Patents

Literature

1125 results about "Laser tracker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser trackers are instruments that accurately measure large objects by determining the positions of optical targets held against those objects. The accuracy of laser trackers is of the order of 0.025 mm over a distance of several metres. Some examples of laser tracker applications are to align aircraft wings during assembly and to align large machine tools. To take measurements the technician first sets up a laser tracker on a tripod with an unobstructed view of the object to be measured. The technician removes a target from the base of the laser tracker and carries it to the object to be measured, moving smoothly to allow the laser tracker to follow the movement of the target. The technician places the target against the object and triggers measurements to be taken at selected points, sometimes by a remote control device. Measurements can be imported into different types of software to plot the points or to calculate deviation from the correct position.

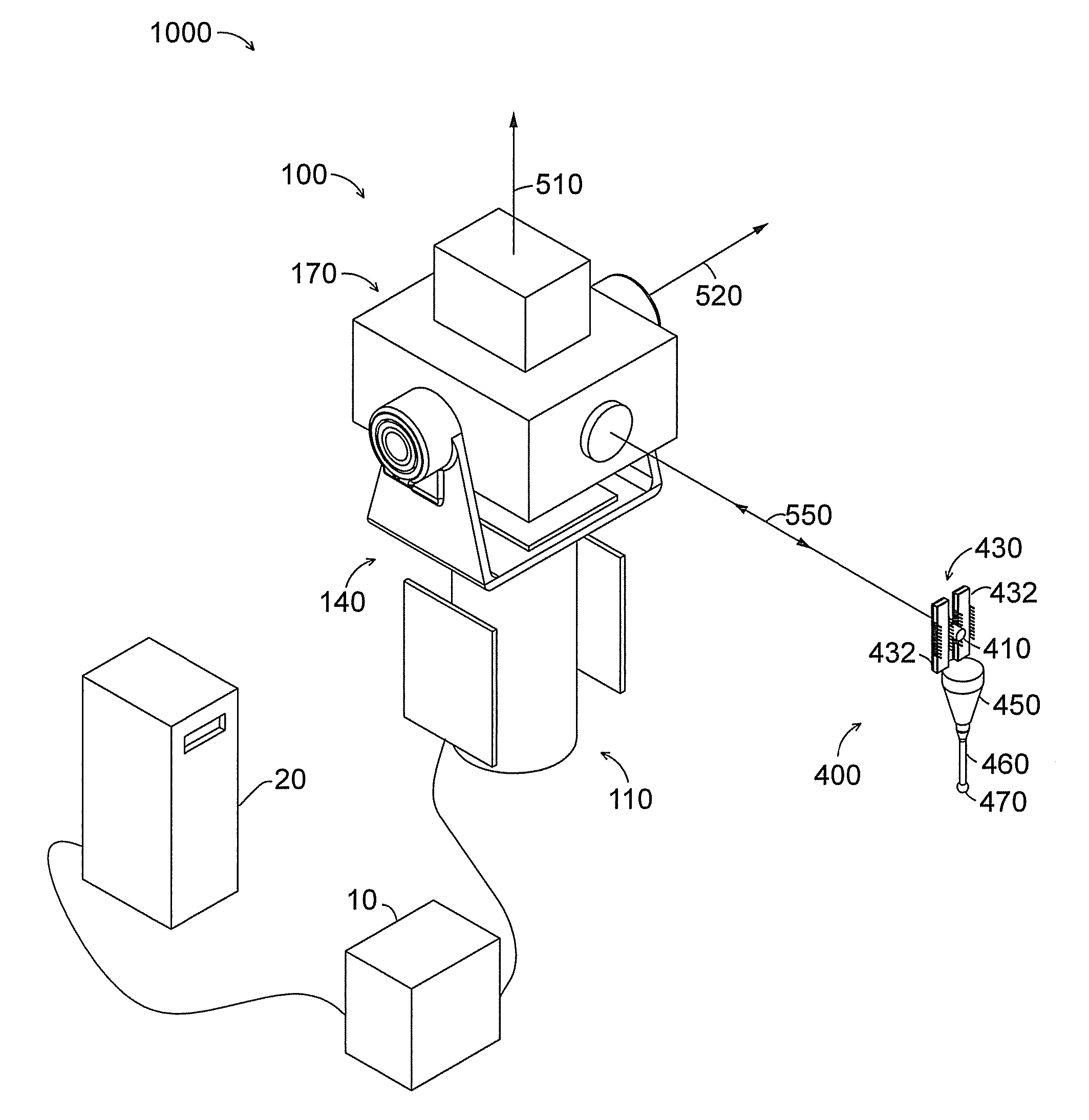

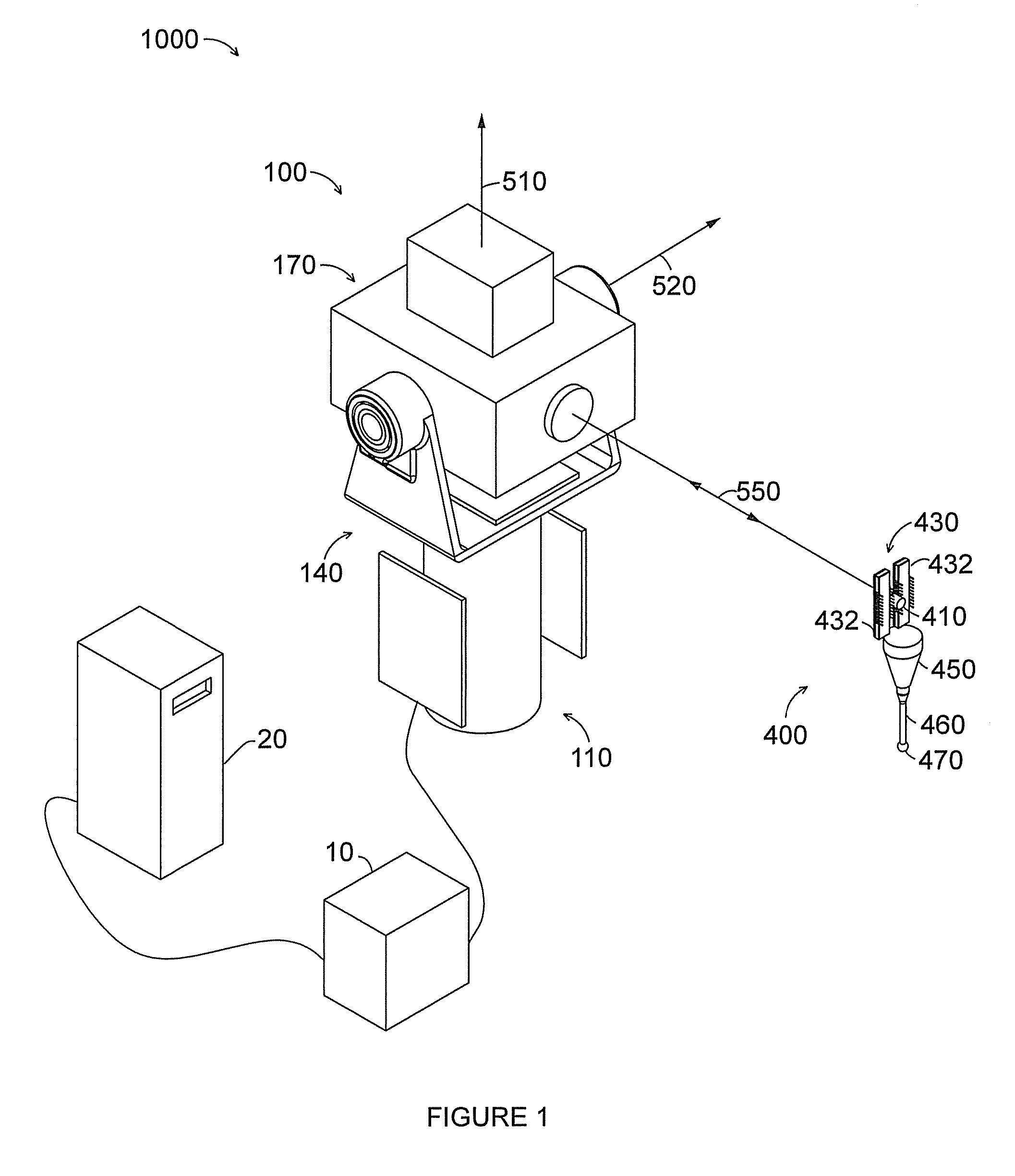

Device and method for measuring six degrees of freedom

InactiveUS20100128259A1Angle measurementBeacon systems using electromagnetic wavesLight beamDegrees of freedom

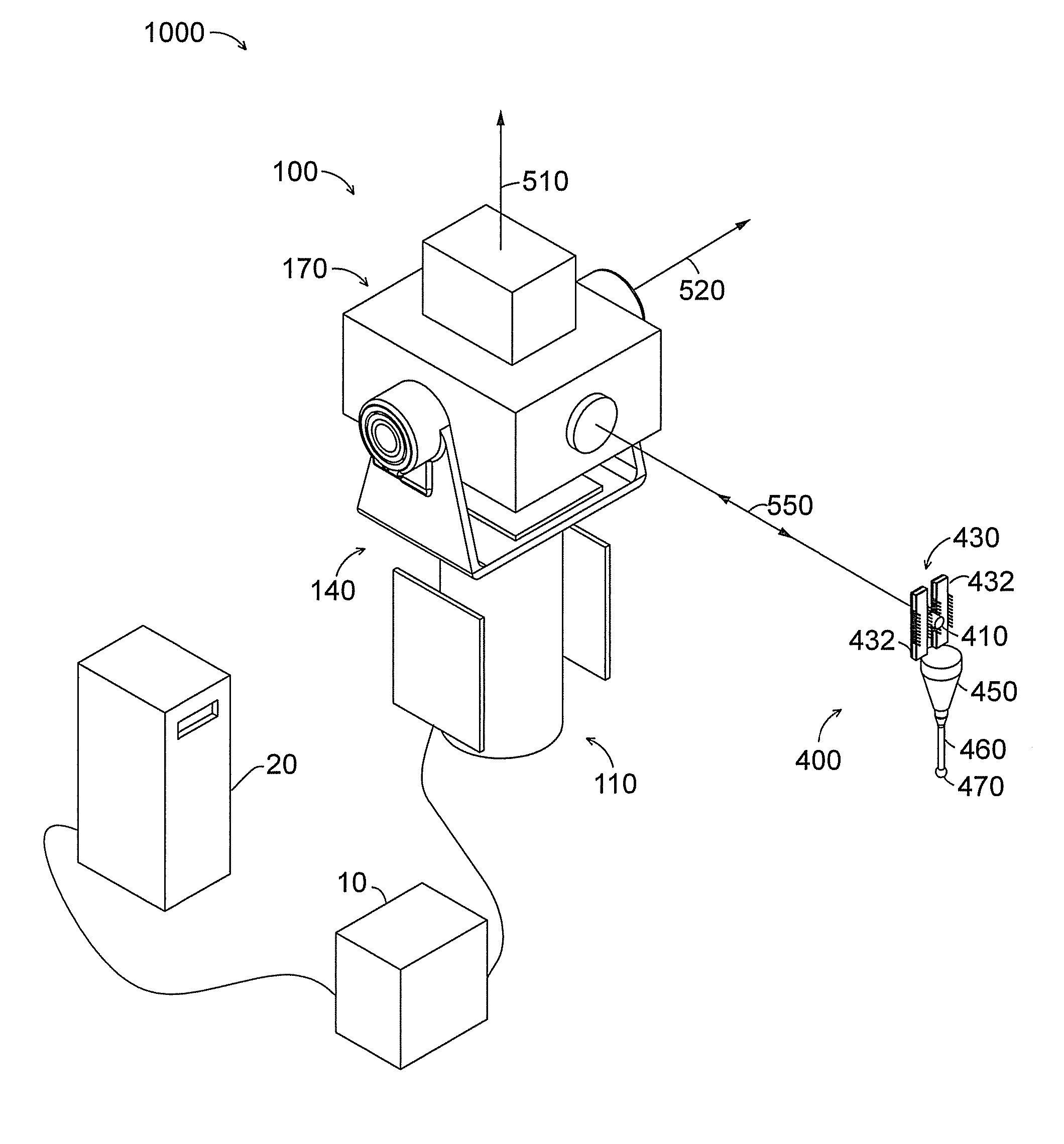

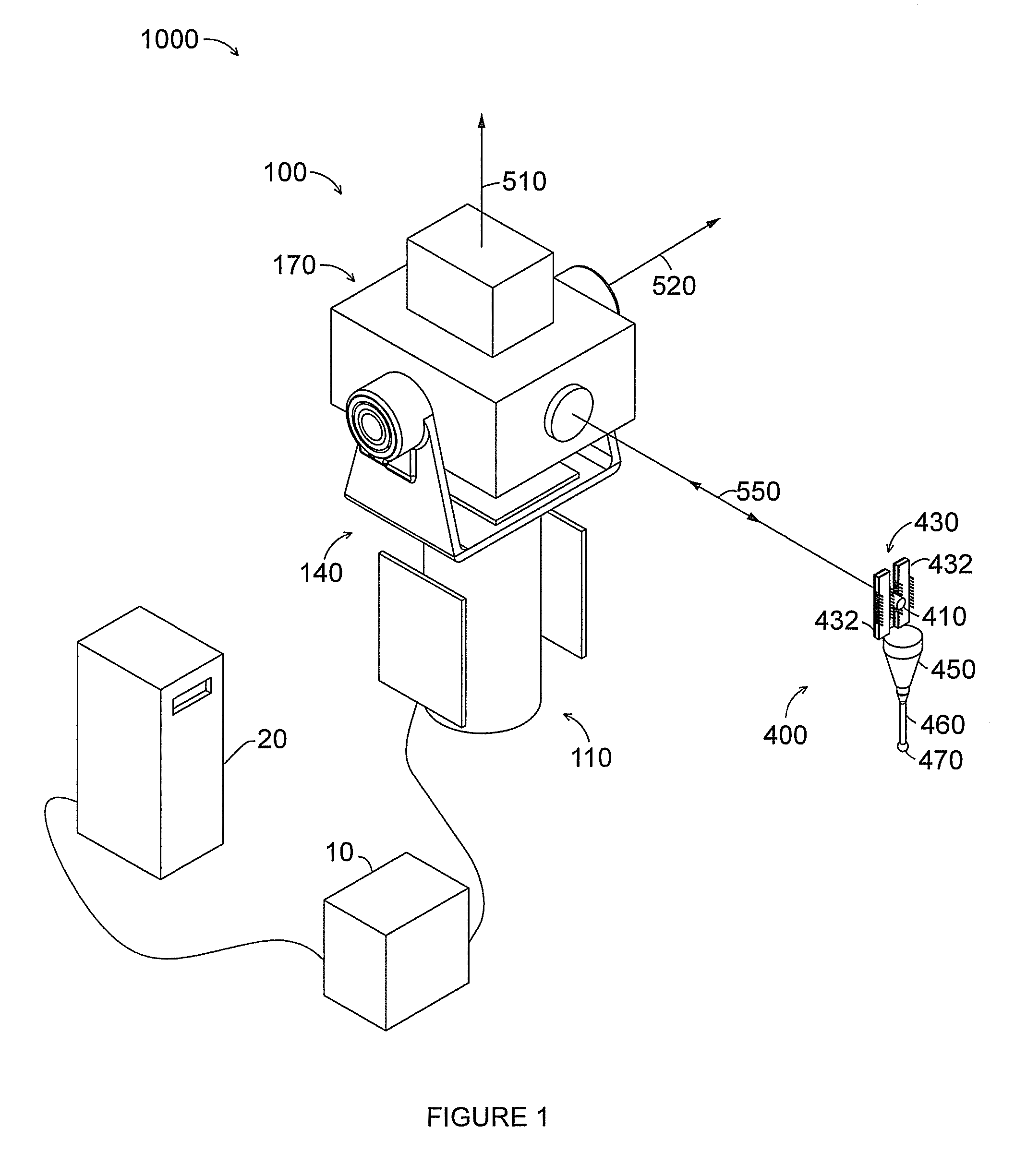

A laser tracker system for measuring six degrees of freedom may include a main optics assembly structured to emit a first laser beam, a pattern projector assembly structured to emit a second laser beam shaped into a two-dimensional pattern, and a target. The target may include a retroreflector and a position sensor assembly. A center of symmetry of the retroreflector may be provided on a different plane than a plane of the position sensor assembly. A method of measuring orientation of a target may include illuminating the target with a laser beam comprising a two-dimensional pattern, recording a position of the two-dimensional pattern on a position sensor assembly to create a measured signature value of the two-dimensional pattern, and calculating an orientation of the target based on the measured signature value.

Owner:FARO TECH INC

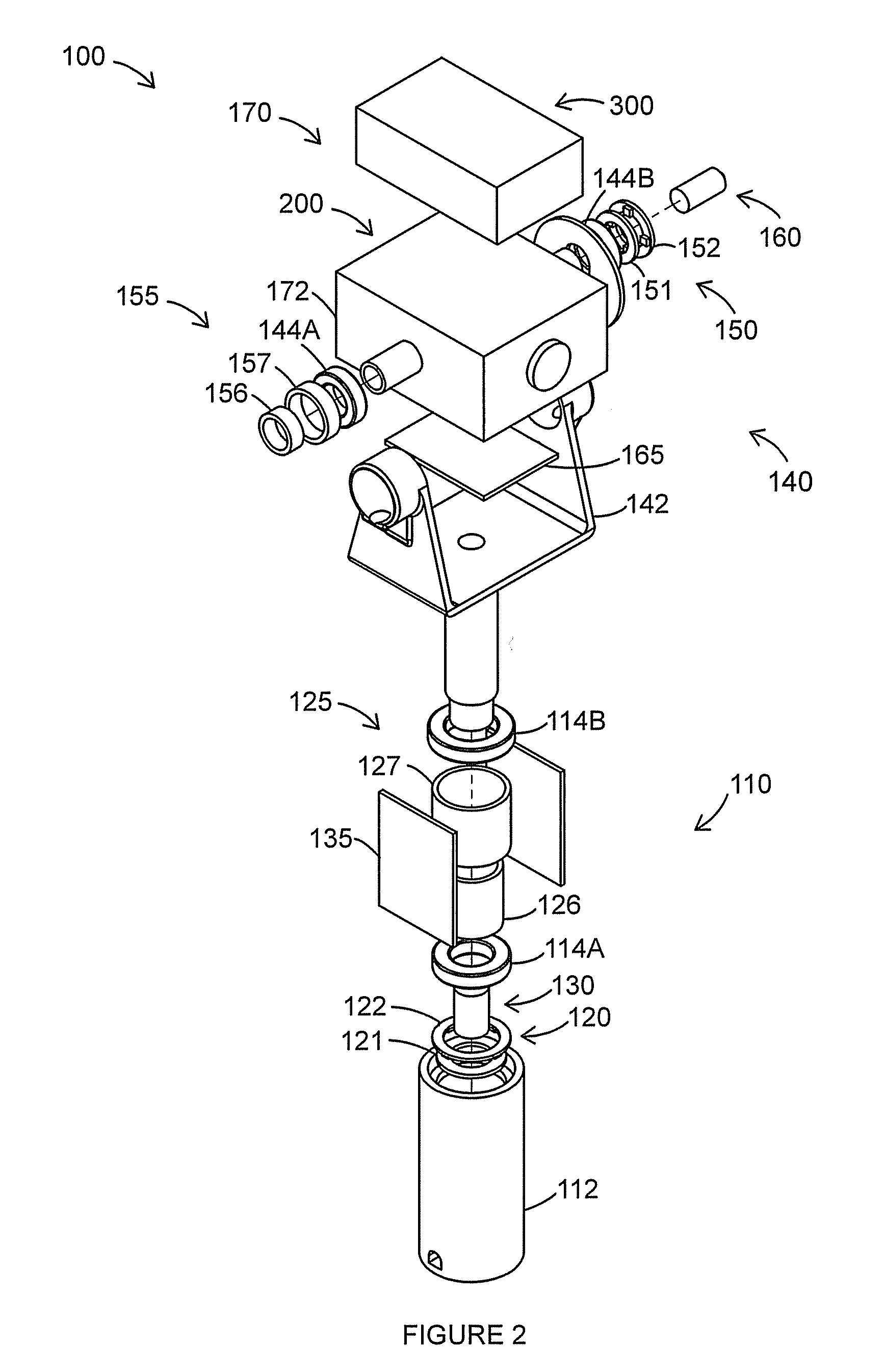

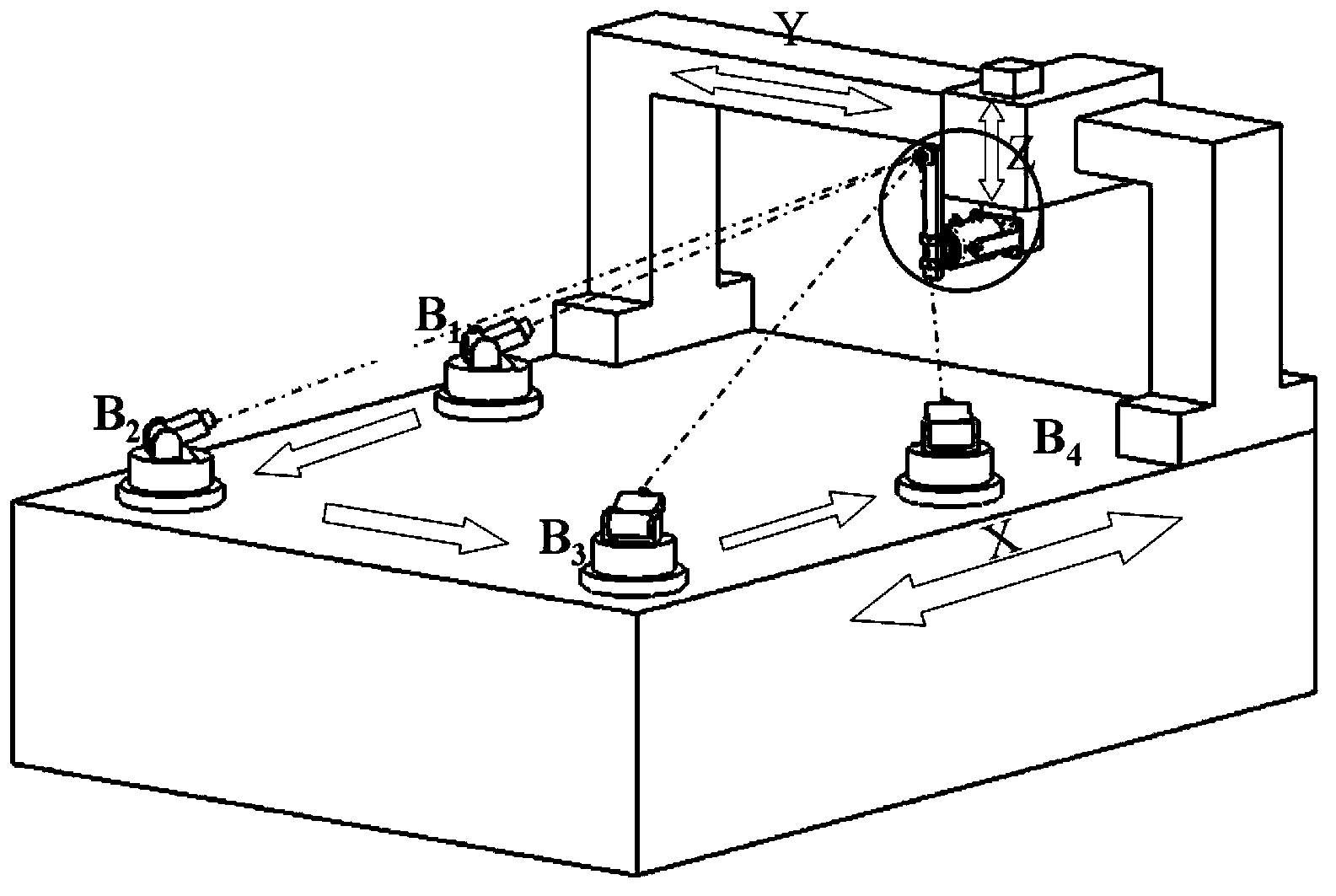

Airplane component attitude adjusting and butting system based on four numeric control positioners, attitude adjusting platform and mobile bracket and corresponding method

InactiveCN102001451ARealize digital positioningRealize dockingAircraft assemblyLaser trackerFuselage

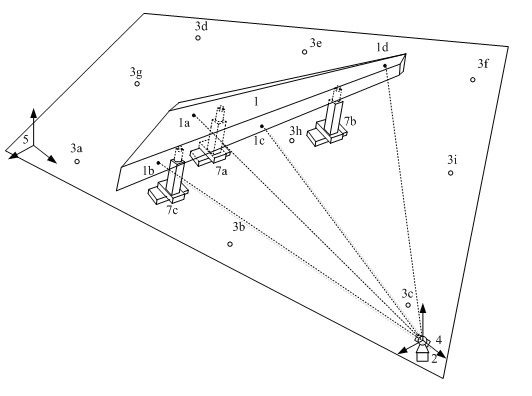

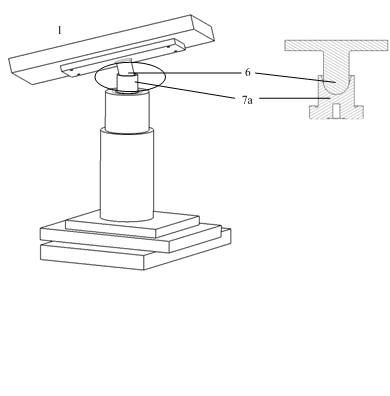

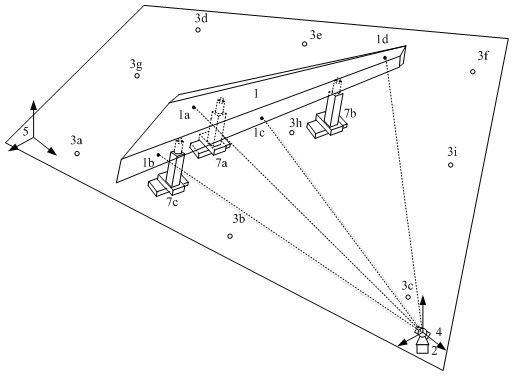

The invention discloses an airplane component attitude adjusting and butting system based on four numeric control positioners, attitude adjusting platform and mobile bracket and a corresponding method. The system comprises a mobile bracket, an attitude adjusting platform, numeric control positioners, a numeric control positioner group guide rail, an upper computer, a ball hinge connection mechanism and a laser tracker. The attitude adjusting and butting method includes the following steps: 1) the mobile bracket is fixed onto the attitude adjusting platform and is supported by the numeric control positioner; 2) fuselage is arranged in place; 3) a site assembly coordinate system and a local coordinate system solidified on the fuselage are established; 4) the current attitude of fuselage A is measured and calculated; 5) motion path of the numeric control positioner is planned; 6) the attitude of the fuselage A is adjusted; 7) coordinates of a butt hole are measured and target attitude offuselage B is calculated; 8) the current attitude of fuselage B is calculated; 9) the attitude of the fuselage B is adjusted; 10) fuselage is butted; 11) the system is reset; 12) the mobile bracket is removed. The invention has the advantages that digitalized attitude adjusting and butting of airplane components are realized and adaptability is strong.

Owner:ZHEJIANG UNIV

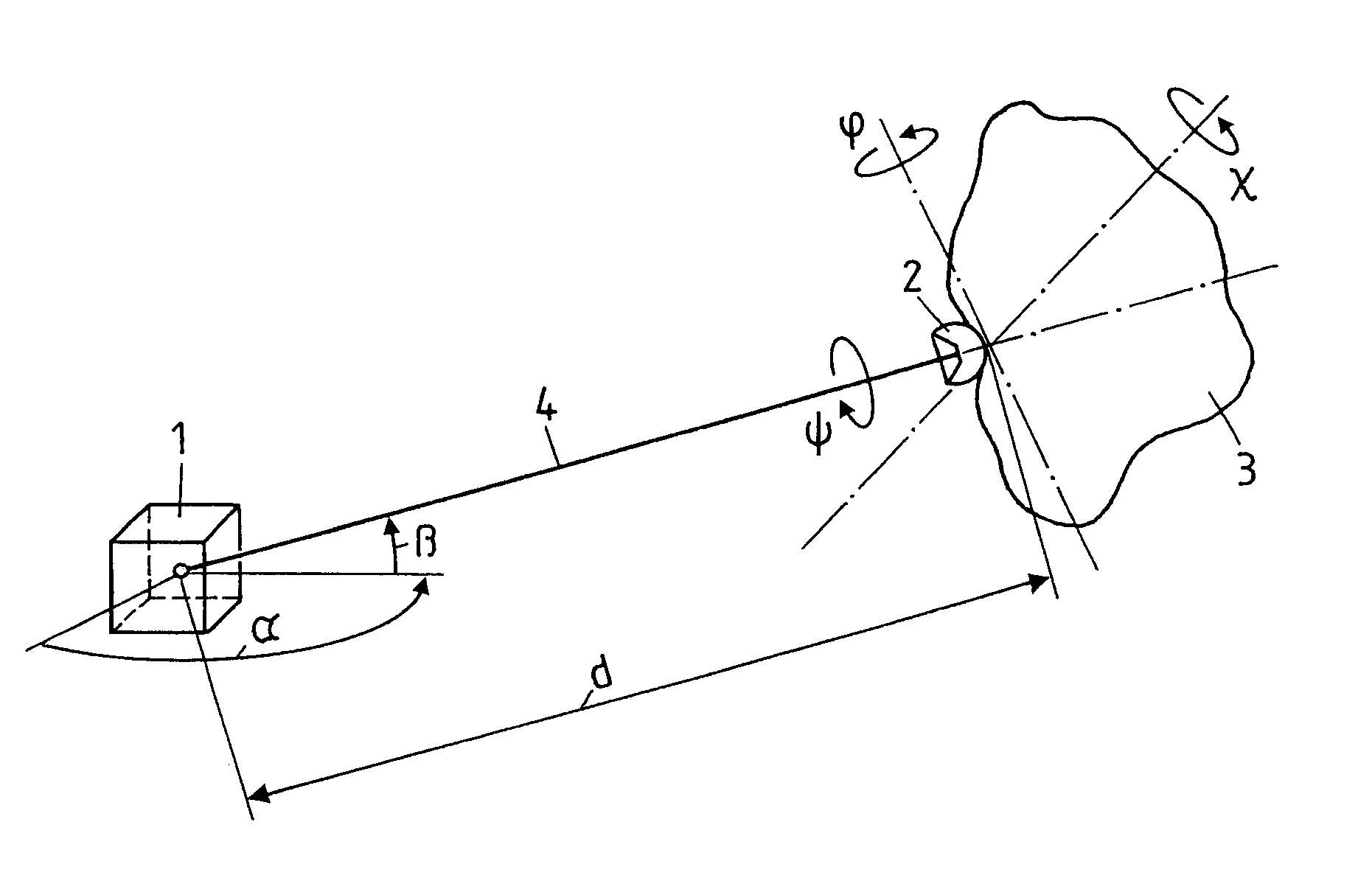

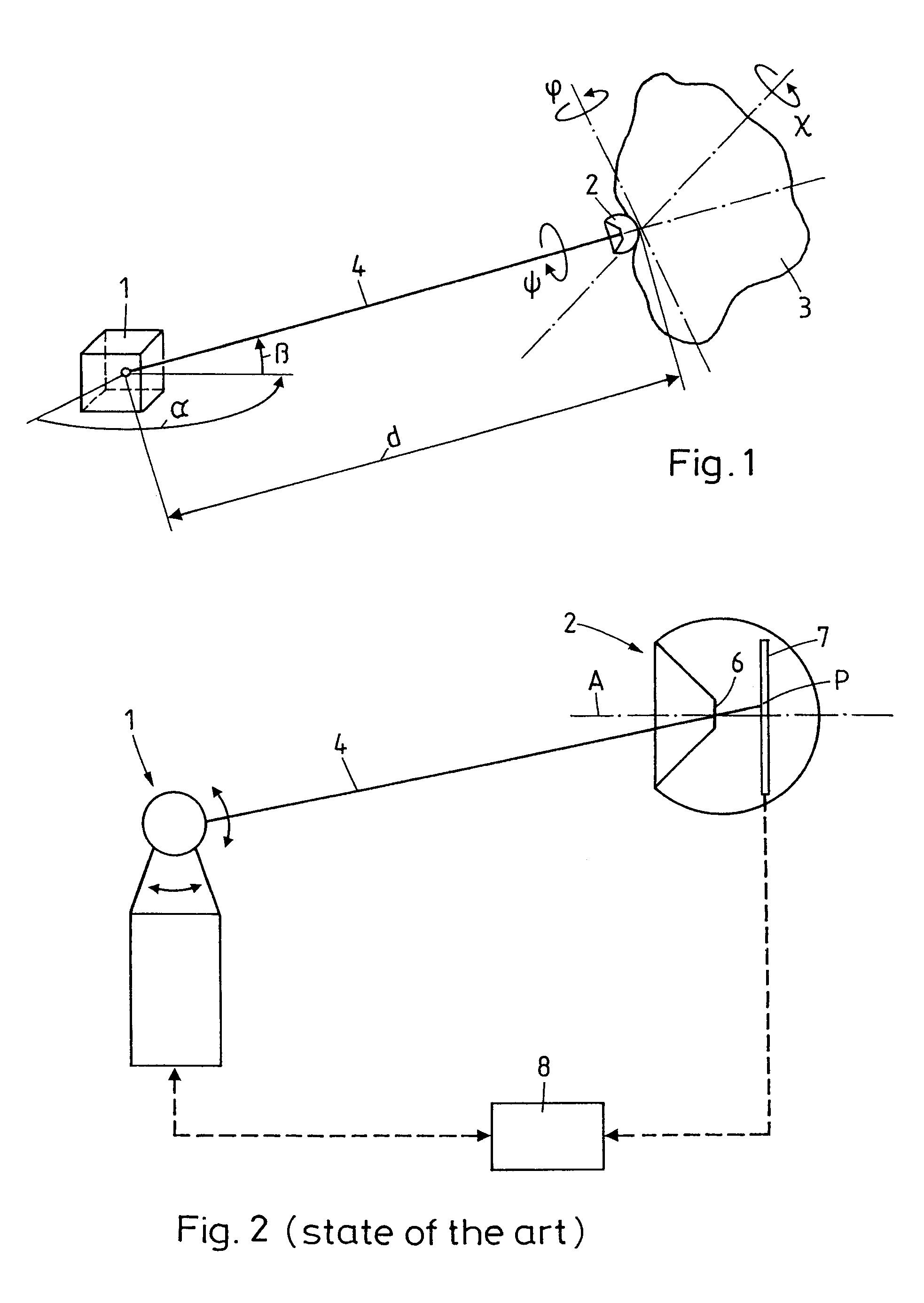

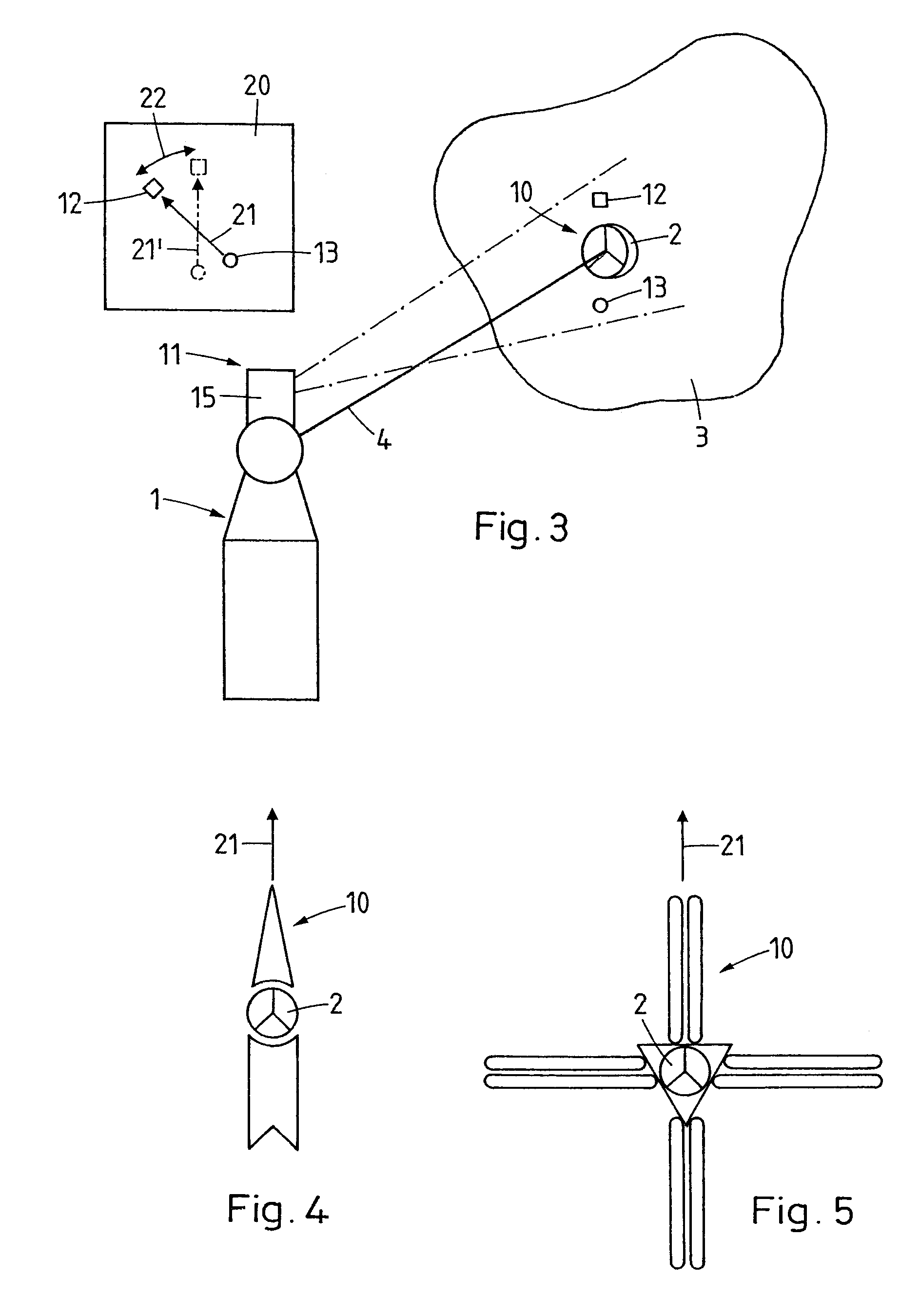

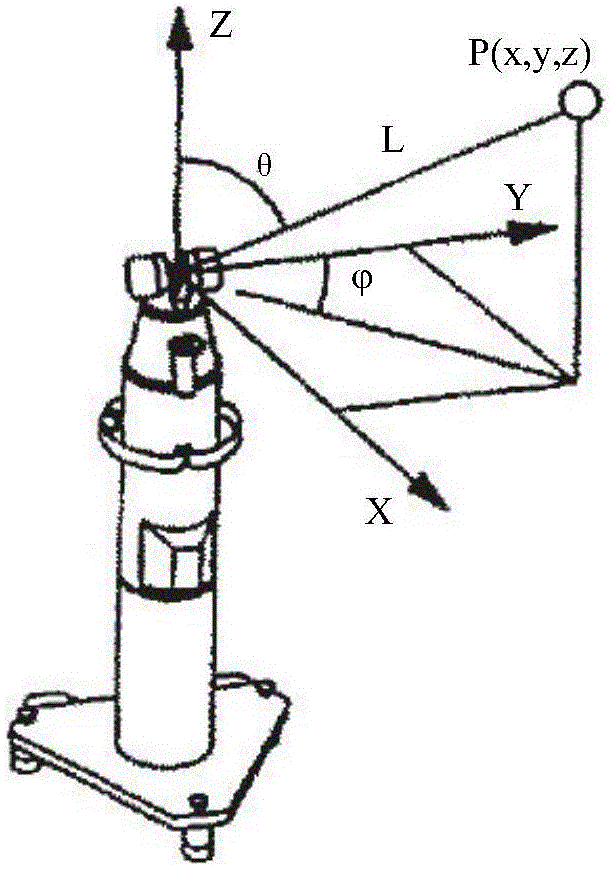

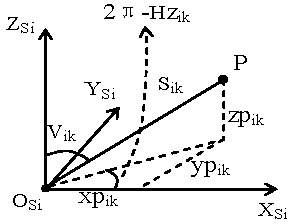

Measurement system for determining six degrees of freedom of an object

A measurement system for determining six degrees of freedom (α, β, d, φ, χ, ψ) of a reflector (2) or of an object (3) on which the reflector is arranged, comprises an angle- and distance measurement apparatus (1), e.g. a laser tracker, operating with a laser beam as a measurement beam (4). The reflector (2) is designed for a parallel reflection of the measurement beam (4) and has an apical opening or surface (6), in a manner such that a part of the measurement beam (4) directed onto the reflector (2), passes through the apical opening or surface (6), and is incident on a light-sensitive surface (7) arranged behind the reflector apex. Five degrees of freedom (α, β, d, φ, χ) of the reflector (2) or the object (3) are computed from measurement data produced by the angle- and distance measurement apparatus (1) and by the light-sensitive surface (7).

