Patents

Literature

163 results about "Direct transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct conversion receiver

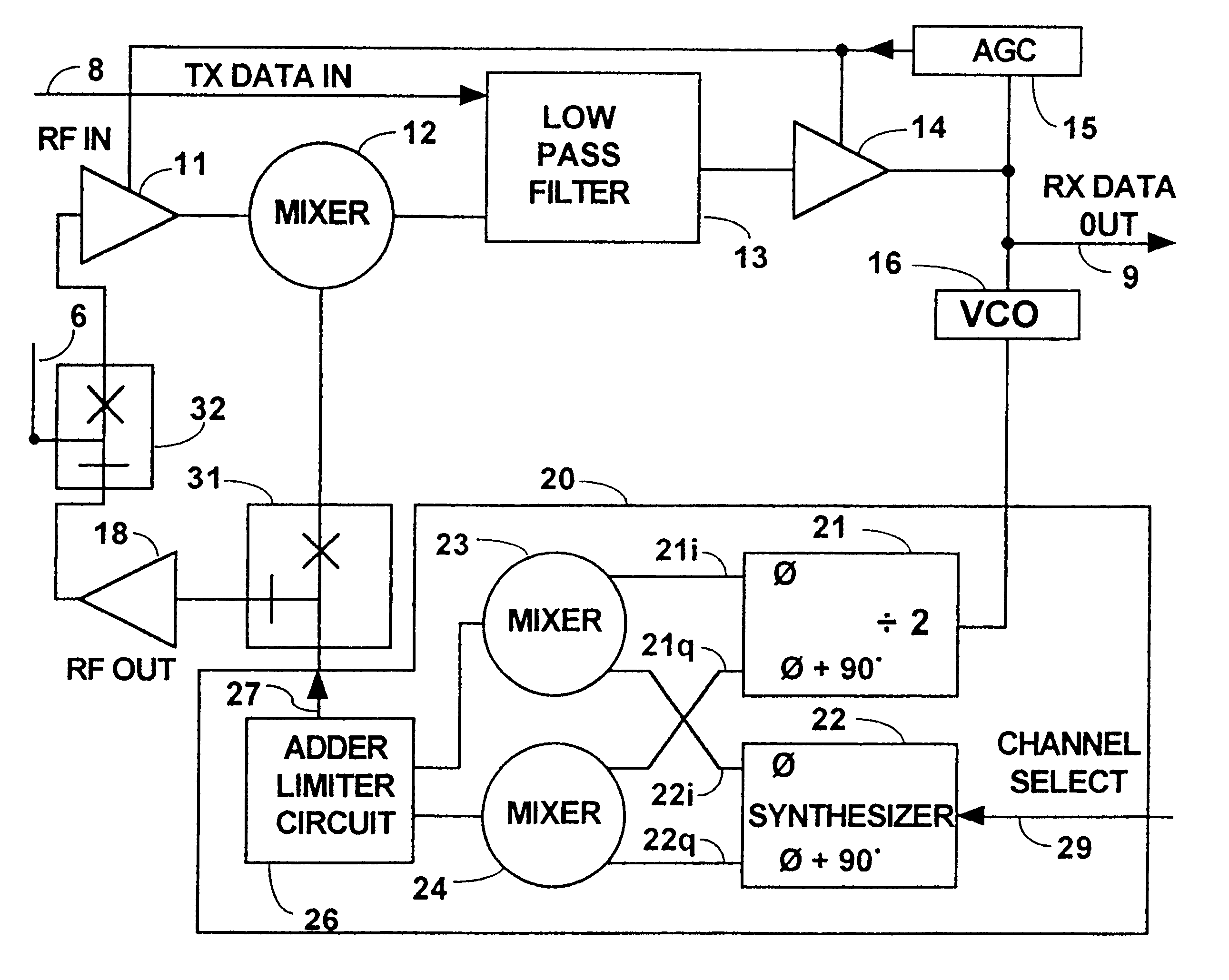

In a frequency modulation radio receiver with direct conversion, a local oscillator signal is generated having a frequency within a preselected frequency range and the frequency is varied in response to a variable low frequency signal; the local oscillator signal is mixed with a received signal to provide a baseband signal. The variable low frequency signal is generated by a controlled oscillator in inverse relationship to a direct current component in said baseband signal. In a frequency modulation radio transceiver a broadcast function is provided by varying the low frequency signal with an information signal with the resulting local oscillator frequency being varied accordingly and amplified for broadcast. The transceiver is controlled to operate alternately in either a receive mode and a broadcast mode at substantially the same frequency. While in the receive mode the controlled oscillator causes the local oscillator signal to be drawn toward the carrier frequency of a received signal yielding preferred direct conversion of modulating information into the base band.

Owner:SIGE SEMICON

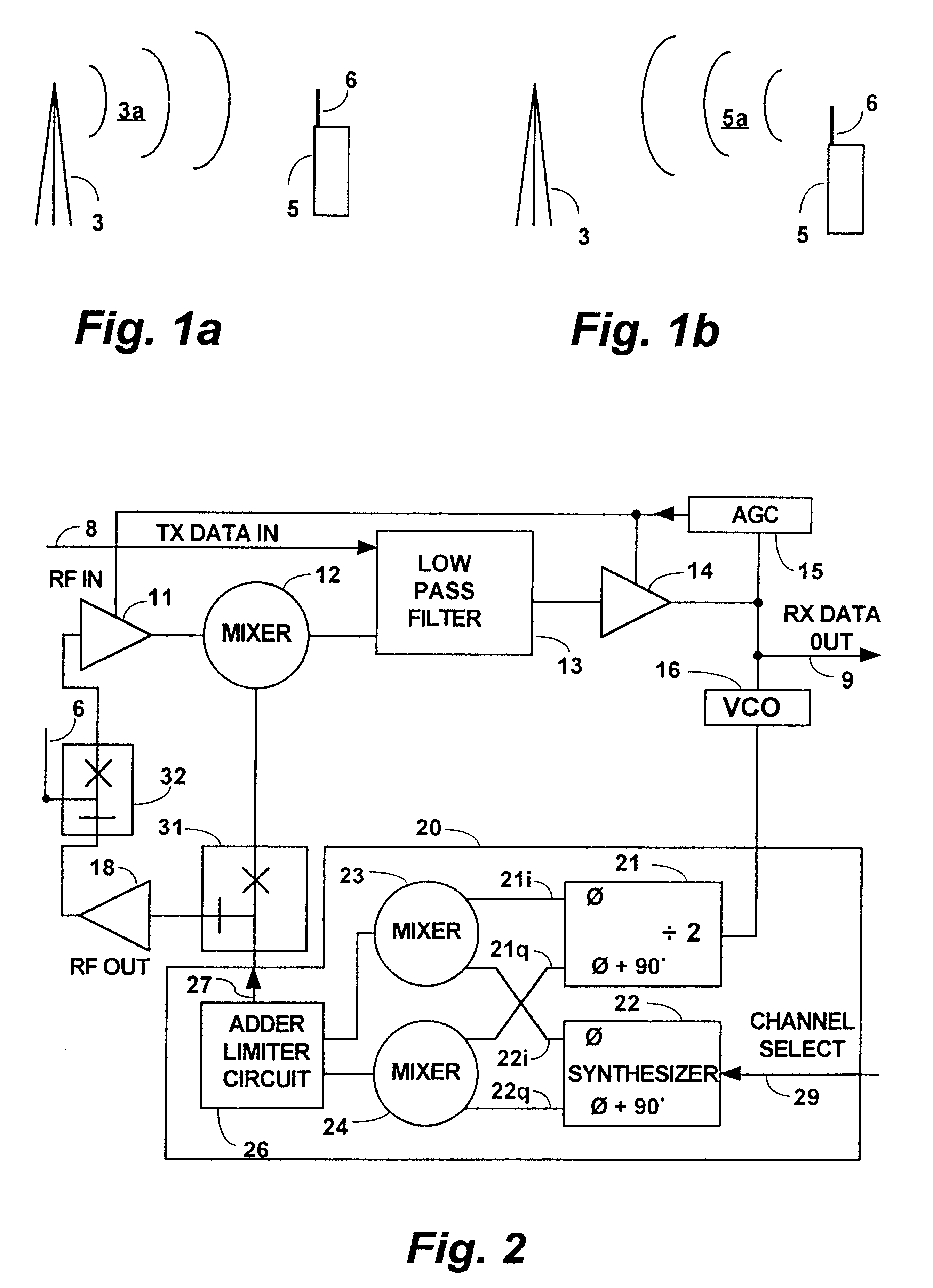

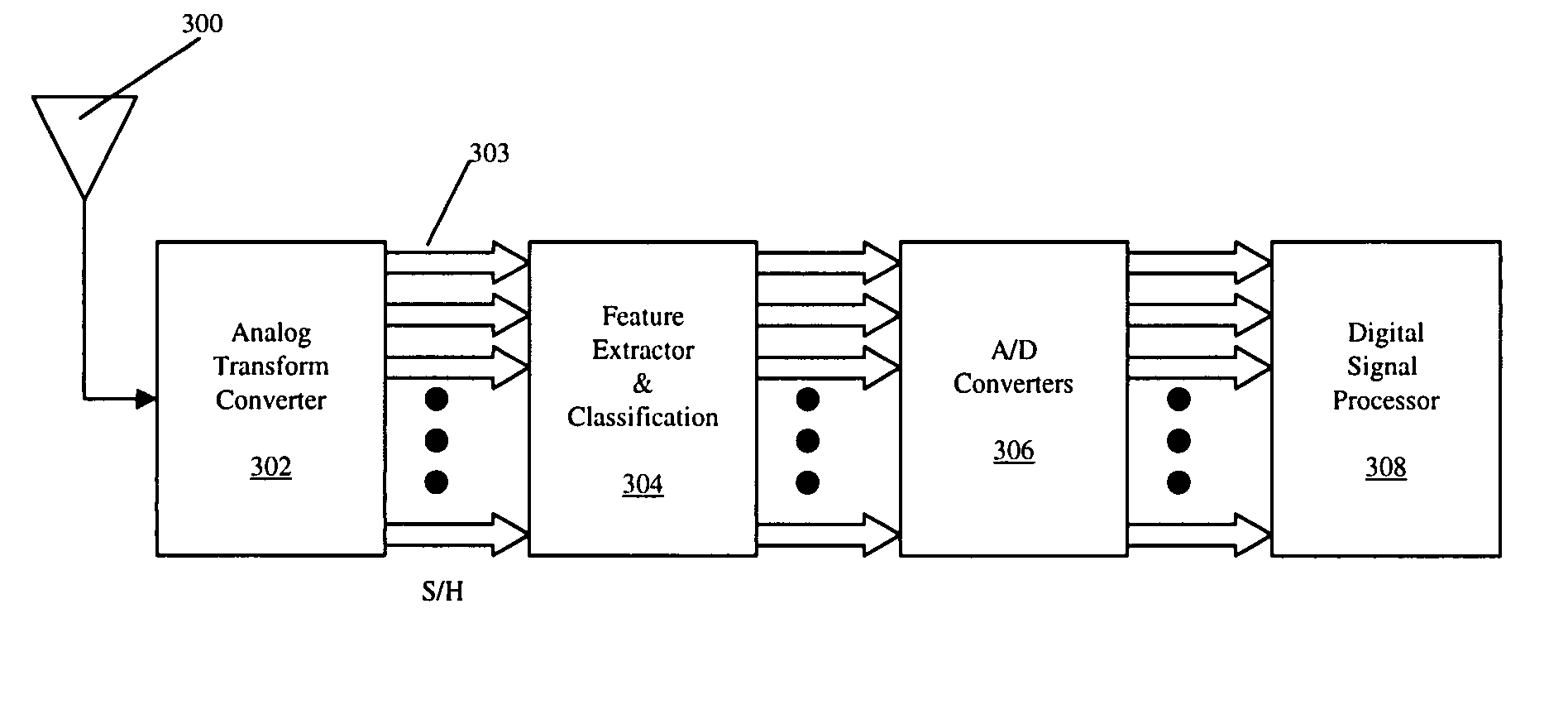

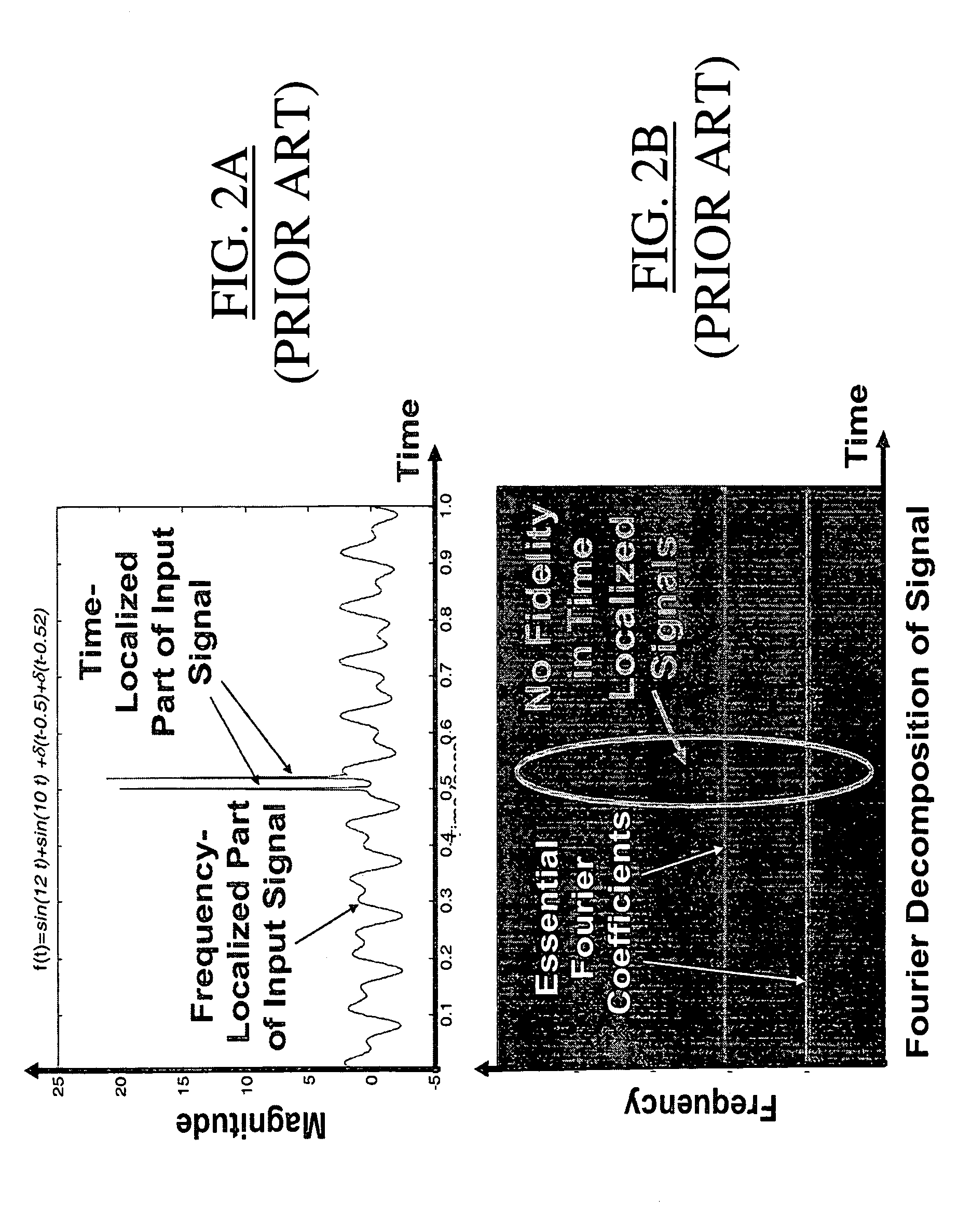

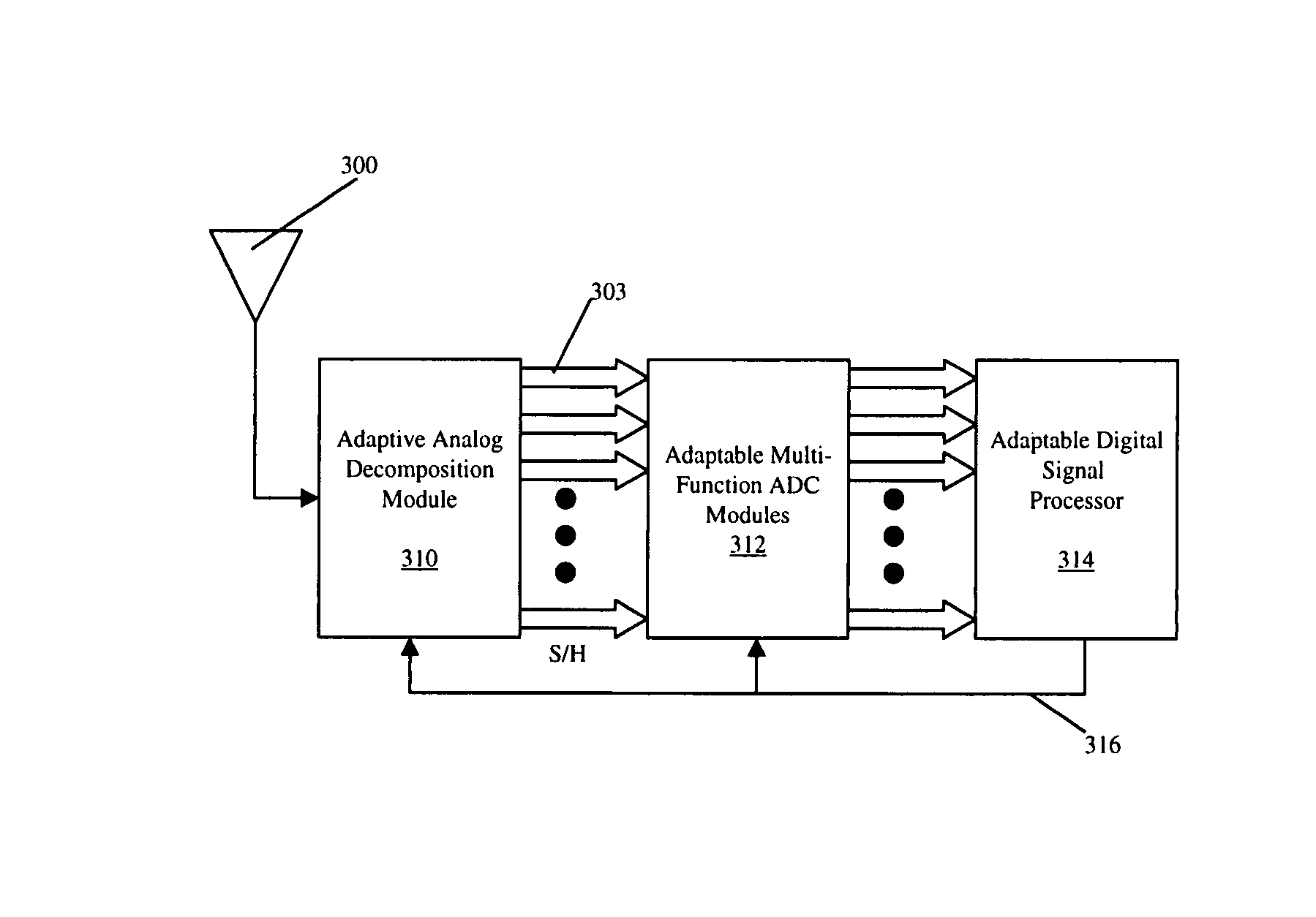

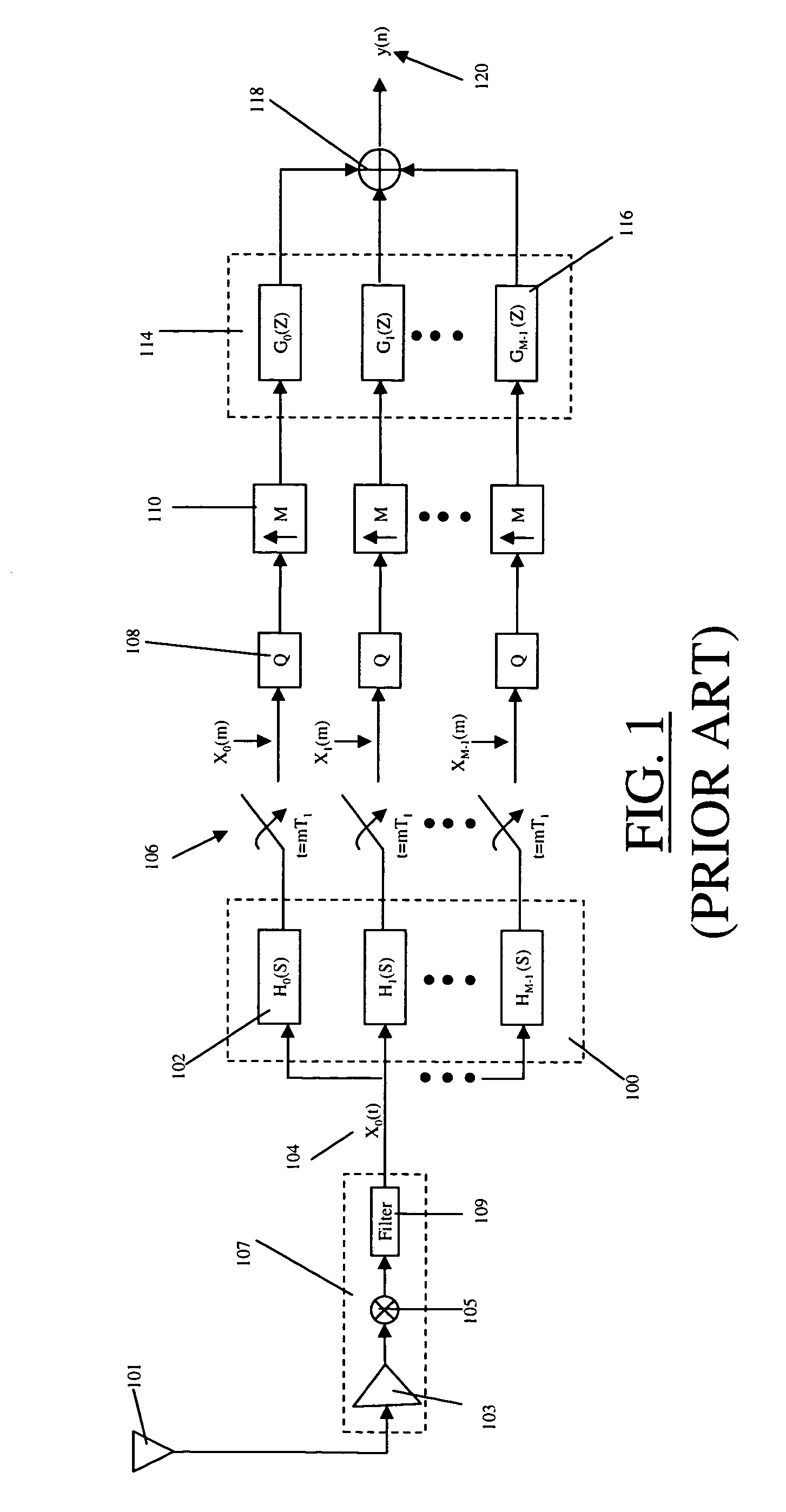

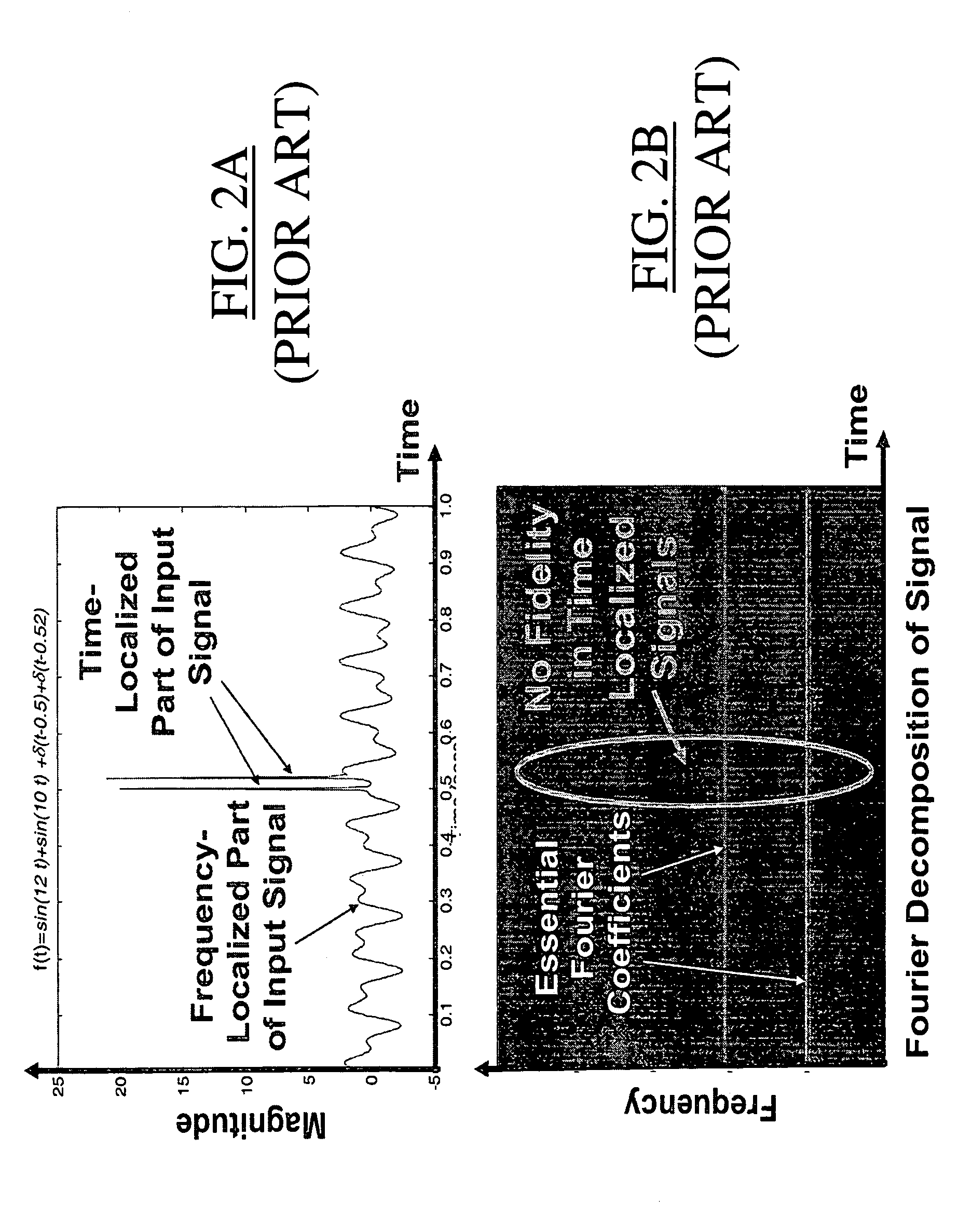

Adaptive, intelligent transform-based analog to information converter method and system

InactiveUS20050156775A1Made preciselyImprove detection rateElectric signal transmission systemsAnalogue conversionFeature extractionAnalog signal

The present invention provides an adaptive, intelligent transform based Analog to Information Converter (AIC) for wideband signals by directly converting an analog signal to information (e.g., features, decisions). This direct conversion is achieved by (i) capturing most of the information of a wideband signal via hardware / software implemented mathematical transformations, (ii) effectively removing unwanted signals such as jammer and interfere from the input signal, and (iii) using novel algorithms for highly accurate decision making and feature extraction (e.g., high probability of detection with low probability of false alarm). The jump in the improvement over today's state-of-the-art is in terms of effective and optimum signal information extraction at high-speed.

Owner:HRL LAB

Adaptive, intelligent transform-based analog to information converter method and system

InactiveUS7324036B2Effectively removing unwanted signalsMade preciselyElectric signal transmission systemsAnalogue conversionFeature extractionAnalog signal

The present invention provides an adaptive, intelligent transform based Analog to Information Converter (AIC) for wideband signals by directly converting an analog signal to information (e.g., features, decisions). This direct conversion is achieved by (i) capturing most of the information of a wideband signal via hardware / software implemented mathematical transformations, (ii) effectively removing unwanted signals such as jammer and interfere from the input signal, and (iii) using novel algorithms for highly accurate decision making and feature extraction (e.g., high probability of detection with low probability of false alarm). The jump in the improvement over today's state-of-the-art is in terms of effective and optimum signal information extraction at high-speed.

