Patents

Literature

253 results about "L-Aspartate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

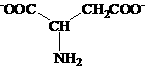

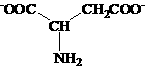

L-Aspartic acid is industrially manufactured by an enzymatic process in which aspartase (l-aspartate ammonia lyase, EC 4.3.1.1) catalyzes the addition of ammonia to fumaric acid. Advantages of the enzymatic production method are higher product concentration and productivity and the formation of fewer byproducts.

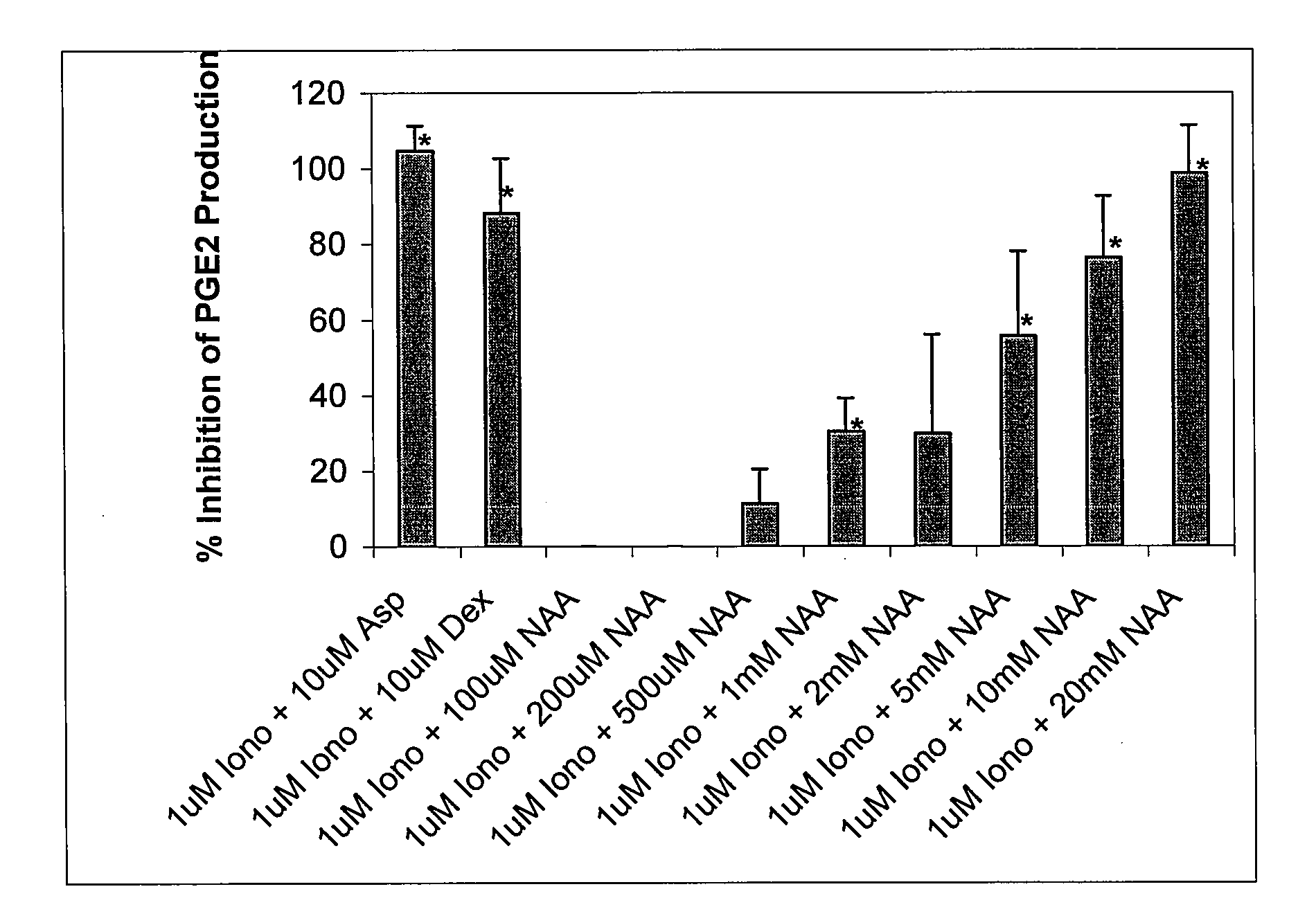

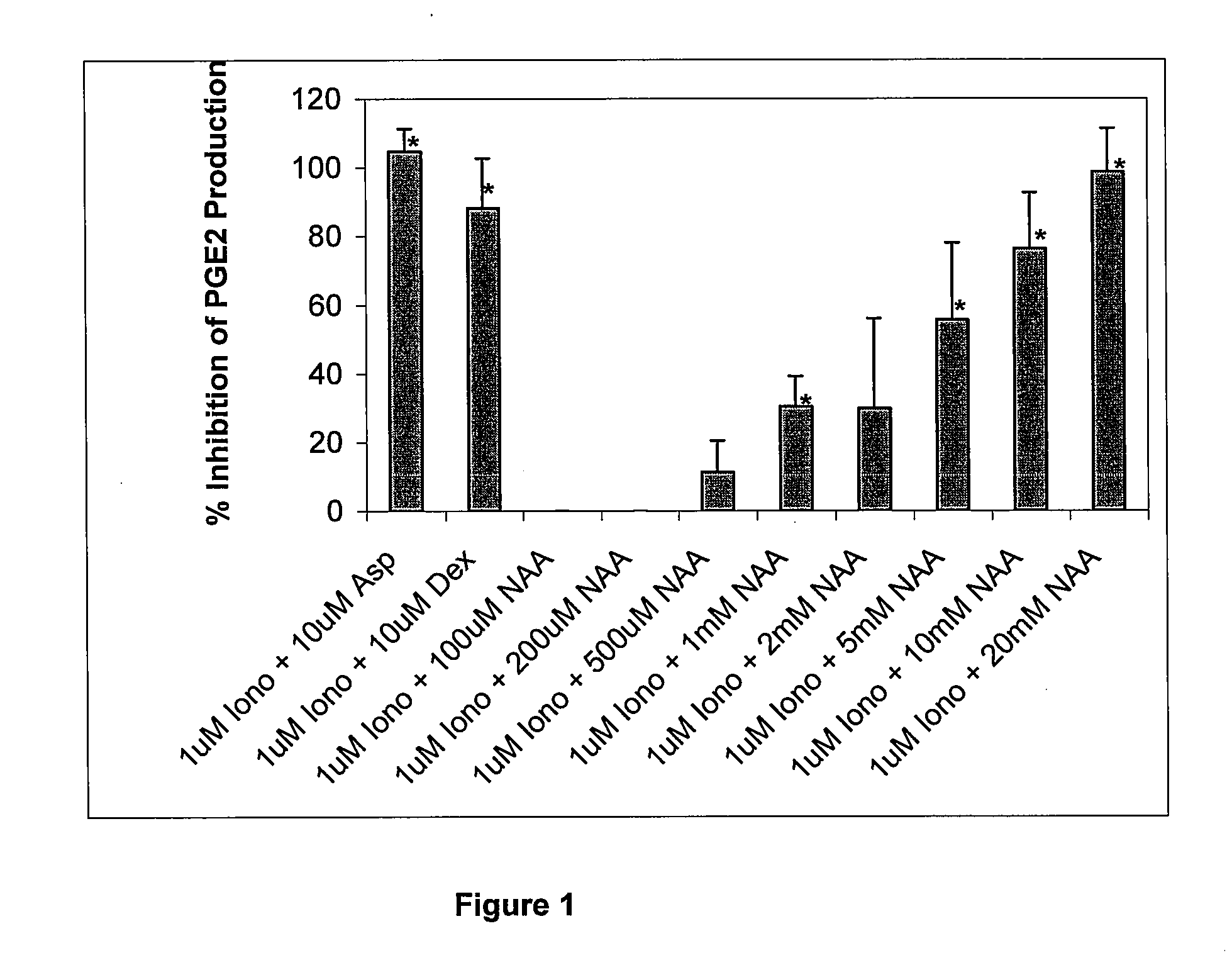

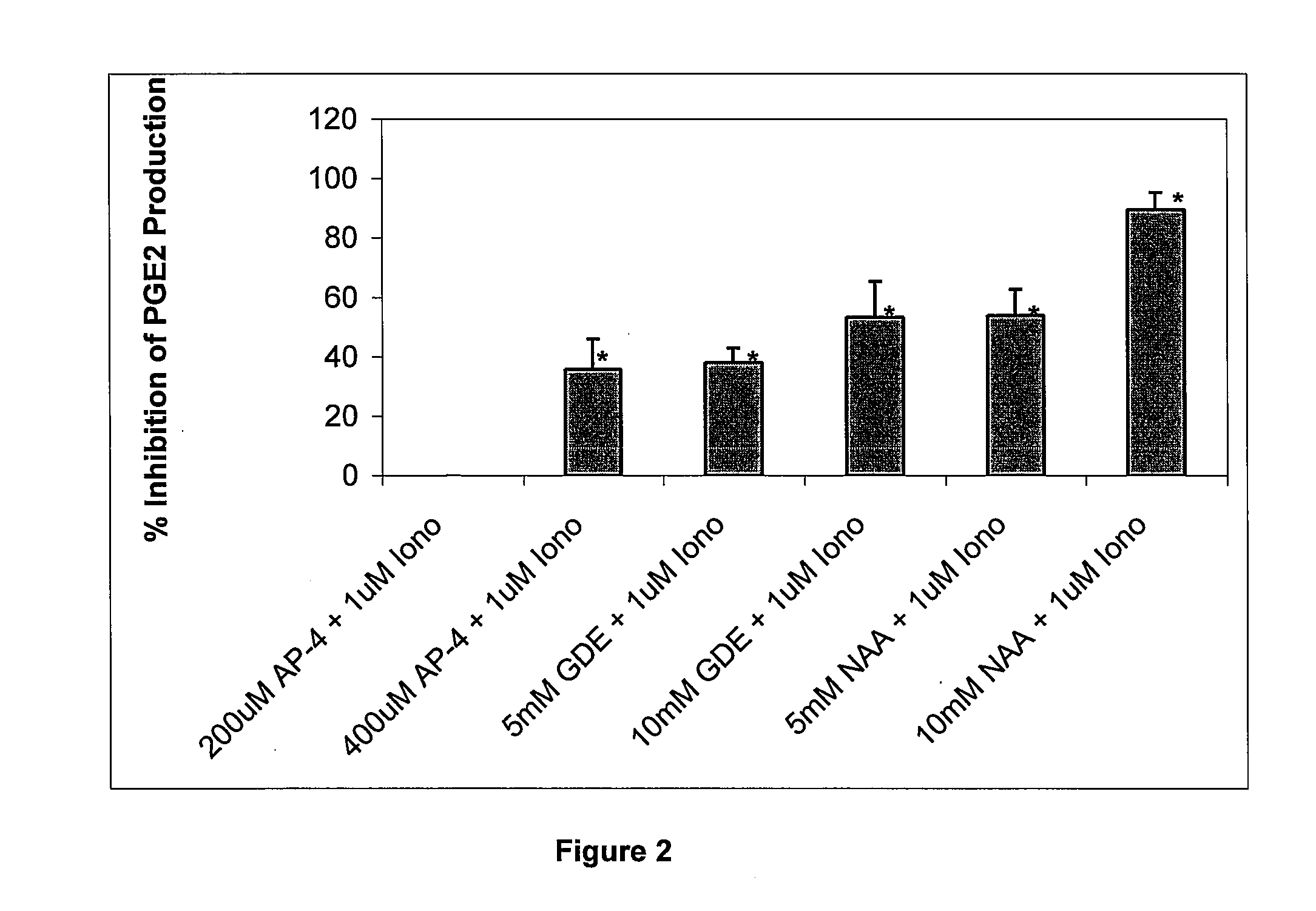

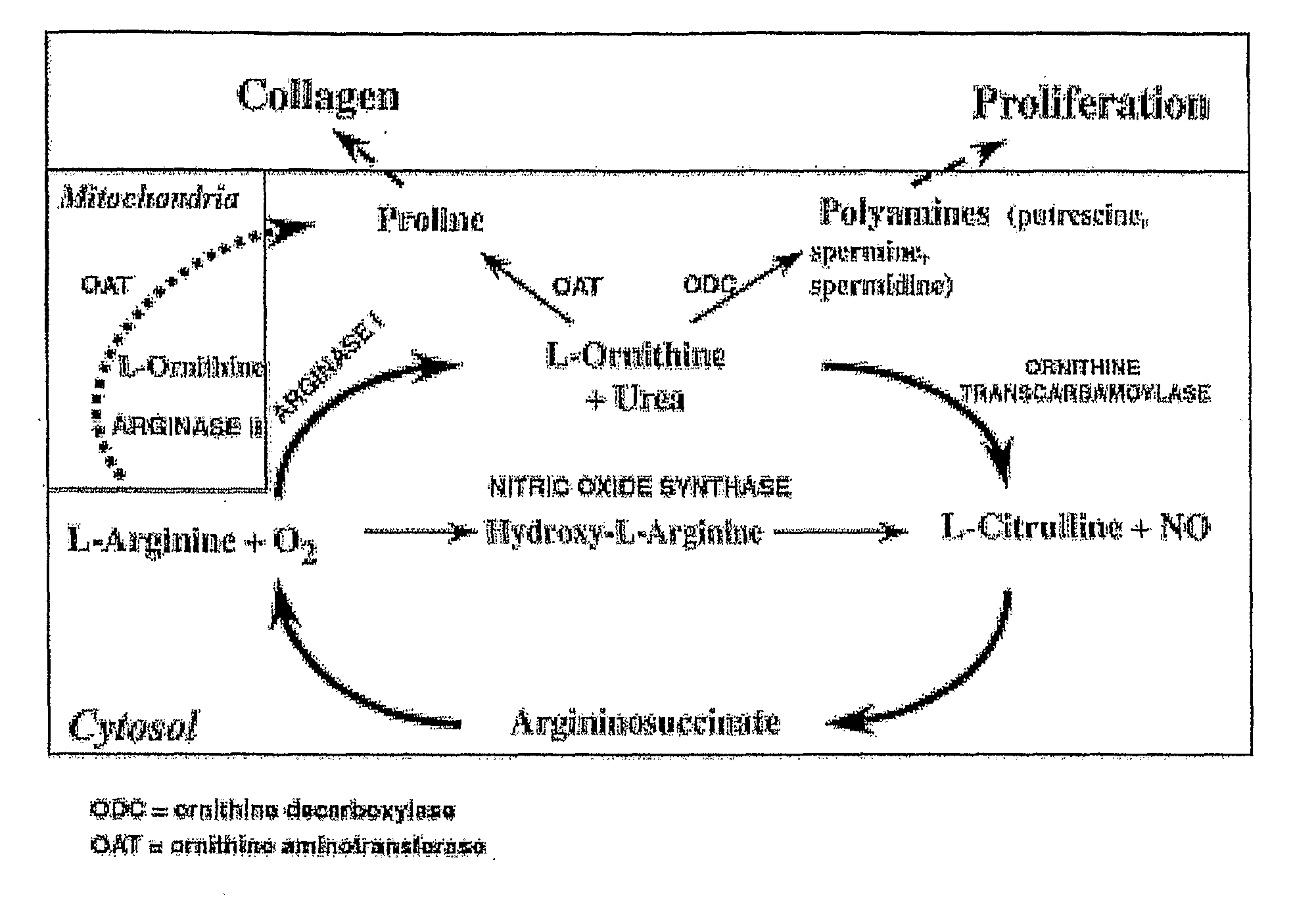

Methods and products which utilize N-acyl-L-aspartic acid

The invention provides therapeutic methods and products for the treatment of inflammation, inflammatory diseases and conditions, and proliferative diseases and conditions. The invention also provides methods and products for inhibiting inflammation in excised cells, tissues and organs. The invention further provides oral care methods and products for the treatment of the tissues of an animal's mouth. Finally, the invention provides personal care methods and products for the treatment of the skin of an animal. All of these methods and products utilize N-acyl-L-aspartic acid or an ester or pharmaceutically-acceptable salt thereof.

