Patents

Literature

146results about "Organic decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the production of five-membered or six-membered cyclic ethers, in particular of anhydropolyols

InactiveUS6013812AImprove stabilityCost of processSugar derivativesOrganic compound preparationPolyolCyclic ether

Owner:EVONIK DEGUSSA GMBH

Preparation of fluorinated olefins via catalytic dehydrohalogenation of halogenated hydrocarbons

ActiveUS20090043136A1Physical/chemical process catalystsPreparation by hydrogen halide split-offHalohydrocarbonHydrogen atom

A process for making a fluorinated olefin having the step of dehydrochlorinating a hydrochlorofluorocarbon having at least one hydrogen atom and at least one chlorine atom on adjacent carbon atoms, preferably carried out in the presence of a catalyst selected from the group consisting of (i) one or more metal halides, (ii) one or more halogenated metal oxides, (iii) one or more zero-valent metals / metal alloys, (iv) a combination of two or more of the foregoing.

Owner:HONEYWELL INT INC

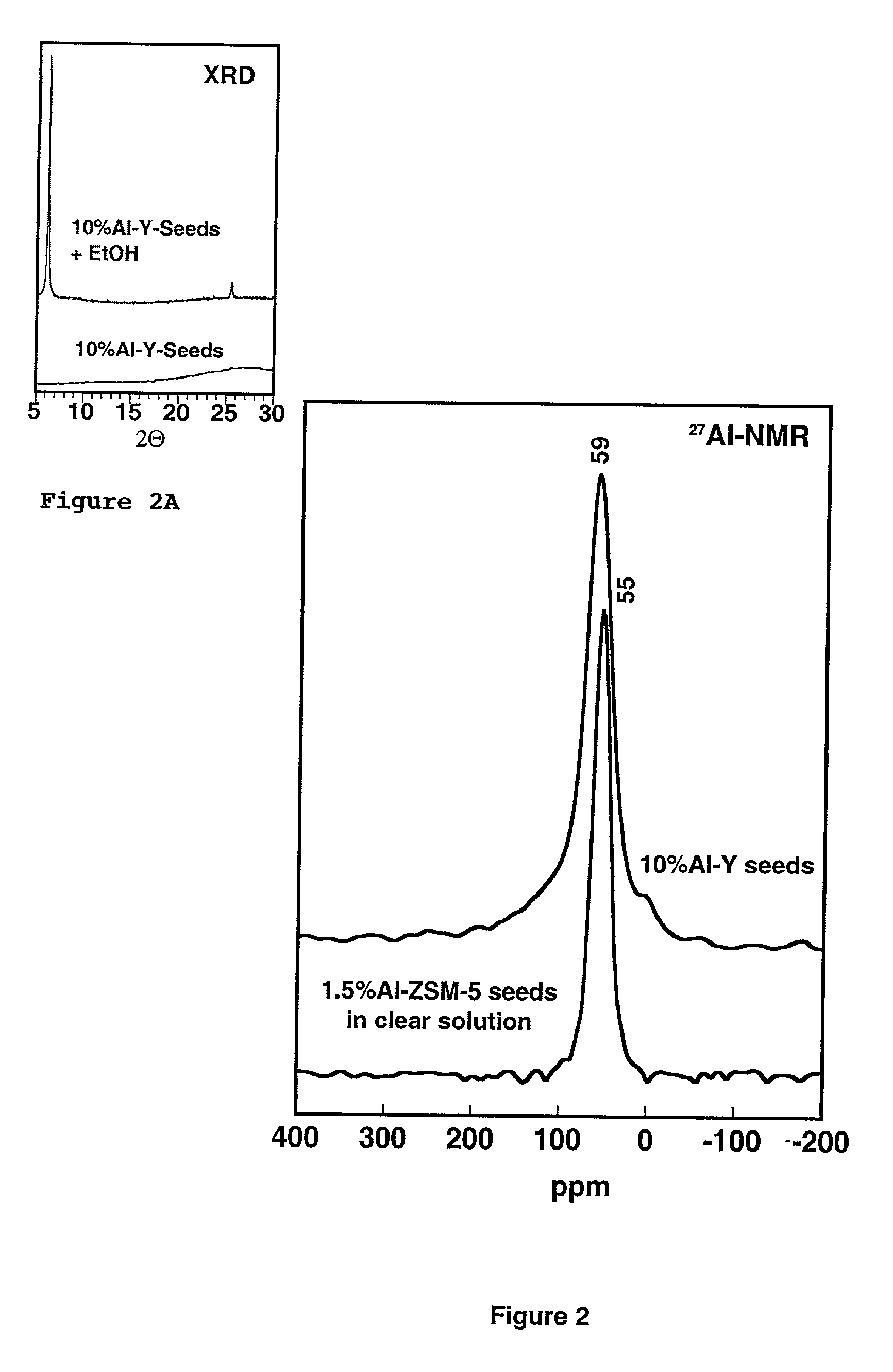

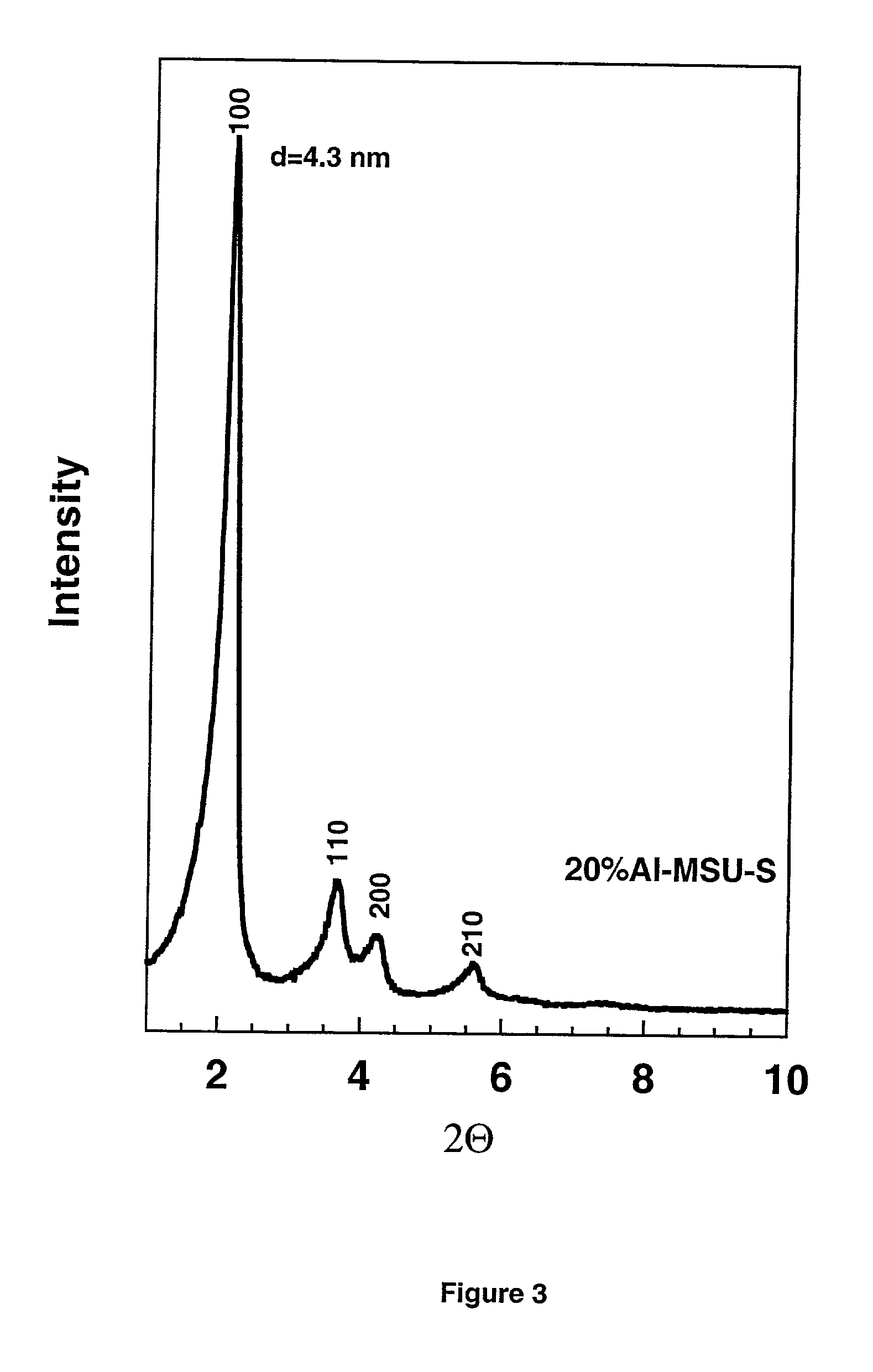

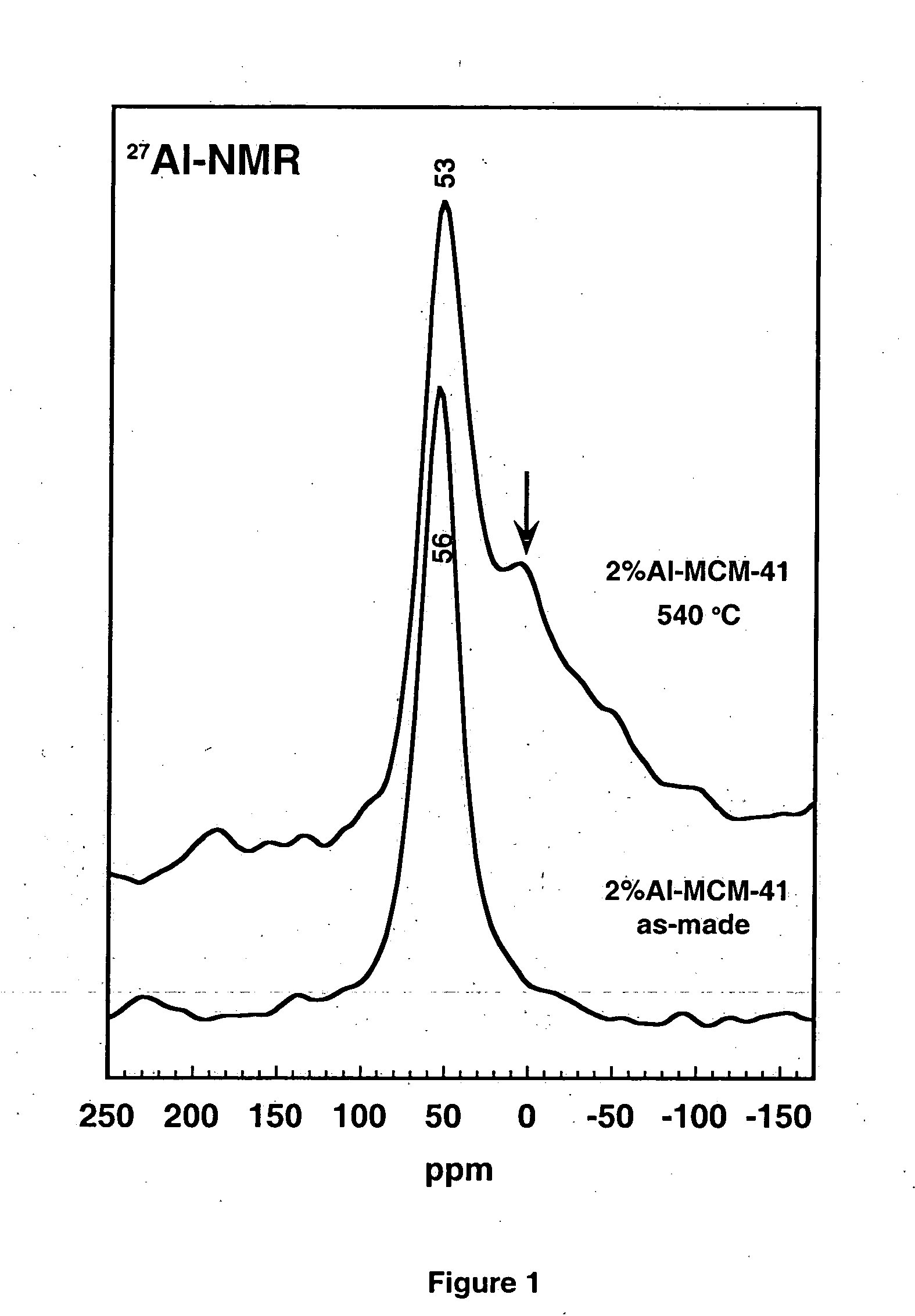

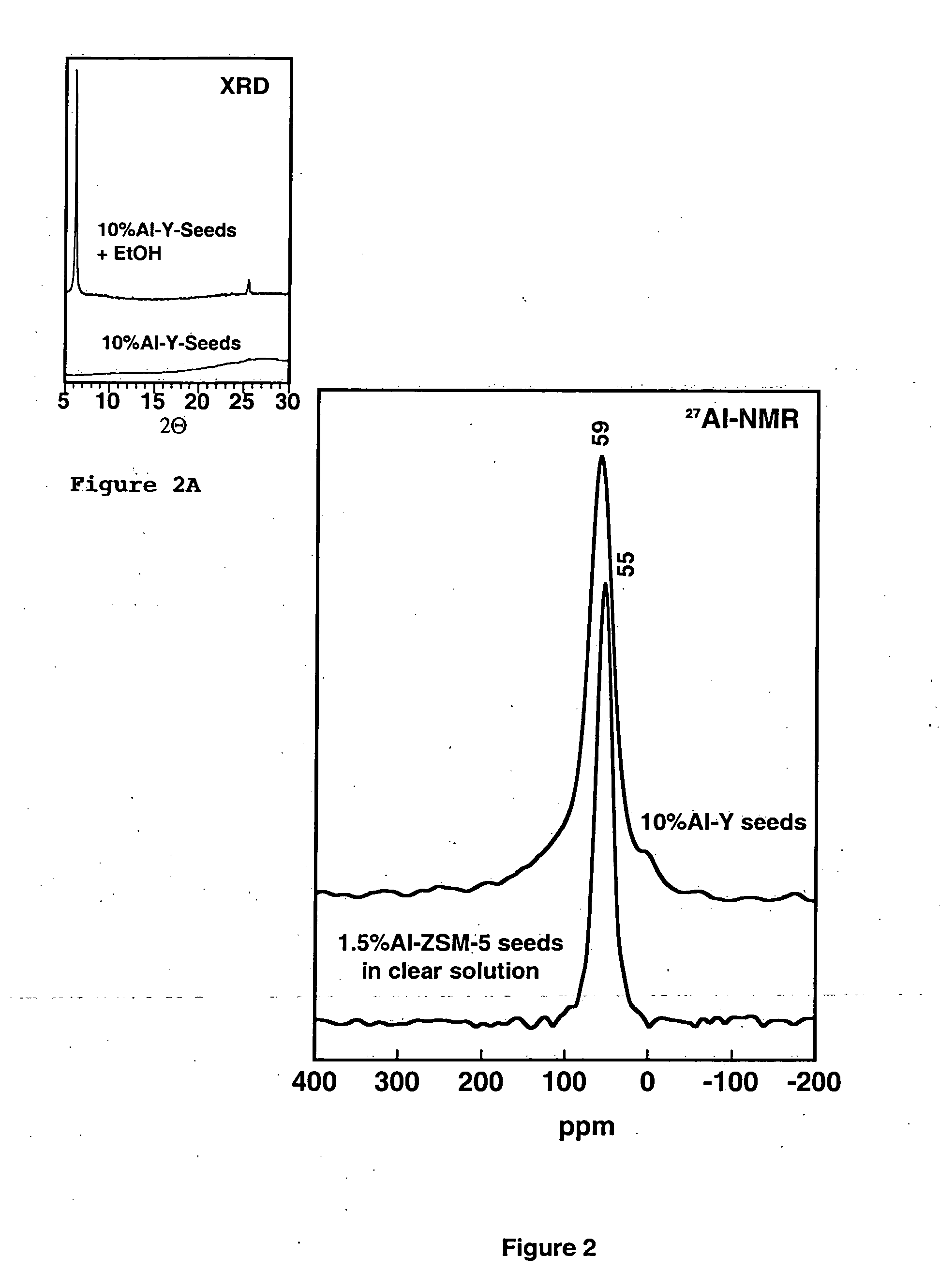

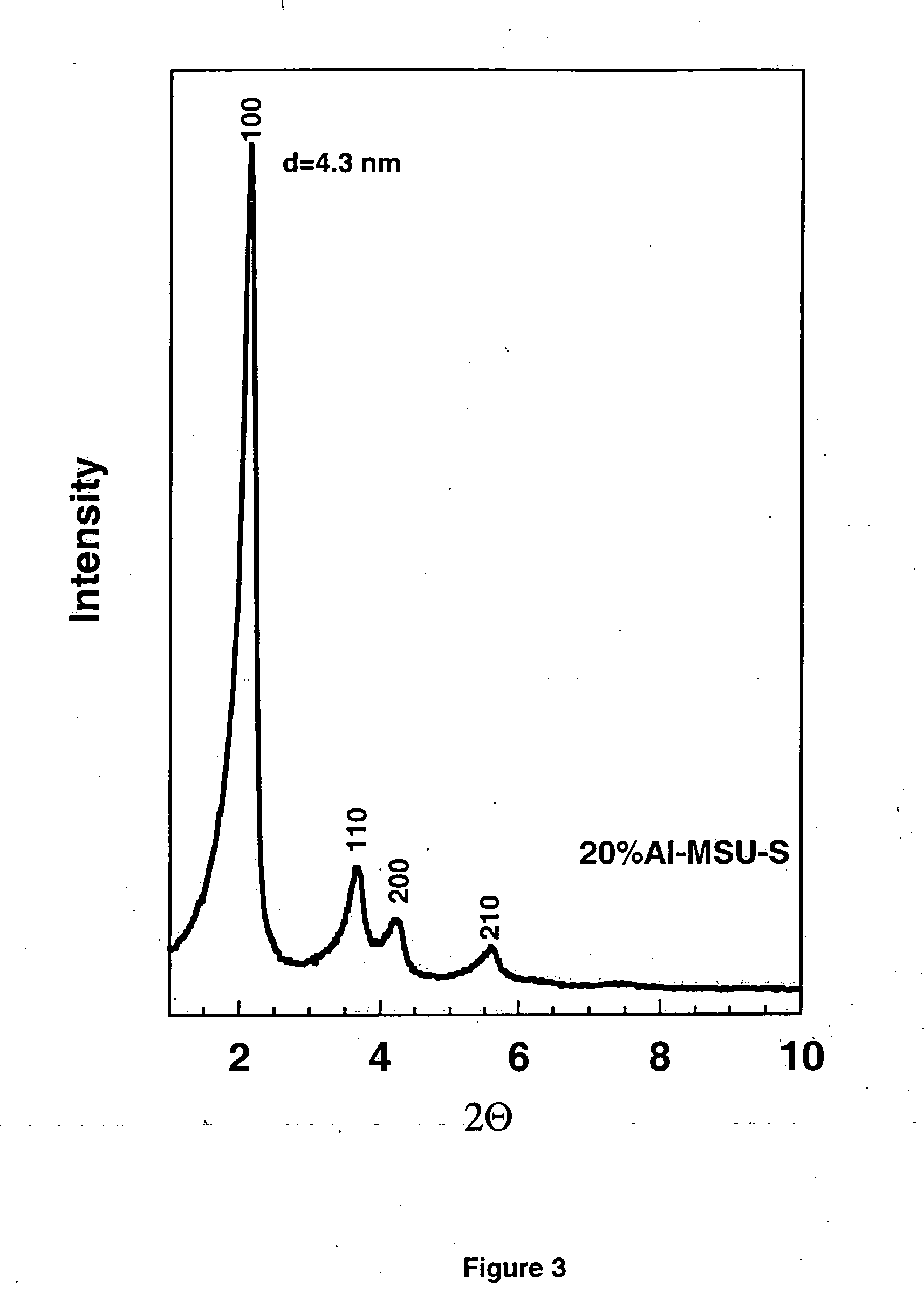

Ultrastable porous aluminosilicate structures and compositions derived therefrom

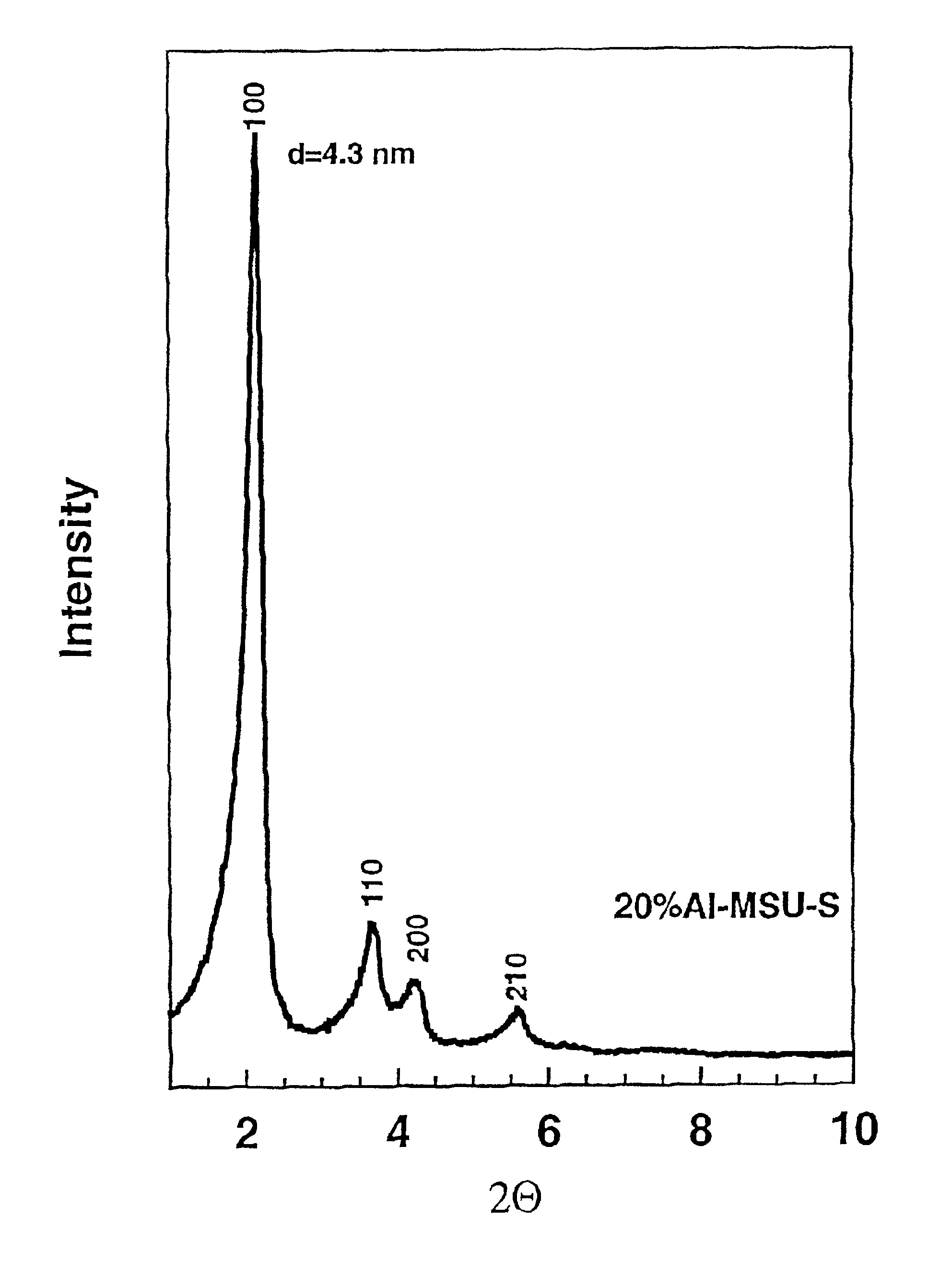

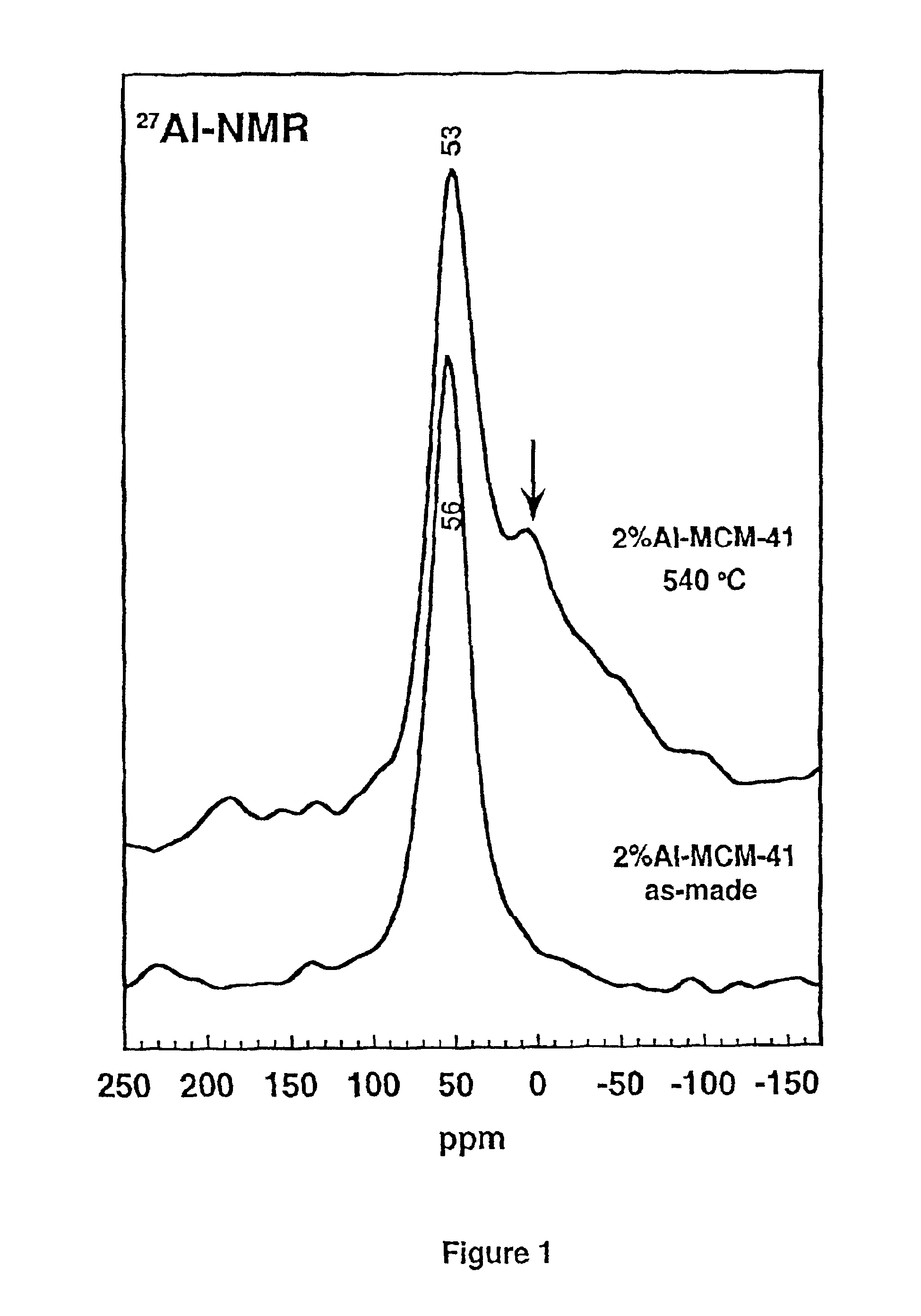

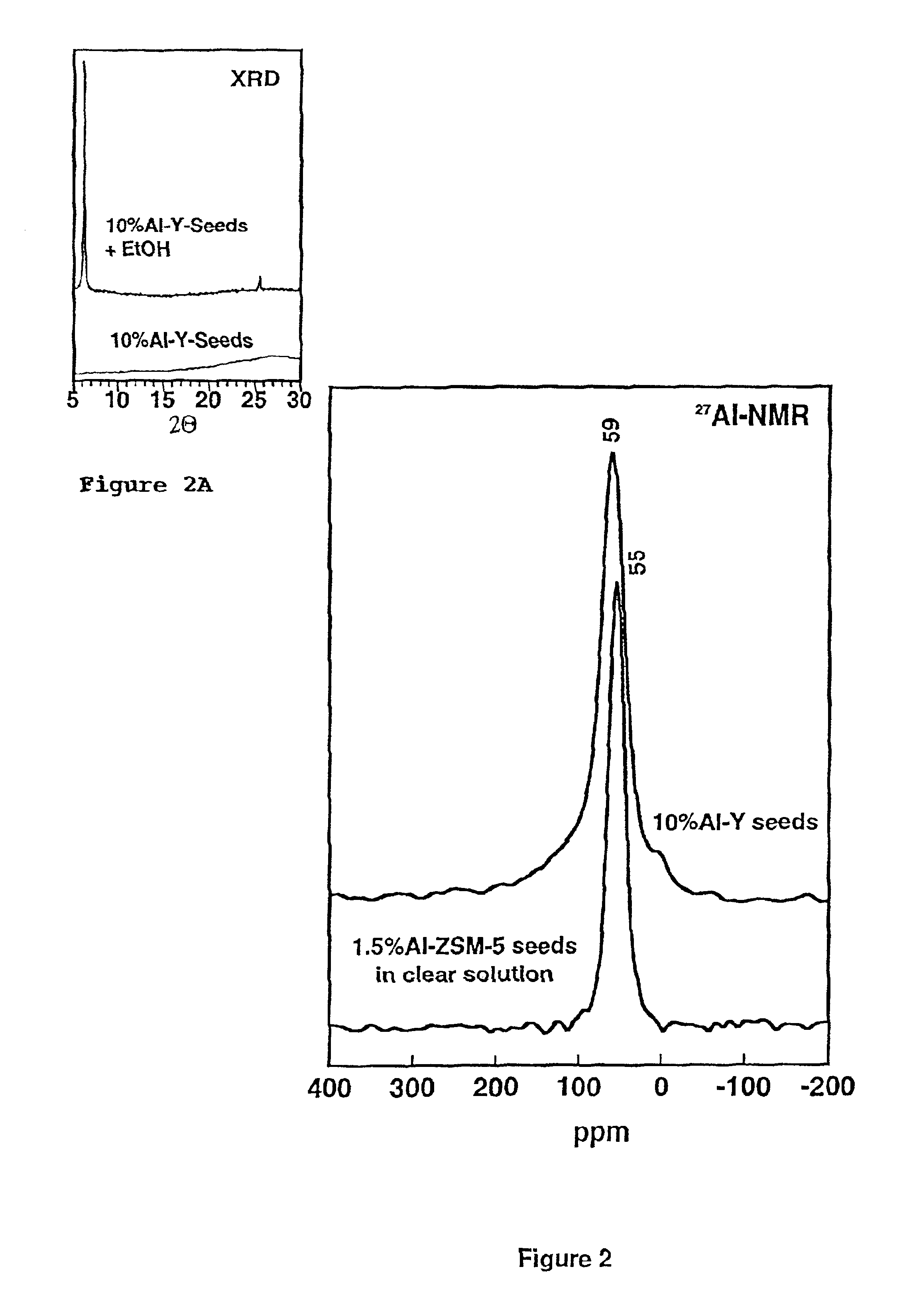

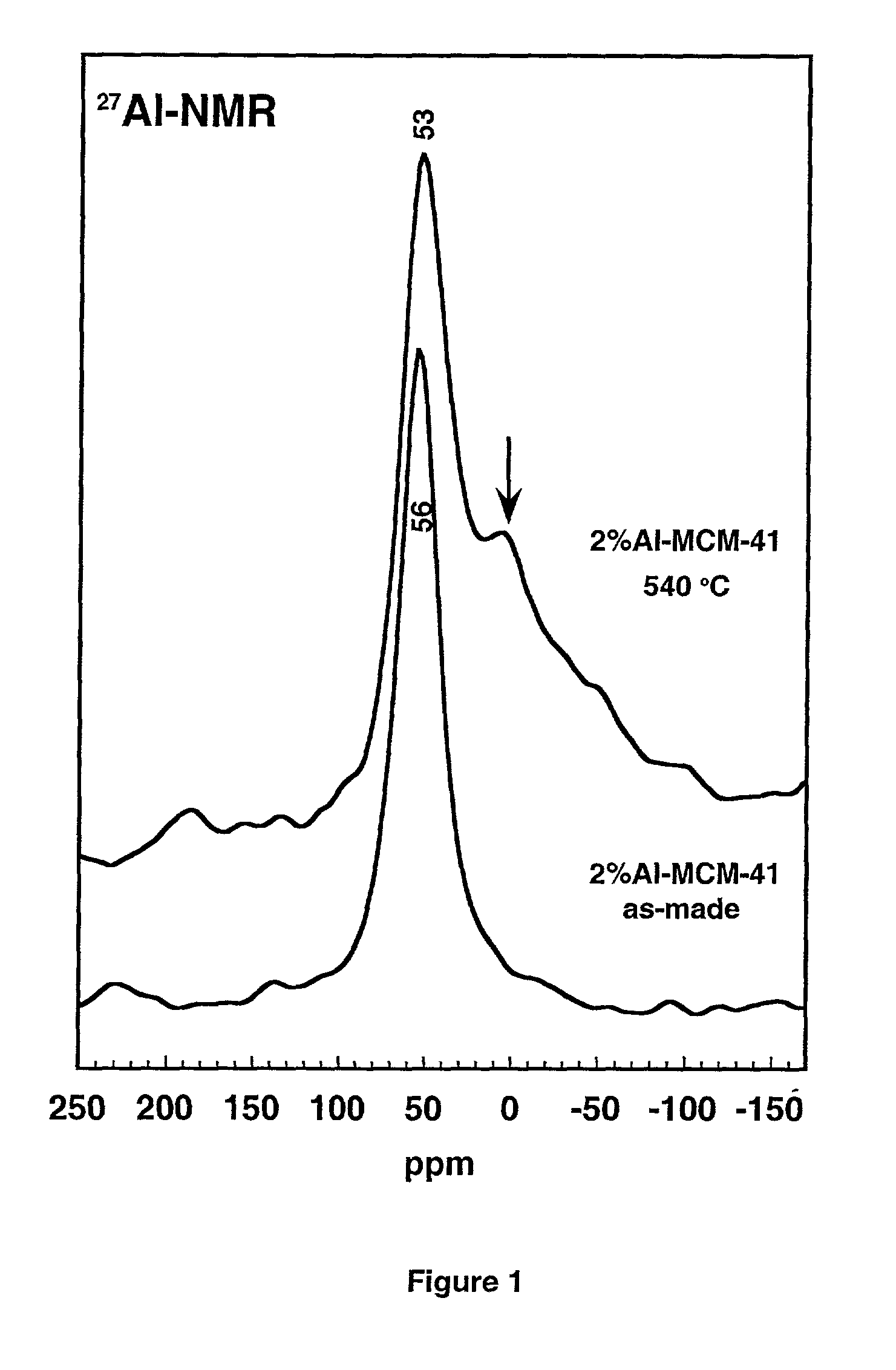

Porous hexagonal, cubic, lamellar, wormhole, or cellular foam aluminosilicates, gallosilicates and titanosilicates derived from protozeolitic seeds or zeolite fragments using an organic porogen directing agent are described. The porous aluminosilicates optionally also can contain zeolite crystals depending upon the aging of the protozeolitic seeds. The silicon and aluminum, gallium or titanium centers in the structures are stable so that the framework of the structure does not collapse when heated in the presence of water or water vapor (steam). The steam stable compositions can be used as catalysts for hydrocarbon conversions, including the fluidized bed catalytic cracking and the hydrocracking of petroleum oils, and other reactions of organic compounds.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Ultrastable porous aluminosilicate structures