Owner:HRL LAB

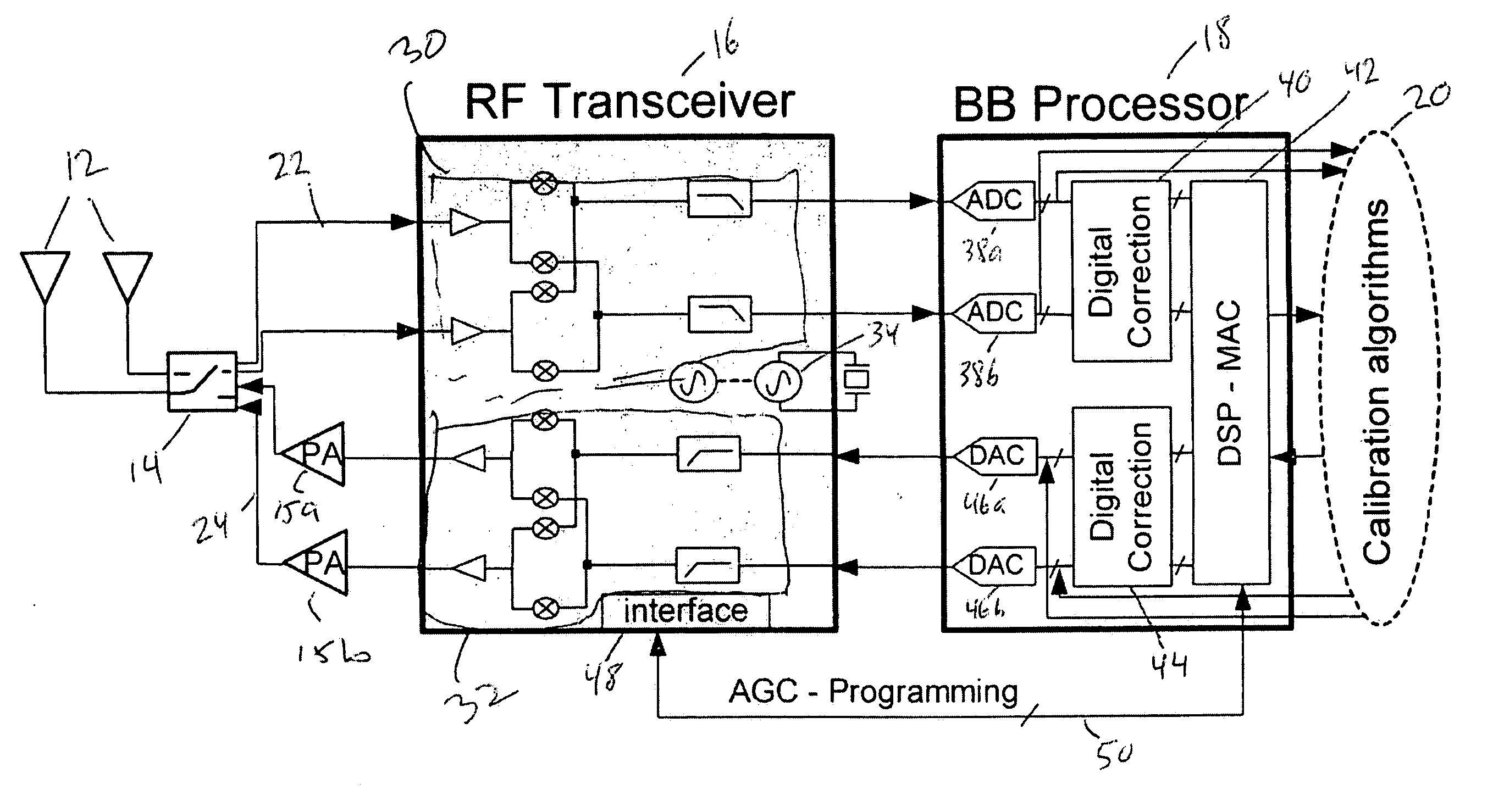

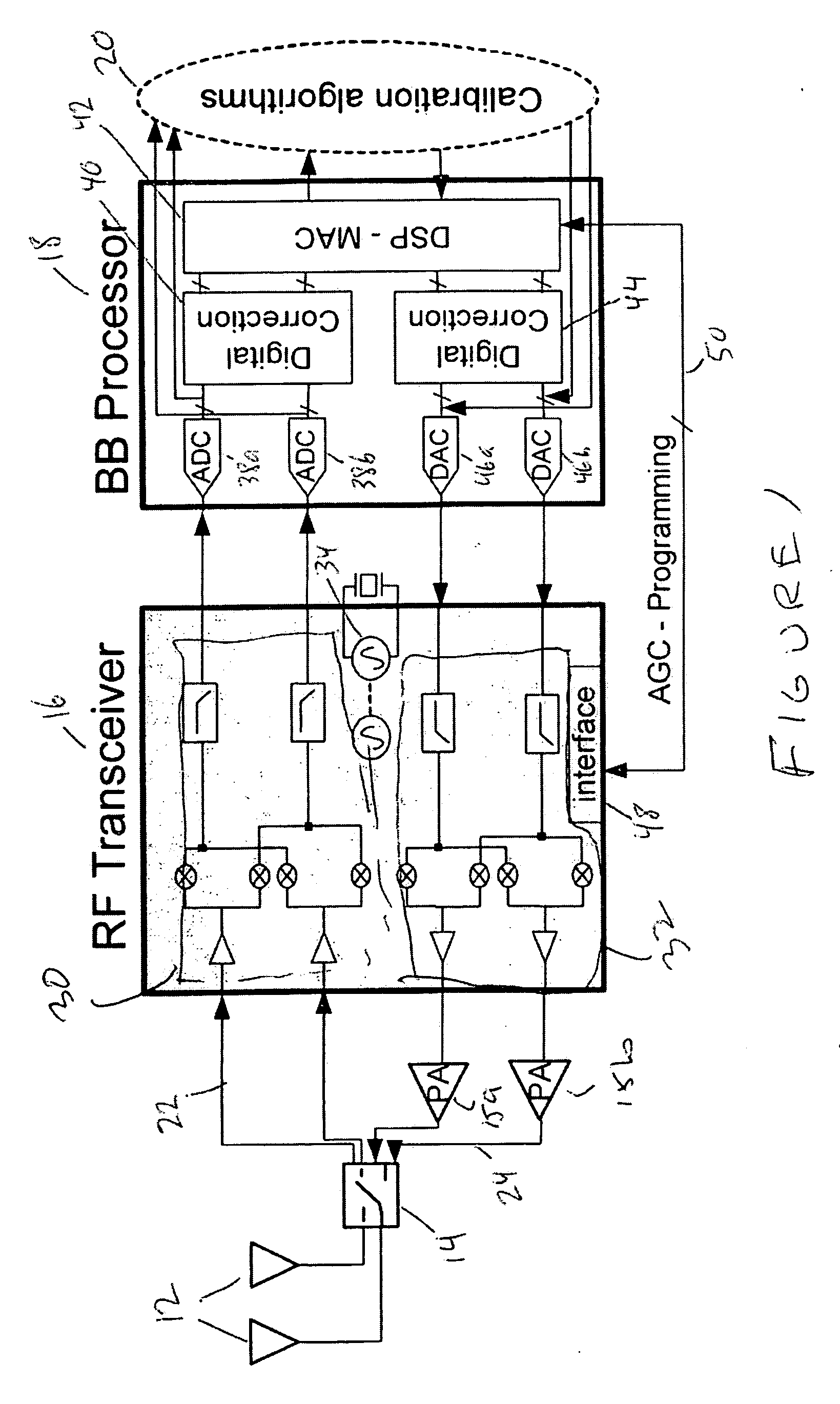

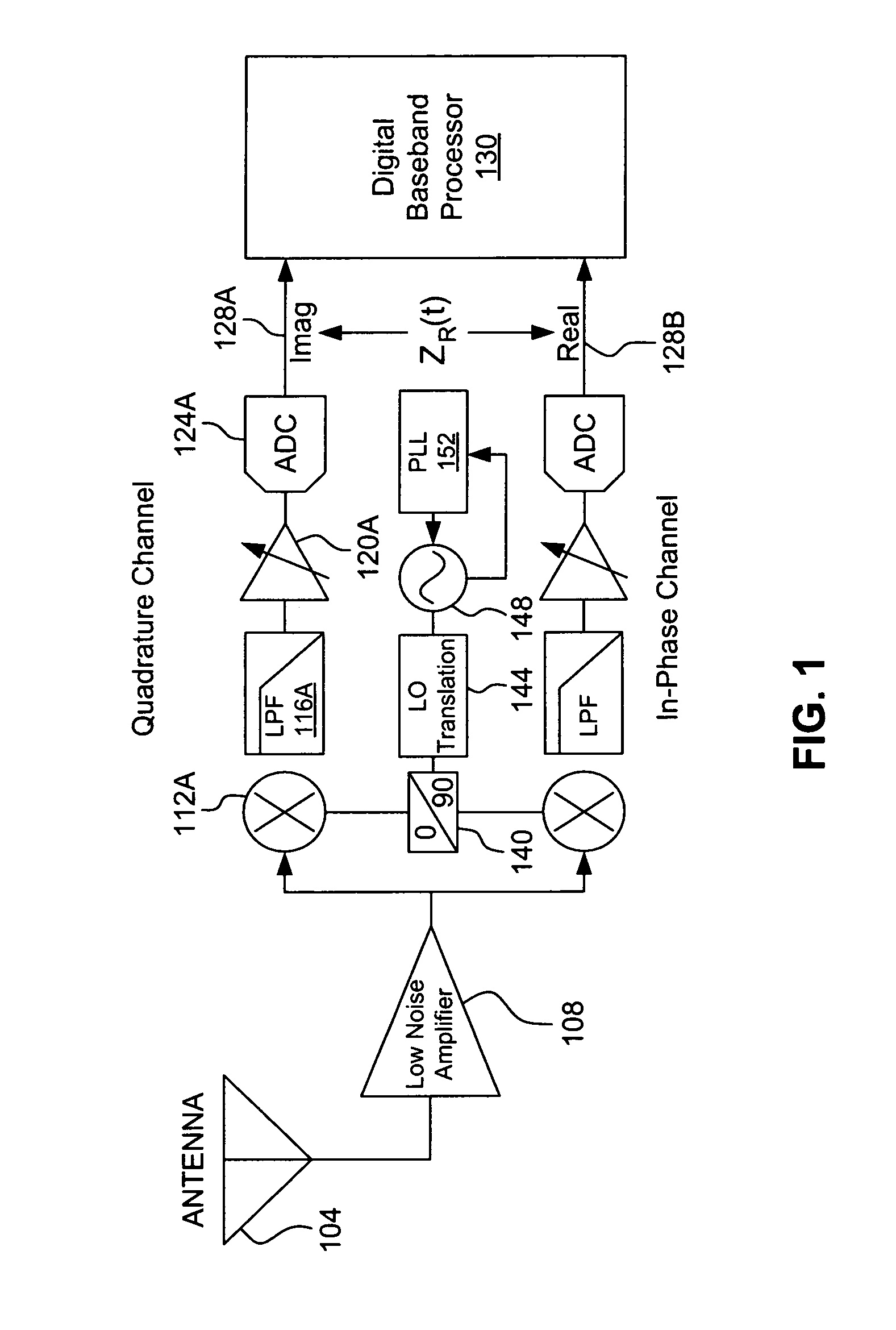

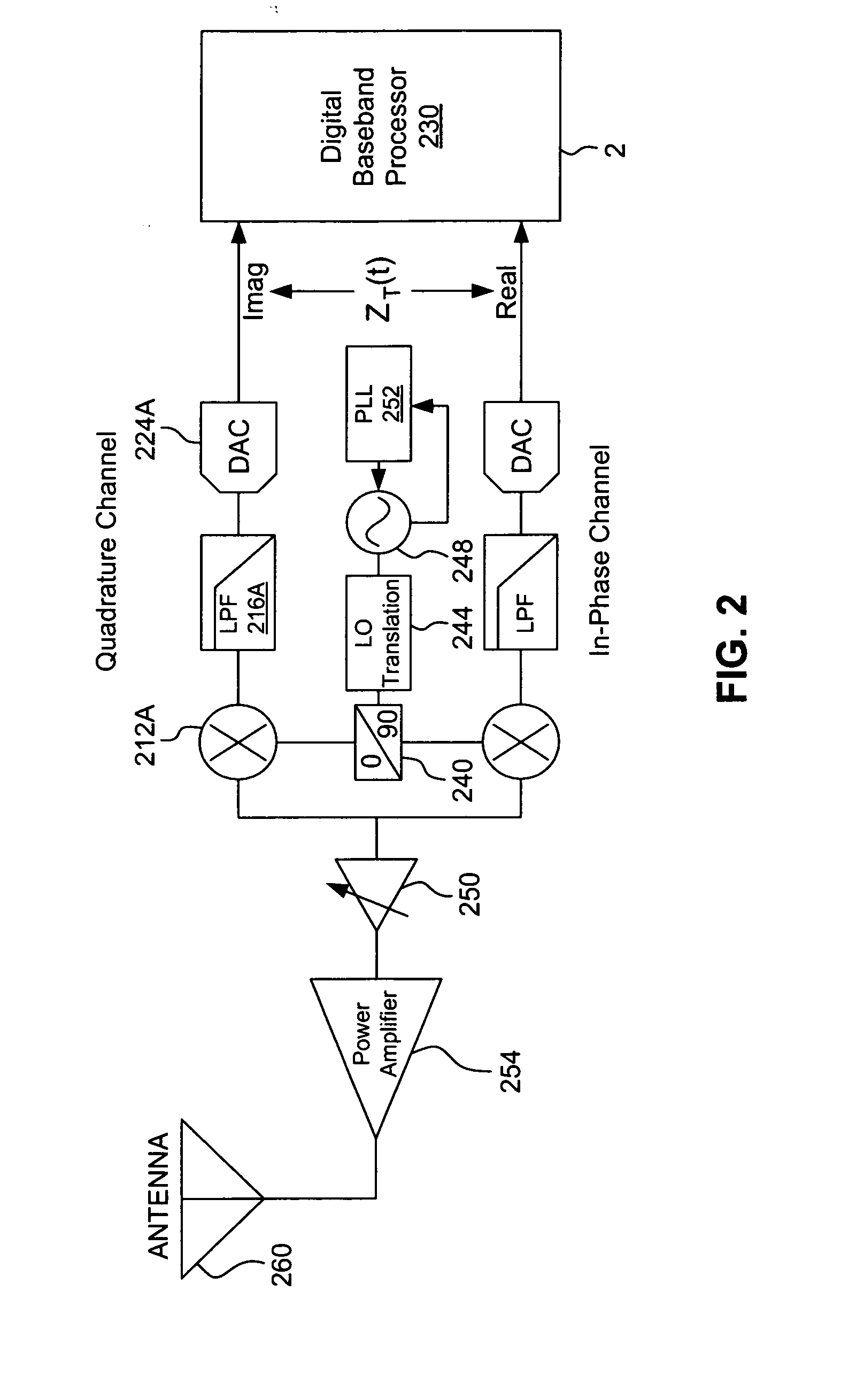

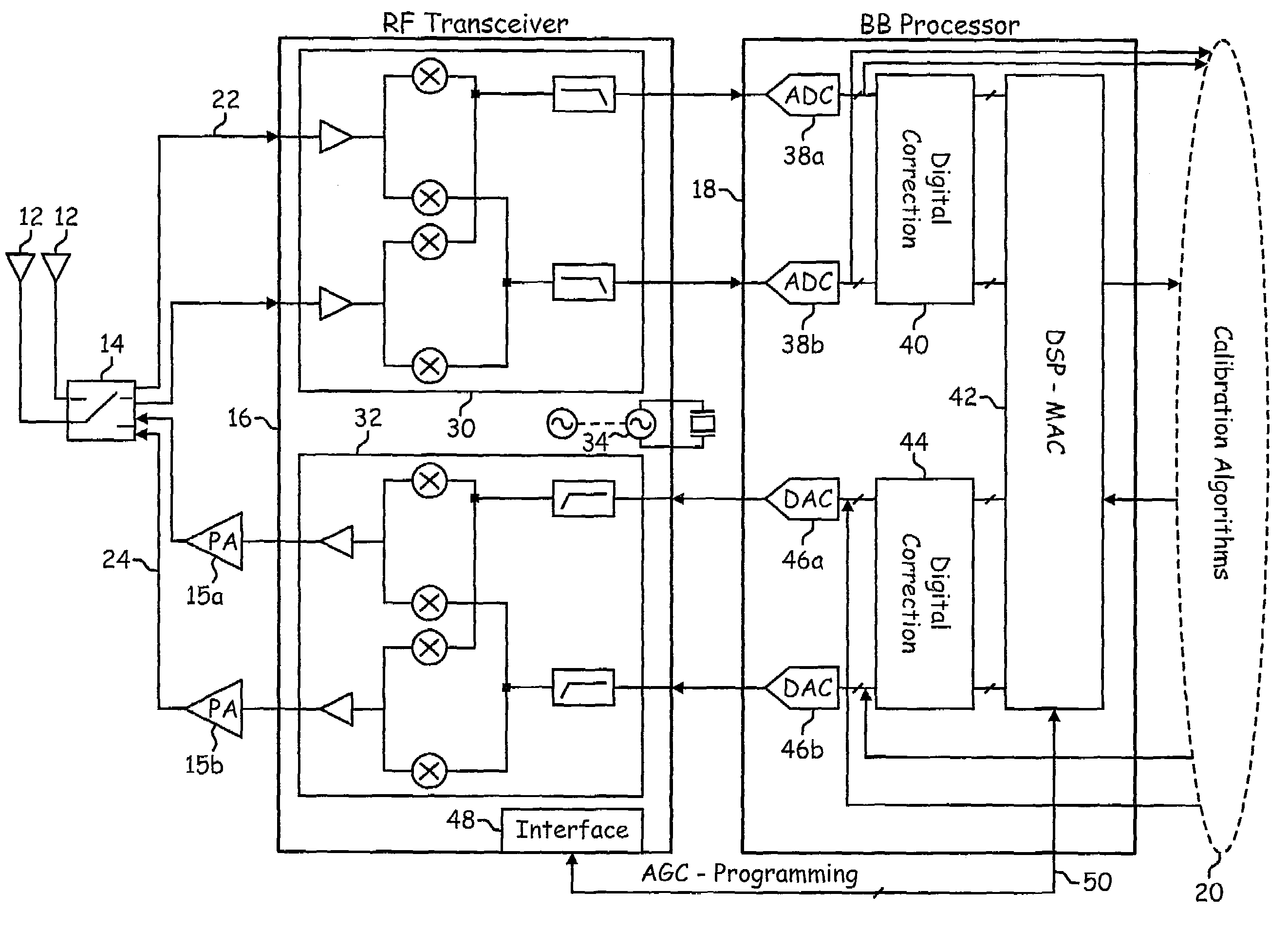

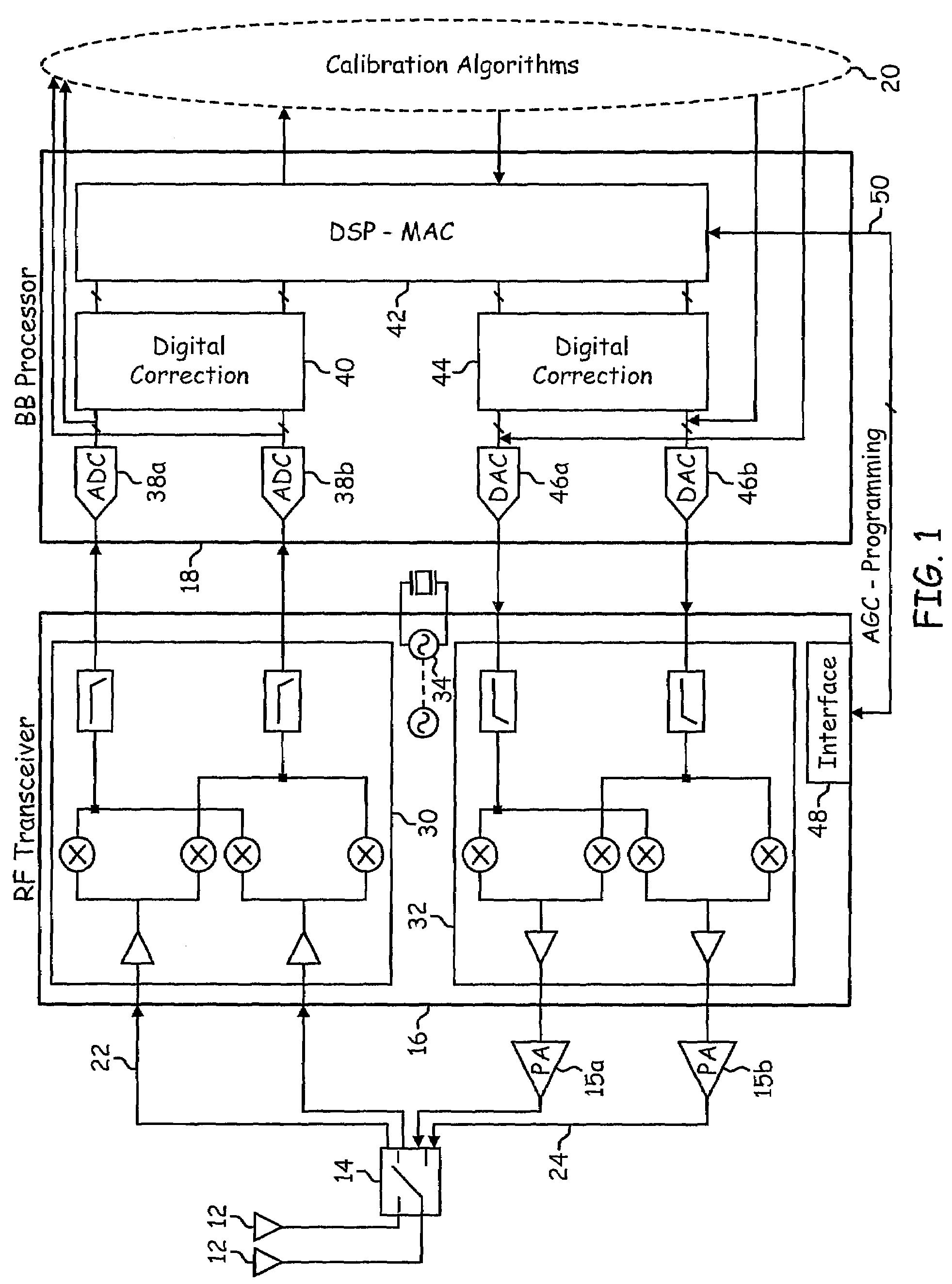

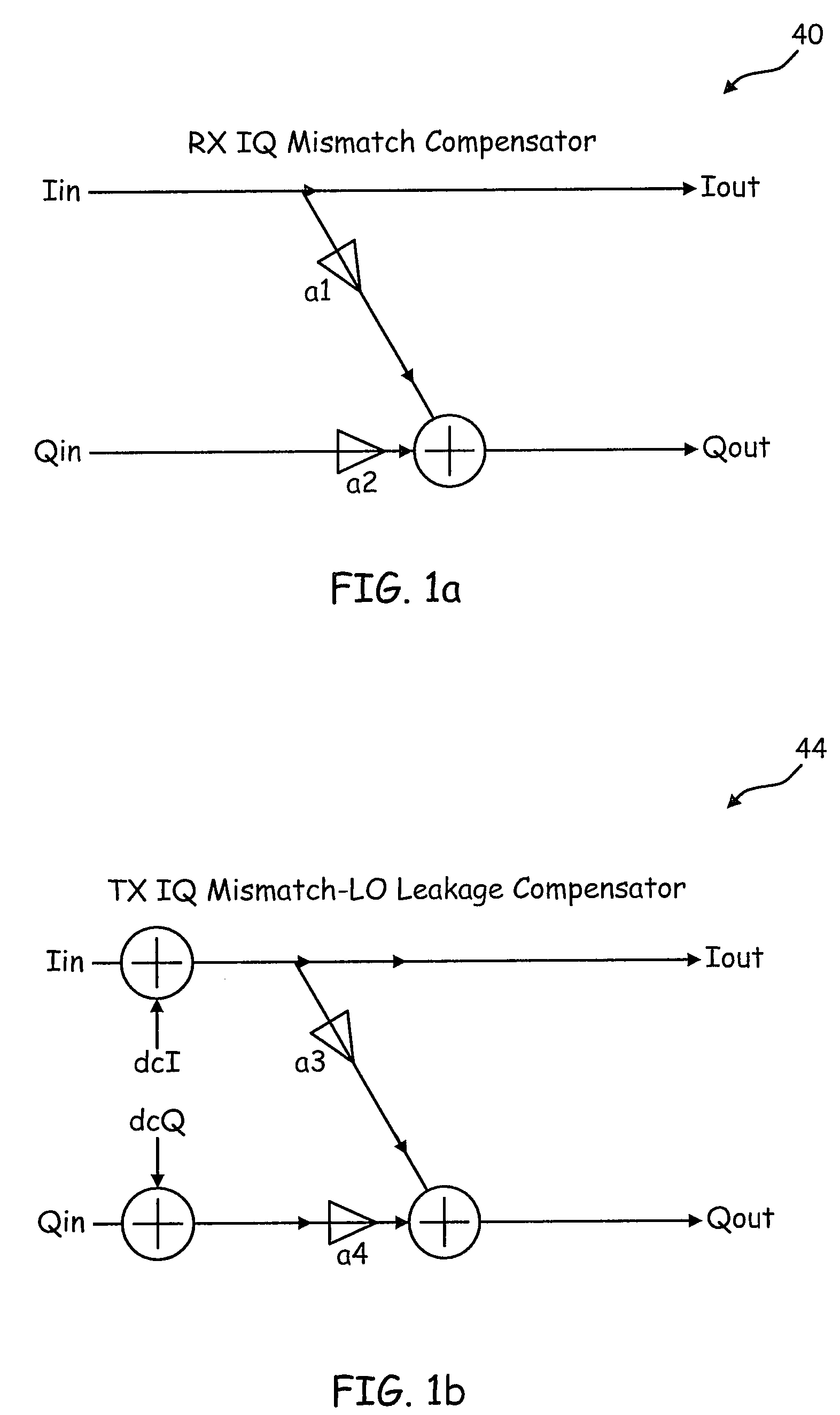

Modified dual band direct conversion architecture that allows extensive digital calibration

ActiveUS20060178165A1MinimizesSufficient performanceResonant long antennasSpatial transmit diversityTransceiverDouble frequency

A dual band direct conversion architecture for both the receive (RX) and transmit (TX) path of a communications transceiver that minimizes the transceiver area by sharing common circuits used in both RX and TX paths is disclosed. The transceiver also allows the use of extensive digital calibration in order to achieve performance adequate to support high bit rate modulation schemes.

Owner:AVAGO TECH INT SALES PTE LTD

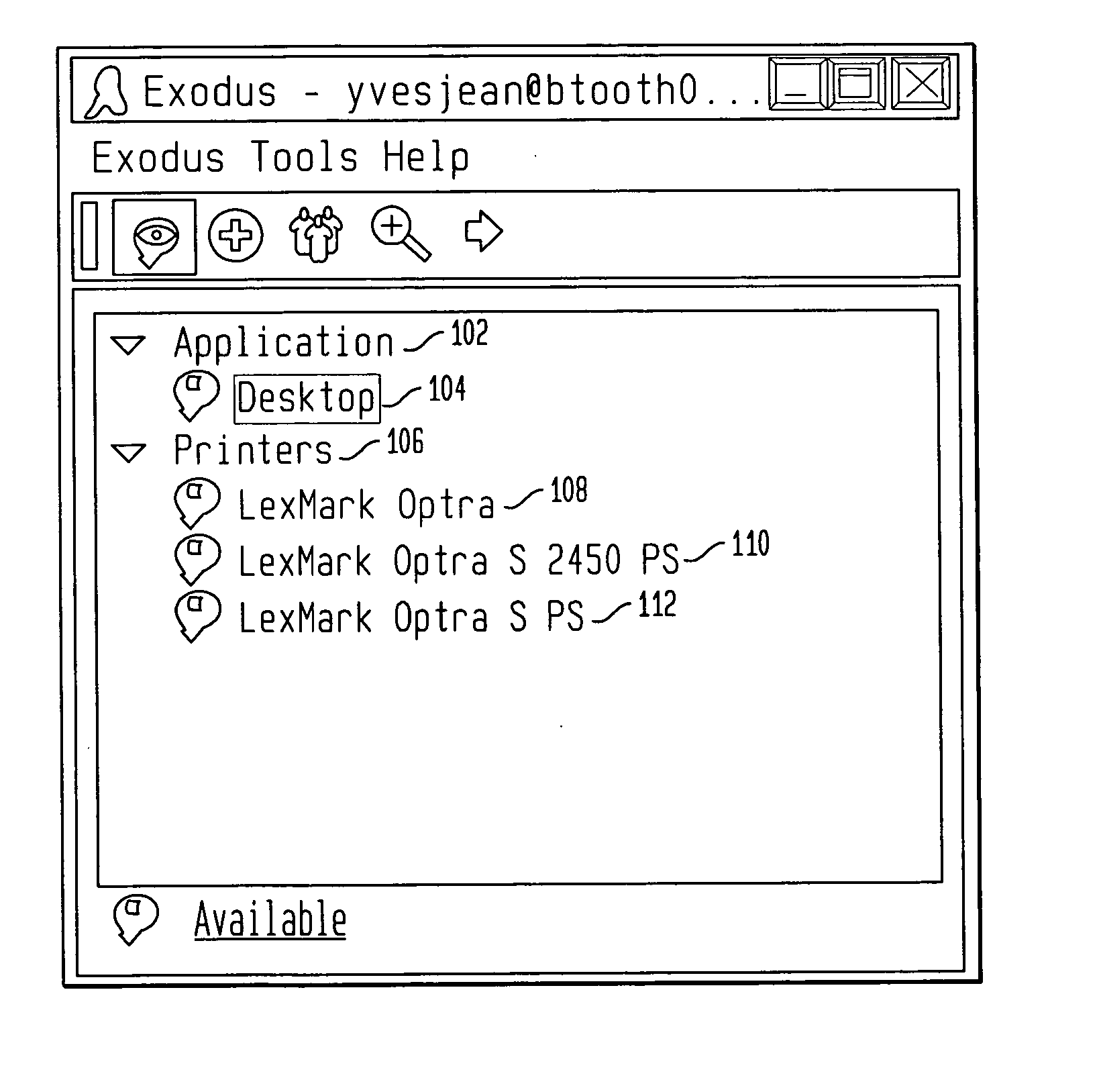

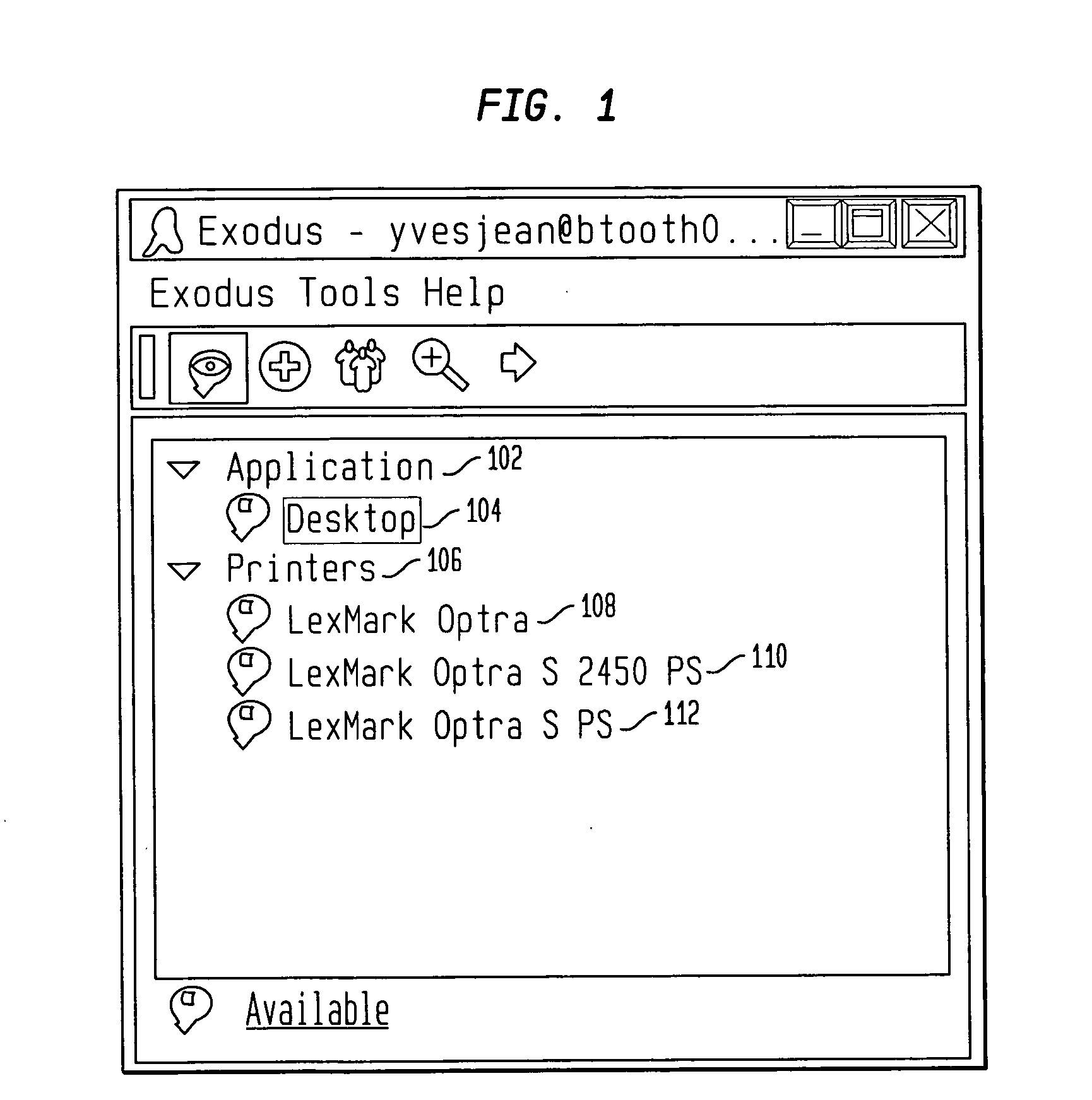

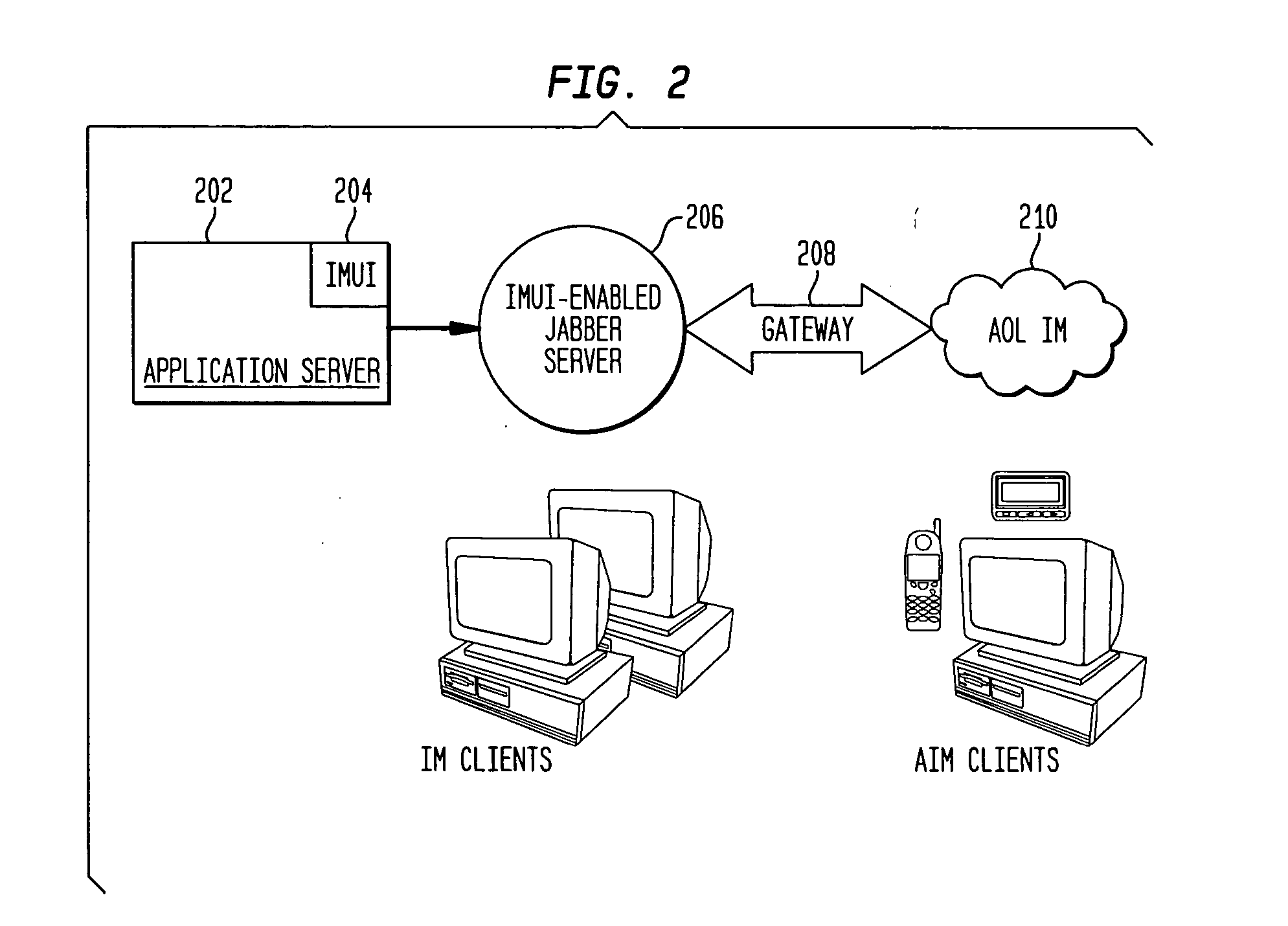

System for presenting applications on instant messaging clients

ActiveUS20050273496A1Easy to useMultiple digital computer combinationsData switching networksGraphicsWeb application

The present invention is a system for accessing applications from even the most basic Instant Message (IM) enabled mobile device. The system utilizes the IM infrastructure of a mobile device to deliver application interfaces and manage the user experience. The invention is particularly applicable to applications with graphical user interfaces (GUI), even typical desktop or web applications. The system performs a direct transformation of application user interfaces into an IM messaging model with minimal functional distortions. The users own application knowledge and experience is leveraged, reducing application customization in the system architecture. The system also incorporates presence-driven mechanisms in the architecture.

Owner:AVAYA INC

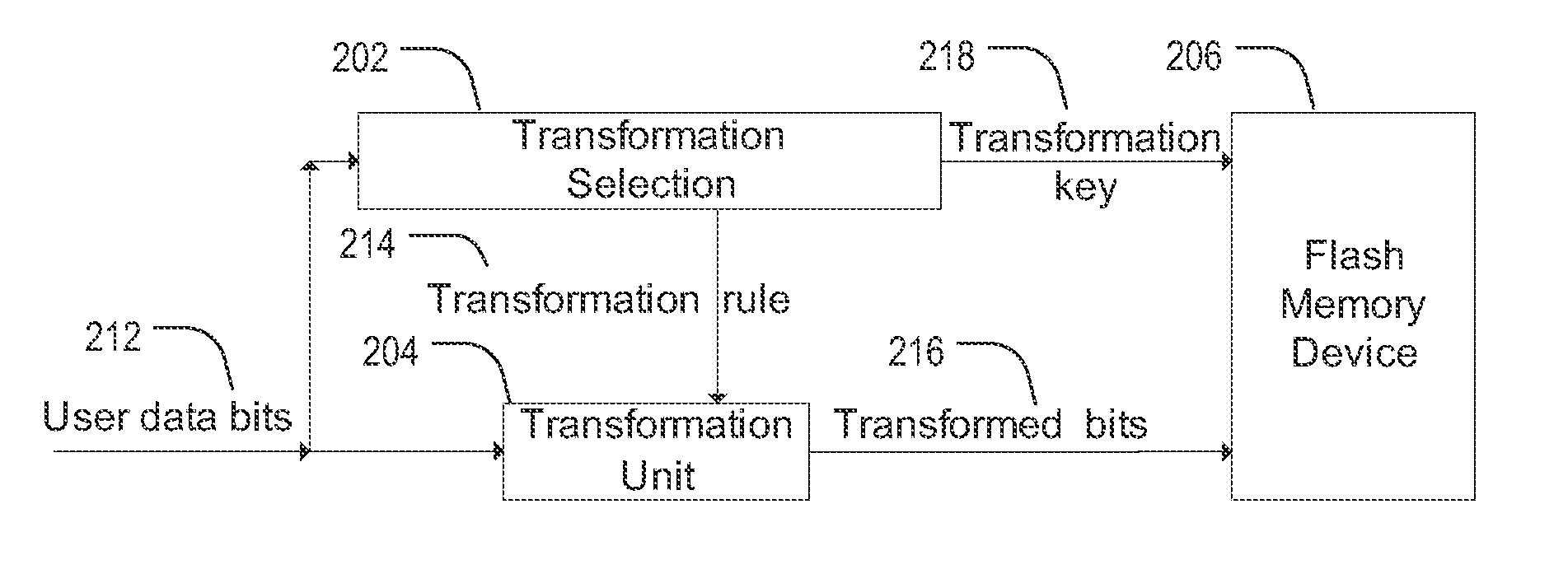

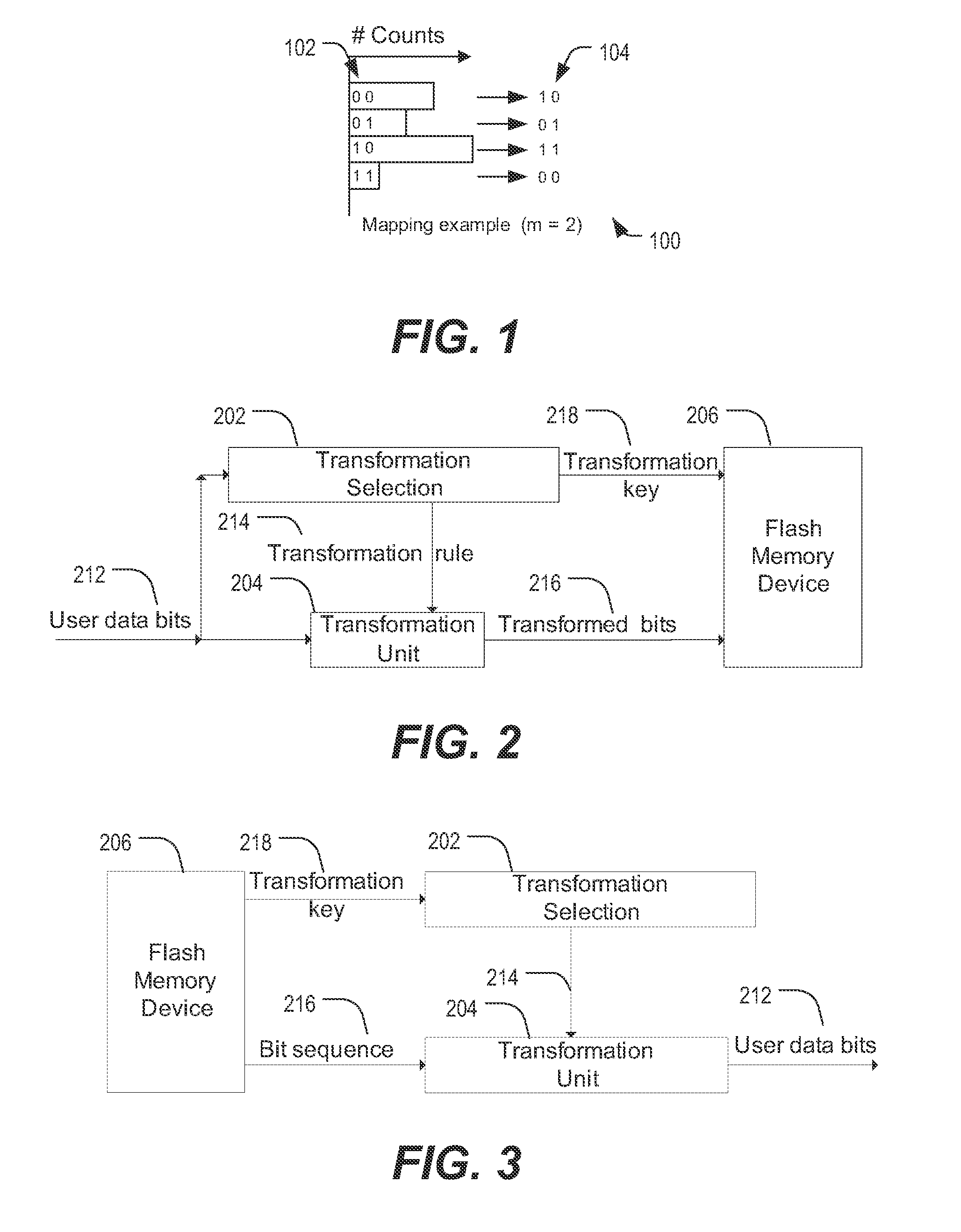

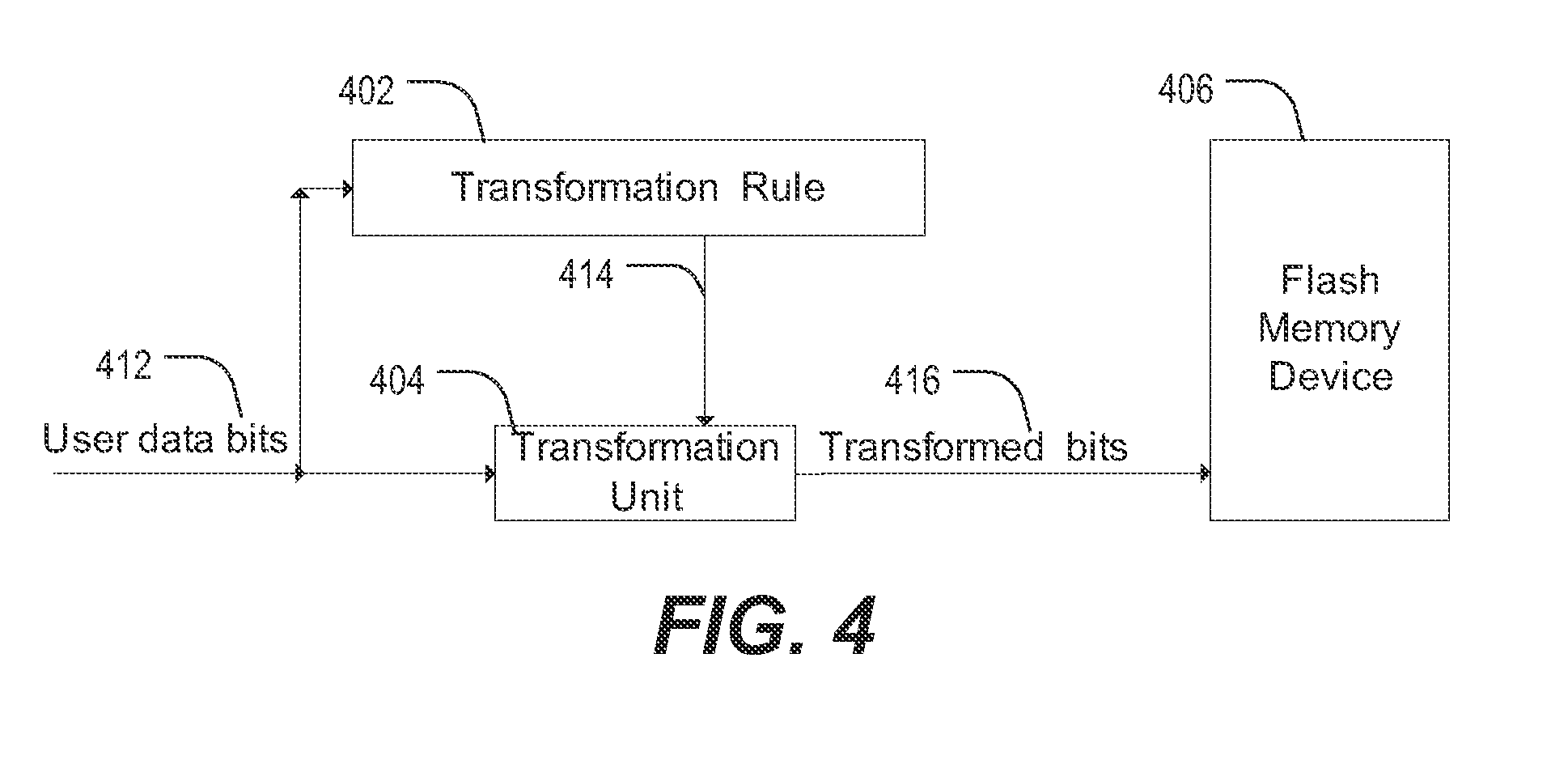

Endurance enhancement coding of compressible data in flash memories

ActiveUS20130103891A1Energy efficient ICTMemory adressing/allocation/relocationError reductionOriginal data

Methods described in the present disclosure may be based on a direct transformation of original data to “shaped” data. The disclosed methods may be performed “on-the-fly” and the disclosed methods may utilize an inherent redundancy in compressible data in order to achieve endurance enhancement and error reduction. In a particular example, a method comprises generating a first portion of output data by applying a mapping of input bit sequences to output bit sequences to a first portion of input data, updating the mapping of the input bit sequences to the output bit sequences based on the first portion of the input data to generate an updated mapping, reading a second portion of the input data, and generating a second portion of the output data by applying the updated mapping of the input bit sequences to the output bit sequences to the second portion of the input data.