Owner:LEICA GEOSYSTEMS AG

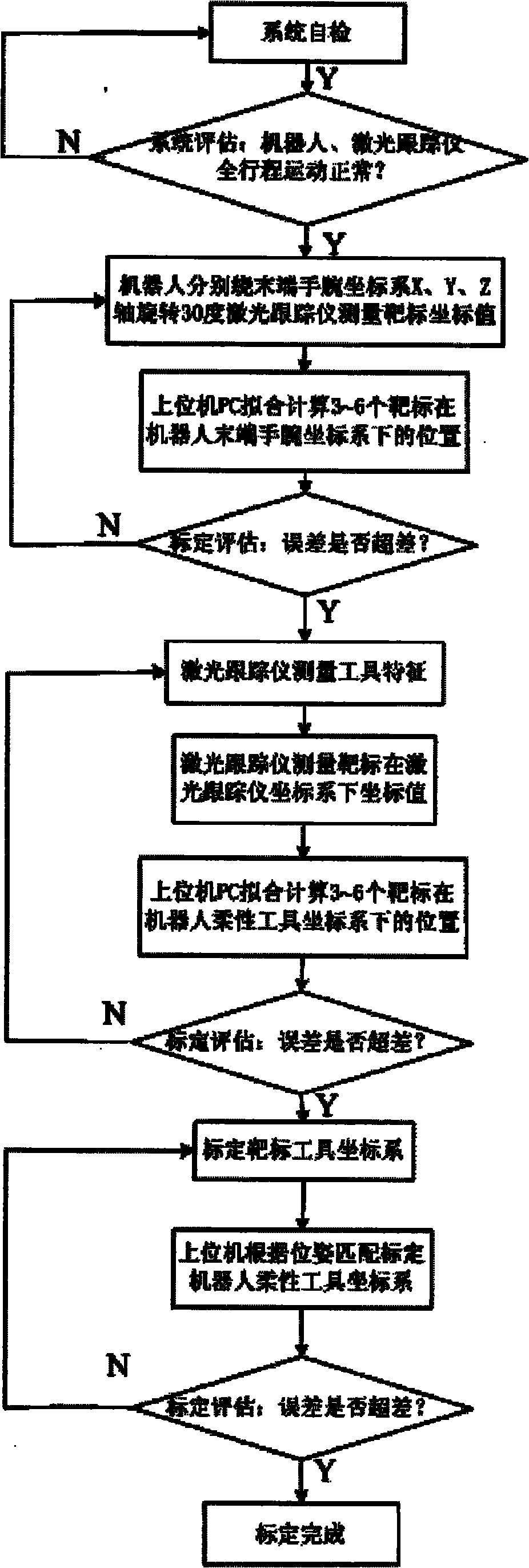

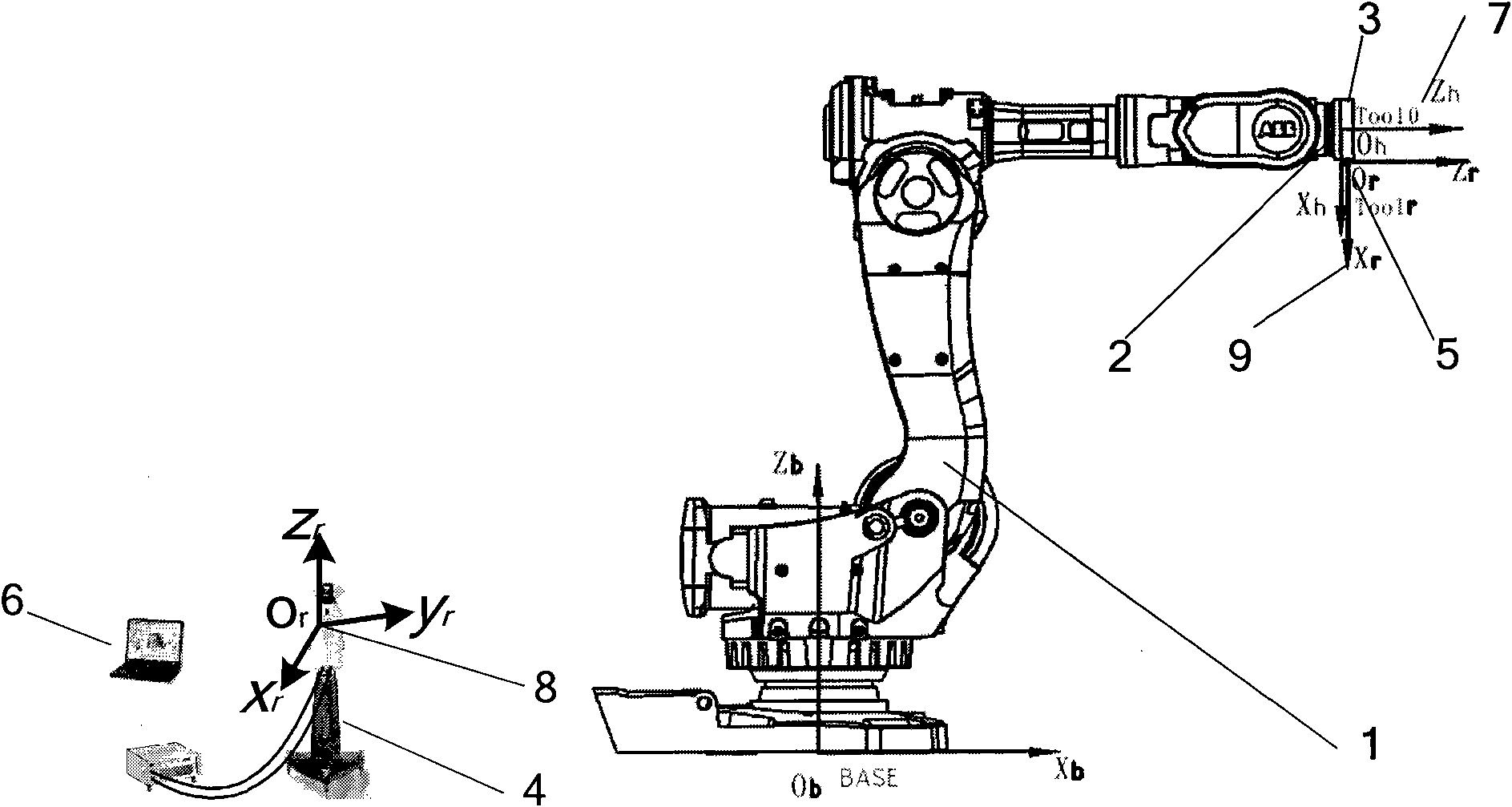

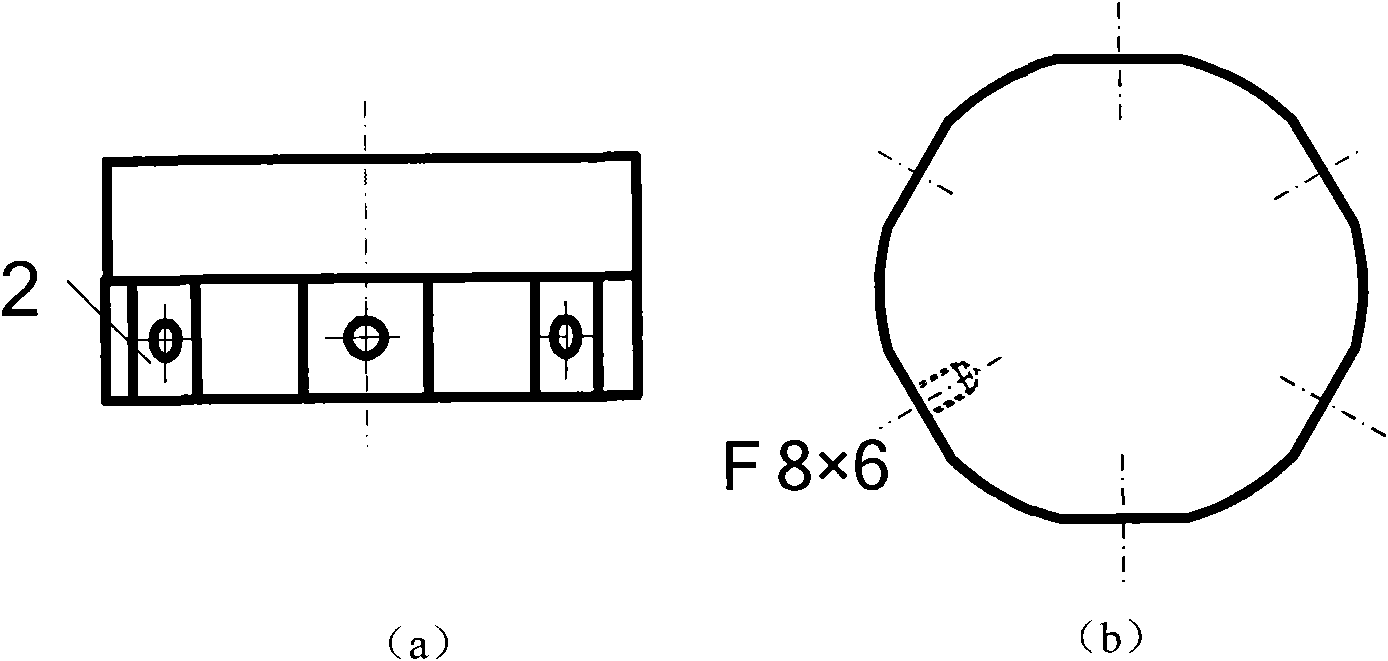

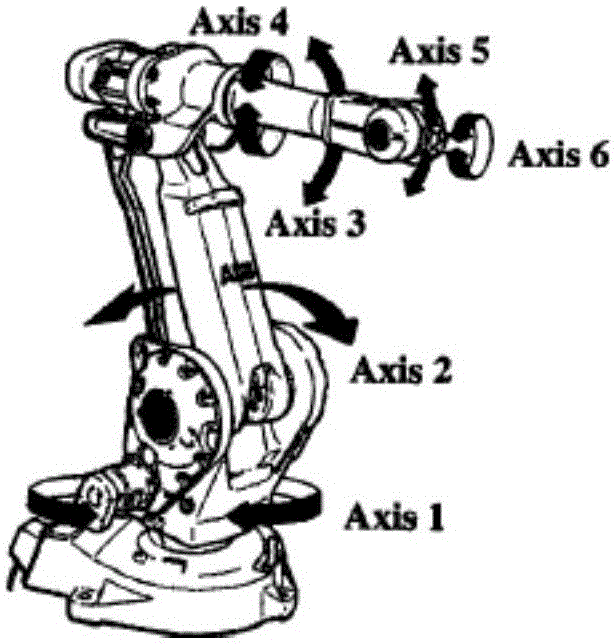

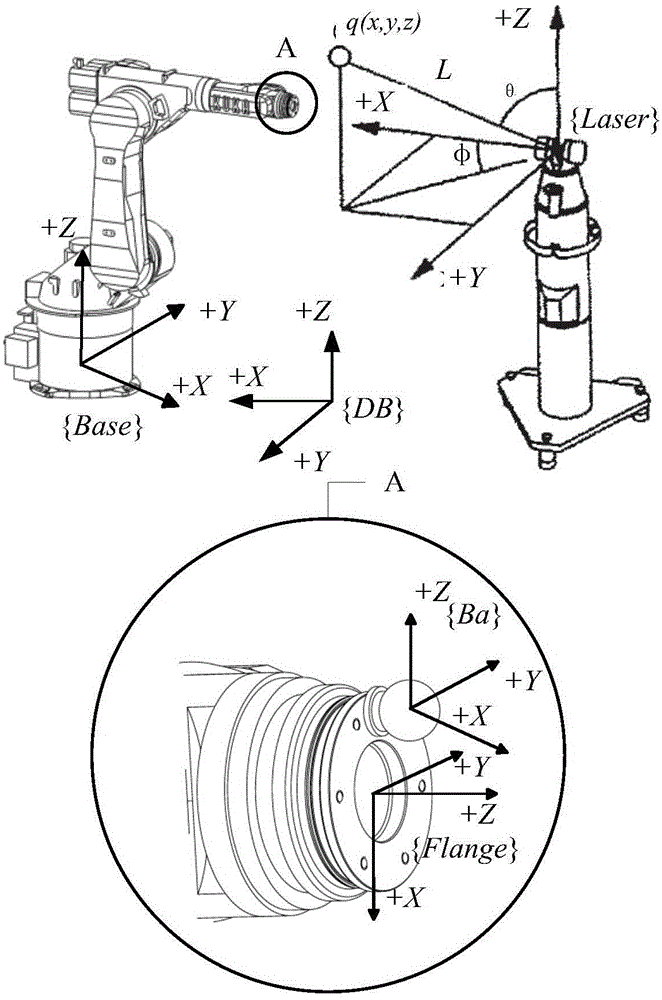

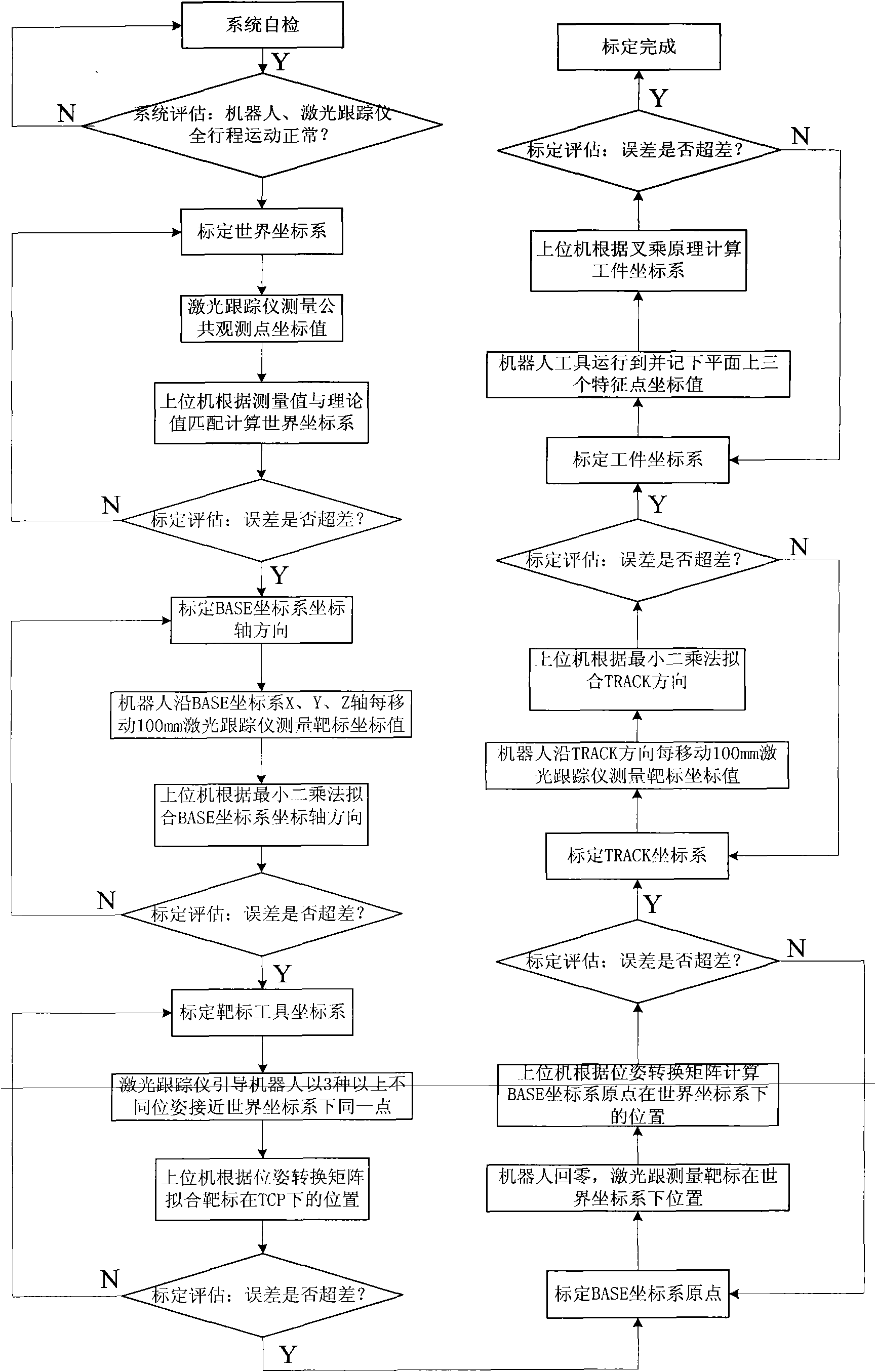

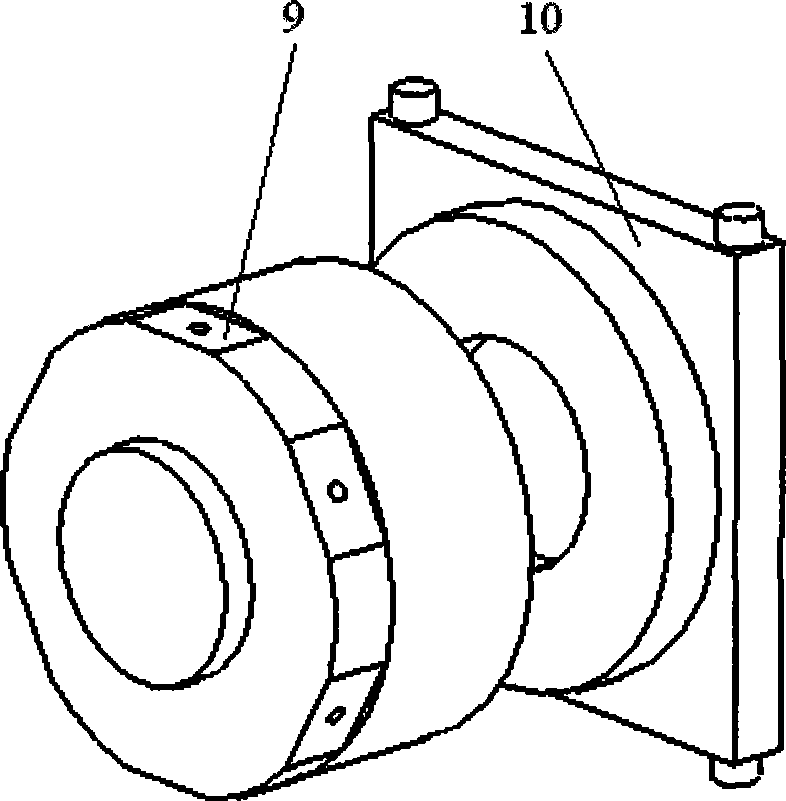

Automatic calibration apparatus for robot tool coordinate system based on laser tracking measurement and method thereof

InactiveCN102087096AAutomated calibration meetsSimplify the calibration processUsing optical meansSimulationCalibration result

The invention discloses an automatic calibration apparatus for a robot tool coordinate system based on laser tracking measurement and a method thereof, wherein the apparatus comprises a robot, a target flange, target installing holes, a laser tracker, a tool and a host computer; the robot is provided with the target flange and the tool; the target flange is provided with six target installing holes; and the external side of the robot is provided with the laser tracker and the host computer. According to the method of the invention, the robot tool coordinate system is calibrated by matching, analyzing and calculating the position relations of three to six targets in a robot end wrist coordinate system and in the robot tool coordinate system. The apparatus and the method provided by the present invention have the advantages that the robot tool coordinate system can be automatically calibrated; calibration operation is simple and is high in precision and high efficiency; calibration results are reliable; and digitalized modeling and digitalized calibrating are realized and the tool possesses versatility when being replaced.

