Patents

Literature

148 results about "Chemical fiber cloth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

ActiveCN102182253AHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsChemical fiber clothMacromolecule synthesis

The invention relates to a manufacturing method of a rubber and chemical fiber synthetic waterproof sheet and a product thereof, and the rubber and chemical fiber synthetic waterproof sheet is formed by compounding three layers of material, wherein the middle layer is a chemical fiber cloth or felt composite layer, and the chemical fiber cloth or felt composite layer is a waterproof layer enabling polymer synthetic rubber composite material and chemical fiber cloth or felt to infiltrate and adhere mutually; when in manufacturing, the chemical fiber cloth or felt of the middle layer is firstlyplaced in a dip coating groove for enabling the chemical fiber cloth or felt to soak polymer synthetic rubber waterproof rubber material, and the middle sheet layer is further manufactured; and two layers of the chemical fiber cloth or felt are stuck on two surfaces of the middle sheet layer respectively, thereby forming the three-layer compound synthetic waterproof sheet. The polymer synthetic rubber waterproof rubber material takes rubber as main material, and a high polymer and other auxiliary materials are added for manufacturing the waterproof rubber material; the auxiliary materials comprise an accelerant, filling material, a softener, a cross-linking agent or an anti-aging agent; and the middle sheet layer can be manufactured by one of three forms respectively, namely the cold working method, the hot working method and the rolling method.

Owner:杨太龙

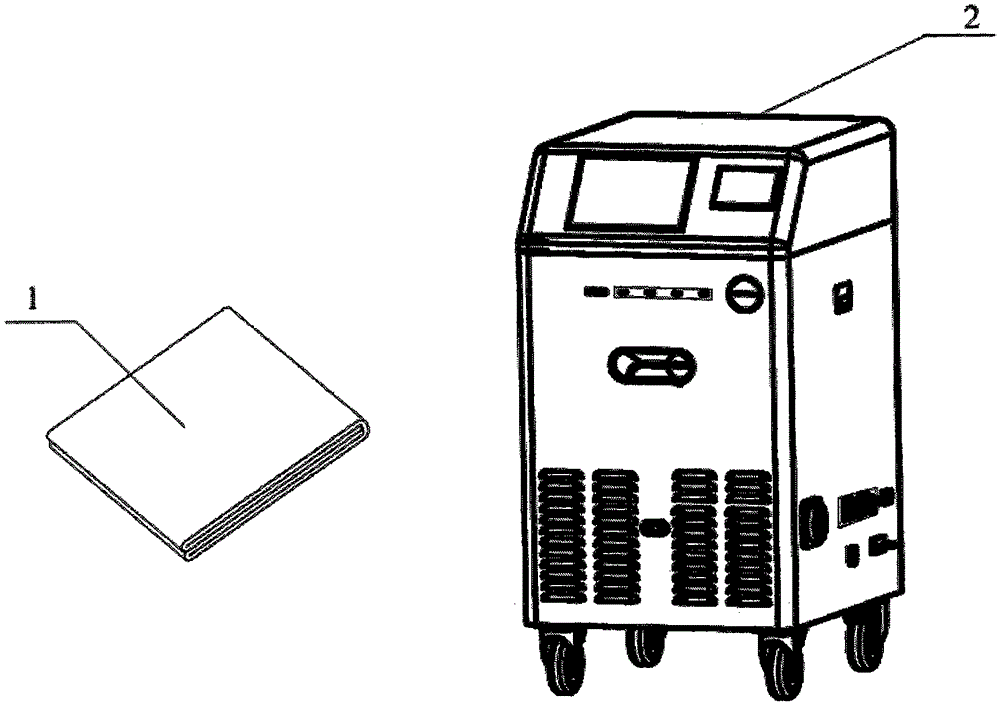

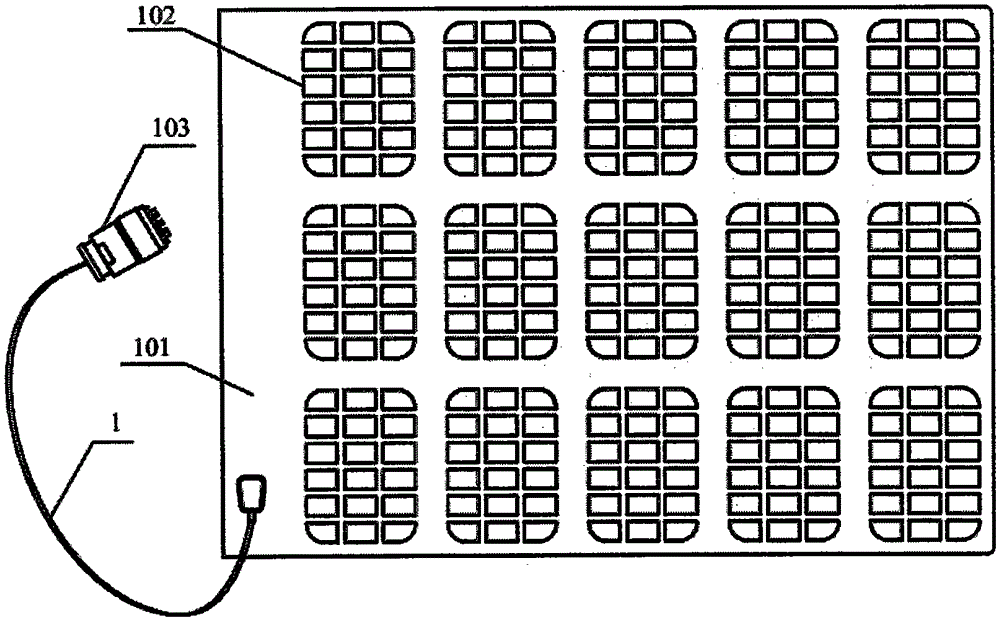

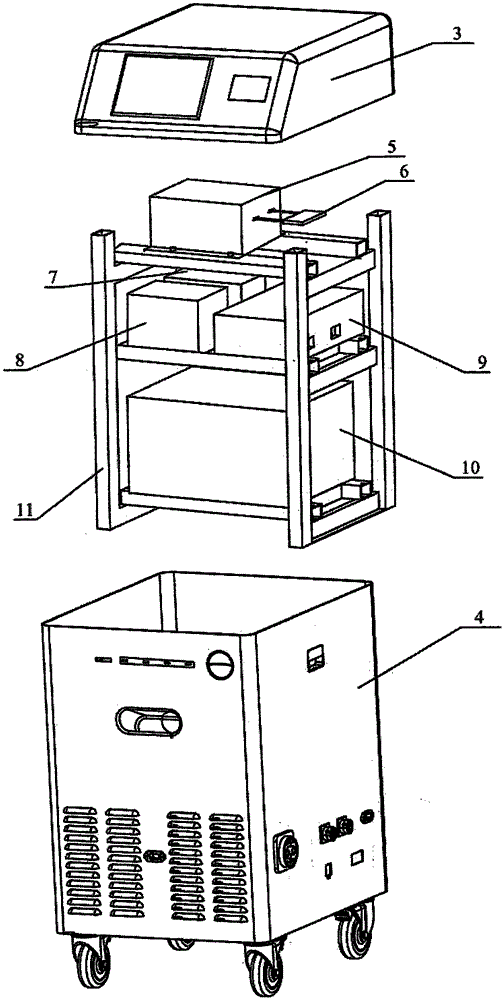

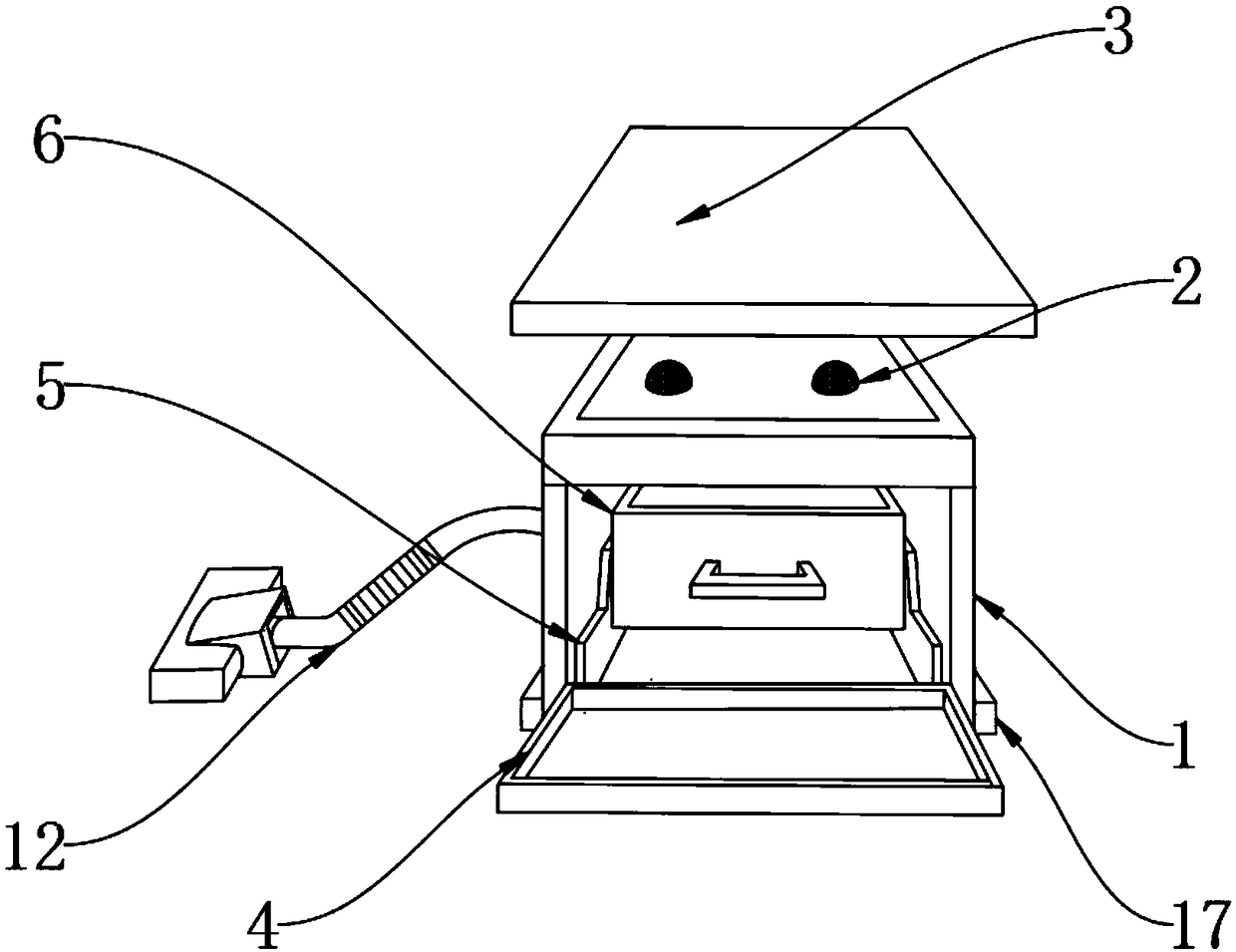

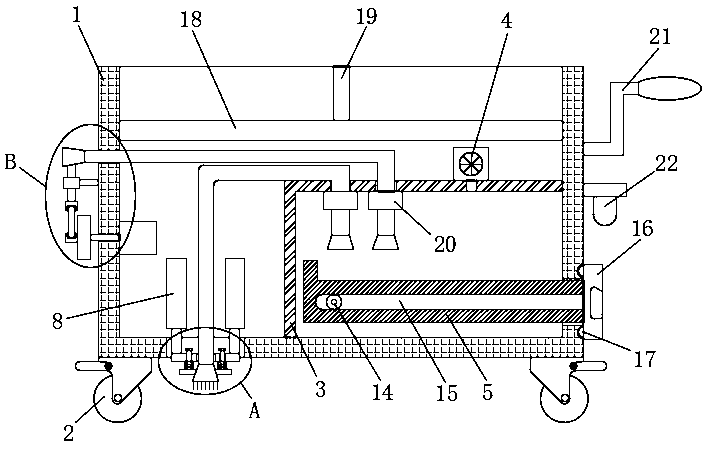

Movable charging pile

PendingCN105337372AEasy to carryImprove light energy utilizationBatteries circuit arrangementsElectric powerChemical fiber clothEngineering

The invention relates to an electric car charging device, in particular to a mobile charging pile. The movable charging pile is composed of a foldable photovoltaic panel and a movable charging box, wherein the foldable photovoltaic panel is used for charging the movable charging box, the movable charging box is used for charging an electric car and a mobile phone, and the movable charging box is charged in a photovoltaic power supply charging mode and a mains supply charging mode. The foldable photovoltaic panel is composed of a chemical fiber cloth body, flexible film photovoltaic panels and a photovoltaic charging plug. The flexible film photovoltaic panels are transversely, vertically and evenly arranged inside the chemical fiber cloth body. The photovoltaic charging plug is arranged at one corner of the outer side of the chemical fiber cloth body. The foldable photovoltaic panel is detachably installed on the movable charging box through the photovoltaic charging plug. Modularization is adopted on a circuit board, and circuit boards are installed in different boxes respectively according to the functions so as to facilitate assembling, disassembling and follow-up maintenance.

Owner:鸥瑞智诺能源科技(天津)有限公司

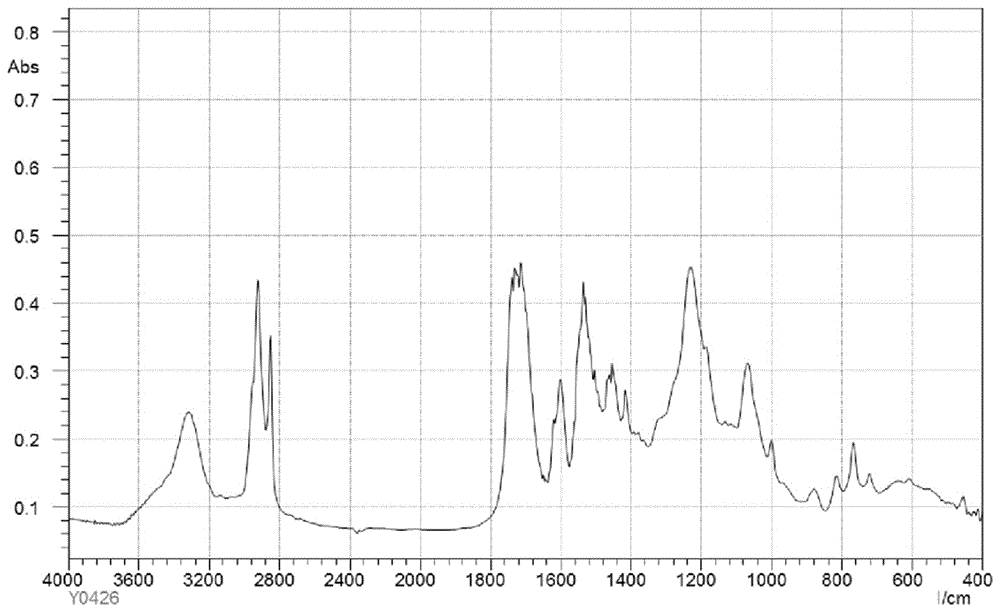

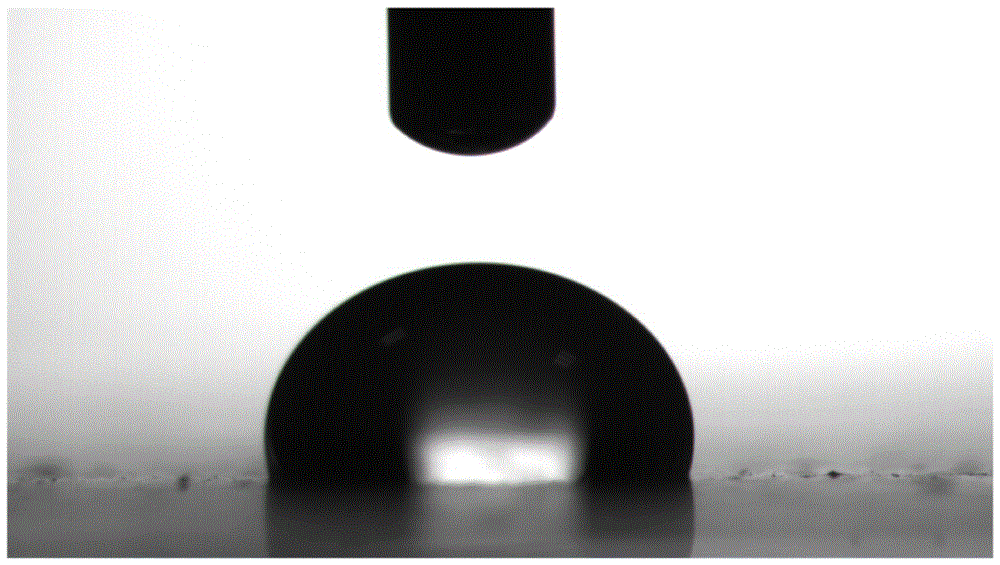

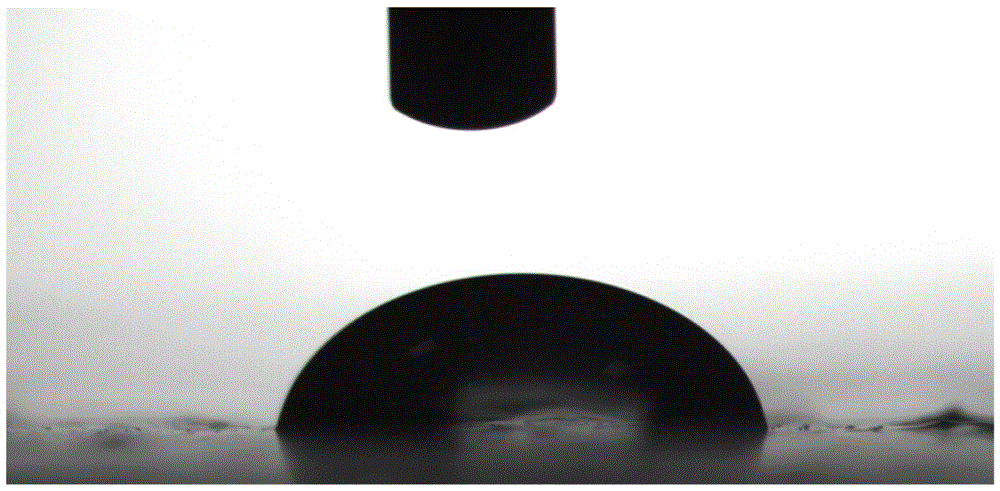

Preparation method of waterborne polyurethane with hyperbranched structure silicone oil side chain