Owner:AMPIO PHARMA

Compositions compromising Dimethyl Sulfoxide (DMSO)

ActiveUS20090312273A1Low intracranialIncrease cerebral blood flowBiocideNervous disorderArginineL-Aspartate

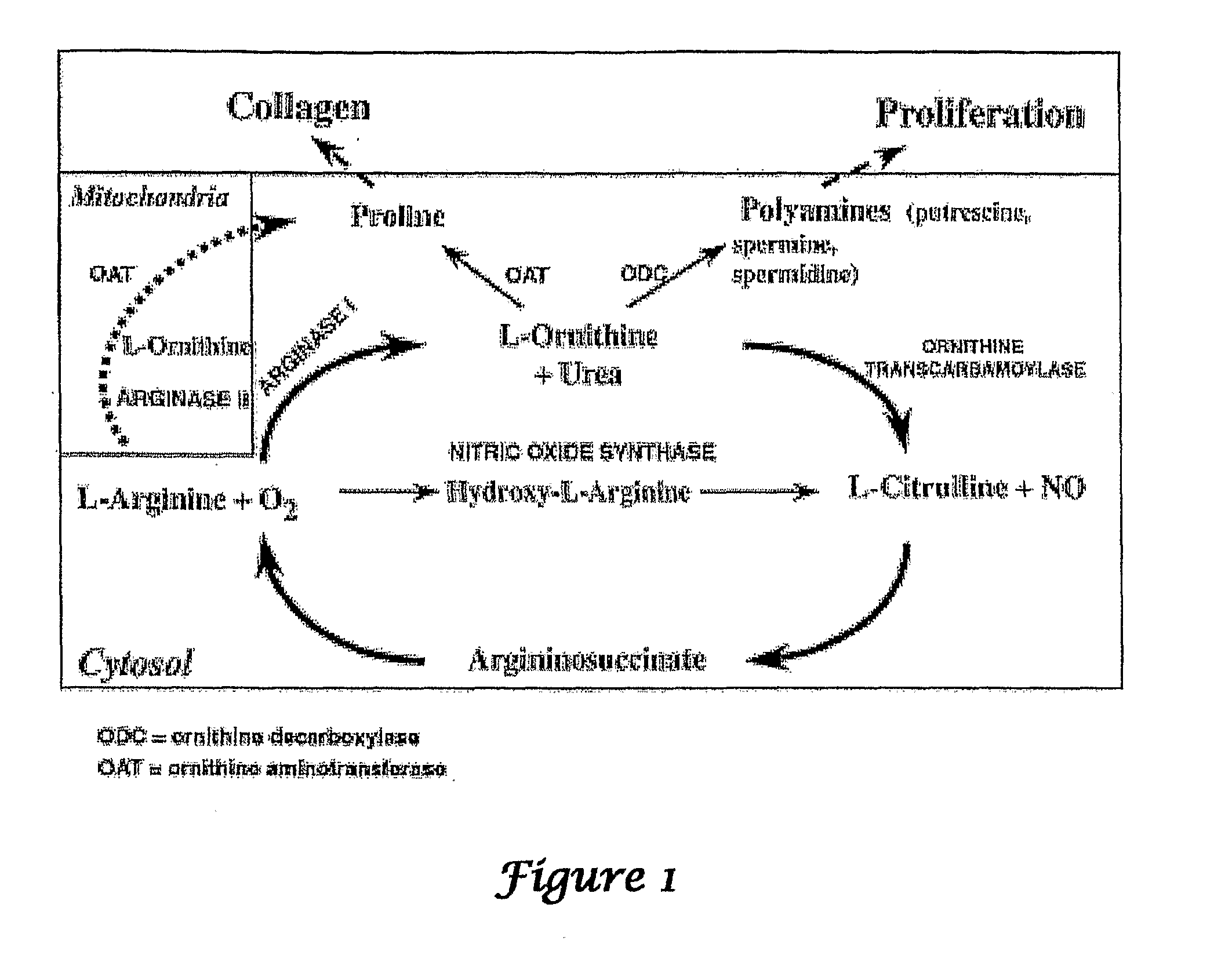

The invention relates generally to compositions comprising dimethylsulfoxide (DMSO) and associated compounds in combination with one or more of the following: fructose 1,6-diphosphate, L-arginine, L-lysine, L-aspartate, and urea. Methods for treating traumatic brain injury, ischemic stroke, atherosclerosis, spinal cord trauma, and neurodegenerative illnesses are also provided.

Owner:ABELA PHARMA

Efficient multi-element compound fertilizer

InactiveCN101591202APromote stoutnessPromote absorptionSuperphosphatesAlkali orthophosphate fertiliserPhosphateInsect pest

The invention discloses an efficient multi-element compound fertilizer, which consists of hexanoic acid 2-(diethylamino) ethyl ester, polypeptide chelated potassium, polypeptide L-aspartate potassium, urea, potassium chloride, diammonium phosphate, calcium superphosphate, potassium dihydrogen phosphate, calcium-magnesium phosphate fertilizer, ammonium chloride, thiamine, zinc chloride, borax, ferrous sulphate, copper sulphate, manganese sulfate, sodium molybdate, cobalt chloride and silicon-manganese phosphate fertilizer. The efficient multi-element compound fertilizer has the advantages of promoting the growth of crops, improving the disease resistance of the crops, resisting falling, insect pests and frozen injury, improving the fertilizer effect, improving the soil, accelerating the growth of branches and leaves, reinforcing the photosynthesis, accelerating the growth of roots, enhancing the drought resistant capacity, improving the yield of the crops and improving the quality of fruits. The yield of grain crops is averagely increased by more than 26 percent, the yield of economic crops is averagely increased by more than 33 percent, and the yield of vegetable crops is averagely increased by more than 42 percent.

Owner:孙承环

Gelling agent for oil

InactiveUS7244419B2Cosmetic preparationsFatty acid chemical modificationAspartic acid residueL-Aspartate

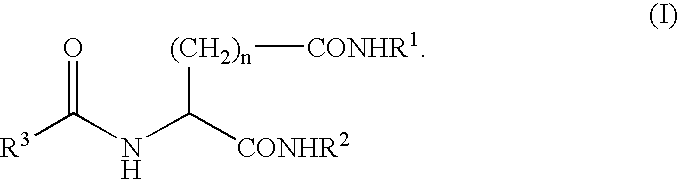

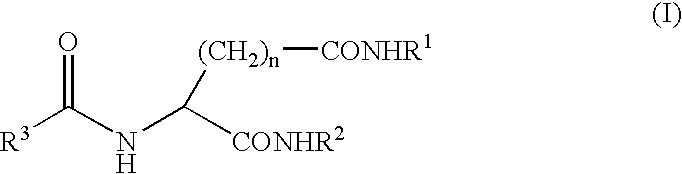

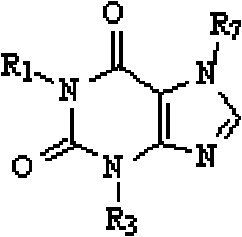

A compound represented by the following general formula (I), wherein R1 and R2 represent a hydrocarbon group having 1 to 26 carbon atoms, preferably a linear or branched alkyl group, R3 represents a hydrocarbon group having 7 to 10 carbon atoms, preferably a linear or branched alkyl group, n represents 1 or 2 provided that the acidic amino acid residue in the molecule is L-aspartic acid residue when n is 1 and said acidic amino acid residue is L-glutamic acid residue when n is 2, and a gelling agent for an oil comprising said compound

Owner:AJINOMOTO CO INC

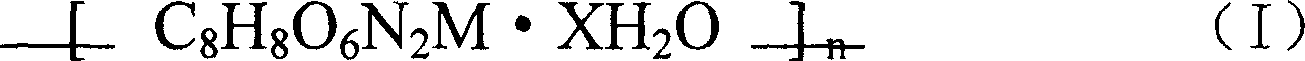

Organic-inorganic composite water-absorbing material based on polyaspartic acid and nano montmorillonite and preparation method thereof

InactiveCN102391512AHigh gel strengthImprove salt toleranceOther chemical processesOrganic fertilisersSalt resistancePolyaspartic acid

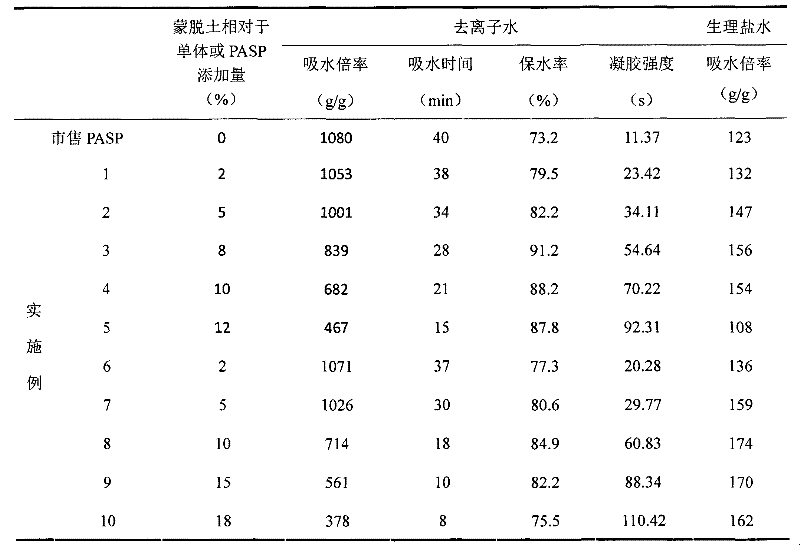

The invention relates to an organic-inorganic composite water-absorbing material based on polyaspartic acid and nano montmorillonite and a preparation method thereof. The preparation method of the composite material can be carried out by two modes such as an in-situ polymerization method and physical blending and modification. In the in-situ polymerization method, a product is prepared by carrying out in-situ polymerization on montmorillonite and L-aspartic acid of polyaspartic acid monomer, and comprises the following components in parts by weight: 100 parts of L-aspartic acid and 2-10 parts of nano montmorillonite. In the blending and modification of the polyaspartic acid / nano montmorillonite, the improvement on the mechanical performance of polyaspartic acid resin is realized by the modification action of the montmorillonite on the polyaspartic acid, and the obtained product comprises the following components in parts by weight: 100 parts of polyaspartic acid and 2-15 parts of nano montmorillonite. The high-performance polyaspartic acid / nano montmorillonite composite material provided by the invention has the advantages of convenience in preparation, excellent water-absorbing performance, high water-absorbing rate, strong repeated water-absorbing capability, good salt resistance and high impact resistance and the like, and can be used for the fields of high-molecular water-absorbing materials and sand fixing agents and the like.

Owner:NANJING TECH UNIV

Feed promoting agent for seawater cultured fishes

InactiveCN102067953ASafe and efficient for long-term useNo side effectsAnimal feeding stuffAccessory food factorsL-AspartateTaurine

The invention relates to a feed additive, in particular to a feed promoting agent for seawater cultured fishes, which comprises the raw materials in weight ratio in the terms of addition per ton of feed: 300-1200g of crystal taurine, 300-1000g of L-glycine, 500-1000g of L-alanine, 500-1200g of L-glutamic acid, 800-1500g of L-aspartate, 500-3000g of betaine hydrochloride, 1000-2000g of dimethyl-beta-propiothetin (DMPT) crude powder and 1100-8000g of degreased condensed fish soluble protein powder. Proved by multiple culture tests in seawater fish feeds, such as Japanese sea bass, sciaenops ocellatus, trachinotus ovatus, garrupa and the like, the feed promoting agent for seawater cultured fishes is capable of remarkably enhancing the food intake of the seawater fishes to the composite feed by above 10 percent and quickening the intake speed as well as remarkably improving the stress-resisting capability of the cultured objects; and the cultured the seawater fishes have the advantages of high survival rate, bright color and strong stress resistance.

Owner:广西粤海饲料有限公司

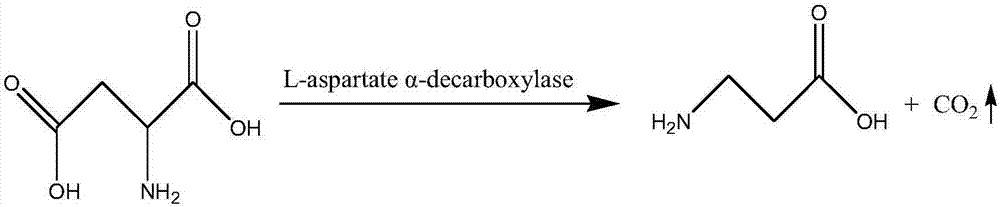

Method for synthesizing beta-alanine by biological catalysis

InactiveCN102851333AImprove qualityLow costMicroorganism based processesFermentationL-AspartateGenus Catellibacterium

The invention provides a method for synthesizing beta-alanine by biological catalysis, and belongs to the field of enzyme engineering. The method comprises the following steps: culturing escherichia coli microbe to obtain aspartase and L-aspartic acid-alpha-decarboxylase, mixing the enzyme-containing escherichia coli cells with an ammonium fumarate aqueous solution, performing an enzyme reaction to generate beta-alanine. The method of the invention is cheap and easily available in raw materials, simple in production process, safe, environment-friendly, mild in reaction condition, high in efficiency, low in production cost, and high in product quality, and has significant economic benefits and environmental protection benefits when compared with traditional methods.

Owner:ANHUI HUAHENG BIOTECH

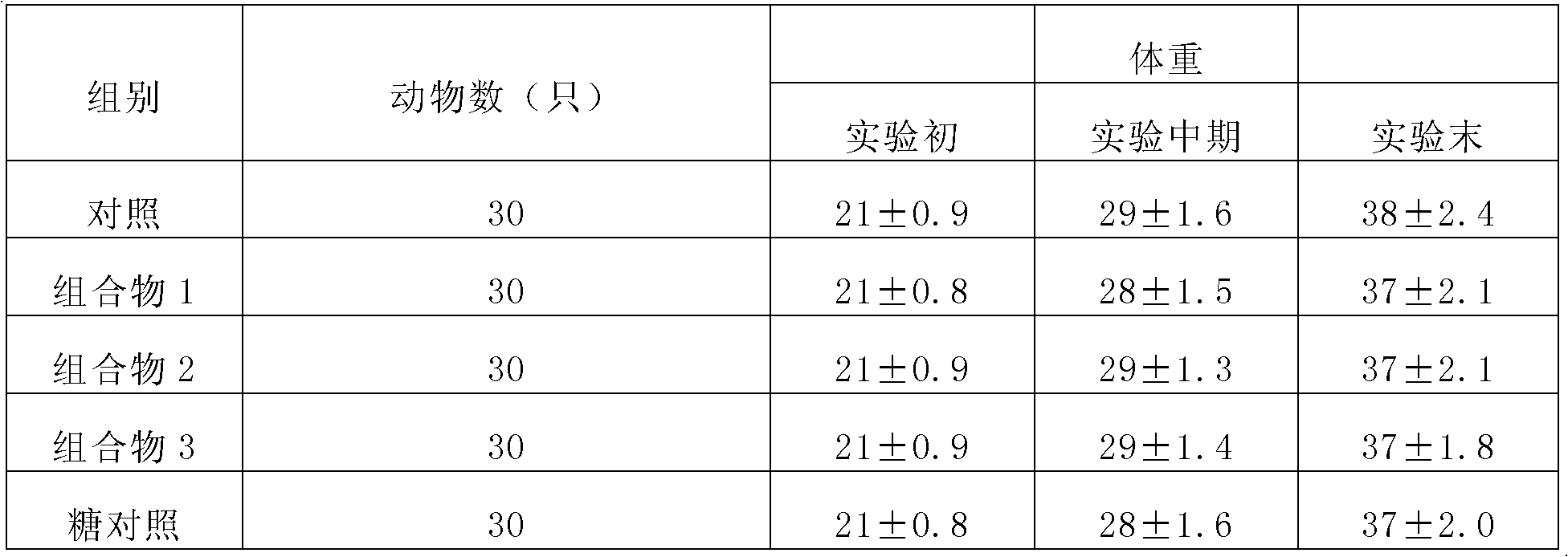

Composition for relieving physical fatigue and enhancing immunologic function, preparation method thereof and application thereof

ActiveCN102100805AImprove immunityRelieve physical fatigue health functionImmunological disordersAnhydride/acid/halide active ingredientsL-AspartateTryptophan

The invention discloses a composition for relieving physical fatigue and enhancing an immunologic function, a preparation method thereof and application thereof. The composite comprises 10 to 100 weight parts of guarana extract, 100 to 800 weight parts of taurine, 1 to 10 weight parts of L-lysine hydrochloride, 1 to 10 weight parts of L-isoleucine, 0.1 to 5 weight parts of L-leucine, 0.2 to 5 weight parts of L-valine, 1 to 15 weight parts of L-aspartate, 0.01 to 0.3 weight part of L-tryptophan, 0.01 to 0.3 weight part of L-phenylalanine, 0.01 to 0.3 weight part of L-threonine, 0.01 to 0.3 weight part of L-methionine, 10 to 100 weight parts of L-alanine, 10 to 100 weight parts of glycine, 1 to 15 weight parts of tea polyphenol and 1 to 20 weight parts of American ginseng extract.

Owner:上海东锦食品集团有限公司 +1

Energy fitness water

A method of making an alternative bottled water comprising as main ingredients, D-ribose, L-carnitine, Coenzyme Q10, Adenosine triphosphate, Taurine, Garcinia combgia, Chromium polynicotinate, or chromium picolate with or without L-Aspartic acid to provide cardiovascular fitness and overall physical energy. Said energy fitness water may also contain a non-nutritive or nutritive sweetener, aroma and coloring. The bottled water prepared from these ingredients has pH range from 3.5 to 7.0 dependent on processing and packaging of the bottled water.

