Patents

Literature

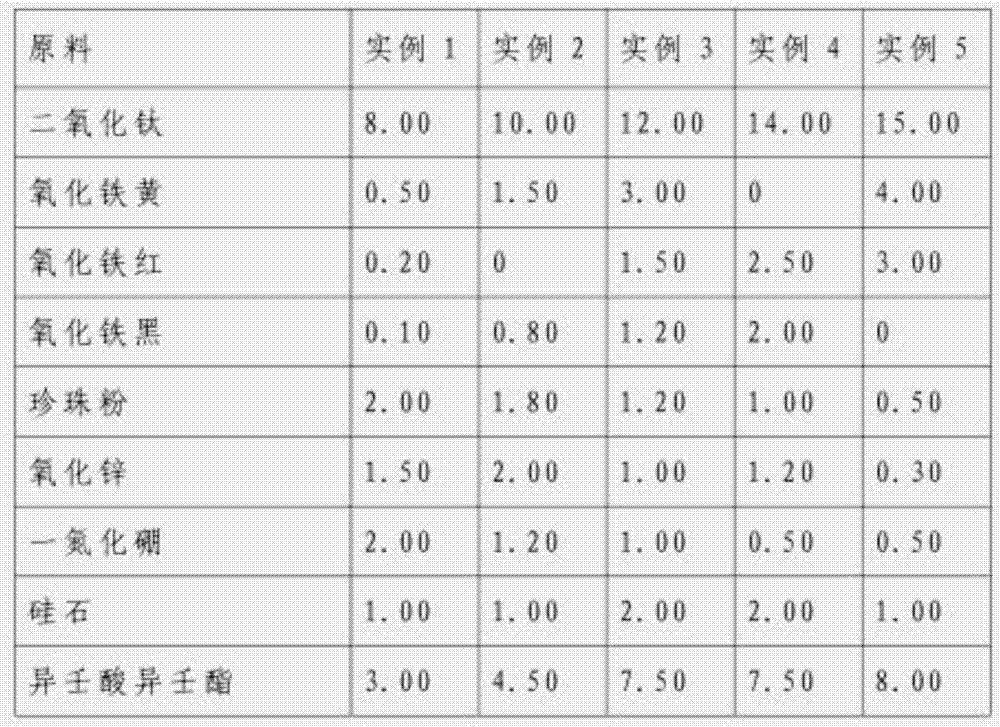

466 results about "Iron oxide yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yellow is the least color-stable form. Yellow iron oxide is a synthetic material of very fine particle size (but not as fine as black or red). Actual yellow iron oxides are around 85% Fe2O3 and about 12% LOI with some impurities (e.g. SiO2, CaO).

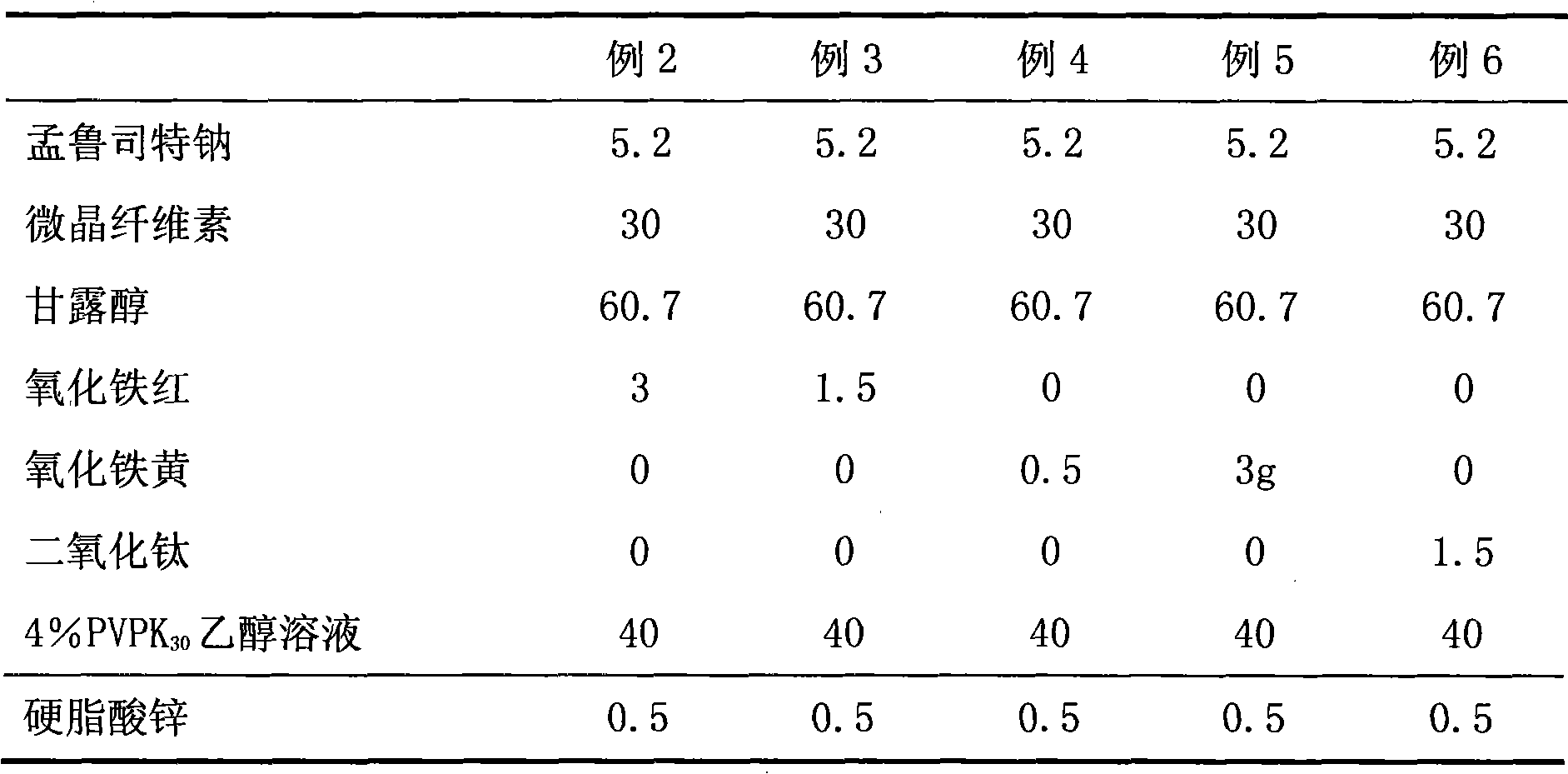

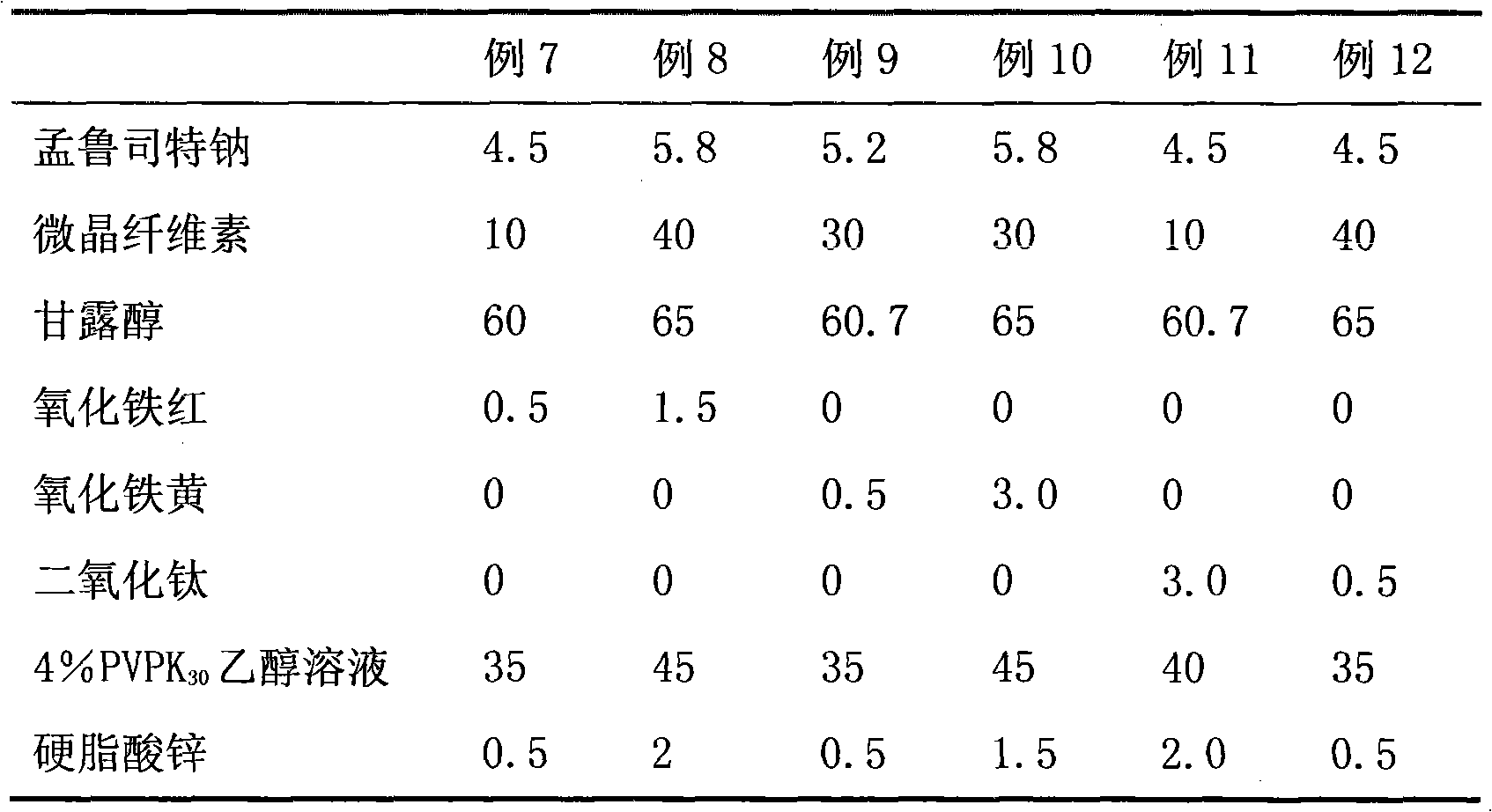

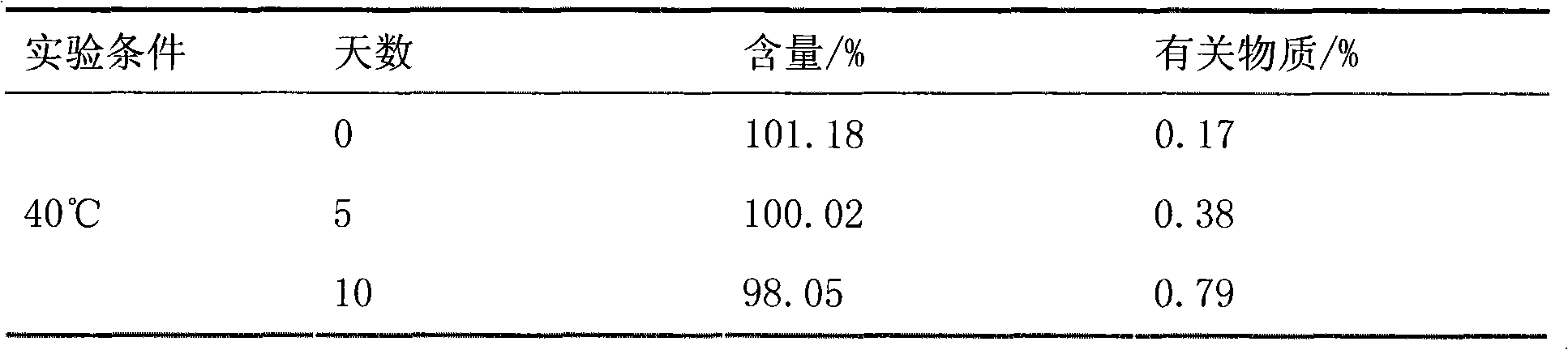

Chewable tablet containing montelukast sodium

ActiveCN101773481AImprove stabilityAvoid photolysisInorganic non-active ingredientsPill deliveryMedicineMontelukast Sodium

The invention belongs to the field of medicine preparations, which particularly relates to a chewable tablet of montelukast sodium. Because the production process of the chewable tablet of the montelukast sodium needs the light shielding operation at present, the mass production is inconvenient, and the chewable tablet of the montelukast sodium has the defect of poorer stability. In the invention, zinc stearate and an opacifier of iron oxide red, iron oxide yellow and titanium dioxide are added into the auxiliary materials of a chewable tablet of montelukast, so that the content of relevant substances can be lowered, and the stability of the chewable tablet is enhanced.

Owner:LUNAN PHARMA GROUP CORPORATION

Method of comprehensively utilizing serpentine

InactiveCN101235440ATake advantage ofFull controlSilicon oxidesProcess efficiency improvementFerric hydroxideSoluble glass

The invention relates to a method for comprehensively utilizing serendipities, which comprises: magnetically separating the serpentinites in a strong magnetic field, obtaining amorphous silica powder which contains silicon dioxide more than 90% through filtering acid dipping solution, dissolving the amorphous silica powder through using caustic soda under high temperature, which is used for manufacturing soluble glass with medium high modulus or taken as raw materials for producing white carbon black, then, mixing sulphuric acid and hydrochloric acid or nitric acid or mixing the sulphuric acid, the hydrochloric acid and nitric acid, adding acid dipping additive to carry out compound alternative and circulating acid dipping for ore powder which is magnetically separated and processed, fractionally depositing, filtering, and removing impurity for magnesium sulfate solution which is filtered through the acid dipping and contains the impurity, through adjusting the pH value, obtaining inorganic industrial dyes which mainly contain iron oxide yellow, ferric hydroxide and aluminum hydroxide, enriching the nickel, which is convenient for abstracting the nickel from the serpentinites, finally obtaining high purity magnesium oxide through refining refined magnesium sulfate solution whose impurity is removed after ammonium hydrogen carbonate and ammonial solution or sodium sulfide is used to deposit, and also obtaining ammonium sulfate or sodium sulfate which contains magnesium and calcium after liquid which is filtered is evaporated.

