Patents

Literature

48results about How to "Appearance unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling synchronous degradation of each layer of co-extrusion composite film by utilizing same biological base

ActiveCN102627013AAppearance unchangedIngenious ideaSynthetic resin layered productsComposite filmAgricultural engineering

The invention discloses a method for controlling the synchronous degradation of each layer of a co-extrusion composite film by utilizing the same biological base. Aiming at the co-extrusion composite film which is in three layers or more than three layers, a biological active additive 'EcoPure' is used as the biological base. The method is characterized by comprising the following steps of: calculating a weight proportion relationship between carbon contents of each layer of the co-extrusion composite film first, then determining the addition concentration of the biological base of each layer according to the weight proportion relationship between the carbon contents of each layer in extruded polymer of each layer before the preparation, and making the degradation rate of each layer of the co-extrusion composite film be accordant. The method disclosed by the invention has the contribution of having a predictable control ability for the biological degradation process and the degradation rate of multi-layer co-extrusion composite film which is composed of different polymers; and by balancing the concentration of the biological base, the biological degradation rate which is suitable for the final processing environment is provided, and the appearance, the function and the physical and mechanism performance of a product before being discarded are ensured to be unchanged.

Owner:圣厦药品食品包装新材料(昆山)有限公司

Zinc-based composite coating for improving corrosion resistance of neodymium-iron-boron magnet

InactiveCN102653643AReduce the impactUniform thicknessLiquid surface applicatorsAnti-corrosive paintsSilicone resinPolytetrafluoroethylene

The invention relates to a zinc-based composite coating for improving corrosion resistance of a neodymium-iron-boron magnet. The zinc-based composite coating is characterized by comprising a zinc-based coating and a reinforced protective coating, wherein the zinc-based coating consists of the following components by mass percent: 65%-95% of flake zinc powder, 1%-30% of flake aluminum powder and 0%-5% of amorphous composite chromic salt compound, the molecular formula of the amorphous composite chromic salt compound is nCrO3.mCr2O3, and n and m are natural numbers; and the reinforced protective coating is one of a wear-resisting organic silicone resin coating, a polytetrafluoroethylene coating and an epoxy resin coating. The zinc-based composite coating provided by the invention has the advantages that the coating is uniform and compact in structure and good in substrate bonding property, is not easy to peel or fall off, is less in magnetic property influence, uniform in thickness, low in porosity and extremely strong in corrosion resistance, is extremely compact and has no corner effect and no hydrogen embrittlement; and the process is environment-friendly.

Owner:BAOTOU RES INST OF RARE EARTHS

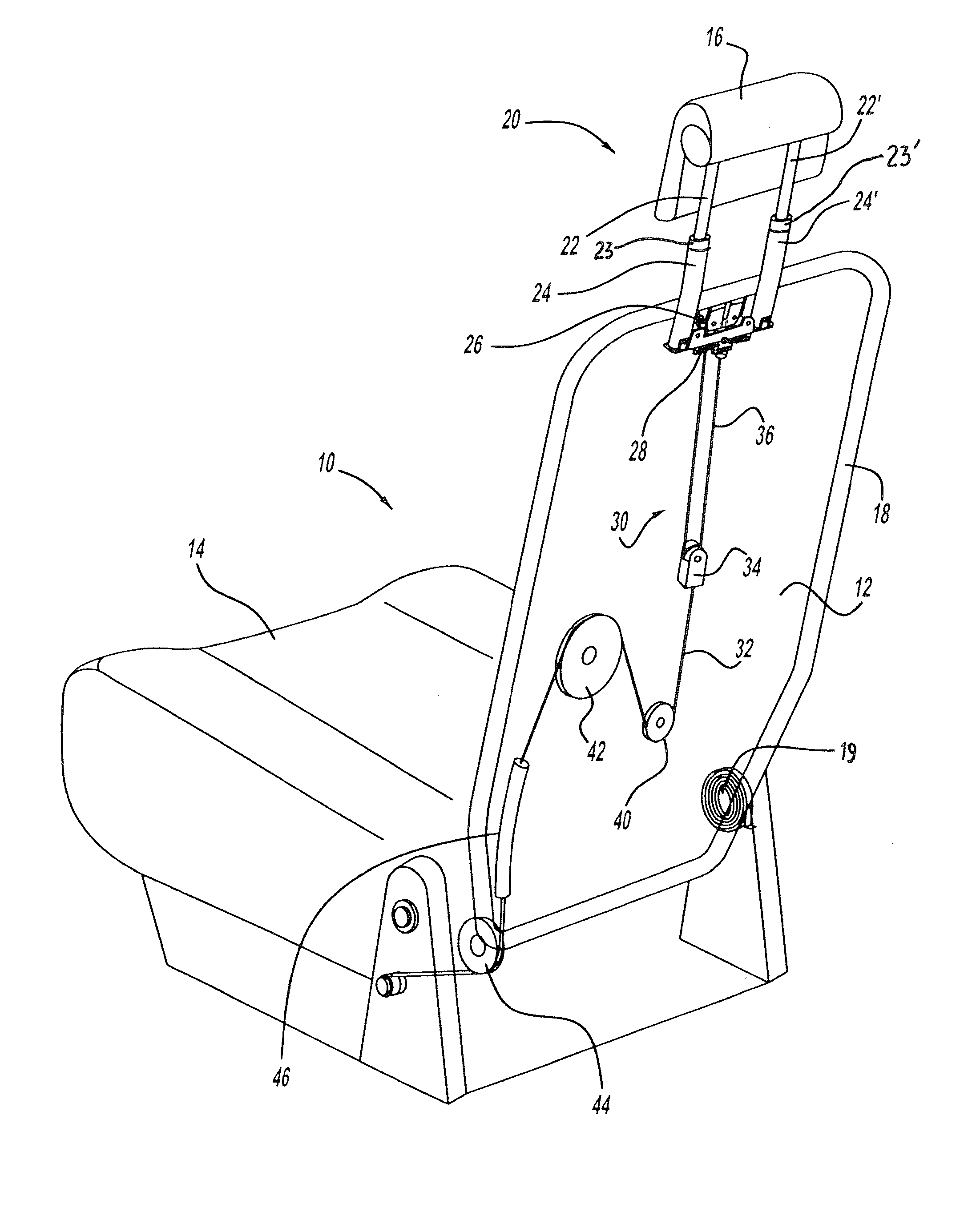

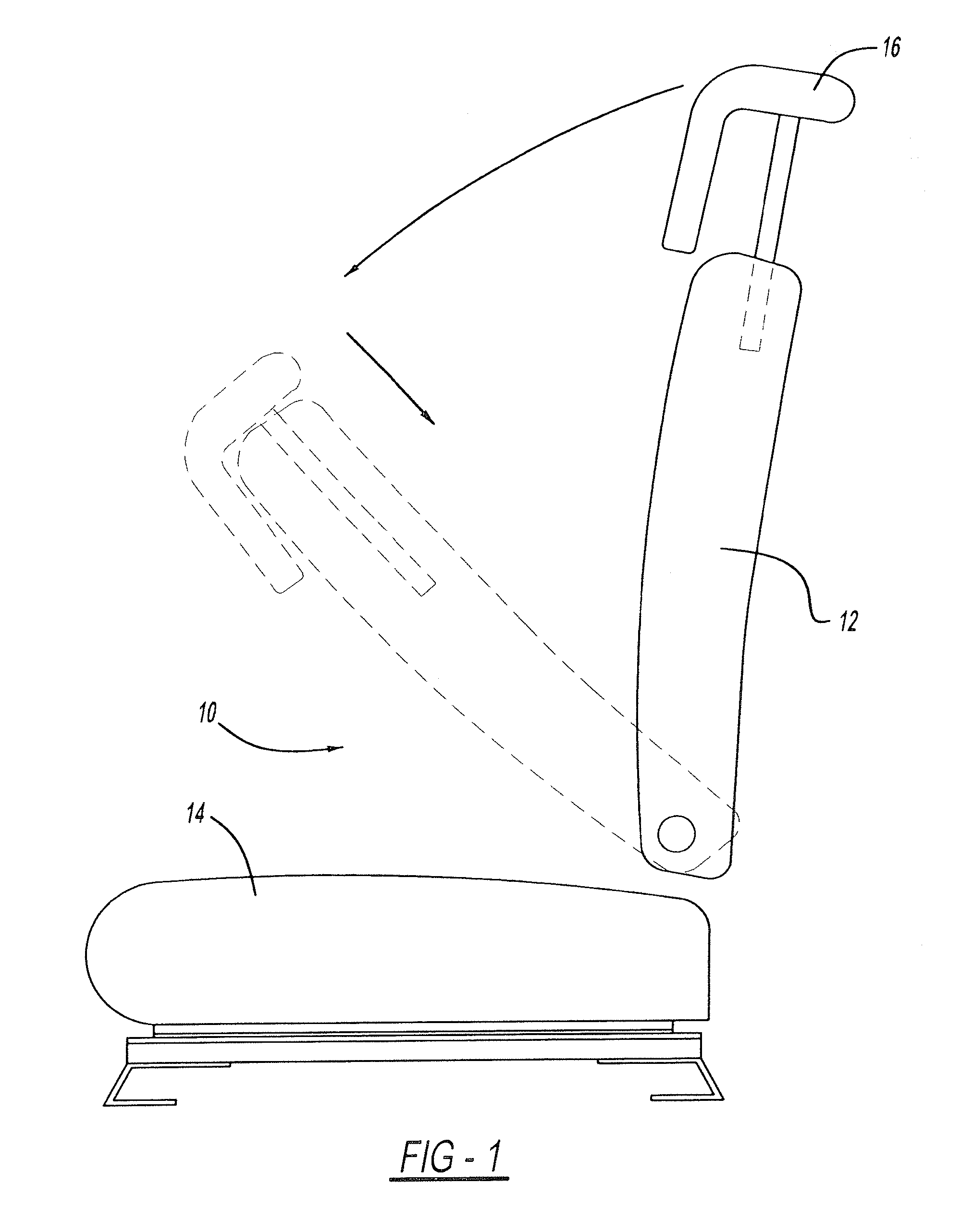

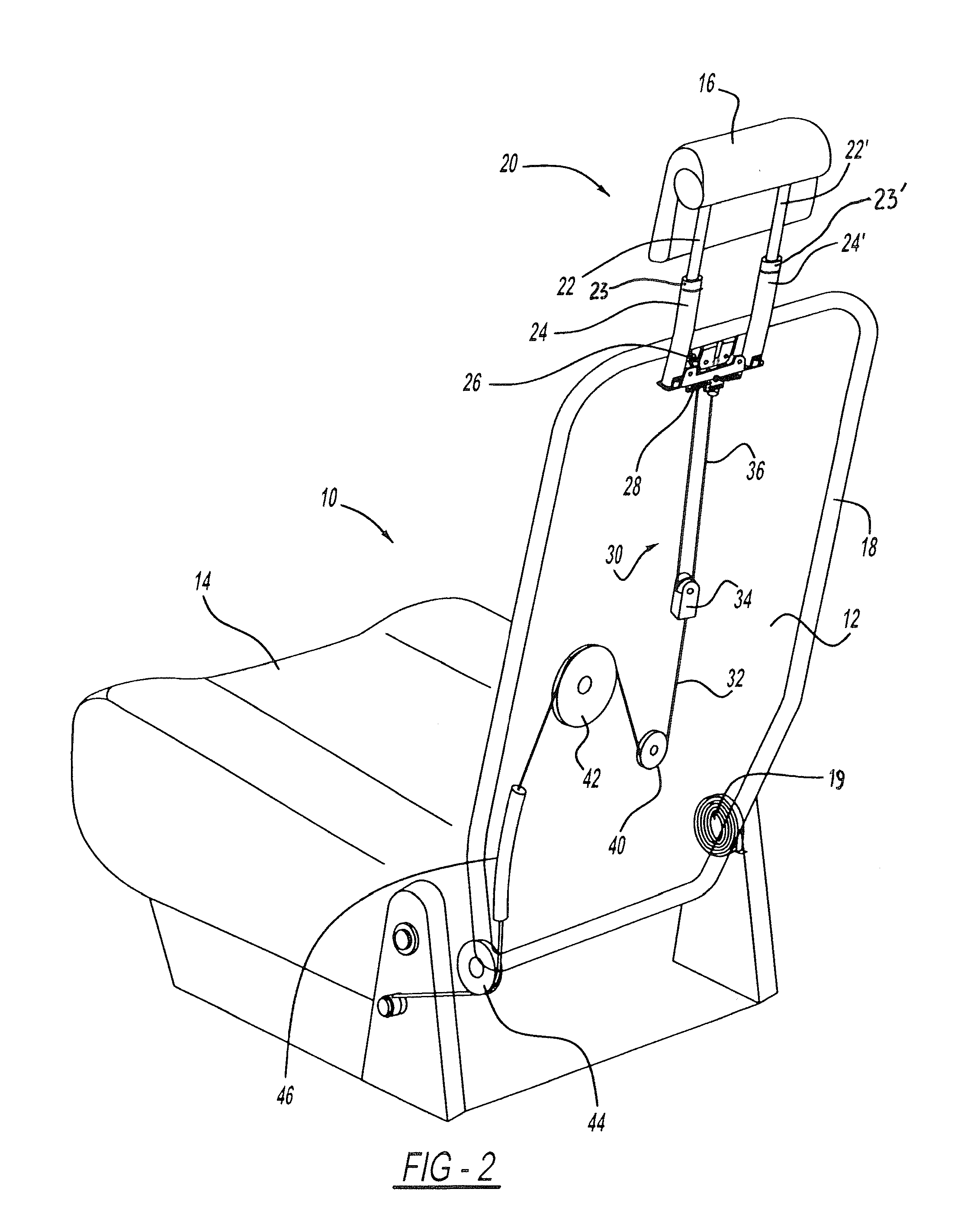

System for seat-actuated head rest extension and retraction

ActiveUS20110101738A1Increase the itineraryLow effortOperating chairsDental chairsMobile vehicleConstant force

A head rest system for an automotive vehicle seat movable between an extended position when the seat back of the vehicle seat is in its upright position and a retracted position when the seat back is in its lowered position. The system includes a seat base, a seat back pivotably attached to the seat base, a head rest movably attached to the seat back by a head rest attachment assembly, and a head rest movement balancing portion. The head rest attachment assembly includes a fixed portion attached to the seat back and a movable portion. The fixed portion includes a spool assembly. The movable portion includes a pair of spaced apart posts attached to the underside of the head rest and a latching assembly. The spaced apart posts are slidably attached to the fixed portion. The head rest movement balancing portion includes a pair of spaced apart constant force springs. Each of the springs has a spool attachment end and a latching assembly attachment end. A cable is provided. One end of the cable is operatively associated with the latching assembly and at the other end is attached to the seat base. A series of pulleys restrain the cable and guide its operation. The disclosed system fixes the head rest at the required height, prevents the passenger from adjusting the head rest when the seat is in an occupiable position, and retracts the head rest automatically when the seat back is folded thereby providing sufficient clearances.

Owner:FORD GLOBAL TECH LLC

Hot-dip galvanizing process

The invention relates to a hot-dip galvanizing process, in particular to the hot-dip galvanizing process for galvanizing repeatedly, which comprises the following steps: 1) surface treatment; 2) acid cleaning; 3) activation of solvent; 4) drying; 5) treatment of liquid zinc; 6) galvanization; 7) repeated operation; 8) passivation; and 9) testing. In the invention, the method of adding a zinc-nickel alloy is adopted for the treatment of the liquid zinc, the effect is more obvious, and nickel can firstly react with silicon when iron is in contact with the zinc for generating an alloy element of a silicide, so as to eliminate adverse effects of the silicon; elements in the zinc-nickel alloy can react with the iron for generating low slag and surface slag respectively, and reducing the solubility of the iron, an excellent iron removing effect is achieved; and the appearance of a cast after treatment by the process steps is unchanged basically after one year of exposure, and the anti-corrosion capability is greatly improved. According to one year of follow-up services of a customer, the phenomena of blackening and variegation can be avoided during water and steam curing.