Owner:SANDISK TECH LLC

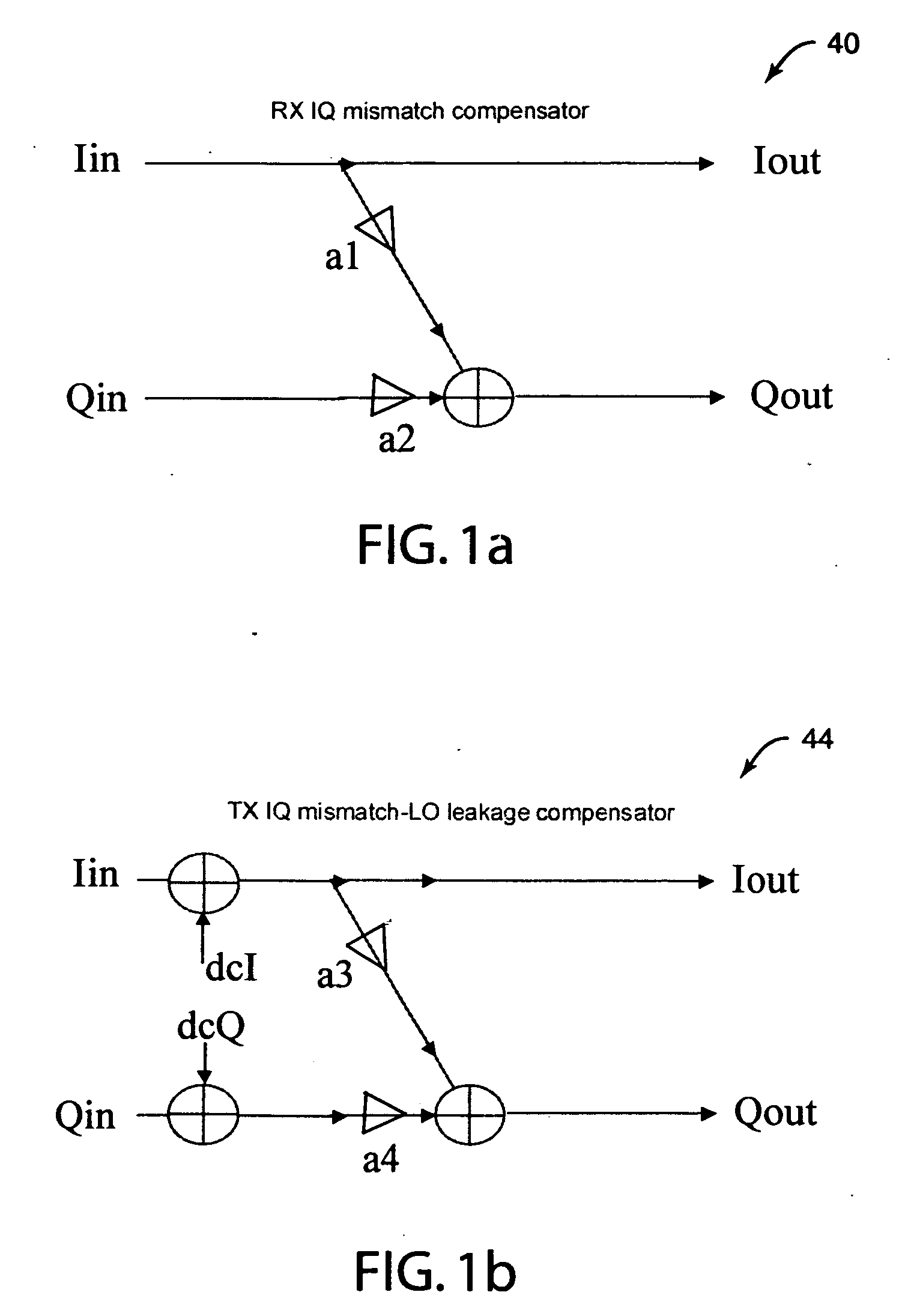

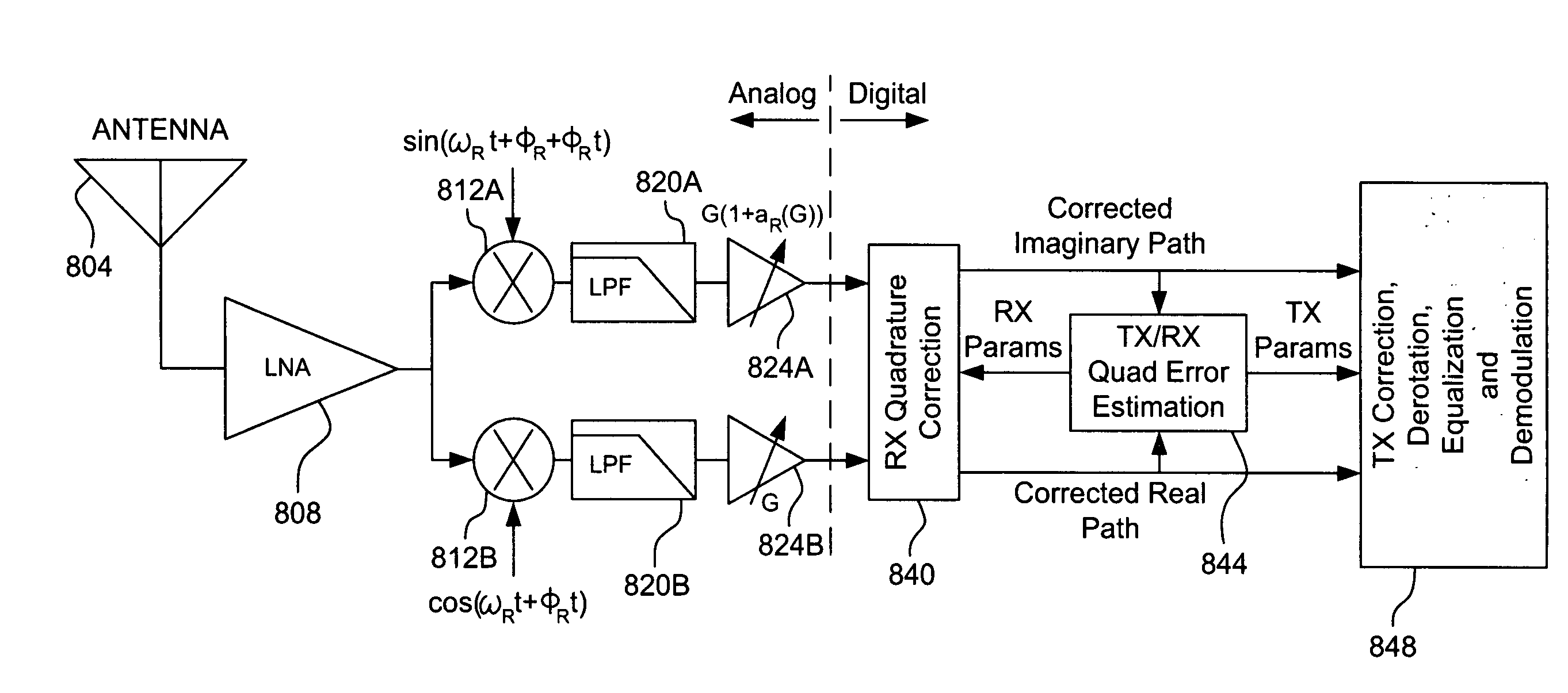

Imbalance compensation for direct conversion communication systems

ActiveUS20100272208A1Reduce the impactReduce and remove transmitter imbalanceSimultaneous amplitude and angle modulationFrequency/rate-modulated pulse demodulationTransceiverEngineering

Most modern integrated circuit transceivers, especially wireless LAN, utilize a direct conversion radio architecture, which is highly advantageous from the perspectives of cost and flexibility, there exist several performance impairments, including gain and phase imbalances between the in-phase (I) and quadrature (Q) of a transmitter or receiver. Disclosed herein is a signal processing methodology and system for compensation of I / Q imbalance for a direct conversion packet-switched OFDM communications system. The imbalance, which accounts for transmitter I / Q imbalance, RX I / Q imbalance, phase / frequency error, and dispersive multipath fading. Both frequency dependent I / Q imbalance and frequency independent cases are considered, covering both wideband and narrowband modulation. The proposed estimation algorithms operate within the fully compliant framework of existing multi-user OFDM radio standards (WLAN, LTE, WimAX). These algorithms accurately estimate and correct transceiver I / Q imbalance on a packet-by-packet basis, all within the receiver's digital baseband.

Owner:SKYWORKS SOLUTIONS INC

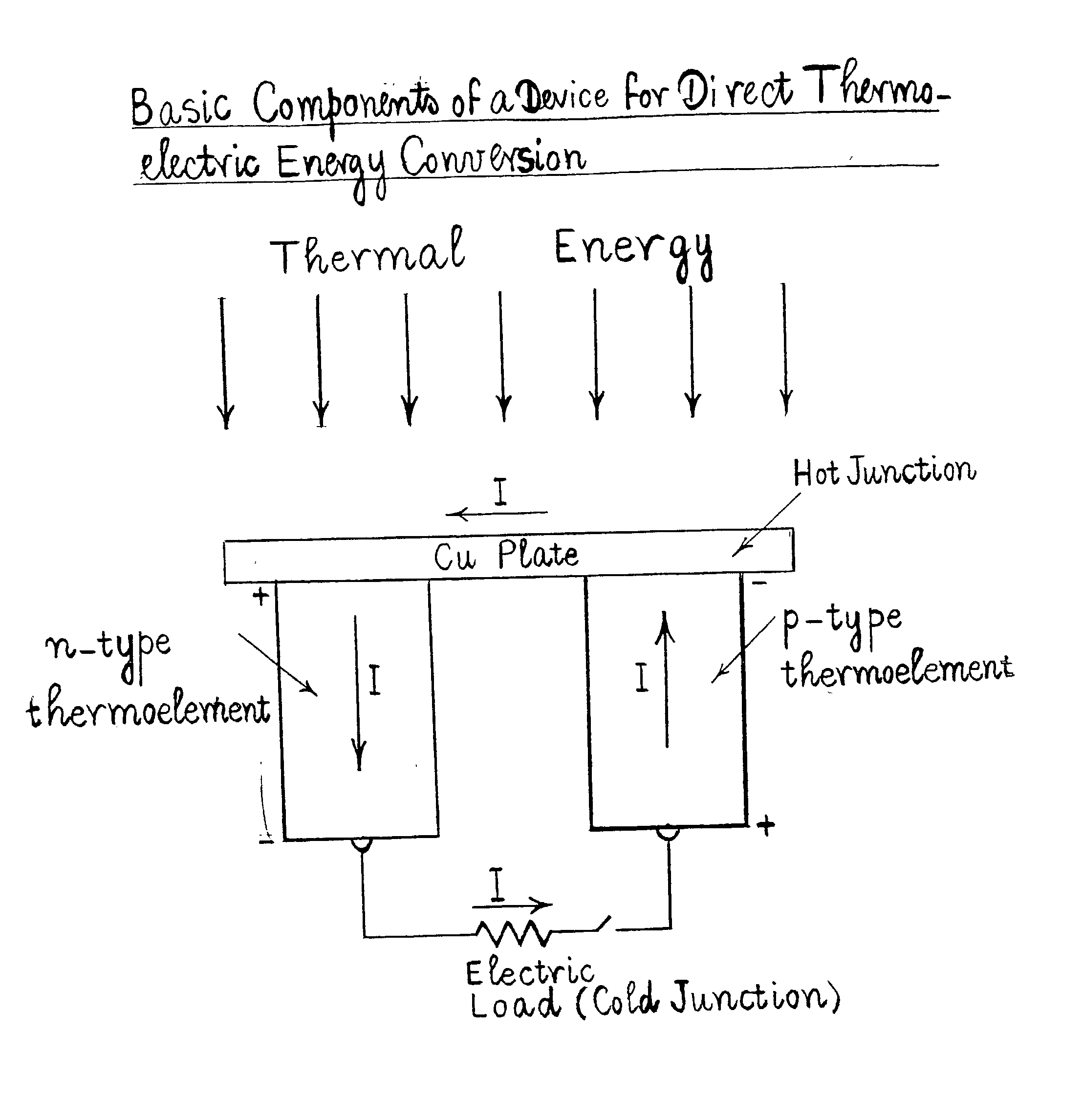

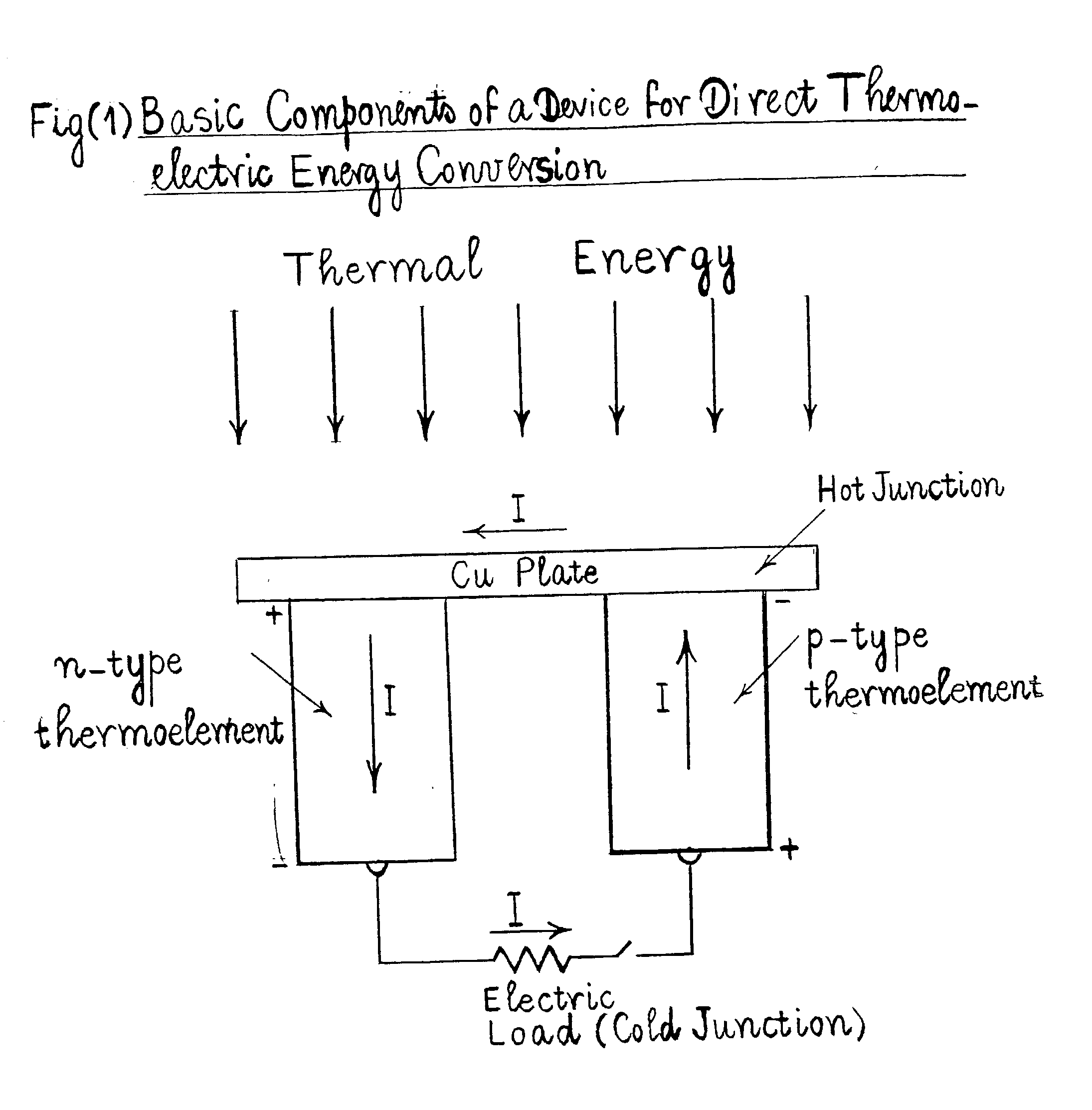

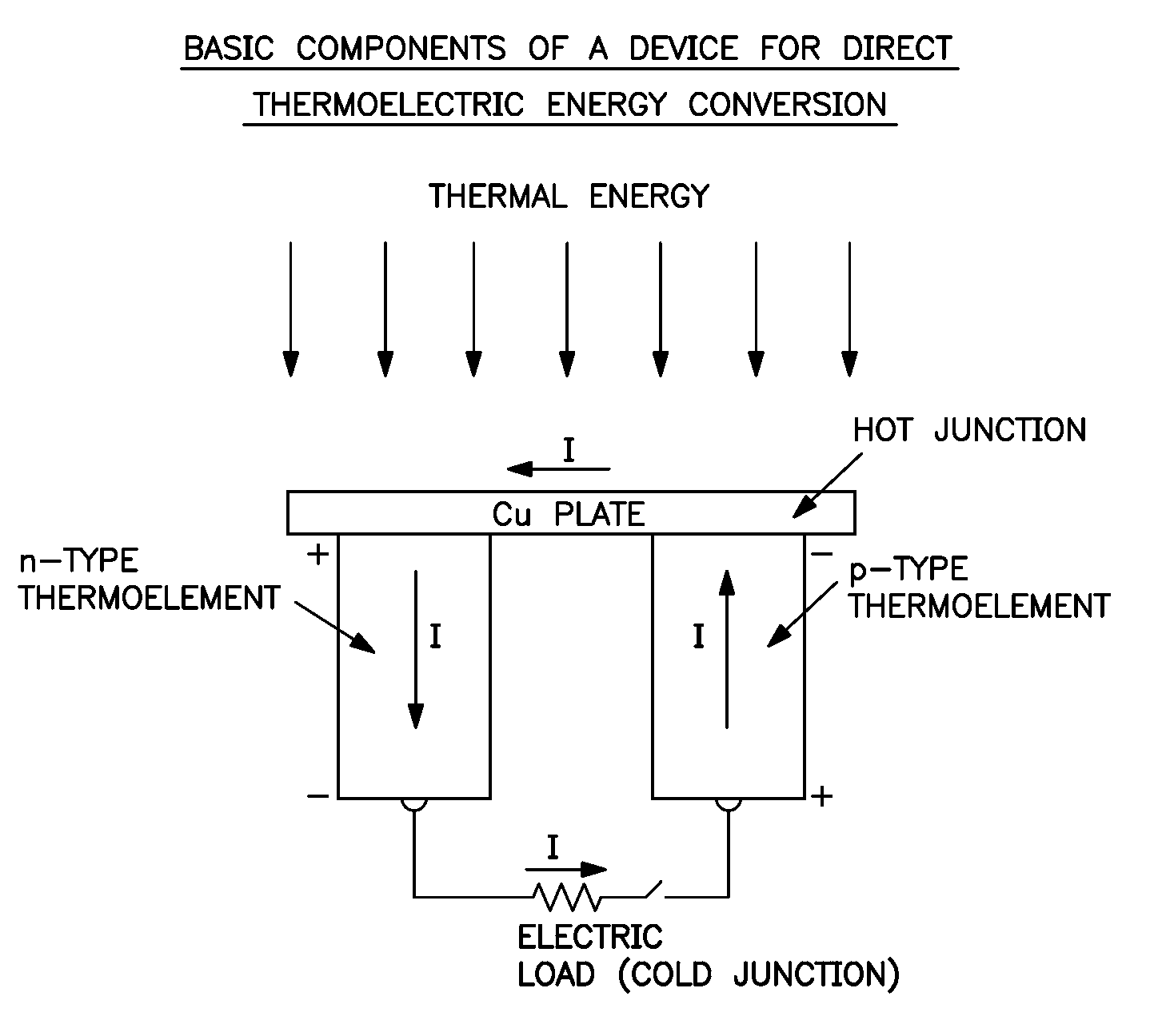

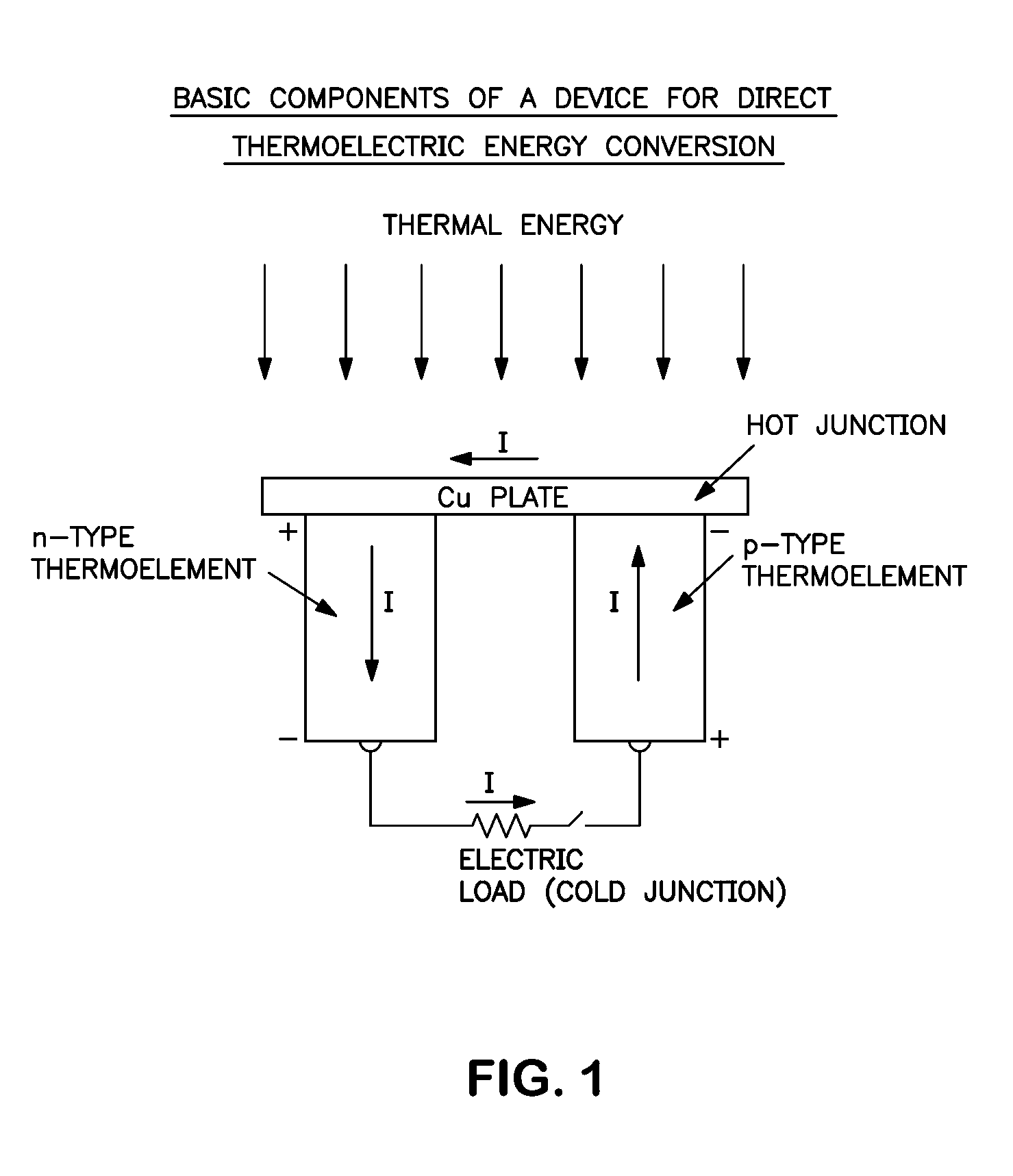

Method for producing a device for direct thermoelectric energy conversion

InactiveUS20030110892A1Polycrystalline material growthThermoelectric device manufacture/treatmentJunction temperatureEngineering

In devices used for the direct conversion of heat into electricity, or vice versa, known in the art as thermoelectric power generators, thermoelectric refrigerators and thermoelectric heat pumps, the efficiency of energy conversion and / or coefficient of performance have been considerably lower than those of conventional reciprocating or rotary, heat engines and / or vapor-compression systems, employing certain refrigerants. The energy conversion efficiency of power generating devices, for example, aside from the hot and cold junction temperatures, also depends on a parameter known in the art as the thermoelectric figure of merit Z=S2sigma / k, where S is the thermoelectric power, sigma is the electrical conductivity and k is the thermal conductivity, of the material that constitutes the p-type, and / or n-type, thermoelements, or branches, of the said devices. In order to achieve a considerable increase in the energy conversion efficiency, a thermoelectric figure of merit of the order of 10-2 K-1, or more, is needed. It is reasonably expected that such an order of magnitude, for the figure of merit, can be realized with a composition of matter, comprising magnesium, silicon, lead and barium, and optionally comprising one, or more, additional doping materials.