Owner:ZHEJIANG UNIV

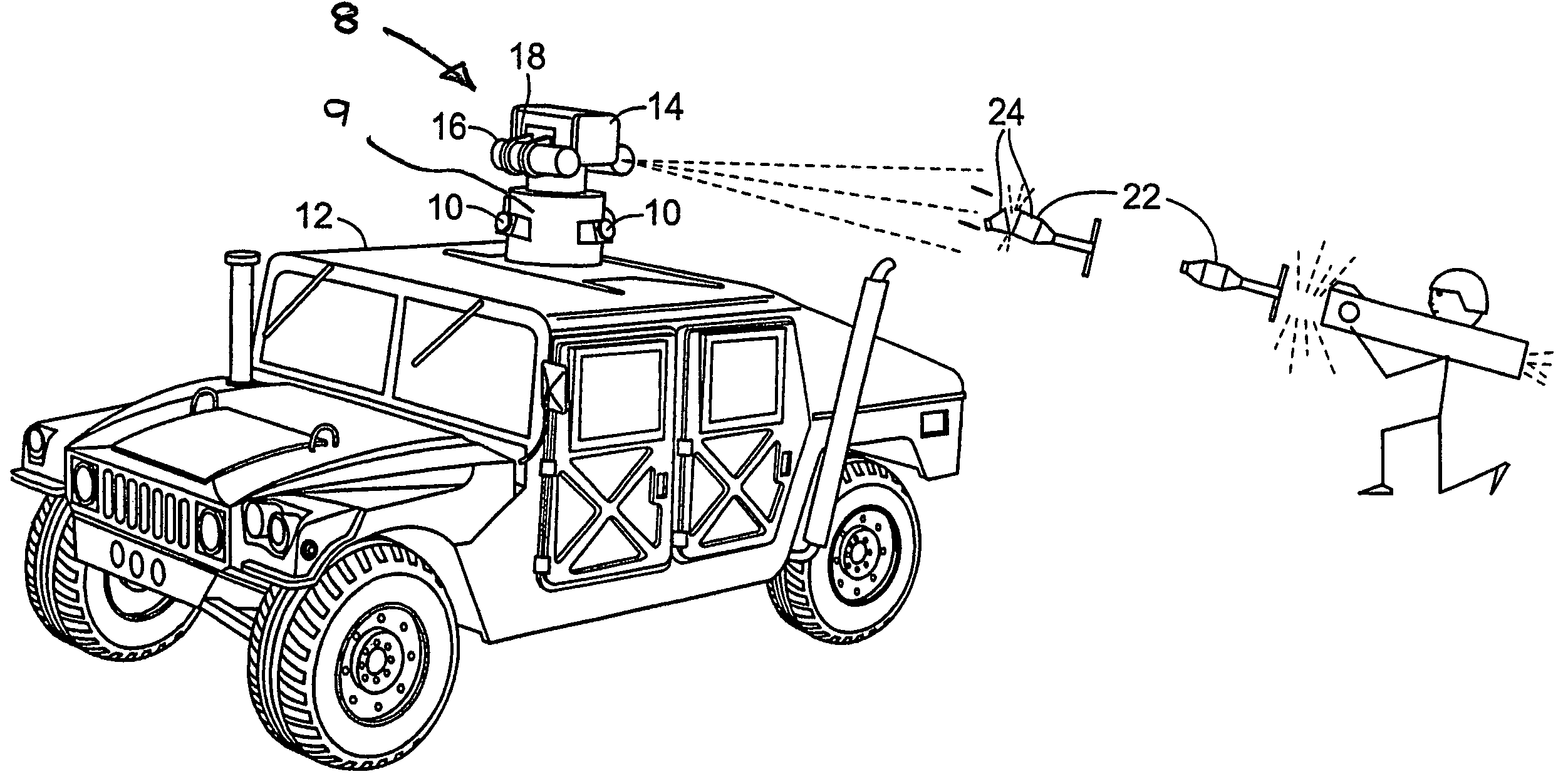

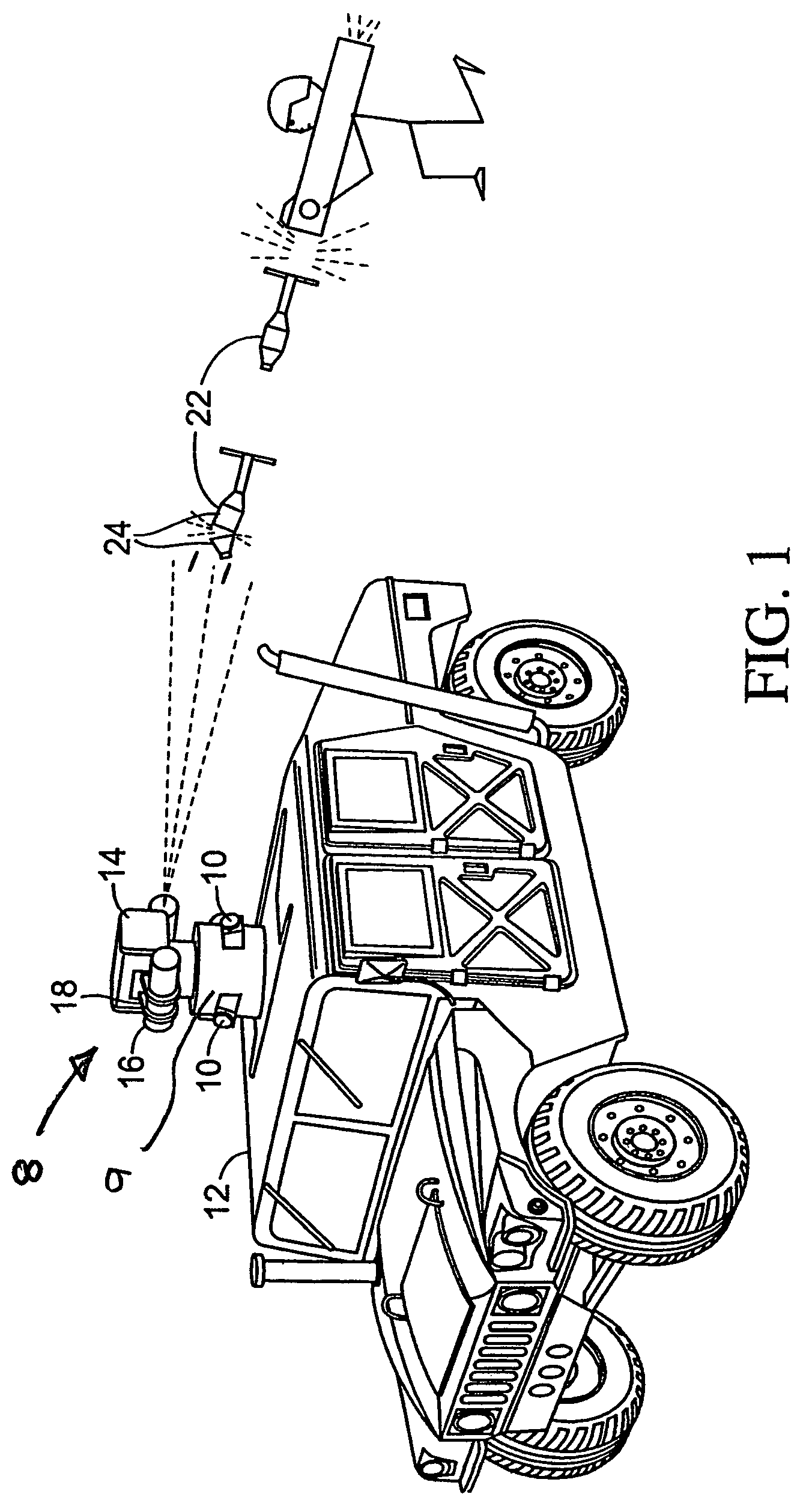

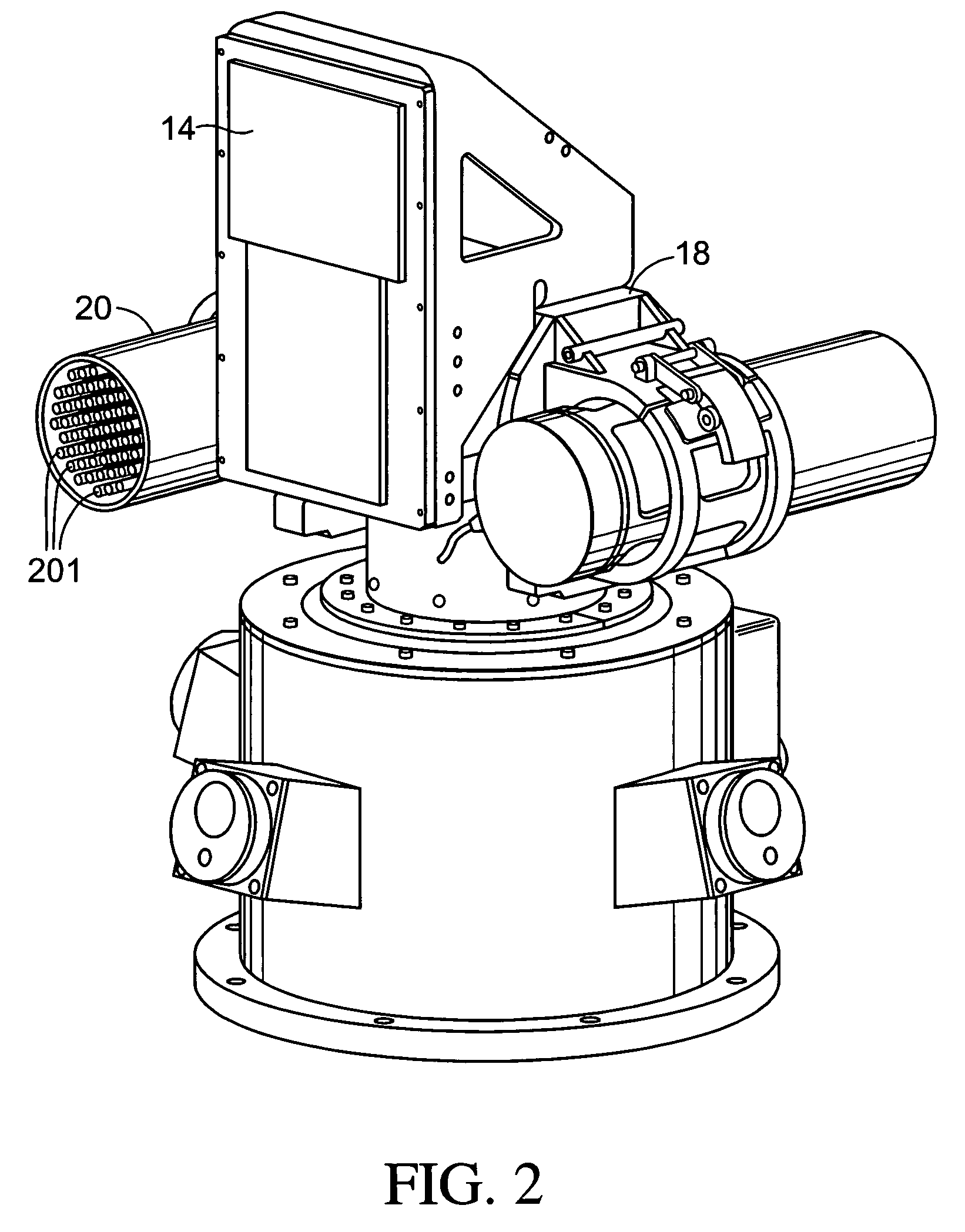

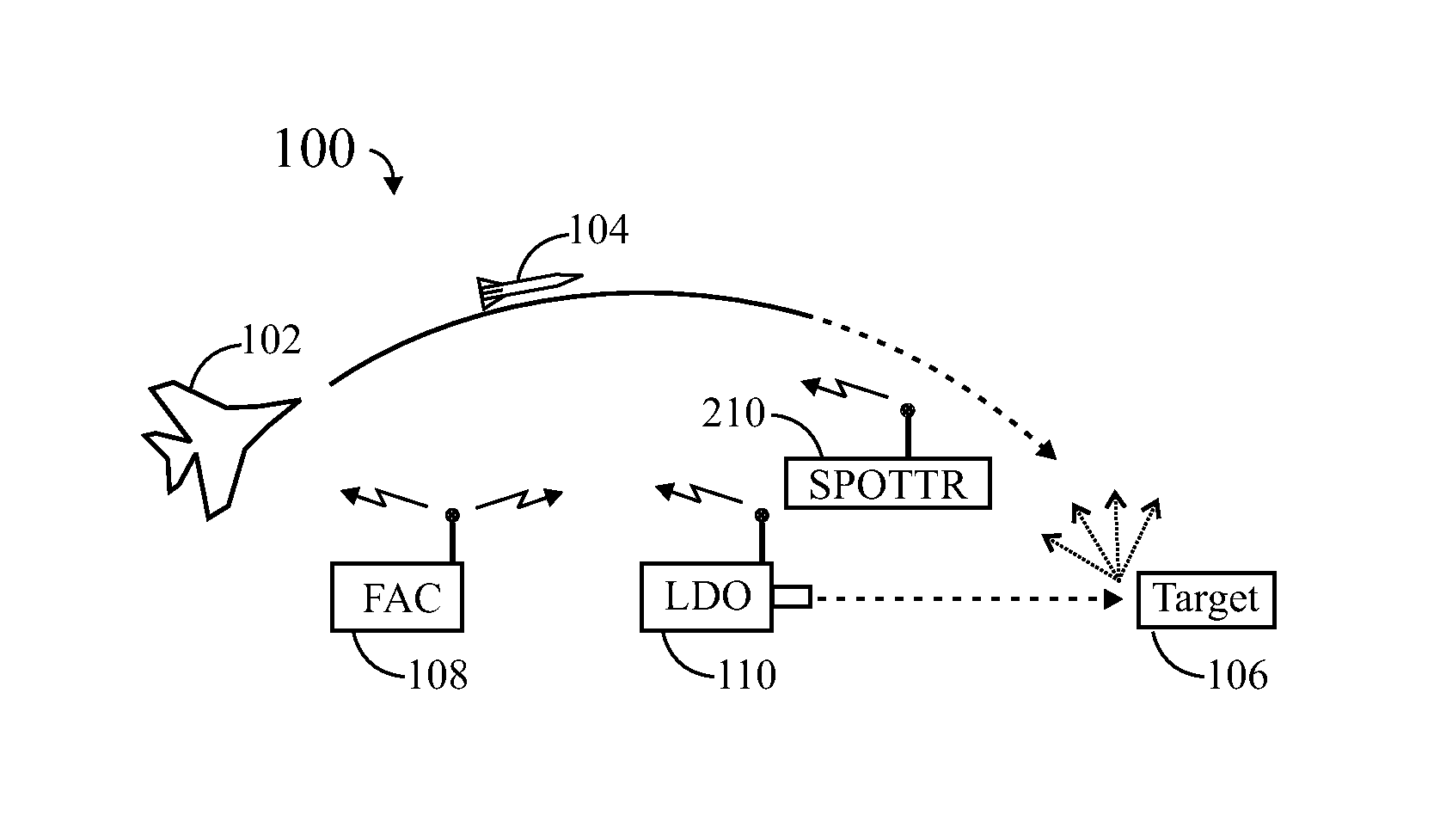

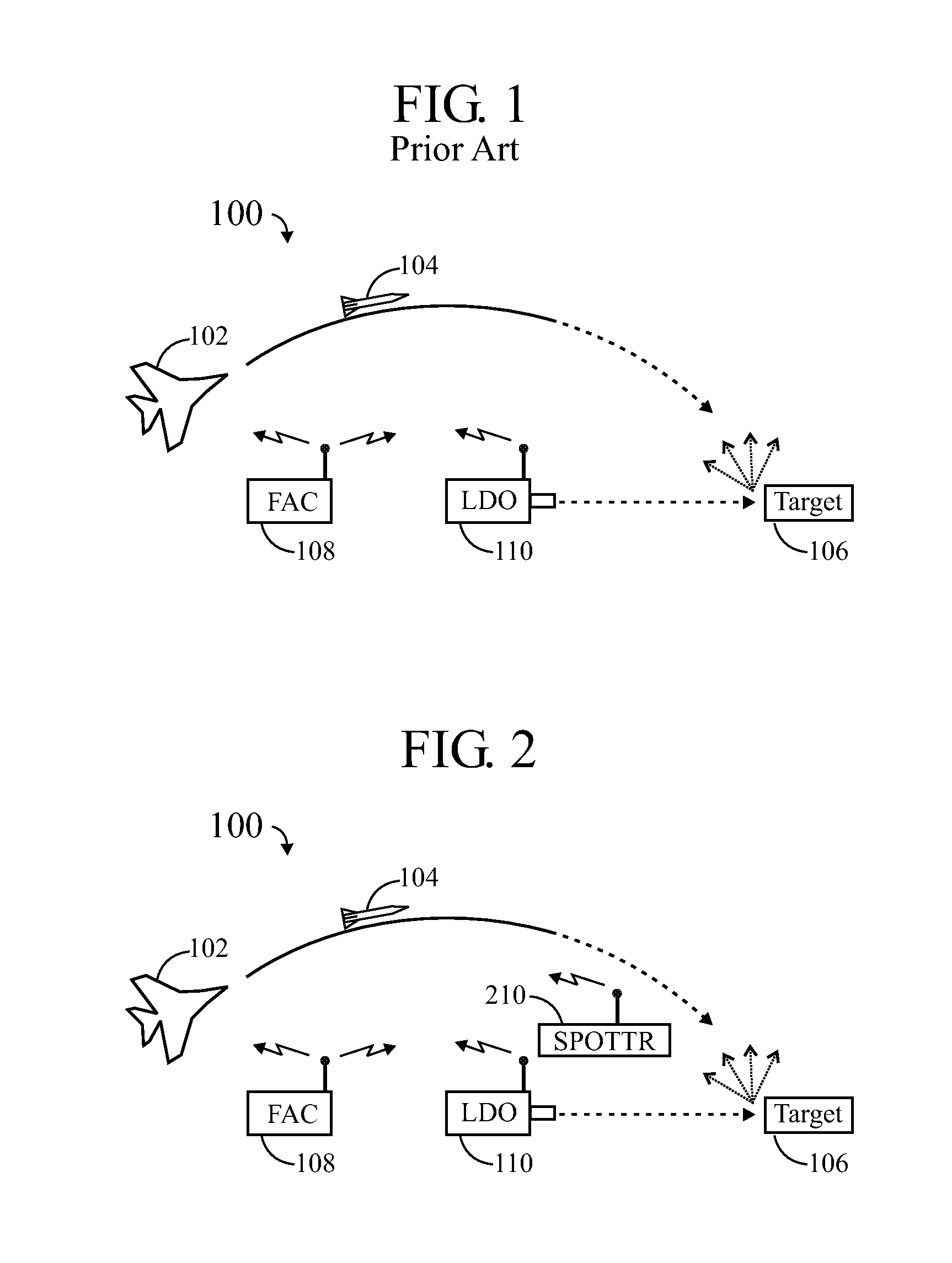

Fast acting active protection system

A fast acting active protection system for military vehicles defeats RPG (rocket propelled grenade) threats fired from close ranges. The system minimizes the hazard to troops and civilians nearby. The system uses a plurality of passive sensors to locate the threat and initialize the system. A low cost radar or laser tracker is used as the means to determine range, velocity, and (if required) angular position of the threat. The countermunition used may be one of several choices, with the requisites being that the countermunition provides fast response with low inertia, and is able to damage or destroy the detected threat. A multi-barrel recoilless gun is the weapon of choice. A launching device is used to deploy and aim the countermunition and the tracking means. On board software and electronics are used to control the system.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

Industrial robot base coordinate system calibration method based on laser tracker

InactiveCN105058387AReduce calibration timeHigh precisionProgramme-controlled manipulatorComputer visionLaser tracker

The invention discloses an industrial robot base coordinate system calibration method based on a laser tracker. The method includes the steps that target bases needed for measurement are installed, a calibration system is preprocessed, coordinate systems needed for calibration are established, the relational expression of posture relation matrixes of the coordinate systems is acquired, data are collected through a control robot and the laser tracker, the corresponding posture matrixes are acquired, and finally the posture relation between a robot base coordinate system and a measurable coordinate system is acquired so as to determine the specific posture of the robot base coordinate system. The robot base coordinate system can be calibrated only through the laser tracker, no repetition is needed after calibration, repeated calibration time is shortened, meanwhile, the accuracy of the laser tracker is high, and the accuracy of acquired data of the base coordinate system is high.

