Preparation method of ultra-pure vanadium pentoxide

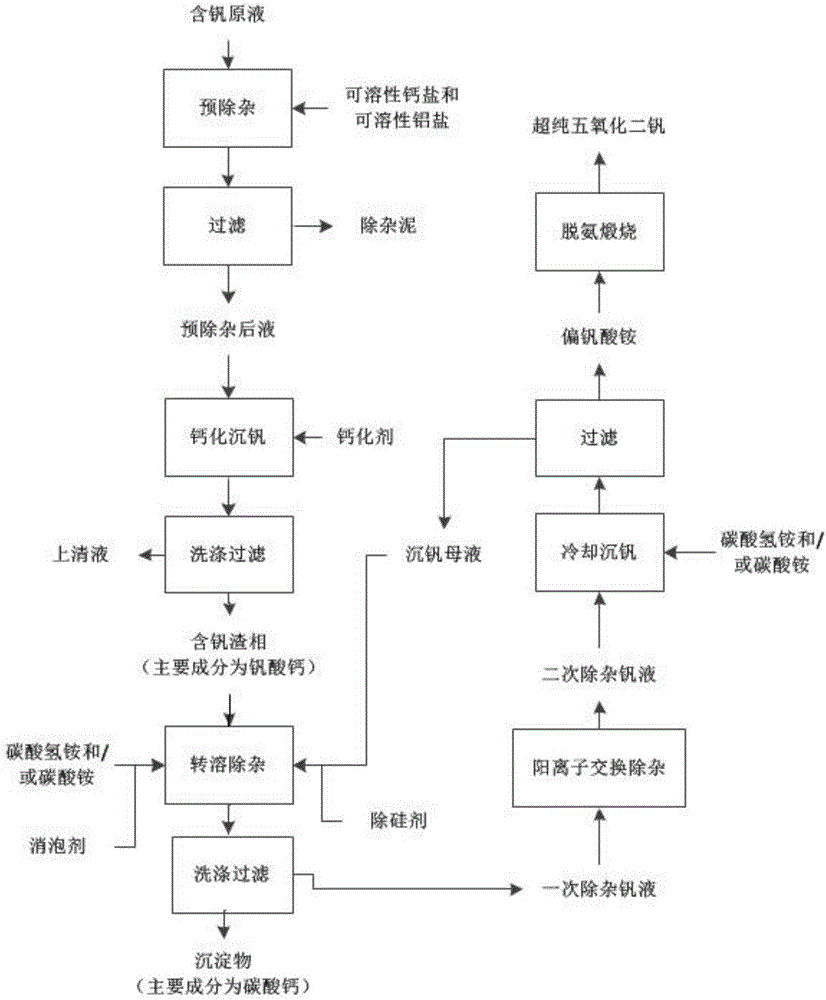

A technology for vanadium pentoxide and vanadium precipitation is applied in the field of preparation of vanadium pentoxide, which can solve problems such as unfavorable industrial production, difficult and unsatisfactory control of product impurities, simplification of operation flow and technological difficulty, and stable product index. Good sex, the effect of reducing the dosage of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] 1) Pre-removal of impurities: the vanadium-containing solution obtained by extracting vanadium from vanadium slag by sodium roasting method is used as a vanadium-containing solution (containing 24.8g / L of vanadium, 92ppm of iron, 351ppm of chromium, 25ppm of manganese, 264ppm of phosphorus, and 650ppm of calcium calcium 59ppm, magnesium 33ppm, aluminum 21ppm, sodium 19.8g / L, potassium 1.5g / L), the dosage of soluble calcium salt is added with the molar ratio=1.1:1 of phosphorus element in its calcium-containing element and vanadium-containing solution, soluble aluminum salt The amount of feed is added according to the molar ratio of the aluminum-containing element to the silicon element in the vanadium-containing solution = 1.2:1, stirred and reacted at 70°C for 30 minutes, and filtered to obtain the pre-removed impurity liquid and the impurity-removed mud;

[0091] 2) Precipitation of vanadium by calcification: add calcium oxide to the pre-removed liquid obtained in step...

Embodiment 2

[0100] 1) Pre-removal of impurities: use the vanadium-containing solution obtained by extracting vanadium from stone coal as the vanadium-containing solution (containing 50.4g / L of vanadium, 25ppm of iron, 110ppm of chromium, 115ppm of manganese, 363ppm of phosphorus, 1521ppm of silicon, 26ppm of calcium, 32ppm of magnesium, aluminum 7ppm, sodium 135ppm, potassium 15ppm), the soluble calcium salt dosage is added with the mol ratio=1.2:1 of phosphorus element in its calcium-containing element and vanadium-containing solution, and the soluble aluminum salt dosage is added with its aluminum-containing element and vanadium-containing solution The molar ratio of silicon element = 1.3:1 was added, stirred and reacted at 80°C for 40 minutes, and filtered to obtain the pre-removed impurity liquid and impurity-removed mud;

[0101] 2) calcification vanadium precipitation: to step 1) add calcium hydroxide in the liquid dissolving liquid after pre-removal of impurities, the charging capac...

Embodiment 3

[0110] 1) Pre-removal of impurities: the vanadium-containing solution obtained by the secondary vanadium-containing waste extraction vanadium is used as the vanadium-containing solution (containing 28.51g / L of vanadium, 33ppm of iron, 28ppm of chromium, 285ppm of manganese, 465ppm of phosphorus, 121ppm of silicon, 16ppm of calcium, magnesium 76ppm, aluminum 33ppm, sodium 16.35g / L, potassium 933ppm), the mol ratio of soluble calcium salt to the phosphorus element in the solution containing calcium and vanadium=1.35:1 is added, and the soluble aluminum salt is charged according to its aluminum content The molar ratio of the element to the silicon element in the vanadium-containing solution = 1.4:1 was added, stirred and reacted at 100°C for 15 minutes, and filtered to obtain the pre-removed impurity liquid and the impurity-removed mud;

[0111] 2) Calcification of vanadium precipitation: add calcium oxide to the pre-removed liquid obtained in step 1), the feeding amount of calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com