Owner:刘湘霖 +1

Preparation process of medium temperature resistant iron oxide yellow

InactiveCN101824235ADoes not change color smallLittle changeInorganic pigment treatmentSulfateSlurry

The invention discloses a preparation process of medium temperature resistant iron oxide yellow; iron oxide yellow is obtained through a wet sulfate oxidation method; before being dried, a filter cake is put into a beating machine when the slurry concentration is controlled to be 10 to 35 percent; additive is added into during the beating process, the heat is insulated to be 70 to 80DEG C after beating for 30min; and then neutralizer is added in to regulate the pH value and the heat is insulated for 30min; and after beating, iron yellow is produced through normal steps, and the medium temperature resistant iron oxide yellow is obtained after solid-liquid separation. The iron oxide yellow which is in needle-like particle crystal shape obtained through the wet sulfate oxidation method can stand 260 to 280DEG C after being treated, does not discolor or has small color changes; and simultaneously, the direction treatment of the filter cake of the iron oxide yellow is adopted, no other procedure is added, and the cost is lower than that of other temperature resistant iron yellow.

Owner:南通宝聚颜料有限公司

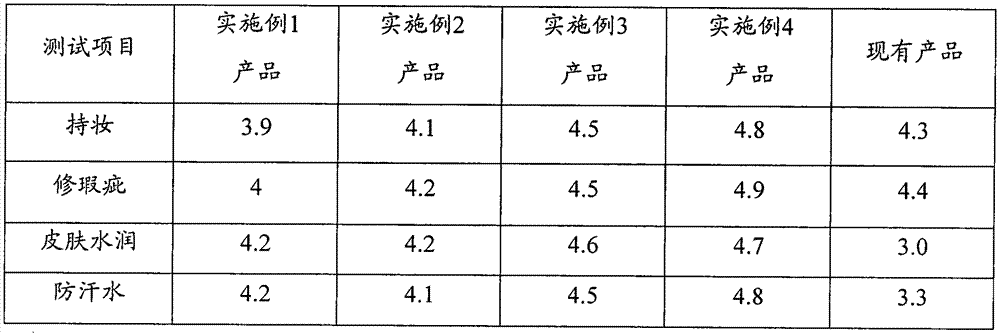

Air cushion BB cream and preparation method thereof

The invention discloses an air cushion BB cream and a preparation method thereof. The air cushion BB cream contains the following components: butanediol, cyclopentasiloxane, glycerol, tridecyl stearate, titanium dioxide, peg-10 polydimethylsiloxane, ethylhexyl Methoxycinnamate, disteardimonium hectorite, polydimethylsiloxane, a sunflower extract, mica, coconut oil, gardenia tahitensis flower, tocopherol, sodium chloride, glucan, folic acid, bacillus acidi lactic or a soybean fermentation product extract, phenoxyethanol, hydrogenated polydecene, a dunaliella salina extract, ethylhexylglycerin, bismuth oxychloride, iron oxide yellow, a Glycyrrhiza glabra extract and water. The preparation method comprises the steps of stirring until a mixture is dissolved every time one component is added, and then adding the next component. The air cushion BB cream disclosed by the invention can ensure that the skin is moisturized, exquisite, tender and smooth, has invisible pores and is uniform in skin color; and the air cushion BB cream has multiple effects of repairing flaws, preventing sweat, keeping the makeup well and the like.

Owner:广州悦瑞生物科技有限公司

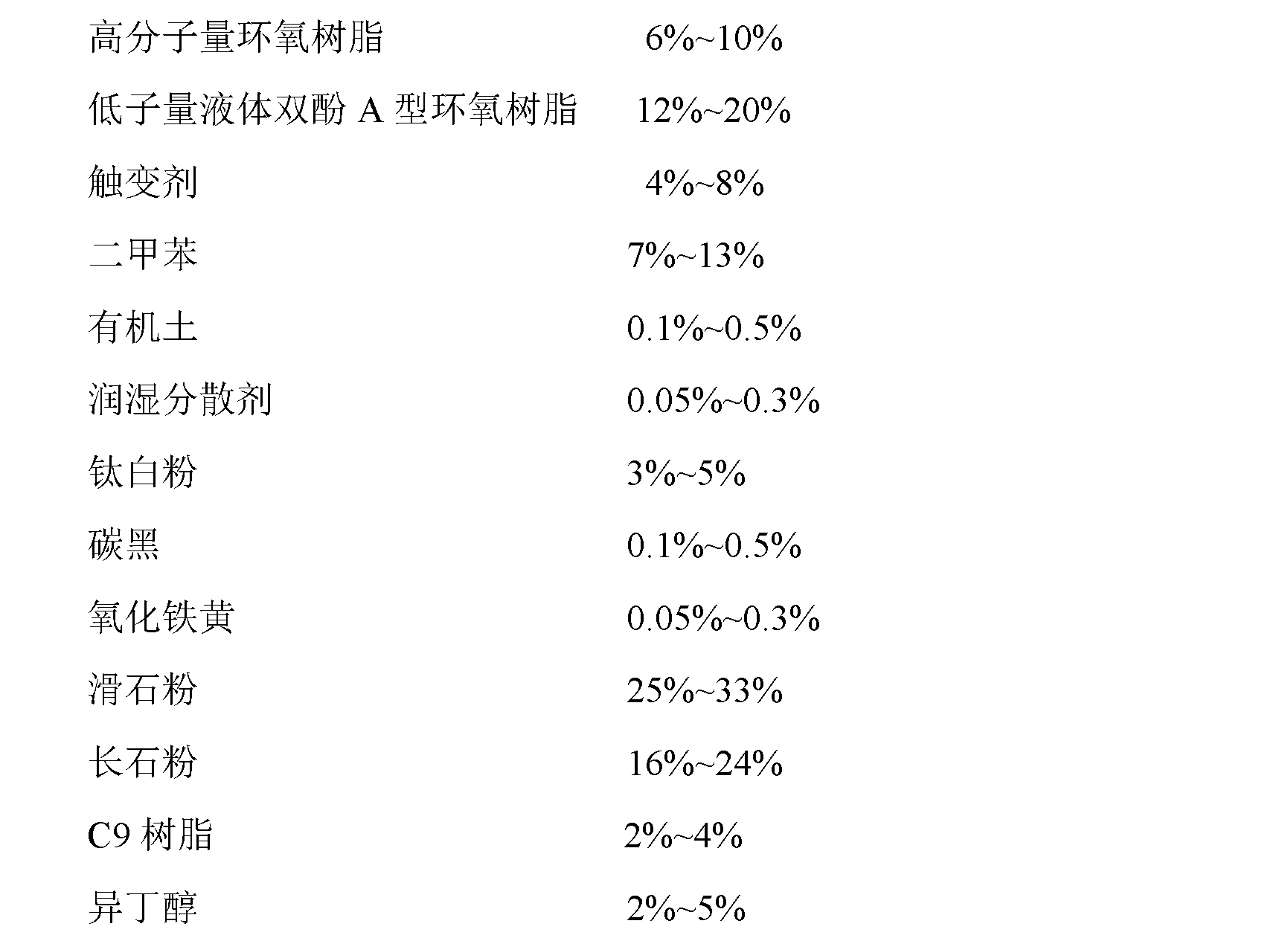

Epoxy universal primer for ships and preparation method thereof

ActiveCN103013276AShorten coating timeEasy constructionAnti-corrosive paintsEpoxy resin coatingsSilanesIsobutyl alcohol

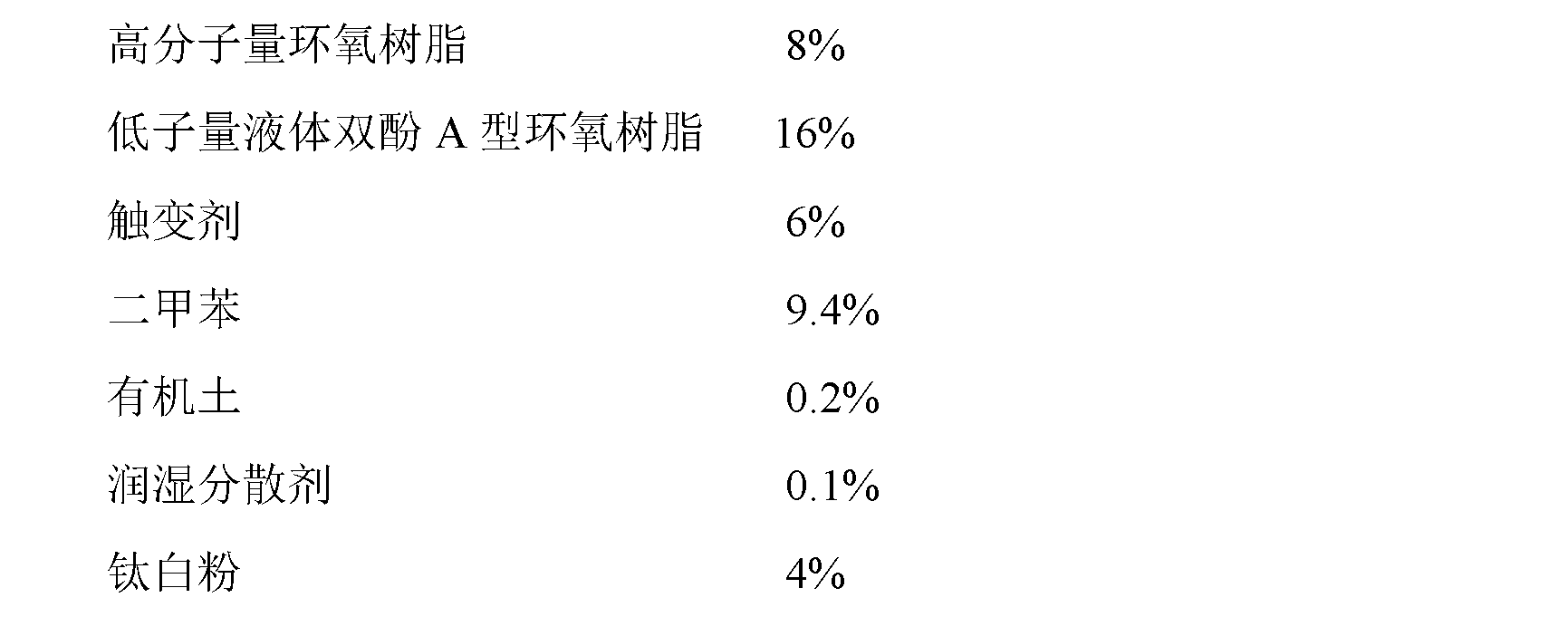

The invention discloses an epoxy universal primer for ships and a preparation method thereof. The epoxy universal primer for the ships comprises components A and components B, wherein the components A comprise the following components in percentage by weight: high molecular weight epoxy resin, low molecular weight liquid bisphenol A epoxy resin, thixotropic agent, dimethylbenzene, organic soil, wetting dispersant, titanium dioxide, carbon black, iron oxide yellow, talcum powder, feldspar powder, C9 resin, isobutyl alcohol and silane auxiliaries; the components B comprise the following components in percentage by weight: polyamide curing agent and epoxy curing accelerator; in a using process, the mixing mass ratio of the components A to the components B is (6-7) to 1. The epoxy universal primer for the ships provided by the invention can be coated to 400 microns by one step without sagging, saves coating time, can be directly matched with the original coating without a transitional layer, is simple to construct, easy to grasp, and time-saving and labour-saving.

Owner:WUXI HUHUANG PAINT

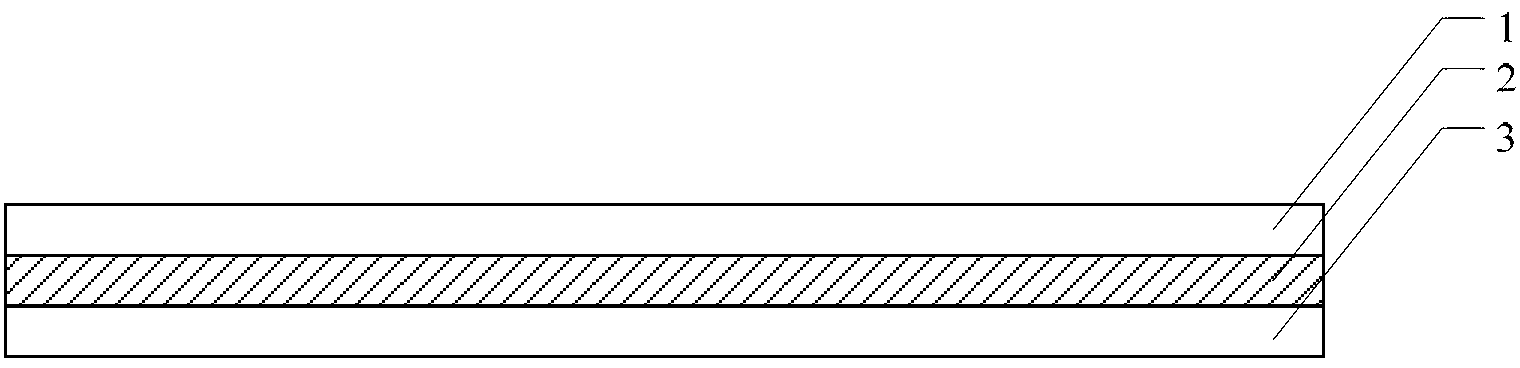

Heat-resisting waterproof wallpaper and production method thereof

InactiveCN106703311AImprove waterproof performanceImprove heat resistanceCovering/liningsFibre treatmentMaterials scienceGlycerol Ethers

The invention discloses a heat-resisting waterproof wallpaper. The heat-resisting waterproof wallpaper comprises a base material layer, a waterproof layer and a heat-resisting layer, wherein the heat-resisting layer is made of waterborne silicon-acrylate resin, hydroxyl-polyacrylate emulsion, cellulose acetate butyrate solution, amino resin, iron oxide red, iron oxide yellow, pearl powder, lauryl mercaptan, dimethylethanolamine, thiethylamine, triethanolamine, 2-amino-2-methylpropanol, ammonium hydroxide, acrylic glycidyl ether, ethylene glycol monobutyl ether, waterborne aluminum powder, charcoal powder, talcum powder, sodium bicarbonate, glass fiber, vermiculite powder, perlite powder, EVA (ethylene-vinyl acetate copolymer) wax, polyethylene wax, nano titanium dioxide, waterborne polyisocyanate curing agent, wetting agent, magnesium stearate, polyoxypropylene glycerol ether, carboxymethyl cellulose and anti-setting agent. The invention also discloses a preparation method of the heat-resisting waterproof wallpaper. The prepared heat-resisting waterproof wallpaper is excellent in heat-resisting and waterproof performance.

