Patents

Literature

308 results about "Burn treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparation of polytetrafluorethylene microporous film for the processing of high-temperature fume and flour dust

InactiveCN101081356ASimple processReduce manufacturing costSemi-permeable membranesDispersed particle separationPolymer scienceBurn treatment

The present invention discloses one kind of microporous teflon film for treating high temperature fume and dust and its preparation process. The preparation process includes mixing powdered teflon resin and powdered catalyst, adding liquid lubricant to the mixture, extruding, rolling, longitudinally stretching, transversely stretching, heat setting and other steps. The microporous teflon film for treating high temperature fume and dust has simple preparation process and low cost. It has pore size of 0.5-5 micron and dioxins eliminating rate at 200 deg.c as high as 95-98 %. It may be applied widely for high temperature tail gas treatment in refuse burning treatment plant, refuse burning power plant, coal burning power plant, cement mill, etc.

Owner:ZHEJIANG SCI-TECH UNIV

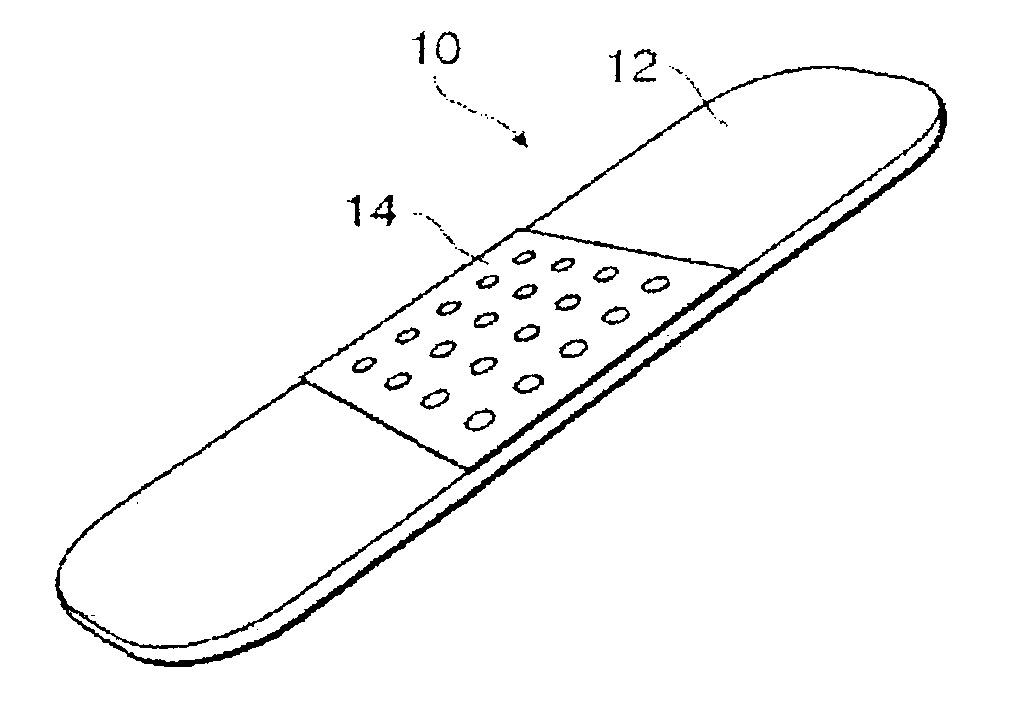

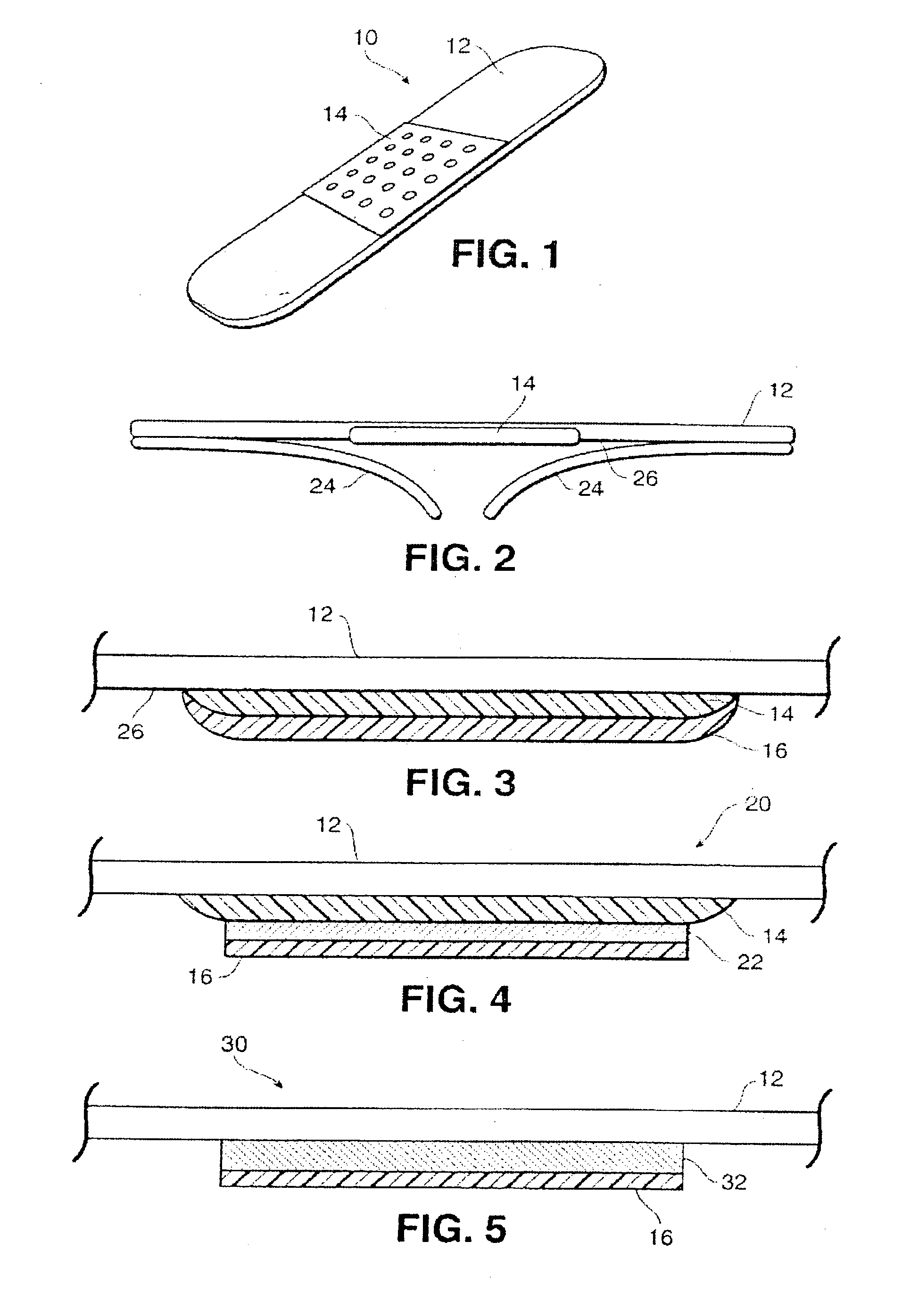

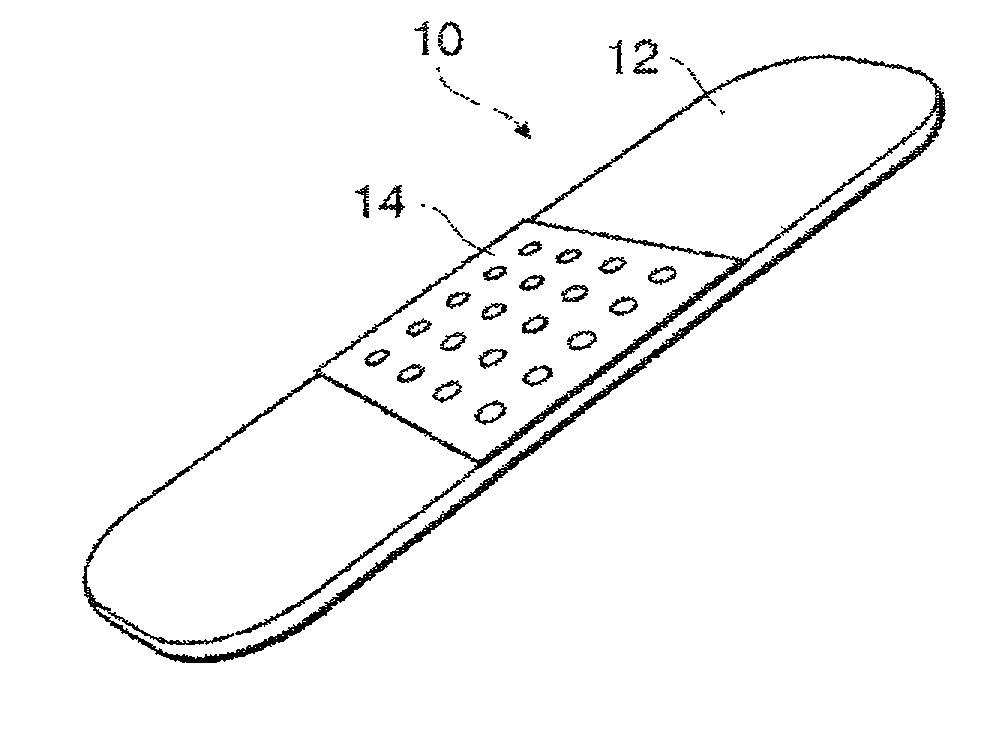

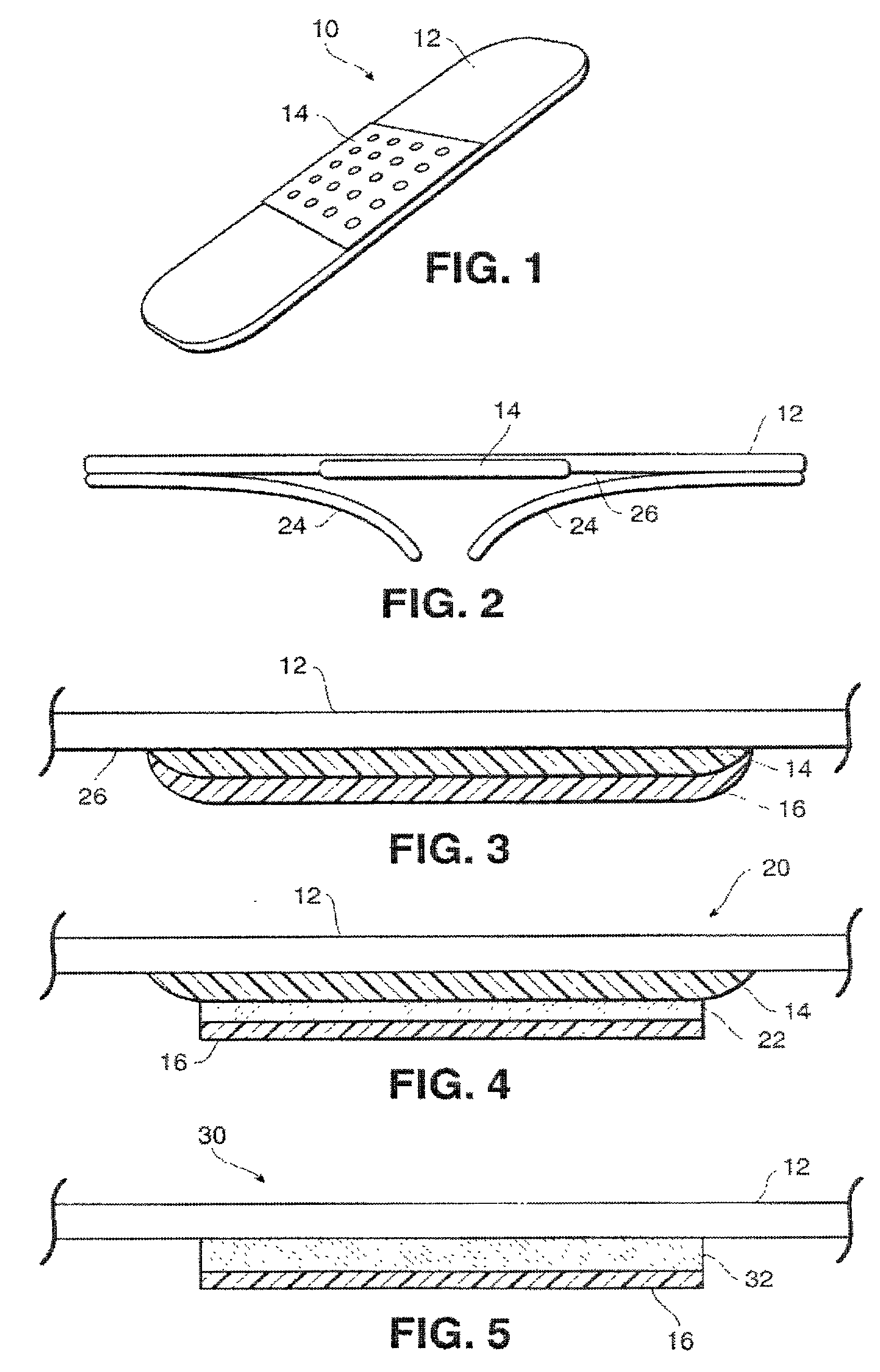

Scar tissue treatment bandage and method

A burn treatment bandage in which a silicone composition, primarily a silicone gel, is located on a bandage of the type having an adhesive strip capable of being attached to a user's skin along with a gauze portion thereon. The silicone and, particularly, the silicone gel is pre-incorporated into the gauze, such that when one attempts to treat a burn or other scar tissue, the user may merely apply the bandage such that the silicone material is in contact with the scar tissue.

Owner:LAWRY ROGER

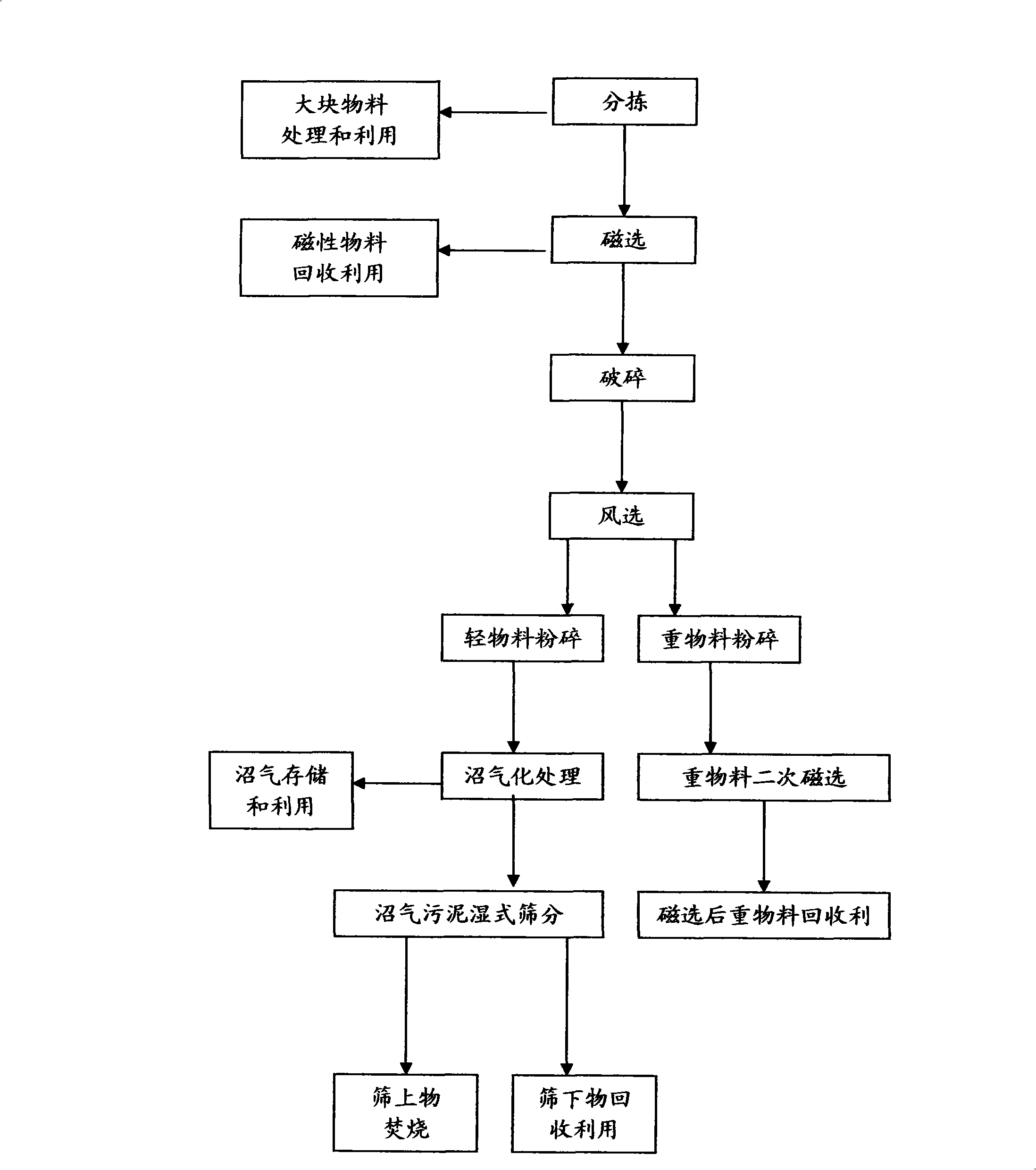

Consumer waste reutilization method

InactiveCN101259479AImprove stabilityReduce pollutionWaste processingSolid waste disposalBurn treatmentSludge

The invention relates to a recycling method for living garbage which comprises the steps: (1) separating: recoverable materials of big blocks and other materials are sorted out; (2) magnetic separation: magnetic materials like an iron block, etc., are separated; (3) cracking: the garbage materials after being separated are cracked to a granularity that is suitable for a subsequent treatment; (4) air separation: heavy materials and light materials are separated; (5) cracking of the heavy materials; (6) secondary magnetic separation of the heavy materials; (7) recycling of the heavy materials after magnetic separation; (8) cracking of the light materials; (9) firedamp treatment of the light materials; (10) firedamp storage; (11) screening of the firedamp mud; (12) burning treatment of the matters on the screen of the firedamp mud screen and (13) recycling of the matters under the screen of the firedamp mud screen, etc. The recycling method is mainly used for treating the living garbage and can better make use of the materials and energies in the garbage to simplify the treatment process and reduce the treatment cost and the pollution to environment.

