Patents

Literature

157results about How to "Adhesive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

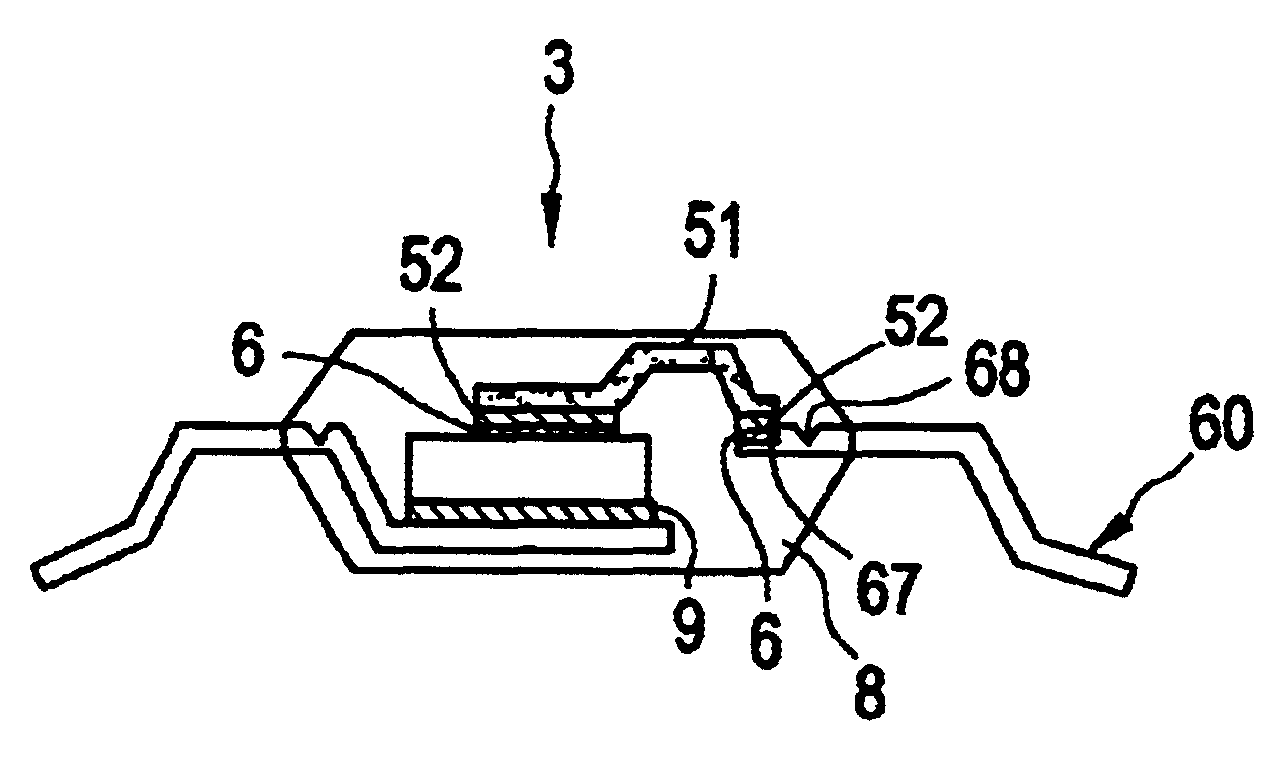

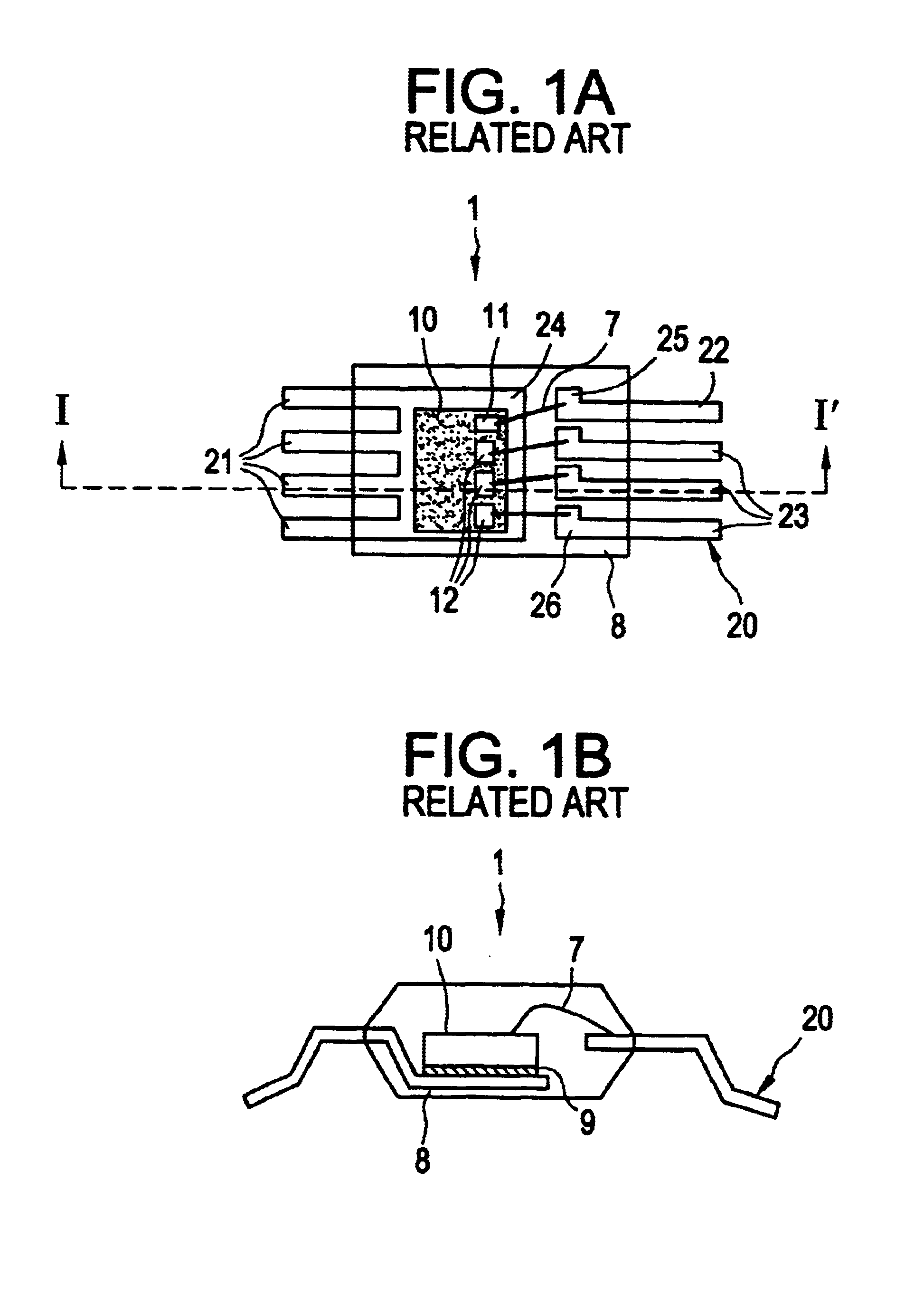

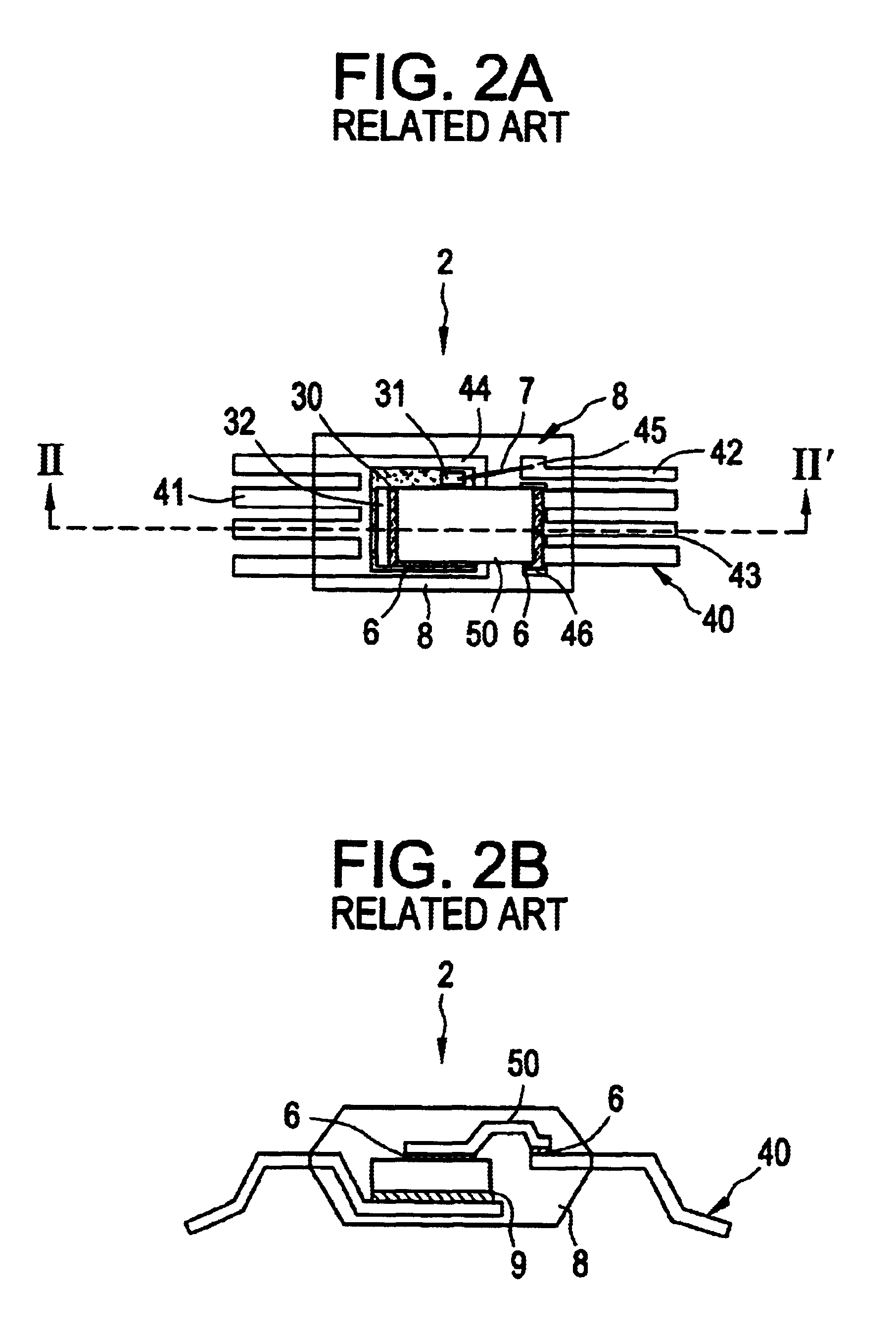

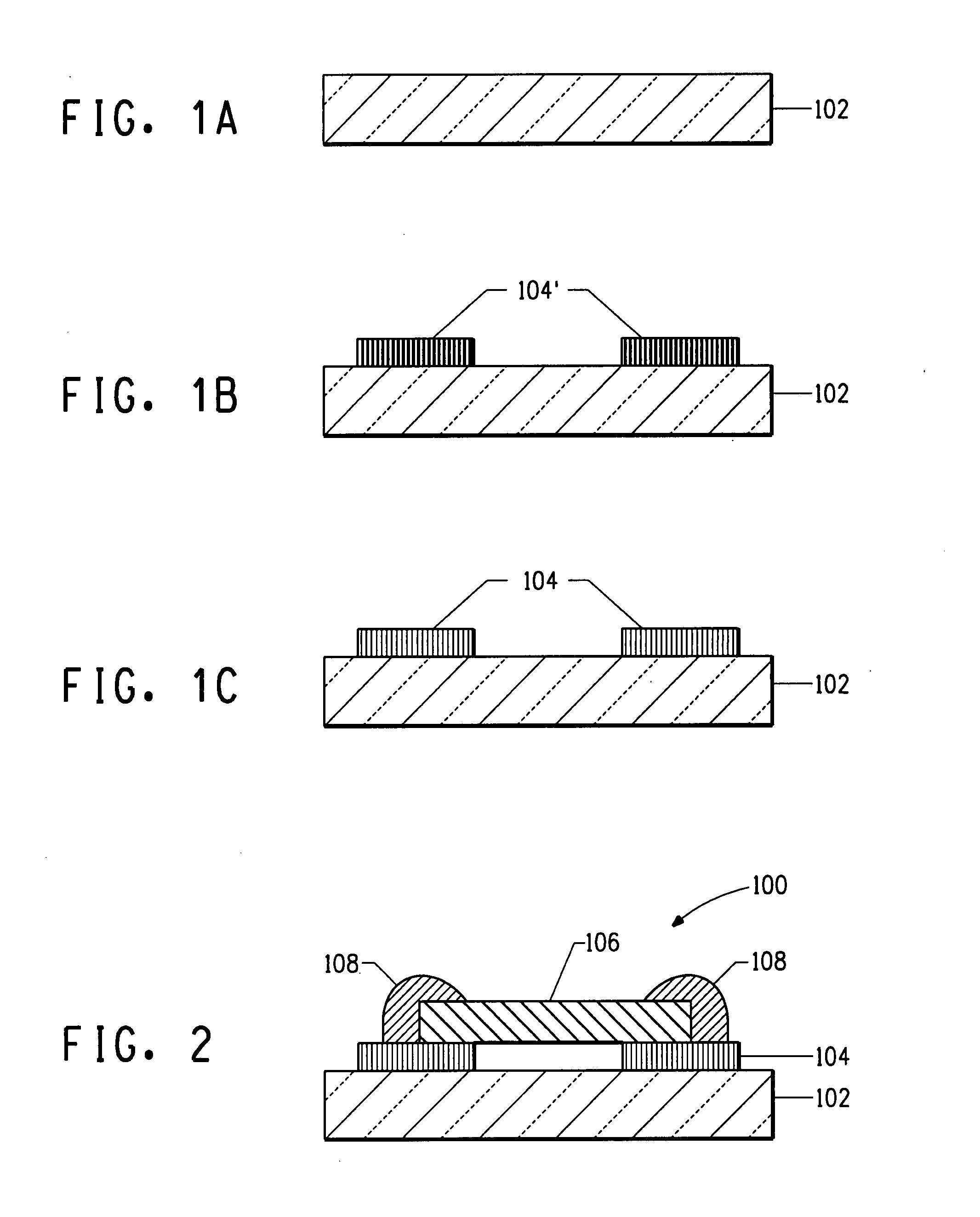

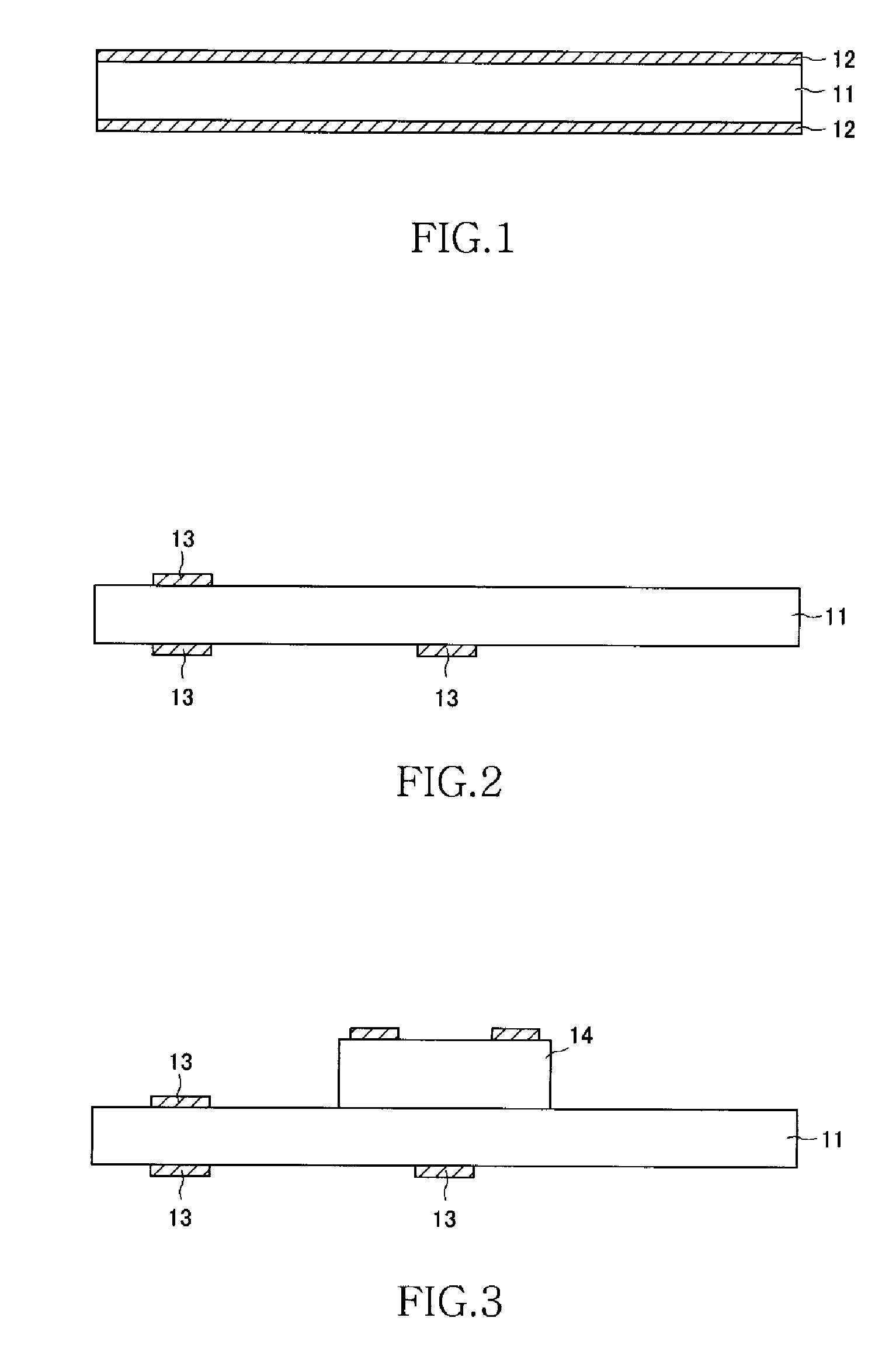

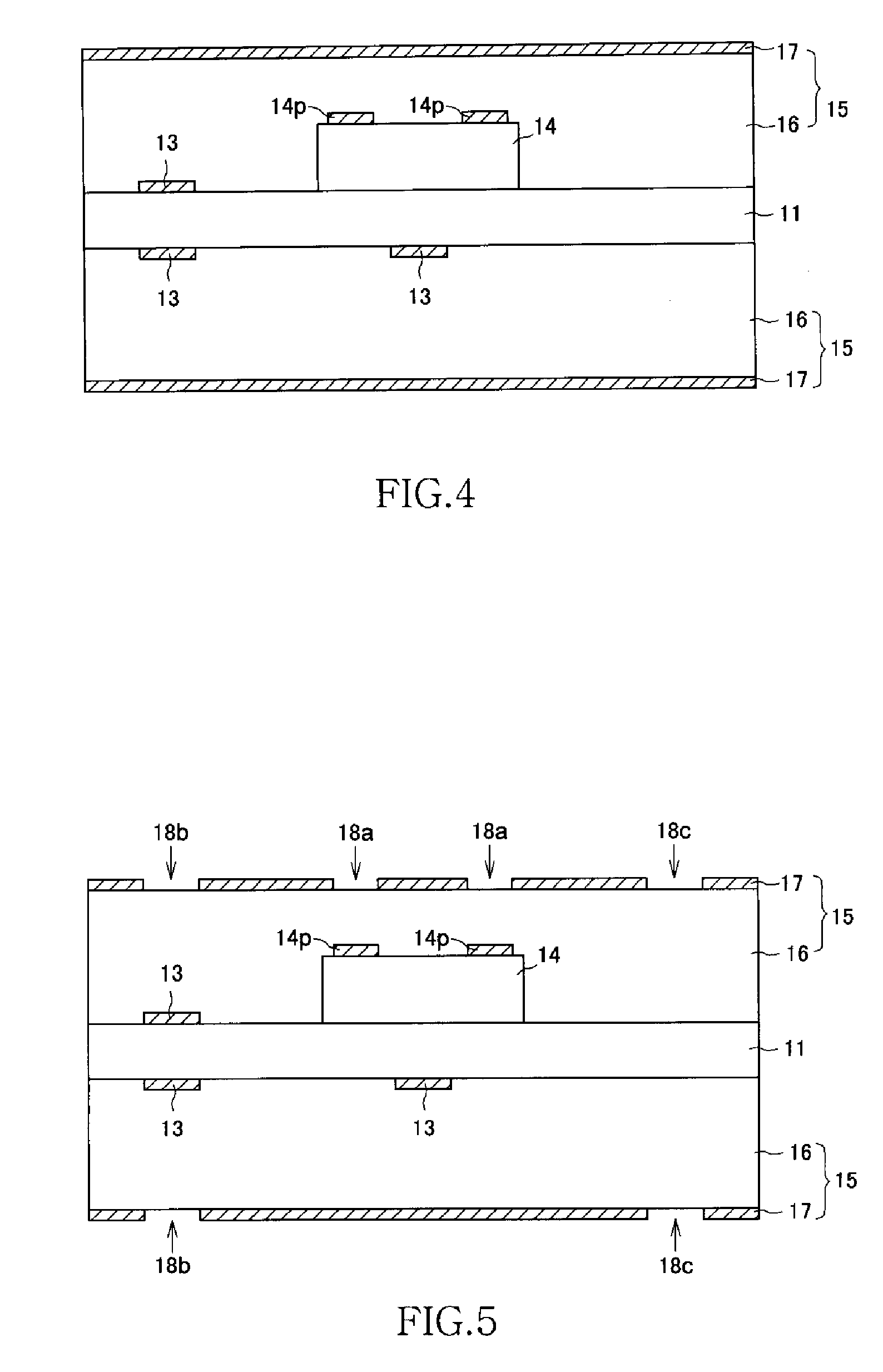

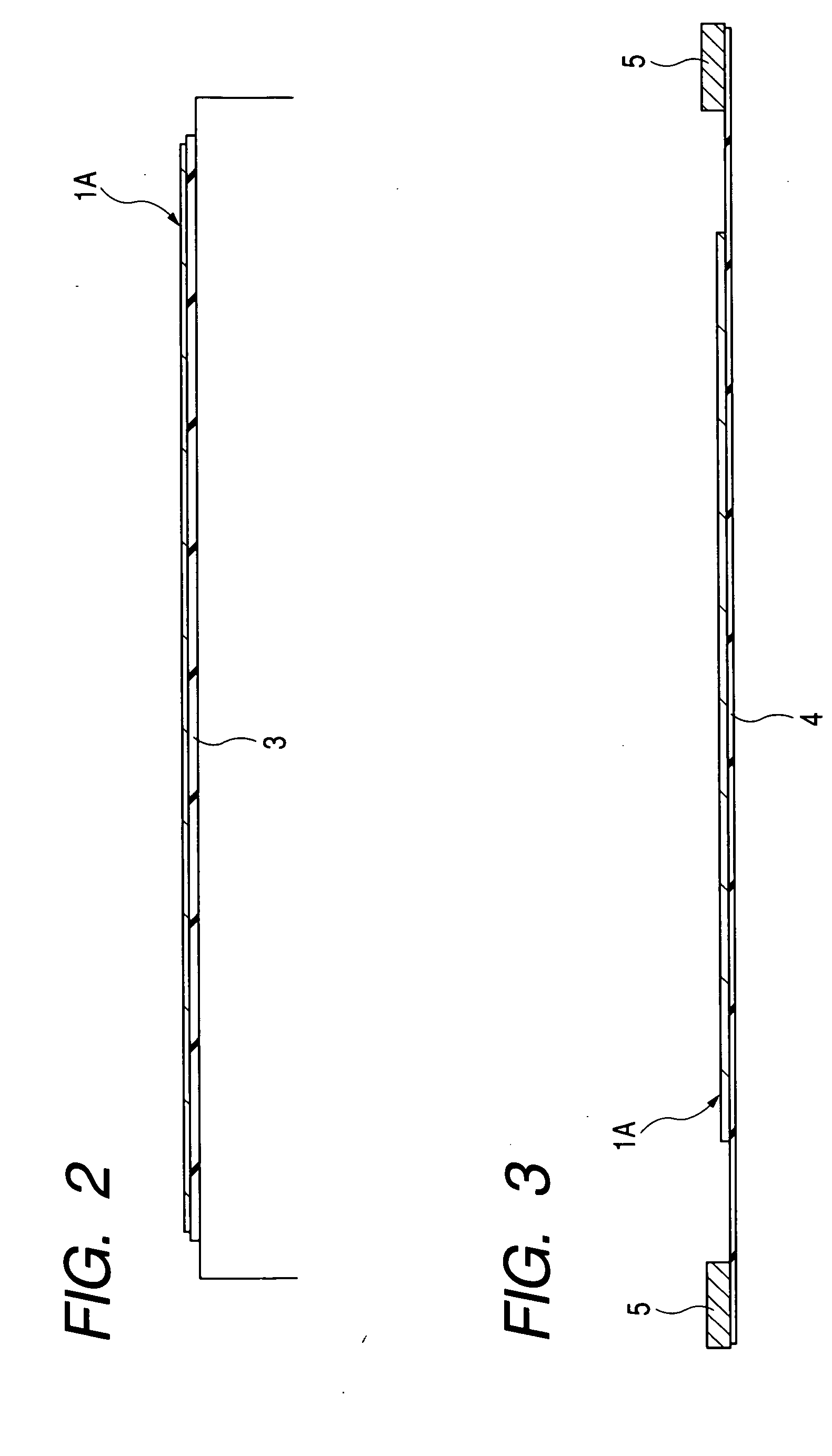

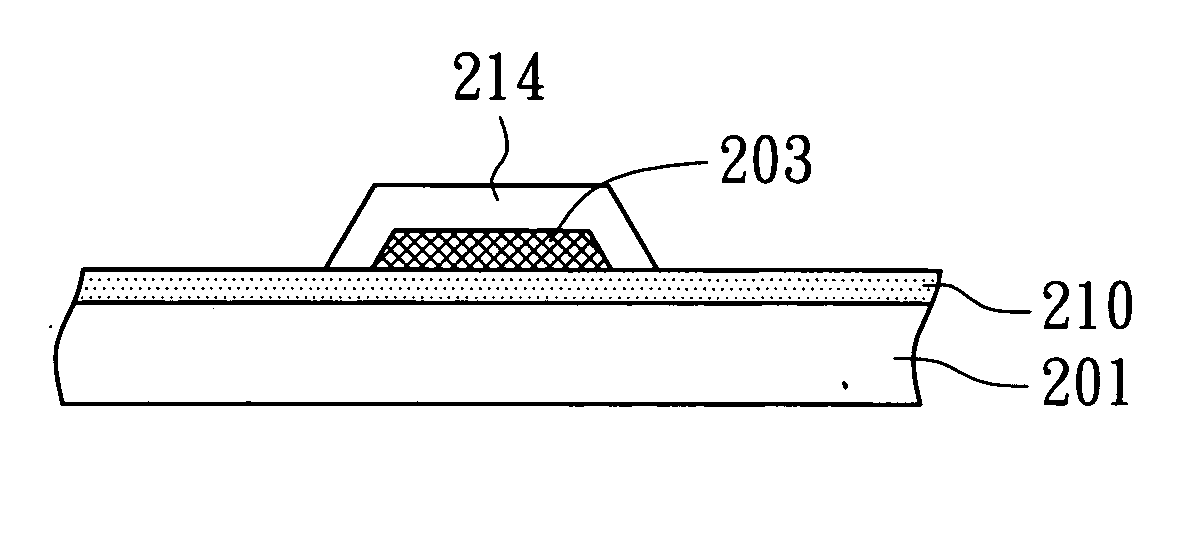

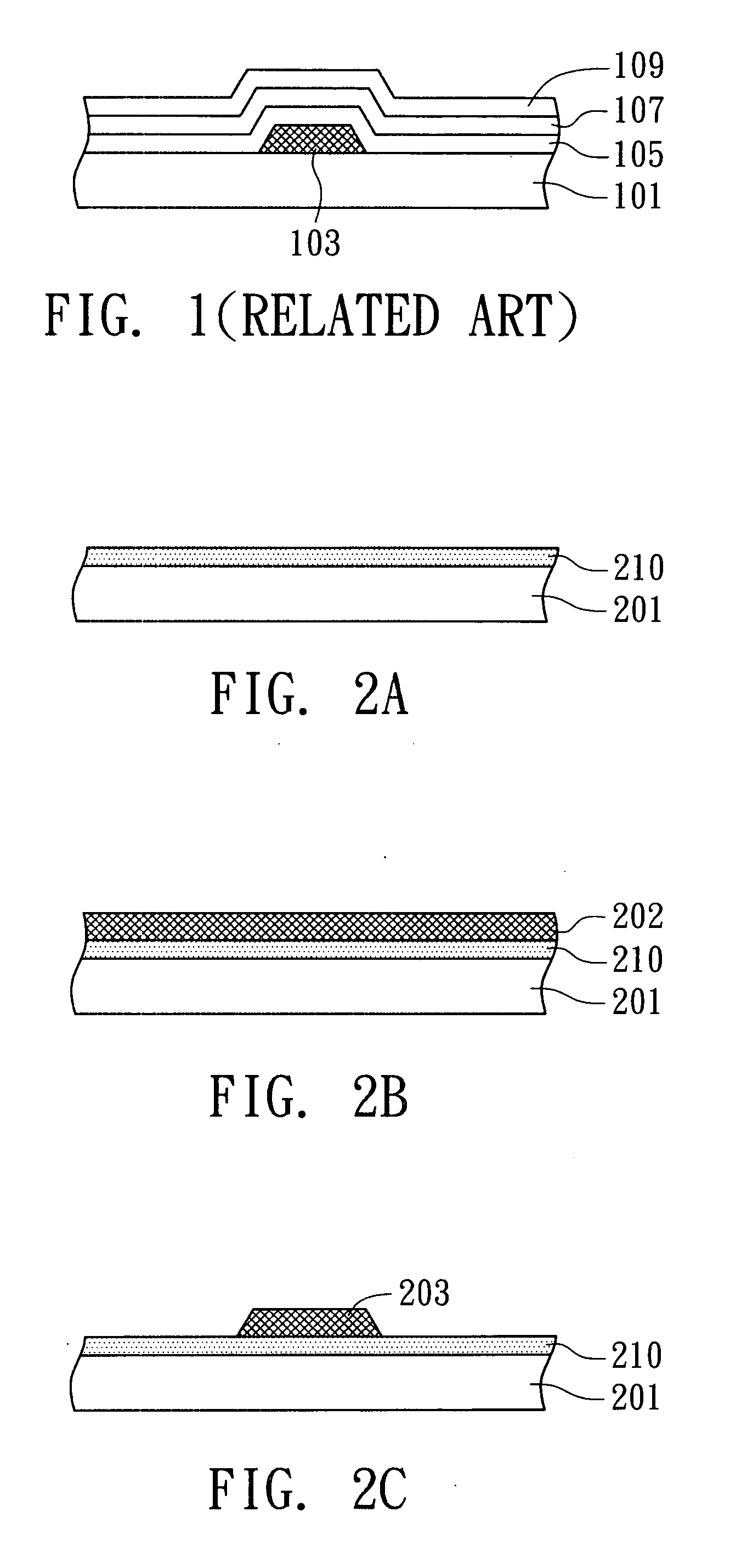

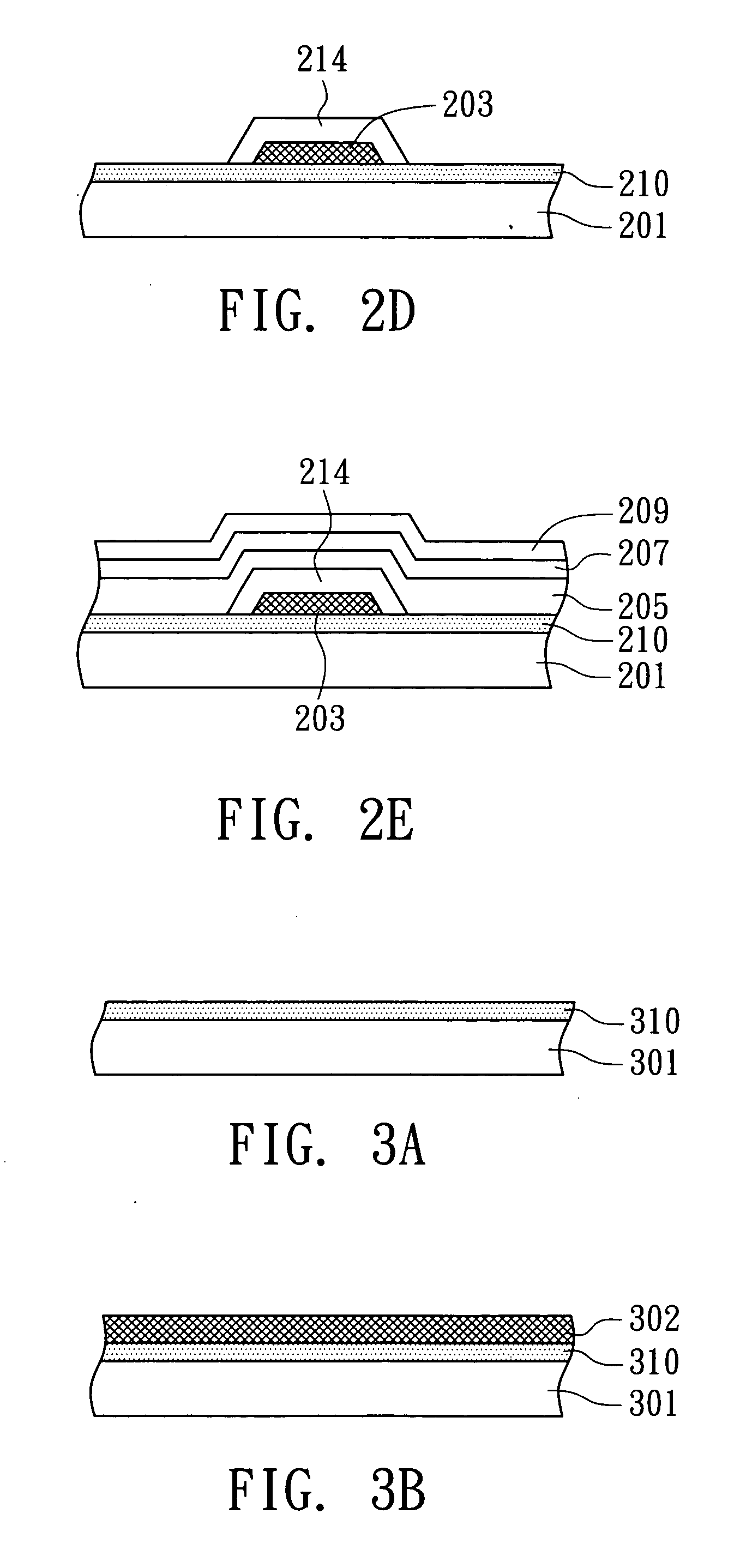

Semiconductor device with uneven metal plate to improve adhesion to molding compound

InactiveUS6849930B2Adhesive strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteSemiconductor chip

The present invention provides a semiconductor device whose reliability is improved by improving the adhesion strength of a metal plate or connecting chip, said plurality of electrodes and a lead frame with a molding resin. Further, the semiconductor device of the present invention prevents flow out of a conductive joining material to be employed for joining a lead terminal and the metal plate other than the joining range of the metal plate and the lead terminal, and mounts the metal plate at high precision. In a semiconductor device (a plastic package) in which a source electrode of a semiconductor chip and source terminal of a lead frame are electrically connected by a copper plate and sealed by a resin, the surface of the copper plate is roughened to improve the adhesion strength to a molding resin. Further, a stepped part is formed in the source terminal to prevent a conductive paste from flowing out. The structure is so formed as to fit claw parts in the lead frame.