Mesoporous hexagonal, cubic, lamellar, wormhole, or cellular foam aluminosilicates, gallosilicates and titanosilicates derived from protozeolitic seeds using an ionic structure directing agent are described. The silicon and aluminum, gallium or titanium centers in the structures are stable so that the framework of the structure does not collapse when heated in the presence of water or water vapor (steam). The steam stable compositions can be used as catalysts for hydrocarbon conversions, including the fluidized bed catalytic cracking and the hydrocracking of petroleum oils, and other reactions of organic compounds.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Process for production of ether carboxylates

The present invention relates to a process for producing an ether carboxylate which includes the steps of (1) reacting an aliphatic monohydric alcohol with an alkylene oxide in the presence of an alkali catalyst; (2) neutralizing a reaction solution obtained in the step (1) with an acid such as hydroxycarboxylic acids to obtain an ether alcohol; and (3-1) reacting the obtained ether alcohol with a monohalogenofatty acid or a salt thereof and an alkali metal hydroxide, or (3-2) subjecting the obtained ether alcohol to catalytic oxidation reaction in the presence of a catalyst. The obtained ether carboxylate has a less odor and a high quality and is therefore suitably used in the applications such as cosmetics and toiletries.

Owner:KAO CORP

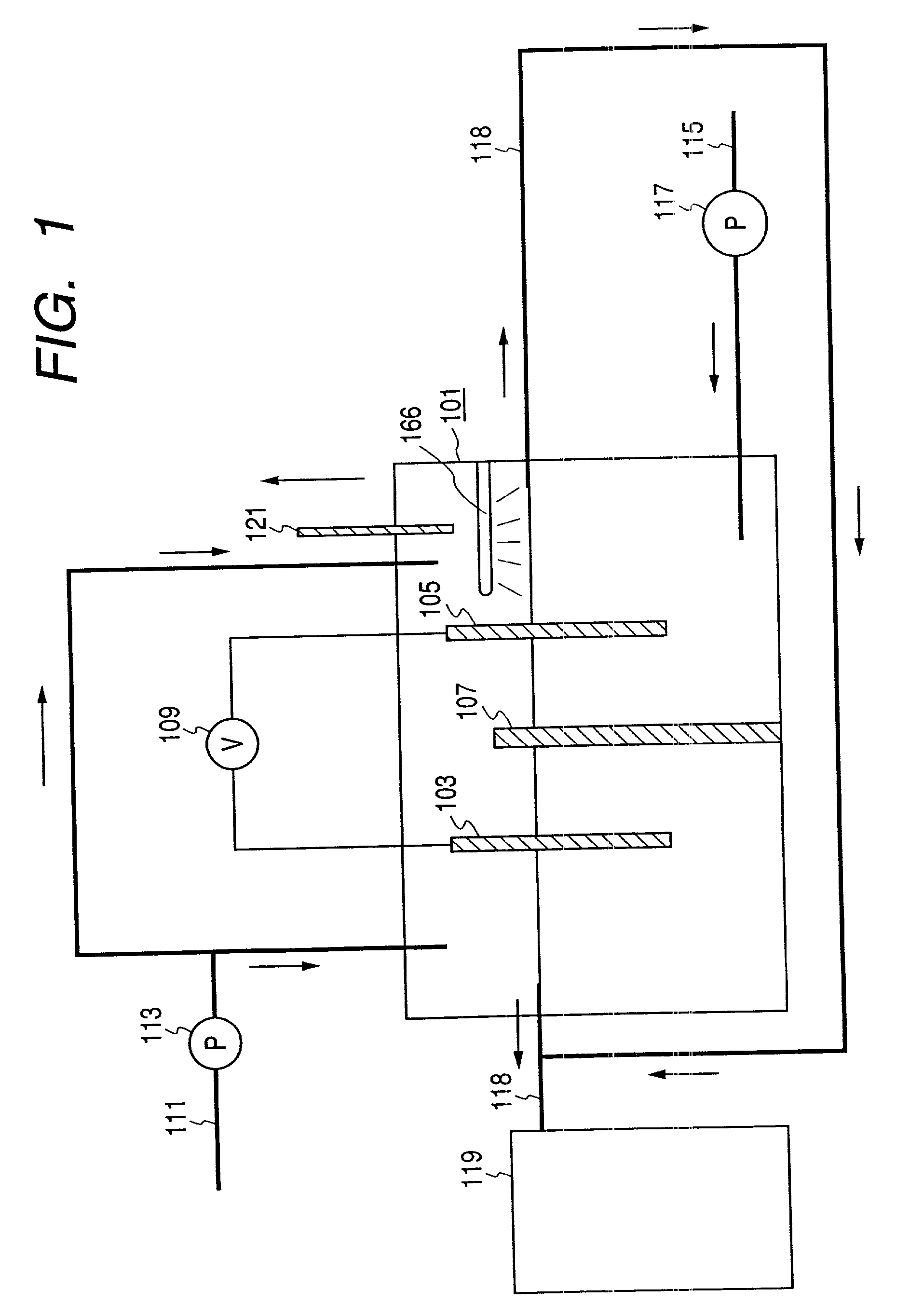

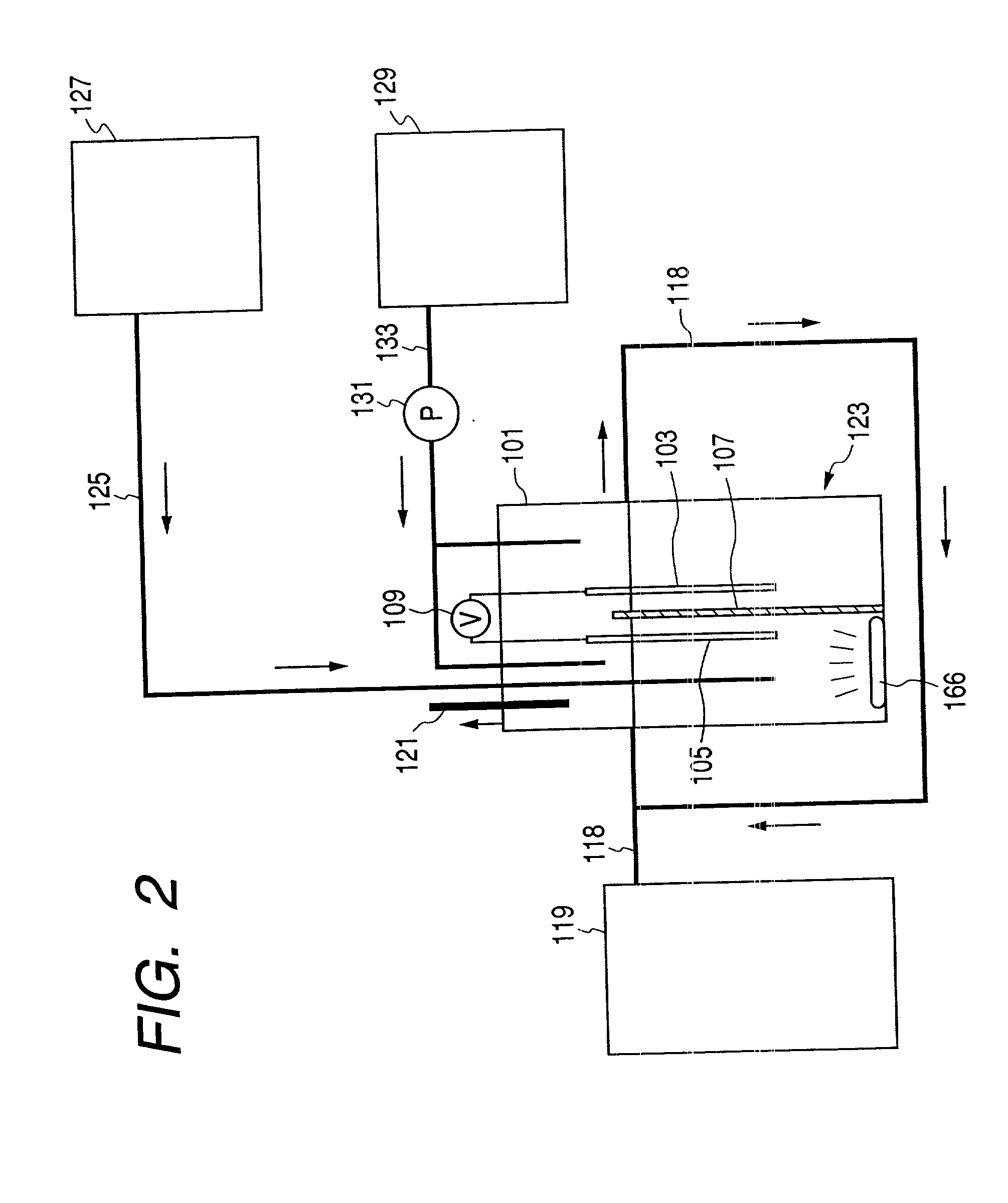

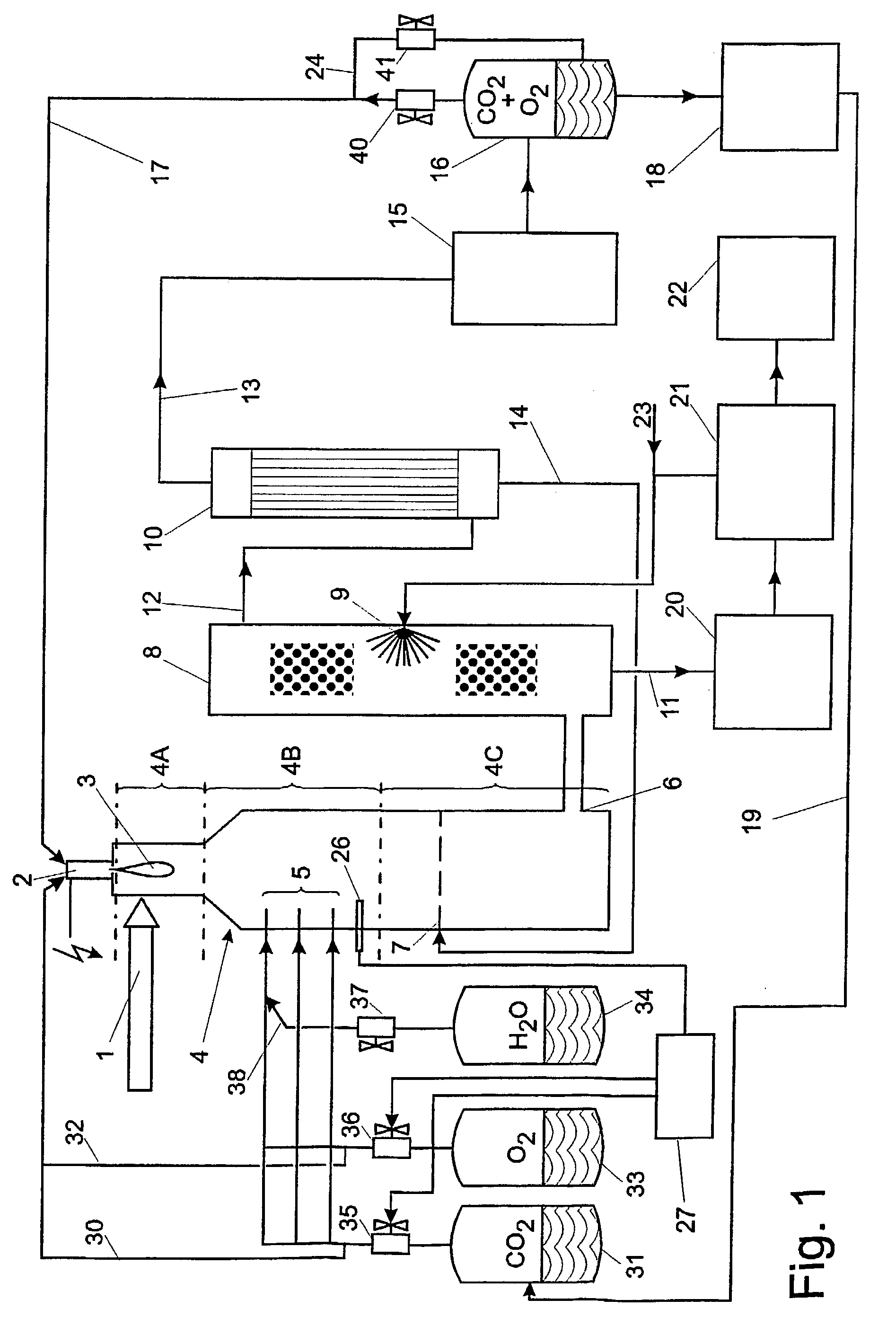

Method of decomposing halogenated aliphatic hydrocarbon compounds or aromatic compounds and apparatus to be used for the same as well as method of clarifying exhaust gas and apparatus to be used for the same

InactiveUS20020130030A1Efficient decompositionEfficient purificationElectrolysis componentsLiquid separation by electricityHydrogen-Ion ConcentrationsPt element

A method for decomposing halogenated aliphatic hydrocarbon compounds or aromatic compounds characterized by contacting the compound to be decomposed with functional water under light irradiation, wherein the functional water is characterized by a hydrogen ion concentration (pH) of 1-4, an oxidation-reduction potential of 800-1500 mV (working electrode: platinum, reference electrode: silver-silver chloride) and a chlorine concentration of 5-150 mg / l, and the irradiation is carried out with light of a wavelength of 300 nm or more, with an intensity of 10 mW / cm.sup.2 or less. This method is carried out at room temperature under the atmospheric pressure. An apparatus for the method is also provided.

