Patents

Literature

395 results about "Height gauge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A height gauge is a measuring device used for determining the height of objects, and for marking of items to be worked on. These measuring tools are used in metalworking or metrology to either set or measure vertical distances; the pointer is sharpened to allow it to act as a scriber and assist in marking out work pieces.

Positioning method and terminal

InactiveCN102075936AImprove experienceSolve the accuracy problemPosition fixationNavigation instrumentsDelayed timeEngineering

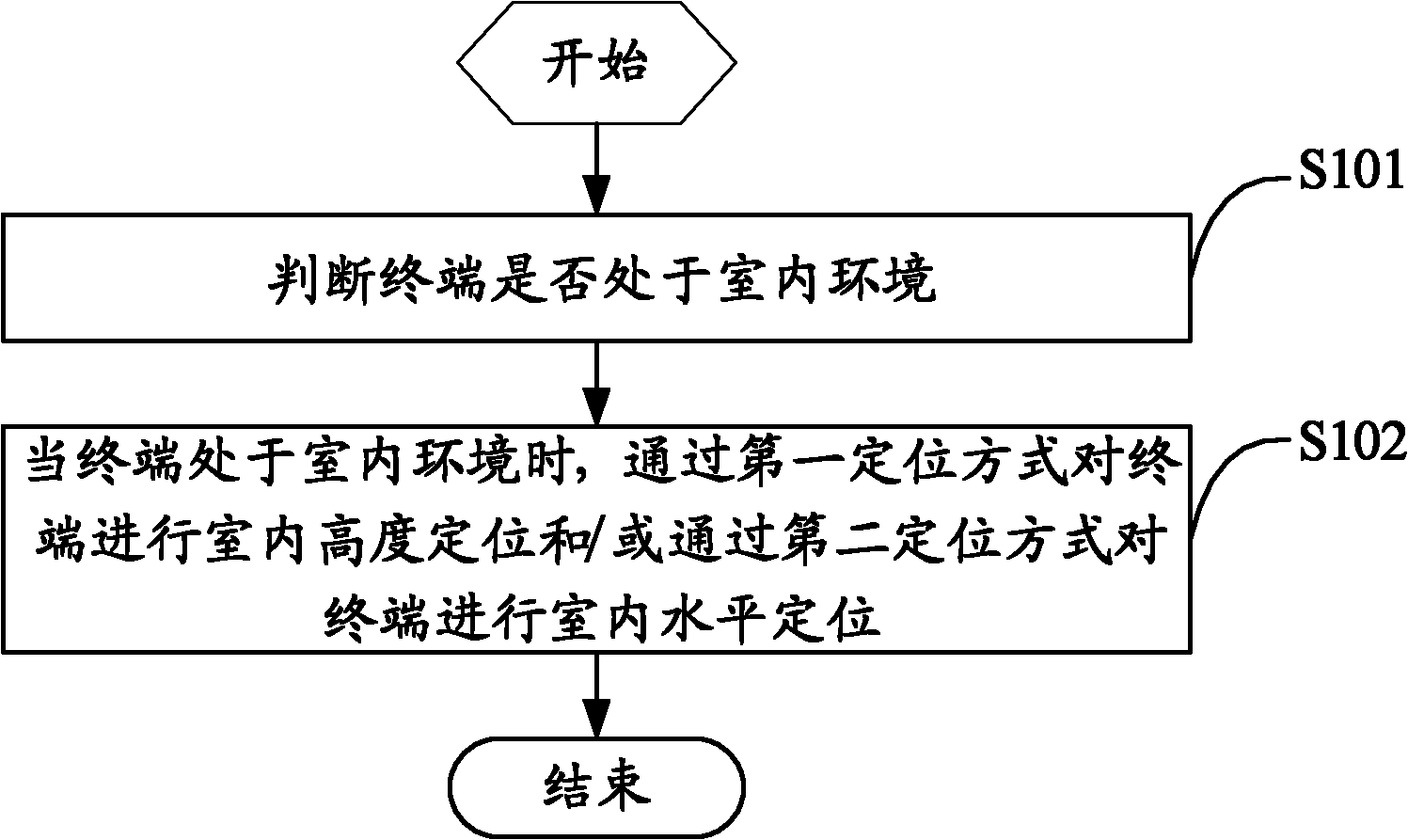

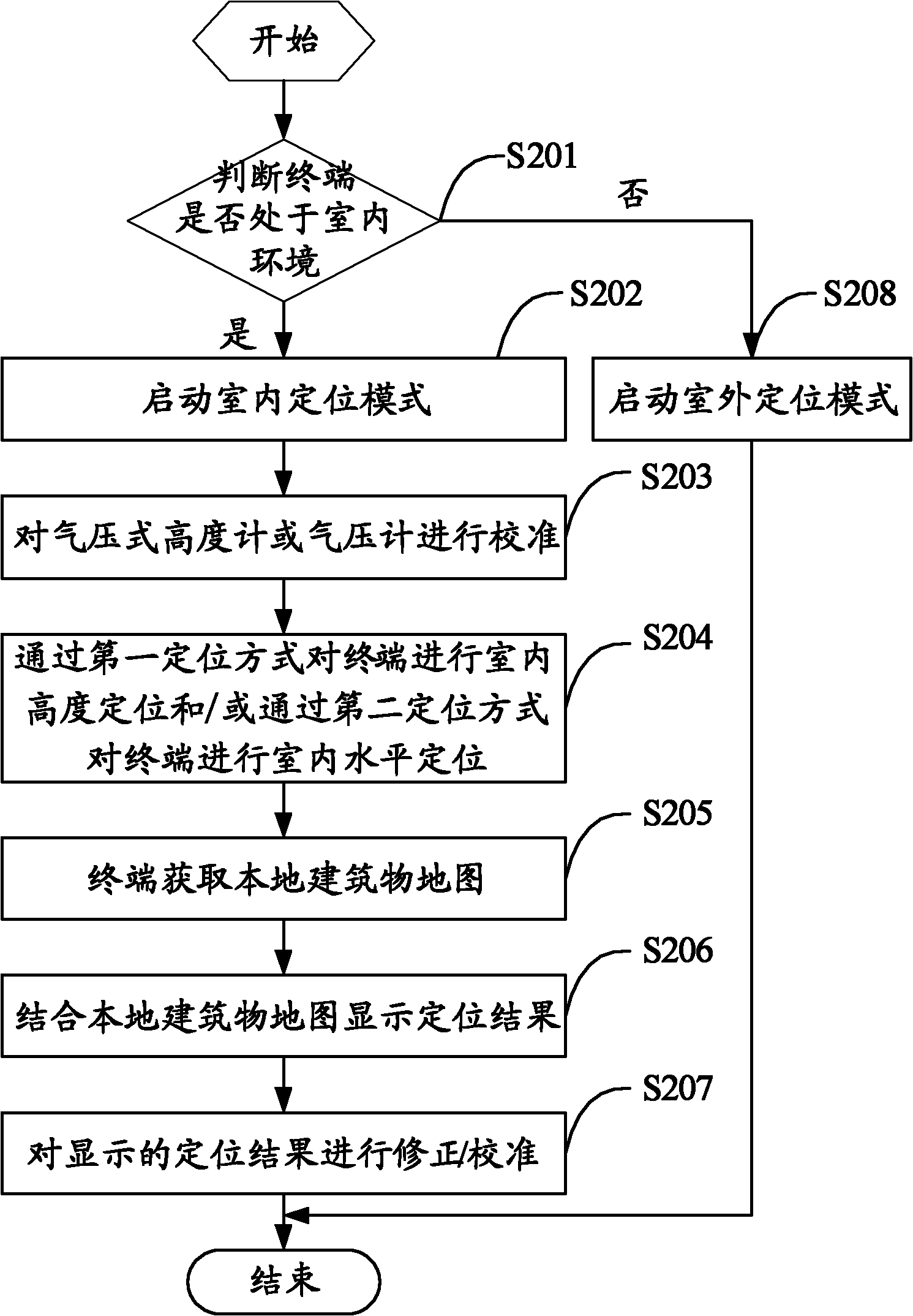

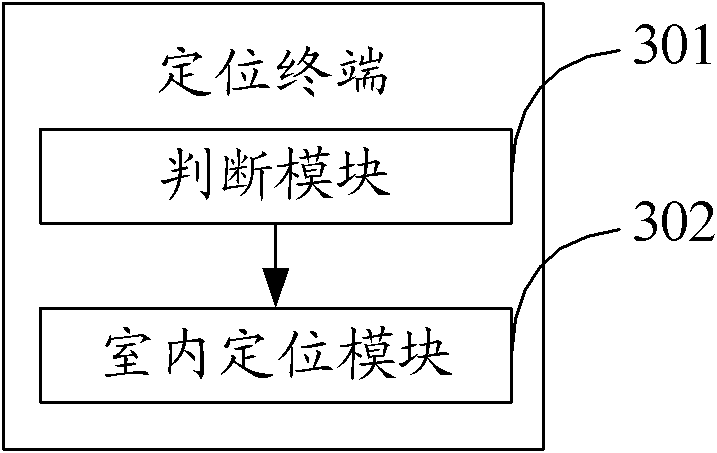

The invention relates to a positioning method and a terminal. The method comprises the following steps of: judging whether the terminal is in an indoor environment or not; and when the terminal is in the indoor environment, positioning the indoor height of the terminal by a first positioning mode and / or positioning the indoor level of the terminal by a second positioning mode. The indoor height of the terminal is positioned by a pneumatic height gauge or an air pressure gauge and / or the indoor level of the terminal is positioned in combination with a height positioning result. By the two positioning modes, the problem of different requirements on height, the positioning accuracy of a horizontal plane and positioning delay time in indoor navigation positioning service is solved, positioning accuracy is enhanced, positioning delay time is shortened, user experience of indoor navigation positioning is improved and various application requirements of indoor navigation positioning and the like are met.

Owner:ZTE CORP

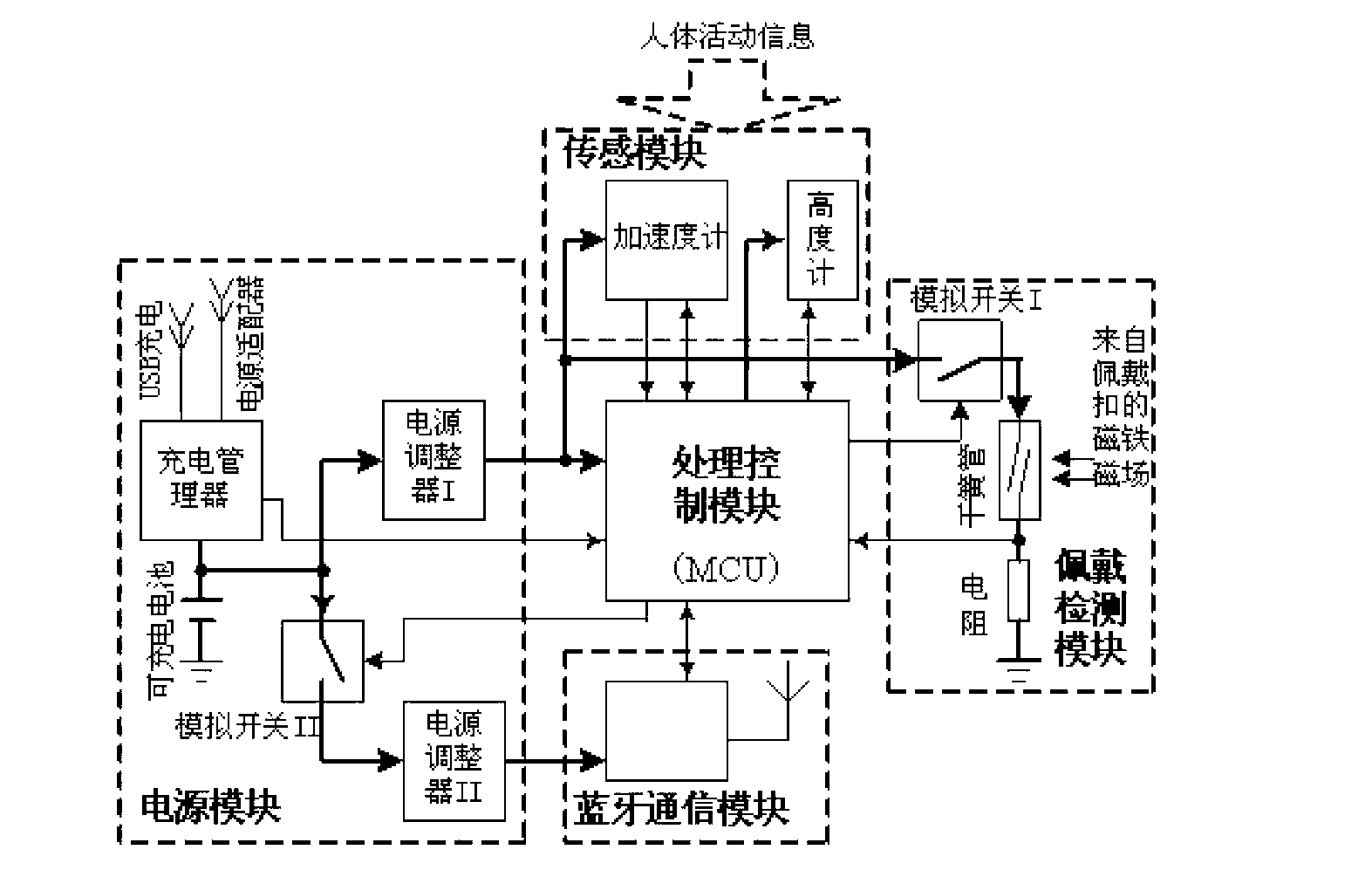

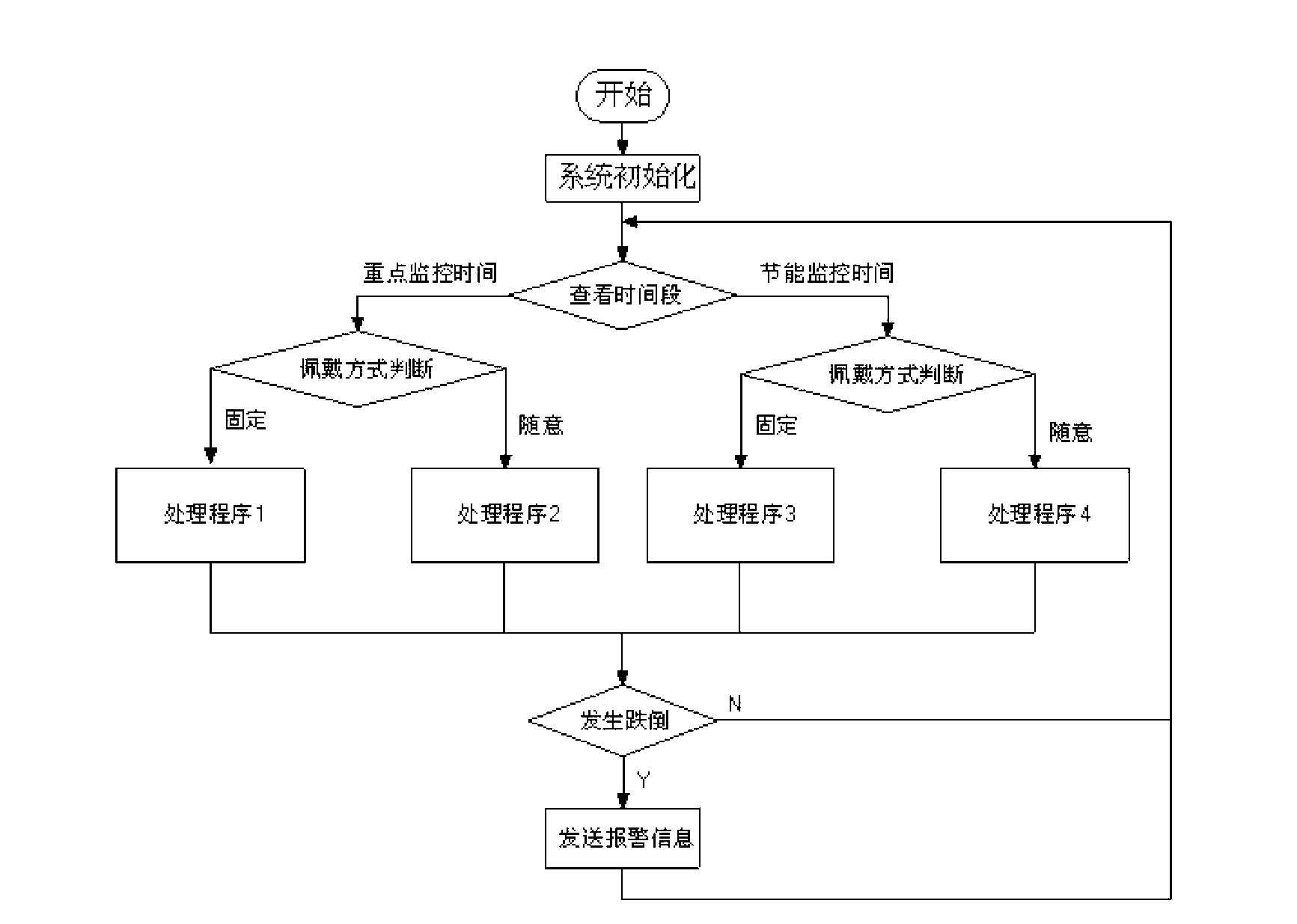

Human body falling monitoring method and device based on acceleration and height information

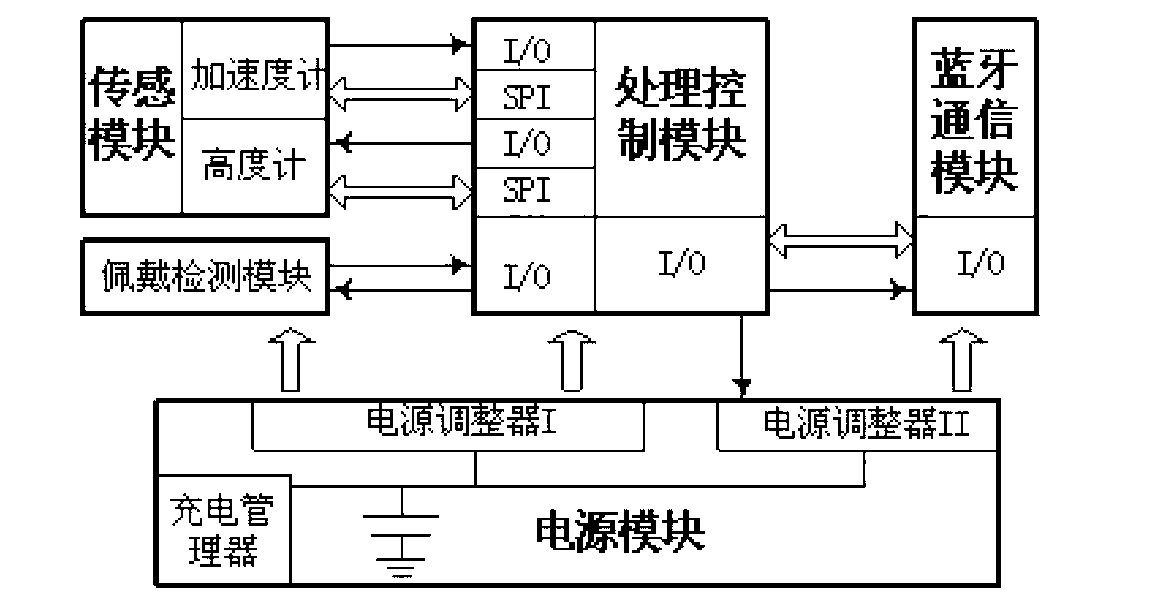

The invention discloses a human body falling monitoring method and a device based on acceleration and height information. The device comprises a sensing module, a processing and controlling module, a communication module, a wear detecting module and a power supply module. The sensing module provided with an accelerometer and a height gauge is connected with the processing and controlling module based on a low power consumption single chip computer, and continuously monitors the acceleration and height change of a wearer in daily activities. The wear detecting module checks the wearing method of the device. The processing and controlling module starts a bluetooth communication module to send alarm information when the device judges that the wearer falls according to collected acceleration and height data. A wearing buckle capable of being placed on a waistband of the wearer comprises a magnet, and therefore the device is capable of inspecting whether position-wearing is achieved. The human body falling monitoring method and the device based on the acceleration and the height information has the advantages that falling occurrence can be found accurately and timely by means of combination of continuously monitored acceleration information and height information, energy consumption is reduced by means of a low-power design and high energy efficiency management, and therefore long-term and continuous working is achieved.

Owner:CENT SOUTH UNIV

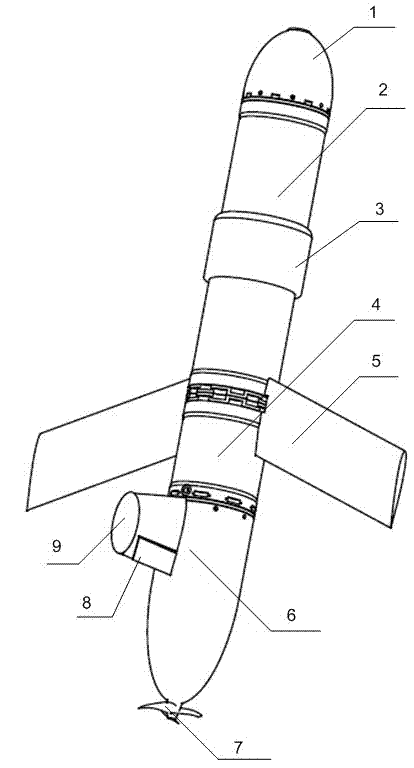

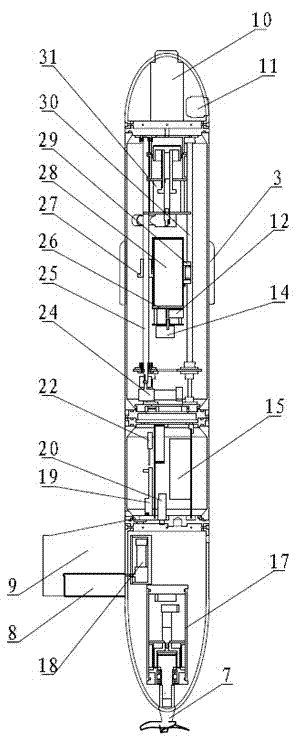

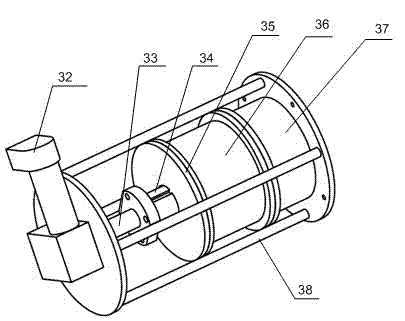

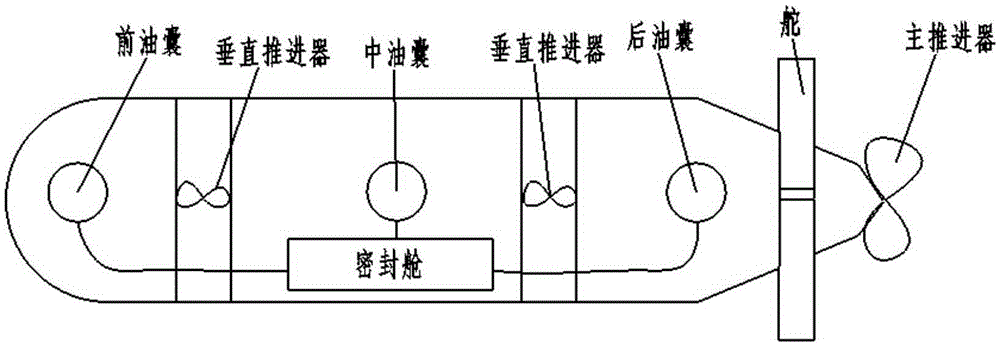

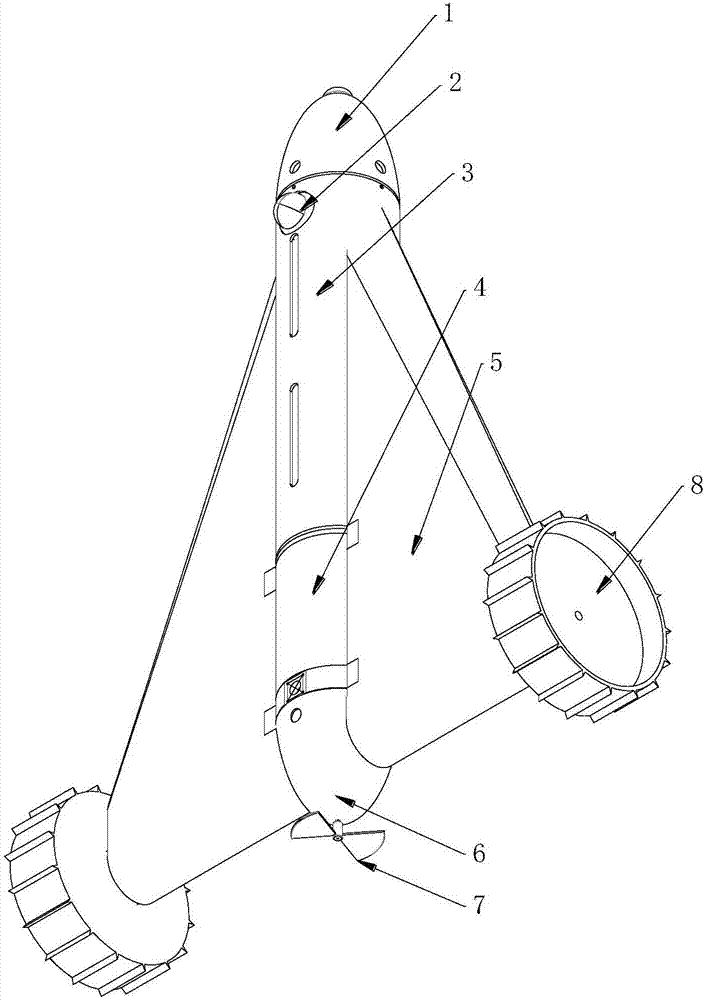

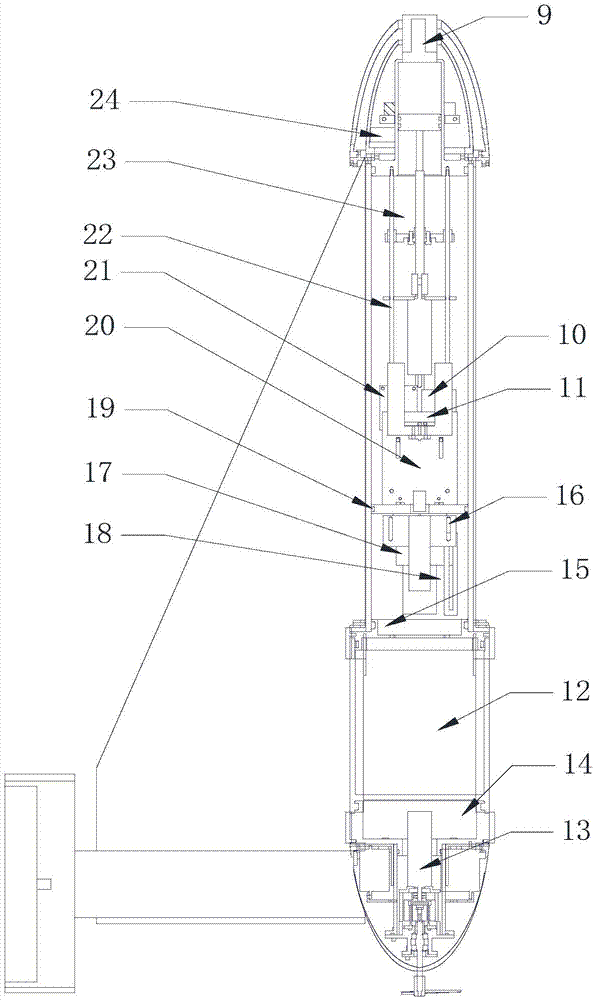

Mixed type underwater navigation detector

InactiveCN102862667AImprove continuous working abilityMeet the needs of stereo observationUnderwater vesselsUnderwater equipmentHybrid typeTransceiver

The invention discloses a mixed type underwater navigation detector which comprises a bow compartment, a main chamber, an electronic control chamber and a peak tank which are coaxially and sequentially connected, wherein the bow compartment and the peak tank are communicated with an outside water area; the main chamber and the electronic control chamber are sealing chambers; two wings are symmetrically installed at a connection position of the main chamber and the electronic control chamber; a sonar height gauge and an acoustic transceiver are installed in the bow compartment; a non-contact electric energy and signal transmission assembly is sleeved outside the main chamber; a gesture adjustment system and a buoyancy adjustment system are installed in the main chamber; the buoyancy adjustment system is installed on the front portion of the main chamber; buoyancy is adjusted through movement of a piston; two sides of the piston are isolated and sealed through rolling membranes; electronic equipment for controlling an aircraft is installed in the electronic control chamber; and a propeller propelling system and a steering control system are fixed on the peak tank. The mixed type underwater navigation detector has characteristics of underwater gliders and autonomous underwater vehicles, and can be abutted with an underwater connection platform to conduct non-contact charging and data transmission, so that continuous operational capability and applied range of underwater aircrafts can be increased.

