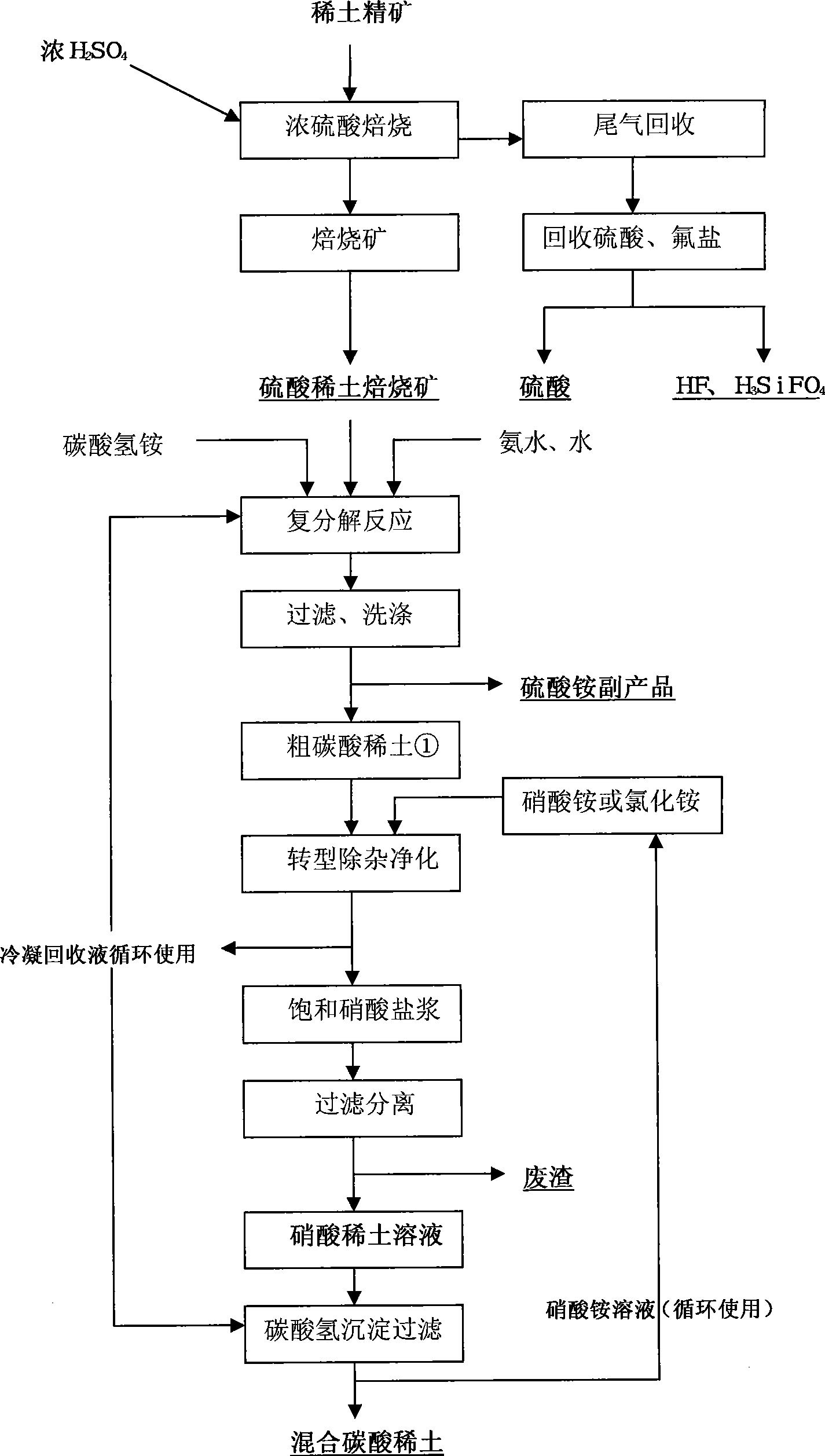

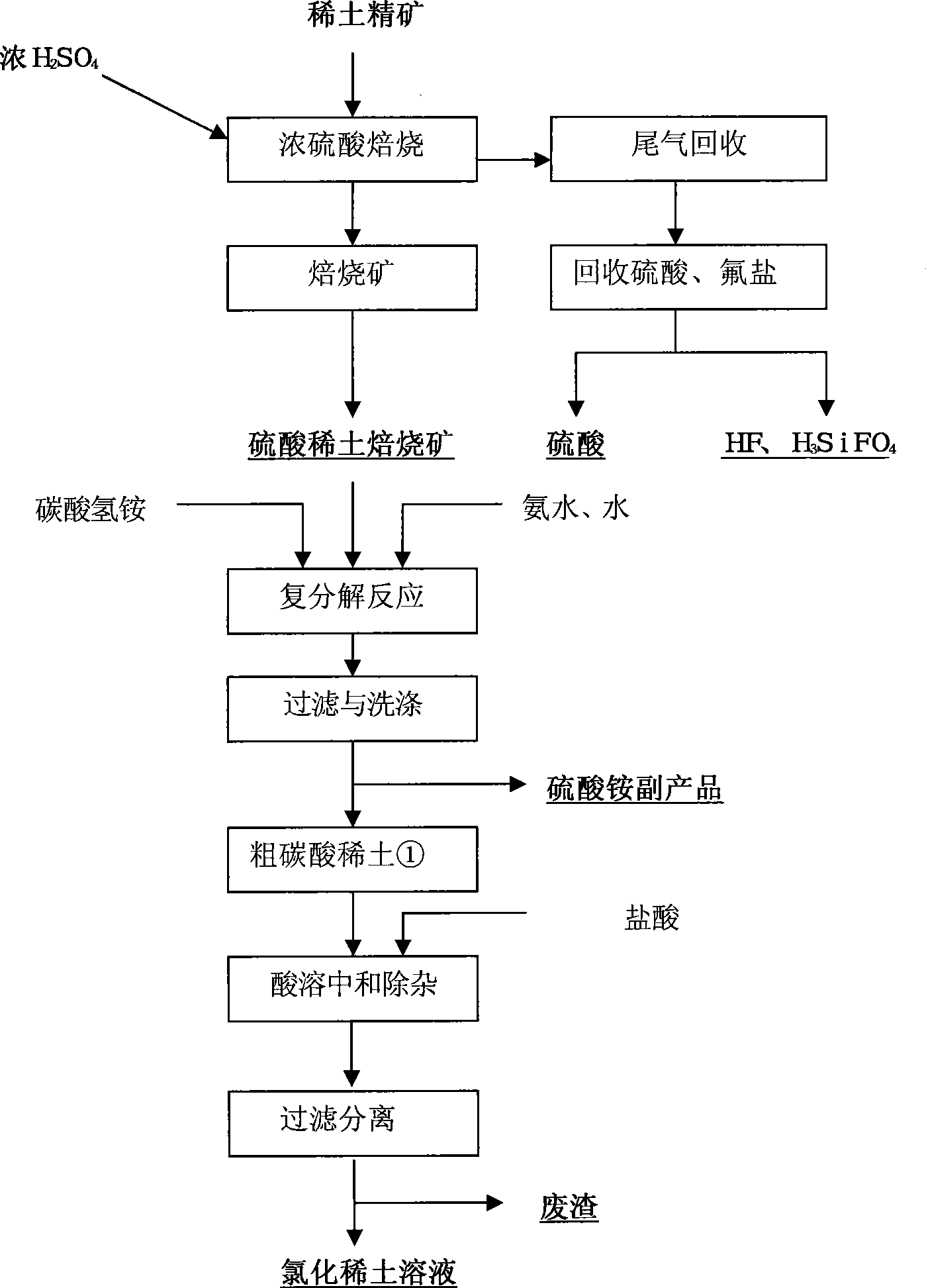

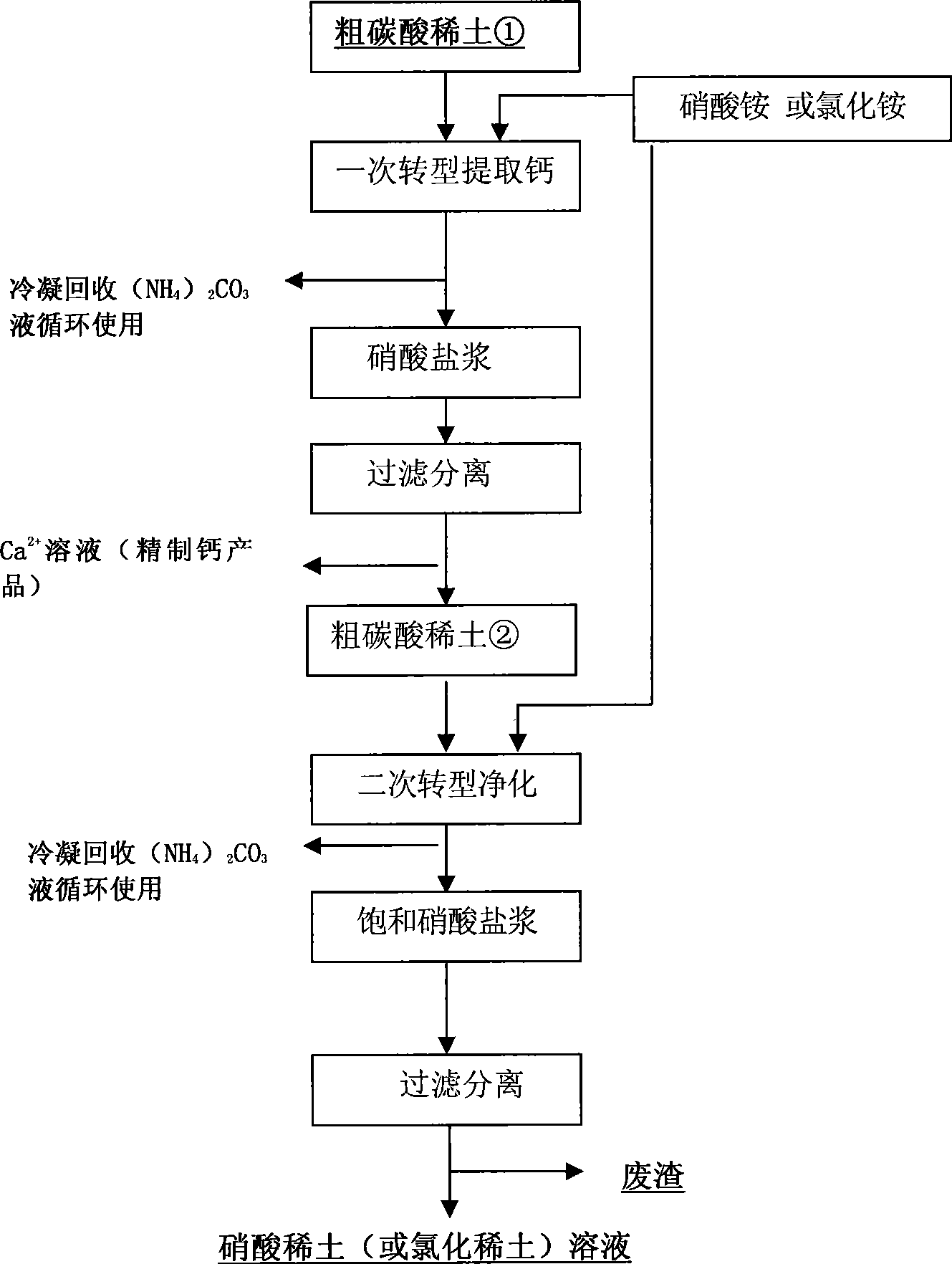

Cleaning production technique for directly transforming rare earth sulfate bake ore to extract rare earth

A rare earth sulfate and production process technology, applied in rare earth hydrometallurgy and chemical industry, can solve the problems of low solution concentration, difficult end-to-end treatment, affecting the yield of rare earth, etc., to achieve clean, clean production, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Unless otherwise specified, the percentages involved in the following examples are all mass percentages.

[0042] Follow the steps below:

[0043] (1) According to the current sulfuric acid roasting production process using Baotou rare earth concentrate as raw material, the rare earth concentrate is roasted