A kind of ozone catalytic oxidation catalyst and preparation method thereof

An ozone catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem that catalyst performance is not stable enough, surface properties are easy to change, repeated Low utilization rate and other problems, to achieve the effect of improving moisture resistance, low cost, and improving adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

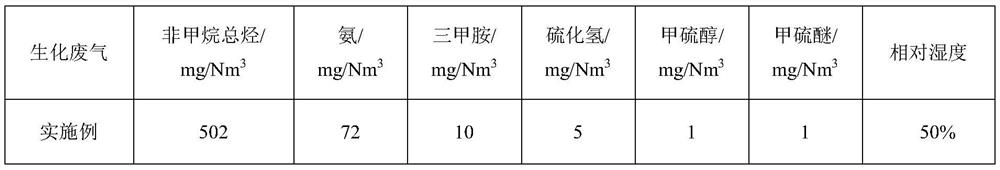

Examples

Embodiment 1

[0062] Embodiment 1: the preparation of carrier

[0063] A carrier preparation

[0064] Activated carbon A (specific surface area 3000m 2 / g, pore diameter 0.5nm) pulverization, pulverization fineness is 50 orders; Activated carbon powder 15g after pulverization and incinerator deposit ash A (specific surface area 400m 2 / g, pore size 3nm) 15g and mix evenly; add citric acid 9g and 3g water to the mixed powder and mix evenly, then knead for 1min; after kneading, extrude into strips with a diameter of 2mm and a length of 5mm; then dry at 100°C for 3h, Calcined at 500°C for 2 hours to obtain the finished product.

[0065] Preparation of B carrier

[0066] Activated carbon A (specific surface area 3000m 2 / g, pore diameter 0.5nm) pulverization, pulverization fineness is 50 orders; The activated carbon powder 15g after pulverization and incinerator deposit ash B (specific surface area 250m 2 / g, pore size 5nm) 15g and mix evenly; add 9g of citric acid and 3g water to the mixe...

Embodiment 2

[0082] Embodiment 2: the preparation of 0# catalyst

[0083] Take 200g of carrier A and put it into a beaker. At the same time, take 40.0mL of magnesium nitrate aqueous solution containing 0.10g / mL magnesium, 40.0mL of nickel nitrate aqueous solution containing 0.15g / mL of nickel, and 40.0mL of manganese nitrate aqueous solution containing 0.10g / mL of manganese. Add 40.0mL of zirconium nitrate aqueous solution containing 0.1g / mL zirconium and 40.0mL of ferric nitrate aqueous solution containing 0.10g / mL iron to the ethanol aqueous solution with ethanol concentration of 5wt%, and prepare an impregnation solution with a total volume of 500.0mL. Mix the impregnating liquid and the carrier in a beaker evenly, keep the temperature at 60°C for 5 hours, filter the impregnating liquid, put the carrier adsorbed with the impregnating liquid in an oven at 180°C for 2 hours; then take out the catalyst, cool to 100°C, and then Calcined at 450°C for 5h in a muffle furnace to obtain 0# catal...

Embodiment 3

[0085] Embodiment 3: the preparation of 1# catalyst

[0086] Take 200 g of the F carrier and put it into a beaker. At the same time, take 40.0 mL of an aqueous solution of magnesium nitrate containing 0.10 g / mL of magnesium, 40.0 mL of an aqueous solution of nickel nitrate containing 0.15 g / mL of nickel, and 40.0 mL of an aqueous solution of manganese nitrate containing 0.10 g / mL of manganese. Add 40.0mL of zirconium nitrate aqueous solution containing 0.1g / mL zirconium and 40.0mL of ferric nitrate aqueous solution containing 0.10g / mL iron to the ethanol aqueous solution with ethanol concentration of 5wt%, and prepare an impregnation solution with a total volume of 500.0mL. Mix the impregnating liquid and the carrier in a beaker evenly, keep the temperature at 60°C for 5 hours, filter the impregnating liquid, put the carrier adsorbed with the impregnating liquid in an oven at 180°C for 2 hours; then take out the catalyst, cool to 100°C, and then Calcined at 450° C. for 5 h in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com