Secondary battery of excellent sealability

a technology of sealability and secondary batteries, applied in the direction of cell components, flat cell grouping, sustainable manufacturing/processing, etc., can solve the problems of accelerating the reduction of reducing the service life of the battery, etc., to reduce the movement of increase the surface area, and reduce the effect of the movement of the moisture or the electroly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

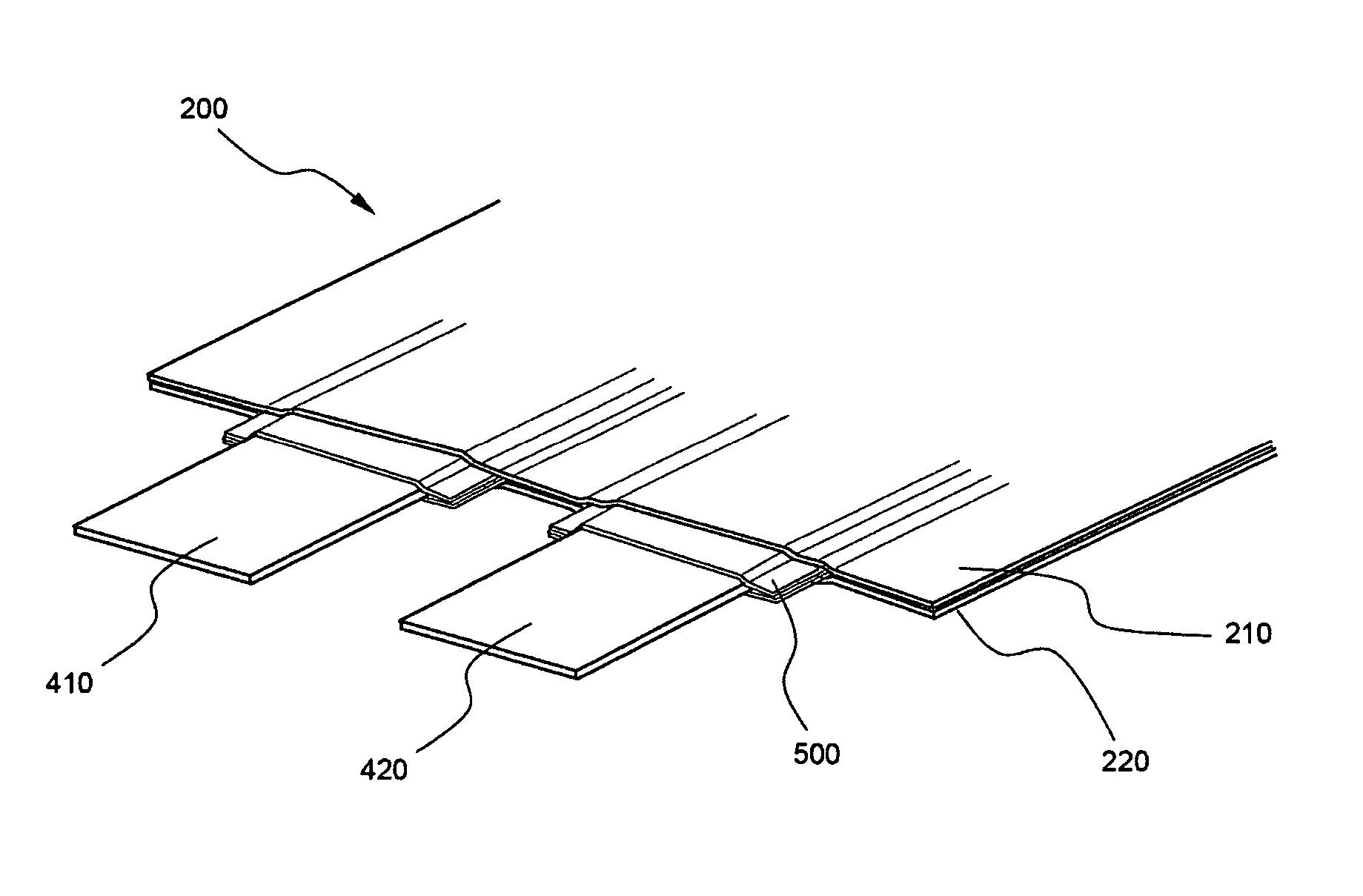

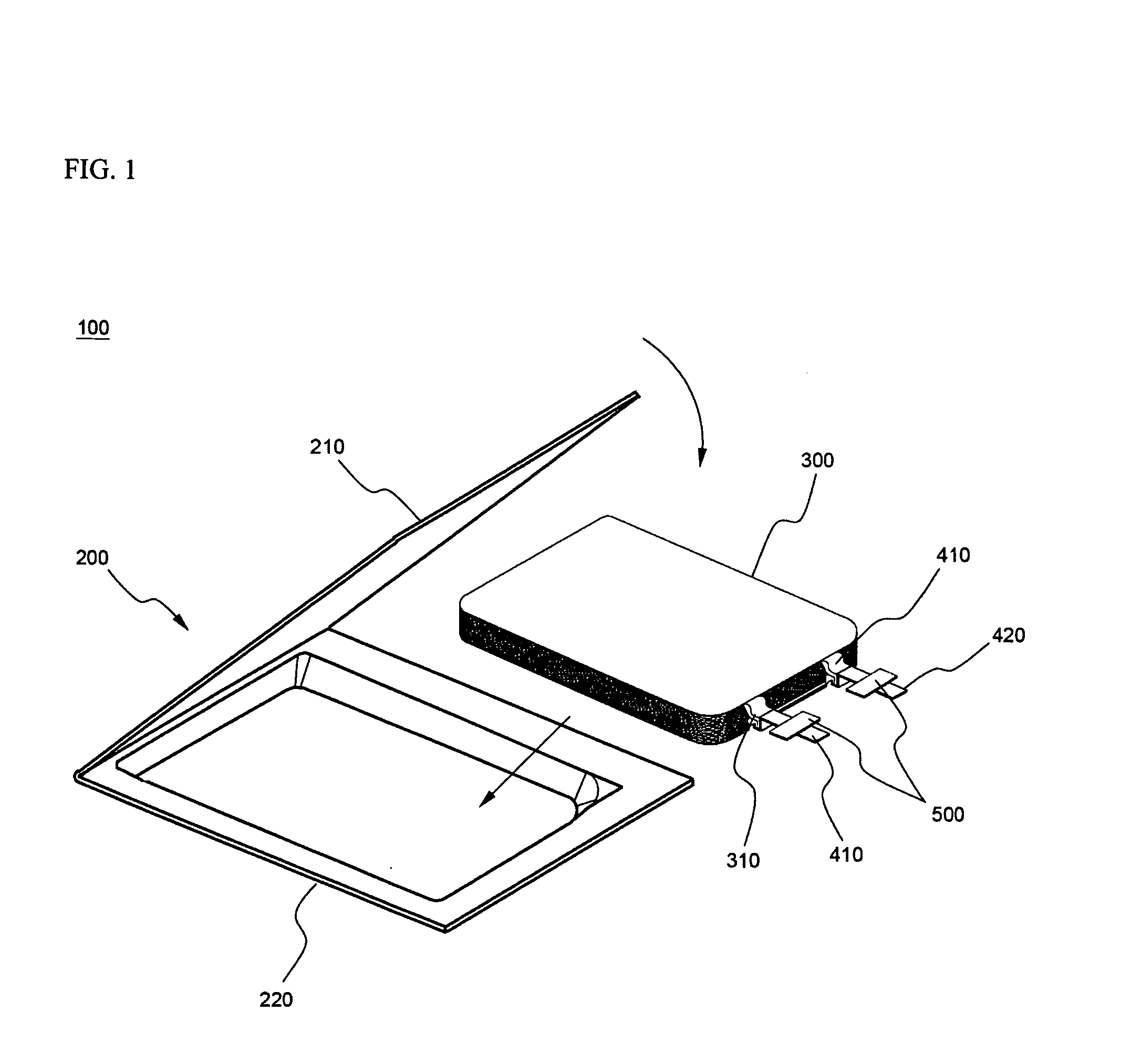

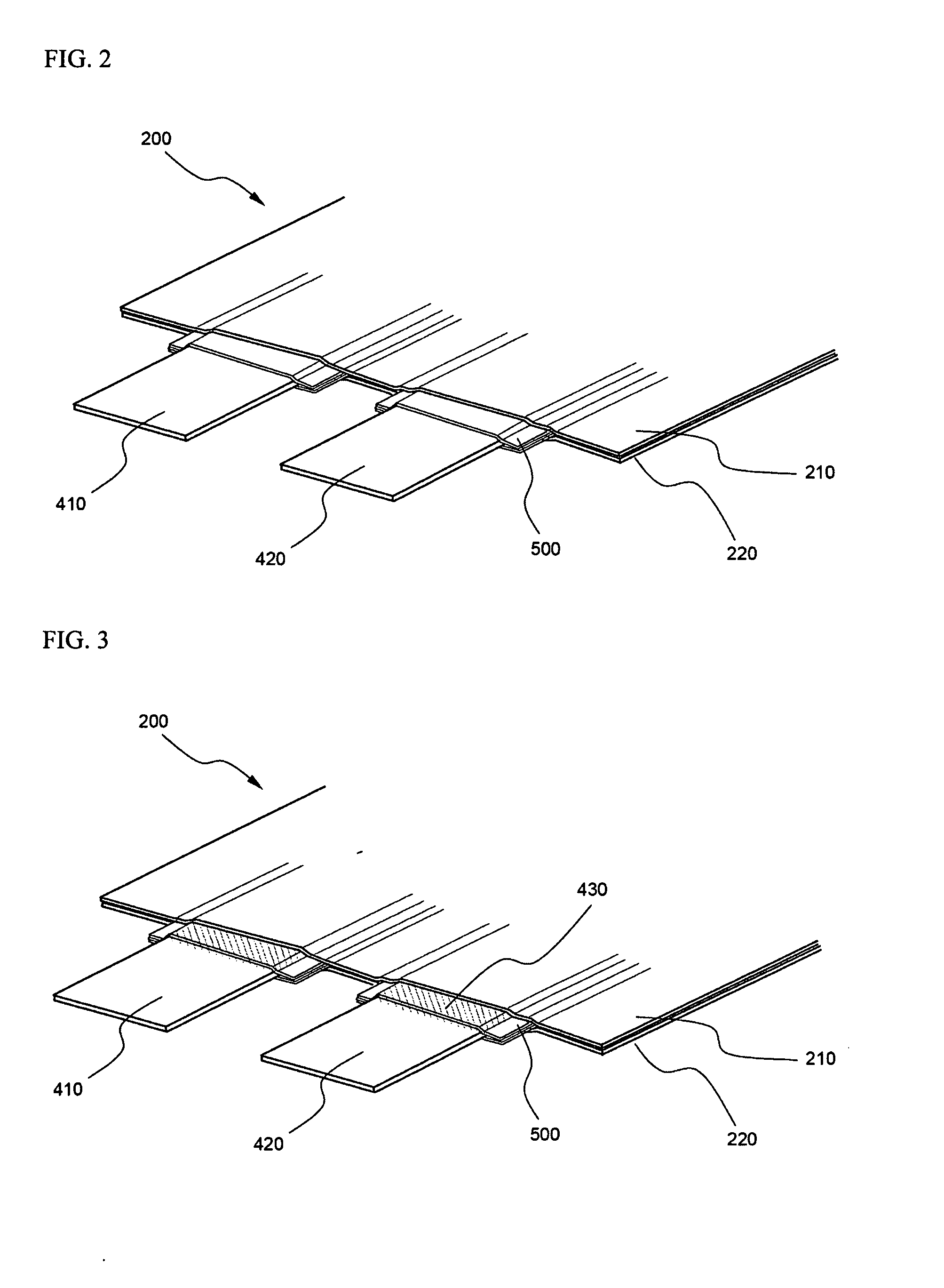

[0047] The surfaces of aluminum foil (foil for the cathode) and copper foil (foil for the anode), each of which has a size of 45 mm×30 mm and a thickness of approximately 350 μm, were rubbed by means of an SiC