Patents

Literature

49 results about "Treatment modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

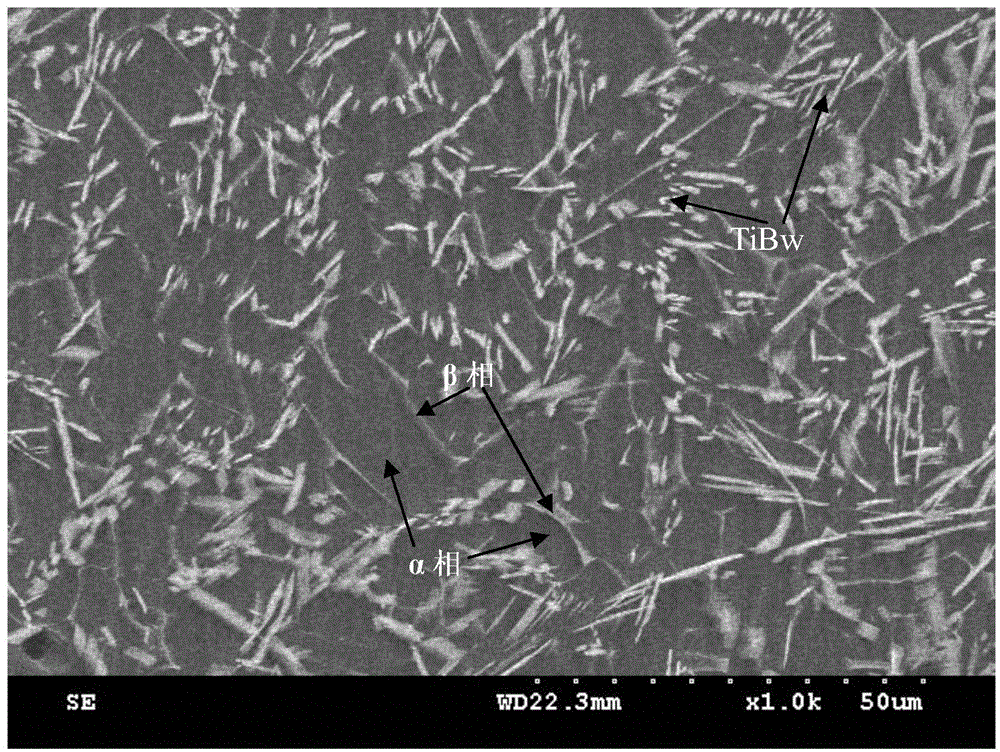

Improvement method for titanium alloy laser 3D printing

ActiveCN104928513AEasy to printImprove wettabilityAdditive manufacturing apparatusTitanium metalTitanium alloy

The invention discloses an improvement method for titanium alloy laser 3D printing and relates to an improvement method for laser 3D printing. The improvement method for titanium alloy laser 3D printing solves the problems that titanium alloy and components prepared through laser 3D printing at present are low in strength level and heat resistant temperature, the metallographic structure is thick and big and not even, the metallographic structure grows to be big in the subsequent heat treatment modification process, the technological parameter selectable range in subsequent heat treatment is narrow, the mechanical property improvement is limited, and the plasticity level of the alloy and the components is low. The improvement method includes the steps that firstly, titanium or titanium alloy powder is evenly mixed with improved raw material powder in a ball milling mode; secondly, laser 3D printing is conducted. The metallographic structure of a laser 3D titanium metal product prepared through the mode of execution is thin and small, a subsequent heat treatment window can be greatly expanded, a balanced structure formed by high-temperature annealing can be achieved, long-time solution strengthening processing or annealing processing can be conducted, the even metallographic structure is obtained, and the mechanical performance of the metallographic structure is greatly improved.

Owner:HARBIN INST OF TECH

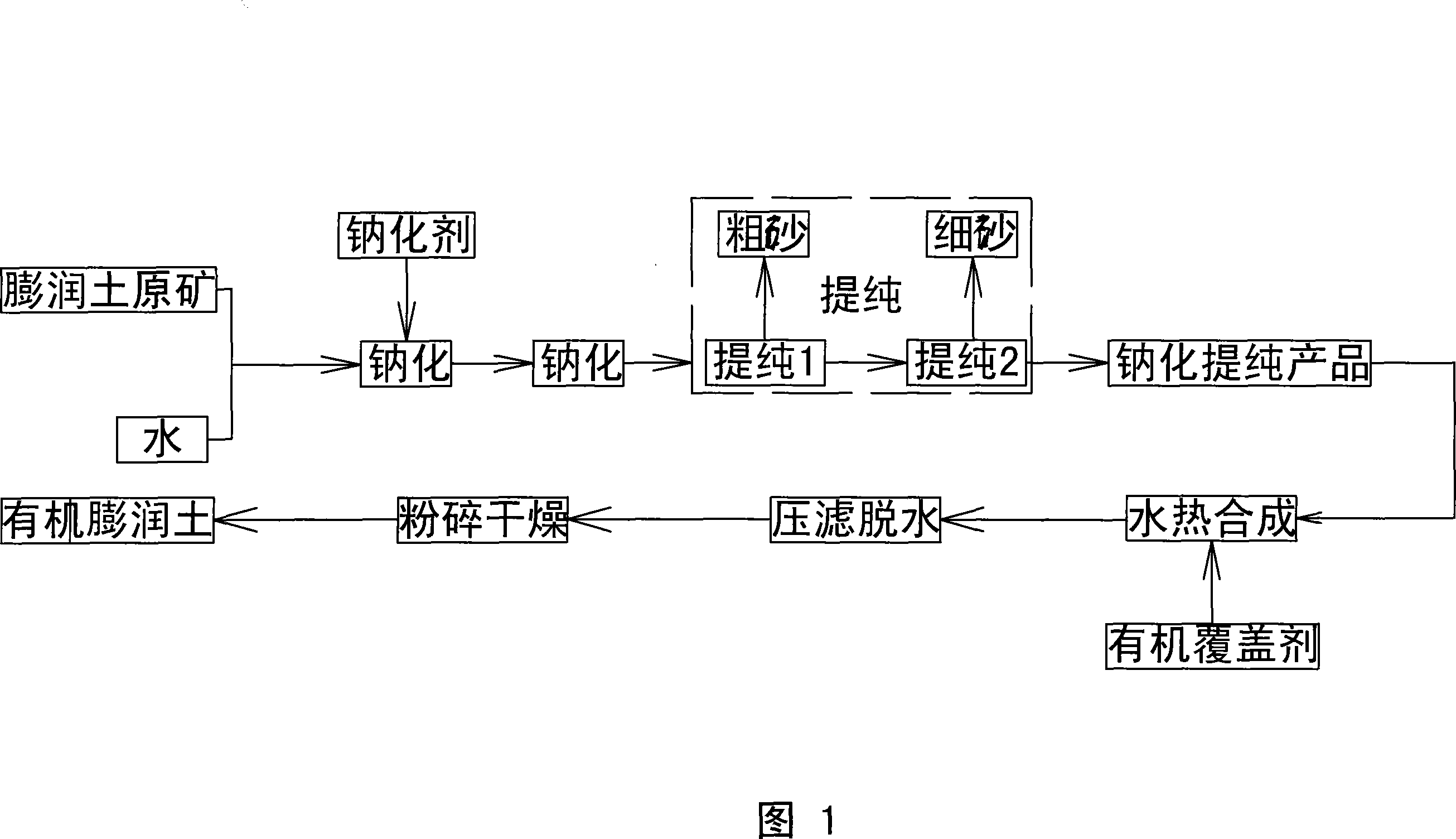

Method for preparing heavy-viscous organophilic bentonite

InactiveCN101224894AContinuously workingImprove stabilityPigmenting treatmentSilicon compoundsSodium BentonitePrinting ink

The invention provides a method for preparing high viscosity organophilic bentonite, which carries out steps of sodium treatment, purification, hydrothermal synthesis, dewatering by filter pressing, crashing and drying operation to bentonite raw ore to obtain the high viscosity organophilic bentonite. The invention can be directly applied to oil paint, printing ink, petroleum drilling slurry and heavy polymer and so on as a thickening suspension agent, a fluid deformation agent and an anti-sagging agent. Through systematic study on technologies of the sodium treatment modification, purification, organic compound and so on of the bentonite, the invention prepares organophilic bentonite jelly glue with stable product quality and excellent performance and determines a proper technical process flow and technical parameters.

Owner:苏州中材非金属矿工业设计研究院有限公司

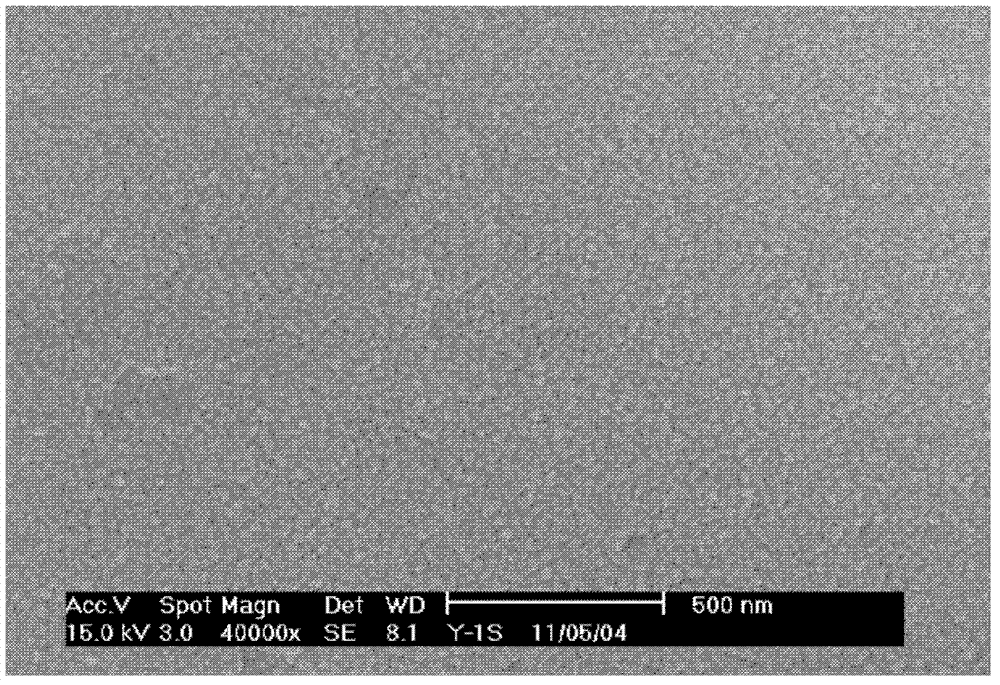

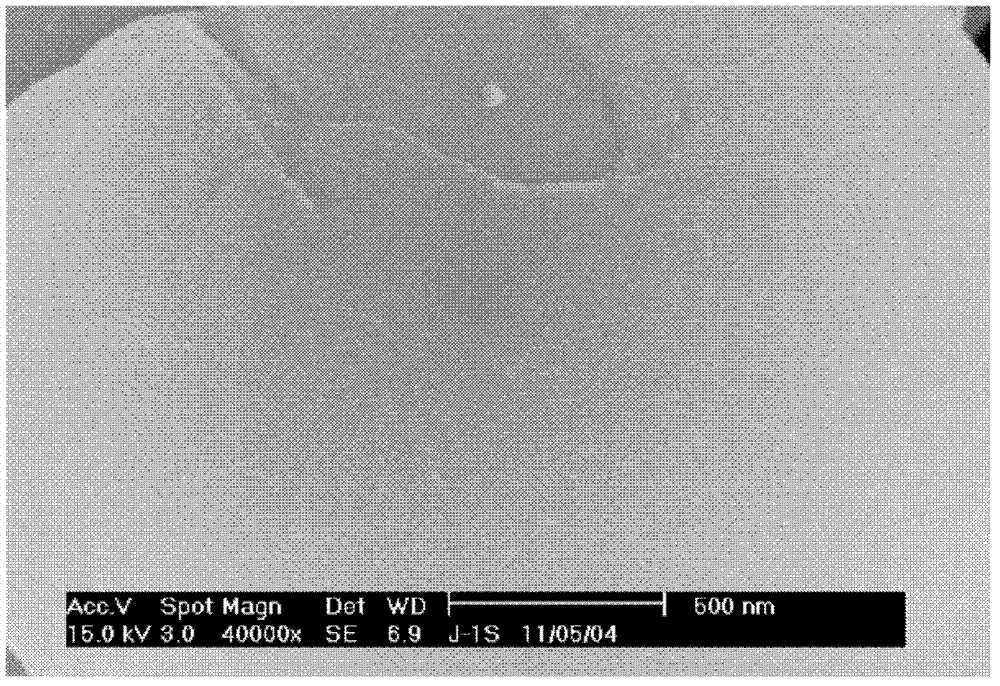

Nano silver in-situ formation silver-plating method based on plasma modification and silver-plated fabric

ActiveCN104988720AIncrease surface areaImprove wettabilityFibre typesUltrasonic/sonic fibre treatmentSilver plateSilver overlay

The invention relates to a nano silver in-situ formation silver-plating method based on plasma modification and a silver plated fabric. In the provided method, a plasma surface treatment modification technology is adopted to crack and etch the surface of synthetic fibers so as to form micro pits and fine cracks on the surface of fibers, thus the surface area of the fibers is enlarged, and the wettability of the fiber surface is improved. At the same time, the surface of the fibers is etched, and the binding strength between the metal coating and the fibers is enhanced. After the fibers are subjected to an oxygen gas plasma technology, hydrophilic and polar groups (-COOH, =C=O) are grafted on the fiber surface, thus silver ions can be adhered on the fiber surface more easily; in the presence of polyvinylpyrrolidone (PVC), sodium borohydride (NaBH4) is taken as the reducing agent to directly reduce the silver ions into nano silver particles, and a compact silver coating is in-situ generated on the etched fiber surface. The provided method has the advantages of simple technology, environment-friendliness, energy saving, and reduced cost. The silver coating on the produced silver-plated fabric is uniform and compact, the binding force between the silver coating and the fabric is strong, and the method is worth to promote.

