Water-based anti-corrosion paint and preparation method thereof

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as corrosion resistance reduction, and achieve the effect of anti-corrosion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

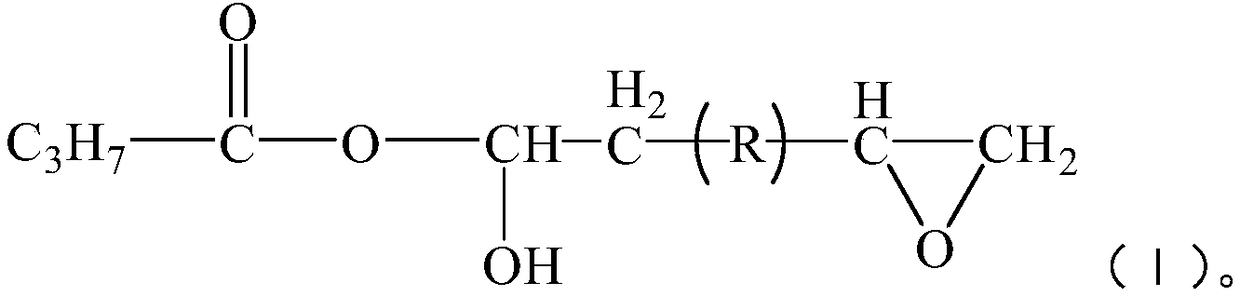

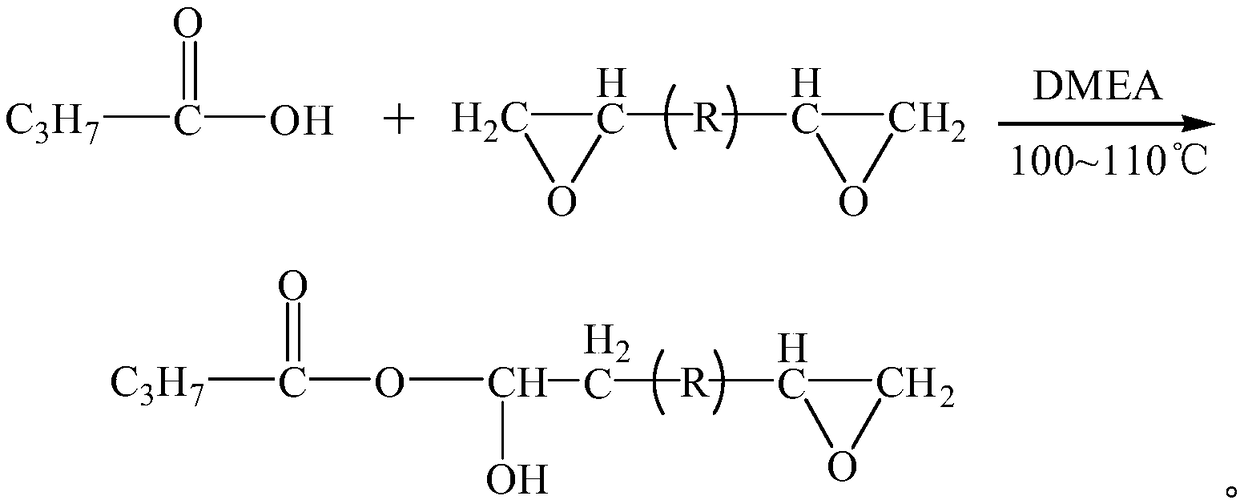

Image

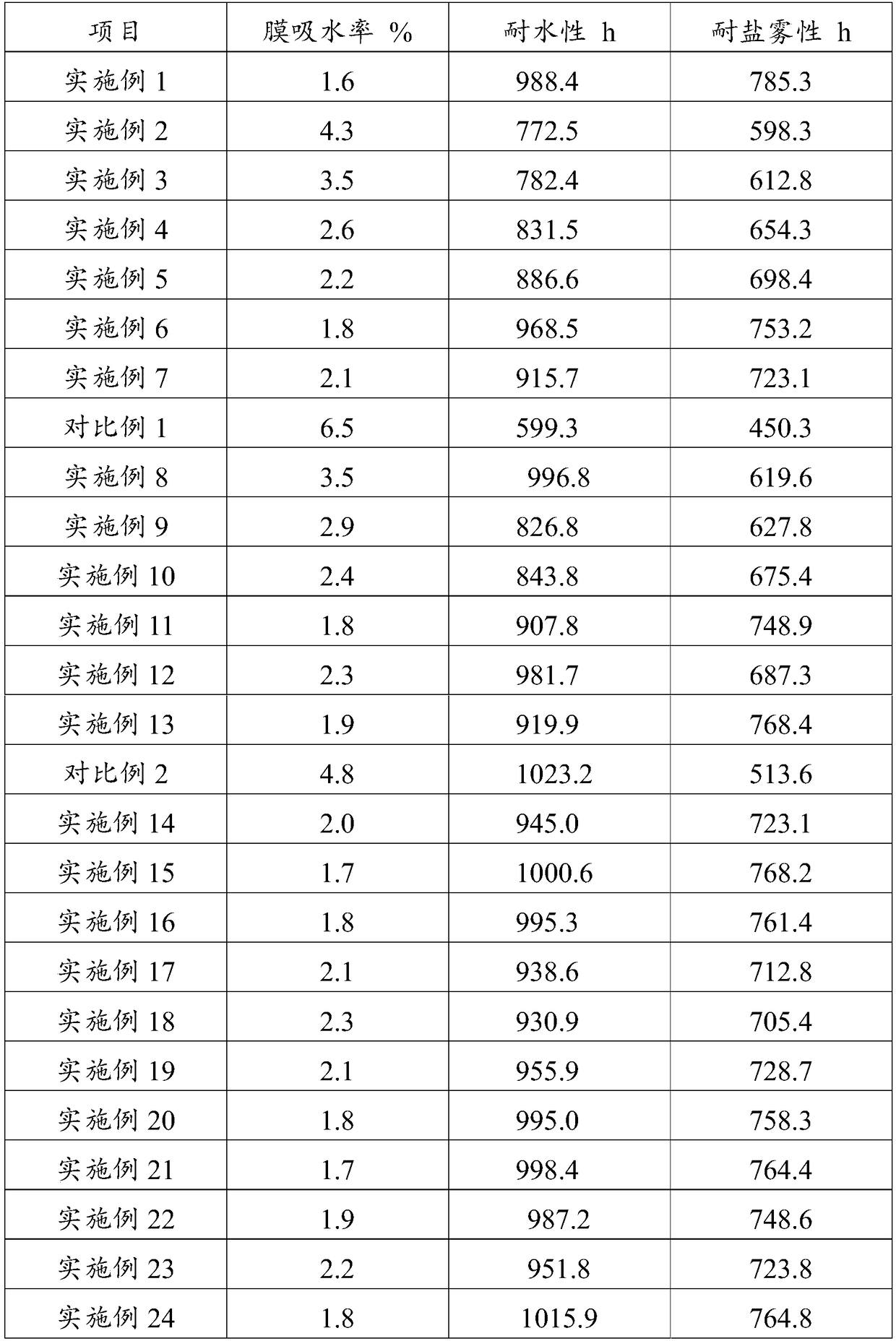

Examples

Embodiment 1

[0030] As a kind of waterborne anticorrosion coating of the embodiment of the present invention, described anticorrosion coating comprises following weight components:

[0031] 100 parts of epoxy acrylate, 4 parts of nano silicon dioxide modified by silane coupling agent surface treatment, 8 parts of curing agent, the curing agent is triisocyanate, and the epoxy acrylate consists of 3 parts by weight Epoxybutyrate, the methyl methacrylate of 35 parts by weight, the butyl acrylate of 40 parts by weight, the styrene synthesis of 45 parts by weight;

[0032] The solid content in the water-based anticorrosion paint is 45%, and the balance is water.

[0033] As the preparation method of the waterborne anticorrosion coating of the embodiment of the present invention, described method may further comprise the steps:

[0034] (1) Methyl methacrylate, propyl acrylate and styrene are mixed evenly and set aside;

[0035] (2) Deionized water is heated to 85 degrees, ammonium persulfate ...

Embodiment 2

[0039] As a kind of water-based anticorrosion coating of the embodiment of the present invention, the only difference between this embodiment and embodiment 1 is: described anticorrosion coating comprises following weight components:

[0040] 100 parts of epoxy acrylate, 0.1 part of nano silicon dioxide modified by silane coupling agent surface treatment, 8 parts of curing agent, the curing agent is triisocyanate, and the epoxy acrylate consists of 3 parts by weight Epoxybutyrate, 35 parts by weight of methyl methacrylate, 40 parts by weight of butyl acrylate, and 45 parts by weight of styrene.

Embodiment 3

[0042] As a kind of water-based anticorrosion coating of the embodiment of the present invention, the only difference between this embodiment and embodiment 1 is: described anticorrosion coating comprises following weight components:

[0043] 100 parts of epoxy acrylate, 0.5 parts of nano silicon dioxide modified by silane coupling agent surface treatment, 8 parts of curing agent, the curing agent is triisocyanate, and the epoxy acrylate consists of 3 parts by weight Epoxybutyrate, 35 parts by weight of methyl methacrylate, 40 parts by weight of butyl acrylate, and 45 parts by weight of styrene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com