Owner:安徽易有墙纸有限公司

Iron oxide yellow granular pigment and manufacturing method thereof

InactiveCN101691455APollution suppressionSettling fastPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsAqueous solutionDust pollution

The invention belongs to the field of chemical pigments, in particular to an iron oxide yellow granular pigment and a manufacturing method thereof, the related iron oxide yellow granular pigment comprises a main component of iron oxide yellow, an additive coating layer is arranged outside the main component of the iron oxide yellow, and the main component of the iron oxide yellow and the coating layer are combined together for constituting the granular pigment; and the pigment is realized by the following steps: firstly preparing additive water solution, heating to 30-100 DEG C, sending the iron oxide yellow into a granulator, evenly spraying the prepared additive water solution on powder materials, gradually forming small grains, further sieving the prepared grains by using a vibration sieve and drying, thereby preparing a finished product. The prepared granular pigment is difficult to diffuse, thereby effectively preventing dust pollution, having the advantages of high color retaining performance, good fluidity, good dispersion and low cost, and being applicable to extensive application on the industry.

Owner:HANGZHOU XIAOXIANG PIGMENT CHEM

Colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of colored oily fertilizer anti-caking agent

The invention relates to a colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of the colored oily fertilizer anti-caking agent. The colored oily fertilizer anti-caking agent comprises the following ingredients in percentage by mass: 2-4% of iron oxide red, iron oxide yellow, iron oxide blue, iron oxide green, iron oxide purple, iron oxide brown or iron oxide black and 98-96% of an oily anti-caking agent, and is prepared by uniformly milling and mixing such ingredients by adopting a horizontal mill. The colored oily fertilizer anti-caking agent is applied to fertilizer coating, and 1.0-1.6 kilograms are used in each ton of a fertilizer, so that a corresponding color of red, yellow, blue, green, purple, brown or black is shown in the appearance of the fertilizer. The colored oily fertilizer anti-caking agent with the corresponding color of red, yellow, blue, green, purple, brown or black is provided for fertilizers with different appearance colors, so that inside and outside colors of the fertilizer are consistent, color difference and materials with inconsistent colors are avoided; the colored oily fertilizer anti-caking agent is stable and uniform in color, strong in coating capability, resistant to light and heat, colorfast and non-discoloring, can also be used as a fertilizer variety distinguishing and anti-counterfeiting mark, and is low in use cost and good in anti-caking performance.

Owner:HUBEI FORBON TECH

Matte epoxy powder coating and preparation method thereof

ActiveCN103160182AImprove aging resistanceImprove wear resistancePowdery paintsPolyamide coatingsEpoxyPolyamide

The invention discloses matte epoxy powder coating and a preparation method of the matte epoxy powder coating. The matte epoxy powder coating comprises, by weight, 500 parts-600 parts of epoxy resin (E-12), 10 parts-15 parts of dicyandiamide (DICY), 8 parts-12 parts of a flatting agent (GLP503), 3 parts-5 parts of brightener (BLC701), 4 parts-6 parts of benzoin, 5 parts-8 parts of modified polyamide wax micro powder, 4 parts-6 parts of degasifier (SA500), 3 parts-5 parts of flow promoter (W-1), 5 parts-10 parts of an extinction agent (XG603-1F), 150 parts-200 parts of extinction barium sulfate, 50 parts-100 parts of torispherical silica powder, 5 parts-8 parts of 2-phenyl-imidazoline, 4 parts-5 parts of carbon black, 7 parts-10 parts of iron oxide yellow, 3 parts-5 parts of iron oxide red and 4 parts-6 parts of titanium dioxide. The prepared matte epoxy powder coating has the advantages of being high in hardness, high in intensity, high in wear resistance, good in heat resistance, good in aging resistance, short in curing time, environment-friendly, pollution-free, and the like. The matte epoxy powder coating is excellent in performance, and is high in performance indexes of acid-base resistance, salt mist resistance, and organic solvent resistance, wherein the organic solvent includes gasoline.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