Owner:RENESAS ELECTRONICS CORP

Conductor paste for ceramic substrate and electric circuit

ActiveUS20090004369A1Adhesive strengthImprove adhesion strengthSemiconductor/solid-state device detailsConductive materialOrganic solventElectrical conductor

A conductor paste for a ceramic substrate contains a) a conductive metal powder comprising a silver powder and a palladium powder; b) a glass powder; and c) an organic solvent, wherein the conductive metal powder has an average particle diameter of not more than 1.2 μm, and the glass powder is a Bi2O3—SiO2—B2O3 type glass powder, and the content of the glass powder is in a range of from 1 to 6 wt % based on the weight of the paste.

Owner:DU PONT CHINA LTD

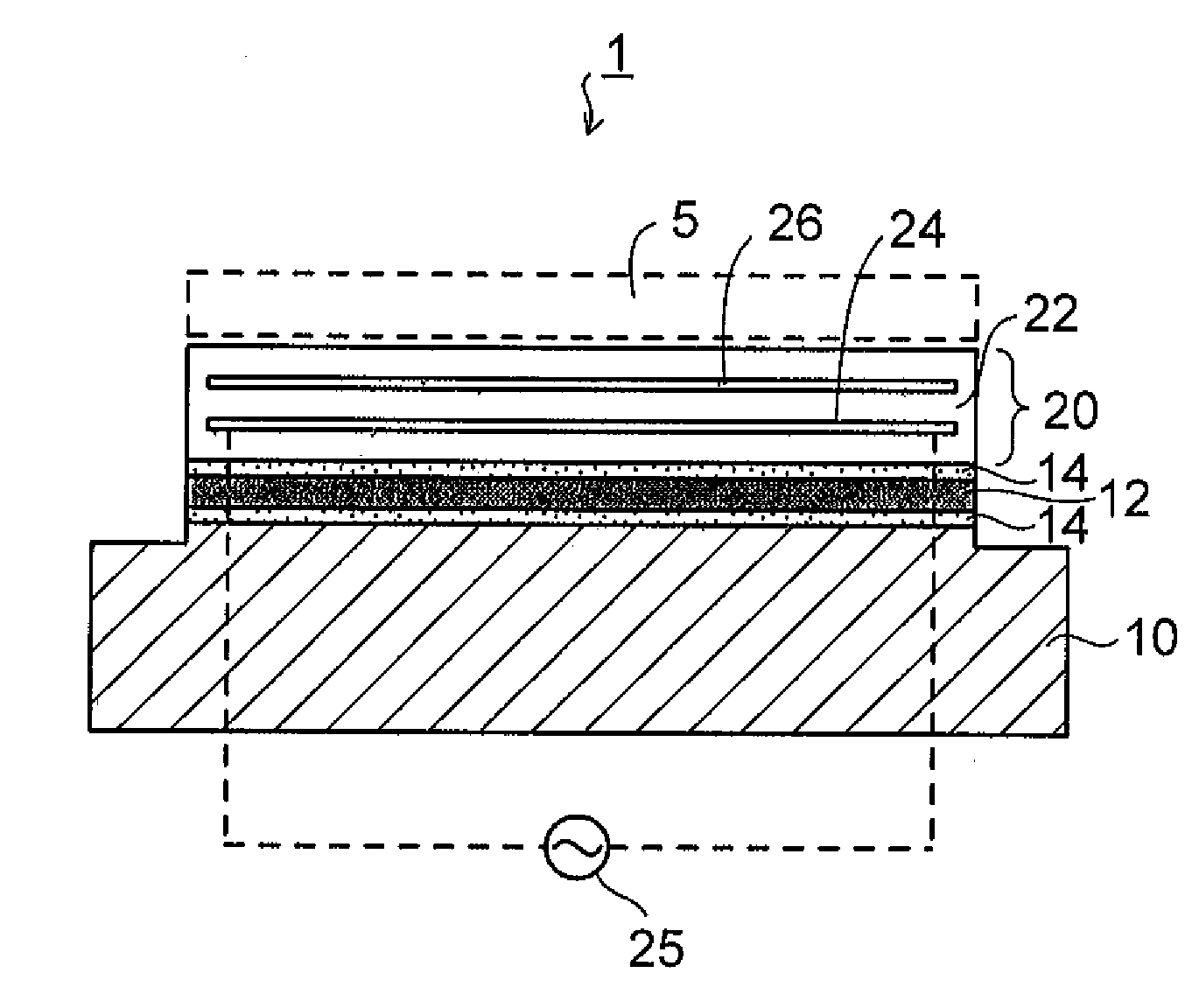

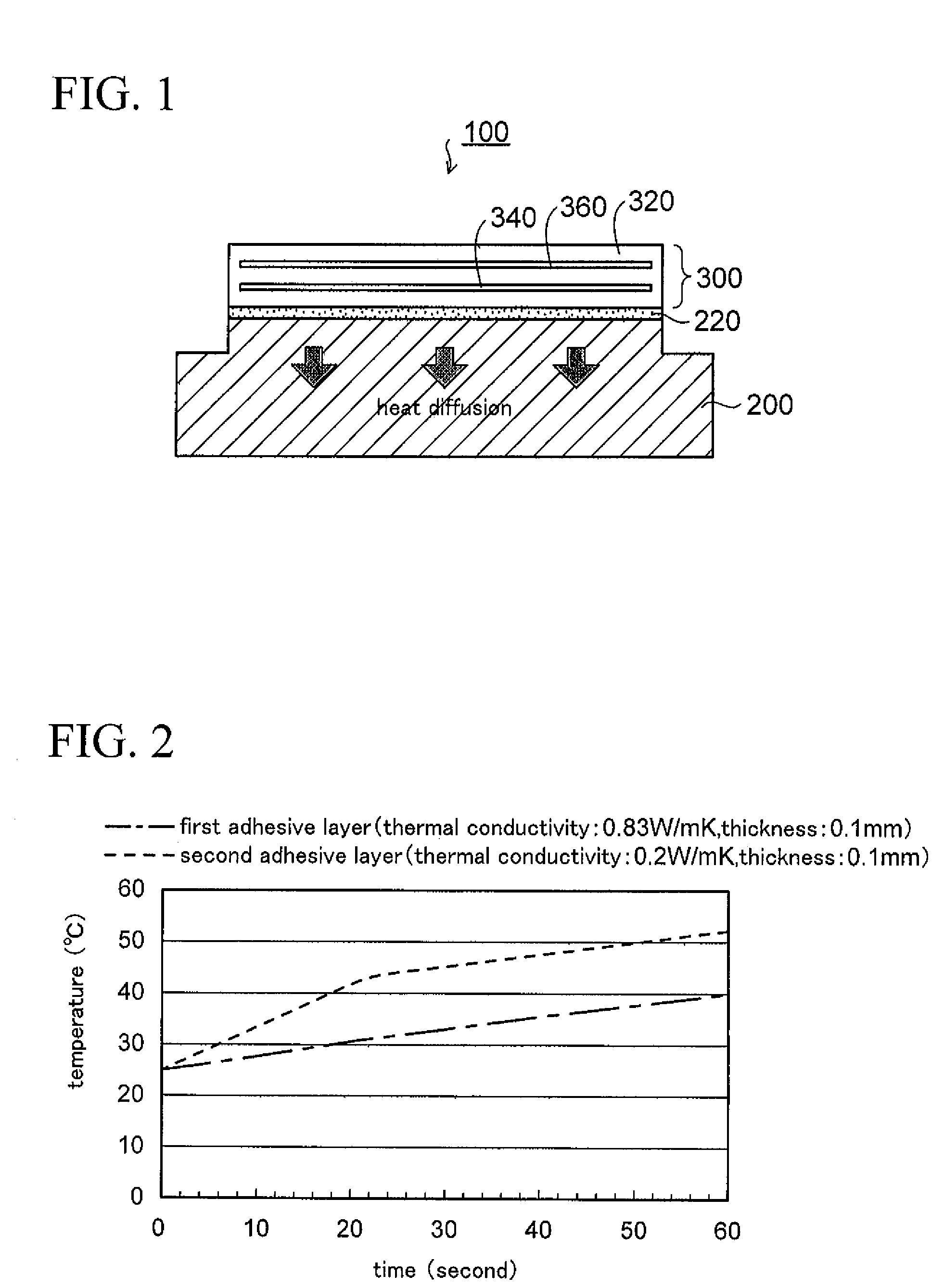

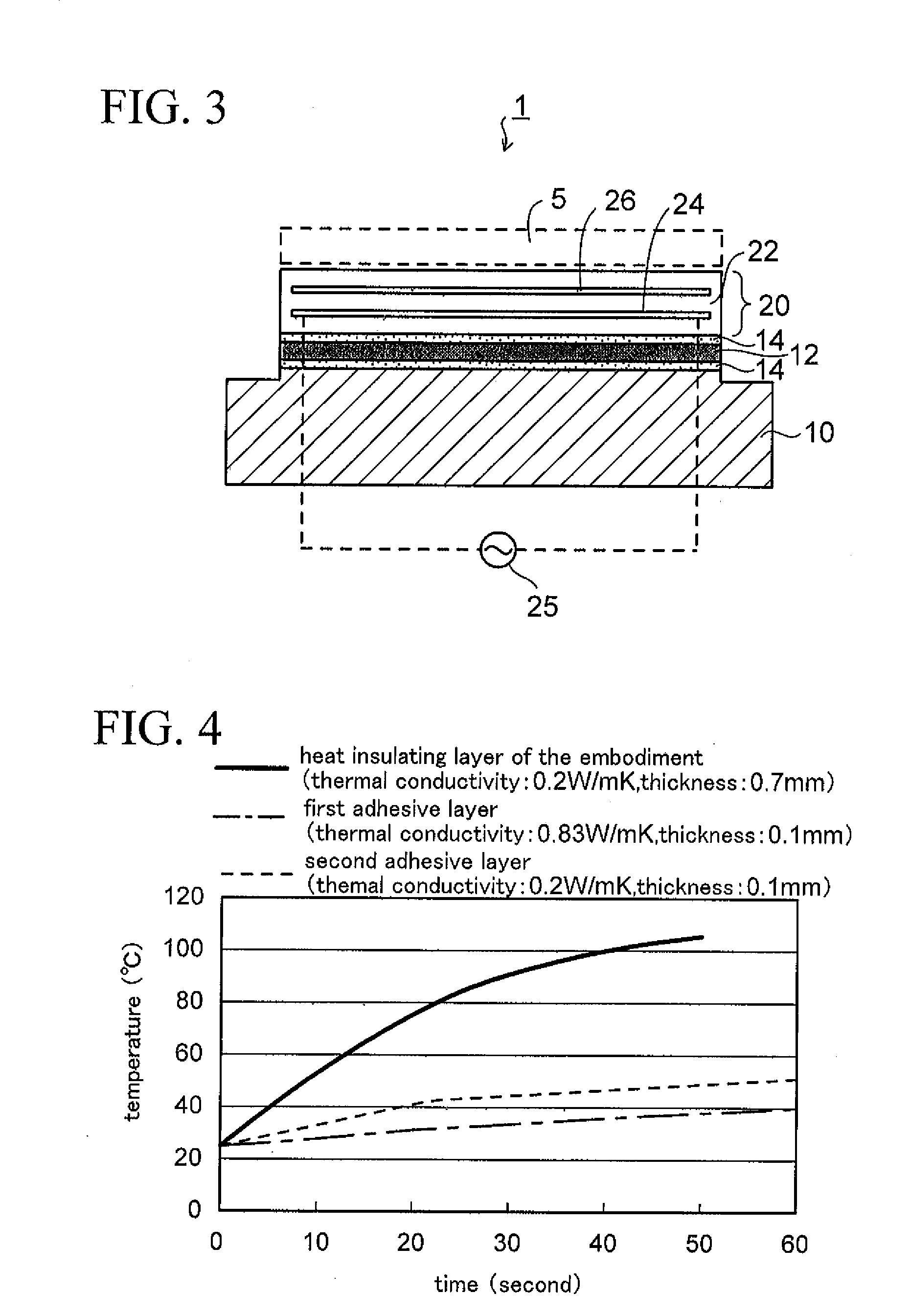

Electrostatic chuck

InactiveUS20090059461A1Adhesive strengthHigh adhesive strengthSemiconductor/solid-state device manufacturingElectrostatic holding devicesEngineeringElectrical and Electronics engineering

An electrostatic chuck of the invention includes a base portion; a heat insulating layer bonded onto the base portion; and a chuck function portion bonded on the heat insulating layer and composed by providing a heater electrode and an electrostatic chuck (ESC) electrode in a ceramic substrate portion. Adhesive layers are respectively provided on the both surface sides of the heat insulating layer. In the case where the base portion and the chuck function portion are bonded together with high adhesion strength, openings are formed in the heat insulating layer and are filled with the adhesive layers.

Owner:SHINKO ELECTRIC IND CO LTD

Method of producing fuel hose and fuel hose obtained thereby

InactiveUS6602565B1Improve bond reliabilityAdhesive strengthLayered product treatmentSynthetic resin layered productsEngineeringThermal aging

A method of producing a fuel hose having superior adhesive reliability with superior initial adhesive strength between a tubular fluororesin inner layer and a thermoplastic resin outer layer and with restrained deterioration in adhesive strength after heat aging and immersion into fuel under severe conditions such as an inside of an engine compartment. The method includes plasma treatment on a peripheral surface of the tubular fluororesin inner layer, at least one treatment of water treatment and silane coupling agent treatment on the plasma treated surface and formation of the thermoplastic resin outer layer on the treated peripheral surface.

