Patents

Literature

45results about How to "Accurate repeatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Maternal-fetal monitoring system

ActiveUS20050267376A1Less riskEliminate the problemElectrocardiographyElectromyographyObstetricsNeural network system

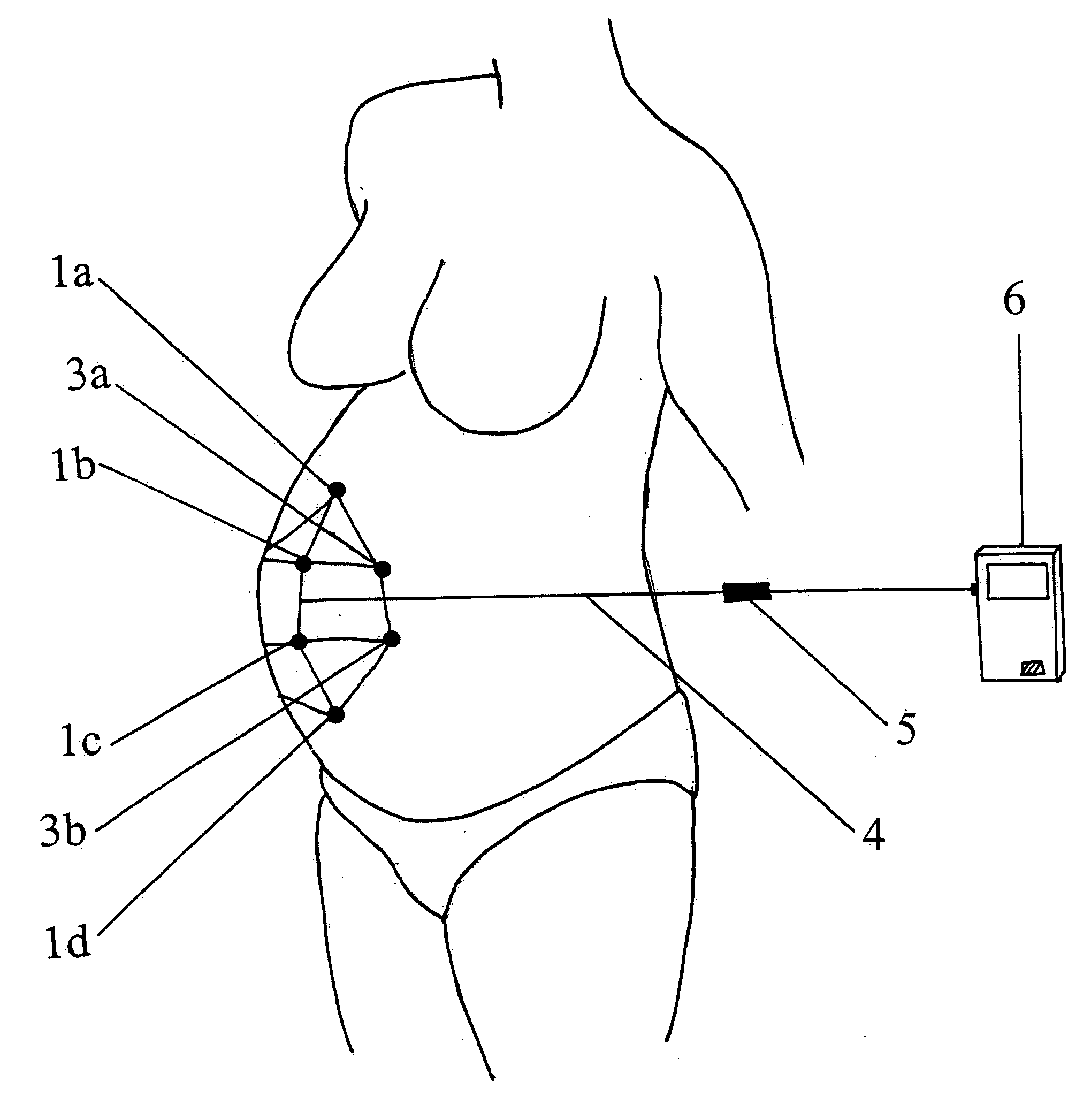

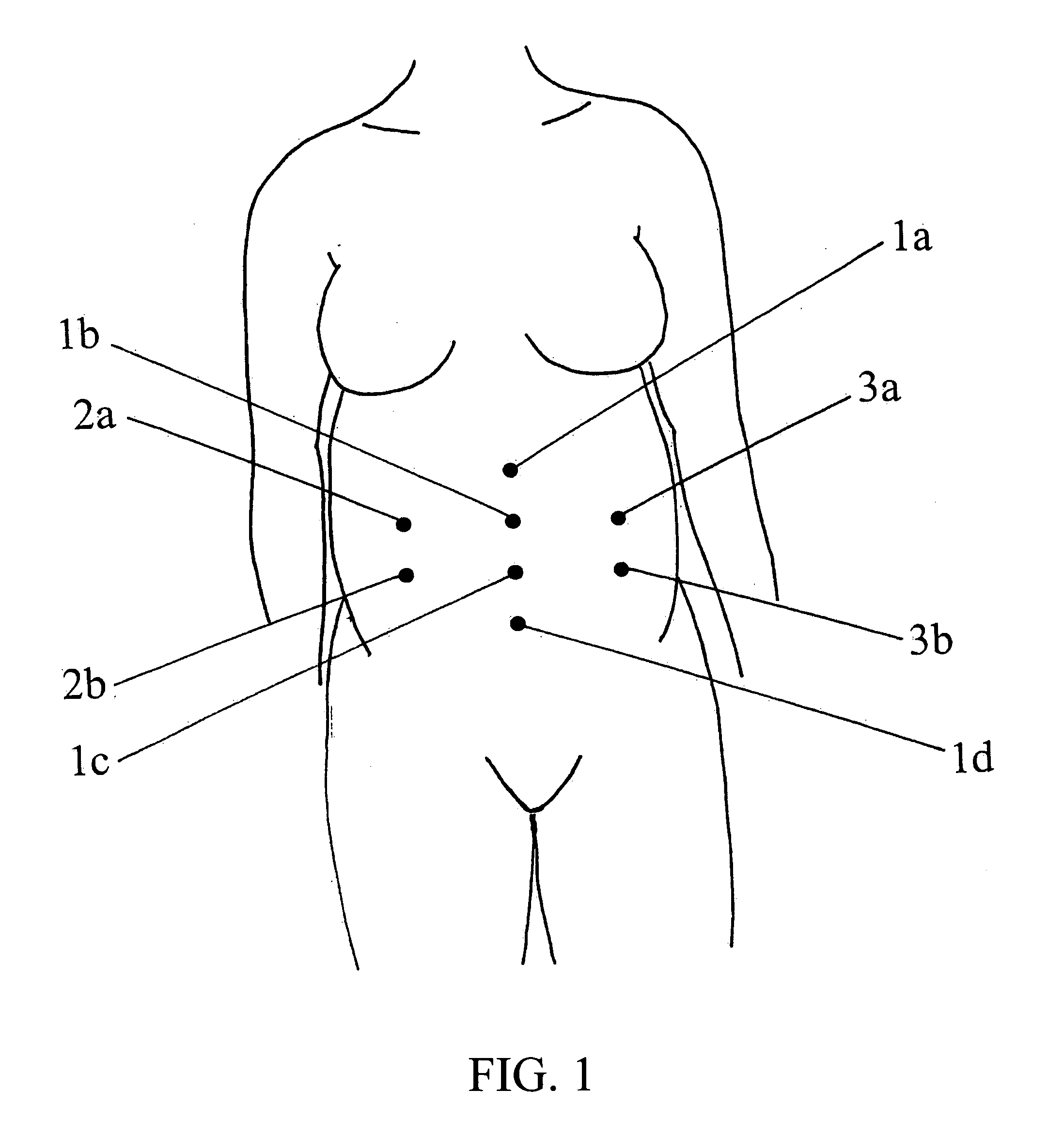

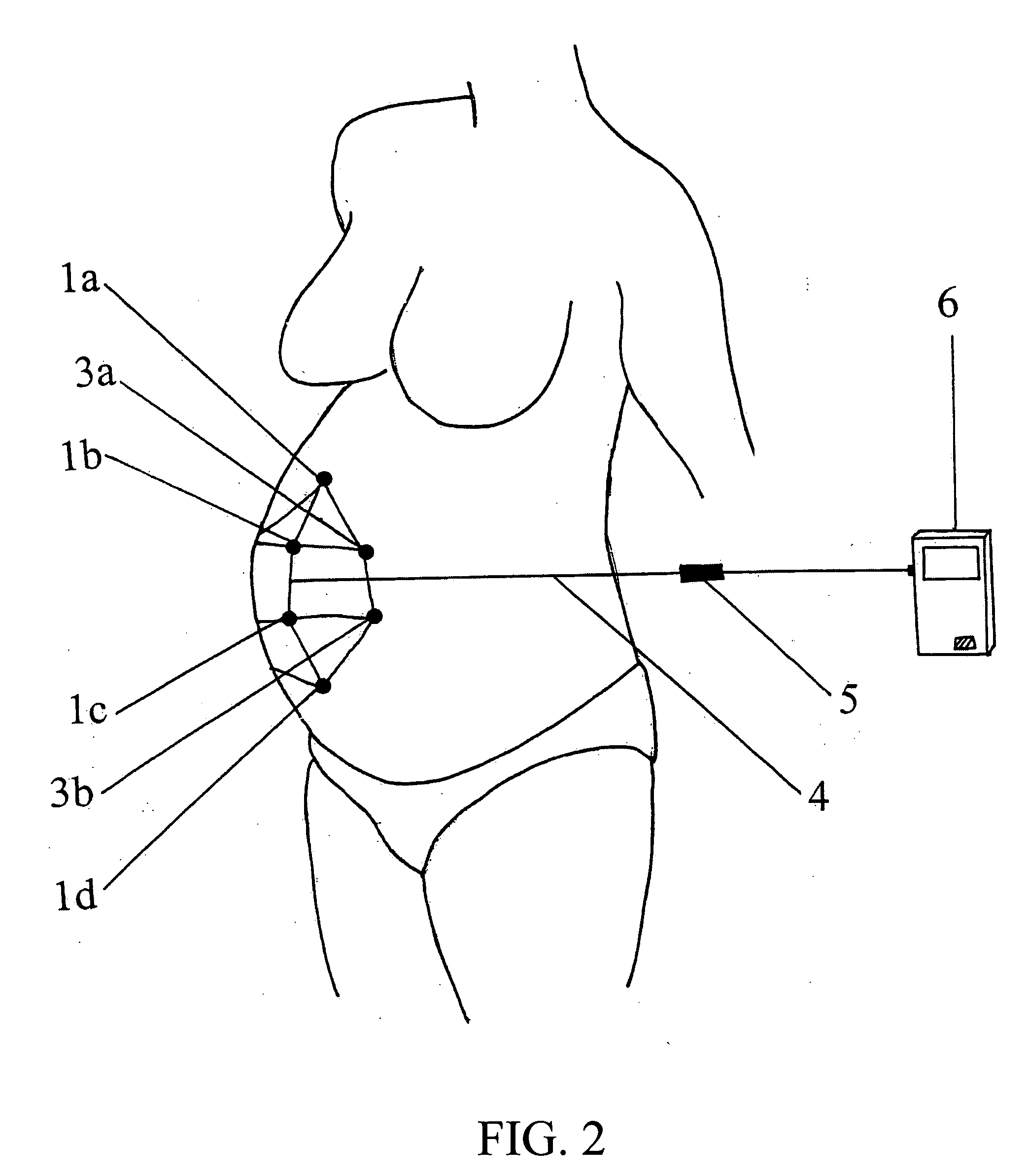

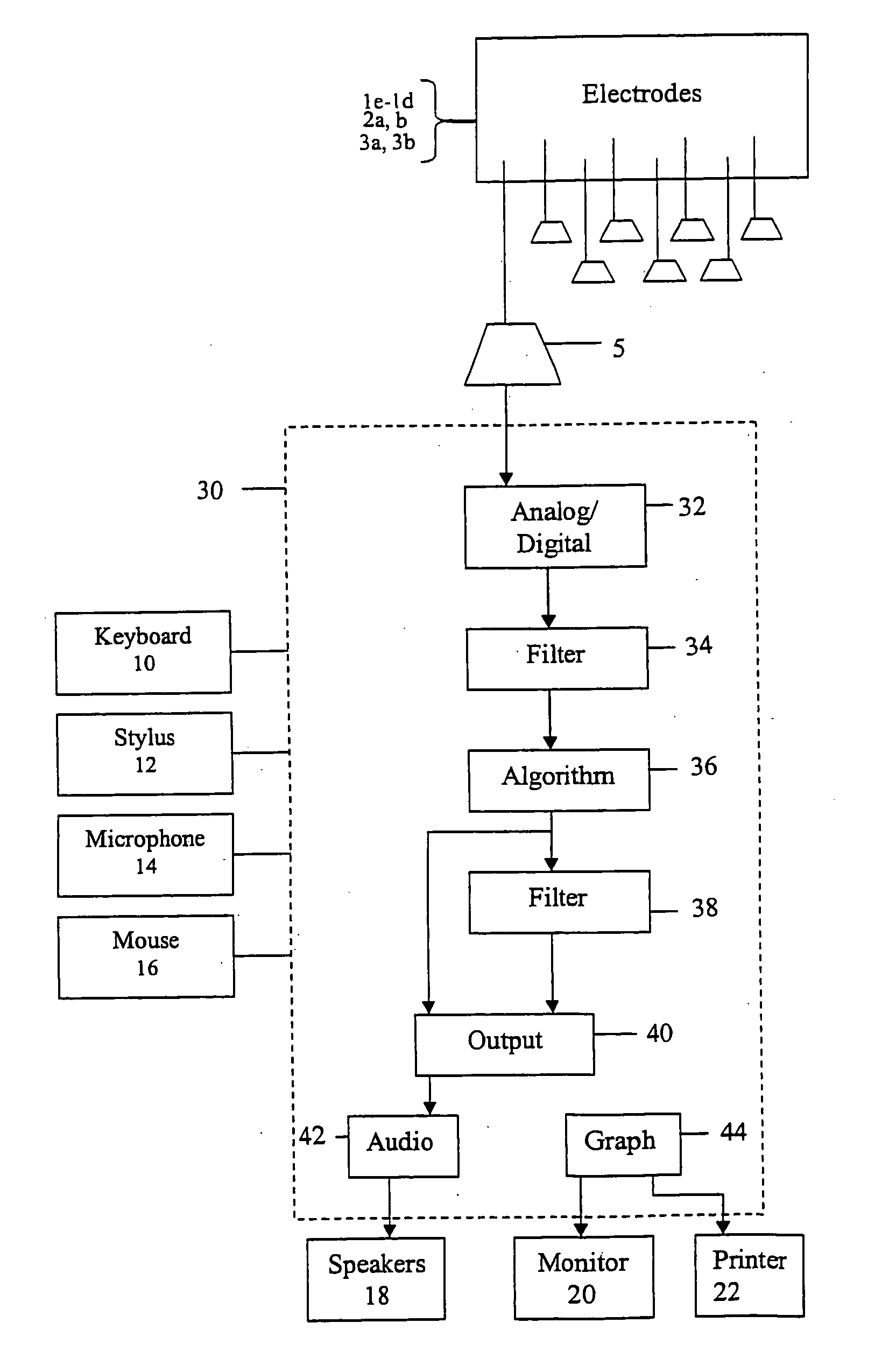

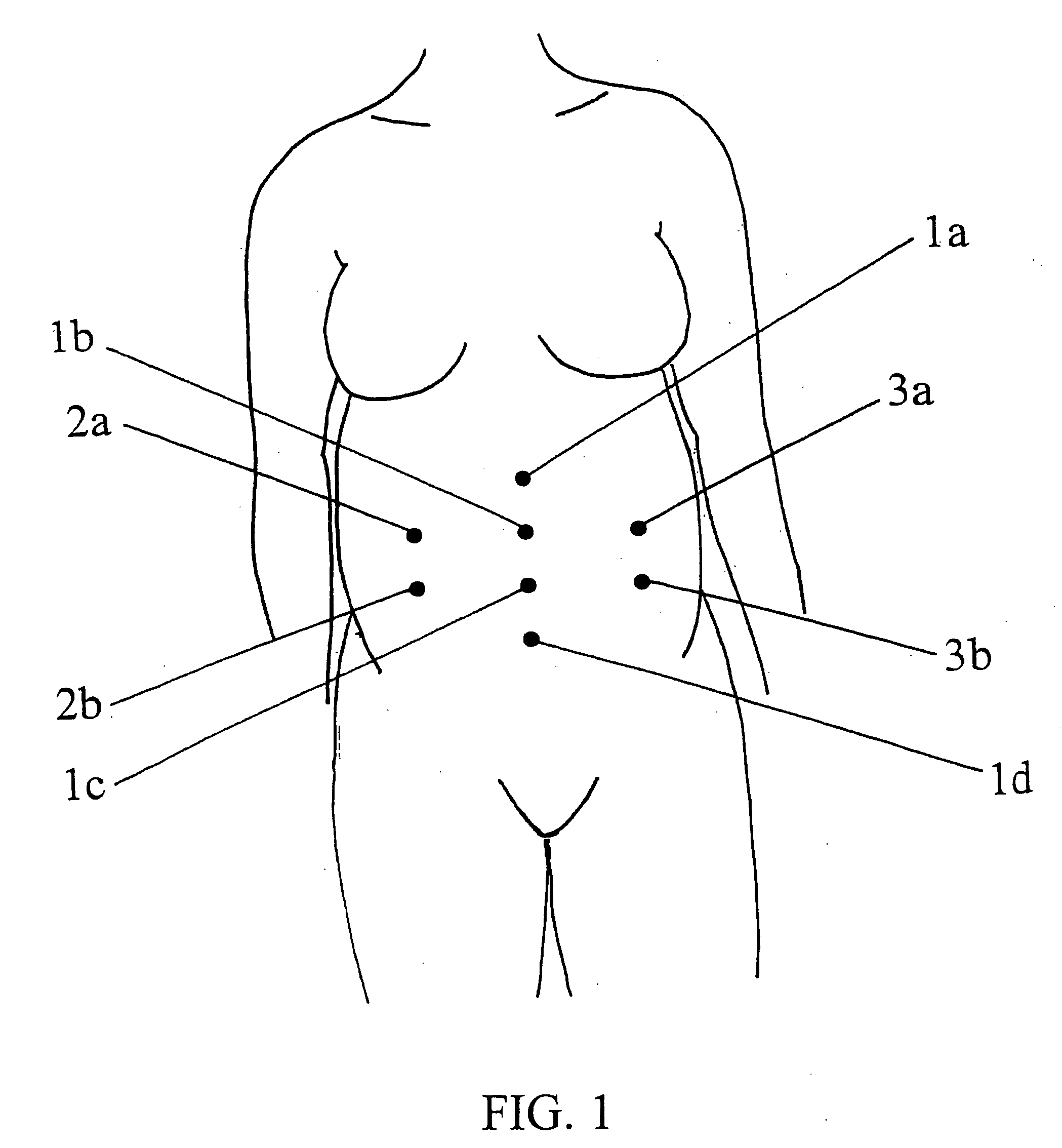

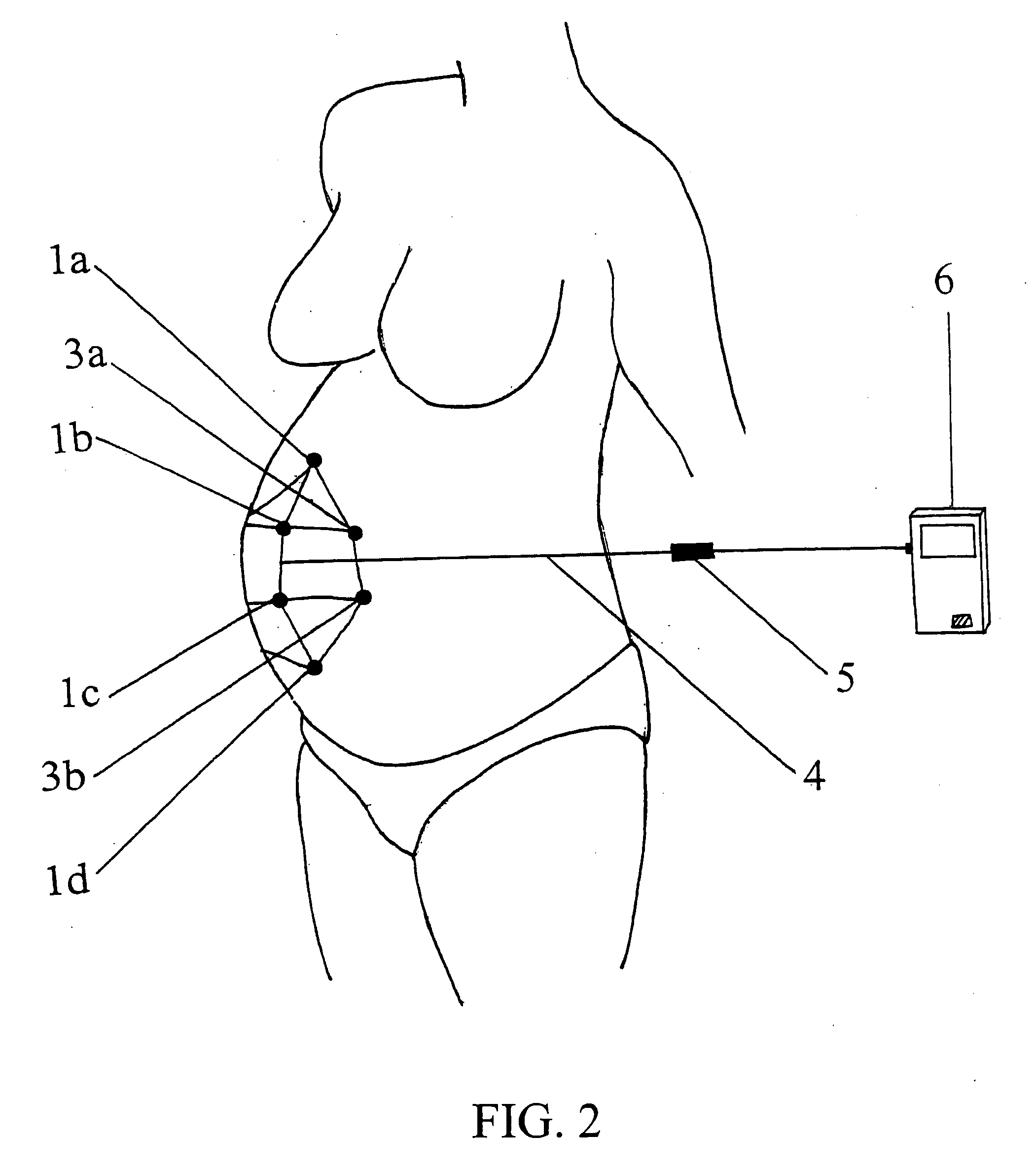

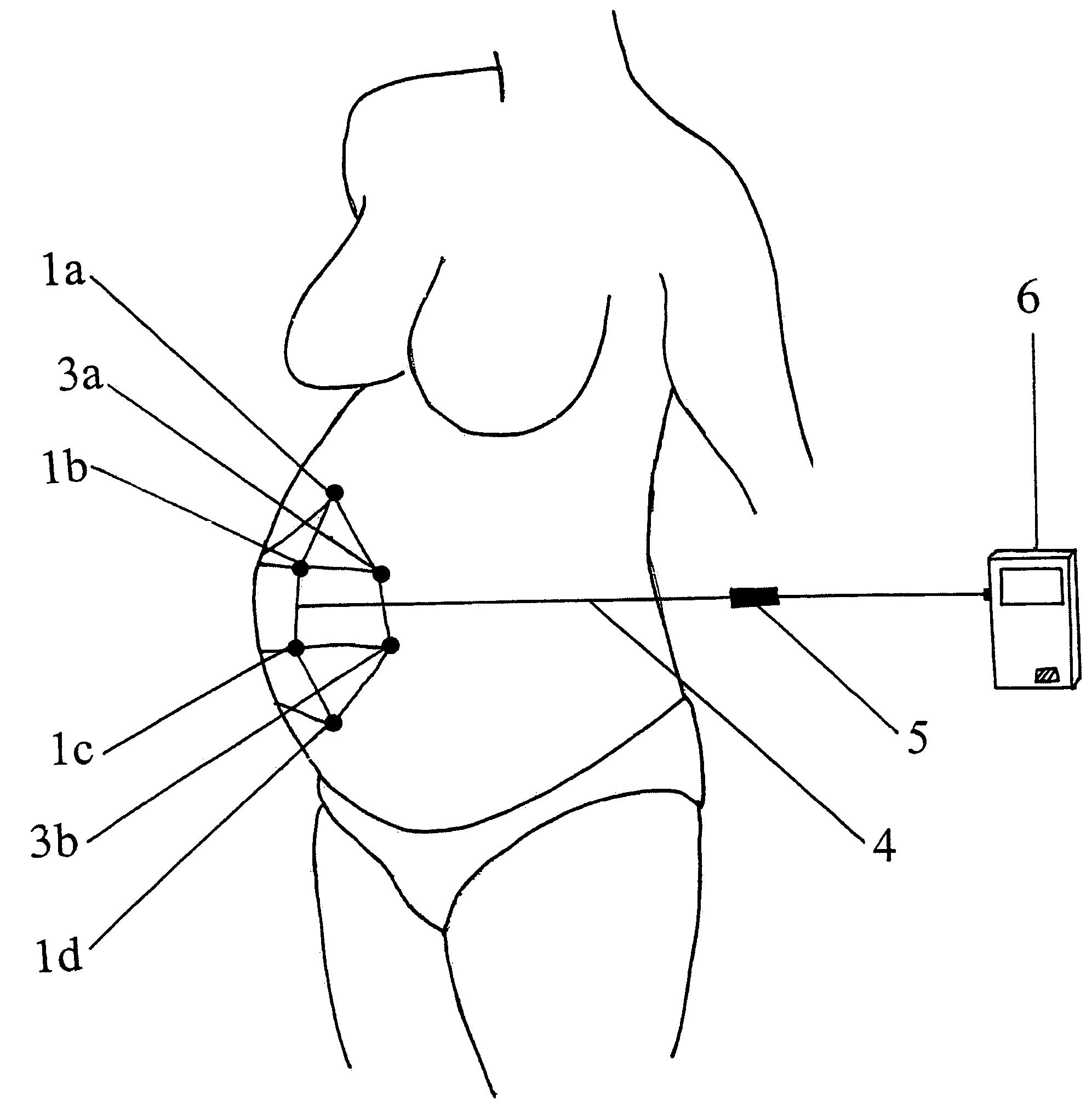

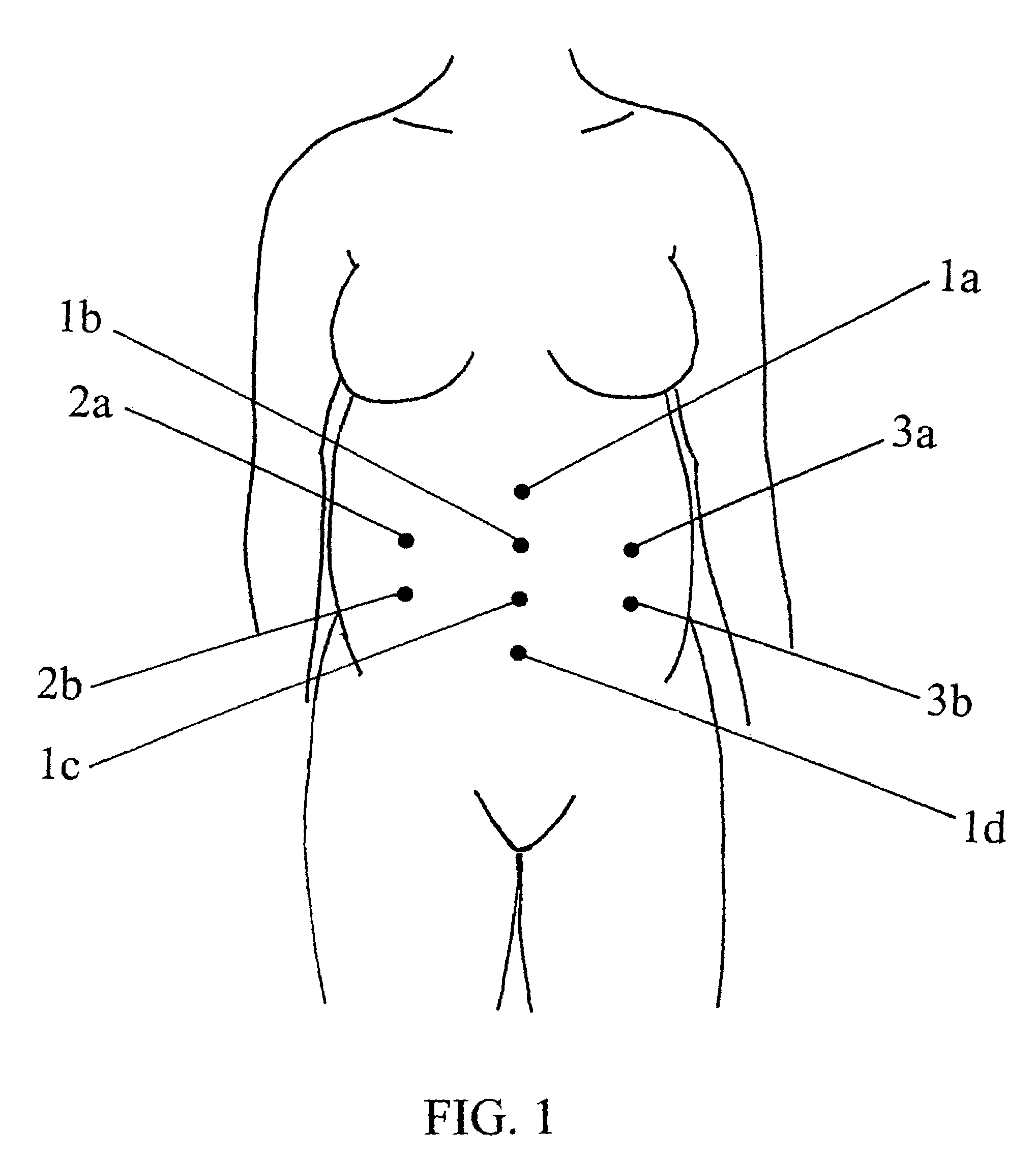

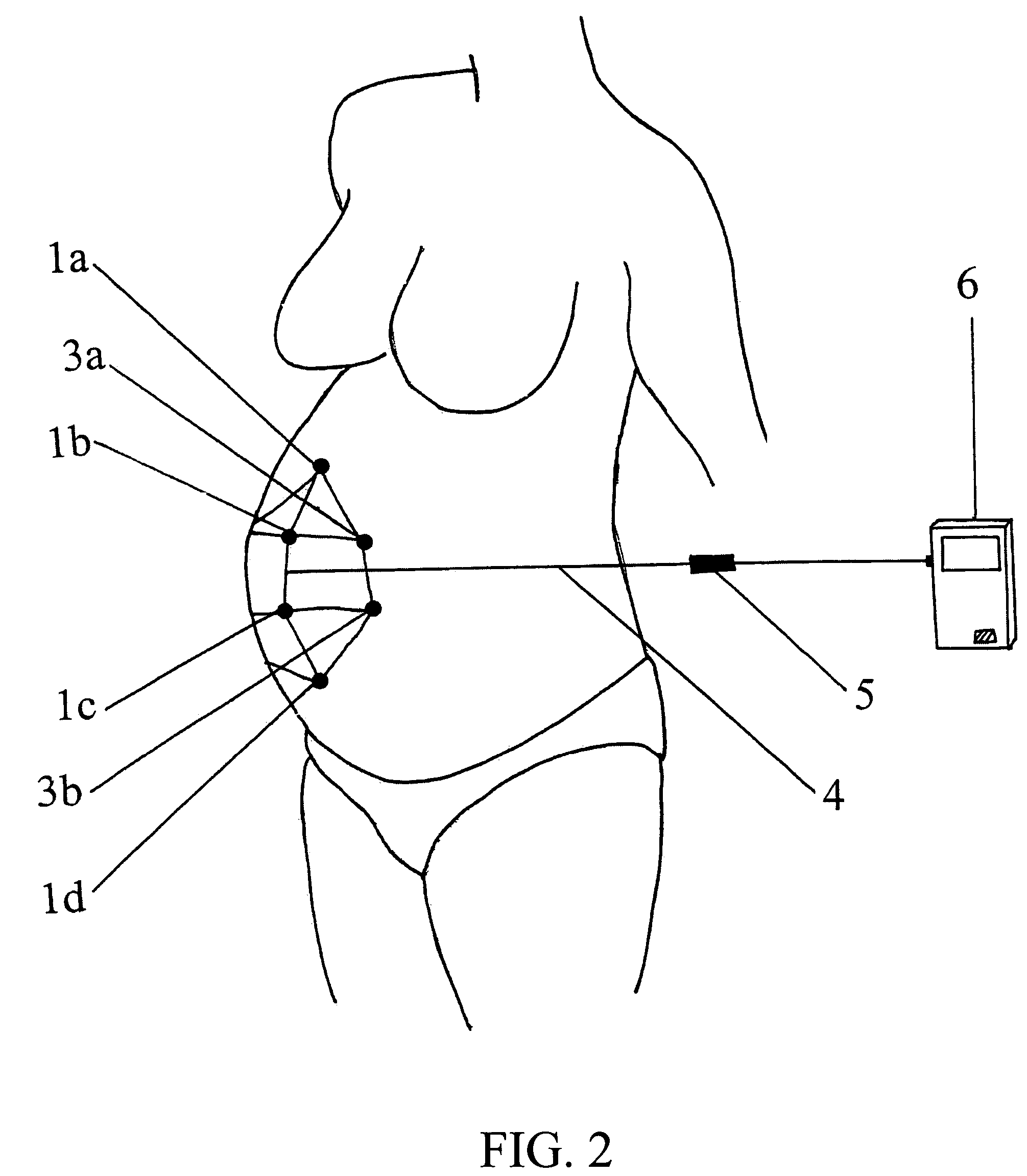

A maternal-fetal monitoring system for use during all stages of pregnancy, including antepartum and intrapartum stages. The maternal-fetal monitoring system of the subject invention comprises (1) a set of sensors; (2) an amplifying / filtering means; (3) a computing means; and (4) a graphical user interface. Accurate clinical data, which can be extracted and provided to the user in real-time using the system of the invention, include without limitation, maternal electrocardiogram (ECG) signals, maternal uterine activity signals (EHG), maternal heart rate, fetal ECG signals, and fetal heart rate. In a preferred embodiment, the maternal-fetal monitoring system of the invention includes an intelligence means, such as a neural network system, to analyze and interpret clinical data for use in clinical diagnosis antepartum, intrapartum and postpartum, as well as delivery strategy.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

Maternal-fetal monitoring system

ActiveUS20050267377A1Accurate repeatabilityImprove signal qualityElectrocardiographyElectromyographyObstetricsNeural network system

A maternal-fetal monitoring system for use during all stages of pregnancy, including antepartum and intrapartum stages. The maternal-fetal monitoring system of the subject invention comprises (1) a set of sensors; (2) an amplifying / filtering means; (3) a computing means; and (4) a graphical user interface. Accurate clinical data, which can be extracted and provided to the user in real-time using the system of the invention, include without limitation, maternal electrocardiogram (ECG) signals, maternal uterine activity signals (EHG), maternal heart rate, fetal ECG signals, and fetal heart rate. In a preferred embodiment, the maternal-fetal monitoring system of the invention includes an intelligence means, such as a neural network system, to analyze and interpret clinical data for use in clinical diagnosis antepartum, intrapartum and postpartum, as well as delivery strategy.