Owner:YUZHOU SHENYUN MACHINERY CO LTD

Corrosion resistant resin of oxirene-ester in high molecular weight and producing method

A formula for preparing epoxy vinyl ester resin is featured as that soft monomer of acrylic acid is used main raw material for synthesis by unsaturated monocarboxylic acid, fumaric acid and toluene diisocyanate are used as chain extendor. The production process of toluene diisocyanate being chain-extended in styrene solution at 60 degree i.e. diluting first and then chain extending is disclosed.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

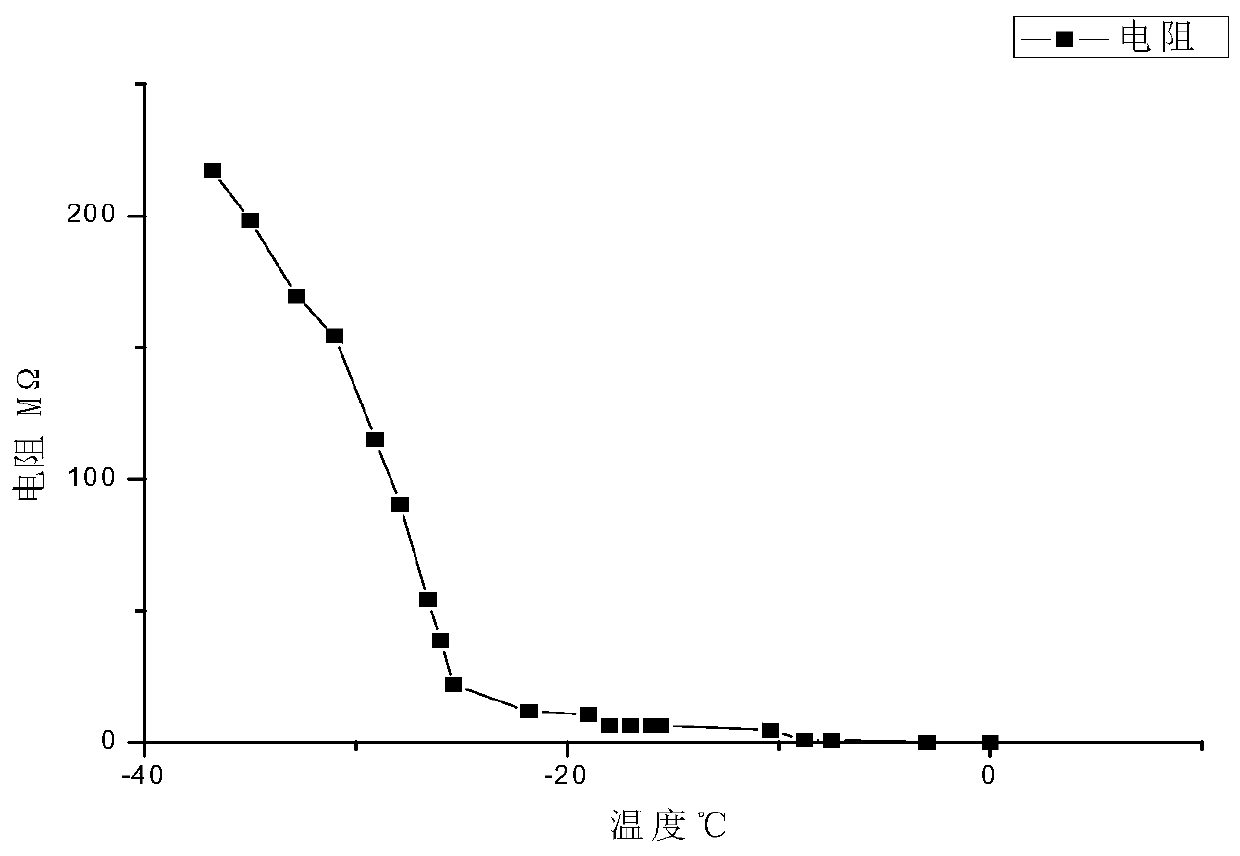

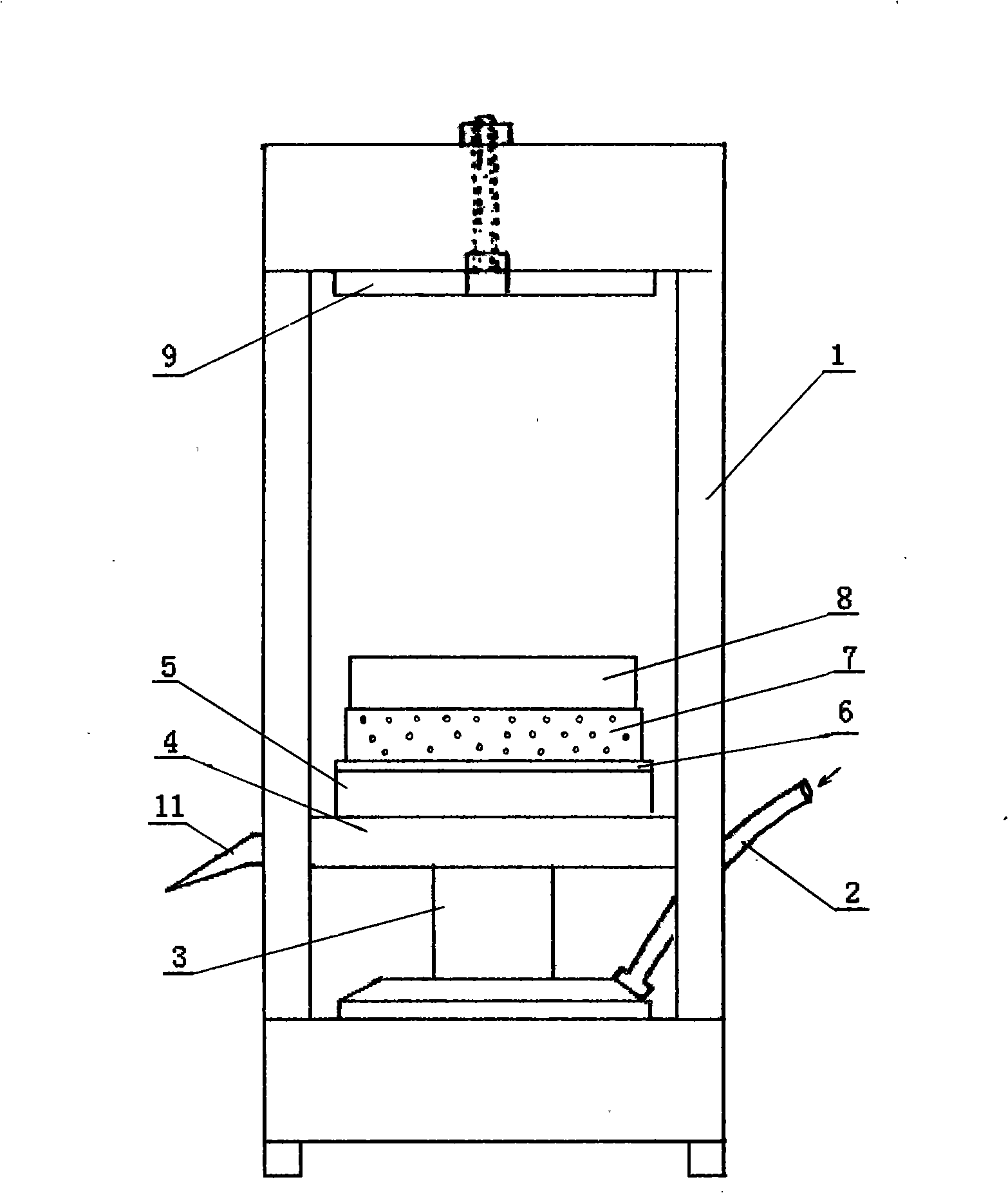

Vacuum freeze-drying method for preserving effective ingredients in radix angelicae sinensis medicinal material

PendingCN111595108AQuality evaluationAppearance unchangedDrying solid materials without heatPreliminary solid treatment for dryingMedicinal herbsFreeze-drying

The invention relates to a vacuum freeze-drying method for preserving effective ingredients in a radix angelicae sinensis medicinal material. The vacuum freeze-drying method includes the following steps of preprocessing, precooling, lyophilization, parsing and sealed preservation. The established radix angelicae sinensis freeze-drying method can better guarantee the quality of the radix angelicaesinensis medicinal material and considers time cost while ensuring the quality of the medicinal material. The radix angelicae sinensis medicinal material obtained through the established radix angelicae sinensis freeze-drying method basically keeps the appearance unchanged, is loose in texture, easy to smash, low in water content and easy to store, meanwhile quite well remains the main effective ingredients in the radix angelicae sinensis medicinal material, has quite high practicability and is suitable for large-scale production.

Owner:云南昊辰食品有限公司

Method for quick preparing salted egg

InactiveCN1465256AIncrease concentrationGood for maintaining concentrationEggs preservationEggshellSalt water

The quickly-pickling method of salted eggs is characterized by placing fresh eggs into a pressure container and adopting the following steps: 1). soaking the fresh eggs in saturated edible salt watercontaining hydrochloride whose concentration is 3-5% and pressurizing for above 6-14 hr.; and 2). soaking the fresh eggs in saturated edible salt water containing sodium hydroxide whose concentrationis 3.6-6% and pressurizing for above 12-28 hr., and the pressure of two above-mentioned procedures is 1.2-4 kg / sq.cm.

Owner:许国珍

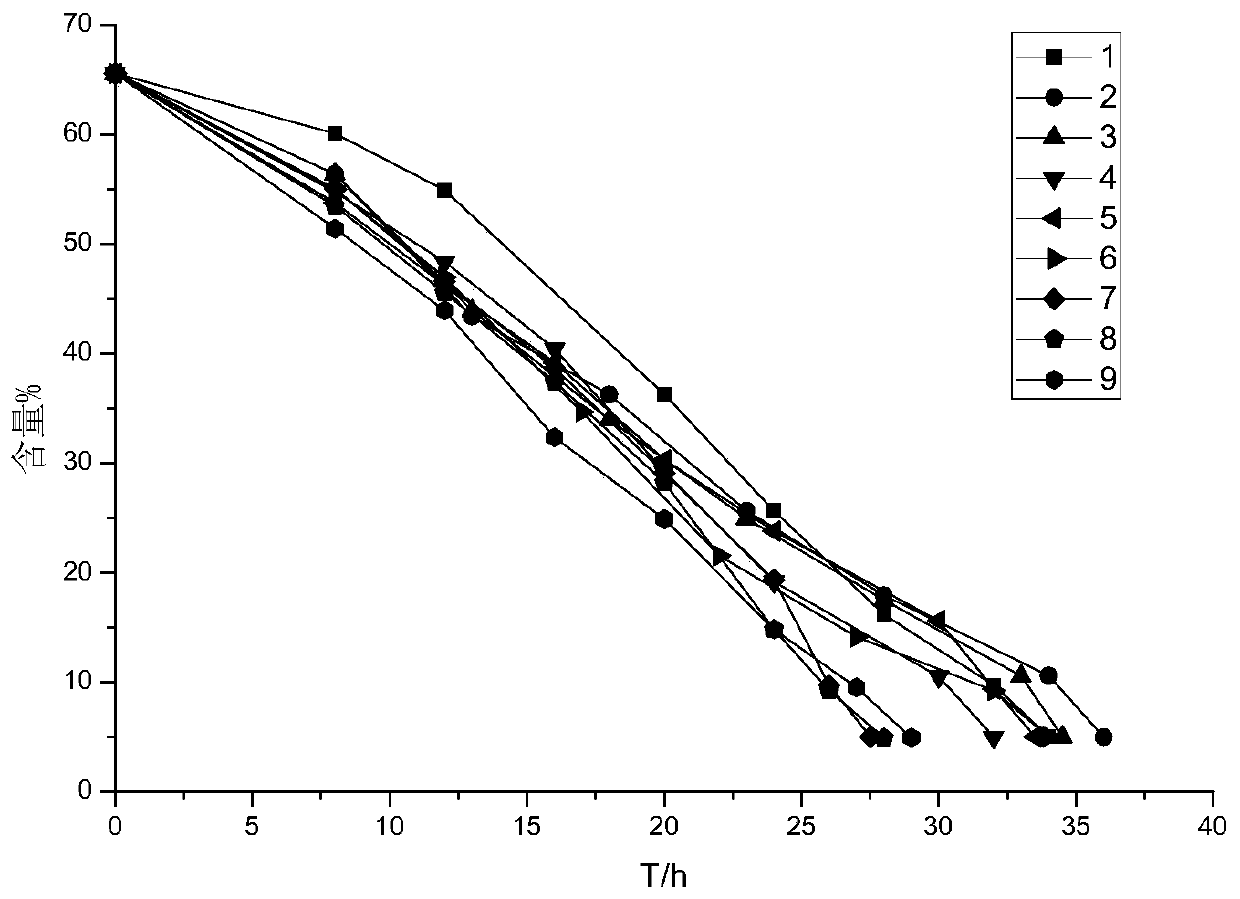

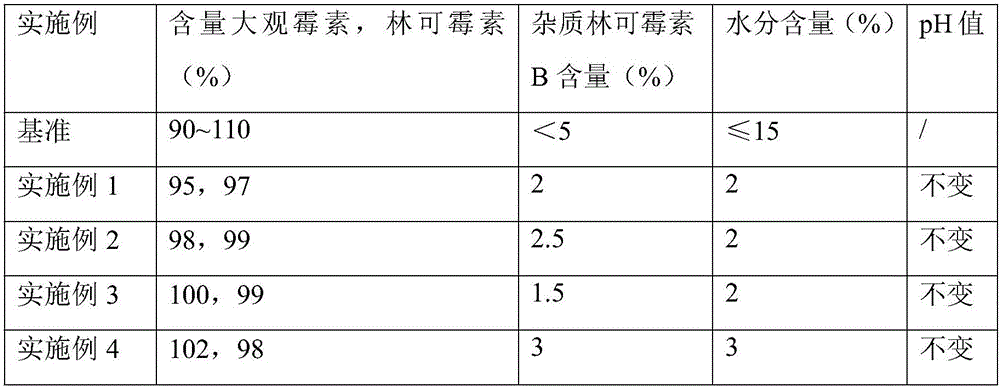

Spectinomycin hydrochloride and lincomycin hydrochloride freeze-dried powder injection and preparation method of spectinomycin hydrochloride and lincomycin hydrochloride freeze-dried powder injection

InactiveCN106420635AGood quality and stabilitySignificant effectPowder deliveryOrganic active ingredientsSpectinomycin HydrochlorideFreeze-drying

The invention relates to a spectinomycin hydrochloride and lincomycin hydrochloride freeze-dried powder injection and a preparation method of the spectinomycin hydrochloride and lincomycin hydrochloride freeze-dried powder injection, and solves the problems of high cost of industrial production and low drug stability in the prior art. The preparation method comprises the steps of firstly preparing a freeze-dried propping agent and antioxidant mixed solution, then preparing a to-be-freeze-dried sample of spectinomycin hydrochloride and lincomycin hydrochloride, and finally preparing the white loose block or powder spectinomycin hydrochloride and lincomycin hydrochloride freeze-dried powder injection in a freeze drying box. According to the spectinomycin hydrochloride and lincomycin hydrochloride freeze-dried powder injection and the preparation method of the spectinomycin hydrochloride and lincomycin hydrochloride freeze-dried powder injection, the drug stability and the bioavailability are high, and the industrial production is realized.

Owner:LESHAN RECONDEX BIOPHARM CO LTD +1

Peanut extracting oil and saving kernel apparatus and method and production of albumen powder, peanut powder

InactiveCN101284429ARetention of active substancesRetain nutrientsFood preparationPressesPeanut mealProcess engineering

The invention relates to a device and the process for extracting peanut oil and leaving whole peanut, and relates to albumen powder and peanut powder made from the degreased peanut. The device for extracting peanut oil and leaving whole peanut includes a hydraulic plant and an oil press system. The hydraulic plant controls the oil press system by a piston, and the oil press system is sequentially composed of a drip tray, a lower ejector plate, an oil flowing plate, a press ring, a pressure dish and an upper ejector plate. The invention adopts the low-temperature method for extracting the peanut oil and leaving the whole degreased peanut, pressure is applied slowly and repeatedly, so that the peanut can not be pressed into meal in oil pressing, the whole nutrient content of the peanut is kept, 70%-80% of the fat in the peanut can be removed, the protein can be improved by more than 70%, the food with high protein and low fat can be formed.

