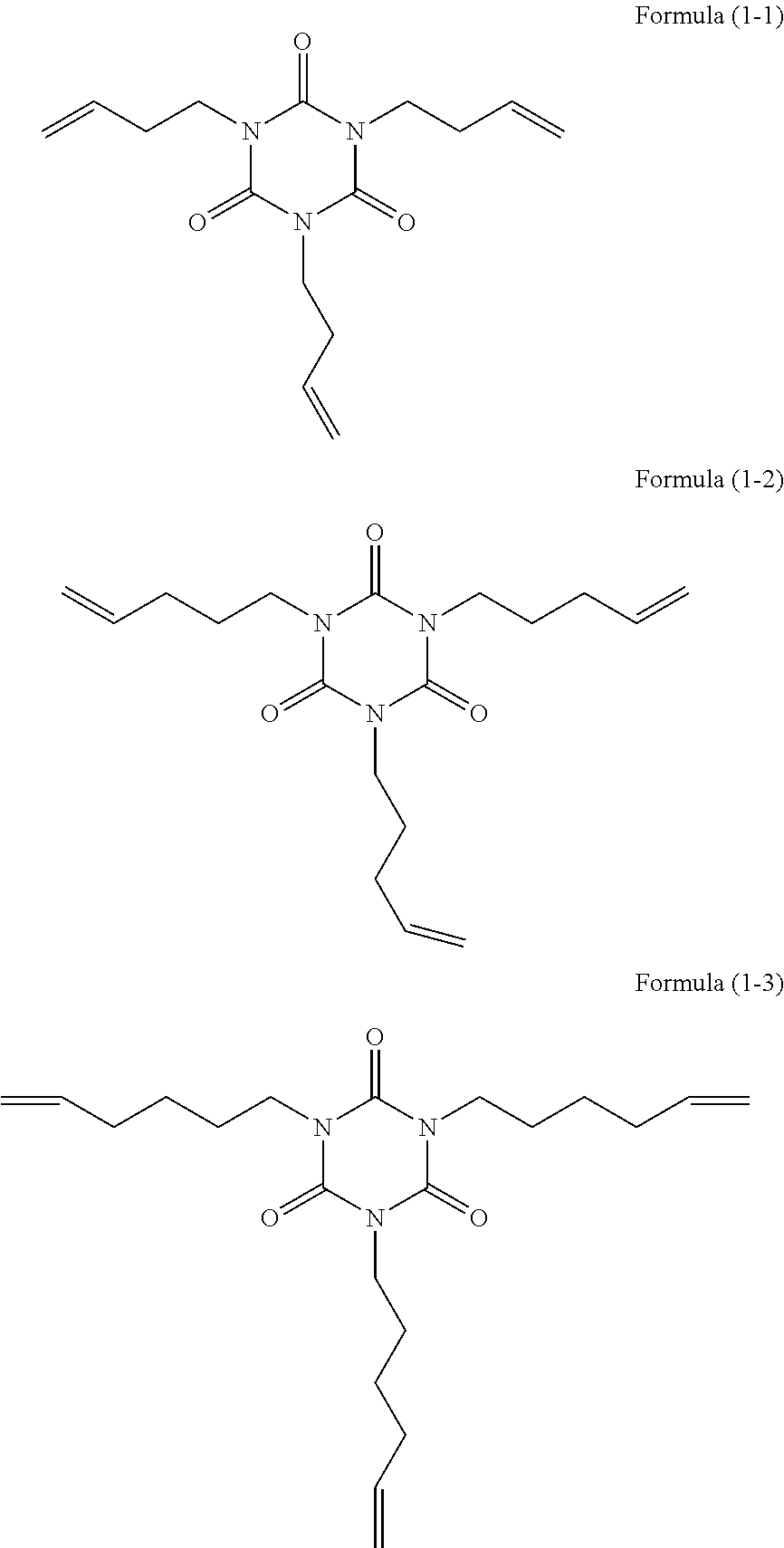

Photo-curable resin composition

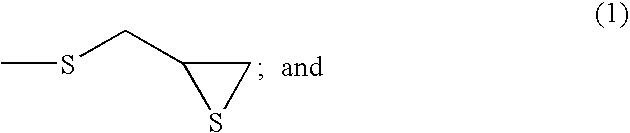

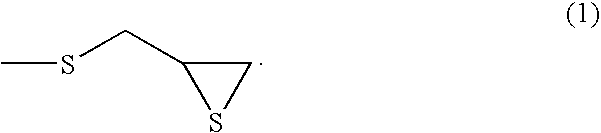

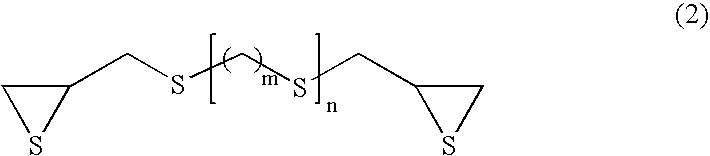

ActiveUS20140235746A1Excellent optical propertyHigh adhesive strengthOrganic chemistryOther chemical processesPolyeneThiol group

There is provided a curable resin composition that exhibits high adhesive properties to materials such as glass, copper, aluminum, PET, and PC, which have been regarded as poor adherends relative to photo-curable compositions, and high adhesive properties also between adherends different from each other. A curable resin composition including a polyene compound of Formula (1):(where n1, n2, and n3 are each independently an integer of 2 to 4; and R1 to R9 are each independently a hydrogen atom or a C1-10 alkyl group). The composition may further include a thiol compound or a photopolymerization initiator. The thiol compound may be a compound having two to six thiol groups in the molecule, or be an aliphatic thiol, or be produced by a reaction of an aliphatic mercapto carboxylic acid and a polyhydric alcohol. The polyhydric alcohol may be an aliphatic polyhydric alcohol or hydroxyalkyl isocyanurate.

Owner:NISSAN CHEM IND LTD

Production method of toner for developing electrostatic image