The invention provides a hyperbranched silicone oil side chain modified waterborne polyurethane polymer and a preparation method thereof. The preparation method of the polymer comprises the following steps: making 100 parts of polyether polyol and 10 parts of hyperbranched amino silicone oil react with 20 to 80 parts of diisocyanate to obtain a polyurethane prepolymer which contains a hyperbranched silicone oil side chain and is blocked by an isocyanate group; adding 2 to 19 parts of small molecular polyol chain extender into the prepolymer and 0.1 to 10 parts of amino-containing small molecular dihydric alcohol for chain extension, and performing quaternization and further emulsification to obtain hyperbranched silicone oil side chain modified polyurethane polymer emulsion. In the hyperbranched silicone oil side chain modified waterborne polyurethane emulsion, a hyperbranched siloxane chain segment is adopted, so that the water contact angle is increased, and the water absorption of polyurethane is lowered; the emulsion can be used as a fluorine-free waterproof agent to be applied to chemical fiber cloth or cotton; the preparation method is simple in process, the reaction speed is moderate and the operating conditions are easy to control; the product belongs to a water-based emulsion, and conforms to the development direction of environmental friendliness.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

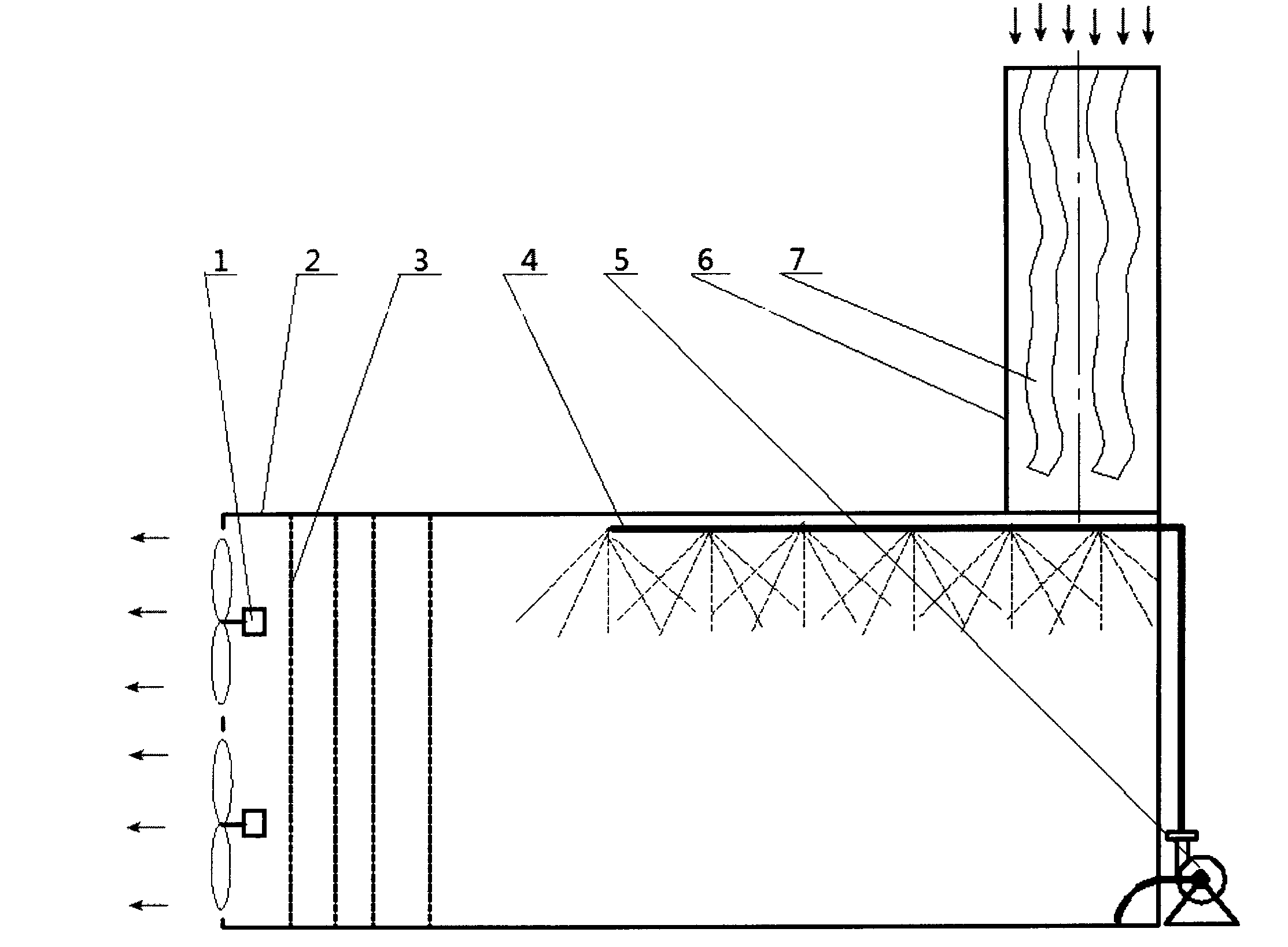

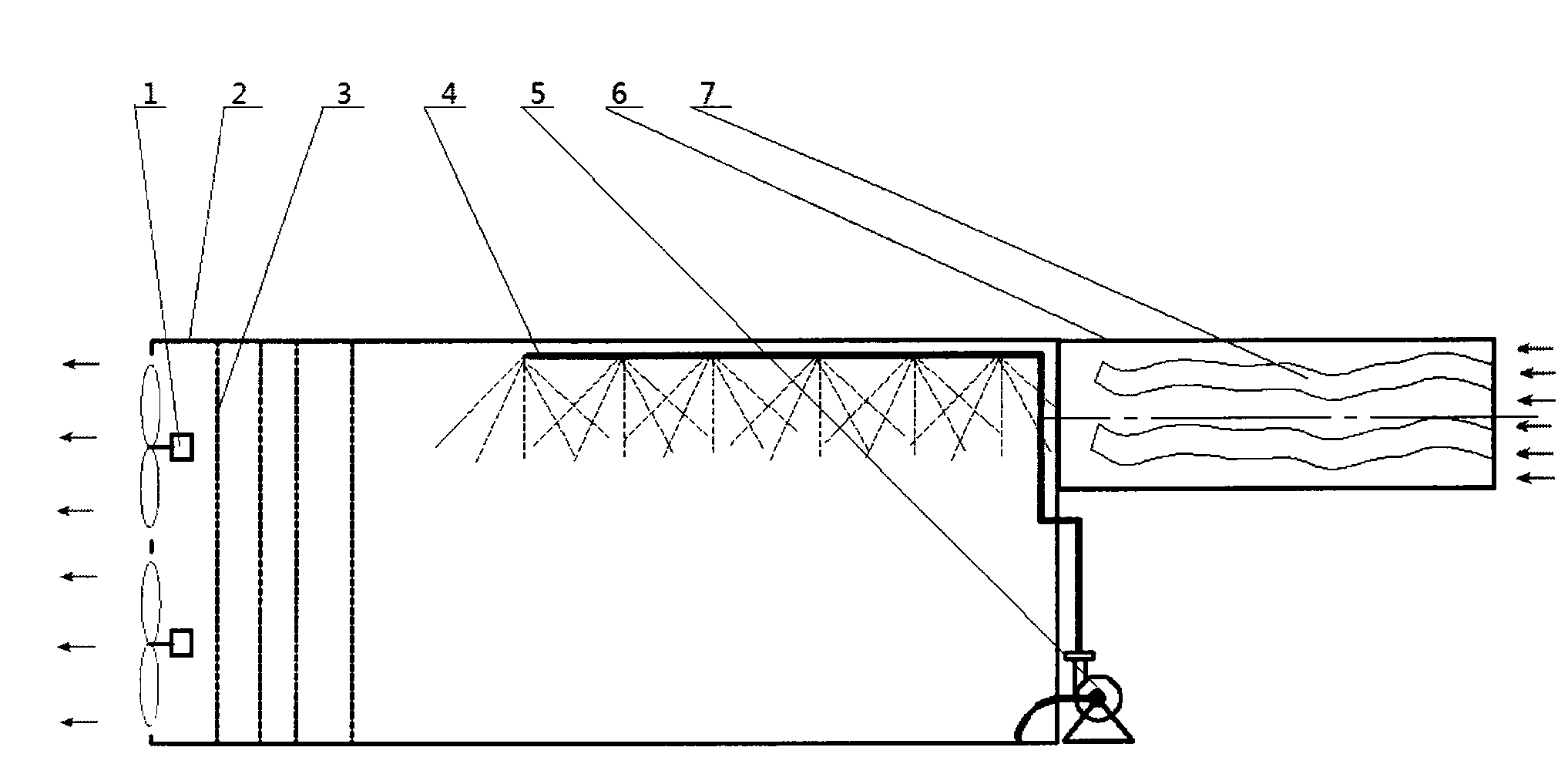

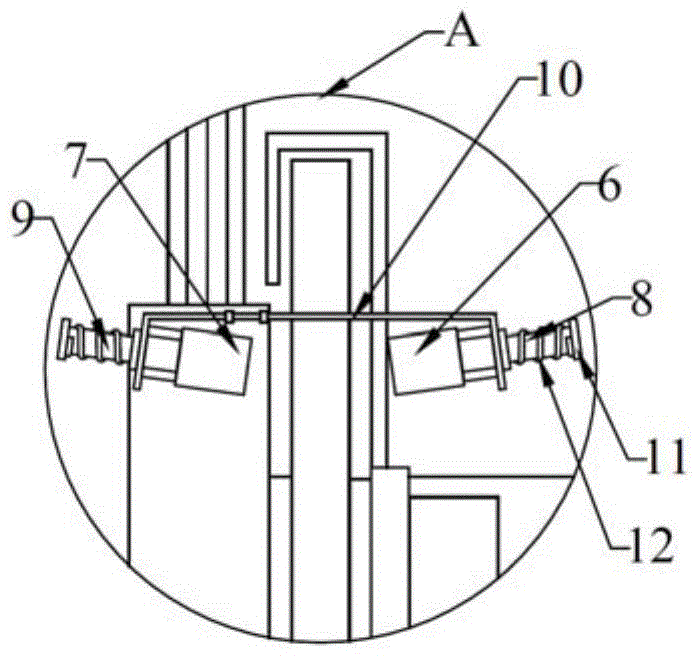

Spray-type haze-dust air purifier

InactiveCN103071351ALarge exhaust air volumeSimple structureUsing liquid separation agentForeign matterParticulates

The haze-dust air is mainly formed by the uniform floatation of a great amount of microscopic dust particles, smoke particles and salt particles in the air and can severely influence the health of the human body. Wind and rain are the bane of the dust-haze. The invention provides a spray-type haze-dust air purifier, and a working principle of the spray-type haze-dust air purifier is as follows: the haze-dust air passes through a draught pipe at a high speed and is rubbed with chemical fiber cloth strips inside the draught pipe to generate static electricity, then the haze-dust air is sprayed by spray water in a box body, after being washed by the spray water, harmful foreign matters of the haze-dust air with the static electricity are absorbed by the water, finally the air passes through a sieve tray, so that the clean air is separated from the sewage to be discharged from an exhaust port, and clean and fresh air can be provided for people nearby the exhaust port. The spray-type haze-dust air purifier can purify the haze-dust air containing 2.5 particulate matters (2.5PM) and subtle dust particles, smoke particles, salt particles and soluble harmful gases.

