Patents

Literature

702 results about "Diammonium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium carbonate is a salt with the chemical formula (NH4)2CO3. Since it readily degrades to gaseous ammonia and carbon dioxide upon heating, it is used as a leavening agent and also as smelling salt.

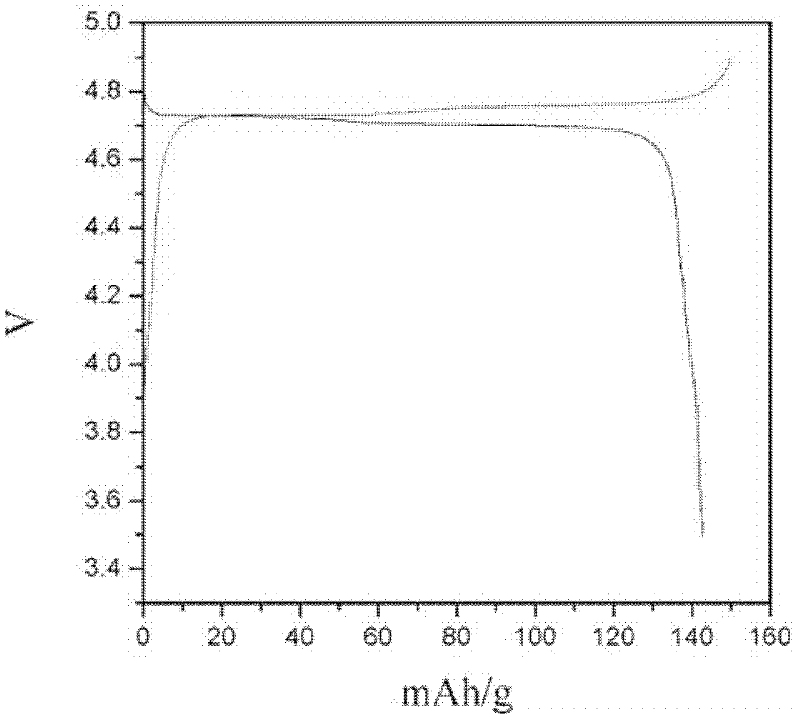

Method for preparing nickel and cobalt doped lithium manganate by using waste and old lithium ionic cell as raw material

InactiveCN101450815ASimultaneous recyclingShort processManganates/permanganatesManganateManganese oxide

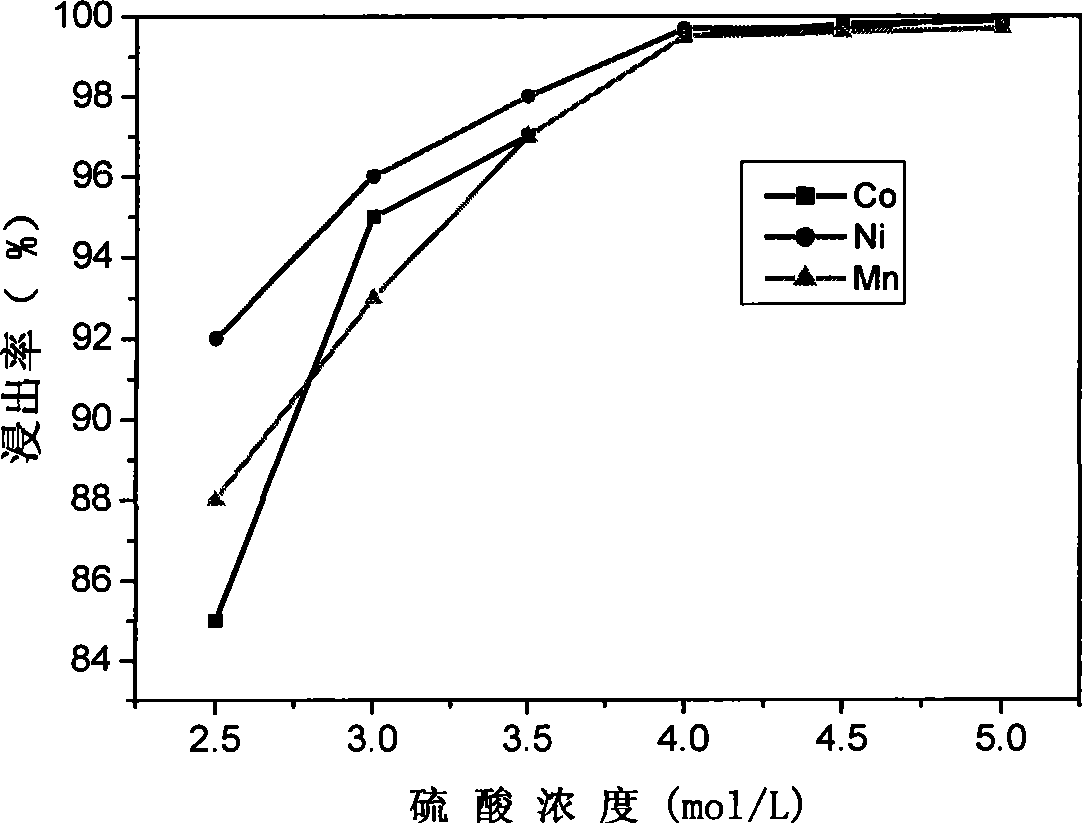

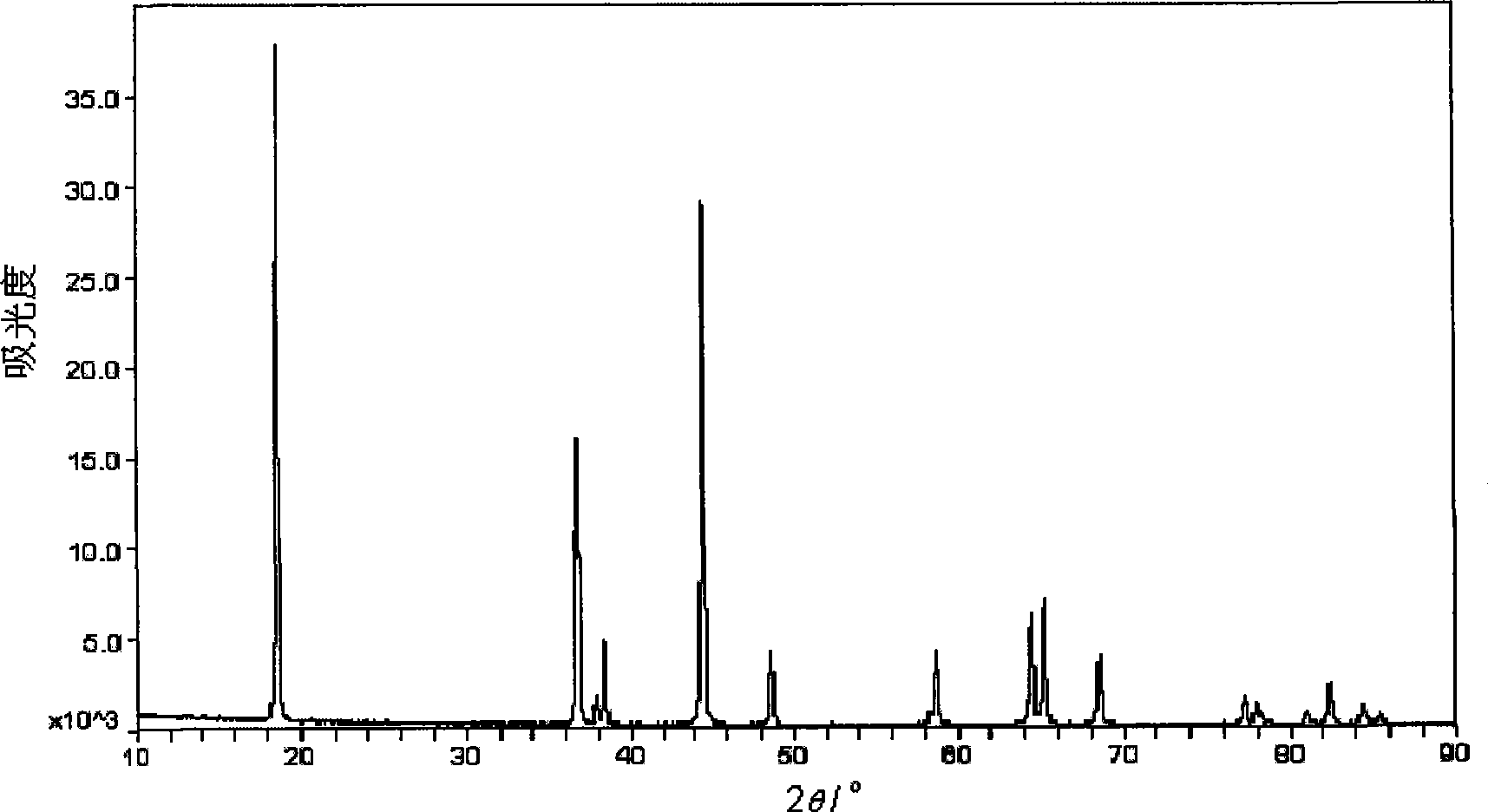

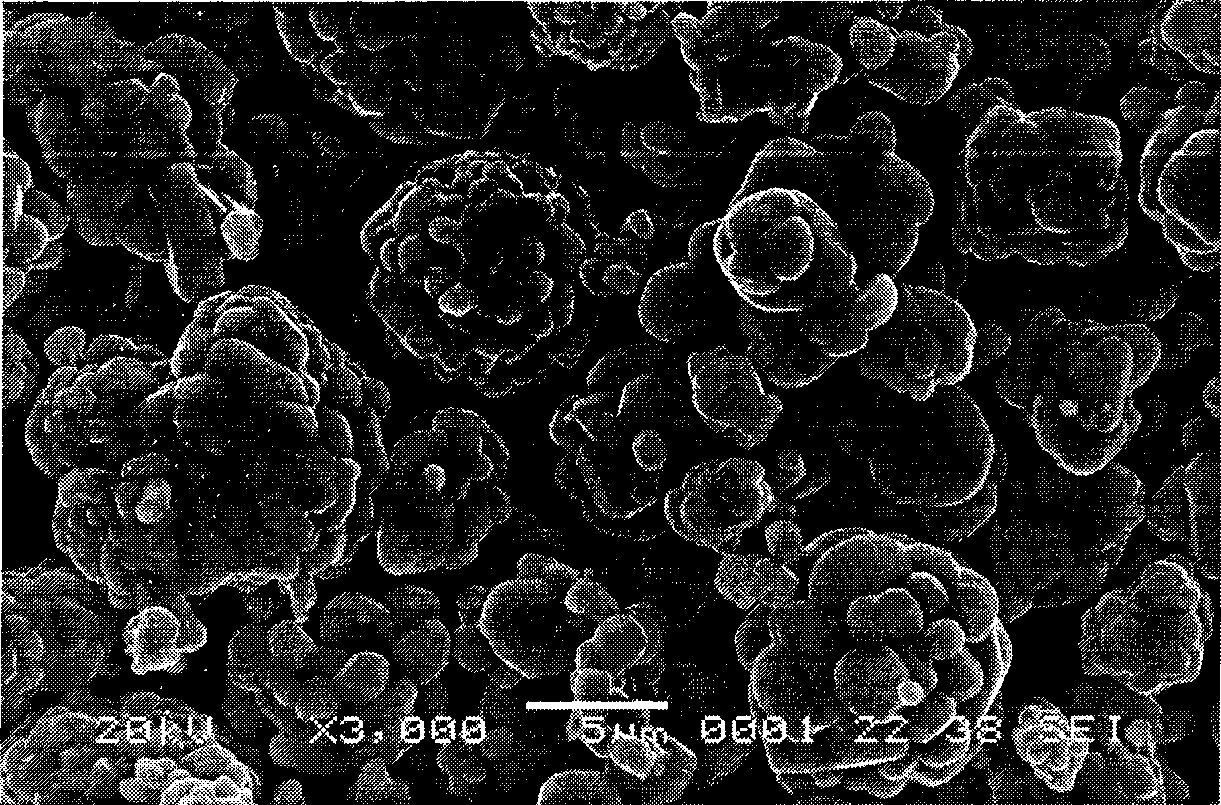

The invention discloses a method for preparing lithium nickel cobalt manganese oxide by taking a waste lithium ion battery as a raw material. The method is mainly characterized in that a waste lithium ion battery taking the lithium nickel cobalt manganese oxide, lithium nickel cobalt oxide and so on as a battery positive material is selected as the raw material and is pretreated through disassembly, separation, crushing, screening and so on, and then processes such as adhesive removal at high temperature and aluminum removal by sodium hydroxide are adopted to obtain an inactivated positive material containing nickel, cobalt and manganese; then a sulfuric acid and hydrogen peroxide system is adopted to leach, and P204 is adopted to remove impurities by extraction to obtain pure nickel, cobalt and manganese solution, and proper manganese sulfate, nickel sulfate or cobalt sulfate is blended to ensure that the mol ratio of nickel, cobalt and manganese elements in the solution is 1: 1: 1; and then ammonium carbonate is adopted to adjust the pH value to form a nickel cobalt manganese carbonate precursor, and then a proper amount of lithium carbonate is blended for high temperature sintering to synthesize a lithium nickel cobalt manganese oxide battery material. The first discharge capacity of the material is 150 mAh / g, the discharge capacity is still kept more than 130mAh / g after the circulation for 30 times, and the material has good electrochemical performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