Owner:SHANHAI CHENLONG TEXTILE NEW MATERIAL CO LTD

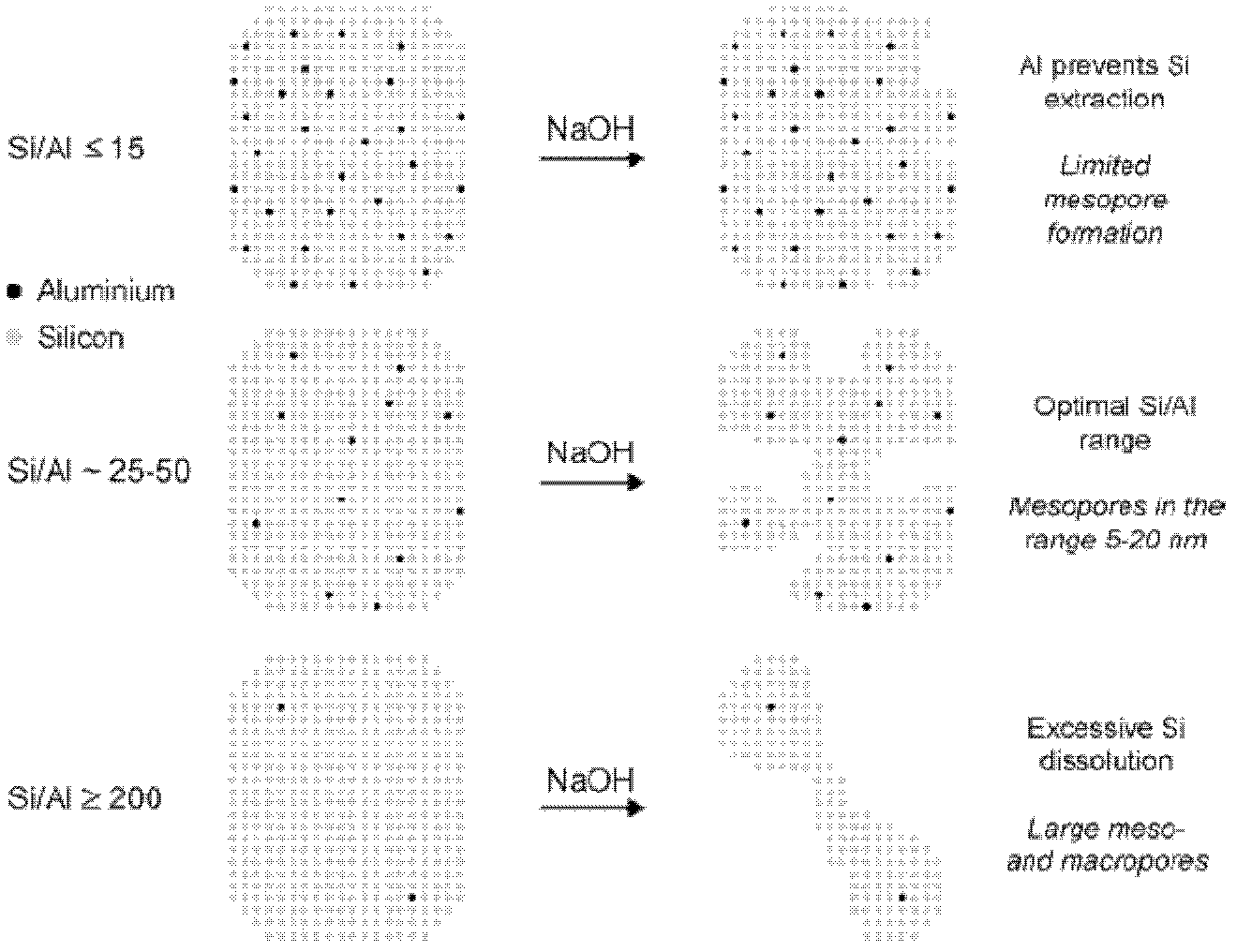

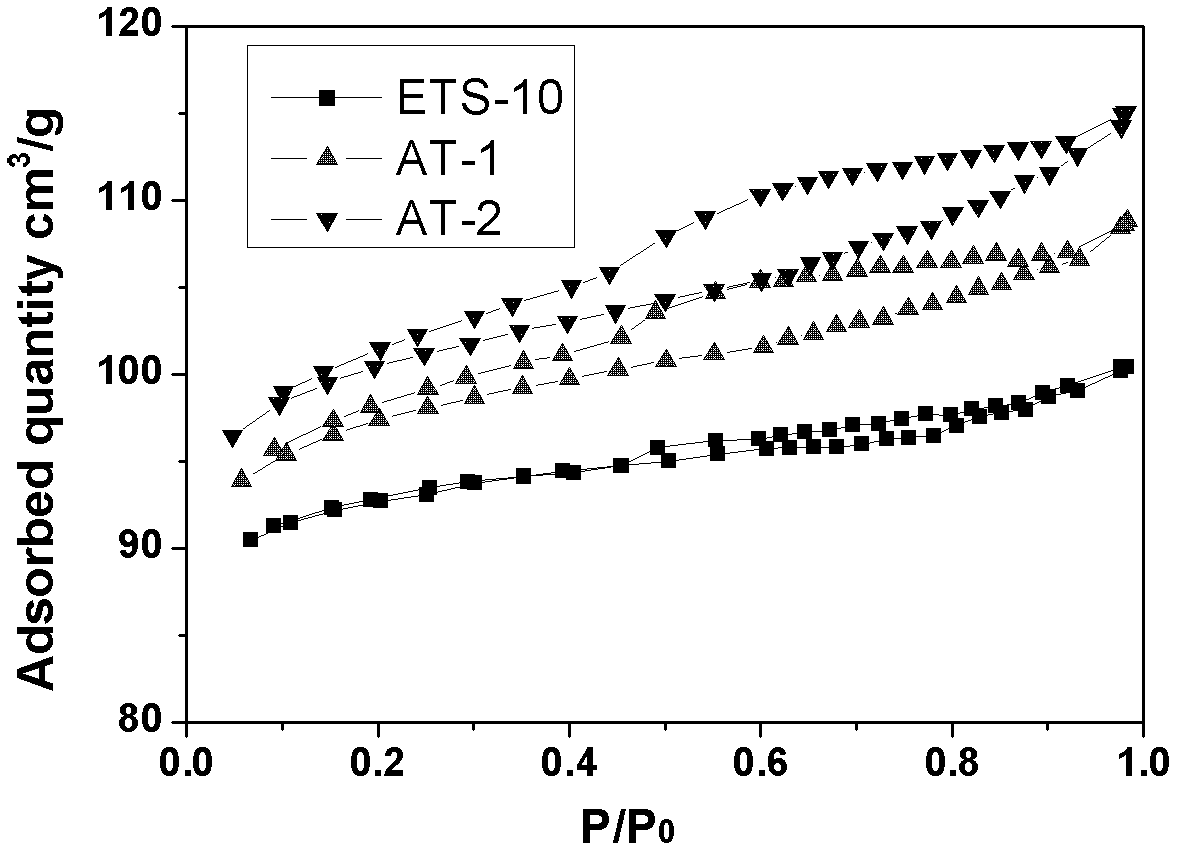

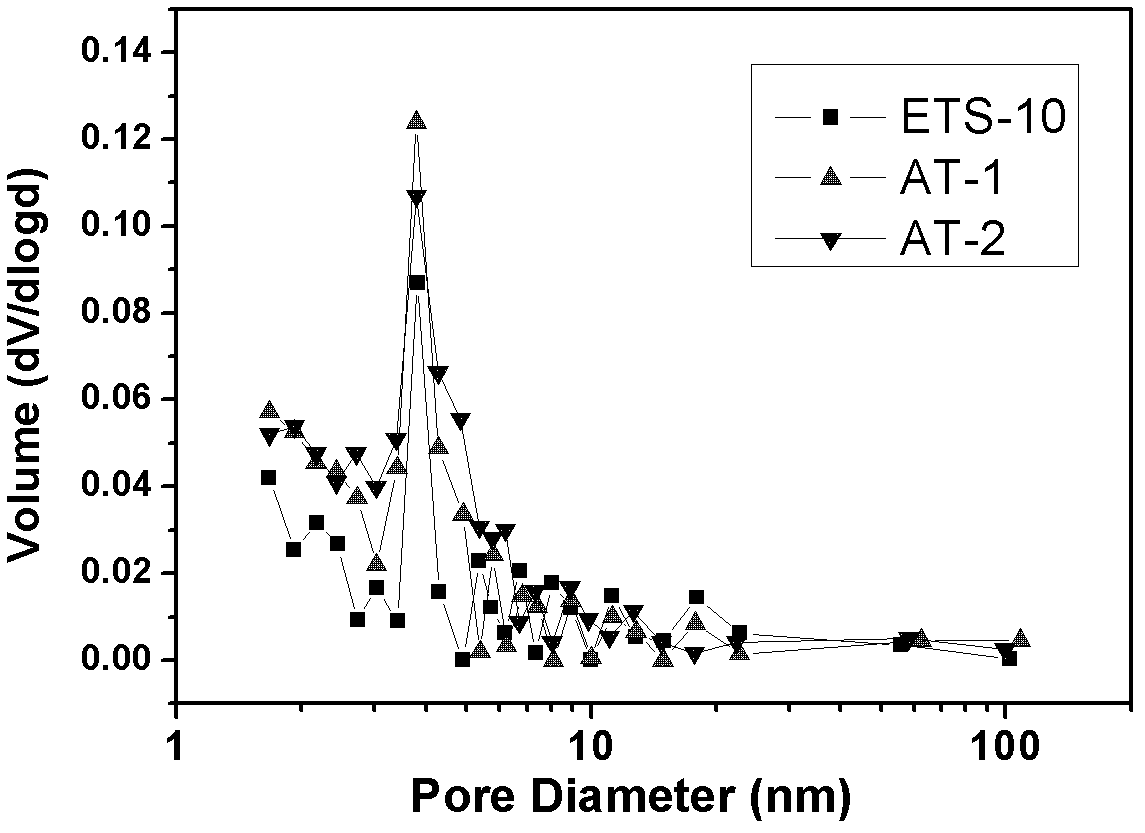

ETS-10 titanium silicalite molecular sieve modification method

ActiveCN102923729ATo achieve rich titaniumHigh activityCrystalline aluminosilicate zeolitesMolecular sieveAluminate

The invention relates to an ETS-10 titanium silicalite molecular sieve modification method. The ETS-10 titanium silicalite molecular sieve modification method provided by the invention comprises the following steps: alkali treatment modification: carrying out alkali treatment modification of EST-10 titanium silicalite molecular sieve raw powder through adopting an alkaline solution, filtering, washing, and drying to obtain alkali treatment modified ETS-10 titanium silicalite molecular sieve; and realuminated modification treatment: carrying out realuminated modification treatment of the alkali treatment modified ETS-10 titanium silicalite molecular sieve through adopting an aluminum salt solution or an aluminate solution, filtering, washing, drying, and roasting to obtain the alkali treatment modification and realuminated modification treated ETS-10 titanium silicalite molecular sieve. The modification method provided by the invention adopts the alkali treatment modification and the realuminated modification treatment of the EST-10 titanium silicalite molecular sieve raw powder to be carried out, so the surface phase of the EST-10 titanium silicalite molecular sieve is rich in titanium and aluminum, abundant meso-structures are introduced, and the skeletal acidity is improved.

Owner:PETROCHINA CO LTD +1

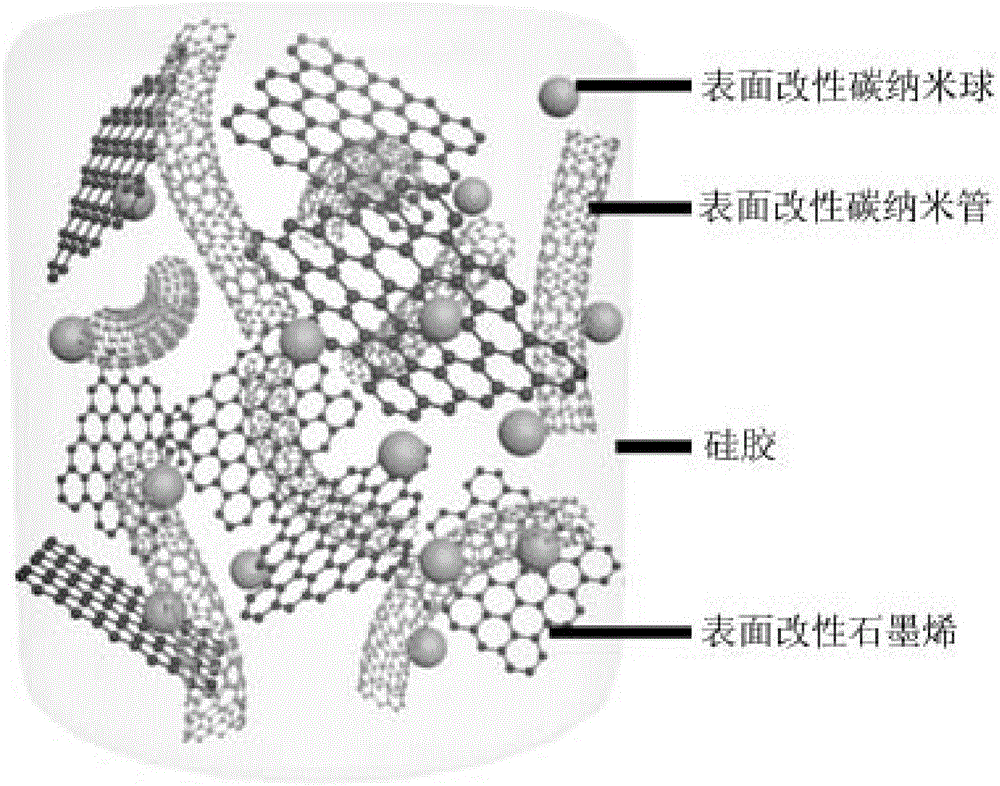

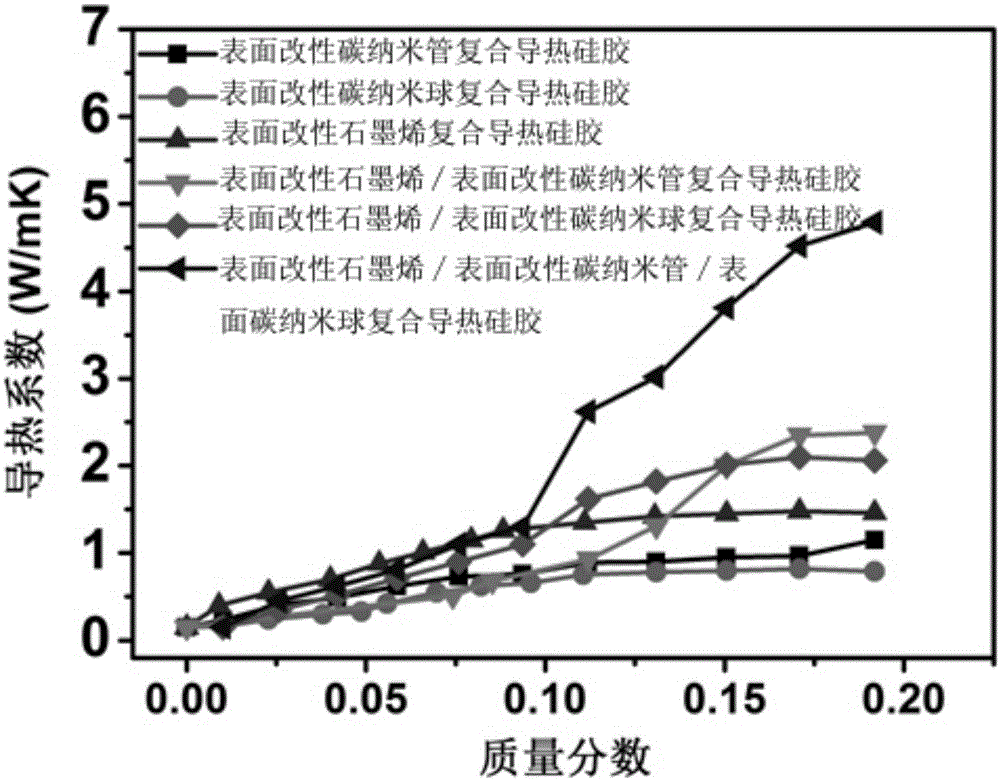

Point, line, surface three-dimensional carbon material composite heat-conduction silica gel and preparation method thereof

The present invention provides a point, line, surface three-dimensional carbon material composite heat-conduction silica gel and a preparation method thereof. The composite heat-conduction silica gel comprises, by weight, 0.1-30% of surface-modified graphene, 0.1-30% of surface-modified carbon nano-tubes, 0.1-30% of surface-modified carbon nano-spheres, and the balance of silica gel, wherein the sum of the mass fractions of the surface-modified graphene, the surface-modified carbon nano-tubes and the surface-modified carbon nano-spheres is more than or equal to 10%, a mass ratio of the surface-modified graphene to the surface-modified carbon nano-tubes to the surface-modified carbon nano-spheres is 1:0.5-2:0.5-4, and the surface-modified graphene, the surface-modified carbon nano-tubes and the surface-modified carbon nano-spheres are prepared through treatment modification with strong acids. According to the present invention, the solubilities and the dispersions of the graphene, the carbon nano-tubes and the carbon nano-spheres in the silica gel are effectively improved, and the three modified carbon materials form the stable and continuous three-dimensional heat-conduction network in the silica gel so as to substantially improve the thermal conductivity of the heat-conduction silica gel.

Owner:江苏华永烯科技有限公司

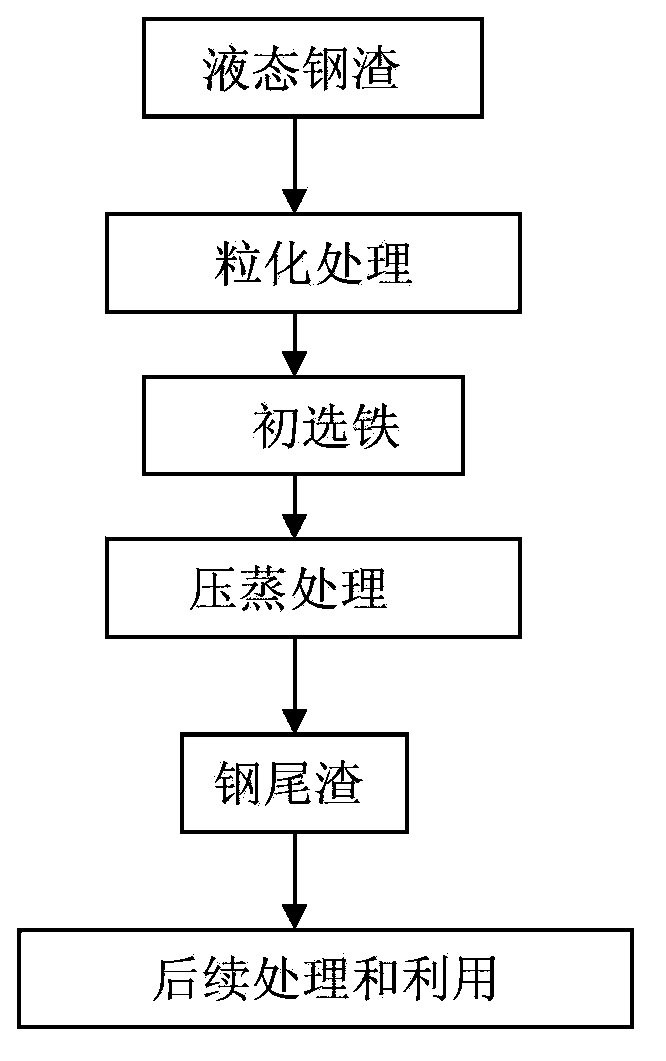

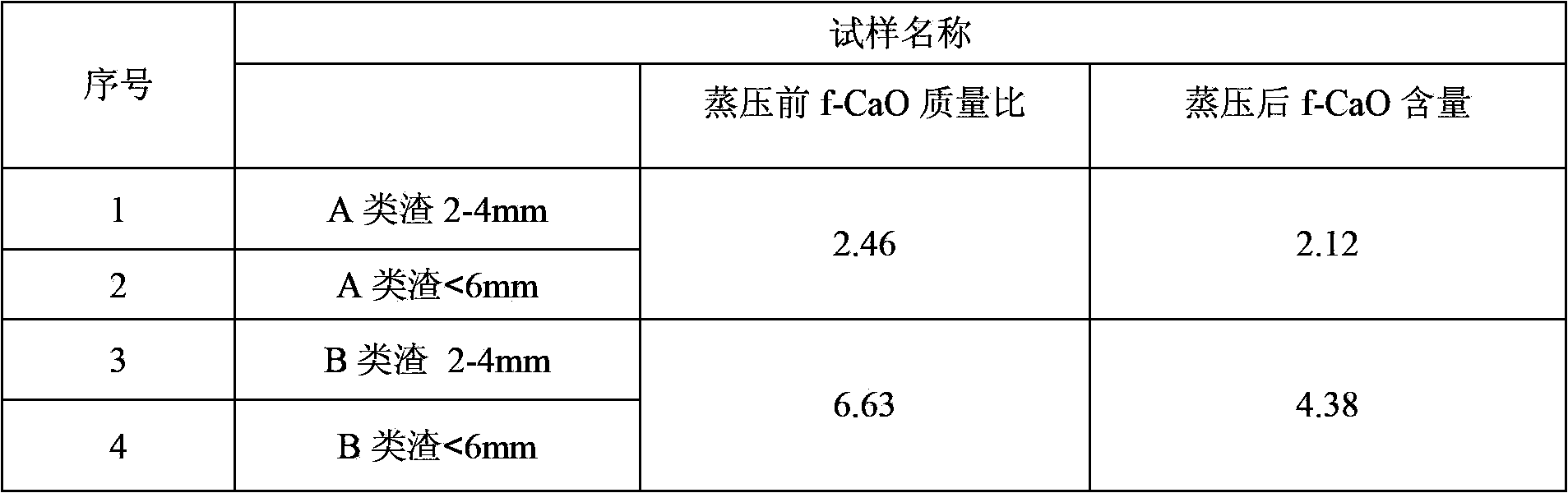

Autoclaving treatment modification technology for converter steel slag and applications thereof

ActiveCN103571983AImprove use valueIncrease added valueRecycling and recovery technologiesSlagAdditional values

The invention relates to the field of steel smelting, and particularly discloses a method of reducing contents of free calcium oxide and magnesium oxide in converter steel slag and improving steel slag stability. The method includes maintaining the temperature of the steel slag by utilization of waste heat after liquid steel slag pelletization treatment, increasing pressure during a temperature maintaining process, and subjecting the pelletized steel slag to autoclaving treatment. By utilization of the technology, the waste heat after steel slag treatment is effectively utilized, and therefore heat lost during treatment processes of the steel slag is utilized reasonably and effectively, thus saving energy, and increasing additional value of steel slag production.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

Alkali treatment modification method of alumina carrier as well as preparation method and application of silver catalyst supported by alumina carrier

ActiveCN103357436ARich in channelsEasy to getCatalyst carriersOrganic chemistryTreatment modificationEthylene

The invention relates to an alkali treatment modification method for forming an alpha-alumina carrier of a silver catalyst used for producing ethylene oxide through ethylene oxidation. The method has the beneficial effect of increasing the pore canal of the carrier by treating the formed alpha-alumina carrier with an alkaline solution at a certain concentration under the heating and stirring conditions. The silver catalyst prepared from and supported by the alpha-alumina carrier prepared by the method is beneficial to diffusion of reaction products. The modified alpha-alumina carrier shows good selectivity when applied to the reaction process of producing ethylene oxide through ethylene oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and device of bentonite cat litter

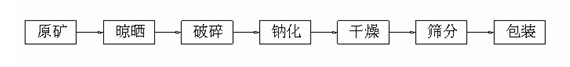

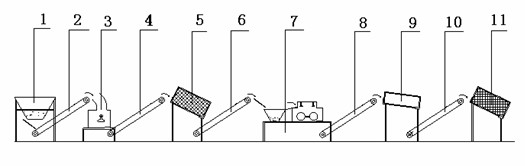

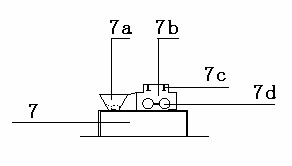

The invention discloses a preparation method and device of bentonite cat litter. The preparation method consists of airing, crushing, sodium-treating, drying, screening and packaging. The device consists of a hammer crusher, a trommel screen, a planet gear mill, a roller drier and a belt conveyor. The raw ore of bentonite is subject to simple airing and manual impurities removal, is crushed and subject to sodium-treatment modification by using the planet gear mill, and is dried and screened to obtain the bentonite cat litter finished product. By adopting the method, grinding and granulating processes required by the conventional method for preparing the bentonite cat litter are saved, the consumption of a sodium-treating agent is less, the process is simple, and the cost is low.

