Patents

Literature

2453results about "Drilling/boring measurement devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

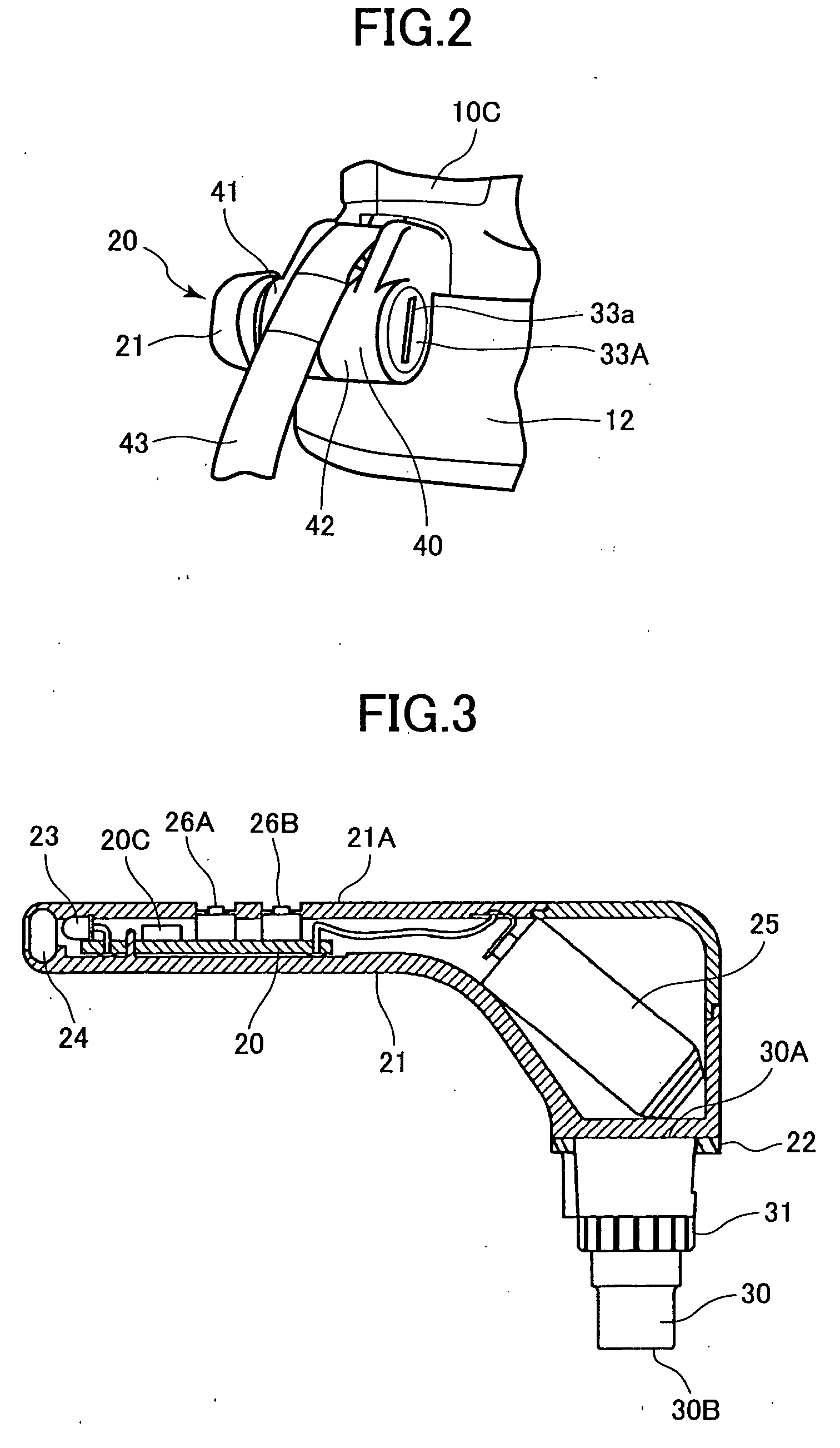

Electric drill apparatus

InactiveUS7121773B2Reduce weight and sizeLow profileDrilling/boring measurement devicesThread cutting machinesRotational axisAnnular cutter

An electric drill apparatus having a low profile is provided which comprises an annular cutter, a motor for rotating the annular cutter, a rotary shaft assembly for rotating the annular cutter attached to its leading end about a rotating, a rotation reduction mechanism disposed between the motor and rotary shaft assembly for transmitting a driving force of the motor to the annular cutter through the rotary shaft assembly, a feed mechanism responsive to an operation of a manual handle, for moving the rotary shaft assembly along with a straight line to advance or retract the annular cutter attached to the rotary shaft assembly with respect to a workpiece, and an adhesion base for securing the electric drill apparatus to the workpiece. The annular cutter has a plurality of cutting blades comprised of cemented carbide tips fixed on its lower end, thereby it is capable of rotating at a high speed. The rotary shaft assembly has a rotating shaft which rotates in a direction different from that of a rotating shaft of the motor, thereby the drill apparatus has a low profile.

Owner:NITTO KOHKI CO LTD

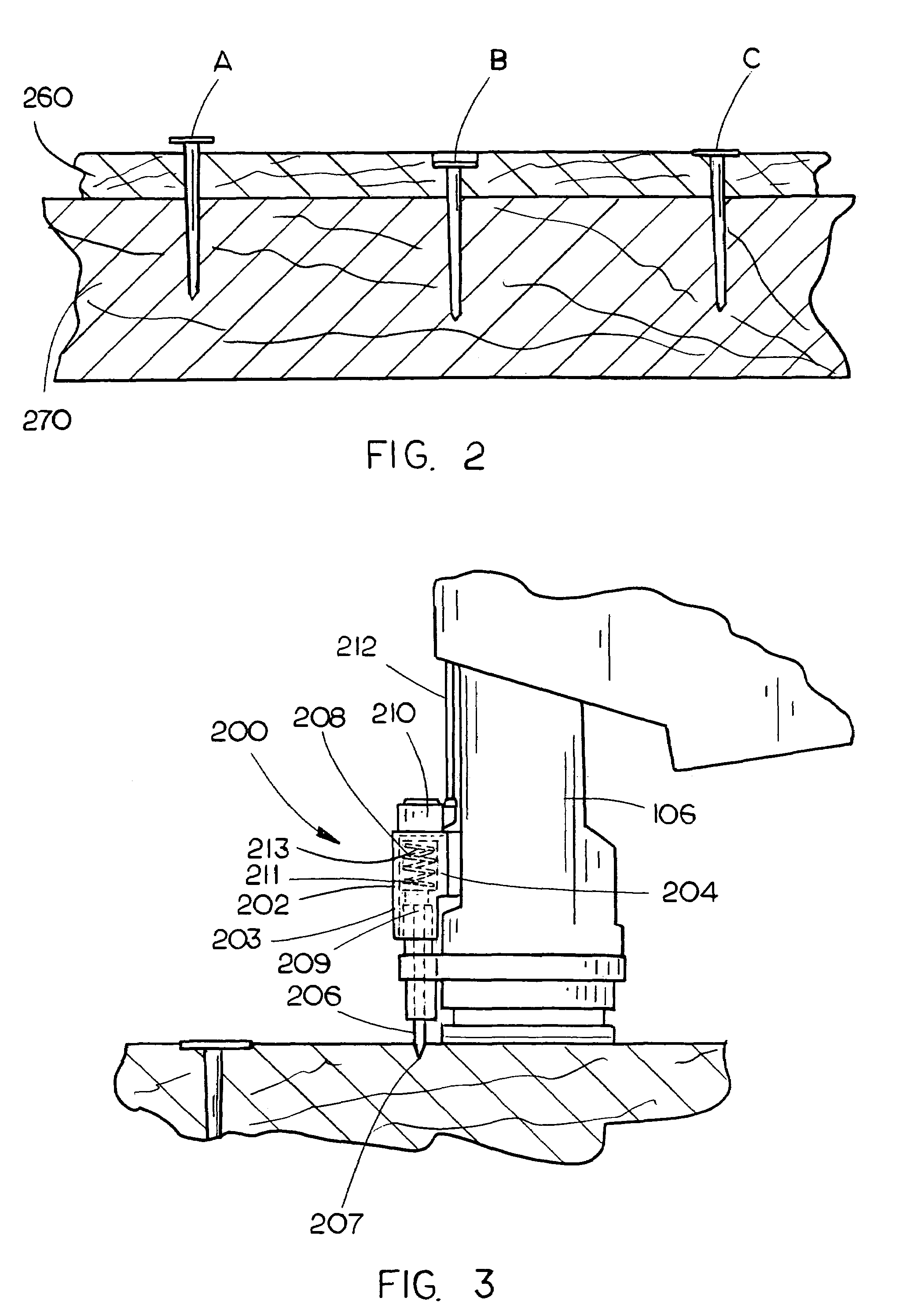

Sleeved stop for a drill bit

A stop for use with an electric drill bit, the stop having at least one threaded sleeve for positioning the stop relative to a surface into which the drill bit will extend. The stop may have both an inner and an outer sleeve. The sleeves are mounted coaxially, one inside the other about the drill bit. One of the sleeves, preferably the inner sleeve, provides coarse adjustment of the position of the shoulder relative to the tip of the bit, while the other, preferably the outer sleeve, provides fine adjustment of the position of the shoulder relative to the top of the bit.

Owner:3D SCAN GUIDE LLC

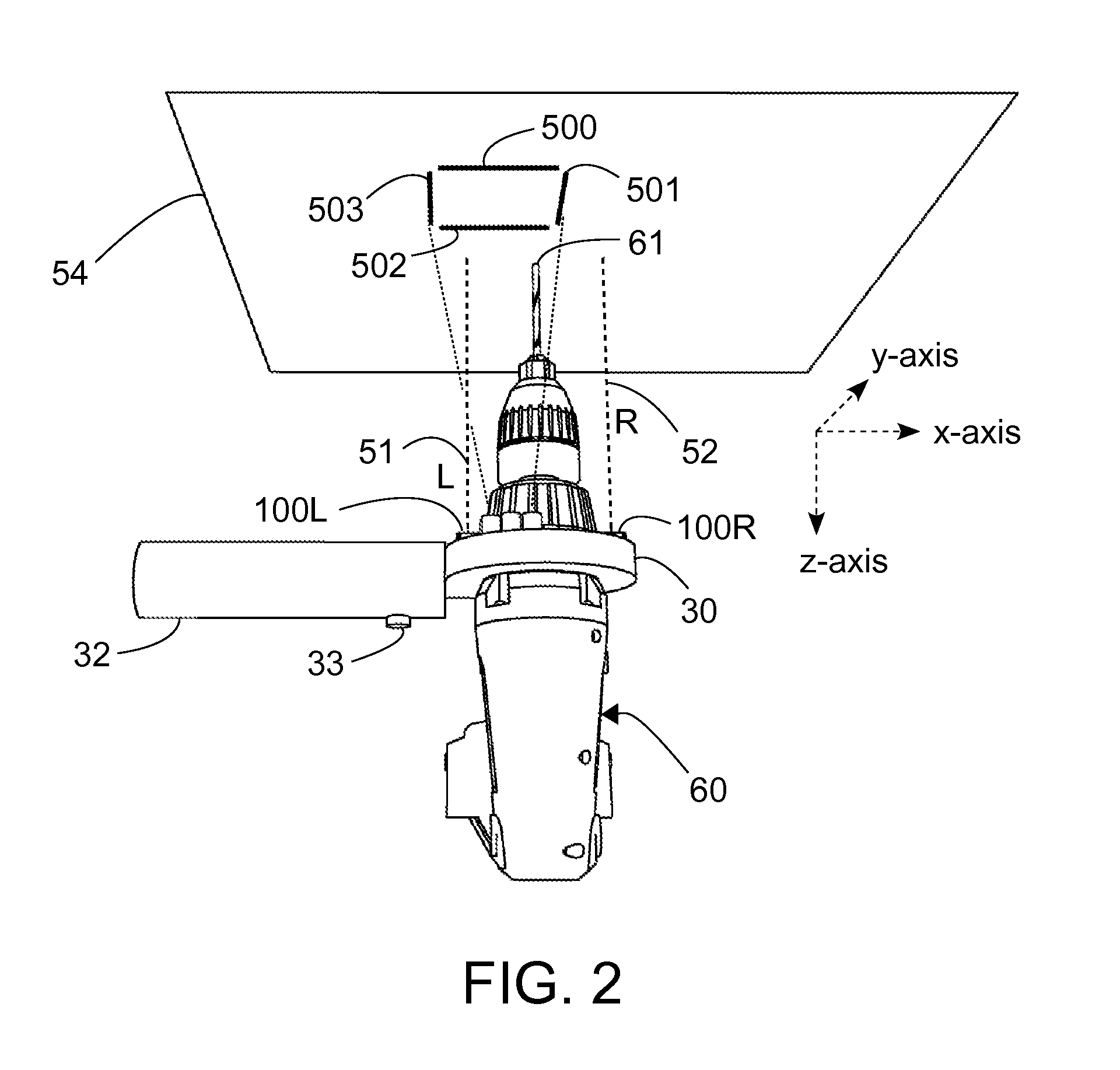

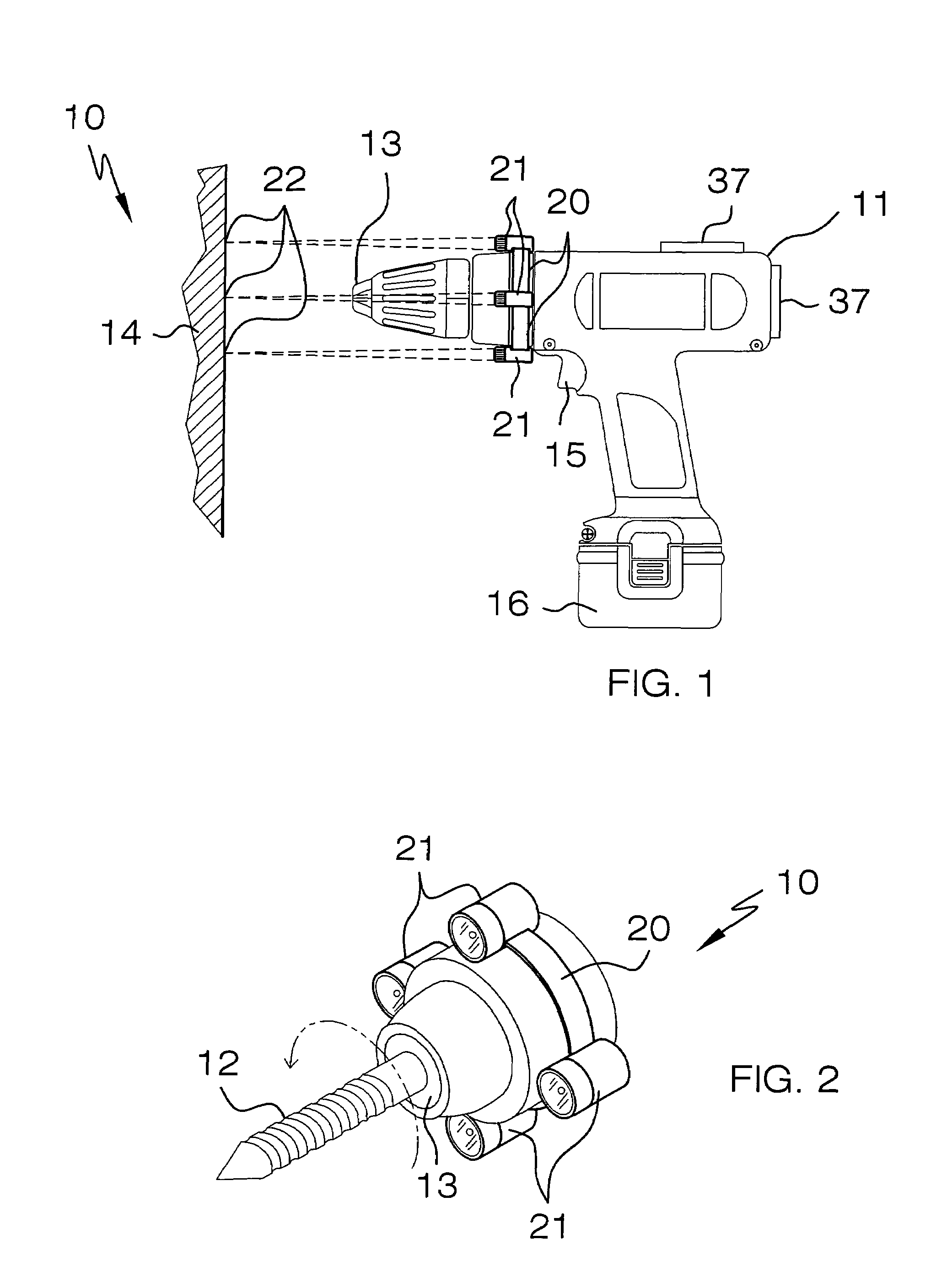

Electronic drill guide

ActiveUS9114494B1Easy to viewStapling toolsDrilling/boring measurement devicesTarget surfaceThree axis accelerometer

One embodiment of an alignment apparatus for aligning an object, such as a tool or other implement, perpendicular with respect to a horizontal or a vertical target surface, comprises a three-axis accelerometer and at least two forward-facing distance sensors and a projection display comprising four addressable laser projectors. The accelerometer and distance sensor outputs are mapped to a predefined graphic symbol representing the orientation of the tool relative to the target surface, in particular when the tool is perpendicular to the target surface. The projection display projects the predefined symbol onto the target surface where it may be easily viewed by the tool operator allowing the operator to make any necessary corrections to the tool position.

Owner:MAH KENNETH JACK

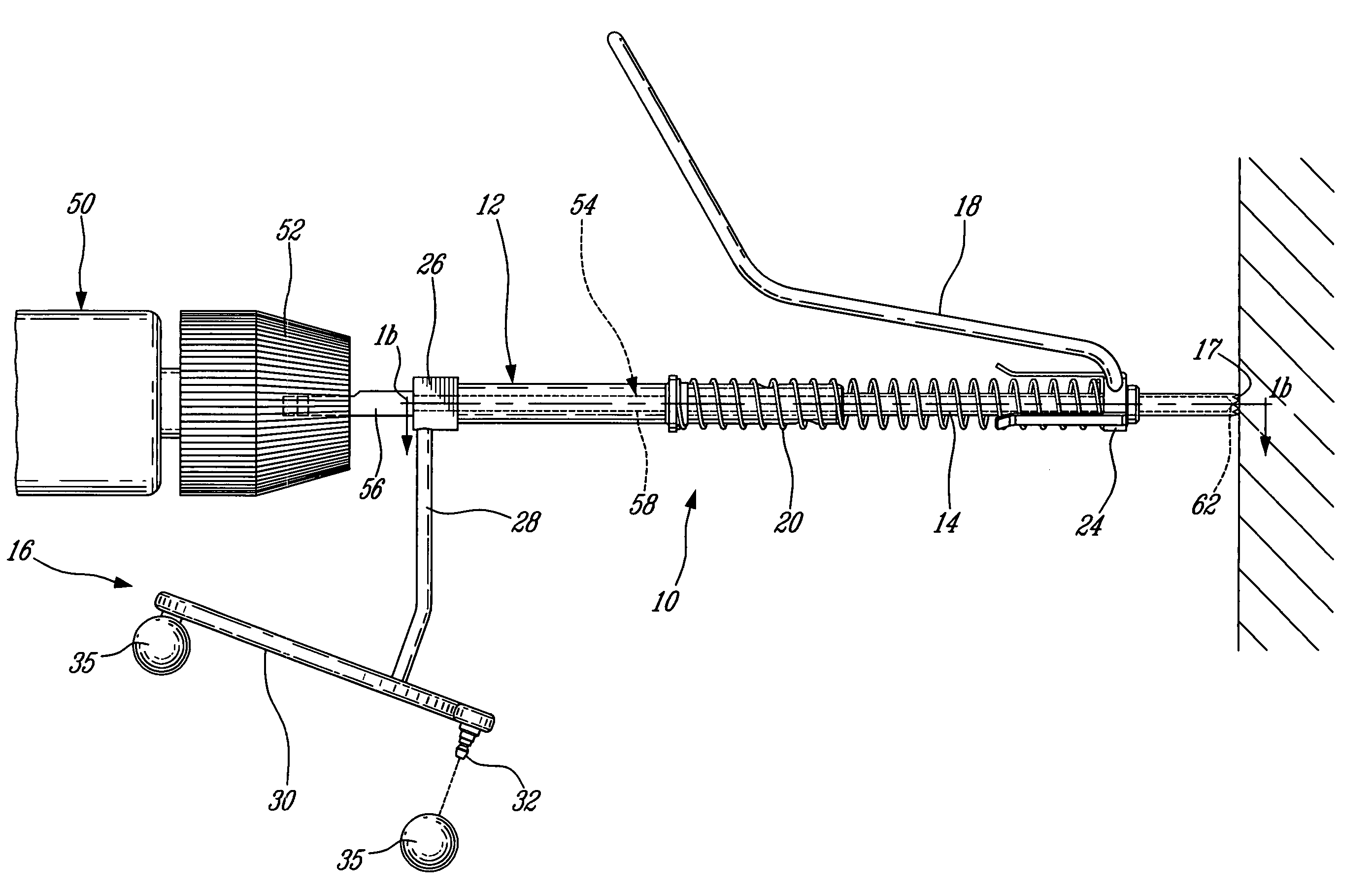

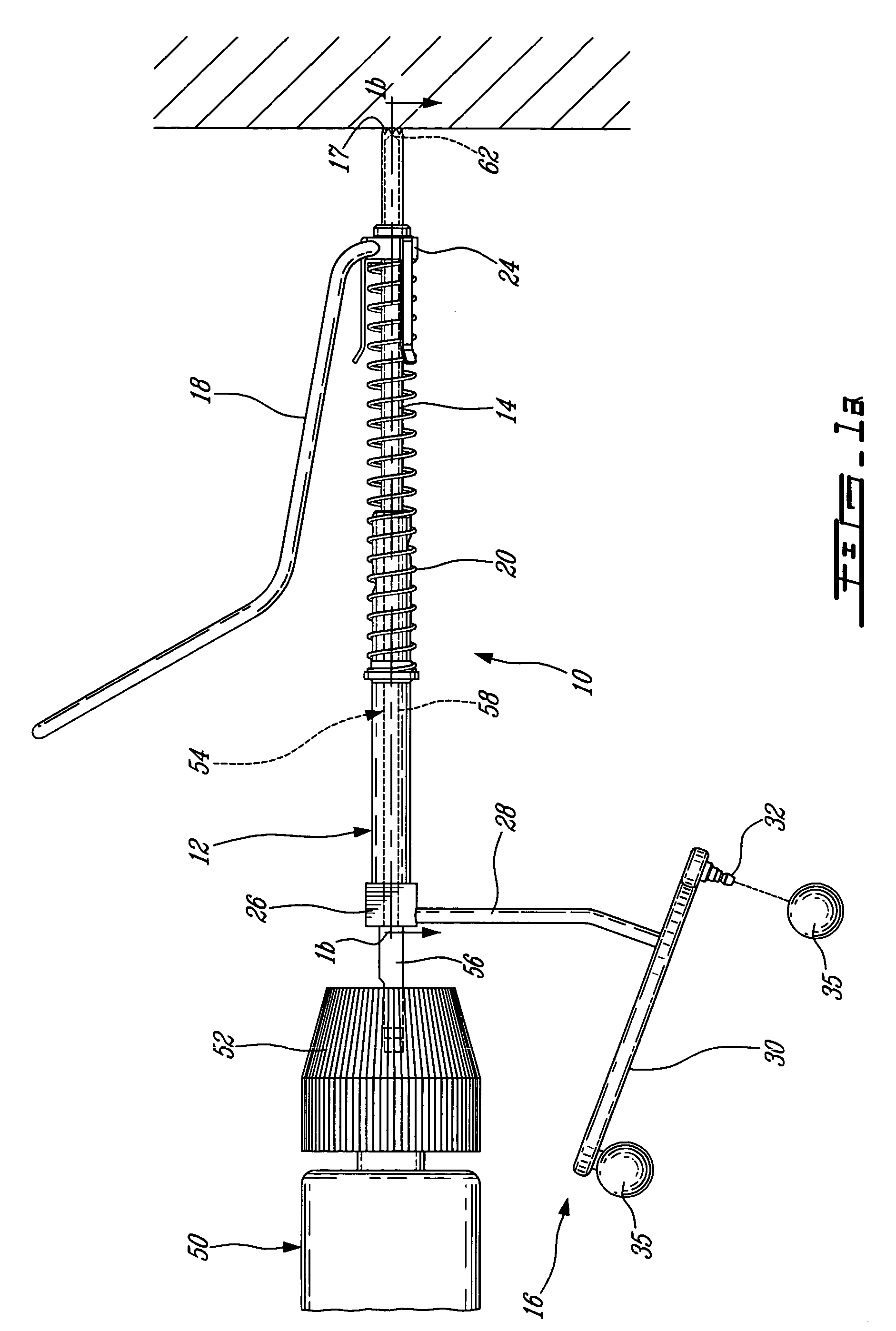

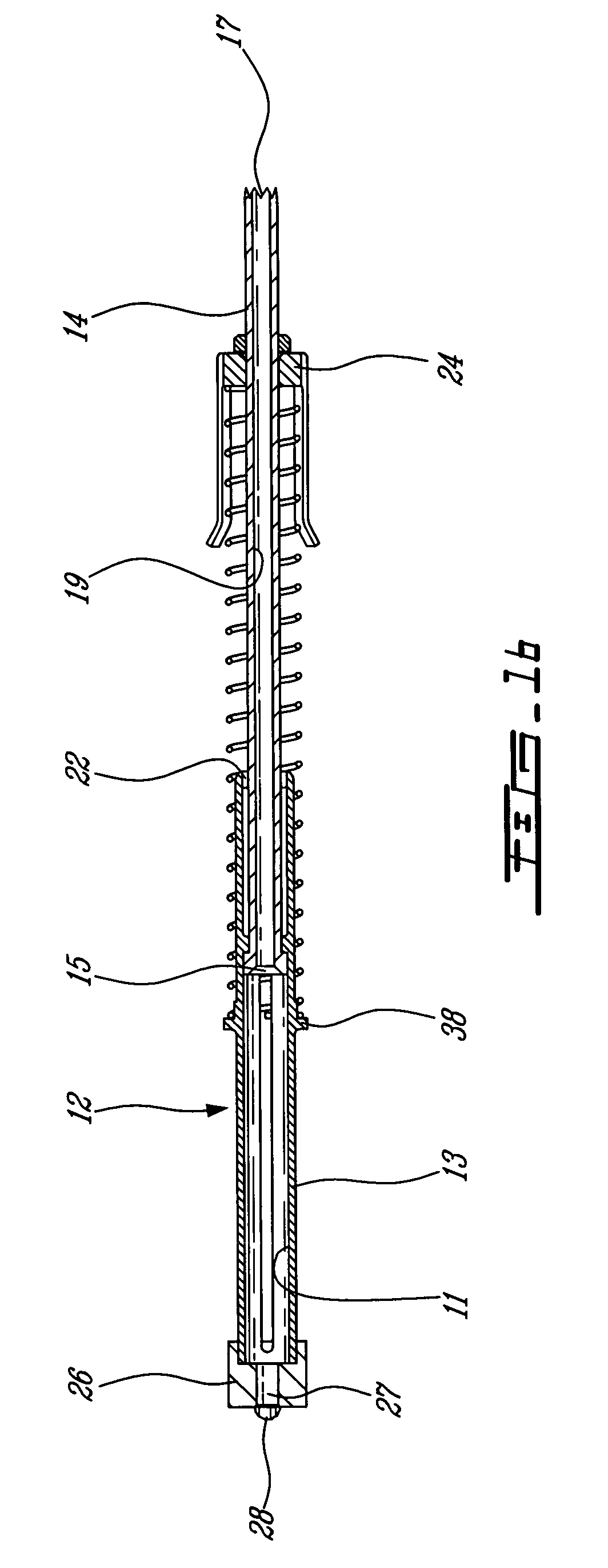

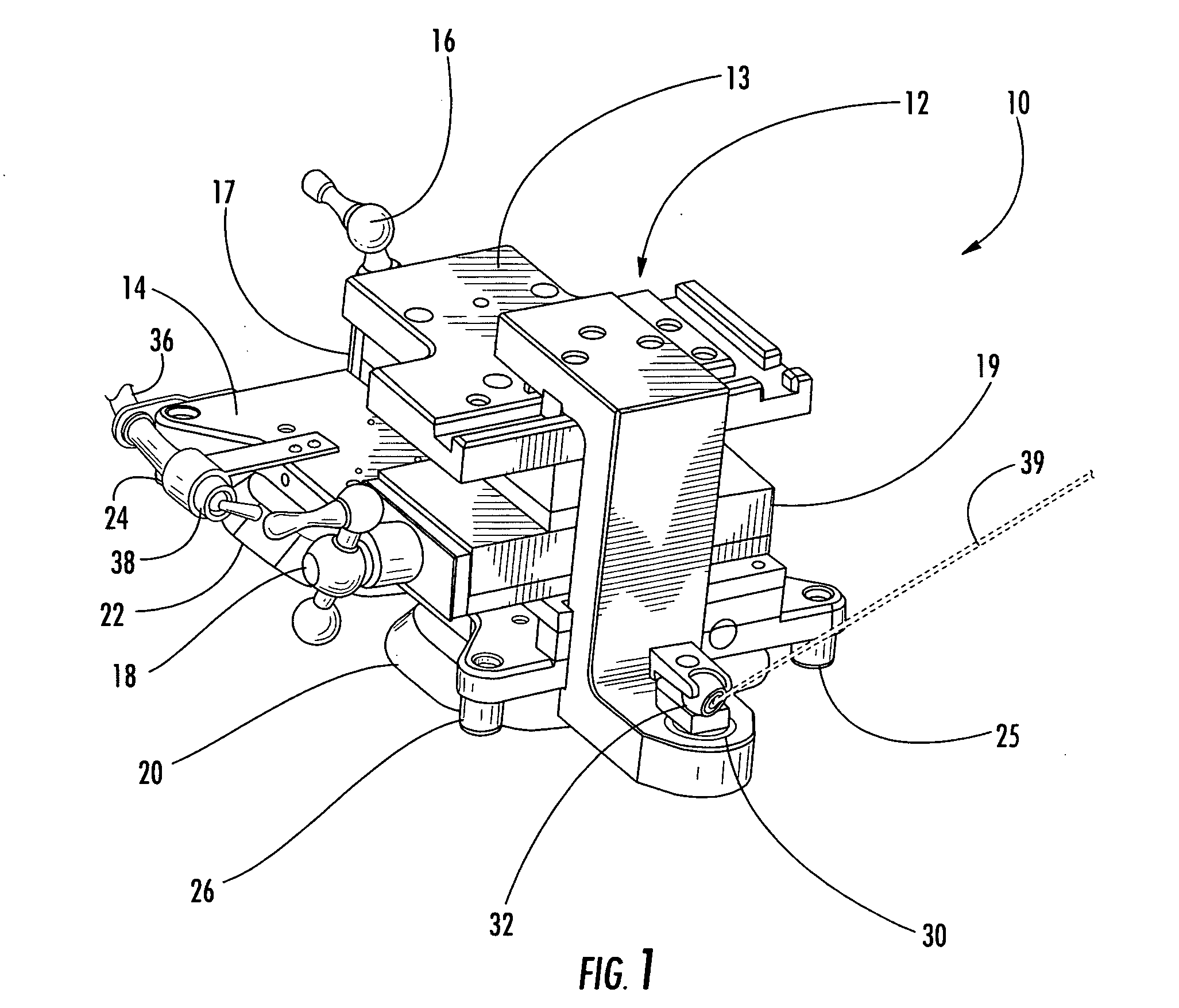

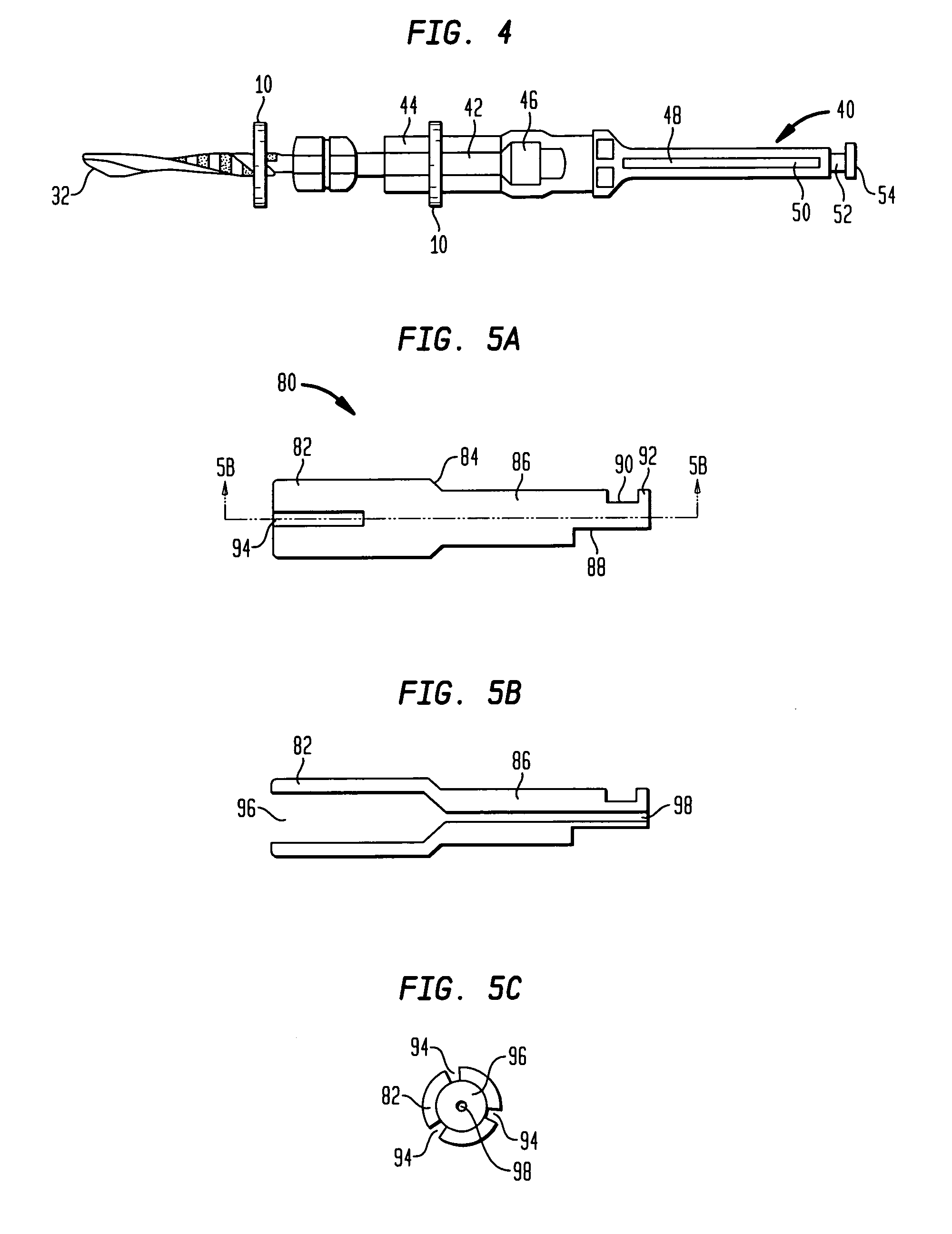

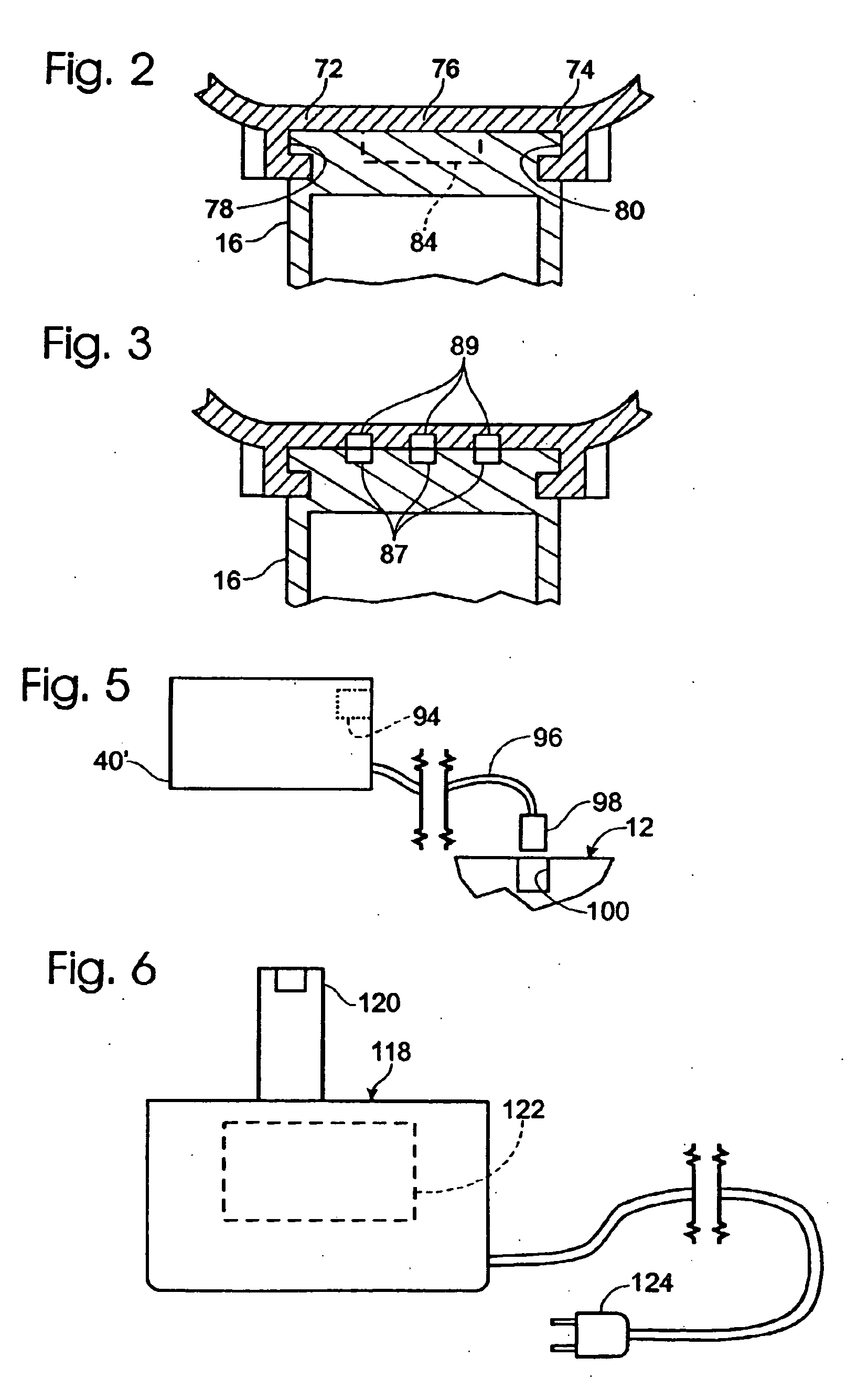

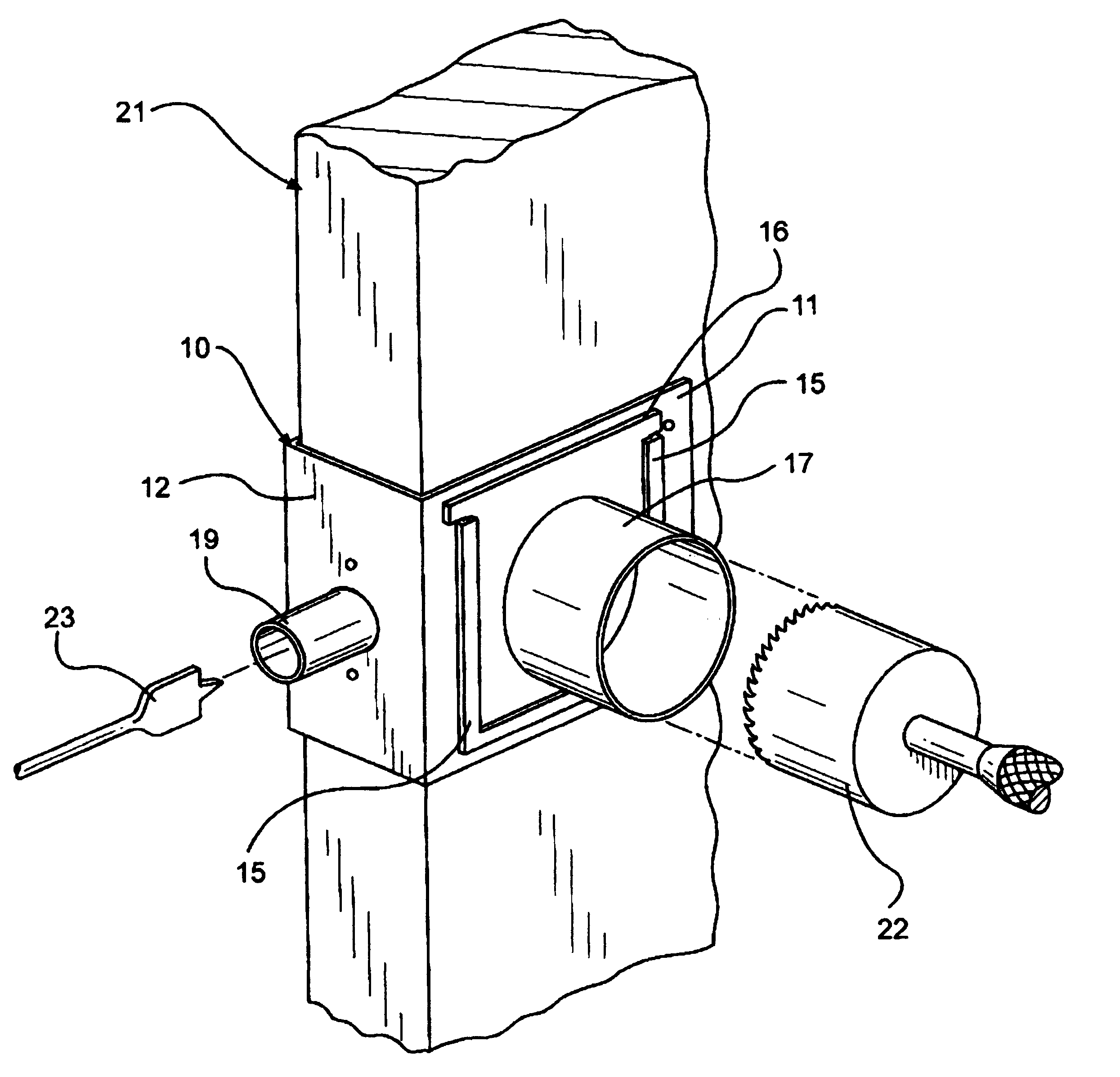

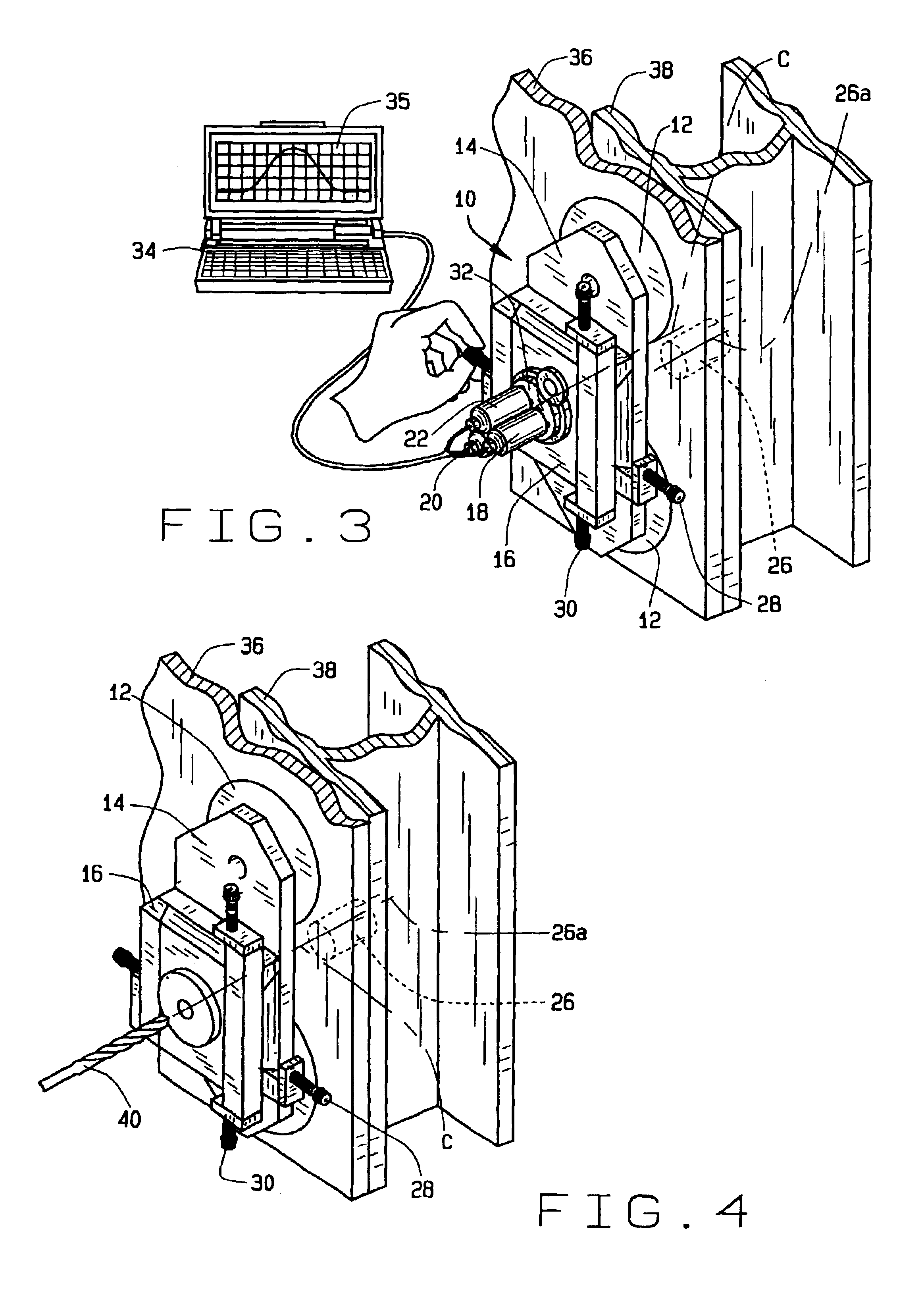

CAS drill guide and drill tracking system

InactiveUS6887247B1Accurate representationDepth accurateDrilling/boring measurement devicesThread cutting machinesThree-dimensional spaceEngineering

A drill guide assembly for a drilling tool having a chuck engaging a bit portion comprising a tip and a length extending from the chuck, the drill guide assembly comprising a first member, a second member and a trackable member. The first member is adapted to abut a workpiece surface and defines a central aperture therethrough adapted to receive the bit portion of the drilling tool. The second member is adapted to be axially displaced with respect to the first member and is axially biased therefrom, and defines a central aperture therethrough adapted to receive the bit portion of the drilling tool. The trackable member, fastened to the second member, comprises a detectable element adapted to be located and tracked in three dimensional space, thereby defining the position and movement of the second member and therefore that of the bit portion of the drilling tool.