A production method of a toner for developing an electrostatic image composed of toner parent particles and external additives adhered to a surface the toner parent particles is disclosed. The method includes steps of preparing toner parent particles dispersion liquid in which toner parent particles are dispersed in a medium, first mixing the dispersion liquid with a quaternary ammonium salt compound and a water soluble organic solvent to prepare liquid mixture, and second mixing the liquid mixture with external additive dispersion liquid in which negative charged external additives are dispersed.

Owner:KONICA MINOLTA BUSINESS TECH INC

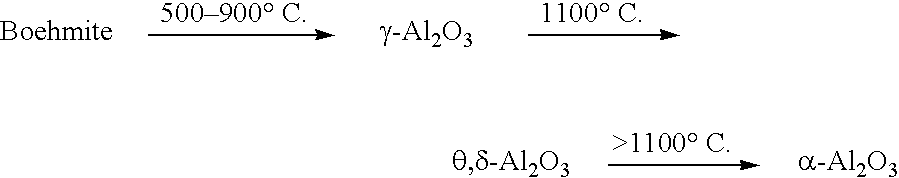

In situ theta alumina coated monolithic catalyst supports

InactiveUS20040072689A1High adhesive strengthHigh bonding strengthCatalyst carriersOther chemical processesCordieriteChemistry

The invention provides a monolithic catalyst support for hydrogenation and hydrotreating and in particular for selective hydrogenation of pyrolysis gasoline. The monolithic catalyst includes (i) a multicellular monolith body, preferably having a honeycomb structure, most preferably a honeycomb structure made of cordierite, the honeycomb structure having an inlet end, an outlet end, and a multiplicity of mutually adjoining cells extending along the length of the body from the inlet end to the outlet end, the cells being separated from one another by porous walls, and, (ii) a coating consisting of theta alumina synthesized in situ on the multicellular monolith body. The in situ theta alumina is strongly bonded with the multicellular monolith body and comprises at least 50% by weight of the washcoat layer, and preferably greater than 90% by weight.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com