Owner:CONVERGENT ENG +1

Maternal-fetal monitoring system

ActiveUS7333850B2Accurate repeatabilityImprove signal qualityElectrocardiographyElectromyographyObstetricsNeural network system

A maternal-fetal monitoring system for use during all stages of pregnancy, including antepartum and intrapartum stages. The maternal-fetal monitoring system of the subject invention comprises (1) a set of sensors; (2) an amplifying / filtering means; (3) a computing means; and (4) a graphical user interface. Accurate clinical data, which can be extracted and provided to the user in real-time using the system of the invention, include without limitation, maternal electrocardiogram (ECG) signals, maternal uterine activity signals (EHG), maternal heart rate, fetal ECG signals, and fetal heart rate. In a preferred embodiment, the maternal-fetal monitoring system of the invention includes an intelligence means, such as a neural network system, to analyze and interpret clinical data for use in clinical diagnosis antepartum, intrapartum and postpartum, as well as delivery strategy.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

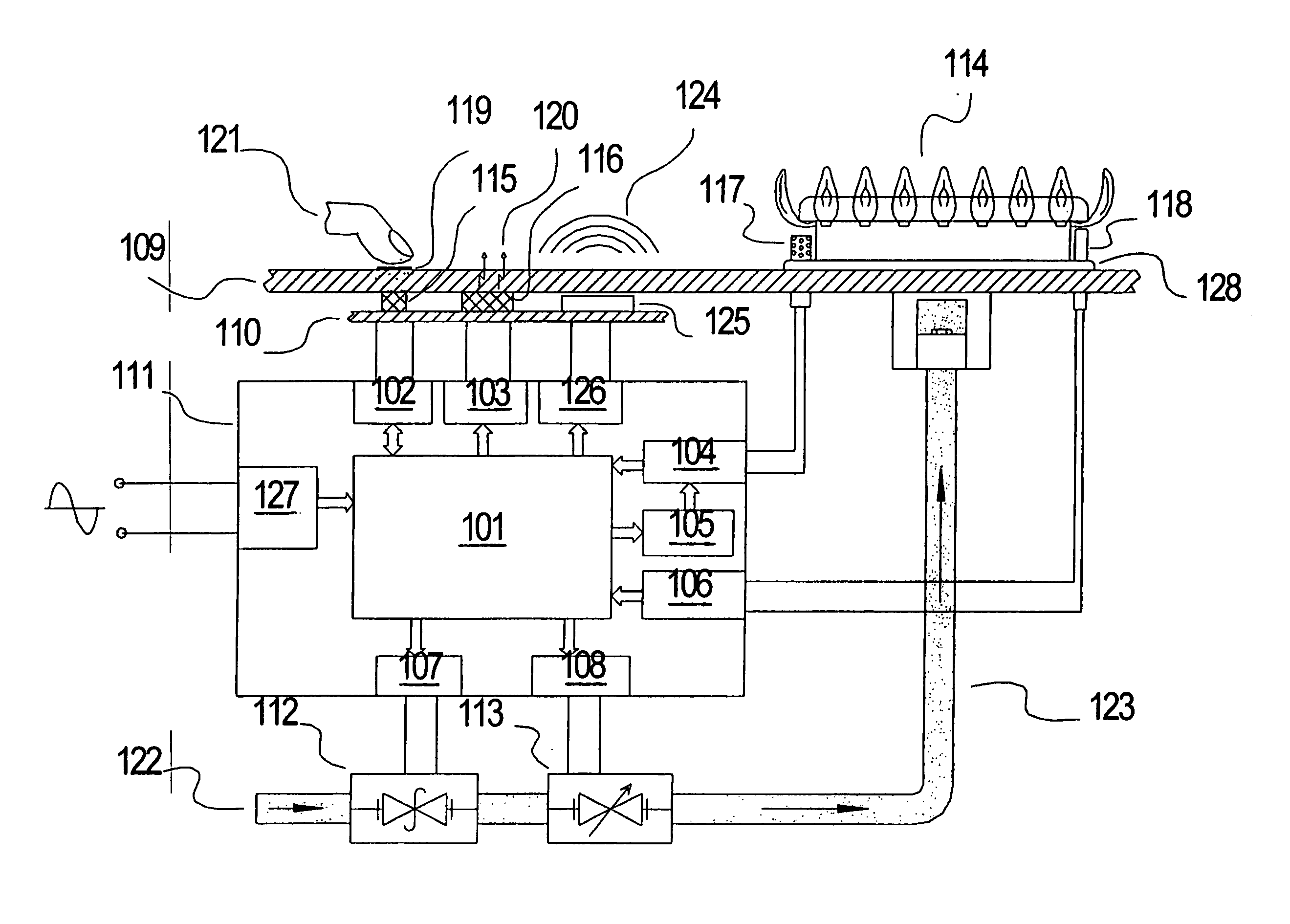

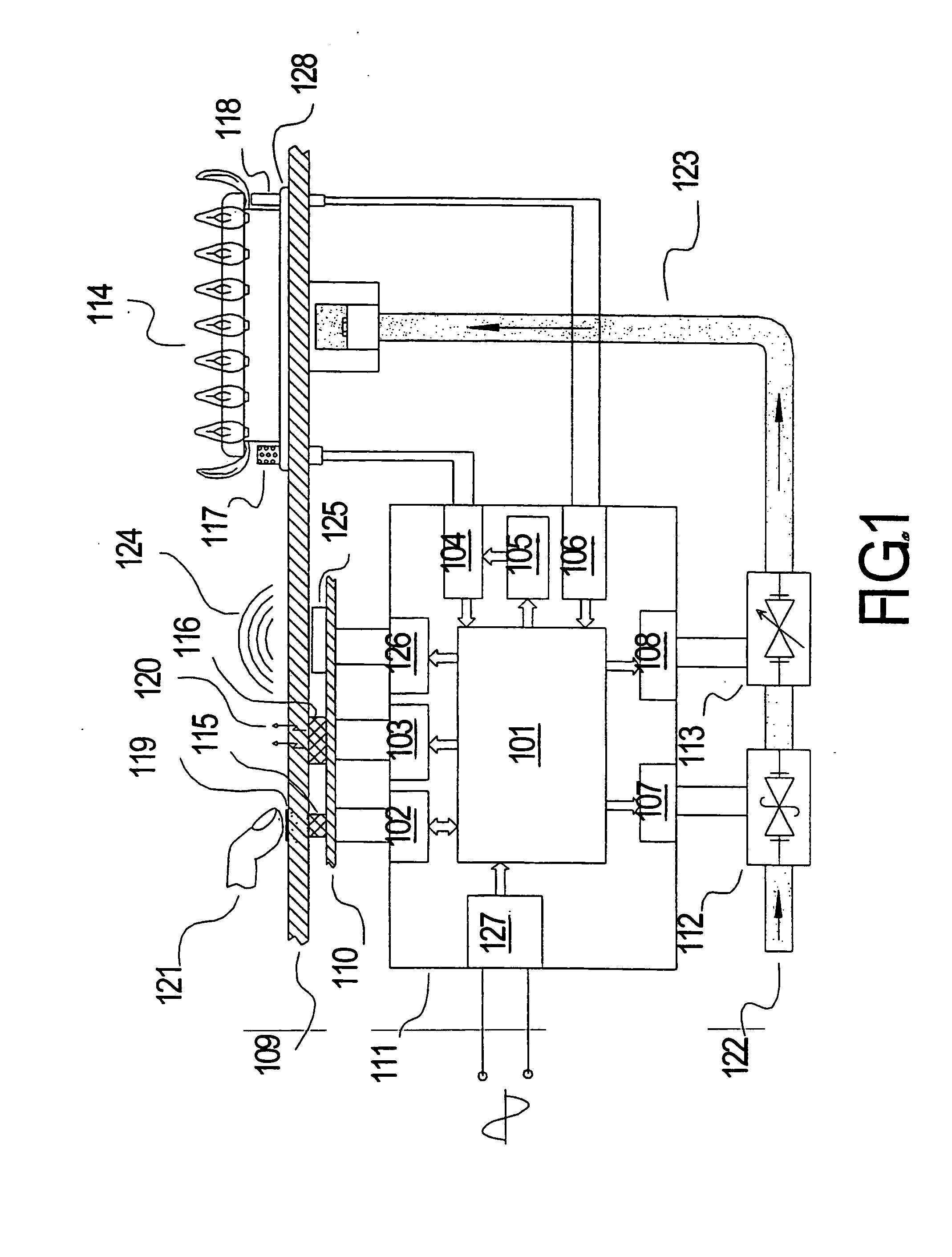

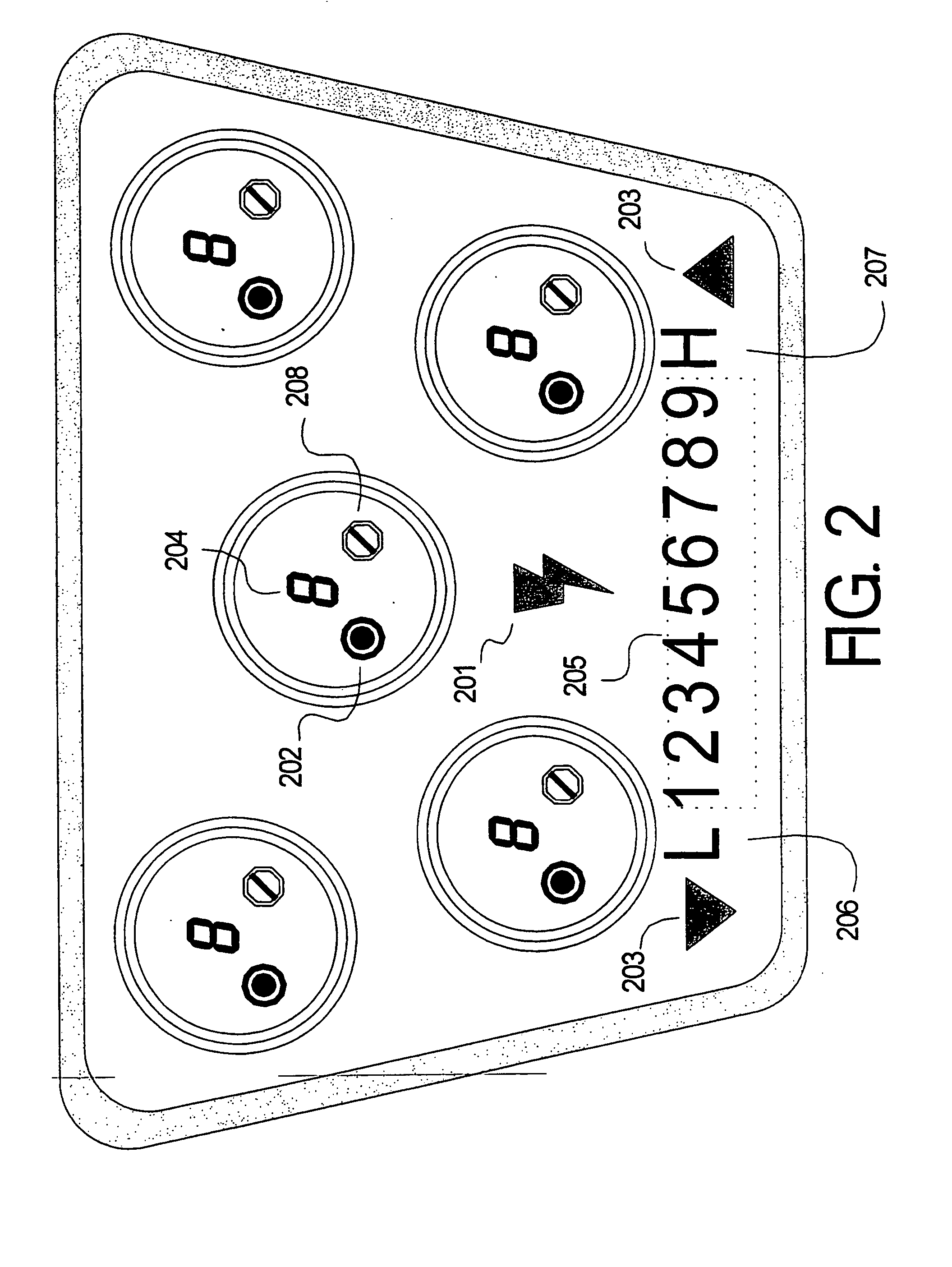

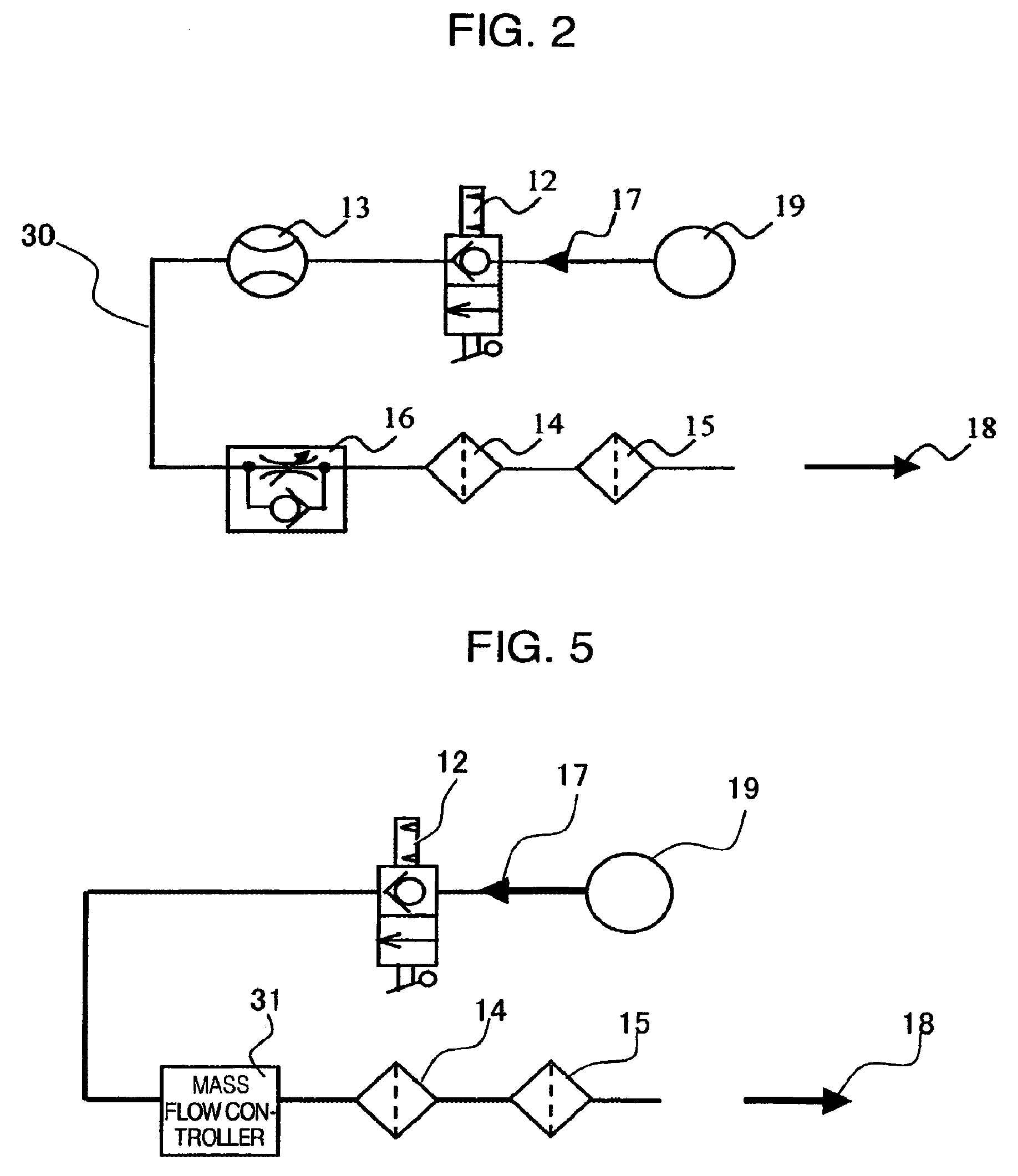

Electronic gas cooktop control with simmer system and method thereof

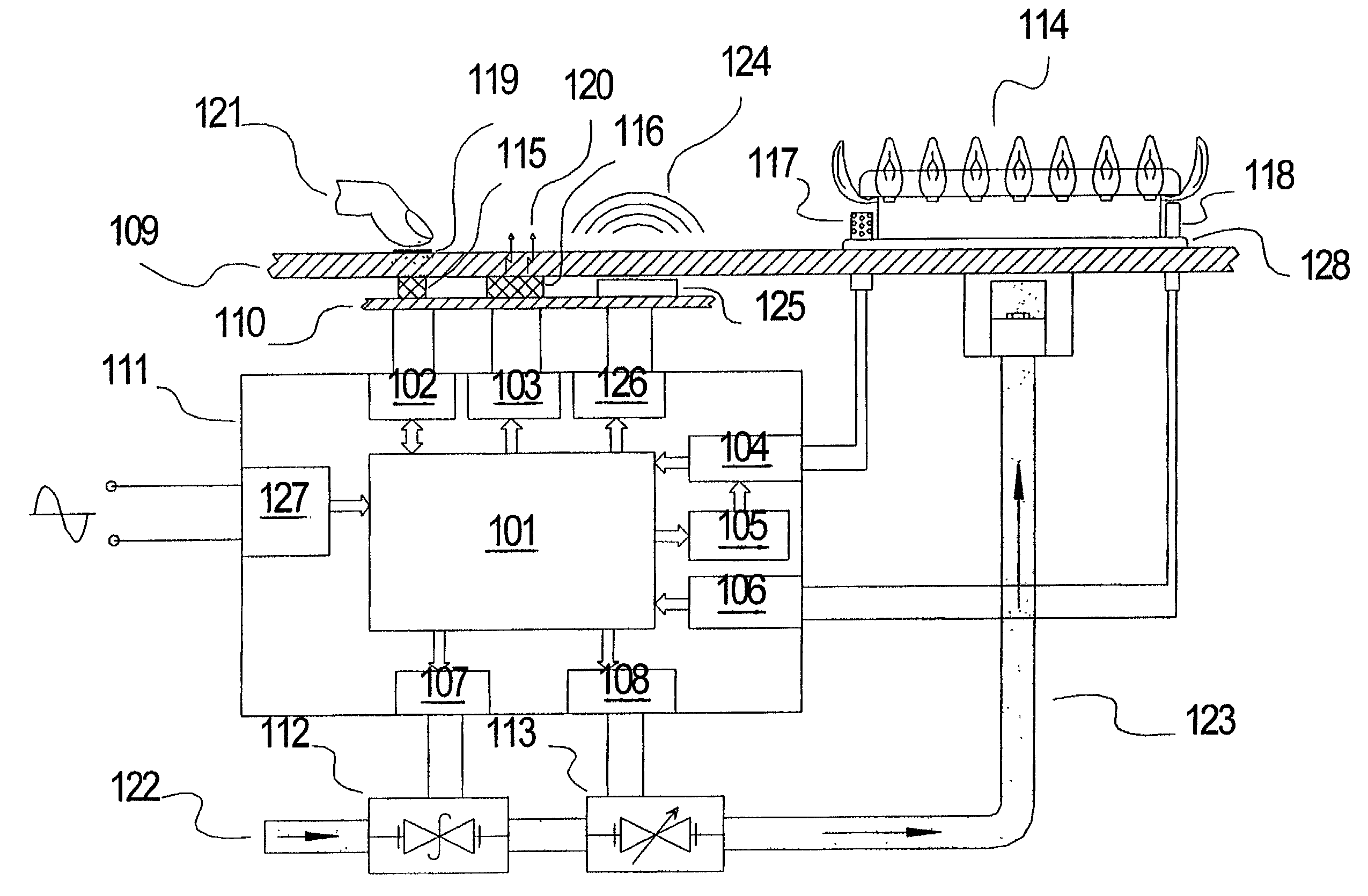

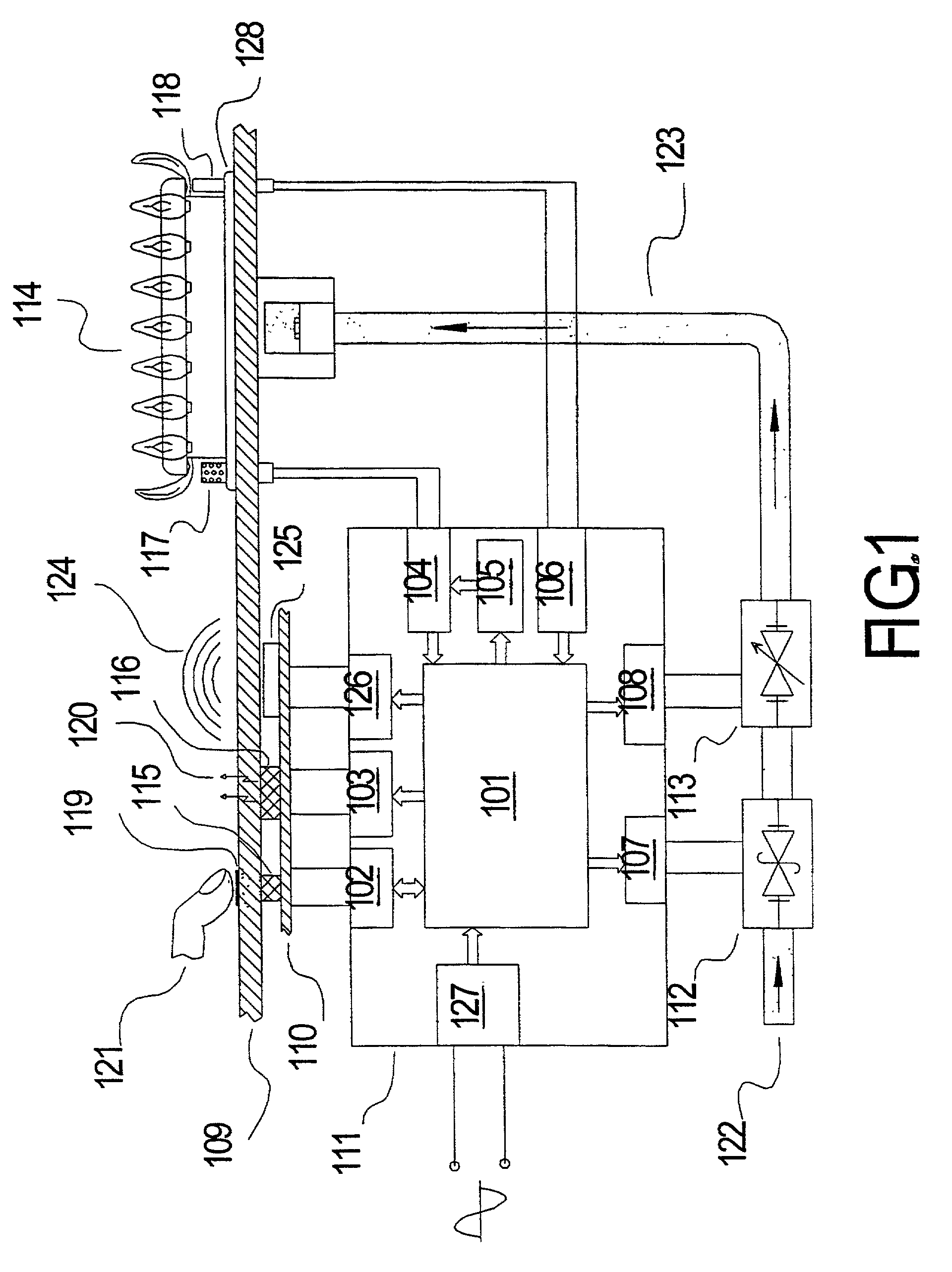

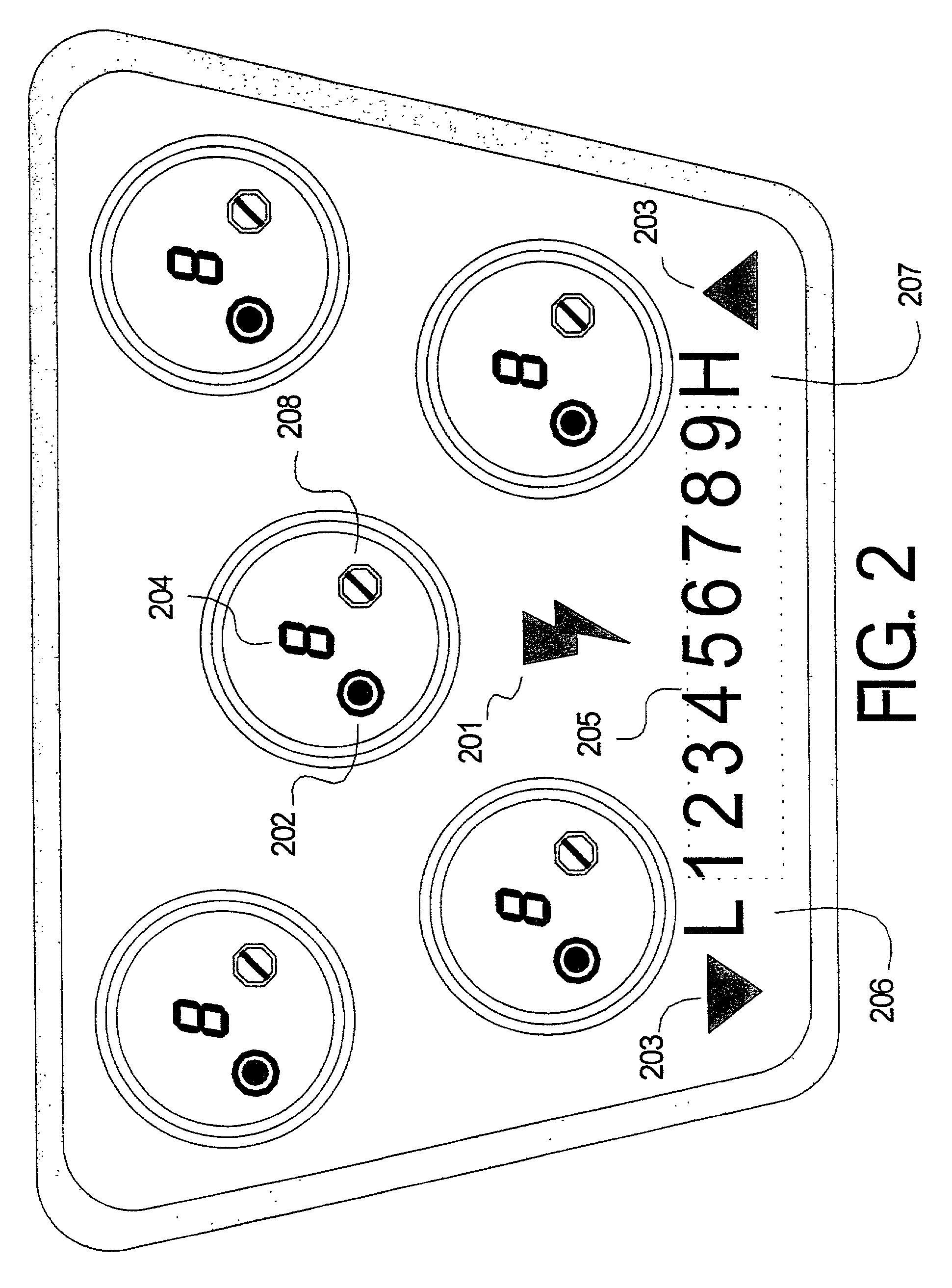

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

Location, identification and telemetry system using strobed signals at predetermined intervals

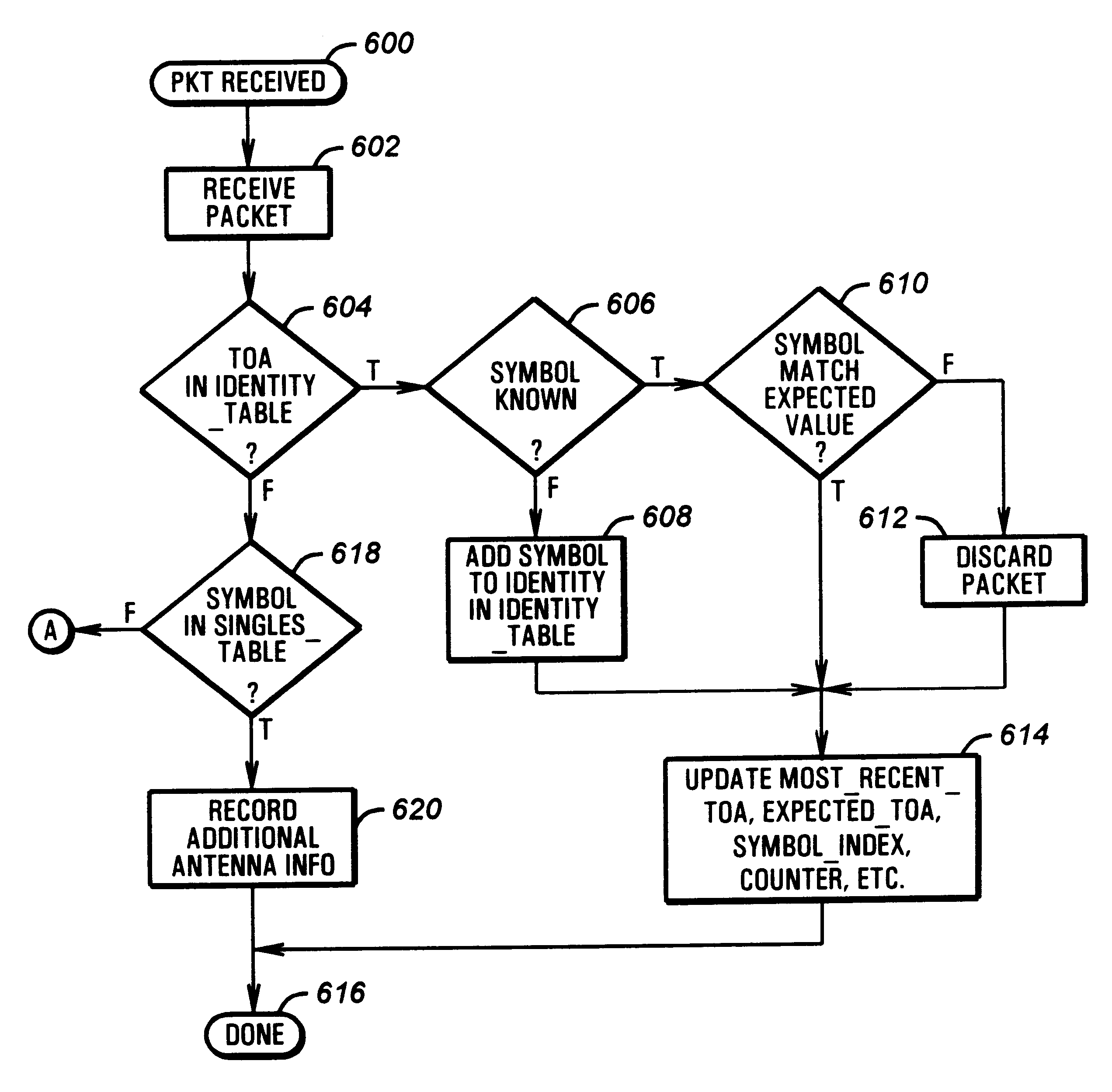

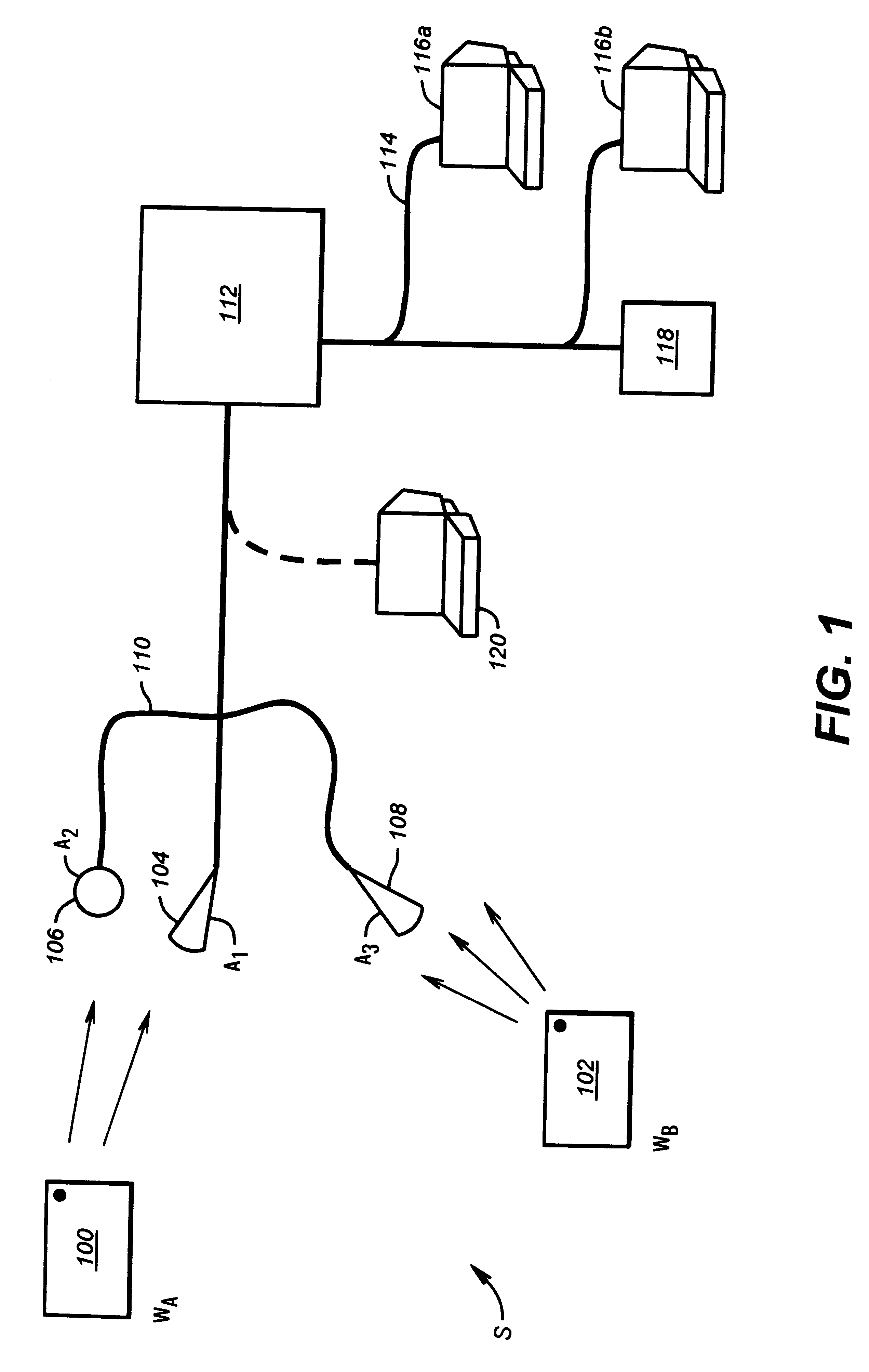

InactiveUS6222440B1Save powerAvailable bandwidthElectric signal transmission systemsDirection finders using radio wavesEngineeringWireless transmitter

A tracking system is implemented according to the invention in which the identification data of a wireless transmitter is divided into multiple bursts. Instead of transmitting the entire identification in a single burst, the identification is split among bursts, so that it takes a period of time to uniquely identify a particular transmitter. However, the time between bursts falls under tight tolerance, so once a transmitter is identified, it can be further identified based on when it transmits as opposed to what it transmits. In this way, high tractability can be maintained without repeatedly transmitting the entire identification code of the transmitter.

Owner:FRESHLOC TECH

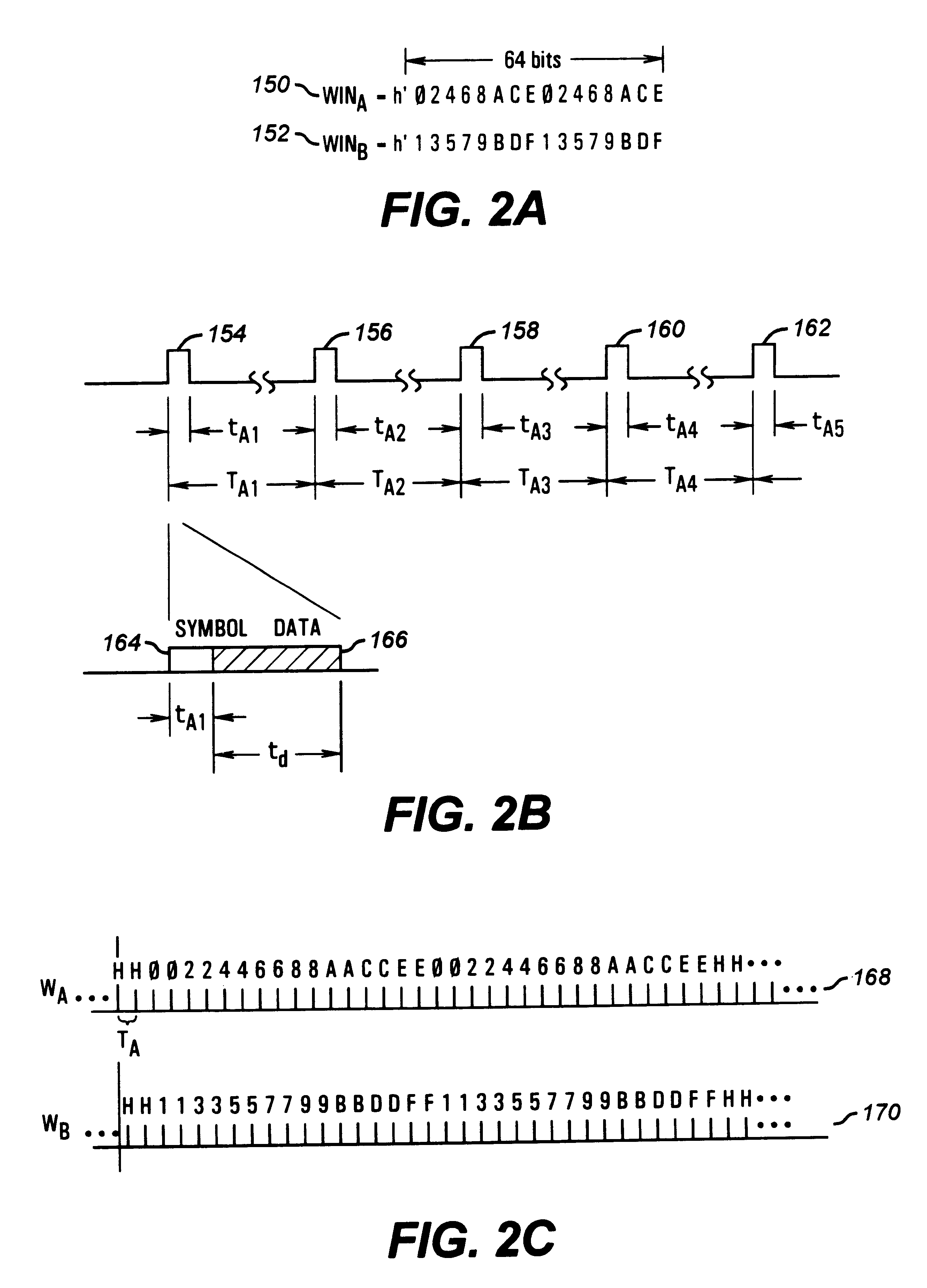

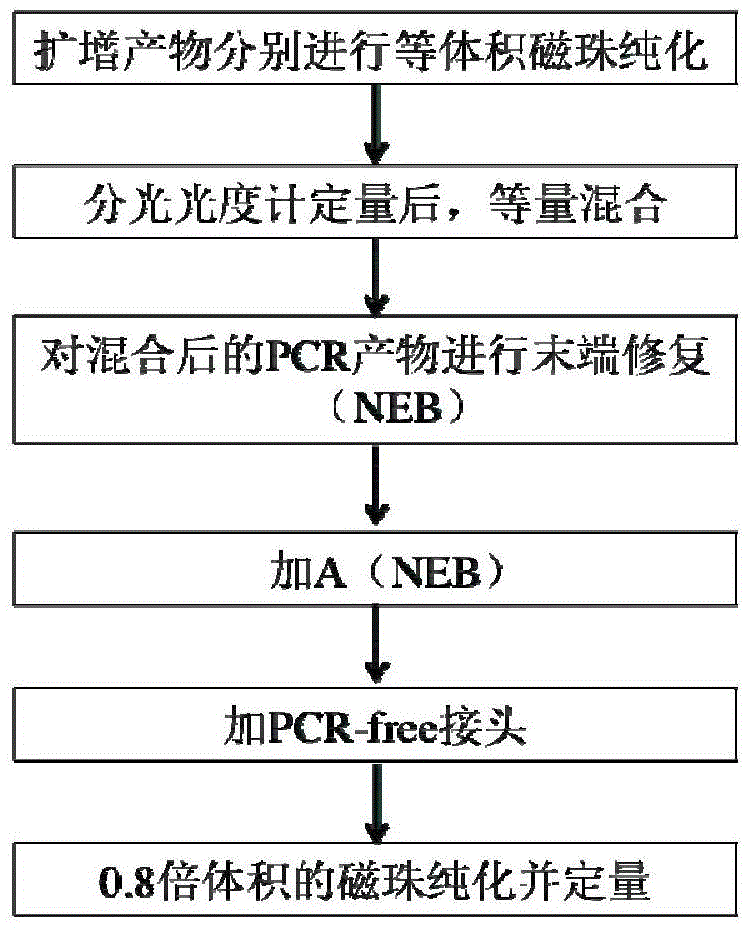

Amplification sublibrary and construction method thereof

InactiveCN104562213AAvoid preferenceAchieve uniformityNucleotide librariesMicrobiological testing/measurementRepeatabilityBiology

The invention provides an amplification sublibrary and a construction method thereof. The construction method comprises the following steps: S1, performing PCR amplification on target fragments of multiple samples to obtain a plurality of amplification products; S2, performing balanced mixing on the amplification products to obtain a mixed product; S3, sequentially performing fragmentation and terminal repairing on the mixed product, and adding A at a terminal 3' of the mixed product to obtain an A-repaired product; S4, jointing the A-repaired product by using a joint of PCR-free to obtain the amplification sublibrary. Through balanced mixing of the amplification products and through joint connection by using the optimized PCR-free, by the construction method, preference generated by PCR as well as chimeras in environmental samples is avoided, so that sequencing data between different samples have good consistency, subsequent clustering analysis and technical repeatability are more reasonable and more accurate, and can more really reflect evolutional relationship between the environmental samples.