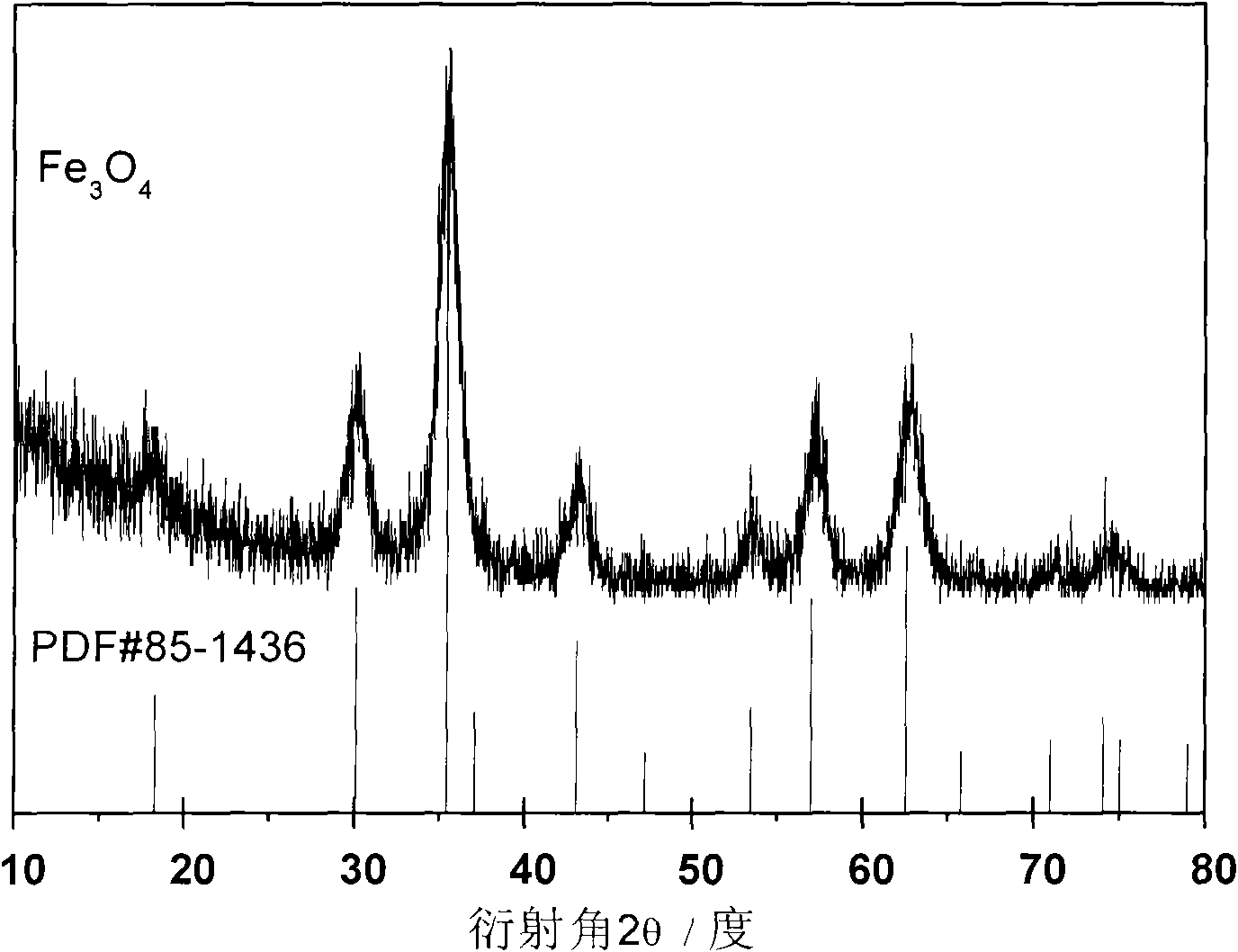

Method for preparing monodisperse Fe3O4 magnetic nanoparticles

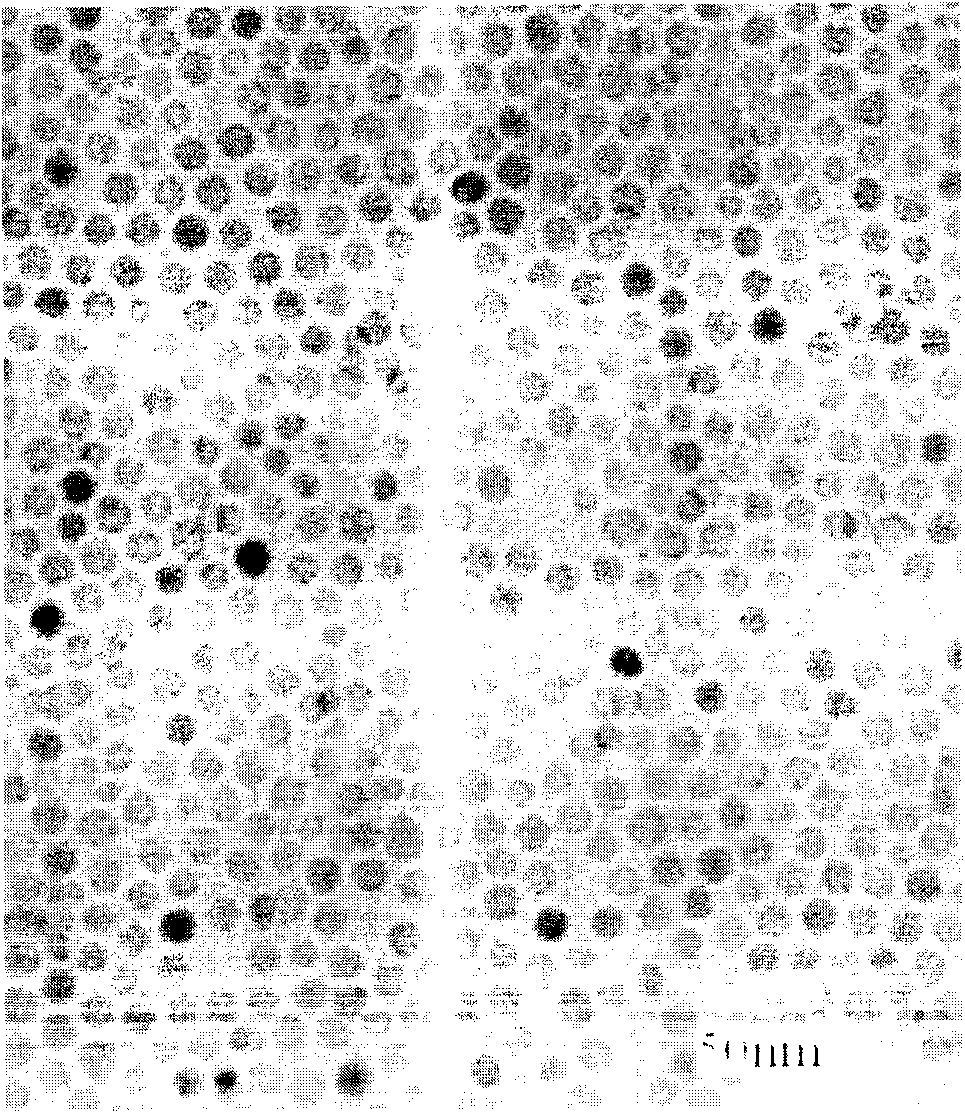

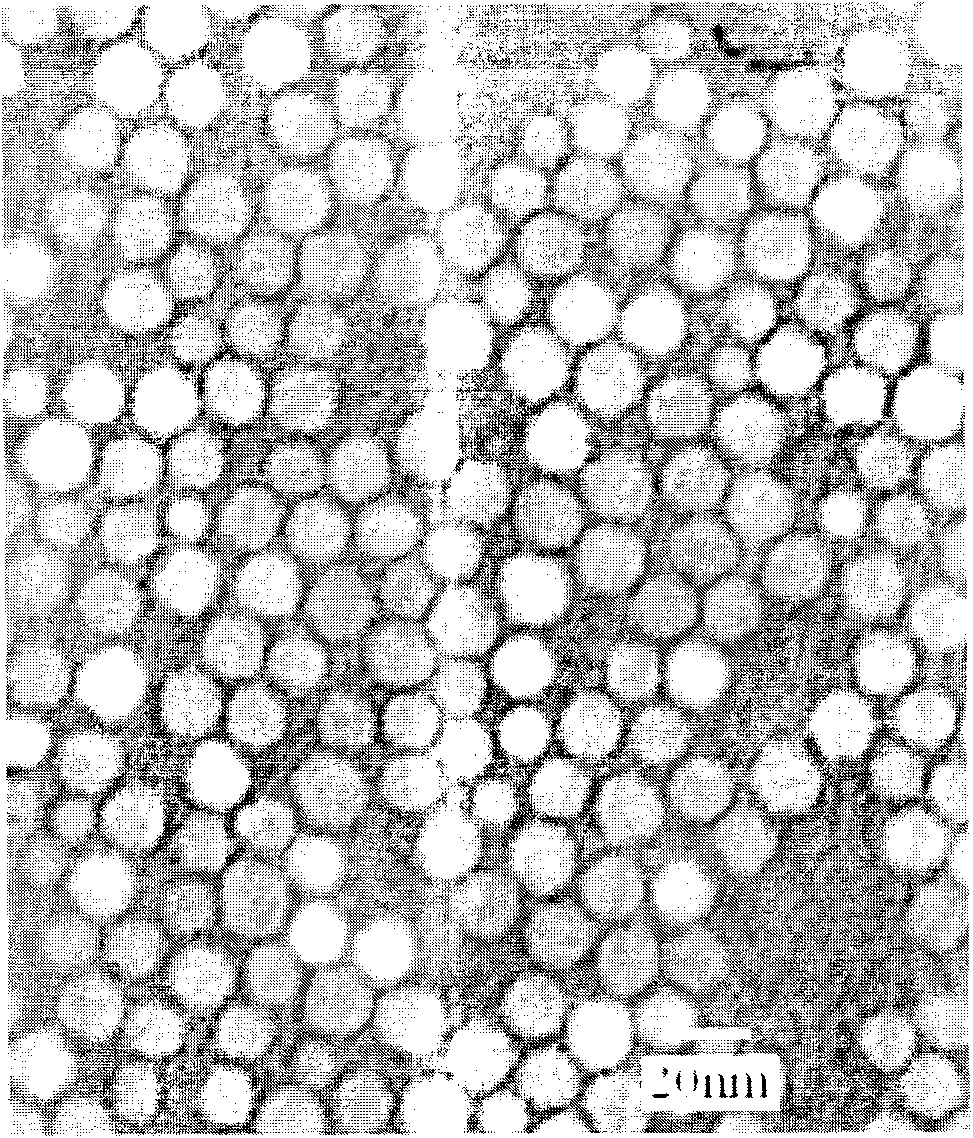

InactiveCN101538068AUnprotectedSmall sizeInorganic material magnetismFerroso-ferric oxidesMagnetic markerSuperparamagnetism

The invention provides a method for preparing monodisperse Fe3O4 magnetic nanoparticles. Precursor is Fe2O3 or iron oxide yellow which has the chemical formula of Fe2O3.H2O; stabilizing agent is oleic acid; high temperature organic solvent is 1-octadecylene (b. p. 318DEG C); precipitating agent is prepared by mixing any two of toluene, dimethyl benzene, ethanol, isopropanol and acetone according to the volume ratio of 1:4-2:3; the mol ratio between the precursor and the stabilizing agent is 1:4-1:9; the mol ratio between the precursor and the high temperature organic solvent is 1:10; inert gas protection is not needed, and the Fe3O4 magnetic nanoparticles which have small sizes, monodisperse, narrow distribution, high saturation magnetization intensity and superparamagnetism. The method can be widely applied to biomedicine fields such as magnetic resonance imaging, biological magnetic separation, magnetic target drug carrier, biological magnetic marker and the like, and the high technical fields such as magnetic sealing, aerospace lubrication, magnetic anti-counterfeiting ink material, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

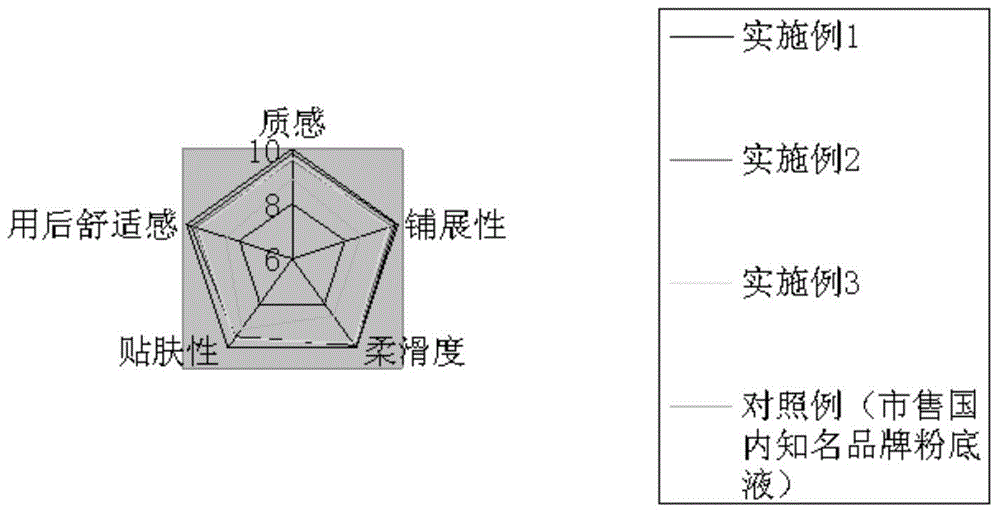

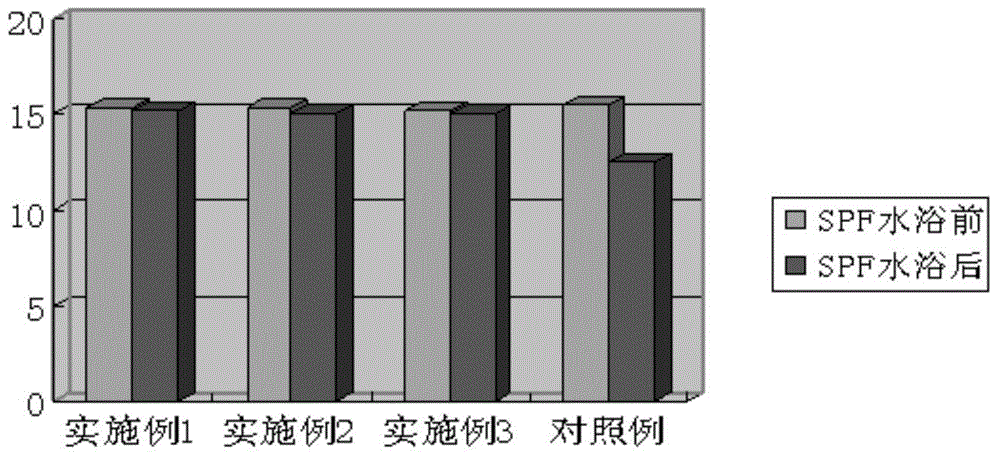

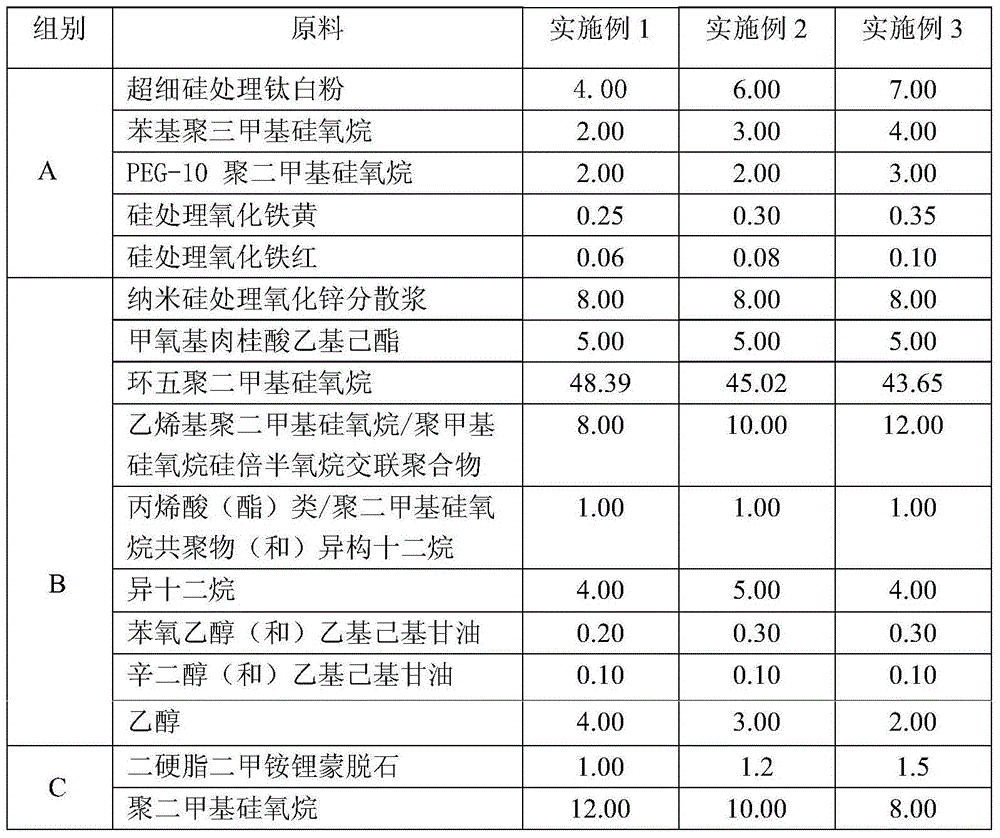

Silky soft skin feeling type essence liquid foundation and preparation method thereof

InactiveCN104434570APrevent moisture from evaporatingGood moisturizing effectCosmetic preparationsBody powdersCross-linkSlurry

The invention provides a silky soft skin feeling type essence liquid foundation. The silky soft skin feeling type essence liquid foundation comprises the following components: decamethylcyclopentasiloxane, polydimethylsiloxane, a vinyl polydimethylsiloxane / polymethylsiloxane silsesquioxane cross-linked polymer, ultrafine silicon treated titanium dioxide, nano silicon treated zinc oxide dispersed slurry, octyl 4-methoxycinnamate, 2,2,4,4,6-pentamethylheptane, ethanol, trimethylphenylsilane, disteardimonium hectorite, acrylic acid (ester) / polydimethylsiloxane copolymer / 2,2,4,4,6-pentamethylheptane, PEG-10 polymethylsiloxane, phenoxyethanol / ethylhexyl glycerin, octylene glycol / ethylhexyl glycerin, silicon treated iron oxide yellow and silicon treated iron oxide red. The silky soft skin feeling type essence liquid foundation is good in water resistance, good in ductility, and fine and smooth in skin feeling.

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

Orange grain type polyester/epoxy powder coating and preparation method thereof

ActiveCN103160194AImprove thermal stabilityImprove scratch resistance and anti-agingPowdery paintsEpoxy resin coatingsEpoxyMicrocrystalline wax

The invention discloses orange grain type polyester / epoxy powder coating and a preparation method of the orange grain type polyester / epoxy powder coating. The orange grain type polyester / epoxy powder coating is made from the following raw material, by weight, of 250-300 parts of polyester resin (P5086), 250-300 parts of epoxy resin (E-12), 160-200 parts of barium sulfate, 50-100 parts of spherical silica powder, 5-10 parts of light calcium carbonate, 5-10 parts of modified microcrystalline wax micro powder, 5-8 parts of wrinkle agent (XG608), 4-6 parts of benzoin, 8-12 parts of organic coated titanium dioxide, 5-10 parts of phenyl-2-imidazoline, 6-8 parts of 2-methyl imidazole, 15-20 parts of iron oxide yellow, 15-20 parts of iron oxide red and 5-10 parts of carbon black. The powder coating prepared with the preparation method has the advantages of being high in hardness, strength and wear resistance, good in heat-resisting performance and anti-aging performance, short in curing time, environment-friendly, free of pollution and the like. Cured coating has the texture effect of being provided with orange grains which are delicate and clear, evenly distributed and brings visual comfort for people, and the coating is excellent in overall performance.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

