Patents

Literature

914results about How to "Improve decomposition efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

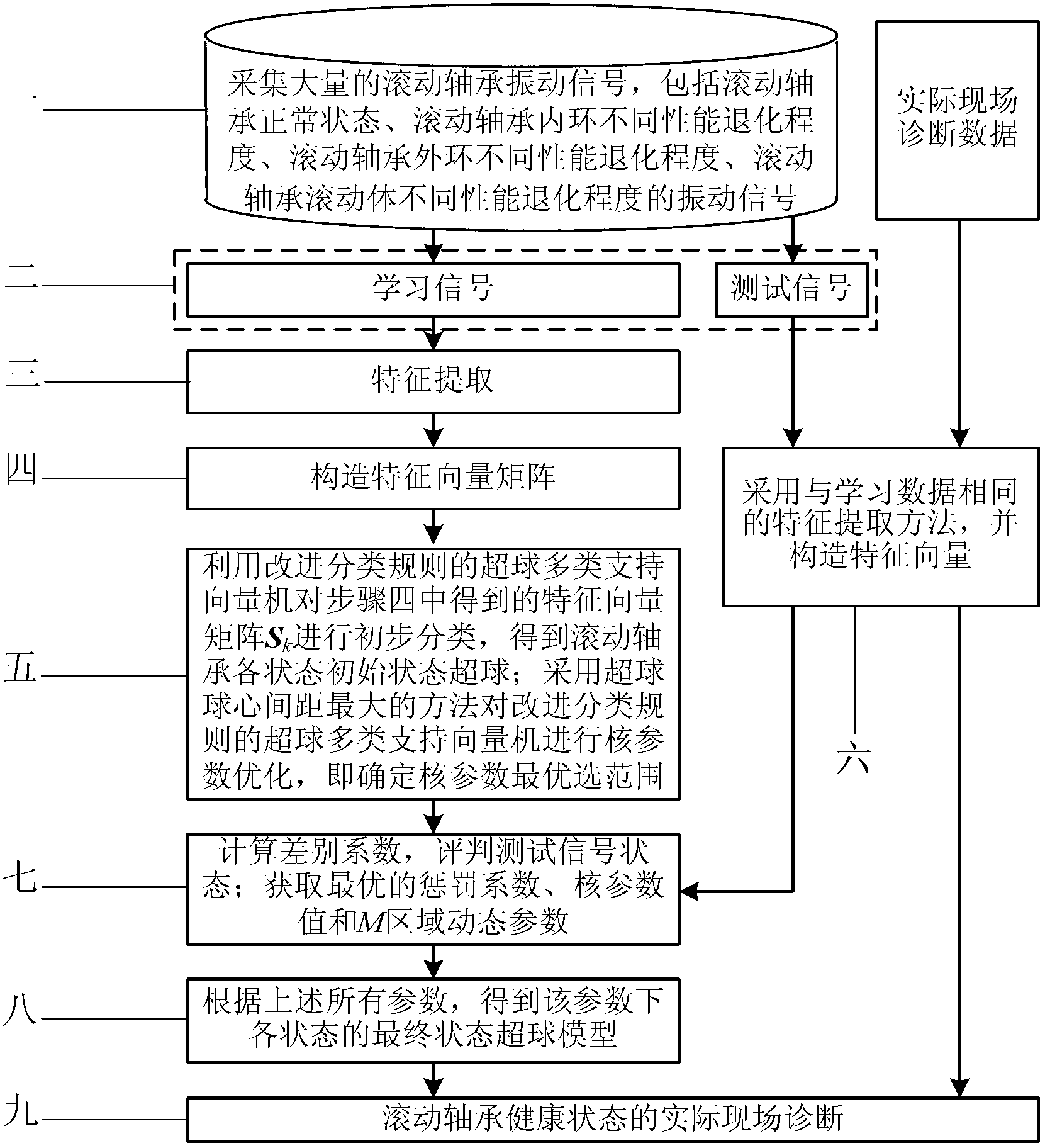

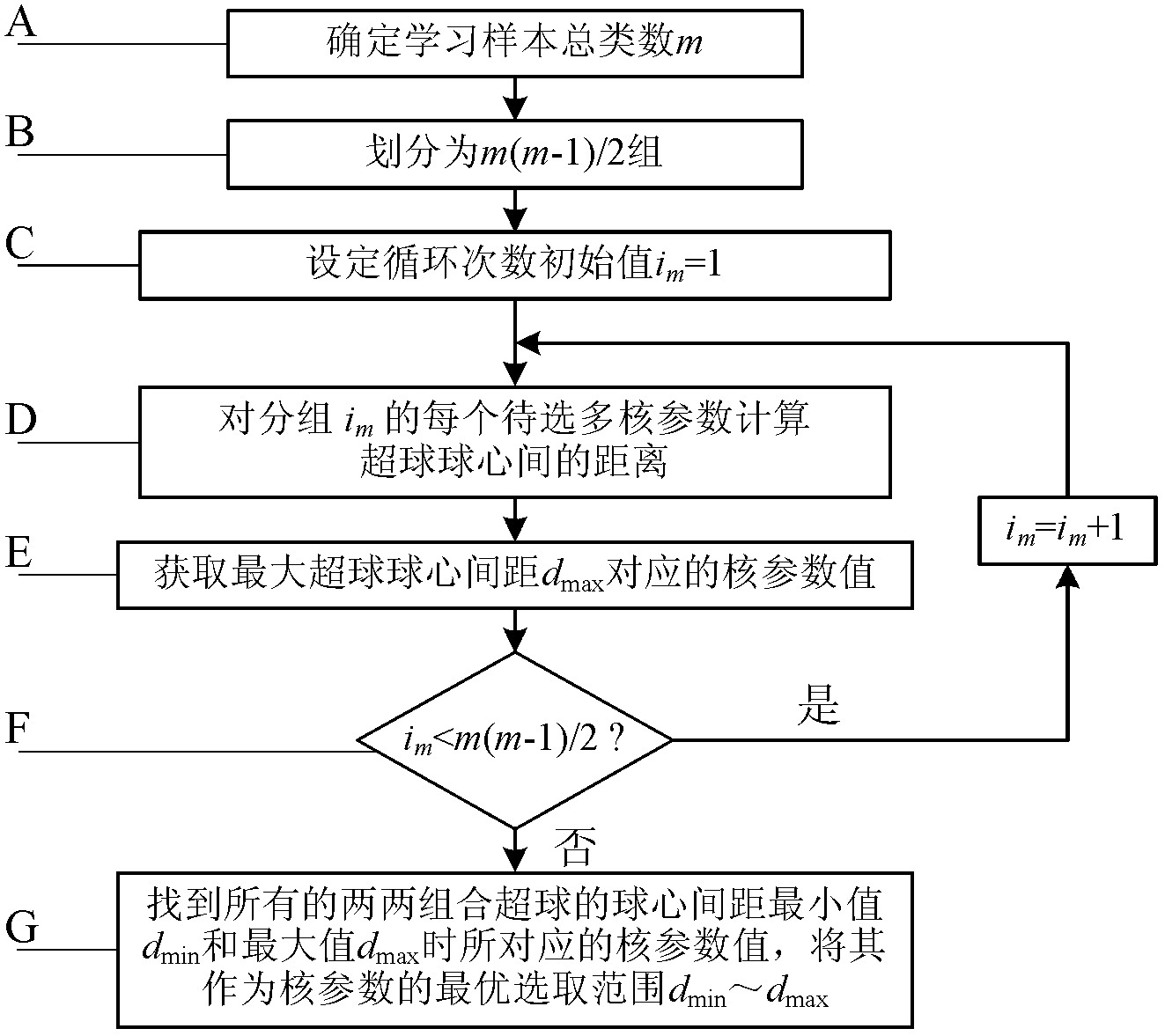

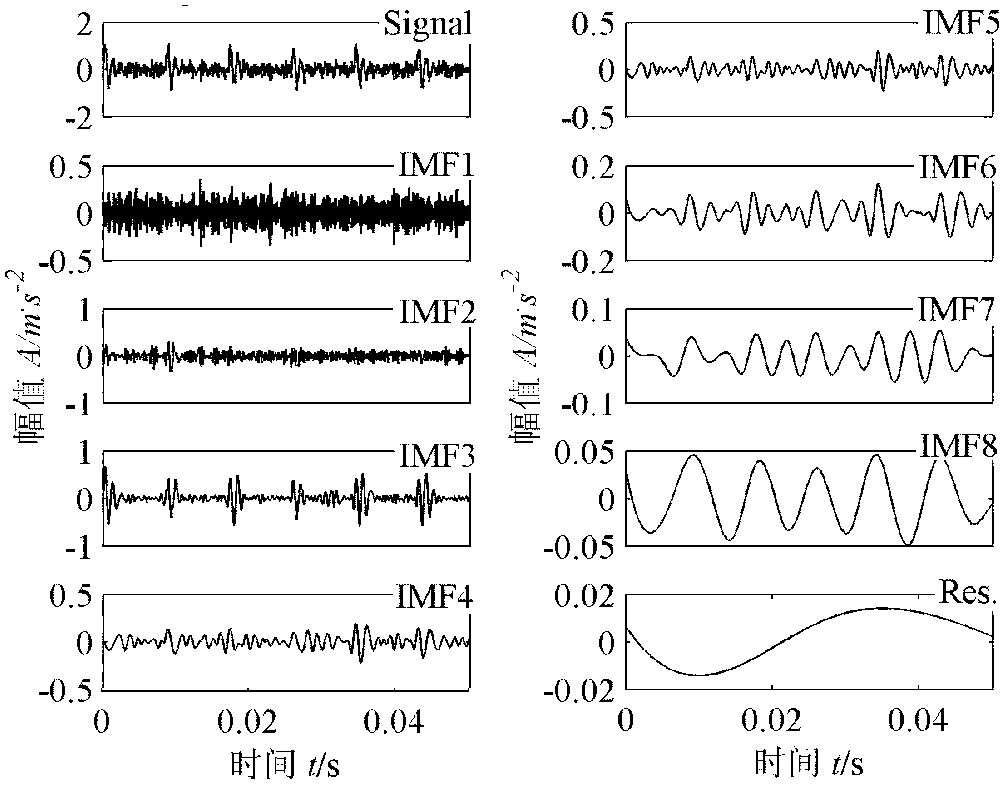

Diagnosis method for fault position and performance degradation degree of rolling bearing

InactiveCN102854015AOptimization determination methodReduce consumptionMachine bearings testingSingular value decompositionSupport vector machine

The invention discloses a diagnosis method for the fault position and the performance degradation degree of a rolling bearing, belonging to the technical field of fault diagnosis for bearings, and solving the problems of low accuracy of diagnosis for fault position and performance degradation degree, and high time consumption of training existing in an intelligent diagnosis method for a rolling bearing in the prior art. A white noise criterion is added in the disclosed integrated empirical mode decomposition method, so that artificial determination for decomposition parameters can be avoided, and the decomposition efficiency can be increased; and via the disclosed nuclear parameter optimization method based on a hypersphere centre distance, the small and effective search region of nuclear parameters in a multi-classification condition can be determined, so that training time is reduced, and the final state hypersphere model of a classifier is given. The intelligent diagnosis method based on parameter-optimized integrated empirical mode decomposition and singular value decomposition, and combined with a nuclear parameter-optimized hypersphere multi-class support vector machine based on the hypersphere centre distance is higher in identification rate compared with the existing diagnosis method. The diagnosis method disclosed by the invention is mainly applied to intelligent diagnosis on the fault position and the performance degradation degree of the rolling bearing.