Owner:CHOUDHRY MUHAMMAD S

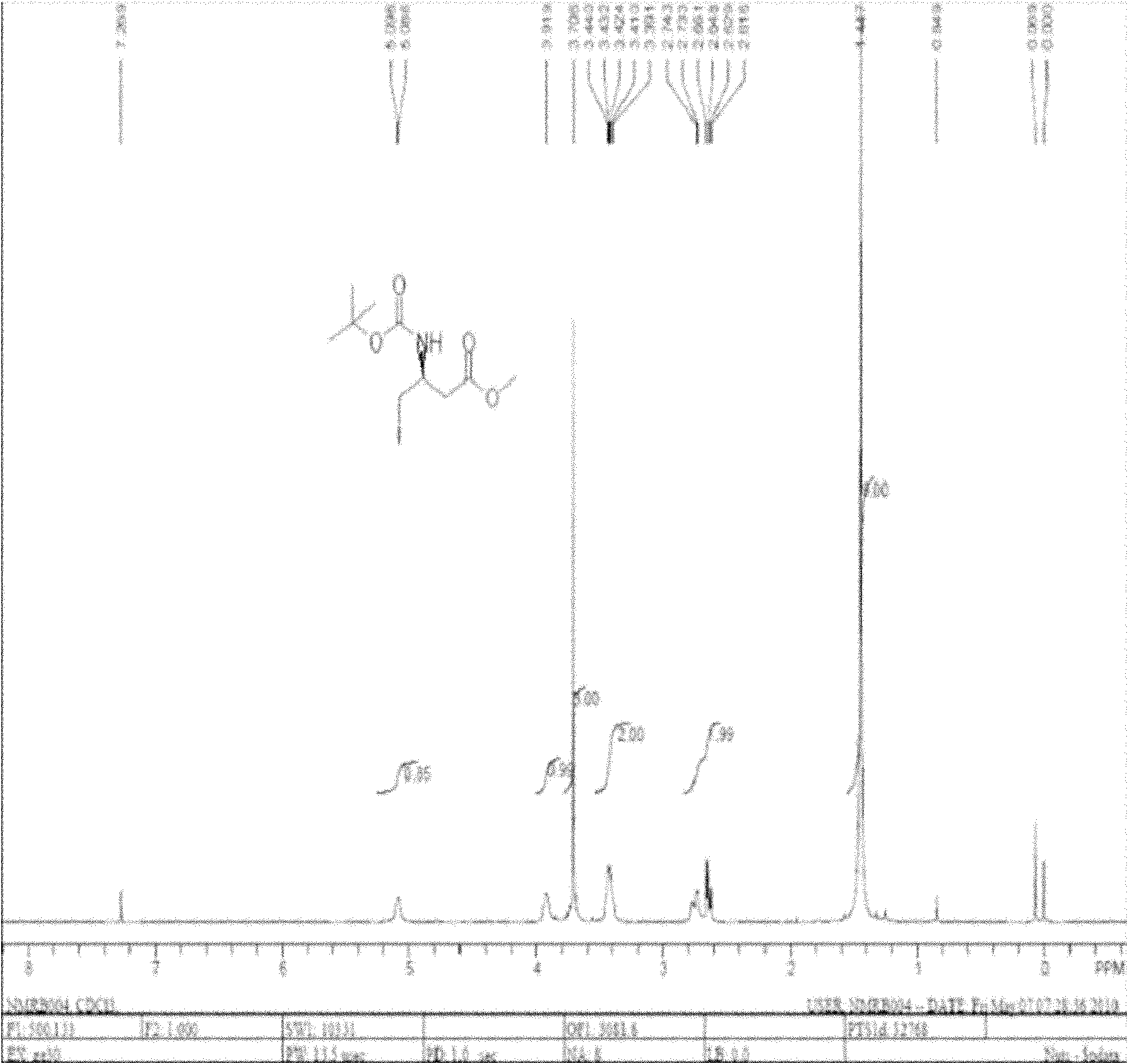

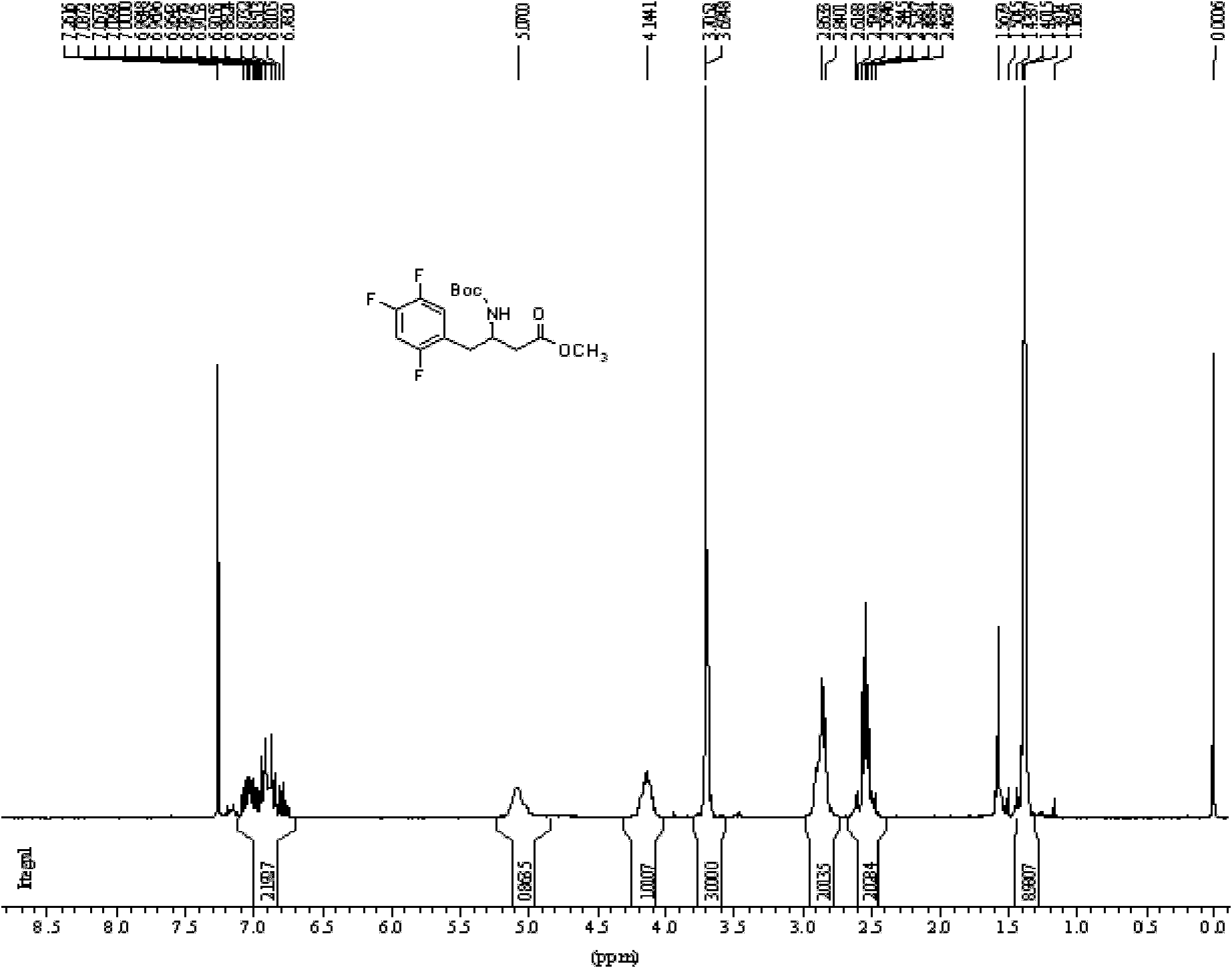

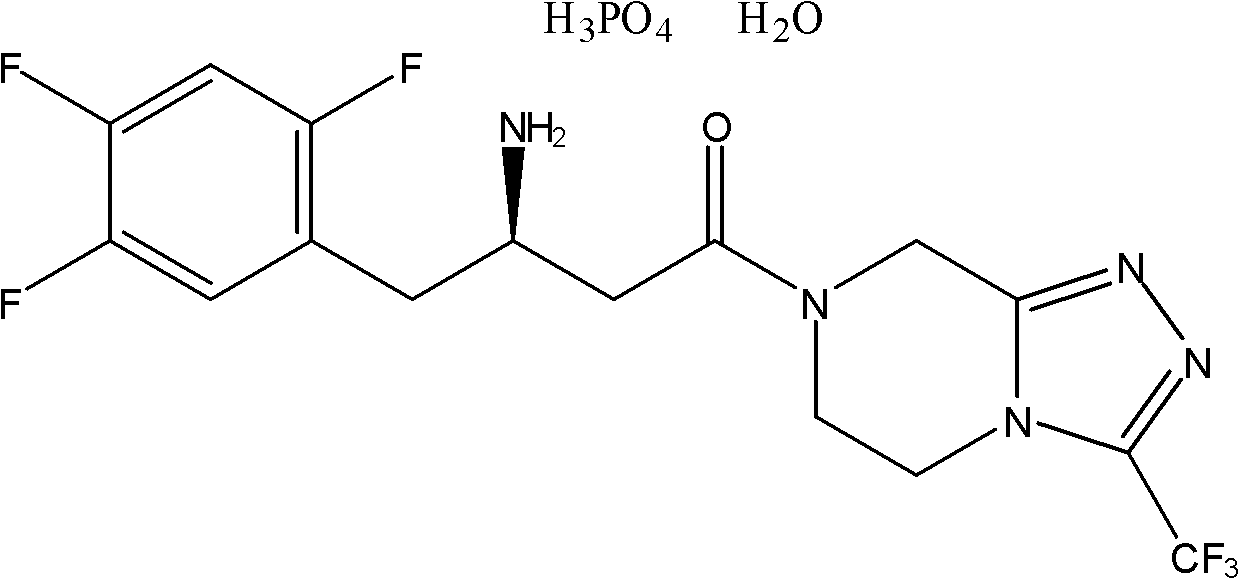

Novel method for synthesizing sitagliptin phosphate and derivative thereof

InactiveCN102153559ARaw materials are easy to getReduce manufacturing costOrganic chemistryBulk chemical productionChemical reactionL-Aspartate

The invention discloses a novel method for synthesizing sitagliptin phosphate and a derivative thereof. The method has the advantages of readily-available raw materials, mild reaction condition, no need of using very expensive catalyst, easy control over optical purity and the like. In the novel method for synthesizing sitagliptin phosphate and the derivative thereof, L-aspartic acid is taken as a raw material, and the chemical reaction steps of amino protection, esterification, reduction, iodination or bromination, coupling, hydrolysis, acylation ammoniation, removal of protecting groups andsalt formation are performed to obtain a sitagliptin phosphate chiral salt and a hydrate thereof. The method comprises the following specific steps of: performing amino protection, esterification, reduction and iodination on L-aspartic acid serving as the raw material to obtain a compound A shown as a formula I; undergoing a coupling reaction on the compound A and a compound B shown as a formula II to obtain a compound C shown as a formula III; and performing hydrolysis, acylation ammoniation, removal of protecting groups and a salt-forming reaction on the compound C to obtain a sitagliptin phosphate hydrate.

Owner:NANJING UNIV OF TECH

Composite for disintoxicating and sobering

The invention discloses a composite (B) for disintoxicating and sobering, which is prepared by glucose and fructose, fruit glucose, honey, L-cysteine, L-alanine, L-ornithine, L-glutamine, L-carnitine according to a certain weight range. In order to enable the effect better, one or more of taurine, L-asparaginic acid or L-aspartate, vitamin B1, vitamin B6, caffeine, L-arginine, L-glutamic acid, L-proline, phaseomannite, vitamin B2, nicotinic acid, folic acid, vitamin B12 and pantothenic acid are also added. The composite can be prepared into liquid preparation and electuary. The composite of the invention can be prepared into food and health food. The invention can quickly disintoxicate, sober, eliminate alcoholism symptom and continued effect of alcohol on a human body, and has no side effect.

Owner:克科

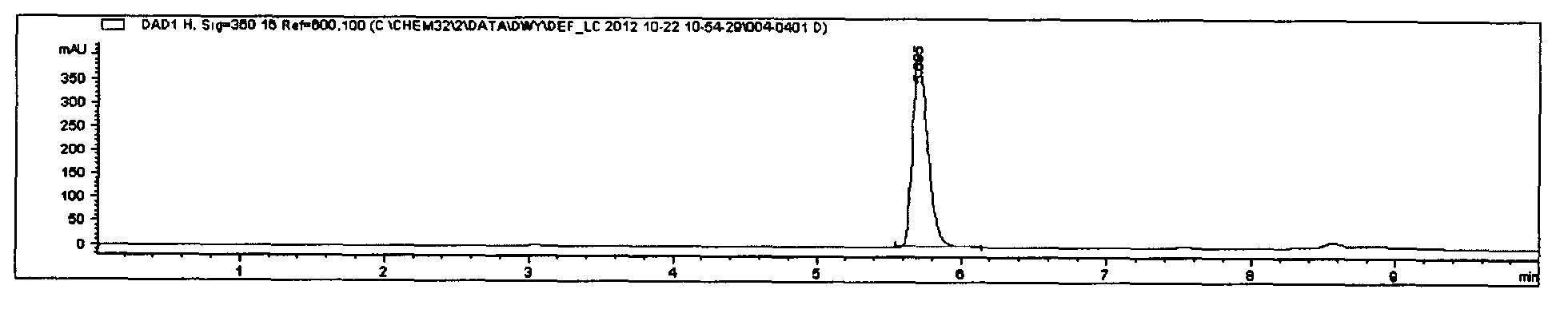

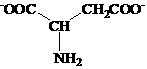

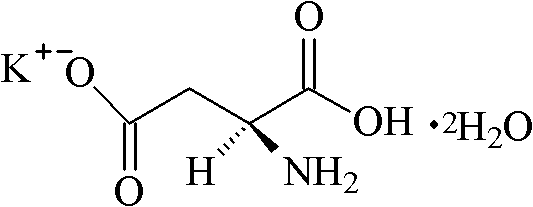

Method for preparing potassium L-aspartate

InactiveCN102875403AImprove securityLow costOrganic compound preparationAmino-carboxyl compound preparationOrganic solventHydrogen

The invention provides a method for preparing potassium L-aspartate. The method comprises the steps as follows: (1) using potassium carbonate or potassium hydroxide and L-asparaginic acid as raw materials; carrying out reaction with water served as the solvent and with the temperature of 70-80 DEG C; calibrating the pH (Potential of Hydrogen) of reacting liquid to reach 6.0 to 7.5 after the reaction; discoloring and filtering the reacting liquid, and concentrating until supersaturation reaches; cooling supersaturation liquid; and (2) transferring the cooled supersaturation liquid to a vacuum freeze drying machine; pre-freezing for 2 to 4 hours at -30 to -20 DEG C; then keeping for 3 to 5 hours at -25 to -15 DEG C; keeping the vacuum freeze drying machine in a vacuum condition with pressure of 4.5 to 6.5Pa. With the adoption of the technical scheme provided by the invention, organic solvent is not used, and therefore, the safety coefficient of production environment can be improved; the product is out of residual solvent, and the cost of the raw materials can be greatly reduced; and furthermore, the input for the equipment and field in the scheme is low; and the water in the product can be controlled well.