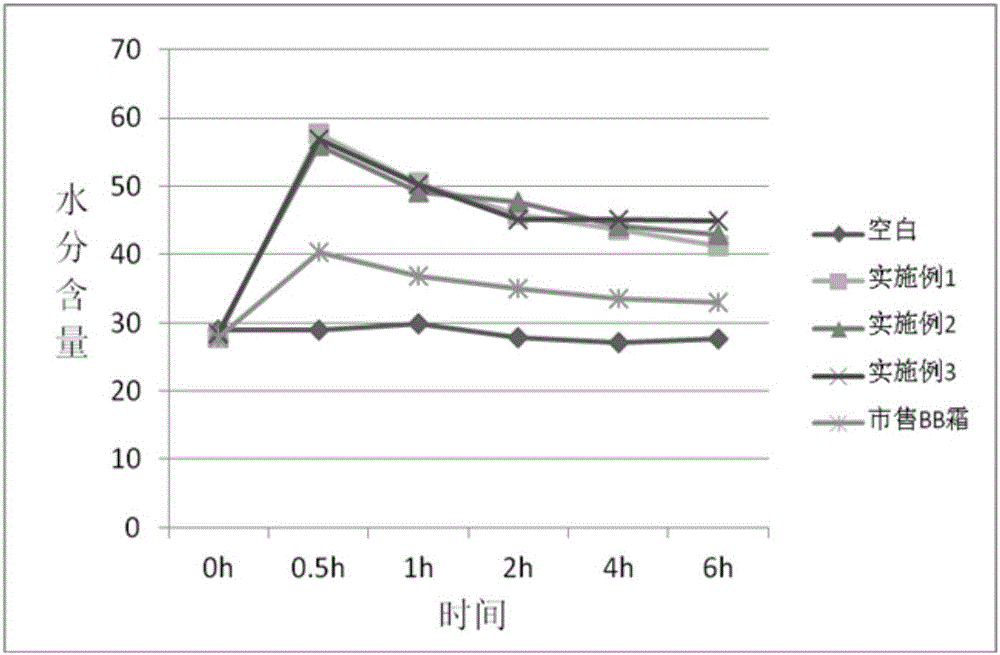

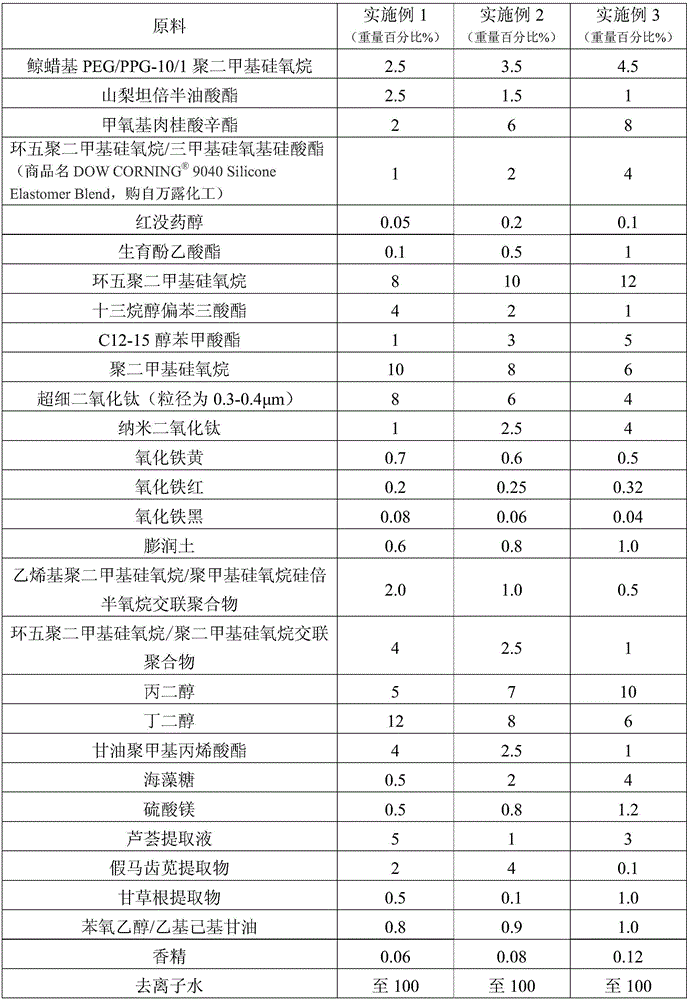

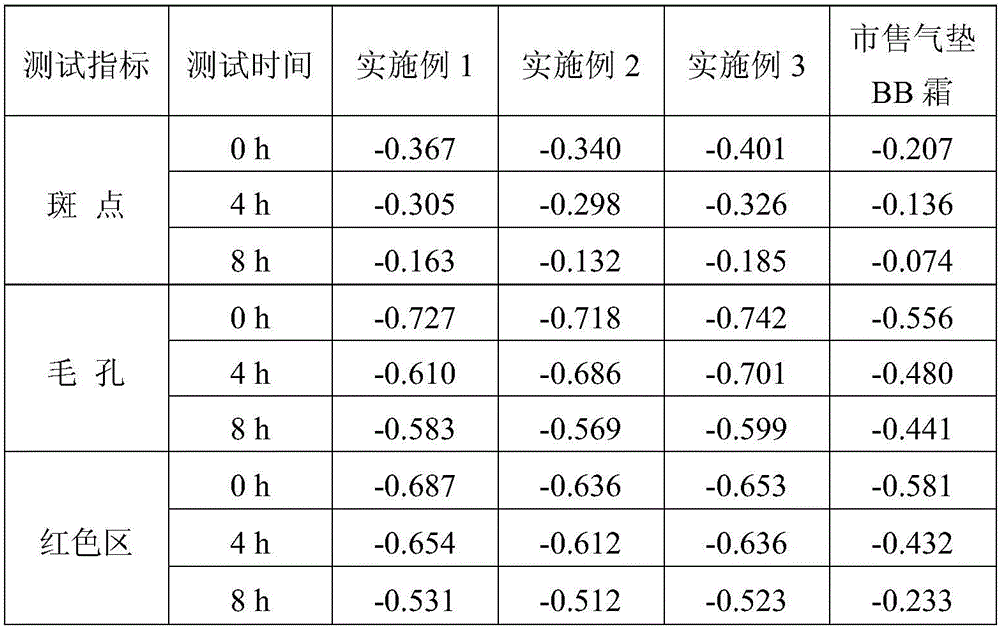

Air cushion BB cream and preparation method thereof

InactiveCN105687045AImprove efficacyHigh oil absorptionCosmetic preparationsMake-upSodium BentoniteC12-15 Alkyl benzoate

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Four-layer-color synthetic resin block and preparation method thereof

ActiveCN103273713AEasy to processGood dimensional stabilitySynthetic resin layered productsArtificial teethPolymer scienceIron oxide black

The invention discloses a four-layer-color synthetic resin block and a preparation method thereof. The four-layer-color synthetic resin block is formed by four layers of structures sequentially, each layer of the structures comprise components as follows: polymethyl methacrylate, iron oxide red, iron oxide black, iron oxide yellow, titanium white, methyl methacrylate and ethylene glycol dimethacrylate. The preparation method comprises the steps as follows: polymethyl methacrylate powder is dried at a temperature of 80-90 degrees; four layers of materials are prepared in proportion respectively, and each layer of the materials are required to be mixed uniformly and kneaded until doughing time, so that a plastic dough material is formed; four layers of the plastic dough material are subjected to hot-pressing and bounded together in order in a die, the hot-pressing temperature is 110-130 DEG C, and the hot-pressing time is 10-20 min; and the four-layer-color synthetic resin block after hot-pressing is subjected to heat treatment at a temperature of 80-90 DEG C for 10-12 h, so that a four-layer-color synthetic resin block product is obtained. A dental model or temporary crown bridge, which is processed through the four-layer-color synthetic resin block, is natural and vivid in developing, and the preparation method is simple.

Owner:SHANDONG HUGE DENTAL MATERIAL CO LTD

Powder coatings special for glass

ActiveCN103160196AGood weather resistanceImprove wear resistancePowdery paintsPolyester coatingsPhysical chemistryPolypropylene

The invention discloses powder coatings special for glass. The powder coatings special for the glass are made of the raw materials which comprise, by weight, 500-600 parts of polyester resin (P2240), 50-70 parts of triglycidyl isocyanurate (TGIC) (PT810), 5-10 parts of wrinkle agents (AS303), 4-6 parts of dobby dispersing agents (AST-W), 100-150 parts of superfine barium sulfate, 50-80 parts of standard spheroidal silica micro powder, 50-100 parts of light calcium carbonate, 3-5 parts of benzoin, 5-8 parts of modified polypropylene wax micro powder, 80-100 parts of organic coated titanium dioxide powder, 5-10 parts of iron oxide yellow, 5-10 parts of iron oxide red and 10-15 parts of carbon black. The powder coatings have the advantages of being high in hardness, high in intensity, high in wear resistance, good in heat resistance, good in aging resistance, fast in solidification time, environment-friendly, free of pollution and the like. The solidified coatings have a texture effect with moire patterns, the moire patterns are exquisite, clear and even in distribution and bring a comfortable visual sense to people, and the coatings are good in overall performance.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Waterproof liquid foundation formula and preparation method thereof

InactiveCN110051553ANon-irritatingHas the effect of isolating external damageCosmetic preparationsBody powdersSkin complexionGlycerol

Owner:广州蔓缇化妆品有限公司

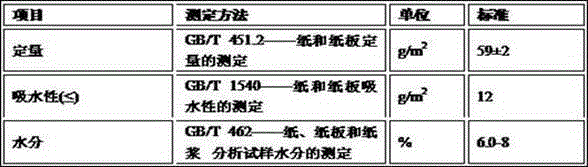

Fruit cultivating bag paper and preparation method thereof

ActiveCN105379594AGuaranteed waterproof performanceGood shading effectCoatingsPlant protective coveringsPaper sheetCarbon black

The invention relates to the field of fruit cultivating bag paper, in particular to fruit cultivating bag paper and a preparation method thereof. Raw paper is correspondingly smeared with an outer coating prepared from iron oxide yellow, iron oxide red, a color fixing agent, a waterproof agent and a water-resistance agent and an inner coating prepared from calcium carbonate, carbon black pigment, a color fixing agent and a waterproof agent, and the fruit cultivating bag paper is obtained through coiling. The fruit cultivating bag paper has good waterproof performance and high shading performance, coating distribution is uniform, and the performance of the fruit cultivating bag paper is excellent. In the production process of the fruit cultivating bag paper, pollution sources are effectively reduced, coating smearing is conducted through a coating method, the shading performance is uniform, and the shading degree is high; meanwhile, the technology is simple, operation is easy, the production cycle is short, and the production efficiency is high.

Owner:NINE DRAGONS PULP PAPER LESHAN CO LTD

Plant fiber composite fireproof plate

ActiveCN103192441AIncrease hydroxylImprove bonding performanceLayered productsDomestic articlesCelluloseAdhesive

The invention provides a plant fiber composite fireproof plate. The plant fiber composite fireproof plate is characterized by sequentially comprising an upper reinforcing layer, a core layer and a lower reinforcing layer from top to bottom, the core layer comprises enzymatic plant fiber powder, modified adhesive, iron oxide yellow, fire retardants and paraffin, and the weight ratio of the enzymatic plant fiber powder to the modified adhesive to the iron oxide yellow to the fire retardants to the paraffin is (75-80):(14-16):(0.5-1):(1-3.5):(4-5). The plant fiber composite fireproof plate has the advantages that by processing steps such as enzymatic reaction and modification for adhesive in a manufacturing method, hydroxyl radicals on surfaces of plant fibers are greatly increased under the condition of guaranteeing that only a small quantity of celluloses is destroyed, the adhesion capacity of the adhesive to the plant fibers is greatly improved, and the water resistance of the plate is strengthened; and properties such as corrosion resistance and heat insulation of the fireproof plate which is a multilayer composite plate are improved.

Owner:琚长林

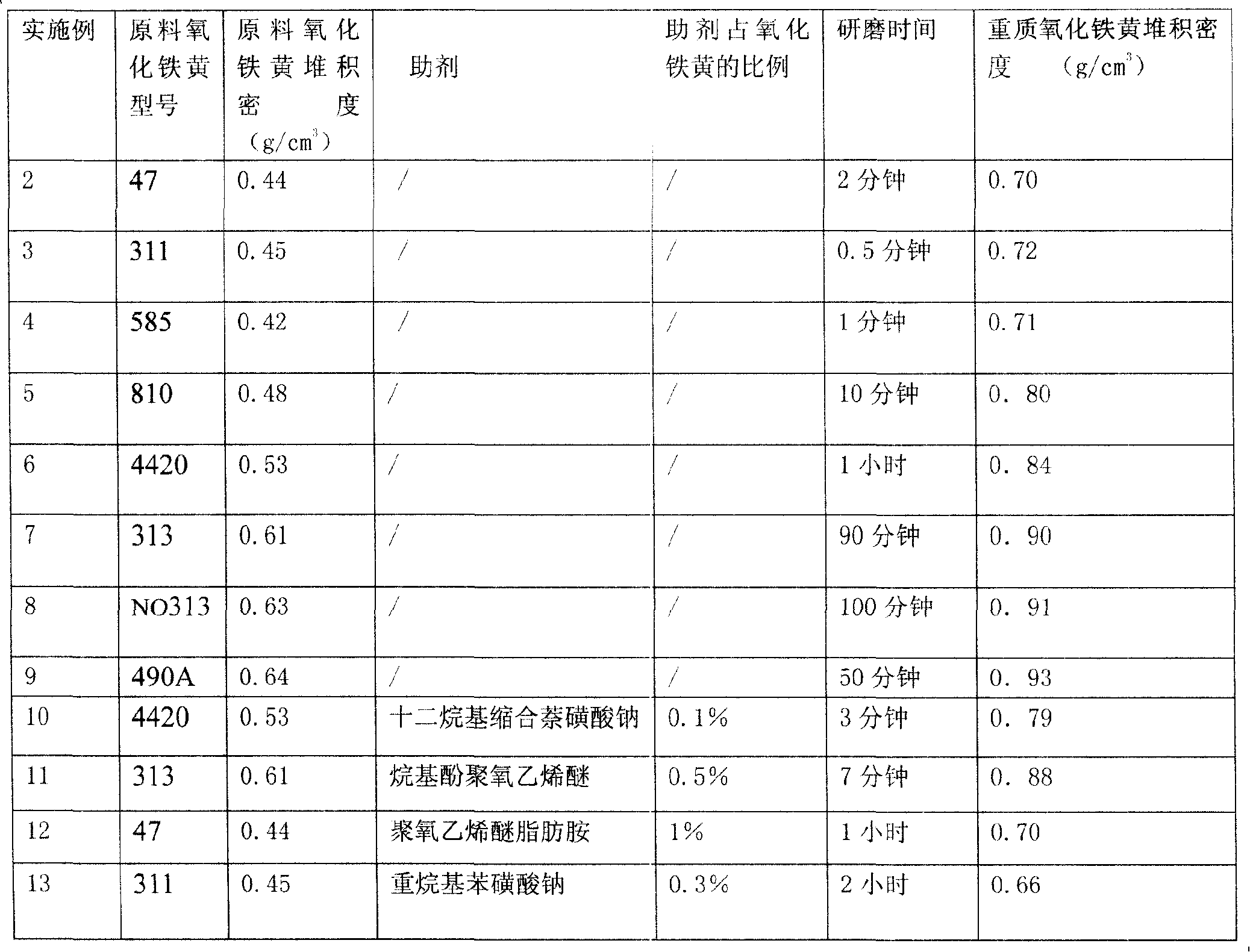

Heavy iron oxide yellow and preparation method thereof

InactiveCN101191022AHigh bulk densitySave storage spacePigment physical treatmentHigh densityBall mill

The invention relate to a heavy iron oxide yellow, which comprises high density iron oxide yellow powder. The high density iron oxide yellow powder is made from the iron oxide yellow powder with a ball mill through vibratory milling or milling. The bulk density of the heavy iron oxide yellow manufactured through milling method is increased by 10-70 percent compared with that of the general iron oxide yellow, therefore, the storage and transportation space occupied by the same amount of iron oxide yellow pigment is greatly reduced, and the transportation cost is lowered. The invention also has the advantages of simple technique and low cost.