Owner:HARBIN UNIV OF SCI & TECH

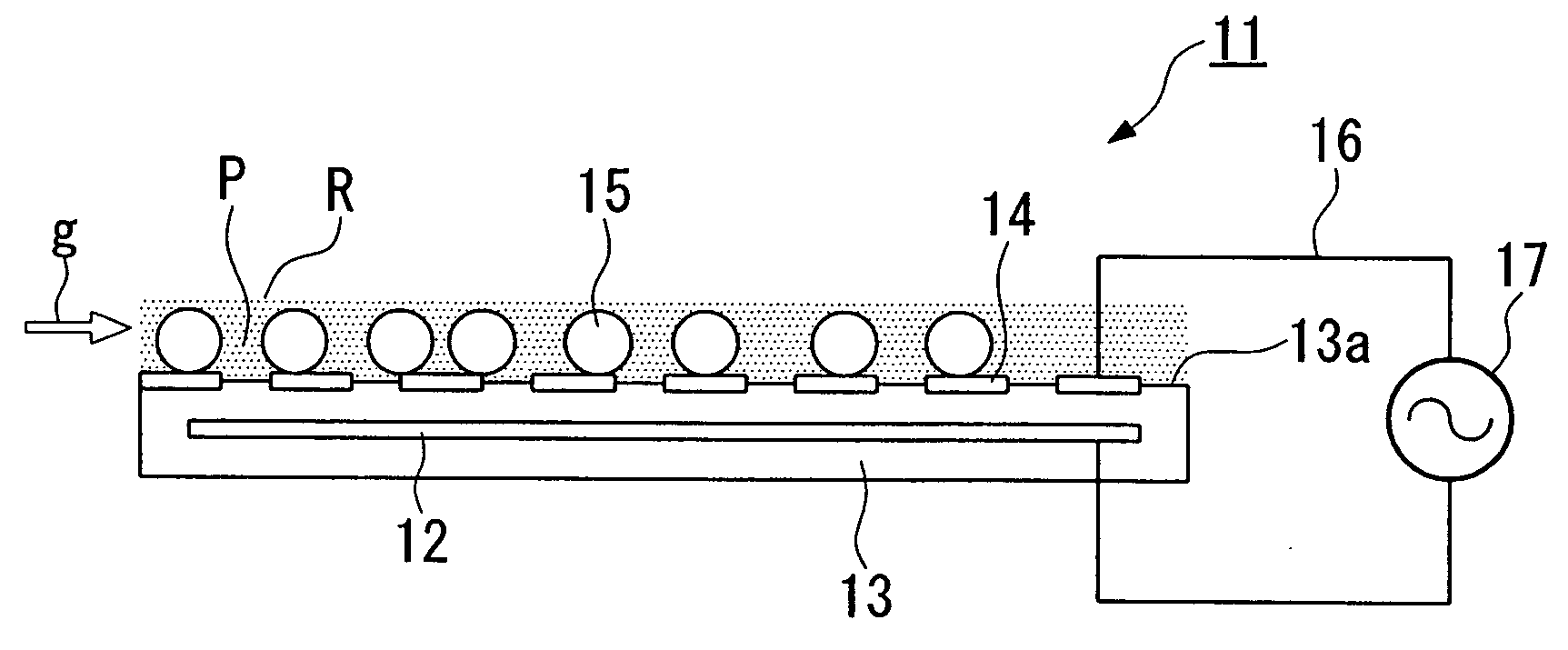

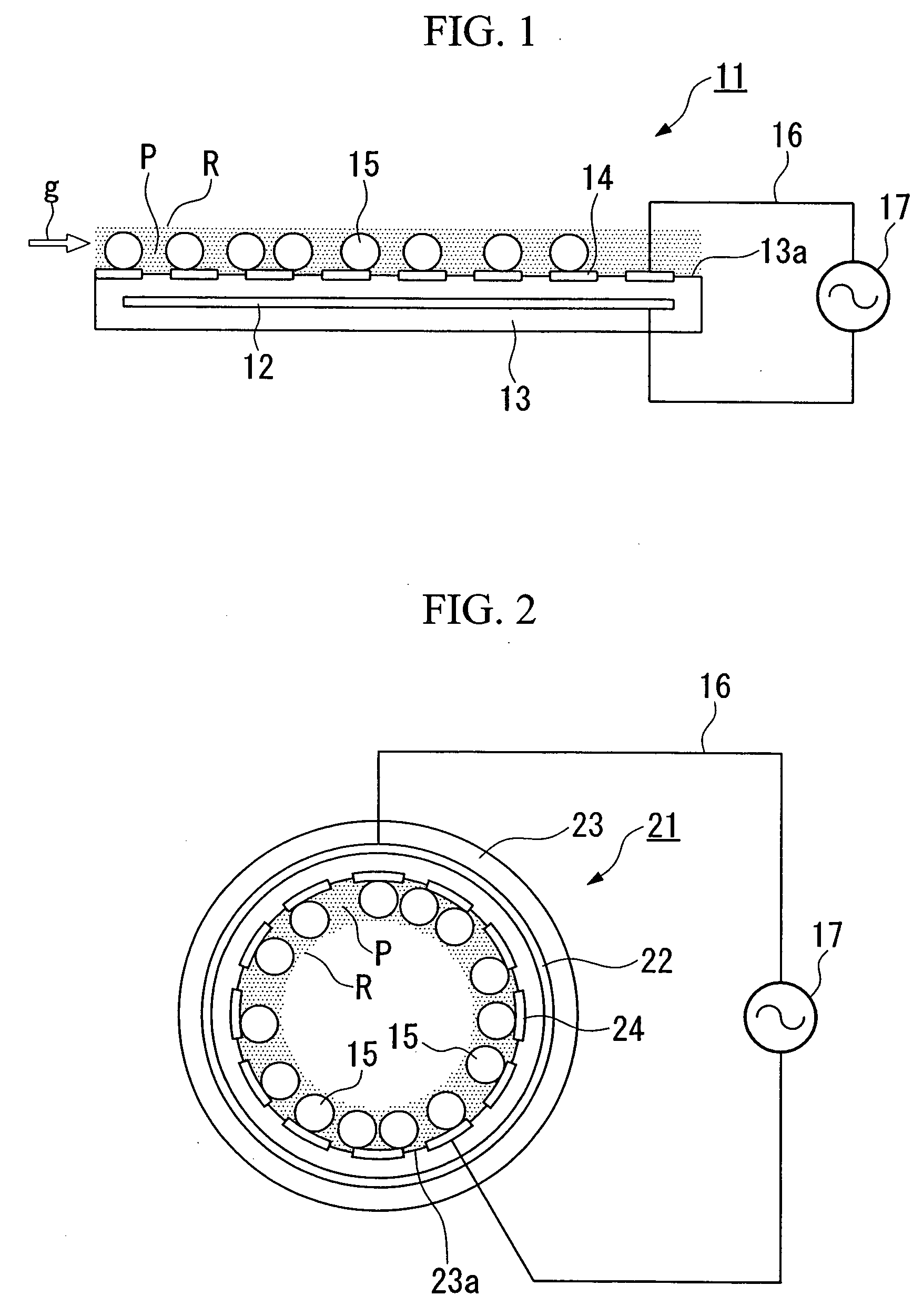

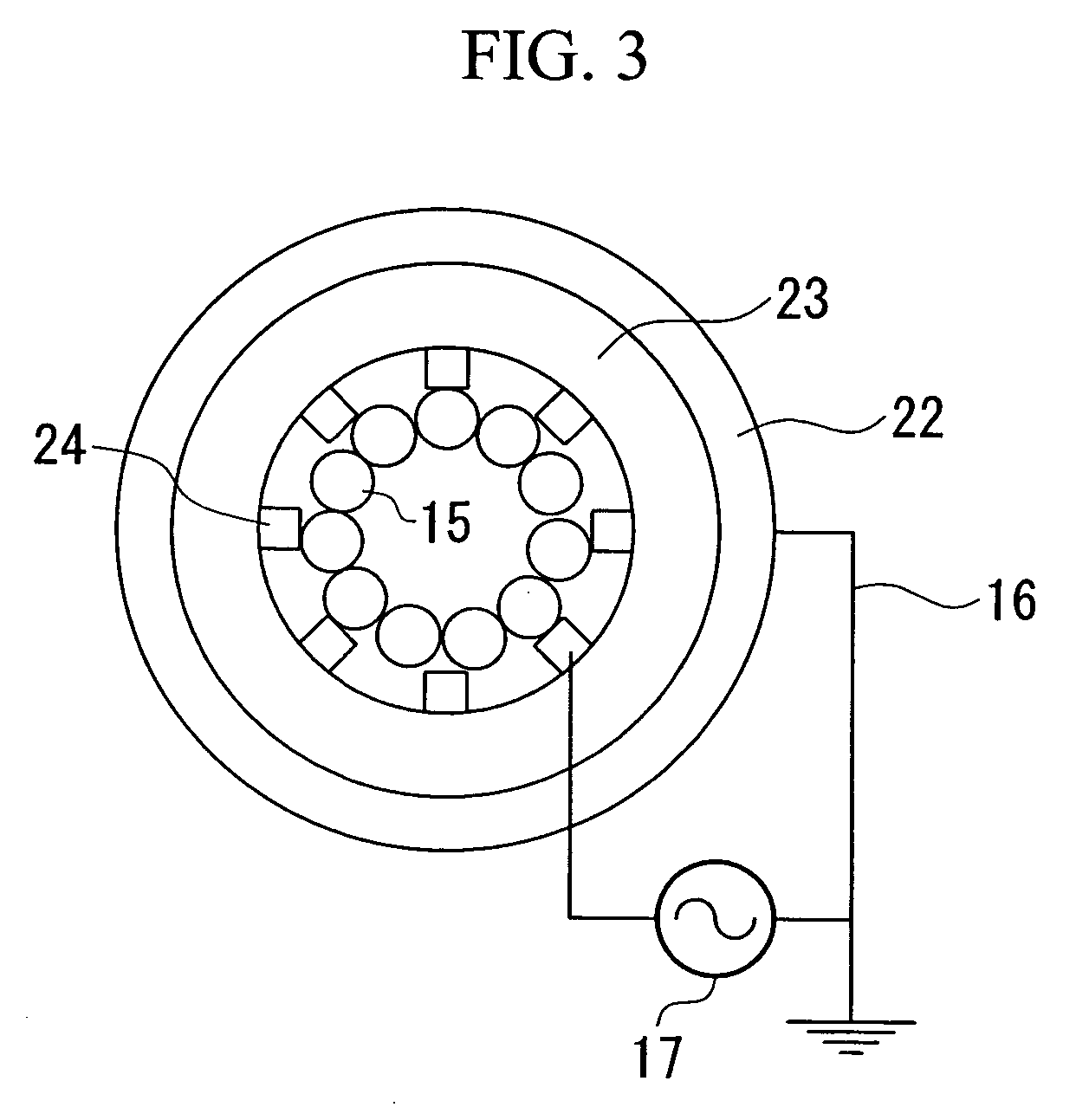

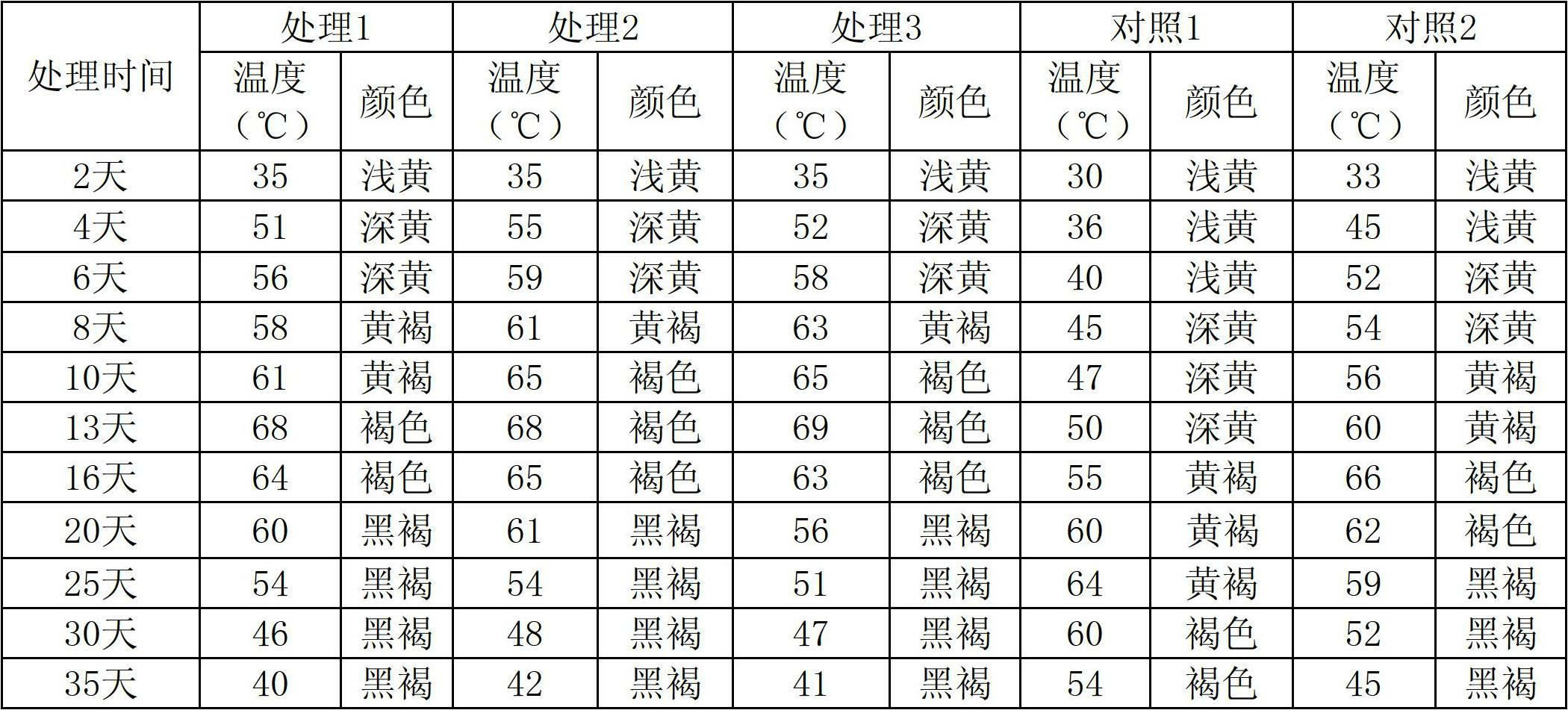

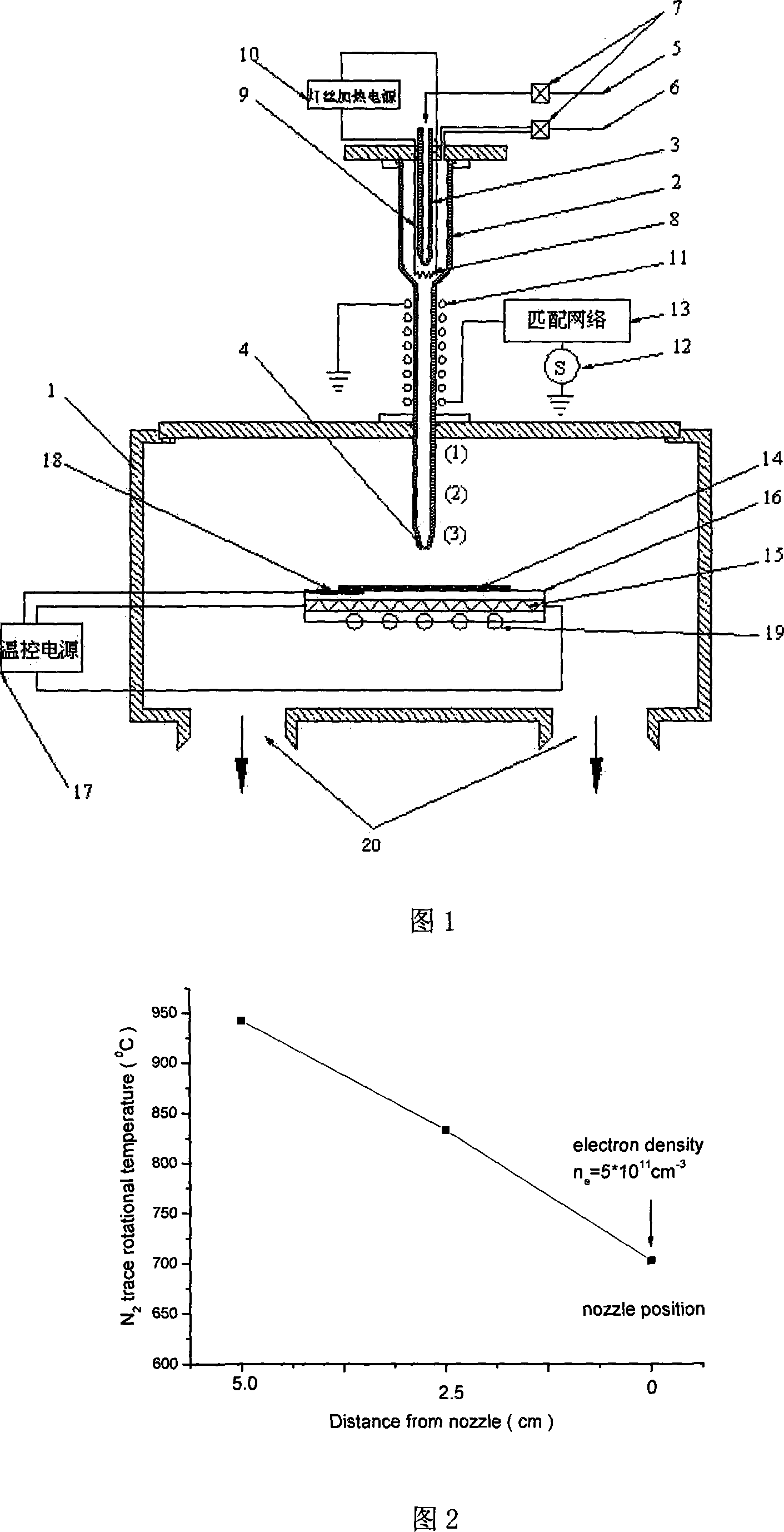

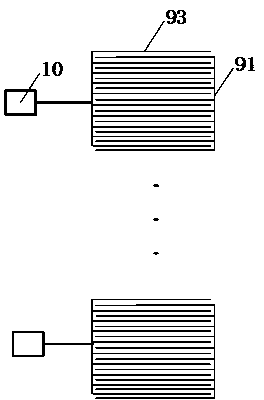

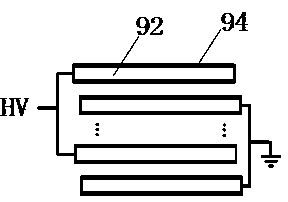

Method and apparatus for gas treatment using non-equilibrium plasma

InactiveUS20050118079A1Low costImprove decomposition efficiencyGas treatmentInternal combustion piston enginesDecompositionCompound (substance)

A gas treatment method is actualized by arranging a plurality of photocatalyst members each including photocatalyst, solid substance, and catalyst in a region of non-equilibrium plasma, which is produced using a surface discharge electrode and into which a treated gas such as an exhaust gas and a harmful gas including harmful chemical substances is introduced and is then subjected to decomposition. The surface discharge electrode comprises a ground electrode, an insulator encompassing the ground electrode, and a plurality of surface electrodes that are arranged relative to the ground electrode via the insulator, by which the non-equilibrium plasma is produced upon electrification. A gas treatment apparatus is constituted by arranging a plurality of surface discharge electrodes, each having a plurality of through holes penetrating in a thickness direction, between which a plurality of photocatalyst members are arranged.

Owner:YAMAHA CORP

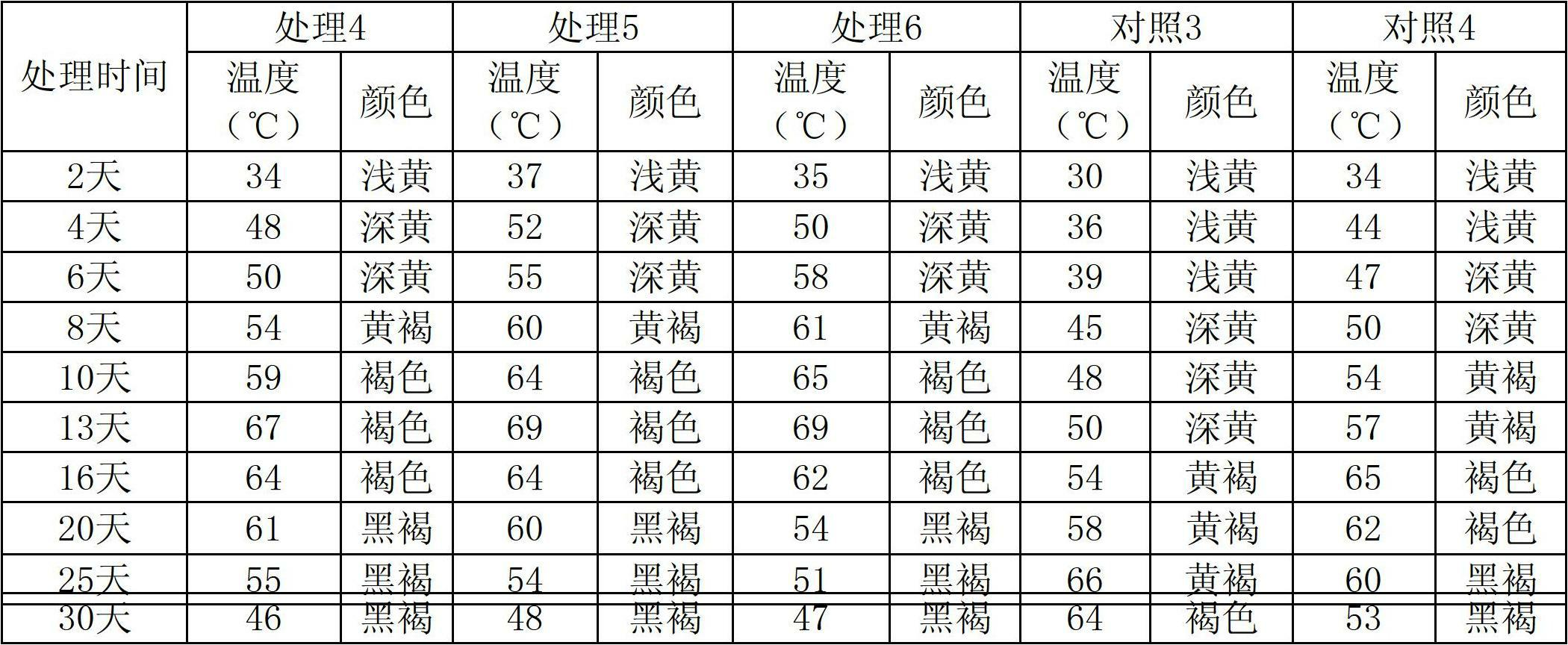

Rapid decomposition method for returning summer maize straws

InactiveCN102020512ANeat emergenceIncrease productionBio-organic fraction processingOrganic fertiliser preparationDecompositionUrea

The invention discloses a rapid decomposition method for returning summer maize straws, which is used for solving the problem of decomposition of the maize straws. The method comprises the following steps of: crushing the maize straws in the fields, and totally and directly returning the crushed maize straws; after the crushed maize straws are returned, broadcasting materials, such as a decomposition agent, accessory ingredients and the like, in a way that 2 to 2.5 kilograms of decomposition agent, 3 to 5 kilograms of accessory ingredients, 0.5 to 1 kilogram of water-retaining agent and 6 to 8 kilograms of urea are broadcast into each acre of land; and timely performing ploughing or rotary tillage and sowing winter wheat after a week. The method has the main advantages that: 1, the summermaize straws are mechanically crushed in situ and then totally and directly returned and utilized, so the problems of difficulties in the collection, transportation and storage of the maize straws are solved; 2, the maize straws are rapidly decomposed, so the straw decomposition rate is increased, soil nutrients are returned, soil conditions are improved, simultaneously seedlings of the followingwinter wheat come out uniformly and the rate of emergence is greatly increased; and 3, farming in the fields is easy to operate and execute, and the method is delightedly accepted by farmers and is convenient to execute.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Compound microbial bacterial preparation for degrading crop straw and preparation method and application of compound microbial bacterial preparation

ActiveCN102690755ASolve shipping problemsSolve storage difficultiesBio-organic fraction processingFungiMetabolitePhosphate

The invention relates to a compound microbial bacterial preparation for degrading crop straw and a preparation method and application of the compound microbial bacterial preparation. The compound microbial bacterial preparation is prepared from bacillus subtilis, bacillus cereus, aspergillus niger, aspergillus flavus, trichoderma reesei, trichoderma longibrachiatum, sporotrichum thermophile and phanerochaete chrysosporium through solid fermentation. The compound microbial bacterial preparation can shorten the decomposition time and improve the decomposition efficiency of the crop straw. Microorganisms generate various effective metabolic products with nitrogen fixation and phosphate solubilizing functions and a high disease and pest resistance effect in the fermentation process, so that the compound microbial bacterial preparation is favorable for improving the soil structure and the yield and the quality of crops.