Owner:江村

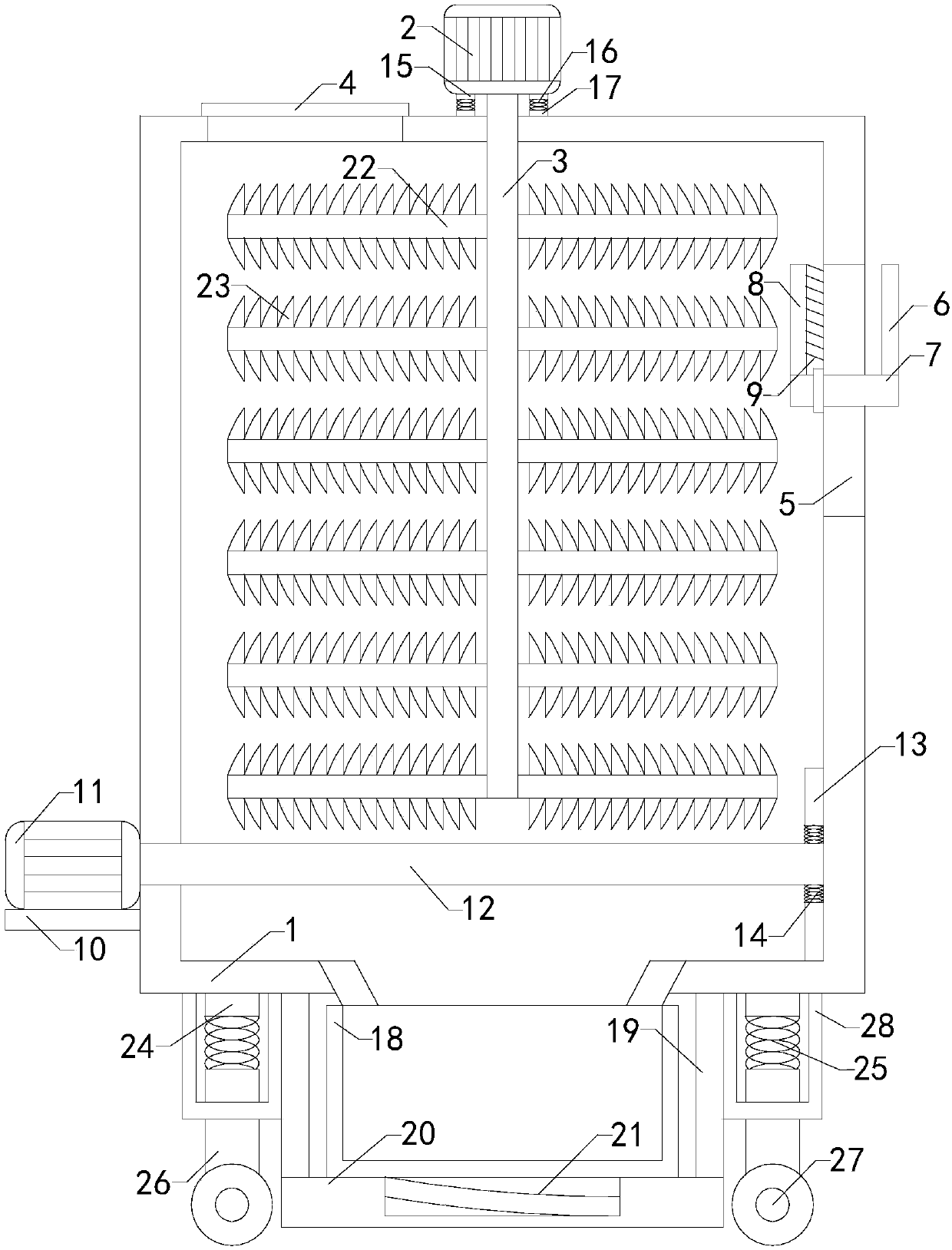

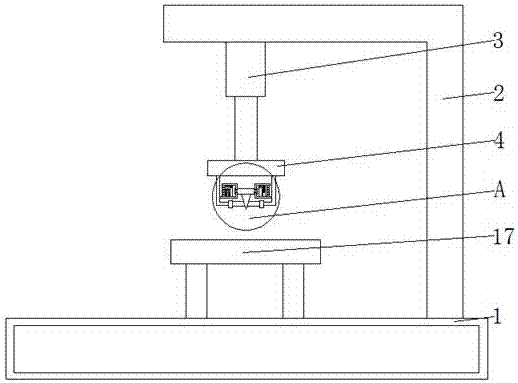

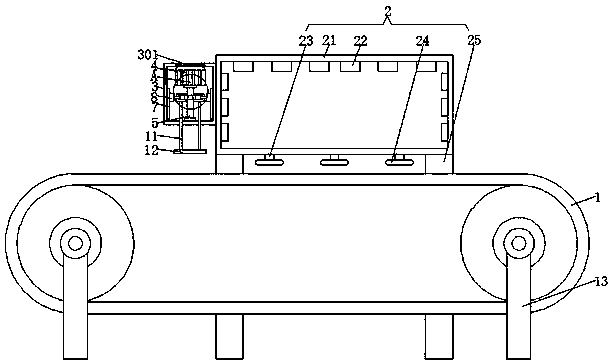

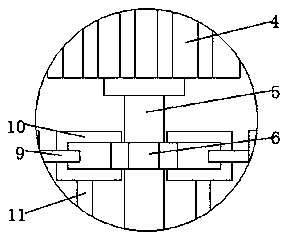

Environment-friendly smashing and recycling device for waste chemical fiber cloth

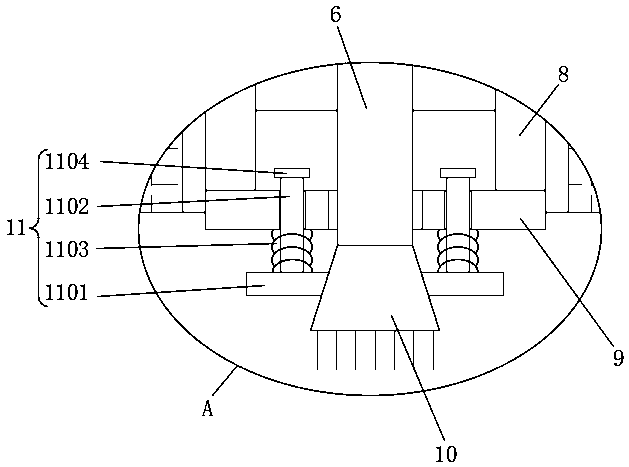

InactiveCN107790270AEasy to filterEasy to observeSievingNon-rotating vibration suppressionDrive shaftChemical fiber cloth

The invention relates to the technical field of smashing accessory devices for chemical fiber cloth, in particular to an environment-friendly smashing and recycling device for waste chemical fiber cloth. When the waste chemical fiber cloth is smashed, the interior of a working cavity can be conveniently observed, and the practicability is improved. In the smashing process of the waste chemical fiber cloth, the completely smashed waste chemical fiber cloth can be screened conveniently, and the use efficiency is improved. The shaking of a rotary motor occurring in use can be buffered, thereby prolonging the service life of the rotary motor and a transmission shaft. The environment-friendly smashing and recycling device comprises a working box, four groups of supports, the rotary motor, the transmission shaft and a smashing device. An observation hole is arranged in the side wall of the working box in a communicating manner, the observation hole is provided with a transparent baffle, andthe environment-friendly smashing and recycling device further comprises a handle, a rotary shaft, a driving shaft, brush hairs, a support plate, a vibration motor, a sieve plate, two groups of auxiliary blocks, two groups of secondary vibration springs, four groups of upper buffer blocks, four groups of buffer springs and four groups of lower buffer blocks, wherein the sieve plate is provided with a sieve net.

Owner:JIANGSU KANGJIE MACHINERY

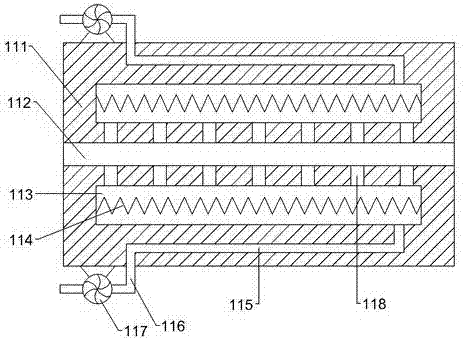

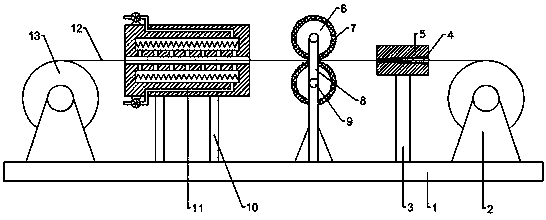

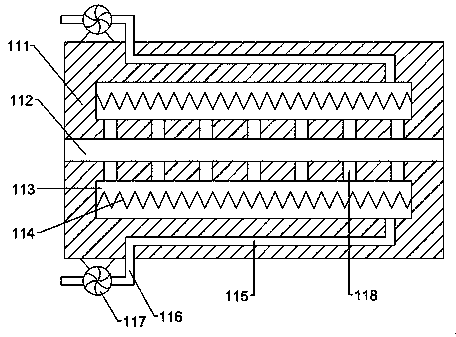

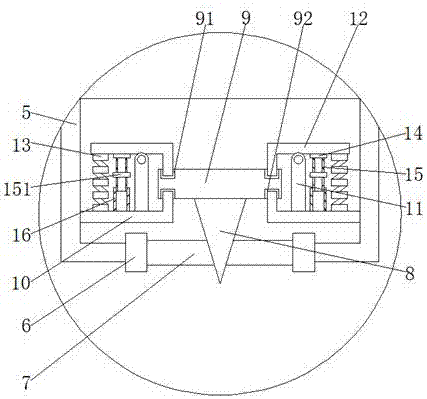

Drying device for cleaned chemical fiber cloth

InactiveCN107421299AReduce moisture contentGuaranteed drynessDrying solid materials without heatDrying gas arrangementsElectrical resistance and conductanceChemical fiber cloth

A cleaning and drying device for chemical fiber fabrics, comprising a base, a cloth take-up roller and a cloth release roller are fixedly connected to both ends of the upper side of the base, cloth is connected between the cloth take-up roller and the cloth release roller, and the right part of the base is fixed The first supporting frame is connected, and the top of the first supporting frame is fixedly connected with a water squeezing body. The water squeezing body is in the shape of a horizontal cylinder. There is a horizontally arranged water squeezing channel inside the water squeezing body, and the cross section of the water squeezing channel is left small and right Large trapezoidal shape; two second support frames are fixedly connected to the base on the left side of the first support frame, and two rotating rods are rotatably connected to the two second support frames. The present invention first squeezes water on both sides of the cloth to remove most of the moisture in the cloth, then uses the heating resistance wire to dry the cloth to ensure the drying effect of the cloth; uses the preheating channel to heat the air in advance, The energy is effectively saved, and the drying effect is improved, which has a certain promotion and application value.

Owner:YANCHENG ZHEN FENG MACHINERY CO LTD

Capparis spinosa fruit gel ointment, production method thereof, and application thereof to antirheumatic medicaments

ActiveCN102068474AEvenly dispersedAffect comfortAntipyreticAerosol deliveryPolyesterTectorial membrane

The invention relates to capparis spinosa fruit gel ointment, a production method thereof, and application thereof to antirheumatic medicaments. The capparis spinosa fruit gel ointment comprises a backing layer, a medicament-containing ointment body and a covering layer protective film, wherein the medicament-containing ointment body is prepared from the following raw materials: a medicinal part of the capparis spinosa and a medicinal excipient; a covering material of the covering layer protective film is one of release paper, a plastic film, a polyester, an aluminum foil-polyethylene composite film and hard gauze; and a backing material of the backing layer is one of cotton cloth, non-woven fabric and chemical fiber cloth. The apparis spinosa fruit gel ointment provided by the invention substitutes the apparis spinosa fruit serving as a medicament for the traditional root bark, so the contradiction between the resource utilization of the apparis spinosa medicinal plants and ecological protection is solved. More importantly, the apparis spinosa fruit gel ointment provided by the invention solves the problems of irritability and hypersensitivity caused by the clinical application of the traditional formulation and administration way of the apparis spinosa, and has the characteristics of long action time, high moisture retention, high air permeability, avoidance of the first pass effect of livers, using comfortableness and high compliance of patients.

Owner:XINJIANG INST OF MATERIA MEDICA

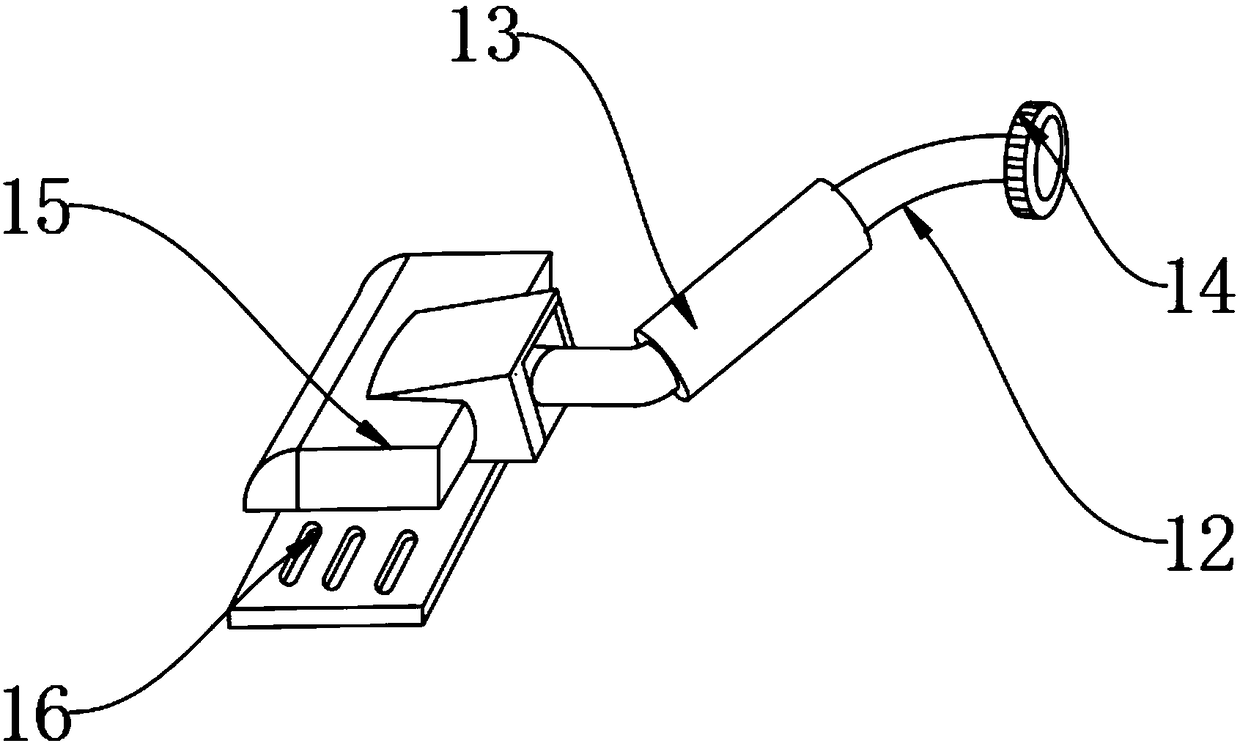

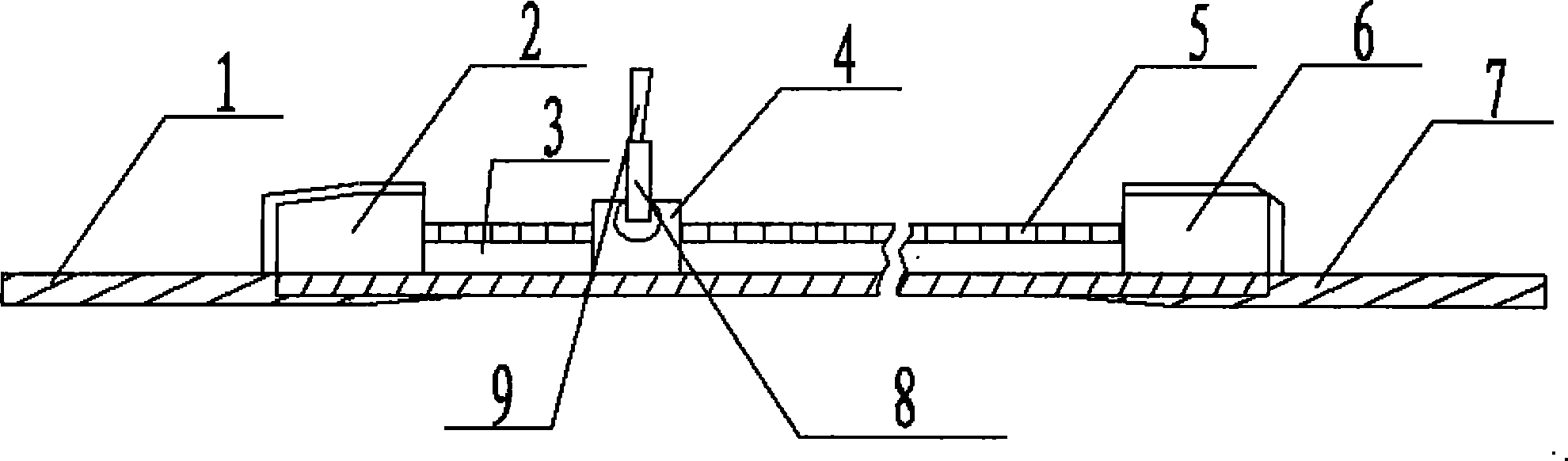

Handheld type heating cloth-cutting device

ActiveCN104060455ASimple structureFirmly connectedTextile selvedgesSevering textilesChemical fiber clothHand held

The invention discloses a handheld type heating cloth-cutting device. The handheld type heating cloth-cutting device comprises a rack, wherein a handheld handle is arranged on the rack; a blade with a round outer profile is arranged on the rack by a connecting part and is connected with the output end of a driving motor by a transmission part; the driving motor is used for driving the blade to rotate. The cloth-cutting device also comprises a heating device for heating the blade. The handheld type heating cloth-cutting device disclosed by the invention has the advantages that the structure is simple; by matching arrangement of the heating device on a cutter, before cloth is cut, the cutter is firstly heated, then the cutter is used for cutting materials such as chemical-fiber cloth, silks, geotextile cloth and plastic braided fabrics, so that the phenomenon of fiber dispersion at cut edges can be completely avoided, the connection among cloths after the cut cloths are sewn is firm, and the use effect is good.

Owner:JIANGSU SUNSHINE

After-washing drying device for chemical fiber cloth

InactiveCN107830717AReduce moisture contentGuaranteed drynessDrying gas arrangementsDrying machines with progressive movementsElectrical resistance and conductanceChemical fiber cloth

An after-washing drying device for chemical fiber cloth comprises a base. A cloth collecting roller and a cloth placing roller are fixedly connected to the two ends of the upper side of the base. Cloth is connected between the cloth collecting roller and the cloth placing roller. A first support is fixedly connected on the right portion of the base. A water squeezing body is fixedly connected to the top end of the first support and is horizontally cylindrical. A horizontally formed water squeezing channel is formed in the water squeezing body. The section of the water squeezing channel is big-end-right trapezoidal. Two second supports are fixedly connected to the part, on the left side of the first support, of the base. Two rotary rods are rotationally connected to the two second supports.According to the after-washing drying device, two-side water squeezing operation is conducted on the cloth first, most water in the cloth is removed, then the cloth is dried with a resistive heater,and the drying effect of the cloth is ensured. Air is heated in advance through a preheating channel, energy is saved effectively, the drying effect is improved, and certain application and popularization value is achieved.