Owner:ZHEJIANG UNIV

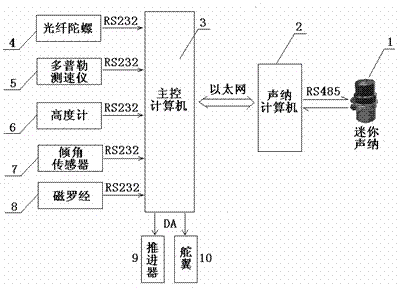

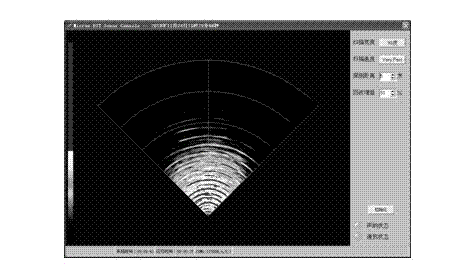

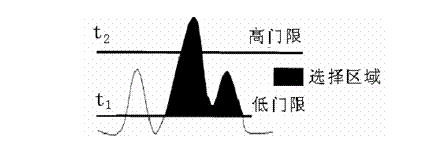

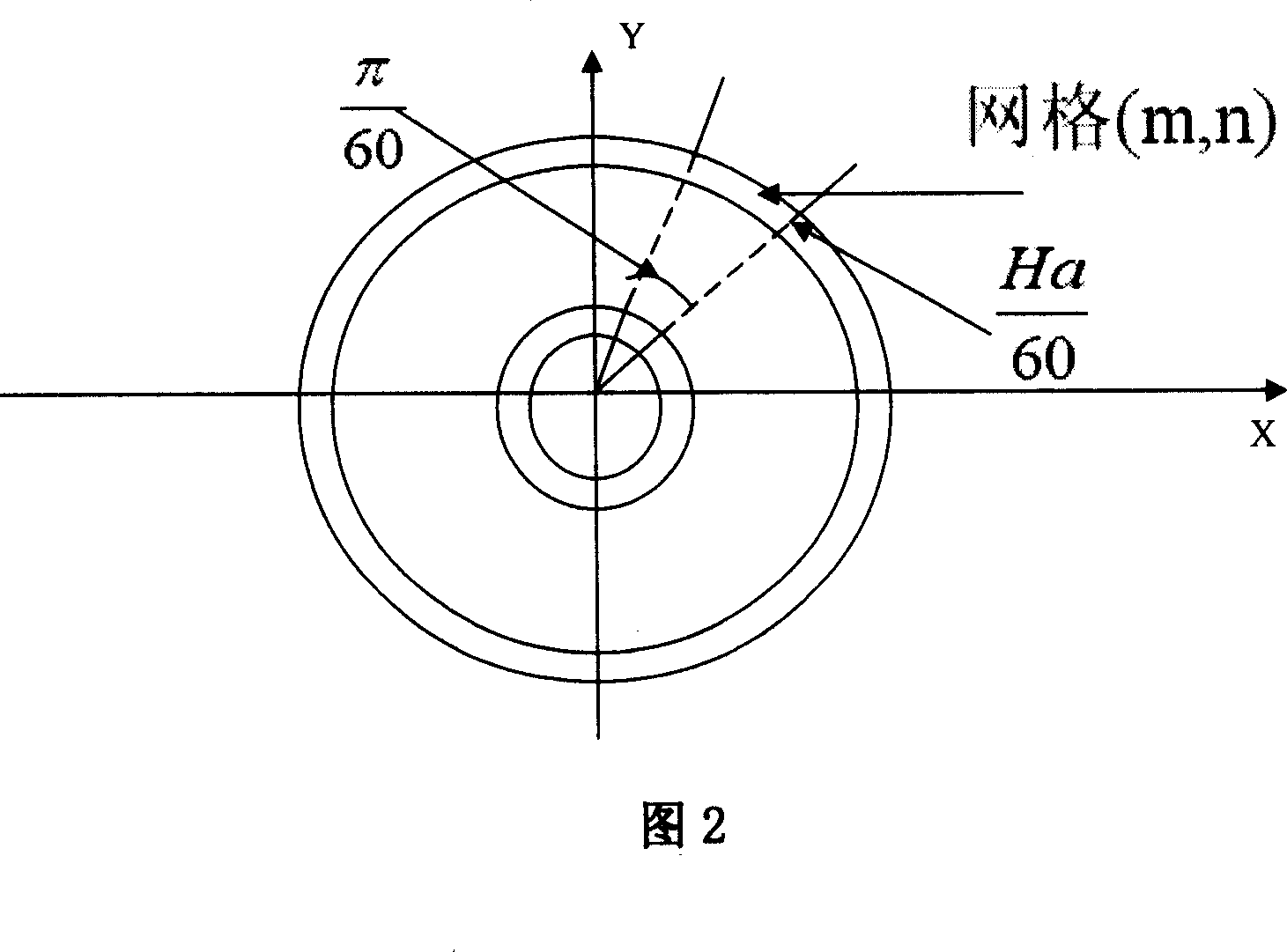

Underwater object detection and autonomous underwater vehicle (AUV) automatic collision prevention method and system based on mini sonar

InactiveCN102231082ARealize automatic collision avoidanceThe test effect is goodPosition/course control in two dimensionsAcoustic wave reradiationPropellerUnderwater object detection

The invention relates to an underwater object detection and autonomous underwater vehicle (AUV) automatic collision prevention system based on mini sonar. The system comprises mini sonar, a sonar computer and a master control computer, wherein the mini sonar communicates with the sonar computer through a serial port RS485; the sonar computer is connected with the master control computer through anetwork; the master control computer is connected with an optical fiber gyro, a Doppler velocimeter, a height gauge, a dip angle sensor and a magnetic compass through a serial port RS232 respectively; and the master control computer is connected with a propeller and a rudder fin through a digital / analog (DA) channel simultaneously. The invention also provides an underwater object detection and AUV automatic collision prevention method based on mini sonar. By the system and the method, an underwater object is detected through the mini sonar, a position of an obstacle is determined, and a collision prevention instruction is given; therefore, an accurate collision prevention decision is made by the AUV.

Owner:中国船舶重工集团公司第七〇二研究所

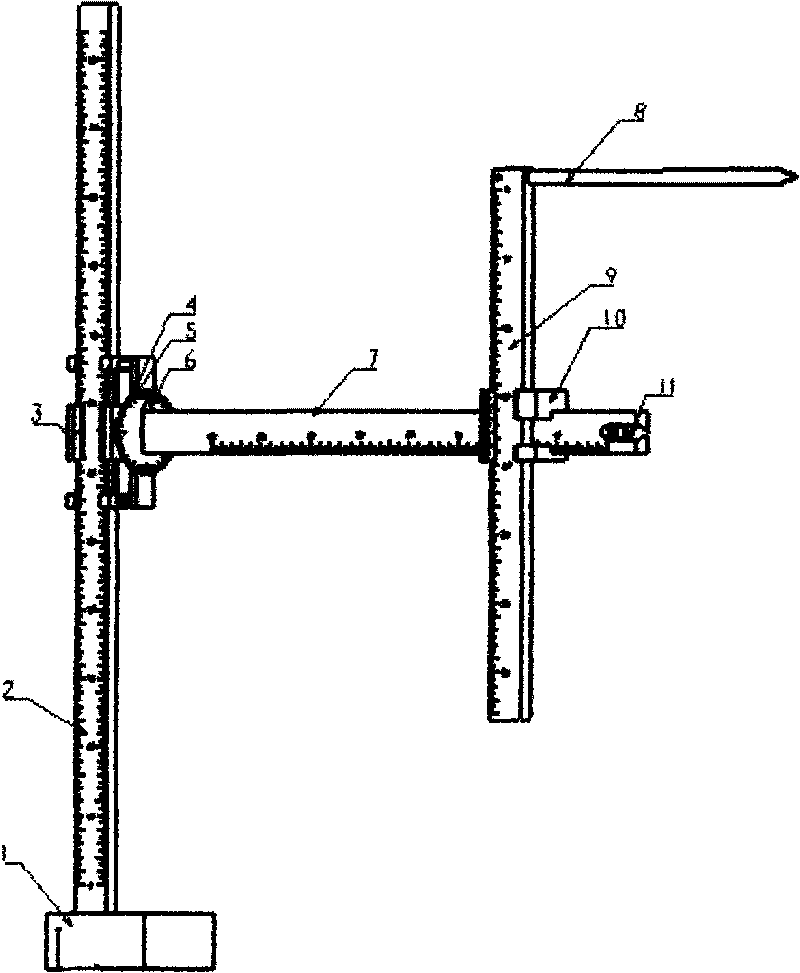

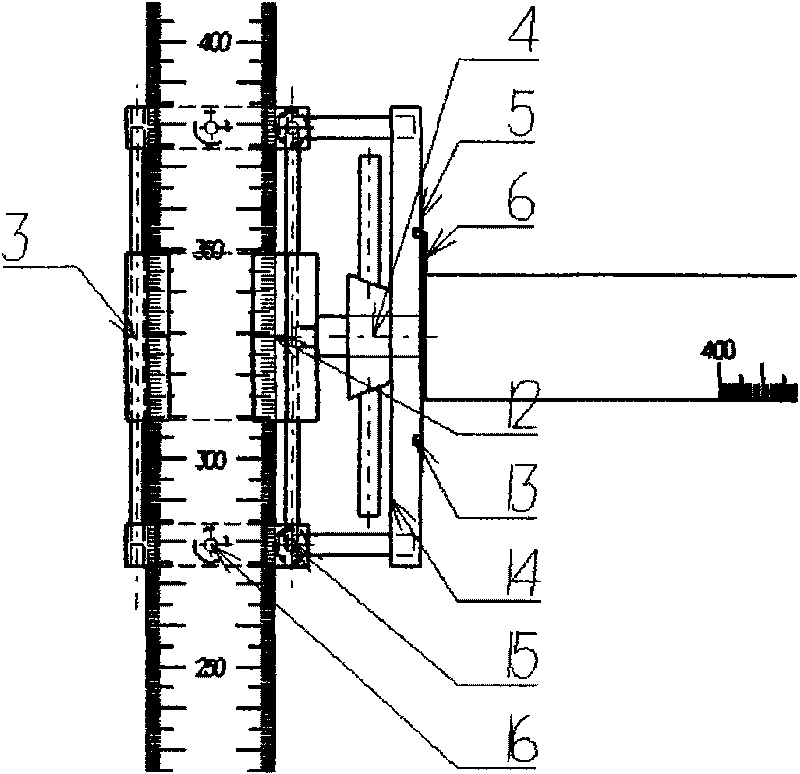

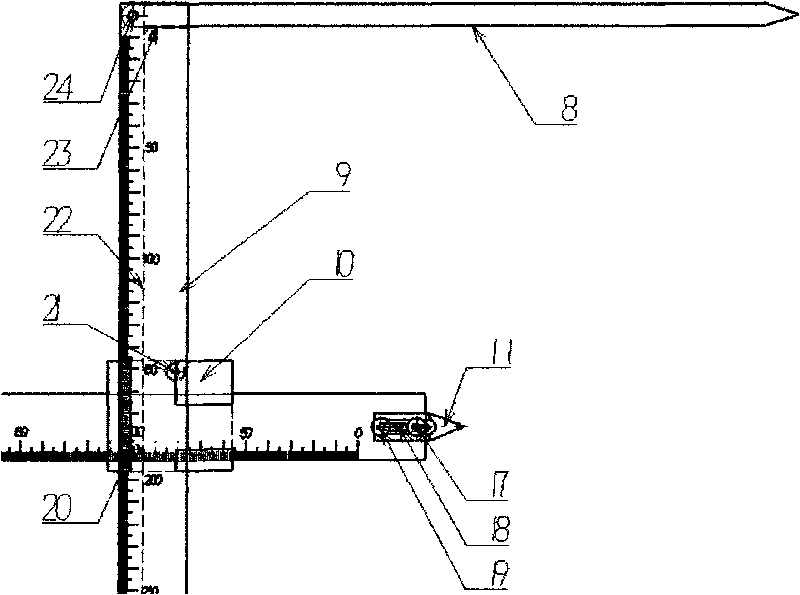

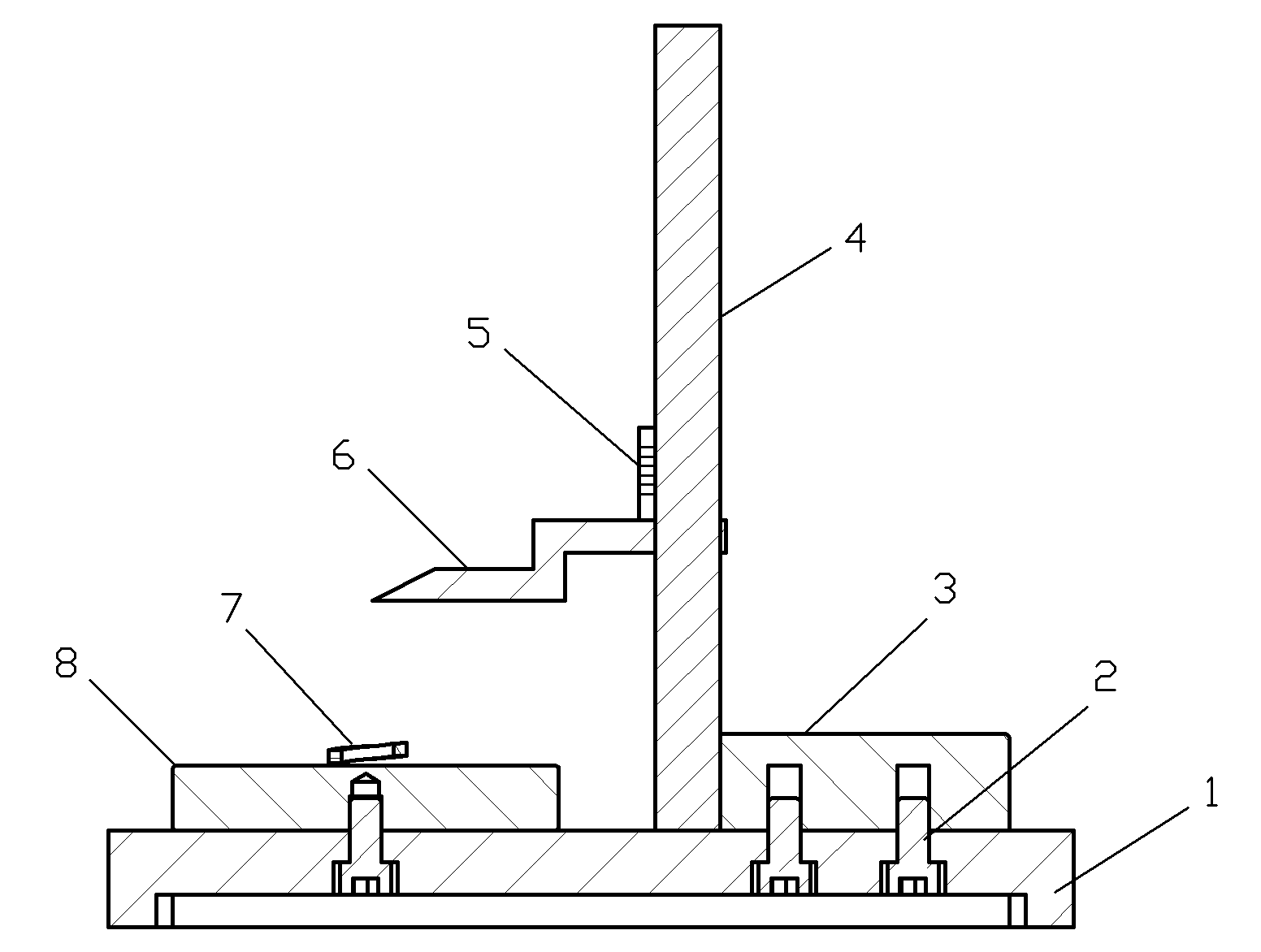

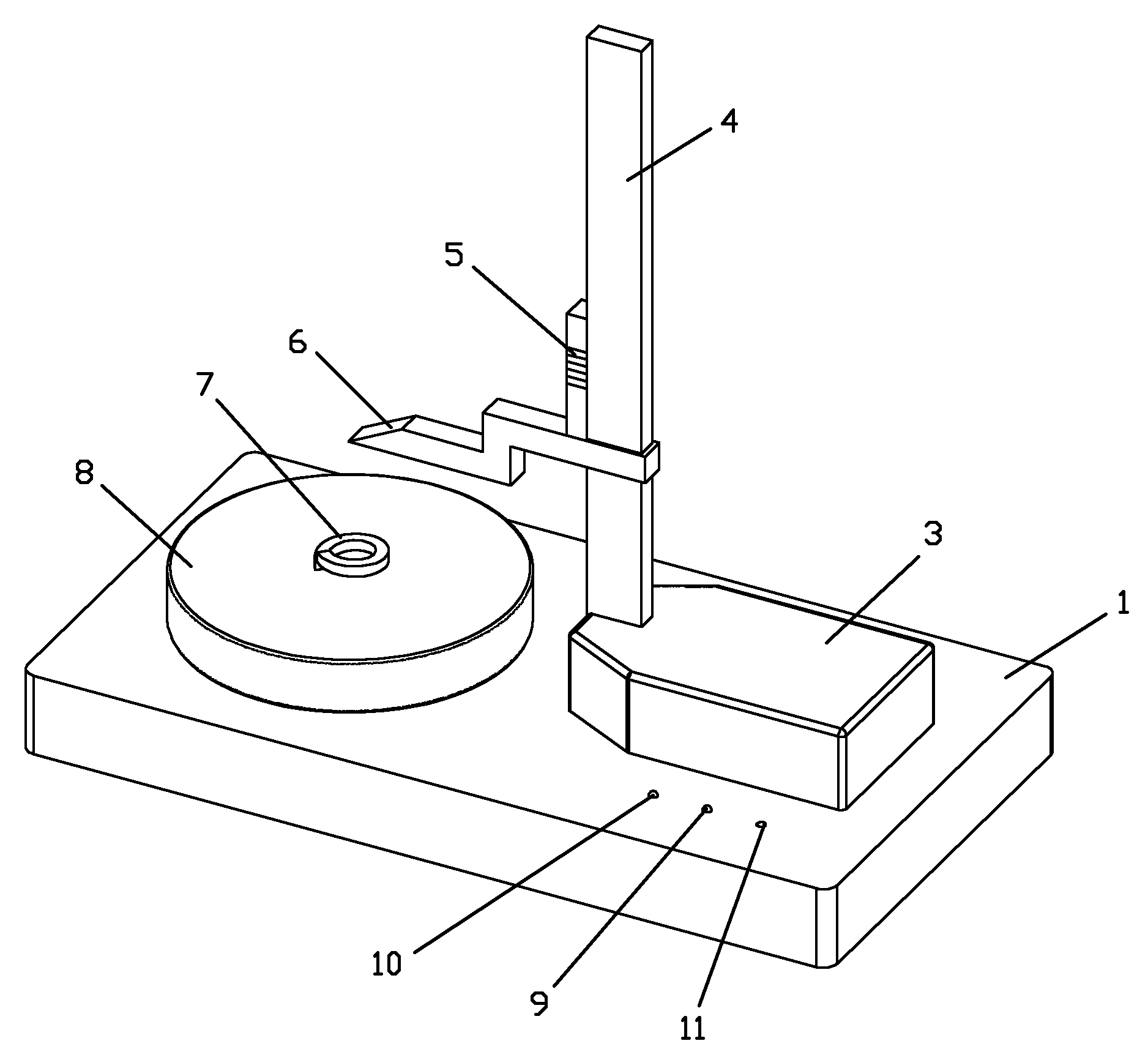

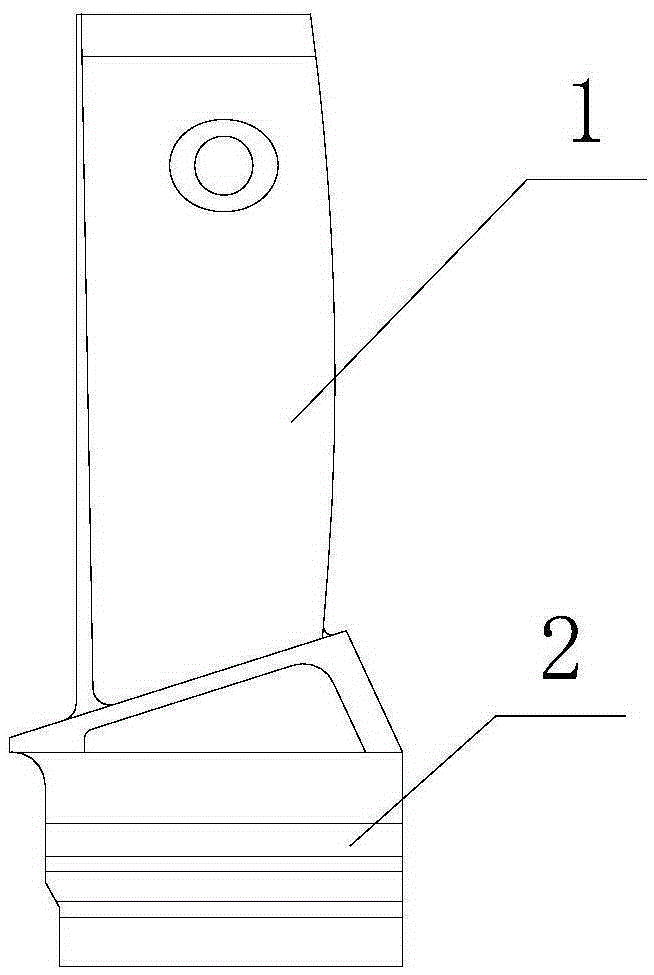

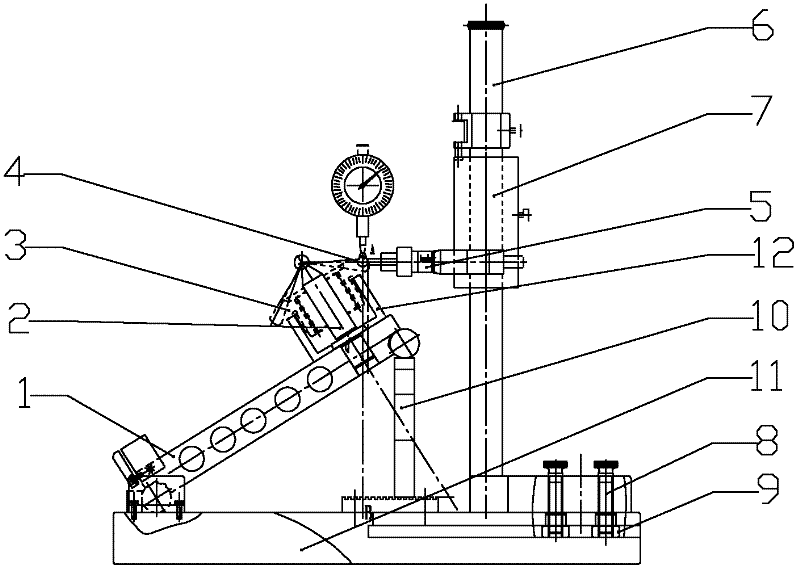

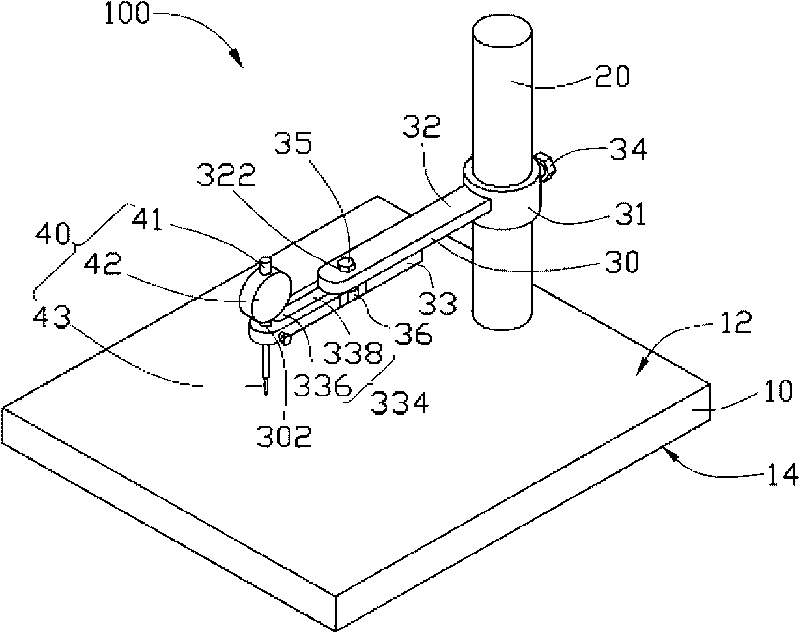

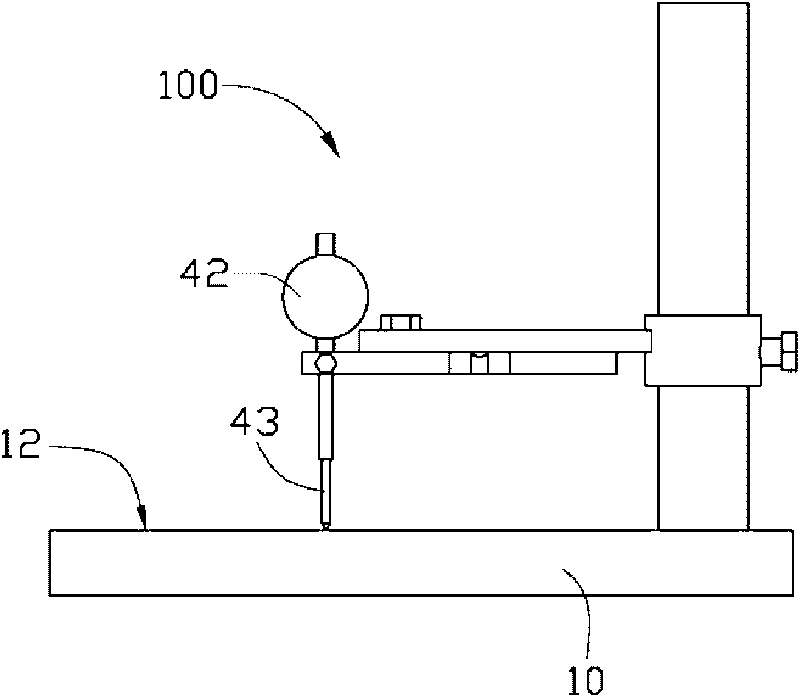

Multifunctional height gauge

ActiveCN101709942AEasy to assemble and disassembleMechanical measuring arrangementsRulers for direct readingEngineeringPlane parallel

The invention discloses a multifunctional height gauge, comprising a base, a stand column, a combined type sliding seat, a leveling instrument, a bi-direction sliding seat, a detecting instrument, a leveling instrument contact arm, a leveling instrument rotation locking unit and an angle dial. The bi-direction sliding seat is installed on the leveling instrument and can slide left and right on the leveling instrument. The detecting instrument which is vertical to the leveling instrument is installed on the bi-direction sliding seat. The angle dial is installed on a mounting board of angle dial. The end of the leveling instrument is provided with a threaded fixing rod, which is connected with the combined type sliding seat by passing through the hole between the angle dial, the mounting board of angle dial and the leveling instrument rotation locking unit and is locked tightly by rotating the leveling instrument rotation locking unit. The height gauge of the invention can measure the related size between two points between any angle lines in the plane parallel to the stand column and the related size between two points on any two planes vertical to the stand column. The assembly and the disassembly are convenient and rapid.

Owner:CHERY AUTOMOBILE CO LTD

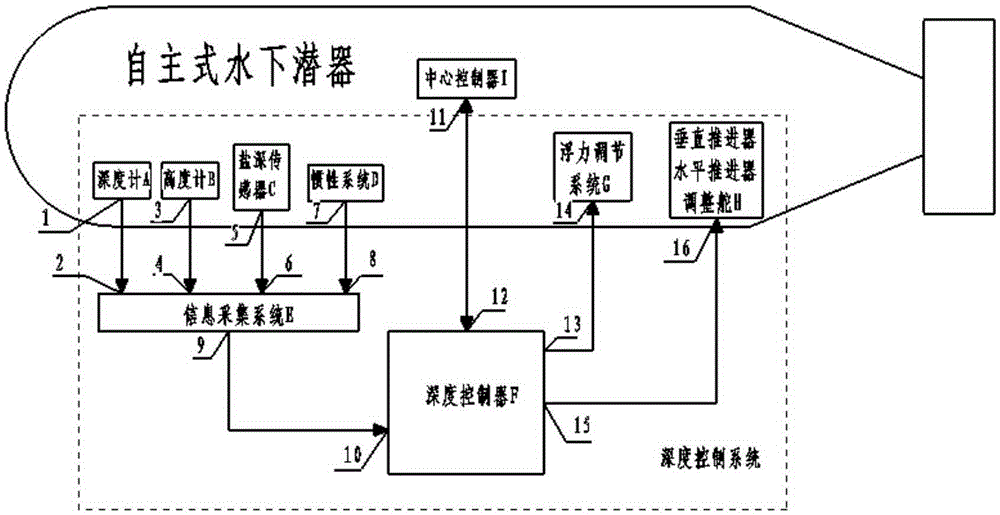

Depth control device of autonomous underwater vehicle

ActiveCN105383654AHighlight substantiveOvercoming the problem of slow responseUnderwater vesselsUnderwater equipmentMarine engineeringCollection system

The invention relates to the technical field of underwater robots, in particular to a depth control device of an autonomous underwater vehicle and a control method thereof. The depth control device can realize fast and accurate depth control on the great-depth and long-endurance condition of the autonomous underwater vehicle. The depth control device of the autonomous underwater vehicle comprises a depth data collection system, a buoyancy adjusting system, a propelling system, a depth controller and a great-depth underwater vehicle buoyancy model. The depth data collection system collects the depth information of the autonomous underwater vehicle through a depth gauge, a height gauge, a salt depth sensor and an inertial system, and the depth information of the underwater vehicle is extracted through signal synchronization and fusion of an information collection system and then is transmitted to the depth controller and the buoyancy model. The buoyancy adjusting system and the propelling system are combined in the design of a depth control system of the underwater vehicle, and therefore the requirement for fastness of system depth control can be met, and the stability and the robustness of depth servo control can be guaranteed.

