Plant fiber composite fireproof plate

A plant fiber and fireproof board technology, which is applied in the pretreatment of molding materials, household components, flat products, etc., can solve the problems of high price, weak surface gluing ability of plant fibers, and poor initial viscosity, so as to improve the gluing ability, Enhance water resistance and improve anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

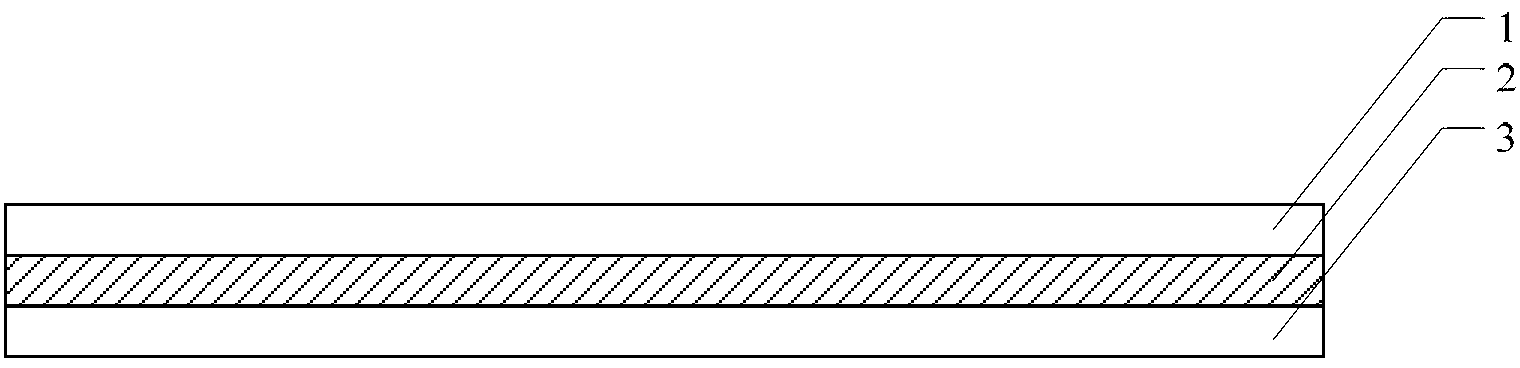

Image

Examples

example 1

[0028] The preparation method of the plant fiber composite fireproof board comprises the following steps:

[0029] Step 1: Crush the plant straw into (20-80) mesh straw powder.

[0030] Step 2: Prepare an acetic acid solution with a pH of 4.0, and add diphenol oxidase at a concentration of 20 U / g to the acetic acid solution to obtain an enzyme reaction solution.

[0031] Step 3. Mix the straw powder in step 1 with the enzyme reaction solution in step 2 at a weight ratio of 1:20, and carry out the enzyme reaction at a temperature of (48-60) ° C. The reaction time is 4-6 hours. The enzymatic straw powder is obtained.

[0032] Step 4: Dry the enzymatic straw powder in step 3 at a temperature of 120-150°C to keep the water content of the straw at (5-8)%.

[0033] Step 5: Mix polysiloxane and urea-formaldehyde resin at a ratio of 1:5 to prepare a modified adhesive.

[0034] Step 6, the stalk powder obtained in step 4, the modified adhesive obtained in step 5, iron oxide yellow, ...

example 2

[0039] The manufacturing method of the plant fiber composite fireproof board comprises the following steps:

[0040] Step 1, crushing the plant stalks into 20-80 mesh straw powder.

[0041] Step 2: Prepare an acetic acid solution with a pH of 5.0, and add diphenol oxidase at a concentration of 30 U / g to the acetic acid solution to obtain an enzyme reaction solution.

[0042] Step 3. Mix the straw powder in step 1 with the enzyme reaction solution in step 2 according to the weight ratio of 1:30, and carry out the enzyme reaction at a temperature of (48-60) ℃, and the reaction time is 4-6 hours. After the reaction, the enzymatic straw powder is obtained.

[0043] Step 4, drying the enzymatic straw powder in step 3 at a temperature of (120-160)°C, so that the water content of the enzymatic straw powder is 5-7%.

[0044] Step 5: Mix polysiloxane and urea-formaldehyde resin at a ratio of 1:60 to prepare a modified adhesive.

[0045] Step 6. Combine the dried enzymatic straw powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com