Owner:BEIJING NOVOGENE TECH CO LTD

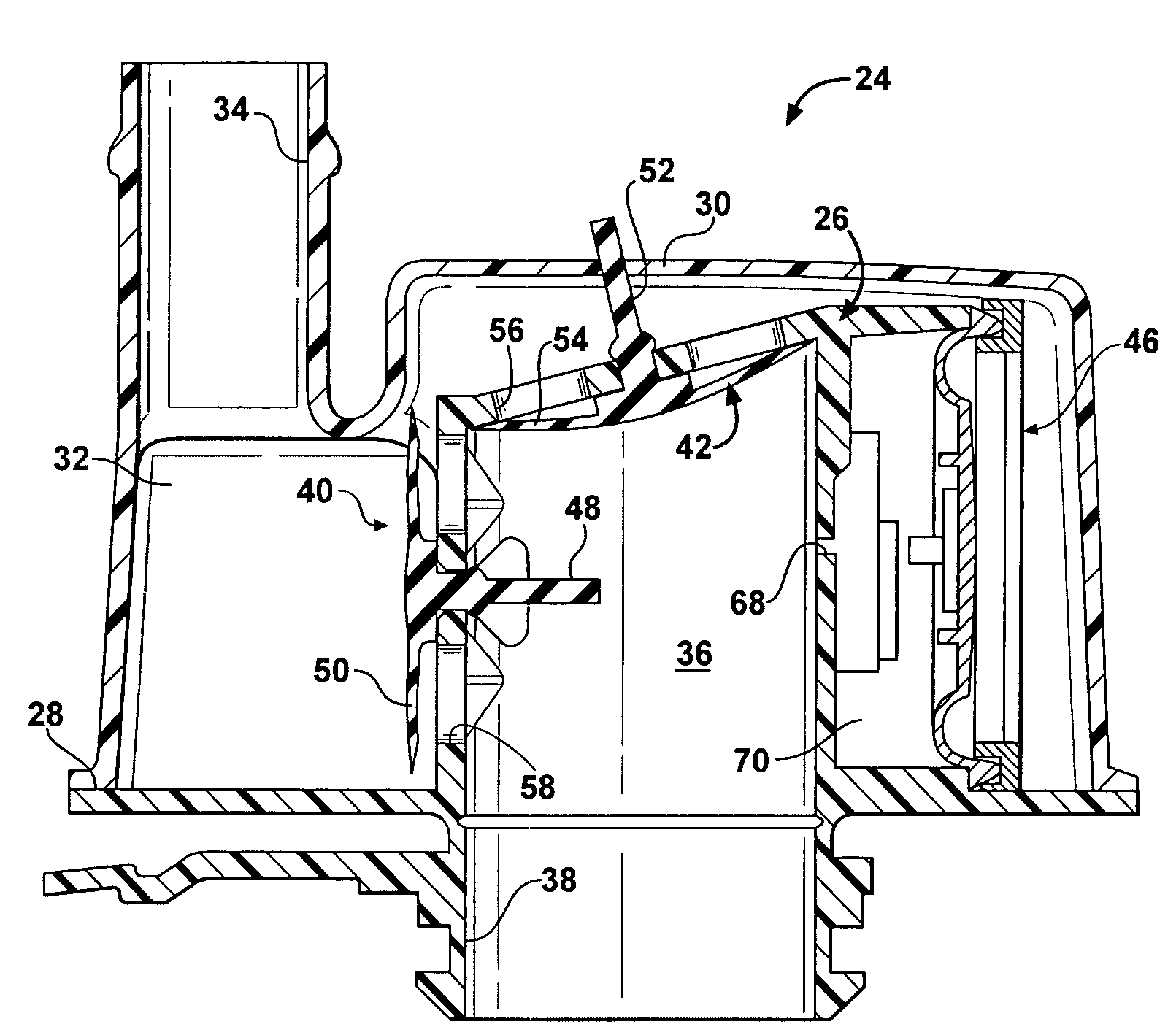

Electronic gas cooktop control with simmer system and method thereof

InactiveUS20050089809A9Facilitate maintenanceEliminate needFuel supply regulationDomestic stoves or rangesProcess engineeringElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

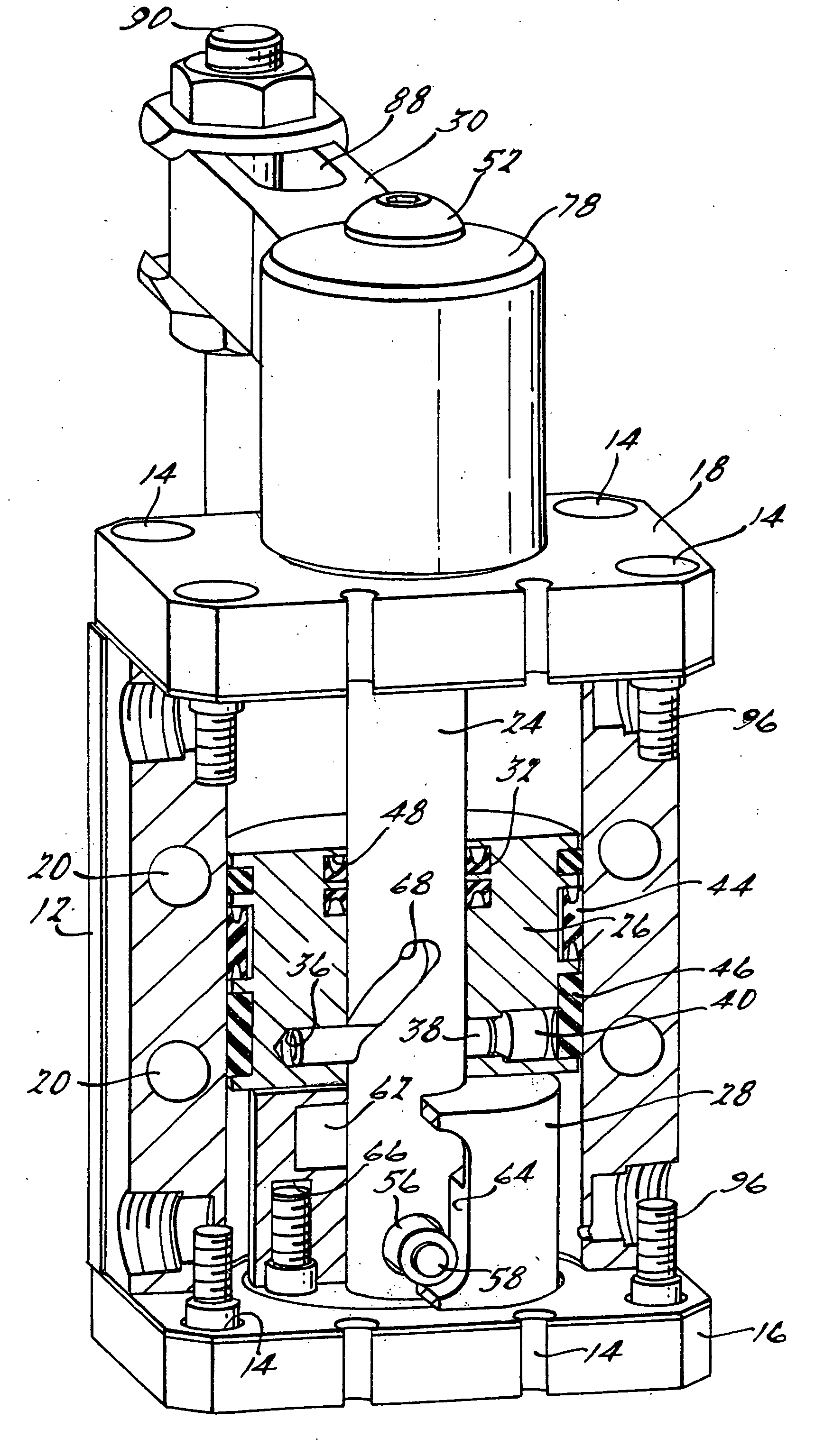

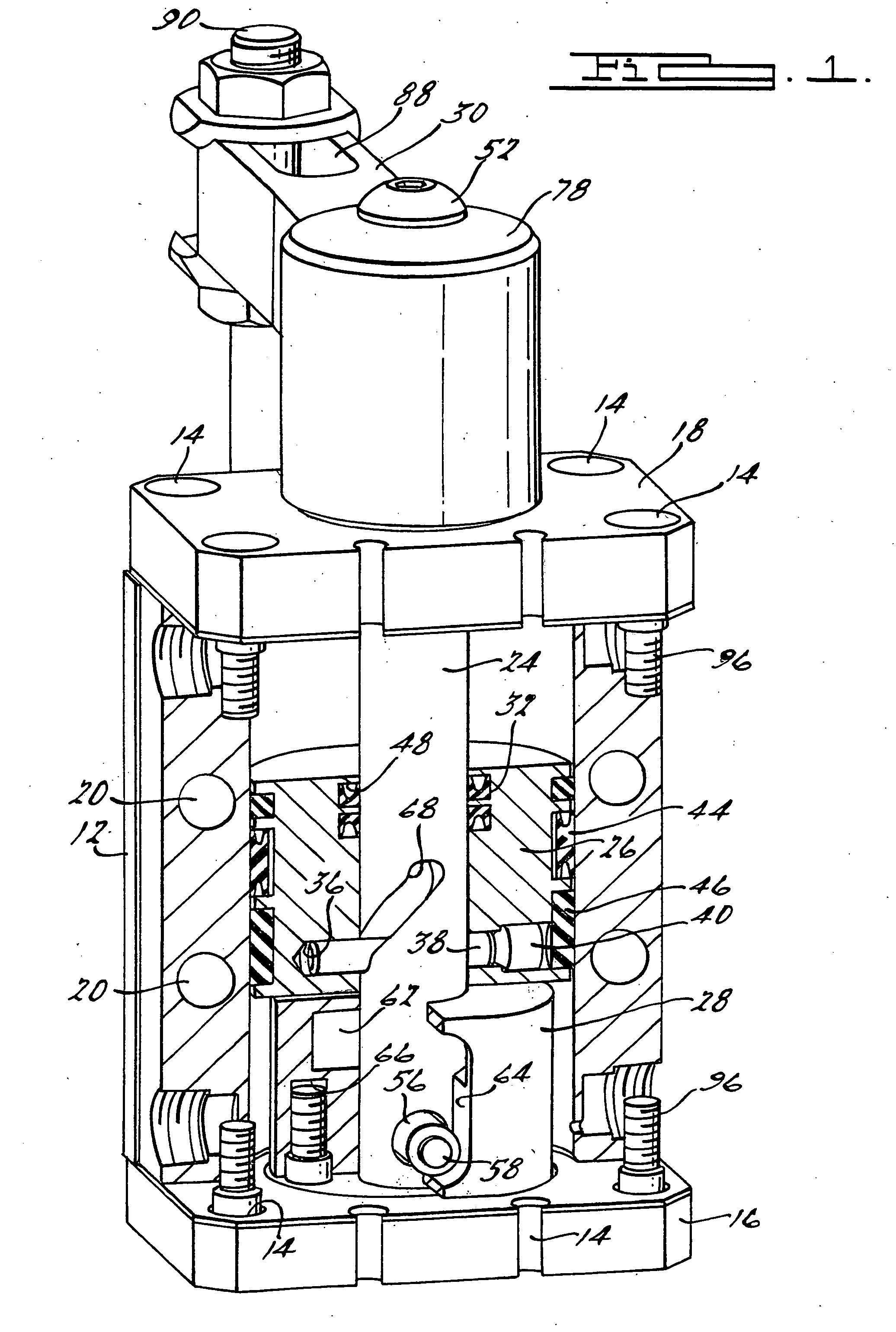

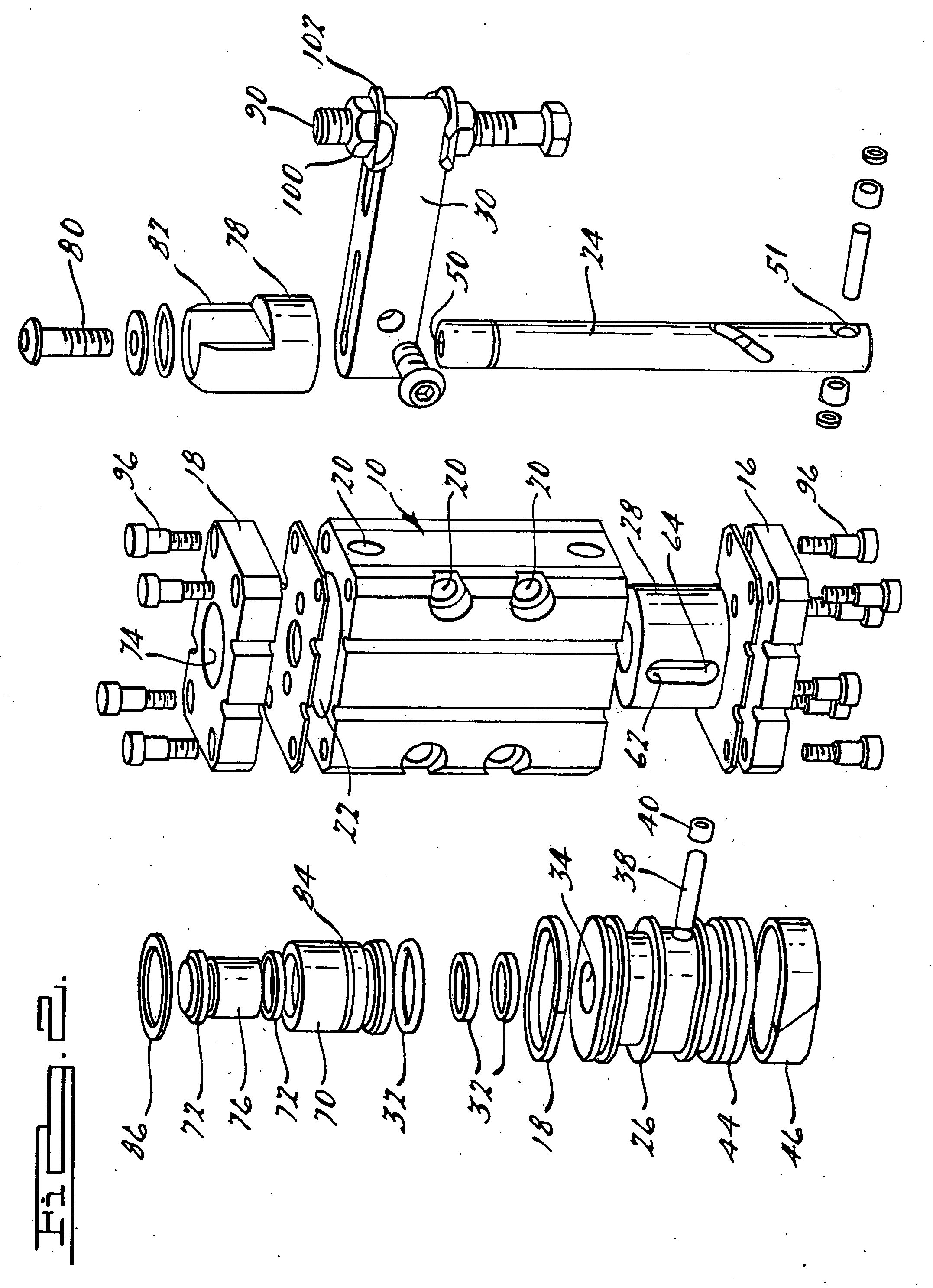

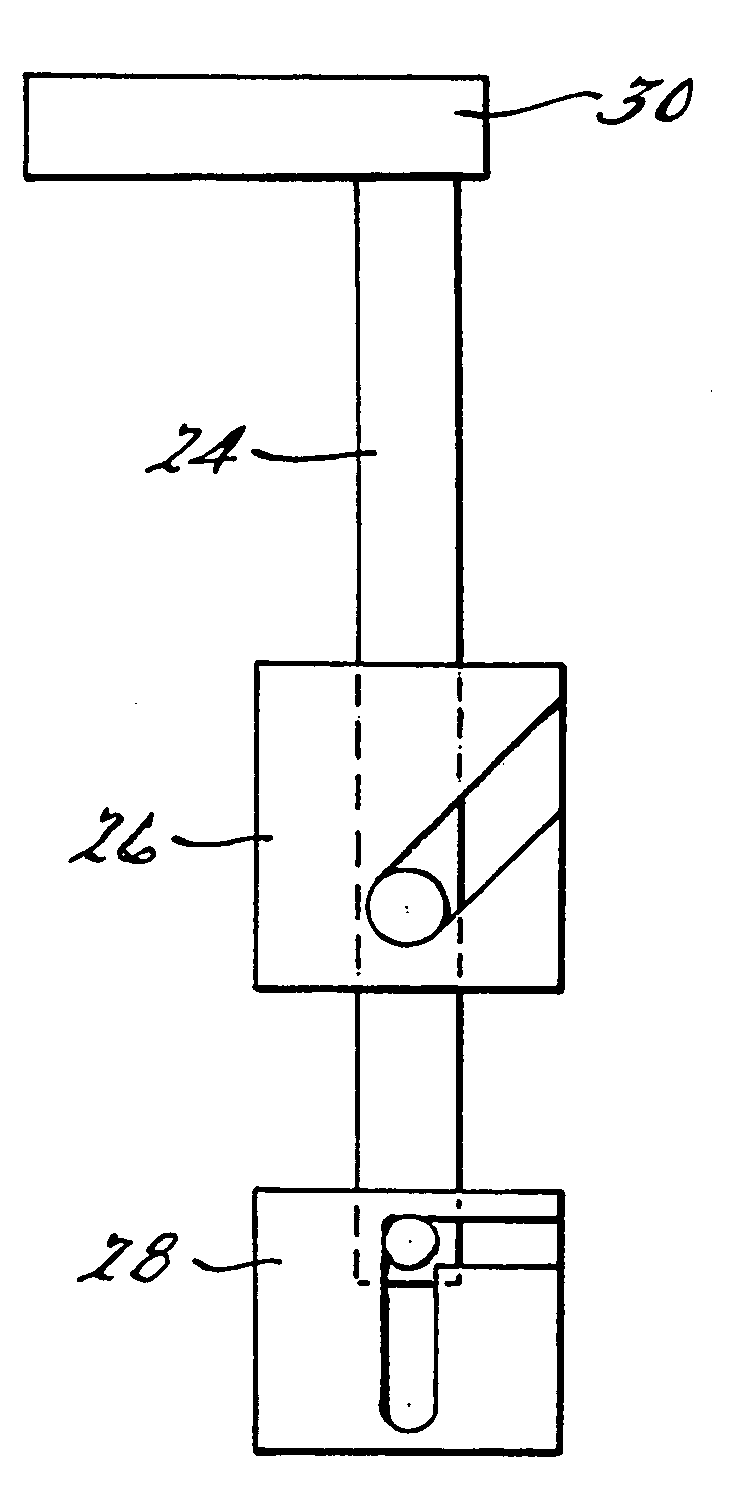

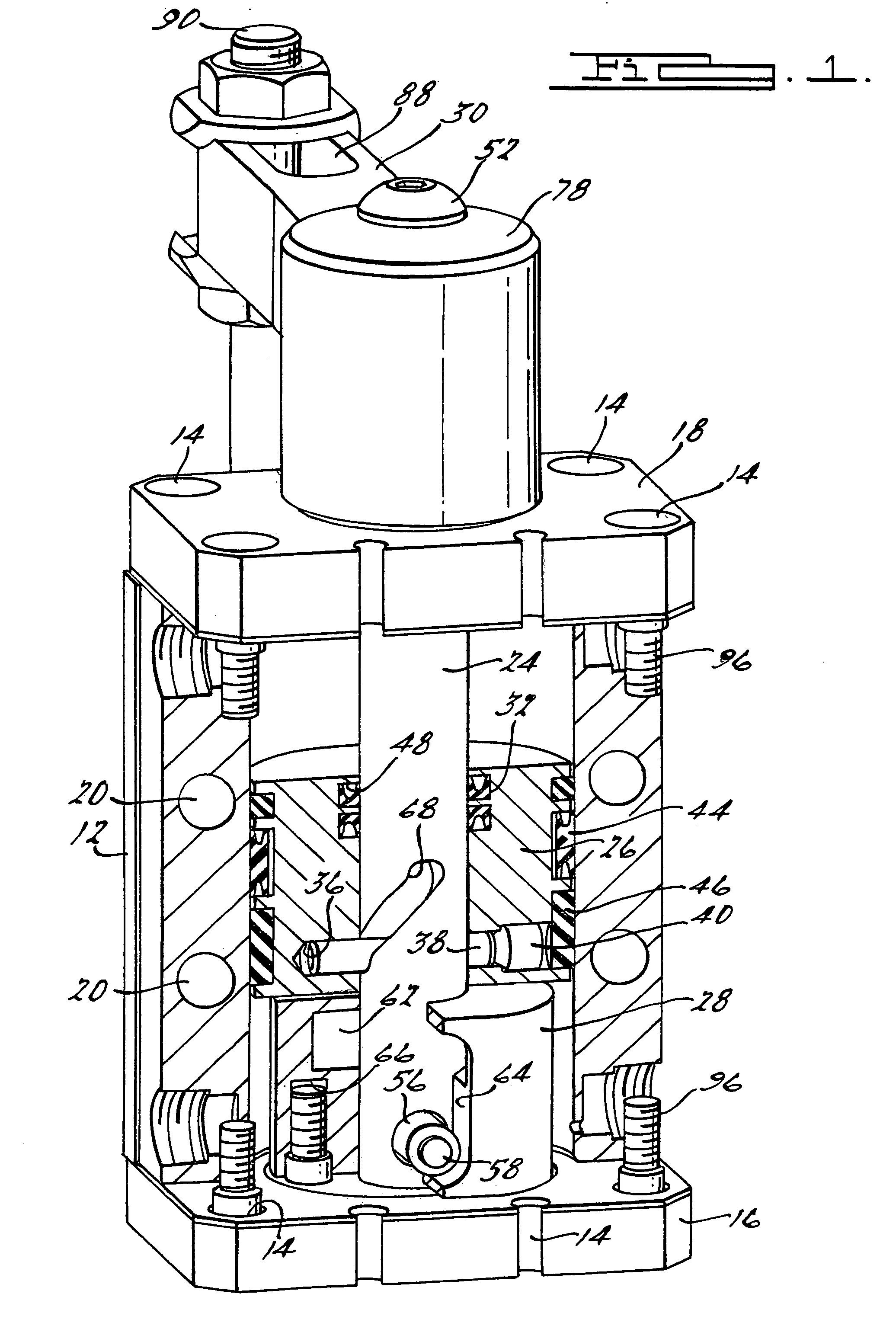

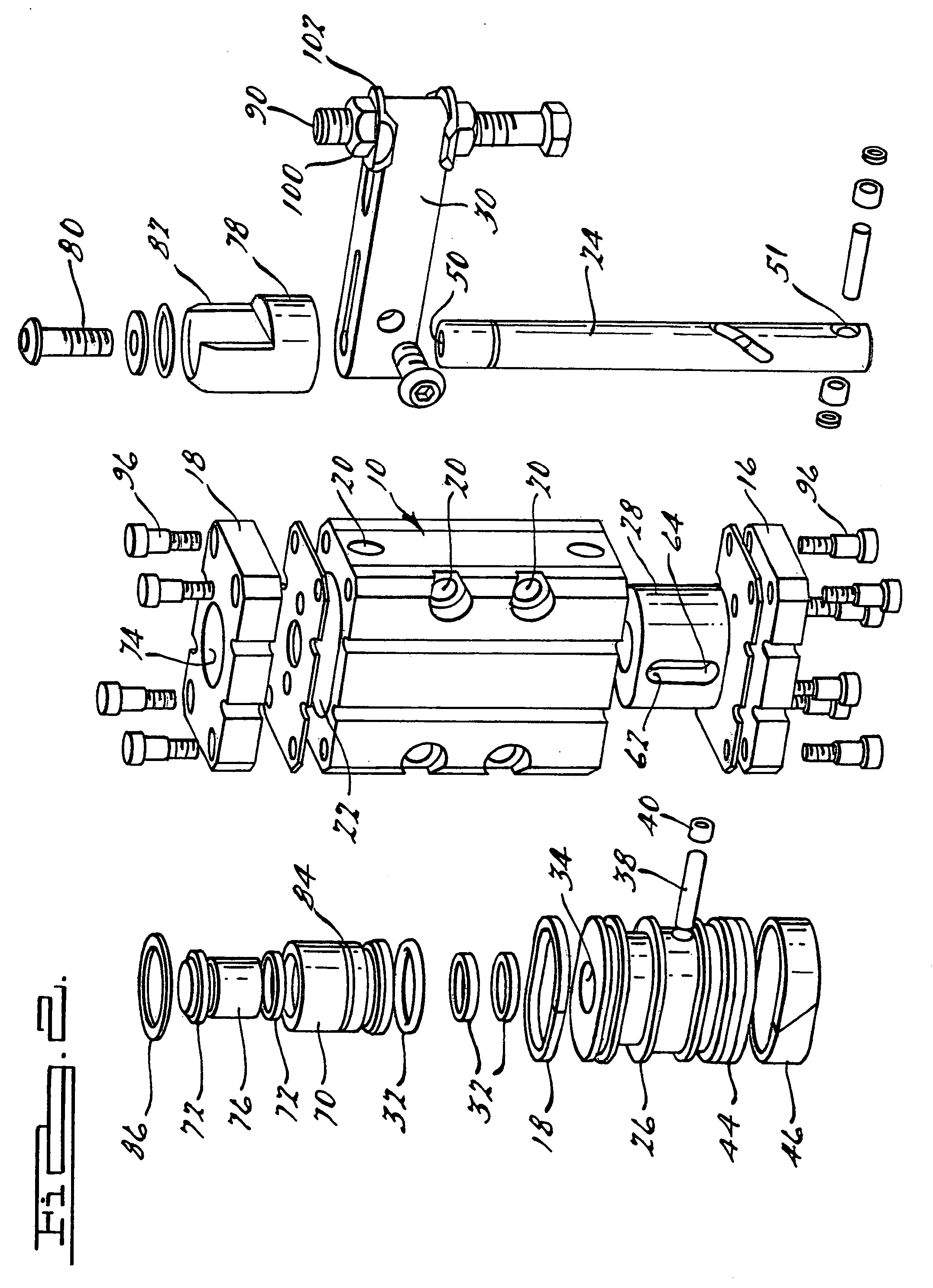

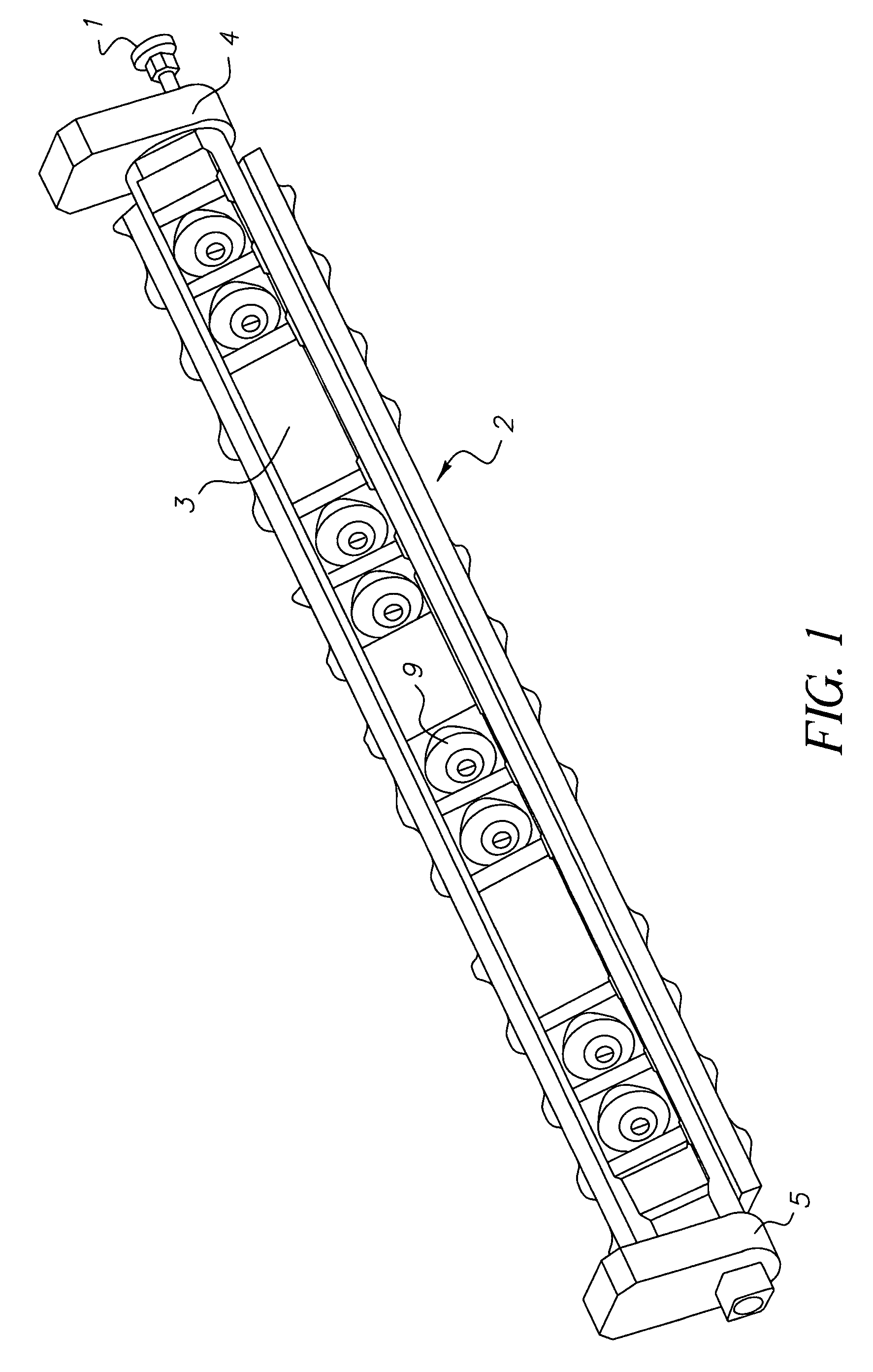

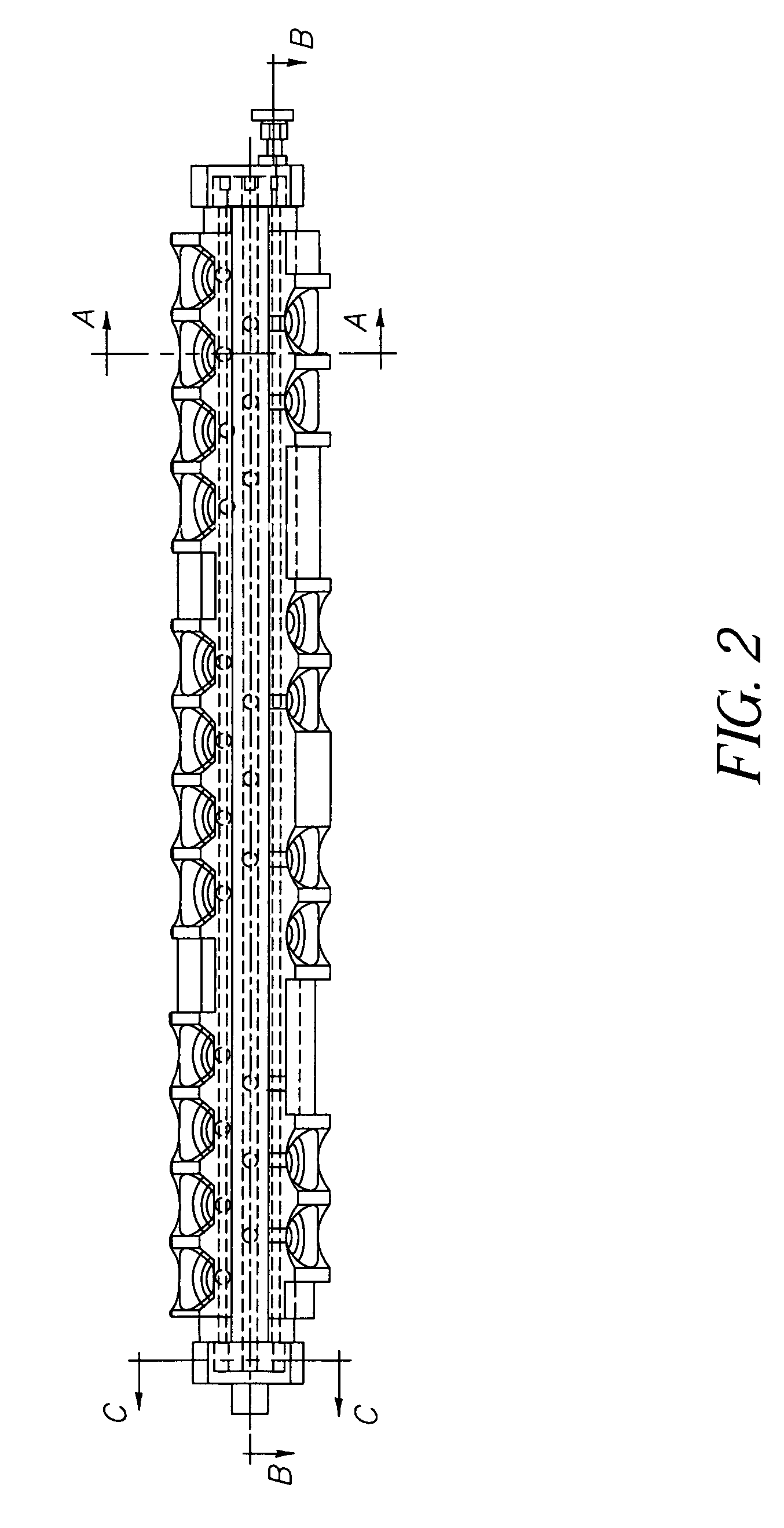

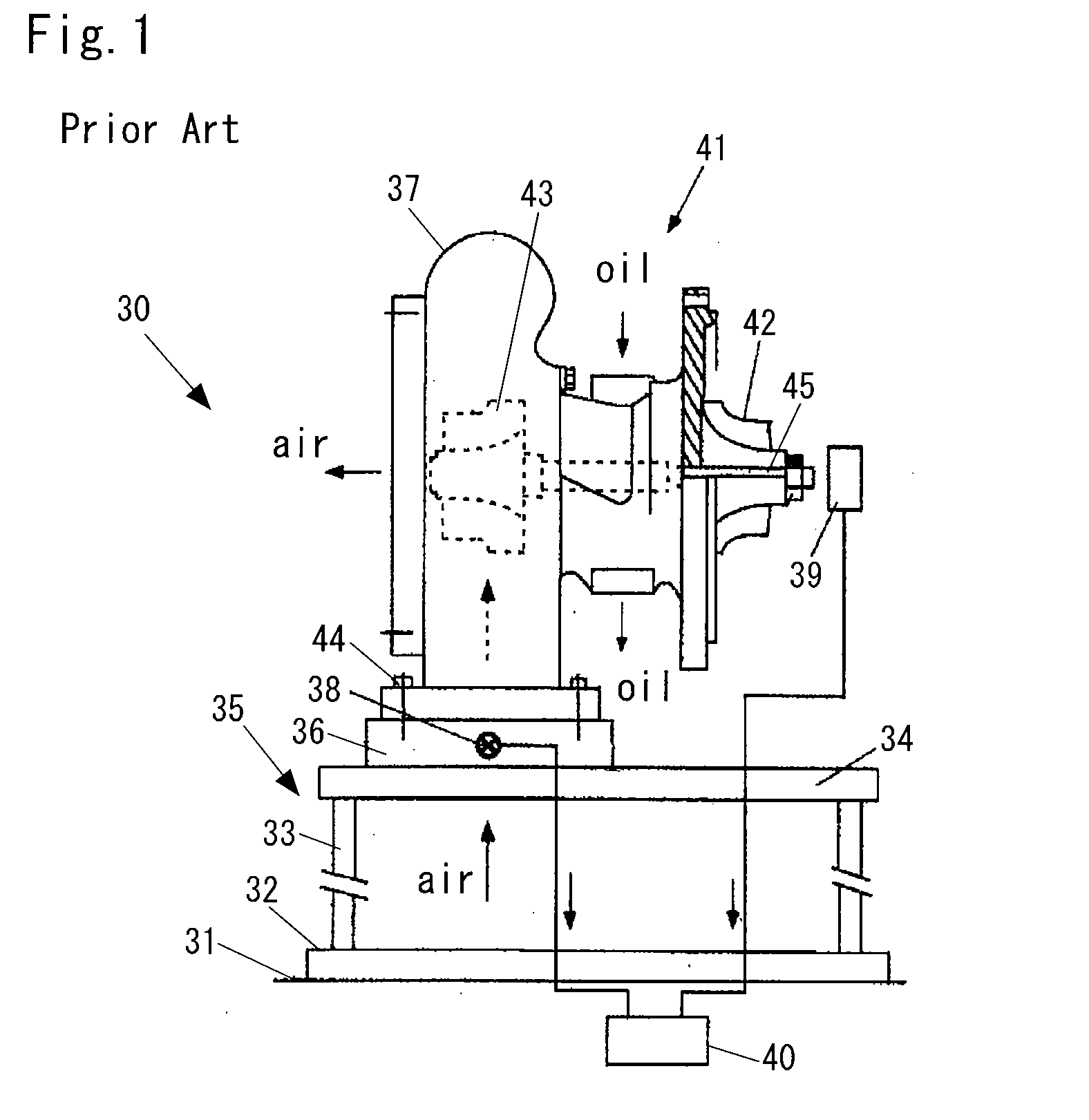

Swing cylinder

ActiveUS20060174760A1Robust and durableAvoid pollutionFluid-pressure actuatorsReciprocating piston enginesEngineeringMechanical engineering

A swing cylinder having a body and an end cap on each end of the body. The cylinder also has a piston arranged within the body. The cylinder has a rod engaged with the piston and has an arm attached to one end thereof. A guide is arranged on the opposite end of the rod. The guide is also attached to one of the end caps.