Owner:ORTHOSOFT ULC

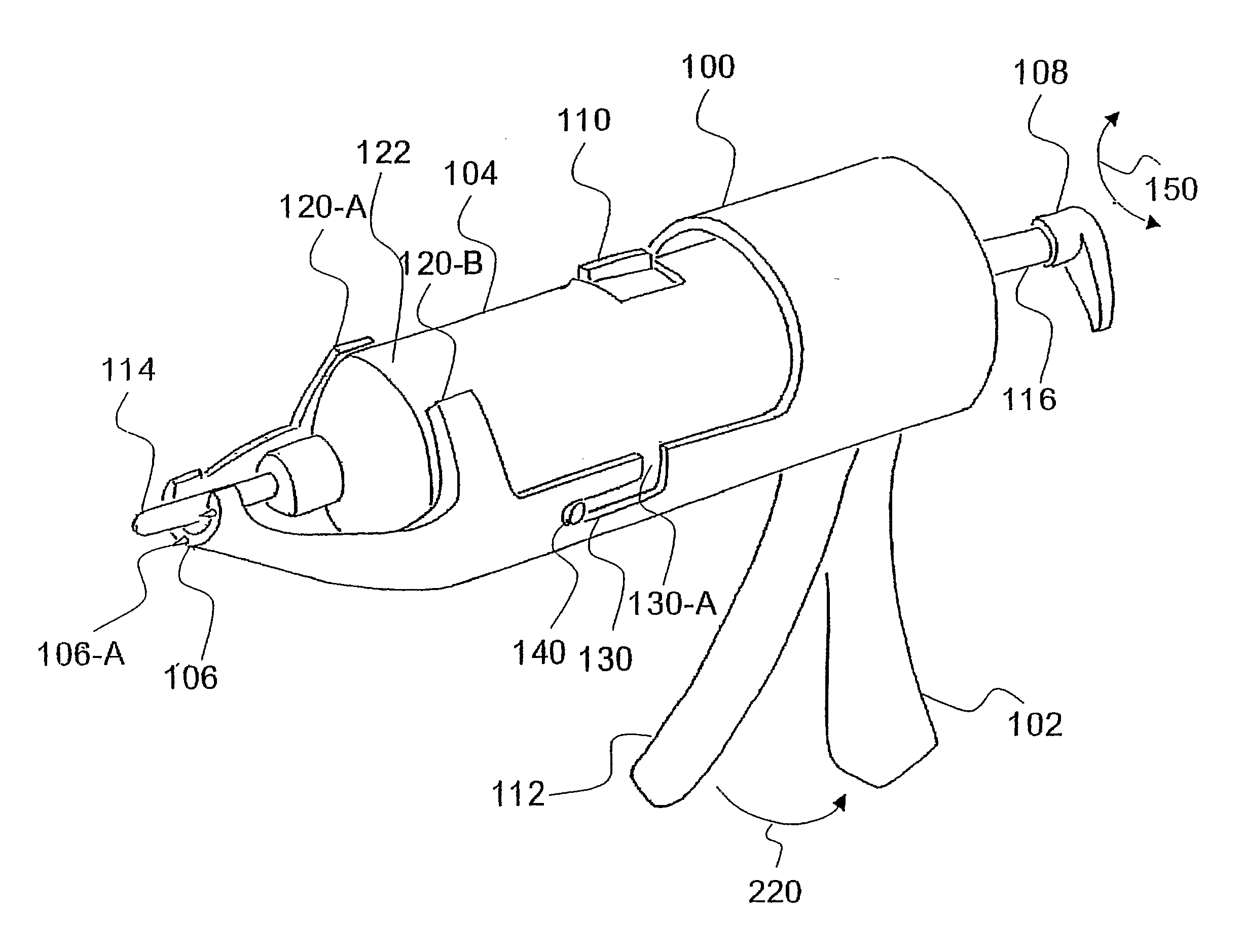

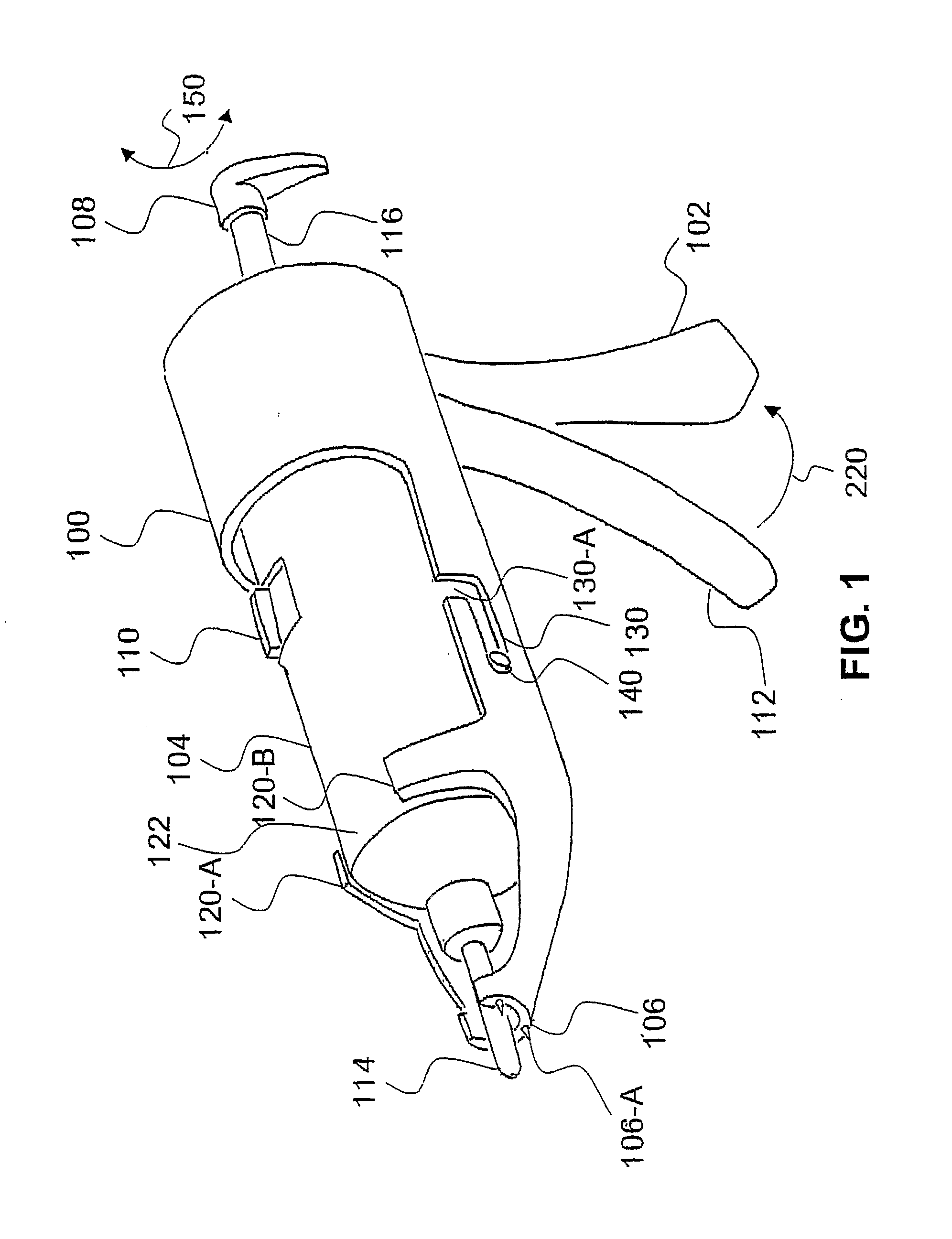

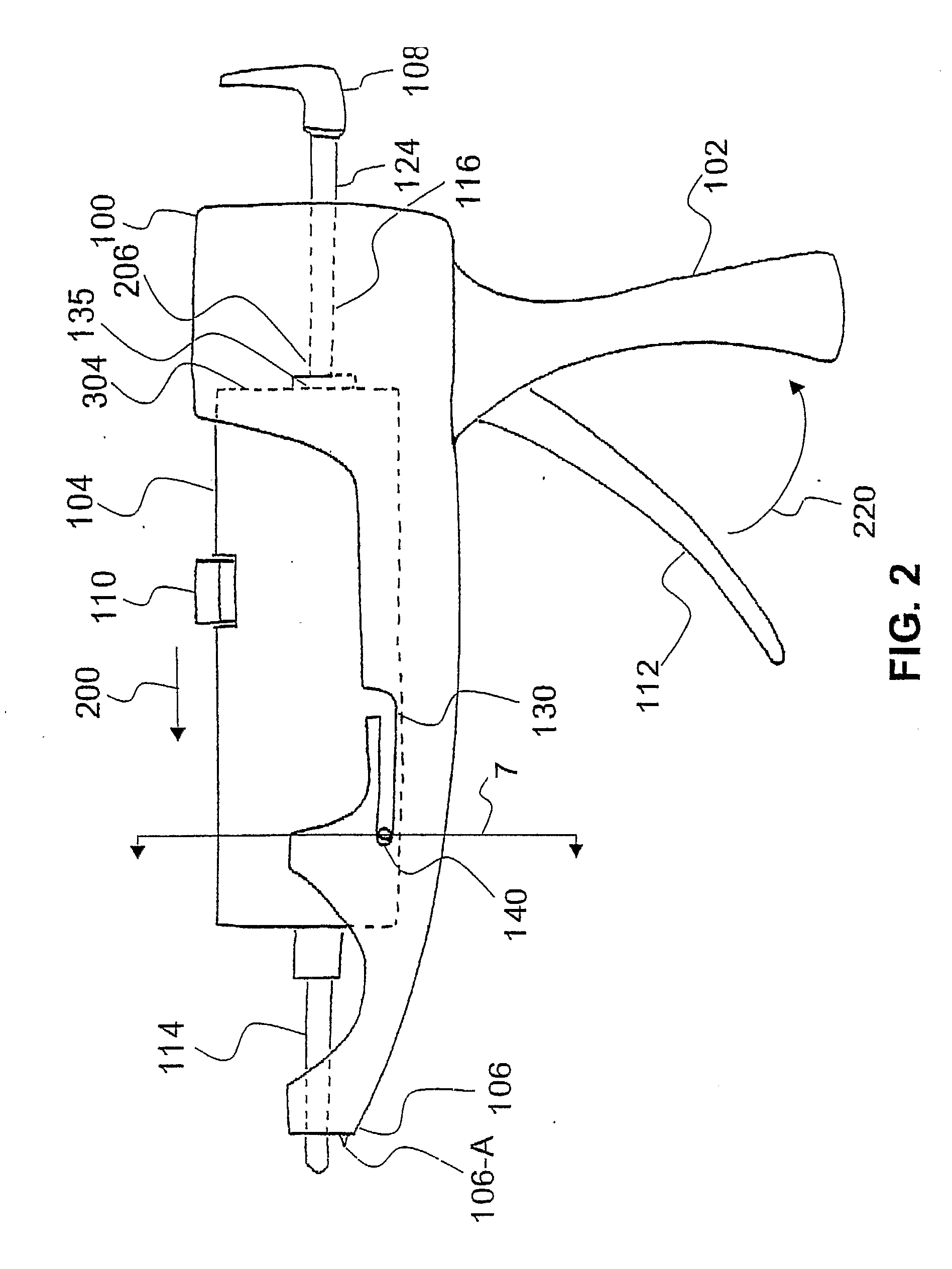

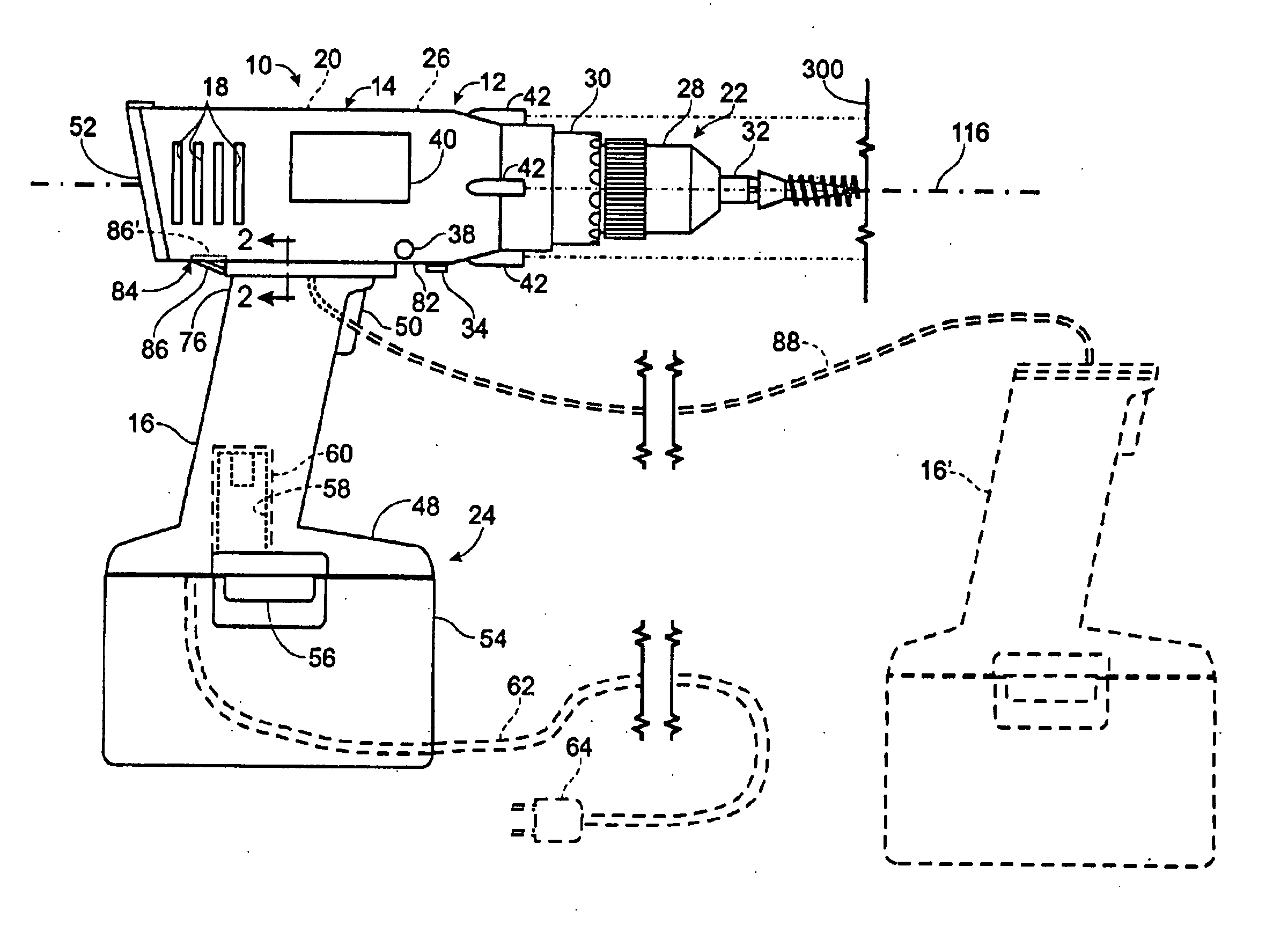

Apparatus and method thereof for drilling holes in discrete controlled increments

InactiveUS20100034605A1Increased level of safety securityShorten the timeDrilling/boring measurement devicesThread cutting machinesBrain biopsyEngineering

An apparatus and method for forming a hole in material for non-medical and medical purposes such as a cranial burr hole for ventriculostomy and brain biopsy procedures. The apparatus includes a main unit upon which a drill unit is located. The drill unit includes a drill bit and an on / off switching means. The main unit includes a handle which is suitable for grasping, and an advancing mechanism including a release / engage mechanism, and an advancing lever and an optional on / off switch. The drill unit is advanced a predetermined distance relative to the main unit each time an advancing lever is pulled. In use, the apparatus is placed in a desired position upon the material to be drilled such a patient's skull and is stabilized by a stabilization platform, the apparatus is then turned on, and the advancing lever is pulled to advance the drill unit a predetermined distance relative to a longitudinal axis of the main unit with each pull of the advancing lever. The procedure is ended when the desired depth of penetration has been reached, or the material such as in the case of skull bone, has been completely penetrated.

Owner:CONCEPTUAL GRAY

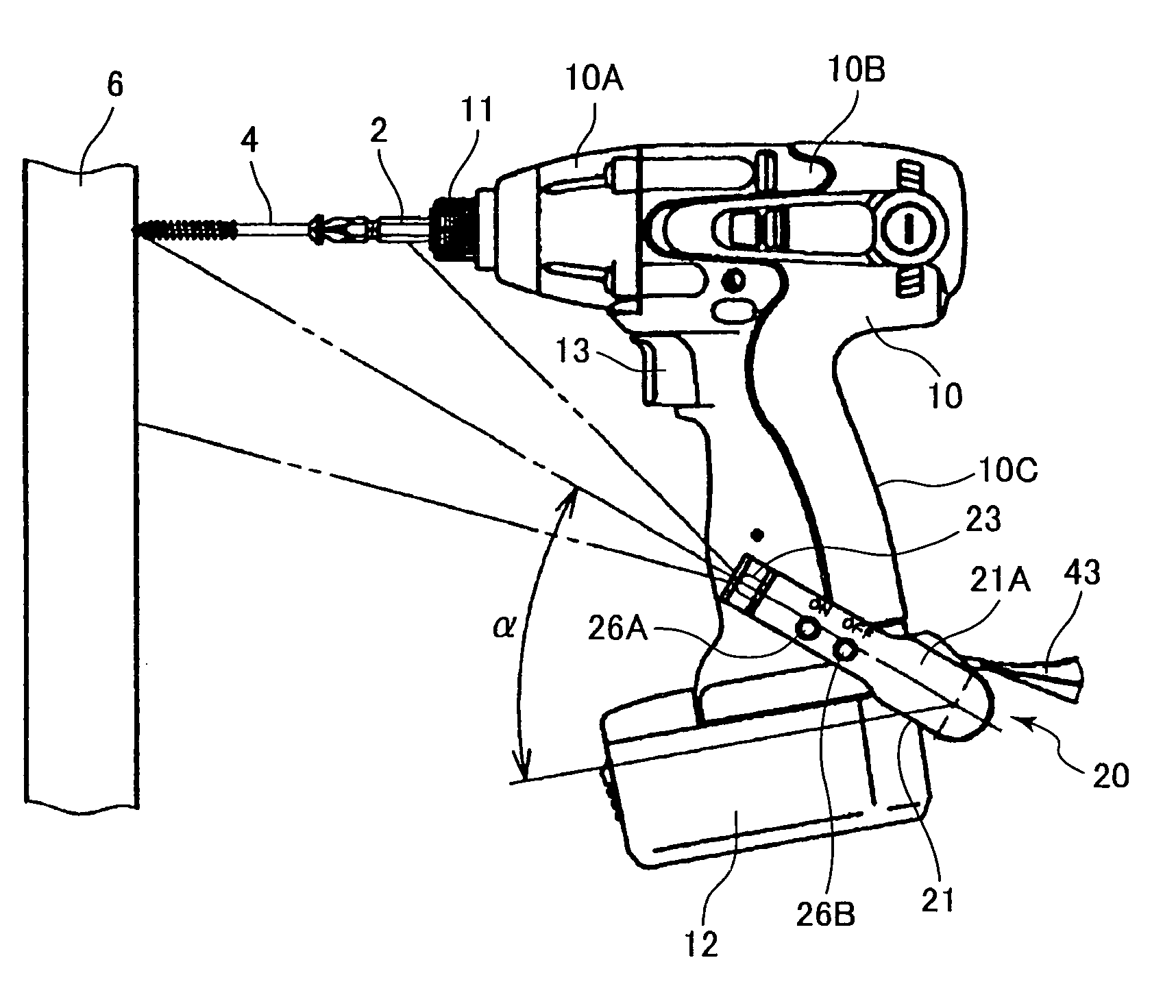

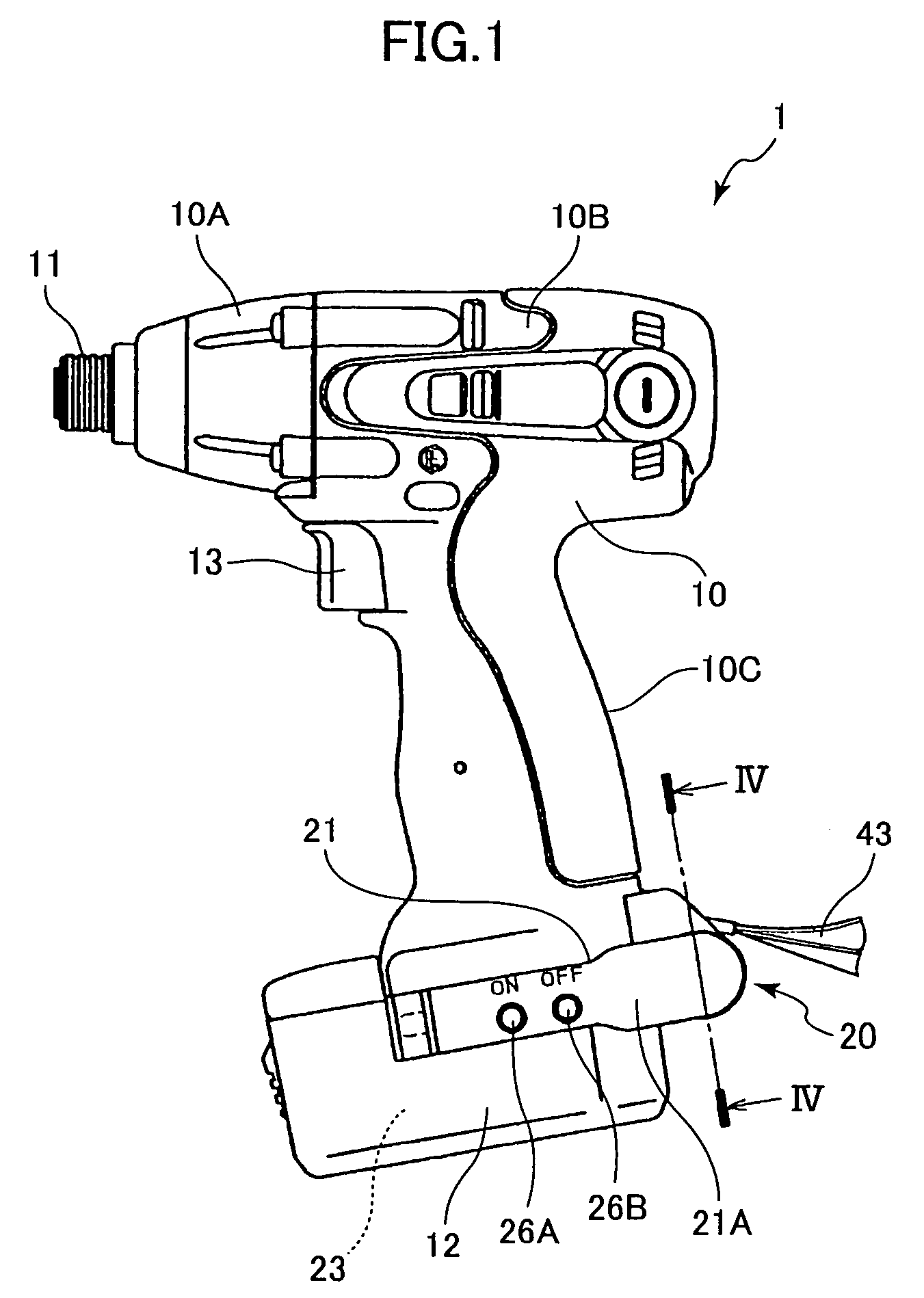

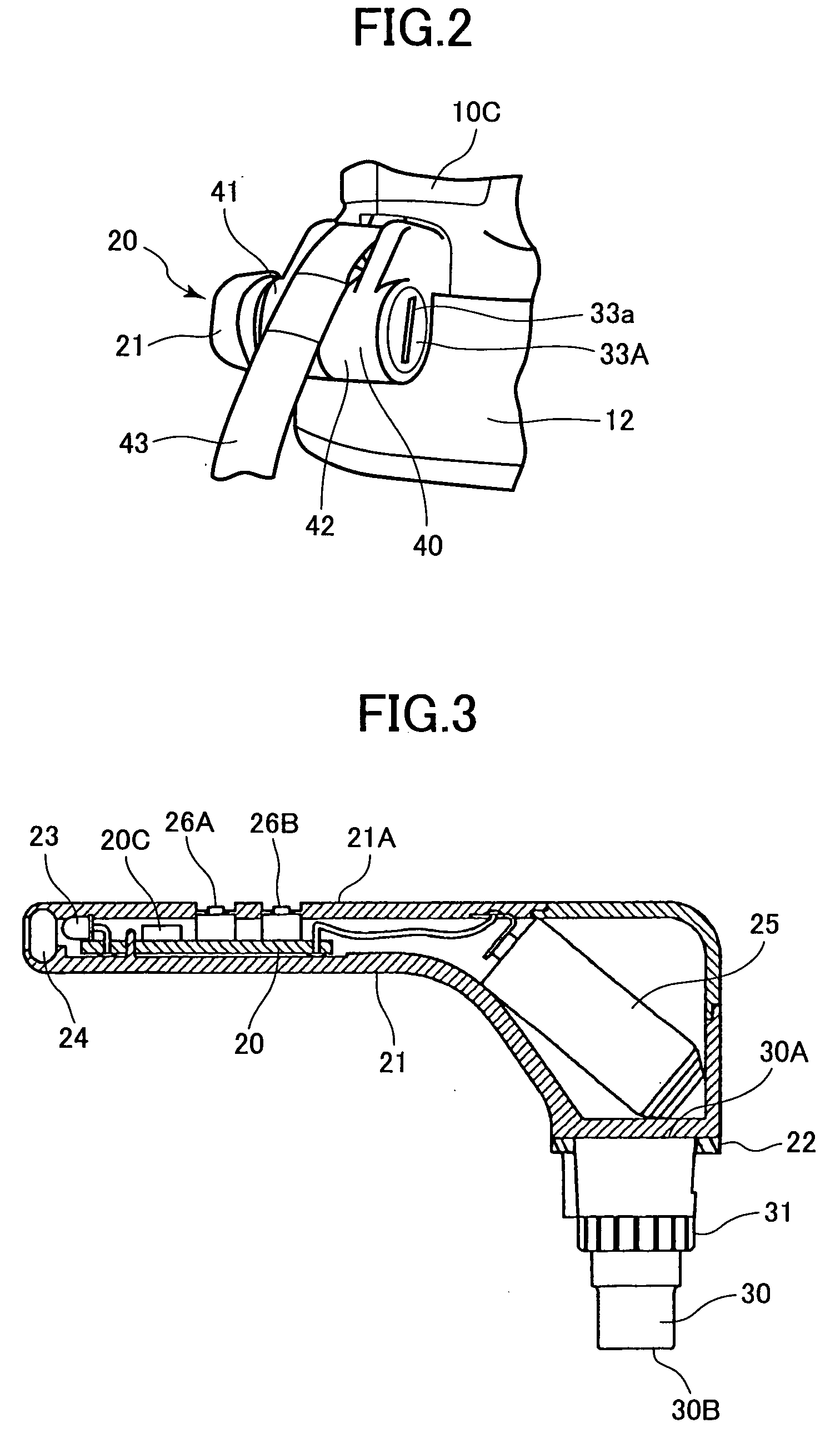

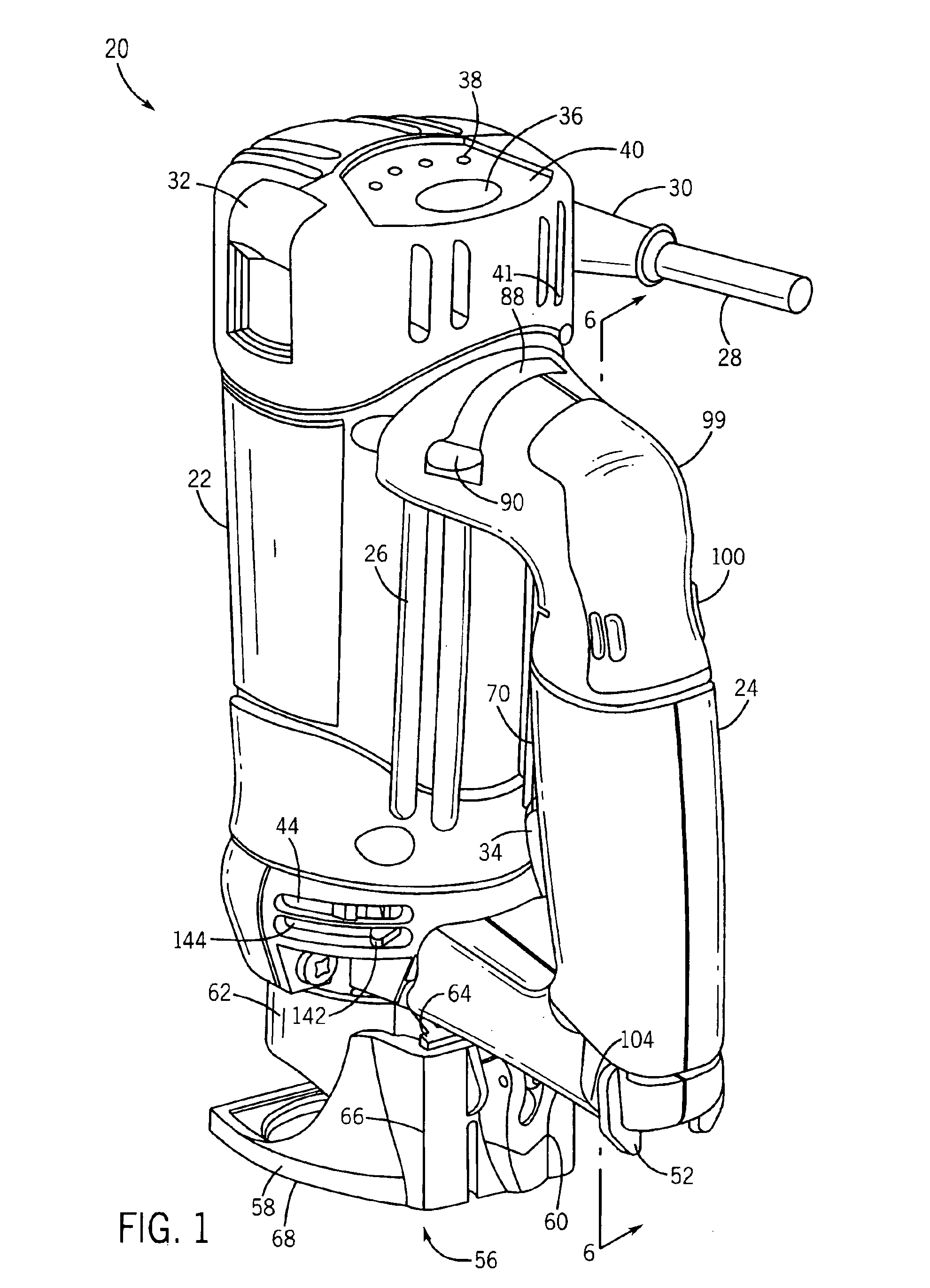

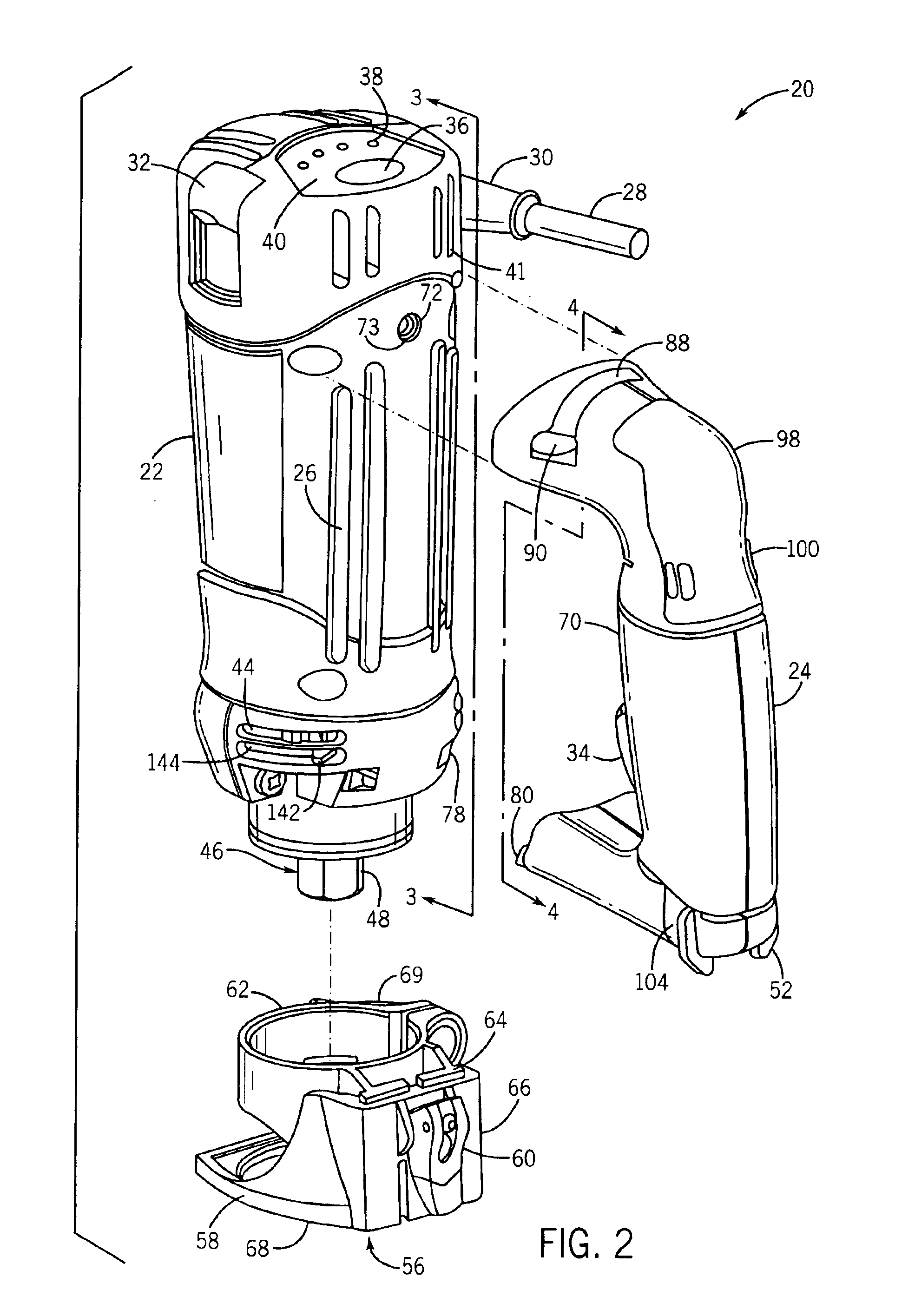

Power tool

InactiveUS7185998B2Stable illuminationImprove usabilityDrilling/boring measurement devicesThread cutting machinesEffect lightEngineering

A power tool has a light unit provided at the bottom part of the handle grip. The light unit can be adjusted to change the lighting angle and can hold the desired lighting angle. The light unit thus disposed does not get in the way, the lighting angle of the light unit is variable and the emitted light does not shake, depletion of the power supply due to the light switch of the light unit being left on is prevented, shadows of the end tool are not easily produced by light from the light unit, lighting contrast is high, wiring failures and continuity faults in the light-emitting element do not occur easily, and a small, economical power tool can be provided. The light-emitting element of the light unit is a yellow LED. The light unit turns off automatically at a predetermined time after the light turns on.