Owner:李连娟

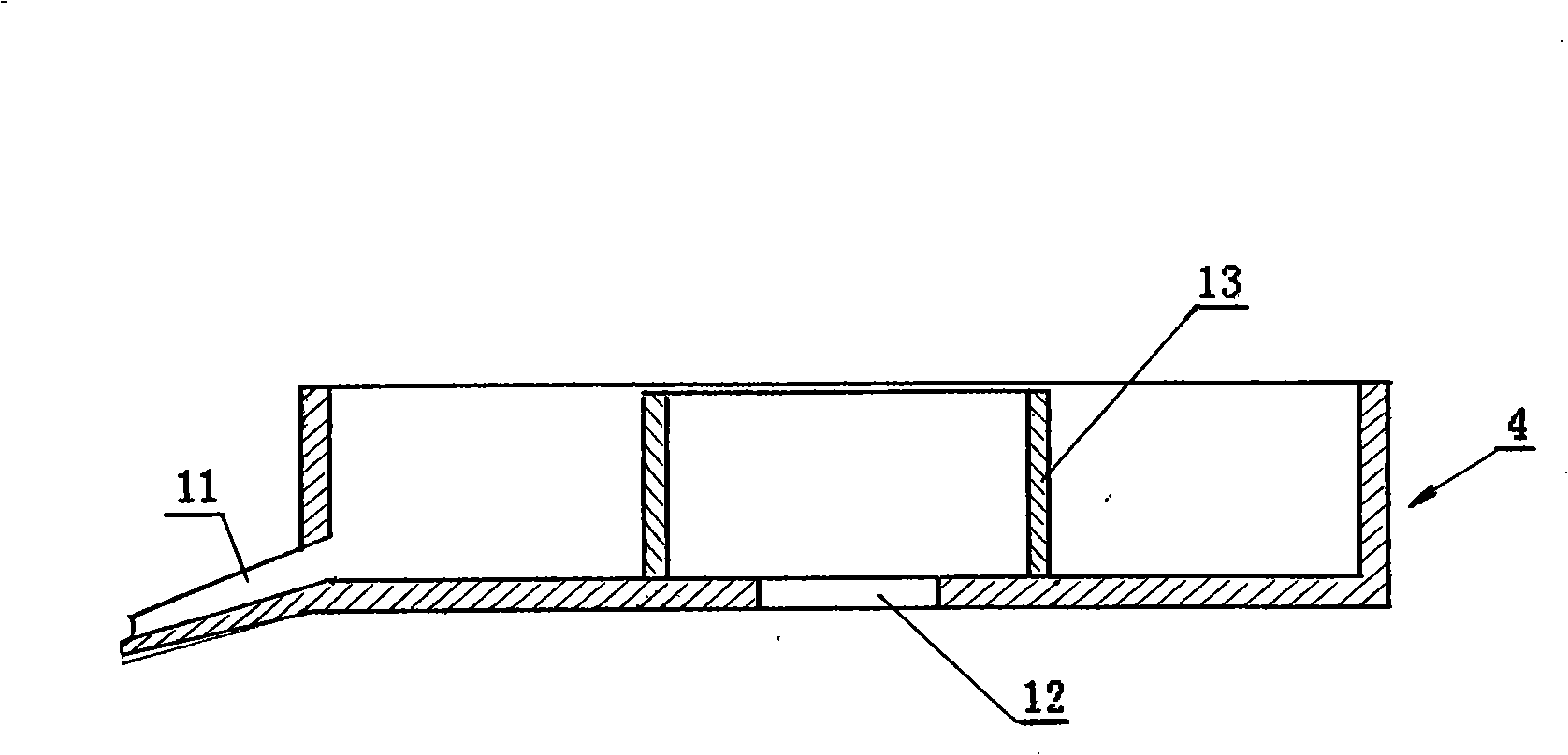

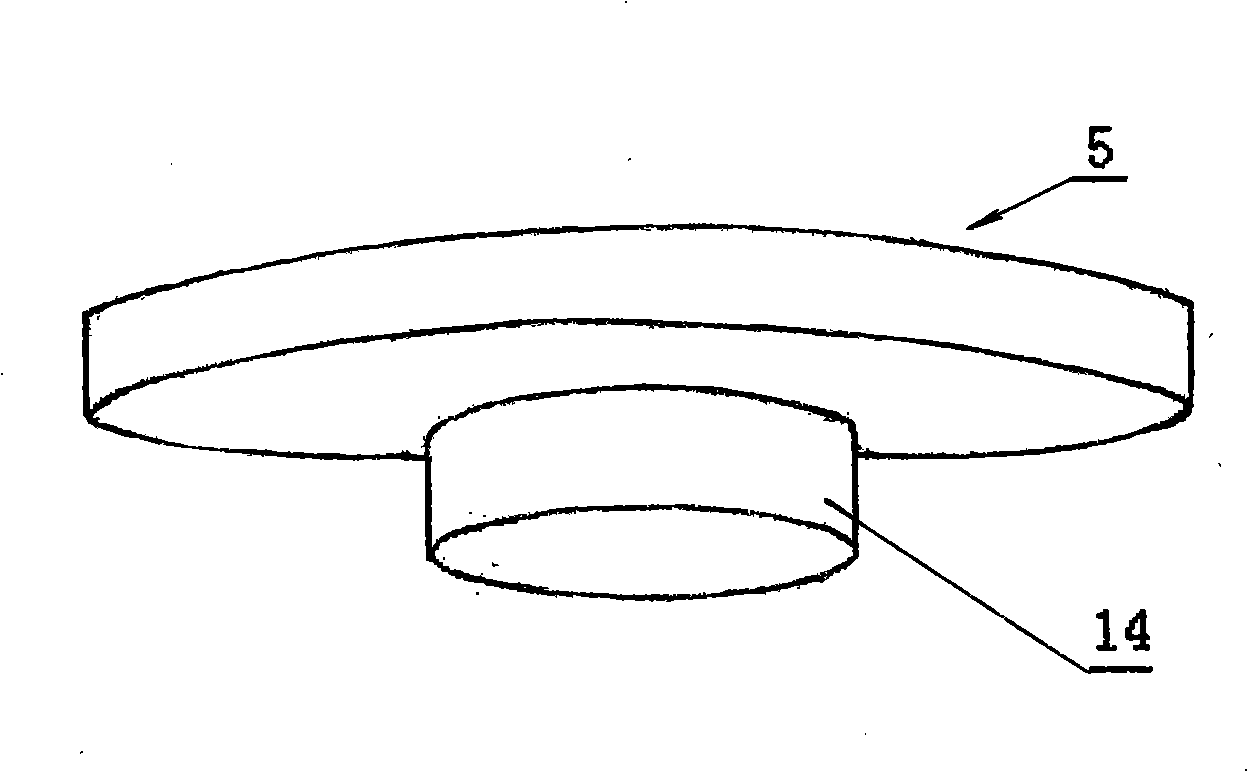

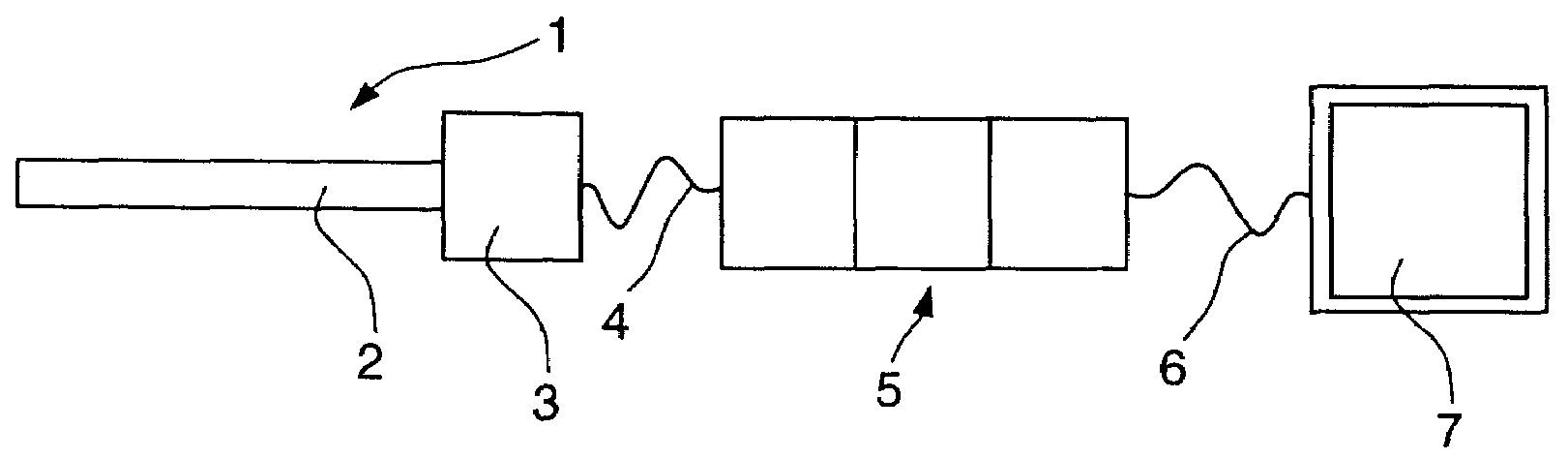

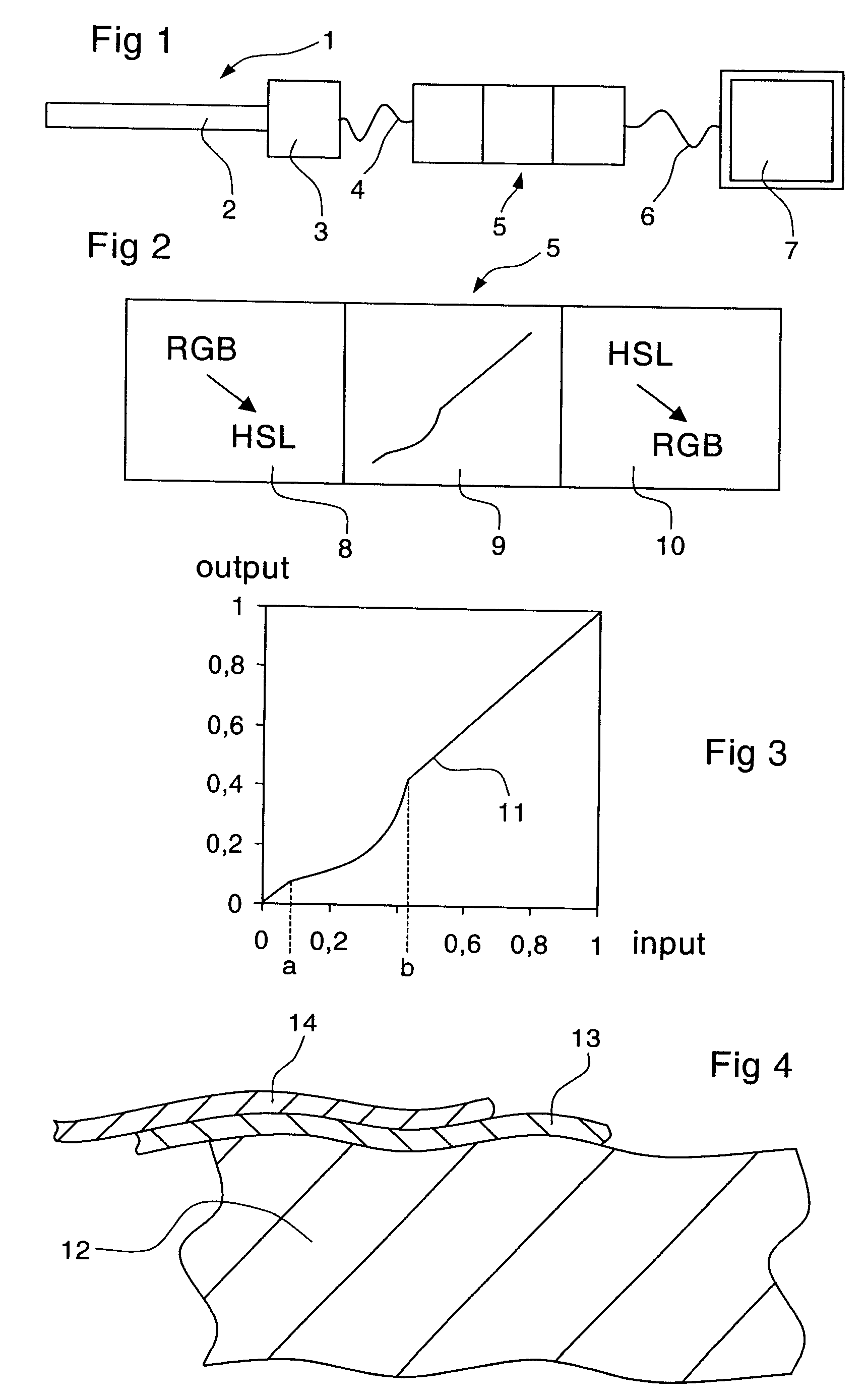

Method and apparatus to process endoscope images

InactiveUS20080284845A1Increase contrastGood lookingImage enhancementImage analysisImaging processingColor saturation

The invention relates to a method improving the images in an image processing unit (5) receiving images from an electronic color video camera (3) of a medical endoscope (1) and then transmitting them to an image display unit (7), and to an endoscope operating on the basis of the said method, where first the pixels of the color components (RGB) are individually mapped into a color space (HSL) wherein the color saturation (S) is independent of the other components (H, L), thereupon the saturation component (S) of each pixel to be mapped is converted by means of a nonlinear mapping function (11) which amplifies the color saturation differential between an upper zone (b->1) and a lower zone (0-b) of the color saturation, lastly the pixels being remapped into an (RGB) color space suitable for image display.