Owner:BEIJING HENGYECUN S&T

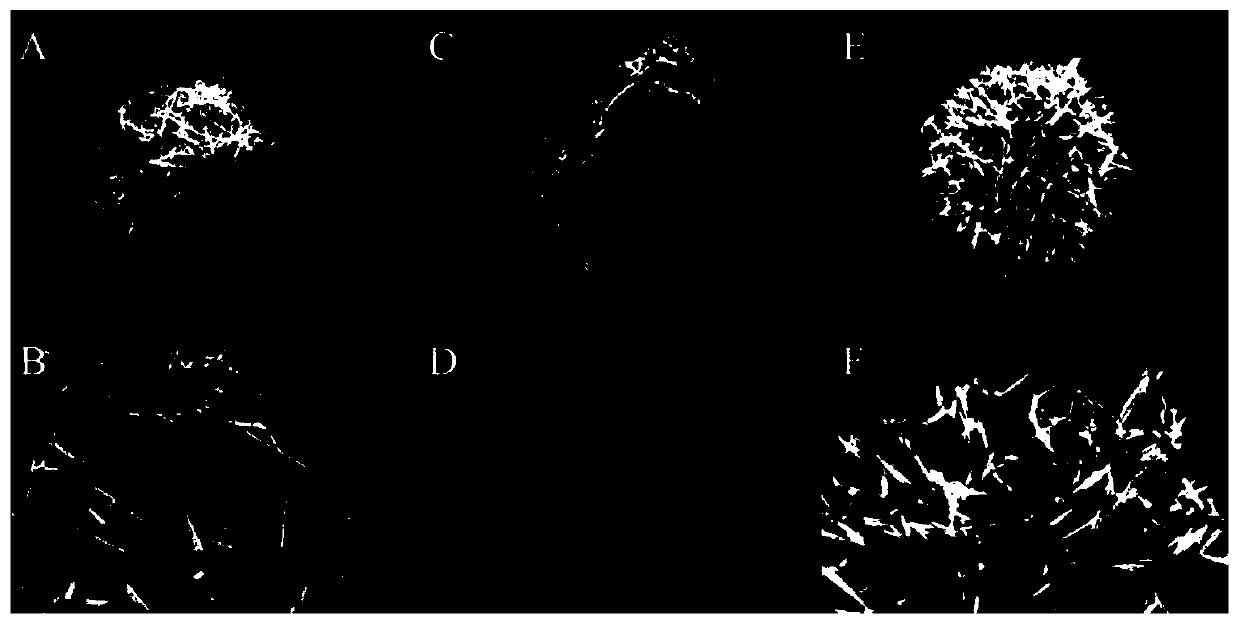

Dialdehyde carboxymethyl cellulose-collagen frozen gel and preparation method thereof

InactiveCN101845226AHigh reactivityImprove mechanical propertiesSurgeryProsthesisBiologic scaffoldPorosity

The invention provides dialdehyde carboxymethyl cellulose-collagen frozen gel and a preparation method thereof. The method comprises the following steps of: first uniformly mixing 1 to 3 mass percent of the aqueous solution of collagen and 0.01 to 1 mass percent of the aqueous solution of dialdehyde carboxymethyl cellulose; then injecting the mixed solution into a mold and storing the mixed solution in a low-temperature reactor at the temperature of -40 to 0 DEG C for 1 to 7 days; and finally, taking the obtained product out and slowly unfreezing the obtained product to obtain the dialdehyde carboxymethyl cellulose-collagen frozen gel. The dialdehyde carboxymethyl cellulose-collagen freezing gel prepared by the method is improved in mechanical property, thermal stability and enzymatic degradation resistance at the same time of maintaining the biological activity of collagen gel per se, has the advantages of porosity, hydrophilicity, water absorbing and preserving property, good market application prospect and the like, and is widely used in biomedical fields, such as biologic scaffolds, cell culture, drug delivery, tissue engineering, wound and burning treatment and the like.

Owner:SICHUAN UNIV

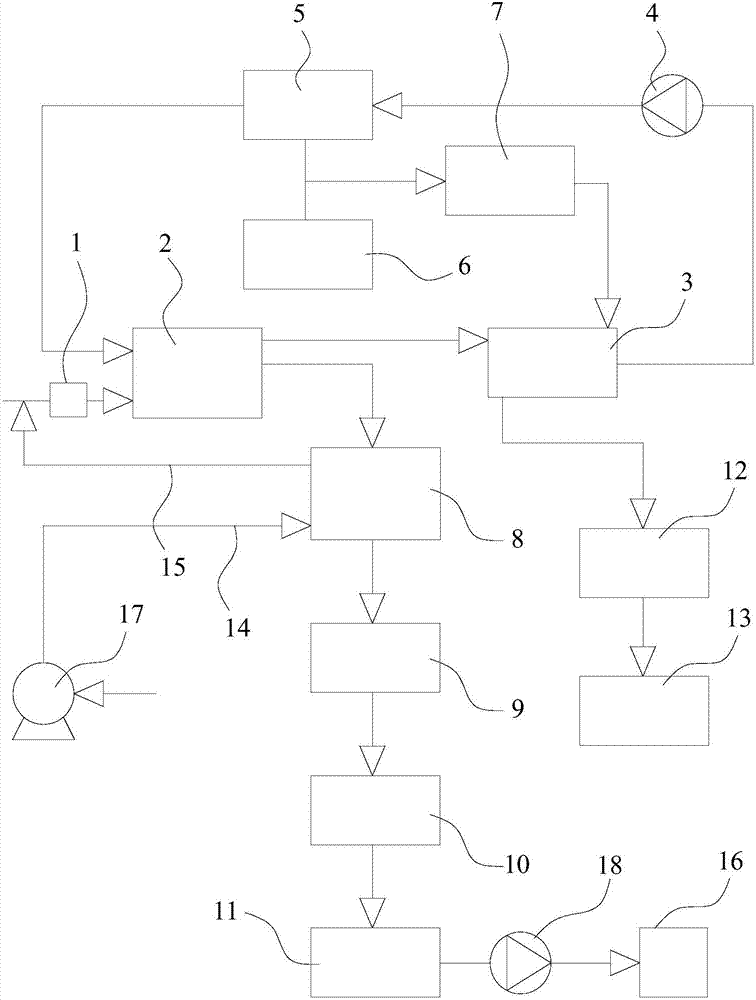

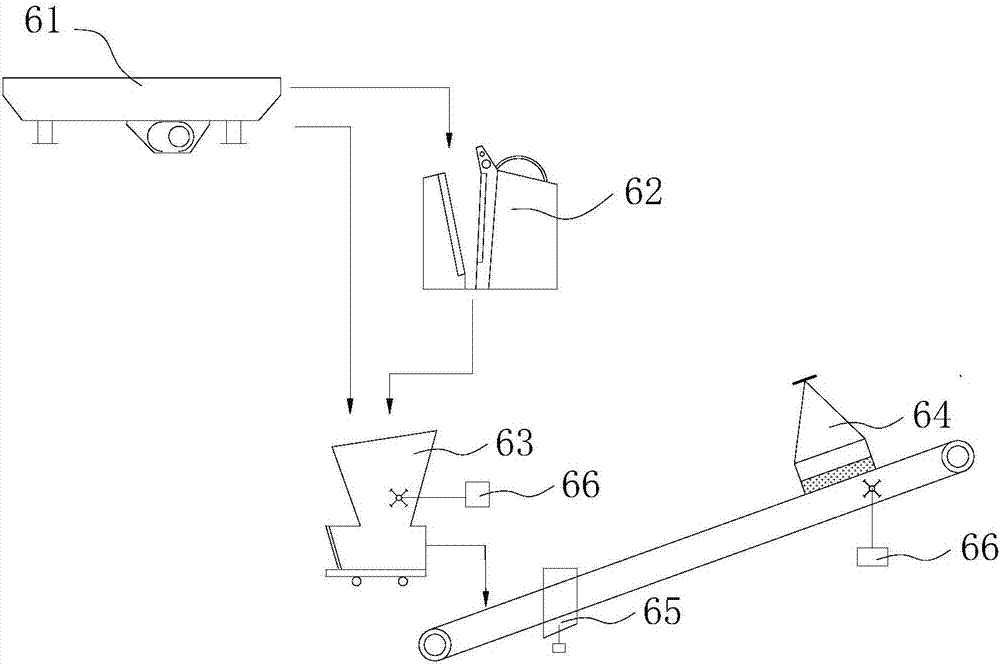

Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

ActiveCN107971330AReduce consumptionEmission reductionCombination devicesDispersed particle filtrationAir preheaterThermal desorption

The invention relates to an efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method. A burner is communicated with a high temperature oxidizingchamber, a high temperature smoke pipe of the high temperature oxidizing chamber is communicated with a rotary kiln heating processing system and an air heat exchanger, a high temperature air outletof the air heat exchanger is communicated with the burner, a smoke pipe of the air preheater is communicated with an inlet of a quench tower, an outlet of the quench tower is communicated with an inlet of a bag-type dust collector, an outlet of the bag-type dust collector is communicated with an inlet of a deacidification tower, an outlet of the deacidification tower is communicated with an air inlet of a second induced draft fan, and an outlet of the second induced draft fan is communicated with a chimney. A part of high temperature flue gas generated by the burner enters a rotary kiln thermal desorption reactor to achieve desorption of organic pollutant and soil drying pretreatment, organic matter enters the high temperature oxidizing chamber through a backflow pipe for burning treatment, and thorough oxidative degradation removal is achieved; and the other part of high temperature flue gas is used for increasing the temperature of combustion air through the air heat exchanger.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Scar tissue treatment bandage and method

A burn treatment bandage in which a silicone composition, primarily a silicone gel, is located on a bandage of the type having an adhesive strip capable of being attached to a user's skin along with a gauze portion thereon. The silicone and, particularly, the silicone gel is pre-incorporated into the gauze, such that when one attempts to treat a burn or other scar tissue, the user may merely apply the bandage such that the silicone material is in contact with the scar tissue.