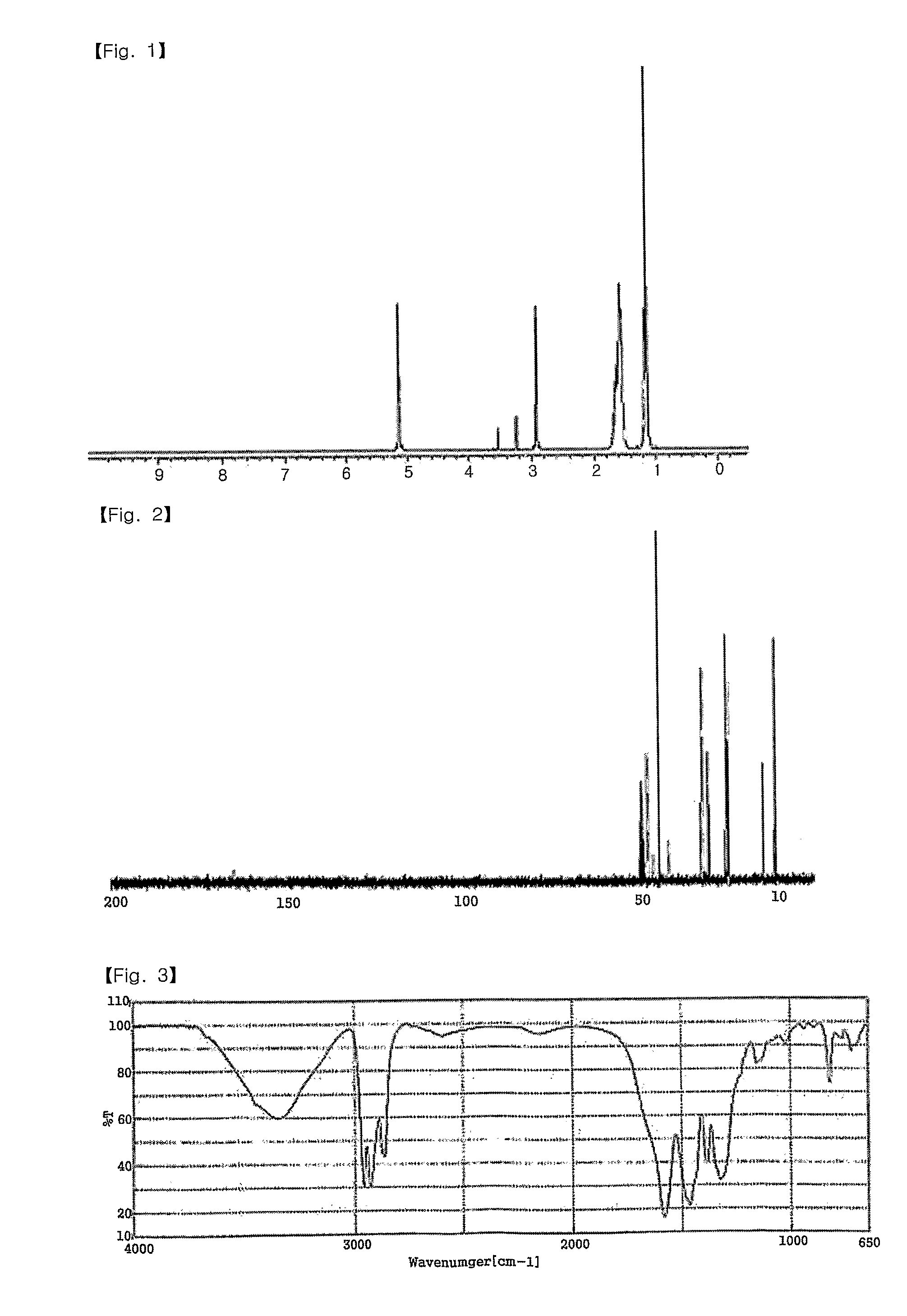

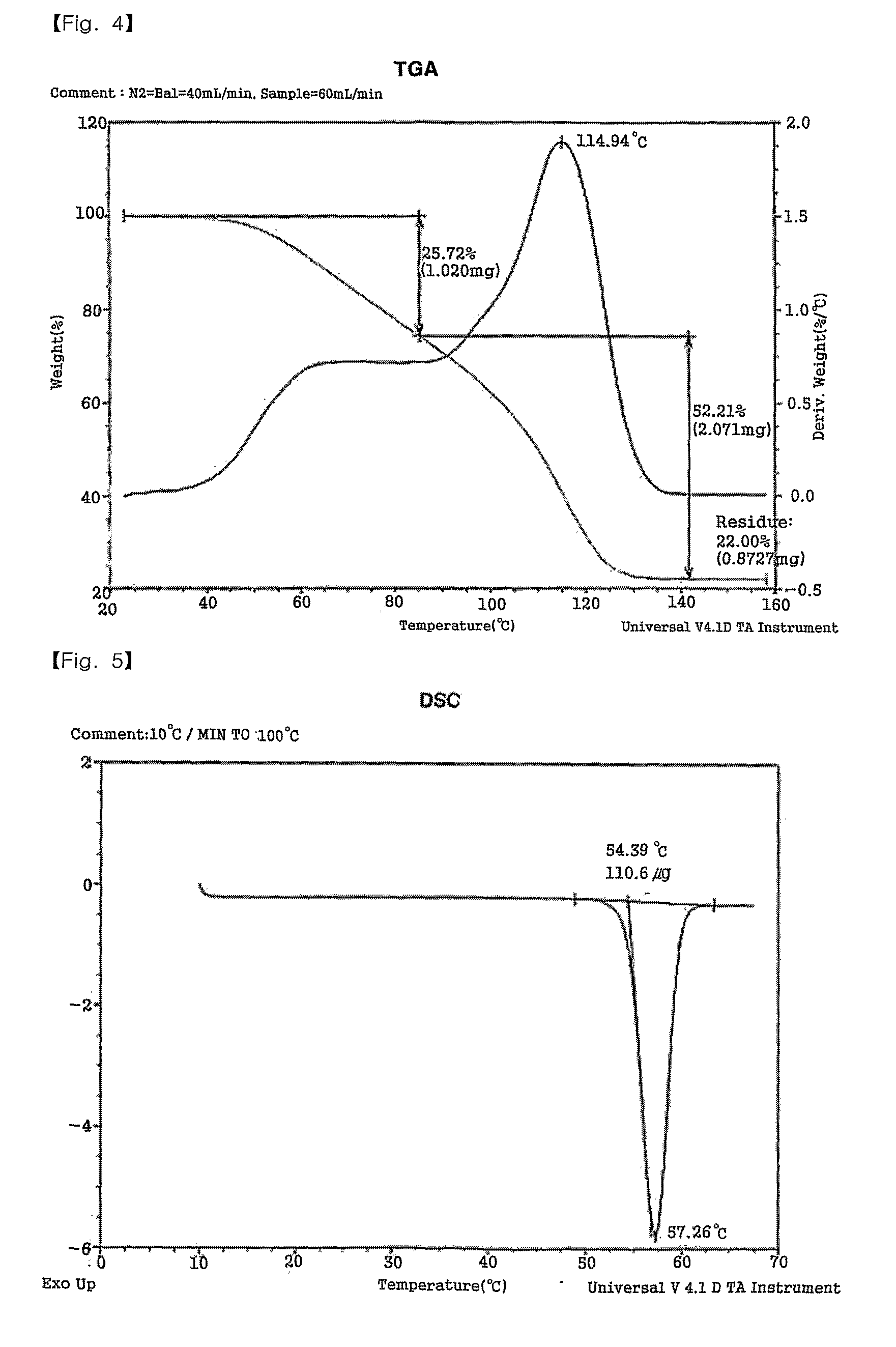

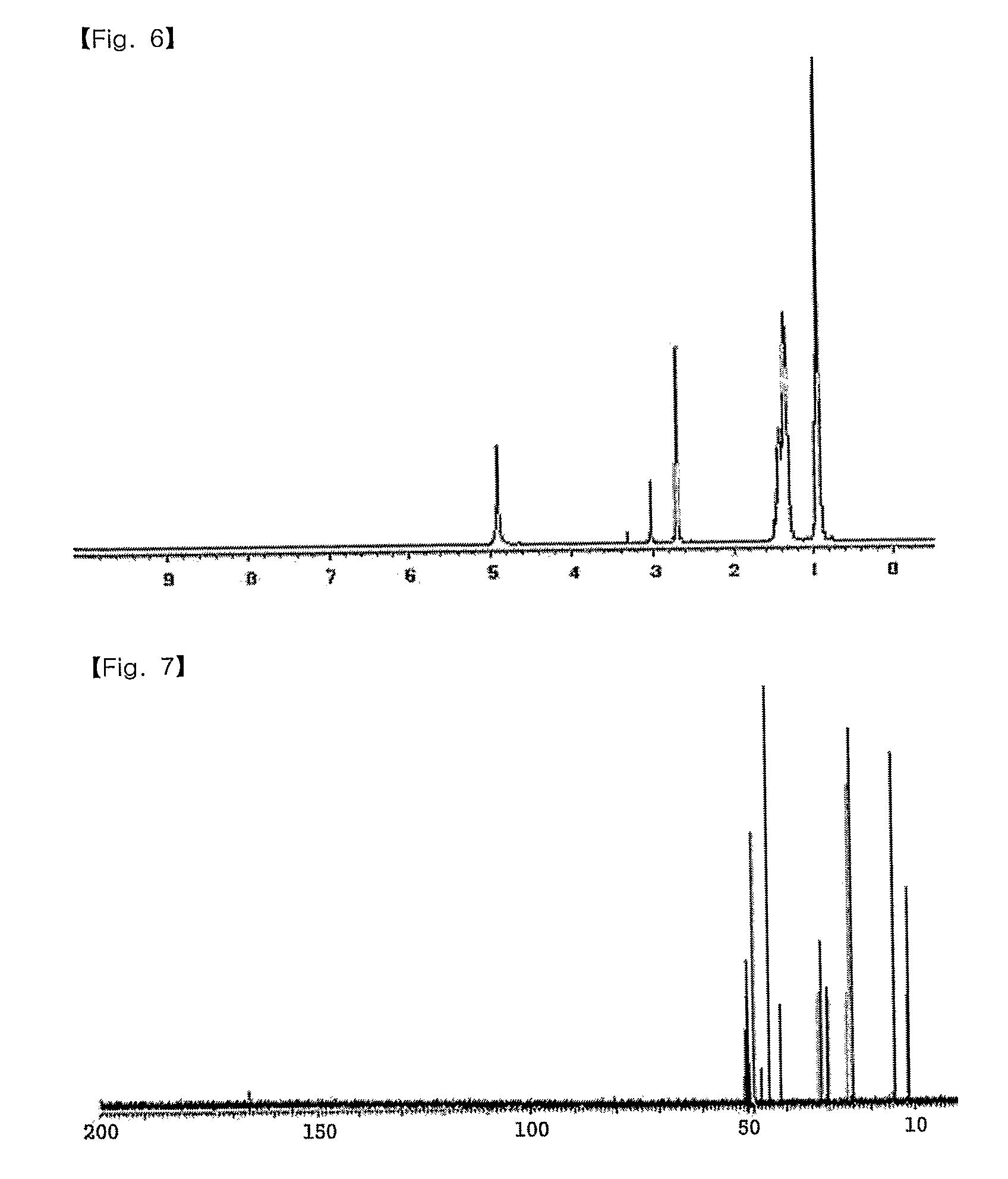

Process for preparation of silver nanoparticles, and the compositions of silver ink containing the same

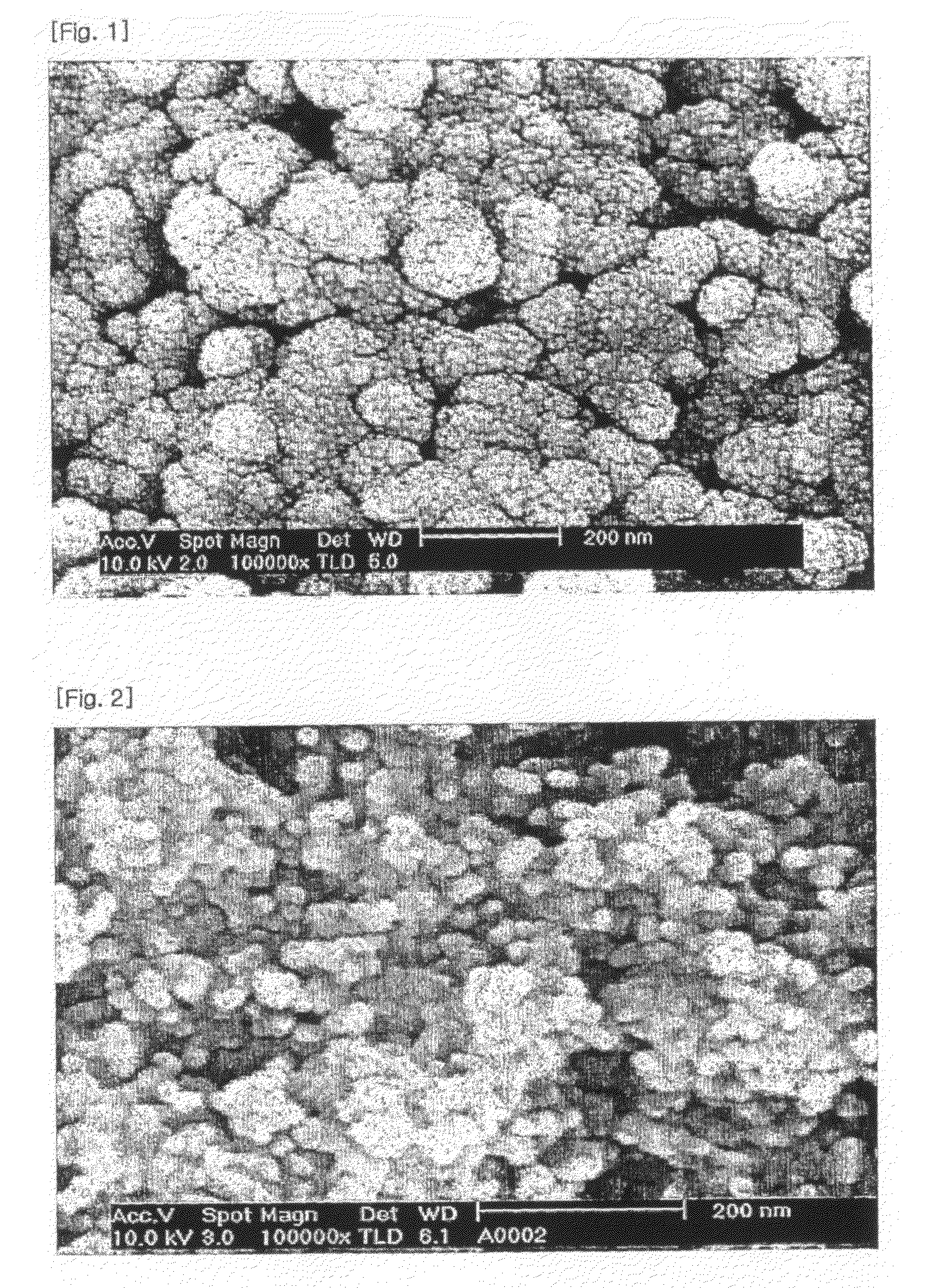

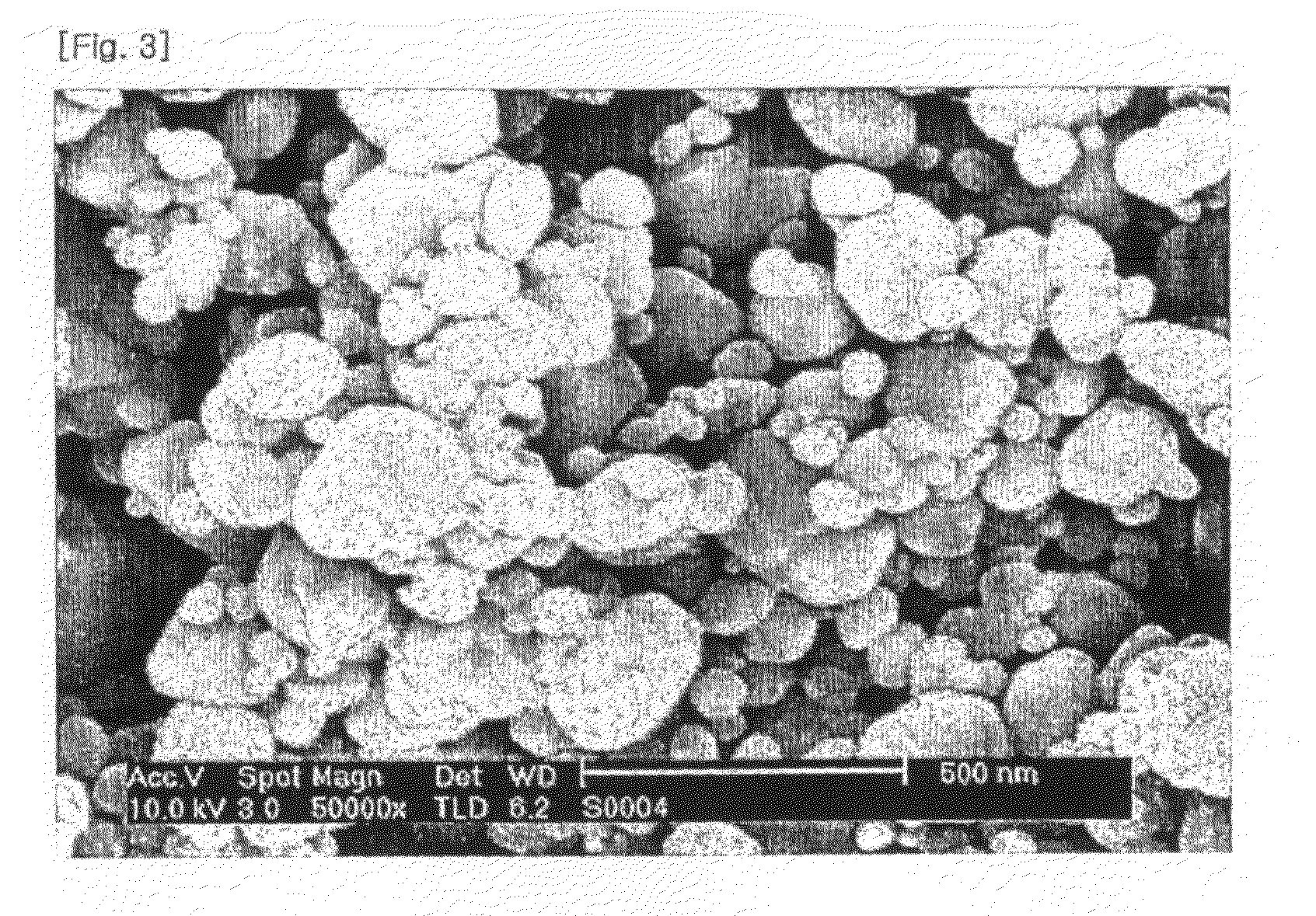

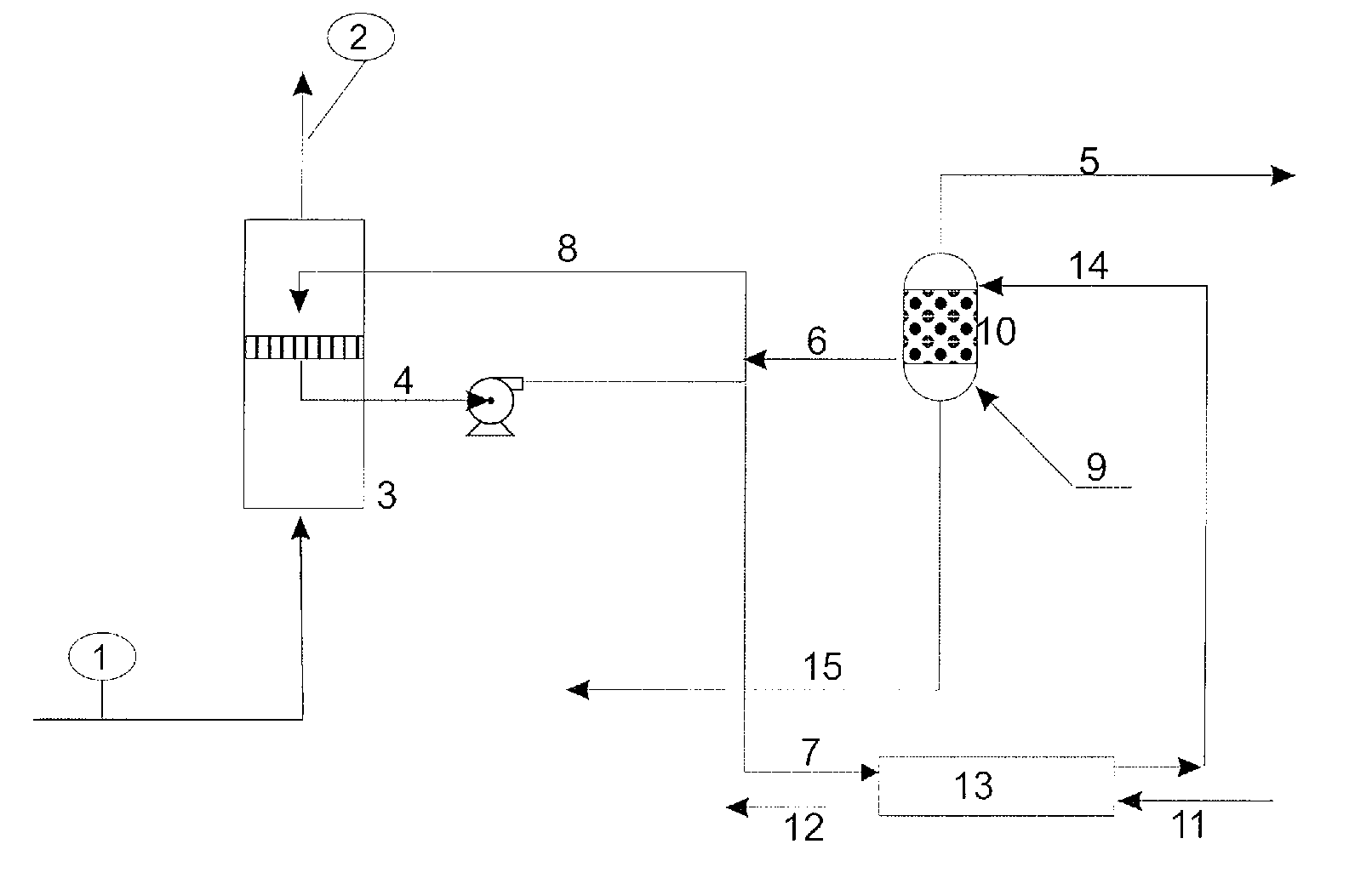

ActiveUS20100189901A1Small sizeGood physical propertiesMaterial nanotechnologyNanostructure manufactureSilver inkAmmonium carbamate

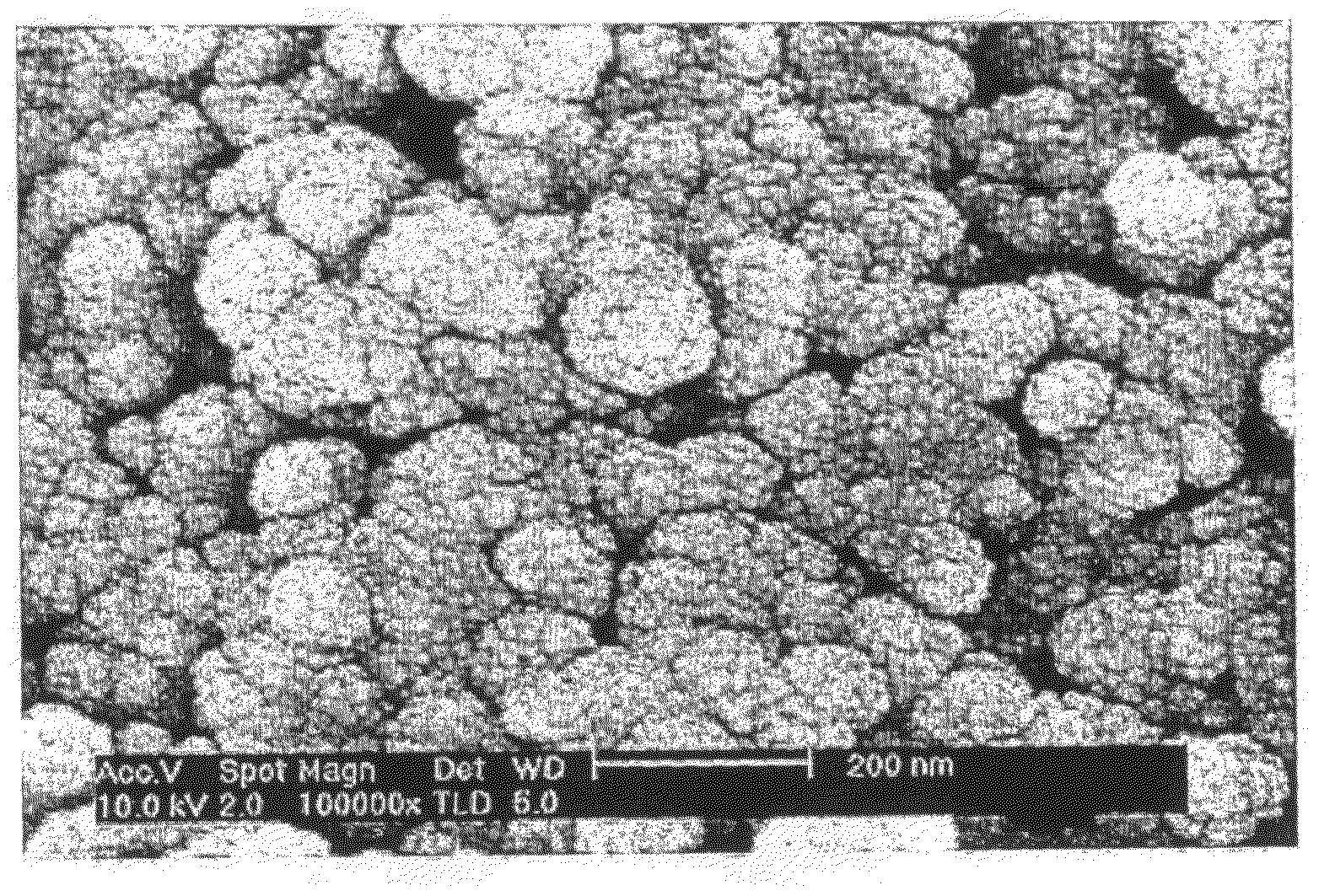

The present invention relates to a process for preparation of silver complex compound and the compositions of silver ink containing the same. The present invention includes a) preparing silver complex compound with special structure by reacting silver compound with at least one or two mixtures selected from ammonium carbamate compound, ammonium carbonate compound or ammonium bicarbonate compound and b) preparing silver nano particles by reacting the silver complex compound with reducer or reducing or pyrolyzing the silver complex compound by applying heat thereto. The preparing method according to the present invention can prepare the silver nano practical with various shapes through a simple preparation process, improve the selectivity of the size of the silver complex compound, fire the silver complex compound even when it is fired at a low temperature of 150° C. or less during a short time, provide the ink compositions capable of forming the coating or the fine pattern showing the high conductivity while facilitating the thickness control of the coating, and provide the ink compositions capable of being applied to the reflective film material, the electromagnetic wave shield, and the antimicrobial agent, etc.