Owner:户田联合实业(浙江)有限公司

Method for producing iron oxide yellow and iron oxide red by using waste hydrochloric acid solution

The invention provides a method for producing iron oxide yellow and iron oxide red by using a waste hydrochloric acid solution. The method comprises the following steps: 1, purifying the waste hydrochloric acid solution: taking a steel waste acid solution, adjusting the pH value, adding a certain amount of waste sheet iron, carrying out controlled temperature hydrolysis for 18-24h, adding a flocculating agent, standing for above 24h, and taking the obtained supernatant; 2, preparing crystal seeds: adding the solution obtained in step 1, liquid alkali and water into a crystal seed tank, controlling the temperature and the pH value, and carrying out a preliminary oxidation reaction on ferrous chloride to generate a small amount of iron oxide nuclei; 3, carrying out an oxidation reaction: pumping the nuclei into an oxidation tank, adding sheet iron and water, and introducing compressed air to fully oxidize in order to generate iron oxide crystals on the nuclei; 4, processing byproducts; and 5, carrying out purifying post-treatment. A raw material used in the invention is the steel cleaning hydrochloric acid waste liquid, and is processed to generate useful products comprising iron oxide red and iron oxide yellow, so the waste is changed to valuables. Pigments produced through the method have the advantages of good staining degree, pure and right color, and good client feedback.

Owner:天津市大港华明化工厂

Anti-corrosion polyurethane-epoxy resin composite emulsion coating

InactiveCN105153907AImprove adhesionGood compatibilityAntifouling/underwater paintsPaints with biocidesCarbon nanotubeDefoamer

The invention discloses anti-corrosion polyurethane-epoxy resin composite emulsion coating, which is prepared from the following raw materials: polyurethane-epoxy resin composite emulsion, fluorocarbon resin emulsion, polytetrafluoroethylene emulsion, polyphenylene sulfide resin, tetrafluoroethylene-hexafluoropropylene copolymer, nano-silicon sol, nano-zinc oxide, zinc phosphate, iron-titanium compound powder, nanometer titania, hexahydro-1,3,5-tri(ethoxy)-s-triazine, water-borne polyaniline, carbon nano tube, hollow microspheres, nanometer aluminum nitride, organic-modified montmorillonite, iron oxide yellow, gamma-isocyanate-triethoxypropylsilane, hydrogenated castor oil, defoamer, cosolvent, alcohol ester-12 and deionized water. The anti-corrosion polyurethane-epoxy resin composite emulsion coating disclosed by the invention has good water tolerance and weather fastness and excellent corrosion resistance and impact resistance and is long in service life.

Owner:TIANCHANG YINHU PAINT

High-density freezing-tolerant concrete

The invention discloses high-density freezing-tolerant concrete. The high-density freezing-tolerant concrete comprises the following raw materials: ordinary Portland cement, sea sand, gravel, water, silicon powder, lithium slag powder, fly ash, iron tailing sand, polypropylene fiber, glass fiber, magnesium powder, hydrogen peroxide, ethylene diamine-tetramethyl phosphoric acid, sodium dodecylbenzene sulfonate, phosphoric butanetricarboxylic acid, iron oxide yellow, sodium thiosulfate, urea, sodium chloride, ethylene glycol and a water-reducing agent. The high-density freezing-tolerant concrete disclosed by the invention has the advantages of good freezing tolerance, high density and good durability.

Owner:WUWEI HENGJI COMML CONCRETE

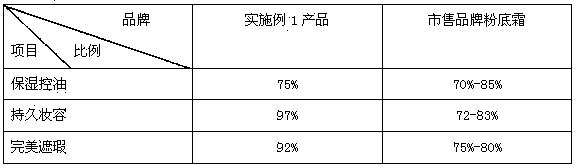

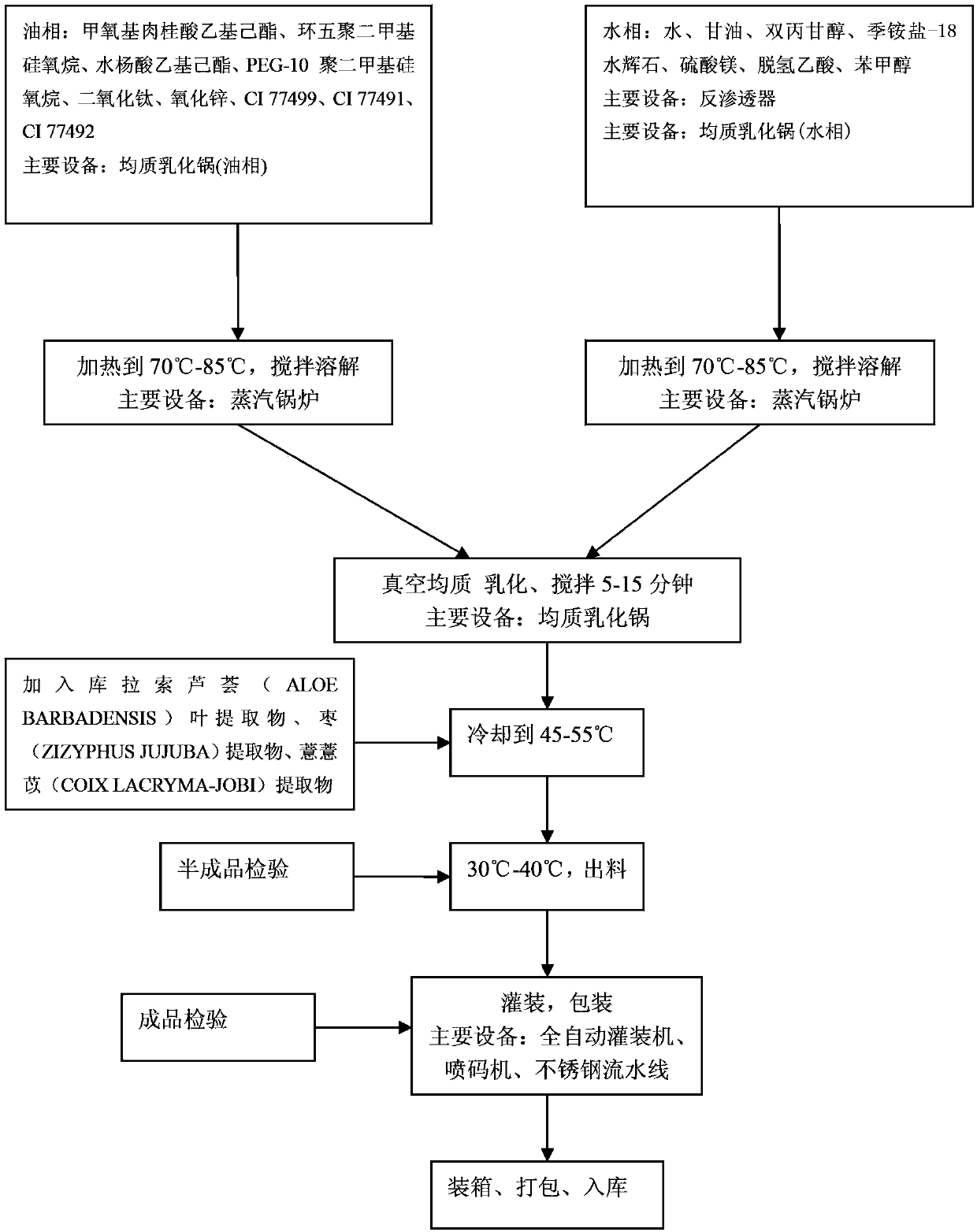

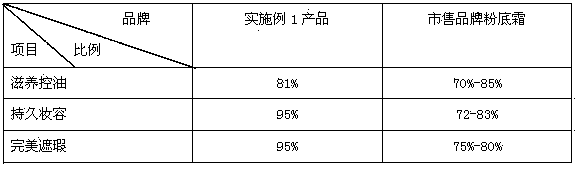

Plant essence-containing sunscreen foundation cream

ActiveCN103356441APrevent photoagingProtection against injuryCosmetic preparationsMake-upDehydroacetic acidAdditive ingredient

The invention discloses a plant essence-containing sunscreen foundation cream. The plant essence-containing sunscreen foundation cream is mainly composed of ethylhexyl methoxycinnamate, zinc oxide, titanium dioxide, ethylhexyl salicylate, cyclopentapolydimethylsiloxane, glycerin, dipropylene glycol, quaternary ammonium salt-18 and hectorite, magnesium sulfate, iron oxide red, iron oxide yellow, iron oxide black, PEG-10 and polydimethylsiloxane, a Curacao aloe extract, a jujube extract, a coix seed extract, dehydroacetic acid, benzyl alcohol and water. The plant essence-containing sunscreen foundation cream is developed through utilizing the effective components of plant extracts against the disadvantages of present foundation creams. The effective plant components deeply nourish and moisten skins, and realize no defects or fine lines of skins, moisture and permeable makeup, even and glossy skin sense, age sign relieving and youthful radiance because of the excellent covering power. The plant essence-containing sunscreen foundation cream can effectively protect skins and resist the ultraviolet and environment harms, and prevents the light ageing of the skins.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

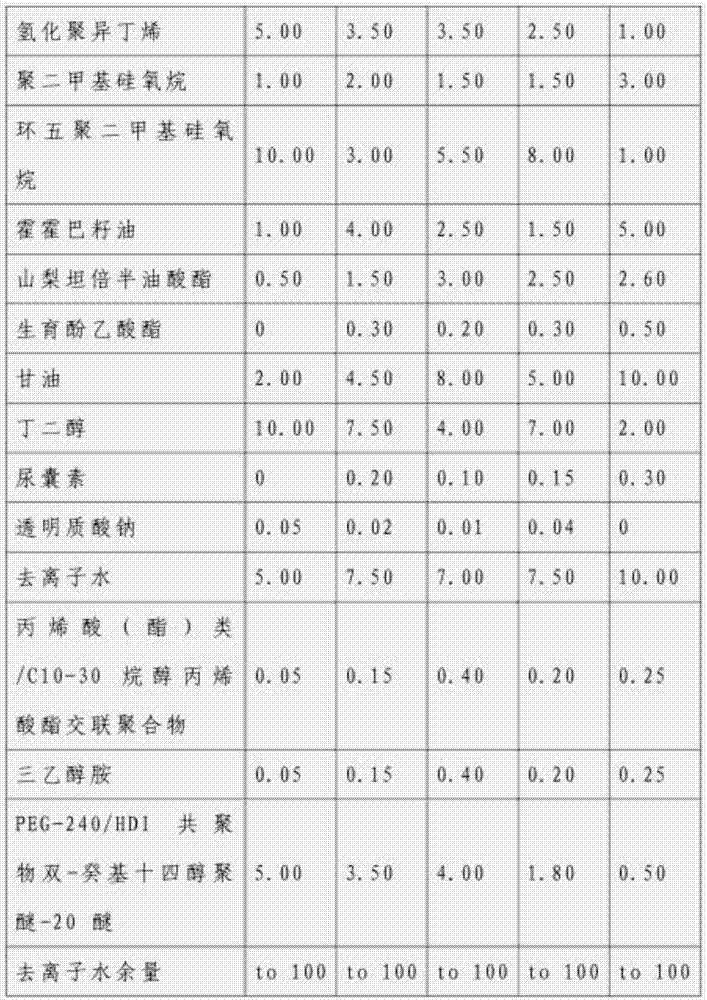

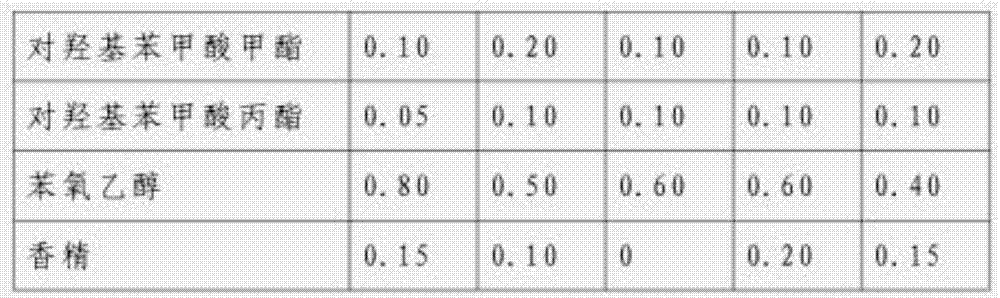

Jelly-like foundation makeup and preparation method of same

InactiveCN107412115ALong-lasting makeupNo greasy feelingCosmetic preparationsMake-upButanediolDimethyl siloxane

The invention discloses a jelly-like foundation makeup and a preparation method of same. The foundation makeup includes the following components: titanium dioxide, iron oxide yellow, iron oxide red, iron oxide black, pearl powder, zinc oxide, boron nitride, silica, isononyl isononanoate, hydrogenated polyisobutene, polydimethylsiloxane, decamethylcyclopentasiloxane, Jojoba seed oil, sorbitan sesquioleate, tocopheryl acetate, glycerol, butanediol, allantoin, sodium hyaluronate, acrylate / C10-30 alkanol acrylate crosslinked polymer, triethanolamine, PEG-240 / HDI compolymer bis-decyl tetradecanol polyether-20 ether, methyl 4-hydroxybenzoate, propyl 4-hydroxybenzoate, phenoxyethanol, essences, and the balanced being deionized water. The jelly-like foundation makeup, through dual-emulsification technology, has long-lasting makeup effects, is water-proofing and oil-proofing, has no greasy sense and integrates moisturizing, concealing, isolating and sun-screening and the like functions. The preparation method can achieve large-scale mass production.