Owner:BEIHANG UNIV

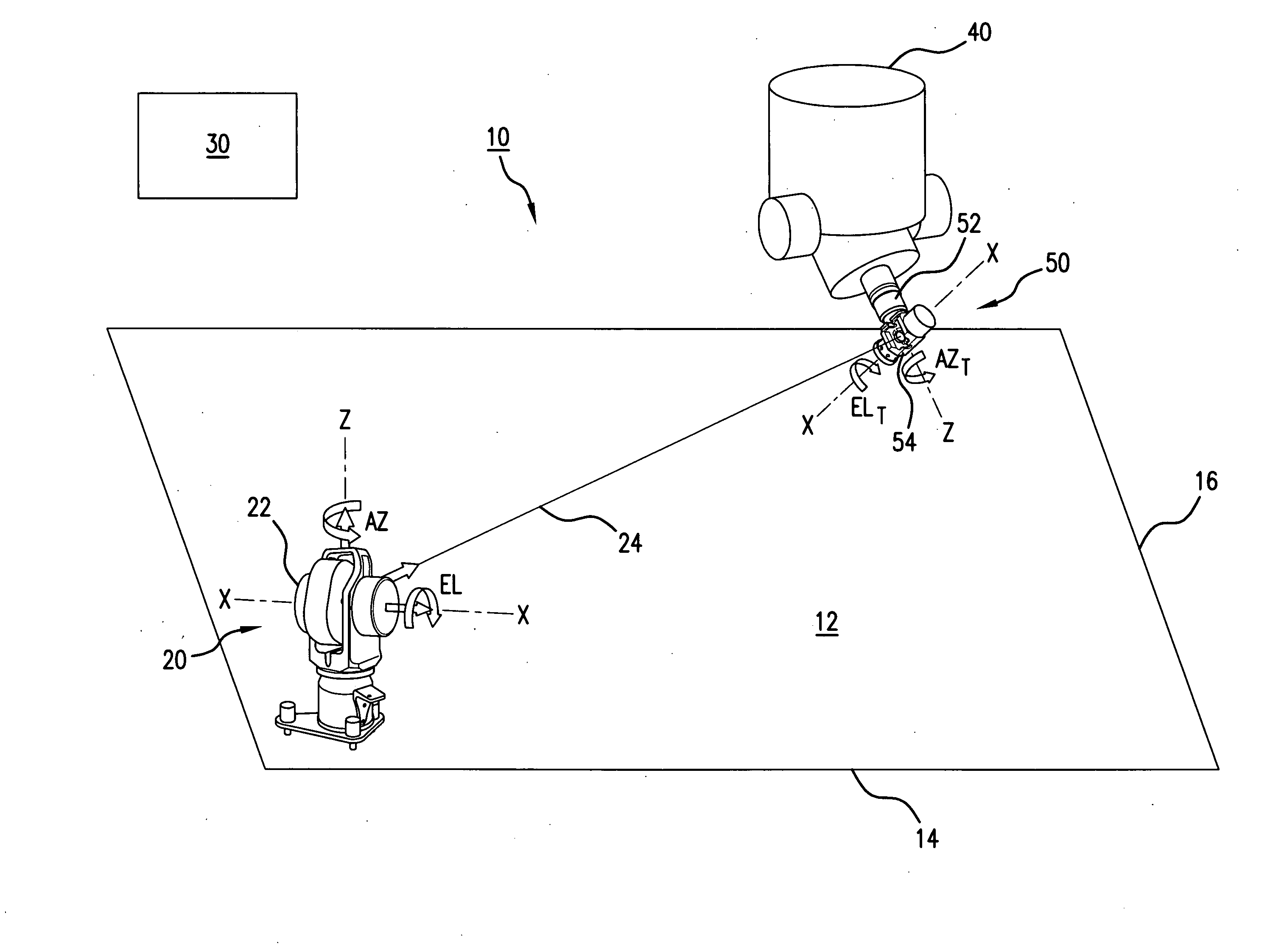

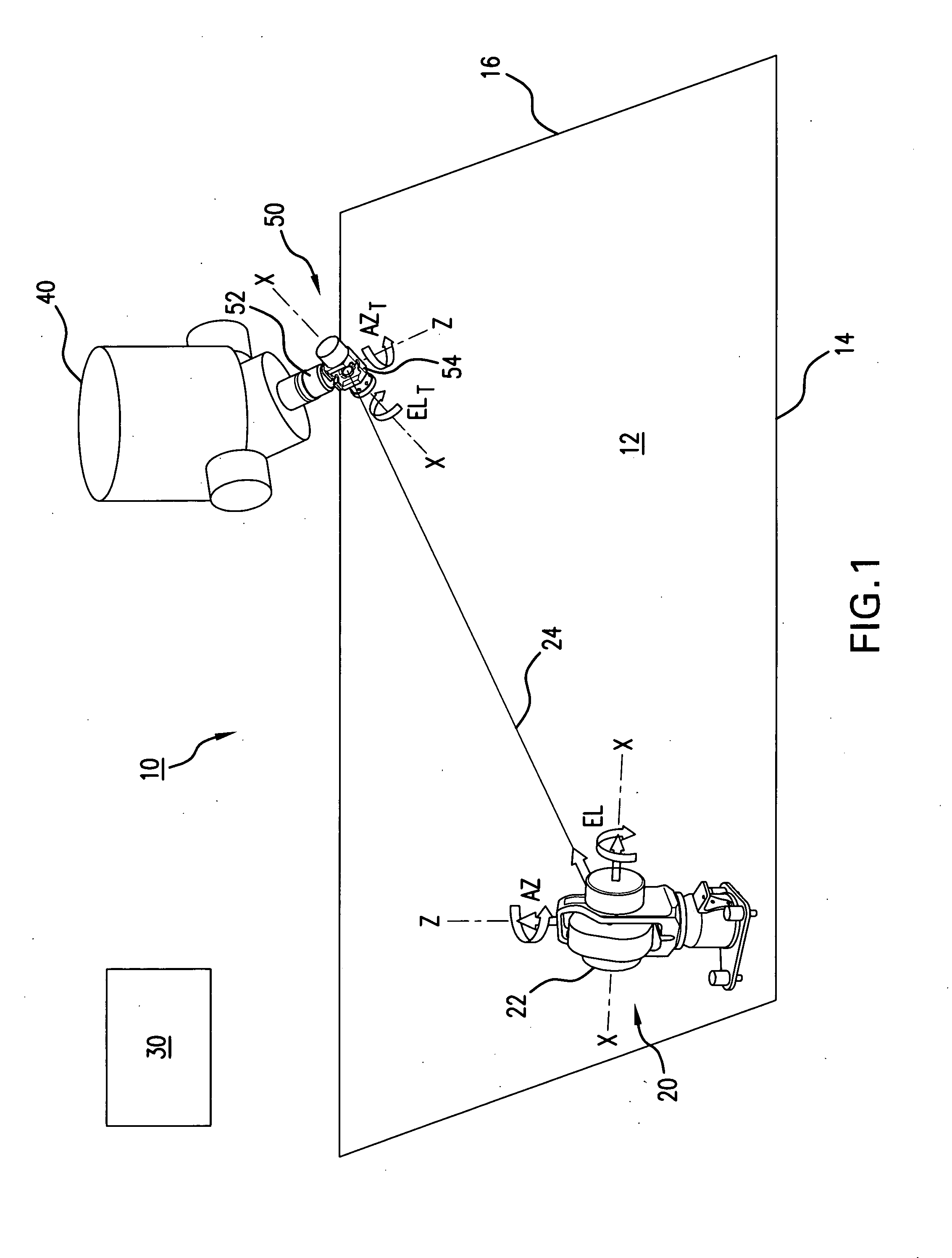

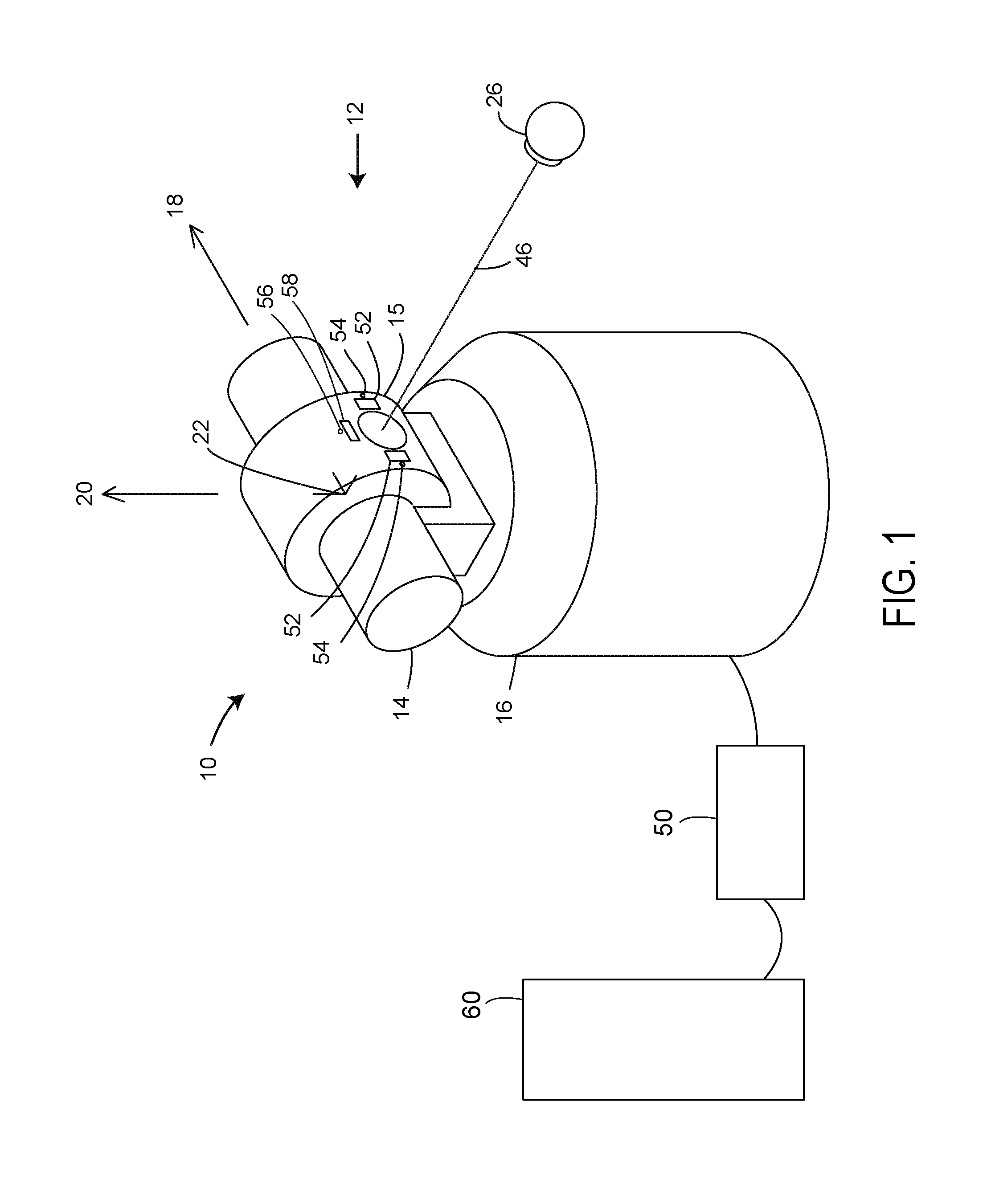

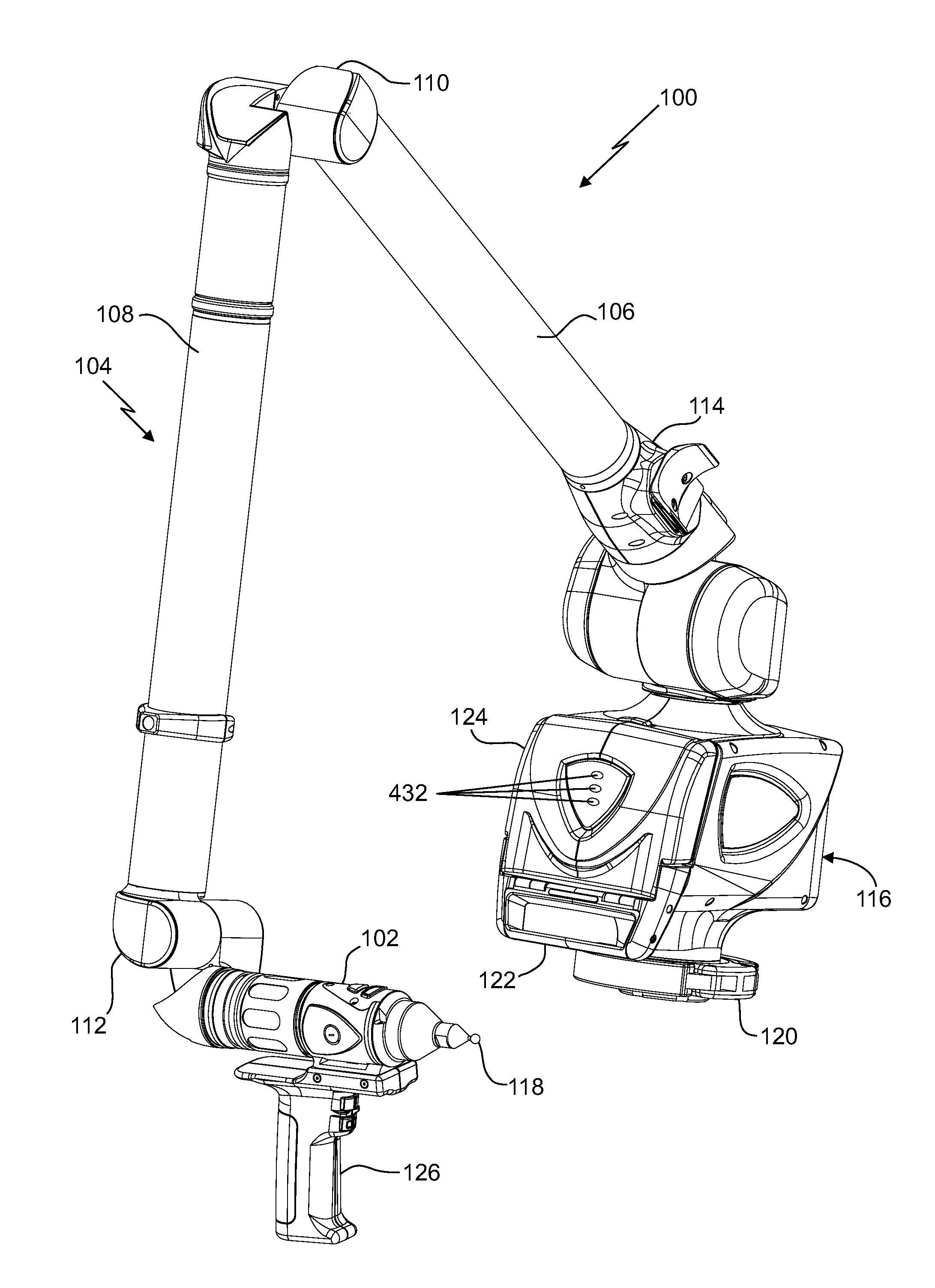

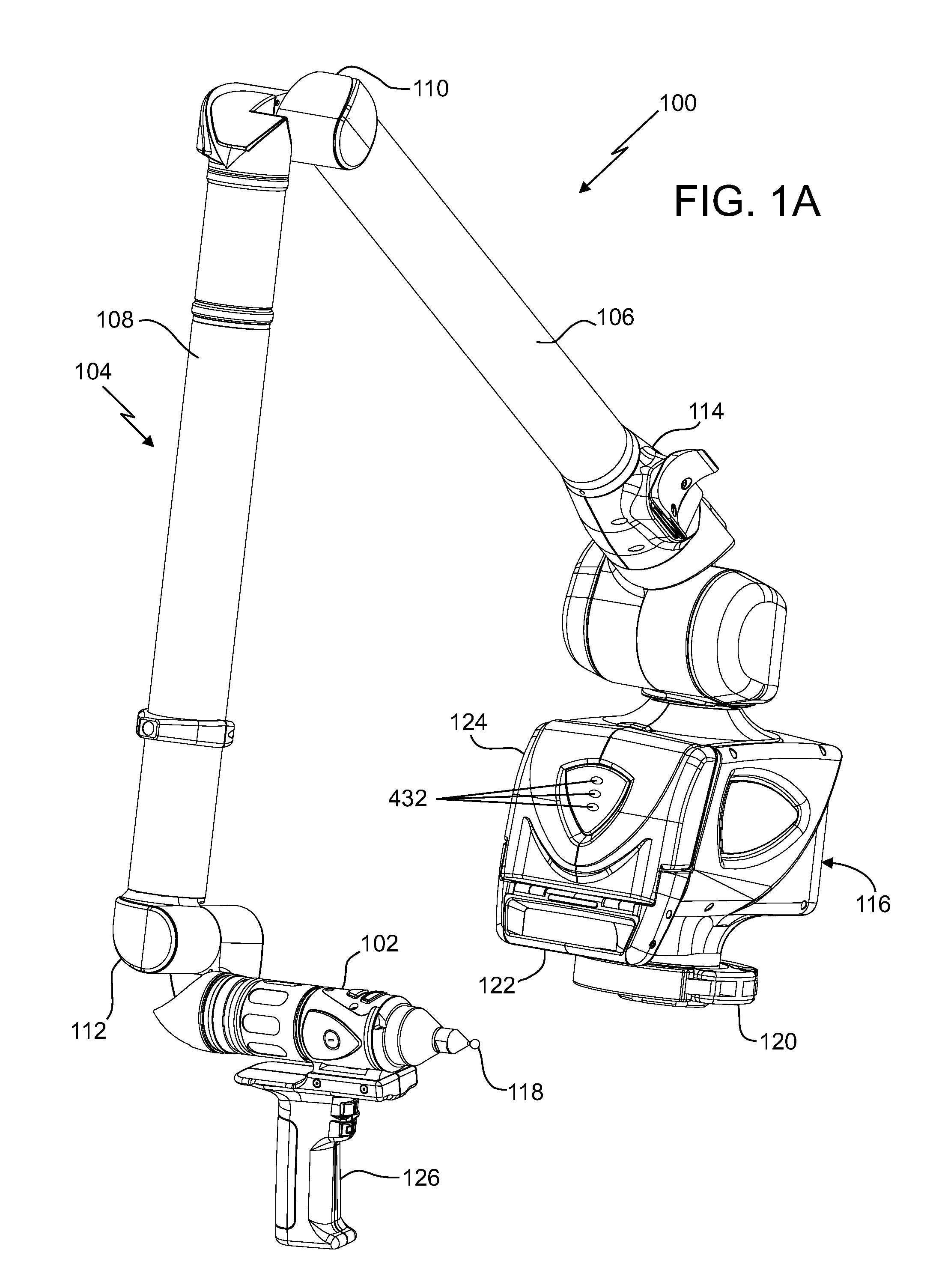

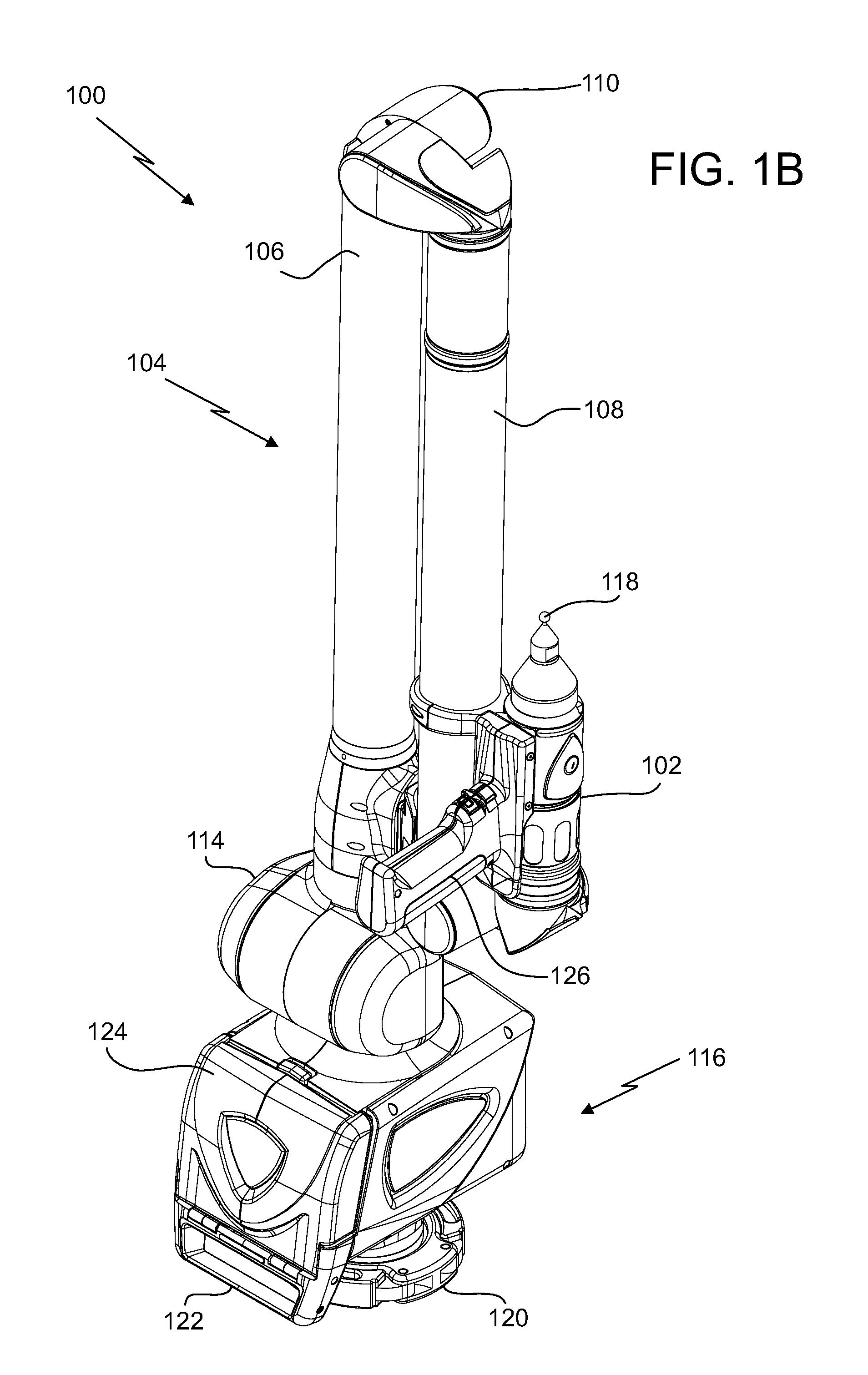

Volumetric error compensation system with laser tracker and active target

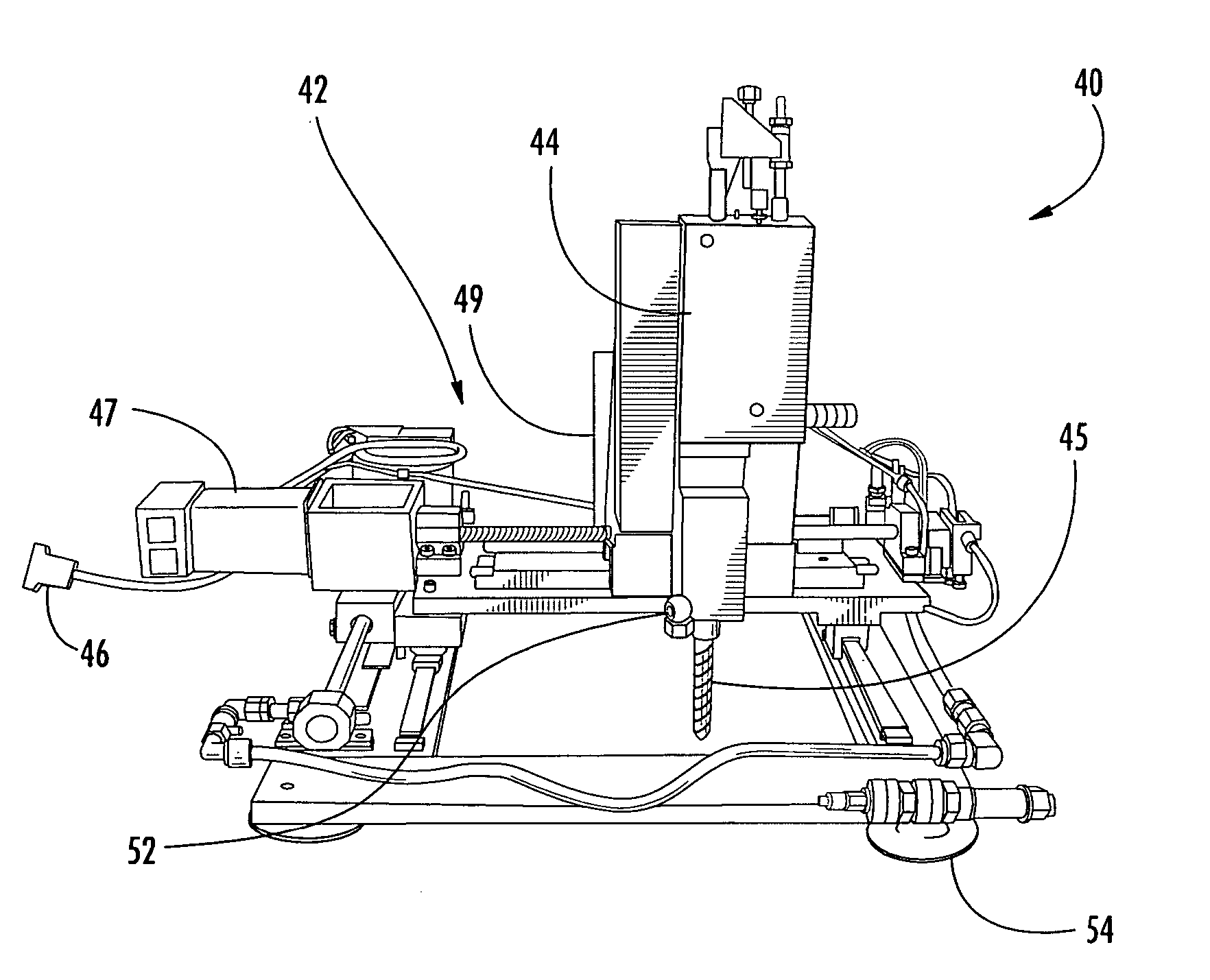

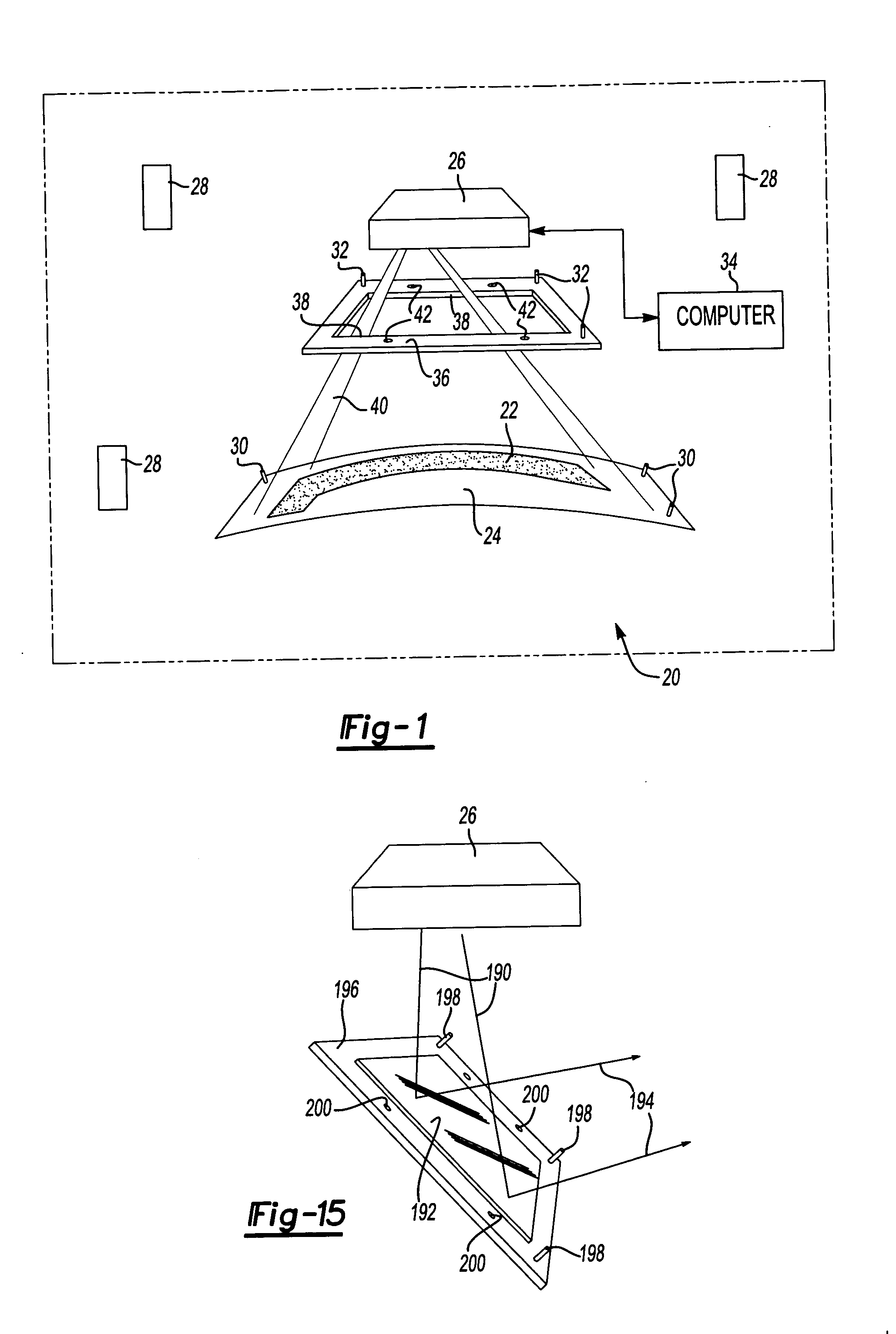

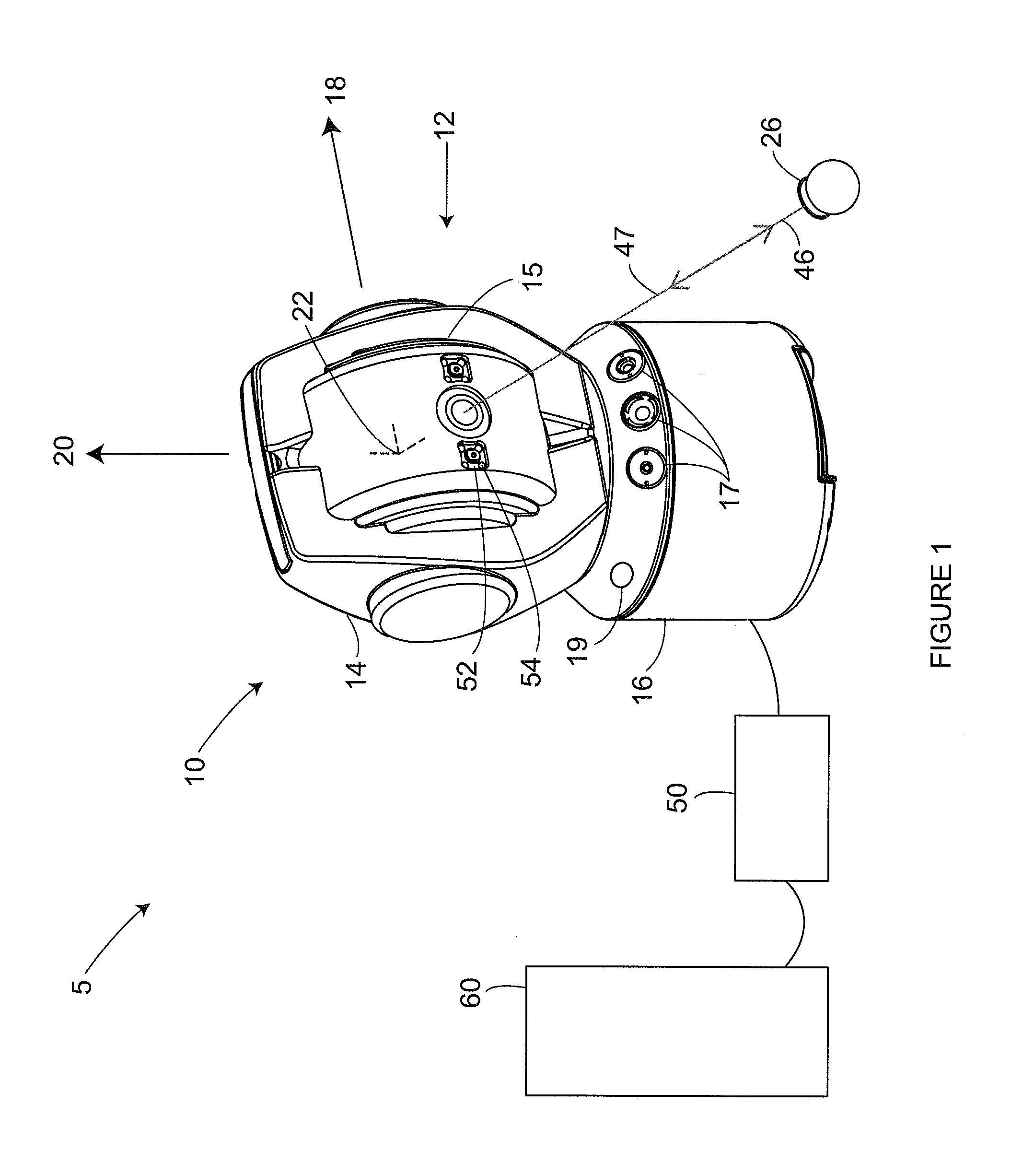

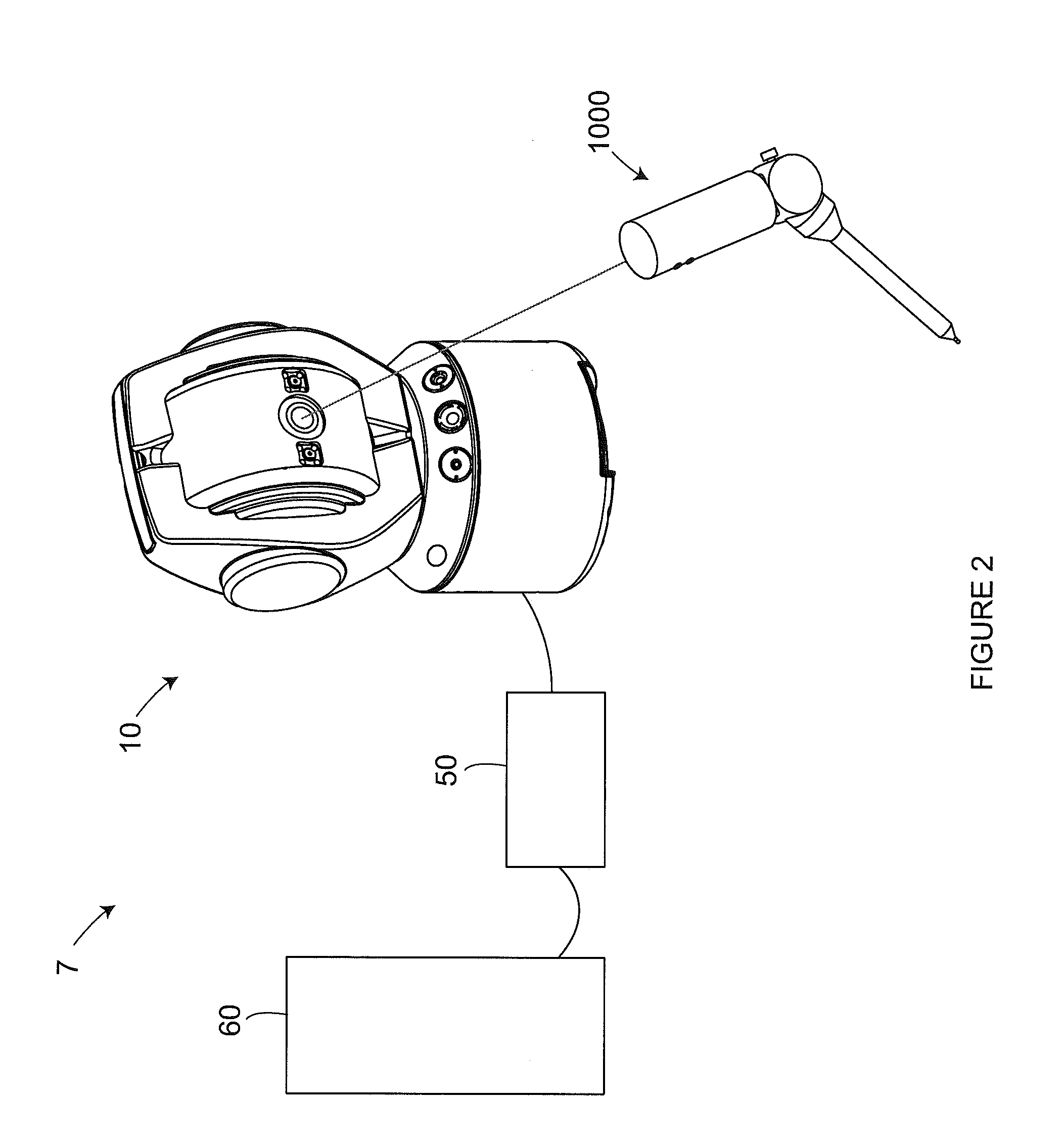

ActiveUS20100176270A1Accurate rotational axis alignmentAccurate repeatabilityProgramme-controlled manipulatorPhotometry using reference valueRotational axisLight beam

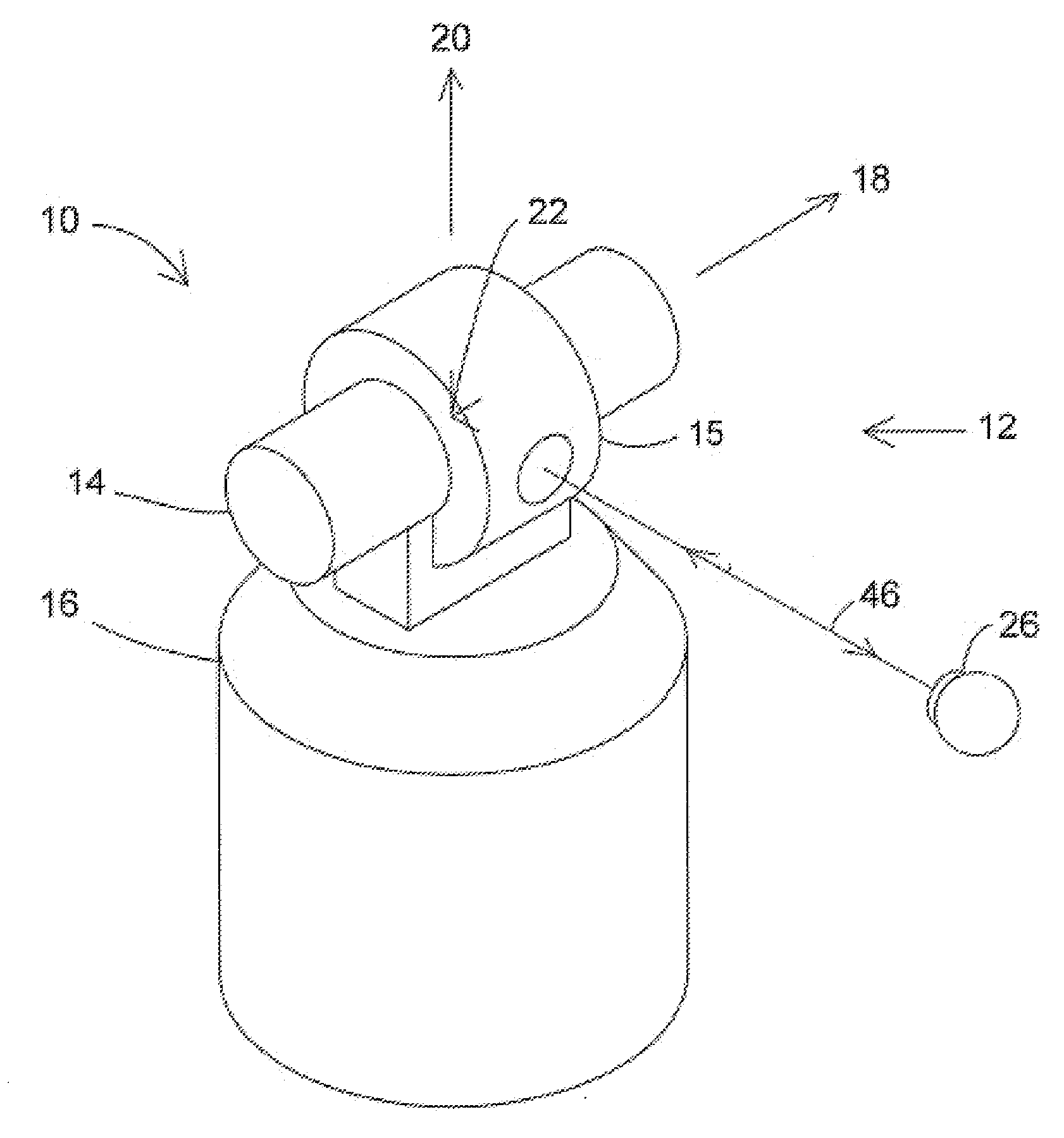

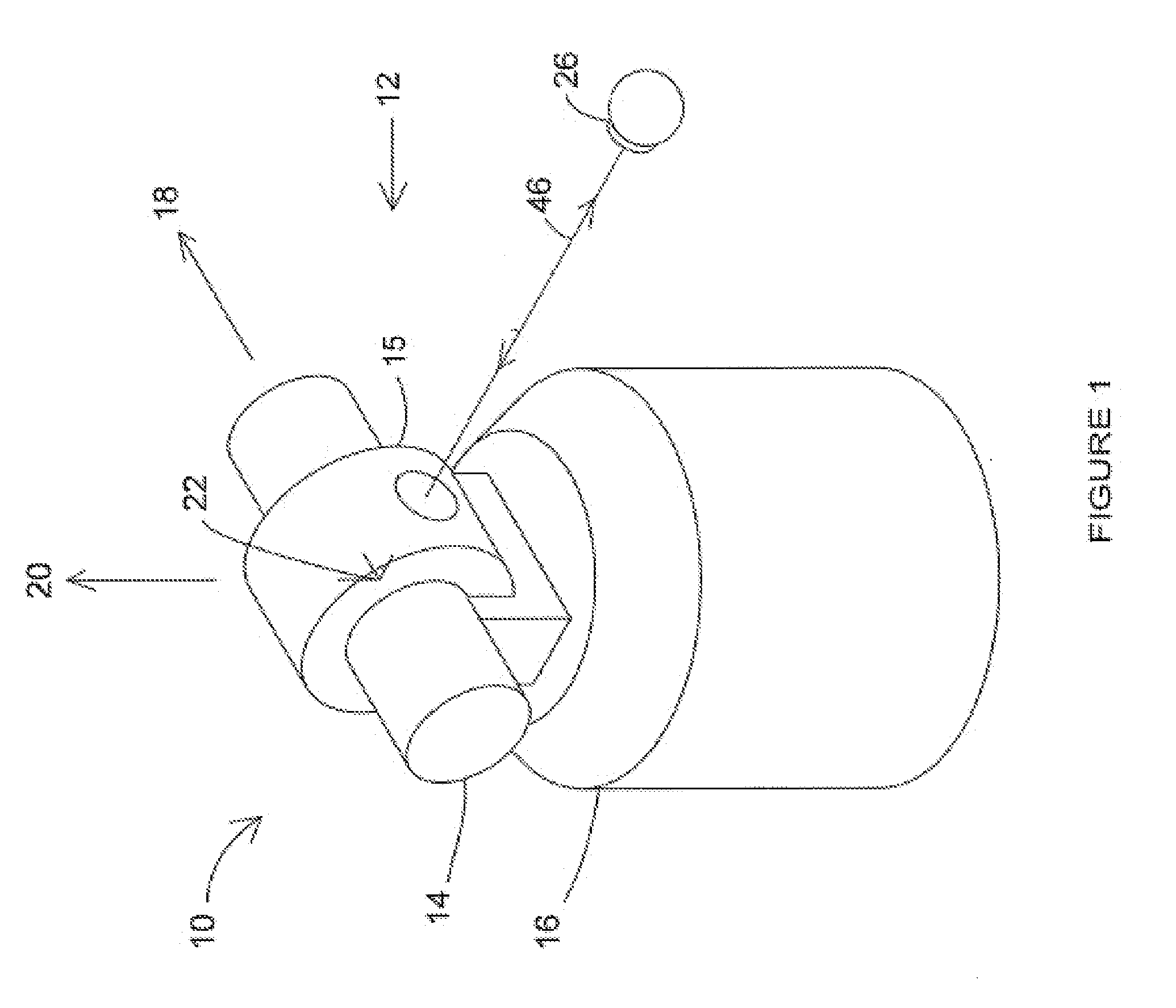

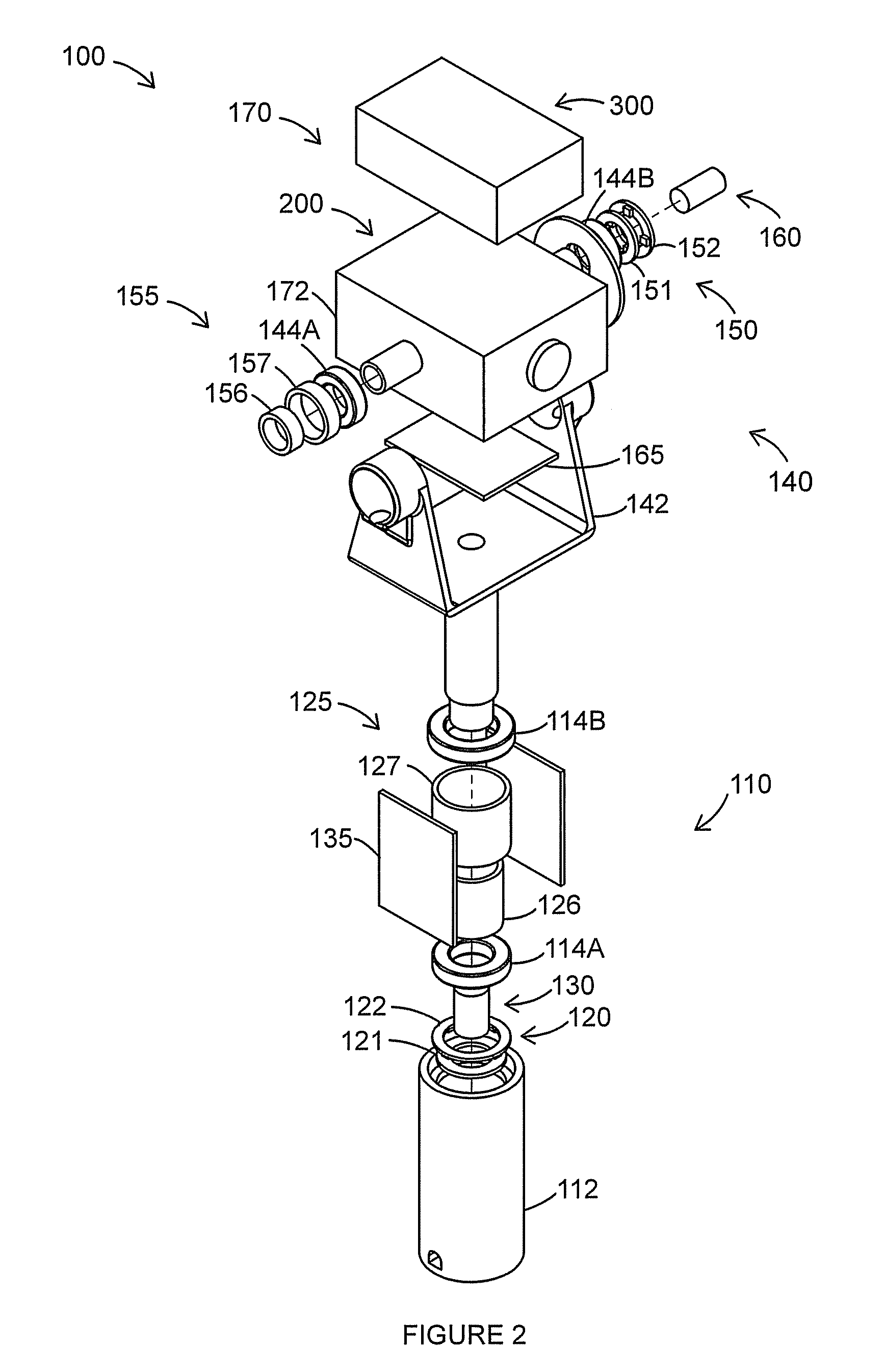

A volumetric error compensation measurement system and method are disclosed wherein a laser tracker tracks an active target as the reference point. The active target has an optical retroreflector mounted at the center of two motorized gimbals to provide full 360 degree azimuth rotation of the retroreflector. A position sensitive detector is placed behind an aperture provided at the apex of the retroreflector to detect the relative orientation between the tracker laser beam and the retroreflector by measuring a small portion of the laser beam transmitted through the aperture. The detector's output is used as the feedback for the servo motors to drive the gimbals to maintain the retroreflector facing the tracker laser beam at all times. The gimbals are designed and the position of the retroreflector controlled such that the laser tracker always tracks to a pre-defined single point in the active target, which does not move in space when the gimbals and / or the retroreflector makes pure rotations. Special mechanism and alignment algorithm are used in the gimbal design and retroreflector centering alignment to achieve accurate rotational axis alignment and repeatability.

Owner:AUTOMATED PRECISION INC

Laser scanner or laser tracker having a projector

A laser scanner or a laser tracker includes a light source that emits a light beam within an environment, and a data capture component that captures the light beam reflected back to the laser scanner or tracker from the environment. The laser scanner or tracker also includes a projector integrated within a body of the laser scanner or tracker or mounted to the body of the laser scanner or tracker at a predetermined location, the projector being operable to project visible information onto an object located within the environment, the projected visible information being indicative of images, data or information, the projected visible information being at least one of design intent information, information acquired by the laser scanner or tracker, or guidance to an operator.

Owner:FARO TECH INC

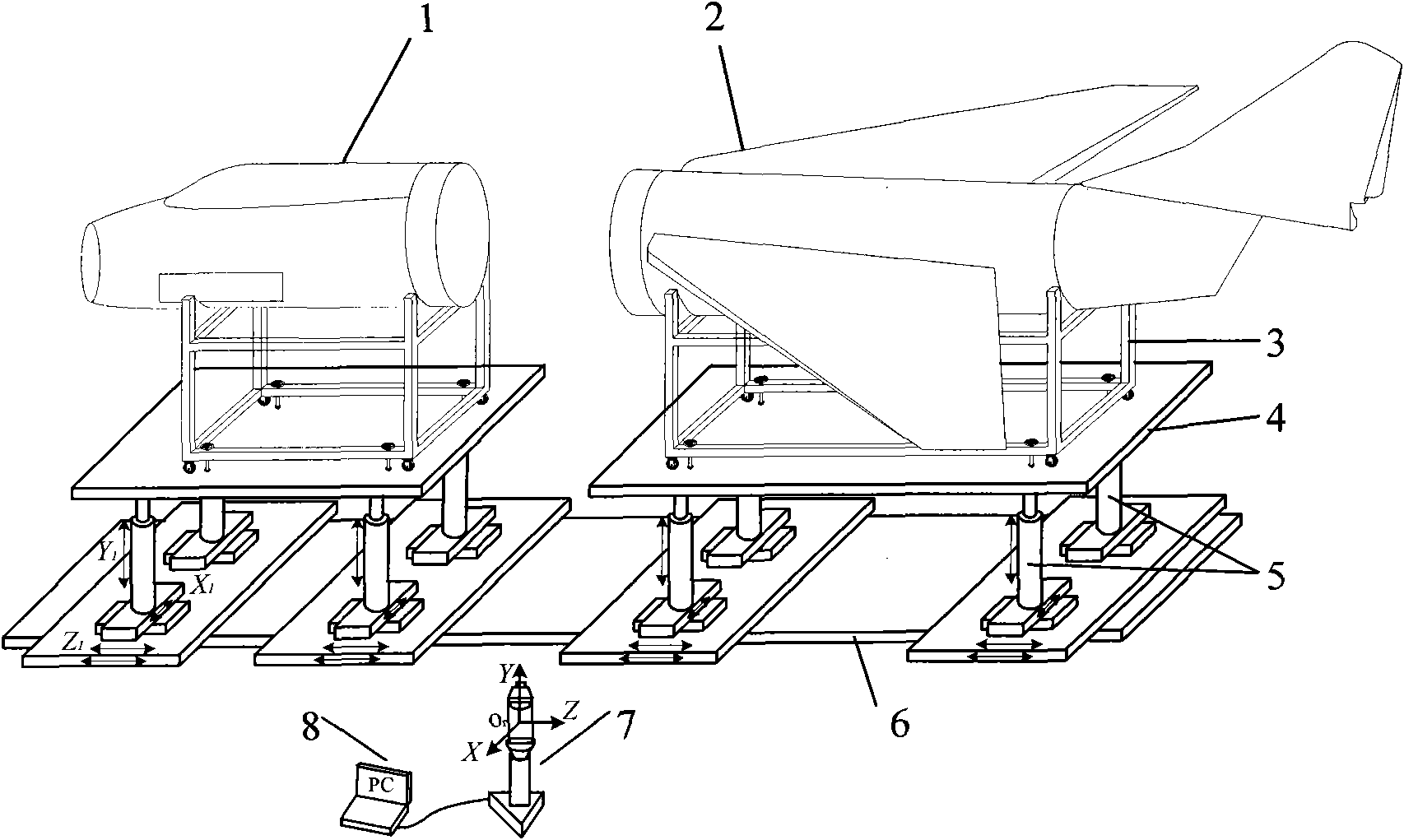

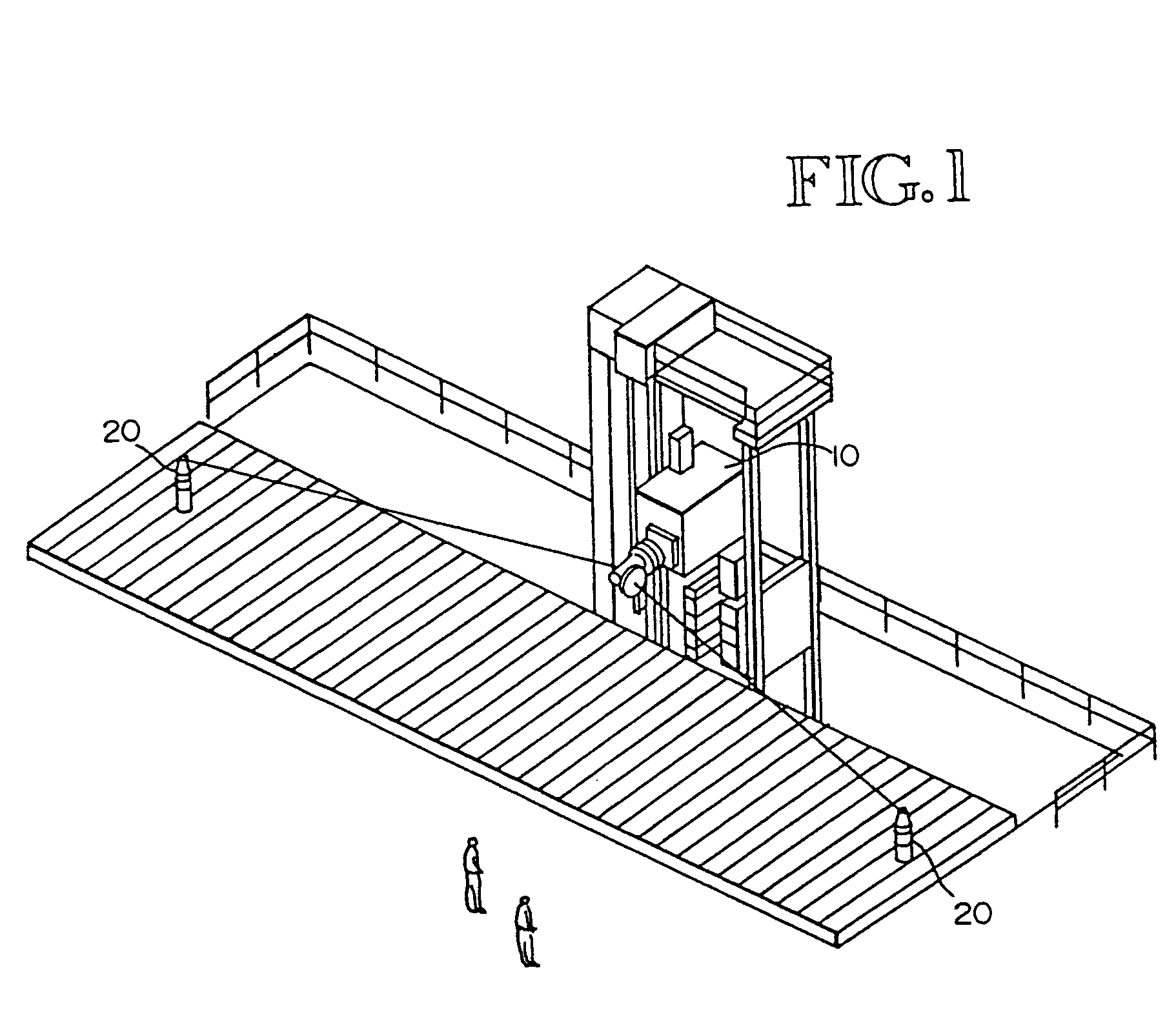

Laser-guided coordination hole drilling

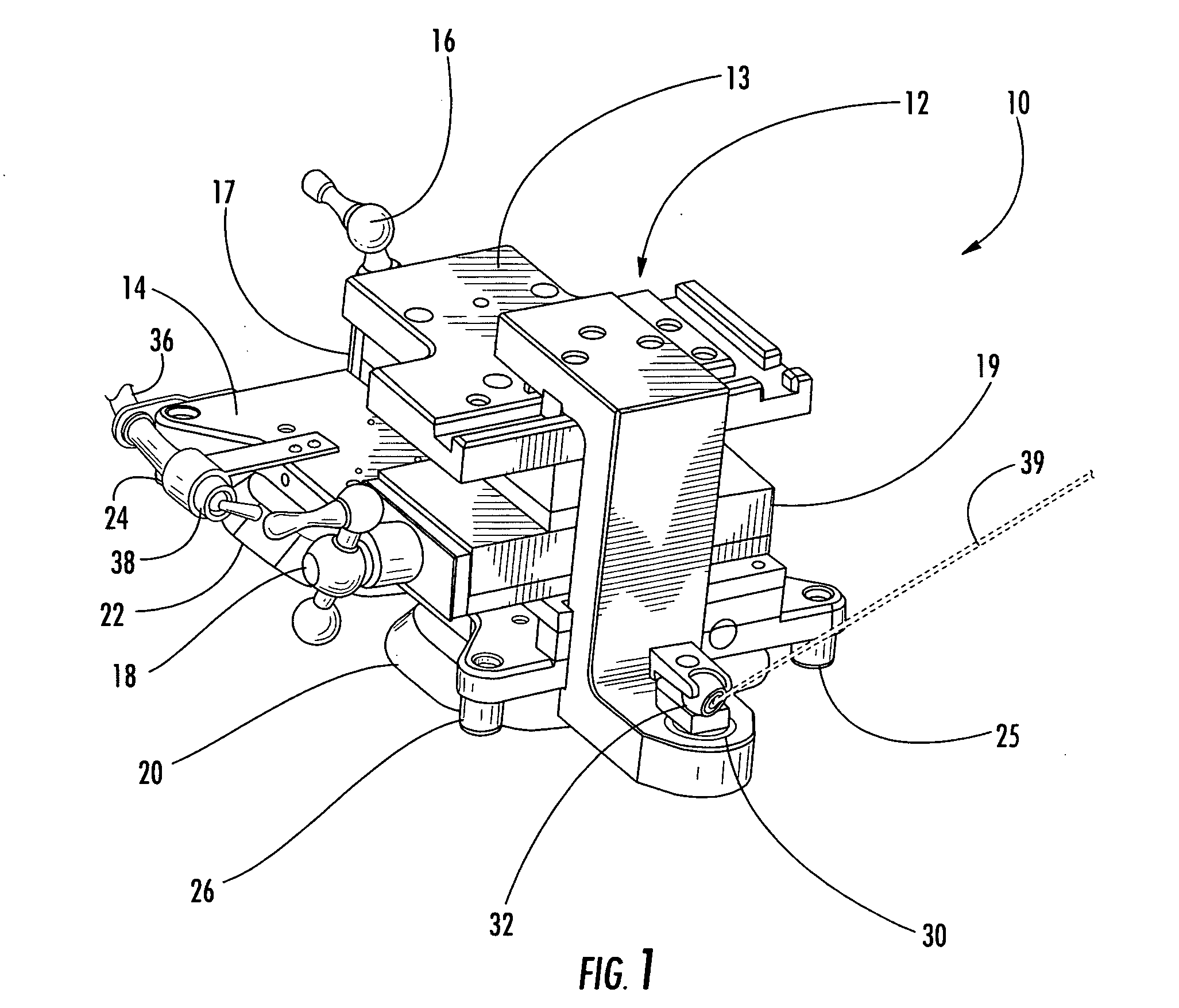

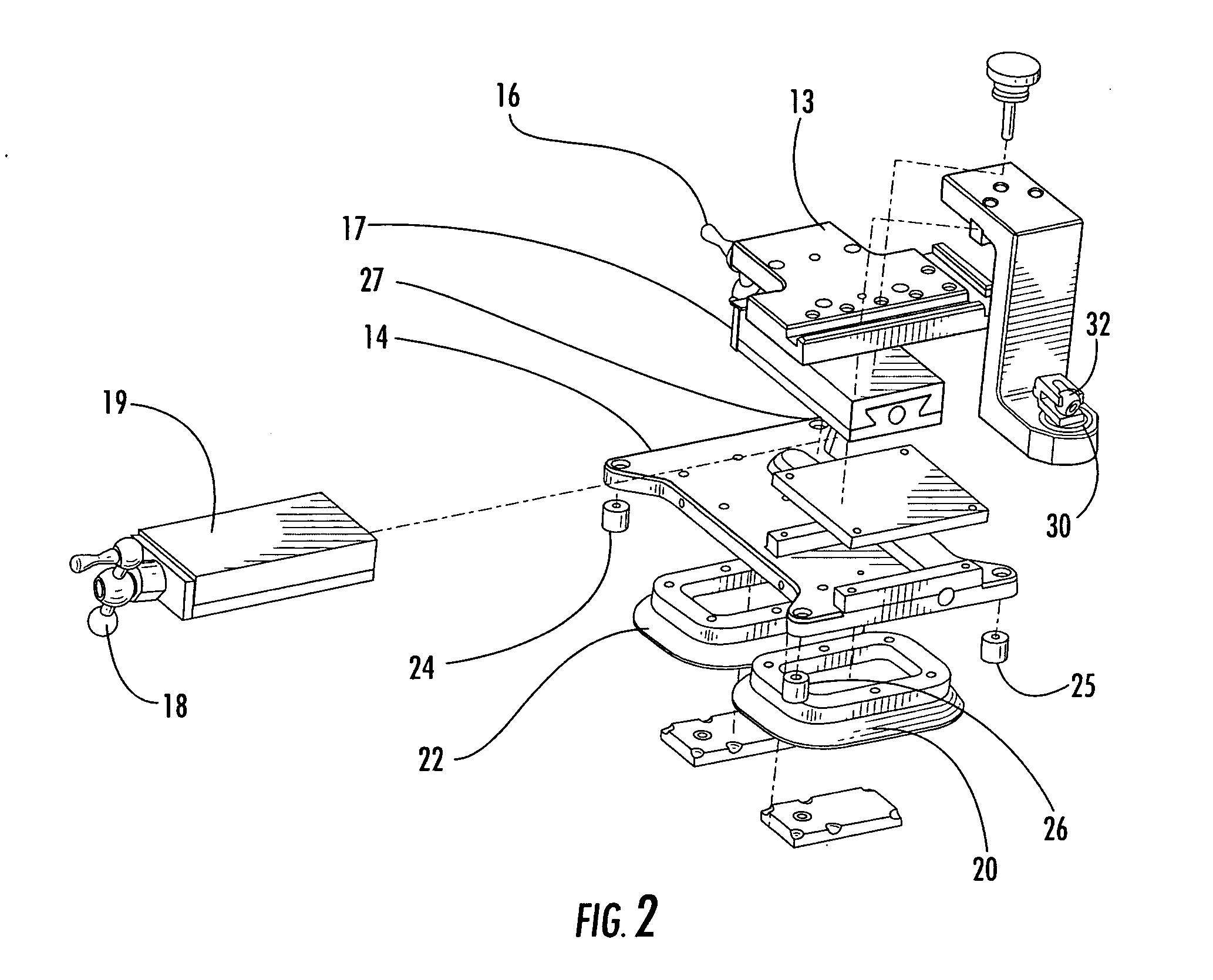

ActiveUS20050147477A1Suitable for machiningEliminate needAircraft componentsDrilling/boring measurement devicesLaser targetLaser tracker