Owner:INKTEC CO LTD

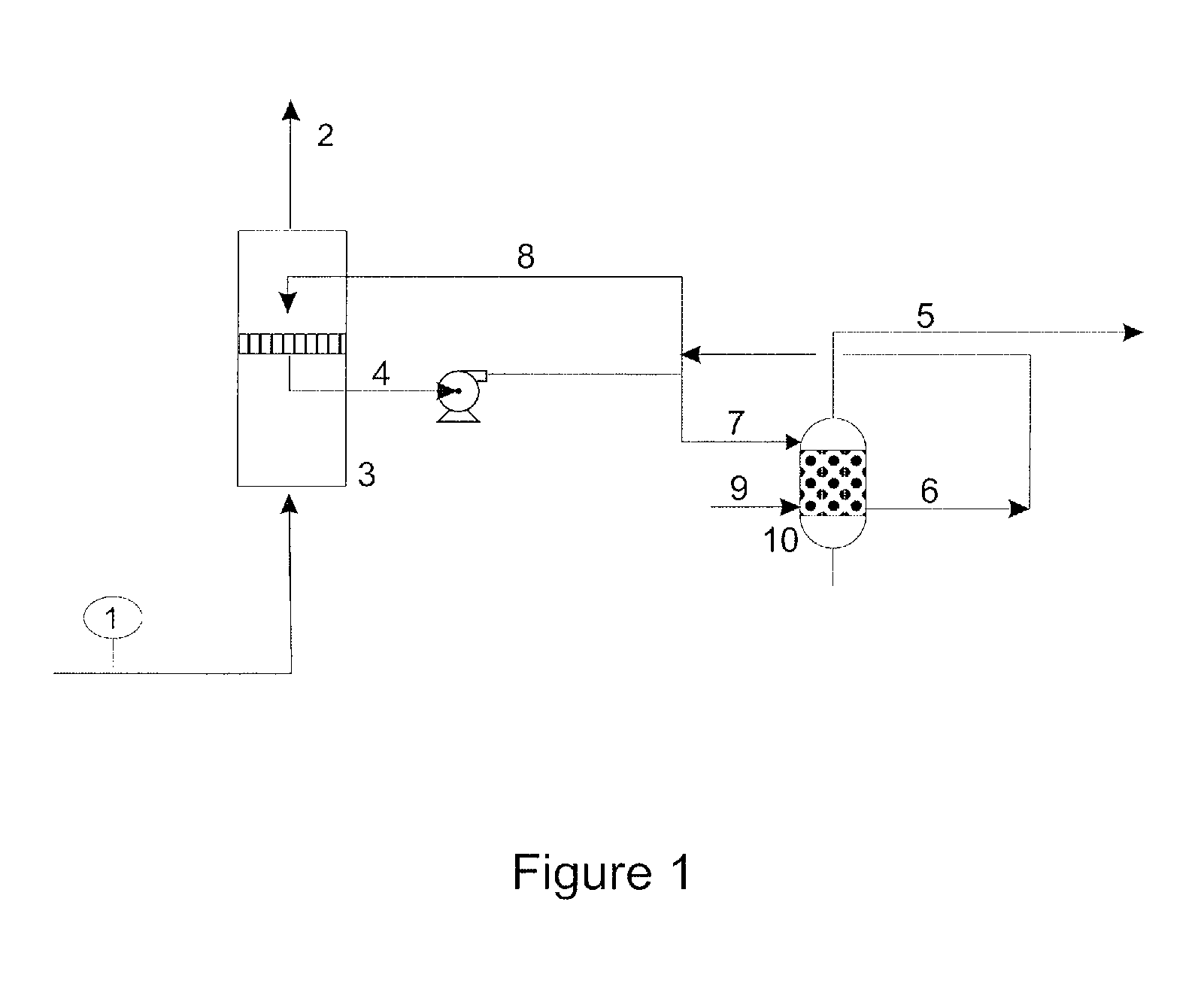

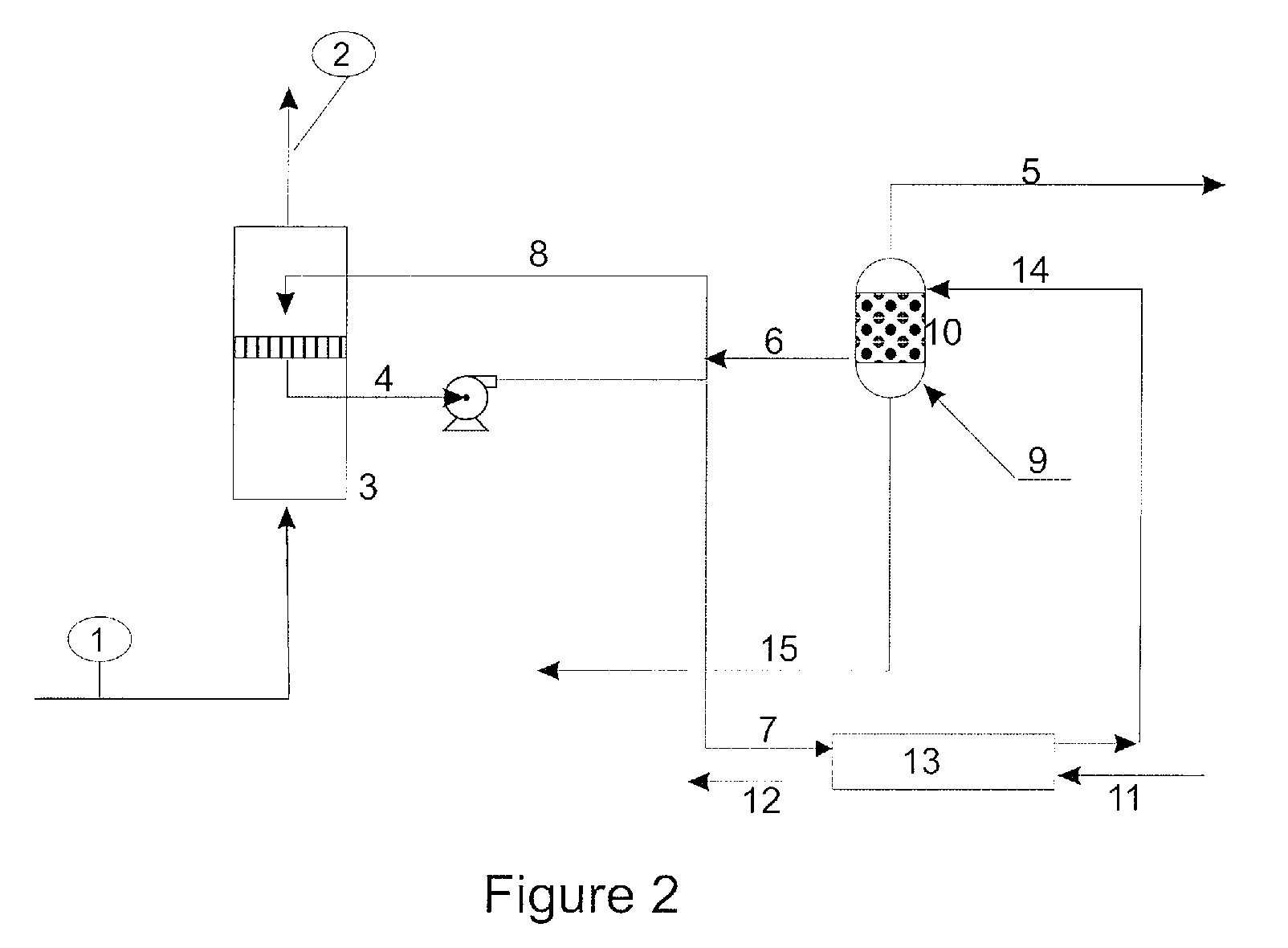

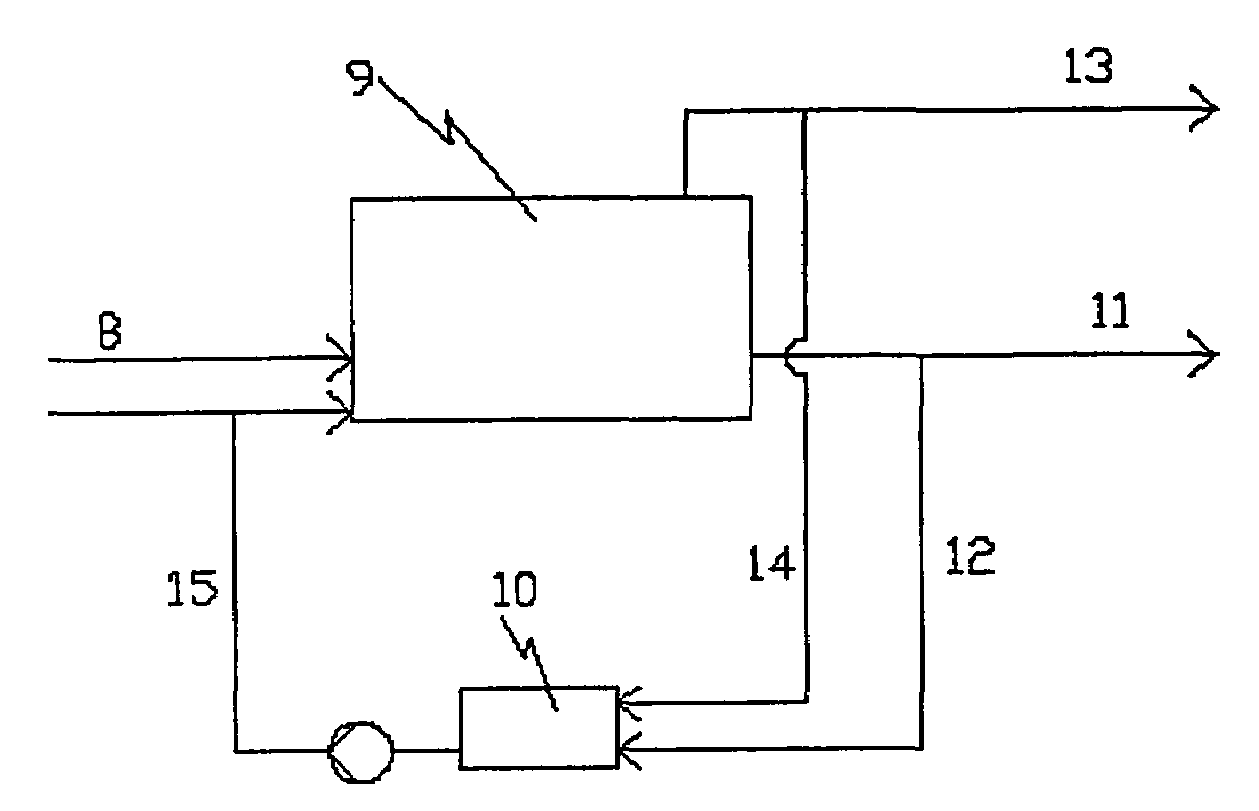

Method for combining desalination and osmotic power with carbon dioxide capture

InactiveUS20110100218A1Good energy efficiency improvementReduces amount and costMembranesGas treatmentHigh concentrationOsmotic power

Carbon Dioxide capture processes utilizing ammonia, or ammonia in water as the capture fluid for carbon dioxide generate concentrated solutions of ammonium carbonate species in water, which are subsequently decomposed to capture the carbon dioxide and recycle the ammonia. Forward osmosis processes utilize ammonium carbonate species as draw solutions to pull water from saline solutions such as seawater in the ammonium carbonate solution. The ammonium carbonate solution is then heated to decompose the ammonium carbonate to ammonia and CO2 which are both reused, while a portion of the aqueous stream is recovered as pure water. Combination of carbon capture process with an integrated forward osmosis process provide great economies over standalone operations. Furthermore, the very high concentrations of ammonium carbonate provide a further opportunity to include osmotic power recovery cycles with the integrated forward osmosis and carbon capture process.