Owner:蒋丹丹

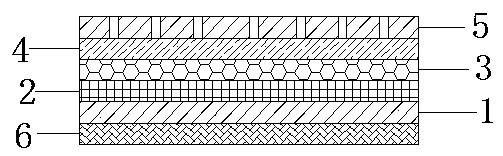

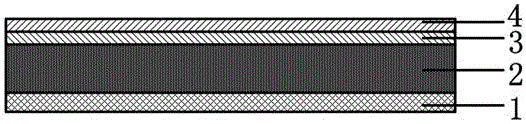

X-ray prevention shielding film and preparation method thereof

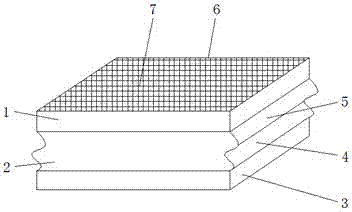

InactiveCN104527172AIncreased durabilityHigh strengthSynthetic resin layered productsShieldingChemical fiber clothX-ray

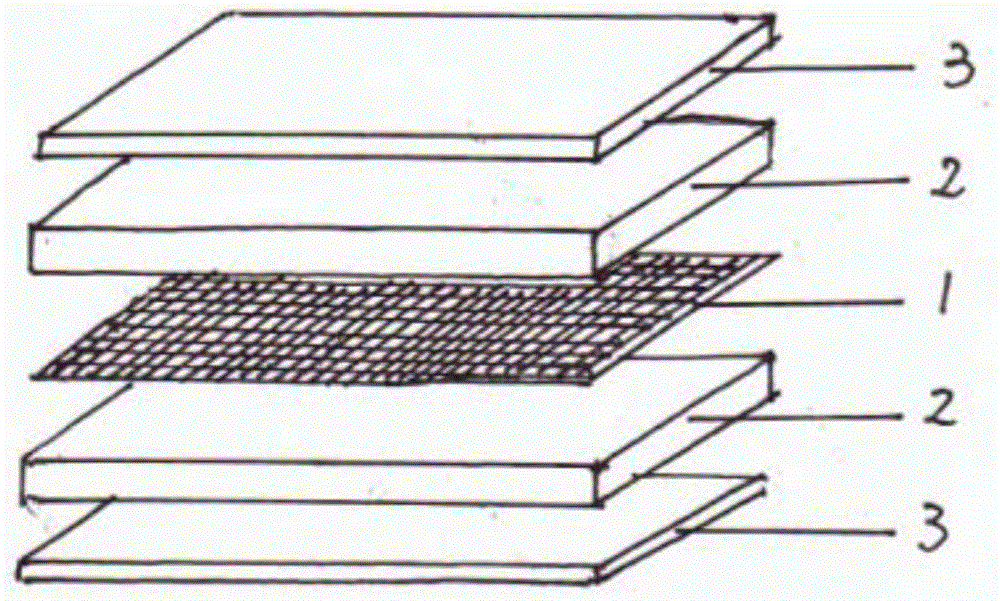

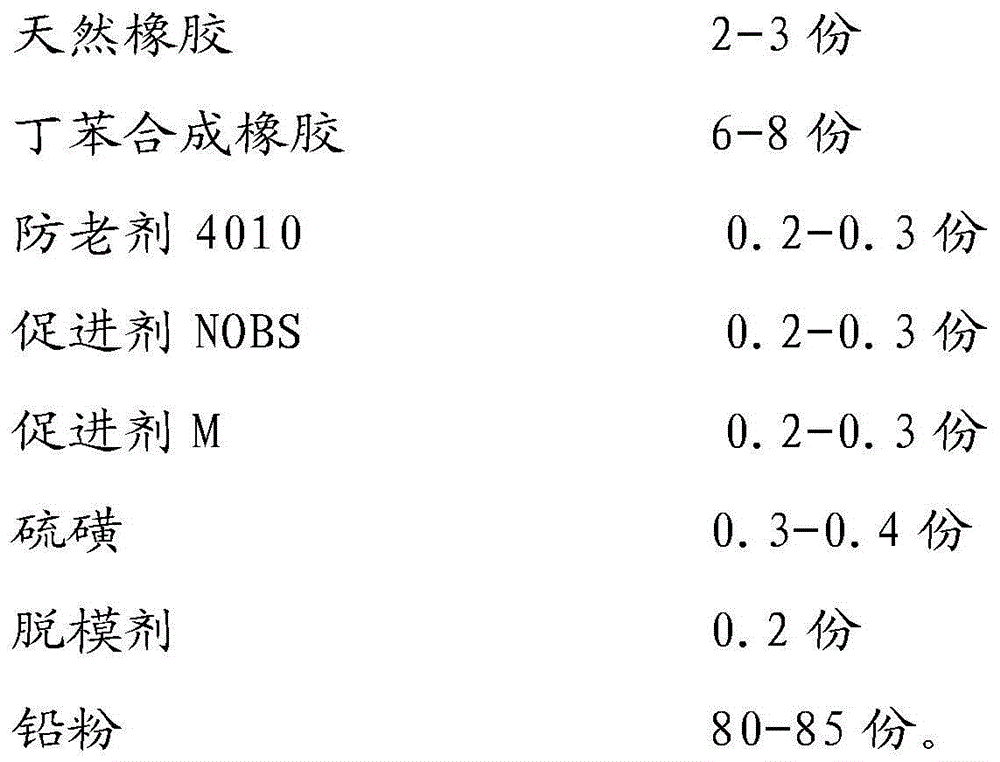

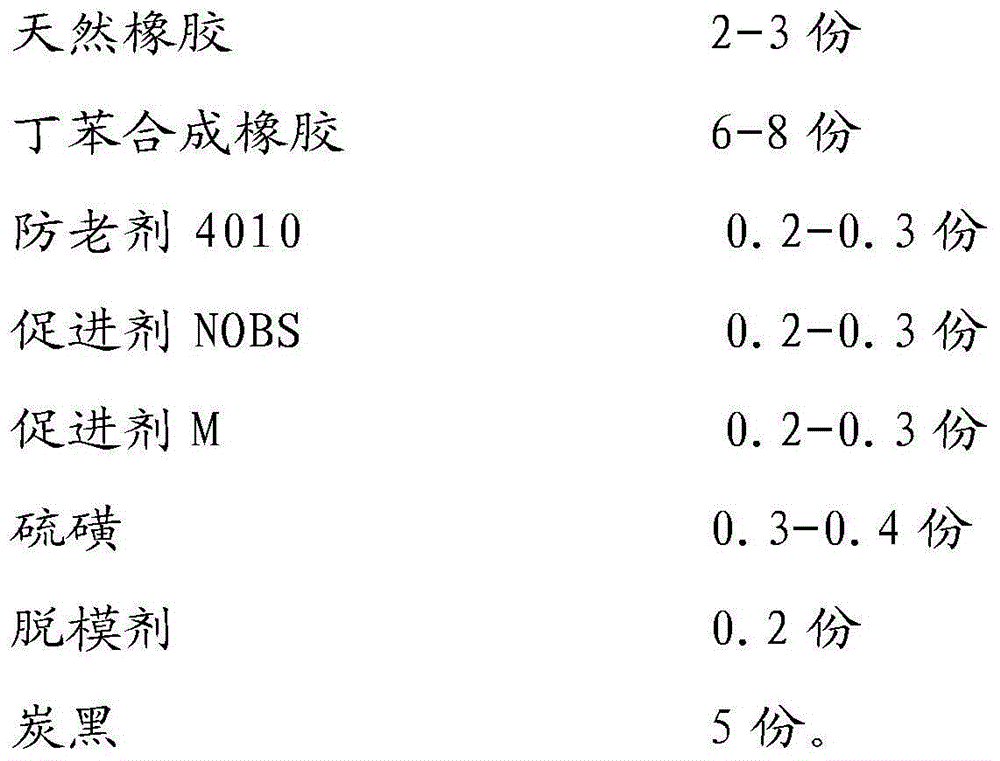

The invention discloses an X-ray prevention shielding film and a preparation method thereof. The X-ray prevention shielding film comprises five layers of structures. The middle layer is a reinforced fabric layer, the outermost layer is a protective layer, a lead rubber layer is arranged between the reinforced fabric layer and the protective layer, and the reinforced fabric layer is made of chemical fiber cloth. The X-ray prevention shielding film is used for safety inspection, reinforced fabric can improve the mechanical strength, lead rubber can achieve the effect of shielding X-rays, abrasion resistance rubber prevents lead powder from being precipitated, the abrasion resistance degree is improved, and the service life is prolonged. According to the X-ray prevention shielding film and the preparation method thereof, traditional lead plastics are changed through lead rubber fusion, the shielding film is made softer, the durability is higher, and the phenomenon that the X rays are leaked and human bodies are injured because of low-temperature hardening of the shielding film due to temperatures is avoided.

Owner:NANTONG ZHONGHAI PLASTIC PROD

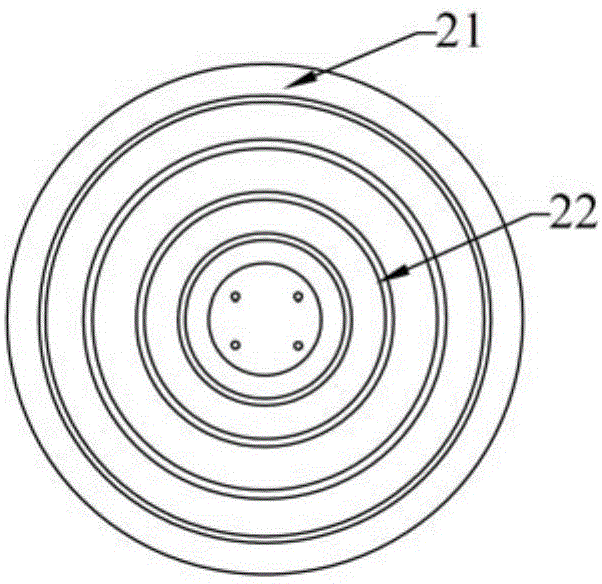

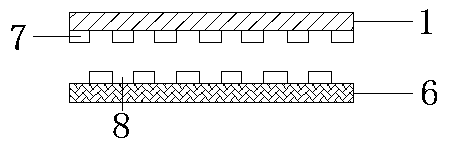

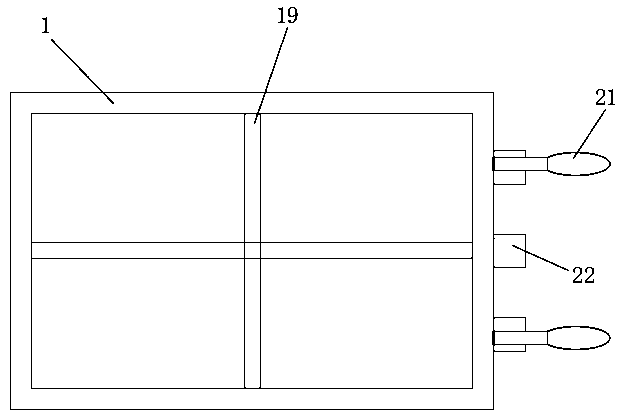

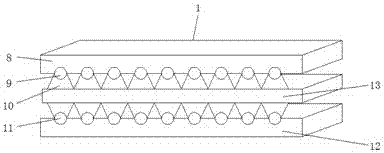

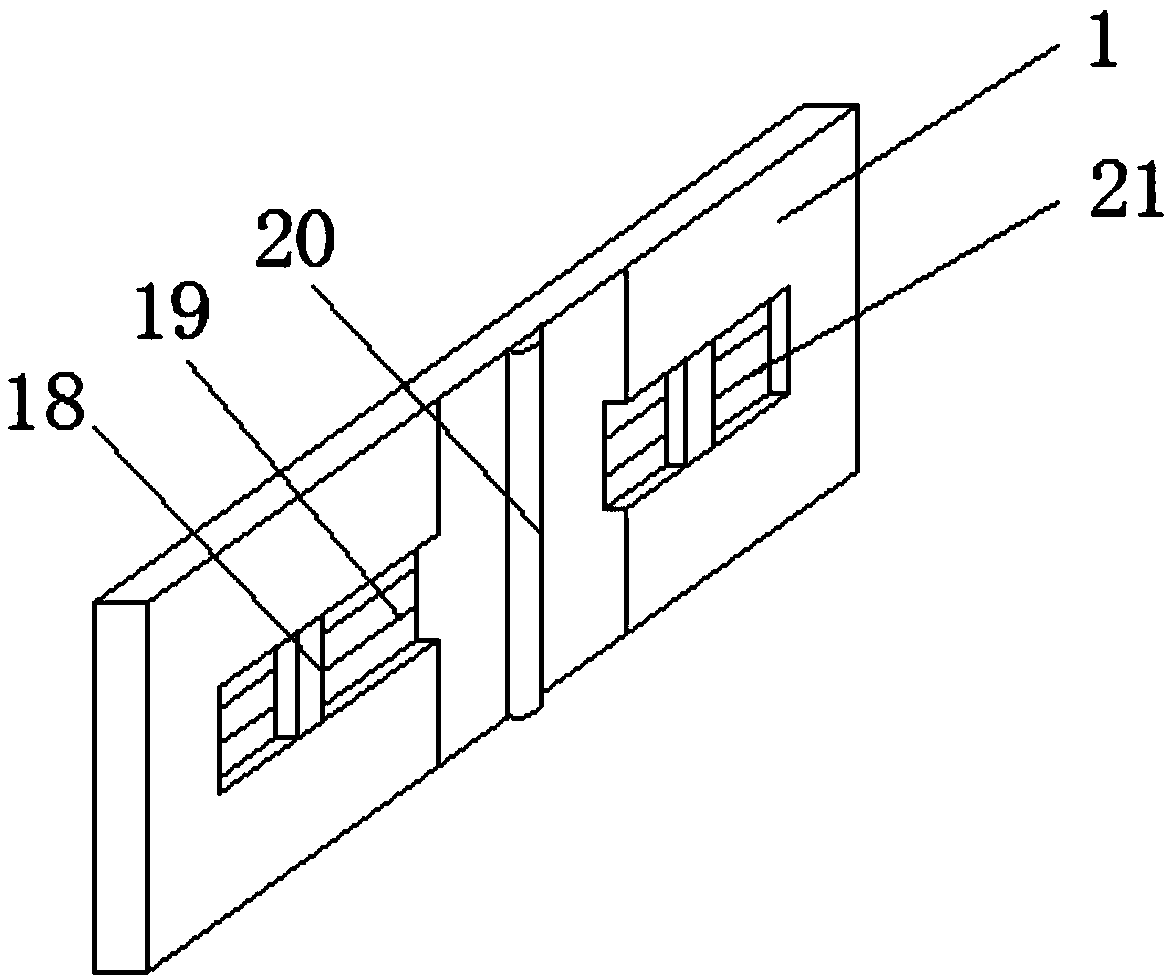

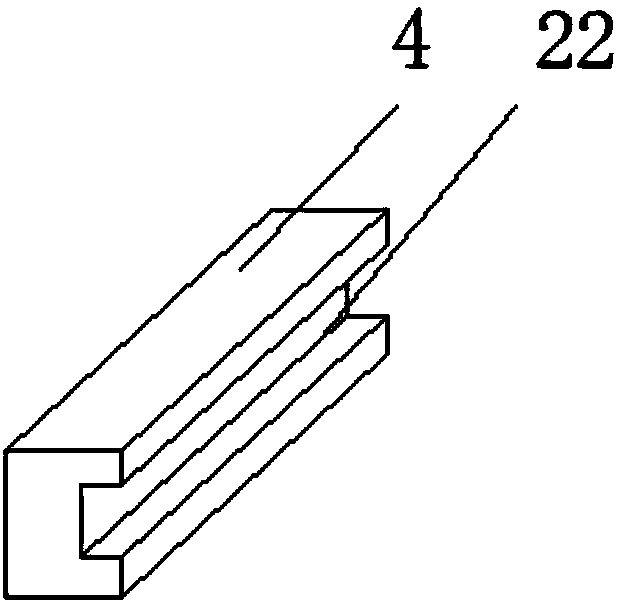

Folding type air purification filtering plate

InactiveCN105688524APrevent mildewOvercome the disadvantage of not being able to reuseHuman health protectionGas treatmentActivated carbonCoupling

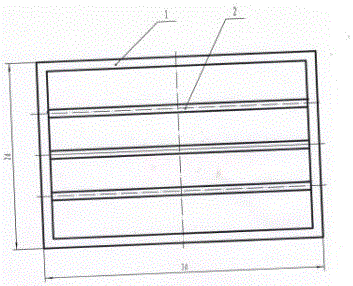

The invention provides a folding type air purification filtering plate.According to the technical scheme, press strips (2) are arranged in a metal groove (1), a chemical fiber cloth (4) is provided with polyurethane foam plastic isolation strips (3), and the surfaces of the two sides of the chemical fiber cloth (4) are coated with an adsorbing material; the adsorbing material takes 40%-50% of silica sol as a diluting and bonding agent and takes 25%-30% of kieselguhr and 25%-30% of zeolite as adsorbing functional packing, and 1%-2% of a hydrophobic material and a coupling agent are added; the polyurethane foam plastic isolation strips with the thickness of 2 mm and the width of 10 mm are oppositely stuck to the two sides of the chemical fiber cloth (4) every other 150 mm, and 4-mm gaps are formed among the folded cloth portions after the folding type air purification filtering plate is folded.The folding type air purification filtering plate has the advantages that the design is reasonable and practical, the whole plate is ventilated and unobstructed, and the functions of a filtering part and an adsorbing part of air purification equipment are achieved; in addition, the defect that a common paper filtering plate and activated carbon adsorption part cannot be repeatedly used is overcome, the service life is prolonged, and the manufacturing and using cost is lowered.