Owner:LAWRY ROGER

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

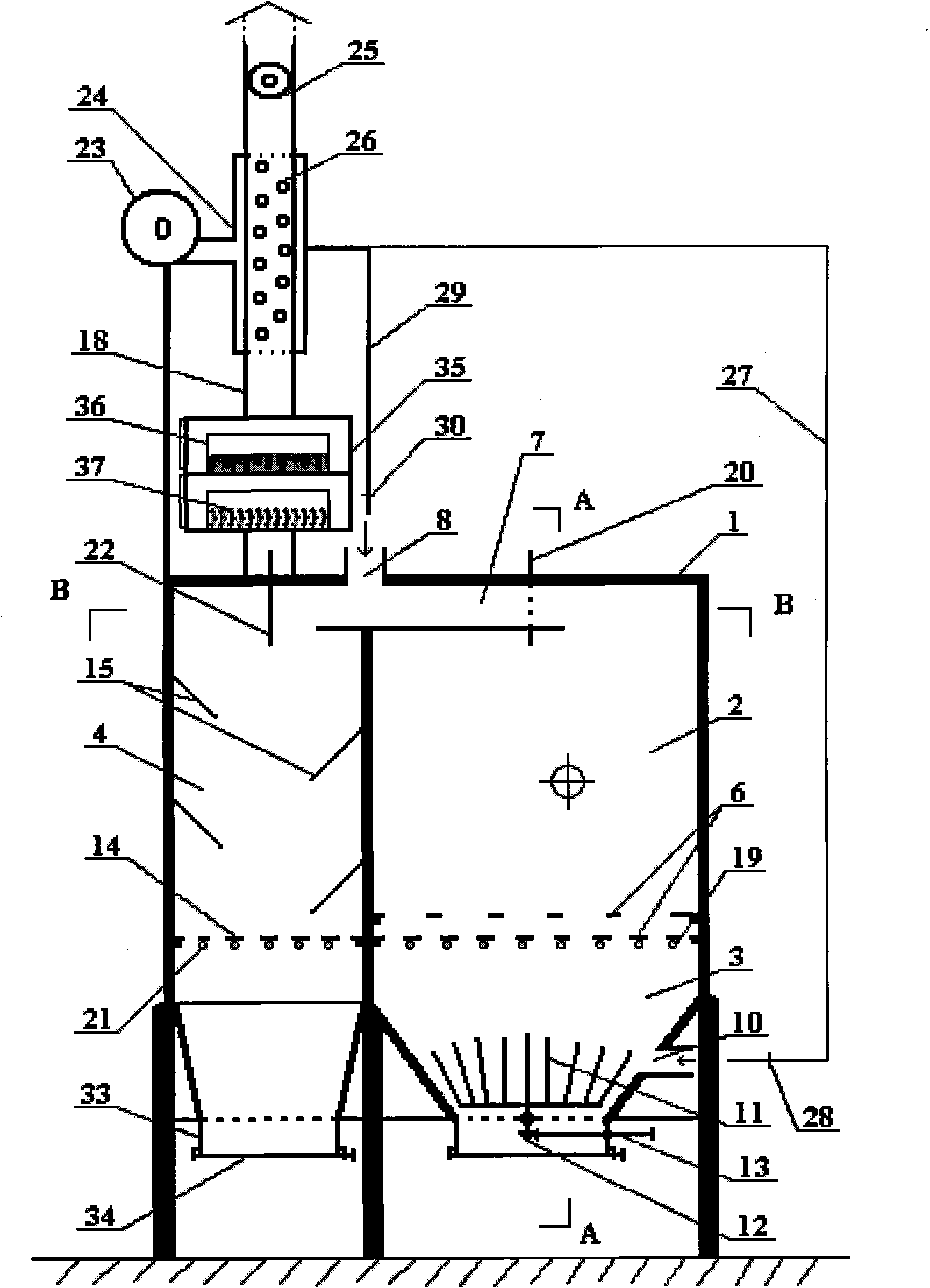

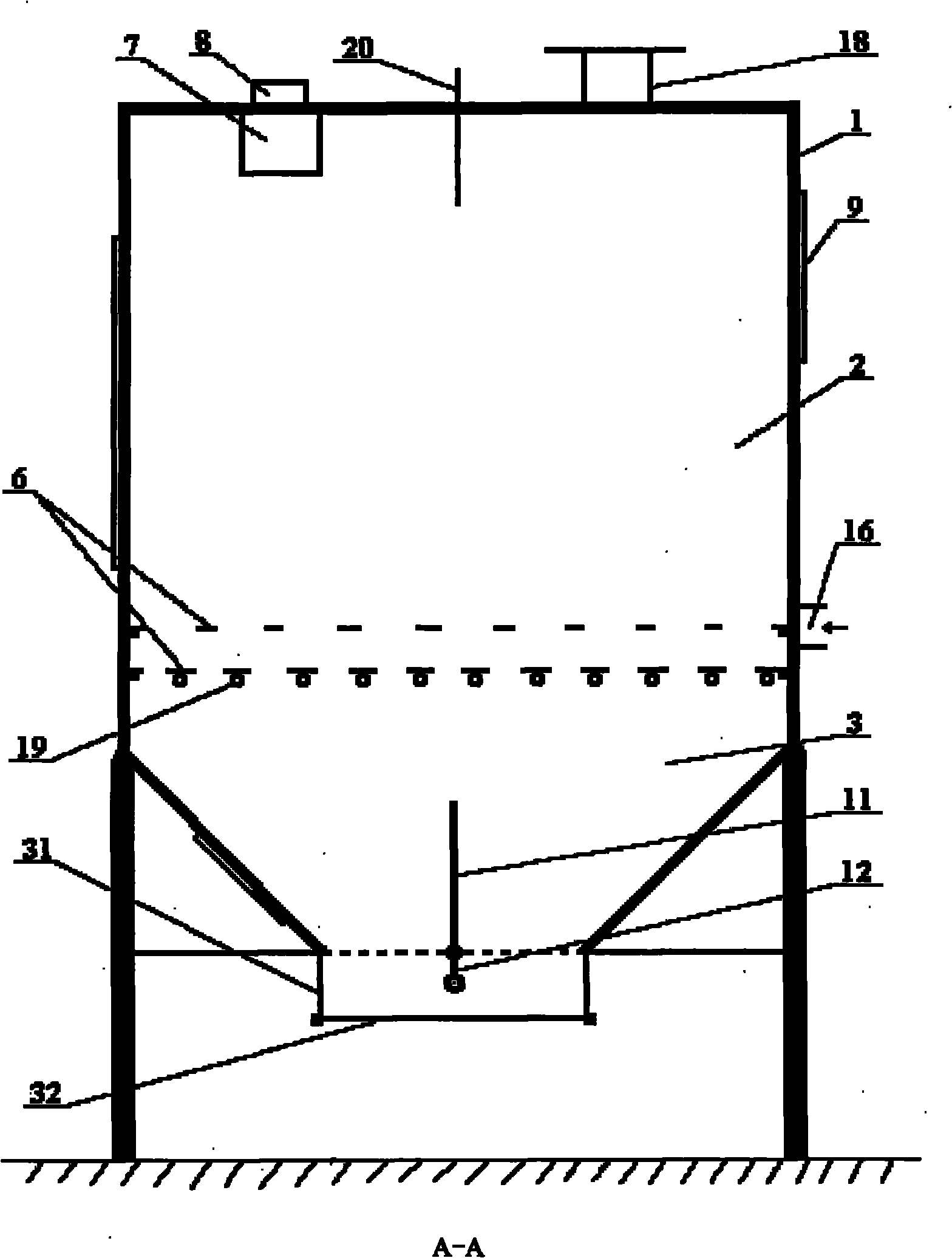

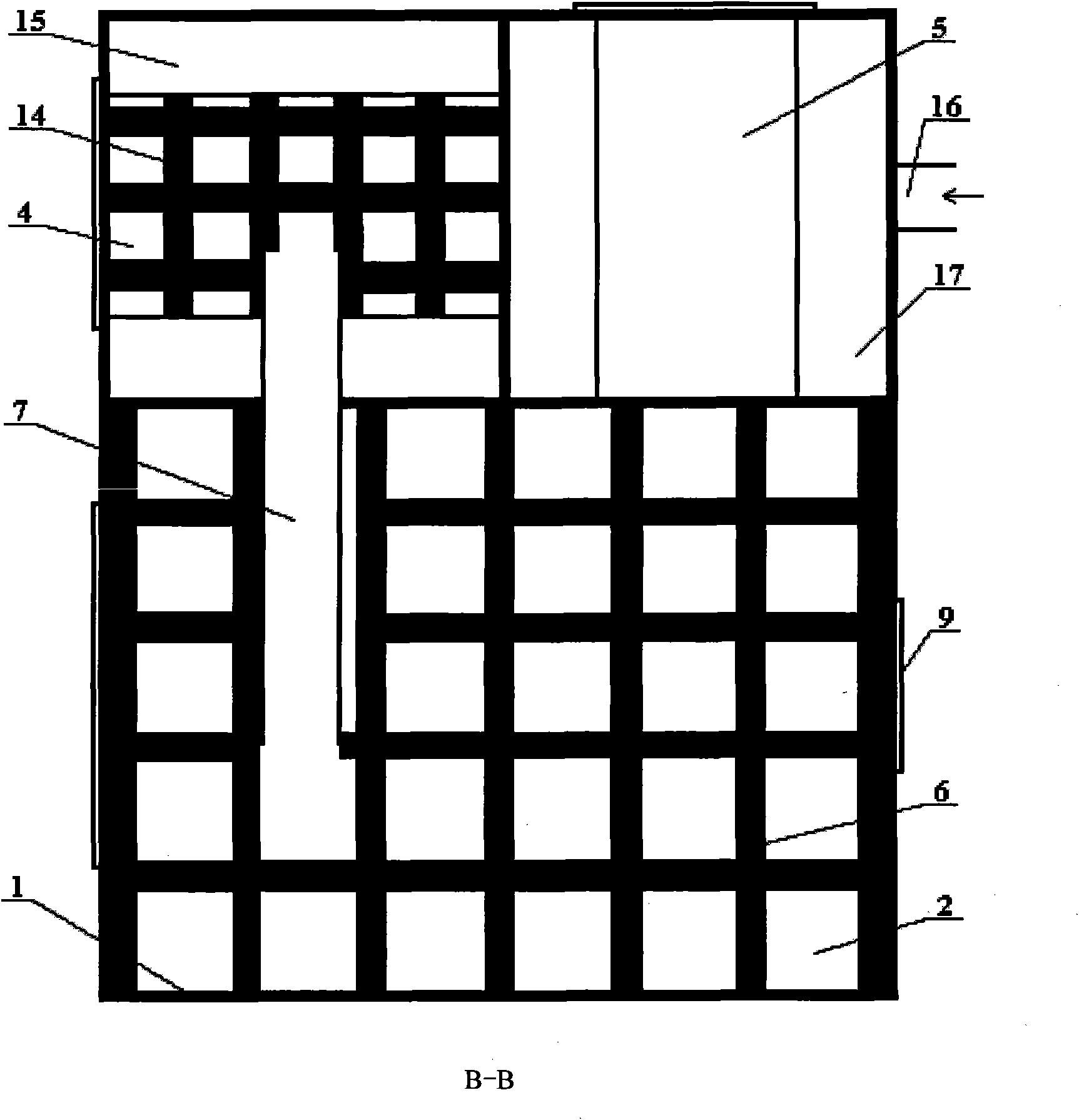

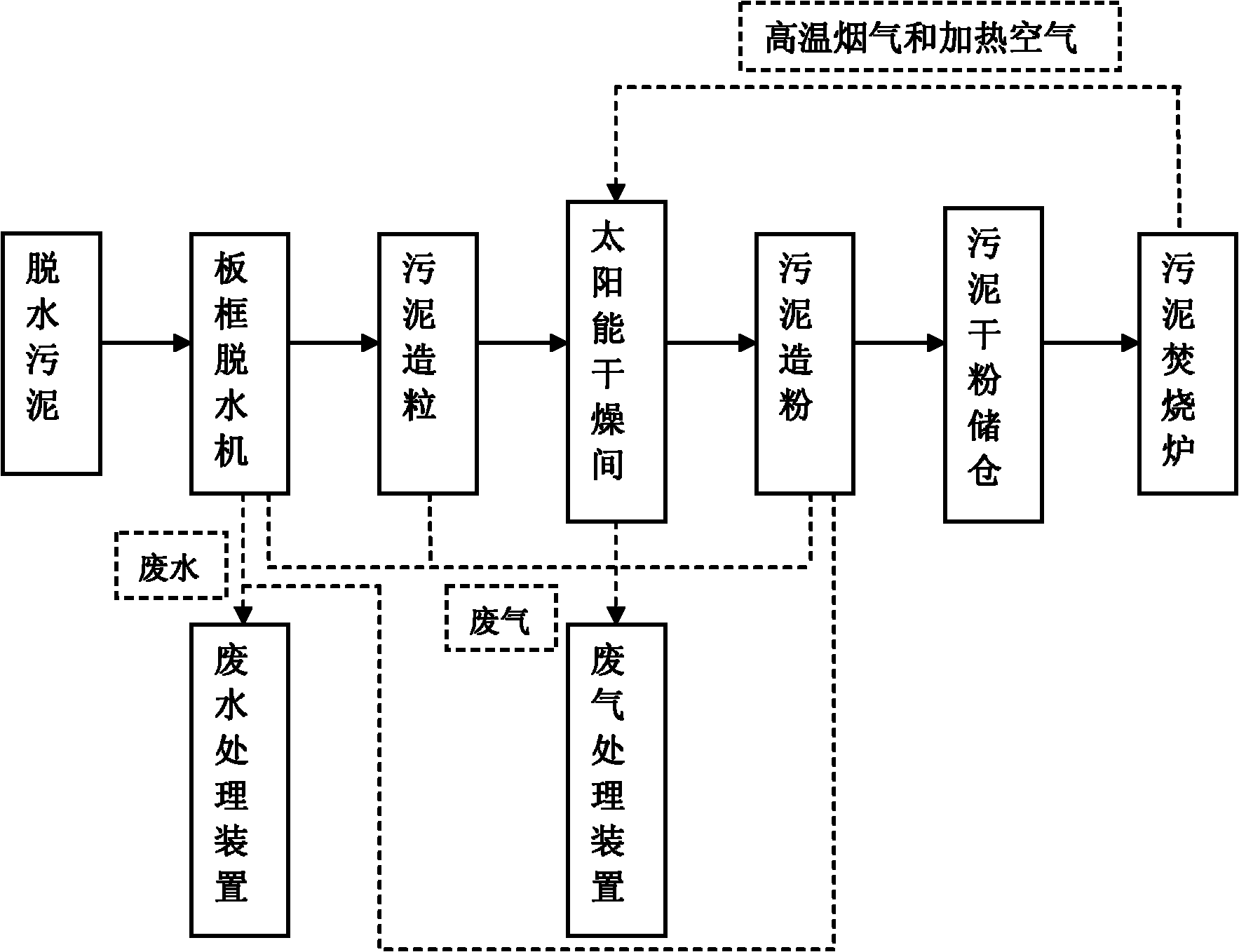

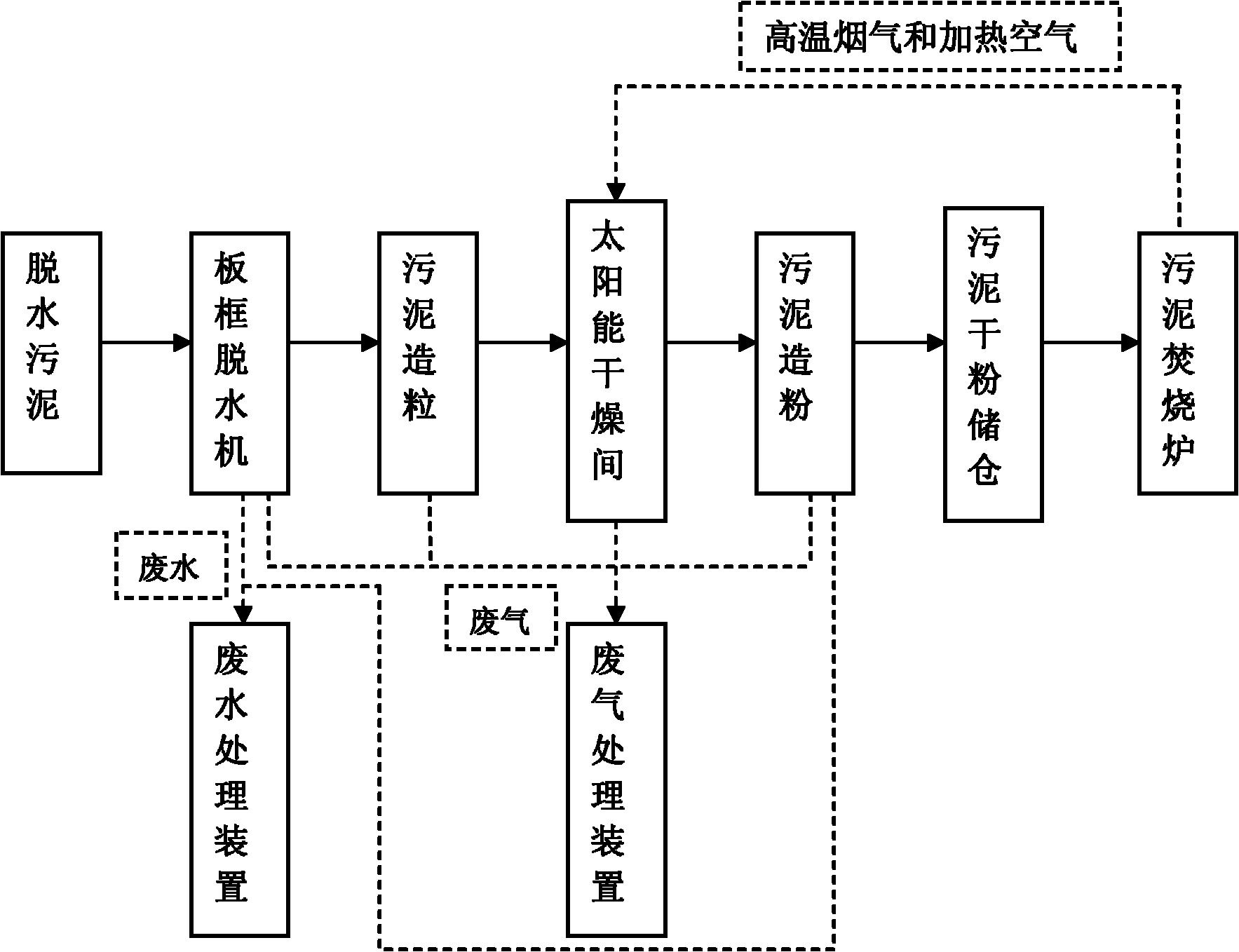

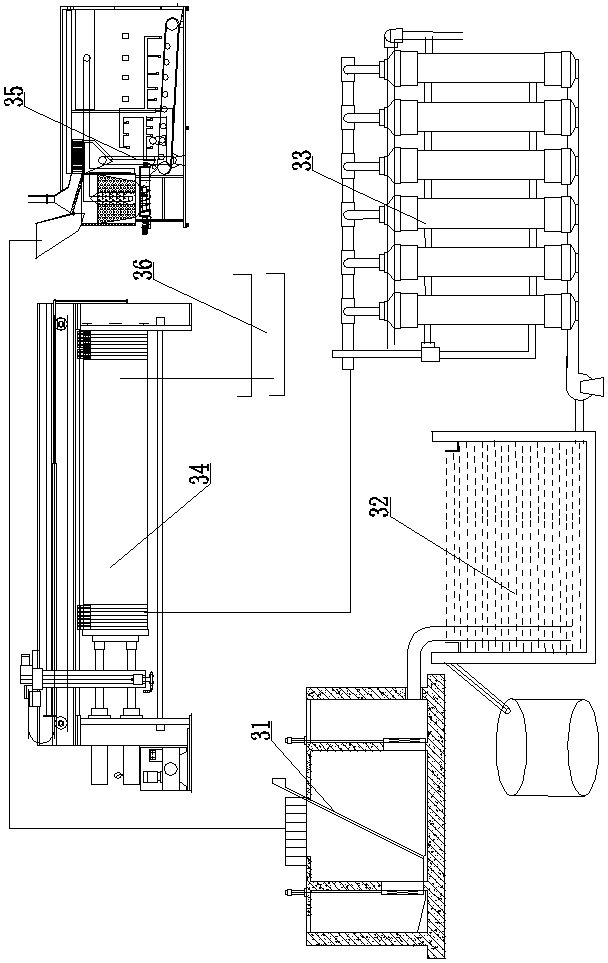

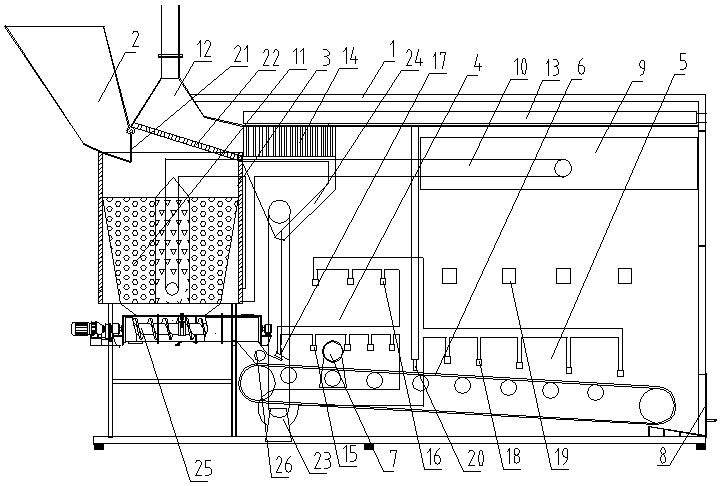

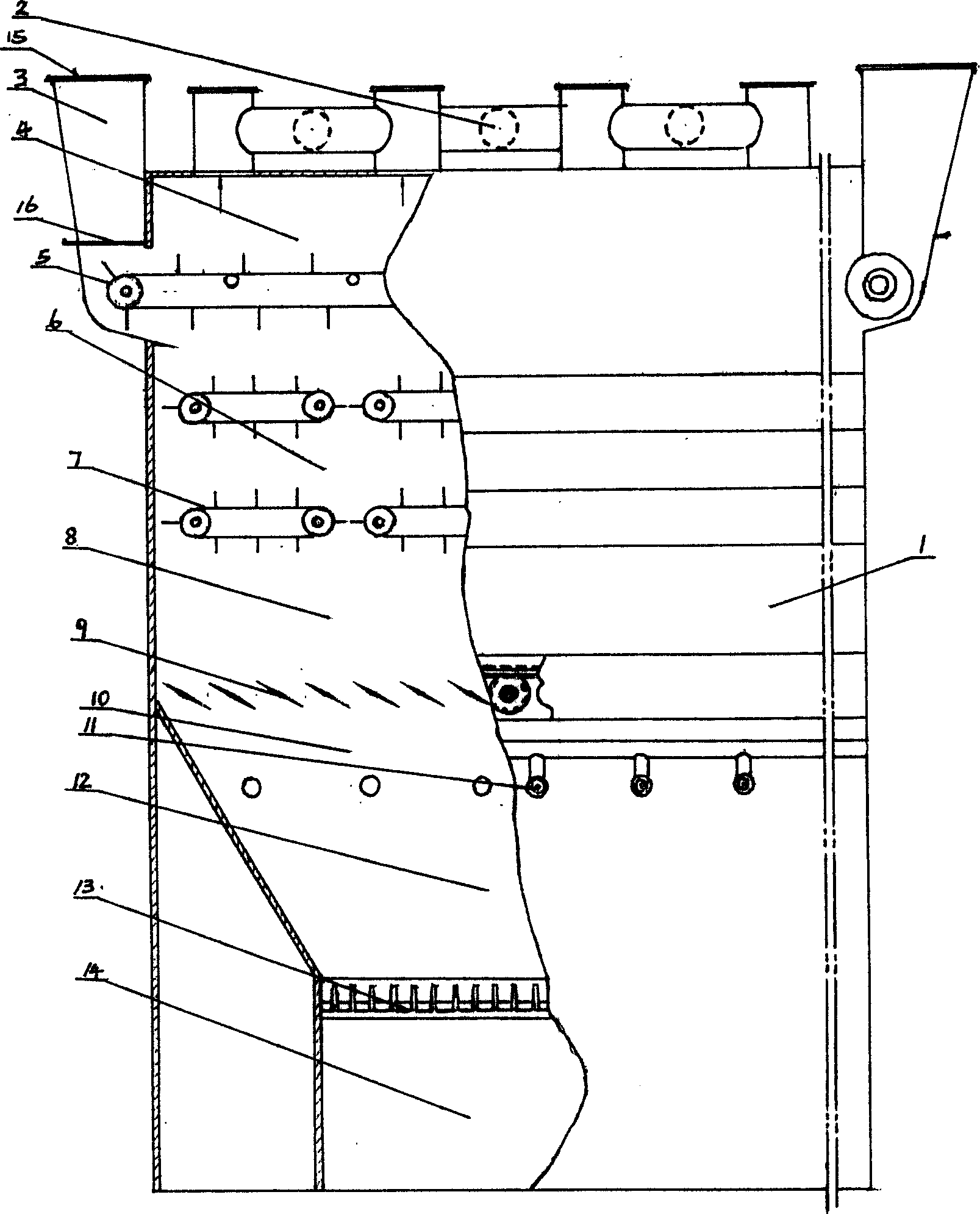

Treatment method of high calorific value excess sludge

ActiveCN102183027AEasy to incinerateReduce energy consumptionSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludge cakeWater filter

The invention provides a treatment method of high calorific value excess sludge. The method comprises the following steps of: feeding the excess sludge to be treated with moisture content of 80 to 90 percent into a plate-and-frame water filter press for dehydration to obtain a filter-pressing dehydrated sludge cake; feeding the obtained sludge cake into a sludge granulation device; crushing the sludge cake into coarse granules at normal temperature; further drying the sludge granules in a heat energy drying room; feeding the dried sludge granules into sludge powdering equipment for further treatment, wherein the grain diameter of the treated sludge powder is 150 to 300 meshes, and the water ratio is 5 to 15 percent; storing sludge dried powder into a sludge dried powder warehouse, and spraying the sludge powder having small grain diameter and having a calorific value of 2,000 to 4,000 kilocalories into a sludge burning furnace to completely burn with a small amount of fuels or without the fuels, wherein the interior temperature of the burning furnace is 800 to 1,000 DEG C, and secondary pollution is avoided; and then conducting high-temperature fume which is generated by burning into a waste heat drying device, and drying the sludge. By the process, the burning treatment of the sludge can be performed conveniently, the energy consumption of sludge drying is reduced, the excess sludge is treated properly, and the secondary environmental pollution is avoided.

Owner:北京方兴科创环境科技有限公司

Kitchen garbage treatment method

A kitchen garbage treatment method comprises the following steps of: sorting collected kitchen garbage, and after separating coarse solid substances, obtaining sorted kitchen garbage; further classifying the separated coarse solid substances, after breaking starch, celluloses, protein and lipid substances, merging the broken substances into the sorted kitchen garbage so as to obtain broken kitchen garbage, and carrying out burning treatment on remaining materials in the coarse solid substances; separating grease out of the broken kitchen garbage so as to obtain degreased kitchen garbage; treating the degreased kitchen garbage by a membrane filtration device so as to obtain desalted kitchen garbage; further dehydrating the desalted kitchen garbage, adding auxiliary materials, and making a hermertia illucens(L.) feed of which the water content is 50-75wt%; and inoculating hermertia illucens(L.) larvae, and supplying the hermertia illucens(L.) feed to the hermertia illucens(L.) larvae to eat, thereby treating and clearing away the kitchen garbage. The hermertia illucens(L.) larvae are used as feed or grease is extracted from the hermertia illucens(L.) larvae for making biodiesel, and remaining residues are used for making organic fertilizers.