Owner:WOLFE THOMAS D

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

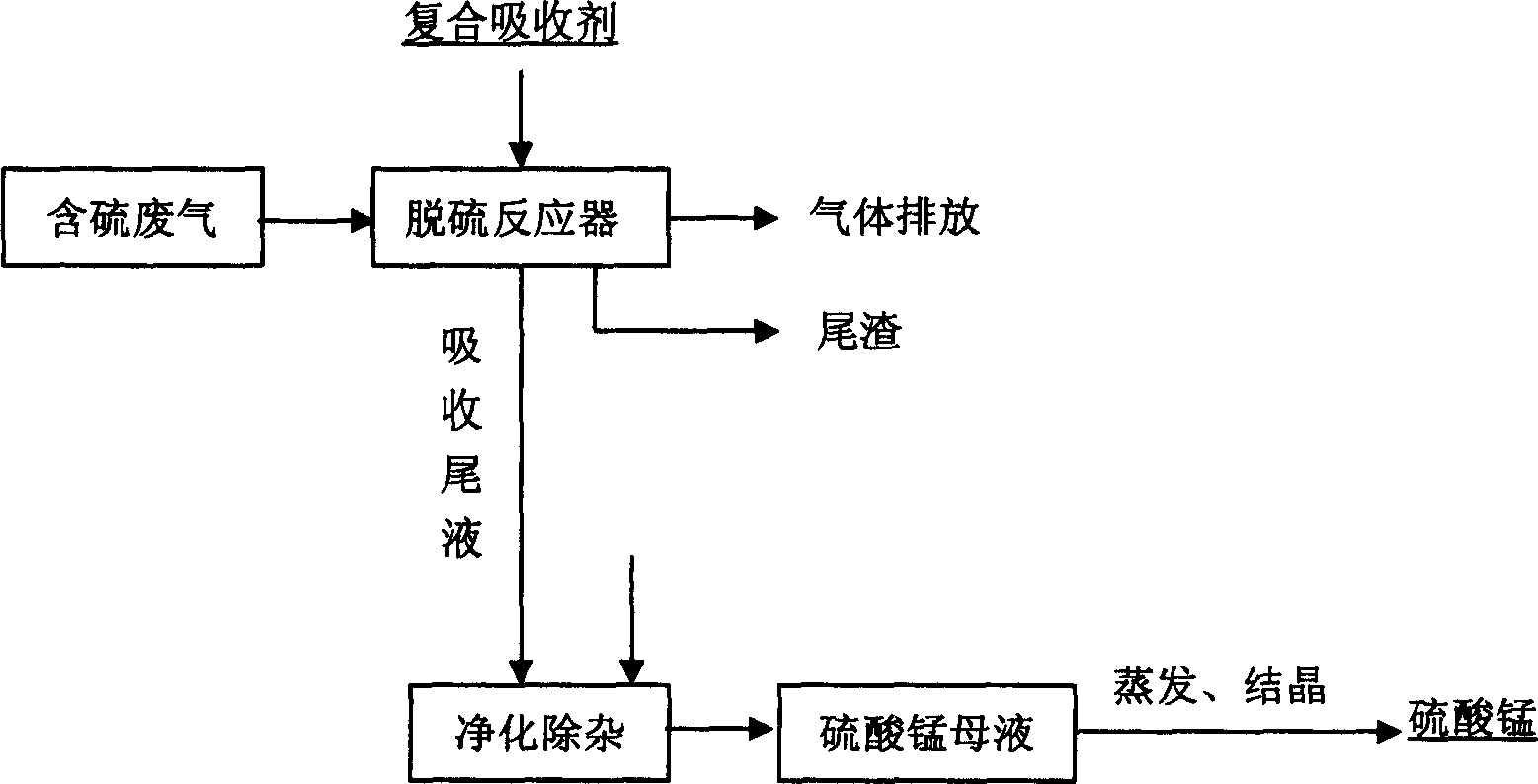

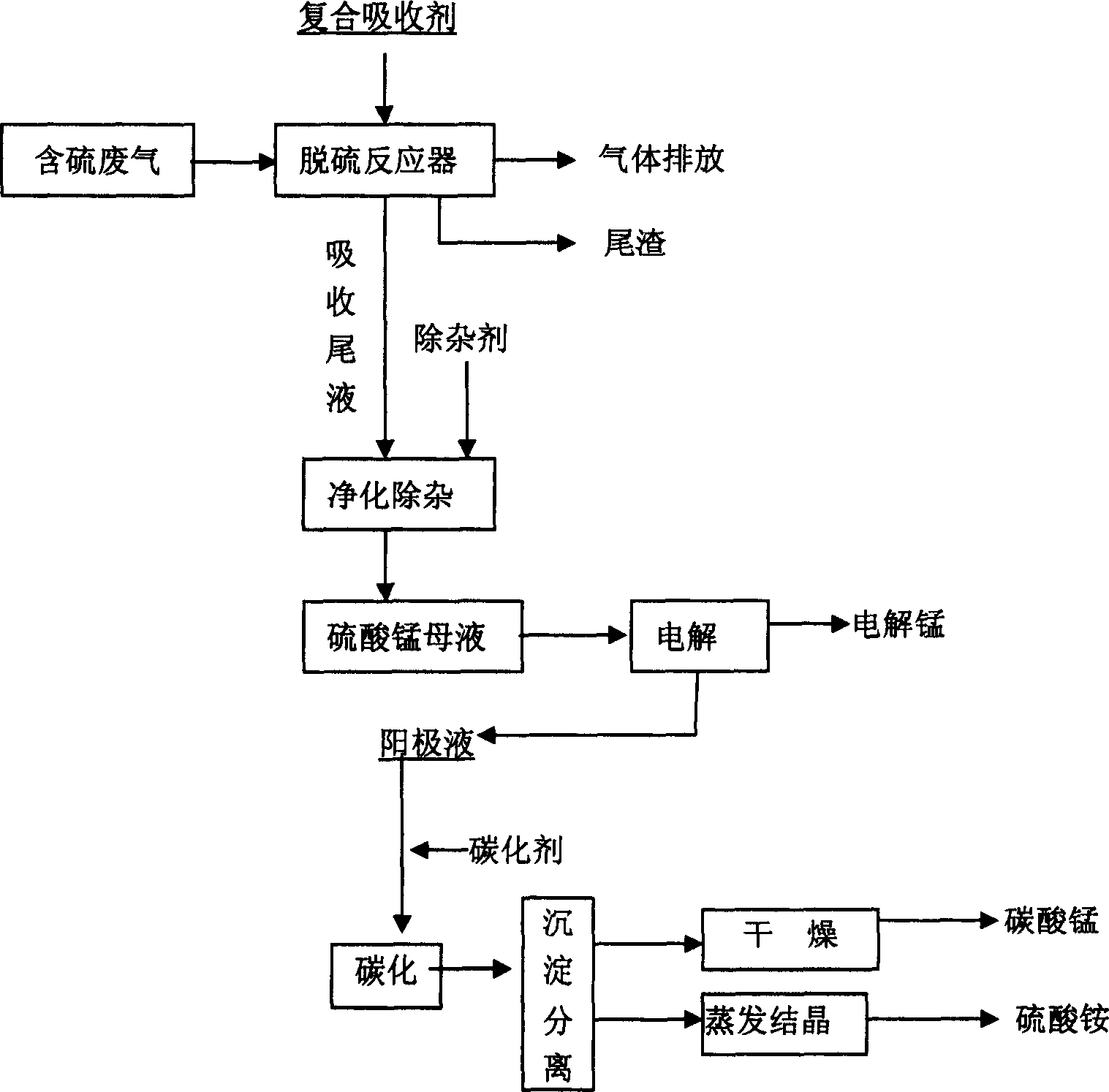

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

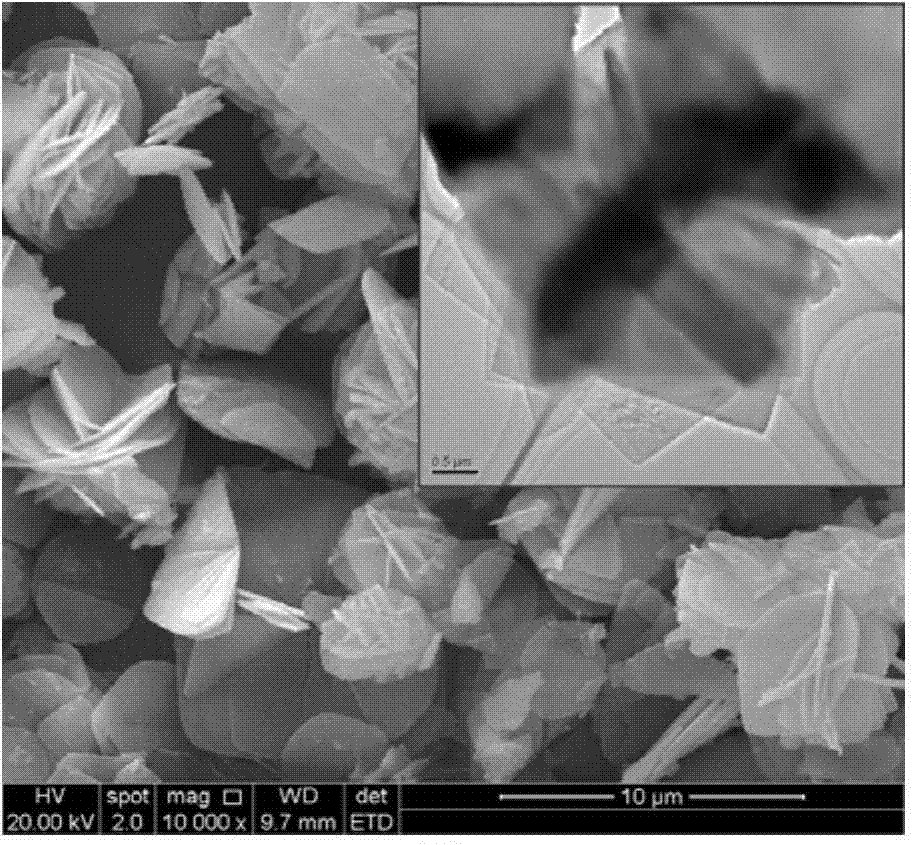

Manganese-based low-temperature denitration catalyst and preparation method thereof

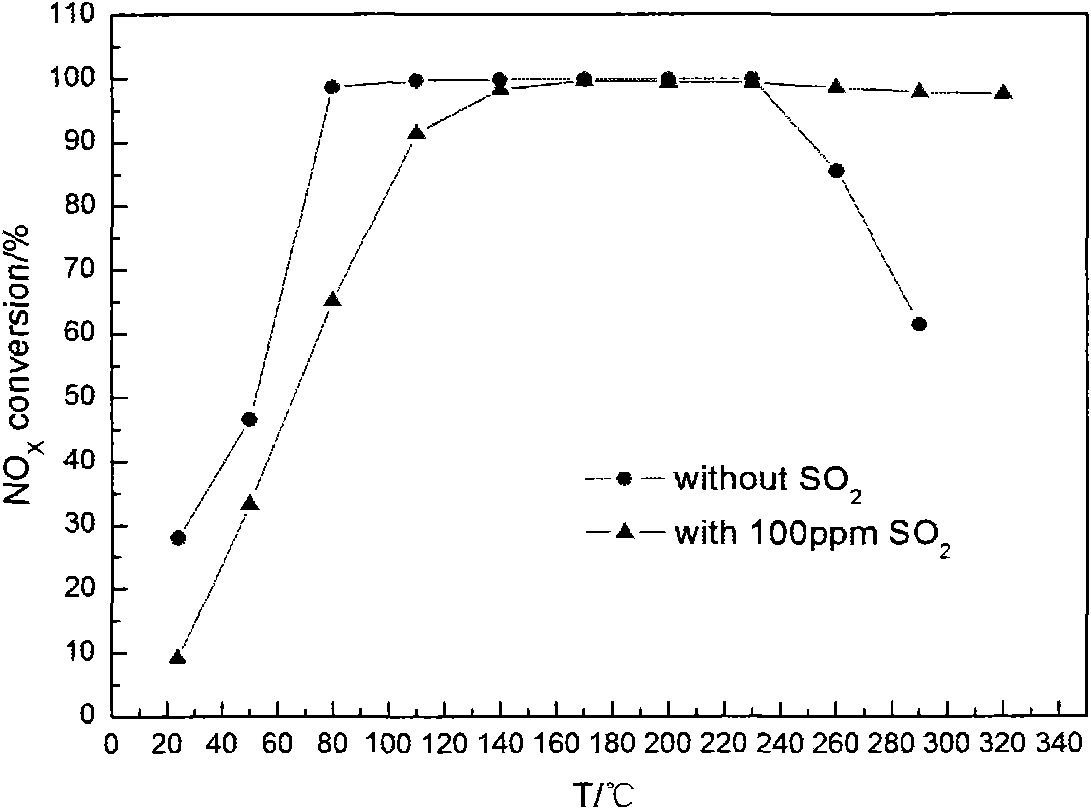

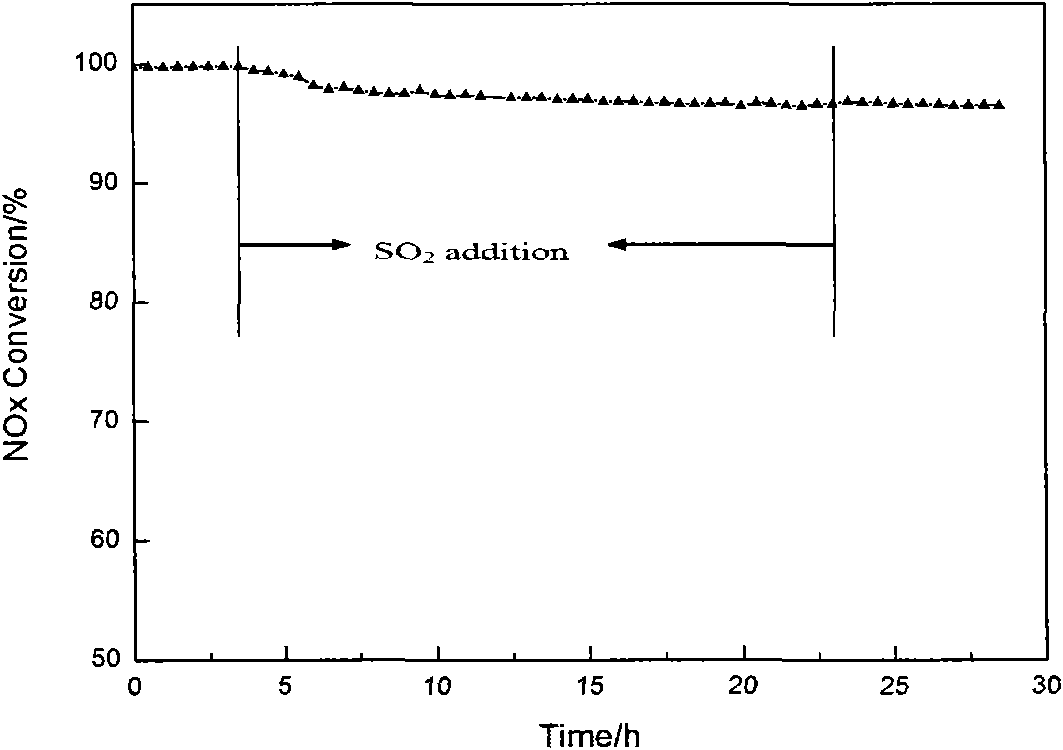

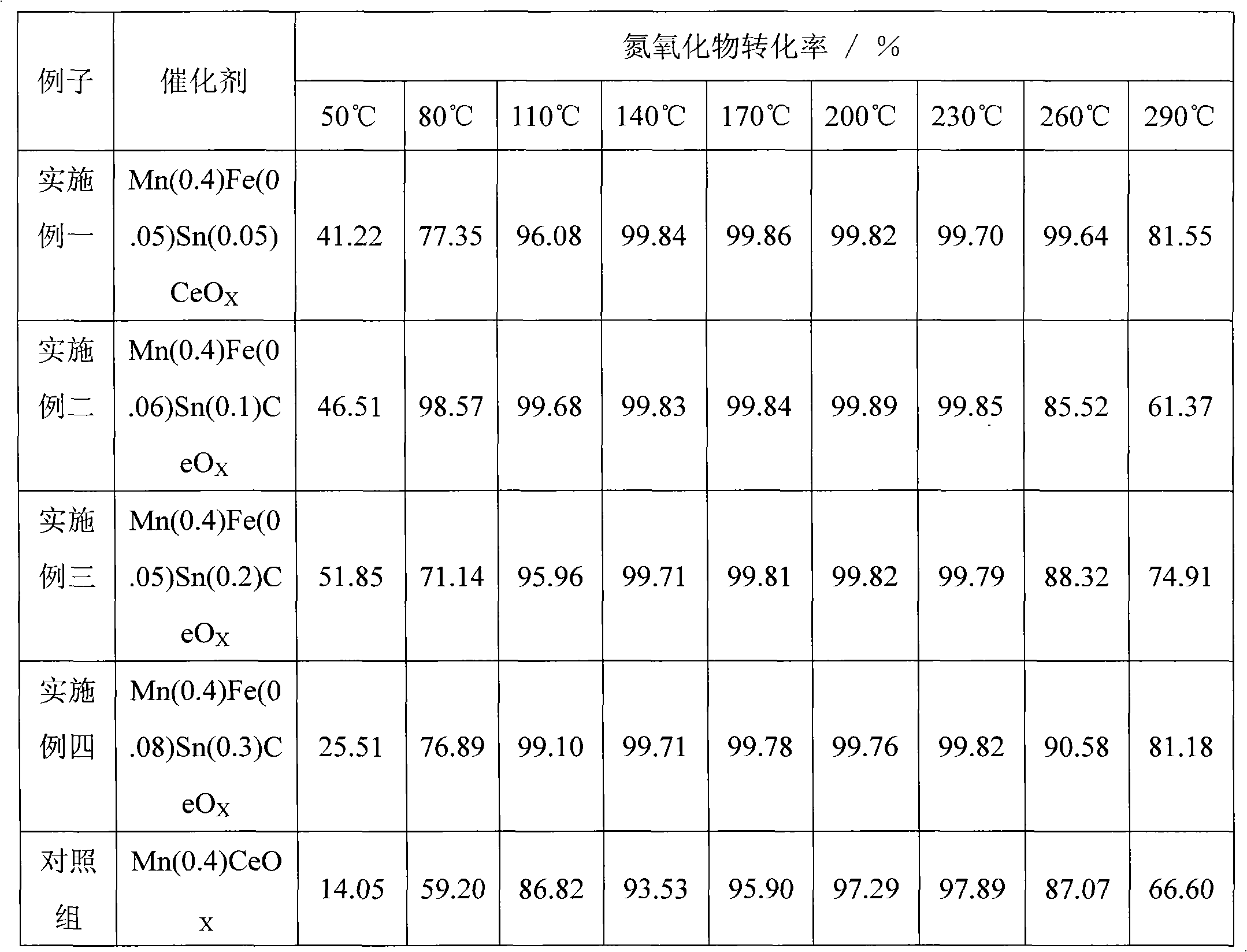

ActiveCN101879452AImprove sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseSlurry

The invention relates to a manganese-based low-temperature denitration catalyst and a preparation method thereof. The preparation method comprises the following steps of: 1, dissolving manganous nitrate, ferric nitrate, crystal tin tetrachloride and cerous nitrate in water at normal temperature, and stirring the mixture to form transparent solution; 2, preparing solution of ammonium carbonate, dripping the solution of ammonium carbonate into the solution prepared by the step 1, and heating and stirring the mixture to obtain slurry; 3, ultrasonically immersing the slurry, leaching the slurry to obtain a filter cake, and then washing the filter cake with deionized water; and 4, drying and roasting the filter cake to obtain the manganese-based low-temperature denitration catalyst MnFeSnCeOx, wherein the molar ratio of Mn: Fe: Sn: Ce in the prepared catalyst is equal to (35-39):(2-5):(9-35):(54-21). The purification efficiency of nitric oxides reaches 71 to 100 percent when the metallic oxide catalyst is at the temperature of between 80 and 250 DEG C. The composite oxide catalyst has high sulfur resistance.