Owner:KOKI HLDG CO LTD

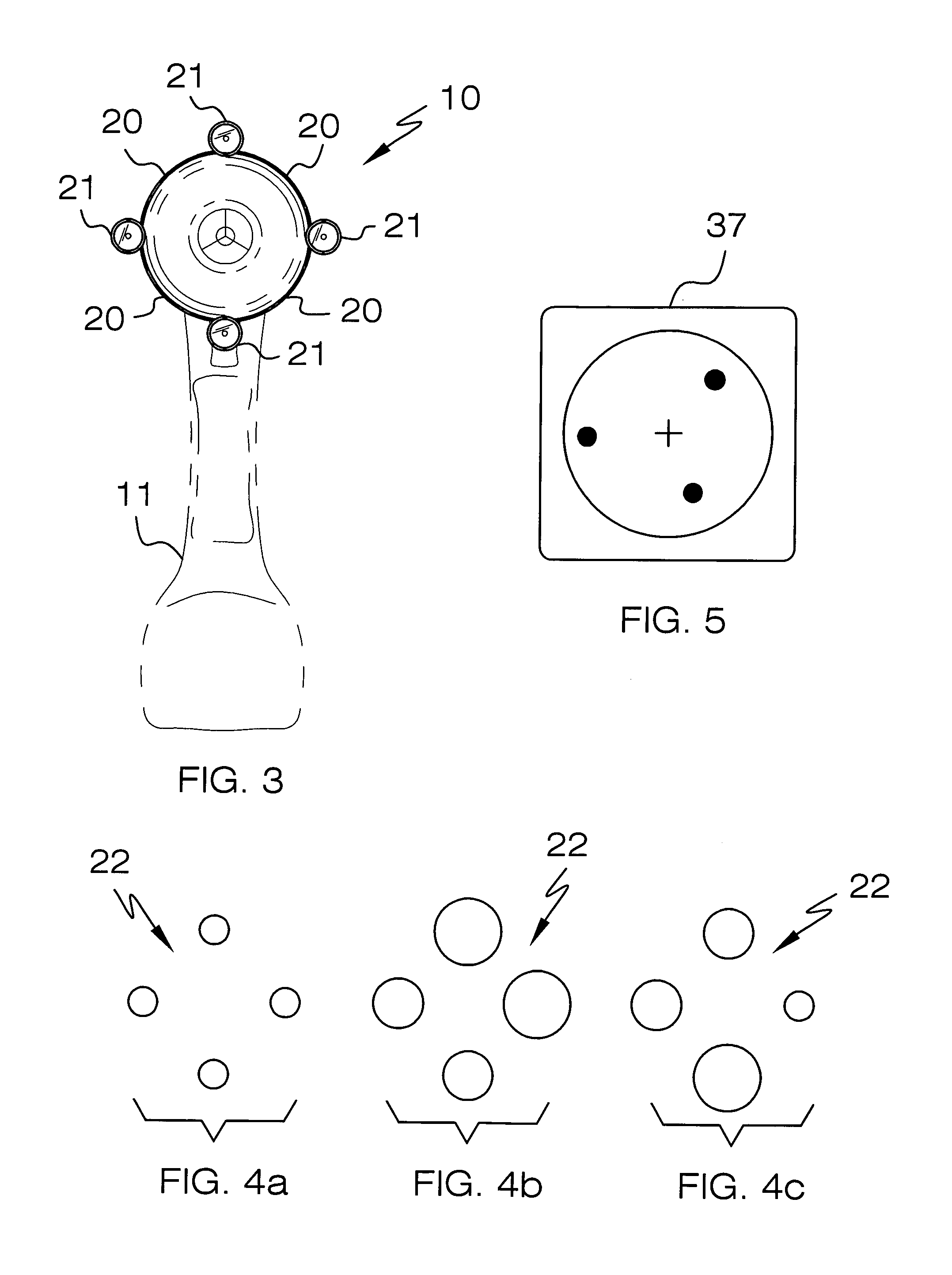

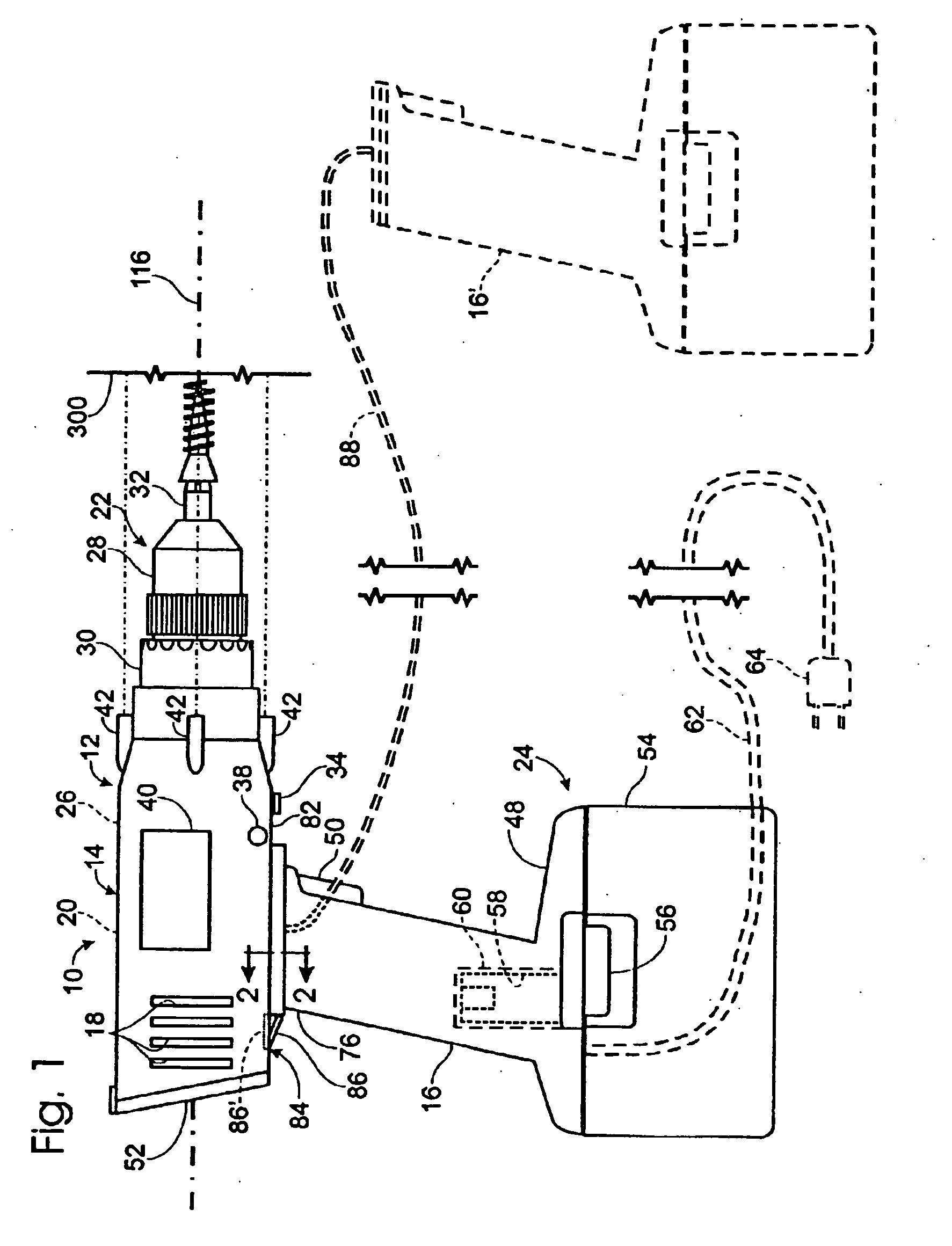

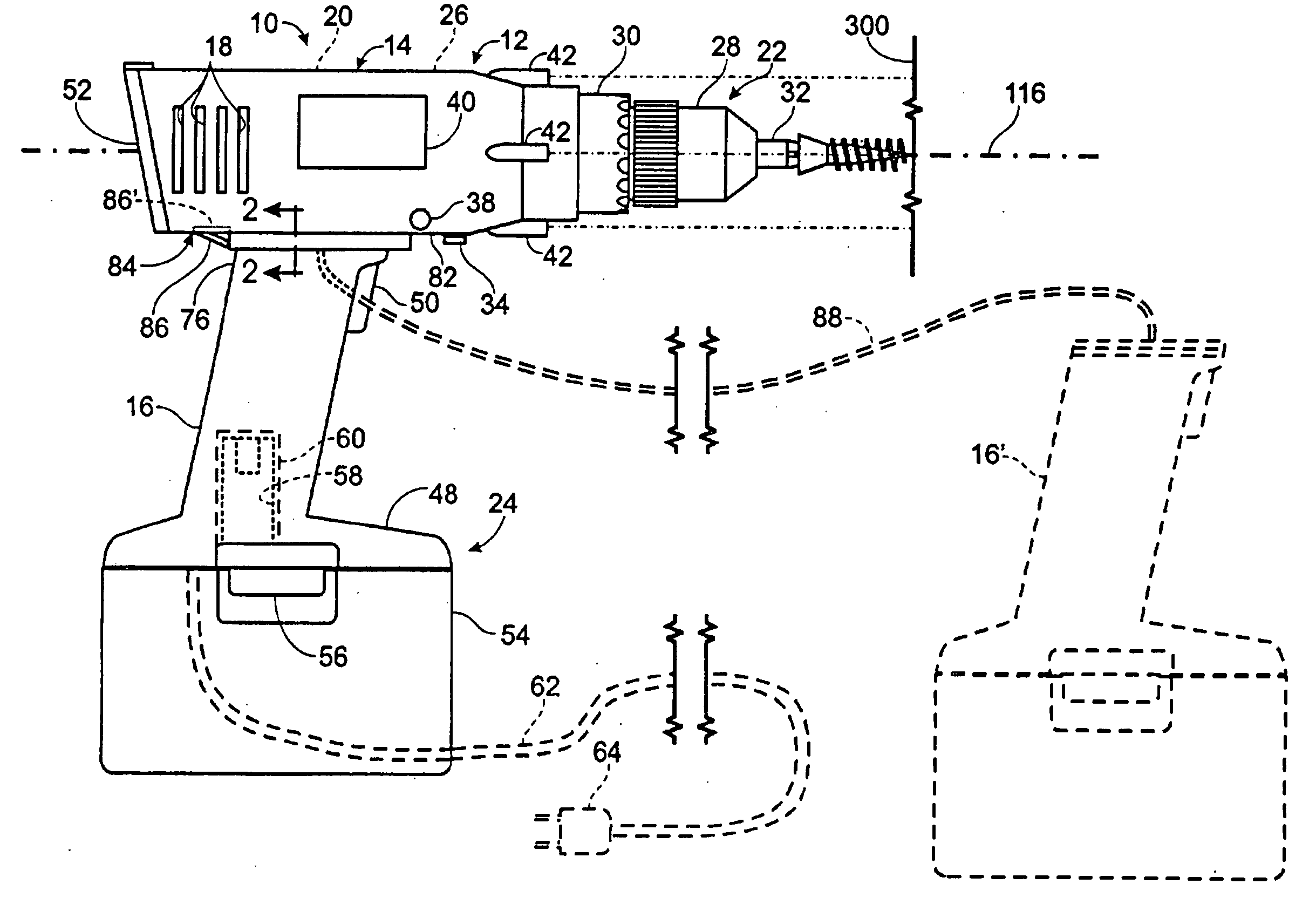

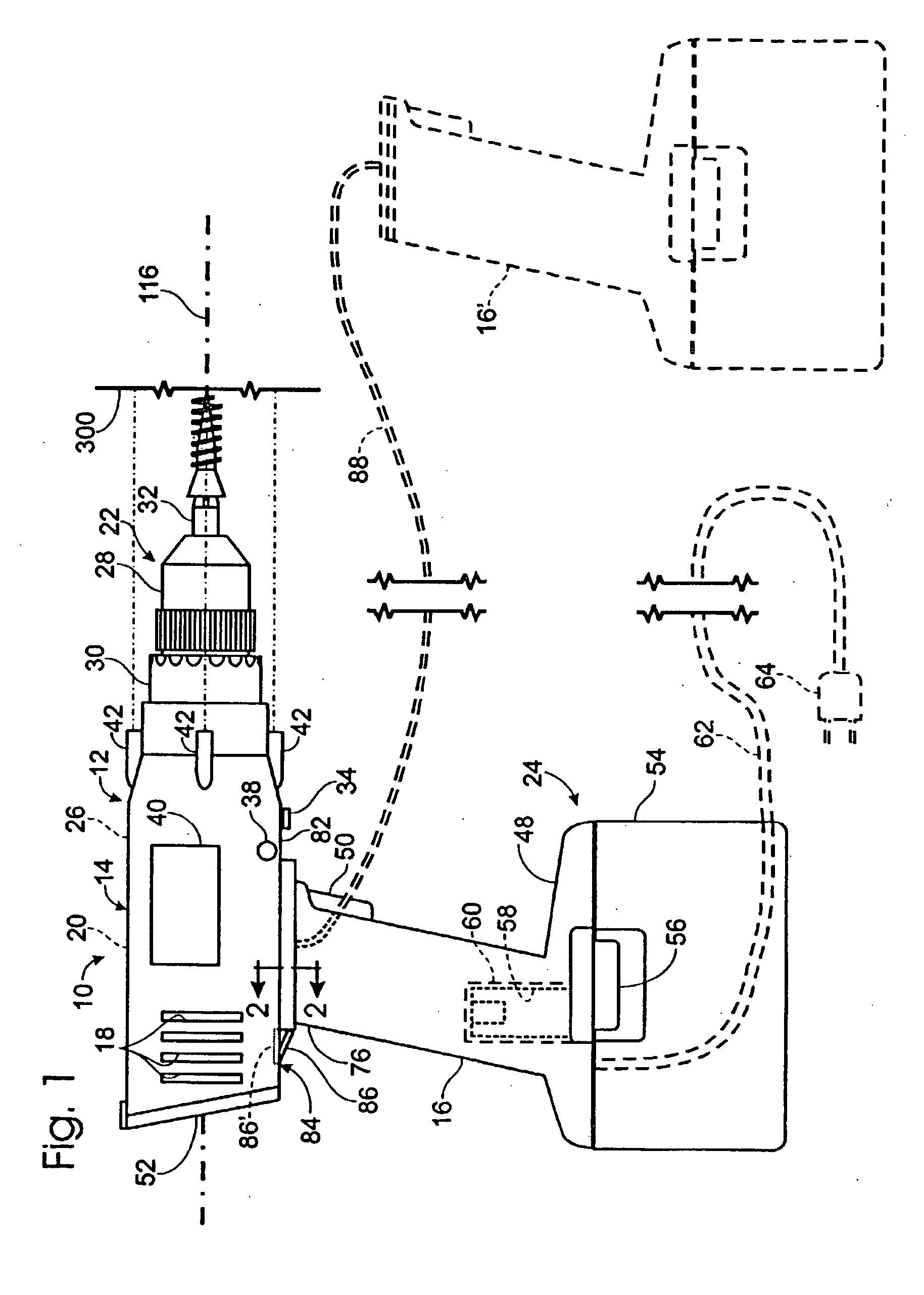

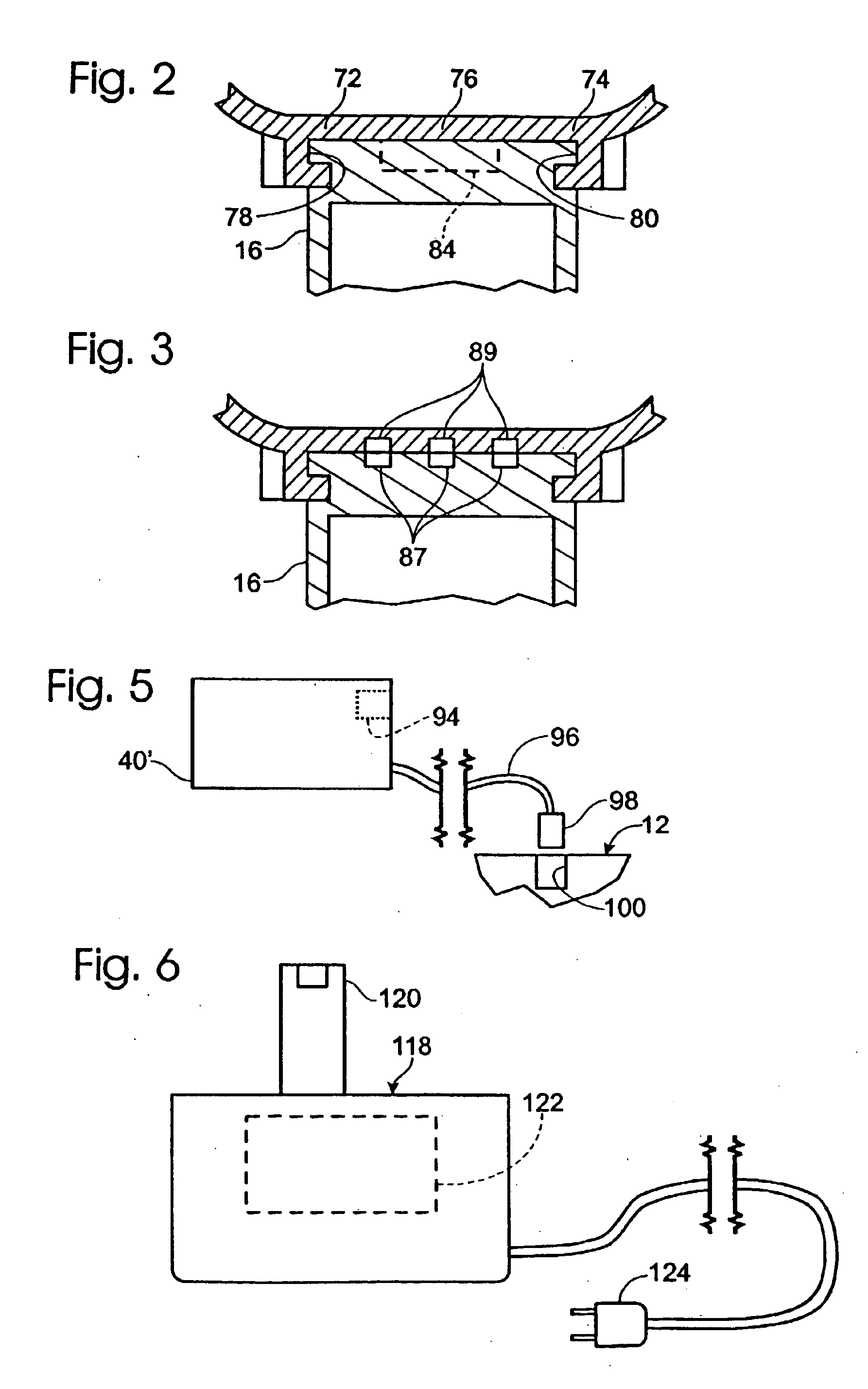

Power tool control system

InactiveUS20060076385A1Quality improvementWell formedStapling toolsDrilling/boring measurement devicesUser needsGraphics

A power tool control system allows a user to operate a power tool through a graphical user interface communicatively coupled with a non-contact measurement and alignment device. The graphical user interface correlates user engageable selectors with a logically related menu of power tool setting options displayed on a display screen in a high quality and easily readable format. The non-contact measurement and alignment device uses one or more lasers to determine power tool settings and establish proper alignment based on user needs. The power tool control system further enables stud detection and visual indication of stud location.

Owner:BLACK & DECKER INC

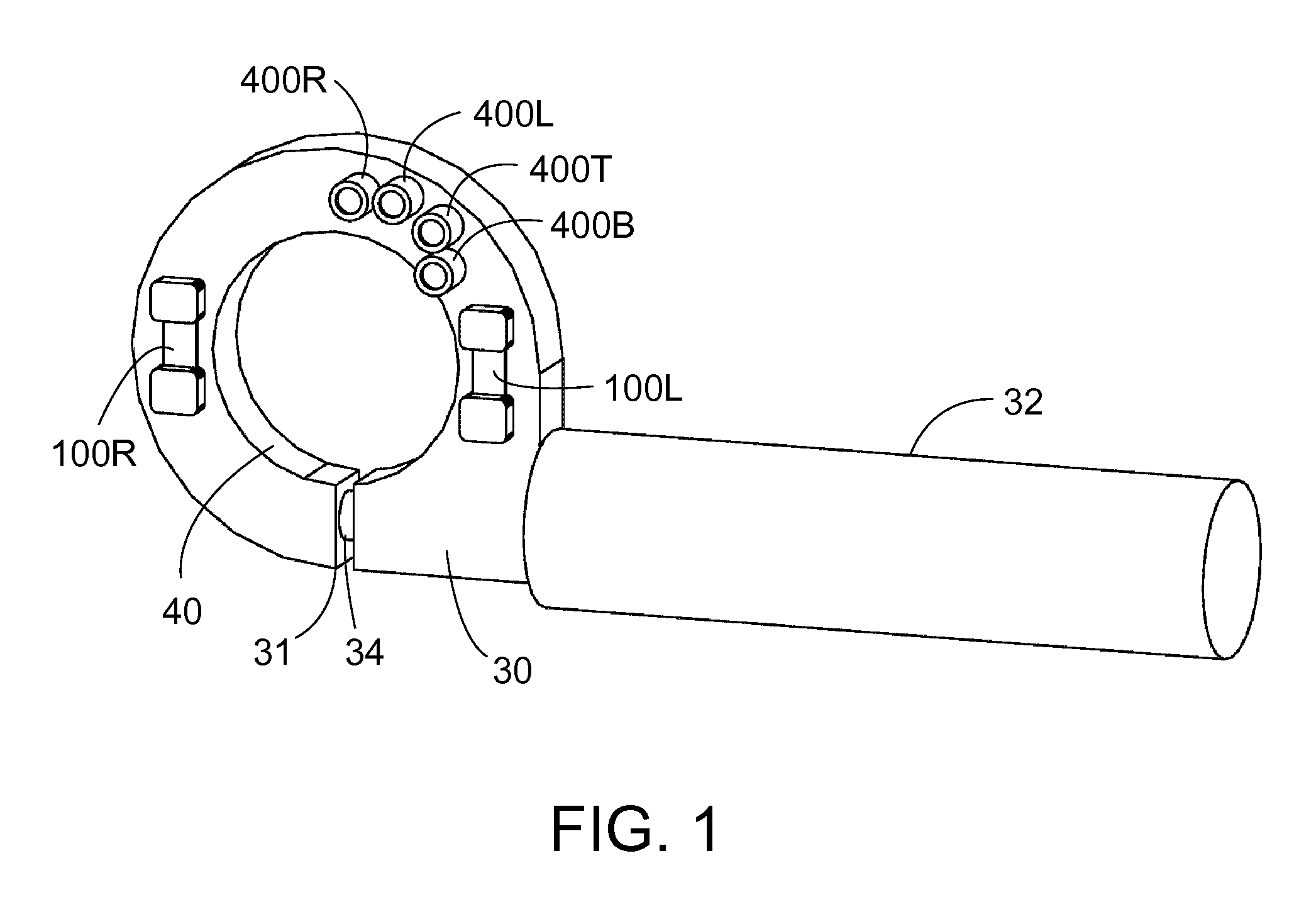

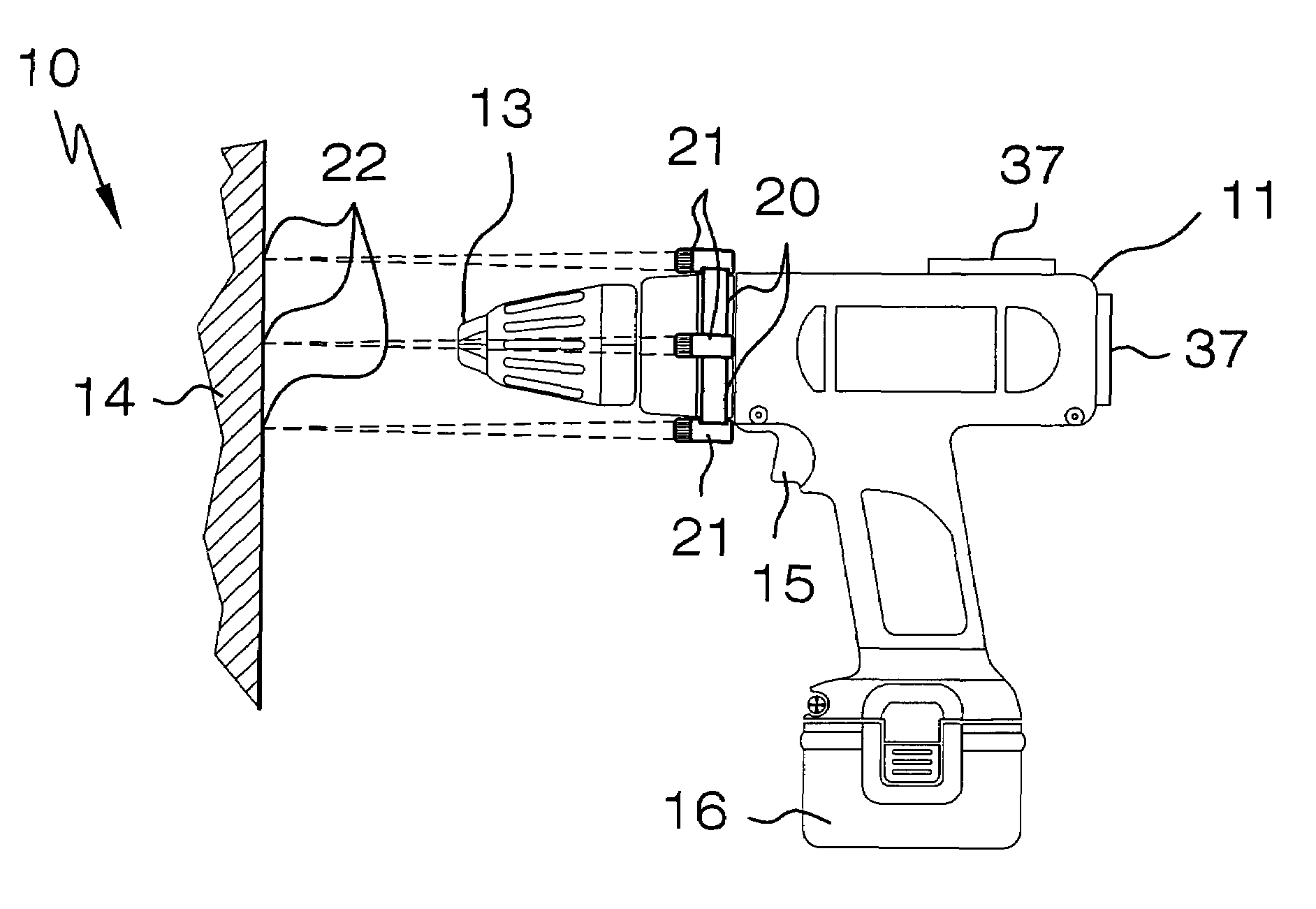

Alignment accessory for portable drills and the like

ActiveUS7200516B1Effectively and conveniently alignedQuickly and efficiently alignDrilling/boring measurement devicesWork benchesTarget surfaceOptoelectronics

An apparatus includes a strap that is positional about a drill and maintains a static relationship therewith while a drill bit and chuck rotate. The apparatus includes a plurality of light sources and sensors. The light sources and sensors face forwardly and emit corresponding light arrays aligned parallel to the drill bit and measure a linear distance to a target surface respectively. Each light source defines a reflection that has a unique diameter when the drill is not perpendicular, notifying the user to adapt the drill such that identical diameters are reflected on the work surface. A mechanism communicates an output signal to a display screen so that a visual representation of the drill bit location becomes displayed on a display screen. The drill bit is aligned perpendicular to the work surface when the light sources are equidistantly spaced from the work surface.

Owner:COWLEY BRIAN J

Power tool control system

InactiveUS8004664B2Quality improvementWell formedStapling toolsDrilling/boring measurement devicesGraphical user interfaceControl system

A power tool control system includes a non-contact measurement and alignment device operative with the power tool and enabled to establish various readings, such as power tool settings. A graphical user interface communicatively coupled with the non-contact measurement and alignment device enables user control over and display of the readings from the non-contact measurement and alignment device.