Owner:HUNAN MINXING INTELLIGENT TECH CO LTD

Use of pharmaceutical composition containing epidermal growth factor (EGF) for diabetic foot amputation prevention

ActiveUS20050107294A1Prevents amputationAssisting in limb preservationOrganic active ingredientsPowder deliveryAngiologyDiabetic foot

The invention relates to the use of Epidermal Growth Factor (EGF) in a preferably-injectable pharmaceutical composition which is administered by means of infiltration into and around chronic cutaneous ischaemic lesions in order to prevent diabetic foot amputation. Said composition can be administered to recently-created surgical surfaces damaged by the effect of acute reperfusion with oxygenated blood following prolonged ischaemia, thereby preventing further surgical procedures and favouring the preservation of the extremity. The aforementioned composition can be used to improve (i) the cell microenvironment, thereby increasing the reparative and defensive capacity and viability of the is tissues and (ii) the cicatrisation of cutaneous ischaemic lesions, thereby stimulating cell proliferation. The invention is suitable for use in human, veterinary and experimental medicine, specifically in vascular angiology and surgery, dermatology, burn treatment and reconstructive surgery and geriatric medicine. Said composition can be used for recalcitrant ulcers which are associated with lesions in the macro and / or microvasculature, patients with inadequate lymphatic and / or venous return and ulcers or other lesions which are difficult to cicatrise and / or heal.

Owner:CENT DE ING GENETICA & BIOTECNOLOGIA

Topical spray for burn treatment and anti-infection

InactiveUS6987133B2Function increaseReduce disadvantagesBiocideCosmetic preparationsCross-linkAntimicrobial drug

This invention relates to a topical spray preparation for burn treatment and microbial infections on human being or animals. This non-aerosol preparation contains an antimicrobial drug, i.e., silver sulfadiazine, as is dispersed or solubilized in a cream or lotion base matrix which can be sprayed directly from a common trigger spray device. The key component of the matrix can be characterized by it having a suitable molecular weight polymer of cross-linked acrylic acid, such as Carbomers or non-ionic surfactants such as polyoxyethylene alkyl ethers, or any combination of the above materials.

Owner:SAGE PHARMA

Thermal cracking gasification oven for city domestic garbage

InactiveCN1687646AIncreasing the thicknessReduce permeabilityIncinerator apparatusCombustible gas productionCombustion chamberBurn treatment

The invention relates to the hot cracking gasifying treatment of the urban rubbish and the equipment. The method can adopts the non-selected rubbish to burn and gasify directly, uses the heat energy produced by the organics of the rubbish to crack the organics, the residual heat of the cracking gas to remove the water in the rubbish and the physical form characteristic of the rubbish to purify the furnace gas. The rectangle gasifying furnace (1) comprises eight main structural parts: the burner gas lead-out assembly (2), the feed cabin (3), the rectangle suction cabin (4), the rectangle drying chamber (6), the rectangle gasifying chamber (8), the fuel return heating combustion chamber (10), the melting combustion chamber (12), the slurry cabin (14). The invention can effectively prevent the producing of dioxin and does not have the high-cost and complex exhaust treatment processes of the usual rubbish burning treatment.

Owner:郭炜明

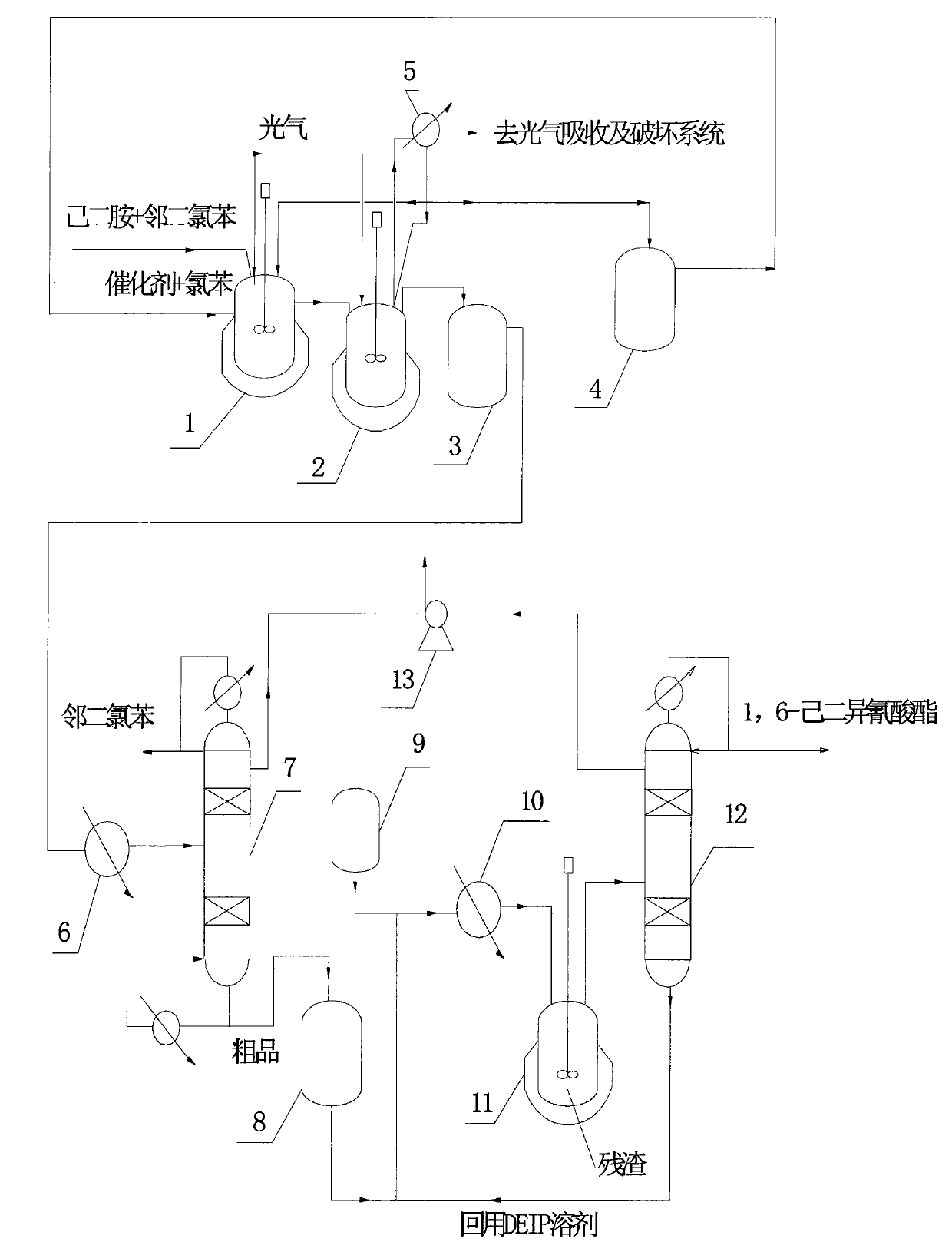

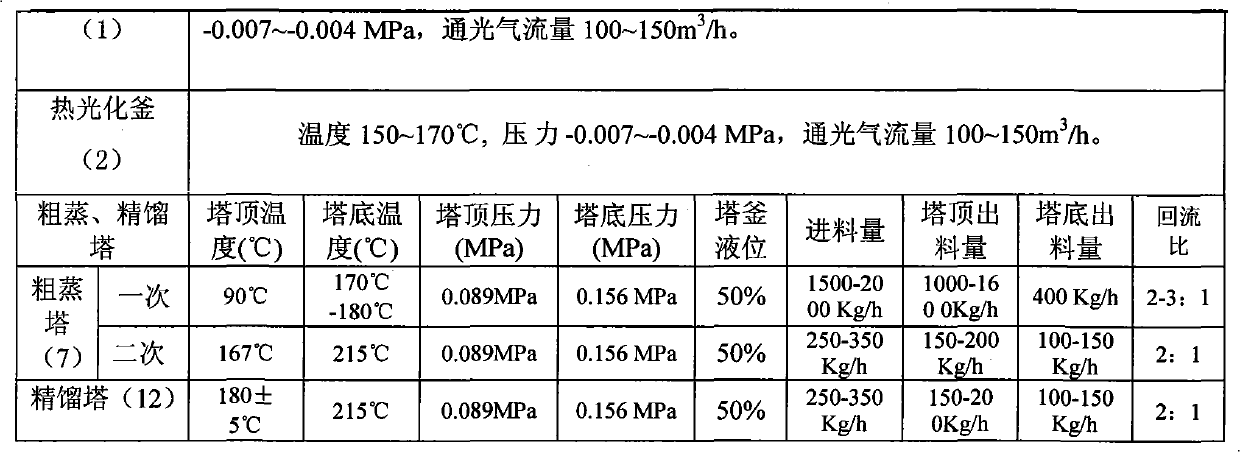

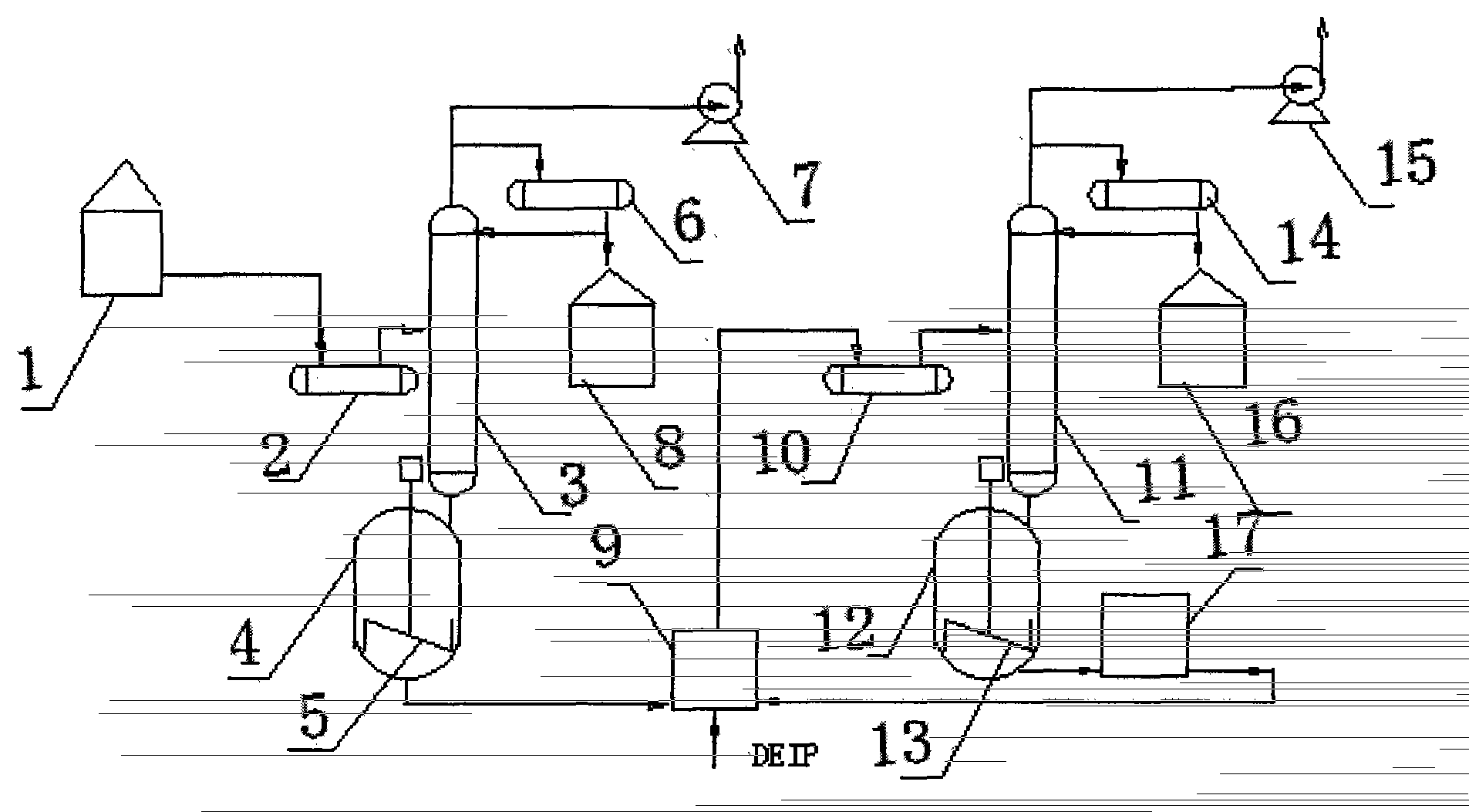

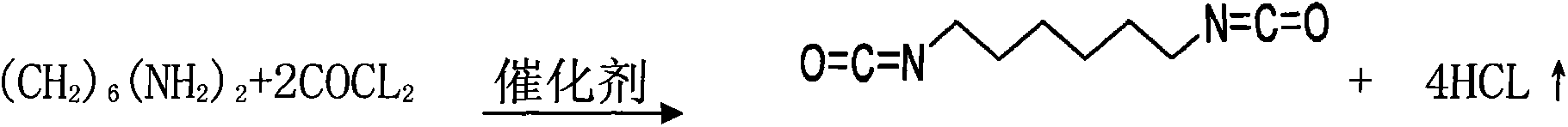

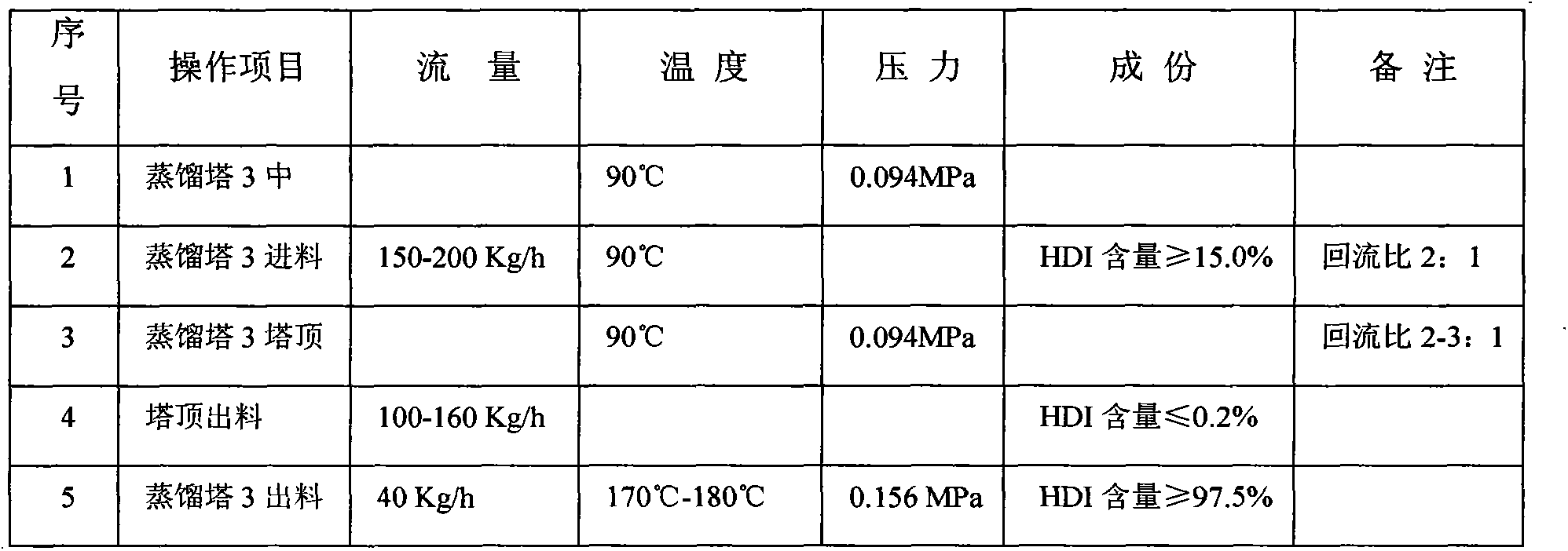

Method for continuously preparing 1,6-hexamethylene diisocyanate

InactiveCN101928235AOrganic compound preparationIsocyanic acid derivatives purification/separationChlorobenzeneBurn treatment

The invention relates to a method for preparing crude 1,6-hexamethylene diisocyanate through the phosgene method and separating pure 1,6-hexamethylene diisocyanate through rectification. The method uses o-dichlorobenzene and chlorobenzene as solvents and comprises the following steps: using hexanediamine and excessive phosgene to perform the two-step reaction of low temperature photochemical reaction and high temperature photochemical reaction under the action of catalyst and generate 1,6-hexamethylene diisocyanate (HDI), removing o-dichlorobenzene through distillation for reuse, continuously distilling to remove by-product chlorinated isocyanate, further mixing with DEIP solvent in a certain ratio through compulsory stirring, heating to perform flash evaporation and rectification, preparing the 1,6-hexamethylene diisocyanate product and DEIP through separation and purification, and regularly discharging the slagged tarry macromolecular compound to perform burning treatment.

