Patents

Literature

59 results about "Ferric oxide yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

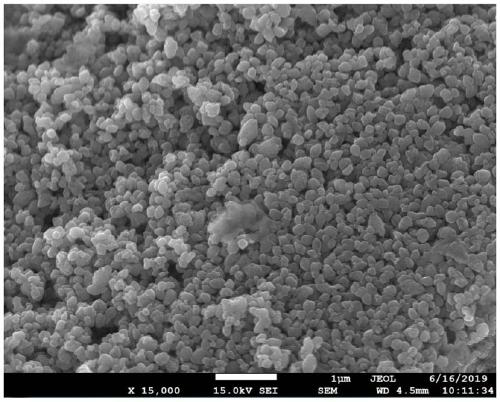

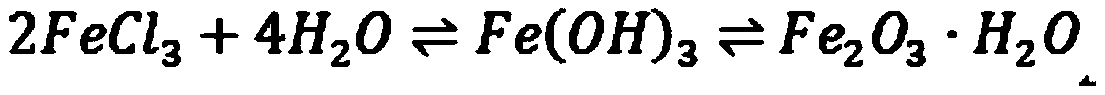

Ferric oxide yellow is an inorganic yellow pigment used in the pharmaceutical industry as a coating pigment. It is also known as yellow iron oxide [FeOH3]. It exists as an amorphous yellow powder, and is primarily used in the cosmetics industry.

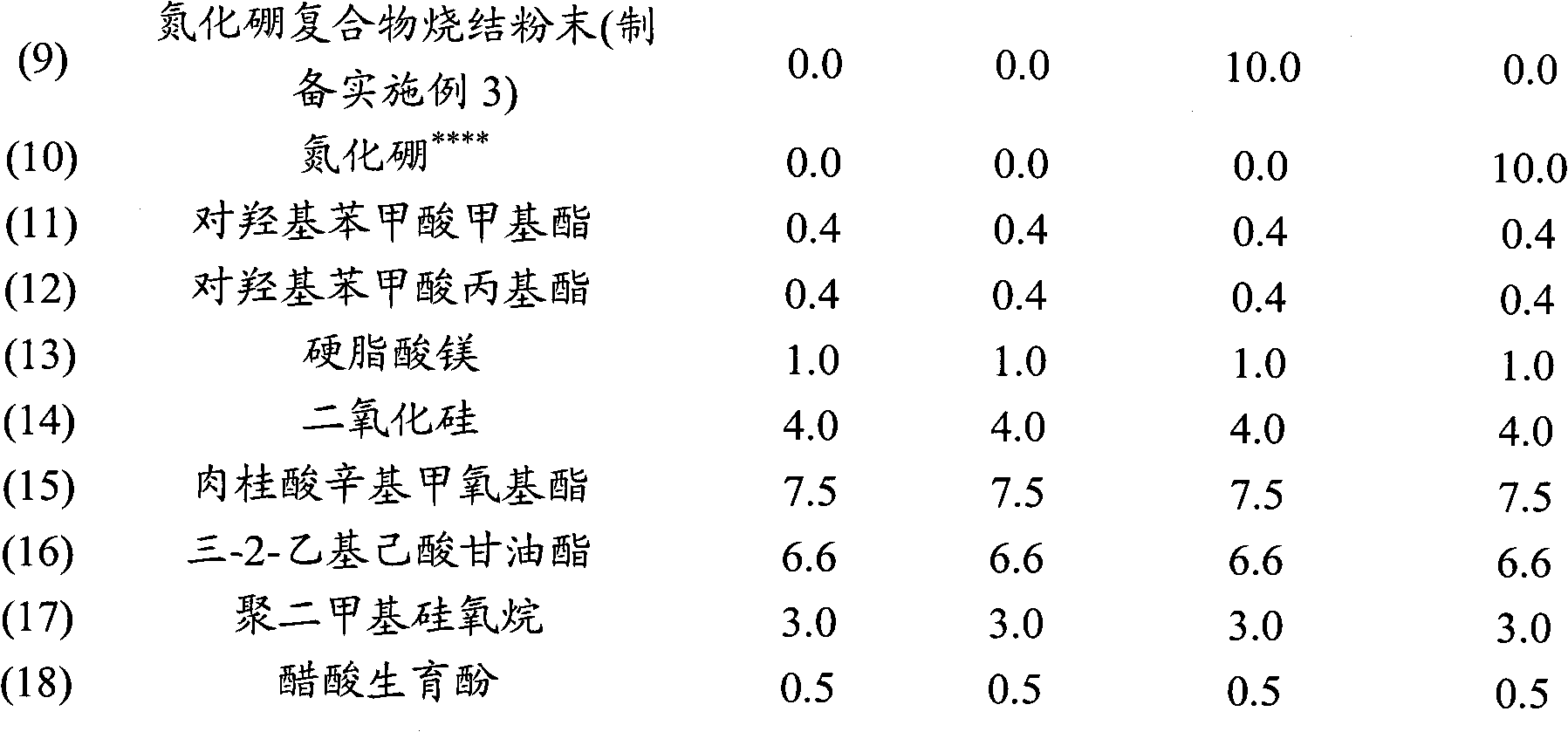

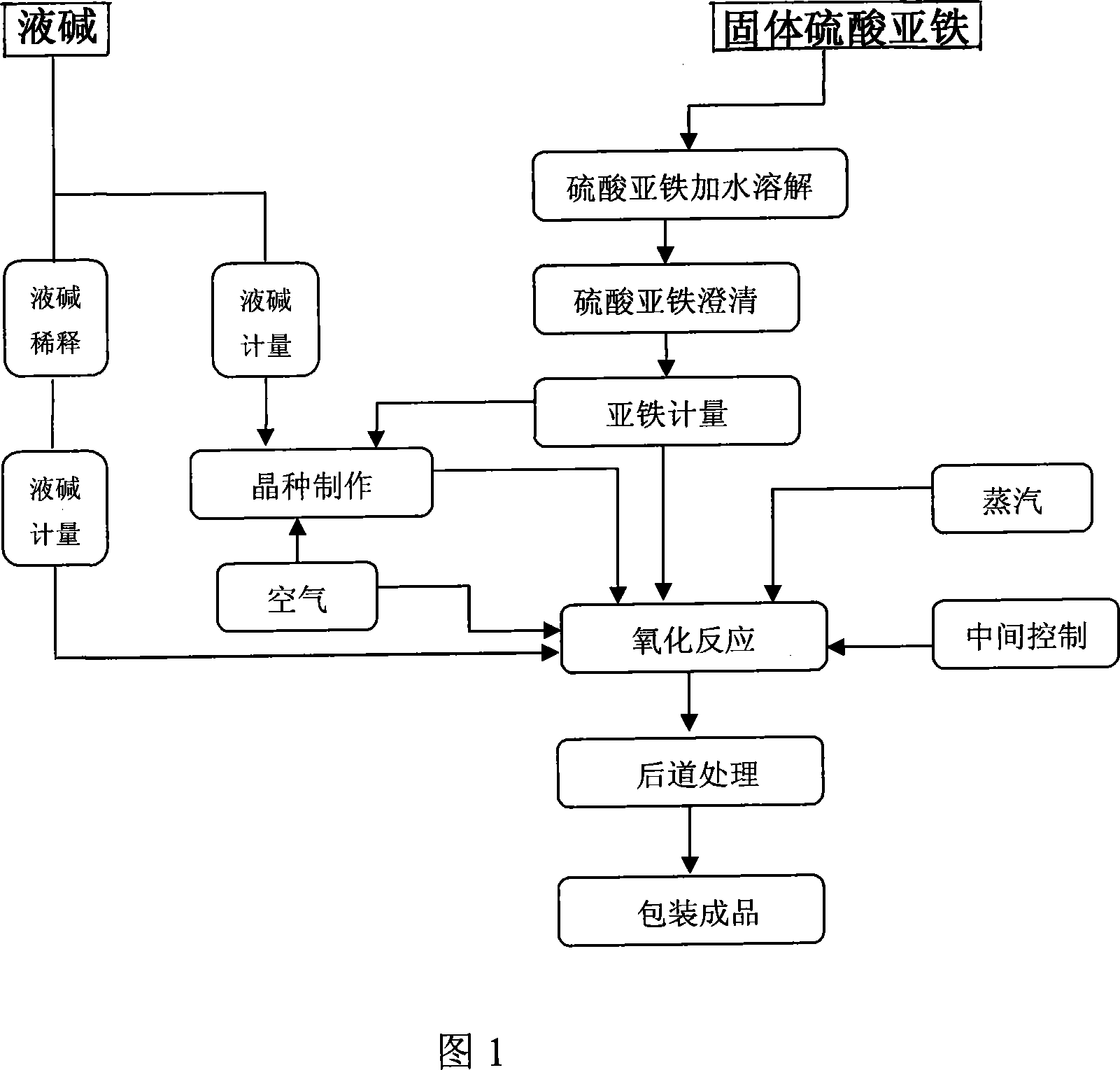

Method for producing the yellow pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415666AHigh recovery rateAchieve the purpose of separationPigmenting treatmentFerric oxide yellowTitanium oxide

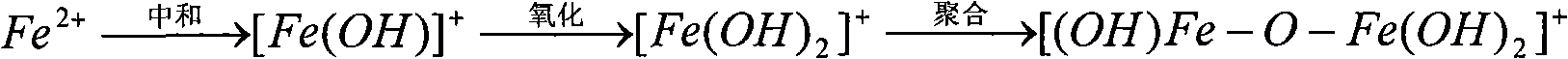

A process for preparing iron oxide yield pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Temperature-resistant iron oxide yellow pigment with flame retardant function and preparation method thereof

The invention provides a temperature-resistant iron oxide yellow pigment with a flame retardant function and a preparation method thereof. Iron oxide yellow is an important inorganic yellow pigment but the iron oxide yellow is poor in temperature resistance and is heated and decomposed at about 177 DEG C to turn red. According to the pigment provided by the invention, the iron oxide yellow is taken as a raw material, and the outer layer of the iron oxide yellow is wrapped with hydrotalcite, so that the heat resistance of the iron oxide yellow is improved to over 240 DEG C so as to use the iron oxide yellow as a colorant in a high molecular material processing process. Meanwhile, as hydrotalcite losses moisture at high temperatures and releases carbon dioxide, so that the pigment has a good flame retardant effect. The composite iron oxide yellow pigment synthesized by the invention has the advantages of good temperature resistance and flame retardant performance, simple synthetic method, low cost, safety, environment-friendliness and the like, and has a wide market application prospect.