Owner:CHANG TYPE INDAL

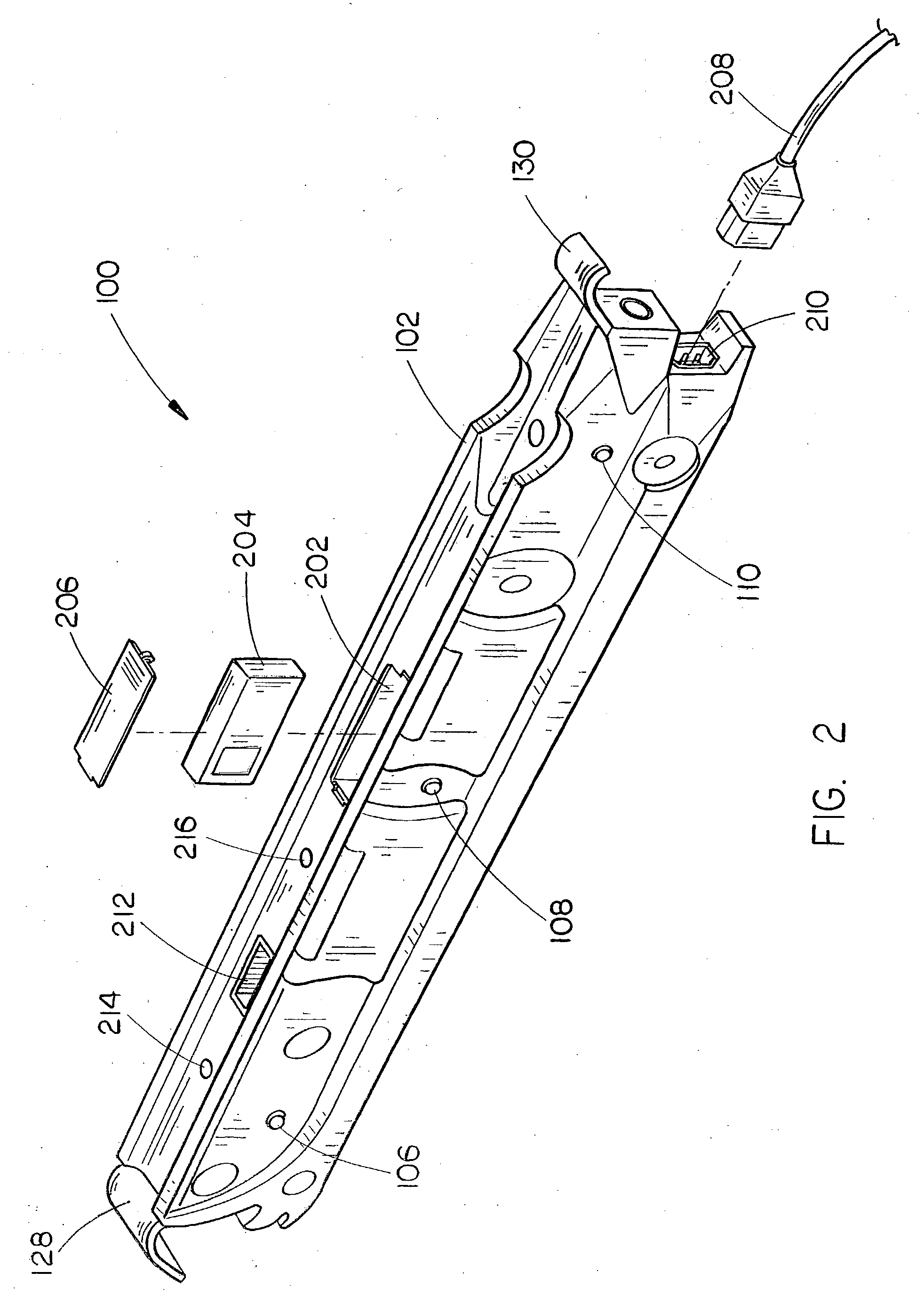

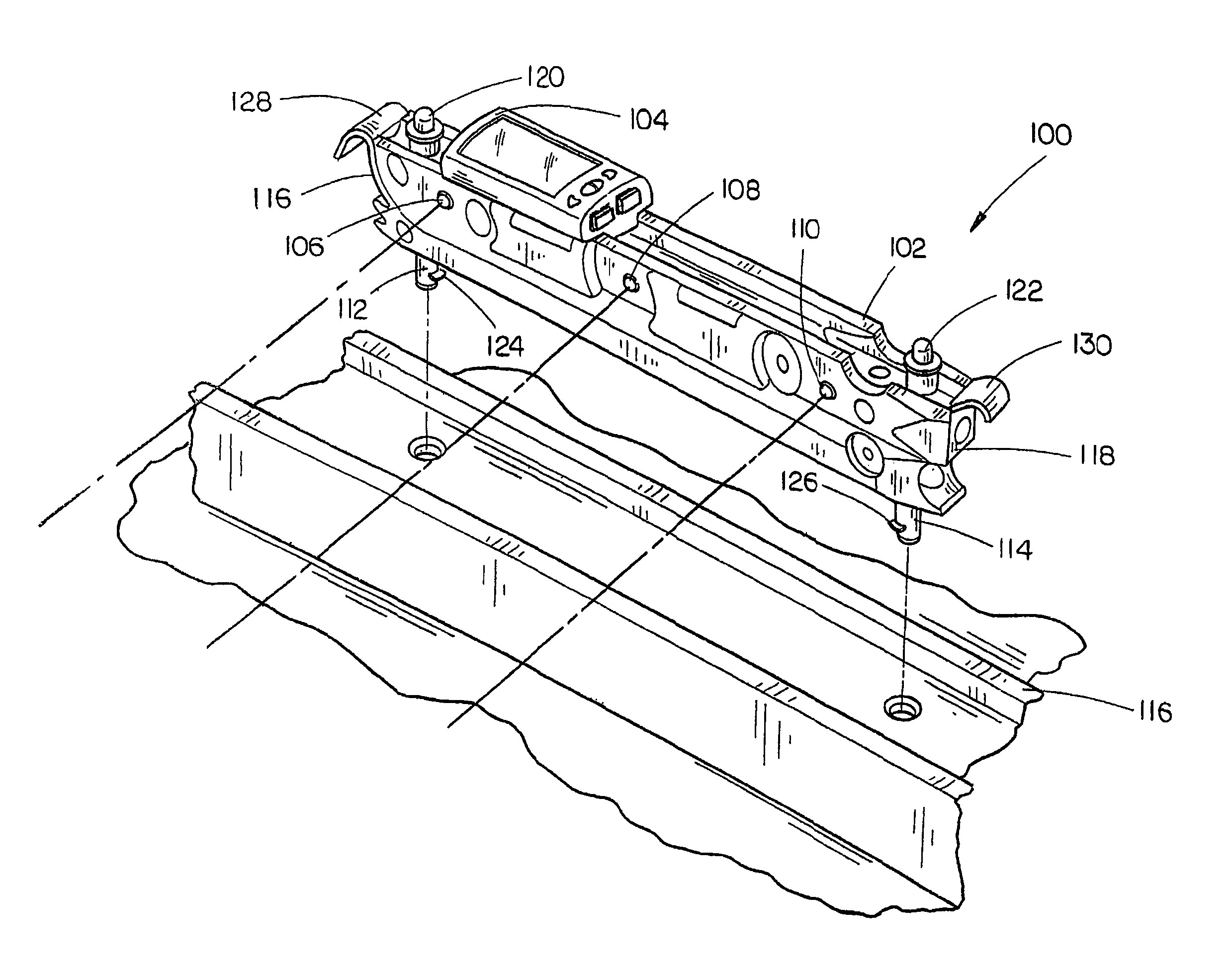

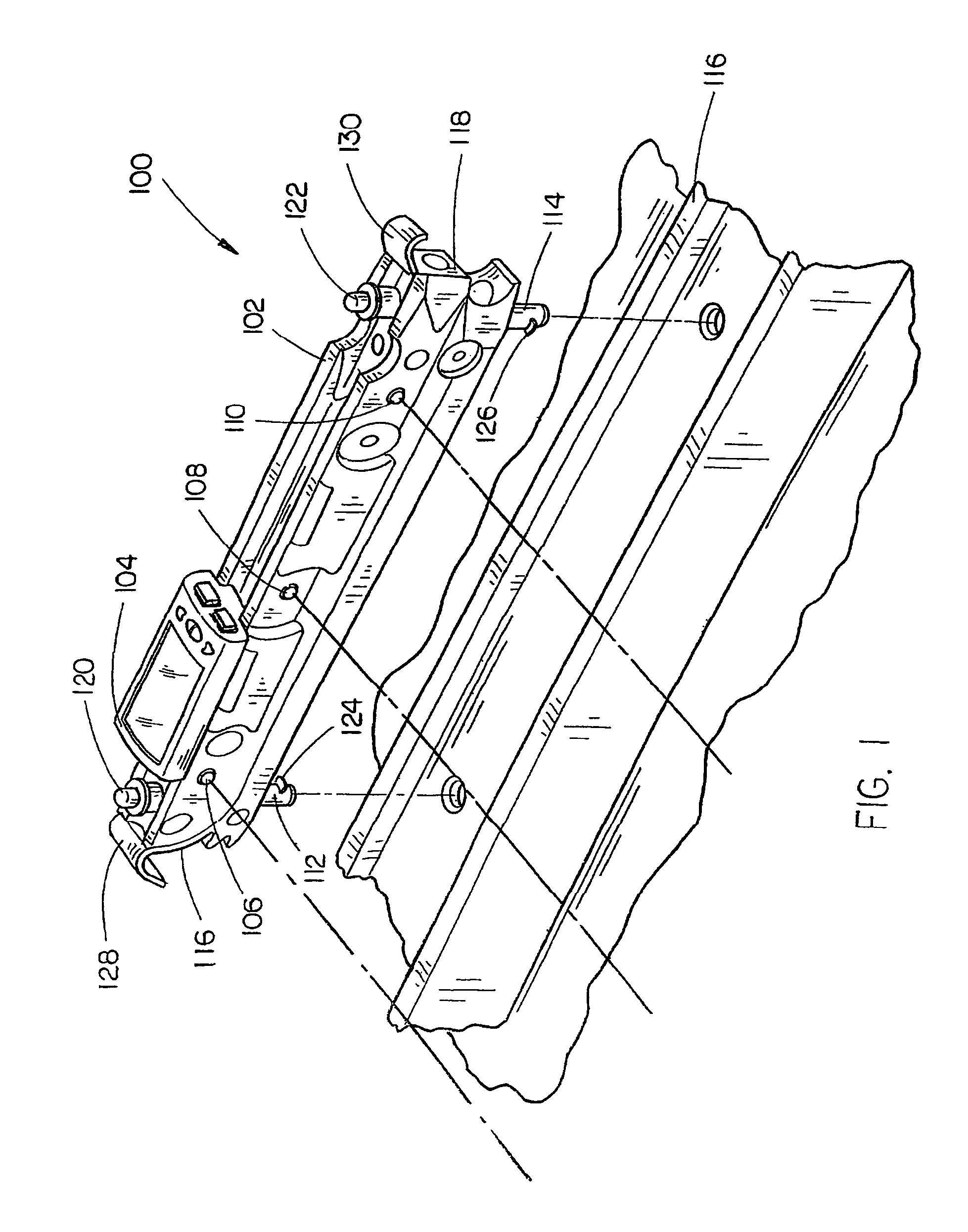

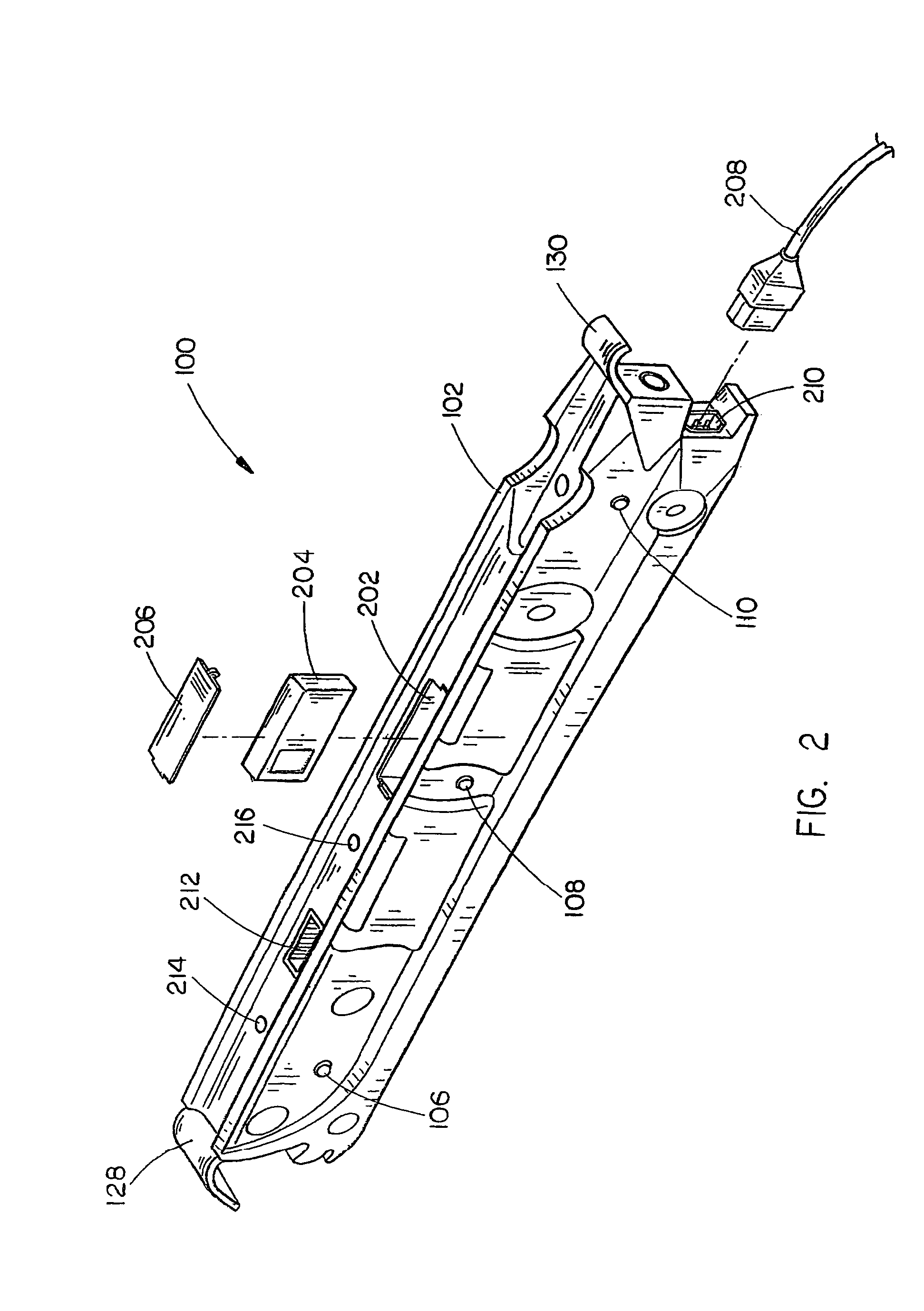

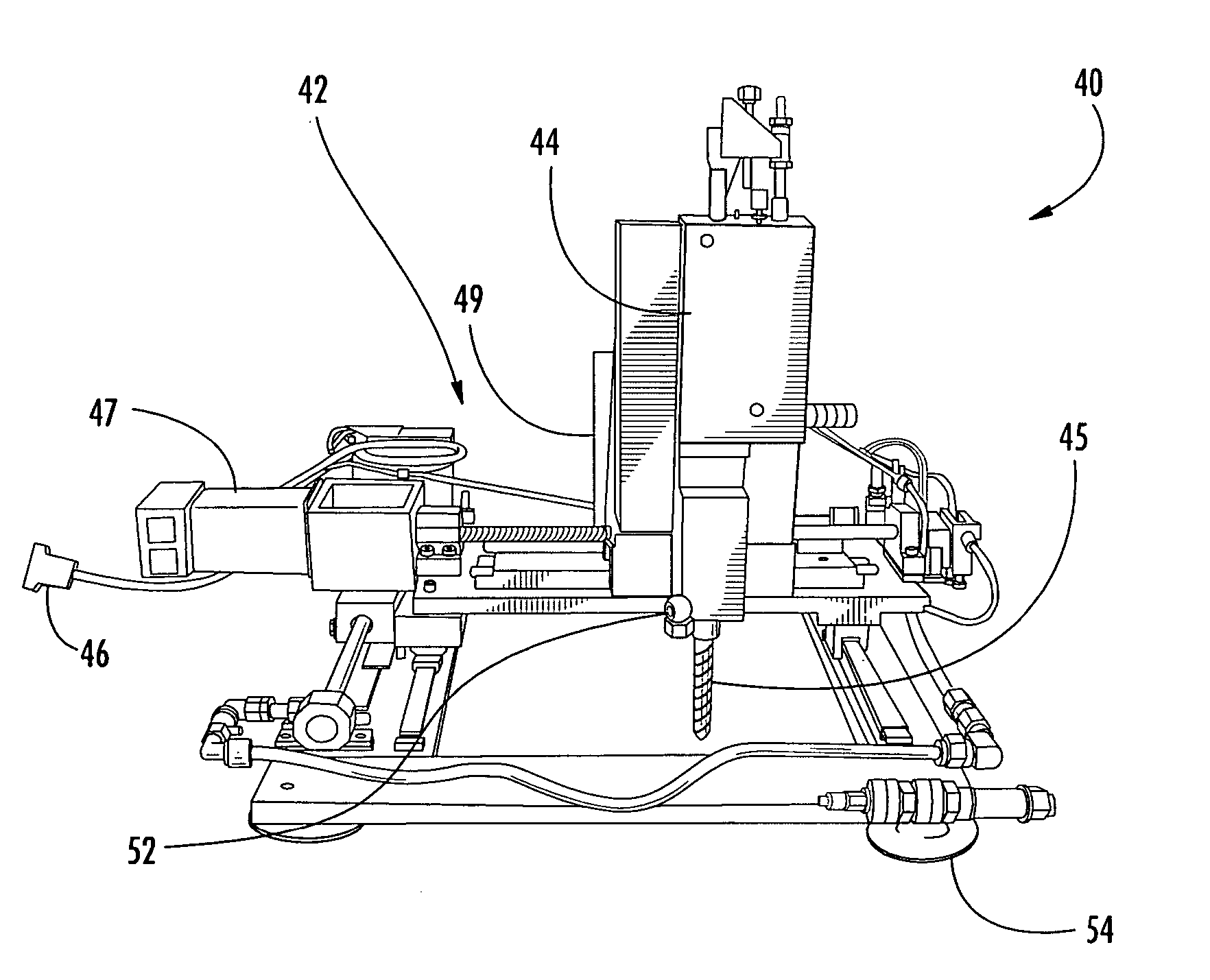

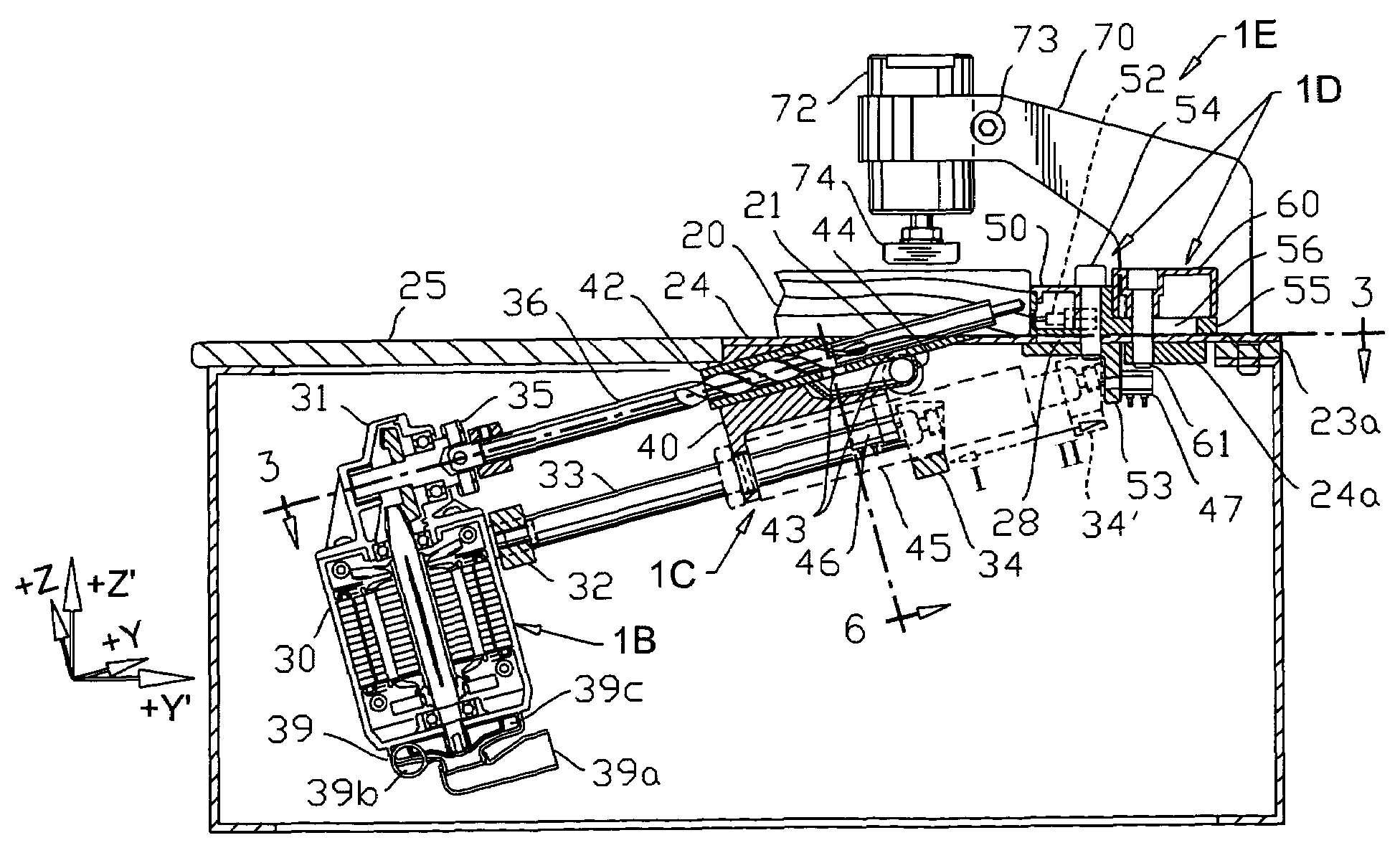

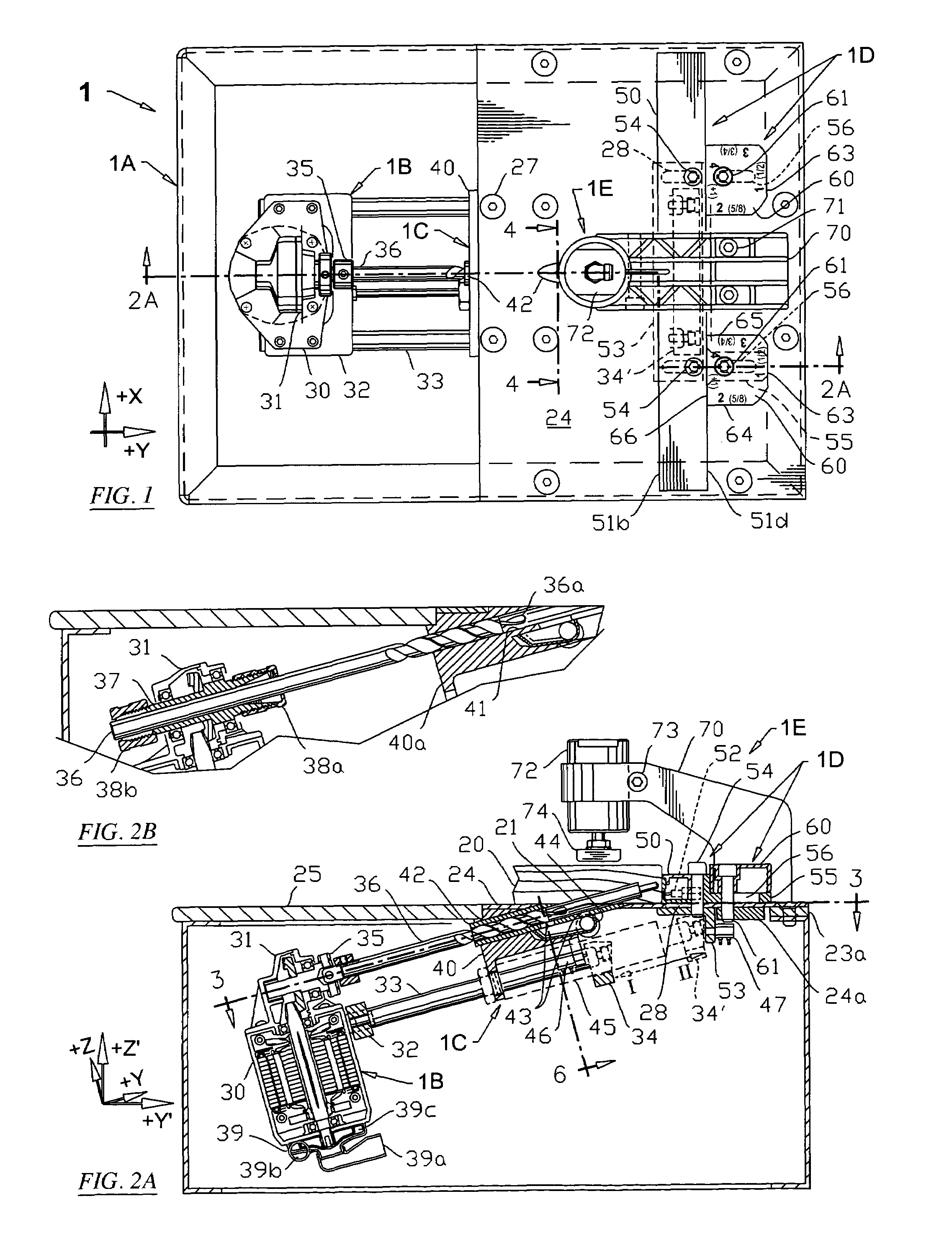

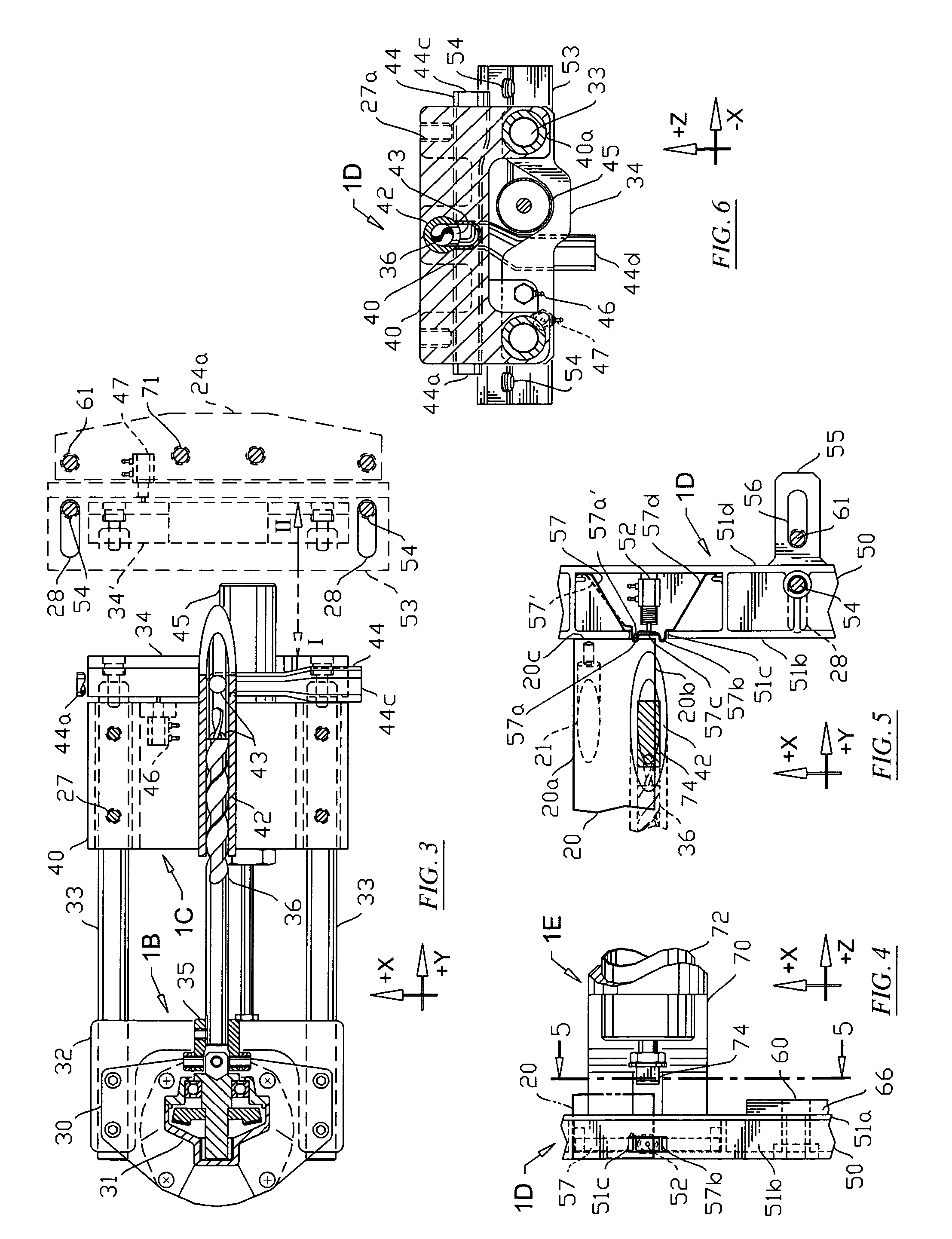

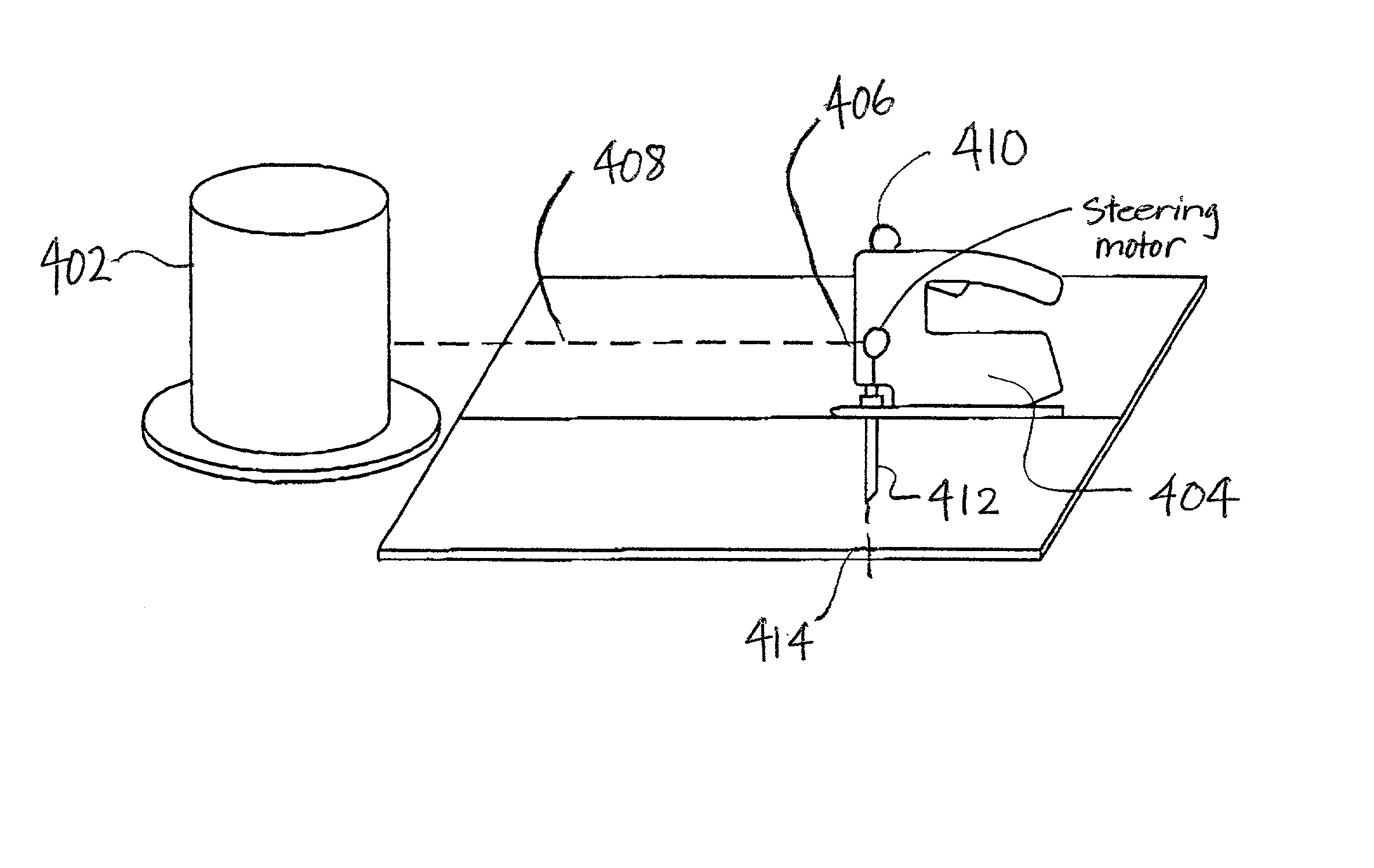

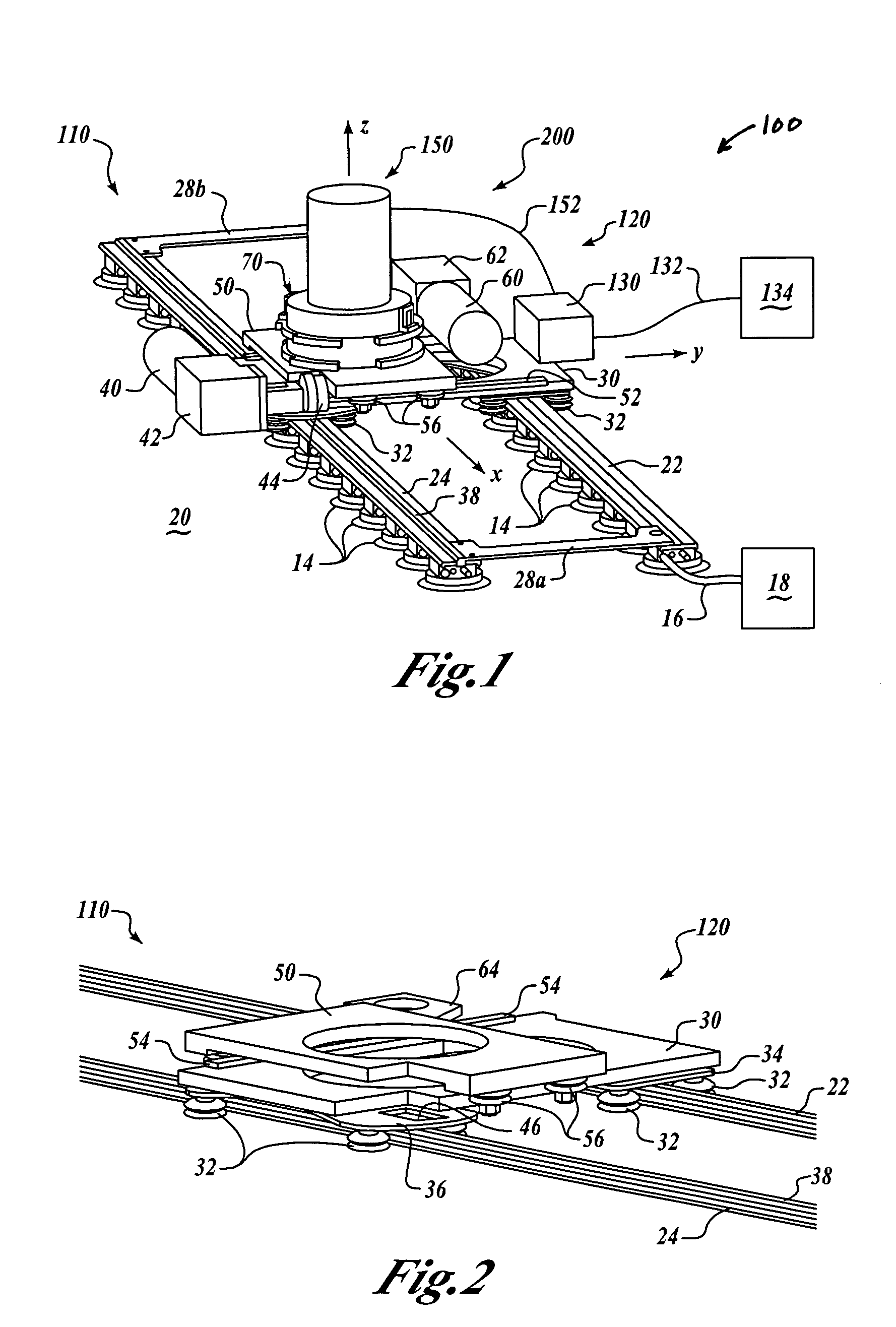

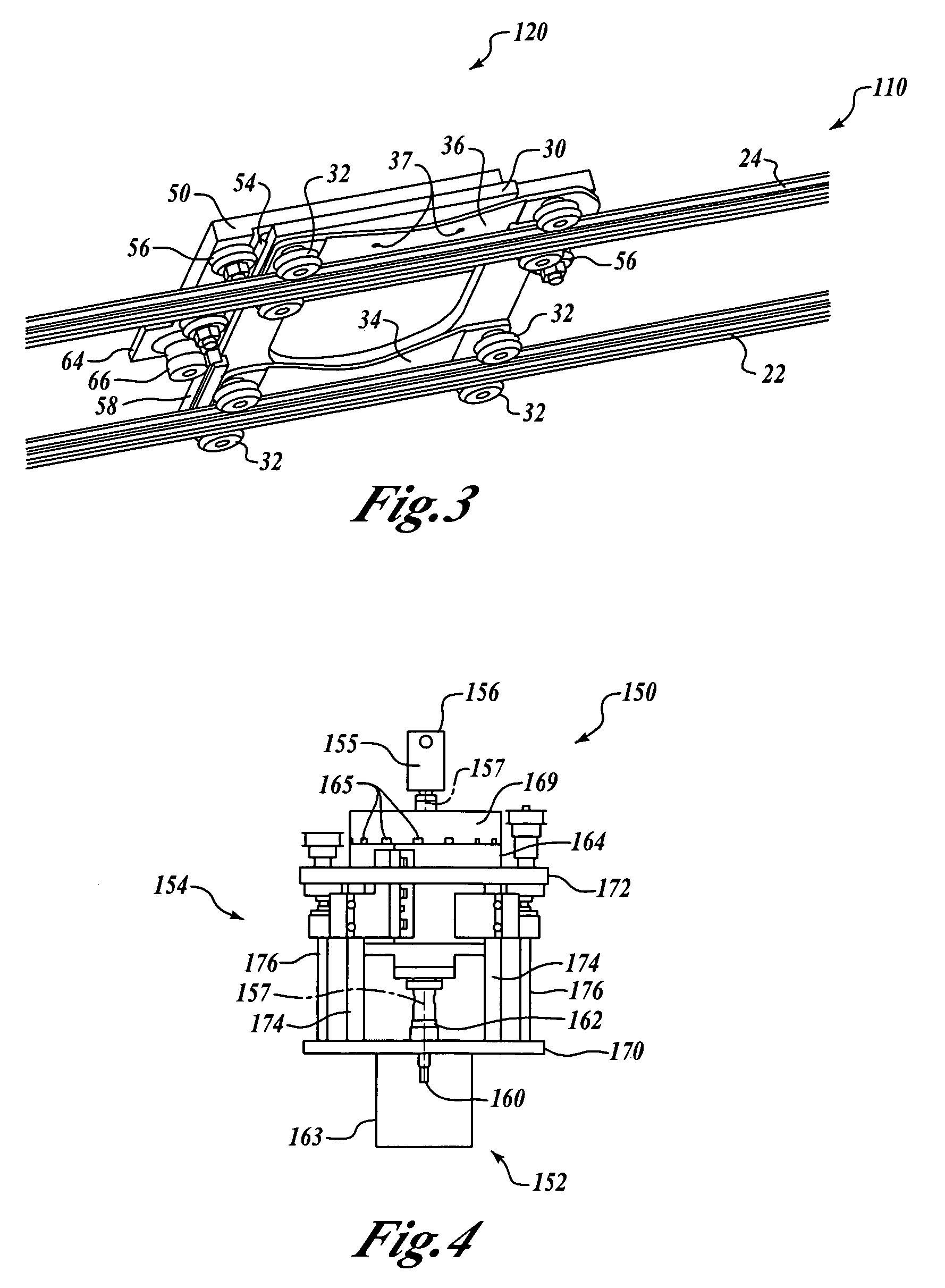

Apparatus for manufacturing operations using non-contact position sensing

InactiveUS6926094B2Improve accuracyImprove efficiencyDrilling/boring measurement devicesThread cutting machinesEngineeringAnalog signal

Apparatus and methods for manufacturing operations using non-contact position sensing are disclosed. In one embodiment, an apparatus includes a track assembly adapted to be attached to a workpiece, a carriage assembly moveably coupled to the track assembly and moveable relative to the workpiece, and a position sensor. The position sensor includes a sensor element adapted to detect at least one edge of an index feature on the workpiece from a distance away from the index feature. In an alternate embodiment, the position sensor may include a sensing circuit that receives an analog signal from the sensing element and provides both analog and digital output signals. In another embodiment, a controller that controls manufacturing operations may be mounted directly on the carriage assembly.

Owner:THE BOEING CO

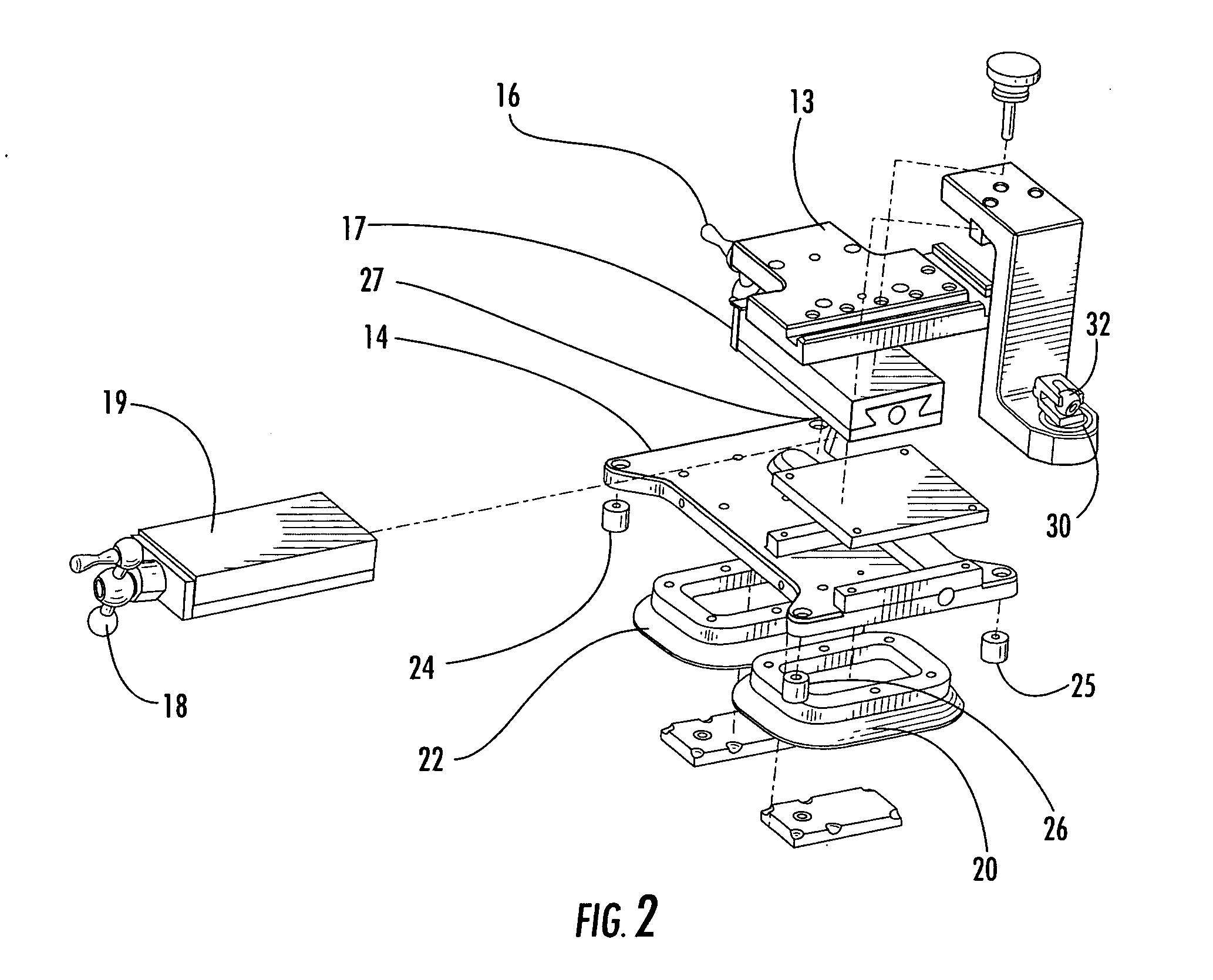

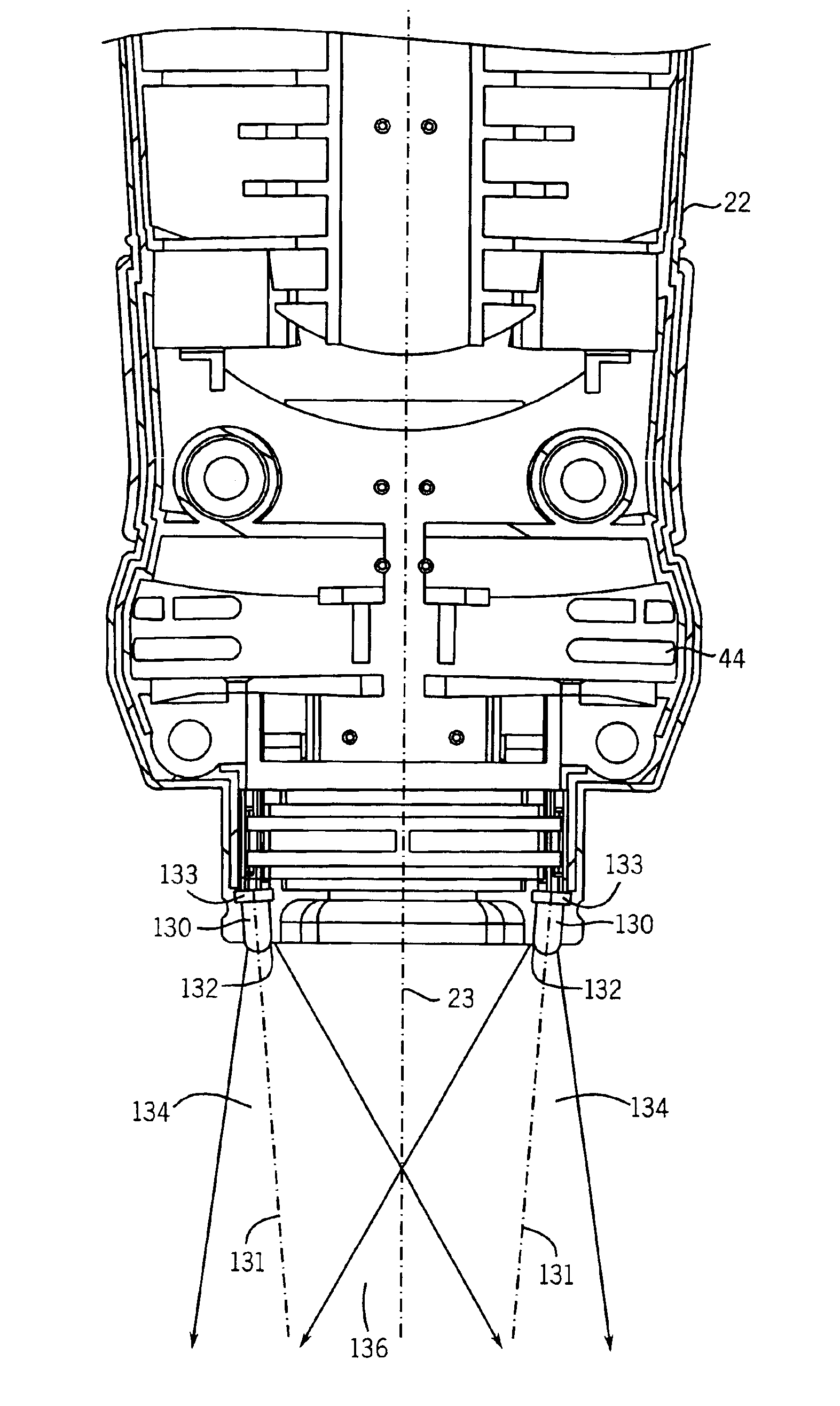

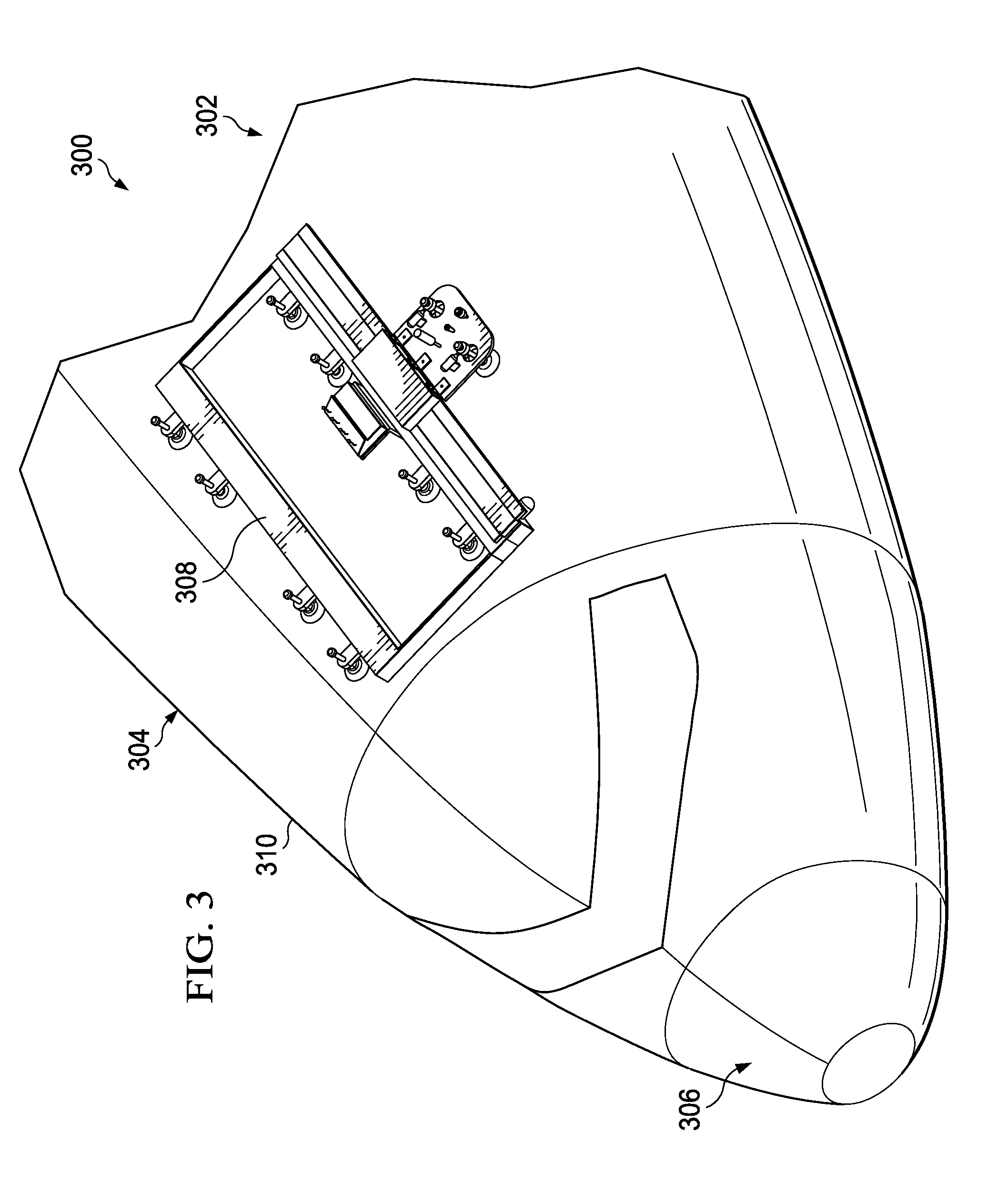

Laser-guided coordination hole drilling

ActiveUS20050147477A1Suitable for machiningEliminate needAircraft componentsDrilling/boring measurement devicesLaser targetLaser tracker

A laser-guided coordination hole tool for precisely drilling holes in large parts includes a positioning table, a bushing cavity for receiving drill bushings, a clamping device, and a laser target. A laser-guided coordination hole tool may include a software interlock to prevent drilling in an improper location on the part. A method of drilling coordination holes includes probing a part to determine its reference frame, rigidly affixing a laser-guided coordination hole tool to the part, probing a target on the laser-guided coordination hole tool to determine the reference frame for the laser-guided coordination hole tool, accurately positioning a drill bushing over the hole location, and drilling a hole. A system for drilling coordination holes includes a laser-guided coordination hole tool, a bushing, a tooling, a drill motor, a laser tracker, and a computer running a coordination-hole drilling program.

Owner:THE BOEING CO

Power tool with light emitting diode

A rotary cutting tool includes a housing and a motor provided within the housing for rotating a cutting accessory coupled to the rotary cutting tool. The rotary cutting tool also includes a plurality of light emitting diodes for illuminating a point of cut of the rotary cutting tool. Each of the plurality of light emitting diodes have a central longitudinal axis, and at least one of the light emitting diodes is couple to the housing such that the central longitudinal axis of the light emitting diode is not parallel to a rotation axis of the cutting accessory.

Owner:CREDO TECH CORP

Drill measurement stops

InactiveUS7048477B2Easy to identifyReduce manufacturing costThread cutting toolsDental implantsEngineeringVisual perception

A depth stop for use with a drill bit comprises a tubular body having an opening therethrough. Used with a drill bit whose bit portion includes a cutting end, and a shank portion, the depth stop is frictionally positionable on the bit portion at a specified point from the cutting end, thereby indicating a specified depth. Depth stops are manufactured in different colors, each color corresponding to a specified range of drill bits that the depth stops will fit. The depth stops, manufactured from a sterilizable material, are intended for single use. The depth stop can be used with a drill bit and drill extender, where one or more depth stops provide multiple visual points of reference for the operator. The depth stops can be quickly mounted onto most any manufacturer's drill bits.

Owner:IDMS

Power tools

InactiveUS20060037766A1Batteries circuit arrangementsDrilling/boring measurement devicesPower toolElectric motor