Owner:DONGYING BAIYANG PETROLEUM TECH CO LTD

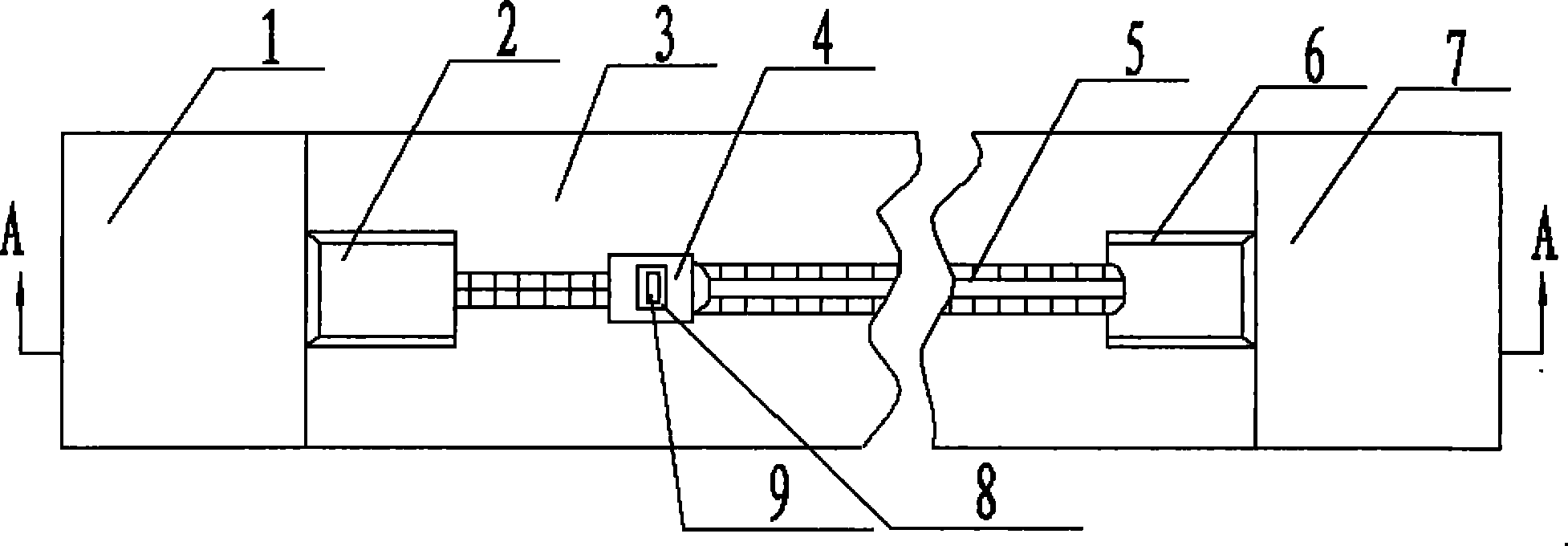

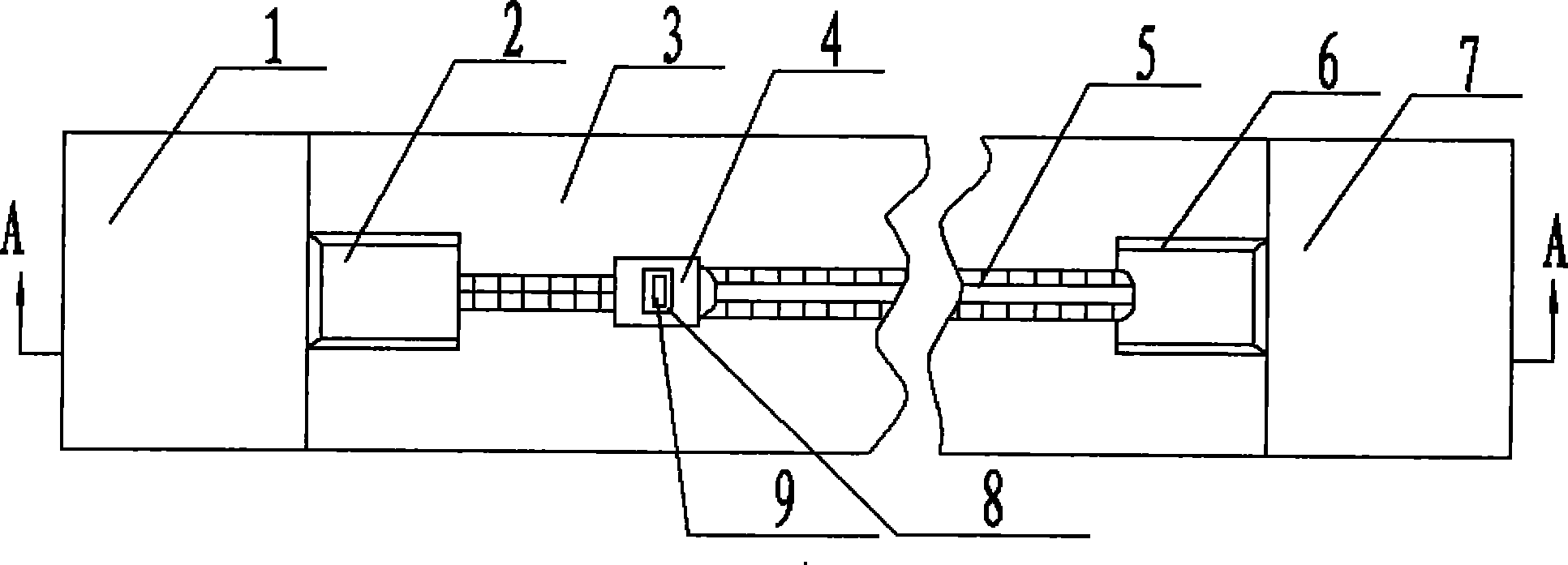

Cutting-off device for chemical-fiber cloth

InactiveCN107964777AQuality improvementEasy to disengageSevering textilesChemical fiber clothEngineering

The invention provides a cutting-off device for chemical-fiber cloth. The cutting-off device comprises a bottom platform and is characterized in that an electric push rod is fixedly mounted on one side of the top of the bottom platform through a standing column, a connecting plate is fixedly mounted at the bottom end of the electric push rod, connecting rods are welded to two sides of the bottom of the connecting plate, a heating pipe is fixedly mounted at one end of each connecting rod through a mounting plate, a blade is arranged between the two heating pipes, a fixing plate is fixedly connected to the top of the blade, a support rod is welded to one side of each connecting rod, a hinge part is fixedly mounted on one side of the top of each support rod, a locking rod is hinged to one side of each hinge part, a connecting spring is fixedly connected to one side of the bottom of each locking rod, a threaded rod is hinged to the other side of the bottom of each locking rod through a bearing, and a threaded tube is connected to the bottom end of each threaded rod in a threaded manner. The cutting-off device has the advantages that the blade can be heated through the heating pipes, thread residues can be avoided when the heated blade is used for cutting the chemical-fiber cloth, and the quality of finished-product chemical-fiber cloth is increased.

Owner:胡和萍

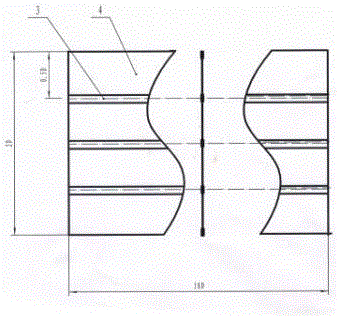

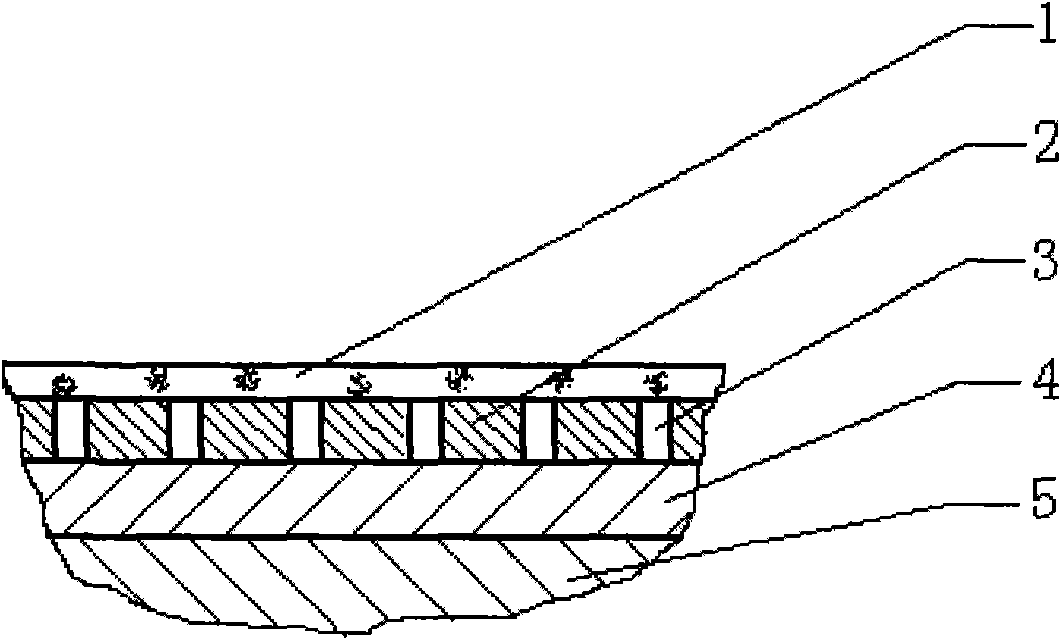

Waterproof chemical fiber cloth

InactiveCN105361307AHigh strengthFeel smoothSynthetic resin layered productsProtective garmentChemical fiber clothWear resistant

The invention relates to the field of chemical fiber cloth, in particular to a waterproof chemical fiber cloth. A reinforcing rib layer, a permeable membrane layer, a water absorption layer and a waterproof layer are arranged above a chemical fiber fabric layer in order. The chemical fiber fabric layer is combined with the reinforcing rib layer by needling and is then combined with the permeable membrane layer, the water absorption layer and the waterproof layer through glue. The reinforcing rib layer is a chemical fiber layer sized. The waterproof layer is made of a TPU (thermoplastic polyurethane) material or a TPE (thermal plastic elastomer) material. A cotton cloth layer is disposed below the chemical fiber layer. The waterproof layer is provided with thin end and thick middle passages passing through in the longitudinal direction. The overall intensity of the waterproof chemical fiber cloth is effectively improved, the cloth is smooth, soft, smooth to touch, elastic, easy to wash, waterproof, scratch resistant and wear resistant and is suitable for use outdoors and in an environment with poor conditions; a plurality of protrusions arranged below the chemical fiber fabric layer, the cotton cloth layer is provided with cavities matching with the protrusions, and better combination stability is achieved; the cloth has a better waterproof effect.

Owner:YANGZHOU JINHUI CHEM FIBER CO LTD

Antibacterial, soundproof and environment-friendly diatomite wallpaper

InactiveCN106499135AWith humidity controlWith deodorizing functionCovering/liningsSynthetic resin layered productsGlass fiberWear resistant

The invention discloses antibacterial, soundproof and environment-friendly diatomite wallpaper which comprises a bottom layer (1), a diatomite layer (2), a pattern color layer (3) and a wear-resistant layer (4) sequentially arranged from top to bottom, wherein the wear-resistant layer (4) is made of a polytetrafluoroethylene material. The thickness of the diatomite layer (2) is 0.1-0.3 mm. The bottom layer (1) is a glass fiber fabric, a nonwoven fabric or chemical fiber cloth. Bamboo carbon black is arranged on the wear-resistant layer (4). Diatomite in the diatomite layer (2) is obtained by adding raw diatomaceous earth with a grain size of 800-3000 meshes and a surface treating agent occupying 0.5-1 percent of the weight of the raw diatomaceous earth into a high-speed stirring machine capable of temperature rise, stirring at a high speed under the condition of 80-120 DEG C and treating for 90 minutes. The diatomite wallpaper disclosed by the invention is good in antibacterial, sound insulation, humidity control and absorption capacities and has good environment-friendly performance compared with a similar product.