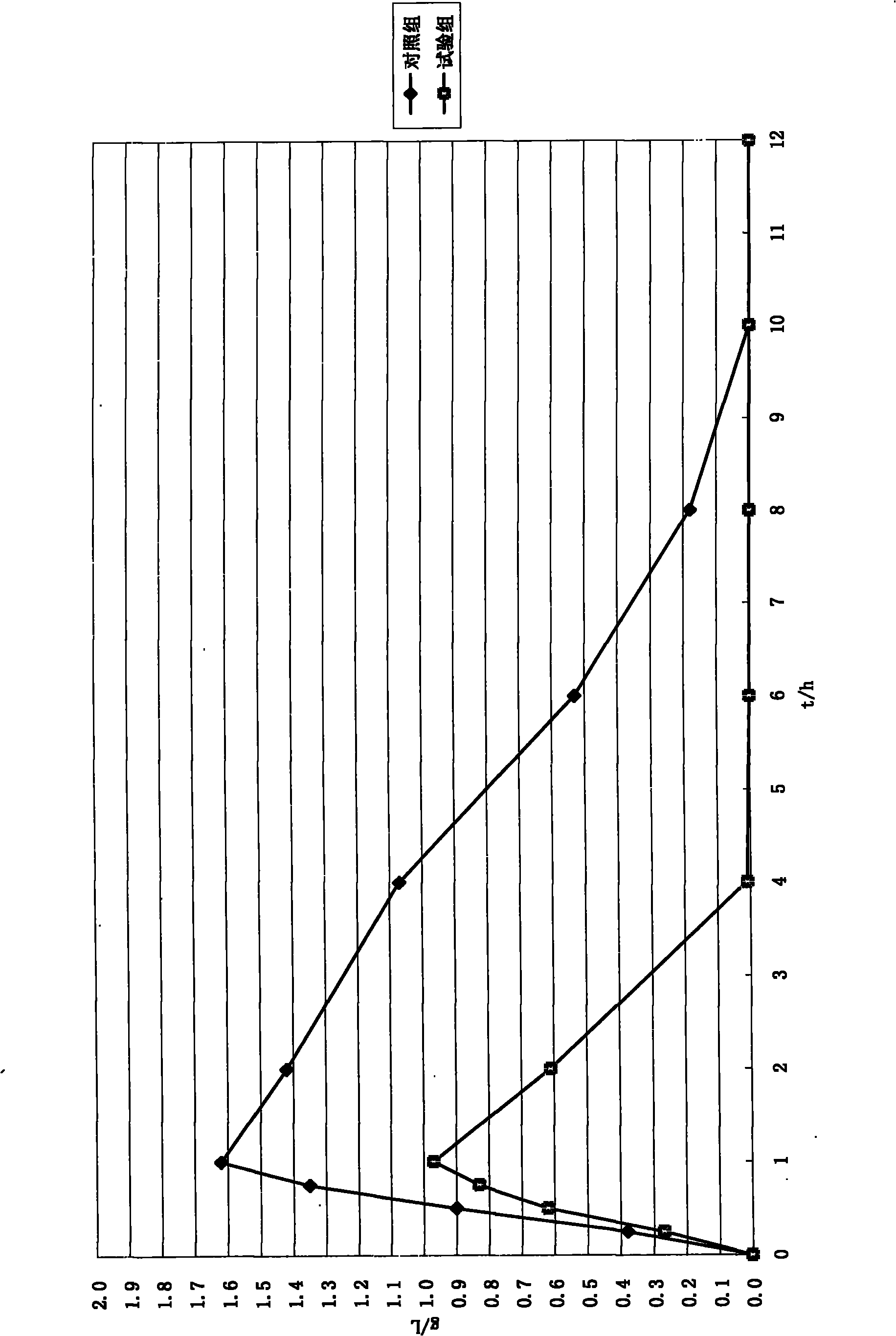

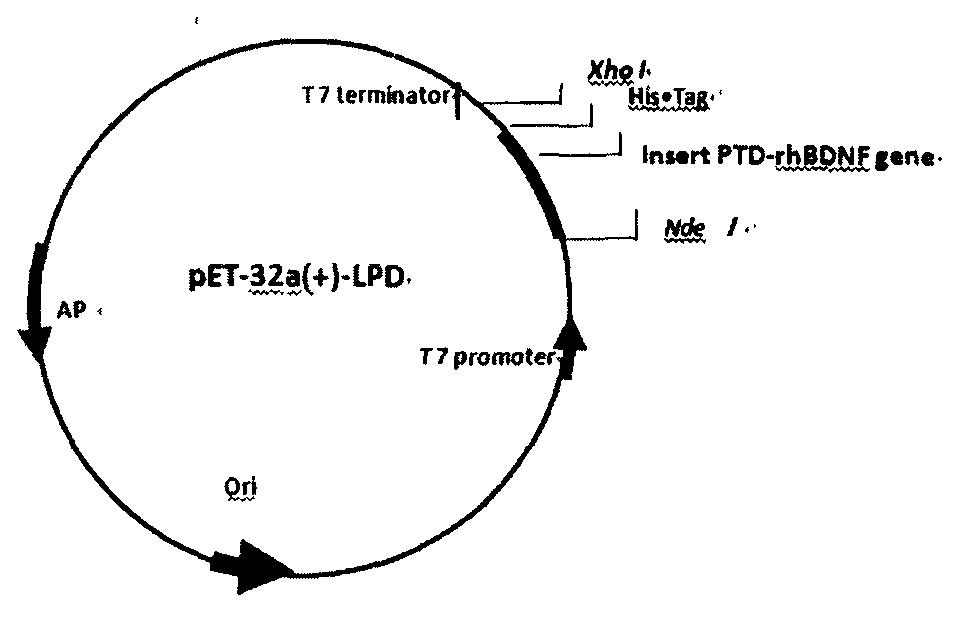

Construction, expression and application of genetic engineering bacteria for high-production of beta-alanine

InactiveCN103898033AImprove synthesis abilityIndustrial Application AdvantagesBacteriaFermentationBiotechnologyL-Aspartate

The invention provides new genetic engineering bacteria used for producing beta-alanine, having strong synthetic ability and having higher enzyme activity, construction, expression and purification of the high-production engineering bacteria, and methods for synthesis of beta-alanine respectively through whole cell transformation and fermentation liquid direct transformation. A synthetic method comprises the steps: an L-aspartic-alpha-alanine decarboxylase (PanD) gene of lactobacillus plantarum is obtained by a gene engineering method and has the gene sequence number of NC-004567.2, the gene is constructed into a high-efficiency expression vector, then the high-efficiency expression vector is transformed into recipient bacteria, and thus the genetic engineering bacteria for producing beta-alanine are obtained. The genetic engineering bacteria are subjected to fermentation culture, 80 g / L of a substrate can be transformed by whole cells, and the beta-alanine content reaches 59.7 g / L; and the substrate is directly added into a fermentation liquid, the transformation concentration can reach 10 g / L, the beta-alanine content reaches 6.8 g / L, and the synthetic ability is higher than that of conventional reported genetic engineering bacteria.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Complex enzyme preparation for sewage treatment and application method thereof

InactiveCN101898830AEasy to handleMonitor effluent qualityTreatment with aerobic and anaerobic processesCelluloseEutrophication

The invention relates to a complex enzyme preparation for sewage treatment. The complex enzyme preparation is compounded by mixing complex enzyme and mineral water, wherein the weight ratio of the complex enzyme to the mineral water is 1:9-50; and the complex enzyme contains the following components in volume content: 50 to 80 mg / L of bromelain, 50 to 80 mg / L of papain, 15 to 30 mg / L of L-aspartase, 15 to 30 mg / L of glutathione, 100 to 150 mg / L of yeast extract and 50 to 80 mg / L of cellulose. The complex enzyme preparation improves the treatment capability of a sewage plant, reduces the running cost, basically achieves zero release of residual organic sludge, prevents environmental secondary pollution of the sewage treatment, improves the self-purification capability of yielding water of the sewage plant, prevents secondary pollution of the yielding water, prevents secondary eutrophication of the yielding water, and radically solves the problem of environmental protection in operation of the sewage treatment plant.

Owner:麦广鸿 +2

Method for preparing magnesium L-aspartate

ActiveCN102875402AImprove securityLow costOrganic compound preparationAmino-carboxyl compound preparationHydrogenOrganic solvent

The invention provides a method for preparing magnesium L-aspartate. The method comprises the steps as follows: using any one of magnesium carbonate, magnesium oxide and magnesium hydrate, and L-asparaginic acid as raw materials; carrying out reaction with water served as the solvent and with the temperature of 70-80 DEG C; calibrating the pH (Potential of Hydrogen) of reacting liquid to reach 6.0 to 7.5 after the reaction; discoloring and filtering the reacting liquid, and concentrating until supersaturation reaches; cooling supersaturation liquid; and carrying out the methods of freeze drying and vacuum drying to directly prepare the supersaturation liquid into the finished product of magnesium L-aspartate. With the adoption of the technical scheme provided by the invention, organic solvent is not used, and therefore, the safety coefficient of production environment can be improved; the demands of the customers on the residual solvent are increased, and the nonuse of the solvent represents the general trend; and meanwhile, the nonuse of the organic solvent can greatly reduce the cost of raw material, and the cost can be reduced by about RMB5000 / ton; and furthermore, the input for the equipment and field in the scheme is low, and the input on the equipment can be reduced by about 20% and the water in the product can be controlled well.

Owner:宜兴市前成生物有限公司

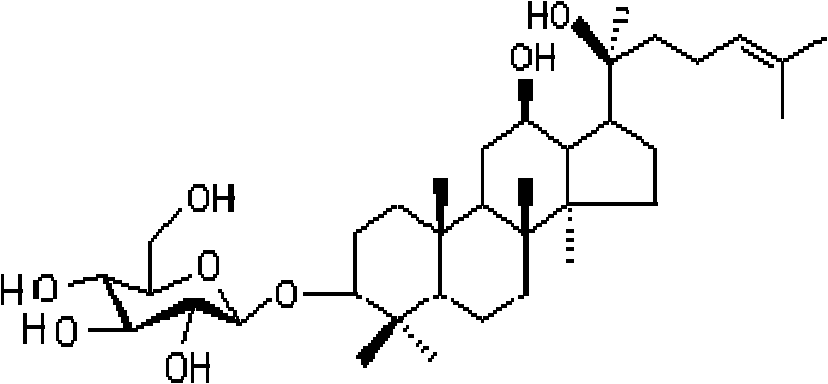

Preparation method and application of chiral MOF nanofiber-graphene hybrid material

InactiveCN107589159ASimple processEasy to industrializeGrapheneMaterial electrochemical variablesEnantiomerL-Aspartate

The invention discloses a preparation method of a chiral MOF nanofiber-graphene hybrid material and an application for detecting chiral enantiomers based on the composite material, and belongs to thefields of nano composite mateirals, catalytic technology and analytical chemistry detection technology. The preparation method comprises the main steps of co-mixing an L-aspartate aqueous solution with a graphene oxide aqueous solution containing Cu (II) positive ions at room temperature, allowing to stand, separating and drying. A chiral sensor constructed by the composite material is used for sensitive detection of the content of the enantiomers of D-(+)-histidine and L-(-)-histidine.

Owner:UNIV OF JINAN

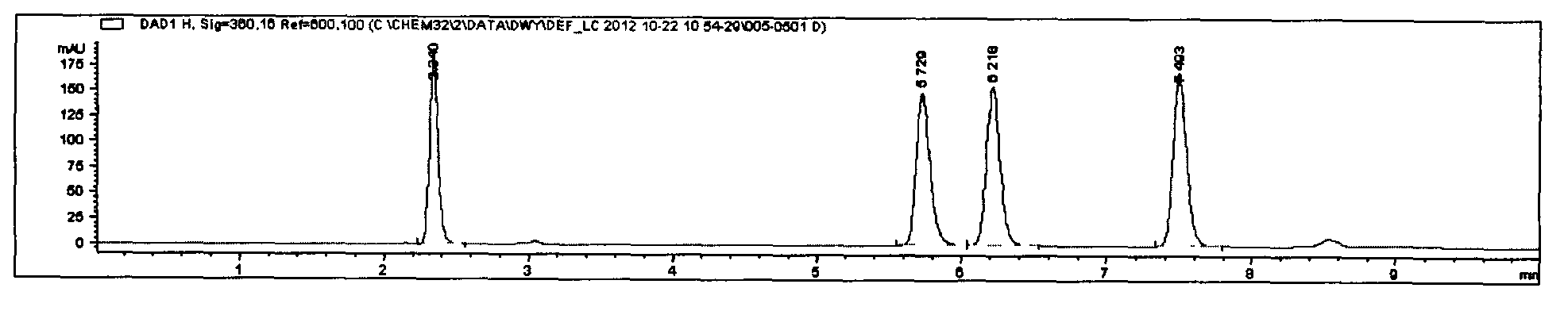

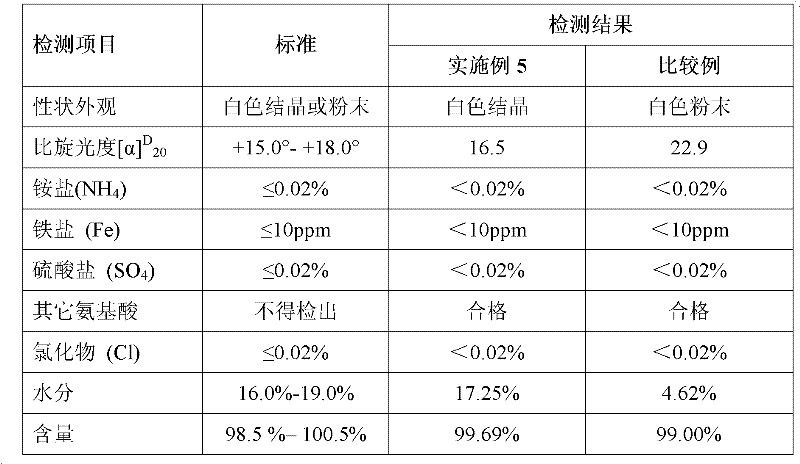

Method for preparing monopotassium L-aspartate dihydrate by separation process

ActiveCN102408347AUniform particlesOrganic compound preparationAmino-carboxyl compound preparationL-AspartatePotassium

The invention discloses a method for preparing a monopotassium L-aspartate dihydrate by a separation process. The method taking L-aspartic acid and potassium carbonate or potassium hydroxide as raw materials comprises the following steps of: adding the raw materials to a reaction vessel; allowing the blended materials to react in the presence of a solvent-deionized water, and then correcting the pH value; decolorizing, filter-pressing, concentrating and cooling the obtained reaction solution; adding a monopotassium L-aspartate dihydrate crystal as a seed crystal to the reaction solution; inducing the monopotassium L-aspartate in the reaction solution to be crystallized so as to form the monopotassium L-aspartate dihydrate crystal with a stable water content; and adding an organic solvent for soaking the monopotassium L-aspartate dihydrate crystal, then directly filtering out a mother liquid, and finally drying to obtain the monopotassium L-aspartate dihydrate. The monopotassium L-aspartate dihydrate obtained by the method has the advantages of large and uniform crystallization granularity and stable water content (based on each batch of the products), thus meeting the requirements for the dihydrate.