Owner:GASS STEPHEN F +1

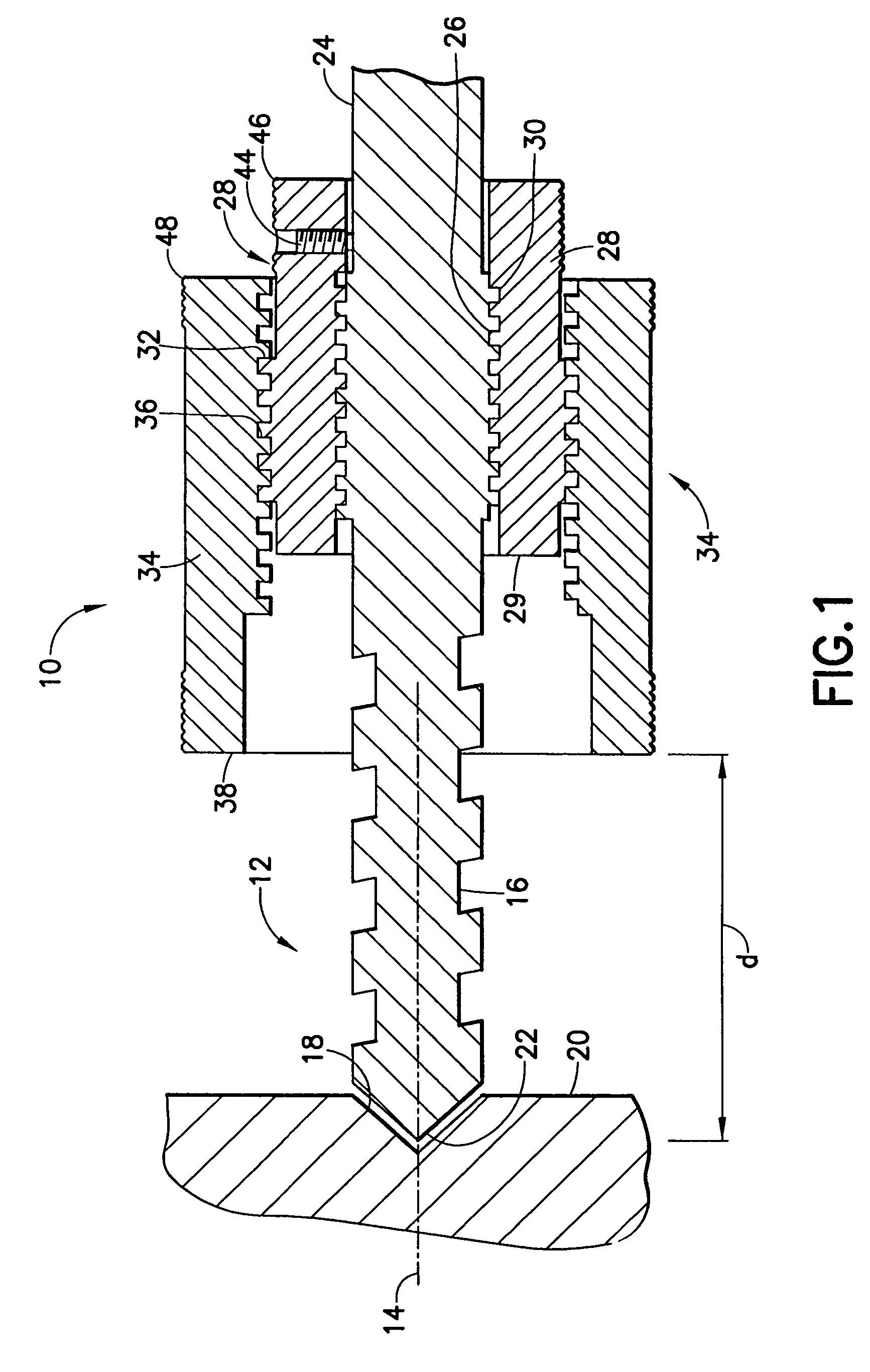

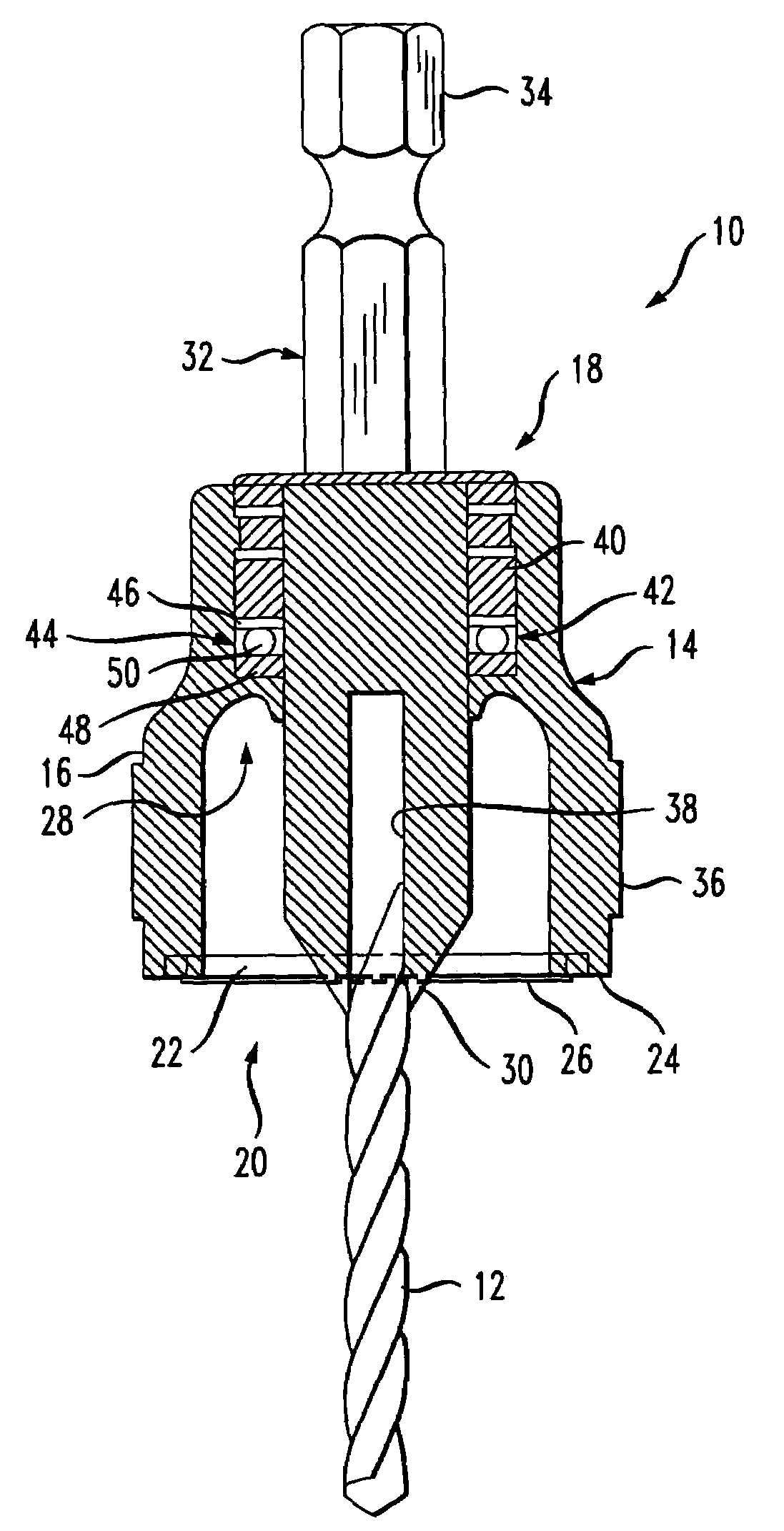

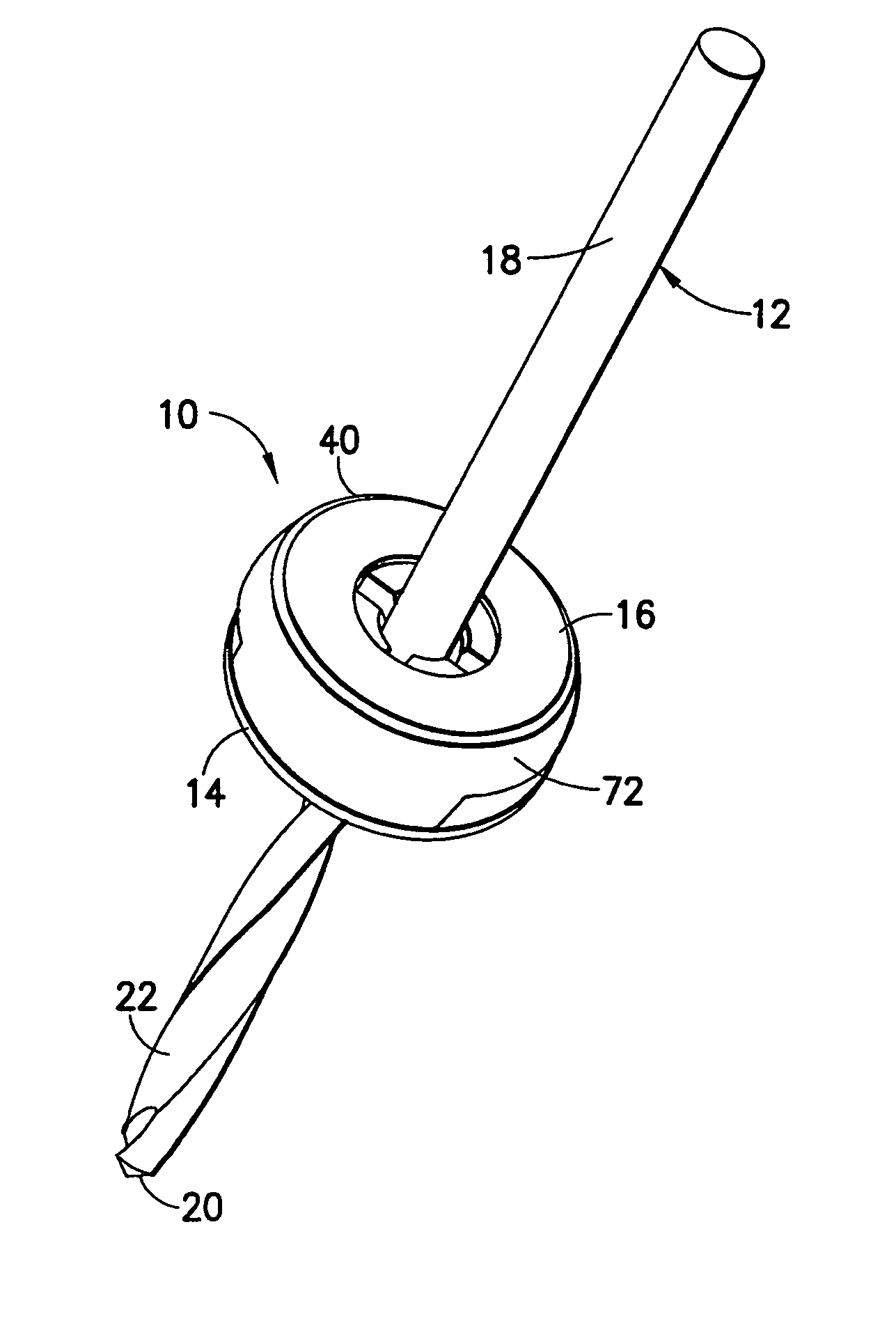

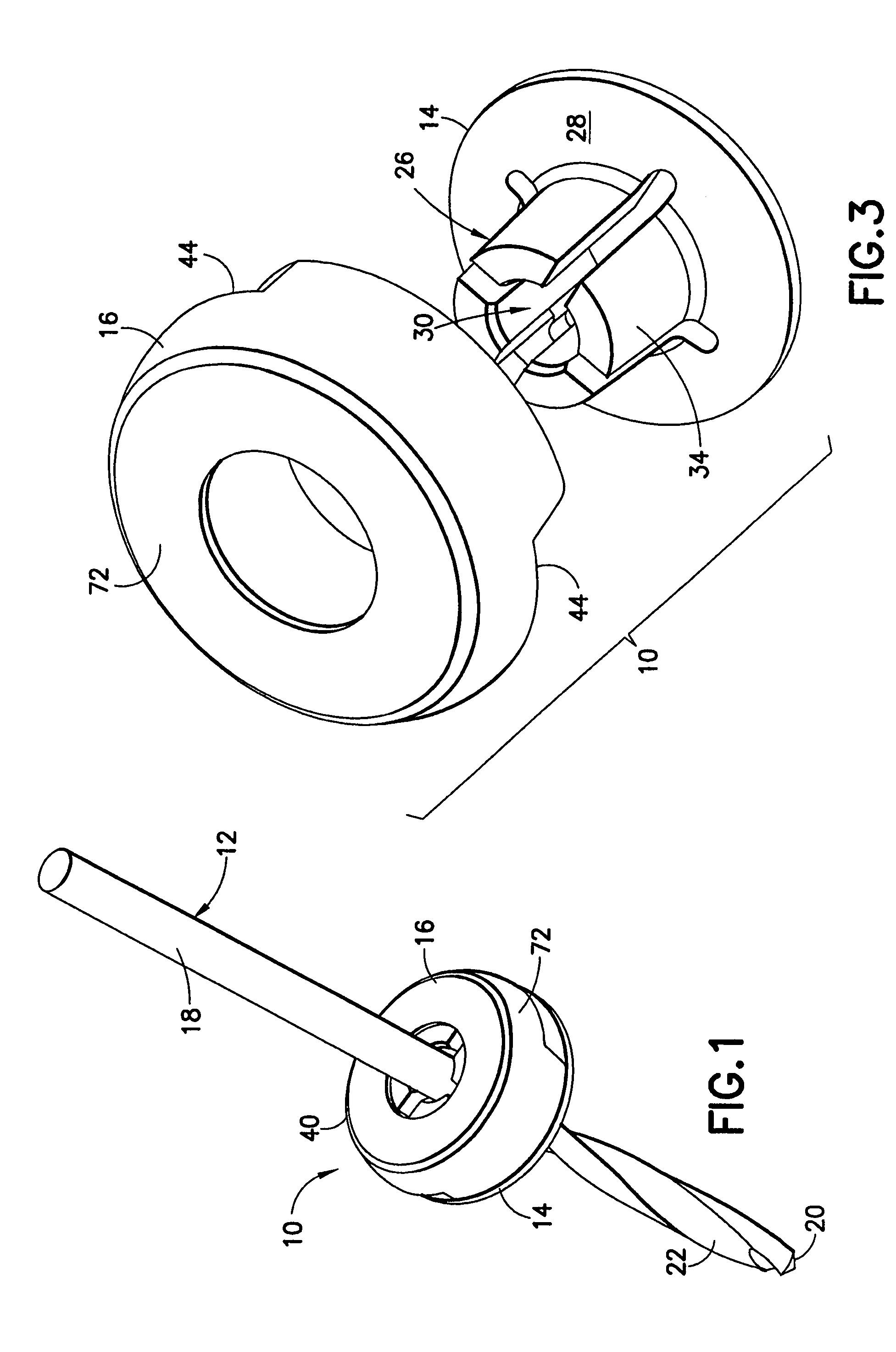

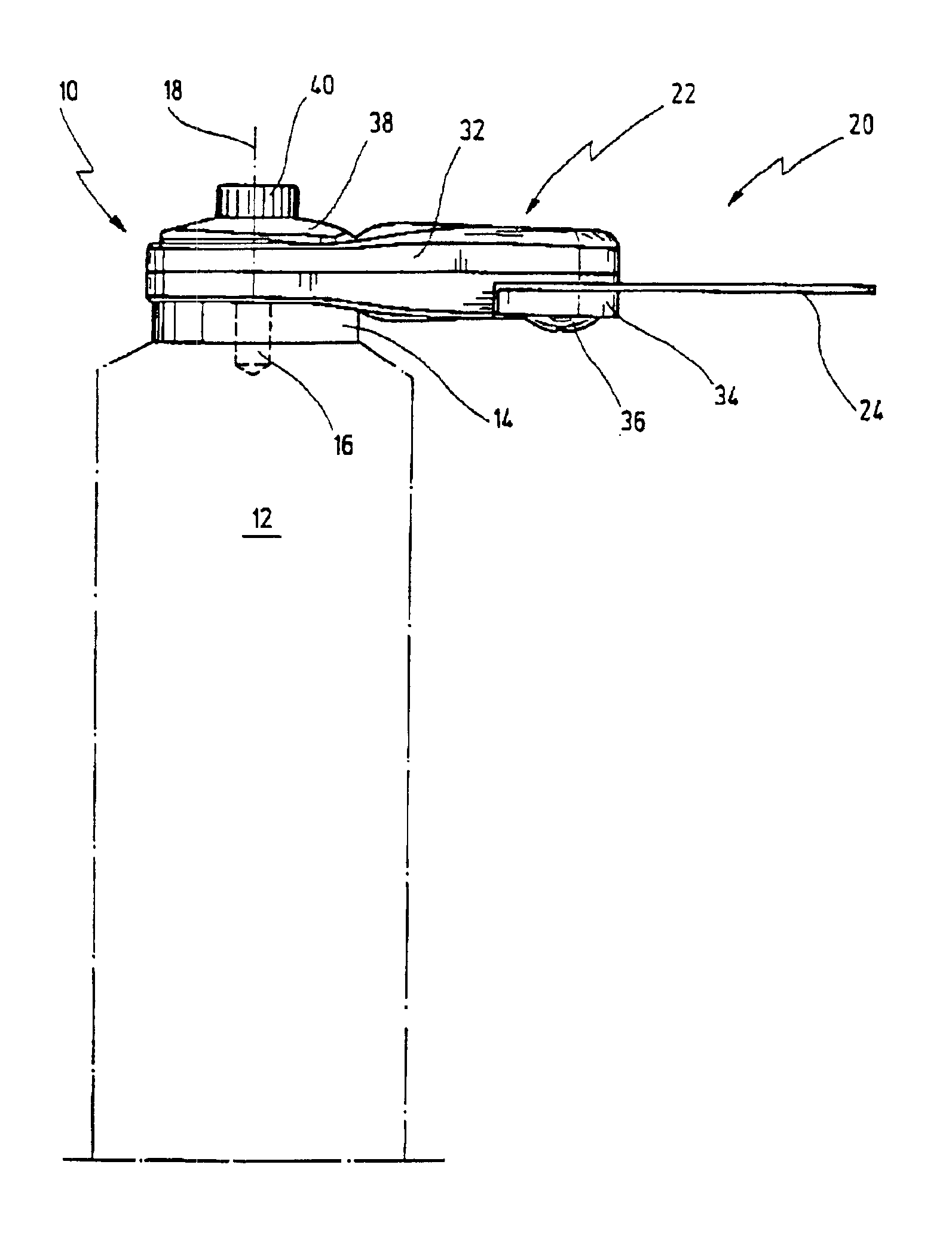

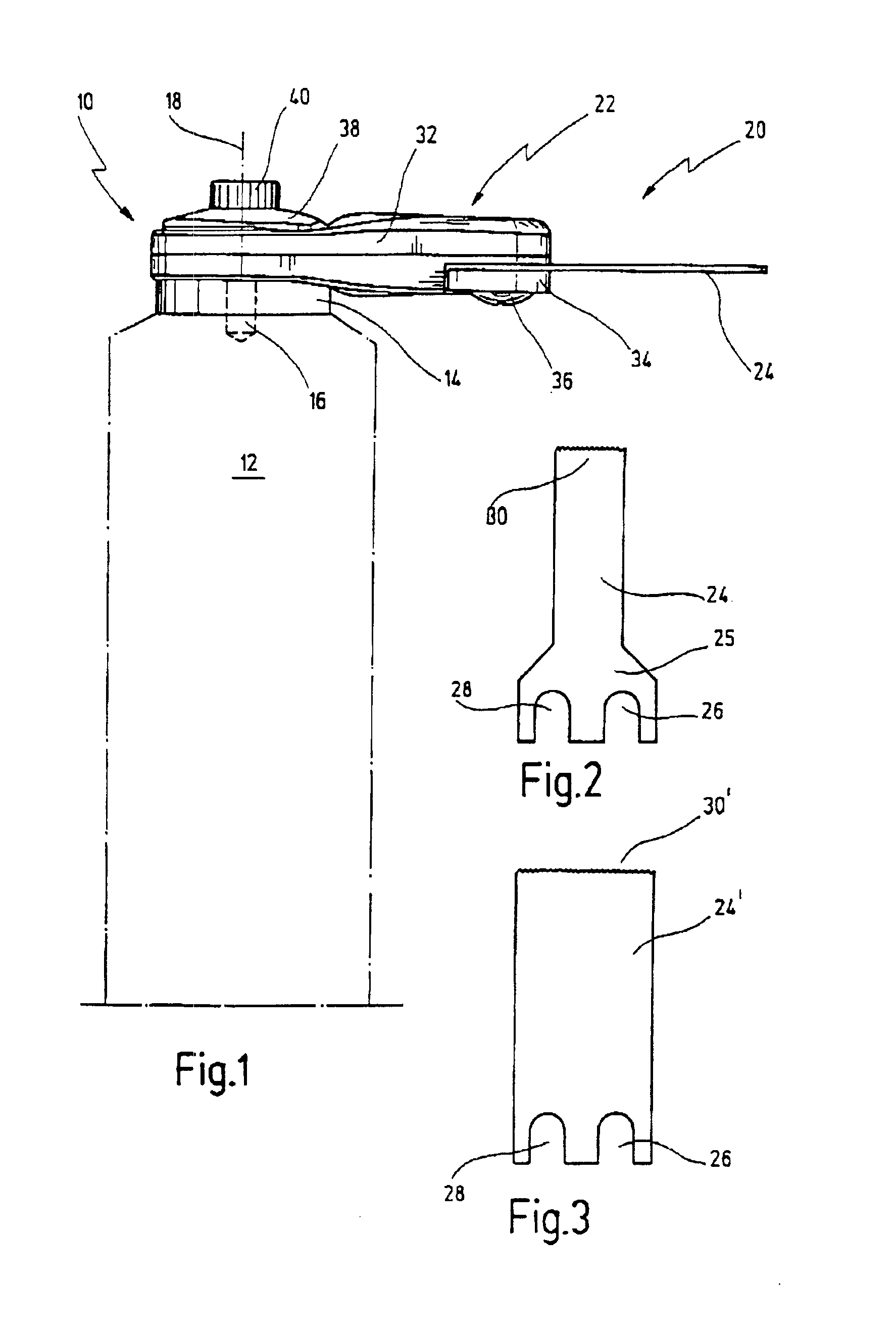

Depth limiting device and hole forming apparatus containing the same

ActiveUS7258513B2Facilitates and promotesAvoid damageThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

A depth limiting device includes a stop collar having a an open end portion and an workpiece engaging portion extending along the open end portion thereof for contacting a workpiece; a spindle extending axially through the shell, the spindle including a first end extending from the exterior of the stop collar for attachment to a hole forming apparatus, and an second end interior to the stop collar for attachment to a hole forming bit, wherein the attached hole forming bit projects through the open end portion of the stop collar at a predetermined length corresponding to the desired depth of the hole in the workpiece; and a bearing assembly operatively associated with the stop collar and the spindle for isolating the rotation of the spindle from the stop collar whereby the stop collar ceases to rotate when contacting the workpiece without generating sufficient frictional contact to mar or otherwise damage the workpiece.

Owner:FAR NORTH

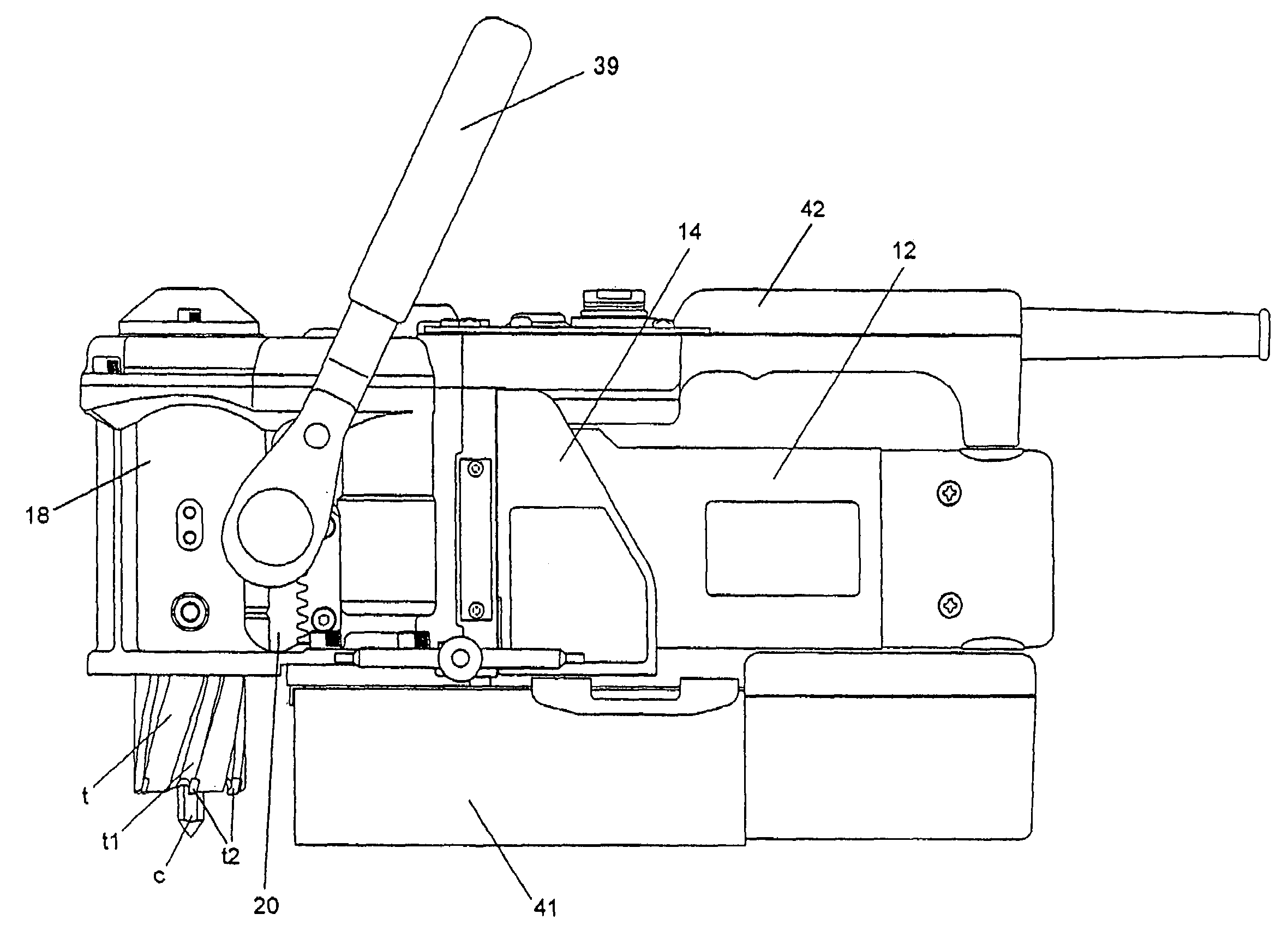

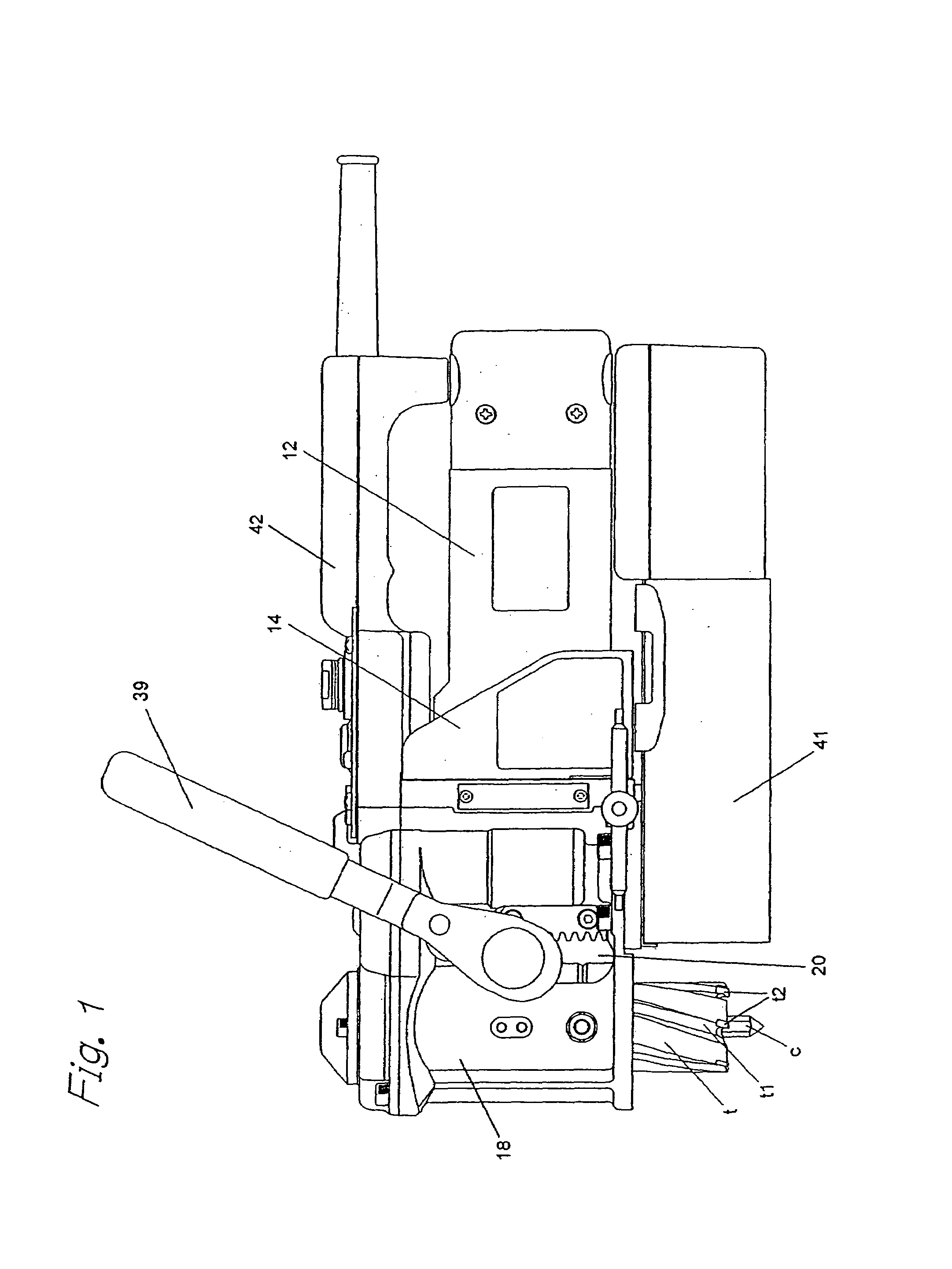

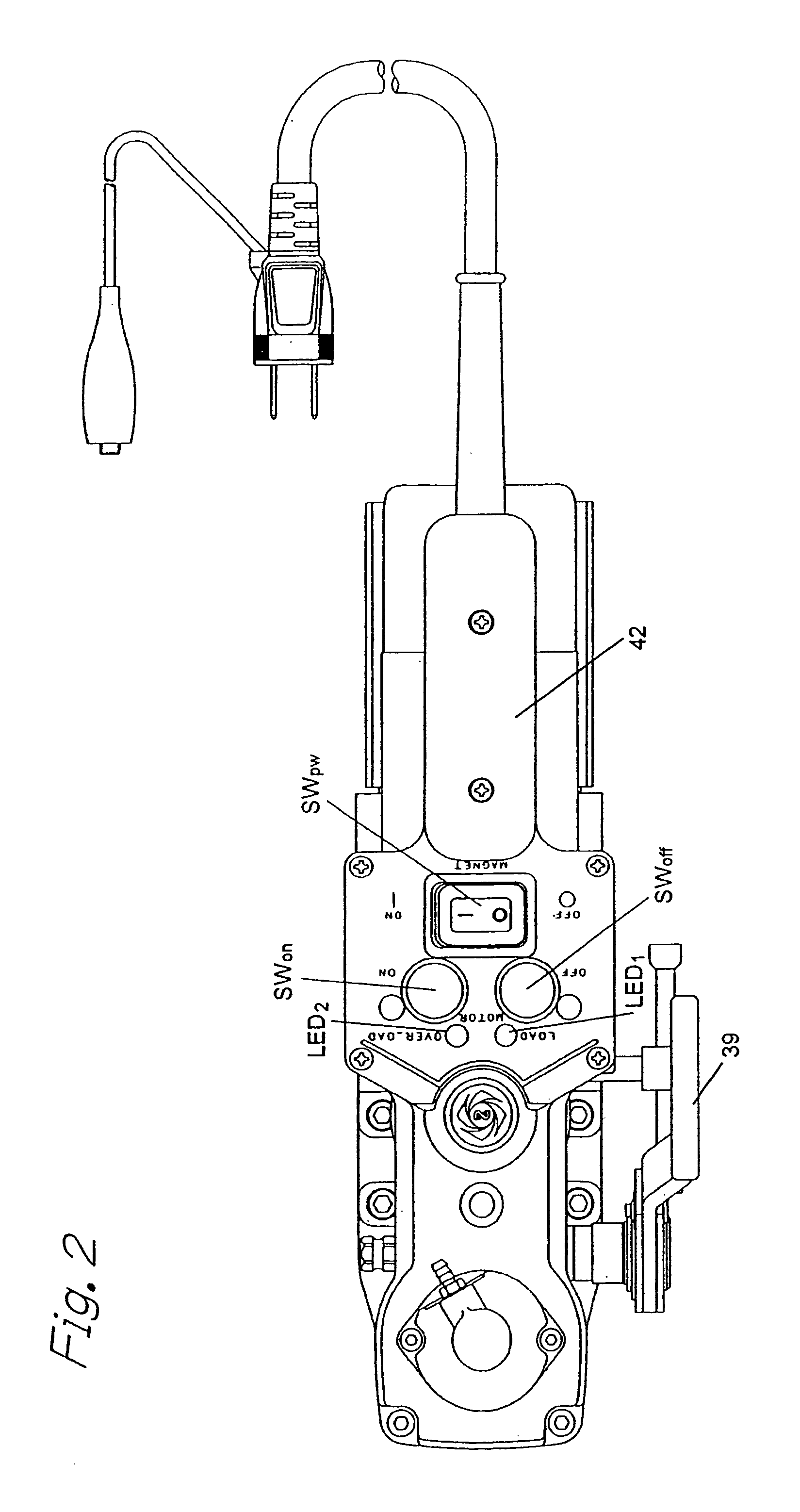

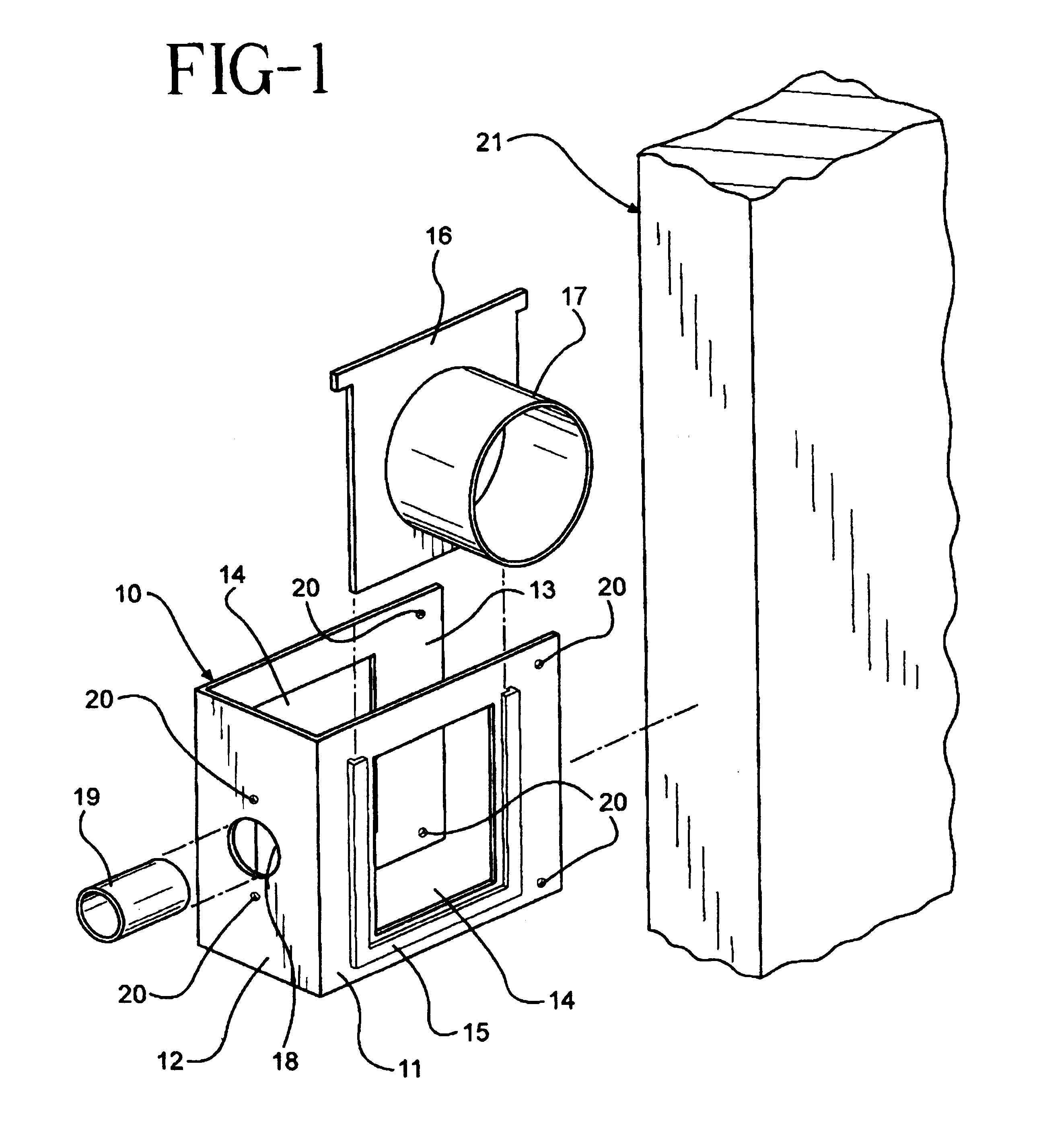

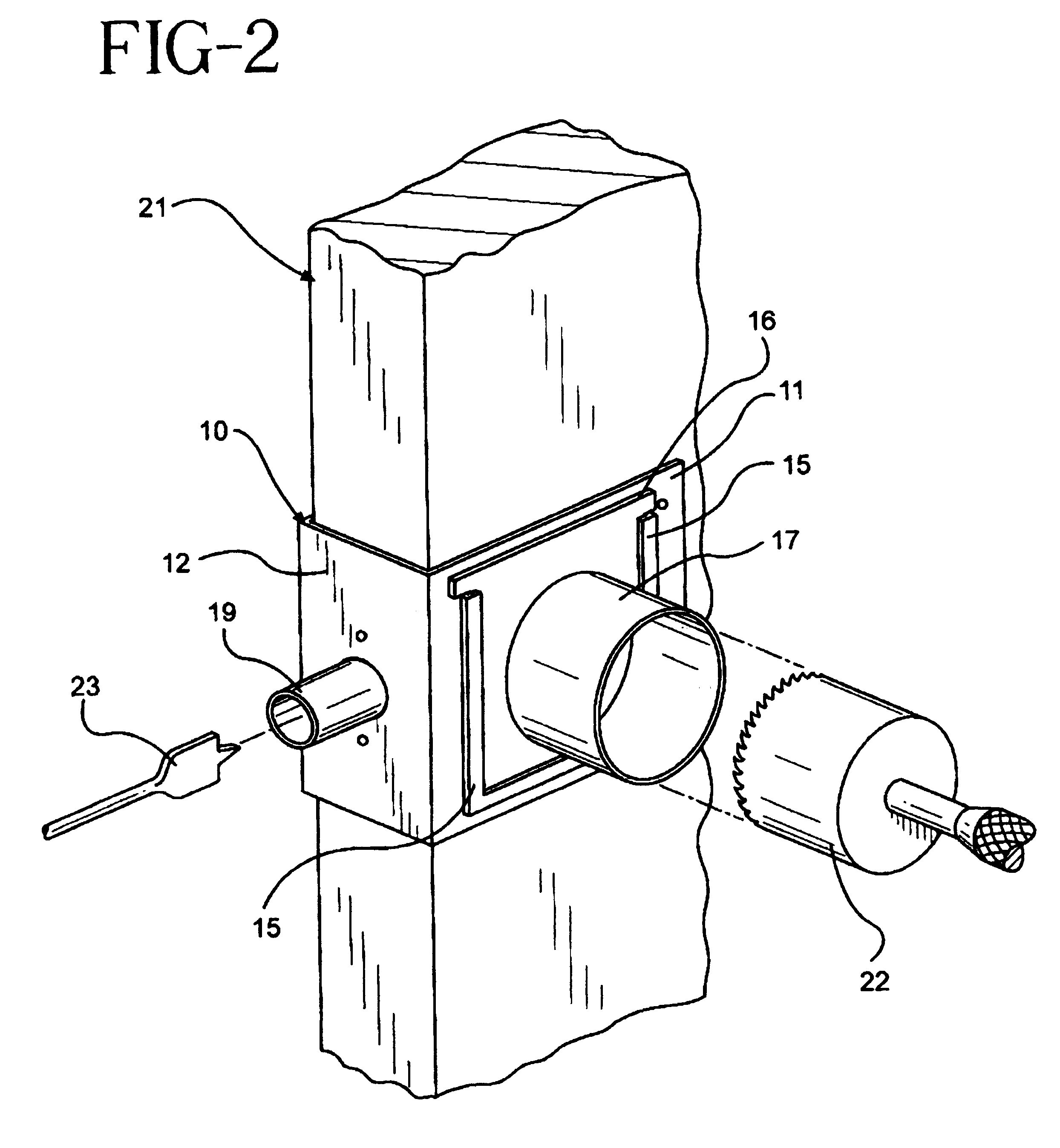

Pocket hole drilling machine

ActiveUS7374373B1Wear minimizationDrilling/boring measurement devicesThread cutting machinesEngineeringActuator

A pocket-hole drilling apparatus for drilling pocket-holes in a workpiece is disclosed. In one embodiment, an initiation switch actuates clamping the workpiece and the movement of a drilling module to cut a pocket-hole. The drilling module has a motor and a step-drill mounted thereon, which is slidably mounted on a guide module. The axis of the drilling module movement intersects work surface. In another embodiment, a movable fence provides the adjustability of pocket-hole depth. In yet another embodiment, two actuator tips are disposed in a fence to prevent the drilling of a pocket-hole through the sidewall of a workpiece. In still another embodiment, a short stroke clamping actuator is used to prevent human finger injury. In still another embodiment, a blower or an ejector pump is used to remove wood chips, wherein the blower is either attached to a drilling motor or to a separate blower motor; the ejector pump is mounted near the drill guide. In still another embodiment, two pocket-drills are slidably mounted on a block so as to drill two pocket-holes and to adjust pocket-hole spacing. In still another embodiment, a mounting structure is disposed either underneath or above the work surface to mount drilling module(s) so as to drill multiple pocket-holes into a wide workpiece at one setup. In still another embodiment, a drill guide forms a clearance for the cutting edges of the step-drill to minimize wear on the edges. In a further embodiment, an actuator provides both clamping and drilling movements, wherein the actuator is an electric motor or a hand lever.

Owner:KREG ENTERPRISES

Power tools

InactiveUS20050103510A1Batteries circuit arrangementsDrilling/boring measurement devicesPower toolElectric motor

An electrically powered hand tool is disclosed. The tool includes a motor, a power source, a work element and a controller. Various alternative features, embodiments and operative configurations are disclosed.