Owner:CANON KK

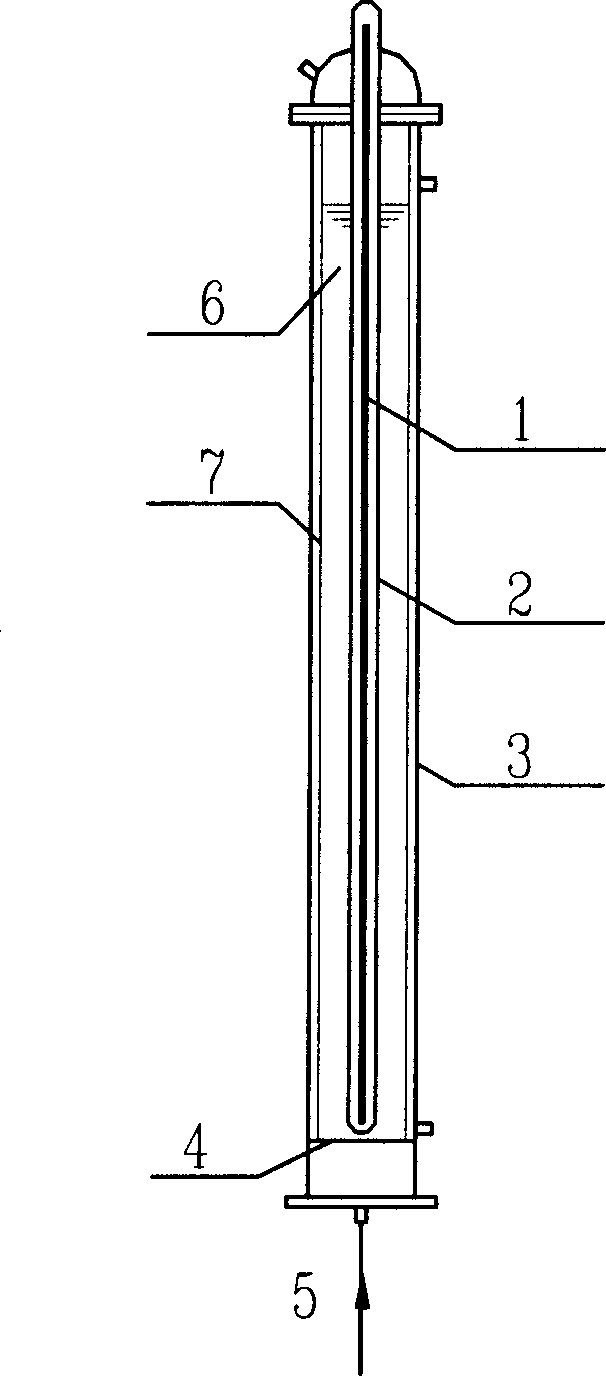

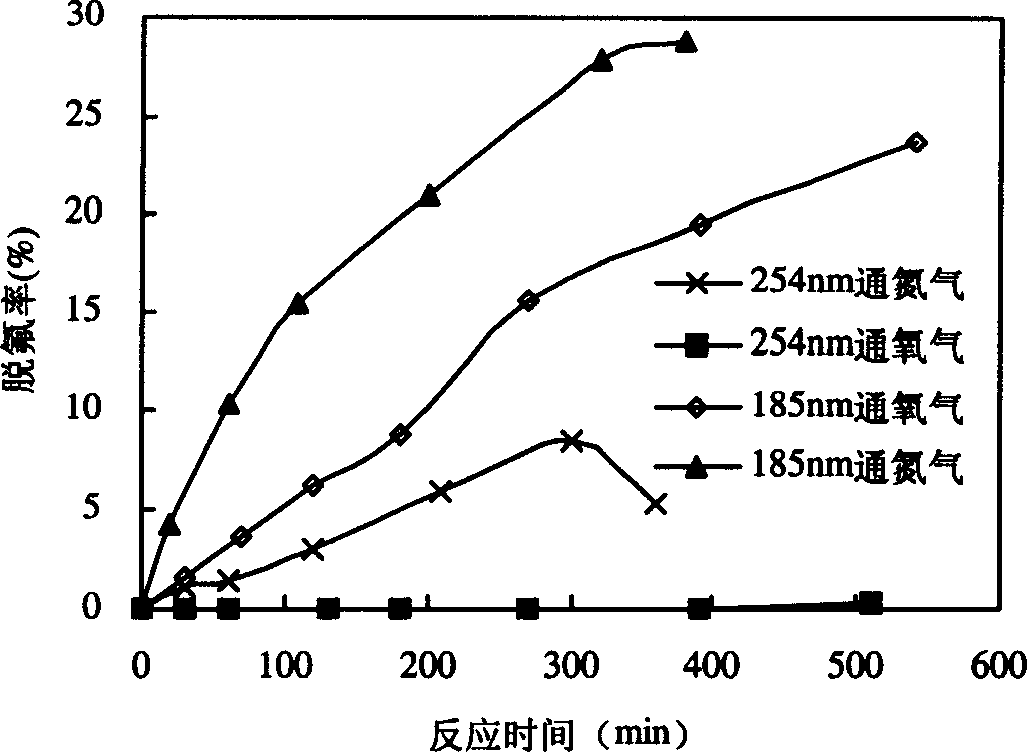

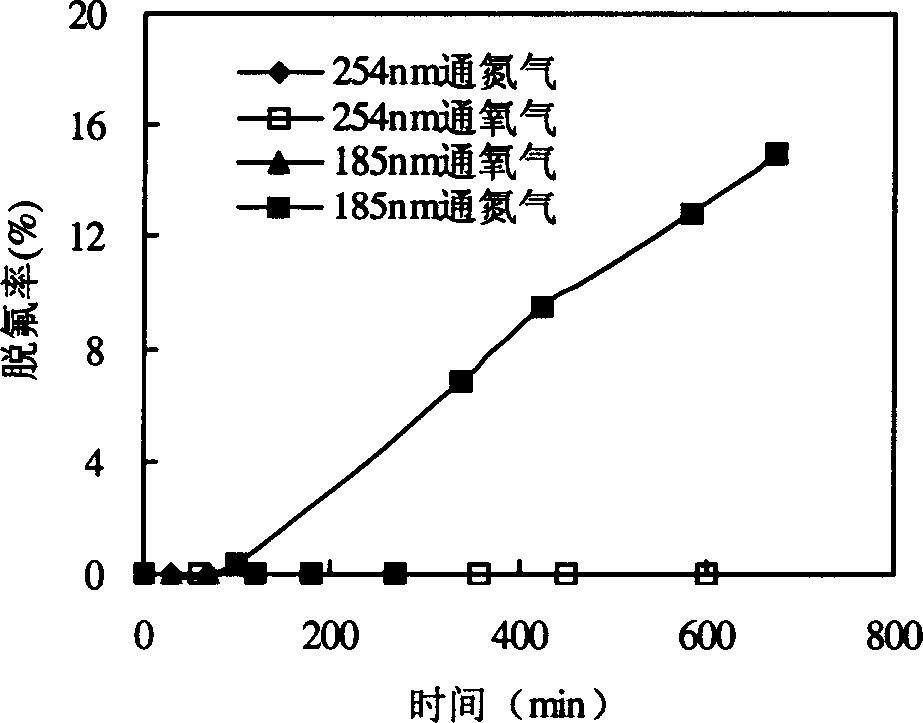

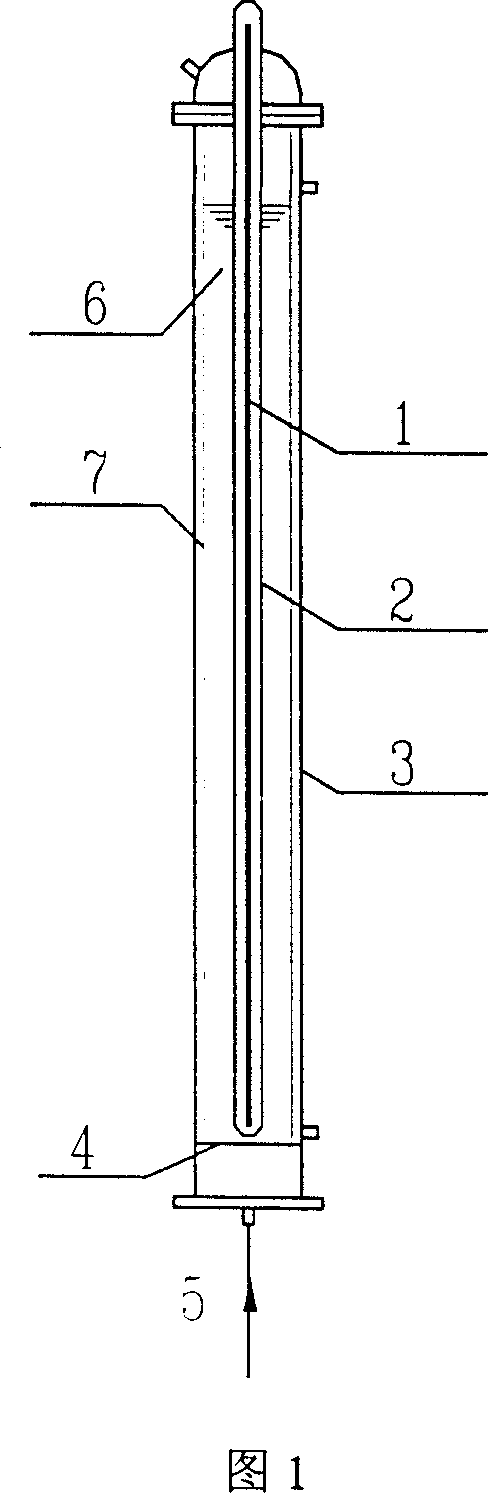

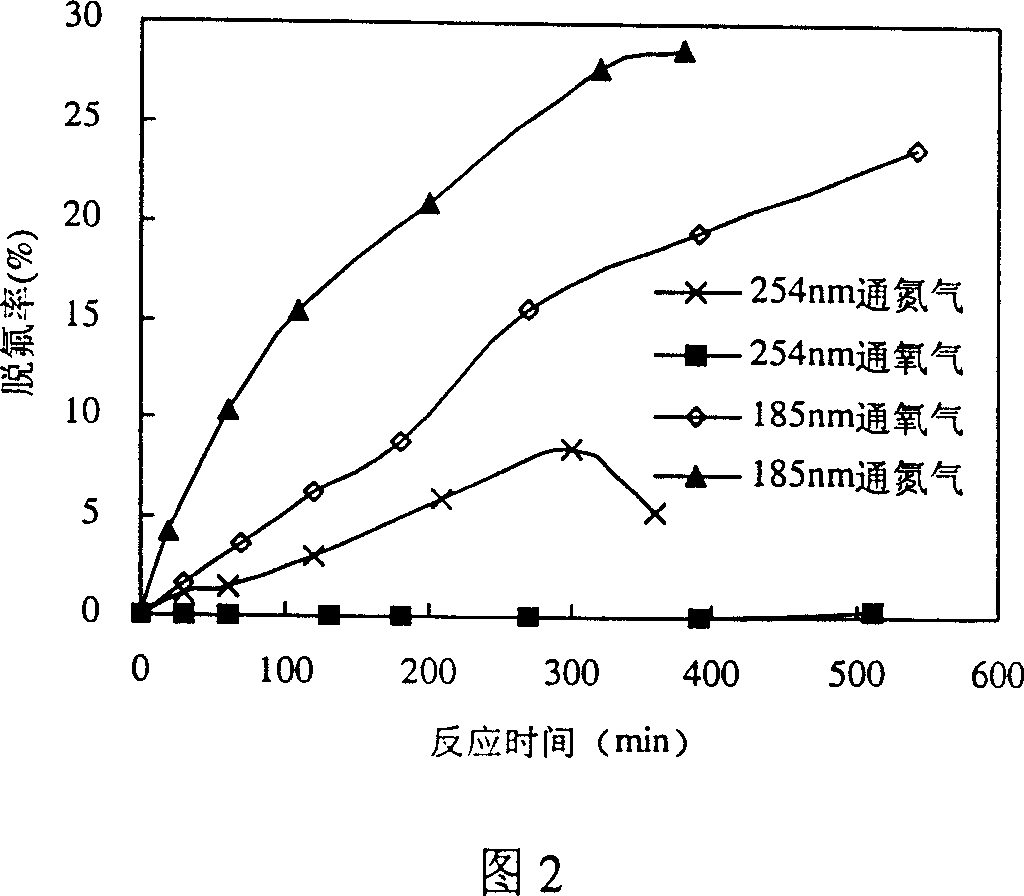

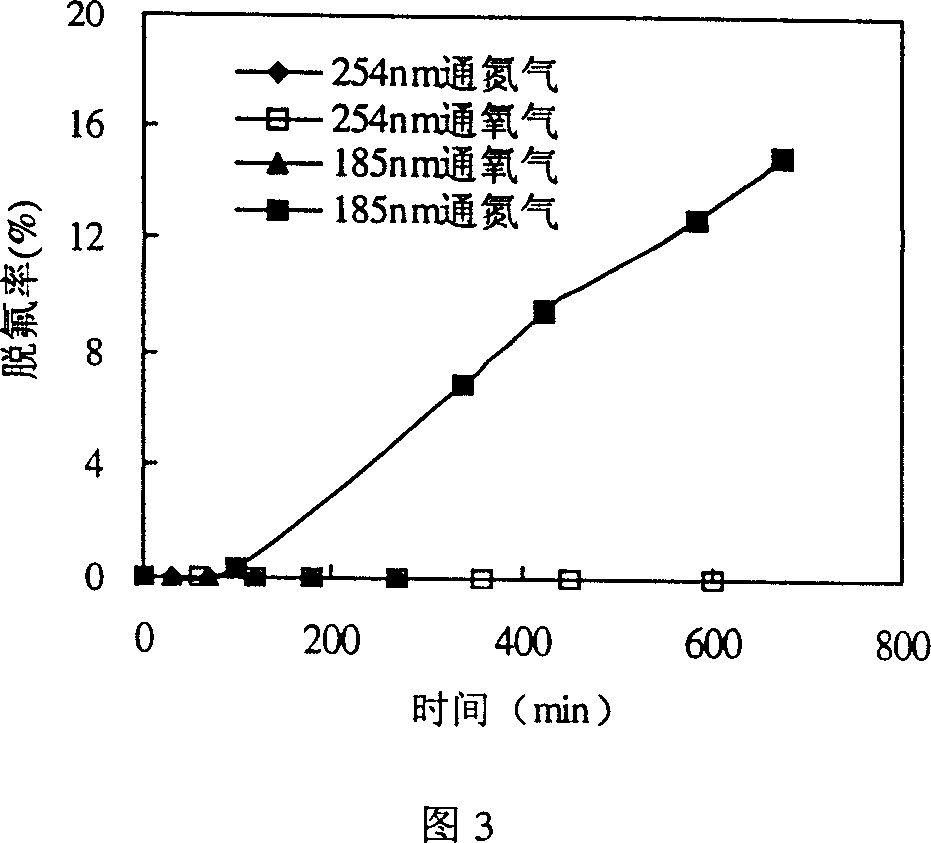

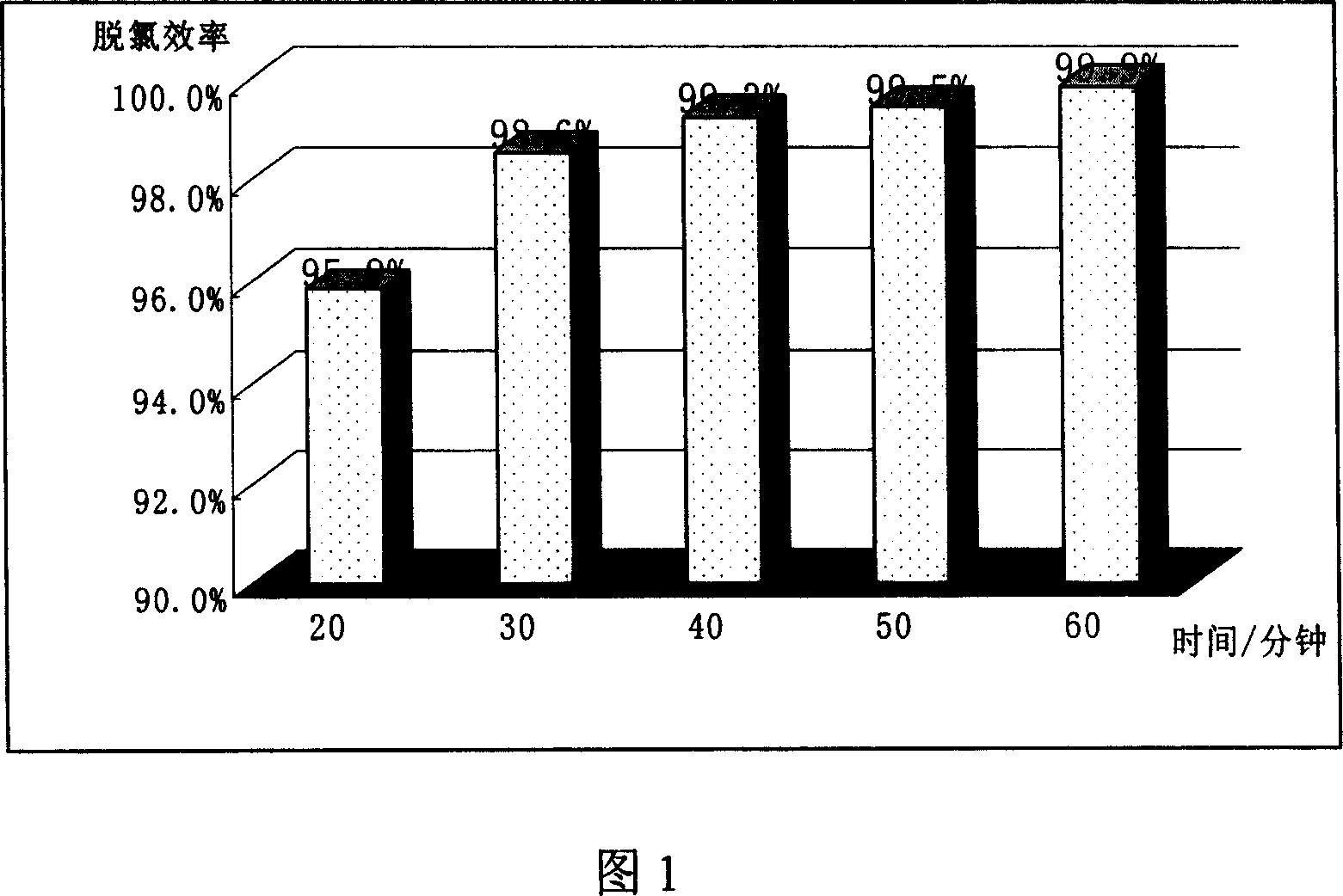

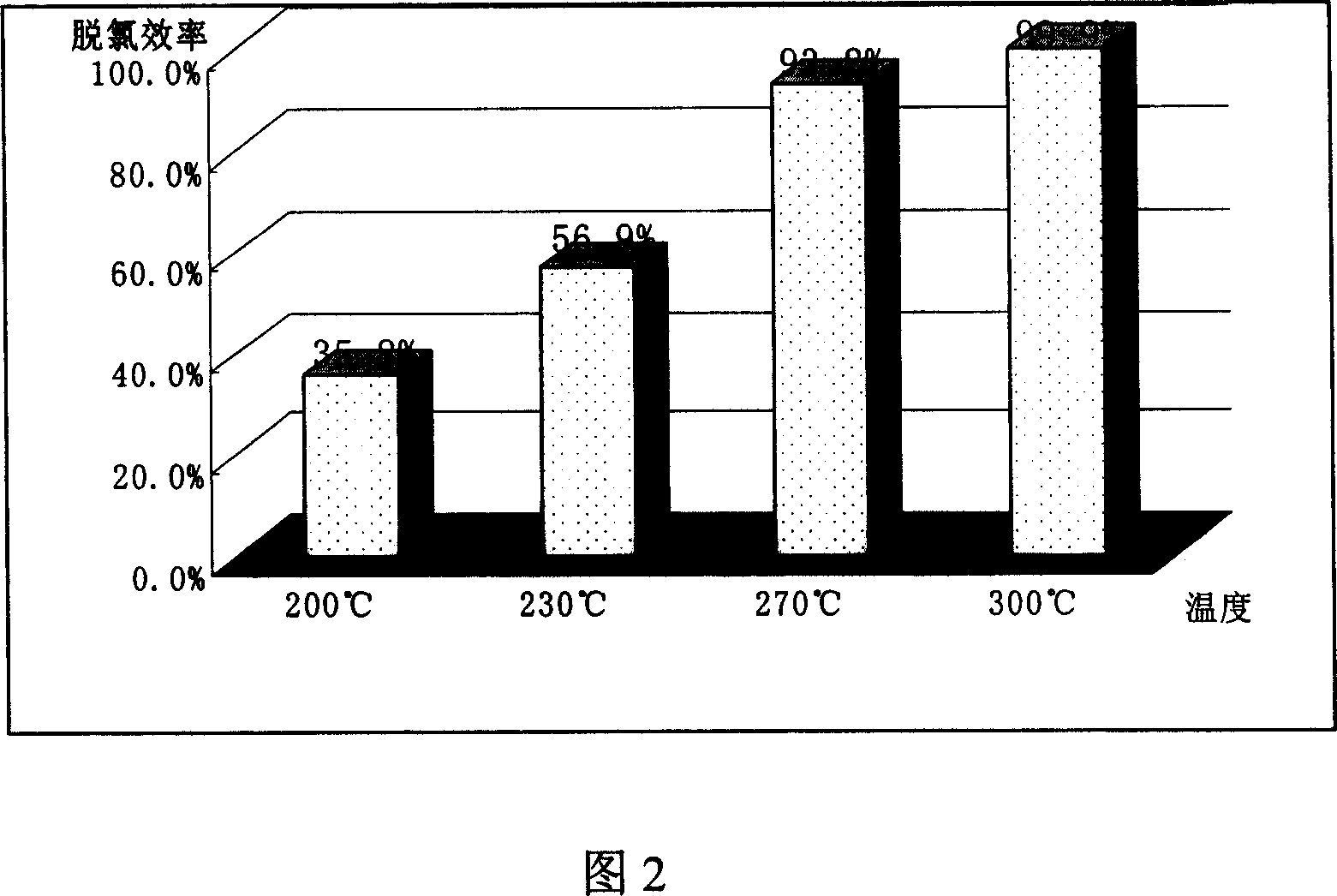

Method for defluorinating and degrading complete fluorine substituted compounds

InactiveCN1680219ALow toxicityEasy to handleSolid waste disposalOrganic decompositionUltravioletLaser light

A defluorinating and degrading method of fluorine substituted compound is characterized by vacuum ultraviolet irradiating PFOS and PFOA etc. fluorine substituted compound at anaerobic condition, defluorinating reacting fluorine substituted compound at irradiation of 185nm ultraviolet mercury vapour light or 172nm xenon quasi molecule laser light, inducing protective inert gas or reducing gas for realizing anaerobic condition, or adding reducing substance or semiconductor catalyst with high conducting band energy level during reacting process to improve defluorinating and decomposing ratio. It achieves simple operation and non-toxic.

Owner:TSINGHUA UNIV

Method for treatment of hazardous fluid organic waste materials

InactiveUS20030171635A1Atomization fastImprove decomposition efficiencyDispersed particle separationOrganic decompositionPlasma torchWater content

Method for treatment of fluid hazardous, organic waste materials, where a plasma of 2000-5000° C. temperature is generated by means of an electric arc in a plasma generator, the plasma torch is directed into a reactor, the reactor consists of three zones (4A, 4B, 4C), the plasma torch being introduced downwards into the uppermost first zone (4A), the fluid waste (1) being sprayed into the plasma torch in the first zone (4A), where it is heated to a temperature range of 1300-1600° C., the mixture of the plasma and the waste is introduced into the second zone (4B) of the reactor, where an oxidizing material is added (5) to the mixture, the combustion gas produced in the second zone (4B) is then led into the third zone (4C) of the reactor, where it is cooled rapidly by water spraying to a temperature range of 120-160° C., the cooled combustion gas is removed from the third zone (4C) of the reactor is led into a cooler. The plasma torch is generated from the mixture of carbon dioxide and oxygen, the oxidizing material introduced into the second zone (4B) of the reactor is a mixture of carbon dioxide and oxygen. Subsequently the water content of the combustion gas is separated by condensing and is removed and the residual combustion gas is removed.

Owner:BERECZKY TAMAS +4

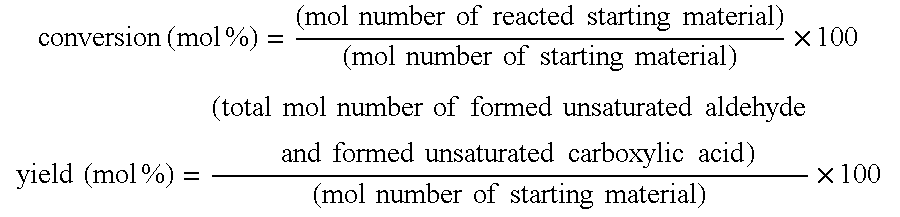

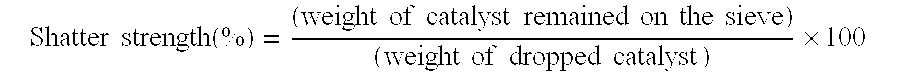

Catalyst for preparation of unsaturated aldehyde and unsaturated carboxylic acid

InactiveUS6784134B2Reduced activityHigh mechanical strengthOrganic compound preparationHeterogenous catalyst chemical elementsFiberGas phase

A catalyst suited for catalytic vapor-phase oxidation of isobutylene, t-butanol or propylene to produce respectively corresponding unsaturated aldehyde and unsaturated carboxylic acid is provided. Said catalyst consists of ring-formed shaped bodies composed of (i) a catalyst composition containing at least molybdenum and bismuth as the active ingredients and (ii) inorganic fibers. The catalyst excels in mechanical strength, can give the object products at high yield and shows little activity degradation with time.

Owner:NIPPON SHOKUBAI CO LTD

Ultrastable porous aluminosilicate structures

Mesoporous hexagonal, cubic, lamellar, wormhole, or cellular foam aluminosilicates, gallosilicates and titanosilicates derived from protozeolitic seeds using an ionic structure directing agent are described. The silicon and aluminum, gallium or titanium centers in the structures are stable so that the framework of the structure does not collapse when heated in the presence of water or water vapor (steam). The steam stable compositions can be used as catalysts for hydrocarbon conversions, including the fluidized bed catalytic cracking and the hydrocracking of petroleum oils, and other reactions of organic compounds.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Method of dehalogenating hydrocarbon containing carbon-carbon double bond

InactiveUS6476284B1Reduce residual fluorine contentOrganic decompositionSolid sorbent liquid separationIsomerizationHalogen

An efficient dehalogenation can be carried out by a method which comprises treating an organic compound containing a compound of halogen, such as fluorine or chlorine, as an impurity and having non-conjugated carbon-carbon double bonds, for example, butene polymer produced with a boron trifluoride catalyst, with an inorganic solid treating agent containing aluminum atoms. When the dehalogenation is conducted in the presence of a basic substance such as ammonia or an amine, it can be continued over long while inhibiting the isomerization of the non-conjugated carbon-carbon double bonds.