Owner:HUZHOU TEACHERS COLLEGE

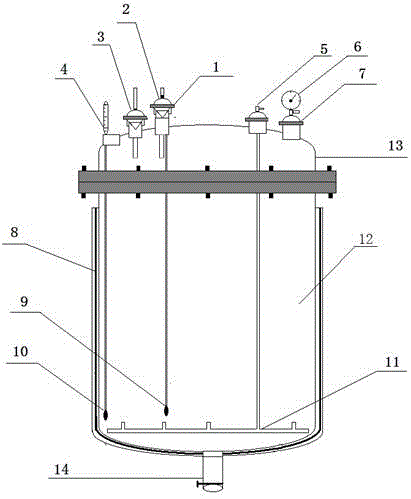

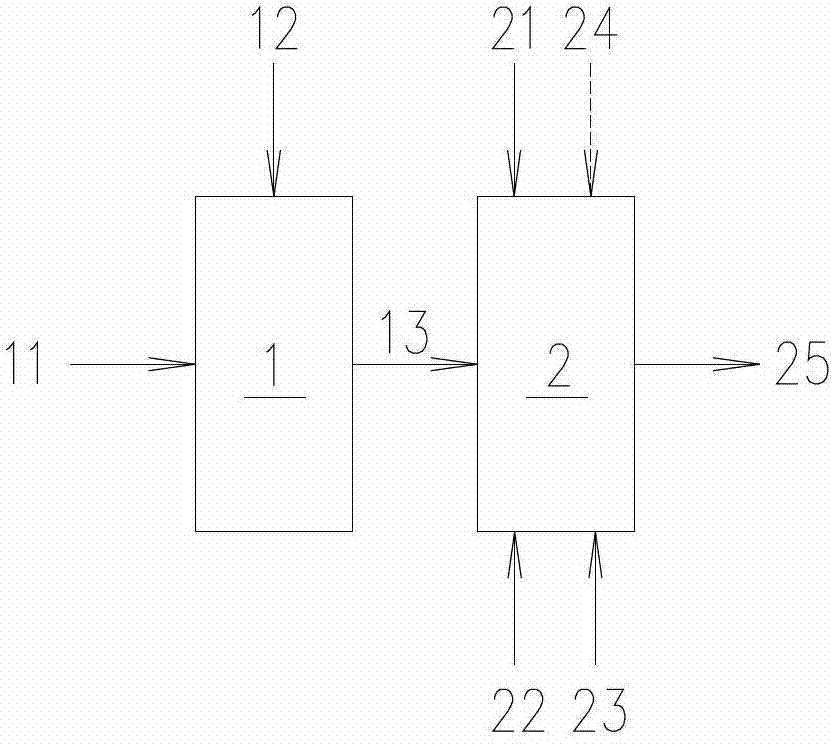

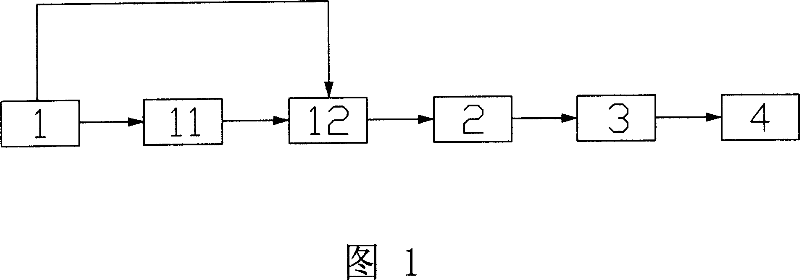

Device and method for preparing ferric oxide yellow

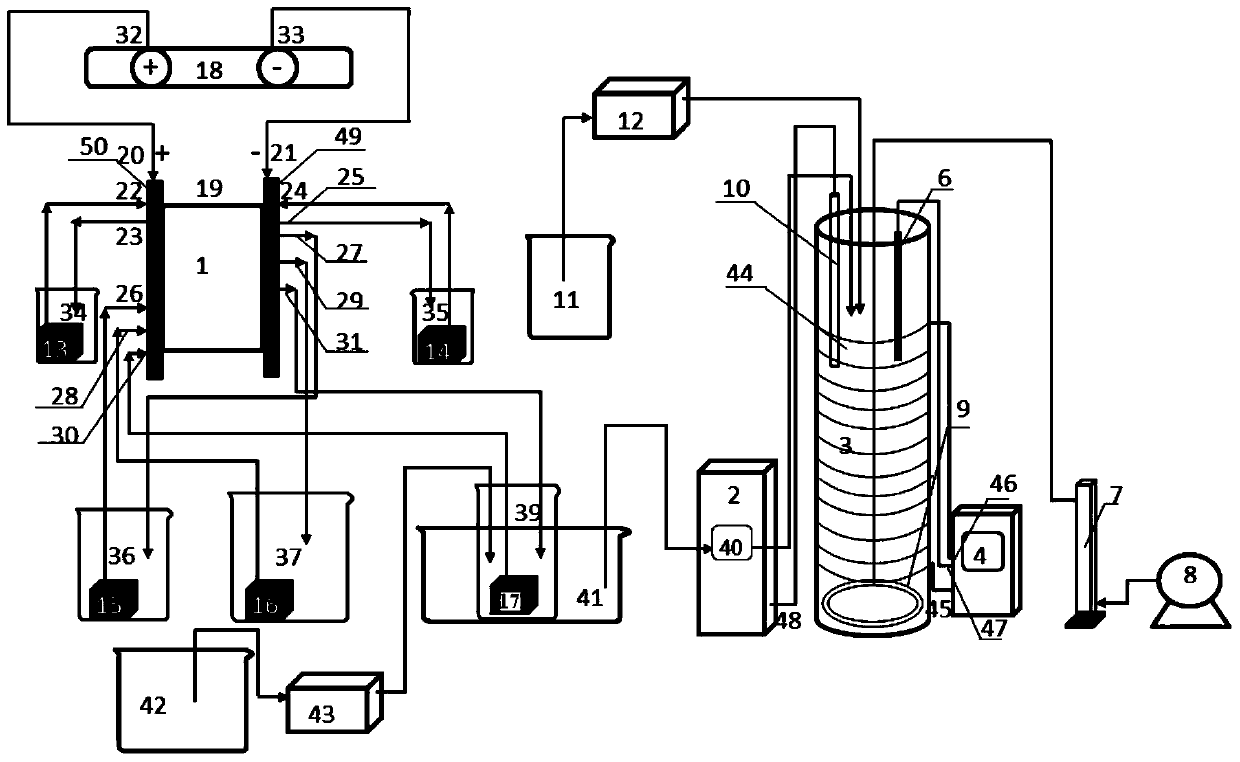

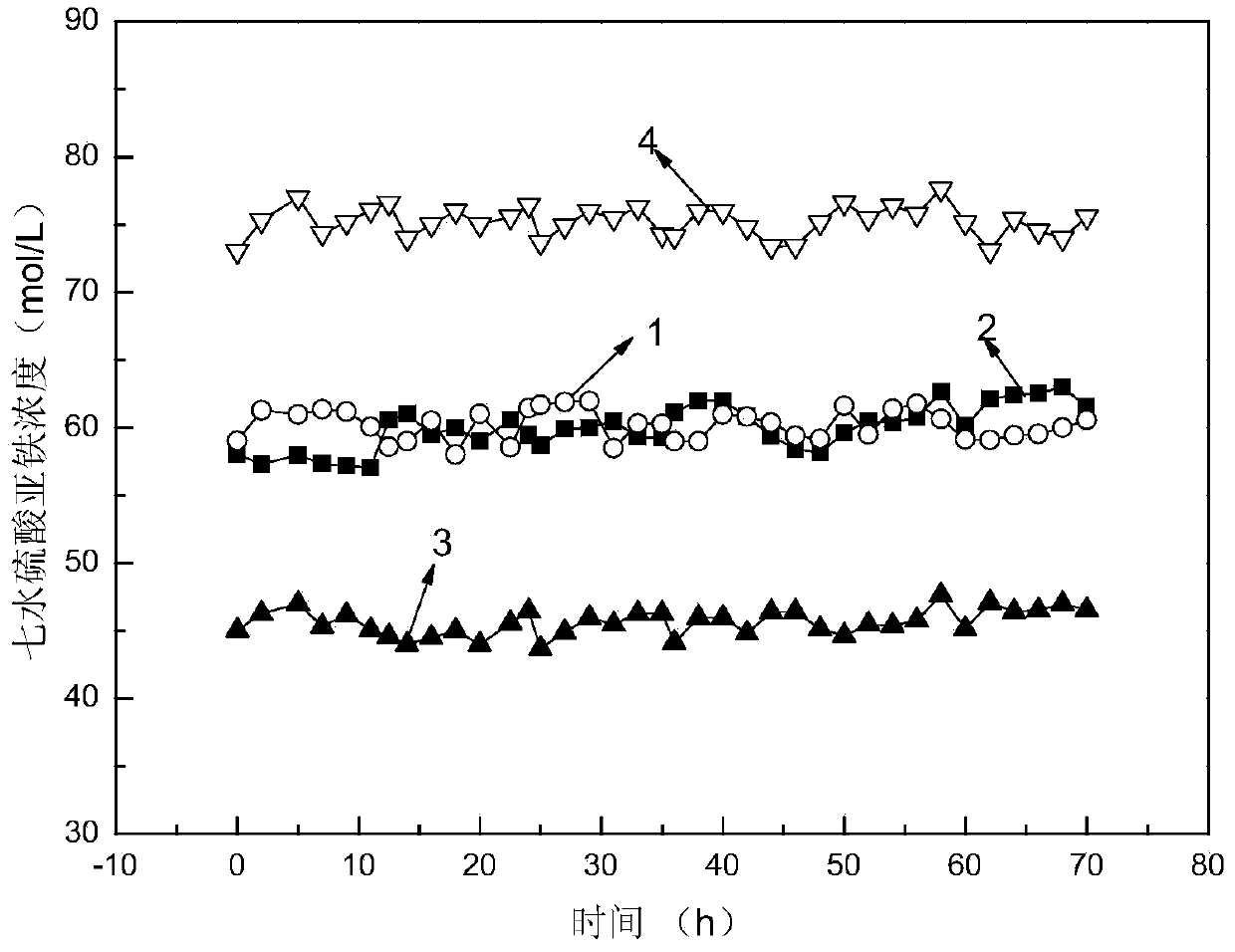

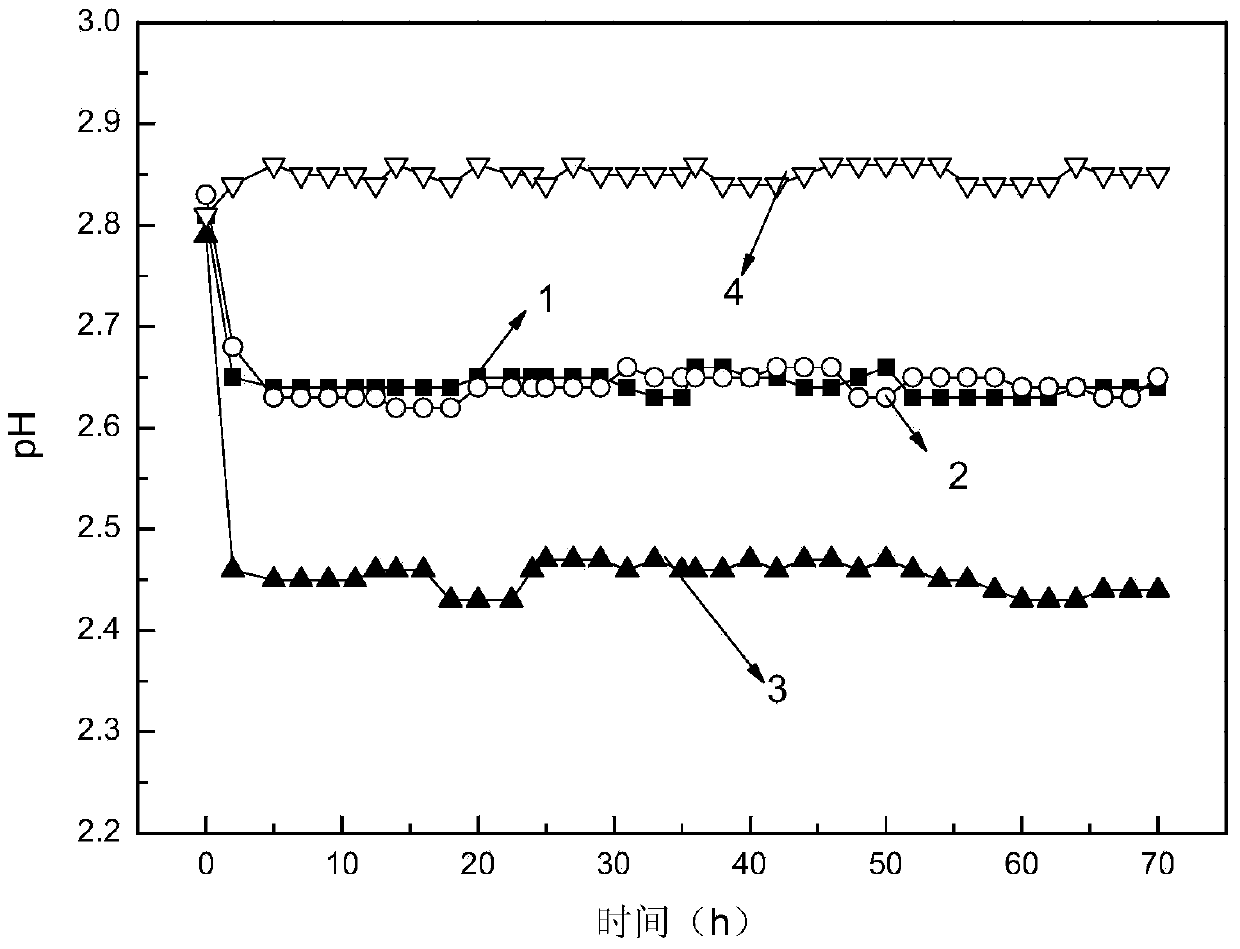

The invention provides a device and a method for preparing ferric oxide yellow. The device comprises 1, a first sample introduction device, 2, a second sample introduction device, 3, a gas inlet device, 4, a reactor of which an inlet is connected to an outlet of the first sample introduction device, an outlet of the second sample introduction device and an outlet of the gas inlet device, 5, a heating device which is used for heating the reactor, 6, a pH adjustment device which is used for adjusting a pH value of the reaction solution in the reactor, and 6, a bipolar-membrane electrodialysis device of which an alkaline chamber outlet is connected to an inlet of the second sample introduction device. The device for preparing the ferric oxide yellow utilizes alkaline liquor produced by the bipolar-membrane electrodialysis device as an antalkali, and adjusts a pH value of the reaction solution in ferric oxide yellow preparation. The method does not utilize an antalkali having a high price to prepare the ferric oxide yellow so that a ferric oxide yellow production cost is reduced. The device and the method realize effective treatment on an inorganic salt waste liquid produced by ferric oxide yellow preparation and realize resource recovery and utilization.