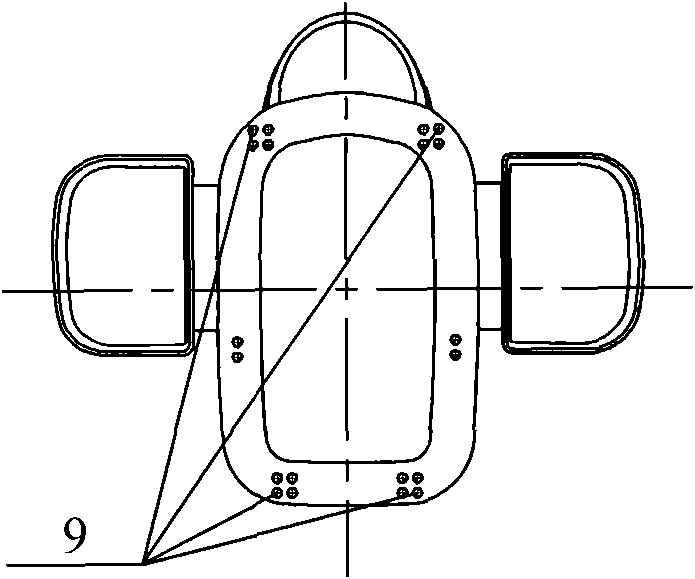

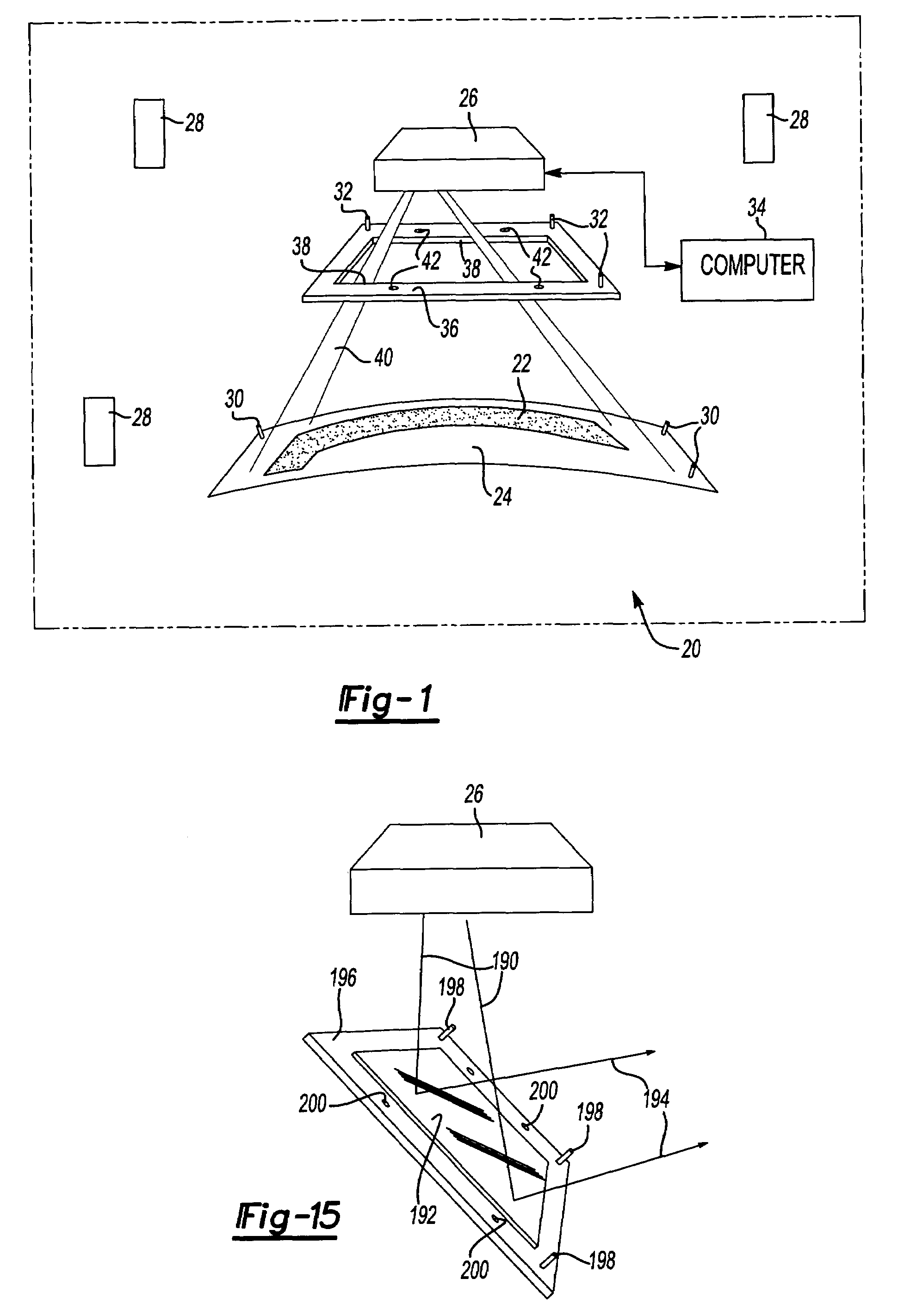

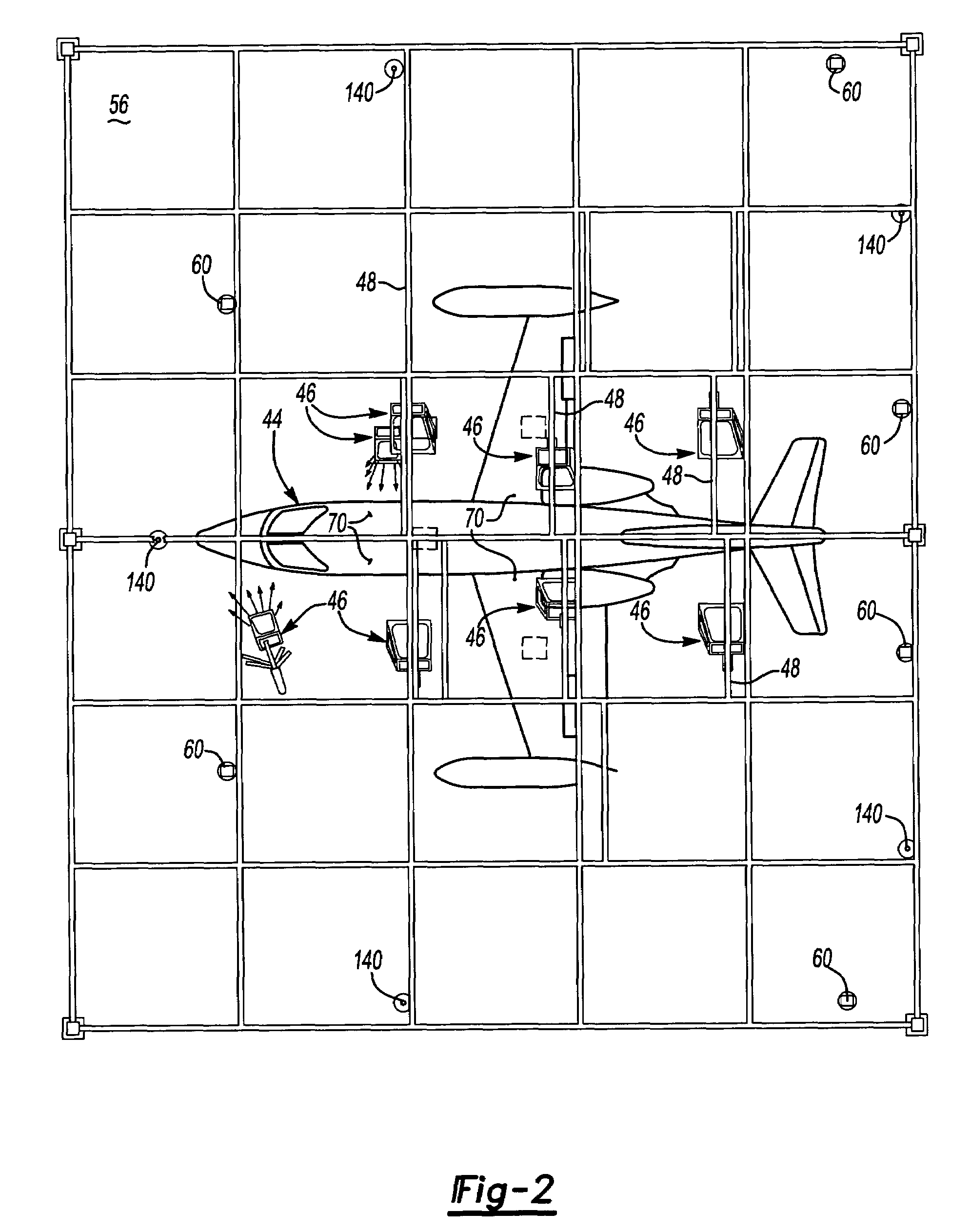

A laser-guided coordination hole tool for precisely drilling holes in large parts includes a positioning table, a bushing cavity for receiving drill bushings, a clamping device, and a laser target. A laser-guided coordination hole tool may include a software interlock to prevent drilling in an improper location on the part. A method of drilling coordination holes includes probing a part to determine its reference frame, rigidly affixing a laser-guided coordination hole tool to the part, probing a target on the laser-guided coordination hole tool to determine the reference frame for the laser-guided coordination hole tool, accurately positioning a drill bushing over the hole location, and drilling a hole. A system for drilling coordination holes includes a laser-guided coordination hole tool, a bushing, a tooling, a drill motor, a laser tracker, and a computer running a coordination-hole drilling program.

Owner:THE BOEING CO

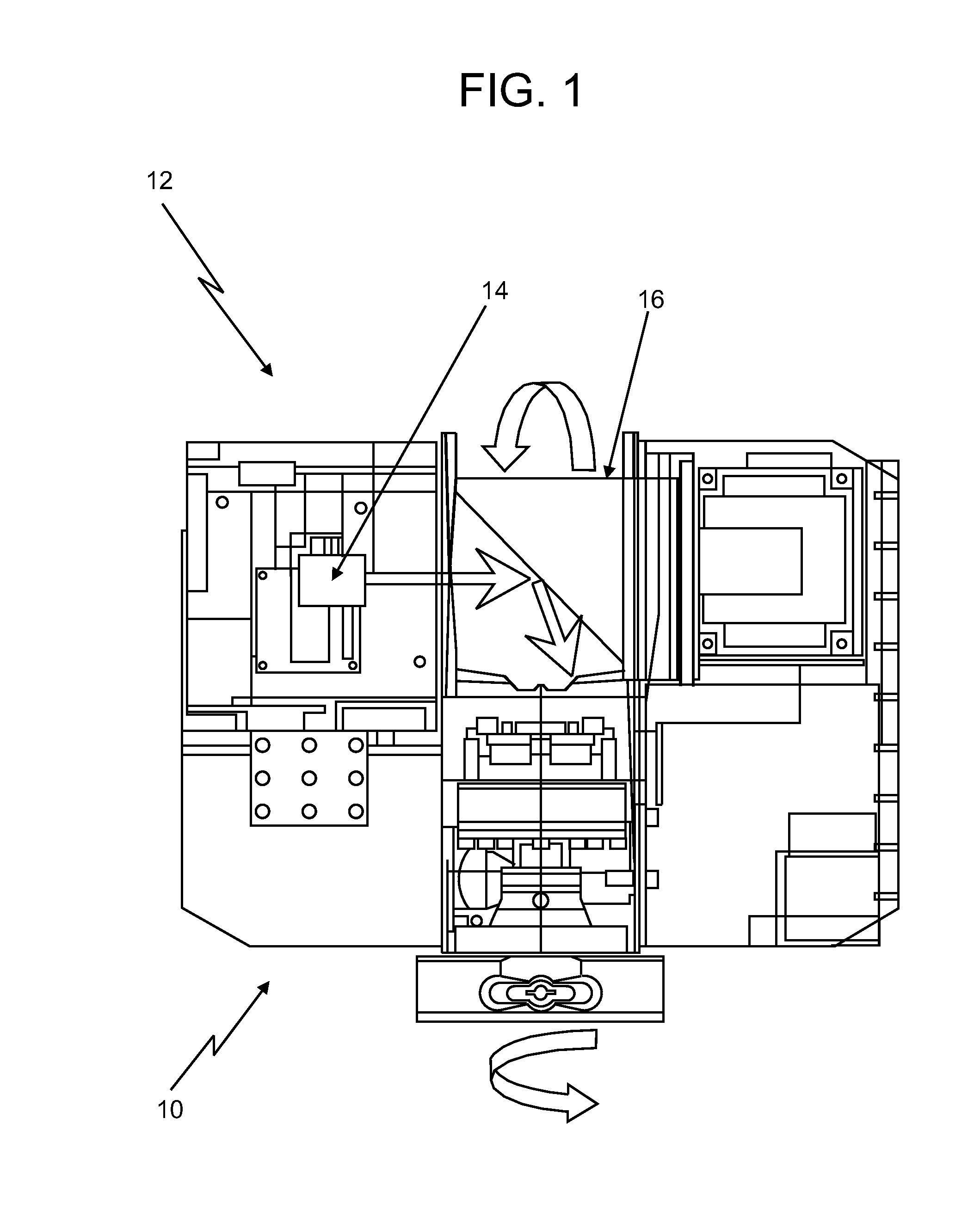

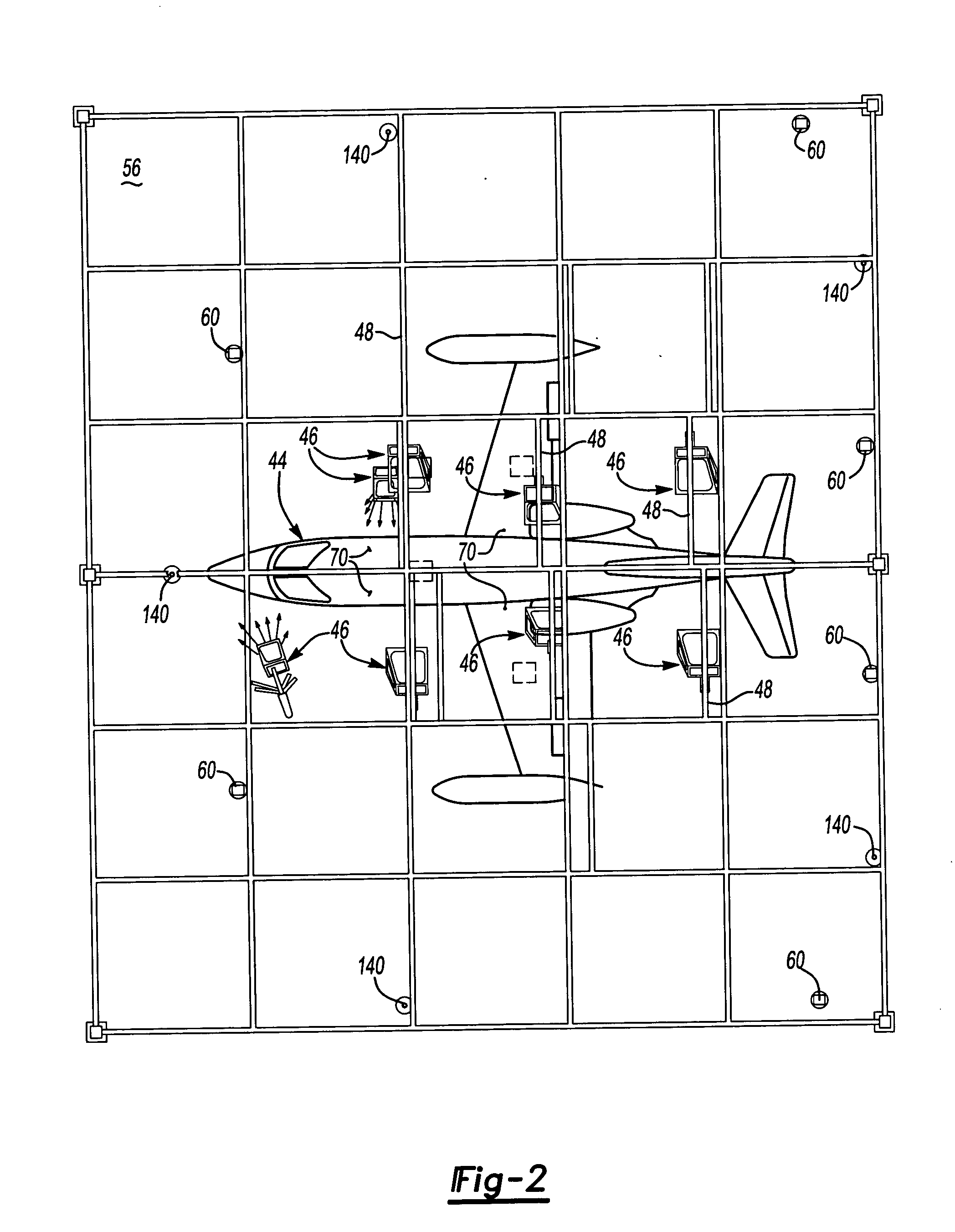

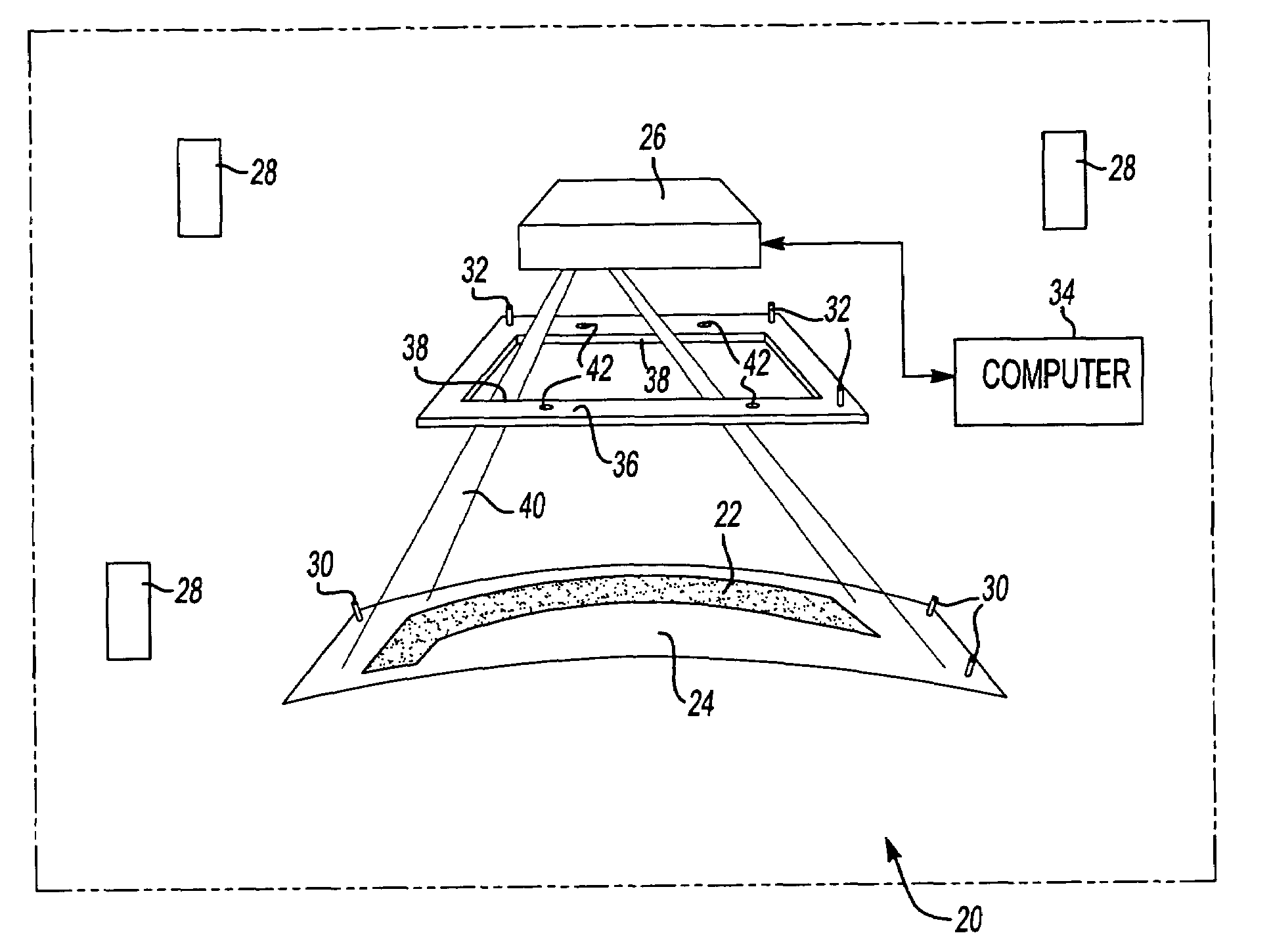

Laser projection systems and methods

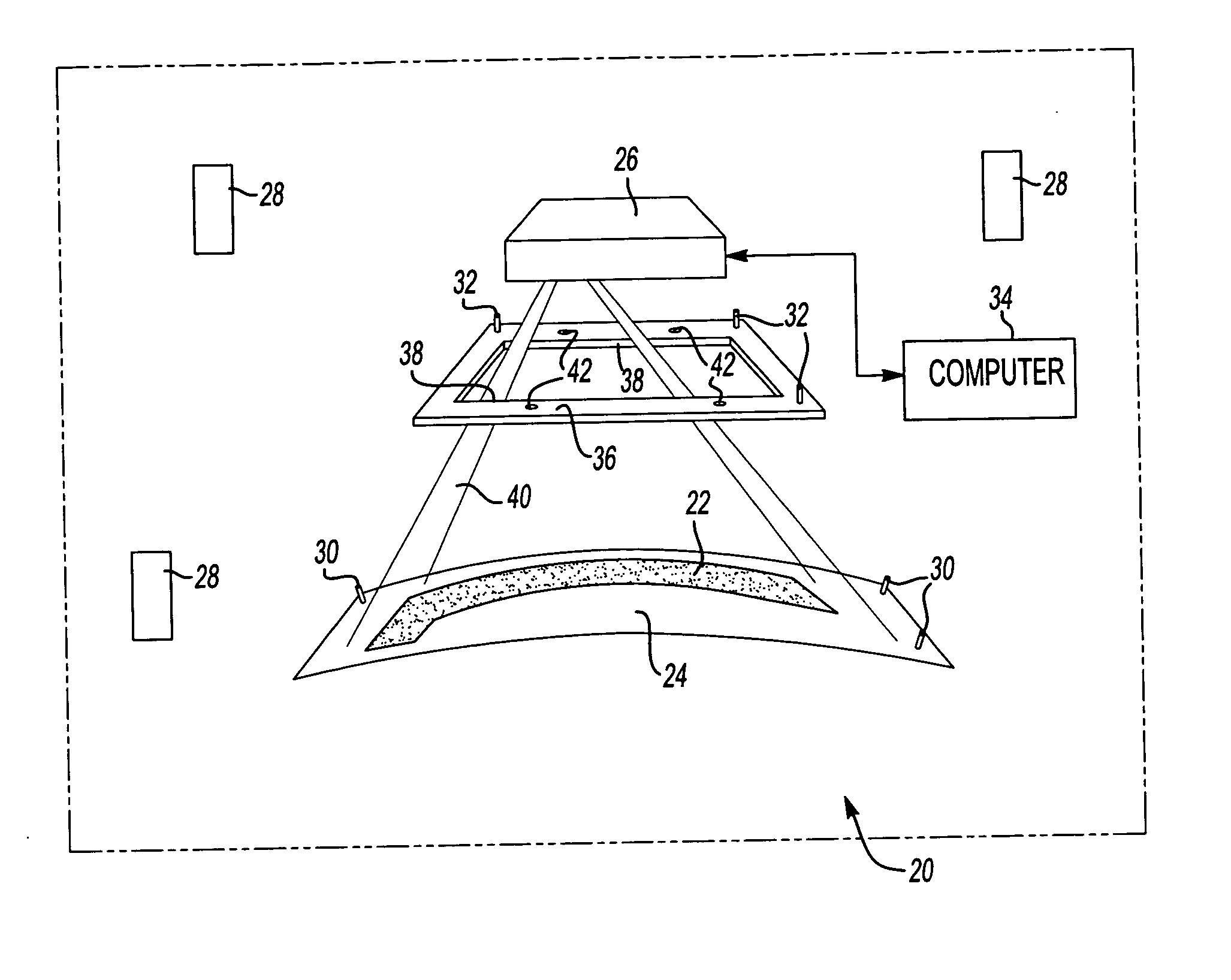

ActiveUS20050082262A1Easy to disassemblePrecise positioningProjectorsPosition fixationMetrologyKinematics

A laser imaging system and method of projecting a laser template on a surface, including independently determining a position and orientation of the surface using an external metrology device, independently determining a position and orientation of a laser projector using the metrology device, generating a signal from the metrology device to a computer and orienting the laser projector relative to the surface to project a laser template. The apparatus includes a plurality of metrology transmitters at fixed locations, a plurality of metrology receivers at fixed locations relative to the surface and a plurality of metrology receivers at fixed locations relative to either the laser projector or laser targets within a field of view of the laser projector. A laser projector and frame assembly is also disclosed, wherein the metrology receivers are located on the frame and the frame includes laser targets for correcting laser drift. Kinematic supports for the metrology receivers are disclosed as well as an independent laser tracker.

Owner:NIKON METROLOGY

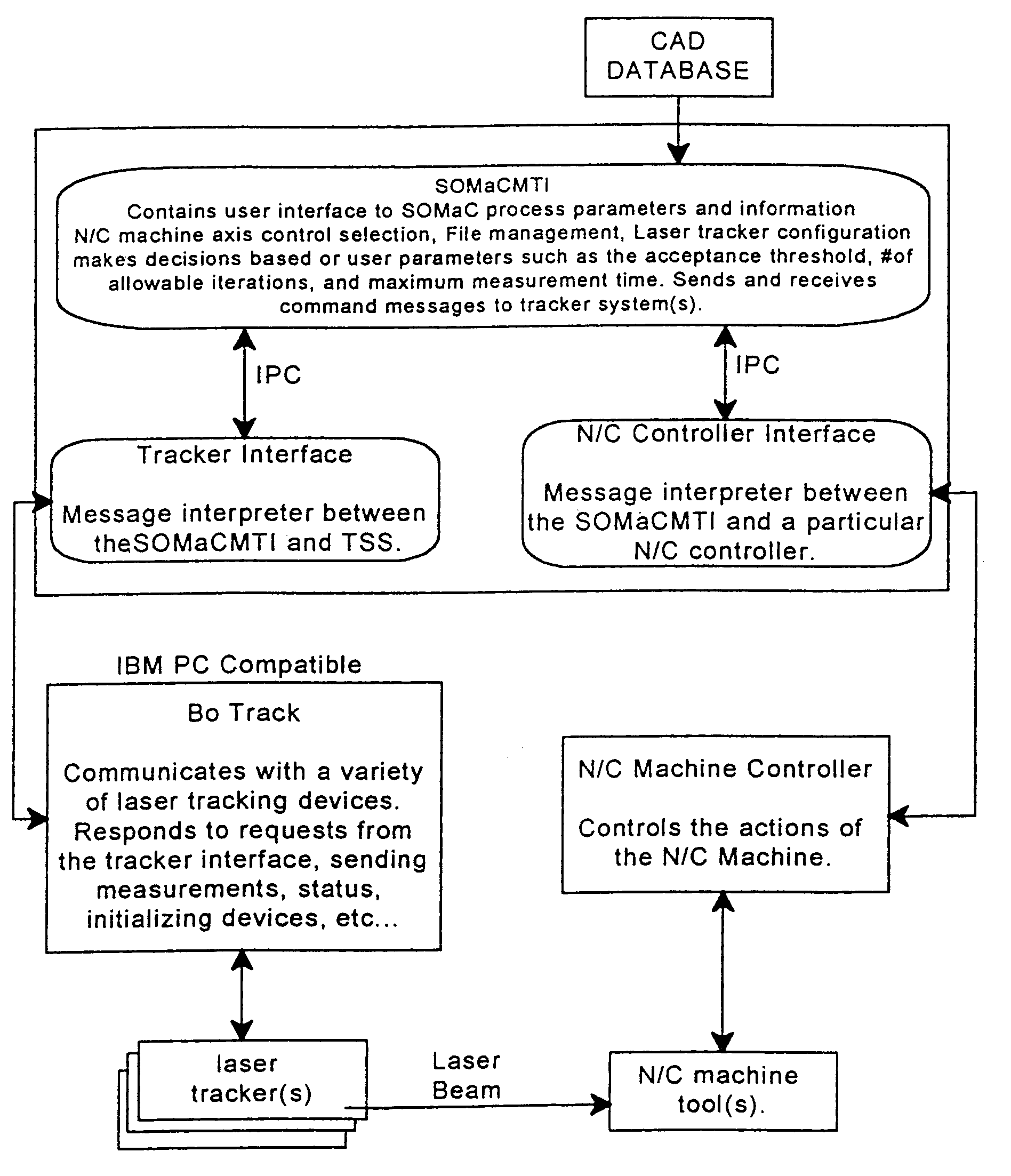

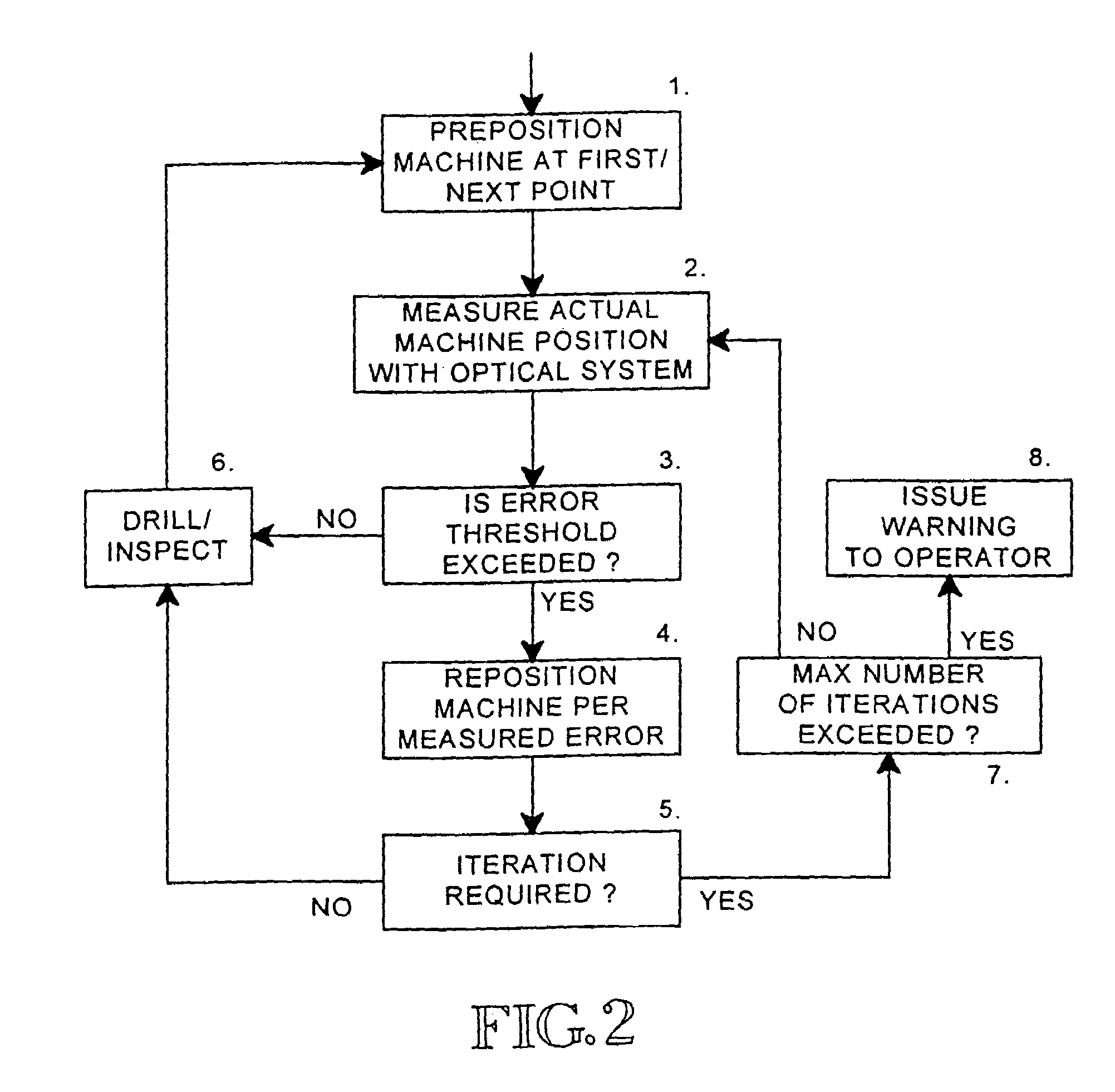

Software for improving the accuracy of machines

InactiveUS6980881B2Overcome mistakesEliminate the effects ofProgramme-controlled manipulatorComputer controlThermal expansionActuator

Large machines, especially those having working envelopes in excess of fifteen feet, exhibit unacceptable errors because of thermal expansion and mechanical misalignments between the axes. The errors have traditionally been minimized by enclosing the machine in a thermal enclosure, by careful calibration, or by mounting a laser interferometer on each axis. These solutions are costly, may require frequent recalibration, and do not correct for small rotations of one axis relative to another axis due to wear etc. The present invention uses an interferometric laser tracker or a comparable 3D position sensor to measure the position of a retroreflector attached to the end effector, e.g. a machine head when the machine comes to rest. A computer compares the measured position to the desired position according to the machine media, and adds the appropriate correction with trickle feed media statements to move the machine to the correct position prior to further machining.

