Treatment method of high calorific value excess sludge

A technology of excess sludge and disposal method, applied in dewatering/drying/concentrating sludge treatment, combustion method, lighting and heating equipment, etc. Achieve the effect of saving energy consumption and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

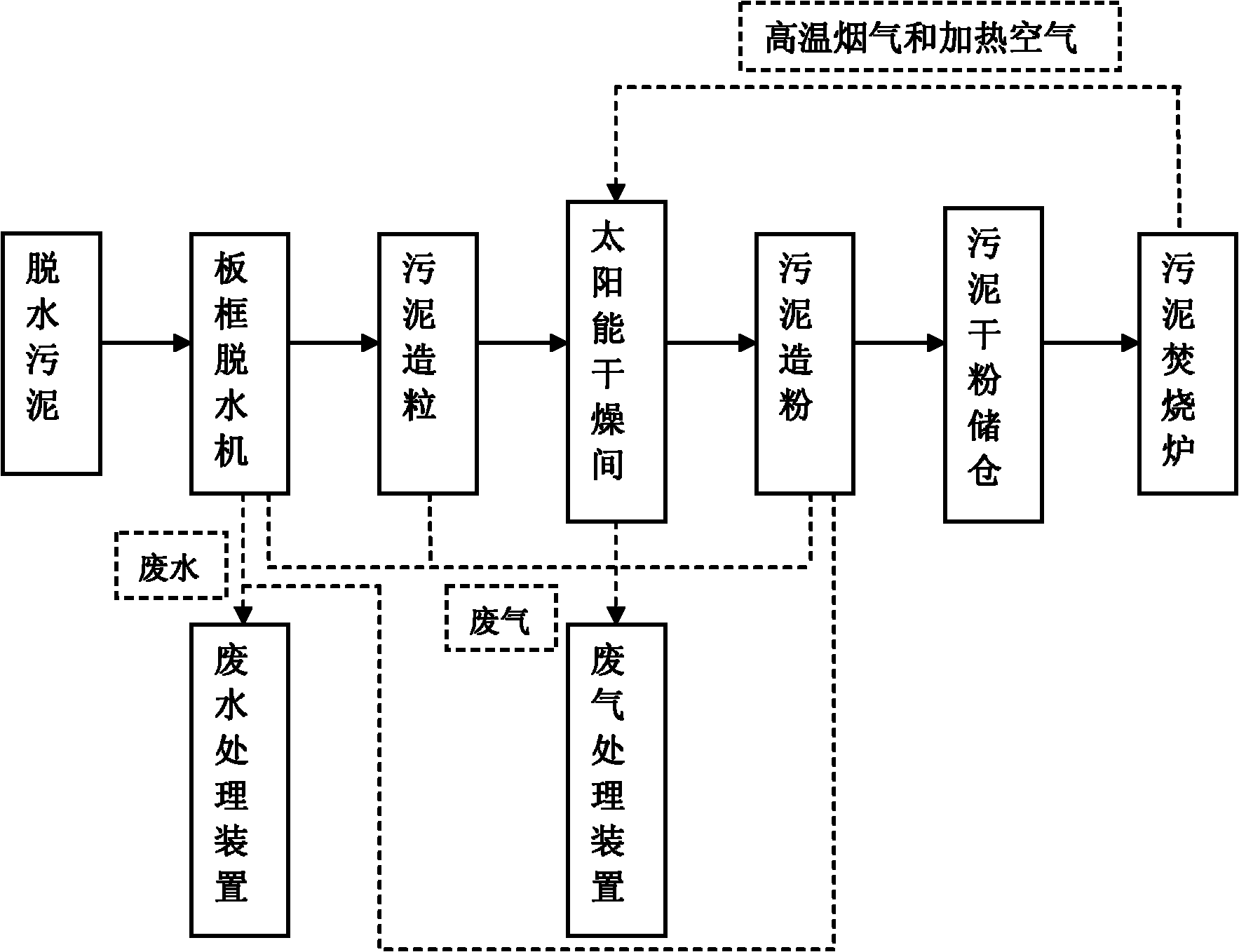

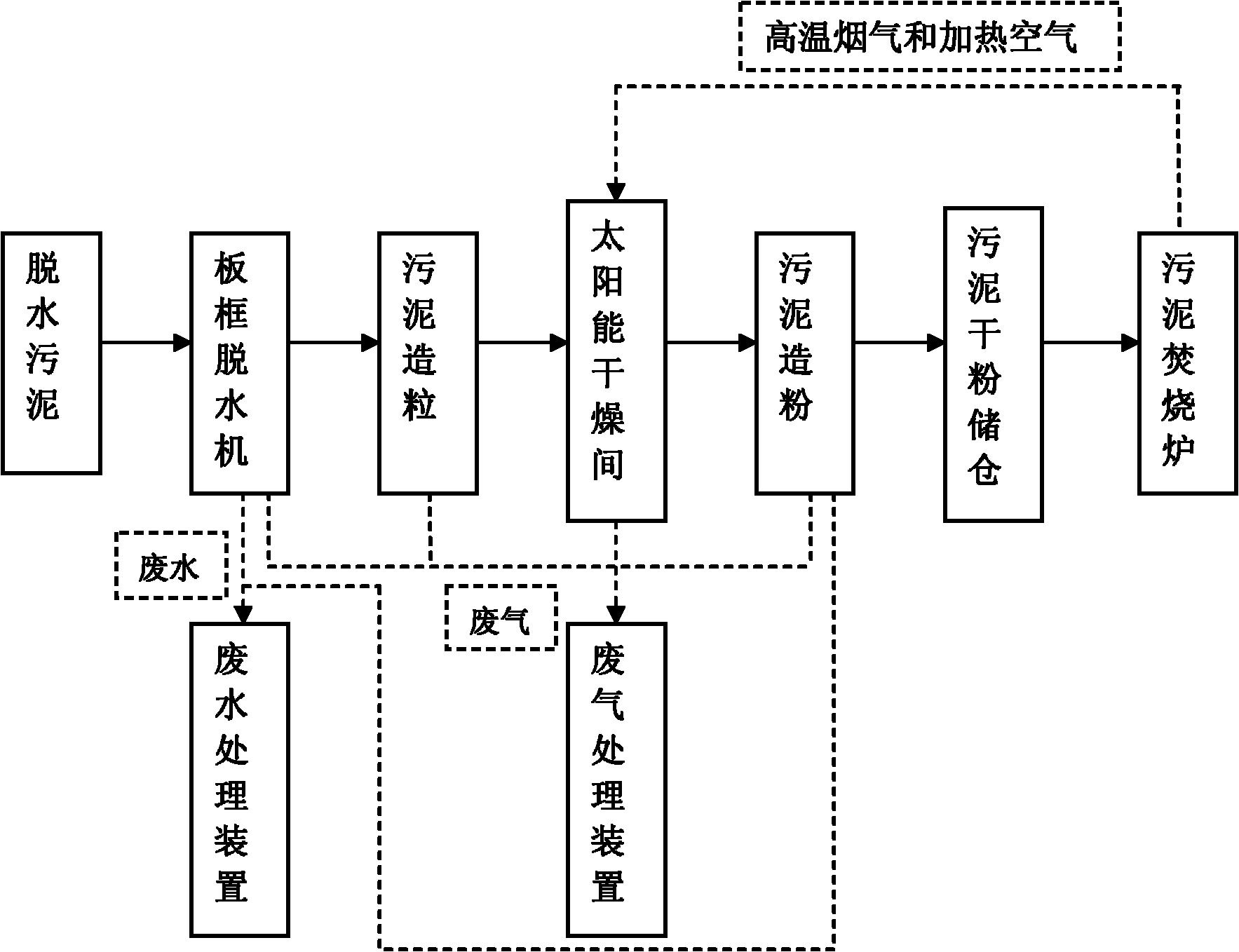

Method used

Image

Examples

Embodiment 1

[0018] The moisture content of the remaining sludge in a sewage treatment plant is 86.2%, and it is sent to the plate and frame filter press, and the hydraulic station provides the plate and frame filter press with a compression pressure of 25MPa. The sludge particles are trapped in the filter chamber to form a semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 50.7%. The semi-dried sludge cake is transported into the sludge granulation device through the sludge cake conveyor, and the sludge granules with a larger specific surface area are produced, and the average particle size of the sludge granules is 3.3mm. The sludge particles are further dried in the thermal energy drying room. The temperature of the flue gas used for drying is 550°C. After drying, the moisture content of the sludge particles drops to 30.5%. Afterwards, the sludge part...

Embodiment 2