Owner:OLYMPUS WINTER & IBE

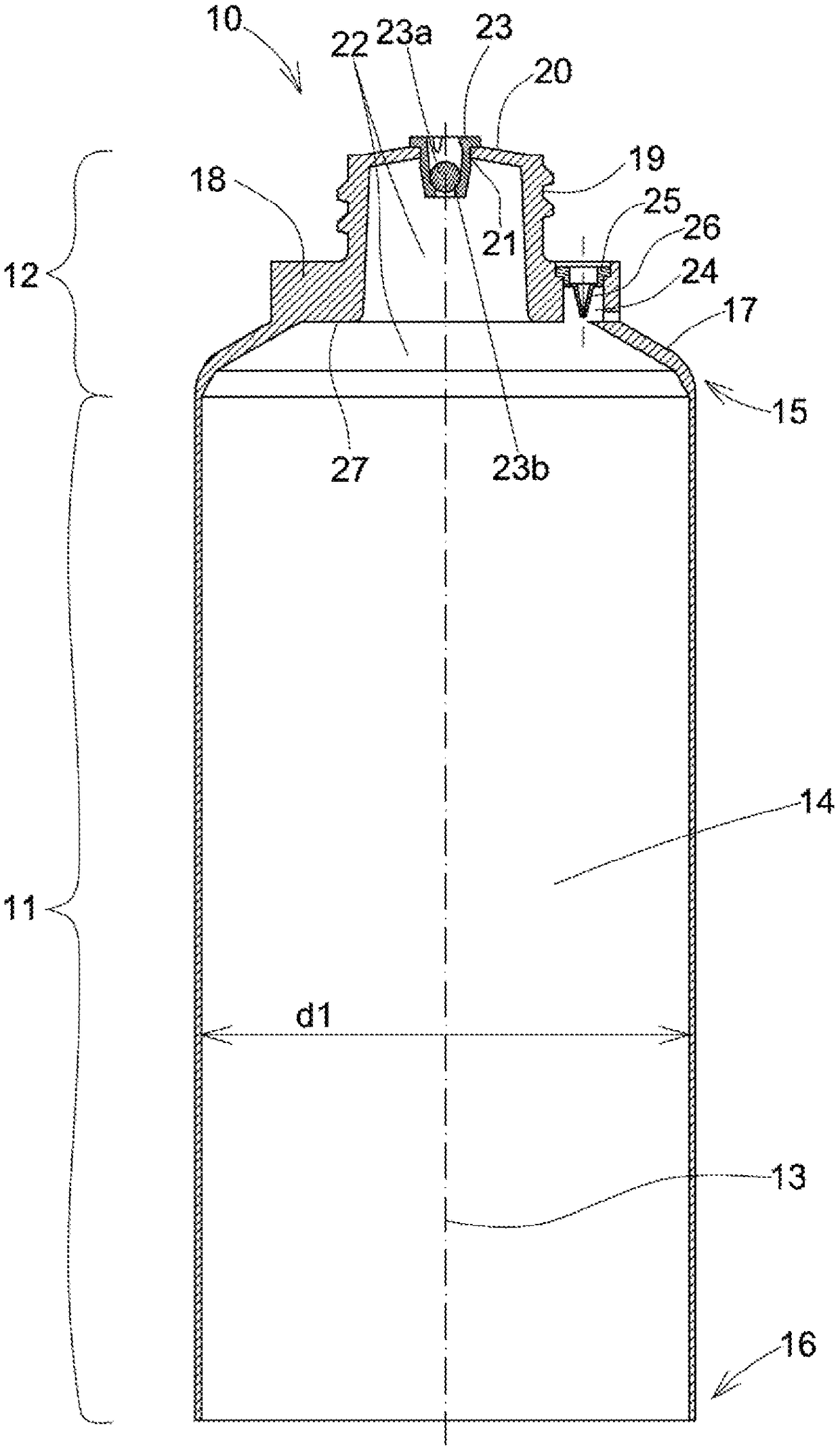

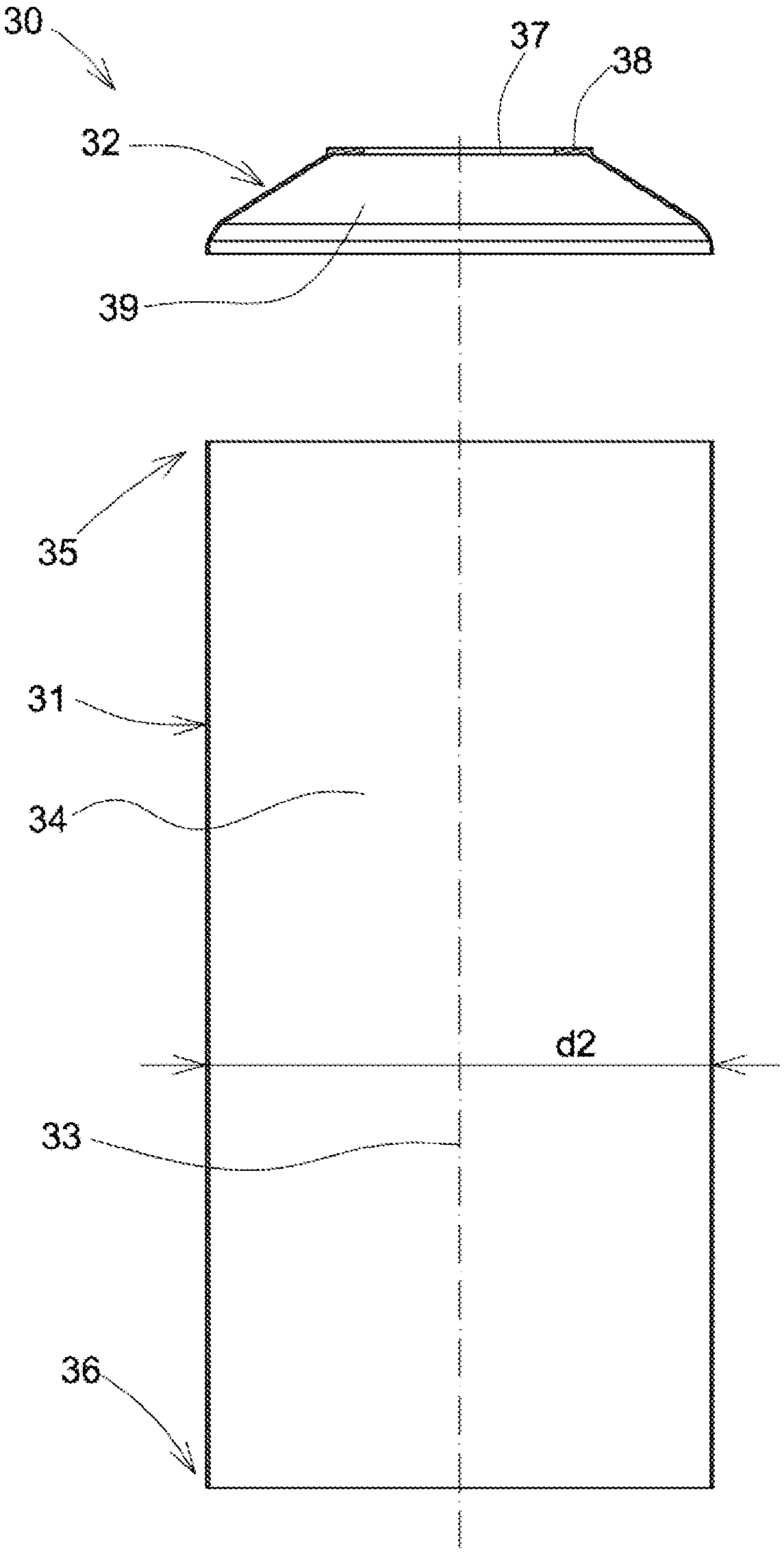

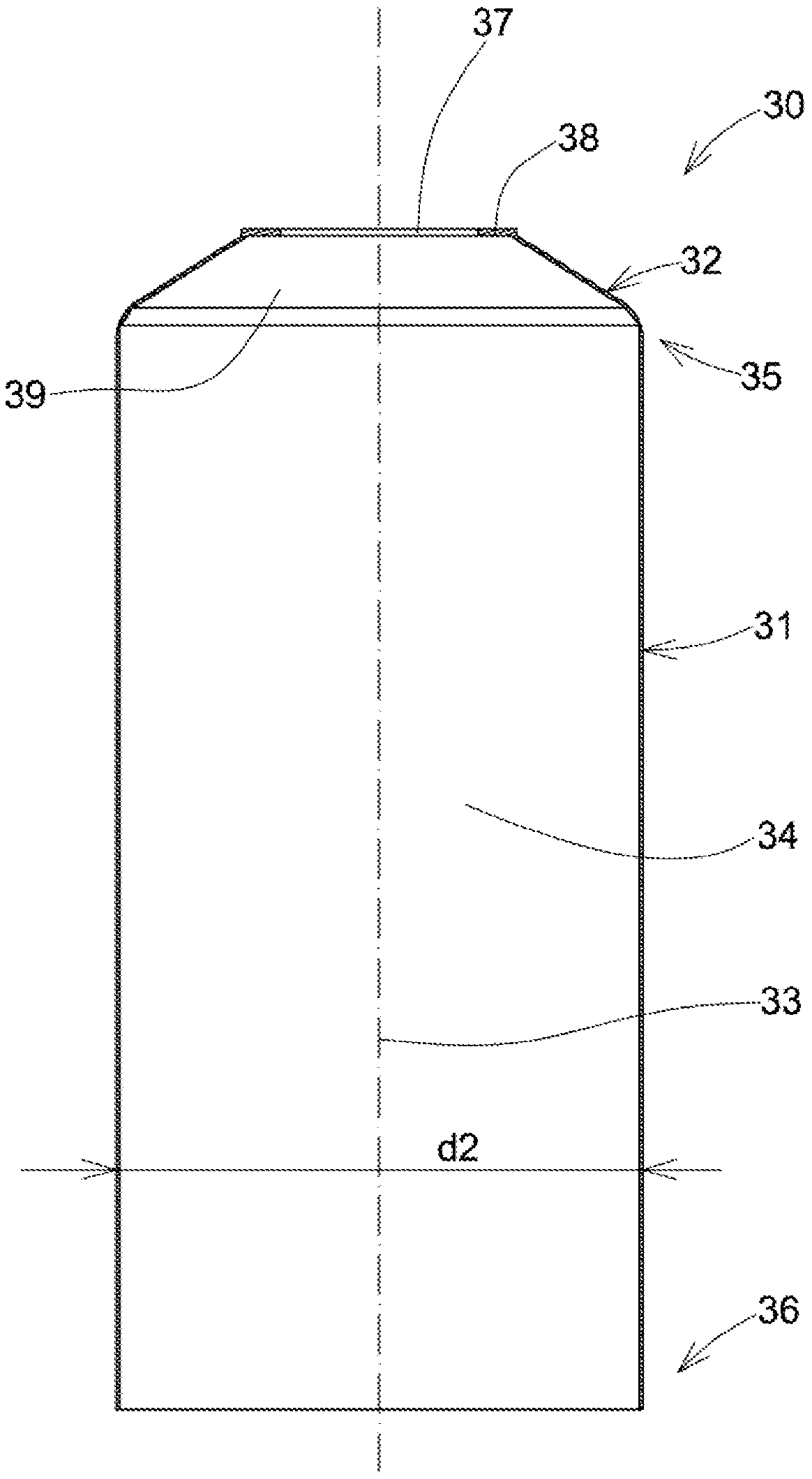

Tubular container with an outer tube and an inner container

InactiveCN108883858AChoose simpleWon't touchVenting meansFlexible containersEngineeringMechanical engineering

Owner:CTL TH PACKAGING S L UNIPERSONAL

Transparent bloomless silicone rubber mixed compound and preparation method

The invention discloses a transparent bloomless silicone rubber mixed compound and a preparation method. The transparent bloomless silicone rubber mixed compound is prepared from the following components: 100 parts of methyl vinyl silicone rubber mixed compound, 0.5 to 1.0 part of DCBP and 0.3 to 1.0 part of alkyl peroxide. The preparation method comprises the following steps: measuring various components according to a ratio, uniformly dispersing the components into 100 parts of silicone rubber mixed compound, extruding molding by virtue of a rubber extruder, shaping and vulcanizing at a temperature of 500 to 600 DEG C for 5 to 30 s, wherein a temperature of a horizontal drying passage is 200 to 300 DEG C, and the time is 1 to 10 min; and preparing an extruded product corresponding to themold. Compared with the product in the prior art, the product disclosed by the invention has the advantages that on the premise of hardly changing the physical mechanical performance, and in the production, 1 to 2 months with blooming are prolonged to 2 years or more without blooming, so that the extruded product can be stored for a long time, the appearance is not changed, the secondary treatment of the product is reduced, and the product security is improved. In addition, the secondary vulcanizing time can also be reduced, the energy consumption can be saved, and the production cost can bedecreased.

Owner:JINAN CHENSHENG MEDICAL SILICONE RUBBER PROD

Formula and production process of high molecular weight corrosion-resistant epoxy vinyl ester resin

The invention discloses a formula and a production process of a high molecular weight corrosion-resistant epoxy vinyl ester resin. According to the formula, unsaturated monocarboxylic acid uses a softmonomer acrylic acid to replace a traditionally used hard monomer methacrylic acid, and a bisphenol A epoxy resin is used as the main raw material for synthesizing the epoxy vinyl ester resin; and fumaric acid and toluene diisocyanate are used as chain extenders to produce the high molecular weight corrosion-resistant epoxy vinyl ester resin, and the styrene solution is the final product, and isnamed the epoxy vinyl ester resin. According to the production process, the chain extension reaction of toluene diisocyanate is performed in a styrene solution at a temperature of 60 DEG C, ie., diluting and chain extending are sequentially performed. According to the present invention, the difficulty on the production operation due to the high viscosity product formed through the chain extensionreaction can be solved.