Owner:UNIV OF SCI & TECH OF CHINA

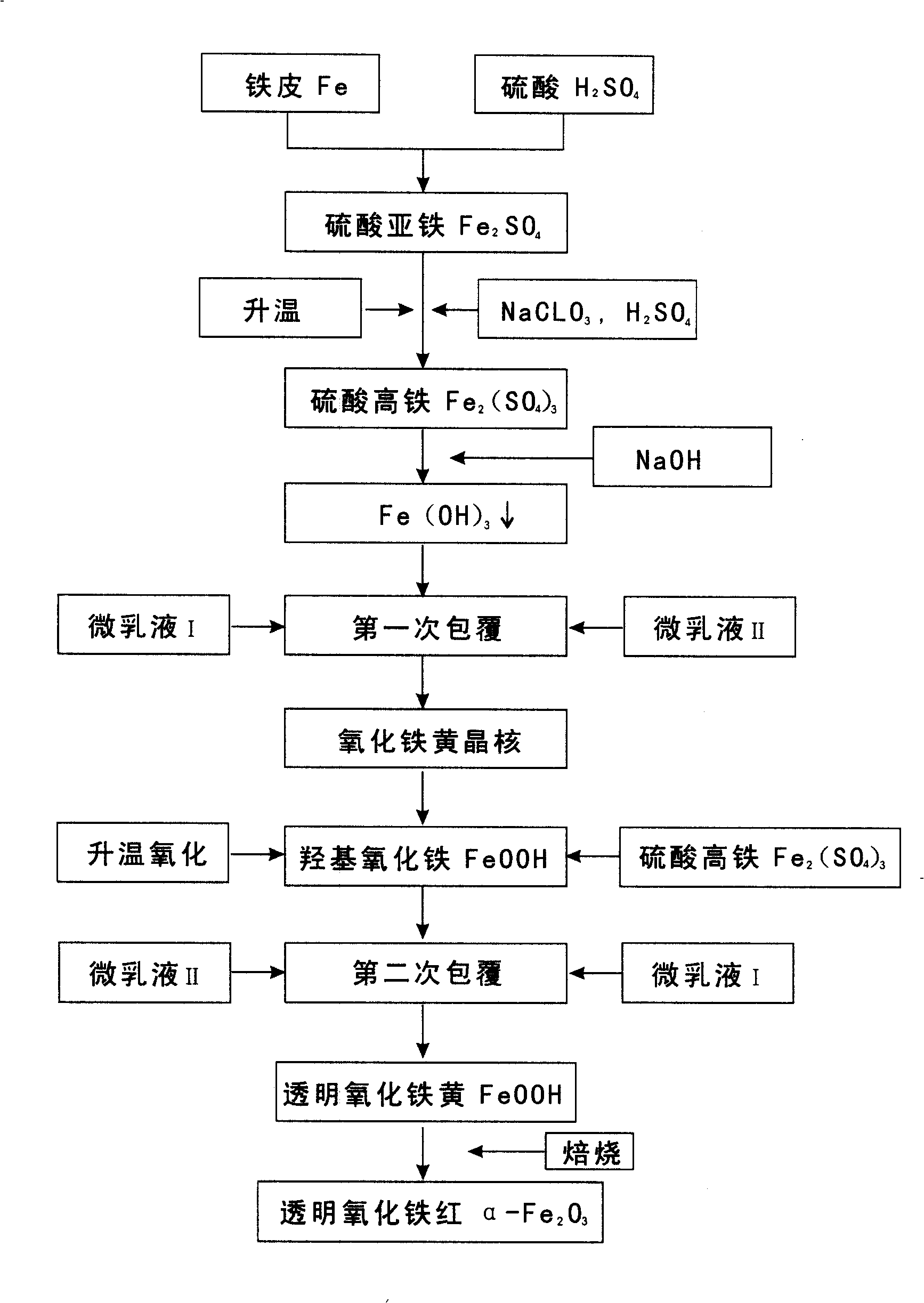

Method for preparing transparent iron oxide pigment with microemulsion method

ActiveCN101319099AImprove product qualityImprove performanceInorganic pigment treatmentFerric oxidesFerric oxide yellowEmulsion

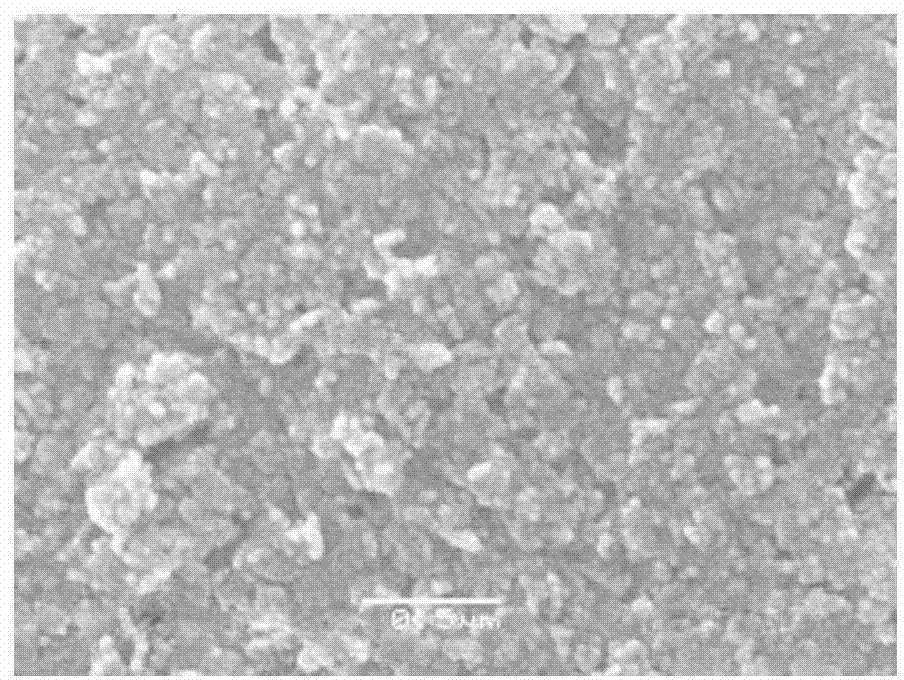

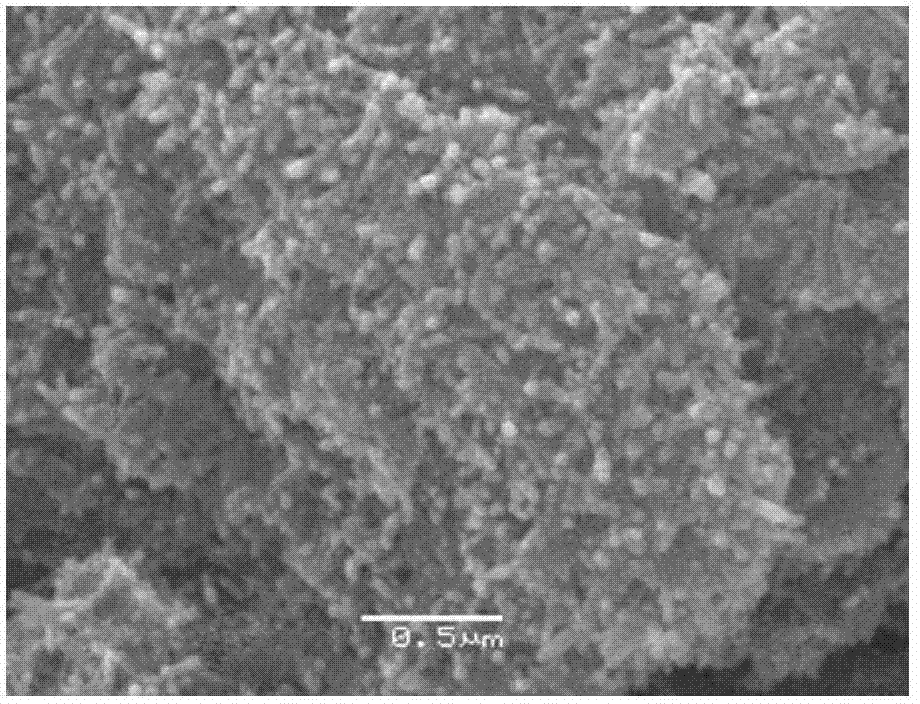

The invention relates to a method for making a transparent ironoxide pigment through adopting a micro emulsion method. The method relates to two key technologies including the preparation and the application of a micro-emulsification dispersing agent as well as the preparation and the subsequent thinning treatment of ferric oxide yellow. The micro-emulsification dispersing agent comprises a hydrophilic micro emulsion I consisting of water, a hydrophilic surface active agent and a coemulsifier and an oleophilic micro emulsion II consisting of oil, an oleophilic surface active agent and a coemulsifier, wherein both micro emulsions are coated layer by layer in turn on demand according to the surface water-soluble or oil-soluble characteristic of a refined particulate material; ferric oxide yellow particle undergoes dispersion and refining treatment so as to reach nanometer scale and make transparent ferric oxide yellow; and the transparent ferric oxide yellow undergoes high-temperature baking so as to generate transparent ferric oxide red. The method has scientific basis, reliable method, simple and feasible process and strong operability.

Owner:王建民

Low-viscosity ferric oxide yellow pigment

InactiveCN104559331ASimple production processSimple processPigment pastesPigment physical treatmentFerric oxide yellowPhysical chemistry

The invention discloses a preparation method of a low-viscosity ferric oxide yellow pigment. The preparation method of the low-viscosity ferric oxide yellow pigment comprises the following steps: (1) preparing the raw material which is common synthetic ferric oxide yellow powder; (2) ball milling, namely preparing a ball milling device and fully milling the ferric oxide yellow powder by moving a steel ball in a manner of circulating from top to two sides and bottom according the moving trajectory of the inner powder under continuous powerful vibration; (3) ultrafine grinding, namely ultrafine grinding the ball-milled ferric oxide yellow powder by using a grinding machine so as to completely break the unbroken cracks in the presence of high-speed shear force; and (4) preparing a finished product, namely detecting the color and the viscosity of the processed ferric oxide yellow powder to prepare the finished product.

Owner:ZHEJIANG UNITED PIGMENT

Preparation method of high-temperature-resistant ferric oxide yellow pigment

ActiveCN105504883AImprove controllabilityGood reproducibilityPigment treatment with non-polymer organic compoundsFerric oxide yellowAluminium hydroxide

The invention relates to a preparation method of a high-temperature-resistance ferric oxide yellow pigment. The method comprises the following steps: dissolving a ferric oxide yellow initial product into water to prepare slurry of which the mass percent is 5-40 percent, and preparing a water suspension; adding a sodium silicate aqueous solution into the water suspension, and reacting at the temperature of 30-90 DEG C and the pH value of 7-10 to coat silicon dioxide; adding a phosphorus compound aqueous solution and an aluminum salt aqueous solution at the temperature of 30-90 DEGC and the pH value of 5-9, and reacting to coat an aluminum phosphate compound; continually adding an aluminum salt aqueous solution, keeping the pH value at 4-10, and reacting at the temperature of 30-90 DEGC to coat aluminum hydroxide; filtering the obtained ferric oxide yellow, washing, drying and performing airflow smashing and organic treatment to obtain the high-temperature-resistance ferric oxide yellow pigment. The preparation method has the advantages of high controllability, high operability and easiness in industrial production, and the prepared ferric oxide yellow pigment has the advantages of high temperature resistance, high color-changing resistance, superior dispersion performance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Coated temperature resistant iron oxide yellow

InactiveCN108485313ACoated evenlyImprove heat resistanceInorganic pigment treatmentPowdery paintsFerric oxide yellowSynthesis methods

The invention relates to iron oxide yellow pigment, in particular to a coated temperature resistant iron oxide yellow. The iron oxide yellow comprises an iron oxide yellow core and alumina and zinc oxide that are coated on the iron oxide yellow core. The preparation method comprises the steps of: 1) putting prepared iron oxide yellow slurry in a reaction kettle, slowly adding an aluminum sulfate solution under stirring, then adding glycerol and zinc carbonate into the feed solution in the reaction kettle, adjusting the pH value of the feed solution in the reaction kettle to 11-12, and when thepH value becomes stable, closing the cover of the reaction kettle; 2) raising the temperature to 220DEG C-250DEG C, and when the temperature in the reaction kettle reaches 220-250DEG C, making the reaction kettle enter a heat preservation and pressure maintaining state; and 3) after heat preservation for 1-3h and cooling to a temperature below 60DEG C, opening the kettle cover, adjusting the pH to 7.5-8.5, after the pH is stabilized, conducting rinsing and pumping filtering, performing drying at 100-120DEG C, and finally carrying out crushing. The coated iron oxide yellow synthesized by the invention has the advantages of good heat resistance, more uniform coating, simple synthesis method, low cost, safety, environmental protection, etc.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

Method for preparing ferric oxide yellow pigment by waste iron hydrochloric acid lotion

InactiveCN101649130ALow costReduce energy costsPigment physical treatmentPigment treatment with non-polymer organic compoundsFerric oxide yellowIron oxide

The invention discloses a method for preparing ferric oxide yellow pigment by waste iron hydrochloric acid lotion, which adopts a wet oxidation method. The method comprises the following steps: processing the waste iron hydrochloric acid lotion; preparing a crystal seed; fading red; carrying out two-step oxidation; pressing and filtering; and drying. The method can rapidly and simply process the waste iron hydrochloric acid lotion with lower ferrous concentration, more impurity iron content and higher acidity, which is discharged by industries, such as metallurgy, steel, machinery, chemistry,pharmacy, and the like, the waste iron hydrochloric acid lotion can reach the Chinese allowed discharge standard, and the ferric oxide yellow pigment which can be used for industries, such as construction, paint, and the like is prepared.