Owner:甘肃银光聚银化工有限公司

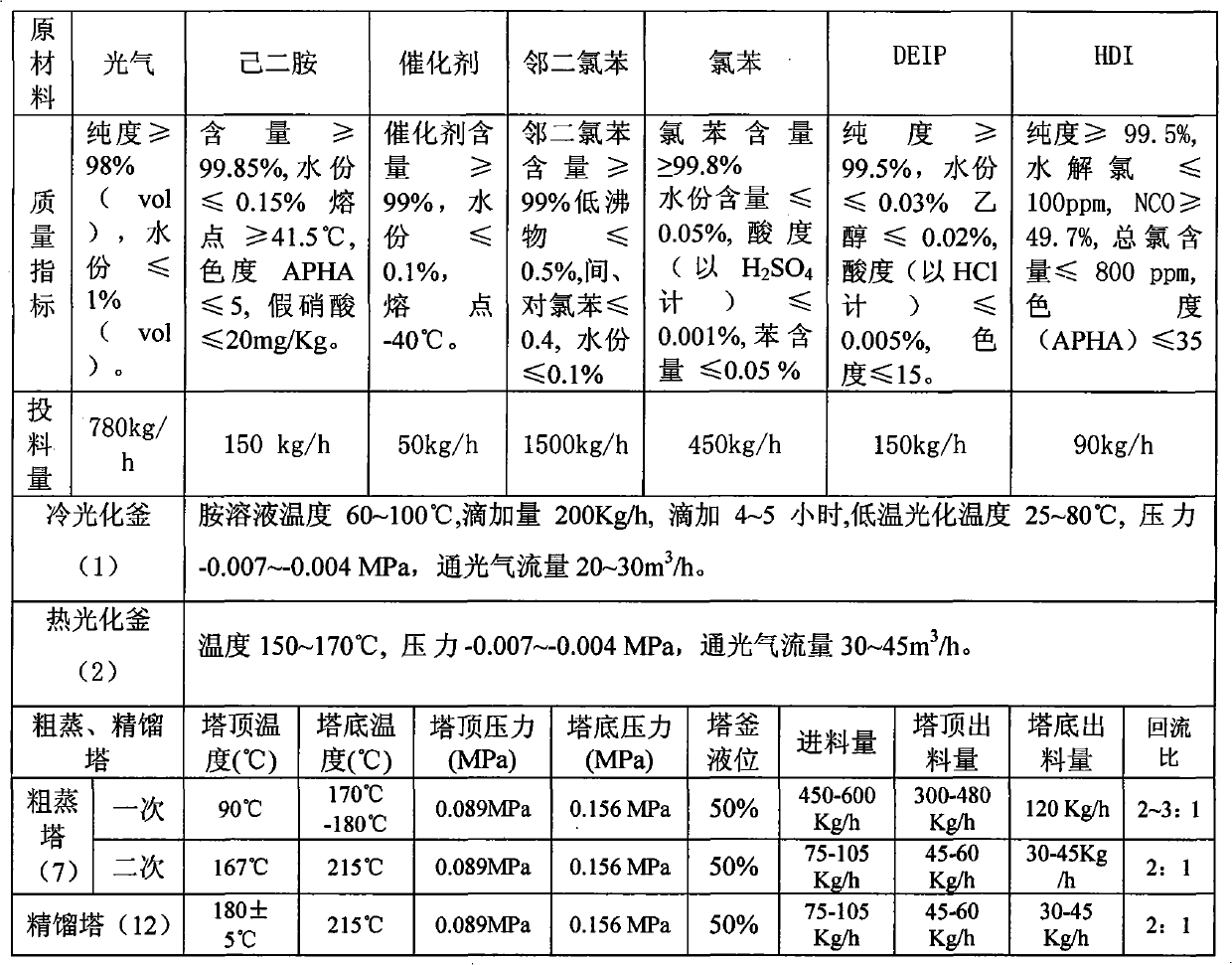

Burning treatment process of waste gas and waste liquid containing chlorosilane in polysilicon production

InactiveCN101968226ASolve the problem of incomplete treatment and the inability to remove chloride ionsSolve problems that cannot be removedIncinerator apparatusLiquid wasteAlkaline hydrolysis

The invention relates to a burning treatment process of waste gas and waste liquid containing chlorosilane in polysilicon production, which comprises the steps of: removing waste gas and waste liquid containing chlorosilane (trichlorosilane, dichloro-dihydro-silicon, silicon tetrachloride and metal chloride) in the production process of polysilicon; using natural gas as fuel in a burning furnace; and hydrolyzing the chlorosilane in the waste gas and the waste liquid at high temperature under the conditions of high temperature of 900 DEG C to 1000 DEG C and pressure of 0.01 to 0.06 barg to generate SiO2, HCl, a small quantity of Cl2 and the like which can be easily processed. In the process, the toxic chlorosilane difficult to process is burned and hydrolyzed at high temperature to generate SiO2, HCl, a small quantity of Cl2 and the like which can be easily processed; therefore, the problems of incomplete performance of absorption of alkaline hydrolysis and neutralization and sedimentation treatment of Ca(OH)2, difficult removal of chlorine ions, serious secondary pollution, generation of a large quantity of waste water and waste dregs, high operating cost and the like are solved. Simultaneously, the waste water and the waste dregs are not generated basically and useful resources are recycled.

Owner:SHAANXI TIANHONG SILICON IND

Method for regenerating and revivifying hydrogenation catalyst

ActiveCN101618354AReduce interactionSimple processCation exchanger materialsCatalyst regeneration/reactivationThiolBurn treatment

The invention discloses a method for regenerating and revivifying a hydrogenation catalyst, which comprises the steps of treating an inactivated hydrogenation catalyst subjected to sulfur burning and carbon burning treatment with organic sulfur compound-containing thioalcohol and / or thioether and roasting a resulting product, wherein the organic sulfur compound-containing thioalcohol and / or thioether accounts for 0.1 to 2.2 percent of the weight of the inactivated hydrogenation catalyst. The method of the invention can effectively weaken the interaction between metal and the carrier to obtain a regenerated hydrogenation catalyst with high activity restoration degree. The method is particularly suitable for vulcanized hydrofining catalysts and hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of urban sewage sludge reduction

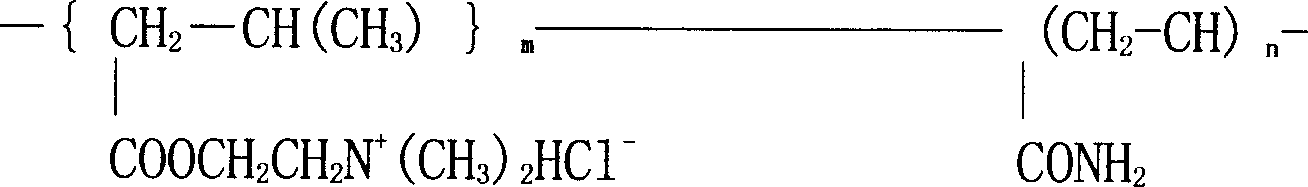

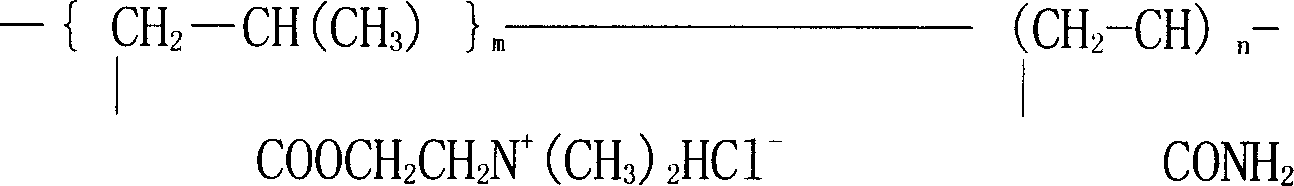

ActiveCN101108751ALower zeta potentialImprove performanceWater/sewage treatment by centrifugal separationWater/sewage treatment by flocculation/precipitationBurn treatmentEmulsion

The invention relates to the processing method of the urban sewage and sludge reduction. The flocculating agent A is first added in the urban sewage and sludge and added with flocculating agent B to further react after emulsion breaking reaction. The flocculating agent A is a quaternary ammonium type cationic polymer and the flocculating agent B is a cationic polymer with aminomethyl polyacrylamide as the basis. The urban sludge processed by the method of the invention has volume greatly reduced, hard mud cake, low water ratio, which can meet the requirement of the subsequent landfill, composting and burning treatment and realize the comprehensive utilization of the sludge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for refining hexamethylene diisocyanate and method thereof

The invention specifically relates to production equipment for refining hexamethylene diisocyanate and a method thereof. A stirrer is respectively arranged in the middle of the bottom of both a distillation column and a rectifying tower which are provided with a stirring device, and stirring wings are a frame type. The method for refining hexamethylene diisocyanate comprises the following steps: (1) letting an synthesized HDI solution enter a distillation column through a heat exchanger, starting a first vacuum pump, and starting a first stirrer in the column bottom while the agitation speed is less than or equal to 60rpm / min; Starting a first condenser on the tower top, evaporating all o-dichlorobenzene, continuously discharging by the distillation column and entering a mixing tank; and (ii) adding a DEIP solvent into the mixing tank, uniformly mixing crude HDI and the DEIP solvent according to the HDI-DEIP ratio of 1:1-1.5, sending the mixture into the rectifying tower to firstly evaporate mono-isocyanate chloride and continuously evaporate the HDI, drawing forth the DEIP for recycling, stirring high polymer residue in a heating vessel and discharging regularly, and carrying out burning treatment. The device and method provided by the invention can be applied in distillation separation and purification production technology which is easy to generate auto-agglutination phenomenon under the distillation condition.