Owner:宜兴市前成生物有限公司

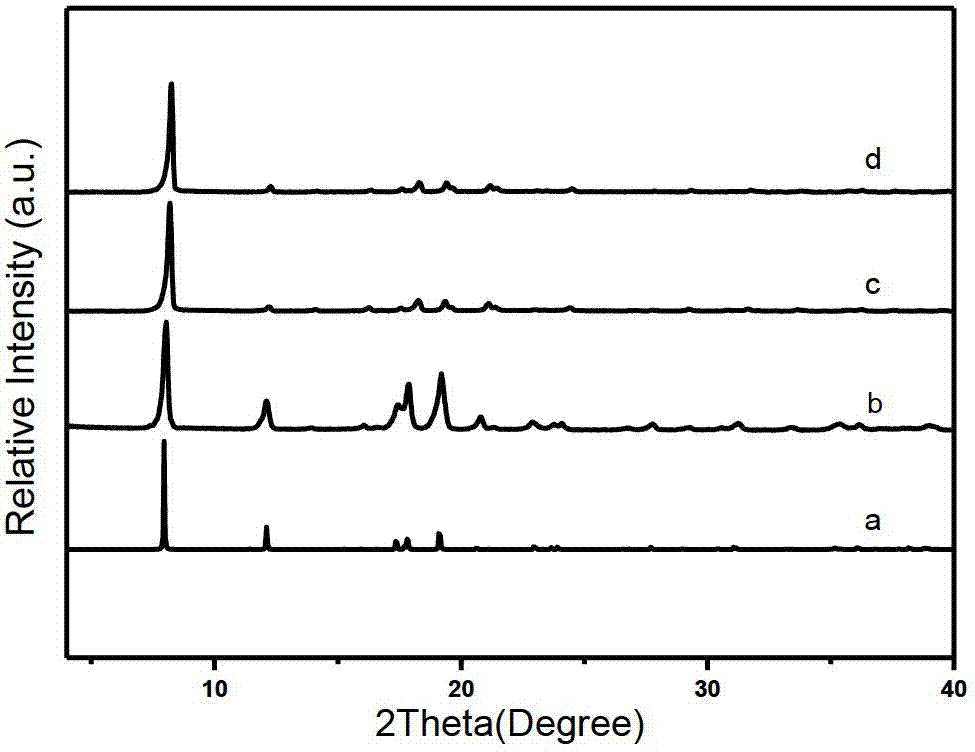

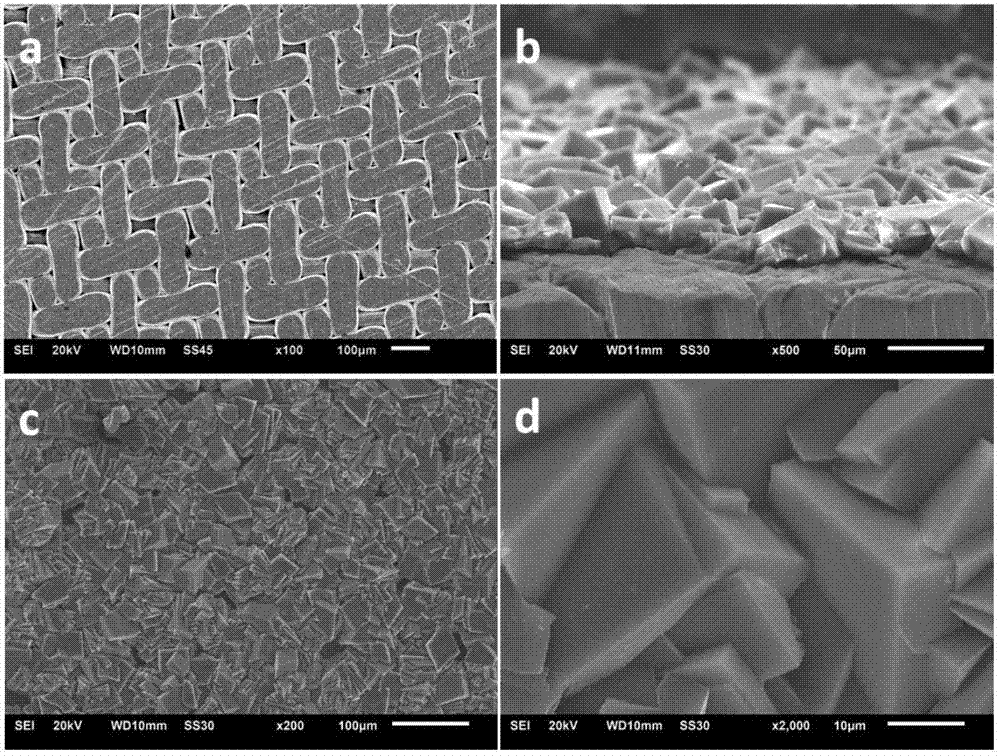

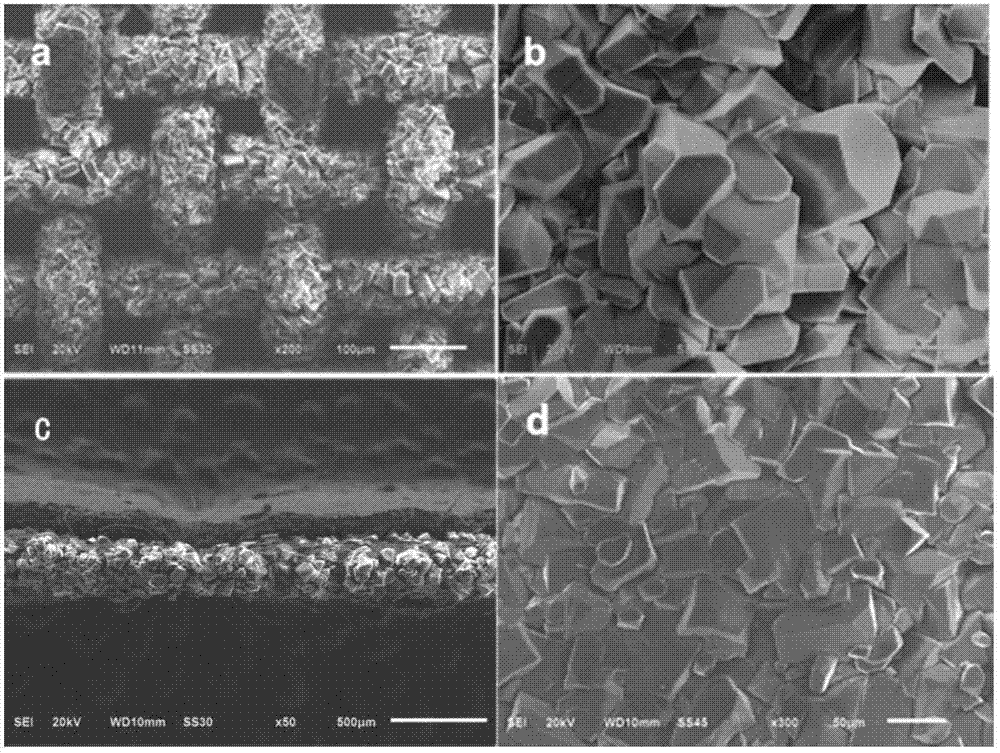

Coordination polymer membrane material, preparation method for same and application of same in membrane separation

InactiveCN102728236ASemi-permeable membranesHydroxy compound separation/purificationPretreatment methodSeparation technology

The invention specifically relates to a coordination polymer membrane material, a preparation method for the same and application of the same in separation of mixed gas or chiral isomers, belonging to the field of membrane materials and separation technology thereof. The referred coordination polymer Ni2(L-asp)2bpy membrane material is a three-dimensional porous material which is formed by coordination between metallic nickel ions and L-aspartic acid (L-asp) and 4,4-bipyridine (bpy) and has a uniform pore channel size, wherein metallic nickel coordinates with oxygen atoms of L-aspartic acid to form a layer which is then propped up by a nitrogen atom coordination column in 4,4-bipyridine to form a three-dimensional skeleton structure. According to the invention, through selection of different carriers and carrier pretreatment methods, the coordination polymer membrane material is prepared by using an in situ or secondary growth method under different solvothermal conditions. Results show that the membrane material provided in the invention has a good separation effect on mixed gas or chiral isomers.

Owner:JILIN UNIV

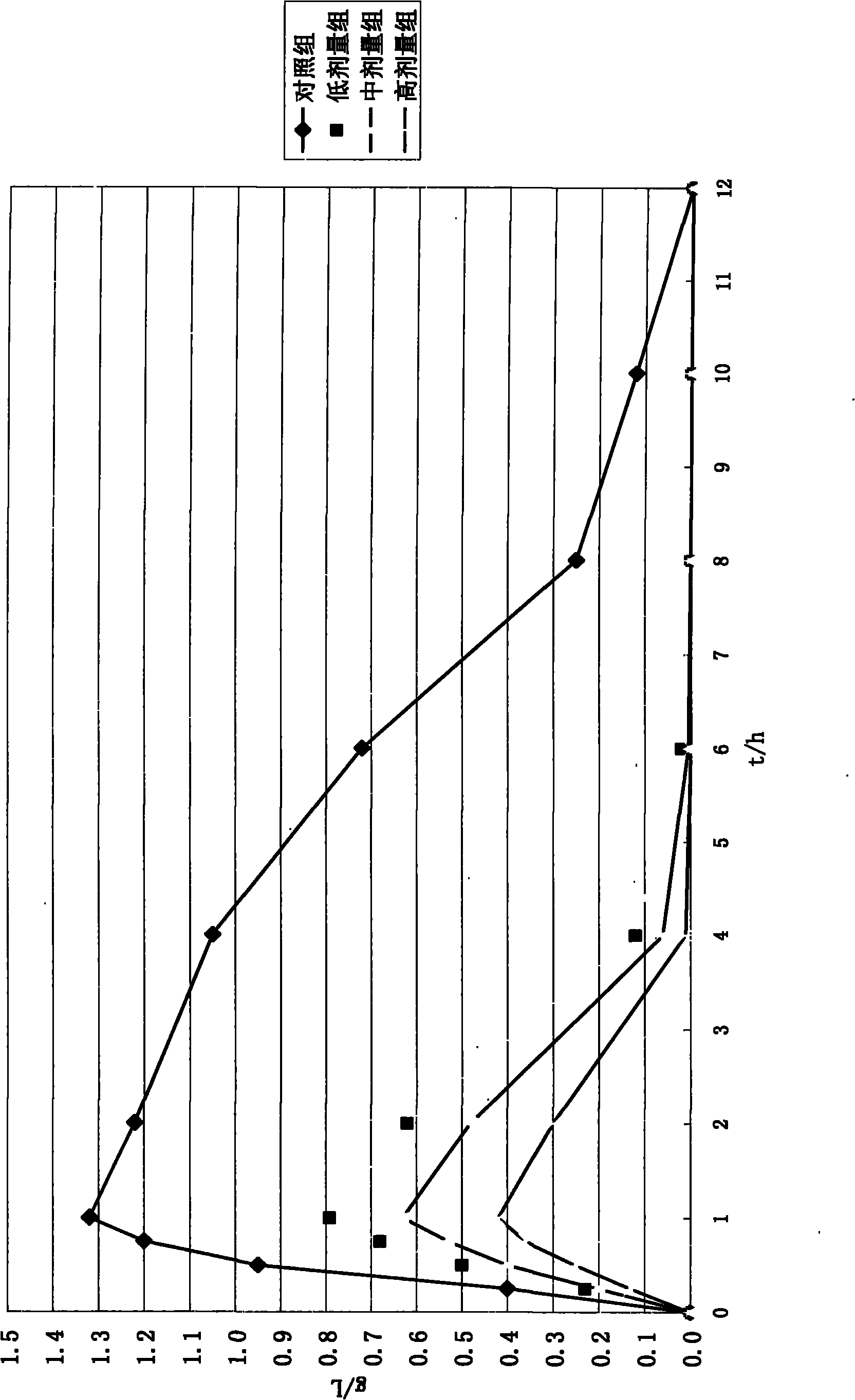

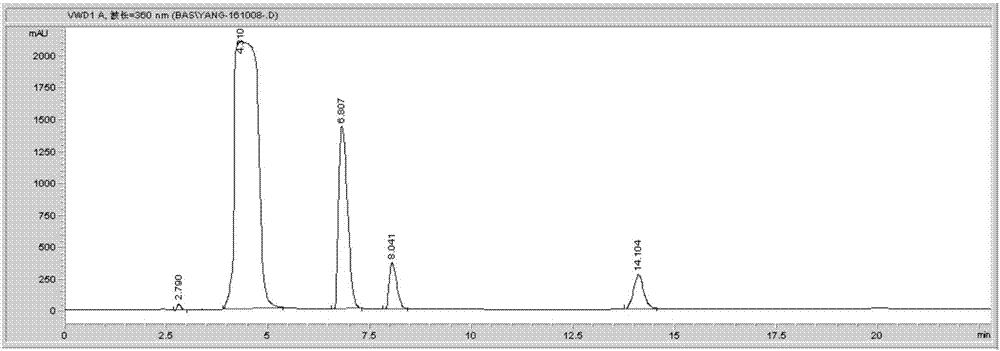

Synthetic method of beta-alanine

InactiveCN104531796AImprove conversion efficiencyIncrease production capacityFermentationFiltrationL-Aspartate

The invention discloses a synthetic method of beta-alanine. The method comprises the steps: a) preparation of a substrate: filling 5g / L-80g / L L-aspartic acid substrate solutions into an enzyme reactor, and regulating pH into 5.0-8.5 by using alkalizers; b) enzymic catalytic reaction: adding enzyme-containing bacterium solutions into the substrate solutions for performing catalytic reaction, adding a proper amount of L-aspartic acid in batch during reaction to regulate pH of a reactant to 5.0-9.0, and performing fermentation culture, condensation and pulverization on the enzyme-containing bacterium solutions by utilizing engineering bacteria of high-yield L-aspartic acid alpha-decarboxylase; and c) filtration, decoloring and crystallizing treatment of the reactant in the enzyme reactor to obtain beta-alanine. L-aspartic acid is further catalyzed by using the enzyme-containing bacterium solutions and converted into beta-alanine, and the beta-alanine is mild in production condition, simple in process, low in environment pollution, high in quality of products and convenient to extract at the downstream; the purity reaches 99.0 percent, and the conversion rate of beta-alanine reaches 99.5 percent.

Owner:ANHUI HUAHENG BIOTECH

Method for catalytic synthesis of polyaspartic acid by using imidazole type ionic liquid

InactiveCN102250352AImprove thermal stabilitySolve volatileScale removal and water softeningBulk chemical productionL-AspartateReaction temperature

The invention discloses a method for catalytic synthesis of polyaspartic acid by using imidazole type ionic liquid, relates to a method for synthesizing the polyaspartic acid, and solves the technical problems of low yield, difficult product separation process and high reaction temperature existing in the conventional method for synthesizing the polyaspartic acid by using chloroaluminate type ionic liquid as a reaction solvent. The method comprises the following steps of: adding the imidazole type ionic liquid and L-aspartic acid into a container; heating to 145-158 DEG C and preserving the heat for 0.5-6 hours to obtain mixed liquid of polysuccinimide and the ionic liquid; cooling the mixed liquid and then adding deionized water to separate the polysuccinimide out; washing the polysuccinimide and then dissolving the polysuccinimide by using a sodium hydroxide aqueous solution; adjusting pH value to be 3.0-3.5 by using hydrochloric acid; precipitating with ethanol to obtain polyaspartic acid precipitate; and filtering and drying to obtain the polyaspartic acid. The yield of the polyaspartic acid is 50-70 percent. The method can be used for synthesizing the polyaspartic acid serving as a water treatment scale inhibitor.