[0020] The moisture content of the remaining sludge in a sewage treatment plant is 84.3%, and it is sent to the plate and frame filter press, and the hydraulic station provides the plate and frame filter press with a compression pressure of 28MPa. The sludge particles are trapped in the filter chamber to form a semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 56.9%. The semi-dried sludge cake is transported into the sludge granulation device through the sludge cake conveyor, and the sludge granules with a larger specific surface area are produced, and the average particle size of the sludge granules is 4.3mm. The sludge particles are further dried in the thermal energy drying room. The temperature of the flue gas used for drying is 465°C. After drying, the moisture content of the sludge particles drops to 30.5%. Afterwards, the sludge part...

Embodiment 3

[0022] The moisture content of the remaining sludge in a sewage treatment plant is 80.6%, and it is sent to the plate and frame filter press, and the hydraulic station provides a compacting pressure of 45MPa for the plate and frame filter press. The sludge particles are trapped in the filter chamber to form a semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 45.4%. The semi-dried sludge cake is transported into the sludge granulation device through the sludge cake conveyor, and the sludge granules with a larger specific surface area are produced, and the average particle size of the sludge granules is 4.1mm. The sludge particles are further dried in the thermal energy drying room. The temperature of the flue gas used for drying is 600°C. After drying, the moisture content of the sludge particles drops to 26.2%. Afterwards, the sludge partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com