Owner:NICOLOAU MICHAEL C

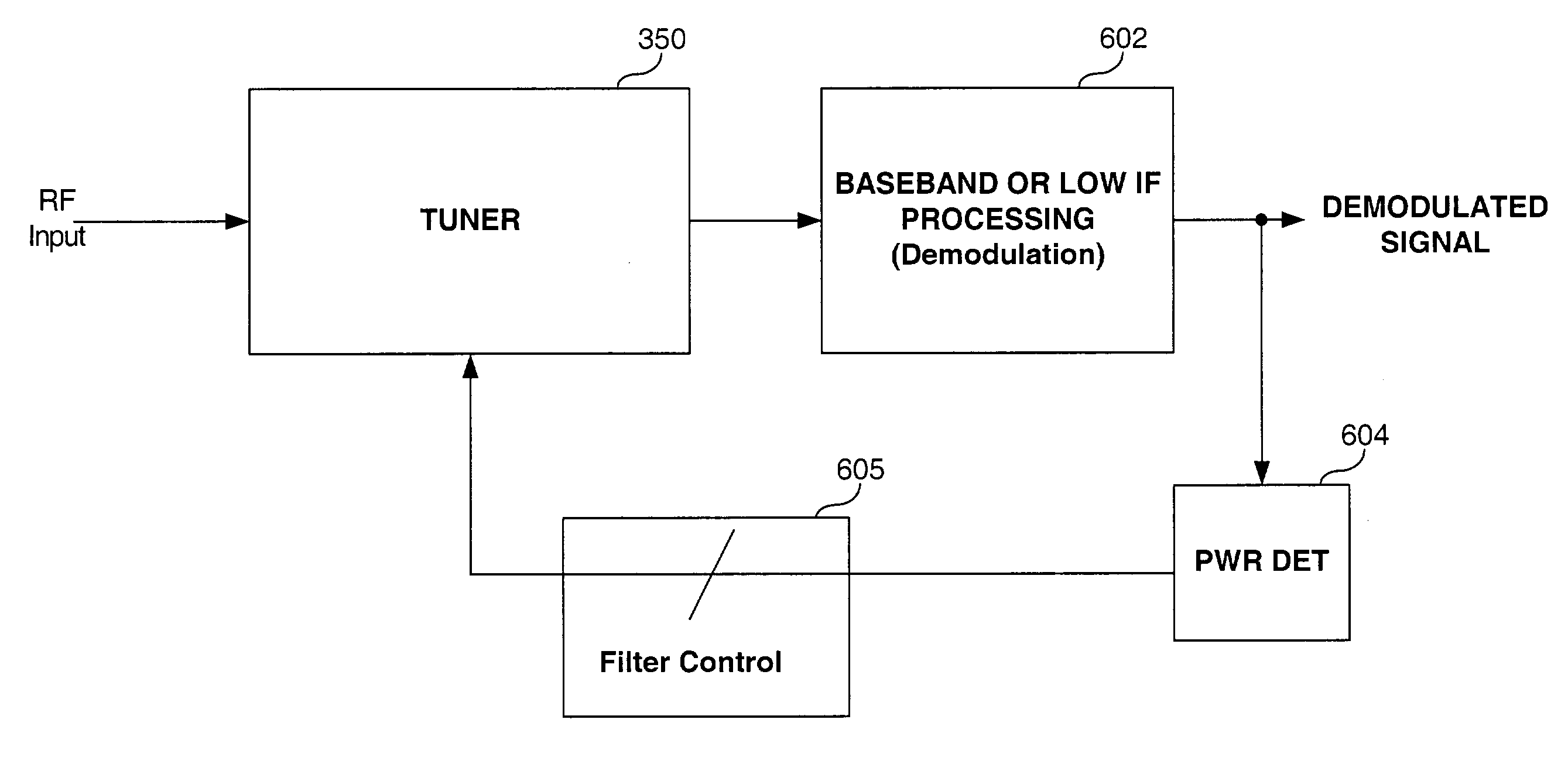

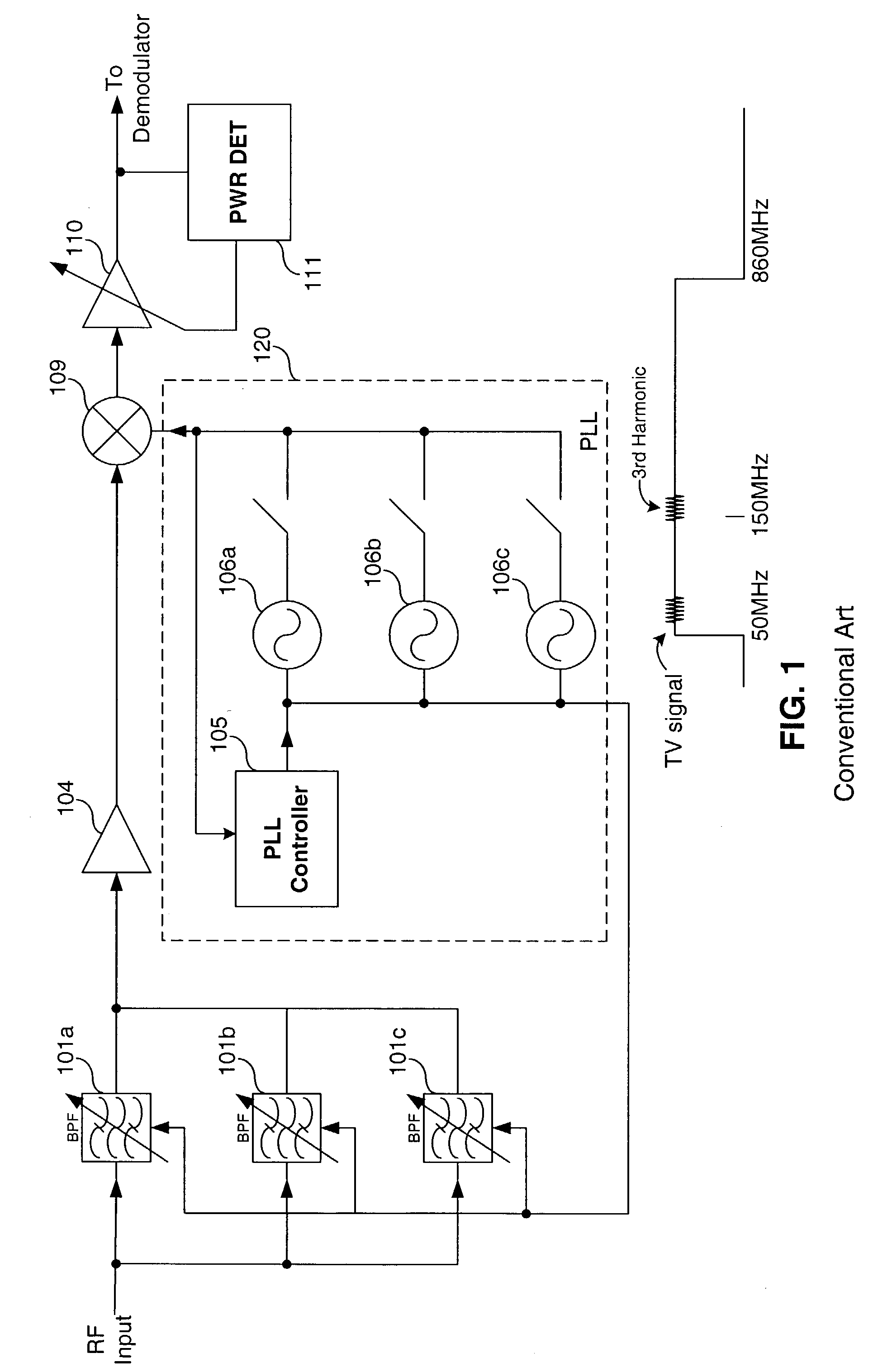

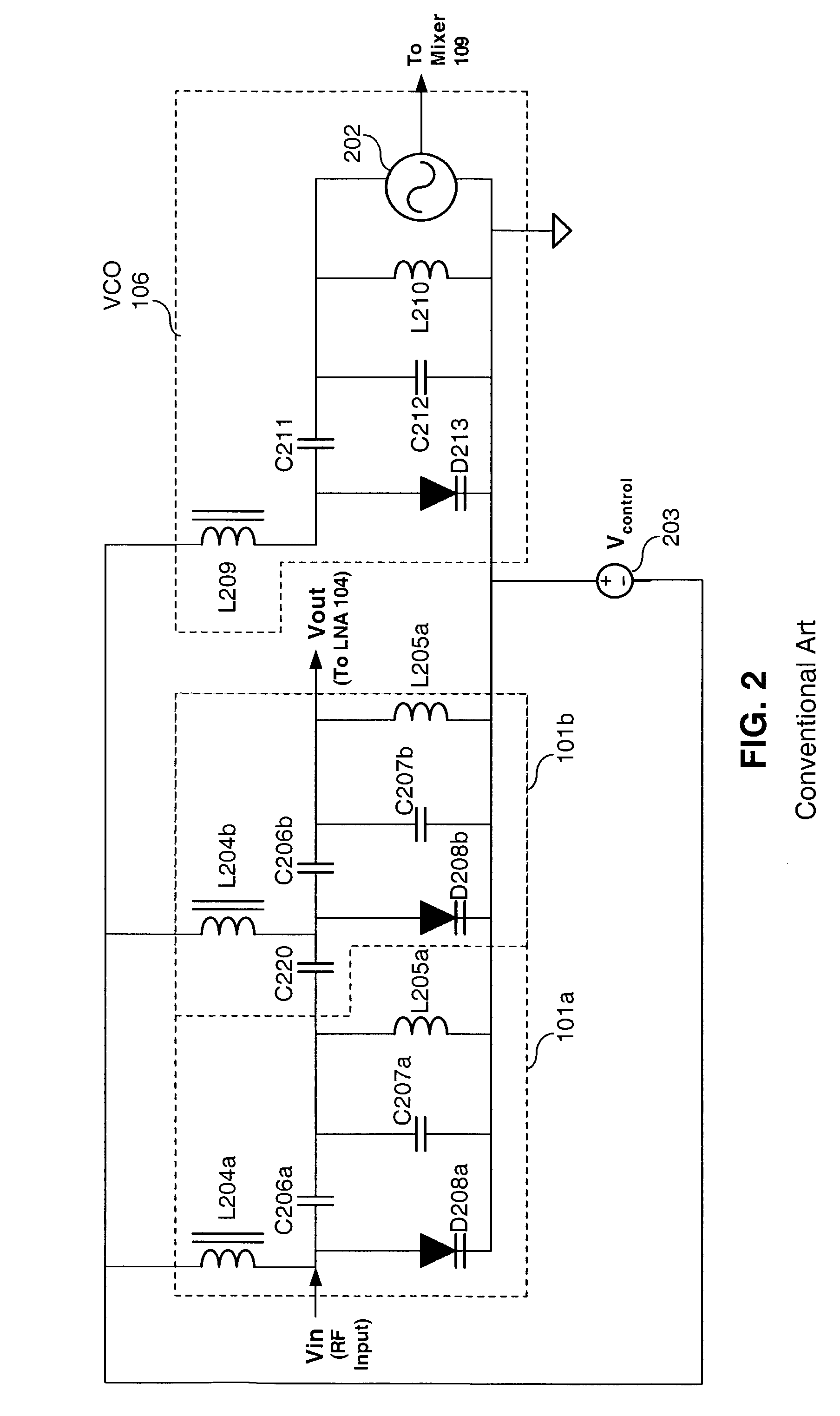

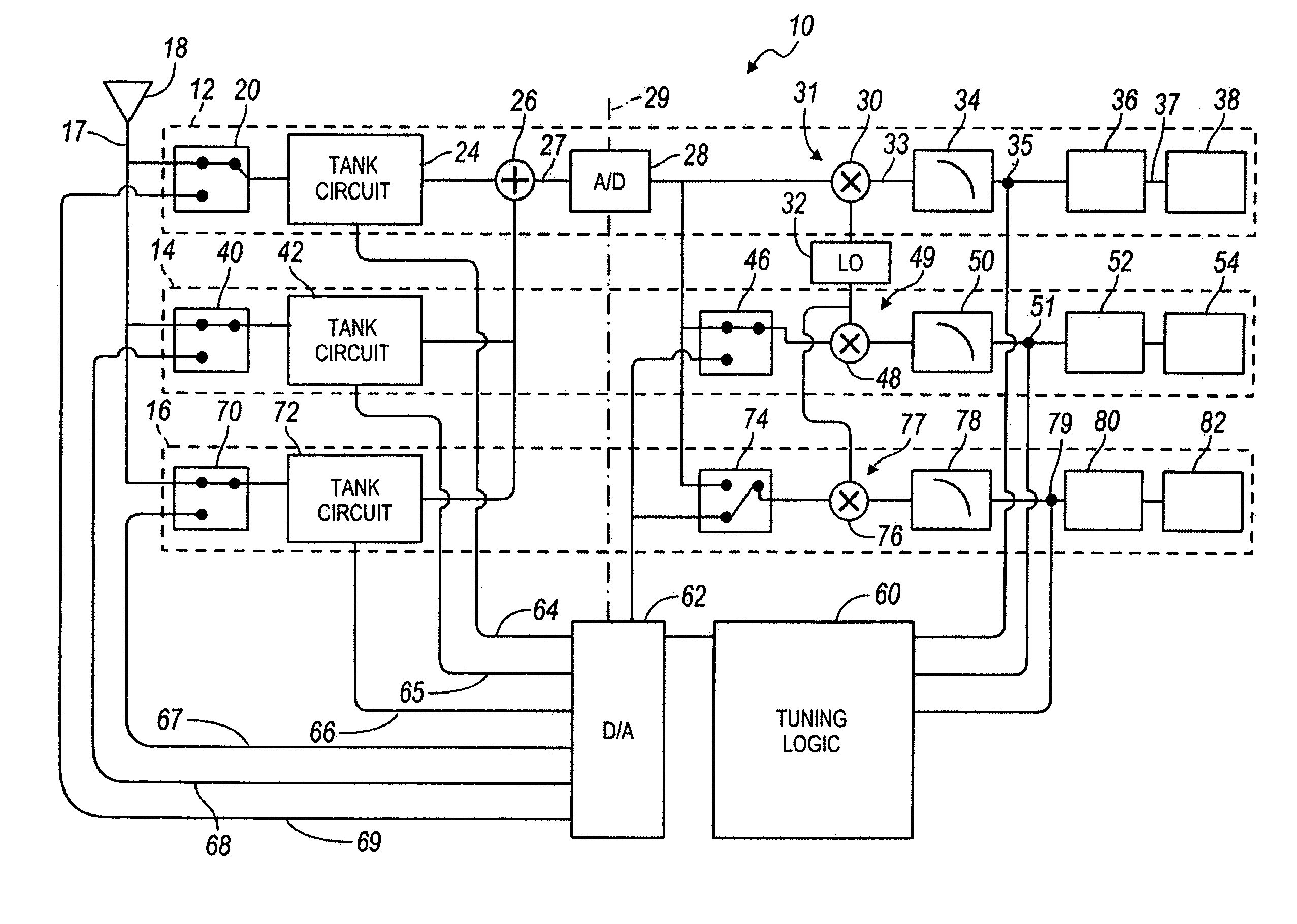

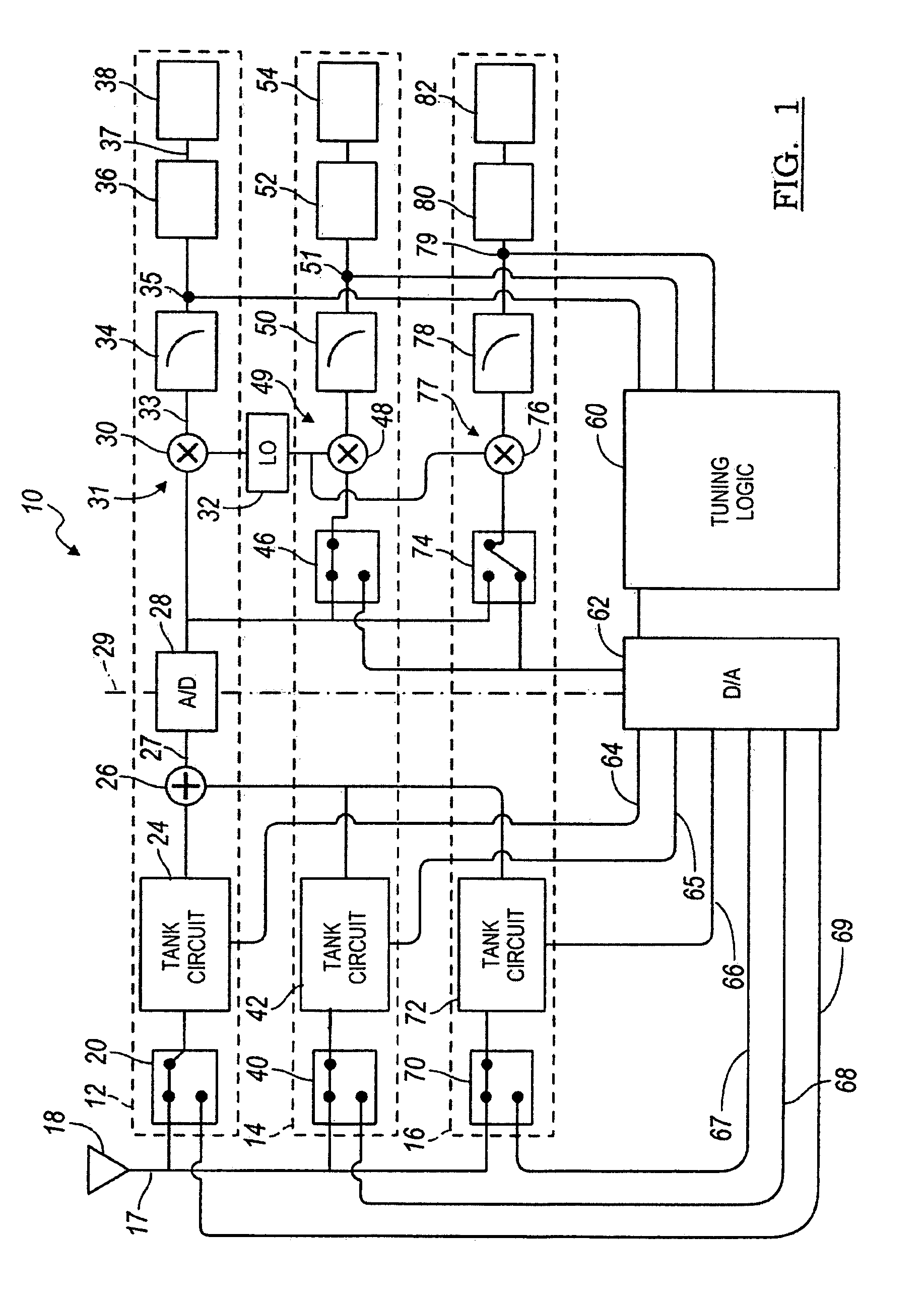

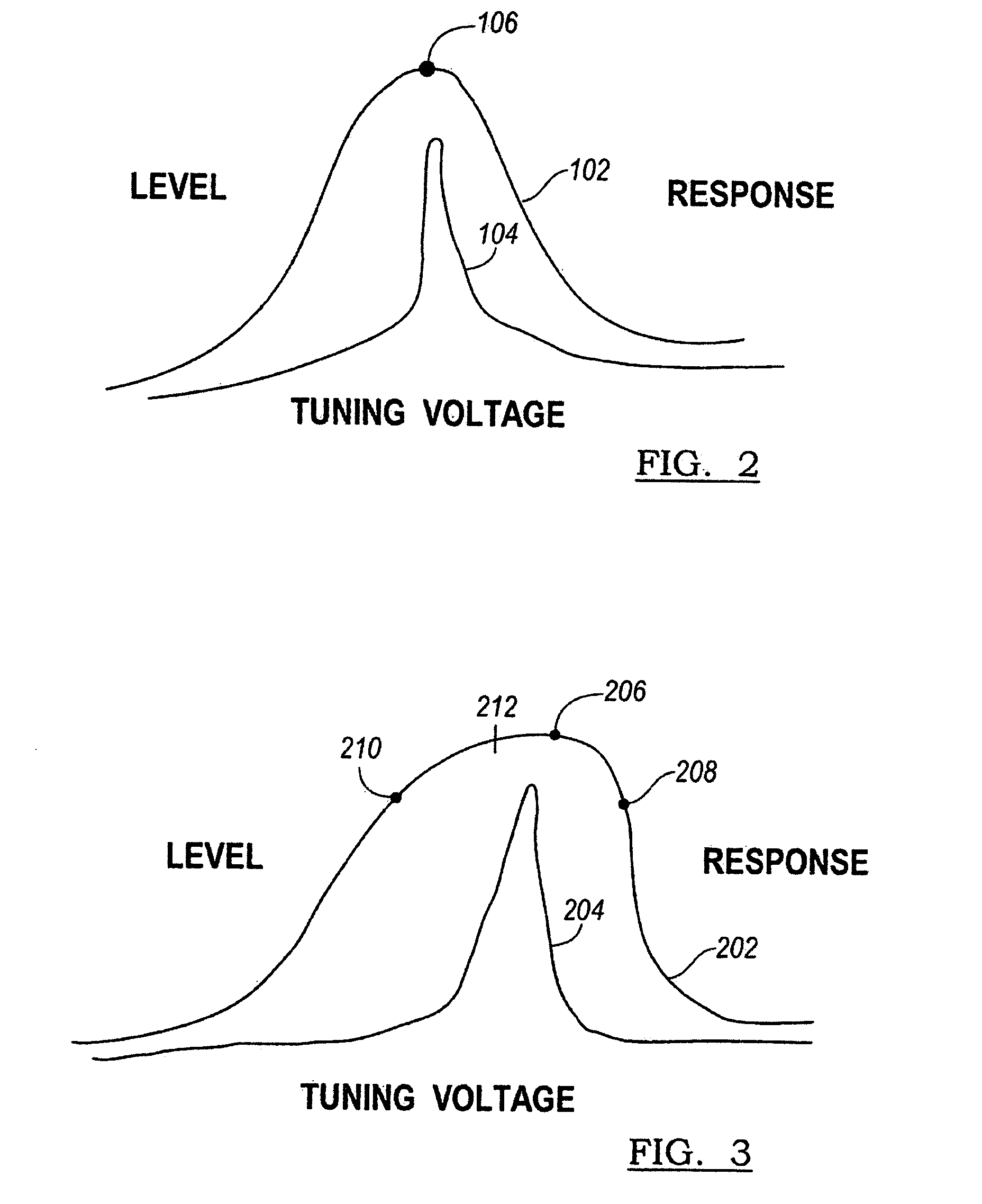

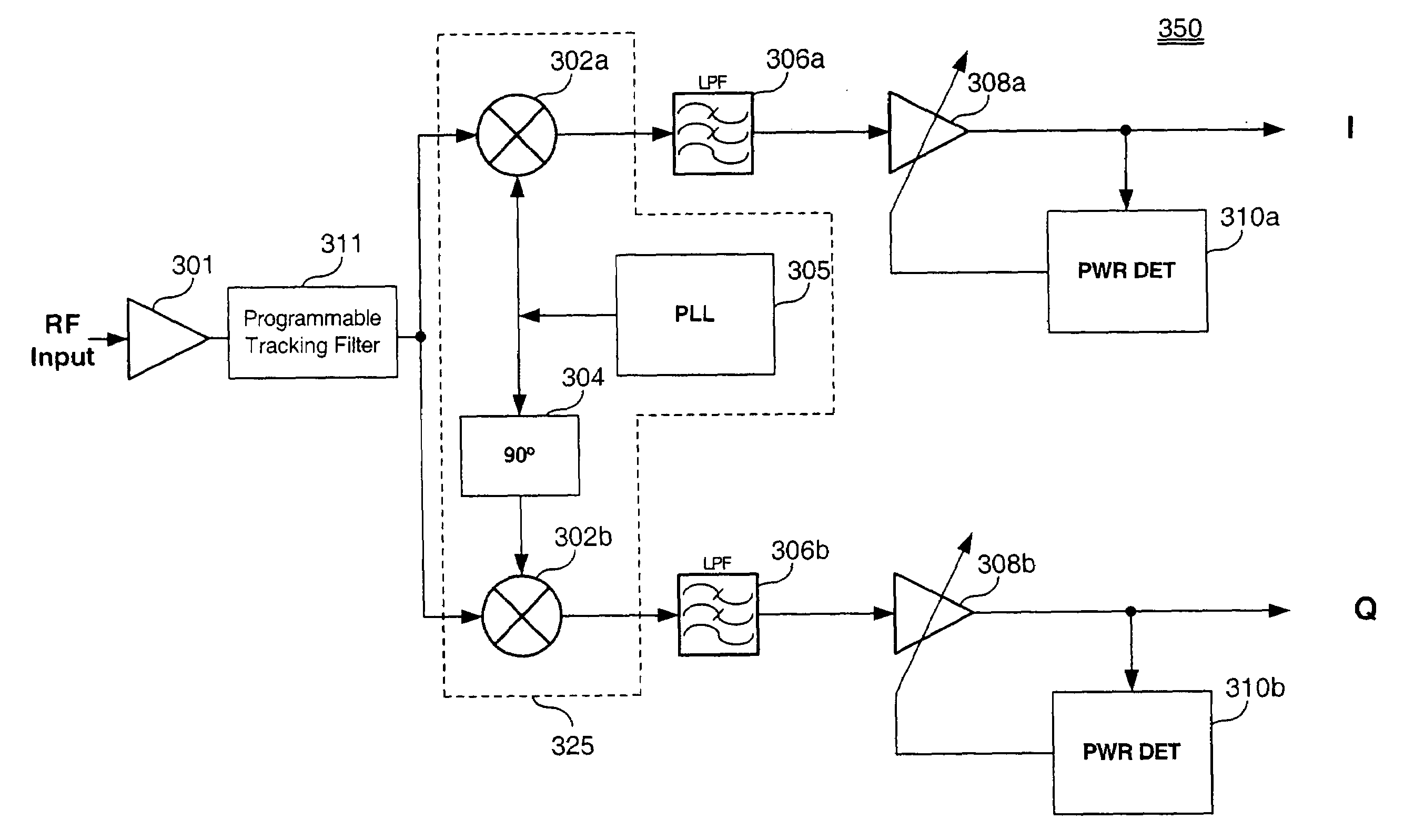

Integrated tracking filters for direct conversion and low-IF single conversion broadband filters

ActiveUS7336939B2Radio transmissionTransmission noise suppressionAudio power amplifierVariable-gain amplifier

A radio frequency (RF) tuner includes a programmable tracking filter bank receiving an RF input and outputting a filtered RF signal. A mixer stage receives the filtered RF signal and outputs a first quadrature component of the filtered RF signal and a second quadrature component of the filtered RF signal. Two variable gain amplifiers receive the first and second quadrature components and output amplitude-controlled I and Q components of the filtered RF signal. In one embodiment, the programmable tracking filter bank includes a plurality of tank circuits each connected to the RF input through an impedance. Each tank circuit include an inductor and a capacitor connected in parallel thereby forming an LC network, and a plurality of switched capacitors in parallel with the LC network and switched in and out of the tank circuit by programmable switches. In another embodiment, the programmable tracking filter bank includes a plurality of peaked low-pass circuits each connected to the RF input through an impedance. Each peaked low-pass circuit includes a capacitor connected to ground, and a plurality of switched capacitors in parallel with the capacitor and switched in and out of the peaked low-pass circuit by programmable switches.

Owner:AVAGO TECH INT SALES PTE LTD

Method for producing a device for direct thermoelectric energy conversion

InactiveUS7166796B2Improve energy conversion efficiencyReduced dimensionPolycrystalline material growthThermoelectric device manufacture/treatmentJunction temperatureEngineering

In devices used for the direct conversion of heat into electricity, or vice versa, known in the art as thermoelectric power generators, thermoelectric refrigerators and thermoelectric heat pumps, the efficiency of energy conversion and / or coefficient of performance have been considerably lower than those of conventional reciprocating or rotary, heat engines and / or vapor-compression systems, employing certain refrigerants. The energy conversion efficiency of power generating devices, for example, aside from the hot and cold junction temperatures, also depends on a parameter known in the art as the thermoelectric figure of merit Z=S2σ / k, where S is the thermoelectric power, σ is the electrical conductivity and k is the thermal conductivity, of the material that constitutes the p-type, and / or n-type, thermoelements, or branches, of the said devices. In order to achieve a considerable increase in the energy conversion efficiency, a thermoelectric figure of merit of the order of 10−2 K−1, or more, is needed. It is reasonably expected that such an order of magnitude, for the figure of merit, can be realized with a composition of matter, comprising magnesium, silicon, lead and barium, and optionally comprising one, or more, additional doping materials.

Owner:NICOLOAU MICHAEL C

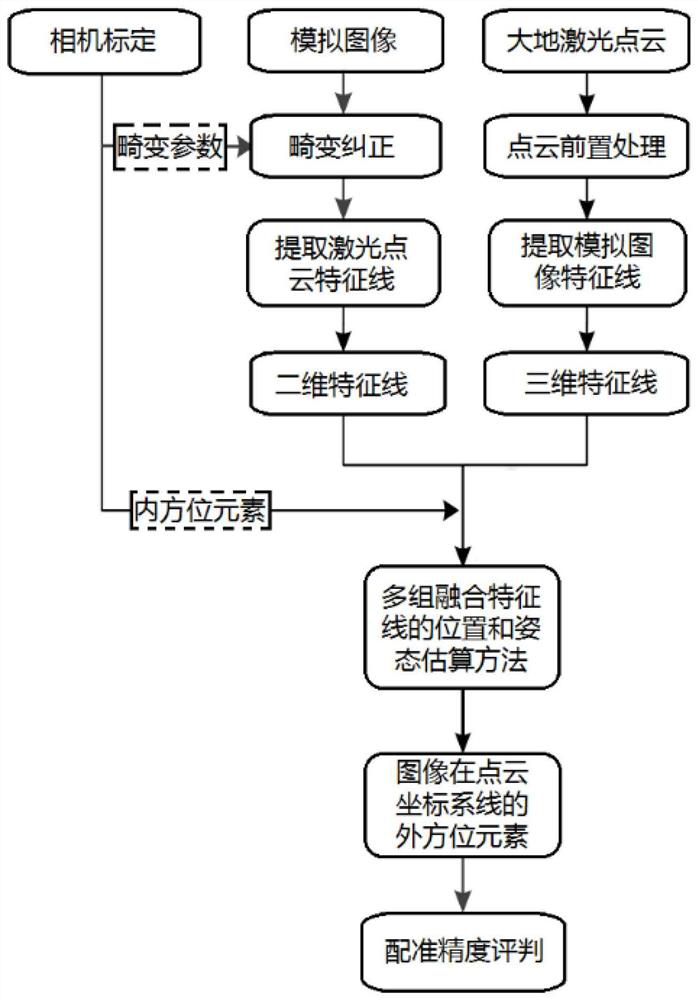

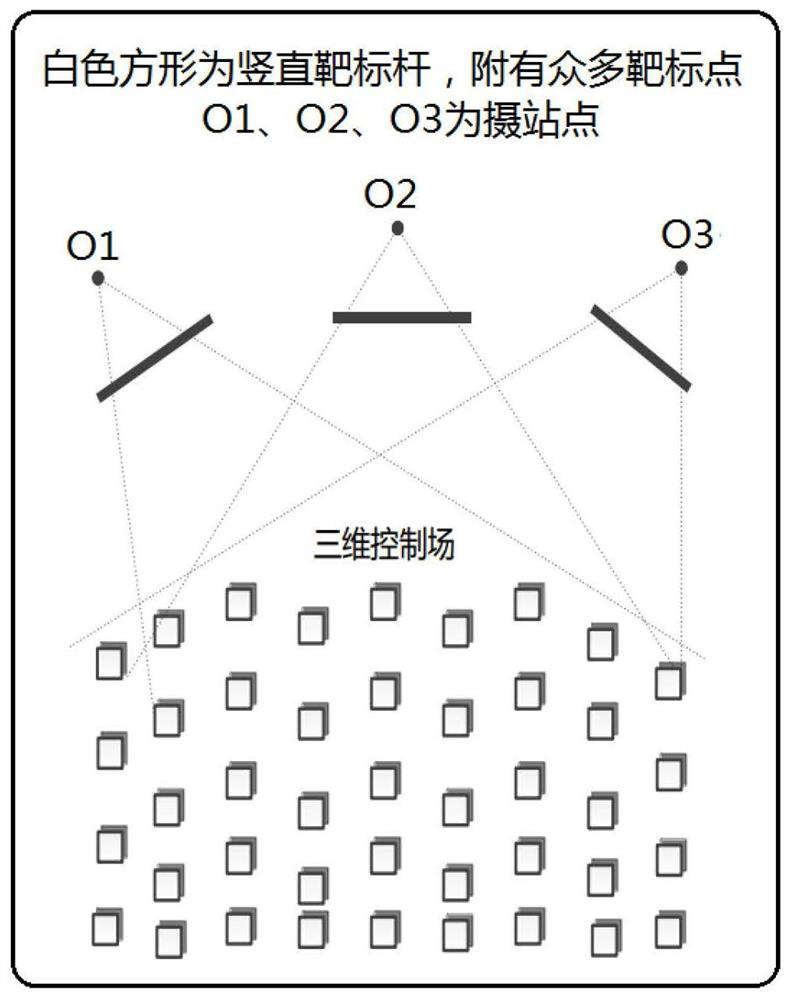

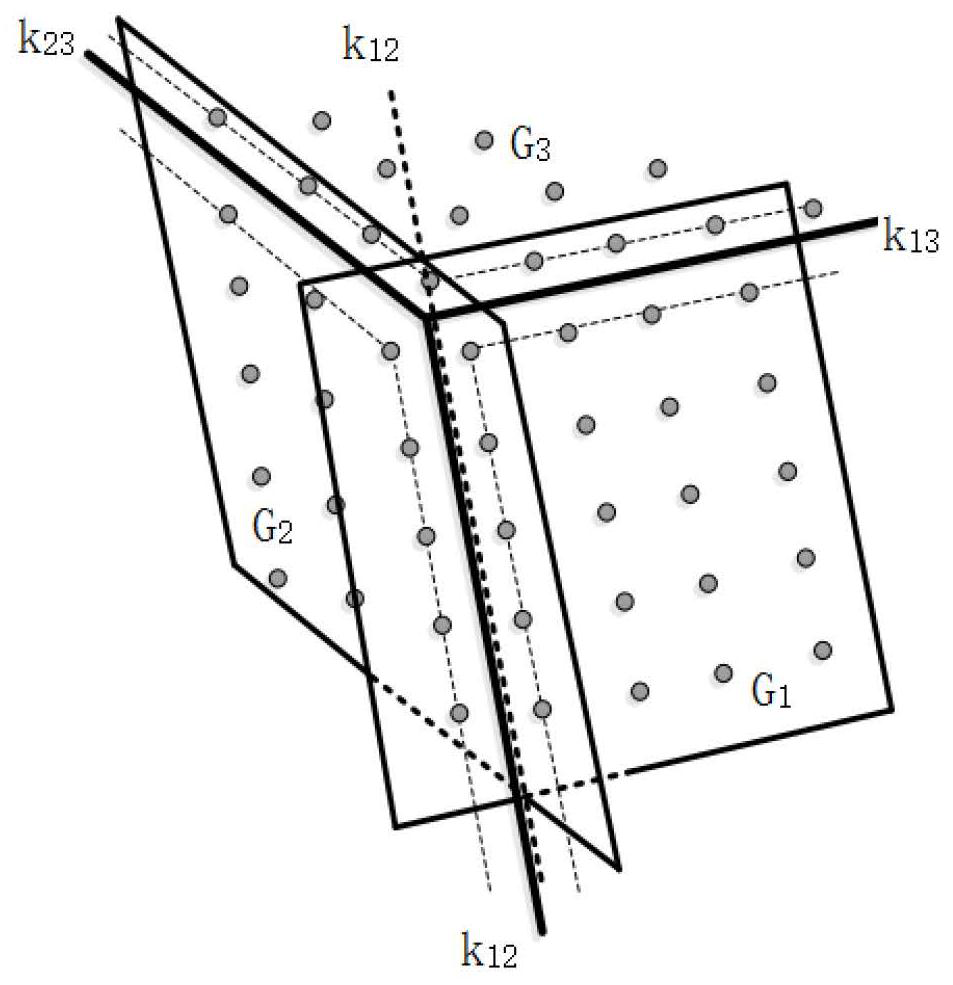

Feature line fused laser point cloud and analog image registration method

PendingCN111709981AImprove binding abilityRealize automatic matchingImage enhancementImage analysisPattern recognitionPoint cloud

The invention provides a feature line fused laser point cloud and analog image registration method, and aims to solve the problems that a point cloud distance intensity image or point feature-based image and point cloud registration method in the prior art has many defects of manual point selection errors, point cloud data interpolation errors, need of many observation values and the like, and theprecision is very limited. The invention provides a laser point cloud and analog image registration method based on two-dimensional and three-dimensional fusion characteristic lines. The method comprises the steps of: establishing a direct transformation model between the image feature line and the point cloud feature line. The requirement on the initial value of the exterior orientation elementof the image is not harsh, the method has high robustness to noise, realizes automatic matching of two-dimensional and three-dimensional fusion features, improves the degree of automation, achieves higher real-time performance, has the advantages of no model error, no need of exterior orientation element initial values, only need of a small number of registration elements and the like, is high incalculation speed, and meets the registration requirements of analog images and ground laser point cloud data.

Owner:高小翎

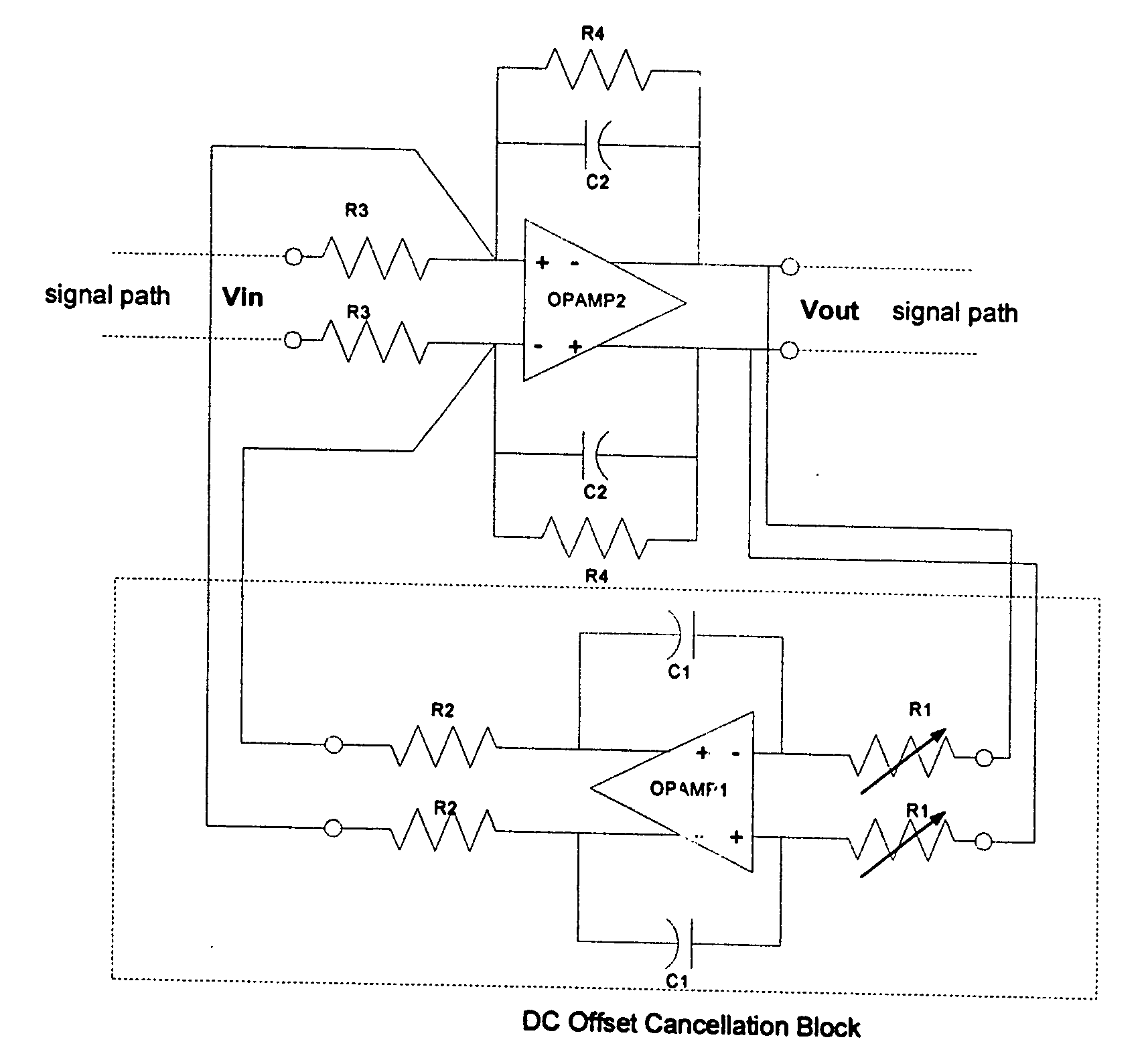

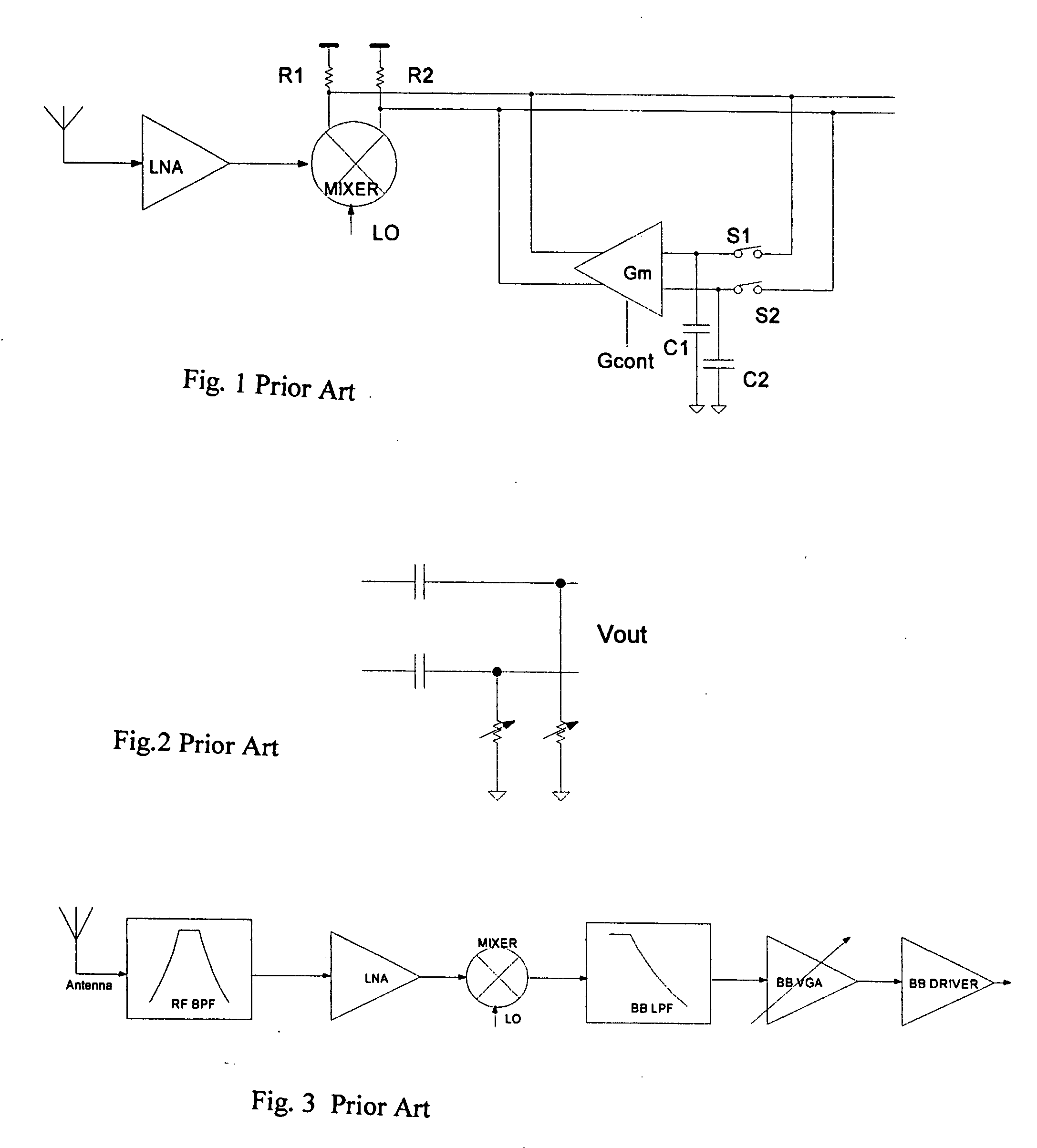

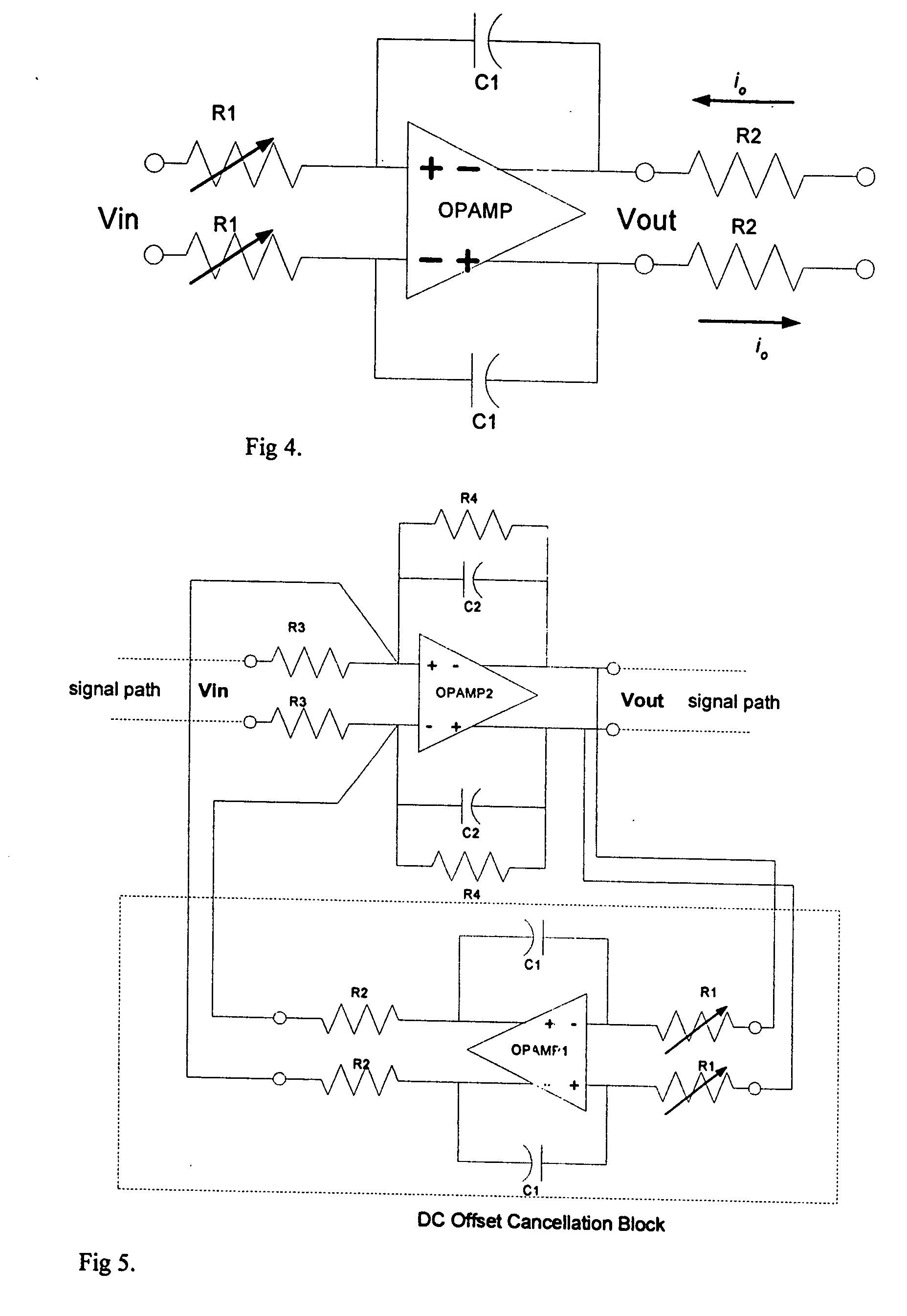

DC offset cancellation in a direct-conversion receiver

InactiveUS20050110550A1Reduce silicon areaSave powerPulse automatic controlDifferential amplifiersCapacitanceIntegrator

The DCOC block is used in ZIF BB to form HPF function to cancel dc offset with a penalty of small silicon area and low power consumption. It is a LPF plus a voltage to current conversion (VIC) resistor, and can hook up with any BB opamp used in signal path, to form a feedback loop, with or without signal gain stages in the loop. The BB opamp is used as a summing point. The summing method is input current summing. The cutoff frequency of the HPF function is thus defined by the integrator, the VIC resistor, and the feedback resistor in the summing opamp. The presence of the VIC resistor can drastically reduce the integrator capacitor and resistor values and thus save silicon area or improve receiver performance.