Owner:DELAWARE CAPITAL FORMATION

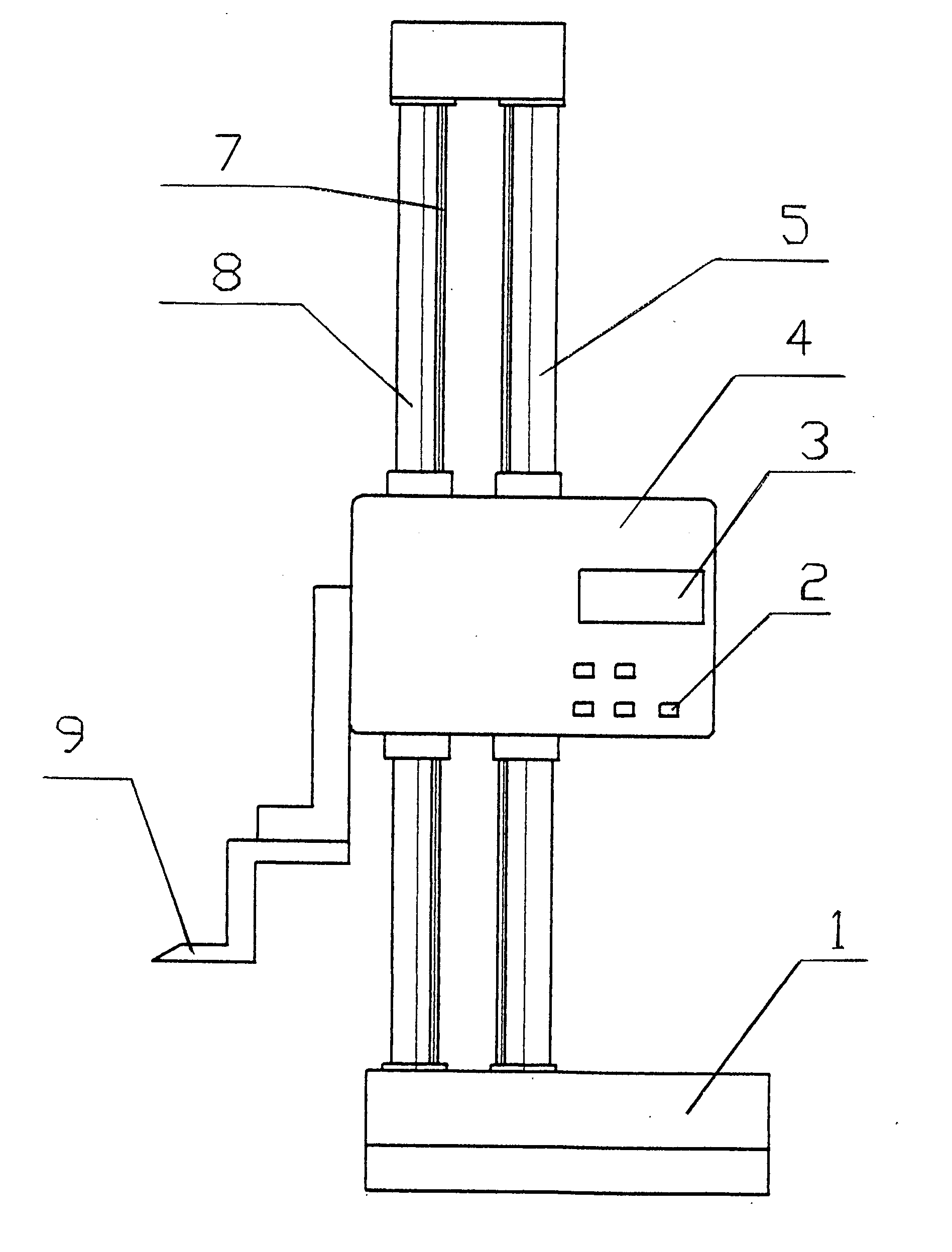

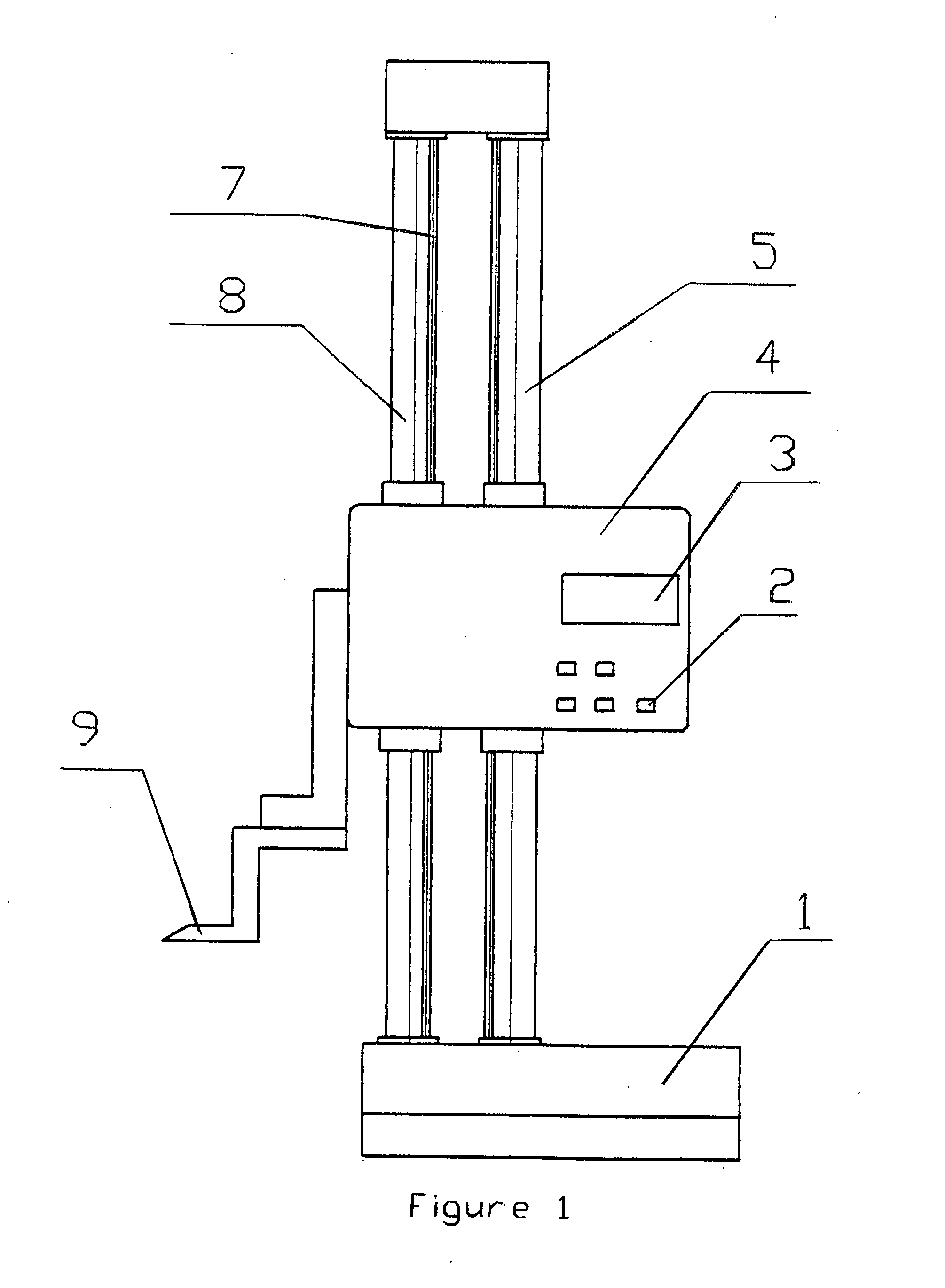

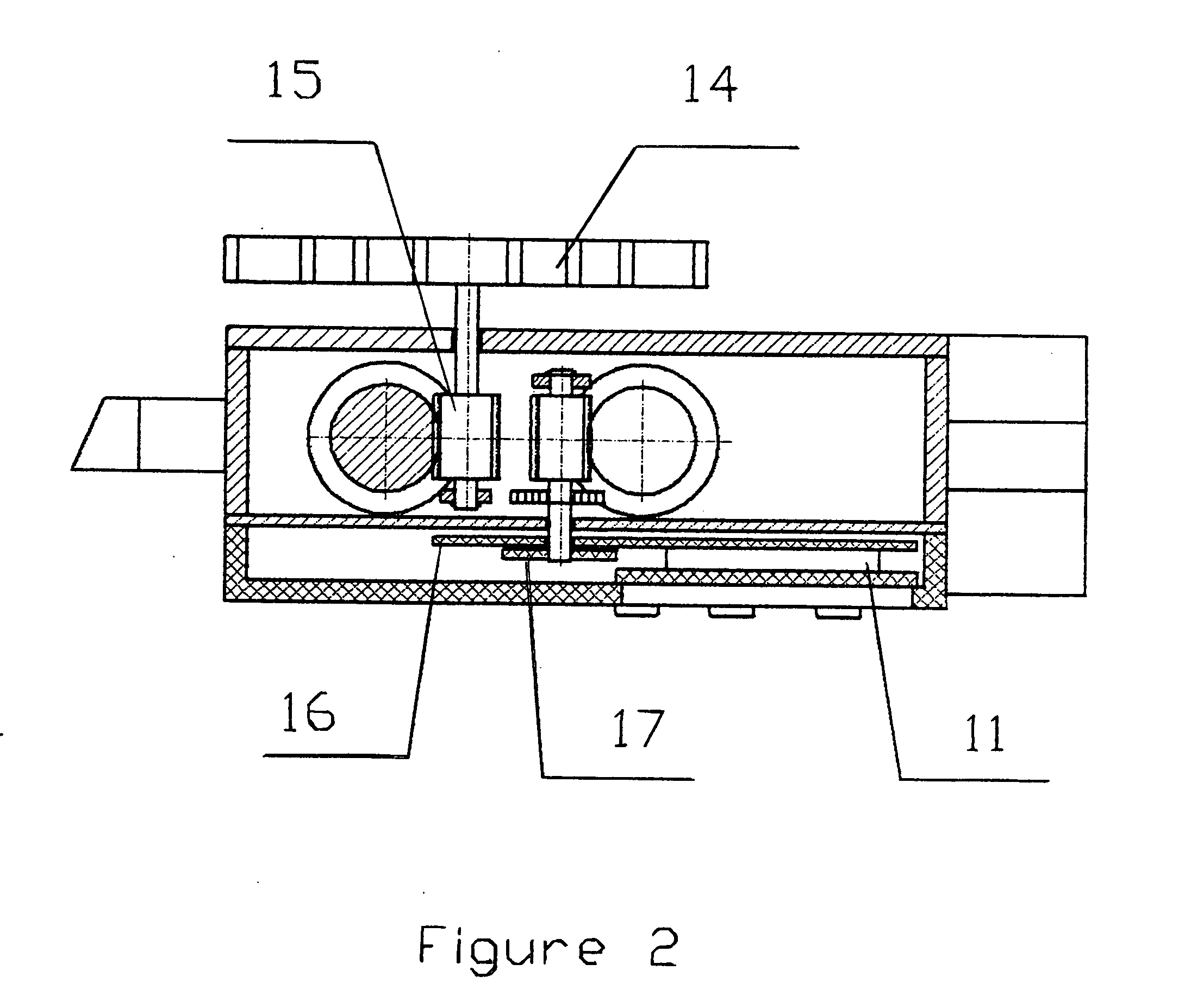

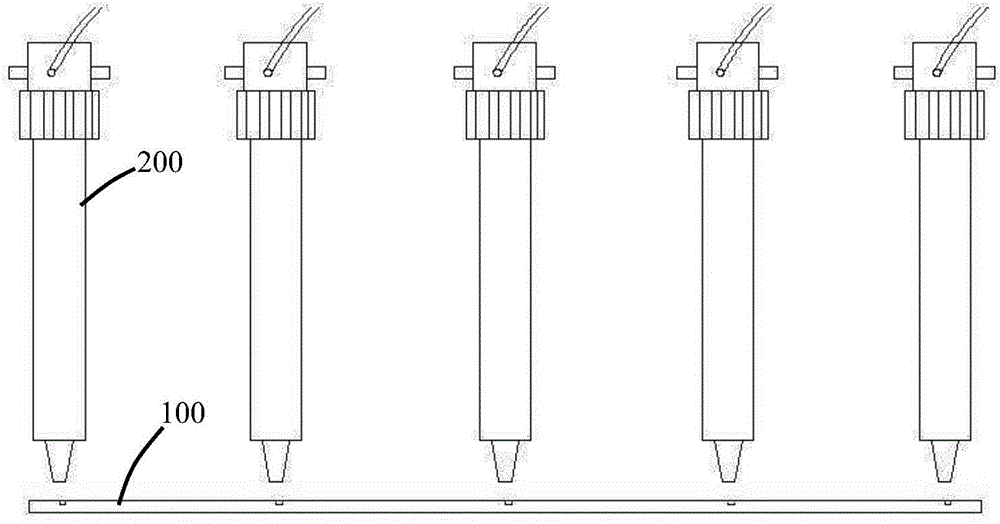

Linear moving capacitive sensor twin column electronic height gauge

InactiveUS20060137204A1Low costReduced measurement accuracyFeeler-pin gaugesUsing electrical meansOn columnEngineering

The present invention is an electronic height gauge utilizing new technology and includes a first column (Column 1) and a second column (Column 2), a display unit with a cover, a measuring scriber, a fixed capacitance sensor and a linear moving capacitance sensor. The fixed capacitance sensor is located on a flat surface on Column 1, flat surface having a length equivalent to the length of Column 1. The linear moving capacitance sensor is located inside the display unit cover positioned to face the fixed capacitance sensor. The fixed capacitive sensor and linear moving capacitive sensors are facing toward each other only, and do not make direct physical contact with the fixed capacitor sensor when the height gauge is operating in upward and downward movements. The fixed and moving capacitive sensors are instead making only electrical contact with each other when the height gauge is making upward and downward movements. This linear direct data non-contact sensor transfer system results in high accuracy of measurements, which also ensures the repeatability of accurate measurements. Also, since the fixed capacitance sensor and the linear moving capacitance sensor have no physical contact with each other, there is no wear and tear damage on either component part, thereby leading to a longer life of use with stability in accurate measurements and repeatability. Because the measuring system is comparatively simple, and easy to assemble and service and maintain compared to the existing rotary capacitive sensor electronic height gauges that exist on the market, the overall cost of production and maintenance is minimized. On the second column (Column 2), a simple rack and gear system is added. These gears of column 2 are connected to a hand wheel located on the rear of the display unit. The handwheel is used for making upward and downward vertical movements. This rack and gear system of column 2 of the present invention is only used to aid the same in making upward and downward movements, and does not affect the measuring accuracy of the height gauge, as it did in the height gauges that have existed on the market.

Owner:INT PRECISION INSTR CORP

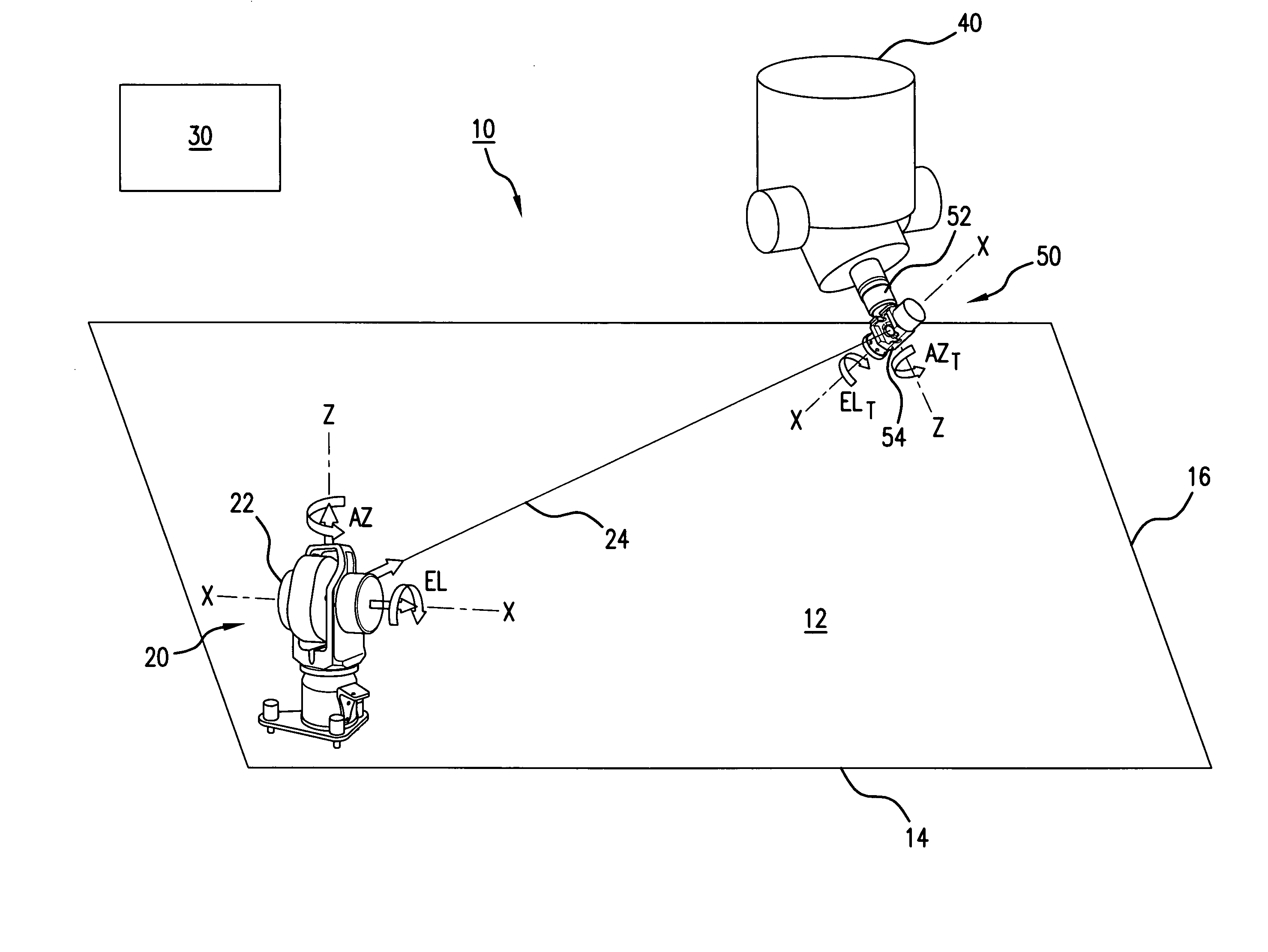

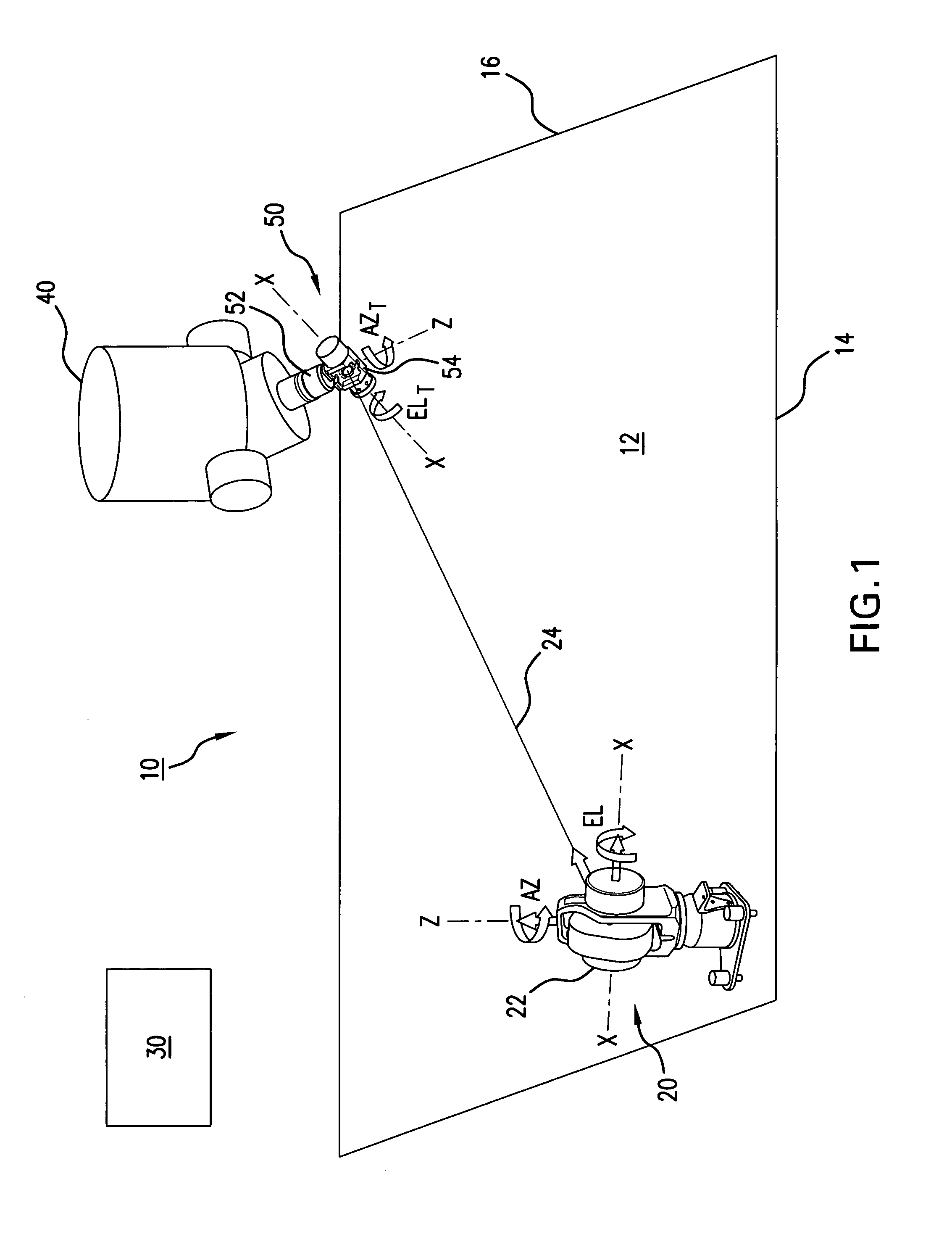

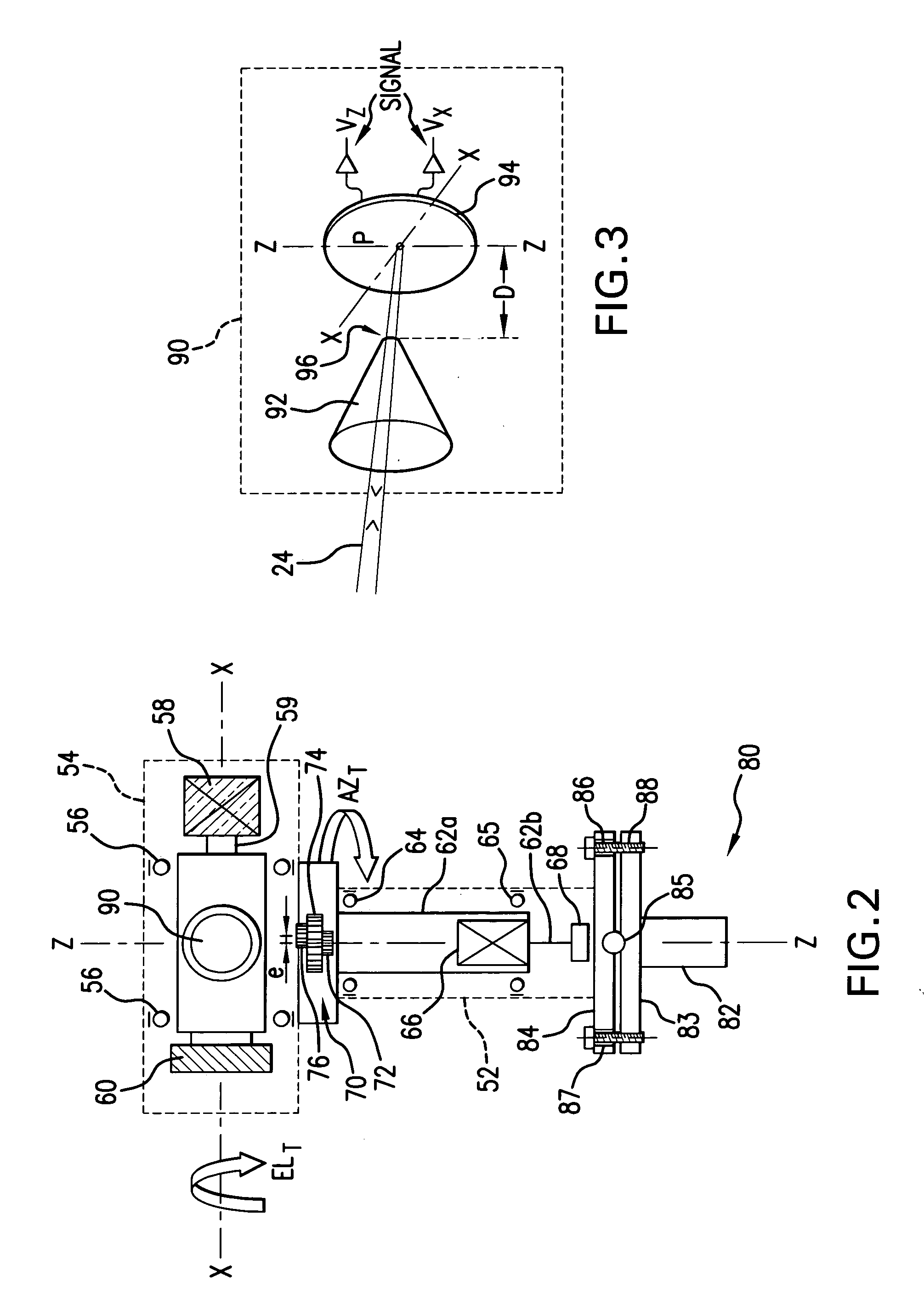

Volumetric error compensation system with laser tracker and active target

ActiveUS8803055B2Accurate repeatabilityGood compensationProgramme-controlled manipulatorAngle measurementRotational axisLight beam

A volumetric error compensation measurement system and method are disclosed wherein a laser tracker tracks an active target as the reference point. The active target has an optical retroreflector mounted at the center of two motorized gimbals to provide full 360 degree azimuth rotation of the retroreflector. A position sensitive detector is placed behind an aperture provided at the apex of the retroreflector to detect the relative orientation between the tracker laser beam and the retroreflector by measuring a small portion of the laser beam transmitted through the aperture. The detector's output is used as the feedback for the servo motors to drive the gimbals to maintain the retroreflector facing the tracker laser beam at all times. The gimbals are designed and the position of the retroreflector controlled such that the laser tracker always tracks to a pre-defined single point in the active target, which does not move in space when the gimbals and / or the retroreflector makes pure rotations. Special mechanism and alignment algorithm are used in the gimbal design and retroreflector centering alignment to achieve accurate rotational axis alignment and repeatability.

Owner:AUTOMATED PRECISION INC

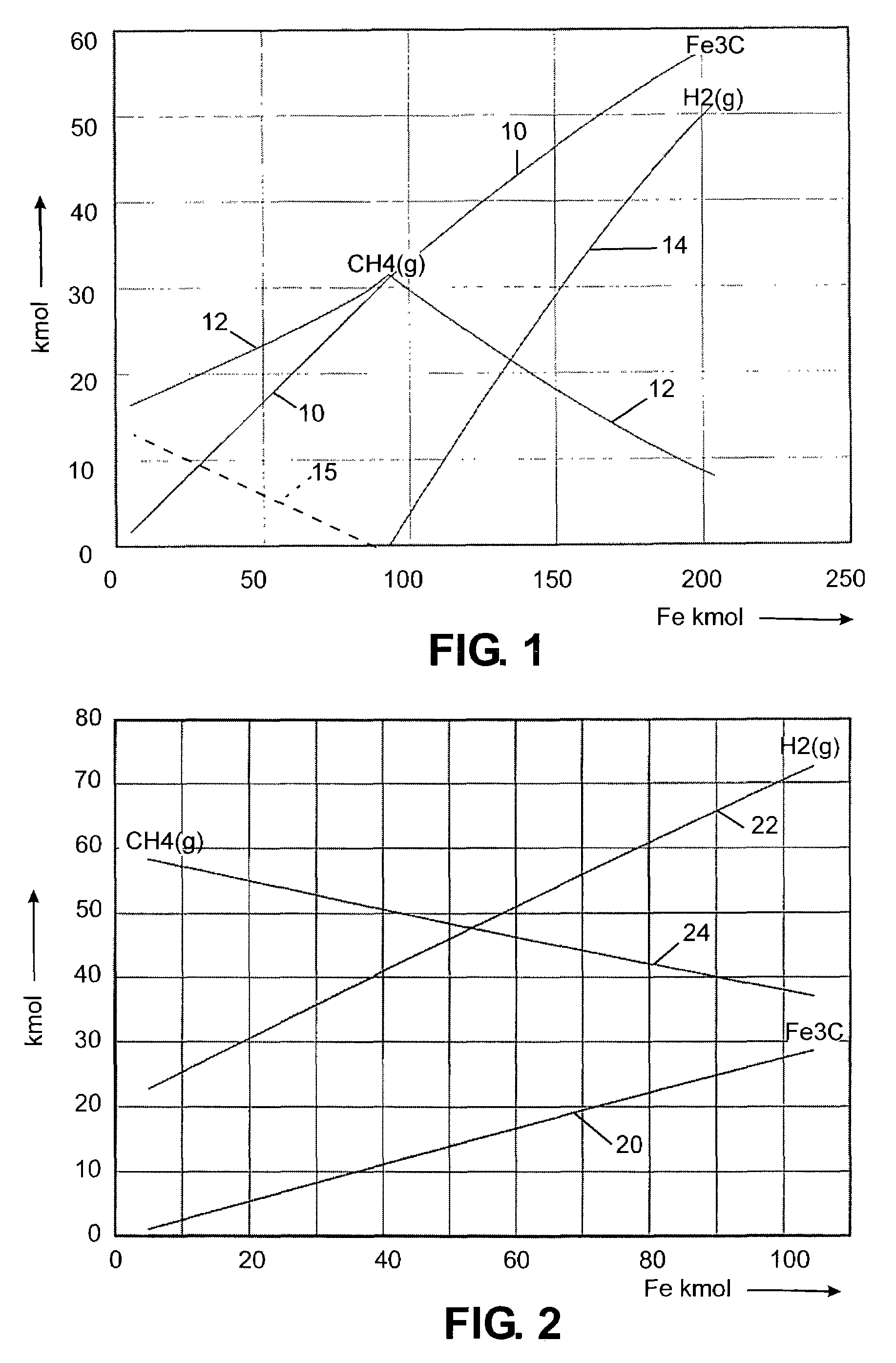

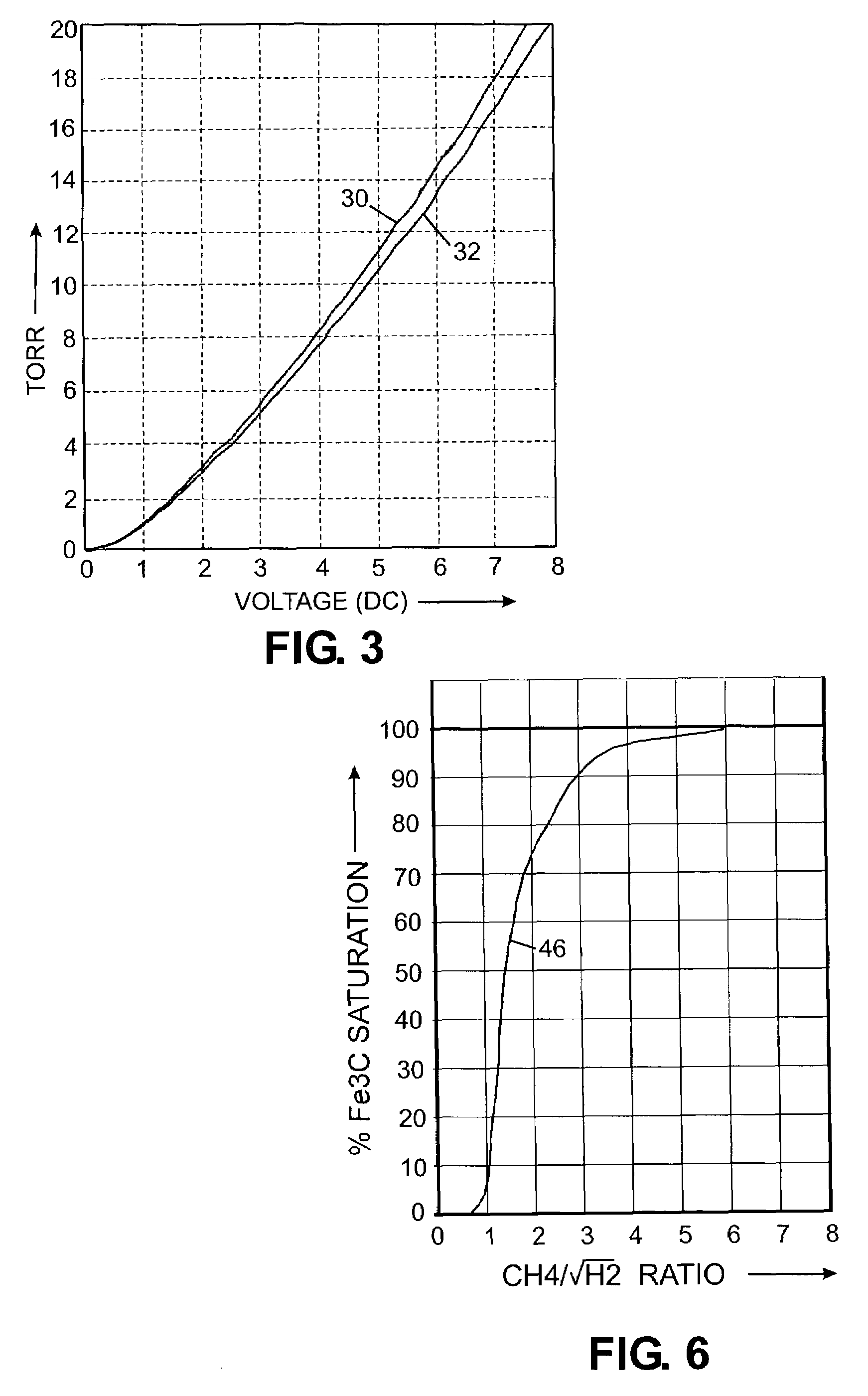

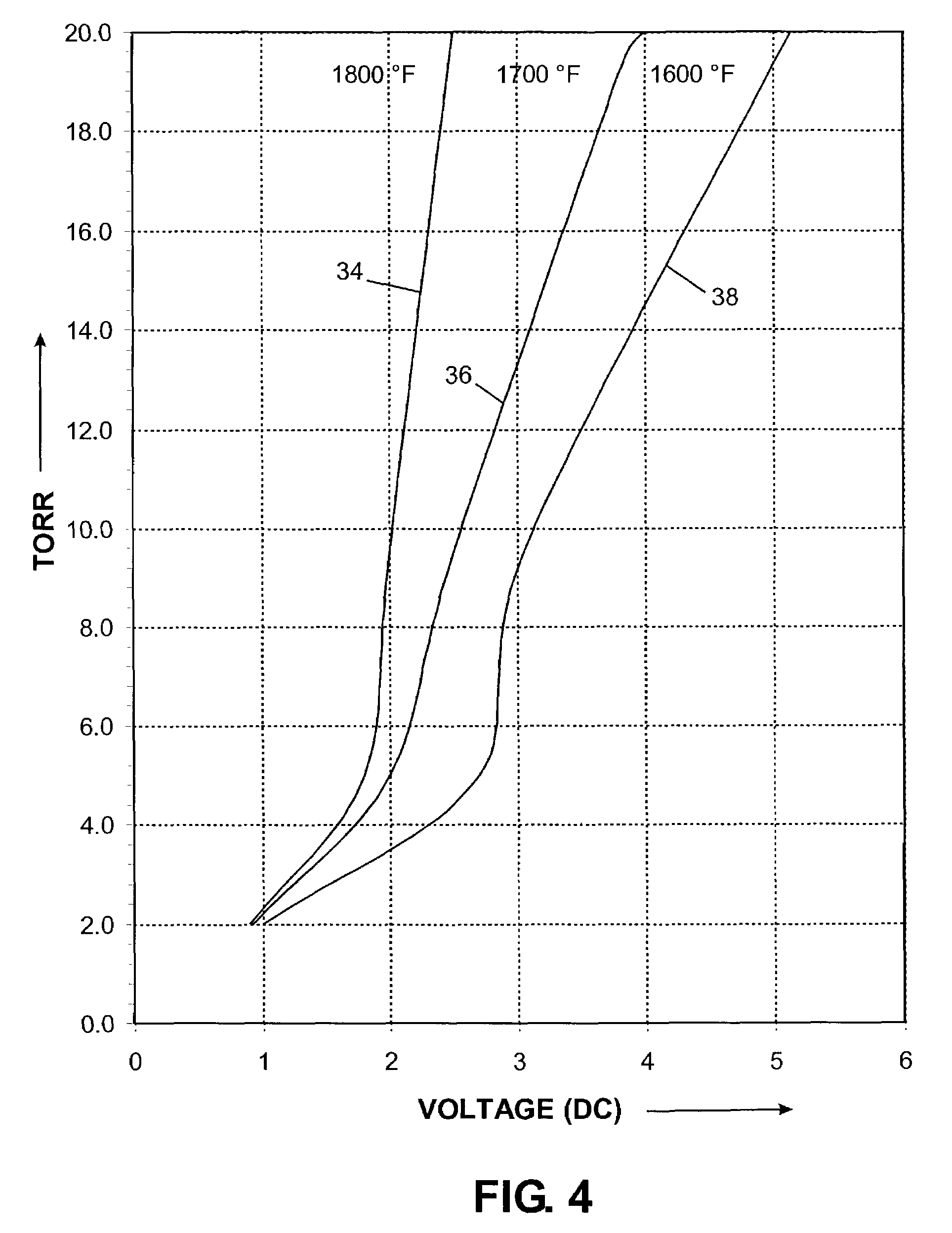

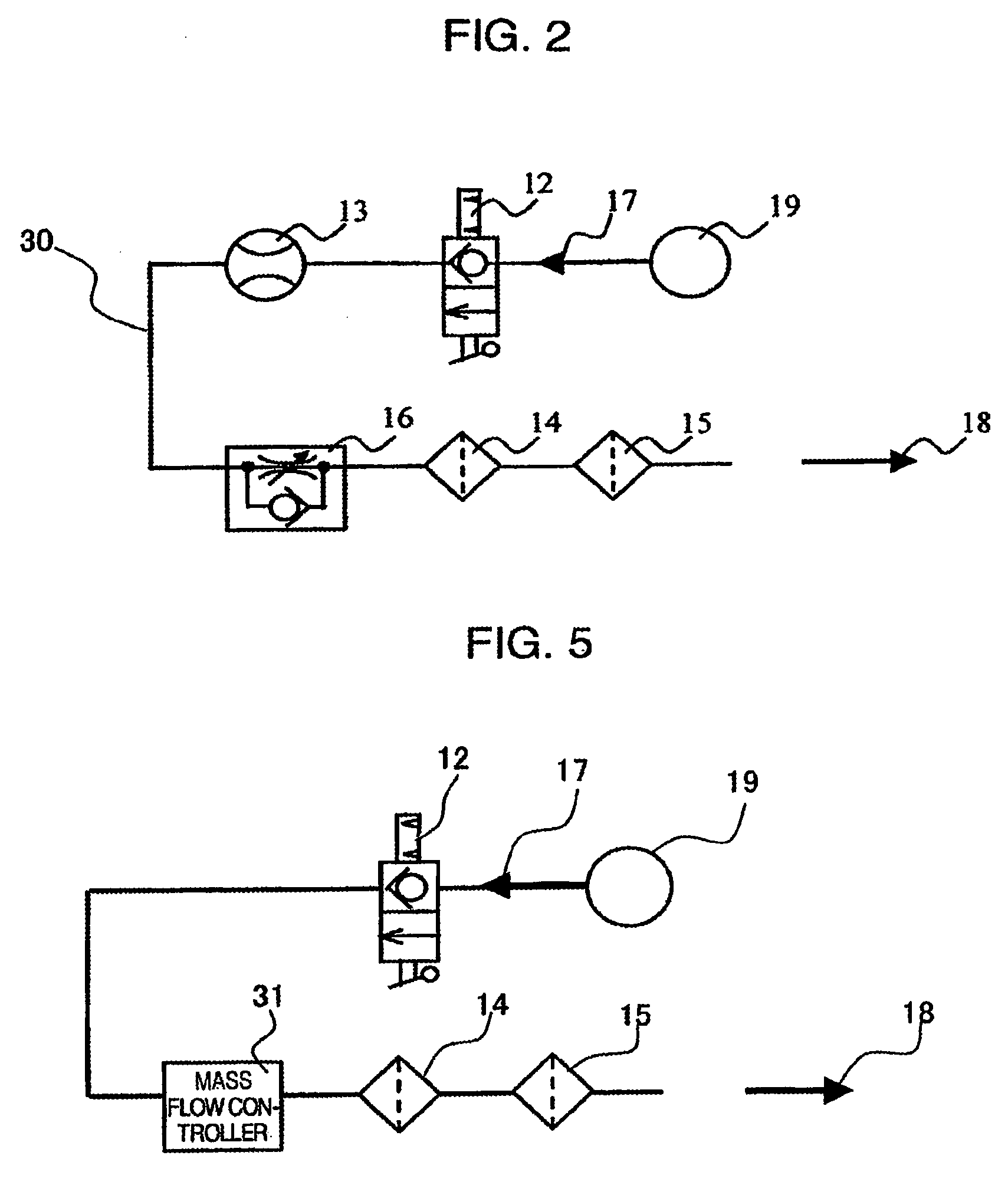

Vacuum carburizing with napthene hydrocarbons

InactiveUS6991687B2Easy to controlAccurate repeatabilitySolid state diffusion coatingHeat treatment process controlCarbon potentialCarbon deposit

Vacuum carburizing of ferrous workpieces is performed at low pressure in a vacuum furnace using a napthene hydrocarbon as the carburizing medium. The furnace is constructed to be generally transparent to the napthene so that cracking tends to occur at the workpiece which functions as a catalyst to minimize carbon deposits. The napthene is supplied in liquid form to fuel injectors which inject the liquid napthene as a vapor at duty cycles and firing orders to produce a uniform dispersion of the hydrocarbon gas about the work resulting in uniform carburizing of the workpieces. An in-situ methane infrared sensor controls the process. Hydrogen is added to the napthene to either assure full carbon potential and produce methane or to perform variable carburizing.