Owner:HARBIN ENG UNIV

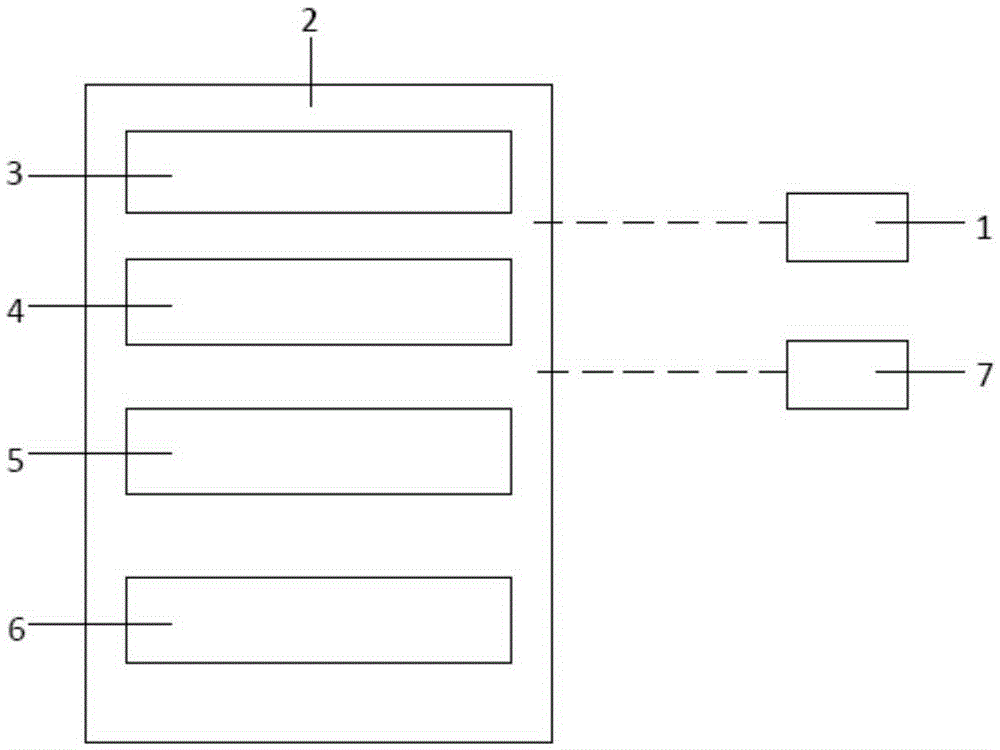

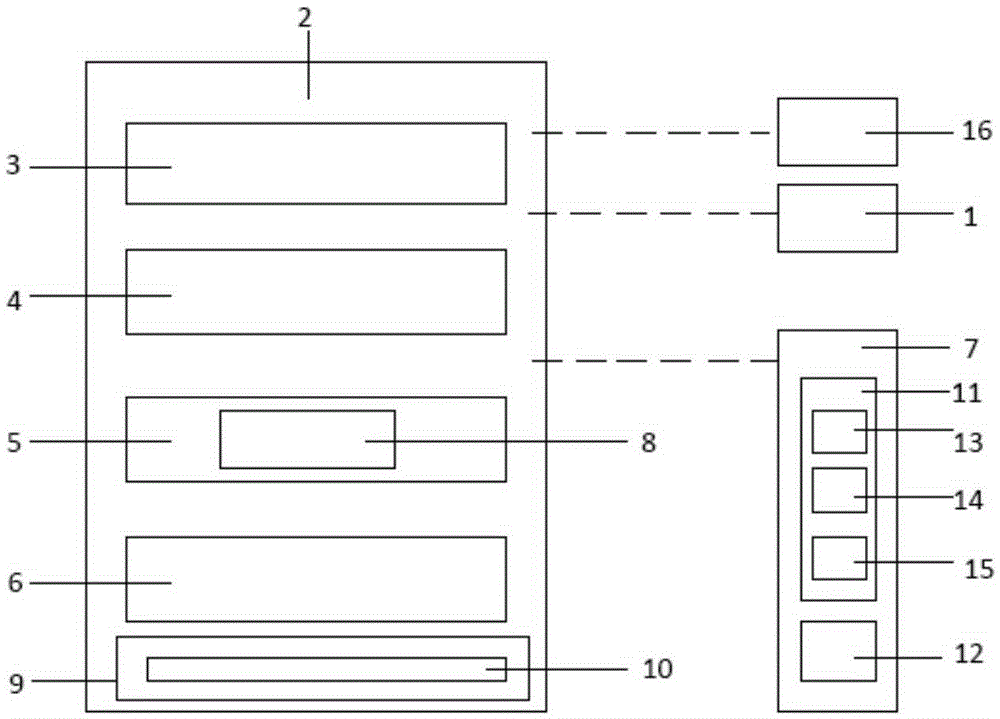

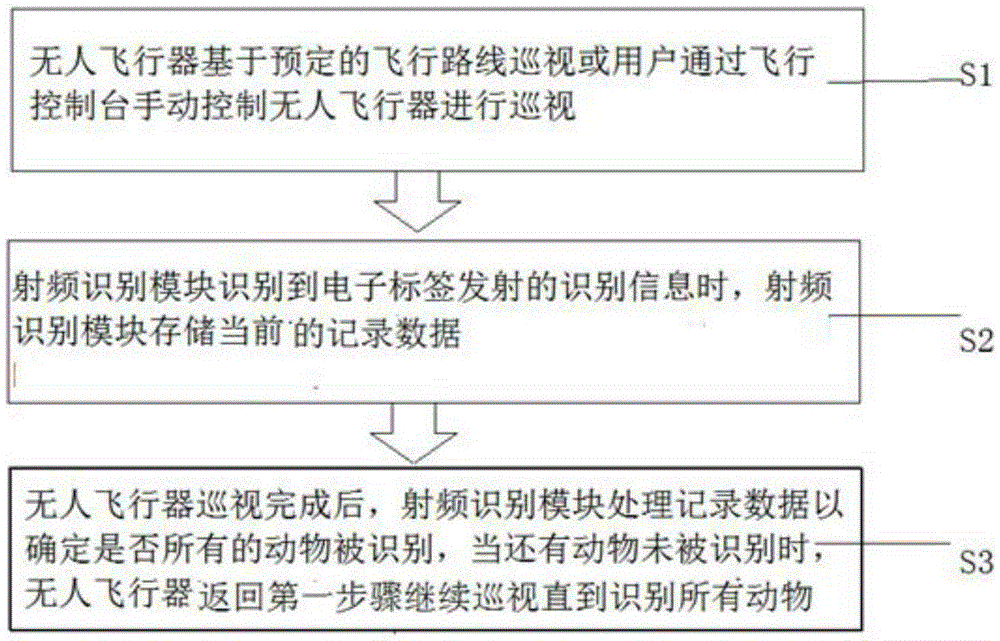

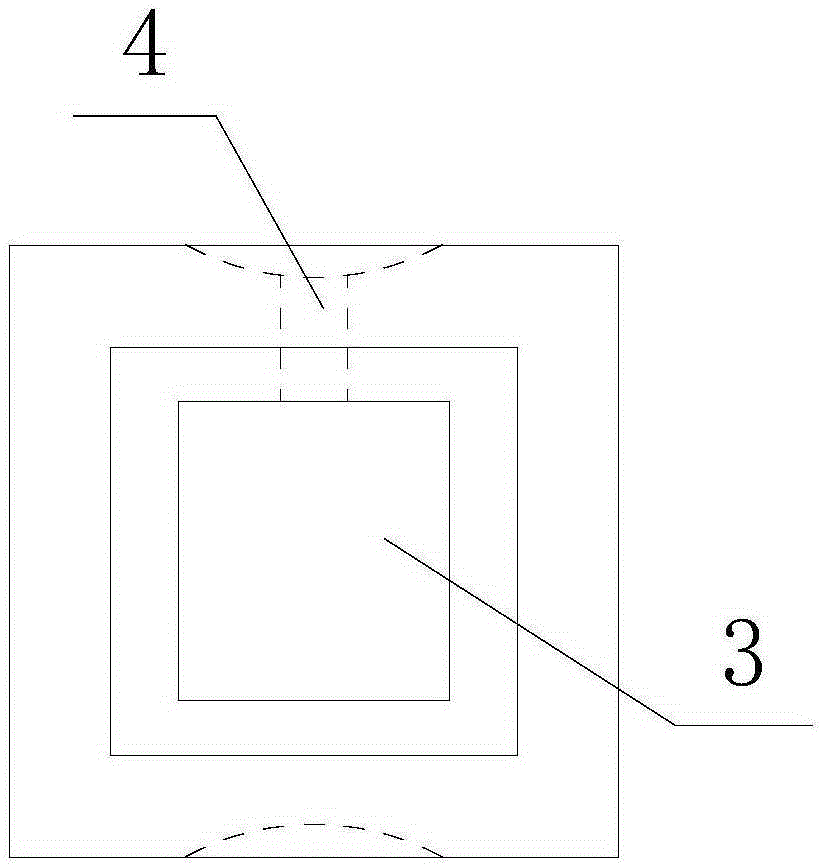

Grazing system based on unmanned aerial vehicle and grazing method thereof

InactiveCN105248308AFacilitate post-management analysisEasy to identifyOther apparatusGrazingElectronic tagging

The invention discloses a grazing system based on an unmanned aerial vehicle and a grazing method thereof. The grazing system comprises an electronic tag (1) arranged on an animal body, a positioning module (3) arranged on the unmanned aerial vehicle (2) and provides the position of the unmanned aerial vehicle, a height gauge (4) for measuring the height of the unmanned aerial vehicle (1) and a radio frequency identification module (5) for receiving identifying information transmitted by the electronic tag (1). When the radio frequency identification module (5) identifies identifying information transmitted by the electronic tag (1), the current identifying time, identifying position and the identifying information form recorded data, the radio frequency identification module (5) stores and process the recorded data, and the identifying position is a circular region where the position of the unmanned aerial vehicle (2) provided by the positioning module (3) is used as the circle and the remote sensing range R of the radio frequency identification module (5) is used as the radius. The remote sensing radius R can be changed by adjusting the height H of the unmanned aerial vehicle (1).

Owner:谭圆圆

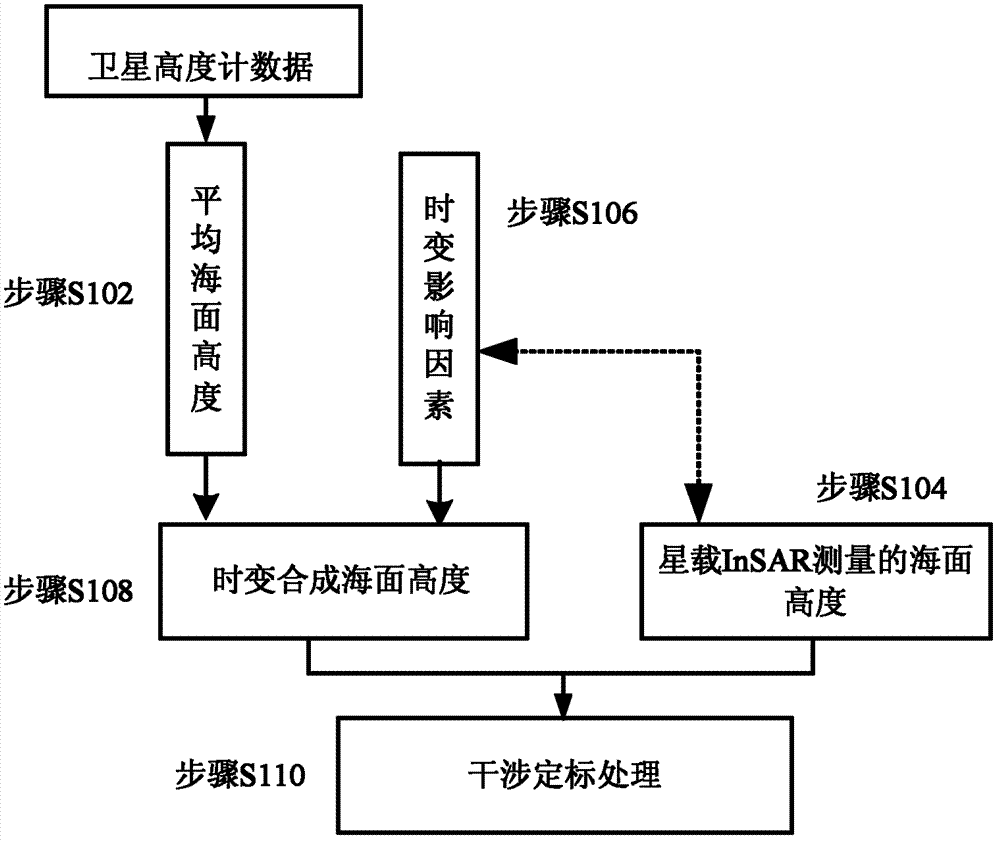

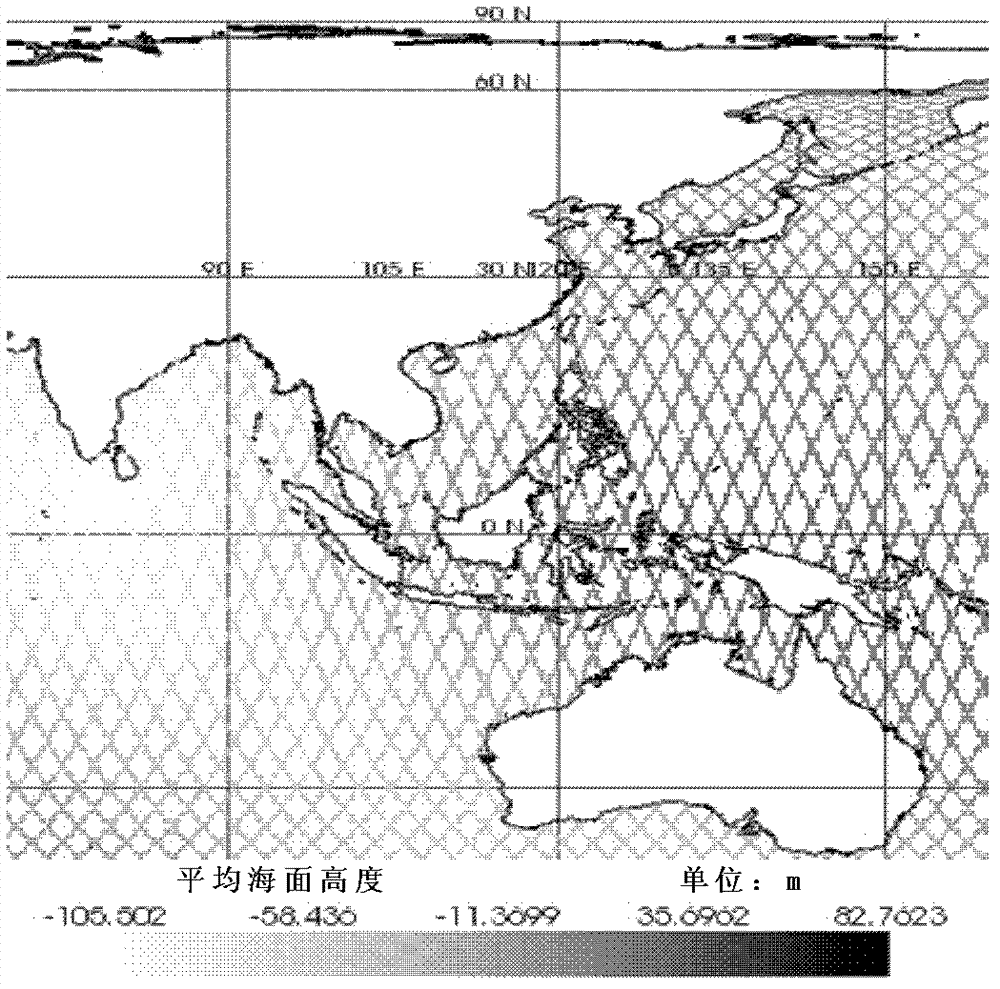

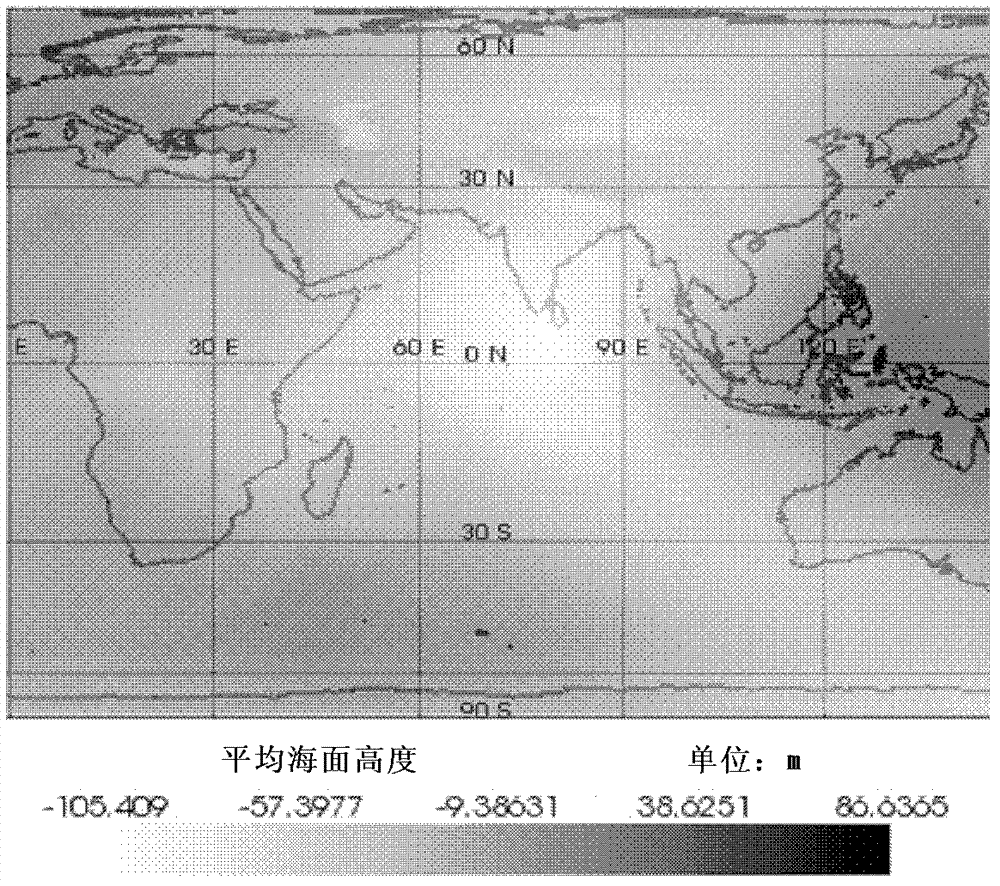

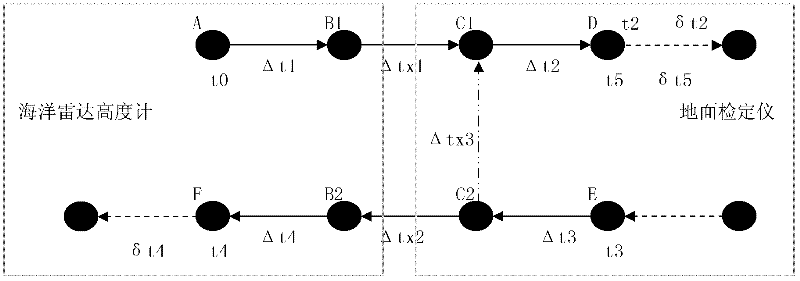

External calibration method of satellite-borne interferometric synthetic aperture radar (InSAR) system

ActiveCN103364766ASolve the shortcomings of difficult long-term dynamic monitoringAvoid Design Implementation DifficultiesWave based measurement systemsNatural satelliteInterferometric synthetic aperture radar

The invention discloses an external calibration method of a satellite-borne interferometric synthetic aperture radar (InSAR) system. The external calibration method comprises that sea surface height data is measured by a satellite height gauge, and average sea surface height data is acquired after time varying influence factors are removed; sea surface height data measured by the satellite-borne InSAR system is acquired through sea images and uncalibrated interference parameters of preset time and space distribution acquired by the satellite-borne InSAR system; sea height variation brought about by the time varying influence factors except for the spreading effect under the condition of the preset time and space distribution is calculated in a simulation mode; time varying synthesized sea surface height data is acquired by the average sea surface height and the sea surface height variation brought about by time varying influence factors except for the spreading effect; and the sea surface height data measured by the satellite-borne InSAR system is corrected by taking the time varying synthesized sea surface height data as standard data, thereby realizing calibration of the satellite-borne InSAR system. According to the invention, an external calibration method based on a sea field is adopted, thereby being capable of carrying out long-term dynamic monitoring on slow variation elements in error of the satellite-borne InSAR system.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

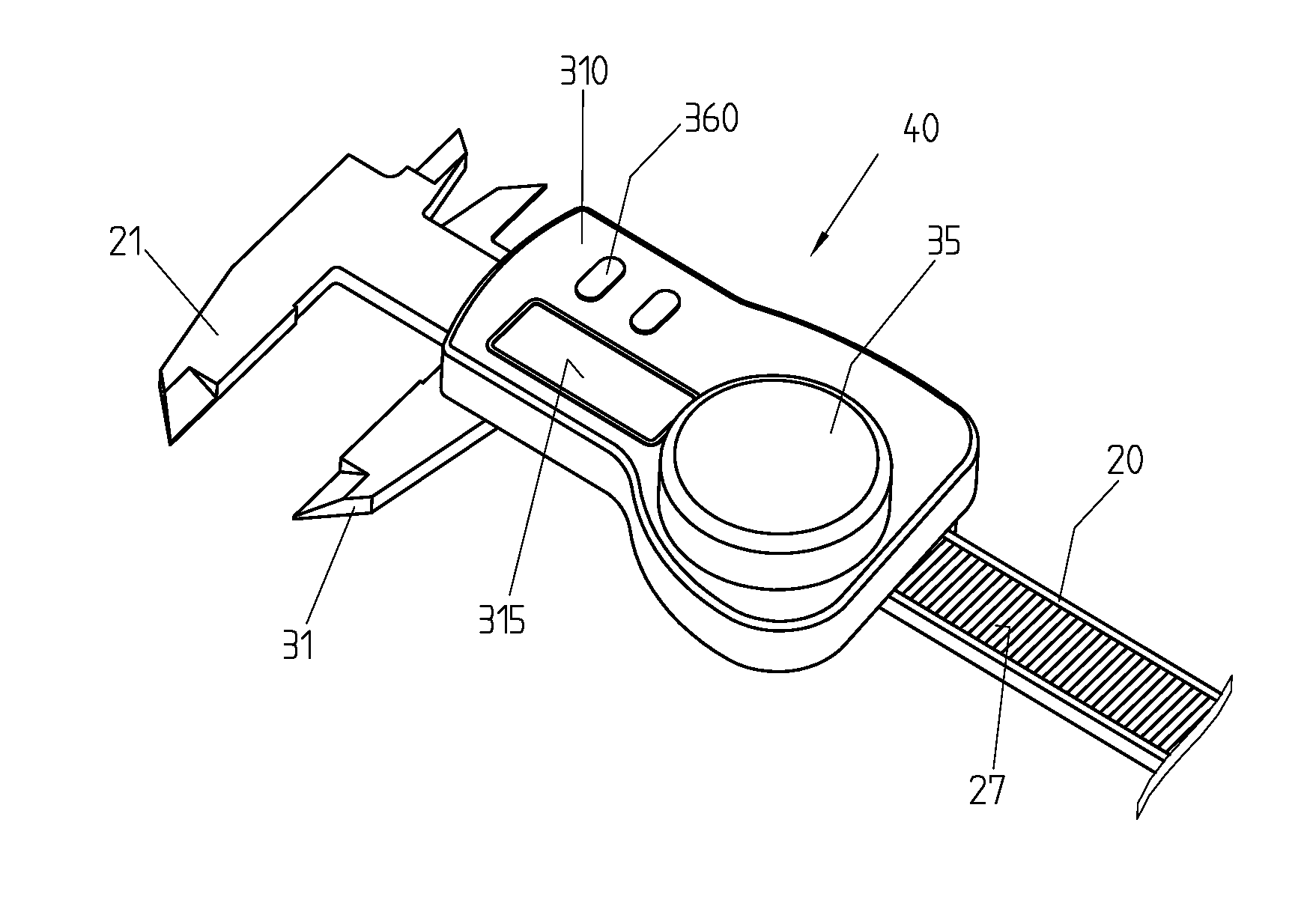

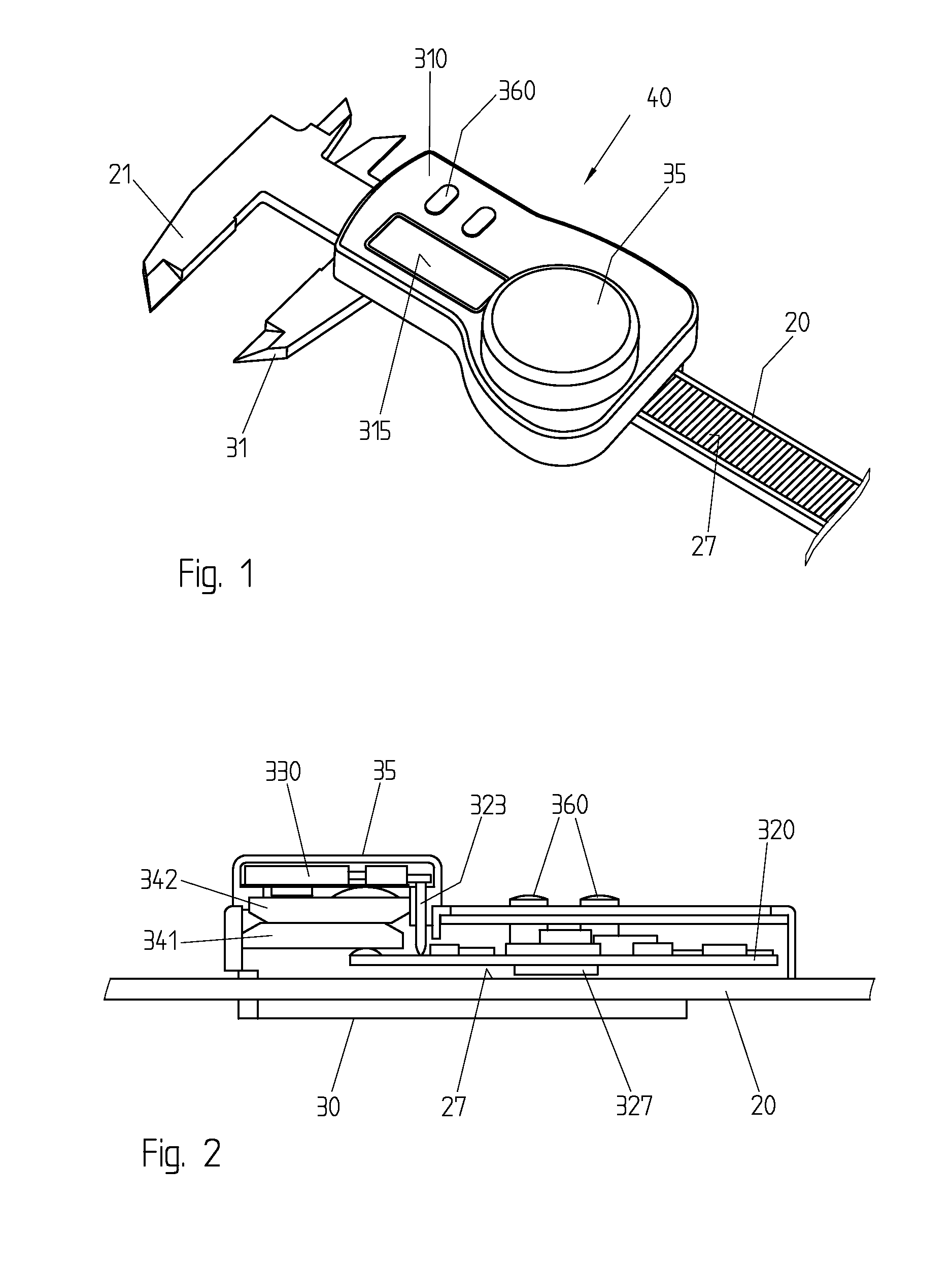

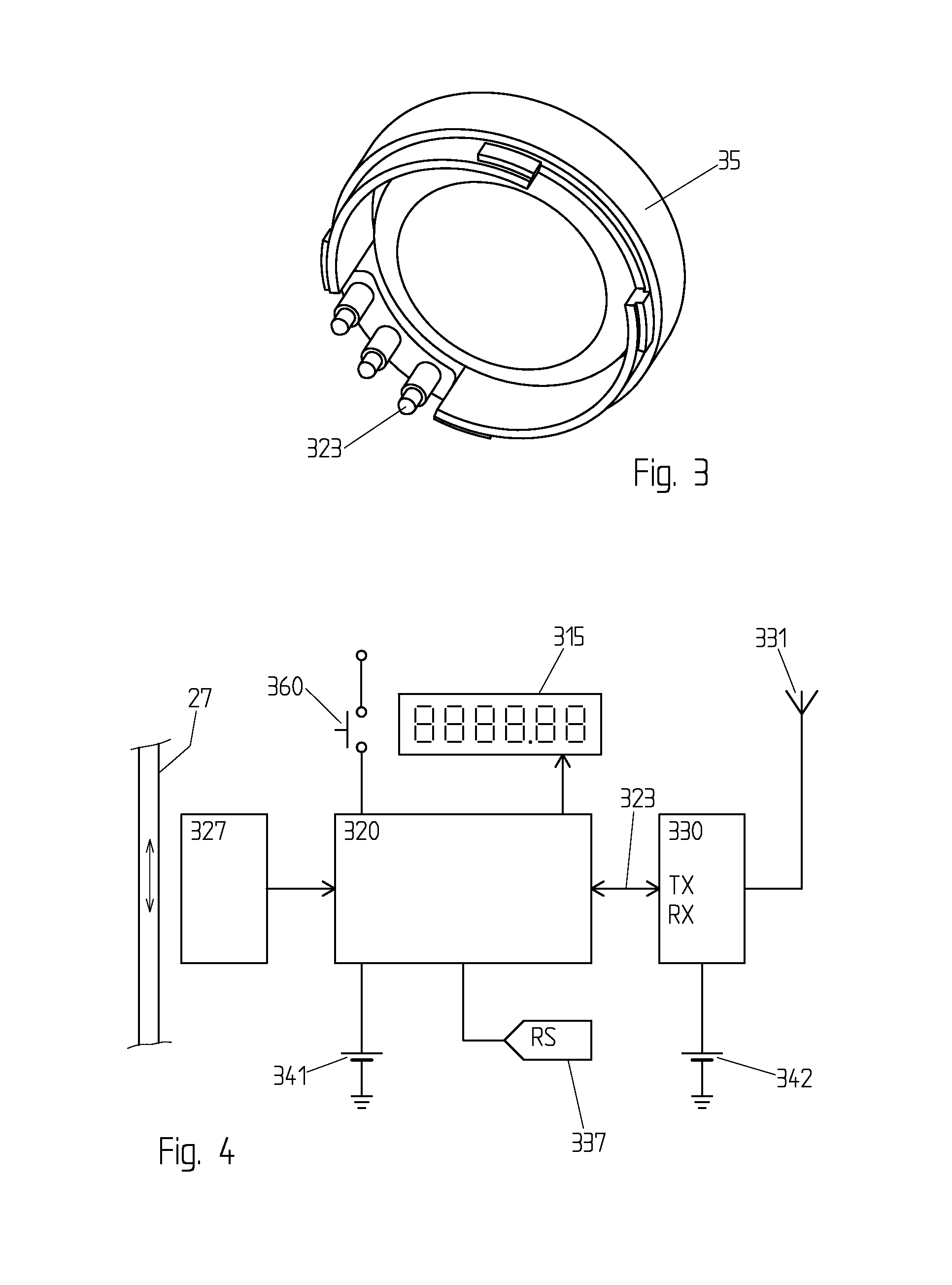

Instrument for measuring dimensions equipped with an interface and corresponding interface

ActiveUS20120203504A1Raise the possibilityGood user interfaceMicrometersTransmission systemsCommunication interfaceMeasuring instrument

Electronic measuring instrument equipped with a removable intelligent processing and radio communication interface. The interface allows managing additional features such as bidirectional communication of commands and measurement data with printers, computers or other external devices, as well as the transmission of instructions or measurement programs to the instrument. The radio interface may be connected with several measuring instruments such as callipers, micrometers, comparators or height gauges. It is integrated into the lid of the battery compartment of the instrument, so that it can be installed and removed easily and without impairing the seal. The cover also includes an extra battery for the processing and radio transmission interface.