Owner:江苏中创清源科技有限公司

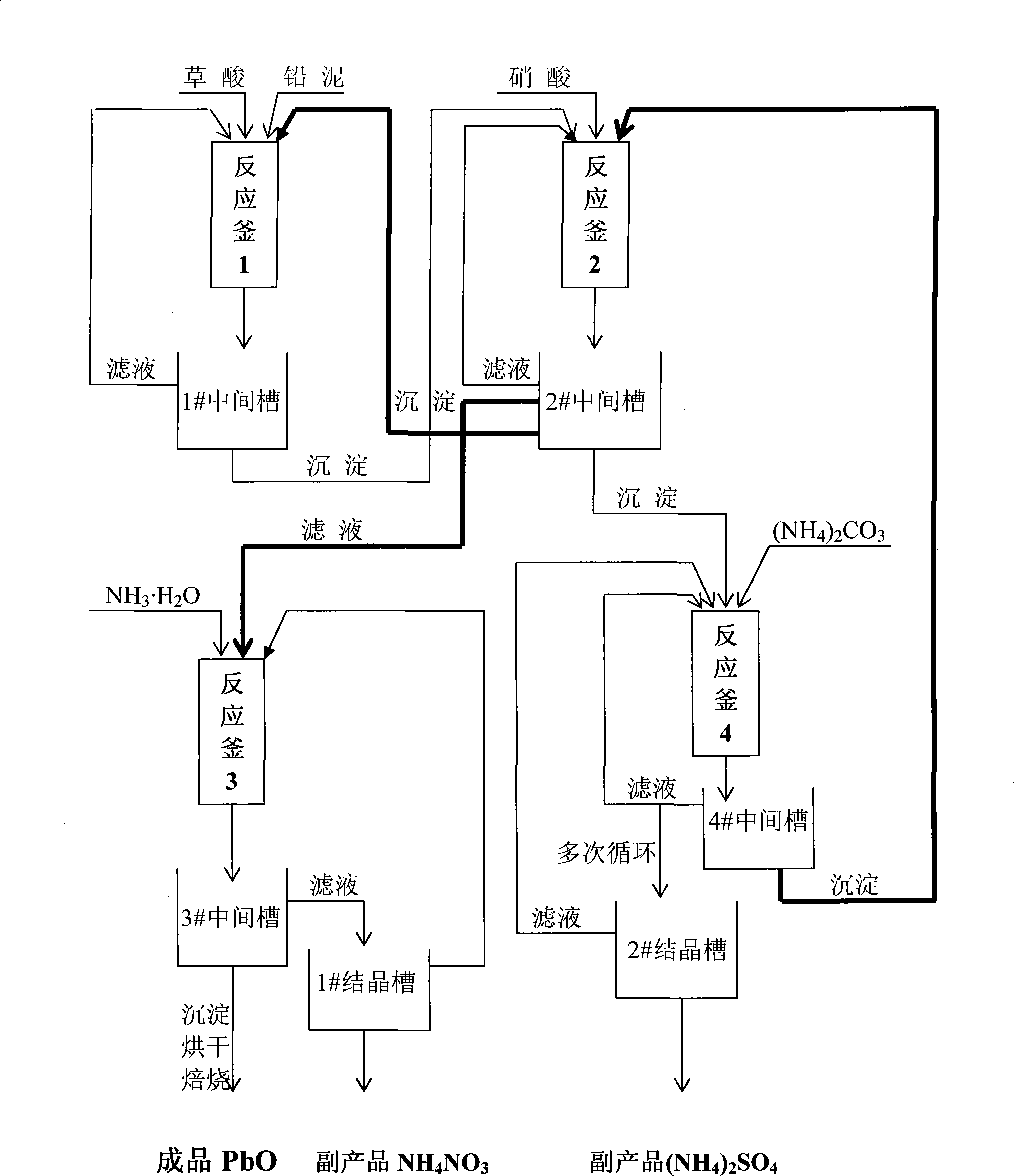

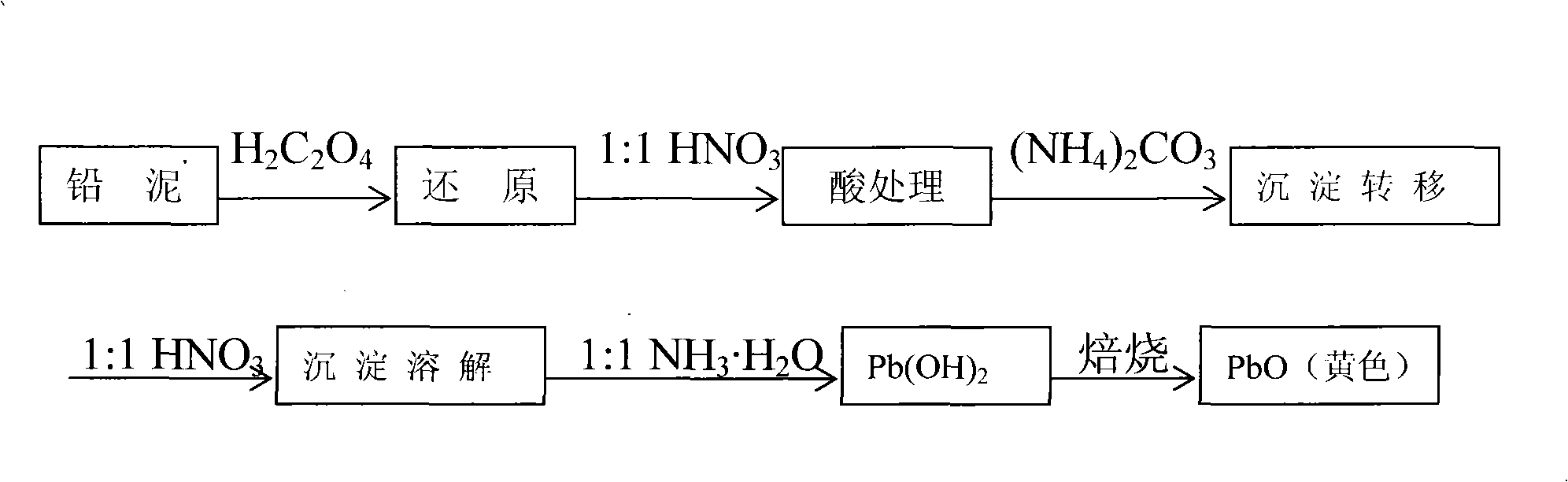

Method for recovering lead oxide by waste lead-acid storage battery

InactiveCN101514395AReduce energy consumptionReduce pollutionProcess efficiency improvementLiquid wasteFiltration

A method for recovering lead oxide by a waste lead-acid storage battery is disclosed. The waste lead-acid storage battery is crushed together with lead slime subsequent to acid cleaning, a grid plate and a filler comprising the lead slime are obtained by screening, the grid plate is fused-cast to an alloy ingot, the filler and the lead slime are ball-milled, and fine stuff is added with saturated oxalic acid solution for reaction at 25-65 DEG C and then for filtering and depositing; the deposition is then treated by excessive 30% nitric acid at the temperature of 40-45 DEG C for subsequent filtration and deposition, and the deposition is reacted with 4wt% sal volatile at the temperature of 25-65 DEG C for subsequent filtration and deposition; the deposition is added into recovered HNO3 to be dissolved at the temperature 40-45 DEG C until no bubble is generated, the filtered filtrate is added with 25% ammonia for reaction, filtration, washing and deposition to be neutral, and the lead oxide is obtained by drying and roasting. Recoverable nitramine and ammonium sulfate are recycled in all the filtrates in the technologies; thereby discharging no waste liquid. The utilization rate of raw material is 90.1-92.1%, the yield is 95.0-96.7%, and the content of PbO is 98.0-98.9%.

Owner:DALIAN WUHUATIANBAO TECH DEV

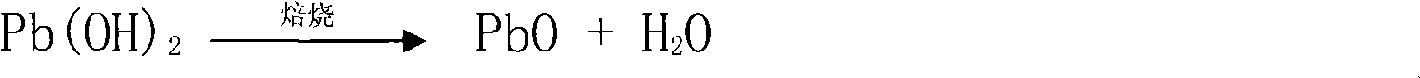

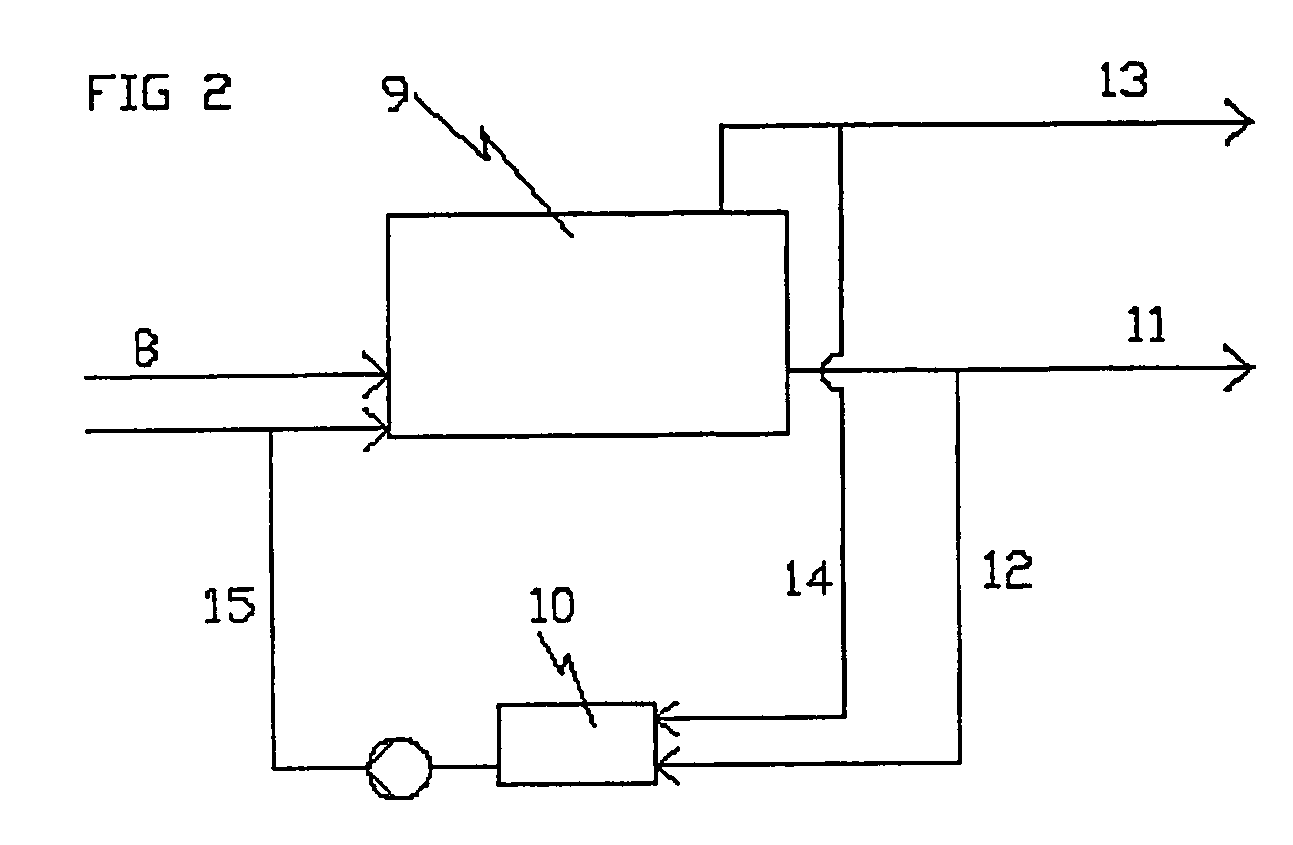

Method and equipment for processing organic material

InactiveUS7160456B2Organic material longerEasy to storeBio-organic fraction processingAnimal corpse fertilisersBuffer solutionAmmonia

A method for processing organic material, in which method bioconversion is performed on the organic material in at least one first reactor, the biogas formed in the bioconversion is treated with ammonia in at least one second reactor and buffer solution produced in the second reactor is recycled to the bioconversion in the first reactor. Thus, the carbon dioxide of the mixed methane / carbon dioxide gas reacts with the ammonia and forms a buffer compound, such as ammonium bicarbonate and / or ammonium carbonate.

Owner:PRESECO

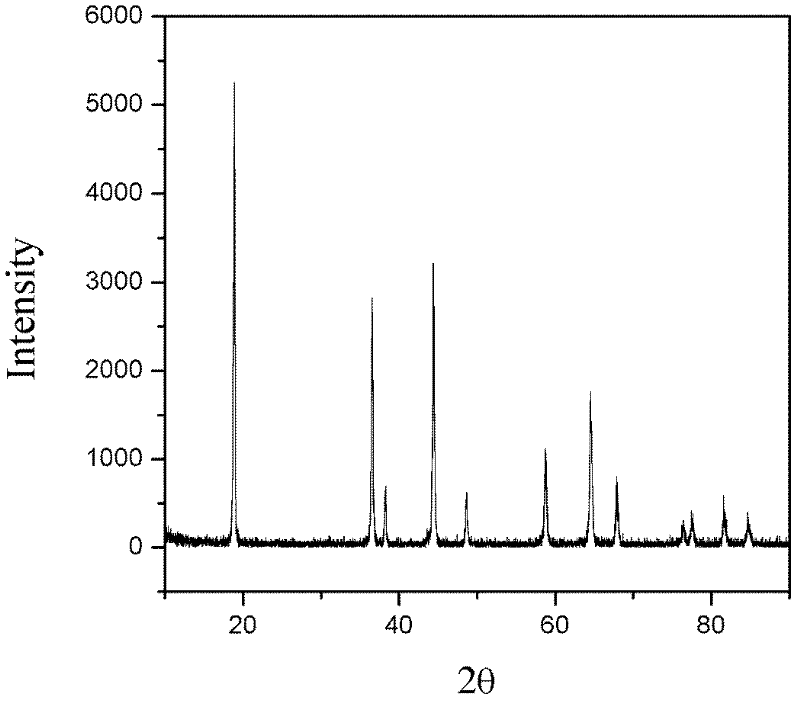

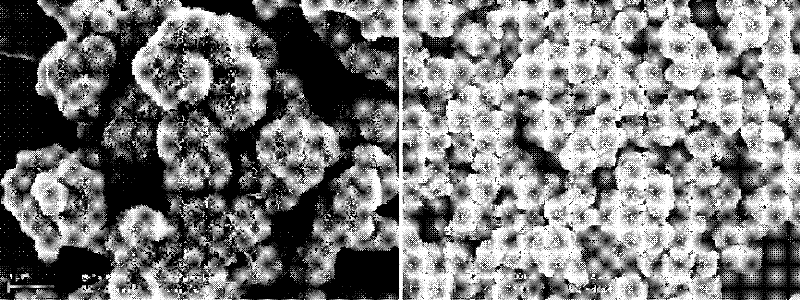

Preparation method of spinel type lithium manganese oxide for spherical high-voltage anode material

The invention discloses a preparation method of spinel type lithium manganese oxide for a spherical high-voltage anode material. The preparation method comprises the following steps of: preparing the spinel type lithium manganese oxide for the spherical high-voltage anode material by utilizing a hydrothermal-solid-phase two-step method; uniformly mixing a nickel source, a manganese source and a doped element chemical solution with a sodium / ammonium carbonate solution; adding surfactant into the mixed solution and preparing under a hydrothermal condition to prepare a spherical lithium manganese carbonate sediment; washing and drying, and then sintering to obtain a spherical lithium manganese oxide; mixing the oxide with a lithium source by liquid-phase ball milling, and drying; and finally, sintering to obtain an anode active material. According to the preparation method disclosed by the invention, the synthesis method is simple, the process is easy to control and the doped elements are introduced; physical and chemical properties of the material are optimized and the grain size of the material is uniform; and the discharge capacity is high and the multiplying power performance is good.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

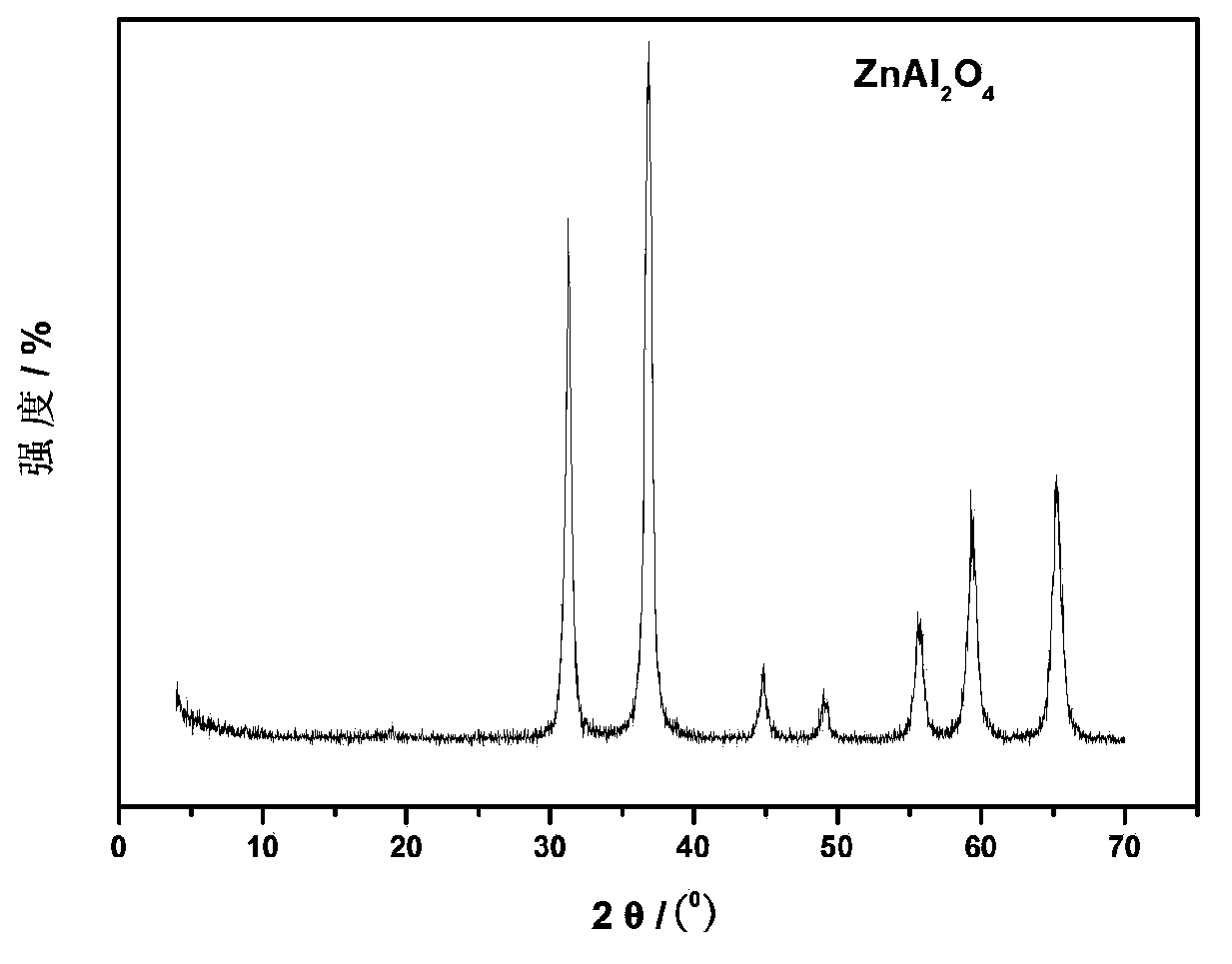

Method for preparing nanometer gahnite

ActiveCN103449503AReduce pollutionGood quality powderZinc oxides/hydroxidesNanotechnologySucroseGlycerol

A method for preparing nanometer gahnite. The preparation method is as below: dissolving zinc salt in water, adding an aluminum source, stirring for 10-30 min, adding a pore-enlarging agent, stirring, ageing at 20-100 DEG C for 30-60 min, drying, and calcining at 500-1200 DEG C. The molar ratio of the raw materials is as below: Zn:Al:water=1:2:16-35; calculated by the weight of zinc oxide being 100%, the addition amount of the pore-enlarging agent is 0.5-30%; and the pore-enlarging agent is one or more selected from sucrose, glycerol, ammonium carbonate, ammonium hydrogen carbonate, polystyrene latex and polyethylene glycol.

Owner:PETROCHINA CO LTD

High-efficiency cleaning mineral separation process of complicated sulfuration mine

The invention discloses an efficient and clean beneficiation method of complex sulfide ore. The method includes the following steps: utilizing an activator selected from one of or some of oxalic acid, ammonium carbonate, ammonium bicarbonate, ammonium sulfate, ammonium bisulfate and ferrous sulfate as a combination; utilizing collectors including xanthate collectors, black collectors, white collectors and thionocarbamate collectors; mixing the activator, the collectors and BC; stirring; and performing flotation separation of the sulfide ore to obtain the sulfur concentrate. The inventive beneficiation method has the advantages of high discrimination property, cleanness and non-toxicity; and is suitable for the flotation separation of the complex sulfide ore, particularly the flotation separation of complex sulfide ore containing pyrrhotites and pyrites with fine dissemination size.

Owner:CENT SOUTH UNIV

Long-acting corn fertilizer

InactiveCN1986497AIncrease productionReduce pollutionAmmonium salt fertilisersUrea compound fertilisersDiammonium carbonateCrop yield

The present invention relates to fertilizer, and is especially one kind of long acting corn fertilizer. The long acting corn fertilizer is prepared with ammonium sulfate 200 weight portions, ammonium chloride 500 weight portions, urea 400 weight portions, ammonium carbonate 50 weight portions, diammonium carbonate 250 weight portions, monoammonium carbonate 200 weight portions, potassium chloride 350 weight portions, zinc sulfate 10 weight portions, borax 2.5 weight portions, NAM persistent agent 2.5 weight portions, and bentonite 150 weight portions, and through mixing, palletizing, stoving at 80-100 deg.c and other steps. It has nitrogen fertilizer, phosphate fertilizer and potash fertilizer in the ratio of 20 to 10 to 10, long fertilizer efficiency, and capacity of meeting the requirement of corn in different growth stages.