Owner:NIPPON PETROCHEMICAL CO LTD

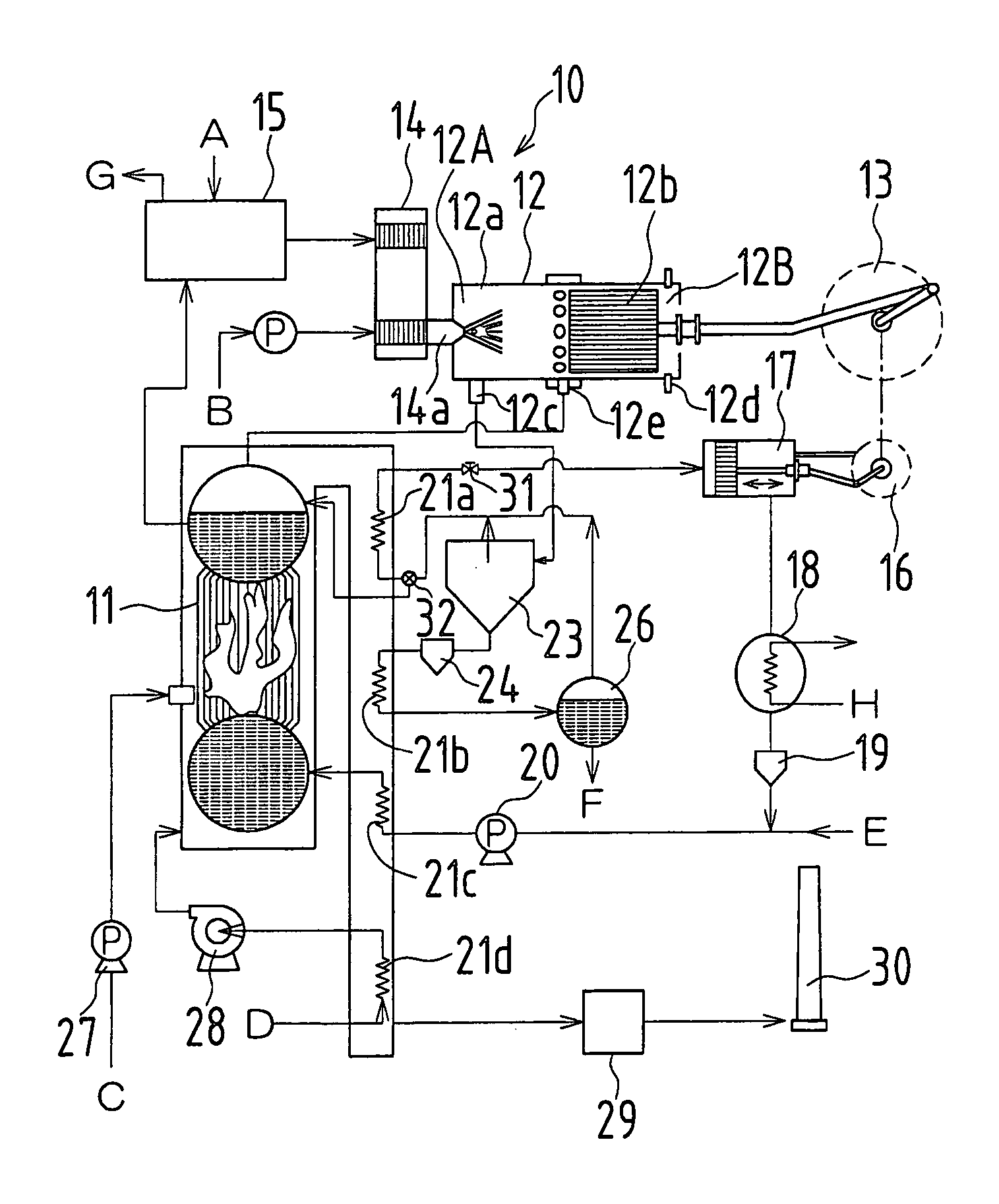

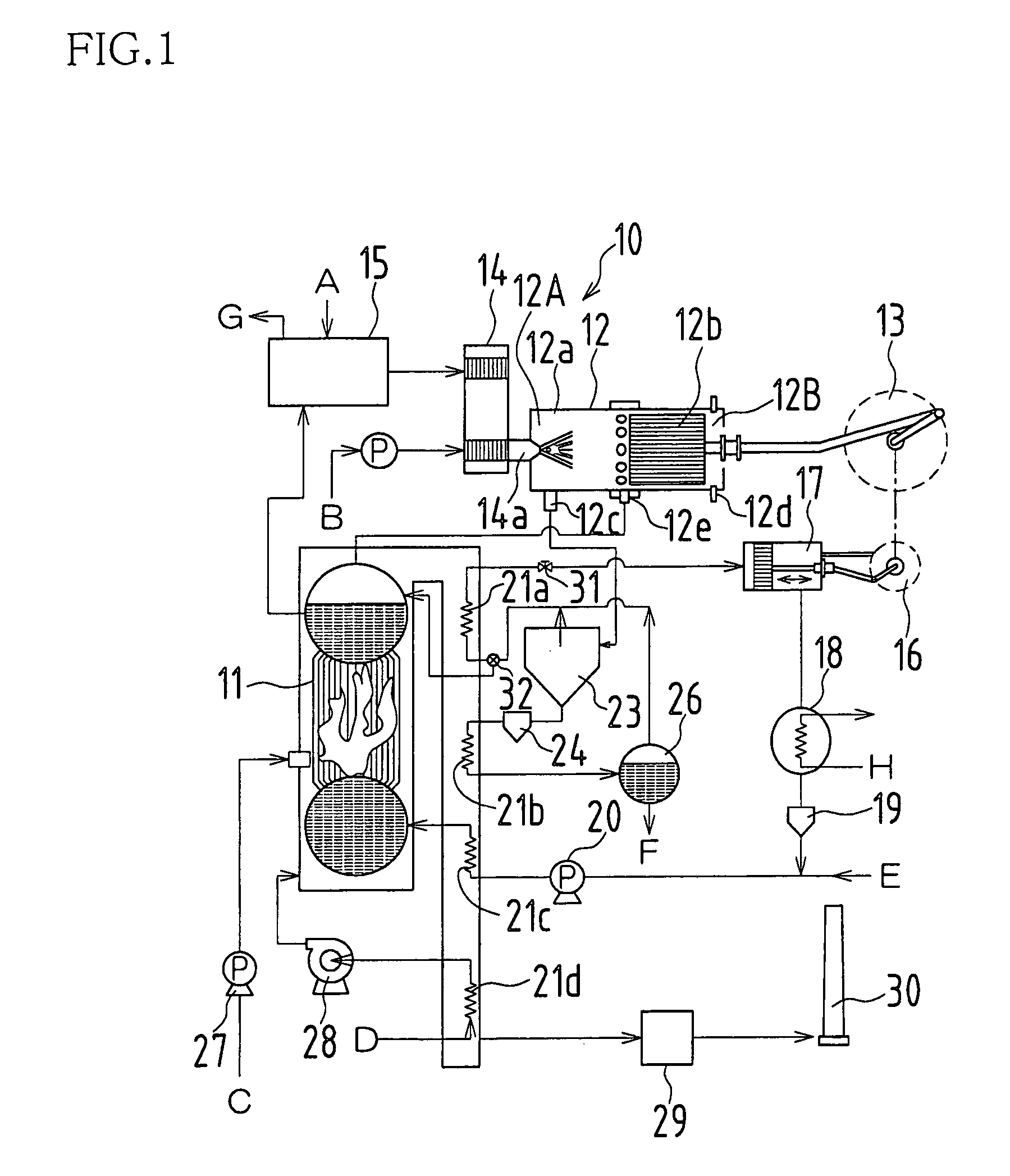

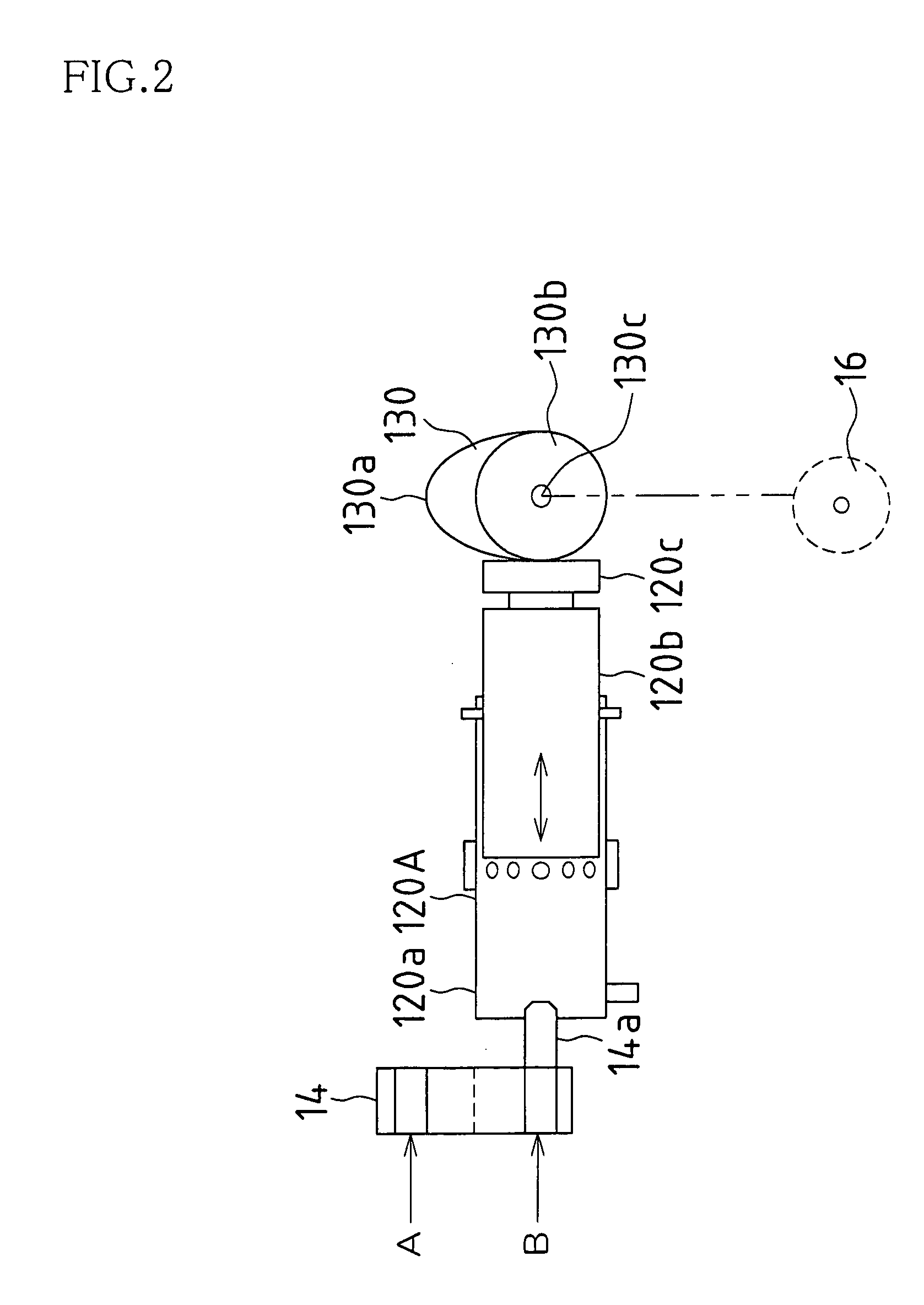

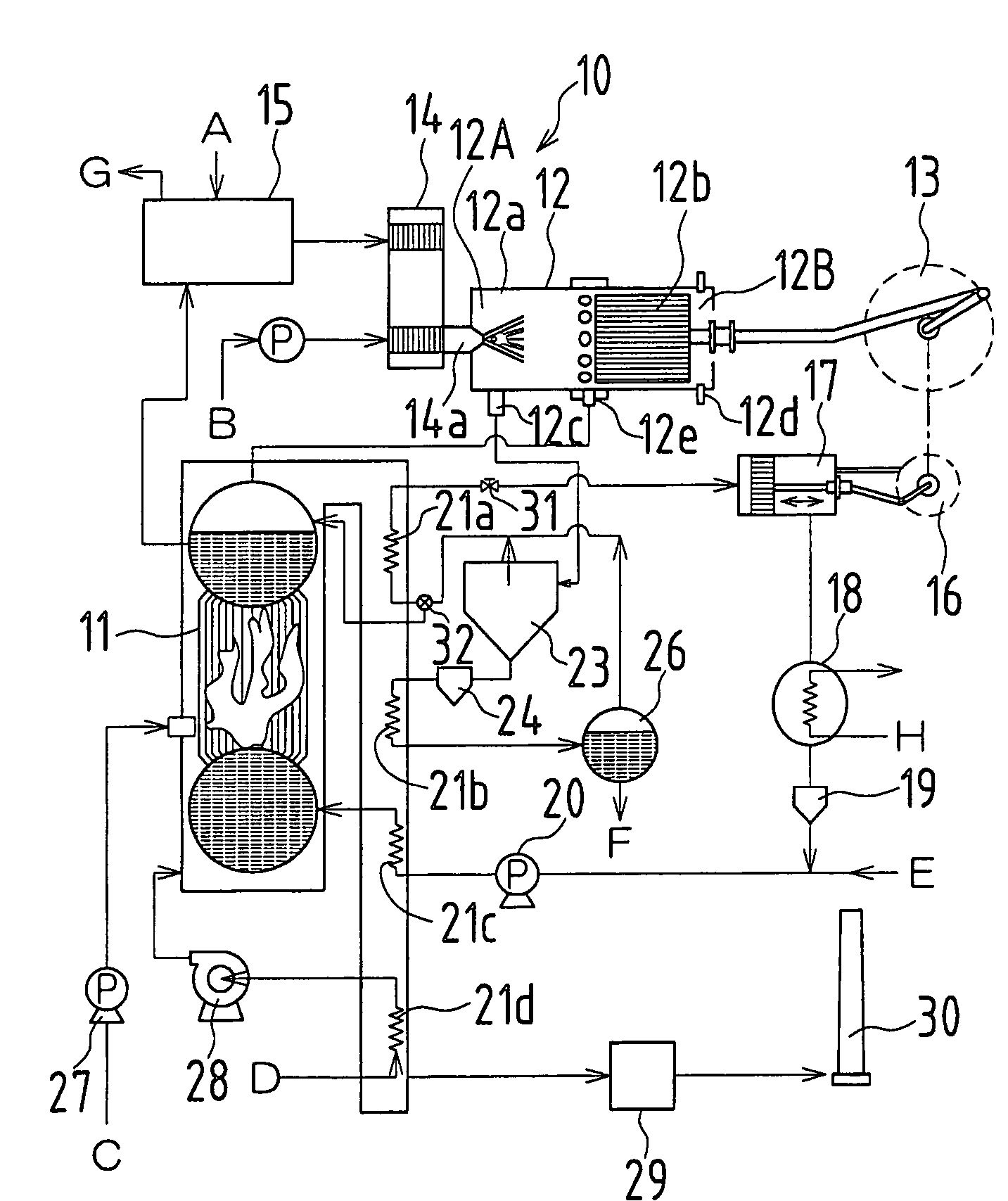

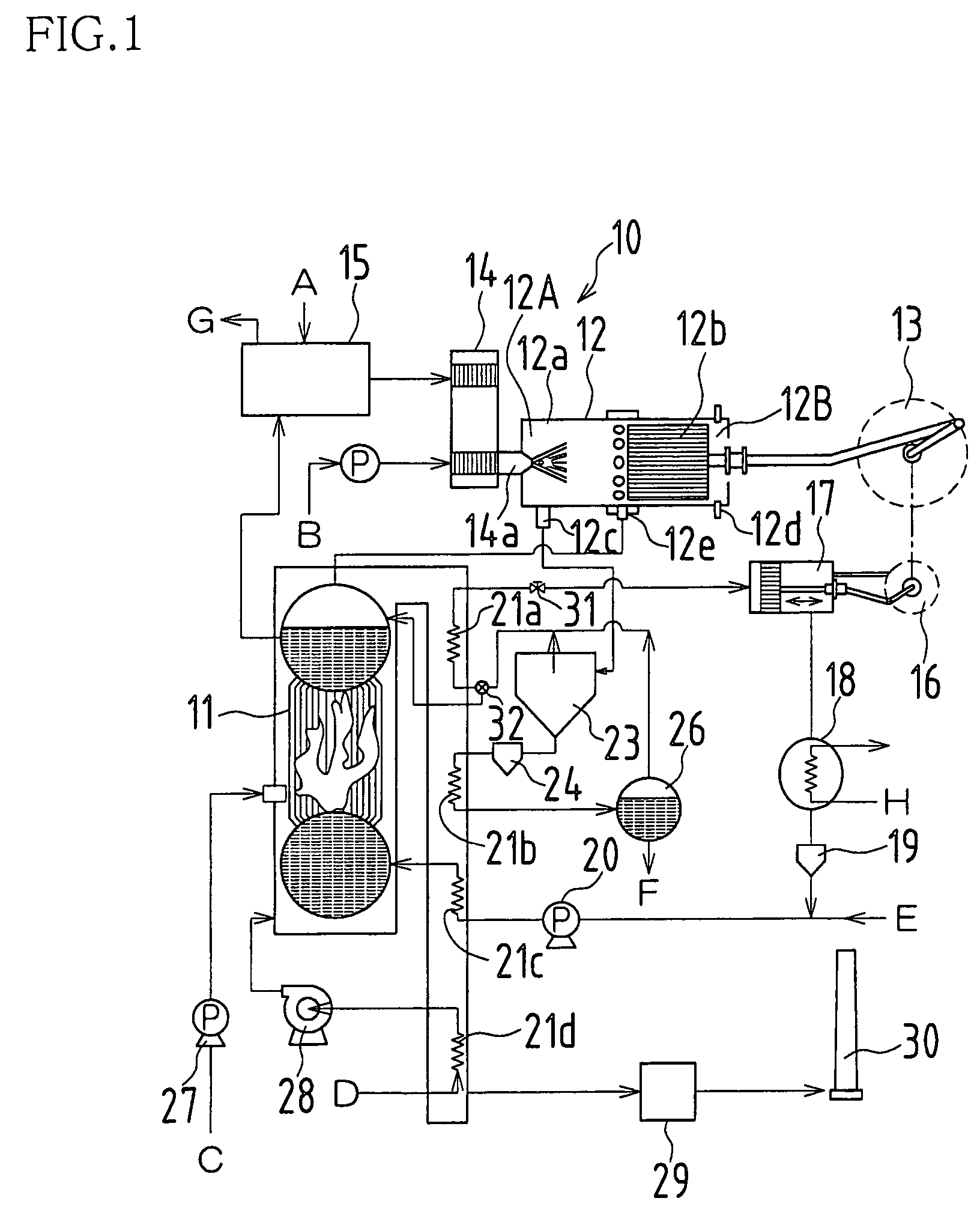

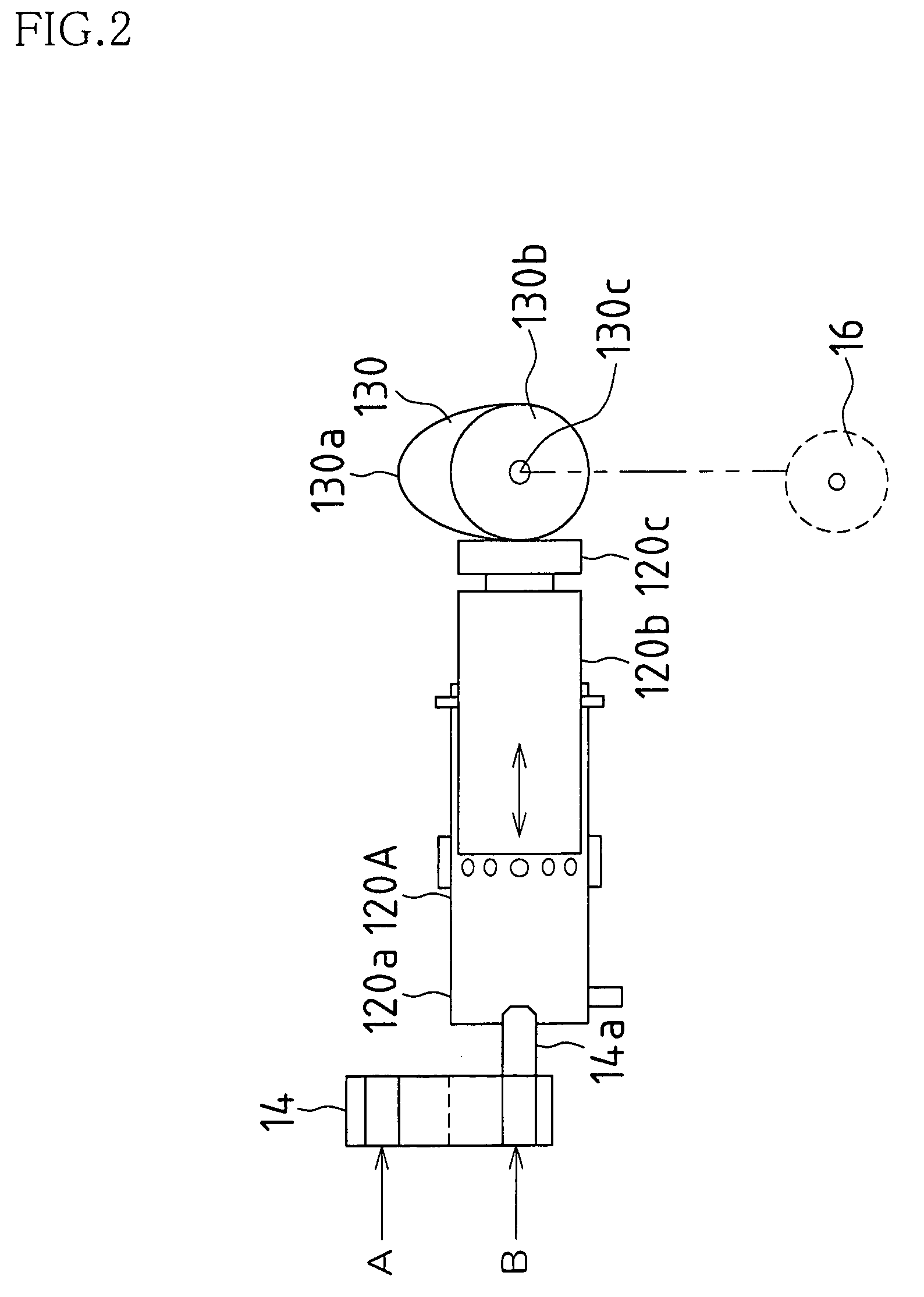

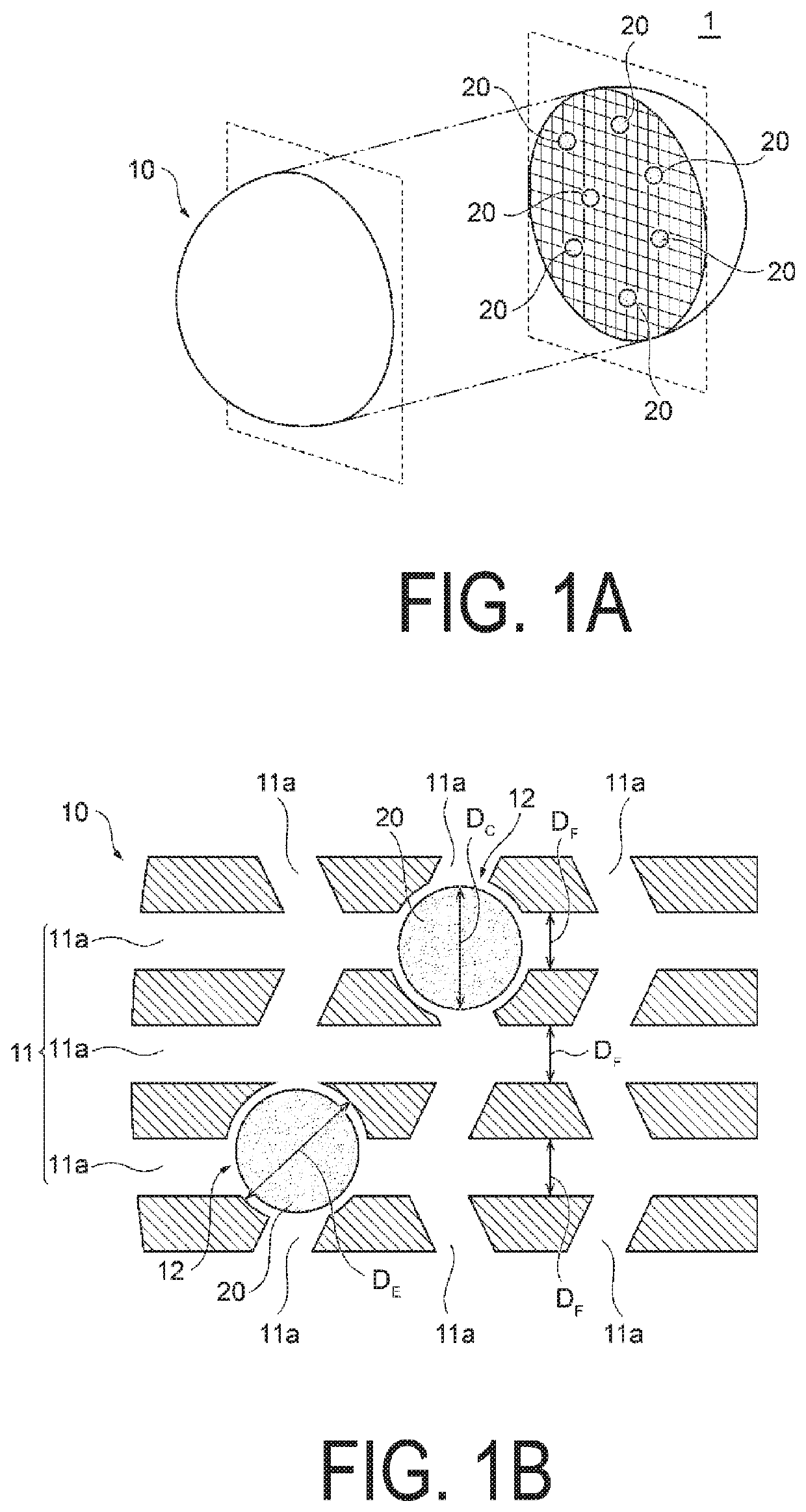

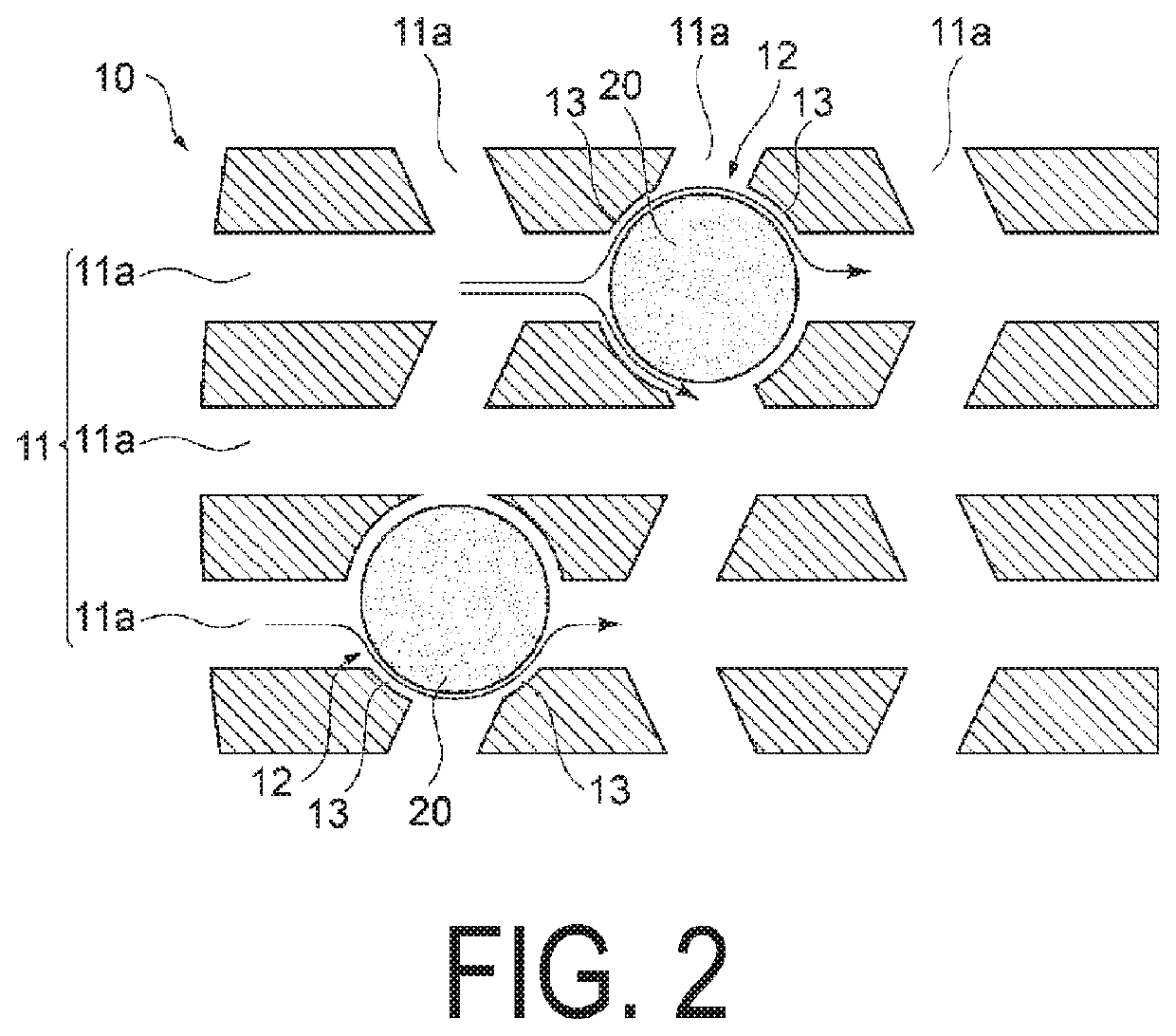

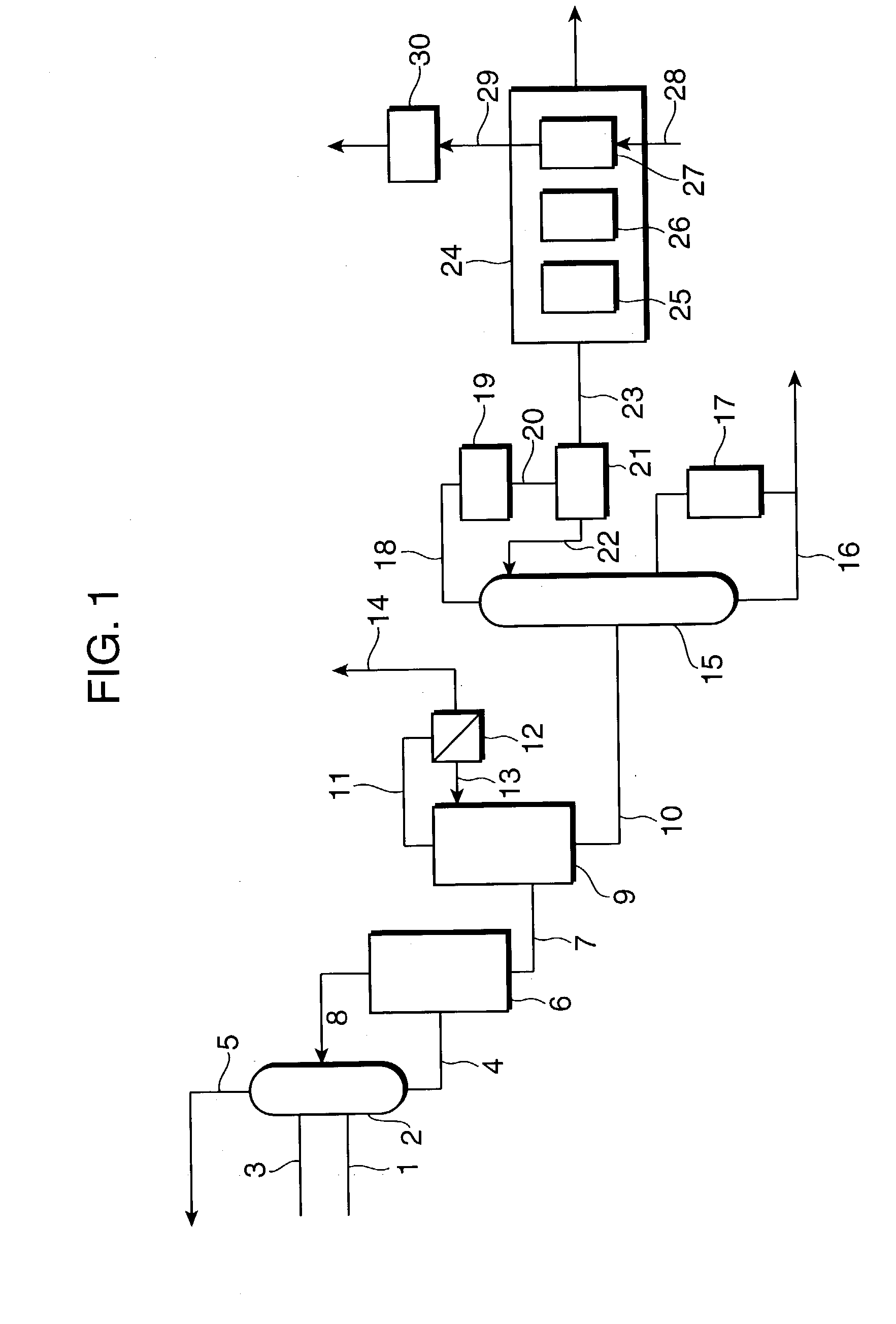

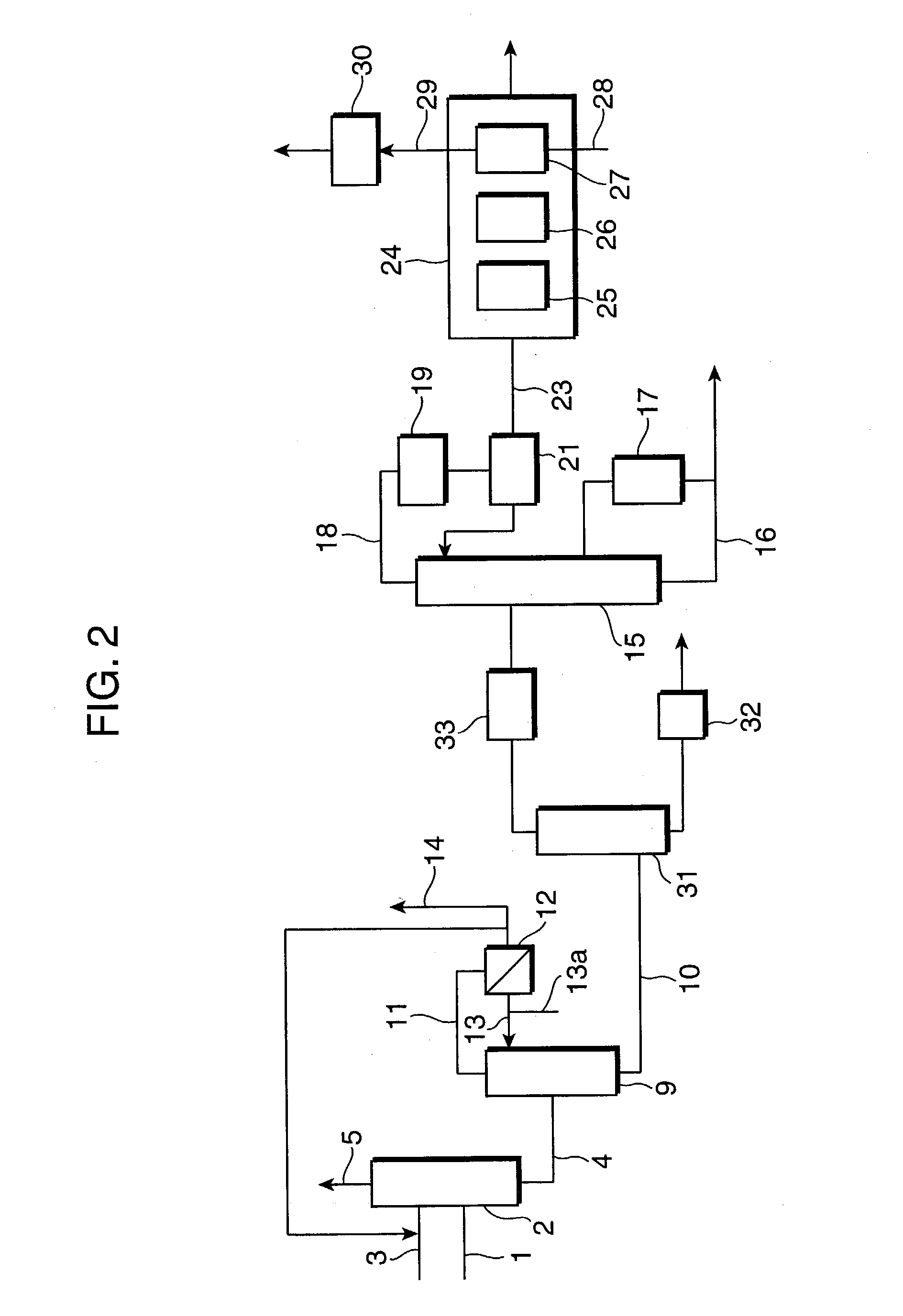

Reaction system of organic substances employing supercritical fluid or subcritical fluid

InactiveUS20040094144A1Less energy consumptionSimple processFatty acid esterificationGas production bioreactorsChemical reactionHigh energy

Disclosed is a reaction apparatus for organic and / or other substance(s) employing supercritical fluid(s) and / or subcritical fluid(s) permitting injection of organic substance(s) and / or other reactant substance(s) in homogeneous state(s) to reactor(s) without occurrence of clogging at location(s) of such injection, and also permitting actuation to occur in industrial fashion and at high energy efficiency. Reactor(s) (12) of this reaction apparatus comprise cylinder(s) (12a) and piston(s) (12b) provided at such cylinder(s) (12a). Actuation in periodic fashion is permitted by operating piston(s) (12b) to compress fluid vapor(s) and obtain supercritical fluid(s) and / or subcritical fluid(s); operating piston(s) (12b) in reverse direction(s) following conclusion of chemical reaction(s) of reactant substance(s), lowering temperature(s) and pressure(s) and stopping reaction(s); and removing, from cylinder(s) (12a), product(s) obtained while at the same time delivering new charge(s) of fluid vapor(s) to cylinder(s) (12a).

Owner:YANMAR CO LTD +2

Reaction apparatus for organic and/or other substances employing supercritical fluid or subcritical fluid

InactiveUS7547539B2Simple processLess energy consumptionFatty acid esterificationGas production bioreactorsChemical reactionHigh energy

Owner:YANMAR CO LTD +2

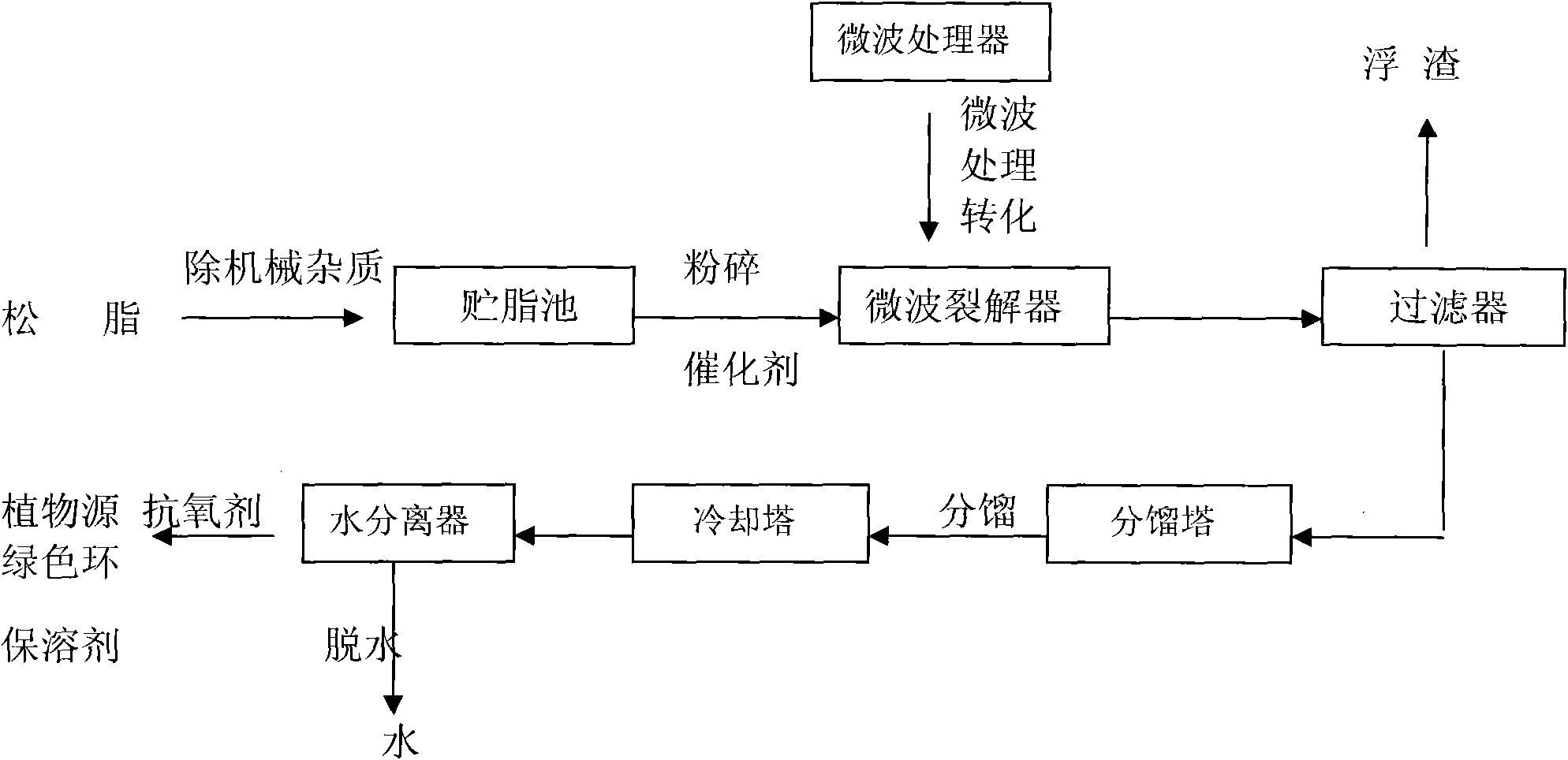

Green plant source environmental protection solvent and preparation method thereof

ActiveCN101642092AReduce releaseReduce energy consumptionBiocideOrganic decompositionAntioxidantTurpentine

The invention provides a green plant source environmental protection solvent and a preparation method thereof. The environmental protection solvent is obtained by the microwave cracking of turpentineunder the action of a certain catalyst. The solvent comprises 15wt% to 35wt% of alpha pinene, 15wt% to 40wt% of D-hesperidene, 5wt% to 15wt% of longifolene, 5wt% to 15wt% of camphene, 1wt% to 5wt% ofterpenol and 