Owner:湖北中非膨润土有限公司

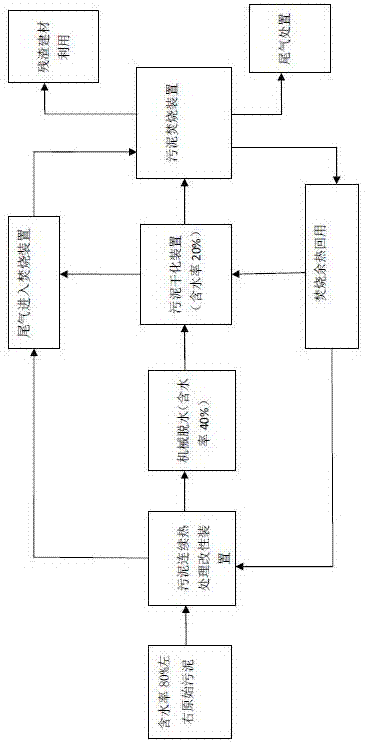

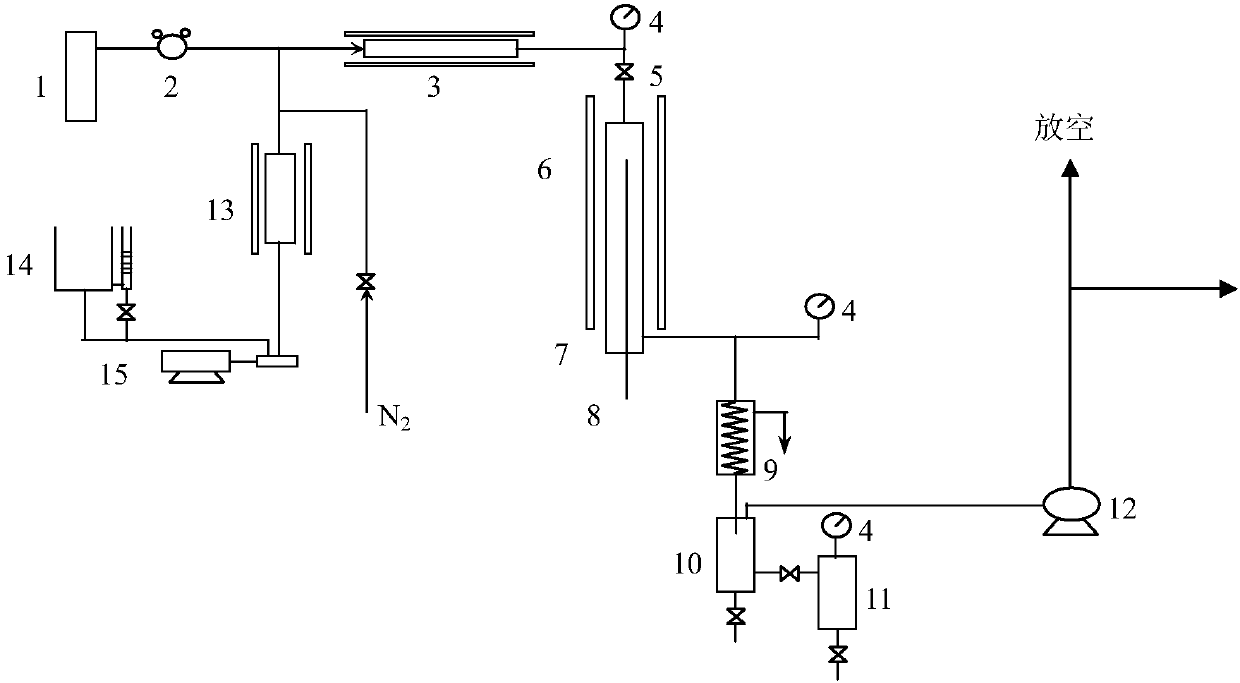

Sludge continuous-heat-treatment modification device and technology of deep dehydrating, drying and incineration

ActiveCN107265821ARealize resource utilizationAvoid it happening againSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringTreatment modification

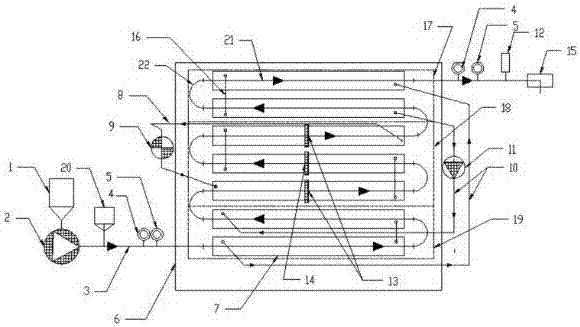

The invention relates to a sludge continuous-heat-treatment modification device and a technology of deep dehydrating, drying and incineration. The sludge continuous-heat-treatment modification device comprises sludge conveying tubes and heat medium spacing casing tubes, wherein the sludge conveying tubes comprises a preheating section, a reacting section and a cooling section, and the sludge conveying tubes of all the preheating section, the reacting section and the cooling section are sleeved by the heat medium spacing casing tubes; the heat medium spacing casing tube of the reacting section communicates with a heat medium heating converter to form a first heat medium circulating loop; the heat medium spacing casing tube of the preheating section communicates with the heat medium spacing casing tube of the cooling section to form a second heat medium circulating loop; and a heat medium heat recovery circulating pump is arranged in the second heat medium circulating loop. The sludge continuous-heat-treatment modification device uses a heat medium to perform indirect heat treatment on sludge and improves the dehydrating property of the sludge, therefore the sludge continuous heat treatment is realized and the recycling use of the heat medium saves more energy and is more friendly to environment at the same time.

Owner:浙江绿治环保技术有限公司 +1

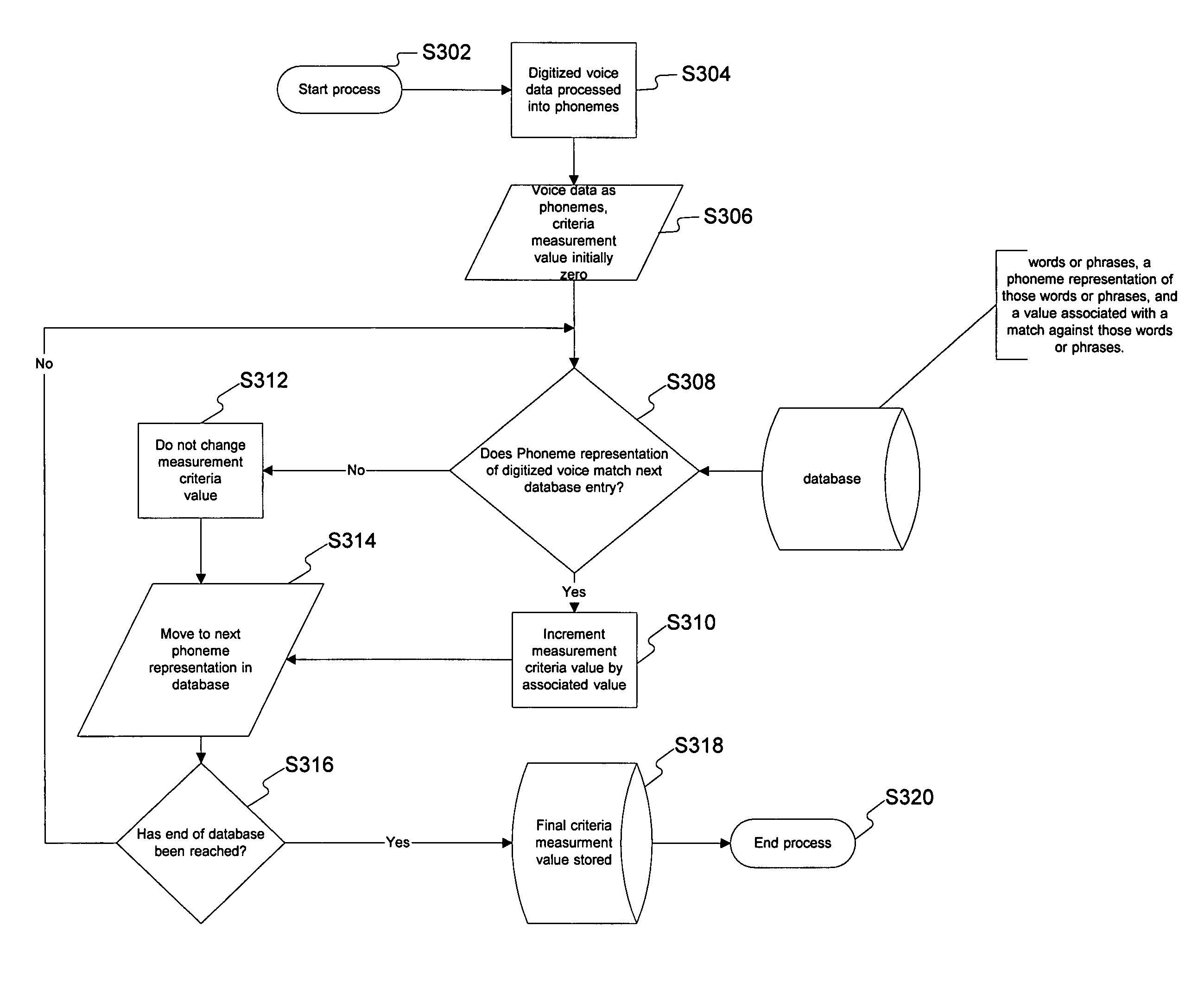

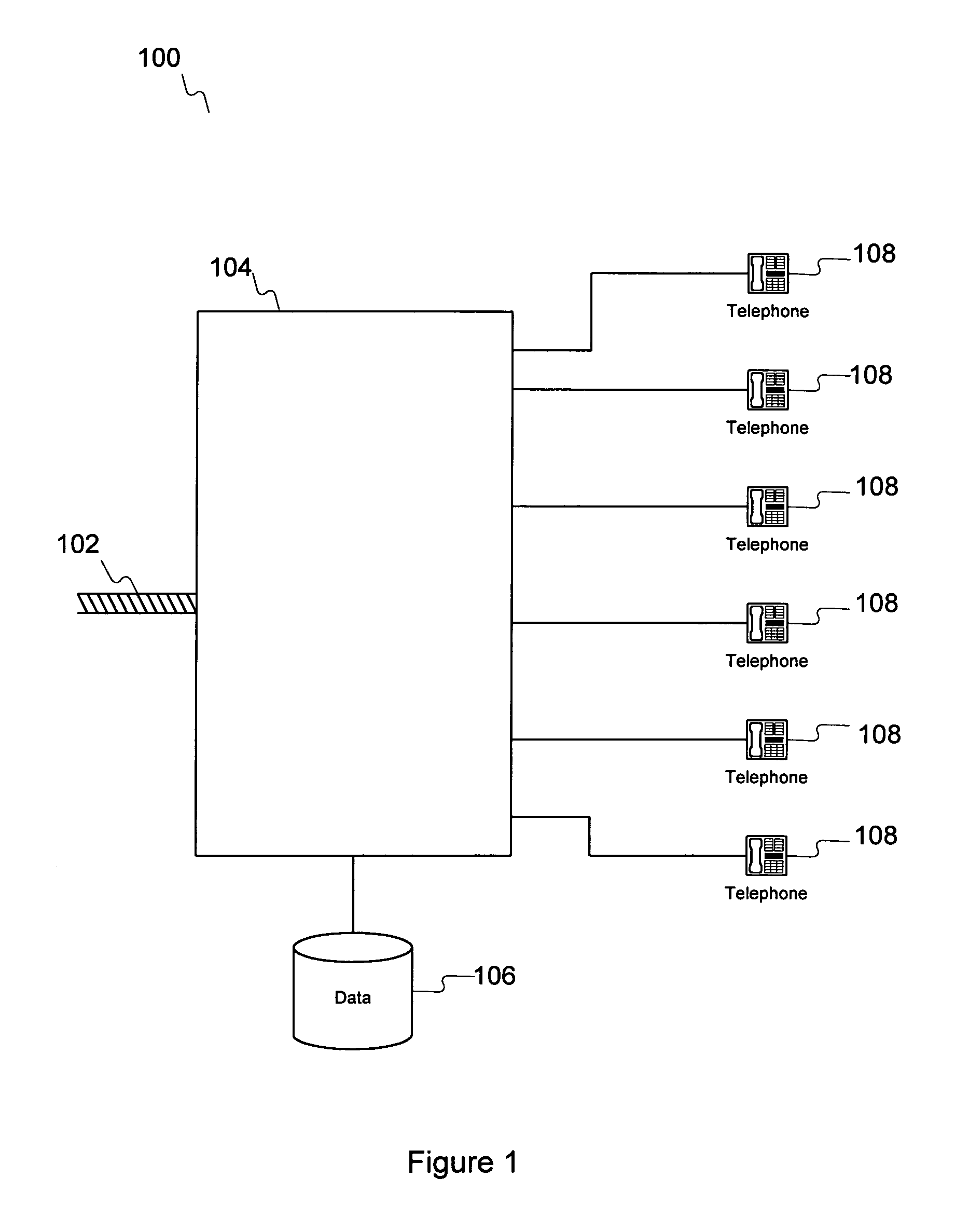

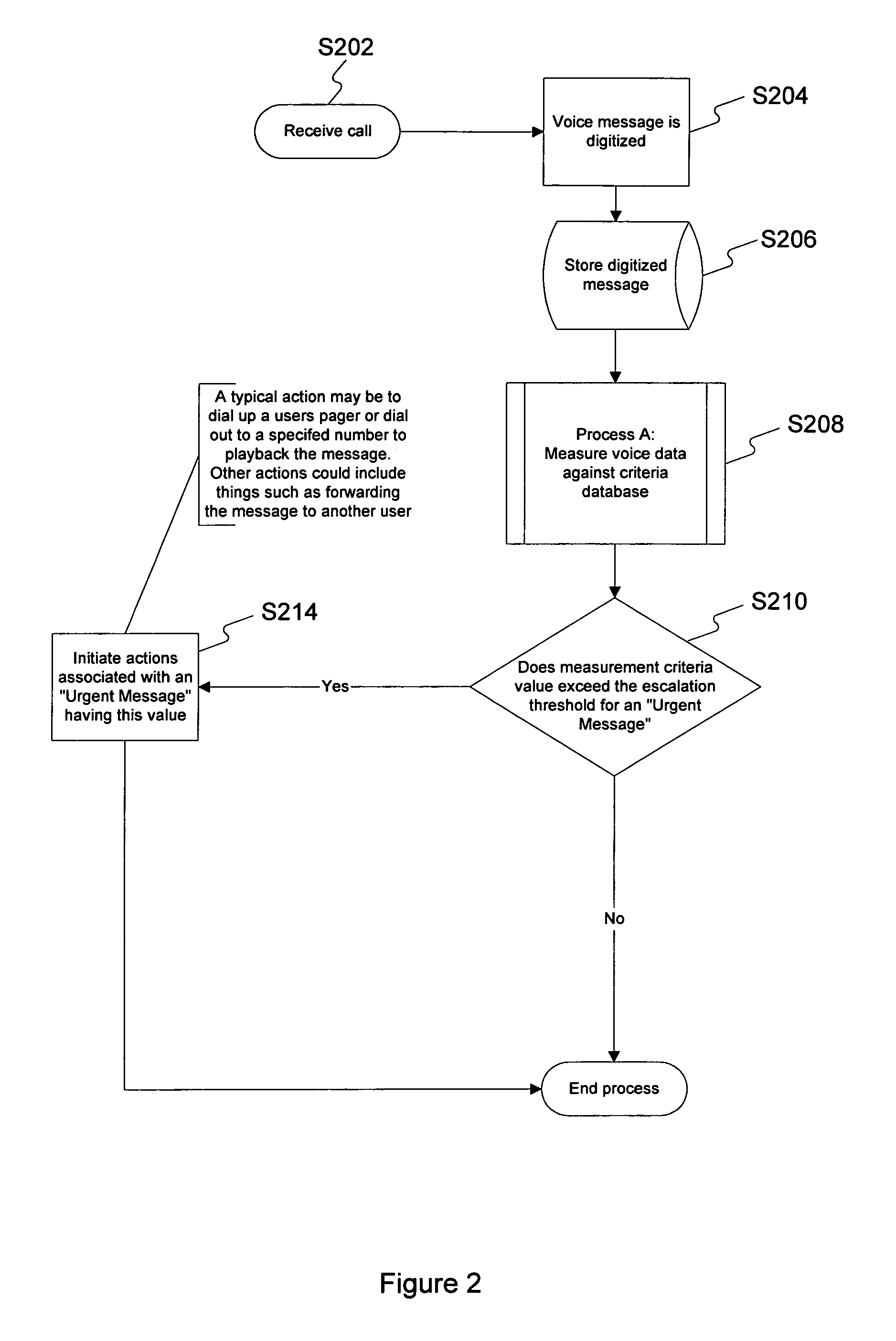

Methods and apparatus for voice recognition for call treatment modification on messaging

Methods and systems for analyzing voice information to determine if specific words or phrases are used or if the voice information exhibits a particular pattern of speech. Depending on which words or phrases are determined to have been used, a specific action or actions is taken. The words or phrases along with the actions may be user specified. In one example, a voice message is analyzed to determine if it includes any of the specified words or phrases or whether it exhibits a particular pattern of speech. If so, a specified action, such as forwarding the voice message to a particular person, is performed. In another example, voice information from a called person is analyzed to gain information regarding the status of a call. This information may be used, for example, for generating call statistics or notifying a supervisor on the status of a call.

