Patents

Literature

43results about How to "Reduce mutual inclusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

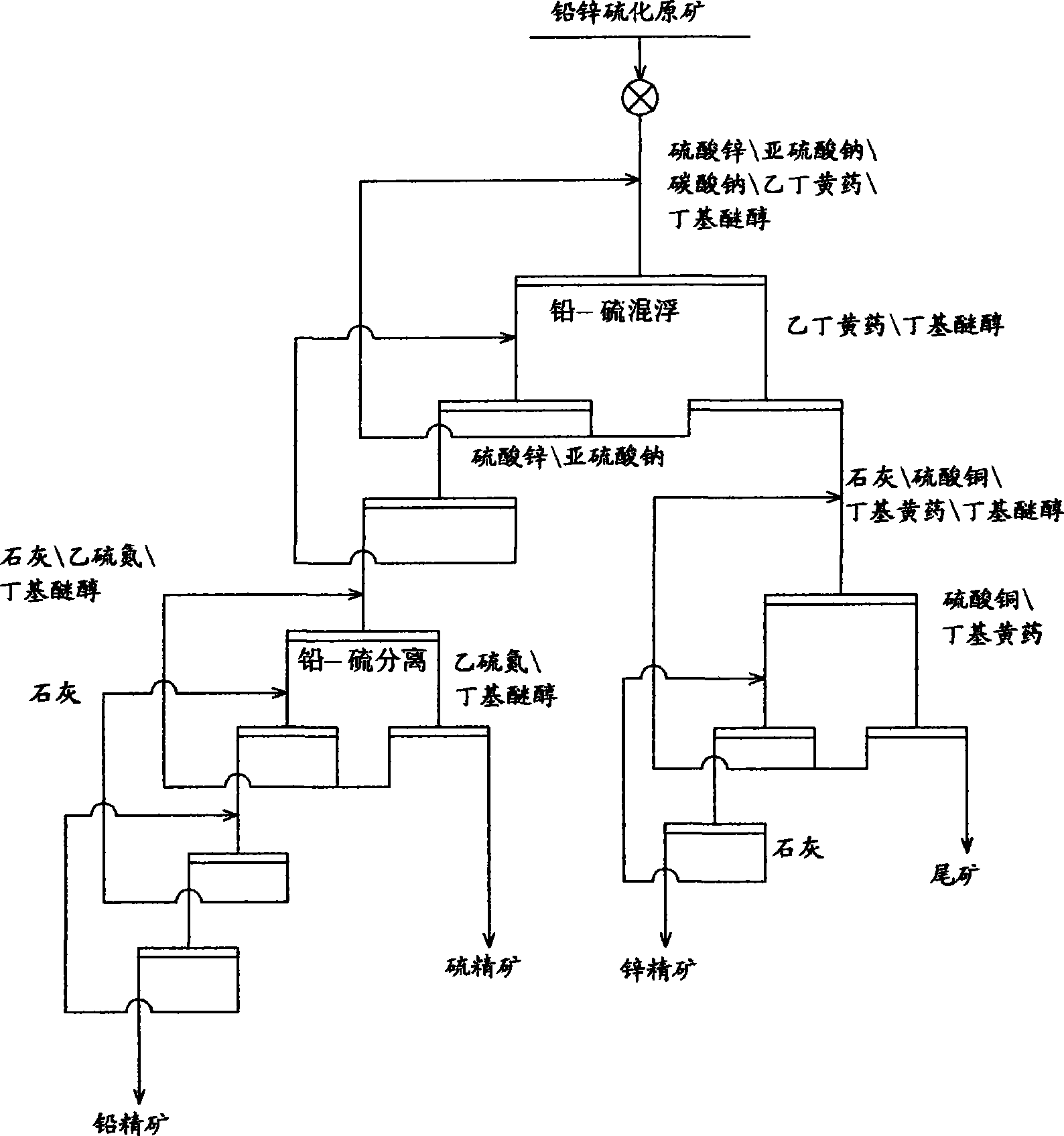

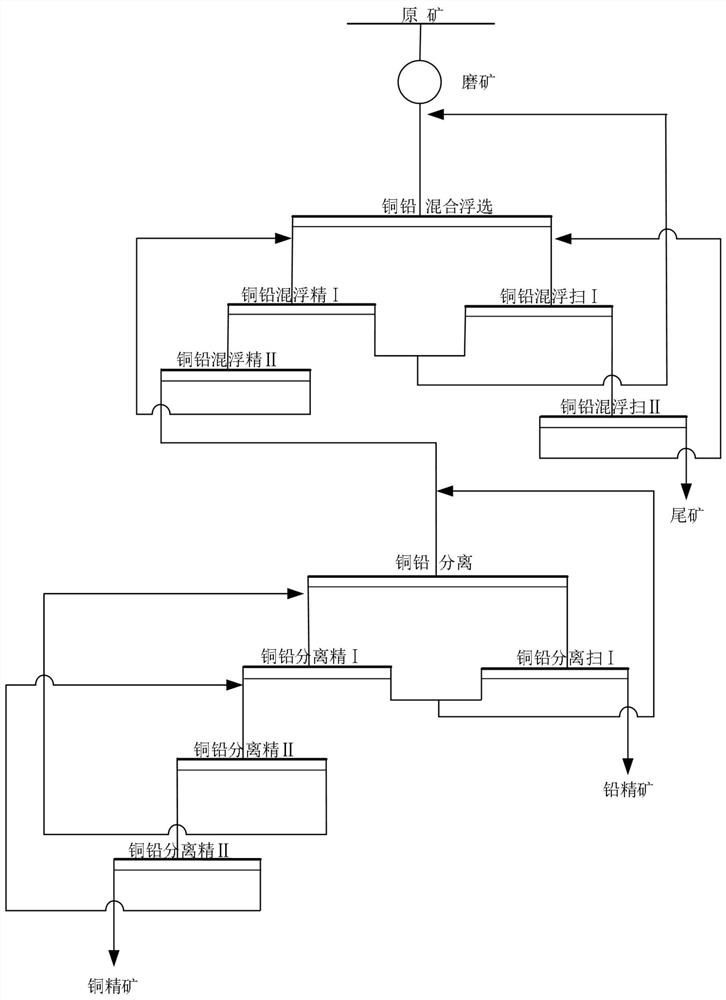

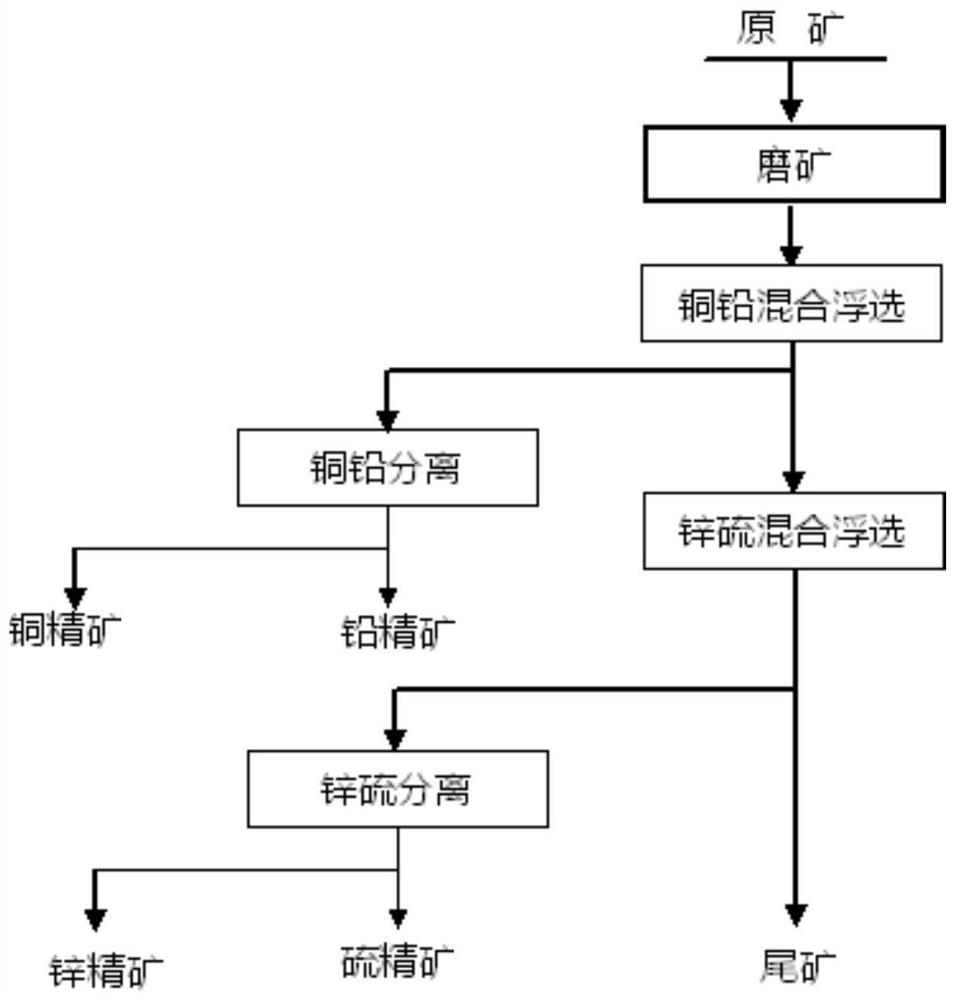

New flotation technique of lead zinc sulphur ore

The invention relates to a new technology for lead zinc sulfide ore floatation. Lead sulfide mineral is preferably carried out with mixed floatation in a neutral or weak alkali medium, then zinc floating and lead sulfur separation are carried out in a high alkali medium. The lead sulfide mineral is firstly floated to enter product, before zinc floating, lead sulfide mixed product is obtained, only pure zinc mineral enters slurry in a zinc floating work zone, thus being beneficial to zinc floatation and avoiding the operation method of heavy pulling and heavy stress; and lead tailing has no sulfur mineral, thus reducing useless poor circulation formed in zinc floating of the sulfur mineral, saving the beneficiation reagent and improving the sorting standard.