Owner:甘肃银光聚银化工有限公司

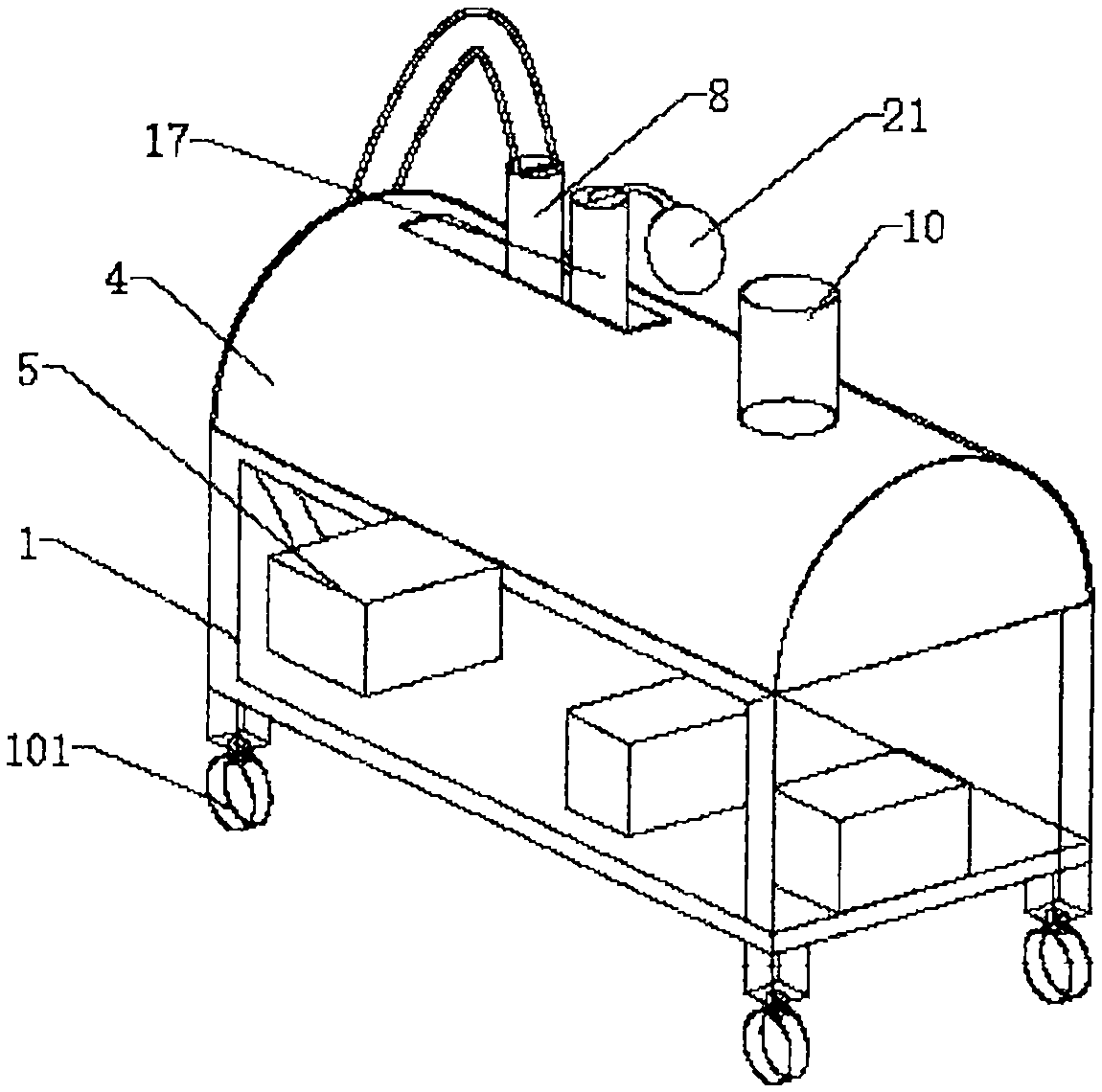

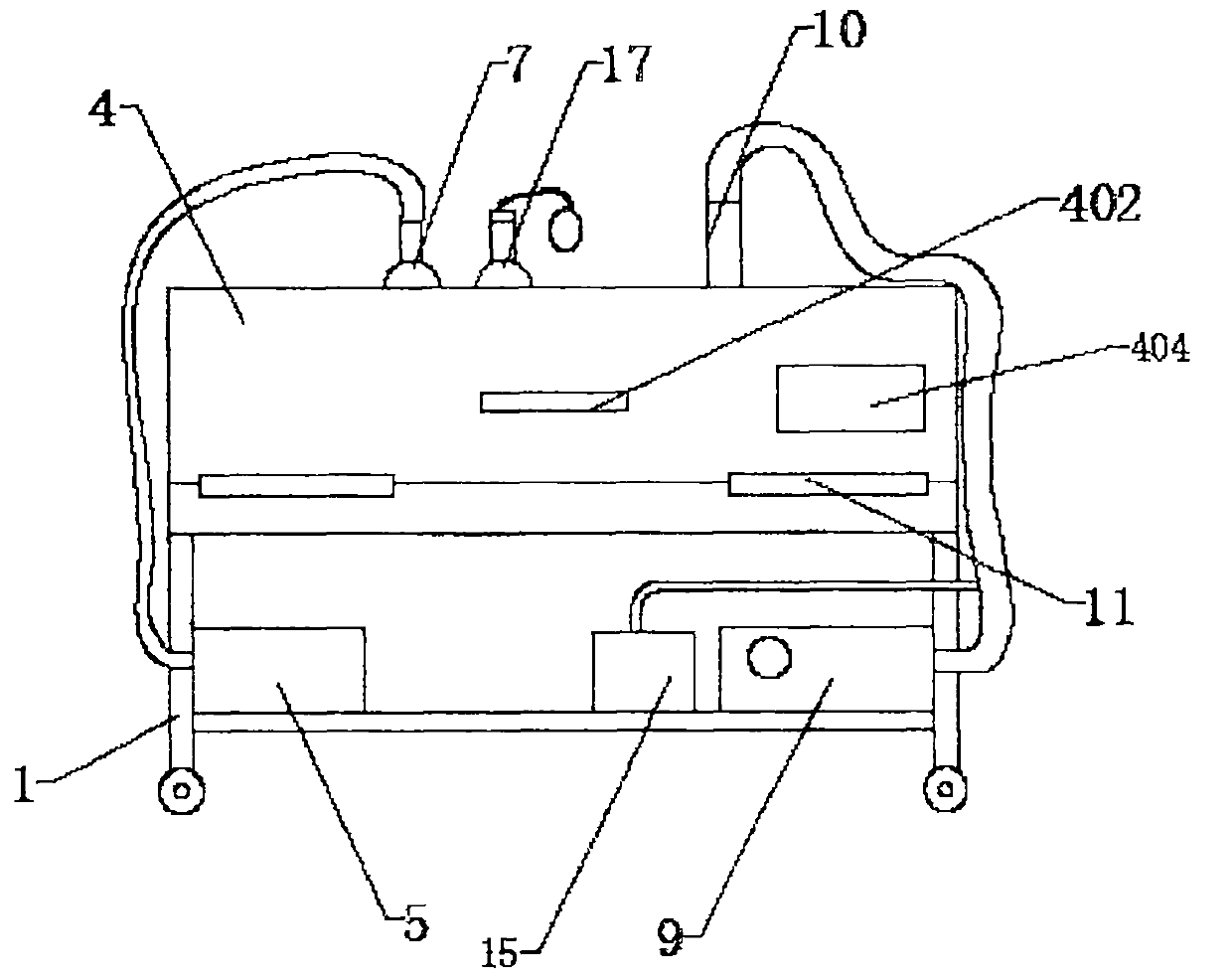

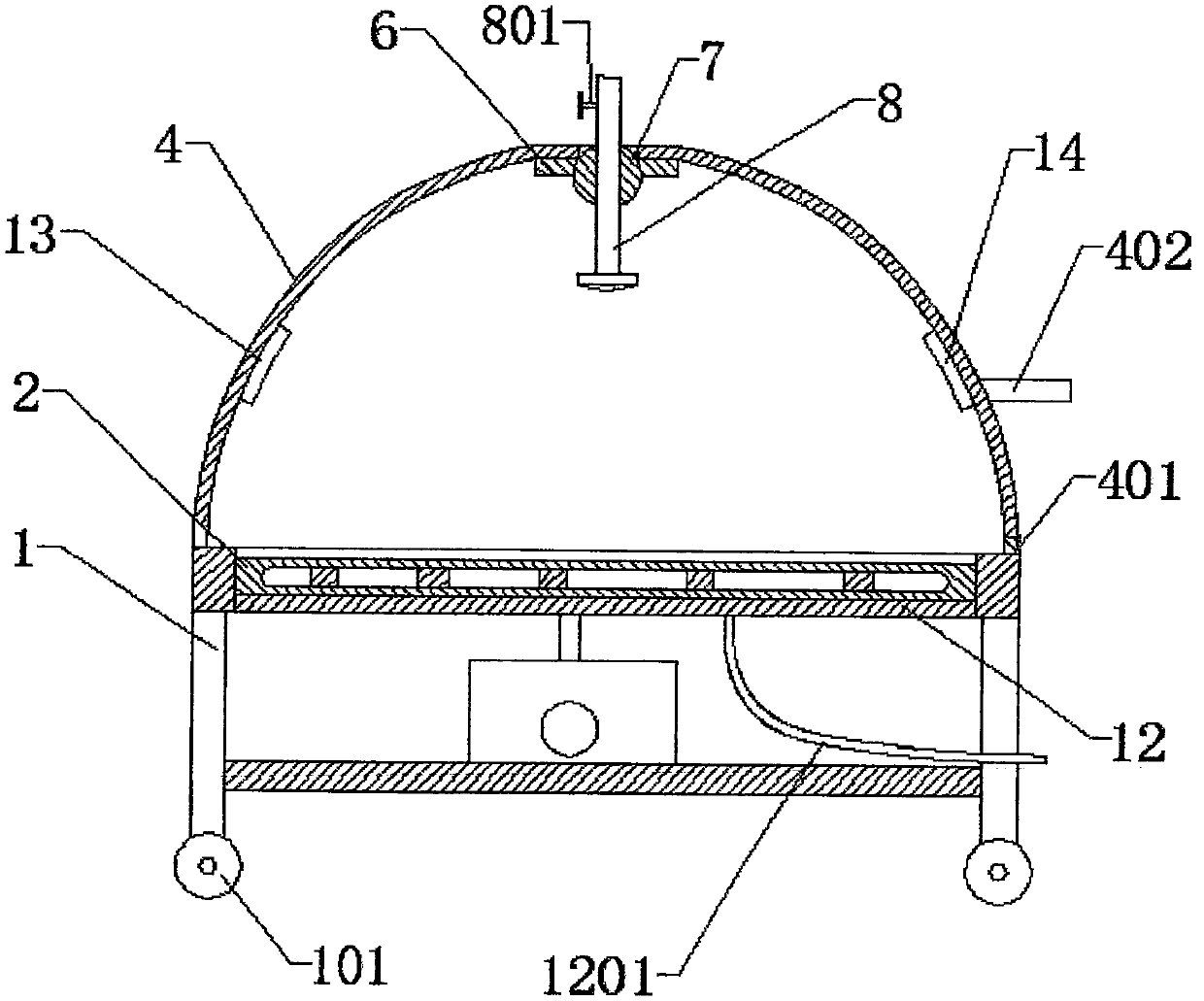

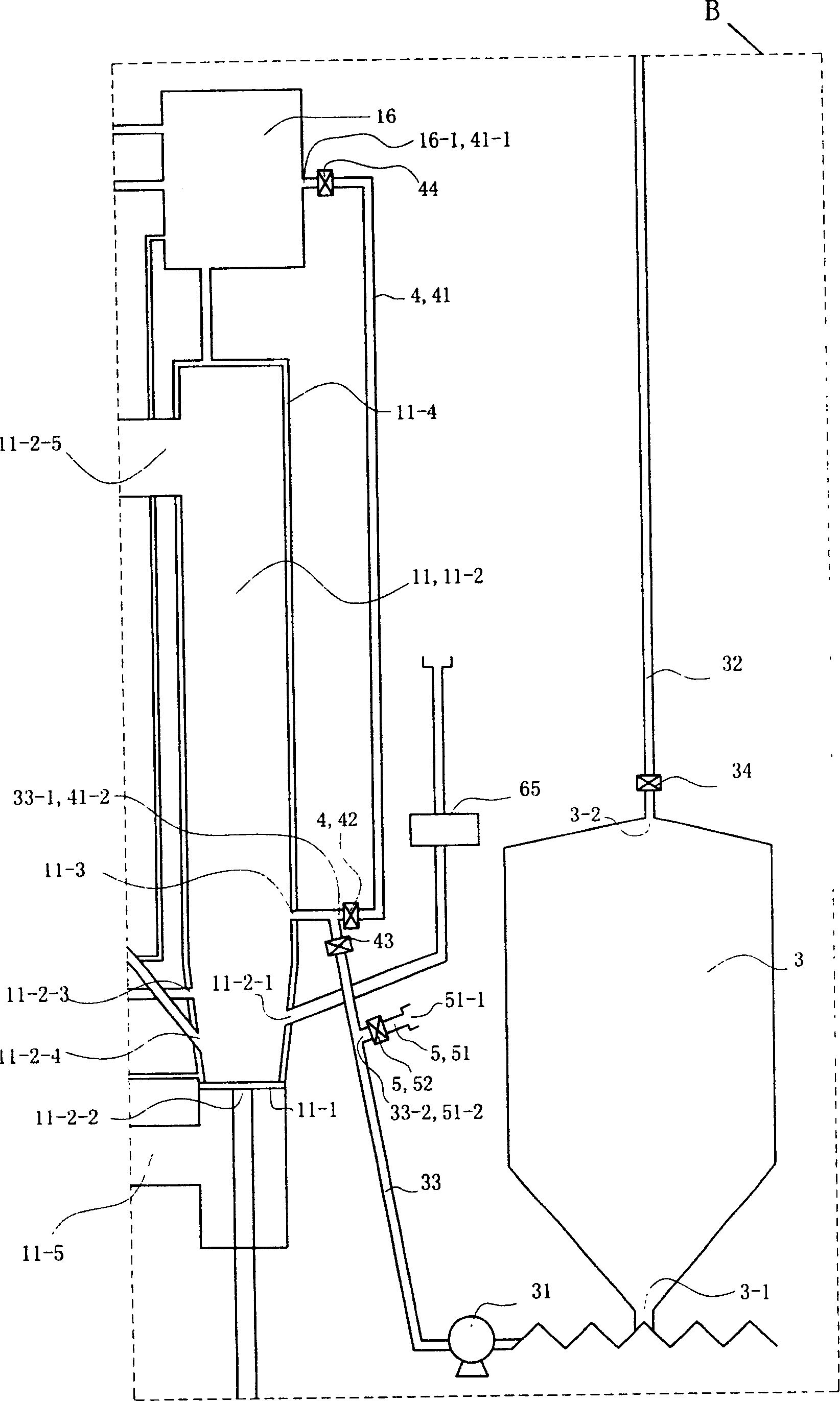

Comprehensive burning treatment couch

InactiveCN105496707ASimple structurePowerfulOperating tablesMedical applicatorsBurn treatmentDisinfectant

The invention discloses a comprehensive burning treatment couch. The comprehensive burning treatment couch comprises a couch rack, a first supporting plate, a second supporting plate, a transparent cover, a disinfectant tank, an assembly plate, a rotating ball, an atomizing nozzle, a blower, an air inlet pipe, a latch, a seal plate, a temperature sensor, a humidity sensor, a humidifier, a second rotating ball, a drug delivery pipe, an extrusion hole, a drug application cloth cover, a seal cap and an air bag. The comprehensive burning treatment couch is simple in structure and powerful in functions, can avoid a wound when a patient is treated in the treatment couch, the wound can be prevented from being pressed, secondary hurt of the wound can be prevented, dust can be effectively prevented from falling on the wound of the patient, wound infection can be avoided, and isolated disinfectant spray and ointment application can be directly provided for patients inside the transparent cover.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

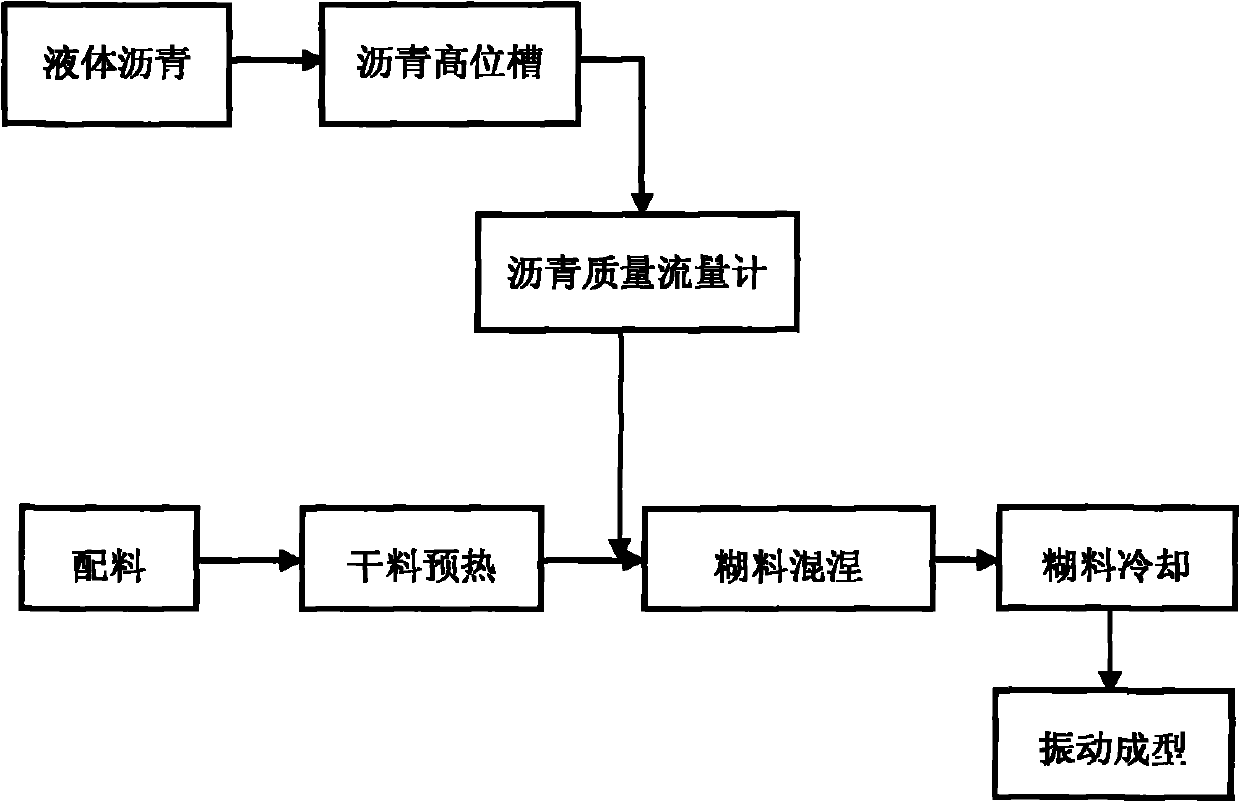

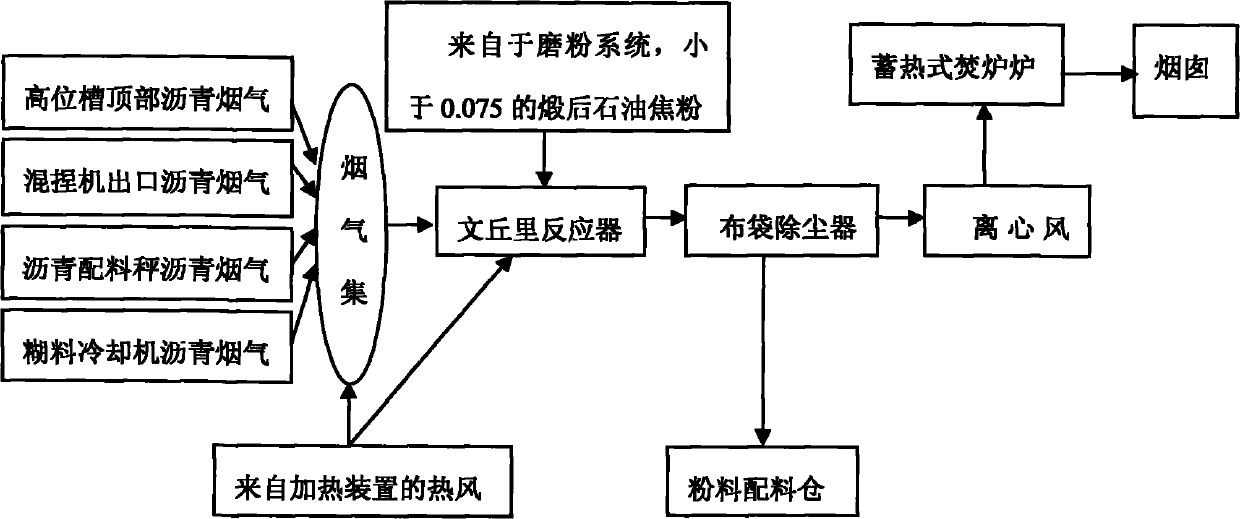

Method for treating asphalt gas efficiently and harmlessly

InactiveCN102000483ACollect completeEfficient collectionDispersed particle filtrationSecondary emissionBenzanthracenes

The invention discloses a method for treating asphalt gas efficiently and harmlessly. The method comprises the following steps of: performing reaction adsorption on the asphalt gas and calcined petroleum coke powder in a Venturi reactor; collecting dust and coke tar from the gas in a bag-type duster remover for recycle; after removing the coke tar and dust-containing steam in the asphalt gas, performing burning treatment by using a regenerative combustion furnace, wherein the burning temperature is higher than 800 DEG C and the burning time is 1 to 2 seconds; and decomposing polycyclic aromatic hydrocarbons such as benzopyrene, benzanthracene and carbazole in the gas after the burning treatment for effectively removing harmful substances of the polycyclic aromatic hydrocarbons such as the benzopyrene, the benzanthracene and the carbazole, wherein the harmful substance content of the treated gas is below 5 mg / m<3>. By using the method, the harmful substances of the polycyclic aromatic hydrocarbons such as the benzopyrene, the benzanthracene, the carbazole and the like are removed effectively; and the harmful substance content of the gas after the treatment is below 5 mg / m<3> which is far below a national secondary emission standard.

Owner:YUNNAN YUANXIN CARBON CO LTD

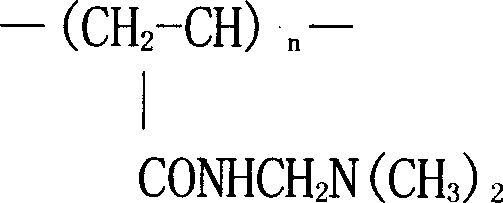

Method for deep dewatering sludge

InactiveCN106542718AConstant organic contentConstant sludge calorific valueSludge treatment by de-watering/drying/thickeningFiberBurn treatment

The invention provides a method for deep dewatering sludge. Dewatering is conducted through plate-frame pressure filtration type sludge dewatering equipment. The method comprises the steps of 1 equipment inspecting, 2 preparing of a polymeric flocculant and a dewatering auxiliary, 3 sludge extracting, 4 dewatering auxiliary and polymeric flocculant adding, dispersing and reacting, 5 sludge pump working, 6 pressure filtration dewatering, 7 sludge discharging, 8 parameter recording and 9 equipment cleaning. According to the method, the adopted polymeric flocculant is a cationic organic polymeric flocculant with a long chain structure, the chain has many active cationic groups which can neutralize negative charges on sludge particles and bond multiple sludge particles simultaneously, and therefore dewatering is promoted; the dewatering auxiliary is high-activity plant fiber and can change and increase the sludge floccule structure and construct a net-shaped skeleton. The water content of the sludge dewatered through the method is lower than 60%, the organic matter contents and the sludge caloric values of the sludge before and after dewatering basically keep invariable, subsequent drying and burning treatment is promoted, and the significant governance advantages are achieved.

Owner:上海广神生态环保科技有限公司 +1

Burn treatment method and composition

InactiveUS20070141168A1Effective barrierProtect the skinBiocideCosmetic preparationsBurn treatmentLavender oil

A composition for burn treatment containing, in % by weight: Almond oil (sweet): 9-10Almond oil (bitter):7-8Lavender oil:4-5Beeswax:8-9Bee Pollen:3-4Purified honey:50-60Propolis:0.2-1 Water: 8-12

Owner:ALKAZEMI WAFA M A R

Medicine for curing burn dressing and method of preparing the same

InactiveCN101249215AGood treatment effectStrong anti-infection effectAnthropod material medical ingredientsHydroxy compound active ingredientsVegetable oilCoptis

Owner:喻永强

Novel burn treatment composition

The invention is directed to a novel topical burn treatment compositions comprising a silicone containing compound, a Vitamin E compound and a local anesthetic. and their use in treating topical burns.

Owner:HEALING SKIN

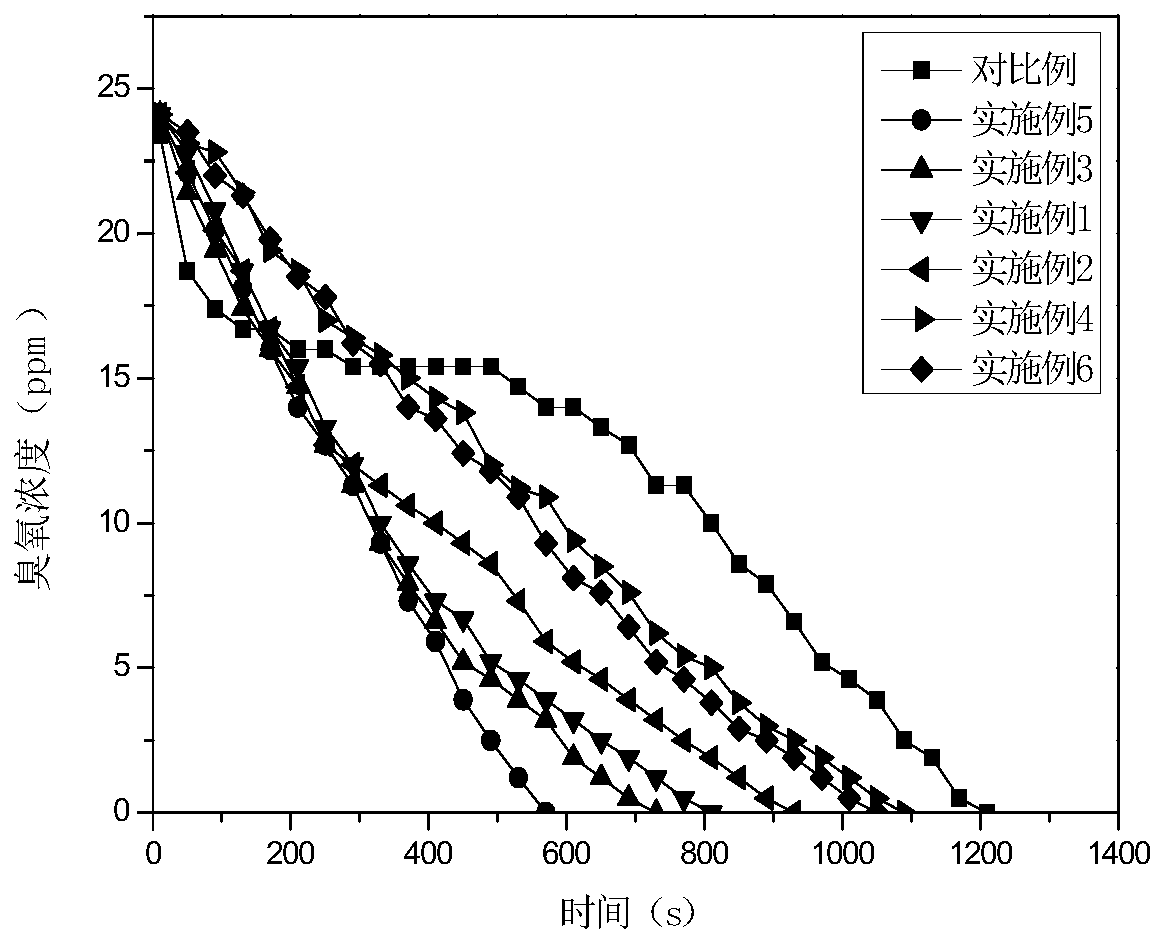

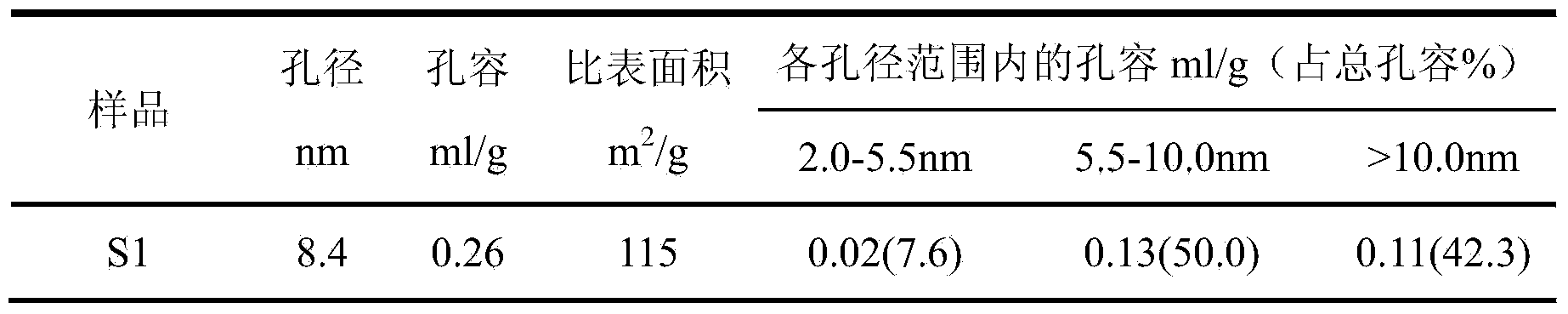

Lanthanum-modified manganese oxide catalyst, and preparation method and application thereof

ActiveCN110420636ALarge specific surface areaEfficient catalytic decompositionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsBurn treatmentPersulfate

The invention provides a lanthanum-modified manganese oxide catalyst, and a preparation method and an application thereof. The preparation method of the lanthanum-modified manganese oxide catalyst includes the following steps: performing hydro-thermal treatment on a bivalent manganese salt and permanganate or persulfate to prepare manganese oxide, doping the manganese oxide with a lanthanum salt,and obtaining the lanthanum-modified manganese oxide catalyst by drying and high temperature burning treatment. The prepared lanthanum-modified manganese oxide catalyst can efficiently catalyze and decompose ozone at room temperature, and enables the time required for decomposing the ozone at room temperature to be greatly shortened compared with manganese oxide without lanthanum modification.