Owner:AVAYA INC

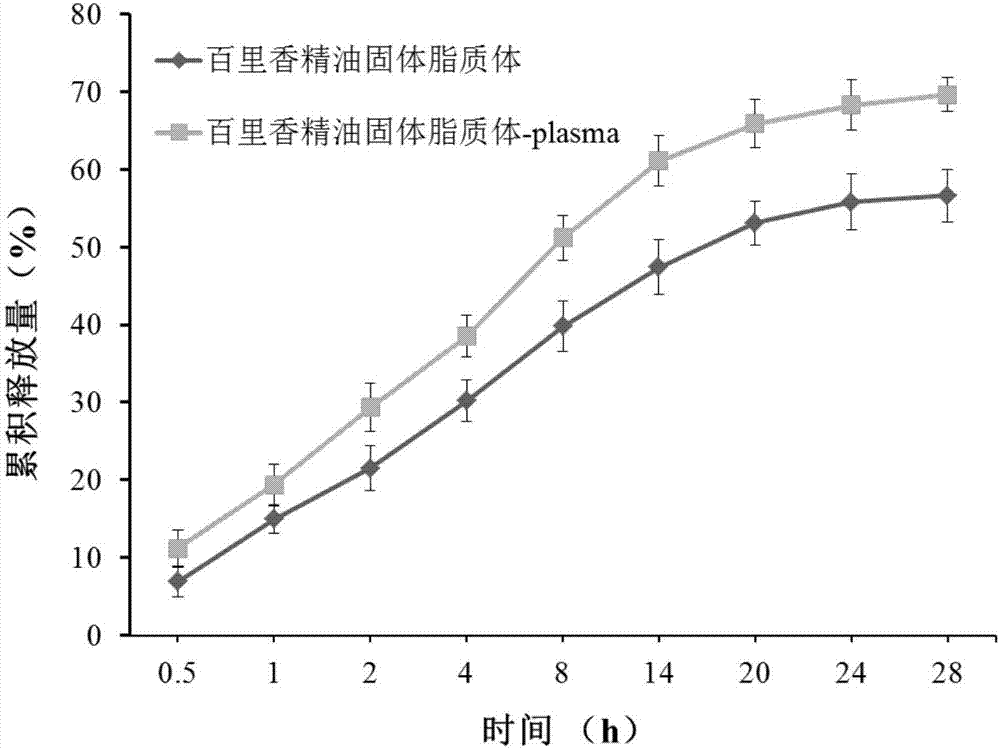

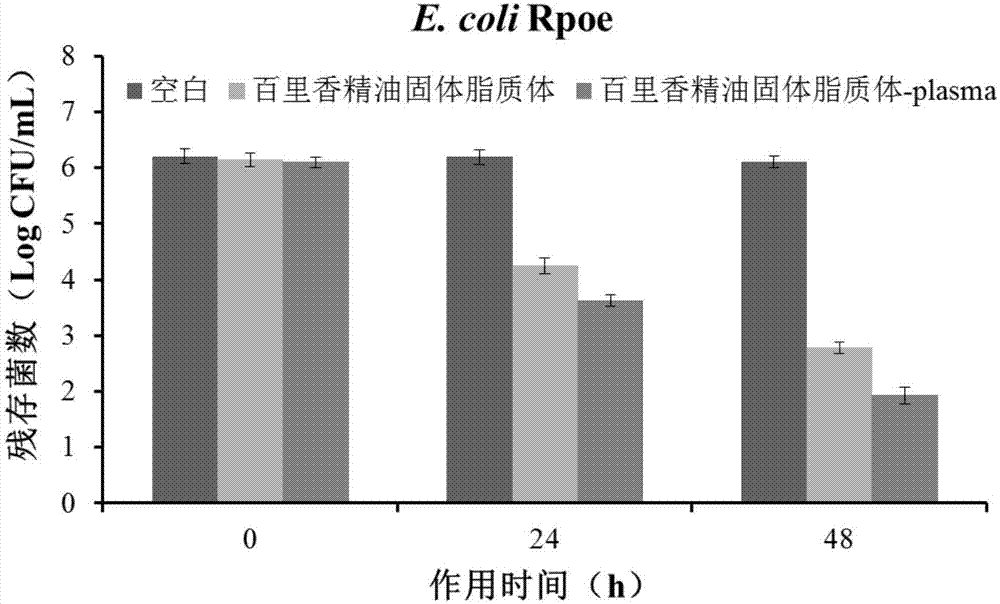

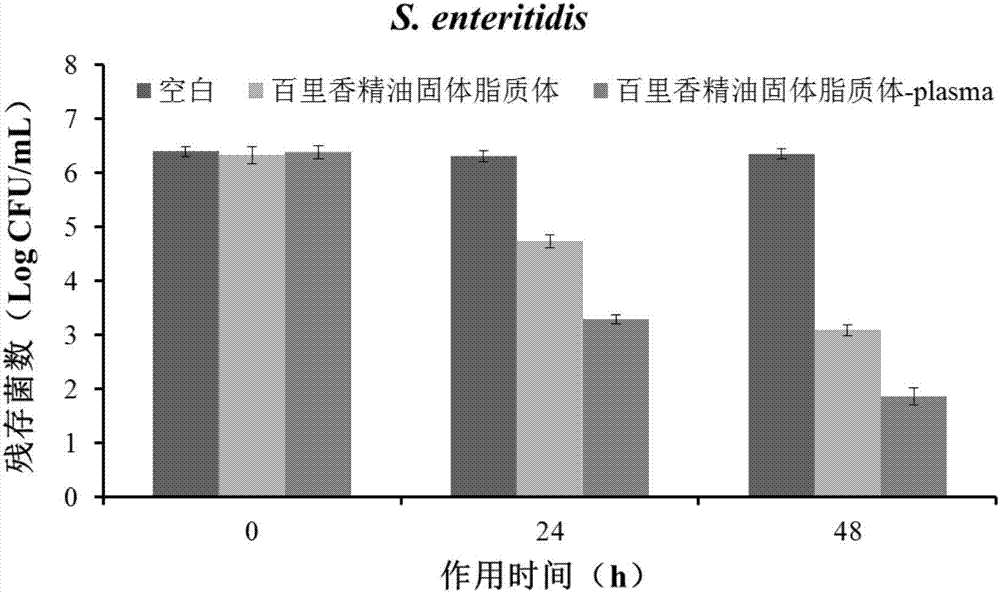

Plant source domestic poultry feed antibacterial additive and preparation method thereof

ActiveCN107535688AGive full play to the superiorityImprove stabilityAntibacterial agentsAnimal feeding stuffFreeze-dryingPlant Sources

Owner:哈尔滨吉粮农牧科技有限公司

Method for preparing polyurethane-nanosilver long-acting antibacterial film by post-heat treatment modification method

The invention relates to a method for preparing a polyurethane-nanosilver long-acting antibacterial film by a post-heat treatment modification method, which includes the following steps: (1) diisocyanate and polytetrahydrofuran are mixed to react; a cross-linking agent and an acetone solution of a chain extender are added, dimethylolpropionic acid and a catalyst are added, reaction takes place, and thereby PU (polyurethane) is obtained; a dimethylformamide solution of silver nitrate is added into a polyurethane solution, a film is formed after uniform stirring, heat treatment is carried out, and thereby a polyurethane-nanosilver film is obtained; (2) 4,4'-dihydroxybenzophenone reacts with long-chain alkyl halide, so that 4,4'-bis-long-chain alkoxy benzophenone is obtained; the 4,4'-bis-long-chain alkoxy benzophenone reacts with hydrazine hydrate, so that 4,4'-bis-long-chain alkoxy benzophenone hydrazone is obtained; and the 4,4'-bis-long-chain alkoxy benzophenone hydrazone undergoes oxidation reaction, so that long-chain alkyl diazomethane is obtained; (3) the long-chain alkyl diazomethane is dissolved into a solvent, and is uniformly applied onto the surface of the polyurethane-nanosilver film, and after heat treatment, the polyurethane-nanosilver long-acting antibacterial film is obtained. The method can be used for realizing long-acting bacteria resistance.

Owner:QILU UNIV OF TECH

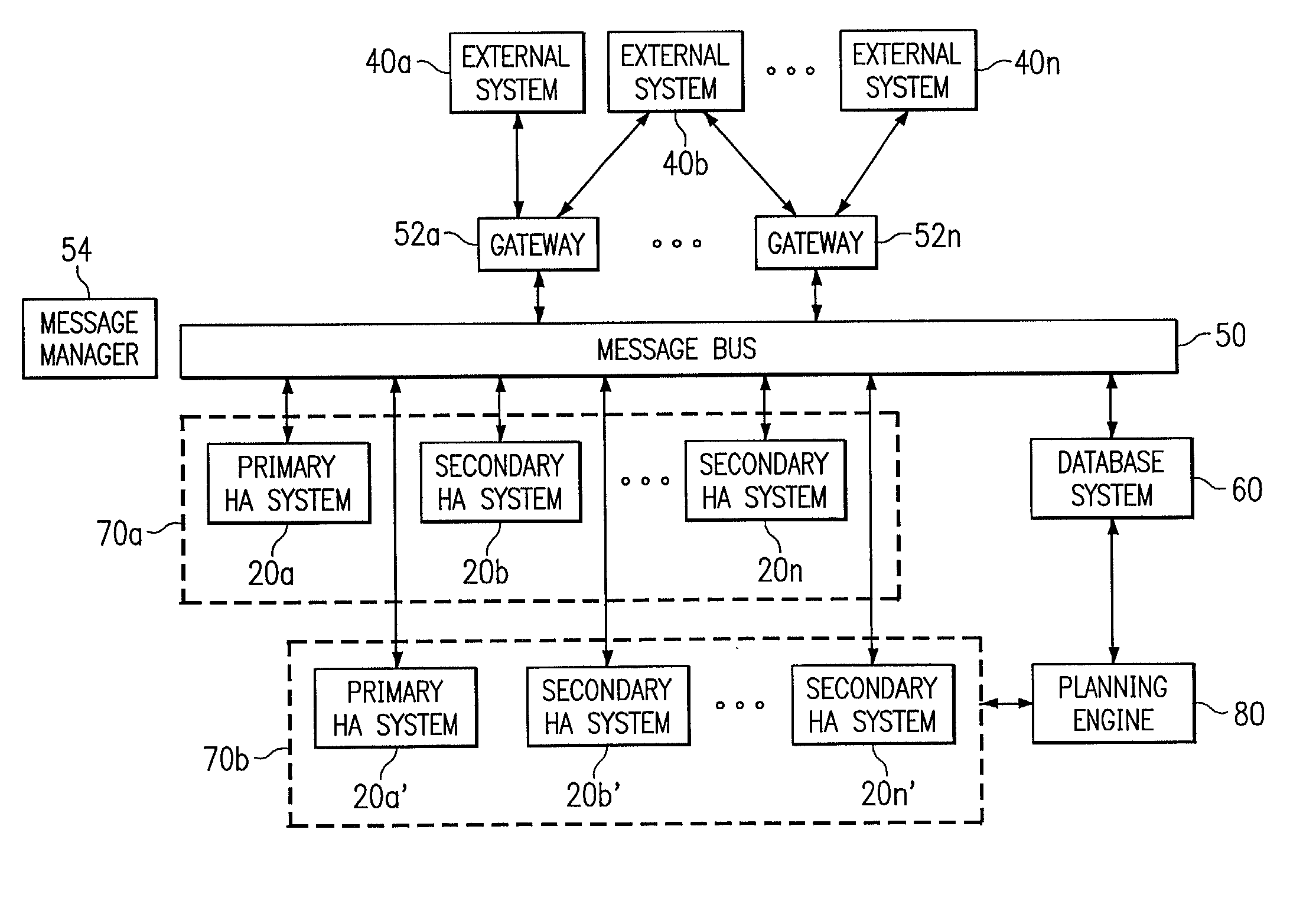

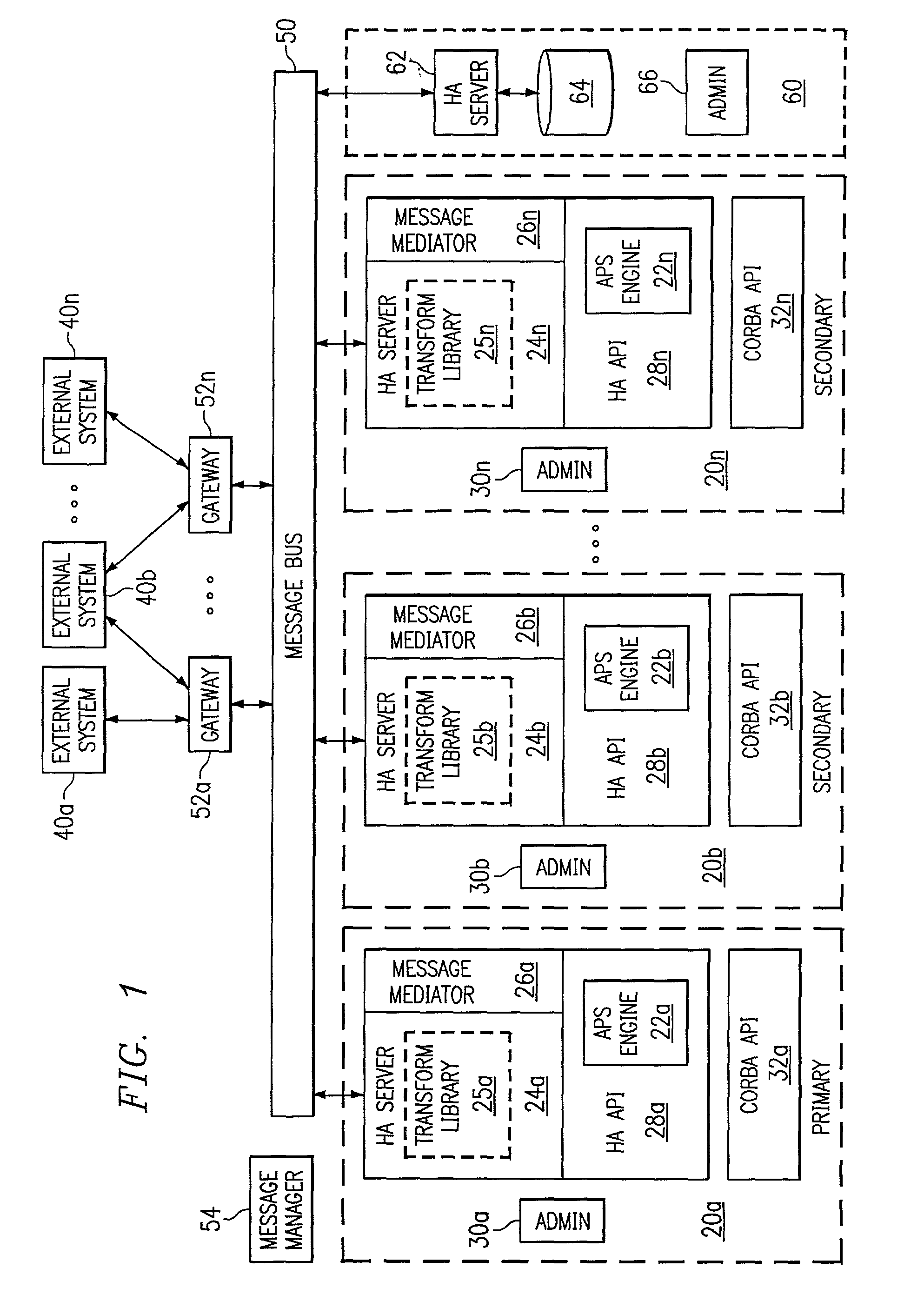

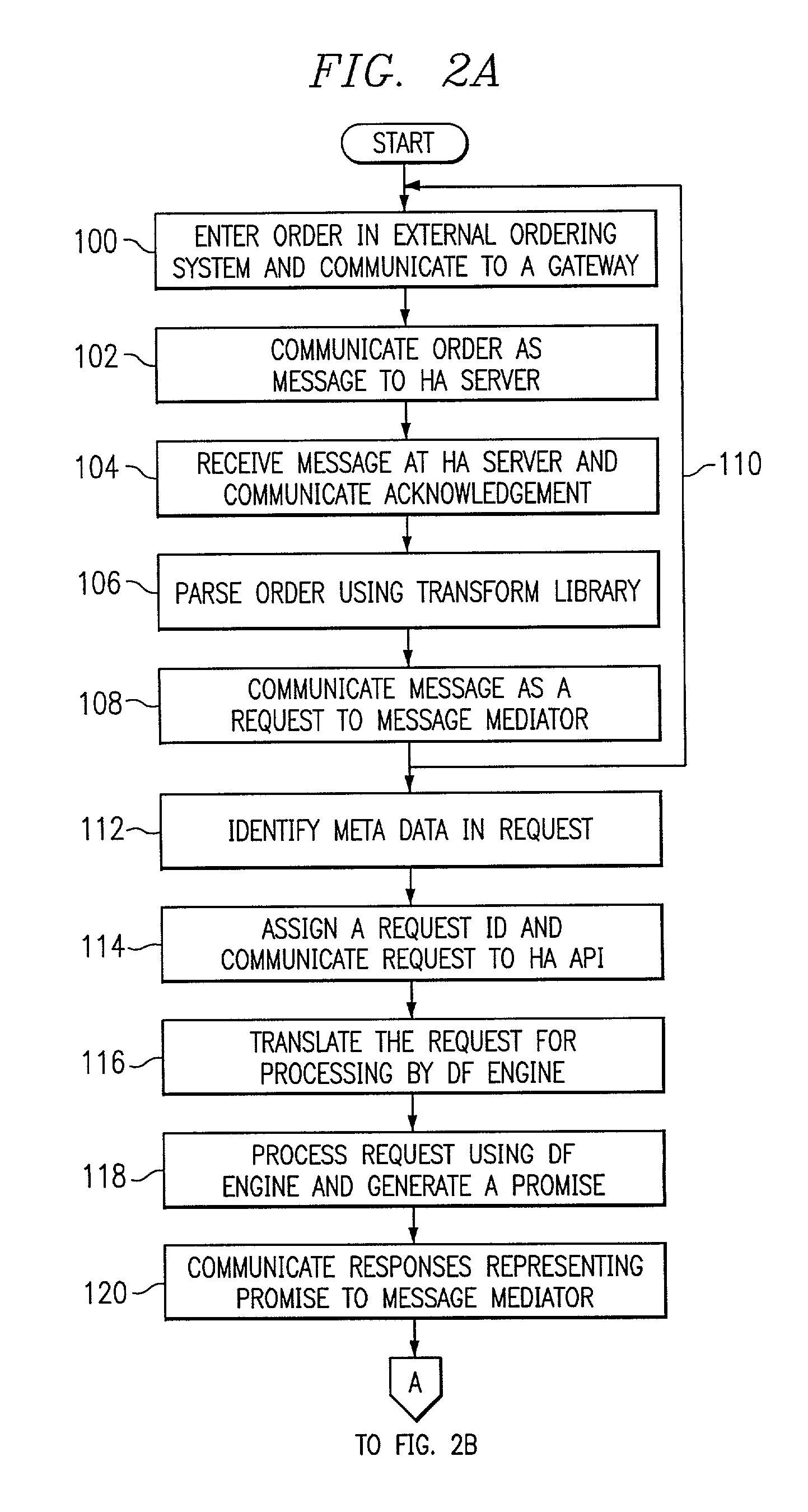

High availability planning and scheduling architecture

ActiveUS7024371B2Disadvantages and and and reduced eliminatedMethods reduced eliminatedComputer controlSimulator controlProgram planningHigh availability