Owner:GASS STEPHEN F +1

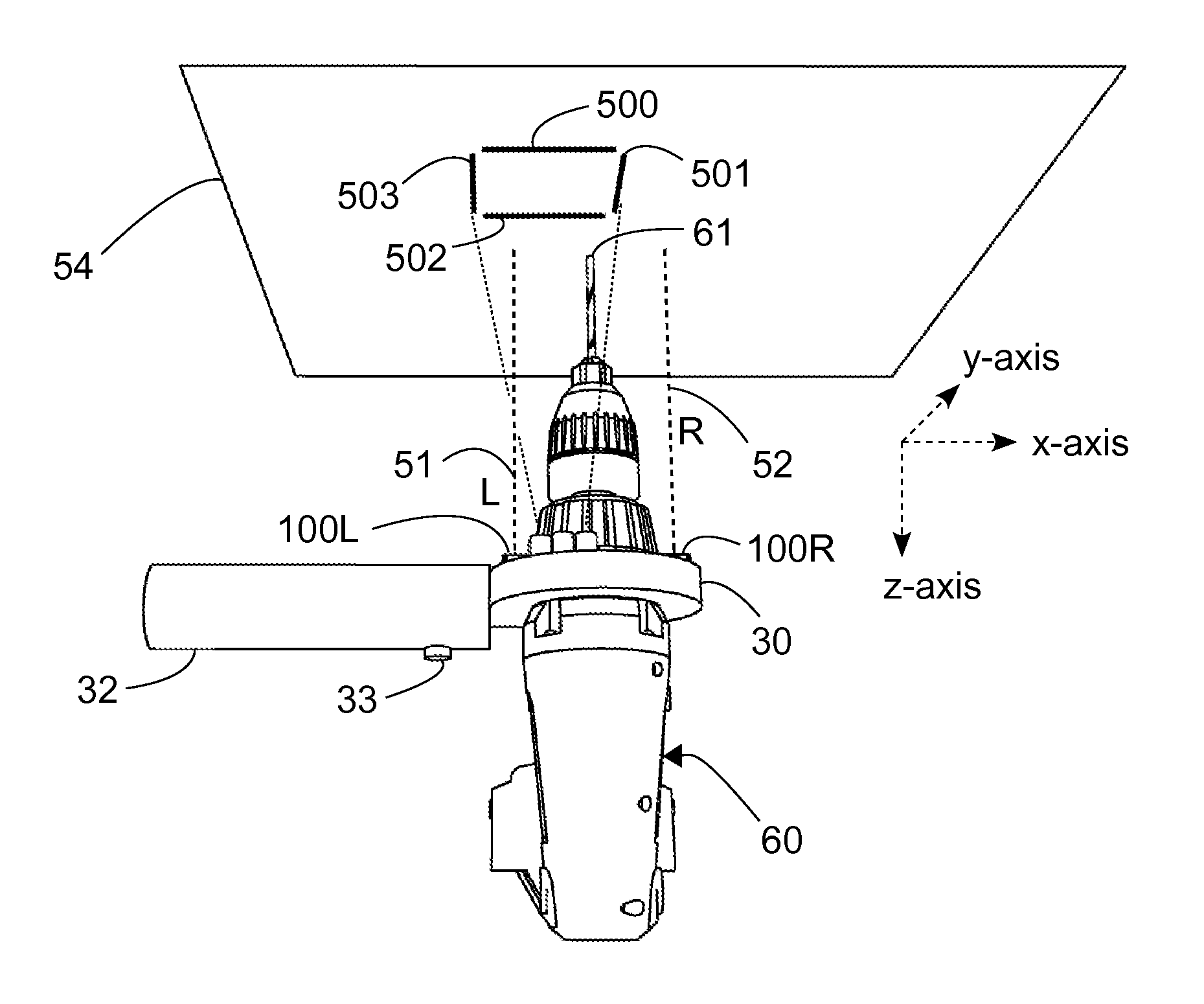

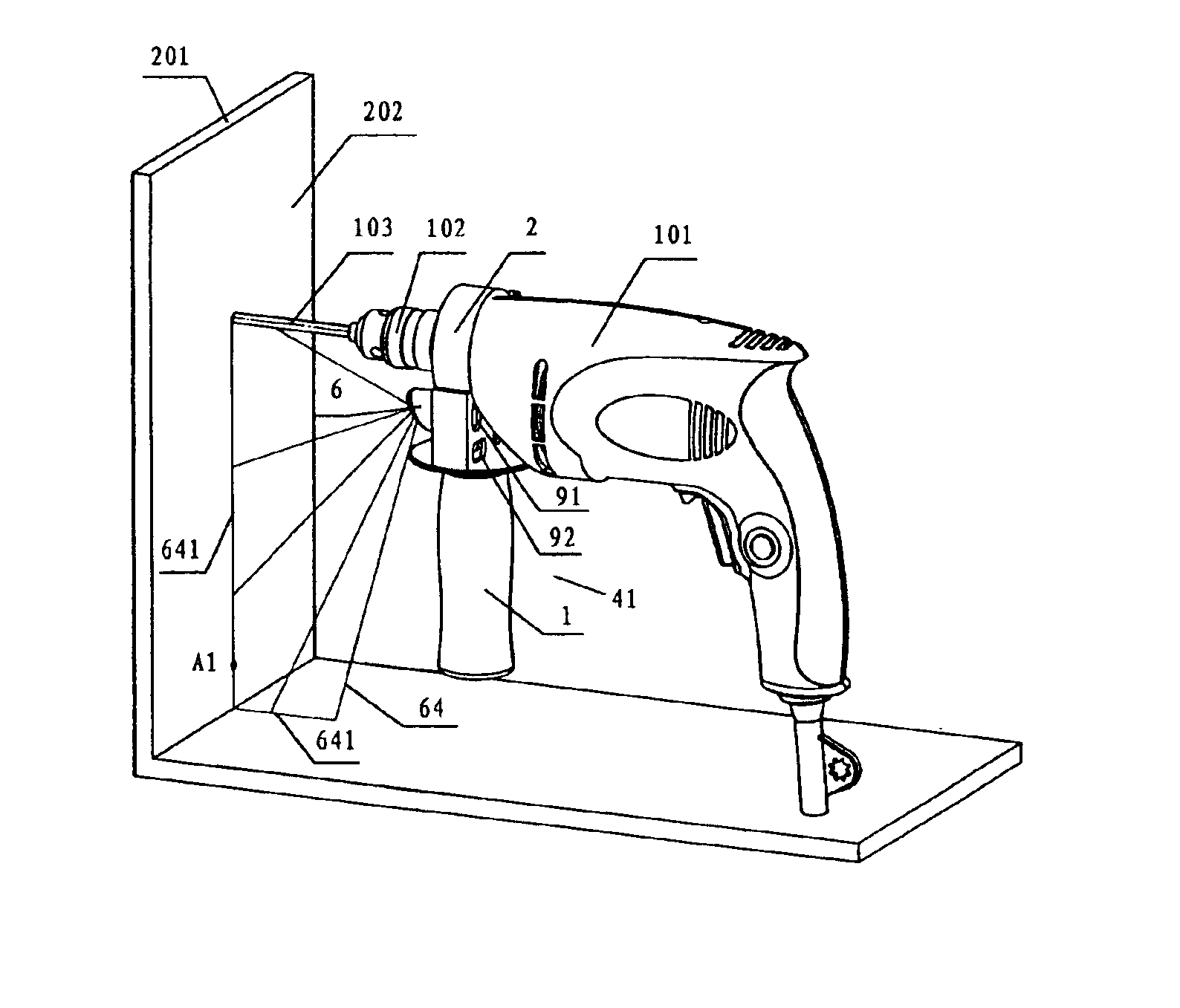

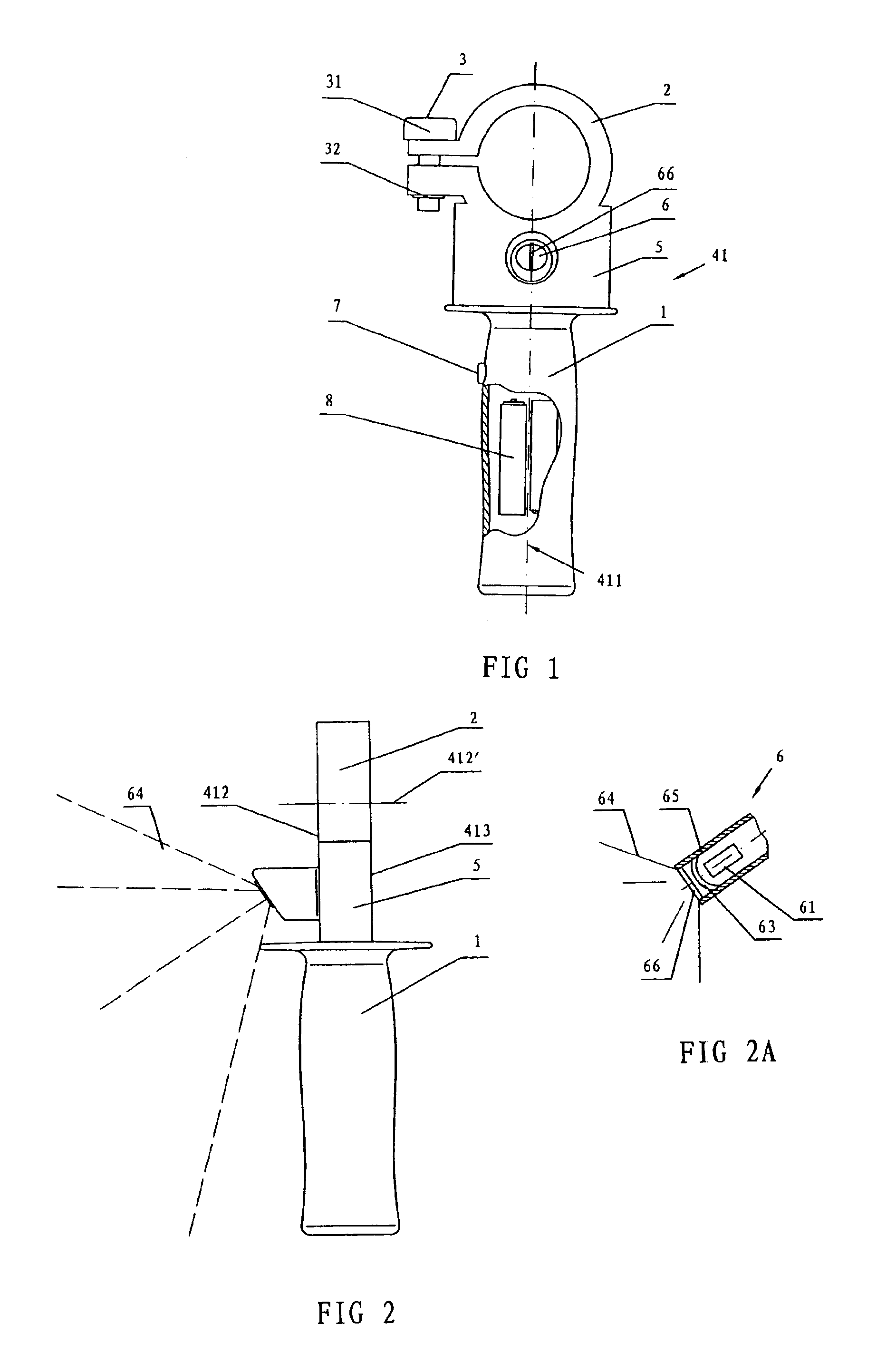

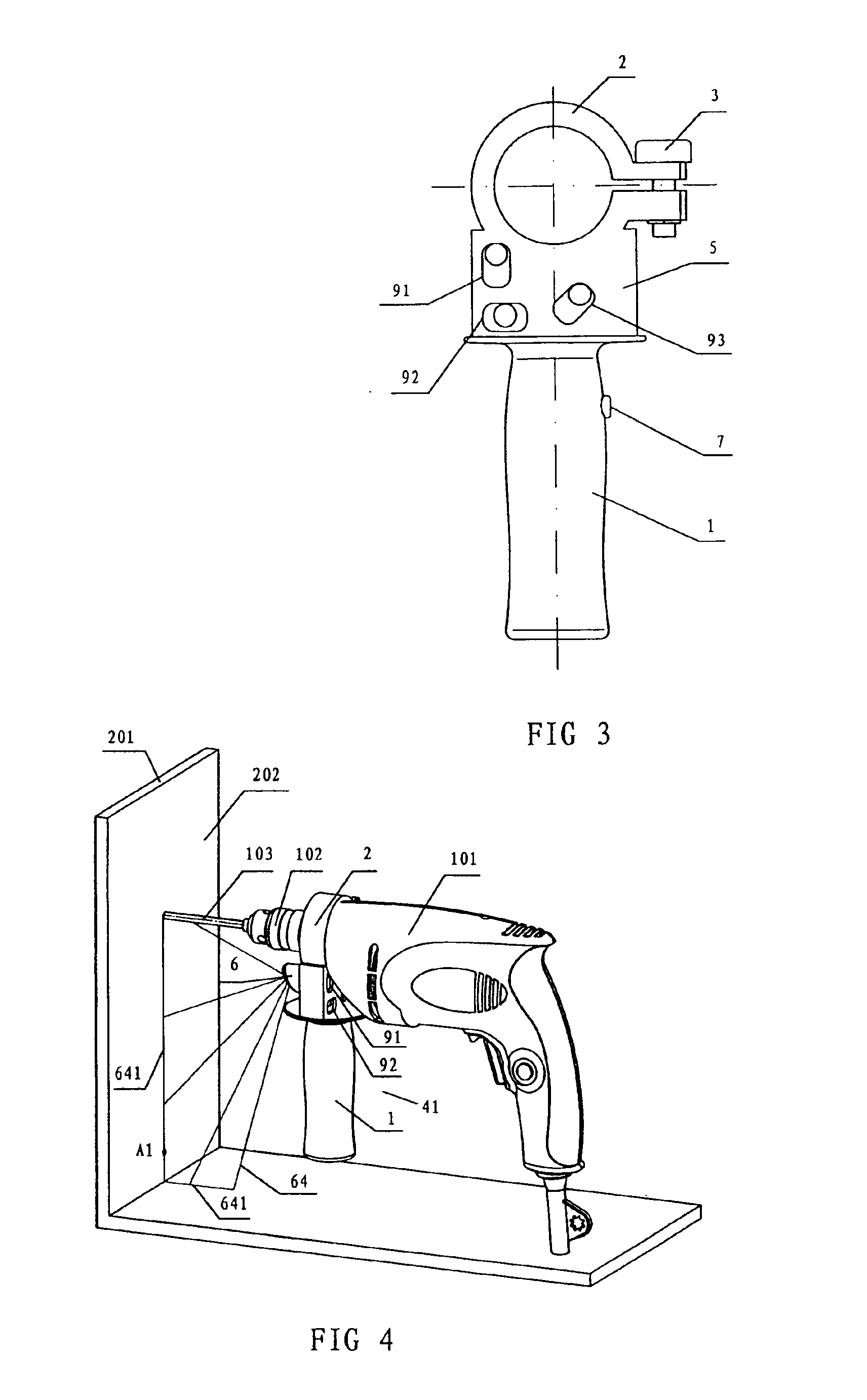

Auxiliary handle with a laser alignment device for drills

InactiveUS6898860B2Precise positioningDrilling/boring measurement devicesThread cutting machinesLight beamShaft collar

An auxiliary handle with a laser alignment device for drills comprises a grip portion for grasping, an opened collar which can be engaged with shoulder of the drill, and a clamp means for locking or loosing the opened collar. The auxiliary handle also comprises a first laser generator which can project a fanned planar laser beam, a battery pack which can be used to power the first laser generator, and a switch for turning on or turning off the first laser generator, the fanned laser beam which is projected by the first laser generator is in alignment with the central axis of the opened collar. Such that the fanned laser beam is in alignment with the central axis of the chuck when the auxiliary handle is mounted on the drill.

Owner:CHERVON INT TRADING

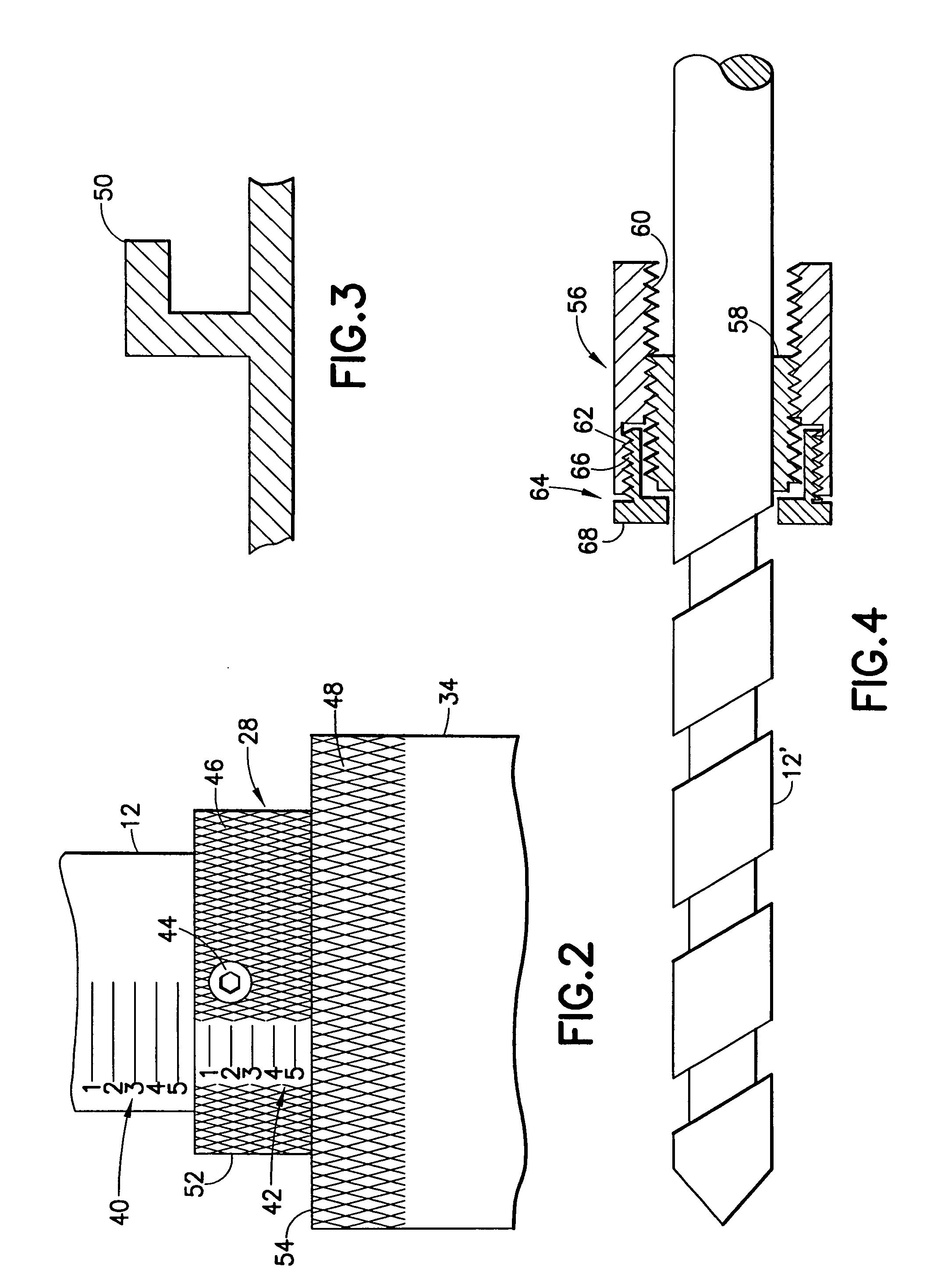

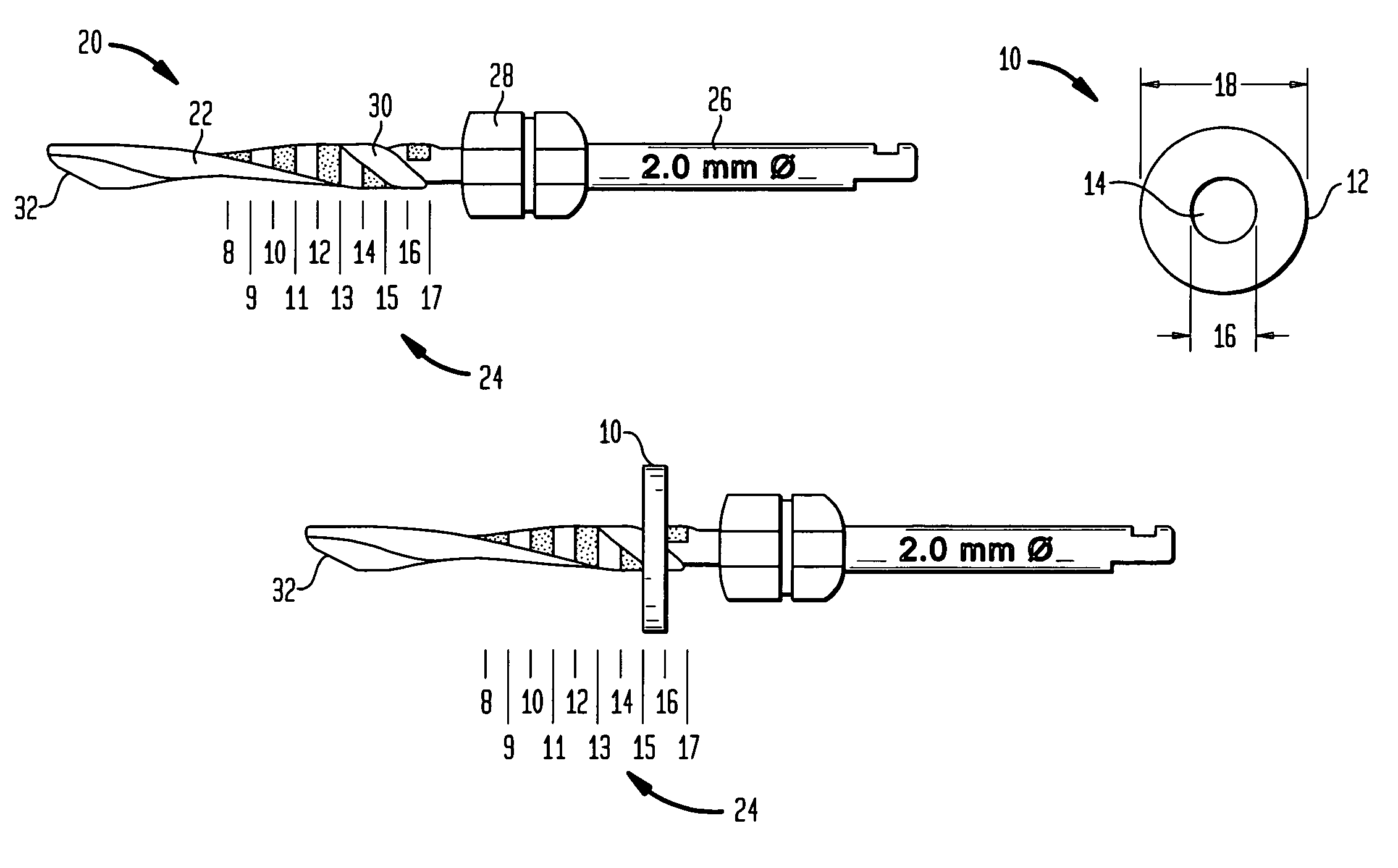

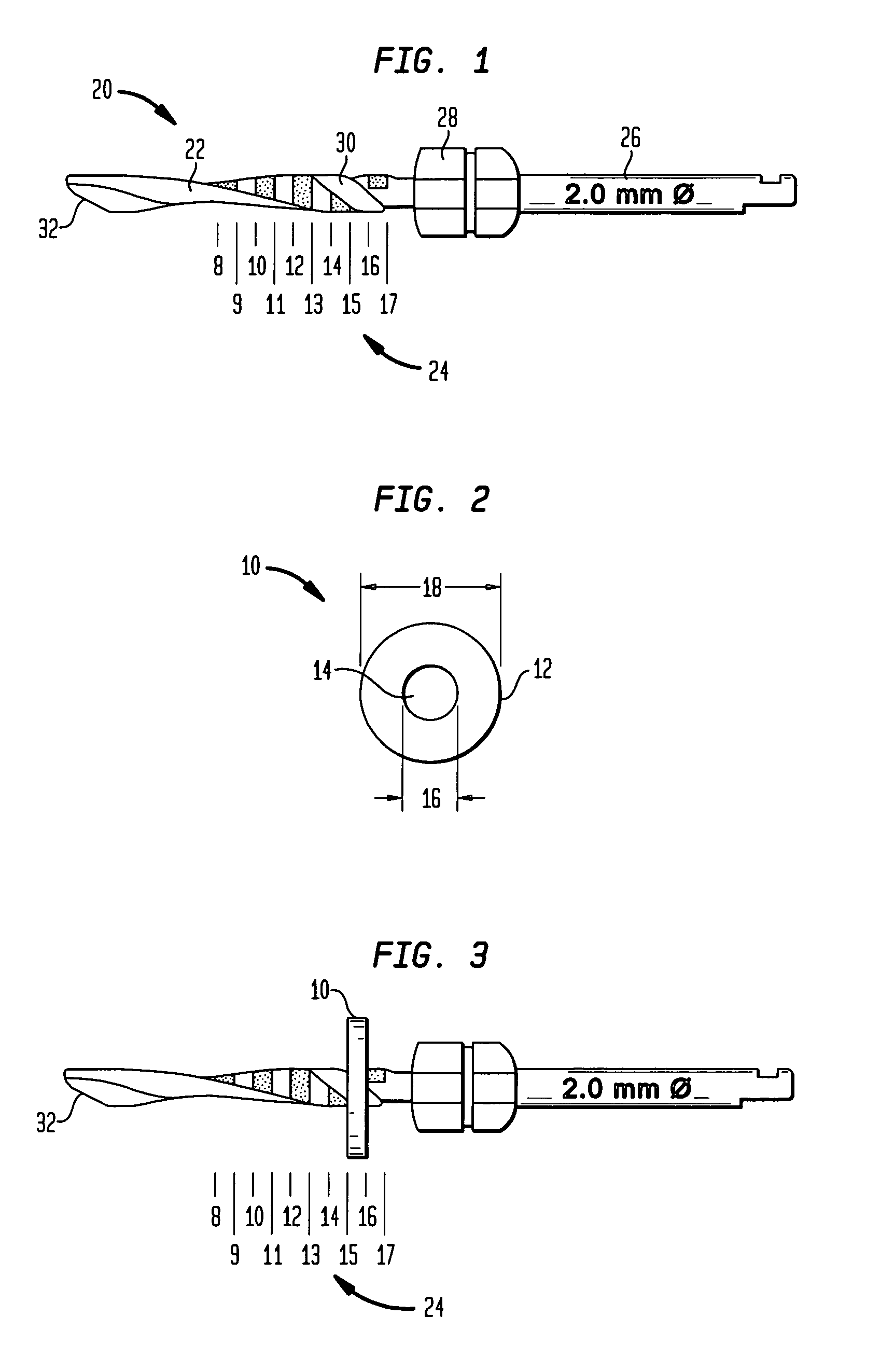

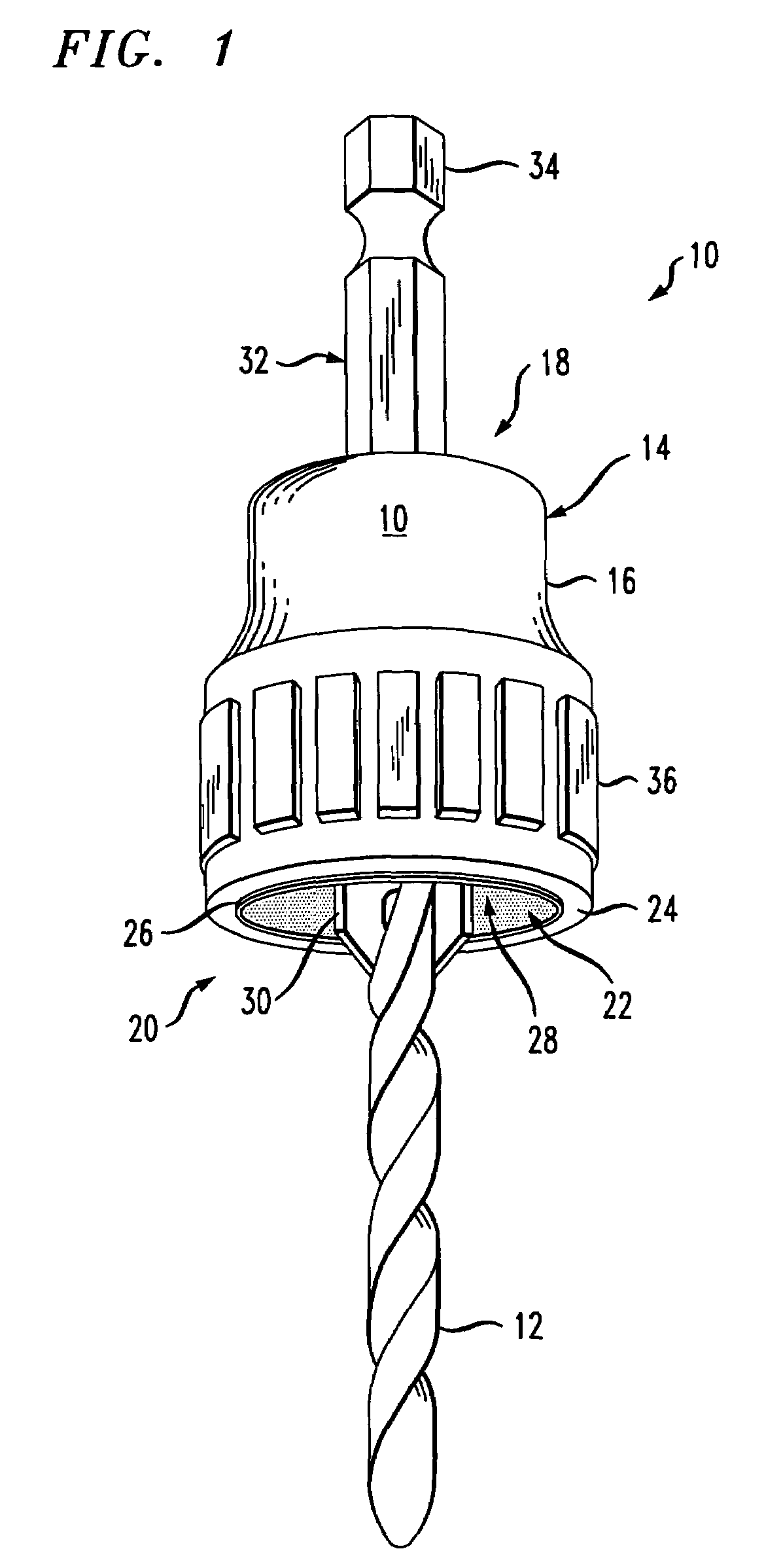

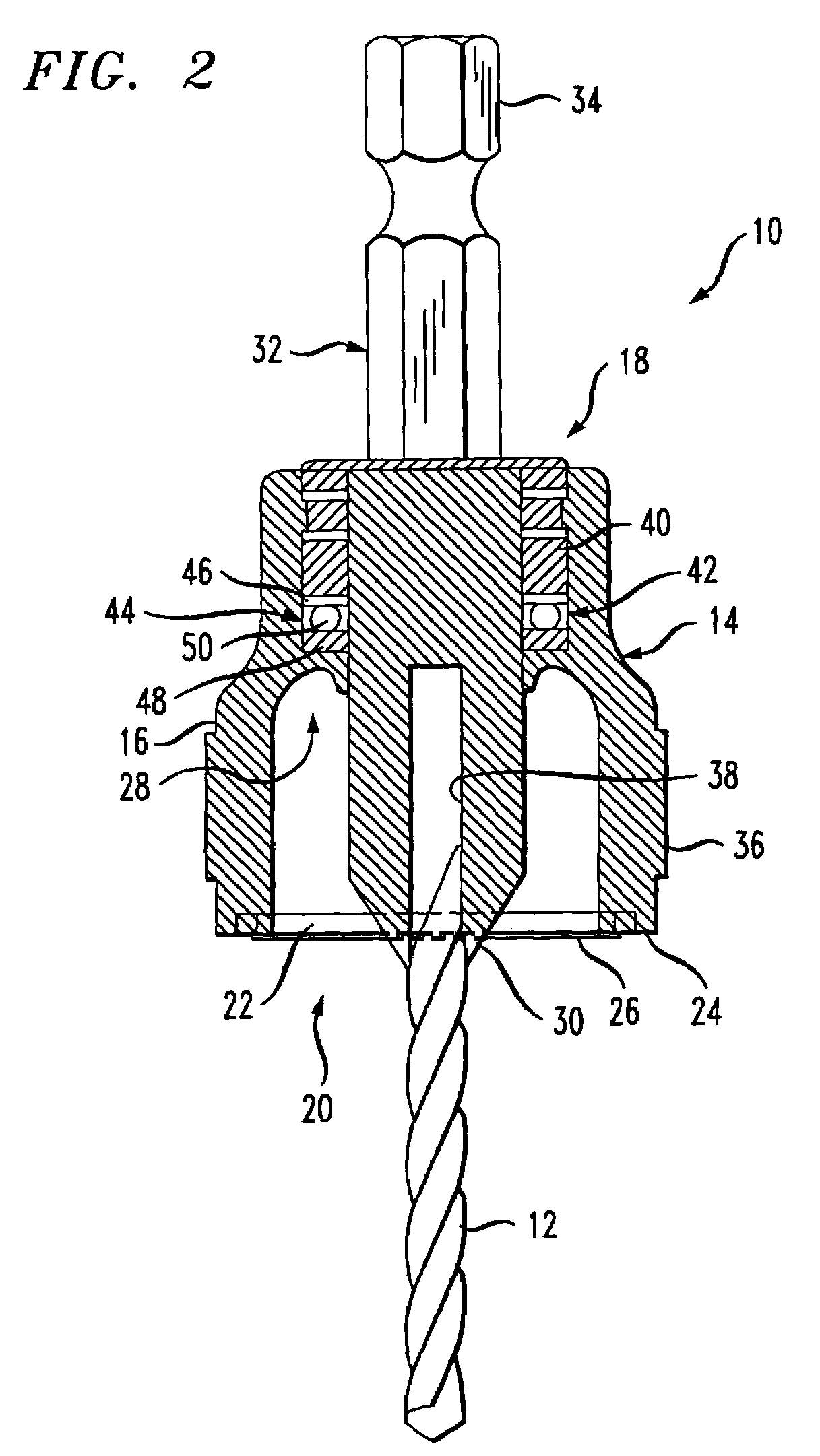

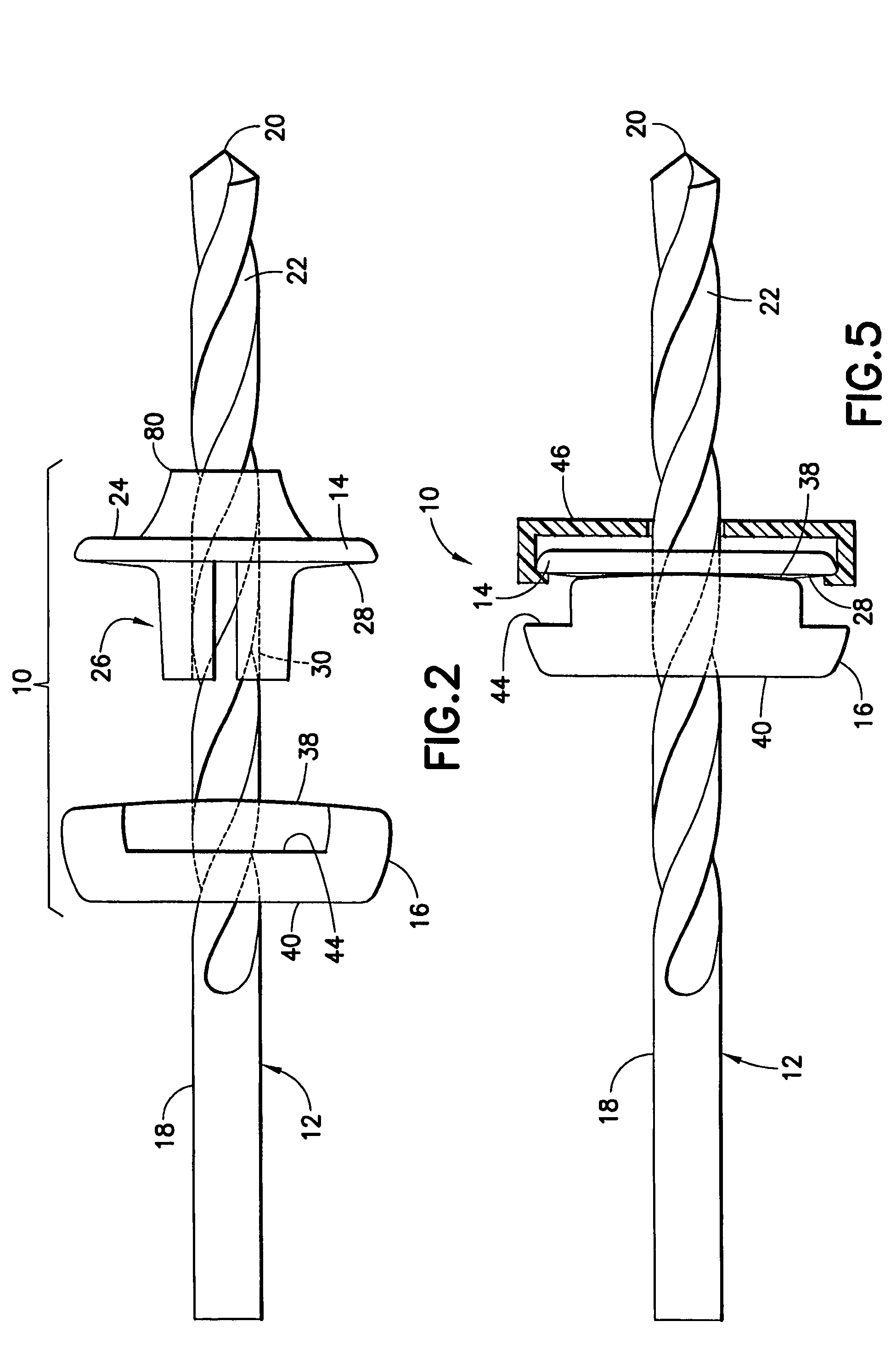

Collet collar stop for a drill bit

InactiveUS7513722B2Thread cutting toolsDrilling/boring measurement devicesDepth of penetrationEngineering

A stop for a drill bit having a shaft, the stop having a first member which includes a collet. The collet is configured to receive the shaft of the drill bit and is positionable along the shaft of the drill bit. The stop also has a second member which includes a clamp, for clamping the first member in a desired position along the shaft of the drill bit by securing the collet in a desired position along the shaft of the drill bit. The stop further has an abutment surface on one of the first and second members, for limiting the depth of penetration of the drill bit into an object, the abutment surface being disposed in a fixed position along the shaft of the drill bit by the clamping of the first and second members.

Owner:GREENBERG SURGICAL TECH

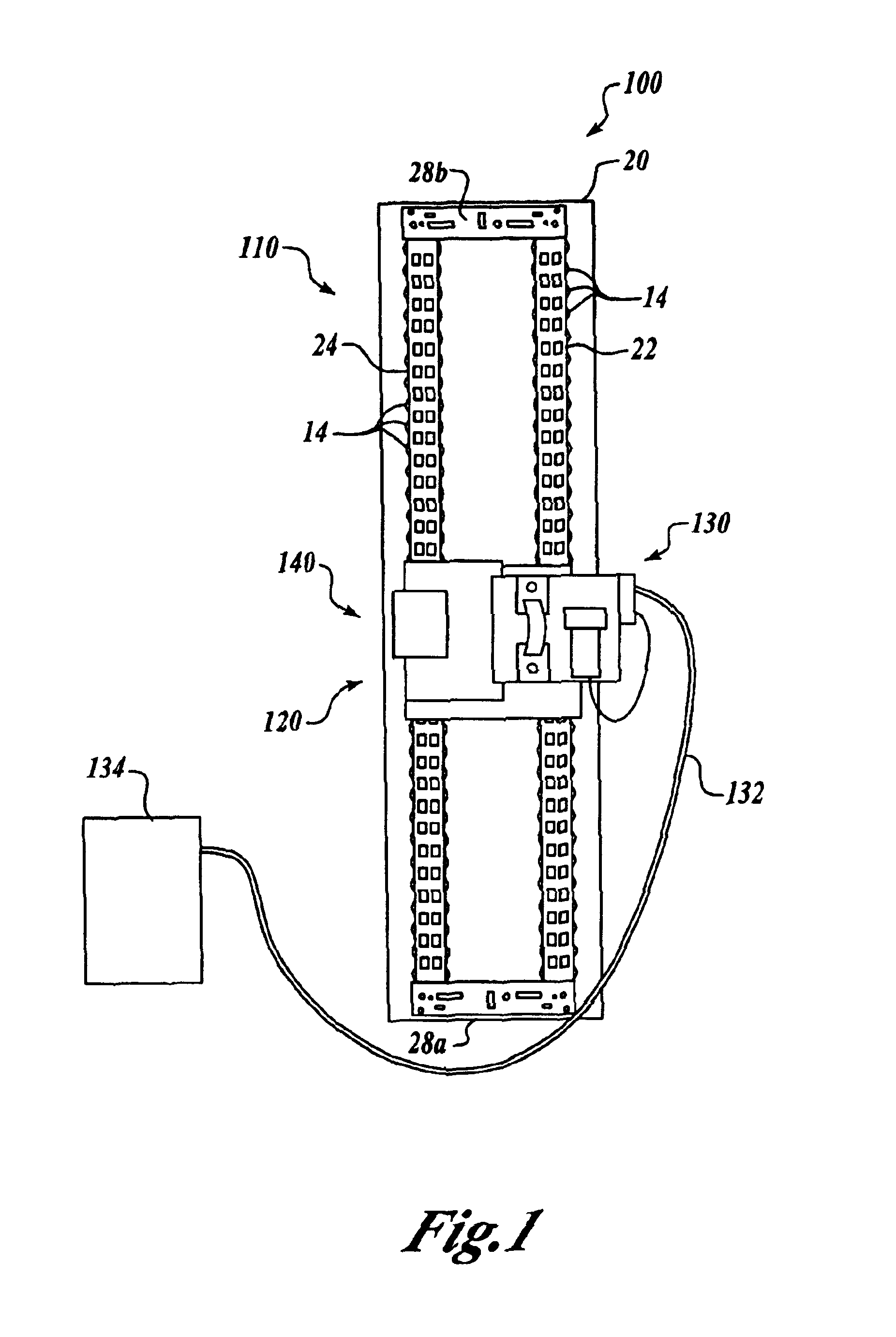

Electromagnetic Crawler Assembly System

ActiveUS20120014759A1Drilling/boring measurement devicesThread cutting machinesEngineeringAssembly systems

A method and apparatus for performing operations on a workpiece. A first frame in a frame system may be held on the workpiece by applying a vacuum to the first frame. A second frame in the frame system may be detached from the workpiece by applying a pressure to the second frame. The second frame may be moved to a location on the workpiece. The second frame may be attached to the workpiece by applying the vacuum to the second frame. An operation may be performed on the workpiece.

Owner:THE BOEING CO

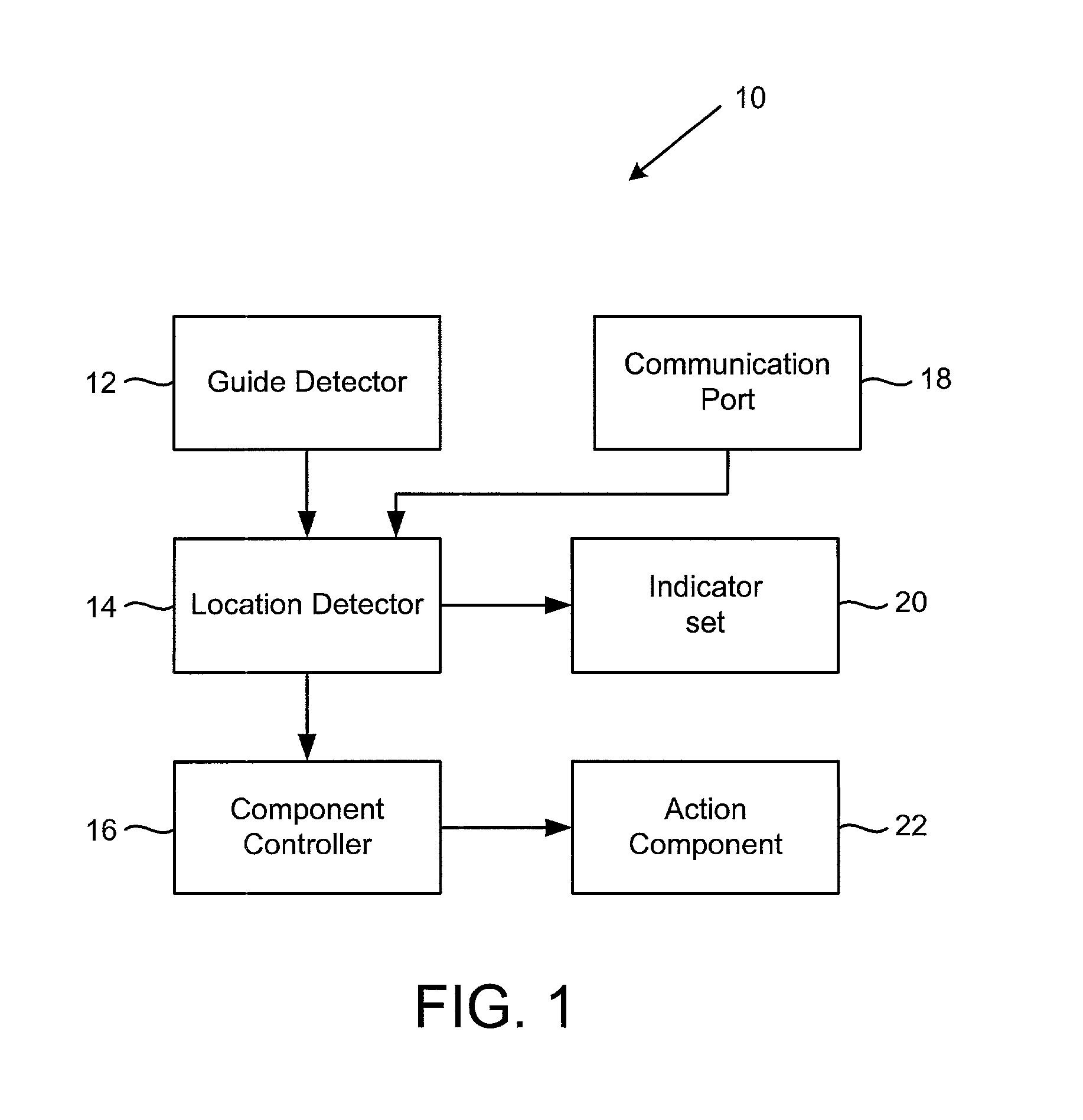

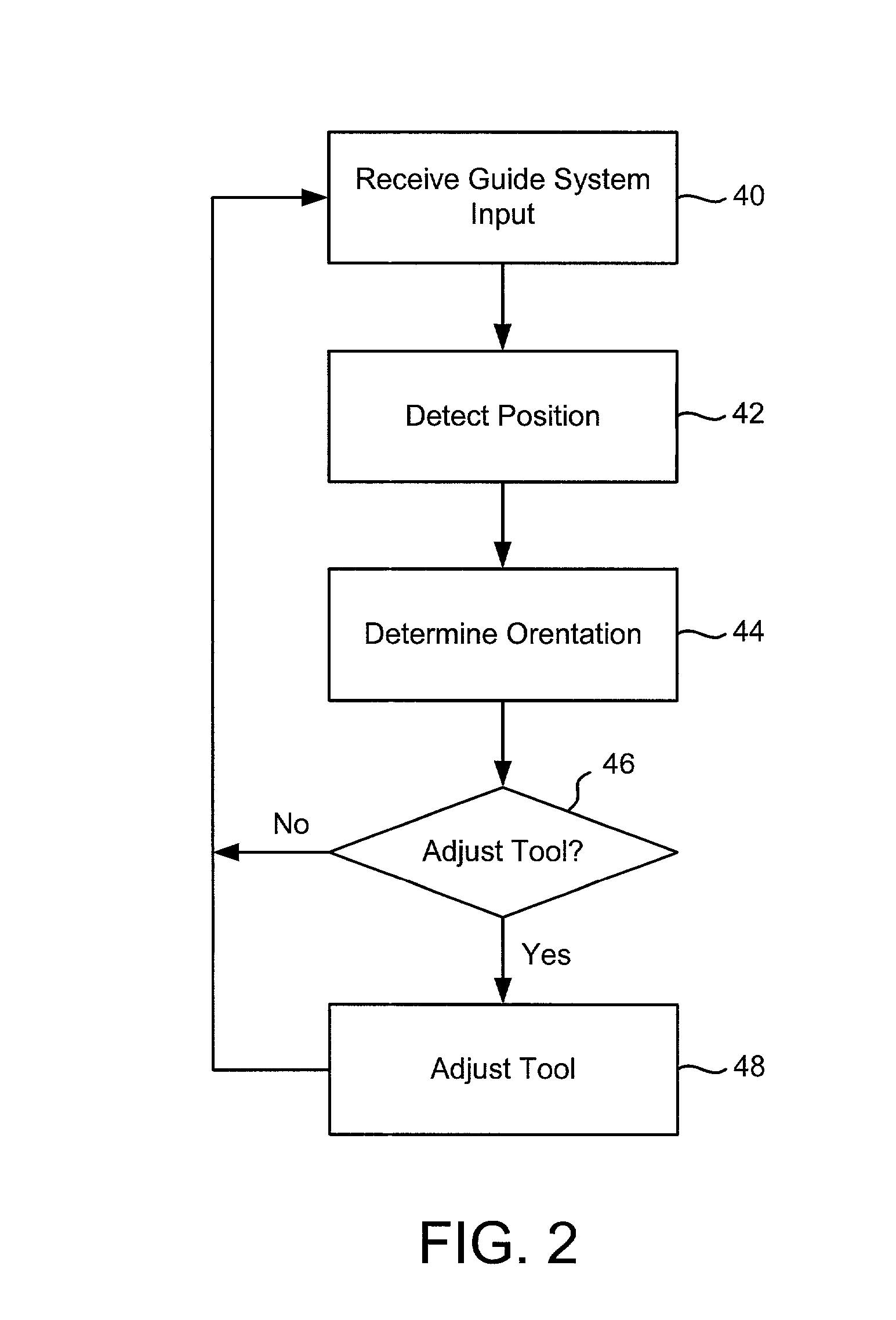

Tools with orientation detection

InactiveUS20030000355A1Stapling toolsDrilling/boring measurement devicesAbsolute orientationEngineering

A tool operates with a guide system to identify the orientation of a tool on a work piece. In one implementation, the tool identifies its orientation with respect to a guide signal supplied by the guide system. In an alternate embodiment, the tool determines its absolute orientation, such as a (x, y) coordinate. The tool includes an action component adapted to alter the work piece, such as a cutting head in a router. A guide detector in the tool detects a position of a guide signal from the guide system. A location detector in the tool receives the position data and employs it to determine the tool's orientation. Based on the detected orientation, the tool decides whether any tool adjustments are necessary. Examples of tool adjustments include the following: adjusting the position of the action component, enabling or disabling the action component, and providing operating indicators to direct a tool operator's use of the tool.