Owner:GUANGZHOU UNIVERSITY

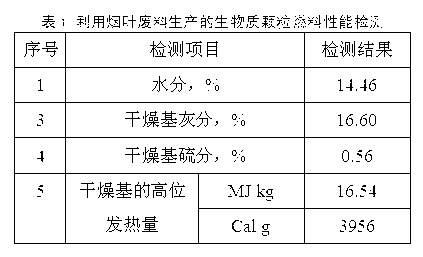

Biomass granular fuel produced by utilizing tobacco waste materials and preparation method thereof

The invention discloses biomass granular fuel produced by utilizing tobacco waste materials and a preparation method thereof. Raw materials of the biomass granular fuel are the tobacco waste materials and water. The preparation method of the biomass granular fuel comprises raw material smashing, water adding and mixing, raw material fermentation, extrusion forming and drying. Waste water and waste gas are not generated in the whole process, not only is the environmental pollution problem caused by burning treatment of the tobacco waste materials solved, but also the ignitability is good, the heat production amount is large, and the biomass granular fuel can be burned in a boiler instead of raw coal. Accordingly, the biomass granular fuel produced by utilizing the tobacco waste materials is environment-friendly and clean energy.

Owner:GUIZHOU HUANENG FUMIN NEW ENERGY TECH

Method for improving activity of distillate oil hydrogenation catalyst

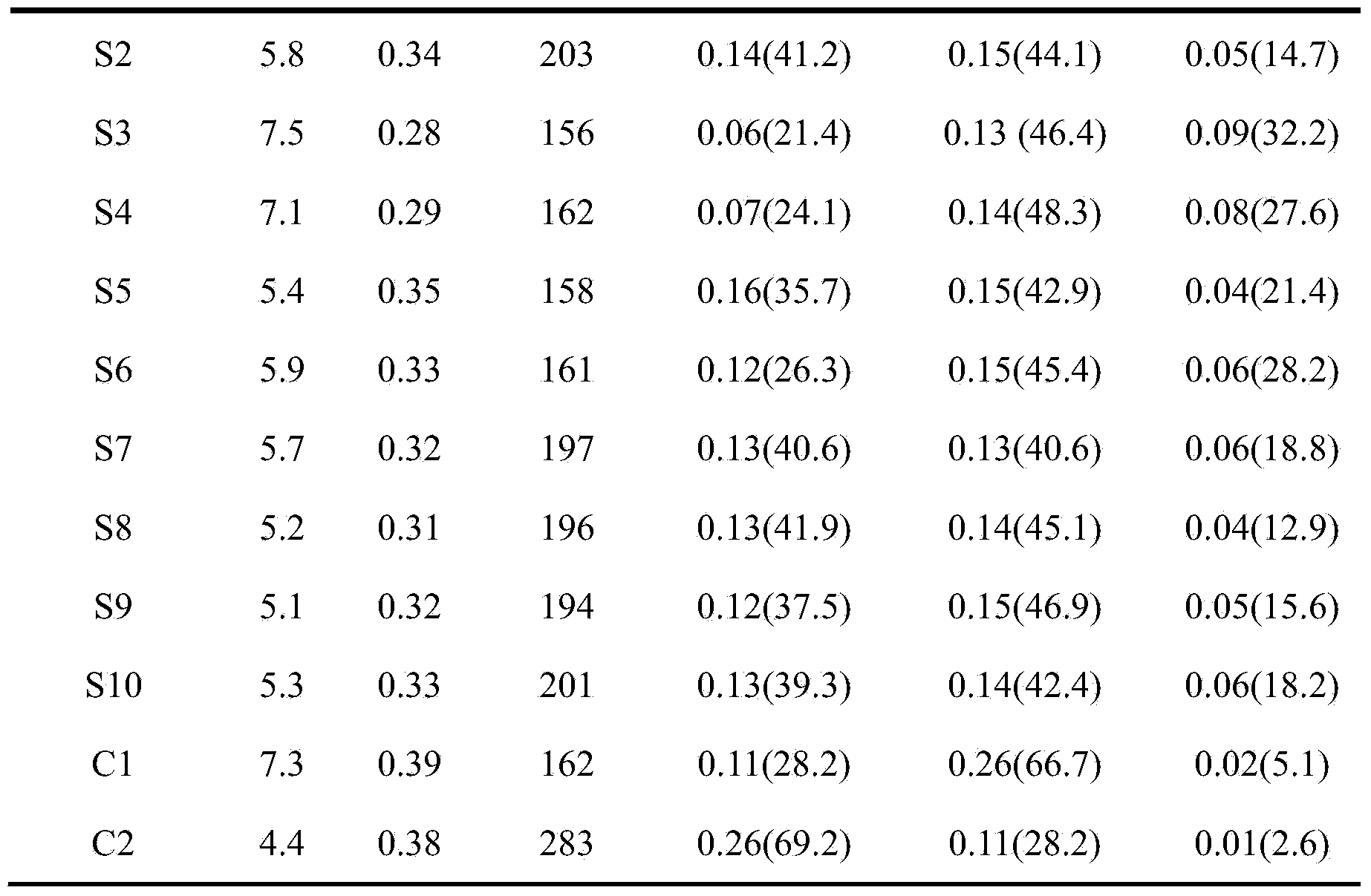

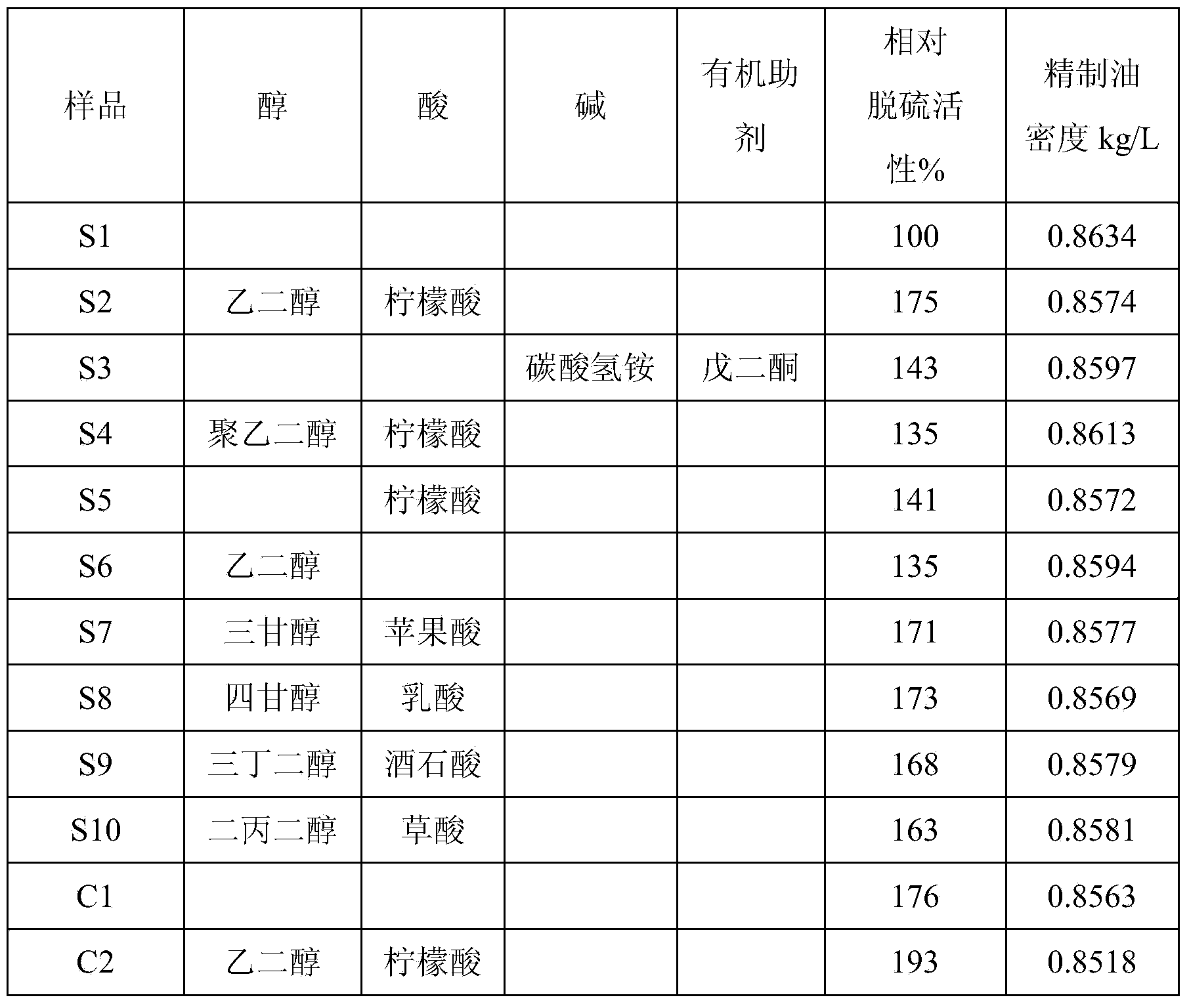

InactiveCN104248995ASimple structureImprove pore structureCatalyst regeneration/reactivationCatalyst activation/preparationOrganic acidAlcohol

The invention relates to a method for improving the activity of a distillate oil hydrogenation catalyst, and is especially suitable for activation and regeneration of carbon deposition and poisoning caused deactivated distillate oil hydrogenation catalyst. The catalyst uses VIB oxide and group VIII oxide as active metal, and is an inactivated catalyst subjected to carbon burning treatment or a fresh catalyst; and the catalyst first fully contacts with a solution containing organic acid and alcohol, and then is subjected to hydro-thermal treatment and low temperature calcination treatment. The method for improving activity of distillate oil hydrogenation catalyst gives consideration to the active phase, pore structure and acidity center of the catalyst, can obviously improve activity of the activated catalyst, and has good industrial application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

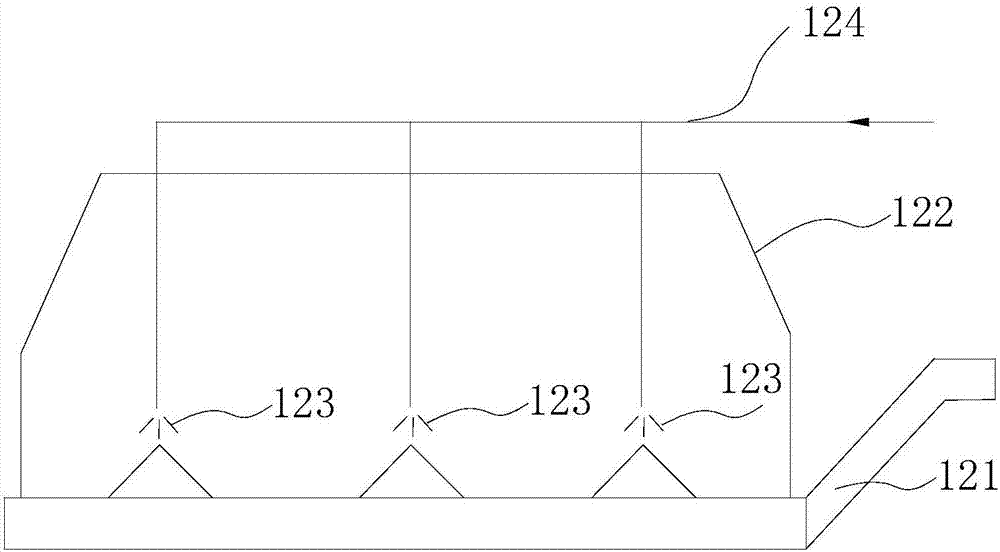

Sludge burning treatment method and system

InactiveCN1270988CImprove combustion efficiencyImprove combustion intensitySludge treatment by oxidationByproduct vaporizationCombustion chamberBurn treatment

The invention relates a treatment method and system for burning sludge, which comprises: conveying the dewatered sludge in moisture percentage of 75-85 % into a combustion chamber of a circulating fluidized bed, and conveying the contaminated gas produced in storing process into the combustion chamber of the circulating fluidized bed, burning the dewatered sludge, contaminated gas and coal together, the end gas discharges by processing. The system comprises circulating fluidized bed boiler, ash separator and sludge storeroom, conveying the dewatered sludge through a sludge carrier pipe and a sludge spraying cap using a screw pump, emitting the sludge into the combustion chamber of the circulating fluidized bed and burning, conveying the said contaminated gas into the chamber of the circulating fluidized bed too. The system also has a steam purging unit and a water high pressure unit which clean the screw pump, sludge carrier pipe and sludge spraying cap nontiming to prevent the clogging by dewatered sludge.