Owner:SURFACE COMBUSTION

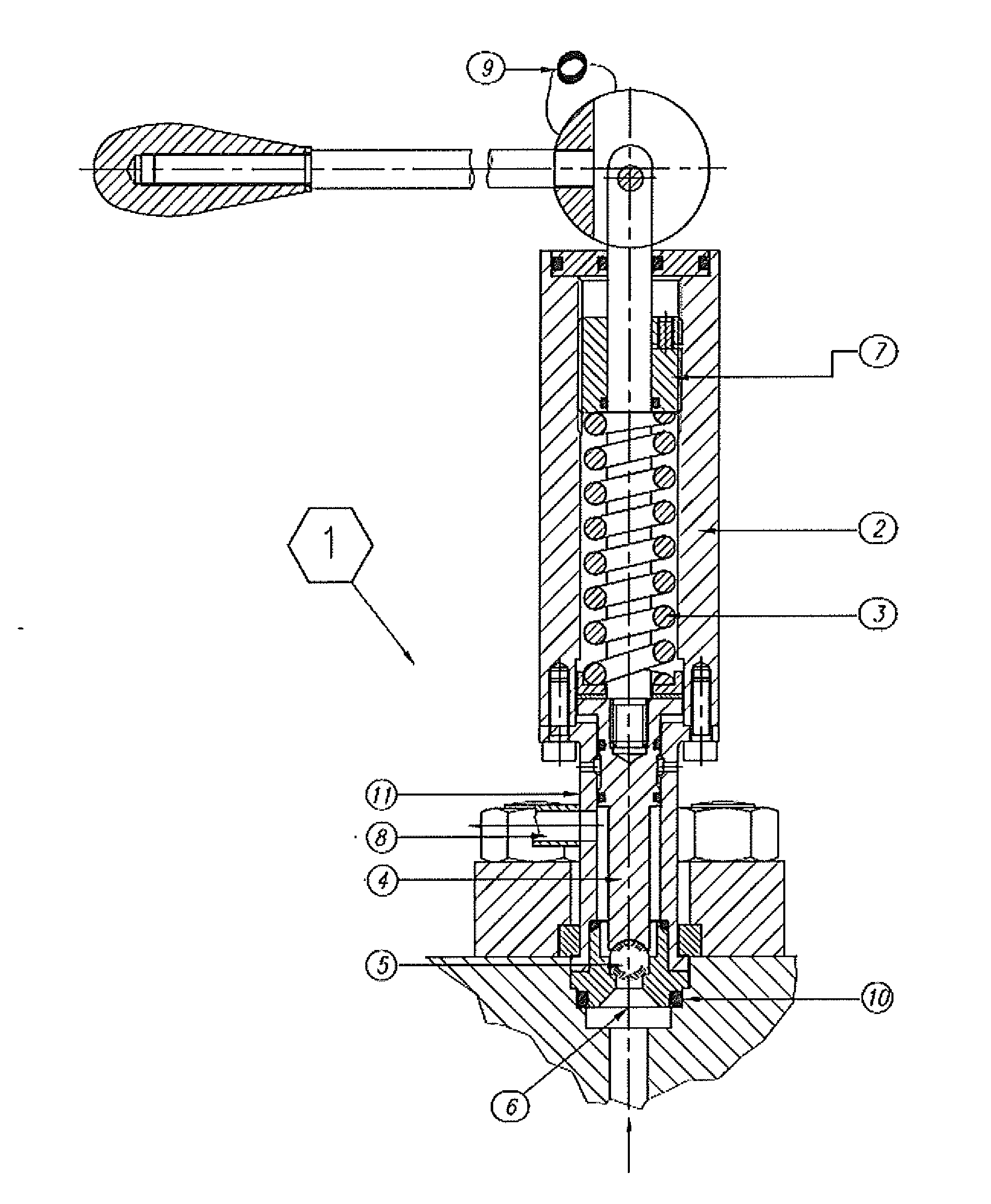

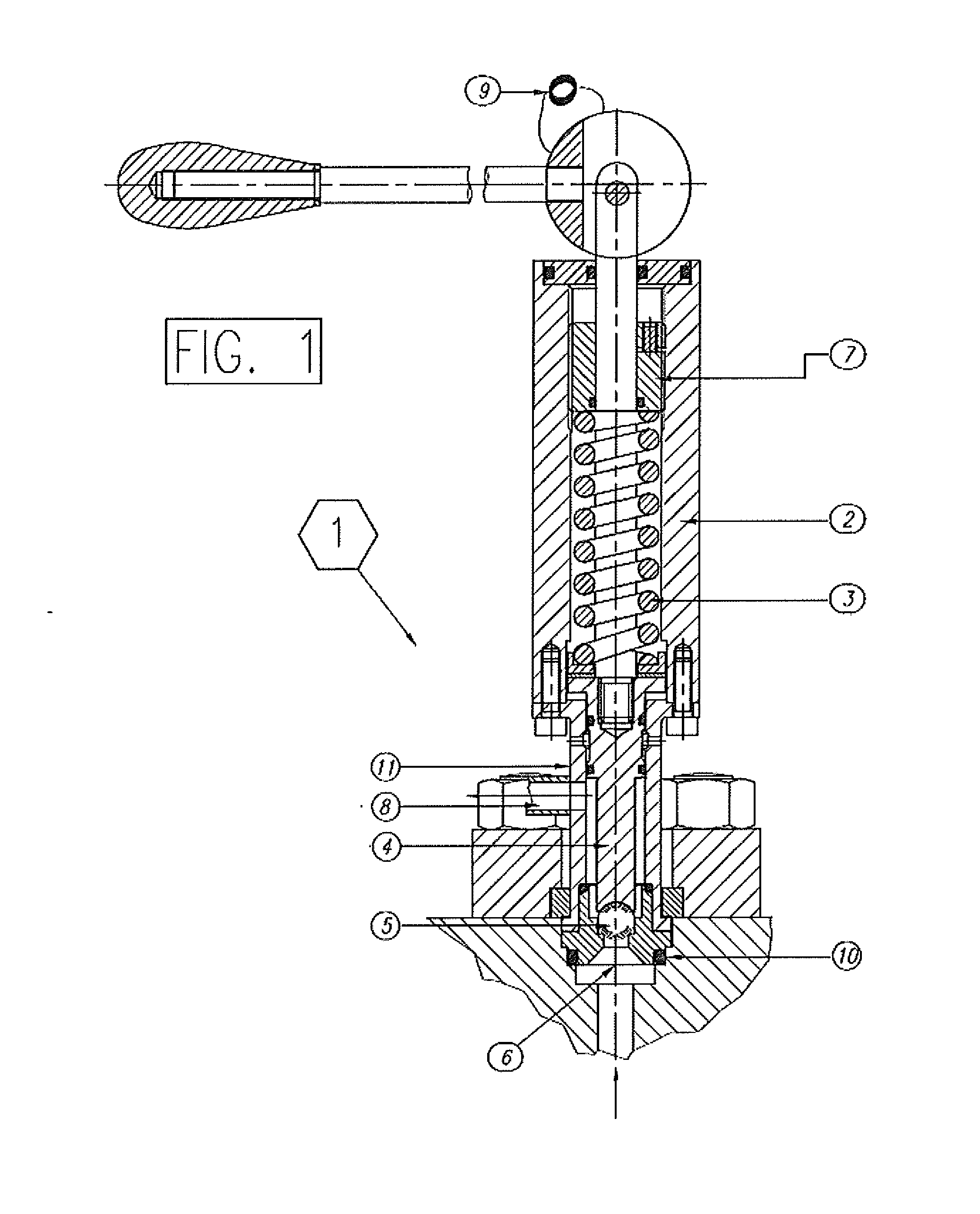

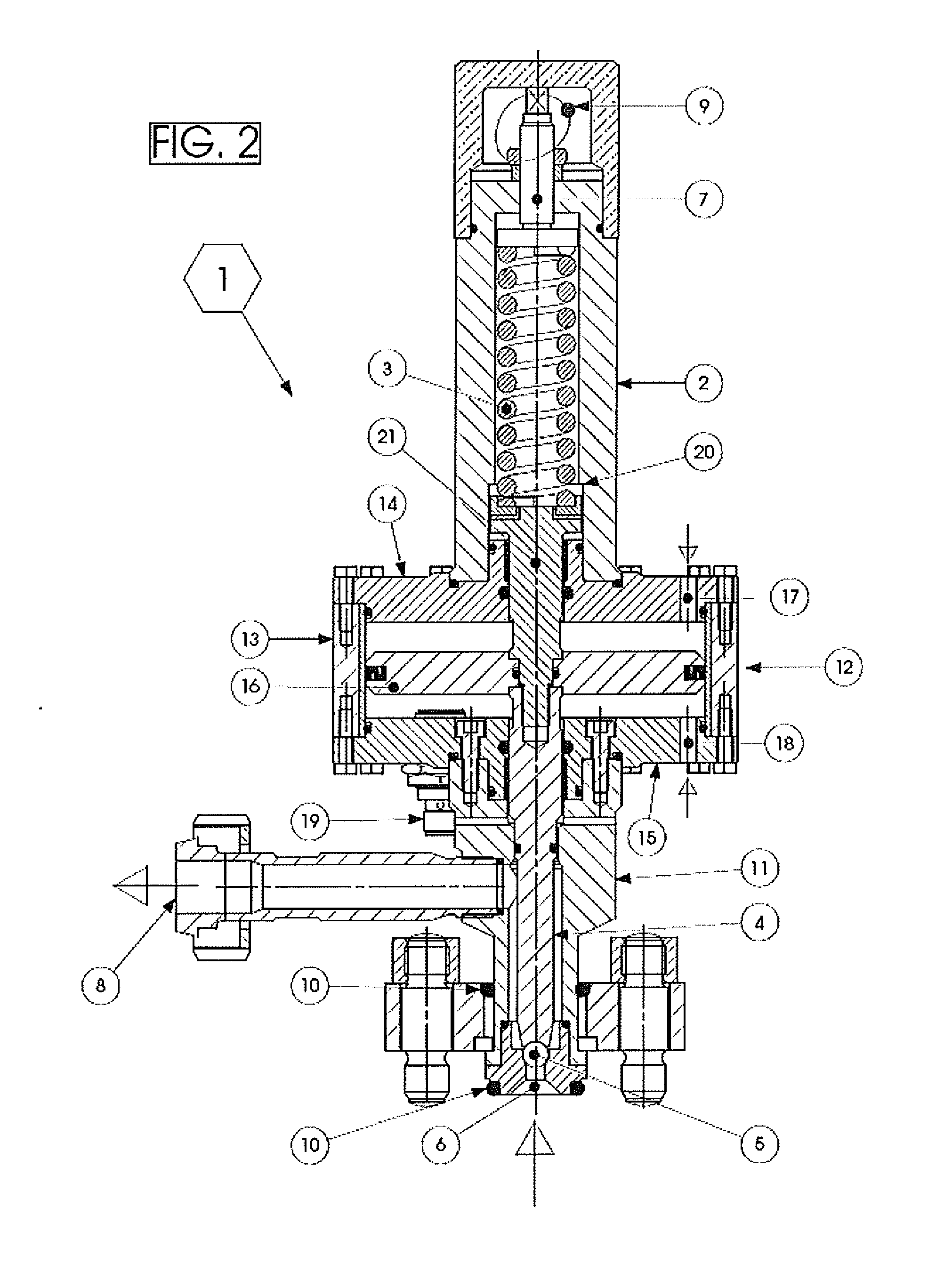

High pressure mechanical safety valve

InactiveUS20120199218A1Accurate CalibrationAccurate repeatabilityOperating means/releasing devices for valvesCheck valvesRemote controlHigh-pressure area

A high pressure mechanical safety valve (1), of the type comprising a body (2) housing elastic means (3) acting on a shutter element (4) normally maintained in a closing position when the pressure in a high pressure area beyond an aperture (6) is lower than the pressure, settable to a fixed calibration value, exerted by the elastic means (3). The safety valve comprises mechanical means for remote control of the valve, interposed between the elastic means (3) and the shutter element (4) to allow both a forced opening or a forced closing of the valve (1) The safety valve may also comprise an optional position sensor for signalling the open or closed status of the valve.

Owner:GEA MECHANICAL EQUIP ITAL

Swing cylinder

ActiveUS7290480B2Improve retentionSmall precise movementFluid-pressure actuatorsReciprocating piston enginesMechanical engineeringPiston

A swing cylinder having a body and an end cap on each end of the body. The cylinder also has a piston arranged within the body. The cylinder has a rod engaged with the piston and has an arm attached to one end thereof. A guide is arranged on the opposite end of the rod. The guide is also attached to one of the end caps.

Owner:DELAWARE CAPITAL FORMATION INC

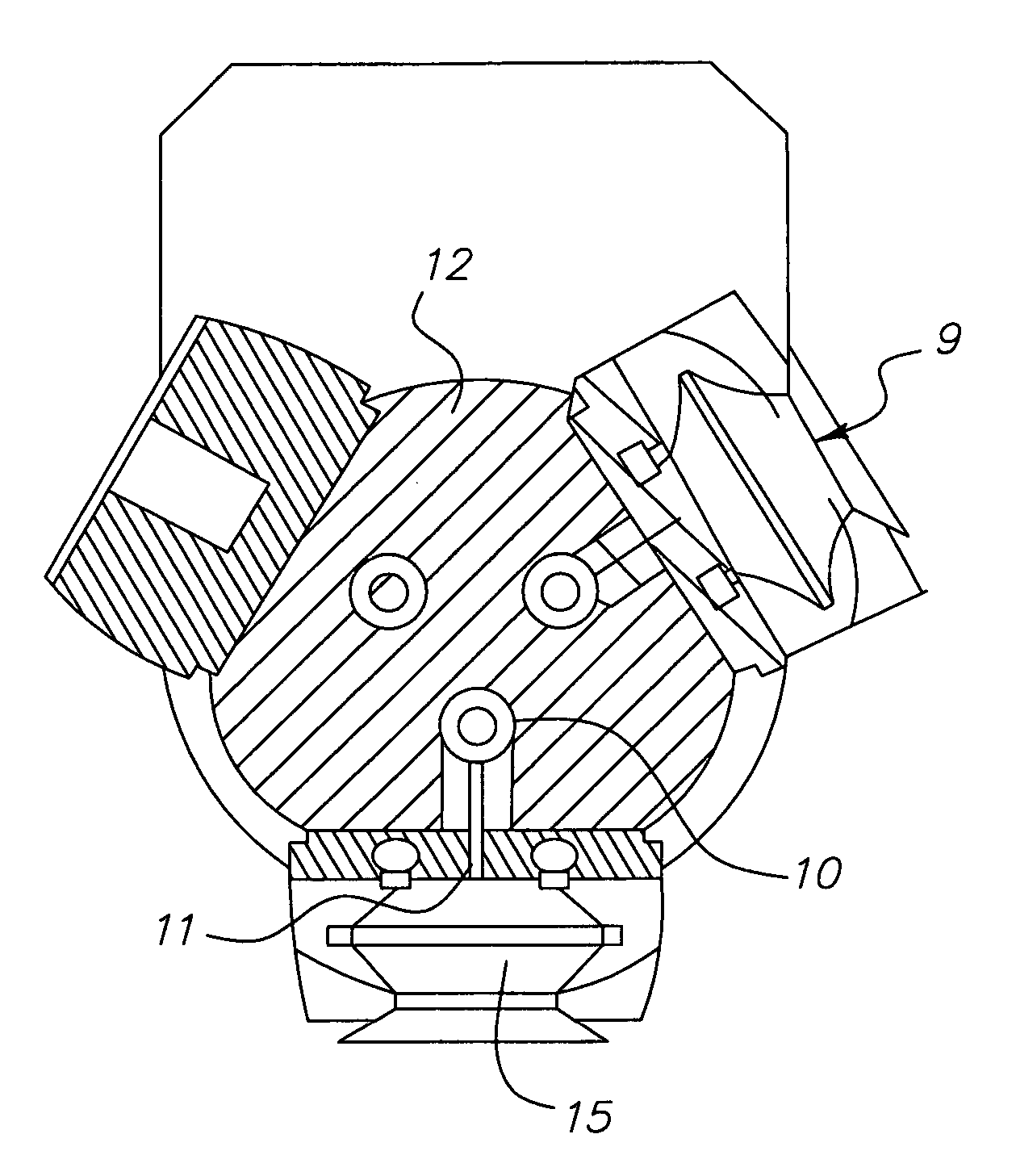

Multi-positionable rotary vacuum head for product processing

InactiveUS20060157997A1Accurate repeatabilityEliminate needGripping headsFurniture partsSuction forceEngineering

An assembly is presented. The assembly includes a rotatable cylinder including product-holding members positioned on the circumference of the cylinder. Several cylinder passageways are deployed within the cylinder, which provides fluid communication between the product holding members and a vacuum. As such, a suction force may be applied from the vacuum through the cylinder passageway to the product-holding member. A locating pin is deployed on one end of the rotating cylinder. The locating pin enables rotation of the cylinder and a positive stop of the cylinder in an aligned position. The locating pin works in conjunction with an O-ring so that vacuum is only applied to one cylinder and one set of product holding members when the locating pin is locked in the positive stop position.

Owner:EASTMAN KODAK CO

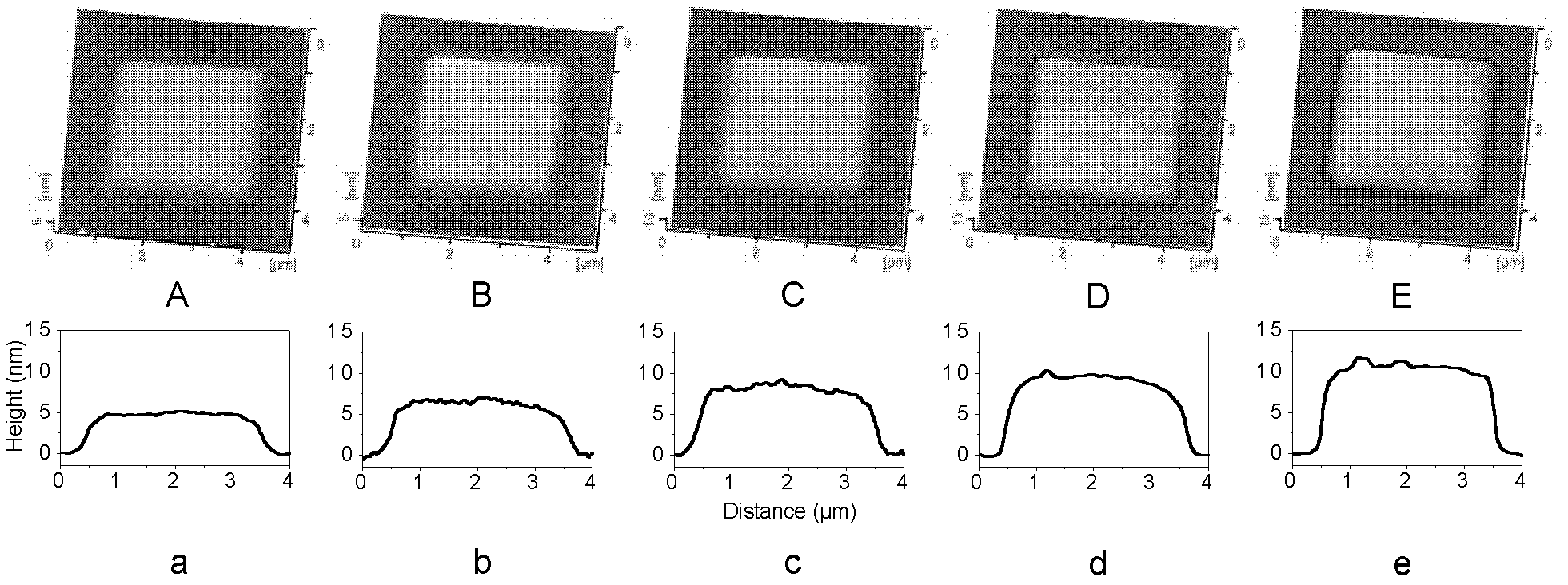

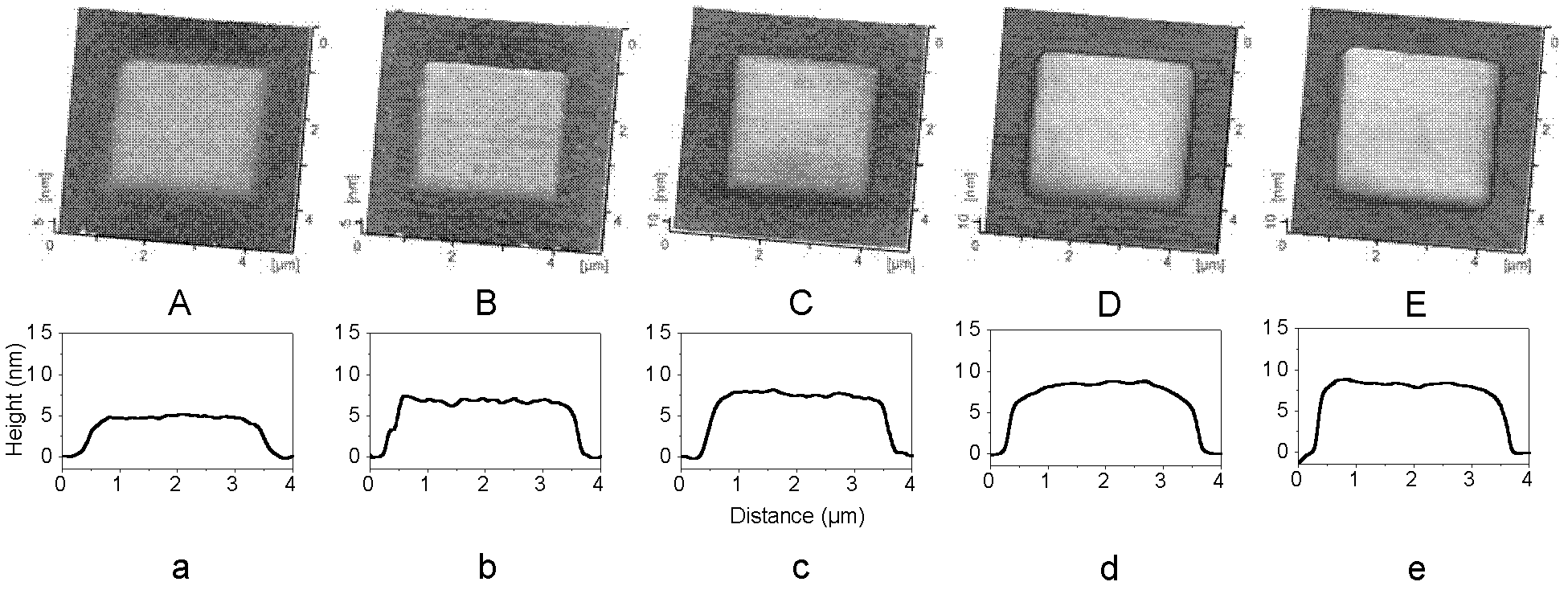

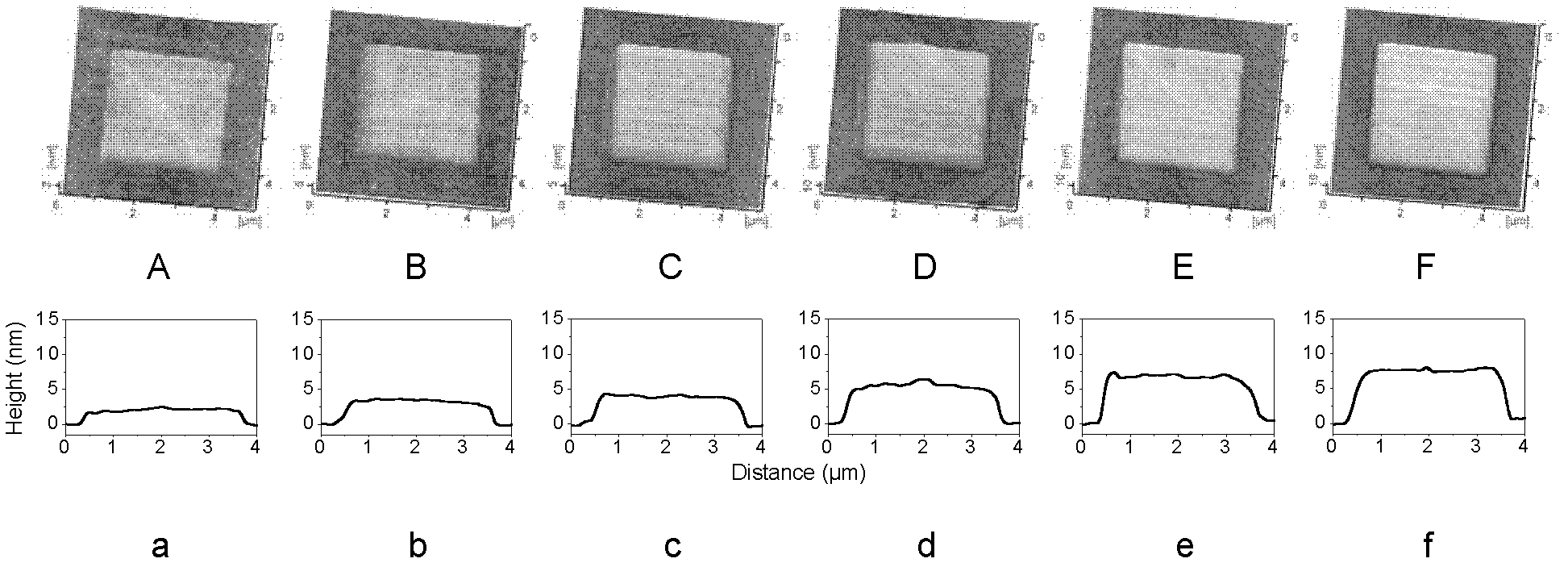

Glass surface nanofabrication method based on friction-induced selective etching

ActiveCN102503155AReduce processReduce the difficulty of operationDecorative surface effectsNanotechnologyConstant loadEtching

The invention discloses a glass surface nanofabrication method based on friction-induced selective etching, which is mainly applied in the processing of the glass surface micro-nanostructure. The specific operation method comprises the following steps of: installing a probe of which the tip is spherical on an atomic force microscope, fixing the cleaned glass on a sample stage, starting the atomic force microscope, applying a constant load F or a variable load F' on the probe, using the probe to scan on the glass surface along a set scanning track according to the cycle number N and the scanning speed v; and after scanning, placing the glass in an HF solution of which mass concentration is 10-20%, and finally corroding for 5-10 seconds. The method does not require a template or mask, three-dimensional nano-patterns such as slopes, steps and arrays are processed on the glass surface through one-time corrosion; and the processing flow is extremely simple, the corrosion rate is extremely high, and the glass surface nanofabrication method is simple, accurate and efficient.

Owner:SOUTHWEST JIAOTONG UNIV

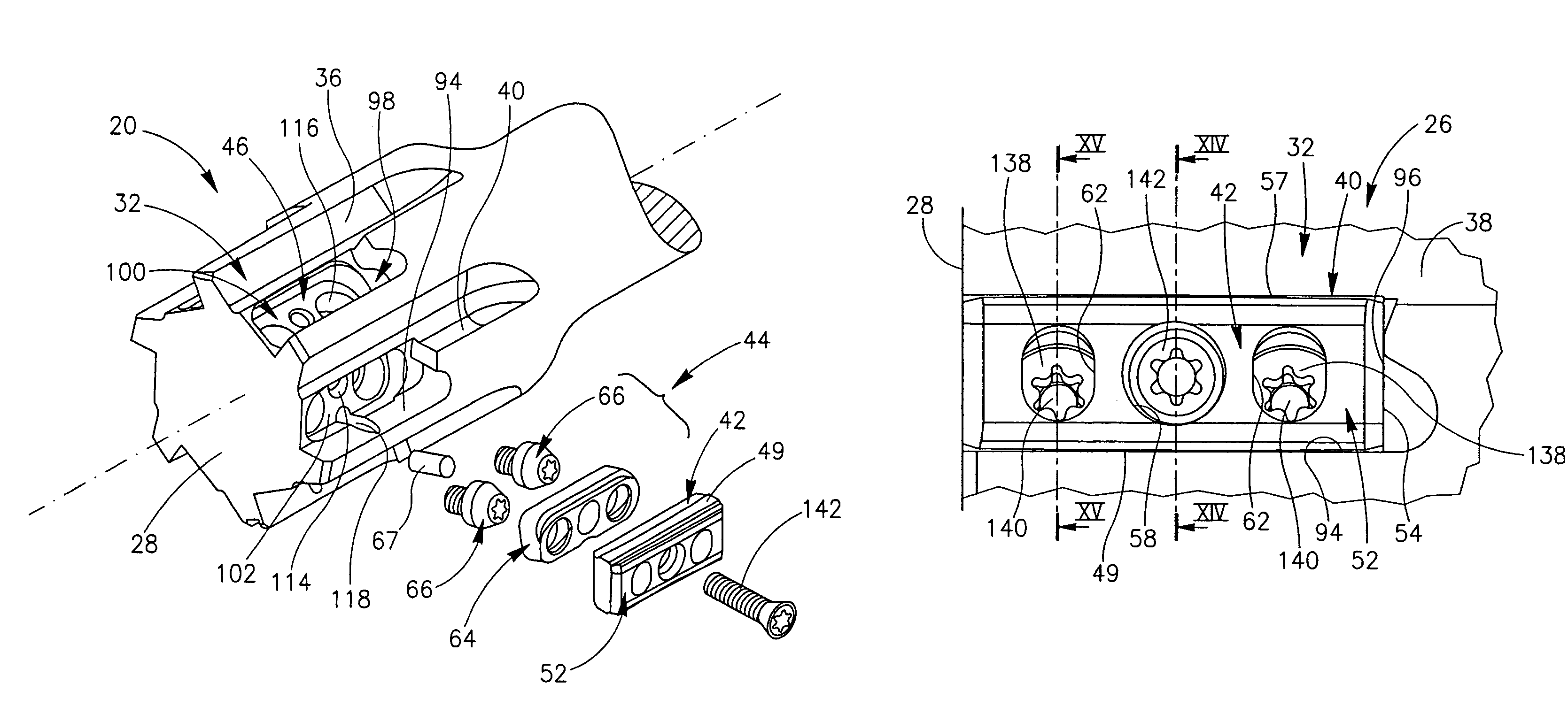

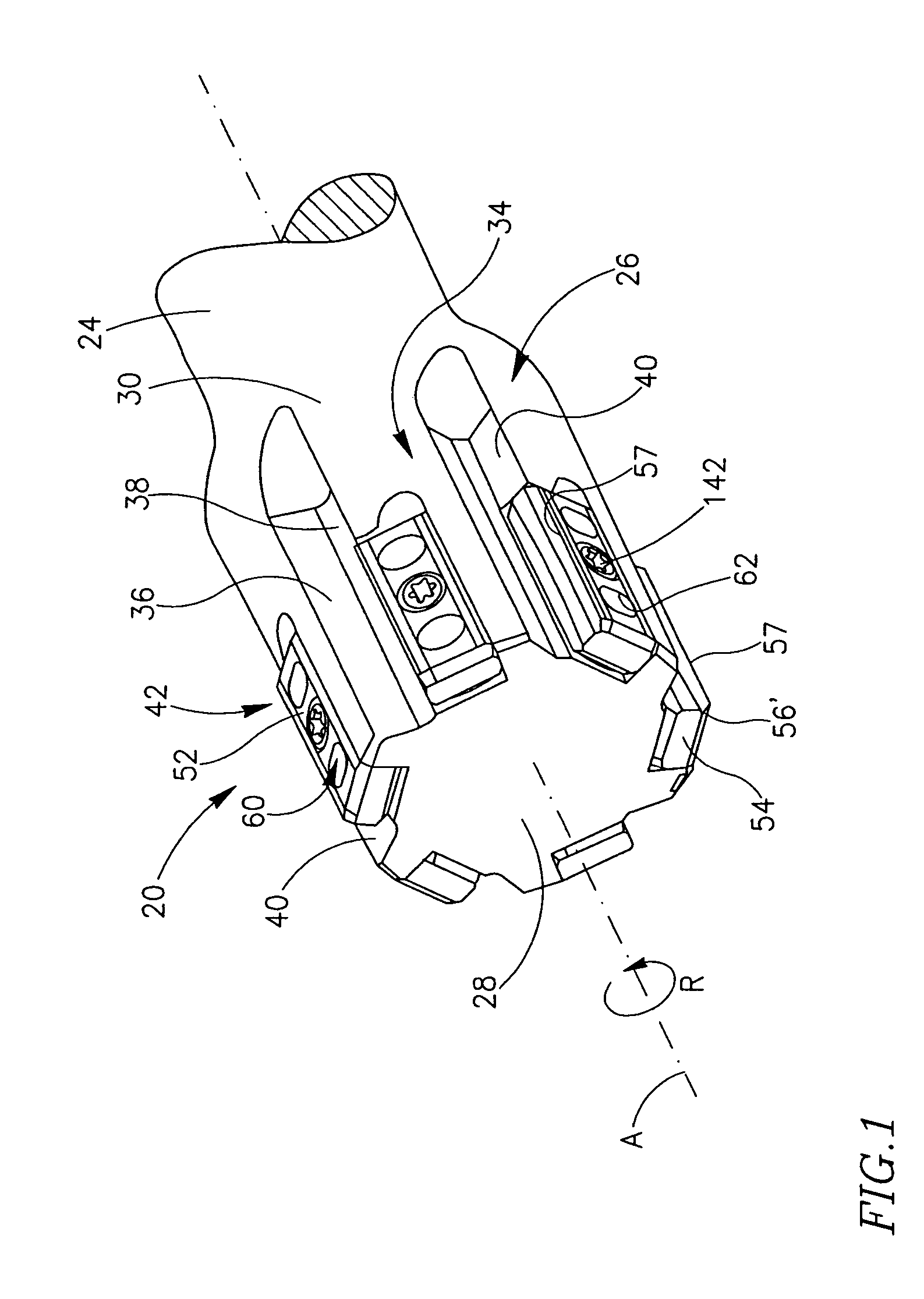

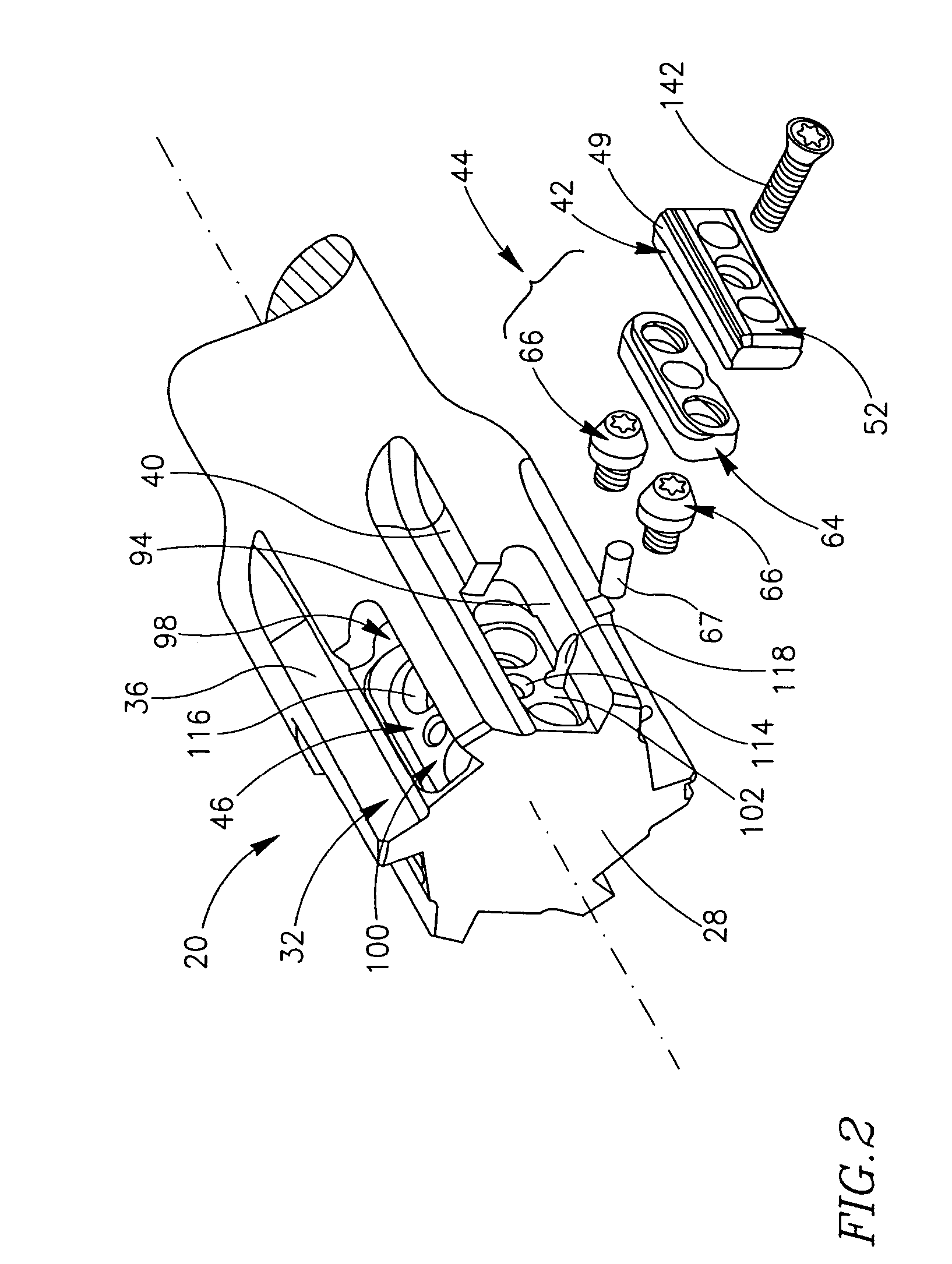

Cutting insert and cutting tool

ActiveUS7311477B2Precise positioningIncrease the number ofThread cutting toolsTransportation and packagingMechanical engineeringMetal cutting

A metal cutting tool is provided with at least one cutting insert mounted in an insert pocket in communication with an adjusting mechanism, the cutting insert comprising at least one insert adjusting slot extending between two opposing major faces thereof and opening out to each major face at an adjusting aperture and the adjusting mechanism comprising at least one adjusting member having an adjusting member top face underlying the cutting insert while being visible and accessible therethrough.