Owner:SUMITOMO RIKO CO LTD

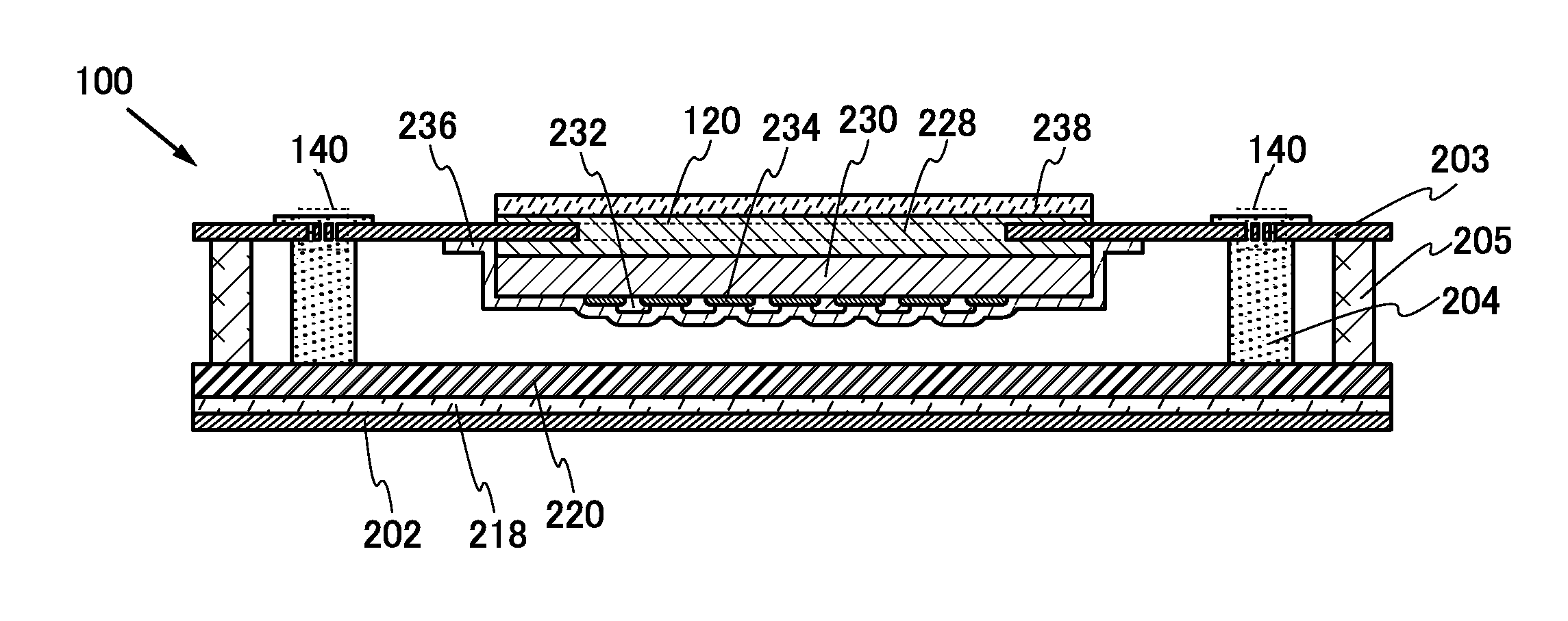

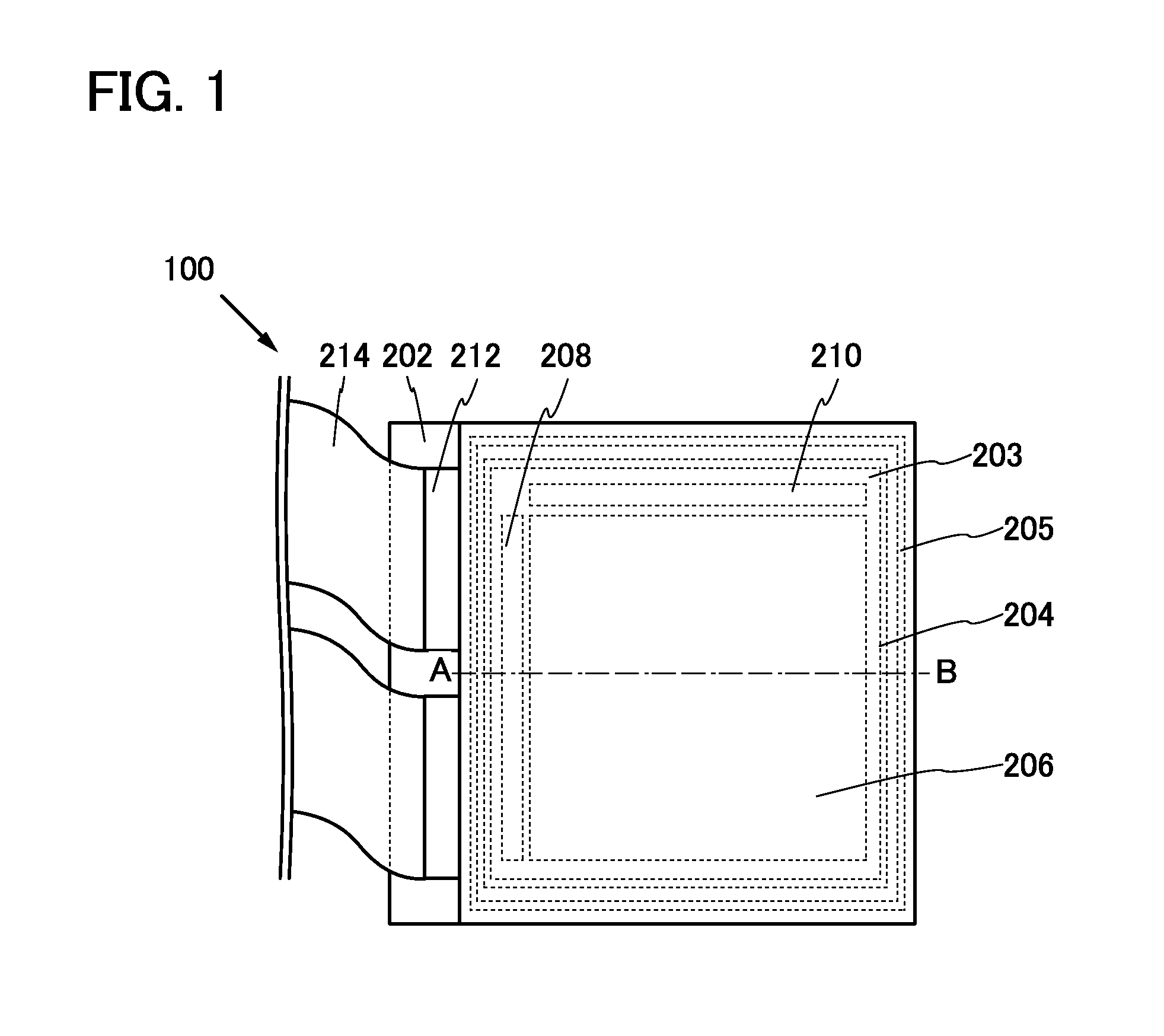

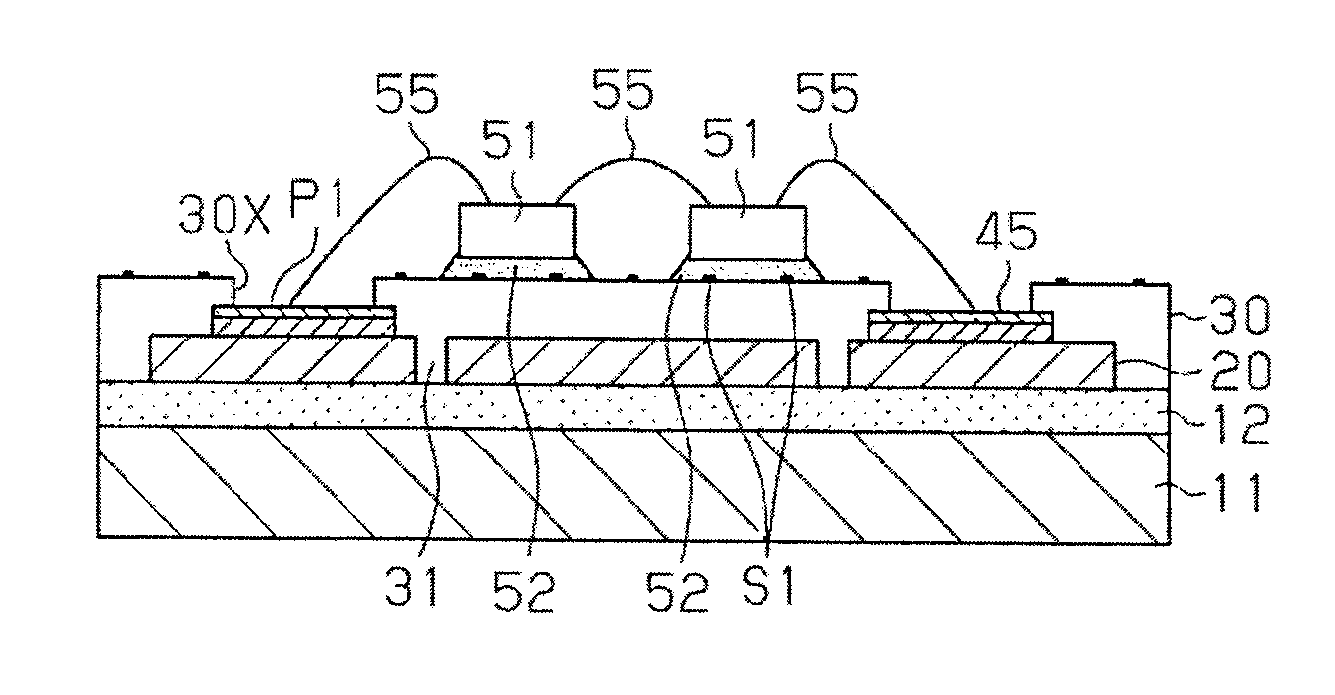

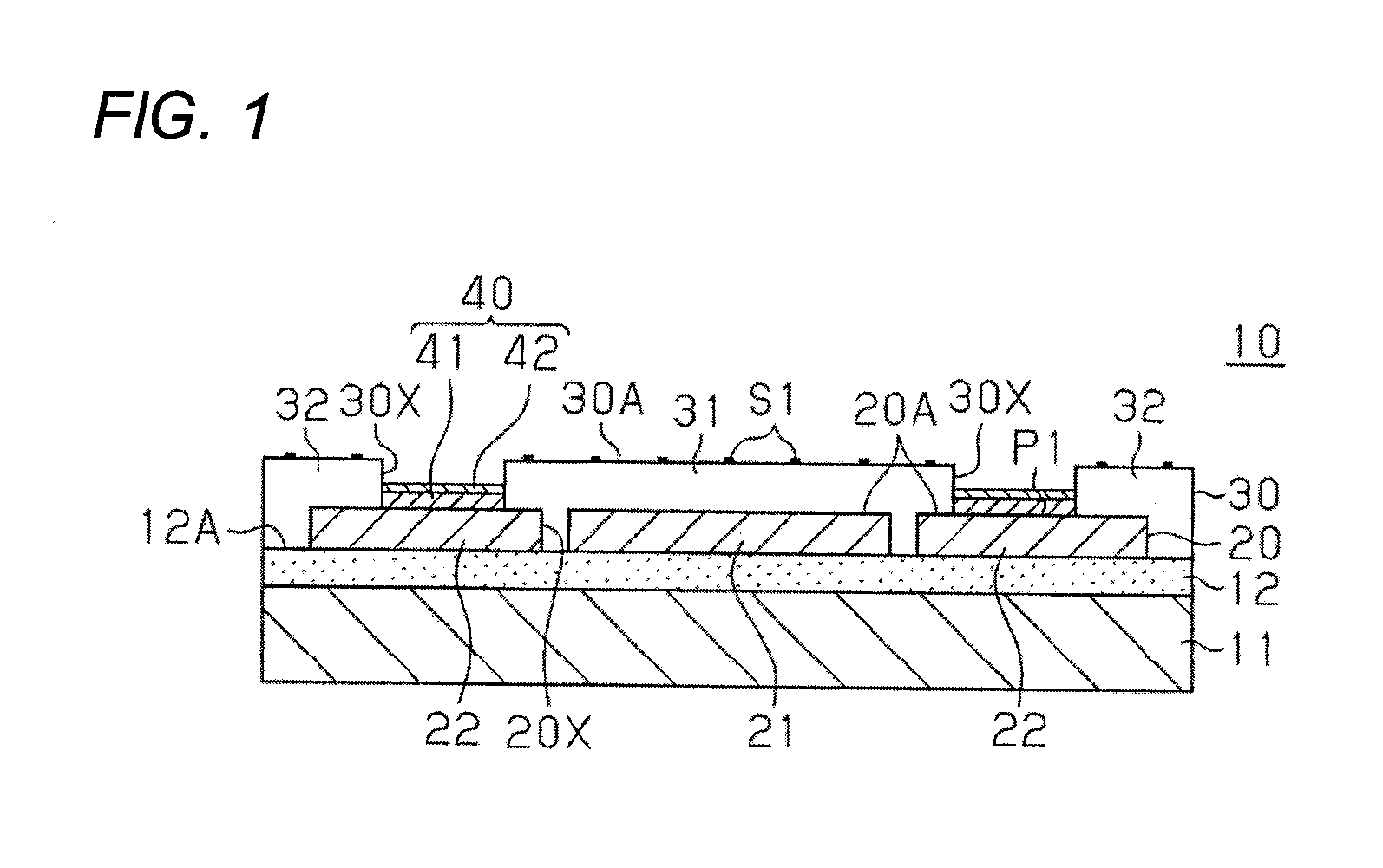

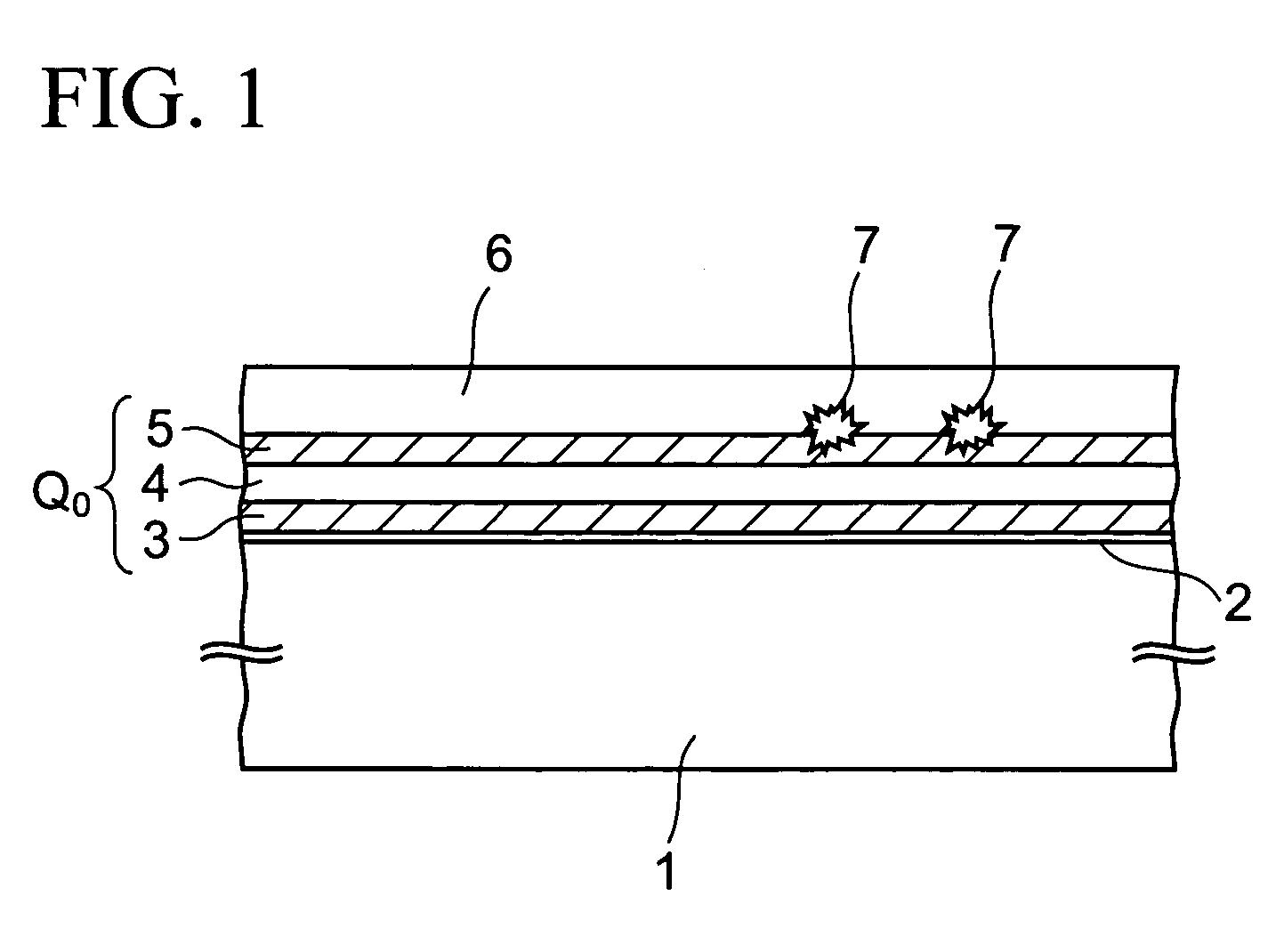

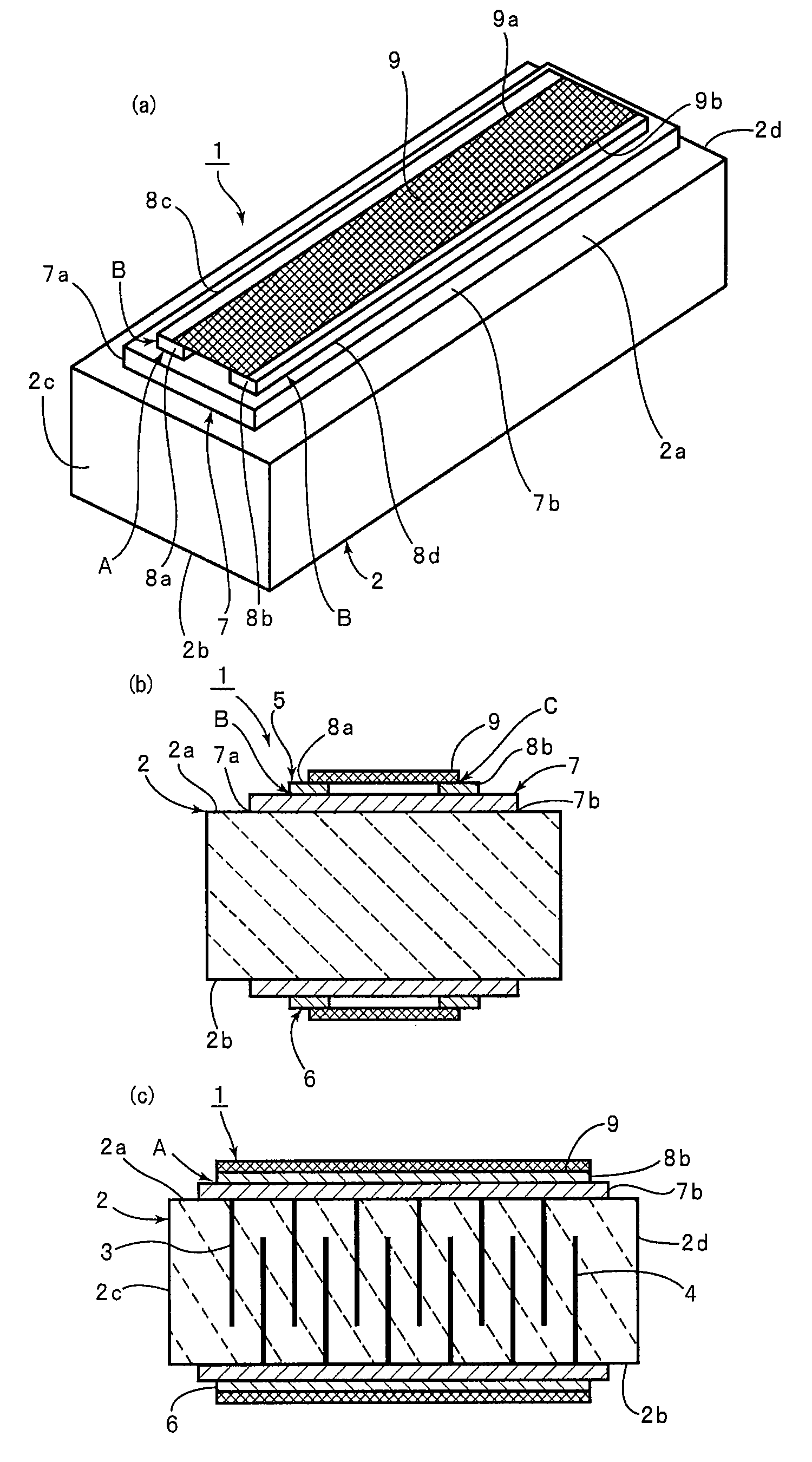

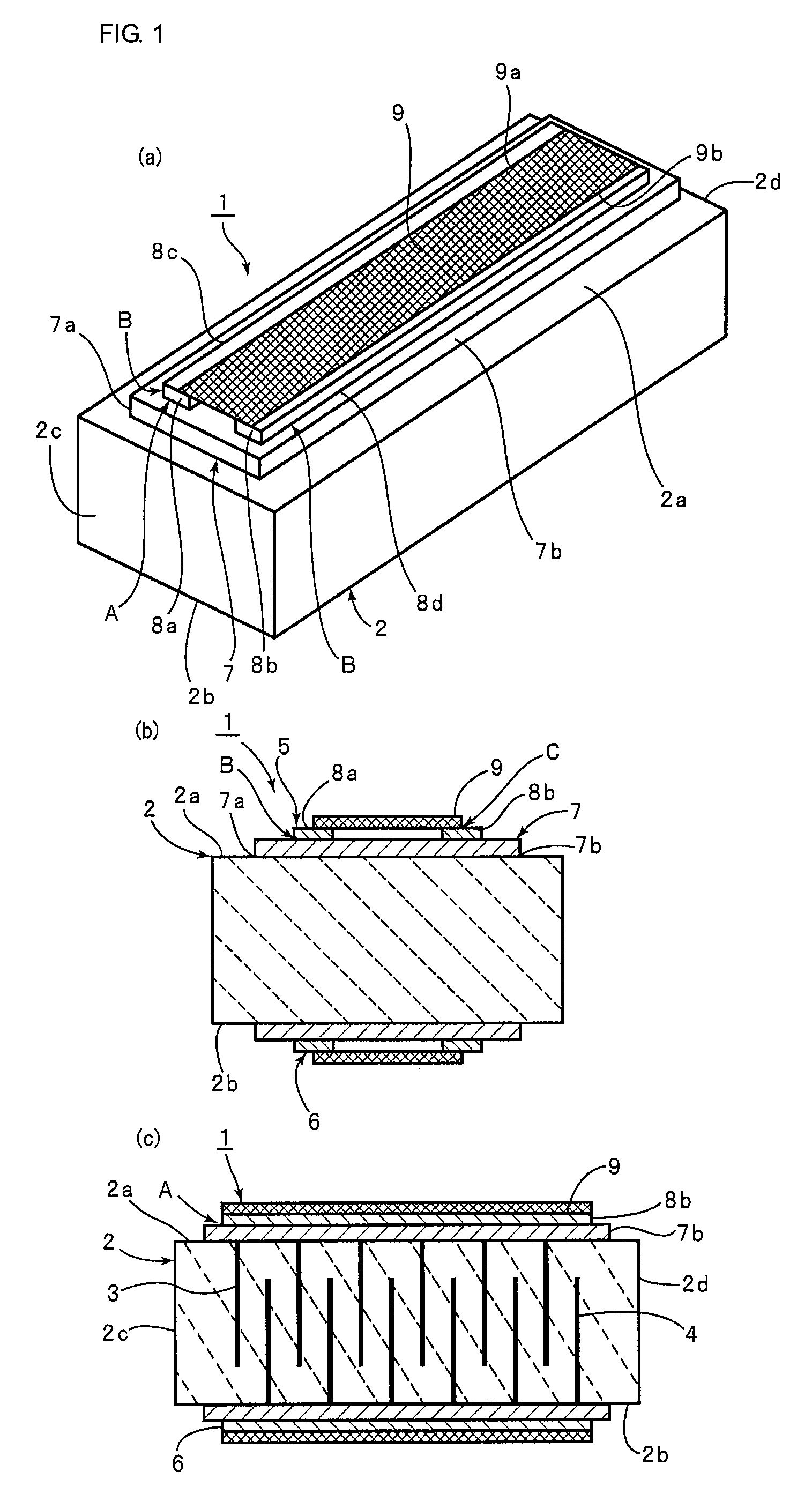

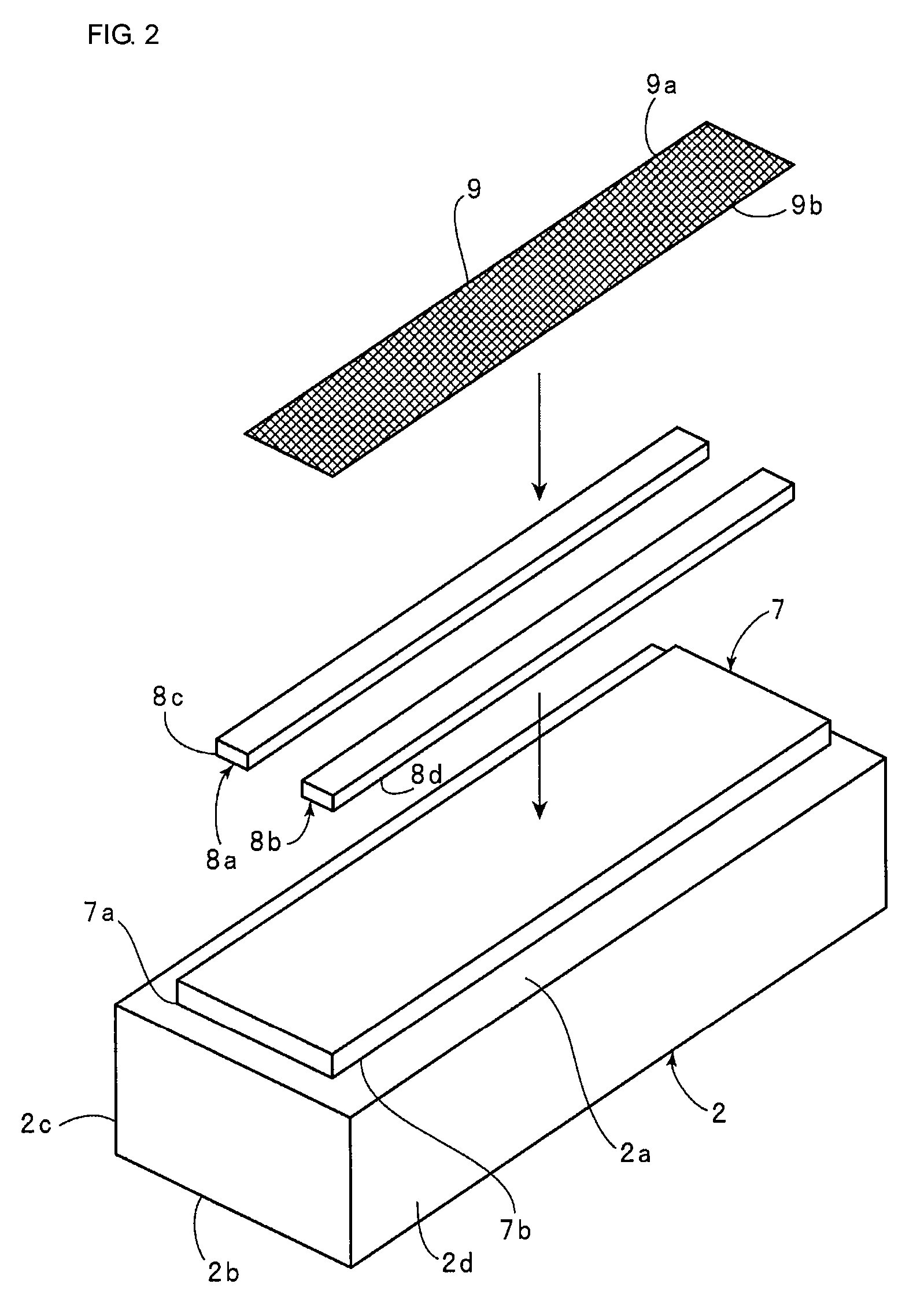

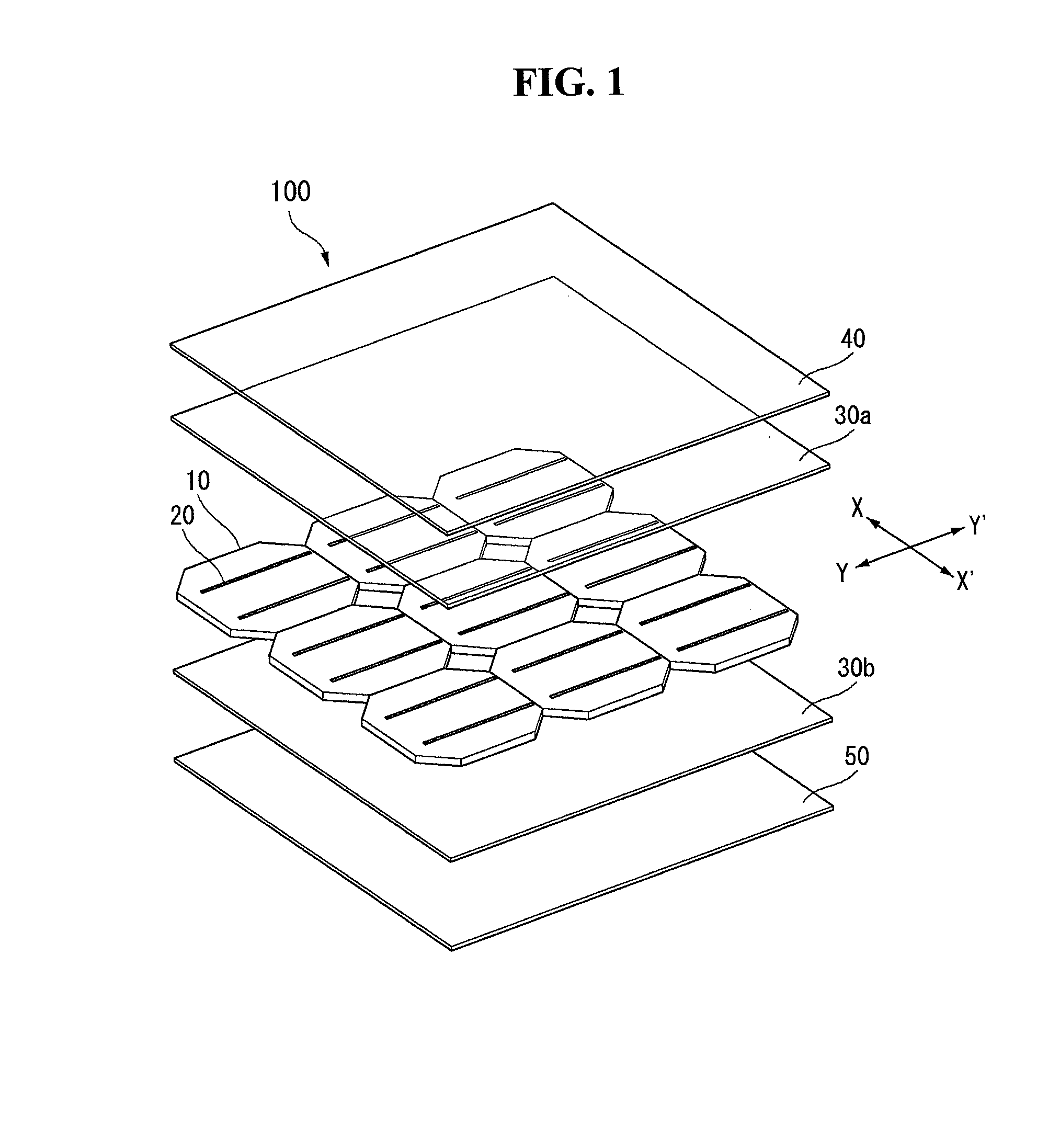

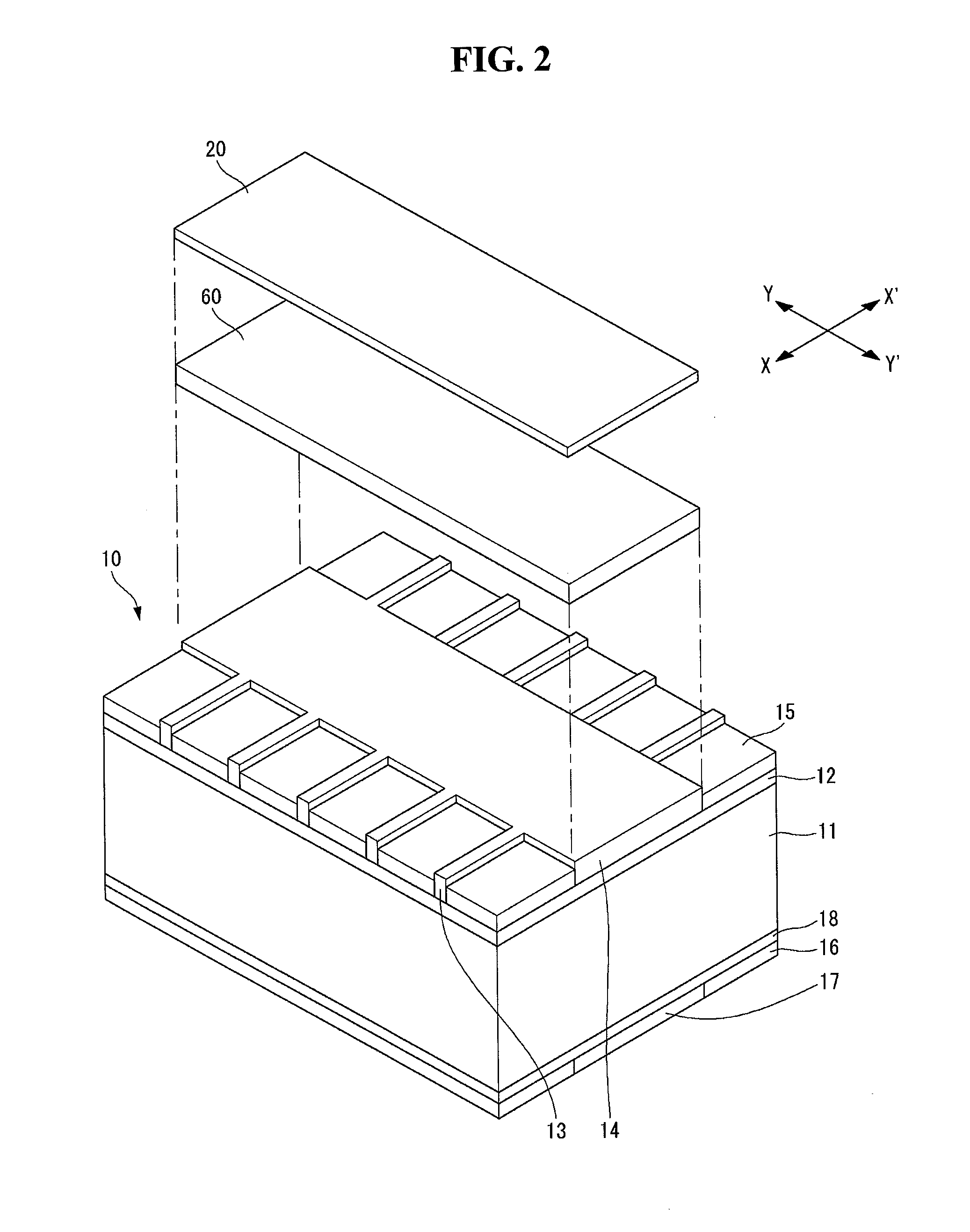

Light-emitting device and manufacturing method thereof

InactiveUS20130300284A1Suppress entryImprove reliabilityDischarge tube luminescnet screensFinal product manufactureFritEngineering

A light-emitting device which is thin and lightweight and has high flexibility, impact resistance, and reliability is provided. Further, a light-emitting device which is thin and lightweight and has high flexibility, impact resistance, and hermeticity is provided. In the light-emitting device in which a light-emitting region including a transistor and a light-emitting element is sealed between a first flexible substrate and a second flexible substrate, an opening is provided in the second flexible substrate around a region overlapping with the light-emitting region, the opening is filled with frit glass containing low-melting glass and bonding the first flexible substrate and the second flexible substrate, and the frit glass is provided so as to be in contact with an insulating layer provided over the first flexible substrate. The second flexible substrate may include an opening in a region overlapping with the light-emitting region.

Owner:SEMICON ENERGY LAB CO LTD

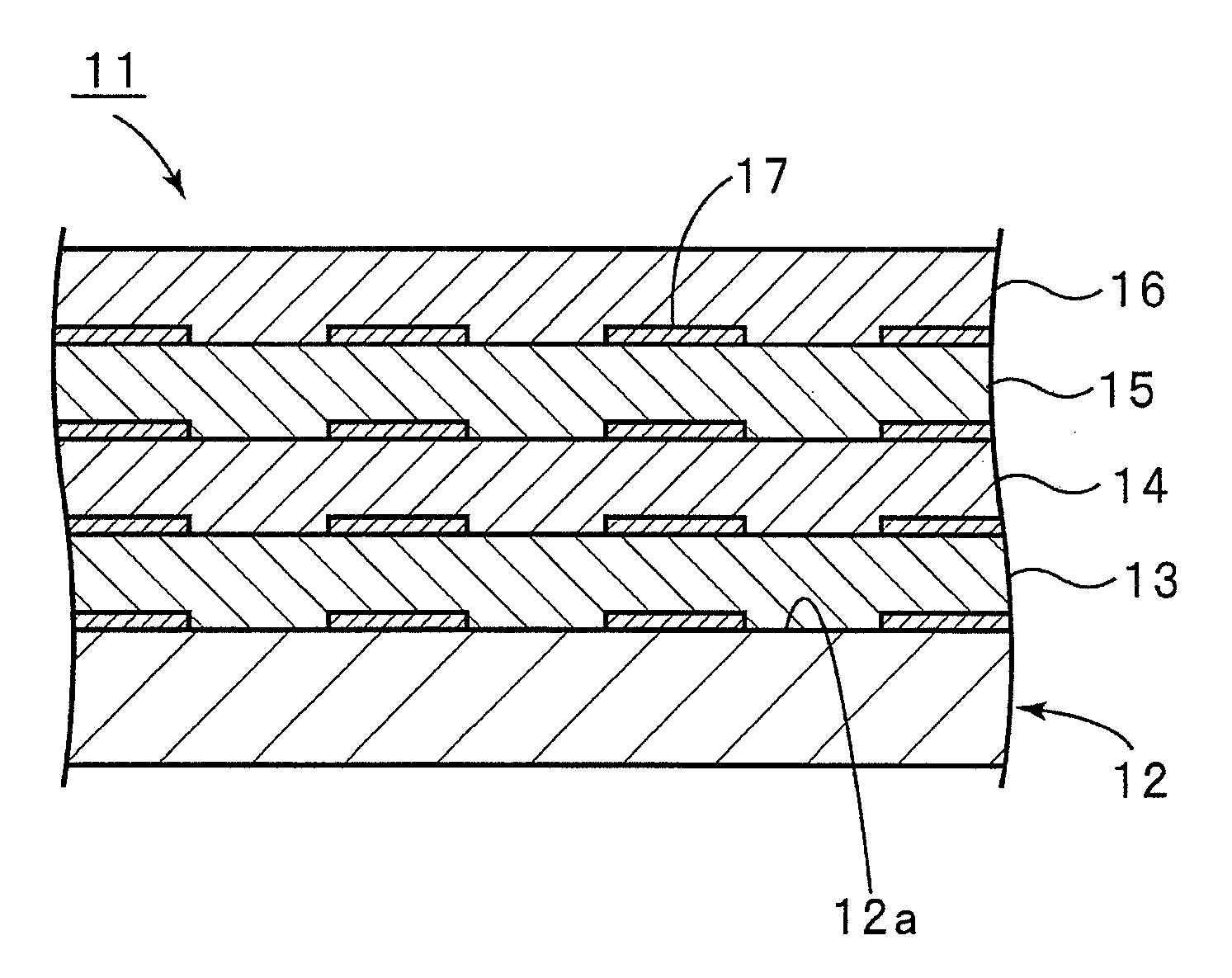

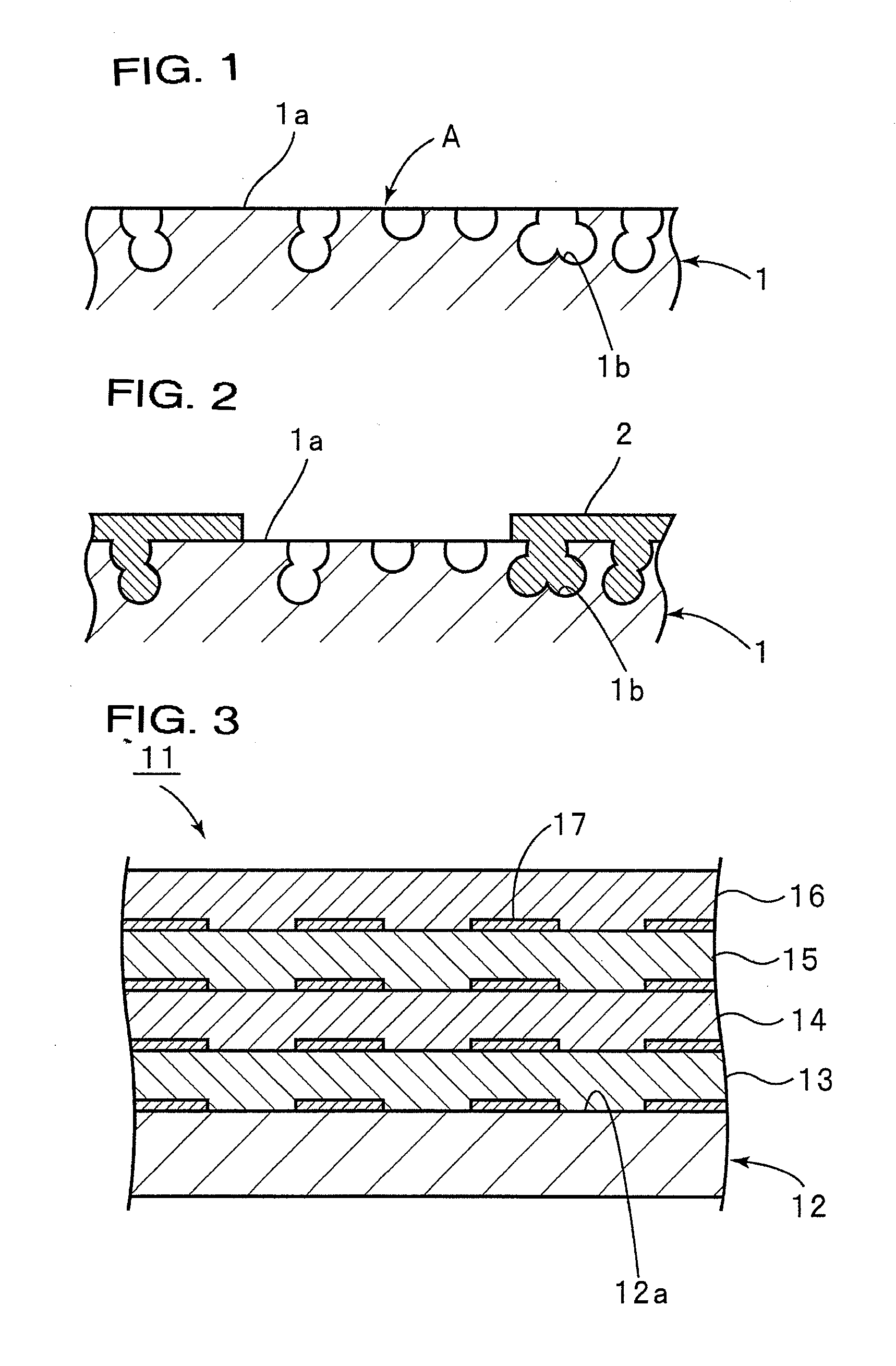

Epoxy resin composition, prepreg, cured body, sheet-like molded body, laminate and multilayer laminate

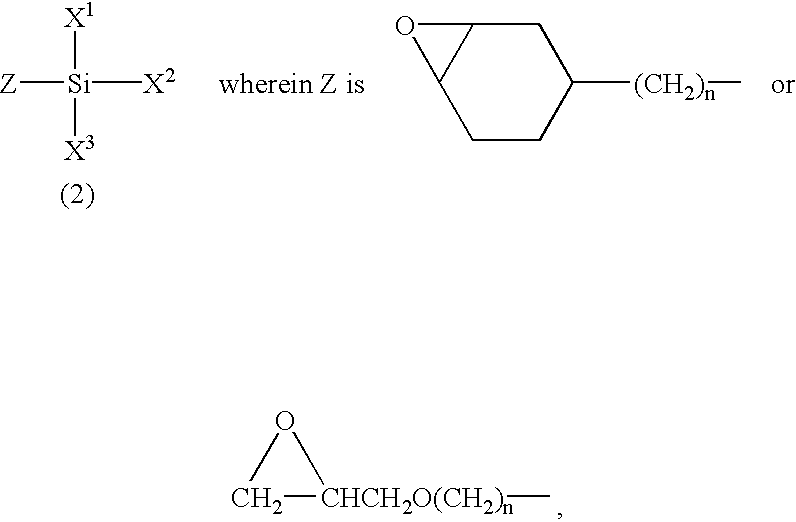

InactiveUS20110189432A1Reduce surface roughnessAdhesive strengthSynthetic resin layered productsPrinted circuit aspectsSilica particleEpoxy

Provided is an epoxy resin composition capable of reducing the surface roughness of the surface of a roughening-treated cured body.The epoxy resin composition includes an epoxy resin, a curing agent, and a silica component obtained by performing a surface treatment on silica particles using a silane coupling agent; and the epoxy resin composition does not include a curing accelerator, or includes a curing accelerator at a content equal to or less than 3.5 parts by weight to a total of 100 parts by weight of the epoxy resin and the curing agent. Mean particle diameter of the silica particles is equal to or less than 1 μm. An amount B (g) of the silane coupling agent used for surface treatment, per 1 g of the silica particles in the silica component, is within a range between 10% to 80% with regard to a value C (g) per 1 g of the silica particles, which is calculated by the following formula (X).C (g) / 1 g of Silica Particles=[Specific Surface Area of Silica Particles (m2 / g) / Minimum Area Coated by Silane Coupling Agent (m2 / g)] Formula (X)

Owner:SEKISUI CHEM CO LTD

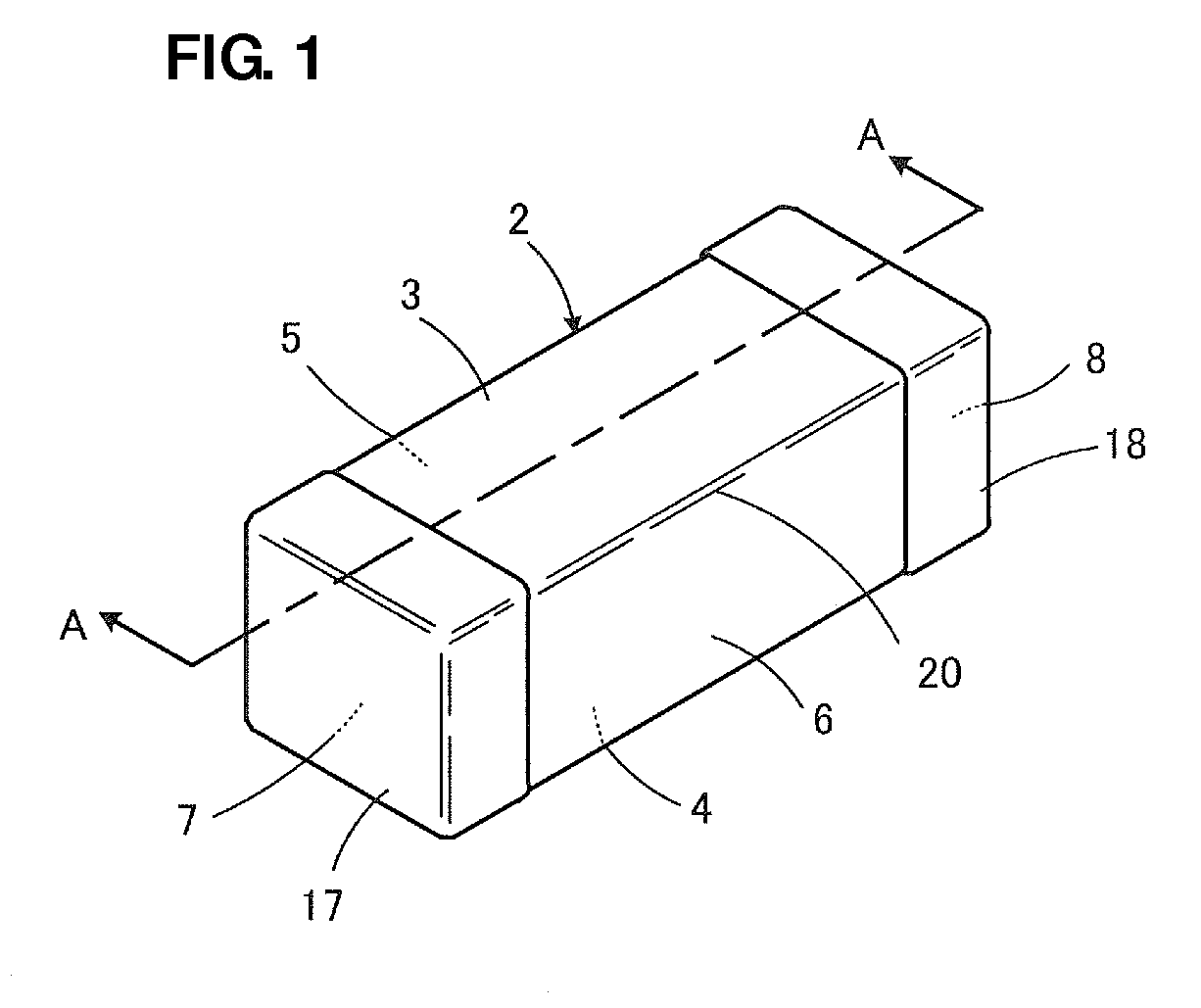

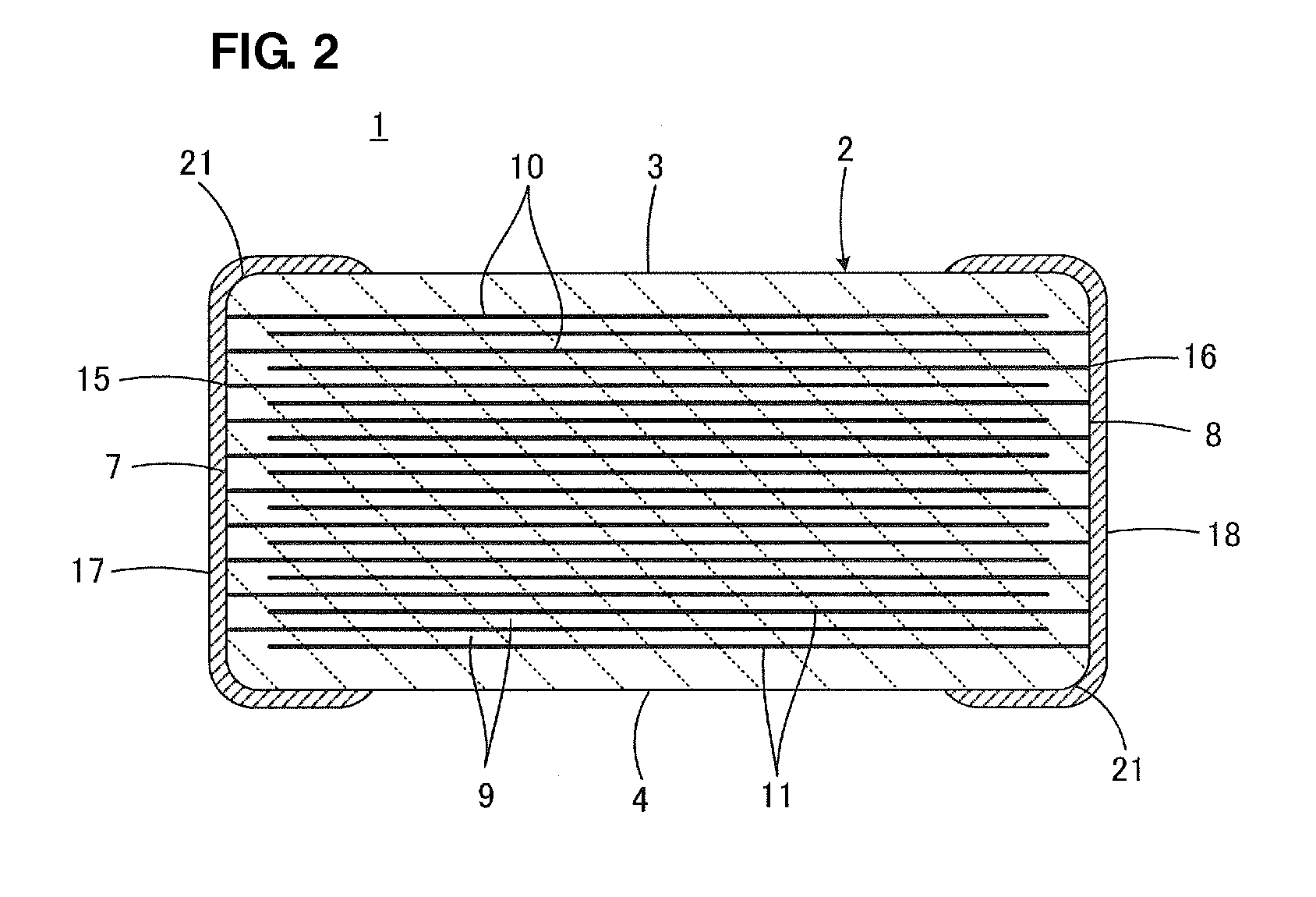

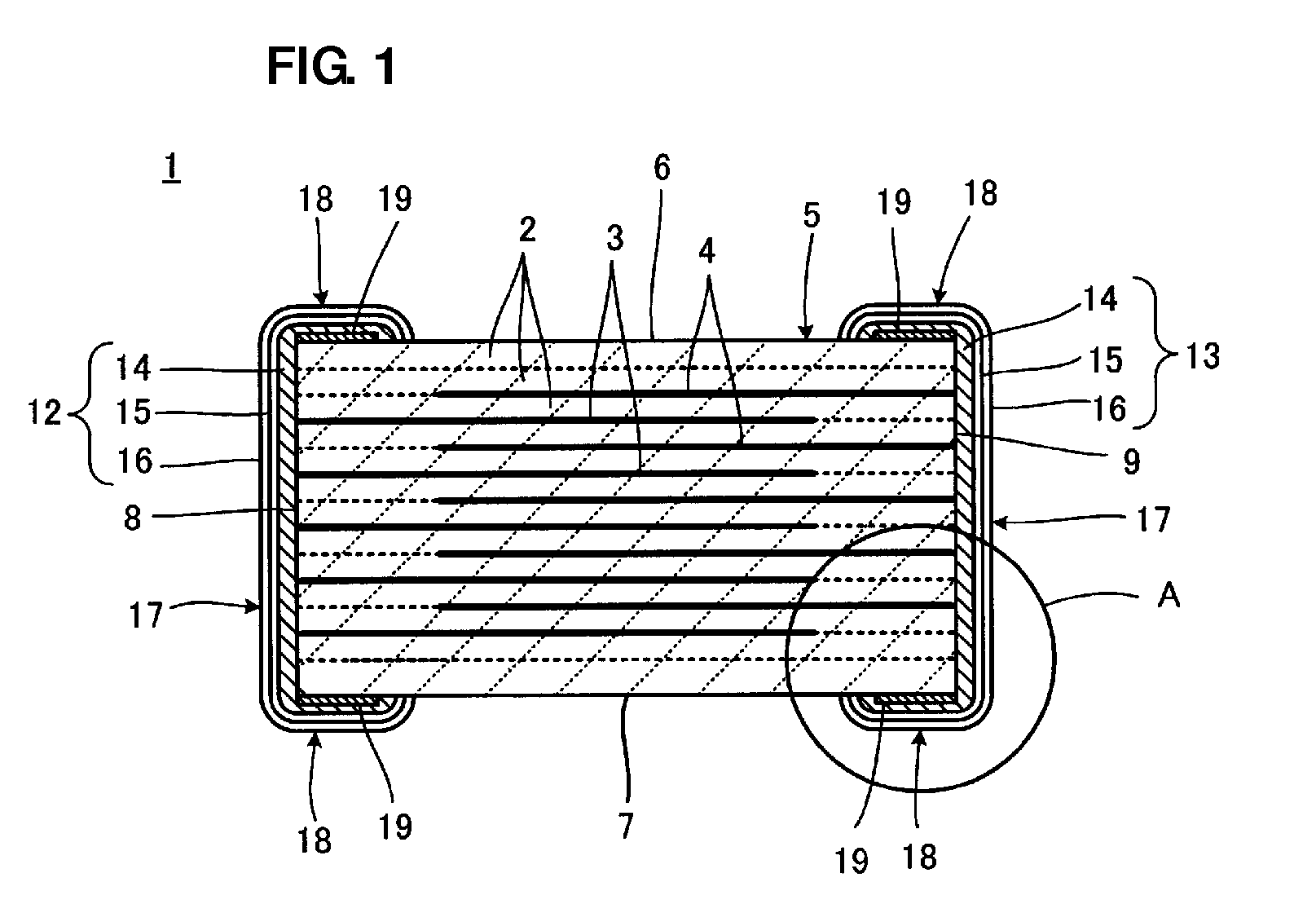

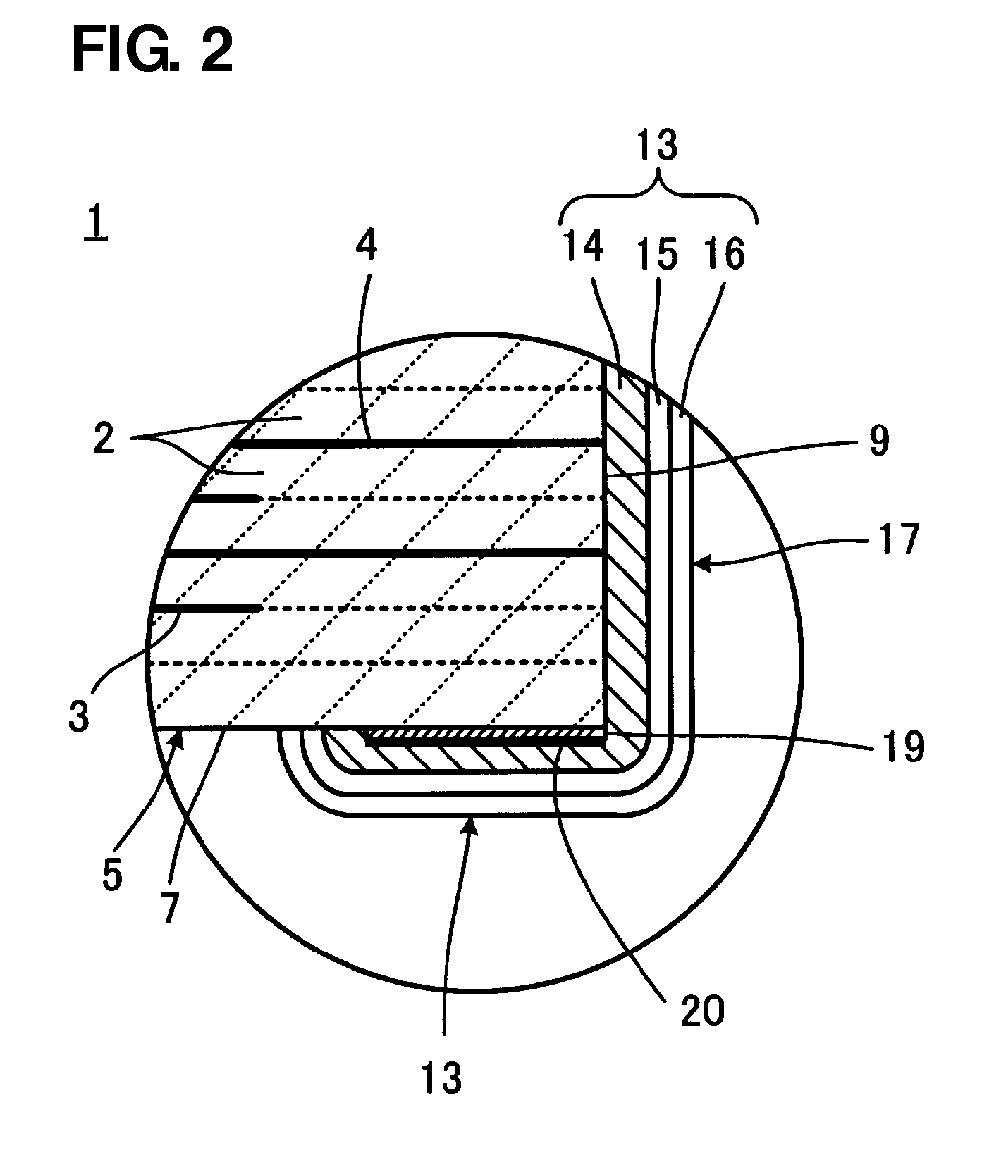

Multilayer ceramic electronic component and a method for manufacturing the same

ActiveUS20120073129A1Adhesive strengthHigh bonding strengthLine/current collector detailsFixed capacitor dielectricSurface layerMetallurgy

In a method of manufacturing a multilayer ceramic electronic component, polishing is performed so that intersection lines extending from external surfaces of a green element body and interfaces between a green chip to be formed into a laminate portion and ceramic side surface layers are each located within a curved-surface formation range of a chamfer portion. Accordingly, since a green ceramic material is extended so as to fill the interfaces like so-called “putty”, and the adhesive strength between the green chip to be formed into the laminate portion and each of the ceramic side surface layers is increased.