Owner:DEZHOU YUANHE AGRI TECH DEVCO

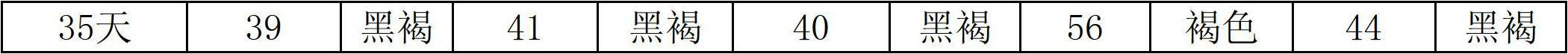

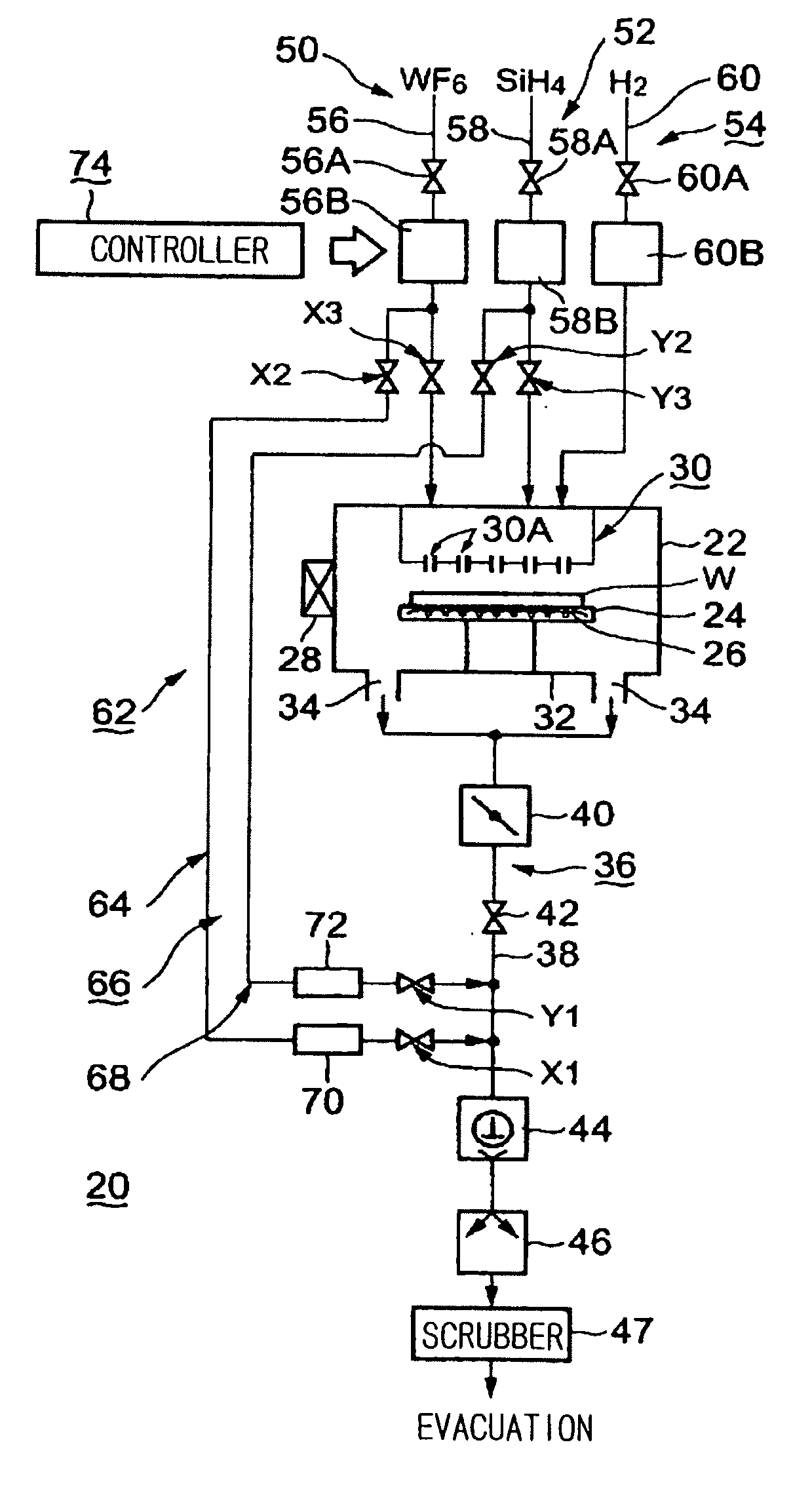

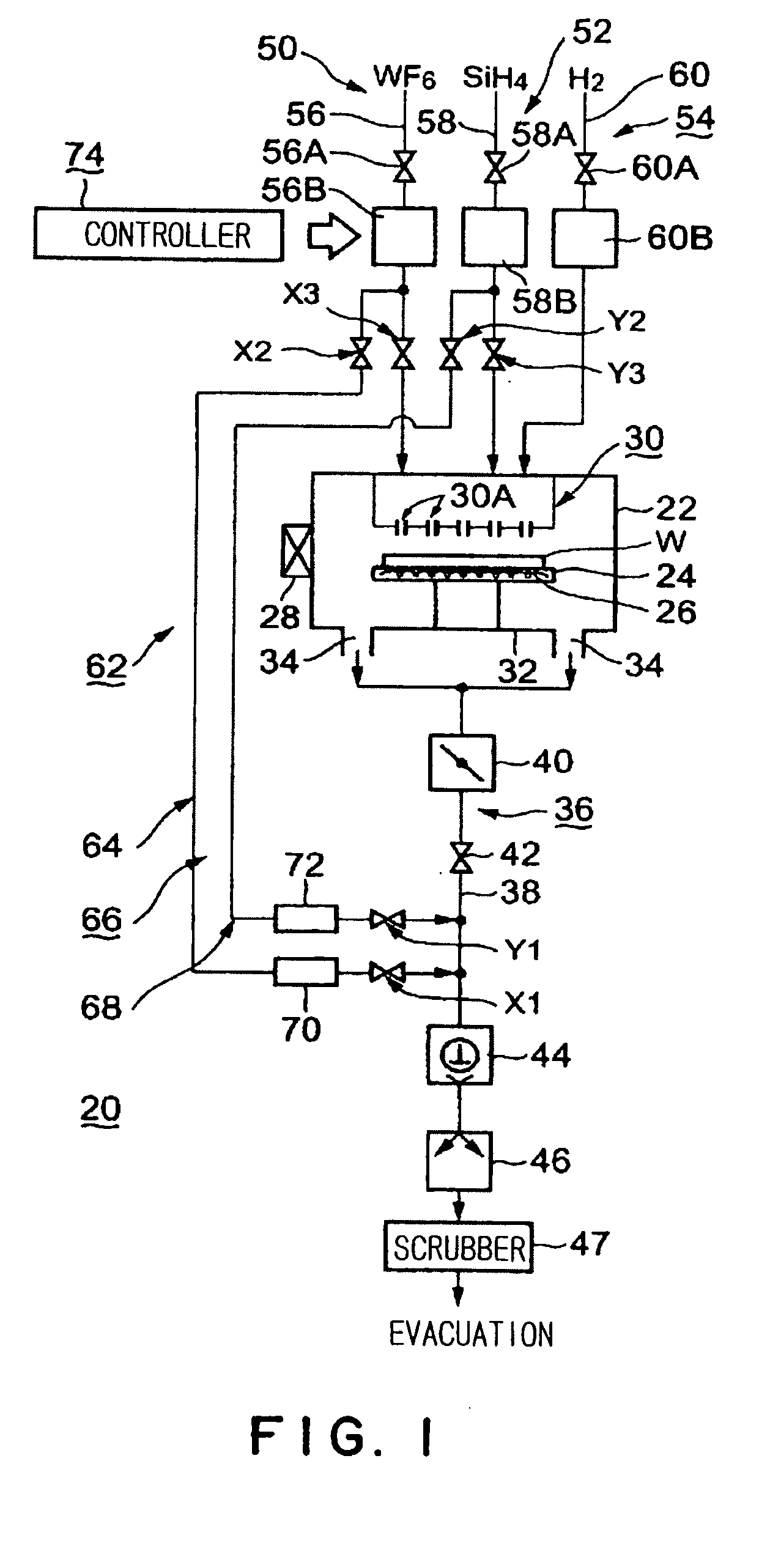

Processing apparatus using source gas and reactive gas

InactiveUS20090211526A1Efficient solutionAvoid failureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasProduct gas

The present invention relates to a processing apparatus for performing a film-deposition process or the like for an object to be processed (such as a semiconductor wafer) by means of a source gas and a reactive gas. The processing apparatus includes: a processing vessel (22) that contains therein an object to be processed (W); a source gas supply system (50) that selectively supplies a source gas into the processing vessel; a reactive gas supply system (52) that selectively supplies a reactive gas into the processing vessel; and a vacuum evacuating system (36) having vacuum pumps (44, 46), the system exhausting an atmosphere in the processing vessel to form a vacuum. The processing apparatus further includes: a source gas by-pass line (62) that selectively feeds the source gas into the vacuum evacuating system with the source gas bypassing the processing vessel; and a reactive gas by-pass line that selectively feeds the reactive gas to the vacuum evacuating system with the reactive gas bypassing the processing vessel. The source gas by-pass line (62) has a source gas escape prevention valve (X1) that prevents an escape of the source gas from the by-pass line into the vacuum evacuating system when the valve is in the closed condition. The reactive gas by-pass line (66) has a reactive gas escape prevention valve (Y1) that prevents an escape of the reactive gas from the by-pass line into the vacuum evacuating system when the valve is in the closed condition.

Owner:TOKYO ELECTRON LTD

Ozone decomposition catalyst and method of producing the same

ActiveCN101402047AHigh ozone decomposition efficiencyImprove decomposition efficiencyMetal/metal-oxides/metal-hydroxide catalystsActivated carbonDecomposition

The invention relates to a catalyst for ozone decomposition and a method for preparing the same. The catalyst uses activated carbon particles or activated carbon fiber as a carrier, and uses manganese, nickel, silver, and cerium as active components of the catalyst. The method for preparing the catalyst comprises the following steps: A. mixing the same volume of a manganese nitrate solution, a nickel nitrate solution, a silver nitrate solution and a cerium nitrate solution to prepare an active component solution; B. selecting the activated carbon particles or the activated carbon fiber as the catalyst carrier, immersing the carrier in the prepared active component solution, and then taking out the carrier for washing and drying; C. taking out the carrier and immersing the carrier in a sodium carbonate solution; and D. taking out the carrier for washing, drying, and baking to obtain a finished product of the catalyst. The method for preparing the catalyst has the advantages of simple process, high ozone decomposition efficiency, low cost, stable performance, long service life, and wide application prospect.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

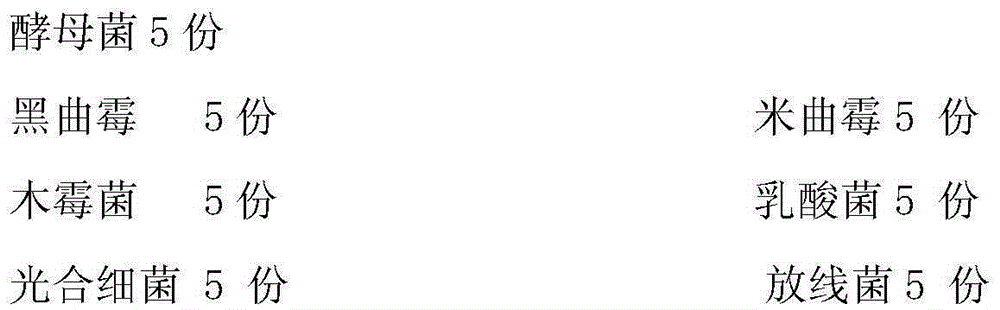

Microbial decomposition agent for animal wastes and straws and preparation method thereof

InactiveCN105296394AFunction increaseHigh content of functional bacteriaFungiBacteriaDecompositionTrichoderma sp.

The invention discloses a microbial decomposition agent for animal wastes and straws and a preparation method thereof. The microbial decomposition agent comprises the following strains in parts by weight: bacillus, saccharomycetes, Aspergillus niger, Aspergillus oryzae, trichoderma sp, lactic acid bacteria, photosynthetic bacteria and actinomycetes. The decomposition agent has diversified functions, can be simultaneously used for composting straws and / or animal wastes, contains multiple functional bacteria and is high in microbe activity, the selected strains achieve a synergistic effect, do not generate antagonism, and the decomposition agent has the advantages of fast temperature rise and high temperature of fermented materials, complete decomposition, short decomposition time and the like. The preparation method of the microbial decomposition agent disclosed by the invention has the advantages of simplicity, feasibility, simple operation and low production cost.