Owner:ZHEJIANG UNIV

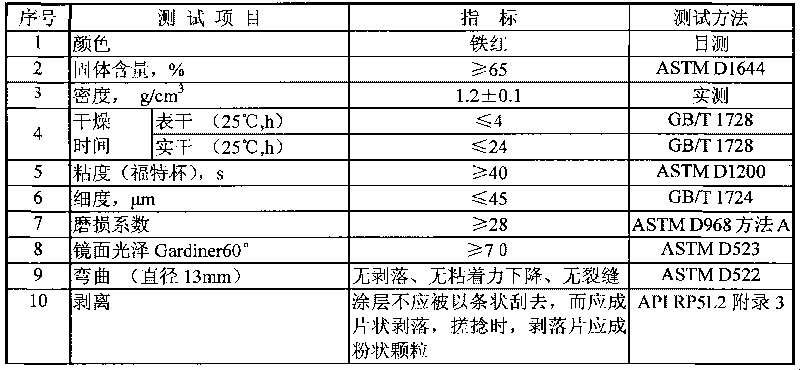

Anti-drag and abrasion-resistant paint for natural gas line

ActiveCN101698773AHigh surface glossPromote wettingEpoxy resin coatingsFerric oxide yellowMicrosphere

The invention discloses an anti-drag and abrasion-resistant paint for a natural gas line. Raw materials of the paint comprise two components A and B, wherein the component A comprises a phenolic aldehyde amine curing agent, a flatting agent, a defoaming agent, a dispersant, a thickening agent, white ceramic powder, red ferric oxide powder, mica ferric oxide, yellow iron oxide powder, light calcium carbonate and an environmentally-friendly mixed solvent; and the component B comprises epoxy resin, the flatting agent and the environmentally-friendly mixed solvent. The anti-drag and abrasion-resistant paint has the following advantages that: 1, compared with the conventional polyamide curing agent, the phenolic aldehyde amine curing agent has the advantages of more convenient construction in winter, better wettability for base materials, high coating crosslinking density, no pinhole and stronger solvent resistance and corrosion resistance; 2, the coating surface of the paint is smooth and specular gloss can reach more than 70 and is improved by15 to 30 percent compared with that of the like products; and 3, the paint is added with an abrasion-resistant filler, such as white ceramic, hollow microsphere and the like, so the abrasion resistance of the coating is greatly improved.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

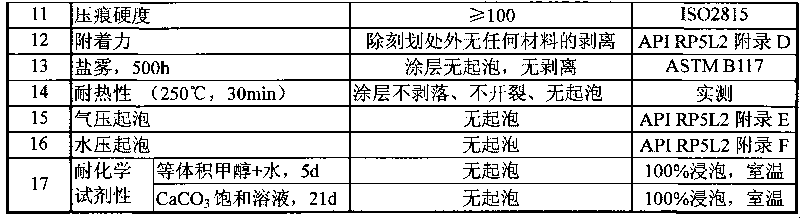

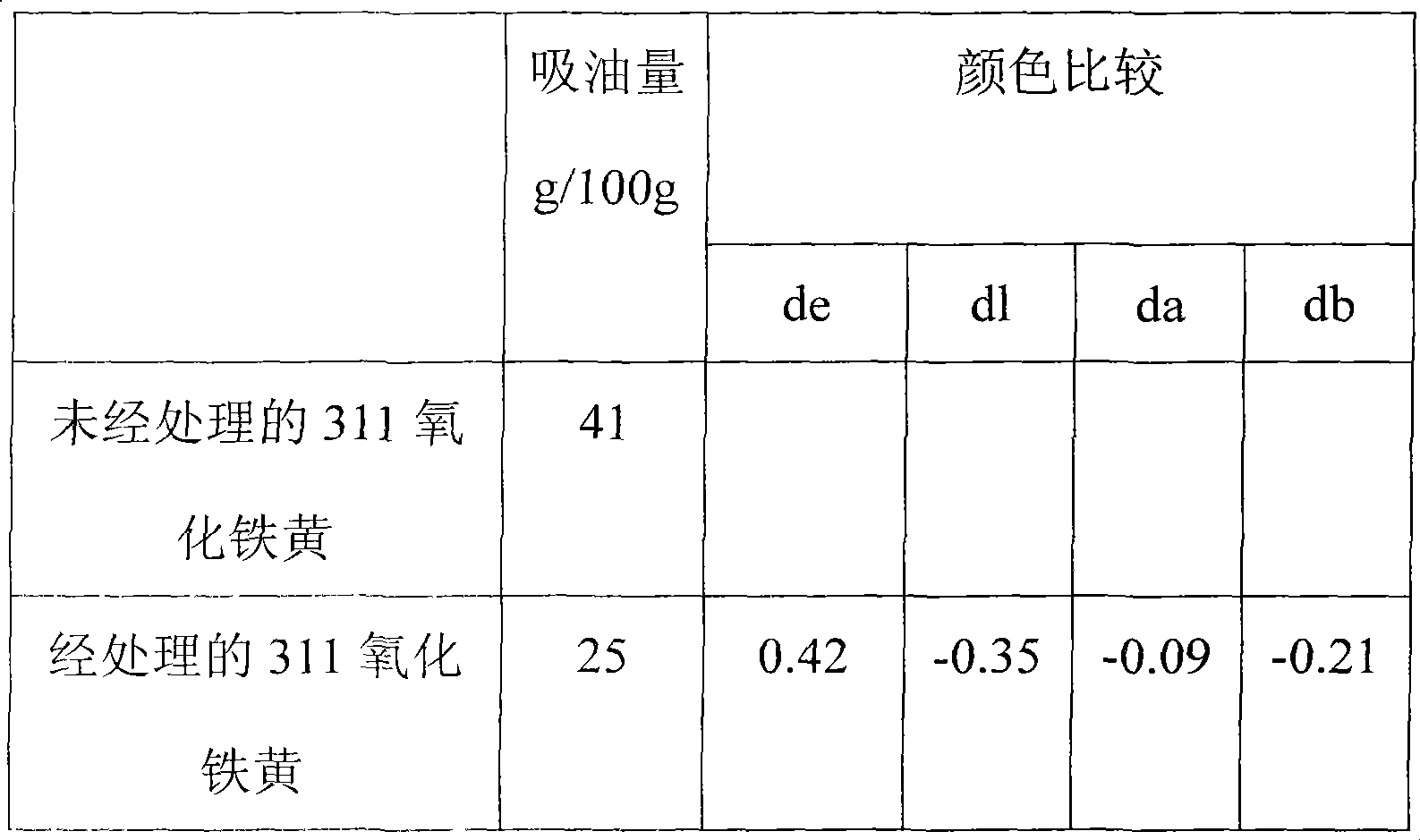

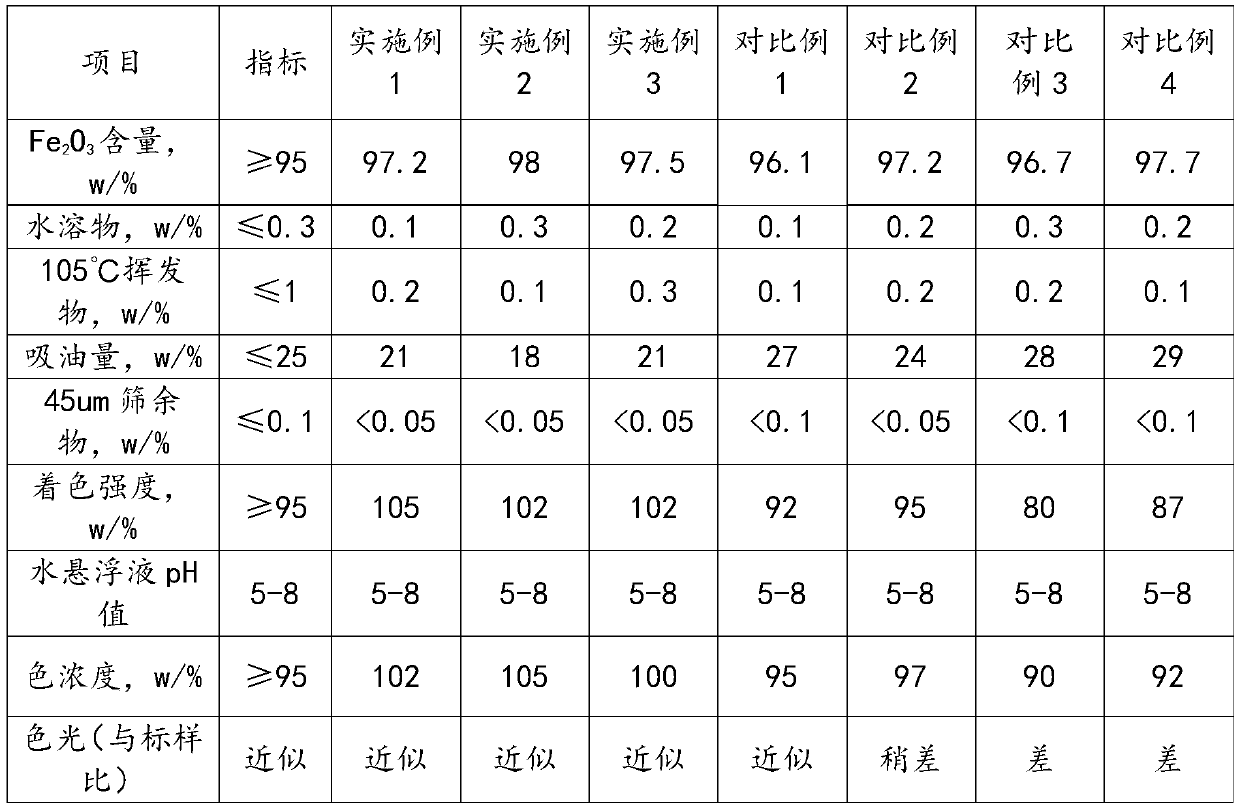

Low oil absorption ferric oxide yellow pigment

The invention discloses ferric oxide yellow pigment with low oil absorption, wherein ferric oxide yellow is obtained by means of wet-method sulfate oxidation, and the dense ferric oxide yellow is crushed to obtain the ferric oxide yellow pigment, wherein the ferric oxide yellow is obtained by means of wet-method sulfate oxidation and then dried, and ferric oxide yellow powder is subjected to densification treatment. In the technology, the product is obtained by acquisition of the ferric oxide yellow by means of wet-method sulfate oxidation, drying, densification of the powder and crushing of the dense ferric oxide yellow. The technology can manufacture the ferric oxide yellow pigment with low oil absorption, and more importantly no organic chemical substance is added during the manufacturing process; and the equipment adopted by the method is wide, simple and easy to operate.