Owner:ROBERT BOSCH CO LTD

Bracket drill template

InactiveUS6193449B1Losing accuracySimple taskDrilling/boring measurement devicesThread cutting machinesRectangular apertureEngineering

A 3 sided bracket shaped template for accurately drilling door knob and lock holes in doors comprising a template plate a at right angle to a lock plate again at a right angle to a reverse plate. The template plate and reverse plate each contain rectangular apertures for drill passage, and the template plate further has zee bracket sleeves on the bottom and both sides of the rectangular aperture for slidably mounting removable plate guides each with different perpendicular cylindrical extension guide for drills of varying sizes. The lock plate also has a centered circular hole with a tubular drill guide perpendicular to the lock plate.

Owner:DIAZ ALBERTO

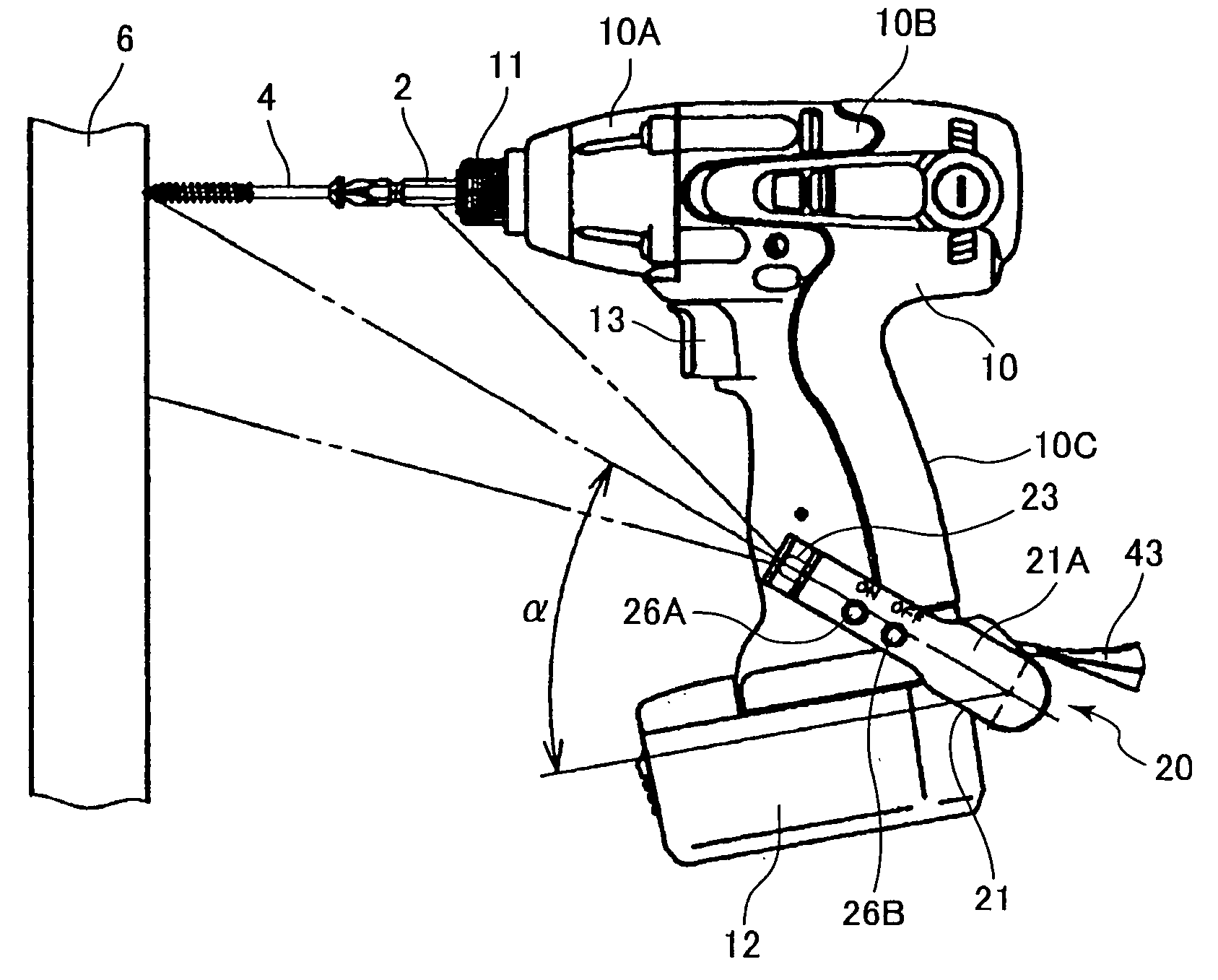

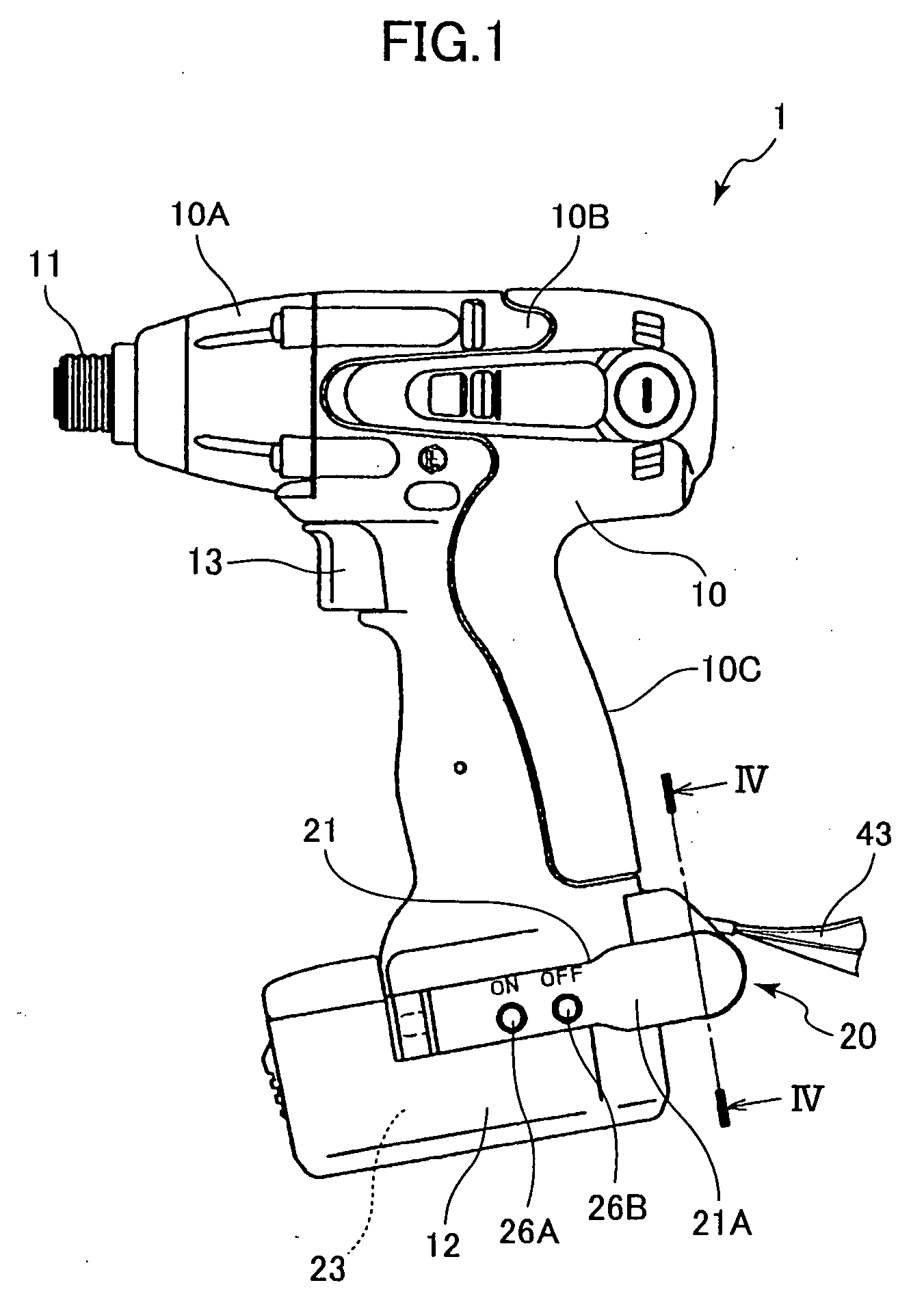

Power tool

InactiveUS20050157489A1Improve usabilityStable illuminationDrilling/boring measurement devicesThread cutting machinesEffect lightEngineering

A power tool has a light unit provided at the bottom part of the handle grip. The light unit can be adjusted to change the lighting angle and can hold the desired lighting angle. The light unit thus disposed does not get in the way, the lighting angle of the light unit is variable and the emitted light does not shake, depletion of the power supply due to the light switch of the light unit being left on is prevented, shadows of the end tool are not easily produced by light from the light unit, lighting contrast is high, wiring failures and continuity faults in the light-emitting element do not occur easily, and a small, economical power tool can be provided. The light-emitting element of the light unit is a yellow LED. The light unit turns off automatically at a predetermined time after the light turns on.

Owner:HITACHI KOKI CO LTD

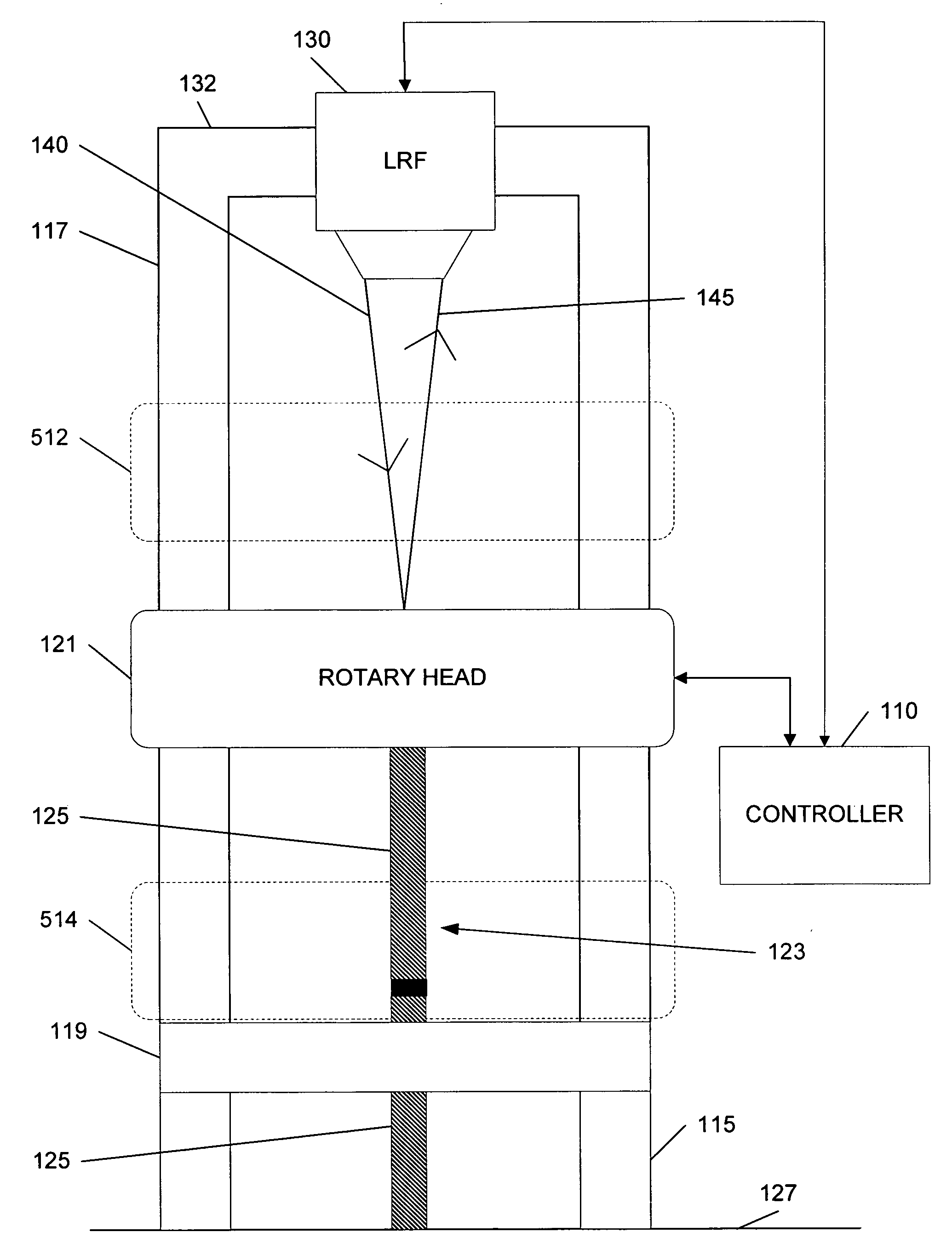

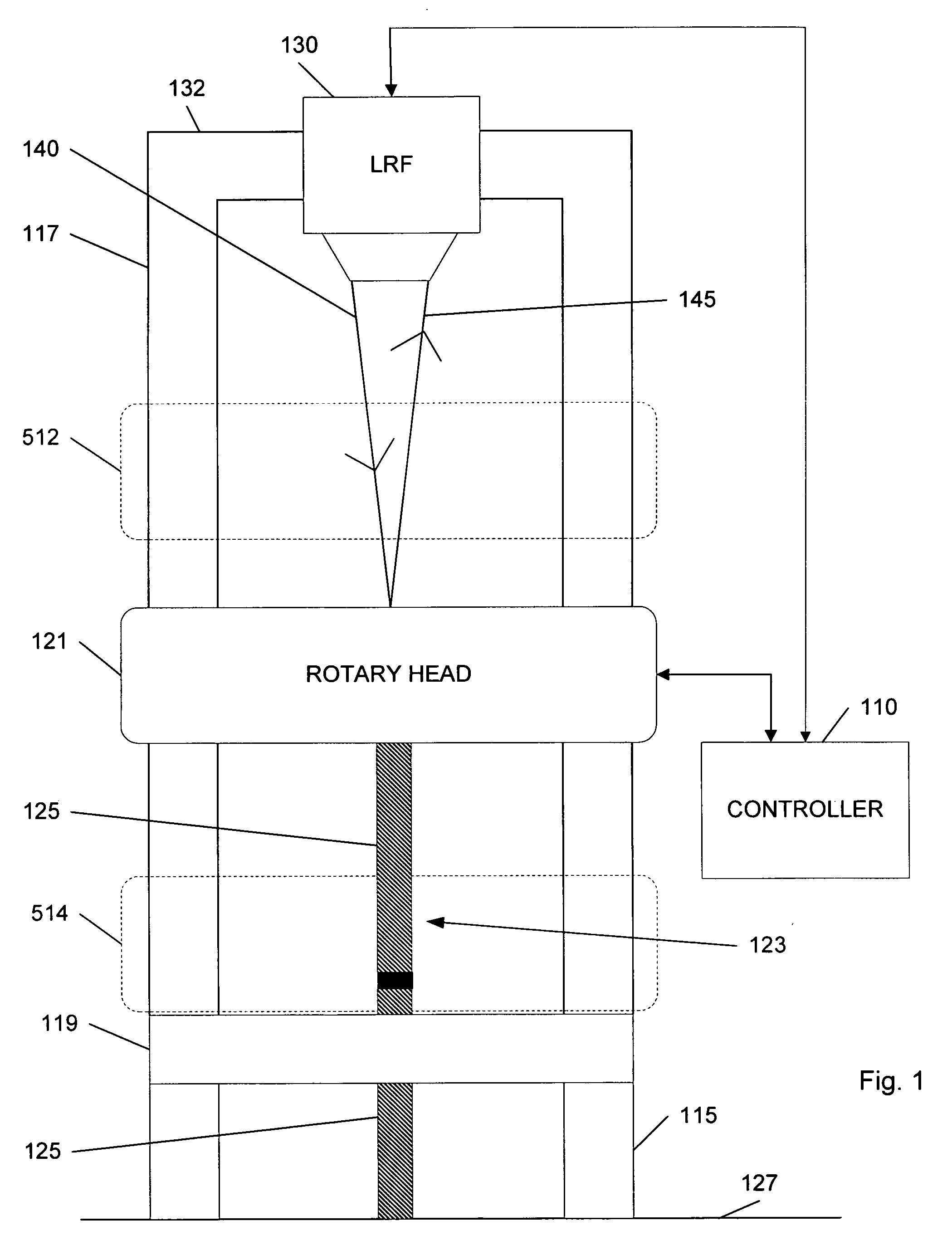

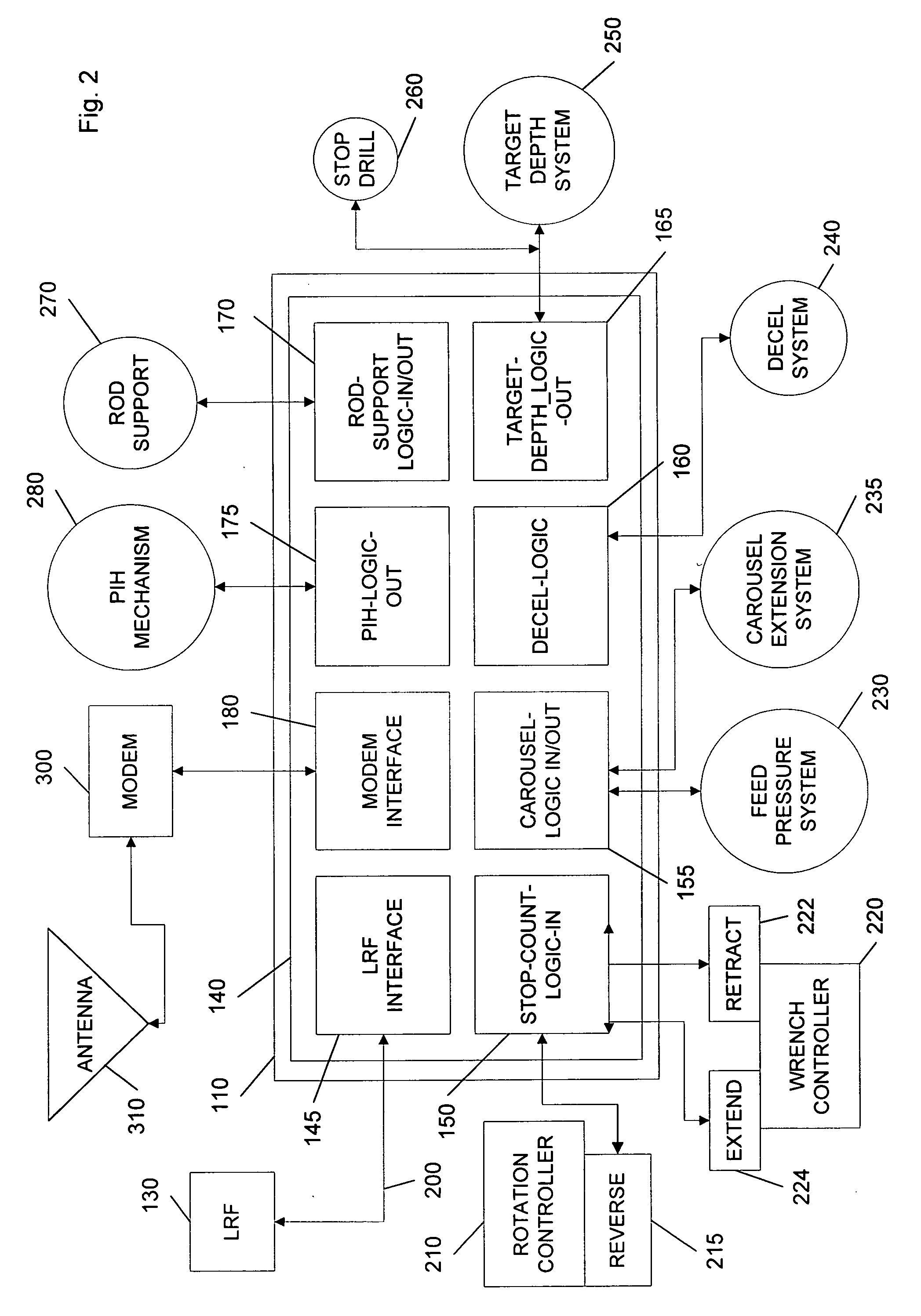

Electronic drill depth indicator

InactiveUS20050169717A1Easy CalibrationEasy to installSurveyDrilling/boring measurement devicesLaser rangingLaser rangefinder

A system for determining a depth of a hole drilled by a drilling machine. The system can include a drill string including one or more drill rods, wherein each of the one or more drill rods has a length; a target; a laser range finder configured to determine a plurality of distance readings, wherein each of the plurality of distance readings includes a distance value between the laser range finder and the target; and a controller configured to obtain the plurality of distance readings from the laser range finder. The controller processes the plurality of distance readings to produce a calculated distance between the laser range finder and the target. The controller may also use the calculated distance and the length of each of the one or more drill rods included in the drill string to determine the depth of the hole drilled by the drilling machine.

Owner:ATLAS COPCO DRILLING SOLUTIONS

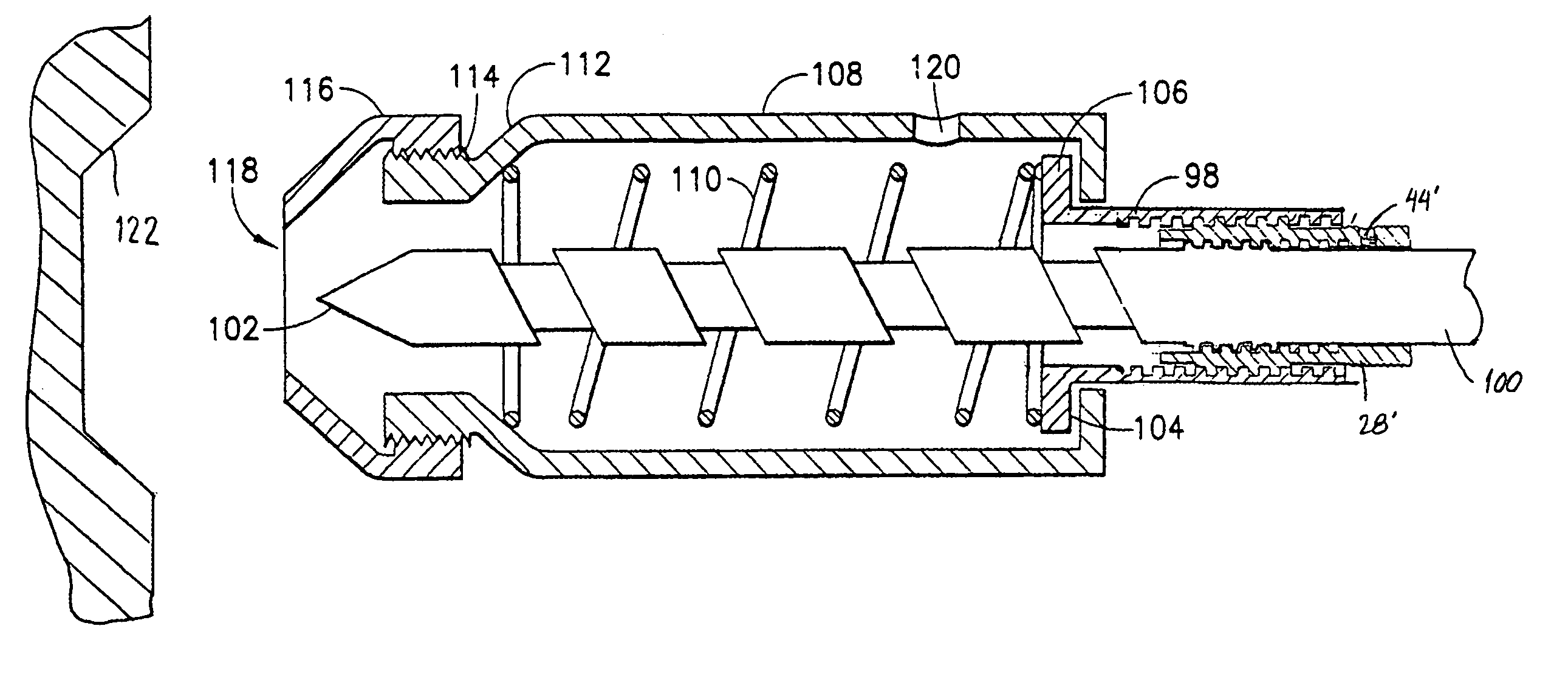

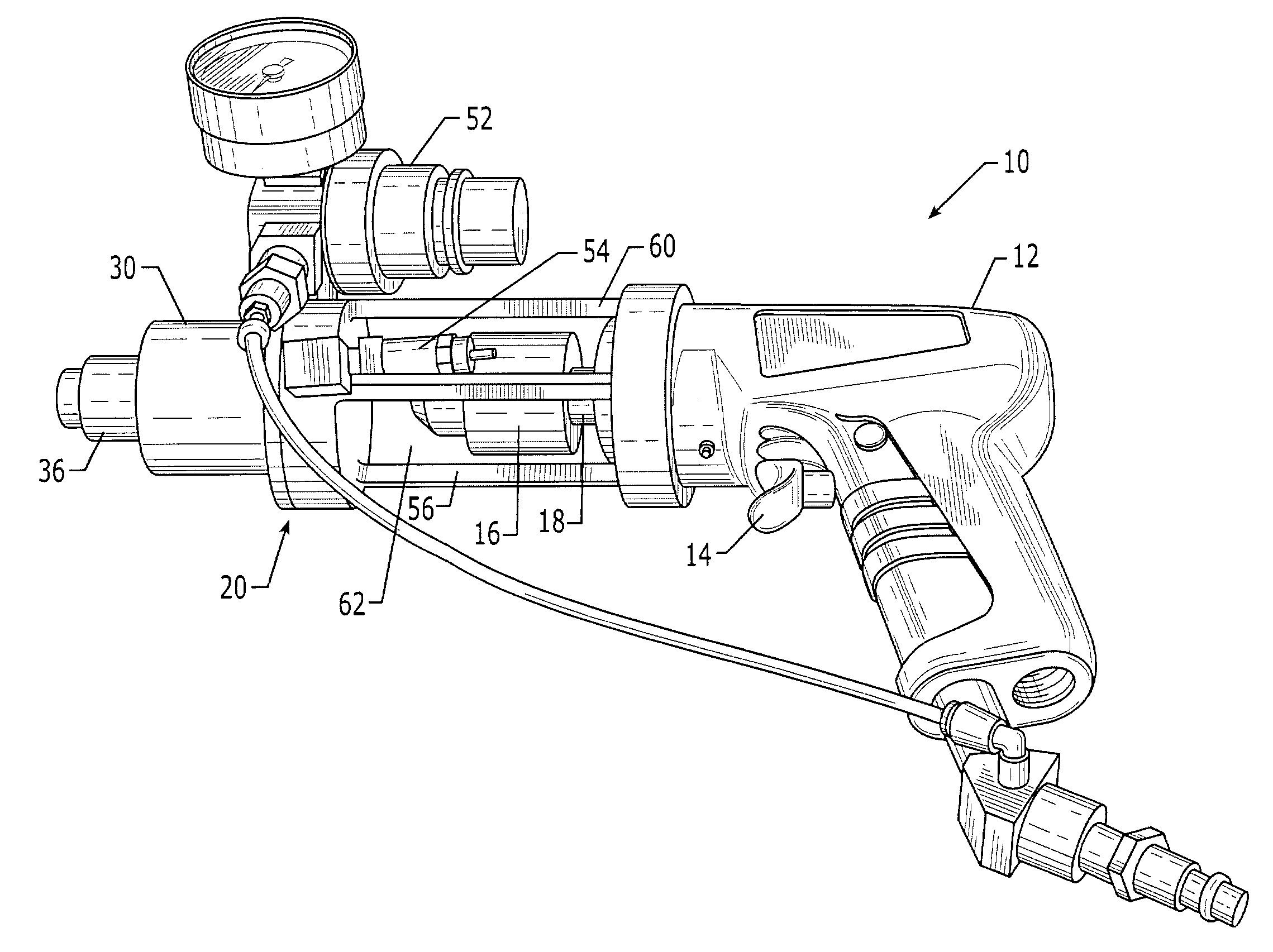

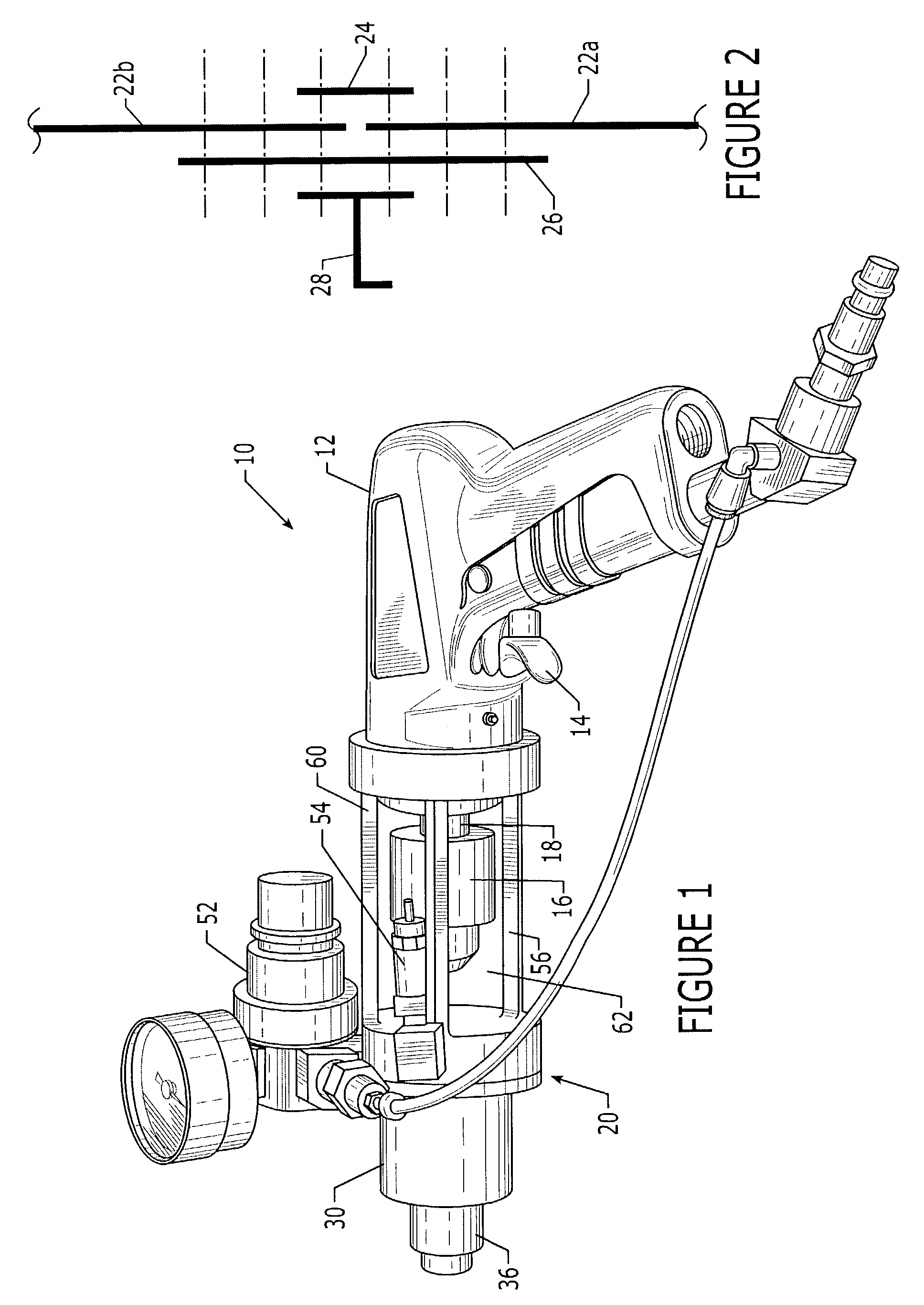

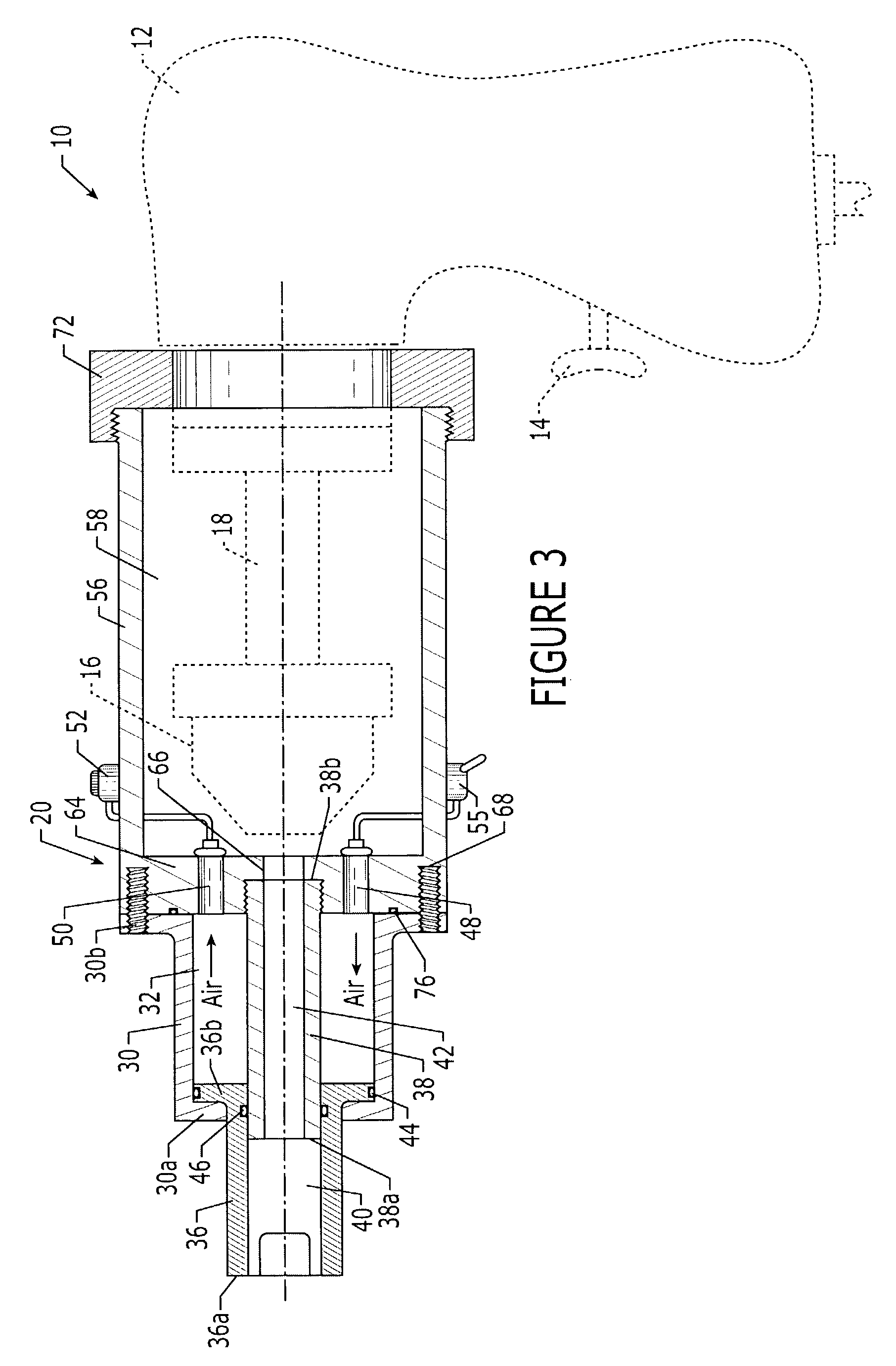

Re-configurable bushing and drill incorporating same

InactiveUS7073989B2Increase speedLower assembly costsAircraft componentsDrilling/boring measurement devicesEngineeringDrill bit

A bushing and associated drill are provided that may be actuated either pneumatically or with a spring in order to be biased into contact with a structure, such as a multi-layer structure, to reduce gaps therewithin. The bushing includes a housing and a nose piece slidably disposed relative to the housing. The bushing also includes a gas inlet in communication with the internal cavity such that the nose piece may be pneumatically urged forwardly relative to the housing and into operable contact with the structure. The bushing may also include a mounting mechanism for releasably attaching the housing to a drill motor. The mounting mechanism permits the housing to be detached from the drill motor to access the internal cavity, thereby permitting a spring to be inserted that will bias the nose piece forwardly relative to the housing. Spring actuation may be an alternative or a supplement to pneumatic actuation.