Owner:MURATA MFG CO LTD

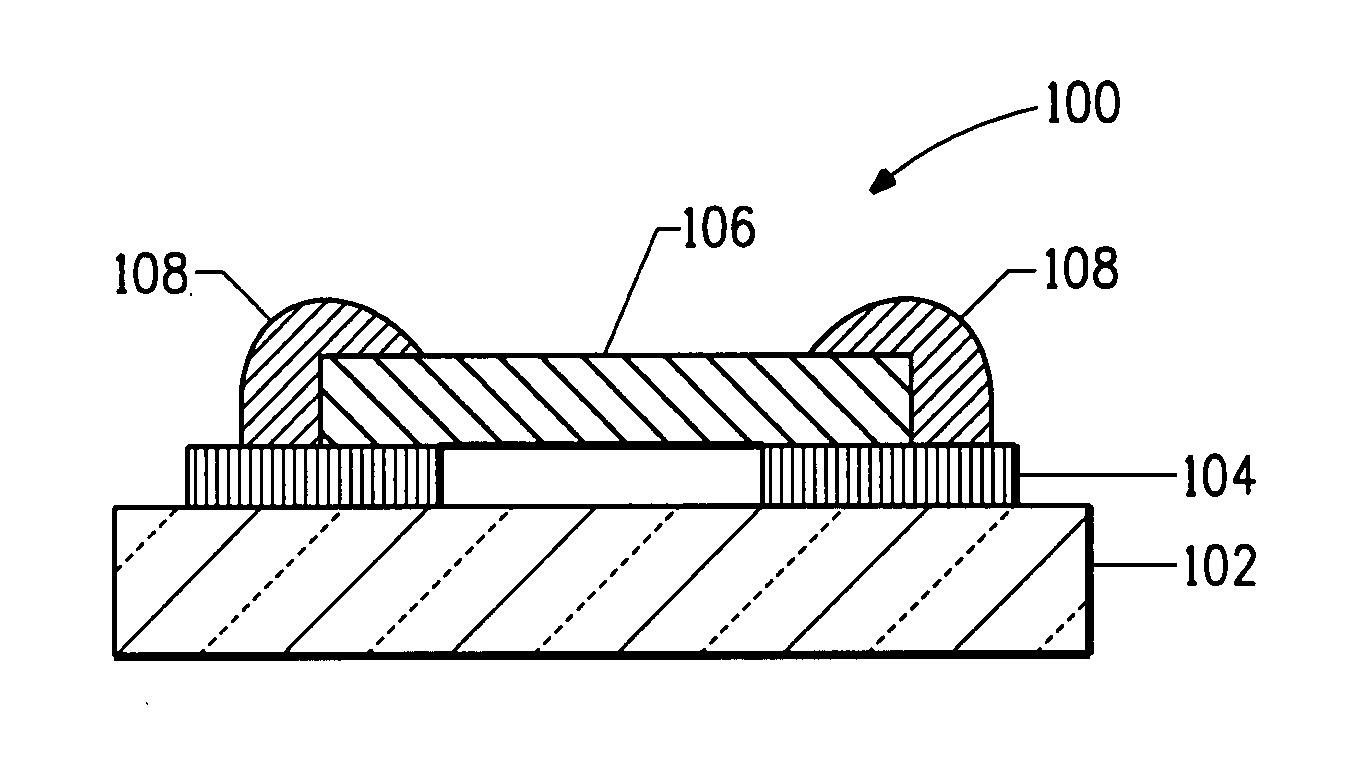

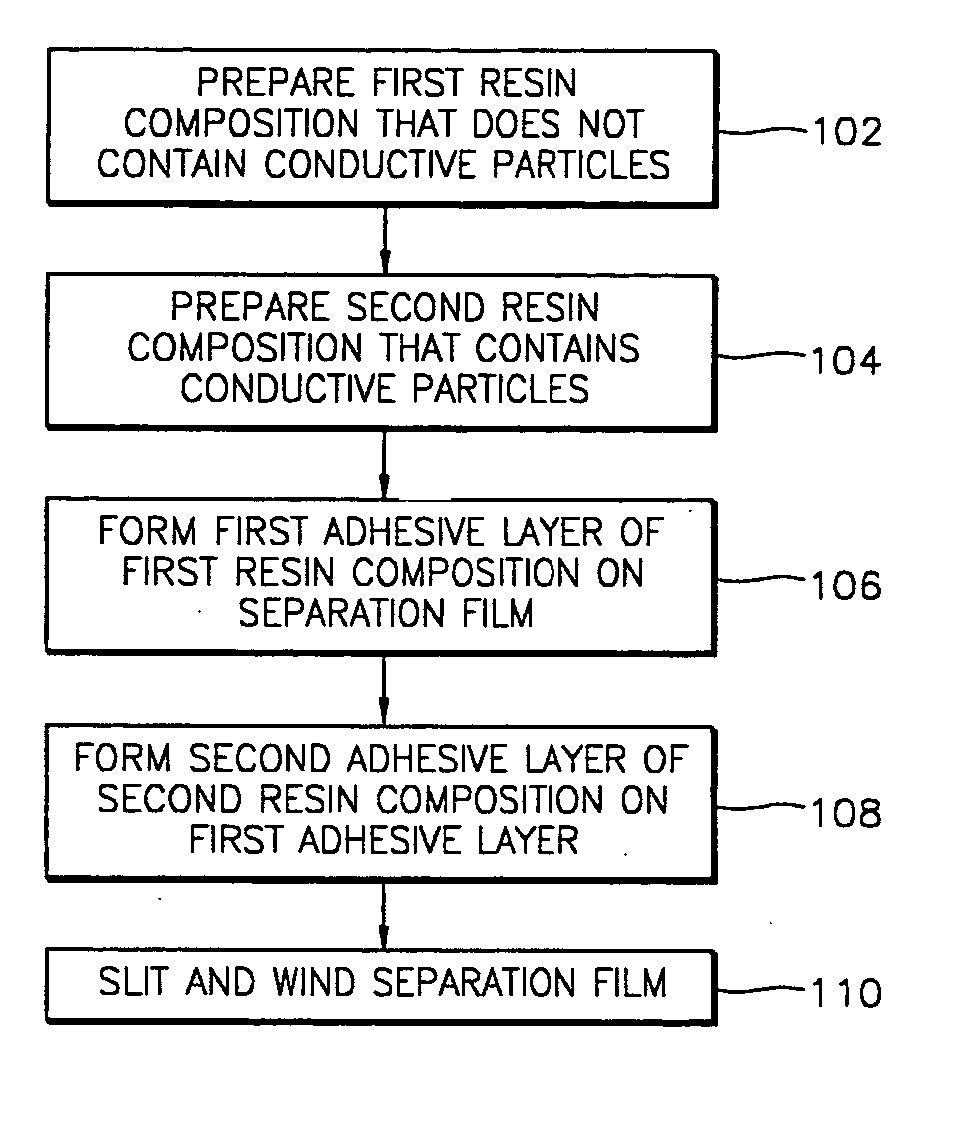

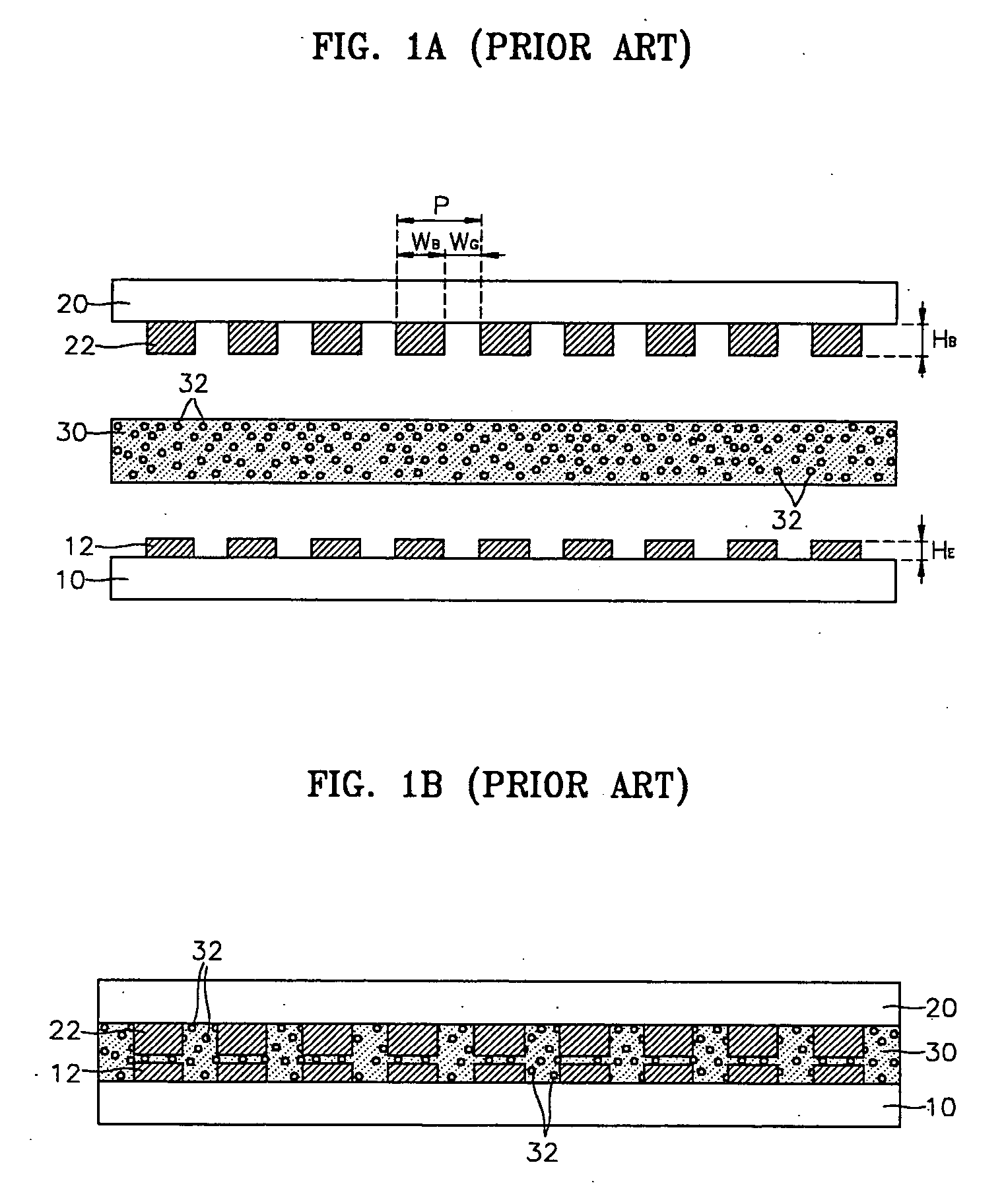

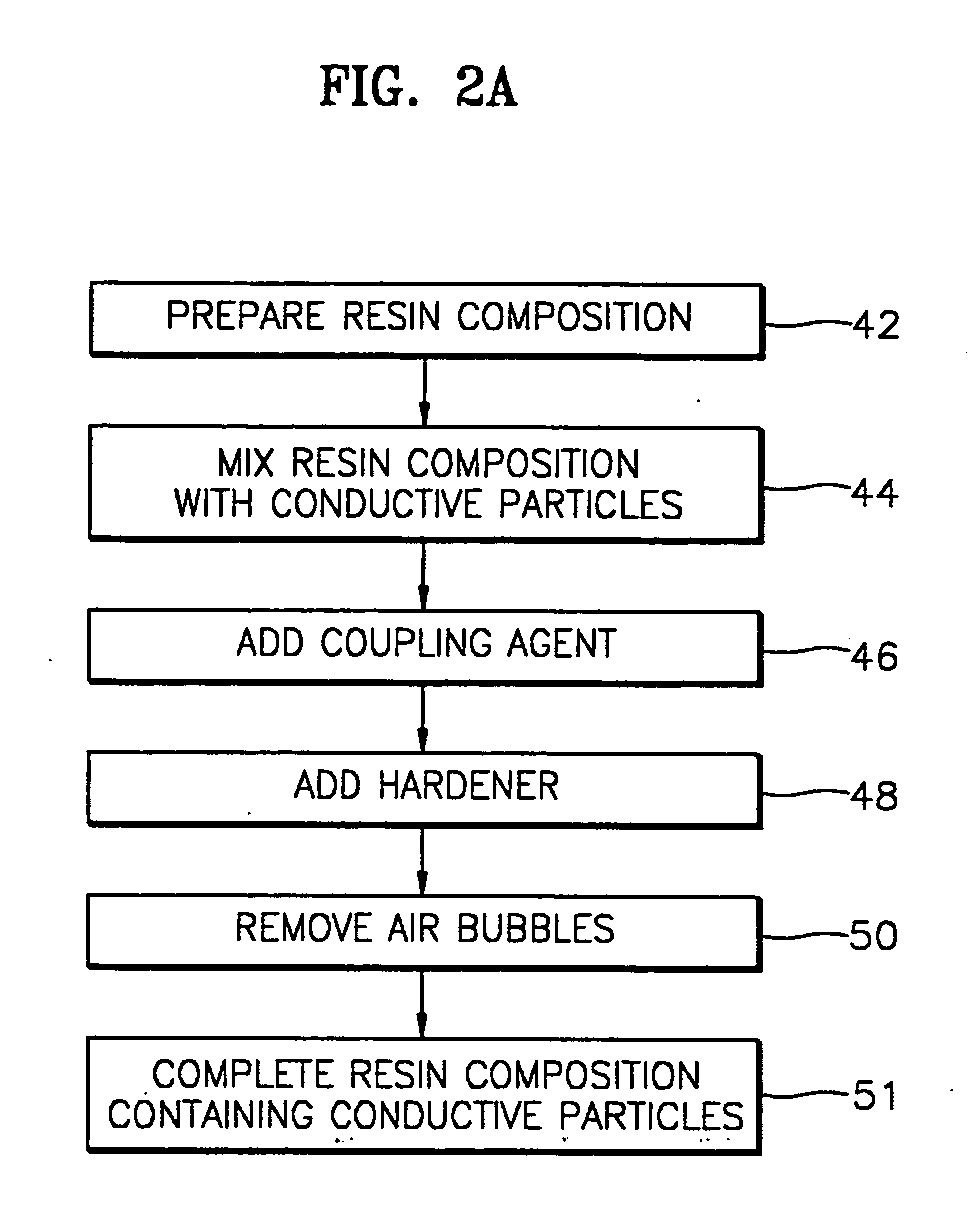

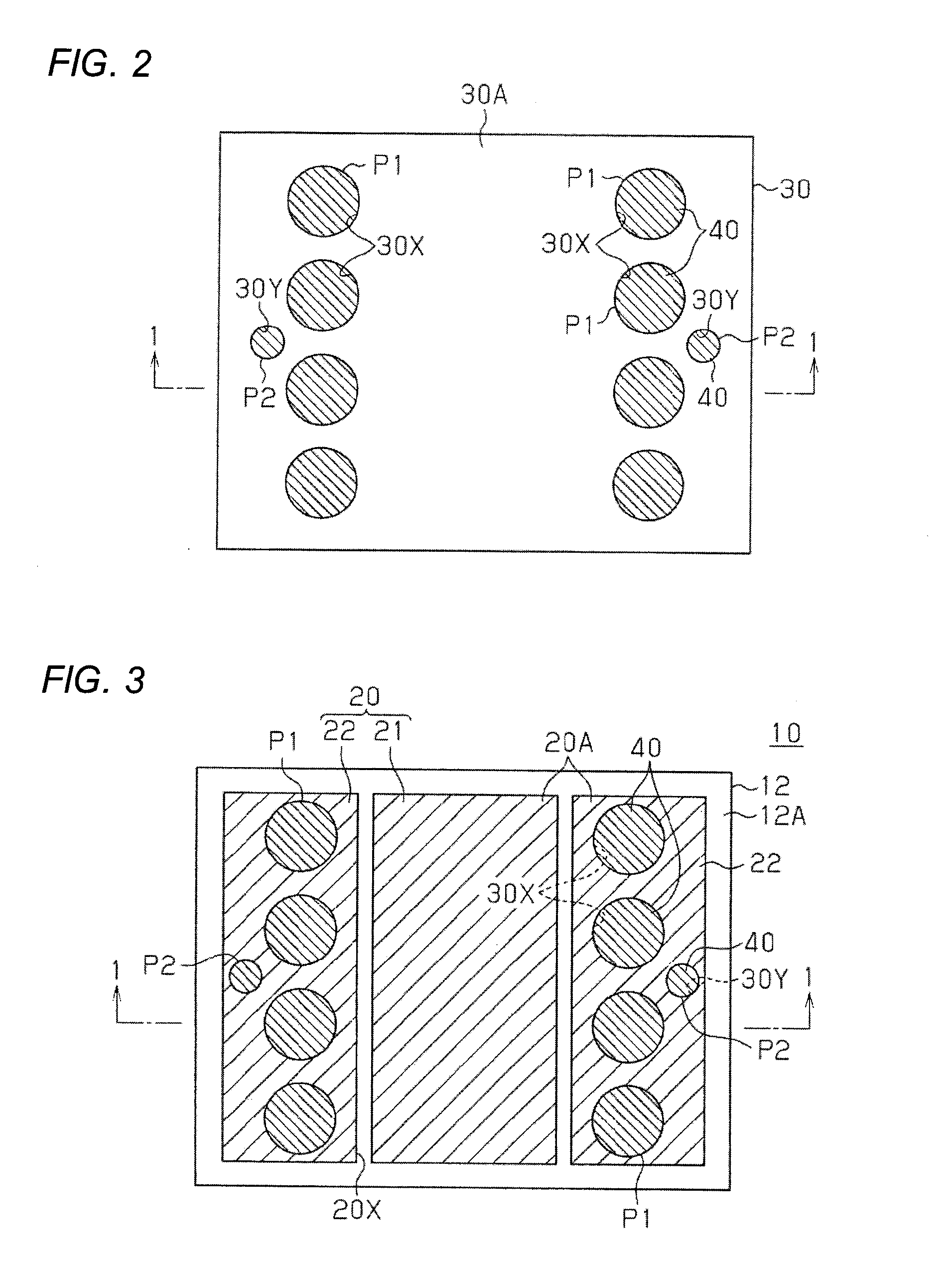

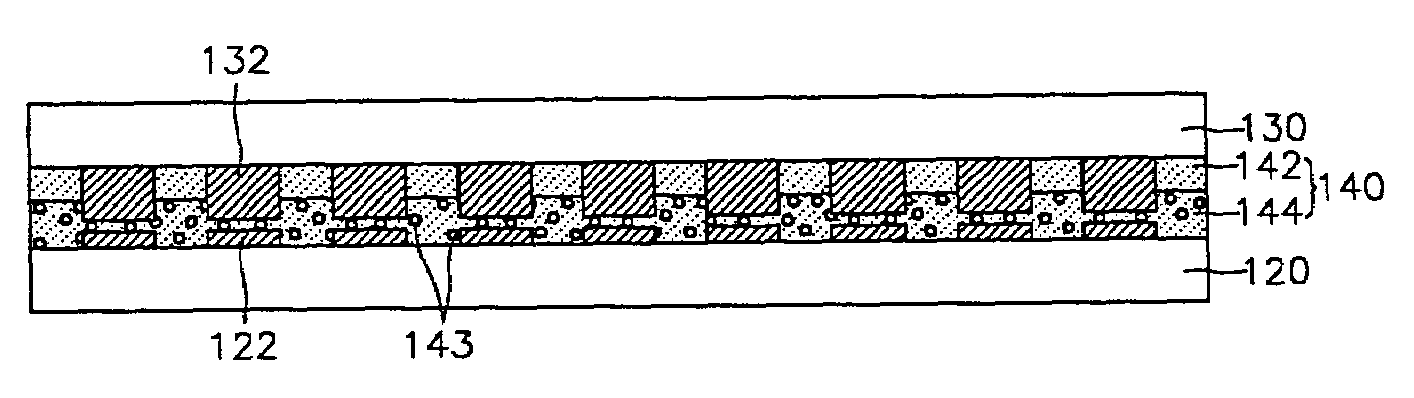

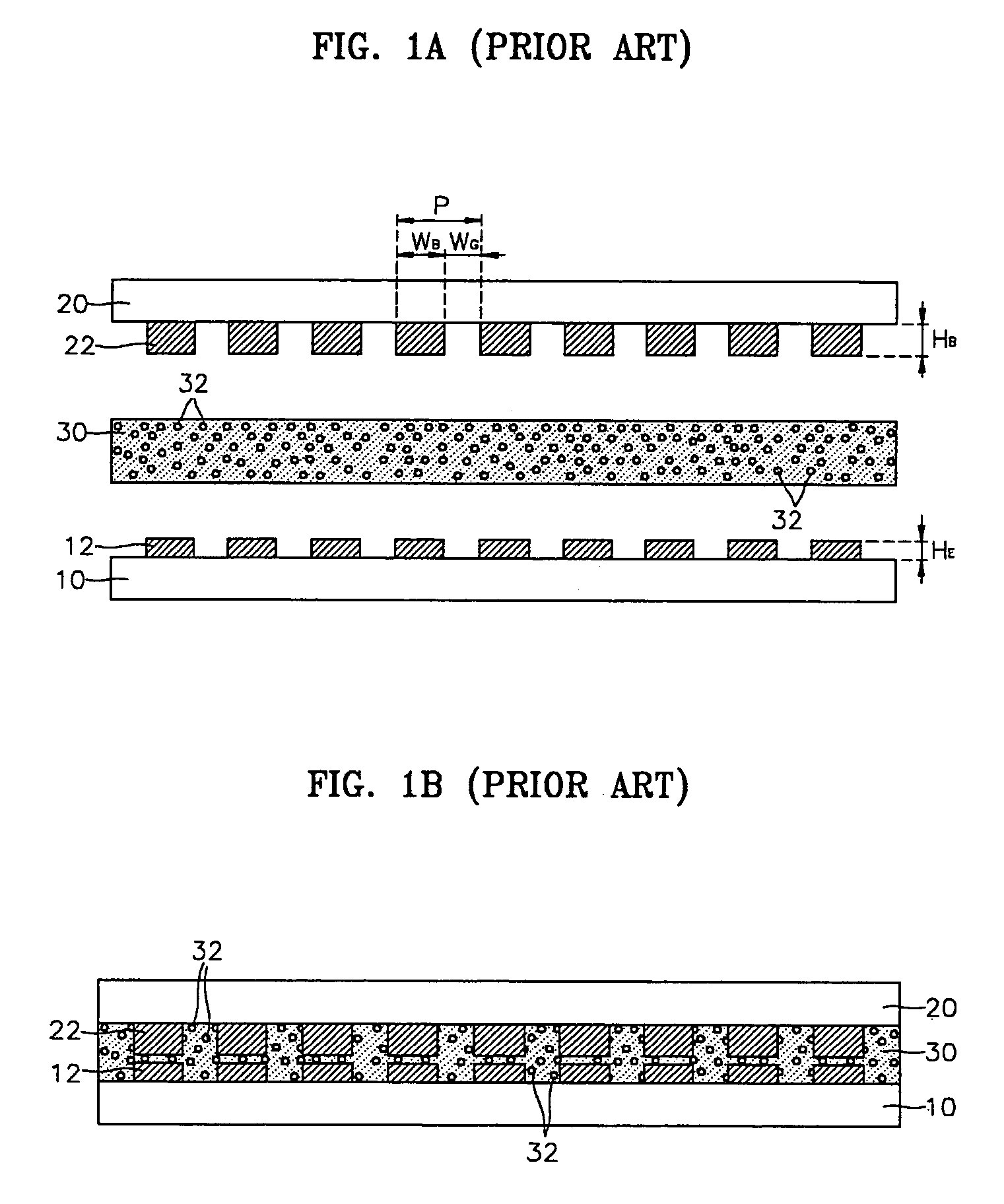

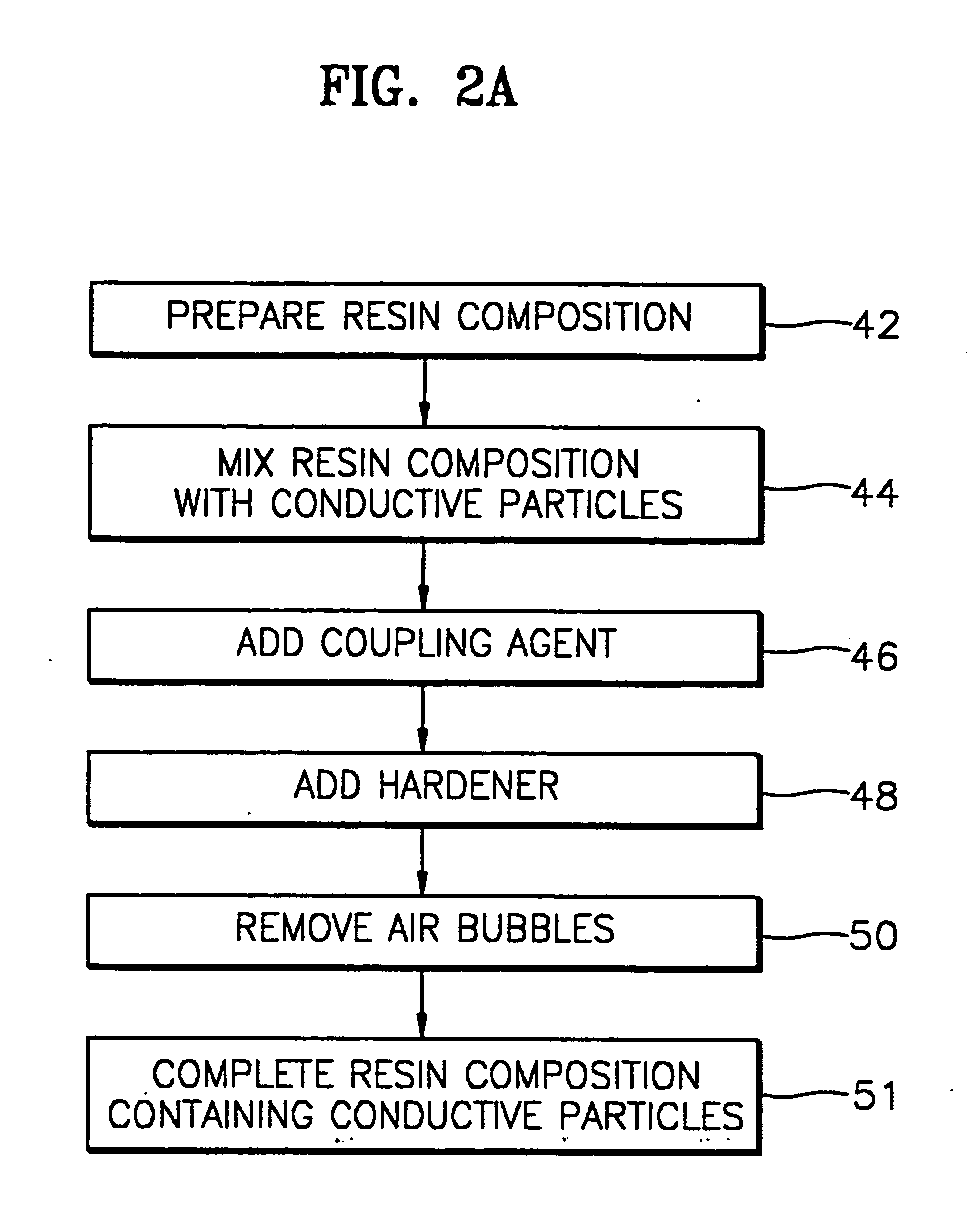

Multilayered anisotropic conductive adhesive for fine pitch

InactiveUS20060033213A1Improve conductivityAdhesive strengthLiquid crystal compositionsSemiconductor/solid-state device detailsAnisotropic conductive adhesiveEngineering

Provided is an anisotropic conductive adhesive for a fine pitch having a conductive adhesive layer and a nonconductive adhesive layer formed on one surface or both surfaces of the conductive adhesive layer. The anisotropic conductive adhesive for a fine pitch can be used to adhere an integrated circuit, on which a plurality of bumps each having a second height are formed, to a substrate, on which a plurality of electrodes each having a first height are formed keeping predetermined distances from each other, so that the integrated circuit is electrically connected to the electrodes. The anisotropic conductive adhesive includes a nonconductive first adhesive layer and a second adhesive layer. The nonconductive first adhesive layer includes a thermosetting resin and a hardener for hardening the thermosetting resin and has a first thickness of ½- 3 / 2 of the second height. The second adhesive layer includes a thermosetting resin, a hardener for hardening the thermosetting resin, and a plurality of conductive particles each having an average particle diameter of ½ or less of the width of gaps between the plurality of electrodes and a first density dispersion, has a second thickness larger than two times the average particle diameter of the conductive particles, and is formed on one surface of the nonconductive first adhesive layer.