Owner:广西多得乐生物科技有限公司

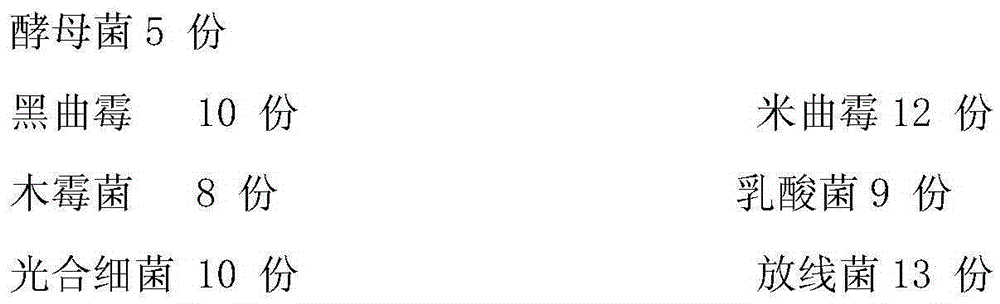

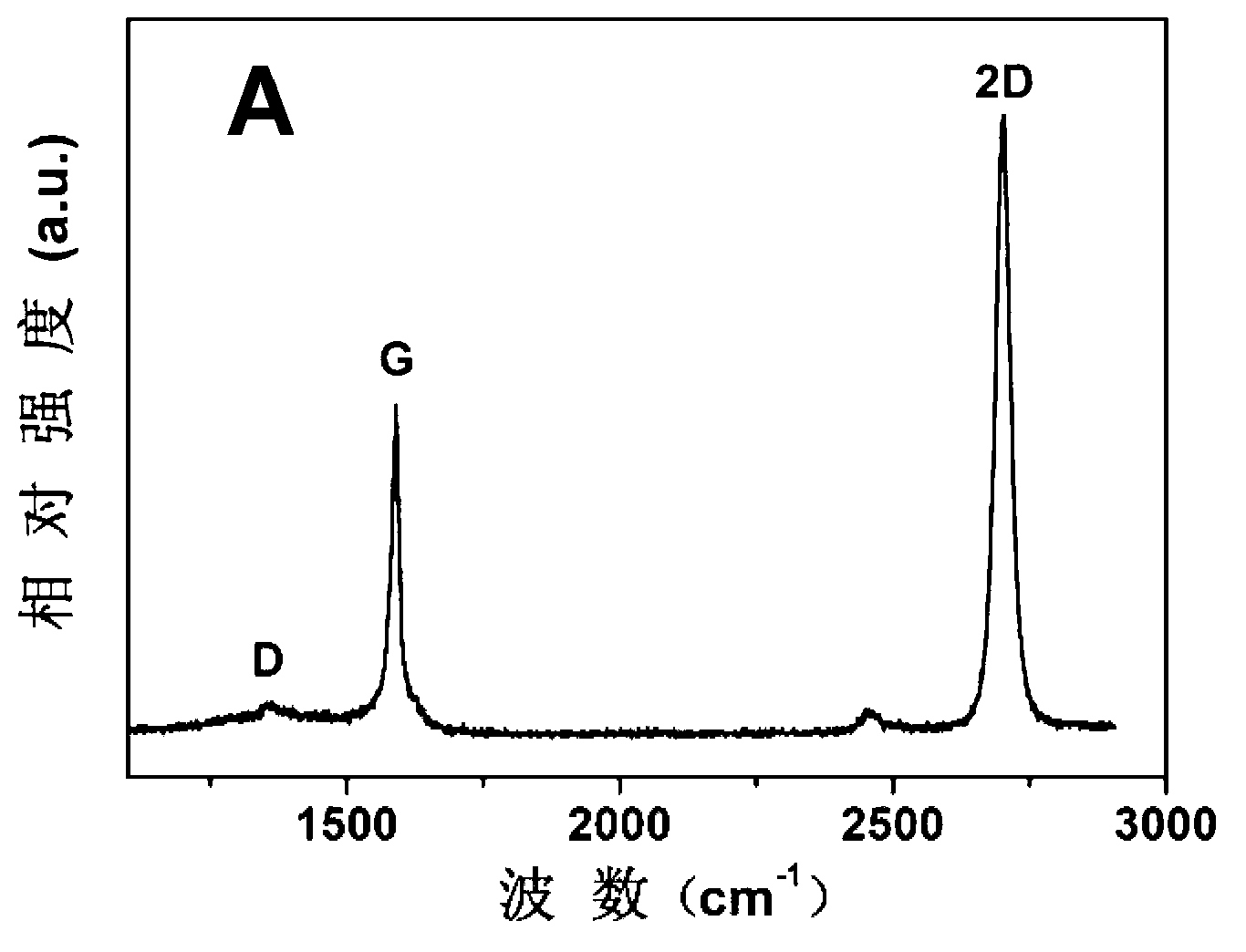

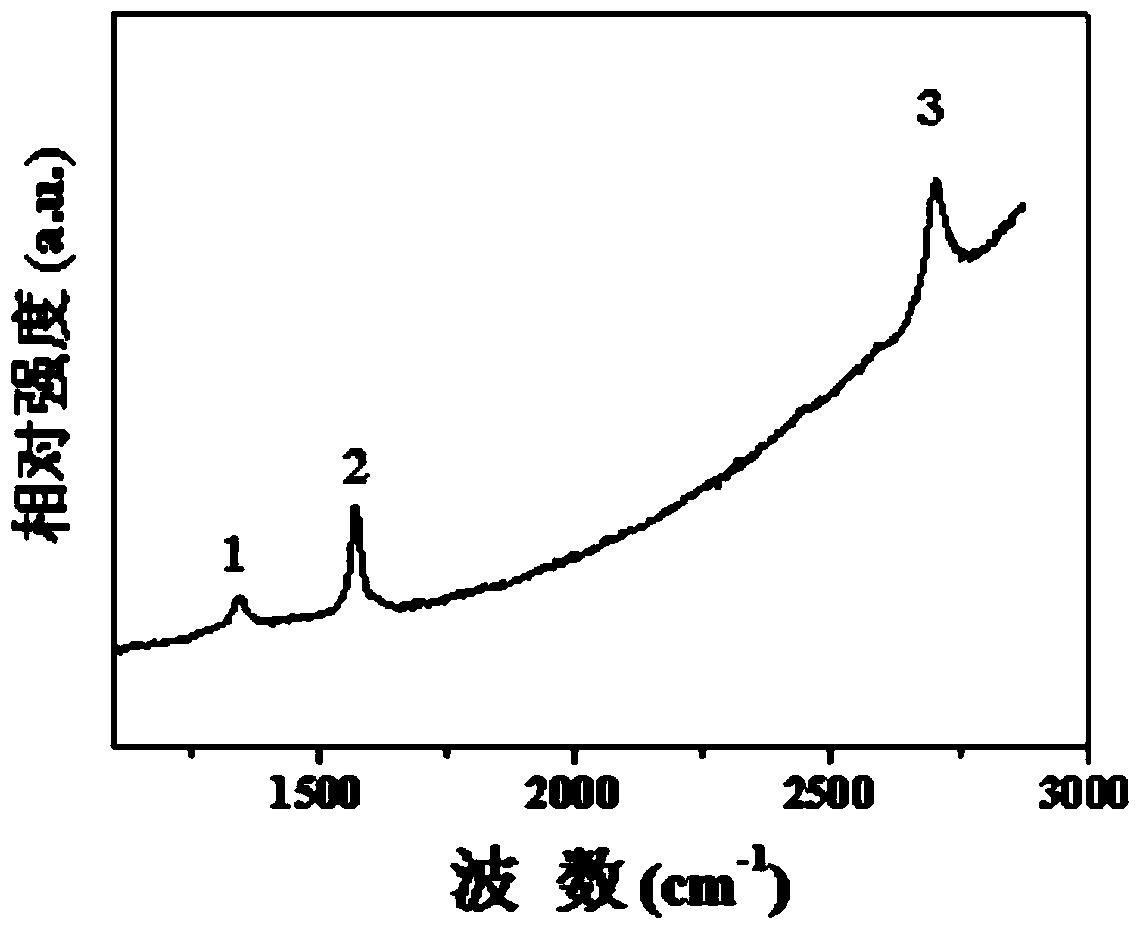

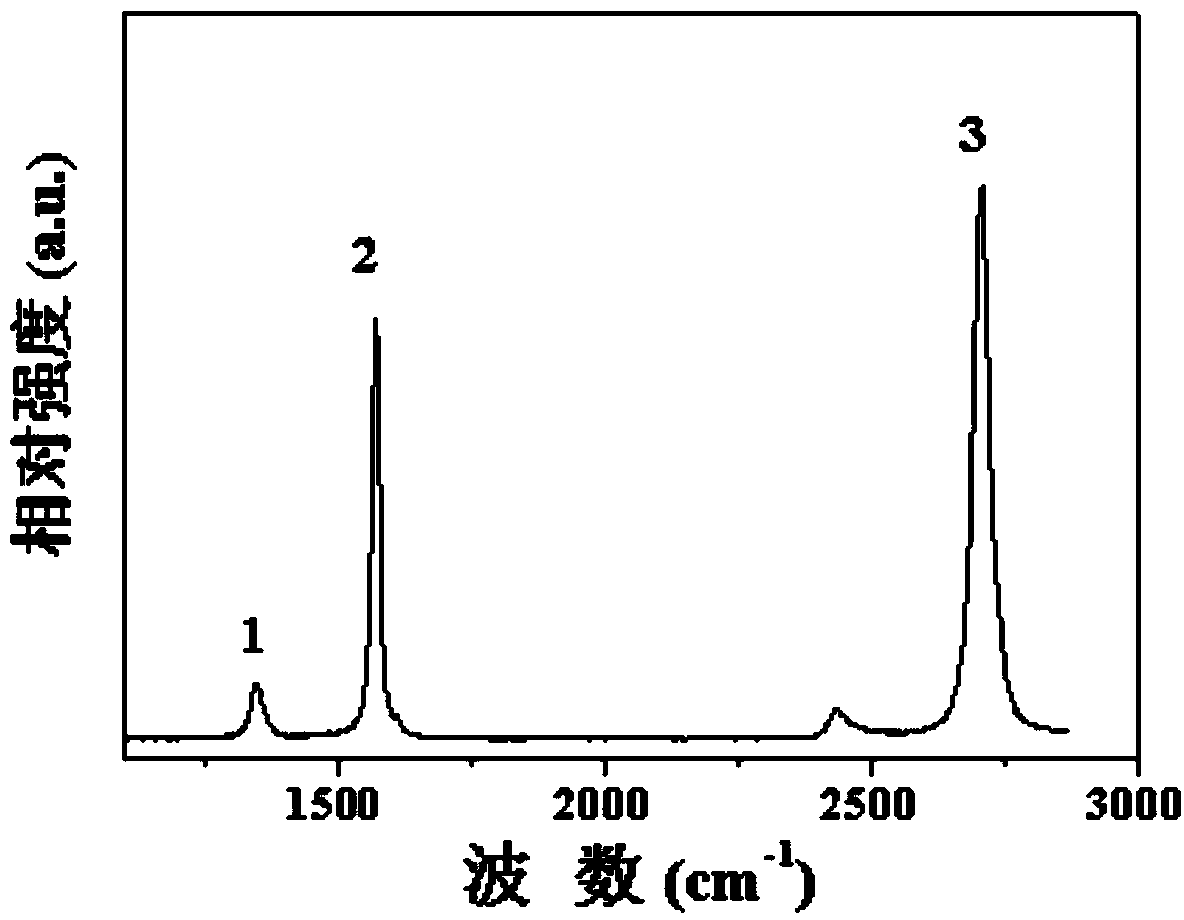

Method for low-temperature and efficient preparation of large-size graphene

ActiveCN103183344AAvoid pyrolysisImprove decomposition efficiencyGrapheneShielding gasRoom temperature

The invention discloses a method for low-temperature and efficient preparation of large-size graphene, and relates to a method for preparing graphene, in order to solve the problems of conventional chemical vapor deposition (VDC) graphene preparation method which is high in preparation temperature, low in preparation duration and comparatively high in cost. The method comprises the following steps of: I, placing a metal substrate in plasmid enhanced chemical vapor deposition equipment, vacuumizing and filling H2, increasing temperature, preserving heat and implementing an annealing treatment; II, further filling Ar and CH4 gases, and depositing; and III, after depositing, turning off a radio frequency power supply and a heating power supply, stopping filling the CH4 gas, taking Ar and H2 as protective gases, and rapidly cooling to room temperature at 10 DEG C / s until graphene uniformly grows from the surface of the metal substrate, to finish. The method disclosed by the invention can finish growth of the graphene within a quite short duration, and can realize low-temperature and efficient preparation of the graphene material; and the method is simple, efficient, low in cost and convenient for industrial production, and the prepared graphene is large in size, high in quality and uniform in surface.

Owner:HARBIN INST OF TECH

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

Method for efficiently preparing graphene-reinforcing copper-based composite brazing filler metal at low temperature

ActiveCN103817466AImprove decomposition efficiencyLow preparation temperatureWelding/cutting media/materialsChemical vapor deposition coatingCvd grapheneCarbon source

Owner:HARBIN INST OF TECH

Alcohol-alleviating anti-fatigue beverage

The invention discloses an alcohol-alleviating anti-fatigue beverage, which is prepared by the following raw materials: 0.1-0.7% of corn oligopeptide, 0.1-0.9% of Hyriopsis cumingii polysaccharide, 0.02-0.3% of Maca powder, 0.05-1.2% of Paullinia cupana extractive, 0.01-0.04% of kudzu vine root, 0.1-0.3% of Turnjujube, 0.1-0.5% of liquorice, 0.01-1.0% of chrysanthemum, 0.02-1.0% of medlar, 0.04-0.06% of taurine, 3.0-6.0% of fructose and / or 3.0-6.0% of honey, 0.1-1.0% of isomaltitol and the balance of water. The beverage is used for alleviating alcohol and obviously improving the alcohol decomposition efficiency, can rapidly reduce the alcohol concentration in blood and has protection effects on livers and stomachs; and the beverage is good for eliminating uncomfortable drunkenness symptoms and has the advantages of anti-fatigue performance, capability of rapidly replenishing energy, refection and the like.