Owner:SUZHOU ANTE COSMETICS CO LTD

Method for preparing iron oxide yellow pigment by using titanium white by-product of ferrous sulfate

InactiveCN101913656AMeet the shade requirementsStable oxidation reactionFerric oxidesSulfateTitanium nitride

The invention relates to a method for preparing an iron oxide yellow pigment by using a titanium white by-product of ferrous sulfate. The preparation method comprises the steps of: refining of the ferrous sulfate, preparation of seed crystal, oxidation synthesis, filteration, water washing, drying and crushing; and the oxidation synthesis specifically comprises the processes of: putting ferrous sulfate yellow seed crystal into an oxidation reaction barrel, heating up to 60-90 DEG C and preserving the temperature, controlling the pH value of a whole reaction system to be 2.5-4, simultaneously adding a refined ferrous sulfate solution, and maintaining the concentration of iron vitriol of the whole reaction system to be 50-65g / L, wherein the whole oxidation reaction time is 80-120h. Because the pH value of the whole oxidation synthesis reaction system changes stably and particles in the reaction system are uniform in size, the prepared iron oxide yellow pigment has uniform particles and good hue.

Owner:TONGLING RELY TECH

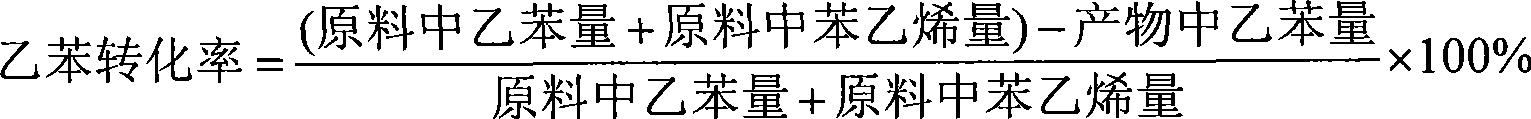

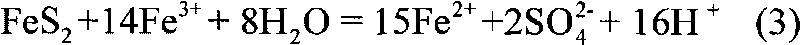

Alkyl-alkenyl arene production catalyst by high-selectivity dehydrogenation of alkyl aromatics

InactiveCN101455968AHigh selectivityImprove one-way yieldHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

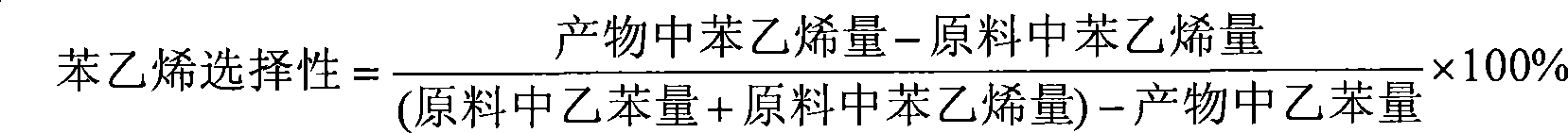

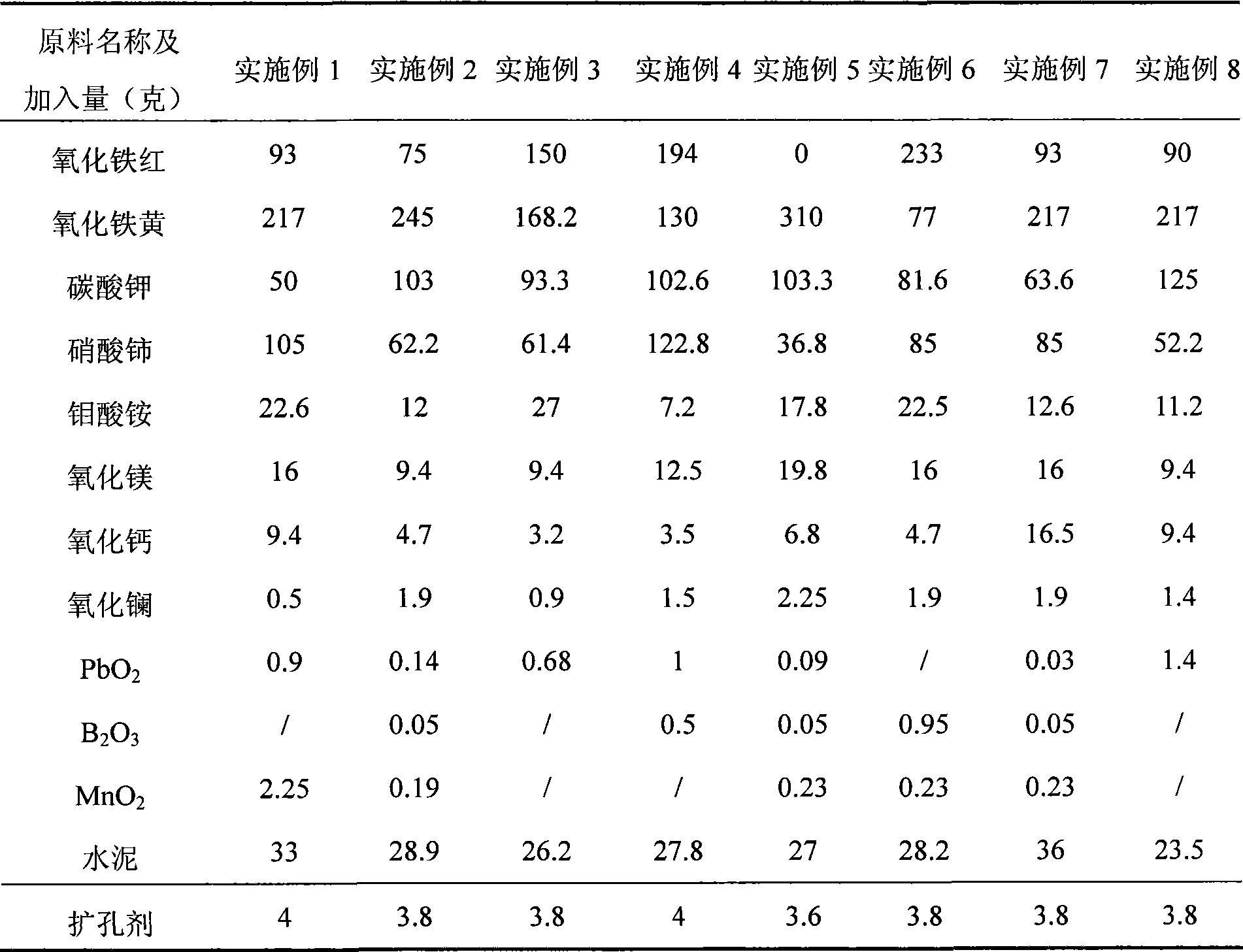

The invention relates to a high-selectivity alkane alkenyl aromatic hydrocarbon catalyst prepared by dehydrogenating alkyl aromatic hydrocarbon, in particular to a styrene catalyst prepared by dehydrogenating phenylethane. The catalyst takes iron-potassium-cerium-molybdenum as a main system, and is characterized by comprising the following main active components by mass percentage: 1) 50 to 85 percent of Fe2O3; 2) 7 to 15 percent of K2O; 3)1 to 6 percent of MoO3; 4) 2 to 13 percent of CeO2; 5) 1 to 6 percent of MgO; 6) 0.5 to 5 percent of CaO; and 7) 0.05 to 0.9 percent of La2O3. The catalyst prepared especially when iron oxide consists of pigment-grade iron oxide red containing no crystal water and pigment-grade iron oxide yellow containing one crystal water in certain proportion and when potassium oxide and iron oxide are selected within a certain proportion range, has the advantages of maintaining high selectivity and simultaneously raising conversion rate so as to obtain high once through yield of styrene.

Owner:PETROCHINA CO LTD

High-temperature-resistant epoxy powder coating for corrosion prevention of pipeline

InactiveCN104497799AGood coating performanceImprove bindingAnti-corrosive paintsPowdery paintsFirming agentPolypropylene

The invention relates to a high-temperature-resistant epoxy powder coating for corrosion prevention of a pipeline. The high-temperature-resistant epoxy powder coating comprises the following raw material components in percentage by weight: 50-60% of modified phenolic epoxy resin, 3-4% of toughened resin, 3-4% of a curing agent, 30-40% of a filler, 1-2% of pigments and 1-2% of additives. The epoxy value of the modified phenolic epoxy resin is 0.2-0.3eq / 100g, and the softening point is 65-75 DEG C; the toughened resin is solid epoxy resin modified by nitrile butadiene rubber; the curing agent is an imidazole curing agent or a modified phenolic curing agent; the filler is titanium dioxide, wollastonite powder, mica powder, barite powder or several types thereof; the pigments comprise phthalocyanine blue and iron oxide yellow; and the additives comprise more of an acrylic acid leveling agent, a benzoin defoaming agent, a fumed silica thixotropic agent and dimethylimidazole. As a bottom-layer coating of a 3PE (polyethylene) / 3PP (polypropylene) anti-corrosion coating, the high-temperature-resistant epoxy powder coating can still keep good binding force at the temperature of 120 DEG C and further ensure that the 3PE / 3PP anti-corrosion coating can still keep stable coating performance at the temperature of 120 DEG C.