Owner:TELEPHUS

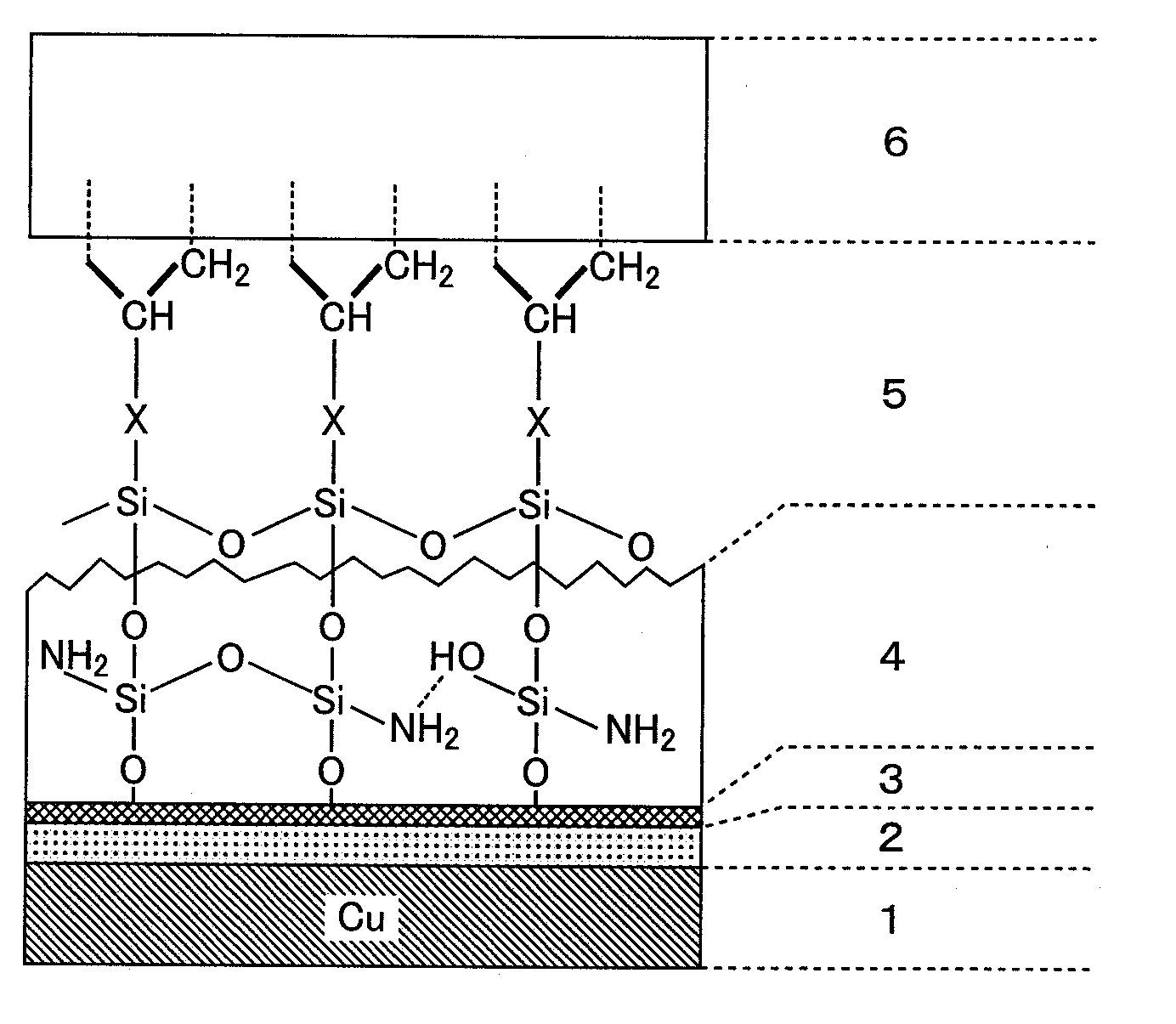

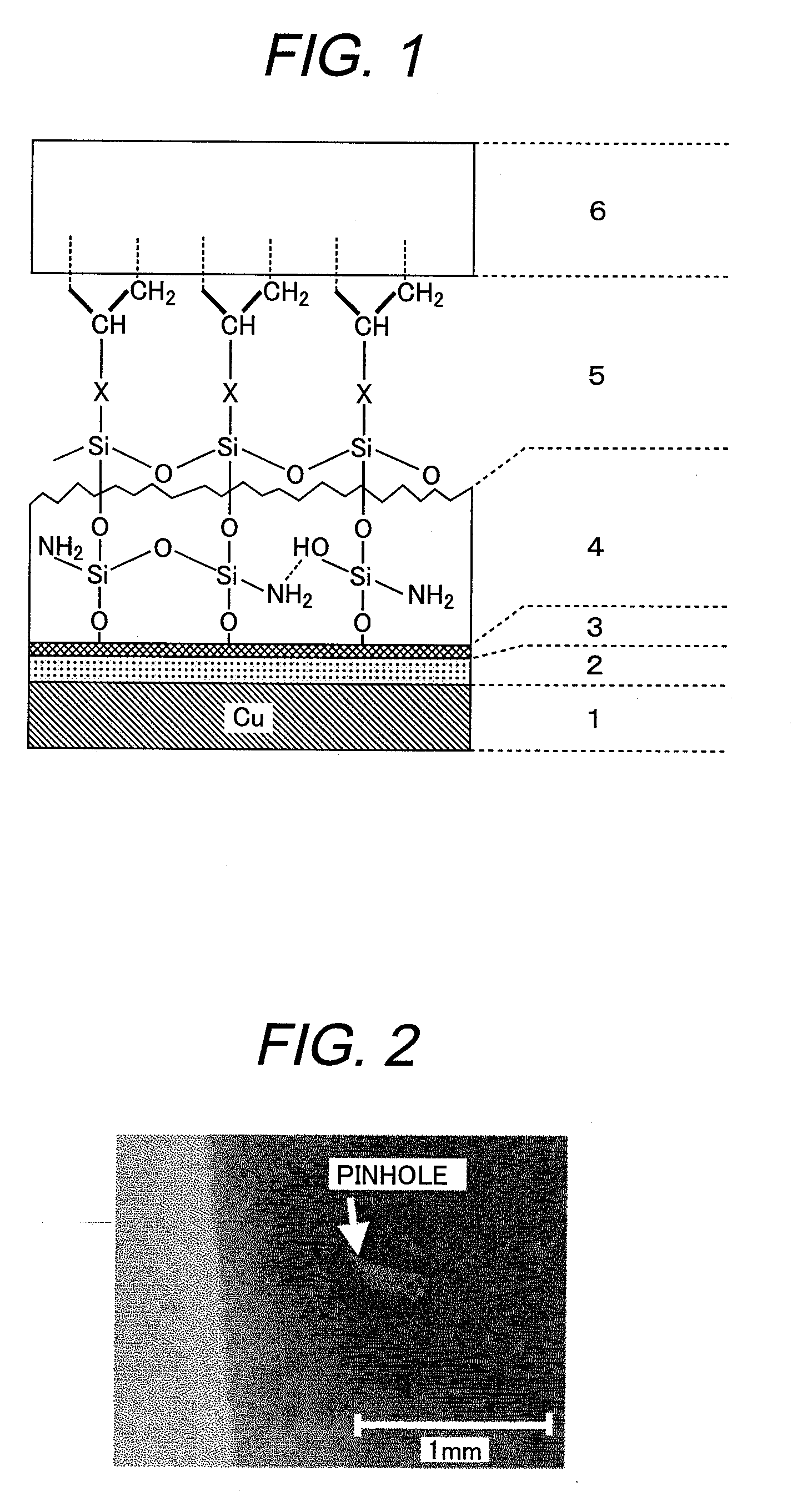

Low dielectric loss wiring board, multilayer wiring board, copper foil and laminate

InactiveUS20110088933A1The material is lowEasy to peelInsulating substrate metal adhesion improvementPrinted circuit aspectsCross-linkDouble bond

A wiring board comprising a copper wiring, and an insulating layer which is a cured product of a resin composition containing a compound having a carbon-carbon unsaturated double bond as a cross-linking component,the wiring board having a surface-treated layer formed on one or both sides of the copper wiring, andthe surface-treated layer having a metal layer (A) containing at least one metallic component selected from the group consisting of tin, zinc, nickel, chromium, cobalt and aluminium,an oxide and / or hydroxide layer (B) of the metallic component on the metal layer (A),an amino-silane coupling agent layer (C) having an amino group in its structure on the oxide and / or hydroxide layer (B), anda vinyl-silane coupling agent layer (D) having a carbon-carbon unsaturated double bond on the amino-silane coupling agent layer (C).

Owner:HITACHI LTD

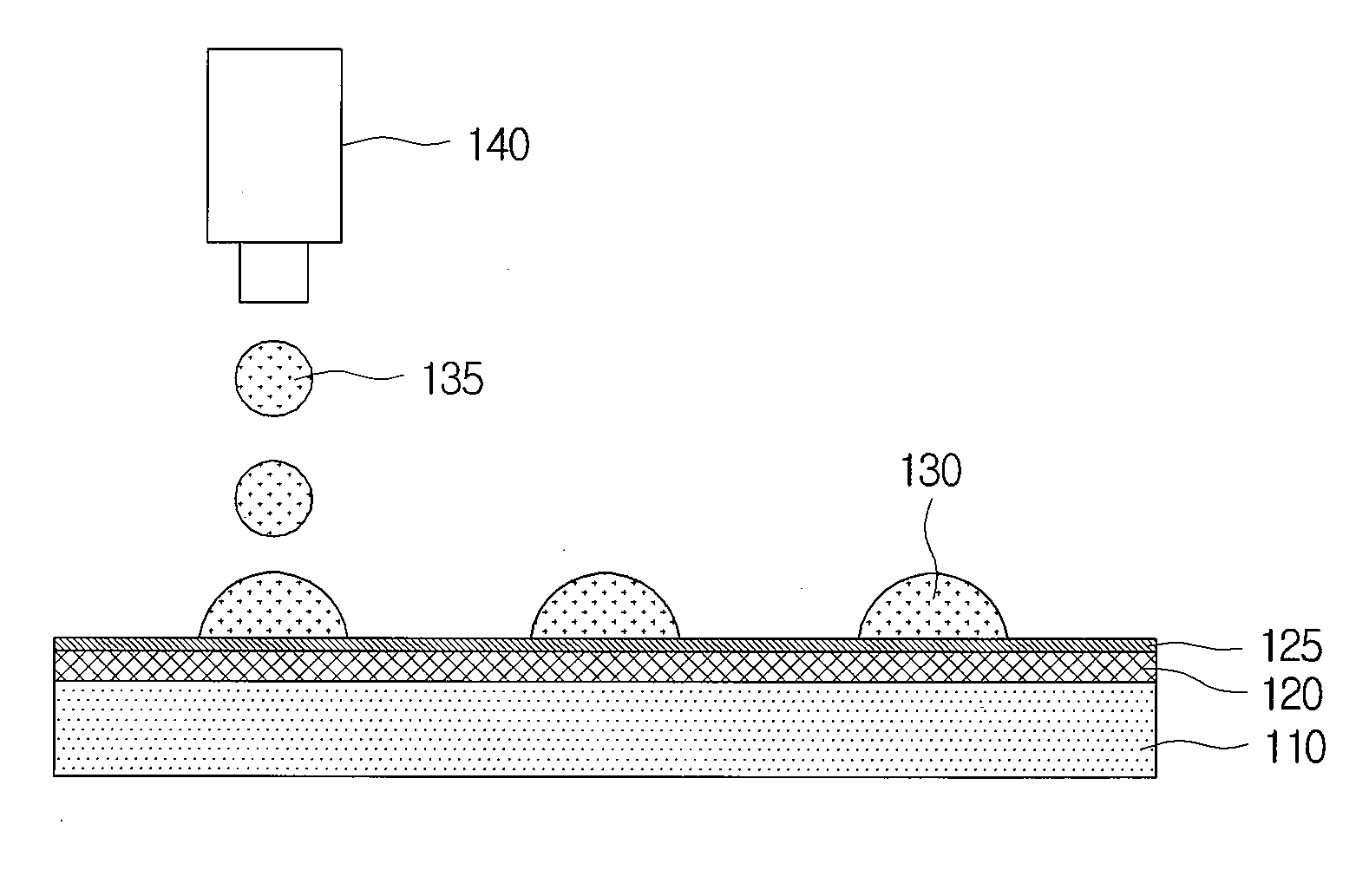

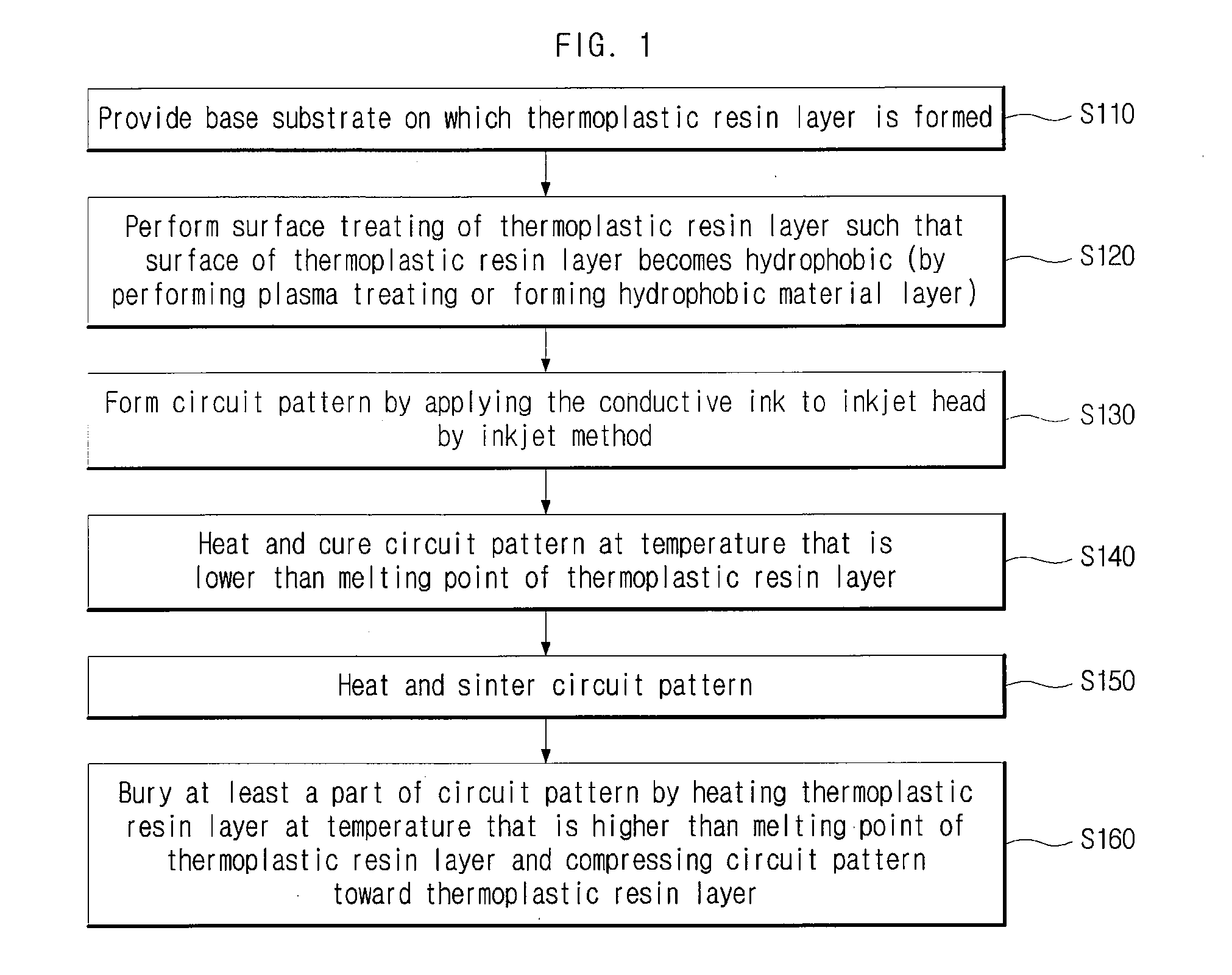

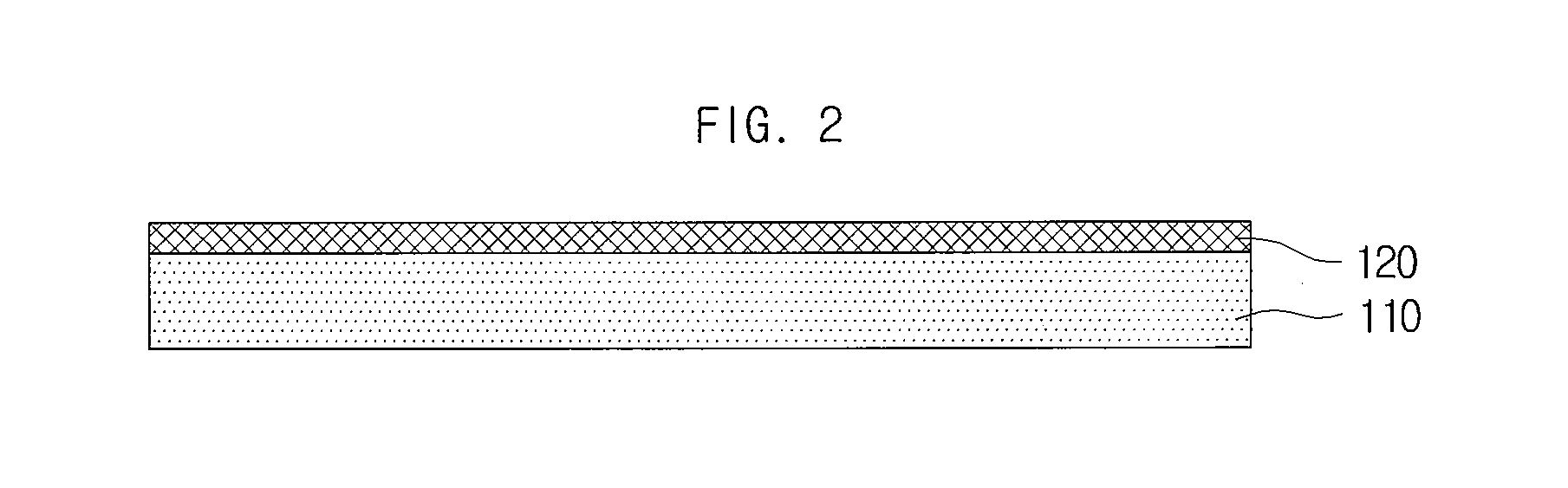

Printed circuit board and manufacturing method

InactiveUS20100059251A1High bonding strengthAdhesive strengthPrinted circuit secondary treatmentConductive pattern formationEngineeringPrinted circuit board

Disclosed are a printed circuit board and a method for manufacturing the same. The method, which includes providing a base substrate in which a thermoplastic resin layer is formed; forming a circuit pattern on the thermoplastic resin layer by discharging a conductive ink by an inkjet method; curing the circuit pattern through the heating at a temperature that is lower than a melting point of the thermoplastic resin layer; sintering the circuit pattern through the heating; and burying at least a part of the circuit pattern in the thermoplastic resin layer by heating the thermoplastic resin layer and compressing the circuit pattern toward the thermoplastic resin layer, can provide a printed circuit board and a method for manufacturing the same, in which a fine circuit pattern can be formed by an inkjet method and the adhesive force between the circuit pattern and the base substrate can be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

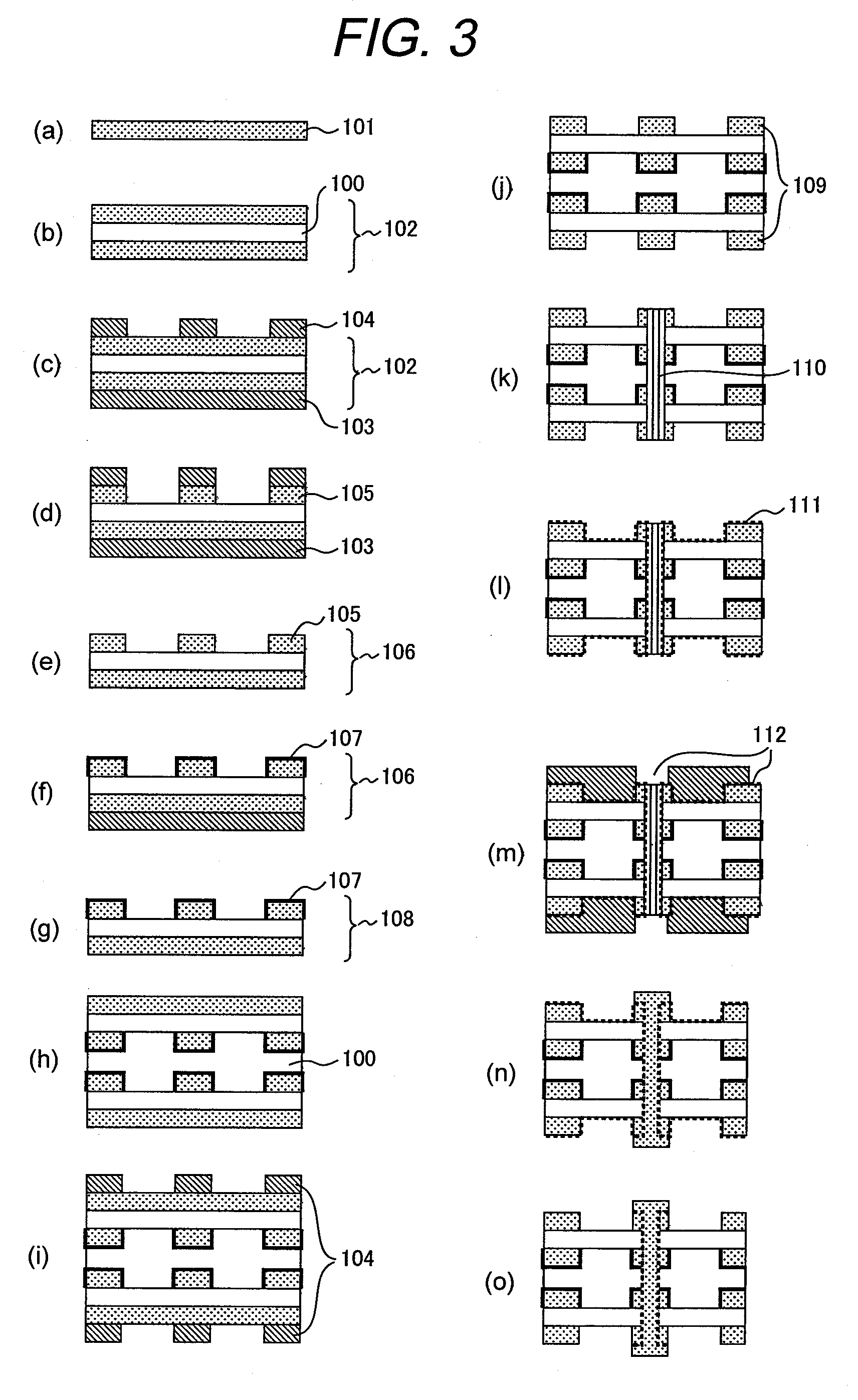

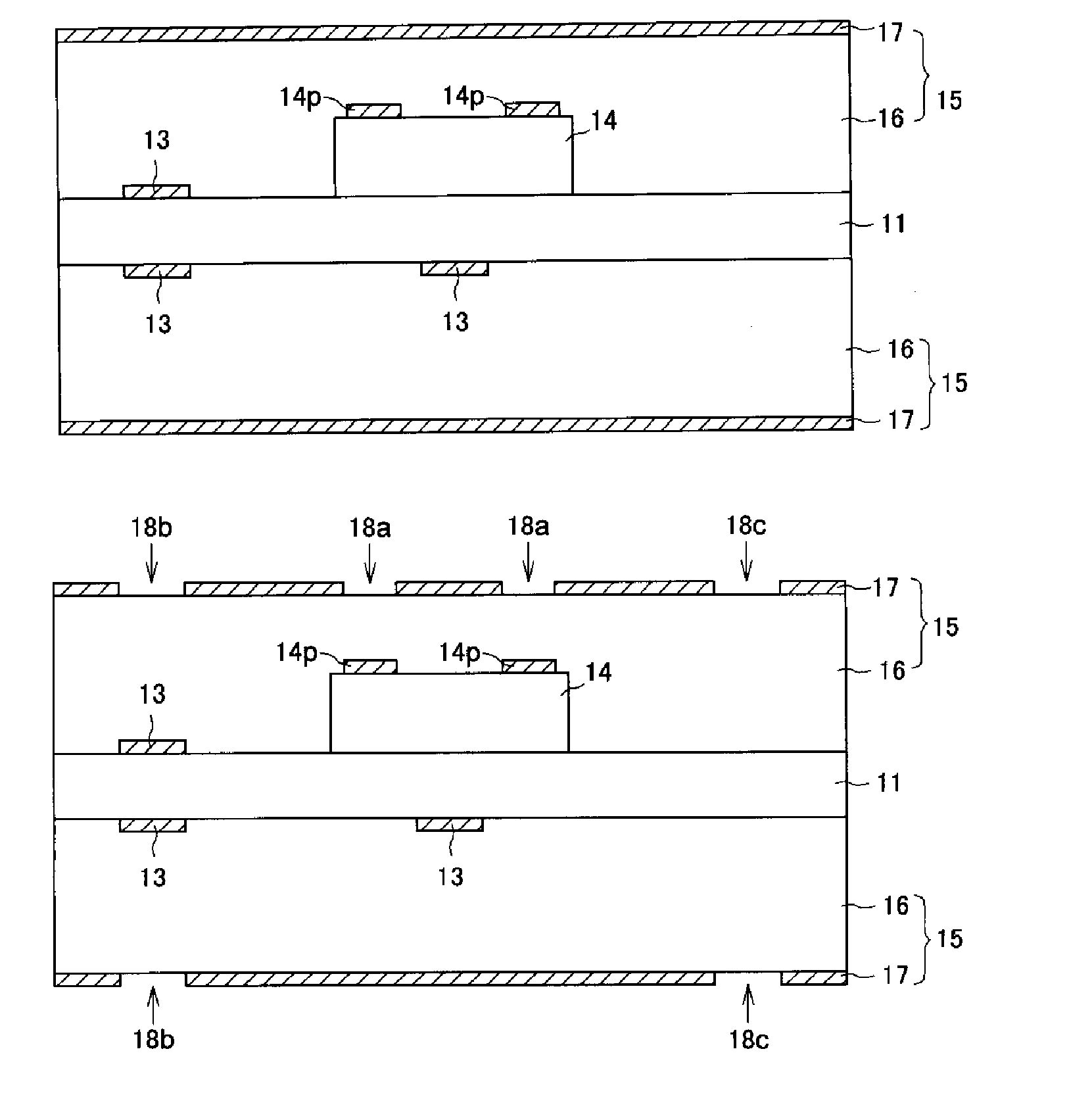

Method for manufacturing ic-embedded substrate

ActiveUS20070141759A1Increase productivityExpand the number of processesPrinted circuit assemblingElectrically conductive connectionsMaterials scienceIntegrated circuit

A method for manufacturing an IC-embedded substrate comprises a first step for encapsulating at least an IC chip having a pad electrode in an insulating layer, a second step for forming a metal layer having at least a first aperture in a location directly above the pad electrode of the IC chip and a second aperture in a location above an area other than the area in which the IC chip is mounted, and a third step for selectively removing the insulating layer by a blasting treatment in which the metal layer is used as a mask, whereby forming a first via hole that corresponds to the first aperture and a second via hole that corresponds to the second aperture.

Owner:TDK CORPARATION

Wiring board and light emitting device

ActiveUS20140264417A1Adhesive strengthHigh bonding strengthPrinted circuit aspectsSolid-state devicesReflective layerSilicon dioxide

Owner:SHINKO ELECTRIC IND CO LTD

Multilayered anisotropic conductive adhesive for fine pitch

InactiveUS7081675B2Stably and reliably connecting drive ICLow costLiquid crystal compositionsSemiconductor/solid-state device detailsAnisotropic conductive adhesiveEngineering

Provided is an anisotropic conductive adhesive for a fine pitch having a conductive adhesive layer and a nonconductive adhesive layer formed on one surface or both surfaces of the conductive adhesive layer. The anisotropic conductive adhesive for a fine pitch can be used to adhere an integrated circuit, on which a plurality of bumps each having a second height are formed, to a substrate, on which a plurality of electrodes each having a first height are formed keeping predetermined distances from each other, so that the integrated circuit is electrically connected to the electrodes. The anisotropic conductive adhesive includes a nonconductive first adhesive layer and a second adhesive layer. The nonconductive first adhesive layer includes a thermosetting resin and a hardener for hardening the thermosetting resin and has a first thickness of ½– 3 / 2 of the second height. The second adhesive layer includes a thermosetting resin, a hardener for hardening the thermosetting resin, and a plurality of conductive particles each having an average particle diameter of ½ or less of the width of gaps between the plurality of electrodes and a first density dispersion, has a second thickness larger than two times the average particle diameter of the conductive particles, and is formed on one surface of the nonconductive first adhesive layer.

Owner:TELEPHUS

Secondary battery of excellent sealability

ActiveUS20060216594A1High bonding strengthIncrease surface areaNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesElectric vehicleUltimate tensile strength

Disclosed herein is a secondary battery comprising electrode leads mounted in a sealed fashion in a battery case while the electrode leads partially protrude from the battery case and resin films disposed between the battery case and the electrode leads wherein the electrode leads are provided at predetermined areas of the surfaces thereof, to which the resin films are applied, with irregular parts, by which the adhesive strength between the electrode leads and the resin films is increased. The adhesive strength between the electrode leads and the resin films is large, and the movement path of moisture or electrolyte, through which the moisture contained in the air or the electrolyte contained in the secondary battery may move, is extended. Consequently, the present invention has the effect of minimizing the reduction in service life of the secondary battery due to introduction of the moisture into the secondary battery and leakage of the electrolyte from the secondary battery. The secondary battery is very useful as a unit cell for medium- or large-sized battery systems, such as hybrid electric vehicles.

Owner:LG ENERGY SOLUTION LTD

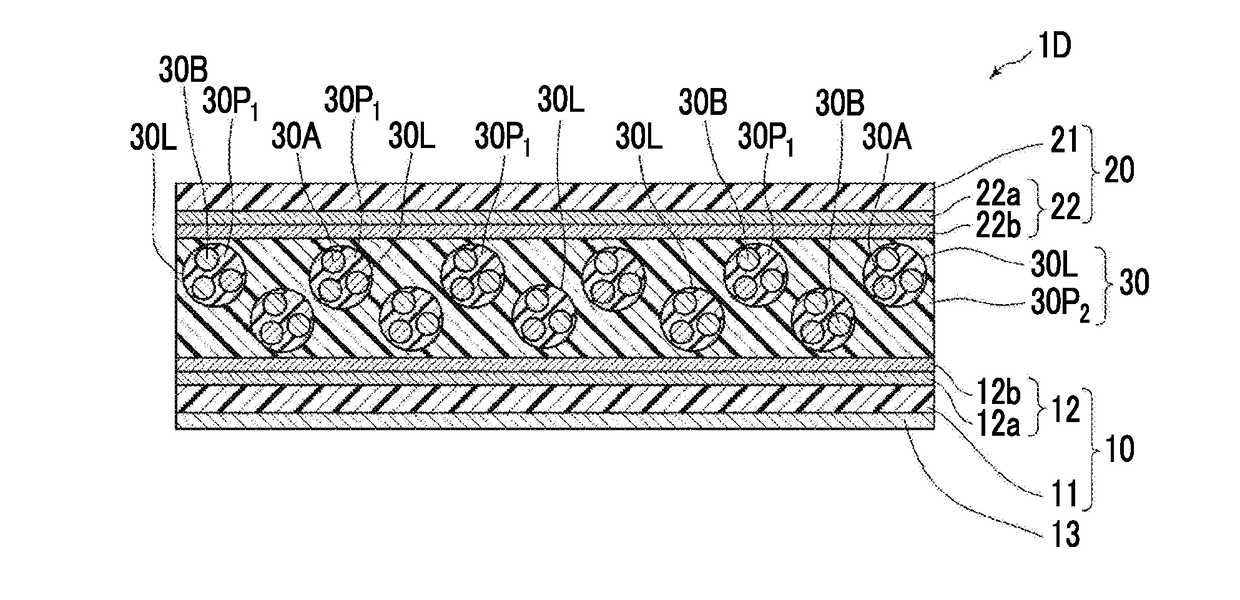

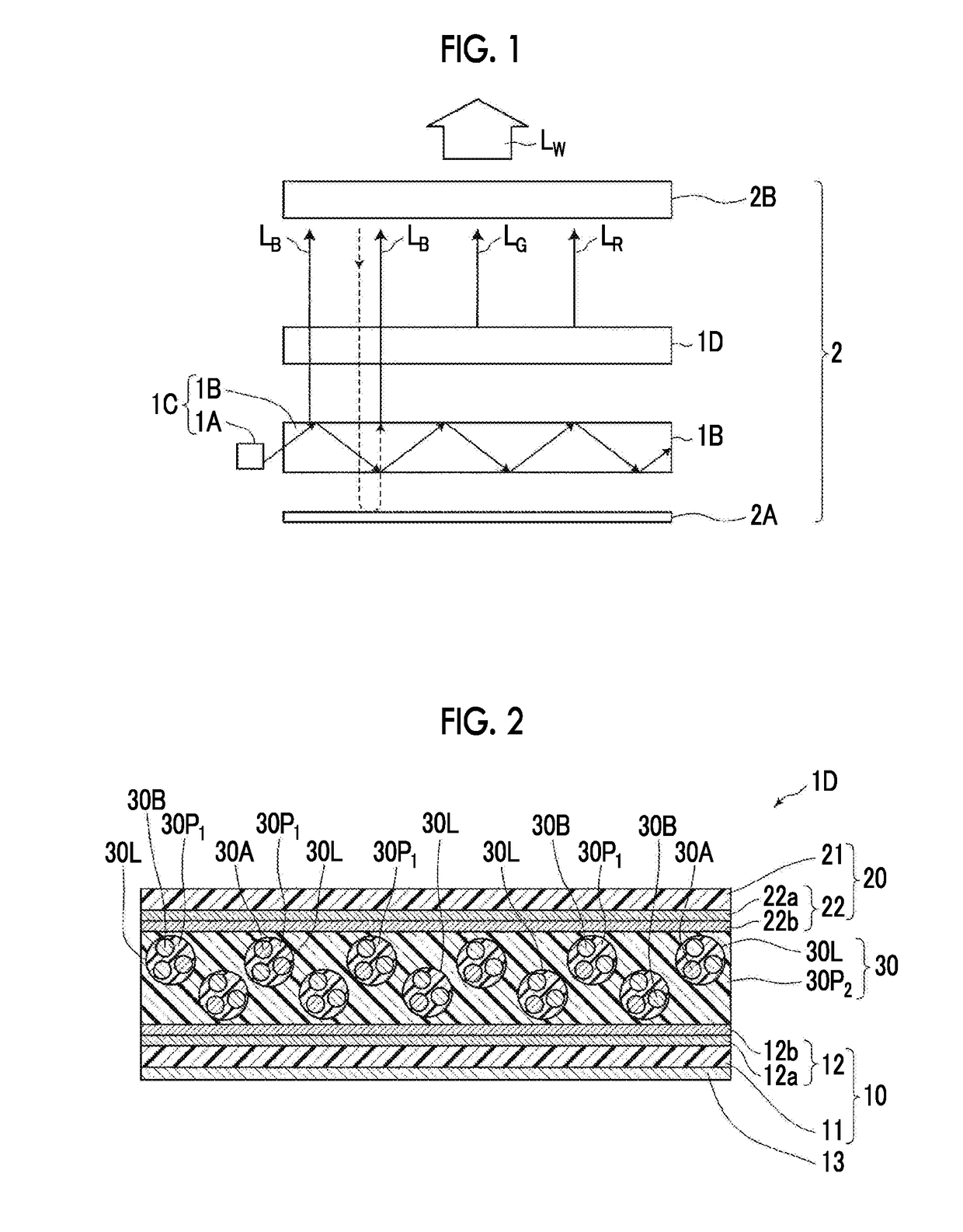

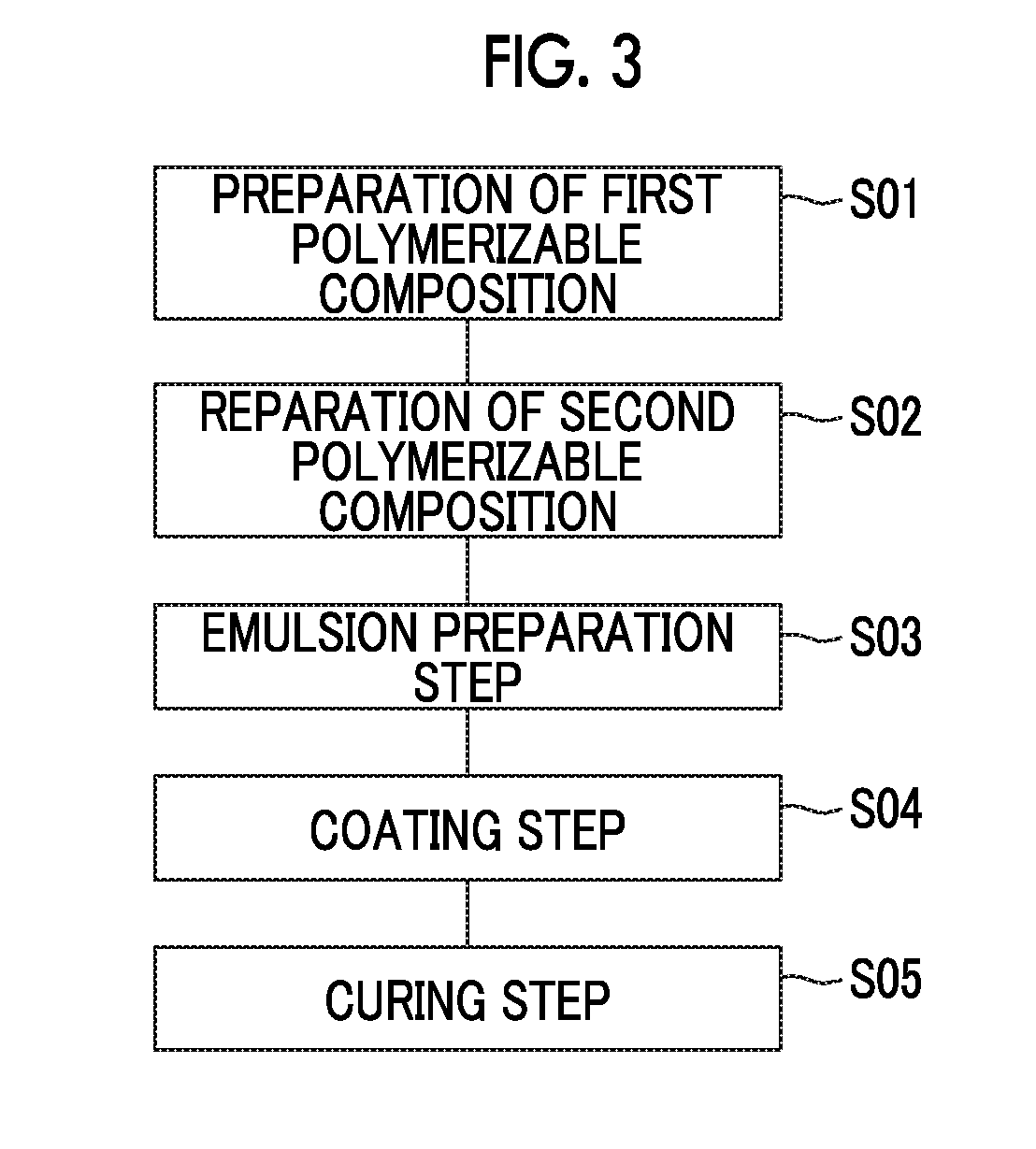

Wavelength conversion member, backlight unit, and liquid crystal display device

ActiveUS20170277002A1Increase contentEmission reductionMechanical apparatusOptical articlesLiquid-crystal displayQuantum dot

The invention provides a wavelength conversion member including a wavelength conversion layer which includes a second cured product and a first cured product dispersed as spheres in the second cured product, the first cured product being obtained by curing a first polymerizable composition including a quantum dot and a first polymerizable compound, and the second cured product being obtained by curing a second polymerizable composition including a second polymerizable compound. The invention further provides a backlight unit and a liquid crystal display device including the wavelength conversion member.