Owner:TESA SE

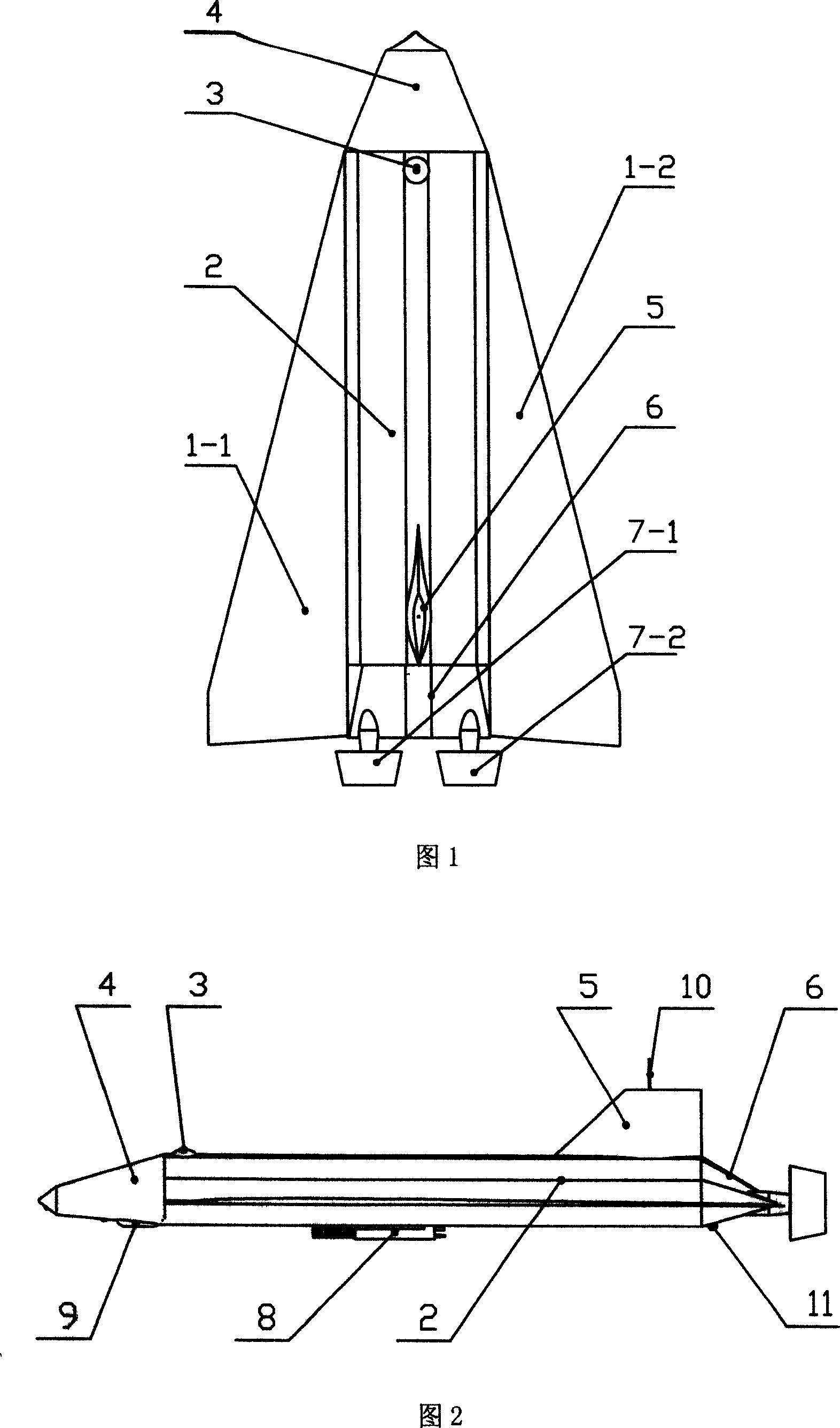

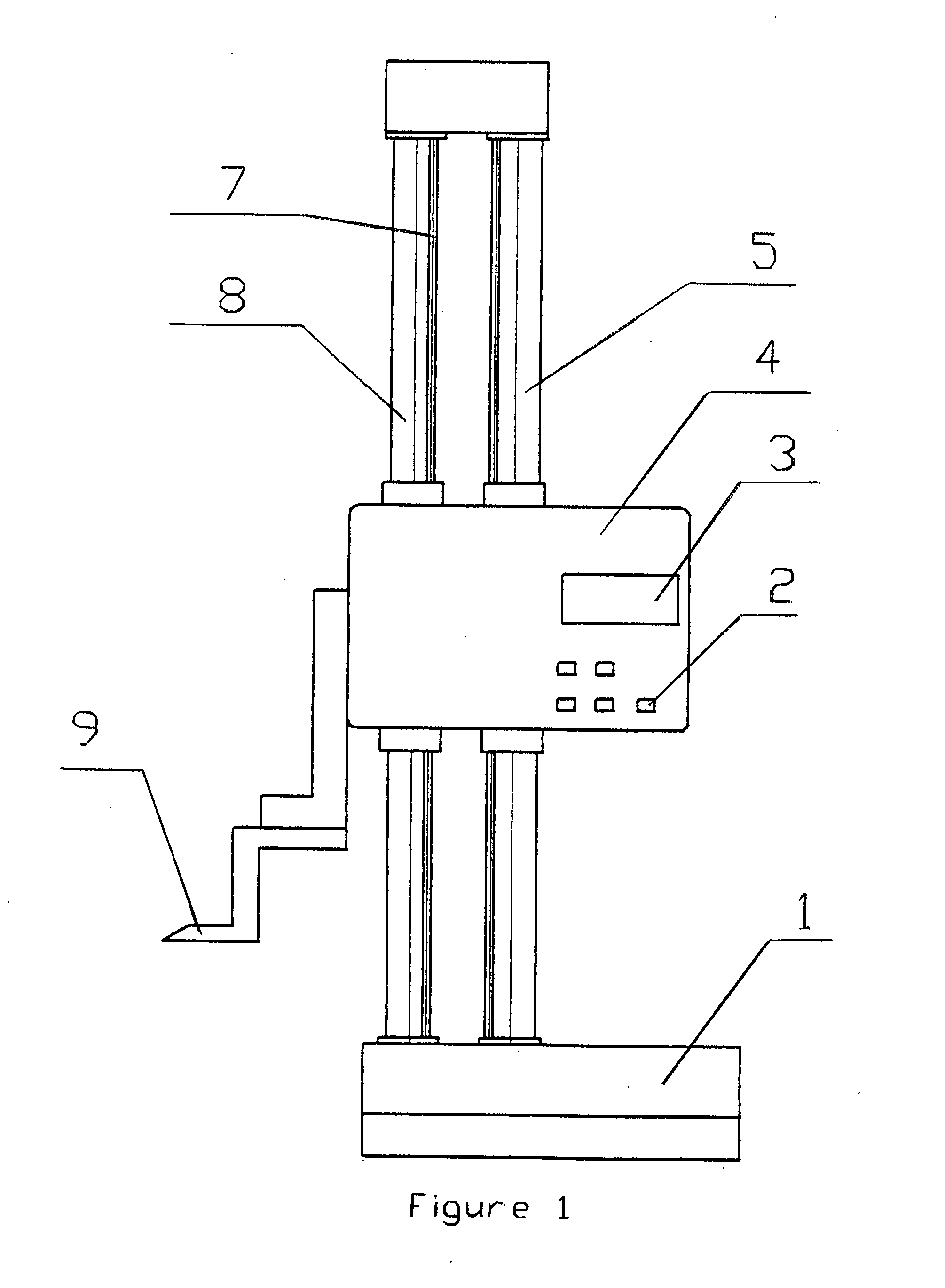

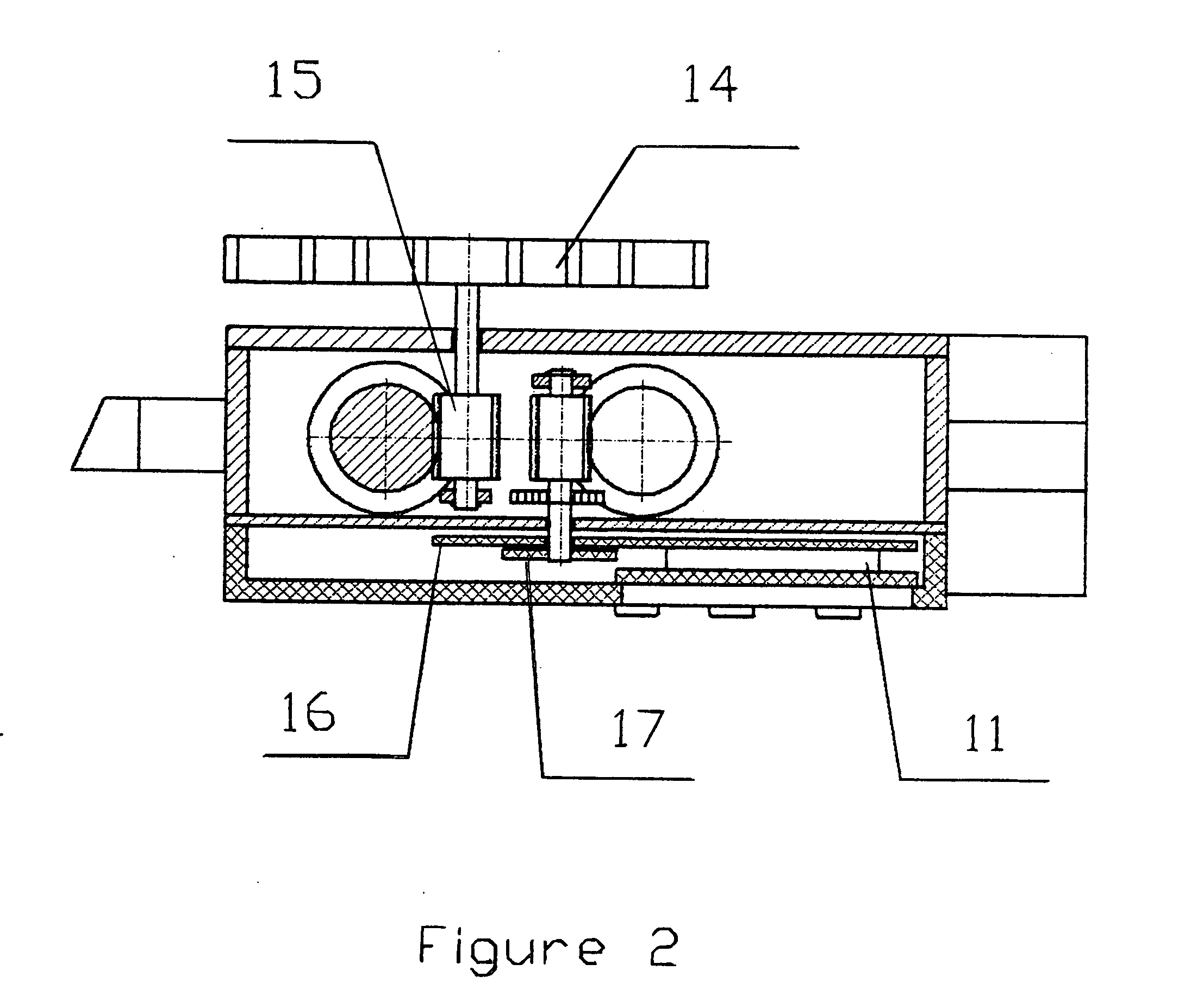

Hybrid type underwater sailing device

ActiveCN101007566ASimple structureEasy to manufactureNavigation by speed/acceleration measurementsUnderwater vesselsHybrid typeControl system

A hybrid underwater craft. It includes framework consisting of head shield, body shield and tail shield; triangular wings and vertical fixing tail rudder installed out the body shield; height gauge installed below the tail shield; navigational module installed in head shield; central pressure resistance cabin installed in the body shield; left and right pressure resistance cabins installed in the body shield; underwater sound communication module installed in the body shield; buoyant force drive system, control system, pitching adjusting module installed between the body shield and central pressure resistance cabin and pitching adjusting module supporting bar used for support pitching adjusting module; two conduit airscrew propeller connected on the rear-end of tail cup firmly and symmetrically. The invention uses the delta wing which both has gliding property and AUV operating performance as wings of craft, the loaded corresponding measuring sensor and the task module can realize monitoring and investigation of large area waters long term, and can monitor, expedite and trace the specific target precisely and rapidly.

Owner:TIANJIN UNIV

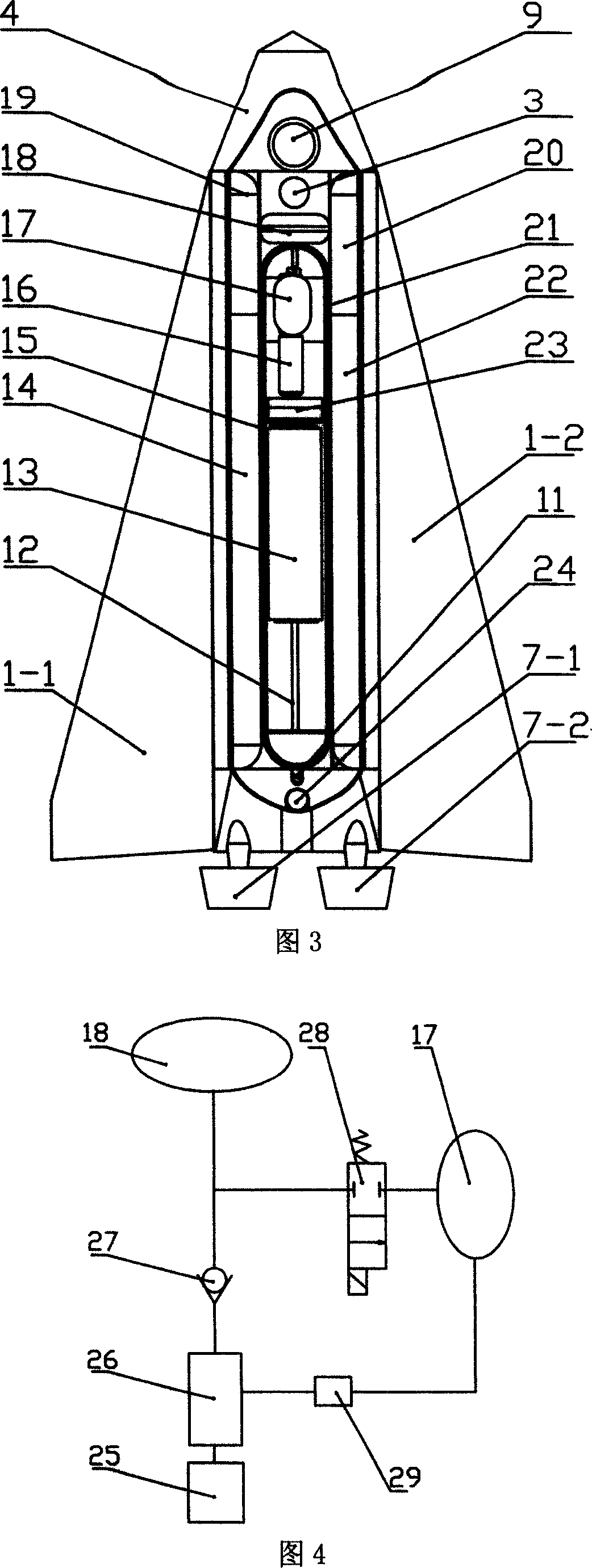

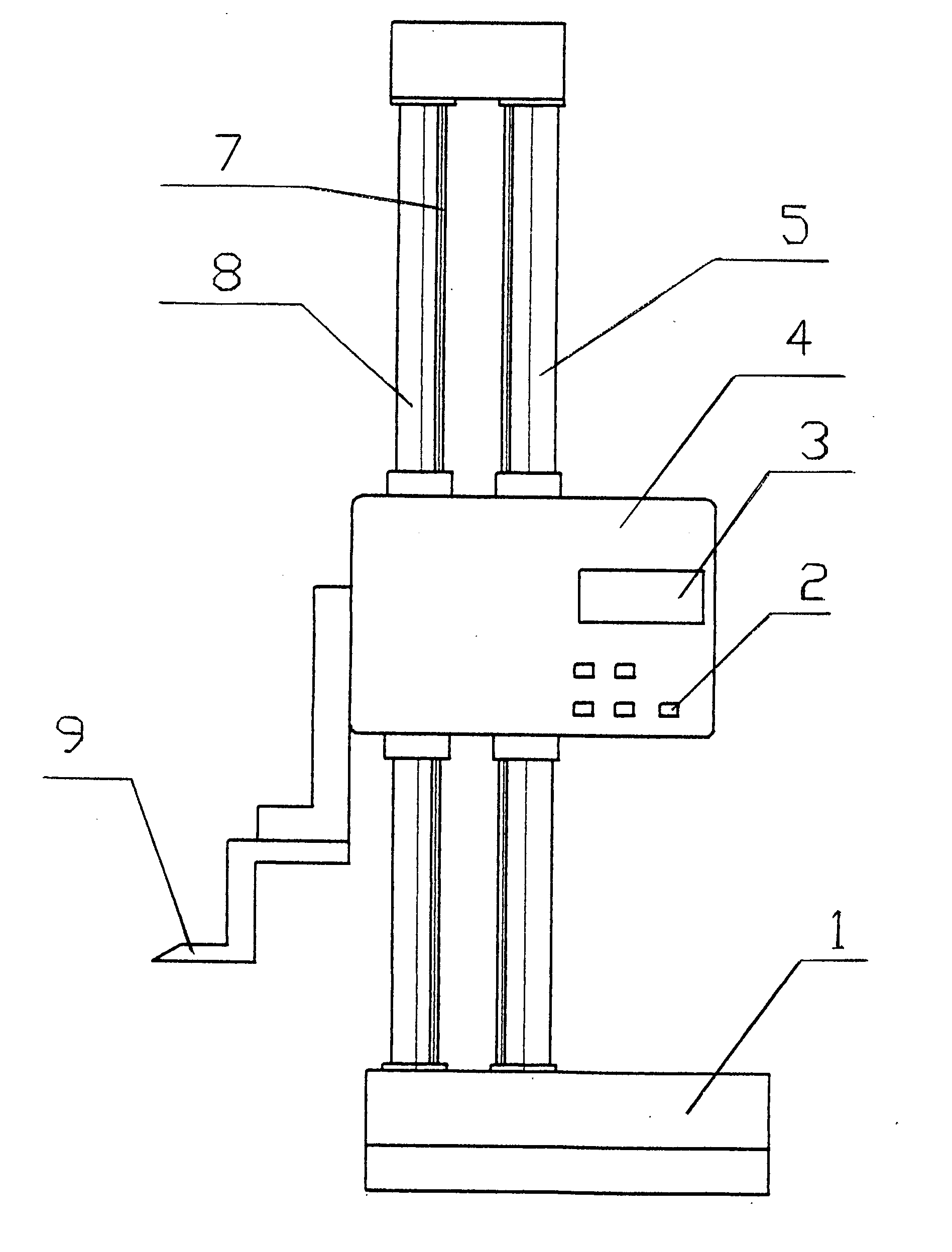

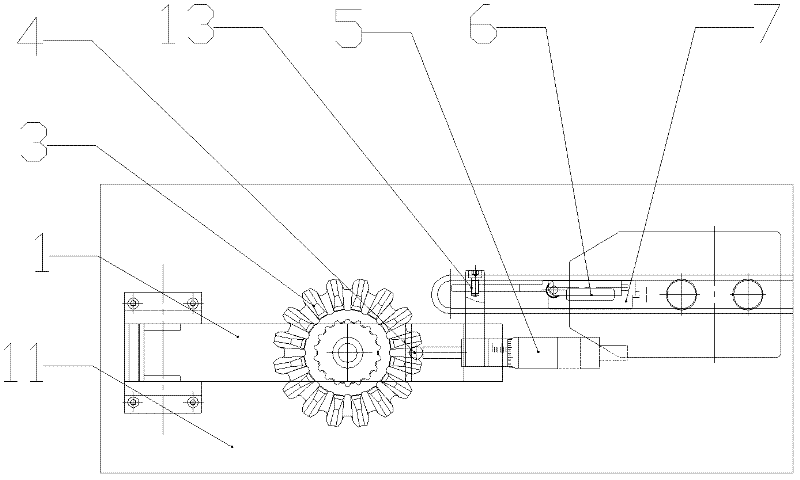

Linear moving capacitive sensor twin column electronic height gauge

InactiveUS20060137204A1Low costReduced measurement accuracyFeeler-pin gaugesUsing electrical meansOn columnEngineering

The present invention is an electronic height gauge utilizing new technology and includes a first column (Column 1) and a second column (Column 2), a display unit with a cover, a measuring scriber, a fixed capacitance sensor and a linear moving capacitance sensor. The fixed capacitance sensor is located on a flat surface on Column 1, flat surface having a length equivalent to the length of Column 1. The linear moving capacitance sensor is located inside the display unit cover positioned to face the fixed capacitance sensor. The fixed capacitive sensor and linear moving capacitive sensors are facing toward each other only, and do not make direct physical contact with the fixed capacitor sensor when the height gauge is operating in upward and downward movements. The fixed and moving capacitive sensors are instead making only electrical contact with each other when the height gauge is making upward and downward movements. This linear direct data non-contact sensor transfer system results in high accuracy of measurements, which also ensures the repeatability of accurate measurements. Also, since the fixed capacitance sensor and the linear moving capacitance sensor have no physical contact with each other, there is no wear and tear damage on either component part, thereby leading to a longer life of use with stability in accurate measurements and repeatability. Because the measuring system is comparatively simple, and easy to assemble and service and maintain compared to the existing rotary capacitive sensor electronic height gauges that exist on the market, the overall cost of production and maintenance is minimized. On the second column (Column 2), a simple rack and gear system is added. These gears of column 2 are connected to a hand wheel located on the rear of the display unit. The handwheel is used for making upward and downward vertical movements. This rack and gear system of column 2 of the present invention is only used to aid the same in making upward and downward movements, and does not affect the measuring accuracy of the height gauge, as it did in the height gauges that have existed on the market.

Owner:INT PRECISION INSTR CORP

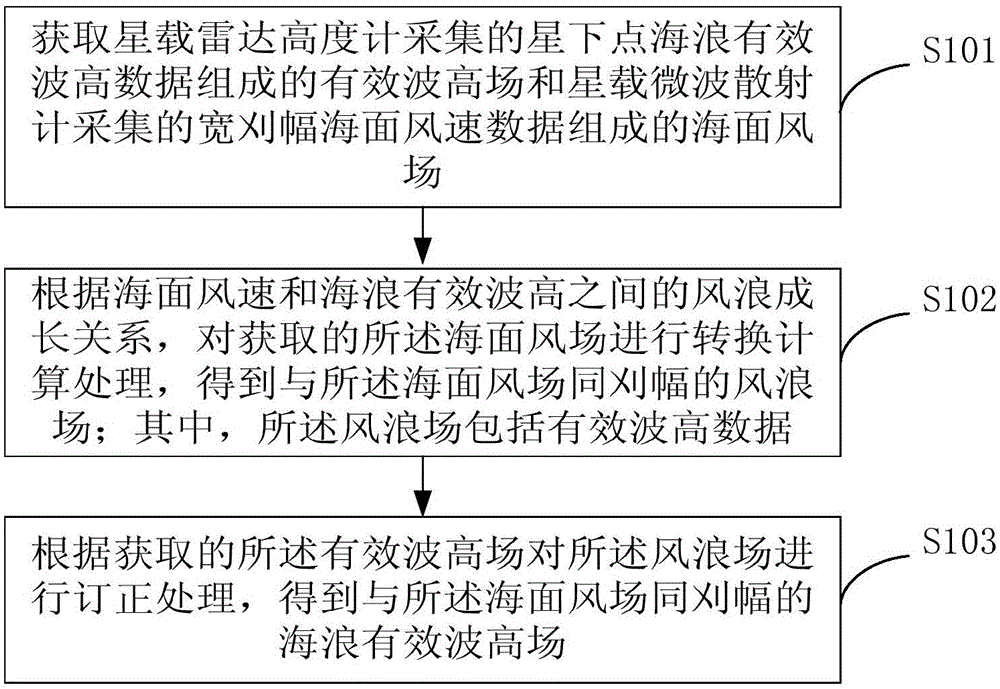

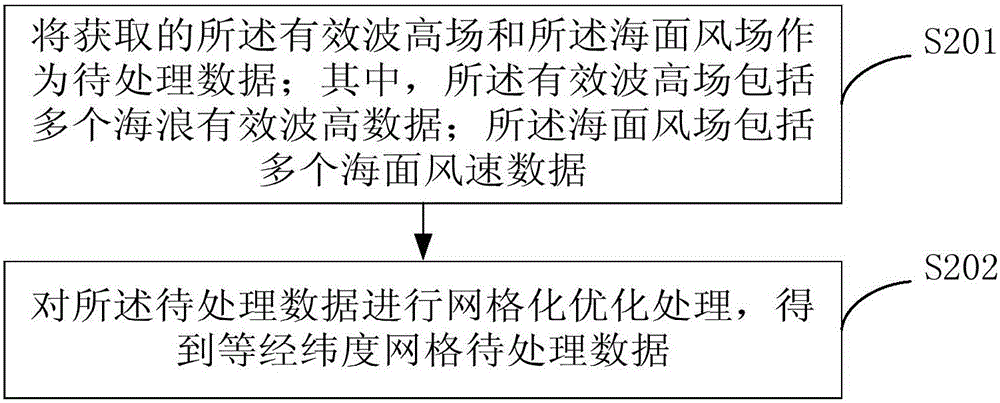

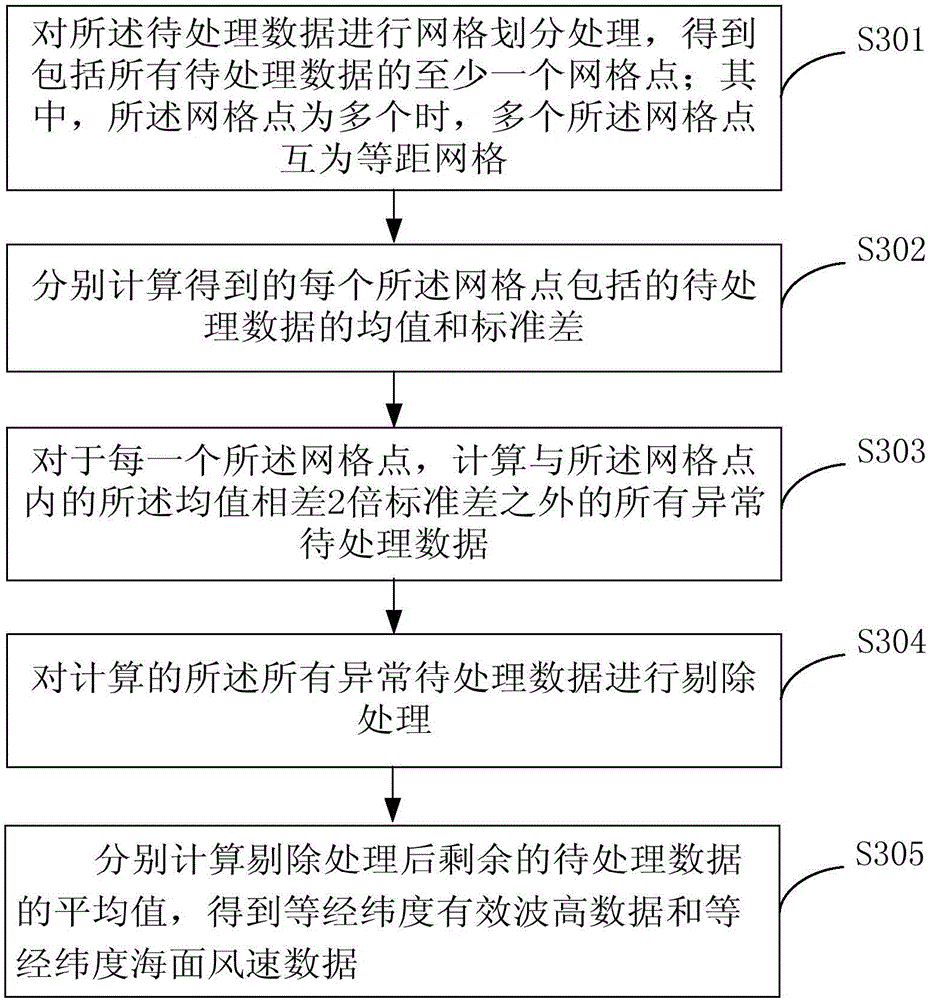

Fusion inversion method and device for sea wave significant wave height field

The invention provides a fusion inversion method and device for a sea wave significant wave height field. The method comprises steps as follows: acquiring a significant wave height field which is acquired by a spaceborne radar height gauge and comprises substellar point sea wave significant wave height data as well as a sea surface wind field which is acquired by a spaceborne microwave scatterometer and comprises wide swath sea surface wind speed data; performing conversion calculation processing on the acquired sea surface wind field according to the wind wave growth relation between sea surface wind speeds and sea wave significant wave heights, and obtaining a wind wave field having the same swath as the sea surface wind field; performing correction processing on the wind wave field according to the acquired significant wave height field, and obtaining the sea wave significant wave height field having the same swath as the sea surface wind field; providing the sea surface wind field with wide swath, high precision and high spatial resolution through the spaceborne microwave scatterometer, converting the sea surface wind field acquired by the scatterometer into the wind wave field according to the wind wave growth relation, performing correction processing on the wind wave field through the significant wave height field of the height gauge, and finally, obtaining the significant wave height field with wide swath, high precision and high spatial resolution.