Owner:爱衡(上海)生物科技有限公司

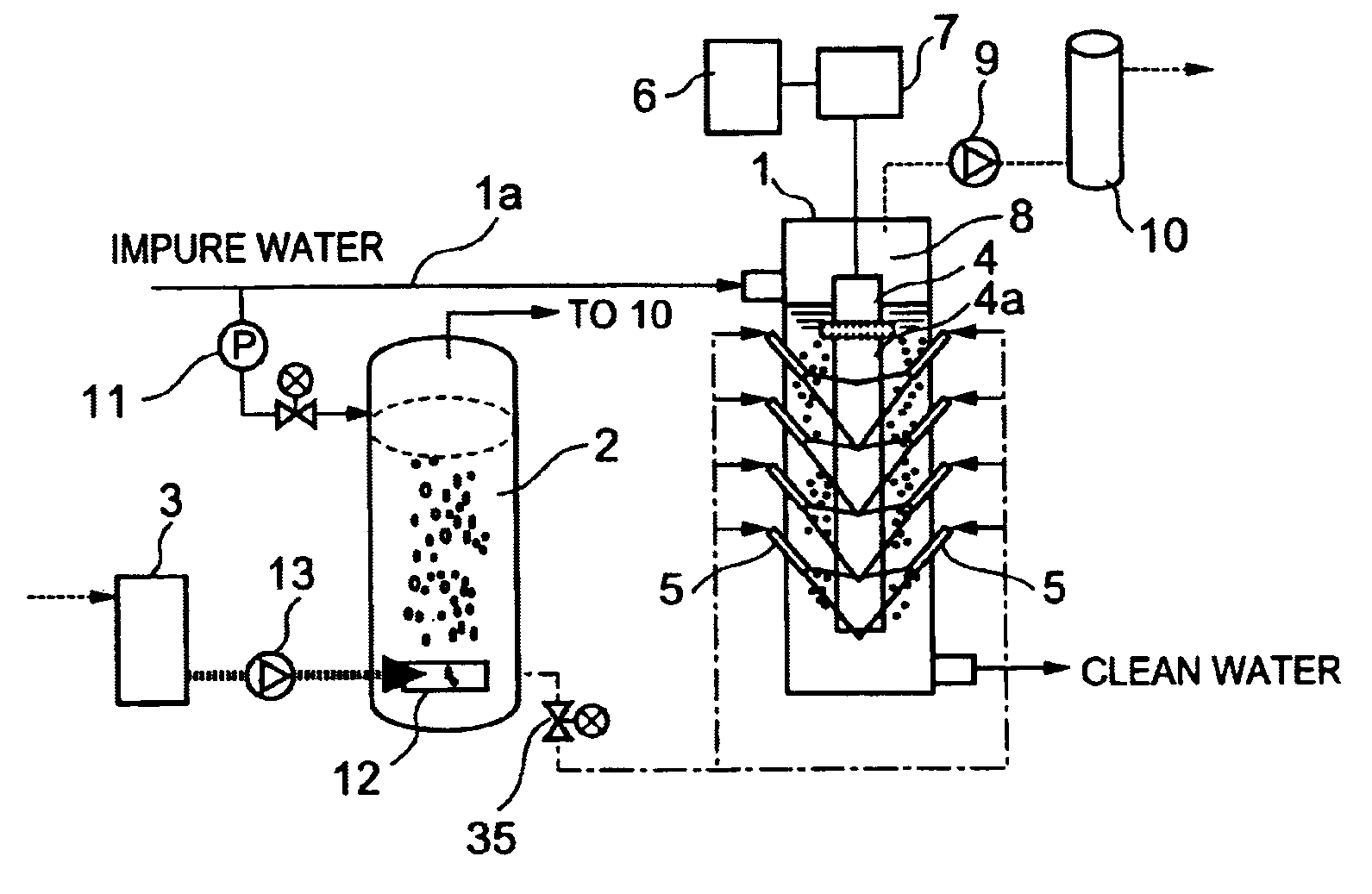

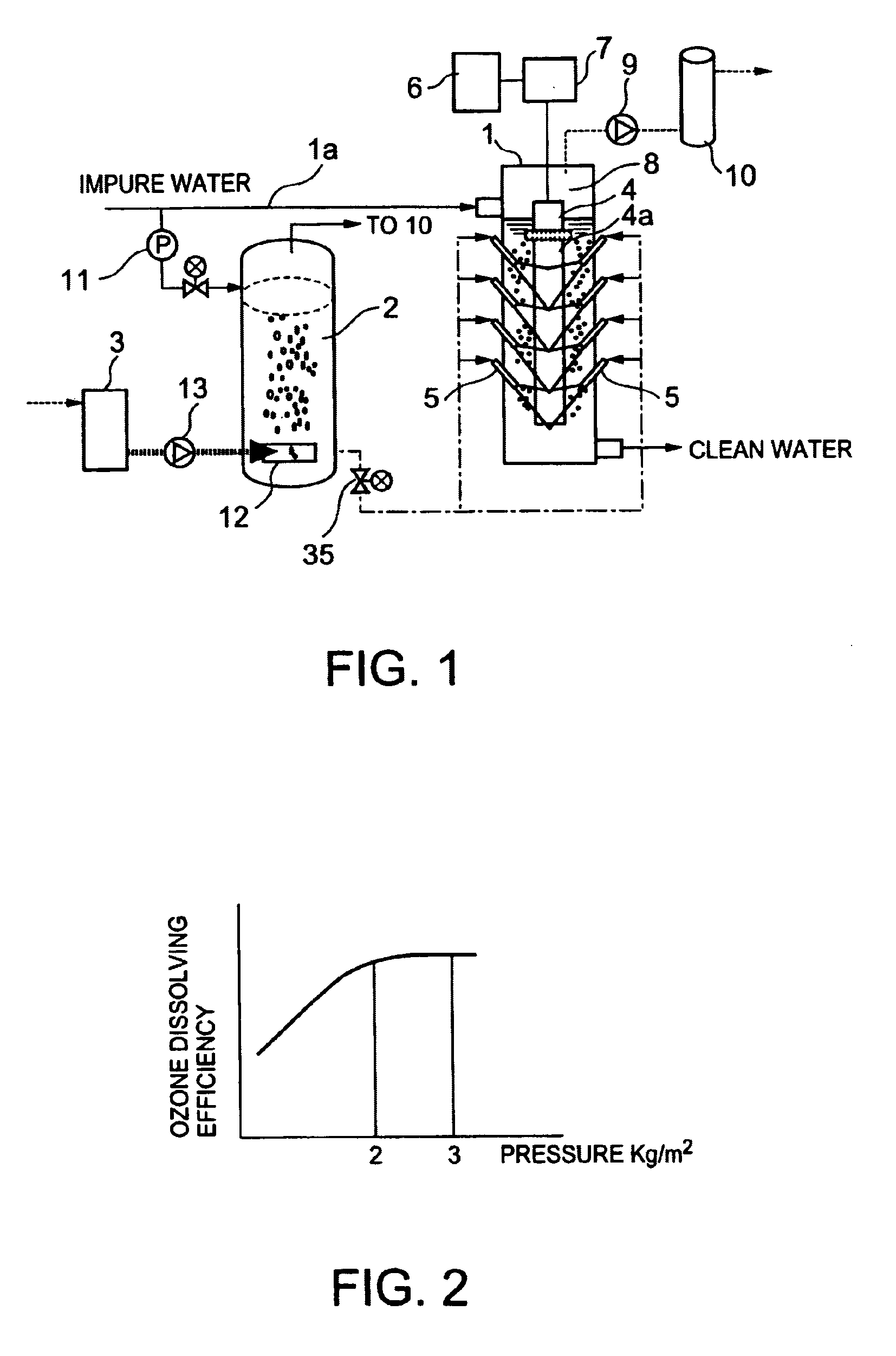

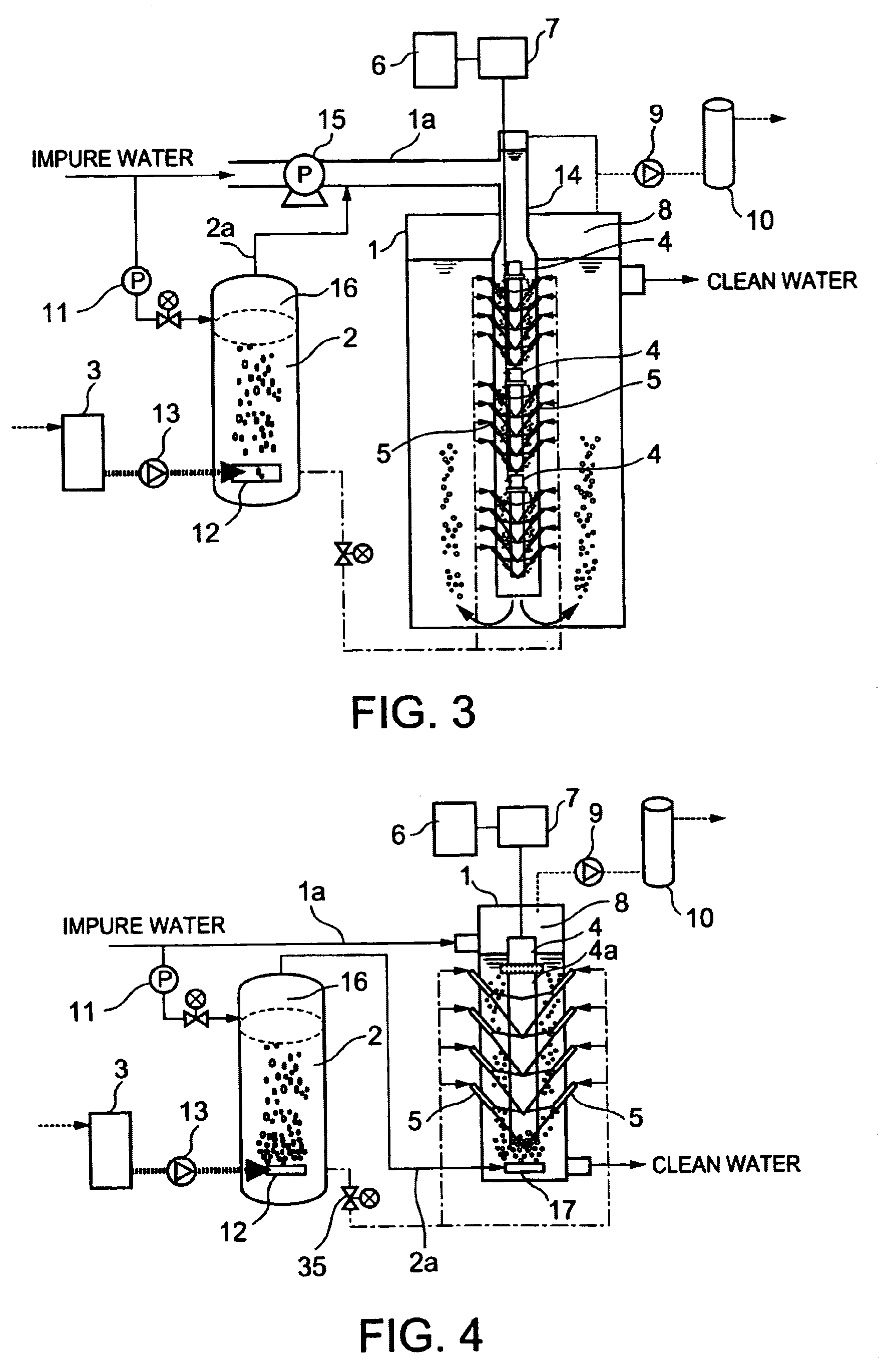

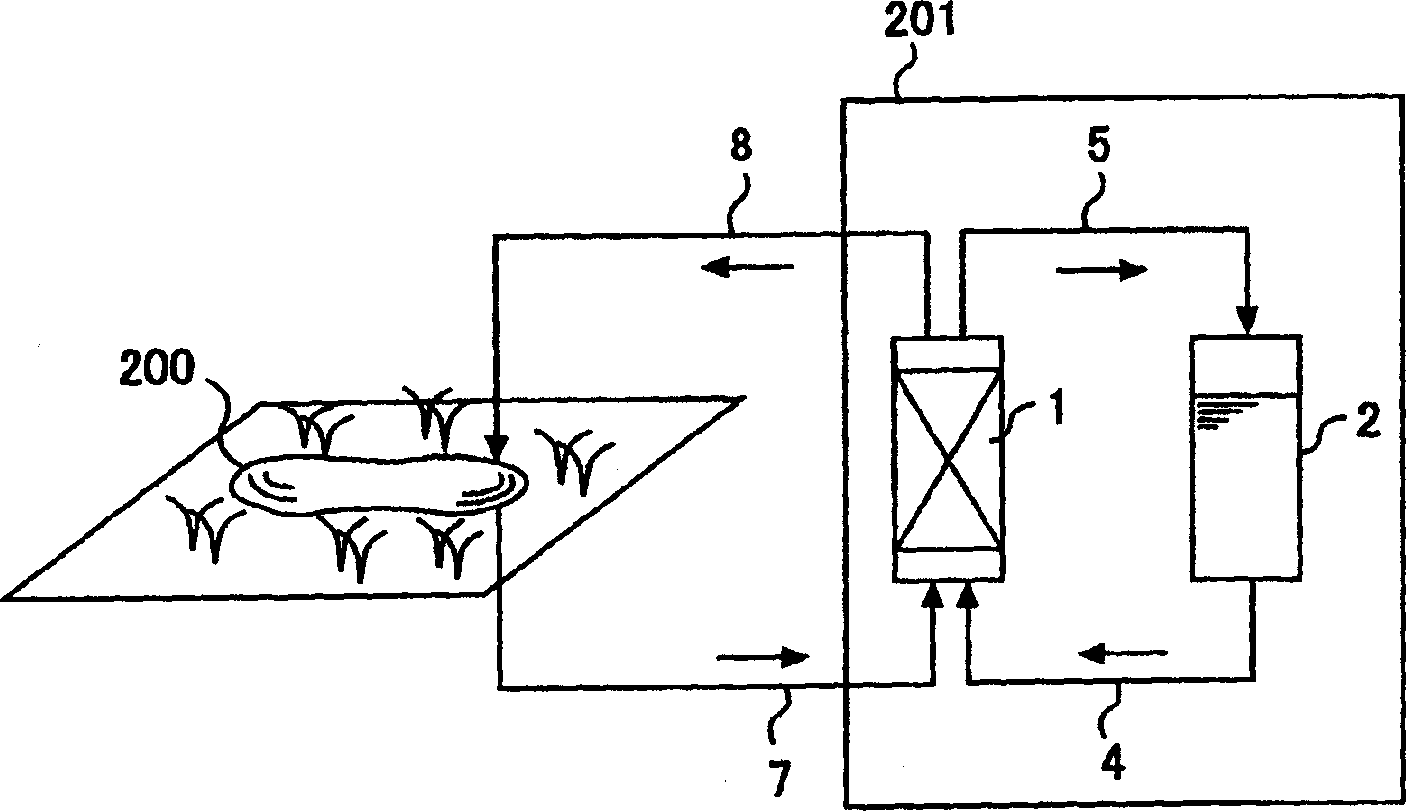

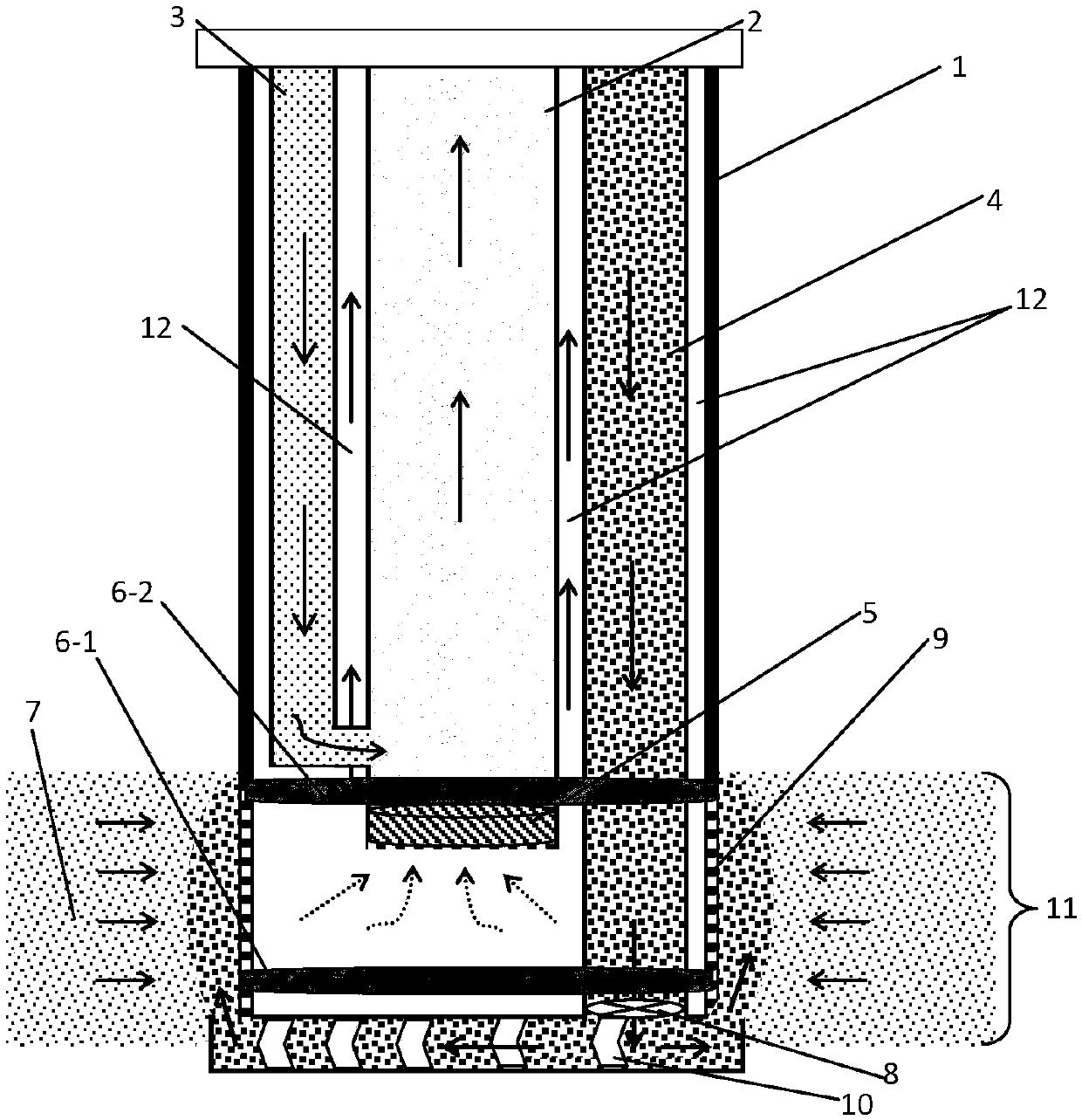

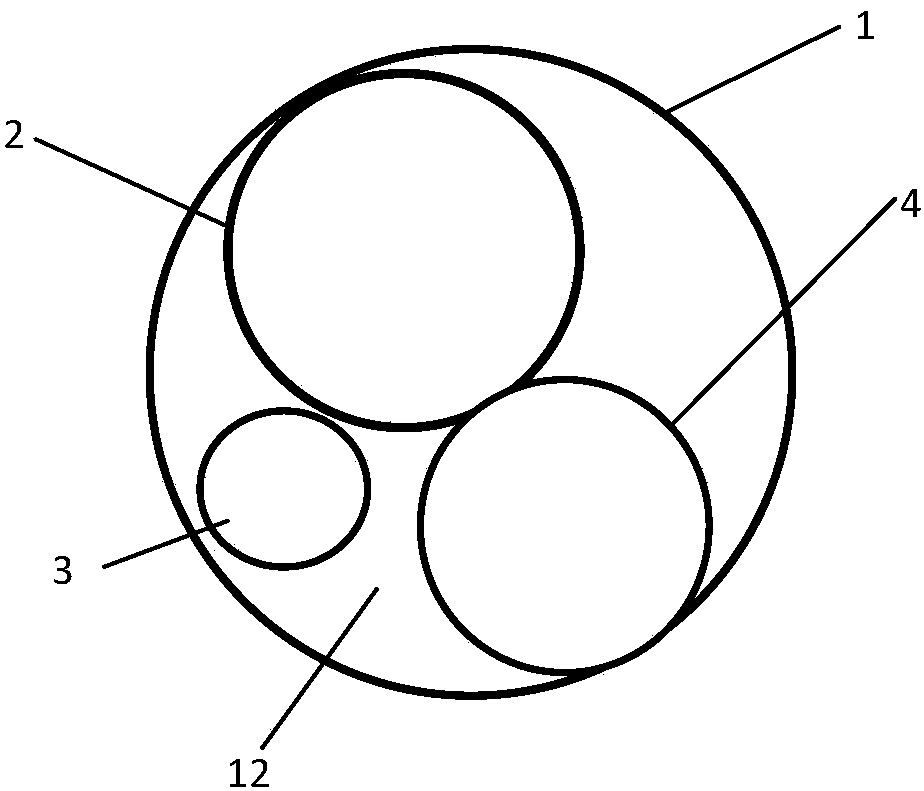

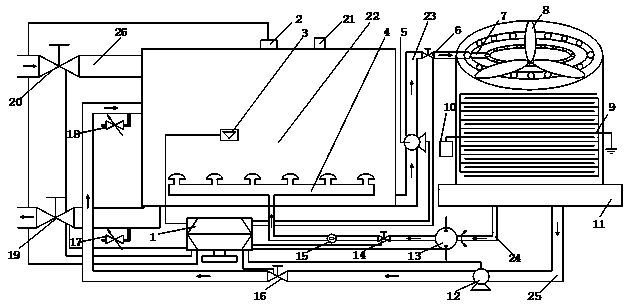

UV-assisted advanced-ozonation water treatment system and advanced-ozonation module

InactiveUS6921476B2Reduce maintenanceImprove decomposition efficiencyWater treatment parameter controlWater/sewage treatment by irradiationWater treatment systemHandling system

A UV-assisted advanced-ozonation water treatment system comprises a water treating tank 1, an ozonic water tank 2, an ozonized gas generator 3, and a UV light source 4 disposed in the water treating tank 1 and having a UV-radiating surface 4a, and an ozonic water jetting device including jetting nozzles 5 for jetting the ozonic water onto the UV-radiating surface of the UV light source. An ozonized gas diffusing device 12 is placed in the ozonic water tank 2. An ozonized gas generated by the ozonized gas generator 3 and compressed by a compressor 13 at a pressure in the range of about 2 to about 3 kg / cm2 is diffused into the ozonic water tank 2 by the ozonized gas diffusing device 12. A high-pressure, a high-ozone-concentration ozonic water produced in the ozonized water tank 2 is jetted through the jetting nozzles 5 onto the UV-radiating surface 4a.

Owner:KK TOSHIBA

Microorganism composite fungus agent for promoting agricultural waste quickly rotten and its making method

InactiveCN1493683AImprove decomposition efficiencyIncrease contentImmobilised enzymesBio-organic fraction processingBiotechnologyYeast

A composite bacteria preparation for quickly putrefying agricultural waste is composed of living bacteria (bacillus, actinomycess, yeast and fungus) and adsorptive carrier (zeolite, bran, bone powder, fish powder and brown sugar). Its advantages are high putrefying efficiency, low cost, less loss of nutrients and improving soil.

Owner:李鸣雷

Method for decomposing thermosetting epoxy resin or composite material thereof by high-temperature water phase

InactiveCN101519505AHigh catalytic activityNo pollution in the processPlastic recyclingEpoxySingle substance

The invention relates to a method for decomposing a thermosetting epoxy resin or a composite material thereof by high-temperature water phases, which belongs to the technical field of regenerative utilization of waste resin materials or treatment of industrial wastes. The method is characterized by comprising the following steps: putting certain amount of thermosetting epoxy resin sheets or granules, and deionization and catalyst heteropolyacid into a high-temperature high-pressure stainless steel reaction kettle; heating the reaction kettle to raise the temperature to a temperature of 250 and 370 DEG C for 30 to 120 hours; and decomposing the water diversion phase so that the decomposed product becomes an oligomer or a single substance which cannot be dissolved in liquid phase and is easy to separate. The method mainly adopts heteropoly acid, phosphotungstic acid, tungstosilicic acid, or molybdenum phosphoric acid as a catalyst, the addition of the catalyst is 0.1 to 3.0 percent of that of deionized water, and a higher decomposition rate of the epoxy resin can be obtained finally. The method does not need to use an organic solvent as a decomposing liquid, but uses water as the decomposing liquid, thus the method has low cost and is pollution-free to the environment; and the method can achieve the aims of waste regeneration and utilization as well as environmental protection.

Owner:SHANGHAI UNIV

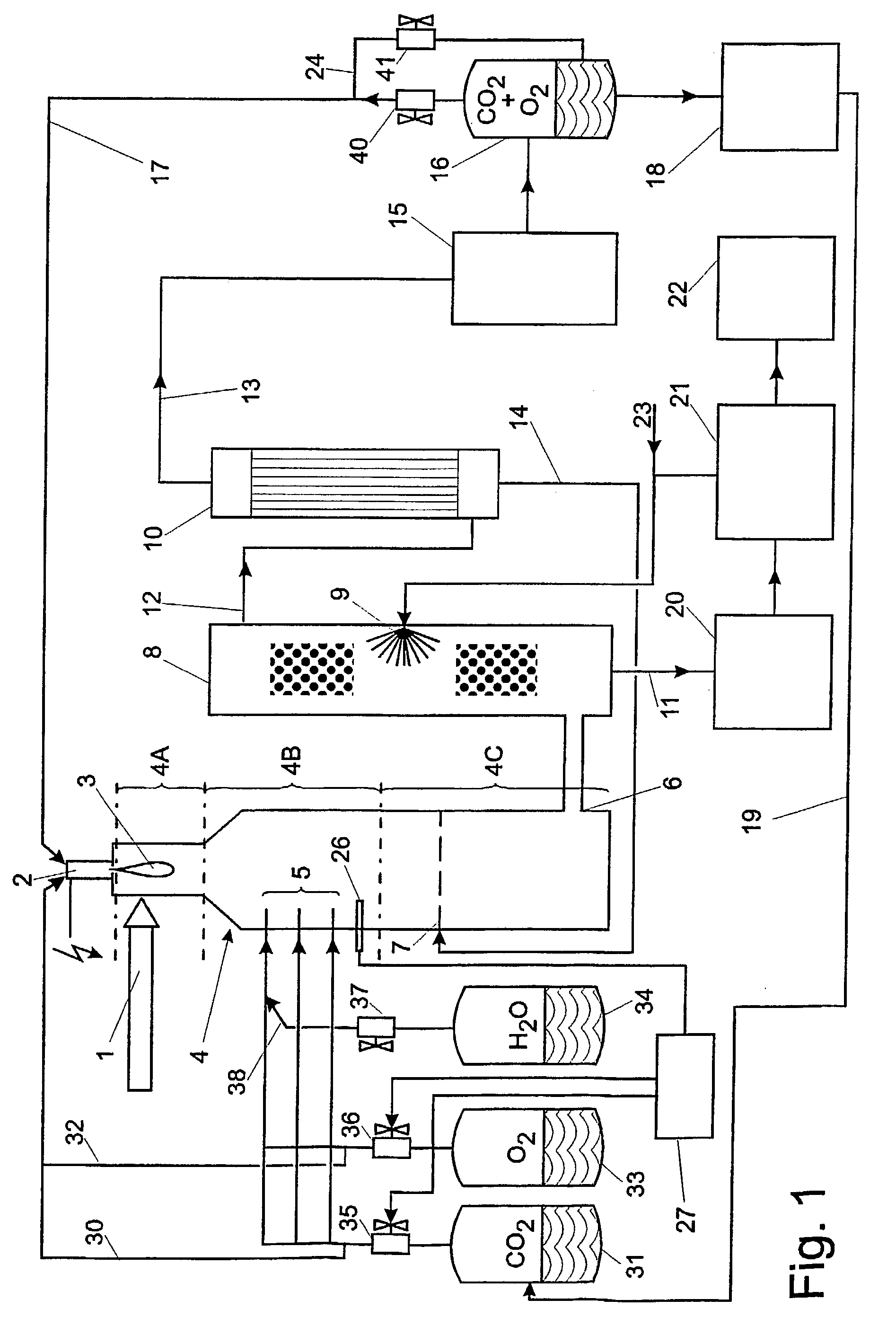

Method for treatment of hazardous fluid organic waste materials

InactiveUS20030171635A1Atomization fastImprove decomposition efficiencyDispersed particle separationOrganic decompositionPlasma torchWater content

Method for treatment of fluid hazardous, organic waste materials, where a plasma of 2000-5000° C. temperature is generated by means of an electric arc in a plasma generator, the plasma torch is directed into a reactor, the reactor consists of three zones (4A, 4B, 4C), the plasma torch being introduced downwards into the uppermost first zone (4A), the fluid waste (1) being sprayed into the plasma torch in the first zone (4A), where it is heated to a temperature range of 1300-1600° C., the mixture of the plasma and the waste is introduced into the second zone (4B) of the reactor, where an oxidizing material is added (5) to the mixture, the combustion gas produced in the second zone (4B) is then led into the third zone (4C) of the reactor, where it is cooled rapidly by water spraying to a temperature range of 120-160° C., the cooled combustion gas is removed from the third zone (4C) of the reactor is led into a cooler. The plasma torch is generated from the mixture of carbon dioxide and oxygen, the oxidizing material introduced into the second zone (4B) of the reactor is a mixture of carbon dioxide and oxygen. Subsequently the water content of the combustion gas is separated by condensing and is removed and the residual combustion gas is removed.

Owner:BERECZKY TAMAS +4

Water-phase decomposition method for thermosetting epoxy resin or composite material thereof

The present invention is process of decomposing thermosetting epoxy resin and other composite material. The decomposing process includes the following steps: 1. feeding thermosetting epoxy resin or other composite material and water into reaction kettle; and 2. heating to compose the thermosetting epoxy resin or other composite material. The process has thermosetting epoxy resin or other composite material decomposing rate of 52-100 %, and the decomposed product may be reused as chemical material. After composite material is decomposed, the reinforcing fiber as the precipitate may be cleaned and stoved for reuse. The technological process of the present invention is simple, low in cost, high in composing rate, low in power consumption and environment friendly.

