Annular pipe jacking machine

A pipe jacking machine and annular technology, which is used in wellbore lining, tunnel lining, underground chamber, etc., can solve the problem of difficult size, and achieve the effect of stable excavation surface, environmental protection, and flexible cross-section shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

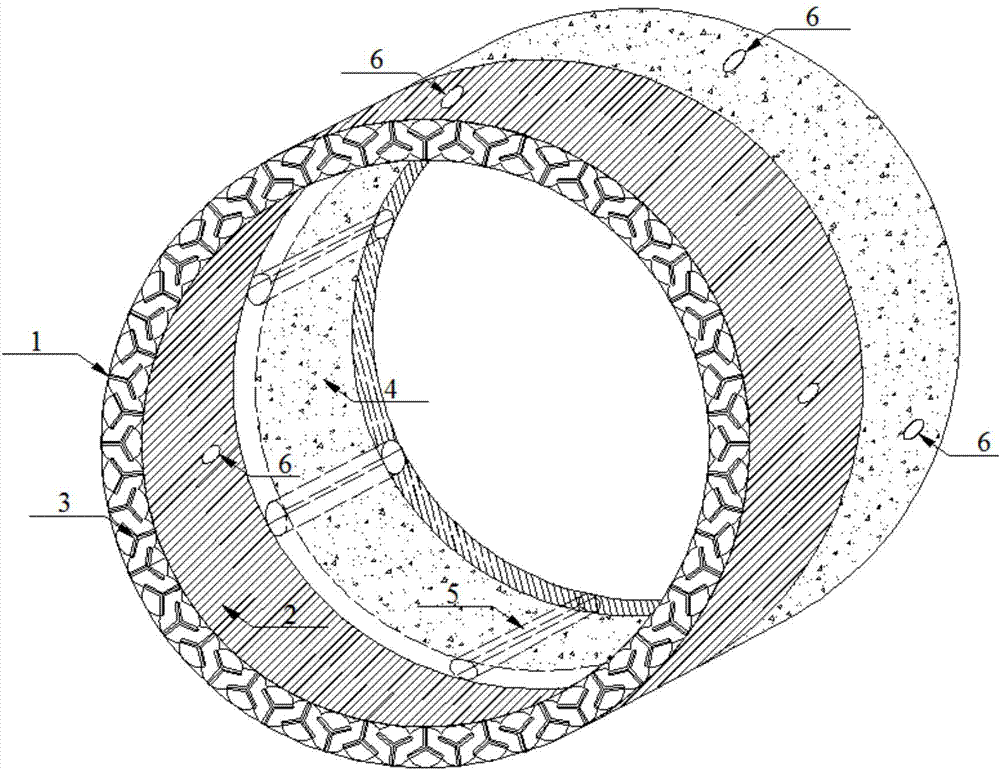

[0035] This embodiment provides an annular pipe jacking machine, which includes an annular shell, a cutting cutter head, a slurry system, a synchronous grouting system, a pushing mechanism, a guiding system and a control system, and a pipe jacking joint 4 is connected to the rear of the machine.

[0036] Such as figure 1 As shown, the annular shell includes an outer shell 1 and an inner shell 2 , which together form an annular cavity for accommodating a cutting disc 3 . The outer shell 1 supports the surrounding stratum soil, and at the same time, the jacking of the pipe jacking joint 4 is completed under the protection of the outer shell 1 . At the place where the structural bending moment of the pipe jacking joint 4 is small, several hollow passages 5 are provided as passages for placing mud inlet and discharge pipes, grouting pipes, cables and hydraulic oil pipes, etc. Several grouting holes 6 are arranged on the side where the outer shell 1 , the inner shell 2 and the pip...