Owner:HUANGSHAPING MINING BRANCH HUNAN NONFERROUS METALS +2

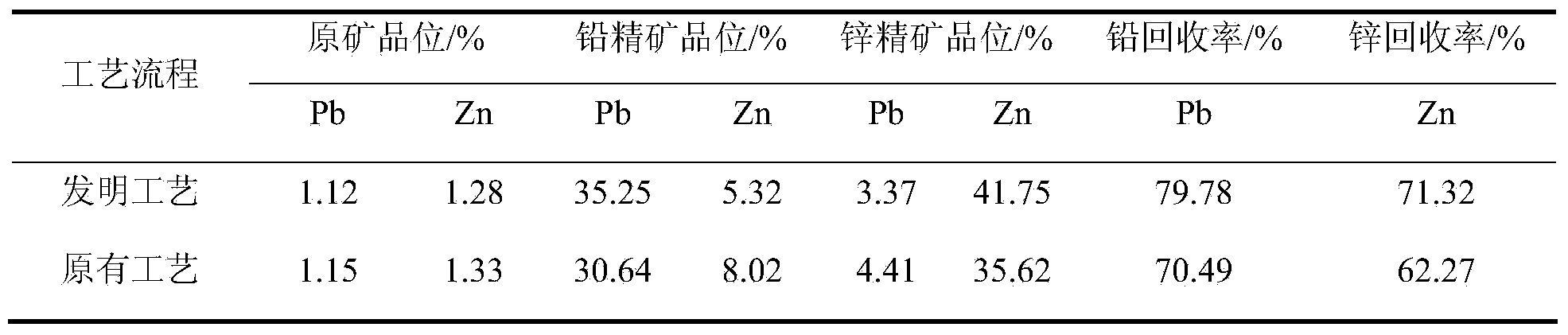

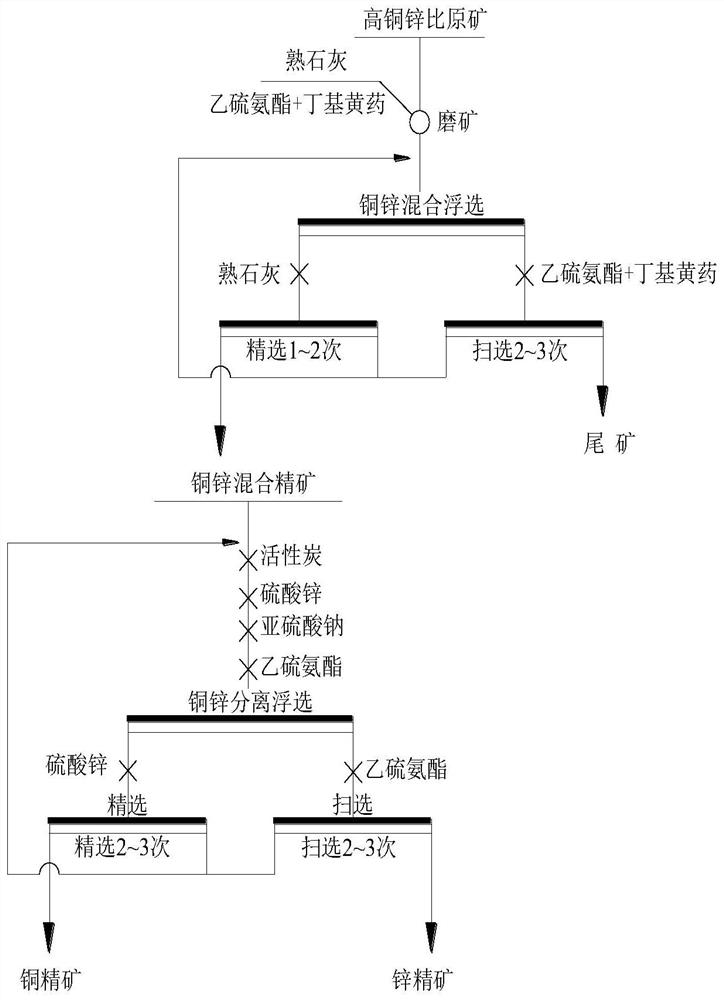

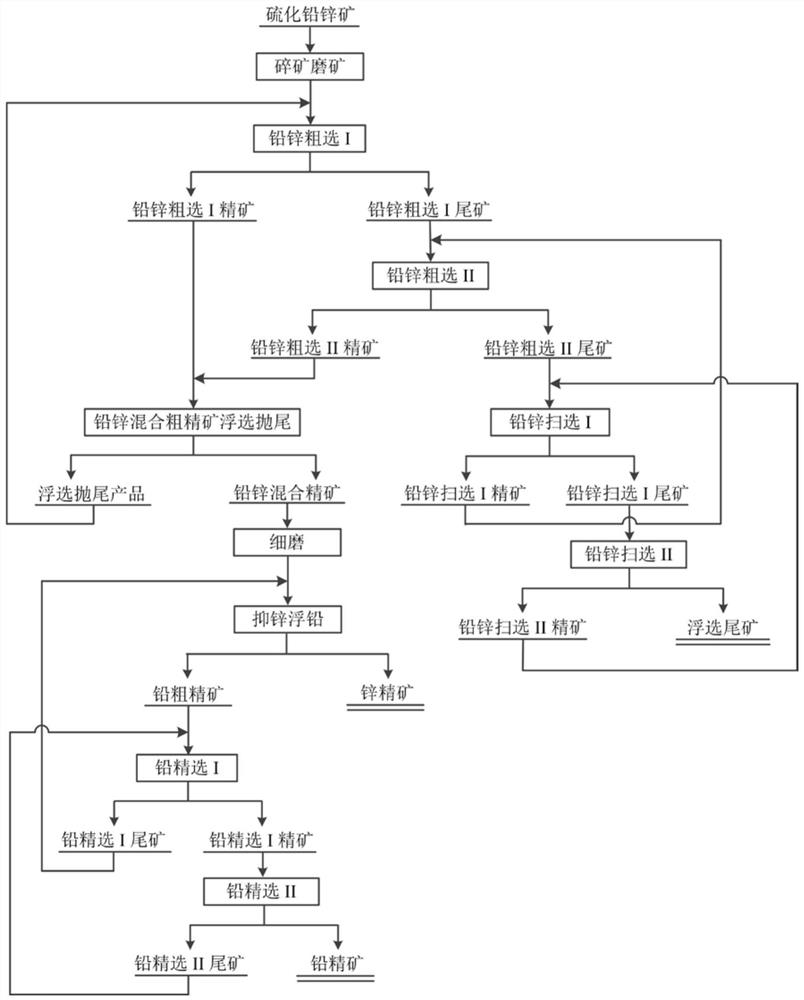

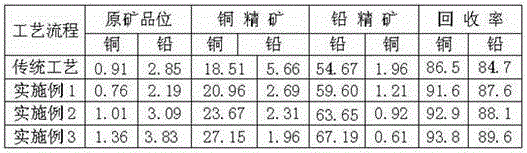

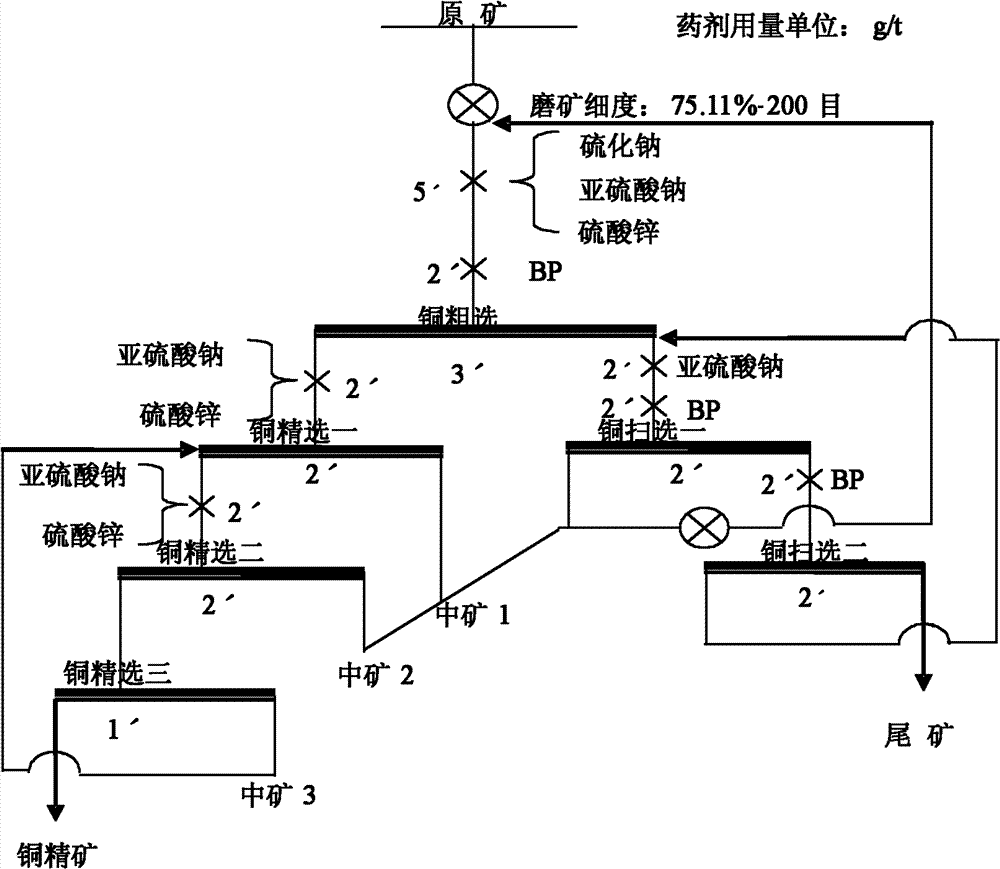

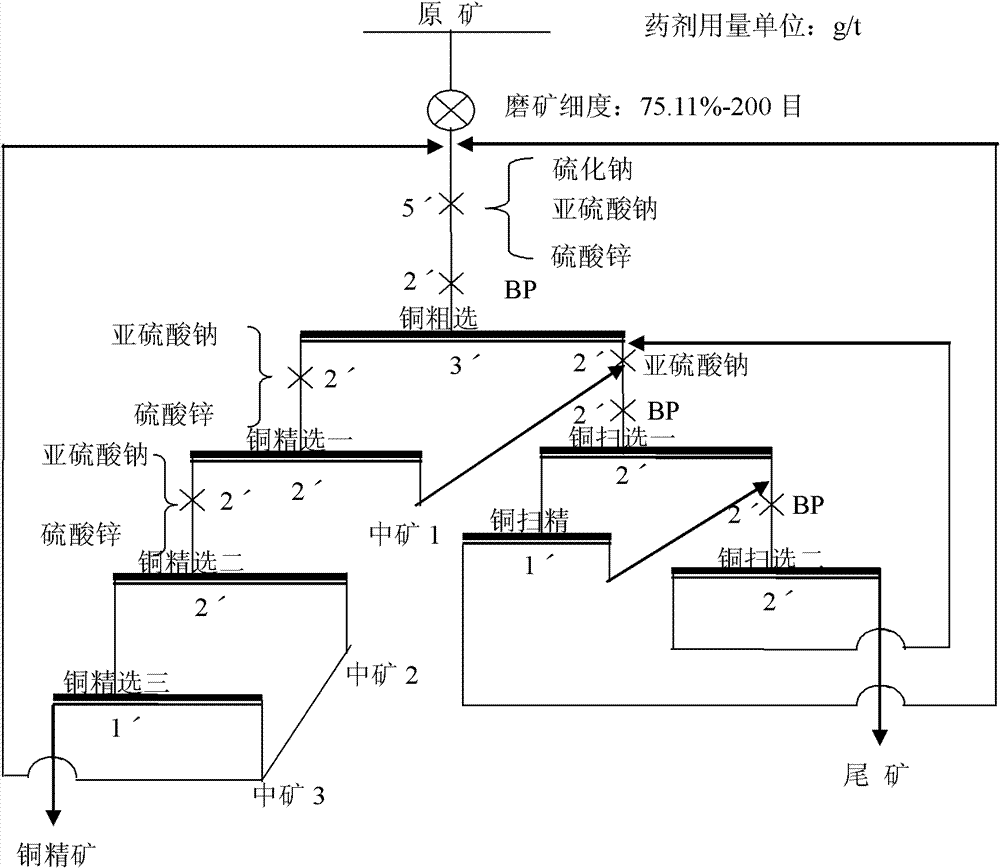

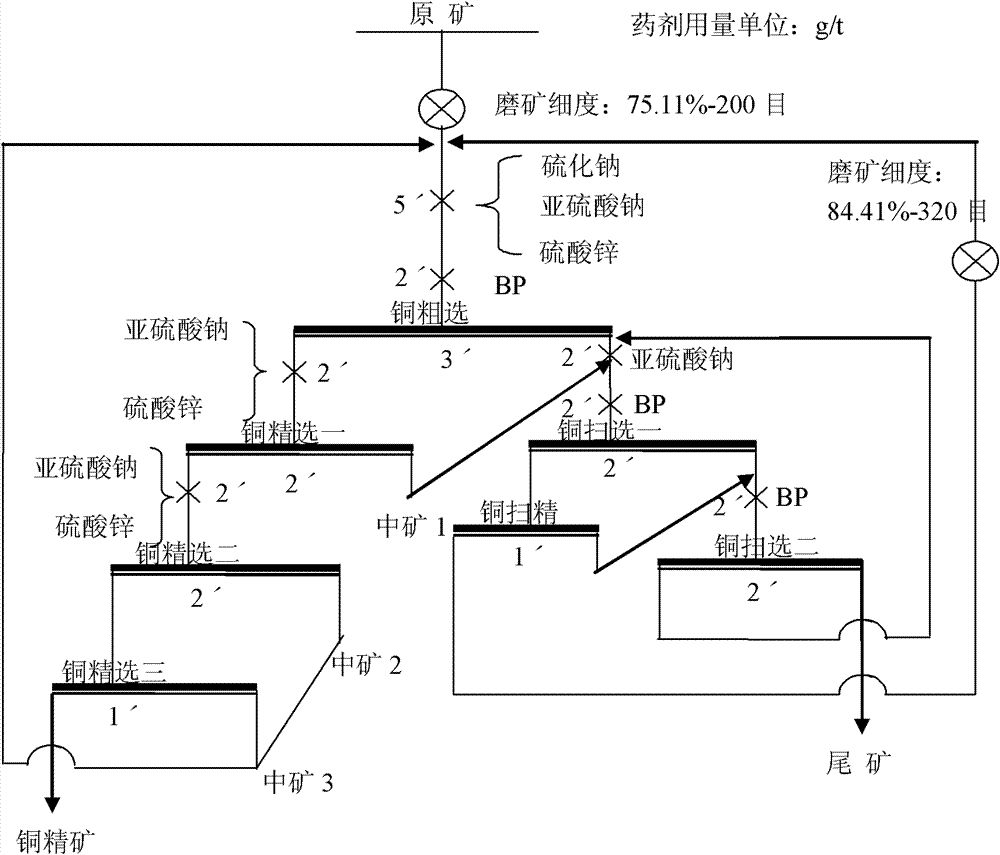

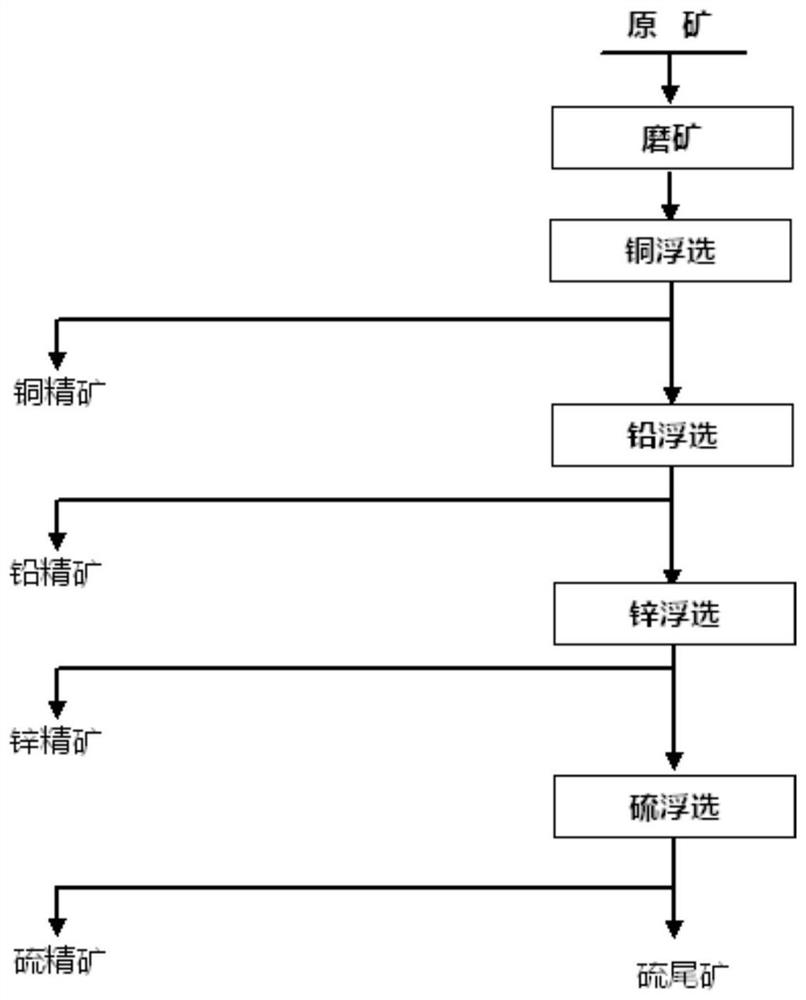

Flotation method for lead and zinc ore difficult to select

InactiveCN103639061AThe process is simple and reliableEasy to operateFlotationDibutyl dithiophosphateSulfite salt

The invention relates to a flotation method for lead and zinc ore difficult to select. The method includes the following steps of lead roughing, two-time lead scavenging, three-time lead fine selection, zinc roughing, two-time zinc scavenging and three-time fine selection. Lime serves as regulators, zinc sulfate and sodium sulfite serve as zinc inhibitor, diethyl dithiocarbamate and ethyl xanthogenate serve as lead collecting agents, copper sulfate serves as zinc activating agents, ammonium dibutyl dithiophosphate serves as zinc collecting agents, and terpenic oil serves as foaming agents. The lead and zinc ore difficult to select is processed by the adoption of lead differential flotation and zinc selection technological processes, and the practical problems that in original technological processes, zinc contains a high content of lead which contains a high content of the zinc, and the lead recovery rate and the zinc recover rate are low are solved. The technological processes are simple, reliable, easy to operate, and good in sorting index. Compared with the original technological processes, the method has the advantages that under the circumstance that raw ore contains the same lead and zinc, mutual containing of the lead and zinc is reduced, and the lead recovery rate and the zinc recovery rate are greatly increased and increased by 9.29% and 9.05% respectively.

Owner:GUANGXI UNIV

Mineral processing process for multi-metal sulfide minerals containing secondary copper

The invention relates to a mineral processing process for multi-metal sulfide minerals containing secondary copper, and belongs to the technical field of mineral processing. According to the method of the mineral processing process for multi-metal sulfide minerals containing the secondary copper, iron powder with the particle size of 1 mm to 150 mm is selected for preparing suspension liquid with the concentration of 1 percent to 10 percent; iron powder with the amount of 0.1 to 1 percent of the mass of solid ore in the ore pulp is added to a mill or an agitator tank, and subsequently conventional flotation method is carried out to obtain final concentrate products; the iron power added into the mill and ore particles form primary batteries, dissociative copper ions in the ore pulp are replaced, excitation of the dissociative copper ions on blende and pyrite is reduced, the floatability difference among the minerals is enlarged, the phenomenon that concentrate products containing one another is reduced, and therefore the index of mineral separation products is improved. The method has the advantages of being good in flotation index, saving chemical, and simplifying mineral processing flow.