A high availability planning and scheduling system includes a number of high availability (HA) systems (20) that are coupled to one or more external systems (40) using a message bus (50). Each HA system (20) includes an HA server (24) that receives and queues requests received from the external systems (40). Each HA system (20) also includes an advanced planning and scheduling (APS) engine (22) that receives a request from the HA server (24) and processes the request using planning information stored in memory of the HA system (20). Furthermore, the APS engine (22) also modifies the planning information according to the processing of the request and generates a response to the external system (40) from which the request originated. The high availability planning and scheduling system further includes a message manager (54) that directs each request received from the external systems (40) to an appropriate HA system (20) using the message bus (50).

Owner:BLUE YONDER GRP INC

Heatproof type easily dispersing ferric oxide yellow pigment and preparation method thereof

ActiveCN107090195AImprove heat resistanceGood dispersionPigment physical treatmentPigment treatment with non-polymer organic compoundsDispersityEnvironmental resistance

The invention relates to a heatproof type easily dispersing ferric oxide yellow pigment and a preparation method thereof. Soluble calcium salt, sodium hexametaphosphate and sodium hydroxide are used as reaction raw materials, an ultrasonic dispersing technique is introduced in a cladding process, calcium phosphate is coated on the surface of the ferric oxide yellow pigment through reaction, and then the sodium stearate organic treatment modification for the surface is performed, so that a composite material is formed. The formed composite material can promote the heat resistance and dispersity of the ferric oxide yellow and can be used as a coloring agent in plastic processing and powder coating application. The cladding type ferric oxide yellow compounded according to the invention has the advantages of excellent heat resistance and dispersity, simple compounding method, low cost, safety, environmental protection, and the like, and has higher industrial application value.

Owner:HUZHOU TEACHERS COLLEGE

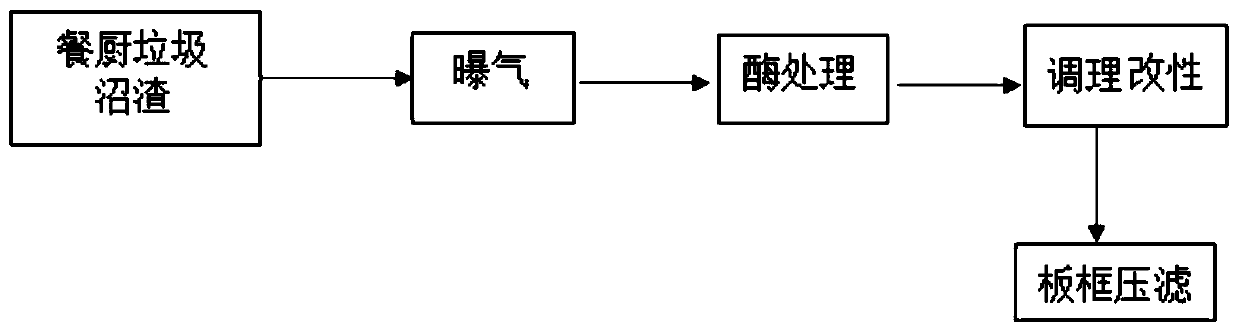

Biological treatment method for improving dehydration property of kitchen waste anaerobic biogas residues

InactiveCN110092558AReduction in hydrophilic substancesLower specific resistanceWater contaminantsBiological sludge treatmentDry weightResource utilization

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

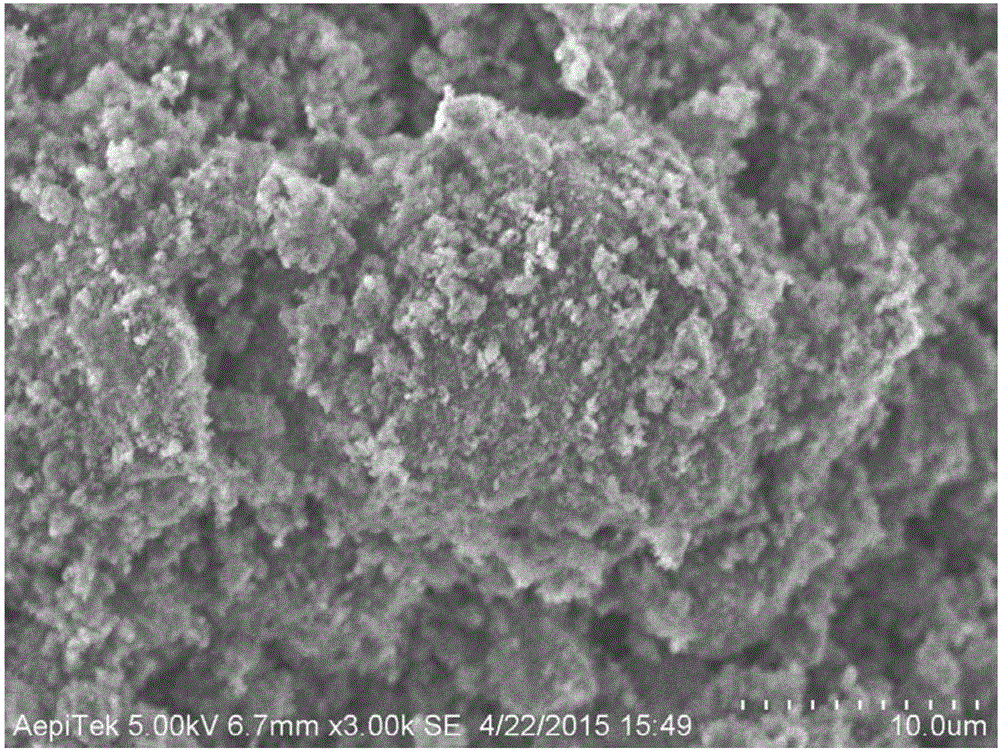

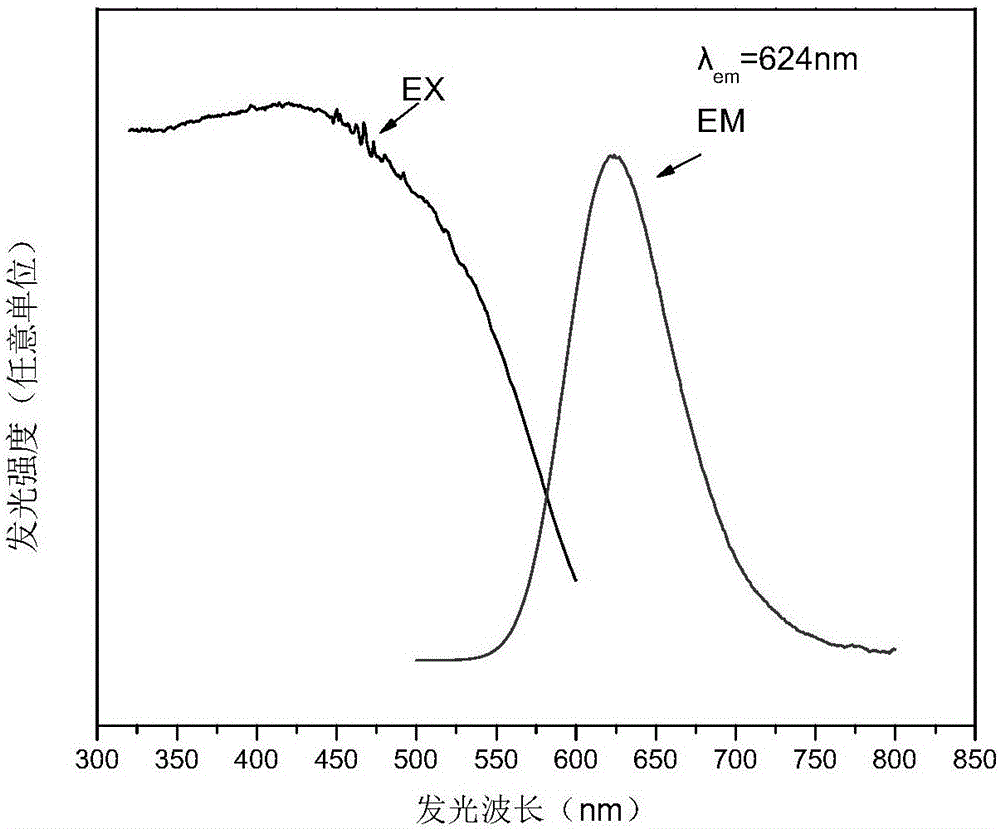

Surface heat treatment modification method of fluorescent powder and COB light source made of fluorescent powder

ActiveCN106753327AImprove stabilityExtend your lifeLuminescent compositionsSemiconductor devicesFluorescenceUltraviolet

The invention relates to a surface heat treatment modification method of fluorescent powder and a COB light source made of the fluorescent powder, belonging to the field of LED inorganic luminescent materials. According to the method, heating treatment is carried out on a (Ca, Q)1-y(Al, Si)2(N, T)3: Ay fluorescent powder material in an oxidative atmosphere to ensure that a compact oxide layer is formed on the surface of the fluorescent powder material; and the surface of the fluorescent powder material is modified to effectively isolate the fluorescent powder material from the external environment, so that the stability of the fluorescent powder is improved and the service life of the fluorescent powder is prolonged. According to the method, the stability of single-phase nitrides can be improved to ensure that the nitrides are beneficial for the absorption and emission of light, thereby improving the performance and stability of nitride red powder after LED packaging. When the nitride red powder prepared through the method is matched with an ultraviolet, near-ultraviolet or blue LED and other light emitting materials such as yttrium aluminum garnet and the like, the COB light source with high power and high coloration can be prepared; and after the COB light source is continuously lightened for 1000 hours, the lumen depreciation is zero.