Owner:HEILONGJIANG UNIV

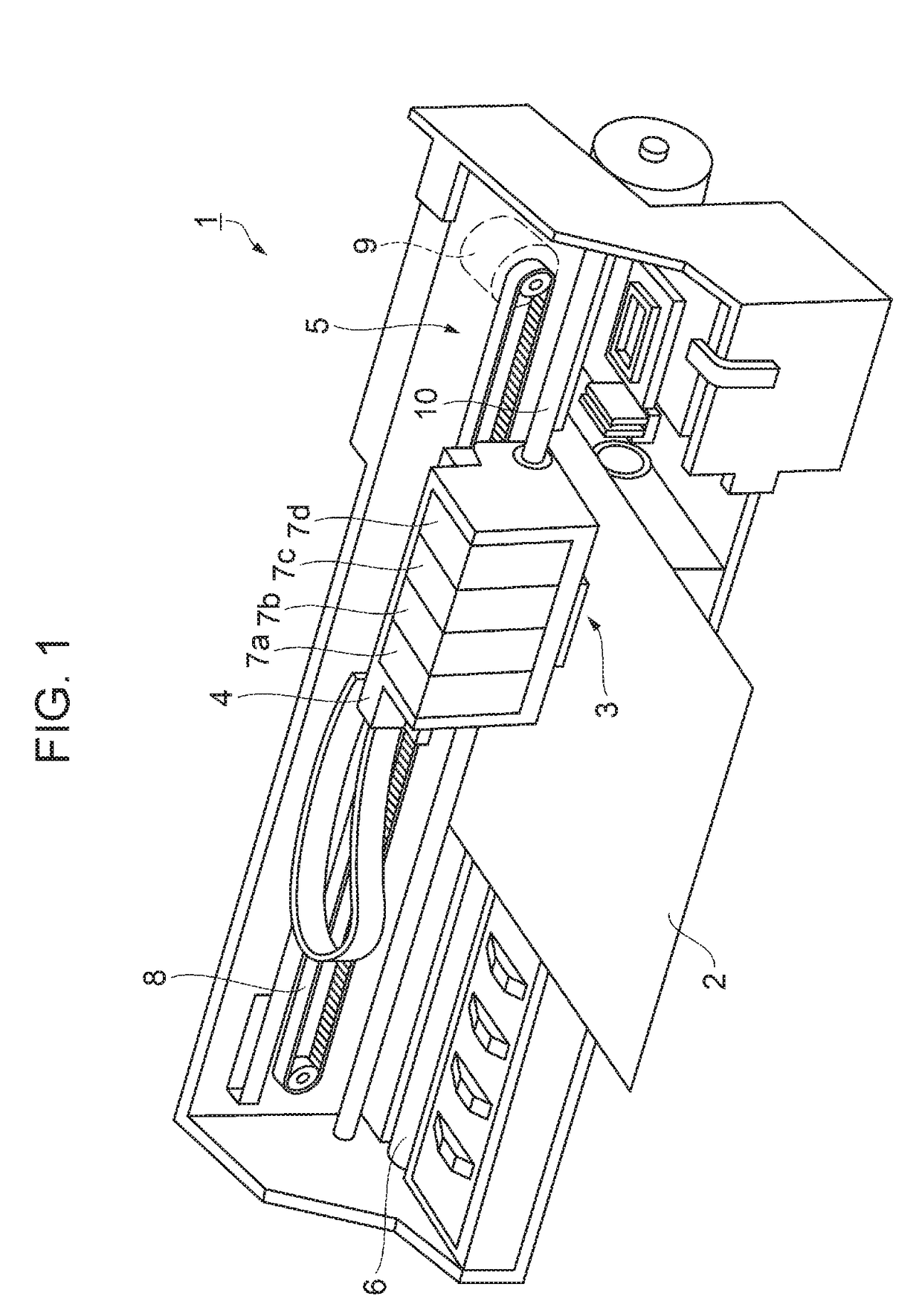

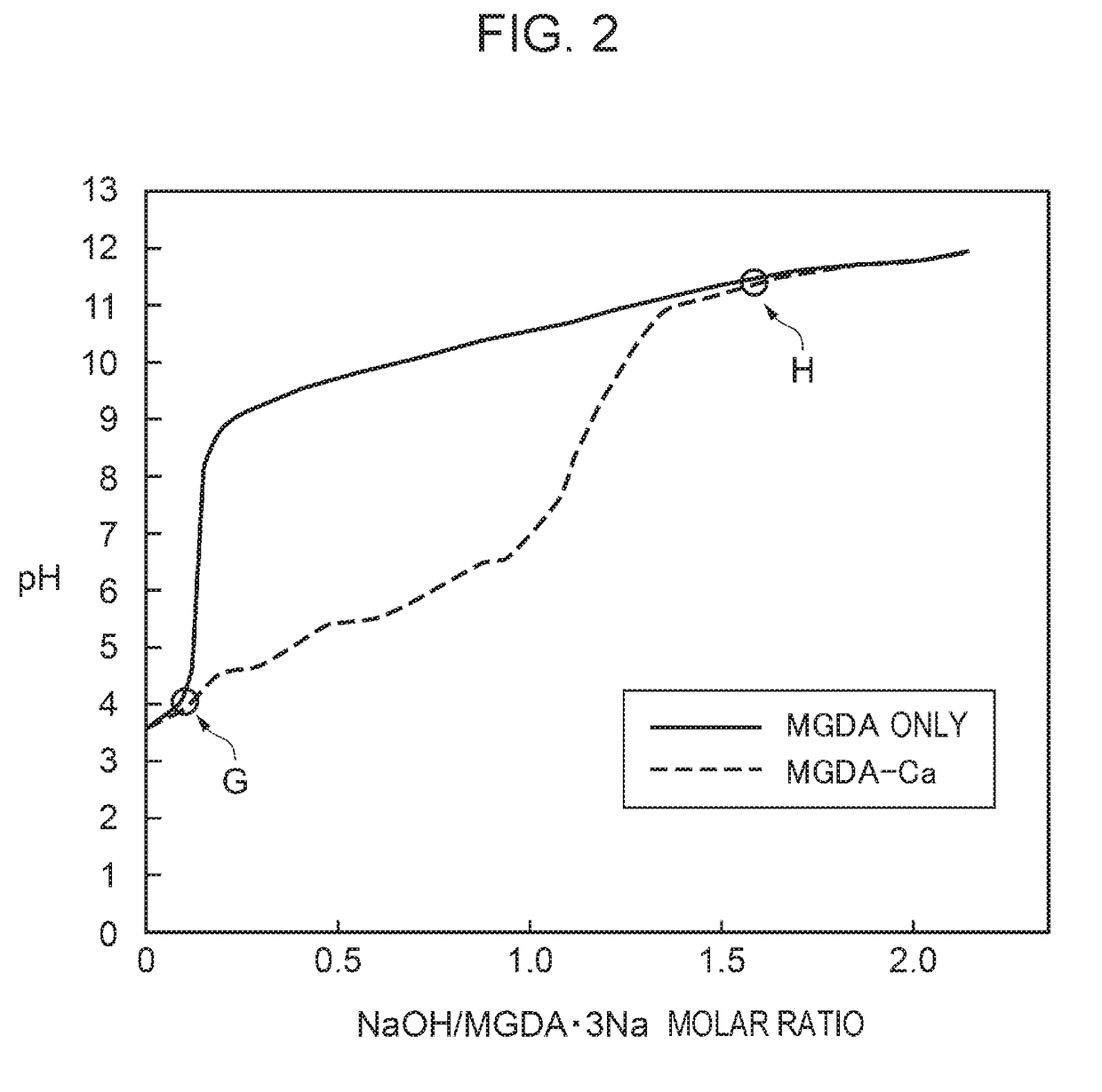

Ink jet textile printing ink composition and ink receiving container

ActiveUS20180086929A1Suppress generationGood environmental compatibilityOrganic chemistryReactive dyesGlycineTextile printer

An ink jet textile printing ink composition includes water; a color material; and a metal chelating agent. In the ink composition described above, the metal chelating agent includes at least one selected from methyl glycine diacetic acid, L-glutamate diacetic acid, L-aspartic diacetic acid, hydroxyethylimino diacetic acid, 3-hydroxy-2,2′-iminodisuccucinic acid, dicarboxymethyl glutamic acid, (S,S)-ethylenediaminedisuccinic acid, and salts thereof, and the pH of the ink composition is 6 to 10.

Owner:SEIKO EPSON CORP

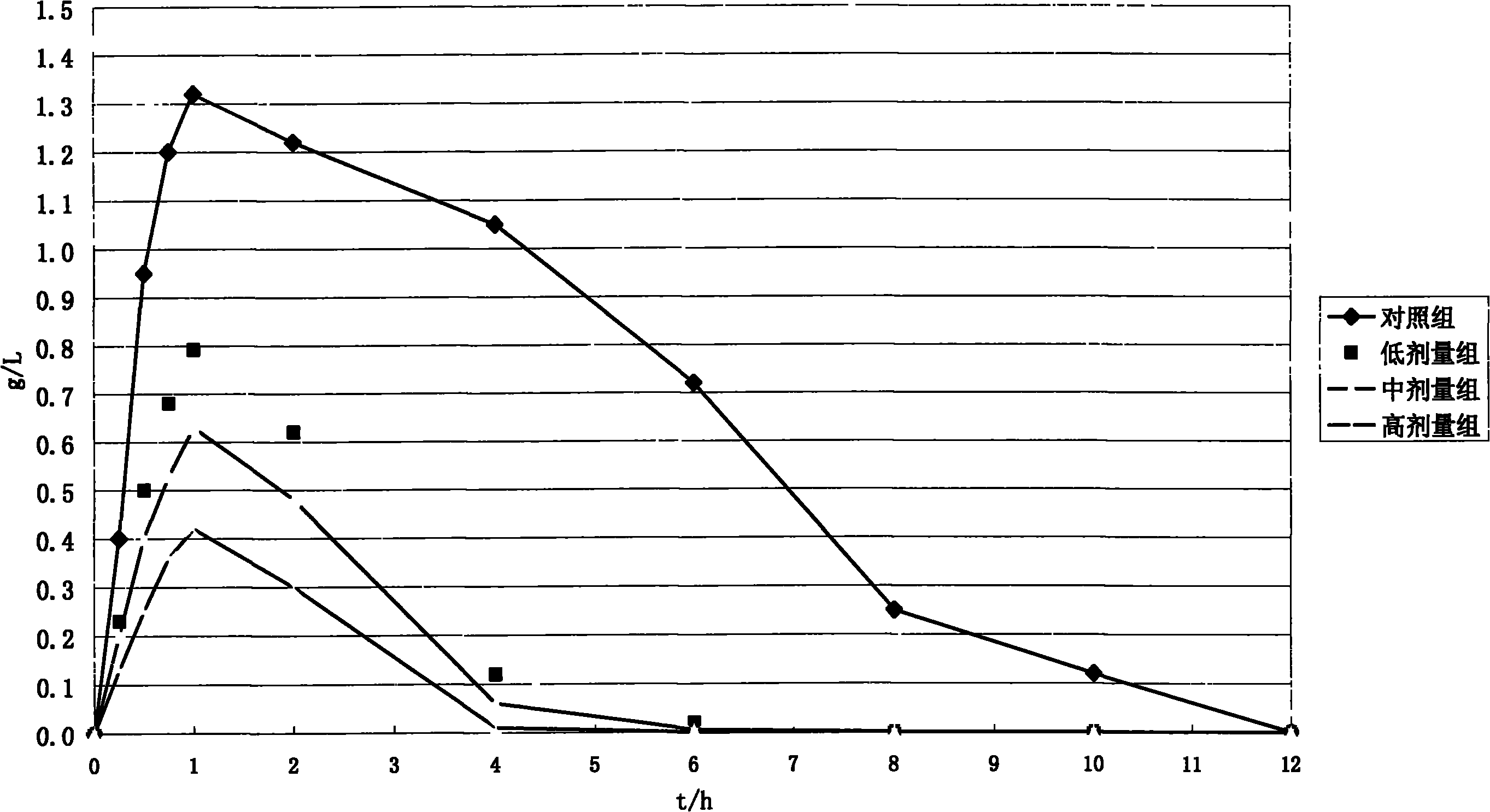

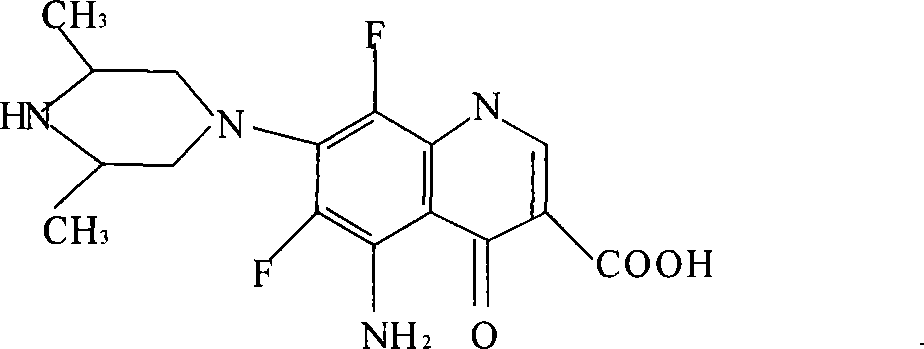

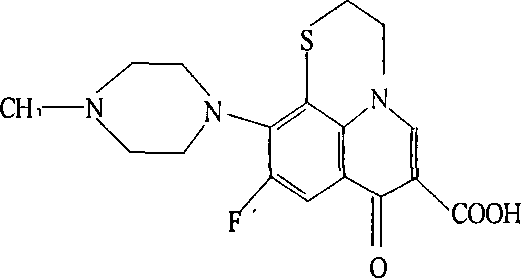

Water-soluble salt of aspartic acid carbostyril series antibacterial drugs and injection dosage forms thereof

The invention provides an aspartate quinolone antibiotics water-soluble salt and the injection formulation thereof, including sparfloxacin, gatifloxacin, rufloxacin, pefloxacin, tosufloxacin, moxifloxacin, and so on; the invention improves the water solubility of quinolone antibiotics and enhances the anti-bacterial effect of quinolone antibiotics. Compared with the oral liquid of quinolone drugs of the prior art, the invention has the advantages that: water solubility of the drug is good, as the drug enters the blood directly, the invention can not only achieve treatment function rapidly, but can also be absorbed by the human body fully, and the invention has significant effects in the two aspects of fast onset of action and low consumption. Compared with the injection of the quinolone drugs of the prior art, the invention has the advantages that: due to the existence of the L-aspartate, the antibacterial activity of quinolone drugs can be enhanced.

Owner:SHENYANG WOSEN PHARMA INST

Surfactant-based composition

ActiveUS20070213248A1Less load to environmentEliminate needOrganic detergent compounding agentsAnionic surface-active compoundsL-AspartatePotassium

A water-addition-type surfactant-based composition, containing: at least one of a fatty acid sodium salt and / or potassium salt, as a surfactant component; and at least one of N,N-bis(carboxymethyl)-L-glutamic acid tetrasodium salt, L -aspartate-(N,N)-diacetic acid tetrasodium salt, N-2-hydroxyethyliminodiacetic acid disodium salt, (S,S)-ethylenediaminesuccinic acid trisodium salt, methylglycinediacetic acid trisodium salt, ethylenediaminetetraacetic acid, nitorilotriacetic acid, diethylenetriaminepentaacetic acid, hydroxyethylethylenediaminetriacetic acid, triethylenetetraminehexaacetic acid, 1,3-propanediaminetetraacetic acid, 1,3-diamino-2-hydroxypropanetetraacetic acid, dihydroxyethylglycine, glycol ether diamine tetraacetic acid, hydroxyethanediphosphonic acid, aminotrimethylenephosphonic acid, 1,2,4-butanetricarboxylic acid, dihydroxyethylethylenediaminediacetic acid, sodium gluconate, sodium glucoheptonate, inositol hexaphosphate, hydroxyethanoic acid, 2-hydroxypropanoic acid, 2-hydroxysuccinic acid, 2,3-dihydroxybutanedioic acid, and 2-hydroxy-1,2,3-propanetricarboxylic acid, as a chelating component.

Owner:FURUKAWA TECHNO MATERIAL +2

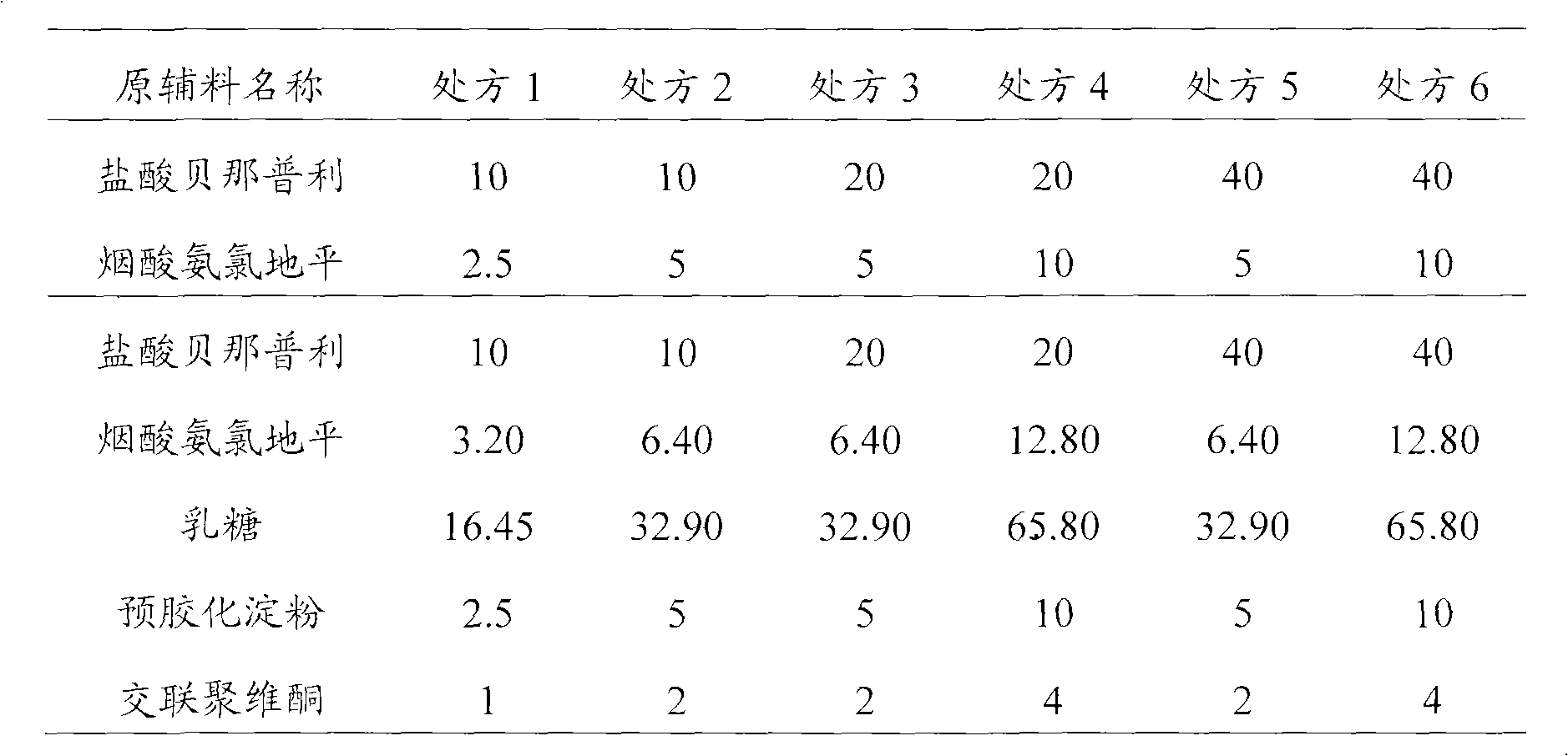

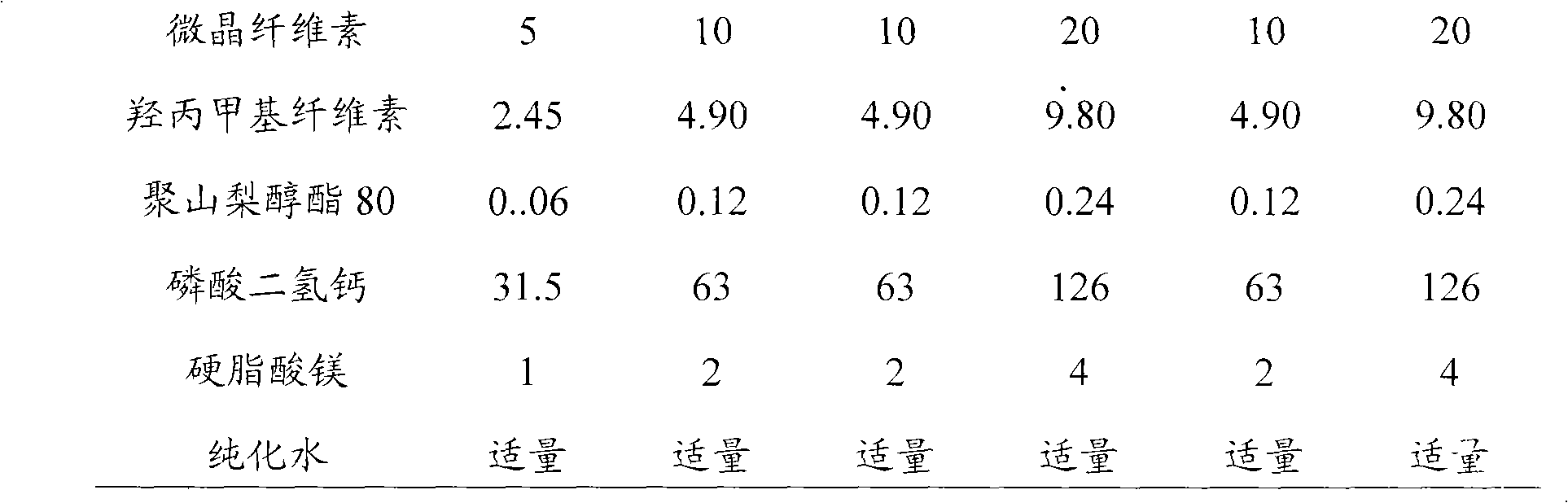

Treatment composition containing amlodipine series salt and pril medicament

InactiveCN101653440AMetabolism disorderHeterocyclic compound active ingredientsL-AspartateAmlodipine

The invention relates to an amlodipine series salt, which particularly comprises nicotinate, camsilate, pyroglutamate, L-aspartate, maleate and mesylate. The invention also relates to a pril compoundor a pharmaceutical composition of a medicinal salt of the pril compound and a preparation method thereof, and a drug combination medicine box containing a composition of the amlodipine series salt and a composition of sartan compounds. The composition of the invention comprises the following components: a) a certain amount of an amlodipine salt; b) a certain amount of the pril compound or a medicinal salt of the pril compound; and c) a medicinal carrier or a diluting agent. The composition or the medicine box can be used for treating the patients suffering from hypertension, angina pectoris,atherosclerosis, and / or hypersphyxia and treating the patients (including the human beings) having heart danger symptoms.