Owner:PROMINENT COMM

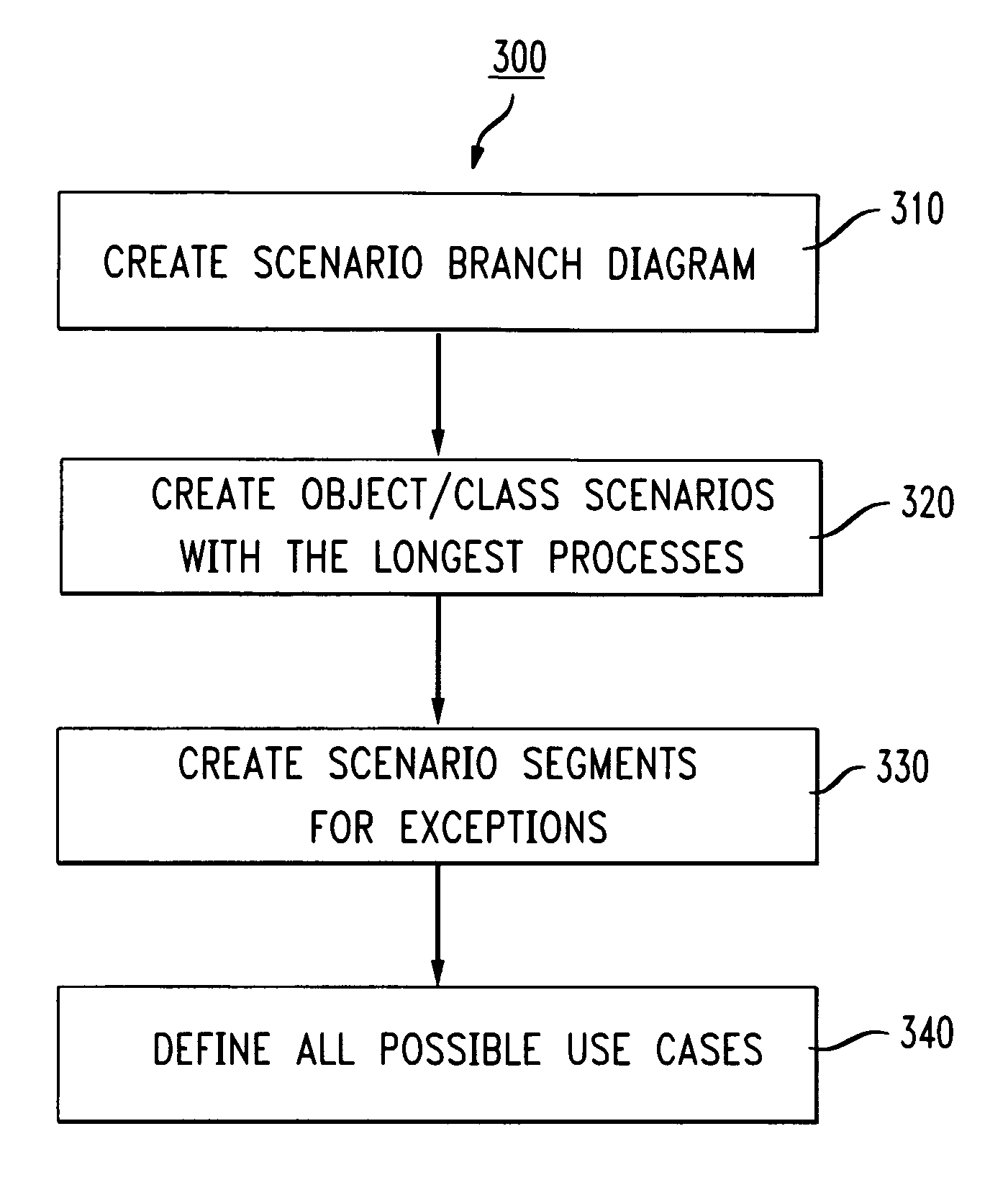

Suite of metrics for software quality assurance and product development

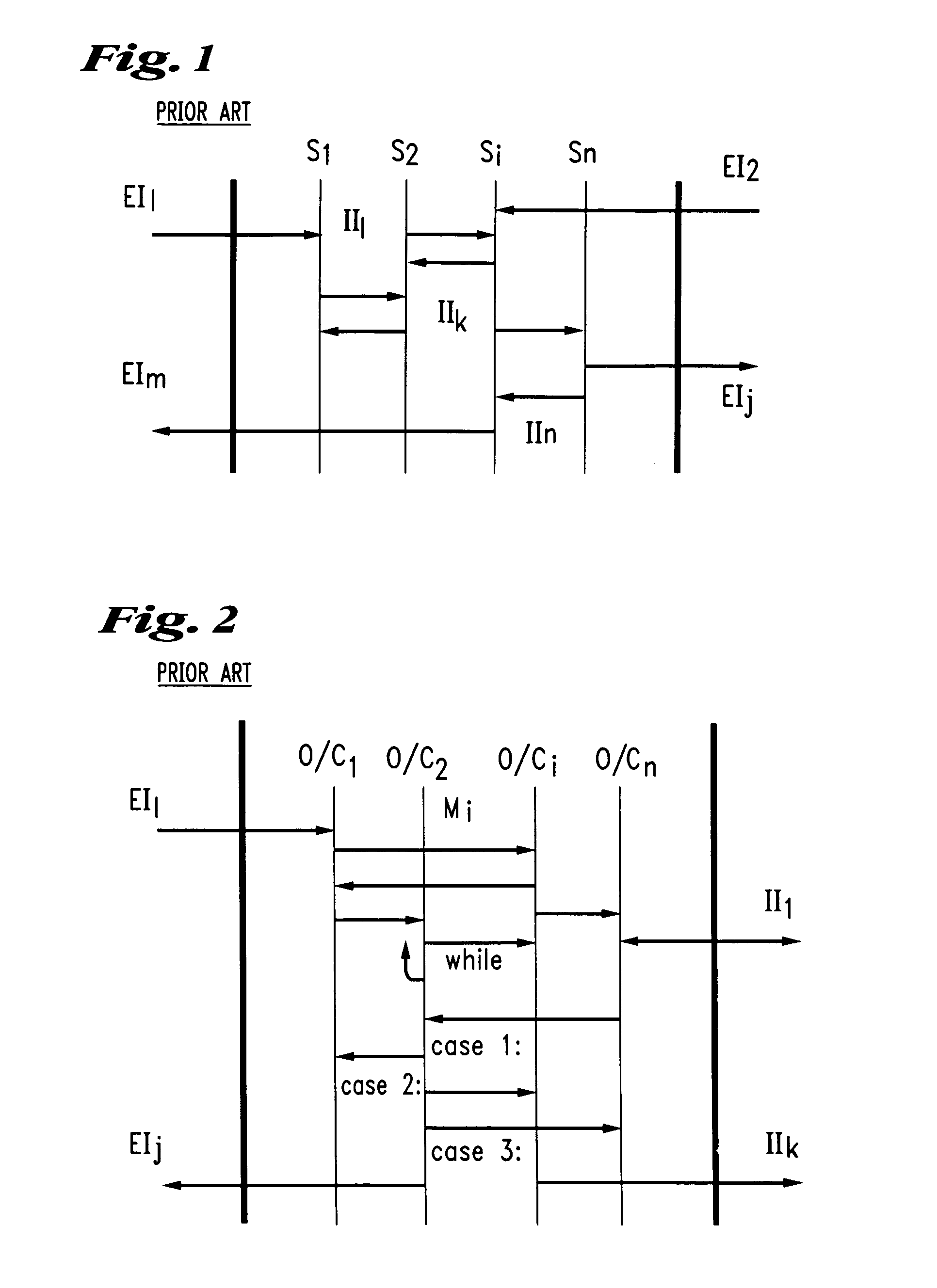

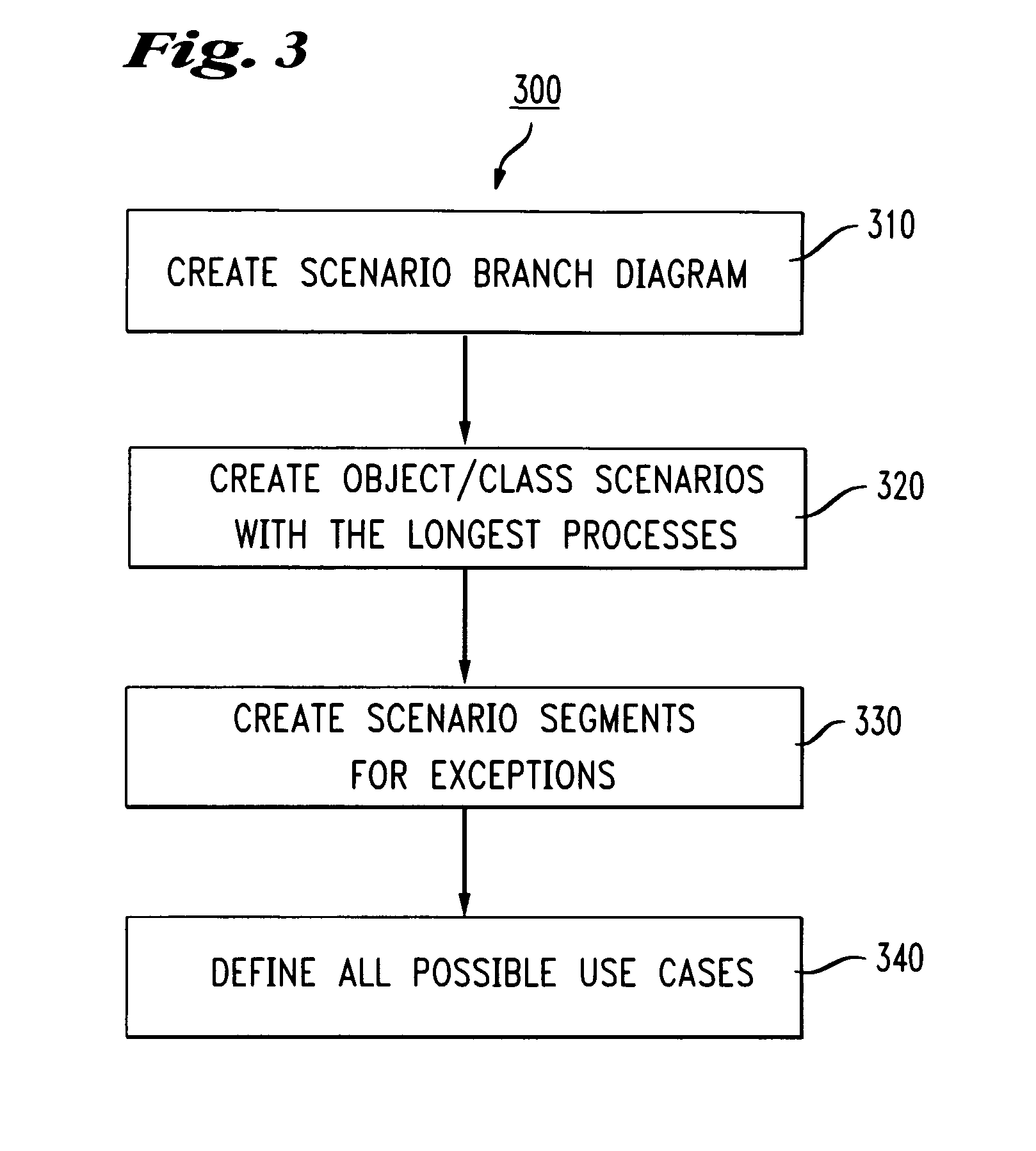

InactiveUS7003766B1Specific program execution arrangementsMemory systemsThree levelSoftware development process

Based on software developed with use-cases, a suite of metrics for the Product / Process (PP) complexity of software systems as well the PP complexity of each stage in the software development process—analysis, design, and testing—is provided. The metrics suite is important for software quality assurance—Validation and Verification (V&V) as well as for understanding new complexities brought into software development by new technologies. The metrics can be collected based on the two most important documents of use-case software development—scenario diagrams and state diagrams. All metrics are CASE tool computable. Thus, each iterative or incremental development process can be quantitatively measured and compared without incurring extra cost or load on the project team. Efficiency metrics for implementation and test stages, normalization rules and logic-metrics for business tables are also presented. A three-level software visualization approach may have impact on graphical programming or direct transformation.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

Zirconium dioxide-based electrode-electrolyte pair (variants), method for the production thereof (variants) and organogel

InactiveUS20060134491A1Improve efficiencyHighly efficient, economically advantageous and durable fuel cellFinal product manufacturePrimary cellsHydrocotyle bowlesioidesEngineering

This invention relates to the field of electric power generation by direct transformation of the chemical energy of gaseous fuel to electric power by means of high-temperature solid oxide fuel cells. The invention can be used for the fabrication of miniaturized thin filmed oxygen sensors, in electrochemical devices for oxygen extraction from air and in catalytic electrochemical devices for waste gas cleaning or hydrocarbon fuels conversion. The technical objective of the invention is the production of a low-cost electrode-electrolyte pair having an elevated electrochemical efficiency as the most important structural part of a highly efficient, economically advantageous and durable fuel cell. Furthermore, the invention achieves additional objectives. The achievement of these objectives is exemplified with two electrode-electrolyte pair designs and their fabrication methods, including with the use of a special organogel.

Owner:HILCHENKO GALINA VITALEVNA +1

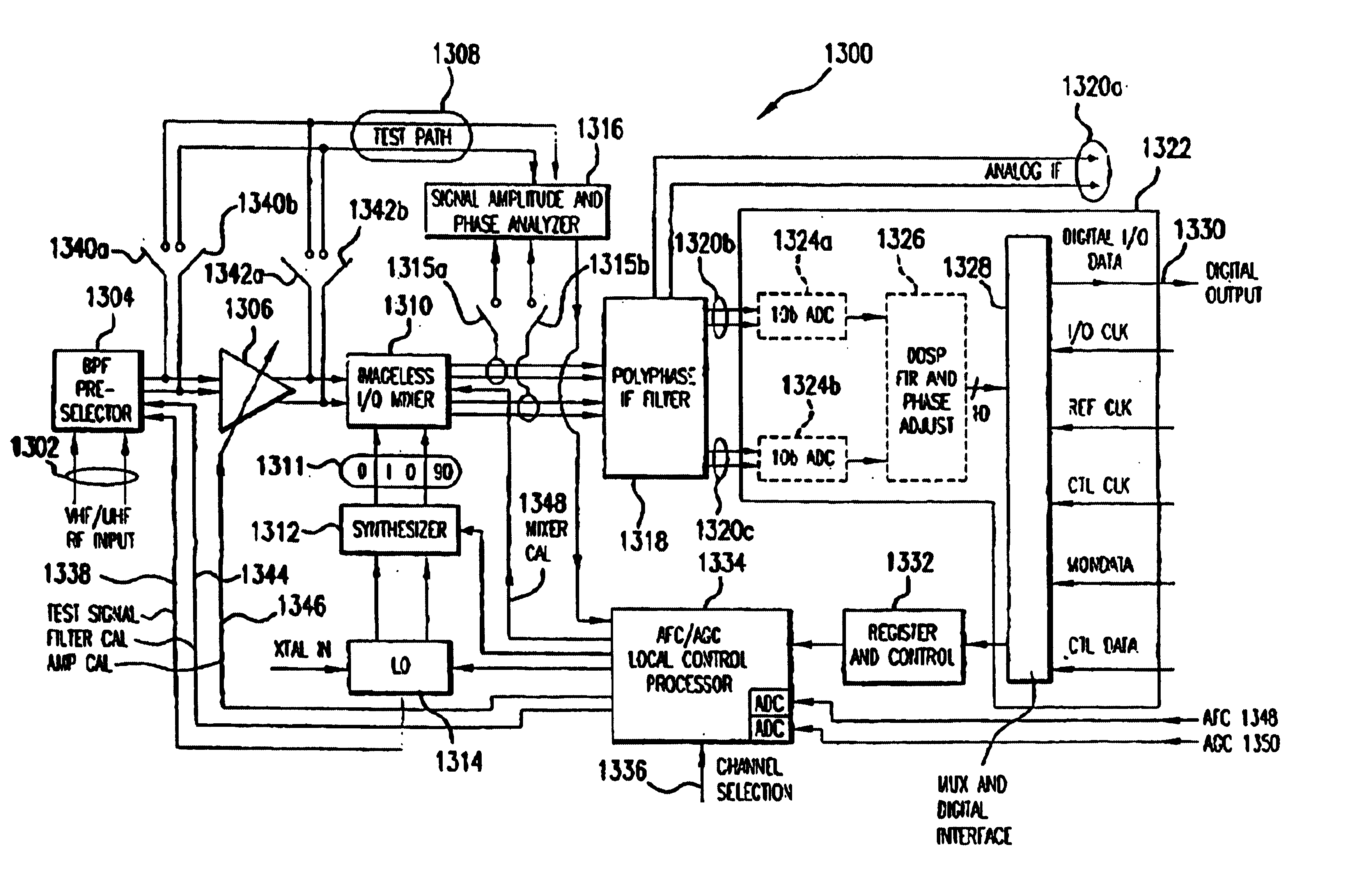

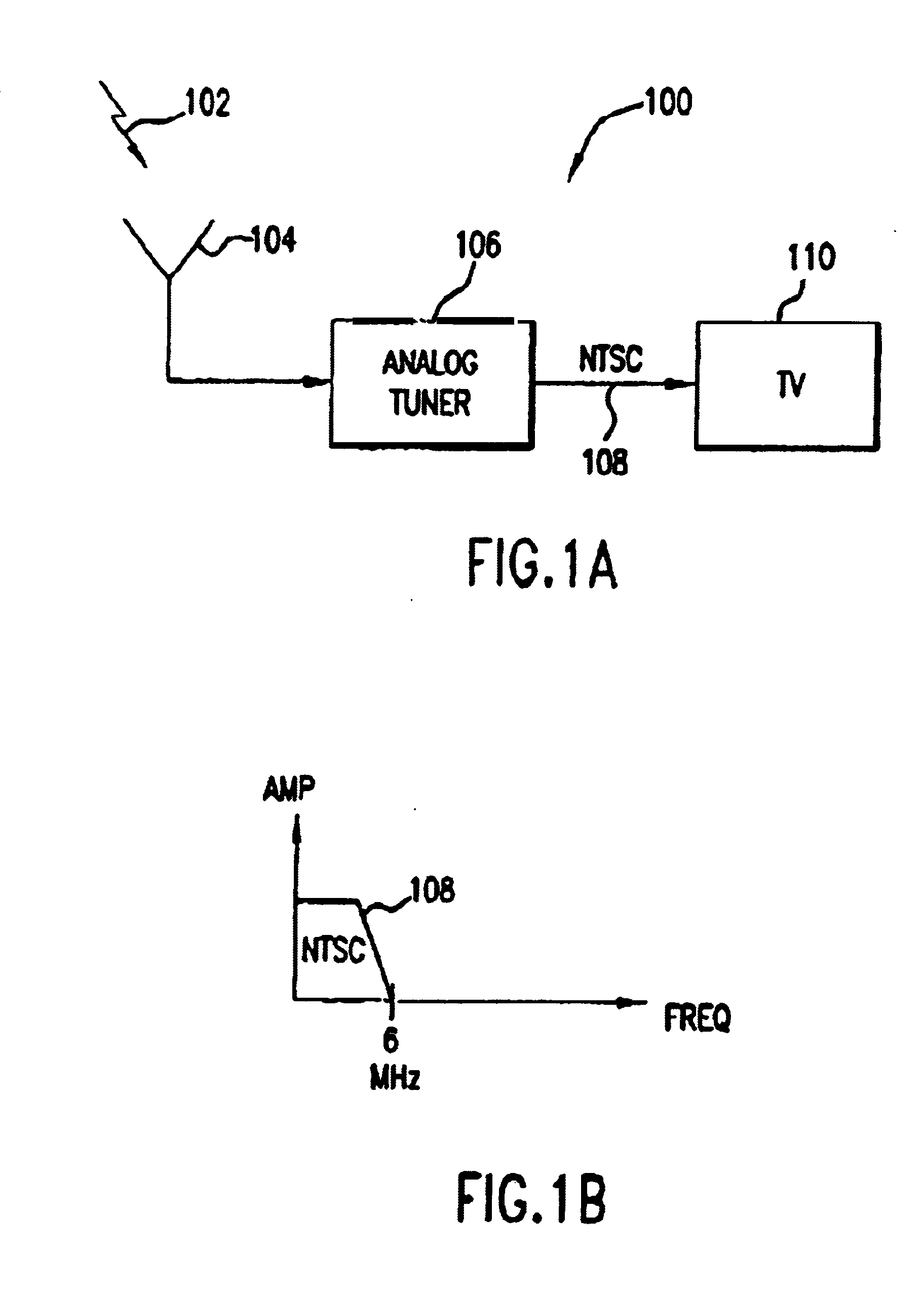

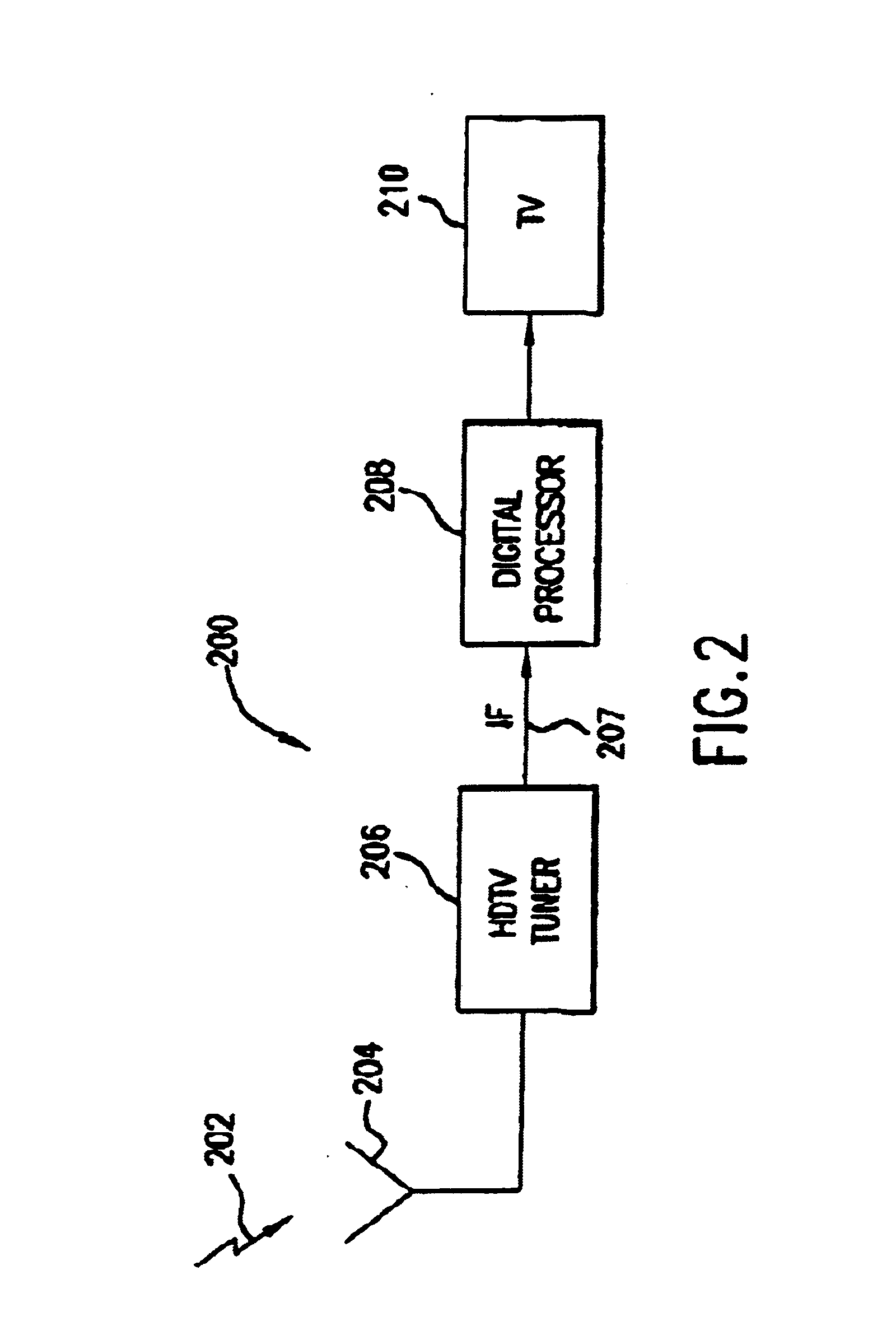

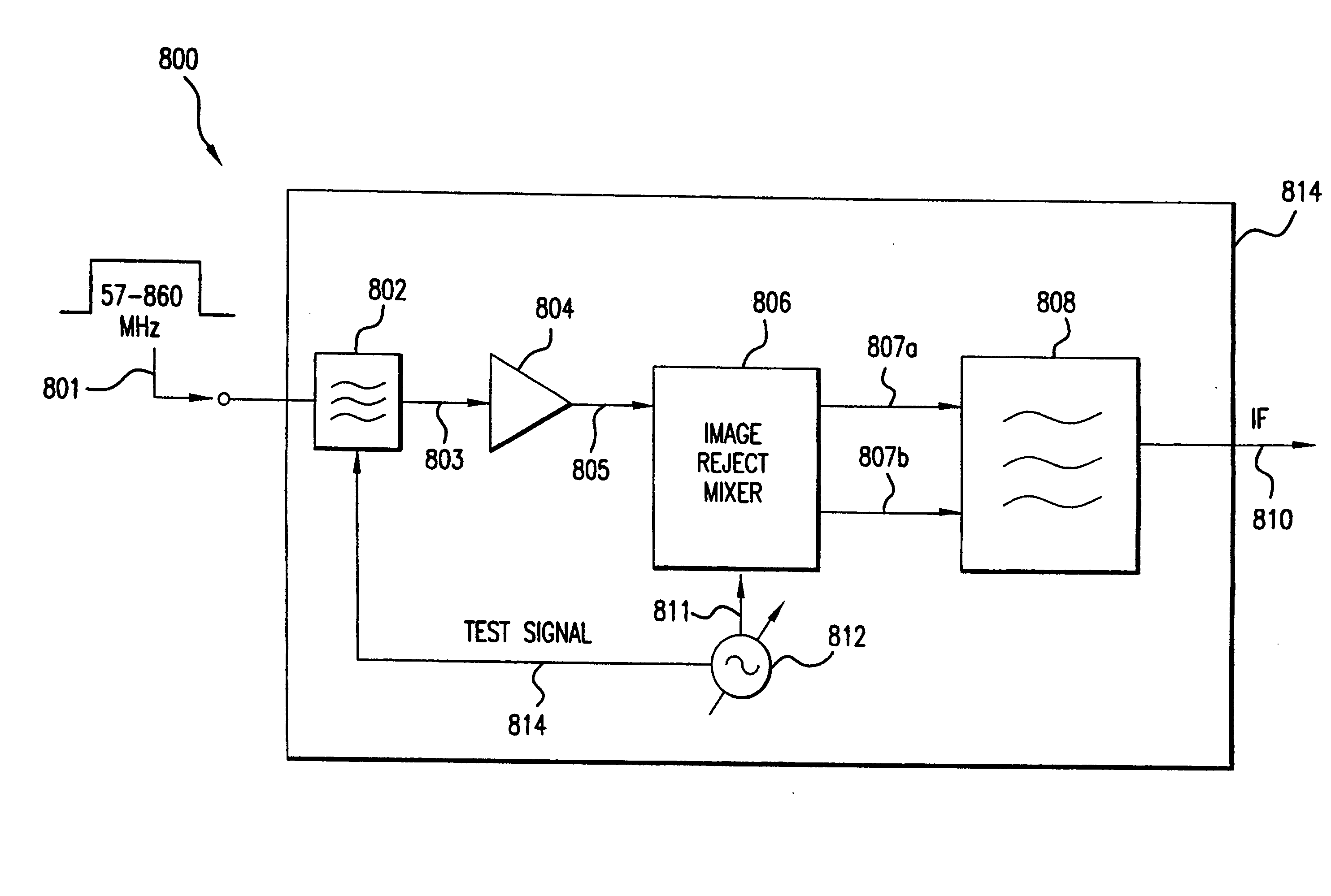

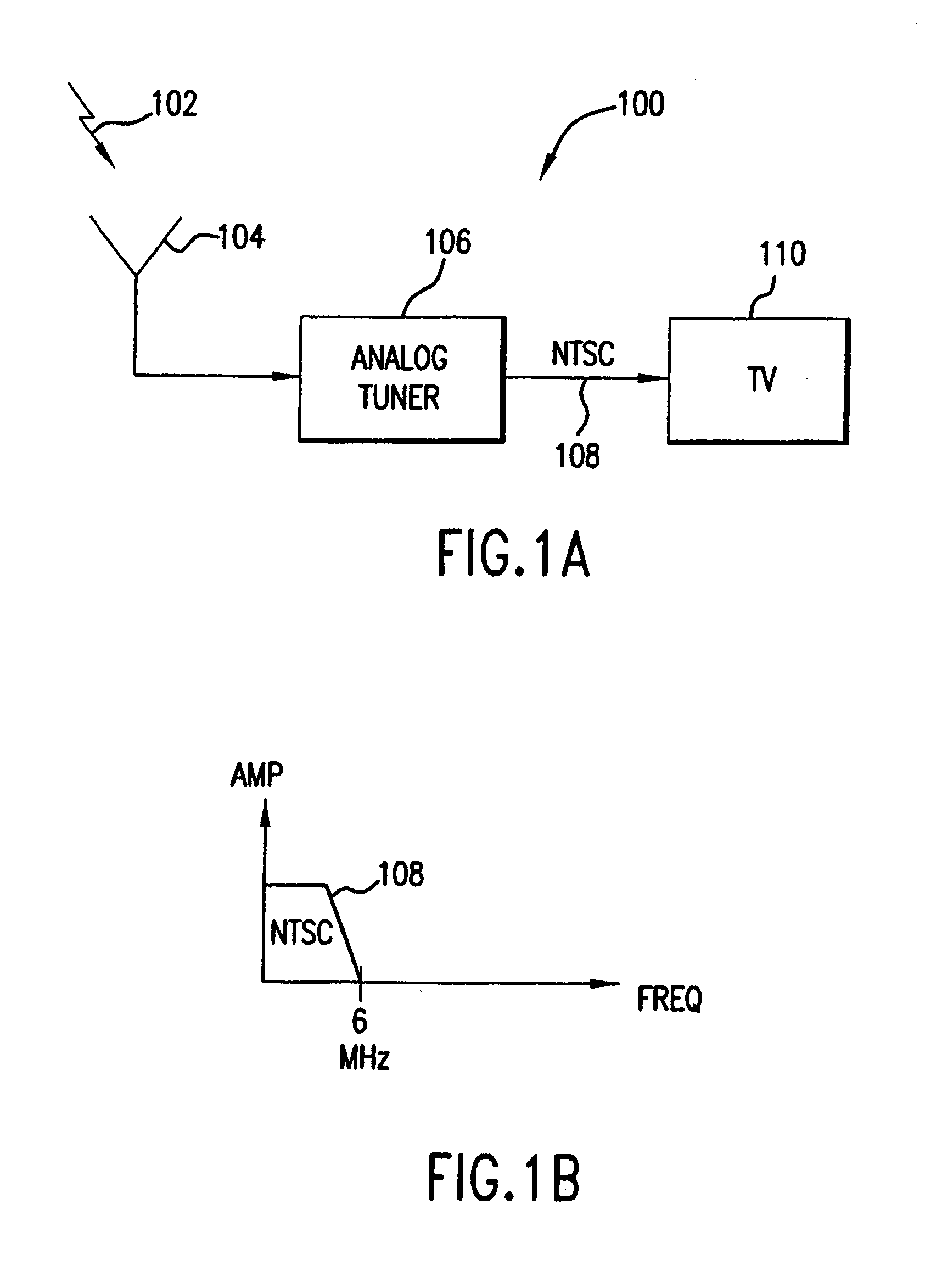

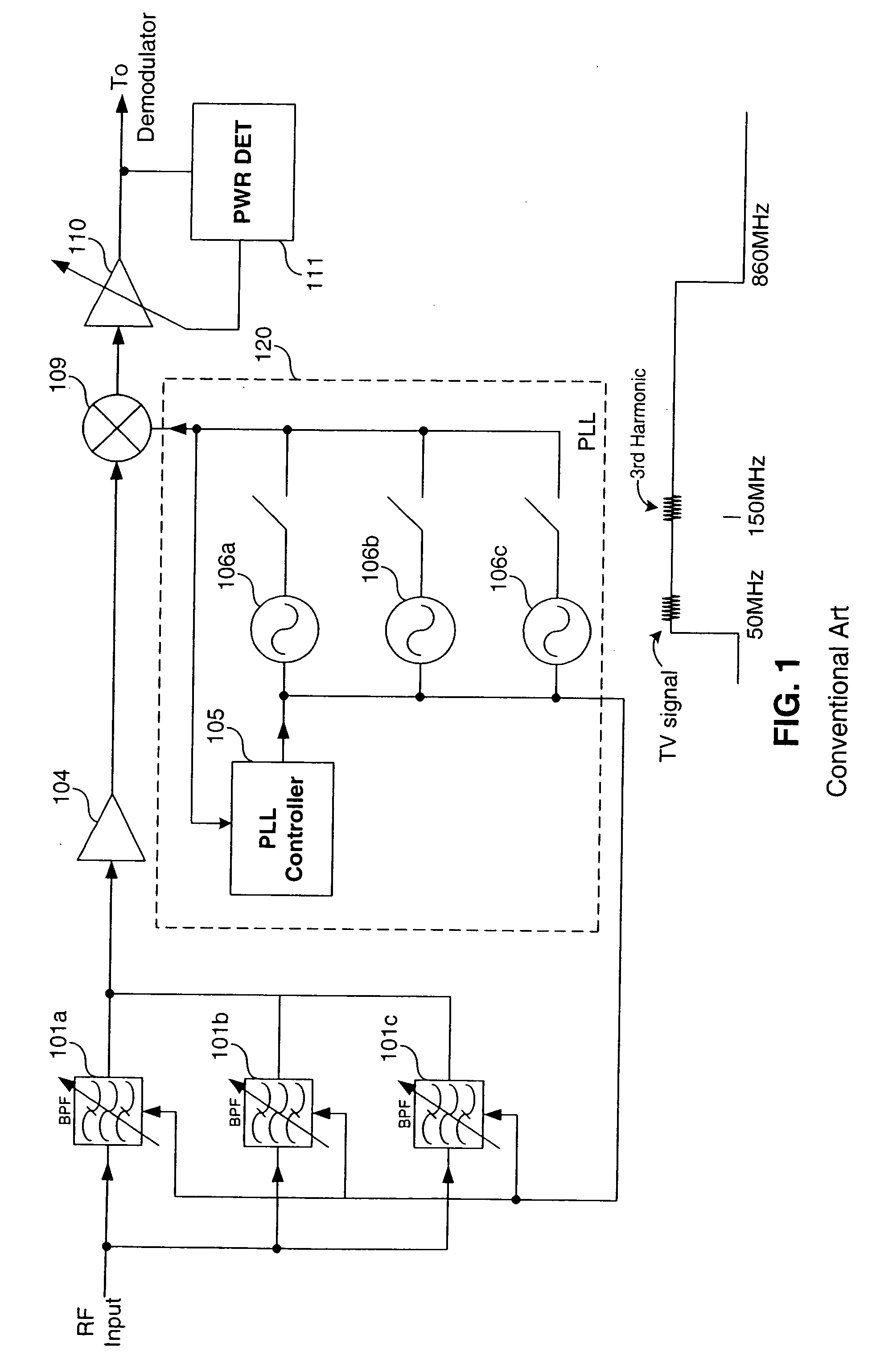

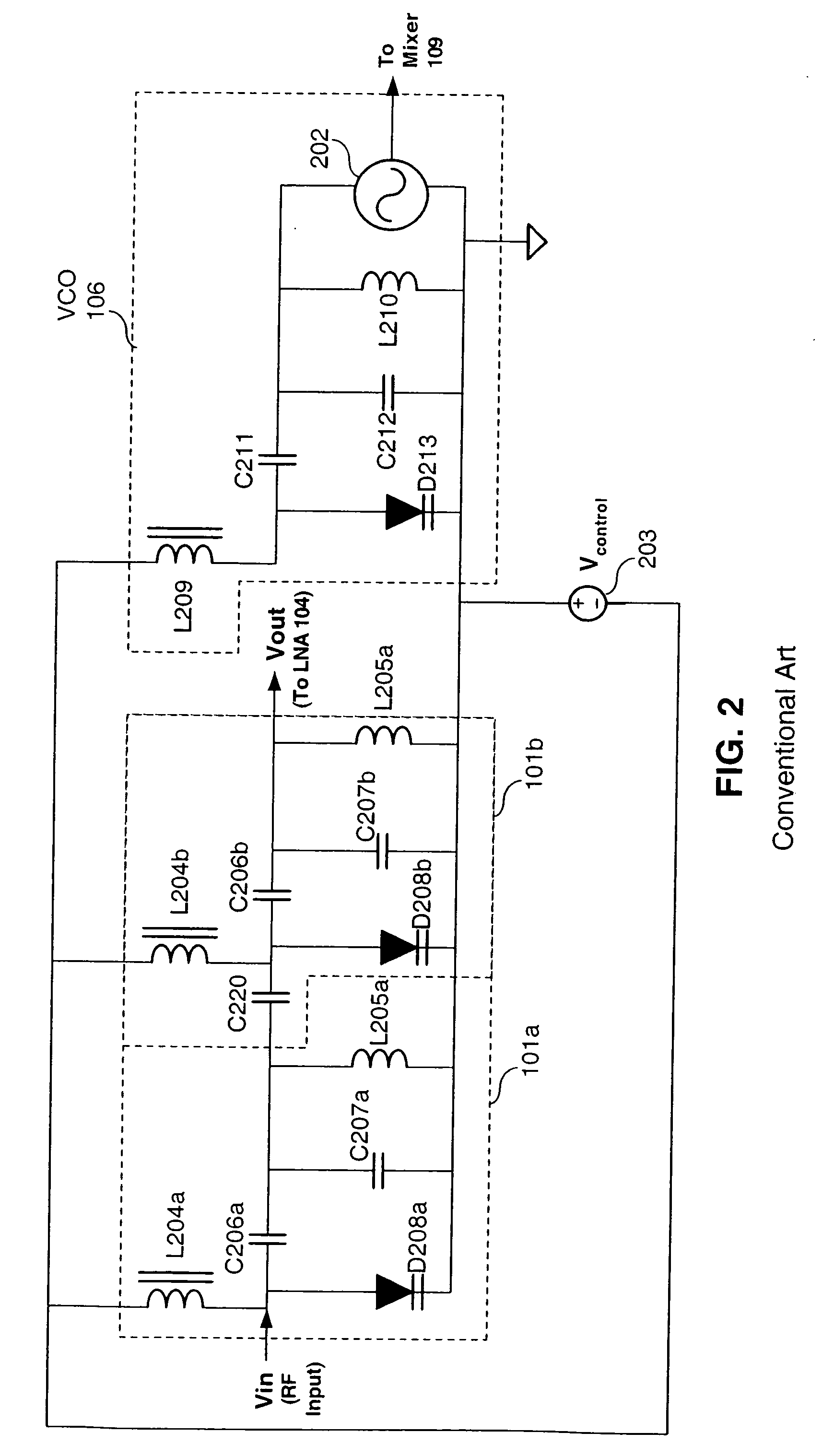

Direct conversion turner

InactiveUS7050778B1Reduced Power RequirementsHigh image rejectionTransmission monitoringTransmission noise suppressionFrequency mixerPhase filter

A direct conversion tuner down-converts television signals, cable signals, or other signals directly from an RF frequency to an IF frequency and / or baseband, without an intermediate up-conversion step for image rejection. The direct conversion tuner includes a pre-select filter, an amplifier, an image reject mixer, and a poly-phase filter. The pre-select filter, amplifier, and the image reject mixer can be calibrated to provide sufficient image rejection to meet the NTSC requirements for TV signals. The entire direct conversion tuner can be fabricated on a single semiconductor substrate without requiring any off-chip components. The tuner configuration described herein is not limited to processing TV signals, and can be utilized to down-convert other RF signals to an IF frequency or baseband.