Owner:WUPING ZIJIN MINING CO LTD

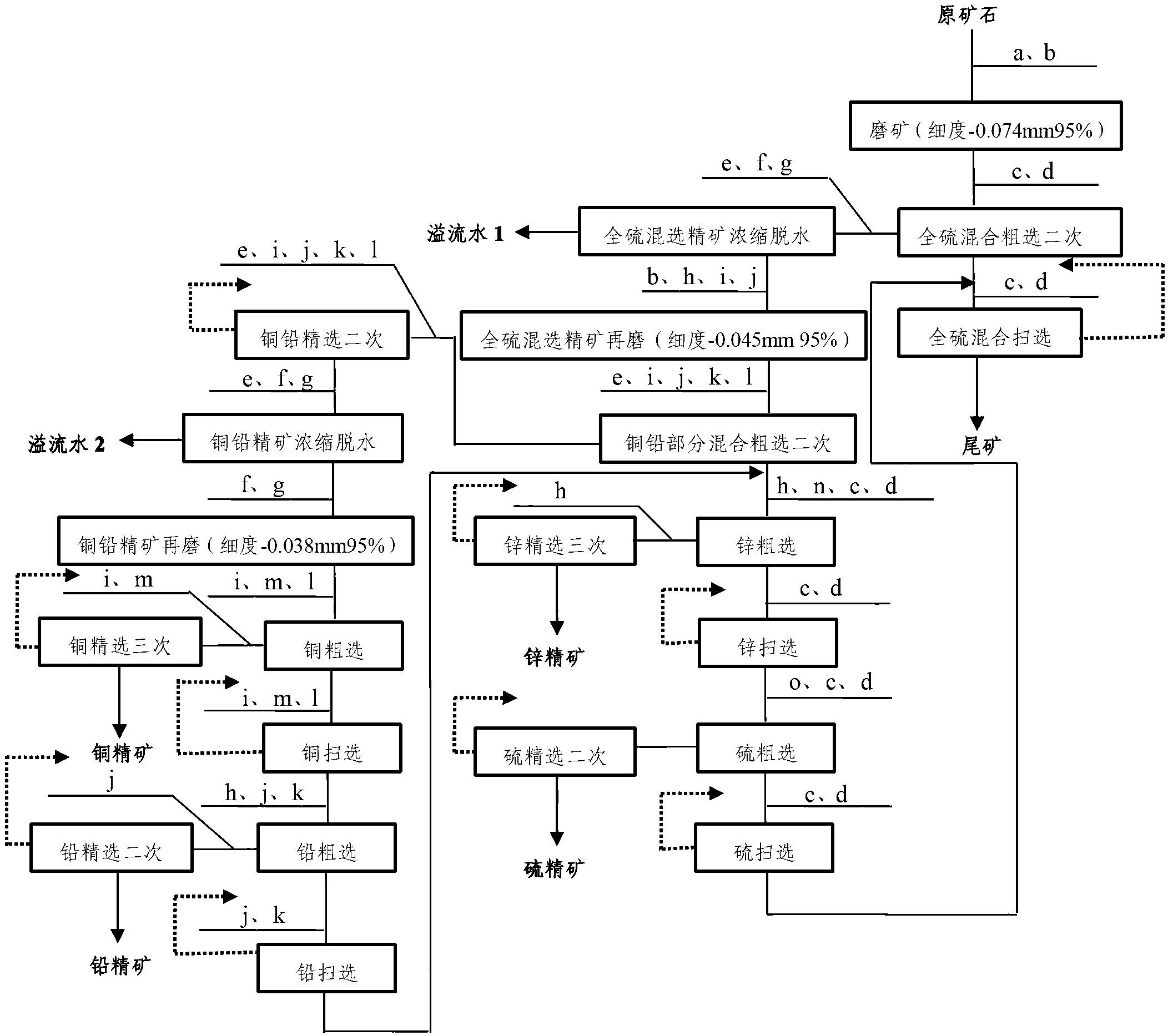

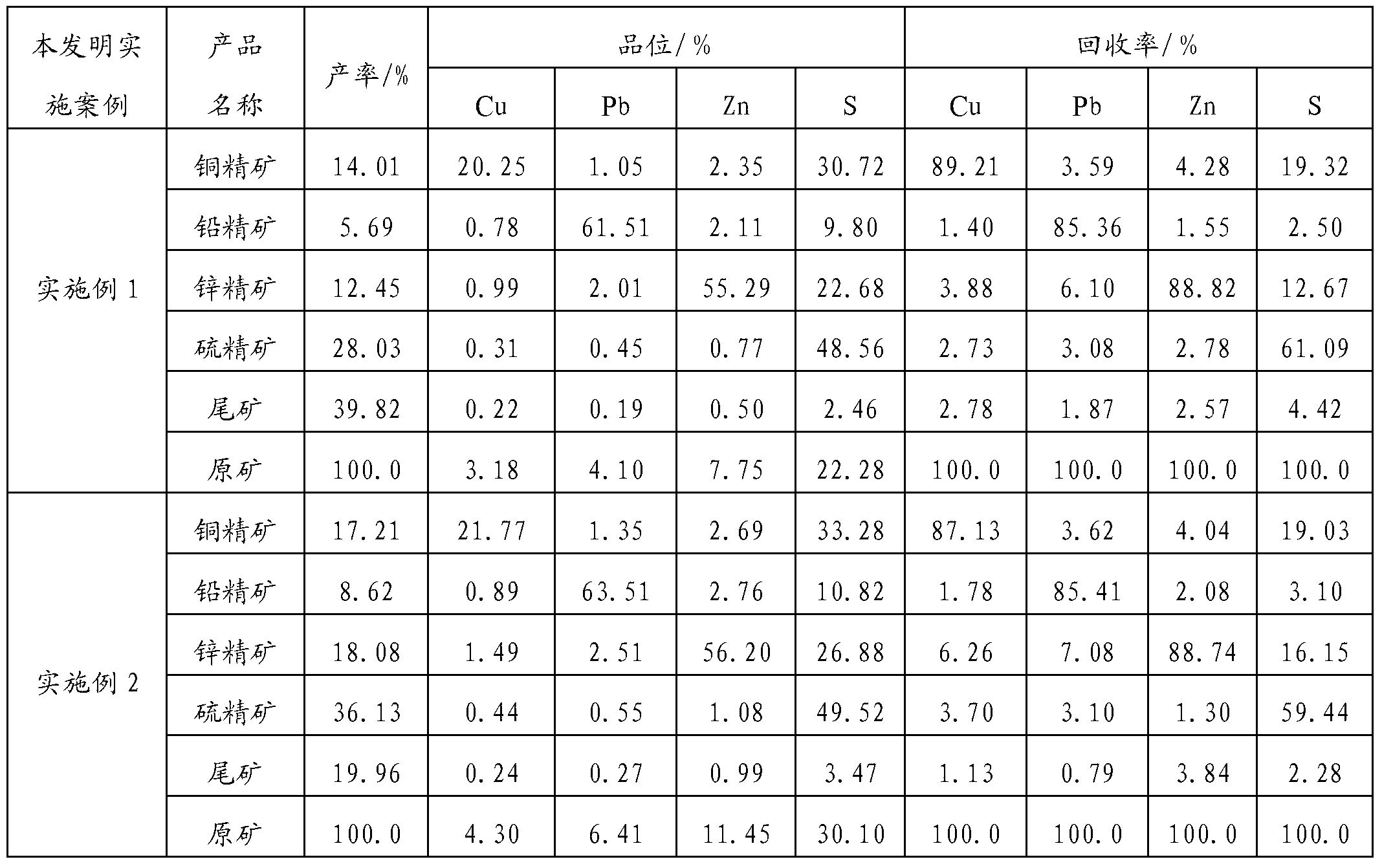

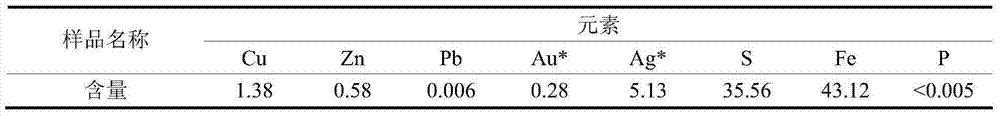

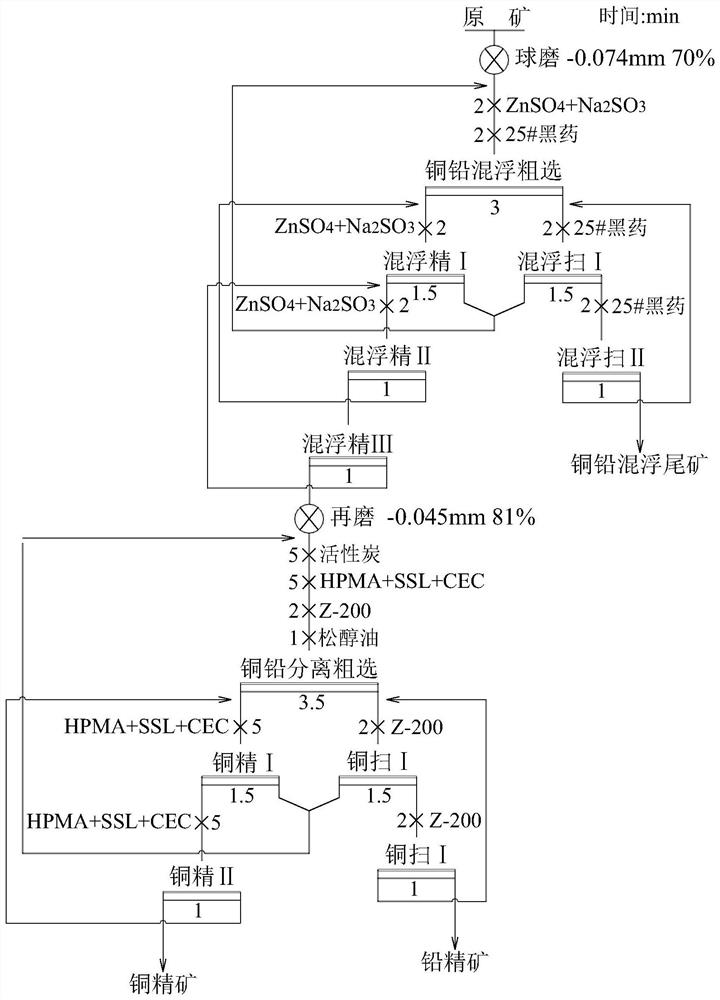

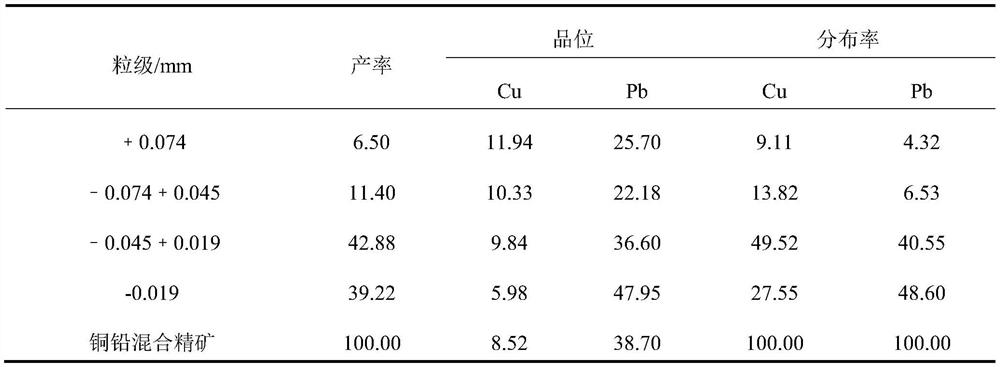

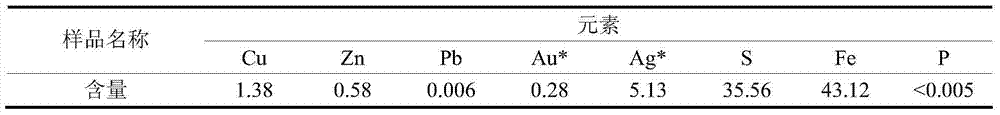

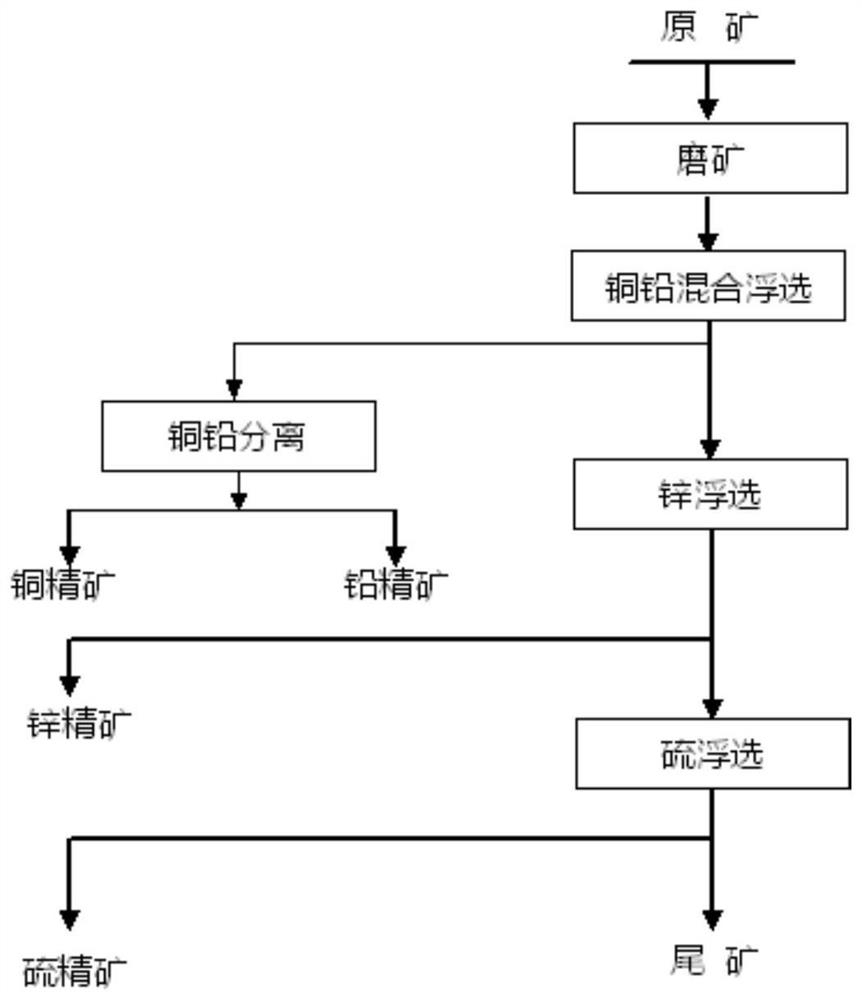

Beneficiation method for veinlet disseminated ore body type copper-lead-zinc-sulfur complex polymetallic ore

The invention relates to a beneficiation method for a veinlet disseminated ore body type copper-lead-zinc-sulfur complex polymetallic ore. The technical scheme adopted is that based on the feature of the veinlet disseminated ore body type copper-lead-zinc-sulfur complex polymetallic ore, a process of total sulfur fixed floating- partial copper-lead mixed floating separation-selective zinc-sulfur flotation is adopted, in combination with a way of concentration and fine grinding, for depth reagent removal, According to the method, the reagent removal is complete, the influence of ore mud on flotation is effectively eliminated, the copper, lead, zinc and sulfur can be divorced and recycle to the maximum extent, and accordingly, the content of other metallic elements in the concentration of the last one metallic element is obviously reduced.

Owner:ZIJIN MINING GROUP

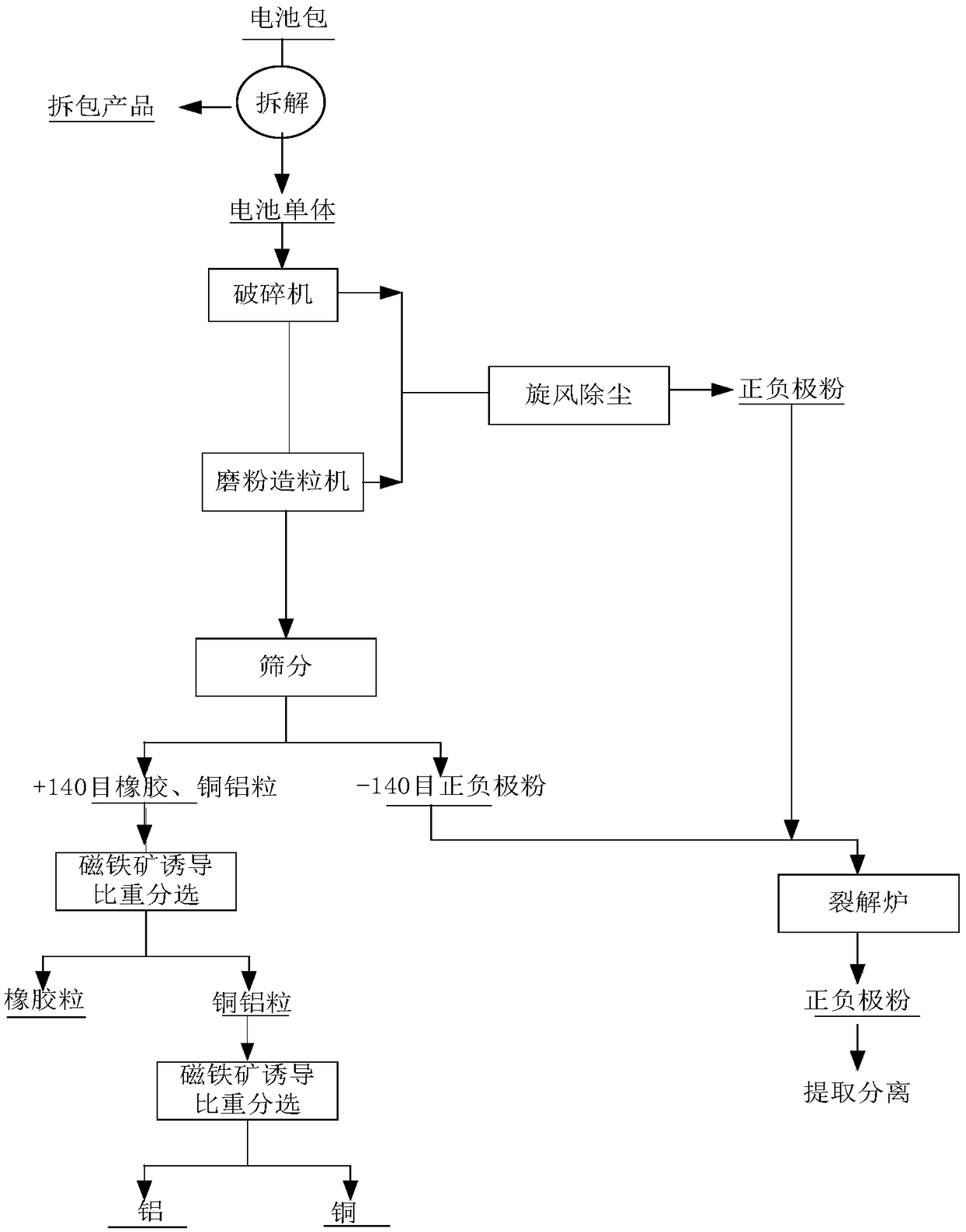

Method for recycling copper aluminum and rubber in waste power lithium battery

ActiveCN109378542ASimple processHigh product purityWaste accumulators reclaimingLi-accumulatorsSpecific gravityGravity separation

The invention discloses a method for recycling copper aluminum and rubber in a waste power lithium battery. The method is characterized by comprising the following steps of 1) disassembly: disassembling a waste power battery pack to obtain a battery unit; 2) crushing and granulation: conducting one-stage crushing and two-stage granulation through an ultra-fine grinding granulator on the battery unit to obtain a product A; 3) screening: screening the product A through a screening device to obtain 100-160-mesh anode and cathode powder under the screening device and a 100-160-mesh product B on the screening device; 4) magnetite induced gravity separation: conducting the magnetite induced gravity separation on the product B first to obtain pure rubber particles and a copper-aluminum mixture and conducting the second magnetite induced gravity separation on the copper-aluminum mixture to obtain pure copper particles and aluminum particles. The ultra-fine high-purity magnetite induced gravityseparation technology is adopted to better recycle the copper-aluminum and the rubber in the waste power lithium battery, and the obtained copper and aluminum and the rubber have low mutual content.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Copper-molybdenum separation electric potential flotation process

The invention discloses a copper-molybdenum separation electric potential flotation process. The copper-molybdenum separation electric potential flotation process comprises the steps of raw ore crushing, ore grinding, mixed flotation and separation flotation. In the separation flotation step, the ph value of pulp is kept at 10-11, and rougher flotation pulp electric potential is controlled to -510 mv to -530 mv; and then 180 ml / min of polyacrylamide modified matter is added as a copper inhibitor, the grade of separation rougher flotation foam molybdenum is controlled to 9%-12%, the copper grade is controlled to 11.2%-15%. Electric potential flotation is adopted, rougher flotation electric potential is controlled to be within a certain range, copper minerals can be restrained to the maximum, the foam grade of corresponding work is stabilized, a large amount of sodium bisulfide can be saved, the molybdenum recovery rate is increased, meanwhile, mutual containing in copper-molybdenum concentrate is lowered, and the effect is also very significant.