Owner:BEIJING ROCK PHARMA

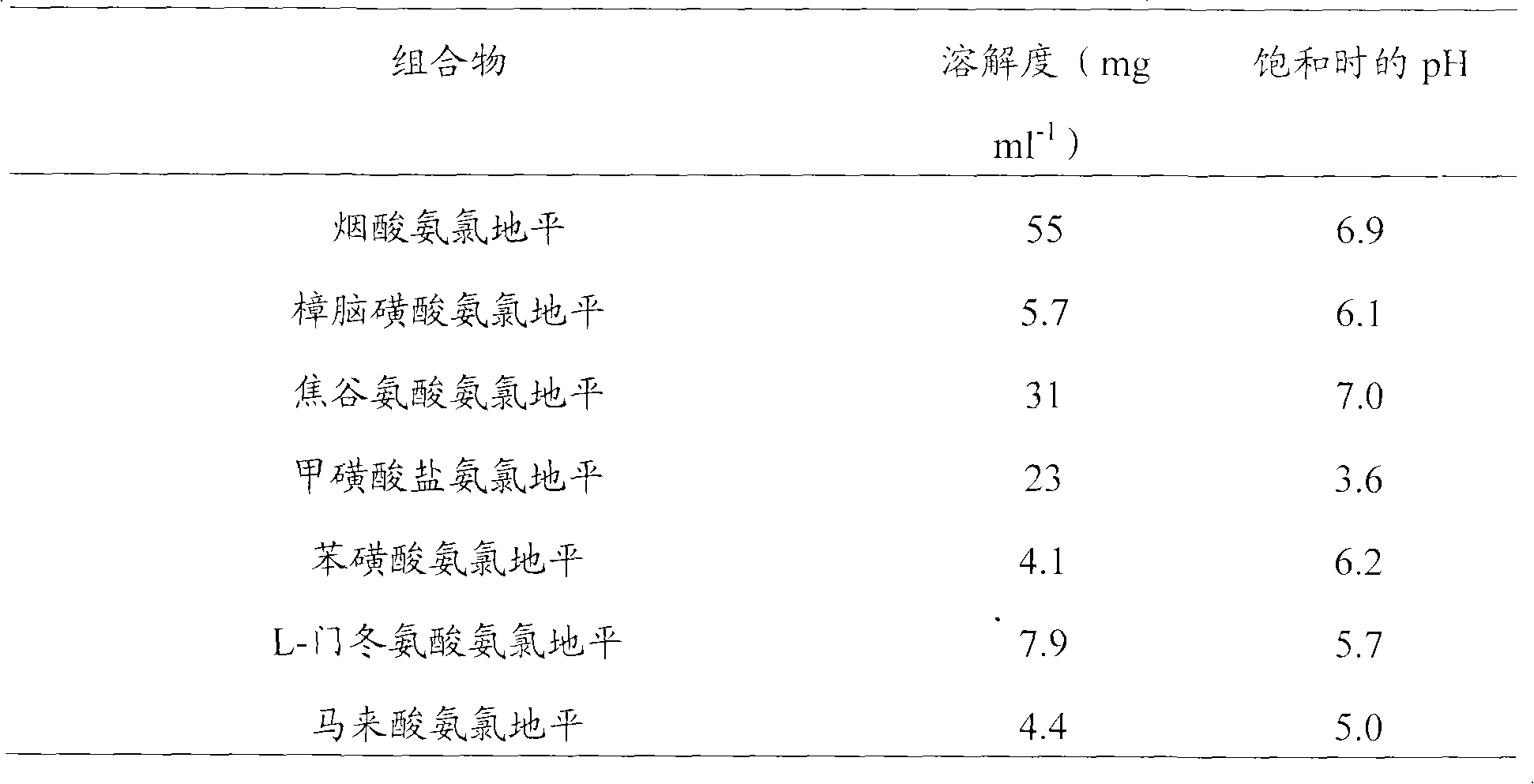

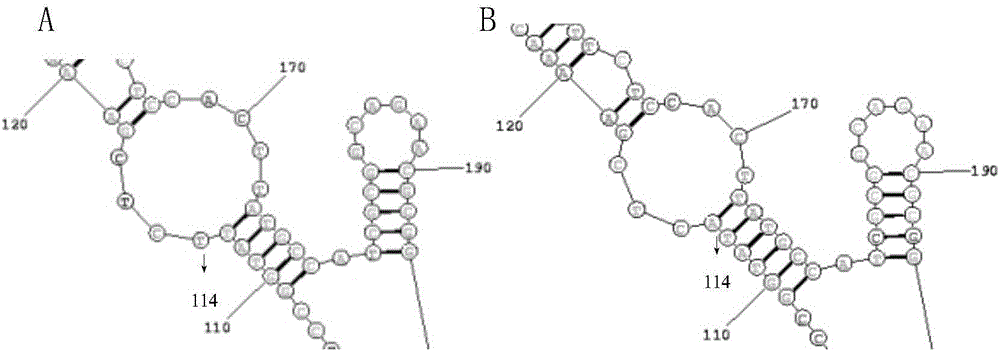

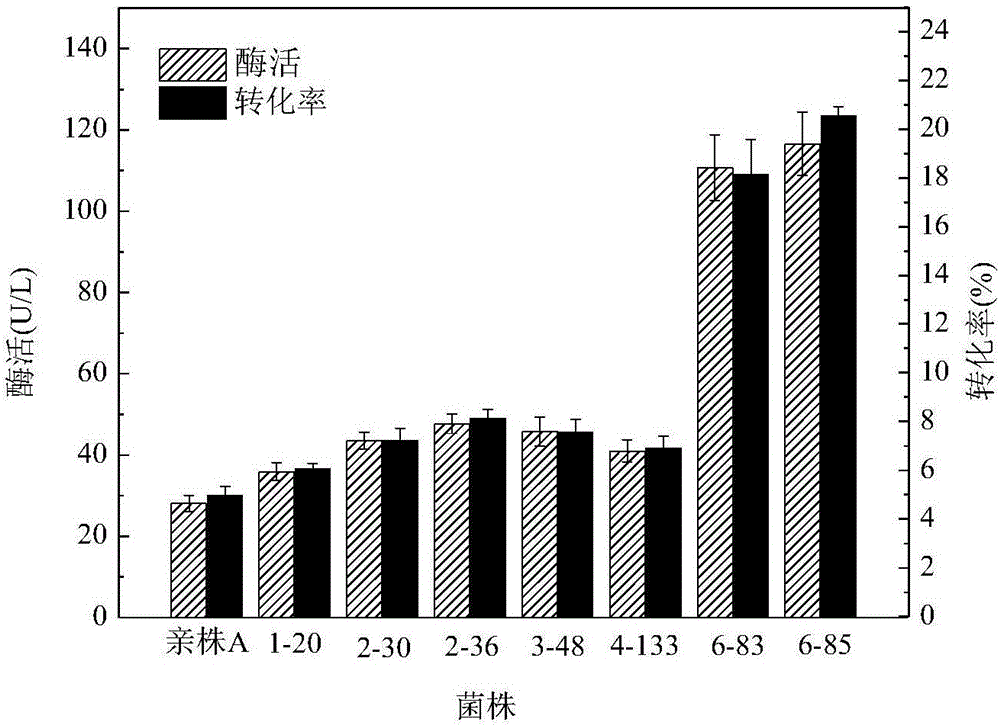

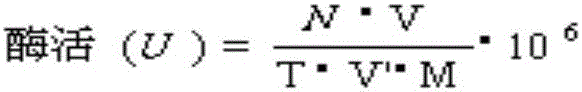

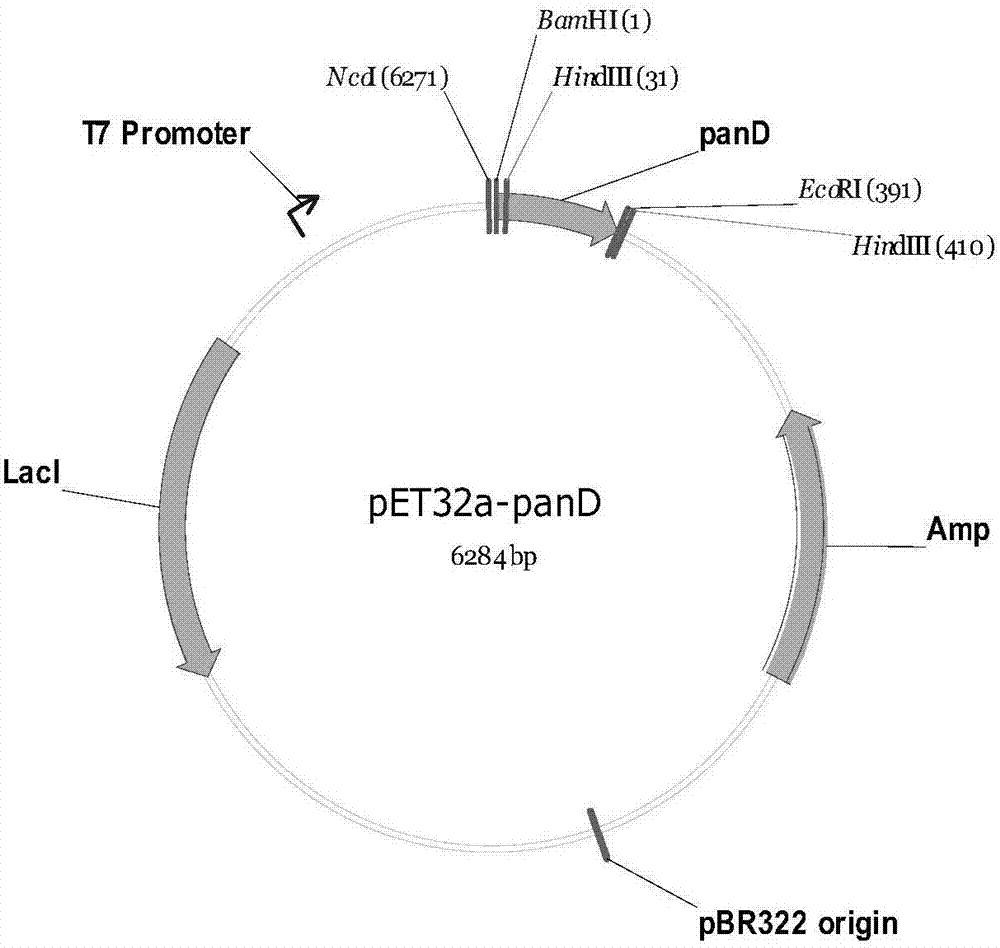

PanD mutant gene, encoded protein, vector, engineering bacterium and application of encoded protein

ActiveCN106754845AImprove efficiencyBreeding goals are clearFermentationVector-based foreign material introductionRandom mutationEscherichia coli

The invention relates to a panD mutant gene, encoded protein, a vector, an engineering bacterium and an application of the encoded protein. Series recombinant escherichia coli, for high-yield production of L-aspartate-[alpha]-decarboxylase (PanD), is obtained by changing codon base of the panD gene through random mutation of error-prone PCR. With the application of gene engineering bacterium for high-yield production of the PanD, the efficient transformation of the L-aspartate is achieved, so that [beta]-alanine can be prepared by virtue of a biological method, wherein PanD enzyme activity of recombinant escherichia coli numbered as 6-85 can reach 250U / L or above and [beta]-Ala yield can reach about 8.5g / L, nearly 4 times and 3 times above that of a parent strain.

Owner:浙江科峰生物技术有限公司

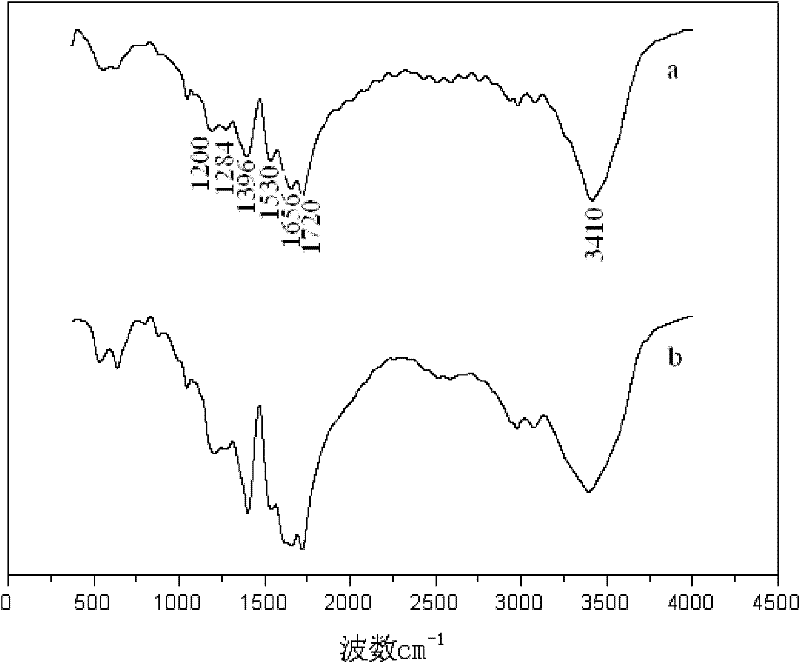

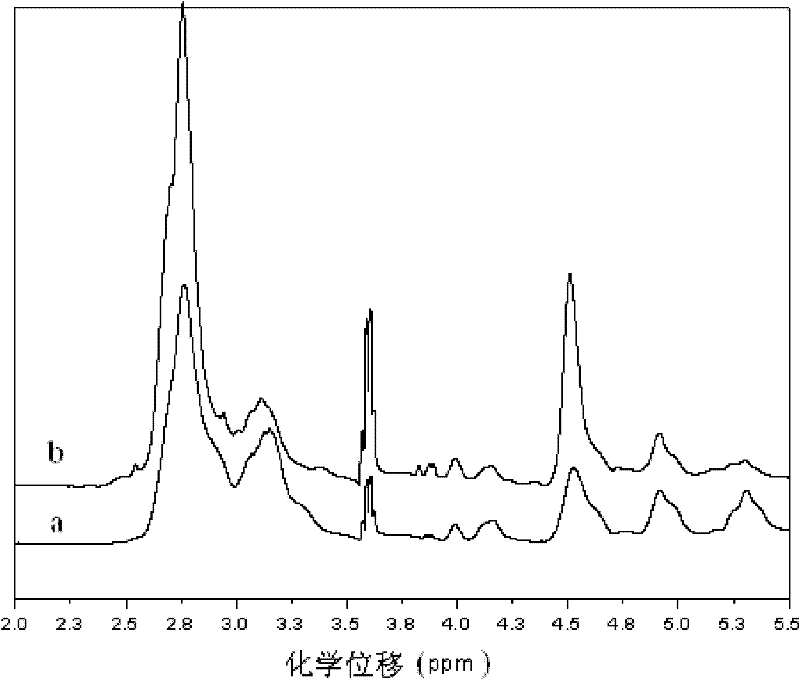

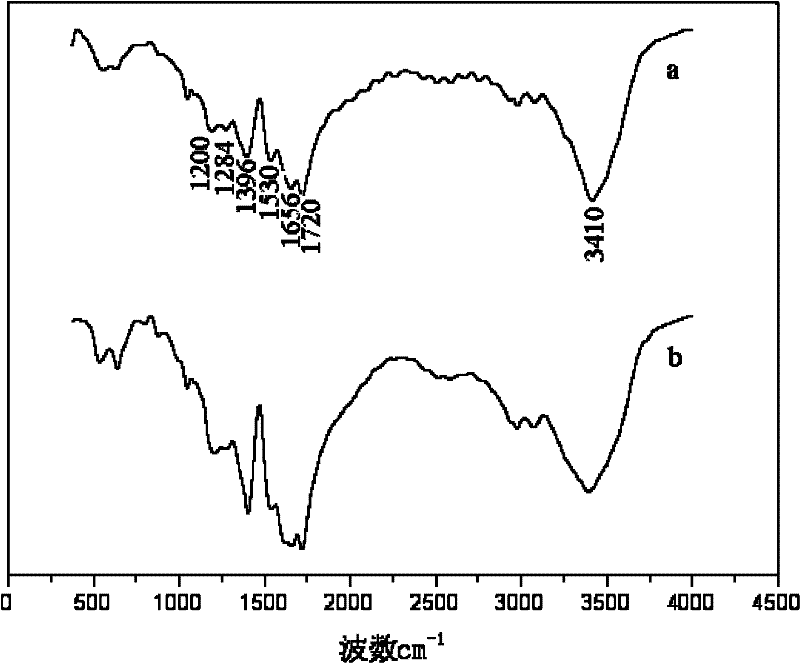

SOD simulated compound with short peptide as ligand and preparation method thereof

The disclosed Mn-SOD with aspartic short peptide as ligand is prepared as following: composing the monomanganese di-L-aspartate with L-aspartic acid (D) and manganese compound of MnO2, MnO, Mn(SO4)3, MnCl6 and Mn(CO3)3; or using the aspartate directly for polycondensation at 160-260Deg. Wherein, representing the product chemical composition and molecular weight by element analysis, IR spectrum and gel chromatography; determining its activity by NBT method. This invention has well bioactivity, stability and yield for wide application.