Owner:BEIJING YUJI SCI & TECH +2

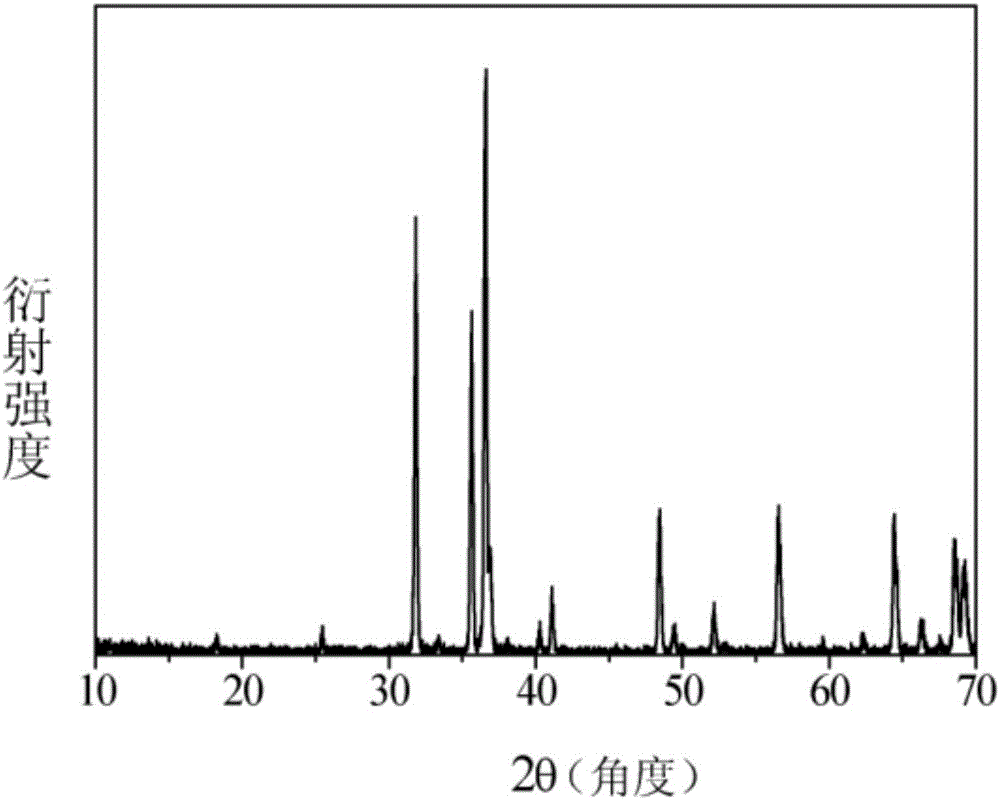

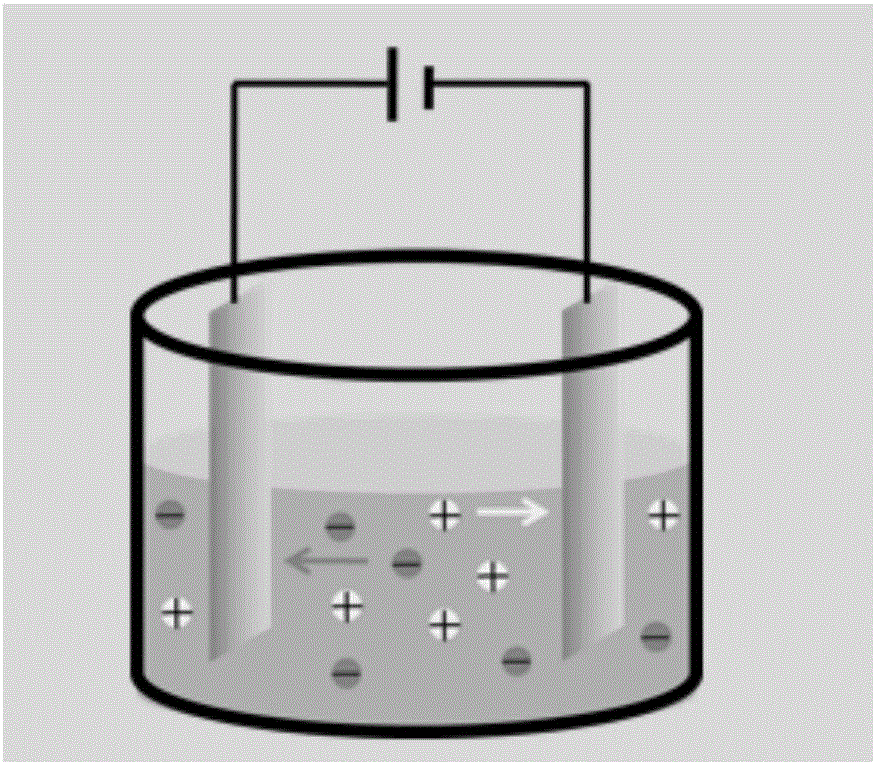

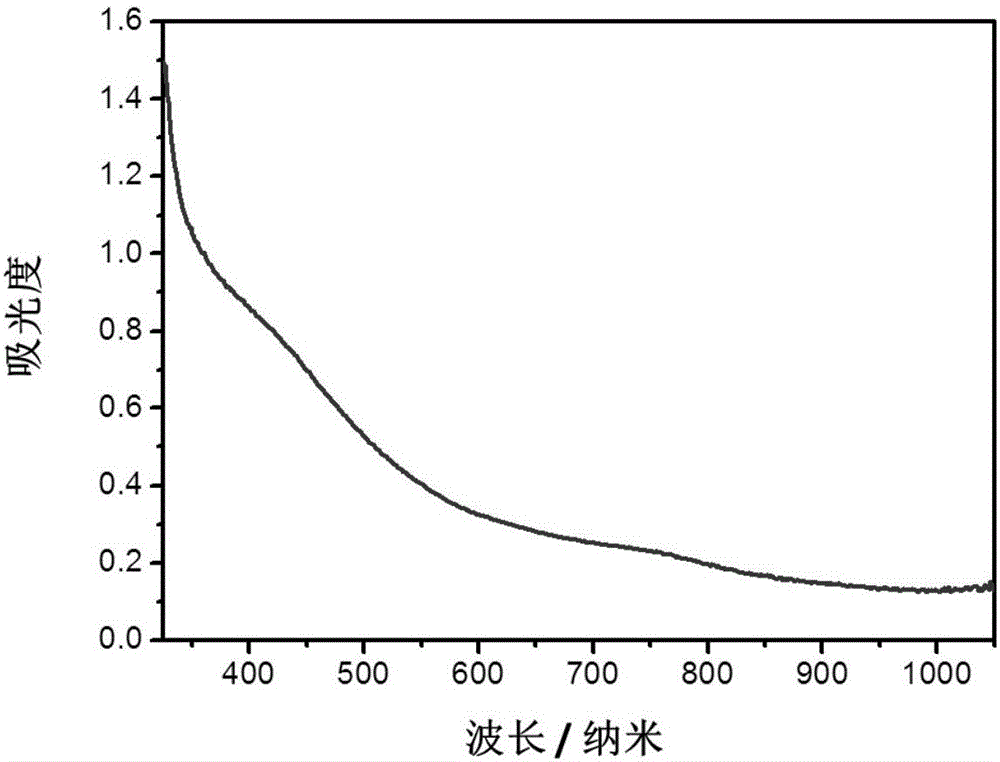

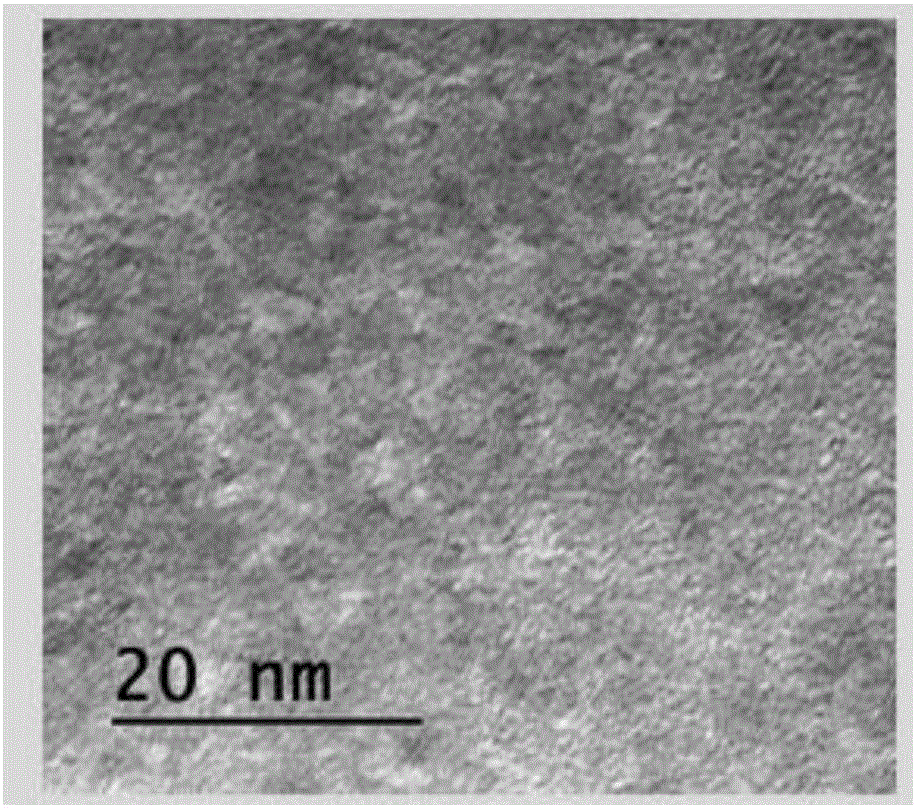

Preparation method of black titanium dioxide nano thin film

ActiveCN106622247AExpand the photoresponse rangeBroad absorption spectrumCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNitrateHydrogen atmosphere

The invention belongs to the technical field of preparation of nano thin films and relates to a preparation method of a black titanium dioxide nano thin film. A technological process comprises three steps including preparation of nanoparticles, preparation of the nano thin film and thickness control of the nano thin film; black titanium dioxide nanoparticles are prepared from titanium tetraisopropoxide and nickel nitrate; the black titanium dioxide nanoparticles are deposited on a stainless steel substrate by adopting an electrophoretic deposition method so as to prepare the black titanium dioxide nano thin film; nickel ion doping is coupled with hydrogen atmosphere heat treatment modification, and effective active sites can be formed on the surface of titanium dioxide by doping nickel ions, and separation of photo-induced electrons and holes is accelerated; the catalytic activity of the titanium dioxide is improved and hydrogen atmosphere heat treatment can expand a photo-response region of the titanium dioxide; white titanium dioxide is turned into black titanium dioxide; the technological process is simple, low in production cost, rapid in deposition speed and high in film-forming quality; an application environment is environmentally friendly and commercialized requirements are met.

Owner:青岛西交蓝海科技有限公司

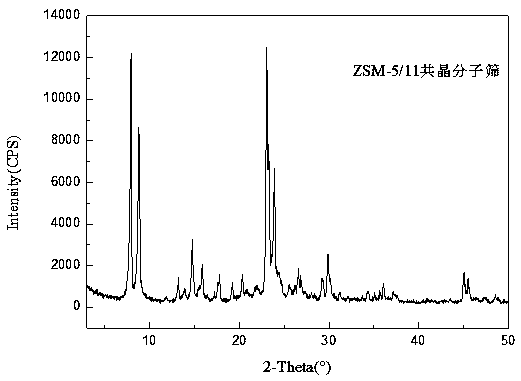

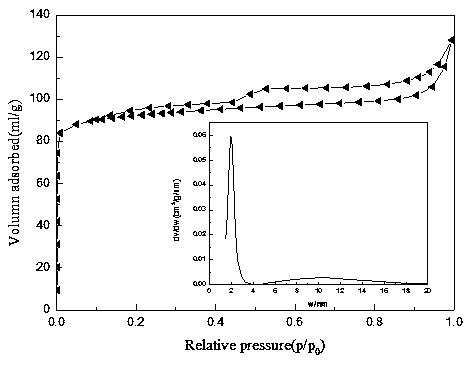

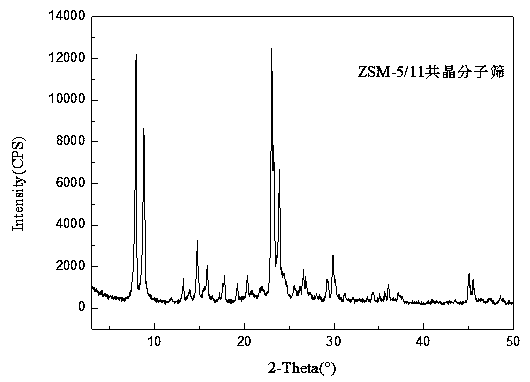

Preparation method of hierarchical pore ZSM-5/ZSM-11 eutectic zeolite molecular sieve

ActiveCN107619054ASimple methodEasy to operateMolecular sieve catalystsPentasil aluminosilicate zeolitePotassium hydroxideTreatment modification

The invention relates to a preparation method of a hierarchical pore ZSM-5 / ZSM-11 eutectic zeolite molecular sieve, mainly solves the problems that in the mode of preparing the hierarchical pore ZSM-5 / ZSM-11 eutectic zeolite molecular sieve by using double template agents or adding seed crystal, steps are tedious, and the price is high, and belongs to the technical field of preparation of inorganic materials. The preparation method comprises the following steps: preparing an aluminum source, a silicon source, an organic template, sodium hydroxide and potassium hydroxide into a raw material mixture; fully stirring the raw material mixture into gel and then transferring the gel into a high-temperature kettle for hydrothermal crystallization; and after washing and filtering, carrying out acid-alkali treatment modification so as to obtain the hierarchical pore ZSM-5 / ZSM-11 eutectic zeolite molecular sieve finally. The preparation method is simple and convenient in process, easy to operateand implement and low in cost, and is environmentally friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

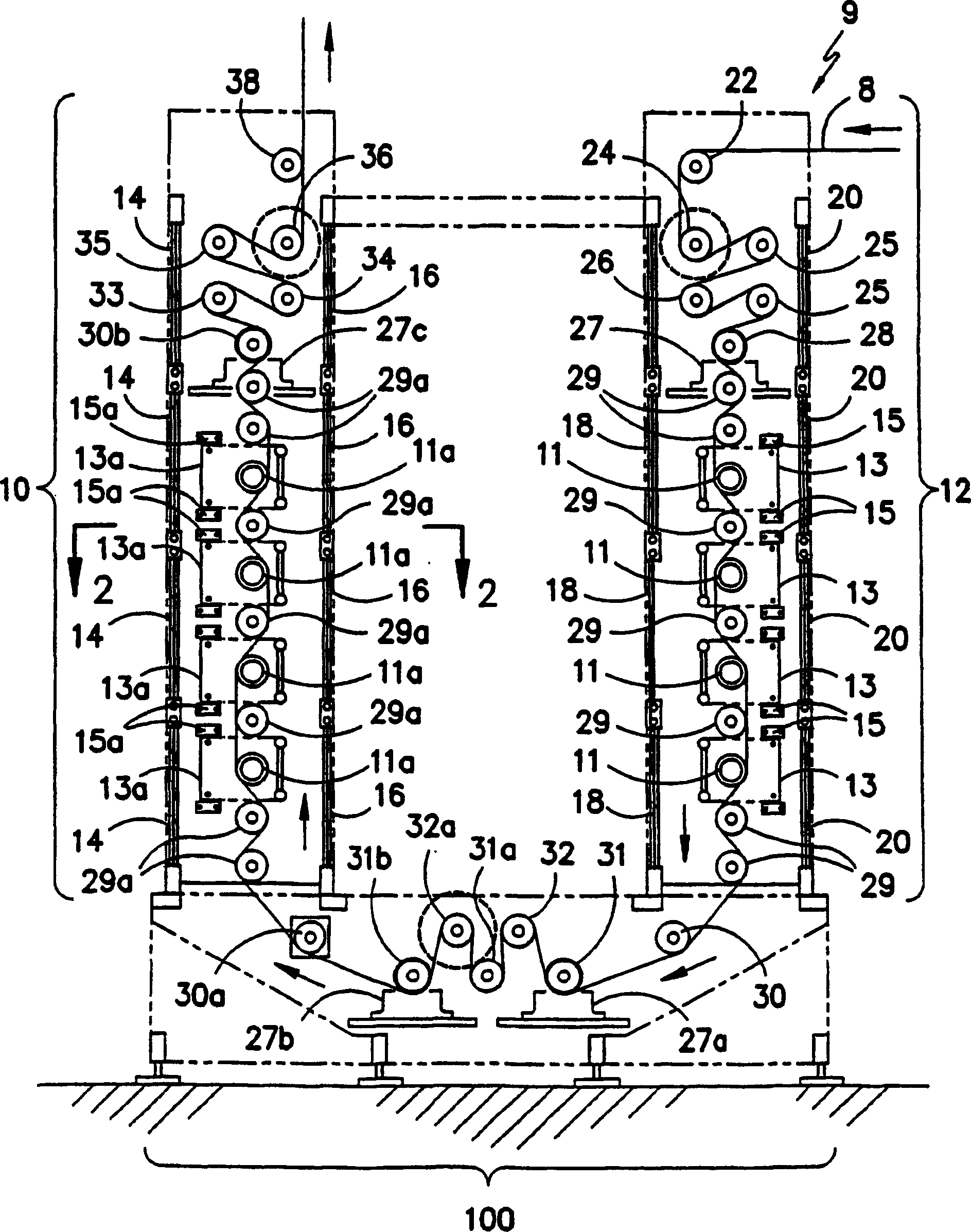

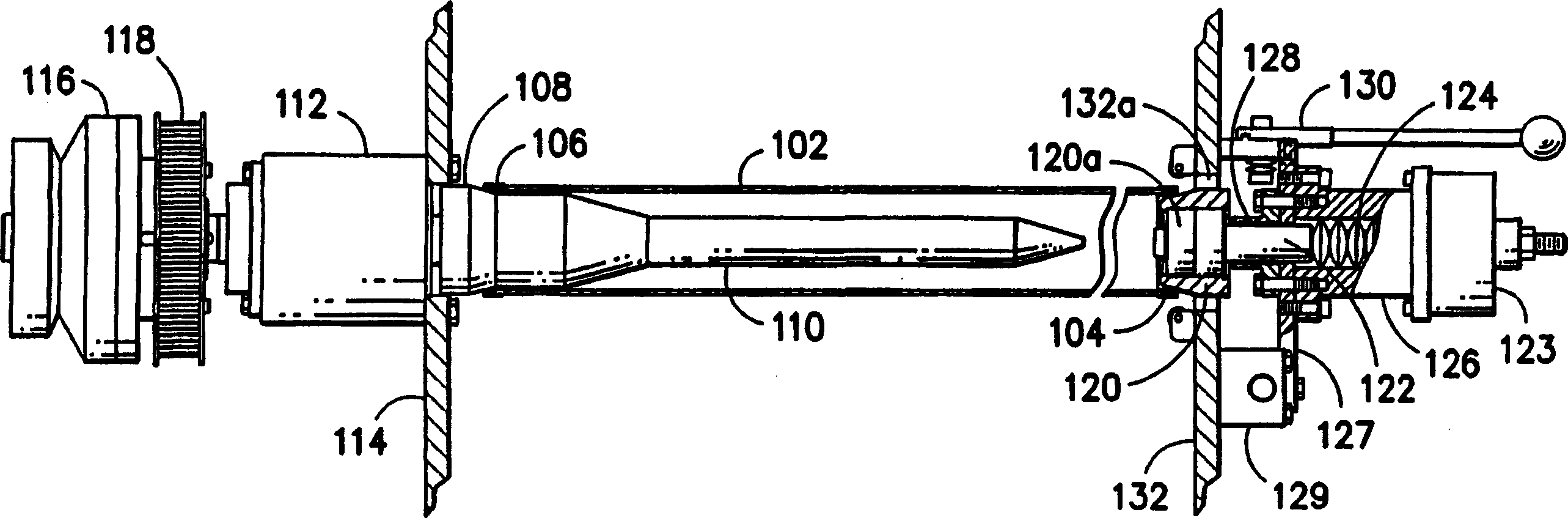

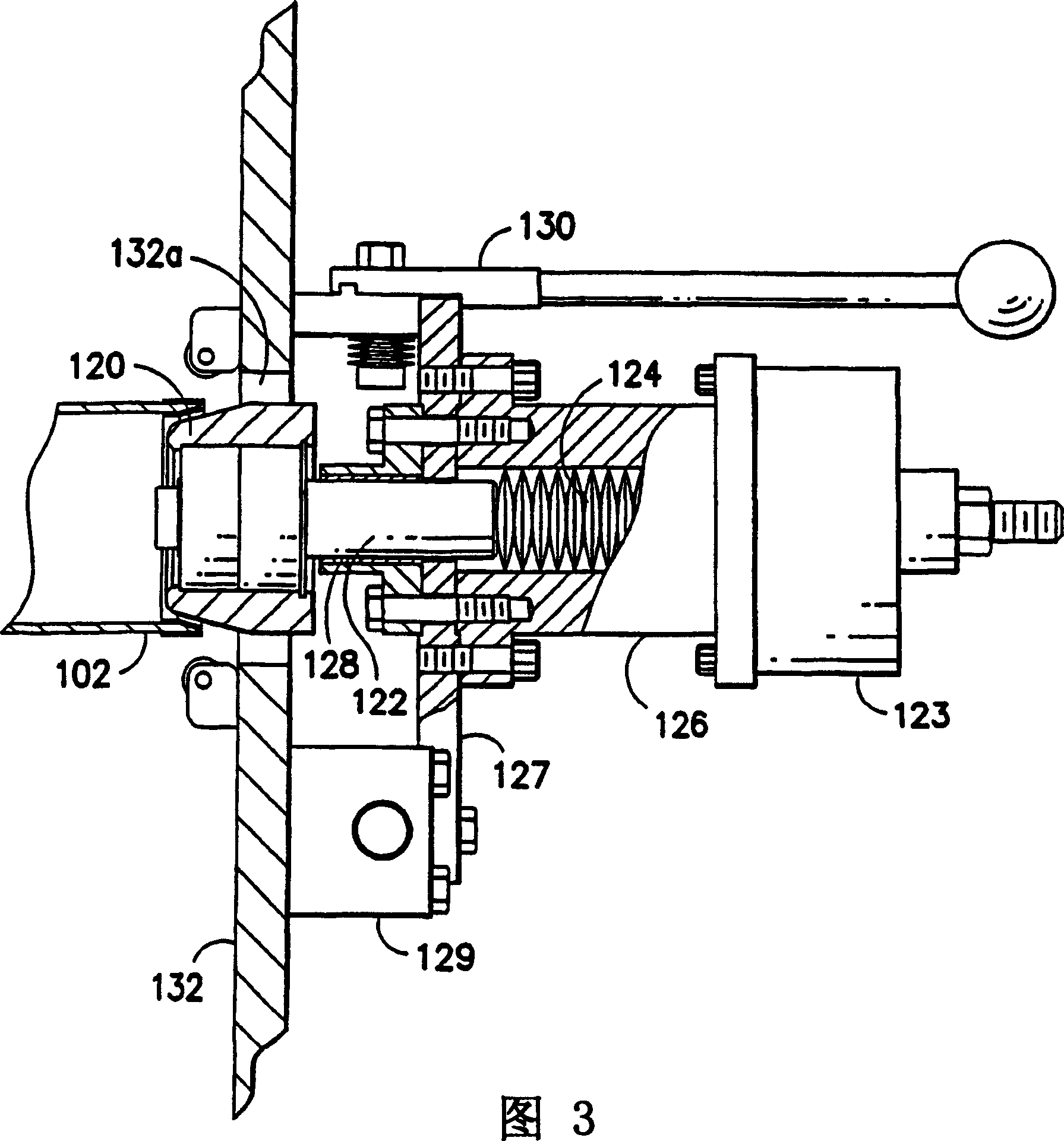

Fabric treatment apparatus comprising easily removable treatment tubes

The present invention concerns easily removable treatment tubes from fabric treatment apparatuses in order to facilitate replacement of such rolls for treatment modification, cleaning, disposal, or any other desirable purposes. Such treatment tubes (102) are generally hollow and may be coated with any standard fabric treatment surface, including sandpaper, diamond grit, wires, brushes, and the like. The ability to easily remove and dispose of such treatment tubes (102) thus provides a significant cost advantage to the manufacturer.