Owner:王忠生

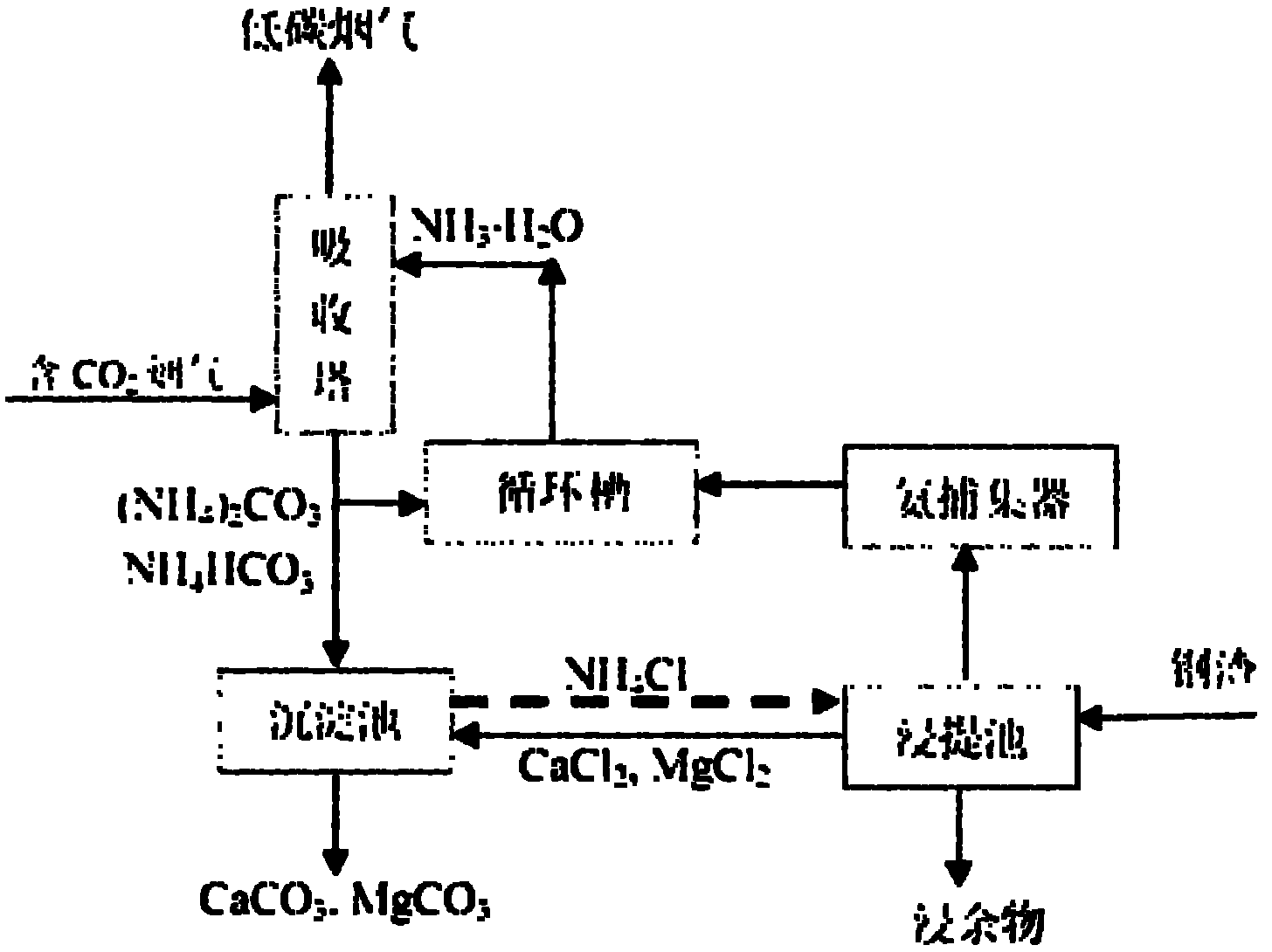

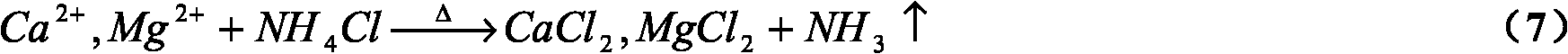

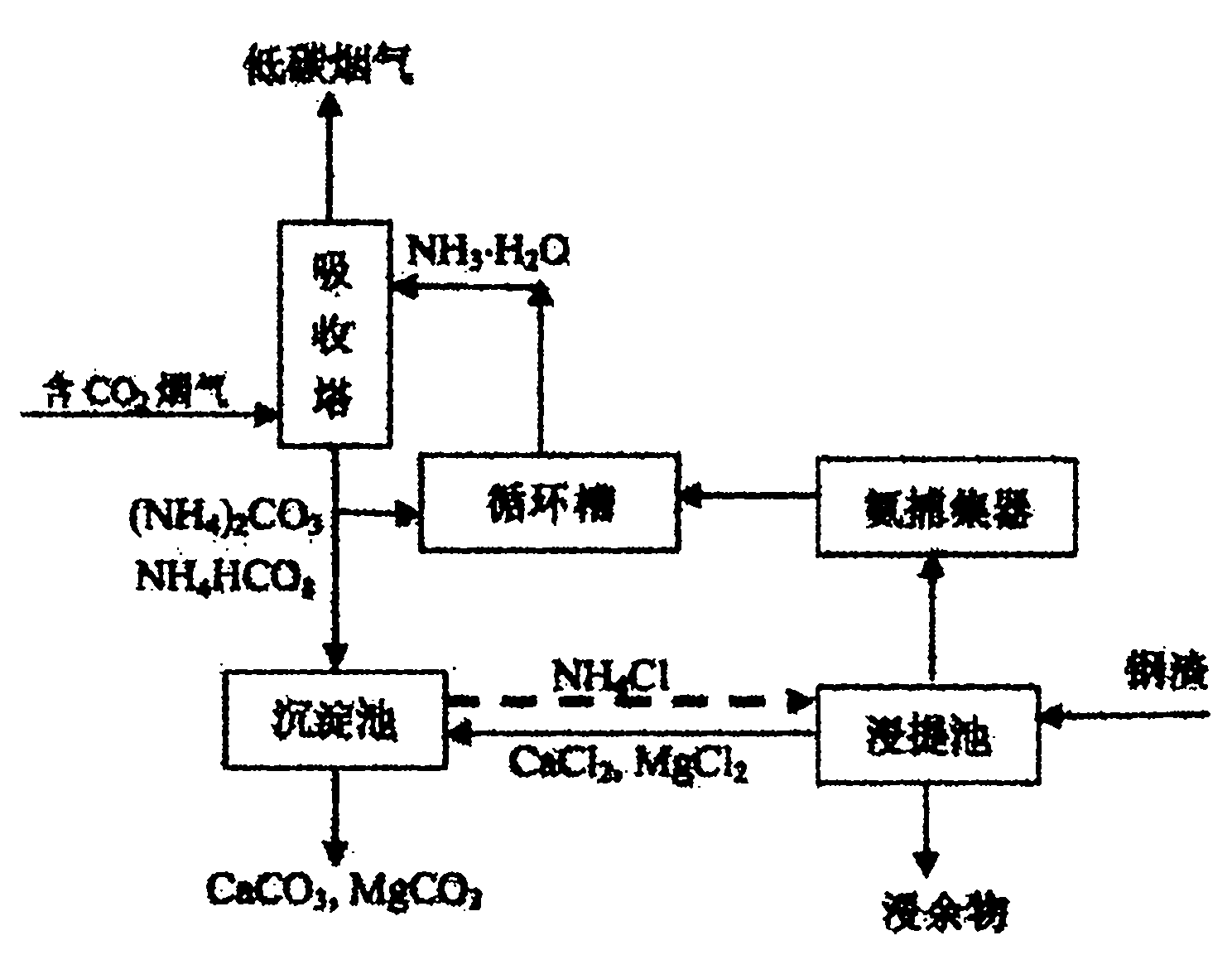

Ammonia-chemical-chain-cycle-based carbon dioxide capture and conversion method

The invention discloses an ammonia recycling method, which belongs to the technical field of steel smelting technologies. The ammonia recycling method comprises the following steps of: absorbing carbon dioxide in flue gas produced in the steel production process through gas-liquid contact of aqueous solution of ammonia in an absorption tower to obtain ammonium bicarbonate or ammonium carbonate; performing extraction treatment on alkaline steel slag by adopting solution of ammonium chloride to obtain solution of calcium chloride or magnesium chloride and ammonia, recovering the ammonia to obtain ammonia water for capturing carbon dioxide, and reacting the solution of calcium chloride or magnesium chloride with the ammonium bicarbonate or the ammonium carbonate to obtain calcium carbonate or basic magnesium carbonate; and finally separating the solution of ammonium chloride for circular extraction of the alkaline steel slag. By the ammonia recycling method, the emission of the carbon dioxide can be reduced and the carbon dioxide is immobilized in the form of calcium carbonate or magnesium carbonate; meanwhile, calcium and magnesium oxides in steelmaking waste slag are recycled, NH3 generated in the whole process flow is circularly used, and the cost is reduced.

Owner:上海交通大学中原研究院

Adsorbent used for separating formaldehyde from air and preparation method thereof

InactiveCN101642698ALow costLow running costOther chemical processesDispersed particle separationSorbentHexamethylenediamine

The invention discloses an adsorbent used for efficiently separating formaldehyde from air and a preparation method thereof. An adsorbent carrier is active carbon, the surface of which is attached with one or more of -NH, -NH2 and -NH3. The precursor of -NH, -NH2 and -NH3 is one of salvolatile, ammonium bicarbonate, ammonium sulfate, ammonium nitrate, ammonium chloride, ethene diamine, hexamethylenediamine, aniline and urea. The adsorbent can absorb and separate formaldehyde in air when space velocity is 20000-80000h<-1> at room temperature. Especially when the formaldehyde and benzene seriesin the air coexist, the adsorbent not only can absorb and separate formaldehyde but also can absorb and separate the benzene series. Therefore, the adsorbent can be widely applied to the purifying treatment of air in hermetic and semi-hermetic limited spaces, such as building interiors, spacecrafts, submarines, undergrounds and the like.

Owner:BEIHANG UNIV

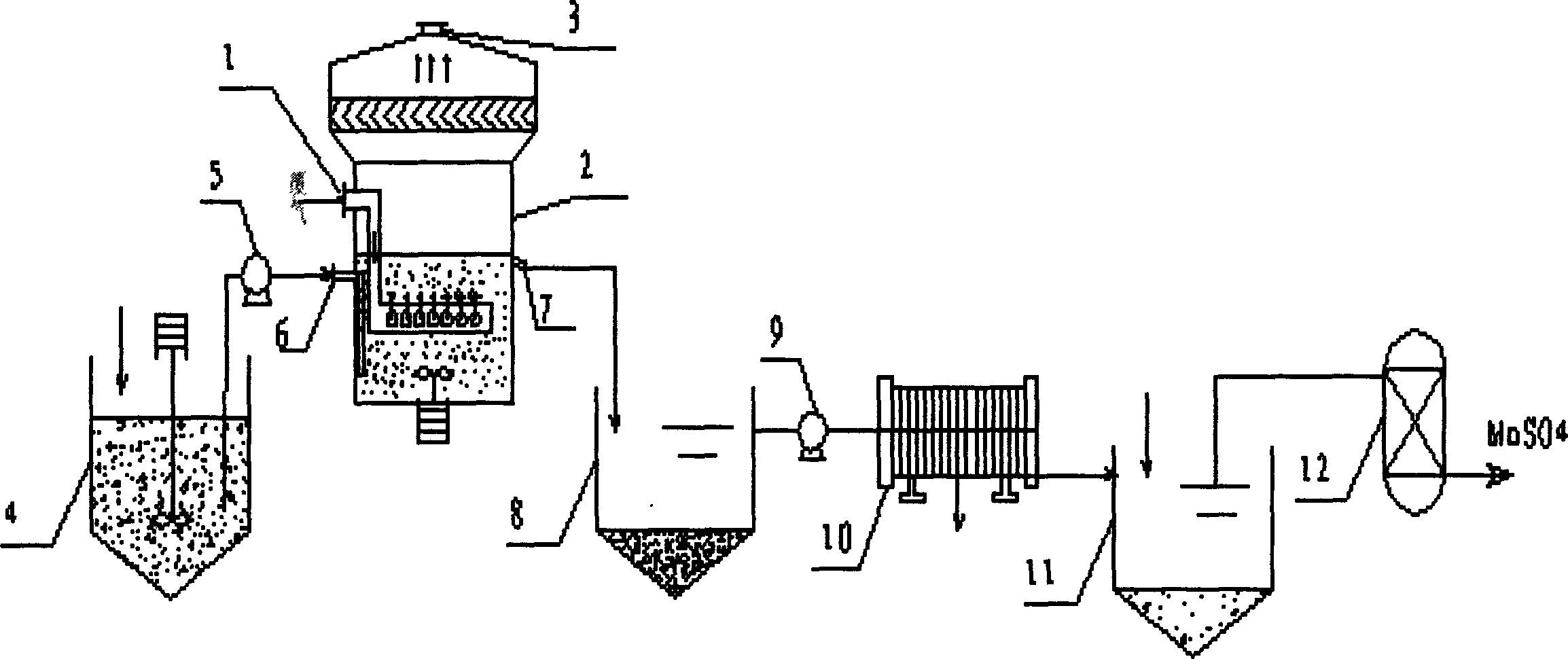

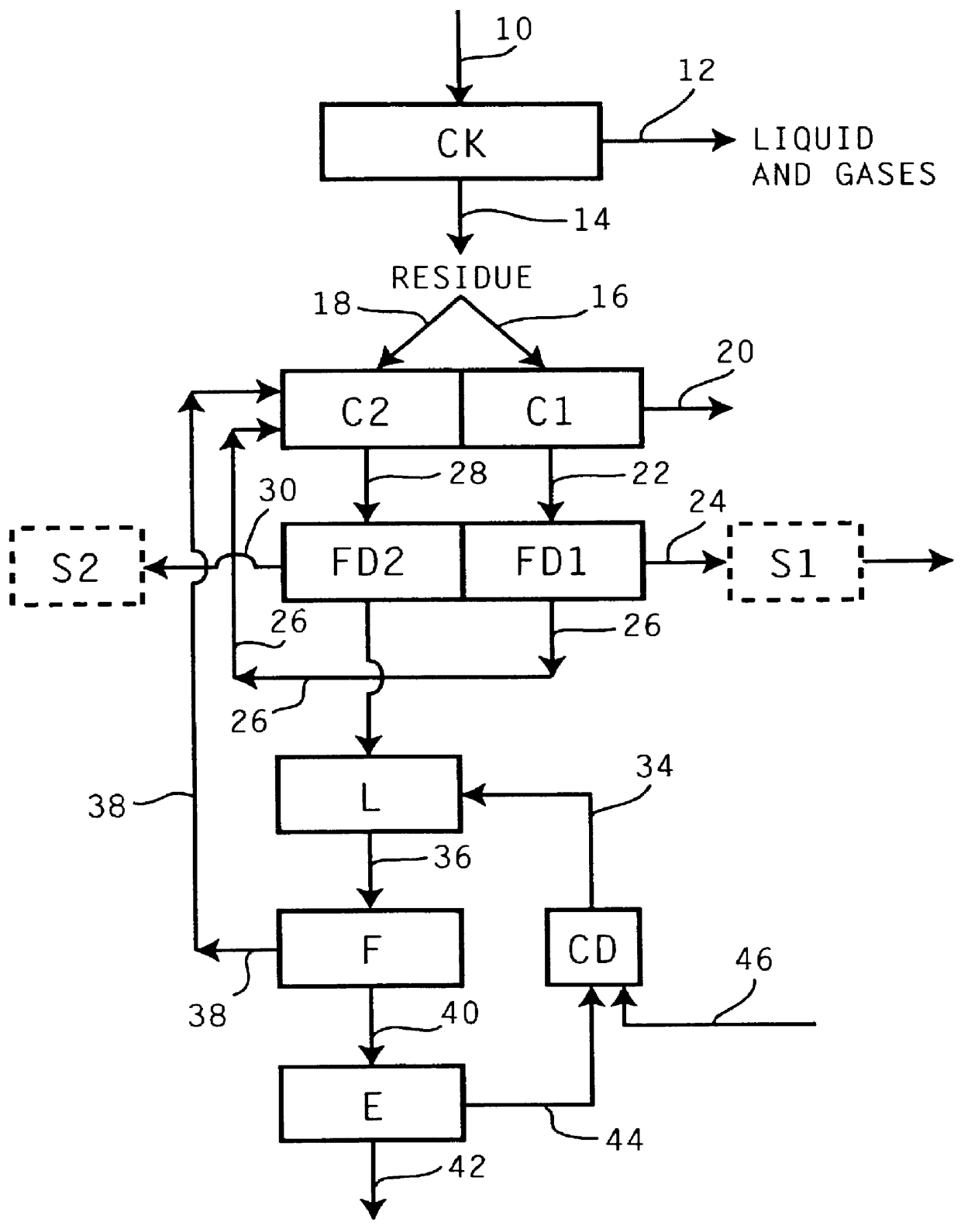

Recovery of the transition metal component of catalyst used in heavy feed hydroconversion

The invention relates to a process for recovering the transition metal component of catalysts used in the hydroconversion of heavy hydrocarbonaceous materials. In accordance with the invention, a slurry of a transition metal catalyst and hydrocarbon is catalytically desulfurized resulting in a desulfurized product and a solid residue containing the transition metal. The transition metal may be recovered by coking the residue and then dividing the coker residue into two portions are combusted with the flue dust from the first combustion zone being conducted to the second combustion zone. The flue dust from the second combustion zone is treated with ammonia and ammonium carbonate in order to obtain ammonium molybdate.

Owner:EXXON RES & ENG CO

Method for producing light-pollution reverse osmosis composite film

ActiveCN1923348AImprove hydrophilicityImproves stain resistanceSemi-permeable membranesComposite filmLight pollution

The invention relates to a method for producing low-pollution composite inverse penetration film. Wherein, it comprises that (1), preparing A solution; (2), preparing B solution; (3), preparing C solution that dissolving polyvinyl alcohol whose average polymer degree is n=500-3000 and saponification degree is 75% into hot water at 60Deg. C to prepare the solution whose density is 2.0%; adding one of fatty group, heat convertible resin, or zirconyl ammonium carbonate at 0.2% and the HCl at 0.1%; mixing for 30mins, to form C solution; (4), coating A solution on polysulfone support layer, to form A solution layer; contacting support layer with B solution, drying to form polysulfone layer; coating C solution on polyamide layer, drying.

Owner:VONTRON TECH CO LTD

Highly effective viscosity-reducing agent for thermodynamic oil extraction process

ActiveCN101235279ASolve the problem of emulsification blockageImprove timelinessDrilling compositionSolubilityPetroleum product

High efficiency viscosity-reducing agent which is used on THE thermal oil extraction technology, which is formed by the following raw materials with percentage by weight, firstly phenyl benzene, fused ring aromatic hydrocarbon or fused ring aromatic hydrocarbon derivative which does not contain chlorine element and sulfur element, secondly liquid petroleum product whose aromatic hydrocarbons content is no more than 5%, petroleum resin which is liquid state under the constant temperature or hydrocarbons natural aggregation which is particle state under the constant temperature, thirdly water-soluble anionic surface active agent, water-soluble non-ionic surface active agent, oil solubility anionic surface active agent or oil solubility non-ionic surface active agent, fourthly fusel oil, fifthly alcohol ether, sixthly oil solubility or water-soluble polymer which respectively has nonpolar portion which has eutectic crystal with ceresin wax molecular and polar portion which can make wax crystal system twisty on main chain and or branch chain, seventhly hyperoxide, eighthly carbamide, ammonium carbonate, ammonium acid carbonate or ammonium nitrite and ninthly ketone. The high efficiency viscosity-reducing agent has strong suitability, strong viscosity-reducing ability, safety and reliability, can largely reduce extract cost and increase the yield of oil pump, and increases the final recovery efficiency of oil reservoir.