Owner:ISCAR LTD

Printed anti-false product and method with self authentication information

InactiveCN101483019AGet rid of dependenceInnovative designStampsIdentification meansGraphicsPrinting ink

Information carrier is printed or pressed with points, lines, graphics, texts or combination of them, which not only has the only characteristic information, but also has information recorded with characteristic information (namely self-certification information). The method includes: printing points, lines, graphics, texts or combination of them on the information carrier, using an image acquisition instrument to read related characteristic information such as microscopic veins, tablet configuration, gaps surrounded by flaws or veins presented by printing ink or dry toner inside the image acquisition instrument, converting the characteristic information into another information expression mode, namely self-certification information, and denotes on the pressed points, lines, graphics, texts or combination of them on a same information carrier; when identification is required, the characteristic information and self-certification information on the anti-counterfeiting products can be read by the image acquisition instrument, performing internal conversion according to the regulation, and then judging whether the two information is coincident in artificial or automatic mode, if coincident, the characteristic information is true, otherwise it is false. The invention has advantages of low cost, capability of large-lot production, capability of easily and accurately identifying, and application in all fields. The counterfeiters can not effectively imitate.

Owner:樊晓青

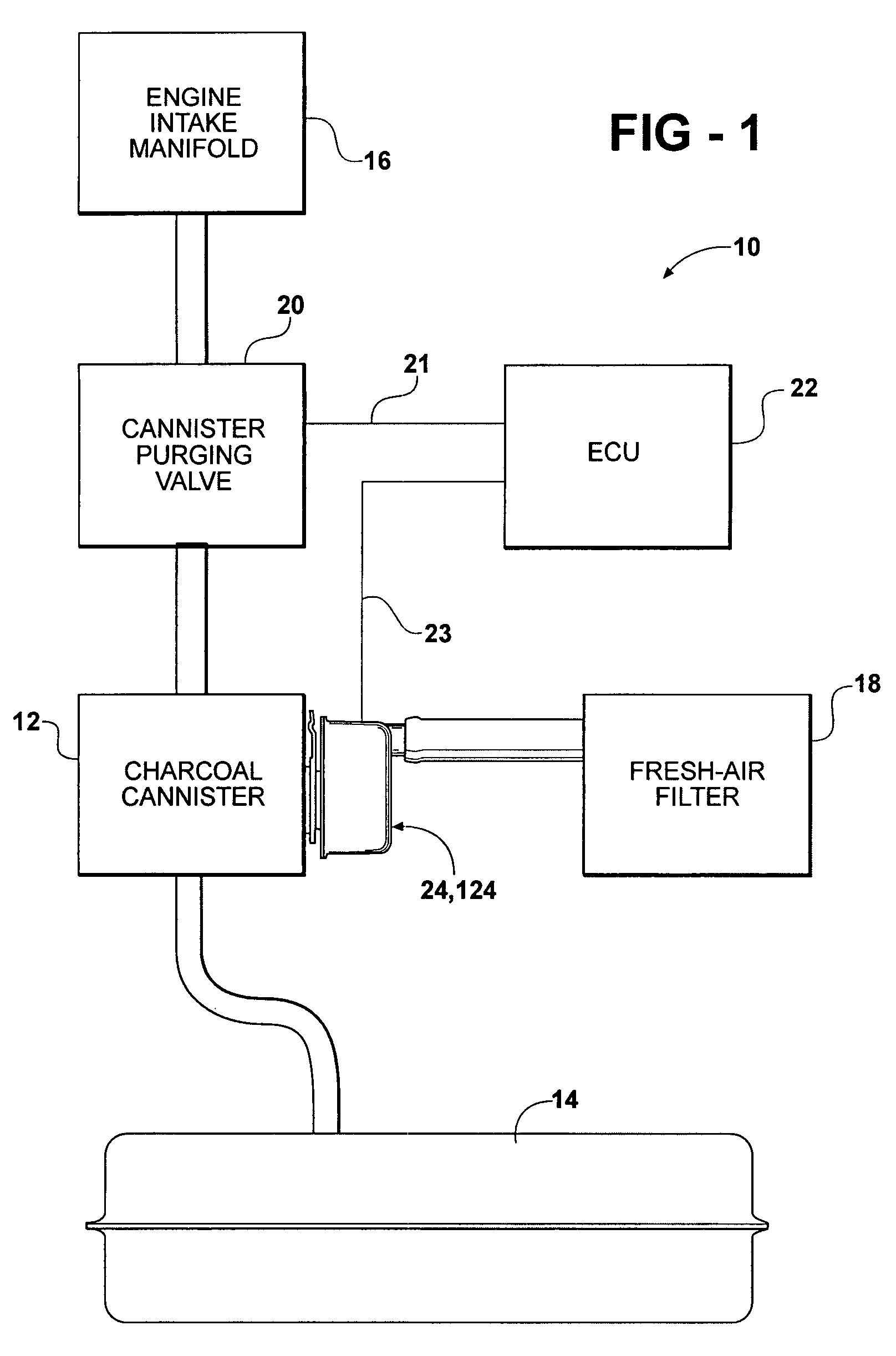

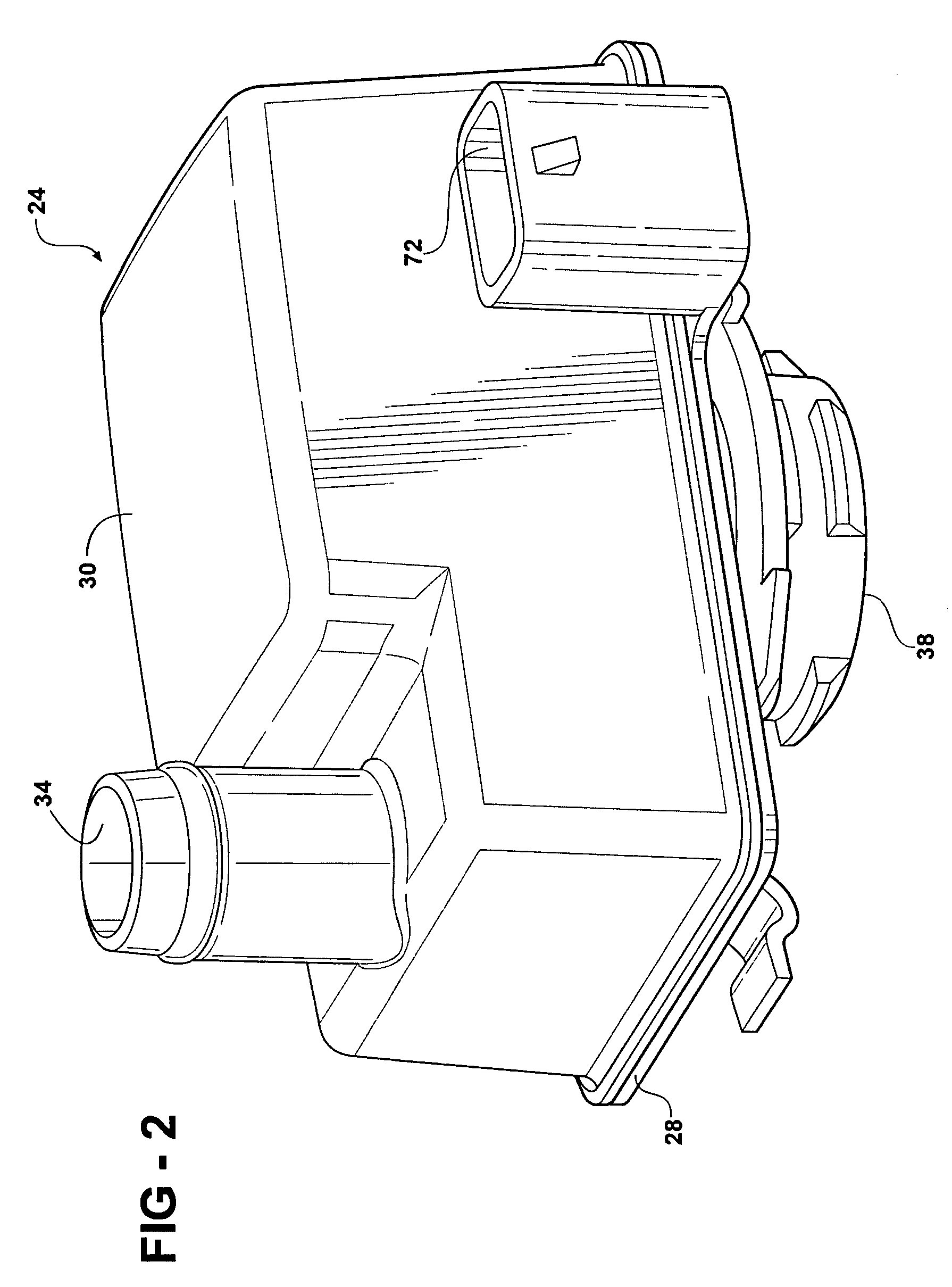

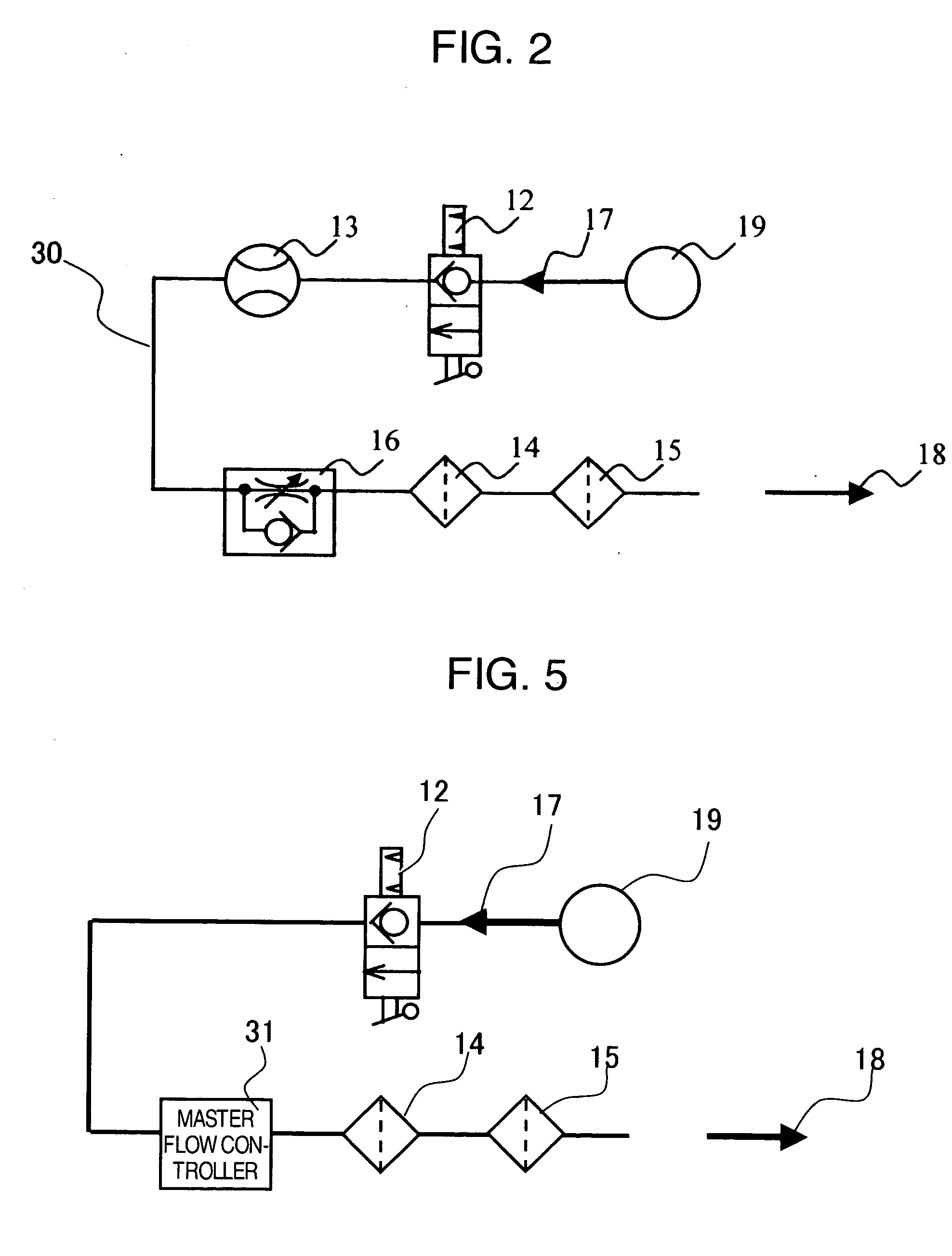

Evaporative emission canister purge actuation monitoring system

InactiveUS7431022B1Reduce in quantityReduce manufacturing costNon-fuel substance addition to fuelEngine controllersPositive pressureMonitoring system

An evaporative emission canister purge actuation monitoring system includes an integrated valve body having a main flow passage, a first one-way umbrella valve mounted to the valve body that is responsive to predetermined positive pressure in the main flow passage to control flow of fluid from a vapor canister to ambient air as well as a second one-way umbrella valve that is responsive to a predetermined negative pressure in the main flow passage to control the flow of ambient air through a fresh air port. A vacuum actuated switch is supported by the integrated valve body and in electrical communication with a control unit. The switch is responsive to negative pressure in the main flow passage to send a signal indicative of the predetermined negative pressure to the control unit.

Owner:MAHLE INT GMBH

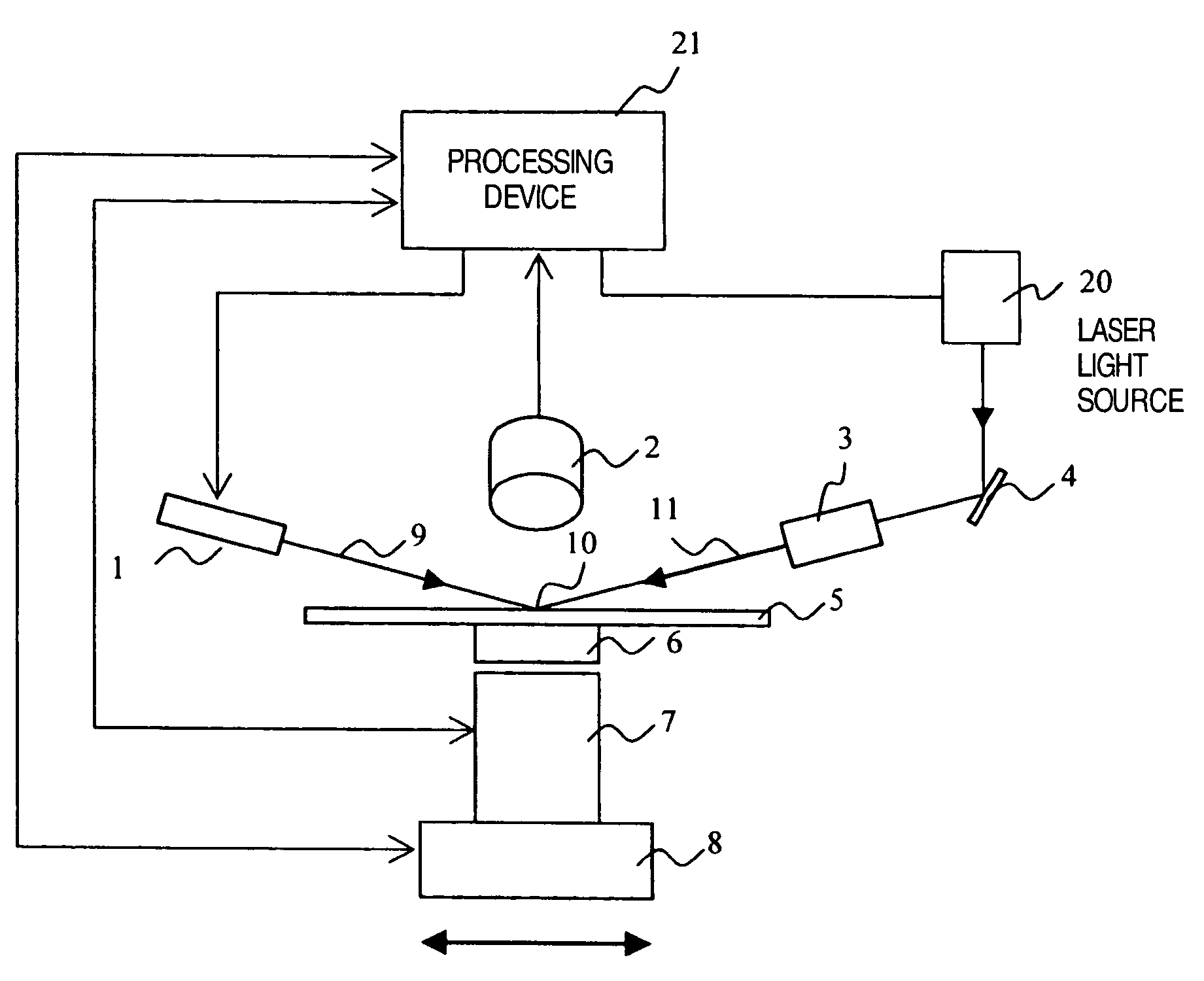

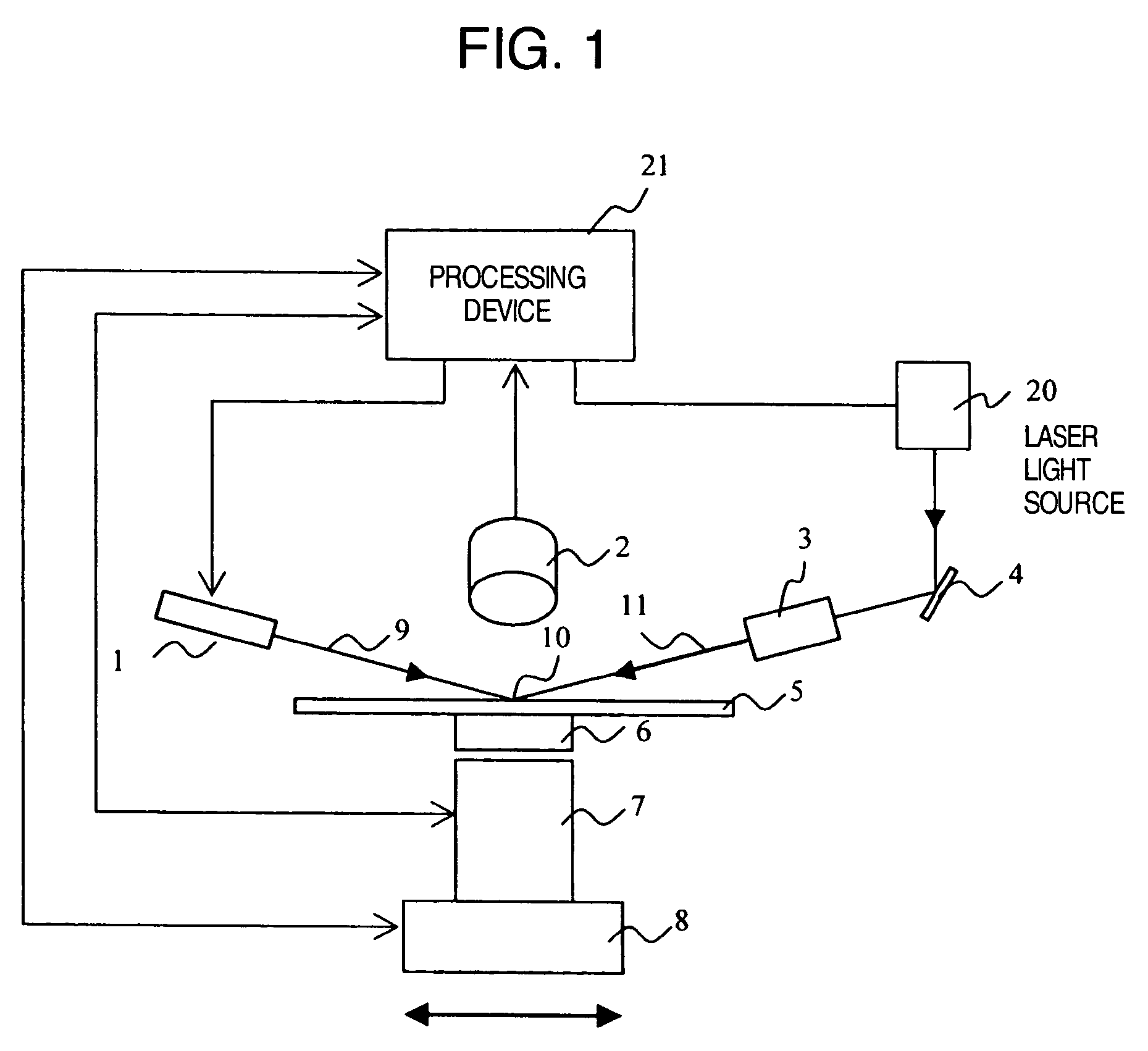

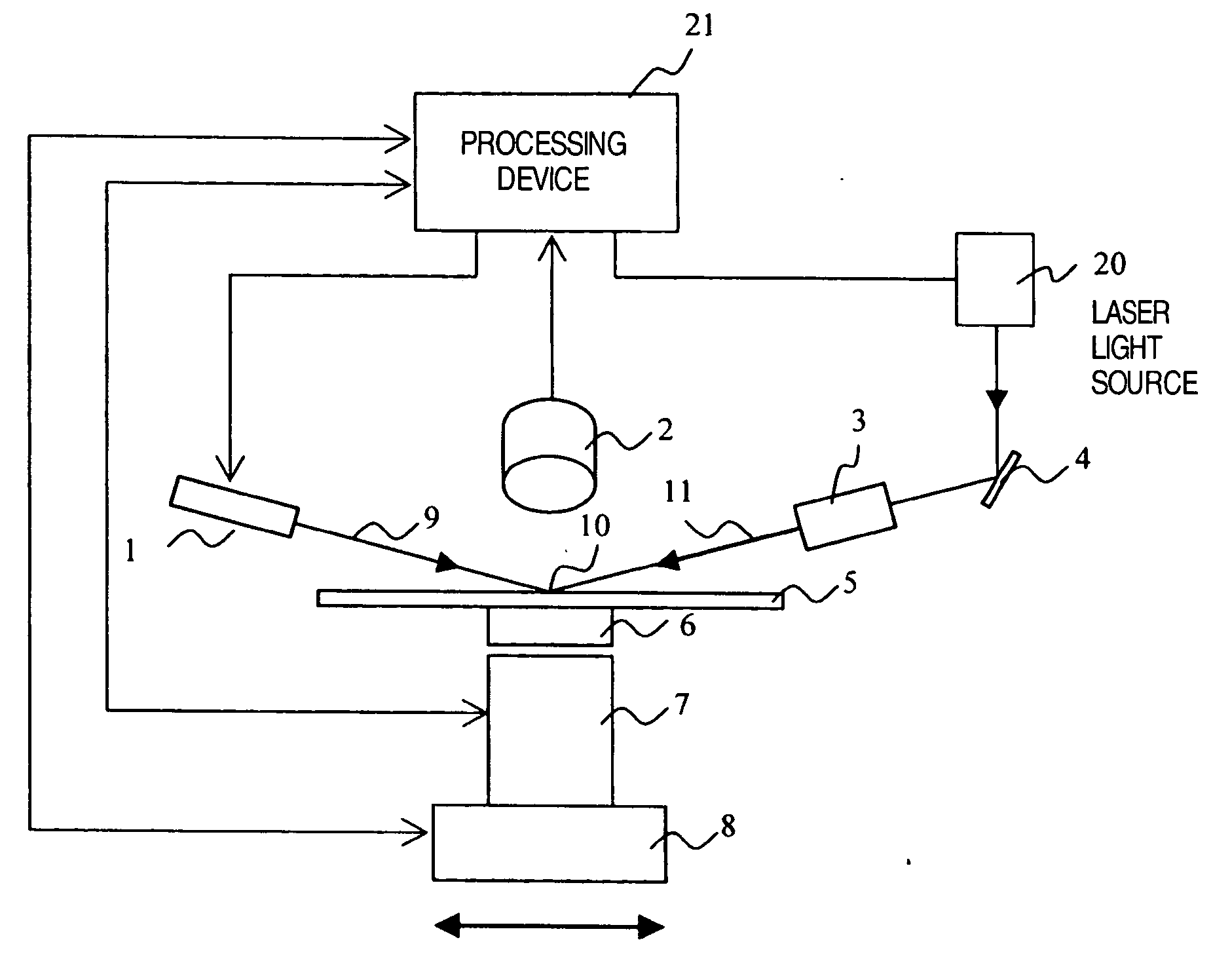

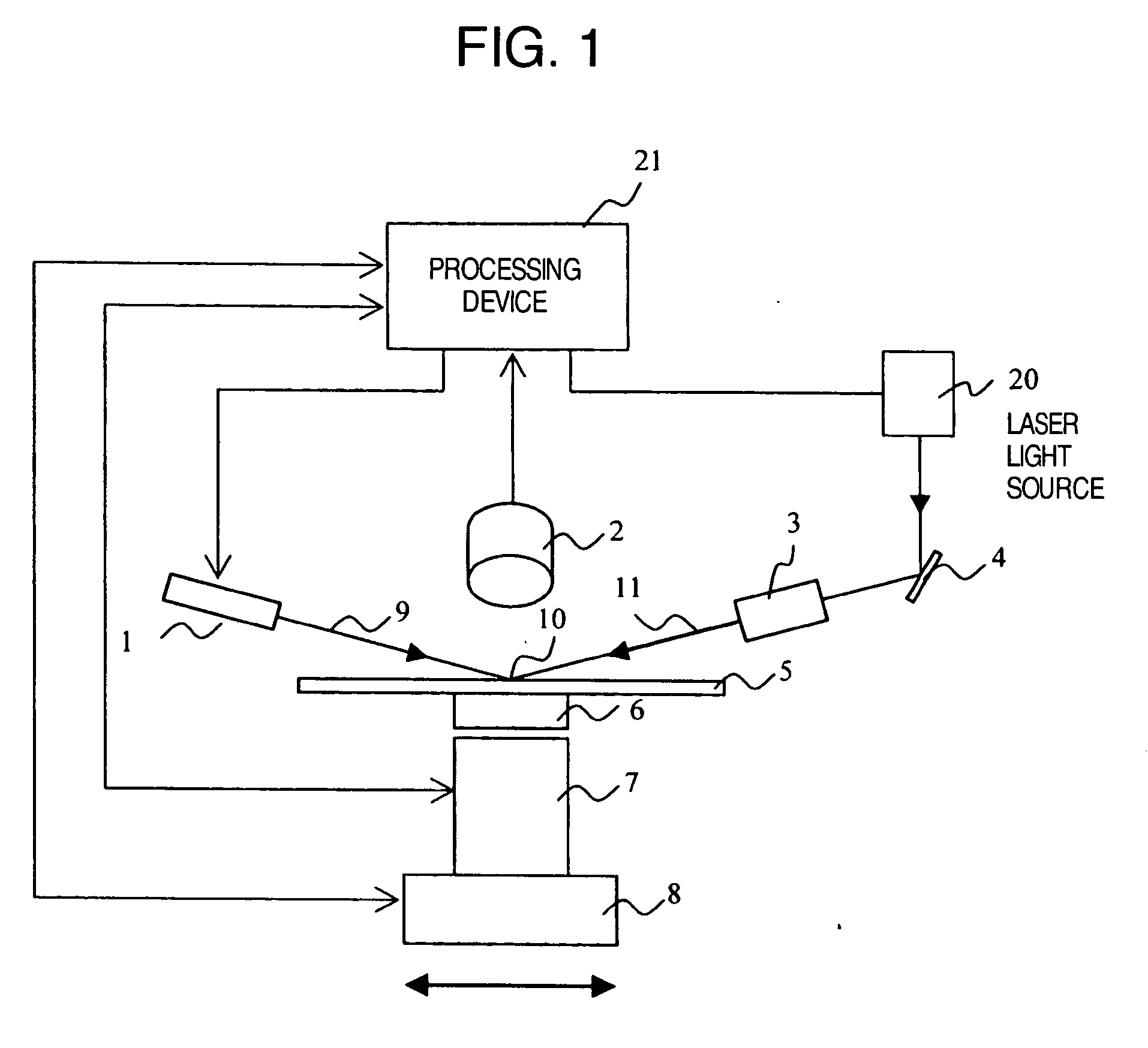

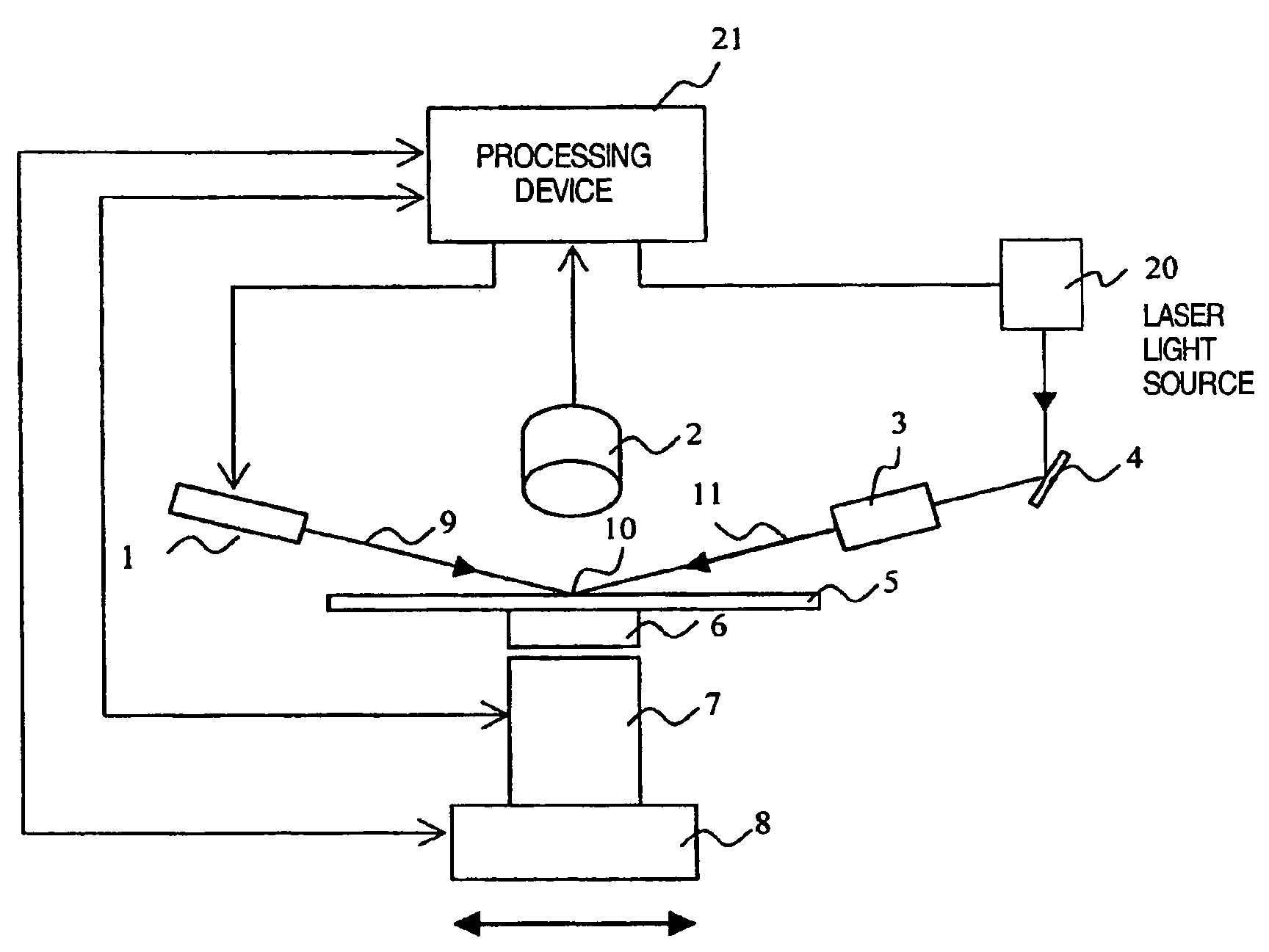

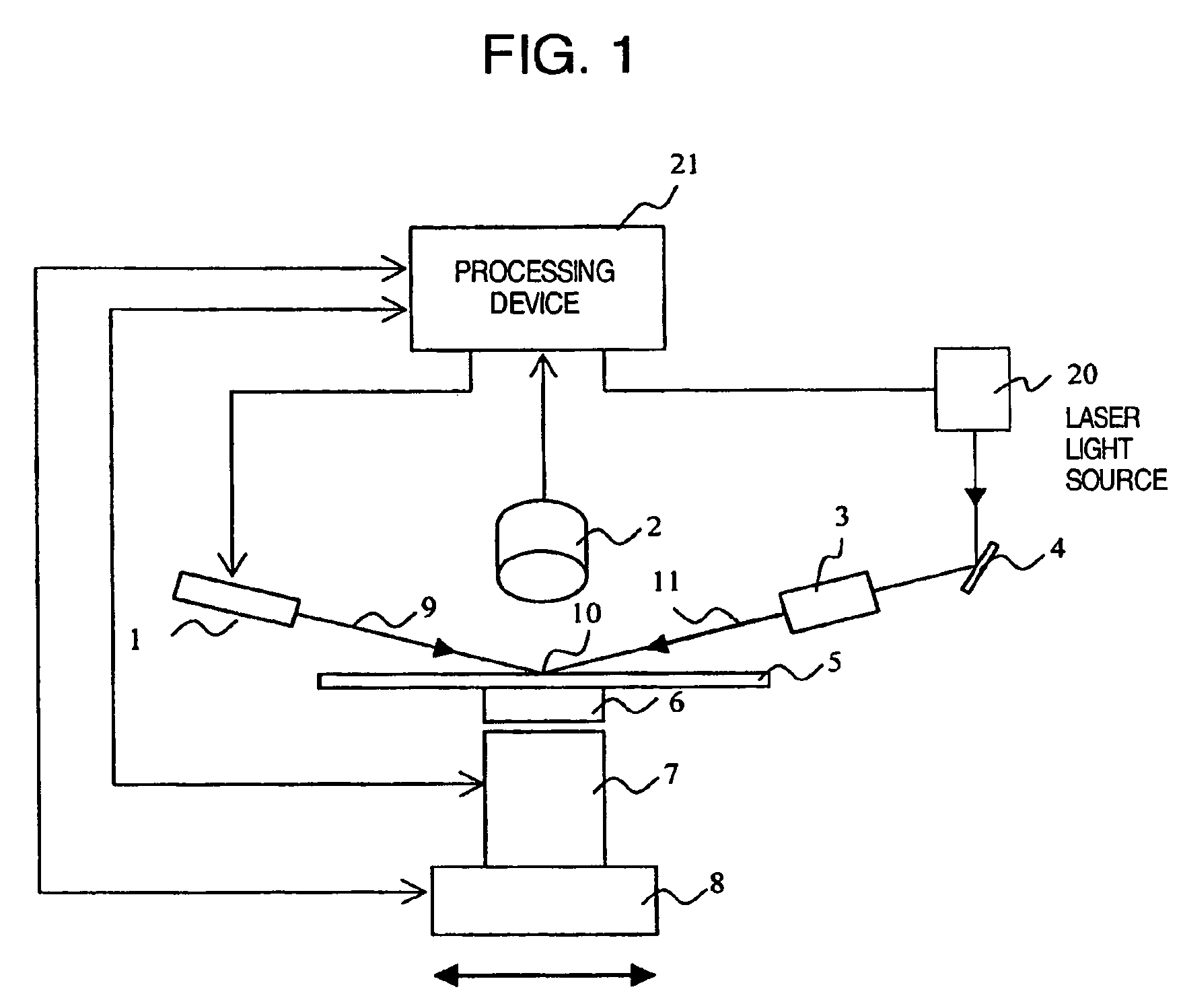

Wafer surface inspection apparatus and wafer surface inspection method

ActiveUS7420668B2Improve cleanlinessWithout lowering detection sensitivityMaterial analysis using wave/particle radiationElectric discharge tubesEngineeringIrradiation

A wafer surface inspection method and apparatus of high sensitivity, and free from performance degradation in terms of cleanliness, coordinate repeatability of foreign particles and the like. Gas for cooling is sprayed onto a laser irradiation position on the wafer surface to prevent an increase in temperature of the foreign particles and to suppress break-down of the foreign particles.