Owner:CHINA GOLD INNER MONGOLIA MINING

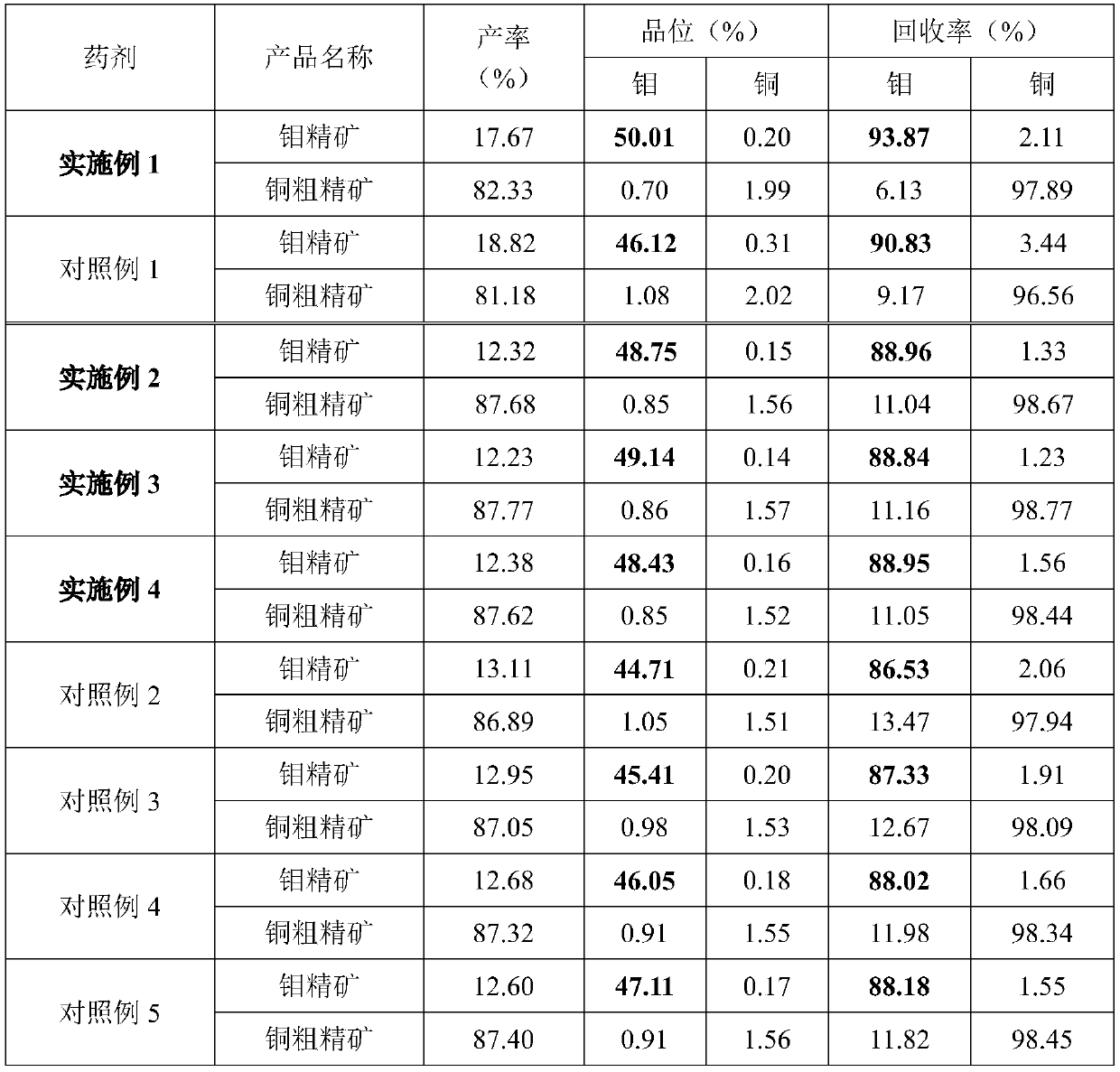

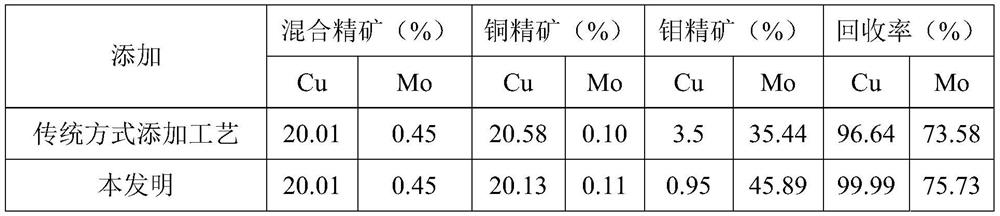

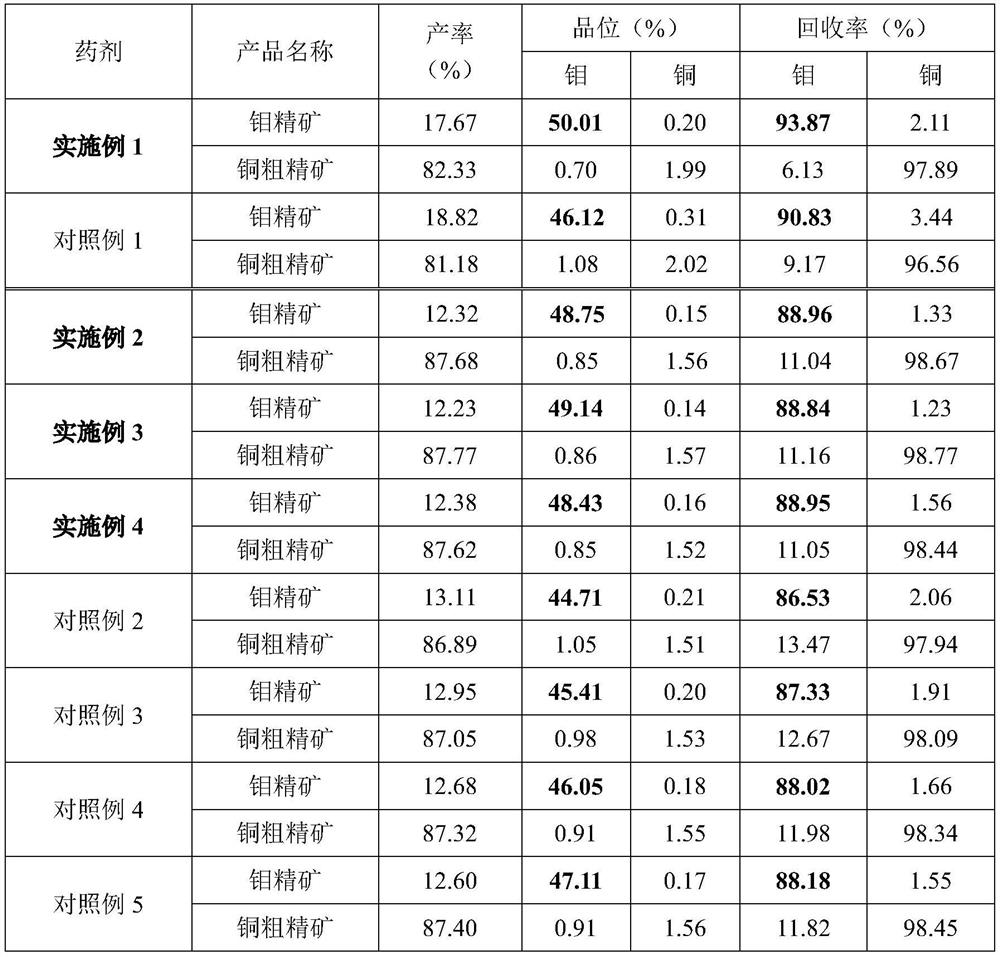

Porphyry copper molybdenum ore copper molybdenum flotation process

InactiveCN106423576AGive full play to the natural buoyancyHigh recovery rateFlotationAlkalinitySolid mass

The invention discloses a porphyry copper molybdenum ore copper molybdenum flotation process. The porphyry copper molybdenum ore copper molybdenum flotation process is characterized by comprising the following steps: under the fineness of -0.074 mm content of 60-70%, the mass percentage concentration of pulp is within 25-40%; lime is added to adjust the pulp system pH in a low-alkalinity range of 7-8.5; a molybdenum mineral capturing agent being 0.005-0.012% of the solid mass in the pulp is added; the flotation is performed for molybdenum ore and one part of copper ore to obtain a copper molybdenum mixed concentrate for separation; flotation tailing is added with a copper mineral capturing agent being 0.004-0.010% of the solid mass in the pulp; and the flotation is performed for the remained copper ore to obtain a copper concentrate. The natural flotability of the molybdenum mineral is fully exerted through low-alkalinity condition; the recovery of the molybdenum mineral is facilitated; the molybdenum ore capturing agent with good selectivity is added to reduce the flotation rate of the copper mineral; the separation of the mixed concentrate is facilitated; the inhibitor use level in the copper mineral in the separation process is reduced; the mutual contents of the copper and molybdenum minerals in copper and molybdenum concentrate products are effectively reduced; and the copper mineral capturing agent with good capturing performance is added in copper flotation to guarantee the recovery rate of the copper mineral.

Owner:CHANGCHUN GOLD RES INST

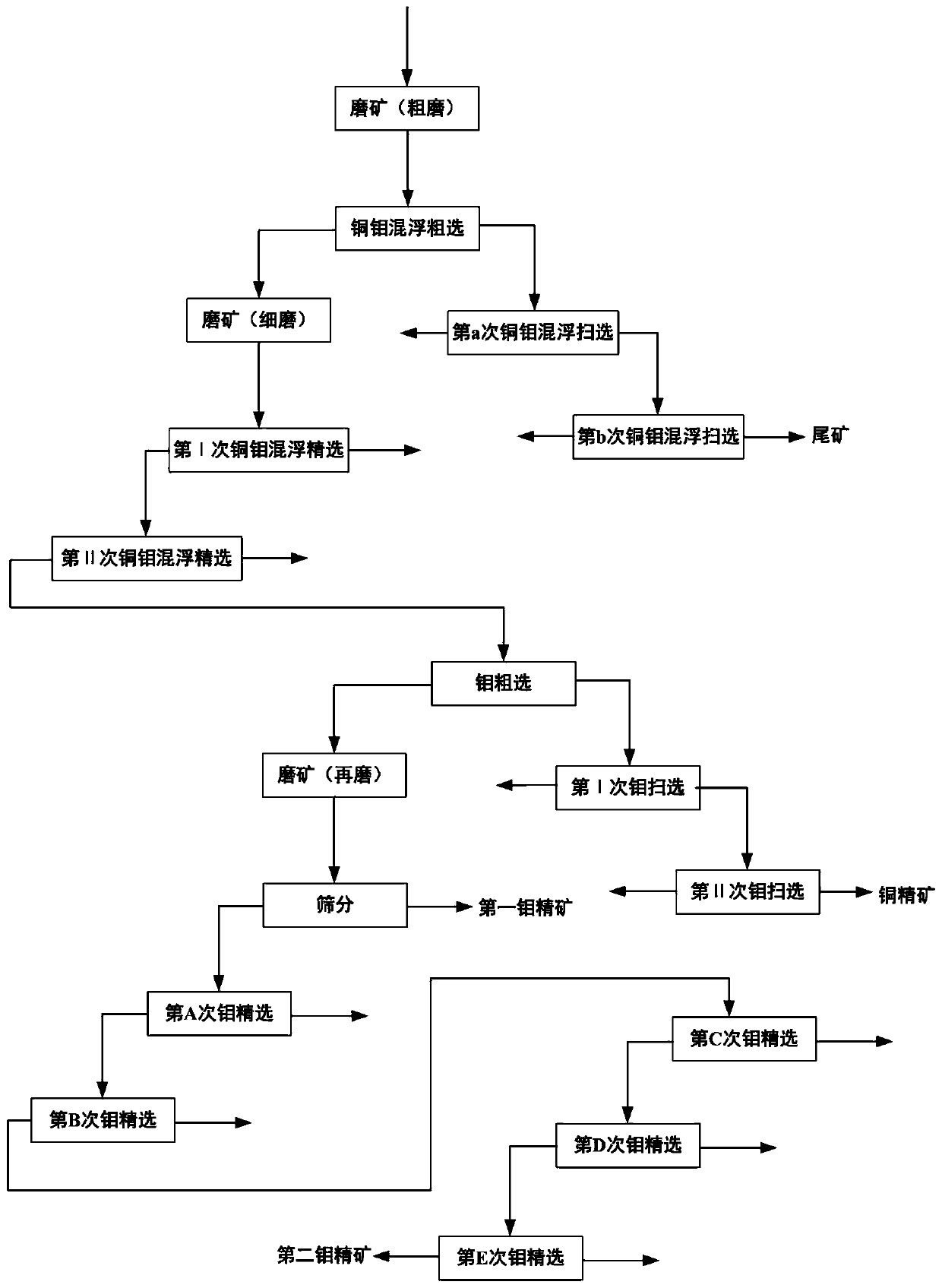

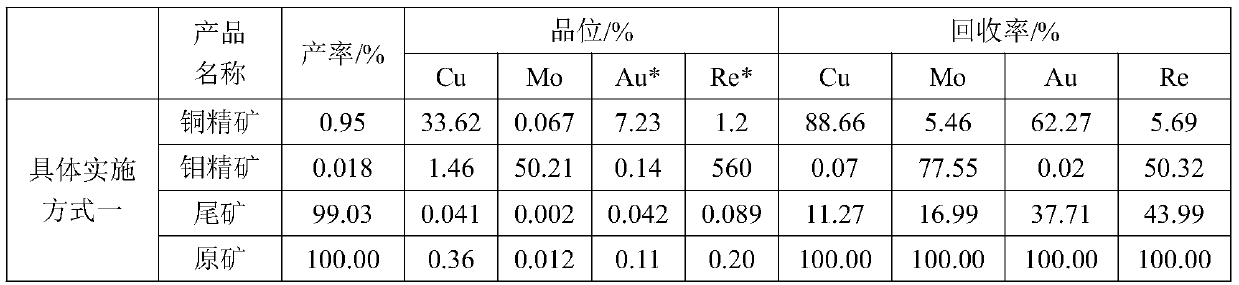

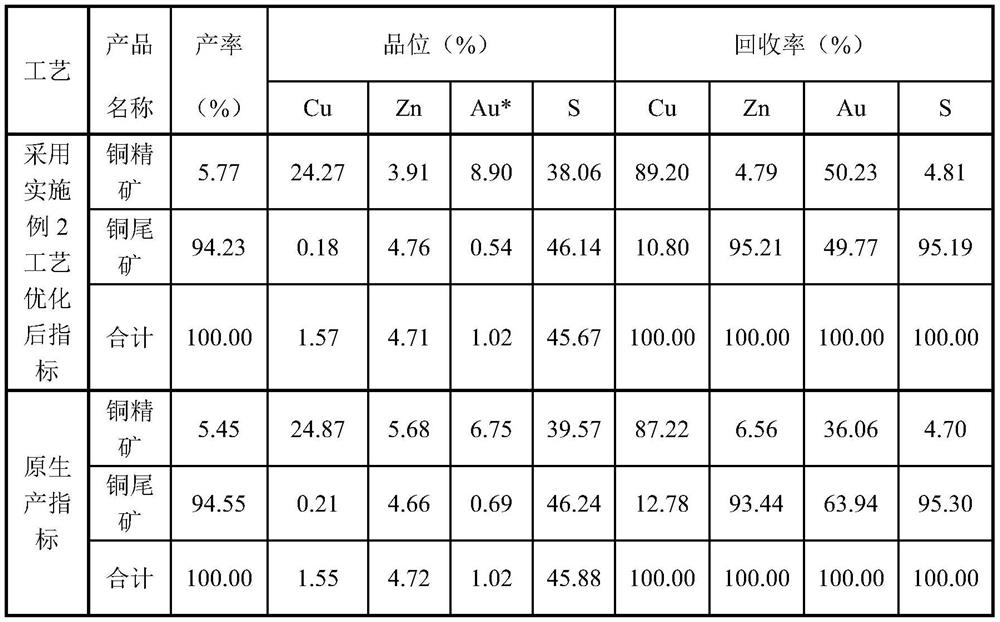

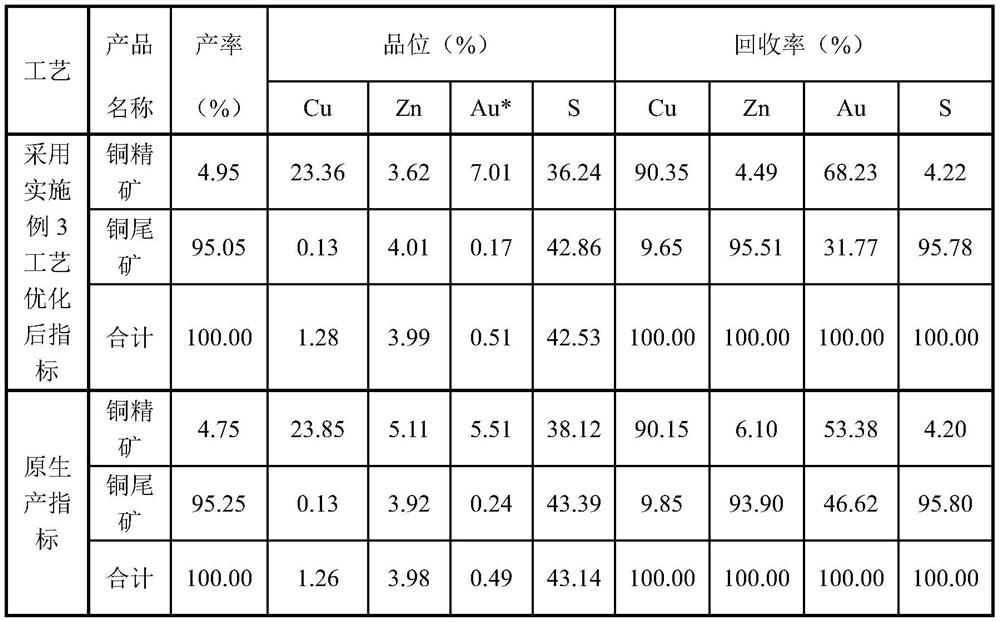

Beneficiation method for efficiently recovering copper and molybdenum associated with gold and rhenium from porphyry type copper-molybdenum deposit

