Modified phenolic resin adhesive

A technology of phenolic resin glue and adhesive, which is applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of low bonding strength of adhesives, and improve the adhesive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

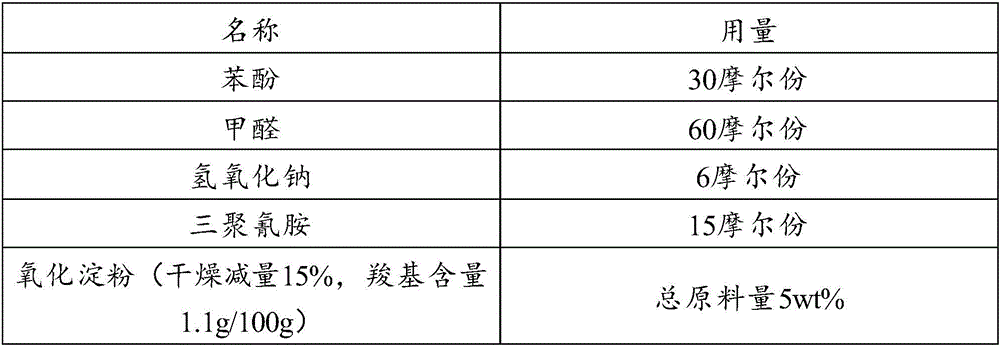

Embodiment 1

[0028] 1) Prepare raw materials:

[0029] name Dosage phenol 30 mole parts formaldehyde 60 mole parts sodium hydroxide 6 mole parts Melamine 15 parts by mole Triglycerides of oleic acid 10 mole parts

[0030] 2) Preparation of modified adhesive

[0031] Add the above 4 kinds of raw materials into the reaction kettle, and control the temperature at 50°C. After reacting for 5 hours, the modified adhesive was obtained.

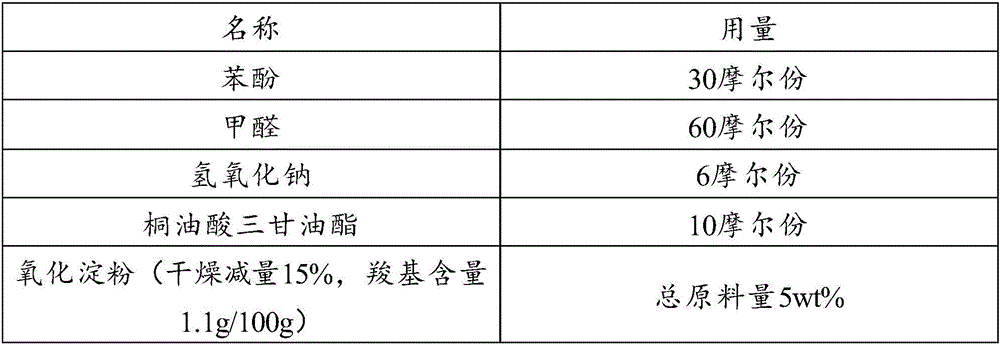

Embodiment 2

[0033] 1) Prepare raw materials:

[0034]

[0035] 2) Preparation of modified adhesive

[0036] Add the above 4 kinds of raw materials into the reaction kettle, and control the temperature at 50°C. After reacting for 5 hours, the modified adhesive was obtained.

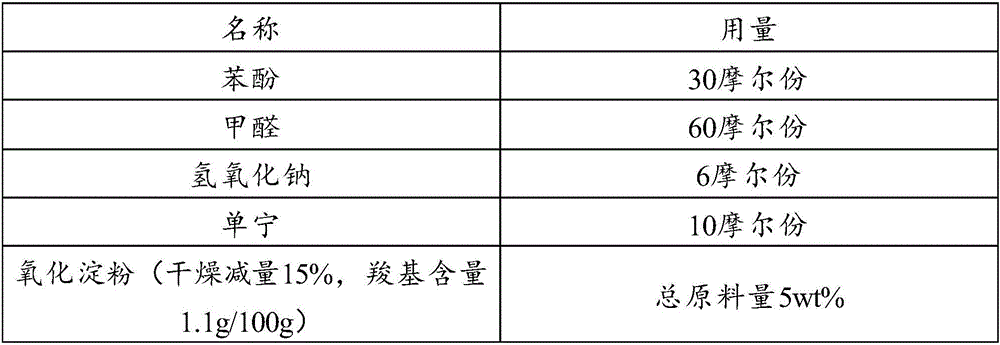

Embodiment 3

[0038] 1) Prepare raw materials:

[0039] name Dosage phenol 30 mole parts formaldehyde 60 mole parts sodium hydroxide 6 mole parts Melamine 15 parts by mole Tannins 10 mole parts

[0040] 2) Preparation of modified adhesive

[0041] Add the above 4 kinds of raw materials into the reaction kettle, and control the temperature at 50°C. After reacting for 5 hours, the modified adhesive was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com