Owner:HARBIN INST OF TECH

Device for rapid large-area preparation of thin film material and setting method

InactiveCN101158034AReduce defectsAvoid damageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh rateEngineering

The invention relates to a thin film material preparation device. The invention seals two to four spray pipes which are used for admitting feed gas and fixed on an admitting sediment cavity. The admitting sediment cavity is arranged on a vacuum sediment cavity. The reacting gas or shipping gas is admitted into the spray pipes through air source. A heating wire is arranged around a spout exit of the spray pipes. An inductance coil driven by power supply is provided on an outer wall of the spray pipes. The inductance coil can generate a plasma body. A through sole platform for growing film is provided in the sediment cavity. A rarefying exit pipe is arranged at the lower part or the lower side part of the sediment cavity. The thin film material preparation device of the invention has the advantages of high film forming quality, high rate of sedimentation, low growing temperature and high gas efficiency and so on.

Owner:NANJING UNIV +1

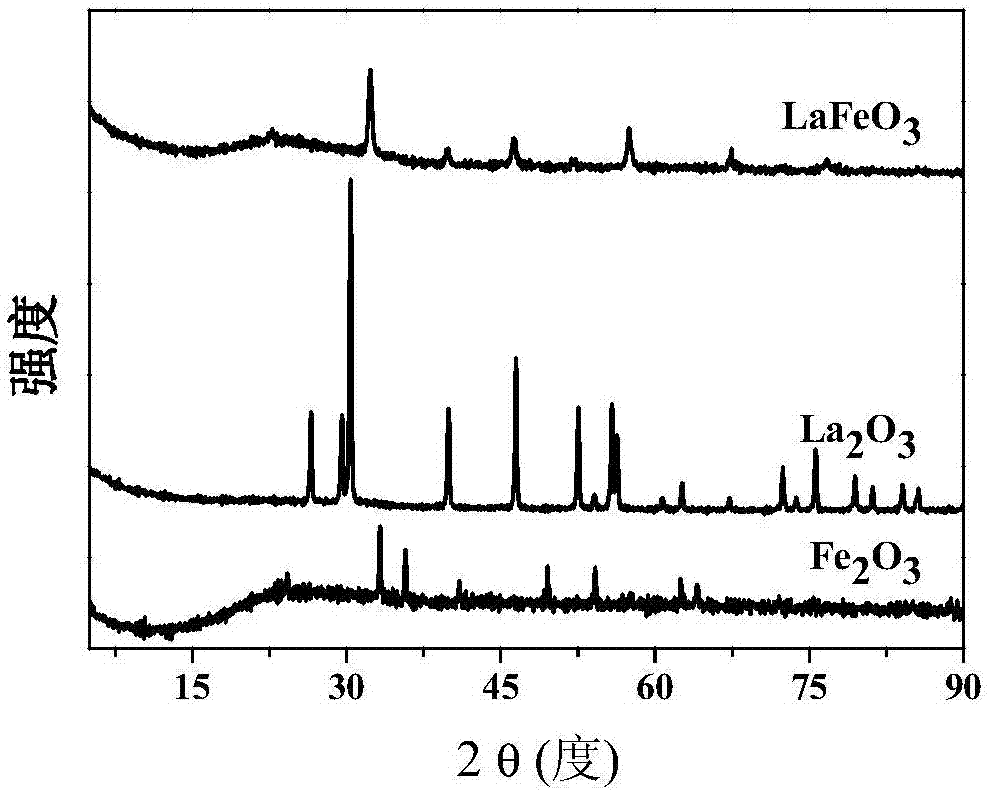

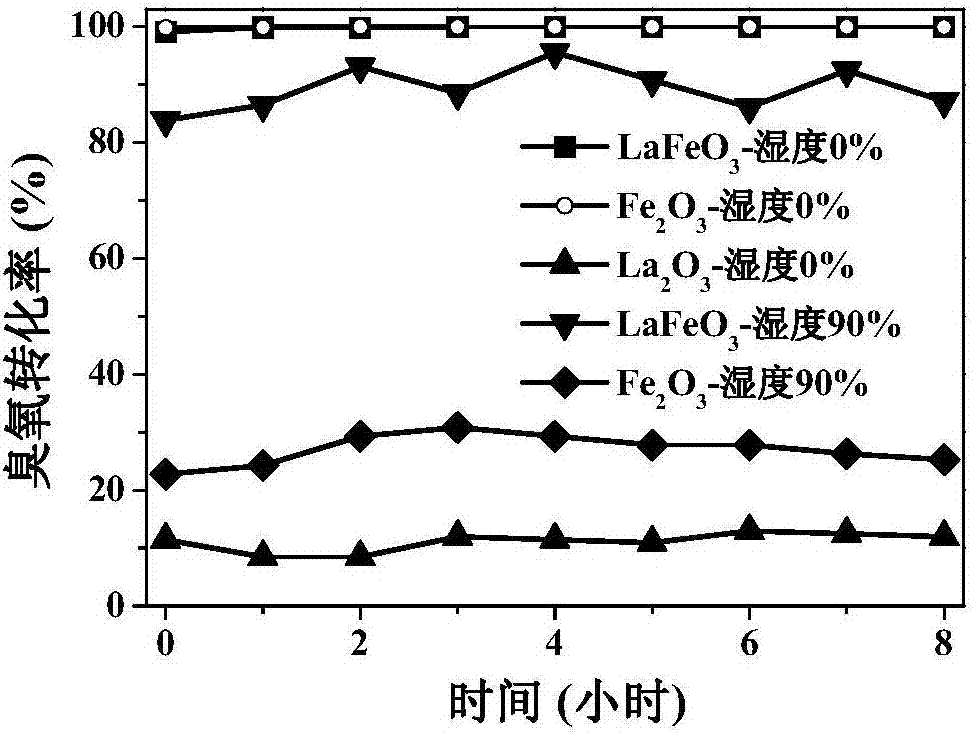

Perovskite ozone decomposition catalyst and preparation method and application thereof

ActiveCN107376926AImprove decomposition efficiencyExcellent catalytic decomposition activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic decompositionStructural formula

The invention relates to a perovskite ozone decomposition catalyst. The active component of the catalyst is pure-phase or transition metal-doped perovskite lanthanum ferrite, wherein the structural formula of the active component of the catalyst is LaMxFe(1-x)O3, wherein M is a transition metal and x is smaller than or equal to 0.2 and greater than or equal to 0. Ferric nitrate, lanthanum nitrate, nitrate of optional transition metal and citric acid ae taken as raw materials, the perovskite ozone decomposition catalyst is synthesized by adopting sol-gel auto-combustion method, and a catalyst with a perovskite crystal phase is obtained through grinding, burning and loading; and the grain size of the obtained catalyst is 10-100nm and the specific surface area is 5-50m<2> / g. The catalyst has excellent catalytic performance on ozone at a room temperature, especially has good humidity resistance, can be applied to catalytic decomposition of the ozone in a high-humidity environment, is simple in preparation technology and mild in condition, and has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

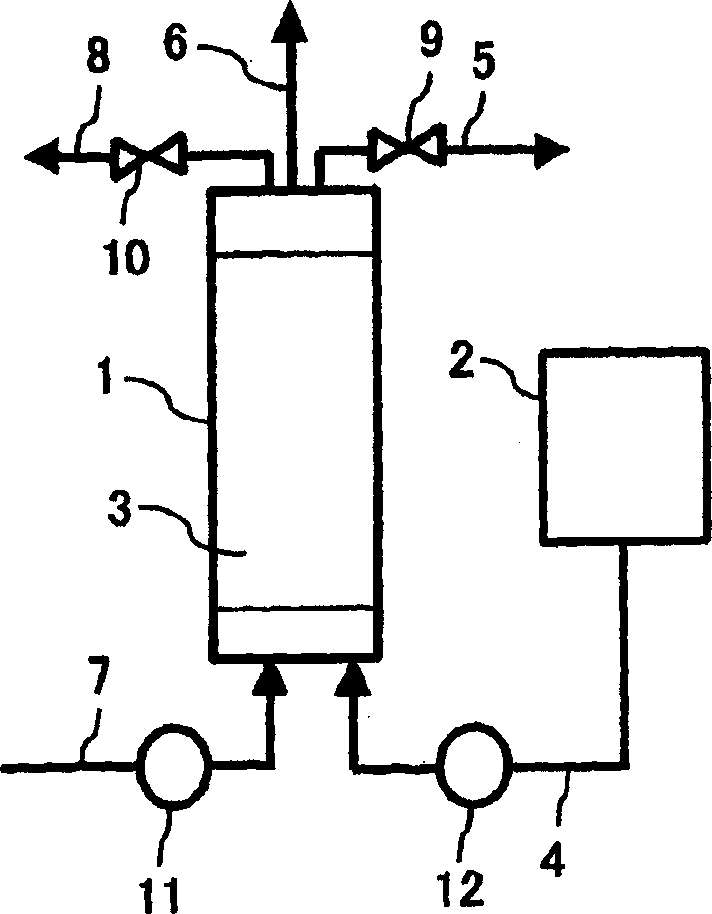

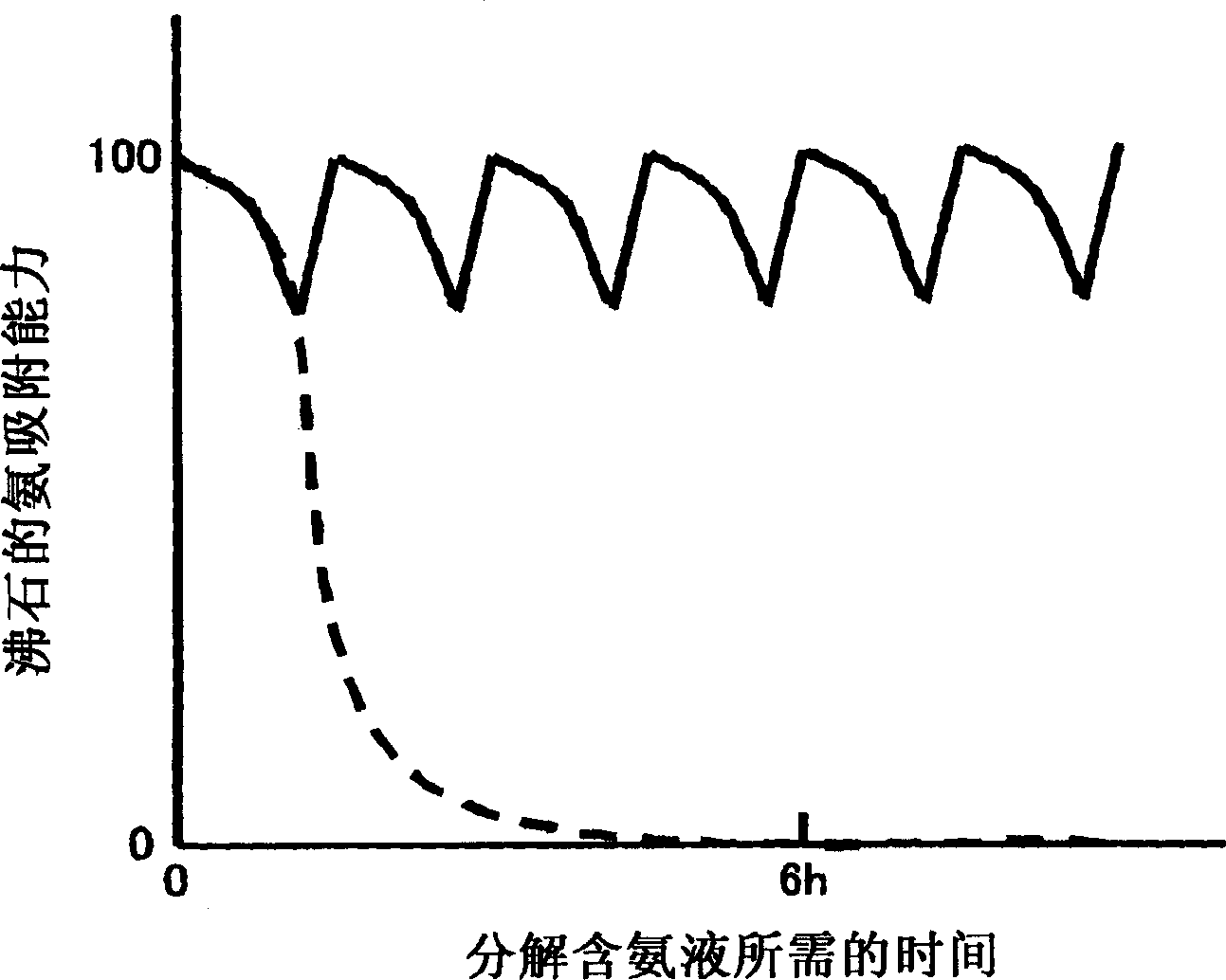

Process and appts. for treating nitrogen compound contg. water

InactiveCN1463253AImprove securityPrevent outflowIon-exchanger regenerationWater contaminantsEutrophicationHypobromous acid

A method of treating water containing a nitrogen compound, and an apparatus of treating water containing a nitrogen compound at high speed without using a biologically unstable treatment causing eutrophication in lakes and swamps. The waste water is introduced into an adsorbing tank that is filled with a zeolite, only nitrogen components are adsorbed by the zeolite, a solution containing hypochlorous acid or hypobromous acid is introduced into the adsorbing tank, and the nitrogen adsorbed in the zeolite is decomposed by the hypochlorous acid or the hypobromous acid.

Owner:MITSUBISHI ELECTRIC CORP

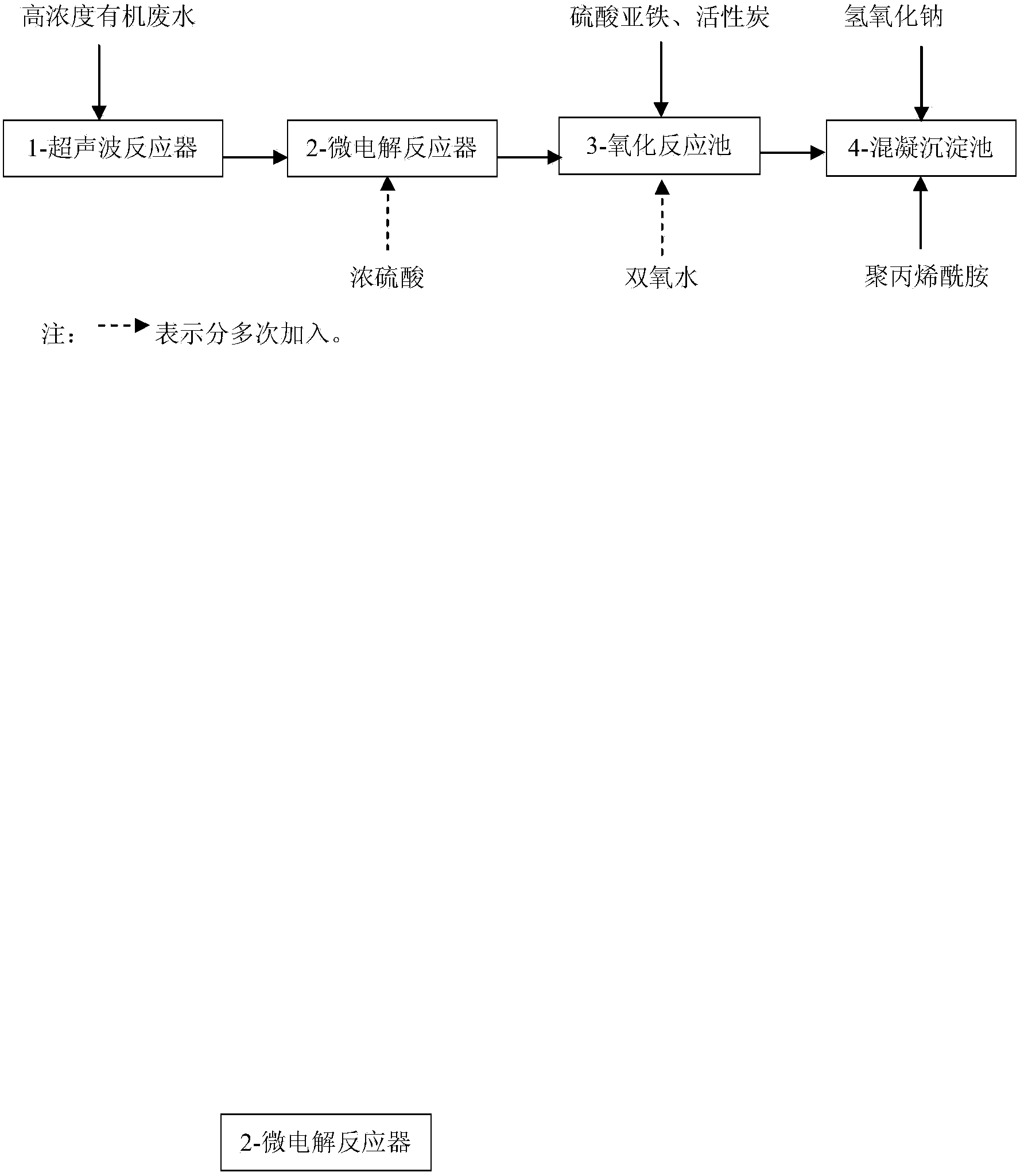

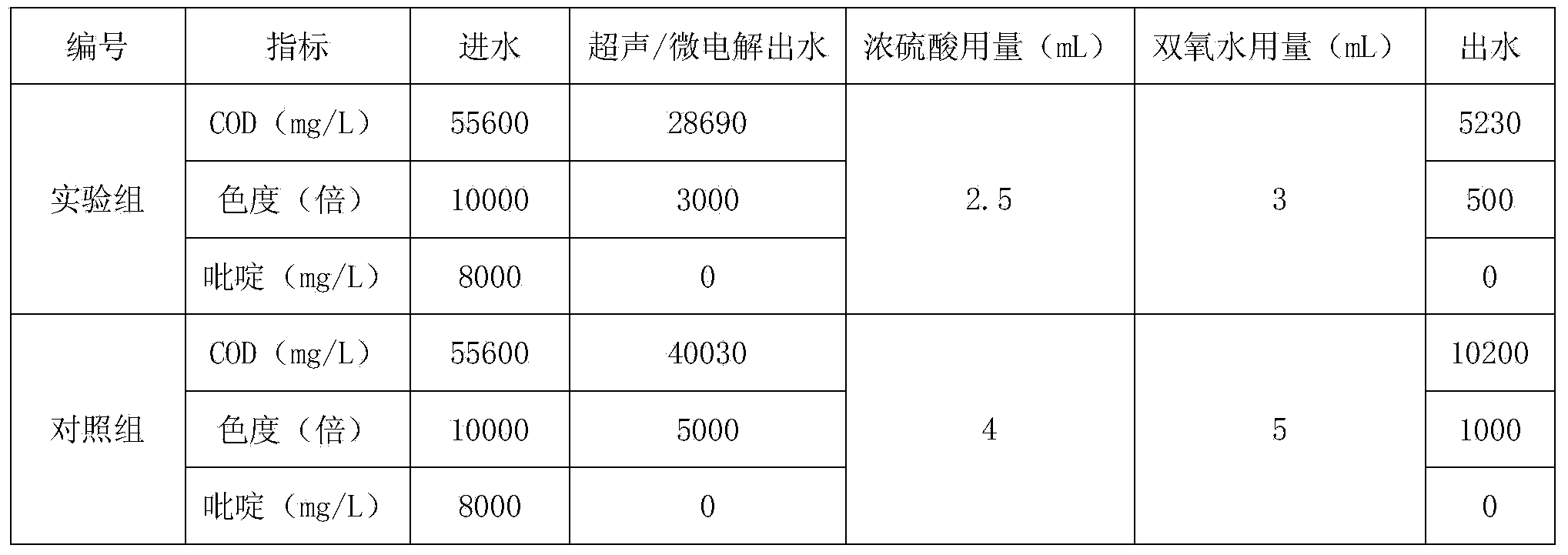

Treatment method of high-concentration organic wastewater

InactiveCN103864250AImprove decomposition efficiencyReduce lossMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a treatment method of high-concentration organic wastewater. The method has a favorable treatment effect on high-concentration organic wastewater of which the COD (Chemical Oxygen Demand) concentration is larger than 50000mg / L and the chromaticity is larger than 10000 times. The hardly degradable substances in the treated wastewater can be degraded, so that the biodegradability of the treated wastewater is improved and the treated wastewater reaches the biochemical treatment requirement. The treatment method smartly combines ultrasonic splitting, micro-electrolytic decomposition and high-grade oxidation, and the problem that the high-concentration organic wastewater which has high COD and large toxicity and is difficulty biochemically degraded is solved.