Owner:AVAGO TECH INT SALES PTE LTD

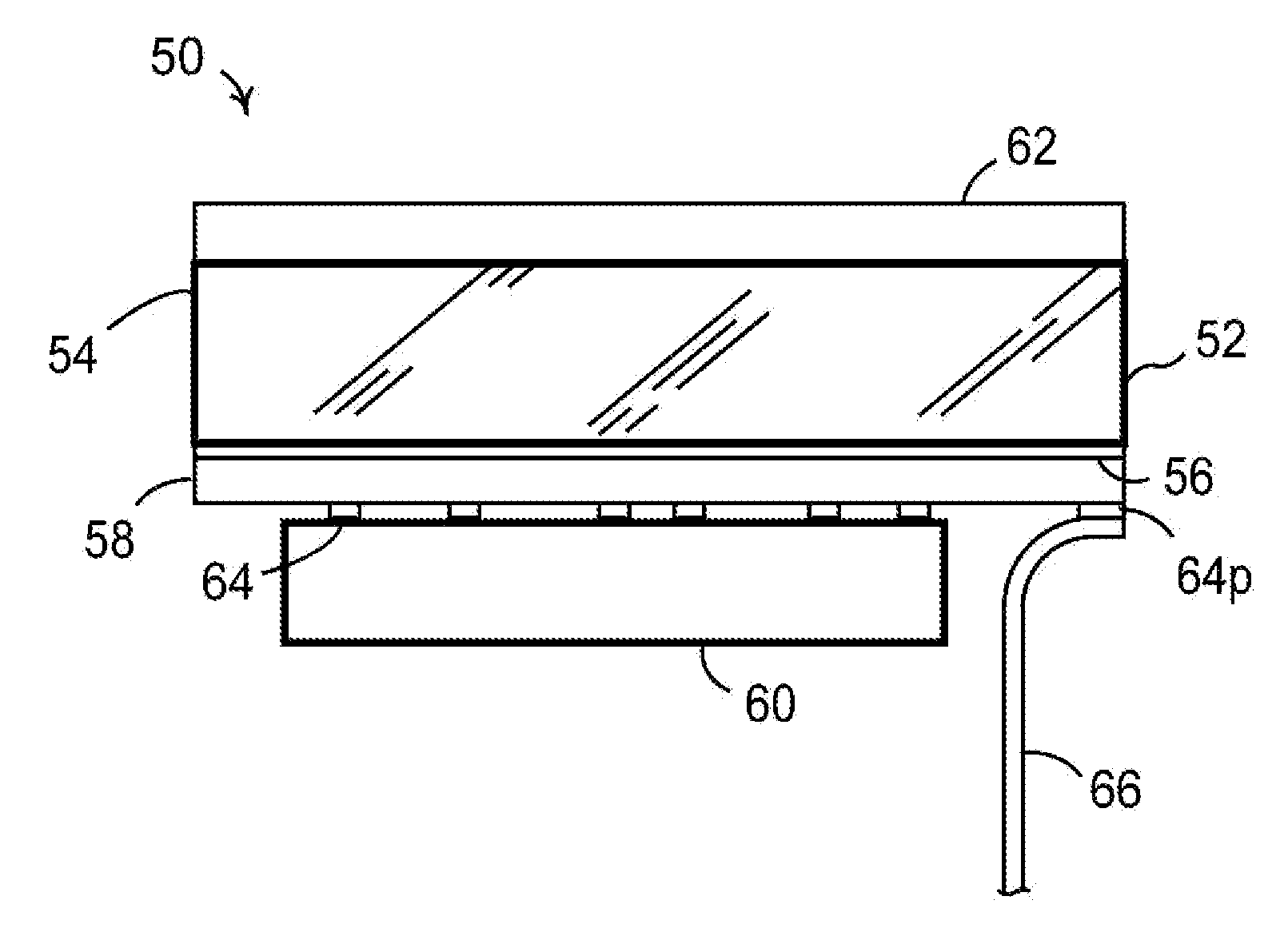

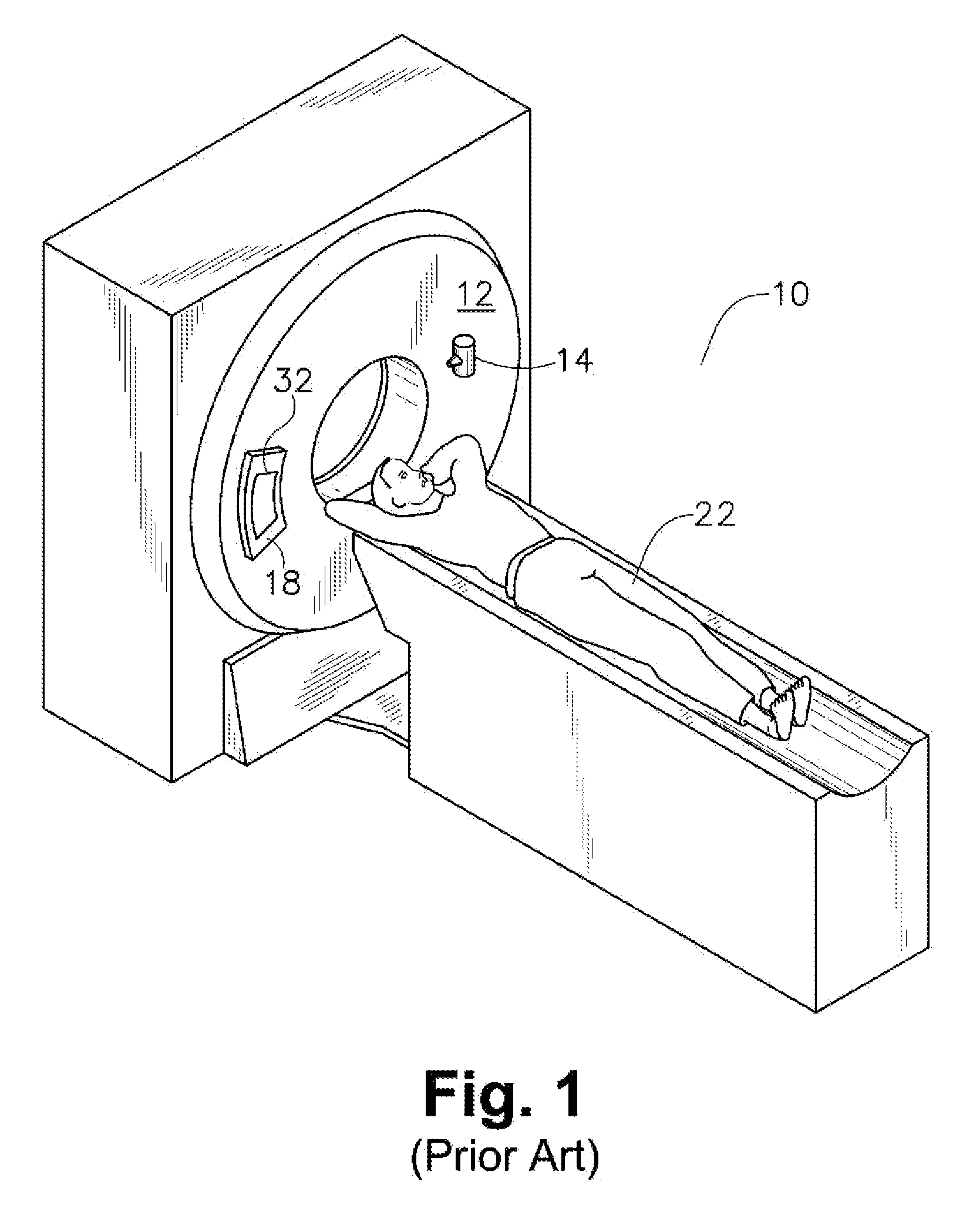

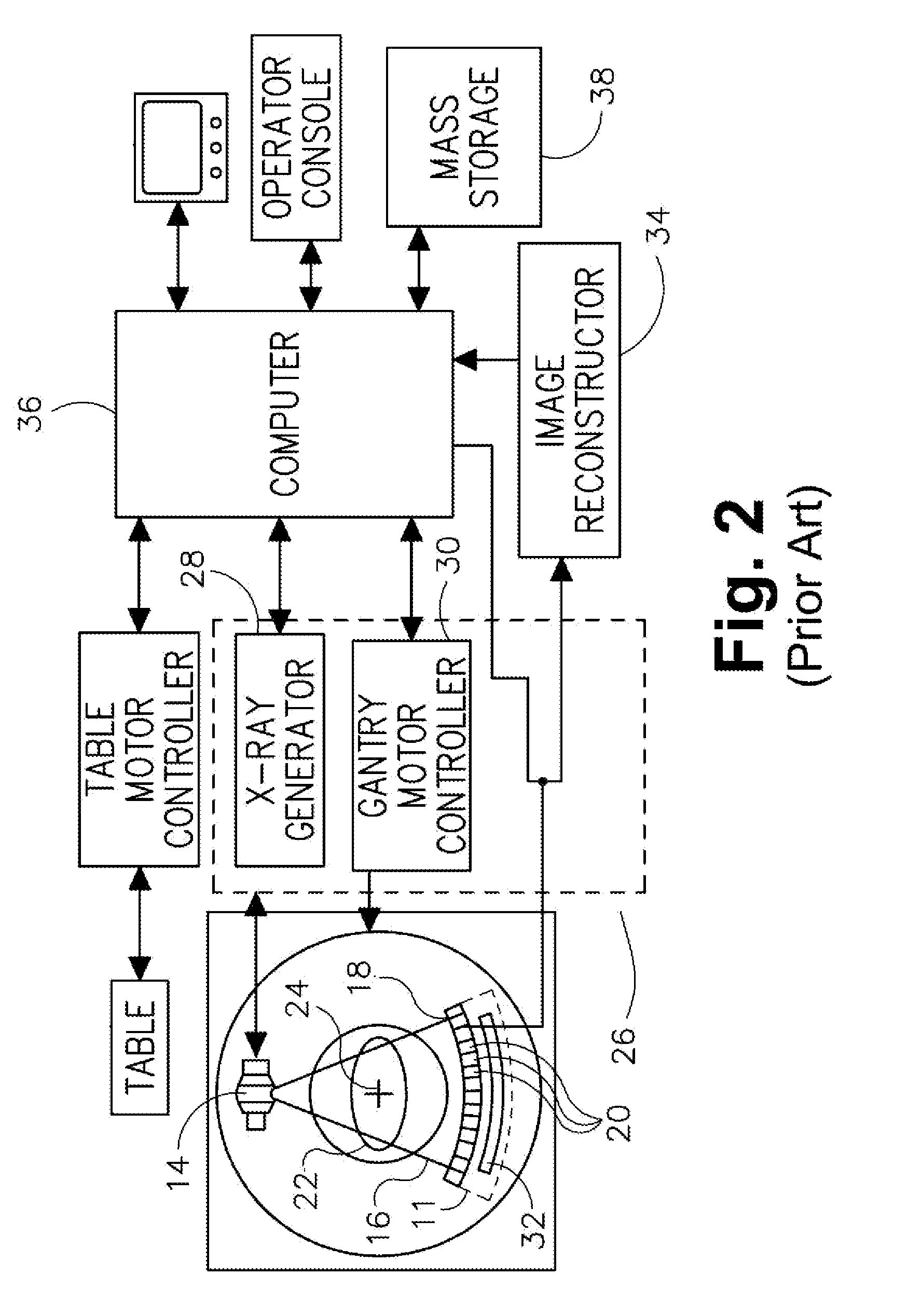

Integrated Direct Conversion Detector Module

InactiveUS20100327173A1Small sizeSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerDirect transformation

A detector module comprises: a direct conversion crystal for converting incident photons into electrical signals, the direct conversion crystal having an anode layer deposited on a first surface and a cathode layer deposited on a second surface; a redistribution layer deposited on the anode layer, the redistribution layer configured to adapt a pad array layout of the direct conversion crystal to a predetermined lead pattern; an integrated circuit in electrical communication with the direct conversion crystal; and a plurality of input / output electrical paths connected to the redistribution layer to provide connectivity between the imaging module and another level of interconnect.

Owner:GENERAL ELECTRIC CO

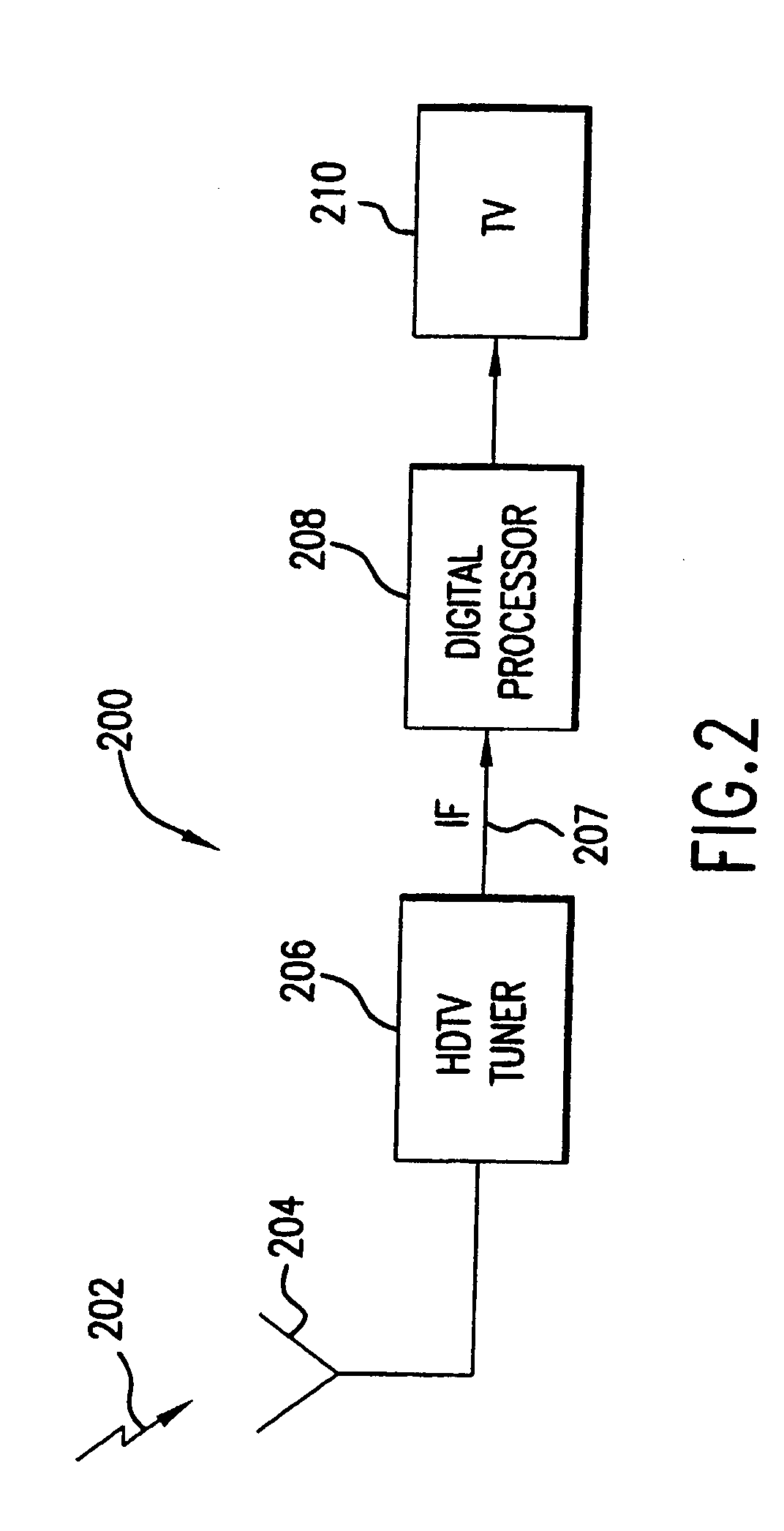

Direct conversion tuner

InactiveUS20060189290A1Reduced Power RequirementsHigh image rejectionTransmission monitoringFrequency-changer modificationsAudio power amplifierPhase filter

A direct conversion tuner down-converts television signals, cable signals, or other signals directly from an RF frequency to an IF frequency and / or baseband, without an intermediate up-conversion step for image rejection. The direct conversion tuner includes a pre-select filter, an amplifier, an image reject mixer, and a poly-phase filter. The pre-select filter, amplifier, and the image reject mixer can be calibrated to provide sufficient image rejection to meet the NTSC requirements for TV signals. The entire direct conversion tuner can be fabricated on a single semiconductor substrate without requiring any off-chip components. The tuner configuration described herein is not limited to processing TV signals, and can be utilized to down-convert other RF signals to an IF frequency or baseband.

Owner:AVAGO TECH INT SALES PTE LTD

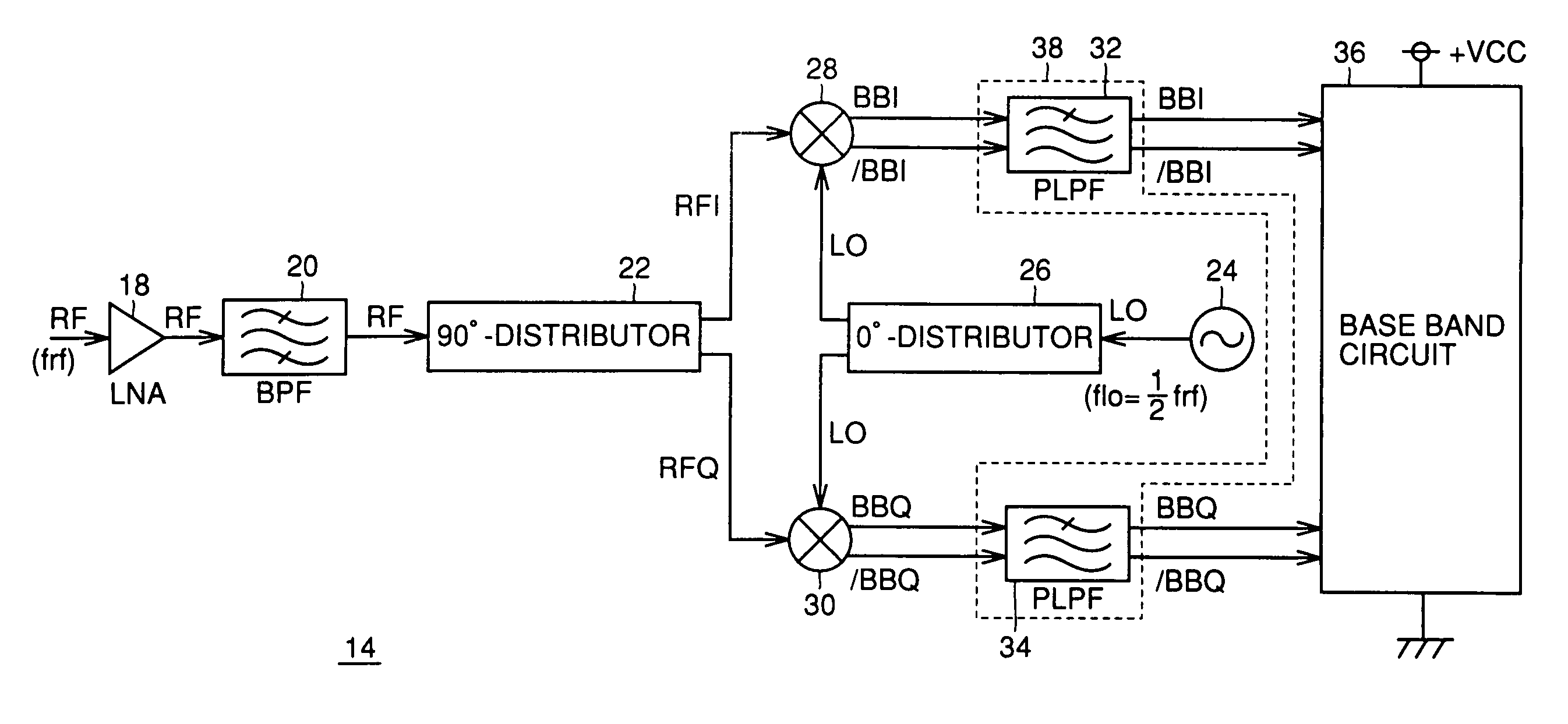

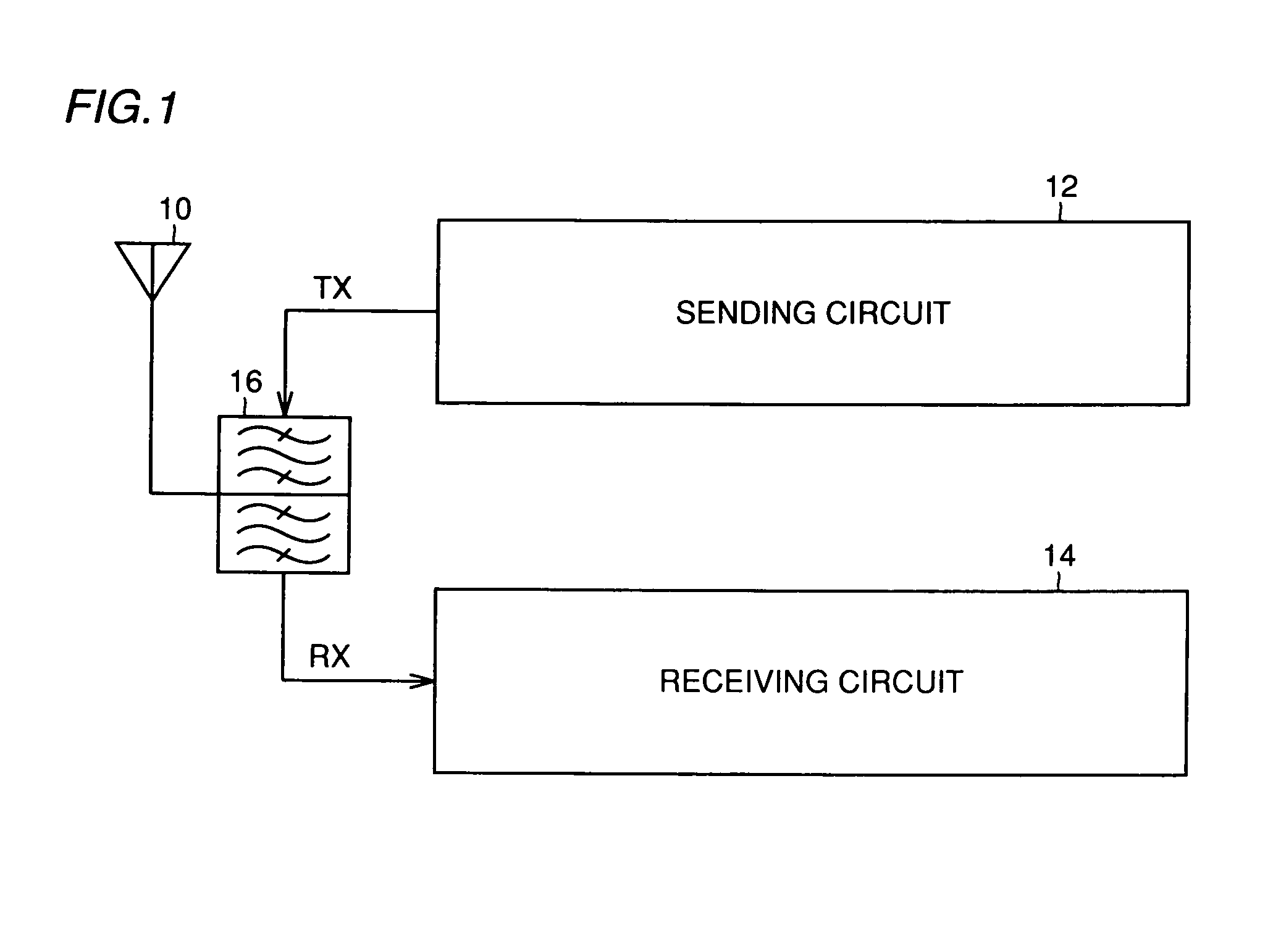

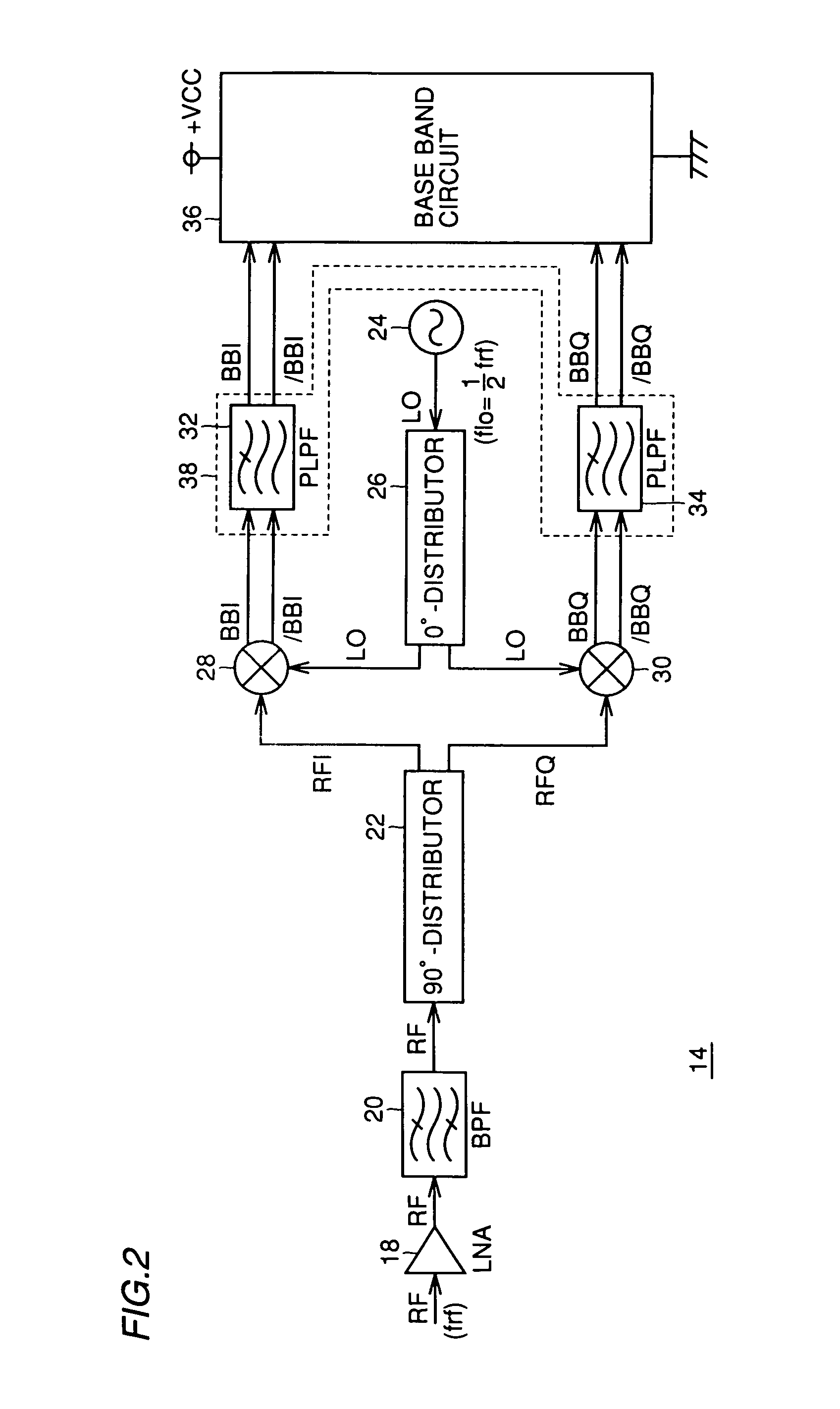

Wireless terminal device

InactiveUS7054610B1Efficient removalModulation transference balanced arrangementsRadio transmissionLow-pass filterTerminal equipment

In a cellular telephone provided with a receiving circuit of a direct conversion type, a passive low-pass filter is arranged between a mixer for an I-channel and a base band circuit for removing interference waves of or above a channel next to a channel neighboring to the I-channel, and another passive low-pass filter is arranged between a mixer for a Q-channel and the base band circuit for removing interference waves of or above a channel next to a channel neighboring to the Q-channel. Since the low-pass filters for removing the interference waves of or above the channel next to the neighboring channel are of a differential type, the circuit scale can be small, and the power consumption is small. Since the interference waves are removed by the passive low-pass filters and the active low-pass filters, only the desired channel can be reliably received.

Owner:MITSUBISHI ELECTRIC CORP

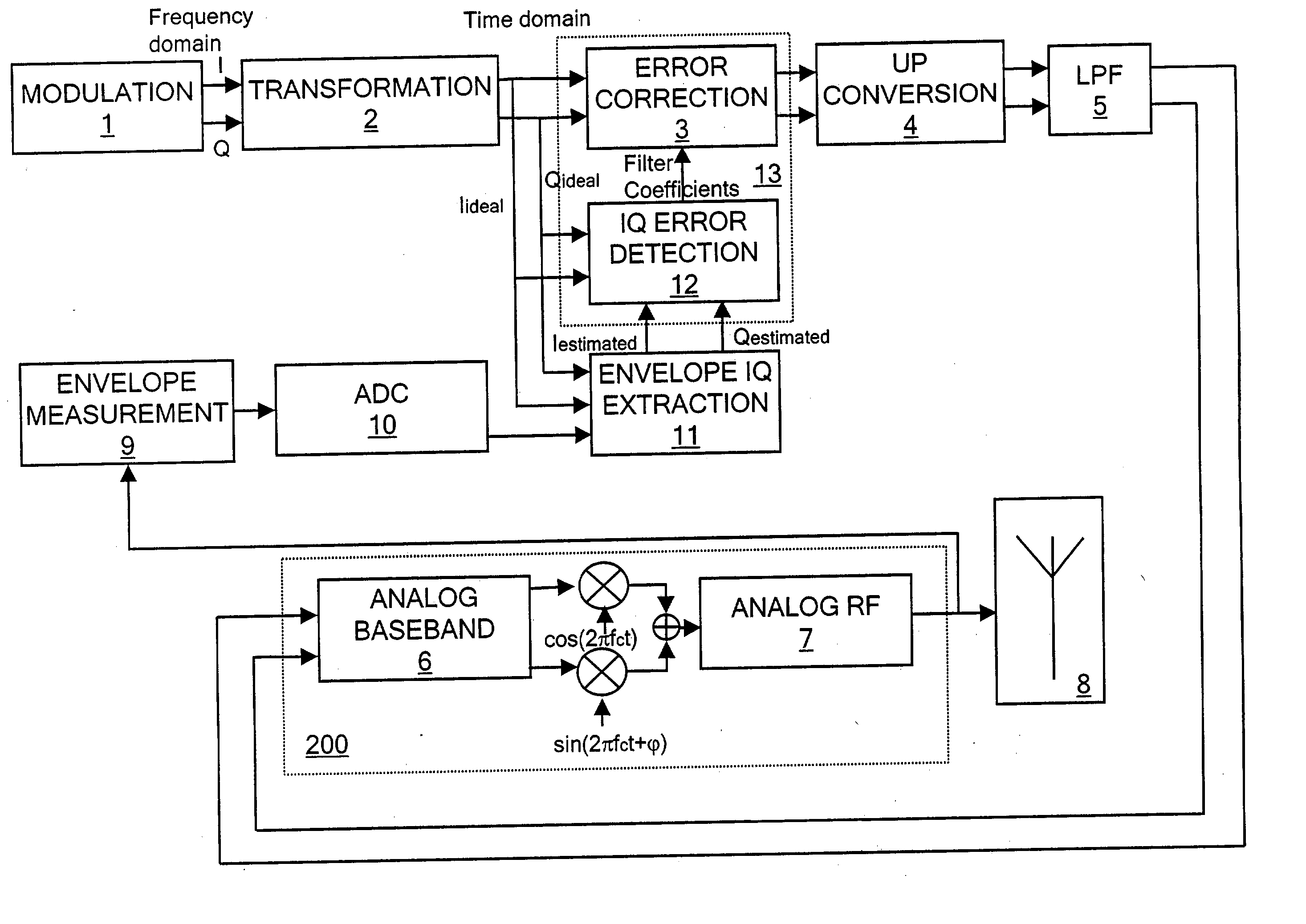

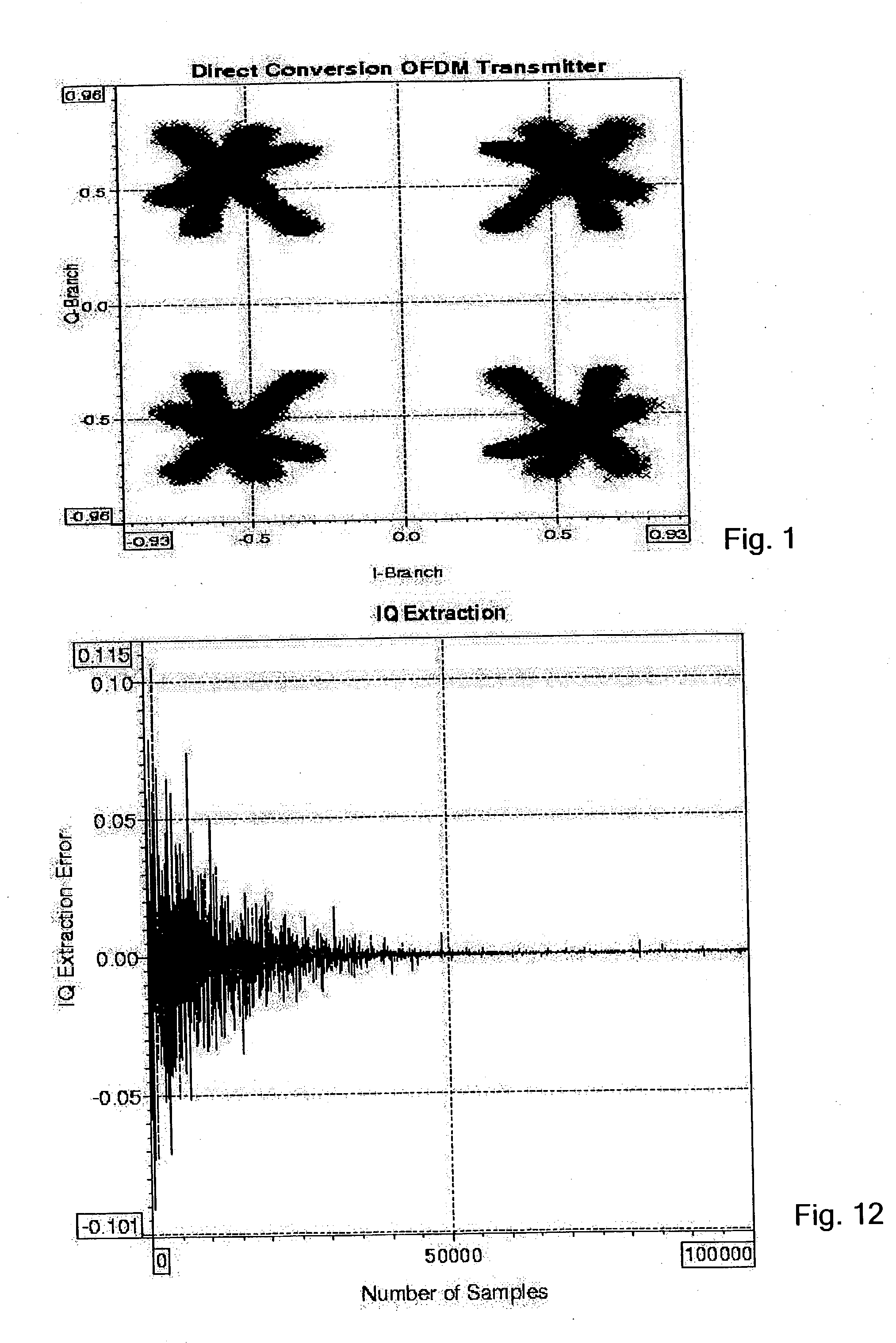

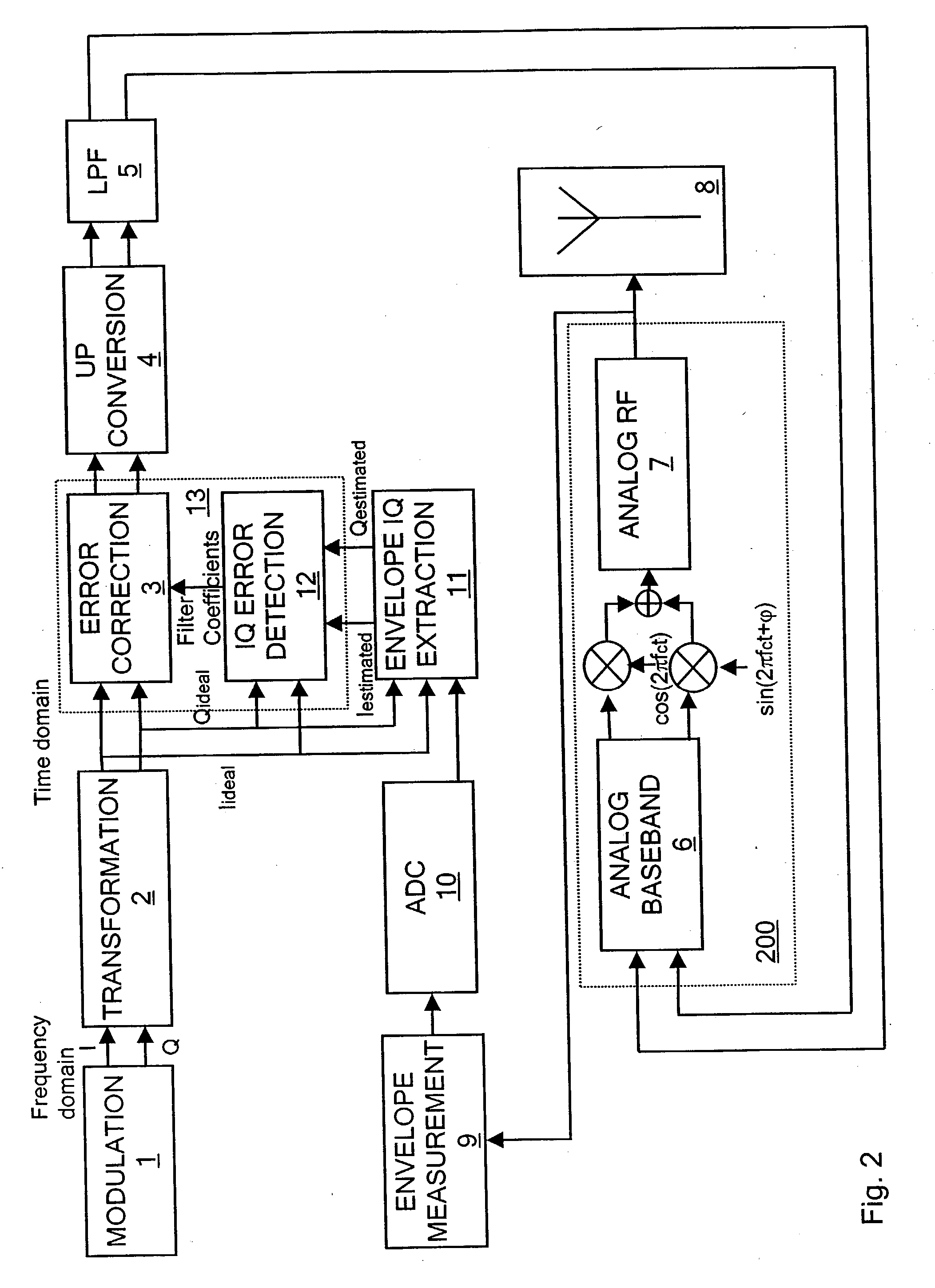

Error adjustment in direct conversion architectures

InactiveUS20040193965A1Secret communicationEmergency protective arrangements for automatic disconnectionSignal processing circuitsReal signal

An error adjustment method of equalizing transmission characteristics of a signal processing circuitry is disclosed. In a first step, an original complex IQ signal is generated, on which error adjustment is performed. Then, the adjusted complex IQ signal is processed in the signal processing circuitry, thereby obtaining a processed real signal. The envelope of the real signal is detected and this real signal envelope and the original complex IQ signal are synchronized. The envelope of the original complex IQ signal is derived and the synchronized real signal envelope is compared with the synchronized original IQ signal envelope at two consecutive time instances. Finally, a processed complex IQ signal is obtained from the real signal envelope on the basis of the comparison result, which processed complex IQ signal is used in performing error adjustment.