0 to 2wt% of antioxidant. Compared with the prior art, the raw material of the green plant source environmental protection solvent completely comes from the turpentine of a pine and has low price and simultaneously, a new prospect is supplied to silvichemicals. The solvent as a natural carrier of pesticide replaces an aromatic solvent and a polar solvent with poor safety environmentalprotection, reduces the release of toxic and harmful organic solvents in the environment and has mild and simple preparation condition and low energy consumption.

Owner:SHENZHEN NOPOSION AGROCHEM

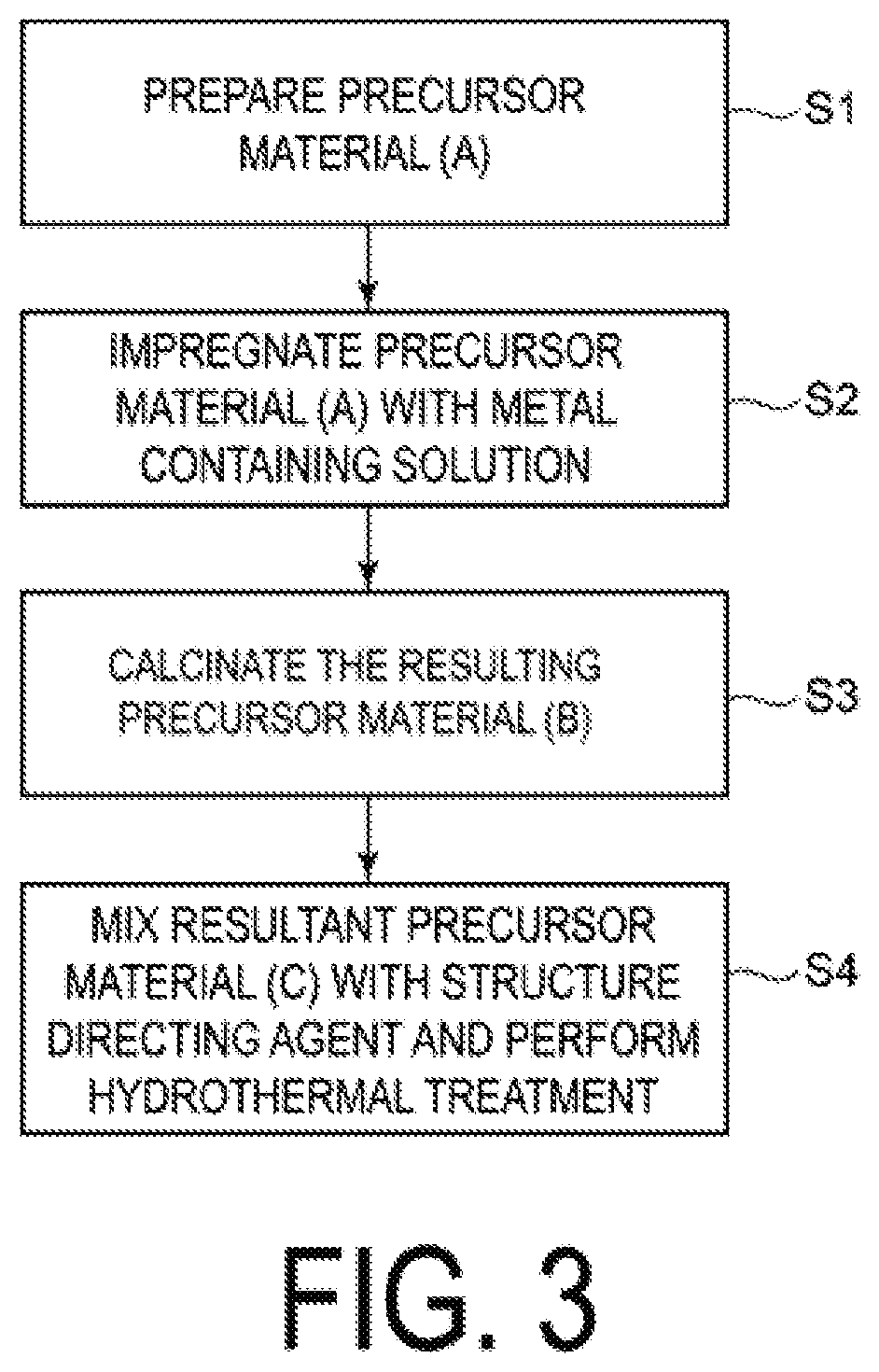

Preparation method of a novel hydrogenation and dechlorination catalyst

InactiveCN101007280AImprove hydrodechlorination performanceOrganic decompositionHydrocarbon from halogen organic compoundsActive componentAlloy

The invention involves a new preparation method of hydrogenation dechlorination accelerant, it loads high scattering Pd atom cluster on nanometer amorphous alloy or nanometer Ni powder through replacement reaction, then prepares new surface NiPd alloy accelerant through crystallization treatment. The accelerant prepared through the invention has characteristics of small dimension of active components, good dispersion degree and high activity, and it applies to catalytic hydrogenation dechlorination reaction.

Owner:NANKAI UNIV

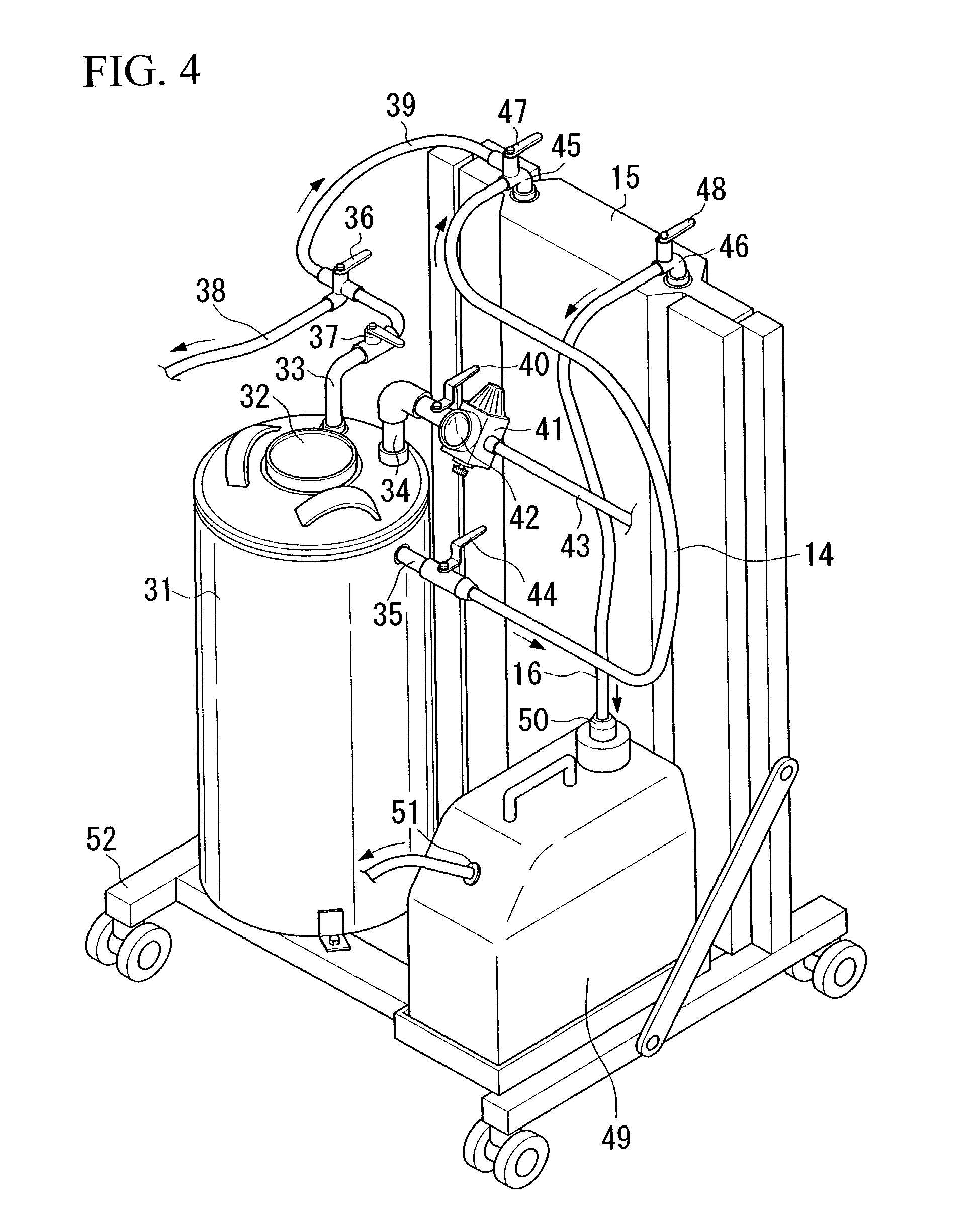

Granular photocatalytic material, functional restoration method therefor, and apparatus for decomposing and removing toxic organic matter using the same

InactiveUS20030104930A1Increased durabilityIncrease surface areaPerfluorocarbons/hydrofluorocarbons captureGlass/slag layered productsPhoto irradiationPhysical chemistry

A granular photocatalytic material in the form of pellets or tablet is produced by compressing a photocatalyst mixture containing photocatalytic particles and a filler in air, a vacuum, or an inert gas at a temperature of 0 to 200.degree. C., a pressure of 500 to 6000 kg / cm.sup.2, and a pressing time of 0.01 to 60 seconds. An alkali slurry is applied on the surface of the granular photocatalytic material. A method of restoring a function of granular photocatalytic material comprises washing the surface of the granular photocatalytic material with the slurry or an alkali solution of sodium hydroxide An apparatus for decomposing and removing toxic organic matter comprises a means of bringing the granular photocatalytic material into contact with the toxic organic matter in a liquid or air, and a means of irradiating the granular photocatalytic material with light having a wavelength of 400 nm or less.