Owner:苏州森荣环保处置有限公司

Preparation method of varicosity polytetrafluoroethylene fibre having function for catalytic decomposition of dioxins

InactiveCN101255615AAvoid pollutionShort processOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationFiberCatalytic decomposition

Disclosed is a process for producing bulky polytetrafluoroethylene fiber with function of catalytically decomposing dioxin, including the steps of mixing bulky polytetrafluoroethylene powder and catalyst powder capable of decomposing dioxin, and then mixing liquid lubricant and thereafter preparing the fiber by processes as follows: extrusion, rolling, longitudinally drawing, sintering stereotype and splitting. The material can be widely used in the treatment of high-temperature tail dedusting and decomposition of emissions. Compared with the previous techniques, the advantages of the present invention are simple process, low cost, no pollution and the like.

Owner:ZHEJIANG SCI-TECH UNIV

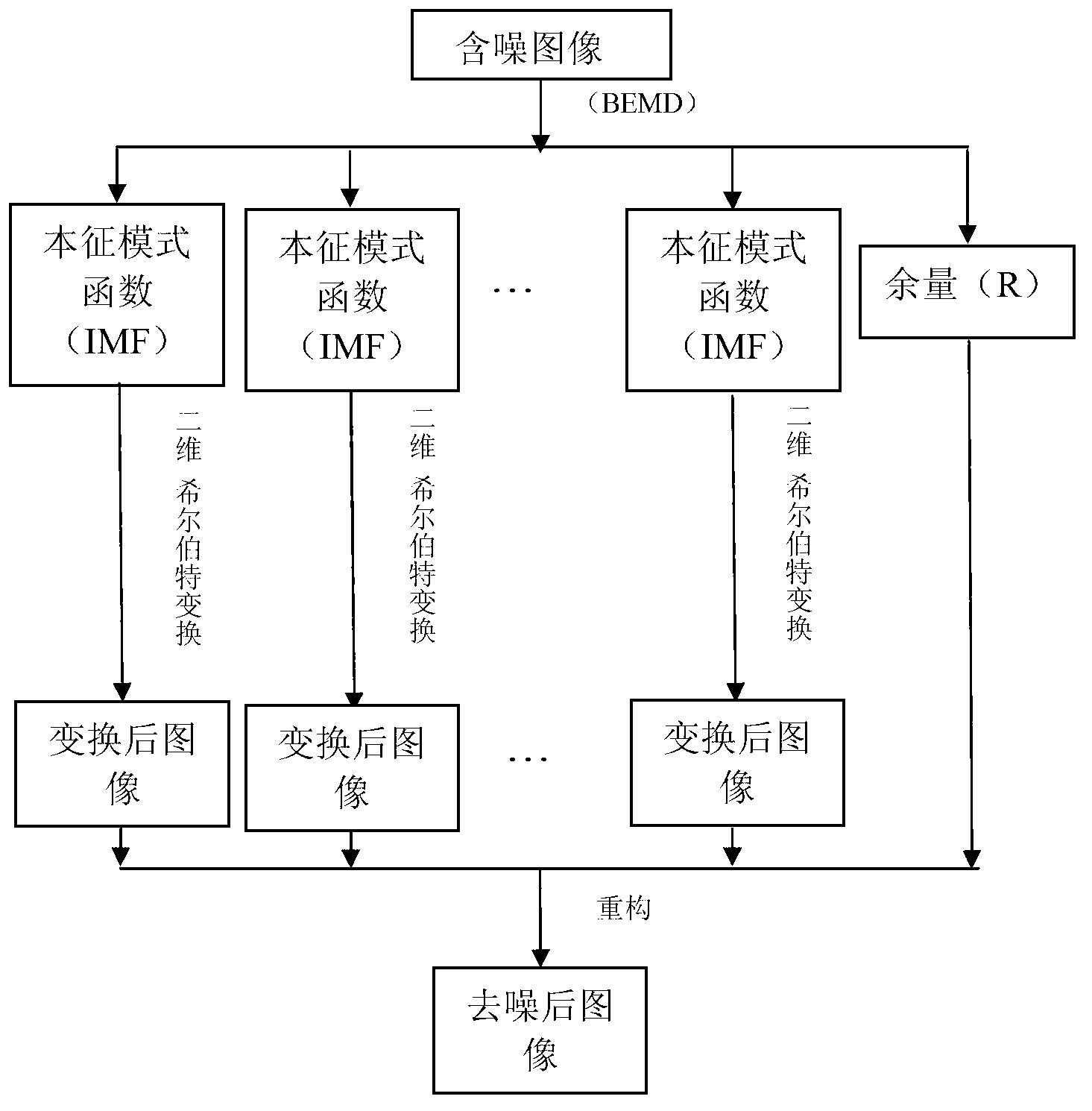

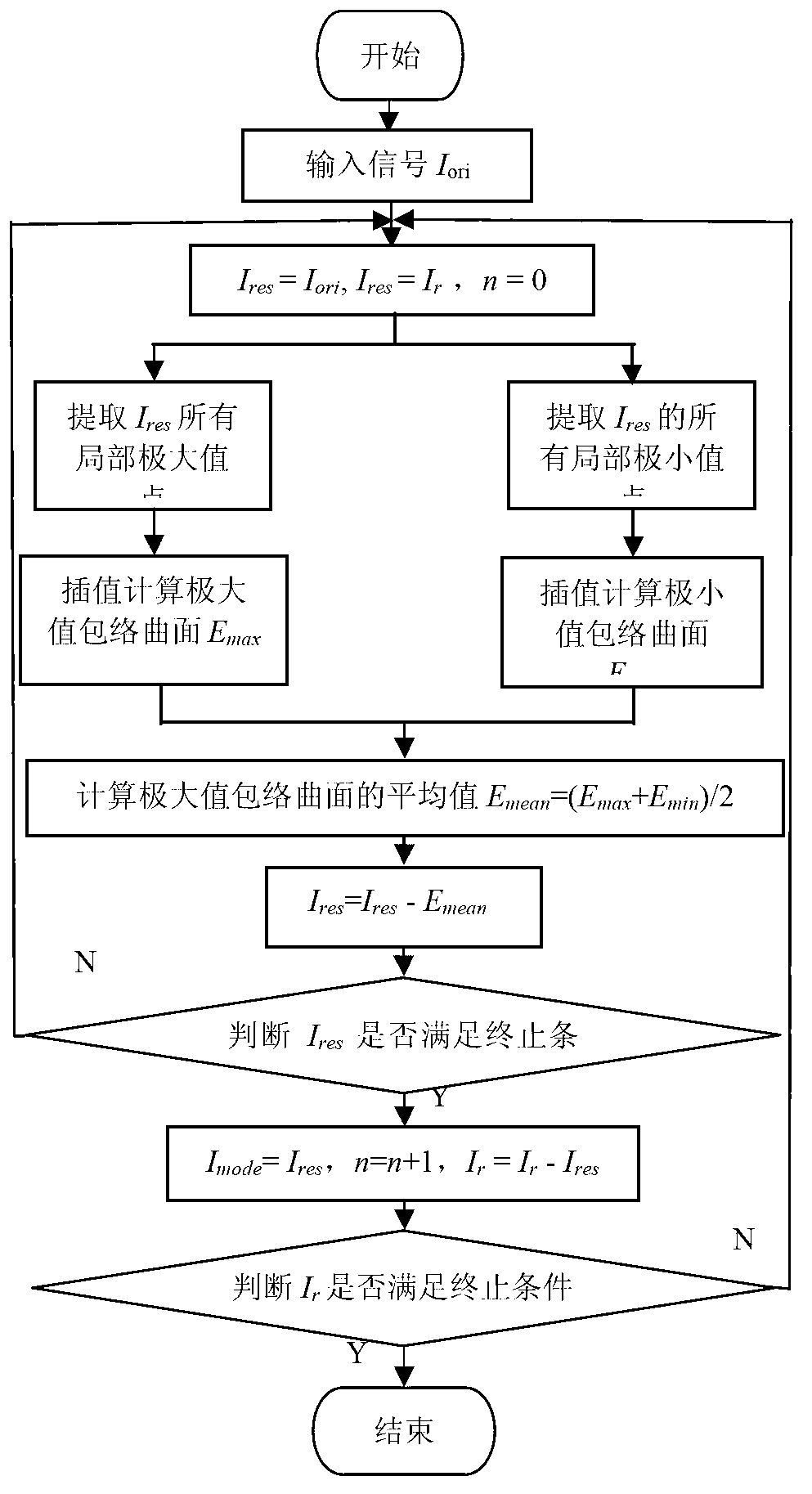

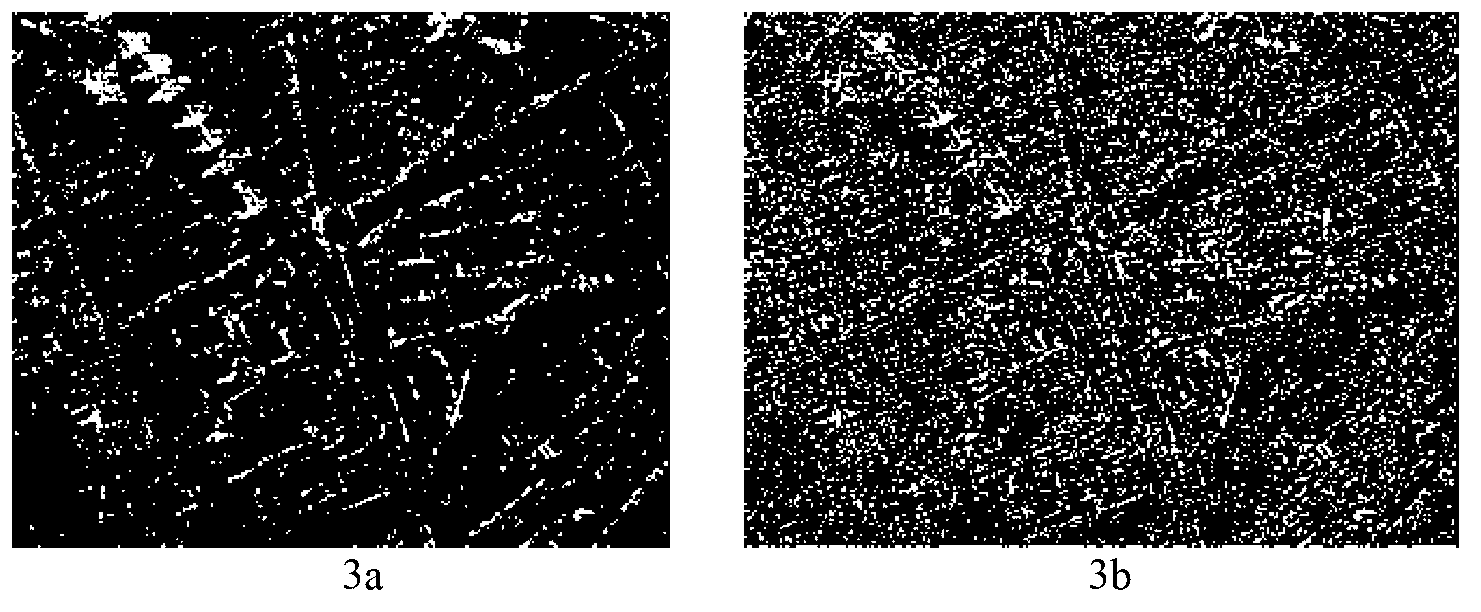

Image de-noising method by combining bidimensional Hilbert transformation with BEMD (bidimensional empirical mode decomposition)

ActiveCN103020916AImprove decomposition efficiencyImprove accuracyImage enhancementDecompositionSalt-and-pepper noise

The invention discloses an image de-noising method by combining bidimensional Hilbert transformation with BEMD (bidimensional empirical mode decomposition). The image de-noising method includes steps of performing BEMD for an image containing noise to obtain an IMF (intrinsic mode function) and R (residue); enabling IMF components to be subjected to the bidimensional Hilbert transformation; and reconstructing images and residues which are obtained after the Hilbert transformation to obtain a de-noise image. The image de-noising method has the advantages that the image can be decomposed by means of BEMD in a multi-scale manner, a local time-frequency characteristic is realized, problems caused by one-scale de-noising by the traditional filter method are solved, and the image decomposition efficiency and efficiency are improved; and the bidimensional Hilbert transformation can realize excellent filter effects for multiplicative noise, Gaussian noise and salt-and-pepper noise of images, influence of the noise in the images to details and critical contents of the images is weakened, and the noise can be effectively removed.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Feed addictive for improving pork quality and increasing efficiency of feed utilization and preparation thereof

ActiveCN103355499AImprove qualityEnhance metabolic functionAnimal feeding stuffAnimal scienceSide effect

The invention provides a feed addictive for improving pork quality and increasing efficiency of feed utilization and preparation thereof, and belongs to the field of feed addictive. The feed addictive is composed of natural Chinese herbal medicine, is capable of improving metabolism function of pig and strengthening immunity function of pig, has no side effects, and thus improves the pork quality. In the same time, the feed addictive can also condition the intestinal tract health, promotes absorption and utilization of feed, increases utilization rate of feed and breeding benefit, and effectively decreases breeding cost and risk. The feed addictive is composed of following components in parts by weight: 5 to 15 parts of eucommia powder, 5 to 10 parts of poria cocos powder, 15 to 20 parts of anemarrhena powder, 5 to 9 parts of matrimony vine enzymolysis powder, 4 to 8 parts of clove, 5 to 8 parts of haw, 8 to 12 parts of composite polysaccharide extract, and 8 to 20 parts of fermented soybean meal. The preparation method is mixing the components mentioned above together.

Owner:GUANGNAN ZHANJIANG JIAFENG FEED

Adsorption decomposition agent and preparation method thereof

ActiveCN101844072ALarge specific surface areaImprove antibacterial propertiesOther chemical processesDispersed particle separationCatalytic decompositionBall mill

The invention discloses an adsorption decomposition agent. 90 to 95 mass percent of bamboo charcoal grains and 5 to 10 mass percent of tourmaline grains form a base material; and titanium dioxide sol serving as photo-catalyst, which accounts for 10 to 20 percent of the total weight of the base material, is added into the base material and is used as an additive. The invention also discloses a preparation method for the adsorption decomposition agent, which comprises the following steps of: 1) performing ball-milling and mixing on the base material to obtain a dry powdery material; 2) adding the titanium dioxide sol serving as the photo-catalyst into the dry powdery material for ball milling and mixing to obtain a mixture; and 3) drying, sieving and thermally processing the mixture to obtain the adsorption decomposition agent. The adsorption decomposition agent has the characteristics of high adsorption, catalytic decomposition in the presence of light and antibacterium.

Owner:上海莱乾新能源有限公司

Marine gas hydrate and mortar replacement exploitation method and device

ActiveCN107676058APrevent large area deficitGuaranteed stabilityConstructionsFluid removalProduction tubingCoarse particle

The invention discloses a marine gas hydrate and mortar replacement exploitation method and device. According to the exploitation method, the sand blocking accuracy of a mechanical screen pipe is properly lowered to enable stratum mud and sand fine particles to flow into a shaft production pipe column and be discharged under the controllable condition, in the meantime, coarse-particle mortar is injected into a hydrate reservoir continuously, and through matching of a hydrate reservoir sand outlet management technology and mortar injection technology, replacement of the coarse-particle mortar and the stratum fine particles as well as the coarse-particle mortar and a hydrate space is achieved. The exploitation device comprises a production sleeve pipe, a production oil pipe, a shaft water injection pipe and a mortar back-injection pipe, the lower end of the production sleeve pipe is connected with the mechanical screen pipe, and the upper end and the lower end in the mechanical screen pipe are further provided with an upper mechanical packer and a lower mechanical packer correspondingly. The inlet end of the production oil pipe is provided with a gas separating device, and the position, above the upper mechanical packer, of the shaft water injection pipe communicates with the production oil pipe. The mortar back-injection pipe penetrates through the upper mechanical packer and the lower mechanical packer, extends to the bottom border of the production layer section of the hydrate reservoir and is connected with a gravel filling tool. Through the method and the device, the purpose of continuous and efficient production is achieved.

Owner:QINGDAO INST OF MARINE GEOLOGY

Preparation method of dual-purpose filter material for dedusting and decomposing dioxins

The invention discloses a preparation method for double action filtering material capable of dedusting and decomposing dioxin. The material comprises the following five-layer structure: a first layer is a dust receiving layer formed by polytetrafluoroethylene fibers through carding process; a second layer is a buffer layer formed by fine denier polytetrafluoroethylene fiber through preneedling processing; a polytetrafluoroethylene film carrying a catalyst is processed into reticular structure fibers by a film splitting method, and a plurality of films are laminated to form a catalysis layer which is a third layer; a fourth layer is a Teflon base cloth reinforced layer; and the four layers are laminated, then the dust receiving layer is laminated on the base cloth reinforced layer, and finally the material is formed through needling processing. The material can be widely applied to the dedusting and dioxin decomposition of high temperature off gas. Compared with the prior art, the preparation method has the advantages of simple and feasible process, low processing cost, and lower requirements on the equipment; and simultaneously the preparation method removes the defects of great fiber loss and a great drag force for the filtering material.