Owner:西宁晶海科教化玻仪器有限公司

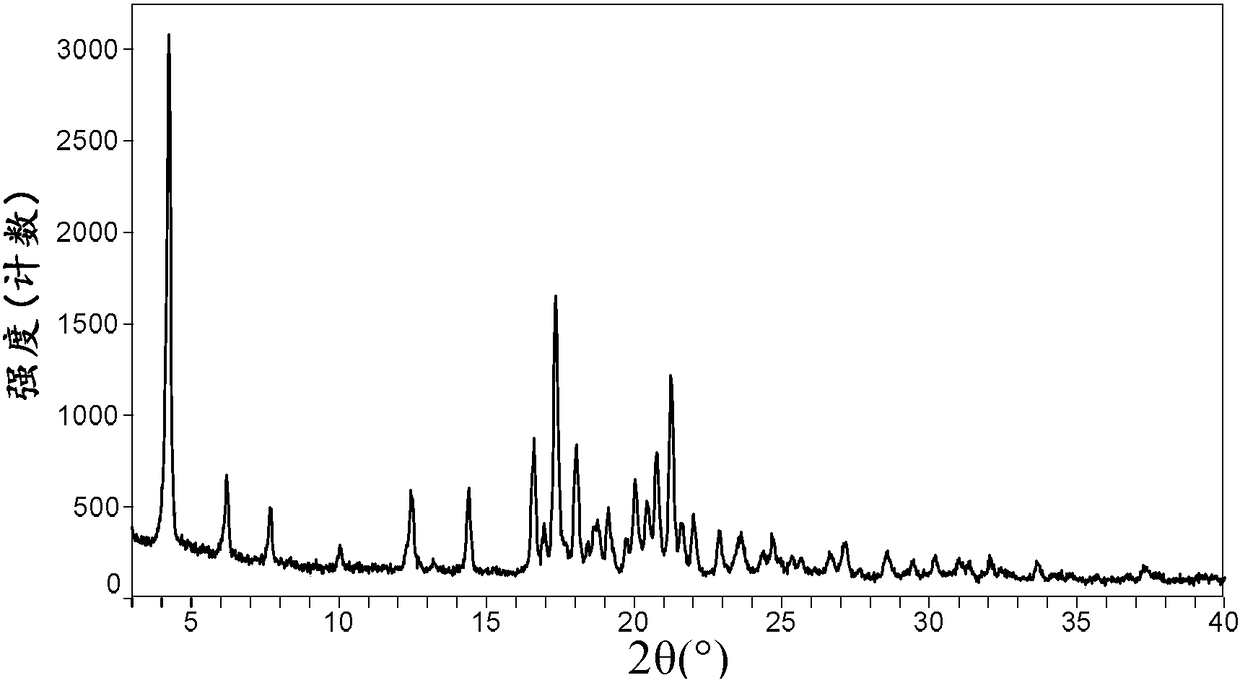

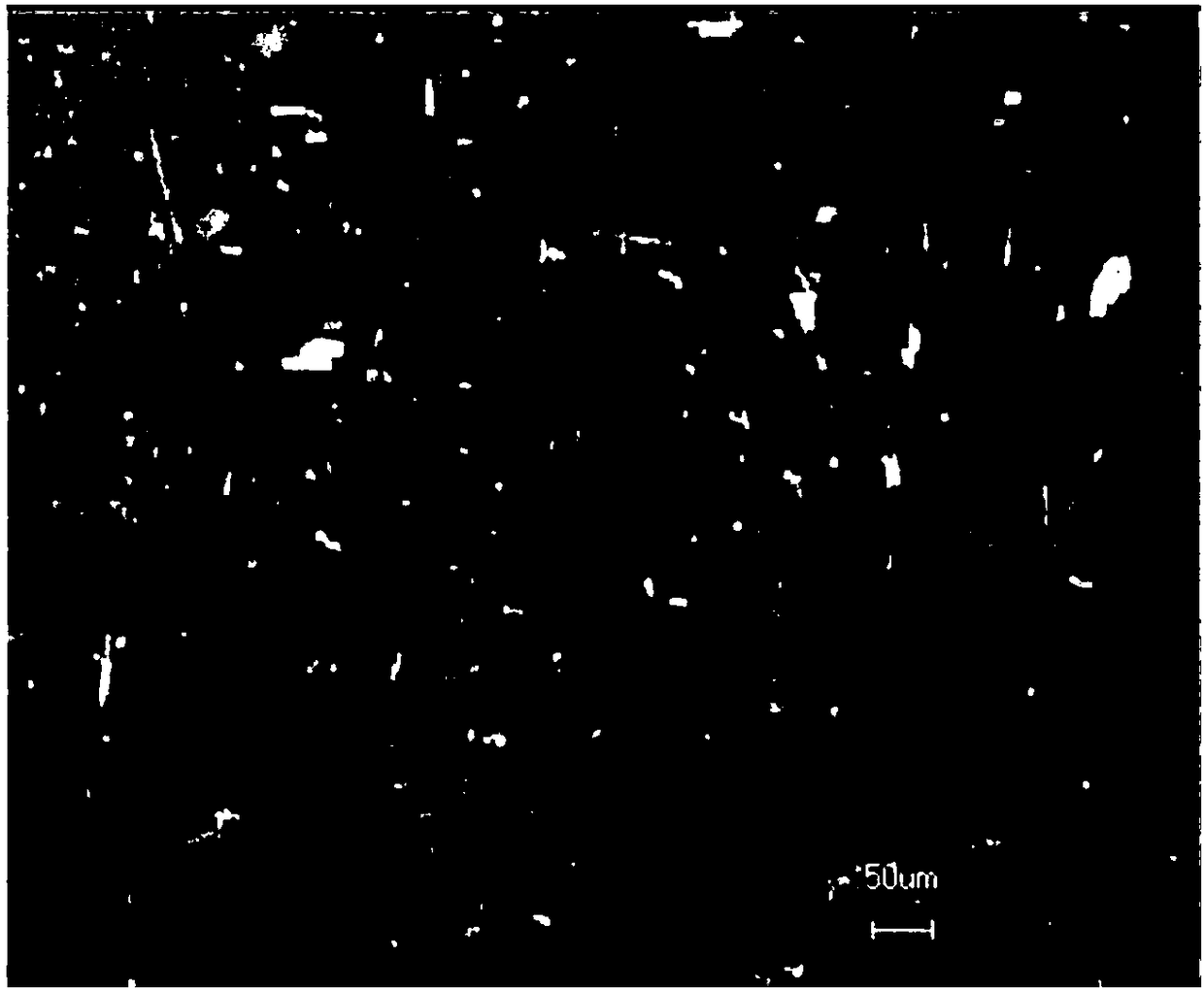

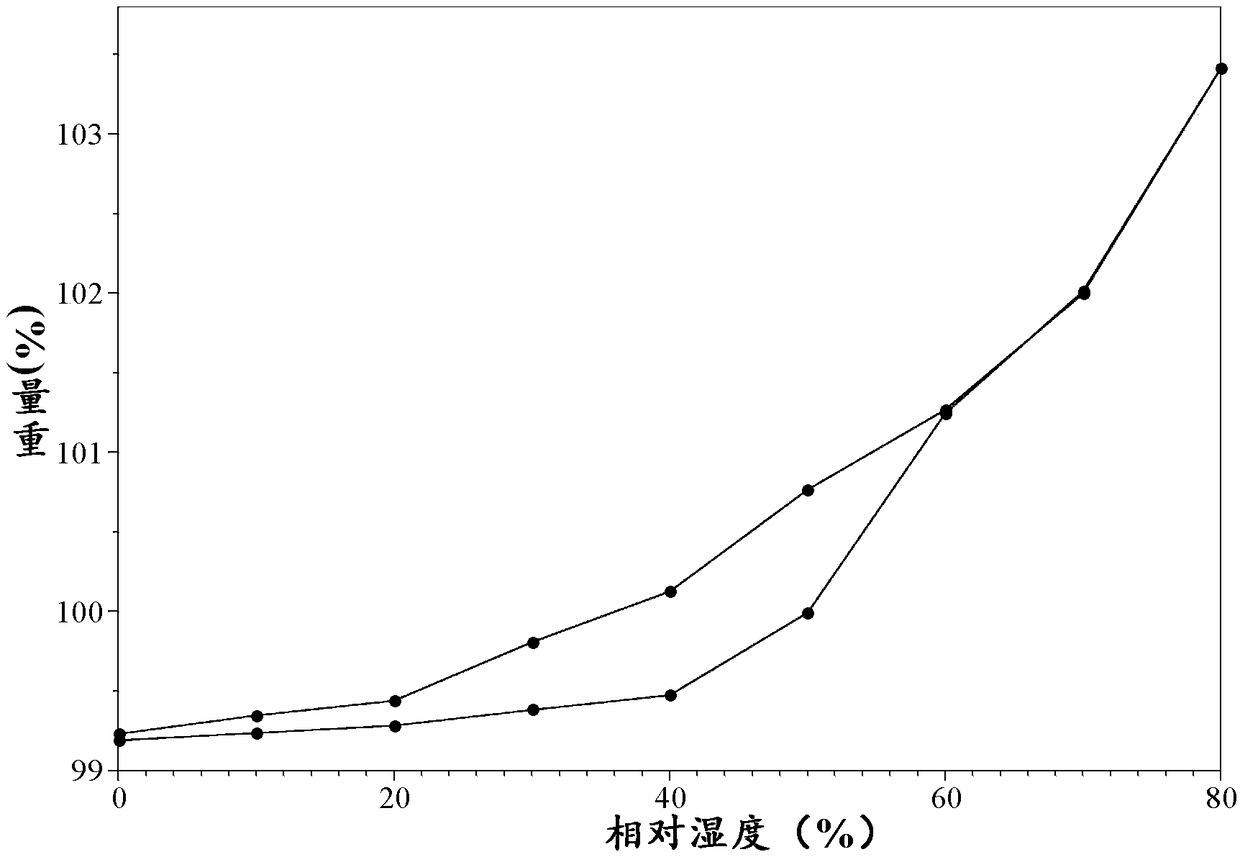

THR1442/L-aspartic acid co-crystal, and preparation method thereof and pharmaceutical composition thereof

ActiveCN108239055AWell mixedImprove stabilityOrganic active ingredientsMetabolism disorderSGLT2 InhibitorL-Aspartate

The invention relates to a SGLT2 inhibitor, i.e., a co-crystal of THR1442 (bexagliflozin) and L-aspartic acid. Compared with conventional THR1442 / diproline co-crystals the THR1442 / L-aspartic acid co-crystal of the invention has one or more improved features. The invention further relates to a preparation method for the THR1442 / L-aspartic acid co-crystal, a pharmaceutical composition of the THR1442 / L-aspartic acid co-crystal and methods for applying the THR1442 / L-aspartic acid co-crystal and the pharmaceutical composition to treatment of diseases or illnesses caused by inhibition of SGLT or SGLT2.

Owner:SOLIPHARMA

Degradable foamed and co-extruded PA barrier thin film

ActiveCN104369509AConsistent biological activityUniform degradation rateSynthetic resin layered productsComposite filmMole ratio

The invention discloses a degradable foamed and co-extruded barrier thin film. The thin film is characterized in that biodegradability of materials in the composite thin film tends to be uniform by introducing a biologic base, adding amount of adding-type master batch in each material is controlled within a range of being 0.3-15% of total mass of the corresponding material; hydrophilic activity of hydrophilic group in the adding-type master batch should be larger than or equal to that of hydrophilic group in each material. By adding the adding-type master batch, mole ratio of the hydrophilic group and carbon atom of each material tends to be uniform, in other words, bioactivity tends to be uniform, so that degrading rate of each layer of the composite thin film tends to be uniform. By balancing the mole ratio of the hydrophilic group and the carbon atom in each layer, bioactivity and biodegradability which tend to be uniform are acquired, and appearance, function and physical and mechanical performance of the thin film remain unchanged.

Owner:KUSN JIAPU PACKING MATERIAL

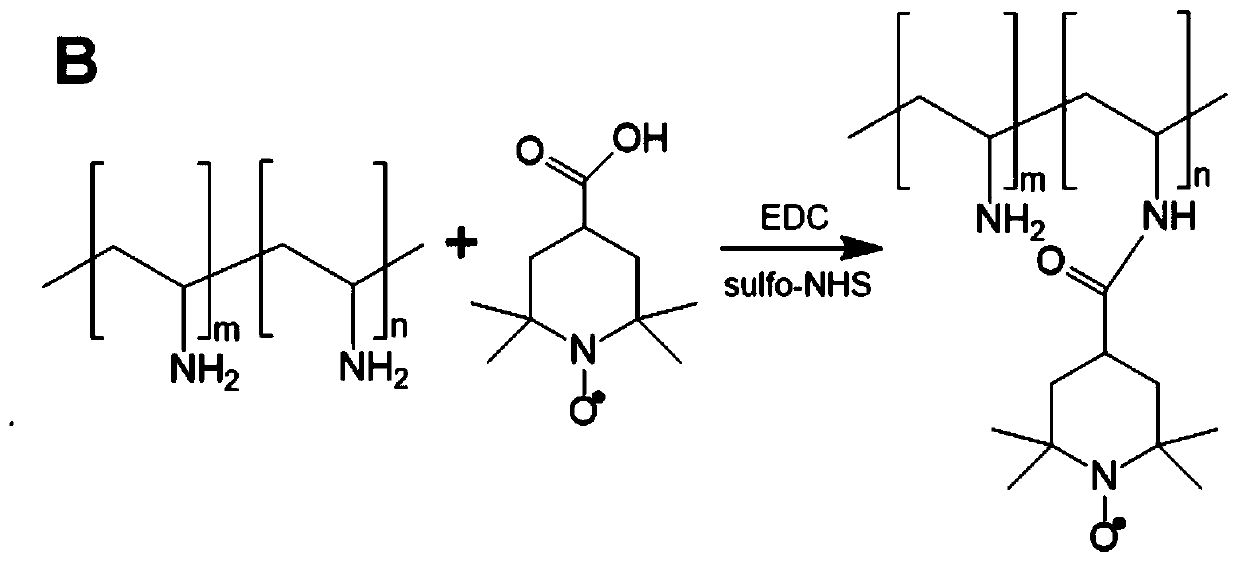

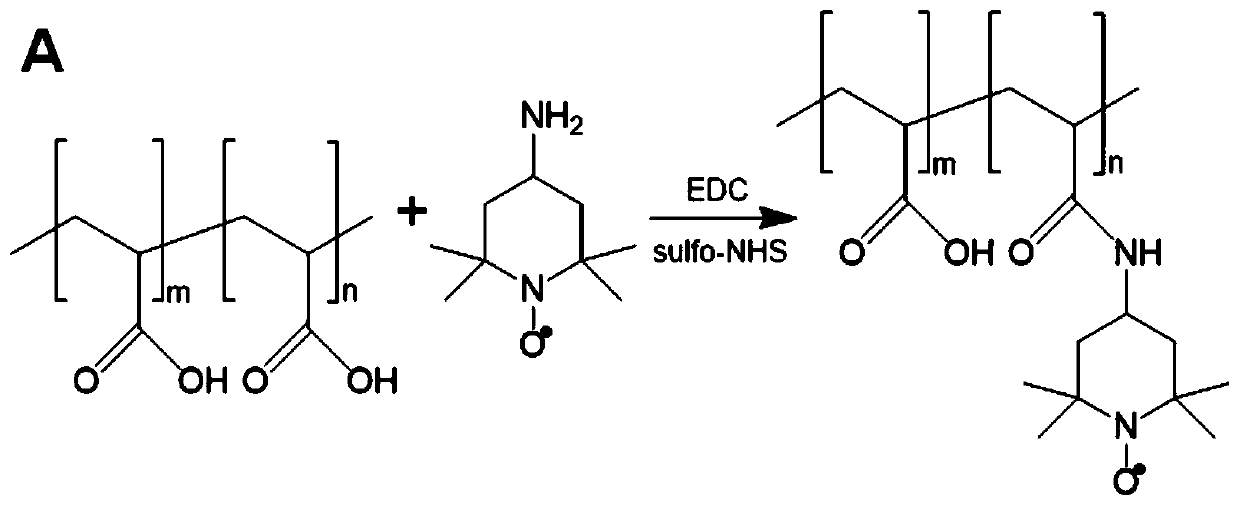

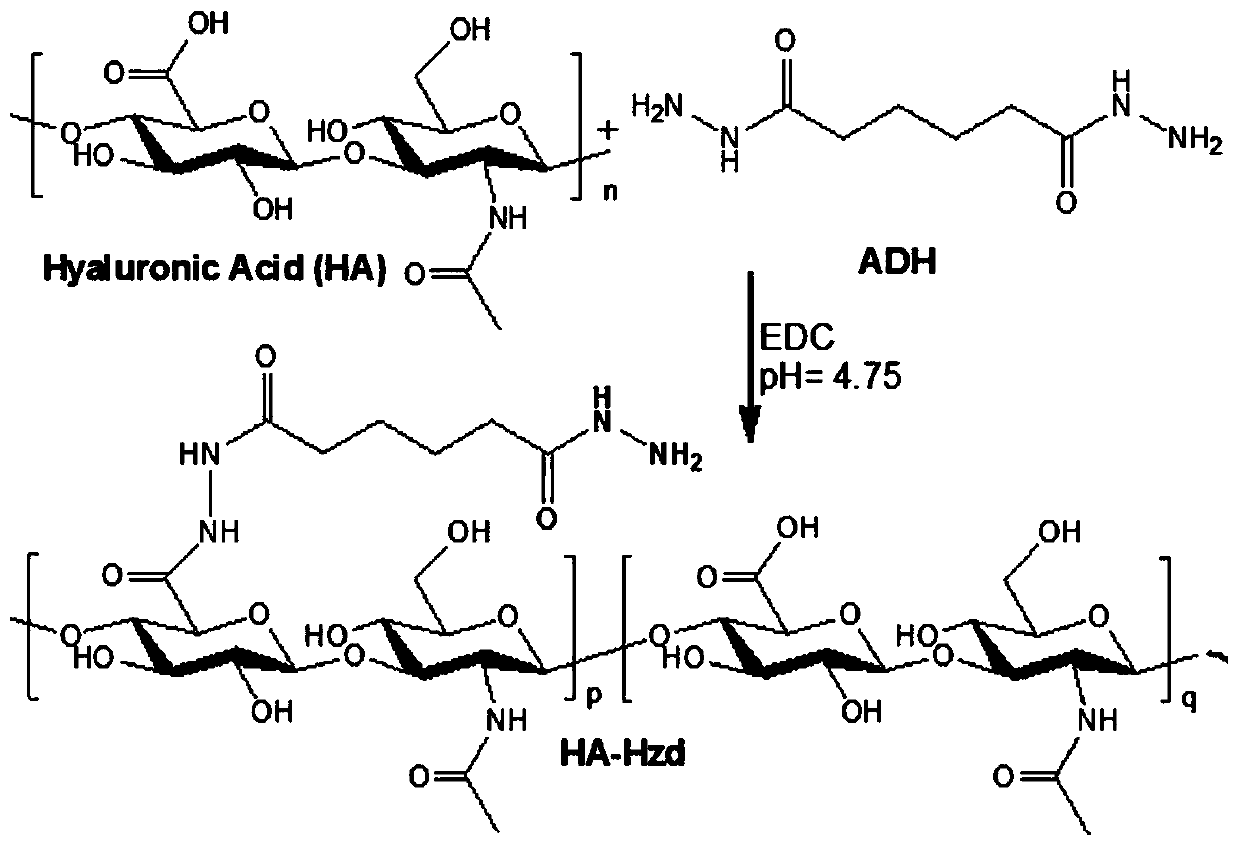

Method for catalytic oxidation and functional modification of hydrogel material

The invention discloses a method for catalytic oxidation and functional modification of a hydrogel material, which is characterized by comprising the following steps: step 1, soaking the hydrogel material in a buffer solution dissolved with a piperidine compound to obtain a mixed system; step 2, adding a laccase solution into the mixed system obtained in the step 1, and then introducing oxygen forcatalytic oxidation to obtain an oxidized hydrogel material; and 3, soaking the hydrogel material oxidized in the step 2 in a hyaluronic acid-adipic dihydrazide solution, and carrying out functionalmodification under a stirring condition to obtain the modified hydrogel material. The method has the advantages that the process is controllable, the water-soluble polymer range is wide, experimentalreagents are easy to obtain, large experimental equipment is not needed, and the reaction is carried out under the conditions of normal temperature and normal pressure. The modified hydrogel materialprepared by the method disclosed by the invention has the advantages of high moisture retention, low protein adsorption capacity, unchanged appearance, light permeability and refractive index and thelike.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for controlling synchronous degradation of each layer of co-extrusion composite film by utilizing same biological base

ActiveCN102627013BAppearance unchangedIngenious ideaSynthetic resin layered productsComposite filmAgricultural engineering

The invention discloses a method for controlling the synchronous degradation of each layer of a co-extrusion composite film by utilizing the same biological base. Aiming at the co-extrusion composite film which is in three layers or more than three layers, a biological active additive 'EcoPure' is used as the biological base. The method is characterized by comprising the following steps of: calculating a weight proportion relationship between carbon contents of each layer of the co-extrusion composite film first, then determining the addition concentration of the biological base of each layer according to the weight proportion relationship between the carbon contents of each layer in extruded polymer of each layer before the preparation, and making the degradation rate of each layer of the co-extrusion composite film be accordant. The method disclosed by the invention has the contribution of having a predictable control ability for the biological degradation process and the degradation rate of multi-layer co-extrusion composite film which is composed of different polymers; and by balancing the concentration of the biological base, the biological degradation rate which is suitable for the final processing environment is provided, and the appearance, the function and the physical and mechanism performance of a product before being discarded are ensured to be unchanged.

Owner:圣厦药品食品包装新材料(昆山)有限公司

Preparation method for medicinal tea

InactiveCN102113579AAppearance unchangedColor unchangedPre-extraction tea treatmentFlavorCooking & baking

The invention relates to a formula and a preparation method for medicinal tea. Raw materials comprise fructus lycii and green tea. In the preparing process of the tea, fructus lycii medicine liquid is atomized, and added in the tea for baking, and then the medicinal tea is obtained. After being drunk, the medicinal tea also has the aging resistance besides the effects of protecting liver, reducing pressure, nourishing kidney and improving eyesight, and enhancing immunity. The preparation method is simple, the raw materials are easy to obtain, and the cost is low. The tea obtained by adding the fructus lycii juice not only keeps the original color and luster, and appearance, is constant in mouthfeeling, special in flavor, and also has the effect of medicine.

Owner:张清音

Novel yoga mat

The invention relates to a novel yoga mat. The novel yoga mat is prepared from the following components in parts by weight: 31 to 39 parts of elastomer, 38 to 47 parts of PVC, 23 to 35 parts of nylon, 27 to 32 parts of plasticizer, 36 to 53 parts of polyvinyl alcohol resin, 18 to 26 parts of calcium powder, 17 to 23 parts of elastomer processing oil, 1.1 to 1.4 parts of stabilizer, 1.1 to 1.8 parts of antioxidant, 4.8 to 6 parts of foaming agent, 3 to 4 parts of softening agent, 16 to 18 parts of ultrahigh molecular weight polyethylene, 8 to 10 parts of water absorbent and 7 to 9 parts of active carbon. The novel yoga mat has the advantages that the formula has different changes according to the requirements of customers: a top level, a middle level and a low level; the novel yoga mat is divided into an environment-friendly type and a non-environment-friendly type, and is diversified in colors; the appearance and the shape are not changed, and the novel yoga mat has an antiskid effect. The product of the novel yoga mat is uniform in pores, moderate in softness and hardness and good in resilience.