Owner:MILLIKEN & CO

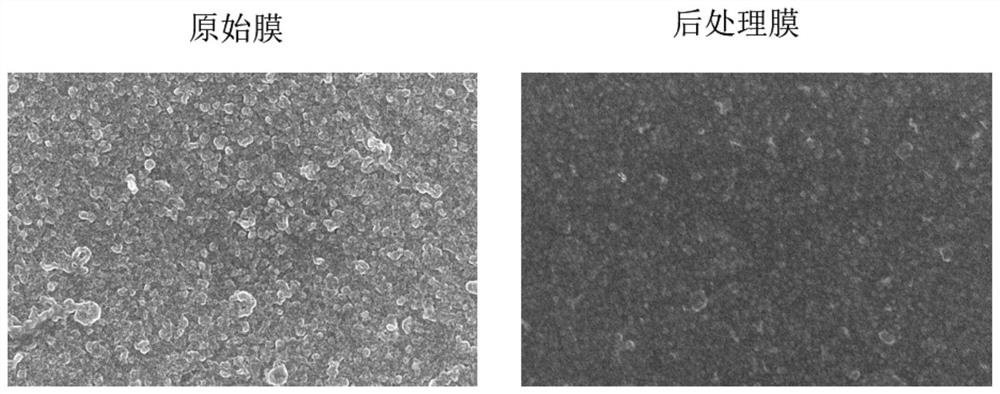

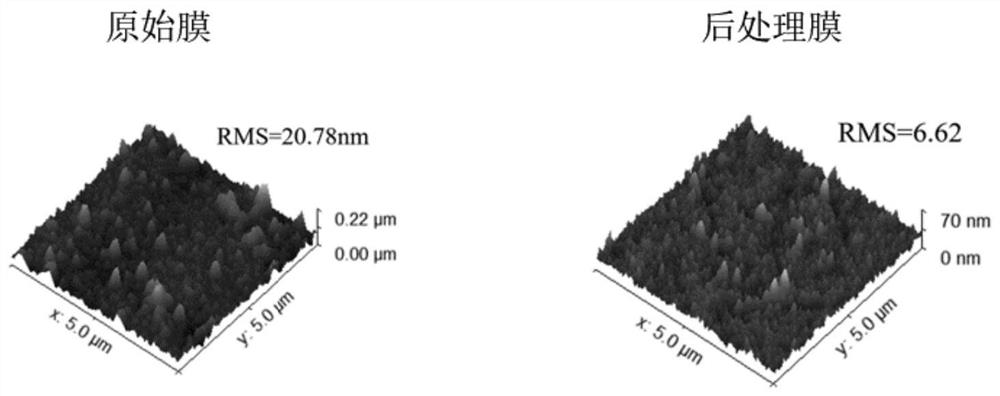

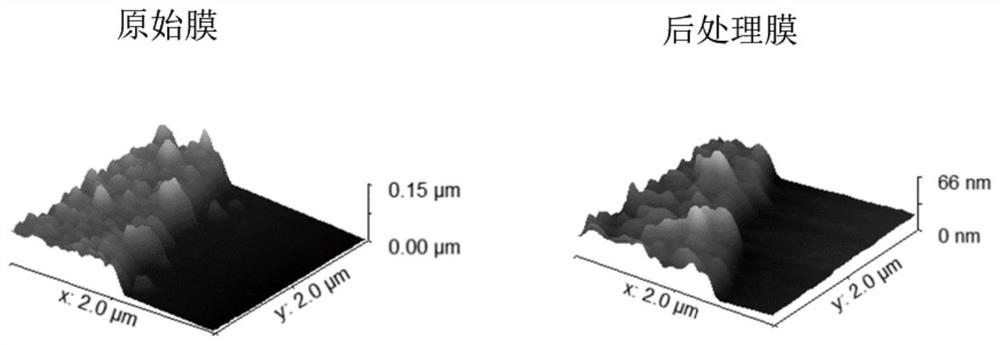

Post-treatment modification method of polyamide composite nanofiltration membrane

PendingCN113019142AIncreased permeability selectivityImprove permeabilityReverse osmosisPolymer scienceMass transfer resistance

The invention discloses a post-treatment modification method of a polyamide composite nanofiltration membrane. The method comprises the following steps: carrying out post-treatment modification on a new nanofiltration membrane by using an alkaline alcohol solution, and dissolving and removing residual macromolecular chains in a polyamide active layer of the nanofiltration membrane by exerting a synergistic effect between an alkaline substance and an alcohol solvent, so that the polyamide active layer is etched and thinned, and the core functional layer which can play a solute interception role is reserved, so that the interception performance of the nanofiltration membrane is guaranteed, the mass transfer resistance of the nanofiltration membrane is greatly reduced, the water molecule permeability of the nanofiltration membrane is improved, the pure water flux is obviously improved, and the improvement amplitude can reach 100%. The post-treatment modification mode provided by the invention is low in cost and easy to operate, the treatment effect is superior to that of other traditional modification methods, and the method is expected to play an important role in performance improvement of the polyamide composite nanofiltration membrane.

Owner:HEBEI UNIV OF TECH

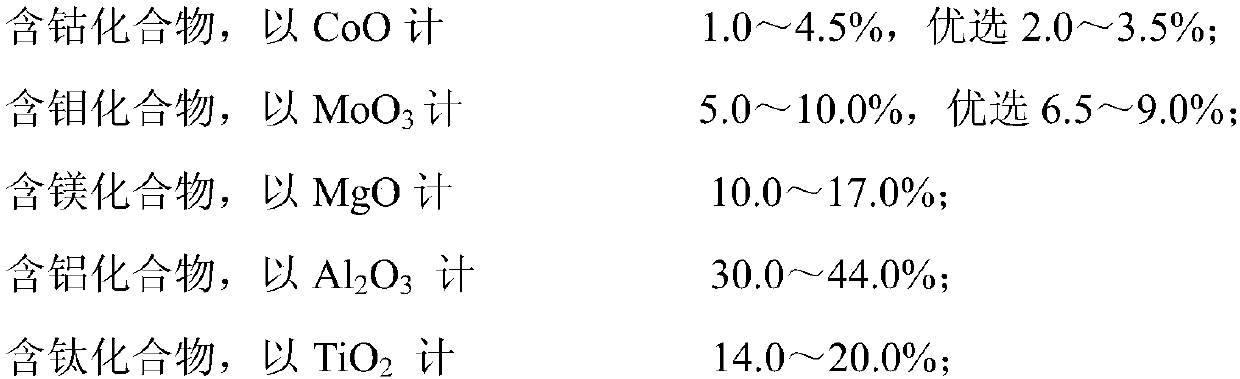

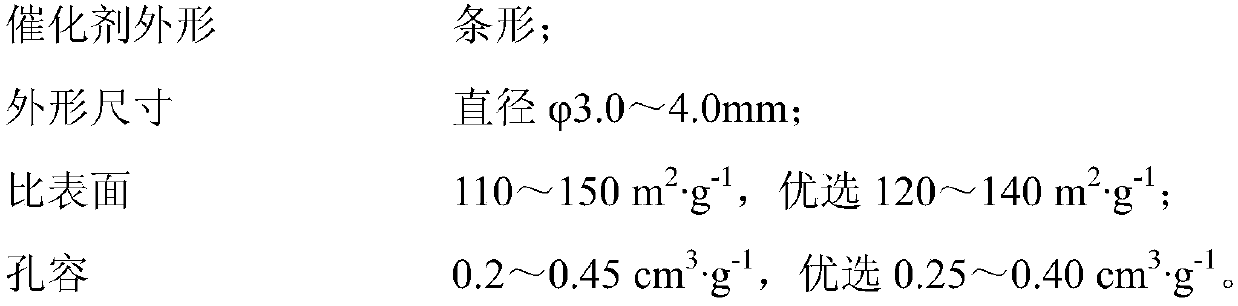

High-pressure low-sulfur-tolerant shift catalyst and preparation method thereof

ActiveCN109621968AFulfil requirementsGood hydration resistanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh pressureHeat treated

The invention belongs to the technical field of sulfur-tolerant shift in coal chemical industry, and particularly relates to a high-pressure low-sulfur-tolerant shift catalyst and a preparation methodthereof, wherein the catalyst comprises a carrier and an active component, the active component is selected from a binary component of cobalt oxide and molybdenum oxide, the raw materials of the carrier are selected from a magnesium-containing compound, an aluminum-containing compound, a titanium-containing compound and a heat-treated modified montmorillonite. According to the present invention,montmorillonite with characteristics of wide source and low cost is subjected to heat treatment modification to be used as the carrier component so as to reduce the catalyst preparation cost; the montmorillonite is subjected to heat treatment so as to avoid the treatment of the waste acid solution; the product is prepared by the mixing kneading method, such that the active components are uniformlydispersed in the carrier and are not easily lost so as to increase the activity stability of the catalyst; and compared with the impregnation method in the prior art, the method of the present invention has the following advantages that the water consumption is saved, the preparation process and the operation process are simplified, the cost advantage is remarkable, and the prepared catalyst hasgood shift activity and good activity stability under low sulfur condition, and further has good economic benefits and popularization and application prospects.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of preparation method of hierarchical porous zsm-5/zsm-11 eutectic zeolite molecular sieve

ActiveCN107619054BSimple methodEasy to operateMolecular sieve catalystsPentasil aluminosilicate zeolitePotassium hydroxideTreatment modification

The invention relates to a preparation method of a hierarchical pore ZSM-5 / ZSM-11 eutectic zeolite molecular sieve, mainly solves the problems that in the mode of preparing the hierarchical pore ZSM-5 / ZSM-11 eutectic zeolite molecular sieve by using double template agents or adding seed crystal, steps are tedious, and the price is high, and belongs to the technical field of preparation of inorganic materials. The preparation method comprises the following steps: preparing an aluminum source, a silicon source, an organic template, sodium hydroxide and potassium hydroxide into a raw material mixture; fully stirring the raw material mixture into gel and then transferring the gel into a high-temperature kettle for hydrothermal crystallization; and after washing and filtering, carrying out acid-alkali treatment modification so as to obtain the hierarchical pore ZSM-5 / ZSM-11 eutectic zeolite molecular sieve finally. The preparation method is simple and convenient in process, easy to operateand implement and low in cost, and is environmentally friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

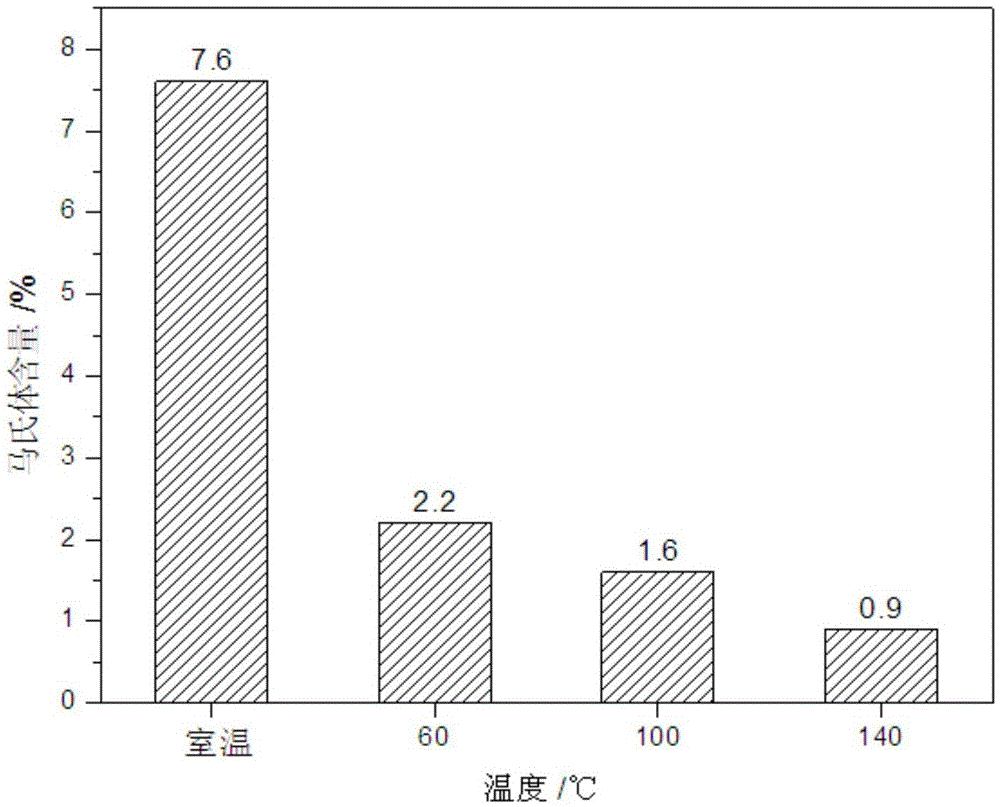

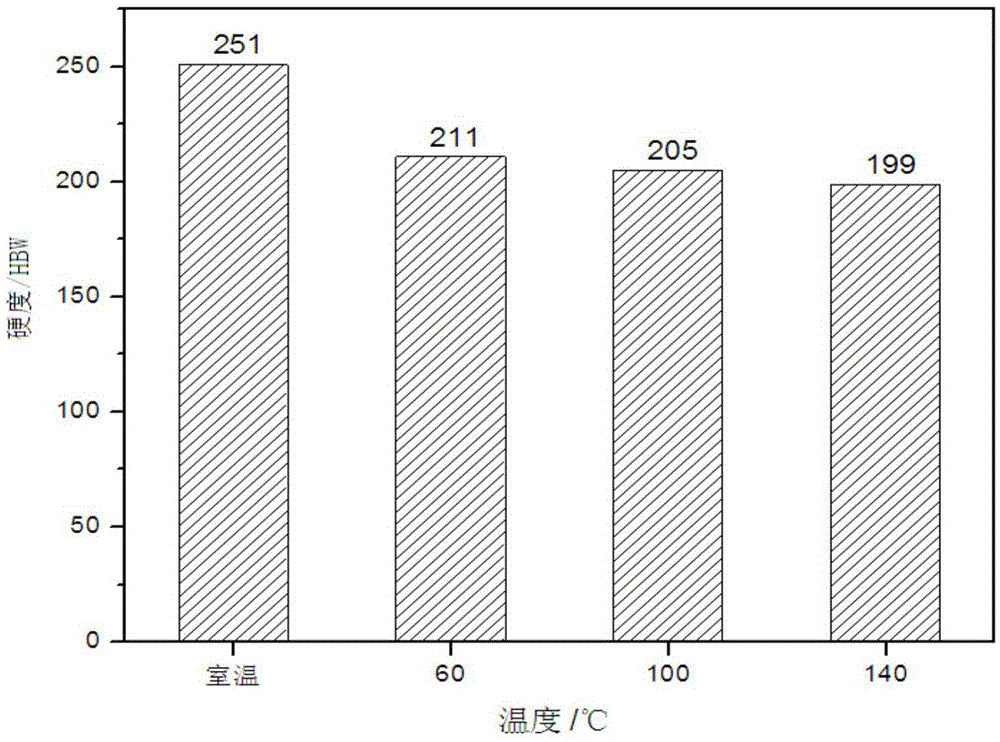

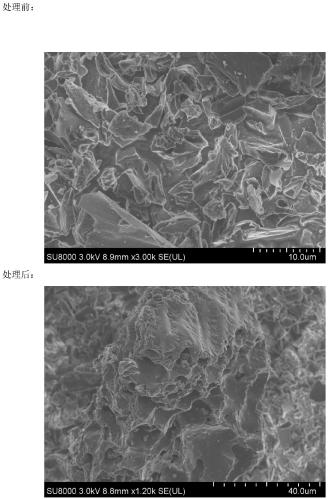

Hot processing technique for restraining martensite phase transformation during austenitic stainless steel deformation

The invention relates to a hot processing technique for restraining martensite phase transformation during austenitic stainless steel deformation. The hot processing technique comprises the steps that the surface of a stainless steel sample is cleaned so that oil dirt and impurities on the surface of the sample can be removed; the cleaned stainless steel sample is put into a heating furnace to be subjected to heat treatment modification; and after heat preservation is finished, stretching deformation is immediately conducted on the stainless steel sample subjected to heat treatment modification. The hot processing technique has the beneficial effects that heating treatment is conducted before deformation, and thus the driving force of the martensite phase transformation can be effectively decreased; the content of martensite in the austenitic stainless steel is obviously decreased after deformation, and the hardness is lowered accordingly, so that the processing hardening degree during stainless steel deformation is reduced, and the cracking tendency is reduced; and the corrosion resistance of products after formation can be effectively improved by decreasing the content of martensite.