Owner:YAMAHA CORP

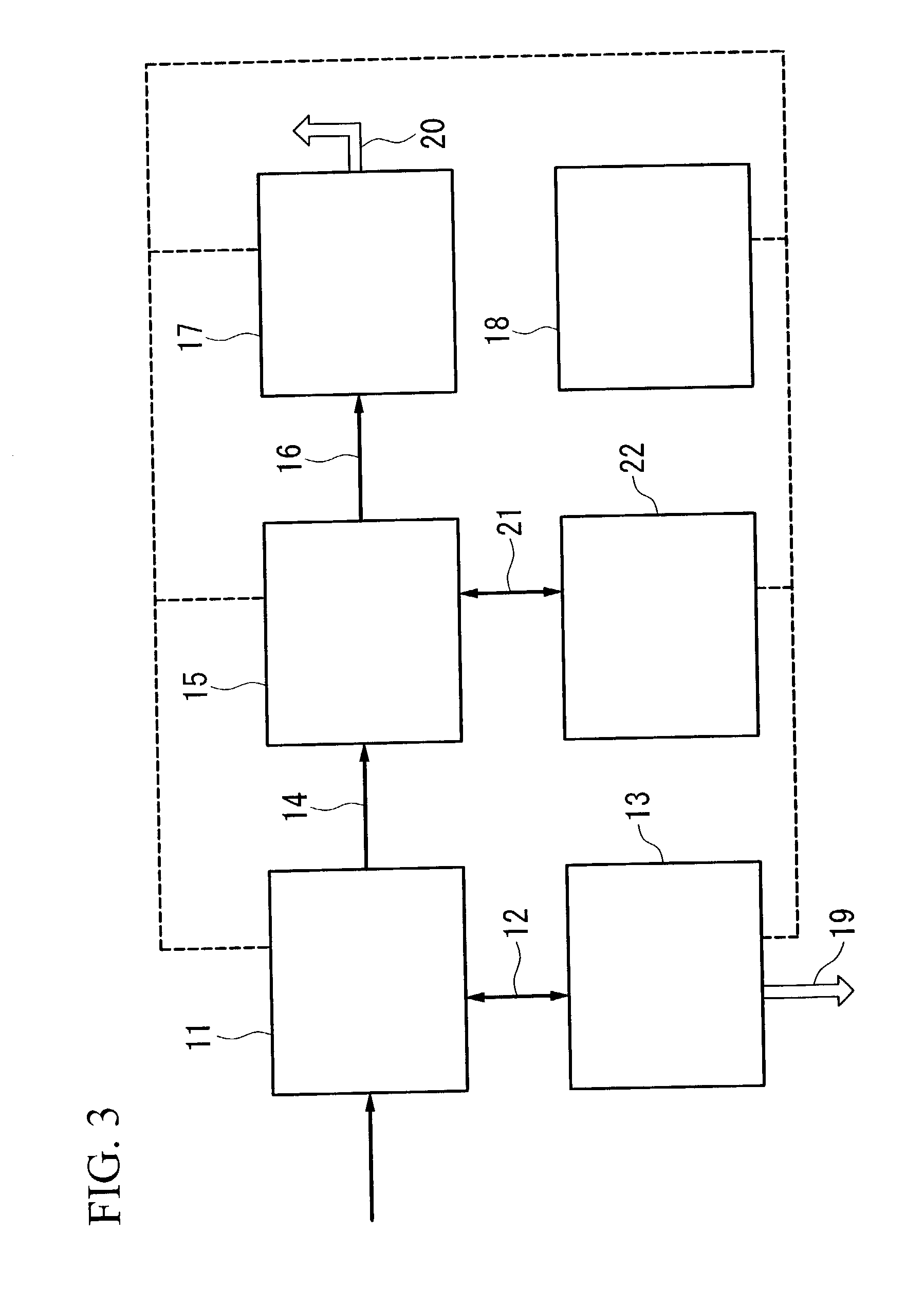

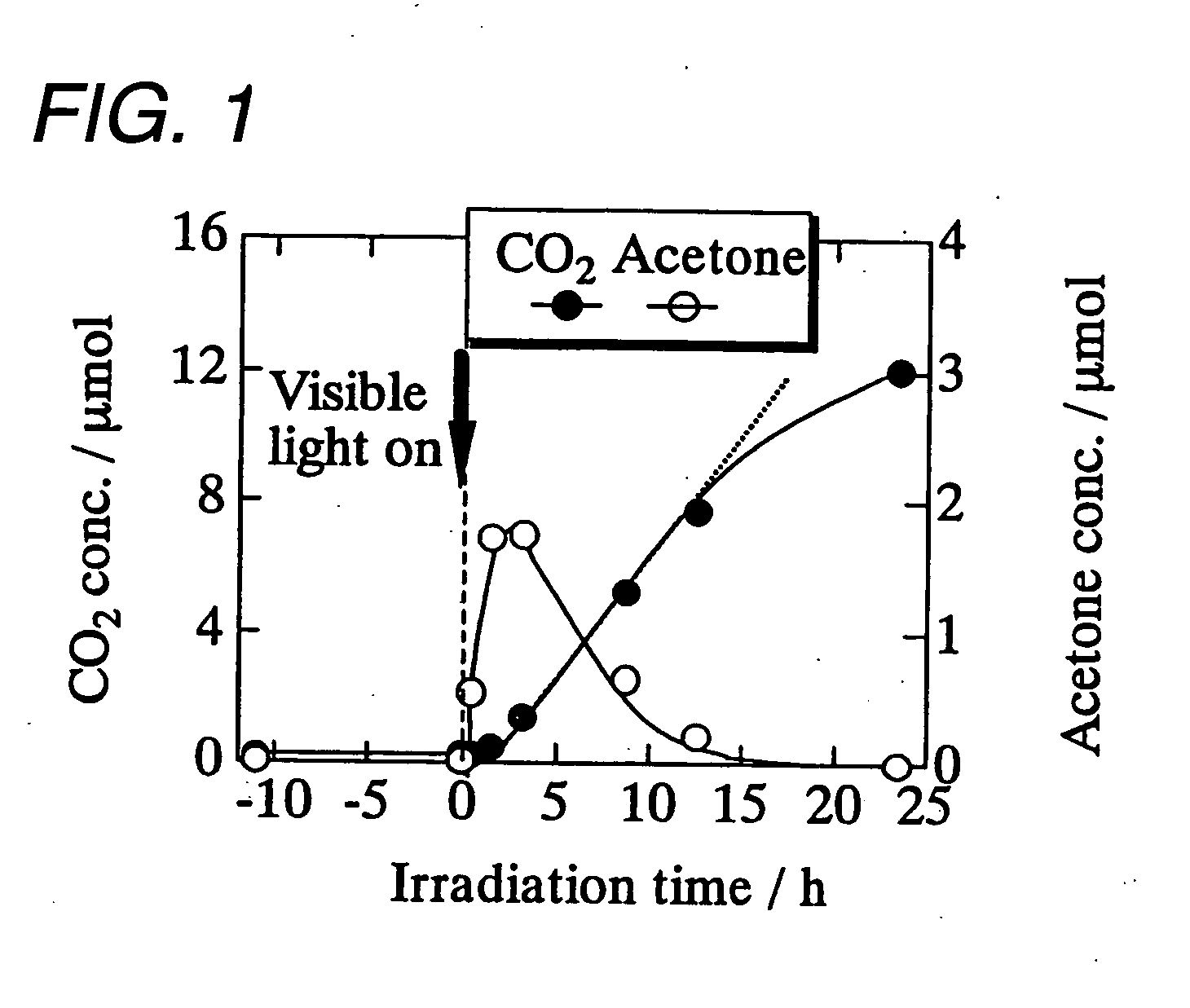

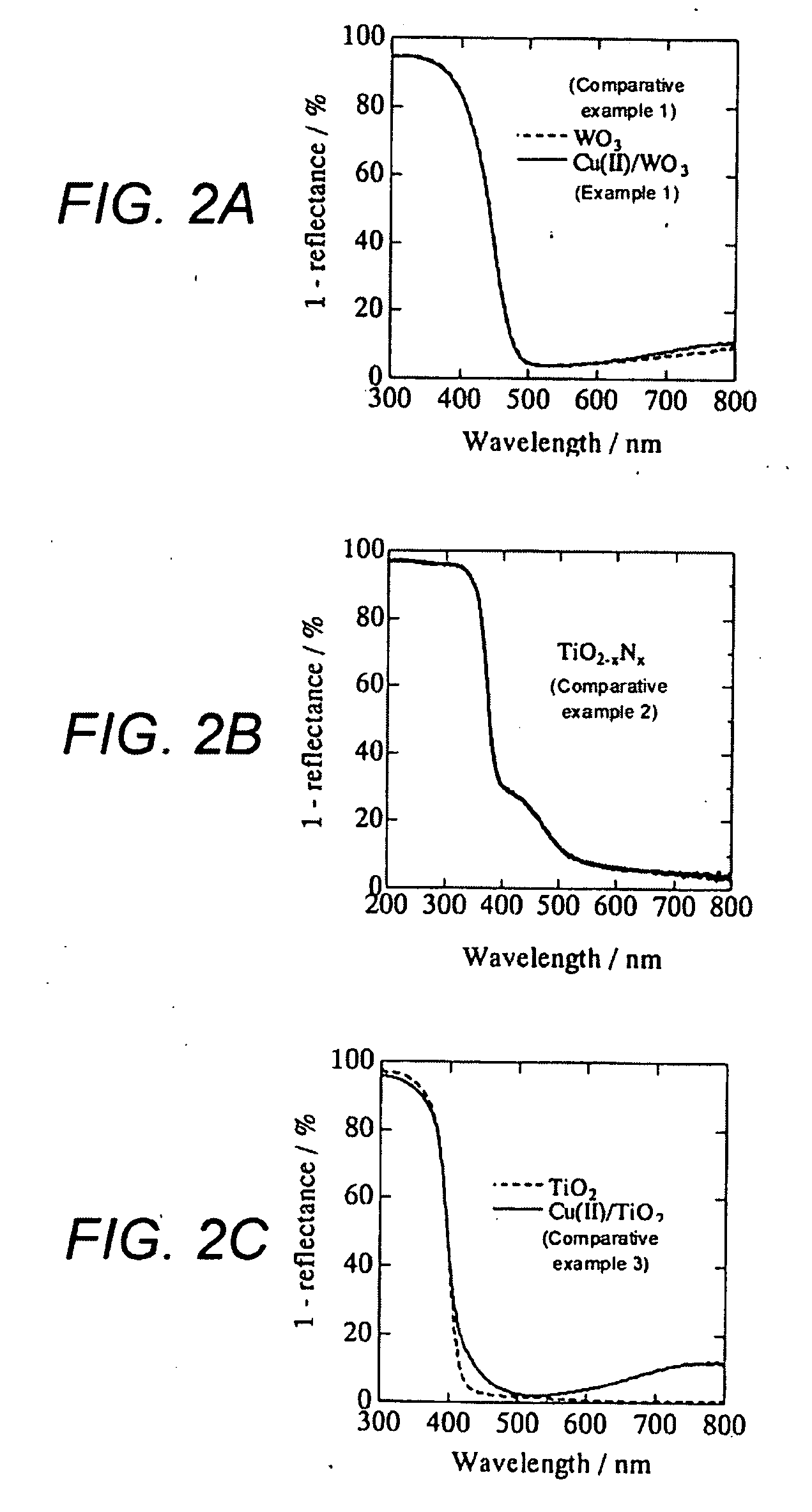

Photocatalyst material, method for decomposition of organic material, interior member, air purification device, and apparatus for preparation of oxidizing agent

ActiveUS20110005916A1Suppressing typical photochromismAppearance unchangedDispersed particle separationOrganic decompositionDecompositionMicroparticle

Owner:PANASONIC CORP +1

Gas-phase dehydration reaction process

InactiveUS6489515B2Avoid decompositionEfficient executionOrganic compound preparationDispersed particle separationDecompositionGas phase

Here is provided a process capable of efficiently carrying out a gas-phase dehydration reaction comprising contacting a raw material gas with a solid oxide catalyst containing an alkali metal element to allow reaction to progress by inhibiting decomposition of the raw material and the objective product. This process comprises using a sintered oxide comprising an alkali metal element and silica and / or alumina as a loading material for preheating of the raw material gas and / or as a supporting material for fixation of the position of the catalyst.

Owner:NIPPON SHOKUBAI CO LTD

Process for producing 2,3,3,3-tetrafluoropropene

ActiveUS20140303409A1Improving HFO-1234yf selectivityReduce presencePreparation by hydrogen halide split-offPhysical/chemical process catalystsHFO-1234yfOrganic chemistry

The present invention relates, in part, to the discovery that the presence of HF in a HCFC-244bb feedstream in a reaction for the preparation of HFO-1234yf results in selectivity changeover from HFO-1234yf to HCFO-1233xf. By substantially removing HF, it is shown that the selectivity to HFO-1234yf via dehydrochlorination of HCFC-244bb is improved.

Owner:HONEYWELL INT INC +1

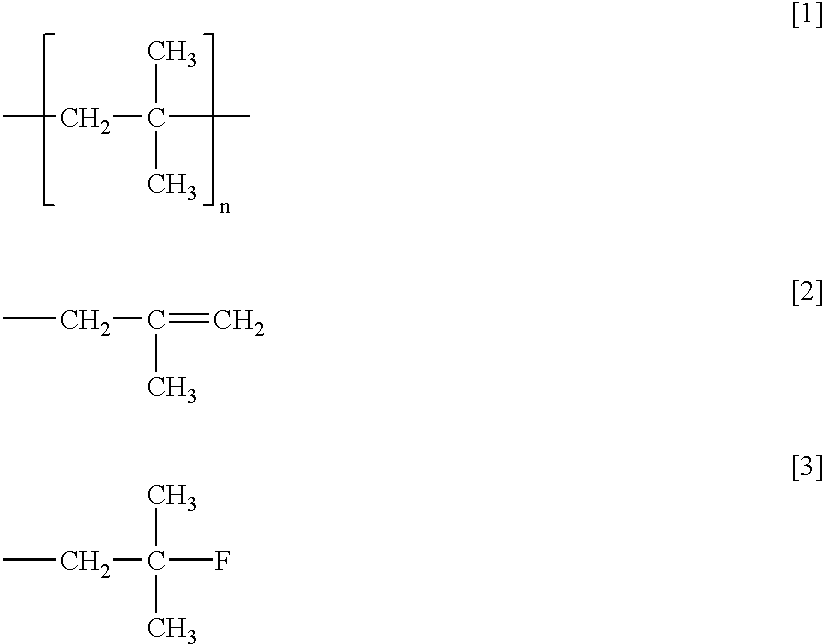

Process for preparing acetylene derivative from a ketone compound

A preparation process of an acetylene derivative comprising reacting a compound having a skeleton represented by the formula (1): in the molecular formula with a compound represented by the formula (2): wherein R1, R2 R3 and R4 are individually an alkyl group having 1 to 6 carbon atoms and can be the same or different, R1 and R3 can bond each other to form a ring, and R1 and R2 or R3 and R4 can be bond each other to form one or two heterocyclic rings: or with a compound represented by the formula (3): wherein R1, R2, R3 and R4 are the same as in the formula (2), and X1 is a chlorine, bromine or iodine atom.

Owner:MITSUI CHEM INC

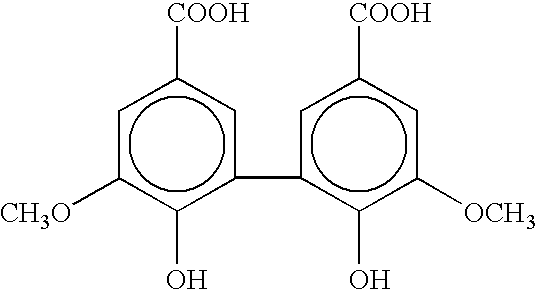

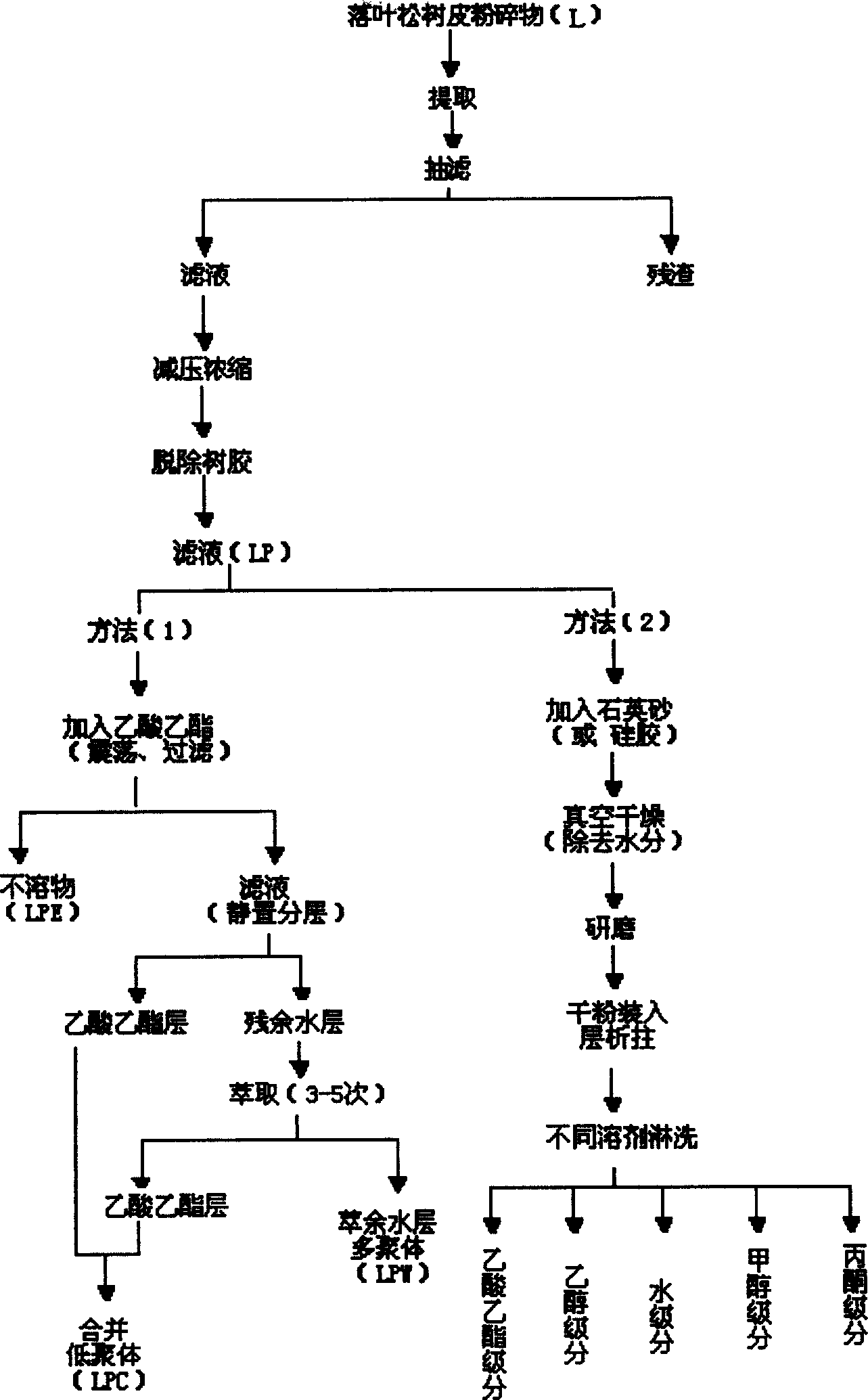

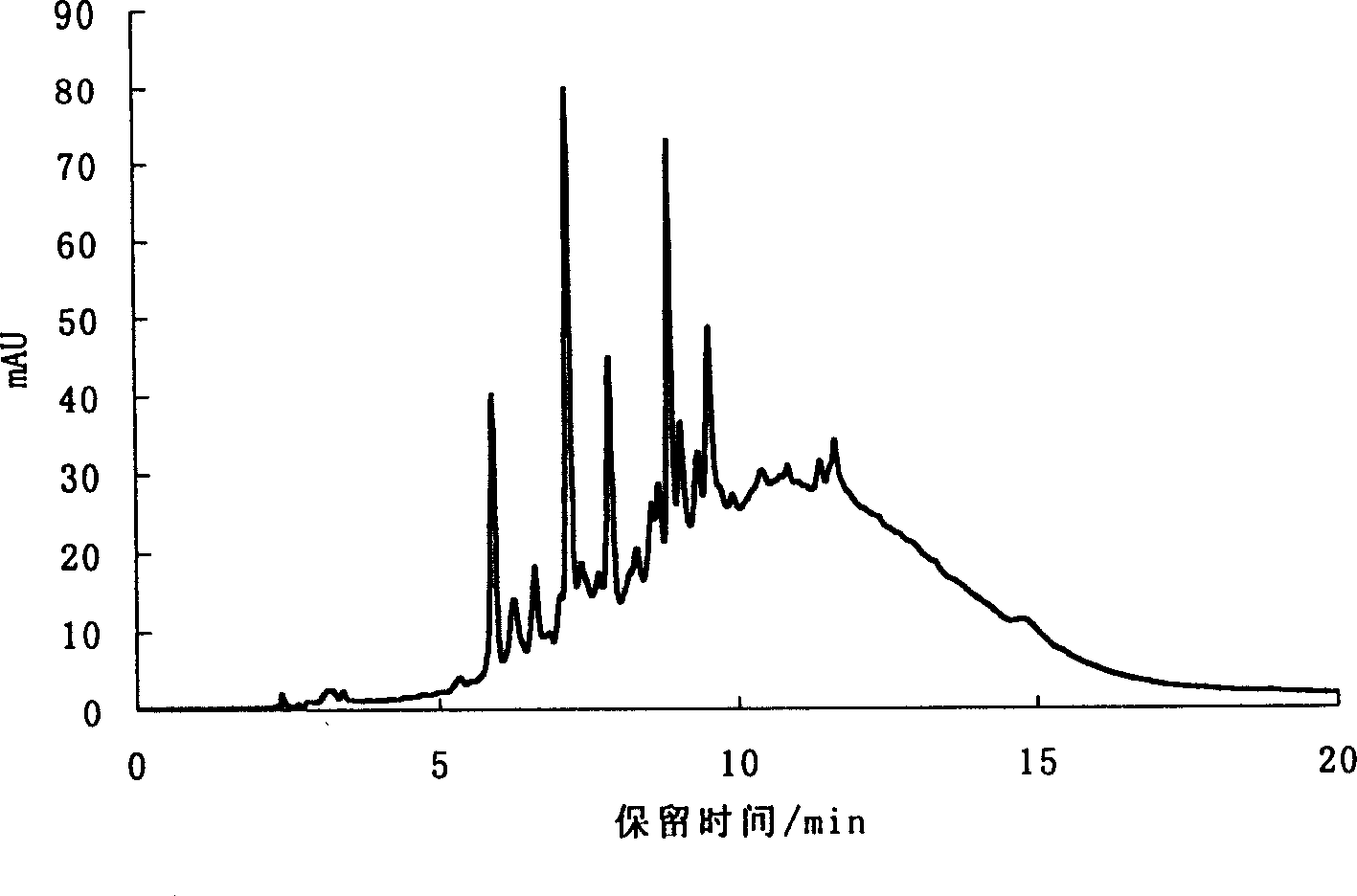

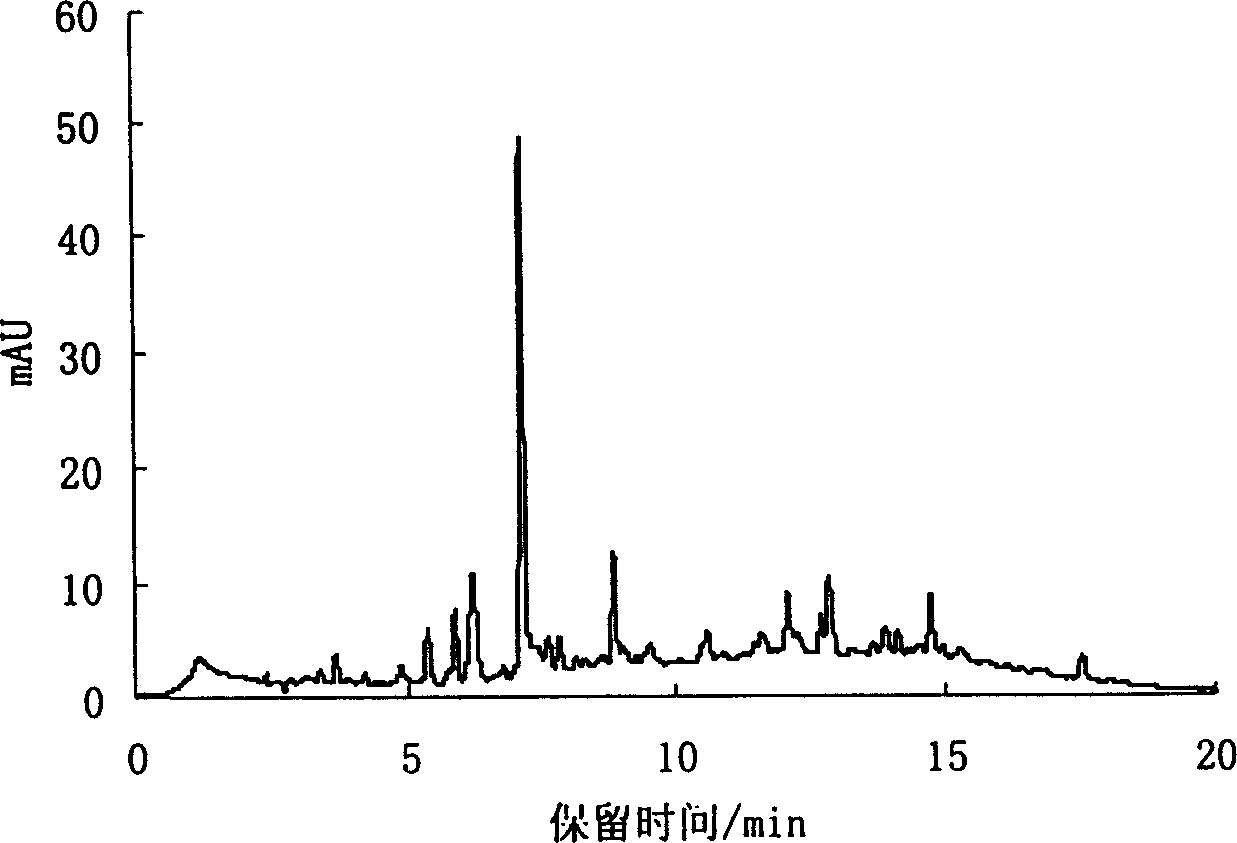

Preparation of oligomer and monomer from tannin by catalytic hydrogen degradation

InactiveCN1583686AImprove biological activityEmission reductionEsterified saccharide compoundsNon-macromolecular adhesive additivesGallic acid esterKetone

A process for preparing oligomer or monomer from vegetative tannin includes such steps as immersing the plant rich in tannin in alcohol or ketone, extracting to obtain liquid extract, recovering solvent , filter, extractin in different solvents to obtain different components, catalytic hydrogendyzing to obtain coarse pdyphenol monomer and oligomer, and purifying to obtain oligoproanthocyaridin, ellagic acid, and gallic acid.