Owner:江苏攸途健身器材有限公司

Production method of vinasse-made gingko flavored food

ActiveCN103549548AMaintain inherent nutritional contentAppearance unchangedFood ingredient functionsFood preparationFlavorOlder people

The invention particularly discloses a production method of a vinasse-made gingko flavored food. The production method is characterized by comprising the following steps: selecting and processing raw materials; steaming and drying; preparing a pickling vinasse material; pickling; seasoning; drying; and packaging and sterilizing. The gingko food with a special flavor keeps the inherent unique mouth feel and nutritional ingredients of gingko and is additionally provided with seasoning substances with the special flavor; the gingko food is chewable and delicious in taste and is suitable for people with bad teeth and old people to eat; the method is simple in processing process, easy to operate and low in cost, and is suitable for industrial production.

Owner:徐州绿之野生物食品有限公司

Herb tea, and preparation method thereof

InactiveCN103704394AAppearance unchangedNo change in tastePre-extraction tea treatmentAlkaloidFlavonoid glycosides

The invention relates to a herb tea, and a preparation method thereof. Raw materials of the herb tea comprise a herbal medicine named?Yehehuan?according?to?the?Chinese?pronounciation, and green tea. The preparation method comprises following steps: Yehehuan juice is atomized, and is added in production processes of green tea; and then finished products are obtained via roasting. It is confirmed by chemical composition qualitative analysis that the herb tea contains flavonoid glycosides and alkaloids with relatively high biological activity; the herb tea is capable of nourishing kidney and tonifying Yang like Yehehuan, and is capable of adjusting viscera, maintaining Jing and nourishing Shen, prolonging life span, cultivating life and preserving health, and adjusting internal secretion. The preparation method is unique; combination of herbal medicine with green tea is novel; the obtained herb tea possesses appearance of tea, and unchanged taste, and also possesses medical effects, is unique in taste, is low in cost, and is convenient for popularization, transportation and storage. Production of the herb tea can be realized by qualified processing factories, and benefits are high.

Owner:罗德宇

Nano easy-welding high-hardness wear-resistant corrosion-resistant decorative alloy catalytic liquid and preparation method thereof

InactiveCN110079794AStrong corrosion resistanceImprove corrosion resistanceLiquid/solution decomposition chemical coatingRare-earth elementWear resistant

The invention discloses a nano, easy-to-weld, high-hardness, wear-resistant, corrosion-resistant and decorative alloy catalytic liquid and a preparation method thereof. The nano, easy-to-weld, high-hardness, wear-resistant, corrosion-resistant and decorative alloy catalytic liquid is compounded by nickel, zinc, rare earth elements and the like as basic raw materials, a lubricating, easy-to-weld, high-hardness, wear-resistant, corrosion-resistant, bright-thickness and accurate-thickness nano-alloy layer can be obtained on the surface of metal by high-temperature catalysis, and the nano easy-to-weld, high-hardness, wear-resistant, corrosion-resistant and decorative alloy catalytic liquid has an appearance decoration effect on the premise of high hardness, high wear resistance, high corrosionresistance and the like, the compact conversion alloy layer formed by catalysis can be stable in a severe environment, and the appearance of the alloy layer can be kept unchanged for a long year.

Owner:深圳市长裕环保有限公司

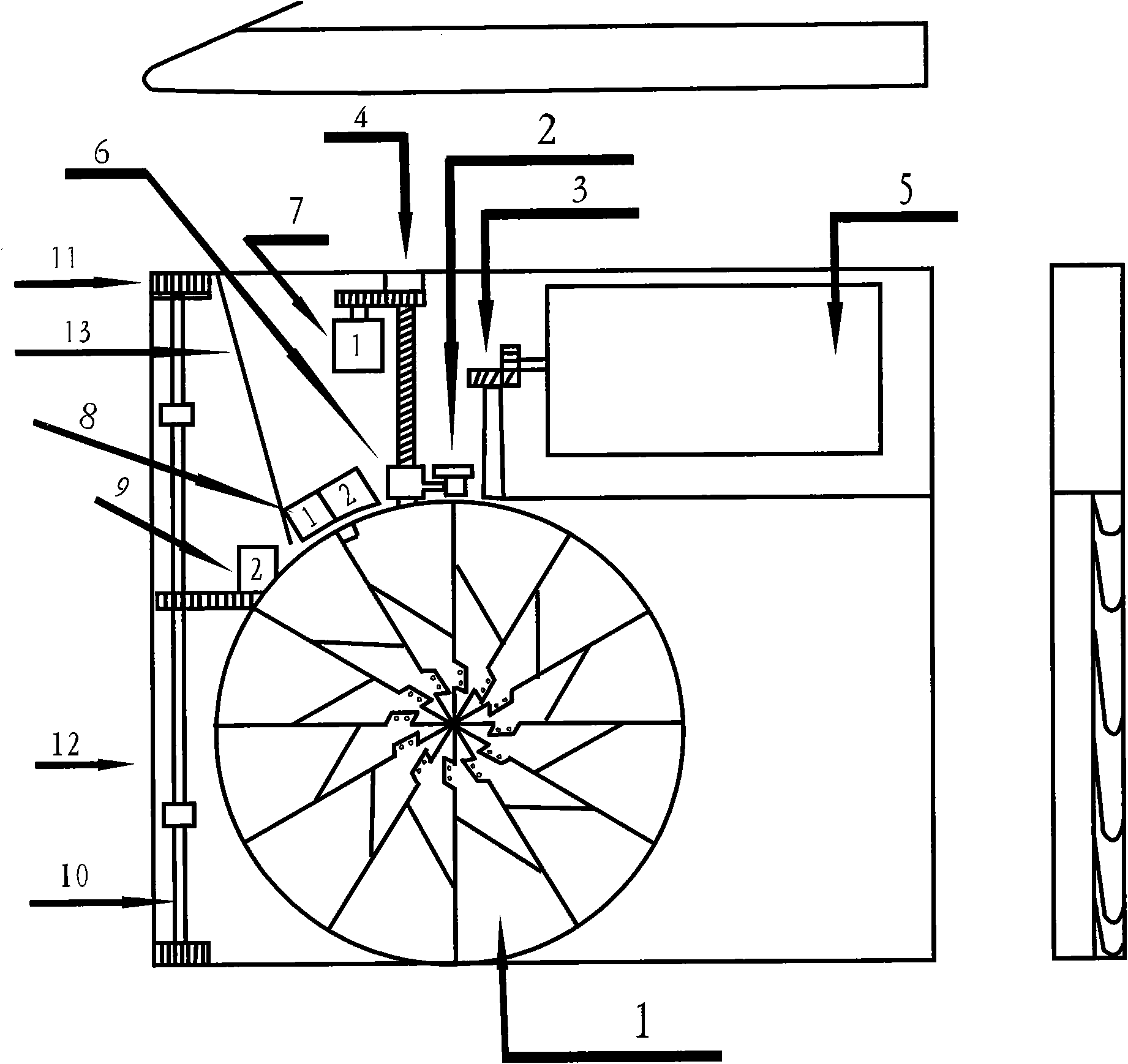

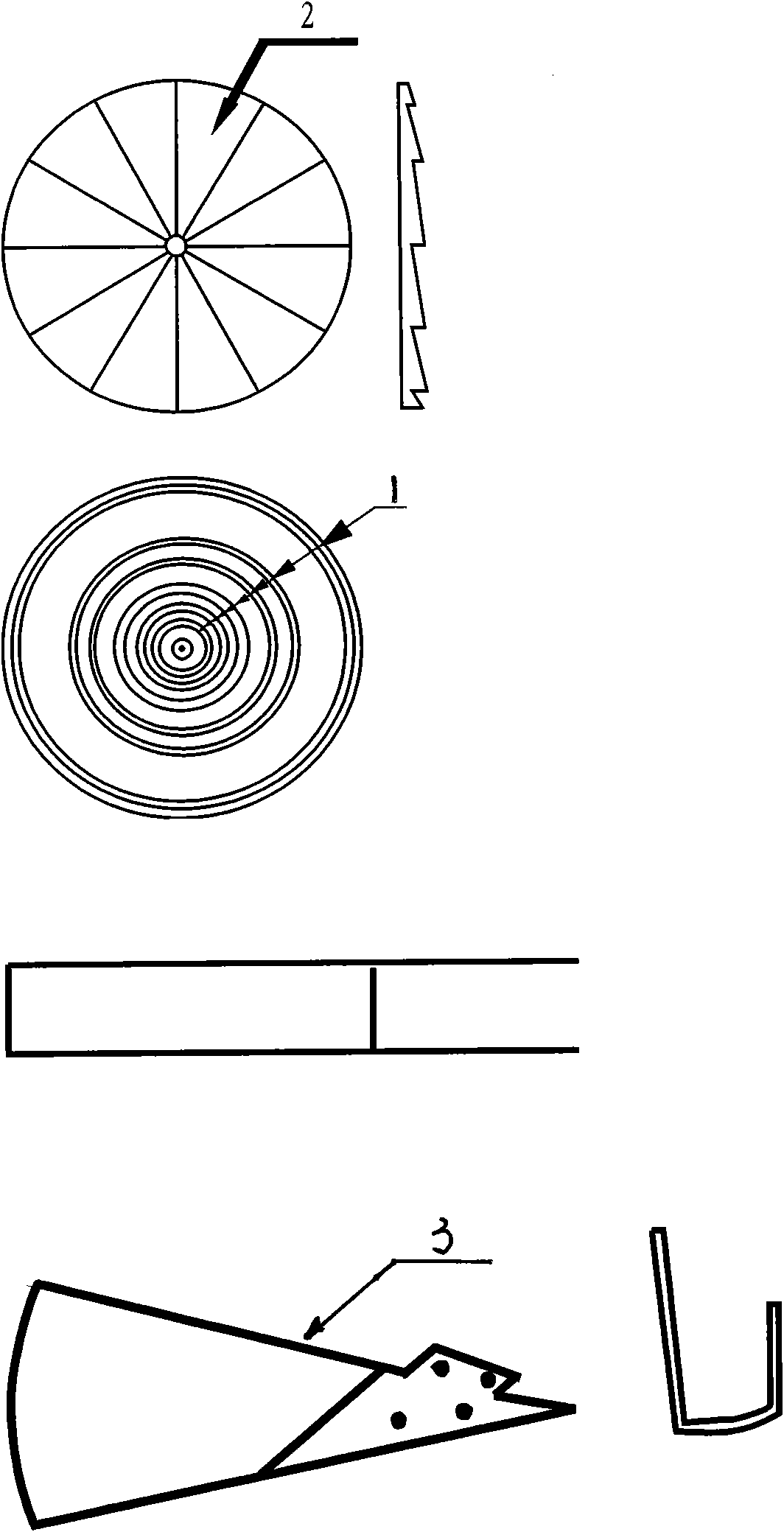

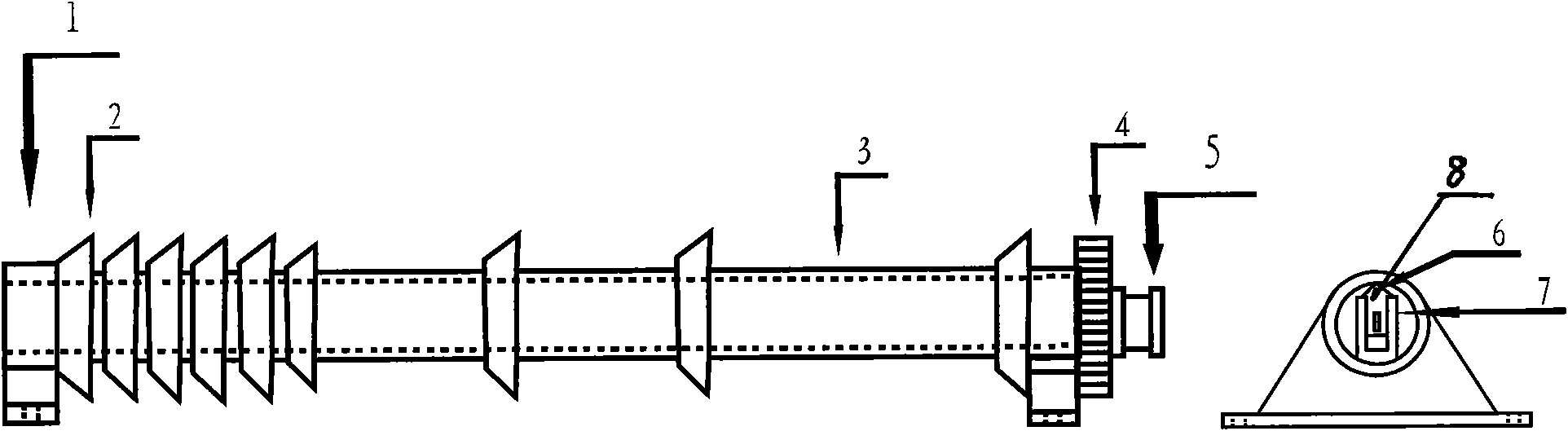

Wind power generation device for driving device

InactiveCN102029918AReduce positionReduce resistanceVehicular energy storageElectric propulsionElectronic control systemDynamo

The invention relates to a wind power generation device for a driving device, which is a clean and environmentally-friendly device which supplies electric energy generated by the transmission of convective current generated in the running process without consuming natural energy and is an energy-saving and emission reduction product which can reduce the discharge of harmful gas and greenhouse effect practically. The invention belongs to the technical field of the improvement of wind power generation and electric energy supply modes of driving devices. In order to solve the technical problem of the wind control over strong or weak convective current generated by the driving speed of the driving device and the rated revolution of a generator, the wind sweeping volume of wind eddy vanes is controlled or the wind sweeping angle of wind vanes is changed by a tandem type nine-stage speed change system or a front ventilation door electronic control system, and a model machine is arranged horizontally and flatly. The wind power generation device can be widely used for being arranged in large and small automobiles, trains, vessels in inland rivers, large and small steamships on sea surfaces and even aircrafts, is assembled and disassembled integrally and is mobile and convenient.

