Device and method for preparing ferric oxide yellow

A technology of iron oxide yellow and sampling device, which is applied in the field of inorganic pigment production, can solve the problems of high price of alkaline neutralizer, increased production cost of iron oxide yellow, and increased cost of waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The device for preparing iron oxide yellow provided by the present invention can use the bipolar membrane electrodialysis device to process the inorganic salt waste liquid produced in the process of preparing iron oxide yellow, use the inorganic salt waste liquid to prepare lye, and use the obtained lye as alkali Neutralizing agent to adjust the pH value of the reaction solution in the process of preparing yellow iron oxide. The present invention does not need to use expensive alkaline neutralizing agent to prepare yellow iron oxide, thereby effectively reducing the cost of producing yellow iron oxide. The invention also effectively treats the inorganic salt waste liquid produced in the process of preparing iron oxide yellow, and realizes the recovery and reuse of resources.

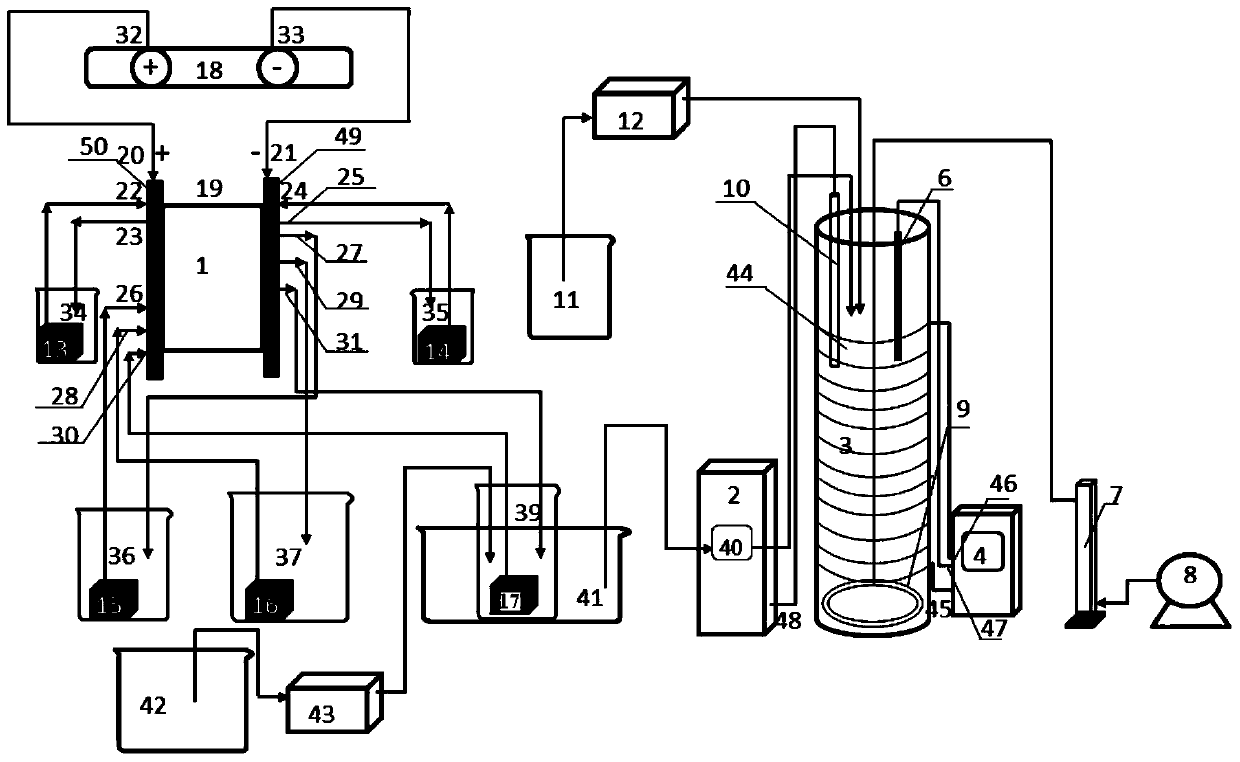

[0071] see figure 1 , figure 1 The structural schematic diagram of the device for preparing iron oxide yellow provided by the embodiment of the present invention, wherein, 1 is a bipolar membrane...

Embodiment 1

[0166] use figure 1 The shown device for preparing iron oxide yellow prepares iron oxide yellow, comprising the following steps:

[0167] Add 2.4L of citrine seeds and 5.6L of pure water into the reaction vessel 3, the total volume of the citrine seeds and pure water accounts for 80% of the volume of the reaction vessel 3.