Owner:HITACHI HIGH-TECH CORP

Temperature measuring device and temperature measuring method

ActiveCN104155019AAccurately obtain temperature valuesTemperature controlThermometer detailsThermometers using electric/magnetic elementsMeasuring instrumentThermocouple

The invention discloses a temperature measuring device and a temperature measuring method. The temperature measuring device comprises an insulated body, a thermocouple, and a temperature measuring instrument, wherein the insulated body is provided with a mounting groove; the thermocouple is arranged in the mounting groove; a wiring groove is formed in the insulated body; the wiring groove is communicated with the mounting groove; a wire is arranged in the wiring groove; one end of the wire is electrically connected with the thermocouple and the other end extends out from the wiring groove; and the temperature measuring instrument is electrically connected with the other end of the wire for receiving electrical signals converted by the thermocouple. The temperature measuring device of the invention can accurately acquire the temperature value on the surface of a cell in the case of hot air welding through simulating the processing environment when the cell is welded, and thus, during the actual welding process of the cell, the temperature on the surface of the cell can be effectively controlled, and cracking can be prevented.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

Magnetron cathodes

ActiveUS20140210340A1Reduce decreaseRobust constructionIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationEngineeringCathode

A magnetron cathode comprises electron emissive material included in a cathode body and a support structure for supporting the cathode body. The support structure has a longitudinal axis and includes a first part having a first cylinder integrally formed with a first end hat and a second part having a second cylinder integrally formed with a second end hat. The first cylinder and the second cylinder have an overlapping region in the longitudinal axial direction and are joined together. The cathode body is located around the first cylinder of the first part of the support structure and is joined to the first cylinder by a brazed joint. The outer surface of the first cylinder is grooved at the brazed joint.

Owner:E2V TECH (UK) LTD

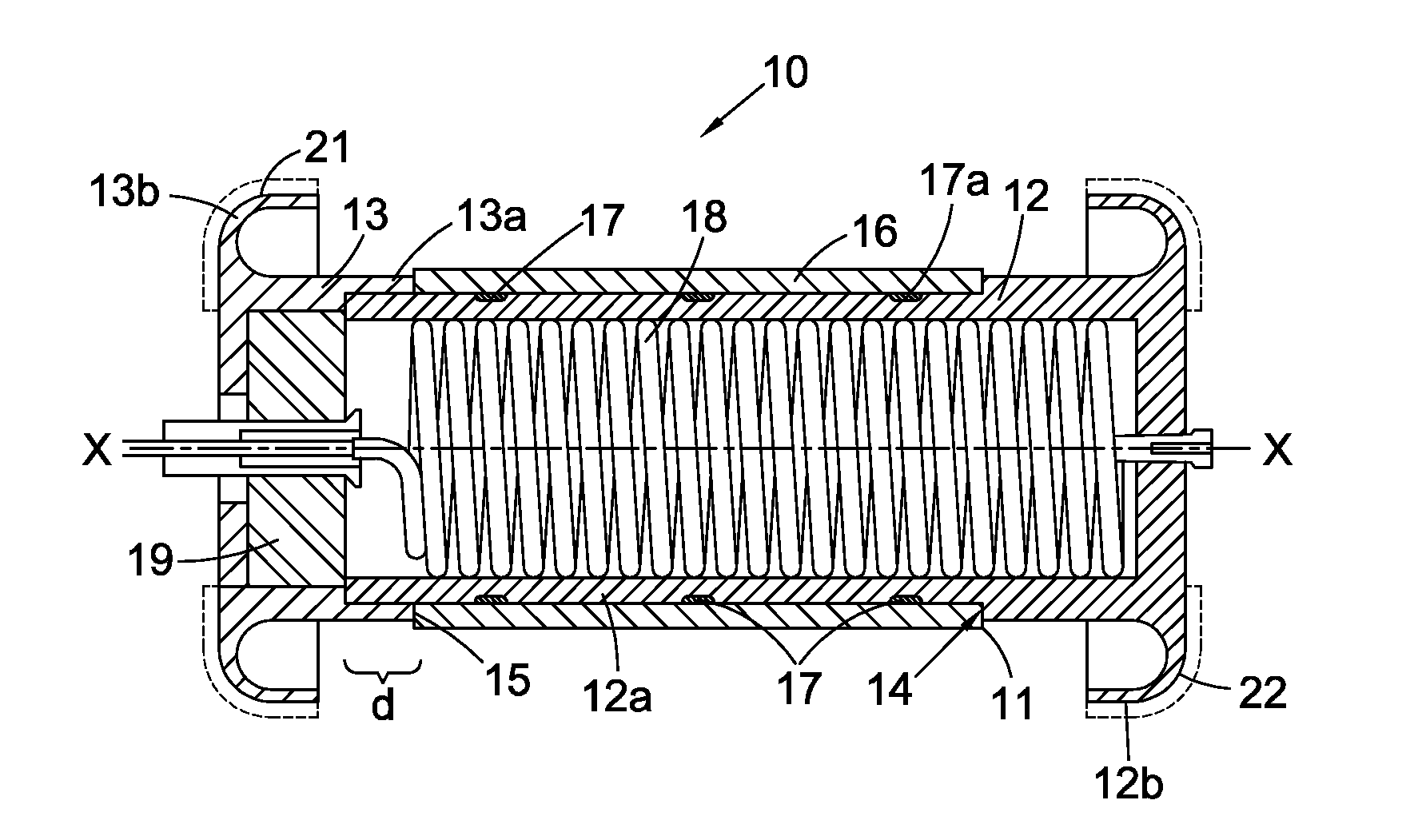

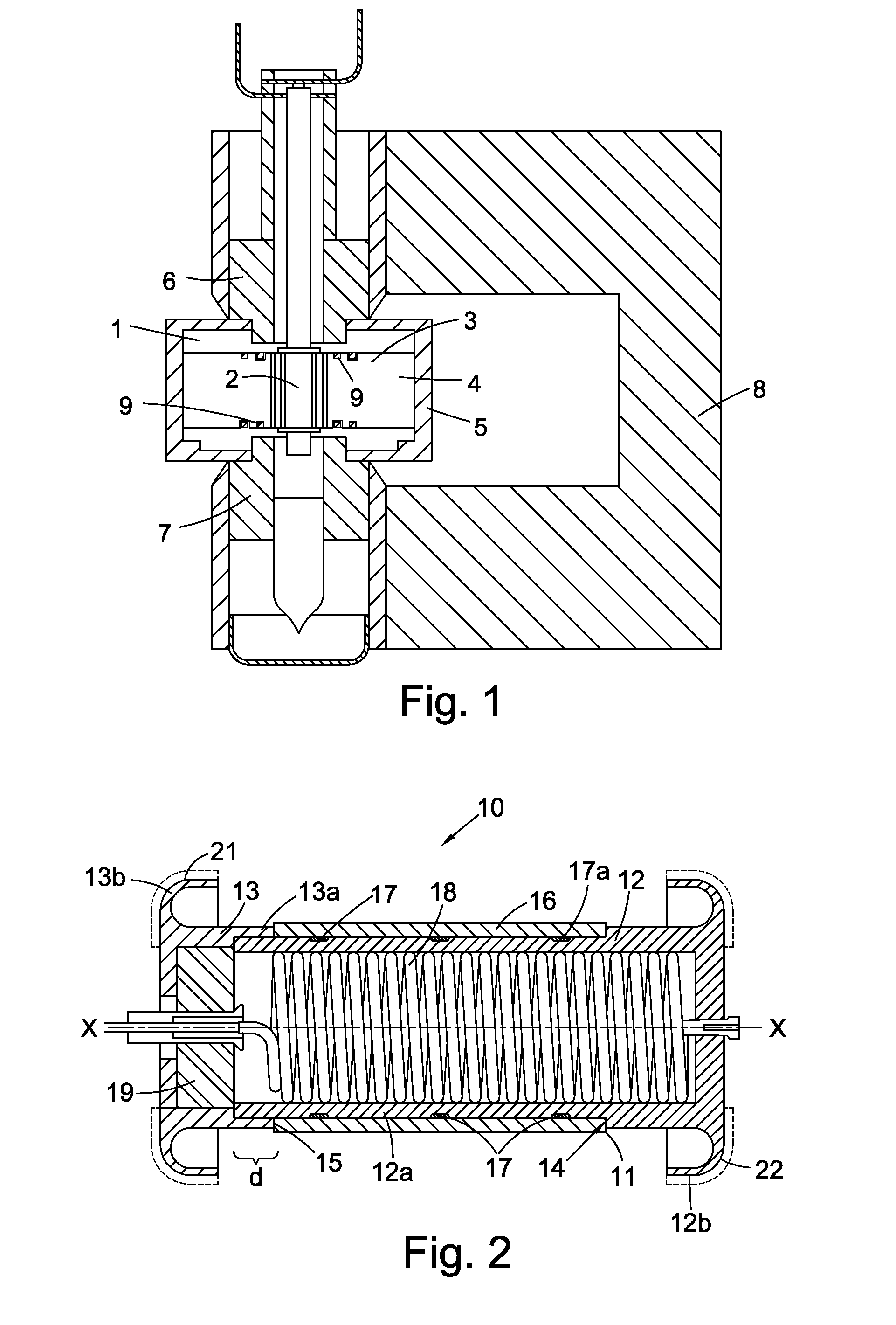

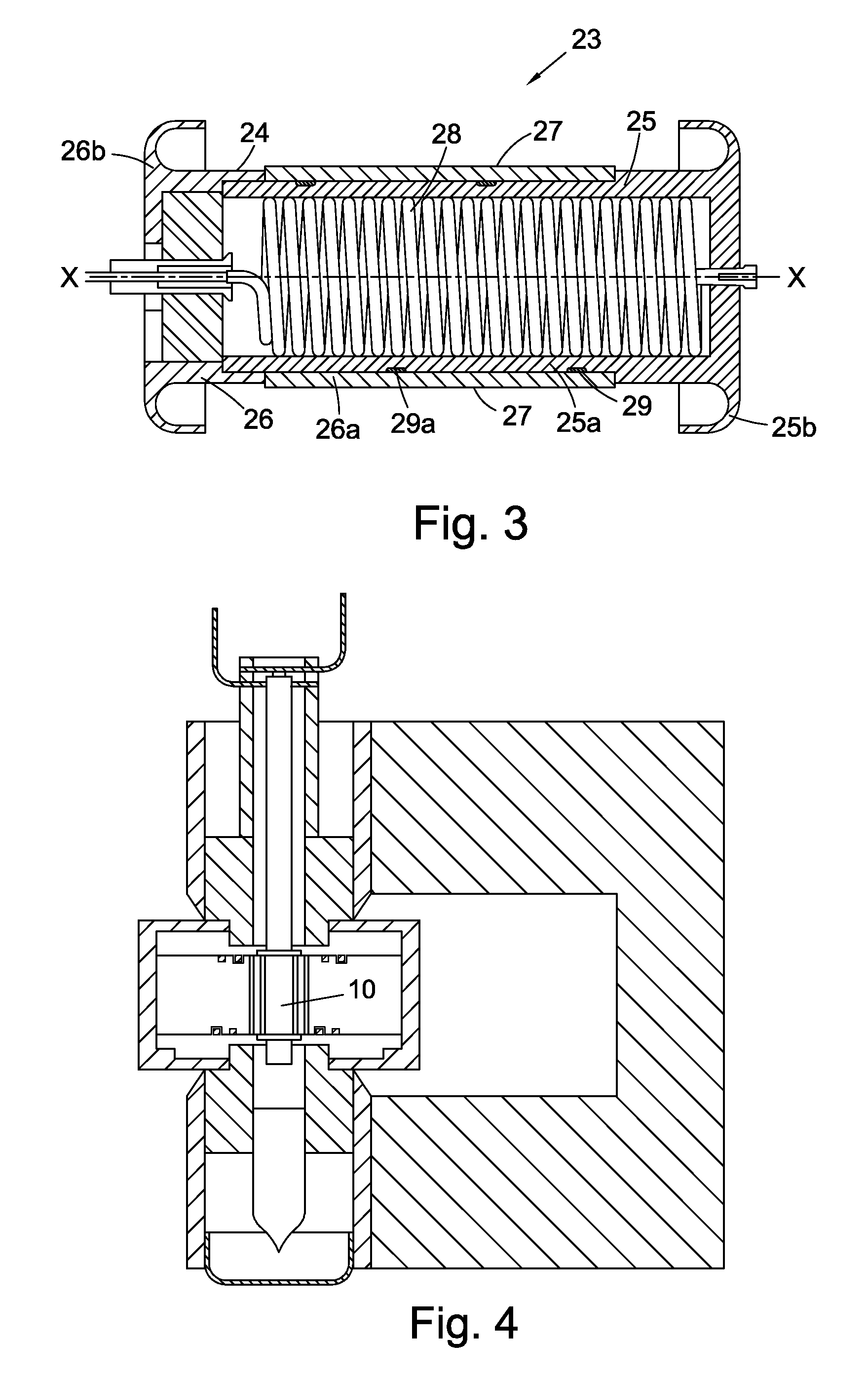

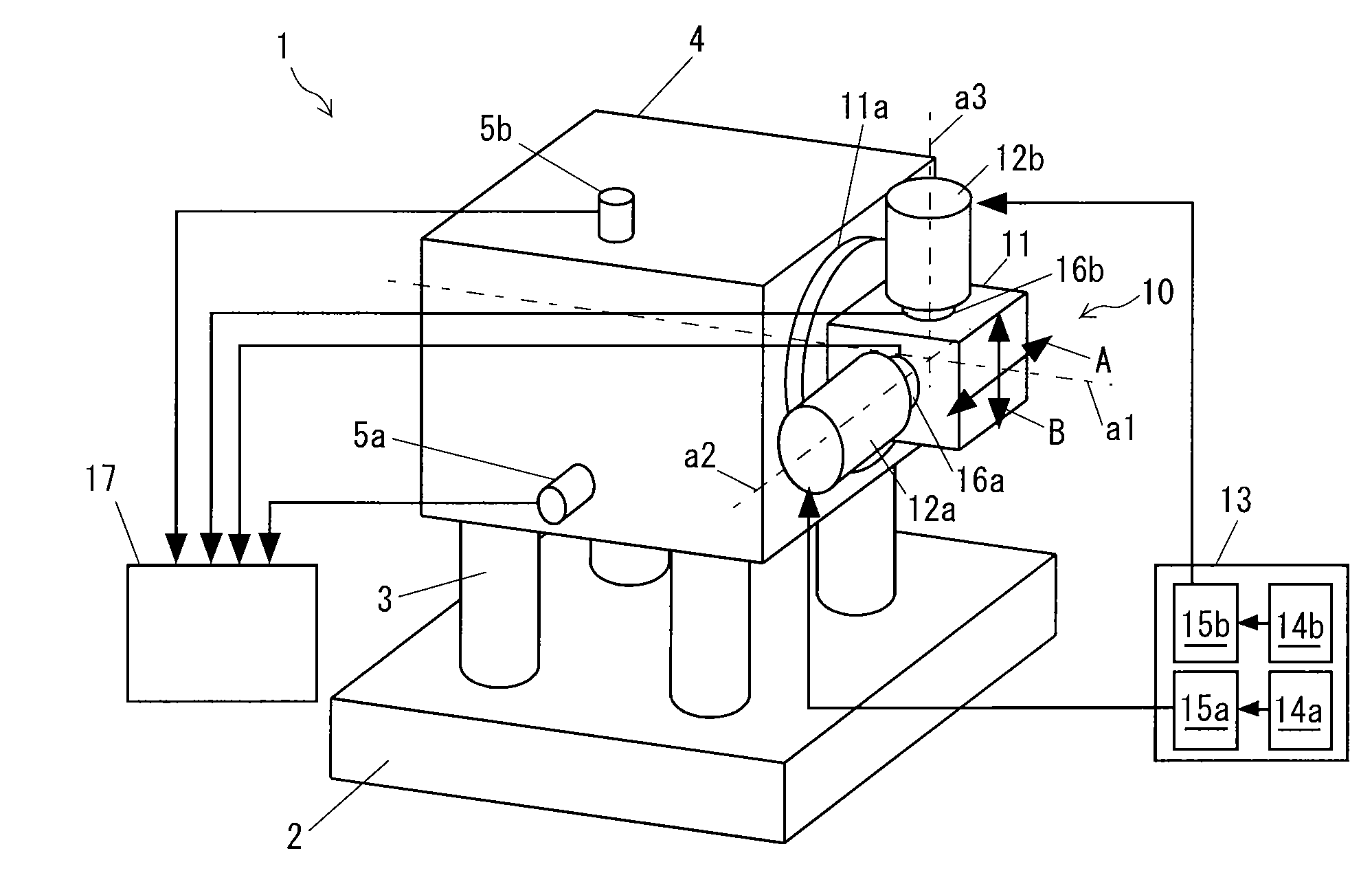

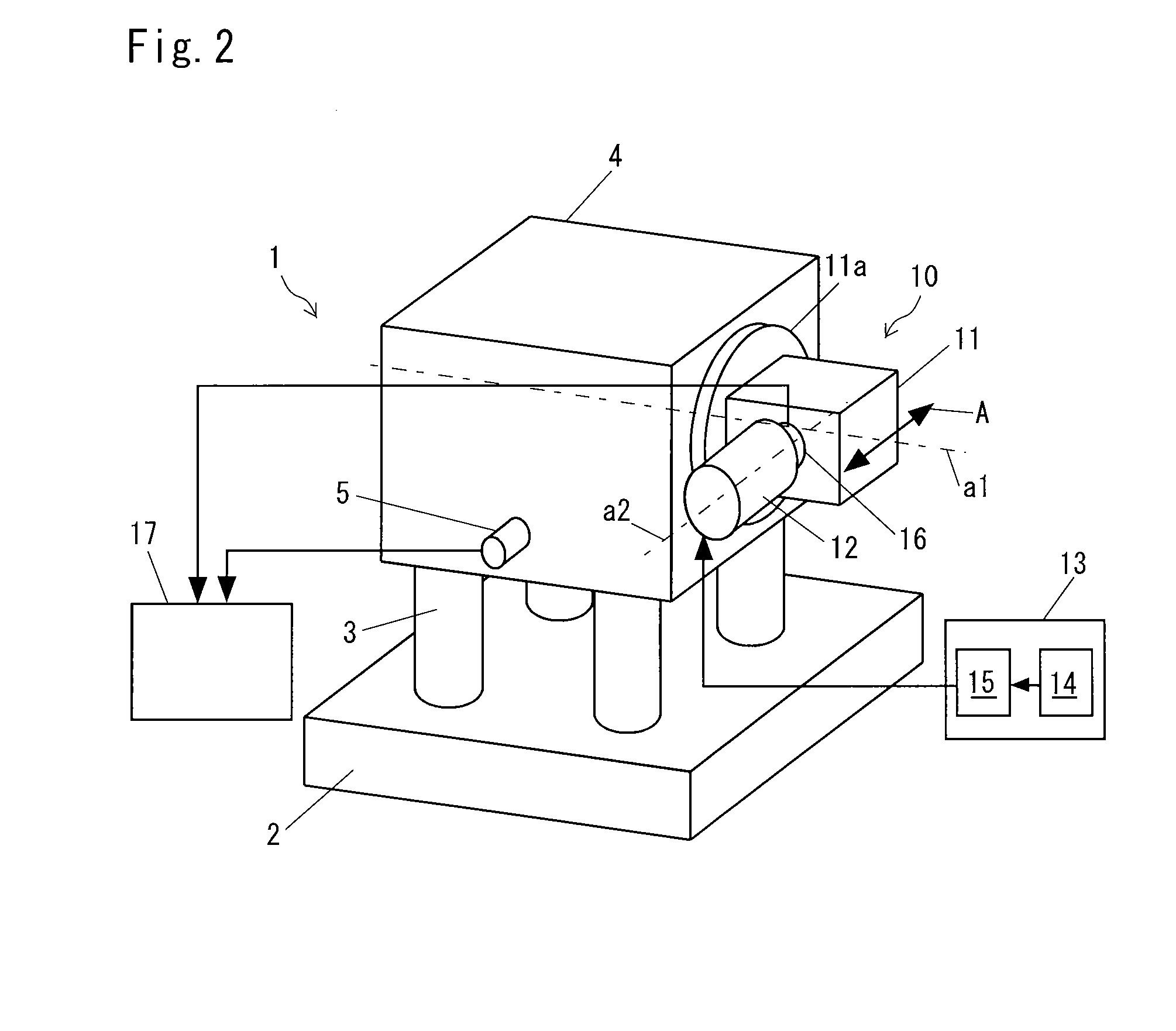

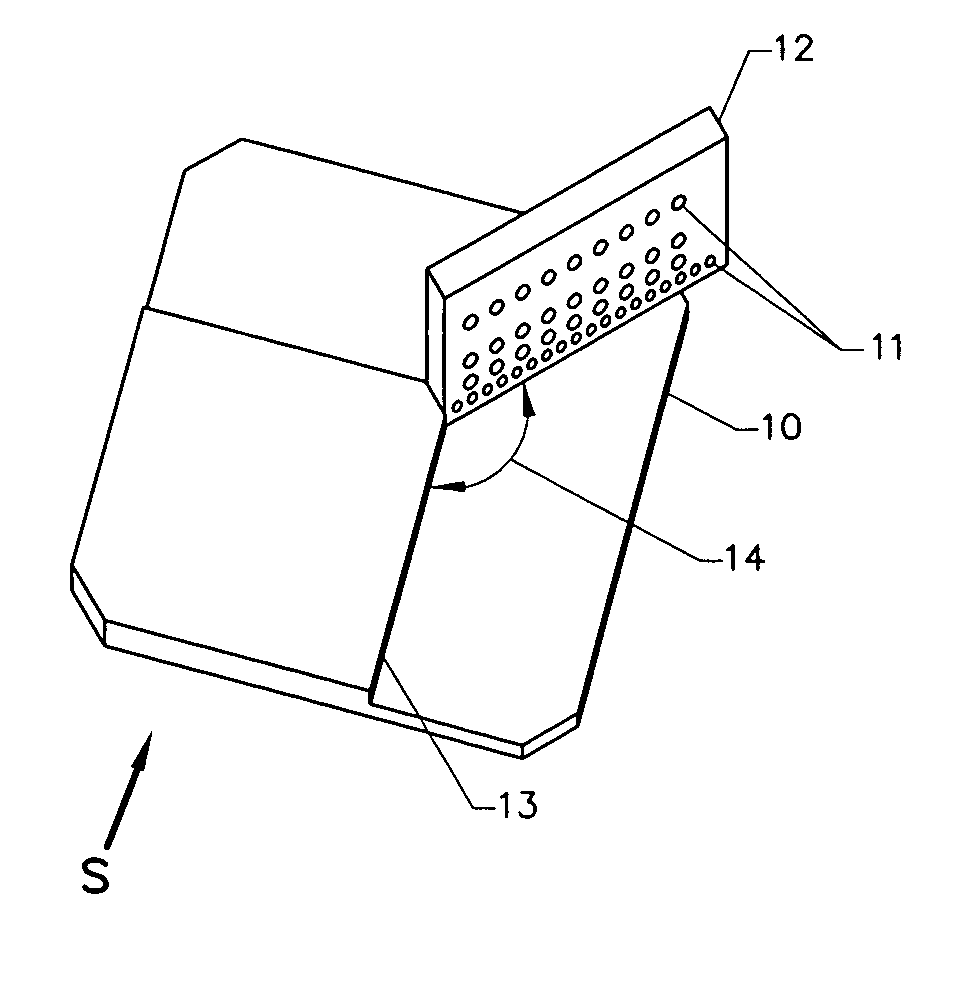

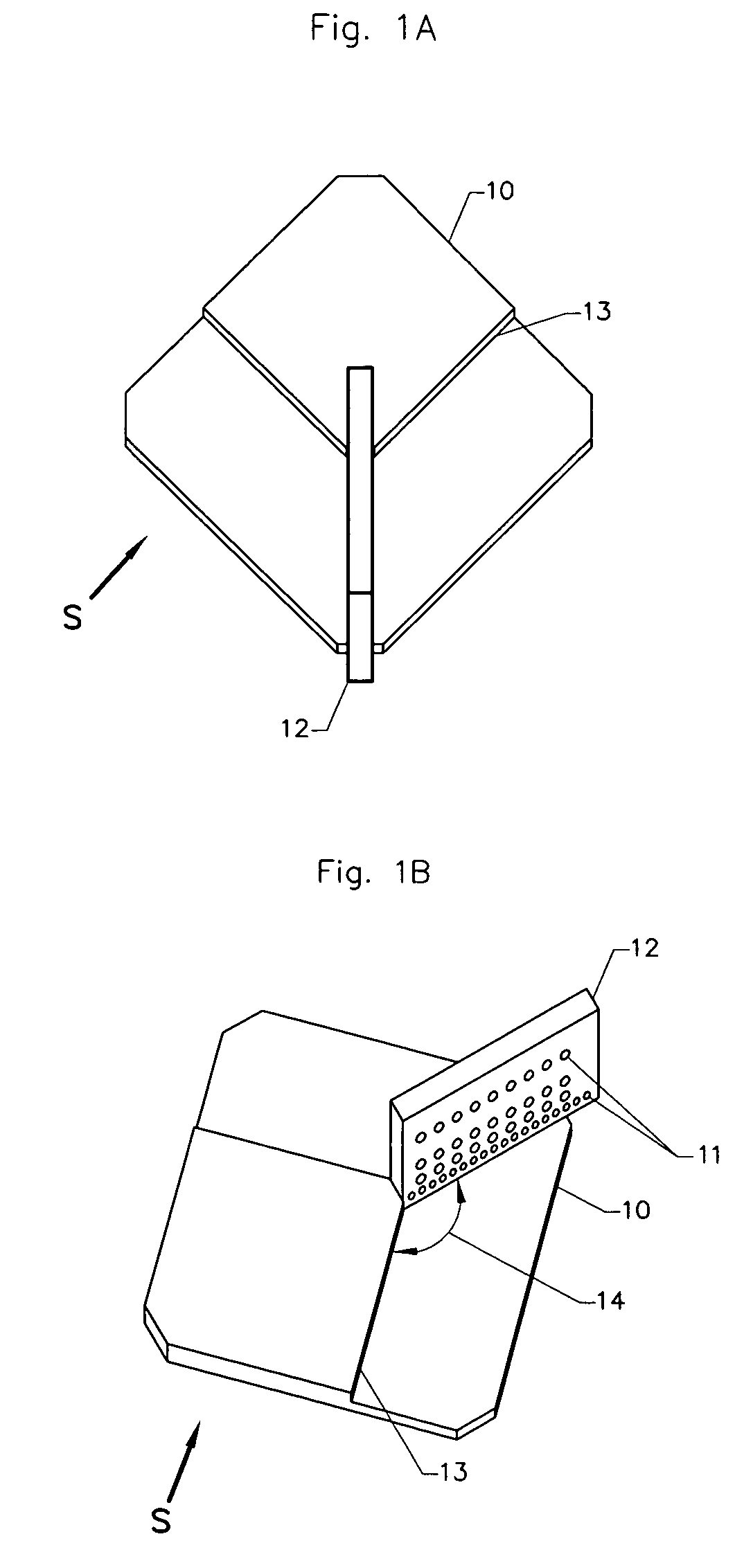

Reference vibrator

ActiveUS20110067494A1Properly check repeatabilityGood repeatabilityStatic/dynamic balance measurementMeasurement deviceEngineering

A reference vibrator 10 of the present invention includes: a vibrator body 11 configured to mount to a mount 4 in an unbalance measurement device 1 to which a rotary product is mounted at the time of unbalance measurement, in a same mounting state as the rotary product; a vibration generator 12 fixed to the vibrator body 11 and that applies vibrations to the vibrator body 11; and a control unit 13 that controls the vibration generator 12. Because vibration is caused by the vibration generator 12 fixed to the vibrator body 11, repeatability of vibration force is high. This makes it possible to apply vibrations for repeatability check to the unbalance measurement device 1 with an accurate vibration force. Thus, variations in vibration force can be eliminated, and the repeatability of the unbalance measurement device 1 can be properly checked.

Owner:IHI CORP

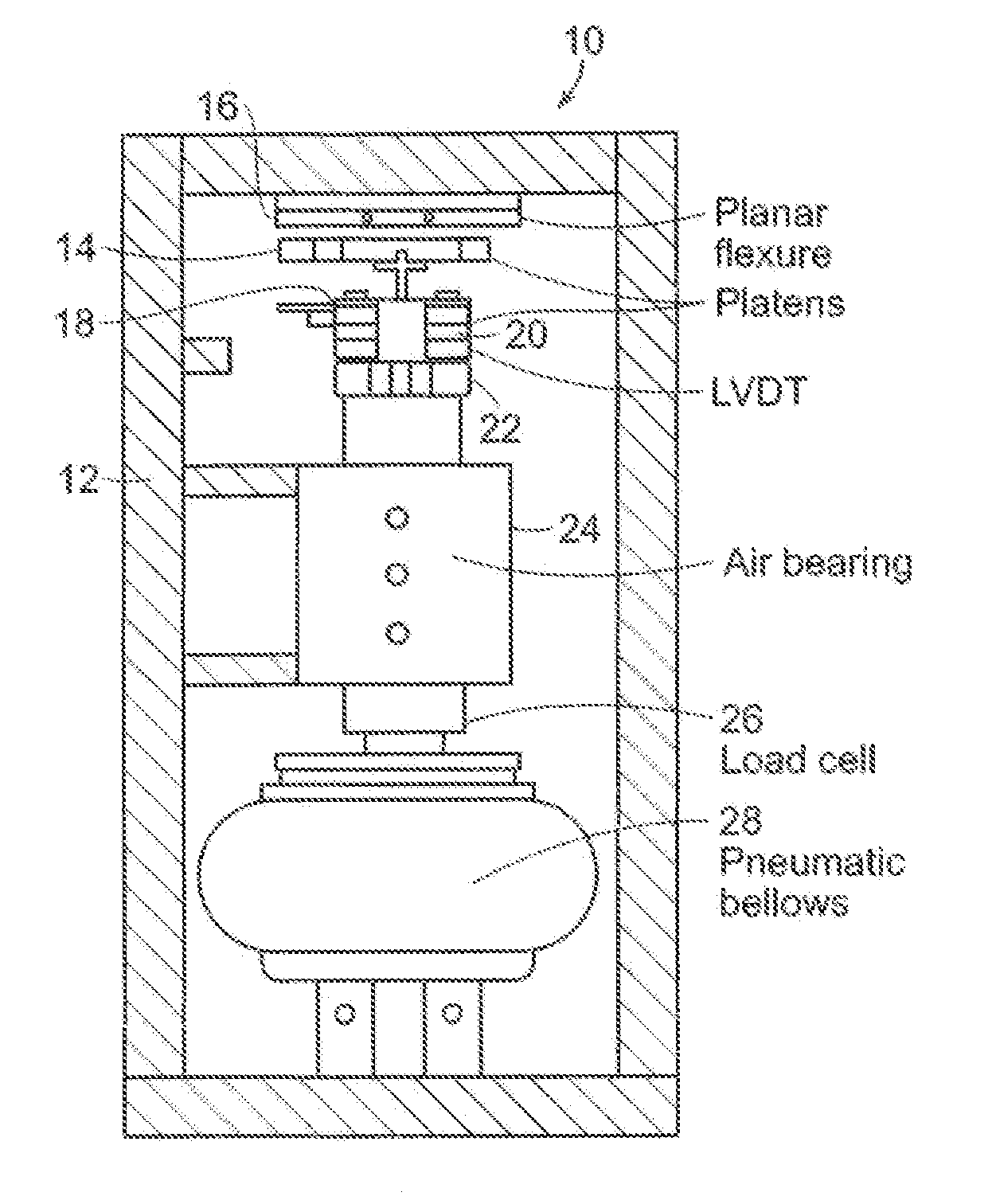

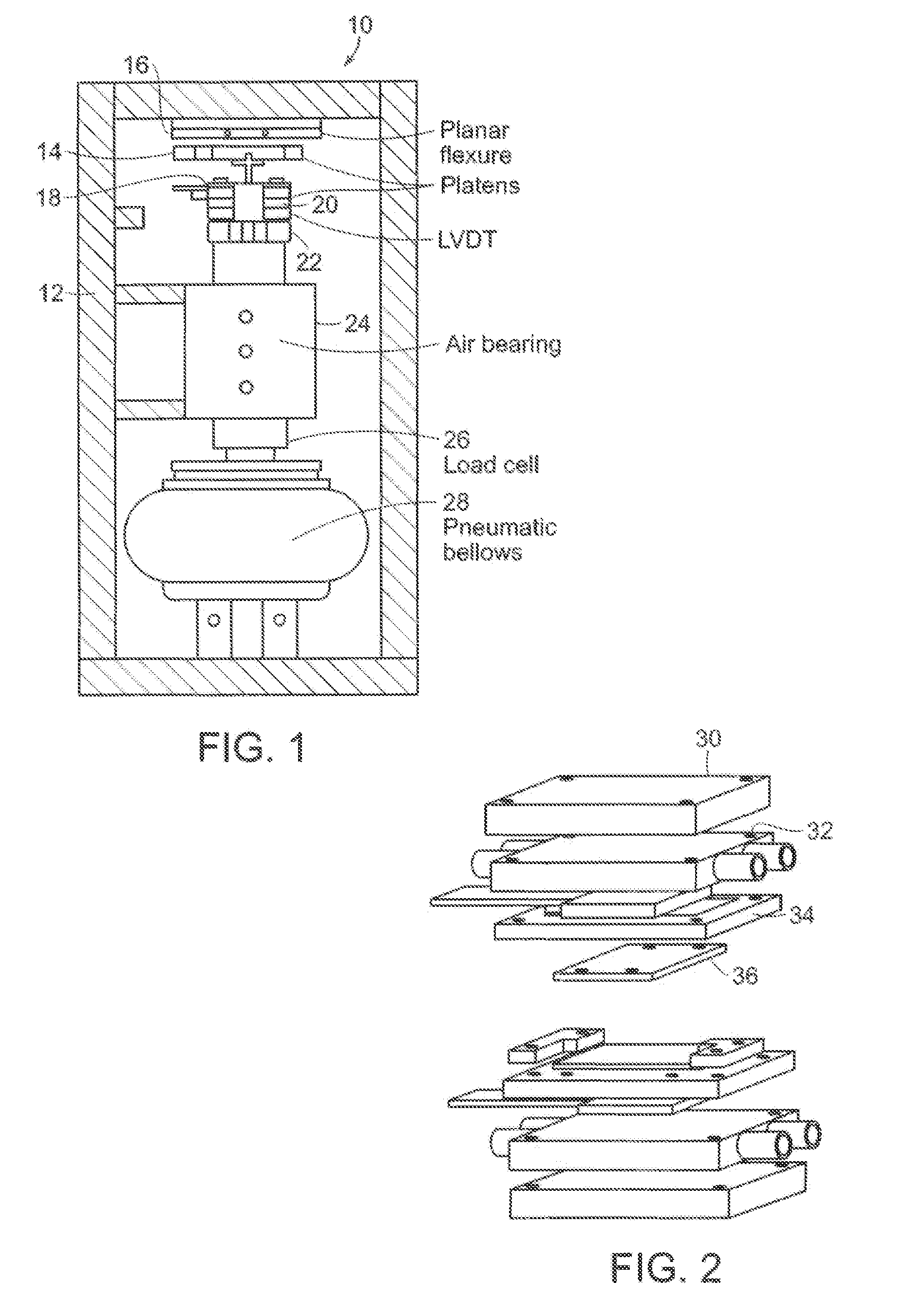

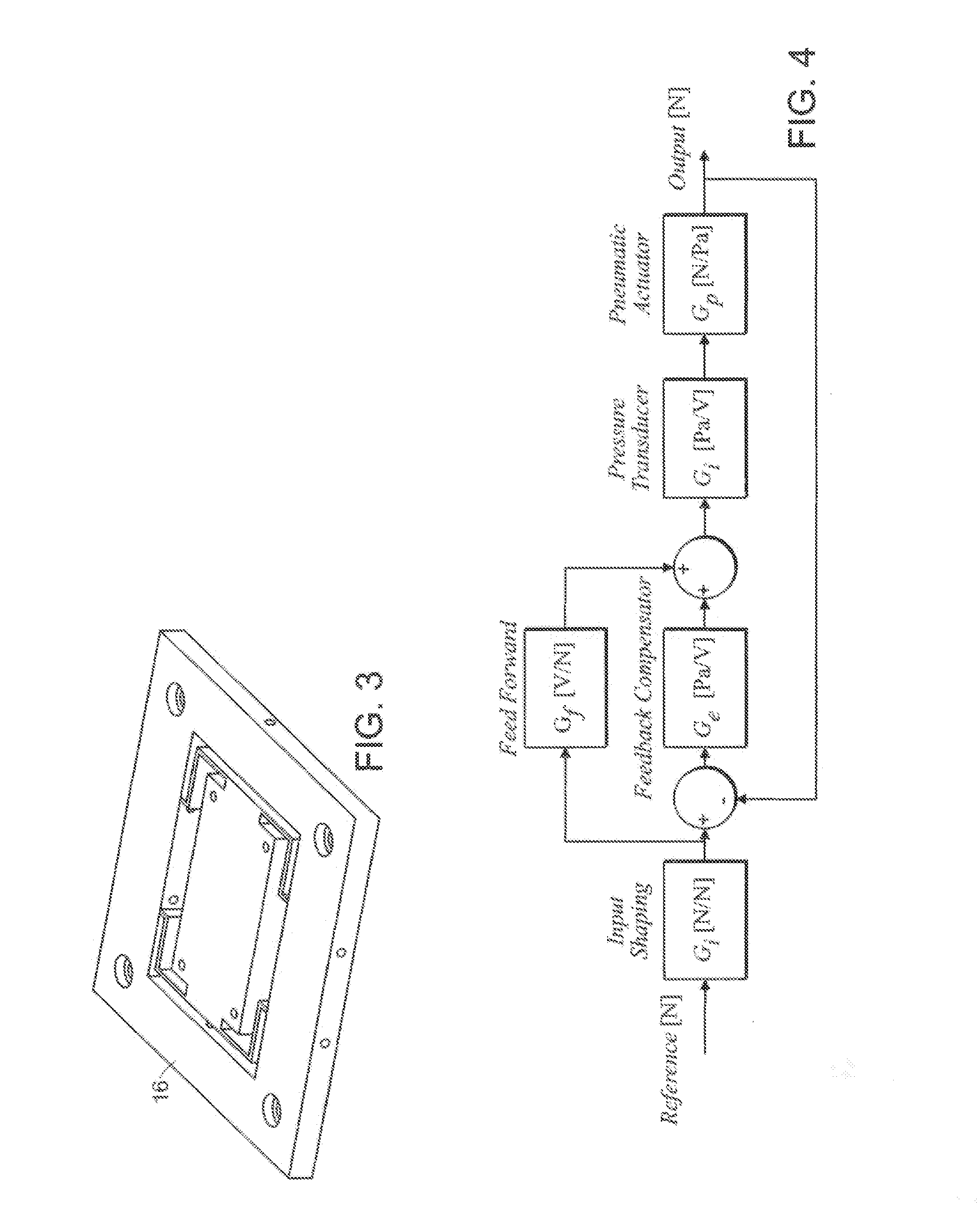

Embossing Press

Precision embossing press. The press includes a rigid symmetric box frame and upper and lower parallel embossing platens mounted within the box frame for movement towards one another to provide an embossing compressive force on a work piece between the platens while maintaining parallelism between the platens. A thermal system controls platen temperature to heat the work piece for embossing and to cool the work piece for de-molding. A pneumatic actuator moves the lower platen toward the upper platen to emboss the work piece. A closed loop control system employing feedback and feed forward control loops controls platen temperatures and embossing force.