The invention discloses a beneficiation method for efficiently recovering copper and molybdenum associated with gold and rhenium from porphyry type copper-molybdenum deposit and belongs to the technical field of mineral processing. The method comprises the following steps: roughly grinding raw ore under the condition of low alkalinity, and carrying out primary mixed flotation roughing, secondary mixed flotation scavenging and tailing discarding to obtain mixed flotation roughing concentrate; finely grinding the mixed flotation roughing concentrate and then carrying out secondary mixed flotation concentrating, primary molybdenum roughing and secondary molybdenum scavenging to obtain copper concentrate with 30 percent or above of copper and molybdenum roughing concentrate; regrinding and sieving the molybdenum roughing concentrate to obtain first molybdenum concentrate; and carrying out molybdenum concentrating for five times on sieved tailings, and alternatively using an inhibitor and partially combining and returning ore in molybdenum to obtain second molybdenum concentrate, wherein the content of molybdenum in comprehensive molybdenum concentrate is 50 percent or above. The beneficiation method disclosed by the invention adopts a technical solution of rough grinding mixed flotation of raw ore, fine grinding recleaning of mixed flotation rough concentrate, regrinding and sieving graded ore grinding sorting of molybdenum concentrate and has the characteristics of simple reagent system, convenient operation and management, good separating effect, stable indexes, good reproducibility and the like.

Owner:HEILONGJIANG DUOBAOSHAN COPPER LTD +1

Flotation separation agent system for copper-molybdenum mixed concentrates and application of flotation separation agent system

The invention discloses a flotation separation agent system for copper-molybdenum mixed concentrates and application of the flotation separation agent system. The flotation separation agent system forthe copper-molybdenum mixed concentrates comprises a copper mineral inhibitor, a molybdenum mineral collector and a foaming agent in a copper-molybdenum flotation separation process. The copper mineral inhibitor comprises the following components in parts by weight: 3-7 parts of sodium hydroxide, 3-6 parts of hydrogen peroxide, 15-25 parts of sodium thioglycolate, 2-5 parts of pentasodium diethylenetriaminepentaacetate and a proper amount of water; the molybdenum mineral collector comprises the following components in parts by weight: 20-30 parts of kerosene and 5-10 parts of tert-dodecyl mercaptan; and the foaming agent is 2-hexanol. The inhibitor and the collector are high in selective adsorption capacity, the synergy performance is excellent, the activity of groups of the foaming agentis high, formed foams are crisp and compact, and the mineralization effect is good. According to the flotation separation agent system for copper and molybdenum, the floatability difference between molybdenum minerals and copper minerals in the complex copper and molybdenum mixed concentrates difficult to separate can be greatly improved, the mutual content of the copper and the molybdenum is effectively reduced, the separation index is excellent, adopted agents are nontoxic and harmless, and the influence on the environment is small.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

A beneficiation process for polymetallic sulfide ore containing secondary copper

The invention relates to a beneficiation process for polymetallic sulfide ores containing secondary copper, belonging to the technical field of mineral processing. The method of the present invention is as follows: take iron powder with a particle size of 10-150 μm and prepare a 1%-10% suspension; add iron powder to the mill or stirring tank according to 0.1%-1% of the ore solid mass in the pulp Suspension, followed by the conventional flotation method to obtain the final concentrate product; the iron powder added to the mill and the mineral particles form a primary battery, so that the free copper ions in the slurry are replaced, reducing the impact of free copper ions on sphalerite The activation of pyrite and pyrite makes the difference in buoyancy between minerals larger, and the intercontainment phenomenon of concentrate products is small, thereby improving the index of mineral processing products. The method of the invention has the advantages of good flotation index, saving chemicals, simplifying the ore dressing process and the like.

Owner:WUPING ZIJIN MINING CO LTD

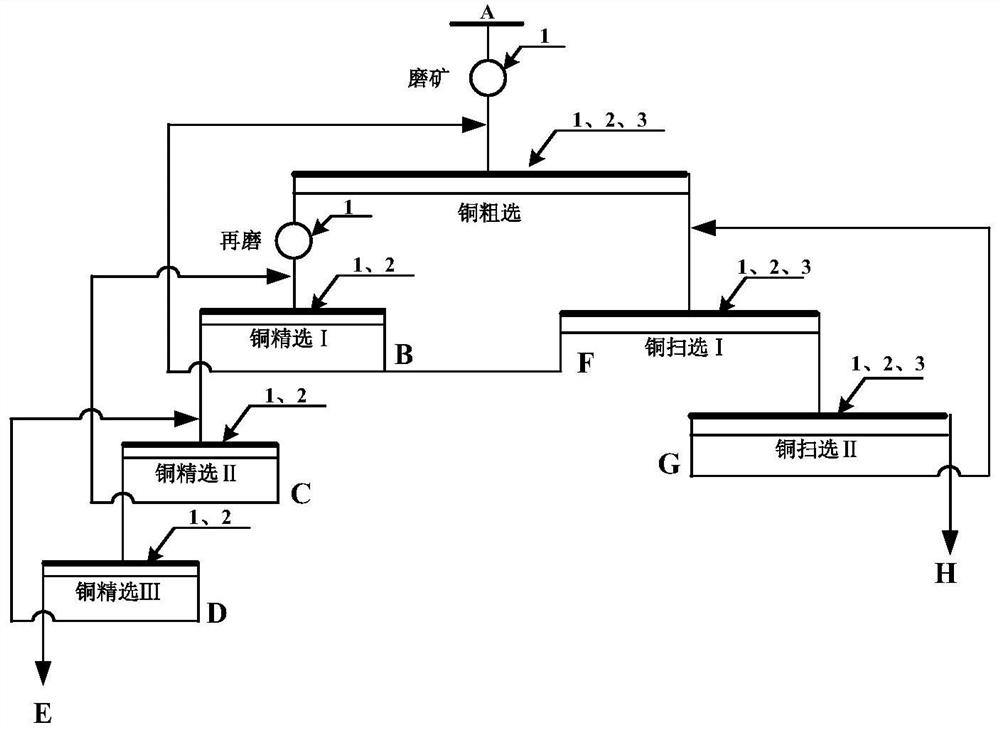

Low-alkali separation method for high-sulfur copper-zinc ore

The invention discloses a low-alkali separation method for high-sulfur copper-zinc ore. The low-alkali separation method comprises the following steps: grinding of raw ore; copper roughing, wherein dry calcium oxide powder, a zinc inhibitor, namely solid sodium pyrosulfite powder and an efficient copper collecting agent are added in the process of copper roughing, and rough copper concentrate andcopper roughing tailings are obtained; multi-stage copper scavenging, wherein the dry calcium oxide powder, the zinc inhibitor solid sodium metabisulfite powder and the efficient copper collecting agent are added in each stage of scavenging operation; regrinding of the rough copper concentrate; and copper concentration, wherein the reground rough copper concentrate is subjected to multi-section concentration operation, and the dry calcium oxide powder and the zinc inhibitor solid sodium metabisulfite powder are added in each section of concentration operation. The method can overcome the defects of existing high-alkali copper-zinc separation processes for the high-sulfur copper-zinc ore and solve the problem of low recovery rate of associated noble metals.