Owner:北京华美天意科技开发有限公司 +1

Surfactant-based composition

ActiveUS7691283B2Less load to environmentEliminate needOrganic detergent compounding agentsAnionic surface-active compoundsL-AspartateFatty acid

A water-addition-type surfactant-based composition, containing: at least one of a fatty acid sodium salt and / or potassium salt, as a surfactant component; and at least one of N,N-bis(carboxymethyl)-L-glutamic acid tetrasodium salt, L-aspartate-(N,N)-diacetic acid tetrasodium salt, N-2-hydroxyethyliminodiacetic acid disodium salt, (S,S)-ethylenediaminesuccinic acid trisodium salt, methylglycinediacetic acid trisodium salt, ethylenediaminetetraacetic acid, nitorilotriacetic acid, diethylenetriaminepentaacetic acid, hydroxyethylethylenediaminetriacetic acid, triethylenetetraminehexaacetic acid, 1,3-propanediaminetetraacetic acid, 1,3-diamino-2-hydroxypropanetetraacetic acid, dihydroxyethylglycine, glycol ether diamine tetraacetic acid, hydroxyethanediphosphonic acid, aminotrimethylenephosphonic acid, 1,2,4-butanetricarboxylic acid, dihydroxyethylethylenediaminediacetic acid, sodium gluconate, sodium glucoheptonate, inositol hexaphosphate, hydroxyethanoic acid, 2-hydroxypropanoic acid, 2-hydroxysuccinic acid, 2,3-dihydroxybutanedioic acid, and 2-hydroxy-1,2,3-propanetricarboxylic acid, as a chelating component.

Owner:FURUKAWA TECHNO MATERIAL +2

Method for constructing engineering bacterium capable of producing beta-alanine and method for producing beta-alanine by adopting engineering bacterium

InactiveCN107338258AIncrease vitalityMeet the needs of industrial scale productionBacteriaFermentationEscherichia coliL-Aspartate

The invention discloses a method for constructing an engineering bacterium capable of producing beta-alanine and a method for producing beta-alanine by adopting the engineering bacterium, belonging to the field of biotechnologies. The invention provides L-aspartate alpha-decarboxylase gene of a bacillus tequilensis strain, as shown in SEQ ID NO.1, and the engineering bacterium comprising the PanD gene. The invention further provides a constructing method of the engineering bacterium capable of producing the L-aspartate alpha-decarboxylase, L-aspartate alpha-decarboxylase obtained through expression and secretion is adopted for transforming L-aspartic acid, and thus beta-alanine is produced. According to the invention, L-aspartate alpha-decarboxylase derived from bacillus tequilensis is adopted for transforming L-aspartic acid for producing beta-alanine for the first time at home and abroad, after the enzyme is expressed in escherichia coli, the generated L-aspartate alpha-decarboxylase has high enzyme activity, the thallus does not need to be crushed and can be directly used for carrying out transformation, L-aspartic acid of 180g / L can be transformed to the maximum, the yield of beta-alanine can achieve 119.8g / L, and the industrial application has the advantages.

Owner:LUDONG UNIVERSITY

A novel chelated calcium

InactiveCN104000191AImprove absorption rateGreat tasteOrganic active ingredientsOrganic compound preparationSide effectCavitation

The invention relates to a novel chelated calcium, which is composed of 50 parts of L-aspartate trehalose, vitamin C37 and sucralose. The chelate calcium is prepared through solution preparation, filtration, chelation, drying and stirring, sieving and sterilization. An international leading chelation theory is adopted, and the collapse of cavitation and high-frequency high-voltage ultrasonic methods are used to reach the molecular resonance frequency, so as to chelate multiple molecules that are extremely difficult to react. The chelated calcium is formed through operations of the molecule chelating nano-energy conversion device. Each calcium ion together with two amino acids chelated therewith is absorbed by intestine in a wrapped manner, and the absorption rate reaches 95%. The chelate calcium has good taste and can be directly taken without side effects. The production process is reasonable, simple, easy to operate and easy to implement in industrial production.

Owner:岳智广

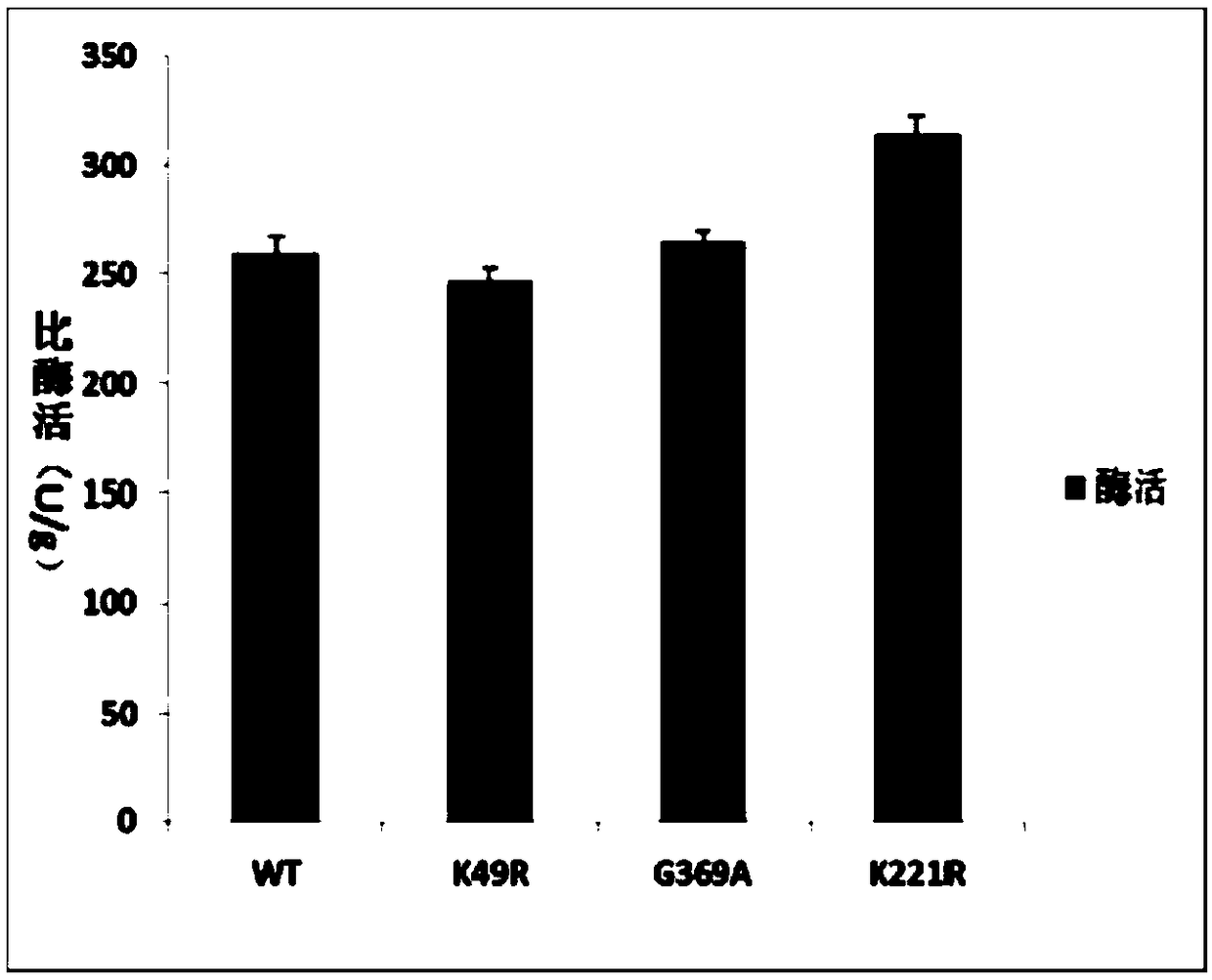

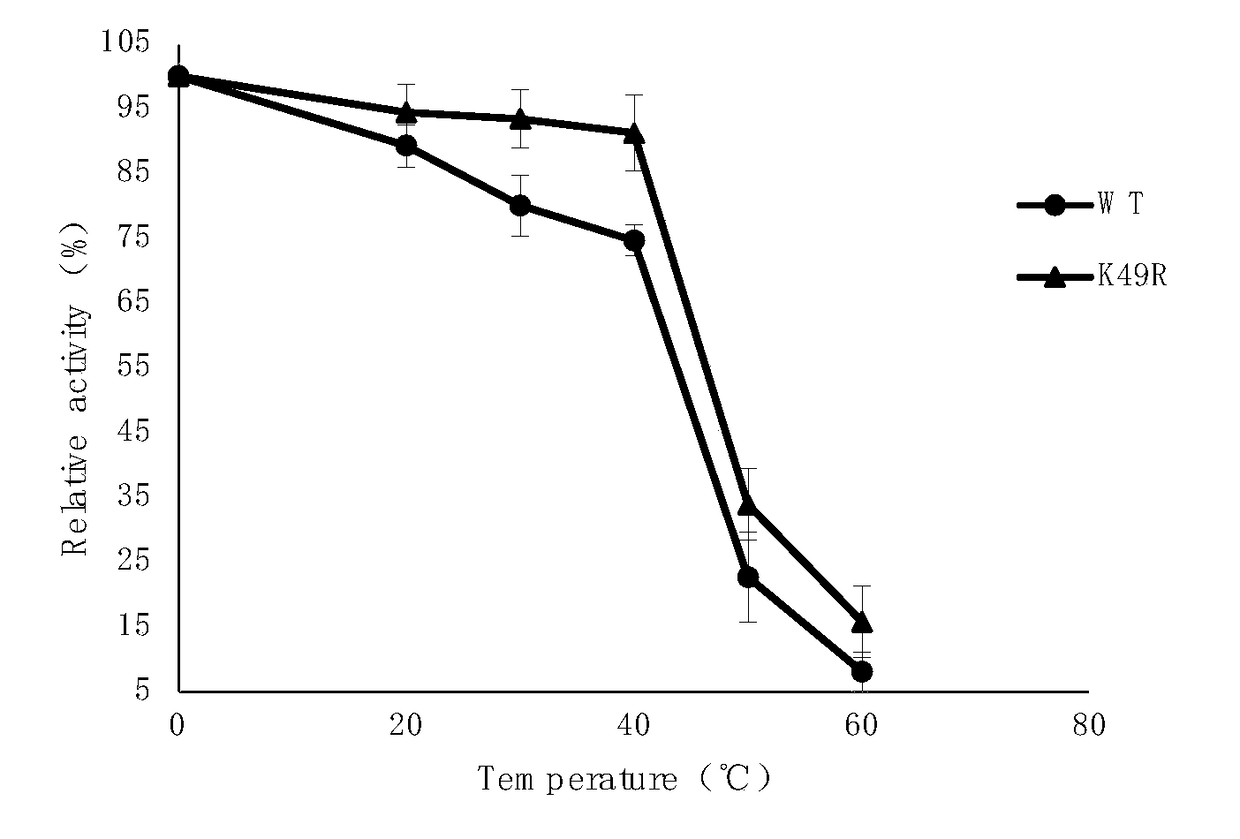

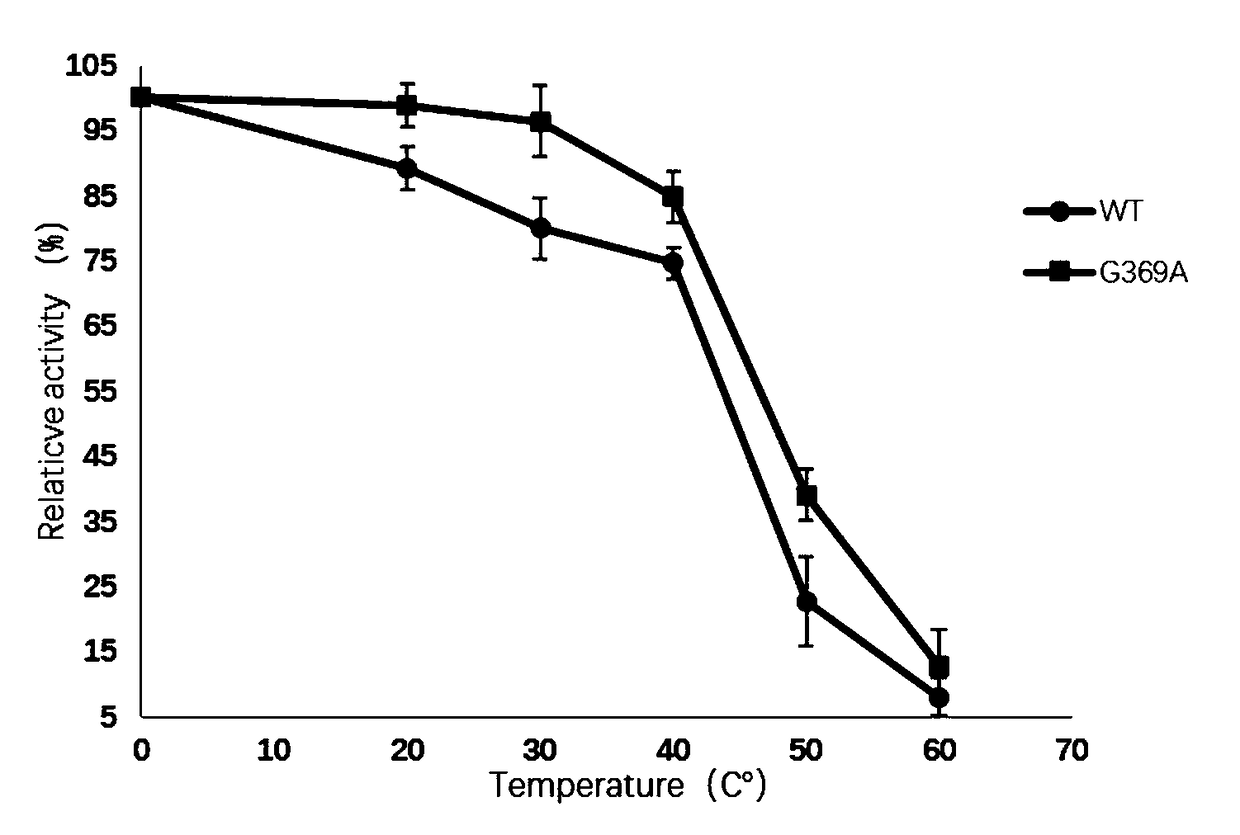

L-aspartate-alpha-decarboxylase with improved thermal stability

ActiveCN109055346AImprove thermal stabilityBacteriaMicroorganism based processesEscherichia coliL-Aspartate

The invention discloses L-aspartate-alpha-decarboxylase with improved thermal stability and belongs to the technical field of gene engineering. Three enzyme mutants including K49R, G369A and K221R areobtained through site-directed mutation of L-aspartate-alpha-decarboxylase from tribolium castaneum, recombinant plasmid of the mutants is transformed into escherichia coli BL21, and a substrate L-aspartic acid is catalyzed to produce beta-alanine after expression separation and purification. At the treatment temperature of 50 DEG C, K49R can improve the thermal stability by 14% as compared withwild enzyme, G369A can improve the thermal stability by 20% as compared with wild enzyme, and K221R can improve the thermal stability by 23% as compared with wild enzyme, wherein K221 can make the enzyme activity reach about 320 U / g and has the enzyme activity improved by 23% as compared with the wild enzyme, and the discovery has important study value for industrial preparation of beta-alanine.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com