Owner:THE BOEING CO

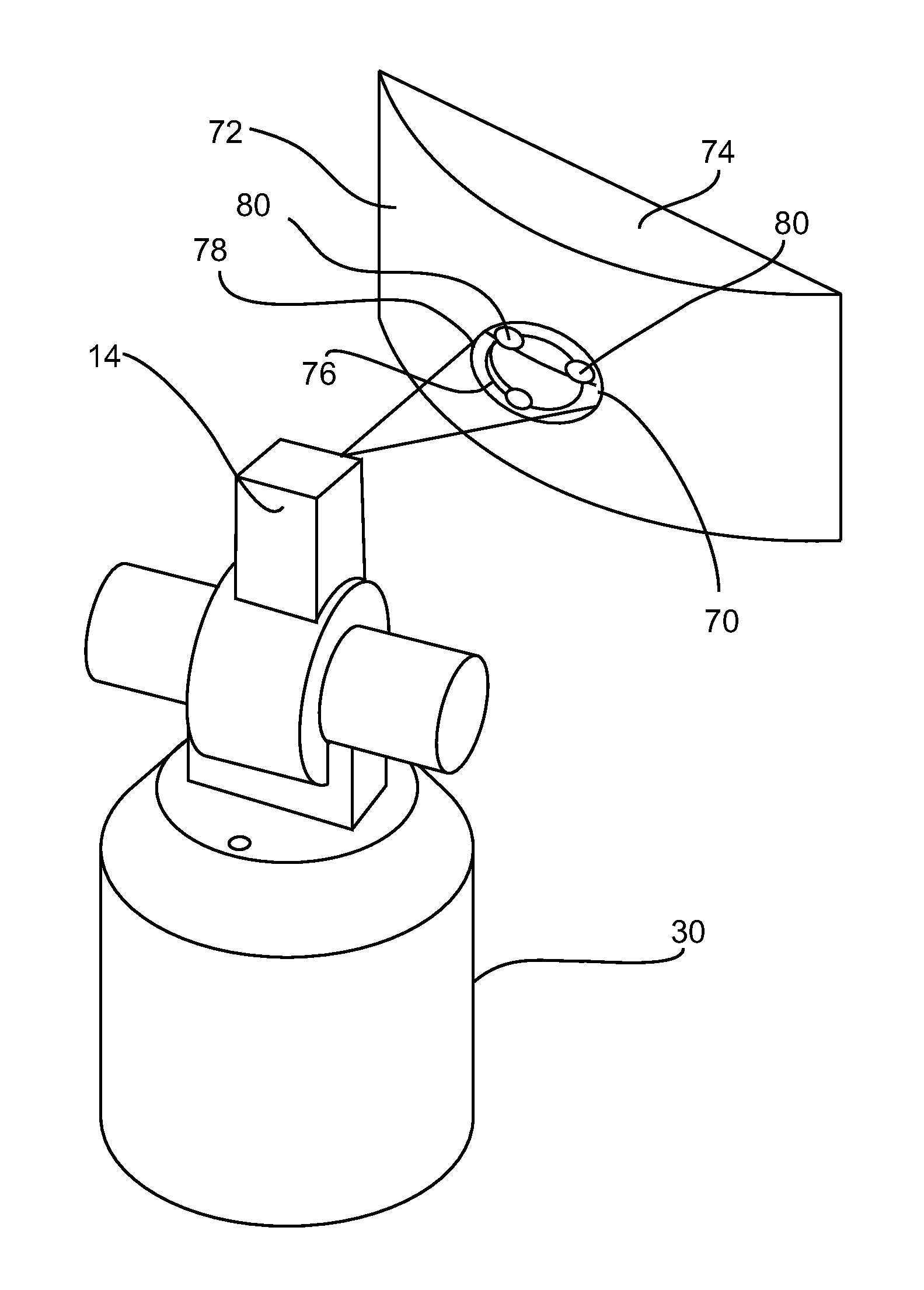

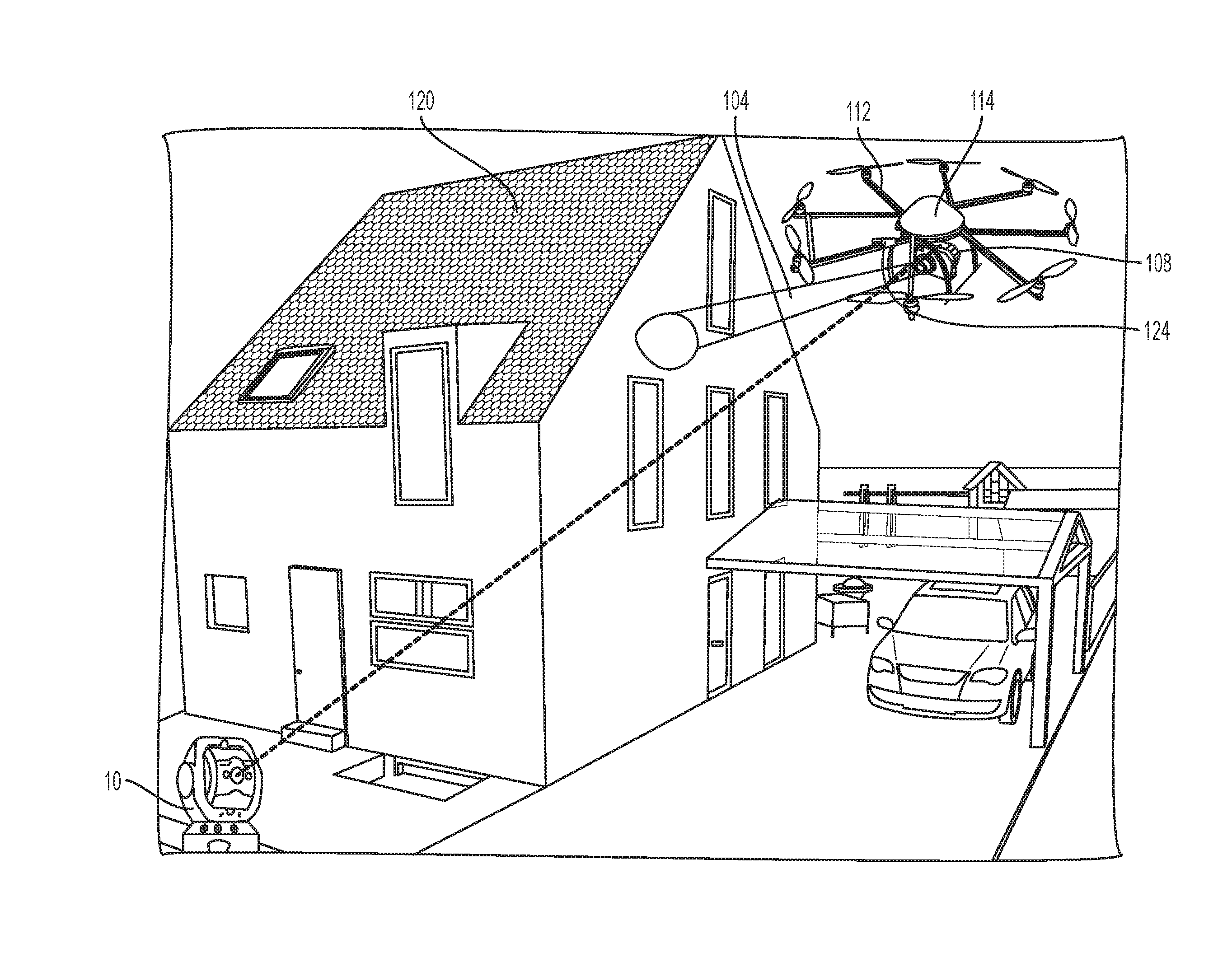

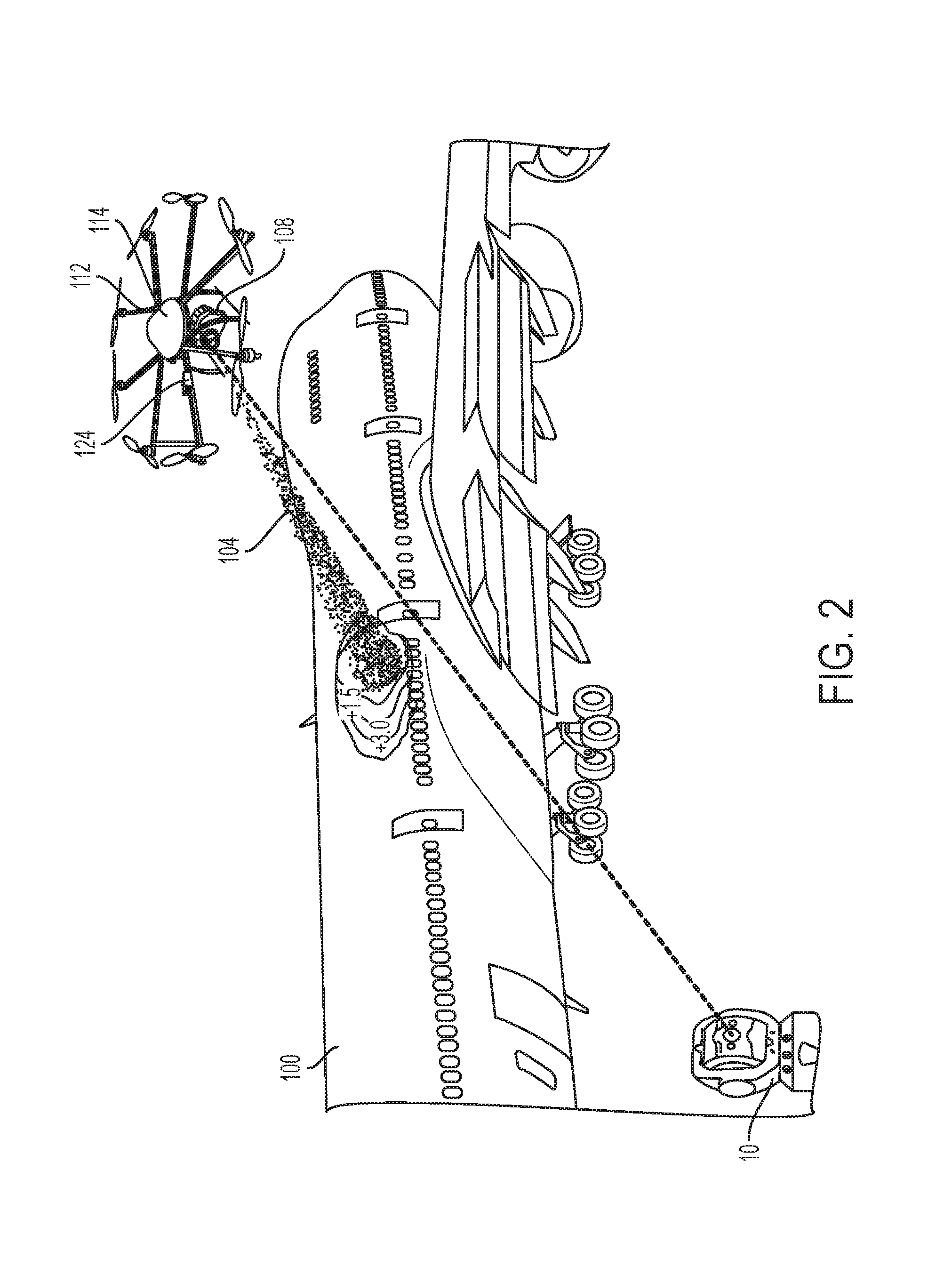

Unmanned aerial vehicle having a projector and being tracked by a laser tracker

An unmanned aerial vehicle (UAV) such as a drone, quadcopter or octocopter having a projector on board for projecting information into physical space such as onto objects or locations while the UAV is in flight, and further with the position and orientation (i.e., the six degrees of freedom) of the UAV in flight being accurately tracked and controlled from the ground, e.g., by a laser tracker or a camera bar, thereby leading to a relatively more stable flight of the UAV.

Owner:FARO TECH INC

Optical measurement system and method for three-dimensional shape of large-scale complex curved surface member

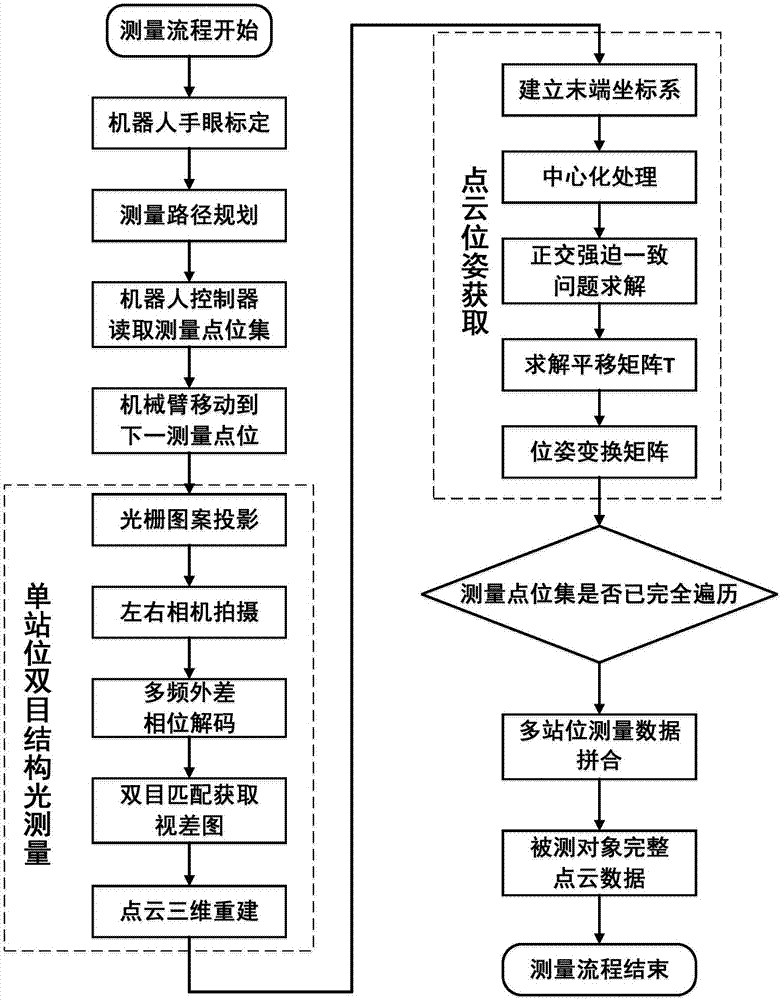

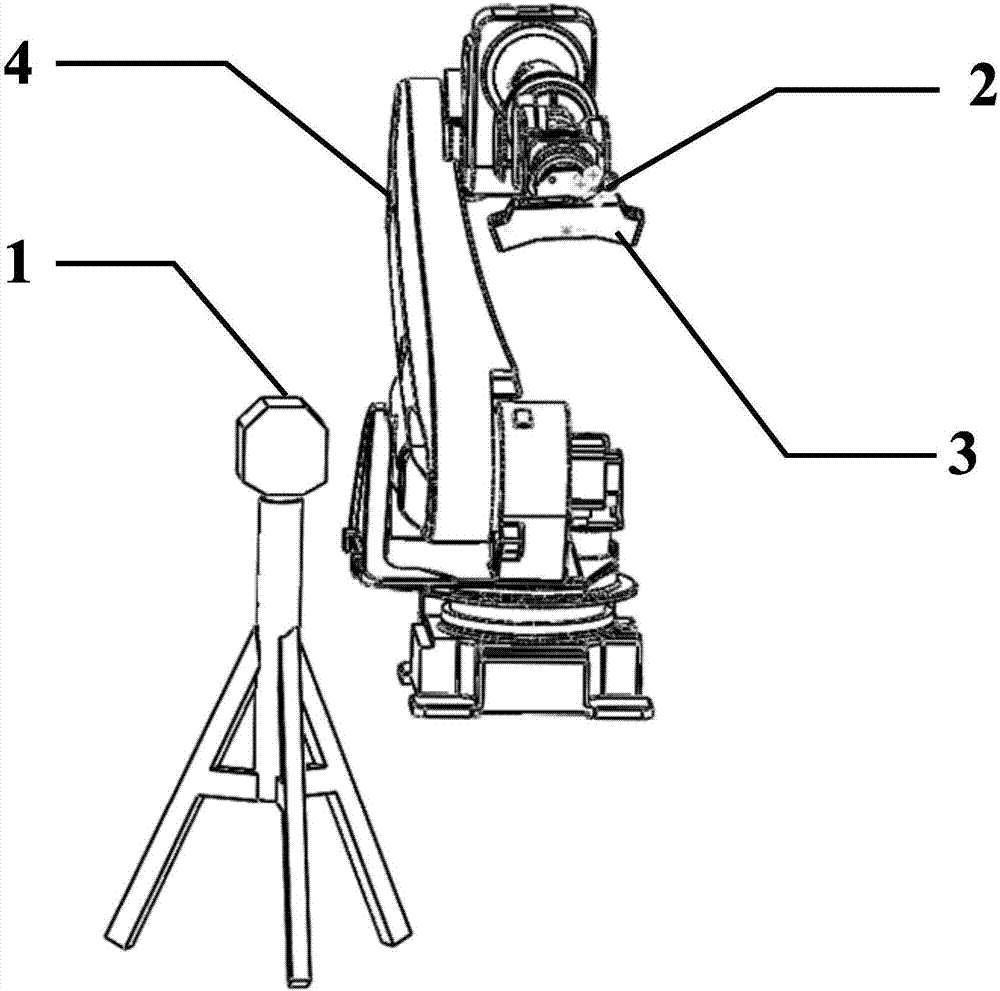

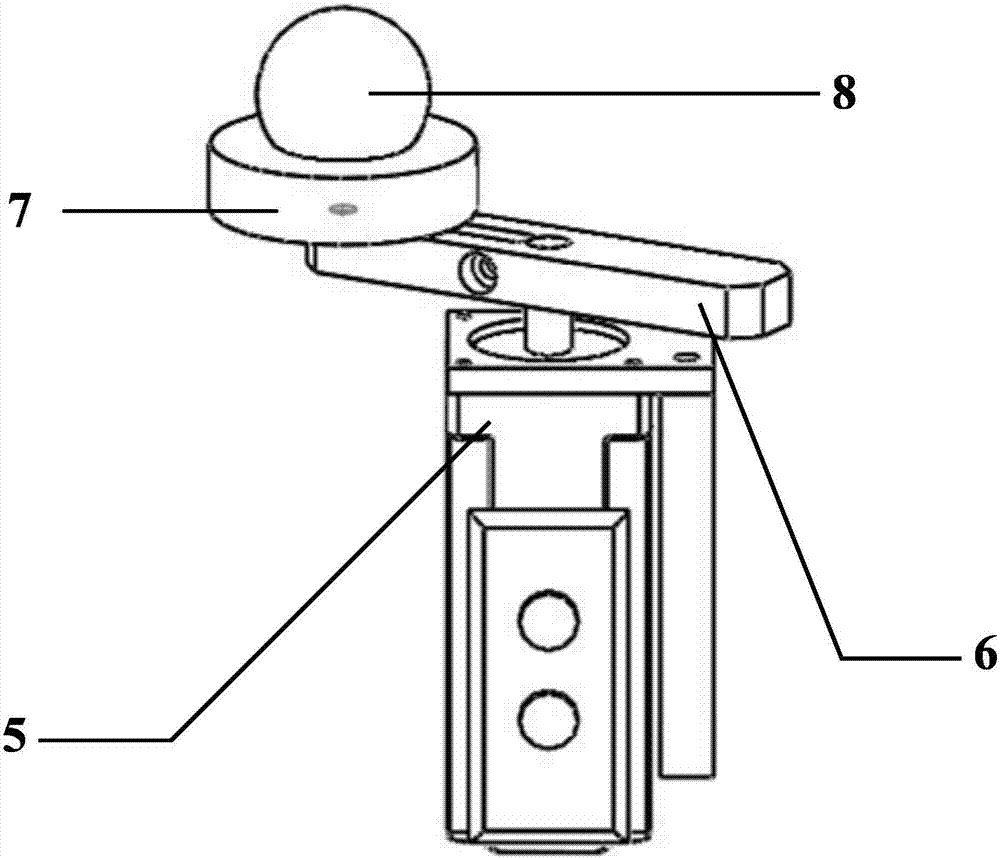

ActiveCN106959080AIntegrity guaranteedGuaranteed measurement efficiencyUsing optical meansGratingData integrity

The invention provides an optical measurement system and method for a three-dimensional shape of a large-scale complex curved surface member. The method is based on binocular optical grating projection measurement technologies, point cloud poses of all station positions during multiple station position measurement are obtained via a laser tracker and a corresponding target ball, point cloud obtained via the multiple station position measurement is converted to be under a unified laser tracker coordinate system according to corresponding pose data, and overall merging of point cloud data of a large-scale complex surface-shaped member can be realized; in the system, a six degree-of-freedom robot is used as a carrier for a point cloud space pose tracking unit and a binocular structured light measurement device, single station position measurement precision is ensured via calibration of the binocular structured light measurement device before measurement work starts, and data integrity and measurement efficiency are ensured via measurement route planning. Via the optical measurement system and method, all kinds of large-scale complex surface-shaped members can be accurately measured in non-contact conditions; practical, reliable and complete original three dimensional shape data can be provided for evaluation of all kinds of processing quality.

Owner:SHANGHAI JIAO TONG UNIV

Laser projection systems and methods

ActiveUS7545517B2Precise positioningEasy to disassembleProjectorsPosition fixationKinematicsLaser target

A laser imaging system and method of projecting a laser template on a surface, including independently determining a position and orientation of the surface using an external metrology device, independently determining a position and orientation of a laser projector using the metrology device, generating a signal from the metrology device to a computer and orienting the laser projector relative to the surface to project a laser template. The apparatus includes a plurality of metrology transmitters at fixed locations, a plurality of metrology receivers at fixed locations relative to the surface and a plurality of metrology receivers at fixed locations relative to either the laser projector or laser targets within a field of view of the laser projector. A laser projector and frame assembly is also disclosed, wherein the metrology receivers are located on the frame and the frame includes laser targets for correcting laser drift. Kinematic supports for the metrology receivers are disclosed as well as an independent laser tracker.

Owner:NIKON METROLOGY

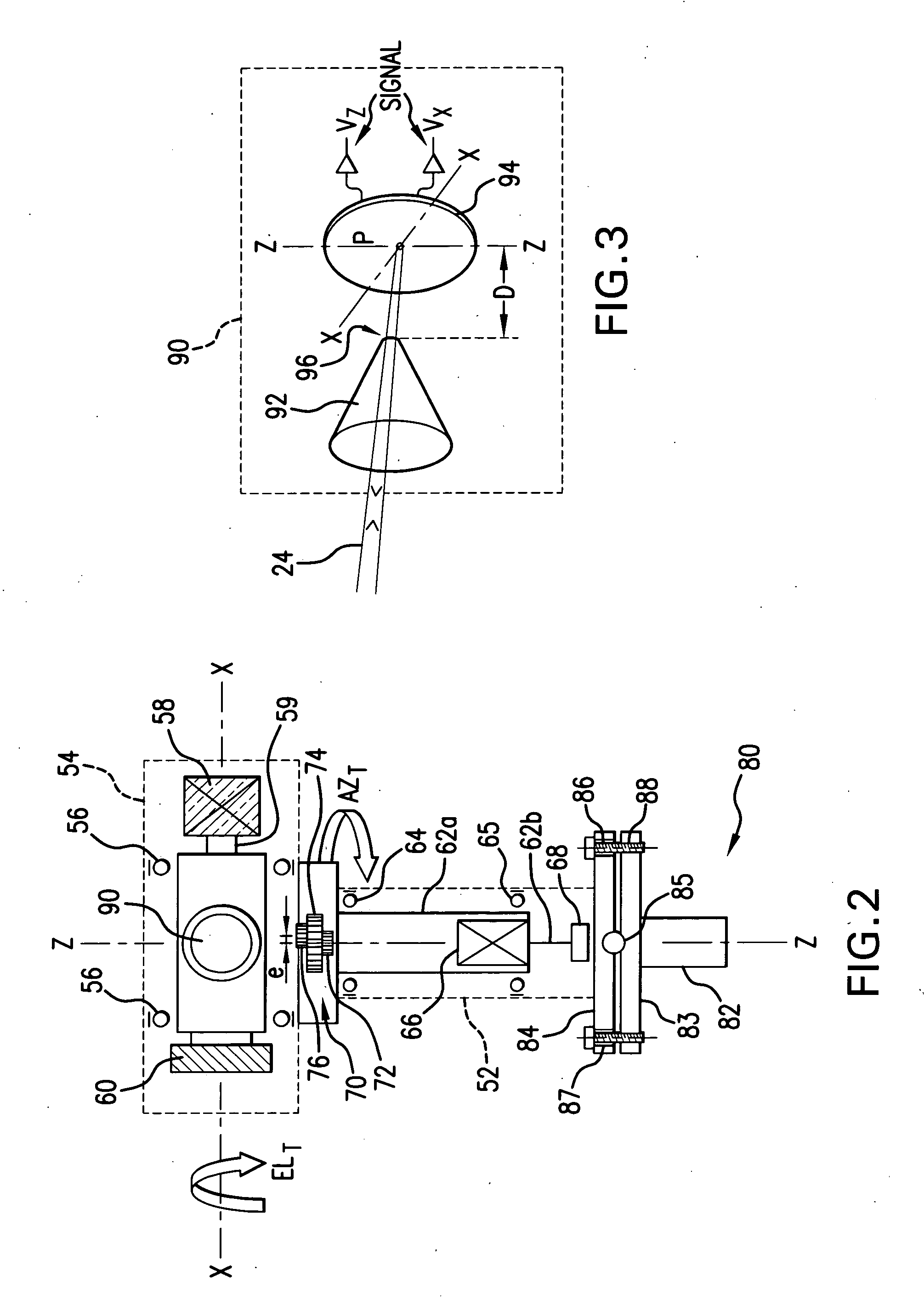

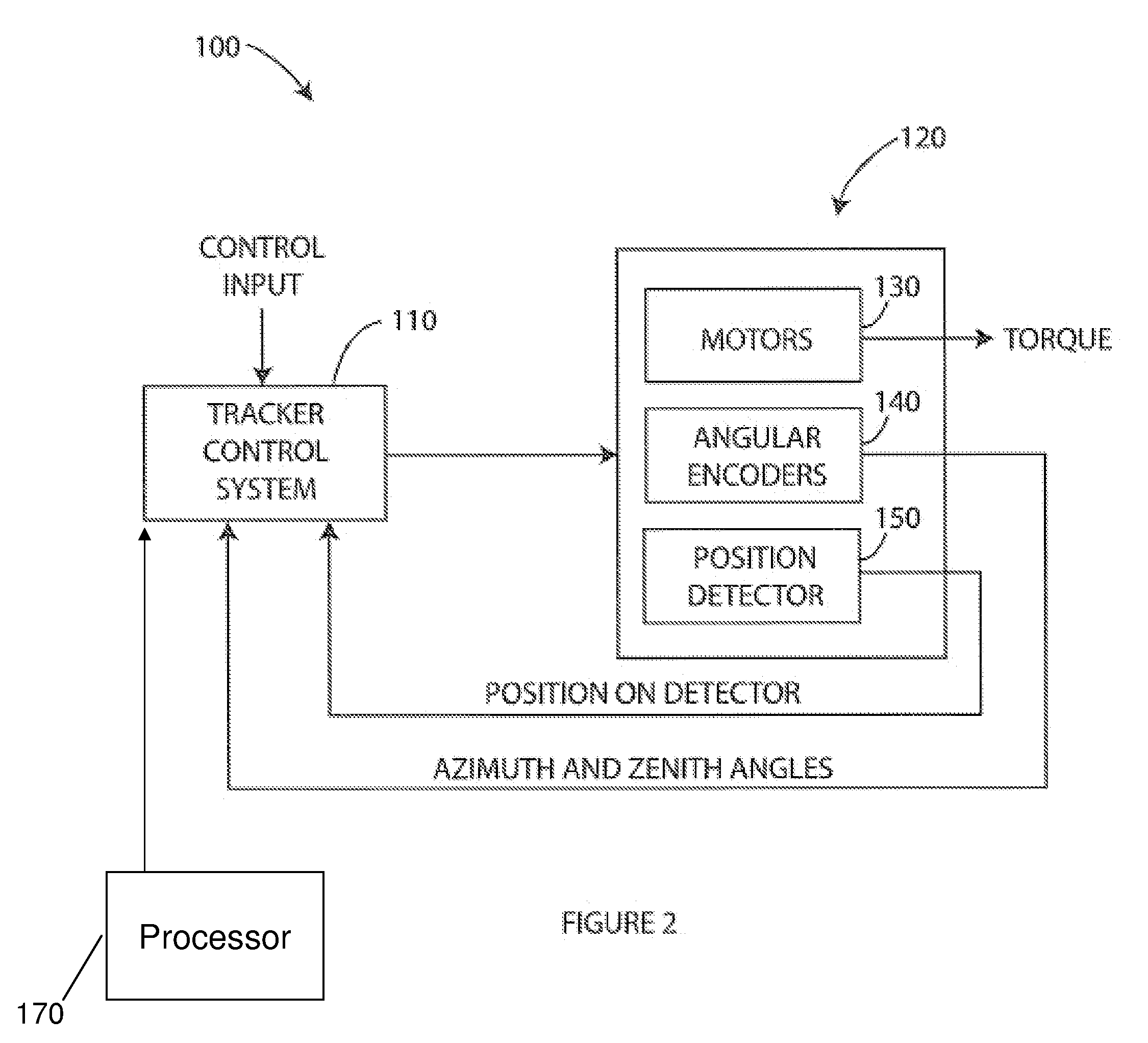

Laser pointing mechanism

InactiveUS20110069322A1Using optical meansElectromagnetic wave reradiationControl systemLaser scanning

A pointing device for use with a laser tracker or laser scanner may include a tracker or scanner control system and a tracker or scanner plant. The tracker plant may include a plurality of motors configured to apply a torque to a mechanism that steers the laser and a plurality of angular encoders configured to send feedback information on the angular position of the mechanism to the tracker control system. The tracker or scanner control system may be configured such that, when the pointing device is operating in a manual adjustment mode, the tracker or scanner control system controls the plurality of motors to provide a torque to the mechanism opposite to a direction of movement caused by the user.

Owner:FARO TECH INC

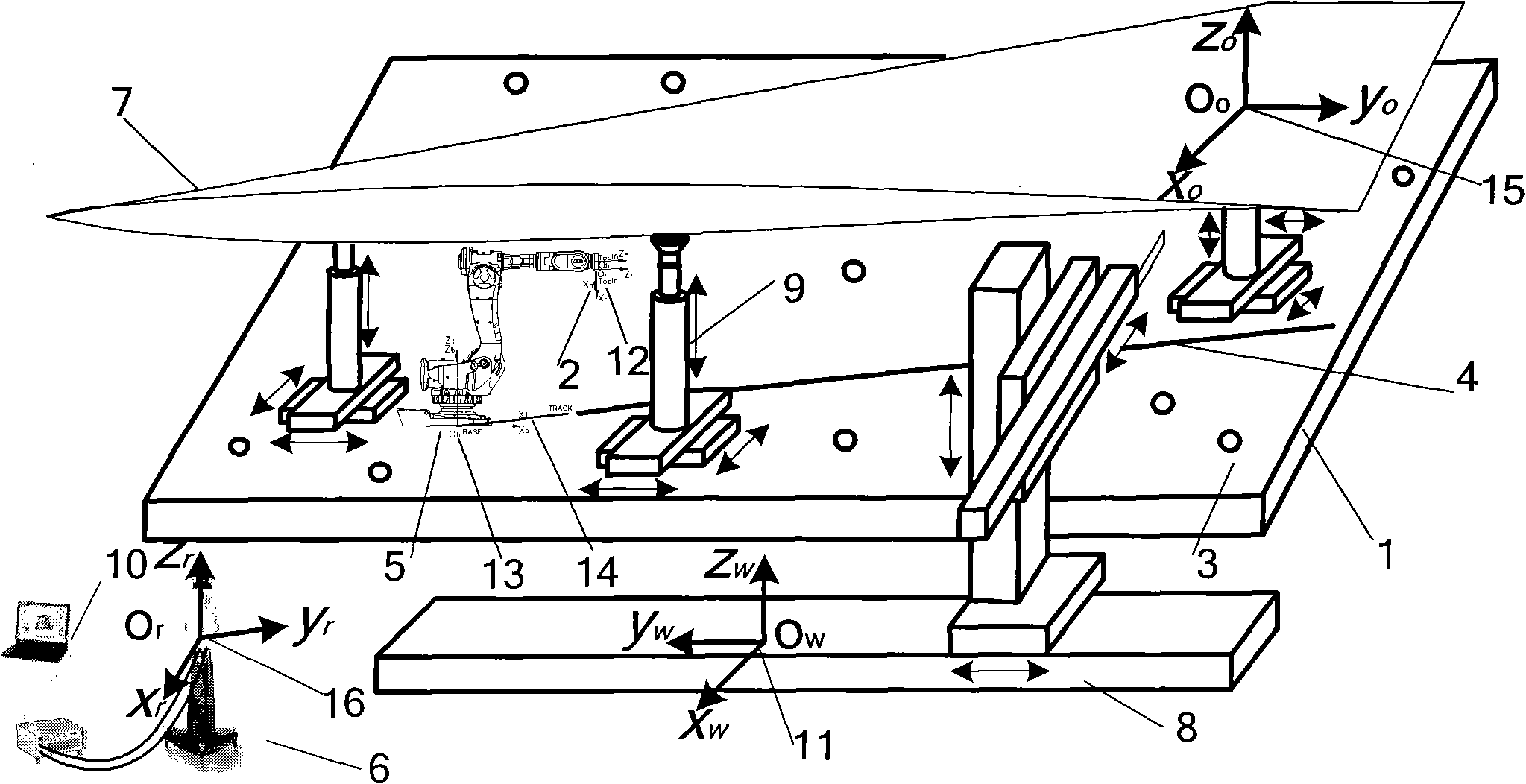

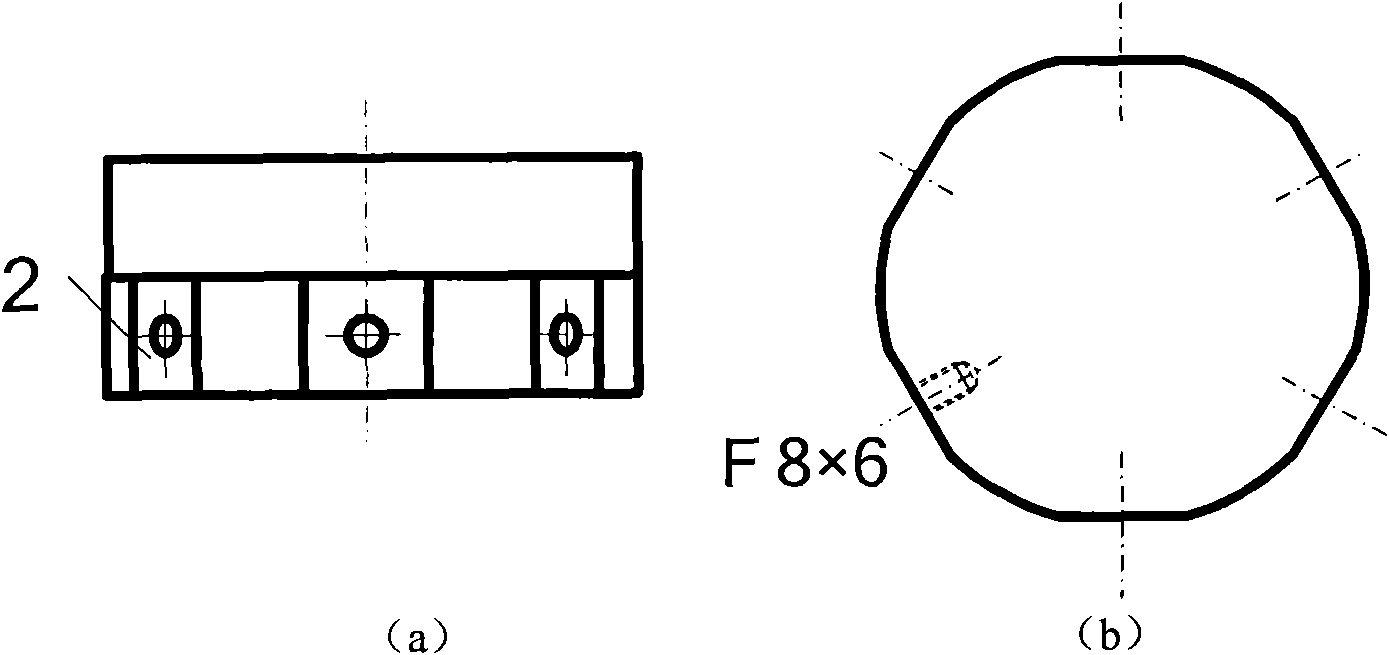

Device for automatically marking additional external axis robot based on laser tracking measurement and method thereof

InactiveCN102062576AThe calibration process is stable and reliableHigh precisionUsing optical meansNumerical controlEngineering

The invention discloses a device for automatically marking an additional external axis robot based on laser tracking measurement and a method thereof. The device comprises a system platform, a target flange, target mounting holes, a robot guide rail, a robot, a laser tracker, a workpiece, a numerical control finish machining machine tool, a three-coordinate numerical control locator, and an upper computer, wherein the system platform is provided with 9 target mounting holes processed by the numerical control finish machining machine tool, the three-coordinate numerical control locator and the robot guide rail; the workpiece is fixed on the three-coordinate numerical control locator; the robot is arranged on the robot guide rail; the target flange is arranged on the robot; 6 target mounting holes are arranged on the target flange; the targets are arranged on the target mounting holes; the numerical control finish machining machine tool, the laser tracker and the upper computer are installed at the outer side of the system platform. The device has the advantages that: (1) the device is capable of automatically marking the robot coordinate system with the additional external axis; (2) the device is high in marking precision and reliable in marking result; and (3) the device is further simple in marking operation and high in efficiency.

Owner:ZHEJIANG UNIV

Method for measuring positioning points based on laser tracker in docking process of airplane parts

InactiveCN102519441AImprove assembly measurement accuracyReduce work intensitySurveying instrumentsUsing optical meansJet aeroplaneObservation point

The invention discloses a method for measuring positioning points based on a laser tracker in a docking process of airplane parts. The method provided by the invention comprises the following steps of 1, establishing a model of transformation between an airplane global coordinate system and a laser tracker measure coordinate system according to common observation points, 2, acquiring current calculating positions of positioning measure points of airplane parts according to a process joint sphere centre position, and 3, controlling and driving a laser tracker to search current accurate positions of the positioning measure points of the airplane parts from the current calculating positions according to a cross helical search method and to carry out automatic measure. The method provided by the invention has the advantages that 1, an advanced laser measure technology is adopted so that the airplane assembling measure precision is improved; and 2, a measure process does not need artificial light introduction and full automatic search measure of a docking assembling process is realized according to an algorithm so that working efficiency and measure precision are greatly improved and working strength of workers is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

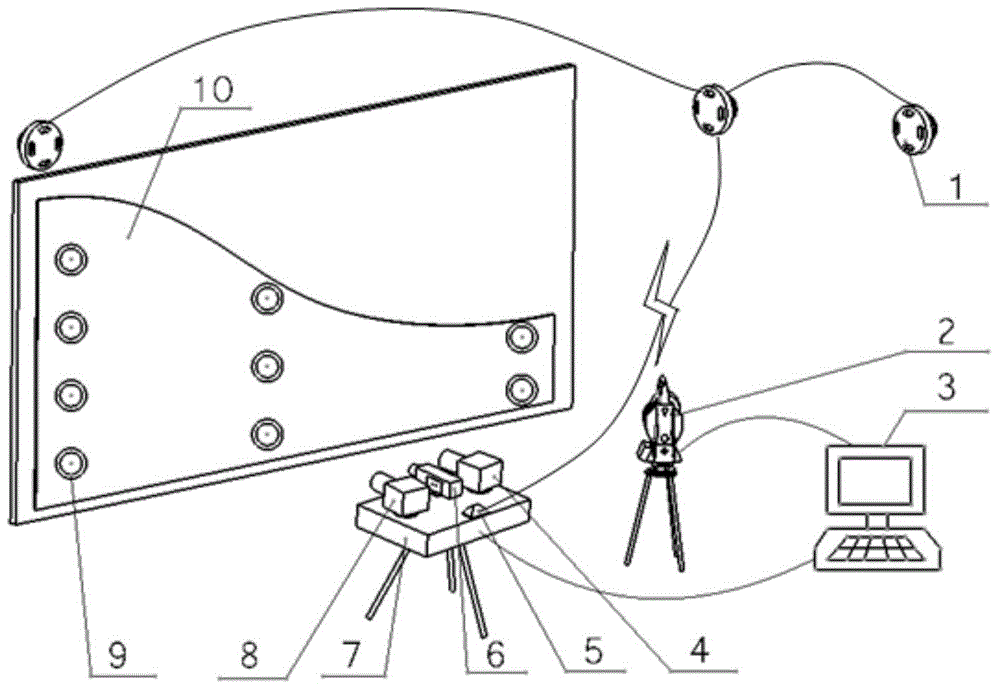

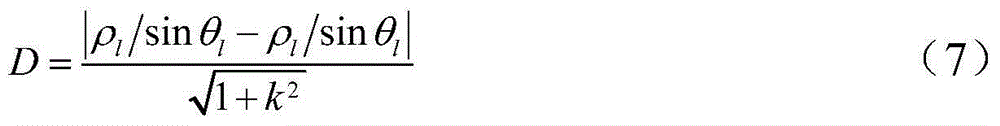

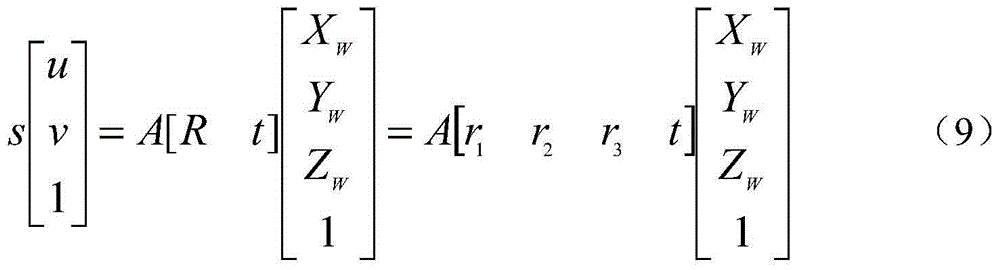

Geometric parameter visual measurement method for large composite board

ActiveCN104457569AAccurate measurementRealize visual calibration workImage analysisUsing optical meansLaser trackerPosition control

The invention relates to a geometric parameter visual measurement method for a large composite board, and belongs to the field of visual measurement. By means of the method, on-site quick three-dimensional reconstruction and geometric parameter measurement of the large composite board can be achieved. According to the method, a binocular vision measurement system, a laser tracker system and an indoor Bluetooth locating system are used for measurement, feature points are distributed on the measured composite board, and reflection targets are pasted to the feature points; the binocular vision measurement system is set up and is composed of a left camera, a right camera, a continuous line laser and an automatic position control platform; the laser tracker system is arranged, and the indoor Bluetooth locating system is mounted, so that measurement is completed. By means of the method, visual calibration of the large composite board can be quickly and precisely achieved, splicing precision of adjacent images is improved, data measurement precision is improved on the whole, and the defects that a traditional measurement method is low in efficiency, precision and stability are overcome.