Owner:常州广源热电有限公司 +1

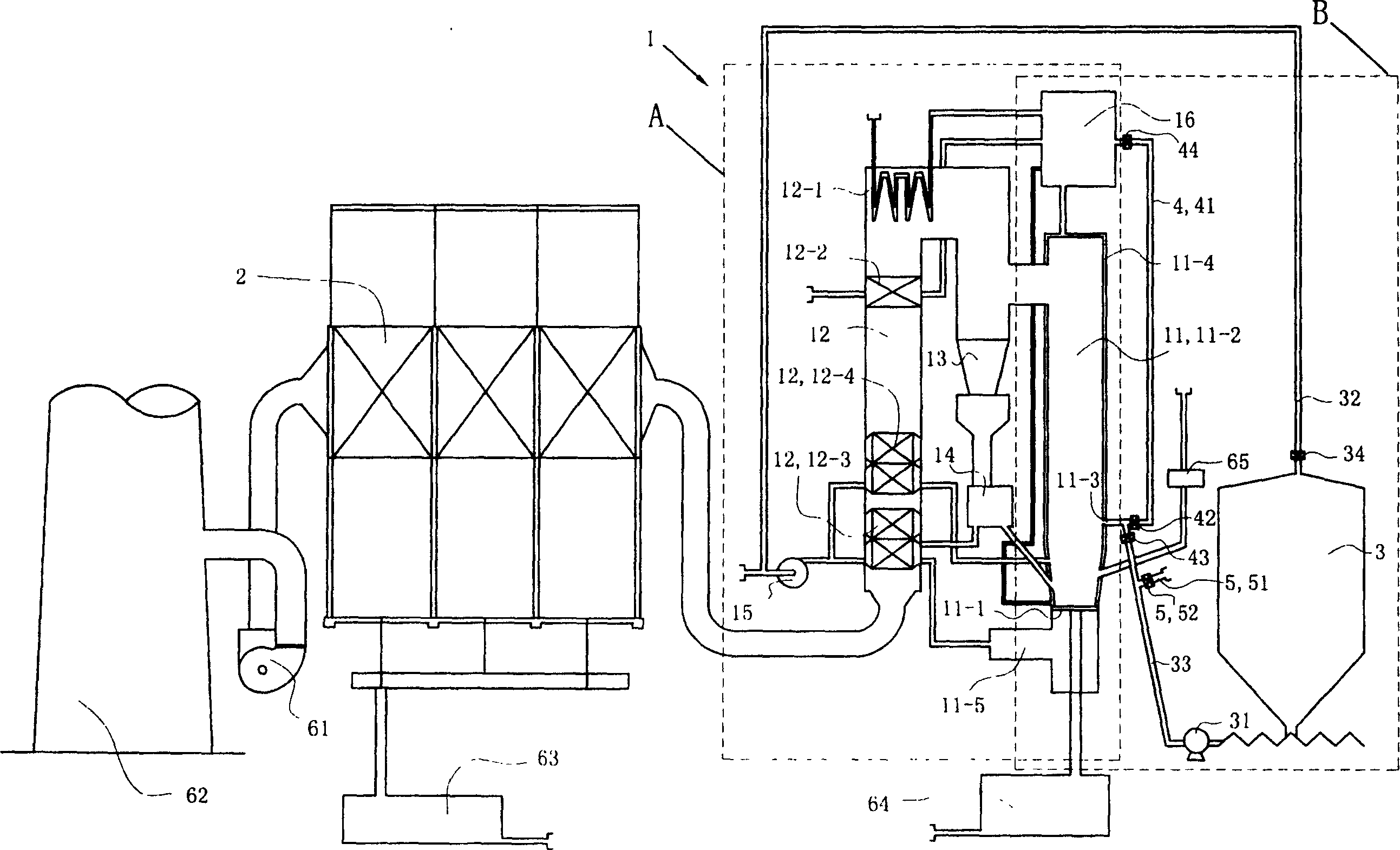

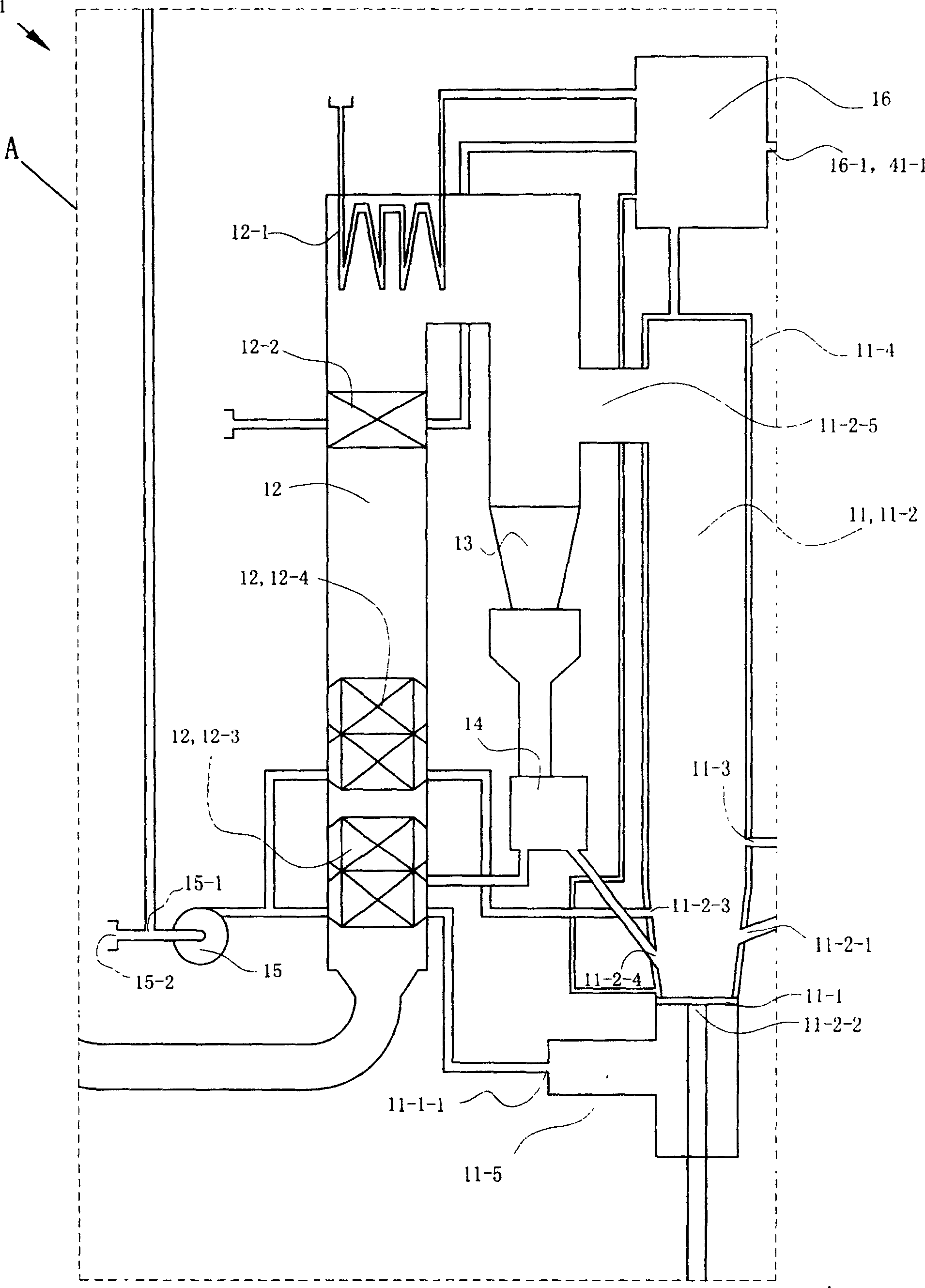

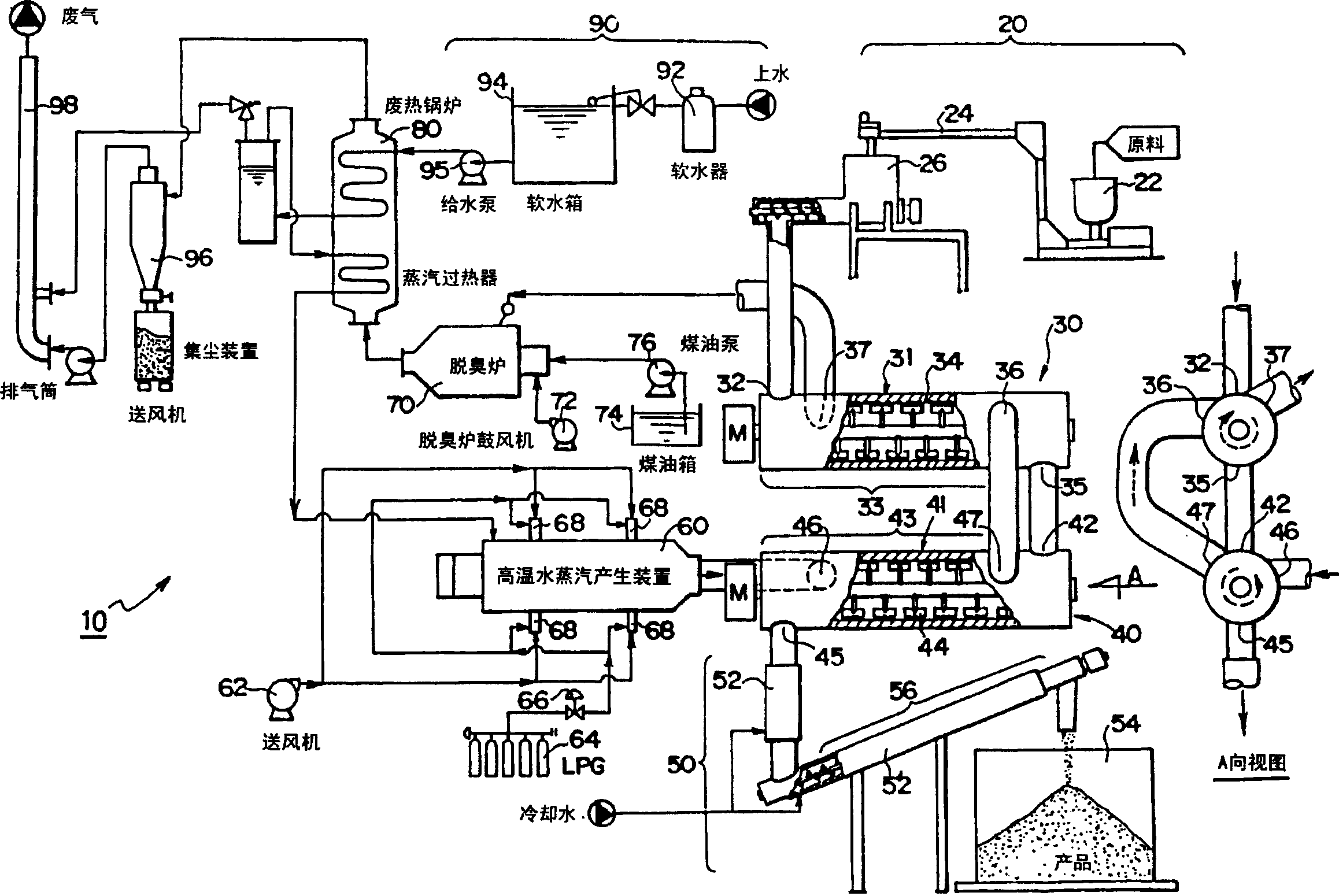

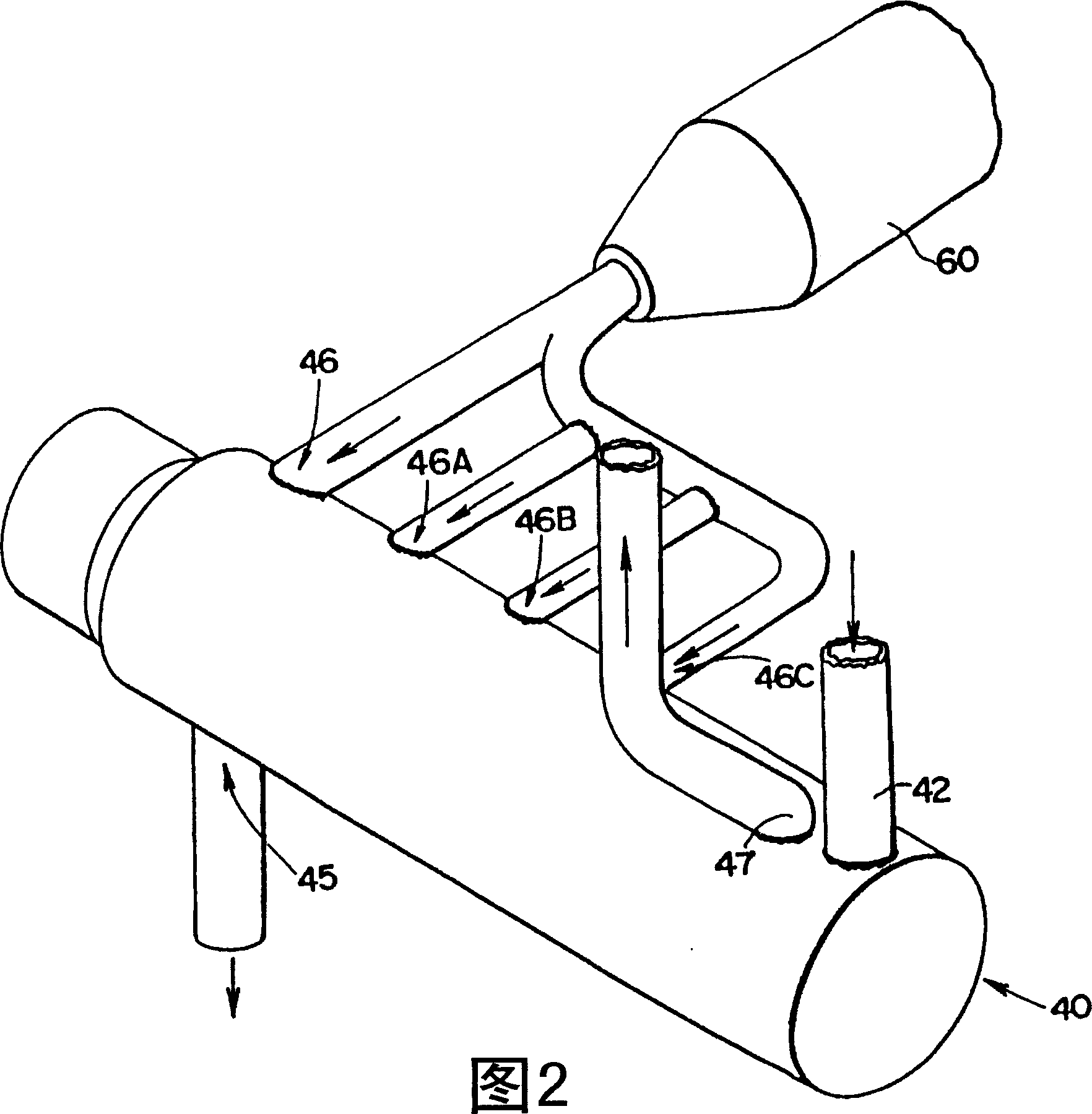

Carbonization apparatus for producing activated carbon

InactiveCN1890349ACheap and easy to generatePromote generationMechanical conveying coke ovensCarbon compoundsActivated carbonBurn treatment

A carbonization apparatus (10) for producing an activated carbon wherein an organic based material to be treated is carbonized, which comprises a carbonization furnace (40) wherein overheated steam is introduced to carbonize a material to be treated and the spent steam is discharged, a drying furnace (30) wherein the steam discharged from the carbonization furnace (40) is introduced to dry the material to be treated and the spent steam is discharged, a high temperature steam generating device (60) wherein steam is introduced and the high temperature overheated steam for use in supplying to the carbonization furnace (40) is formed, a deodorizing furnace (70) wherein impurities contained in the spent steam discharged from the drying furnace (30) are heated to deodorize them through burning and discharging a high temperature an exhaust gas is discharged, and a waste heat boiler (80) wherein water is heated by using the high temperature exhaust gas discharged from the deodorizing furnace (70) and the steam for supplying to the high temperature steam generating device (60) is formed. The carbonization apparatus allows the production of an activated carbon having high quality at a low cost, by recovering and reutilizing the heat contained in the exhaust gas which has been discharged from a deodorizing furnace and has been subjected to a burning treatment.

Owner:INTPROP BANK CORP (JP)

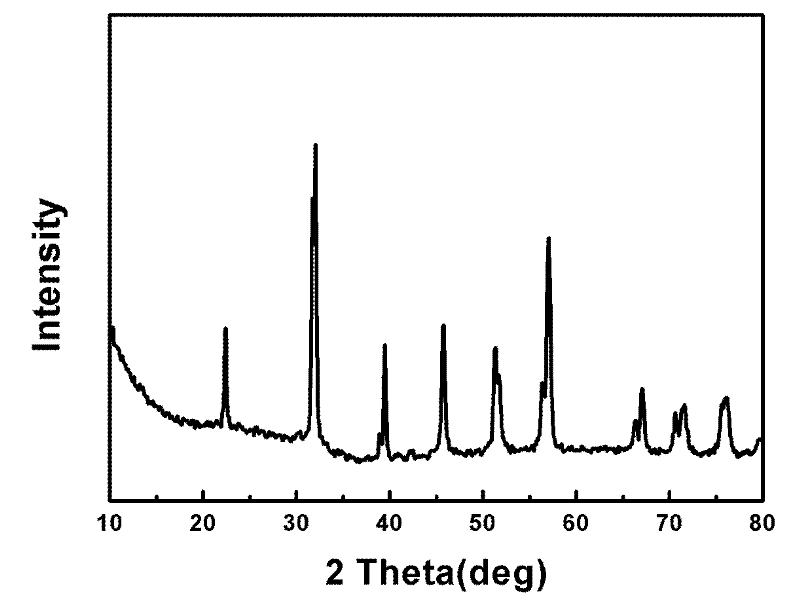

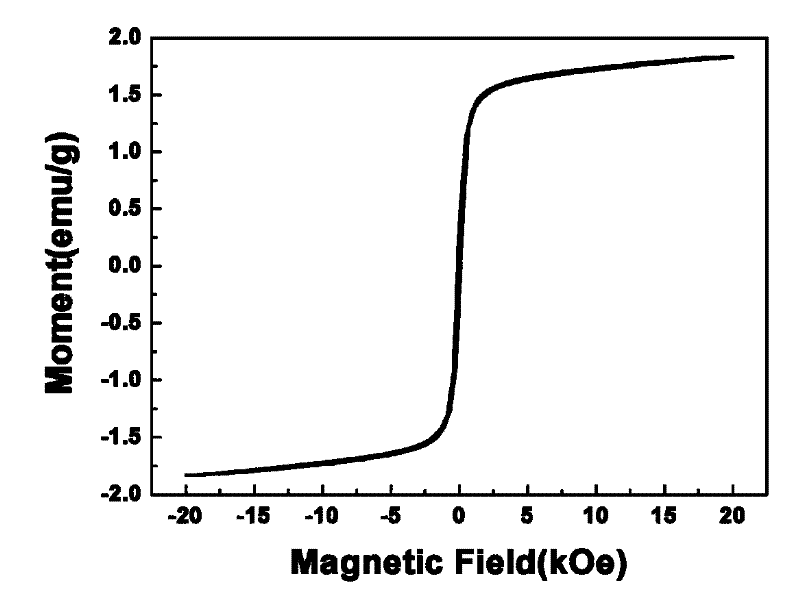

Method for preparing multiferroic single-phase bismuth ferric ceramic

A method for preparing multiferroic single-phase bismuth ferric ceramic belongs to the technical field of material science. The method provided by the invention comprises the following concrete steps of: carrying out two pre-burning treatments on the bismuth ferric xerogel produced by the sol-gel method, namely heating to 400DEG C from room temperature at the heating rate of 1-5 DEG C / min for twotimes, to obtain a bismuth ferric precursor powder; pressing the bismuth ferric precursor powder into a sheet at a pressure of 2-4MPa, followed by sintering at low temperature, namely heating up fromroom temperature to 450-550 DEG C at the heating rate of 3-5 DEG C / min, to obtain the textural single-phase bismuth ferric ceramic made of nanometer particles whose particle size is less than 62nm. The bismuth ferric ceramic prepared by the method in the invention has good single-phase and insulating properties, saturated magnetic hysteresis loops and electric hysteresis loops at room temperatureas well as highly saturated magnetic intensity and remanent polarization. In addition, the method for preparing the multiferroic single-phase bismuth ferric ceramic requires simple equipment as well as a simple preparation technology, adopts the low temperature sintering technology, saves energy and has low cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

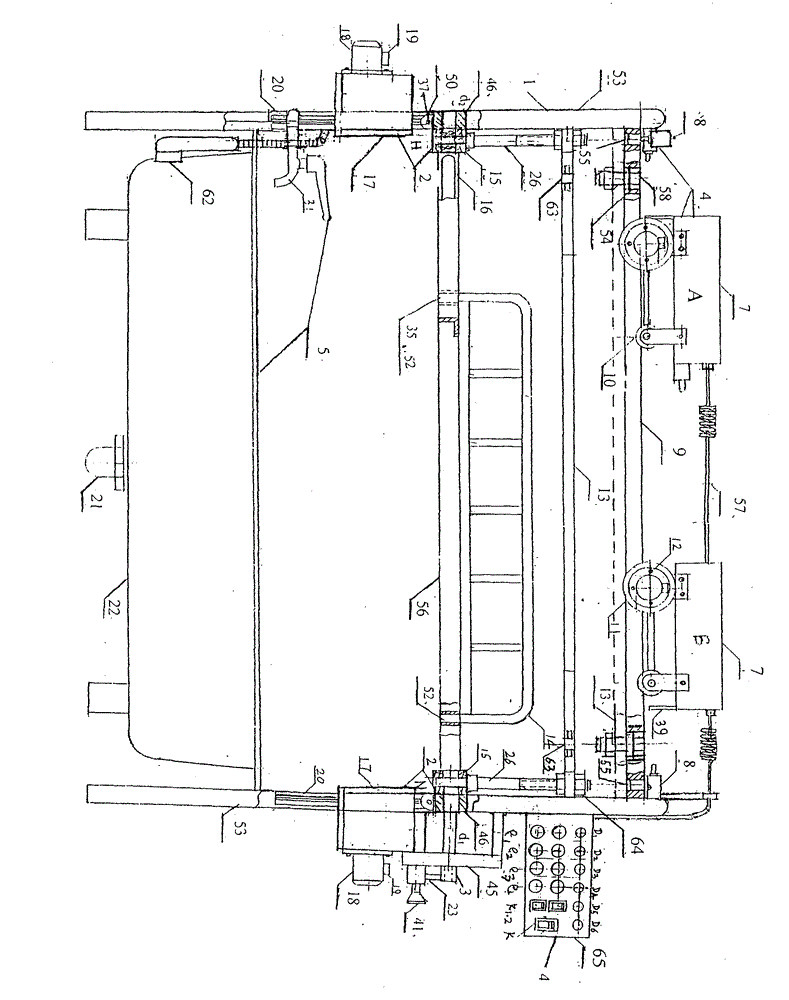

Comprehensive burn treatment bed

The invention discloses a comprehensive burn treatment bed which is novel in structure, convenient and safe to use and capable of conducting automatic operation, reducing treatment time, improving treatment effects and reducing working intensity and is driven by a machine. The bed comprises a bed body, a lifting mechanism, a rotating mechanism, an electric device and an immersion bath. A body turning bed and a body turning frame are arranged and matched in use, a patient lies flatly when the bed is turned upwards, transposition is conducted when the bed is turned downwards, irradiation treatment is conducted on the patient on the body turning frame, and pains of the patient caused by the fact that the patient is bound and hung for back irradiation are removed. An automatic location fixed separation moving device is arranged to replace manual transportation of the body turning frame, an infrared electric heater case all-dimensional radiation effect is achieved in use, the immersion bath is added clinically, and ventilation suspension is conducted on the patient on time to prevent pressure sores. A worm reducer and a bedside guardrail are provided to ensure clinical safety of the patient. The treatment bed is clinically applied to moderate and severe burn patients.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com