Owner:厦门紫金矿冶技术有限公司

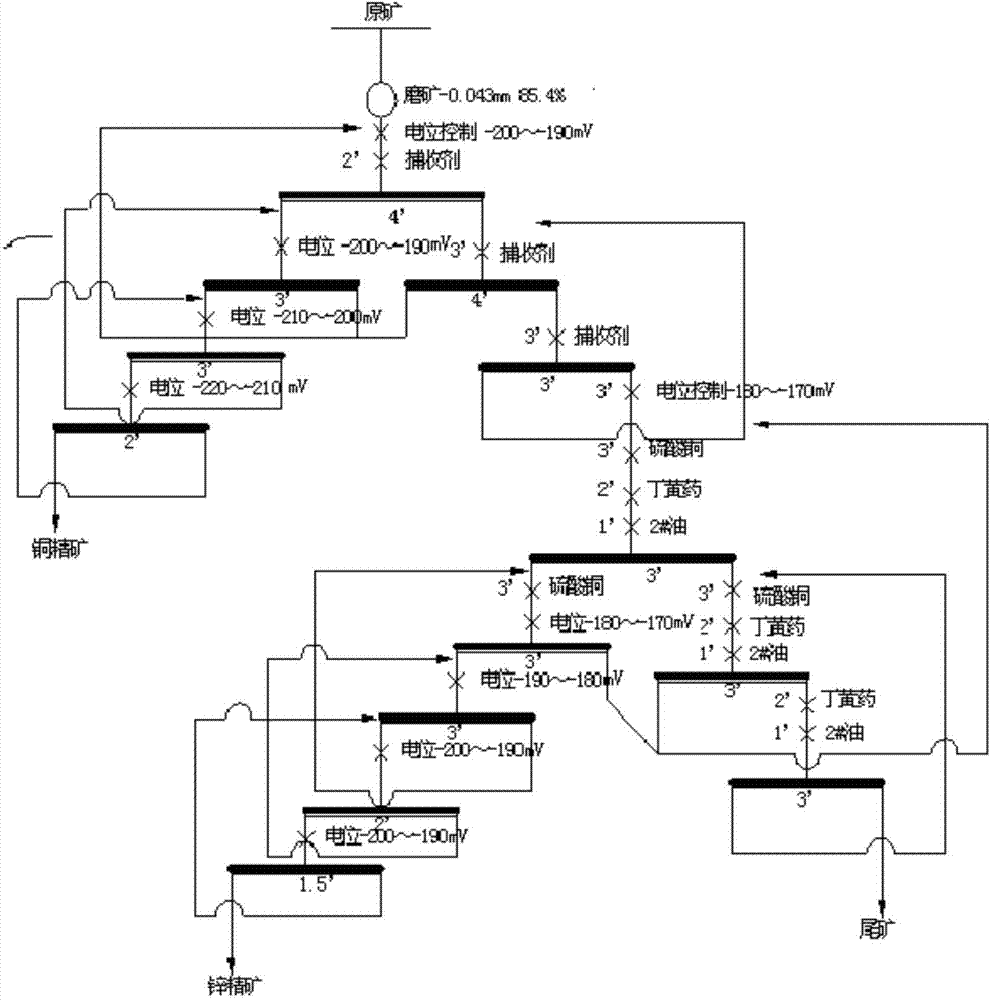

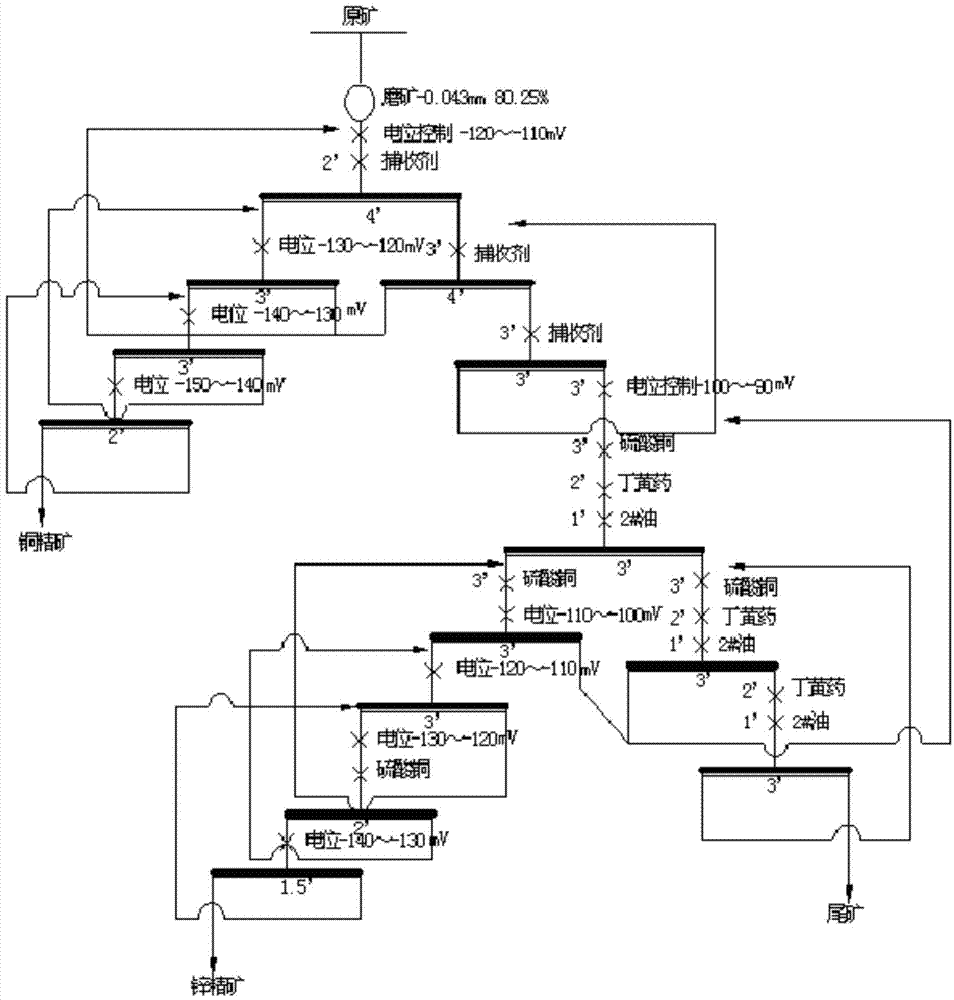

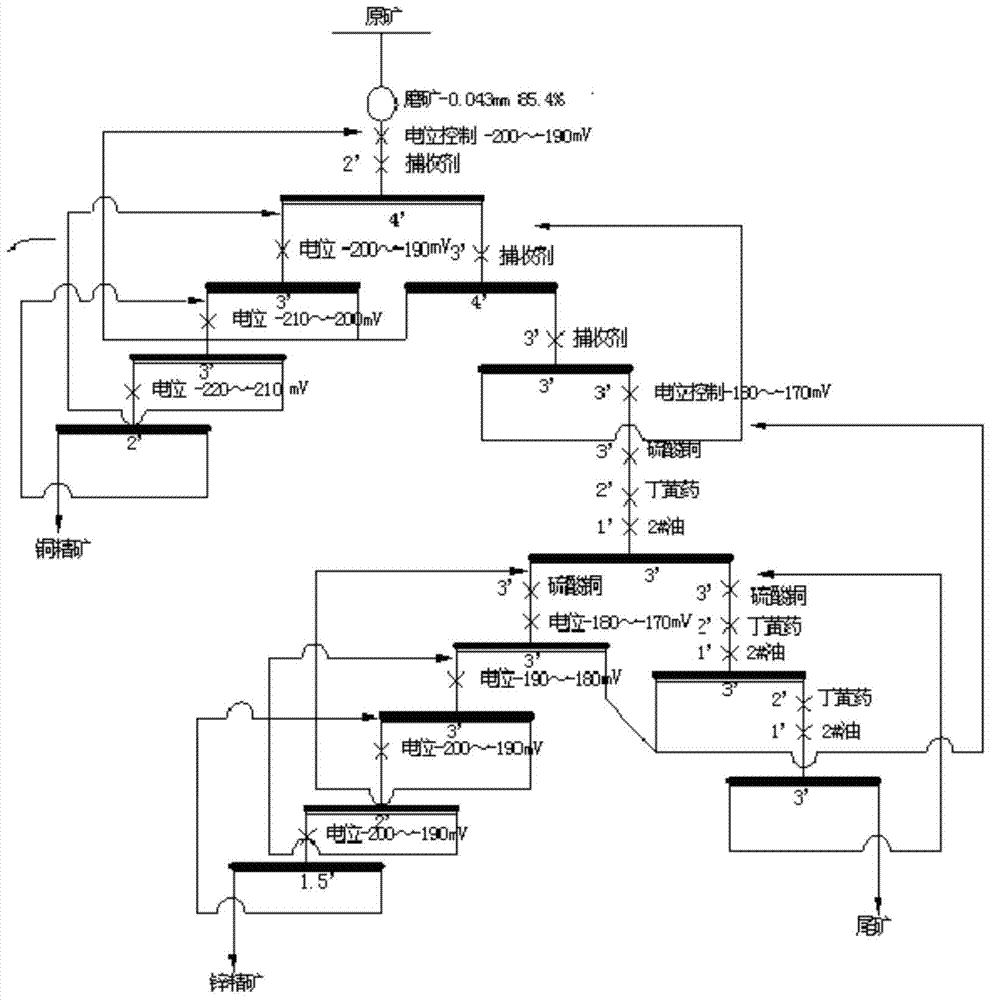

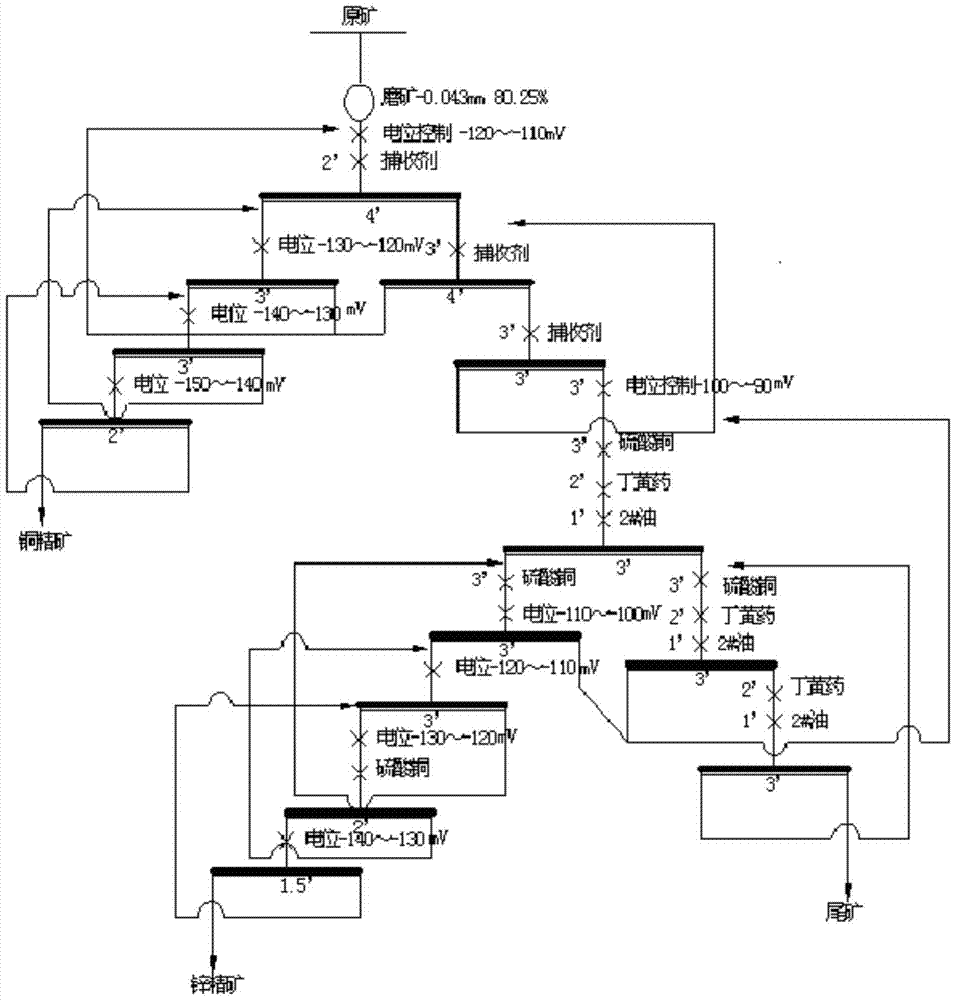

Inhibitor-free floatation separation method for high-sulfur copper and zinc sulphide ore difficult to float

The invention relates to a metal sulphide ore floatation separation technology, in particular to an inhibitor-free floatation separation method for high-sulfur copper and zinc sulphide ore difficult to float. The floatation separation method comprises the following steps that (1) lime is used for adjusting the electric potential of ore pulp under appropriate grinding fineness, the electric potential of the ore pulp is controlled to be -250 mV to -100 mV, copper collectors such as thionocarbamate and xanthate are added, no sphalerite inhibitor is added, and copper is floated preferably; (2) copper tailings are floated to be added with copper sulfate so as to activate sphalerite, the electric potential of the ore pulp is controlled to be -220 mV to -70 mV, xanthate and number two oil are used for floating zinc, and finally a copper concentrate and a zinc concentrate are obtained. Compared with the prior art, by adjusting the electric potential of the ore pulp, the floatability of a copper mineral and the floatability of a zinc mineral are changed, and thus inhibitor-free copper and zinc floatation separation can be realized. The technological process is simple, controlling is easy, meanwhile, drug cost can be saved, and the drug cost can be lowered by 5%-10% compared with a traditional technology.

Owner:厦门紫金矿冶技术有限公司

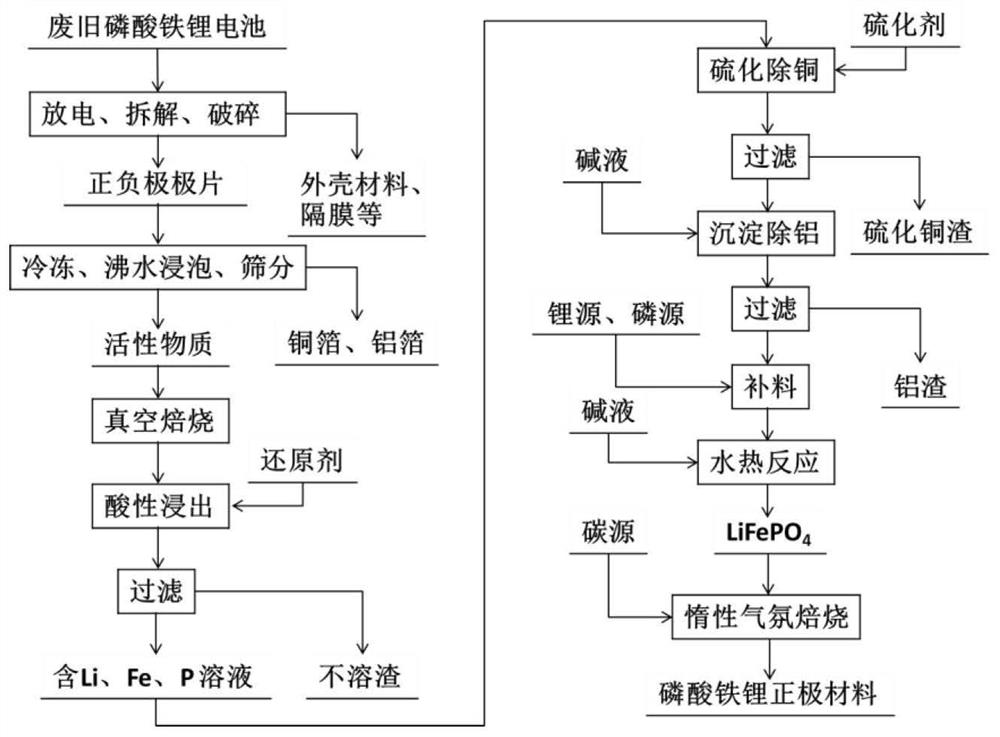

Method for preparing lithium iron phosphate cathode material by recycling waste lithium iron phosphate battery

ActiveCN110112481BReduce mutual inclusionEasy to separateWaste accumulators reclaimingBattery recyclingLithium iron phosphatePhysical chemistry

Owner:GUANGDONG GUANGHUA SCI TECH

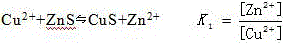

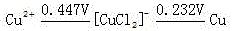

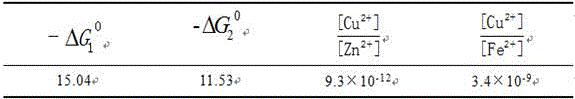

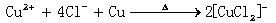

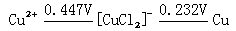

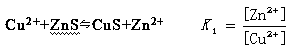

Method for eliminating copper ions in secondary copper sulphide multi-metal ore pulp solutions

The invention discloses a method for eliminating copper ions in secondary copper sulphide multi-metal ore pulp solutions and belongs to the technical field of mineral processing. The method is characterized in that the beneficiation process of the method sequentially comprises the steps that raw ore is ground till monomer separation is conducted, and the ground raw ore is fed into a stirring groove; copper powder is added into the stirring groove, added with hydrochloric acid, heated and stirred; and pulp conditioning and dosing are conducted, common floatation is carried out, and concentrate products are obtained. According to the method for eliminating the copper ions in the secondary copper sulphide multi-metal ore pulp solutions, the hydrochloric acid and the copper powder react with Cu2+; a coordination compound [CuCl2]-, capable of stably staying in a water solution, of Cu(I) can be generated; and the Cu2+ is removed before floatation operation is conducted, sphalerites, pyrites, magnetic pyrites and other sulfide minerals are prevented from being activated through the ion Cu2+, and good beneficiation indexes can be acquired through the common floatation process. The method for eliminating the copper ions in the secondary copper sulphide multi-metal ore pulp solutions has the advantages of being good in beneficiation index, capable of saving medicaments and the like.

Owner:KUNMING UNIV OF SCI & TECH

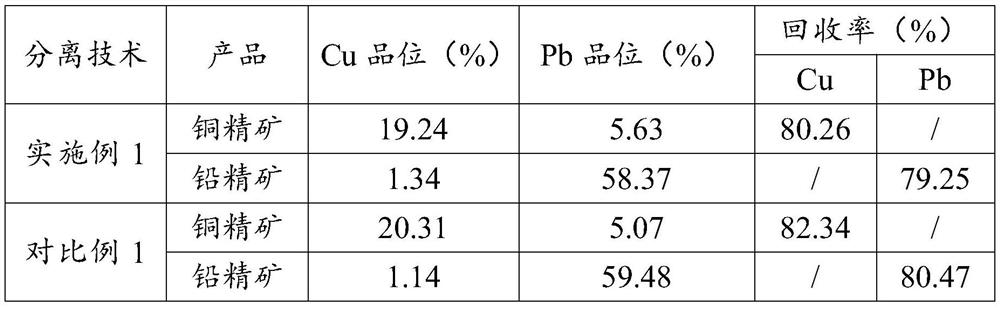

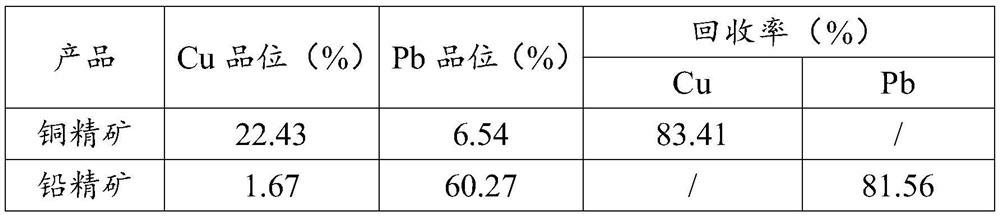

Combined inhibitor for flotation separation of complex refractory copper-lead sulfide ore and application of combined inhibitor

ActiveCN114054214AEasy to separateImprove work efficiencyFlotationProcess efficiency improvementCelluloseLead sulfide

The invention discloses a combined inhibitor for flotation separation of complex and refractory copper-lead sulfide ore. The combined inhibitor comprises sodium perborate, quaternary ammonium starch ether and hydroxypropyl methyl cellulose. The inorganic inhibitor and the organic inhibitor are combined, so that the synergistic effect of the agents is fully exerted, the inhibition effect on galena is enhanced, the mutual inclusion of copper and lead is reduced, and the copper-lead separation effect is good; the sodium perborate solution is added, so that oxidation sites on the surface of galena are improved, more quaternary ammonium starch ether and hydroxypropyl methyl cellulose are adsorbed on the surface of galena, and the inhibition effect on galena is enhanced; the flotation steps of bulk flotation and then flotation separation are adopted, non-target minerals can be removed to the maximum extent in the bulk flotation process, the workload of the follow-up flotation process is reduced, and the working efficiency of ore flotation is improved; and compared with a single galena inhibitor and a traditional inhibitor dichromate, the combined inhibitor has the advantages of being low in agent consumption, high in inhibition capacity, non-toxic and environmentally friendly.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

A method for eliminating copper ions in secondary copper sulfide polymetallic slurry solution

The invention discloses a method for eliminating copper ions in secondary copper sulphide multi-metal ore pulp solutions and belongs to the technical field of mineral processing. The method is characterized in that the beneficiation process of the method sequentially comprises the steps that raw ore is ground till monomer separation is conducted, and the ground raw ore is fed into a stirring groove; copper powder is added into the stirring groove, added with hydrochloric acid, heated and stirred; and pulp conditioning and dosing are conducted, common floatation is carried out, and concentrate products are obtained. According to the method for eliminating the copper ions in the secondary copper sulphide multi-metal ore pulp solutions, the hydrochloric acid and the copper powder react with Cu2+; a coordination compound [CuCl2]-, capable of stably staying in a water solution, of Cu(I) can be generated; and the Cu2+ is removed before floatation operation is conducted, sphalerites, pyrites, magnetic pyrites and other sulfide minerals are prevented from being activated through the ion Cu2+, and good beneficiation indexes can be acquired through the common floatation process. The method for eliminating the copper ions in the secondary copper sulphide multi-metal ore pulp solutions has the advantages of being good in beneficiation index, capable of saving medicaments and the like.

Owner:KUNMING UNIV OF SCI & TECH

Flotation method for separation of copper-lead mixed concentrate adopting sodium hydroxide

The invention discloses a flotation method for separation of copper-lead mixed concentrate adopting sodium hydroxide. The flotation method lies in that sodium hydroxide and zinc sulfate are taken as a lead mineral inhibitor, isopropyl ethylthionocarbamate is taken as a copper mineral collector, after copper-lead mixed concentrate is subjected to roughing separation, the tailings is subjected to multi-stage copper scavenging to obtain lead concentrate, the concentrate is subjected to multi-stage copper concentration to obtain copper concentrate, so that high efficiency separation of copper-lead mixed concentrate is realized, the copper concentrate and lead concentrate obtained are high in recovery rate and low in mutual inclusion. According to the flotation method for separation of copper-lead mixed concentrate adopting sodium hydroxide, reagent removal and dehydration are not needed, mixed concentrate is directly subjected to separation, the flow structure is simple, reagents are fewer and low in dosage, and the process is environment-friendly and free from contamination.