Owner:DALIAN UNIV OF TECH

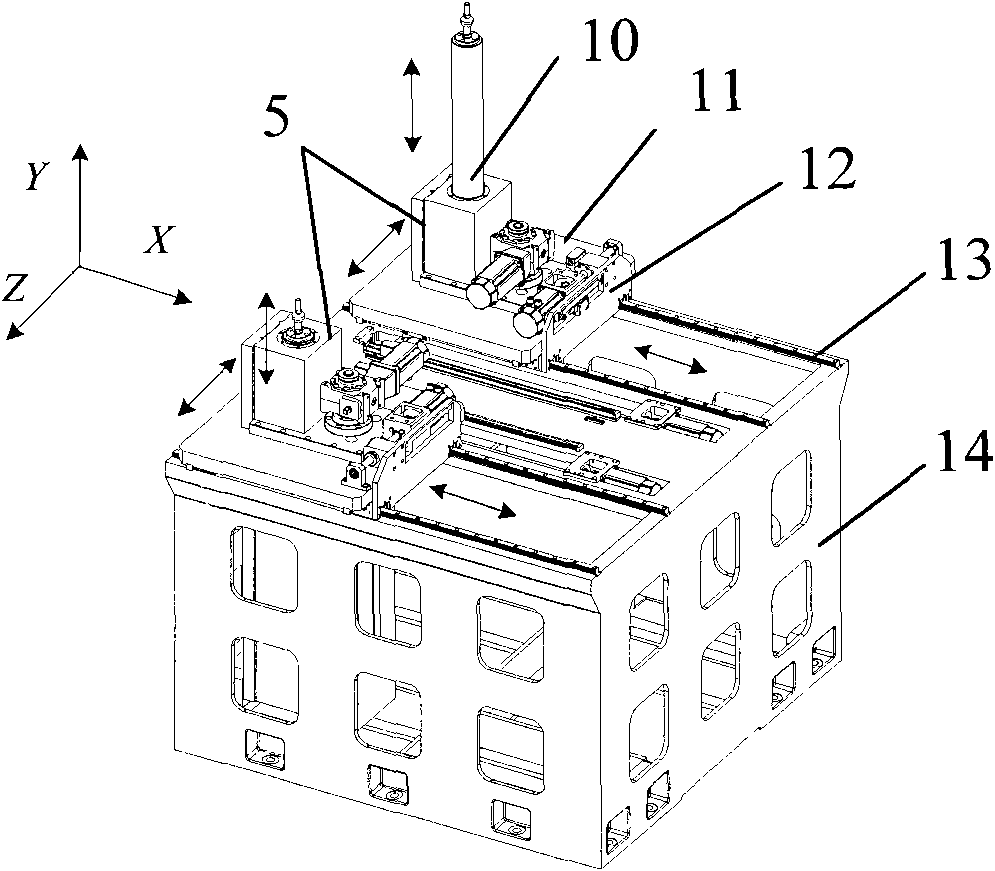

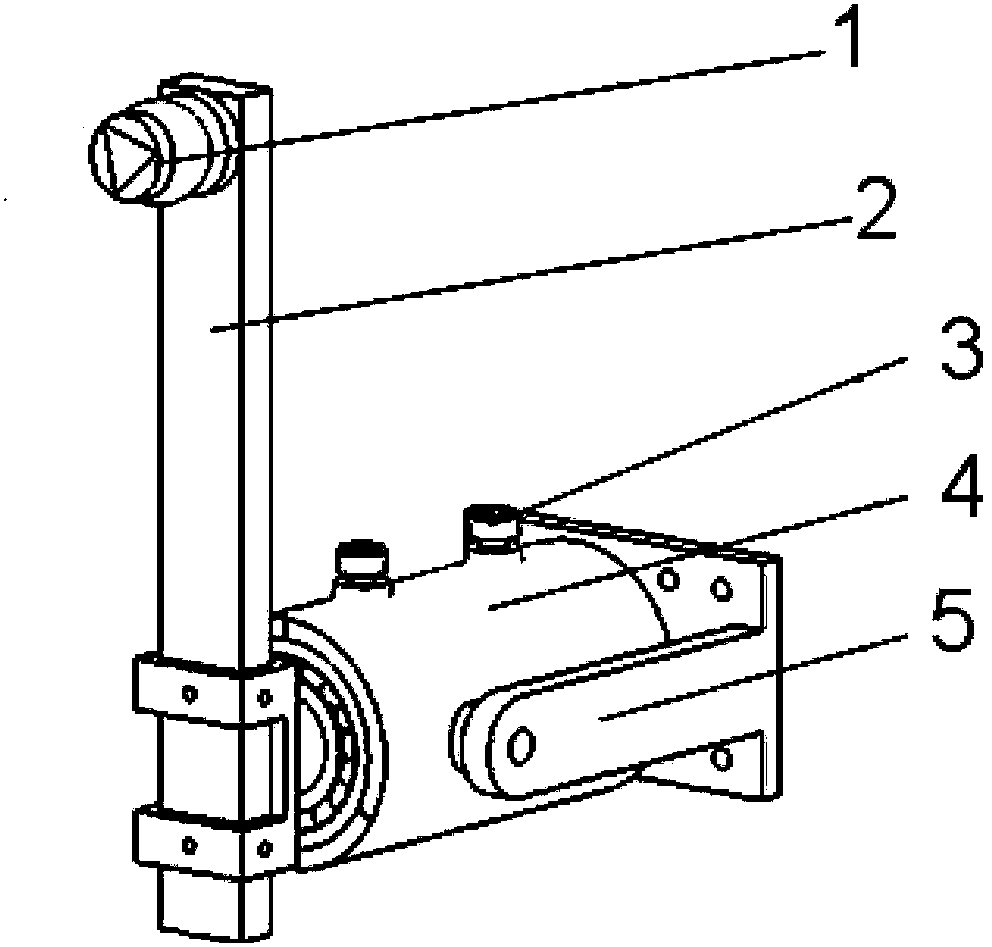

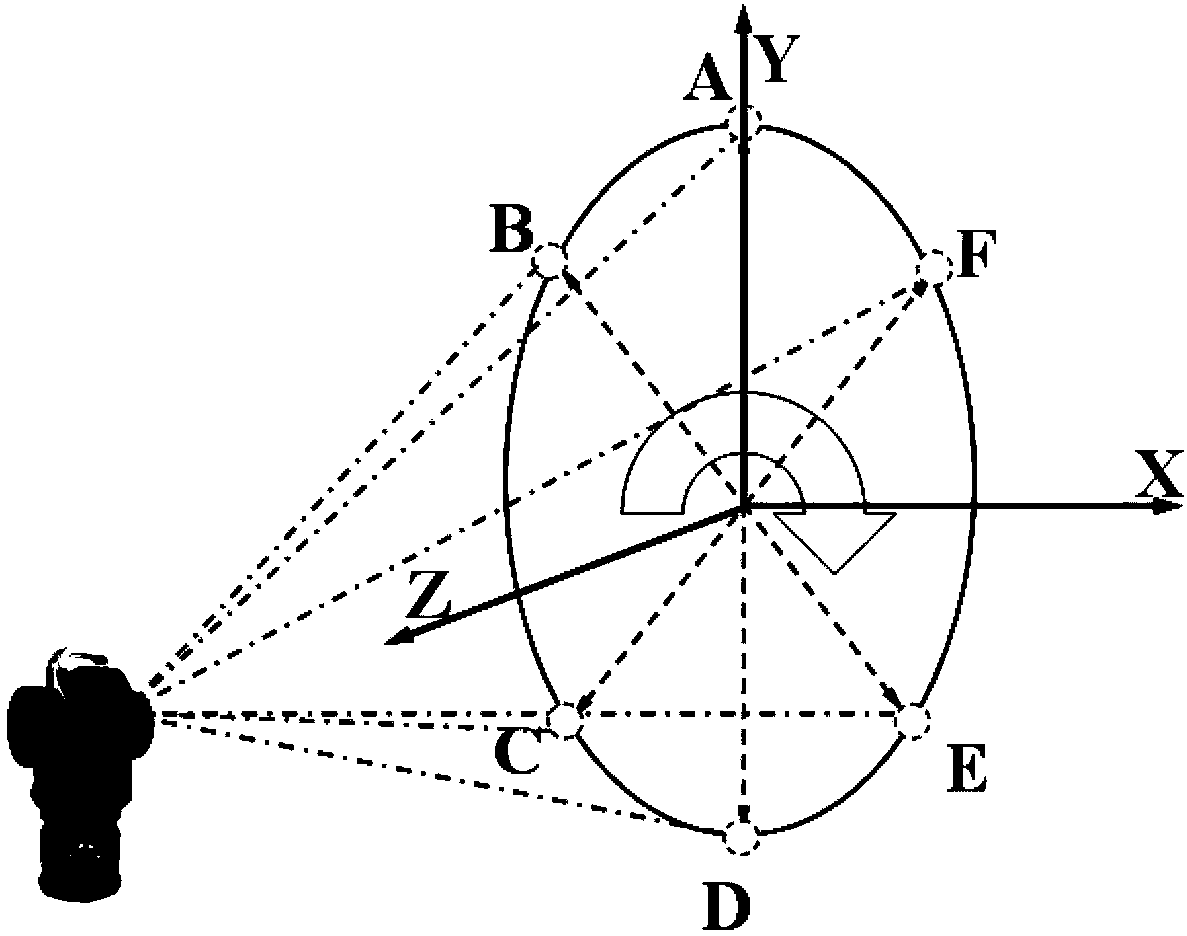

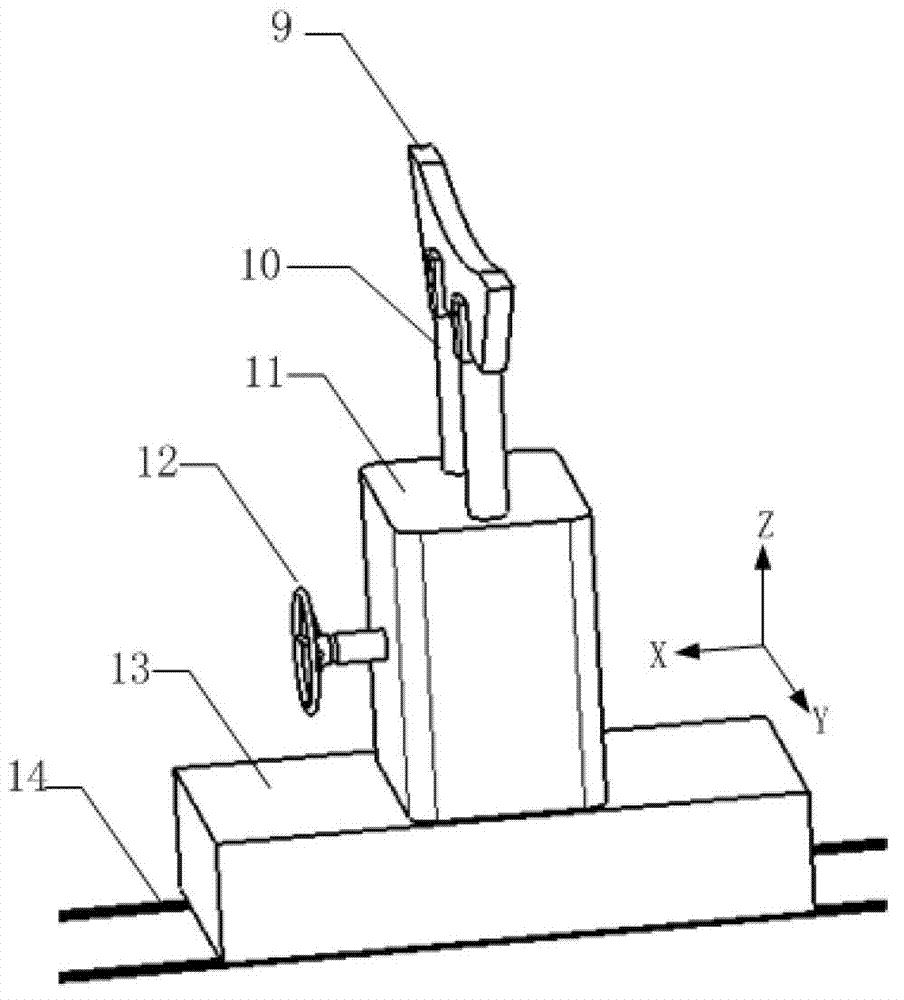

Numerical control machine tool translational shaft geometric error measuring device and measuring and identifying method

ActiveCN103447884AHigh precisionOperation diversificationMeasurement/indication equipmentsGeometric errorNumerical control

The invention discloses a numerical control machine tool translational shaft geometric error measuring device and measuring and identifying method. A laser tracker is used for successively measuring axial feed movements of three fixed points of a single machine tool translational shaft at four different positions, the real-time poses of the translation shaft is calculated by the special continuous moving trajectory of the three fixed points, and errors of a machine tool are identified. Due to the fact the real-time poses of the translation shaft are measured, the acquired machine tool information is much richer than the information acquired by only measuring cutter moving trajectory, and error identification algorithm is quite simple. The method suitable for fast data processing, machine tool error fast compensation and precision detection in the field of machine tools has the advantages of high precision, fast and simple operation, rich measuring information, and the like.

Owner:XI AN JIAOTONG UNIV

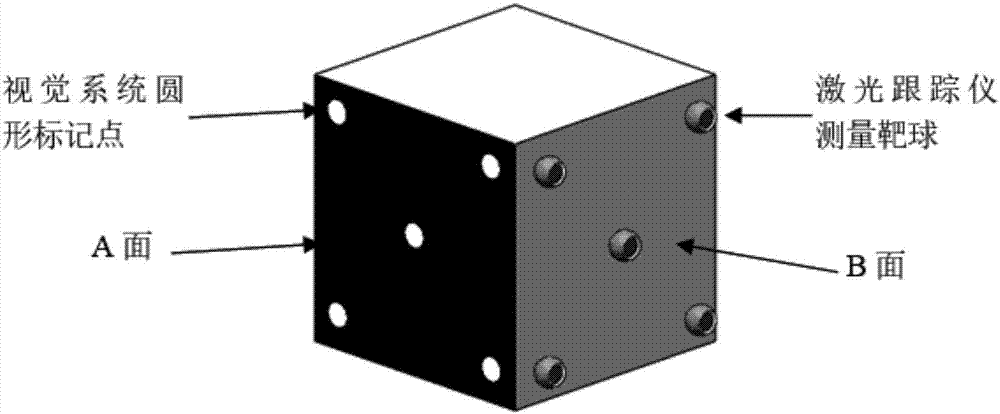

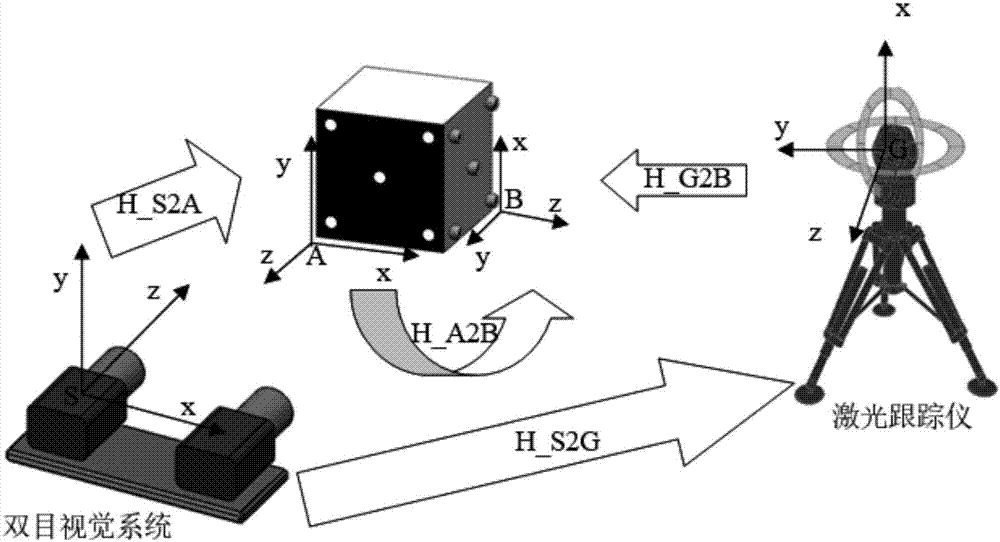

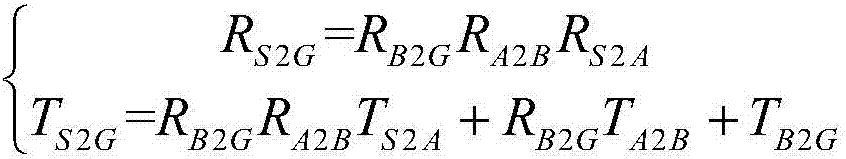

Global calibration method based on binocular visual system and laser tracker measurement system

ActiveCN107883870AReduce difficultyAvoid measurement errorsUsing optical meansObservational errorCalibration result

The invention discloses a global calibration method based on a binocular visual system and a laser tracker measurement system. Firstly a rigid stereoscopic target of which the A side is provided withbinocular visual system circular mark points and the B side is provided with laser tracker measurement target balls is manufactured; then the A side coordinate system and the B side coordinate systemof the stereoscopic target are established; the transformation relation between the A side coordinate system of the stereoscopic target and the left camera coordinate system of the binocular visual system and the transformation relation between the B side coordinate system of the stereoscopic target and the laser tracker world coordinate system are solved; the transformation relation between the Aside coordinate system and the B side coordinate system is solved according to the transformation relation solved in the last step; and finally the transformation relation between the left camera coordinate system of the global calibration binocular visual system and the laser tracker world coordinate system is solved. The difficulty of directly processing and maintaining the high-precision stereoscopic target can be reduced so that the measurement error caused by direct measurement can be solved and the more accurate calibration result can be acquired.

Owner:四川雷得兴业信息科技有限公司

Device and method for measuring six degrees of freedom

InactiveUS8525983B2Angle measurementBeacon systems using electromagnetic wavesLight beamDegrees of freedom

A laser tracker system for measuring six degrees of freedom may include a main optics assembly structured to emit a first laser beam, a pattern projector assembly structured to emit a second laser beam shaped into a two-dimensional pattern, and a target. The target may include a retroreflector and a position sensor assembly. A center of symmetry of the retroreflector may be provided on a different plane than a plane of the position sensor assembly. A method of measuring orientation of a target may include illuminating the target with a laser beam comprising a two-dimensional pattern, recording a position of the two-dimensional pattern on a position sensor assembly to create a measured signature value of the two-dimensional pattern, and calculating an orientation of the target based on the measured signature value.

Owner:FARO TECH INC

Six degree-of-freedom laser tracker that cooperates with a remote projector to convey information

A method of conveying information to a user of a coordinate measurement device, includes providing a first target projector, sending a first light beam from the device to a retroreflector; receiving a second light beam from the retroreflector; measuring the orientational and translational sets, the translational set based on the second light beam; selecting first information to be conveyed from the group consisting of one or more positions on the object, a direction indicated by a moving pattern, a message that includes one or more symbols or alphanumeric characters, a hidden feature, a measured object characteristic, a modeled characteristic, a magnified representation of surface characteristics, a pattern having meaning according to a rule, and combinations thereof; determining a first light pattern corresponding to the information; storing the first light pattern; and projecting the first light pattern onto the object based on the translational and orientational sets.

Owner:FARO TECH INC

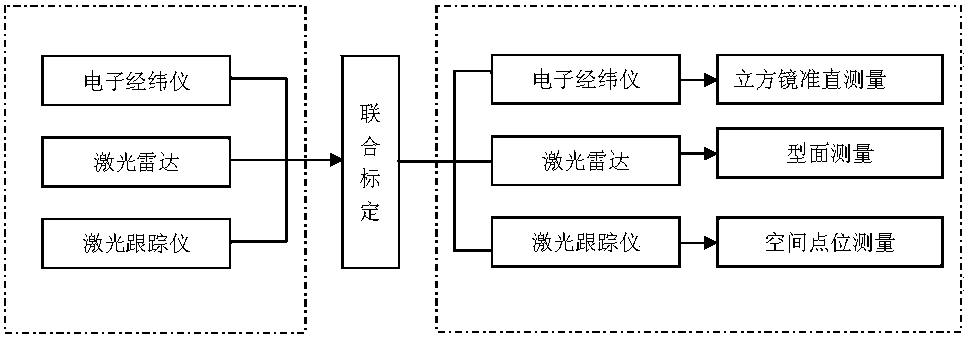

Mixed measurement analysis method for satellite antenna

The invention relates to a mixed measurement analysis method for a satellite antenna. The method effectively solves the problems that various measurement devices are used for co-measurement to reduce detection difficulty and improve detection efficiency during a measurement process of the satellite antenna. The method comprises the steps: cubic mirror collimating measurement is carried out by electronic theodolites during antenna installation and detection processes, scanning measurement of an antenna shaped surface is carried out by a laser radar, a space point position is measured by a laser tracker, and thus the measurement of the satellite antenna is jointly completed by the various measurement devices; union calibration algorithm of 'six freedom degree measurement station three-dimensional network' is employed, a conversion relationship between measurement station coordinates and measurement coordinates is utilized, various observed value error equations are directly listed, so as to overcome shortcomings of a traditional algorithm and improve adaptability of the algorithm. The method provided by the invention is simple, is easy to operate, enables an initial value to be fast acquired, has low requirements for precise degree of the initial value, has a few iteration times, is quick in convergence speed, theoretically is an optimal solution, and has strong algorithm adaptability, high measuring efficiency, fast speed and high precision.

Owner:BEIJING SATELLITE MFG FACTORY +1

Measurement machine utilizing a barcode to identify an inspection plan for an object

Embodiments of the present invention relate to a measurement machine for measuring an object, and more particularly to a measurement machine such as a portable articulated arm coordinate measuring machine or a laser tracker that measures an object according to a measurement or inspection plan that is identified by a machine readable information symbol located on the object to be measured or on a drawing (e.g., a CAD drawing) of the object.

Owner:FARO TECH INC

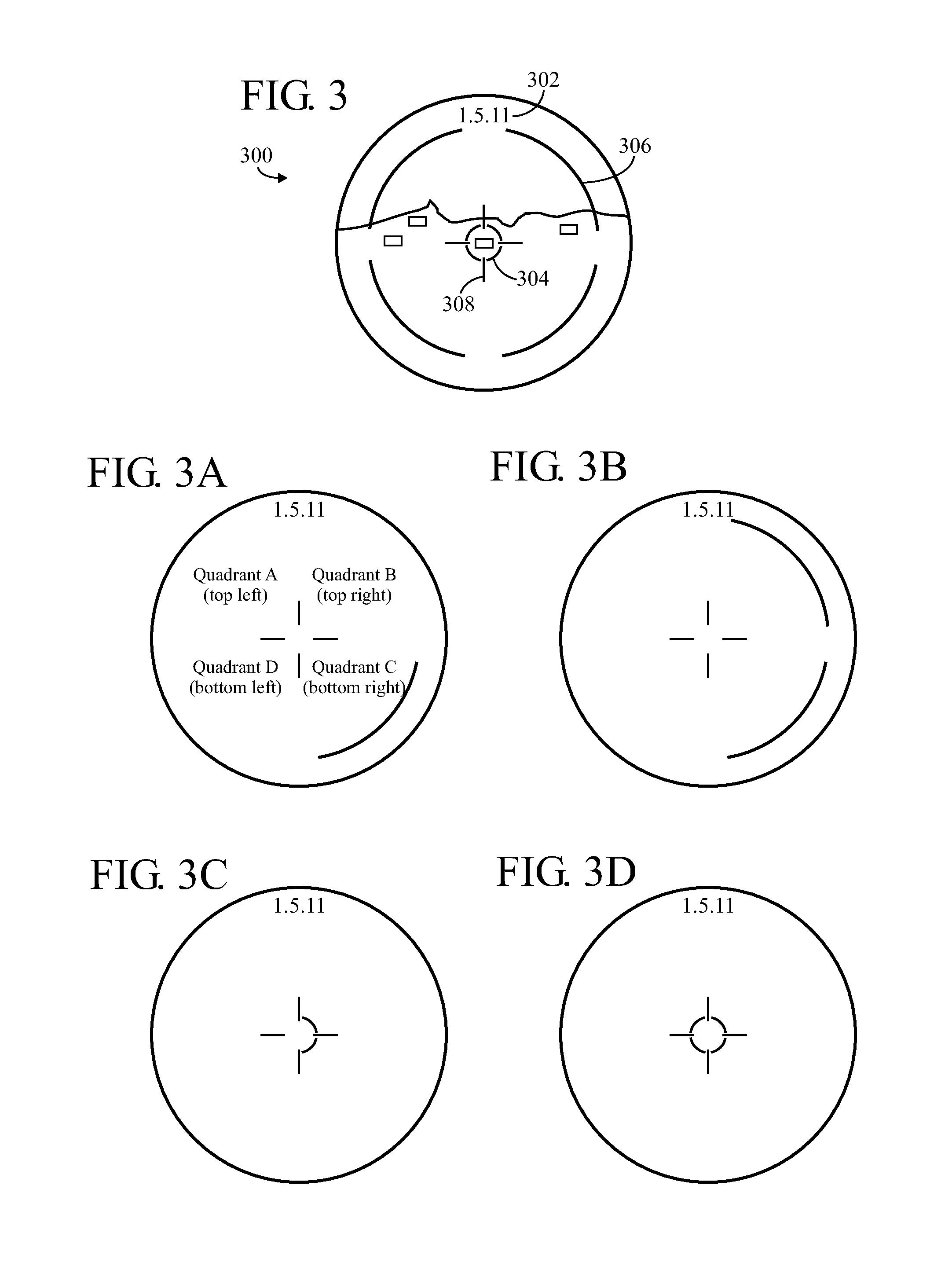

Laser spot tracking with off-axis angle detection

ActiveUS8451432B2Improve abilitiesShorten the timeOptical rangefindersDirection controllersLaser lightLaser tracker

A laser spot tracker comprising a quadrant detector. A portion of a spot of laser light reflected from an object being illuminated (OBI) may be defocused to occupy a significant portion such as one-third of the field of view, while another portion remains focused, therefore allowing for quick calculation of the spot centroid. With such a “composite spot”, multiple target (OBI) positions may simultaneously be defined in elevation and azimuth with respect to null by analyzing the energy in each quadrant. The X and Y angle information (off null) for multiple targets (OBIs), and their codes may be displayed. For a large, defocused spot, two segmented multi-element detectors may be used, one in front of and the other behind the focal plane to reduce the effects of hot spots in a spot of laser light collected from an object being illuminated.