Owner:南通宝聚颜料有限公司

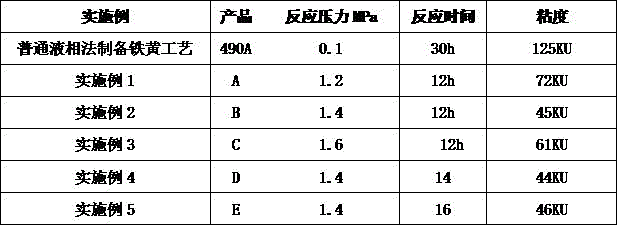

Low-viscosity iron oxide yellow

The invention discloses low-viscosity iron oxide yellow. A preparation method of the iron oxide yellow comprises the steps that ferrous sulfate and sodium hydroxide are reacted at the temperature of 25-35 DEG C to prepare ferric oxide yellow seed crystal, the prepared seed crystal is placed into a high-pressure reaction kettle, meanwhile, the temperature is increased to 70 DEG C, at the moment, air pressure in the reaction kettle is the same as that of the outside world, a sodium hydroxide solution with the concentration of 8-12 mol / L is added when the temperature reaches 70 DEG C, the added alkaline liquid amount is determined based on the pH value, adding of alkaline liquid is stopped when pH reaches 3.8-4.2, a valve of the high-pressure reaction kettle is turned off after the pH reaches the specific value, the high-pressure reaction kettle is pressurized through a high-pressure air pump, air is continuously pumped into the reaction kettle from the bottom through the high-pressure pump in the reaction process, meanwhile, air is exhausted from the top of the reaction kettle to ensure that sufficient oxygen participates in reaction, the system air pressure is controlled to be about 1.2-1.7 MPa, the reaction temperature is 70 DEG C, the reaction time is controlled to be 12-14 h, and finally rinsing, suction filtration, drying and smashing are carried out, so that the low-viscosity iron oxide yellow is obtained.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT

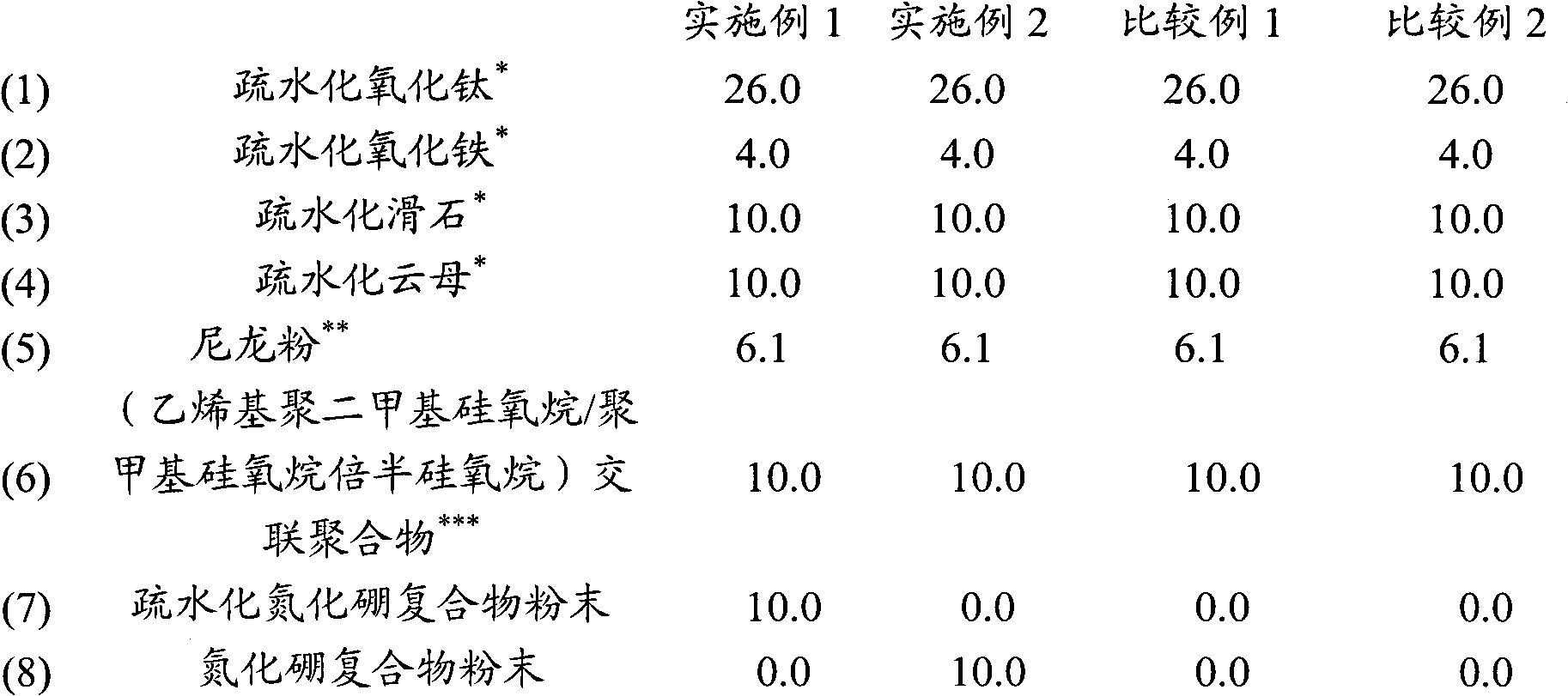

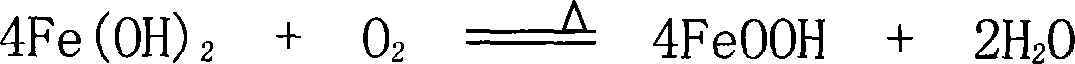

Cosmetic composition comprising boron nitride complex powder

A cosmetic composition comprising a boron nitride complex powder in which particles of metal oxide are attached to at least a part of the surface of a base material consisting of boron nitride. The metal oxide is preferably a combination of titanium dioxide, yellow iron oxide, red iron oxide and black iron oxide. Preferred compositions include liquid or powder foundation, lipstick, eye shadow, eye liner and mascara. The cosmetic composition comprising a cosmetic powder is capable of imparting smoothness to the touch, lively finish with fine texture and natural glow, and adhesion to the skin when applied to the skin.

Owner:CHANEL PARFUMS BEAUTE SAS

Special iron oxide yellow pigment for tobacco and production method thereof

ActiveCN101225246AHigh puritySave iron resourcesPigmenting treatmentTobacco treatmentFerric oxide yellowGranularity

The invention relates to an iron oxide yellow pigment for tobacco and the production method, which resolves the technical problem and aims at providing a new liquid-liquid reacting iron oxide yellow pigment and the production method for tobacco, thus can ensure that the granularity of the product is more refined, more symmetrical and brighter than that made by iron filing method. The iron oxide yellow pigment for tobacco also aims at controlling the content of arsenic and lead in product in order to reach the requirement of tobacco industry. The production method adopts the technical proposal that the iron oxide yellow pigment is obtained by the reaction of 4500 to 5000 weight parts of solid green copperas with 80 to 88 percent content and 2500 to 300 weight parts of sodium hydroxide solution with 32 percent concentration. The production method comprises the inoculating seed preparation and the second oxidation. The an iron oxide yellow pigment can be widely used in tobacco industry, such as tipping paper makers and printing ink makers.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT

Method for preparing iron oxide yellow

The invention relates to a method for preparing iron oxide yellow, which comprises the following steps: step 1: using sulfuric acid to react with iron in a reaction tank to prepare an FeSO4 solution; step 2: under the condition of stirring, adding the FeSO4 solution prepared in the step 1 as well as an NaO solution and a deflocculant solution into a sedimentation tank simultaneously to prepare a ferrous hydroxide sizing agent; step 3: under the condition of stirring, leading air in the sedimentation tank to oxidize the ferrous hydroxide sizing agent prepared in the step 2 to obtain a ferric hydroxide sizing agent; and step 4: washing, filtering, drying and grinding the ferric hydroxide sizing agent prepared in the step 3 to obtain the iron oxide yellow product. According to the invention, the method is simpler, is more environment-friendly, and the spherical iron oxide yellow can be prepared.

Owner:张学政

Heatproof type easily dispersing ferric oxide yellow pigment and preparation method thereof

ActiveCN107090195AImprove heat resistanceGood dispersionPigment physical treatmentPigment treatment with non-polymer organic compoundsDispersityEnvironmental resistance

The invention relates to a heatproof type easily dispersing ferric oxide yellow pigment and a preparation method thereof. Soluble calcium salt, sodium hexametaphosphate and sodium hydroxide are used as reaction raw materials, an ultrasonic dispersing technique is introduced in a cladding process, calcium phosphate is coated on the surface of the ferric oxide yellow pigment through reaction, and then the sodium stearate organic treatment modification for the surface is performed, so that a composite material is formed. The formed composite material can promote the heat resistance and dispersity of the ferric oxide yellow and can be used as a coloring agent in plastic processing and powder coating application. The cladding type ferric oxide yellow compounded according to the invention has the advantages of excellent heat resistance and dispersity, simple compounding method, low cost, safety, environmental protection, and the like, and has higher industrial application value.

Owner:HUZHOU TEACHERS COLLEGE

Plant fiber fire prevention water-fast type floor

The invention provides a plant fiber floor. A board structure of the floor is a plant fiber bottom layer, a reinforcing layer and a surface paint layer in sequence from bottom to top, wherein the plant fiber bottom layer comprises plant fiber powder, and the plant fiber bottom layer is composed of the plant fiber powder, a modified adhesive, ferric oxide yellow, fire retardant and paraffin. Through processing steps such as an enzyme reaction, adhesive modification, structure improvement in a preparation method, on the condition that less damage to cellulose is guaranteed, hydroxide radical of a plant fiber surface is greatly increased, gluing capacity of adhesives to plant fiber is improved, water-fast performance of the floor is strengthened, and performance such as corrosion prevention and heat insulation of the floor is improved through preparation of multi-layer composite boards.

Owner:琚长林

Preparation method of ferric oxide yellow

InactiveCN103663567ATake advantage ofHas practical valueFerric oxidesFerric hydroxideFerric oxide yellow

The invention discloses a preparation method of ferric oxide yellow in the field of pigments. The method comprises the following process steps: (1) preparing refined green vitriol into a solution with the Fe<2+> concentration of 1.5mol / L, wherein the refined green vitriol is obtained after Mn<2+> and Ti<4+> in green vitriol as a side product of titanium dioxide are removed; (2) adding waste sulfuric acid and an oxidizing agent sodium chlorate into the refined green vitriol solution at the temperature of 410-500 DEG C under a vibration condition, reacting for 400min, and oxidizing Fe<2+> to form Fe<3+>; (3) adding an NaOH solution into a solution with high ferrum content at the temperature of 40 DEG C, and vibrating at the speed of 150r / min to finish the preparation of colloid ferric hydroxide; (4) adding the solution with high ferrum content and a ferric sheet into the ferric colloid, and reacting at the temperature of 90-100 DEG C for 10-15h to finish the conversion of the ferric colloid to the ferric oxide yellow; and (5) filtering and drying to finally obtain ferric oxide yellow powder. The preparation method is economic, environmental friendly and high in practical value.

Owner:QINGDAO WINCHANCE TECH

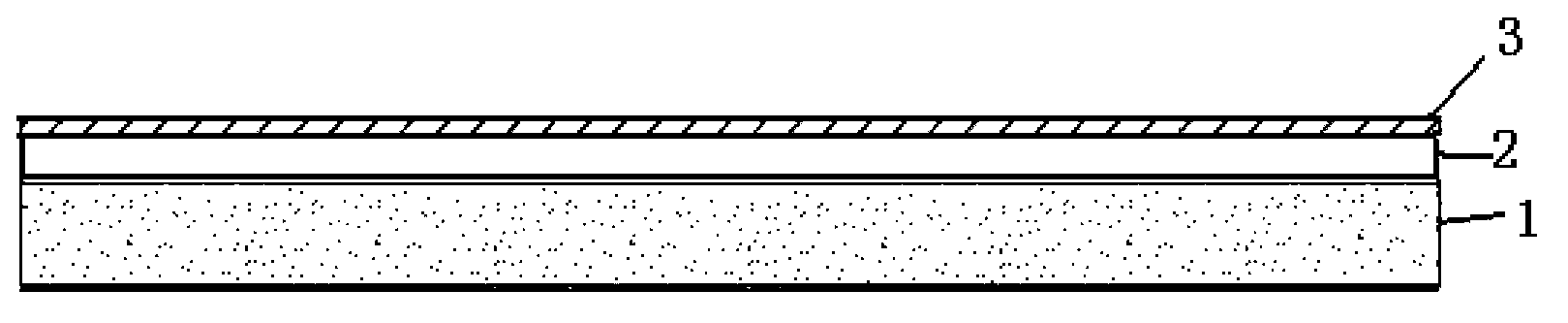

Efficient antirust heat-resistant chip

InactiveCN104449084ASolve flame retardancySolve rust problemsFireproof paintsAnti-corrosive paintsWater basedFerric oxide yellow

The invention provides an efficient antirust heat-resistant chip, comprising three coatings which are sequentially superposed from top to bottom, wherein the three coatings comprise the following raw materials in parts by weight: 45-65 parts of a water-based polyethylene wax emulsion, 25-40 parts of ferric oxide yellow, 5-12 parts of polyacrylic acid, 2-6 parts of aluminum dihydrogen phosphate, 1-3 parts of sodium benzoate, 15-25 parts of activated aluminum oxide, 1-3 parts of magnesium hydrate, 1.5-2.5 parts of hydroxyethyl cellulose, 0.5-1.5 parts of methylbenzotriazole, 0.1-0.5 part of dodecanol ester, 1-2 parts of polydimethylsiloxane and 40-60 parts of deionized water. The coatings have the advantages of rust resistance, flame retardant property and high-temperature resistance.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