Owner:国家海洋环境预报中心 +1

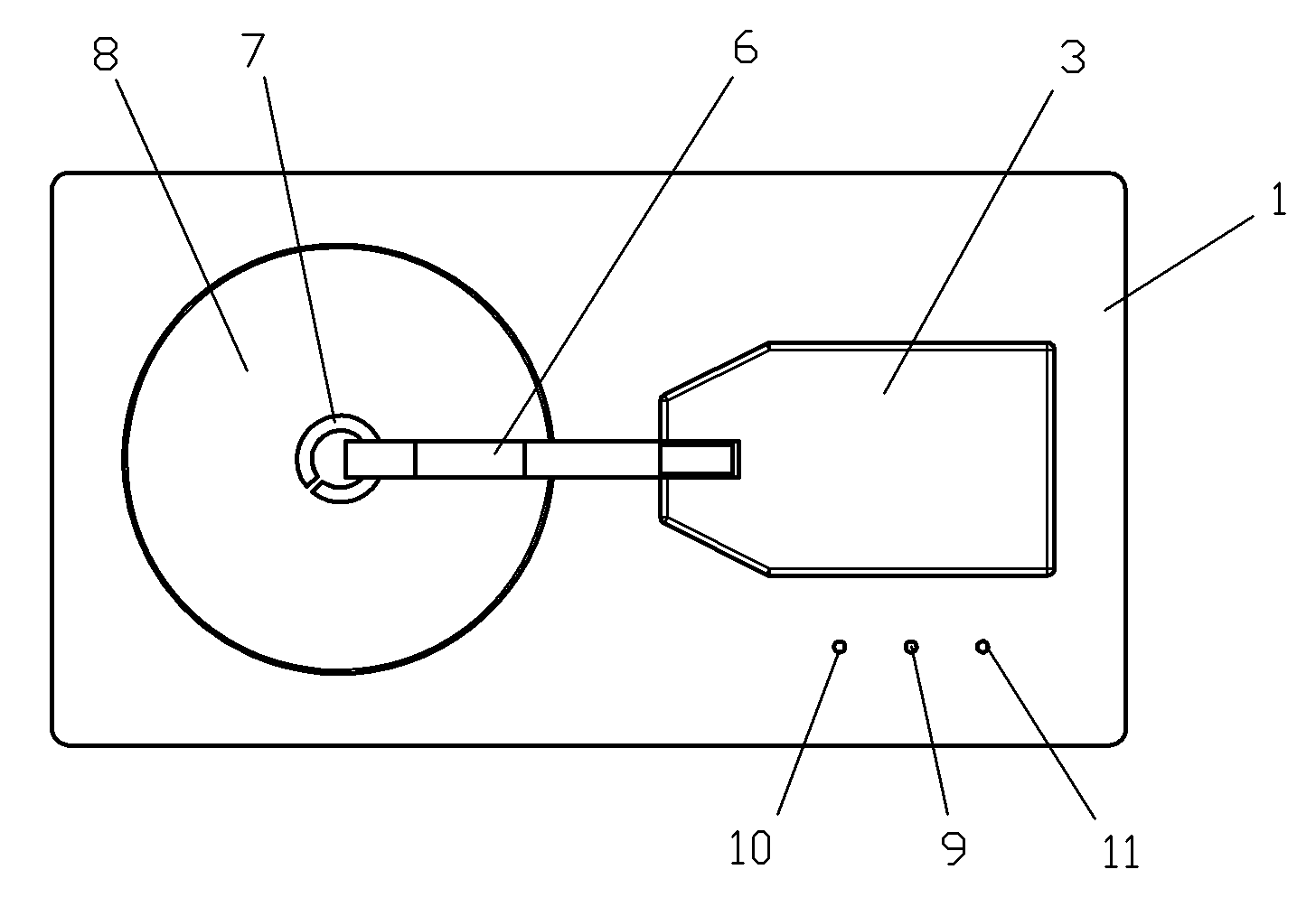

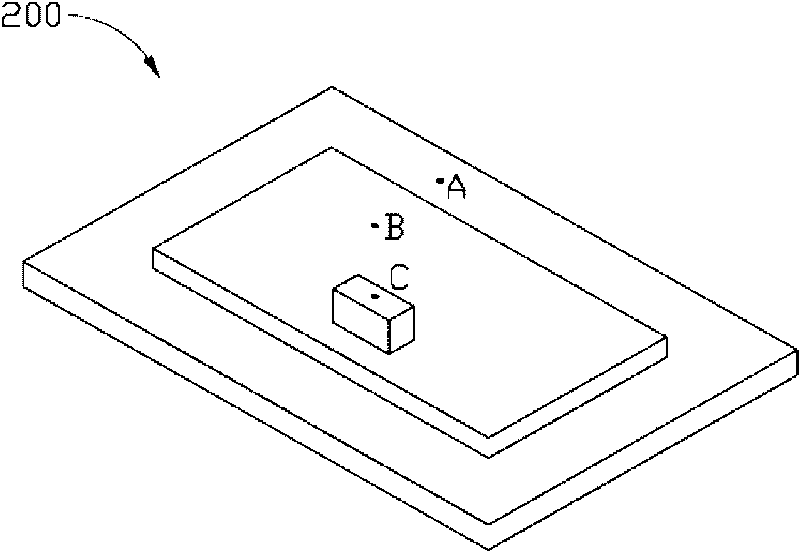

Height measuring device of spring washer elasticity test

ActiveCN102062568AMeasurements are the sameReduce mistakesMechanical measuring arrangementsInvestigating material hardnessTest efficiencyElectricity

The invention discloses a height measuring device of a spring washer elasticity test, comprising a height gauge, a base, a metal bedplate and a control circuit. The height gauge comprises a substrate, a ruler, a vernier and a fine adjusting device and is characterized in that the metal bedplate and the height gauge are arranged on the base, the vernier is arranged right above the metal bedplate, the base is also provided with a contact indicator lamp and / or a buzzer, the control circuit is electrically connected with the metal bedplate, the indicator lamp and / or the buzzer and drives the indicator lamp and / or the buzzer to be powered on and work after the vernier comes into contact with a washer to be measured. The height measuring device is simple and practical and has the advantages of higher testing efficiency, higher testing accuracy and higher result consistency.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +1

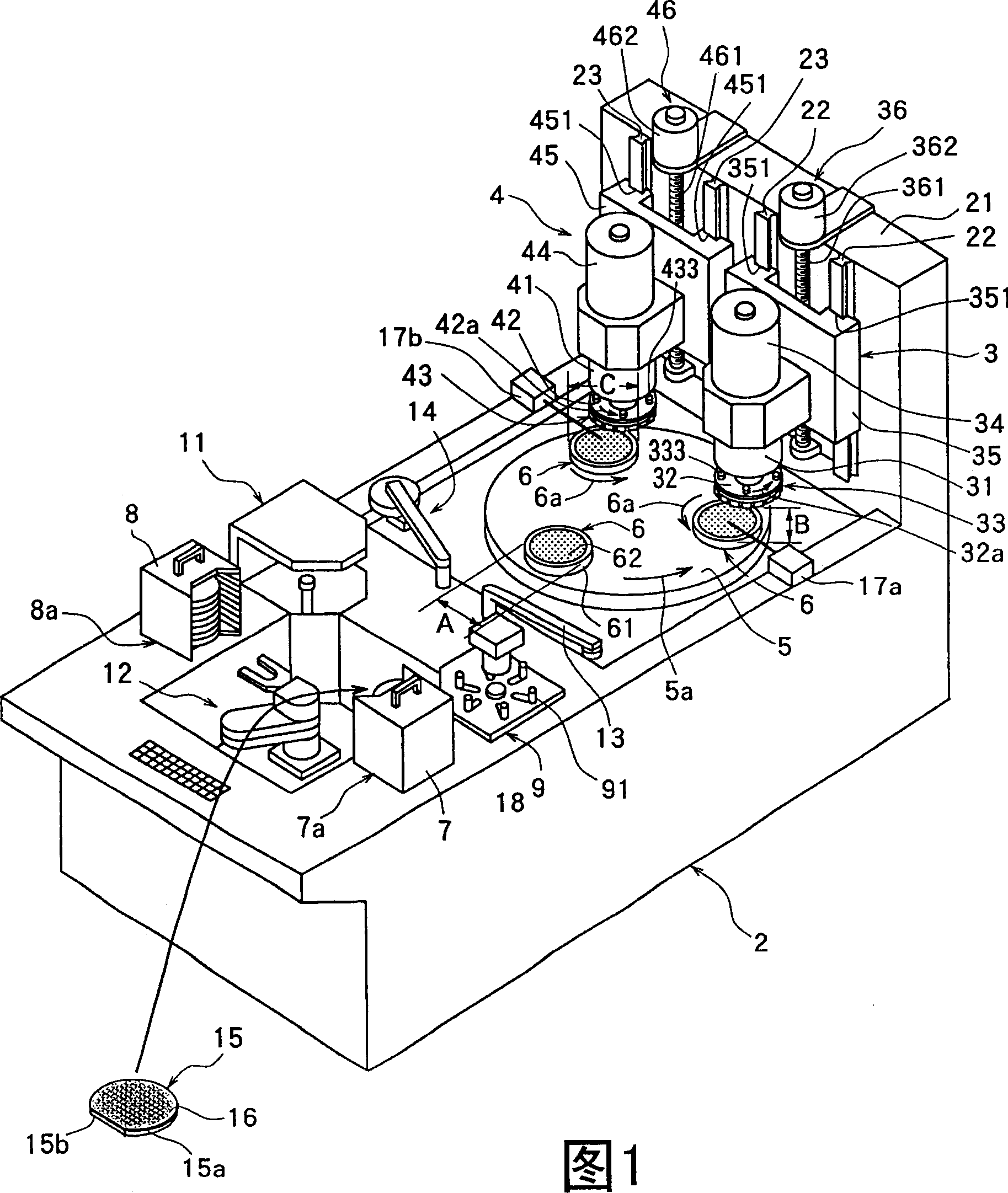

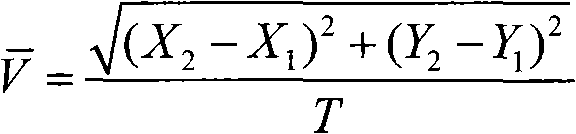

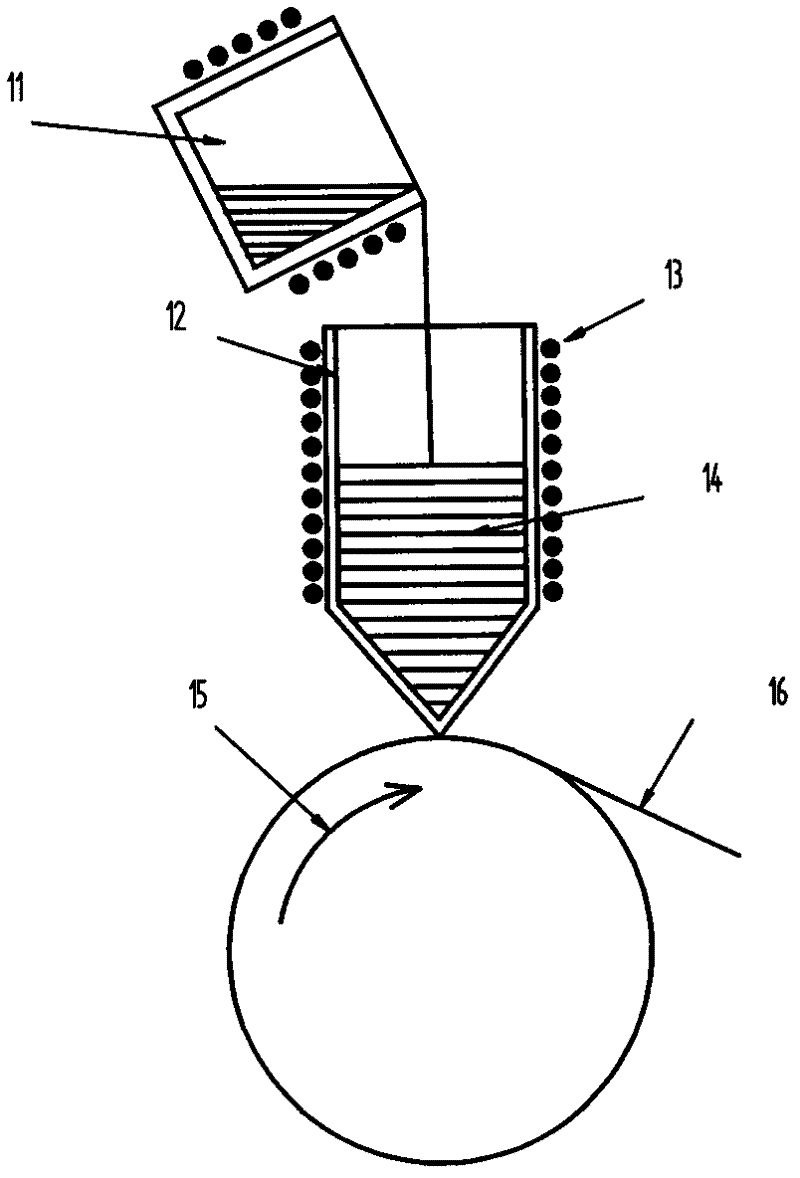

Grinding device

InactiveCN1718370ASemiconductor/solid-state device manufacturingGrinding feed controlEngineeringPerpendicular direction

PROBLEM TO BE SOLVED: To provide a grinding apparatus capable of grinding a workpiece to the predetermined finishing thickness, without being influenced by a variation in the thickness of a protective tape, even if a reverse surface is ground by sticking the protective tape to a surface of the workpiece. ŽSOLUTION: This grinding apparatus has a chuck table having a holding surface for holding the workpiece, a grinding means for grinding the workpiece held by the holding surface of the chuck table, a grinding feeding means for feeding the grinding means for grinding in the perpendicular direction to the holding surface of the chuck table, and a height gauge for detecting a height position of an upper surface of the workpiece held by the chuck table; and has a thickness measuring apparatus for detecting the thickness of the workpiece, and a control means for controlling the grinding means and the grinding feeding means on the basis of detecting data from the thickness measuring apparatus and the height gauge. The control means calculates a target grinding quantity from the thickness of pre-processing workpiece detected by a thickness detector and finishing thickness data on the workpiece, and grinds up to reaching a height position corresponding to the target grinding quantity from the height position of the pre-processing workpiece on the basis of the detecting data from the height gauge. Ž

Owner:DISCO CORP

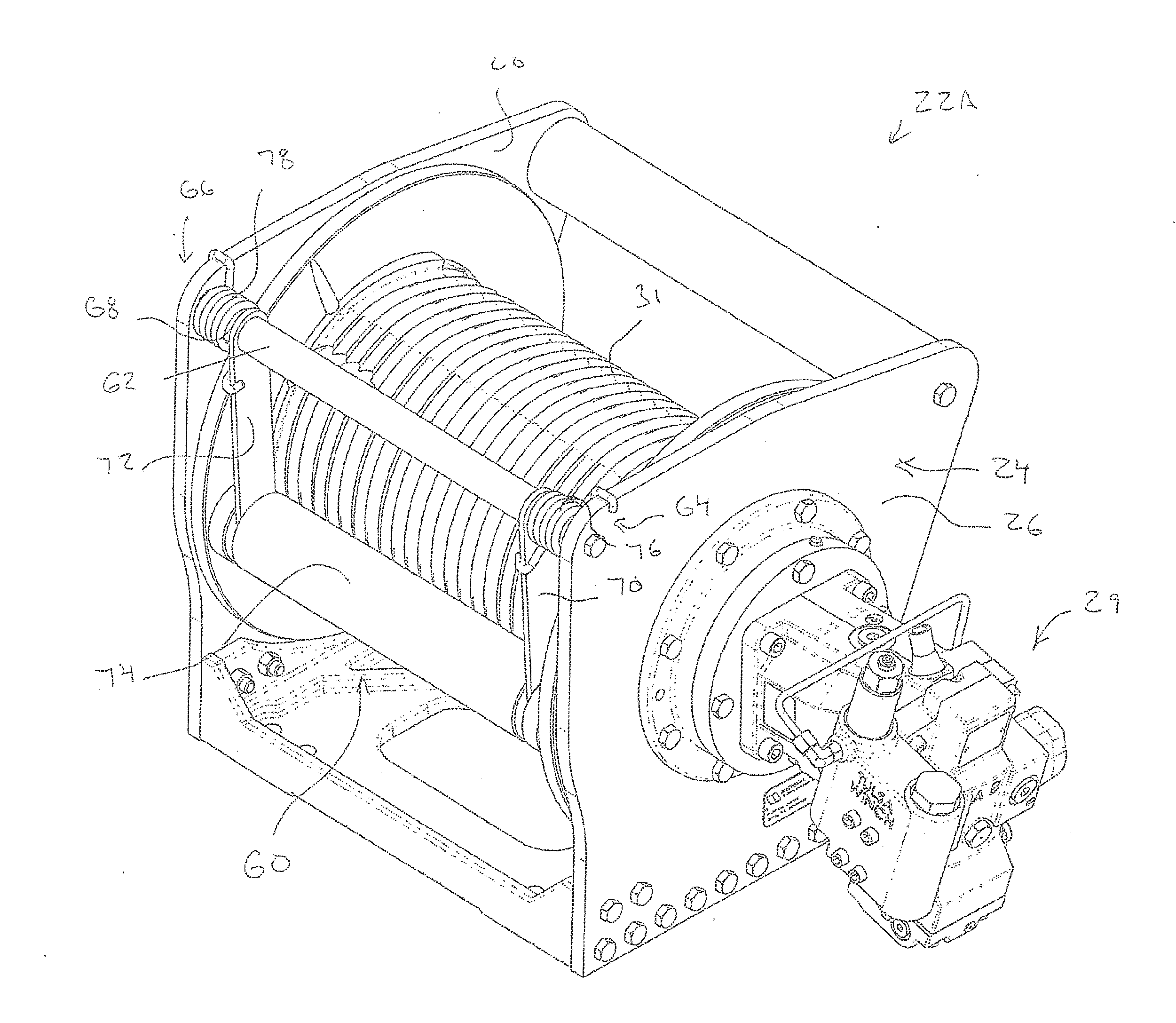

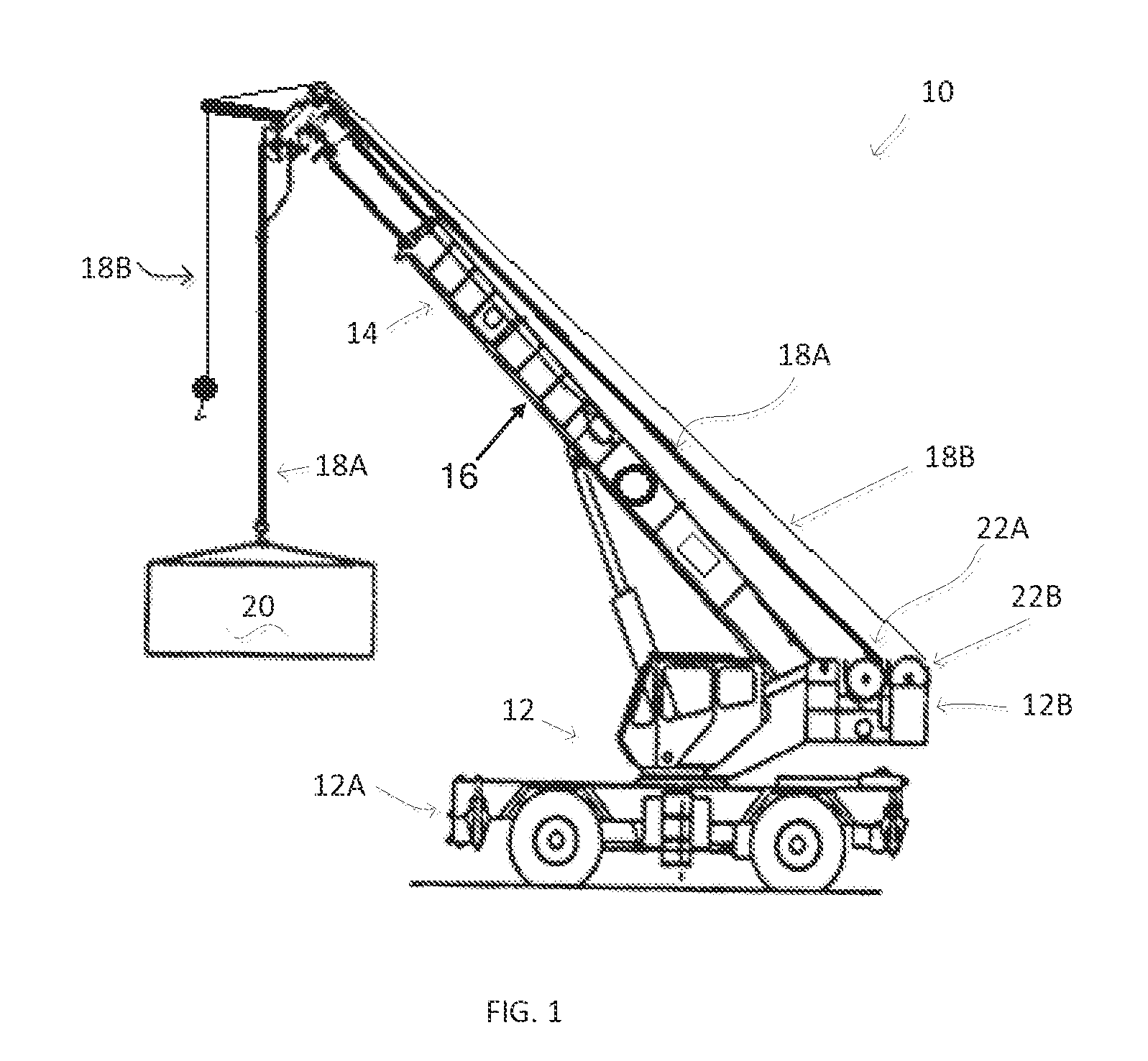

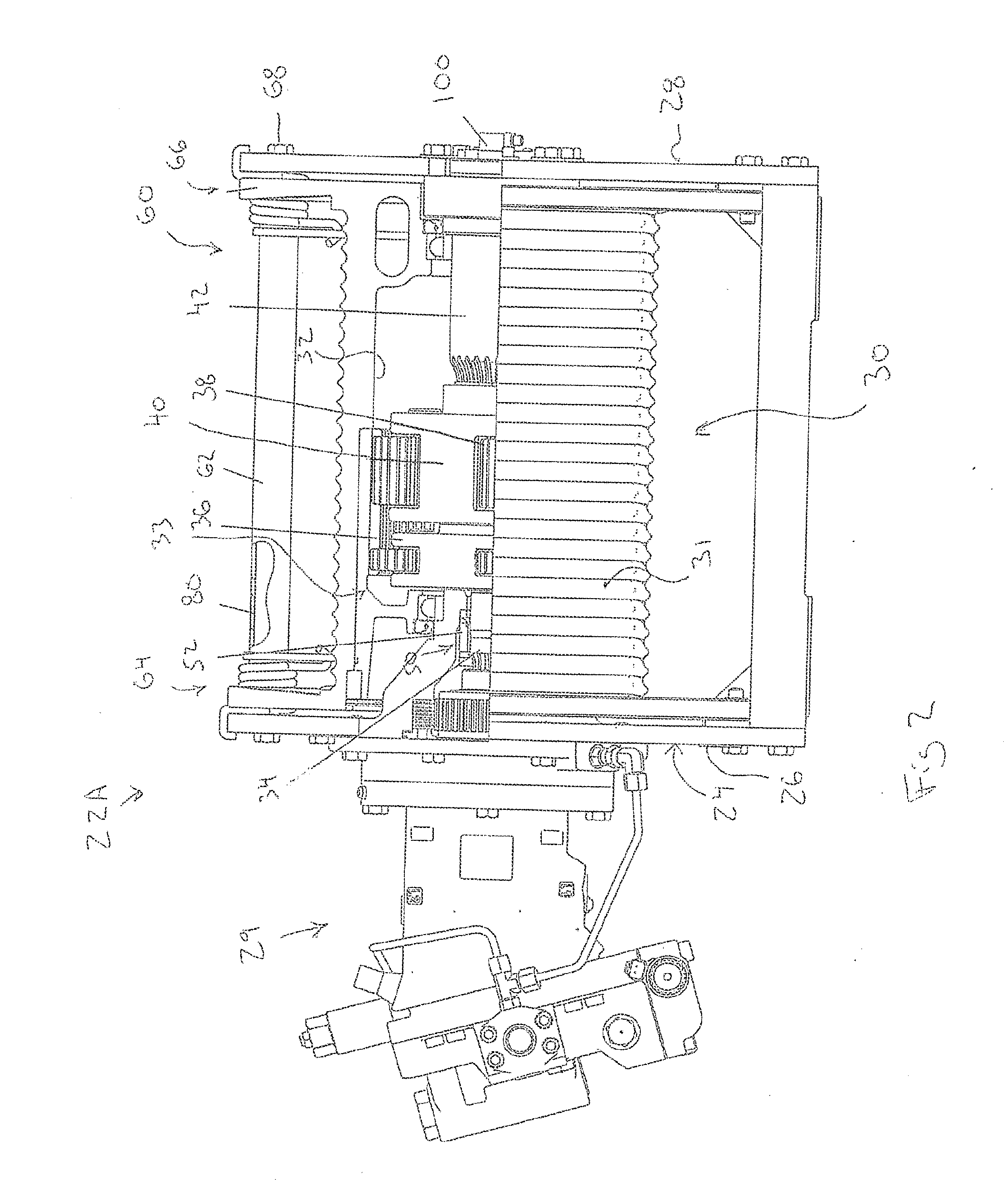

Embedded hoist human-machine interface

ActiveUS20150379783A1Registering/indicating working of machinesWork measurementMechanical engineeringHuman system interface

A cable drum receives a length of working cable that is wound in and out from the drum in response to powered rotation of the drum with an uppermost layer of working cable on the drum forming a working surface. A torque sensor in communication with the cable drum measures a torque applied to the cable drum due to tension on the working cable from a load. A drum height gauge is provided for measuring a height of the working surface of the cable on the cable drum. A processor receives the torque value from the torque sensor and the height of the working surface from the drum height gauge and computes a force applied to the length of working cable due to the load based on the torque and height of the working surface. The work performed by the cable may be calculated to assist in determining cable health.