Owner:ANALOG MODULES

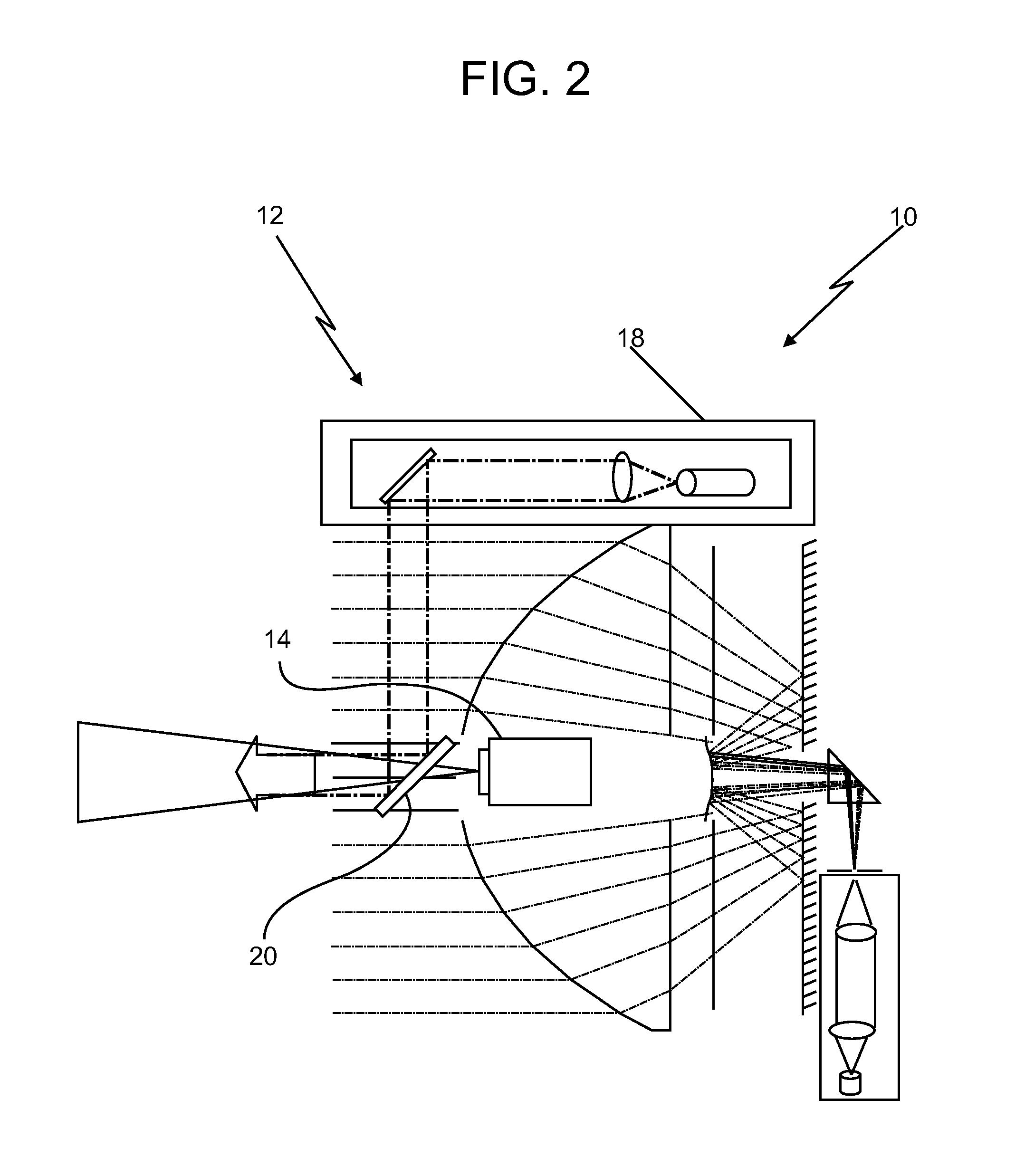

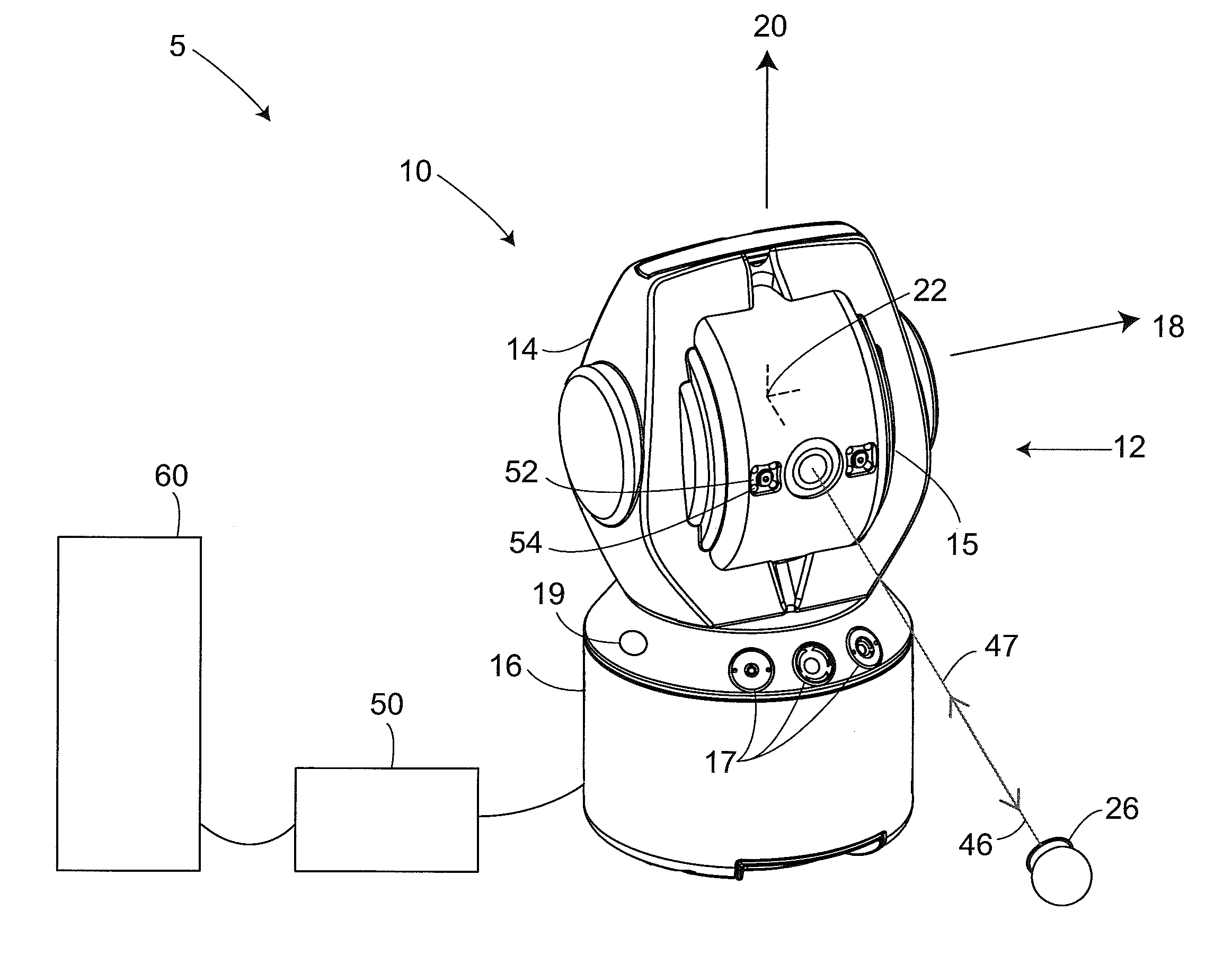

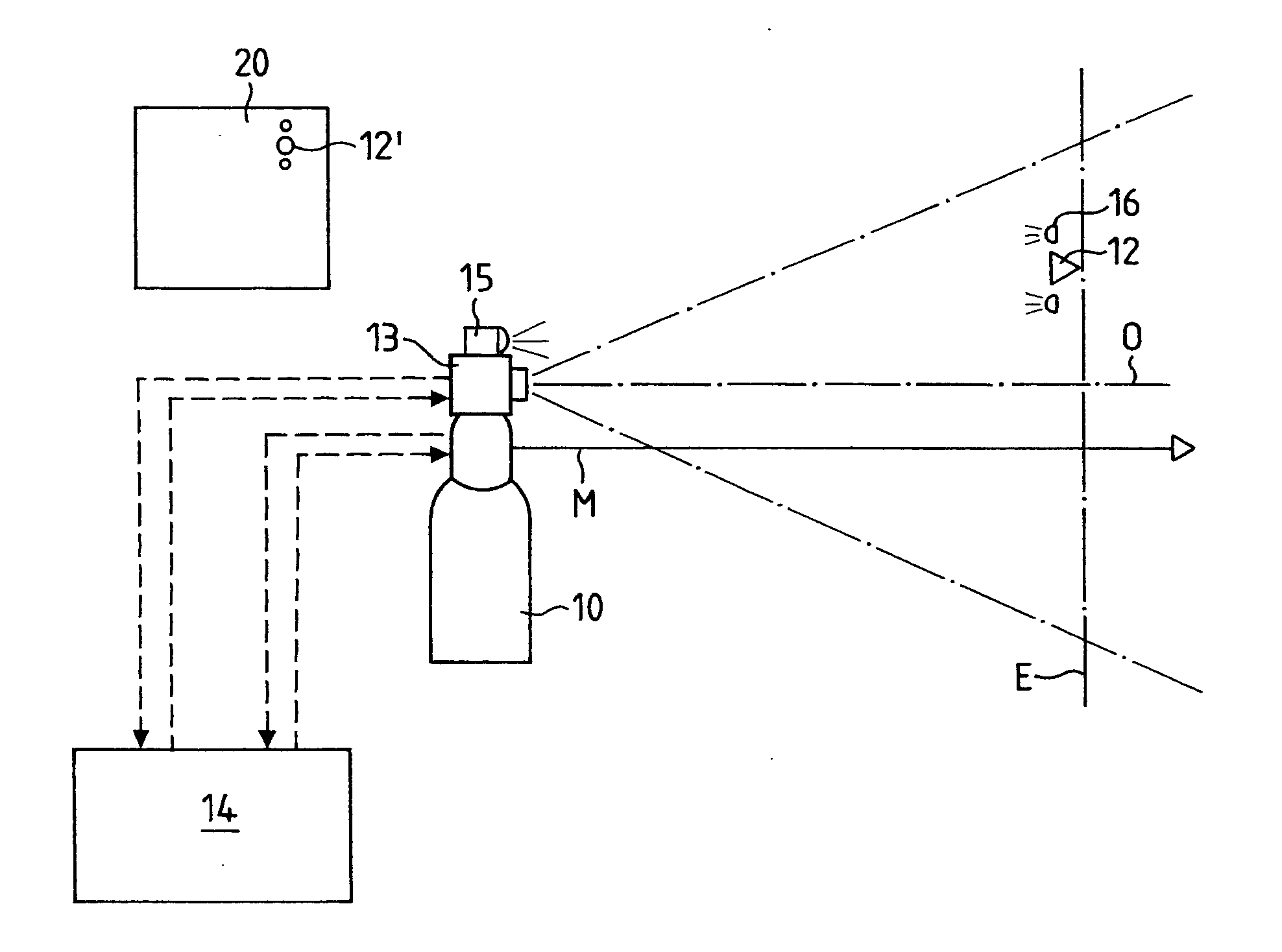

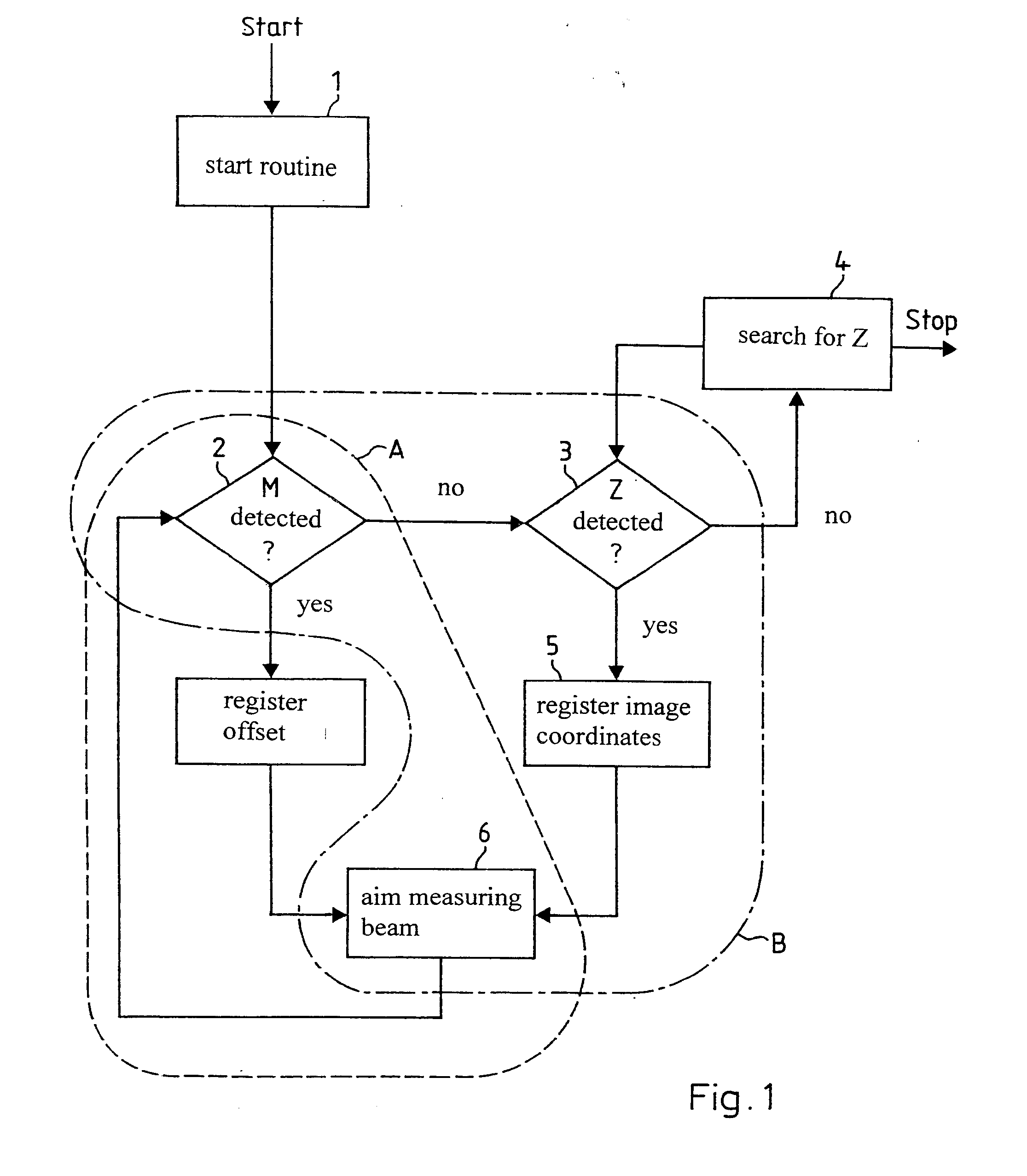

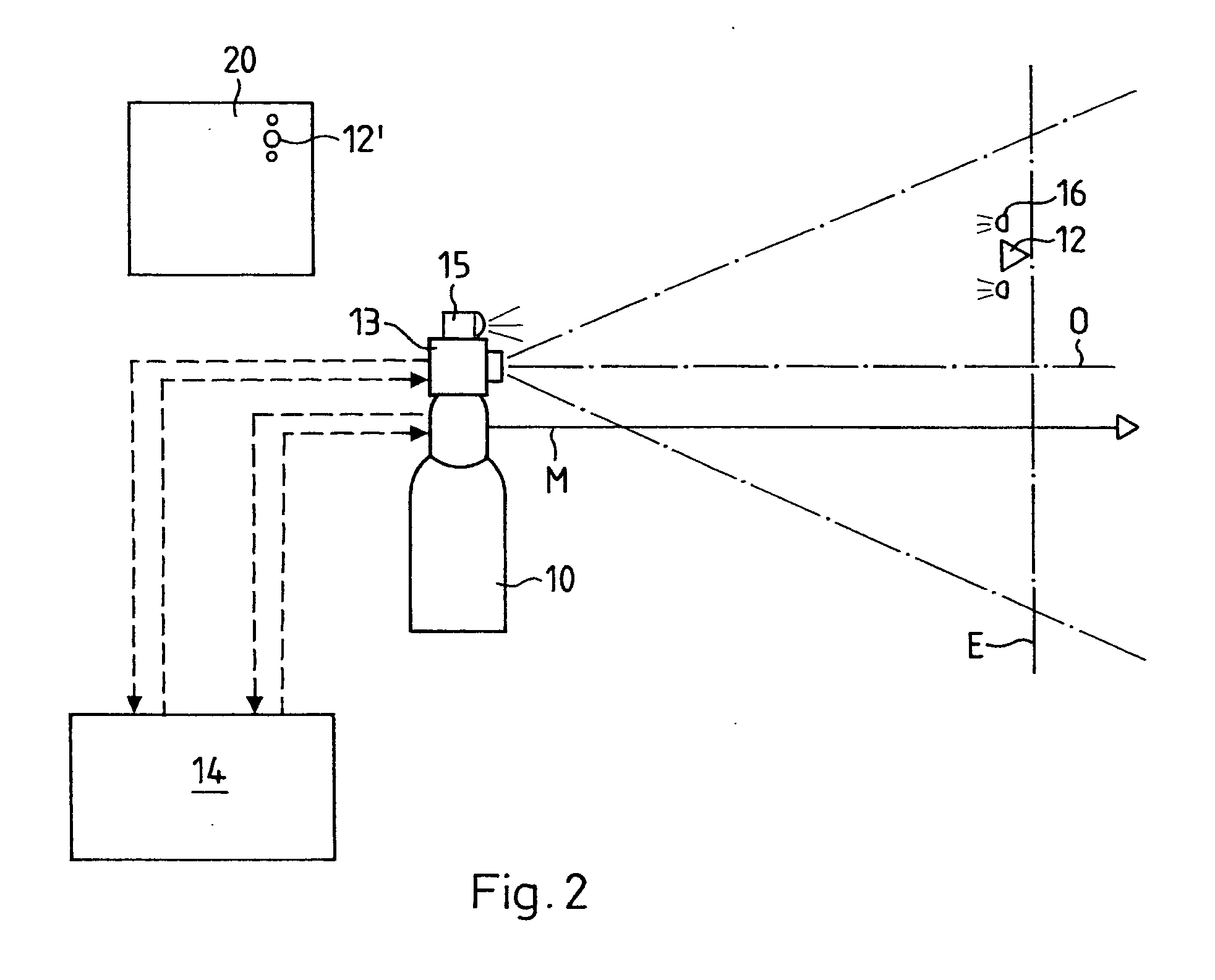

Tracking method and measuring system comprising a laser tracker

ActiveUS20110181872A1Angle measurementActive open surveying meansMeasurement deviceClassical mechanics

A measuring system includes a laser tracker (10), a target point marked by a reflector (12), a surveying apparatus (13), and an arithmetic and control unit (14). The laser tracker emits a measuring beam (M) which is reflected by the reflector, a process that is used for determining the distance between the laser tracker (10) and the reflector (12). The surveying apparatus has a known position and orientation relative to the measuring beam (M) while preferably being embodied as a survey camera. The inventive measuring system is designed so as to track the reflector (12) via the measuring beam (M). In a normal tracking mode (A), a measured value for controlling the orientation of the measuring beam (M) is derived from the detection of the measuring beam reflected by the reflector (12). If the measuring beam is not directed onto the reflector, the system switches to a special tracking mode in which the measured value for controlling the orientation of the measuring beam (M) is derived from an image (20) of the survey camera (13).

Owner:LEICA GEOSYSTEMS AG

Numerical control machine tool rotating shaft geometric error three-wire measurement method

InactiveCN103737426AHigh precisionEasy to operateMeasurement/indication equipmentsNumerical controlRotational axis

Disclosed is a numerical control machine tool rotating shaft geometric error three-wire measurement method. High-accuracy calibration of space coordinates of a laser tracker base station can be rapidly finished by the aid of a cat eye and a rotatable cat eye bracket, the influence of a machine tool system error is eliminated by calibration accuracy, rotating movement of three fixed points of a single rotating shaft of a machine tool around an axial line is successively measured at four different measurement positions by the aid of one laser tracker, the cat eye and the rotatable cat eye bracket, real-time poses of the rotating shaft are calculated by the aid of continuous movement tracks of the three fixed points in a space, errors of the rotating shaft of the machine tool are identified, acquired information of the machine tool is rich as the real-time poses of the moving shaft are measured, an error identification algorithm is quite simple and applicable to rapid data processing and rapid compensation of the machine tool errors. The numerical control machine tool rotating shaft geometric error three-wire measurement method has the advantages of low cost, high accuracy, rapidness and simplicity in operation, rich measurement information and the like, and is suitable for accuracy detection in the field of numerical control machine tools.

Owner:XI AN JIAOTONG UNIV

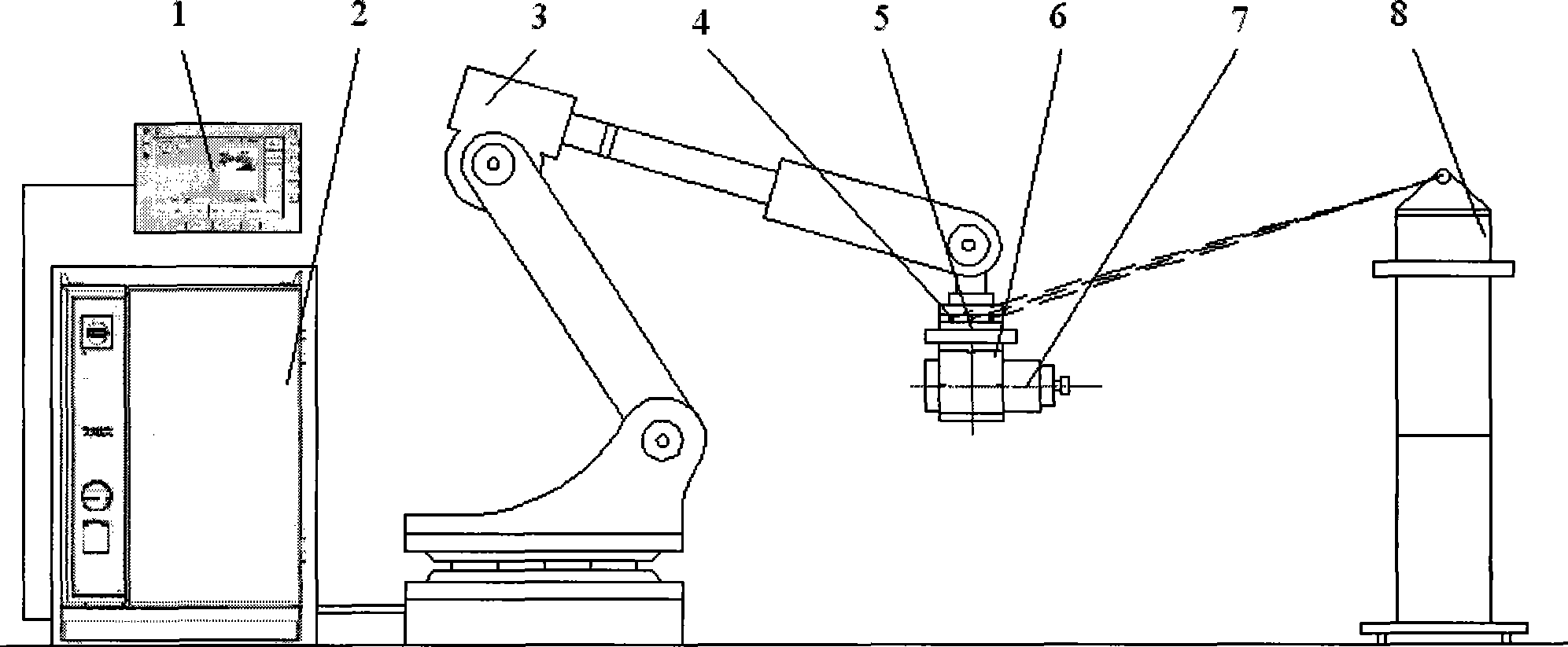

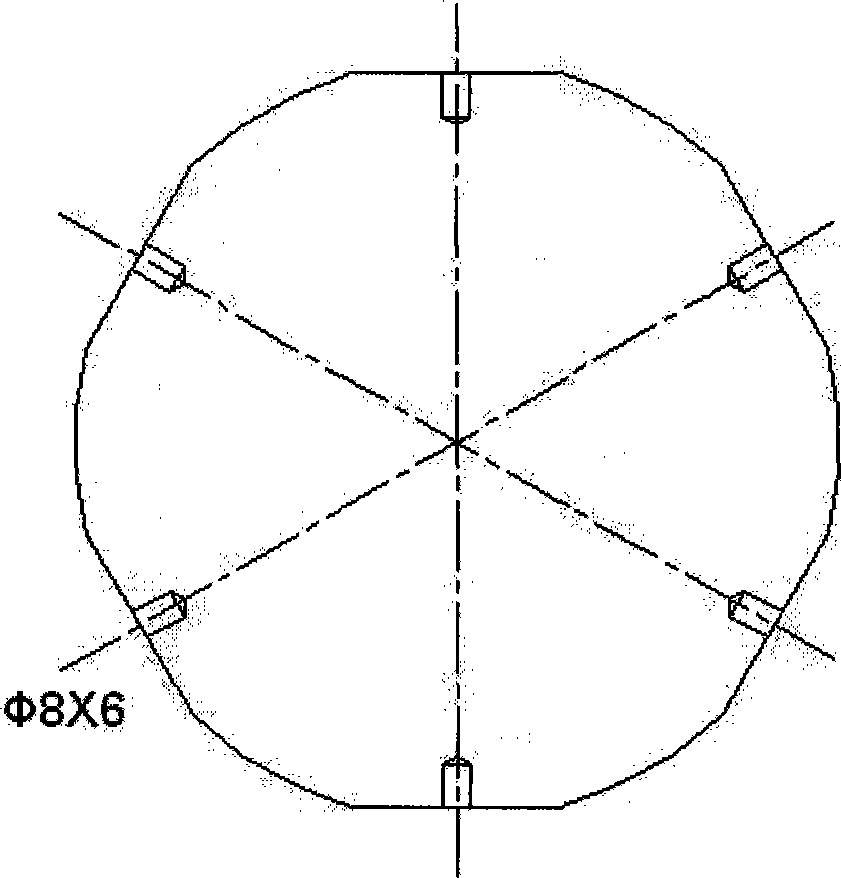

Industrial robot cutting and processing system applied to auxiliary assembly of airplane as well as method

InactiveCN101372079ARealize cutting functionMeet the machining accuracy requirementsMeasurement/indication equipmentsLarge fixed membersEngineeringLaser tracker

The invention discloses an industrial robot cutting processing system and a method applied to aircraft auxiliary assembly, comprising a six-axis joint typed industrial robot, a robot controller, an operation panel, a high speed electric mainshaft, a tool clamping process device, a tool quick exchanger, a target installation flange and a laser tracker; high speed cutting technique is adopted; process methods and hole preparing process of boring, reaming by milling and final reaming are sequentially carried out so as to improve the diameter precision of the hole; meanwhile, the cutting force can be controlled by finishing the reaming hole; rough milling is carried out firstly, fine milling is subsequently carried out; furthermore, the cutting depth is not more than 0.15mm during the fine milling process, thus ensuring the planeness of the processing surface; the industrial robot cutting processing system can realize various cutting processes of the soft metal (such as aluminium alloy) as follows: boring, hole enlarging, reaming, dimpling, surface milling, cutting, etc. The invention integrates normal robot, high speed electric mainshaft, quick exchanger, etc., and can solve the cutting process problems of operations such as fine processing, skin cutting, and the like of radar cover installation hole in the field of aircraft assembly.

Owner:ZHEJIANG UNIV +1

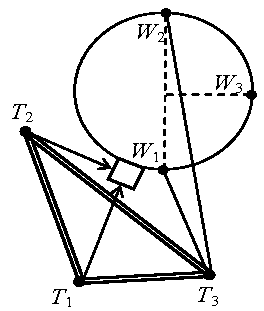

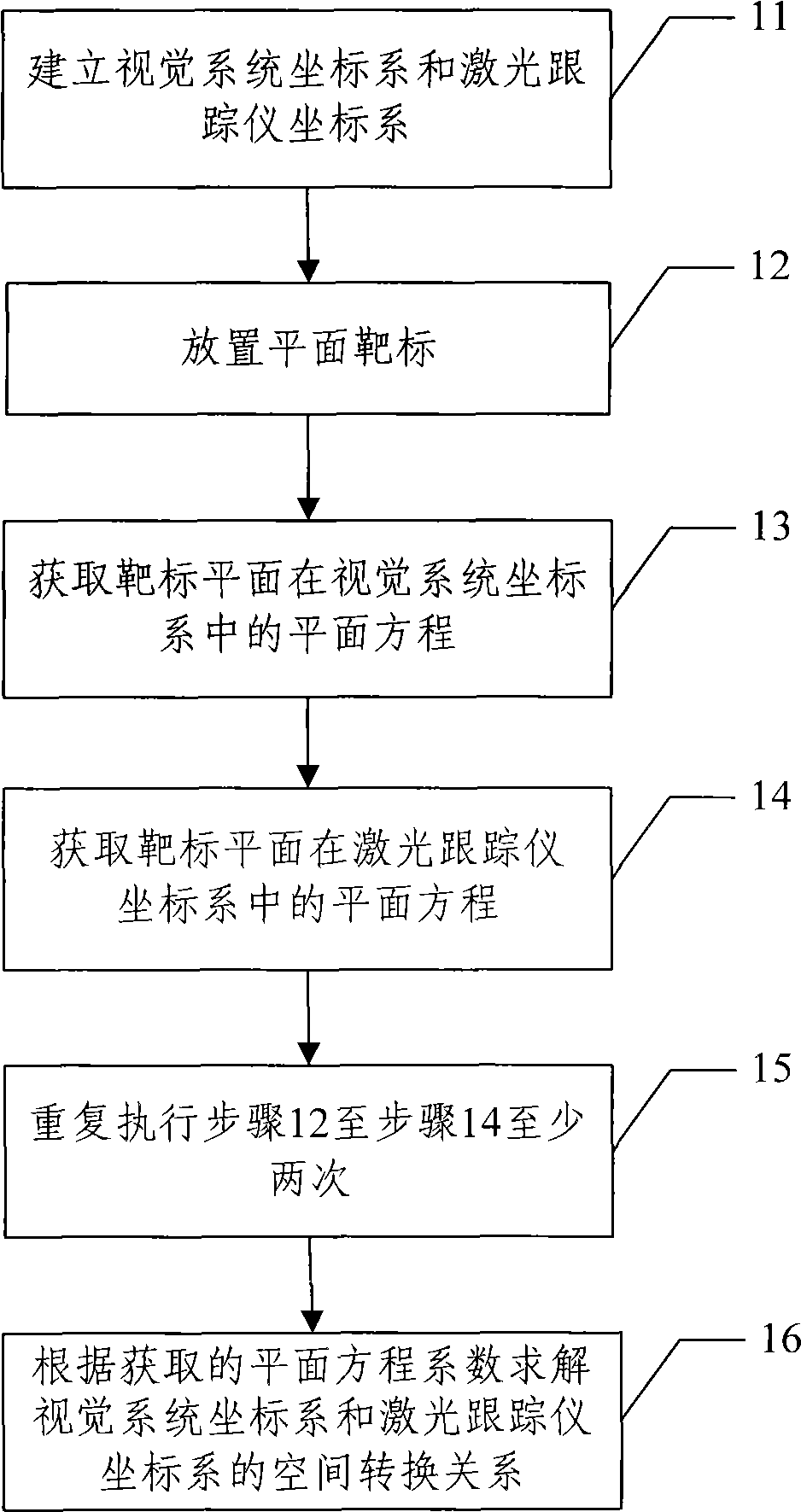

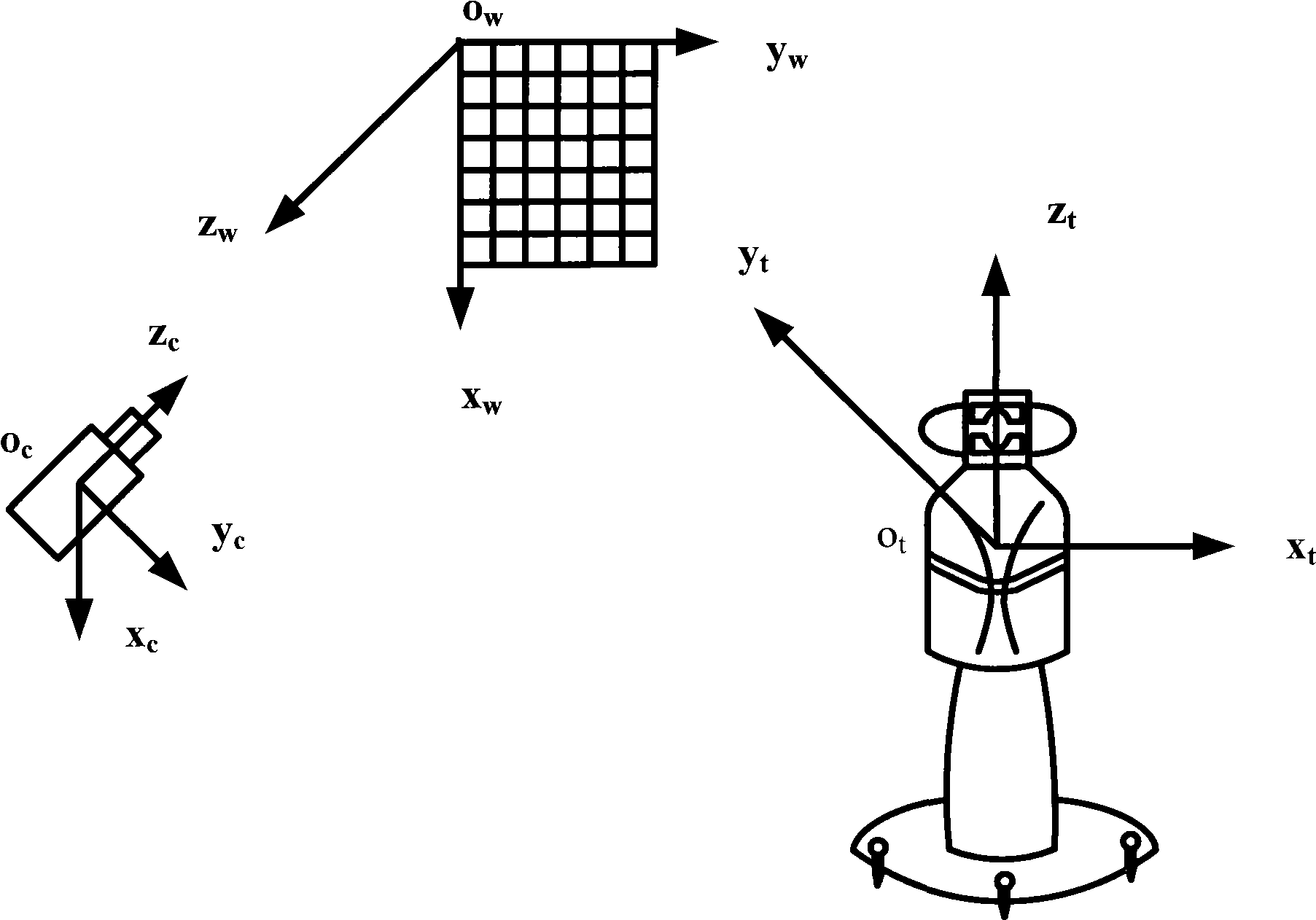

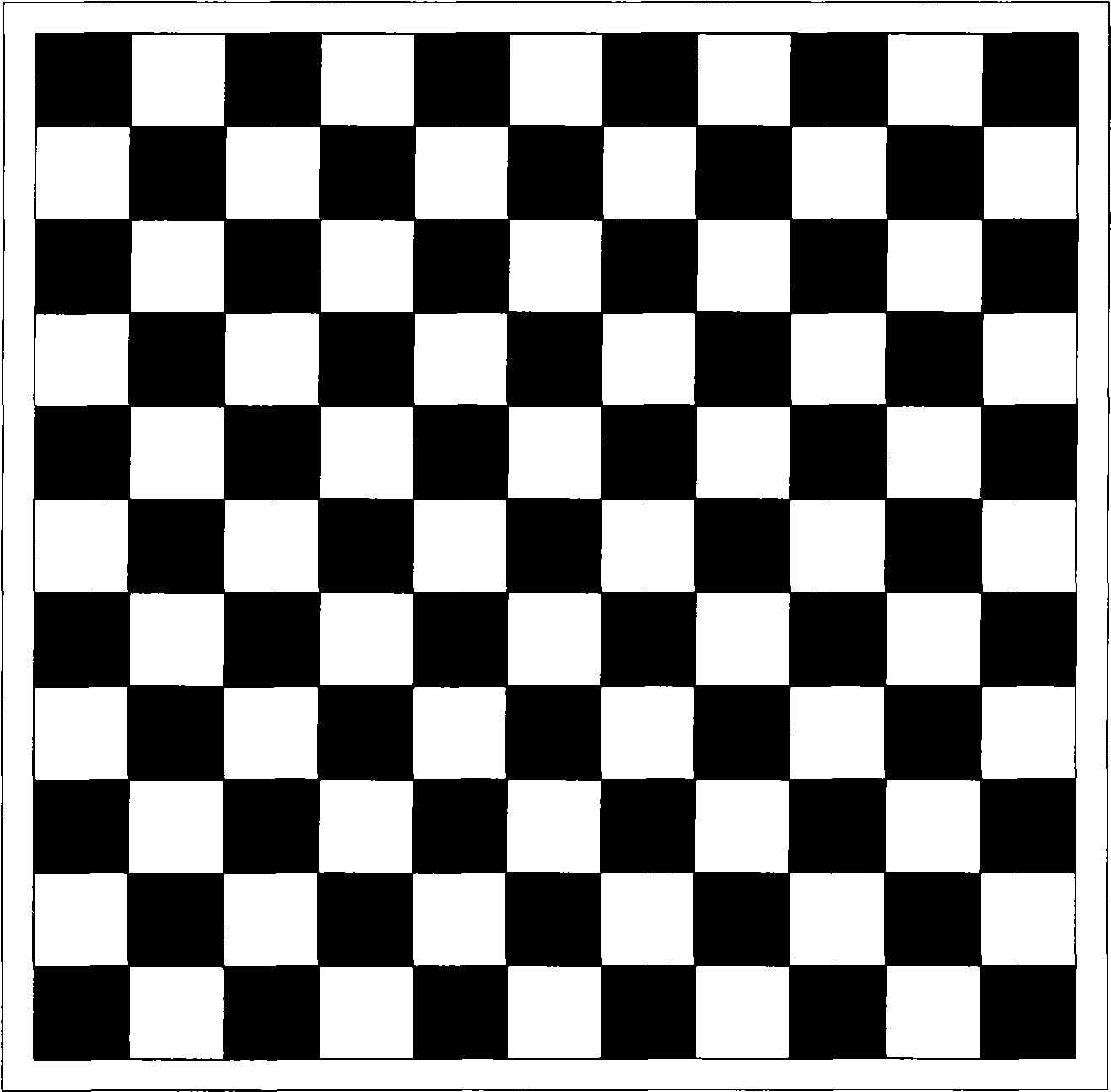

Global calibration method of laser tracking visual guidance measurement system

InactiveCN101532821AGlobal Calibration ImplementationImplement automatic assemblyUsing optical meansButt jointPlane equation

A global calibration method of a laser tracking visual guidance measurement system comprises the steps of determining a visual system coordinate system and a laser tracker coordinate system; putting a plane target for at least three times and obtaining plane equations of the target plane, where the plane target is located in the visual system coordinate system and the laser tracker coordinate system at each putting position; and calculating a spatial transformation relation of the visual system coordinate system and the laser tracker coordinate system according to the coefficients of the obtained plane equations. The global calibration method of a laser tracking visual guidance measurement system in the invention realizes the global calibration of the laser tracking visual guidance measurement system by obtaining the plane equations of the target plane in the visual system coordinate system and the laser tracker coordinate system at the at least three positions of the plane target, so as to realize automatic assembly and butt joint of large-sized components, to improve assembly efficiency, and to save assembly cost.

Owner:BEIHANG UNIV

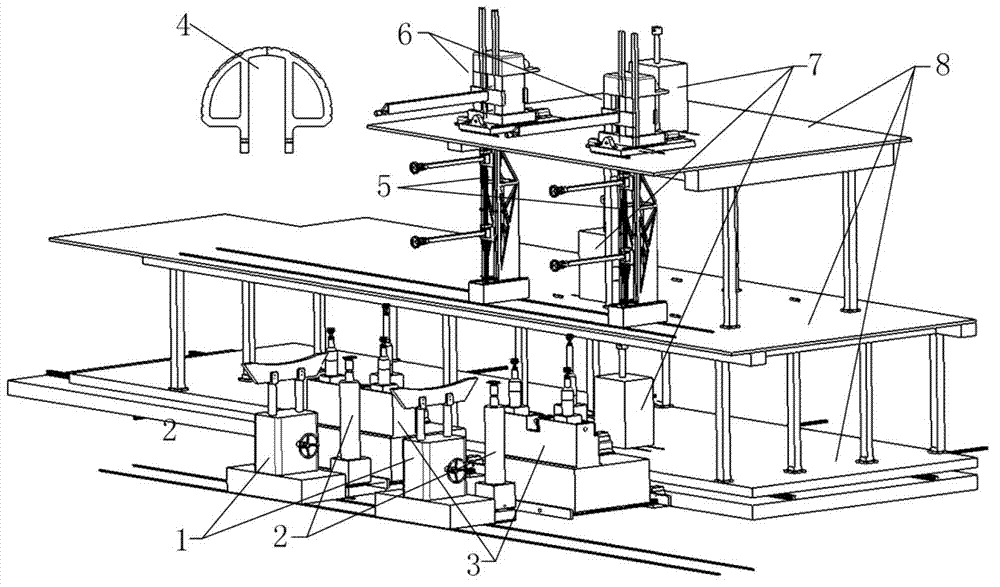

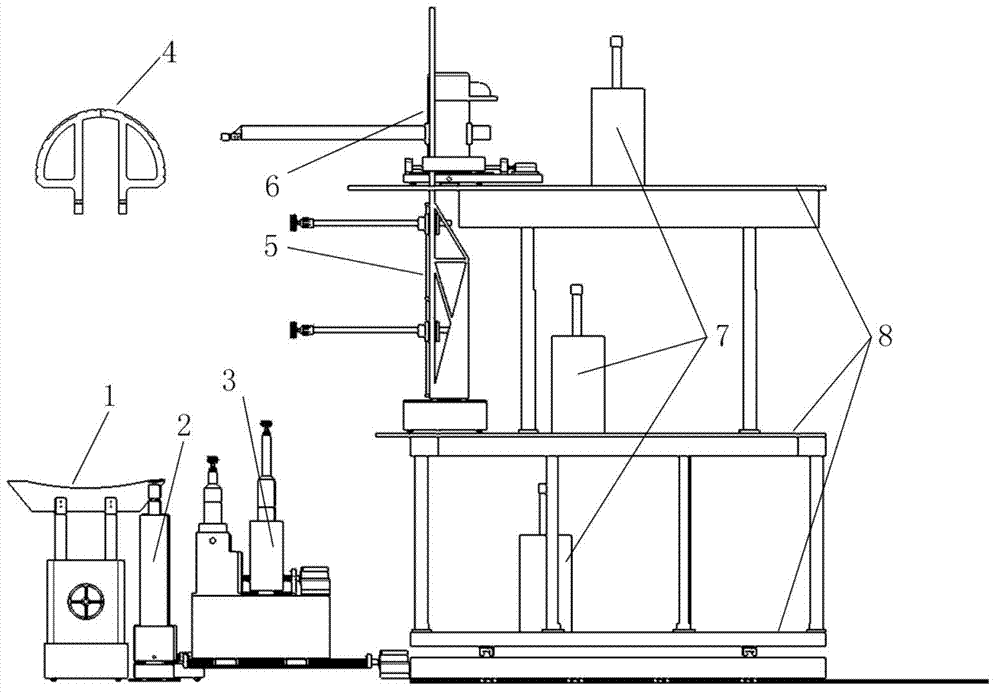

Method and device for folding and flexibly positioning body wallboard

ActiveCN102765489AAchieve six degrees of freedomRealize multi-posture adjustmentAircraft assemblyLaser trackerFuselage

The invention provides a method and a device for folding and flexibly positioning a body wallboard. Due to the method and the tool for folding and flexibly positioning the body wallboard, lots of special clamping boards are not needed and good flexibility is achieved; a positioner clamping mechanism can be adsorbed on a positioning support surface of the wallboard, so that six-freedom-degree and multi-pose regulation of the body wallboard can be achieved; laser trackers distributed on a first layer of working table, a second layer of working table and a third layer of working table can feed back assembling information at real time, thus drastically improving assembly accuracy; the body wallboard is fixed by the adsorption positioning mechanism, thus being simple in assembly and disassembly, reducing manual operation and improving assembly efficiency; and in addition, the method and the device have good generality, so that the method and the device can be suitable for folding process of body wallboard structures with different sizes and satisfy folding requirement of various body wallboards.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com