Owner:营口渤海科技有限公司

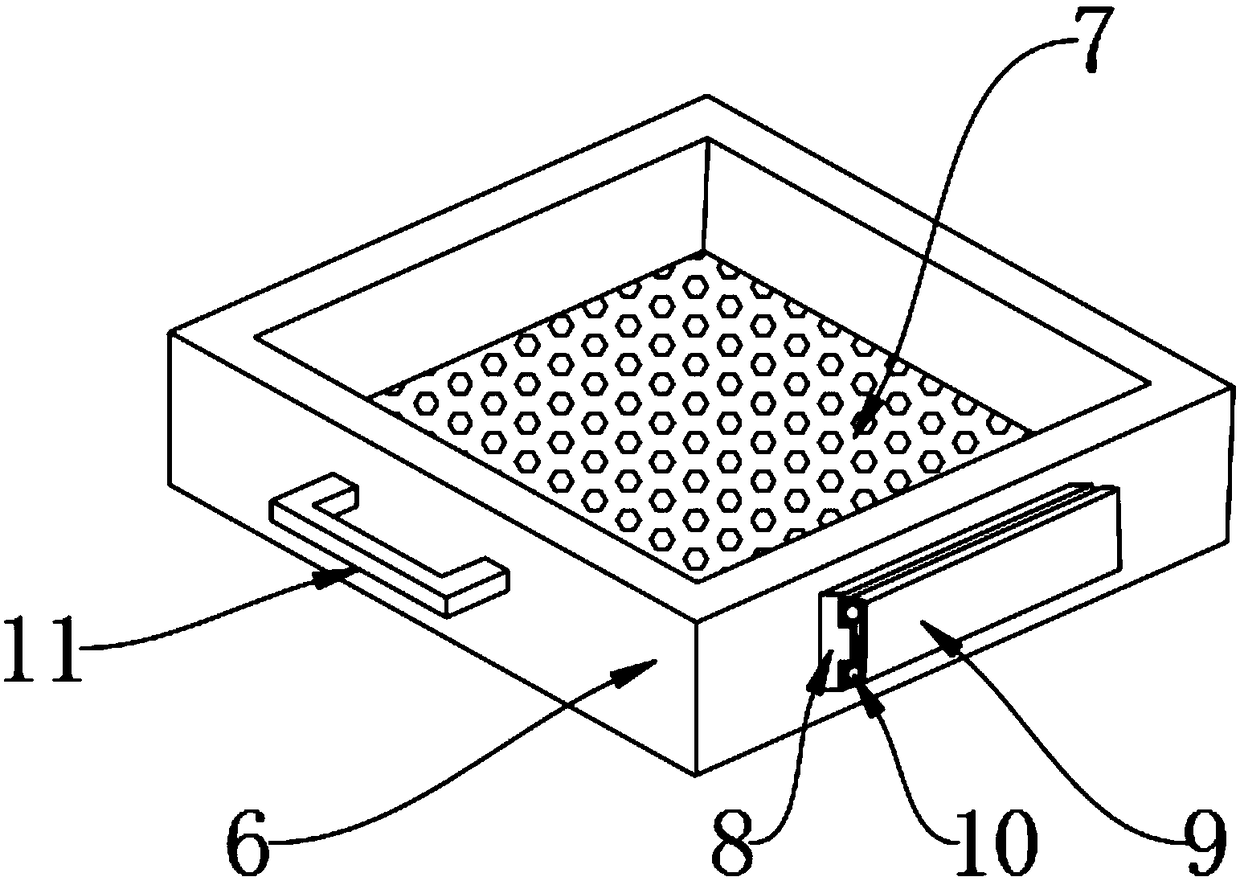

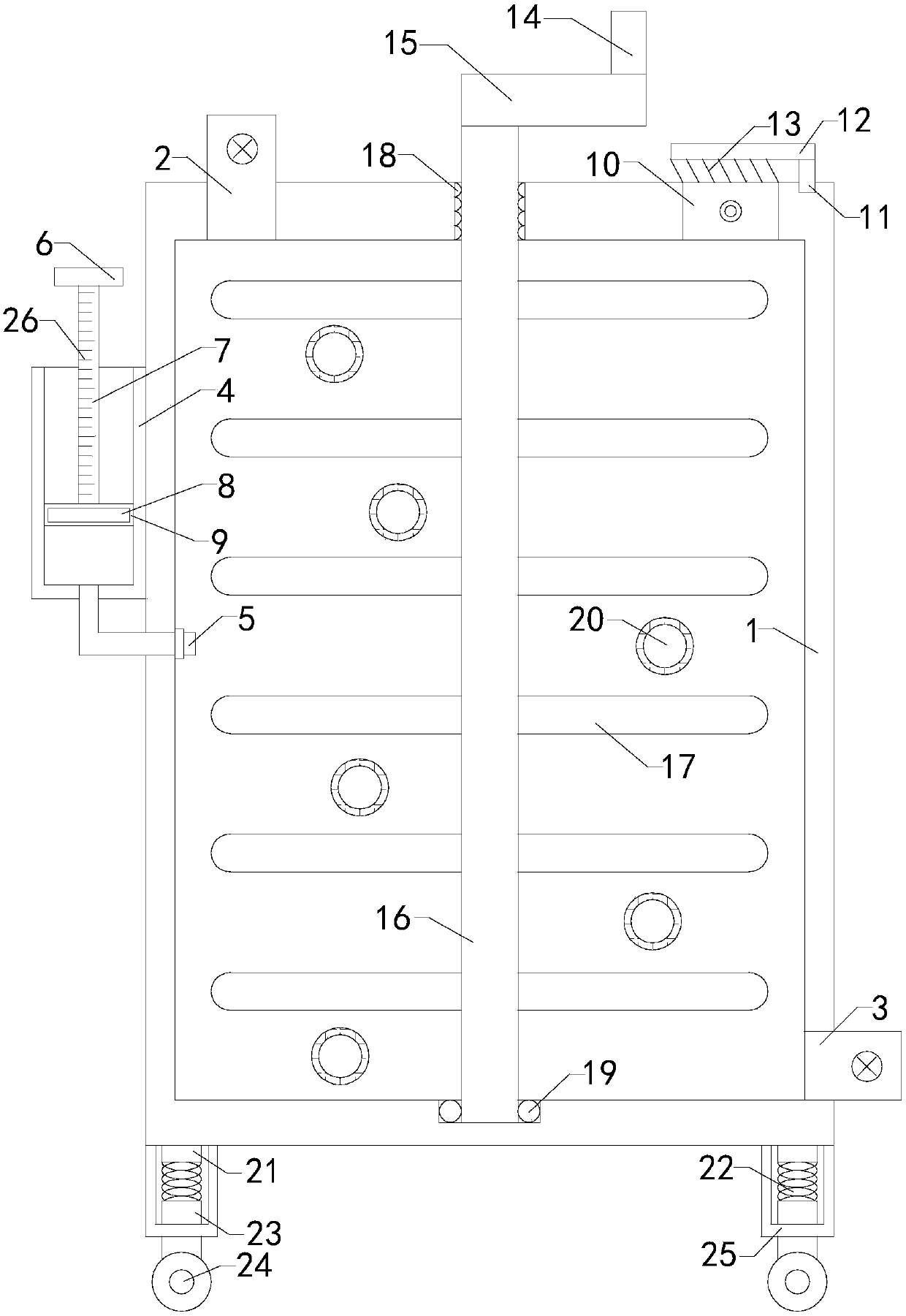

Textile waste collection device of chemical fiber cloth

InactiveCN109465248AScientific and reasonable structureEasy to useSievingScreeningProduction lineChemical fiber cloth

The invention discloses a textile waste collection device of chemical fiber cloth, including a metal casing. A lining plate for prevent abrasion is arranged at the bottom end of the inner side of themetal casing. A waste collecting box is arranged on one side of the lining plate. A base is installed at the bottom end of the metal casing. The structure of the invention is scientific and reasonable, and the invention is safe and convenient to use. Through the function of a fine filter screen, filtration of collected waste in the waste collection box is performed, so as to classify the waste andincrease the value of waste. With the help of a metal plate, a pipeline, a connecting cover and a suction floor brush, the solid waste is sucked into the waste collecting box. The device avoids a manual method to collect the solid waste, saves time and labor, improves the efficiency of waste collection of the device, facilitates the movement of the whole device through the action of universal wheels, improves the convenience of the device, and is convenient for large-scale and large-area waste collection on the production line, and is reasonable in arrangement and comfortable in use.

Owner:长兴一盛纺织有限公司

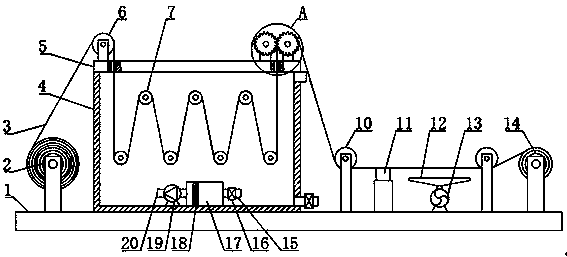

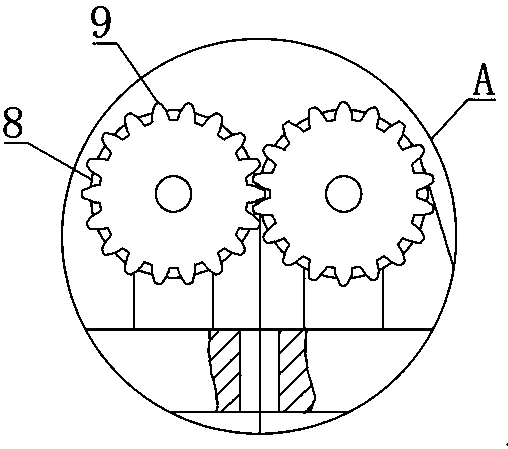

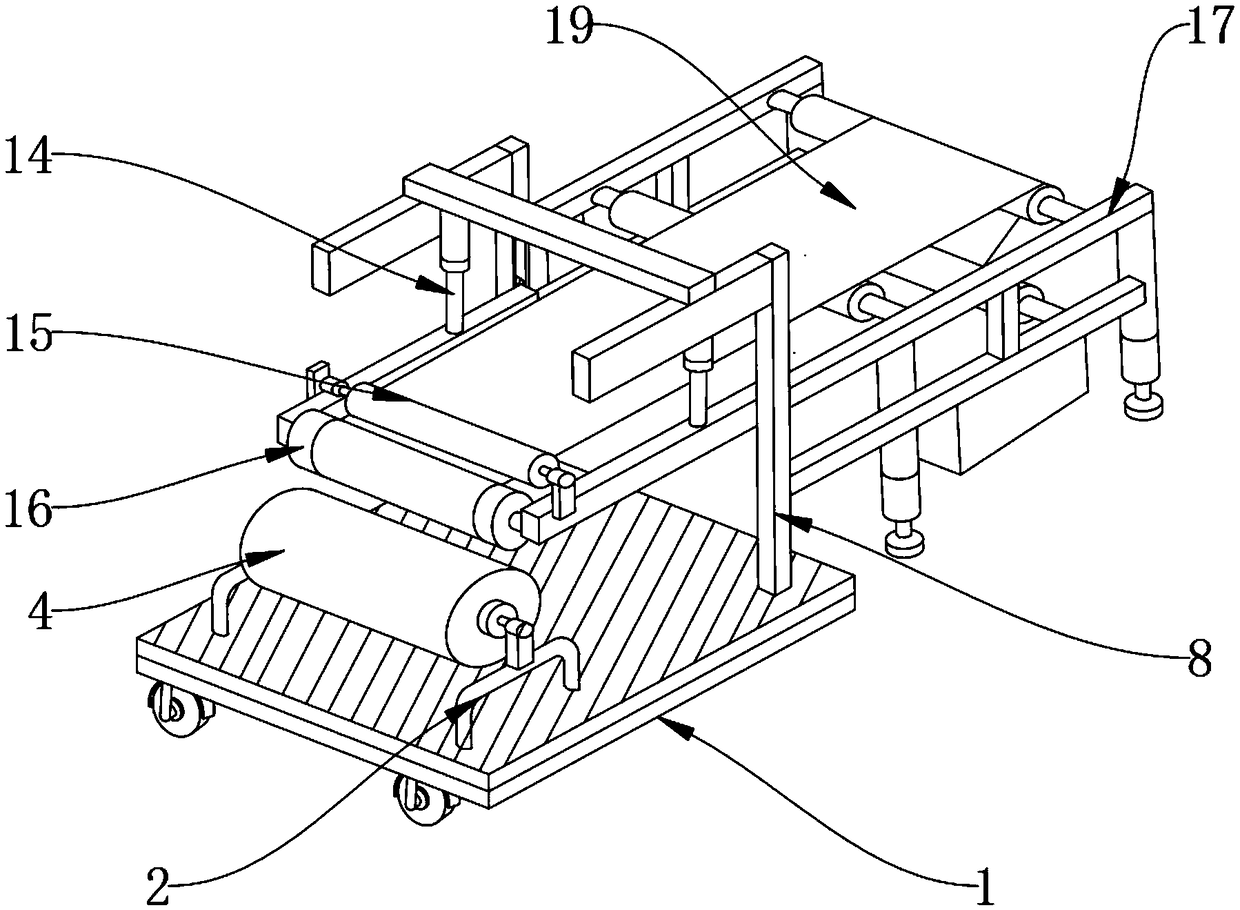

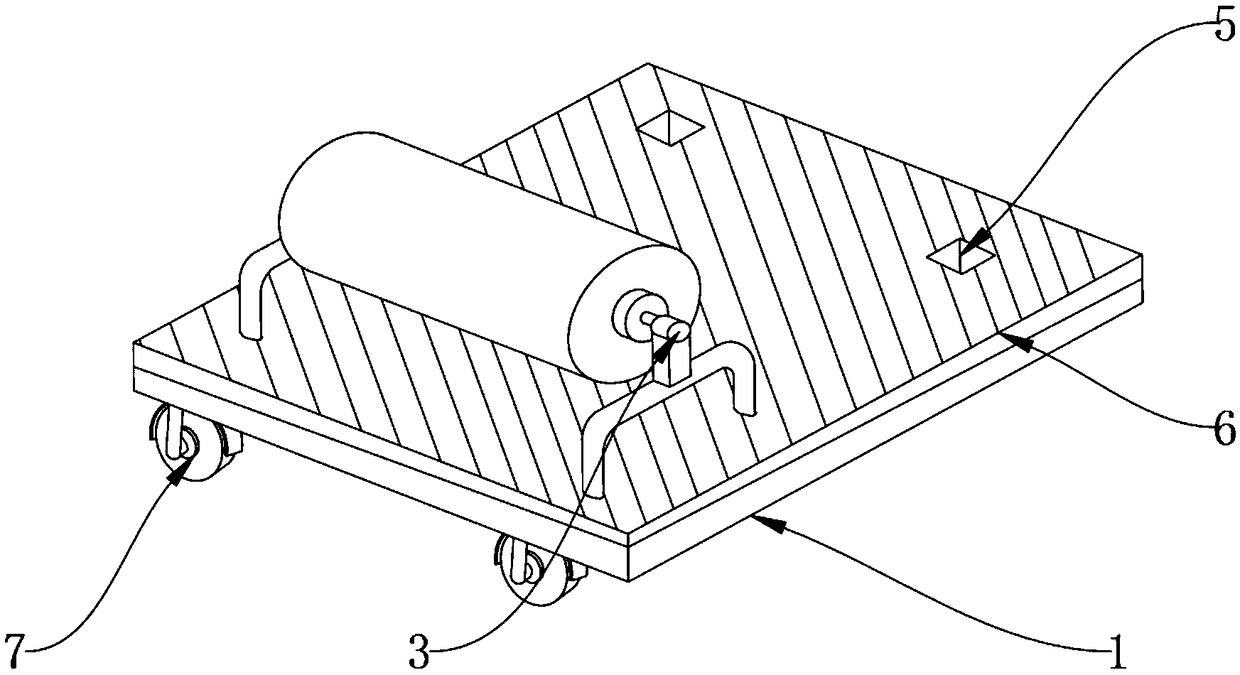

Cleaning and drying device for chemical fiber cloth

PendingCN108560175AEfficient removalSpeed up evaporationLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsChemical fiber clothEngineering

The invention discloses a cleaning and drying device for chemical fiber cloth. The device comprises a base, a cleaning box is arranged on the base, a top plate is arranged on the top of the cleaning box, two extrusion rollers are rotatably connected to the right side of the top plate through a bracket, gears are fixedly connected to the front end faces of the two extrusion rollers, and the two gears are meshed with each other; a discharging roller is rotatably connected to the left side of the base through a bracket, and the chemical fiber cloth is wound around the discharging roller; two third guide rollers are rotatably connected to the base through brackets, the third guide rollers are located at the right side of the cleaning box, a hot-air blower is further arranged on the base, a fancover is connected to the top of the hot-air blower, and the hot-air blower is located between the two third guide rollers; a receiving roller is rotatably connected to the right side of the base through a bracket. The cleaned cloth is extruded by the two extrusion rollers, and moisture in the cloth can be effectively removed for subsequent convenient drying; the top plate can be demounted from the cleaning box so that the inside of the cleaning box can be cleaned, and the device cleanliness is ensured.

Owner:盐城元之元机械有限公司

Polyurethane water vapor seal zipper and preparation method thereof

The invention discloses a polyurethane water vapor seal zipper and a preparation method thereof. The preparation method of the invention comprises the following steps: (1) preparing polyurethane base cloth: arranging polyurethane plastic films on both sides of high tenacity polyester or nylon chemical fiber cloth to obtain the polyurethane base cloth; (2) assembling chains on the base cloth: firstly, respectively assembling an unilateral chain on the two pieces of the polyurethane base cloth by a toothing machine, and then combining the two unilateral chains to form a zipper by a zipper head; and (3) preparing the polyurethane water vapor seal zipper. The invention has the beneficial effects that the polyurethane base cloth has good use manufacturability, cold resistance, softness, oil resistance and wear resistance, can not be easily corroded by oil stain and is soft and wear resistant, thus the zipper made of the polyurethane base cloth has good quality and long service life; when in use, the zipper does not pollute the environment and has high production efficiency, the quality of the zipper can be ensured, and the zipper manufactured by the method does not have residual glue and can not pollute a product when the zipper is connected with the product, thus the product is tidier and more beautiful; and hot pressing by an injection molding machine is adopted for sealing the two ends of the zipper, thereby the time is short, the efficiency is high and the sealing effect is good.

Owner:谢彦博

Textile waste collection device for textile production of chemical fabrics

ActiveCN110552093AReduce the burden onHigh speedDirt cleaningTextiles and paperChemical fiber clothWaste collection

The invention discloses a textile waste collection device for textile production of chemical fabrics. The device comprises a storage tank, four locking universal wheels are arranged at the four corners of the side wall of the lower end of the storage tank, and a sealing box is fixedly connected with the side wall of the storage tank; a negative pressure pump is arranged on the side wall of the upper end of the sealing box, a collection box is slidably connected with the inside of the sealing box and penetrates through the side wall of the storage tank, and a first conduit and a second conduitare respectively arranged on the side wall of the upper end of the sealing box; the first conduit and the second conduit penetrate through the side wall of the upper end of the sealing box and are connected with the sealing box hermetically, an opening is formed in the side wall of the lower end of the storage tank, and two electric telescoping rods are fixedly connected with the inner wall of thestorage tank and respectively located on the two sides of the first conduit. The textile waste collection device can quickly and efficiently collect and remove textile waste on the ground and textilewaste floating in the air, provides convenience for processing in the later period, and is simple in structure and high in practicability.