Owner:FUJIFILM CORP

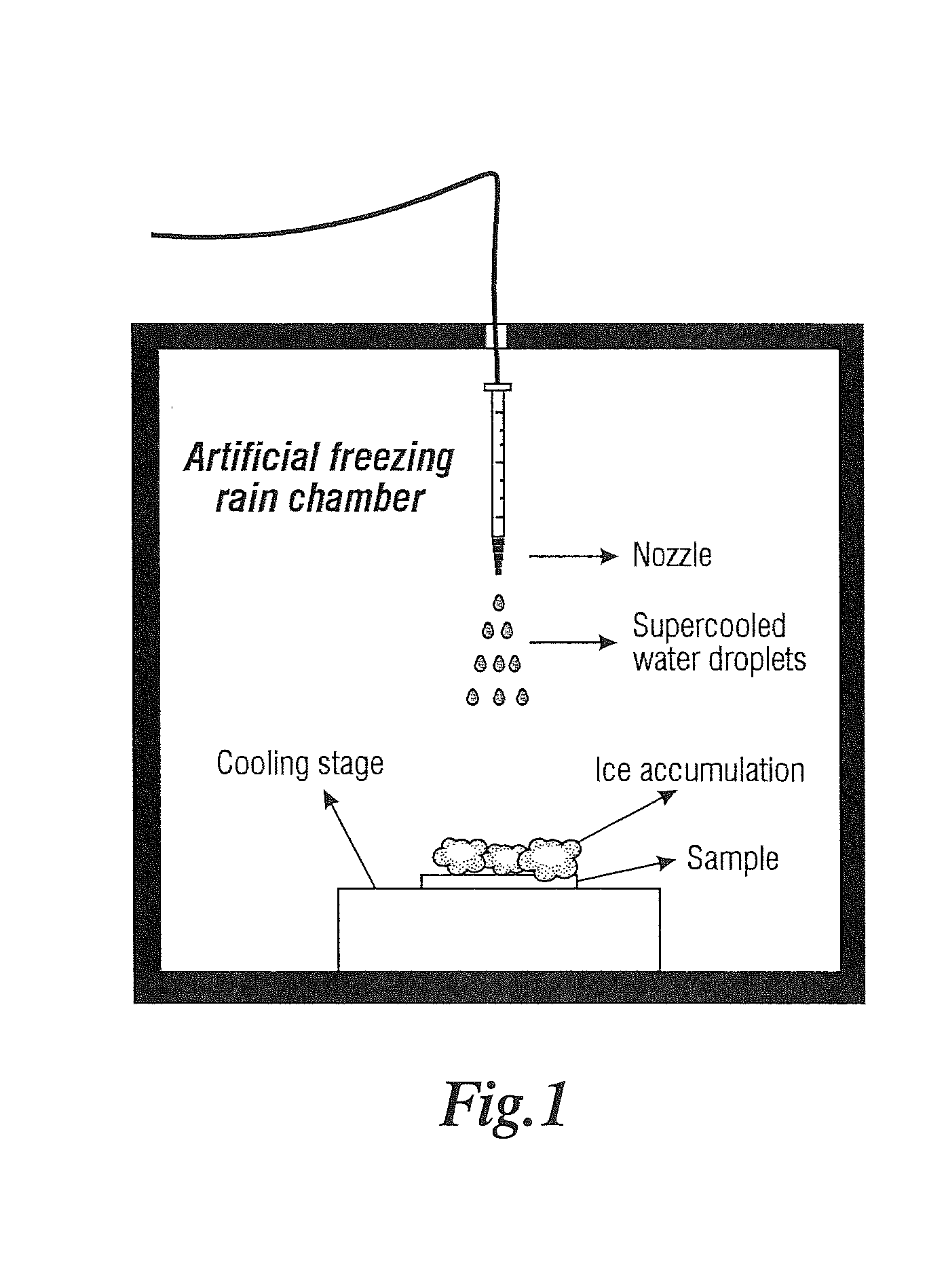

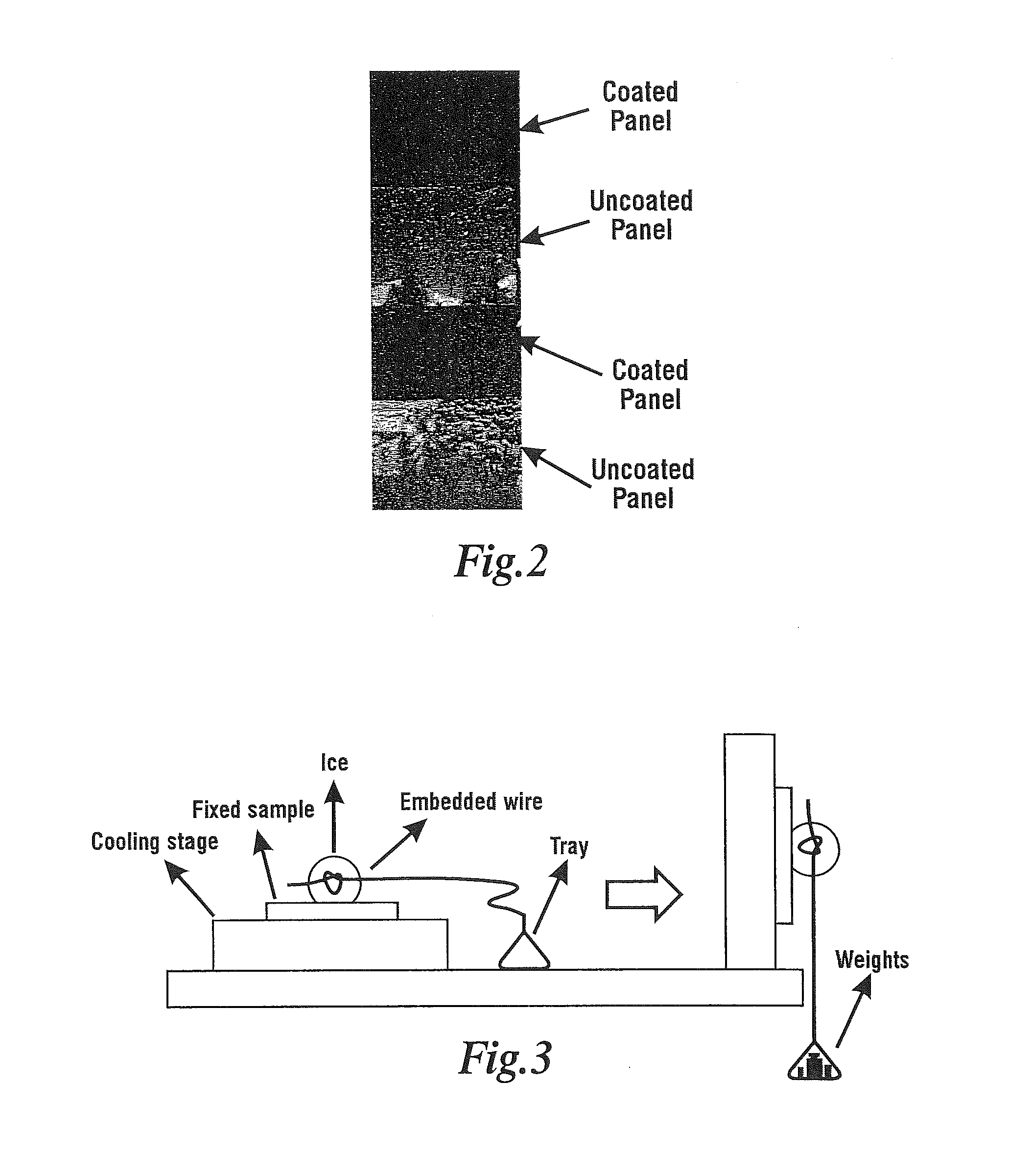

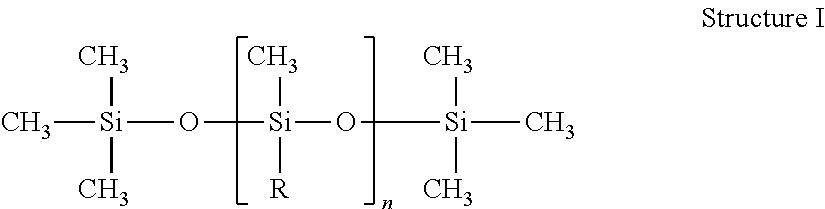

Compositions for prevention of ice build-up

ActiveUS20150361319A1Adhesive strengthPrevent freezingOther chemical processesCoatingsCross-linkAryl

A composition comprising a silicone oil or fluorosilicone fluid infused in a cross-linked silicone resin matrix. The silicone oil or fluorosilicone fluid may comprise a linear or branched polymeric siloxane that may be functionalized with one or more of: alkyl, fluoroalkyl, aryl, benzyl, halo, hydride, hydroxyl, -alkyl-OH, -alkyl-SH, halo, -aryl-halogen, -alkyl-COOH, -alkyl(COOH)-alkyl-COO-alkyl, alkenyl, vinyl, -alkyl-acryloyl, -alkylamino, -alkyl-NH-alkyl-NH2, -alkyl-OOC—NH-alkyl-NCO, -alkyl-O-oxiranyl, monofluoromethyl, difluoromethyl, trifluoromethyl, or alkeneoxide co-polymer.

Owner:UNIVERSITY OF PITTSBURGH

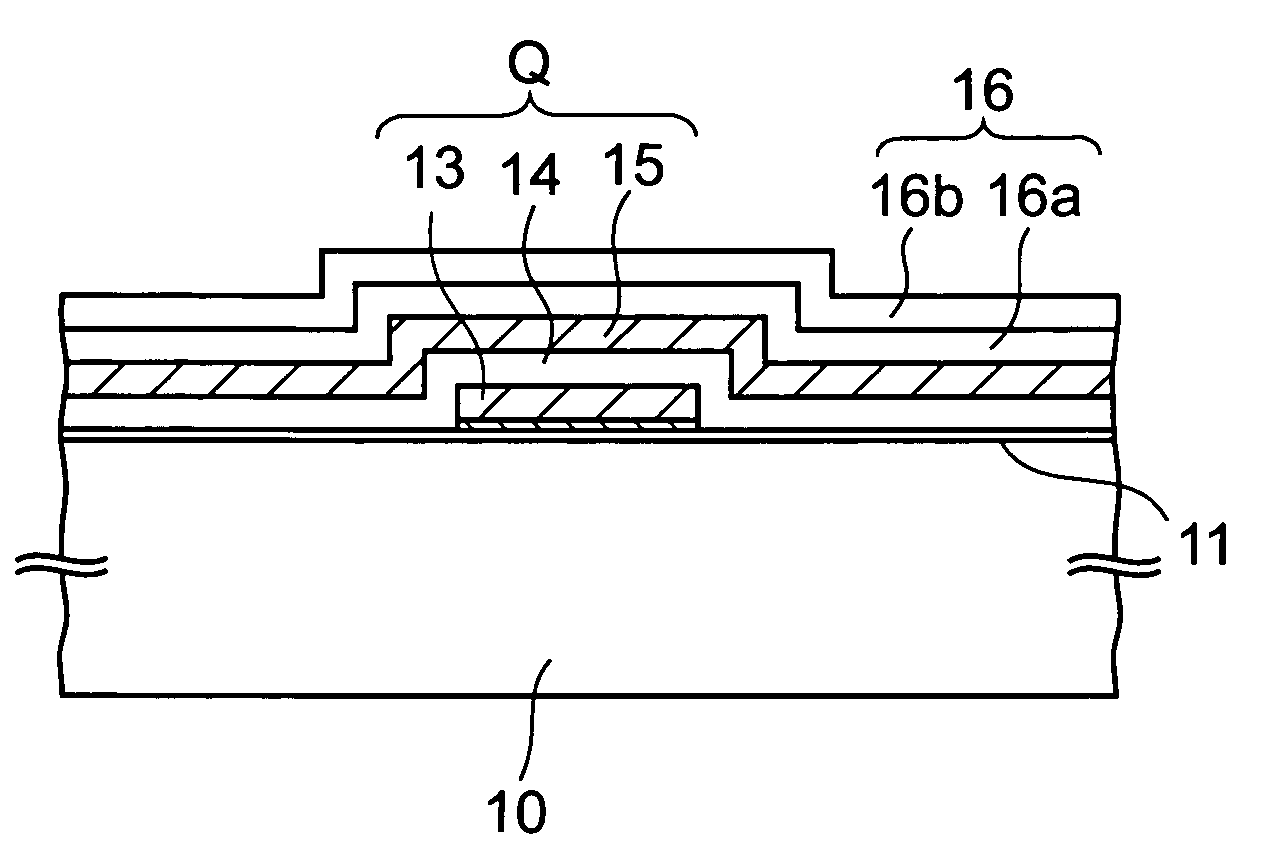

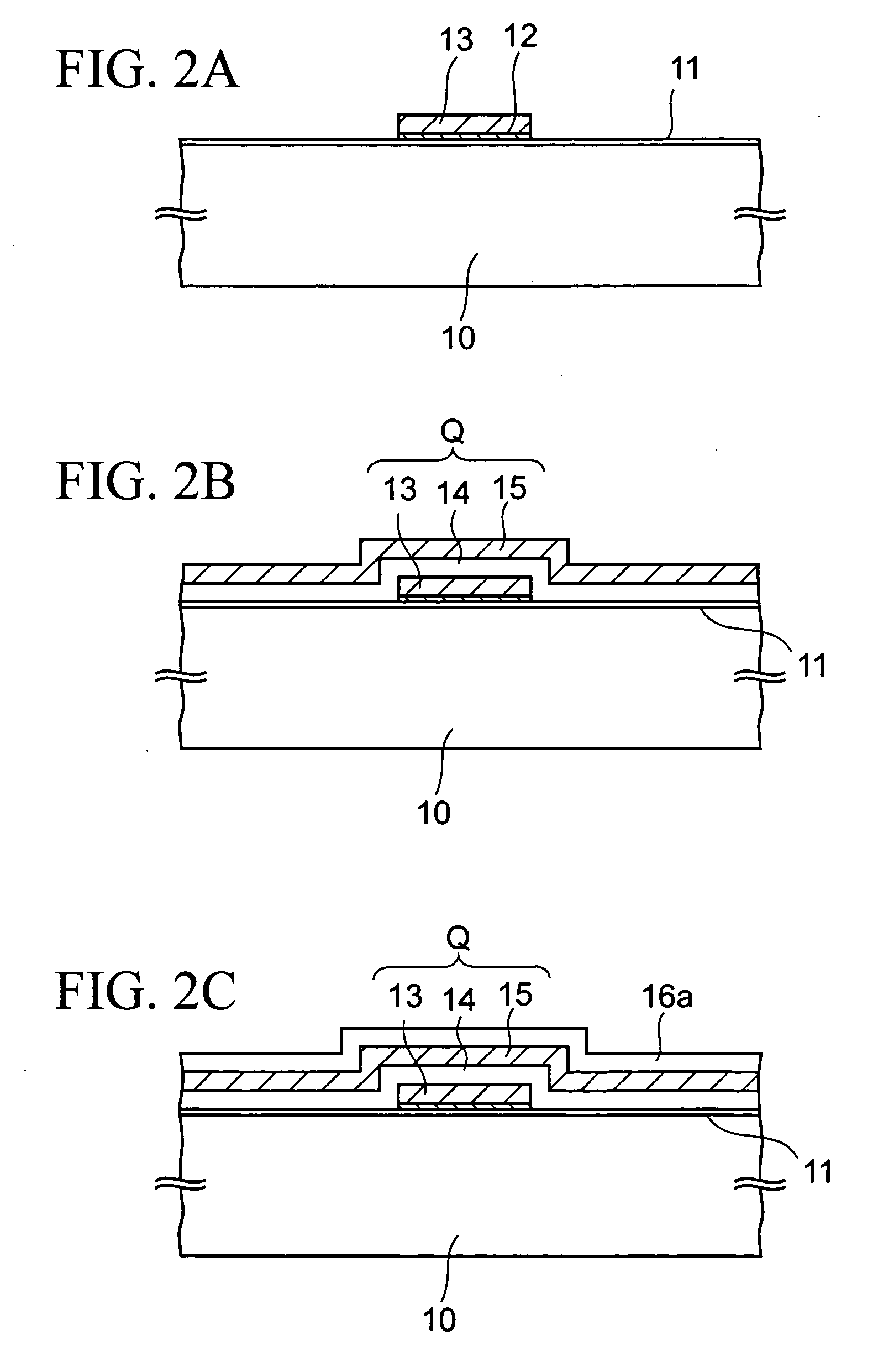

Capacitive element, semiconductor device, and method of manufacturing the capacitive element

InactiveUS20060211212A1Prevent peelingImprove protectionTransistorSolid-state devicesCapacitanceDielectric

A capacitive element includes a base member 10, an underlying insulating film 11 formed on the base member 10, a capacitor Q constructed by forming a lower electrode 13, a capacitor dielectric film 14, and an upper electrode 15 sequentially on the underlying insulating film 11, a lower protection insulating film 16a formed on the upper electrode 15 to cover at least a part of the capacitor Q, and an upper protection insulating film 16b formed on the lower protection insulating film 16a and having a wider energy band gap than the lower protection insulating film 16a.

Owner:FUJITSU LTD

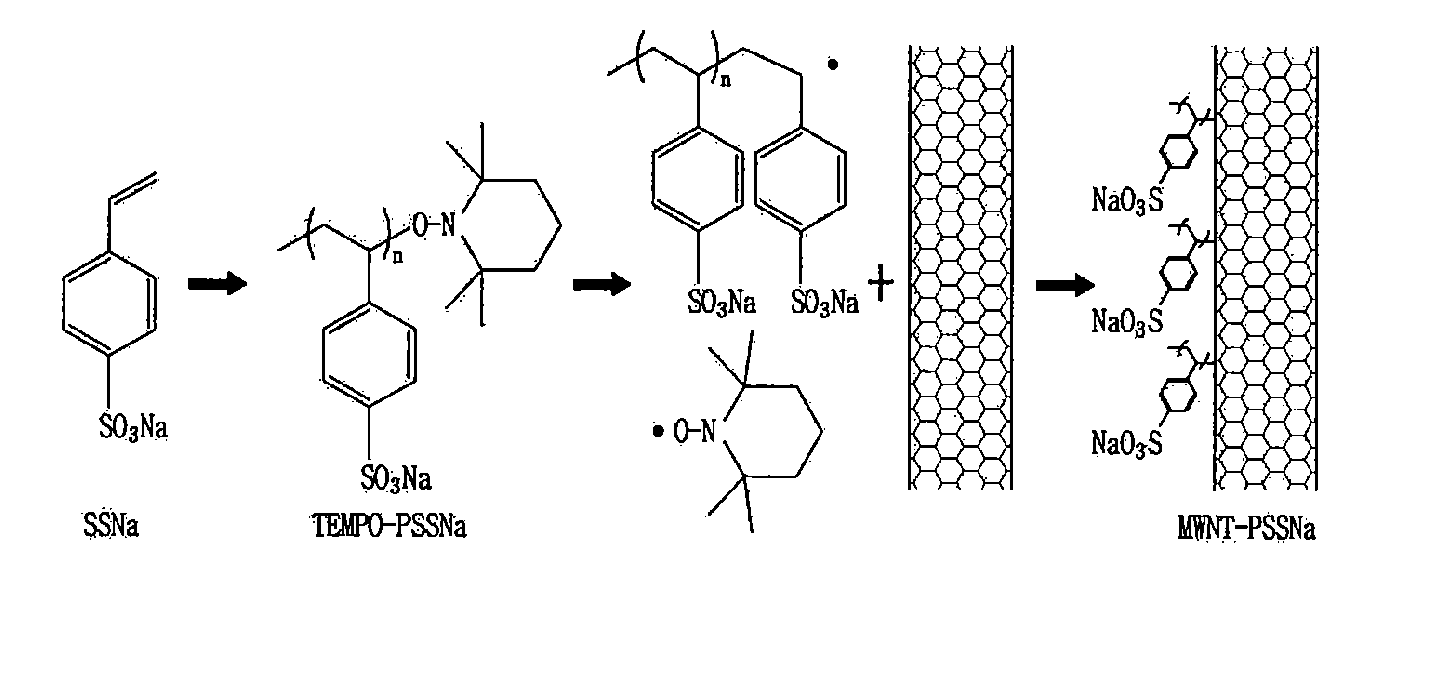

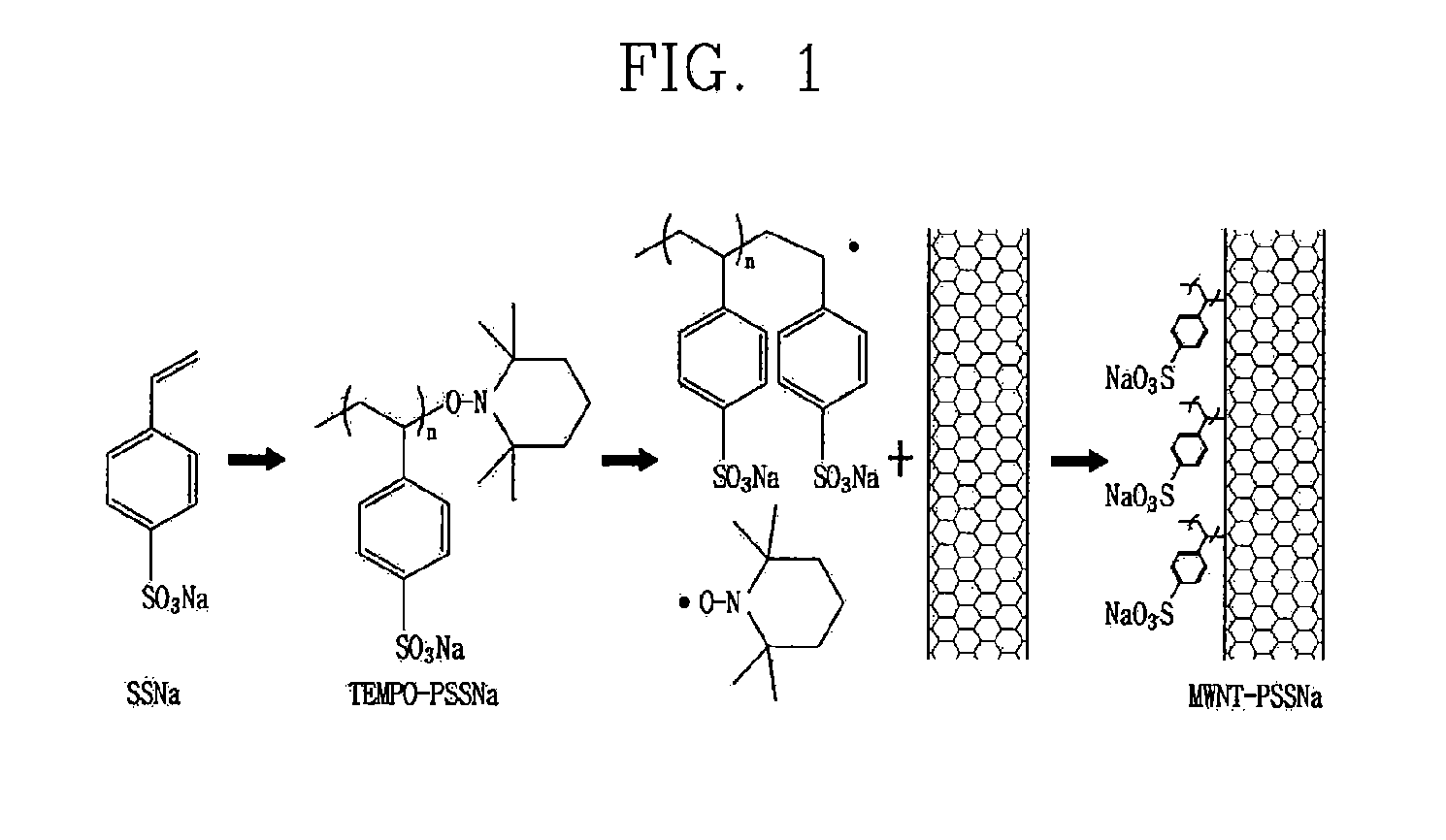

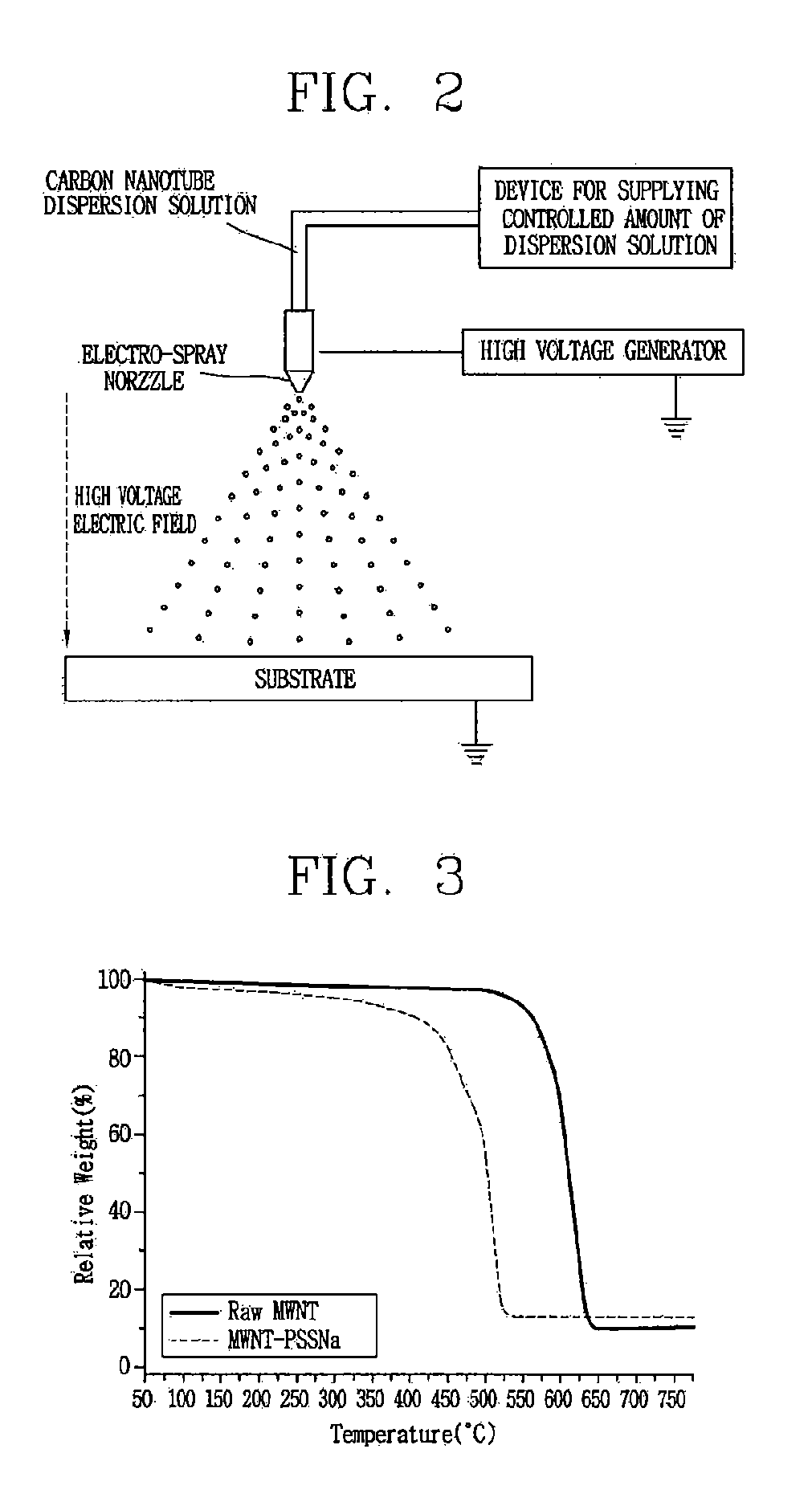

Modified carbon nanotube grafted by living polymer, carbon nanotube electrode and dye-sensitized solar cell using the same, and each preparation method thereof

InactiveUS20100084007A1Minimizing lowering of physical propertyGood dispersionMaterial nanotechnologyElectrolytic capacitorsEnd-groupElectro spray

Disclosed are to provide a modified carbon nanotube obtained by reacting a polymer to a carbon nanotube by a radical graft method, capable of minimizing lowering of a physical property of a carbon nanotube caused when being modified, and capable of enhancing dispersibility of the carbon nanotube and an adhesion strength between carbon nanotubes, the polymer having a molecular weight controlled by a living radical polymerization and still having a living radical end group.Also disclosed are to provide a carbon nanotube electrode and a dye-sensitized solar cell using the same, capable of forming a carbon nanotube film having a thickness thinner than that of the conventional electrode by directly spraying, on a substrate, by an electro-spray process, a uniform dispersion solution that the modified carbon nanotube is dispersed in a proper solvent without requiring an additional organic binder, capable of exhibiting an excellent catalytic characteristic owing to a close adhesion strength between carbon nanotubes and an increased relative density of the carbon nanotube film, and capable of implementing an excellent long-term stability owing to a strong bonding force between a carbon nanotube and a substrate.