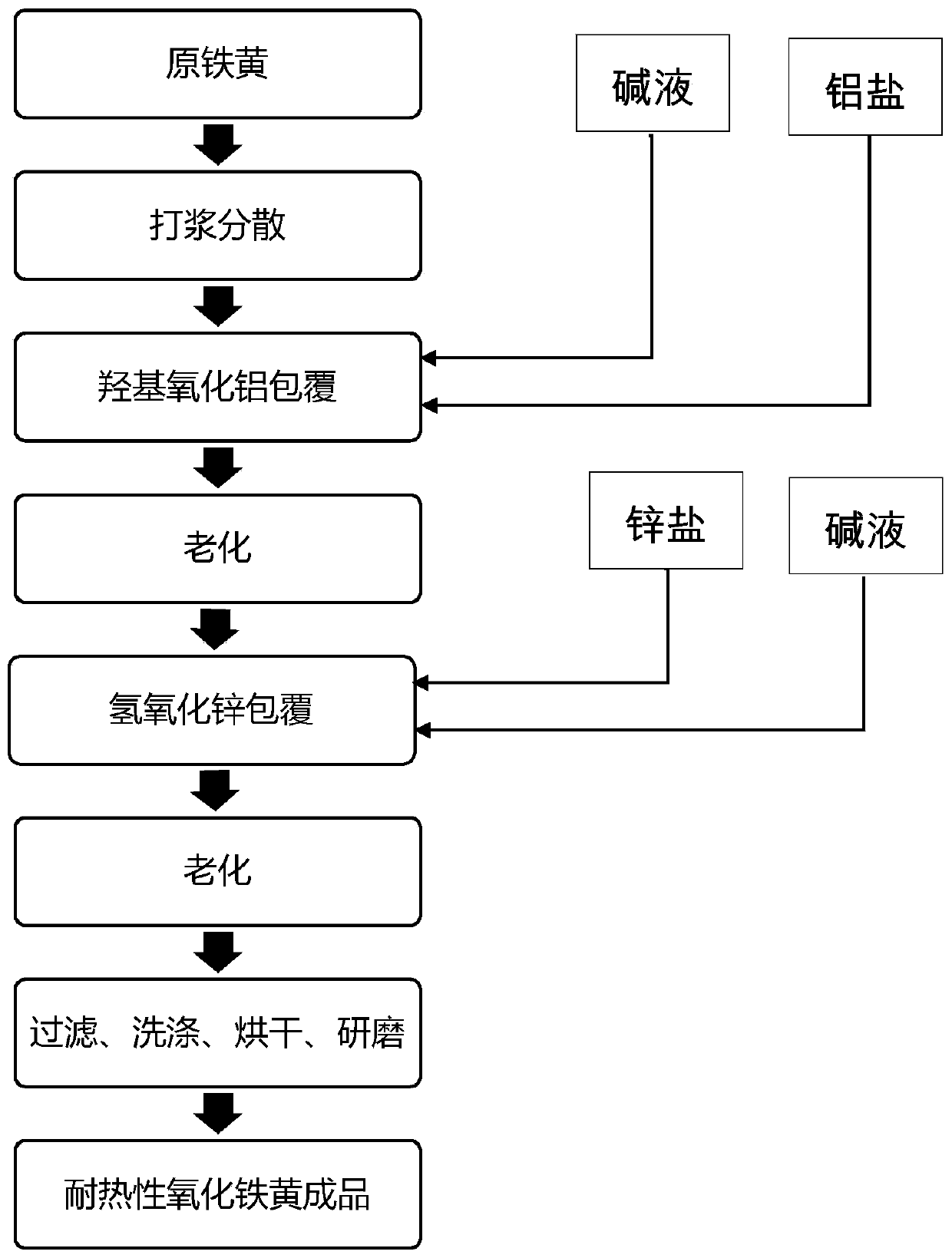

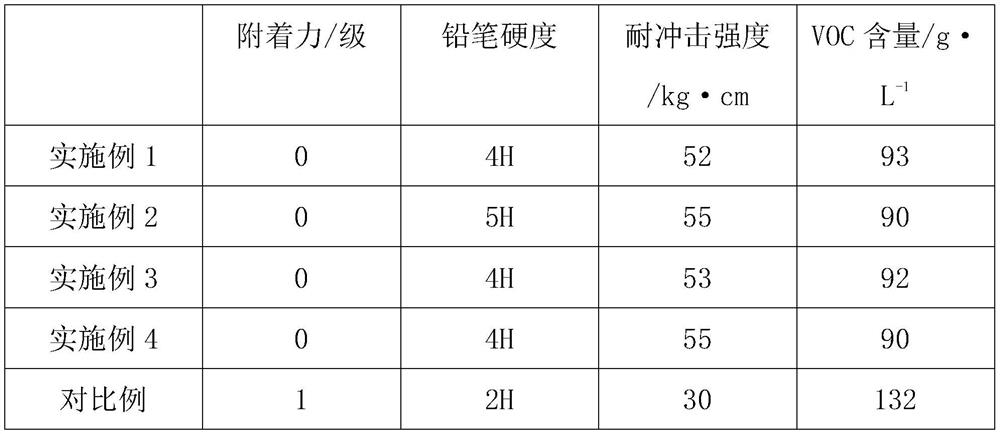

High temperature resistant iron oxide yellow pigment and preparation method thereof

ActiveCN110527322AImprove heat resistanceInhibit entryInorganic pigment treatmentCoatingsZinc hydroxideFerric oxide yellow

The invention provides a high temperature resistant iron oxide yellow pigment and a preparation method thereof. The high temperature resistant iron oxide yellow pigment is a double-layered core-shellstructure, wherein the core structure is an iron oxide yellow pigment, the core structure is coated with a hydroxyl alumina layer and a zinc hydroxide layer from inside to outside in order, a coatingamount of the hydroxyl alumina layer is 1-50% of a weight of the iron oxide yellow pigment, and a coating amount of the zinc hydroxide layer is 1-10% of a weight of the iron oxide yellow pigment. By coating the surface of iron oxide yellow nanoparticles with hydroxyl alumina / zinc hydroxide, heat can be inhibited from entering the inside of the iron yellow particles, so that heat resistance of theiron yellow is greatly improved, heat resistance of the iron oxide yellow is that the iron oxide yellow can withstand for at least 30 minutes in an oven above 240 DEG C, and it can be expected that the product is suitable for high temperature coil coating materials and plastic processing industries.

Owner:ZHEJIANG UNIV OF TECH

Low-VOC high-corrosion-resistance environment-friendly epoxy coating material and preparation method thereof

InactiveCN113480919ALow viscosityImprove anti-settlingAnti-corrosive paintsEpoxy resin coatingsEpoxyMeth-

The invention discloses a low-VOC high-corrosion-resistance environment-friendly epoxy coating material, which is prepared from the following components, by mass, 20-25% of epoxy resin, 1.5-2% of petroleum resin, 5-8% of methyl isobutyl ketone, 1-2% of polyamide wax, 0.5-0.8% of a wetting dispersant, 0.2-0.4% of an acrylate defoaming agent, 4-6% of titanium dioxide, 0.2-0.4% of iron oxide yellow, 0.3-0.5% of carbon black, 25-35% of aluminum oxide, 25-35% of feldspar powder, 2-3% of n-butyl alcohol, 0.3-0.6% of methylsilane and 3-5% of a reinforcing filler, wherein the reinforcing filler is a TiO2 / ZIF-8 composite material modified by a polymer. The invention also discloses a preparation method of the epoxy coating material. The prepared epoxy coating material is low in VOC content, good in stability, good in corrosion resistance and excellent in mechanical property.