Embodiment 2

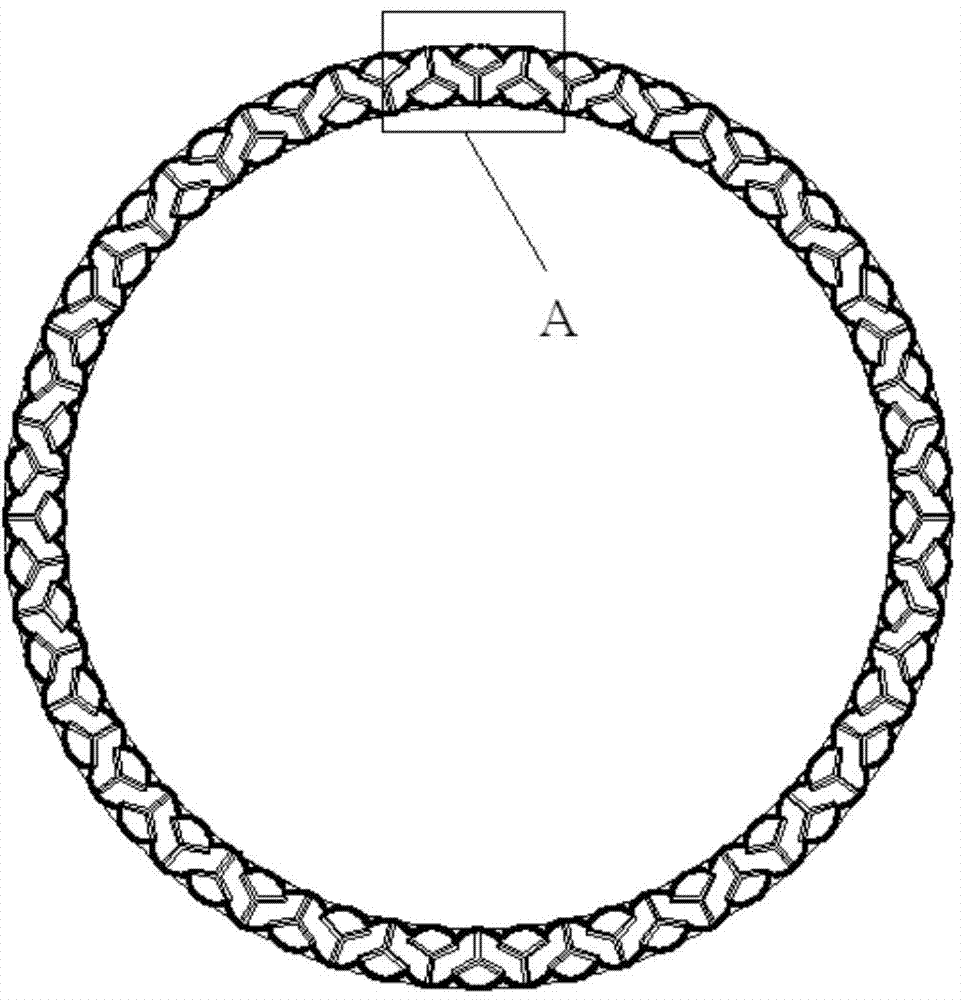

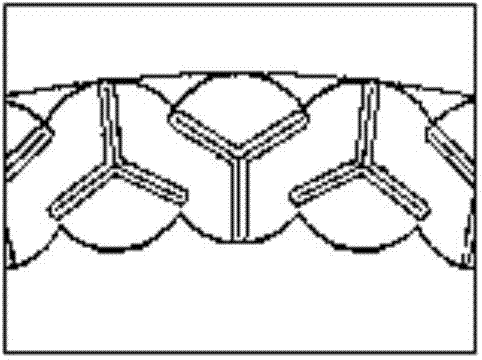

[0046] Such as Figure 4-5 As shown, the cutting disc 3 is composed of a plurality of staggered small discs, which detachably cover the entire annular area, and the rest are the same as in the first embodiment.

[0047] Such as Figure 7 As shown, the specific working steps of the above ring pipe jacking machine include the following points:

[0048] (1) Use the construction technology of the existing pipe jacking method to construct the working well 27, the receiving well 28 and the retaining wall 29, and reinforce the soil on the working face of the annular pipe jacking machine;

[0049] (2) Hoist ring pipe jacking machine, top iron 30, jack 25, lay mud inlet pipeline 14, mud discharge pipeline 15, grouting pipe 16, hydraulic oil pipe 31, cable 26, install mud-water separation treatment equipment, mud pump, etc. Grouped equipment;

[0050] (3) The circular pipe jacking machine is started, the starting operation is completed, and the pipe jacking section 4 is hoisted;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com