Owner:瑞安市兴源塑料制品有限公司

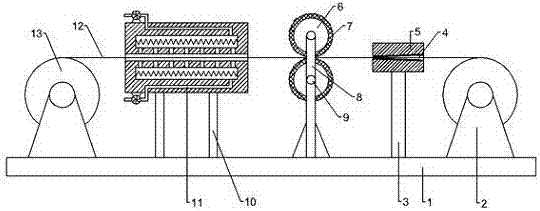

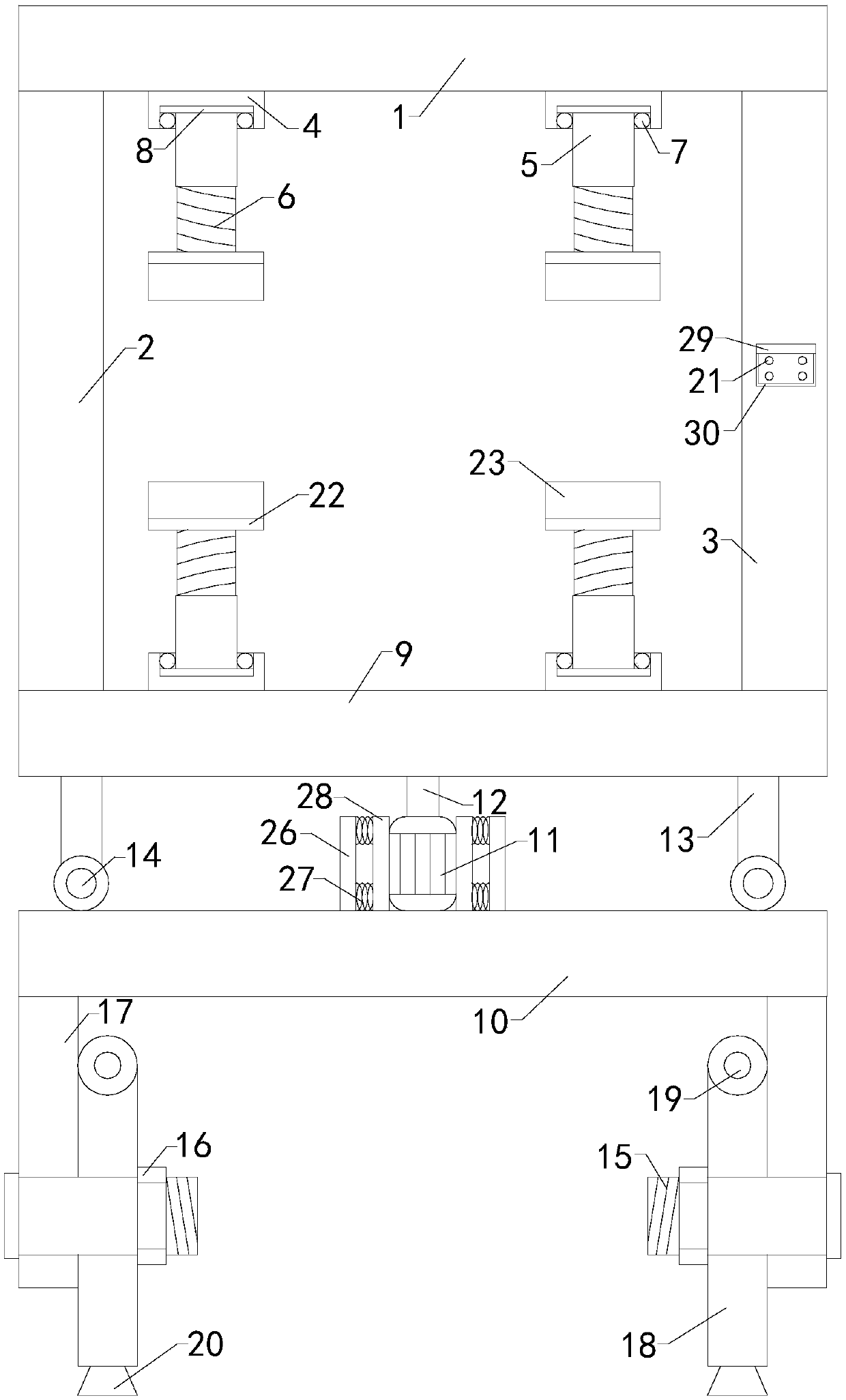

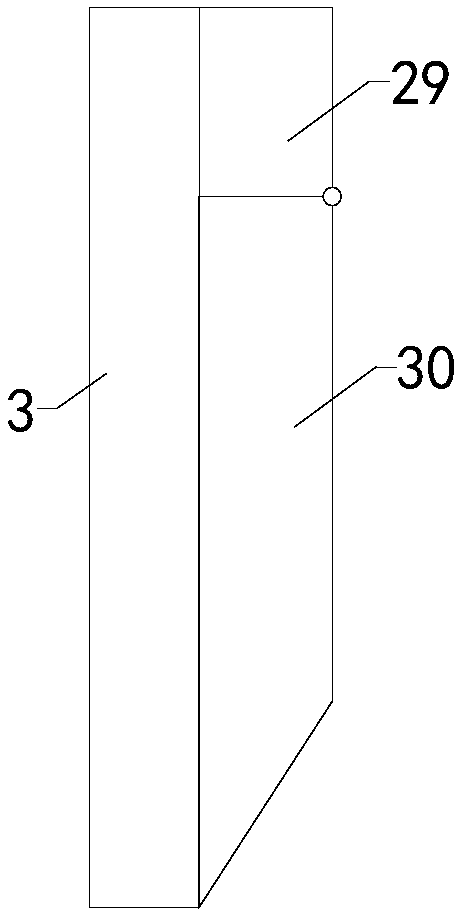

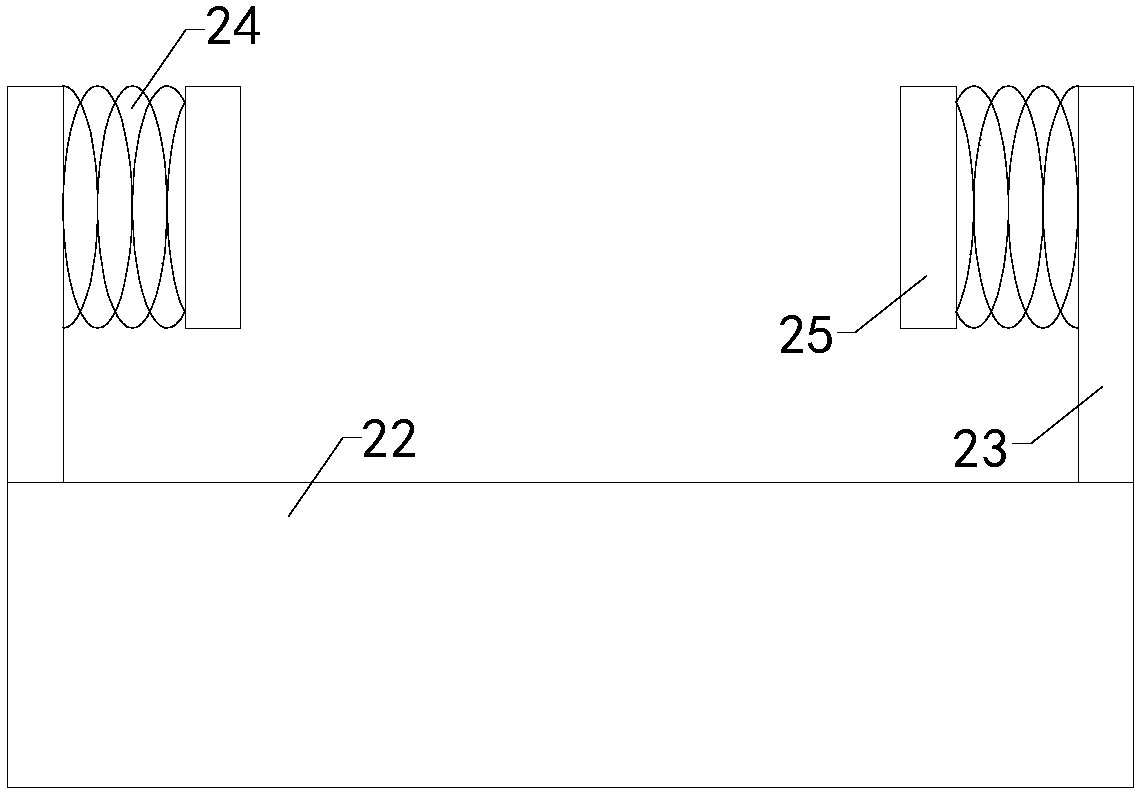

Drying device for chemical fiber cloth production

InactiveCN107763993AEasy to moveImprove natural drying speedDrying gas arrangementsDrying machines with non-progressive movementsDrive shaftChemical fiber cloth

The invention relates to the technical field of chemical fiber cloth drying accessory devices, in particular to a drying device for chemical fiber cloth production. According to the drying device, twoupper fixing devices and two lower fixing devices can be conveniently adjusted according to the size of chemical fiber cloth, so that adaptability is improved; the natural drying speed of the cloth is increased, and working efficiency is improved; and a bottom plate can conveniently move, so that practicability is improved. The drying device comprises a top plate, the bottom plate, a left side plate, a right side plate and four supports; the two upper fixing devices each comprise an upper sliding block, an upper threaded pipe, an upper threaded rod and an upper fixing clamp; the two lower fixing devices each comprise a lower sliding block, a lower threaded pipe, a lower threaded rod and a lower fixing clamp; the bottom plate comprises an upper plate body and a lower plate body, and further comprises a motor, a transmission shaft, two supporting columns and two pulleys; the four supports each comprise a bolt, nuts, a supporting leg and a rotating column, wherein rollers are arranged atone ends of the four rotating columns, and suckers are arranged at the other ends of the four rotating columns.

Owner:JIANGSU KANGJIE MACHINERY

Zirconia-corundum super coating abrasive cloth

The invention provides zirconia-corundum super coating abrasive cloth, and relates to abrasive cloth for grinding, in particular to corundum super coating abrasive cloth. The zirconia-corundum super coating abrasive cloth adopts the following technical proposal: firstly selecting carrier pure chemical fiber raw cloth for special treatment, fluffing the surface of the raw cloth, clipping off fluff evenly on the surface of the raw cloth, rinsing and drying the raw cloth, carrying out forming by high temperature at 210 to 250 DEG C, and then carrying out twice rolling, front coating and back coating for recipe; and finally manufacturing the abrasive cloth, adopting a zirconia-corundum abrasive material and a high temperature calcination brown corundum abrasive material, carrying out zirconia-corundum electrostatic sand planting and gravity sand planting according to the proportion of zirconia-corundum to brown corundum 7:3; and adopting first and second rubber covering. The abrasive cloth is mainly used for the polishing and the grinding in the metal field such as stainless steel, which is impractical for other abrasive cloth.

Owner:张刚

Multifunctional cloth

InactiveCN101333721AHigh far infrared emission effectOvercome limitationsWoven fabricsChemical fiber clothNatural fiber

The invention relates to a multifunctional cloth, in particular to a health-care cloth processed by industrial method, which contains a soybean fiber, a bamboo charcoal fiber and a magnetic fiber. The present cloth in the market mainly comprises natural fiber cloth and artificial fiber cloth. The manufacturing cost of the natural fiber cloth is very high, and chemical fiber cloth has plural varieties, while the wearing comfort of the chemical fiber cloth is poor and the function of the chemical fiber cloth is single, and the chemical fiber cloth can not achieve the aim of health care and health improvement with the sole function of wearing, so the chemical fiber cloth may not meet the requirements of the consumers. The health-care cloth can make up for the deficiency of the present products in the market. The health-care cloth comprises a soybean fiber, a bamboo charcoal fiber and a magnetic fiber, wherein, the soybean fiber is 20 to 60 parts by weight; the bamboo charcoal fiber is 20 to 40 parts by weight; and the magnetic fiber is 20 to 50 parts by weight. The health-care cloth can be applied in various fields.

Owner:HEILONGJIANG HUASHEN SCI & TECH DEV

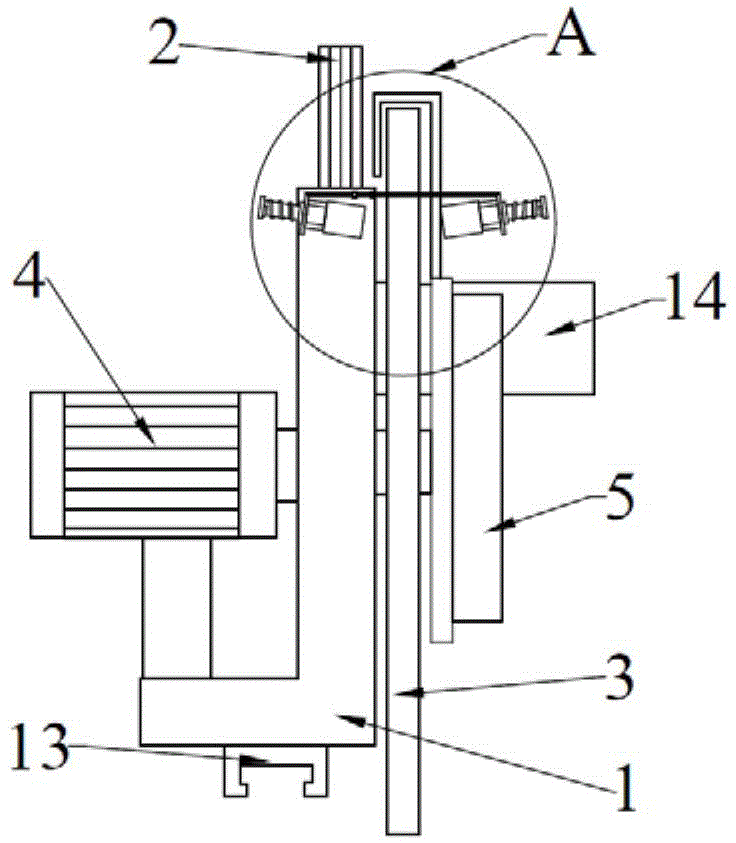

Drying device for chemical fiber cloth

InactiveCN108592580AImprove drying rateIncrease productivityDrying gas arrangementsDrying machines with progressive movementsChemical fiber clothCoupling

The invention provides a drying device for chemical fiber cloth. The drying device comprises a conveying belt, a drying mechanism is arranged on one side of the conveying belt, a shell is welded to one side of the drying mechanism, a motor is fixedly installed at the top of the inner cavity of the shell, one end of a rotating shaft of the motor is in transmission connection with a threaded rod through a coupling, the outer surface of the threaded rod is in threaded connection with a threaded sleeve pipe, the two sides of the inner wall of the shell are connected with sliding blocks through sliding rails in a sliding mode, first connecting rods are welded to one sides of the sliding blocks, second connecting rods are welded to the two sides of each first connecting rod, furthermore, supporting rods are welded at the bottoms of the second connecting rods located on the lower sides, and a pressing plate is fixedly connected between the two supporting rods. According to the drying device for the chemical fiber cloth, the motor, the threaded rod and the threaded sleeve are arranged and cooperate with the sliding rails and the sliding blocks as well as the first connecting rods and the second connecting rods, and therefore, the pressing plate can be used for squeezing water thoroughly on the rinsed chemical fiber cloth, then drying is carried out on the chemical fiber cloth, and thedrying rate of the chemical fiber cloth is improved.

Owner:侯如升

Automobile cover cloth

InactiveCN102241167AStrong fastnessNot easy to tearLaminationLamination apparatusPolyesterSurface layer

The invention discloses automobile cover cloth. The surface layer of the automobile cover cloth is provided with a waterproof film, the middle layer is made of chemical fiber cloth, and the bottom layer is made of cotton, wherein the chemical fiber cloth and cotton are bonded without a medium, and the waterproof film covers the surface of the chemical fiber cloth in a heat sealing manner; the surface layer can be a PE (polyurethane) film or PVC (polyvinyl chloride) film; the middle layer can be made of polyester taffeta or oxford cloth; and the bottom layer can be made of acupuncture cloth or hot air cotton. An automobile cover made from the material has the functions of common automobile covers, is not easily torn due to high firmness and can resist water while preventing the scratch of automobile paint.