Owner:NOKIA CORP

Modified dual band direct conversion architecture that allows extensive digital calibration

A dual band direct conversion architecture for both the receive (RX) and transmit (TX) path of a communications transceiver that minimizes the transceiver area by sharing common circuits used in both RX and TX paths is disclosed. The transceiver also allows the use of extensive digital calibration in order to achieve performance adequate to support high bit rate modulation schemes.

Owner:AVAGO TECH INT SALES PTE LTD

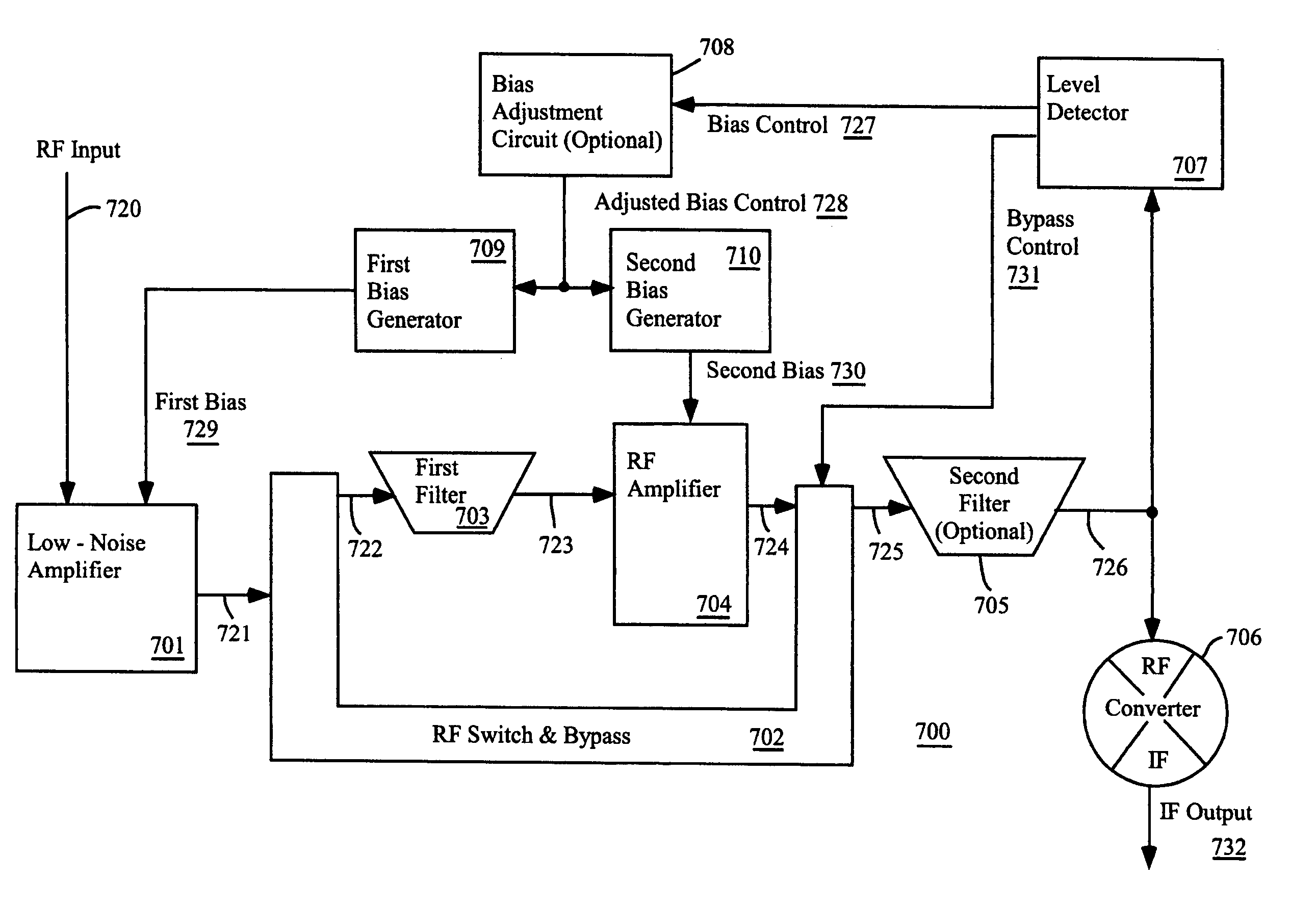

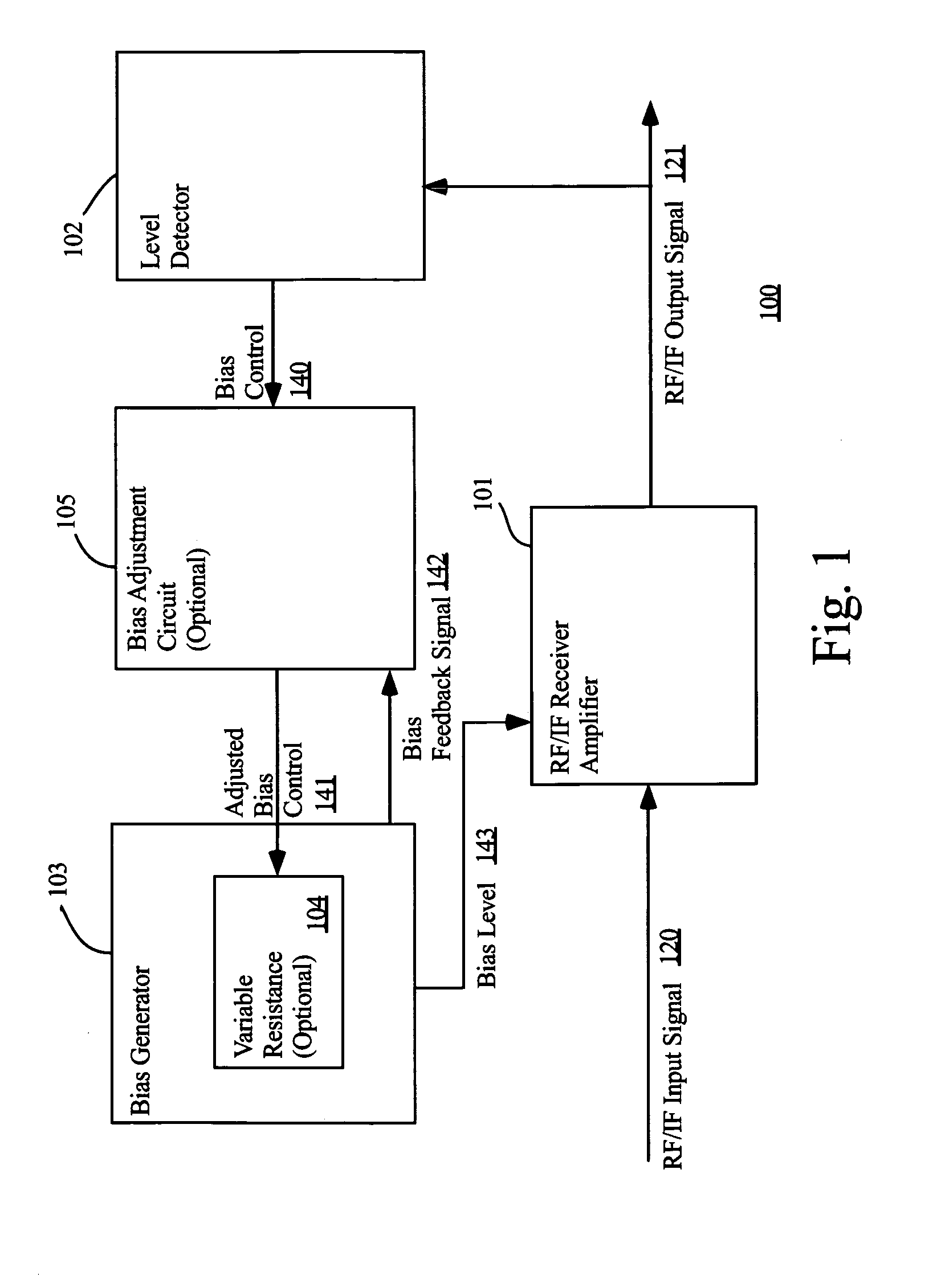

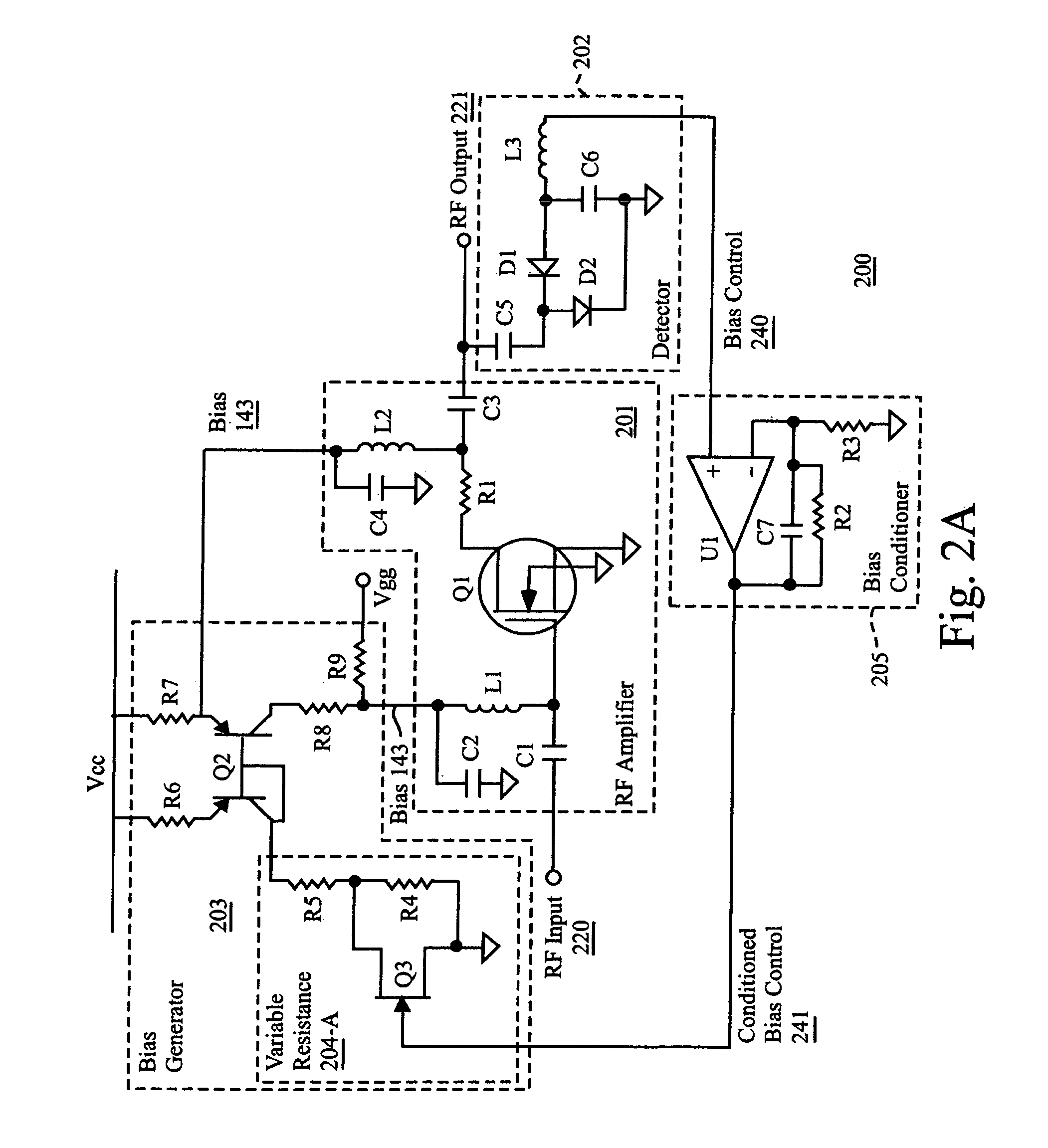

Direct conversion of low power high linearity receiver

InactiveUS7079825B2Reduced Linearity RequirementsIncreasing intermodulation susceptibilityNegative-feedback-circuit arrangementsGain controlAudio power amplifierControl signal

A radio frequency receiver includes an amplifier and a detector that produces a bias control signal indicating the level of the signal environment in which the receiver is currently operating. A bias generator sets the bias level of the amplifier according to the bias control signal, where the bias level tends to increase as the signal level increases. Further, the receiver, includes a first circuit adapted to receive a radio frequency input signal, the circuit having an adjustable bias level, a bias control having more than one level of control for generating a bias control signal based upon a base-band signal for controlling the first circuit and generating an output signal; and an alternative bypass switch across the first circuit so as to send a DC signal corresponding to the total power generated by said feedback means.

Owner:SONY CORP +1

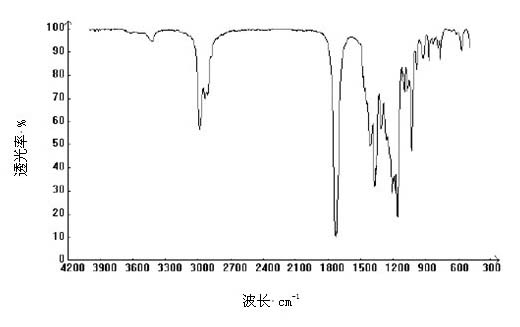

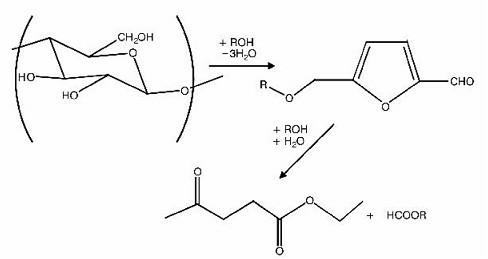

Direct transformation process of ethyl levulinate by hydrolysis of cellulose materials

ActiveCN102030646AHigh yieldAvoid attenuationOrganic compound preparationCarboxylic acid esters preparationCelluloseSolid acid

The invention belongs to the technical field of preparing ethyl levulinate, in particular to a direct transformation process of ethyl levulinate by hydrolysis of cellulose materials. The process comprises the following steps: adding the cellulose materials into a reaction system comprising ethanol, liquid acid catalyst / solid acid catalyst, and cosolvent, hydrolyzing for 2 to 60 minutes at the temperature of 150 to 230 DEG C to obtain hydrolyzate containing the ethyl levulinate, and purifying the hydrolyzate to obtain the ethyl levulinate. In the invention, the cosolvent is added into the hydrolysis system of the cellulose materials, and the intermediate products such as hydromethyl furfural, the levulinic acid and the like generated during the hydrolysis of the cellulose materials can be extracted into an organic phase containing the cosolvent in the presence of the cosolvent, thereby preventing the further reduction of the intermediate products, facilitating the reduction of by-products and facilitating the yield increase of ethyl levulinate.

Owner:ZHENGZHOU UNIV

Biomass Pyrolysis Refining-Method of Hierarchical Directional Conversion

InactiveCN102266864ADifferent pyrolysis propertiesBiological substance pretreatmentsSilicaSlagDrug biotransformation

The invention relates to a biomass pyrolysis refining-grading directional conversion process. Based on the fact that the main chemical components (cellulose, hemicellulose and lignin, etc.) of biomass raw materials have different thermal decomposition characteristics, the present invention uses pyrolysis refining as the technical platform to propose a technology of gradient heating and step-by-step collection scheme, the pyrolysis products are graded and directed transformations as platform compounds. Among them, the water-soluble pyrolysis oil fraction has fermentation properties and can undergo selective biotransformation; the fat-soluble pyrolysis oil fraction is used to refine high-quality bio-oil, and the pyrolysis residue is used to prepare high-quality activated carbon or nano-silica. Biomass pyrolysis refining-graded directional conversion solves the problems of the use of a large number of enzyme catalysts and the difficulty of collecting, transporting and storing raw materials in the process of using biomass raw materials as energy. It is a high-efficiency and high-value utilization process of biomass.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

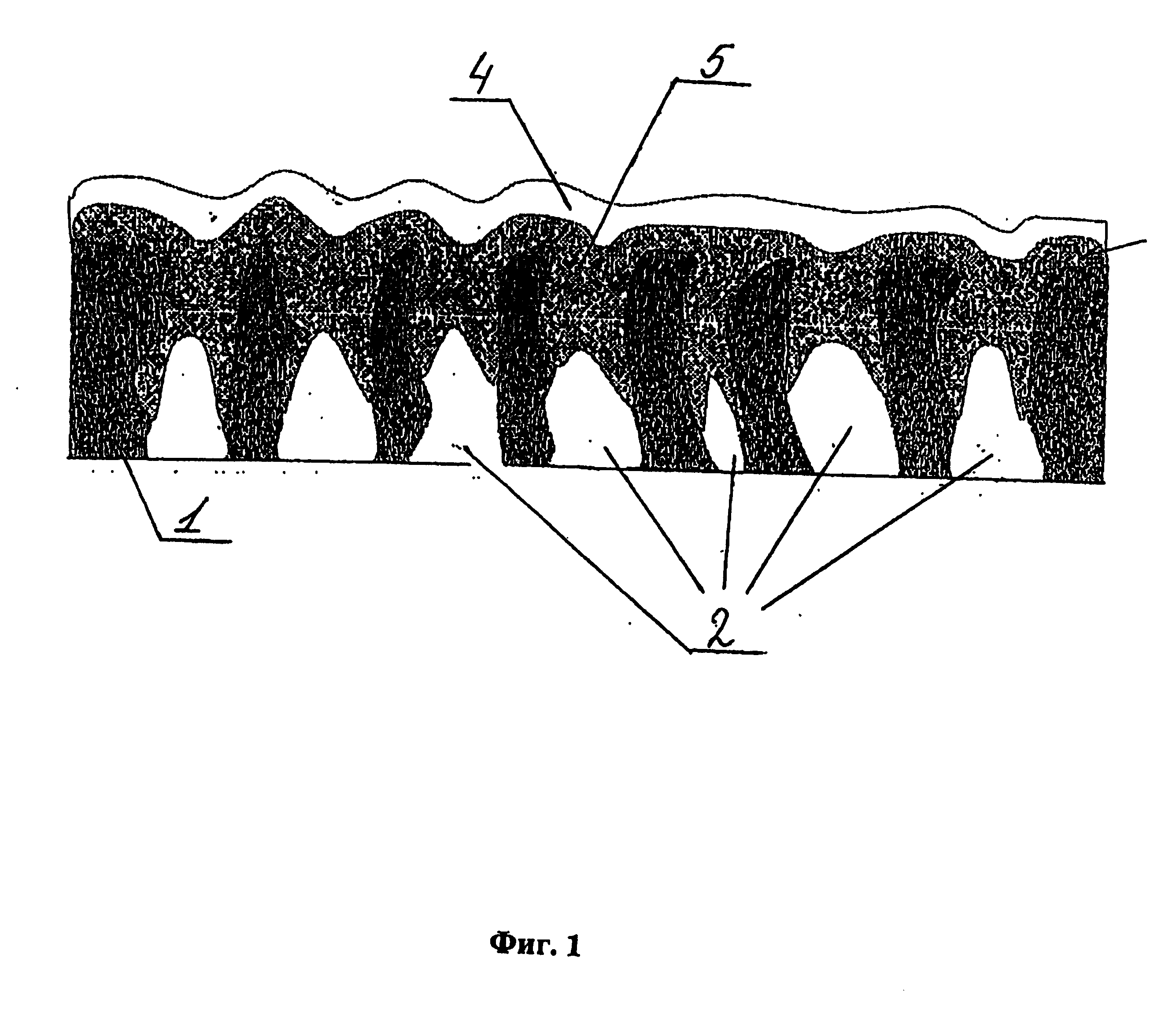

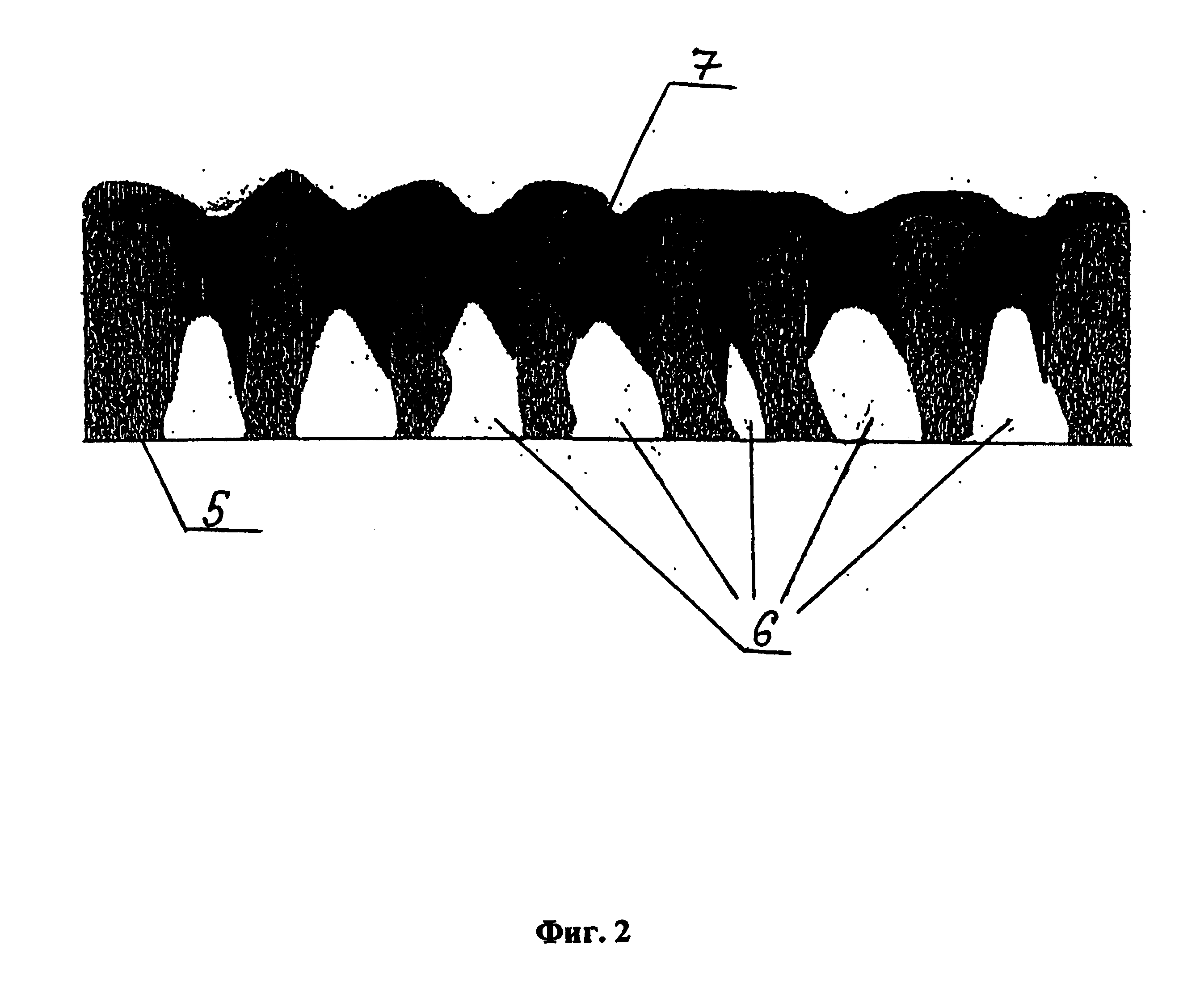

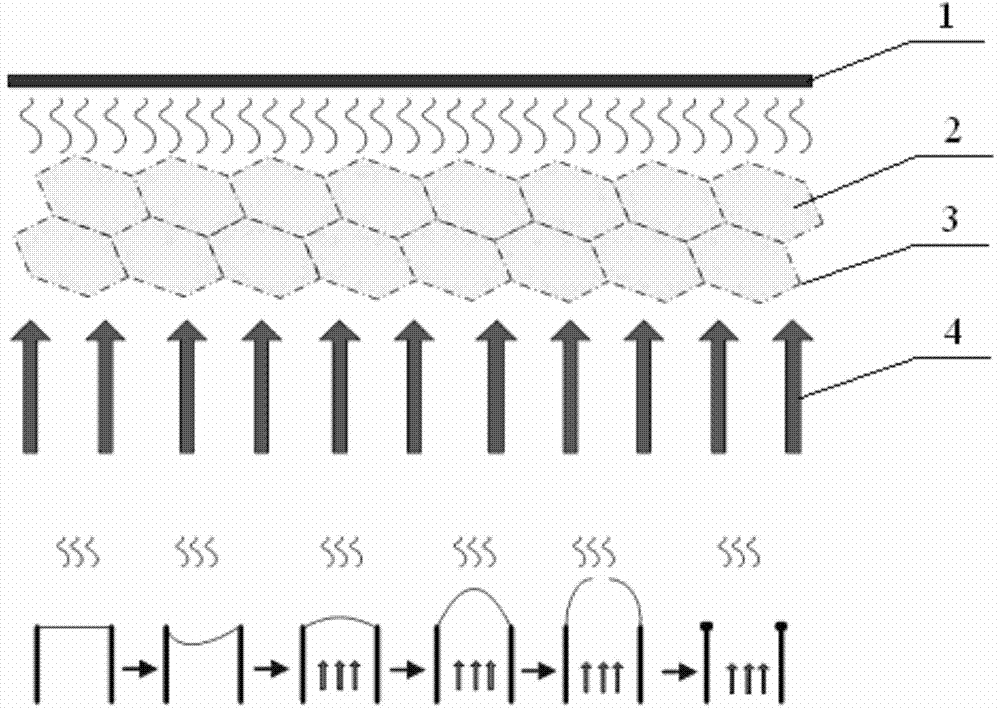

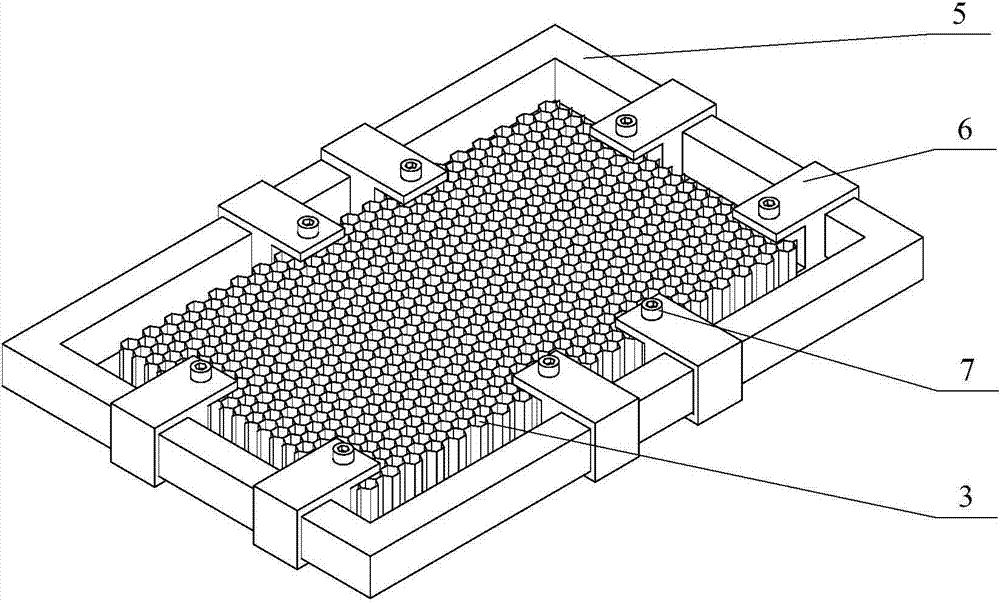

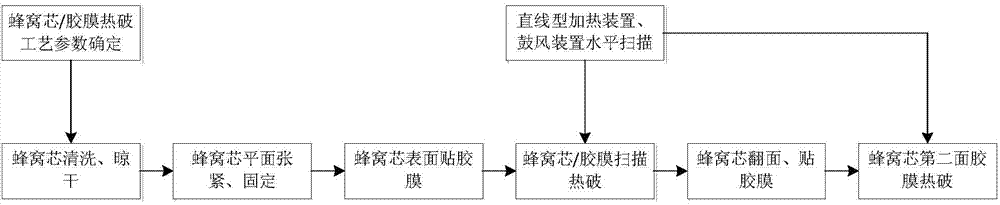

Honeycomb core end surface gridding sizing process method based on adhesive film thermal fracture

ActiveCN104494276AUniform densityUniform DisposableLaminationLamination apparatusState variationAdhesive

The invention relates to a honeycomb core end surface gridding sizing process method based on adhesive film thermal fracture. The honeycomb core end surface gridding sizing process method comprises the following steps of: tensioning the end surface of a honeycomb core by designing a special tool; instantly heating the upper surface of the adhesive film which is flat adhered to the end surface of the honeycomb core by adopting a linear type heating device and a heat air blowing device so that the upper surface of the adhesive film is heated to be softened and inwards recessed into a honeycomb core grid under the action of gravity; reversely exerting high-pressure heat air on the adhesive film along the axial direction of the honeycomb core grid so that the adhesive film is expanded, fractured, shrunk and uniformly collected on the end surface of the seamed edge of the honeycomb core grid, and thus the direct transformation of an adhesive from an adhesive film state to a honeycomb gridding state is realized. The honeycomb core end surface gridding sizing process disclosed by the invention realizes the large-area, one-time, uniform and gridding sizing of the end surface of the honeycomb core by carrying out synchronous and horizontal heating / blowing scanning on the honeycomb core / adhesive film and sufficiently utilizing the advantage of uniformity of the surface density of the structural adhesive film and meets the requirements for small chemical state change and uniform physical distribution state of the large-area honeycomb core gridding sizing on the adhesive.