Owner:厦门紫金矿冶技术有限公司

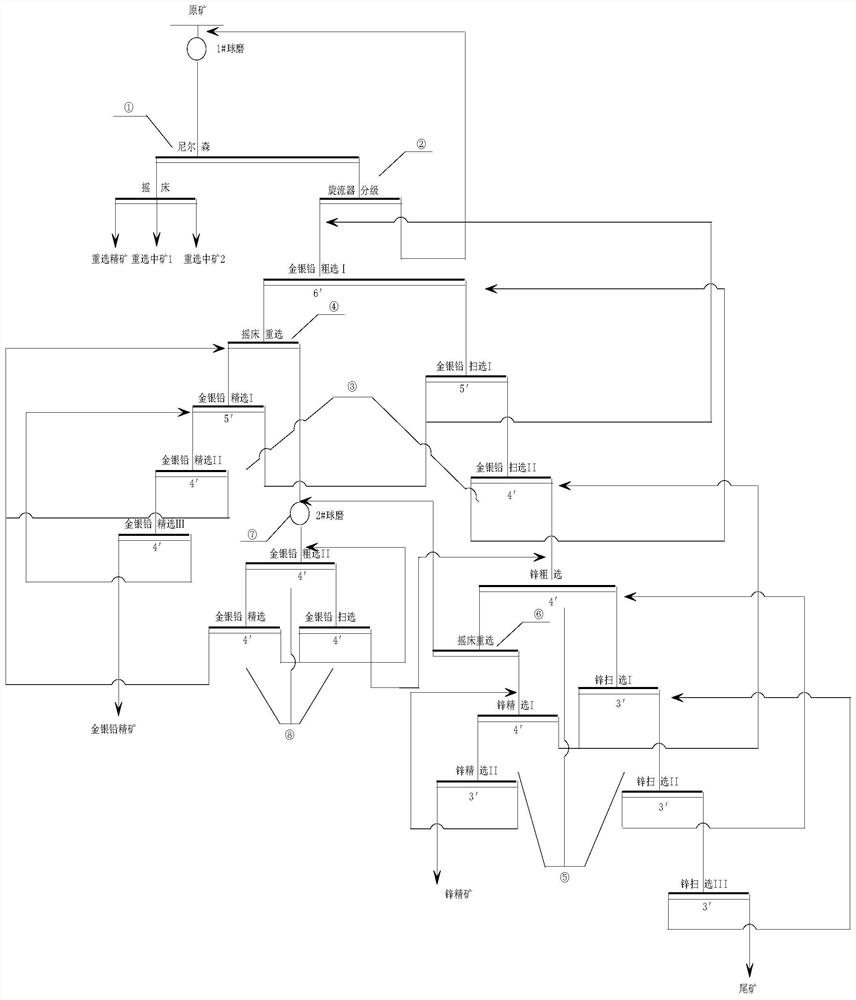

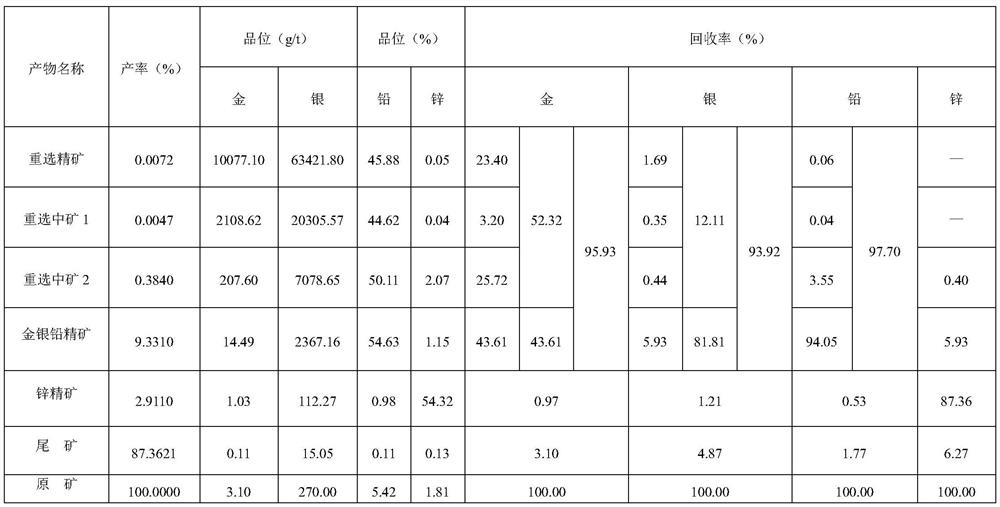

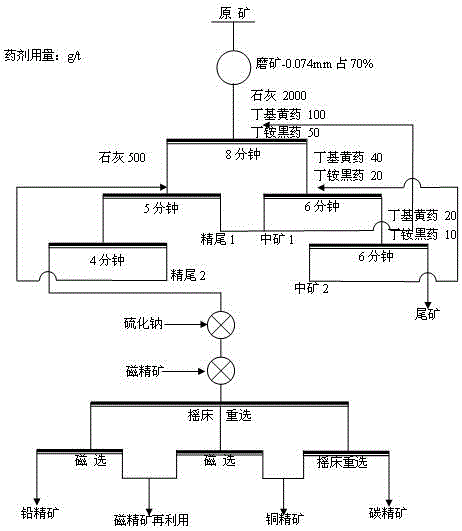

Beneficiation process for polymetallic ore containing gold, silver, lead and zinc

PendingCN114029158AReduce addEasy to recycleSolid separationProcess efficiency improvementEngineeringGalena

The invention belongs to the technical field of beneficiation process methods, and particularly relates to a beneficiation process for polymetallic ore containing gold, silver, lead and zinc. The process comprises the steps of Nelson + table gravity separation operation, cyclone classification, gold, silver and lead flotation operation, gold, silver and lead rough concentrate table gravity separation operation, gold, silver and lead flotation tailings zinc separation operation, zinc rough concentrate table gravity separation operation, lead rough concentrate table tailings and zinc rough concentrate table concentrate grinding operation, lead of the lead rough concentrate table tailings and the zinc rough concentrate table concentrate, and zinc separation operation. The process is suitable for mineral separation of polymetallic ore containing gold, silver, lead and zinc, and lead and zinc are separated through a physical method according to the specific gravity difference of galena and sphalerite in the conventional mineral separation process of the polymetallic ore containing gold, silver, lead and zinc; and the technological process is simple, easy to implement and capable of being widely applied and popularized, and rich economic returns are obtained.

Owner:CHANGCHUN GOLD RES INST

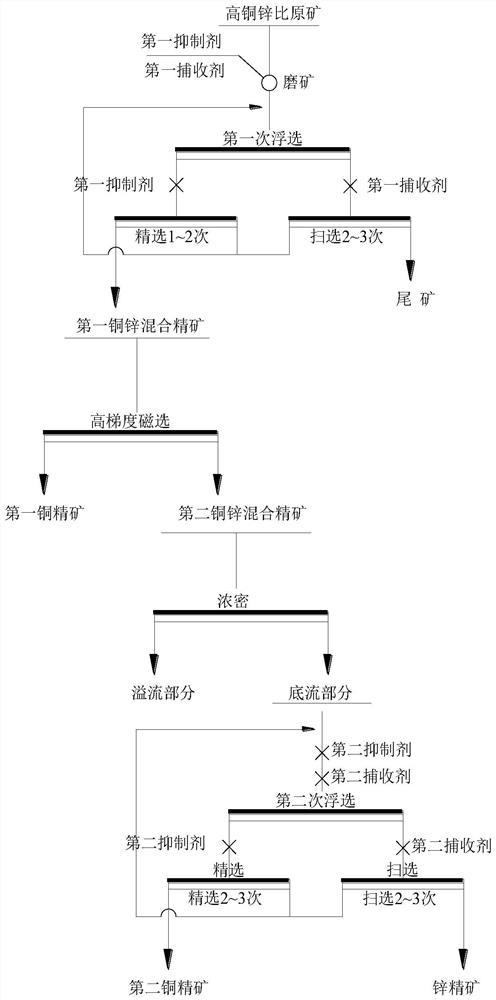

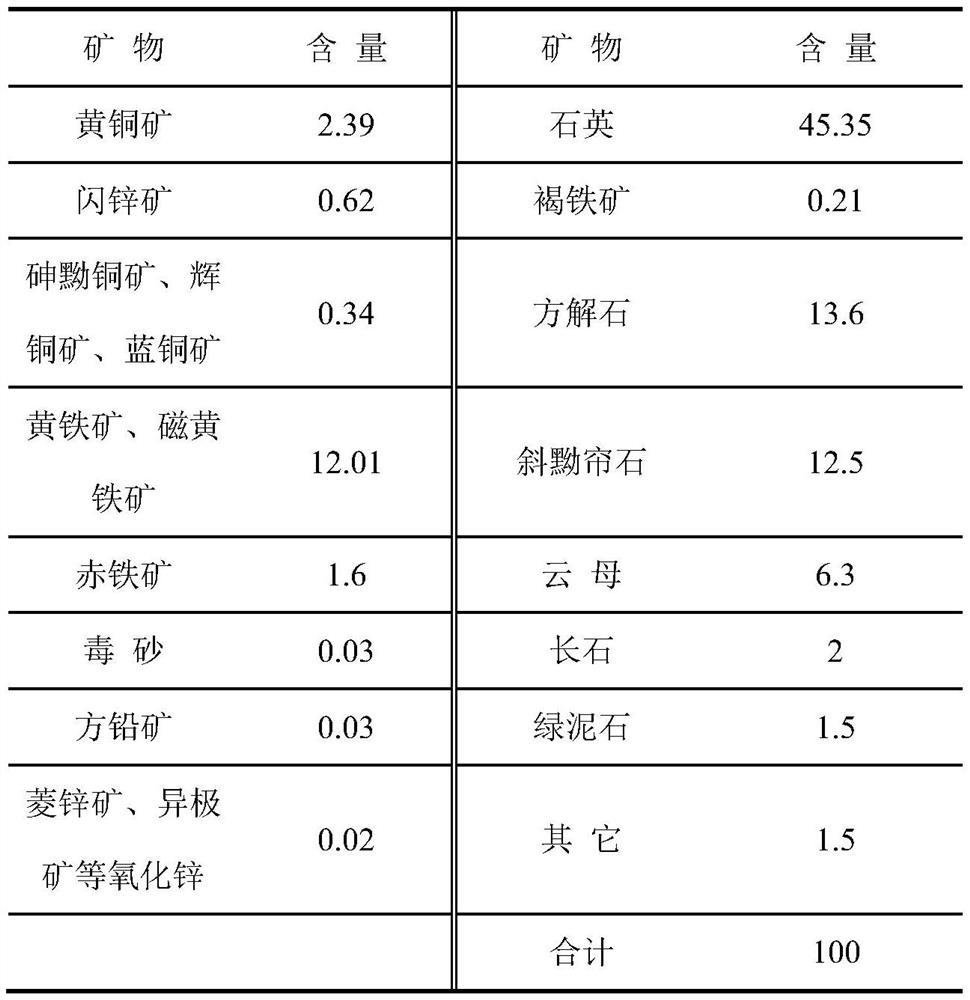

Beneficiation separation method for copper-zinc sulfide ore with high copper-zinc ratio

ActiveCN114589002AReduce mutual inclusionSimple processFlotationMagnetic separationAnilineCopper sulfide

The invention discloses a beneficiation separation method for copper-zinc sulfide ore with a high copper-zinc ratio, which comprises the following steps: by taking copper-zinc sulfide raw ore with the high copper-zinc ratio as a raw material, mixing the copper-zinc sulfide raw ore with the high copper-zinc ratio with slaked lime and aniline black to prepare a first inhibitor, a first collecting agent and water to prepare raw ore pulp; carrying out primary flotation separation on the raw ore pulp to obtain first copper-zinc bulk concentrate and mixed tailings, and carrying out magnetic separation on the first copper-zinc bulk concentrate in an environment with magnetic field intensity of 1.3 T to obtain second copper-zinc bulk concentrate and product first copper concentrate; and thickening the second copper-zinc bulk concentrate, and carrying out secondary flotation on the thick underflow to obtain second copper concentrate and second zinc concentrate. According to the beneficiation separation method, the copper-zinc sulfide raw ore with the high copper-zinc ratio can be effectively separated, the separation process is simple, the types of agents needing to be added are reduced, and the dosage of the agents is also greatly reduced; the zinc content in the copper concentrate product is low, the copper content in the zinc concentrate product is low, the zinc recovery rate is increased, and the product quality is also effectively improved.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY +1

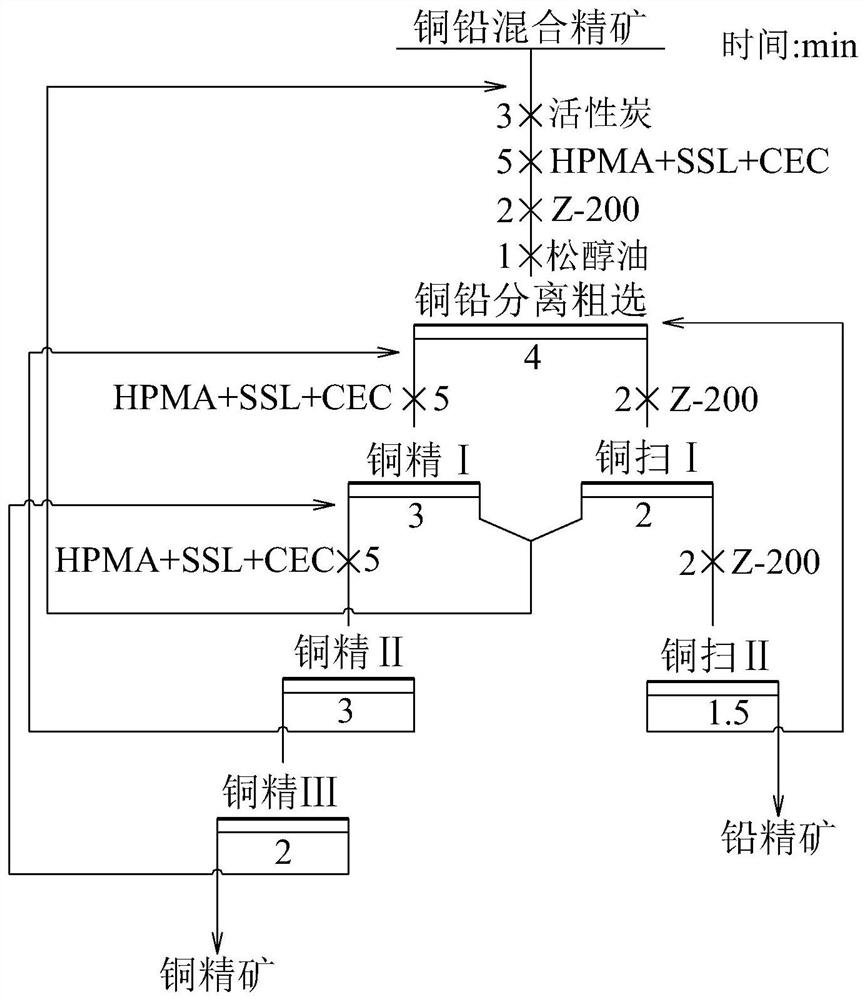

Combined lead inhibitor for micro-fine particle galena and application of combined lead inhibitor

The invention discloses a combined lead inhibitor for micro-fine particle galena and application of the combined lead inhibitor. The active components of the combined lead inhibitor are composed of polymaleic acid, water glass and carboxyethyl cellulose, and a mass ratio of the polymaleic acid to the water glass to the carboxyethyl cellulose is (1-6): (2-5): (0.25-2). According to the invention, the organic inhibitors including the polymaleic acid and the carboxyethyl cellulose and the inorganic inhibitor water glass are combined according to the certain mass ratio, and through the synergisticeffect of the agents, the dosage of the combined lead inhibitor is reduced compared with the dosage of the agents used alone, and the inhibition performanceof the combined lead inhibitor is also significantly enhanced. The combined inhibitor can efficiently and selectively inhibit coarse and medium-sized galena, has a good inhibition effect on micro-fine particle galena, basically does not influence flotation of chalcopyrite, and achieves the purpose of selective separation. The combined inhibitor is formed by combining water-soluble micromolecular carboxylic acid, high-molecular organic matter CEC and conventional inhibitors, and is simple to prepare and easy to industrially implement; and meanwhile, HPMA is an excellent water treatment agent and can be used for complexing heavy metal ions in beneficiation wastewater, so wastewater recycling difficulty is greatly reduced.