Owner:方根法

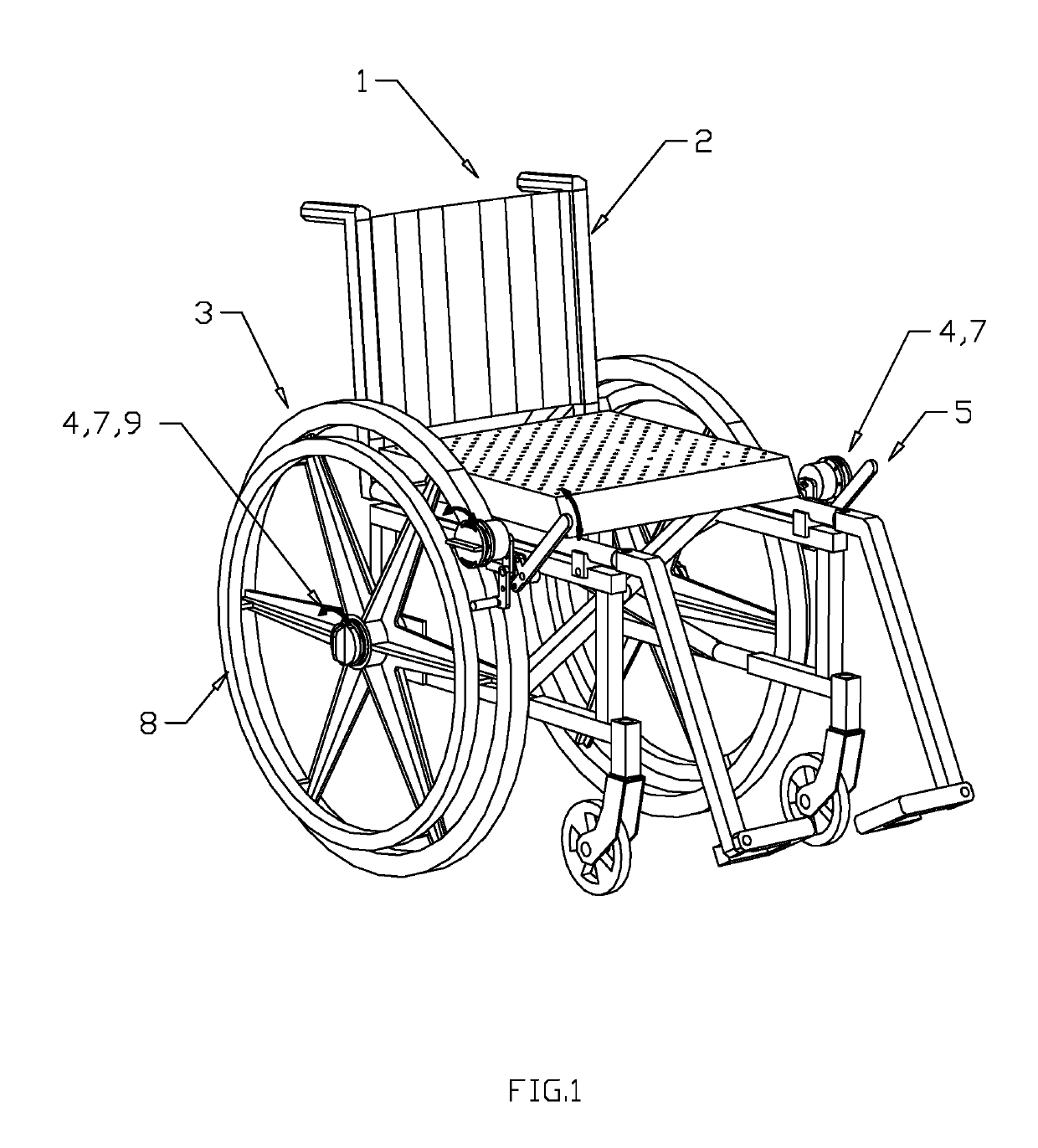

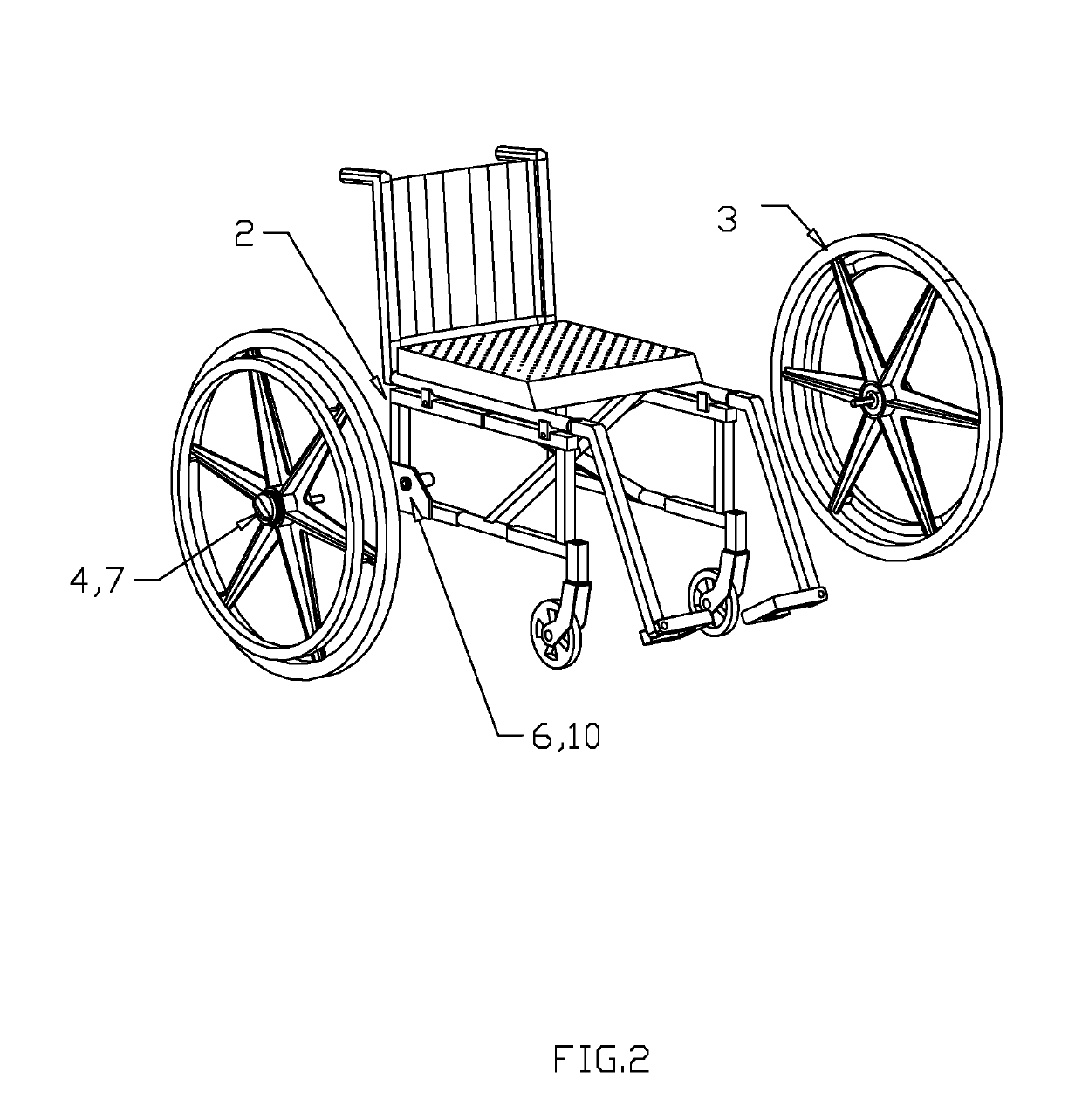

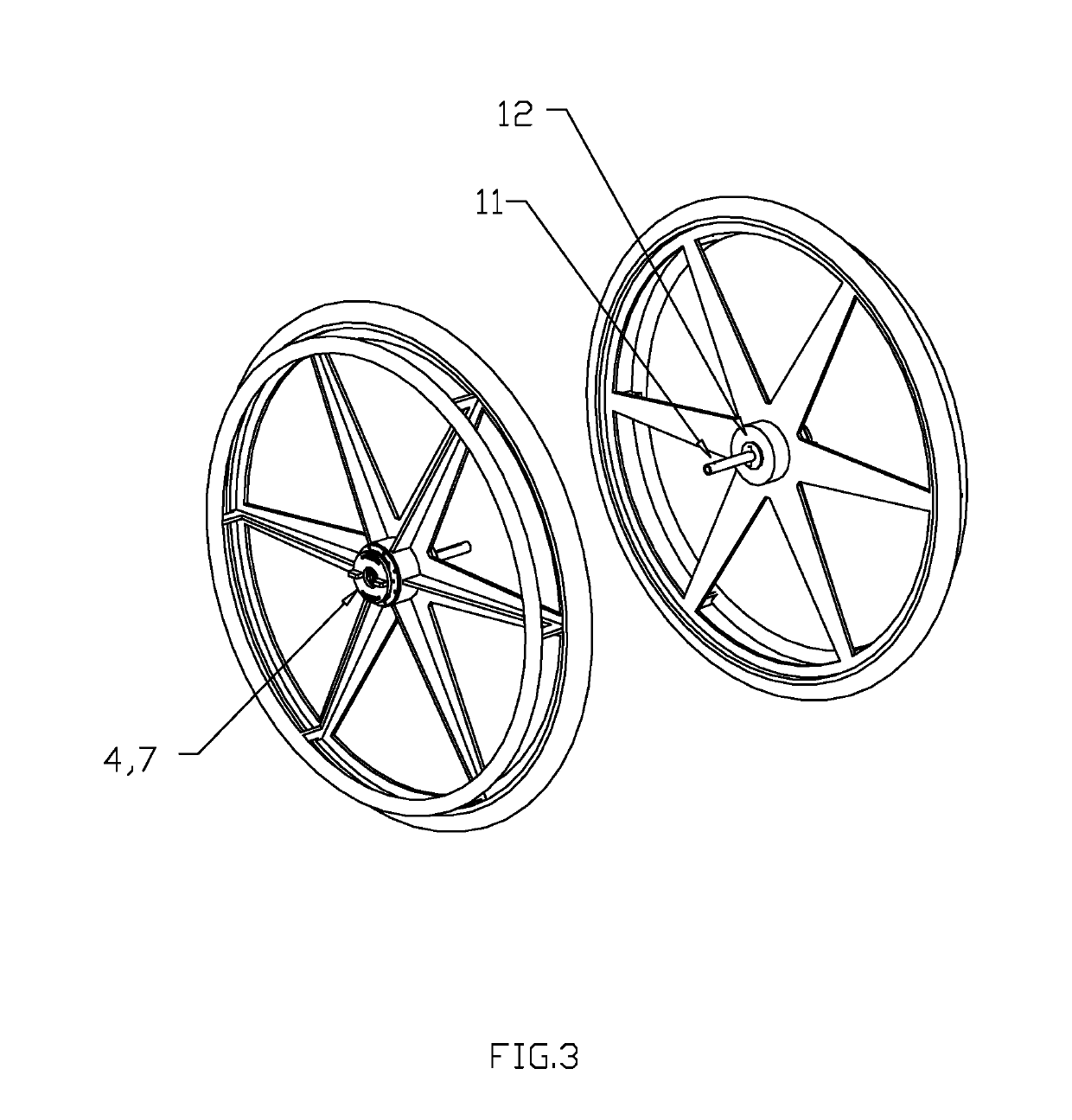

Anti-rollback wheelchair device

ActiveUS10470953B1Appearance unchangedWheelchairs/patient conveyanceAutomatic clutchesFree rotationWheelchair user

A wheelchair anti-rollback device utilizes one-way roller clutches which incorporate a selectable free-rotation functionality such that the wheelchair user can select between anti-rollback and free-wheeling modes. The anti-rollback mode is of utility when the wheelchair user is propelling up ramps. The modal selection is by means of a knob positioned on the centerline rotation axis of the mechanism. The mechanism also included functionality that allows mode change from anti-rollback to free-wheeling to be made at any time, including while the chair is on an inclined ramp. The invention can incorporated into the hub of the rear wheels of a wheelchair or into the toggle mechanism of typically used to actuate parking brakes. When incorporated into a wheelchair, the invention gives the wheelchair user greater control and ease in ascending ramps.

Owner:GREEN STEPHEN

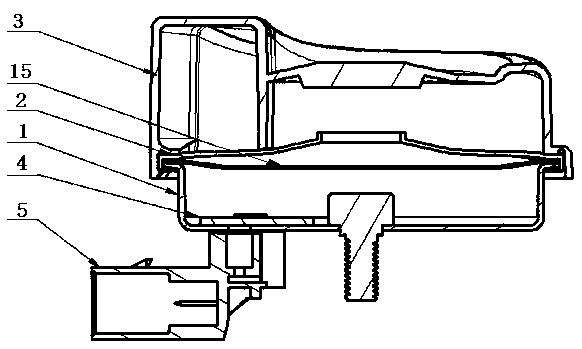

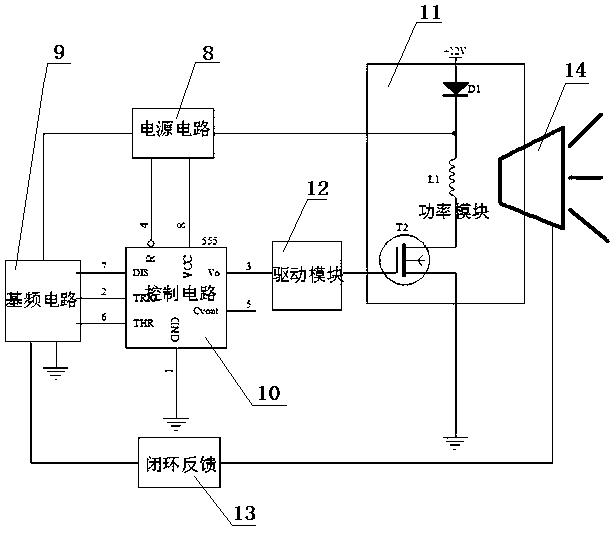

Electronic horn using piezoelectric ceramic buzzer as diaphragm and sounding method thereof

Provided are an electronic horn using a piezoelectric ceramic buzzer as a diaphragm and a sounding method thereof. At present, that horn used for automobile whistle are all made of ferrous metal diaphragm as the sounding diaphragm, and the vibration frequency is 300Hz-600 Hz. As that metal diaphragm is to be vibrated, the driving power is required to be large enough, the energy consumption is high, and the sound production efficiency is low. A method and apparatus for manufacture that present invention comprises the follow steps of: Case (1), a piezoelectric ceramic diaphragm (15) is arrangedbetween the housing and the pressure cap (2), the housing, the pressure gland is respectively connected with a loudspeaker housing (3), The PCB circuit board is connected with the piezoelectric ceramic membrane through a conductor. The PCB circuit board has a connection terminal (5). The shell is connected with a knurling connection device (6). The knurling connection device is connected with a fixing bracket, and the fixing bracket is fixed on a locomotive. The invention is used for an electronic horn.

Owner:HARBIN GOODTIME ELECTRONICS

Fresh keeping agent for fruits and vegetables

InactiveCN109418387ARespiratory suppressionAppearance unchangedFruit and vegetables preservationSucroseSodium ascorbate

The invention relates to a fresh keeping agent for fruits and vegetables. The fresh keeping agent comprises the following components in parts by weight: 40-60 parts of a clove extract, 20-30 parts ofaleic hydrazide, 15-30 parts of a chitosan solution, 15-20 parts of galangal, 12-19 parts of sodium ascorbate, 40-50 parts of a fructus forsythiae extract, 8-11 parts of a malabar spinach extract, 22-29 parts of licorice root residues, 7-11 parts of potassium sorbate, 4-8 parts of sucrose fatty acid ester, 8-13 parts of Chinese toon juice, 7-12 parts of atractylodes rhizomes, 15-20 parts of winterjasmines, 1-5 parts of citric acid and 5-10 parts of thiabendazole. According to the fresh keeping agent disclosed by the invention, the clove extract, the Chinese toon juice, the fructus forsythiaeextract, the malabar spinach aqueous extract and the winter jasmines are all natural substances, so that the fresh keeping agent has significant effects of resisting insects, resisting permeation, resisting bacteria and resisting viruses.

Owner:刘佳

Corrosion resistant resin of oxirene-ester in high molecular weight and producing method

A formula for preparing epoxy vinyl ester resin is featured as that soft monomer of acrylic acid is used main raw material for synthesis by unsaturated monocarboxylic acid, fumaric acid and toluene diisocyanate are used as chain extendor. The production process of toluene diisocyanate being chain-extended in styrene solution at 60 degree i.e. diluting first and then chain extending is disclosed.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