Owner:TULSA WINCH INC

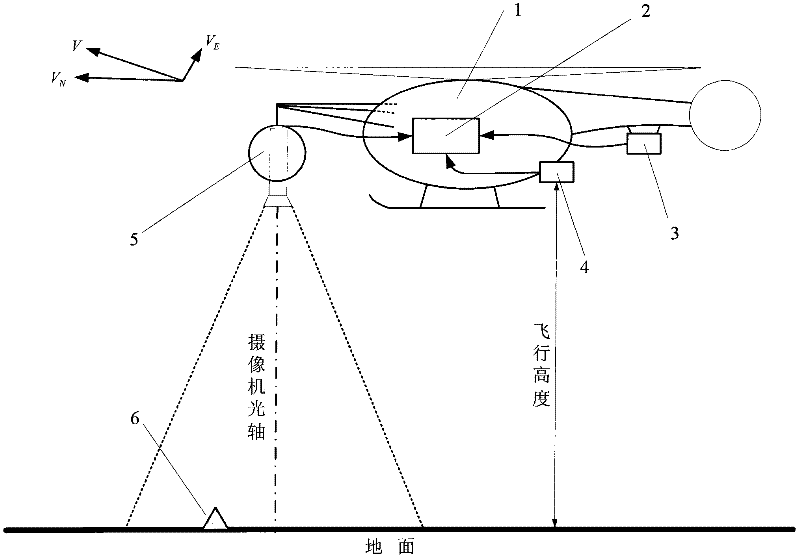

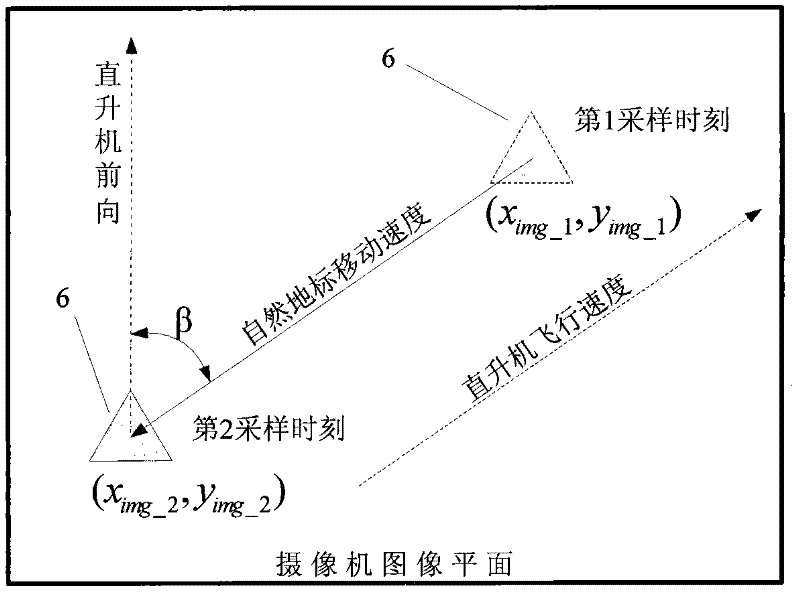

Natural-landmark-based unmanned helicopter visual speed measurement method

InactiveCN102175882ASimple structureImprove reliabilityDevices using optical meansVideo imageGlobal Positioning System

The invention discloses a natural-landmark-based unmanned helicopter visual speed measurement method, which belongs to the technical field of unmanned aerial vehicles. The method is characterized in that: the method is implemented by an unmanned helicopter, a flight control computer, a magnetic course sensor, a height gauge and an airborne video camera, and comprises that: in the flight process of the unmanned helicopter, the flight control computer obtains the height of the unmanned helicopter from the ground by the height gauge; the flight control computer calculates the horizontal flight rate of the unmanned helicopter relative to the ground by detecting the motion rate of a natural landmark on the ground in an image of the video image; and the flight control computer obtains a course angle of the unmanned helicopter by the magnetic course sensor, and calculates the horizontal flight speed of the unmanned helicopter. The method is free from the influence of global positioning system (GPS) signals and wind speed, and is particularly applied to the accurate speed measurement of the unmanned helicopter in a low-altitude complex environment suck as an inter-building environment, a grove environment even an indoor environment without increasing the takeoff weight of the unmanned helicopter.

Owner:TSINGHUA UNIV

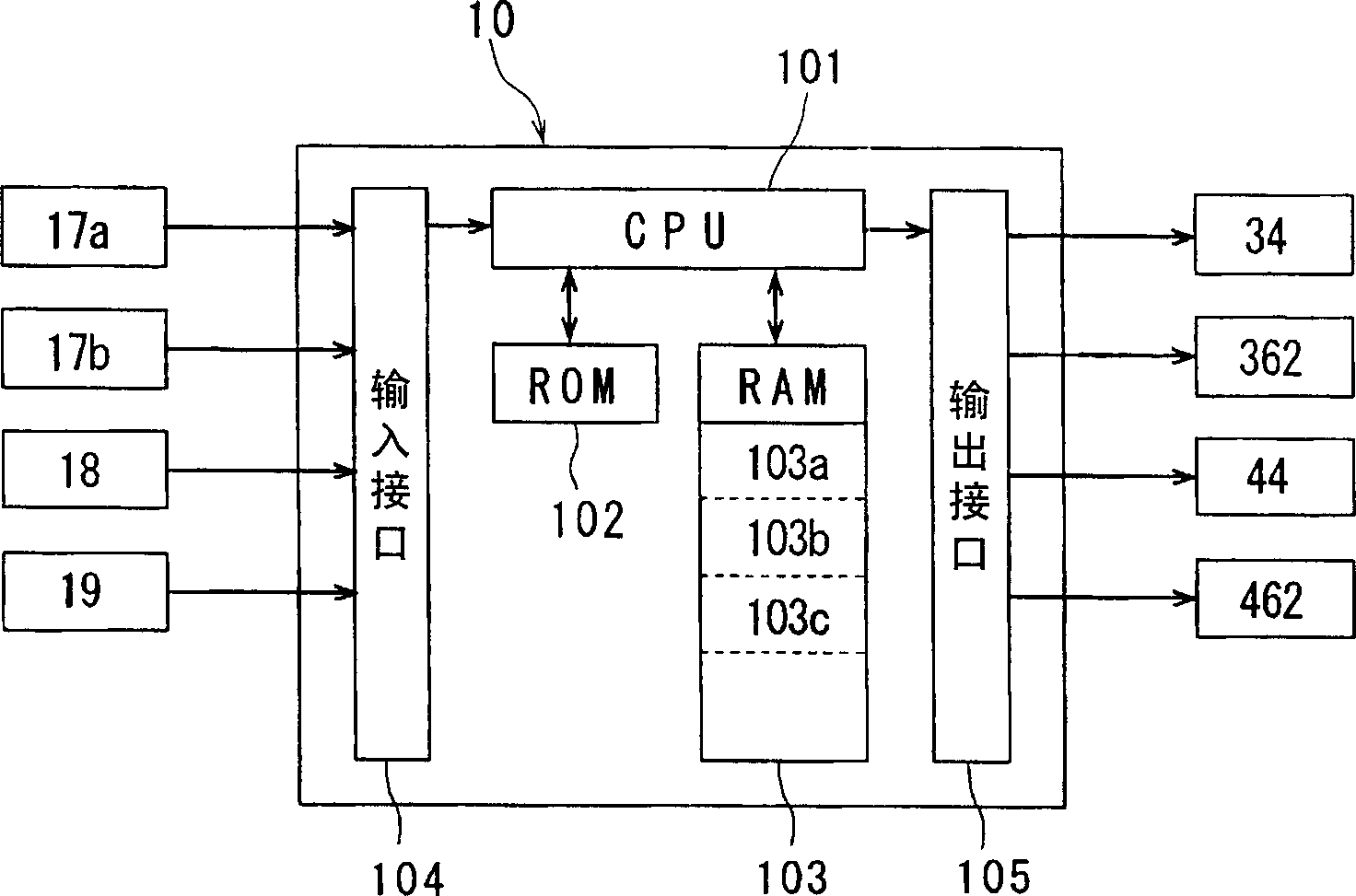

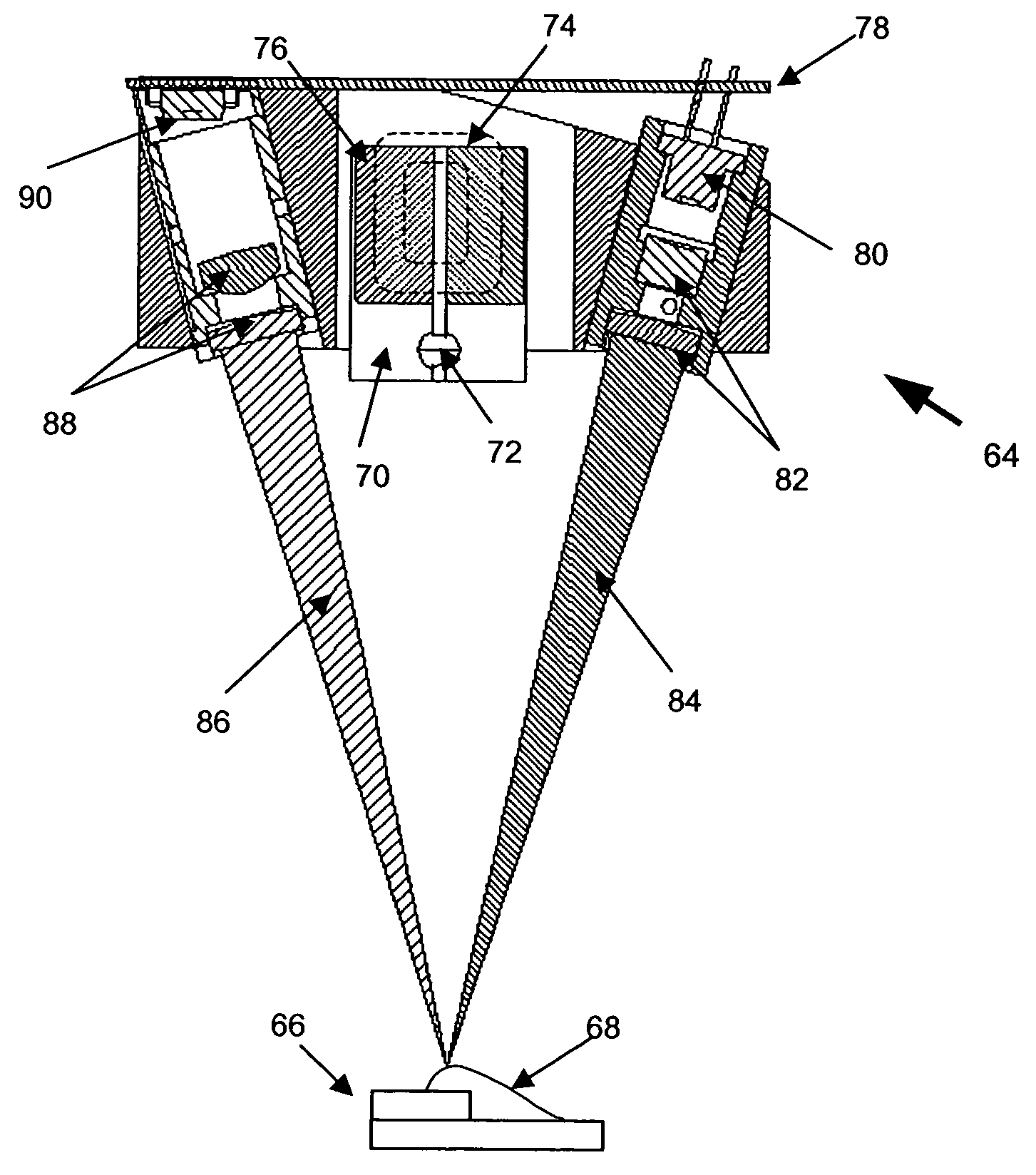

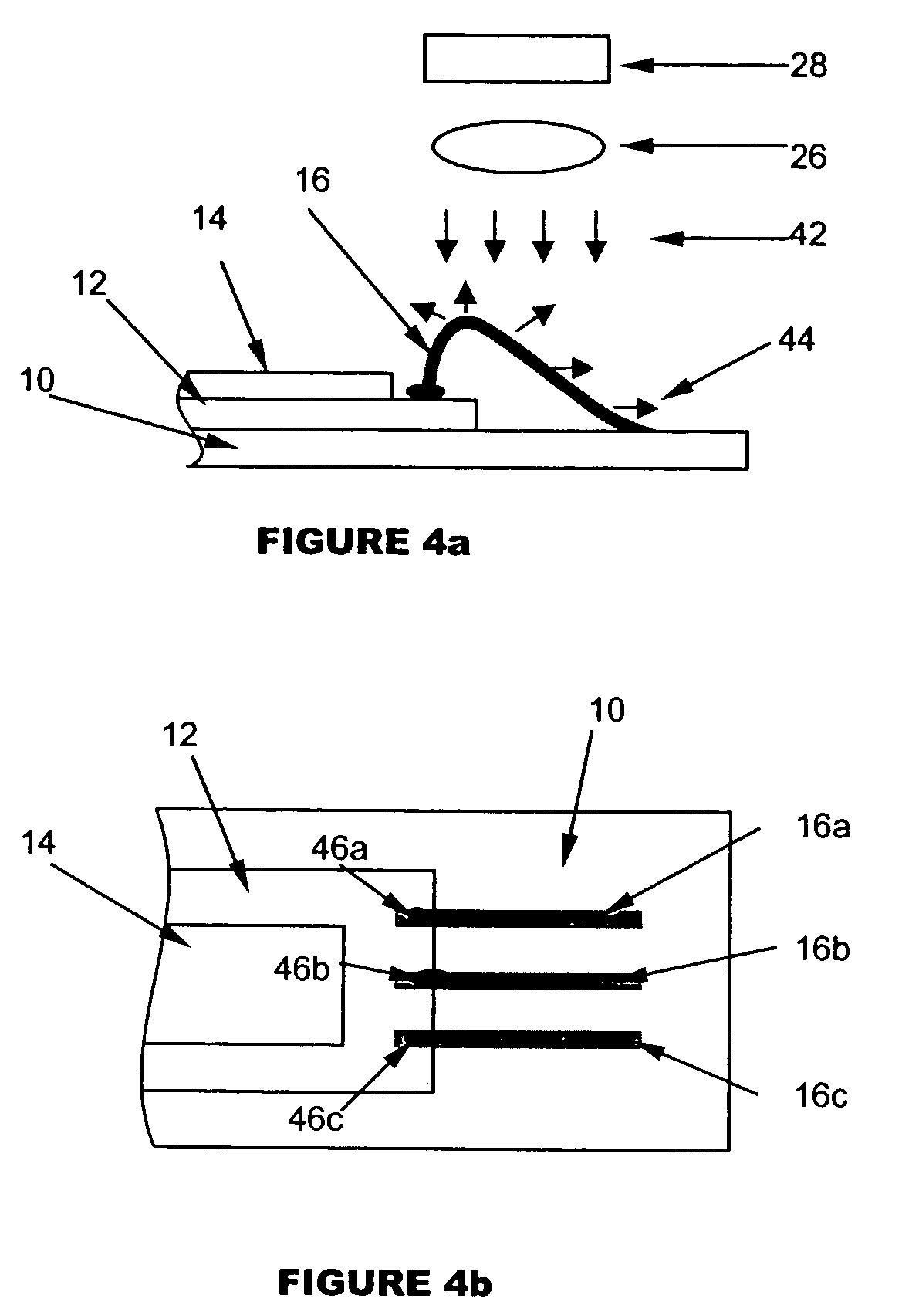

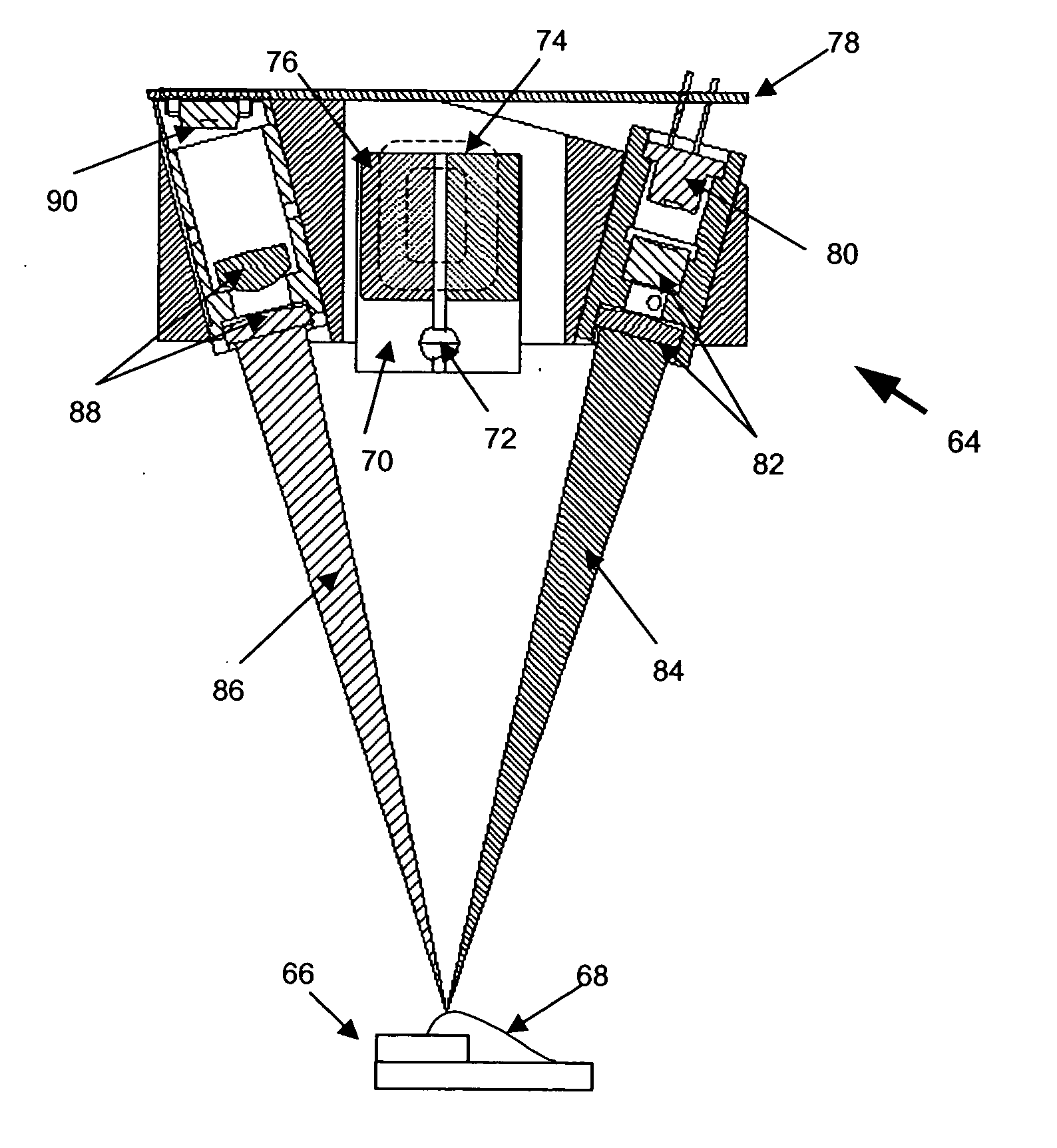

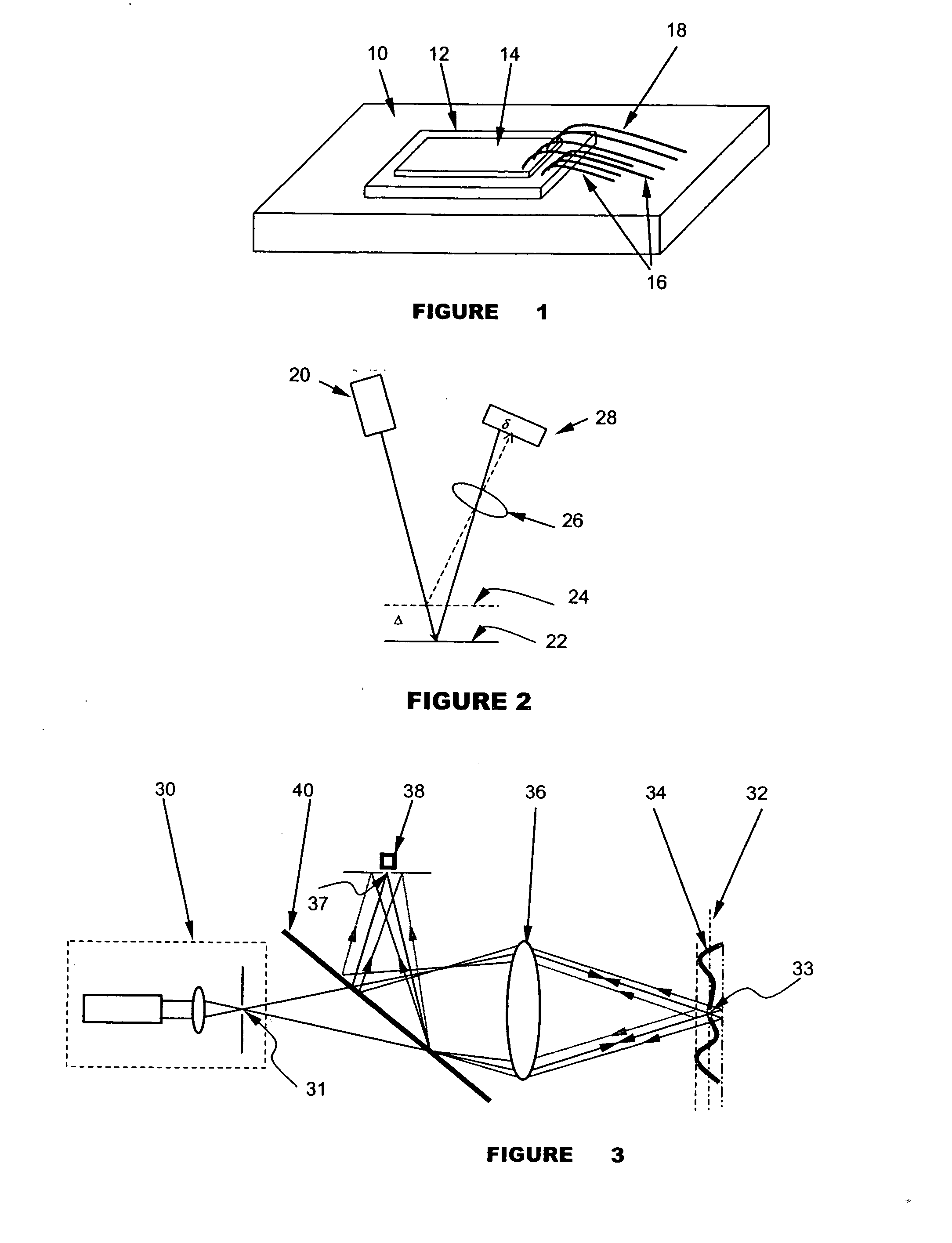

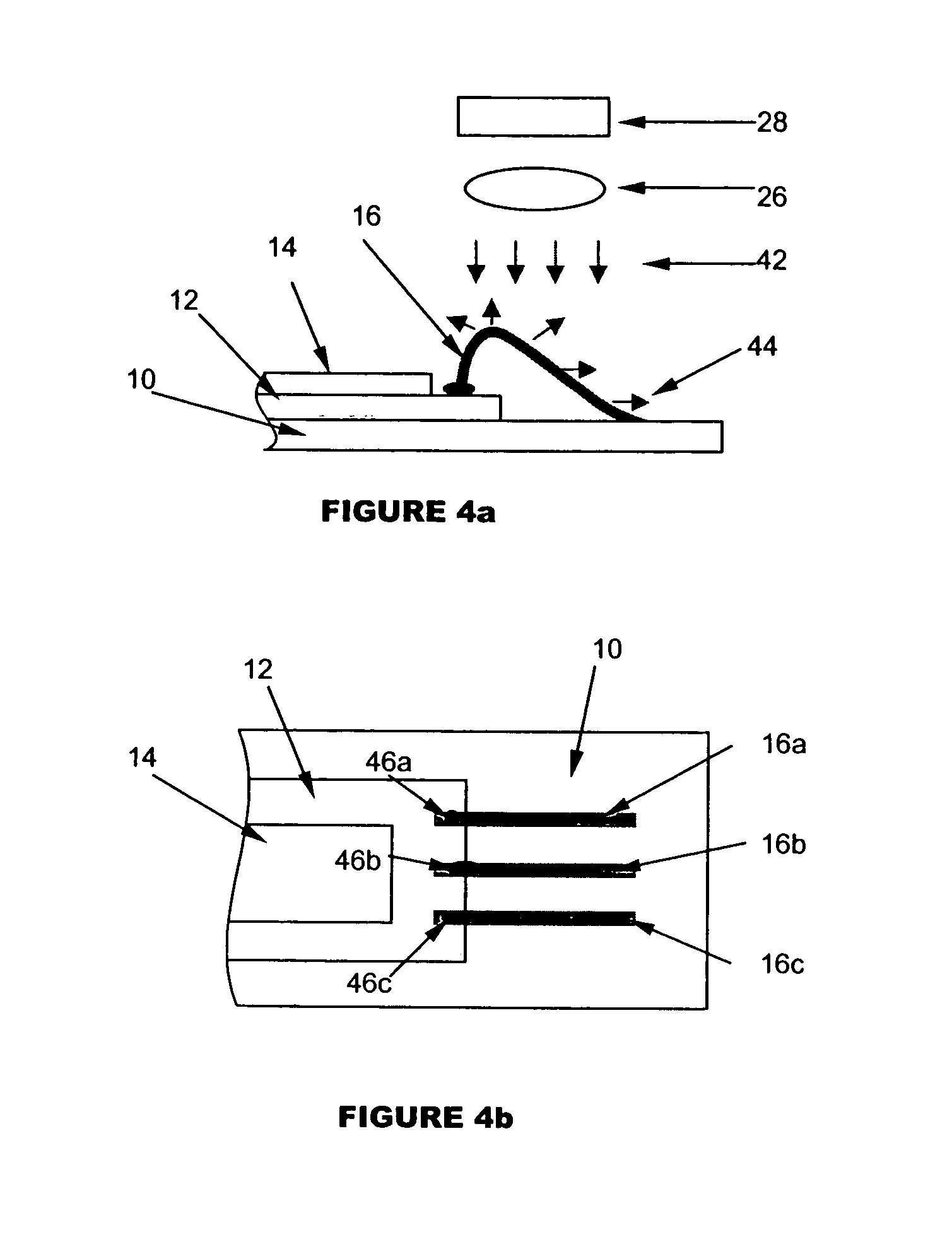

Wire loop height measurement apparatus and method

ActiveUS7145162B2Accurate measurementAvoid disadvantagesImage enhancementImage analysisAltimeterPhysics

The invention provides a method and an apparatus for determining a height of a point on a wire loop. A height gauge device is positioned over the point on the wire loop to be measured. Incident light is projected from the height gauge device for illuminating the point. The height gauge device receives reflected light produced from the incident light and a processor coupled to the height gauge device determines from a characteristic of the reflected light the height of the said point relative to a reference surface. Further methods and apparatus for finding a position and height of a highest point on the wire loop are also provided.