Owner:MASSACHUSETTS INST OF TECH

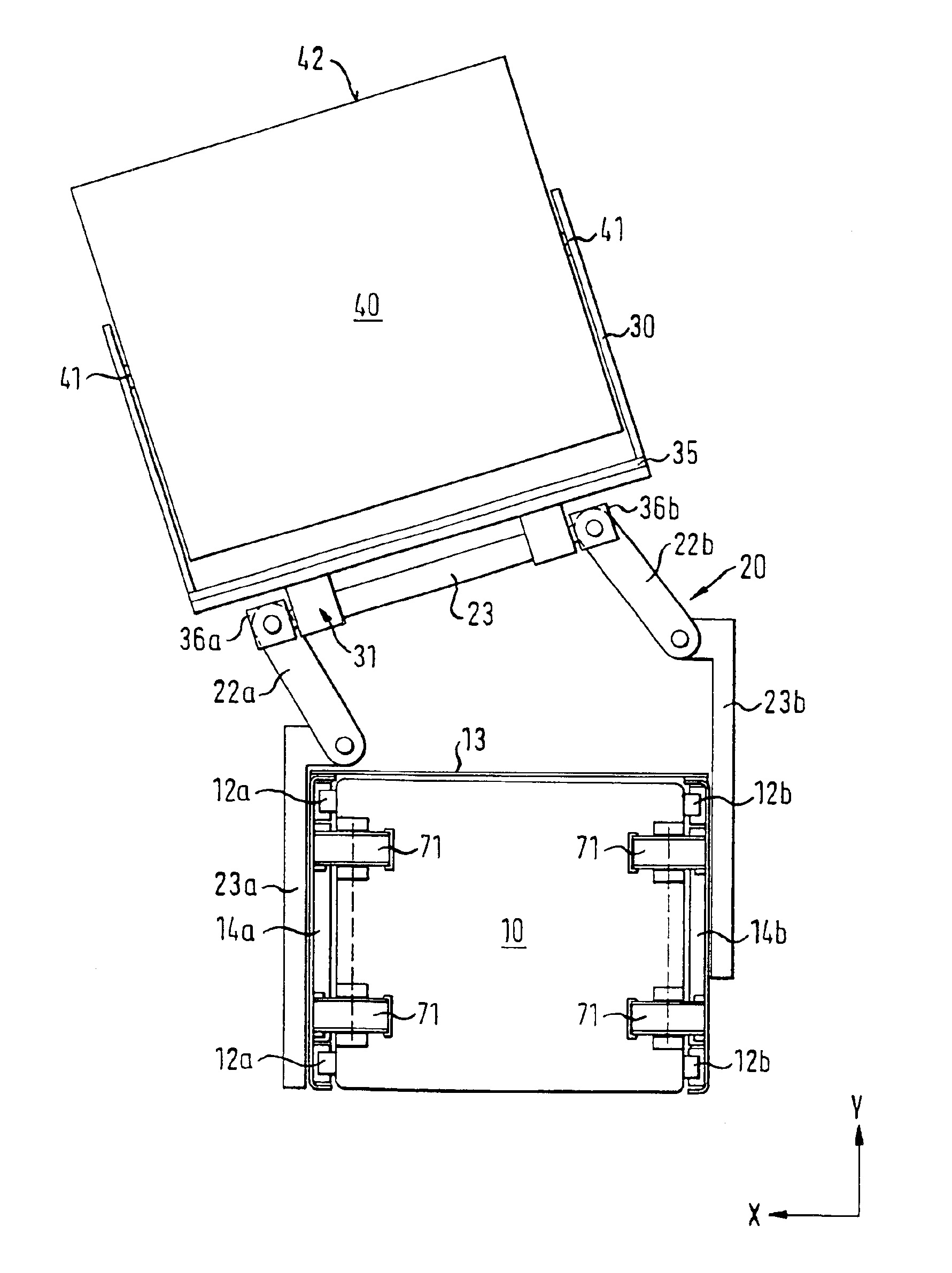

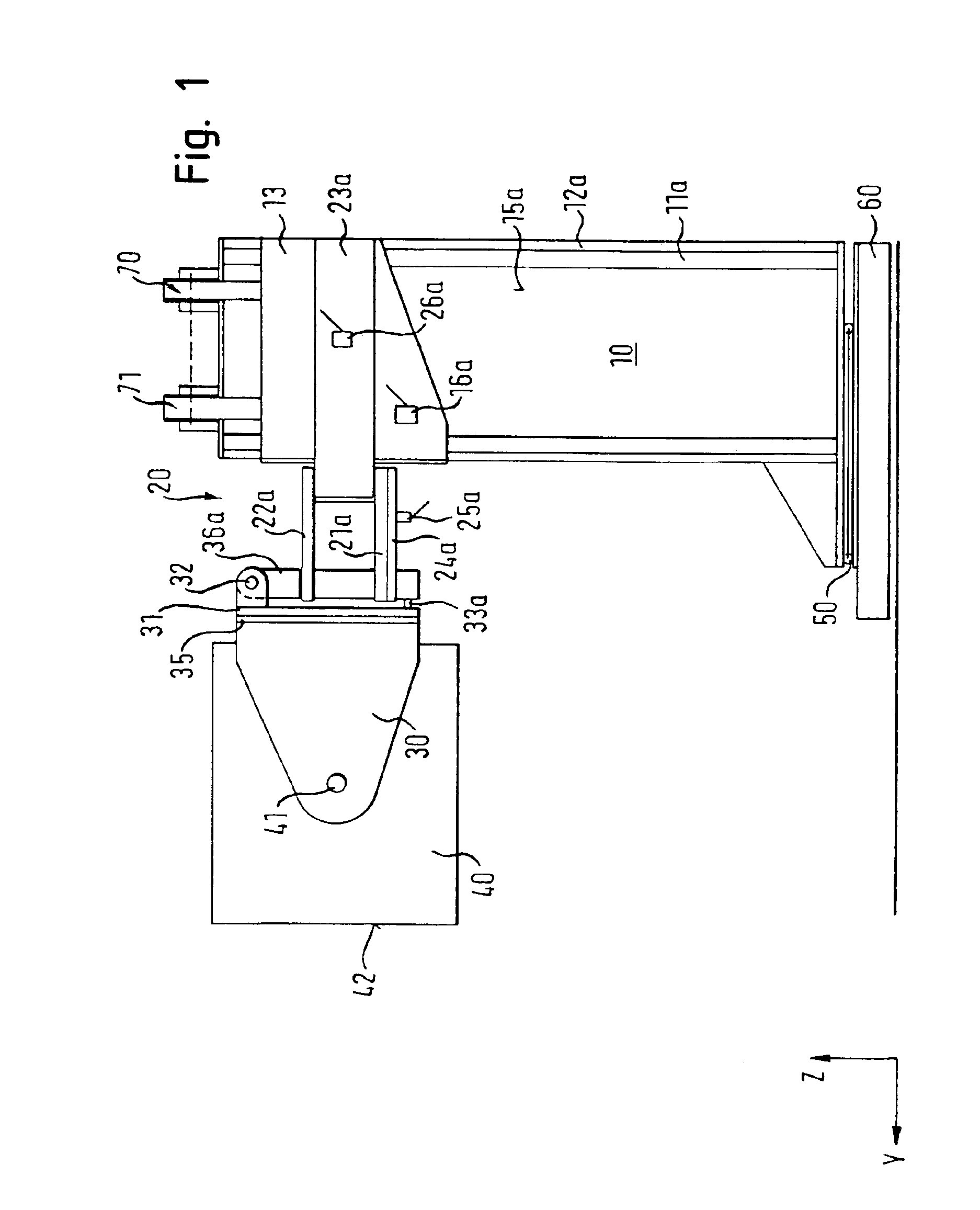

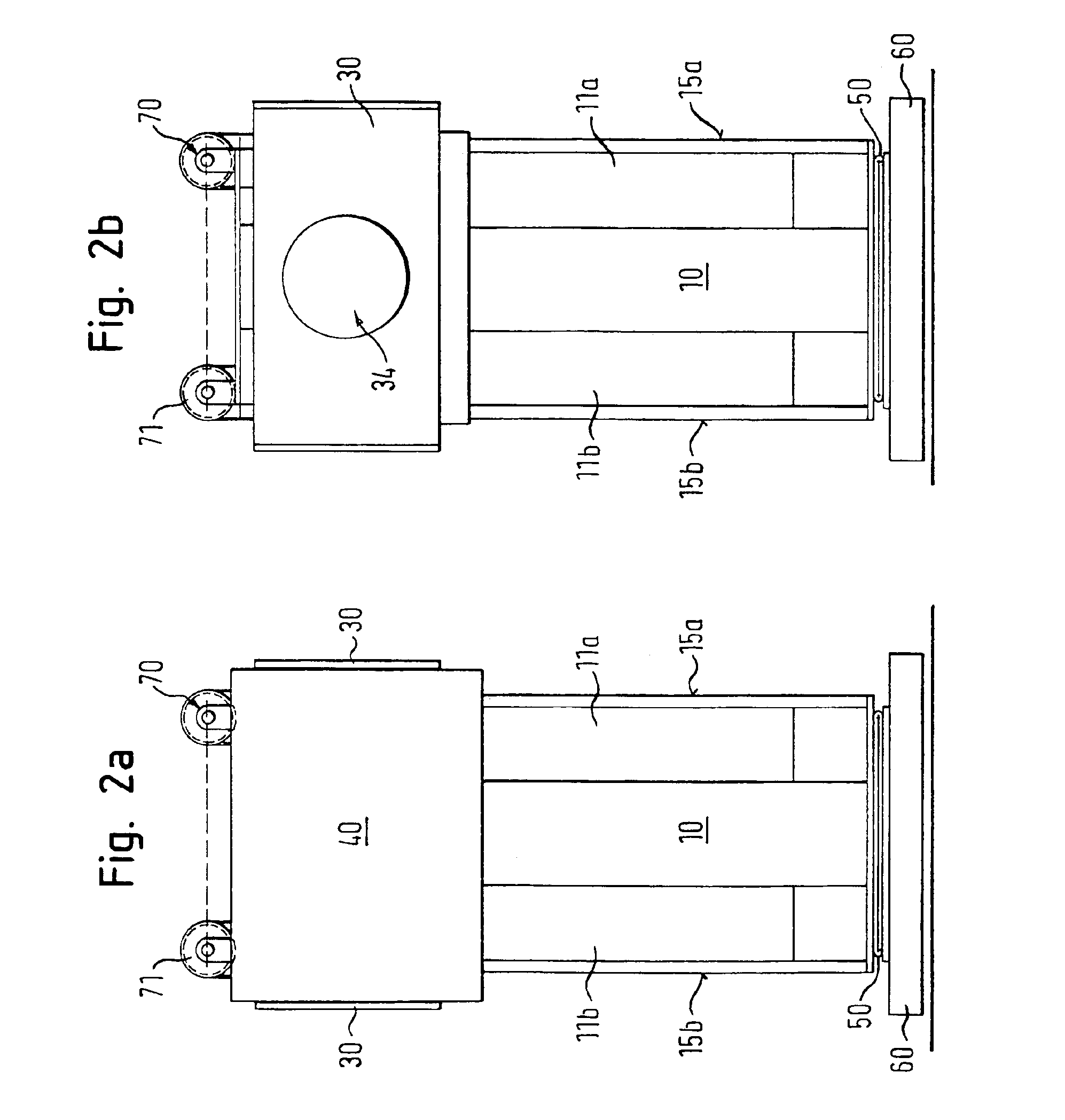

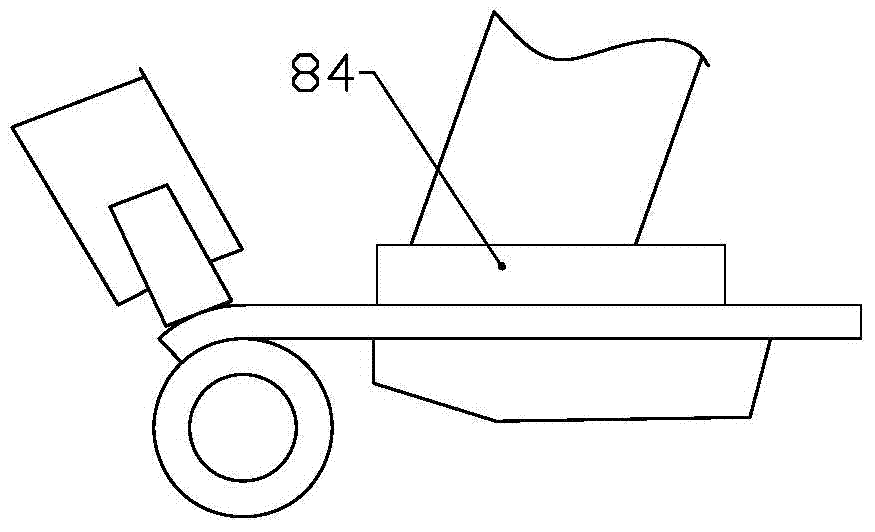

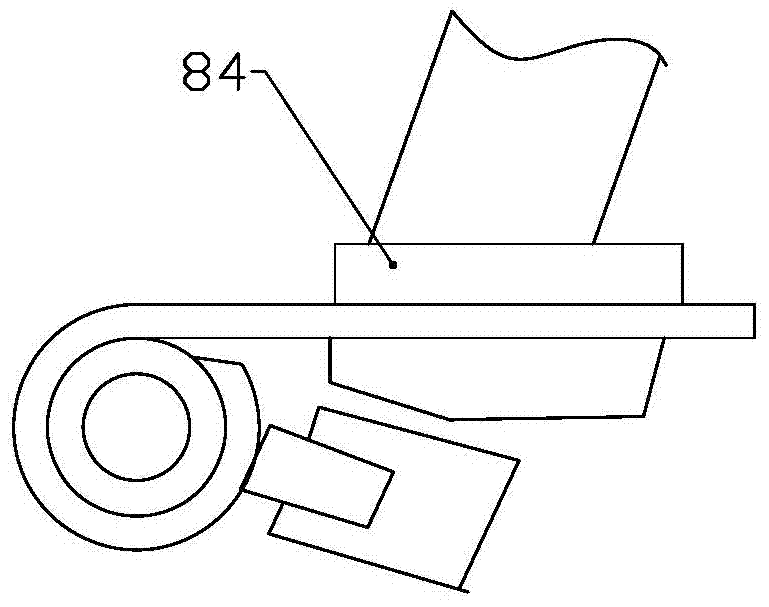

Handling device, especially for positioning a test head on a testing device

InactiveUS6940273B2Smooth and precise positioningReduce loadElectronic circuit testingInstrumental componentsEngineeringTest fixture

Disclosed is a handling device, especially for positioning a test head on a testing device, including a holder for a test head and a column. Positioning apparatus adjustable in a vertical direction is connected to the test head on the column. The handling device advantageously has a simple and compact structure and an exactly reproducible, smooth movement of the test head, because the positioning apparatus has at least one pair of interspaced articulated arms in which one end thereof is respectively articulated on the holder and the other end thereof is articulated on a carriage which can be displaced in a horizontal direction. The articulated arms can be pivotably arranged around a vertical axis. The carriages can move independently from each other.

Owner:HEIGL MR HUBERTUS

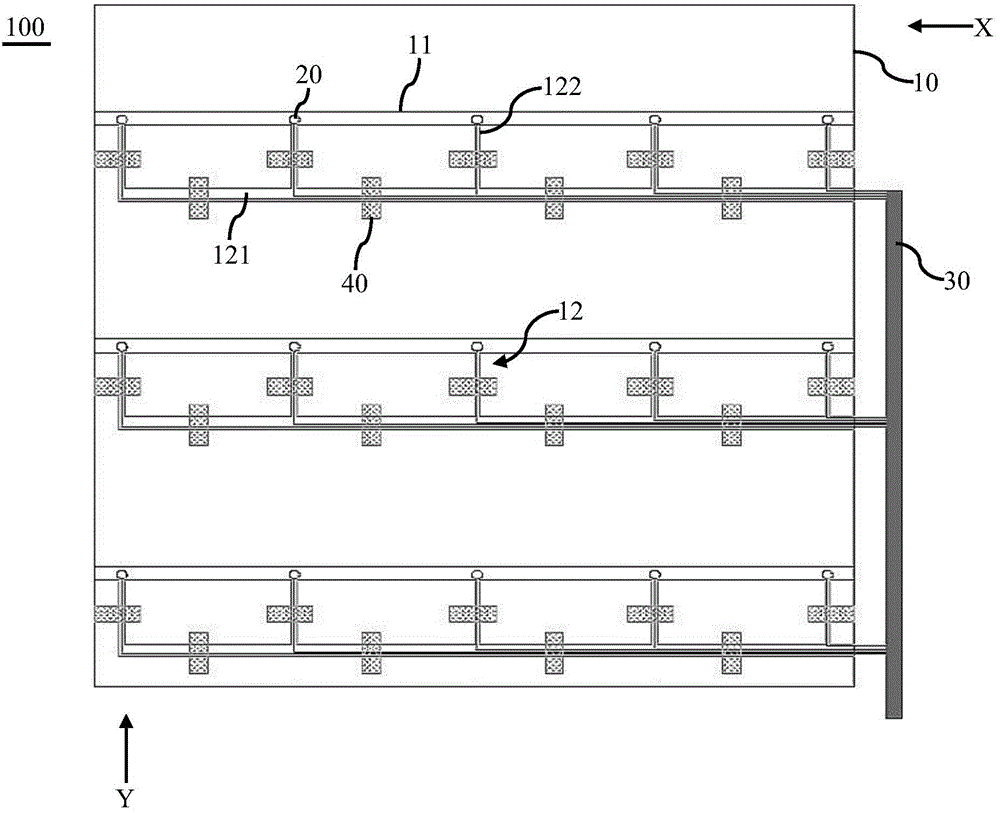

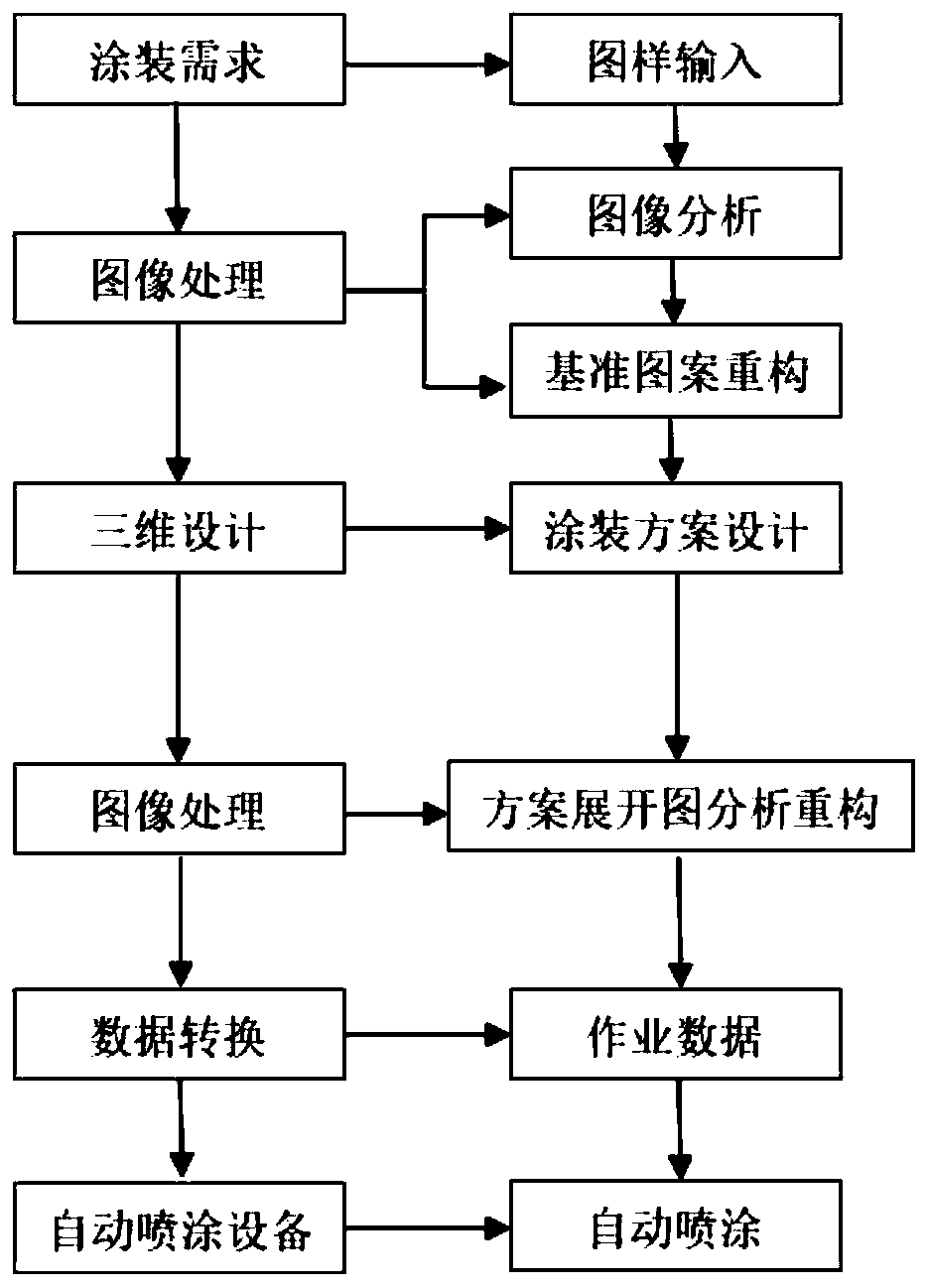

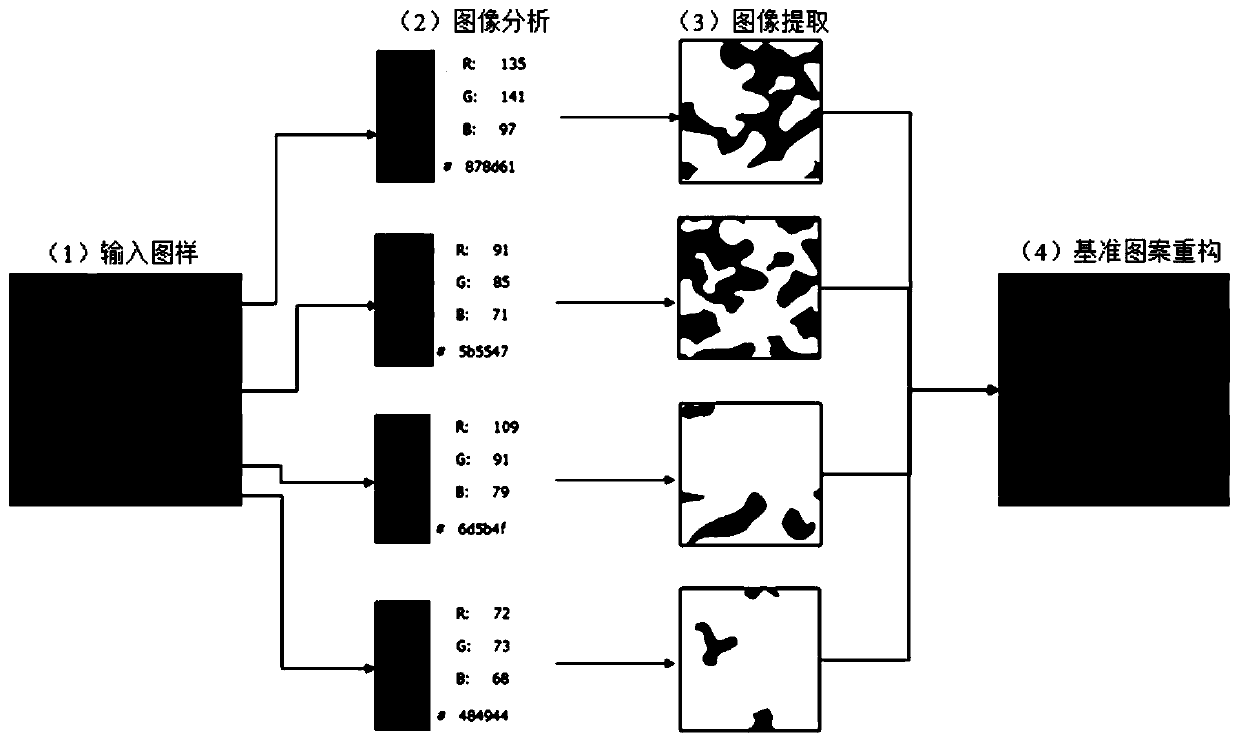

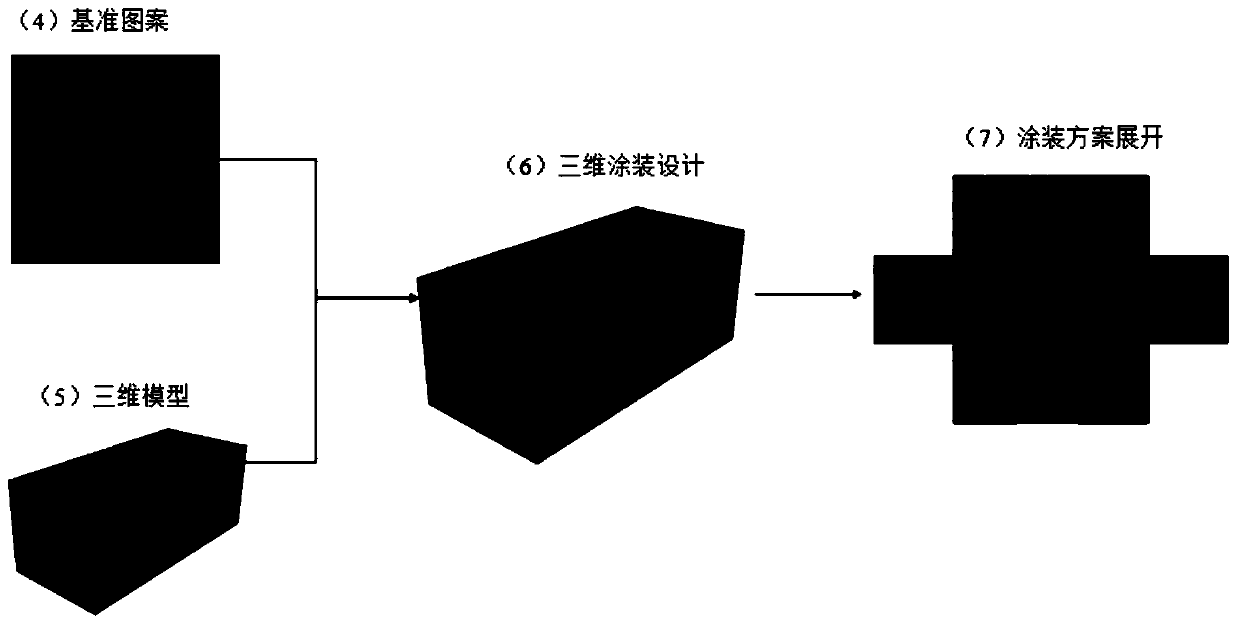

Camouflage spraying method

InactiveCN110624800ASolve the problem of automatic operationImprove work efficiencySpecial surfacesCoatingsImaging analysisRepeatability

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Wafer surface inspection apparatus and wafer surface inspection method

ActiveUS20070182957A1Increase energy densityPreventing lowering of detection sensitivityMaterial analysis using wave/particle radiationElectrical apparatusForeign matterEngineering

A wafer surface inspection method and apparatus of high sensitivity, and free from performance degradation in terms of cleanliness, coordinate repeatability of foreign particles and the like. Gas for cooling is sprayed onto a laser irradiation position on the wafer surface to prevent an increase in temperature of the foreign particles and to suppress break-down of the foreign particles.

Owner:HITACHI HIGH-TECH CORP

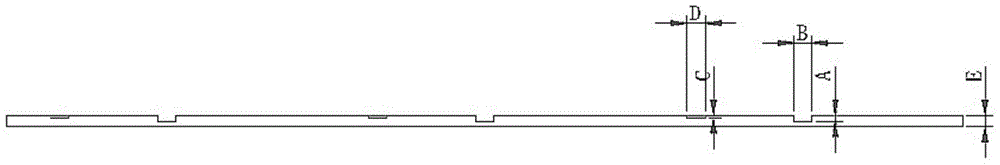

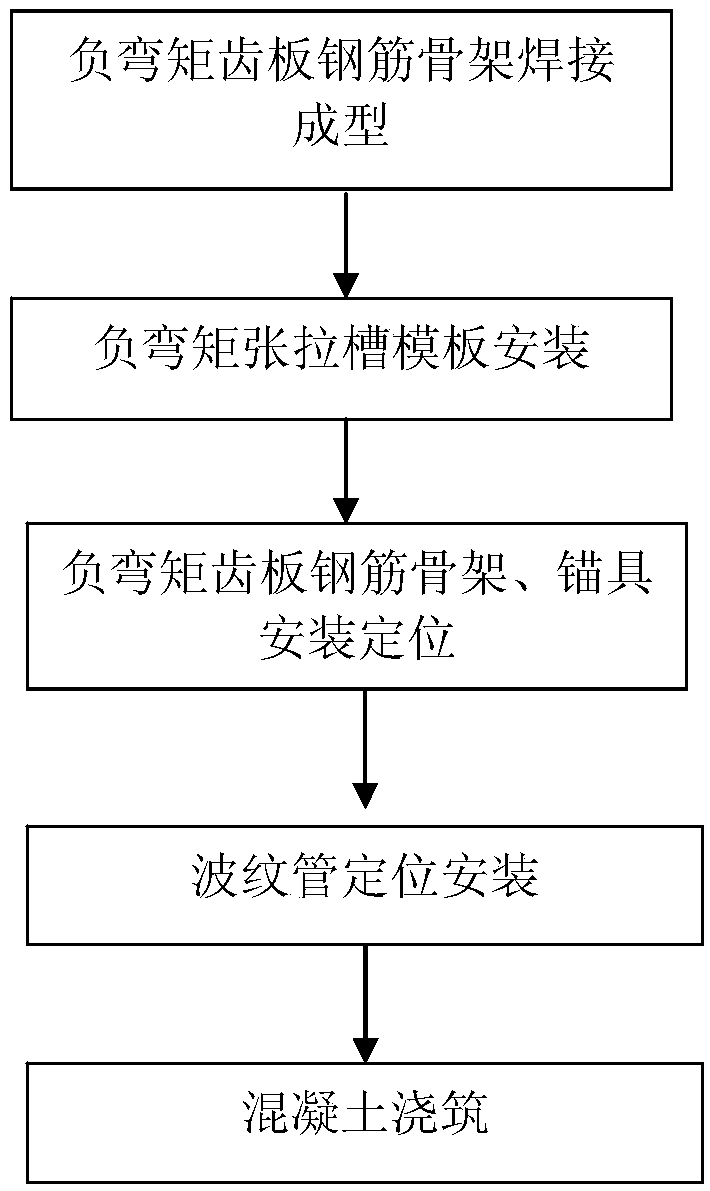

Construction method of prefabricated beam hogging moment tensioning groove

ActiveCN108858740AAccurate demolitionAccurate repeatabilityCeramic shaping apparatusRebarBending moment

The invention discloses a construction method of a prefabricated beam hogging moment tensioning groove. The construction method comprises the following steps that 1, a hogging moment tooth plate steelreinforcement framework is welded and formed; 2, a hogging moment tensioning groove formwork is installed; 3, the hogging moment tooth plate steel reinforcement framework and an anchorage device areinstalled and located; 4, a corrugated pipe is installed; and 5, concrete is poured, wherein after installing of a top plate steel bar is completed, a gap is reserved in the formwork for blocking, theconcrete is used for carrying out one-time pouring and forming from the middle to the two ends, in the pouring process, attention is paid to that pouring is carried out on a tooth plate firstly and then on a top plate, vibrating of the intensive portion of the steel bar is reinforced, and after the concrete is subjected to later-period preserving, the prefabricated beam hogging moment tensioninggroove is obtained. According to the construction method, locating precision of the anchorage device and the corrugated pipe in the hogging moment tensioning groove in the prefabricating process of abeam body can be improved effectively, the probability that the concrete on the top plate is pulled and cracked in the hogging moment tensioning construction process can be reduced, channeling blocking of the corrugated pipe is reduced, steel strands can be threaded smoothly, and the method has high market popularization value.

Owner:GUANGXI CHANGCHANG ROAD & BRIDGE CONSTR

Limiting and adjusting mechanism for forming lug holes of lug winding machine

ActiveCN103480710AImprove location reliabilityMeet the needs of curling earsWinding machineEngineering

The invention discloses a limiting and adjusting mechanism for forming lug holes of a lug winding machine. The limiting and adjusting mechanism comprises an oil cylinder, a connecting plate, a fixed seat, a guiding column and a pressing block, wherein the fixed seat is internally provided with a first axle hole and a second axle hole which are formed in parallel; a worm wheel is sheathed in the first axle hole, and a worm meshed with the worm wheel is arranged at one side of the fixed seat; the oil cylinder with outer threads on the outer surface is engaged at the axis of the worm wheel; the guiding column is sheathed in the second axle hole in a sliding-matching manner, and the lower end of a piston rod of the oil cylinder and the lower end of the guiding column are fixedly connected on the pressing block simultaneously; the connecting plate is arranged between the top part of a body of the oil cylinder and the guiding column; a screw locking structure is arranged between the oil cylinder and the fixed seat. The limiting and adjusting mechanism disclosed by the invention has the advantages that the process of pressing down a pressing plate is finished by the oil cylinder, a piston column reaches the bottom of the cylinder in the process of every processing, so that the position reliability is high.

Owner:山东森德数控机械有限公司

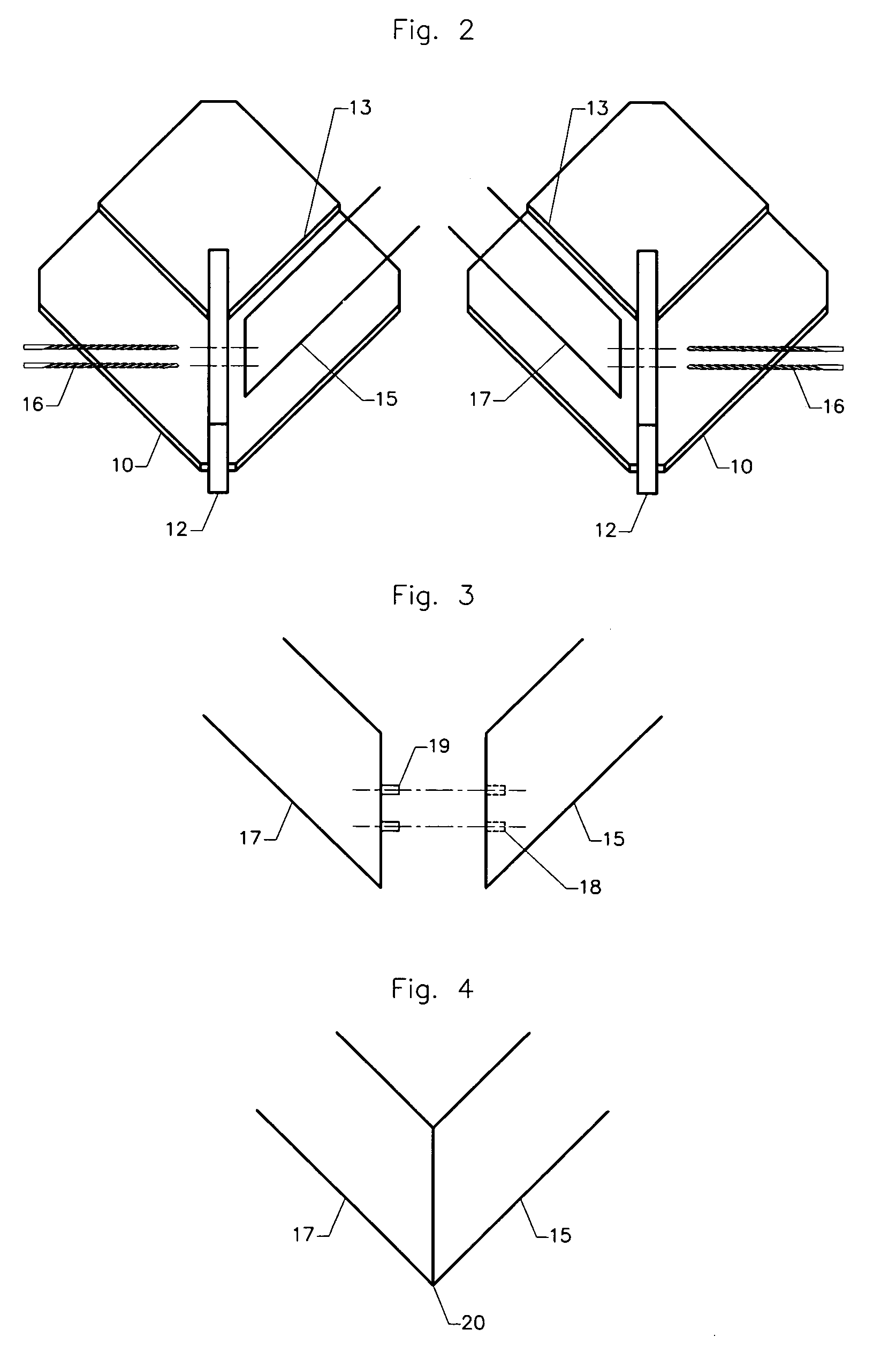

Miter dowel jig

InactiveUS20060072974A1Increase flexibilityPrecision and repeatabilityDrilling/boring measurement devicesThread cutting machinesDrill holeEngineering

Owner:JOHNSON ERIC

Wafer surface inspection apparatus and wafer surface inspection method

InactiveUS20080297782A1Improve cleanlinessWithout lowering detection sensitivityOptically investigating flaws/contaminationEngineeringRepeatability

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com