Owner:CHANGZHOU UNIV

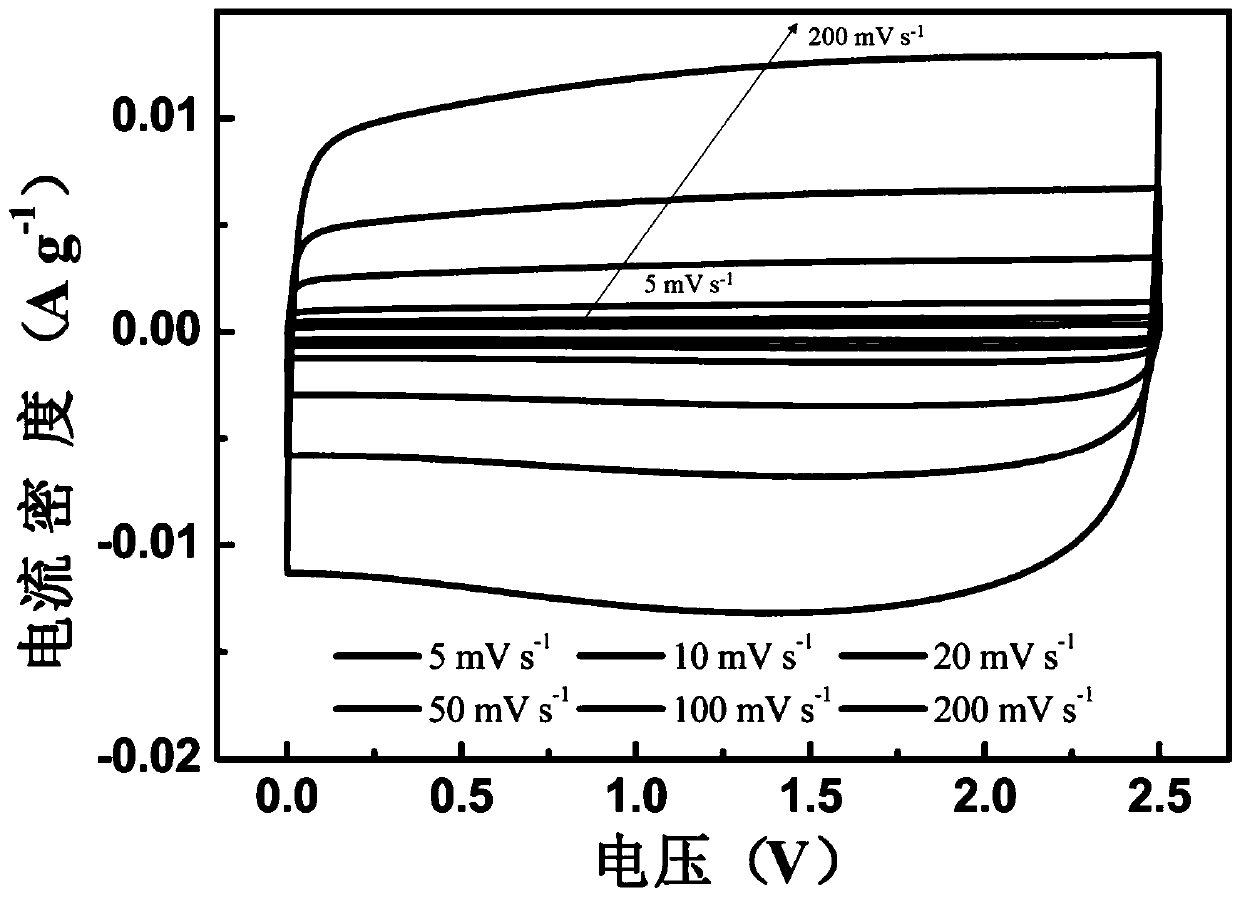

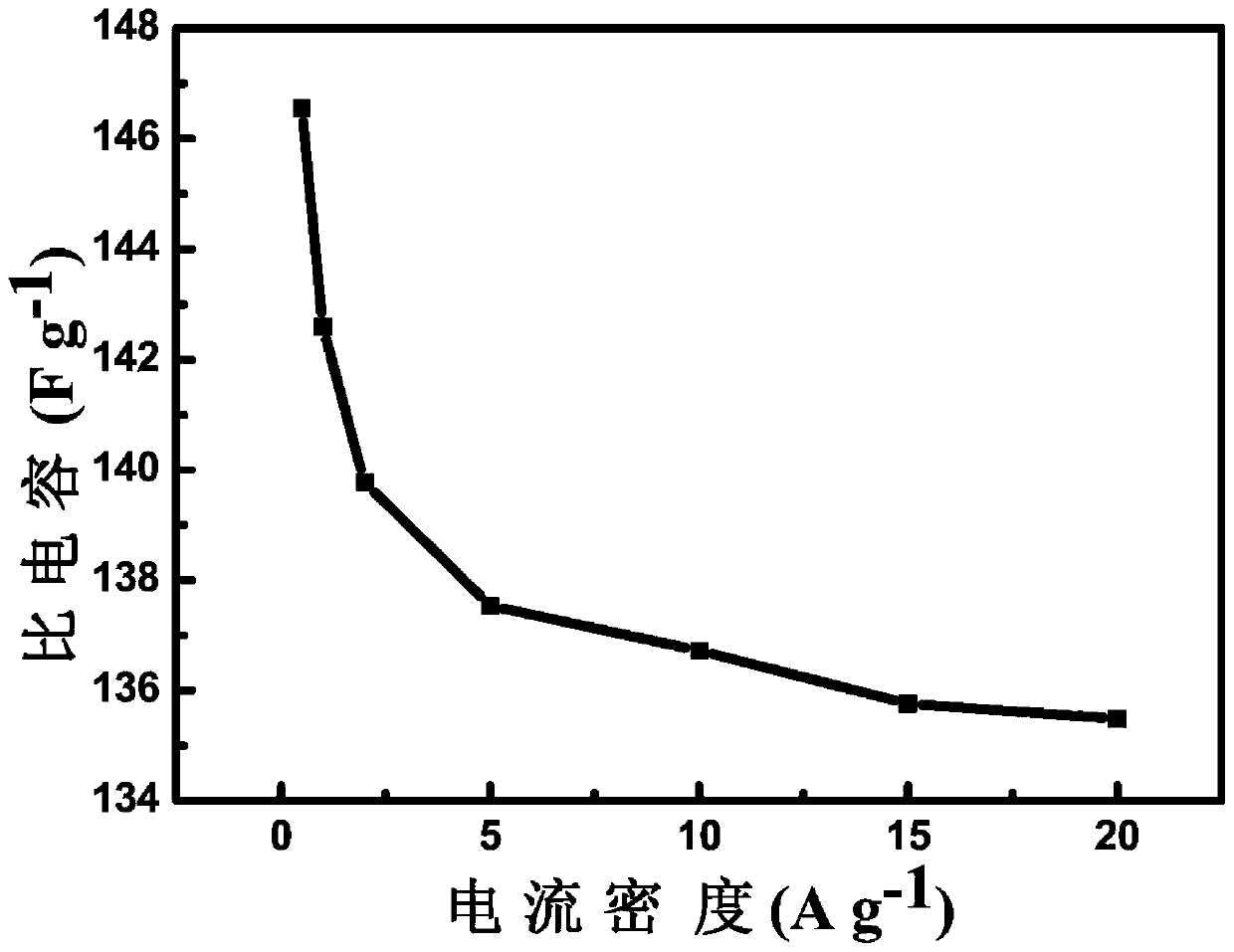

Modification method for rice husk based capacitance carbon material

InactiveCN109704338ASolve the problem of high self-discharge rateEasy to makeCarbon compoundsHybrid capacitor electrodesElectricityCapacitance

The invention aims at providing a modification method for a rice husk based capacitance carbon material. Aiming at the problem that the self-discharging rate of super-capacitors utilizing rice husk based capacitance carbon is great, a preparation method of rice husk based capacitance-carbon is improved and the self-discharging rate of rice husk based capacitance carbon super-capacitors is reduced.The modification method adopts a simple heat treatment modification method, has the characteristics of convenience for operation, greenness and environment protection and is easy to popularize in theaspect of industry.

Owner:JILIN UNIV

High-pressure-resistant insulation electric pump and surface heat-treatment modification process thereof

InactiveCN107868495AImprove corrosion resistanceImprove insulation performanceCoatingsFiberWater based

The invention discloses a high-pressure-resistant insulation electric pump. A high-pressure-resistant insulation layer is covered on an outer shell of the electric pump, and comprises a high-pressure-resistant layer and an insulation layer; the high-pressure-resistant layer and the insulation layer are compounded according to the proportion of the high-pressure-resistant layer to the insulation layer being equal to 3:2; the high-pressure-resistant layer is prepared from the components in parts by mass: 3 to 9 parts of water-based resin emulsion, 13 to 19 parts of silicon carbide micro powder,29 to 32 parts of polypropylene carbonate, 10 to 14 parts of 1-butanol, 10 to 15 parts of polypropylene carbonate, 13 to 18 parts of barium sulfate, 22 to 29 parts of lime powder, 3 to 11 parts of calcium-zinc compound stabilizer, 29 to 32 parts of defoaming agent, 11 to 19 parts of coupling agent, and 22 to 28 parts of fire retardant; the insulation layer is prepared from the components in partsby mass: 9 to 15 parts of nanosilicon dioxide, 2 to 9 parts of butyl acrylate, 10 to 15 parts of silane coupling agent, 22 to 29 parts of wood fiber powder, 15 to 19 parts of carbon fiber powder, 11 to 15 parts of vapor phase inhibitor, 18 to 21 parts of coalescing agent, 20 to 24 parts of thickening agent, 9 to 13 parts of defoaming agent, and 20 to 28 parts of curing agent.

Owner:博维恩冷冻科技(苏州)有限公司

Strong-acid-resistant high-strength metal valve and surface heat treatment modification process thereof

InactiveCN107903679AImprove corrosion resistanceSo as not to damageSolid state diffusion coatingFurnace typesFiberEpoxy

The invention discloses a strong-acid-resistant high-strength metal valve. The outer surface of the metal valve is coated by a strong-acid-resistant high-strength layer, the strong-acid-resistant high-strength layer is formed by compounding of an A component and a B component, wherein the A component comprises the following materials: 9-13 parts of epoxy resin, 6-13 parts of polyurethane, 8-15 parts of titanium dioxide, 3-7 parts of graphite fluoride, 19-24 parts of barium sulfate, 8-13 parts of a thixotropic auxiliary agent, 14-19 parts of a base-material emulsion, 3-9 parts of an antifreezing agent, 20-25 parts a filler, and 33-39 parts of an auxiliary material; and the B component comprises the following materials: 13-19 parts of nano silicon dioxide, 11-19 parts of butyl acrylate, 1-7parts of a silane coupling agent, 14-19 parts of xylem fiber powder, 20-25 parts of carbon fiber powder, 8-14 parts of a vapor phase corrosion inhibitor, 10-14 parts of antimony trioxide, 19-22 partsof a film forming auxiliary agent, 15-19 parts of a thickener, 4-9 parts of a defoaming agent, and 10-15 parts of a curing agent. The metal valve provided by the invention improves working efficiency,reduces pollution to the environment, and reduces production costs, and the process has simple steps, and is convenient for operation.

Owner:张剑

Wear-resistant and rust-proof valve handle and vacuum heat treatment modification process thereof

InactiveCN107828262AImprove corrosion resistanceSo as not to damagePretreated surfacesSolid state diffusion coatingWear resistantRoom temperature

The invention discloses a wear-resistant and rust-proof valve handle. The surface of a metal valve is coated with a wear-resistant and rust-proof layer, and specific operation of coating the wear-resistant and rust-proof layer comprises steps as follows: (1) cleaning the valve handle with purified water at a temperature of 95-100 DEG C, performing blow drying at a temperature of 80-90 DEG C, cooling the valve handle naturally to the room temperature, cleaning the rubber surface 5-6 times with an aliphatic hydrocarbon solvent with respect to the dried valve handle surface, washing the surface with purified water at the temperature of 45 DEG C, and finally drying the surface by a fan for standby application; (2) preparing a wear-resistant and rust-proof layer coating which is prepared from the following components in parts by mass as shown in the description; (3) sending the valve handle treated in the step (1) to a heating furnace for preheating to 300-350 DEG C, and then sending the preheated valve handle into a spraying device, evenly spraying fine sand to the valve surface for thickness of 0.01-0.03 mm by using a spraying gun, then performing heating curing rapidly, repeating thespraying process until the film thickness is 0.06-0.08 mm; (4) cooling the valve handle coated with the wear-resistant and rust-proof layer, cooling the valve handle to room temperature, and inspecting and warehousing the valve handle.

Owner:朱建海

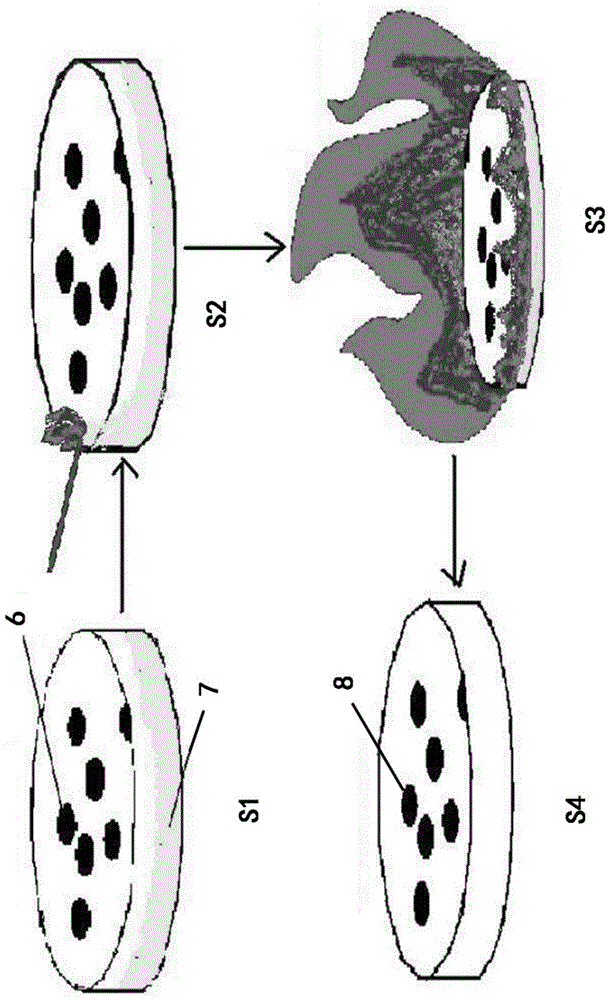

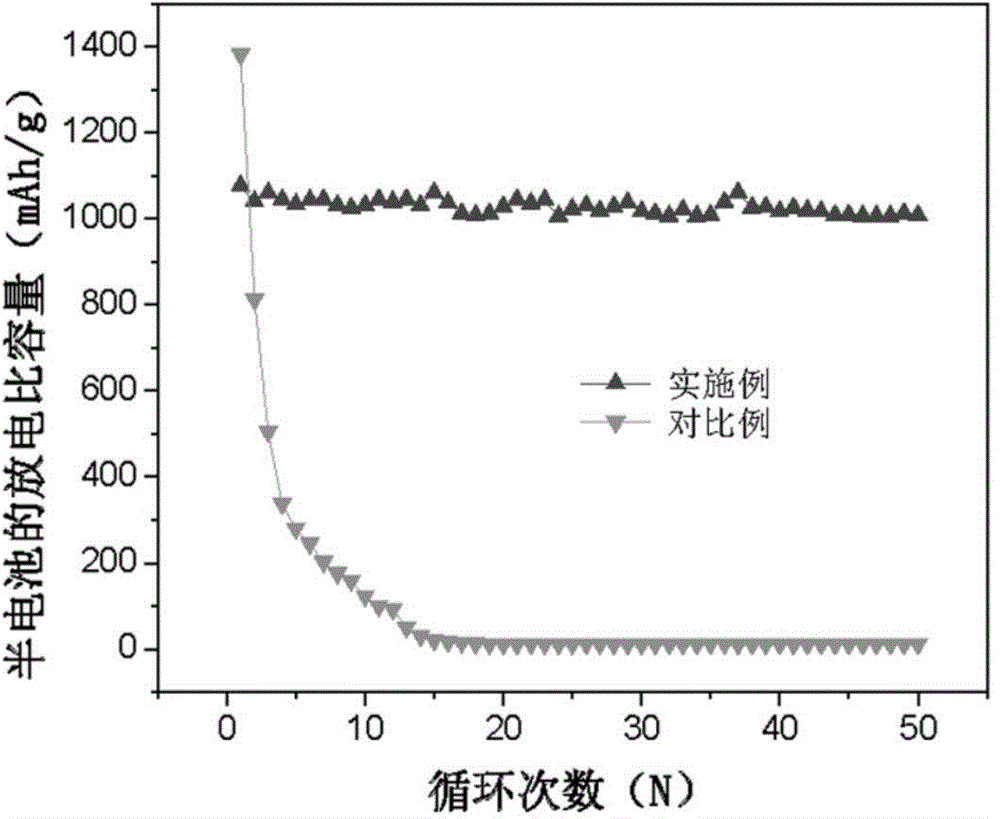

One-step method for flame soaking heat treatment modification of silicon electrode

ActiveCN104409687AExcellent cycle characteristicsChange surface propertiesCell electrodesPolymer adhesiveOptoelectronics

The invention provides a one-step method for the flame soaking heat treatment modification of a silicon electrode. The one-step method comprises the following steps: (a) preparing a polymer adhesive substrate solution; (b) preparing electrode slurry; (c) coating the electrode slurry; (d) curing and drying the silicon electrode; (e) laying the silicon electrode which is obtained by step (d) and covered with an active substance in a thermally-stable vessel where a combustible organic matter for soaking, then igniting the combustible organic matter, and obtaining the heat-treated modified silicon electrode after the combustible organic matter is burnt out. According to the technical scheme, the first charging and discharging efficiency of the modified silicon electrode is high, and the attenuation of a crystalline silicon material in the electrode can be remarkably retarded; compared with an unmodified silicon electrode, the modified silicon electrode has better effects; the one-step method is convenient, low in cost and easy for industrial production, and actual production requirements can be met.

Owner:JIANGXI ADVANCED NANOFIBER S&T CO LTD

Water-based anti-corrosion paint and preparation method thereof

InactiveCN109321075AImprove mechanical propertiesImprove water absorptionAnti-corrosive paintsEpoxyWater based

The invention provides water-based anti-corrosion paint. The paint is prepared from the following components in parts by weight: 80-120 parts of epoxy acrylate, 0.1-8 parts of nano-silica subjected tosilane coupling agent surface treatment modification and 1-15 parts of curing agent, wherein the curing agent is selected from at least one of diisocyanate and triisocyanate, and the epoxy acrylate is synthesized by means of 1-6 parts by weight of epoxy butyrate, 30-50 parts by weight of methyl methacrylate, 30-50 parts by weight of butyl acrylate and 30-50 parts by weight of styrene. The mechanical performance, the water adsorption and the corrosion resistance of the paint are improved.

Owner:广东华科新材料研究院有限公司

Powder treatment modification method

InactiveCN108727870ALow oil absorptionGood dispersionInorganic pigment treatmentDispersityPolyvinyl chloride

The invention discloses a powder treatment modification method which is characterized in that the needed raw materials comprise a modifier, water and slurry, wherein the modifier is pasty white emulsion, has the pH value of 7-8, needs to be shaded, enclosed and stored under the condition of 10-25 DEG C and has the storage time of 6 months; the water has the temperature of 80 DEG C. The modifier isadded into the powder, so that the modified powder has low oil absorption value, high dispersity, excellent fluidity and other characteristics; when the powder is applied to silicone adhesive products, the elongation, fluidity and weather resistance of the product can be improved; the powder modified by the modifier is simultaneously applicable to production of PVC (Polyvinyl Chloride) pipes, wire and cable granules and other products, and the quality of the product can be obviously improved; the modifier disclosed by the invention can be applied to modification of artificial marble and artificial quartz stone powder, the resin dose can be reduced, and the surface smoothness effect of the stone products is obviously improved.

Owner:江门俊玮环保新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com