Owner:THE BOEING CO

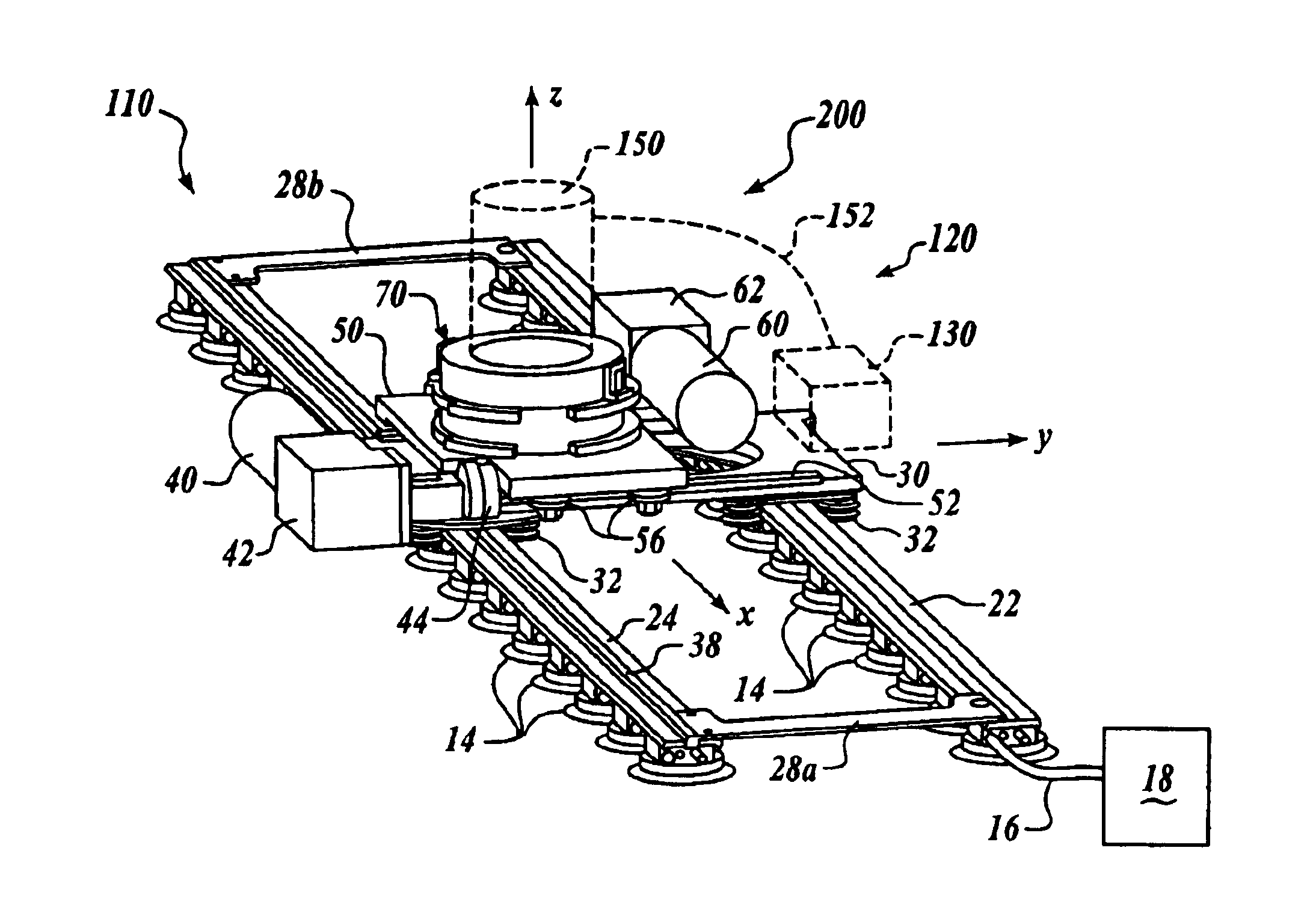

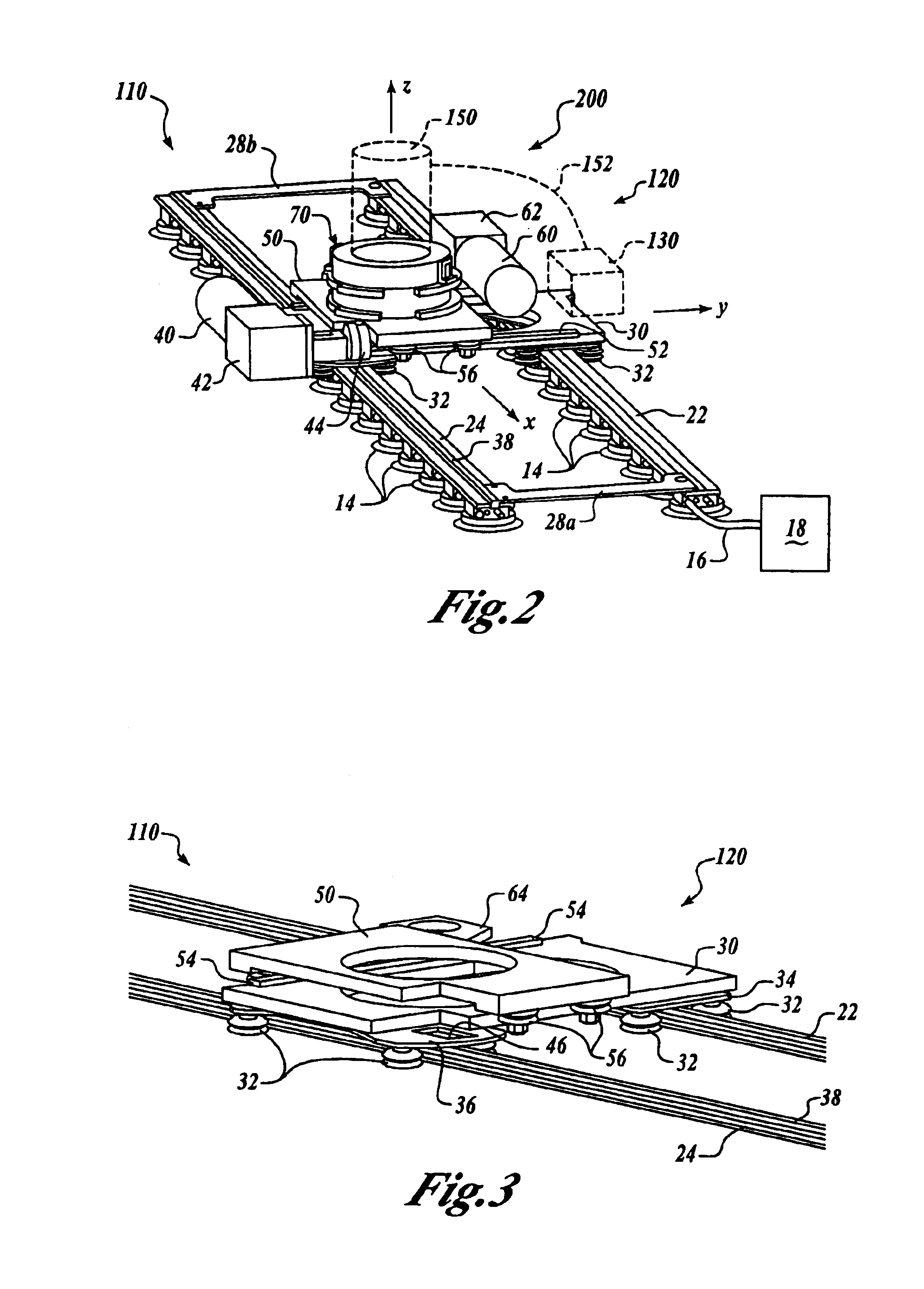

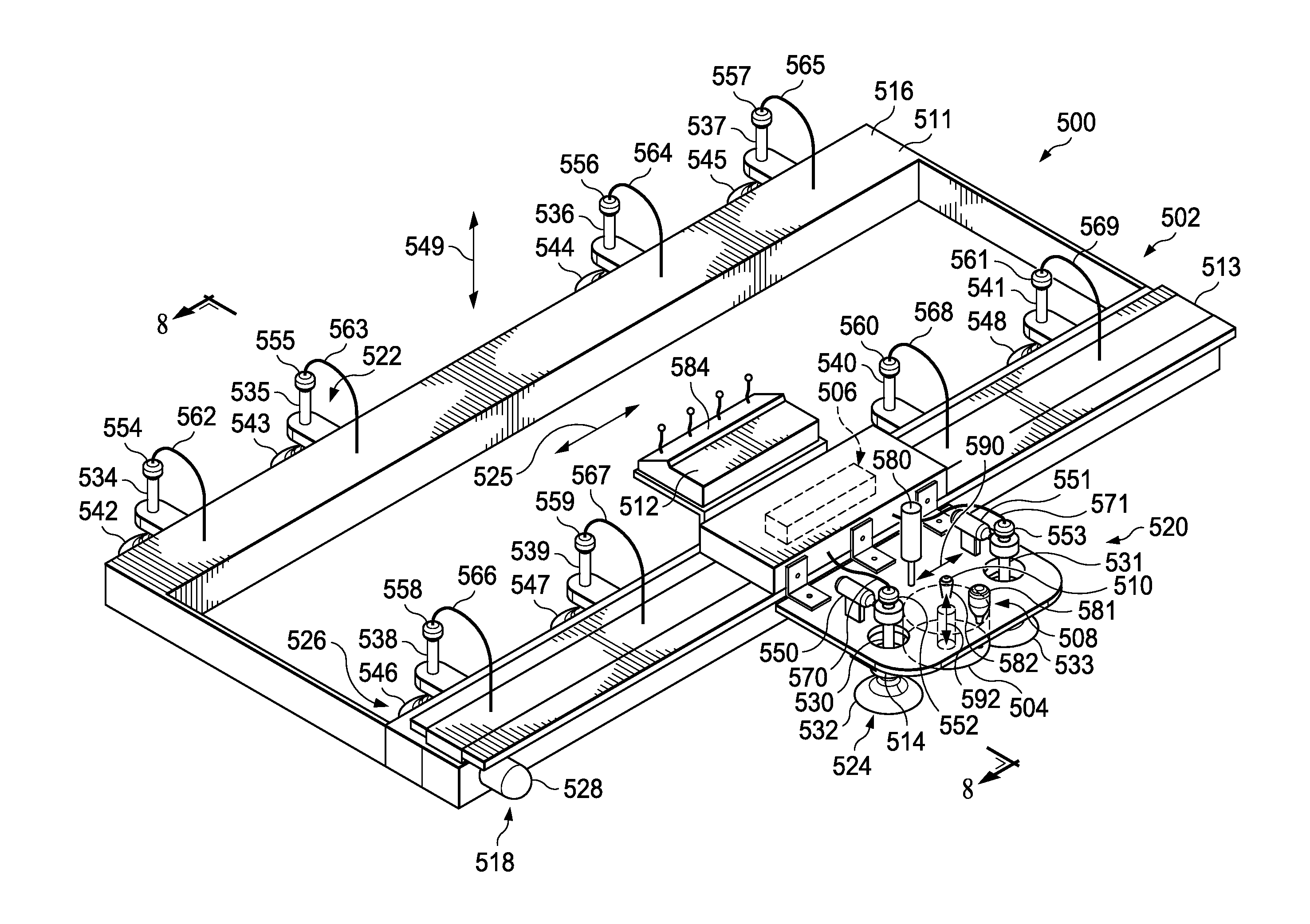

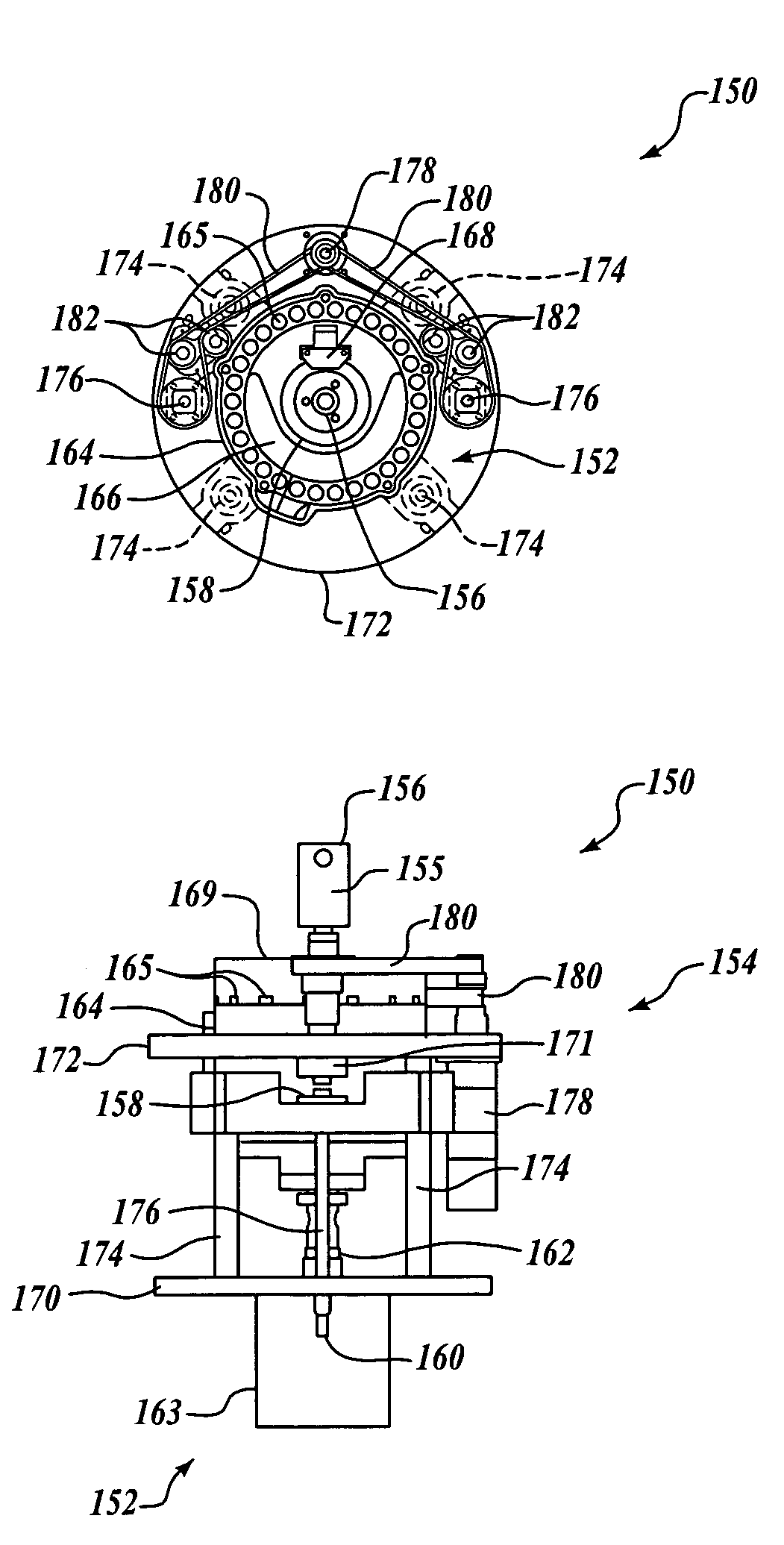

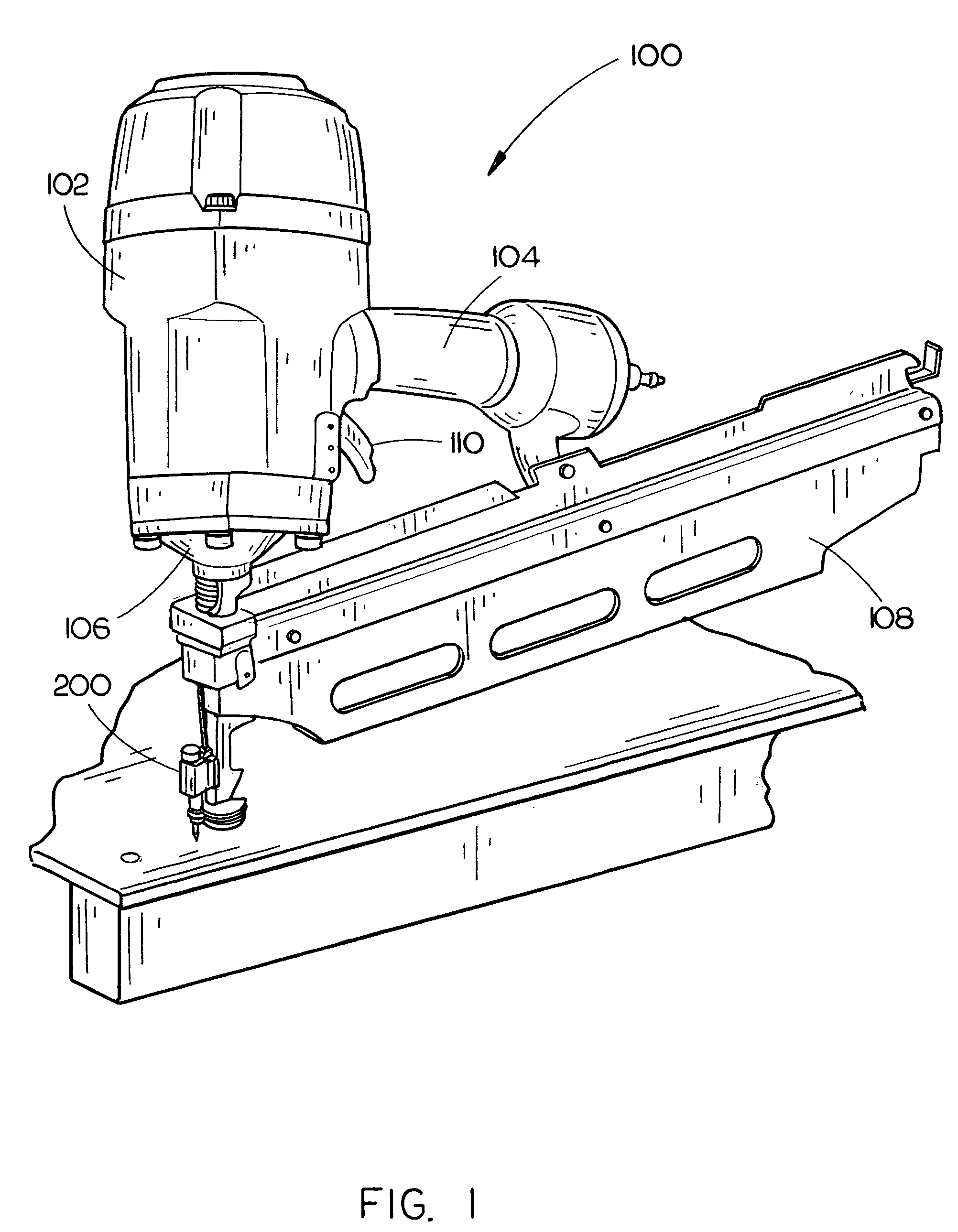

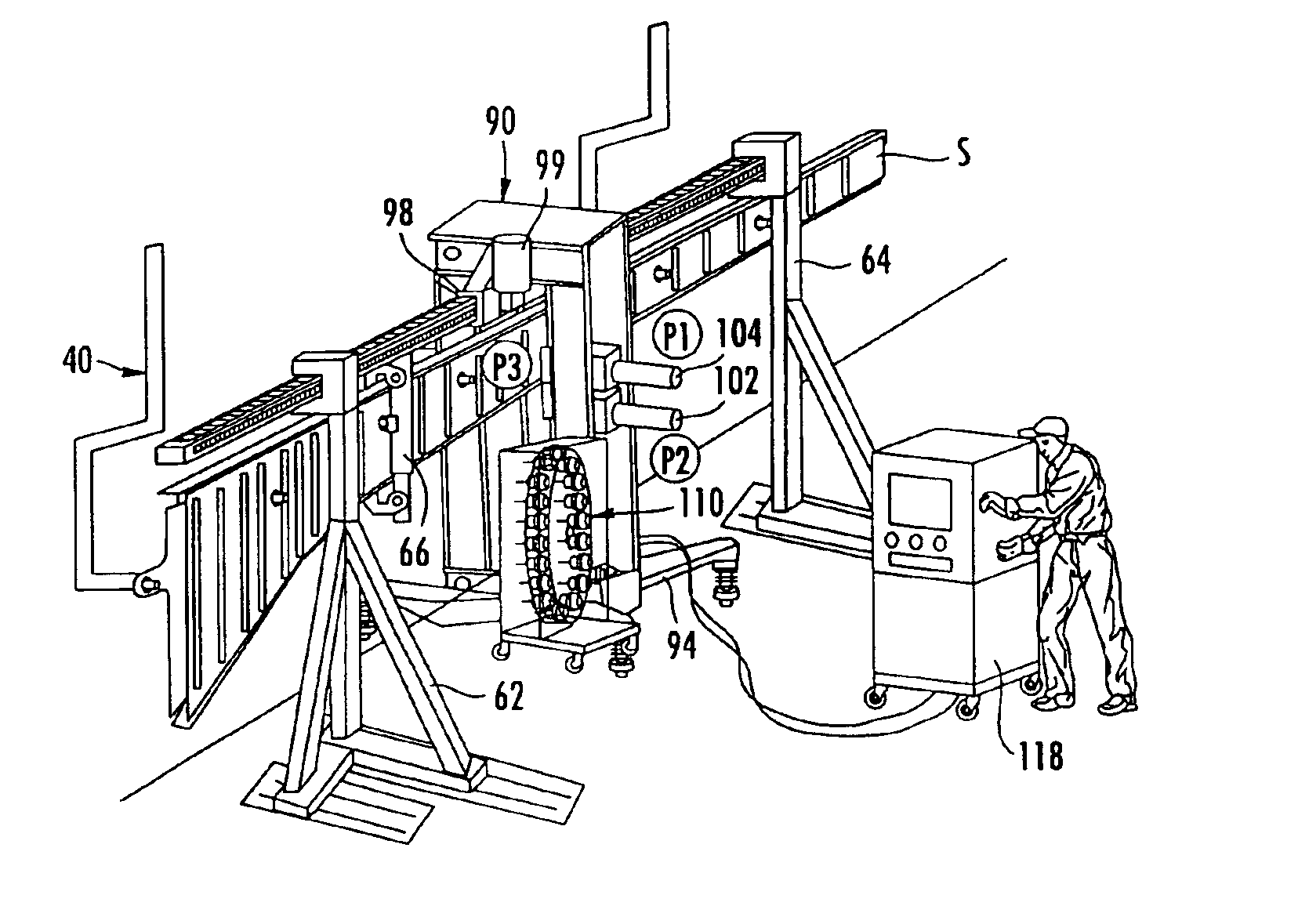

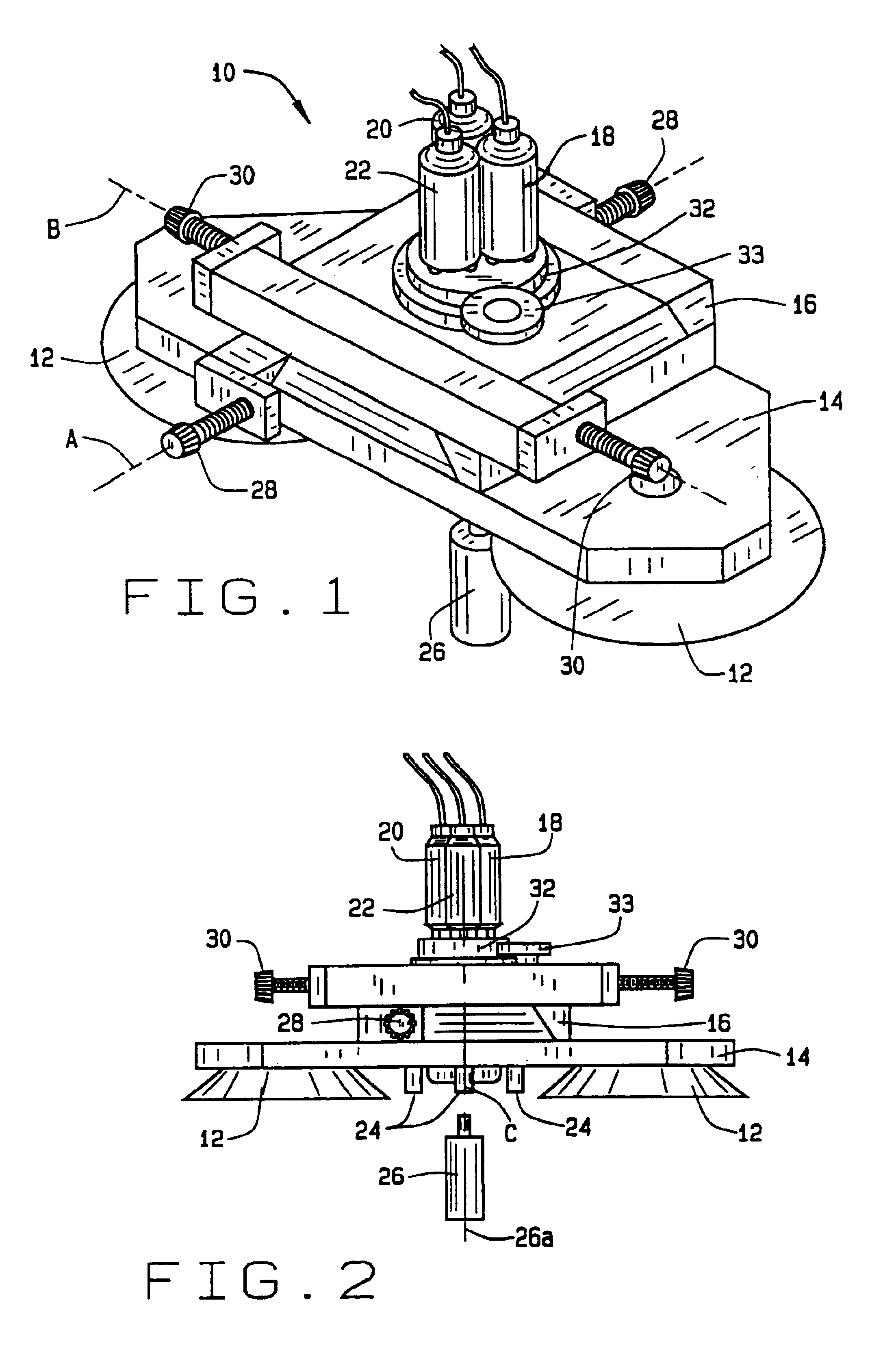

Apparatus and methods for servo-controlled manufacturing operations

ActiveUS7264426B2Improve accuracyImprove efficiencyAircraft componentsDrilling/boring measurement devicesMotor driveControl theory

Apparatus and methods for servo-controlled manufacturing operations are disclosed. In one embodiment, an apparatus includes a base member, a drive platform spaced apart from the base member by a separation distance, and a plurality of guide members extending between the drive platform and the base member. At least one of the drive platform and the base member are moveable along the guide members to increase or decrease the separation distance. The apparatus also includes a drive member operatively coupled between the drive platform and the base member, and a servo motor operatively coupled to the drive member. As the servo motor drives the drive member, the separation distance is varied. In an alternate embodiment, a manufacturing tool may be coupled to at least one of the drive platform and the base member.

Owner:THE BOEING CO

Gauge for use with power tools

InactiveUS7243440B2Improve efficiencyEasy to operateStapling toolsDrilling/boring measurement devicesEngineeringPower tool

Owner:BLACK & DECKER INC

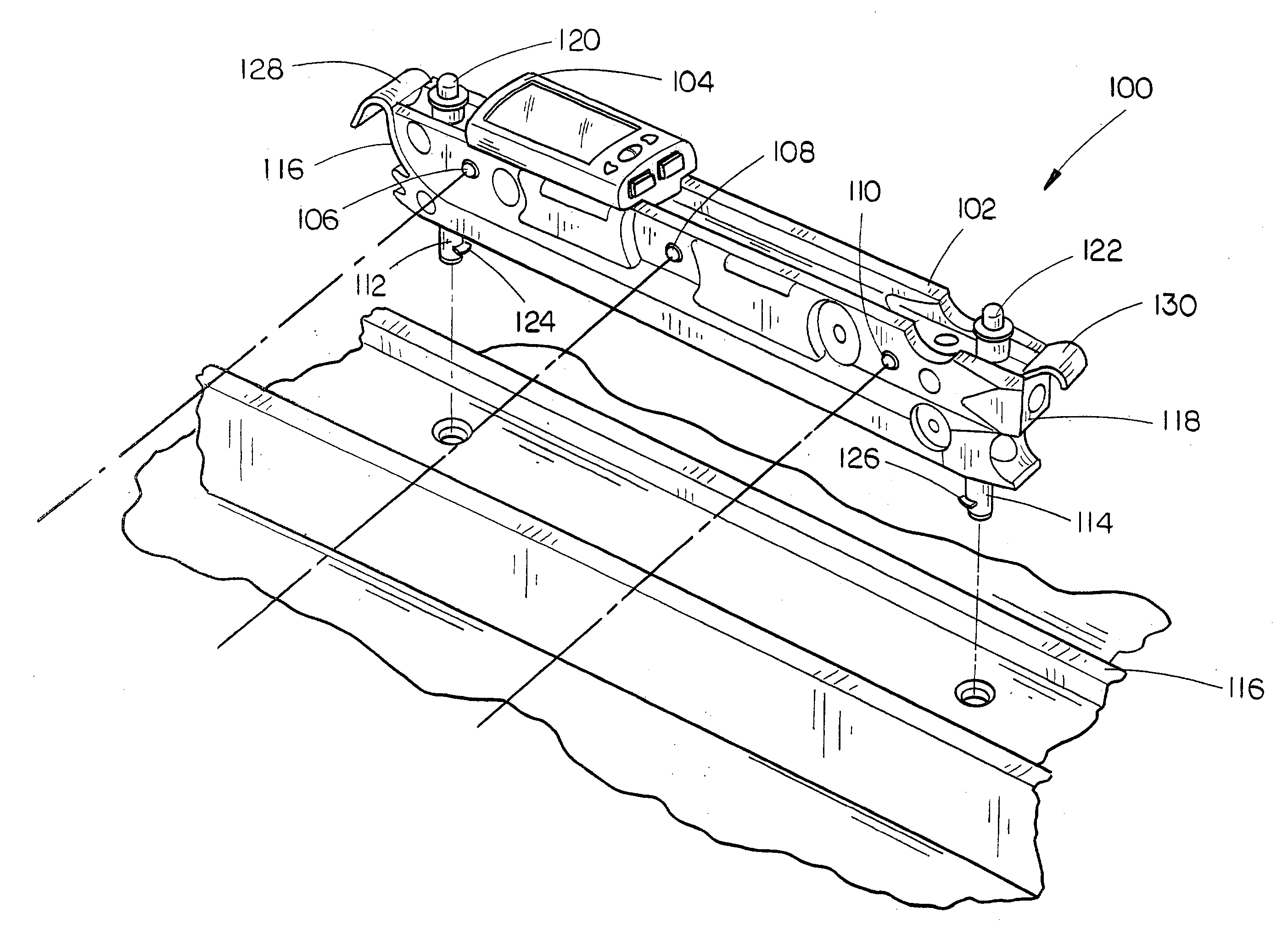

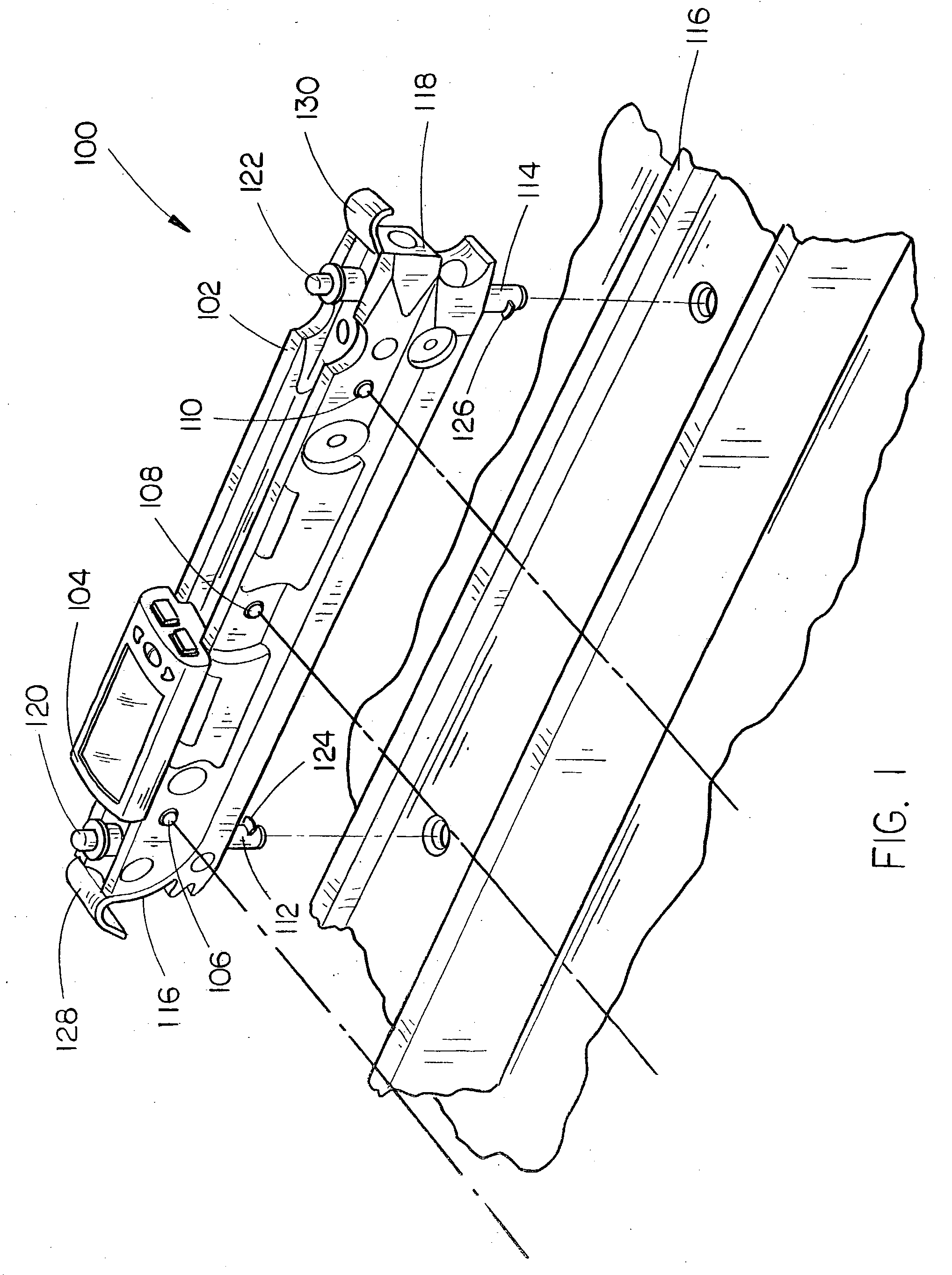

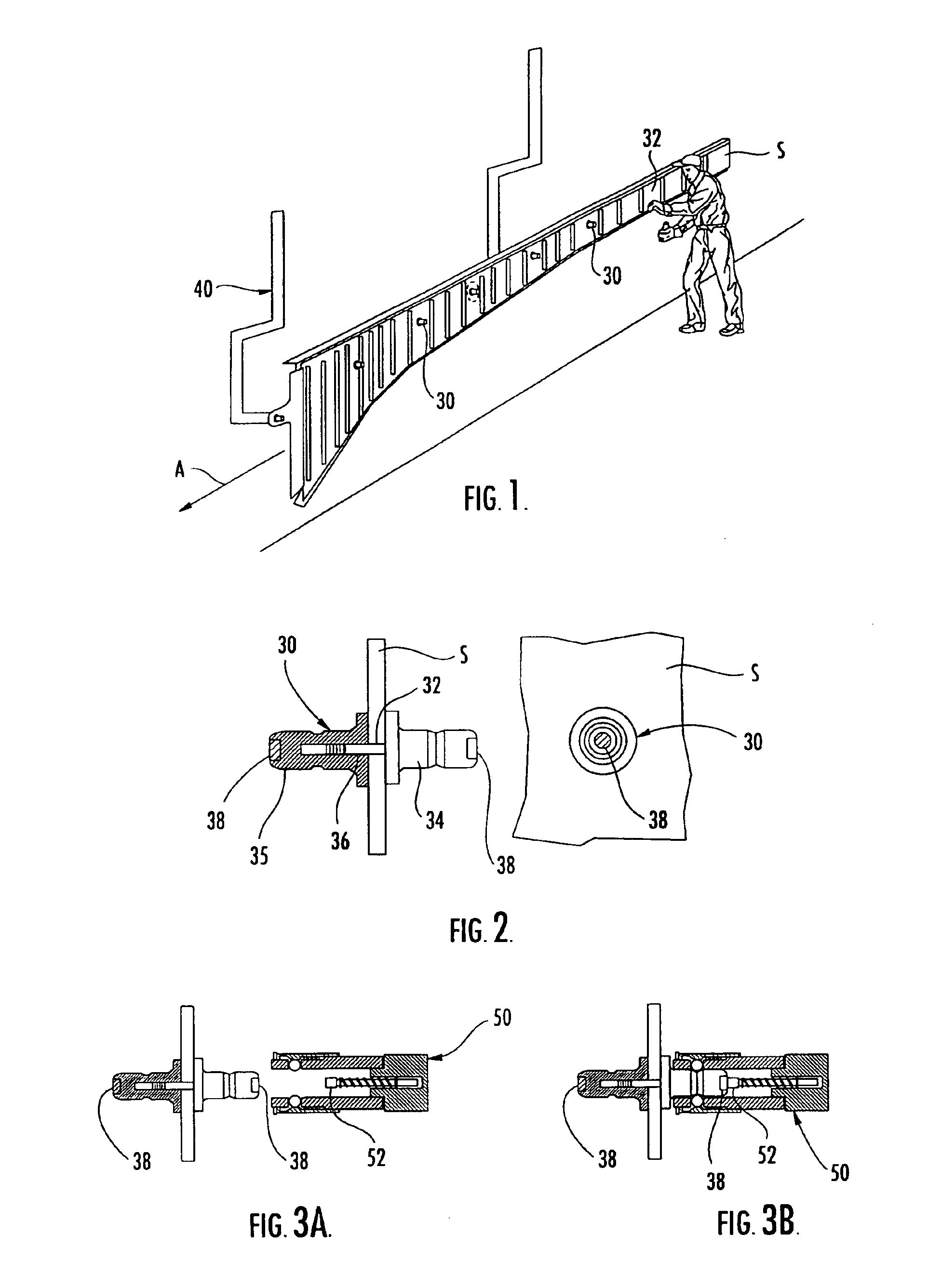

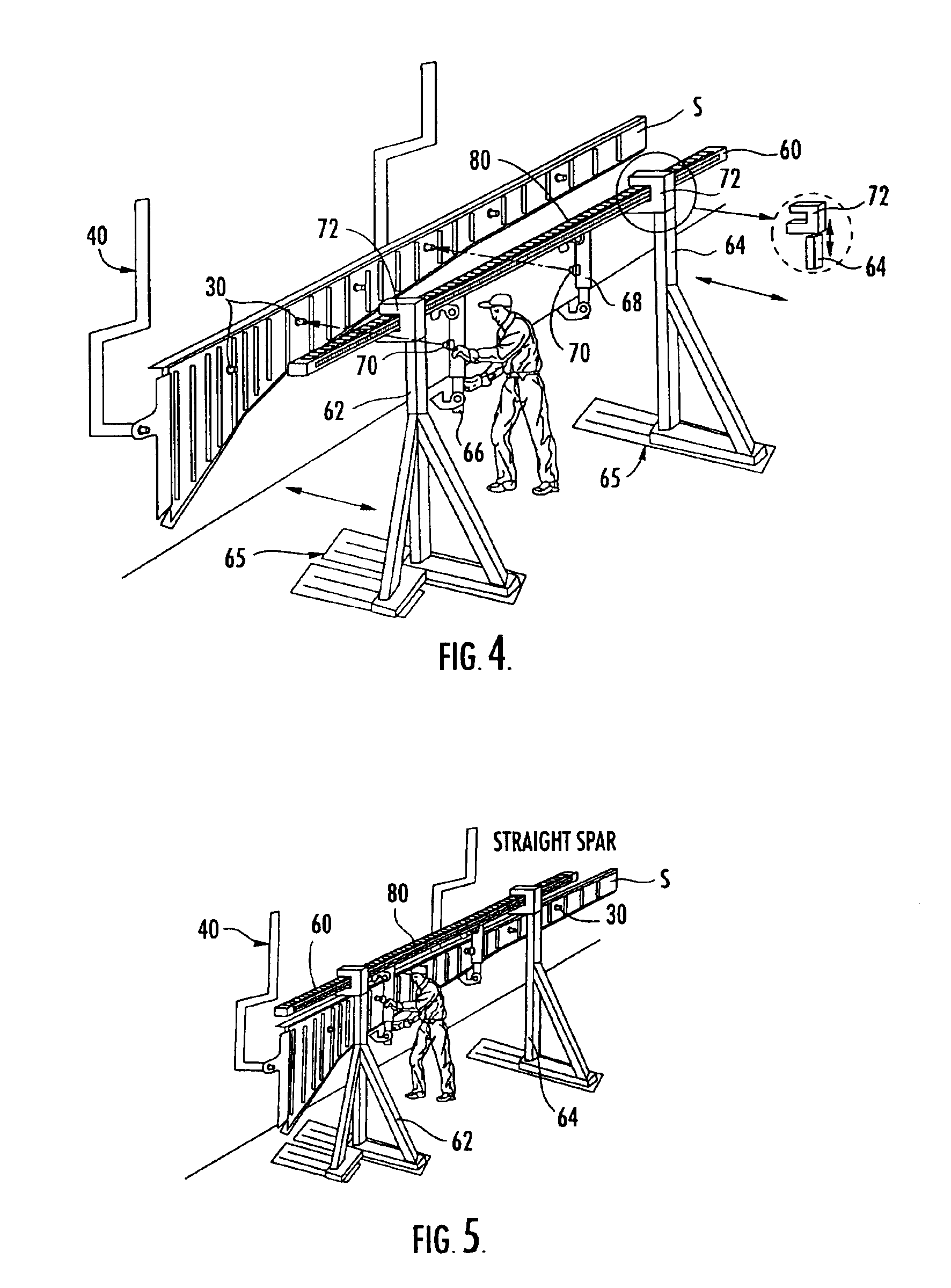

Manufacturing system for aircraft structures and other large structures

InactiveUS6855099B2Accurate locationDrilling/boring measurement devicesThread cutting machinesComputer moduleEngineering

A production system for manufacturing a workpiece comprises an index system including a plurality of index devices removably mounted on the workpiece at known longitudinally spaced locations therealong, and a longitudinally extending index member releasably engaged with at least two of the index devices such that a position and orientation of the index member are fixed relative to the workpiece by the index devices, the index member having position-indicating features distributed therealong. The production system further comprises a machine module mounted for longitudinal movement along the index member and operable to perform an operation, the machine module being operable to detect the position-indicating features on the index member and thereby determine a position of the machine module relative to the workpiece.

Owner:THE BOEING CO

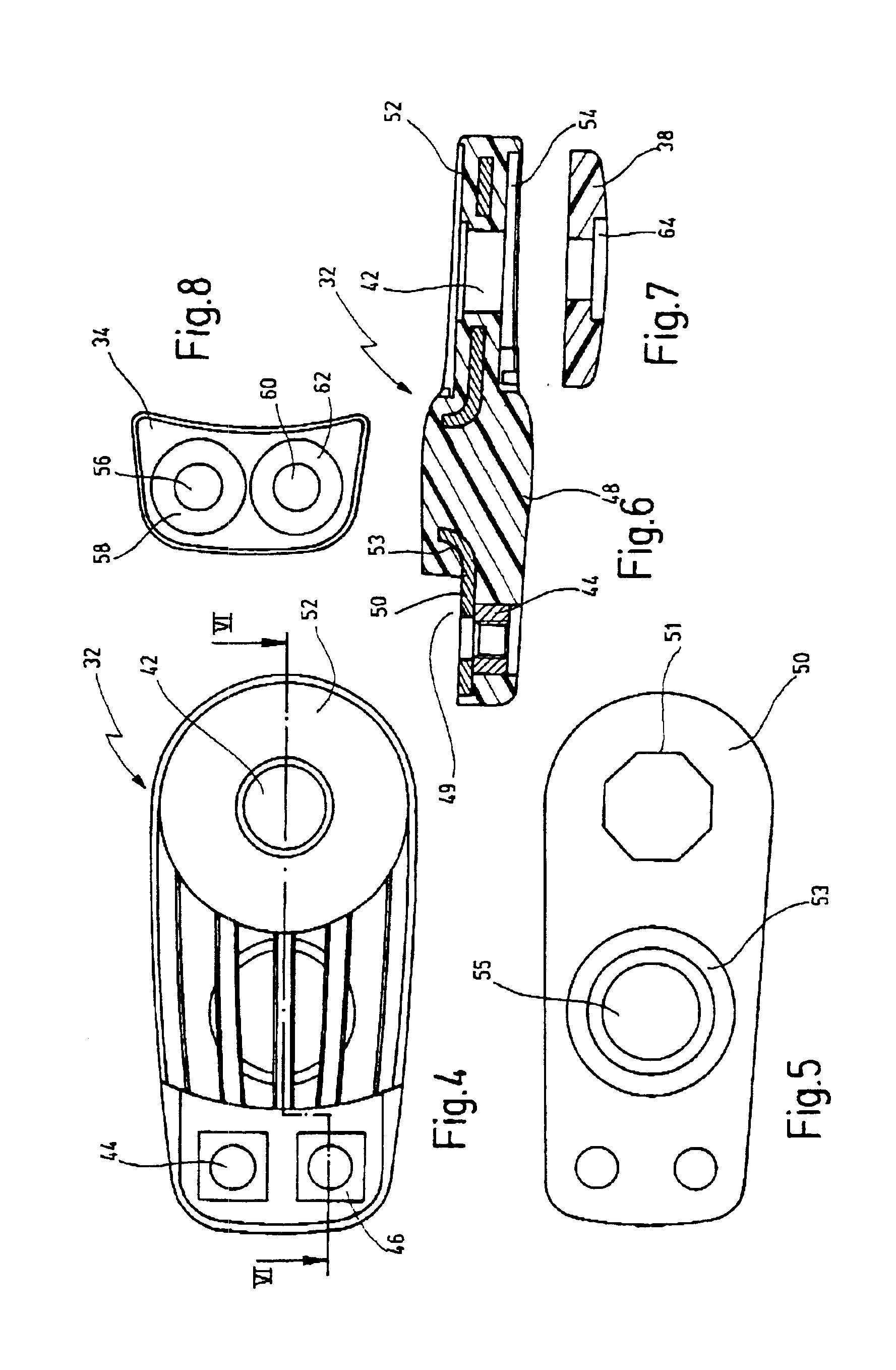

Tool having a holder for mounting on a drive shaft

InactiveUS6865813B2Low costEasy to produceMetal sawing devicesDrilling/boring measurement devicesDrive shaft

A tool is disclosed having a holder provided with a mounting opening for mounting on a drive shaft, which may be driven in oscillating fashion, and having further a fixture for mounting a working element. The working element comprises at least two holding sections, spaced one from the other in tangential direction to the mounting opening, and wherein a mounting plate is provided which is engaged by releasable securing elements that coact with the holding sections for clamping the working element against the holder.

Owner:C & E FEIN

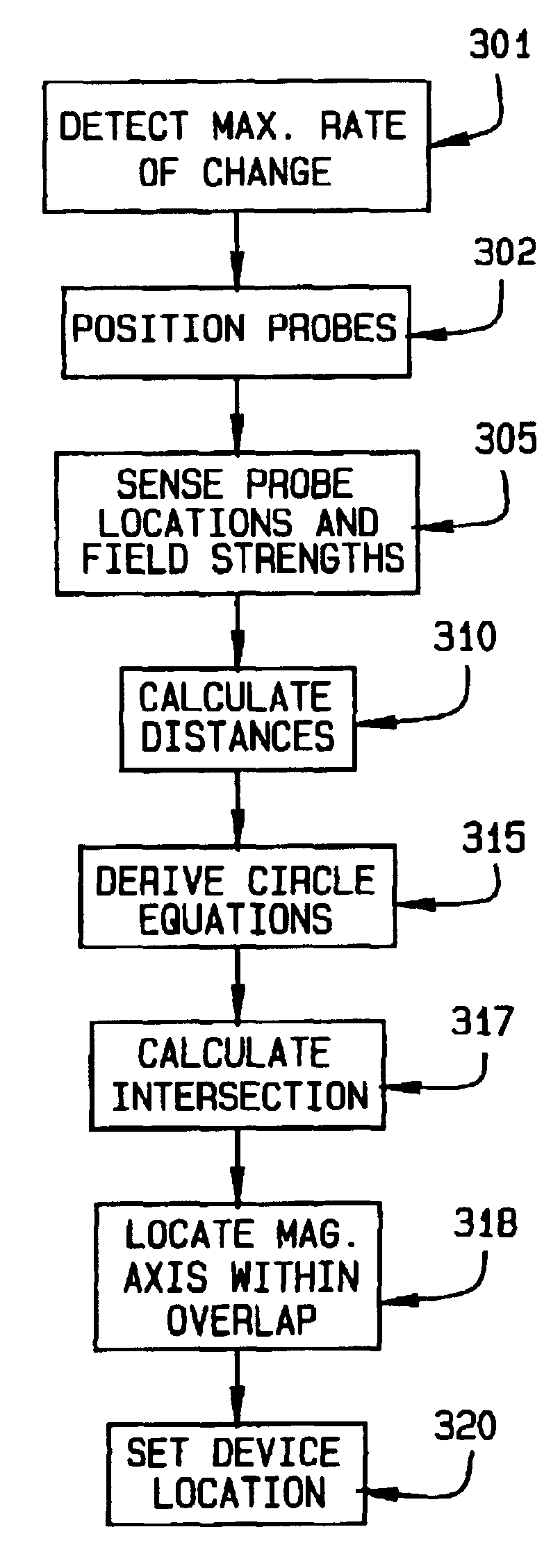

Control system and method for a magnetic indexer for high accuracy hole drilling

InactiveUS6927560B2Accurately work surfacePrecise positioningAircraft componentsDrilling/boring measurement devicesControl systemUltimate tensile strength

A method for locating a device producing a magnetic field in a blind or inaccessible position of a work piece. A magnet is initially placed on a first side of the work piece such that a magnetic field produced by the magnet extends through the work piece. Probes are then positioned over a second surface of the work piece to determine the location of the axis of the magnet via the strength of the sensed magnetic field and the location where the strength measurements are made. Once the position of the axis of the magnet is determined, the work surface is either marked or worked on through the platform on which the probes are positioned. In particular, the present invention allows a very accurate positioning of a work tool on the second surface without the need to first visualize the first surface of the work piece.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com