Owner:ZHEJIANG SCI-TECH UNIV

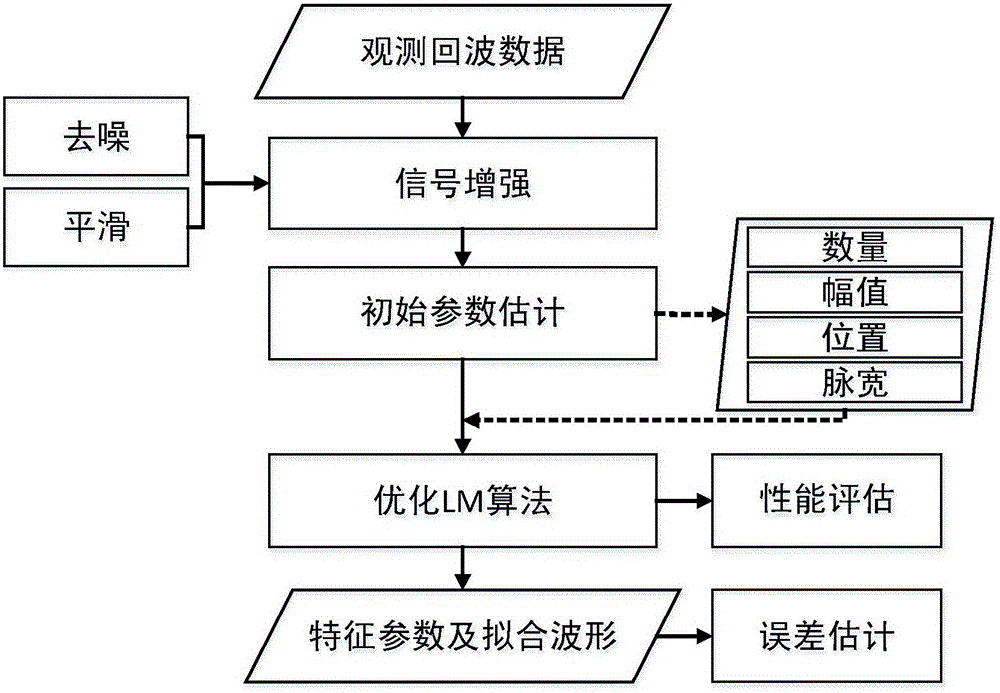

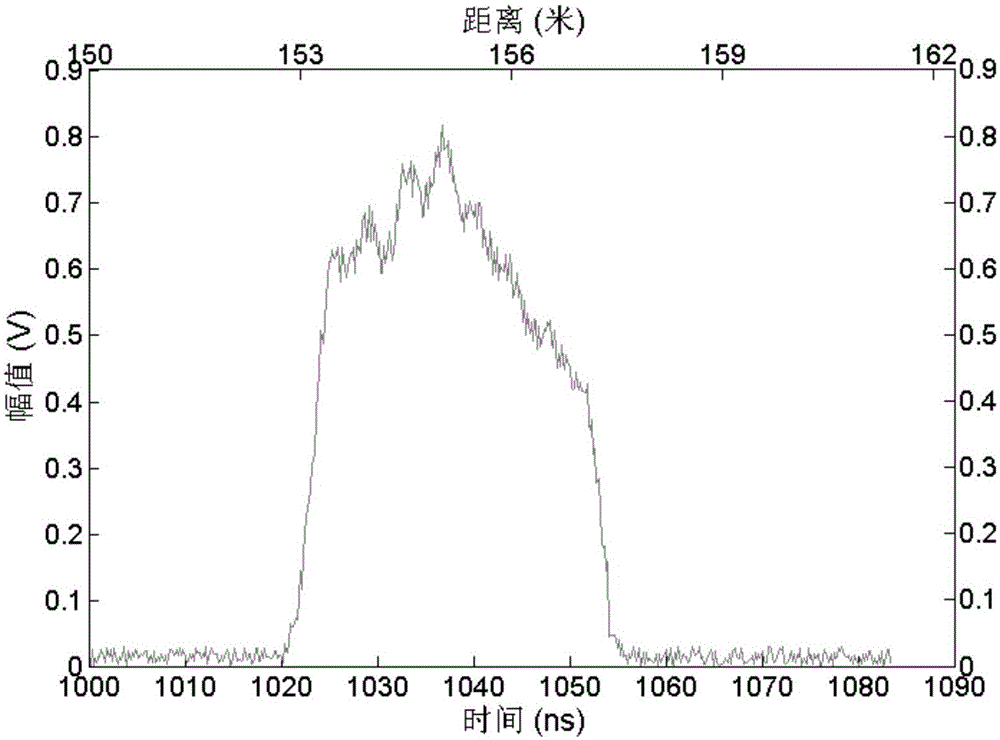

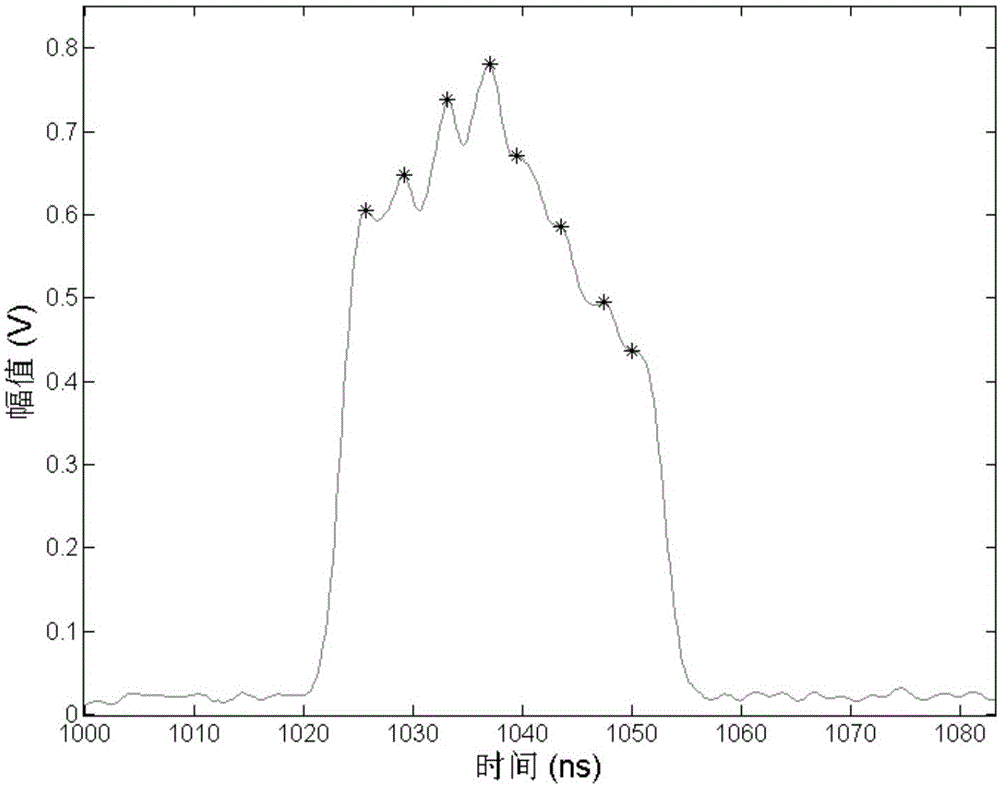

Optimized-LM-algorithm-based laser radar waveform decomposition method

ActiveCN105093207AReduce the number of changesImprove convergence performanceWave based measurement systemsObservation dataRadar waveforms

The invention discloses an optimized-levenberg-marquardt (LM)-algorithm-based laser radar waveform decomposition method. The method comprises the following steps that: (1), a laser radar system records observation waveform data of back scattering in a digital mode; (2), signal enhancement is carried out on the observation waveform data, wherein the signal enhancement contains noise processing and smoothing processing; (3), a threshold value is set, peak-inflection point detection is carried out on the enhanced signal, and initialization estimation values containing a number, an amplitude, a position, and a pulse width initialization parameter are determined; (4), a standard LM algorithm is corrected by using an improved training module and iteration is carried out on the initialization estimation values to obtain feature parameters, including amplitudes, positions, and pulse widths, of all components of the enhanced signal; and (5), goodness of fit is calculated by using fitting data and original observation data and precision of the goodness of fit is determined; and an efficiency of a fitting algorithm is determined by using the number of times of iteration.

Owner:NANJING UNIV

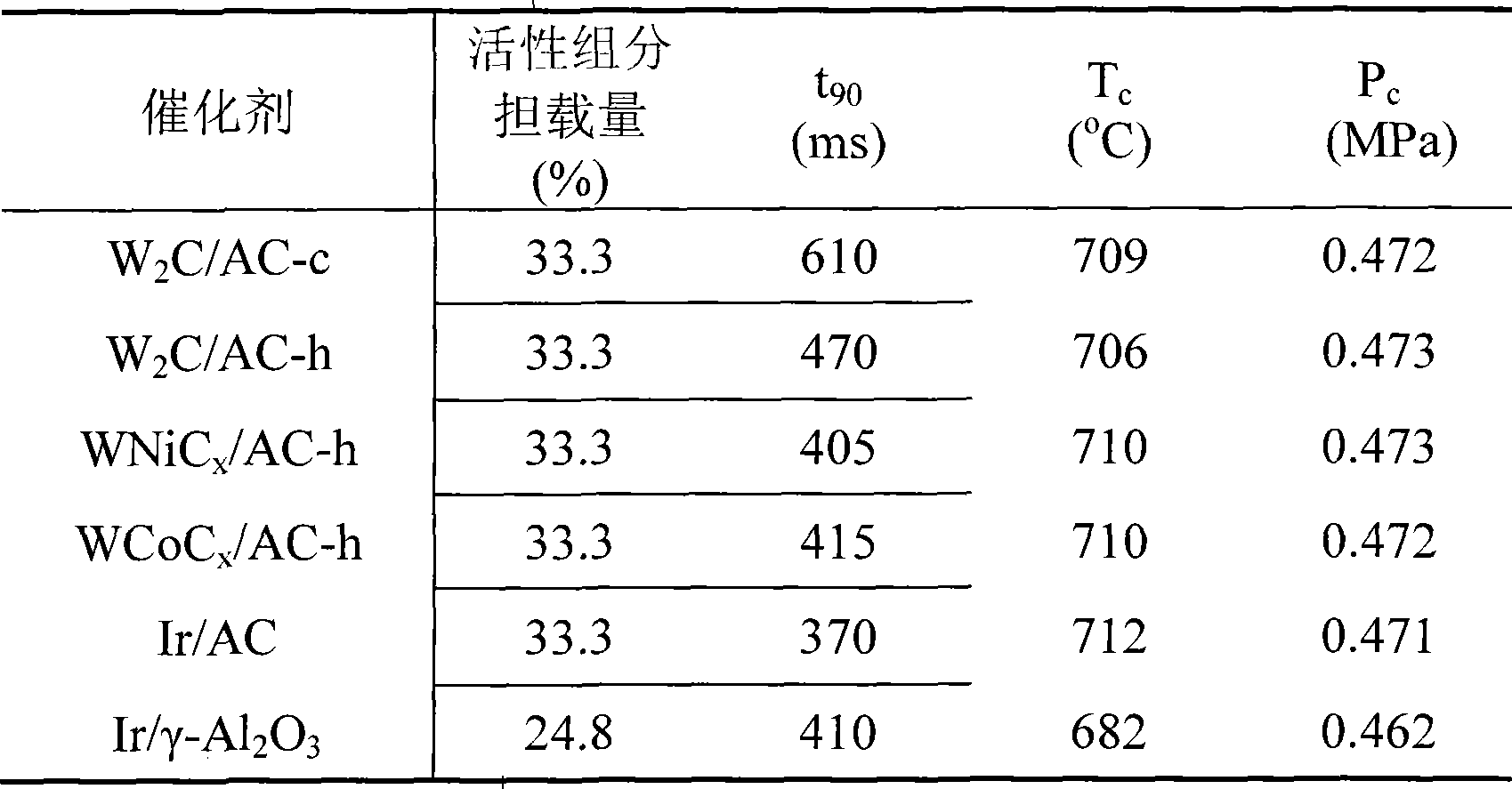

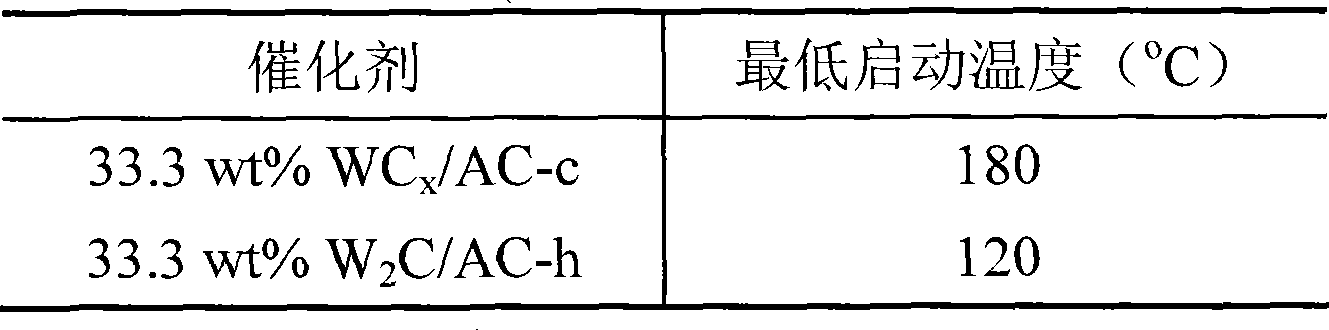

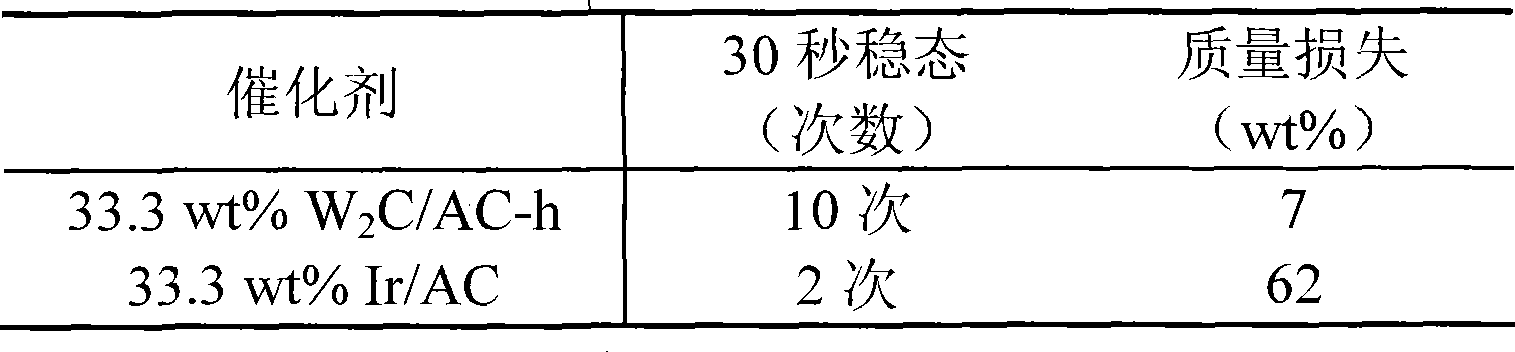

Use of carbon-supported transitional metal carbides catalyst in hydrazine decomposition reaction

InactiveCN101411975ASimple preparation processReduce manufacturing costMetal/metal-oxides/metal-hydroxide catalystsTransition metal carbidesHydrazine compound

The invention relates to a catalyst for hydrazine decomposition reaction, in particular to a hydrazine decomposition catalyst loaded by a charcoal carrier. The active composition is carbide of W, Mo, Ni, Co, Cr, Fe, V, Nb, Ti, Zr and other transition metals. The catalyst has similar hydrazine decomposition performance with traditional Ir / Al2O3 and has good application prospect in various power systems taking liquid hydrazine as fuel and gas generating systems.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-pressure atomizing dielectric barrier discharge plasma water treatment device

ActiveCN103693714AFully degradedImprove decomposition efficiencyWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationVapor–liquid separatorHigh pressure water

The invention relates to a high-pressure atomizing dielectric barrier discharge plasma water treatment device which comprises a sewage treatment cavity and a discharge reaction chamber, wherein a sewage outlet II is formed in the side wall of the sewage treatment cavity, and a dosing device for feeding ferrous sulfate into the sewage treatment cavity and a gas outlet are arranged in the top wall; the sewage outlet II is communicated with one end of a sewage pipe I; an array type high-pressure atomizing spray head is arranged at the other end of the sewage pipe I and positioned at the top of the discharge reaction chamber; a high-pressure water pump is arranged on the sewage pipe I; a fan for blowing the high-pressure atomized sewage into the discharge reaction chamber is arranged at the top of the discharge reaction chamber, and the bottom is communicated with a gas-liquid mixture inlet of a gas-liquid separator; the gas-state substance (mixture of air and ozone) and liquid-state substance (sewage and hydrogen peroxide) separated by the gas-liquid separator are fed into the sewage treatment cavity respectively. The device provided by the invention makes full use of the incomplete-reaction strong-oxidizing substances, increases the contact area between sewage and plasma, improves the sewage treatment efficiency and reduces the operation cost.

Owner:CHONGQING UNIV

Mixed milk replacer and preparation method thereof

InactiveCN103750068AReduce wasteNo increase in workloadAnimal feeding stuffFood shapingAmylaseCalcium formate

The invention discloses a mixed milk replacer and a preparation method thereof; the mixed milk replacer comprises the following raw materials in parts by weight: 16-20 parts of hulled corn, 15-20 parts of extruded corn, 6-10 parts of flour, 3-5 parts of white fish meal, 4-8 parts of debarked bean pulp, 2-5 parts of chyle fat powder, 2-3 parts of fermented bean pulp, 5-10 parts of whey powder, 3-6 parts of milk powder, 1-3 parts of white sugar, 2-3 parts of glucose, 0.4-0.5 part of monocalcium phosphate, 0.012-0.015 part of calcium formate, 0.01-0.03 part of high-temperature protease, 0.2-0.5 part of amino acid, 2-5 parts of thermostable amylase and culture thereof, 0.04-0.06 part of decavitamin and 0.2-0.6 part of compound microelements. The raw materials are mixed after being prepared to have the particle diameters of 2.0-3.0 mm and 10-15 mm; the mixed milk replacer pays attention to weak piglets and healthy piglets, reduces the feed waste, improves the food calling capacity and the food consumption, modifies the daily gain, and reduces the phenomena of negative gain and growth retardation caused by the weaning stress.

Owner:LIAONING WELLHOPE AGRI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com