Owner:盘锦河升大地石油科技有限公司

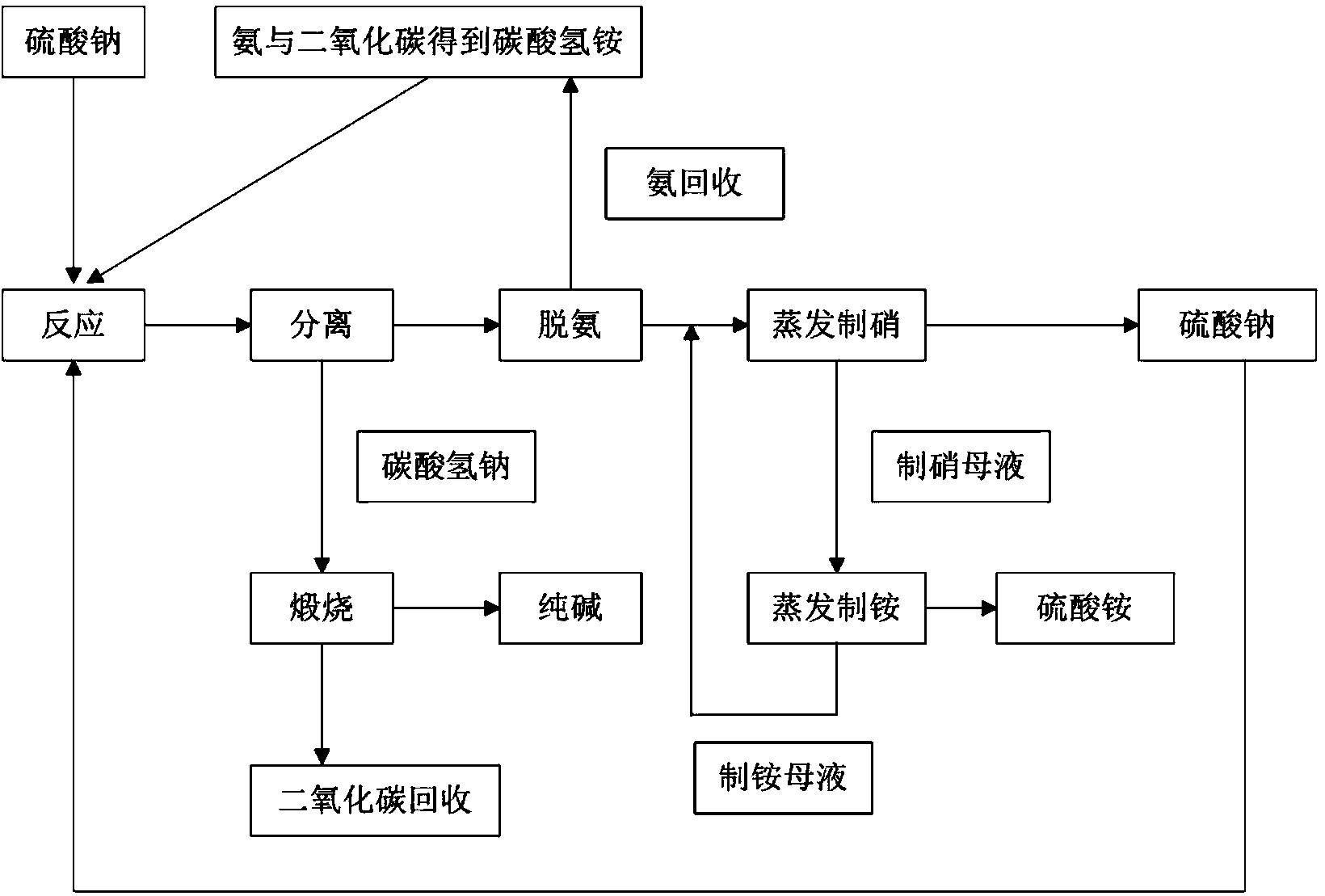

Thermal circulation technology of utilizing sodium sulfate solution or carrier to cogenerate sodium carbonate and ammonium sulfate

ActiveCN104355326AIncrease added valueReduce energy consumptionAmmonium sulfatesCarbonate preparationAmmonium Hydrogen CarbonateSodium sulfate

The invention provides a thermal circulation technology of utilizing sodium sulfate solution or a carrier to cogenerate sodium carbonate and ammonium sulfate. The thermal circulation technology comprises the following steps: regarding an ammonium hydrogen carbonate solution prepared from sodium sulfate, ammonia and carbon dioxide as a raw material to be conducted with a replacement reaction, then carrying out separation to obtain sodium hydrogen carbonate (which can be calcined to obtain a pure alkali product) and an alkali preparing mother solution containing ammonium sulfate, sodium sulfate, ammonium hydrogen carbonate and ammonium carbonate; preheating the alkali preparing mother solution to a high temperature to remove ammonium hydrogen carbonate and ammonium carbonate, and then obtaining the deaminized mother solution containing ammonium sulfate and sodium sulfate; evaporating the deaminized mother solution at a high temperature to obtain sodium sulfate and a niter preparing mother solution; evaporating the niter preparing mother solution at a low temperature to obtain ammonium sulfate and an ammonium preparing mother solution; circulating the sodium sulfate to the replacement reaction working procedure; circulating the ammonium preparing mother solution to the deaminized mother solution high-temperature evaporation working procedure. The main products and byproducts prepared by thermal circulation technology disclosed by the invention are high in quality and added value; the thermal circulation technology is well-adapted in raw materials, low in sodium sulfate theoretical use ratio, production cost and energy consumption, closed circulating, free of three-waste discharge, and capable of saving energy and reducing emission.

Owner:CHINA LIGHT IND INT ENG CO LTD

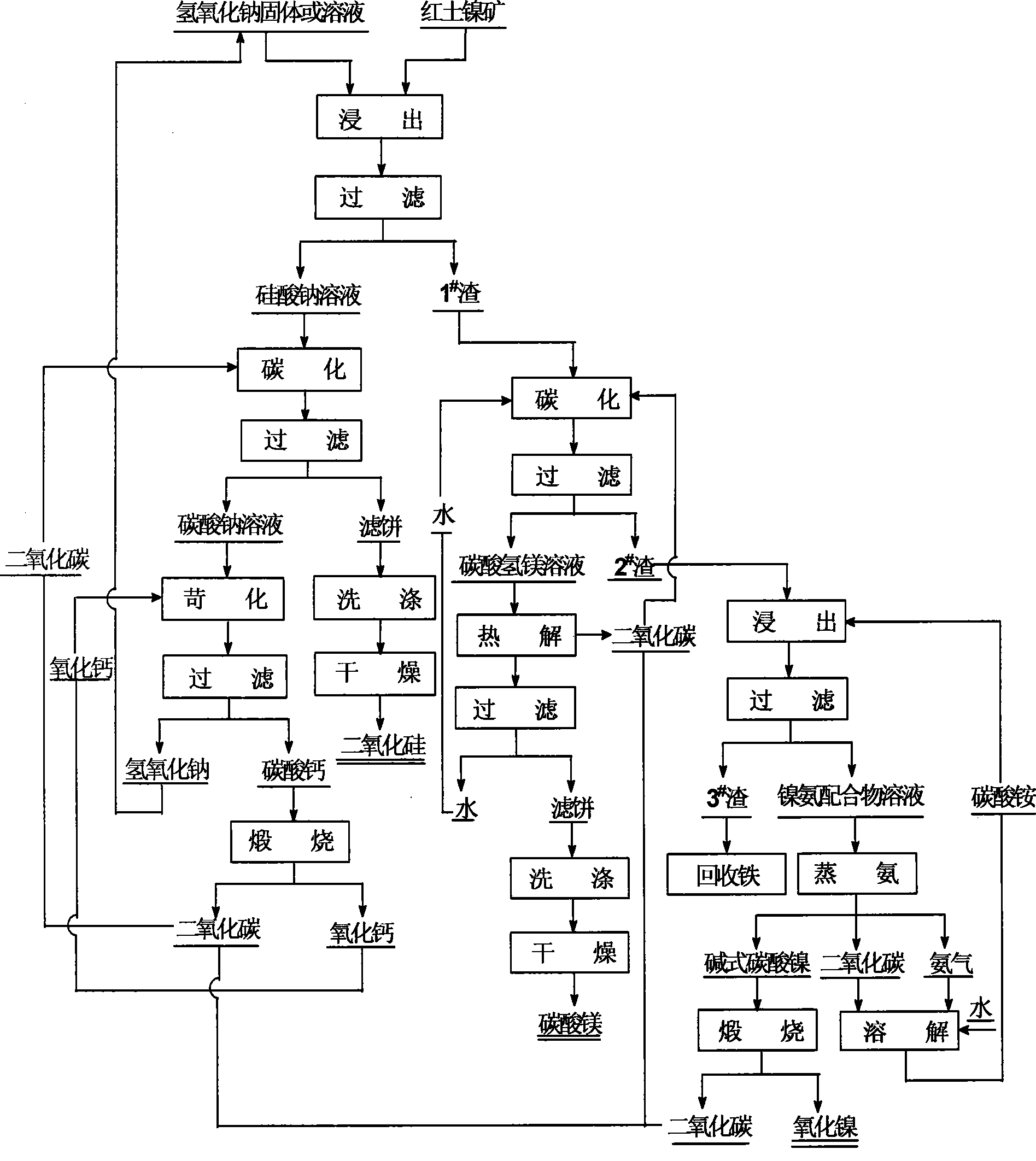

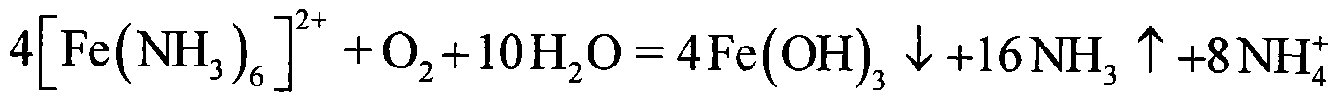

Method for extracting nickel oxide from lateritic nickel

InactiveCN101423897AProcess efficiency improvementNickel oxides/hydroxidesDiammonium carbonateDecomposition

The invention provides a method for extracting nickel oxide from lateritic nickel ores. The method comprises the following steps: the lateritic nickel ores are adopted to react with alkali; an obtained sodium silicate solution is used for preparing silicon dioxide through carbonization and decomposition; filter residue is carbonized and leached so as to obtain a magnesium bicarbonate solution; the magnesium bicarbonate solution is heated and decomposed so as to obtain magnesium carbonate; the remaining filter residue reacts with ammonium carbonate and then is filtered; and the nickel oxide is prepared from filtrate through ammonia distillation and calcinations. The remaining filter residue is mainly ferric oxide containing a few impurities, and can be used as an ironmaking raw material or to be deeply processed into the products with high additional value. The method has the advantages that the method is suitable for treating various lateritic nickel ores, simple in process flow and convenient in equipment, realizes the high-additional-value environment-friendly comprehensive utilization of lateritic nickel ore resources and the recycling of chemical raw materials, emits no waste residue, waste liquid or waste gas, and meets the requirements of industrial production.

Owner:NORTHEASTERN UNIV

Alumina supporter and preparation method thereof

ActiveCN101462074AImprove hydrogenation reactivityLower Diffusion LimitsCatalyst carriersPore distributionSlurry

The invention relates to an alumina carrier and a preparation method thereof. The pore distribution of the alumina carrier is as follows: the pore volume of holes with the pore diameter of less than 10 nanometers accounts for less than 10 percent of the total pore volume; the pore volume of holes with the pore diameter between 10 and 50 nanometers accounts for 40 to 80 percent of the total pore volume; the pore volume of holes with the pore diameter between 100 and 1,000 nanometers accounts for 1 to 40 percent of the total pore volume; and the pore volume of holes with the pore diameter between 5,000 and 10,000 nanometers accounts for 1 to 20 percent of the total pore volume. The preparation method for the alumina carrier comprises: adopting a small quantity of starch and / or carbon black as crystal seeds, adopting a method of co-current flow first and swing then to prepare a serum containing aluminum hydroxide, using ammonium carbonate and / or ammonium bicarbonate to adjust the pH value, and finally preparing the alumina carrier. Alumina obtained by the method still maintains high strength under the condition of enlarged pore volume and pore diameter. The alumina carrier is particularly suitable to be a carrier of a residual oil hydrotreating catalyst.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Nano-selenium-containing amino acid foliar fertilizer and preparation method thereof

InactiveCN104387192ASolve the problem of resource reuseSolve pollutionCalcareous fertilisersAnimal corpse fertilisersBiotechnologyActive agent

The invention discloses a nano-selenium-containing amino acid foliar fertilizer and a preparation method thereof. The nano-selenium-containing amino acid foliar fertilizer is prepared from such raw materials as molasses, animal hair, selenium dioxide, sulfuric acid, copper sulfate, manganese sulfate, zinc oxide, ferrous sulfate, ammonium carbonate, ammonium molybdate, urea, potassium chloride, boric acid, fulvic acid, a surfactant, ethylene glycol, sodium carbonate, quick lime or calcium hydroxide, phosphoric acid and water. The preparation comprises the steps of reducing selenium dioxide by use of the molasses to obtain nano-selenium, hydrolyzing the animal hair into an amino acid solution, and then performing the reactions of neutralization, complexing, emulsification and the like to obtain the nano-selenium-containing amino acid foliar fertilizer. According to the nano-selenium-containing amino acid foliar fertilizer, the problem of transforming inorganic selenium into nano-selenium and the problem of recycling waste both are solved; the fertilizer is capable of improving the water retention and drought resisting capability of plants and increasing the content of the organic selenium element content in crops; the preparation method of the fertilizer is mild in reaction conditions, simple in process, relatively low in production cost and prone to industrial production, and has excellent economic benefit, social benefit and ecologic benefit.

Owner:GUANGXI UNIV FOR NATITIES

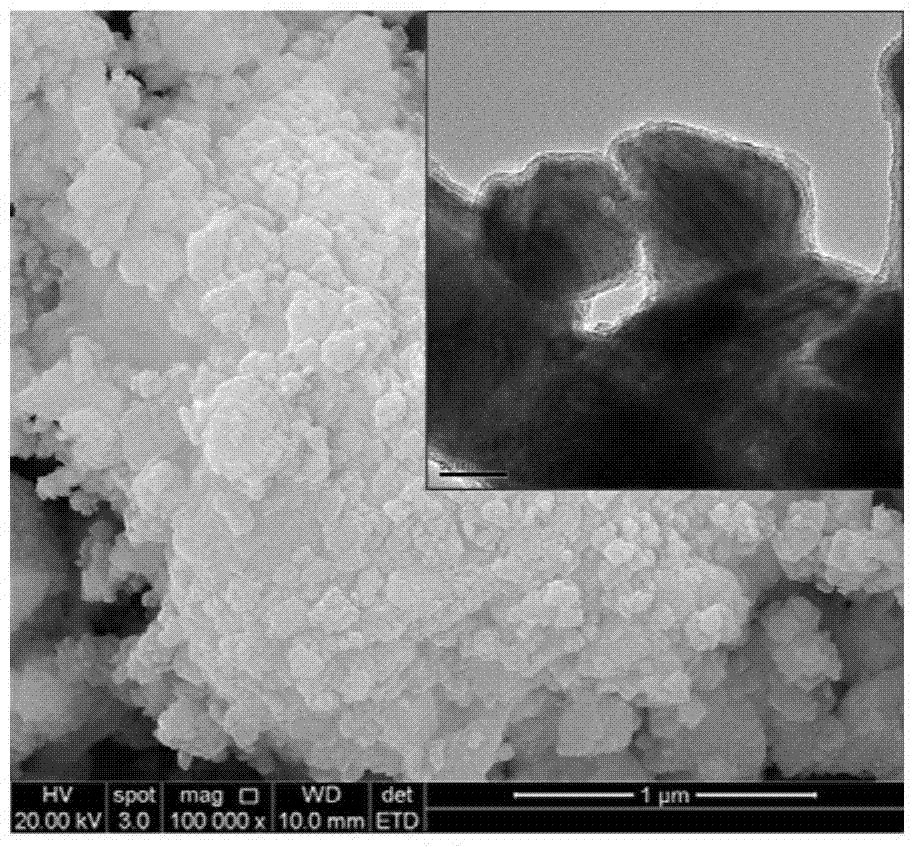

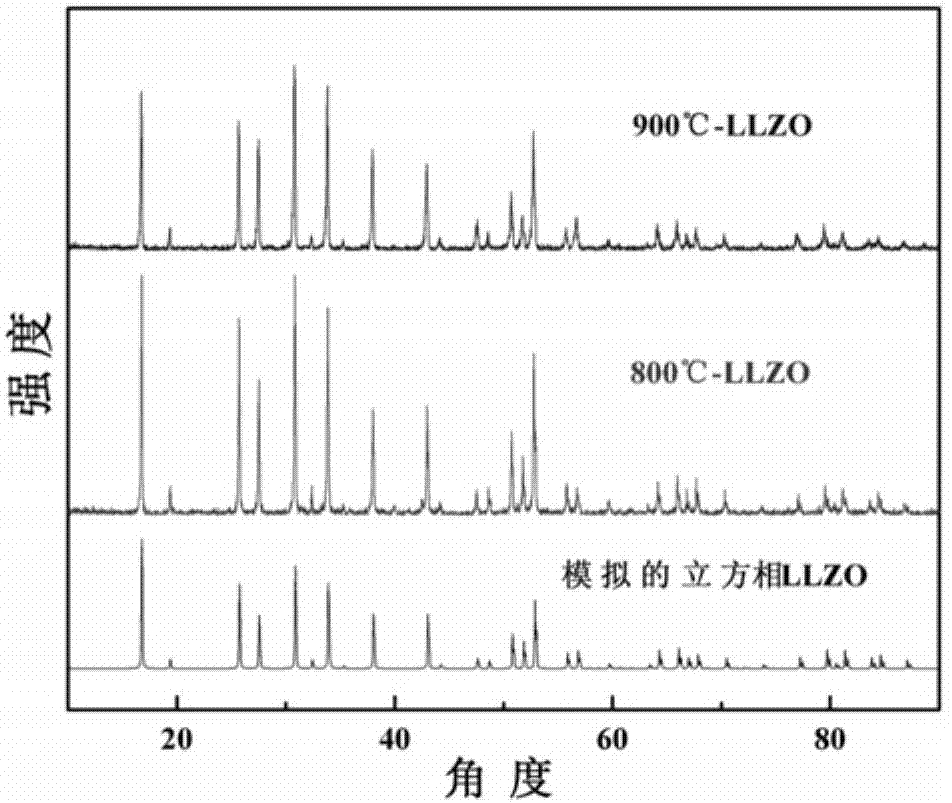

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

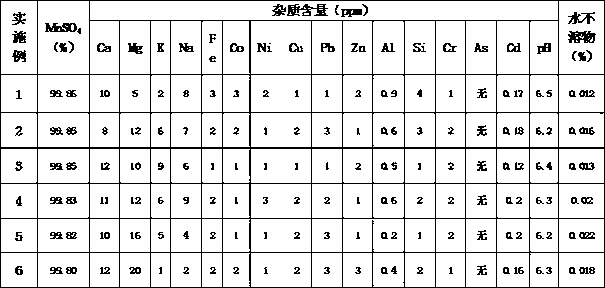

Method for production of high purity manganese sulfate by using pyrolusite as raw material