Owner:SHANGHAI HILONG PETROCHEM RES INST +2

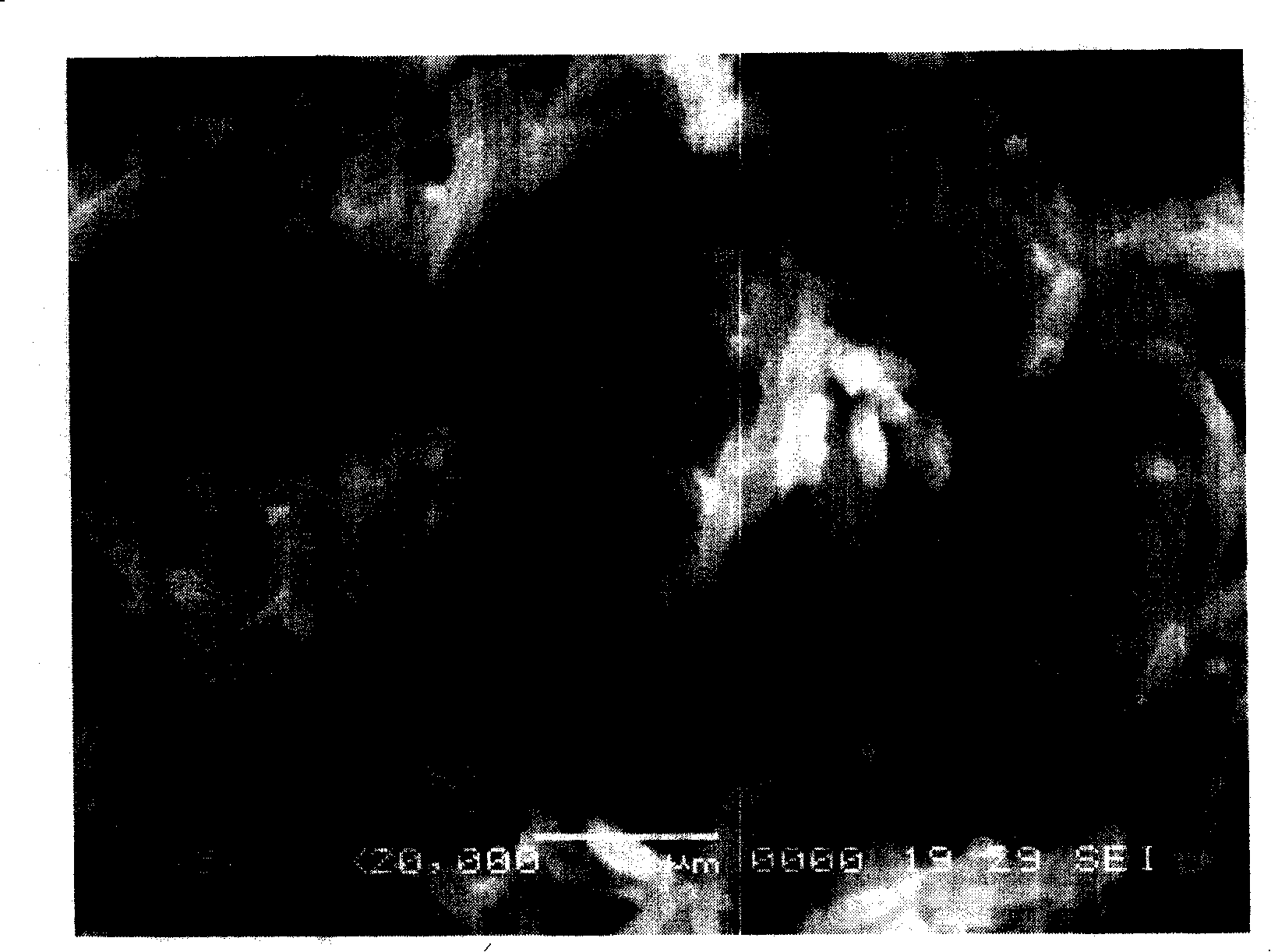

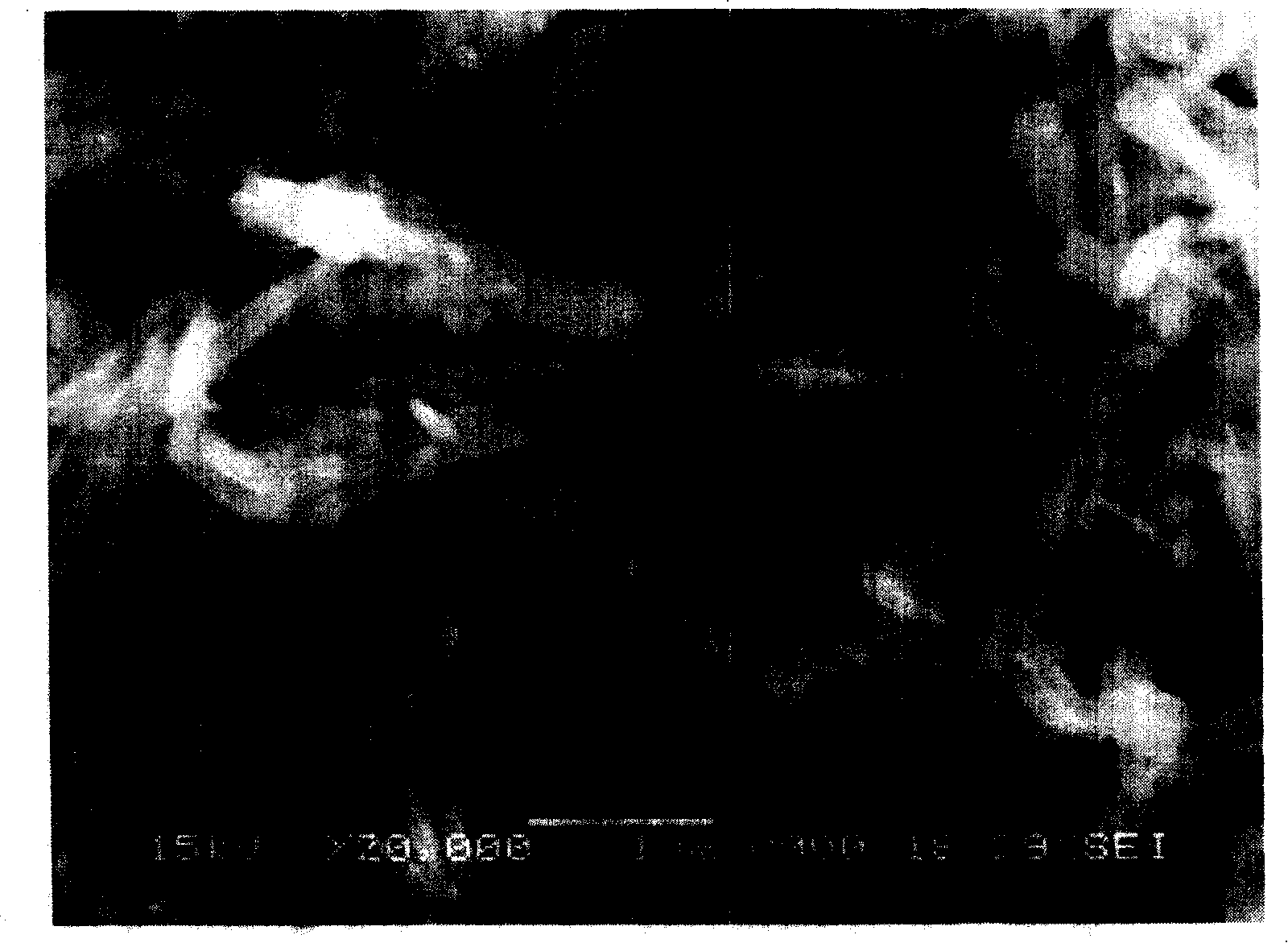

Method of preparing iron oxide yellow by using titanium dioxide by-product

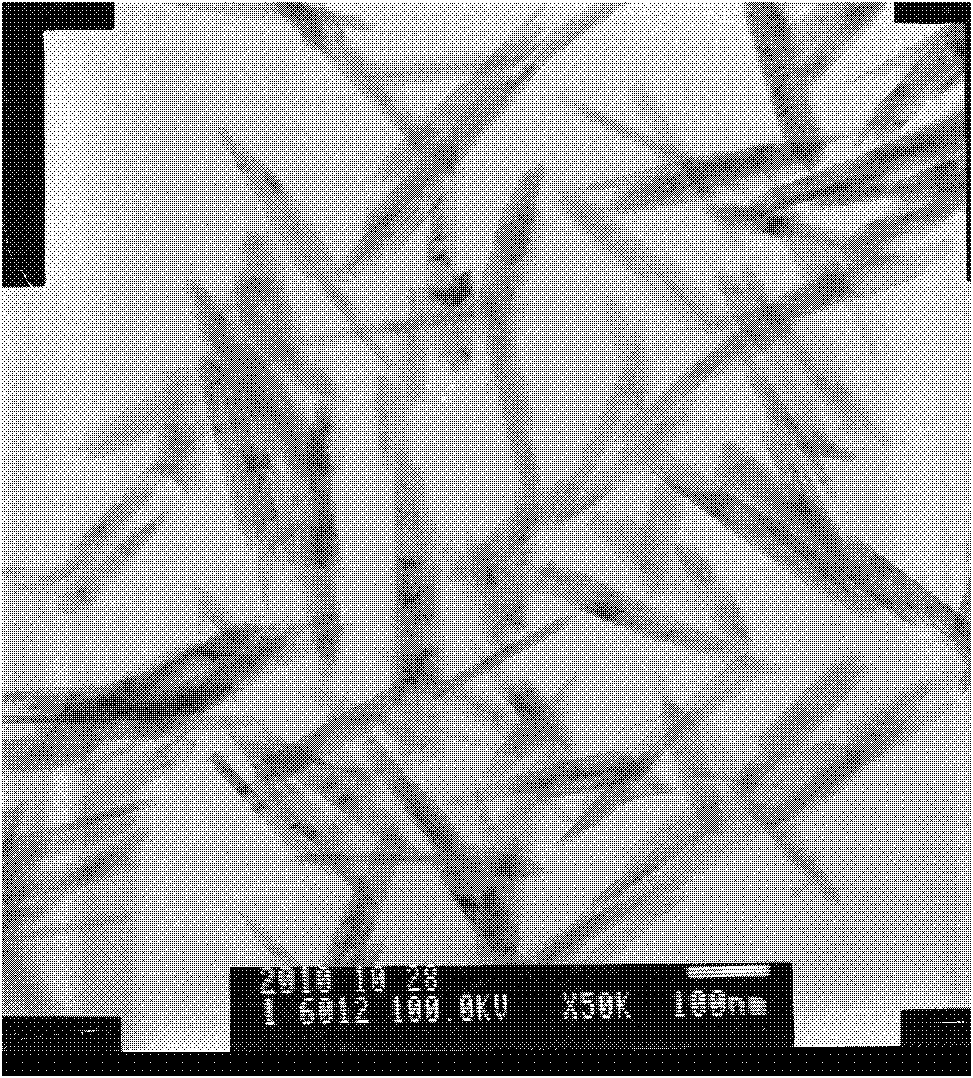

ActiveCN103145194AGood dispersionEffective control of nucleationFerric oxidesIron sulfatesTitanium tetraisopropoxideManganese

The invention provides a method of preparing iron oxide yellow by using a titanium dioxide by-product ferrous sulphate, belonging to a field of chemistry. The method comprises refining of ferrous sulphate, neutralization reaction, seed preparation, and oxidation synthesis; and the method controls a pH value of a solution during refining of the ferrous sulphate, and thus effectively removes impurities such as manganese, magnesium and zinc. In addition, by separating a seed preparation process into a neutralization reaction process and a seed preparation process, a preparation process of Fe(OH)2 suspension and an oxidation process are separated, thereby effectively controlling the seed to be spindle-shaped or needle-shaped, and improving dispersibility of the seed. The method is good in impurity removal effects, and can effectively control the seed to be spindle-shaped or needle-shaped and improve dispersibility of the seed; and the prepared iron oxide yellow has advantages of good color and high tinting strength.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Metal antirust paint and preparation method thereof

The invention provides a metal antirust paint and a preparation method thereof. The metal antirust paint consists of the following ingredients in parts by mass: 35-45 parts of styrene-acrylic emulsion, 16-25 parts of iron oxide yellow, 8-16 parts of antirust yellow, 15-23 parts of zinc phosphate, 2-6 parts of zinc oxide, 2.5-5.5 parts of sodium dodecyl benzene sulfonate, 7-13 parts of mica powder, 2.3-5.5 parts of gallotannic acid, 2.2-5.8 parts of dihydric phosphate, 3-4.5 parts of polyacrylic copolymer emulsion, 1.3-3.7 parts of organic siloxane, 2.3-3.2 parts of sodium nitrite and 80-92 parts of deionized water. The metal antirust paint disclosed by the invention is harmless to the human body and the environment; a paint film is dried rapidly; furthermore, a metal is enabled to have passivation, rusting and rust prevention functions, and the metal can be directly painted without a rust prevention treatment, so the labor and time are saved.

Owner:SUZHOU CITY BANGCHENG ELECTRICITY TECH

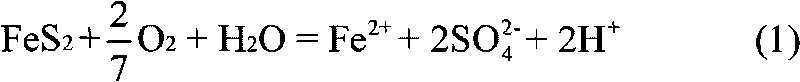

Method for preparing iron oxide yellow pigment by carrying out resourceful treatment on pyrite wastewater

InactiveCN101746835ARealize resource processingWaste water treatment from quariesWater contaminantsIron powderPyrite

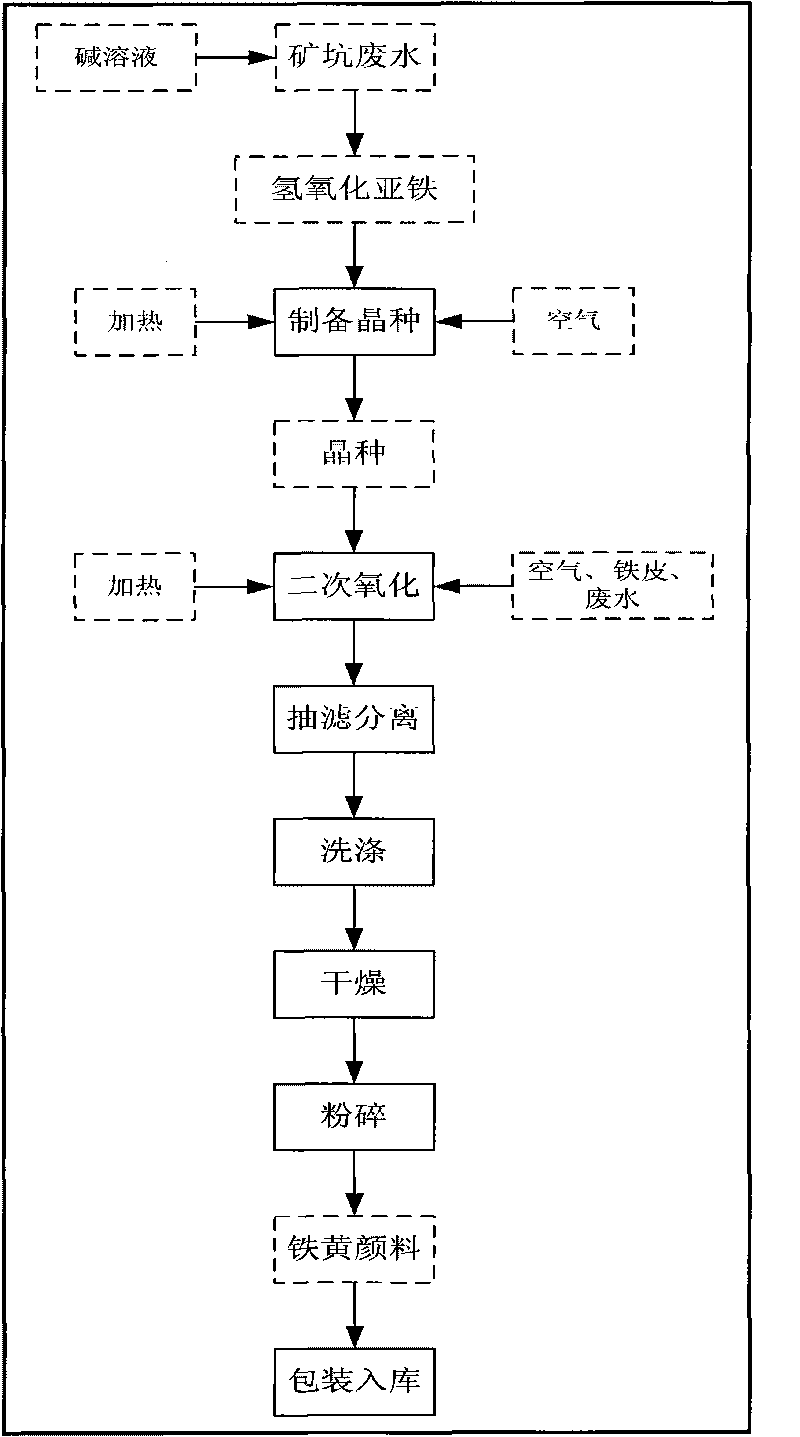

The invention discloses a method for preparing an iron oxide yellow pigment by carrying out resourceful treatment on pyrite wastewater. The method comprises the following steps: using the pyrite wastewater as the crystal seed raw material; adding alkaline solution into the pyrite wastewater and adjusting a pH value to between 5 to 7.5; standing the mixture and putting the sediments into a reactor; pumping air into the reactor; making the sediments and the air react with each other by heating and stirring to prepare iron oxide yellow crystal seed; adding the iron oxide yellow crystal seed, the raw material pyrite wastewater the volume of which is 1.5 to 2.5 times of that of the iron oxide yellow crystal seed, and iron powders excessive relatively to ferrous sulphate in the raw material pyrite wastewater, pumping the air into the mixture, making the mixture and the air react with each other by heating and stirring, controlling a temperature of between 70 and 85 DEG C and an air adding amount of between 3 and 5m3 / h; tracking the reaction product in the reaction liquid and sampling to test chromatic light; and when the chromatic light of the reaction product is consilient with that of a sample of iron oxide yellow pigment by comparing the reaction product with the sample of iron oxide yellow pigment, stopping the reaction, and processing the reaction liquid to obtain the iron oxide yellow pigment. The invention not only processes the acid pyrite wastewater to make the acid pyrite wastewater discharged after reaching standards, but also utilizes useful components in the pyrite wastewater to prepare the iron oxide yellow pigment, and realizes the resourceful treatment of the waste.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com