Owner:ASM ASSEMBLY AUTOMATION LTD

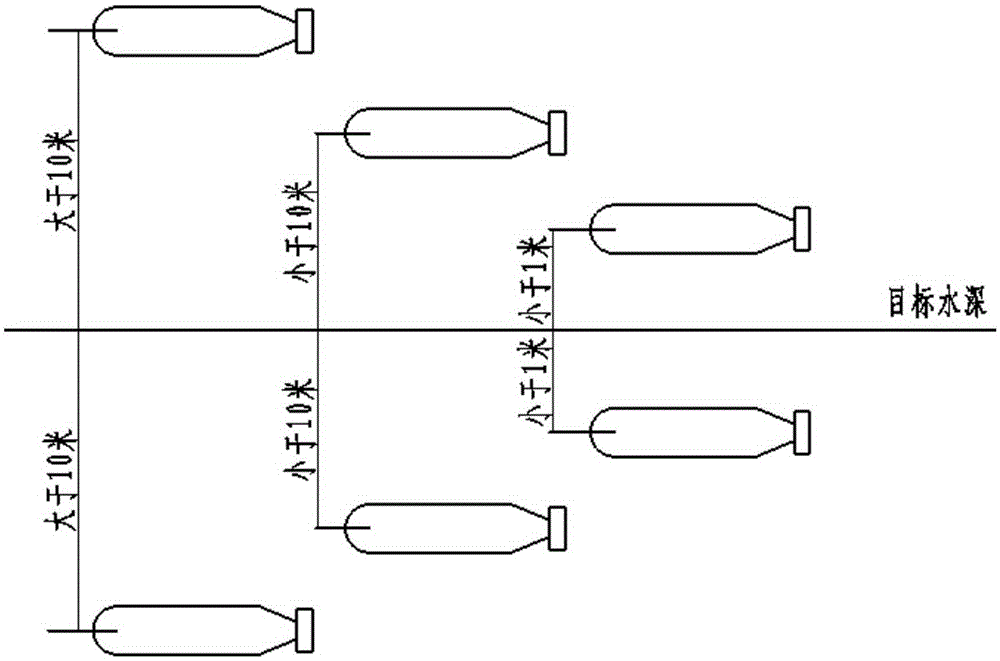

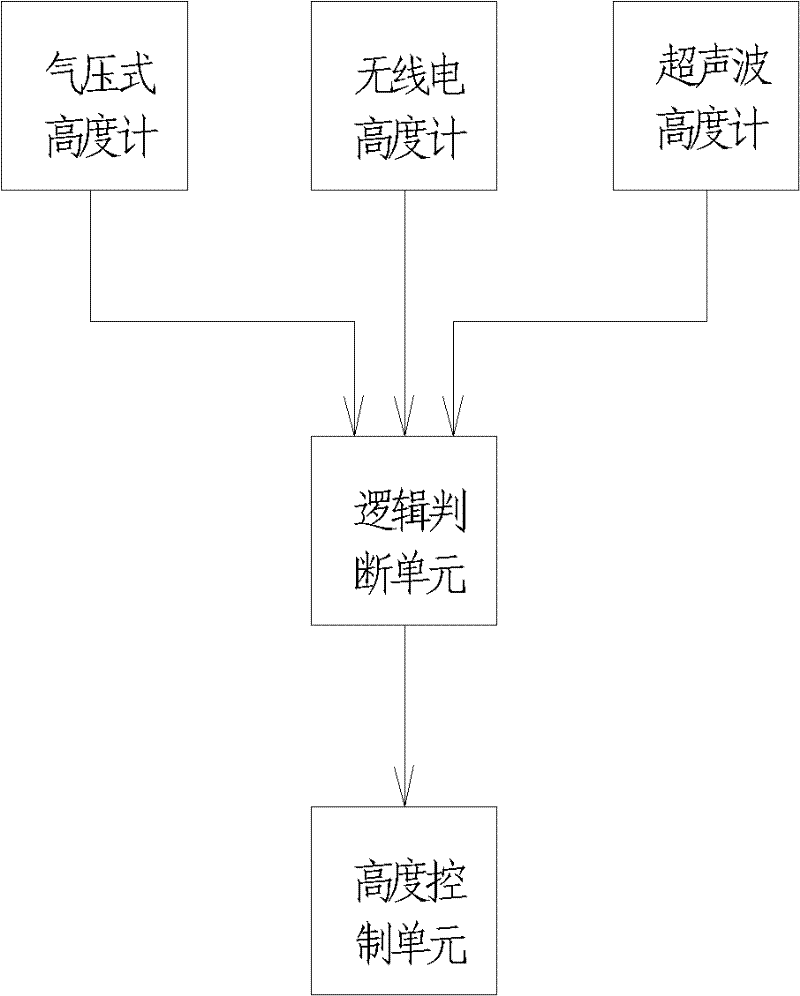

Combination height control method and system for unmanned aerial vehicle

InactiveCN102541054AAchieve high-precision height measurementUninterrupted high-precision height measurementVehicle position/course/altitude controlPosition/direction controlAutomatic controlControl system

The invention relates to a combination height control method and a system for an unmanned aerial vehicle. The combination height control system for the unmanned aerial vehicle comprises an air-pressure type height gauge, a wireless height gauge, an ultrasonic wave height gauge, a logical judgment unit and a height control unit, wherein the air-pressure type height gauge, the wireless height gauge and the ultrasonic wave height gauge are arranged on the unmanned aerial vehicle; the wireless height gauge selects, calculates and outputs output height values of the air-pressure type height gauge, the wireless height gauge and the ultrasonic wave height gauge; and the height control unit is used for automatically controlling the height of the unmanned aerial vehicle. The combination height control method and the system for the unmanned aerial vehicle solve the technical problem existing in the background technology and achieve accurate height control of the unmanned aerial vehicle.

Owner:XIAN WIDE WORLD ZENITH AVIATION TECH

Plunger type equal-liquid-level pressure amorphous strip maker

The invention discloses a plunger type equal-liquid-level pressure amorphous strip maker. According to the invention, liquid level height is used to generate pressure (0.3-0.4kg / cm<2>) so as to make an amorphous or amorphous nanocrystalline strip (less than 30 mu m), and a movable plunger is used to keep the liquid level height. The plunger type equal-liquid-level pressure amorphous strip maker comprises a non-vacuum induction furnace (71), a pressure sensor (72), a molten steel tank (73), a liquid level height gauge (74), a nozzle bag (75), a heating globar (76), a cooling roller (77), a plunger (78), a plunger lifting rod (79), a magnetic scale (710) and a lifting motor (711). The plunger type equal-liquid-level pressure amorphous strip maker has the characteristics of accurate pressure and convenience in operation, and has the advantages of low cost and high yield as compared with a strip injection machine using gas to apply pressure.

Owner:TENGZHOU GAOKEKANGNA ALLOY MATERIAL CO LTD

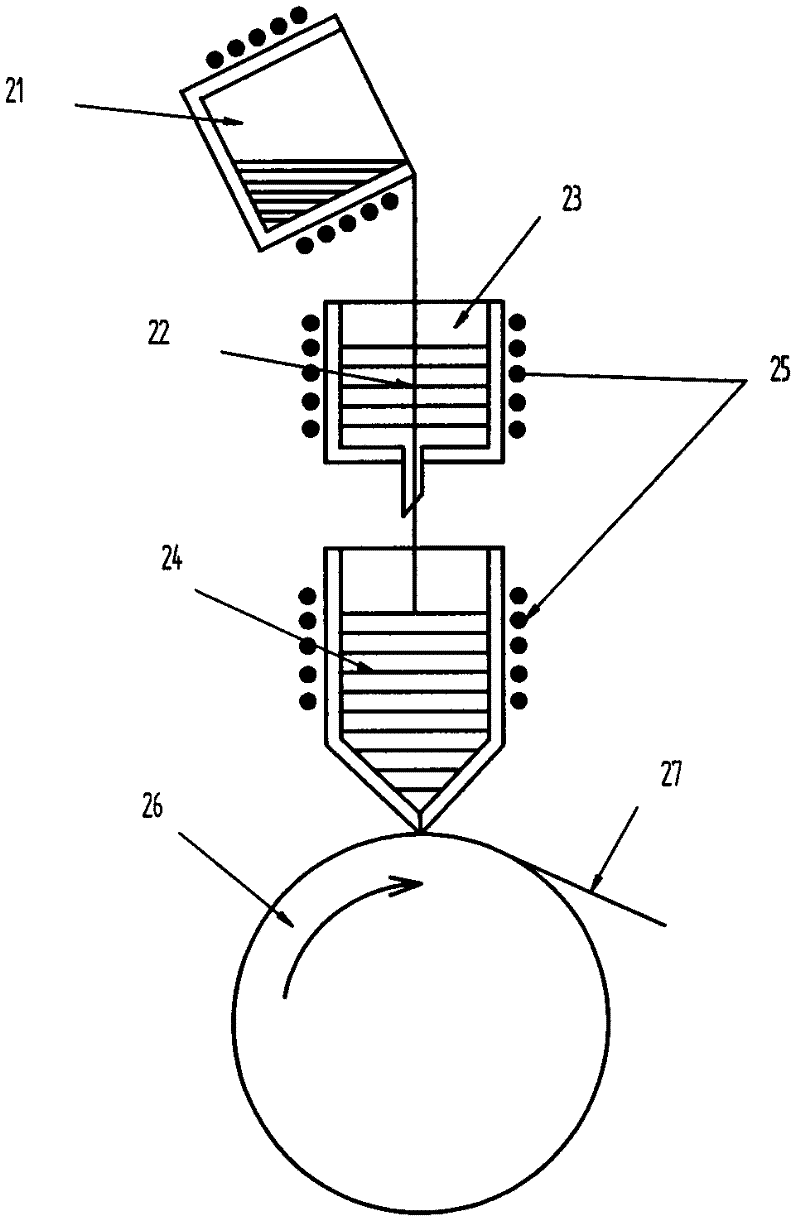

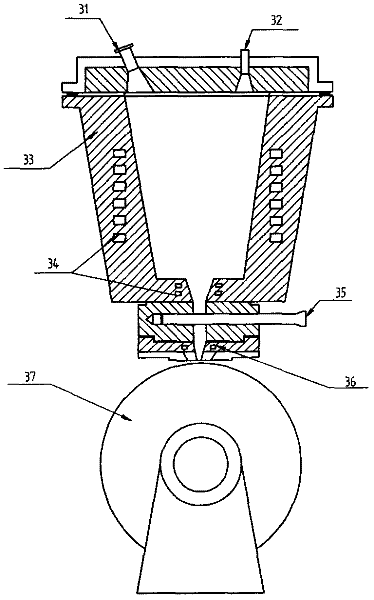

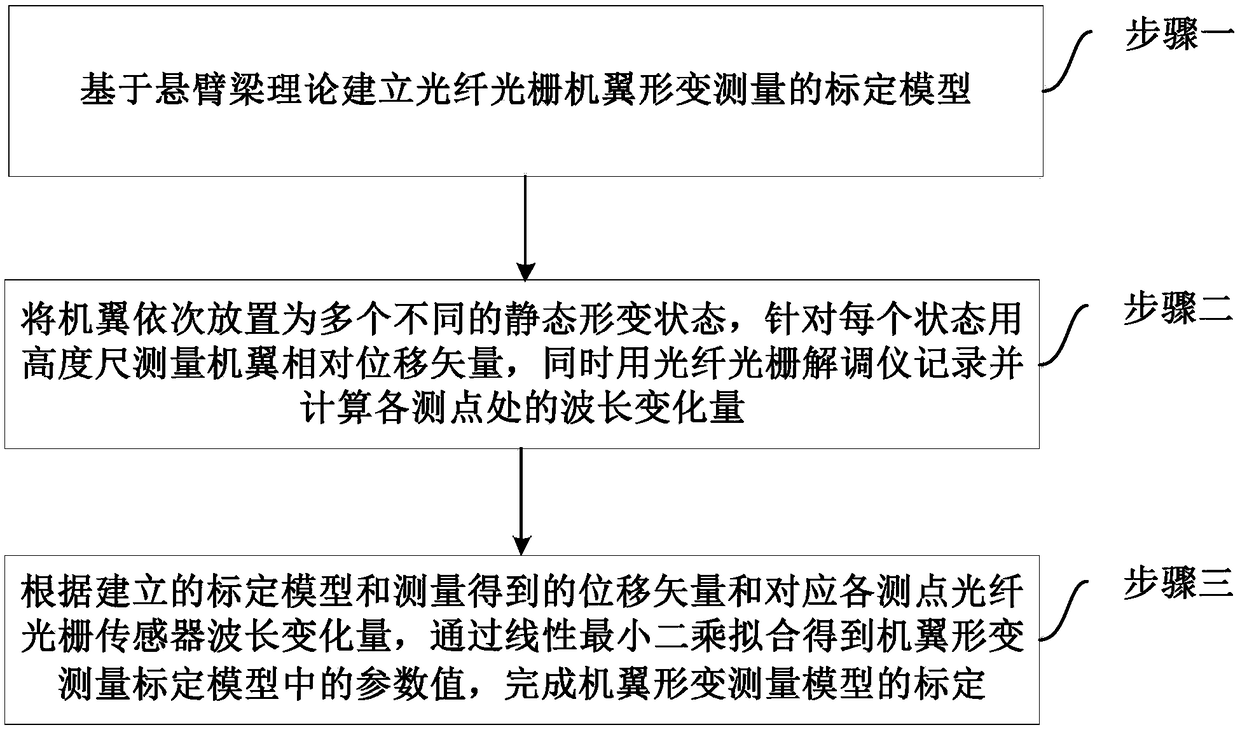

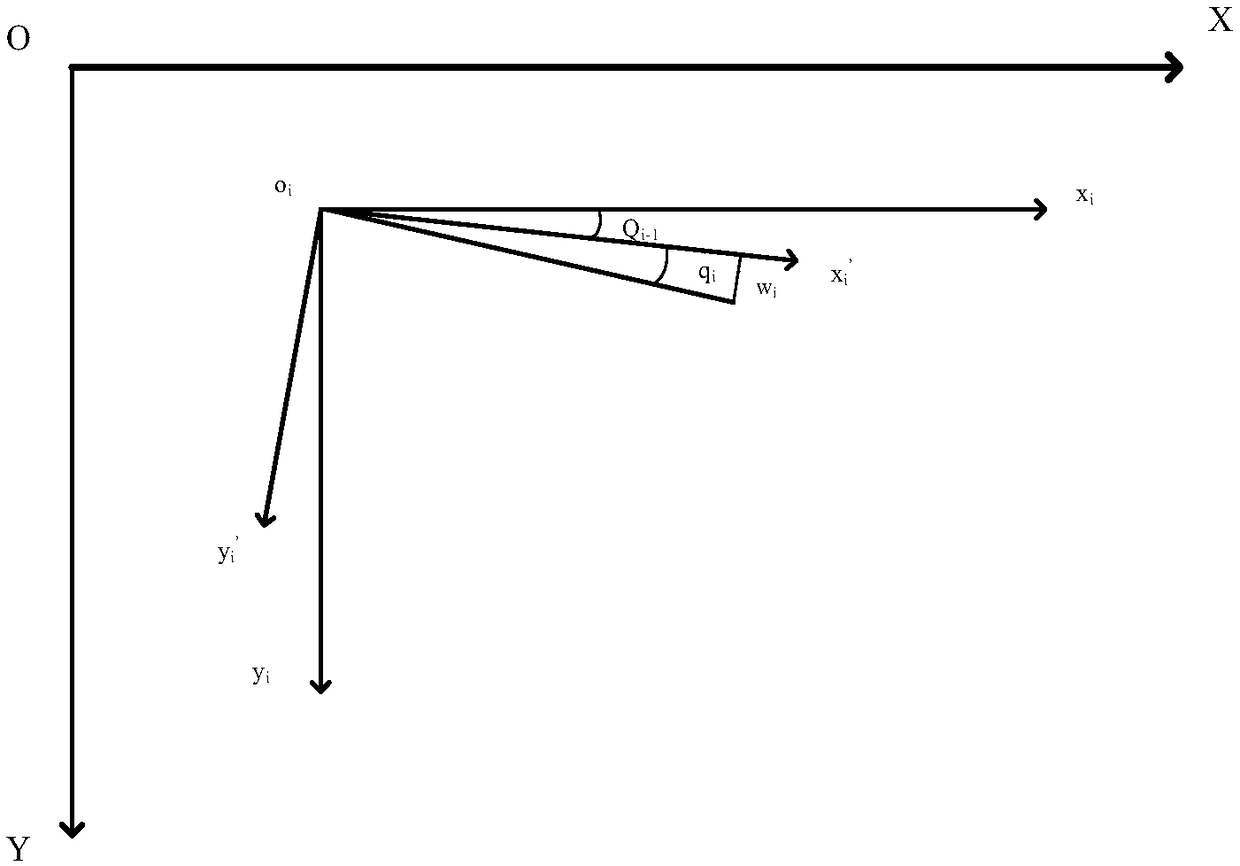

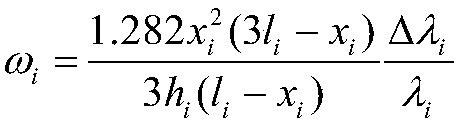

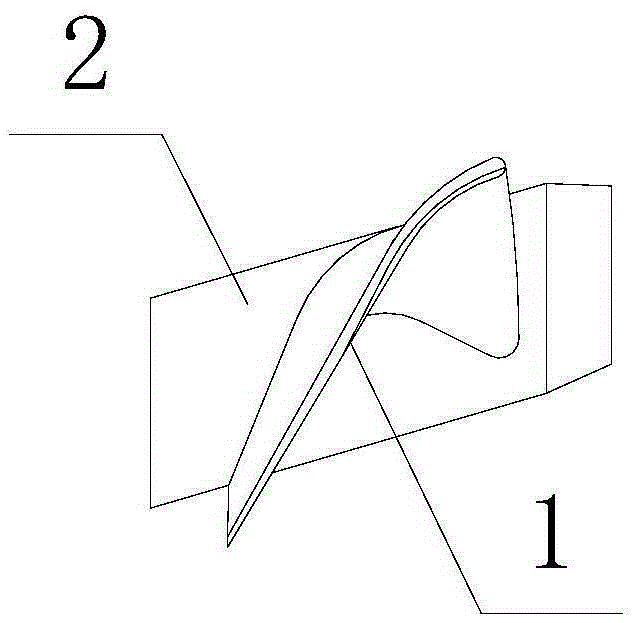

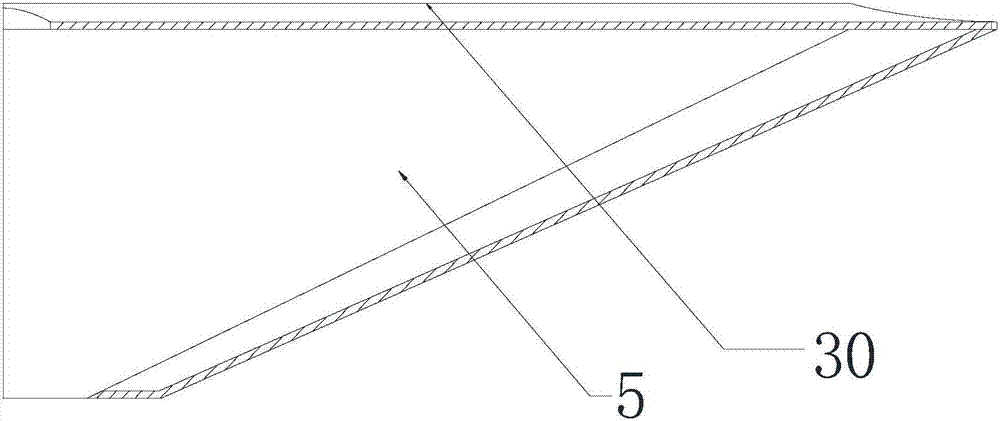

Cantilever beam theory-based fiber bragg grating wing deformation measurement modeling and calibration method

ActiveCN108801166AOvercoming the difficult problem of precise description of flexible changesUsing optical meansRadio wave reradiation/reflectionFiberLinear least squares

The invention discloses a cantilever beam theory-based fiber bragg grating wing deformation measurement modeling and calibration method. The method includes the following steps that: a fiber bragg grating wing deformation measurement calibration model is established based on the cantilever beam theory; a wing is arranged into a plurality of different static deformation states sequentially, the relative displacement vector of the wing is measured with a height gauge for each state, and at the same time, a fiber bragg grating demodulator is adopted to record and calculate a wavelength variationquantity at each measuring point; and parameter values in the wing deformation measurement calibration model can be obtained through linear least squares fitting, and the calibration of a wing deformation measurement model can be completed. With the method of the invention adopted, difficulty in accurately describing flexibility change of a baseline between the phase centers of a primary IMU (Inertial Measurement Unit) and a secondary IMU which is caused by the dynamic change of the baseline of the elastic deformation of the body structure of an aircraft can be eliminated; and a dynamic modelof the change of the flexible baseline with the time is not required to be established, after the wing deformation measurement model is calculated, and a wing deformation displacement vector can be obtained.

Owner:BEIHANG UNIV

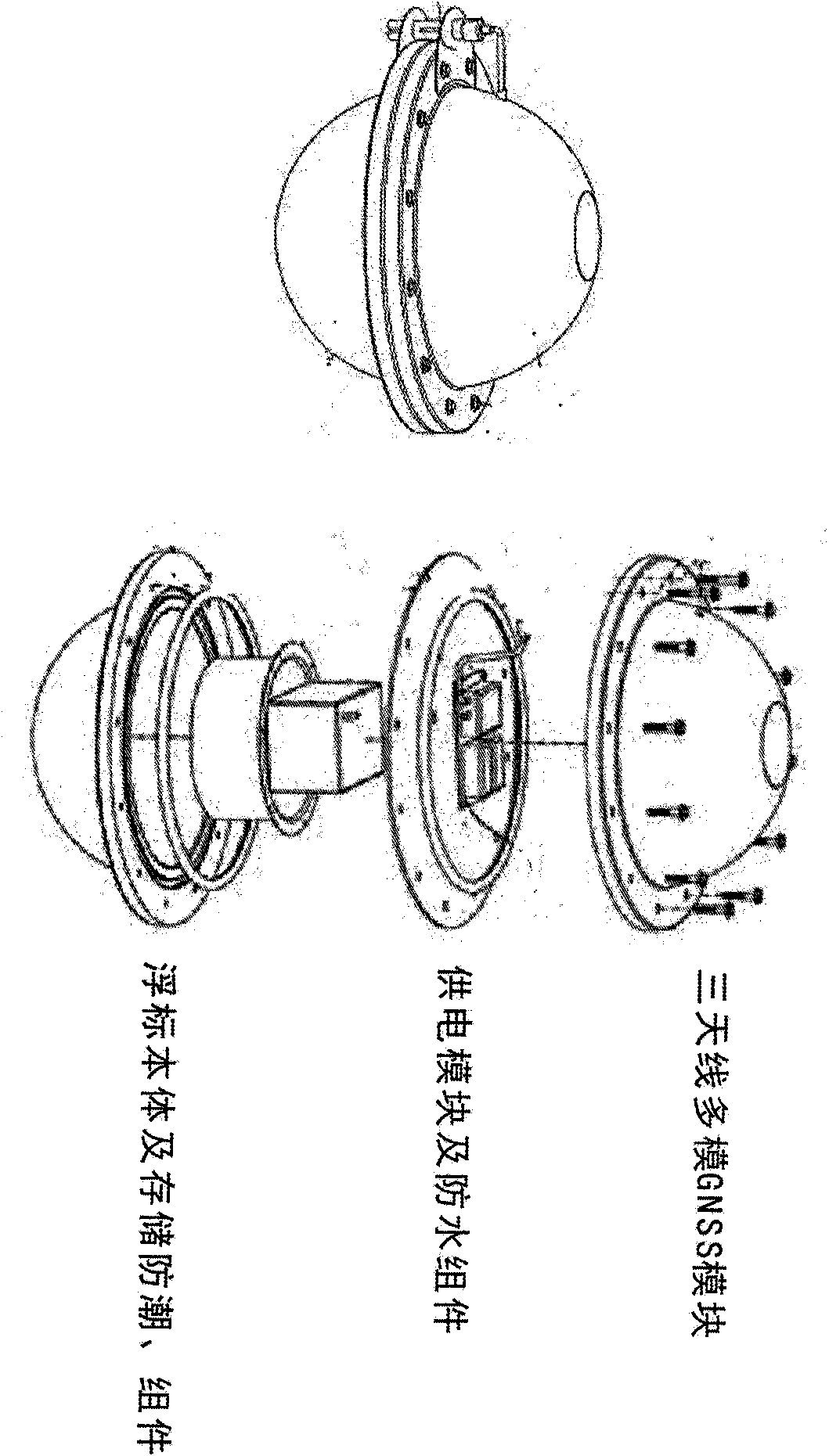

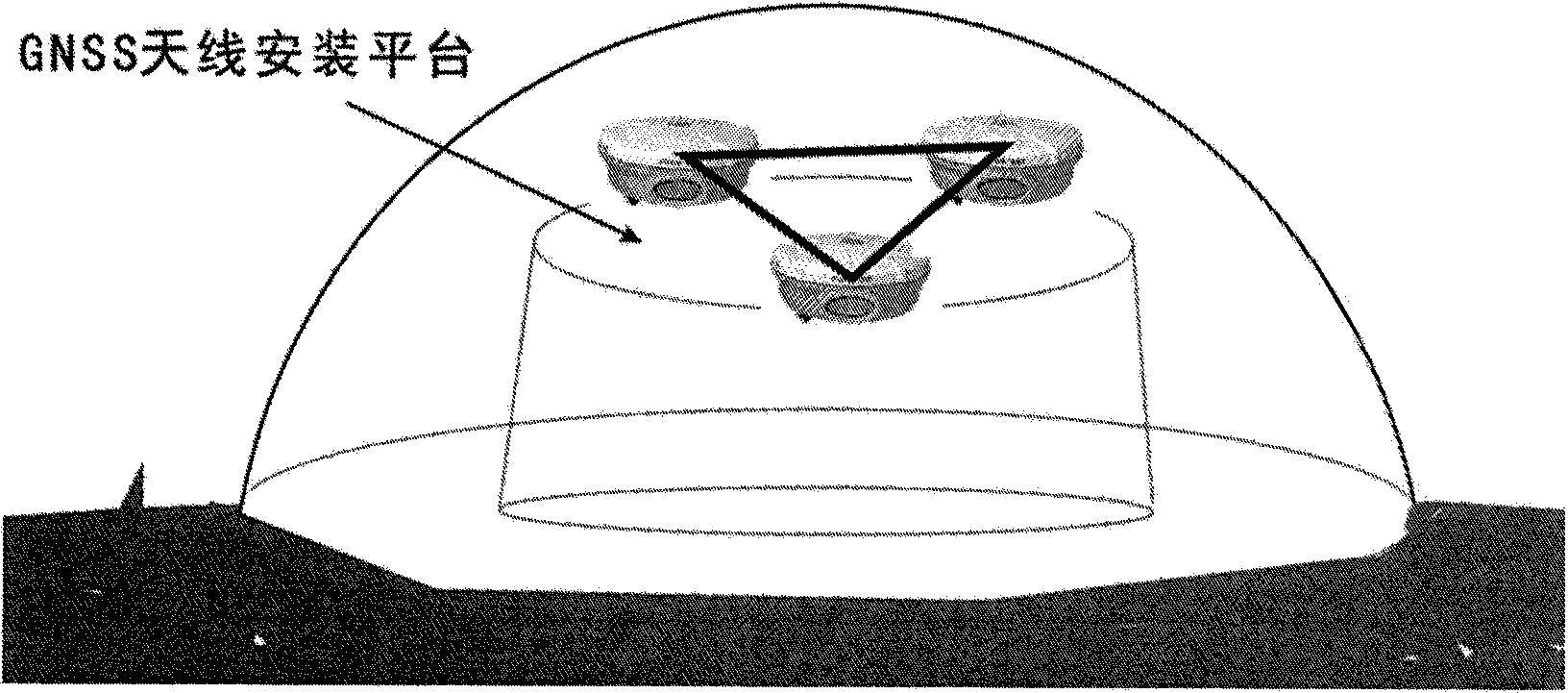

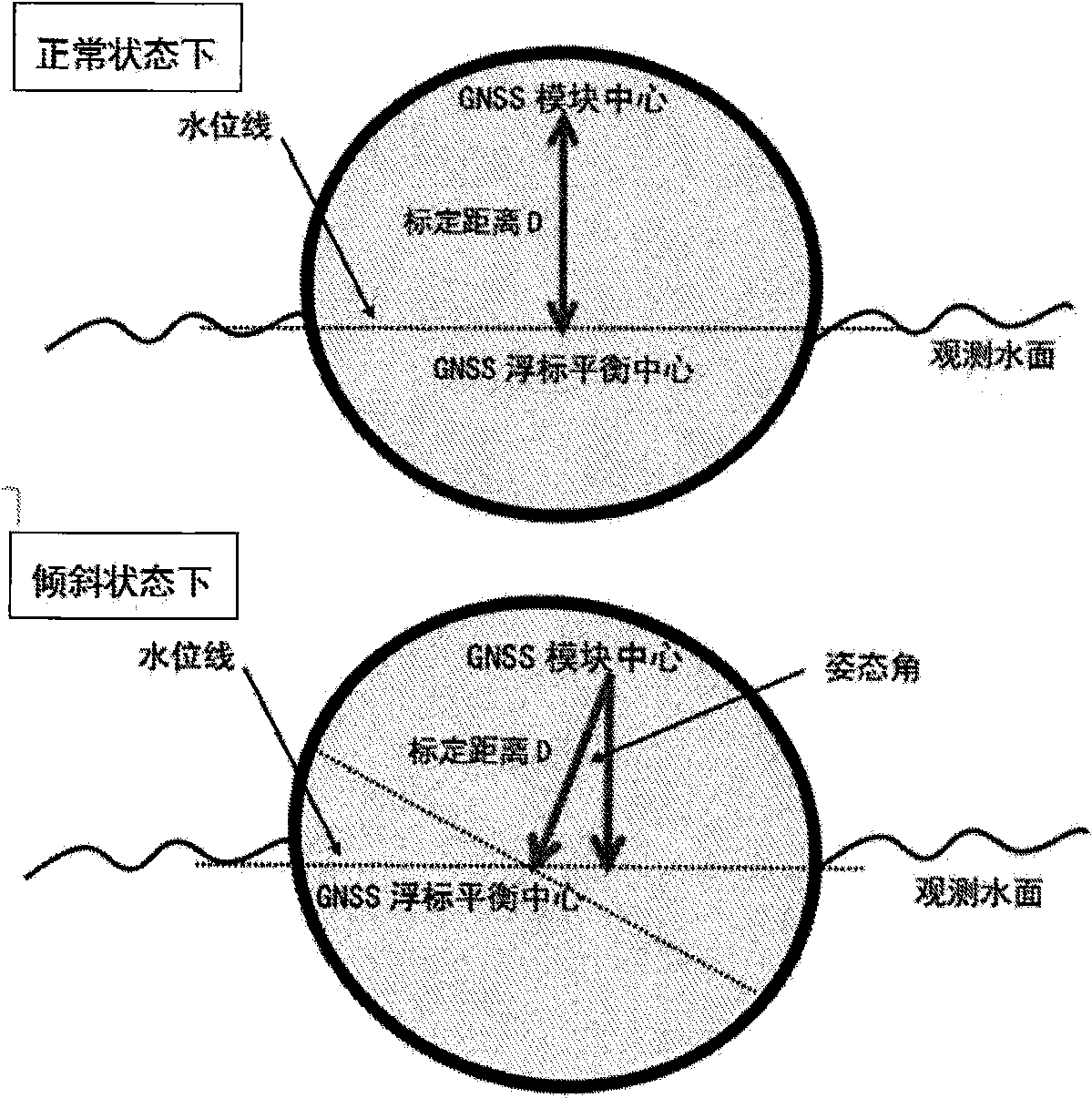

Scaling buoy of three-antenna multi-mode GNSS (Global Navigation Satellite System) satellite height gauge

InactiveCN103364056AImproved positioning accuracyHigh precisionWave based measurement systemsTesting/calibration apparatusNatural satelliteBuoy

The invention relates to a sea level height scaling buoy of a satellite height gauge, wherein the seal level height scaling buoy is mainly used for accurately determining sea level height and belongs to the technical field of ocean monitoring instruments. The scaling buoy fills the blank of GNSS scaling buoy high-accuracy instruments of the satellite height gauge, a three-antenna multi-mode GNSS is introduced for completely utilizing the superiority of three-antenna combination and accurately calculating instantaneous gesture of the GNSS scaling buoy, so that the accuracy and reliability of determining the water level height of the GNSS scaling buoy are improved. The scaling buoy overcomes the defects of too small distance between antennas and water level and great influence on water level multi-path effect caused by the fact that the antenna phase center of the GNSS and the barycenter of the scaling buoy are overlapped, and the designed three-antenna multi-mode GNSS scaling buoy can extend a GNSS observation module over the water level, so that the influence of water level multi-path effect on GNSS positioning resolving accuracy is prevented. The scaling buoy is applied to the satellite height gauge for observing accurate scaling.