Owner:SUZHOU COLOR WAY ENTERPRISE DEV

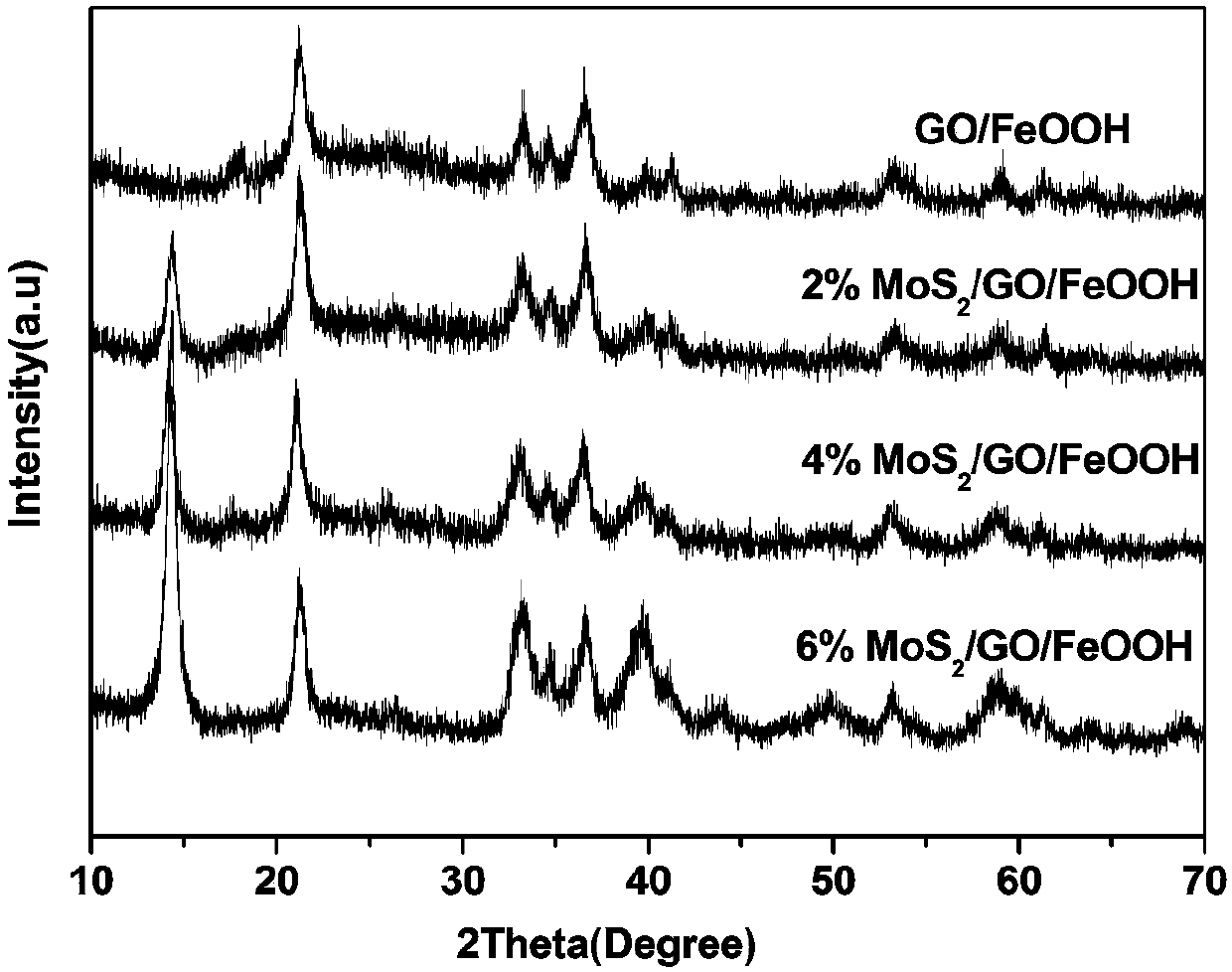

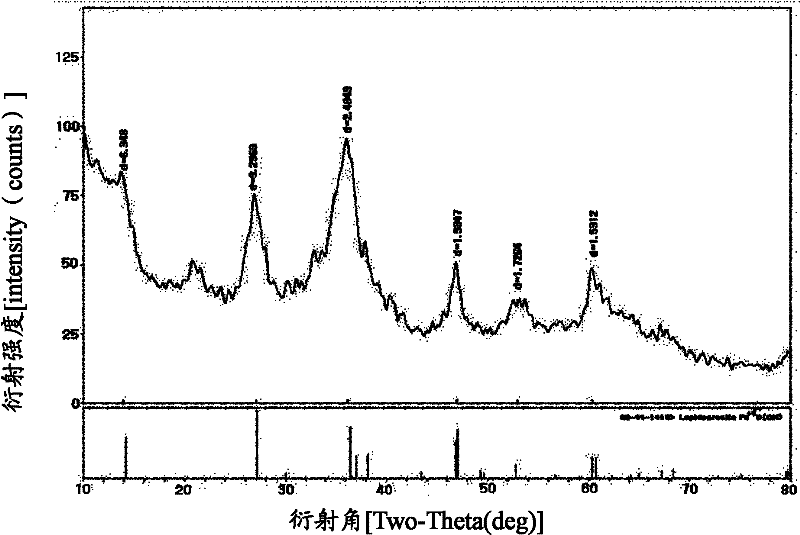

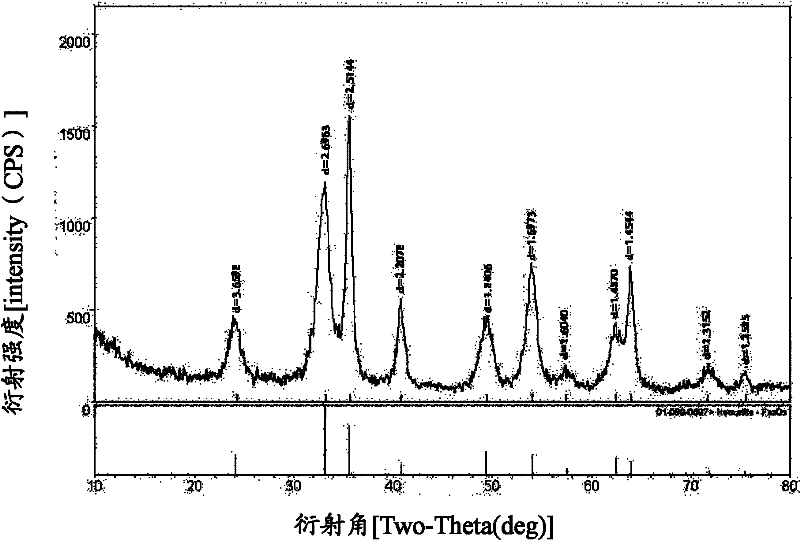

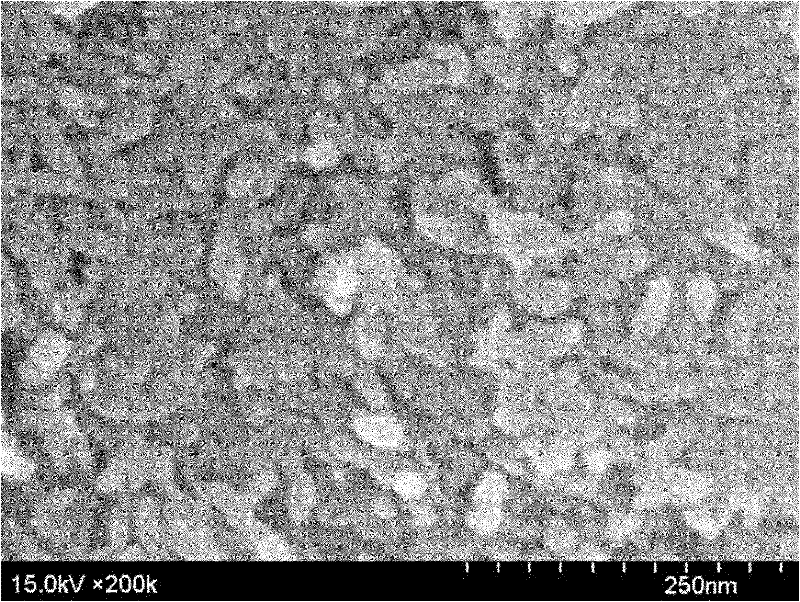

Preparation method and application of high-performance molybdenum disulfide/oxidized graphene/ferric oxide yellow composite catalyst

ActiveCN107855129AImprove catalytic performanceLarge specific surface areaPhysical/chemical process catalystsWater contaminantsWater bathsFerric oxide yellow

The invention discloses a preparation method and application of high-performance molybdenum disulfide / oxidized graphene / ferric oxide yellow composite catalyst. Molybdenum disulfide, oxidized grapheneand ferrous sulfate are mixed; after uniform ultrasonic dispersion, water-bath heating reaction is performed to obtain the molybdenum disulfide / oxidized graphene / ferric oxide yellow composite catalyst; the composite catalyst can be used as a catalyst in trifluralin catalytic reduction reaction. Laminar molybdenum disulfide is added into the prepared composite catalyst, so that the catalytic performance of the composite catalyst is greatly improved.

Owner:ANHUI UNIVERSITY

High-temperature resistant water-borne flashing coating used for photo frames

InactiveCN106085064AOrientation effect is goodImprove high temperature resistanceFireproof paintsPolyurea/polyurethane coatingsSodium bicarbonateFerric oxide yellow

High-temperature resistant water-borne flashing coating used for photo frames is disclosed. Raw materials of the coating include water-borne resin, hydroxy-containing polyacrylate emulsion, a cellulose acetate butyrate solution, amino resin, iron oxide red, iron oxide yellow, pearl powder, lauryl mercaptan, dimethyl ethanolamine, triethylamine, triethanolamine, 2-amino-2-methyl-1-propanol, ammoniacal liquor, glycidyl acrylate, 2-butoxyethanol, aqueous aluminium powder, charcoal powder, talcum powder, sodium bicarbonate, glass fibers, vermiculite powder, perlite powder, EVA wax, polyethylene wax, nanometer titanium dioxide, a water-borne polyisocyanate curing agent, a wetting agent, a dispersant, a defoaming agent, a levelling agent and an anti-settling agent BYK-420. The flashing coating has excellent resistance to high temperatures.