paper having a roughness of #800 grit at a rotating speed of 1000 to 1200 rpm for 3 minutes (SiC paper grinding). As a result of observation of the surfaces of the aluminum foil and the copper foil using a transmission electron microscope, it was confirmed that grooves having an average size of 4 to 5 μm were formed on the surfaces of the aluminum foil and the copper foil. The aluminum foil and the copper foil, the surfaces of which were treated as described above, were attached to the electrode taps of the electrode assembly by welding, and then resin films, which are made of polypropylene, were attached to the upper end surfaces and the lower end surfaces of the aluminum foil and the copper foil. Subsequently, the electrode assembly was mounted in the pouch-shaped battery ca...

example 2

[0048] A lithium-ion polymer battery was manufactured in the same manner as Example 1, except that the surfaces of the aluminum foil and the copper foil were treated by sand blasting instead of the above-mentioned SiC paper grinding. It was confirmed that grooves having an average size of 5 to 6 μm were formed on the surfaces of the aluminum foil and the copper foil by the sand blasting.

example 3

[0049] A lithium-ion polymer battery was manufactured in the same manner as Example 1, except that the surfaces of the aluminum foil and the copper foil were treated by sand blasting, followed by phosphate treatment. It was confirmed that grooves having an average size of 5 to 6 μm were formed on the surfaces of the aluminum foil and the copper foil by the above-mentioned surface treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com