with concentrated sulfuric acid to obtain 1000g of rare earth sulfate roasted ore, mixed with water, and under the condition of stirring, add hydrogen carbonate at 55°C Ammonium 970g was reacted, the concentration of ammonium bicarbonate was controlled to 15%, a certain amount of ammonia solution was added, the pH value of the reaction process was controlled to be 6-9, and the reaction time was 7 hours. After the reaction was complete, it was filtered to obtain crude rare earth carbonate and ammonium sulfate solution;

[0044] (2) After the ammonium sulfate solution obtained in the step (1) is directly through evaporation, concentration and crystallization, the ammon...

Embodiment 2

[0049] Unless otherwise specified, the percentages involved in the following examples are all mass percentages.

[0050] Follow the steps below:

[0051] (1) According to the current sulfuric acid roasting production process using Baotou rare earth concentrate as raw material, the rare earth concentrate is roasted with concentrated sulfuric acid to obtain 1000g of rare earth sulfate roasted ore, mixed with water, and under the condition of stirring, add hydrogen carbonate at 55°C React with 970g of ammonium, control the concentration of ammonium bicarbonate to 15%, add a certain amount of ammonia solution, control the pH value of the reaction process = 6-9, and the reaction time is 7 hours. After the reaction is complete, filter to obtain crude rare earth carbonate and ammonium sulfate solution;

[0052] (2) After the ammonium sulfate solution obtained in the step (1) is directly through evaporation, concentration and crystallization, the ammonium sulfate product is obtained; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com