Owner:鲍李峰

Method for meeting positioning requirement of complex-shaped workpiece through alloy casting

ActiveCN105382202AAvoid clampingStrong application spaceFoundry mouldsFoundry coresTurbine bladeAlloy

The invention discloses a method for meeting the positioning requirement of a complex-shaped workpiece through alloy casting and belongs to the field of machining. The method relates to a turbine blade. The turbine blade is composed of a blade body and a tenon. The method comprises the following steps that a square box and a pouring body are prepared; an upper front template and an upper rear template of the pouring body are taken down; the square box is installed, and the turbine blade is arranged; alloy casting is conducted; the square box is taken out; extra alloy is removed; whether the tenon of the turbine blade is located in the center of the square box or not is detected through a height gauge; if the tenon of the turbine blade is located in the center of the square box, the tenon of the turbine blade is ground through the square box; if the tenon of the turbine blade is not located in the center of the square box, casting is conducted for height adjustment; and after the tenon of the turbine blade is ground, the alloy is melted, the turbine blade is taken out, and the square box and the pouring body are used repeatedly for machining the next turbine blade. By means of the method, the clamping and positioning requirements can be met, installation is convenient, and clamping machining is facilitated.

Owner:SICHUAN CRRC YUCHAI ENGINE CO LTD

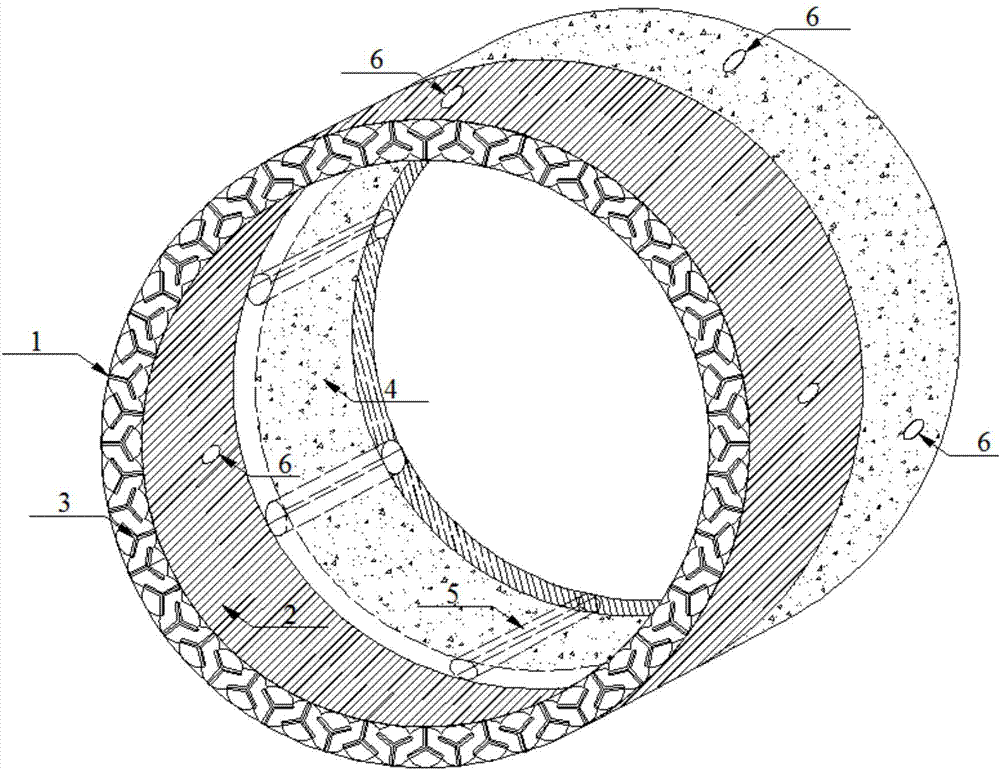

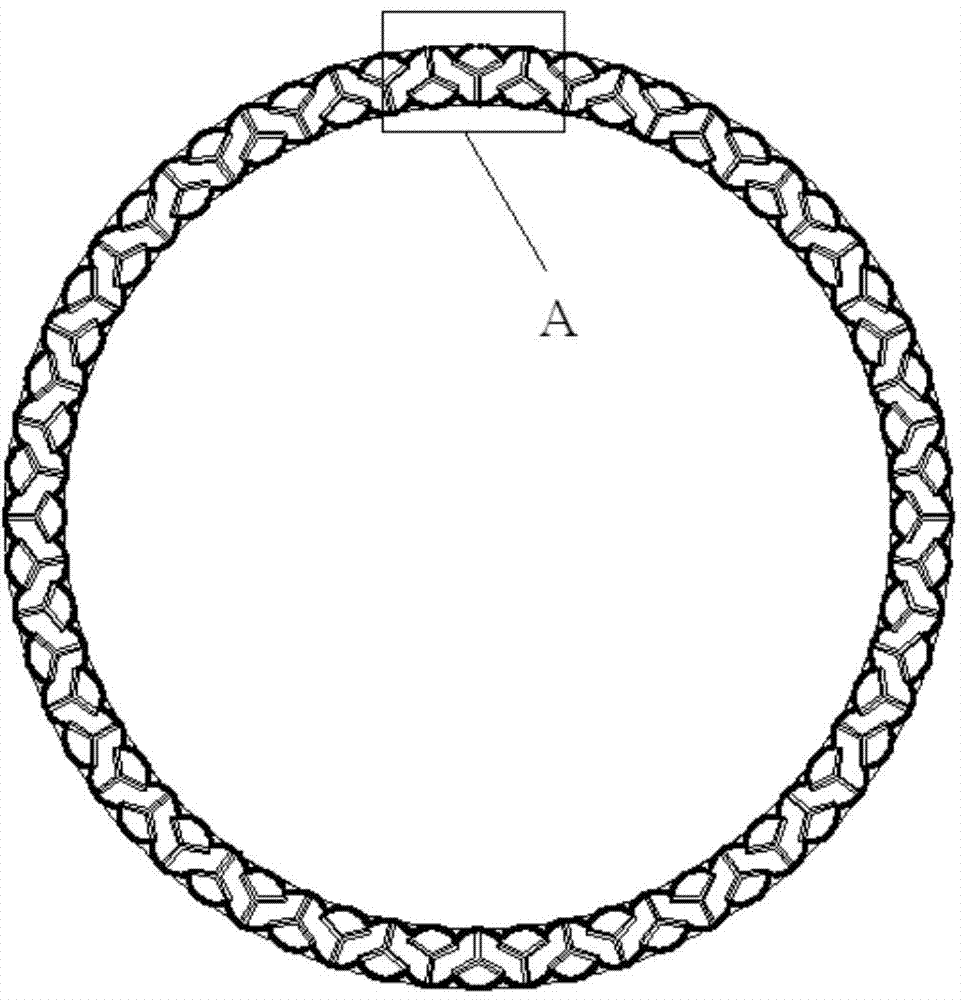

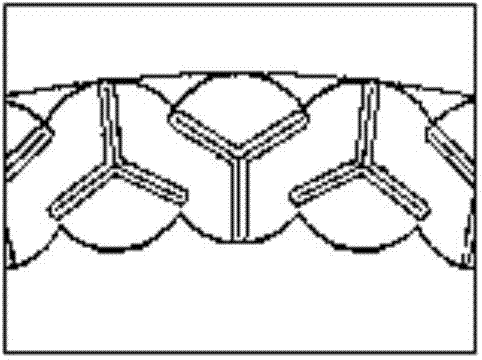

Annular pipe jacking machine

InactiveCN104712339ASolve construction problemsFlexible section shapeUnderground chambersTunnel liningGyroscopeControl system

The invention relates to an annular pipe jacking machine which comprises an annular shell, a cutter head, a muddy water system, a synchronous grouting system, a jacking mechanism, a guide system and a control system. The annular shell comprises an outer-layer shell body and an inner-layer shell body, the cutter head is arranged in the annular shell, the muddy water system comprises a mud inlet and outlet pipeline and a mud and water separation treatment device, the mud and water separation treatment device is arranged on the ground, grouting pipes of the synchronous grouting system are arranged in the annular shell and sections of a jacking pipe respectively, thixotropic slurry is injected through a grouting hole, the jacking mechanism is arranged in a jacking pipe work well and used for jacking the sections of the jacking pipe, the guide system comprises a gyroscope, a tilt meter and a height gauge which are used for determining the posture of the annular pipe jacking machine and tunneling precision, and the control system is arranged on the ground and used for performing cooperative control on the cutter head, the muddy water system, the synchronous grouting system, the jacking mechanism and the guide system. Compared with the prior art, an excavated section is small, the shape of the section is flexible, and the annular pipe jacking machine is suitable for building tunnels with large sections and extra-large sections.

Owner:TONGJI UNIV

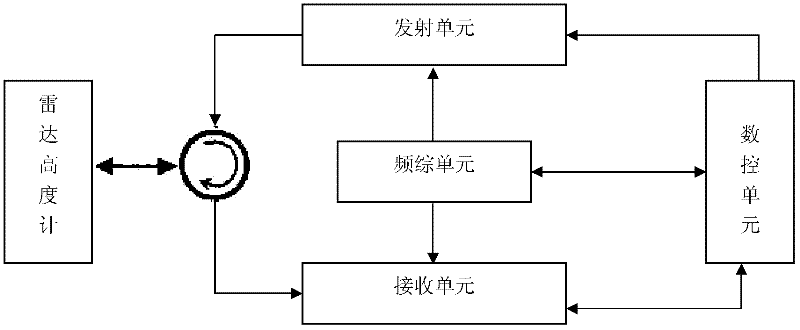

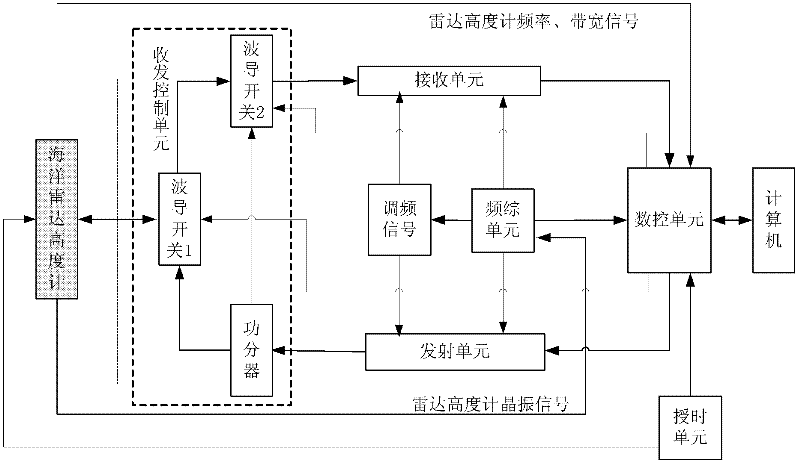

Ground verification instrument of satellite-based marine radar height gauge

InactiveCN102565767AAbsolute Scaling ImplementationEliminate delaysWave based measurement systemsNumerical controlAbsolute calibration

The invention provides a ground verification instrument of a satellite-based marine radar height gauge, which is used for performing absolute calibration, performance examination and function test on the satellite-based marine radar height gauge in a laboratory. The ground verification instrument of the satellite-based marine radar height gauge comprises a time service unit, a transceiving control unit, a transmitting unit, a receiving unit, a frequency heald unit and a numerical control unit. The frequency heald unit utilizes an ultra-stable crystal oscillator signal provided by a radar height gauge to be verified as a clock. The time service unit takes charge of providing accurate synchronous time service for the numerical control unit and the radar height gauge. The transceiving control unit takes charge of respectively and simultaneously sending signals transmitted by the transmitting unit to the receiving unit and the radar height gauge and also controlling the receiving unit to receive the signals transmitted by the radar height gauge or the signals transmitted by the transmitting unit. The numerical control unit takes charge of eliminating channel influences of a verification instrument system, generating calibration signals, simulating echo signals of various target scenes and controlling the transceiving control unit, the receiving unit, the transmitting unit and the frequency heald unit.

Owner:NAT SPACE SCI CENT CAS

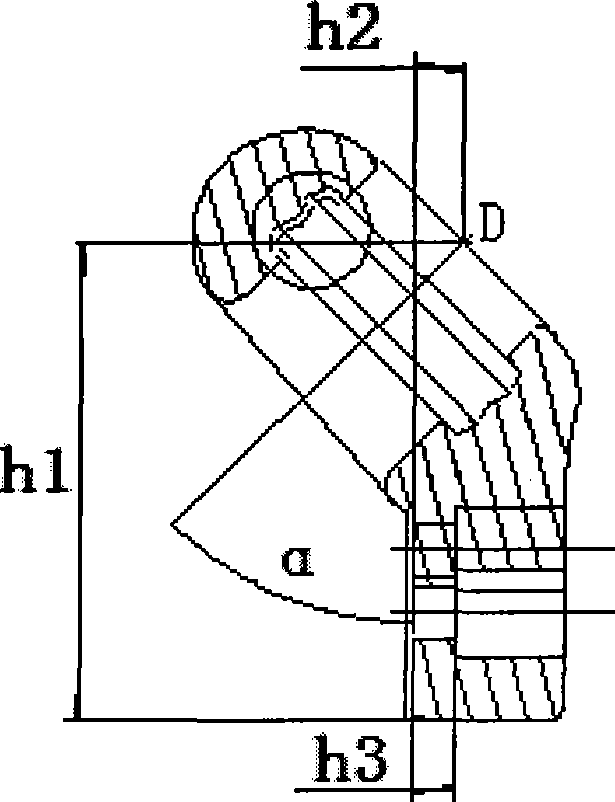

Special-shaped conductor part dimension measurement method

ActiveCN101387487APrevent cascadingGuaranteed coincidenceAngles/taper measurementsElectrical conductorDimension measurement

The invention discloses a method for measuring the dimensions of specially-shaped conductor parts, which comprises the following steps: firstly, preparing a mandrel with the corresponding diameter according to the inclination aperture of the part to be measured, wherein one end of the mandrel is provided with an inclined plane intersecting with the mandrel end face, the intersecting line of the two planes passes through the diameter of the mandrel, and the angle of the inclined plane is in accordance with the inclination angle of the central line of an inclination hole of the part to be measured; secondly, connecting a limiting plate to the mandrel end face intersecting with the inclined plane of the mandrel; thirdly, placing the part to be measured on a detecting platform, inserting the mandrel along the inclination hole of the part, using the limiting plate to cause the end face having the inclined plane of the mandrel to superpose with the end face of the inclination hole of the part to change the inclined plane of the mandrel into a plane, and leading out the intersection point, namely an imaginary point D, of the end face of the inclination hole of the part and the central line thereof; and finally, using a measuring head of a height gauge to approach the intersecting line of the mandrel end face and the inclined plane so as to measure the height dimension H of the part. The method transforms the measurement imaginary point D of the part into a measurable point so as to satisfy the space and angle dimensions of the specially-shaped conductor of an isolating switch which cannot be measured by the prior method.

Owner:CHINA XD ELECTRIC CO LTD

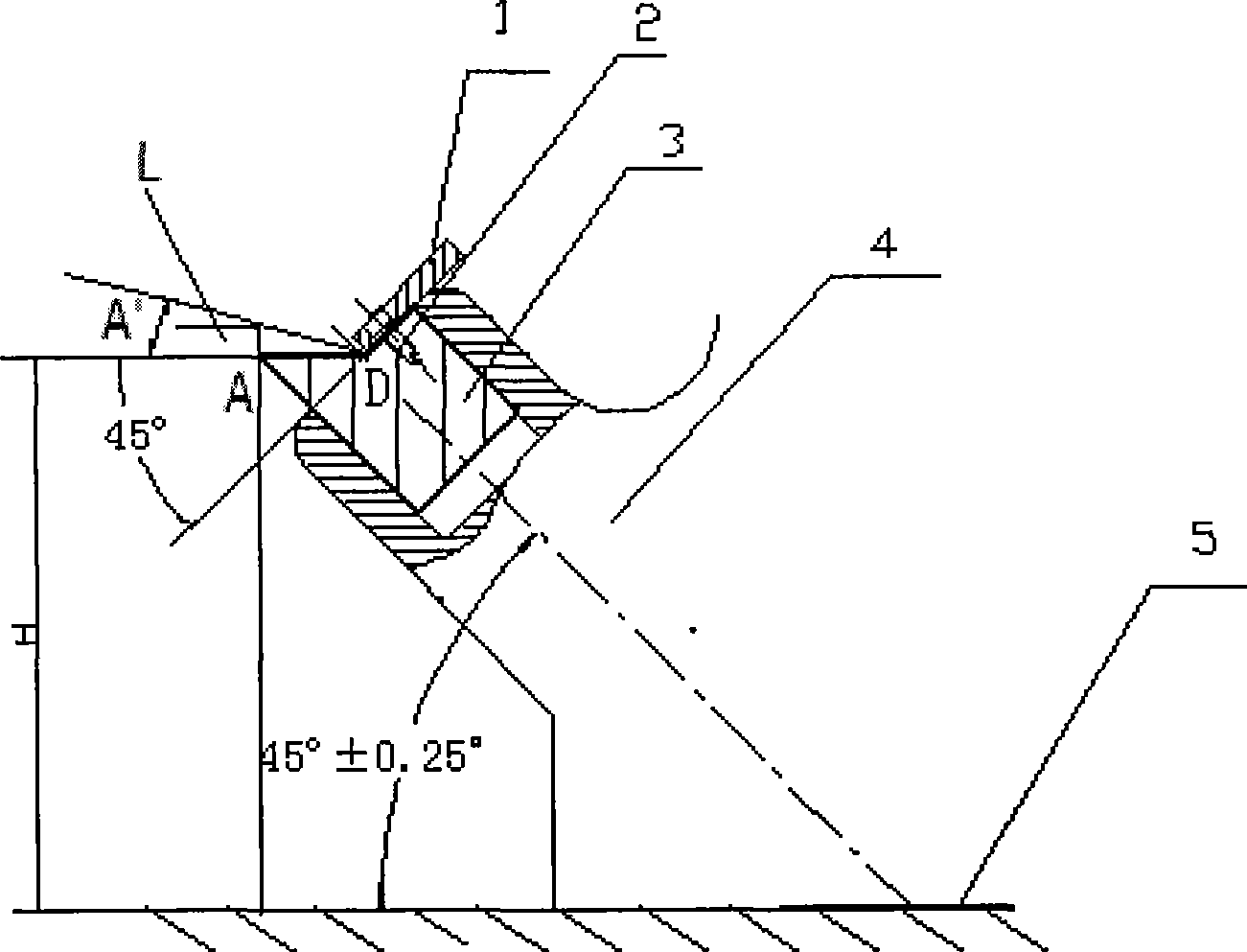

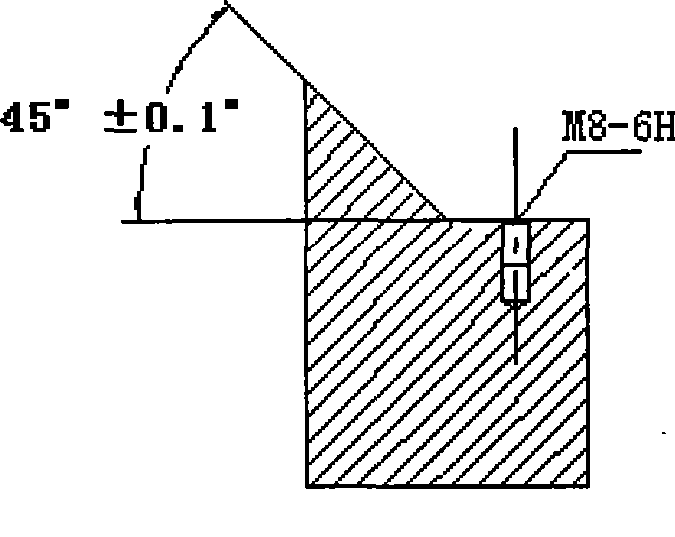

Bevel gear tooth thickness measurer

The invention provides a bevel gear tooth thickness measurer, which comprises an operation table, a sine gauge, a mandrel, a right-angled curved ruler, a height gauge, a gauge block and a micrometer. The bevel gear tooth thickness measurer is characterized in that the sine gauge and the right-angled curved ruler are mounted at two ends of the operation table respectively, mounting angles of the sine gauge and the right-angled curved ruler are mutually parallel, the height gauge and an adjusting sleeve are arranged on the right-angled curved ruler and movably connected with the operation table, the micrometer with a holder, an anvil and a locking device removed is mounted on the adjusting sleeve, the micrometer is parallel to a basal plane of the operation table, an axillary steel ball is placed in the middle of a tooth space of the bevel gear to be measured and slightly close to a small end, and positioned in the middle of a contact area, and then relevant dimensional data are measured. The tooth thickness of a portion, where the steel is positioned, of the bevel gear is obtained by calculating, and the tooth thickness of a large end of the measured bevel gear is obtained. The bevel gear tooth thickness measurer can be used for measuring the thickness of optional-section teeth, especially in the middle of the contact area, and no back cone needs to be used as a measurement datum.

Owner:天津天海同步科技有限公司

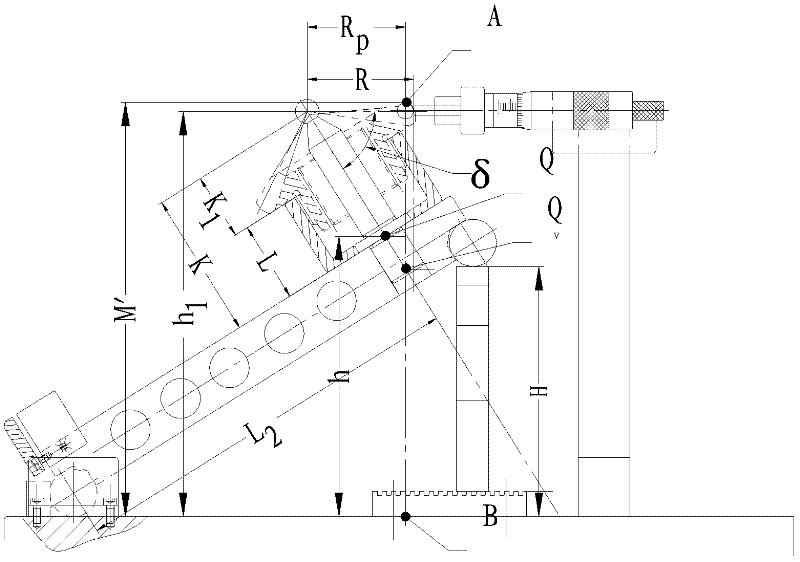

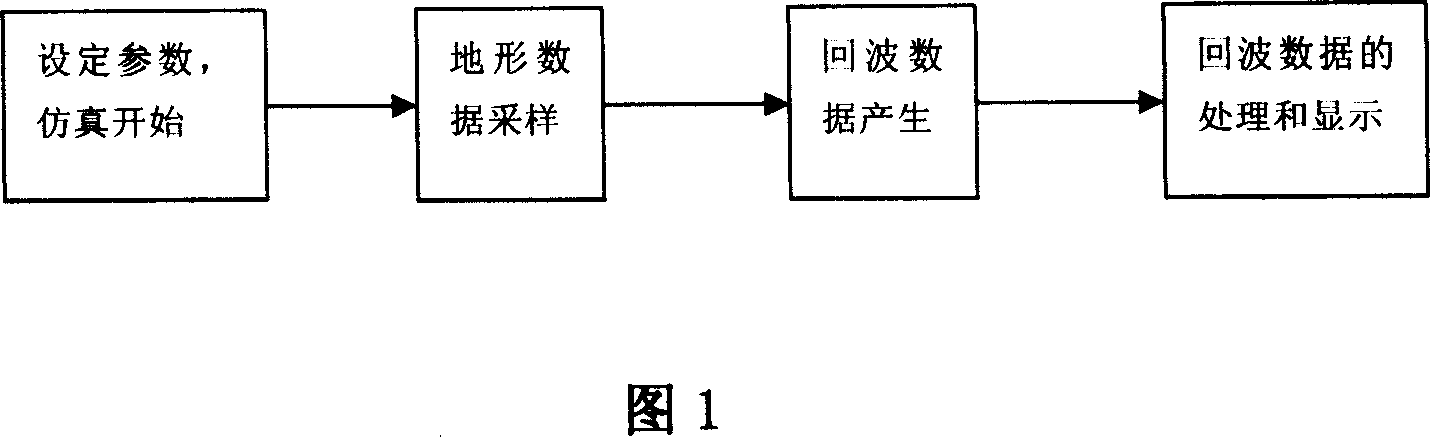

Simulation algorithm of echo waveform of laser pulse with large footprint

An echo waveform artificial algorithm of wide foot print laser pulse includes decomposing emitted laser pulse to be innumerable Gauss pulses incoming to various points on wide footprint, receiving these Gauss pulses by laser height gauge after said Gauss pulses are emitted by corresponding point of wide footprint in order to obtain product formula of echo power corresponding to laser pulse, carrying out topographic division to obtain simple formula of said echo power and programming to obtain waveform of wide footprint laser pulse echo.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI +1

Under-ice exploration robot

PendingCN107878712ARich detection methodsGuaranteed uptimeWatercraft hull designUnderwater vesselsTransceiverFuselage

The invention relates to an under-ice exploration robot. The under-ice exploration robot comprises a bow compartment, a main cabin, an electronic control cabin and an after-peak tank which are coaxially and sequentially connected, wherein the main cabin, the electronic control cabin and the after-peak tank form a robot body, the bow compartment and the after-peak tank are communicated with an external water area, and the main cabin and the electronic control cabin are sealed cabins; a sonar height gauge and an acoustic transceiver are arranged in the bow compartment; a non-contact electric energy and signal transmission component sheathes outside the main cabin, an electromagnetic coupling coil is arranged in the non-contact electric energy and signal transmission component, and an attitude adjustment system and a buoyancy force regulating system are arranged in the main cabin; a depth gauge, a main control circuit board, a navigation and communication component and an electronic compass are arranged in the electronic control cabin; the under-ice exploration robot also comprises symmetrically arranged wings, the wings are extended, tiled and arranged from front to back along the robot body, and anti-skid wheels which can move along the lower surface of an ice layer are arranged at the left edge and the right edge of the tail of each wing; and a propeller propulsion system and an anti-skid wheel driving system are fixed on the bow compartment, and the anti-skid wheels are connected with the anti-skid wheel driving system which drives the anti-skid wheels to move.

Owner:HANGZHOU DIANZI UNIV

Height measuring instrument

InactiveCN101713629AExpand the measurement areaImprove measurement efficiencyMechanical measuring arrangementsMeasuring instrumentEngineering

The invention provides a height measuring instrument which comprises a base, a guide rod, an extension rod and a height gage, wherein the guide rod is fixed on the base; the extension rod comprises a slide part which can be slidably sleeved on the guide rod and used for the axially moving along the guide rod; the height gage is arranged at one end of the extension rod away from the guide rod; theextension rod is provided with a first extension part and a second extension part parallel to the first extension part; one ends of the first extension part and the second extension part, which are away from the guide rod, are respectively provided with a connecting part used for connecting the first extension part and the second extension part; and the second extension part can slide and rotate relative to the connecting part. The invention also provides a height measuring method utilizing the height measuring instrument to measure.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Wire loop height measurement apparatus and method

ActiveUS20050094865A1Accurate measurementAvoid disadvantagesImage enhancementImage analysisAltimeterPhysics

The invention provides a method and an apparatus for determining a height of a point on a wire loop. A height gauge device is positioned over the point on the wire loop to be measured. Incident light is projected from the height gauge device for illuminating the point. The height gauge device receives reflected light produced from the incident light and a processor coupled to the height gauge device determines from a characteristic of the reflected light the height of the said point relative to a reference surface. Further methods and apparatus for finding a position and height of a highest point on the wire loop are also provided.

Owner:ASM ASSEMBLY AUTOMATION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com