Owner:KOREA INST OF SCI & TECH

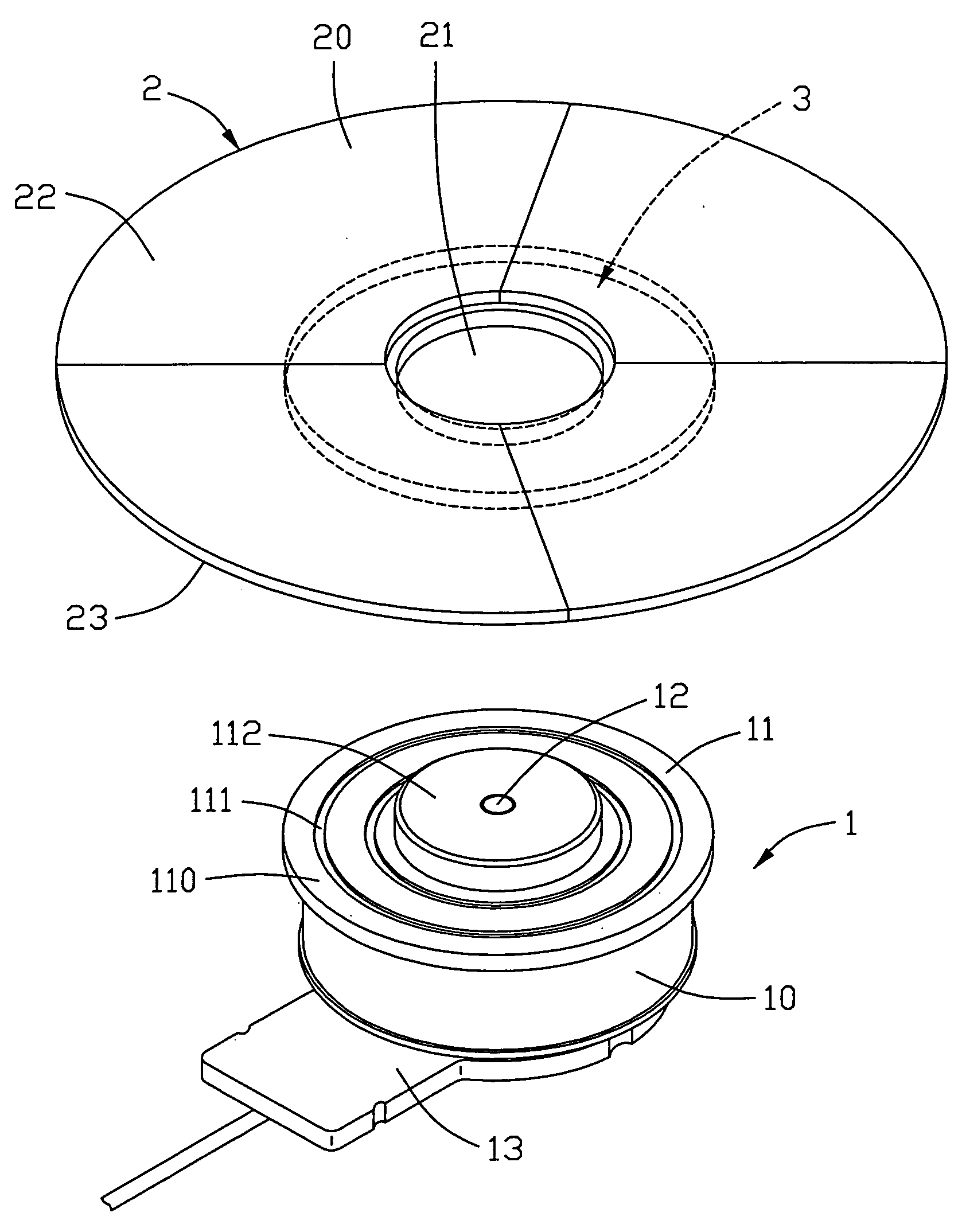

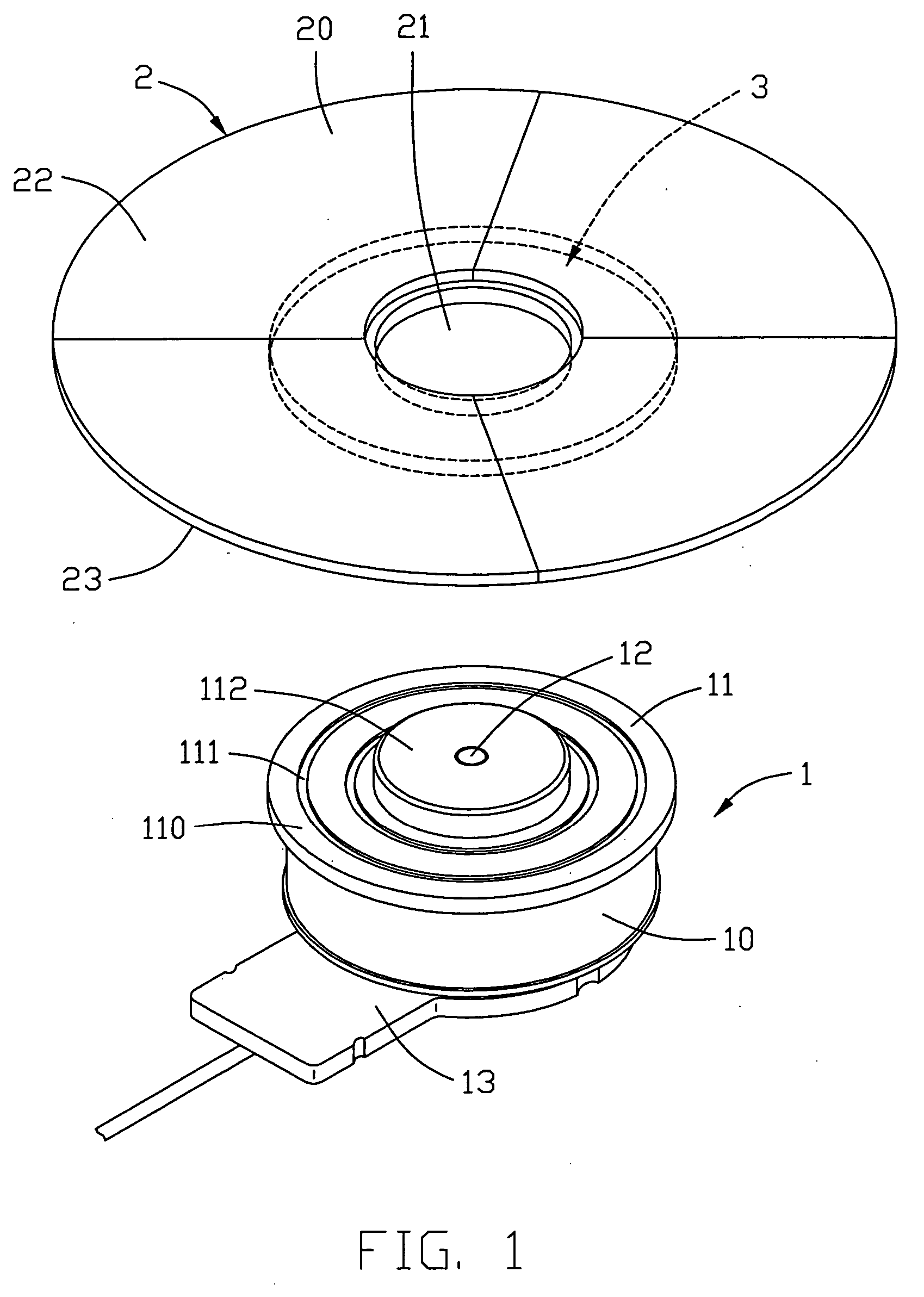

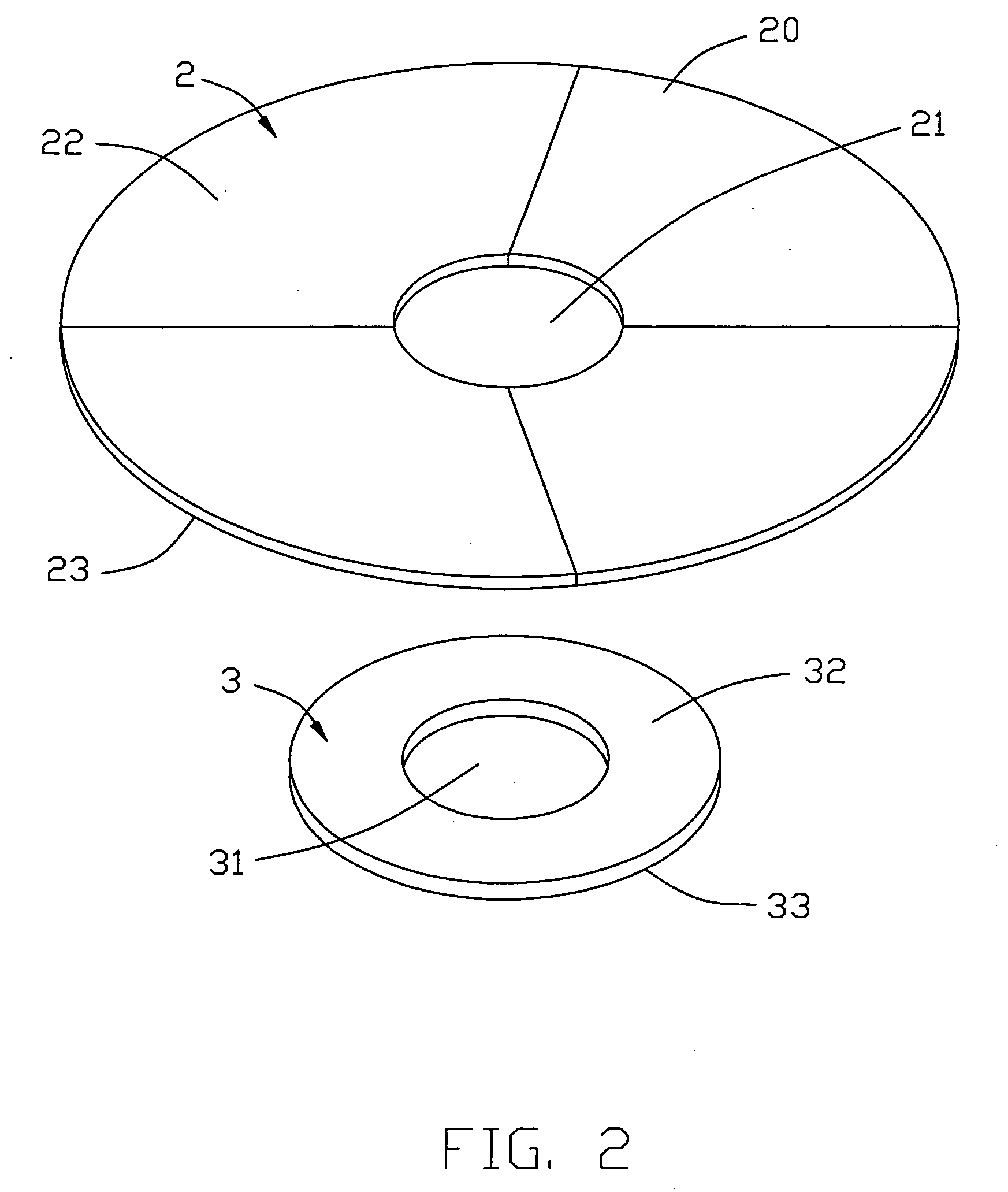

Color wheel and its manufacturing method

InactiveUS20060126199A1Reduce riskSolve the real problemProjectorsColor television detailsColor wheelRotating disc

A color wheel, for use in a Digital Light Processing (DLP), capable of preventing a color filter from escaping away is disclosed. The color wheel includes a motor having a spindle to which a rotating disc is mounted, and a filter element mounted to the rotating disc. The filter element includes a filter ring comprising a plurality of sectors having radially extending edges jointed to each other and forming a joint line between jointed edges, and a positioning ring coaxially mounted to the filter ring to hold the sectors together, the positioning ring being positioned on and fixed to the rotating disc and interposed between the filter ring and the rotating disc to fix the filter ring to the rotating disc.

Owner:ASIA OPTICAL CO INC

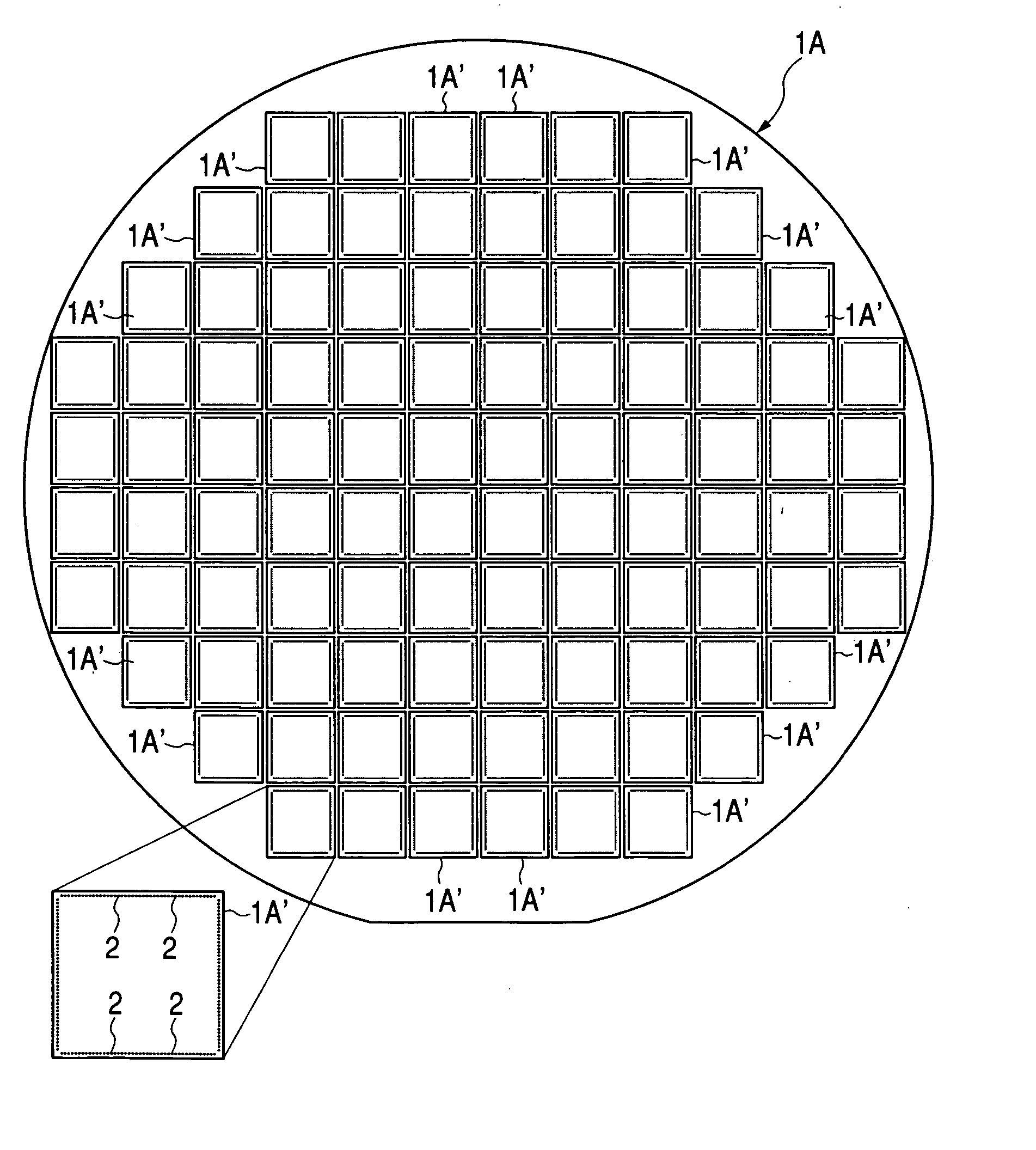

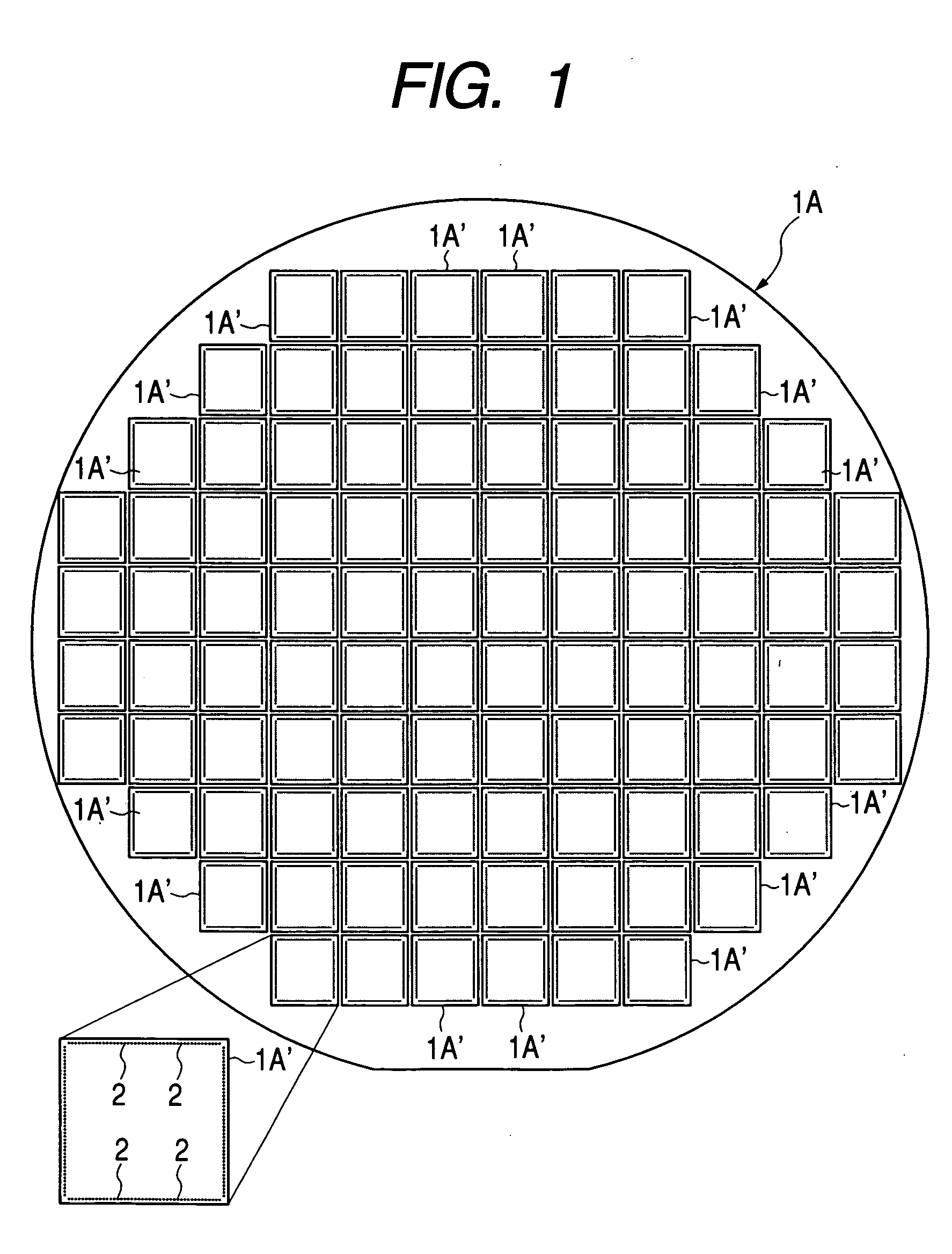

Method of manufacturing a semiconductor device

ActiveUS20050009299A1Reduced strengthAdhesive strengthSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialSemiconductor chip

The present invention provides a manufacturing method of a semiconductor device which can speedily peel extremely thin chips which are laminated to an adhesive tape without generating cracks or chippings. A head of a vibrator is brought into contact with a back surface of an adhesive tape to which a plurality of semiconductor chips obtained by dividing a semiconductor wafer are laminated. By applying longitudinal vibrations having a frequency of 1 kHz to 100 kHz and an amplitude of 1 μm to 50 μm, the chip is peeled from the adhesive tape. In applying the longitudinal vibrations to the adhesive tape, a tension in a horizontal direction is applied to the adhesive tape.

Owner:RENESAS ELECTRONICS CORP +1

Copper gate electrode of liquid crystal display device and method of fabricating the same

ActiveUS20060138659A1Improve electrical performanceAdhesive strengthSemiconductor/solid-state device detailsSolid-state devicesRheniumLiquid-crystal display

A copper gate electrode, applied in a thin-film-transistor liquid crystal display (LCD) device, at least comprises a patterned copper layer formed on a glass substrate, and a barrier layer formed on the patterned copper layer. The barrier layer comprises at least one of nitrogen and phosphorus, or comprises an alloy formularized as M1M2R wherein M1 is cobalt (Co) or molybdenum (Mo), M2 is tungsten (W), molybdenum (Mo), rhenium (Re) or vanadium (V), and R is boron (B) or phosphorus (P).

Owner:AU OPTRONICS CORP

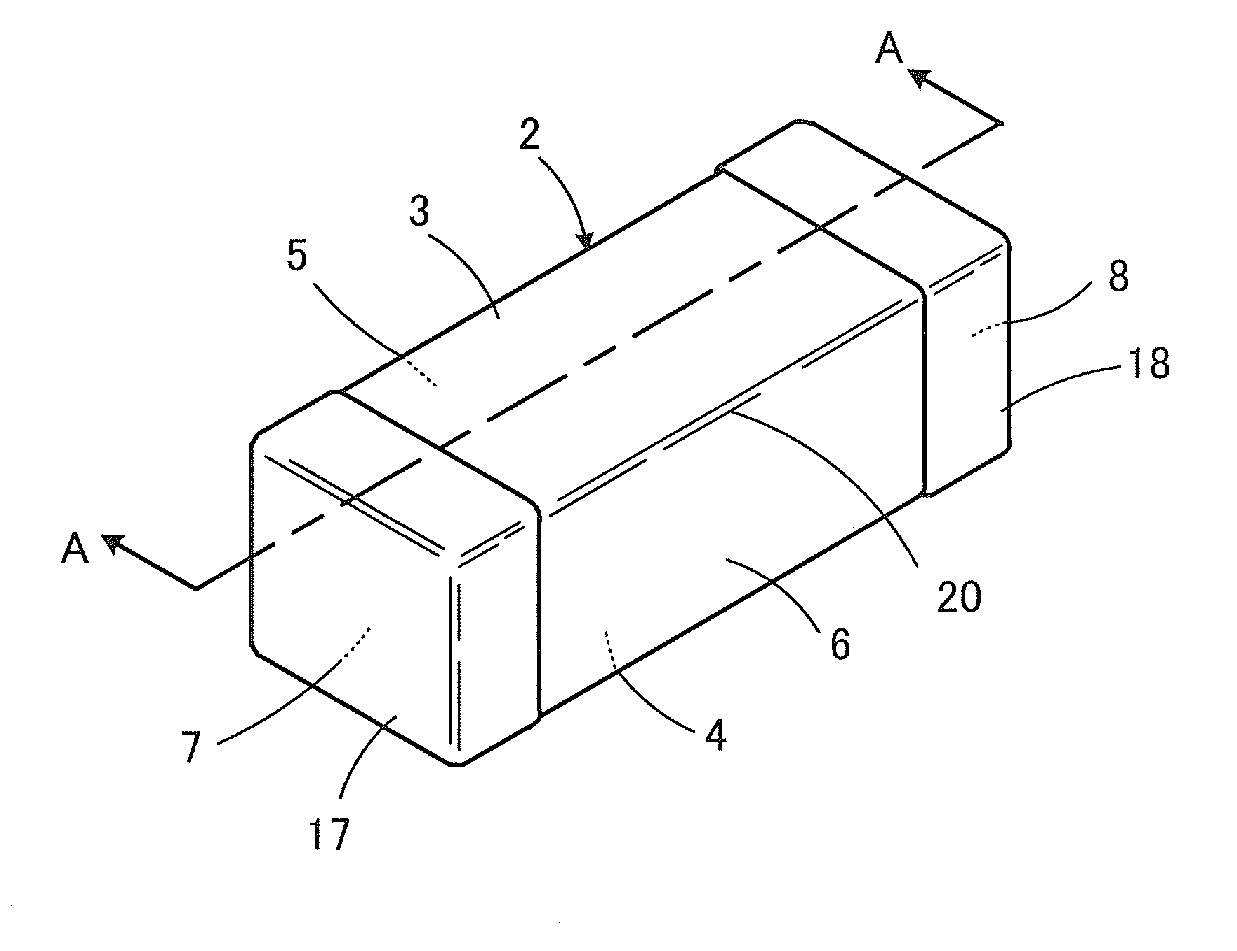

Piezoelectric Actuator

ActiveUS20080007144A1Adhesive strengthFaulty conduction of the external conductor is still further suppressedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorPiezoelectric actuators

A piezoelectric actuator includes external conductors formed on an outer surface of a piezoelectric component. The external conductors each include a thick-film conductor and a conductive reinforcer. The thick-film conductor is provided with a first thick-film conductor formed on the outer surface of the piezoelectric component, second thick-film conductors which are formed on part of an outer surface of the first thick-film conductor and which are in surface-contact with the outer surface of the first thick-film conductor. The conductive reinforcer is attached to outer surfaces of the second thick-film conductors.

Owner:MURATA MFG CO LTD

Sealing resin composition and sealing sheet

ActiveUS20160244590A1Stabilizing luminescence operationEfficiently extract lightSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyHydrotalcite

The present invention aims to provide a resin composition superior in all of resistance to moisture permeability, adhesive strength and transparency. This object is achieved by a resin composition containing 3-38 parts by mass of (B) calcined hydrotalcite, 1-16 parts by mass of (C) talc, and 1-16 parts by mass of (D) silica based on 80 parts by mass of (A) an epoxy resin.

Owner:AJINOMOTO CO INC

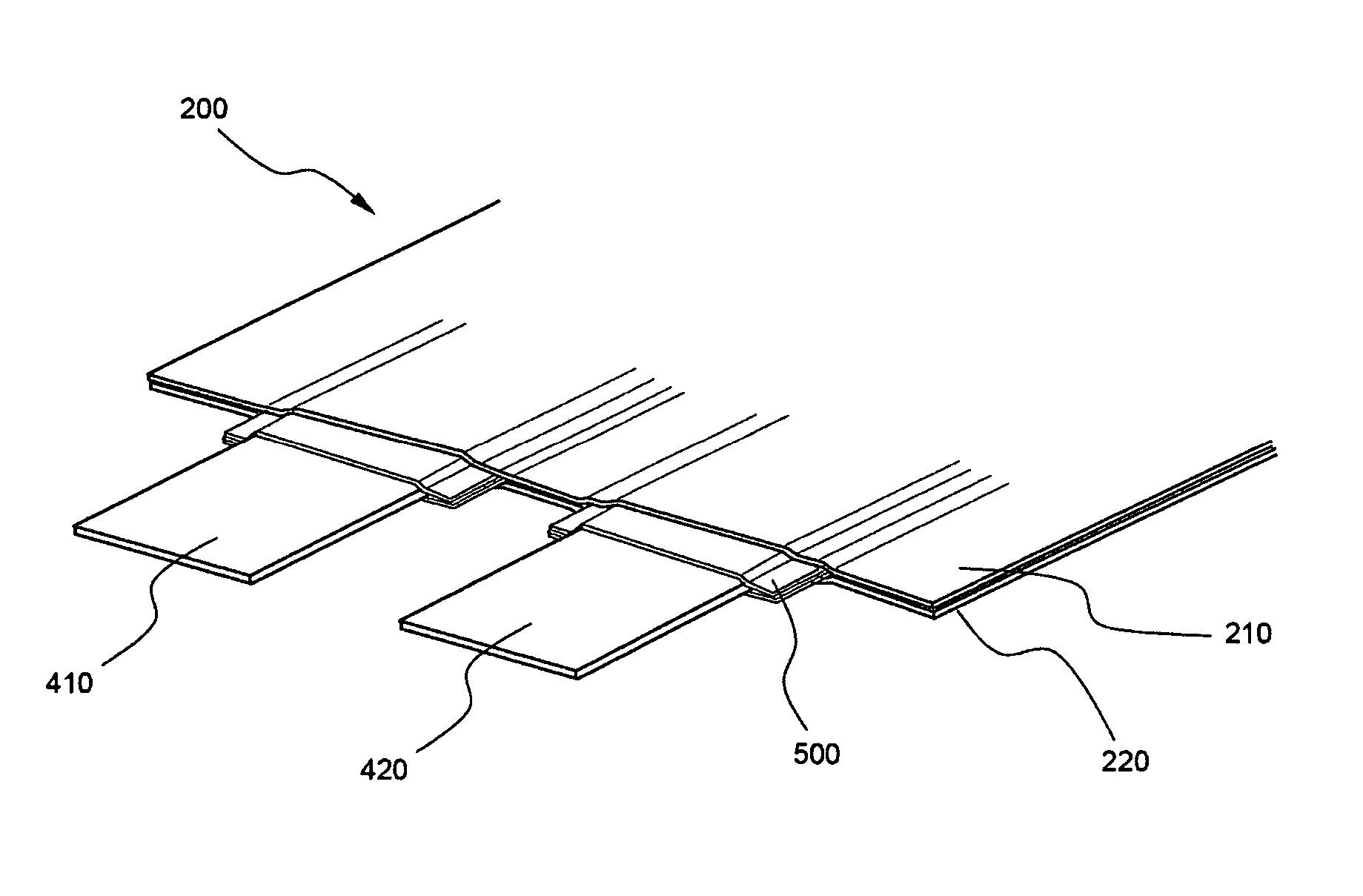

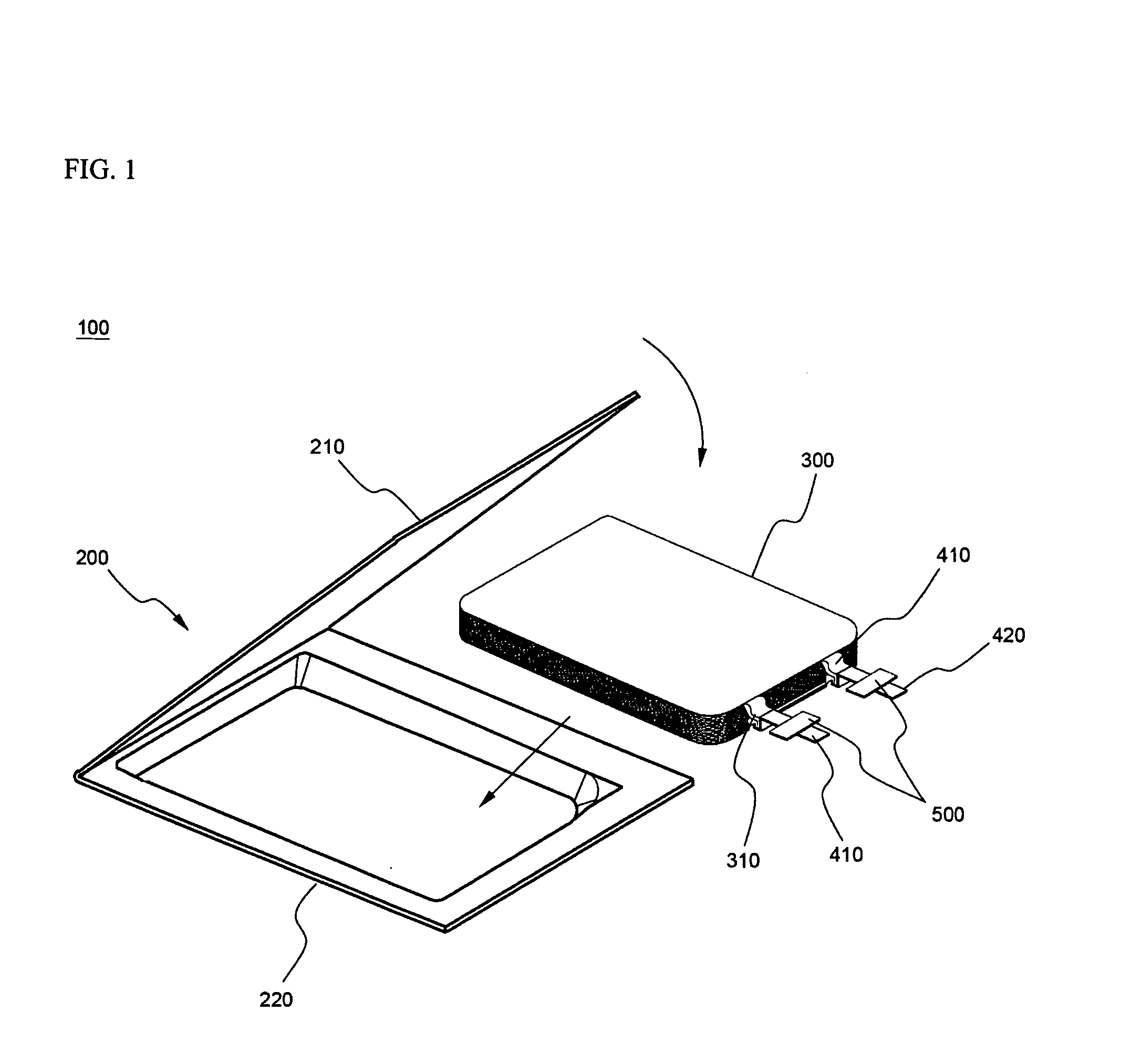

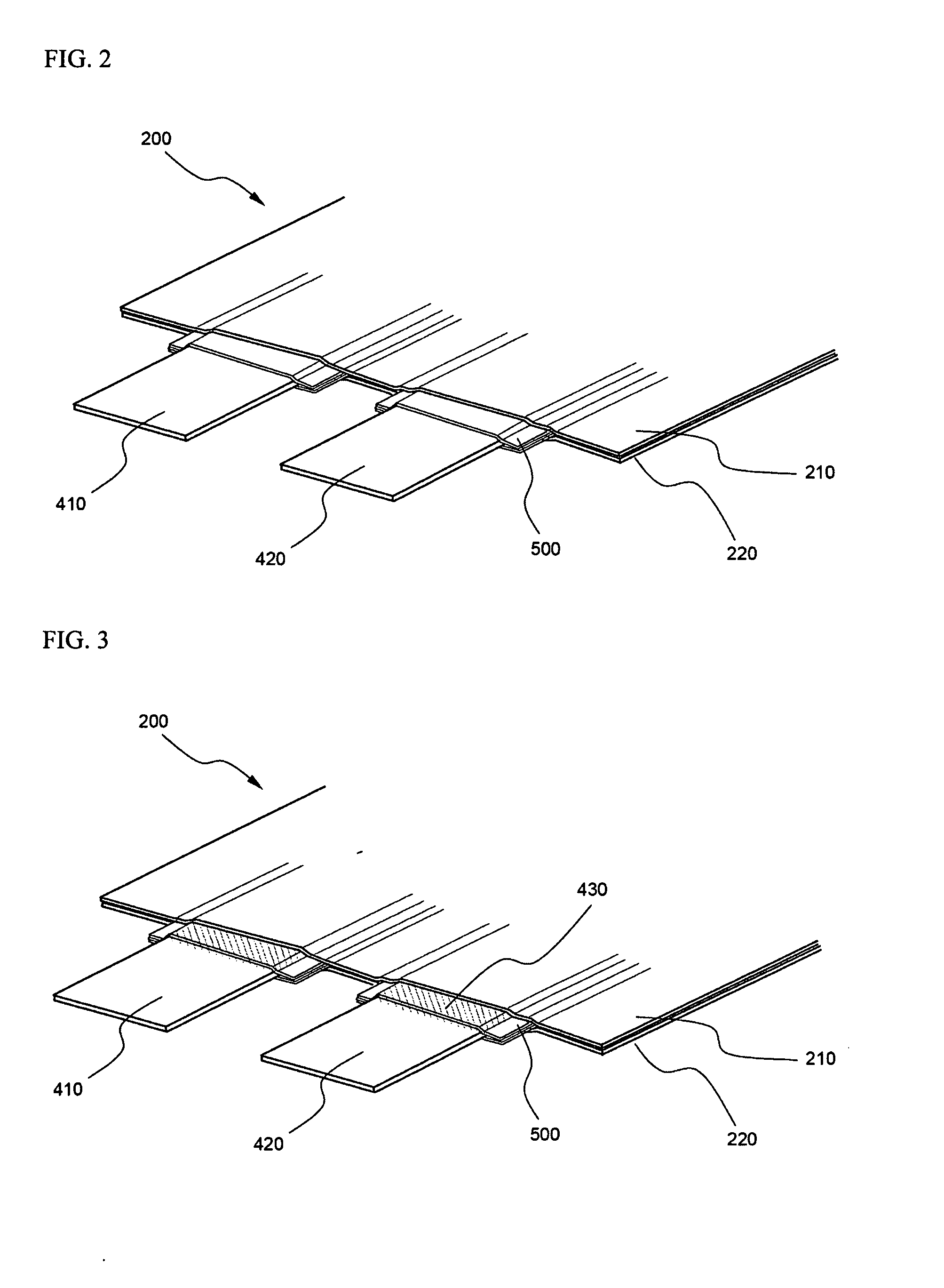

Interconnector and solar cell module having the same

InactiveUS20140261619A1Adhesive strengthHigh bonding strengthNon-insulated conductorsPV power plantsInterconnectorBand shape

An interconnector is discussed, which includes a conductive metal of a band shape including a first surface and a second surface opposite the first surface; and a solder coated on the first surface, wherein the first surface of the conductive metal includes at least a flattened peak extending in a length direction of the conductive metal, the flattened peak including an inclined portion and a flat portion extending in a width direction of the conductive metal, and wherein a length of the inclined portion is less than a length of the flat portion in the width direction of the conductive metal.