Owner:蚌埠市禹会区贵宾装饰材料商行

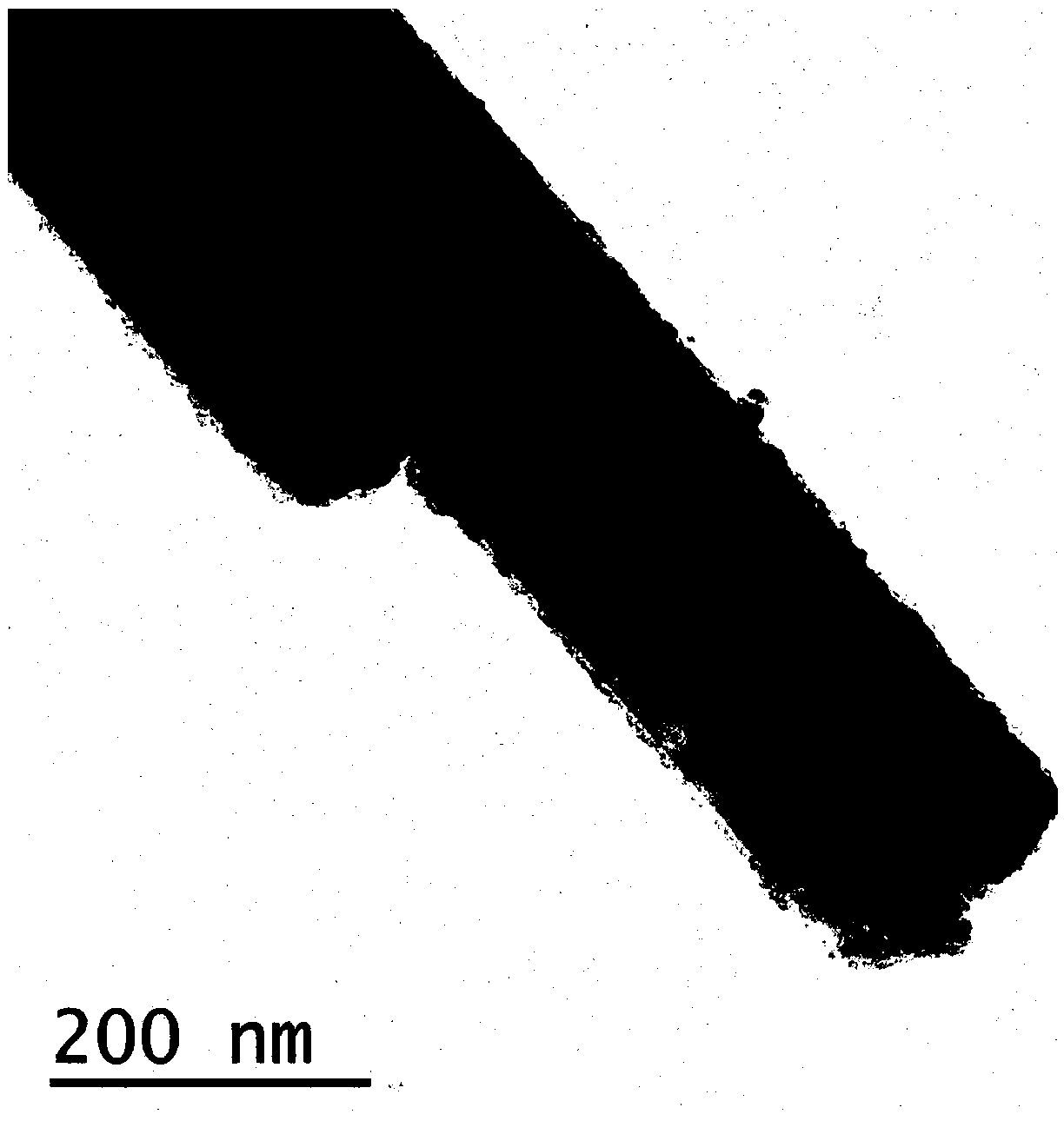

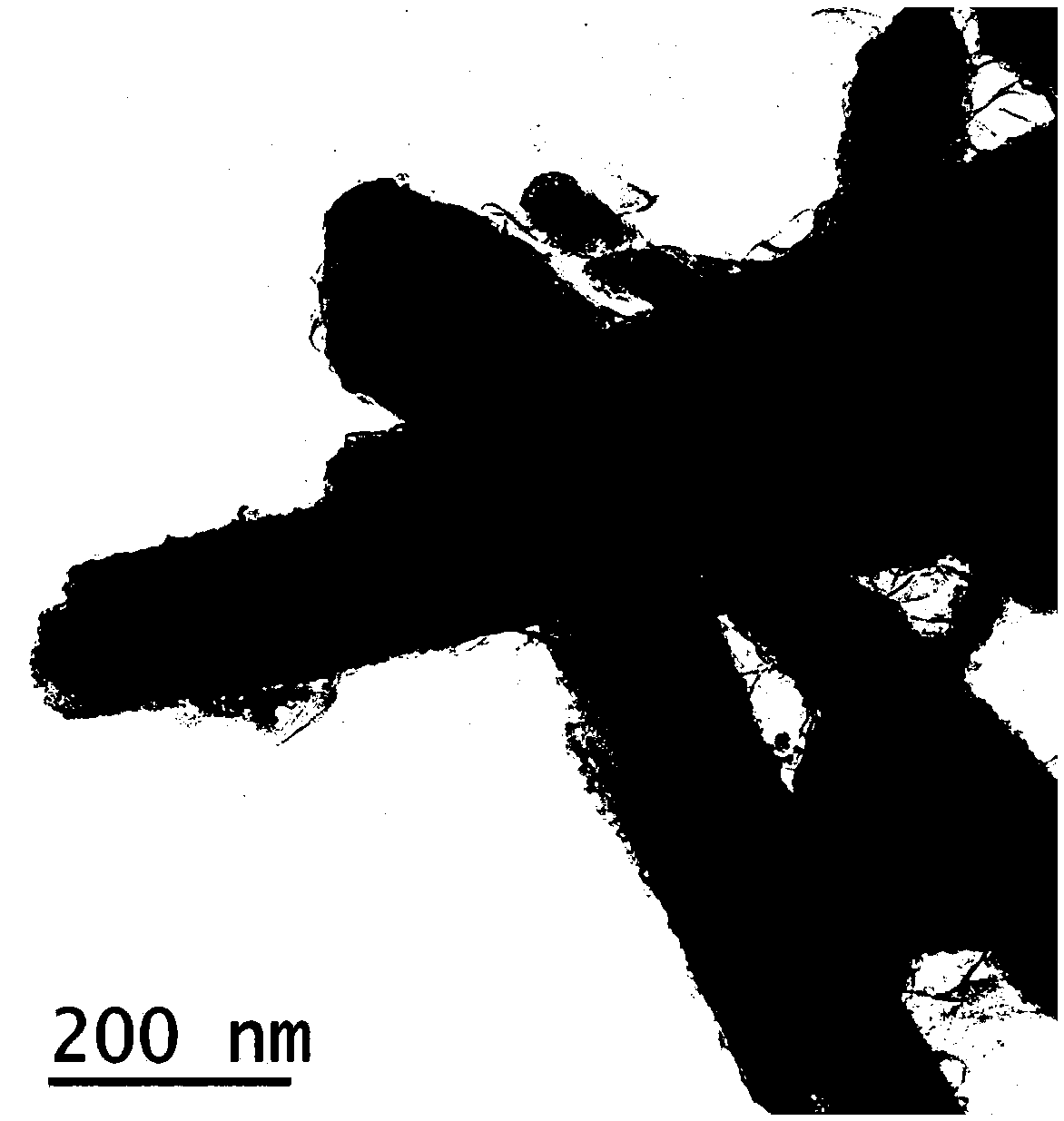

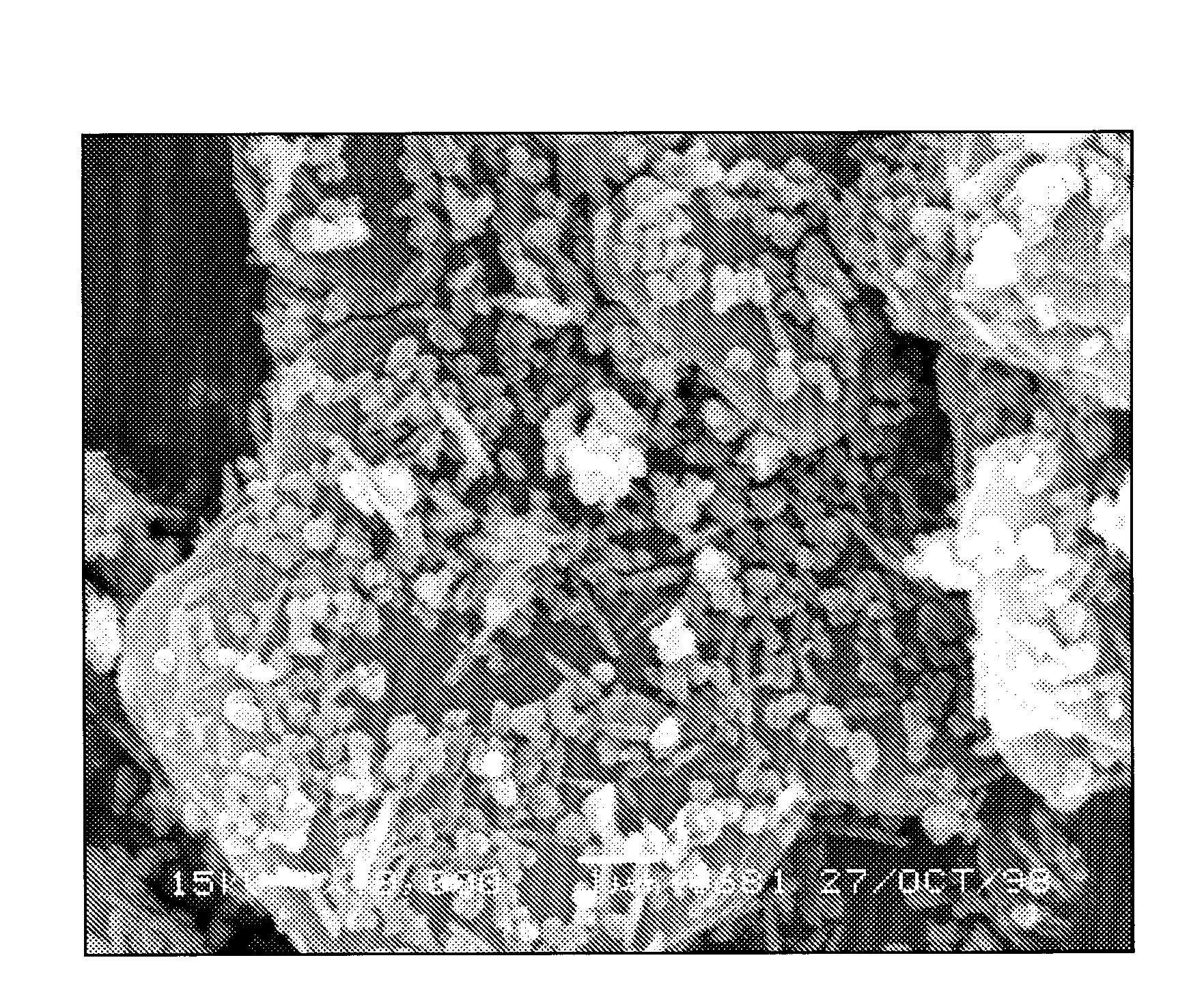

Preparation method of nano iron oxide yellow or nano iron oxide red

InactiveCN102092794BGood crystal formImprove performanceNanotechnologyFerric oxidesReaction systemOxidizing agent

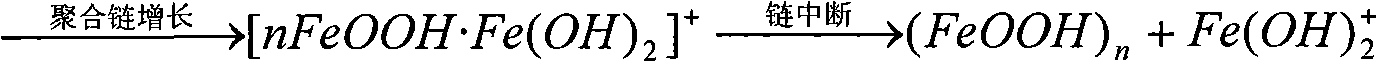

The invention discloses a preparation method of nano iron oxide yellow or nano iron oxide red. The preparation method comprises the following steps: (a) adding a polymerization inhibitor in a ferrite solution with iron ion concentration of 0.05mol / L-1.2mol / L, and dropwise adding a precipitator until the pH value is 3.5-5.0 so as to form a reaction system; (b) continuously reacting for 90-120 minutes to obtain a product after dropwise adding an oxidant in the reaction system; (c) filtering the product obtained from the step (b), washing and drying the obtained filter cake so as to obtain the nano iron oxide yellow; and (d) firing the nano iron oxide yellow obtained from the step (c), cooling the fired nano iron oxide yellow to obtain the nano iron oxide red. By using the method, the particle size of the product can be effectively controlled between 20-100 nanometers, and the nano iron oxide yellow and nano iron oxide red are obtained by subsequent processing; and the method has the characteristics of simple process, small pollution, low energy consumption and short period.

Owner:ZHEJIANG UNIV

Heat-resistant iron oxide yellow pigment and method for preparing same

InactiveCN107033656AImprove heat resistanceHigh industrial application valueInorganic pigment treatmentPowdery paintsAlkaline earth metalFerric oxide yellow

The invention relates to heat-resistant iron oxide yellow pigment and a method for preparing the same. The heat-resistant iron oxide yellow pigment and the method have the advantages that soluble alkaline-earth metal salts, sodium hexametaphosphate and sodium hydroxide are used as reaction materials, ultrasonic dispersion technologies and organic dispersing agents are introduced into coating procedures, alkaline-earth metal phosphate is coated on the surfaces of iron oxide yellow pigment by means of reaction, accordingly, the heat resistance of iron oxide yellow can be improved by formed composite materials, and the heat-resistant iron oxide yellow pigment can be used as a colorant during plastic processing and powder coating application; the coated iron oxide yellow is good in heat resistance, the method for synthesizing the heat-resistant iron oxide yellow pigment is simple, safe and environmentally friendly and is low in cost, the heat-resistant iron oxide yellow pigment and the method have high industrial application value, and the like.

Owner:HUZHOU TEACHERS COLLEGE

Iron oxide yellow and preparation method thereof, iron oxide red and preparation method of iron oxide red

The invention relates to the technical field of preparation of pigments, and provides a preparation method of iron oxide yellow. The preparation method of iron oxide yellow comprises the following steps: adding a first part of a ferric salt solution and a first part of an alkaline precipitant into a reaction container, and performing heating; continuously adding a second part of the alkaline precipitant into the reaction container, and stopping the addition of the second part of the alkaline precipitant when the pH value reaches 1-2 in order to prepare iron oxide yellow seeds; and preparing the iron oxide yellow from the yellow iron oxide seeds. The method has a high preparation efficiency. The iron oxide yellow is prepared by the preparation method. A preparation method of iron oxide redcomprises the following steps: preparing the iron oxide yellow through the preparation method of the iron oxide yellow; and calcining the iron oxide yellow. The preparation method of the iron oxide red has the advantages of high efficiency and low cost, and the obtained iron oxide red product has the advantages of approximate elliptic primary particle size, uniform particle size distribution and high tinting strength. The iron oxide red is prepared by the preparation method of the iron oxide red, and has a good quality.

Owner:正太新材料科技有限责任公司

Color attapulgite mud for inserting fresh flowers and production method thereof

InactiveCN101874466ADead plant preservationCultivating equipmentsFerric oxide yellowMonopotassium phosphate

The invention discloses color attapulgite mud for inserting fresh flowers and a production method thereof. The technical scheme of the invention is characterized in that the production method comprises the following steps of: adding deionized water into a stirrer; then adding urea, monopotassium phosphate, brown granulated sugar, methylparaben and propylparaben into the deionized water for stirring; after the urea, the monopotassium phosphate, the brown granulated sugar, the methylparaben and the propylparaben are dissolved into the deionized water and become a nutrient solution, adding high-viscosity attapulgite clayey silt, ferric oxide red powder, ferric oxide green powder, ferric oxide yellow powder, ferric oxide blue powder and ferric oxide black powder into the nutrient solution for stirring to form a semi-finished product of the color attapulgite mud for inserting fresh flowers after uniformly stirring and mixing; slowly adding a gelatin solution into the semi-finished product of the color attapulgite mud for inserting fresh flowers for uniformly stirring to form a mixture, i.e. a finished product of the color attapulgite mud for inserting fresh flowers. The color attapulgite mud for inserting fresh flowers has high viscosity, good flexibility and plasticity, can be designed into different colors of mud for inserting fresh flowers by adjusting proportion, and is suitable for keeping flowers in flower shops, hotels, office buildings and houses fresh.

Owner:JIANGSU DAHAI PLASTIC

Preparation method of colored hollow fiber membrane

InactiveCN101450287AMaintain separation performanceNo side effectsSemi-permeable membranesHollow fibre membraneFiber

The invention relates to a preparation method for a colored hollow fiber membrane. The preparation method is characterized in that firstly pigments are selected according to the color design requirement of a product and are added into a membrane forming material system together with a dispersant after being evenly mixed with the dispersant through high-speed agitation; a conventional solution spinning method or a fusion spinning method is adopted to prepare the hollow fiber membrane; the pigments are one or more of titanium white, carbon black, ferric oxide yellow, organic pigment yellow 138, iron red, organic pigment red 122 and / or ultramarine; the average grain size of the pigments is less than 10 microns; the dosage of the pigments is 0.2 to 5 percent of the mass of polymers in the membrane forming material system; the dispersant can be titanate, white paraffin or Tween-80; and the dosage of the dispersant is 0.1 to 3.0 percent of the mass of the pigments.

Owner:TIANJIN POLYTECHNIC UNIV

Purple sand clay-containing colored glaze

The invention discloses purple sand clay-containing colored glaze. The purple sand clay-containing colored glaze is characterized by comprising the following components in parts by mass: 90-110 parts of purple sand clay, 4-12 parts of sodium nitrate, 16-20 parts of cuprous oxide, 17-25 parts of lead dioxide, 10-12 parts of sodium chloride, 12-16 parts of small bluestone, 6-10 parts of calcium carbonate antimony oxide, 15-22 parts of talcum, 6-10 parts of lithium carbonate, 2-4 parts of explosion-proof fiber, 1-8 parts of starch, 1-8 parts of charcoal powder, 4-8 parts of potassium feldspar, 2-16 parts of magnesium carbonate, 1-5 parts of phenol-formaldehyde resin, 17-22 parts of quartz sand, 9-11 parts of aluminum sesquioxide, 5-9 parts of cerium dioxide, 20-30 parts of ferric oxide yellow, 4-8 parts of zirconium oxide, 2-4 parts of TEOS and 3-6 parts of polytetrafluoroethylene. The invention provides the purple sand clay-containing colored glaze which is good in glaze gloss, non-fading and more environmentally friendly; the production process is simplified, the efficiency is improved, the process time is shortened, and the production cost is reduced.

Owner:太仓市科教新城琉璃艺术策划中心

Method for preparing high purity iron oxide yellow and iron oxide red using titanium dioxide byproduct ferrous sulfate

InactiveCN100357361CLow purityReduce energy consumptionPigmenting treatmentIron oxides/hydroxidesFerric oxide yellowManganese

The invention relates to a method to prepare high-pure iron oxide yellow and iron oxide red by ferrous sulfate as byproduct in titanium white, which comprises: when temperature under 60Deg, refining the material to remove impurity; with oxidant, adjusting pH value of solvent to hydrolyze and remove Ti and co-precipitate to remove metal ion; regulating pH value and feeding air for oxidation at normal temperature; obtaining the products with different reaction conditions. This method is simple, needs low cost and obtains product with high purity.

Owner:奚长生

Coating for environment-friendly tipping paper

PendingCN109267429AKeep the colorReduce harmSurface covering paperDefoamers additionFerric oxide yellowAlcohol

The invention provides coating for environment-friendly tipping paper. The coating is at least prepared from the following components in parts by weight: 20-30 parts of self crosslinking acrylic acidcopolymer resin, 10-20 parts of polyvinyl butyral, 10-20 parts of chitosan, 1-5 parts of ferric oxide red powder, 1-5 parts of ferric oxide yellow powder, 1-2 parts of talcum powder, 4-10 parts of spherical hydroxyapatite, 50-70 parts of pure water, 20-40 parts of ethyl alcohol, 5-15 parts of plant oil, 0.5-1.5 parts of defoaming agent and 0.5-1.5 parts of dispersing agent. The coating for environment-friendly tipping paper adopts chitosan to wrap pigment, on the one hand, the color of the pigment is kept, on the other hand, the possibility that the pigment is directly contacted with the humanbody is reduced, so that no harm is made to the human body. Meanwhile, chitosan and spherical hydroxyapatite are added into the network formed by the self crosslinking acrylic acid copolymer resin and polyvinyl butyral, thus the coating can absorb tar and fume, and the harms to the human body are reduced.

Owner:NANJING WANXIN FILM PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com