[0168] The sensitive parts of the pH meter 10 and the temperature sensor 6 are placed below the liquid level of the reaction solution in the reaction vessel 3 .

[0169] Fill 1L saturated ferrous sulfate aqueous solution in feed liquid tank 11, the volume of saturated ferrous sulfate aqueous solution accounts for 90% of feed liquid tank 11 volumes, in the process of preparing iron oxide yellow, ensure that there is enough saturated sulfuric acid in feed liquid tank 11 Aqueous ferrous solution.

[0170] In the anode chamber tank 34 and the cathode chamber tank 35, perfusion 1L molar concentration is the sodium sulfate solution of 0.3mol / L respectively; T...

Embodiment 2

[0189] Iron oxide yellow was prepared by the method in Example 1.

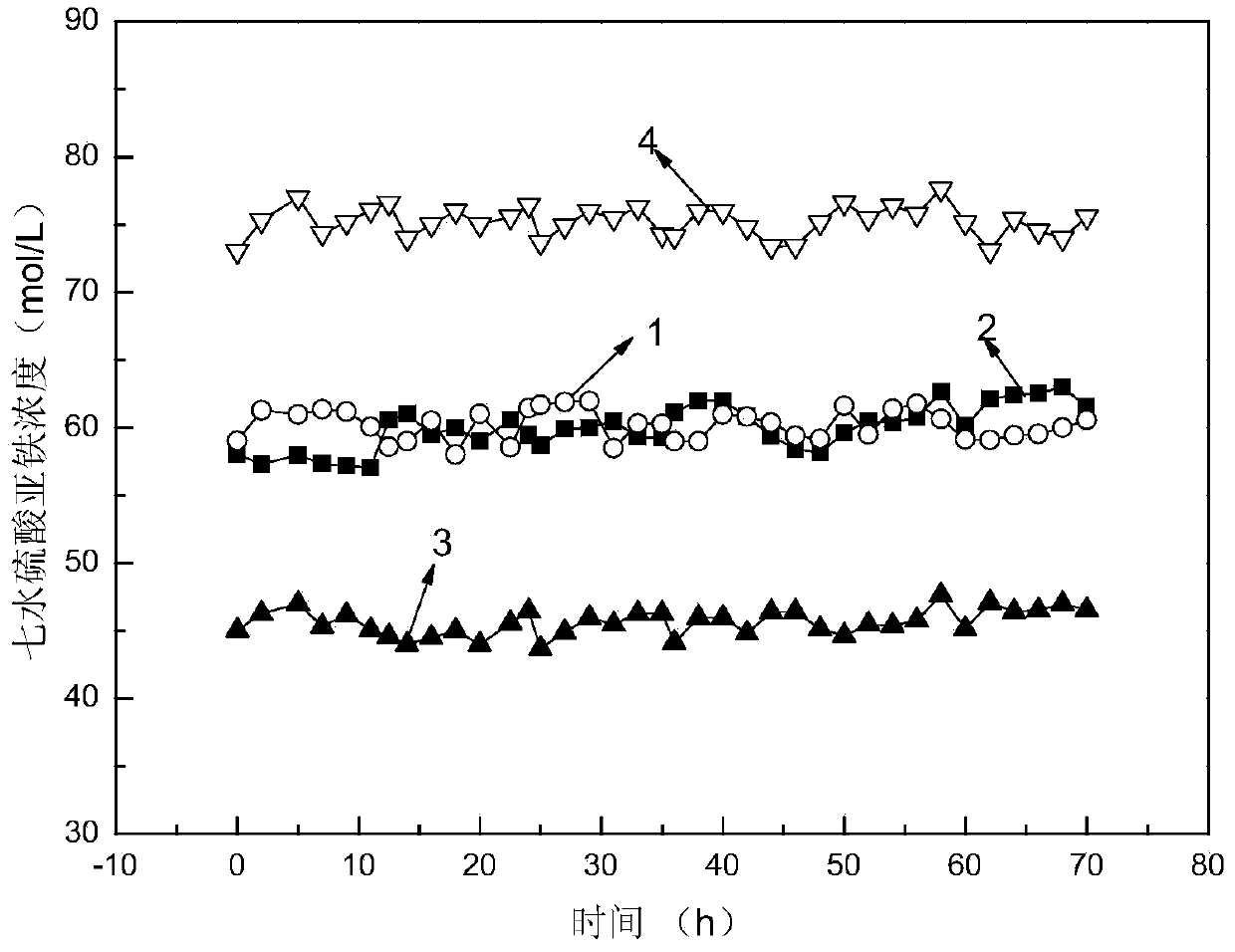

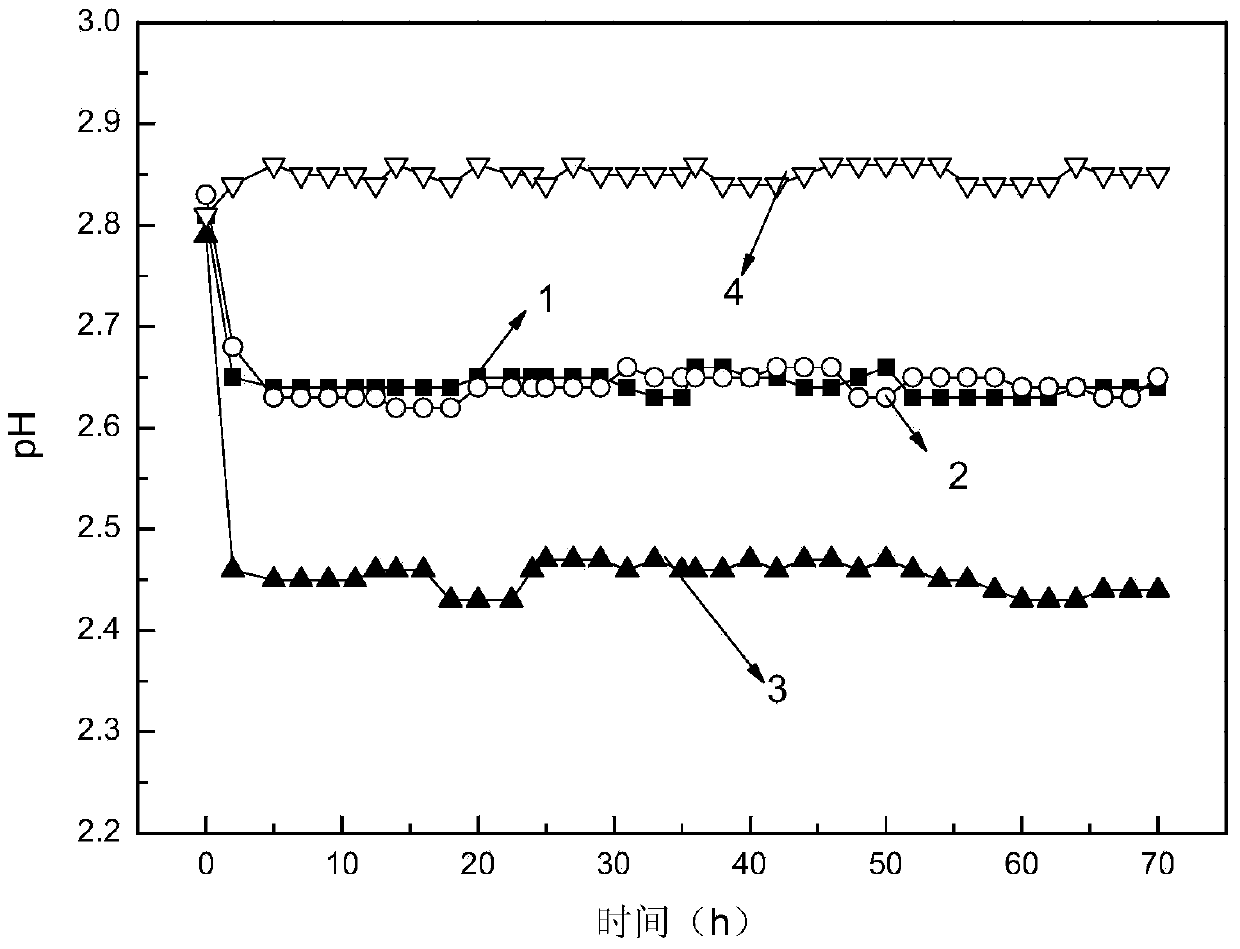

[0190] Test the mass concentration of ferrous sulfate, the pH value of the reaction solution and the molar concentration of lye in the process of preparing iron oxide yellow in Example 2 according to the method of Example 1, the test results are as follows Figure 2 ~ Figure 4 shown. figure 2 Middle curve 2 is the curve that the mass concentration of ferrous sulfate varies with time in the reaction solution that embodiment 2 obtains; image 3 Middle curve 2 is the curve that the pH value of the reaction solution that embodiment 2 obtains changes with time; Figure 4 Middle curve 2 is the curve that the molar concentration of the lye that embodiment 2 obtains changes with time. The test results show that the method for preparing yellow iron oxide provided in Example 2 of the present invention can make the concentration of ferrous sulfate, the pH value of the reaction solution and the concentration of lye mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com