Owner:SICHUAN UNIV

Process for production of ether carboxylates

The present invention relates to a process for producing an ether carboxylate which includes the steps of (1) reacting an aliphatic monohydric alcohol with an alkylene oxide in the presence of an alkali catalyst; (2) neutralizing a reaction solution obtained in the step (1) with an acid such as hydroxycarboxylic acids to obtain an ether alcohol; and (3-1) reacting the obtained ether alcohol with a monohalogenofatty acid or a salt thereof and an alkali metal hydroxide, or (3-2) subjecting the obtained ether alcohol to catalytic oxidation reaction in the presence of a catalyst. The obtained ether carboxylate has a less odor and a high quality and is therefore suitably used in the applications such as cosmetics and toiletries.

Owner:KAO CORP

Preparation of fluorinated olefins via catalytic dehydrohalogenation of halogenated hydrocarbons

ActiveUS9040759B2Preparation by hydrogen halide split-offPhysical/chemical process catalystsHalohydrocarbonHydrogen atom

A process for making a fluorinated olefin having the step of dehydrochlorinating a hydrochlorofluorocarbon having at least one hydrogen atom and at least one chlorine atom on adjacent carbon atoms, preferably carried out in the presence of a catalyst selected from the group consisting of (i) one or more metal halides, (ii) one or more halogenated metal oxides, (iii) one or more zero-valent metals / metal alloys, (iv) a combination of two or more of the foregoing.