Owner:BEIJING SATELLITE MFG FACTORY

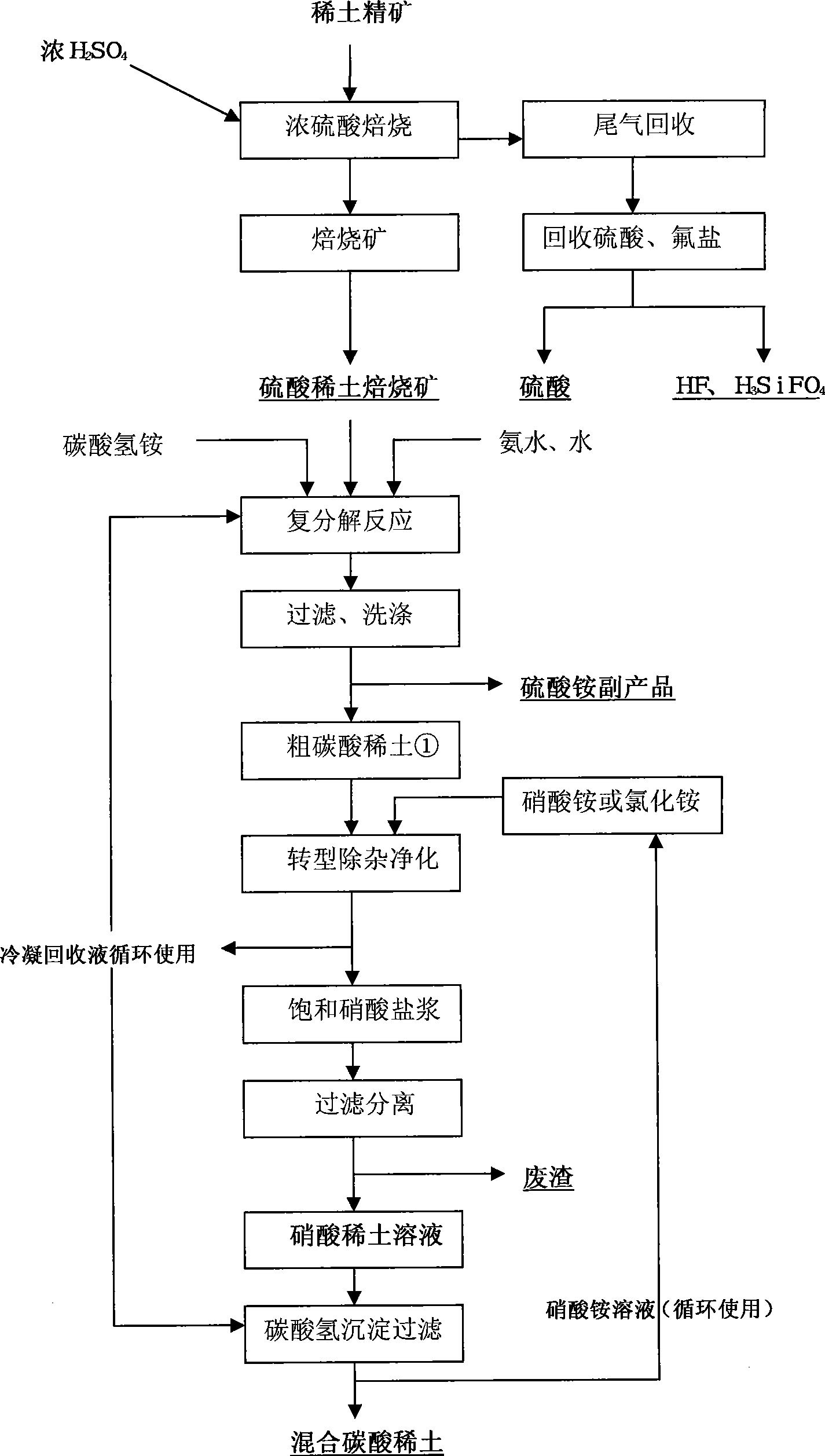

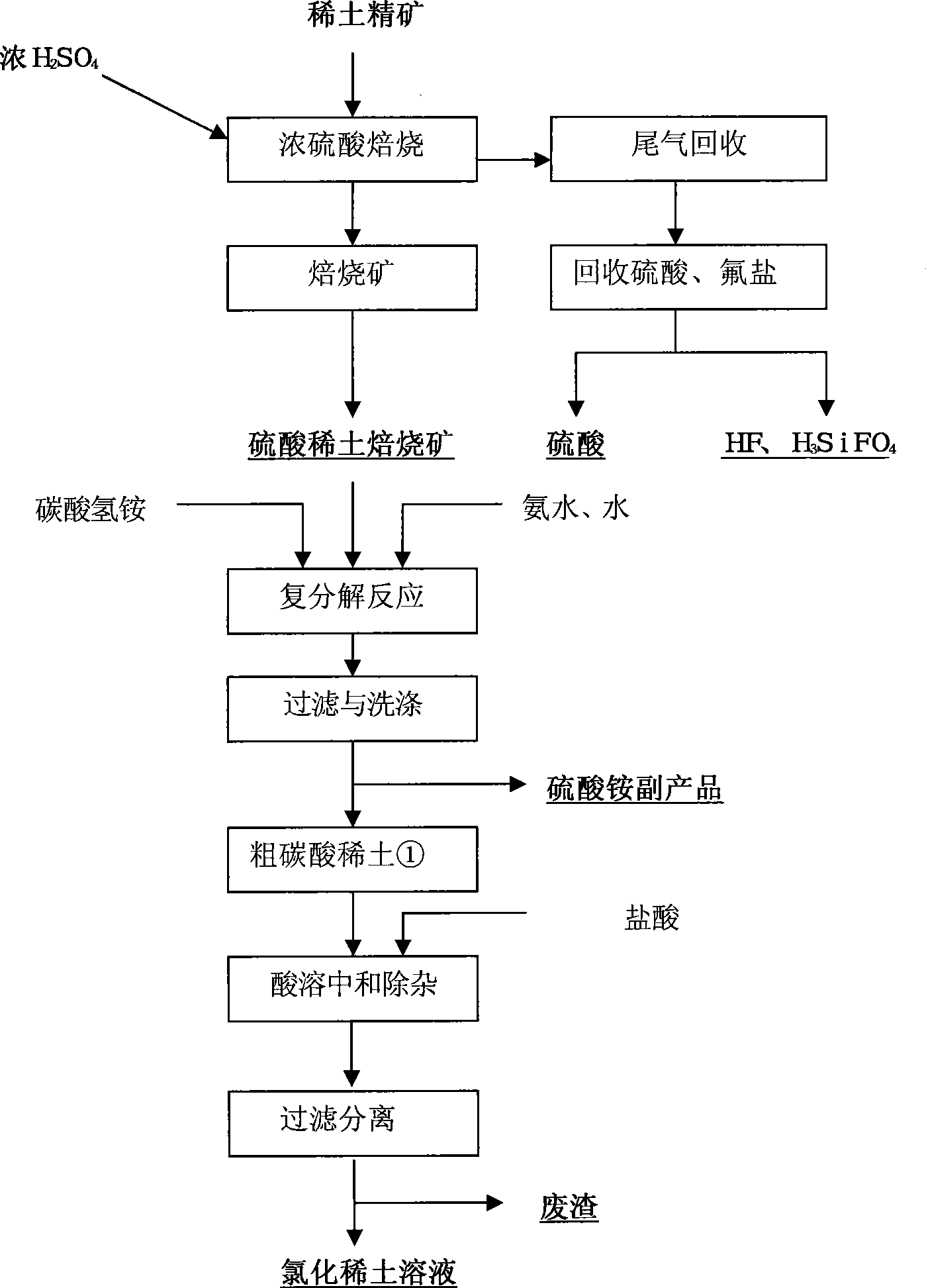

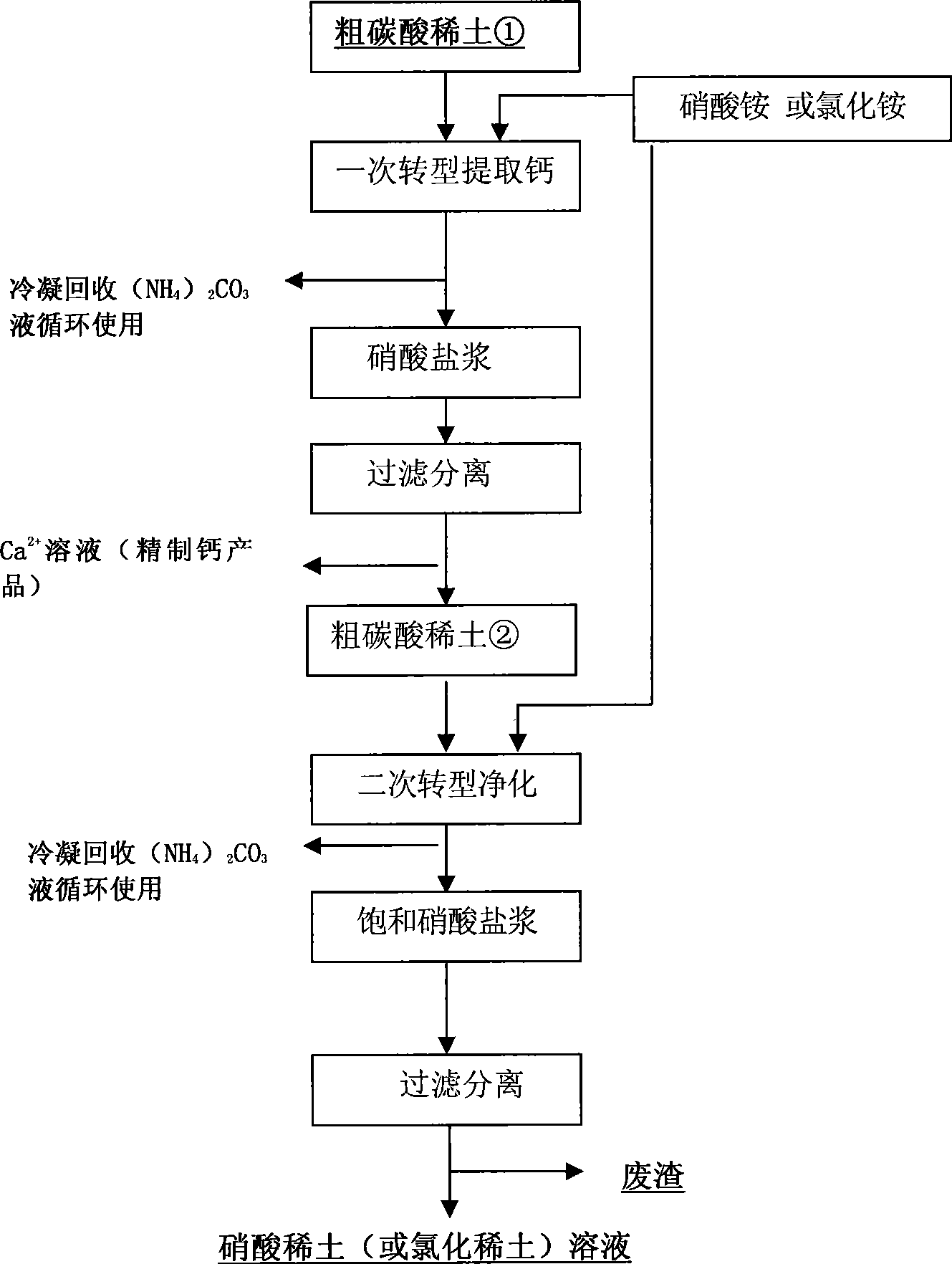

Cleaning production technique for directly transforming rare earth sulfate bake ore to extract rare earth

The invention belongs to the field of rare earth wet metallurgy and industrial chemistry, and relates to a clean production technology for roasting rare earth concentration to leach rare earth by the sulphate method. Aiming at the prior roasting production technology by the sulphate method taking Baotou rare earth concentration as raw materials, the technological process of the clean production technology realizes direct transformation production from sulphate to carbonate by the transformation technology of double decomposition reaction in chemical process and according to the principle of mutual transformation between solid substances with different solubility products. Non-rare-earth compounds (such as ammonium sulphate and ammonium carbonate) and the like are fully recovered with low cost; simultaneously, water can be fully recycled and used; the intermediate impurity removing technology is adopted to recover non-rare-earth substances such as Ca from rare earth ore. Therefore, the purpose of full-recycling and clean production in rare earth leaching process by the sulphate roasting method is realized. The technology has the advantages that the production process of rare earth ore sulphate method fully recovers rare earth elements and valuable elements from mineral products with lower cost, and clean production without sewage emission is realized.

Owner:UNIV OF SCI & TECH BEIJING

Direct conversion receiving architecture with an integrated tuner self alignment function

InactiveUS20090163162A1Low costIncreased component costTransmission monitoringResonant circuits using central processing unitsFrequency changerDigital up converter

A direct conversion receiver with an integrated self alignment tuner. The system includes a tank circuit, an analog to digital converter, a digital down converter, a digital up converter, a local oscillator, and a digital to analog converter. The tank circuit receives a radio frequency signal from an antenna input. The analog to digital converter is connected to the tank circuit to digitize the tank output signal and generate a corresponding digital signal. The digital down converter is in communication with the analog to digital converter and generates an intermediate frequency signal based on the digital signal and the output of the local oscillator. The digital up converter is in communication with the digital to analog converter to generate a radio frequency test signal, where the digital to analog converter provides the radio frequency test signal to the antenna input.

Owner:VISTEON GLOBAL TECH INC

Integrated tracking filters for direct conversion and low-IF single conversion broadband filters

A radio frequency (RF) tuner includes a programmable tracking filter bank receiving an RF input and outputting a filtered RF signal. A mixer stage receives the filtered RF signal and outputs a first quadrature component of the filtered RF signal and a second quadrature component of the filtered RF signal. Two variable gain amplifiers receive the first and second quadrature components and output amplitude-controlled I and Q components of the filtered RF signal. In one embodiment, the programmable tracking filter bank includes a plurality of tank circuits each connected to the RF input through an impedance. Each tank circuit include an inductor and a capacitor connected in parallel thereby forming an LC network, and a plurality of switched capacitors in parallel with the LC network and switched in and out of the tank circuit by programmable switches. In another embodiment, the programmable tracking filter bank includes a plurality of peaked low-pass circuits each connected to the RF input through an impedance. Each peaked low-pass circuit includes a capacitor connected to ground, and a plurality of switched capacitors in parallel with the capacitor and switched in and out of the peaked low-pass circuit by programmable switches.

Owner:AVAGO TECH INT SALES PTE LTD

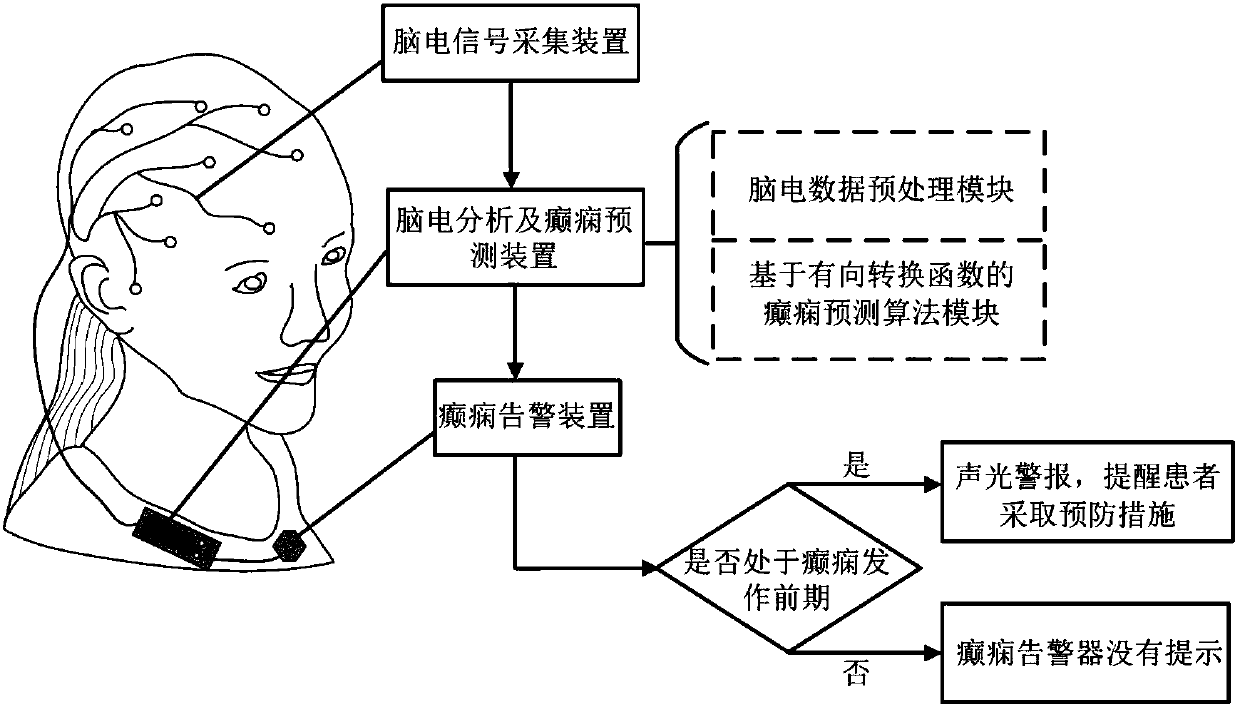

Electroencephalogram monitoring device and method with epileptic seizure predicting function

InactiveCN107616793ADiagnostic recording/measuringSensorsMonitoring systemScalp electroencephalogram

The invention discloses an electroencephalogram monitoring device with an epileptic seizure predicting function and a method. The electroencephalogram monitoring device and method can be applied to ascalp electroencephalograph machine or an embedded cortex electroencephalogram monitoring system. The method of the device comprises the following steps of 1, acquiring an electroencephalogram signalof a patient through an electroencephalogram acquisition device; 2, transmitting the electroencephalogram signal to an epileptic predicting alarming device; 3, judging the state of the patient throughan epilepticprediction algorithm module in the epileptic predicting alarming device, and once the epileptic measurement module judges that the patient is in the early stage of anepileptic seizure, sound-lightalarm can be triggered, and the patient and his / her dependents are prompted to take prevention measures. The epilepticprediction algorithm moduleuses a directed transformation function as a basis and characteristics of a connection matrix among electroencephalogram signals as parameters for predicting the epilepticseizure of the patient, the epileptic seizure can be predicted several dozens of minutes in advance, and the electroencephalogram monitoring device and method have high clinical and practical significance.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

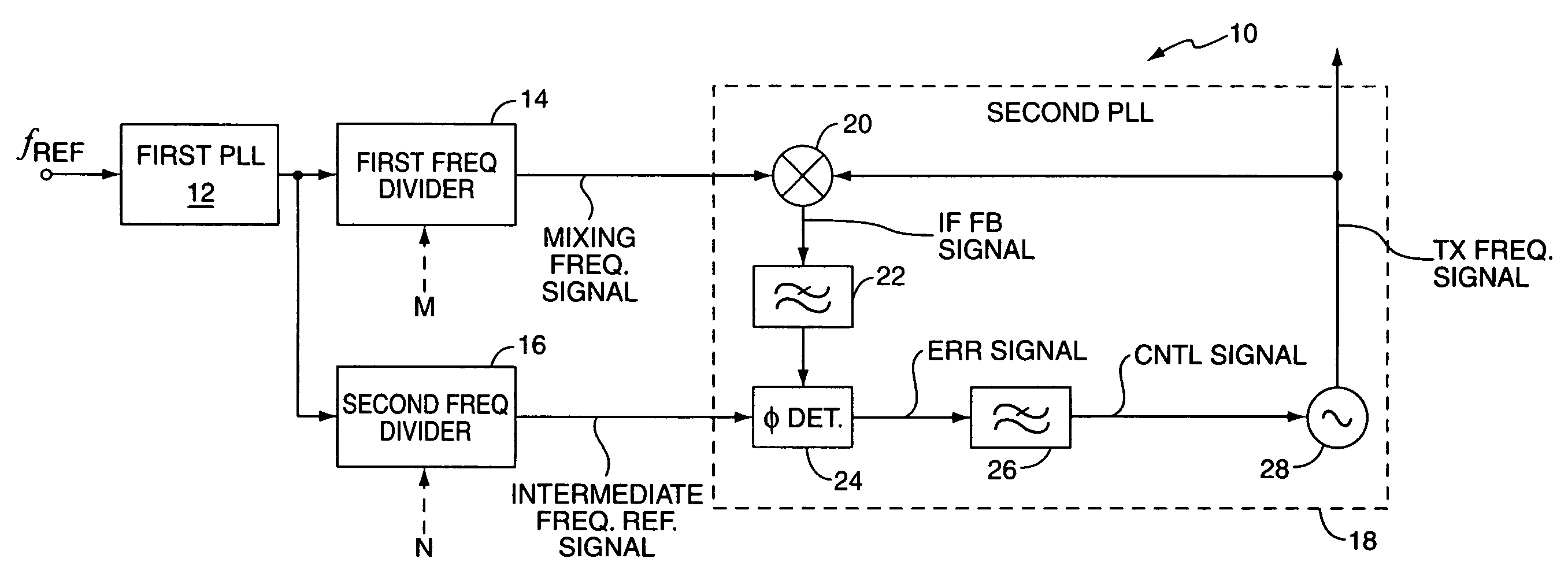

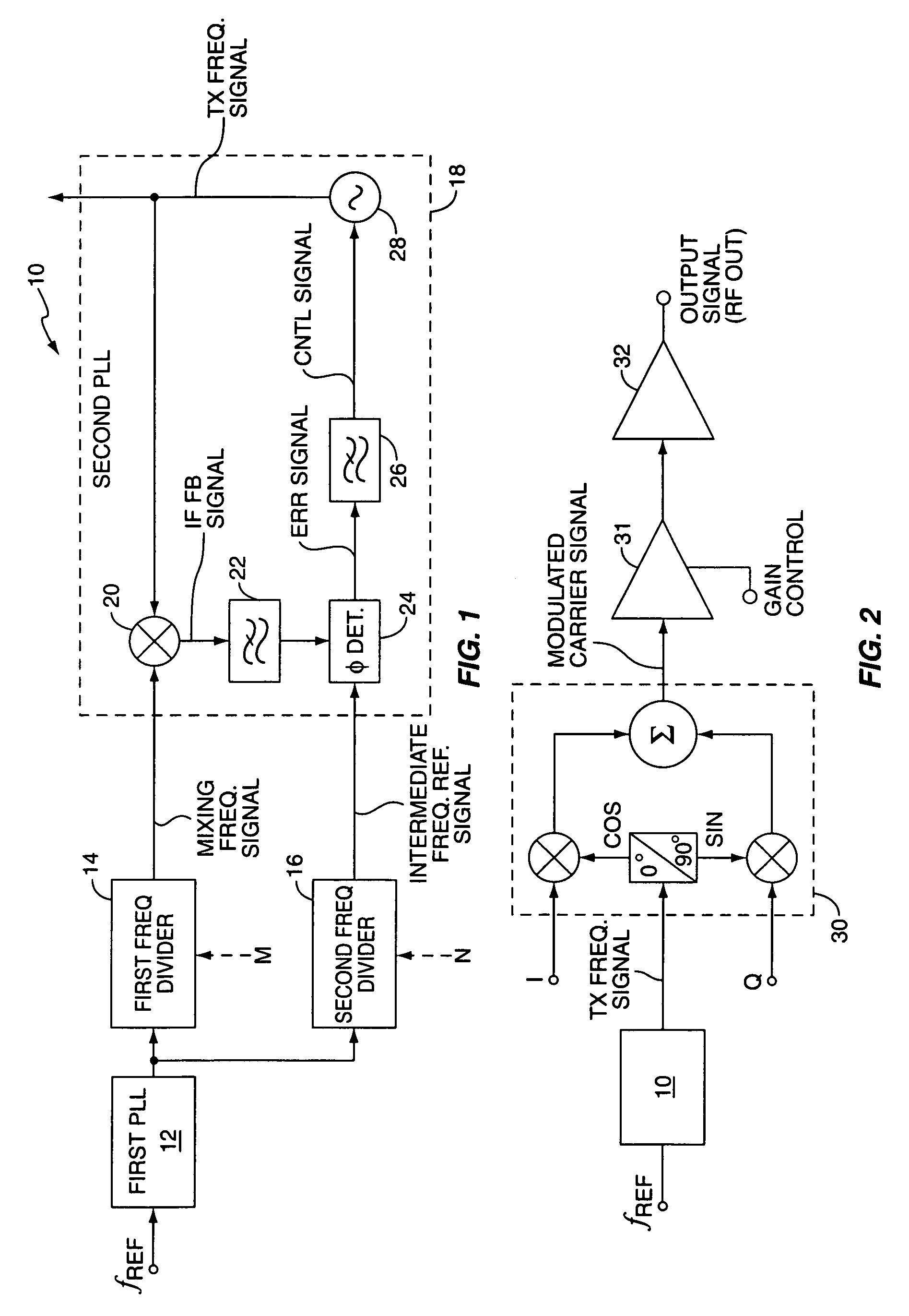

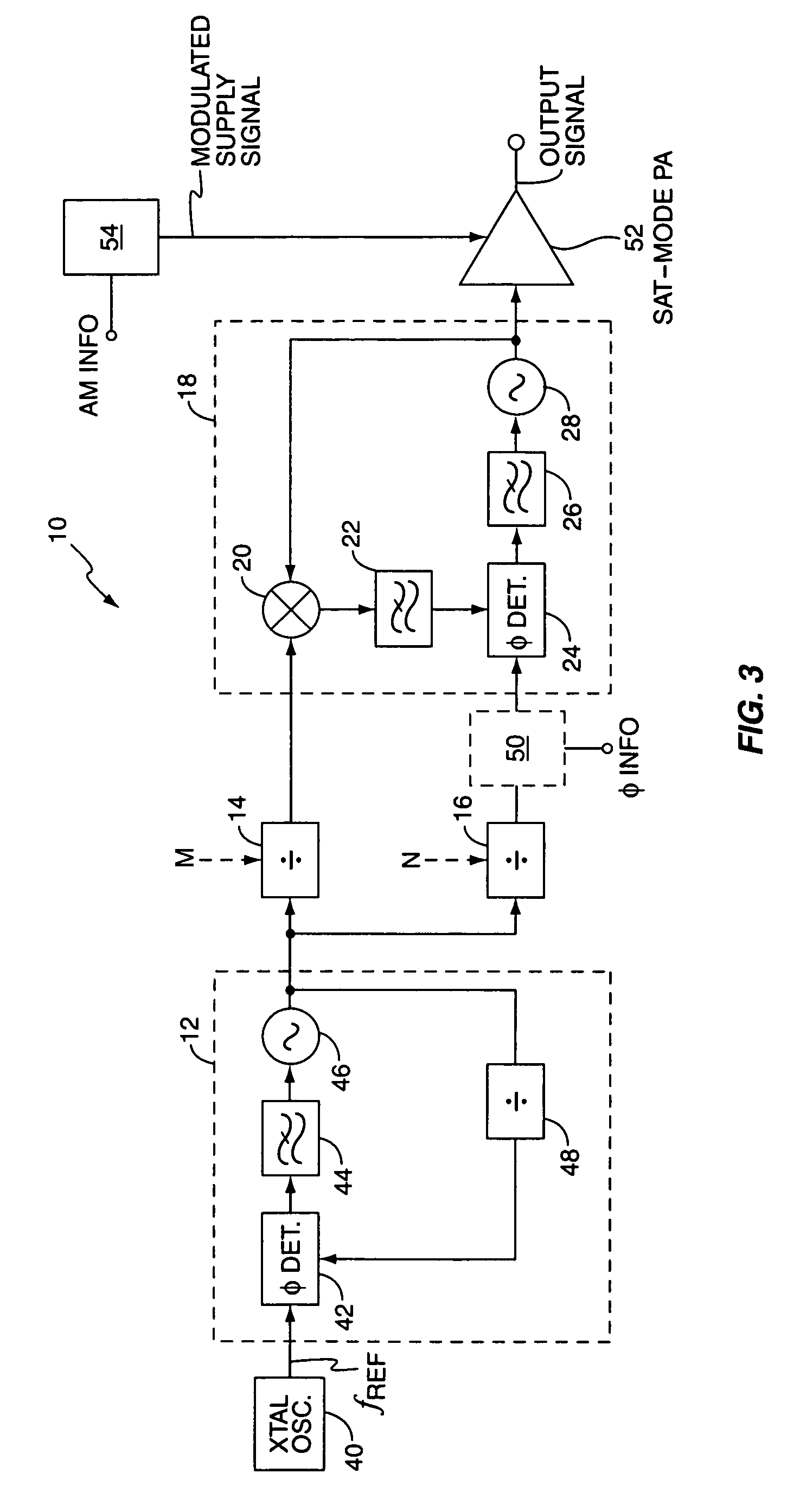

Method and apparatus for frequency synthesis in direct-conversion transmitters

ActiveUS7409192B2Good resistance to VCO pulling effectConveniently and economically obtainSimultaneous amplitude and angle modulationResonant long antennasQuadrature modulatorLinear power amplifier

A method and apparatus for direct-conversion transmission generates a first frequency signal that is non-harmonically related to a transmit frequency signal, divides the first frequency signal to obtain a mixing frequency signal, divides the first frequency signal to obtain an intermediate frequency reference signal, generates the transmit frequency signal by using the mixing frequency signal to downconvert the transmit frequency signal into an intermediate frequency feedback signal, and phase-locks the intermediate frequency feedback signal to the intermediate frequency reference signal. The transmit frequency signal may be phase modulated, and may serve as an input to a saturated-mode power amplifier that can be configured for corresponding amplitude modulation. Alternatively, the un-modulated transmit frequency signal serves as the carrier signal input to a quadrature modulator, which imparts I / Q modulations to it, thereby producing a modulated carrier signal for input to a linear power amplifier.

Owner:TELEFON AB LM ERICSSON (PUBL)

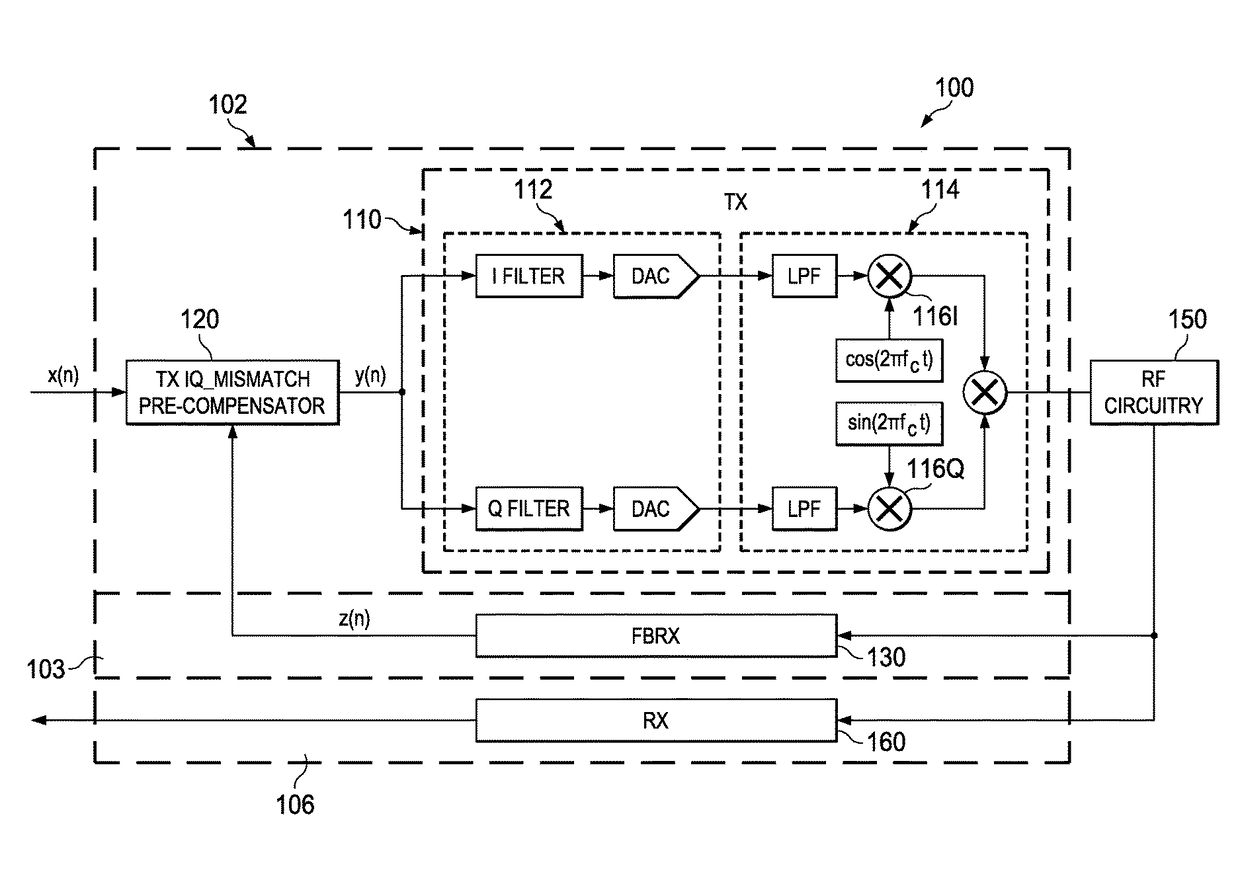

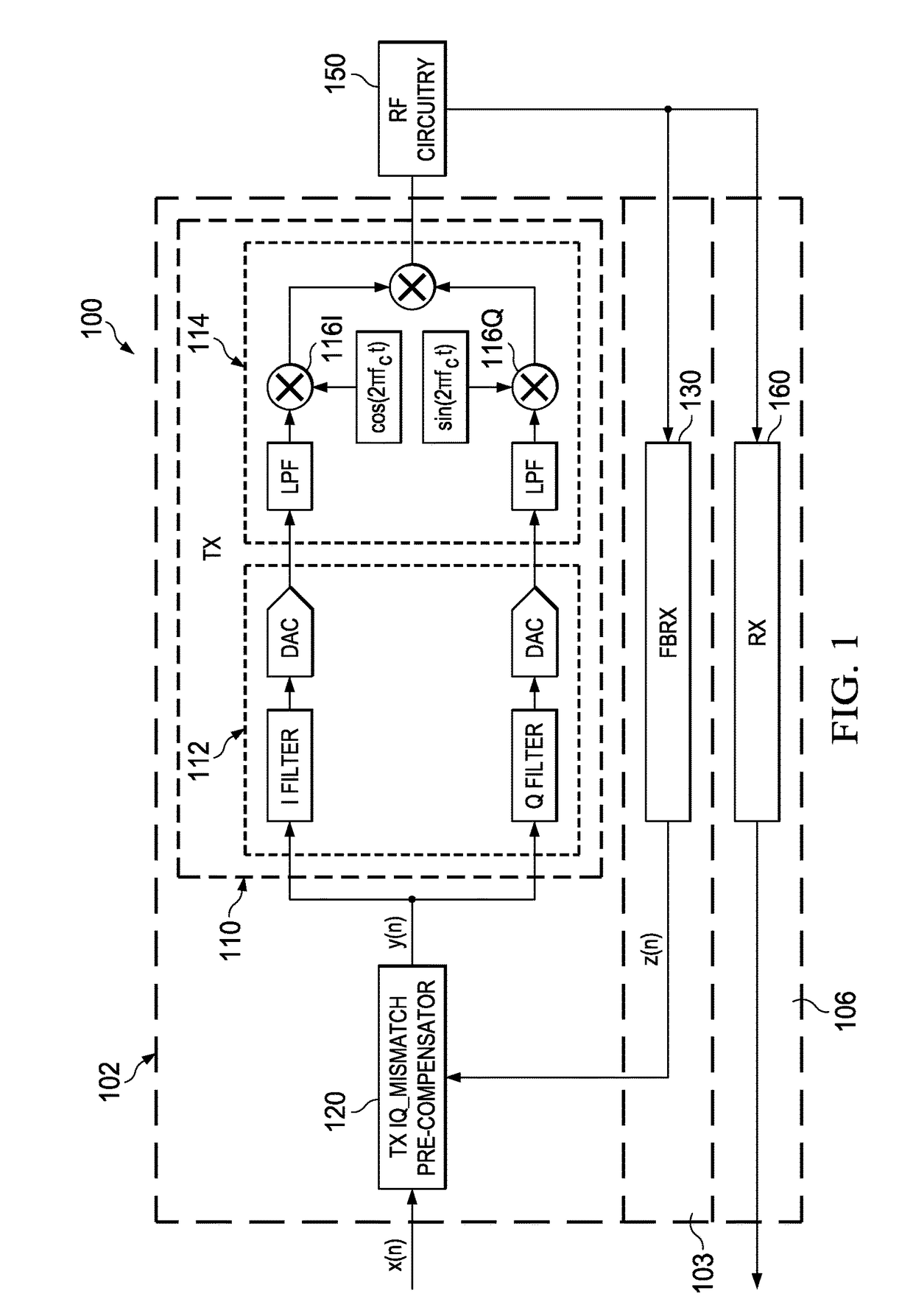

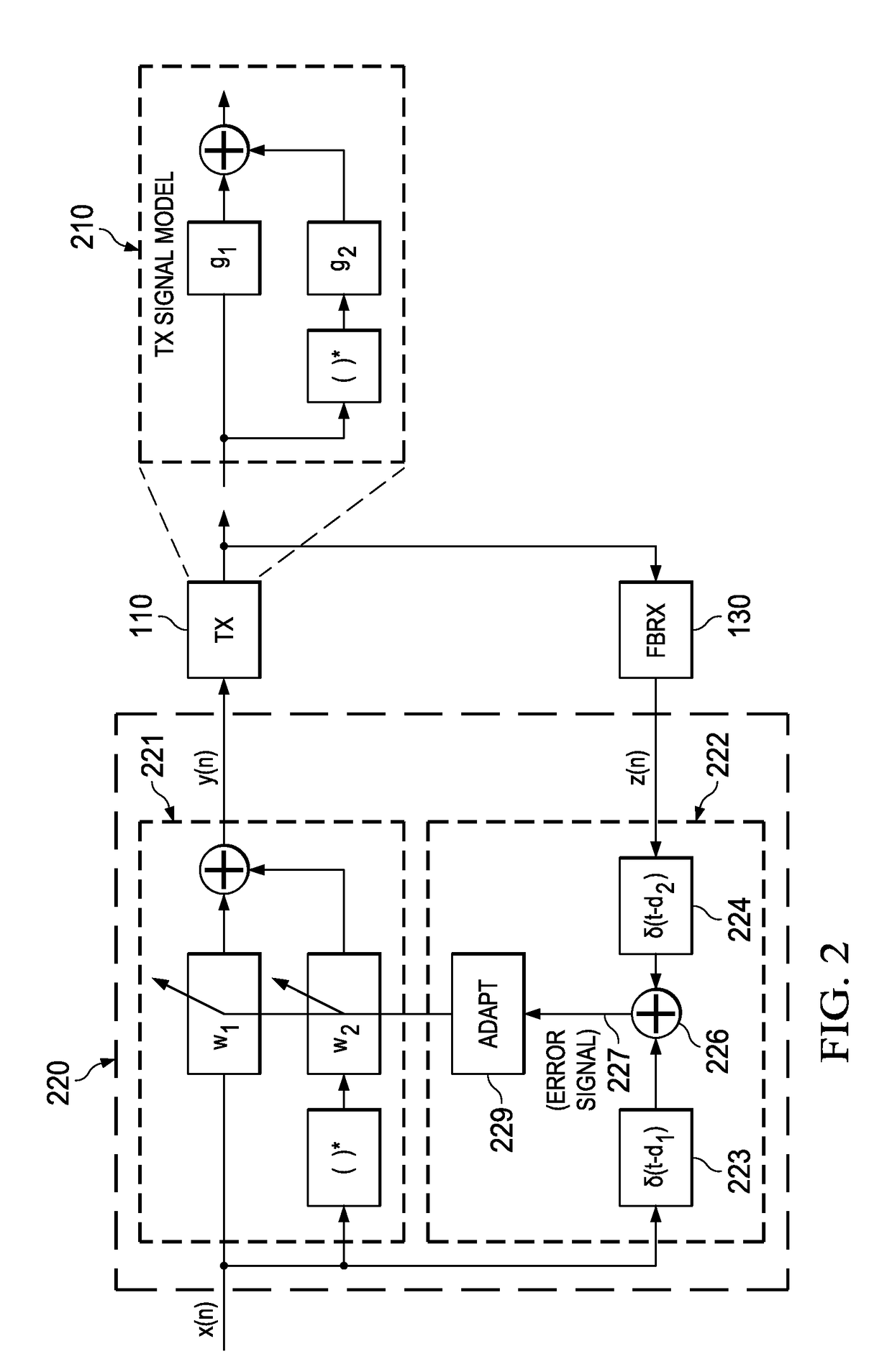

TX IQ mismatch pre-compensation

ActiveUS10097396B2Analogue/digital conversionElectric signal transmission systemsDigital signal processingSelf adaptive

A direct conversion wireless transmitter includes IQ mismatch pre-compensation using direct learning adaptation to adjust IQ pre-compensation filtering. Widely-linear IQ_mismatch pre-compensation filtering compensates for IQ mismatch in the TX analog chain, filtering of input data x(n) to provide pre-compensated data y(n) with a compensation image designed to interfere destructively with the IQ_mismatch image. A feedback receiver FBRX captures feedback data z(n) used for direct learning adaptation. DL adaptation adjusts IQ_mismatch filters, modeled as an x(n)_direct and complex conjugate x(n)_image transfer functions w1 and w2, including generating an adaptation error signal based on a difference between TX / FBRX-path delayed versions of x(n) and z(n), and can include estimation and compensation for TX / FBRX phase errors. DL adaptation adjusts the IQ pre-comp filters w1 / w2 to minimize the adaptation error signal. Similar modeling can be used for IQ mismatch. The IQ_mismatch pre-compensator can be implemented as a combination of digital signal processing and hardware acceleration.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com