Heavy iron oxide yellow and preparation method thereof

A technology of iron oxide yellow and iron oxide, which is applied in the directions of dyeing physical treatment, fibrous filler, etc., can solve the problems of color change, increased production cost, complicated production process, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

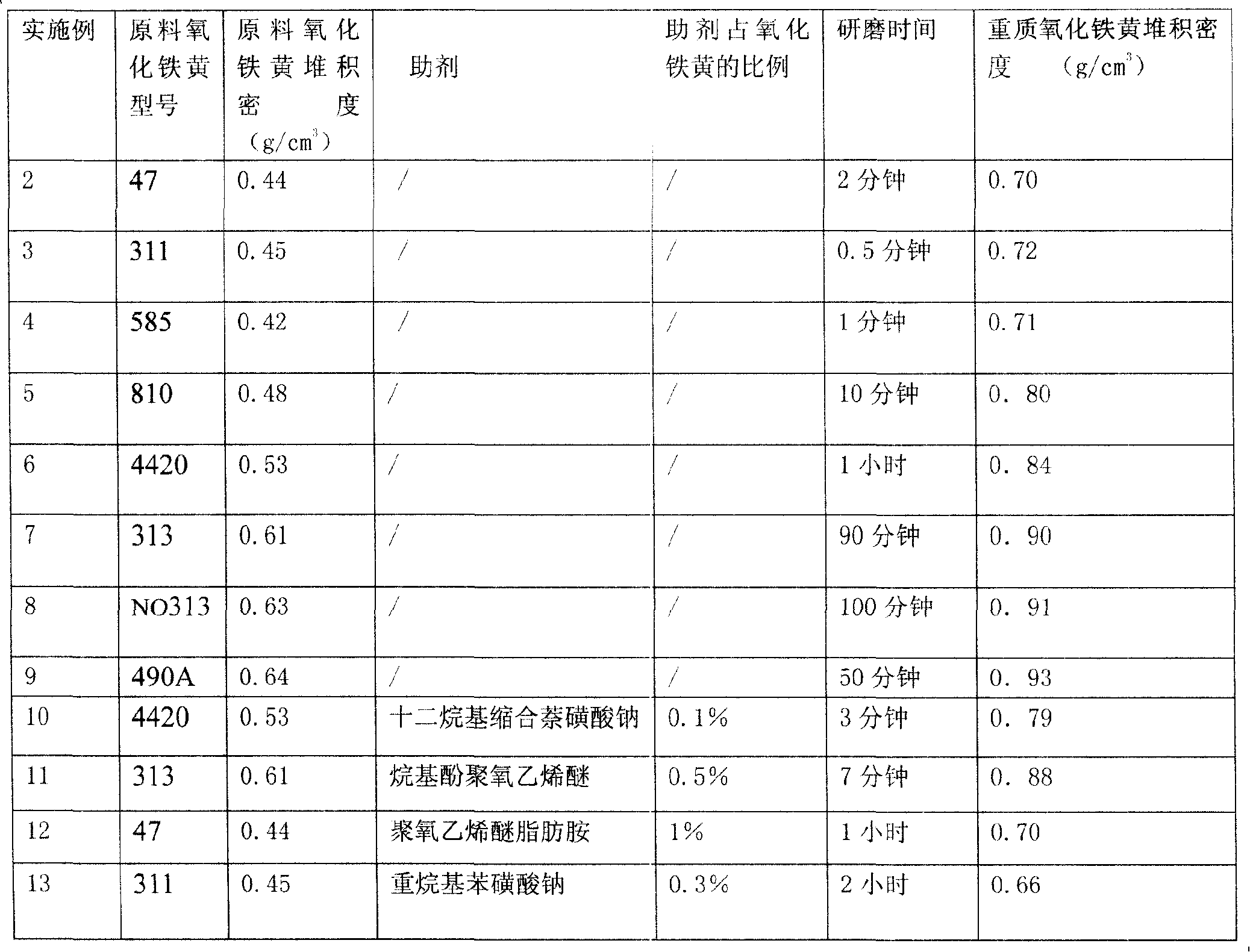

[0044] Iron oxide yellow powder 311 (iron oxide yellow powder 311 produced by Deqing Kaifu Pigment Co., Ltd.), the measured bulk density is: 0.45, the iron oxide yellow powder is fed into a mechanical ball mill, and the grinding balls are made of stainless steel. Turn on the ball mill for ball milling 10 minutes; hit, take out the heavy iron oxide yellow, detect the heavy iron oxide yellow, the bulk density is 0.85. The results are shown in Table 1:

[0045] Table 1

[0046] serial number

Embodiment 2~21

[0048] Examples 2-4 The heavy iron oxide yellow is made of iron oxide yellow powder, and the iron oxide yellow powder is sent into a mechanical ball mill, and the grinding balls are made of stainless steel, and the heavy iron oxide yellow is obtained by continuous ball milling for a certain period of time.

[0049] Examples 5-6 The heavy iron oxide yellow is made of iron oxide yellow powder, and the iron oxide yellow powder is sent into a mechanical ball mill for continuous vibration ball milling. The grinding balls are made of carbon steel, and the heavy iron oxide is obtained after a certain period of time. yellow.

[0050] Examples 7-9 The heavy iron oxide yellow is made of iron oxide yellow powder, and the iron oxide yellow powder is sent into a rotating vertical barrel ball mill, and the grinding balls are made of stone, and the heavy iron oxide is taken out by intermittent ball milling for a certain period of time. Iron oxide yellow, the total ball milling time is shown ...

Embodiment 12

[0052] Example 12 Heavy iron oxide yellow is made of iron oxide yellow powder and additives. First, the iron oxide yellow powder is sent into a rotating horizontal barrel ball mill, and the grinding balls are made of stainless steel for intermittent grinding. First, the ball mill is 30 Minutes, add additives and continue grinding for 30 minutes, take out heavy iron oxide yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com