Owner:LG ELECTRONICS INC

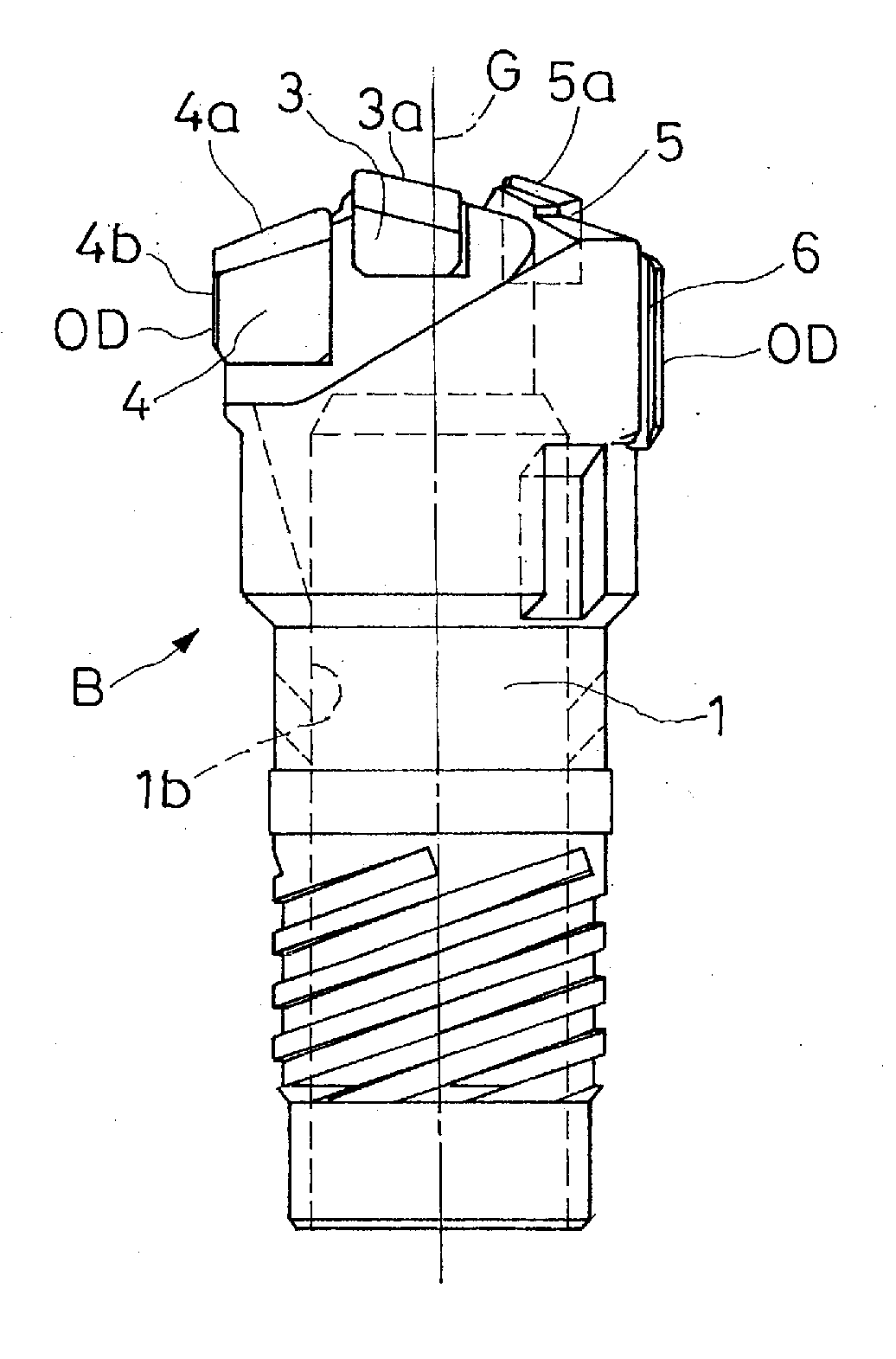

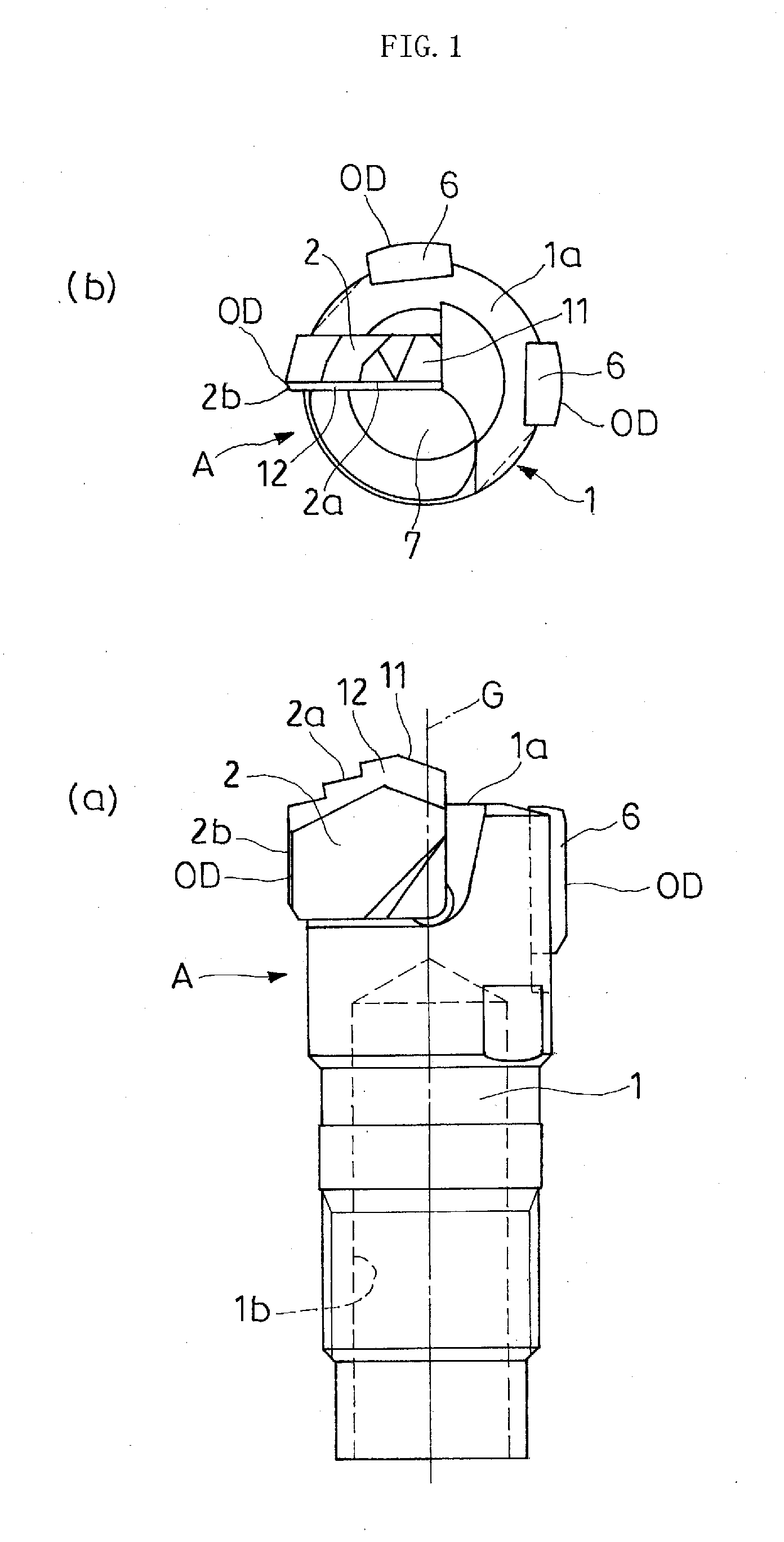

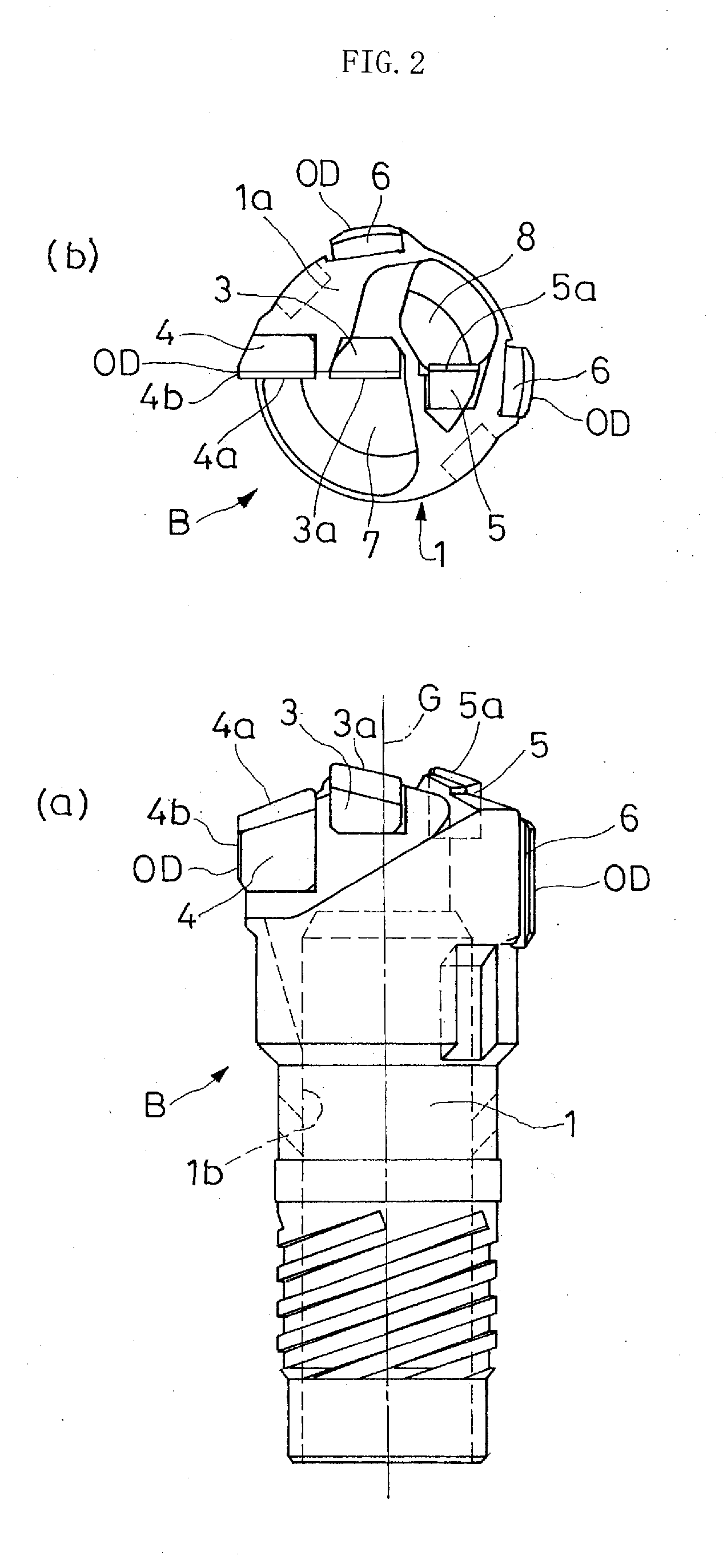

Drill Head Manufacturing Method and Drill Head

InactiveUS20110176878A1Excellent abrasion resistanceImprove heat resistanceDrilling/boring measurement devicesTool workpiece connectionBiomedical engineeringDrill bit

A drill head manufacturing method calls for a cutting tip to be CVD coated, brazed to a distal end of a drill head, polished and then PVD coated. The process effectively utilizes features of a CVD coating, which renders a tool service life longer and enables a drill head more suitable for high-speed cutting to be manufactured. A cutting tip having been CVD coated with a hard material is brazed at a brazing temperature to a predetermined portion at a distal end side of a head main body. An outer diameter portion OD of the brazed tip about a rotation axis of the head main body is polished. Then, the cutting tip and the head main body are PVD coated with a hard material at a second temperature lower than the brazing temperature.

Owner:YUNITAKKU

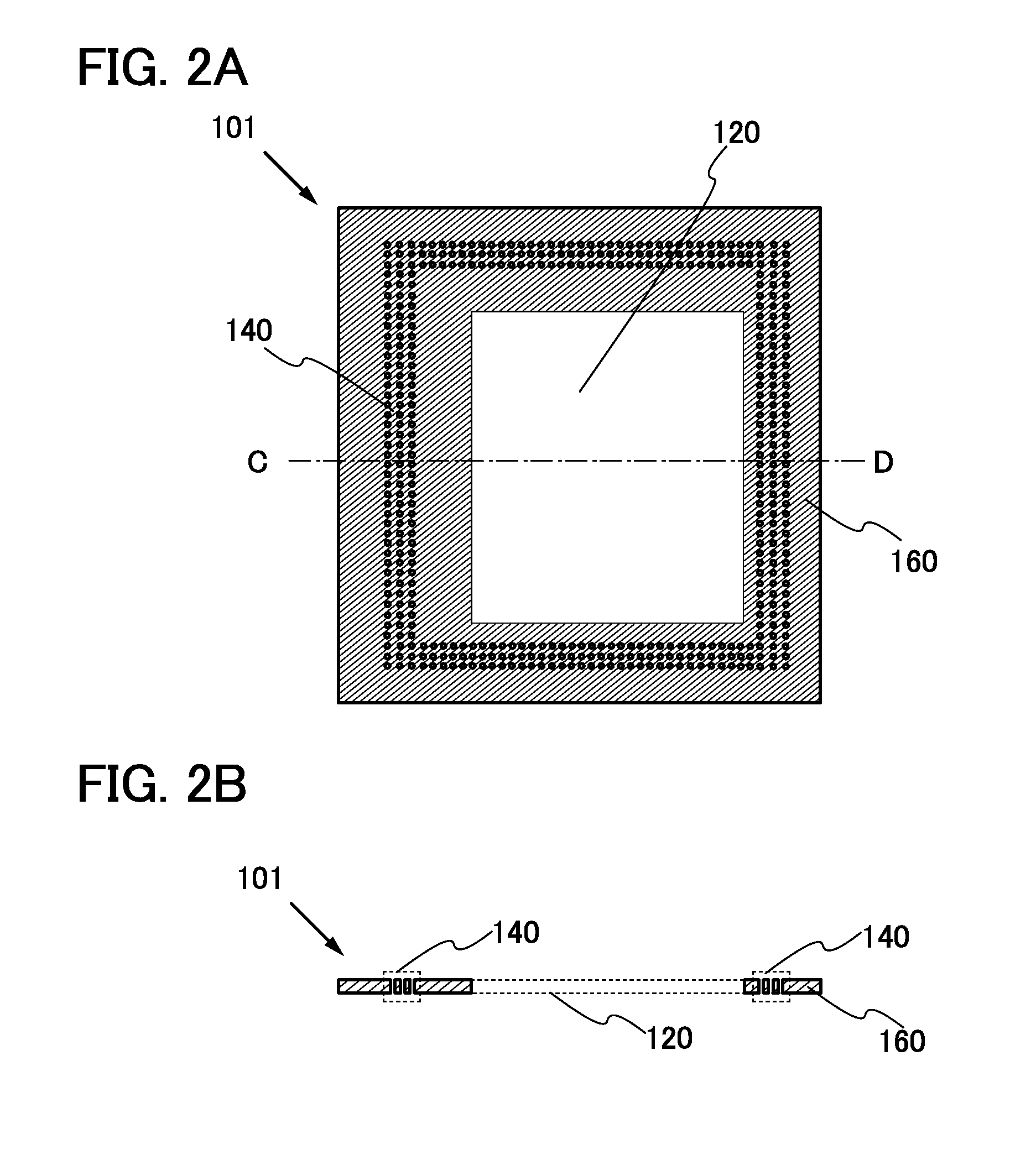

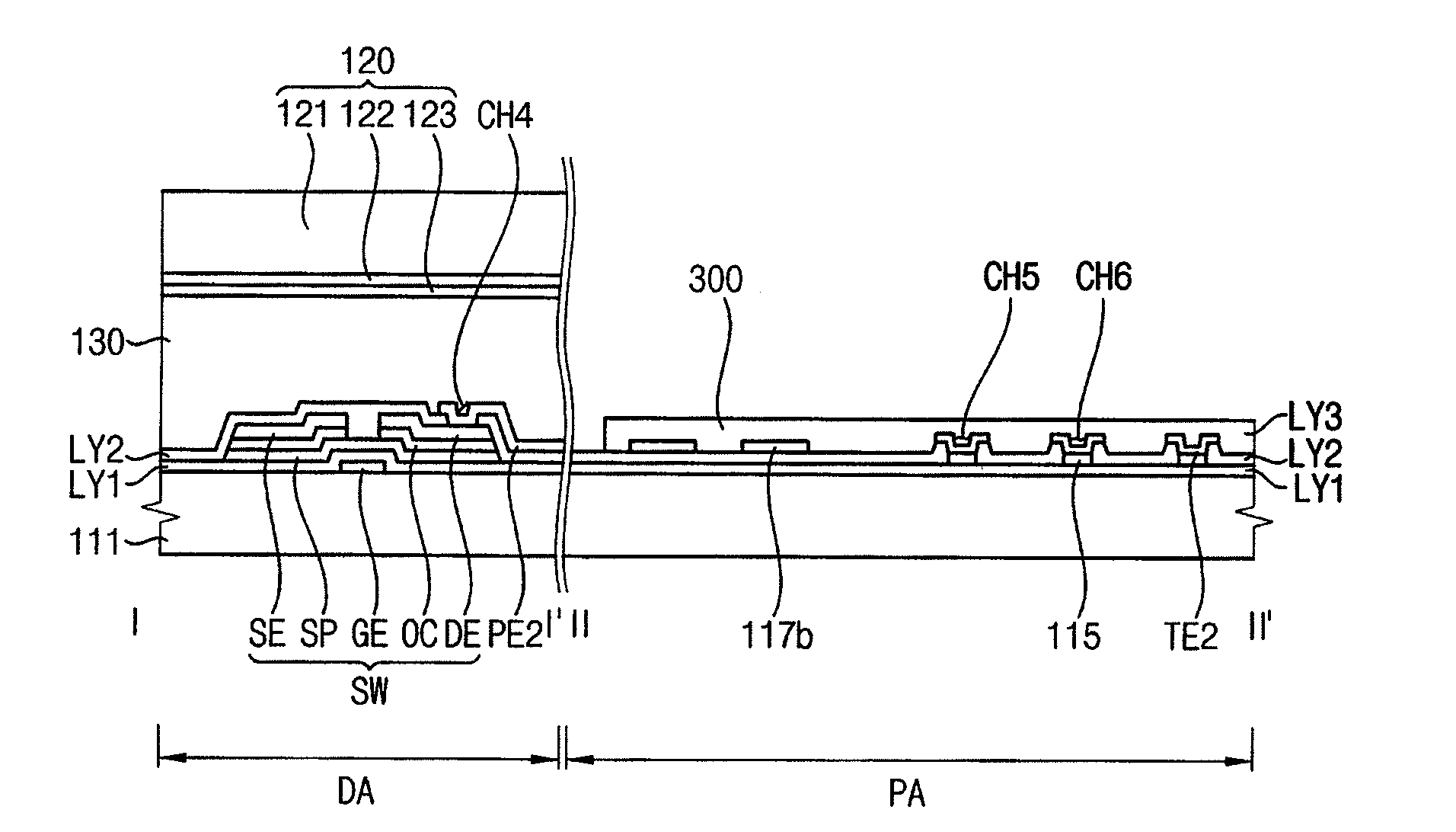

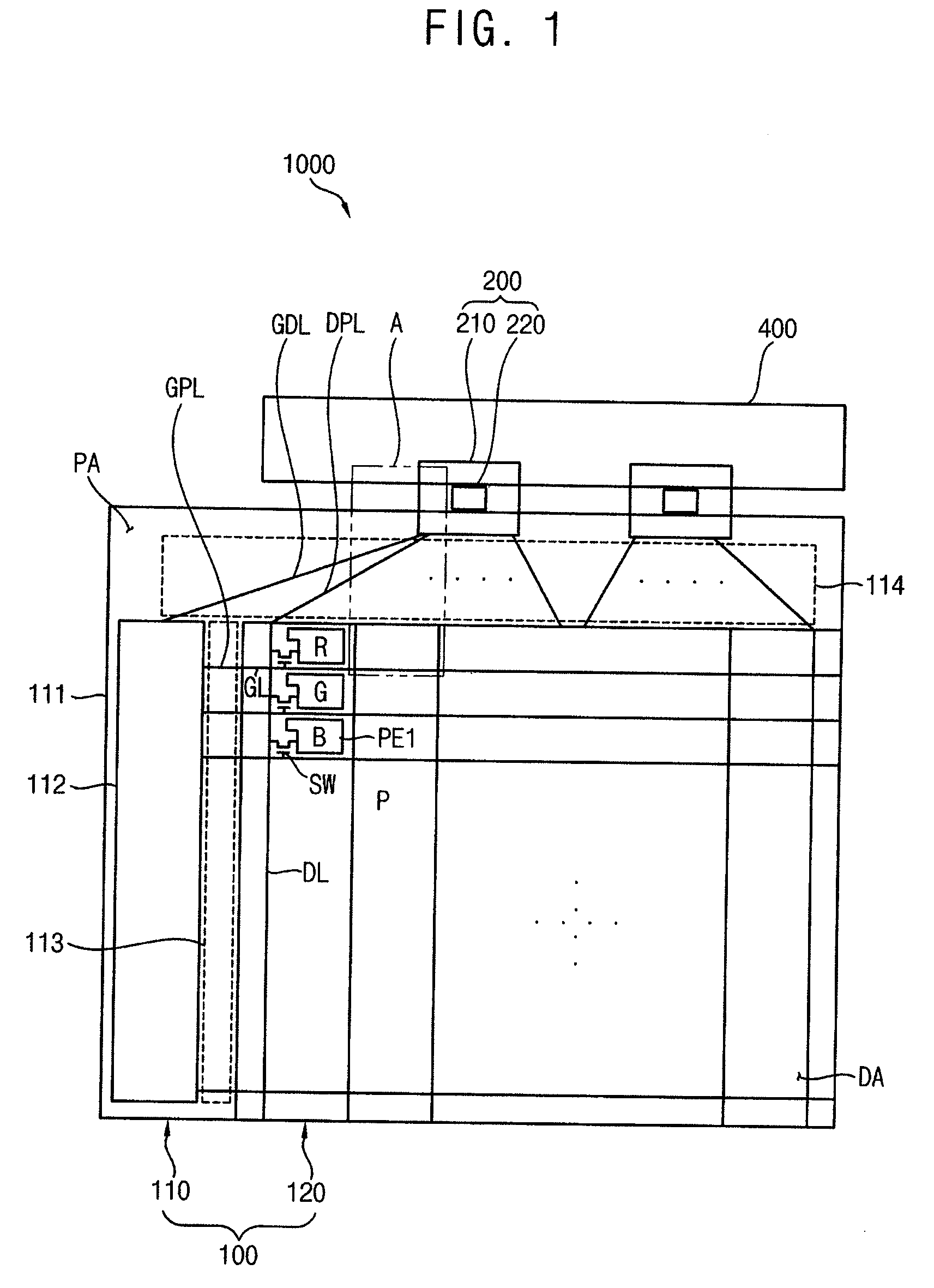

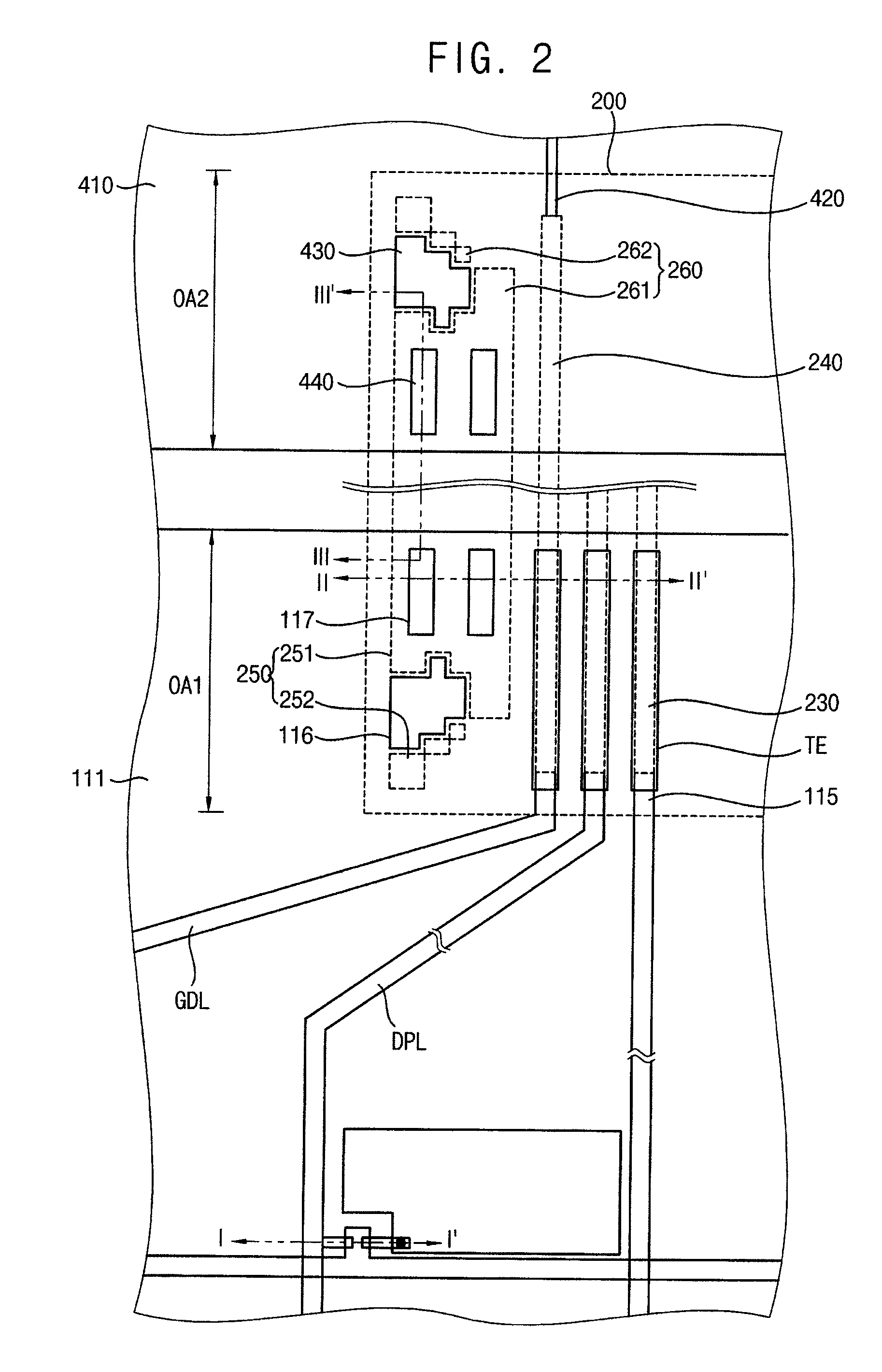

Display device and a method of manufacturing the same

InactiveUS20120256199A1Improve display reliabilityAvoid separationSemiconductor/solid-state device detailsSolid-state devicesDisplay device

A display device includes an array substrate, a driving film and an adhesive member. The array substrate includes a first base substrate, a plurality of first signal pads formed on the first base substrate and a first dummy pad formed adjacent to the first signal pads. The driving film includes a base film, a plurality of output terminals formed on the base film and a first alignment mark formed adjacent to the output terminals. The adhesive member adheres the first signal pads to the output terminals, and adheres the first dummy pad to the first alignment mark.

Owner:SAMSUNG DISPLAY CO LTD

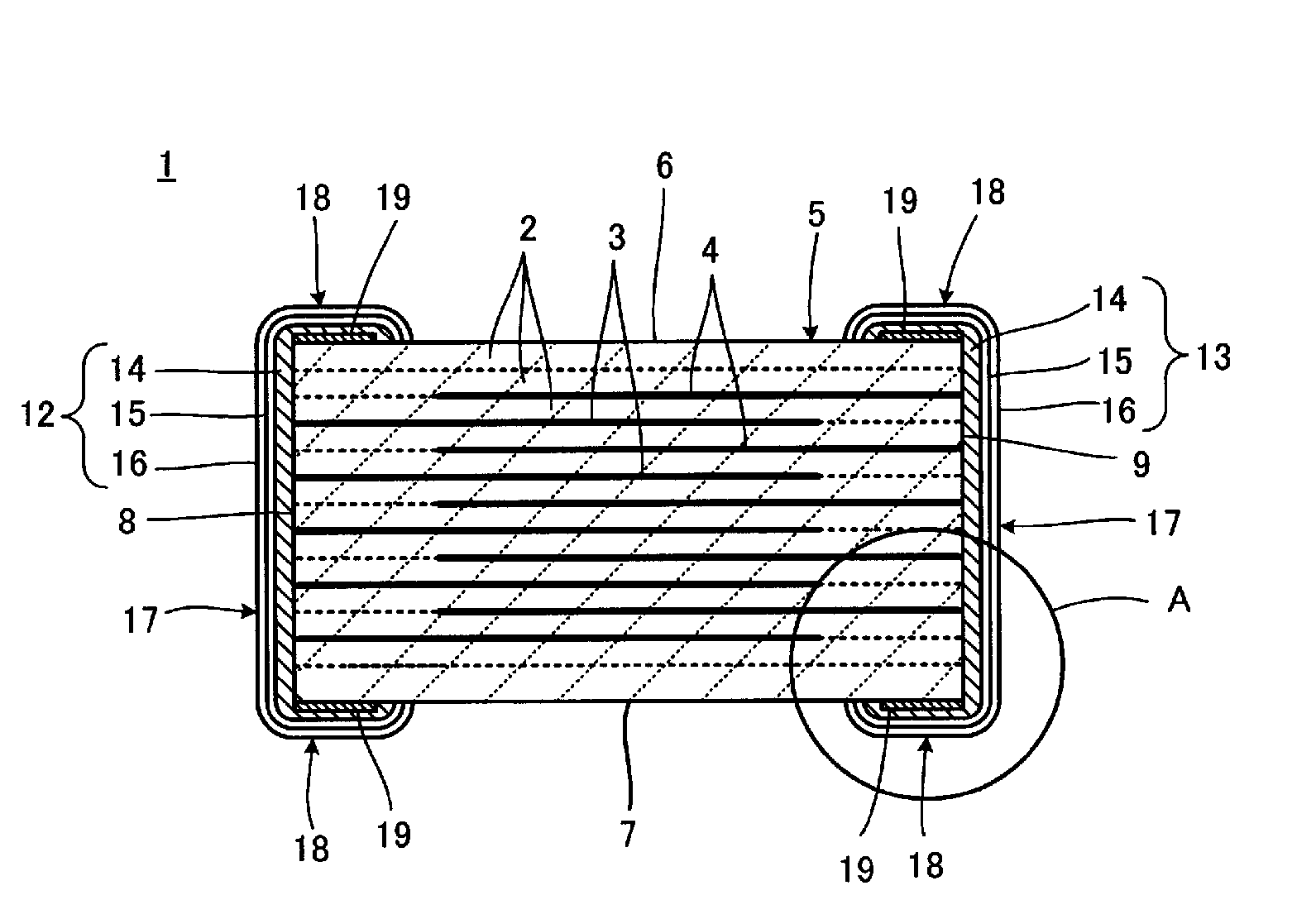

Laminated ceramic electronic component and manufacturing method thereof

ActiveUS8254081B2Prevent moisture intrusionImproving moisture load resistant propertyFixed capacitor electrodesFixed capacitor dielectricElectronic componentUltimate tensile strength

In a laminated ceramic electronic component in which, by directly carrying out a plating process on an outer surface of a component main body, an external electrode is formed thereon, an attempt is made to improve the adhesion strength between a plated film forming the external electrode and the component main body. A brazing material containing Ti is applied to at least one portion of a surface on which external electrodes of a component main body is formed, and by baking this brazing material, a metal layer containing Ti is formed. Moreover, the external electrodes are formed by a plating process so as to coat at least the metal layer, and a heating process is then carried out so as to cause counter diffusion between the metal layer and the plated film that is to form the external electrodes.

Owner:MURATA MFG CO LTD

Silicone pressure-sensitive adhesive composition

ActiveUS20090305036A1Adhesive strengthHigh bonding strengthLayered productsThin material handlingPressure sensitiveReaction inhibitor

A silicone pressure-sensitive adhesive composition exhibiting powerful adhesive strength to silicone rubbers. The composition includes (A) a polydiorganosiloxane composed of components (A1) and (A2) described below and having a mass ratio of (A1) / (A2) within a range from 100 / 0 to 10 / 90,(A1) a linear polydiorganosiloxane having two or more alkenyl groups within each molecule,(A2) a linear polydiorganosiloxane having SiOH groups at the terminals and having no alkenyl groups,(B) a polyorganosiloxane containing R33SiO0.5 units, SiO2 units and silanol groups and having a molar ratio of R33SiO0.5 units / SiO2 units within a range from 0.5 to 0.9,(C) a polyorganohydrogensiloxane containing three or more SiH groups,(D) a reaction retarder,(E) a platinum group metal-based catalyst, and(F) at least one metal compound having a formula MYx wherein M represents a metal element having an atomic valence of 3 or 4 such as aluminum, x represents a number equal to the atomic valence of M, and Y represents a ligand.The composition is useful for producing a pressure-sensitive adhesive tape.

Owner:SHIN ETSU CHEM IND CO LTD

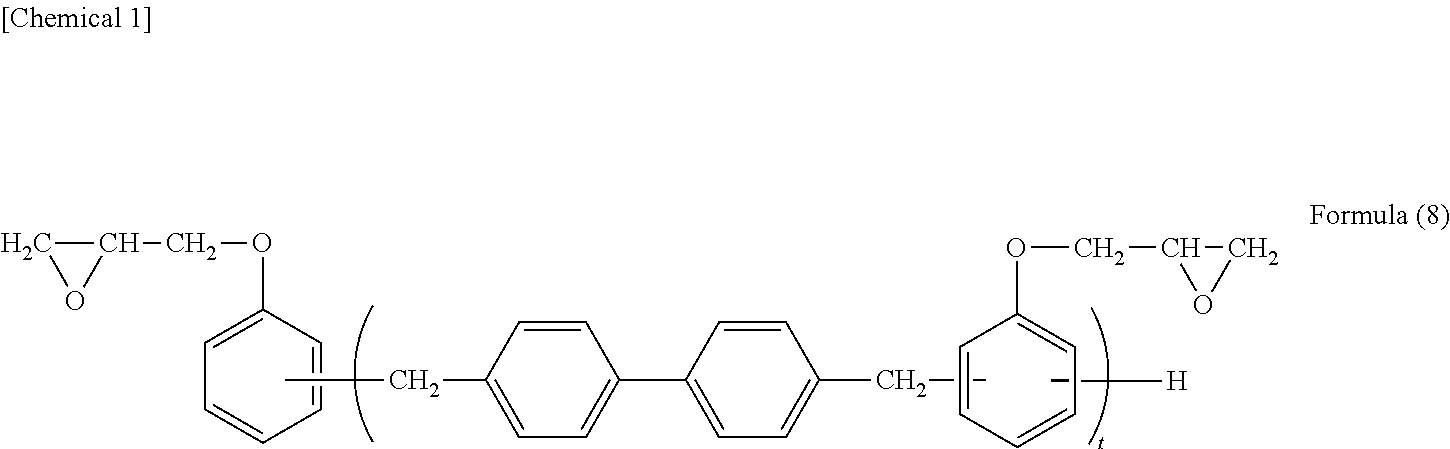

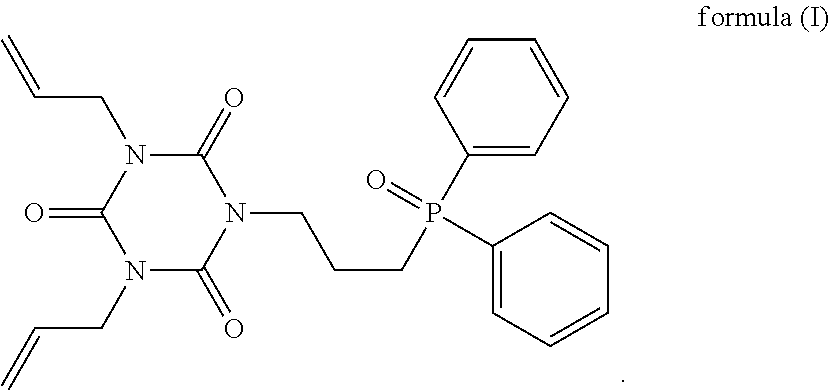

Resin composition, pre-preg, metal-clad laminate, and printed circuit board using the same

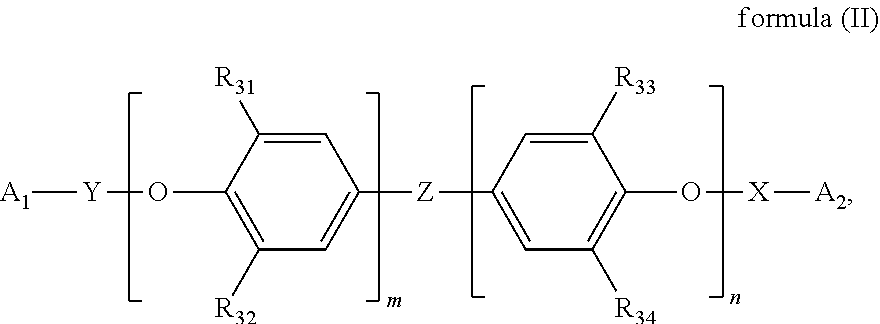

ActiveUS20190367727A1Improve liquidityReduce the amount of solutionSynthetic resin layered productsElectrical equipmentCross-linkEther

A resin composition is provided. The resin composition comprises:(A) a polyphenylene ether resin which has an unsaturated functional group; and(B) a first cross-linking agent represented by the following formula (I):

Owner:TAIWAN POWDER TECH CO LTD

Plating resin molded article and process for producing the same

InactiveUS20030059621A1Adhesive strengthHigh bonding strengthSynthetic resin layered productsPretreated surfacesPolymer scienceChemical plating

The present invention is a process of producing a plating resin molded article, wherein metal plating is carried out on the surface of a thermoplastic resin molded article and either of requirements (1), (2) and (3) described below is included: (1) the thermoplastic resin molded article contains a thermoplastic resin and a water-soluble substance, a step of carrying out the removal of fat of the resin molded article and a step of electroless plating are provided in combination, and a step of etching by an acid containing a heavy metal is not included; (2) the thermoplastic resin molded article contains a polyamide-based resin and a styrene-based resin, a step of carrying out the removal of fat of the resin molded article and a step of electroless plating are provided in combination, and a step of etching by an acid containing a heavy metal is not included; or (3) a step of contact-treating the thermoplastic resin molded article with an acid or base not containing a heavy metal as the pre-treatment of the metal plating step is included. The present invention provides further the plating resin molded article obtained by the above-mentioned step. Although an etching treatment by chromic acid is not carried out, the plating resin molded article having a high adhering strength of a plating layer is provided.

Owner:DAICEL POLYMER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com