Owner:杭州汇龙汽车用品有限公司

Cleaning equipment for processing chemical fiber cloth

InactiveCN107780076AEasy to cleanIncrease contact strengthTextile treatment machine arrangementsTextile treatment cleaning apparatusBristleChemical fiber cloth

The invention relates to the technical field of accessory devices for cleaning chemical fiber cloth, in particular to cleaning equipment for processing the chemical fiber cloth. According to the cleaning equipment disclosed by the invention, the input amount of a cleaning solution can be conveniently controlled, so that practicability of the cleaning equipment can be increased; a cleaning situation of the inner part of a working cavity can be conveniently observed, so that the using reliability of the cleaning equipment can be increased; the chemical fiber cloth is relatively easy to clean, sothat the working efficiency of the cleaning equipment can be increased. The cleaning equipment comprises a working box, four groups of supports, a containing box, a communicating pipe, a pushing plate, a pushing rod, a pressing plate, a sliding plate, a driven plate, bristles, a handle, a connecting plate, a rotating shaft and a stirring blade group, wherein a liquid inlet pipe is arranged on thetop end of the working box in a communicating way; a liquid outlet pipe is arranged under the right side of the working box in the communicating way; a sealing layer is arranged at the outer side ofthe pressing plate in a sleeving way; an observation hole is formed in the top end of the working box in the communicating way, and the observation hole is in axis connection with a transparent baffleplate; a sliding groove is formed in the top end of the working box in a back-and-forth direction; the stirring blade group is arranged on the rotating shaft.

Owner:JIANGSU KANGJIE MACHINERY

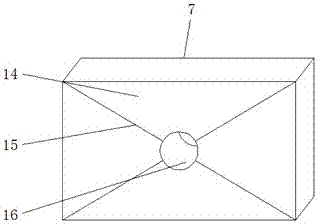

Submarine sound absorption jacket

InactiveCN101628618AImprove concealmentSimple structureUnderwater vesselsUnderwater equipmentChemical fiber clothAcoustic wave

The invention discloses a submarine sound absorption jacket composed of a fixing basal layer, a noise reduction pore layer and a chemical fiber layer; wherein, the fixing basal layer is made of plastic or rubber and fixed on the submarine shell by glue; the noise reduction pore layer is made of rigid foam, is internally provided with a plurality of pores which can be penetrated through up and down, and is fixed on the fixing basal layer by glue; and the chemical fiber layer is made of comparatively loose chemical fiber cloth and is fixed on the noise reduction pore layer by glue. The invention is simple in structure, when in use, both the self vibration noise of the submarine and the sound wave from outside can be absorbed by the chemical fiber layer, the pores and the rigid foam, thus improving concealment of the submarine and being suitable for all submarines.

Owner:SOUTHWEST JIAOTONG UNIV

Antibacterial coating chemical fiber cloth

InactiveCN107160806AEasy to useGood workmanshipBiochemical fibre treatmentLayered productsActivated carbonChemical fiber cloth

The invention discloses antibacterial coating chemical fiber cloth which comprises an antibacterial layer, a coating fabric body and a bacteria blocking net. The bottom end of the coating fabric body is connected with a chemical fiber layer, the upper end of the chemical fiber layer is connected with an air permeable layer, the upper end of the air permeable layer is connected with an activated carbon layer, a connecting layer is arranged on the side walls of the air permeable layer and the activated carbon layer, the air permeable layer and the activated carbon layer are fixedly connected through the connecting layer, the bacteria blocking net is fixedly paved on the upper surface of the antibacterial layer and comprises a bottom block, a plurality of fastening nets and a plurality of elastic holes, the elastic holes are connected at a central end of the bacteria blocking net, the fastening nets are connected on the outer sides of the elastic holes, and the bottom block is connected at the rear ends of the fastening nets and the elastic holes. Connection is assisted through the fastening nets and the elastic holes, so that fabric is more flexible; bacterial blocking is assisted through the bacteria blocking net, so that the fabric is more user-friendly; through the air permeable layer, convenience is brought to air permeation of the inside, and the antibacterial coating chemical fiber cloth is convenient to use.

Owner:CHANGXIN HENGFENG TEXTILE CO LTD

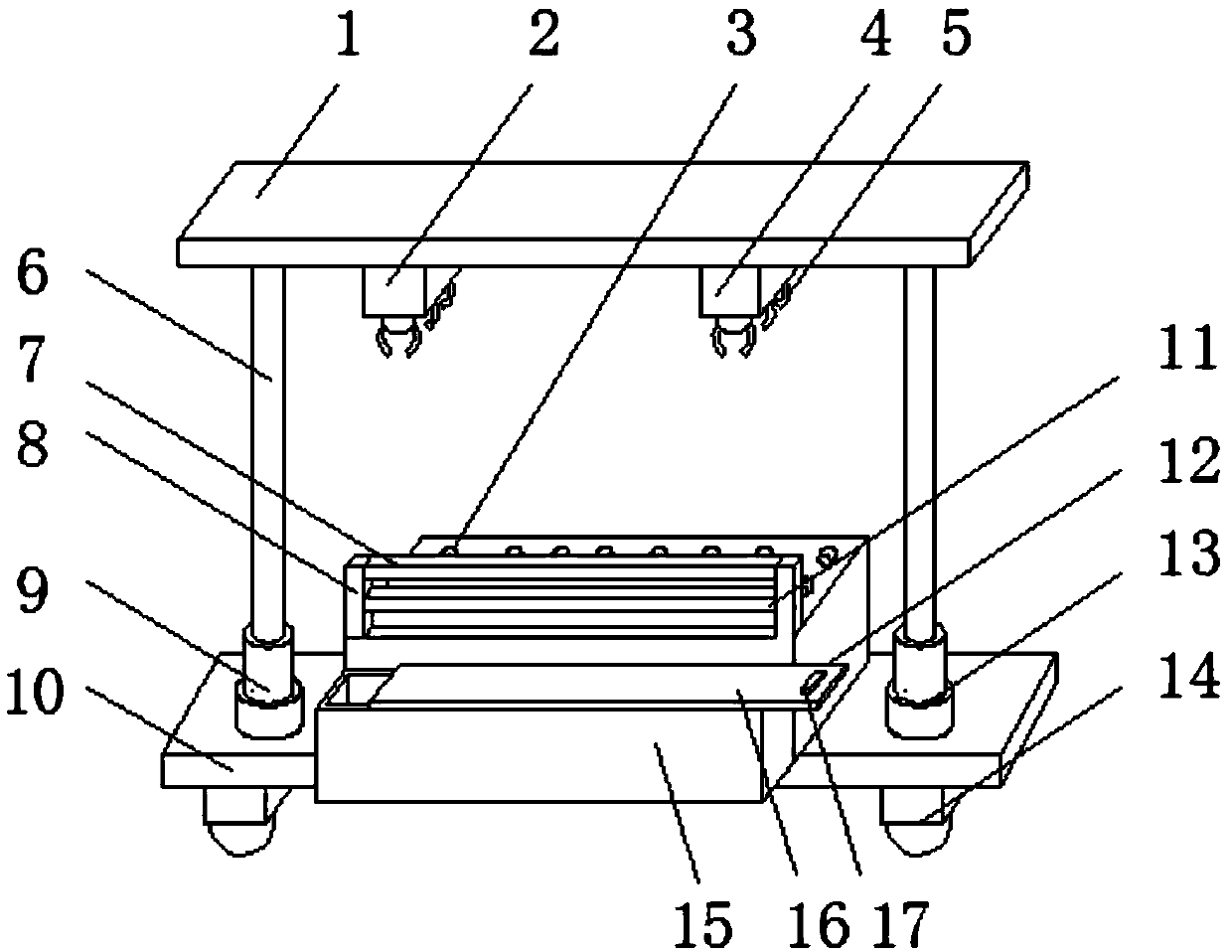

Fabric hanger for production of chemical fiber fabrics

InactiveCN109837682AAvoid intertwiningAdjustable widthMechanical cleaningPressure cleaningHydraulic cylinderChemical fiber cloth

The invention discloses a fabric hanger for production of chemical fiber fabrics. The fabric hanger comprises a support plate and claws. A first hydraulic cylinder and a second hydraulic cylinder arearranged at the upper end of the support plate; each of the first and second hydraulic cylinders is provided with a piston rod; a fixing plate is arranged on the piston rods; a first slide rail and asecond slide rail are arranged on the back of the fixing plate; an ultraviolet lamp is arranged between the first slide rail and the second slide rail; a heating box is arranged between the first hydraulic cylinder and the second hydraulic cylinder and is mounted on the support plate; pillars are arranged at the two ends of the surface of the heating box; an upper fixing plate and a lower fixing plate are arranged between the pillars; the lower end of the upper fixing plate is provided with lower clamp pins; the upper end of the lower fixing plate is provided with upper clamp pins; an air heater is arranged inside the heating box; a collecting box is arranged at the front end of the heating box; a box cover is arranged on the collecting box; the lower end of the support plate is provided with rollers. The fabric hanger allows a fabric to be hung conveniently and allows the surface of the fabric to be cleaned and dried.

Owner:黄敬匀

Method for producing dust-sticking cloth

InactiveCN101756680AStickyImprove adsorption capacityCarpet cleanersLayered productsChemical reactionChemical fiber cloth

The invention discloses a method for producing dust-sticking cloth. The method includes the following steps that: in the first step, dust-adsorbing coating is first coated on the surface of a substrate; in the second step, the substrate coated with the dust-adsorbing coating is dried, so that a piece of dust-sticking cloth is produced; and in the third step, the dried dust-sticking cloth is cut and packaged. The dust-adsorbing coating coated on the surface of the substrate comprises hexane, polyisobutene and preservative, and thereby is sticky, the surface of the dust-sticking cloth is smooth and is not polluted, the dust-sticking cloth has a good adsorbing effect, consequently, the dust-sticking cloth can directly wipe off dust, use is convenient, the use effect is good, moreover, fabrication is simple, the fabrication cost is low, and during wiping, no glue is left. Meanwhile, the dust-sticking cloth cannot generate static electricity and chemically react with chemicals. Because the substrate is absorbent gauze, cotton material or artifical fiber or chemical fiber cloth, the dust-sticking cloth cannot pill or shed paper powder, and moreover, the dust-sticking cloth is highly tough, and cannot scratch the surface of an object.

Owner:姚洁

Light waterproof shoes and preparation process of light waterproof shoes

The invention relates to the technical field of shoes, in particular to a pair of light waterproof shoes and a preparation process of the light waterproof shoes. The light waterproof shoes and the preparation process of the light waterproof shoes are characterized in that Tyvek special paper is adopted as vamp materials; the shoe produced by adopting the Tyvek special paper has the characteristics that the intensity is high, the weight is light, softness and smoothness are realized, the fuzzing cannot easily occur, waterproof effect, acid and base resistance, anti-static effect, fold resistance, abrasion resistance, aging resistance and environment protection are realized, and the like; the weight of the vamp is only a half of that of leather with the same area, and the ponderous defect of the traditional leather is overcome; in addition, the portability of the vamp formed by weaving chemical fiber cloth is realized, or even more portable and comfort characteristics are realized, and in addition, a good waterproof effect is realized; in addition, during the harmless burning treatment on the shoes which are broken after being worn, the first-stage flammability is realized, and the low-carbon and environment-protection requirements are met.

Owner:李向东

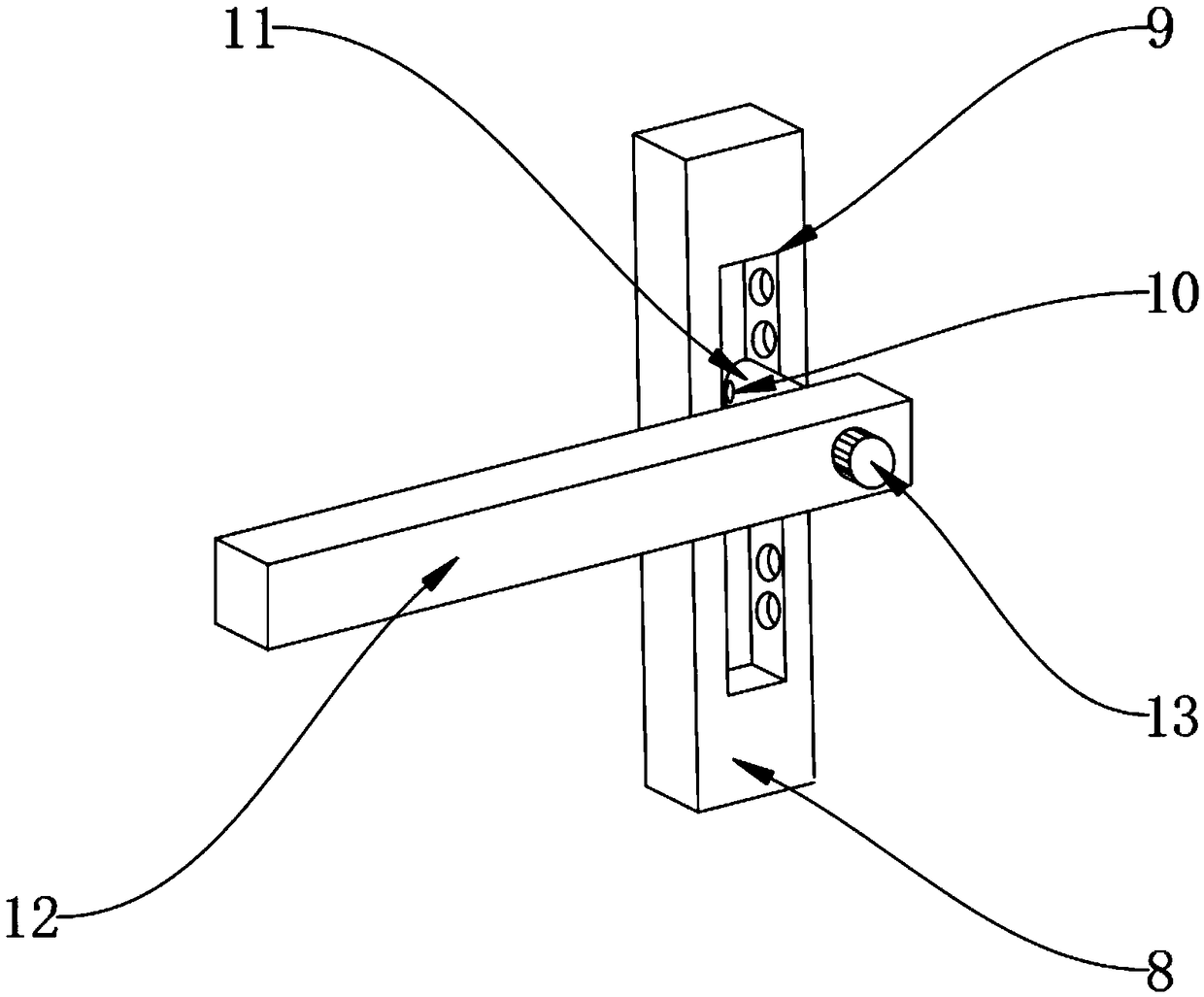

Cloth rolling device for chemical cloth fabric

The invention discloses a cloth rolling device for a chemical cloth fabric. The cloth rolling device for the chemical cloth fabric comprises a bottom plate, wherein a first support is arranged on oneside of the top end of the bottom plate; a second support is arranged on the other side of the top end of the bottom plate; and a fixed rod is arranged on the surface of one side of the second support. The cloth rolling device for the chemical cloth fabric provided by the invention is scientific and reasonable in structure, and safe and convenient to use; through the functions of the bottom plateand a groove, the first support and the second support are conveniently fixed, and the occurrence of the phenomenon that a cloth rolling device with a traditional structure is easy to shake due to instability when being adopted for cloth rolling is avoided; by utilizing the functions of a rotary knob and a lock pillar, a sliding block sliding to the appropriate position can be conveniently lockedand fixed, and the occurrence of the phenomenon that when the number of dye cloths winding on a first rotary shaft is increased and a connecting rod upwards moves through a piston rod, the other end of the connecting rod cannot be fixed is avoided; and through the function of a conveyor belt, the chemical cloth fabric can be conveyed conveniently, so that the occurrence of the phenomenon that thecloth is enabled to pass through a roller shaft by manpower during cloth rolling every time is avoided.

Owner:长兴一盛纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com