Owner:HONEYWELL INT INC

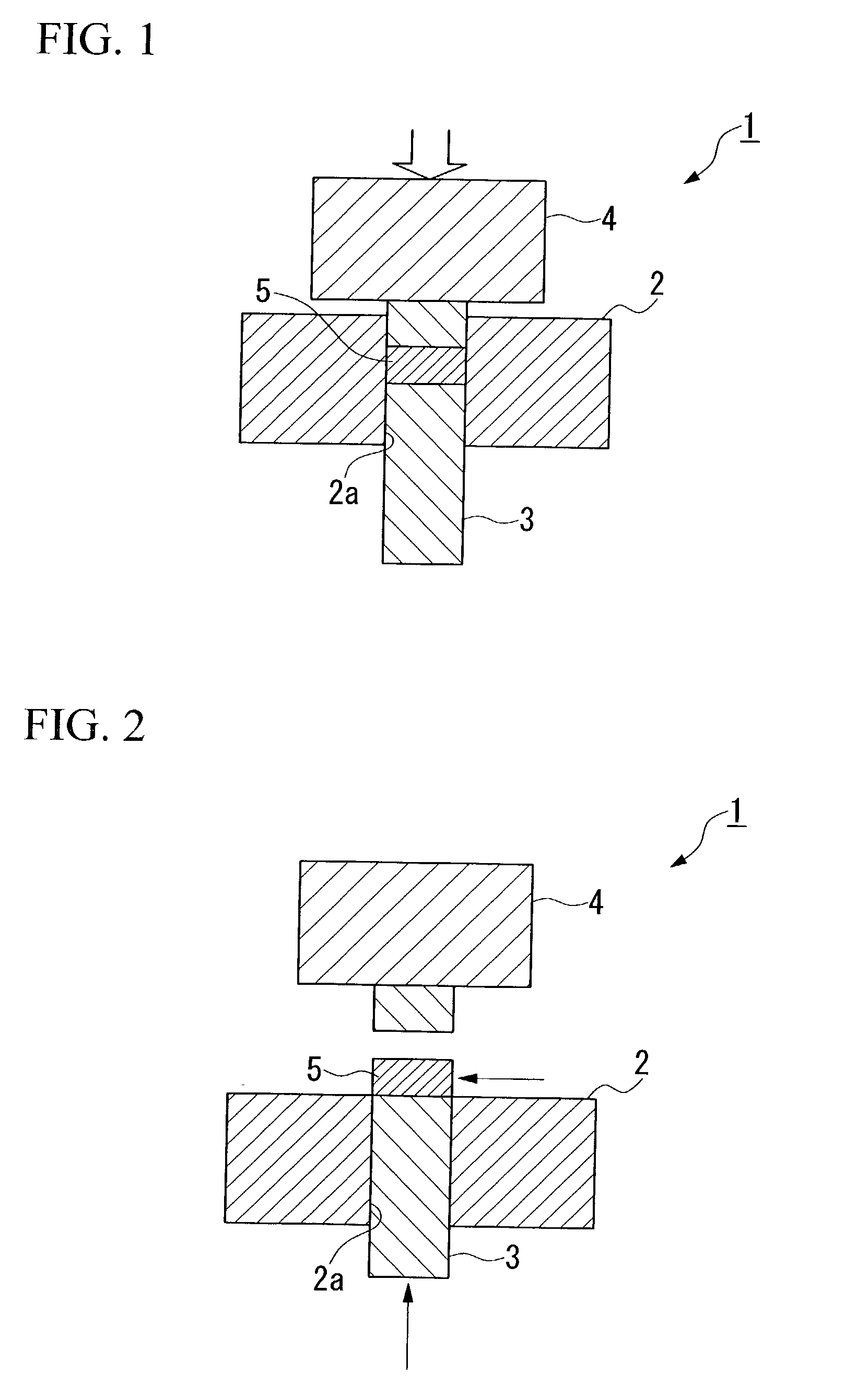

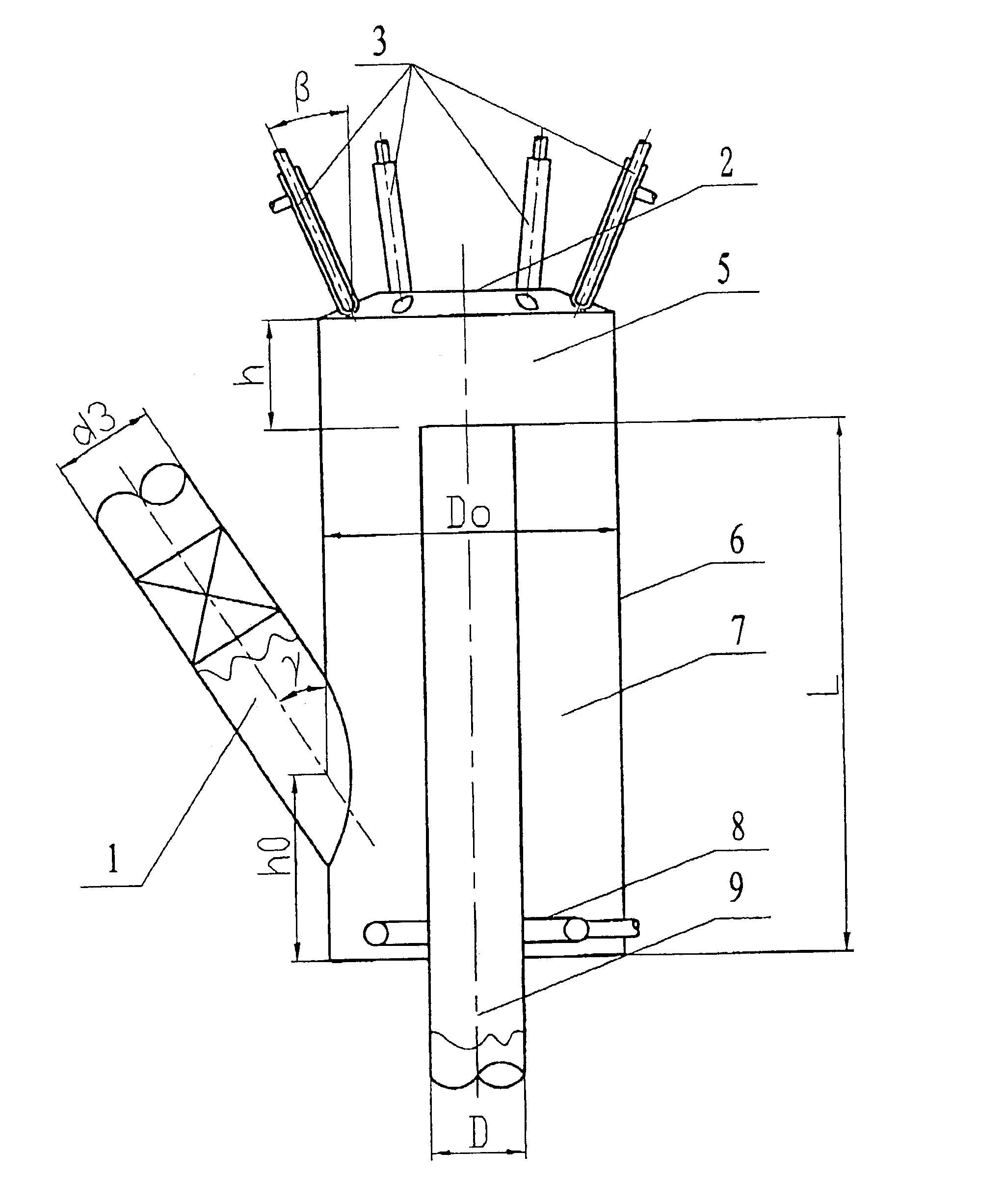

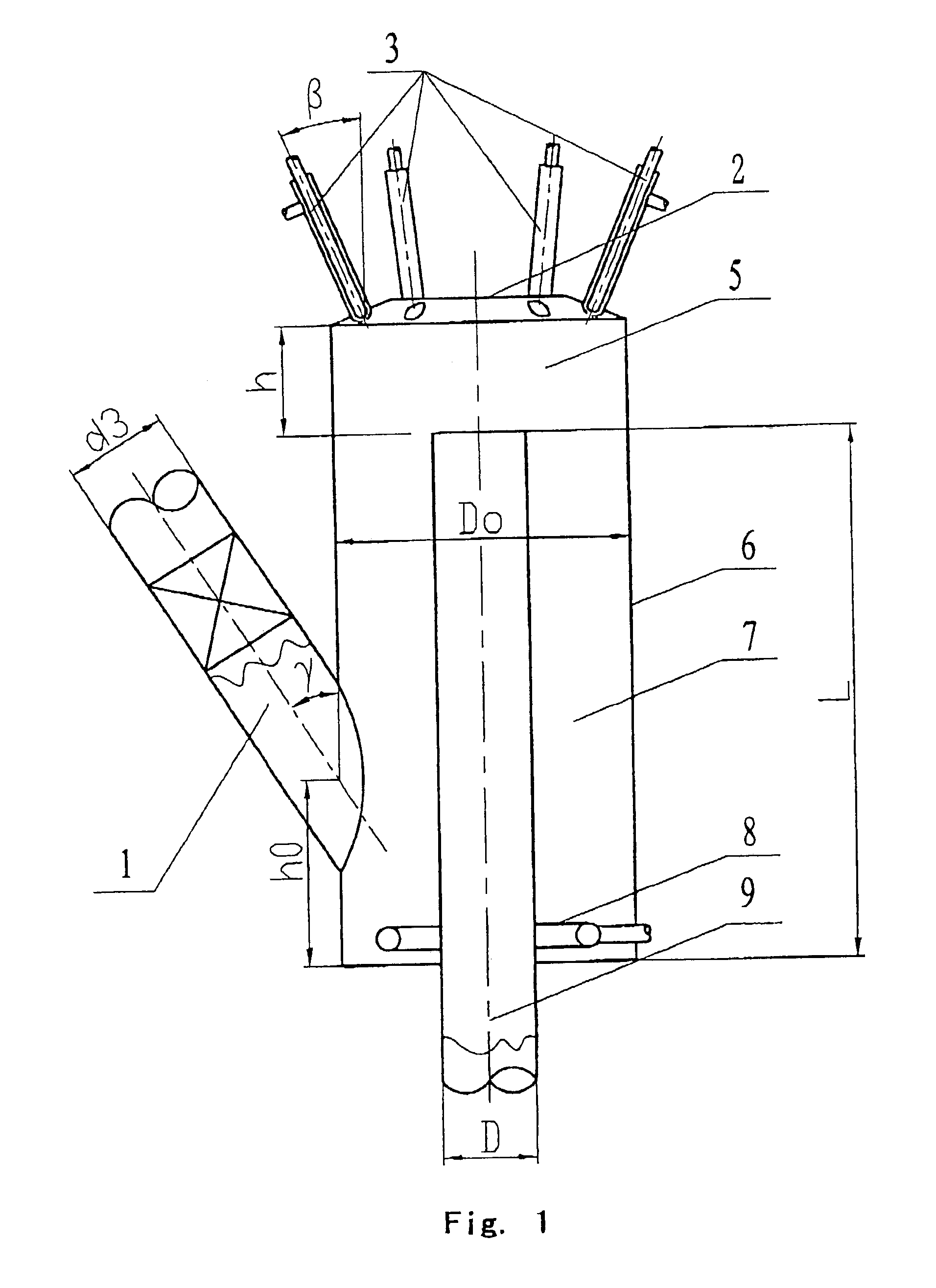

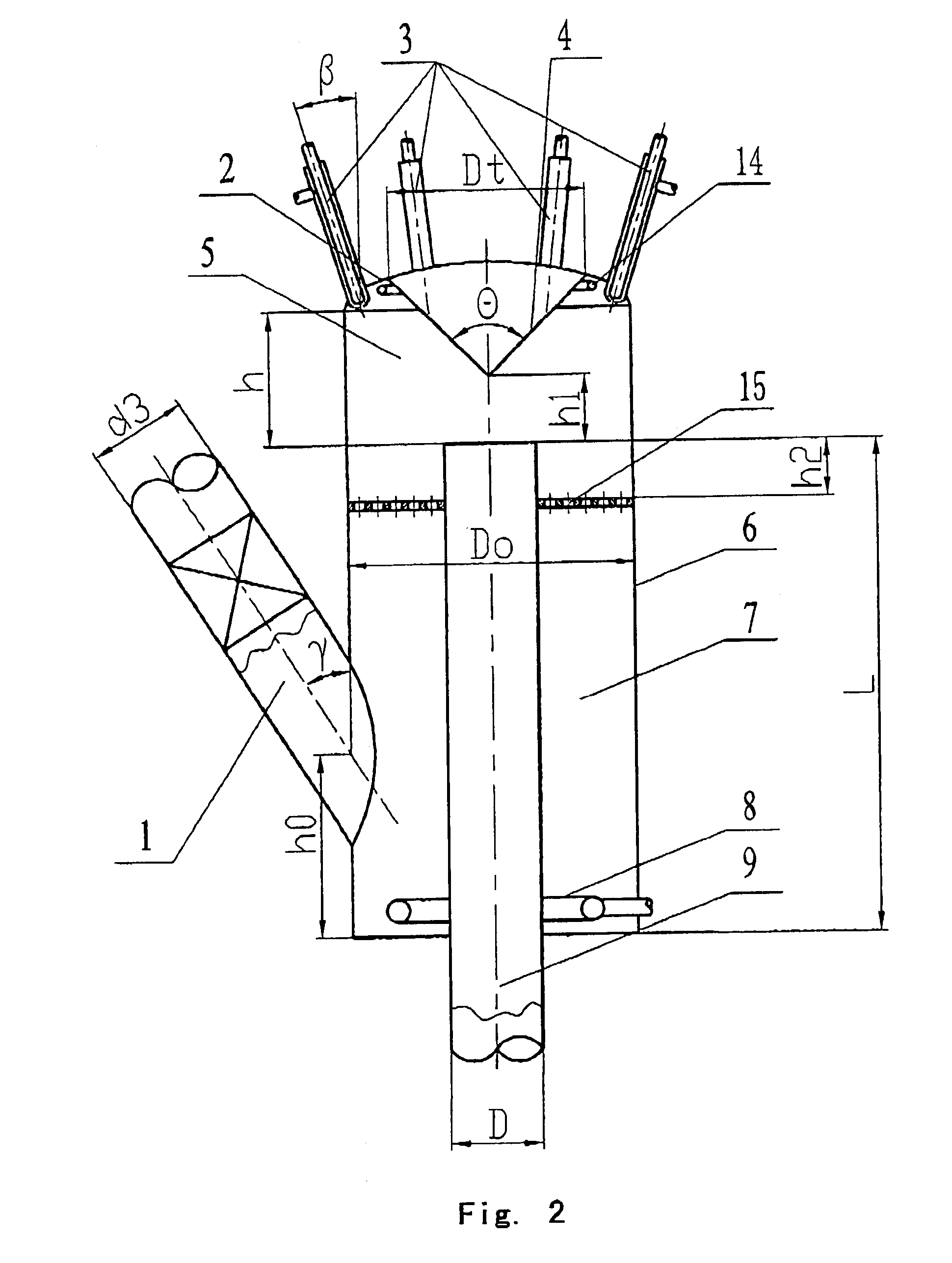

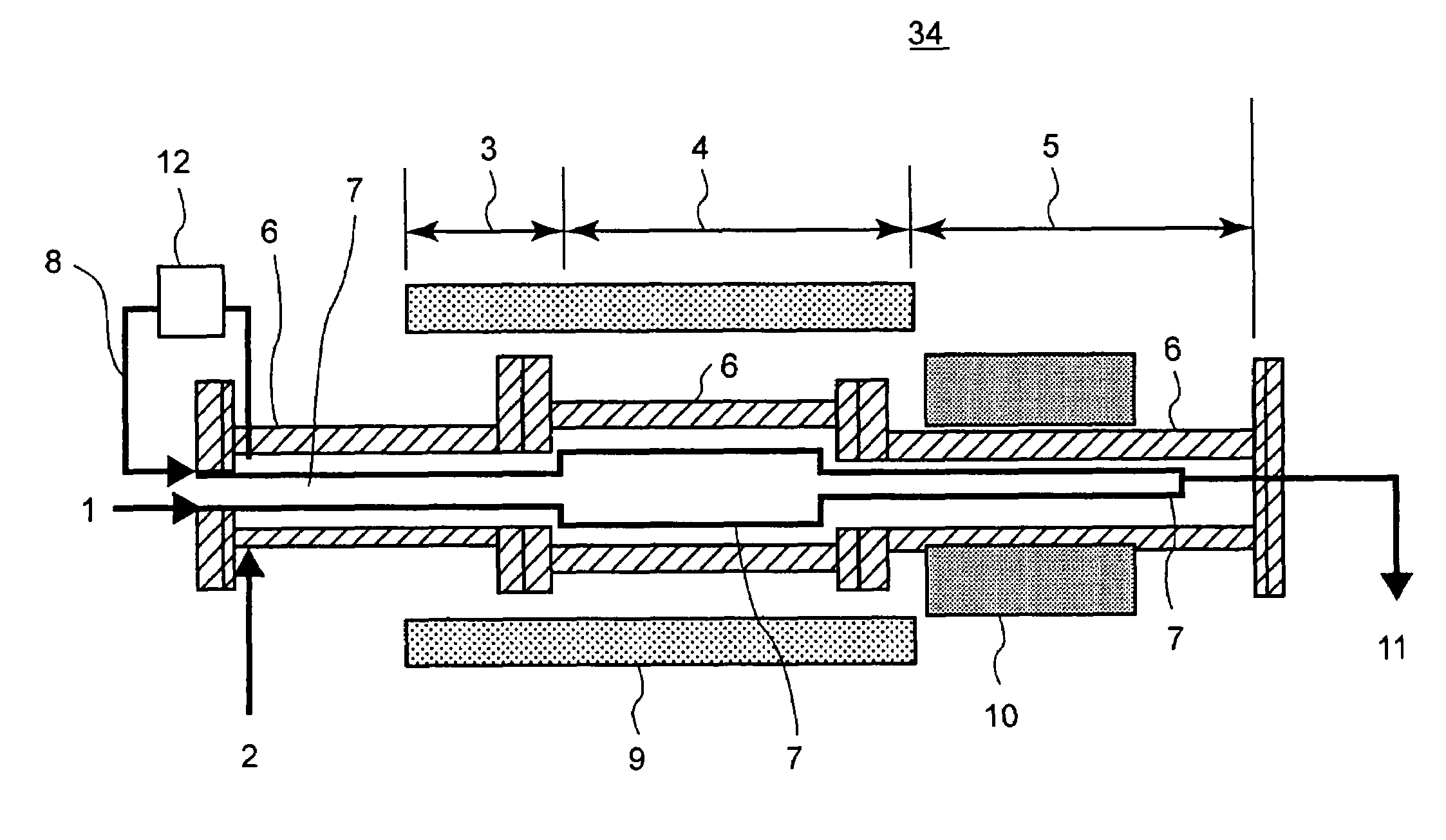

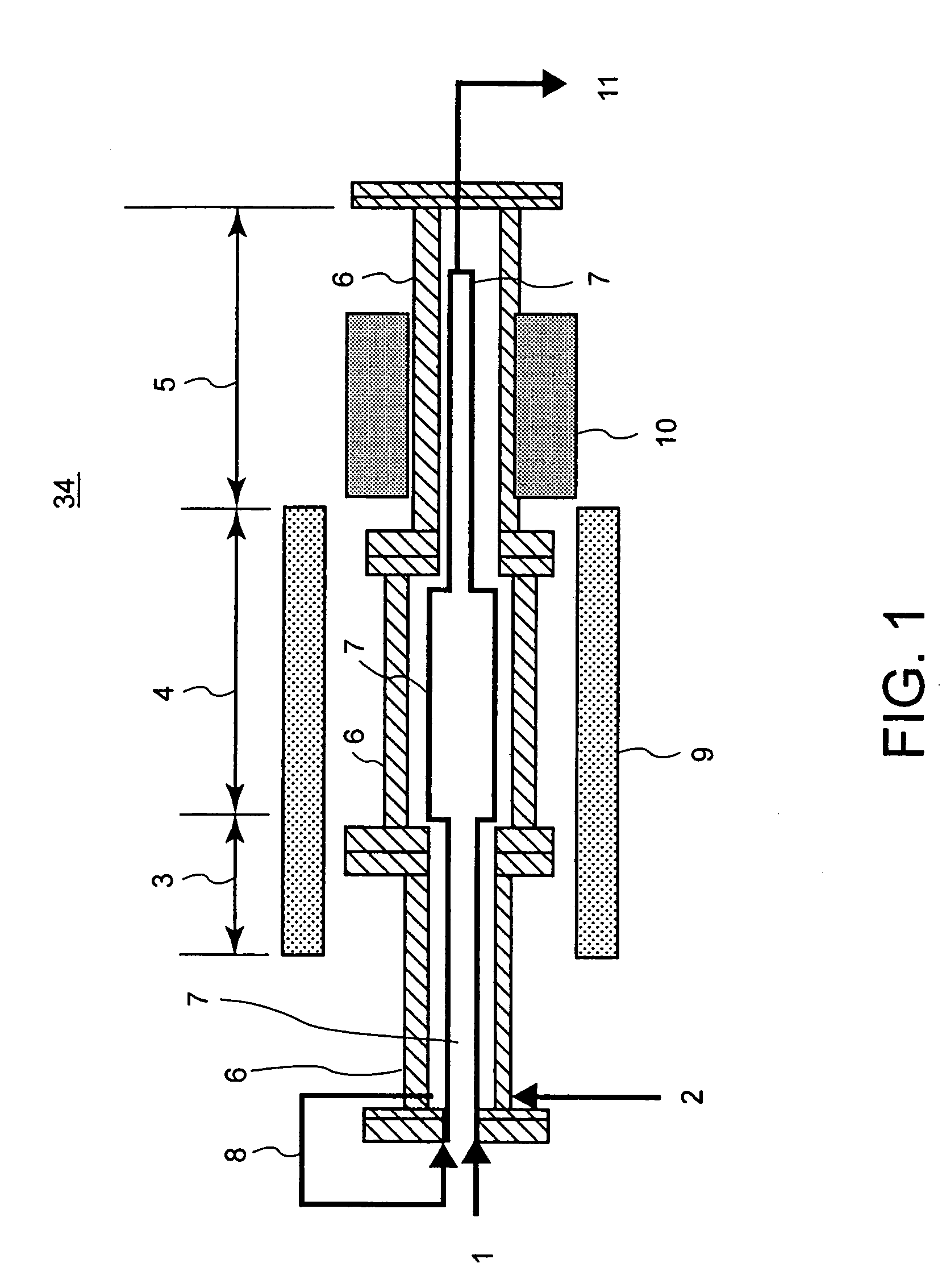

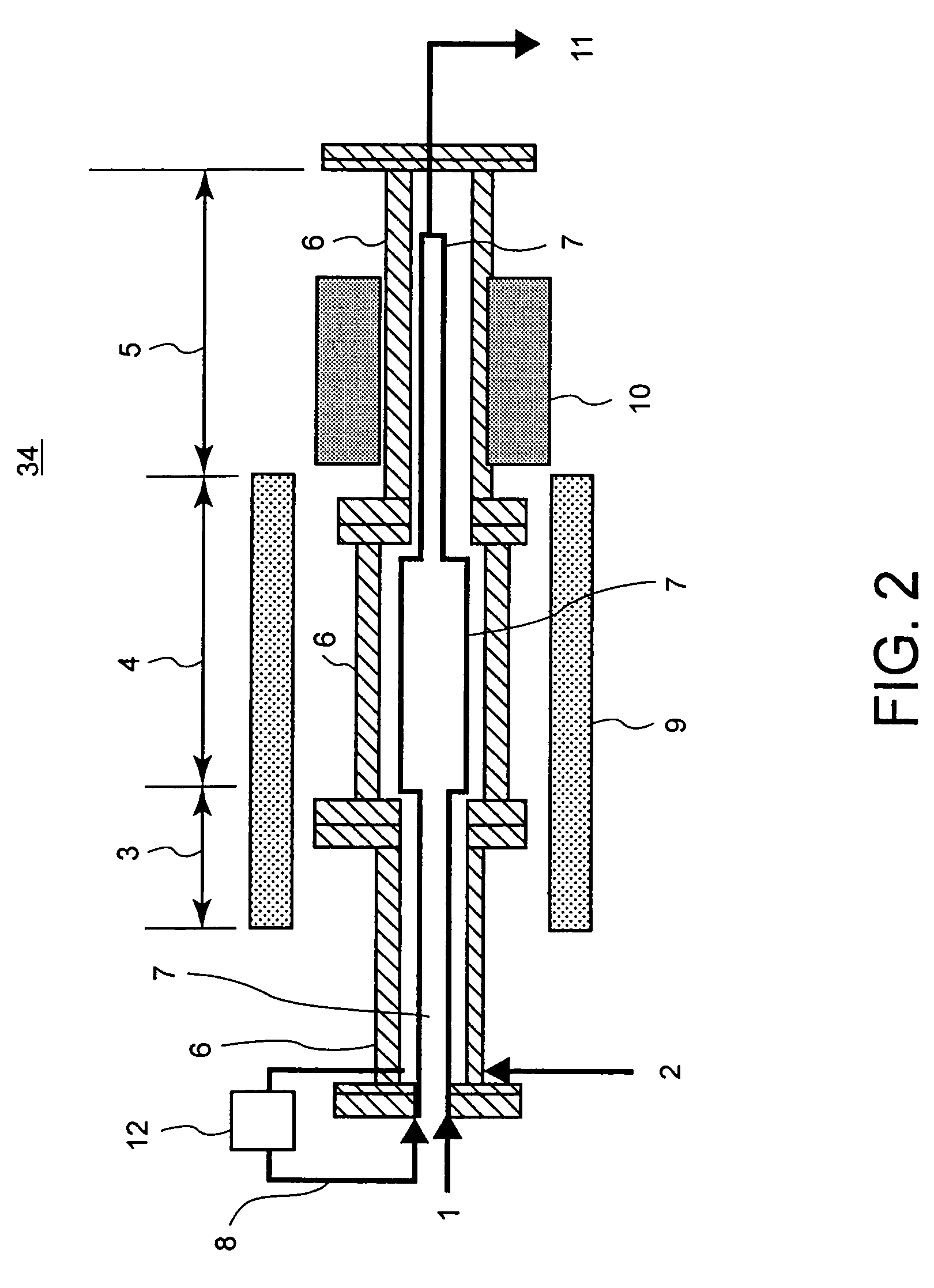

Downflow catalytic cracking reactor and its application

ActiveUS7153478B2Improve responseHigh oil/catalyst contact efficiencyCatalytic crackingSynthetic resin layered productsEngineeringNozzle

A downflow catalytic cracking reactor, comprising the following components: catalyst delivery pipe (1), reactor top cover (2), feed nozzle (3), reactor vessel (6), downflow reaction pipe (9), the upper end of the outer body is close connected to top cover (2) along the direction of circumference; the bottom of the outer wall body is close connected to the outer wall of the downflow reaction pipe; the upper section of the downflow reaction pipe is located inside the reaction vessel, while the lower section extends from the bottom of the outer body; feed nozzle (3) is located on the top cover (2) and / or side wall of the reactor vessel (6) with the outlet of the feed nozzle being above the inlet of the downflow reaction pipe; catalyst delivery pipe (1) is fixedly joined to the reactor vessel and in communication with catalyst lifting zone (7) formed by the reaction vessel and the downflow reaction pipe.

Owner:CHINA PETROCHEMICAL CORP +1

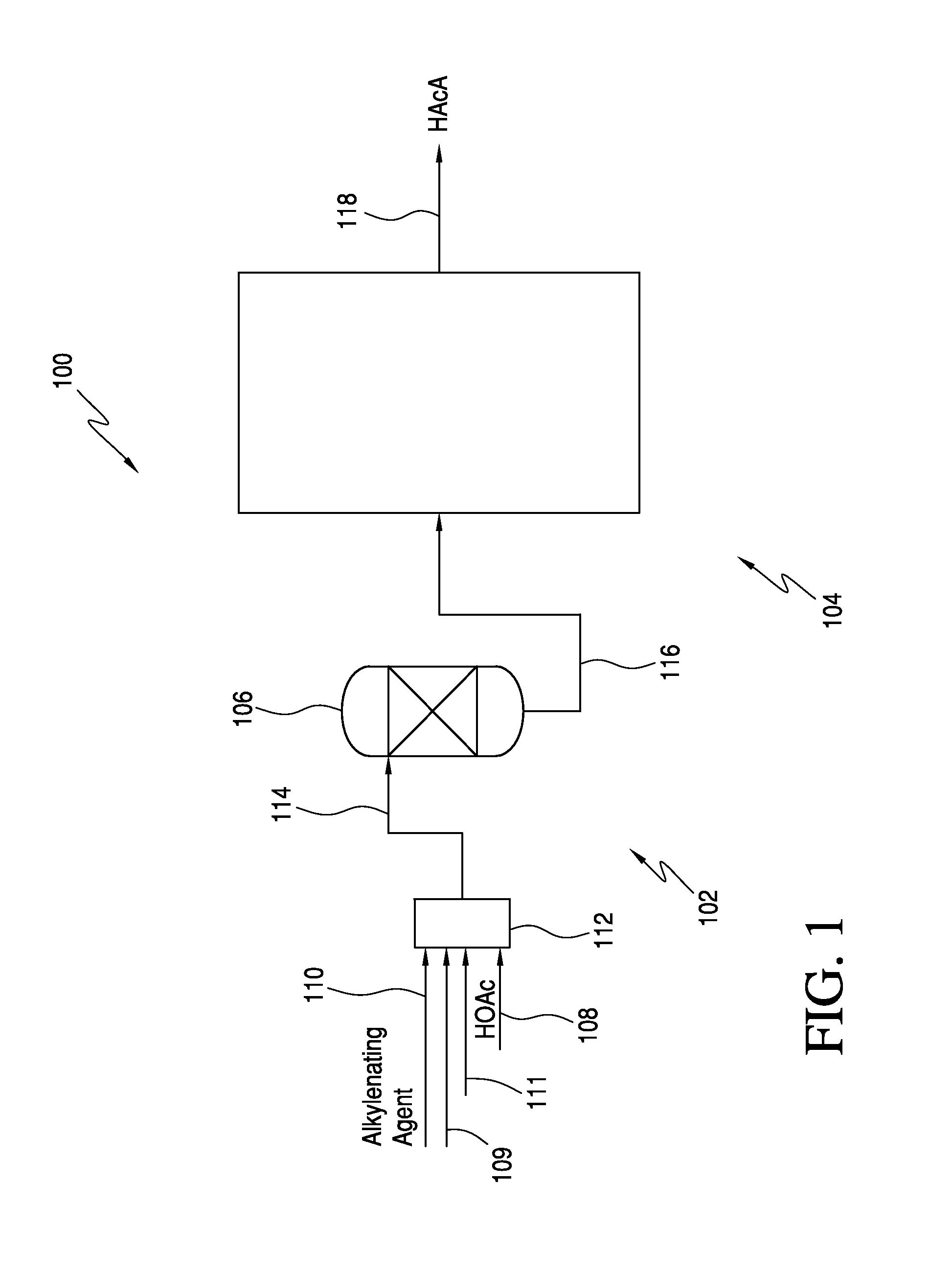

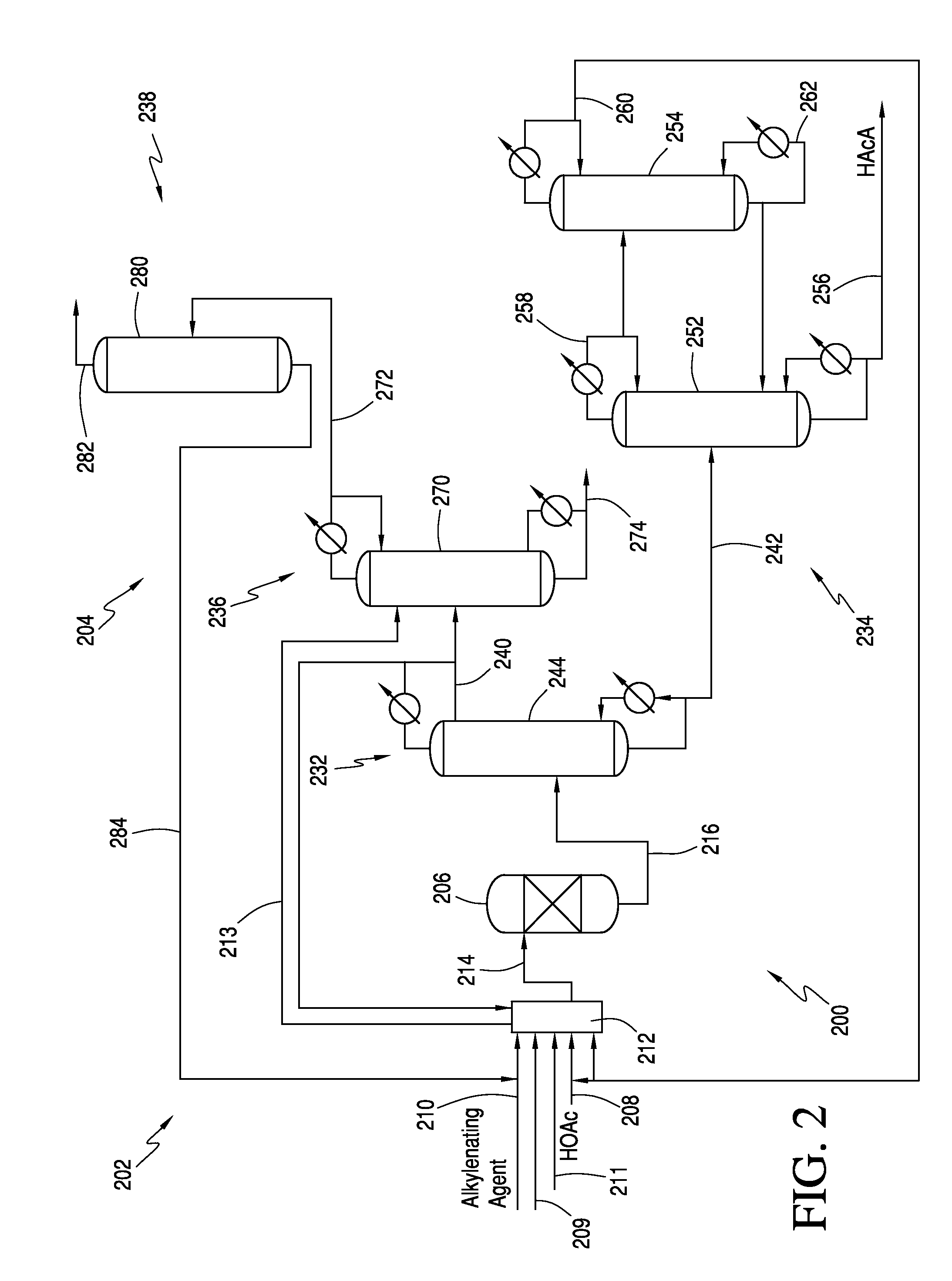

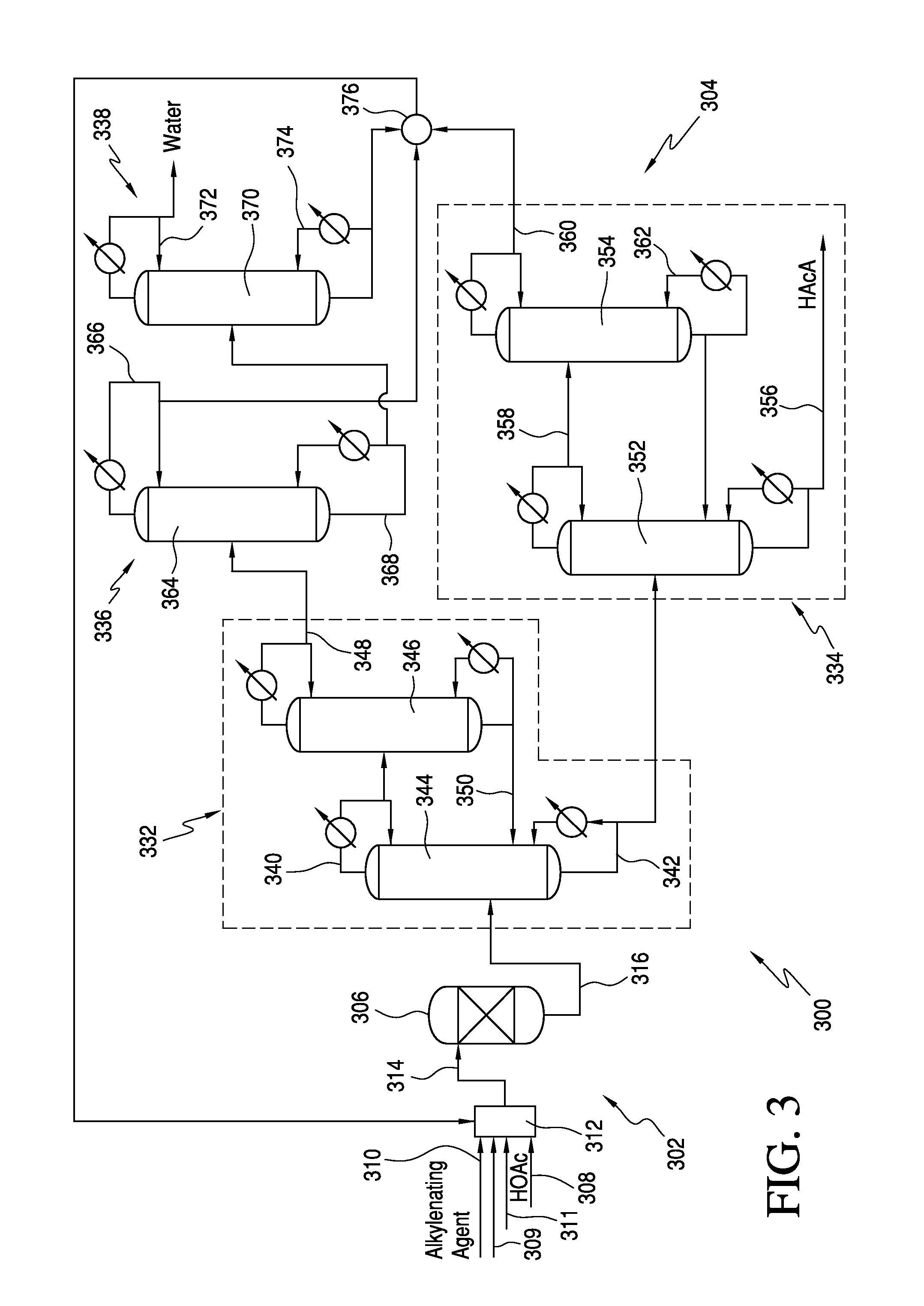

Processes for producing acrylic acids and acrylates

ActiveUS8658822B2Organic compound preparationCarboxylic acid esters preparationOrganic chemistryAlkanoic acid

In one embodiment, the invention is to a process for producing an acrylate product. The process comprises the step of reacting an alkanoic acid and an alkylenating agent under conditions effective to produce a crude acrylate product. A molar ratio of alkylenating agent to alkanoic acid is maintained at a level of at least 1.

Owner:CELANESE INT CORP

Structured photocatalyst, structured photocatalyst composition, photocatalyst coated material, method for producing structured photocatalyst, and method for decomposing aldehydes

InactiveUS20200114336A1Effectively prevent aggregationMaintaining their functionalityGas treatmentMolecular sieve catalystsMetal oxide nanoparticlesOrganic chemistry

An object of the present disclosure is to provide a structured photocatalyst that can effectively prevent aggregation of photocatalyst particles and maintain favorable photocatalytic functionality over a long period of time. A structured photocatalyst including a support of porous structure including a zeolite-type compound and at least one photocatalytic substance present in the support, the support including channels connecting with each other, and the photocatalytic substance including metal oxide nanoparticles and being present at least at the channels of the support.

Owner:FURUKAWA ELECTRIC CO LTD

Method for defluorinating and degrading complete fluorine substituted compounds

InactiveCN100347137CLow toxicityEasy to handleSolid waste disposalOrganic decompositionUltravioletPerfluorooctanyl sulfonate

A defluorinating and degrading method of fluorine substituted compound is characterized by vacuum ultraviolet irradiating PFOS and PFOA etc. fluorine substituted compound at anaerobic condition, defluorinating reacting fluorine substituted compound at irradiation of 185nm ultraviolet mercury vapour light or 172nm xenon quasi molecule laser light, inducing protective inert gas or reducing gas for realizing anaerobic condition, or adding reducing substance or semiconductor catalyst with high conducting band energy level during reacting process to improve defluorinating and decomposing ratio. It achieves simple operation and non-toxic.

Owner:TSINGHUA UNIV

Process for treating wastes from acrylic acid and polyacrylic acid production processes

Disclosed is a process for treating wastes discharged from an acrylic acid production process and a consecutive polyacrylic acid production process in which at least one waste selected from the group consisting of waste oil, waste water, and waste gas from said acrylic acid production process, and waste water and / or waste gas from said polyacrylic acid production process are combusted simultaneously.

Owner:NIPPON SHOKUBAI CO LTD

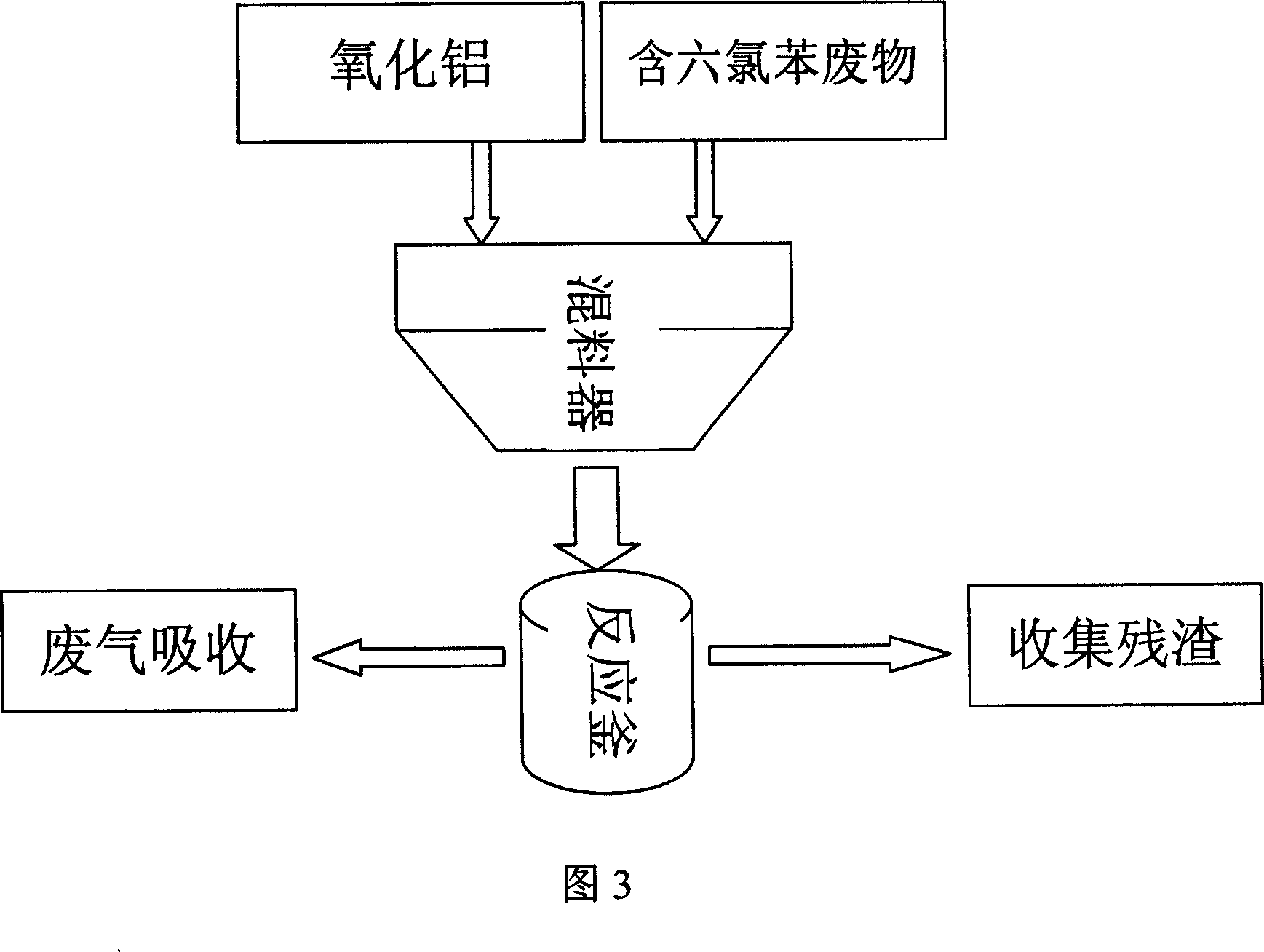

Halogenated arene degraded by aluminum oxide

InactiveCN101077847AAchieve complete dechlorinationOrganic decompositionPolychlorinated biphenylHexachlorobenzene

The present invention provides method of degrading halogenated arene with Al2O3 as dehalogenating agent. Hexachlorobenzene and dehalogenating agent Al2O3 in the amount of 5-100 times of hexachlorobenzene weight are mixed inside some container and reacted at 200-500 deg.c for 0.5-1.5 hr, so as to degrade hexachlorobenzene. The present invention has low cost, simple apparatus, short reaction period, low power consumption and other advantages, and can degrade halogenated arene in relatively low temperature. The method of the present invention is also suitable for degrading other halogenated arene, such as polychlorinated biphenyl, polybrominated biphenyl, BHC and DDT.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Treatment apparatus and treatment method for organic waste

ActiveUS7329395B2Safely and continuously decomposing organic wastePhysical/chemical process catalystsDispersed particle separationDecompositionEnvironmental engineering

A treatment apparatus for organic waste including a reaction vessel for introducing and decomposing organic waste and pulling out decomposed organic waste as a treated fluid. The reaction vessel includes an internal vessel made of corrosion-resistant material, an external vessel made of pressure-resistant material provided for surrounding the internal vessel via a gap, and an interconnection pipe for interconnecting the gap and the internal vessel outside the external vessel, thereby to control inside the gap and inside the internal vessel to practically equal pressure. The internal vessel has a heating zone for heating the introduced organic waste to a temperature higher than a critical point of water, a reaction zone for holding and decomposing the organic waste at a temperature higher than the critical point of water, and a cooling zone for cooling the treated fluid containing a decomposition product of the organic waste to lower than 100° C. The gap is adapted to be charged with high-pressure water or hydrogen peroxide water.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com