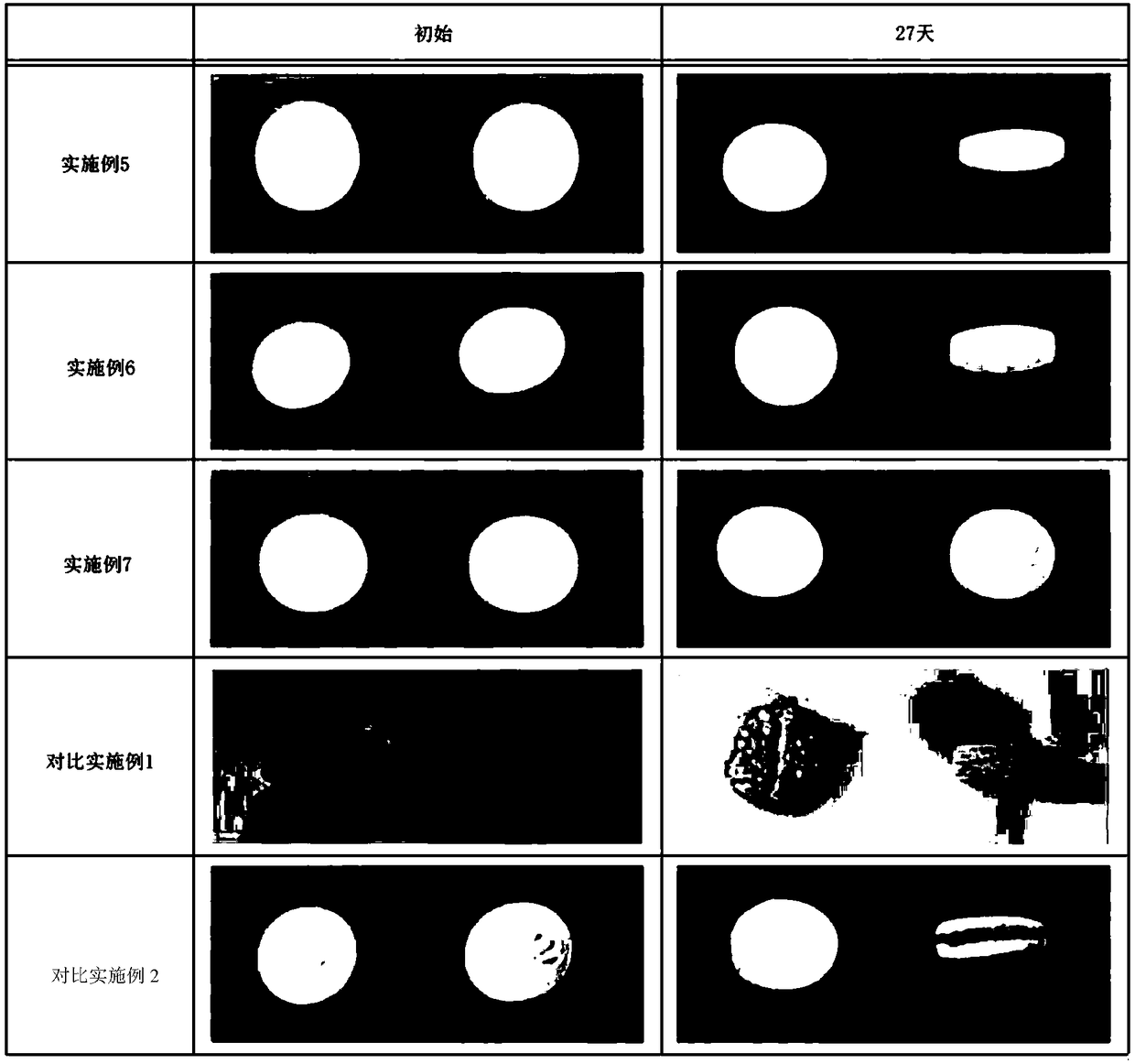

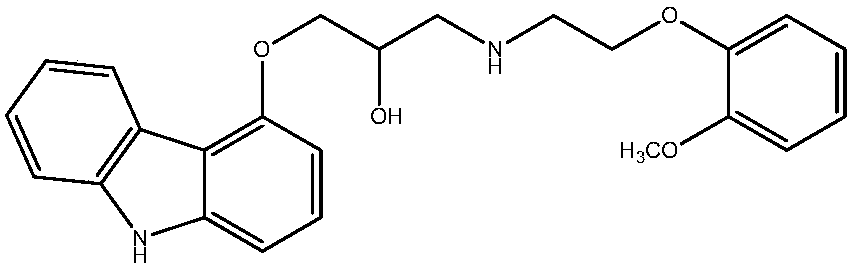

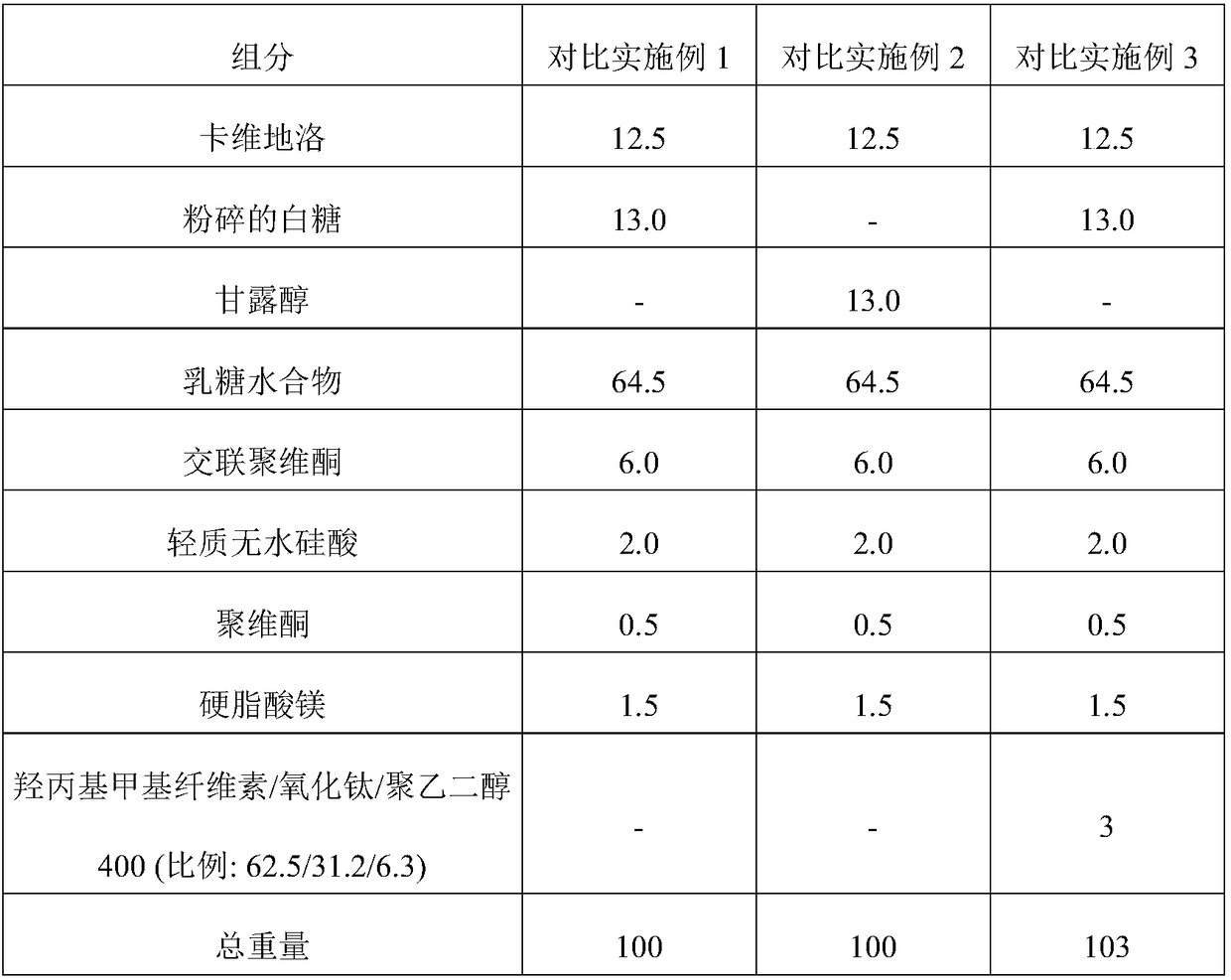

Carvedilol immediate release formulation having improved madescent

InactiveCN108601742AAppearance unchangedExcellent immediate release propertiesOrganic active ingredientsCapsule deliveryWaxImmediate release

Owner:SAMJIN PHARMA

Improved cigarette

InactiveCN106347874AAppearance unchangedContainers for flexible articlesPackaging cigaretteDiseaseEngineering

The invention belongs to further improvement of cigarettes. Spongy tops of original cigarettes are located in the opening positions, multiple adverse factors exist, the cigarettes are difficult to draw out when a cigarette case is opened, unclean hands contact the spongy tops multiple times, thus, the spongy tops are naturally polluted by sweat, viruses and bacteria, finally, people smoke the badly polluted cigarettes in the mouth, and the problem of diseases propagated through the cigarettes is caused. After a cigarette is improved, one end of the spongy top of the cigarette is put at the bottom of the cigarette case, other technological processes are not required to be changed, the cigarette is easy to draw out with the adoption of the new package, the spongy top is clean even the cigarette is drawn out with dirtier hands, all pathogenic bacteria of a pollution source at the other end are immediately killed by the aid of a lighter, the newly improved cigarette is obtained, the condition that diseases are spread among the public due to smoking is avoided, and particularly, the green, hygienic and environment-friendly idea is reflected.

Owner:杜光学

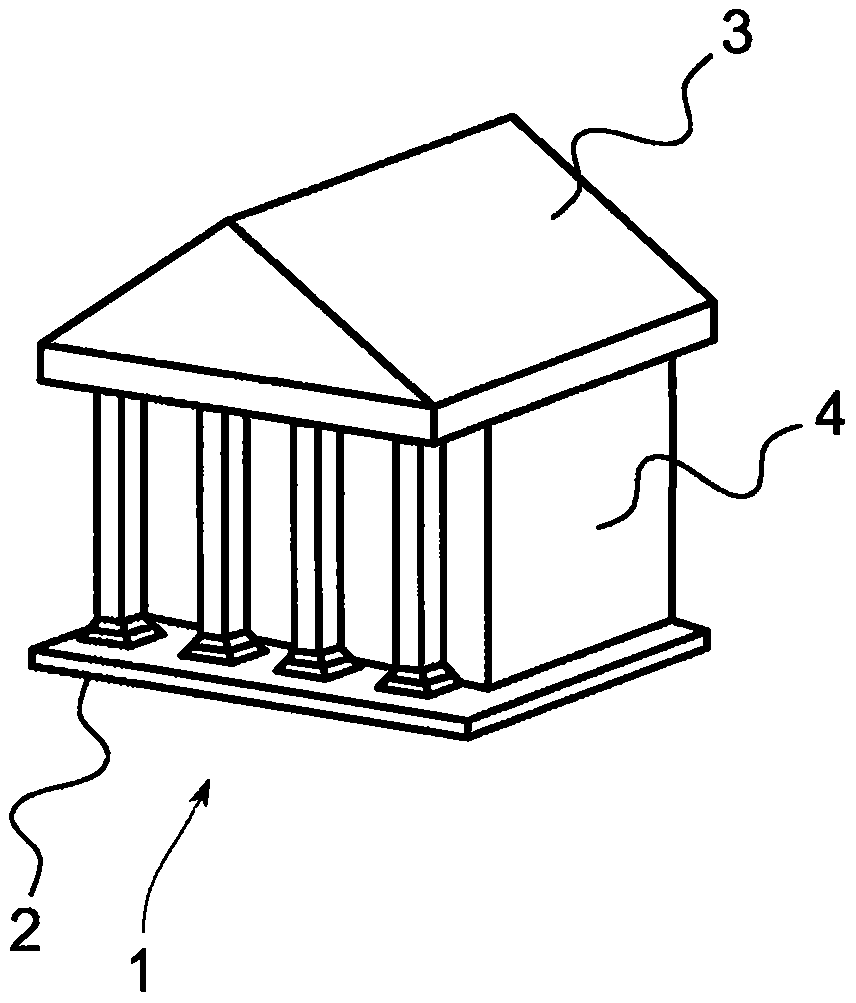

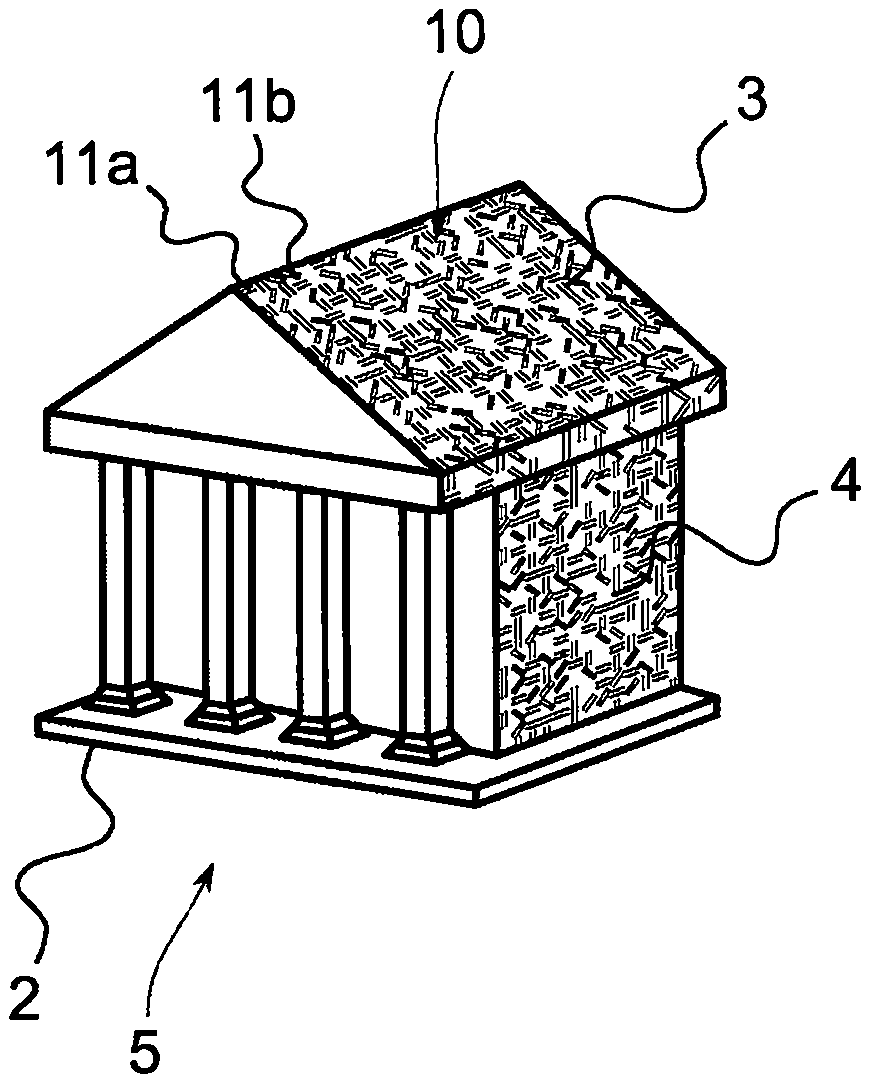

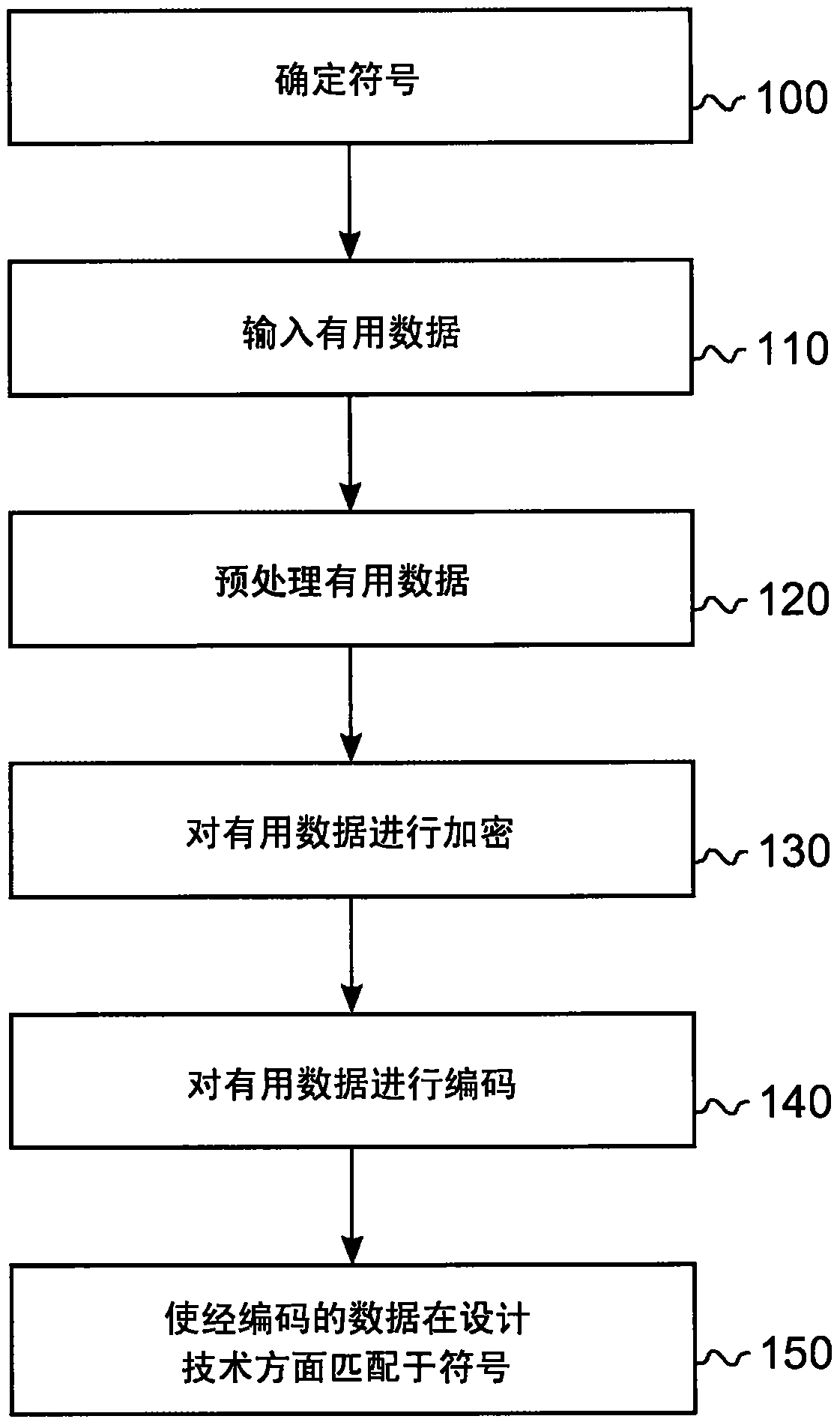

Encoding/decoding of information in graphic information units

InactiveCN105760912BAppearance unchangedIntuitive interaction possibilitiesImage analysisDetails involving 3D image dataGraphicsComputer vision

Owner:计算机科学应用促进会 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com