ActiveCN103011297AImprove controllabilityGood reproducibilityManganese sulfatesPyrolusiteAcid dissolution

The invention relates to a production method for high purity manganese sulfate. The production method is characterized in that pyrolusite is used as a raw material and is reduced by using a carbon fire method, then an acid is added for leaching, a vulcanizing agent is used to remove heavy metals consisting of cobalt and nickel, a fluoride is employed to remove calcium and magnesium, then filtering is carried out, ammonium bicarbonate or ammonium carbonate is added into a filtrate for deposition of manganese to realize separation of potassium and sodium, an obtained filtrate is used for recovery of the by-product ammonia sulfate for usage as an additive for metal manganese, the filter residue manganese carbonate is washed and then subjected to acid dissolution so as to obtain a manganese sulfate solution, and then crystallization is carried out to obtain a high purity manganese sulfate product, wherein mother liquor can be returned to a high purity system for reutilization. With the method provided by the invention, the high purity manganese sulfate product in which MnSO4 content is more than 99.8% and respective content of impurities consisting of Ca, Mg, K and Na is lower than 10 ppm is produced.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

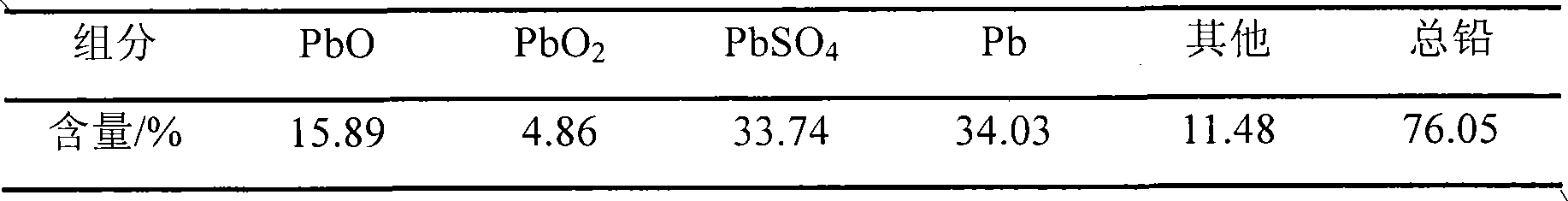

Method for preparing lead nitrate and lead oxide by using lead plaster of waste lead accumulator

InactiveCN101857919ASimple processNo waste dischargeProcess efficiency improvementGranularityLead nitrate

The invention discloses a method for preparing lead nitrate and lead oxide by using lead plaster of a waste lead accumulator, which comprises the following steps of: mixing the lead plaster with the granularity of less than 100 microns and 4.5 to 6.5 percent ammonium carbonate solution in a weight ratio of 1: 10-12, then reacting the mixture for 2 to 3 hours at the temperature of between 60 and 100 DEG C with stirring, separating and washing the reaction product, and collecting filter cakes; then mixing the filter cakes, 6 to 12 percent diluted nitric acid and 28 to 30 percent hydrogen peroxide in turn in a weight ratio of 1: 8-10 and 1: 0.05-0.2 respectively, reacting the mixture for 1 to 1.5 hours at the temperature of between 40 and 60 DEG C with stirring, separating and washing the reaction product, and collecting filtrate; concentrating the filtrate till the density of the solution is 1.30 to 1.45 g / cm<3>, adding 65 to 70 percent nitric acid into the solution in a volume ratio of 1: 8-10 and mixing the solution, reacting the solution for 1 to 2 hours with stirring, separating and washing the reaction product, and drying and dehydrating the filter cakes to obtain a lead nitrate product; and performing reaction conversion on the lead nitrate and sodium hydroxide solution, and calcining the reaction product to obtain a lead oxide product. The purities of both the lead nitrate and the lead oxide are more than or equal to 99 percent. The process adopts closed cycle and has no three-waste emission.

Owner:HEFEI UNIV OF TECH +1

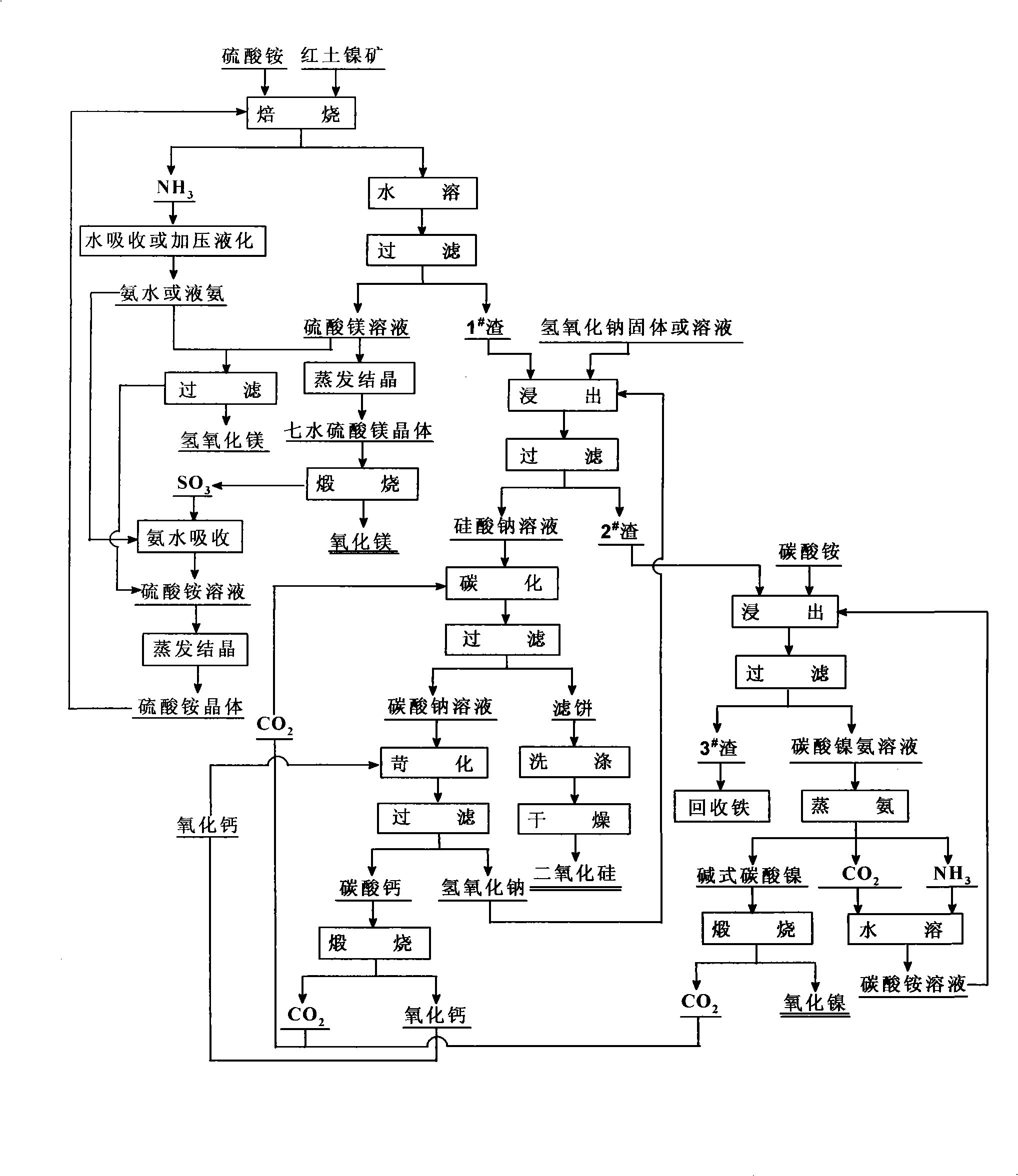

Method for preparing magnesia, silicon dioxide and nickel oxide products from lateritic nickel ore

InactiveCN101525143AHigh value-added comprehensive utilizationCause secondary pollutionSilicaNickel oxides/hydroxidesDiiron TrioxideSODIUM SILICATE SOLN

The invention relates to a method for preparing magnesia, silicon dioxide and nickel oxide products from lateritic nickel ores. The method comprises the following steps: (1), crushing, grinding and roasting the lateritic nickel ores with ammonium sulfate; (2), dissolving and filtering roasted products; (3), evaporating, condensing and crystallizing filtrate to prepare magnesium sulfate; (4), dehydrating and calcining the magnesium sulfate to prepare magnesia; (5), reacting filter residue with an alkaline solution or molten caustic soda, leaching and filtering the product of reaction to obtain a sodium silicate solution; (6), carbonizing, decomposing, filtering, washing and drying the sodium silicate solution to prepare the silicon dioxide; (7), leaching and filtering the residual filter residue by an ammonium carbonate solution; and (8), distilling ammonia from the filtrate and calcining the filtrate to prepare the nickel oxide. The residual residue is ferric oxide containing a small amount of impurities and can be used as an iron-making raw material or deep processed into a product with a high added value. The method is suitable for processing various lateritic nickel ores, has simple technological process and simple and convenient equipment, does not emit solid, liquid and gas waste or cause secondary pollution and uses lower cost to realize the high added value comprehensive utilization of lateritic nickel ore resources.

Owner:NORTHEASTERN UNIV

Chemical process

This invention provides a process for preparing sodium ferric gluconate complex in sucrose using the following steps: a) combining a ferric salt solution with a weak alkali chosen from the group consisting of alkaline earth metal and ammonium salts, such as sodium carbonate, sodium bicarbonate, lithium carbonate, potassium carbonate, potassium bicarbonate, ammonium carbonate, ammonium bicarbonate and mixtures thereof, to form the ferric oxyhydroxide; b) combining ferric oxyhydroxide and sodium gluconate in solution to yield the sodium ferric gluconate complex; c) isolating the sodium ferric gluconate complex; and d) combining the sodium ferric gluconate with sucrose in solution to yield the desired sodium ferric gluconate complex in sucrose.

Owner:GENEVA PHARMA INC

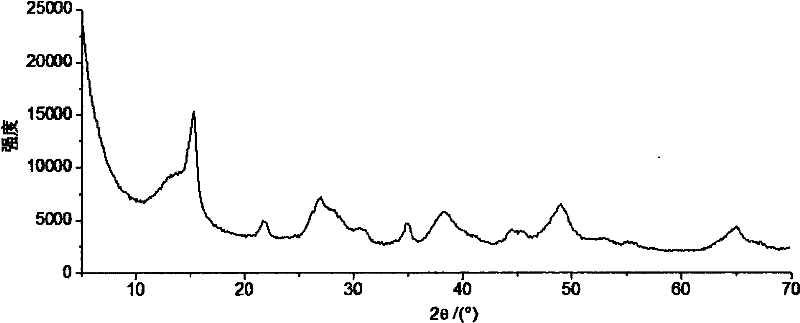

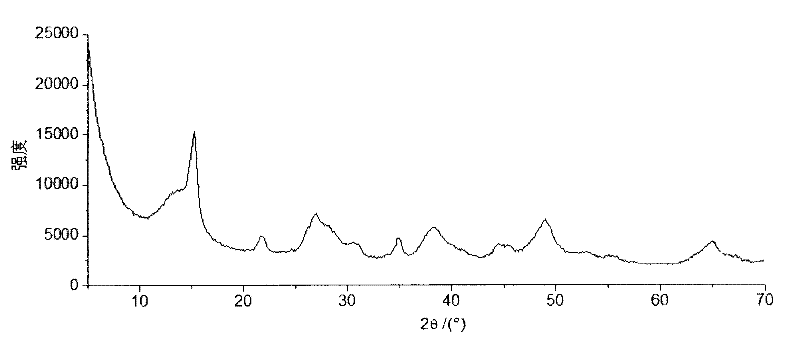

A kind of hydrated alumina and preparation method thereof

ActiveCN102259900AExcellent hole expandabilityImprove pore structureAluminium oxides/hydroxidesAlumina hydrateSodium aluminate

The present invention provides a hydrated alumina containing pseudo-boehmite, wherein the hydrated alumina further contains basic aluminum ammonium carbonate. The present invention also provides a method for preparing hydrated alumina, the method comprising contacting sodium metaaluminate and / or sodium aluminate with an acidic solution, and aging the mixed slurry obtained after the contact reaction in the presence of an aging agent The conditions of the contact reaction include: the reaction pH value is 4.5-9, and the reaction temperature is 15-75°C; the aging conditions include: the temperature is 20-60°C, and the time is 2-6 hours; the aging agent Ammonium carbonate and / or ammonium bicarbonate. The alumina carrier prepared by using the hydrated alumina prepared by the method for preparing hydrated alumina according to the present invention has significantly improved most probable pore diameter, average pore diameter, pore volume and pore volume with a diameter of 10-60 nanometers.

Owner:CHINA PETROLEUM & CHEM CORP +1

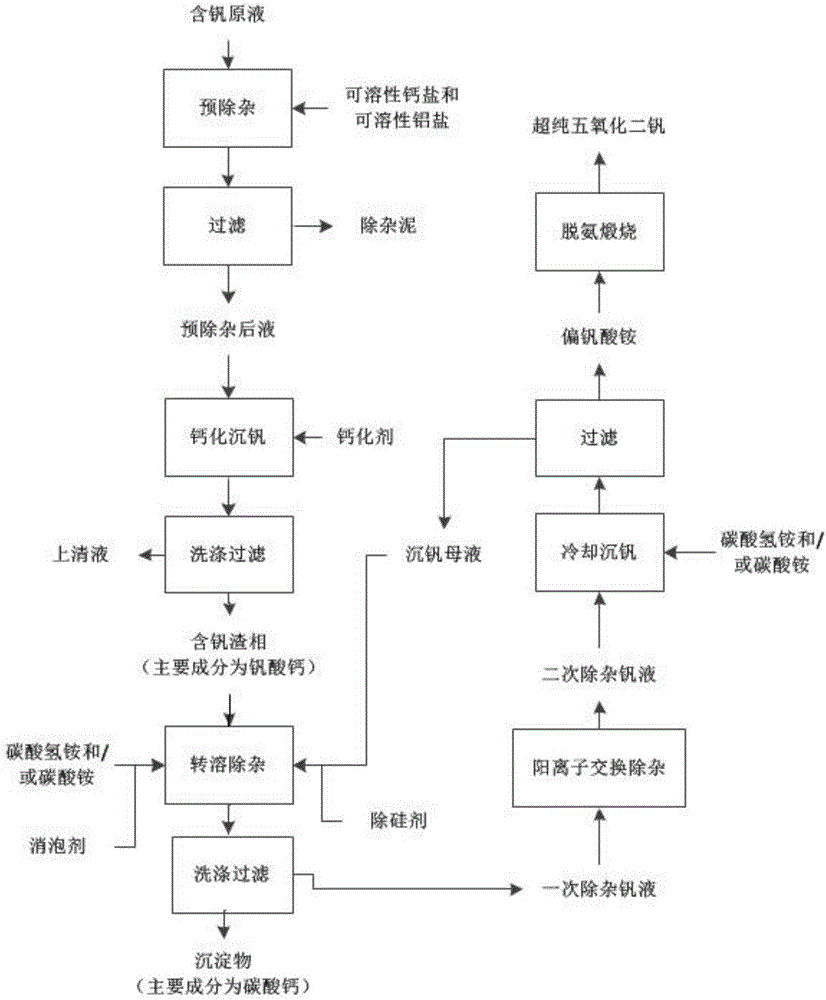

Preparation method of ultra-pure vanadium pentoxide

The invention discloses a preparation method of ultra-pure vanadium pentoxide. The preparation method comprises the following steps of: removing impurities in advance; transferring phosphorus and silicon in a vanadium-containing solution into a solid phase for removal; performing calcification and vanadium precipitation; transferring vanadium in a liquid phase into a calcium vanadate phase; leaving the impurities such as chromium, manganese, potassium and sodium in the liquid phase for removal; performing solubilization reaction of vanadium in the calcium vanadate into the liquid phase through ammonium bicarbonate and / or ammonium carbonate; leaving the calcium, phosphorus, silicon, iron and magnesium in the solid phase for removal; replacing residual trace cations of the liquid phase with ammonium ions by an ammonium type cation exchange system to realize deep purification; and performing cooling vanadium precipitation and deamination calcination to obtain vanadium pentoxide. In the invention, the process route is simple, the drug consumption is low, the vanadium pentoxide with purity of over 99.95% can be stably obtained, and the content of main impurities such as iron, chromium, manganese, silicon, phosphorus, calcium, sodium, magnesium, potassium and aluminum is all lower than 0.002%.

Owner:HEBEI IRON AND STEEL

Organic Silver Complexes, Their Preparation Methods and Their Methods for Forming Thin Layers

ActiveUS20090120800A1Superior stability and solubilityEasy to prepareGroup 1/11 organic compounds without C-metal linkagesRadiation applicationsThin layerAmmonium carbamate

Owner:INKTEC CO LTD

Method for producing ammonium sulphate with phosphogypsum as raw material

ActiveCN101269823AImprove conversion rateLess complex process of purificationCalcium/strontium/barium carbonatesAmmonia compoundsFiltrationResource utilization

The invention discloses a method using phosphogypsum as the raw material to produce ammonium sulfate, and the method comprises steps as follows: 1750 shares of crude phospho gypsum which contains 20 percent of free water is taken, and 2 to 5 percent of the amount of the crude phospho gypsum of activator is added the aging for 2 to 8 days; then, a reaction tank and an ammonium carbonate solution are added to carry out the conversion reaction, in the reaction process, the concentration of the ammonium carbonate solution is 40 to 42 percent, the carbonized ratio CO2 / 2NH3 is 1.34 to 1.37, the quality is 1840 to 2000g, the reaction temperature ranges from 55 to 70 DEG C, the stirring speed ranges from 200 to 240 turns per minute, and the reaction time ranges from 1.5 to 2.5 hours; after filtration, the ammonium sulfate solution is obtained, the ammonium sulfate solution is neutralized by sulfate to obtain a PH value ranging from 6.9 to 7.02, and then, an ammonium sulfate excellent grade product is obtained through multi-effect evaporation crystallization and drying. The method can solve problems of waste piling and pollution of phosphogypsum, which restrict the development of the phosphate chemical industry, and realize the resource utilization of the phosphogypsum.The production cost is low, and the industrial production can be realized.

Owner:WENGFU (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com