Owner:CENT SOUTH UNIV

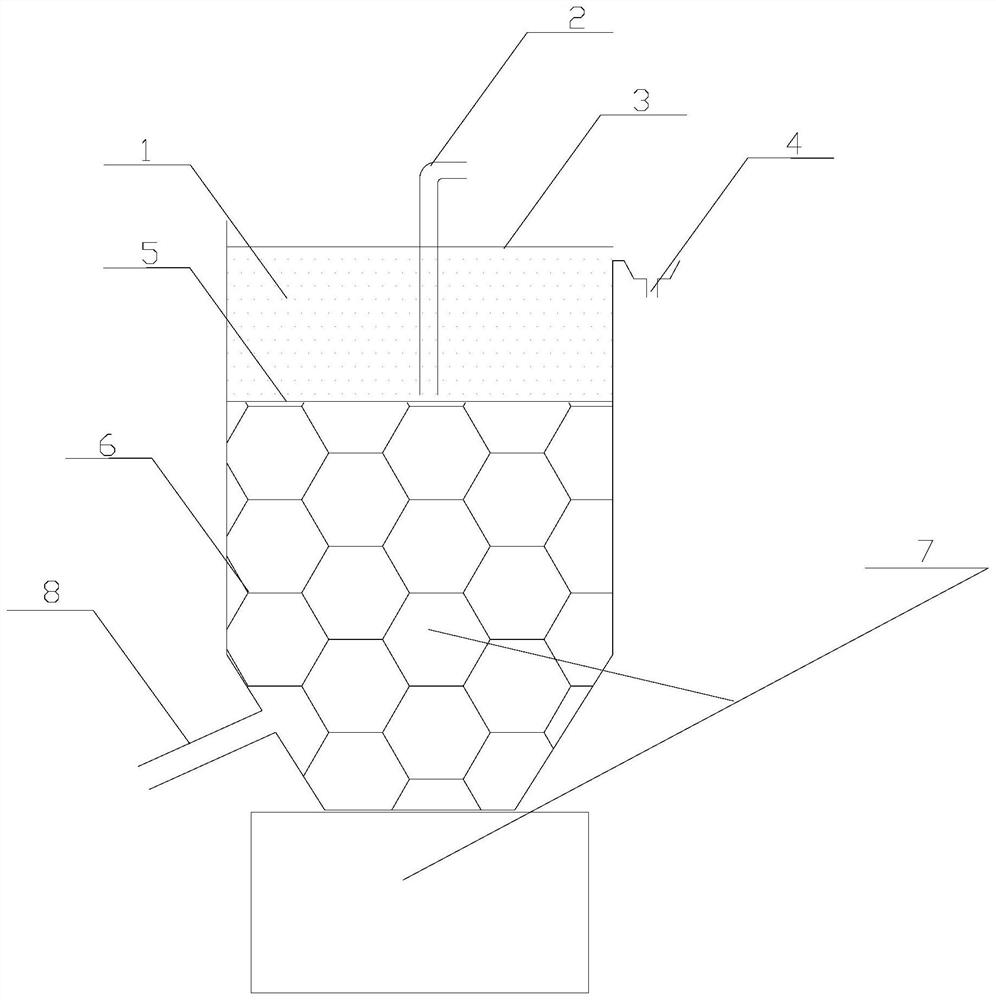

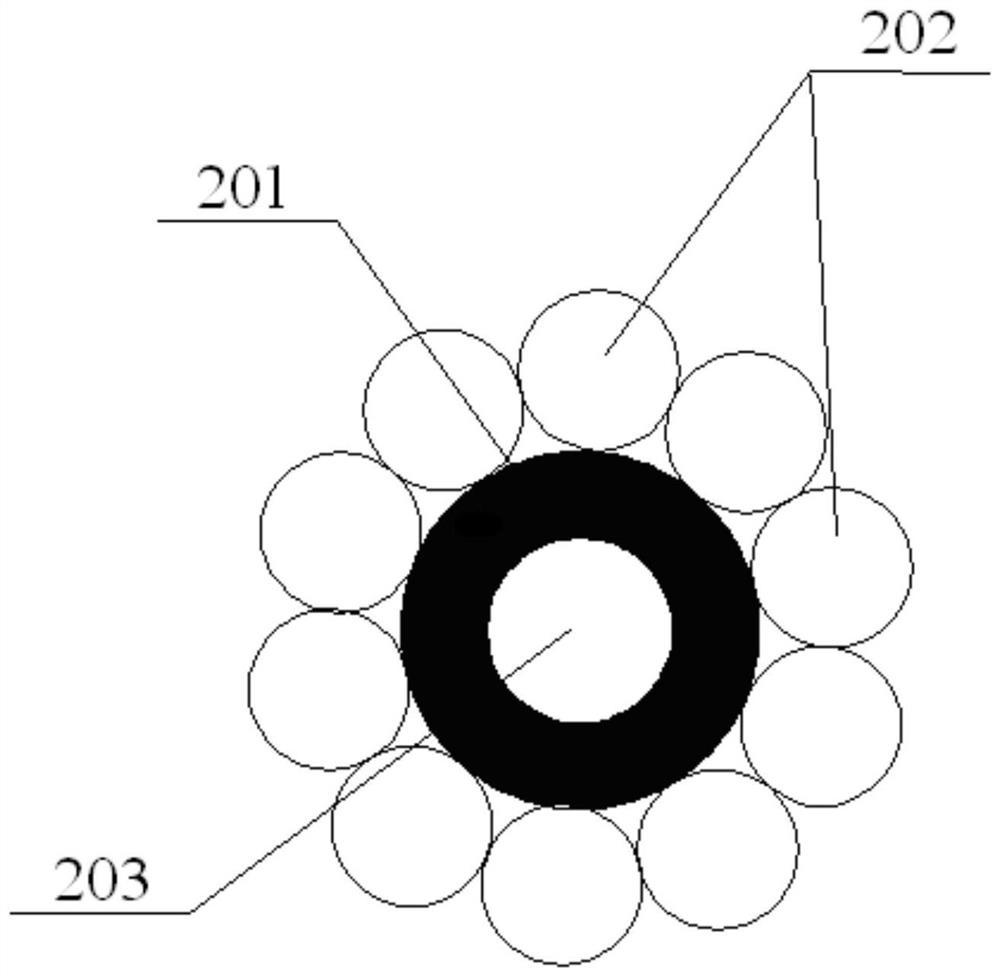

A targeted dosing method in the process of sulfide ore flotation polymetallic separation

ActiveCN110216022BReinforcement and EffectReduce mutual inclusionFlotationPhysical chemistrySulfidation

The invention relates to a targeted dosing method in the process of sulfide ore flotation polymetallic separation, which belongs to the method of adding inhibitors in the process of sulfide ore flotation polymetallic separation. The selected foam enters the vertical spiral agitating mill for scrubbing and grinding, and the inhibitor adding pipeline is surrounded by multiple clean water flushing water pipelines, and the pipelines are combined with water outlets and chemical outlets, and go down to the pulp of the vertical spiral agitating mill Below the surface and above the steel ball interface; the pipeline group is connected to the clean water flushing water and the inhibitor is fed into the vertical spiral stirring mill at the same time to ensure the pressure of the clean water. The advantages are: the effect of the inhibitor is enhanced, and the dosage of the inhibitor is reduced, which not only saves the production cost, but also reduces the amount of residual inhibitor in the backwater, makes the return of the backwater more flexible, and eliminates the impact on the front-end mixing flotation.

Owner:CHANGCHUN GOLD RES INST

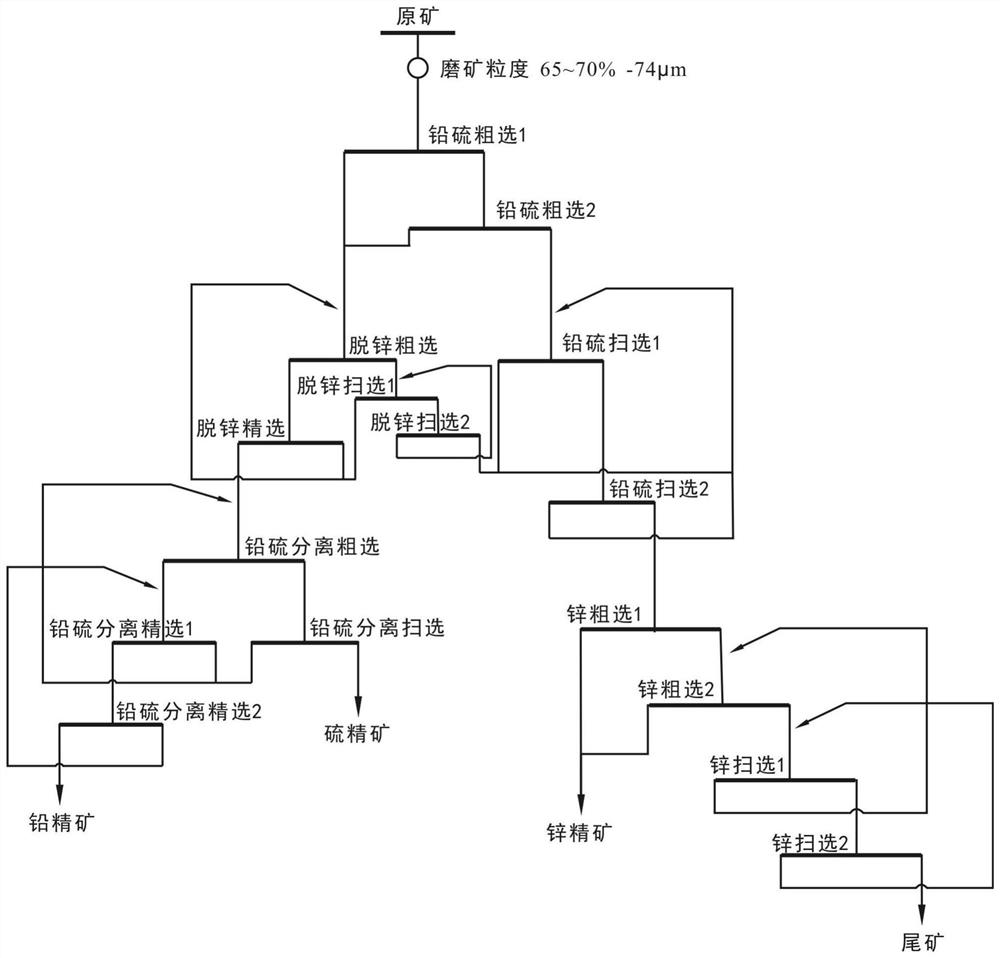

A kind of method of flotation of high-sulfur lead-zinc ore

The invention discloses a method for efficient flotation of a high-sulfur lead zinc ore. The method comprises the steps that A, ore grinding is conducted; B, lead and zinc are initially separated, specifically, ground ore pulp is subjected to lead sulfur-zinc initial separation with two stages of roughing and two stages of scavenging, ore concentrates in two-time roughing are combined into lead-sulfur mixed rough concentrates, and middlings in two-time scavenging are returned to previous-layer operation; C, the lead-sulfur mixed rough concentrates are subjected to one stage of dezincificationroughing, one stage of dezincification concentration and two stages of dezincification scavenging, thus lead-sulfur mixed concentrates are obtained, and middlings in dezincification concentration anddezincification scavenging 1 are returned to dezincification roughing, and tailings in dezincification scavenging 2 are returned to lead-sulfur scavenging 1; D, tailings produced in lead-sulfur scavenging 2 are subjected to zinc flotation operation with two stages of roughing and two stages of scavenging, and zinc concentrates and tailings are obtained; and E, the lead-sulfur mixed concentrates are subjected to lead-sulfur separation operation with one stage of roughing, one stage of scavenging and two stages of concentration, and qualified lead concentrates and sulfur concentrates are obtained. According to the method, the separation index is excellent, the separation efficiency is high, the chemical agent cost is low, water returning treatment is easy, the energy saving and environmentalprotection effects are good, and applicability is good.

Owner:KUNMING METALLURGY INST

Flotation separation method of vulcanized lead zinc minerals containing intergrowths

ActiveCN111659531AAchieving simultaneous enrichmentReduce processingFlotationLead sulfideMineral processing

The invention discloses a flotation separation method of vulcanized lead zinc minerals containing intergrowths and belongs to the technical field of mineral processing. The method comprises the stepsof conducting enrichment on the vulcanized lead zinc minerals containing the intergrowths through mixed flotation to obtain lead zinc mixed rough concentrates and flotation tailings; and adding a combined gangue inhibitor to the lead zinc mixed rough concentrates to conduct flotation to discharge tailings to obtain lead zinc mixed concentrates with high lead zinc content and with the mineral amount remarkably reduced, conducting fine grinding treatment on the lead zinc mixed concentrates, and conducting flotation separation through the zinc inhibition and lead flotation process to obtain zincconcentrates and lead concentrates. According to the method, the lead zinc minerals in minerals are enriched synchronously through mixed flotation; the lead zinc mixed rough concentrates are subjectedto flotation to discharge the tailings, the lead zinc grade is improved, and the mineral treatment capacity through the fine grinding process is reduced; moreover, monomer separation of the lead zincminerals in the mixed concentrates is realized through fine grinding, zinc inhibition and lead flotation are facilitated, the problem of flotation separation of the vulcanized lead zinc minerals containing the intergrowths is solved, and the comprehensive utilization rate of lead zinc resources is increased.

Owner:KUNMING UNIV OF SCI & TECH

A kind of inhibitor-free flotation separation method for refractory high-sulfur copper-zinc sulfide ores

The invention relates to a flotation separation technology for metal sulfide ores, in particular to a depressant-free flotation separation method for refractory high-sulfur copper-zinc sulfide ores. The described flotation separation method comprises the following steps: (1) under a suitable grinding fineness, lime is used to adjust the pulp potential, so that the pulp potential is controlled at -250 to -100mV, adding copper sulfide such as thiourethane and xanthate (2) Add copper sulfate to activate sphalerite in copper tailings, control the pulp potential -220~-70mV, and use xanthate and 2# oil for zinc selection , and finally obtain copper concentrate and zinc concentrate. Compared with the prior art, the present invention changes the buoyancy of copper and zinc minerals by adjusting the slurry potential, thereby realizing the depressant-free copper-zinc flotation separation. The technological process is simple and easy to control; at the same time, it can save the cost of the medicine, which can reduce the cost of the medicine by 5-10% compared with the traditional process.

Owner:厦门紫金矿冶技术有限公司

A kind of recovery method of carbon-containing refractory copper-lead ore

ActiveCN104941788BReduce pollutionImprove concentrate qualityFlotationWet separationRecovery methodMagnetite

The invention discloses a recovery method for carbon-contained copper and lead ore difficult to separate. The recovery method includes the following steps that step1, according to smashing and grinding, the raw ore is smashed and ground to be at the size fraction of -0.074 mm by 70-80%; step2, bulk concentrate is obtained through bulk flotation; step3, reagent removal solution is prepared; step4, reagent removal is performed; step5, slurry mixing is performed; step6, shaking table reselection is performed; step7, according to purification, bulk concentrate of lead and magnetite and bulk concentrate of copper and magnetite are placed into a magnetic separator to be separated so as to obtain lead concentrate and copper concentrate, the magnetite can be repeatedly utilized, and bulk concentrate of copper and carbon is placed in a shaking table to be separated to obtain copper concentrate and carbon concentrate. The recovery method has the advantages that a gravity and magnetic levitation combination method is adopted for recovering lead and copper, inhibitor is not needed, environmental pollution is small, economic benefits are high, the lead concentrate and the copper concentrate are high in quality, mutual inclusion is low, and the technology process is simple; the recovery method has great economic benefits and social benefits.

Owner:铜陵有色金属集团股份有限公司

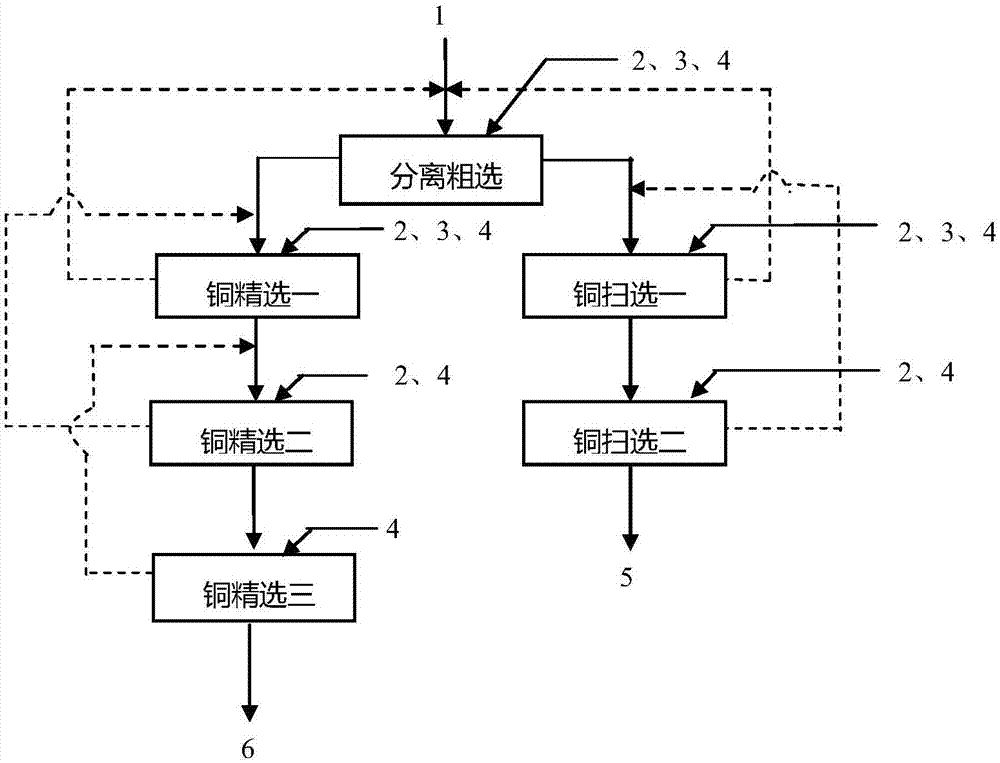

Complex copper-lead ore beneficiation separation method adopting middling returning and regrinding technology

The invention relates to a complex copper-lead ore beneficiation separation method adopting a middling returning and regrinding technology, comprising the following steps of: carrying out ore grinding on raw ores, and then carrying out copper roughing; carrying out copper choiceness by adopting flotation on rough concentrates obtained through the copper roughing; and carrying out copper scavenging on tailings obtained through the copper roughing. The complex copper-lead ore beneficiation separation method is characterized in that in the copper-lead separation process of the copper choiceness,middling chosen in a first copper choiceness process is returned to a first copper scavenging process, and the middling chosen in a second copper choiceness process and the middling chosen in a thirdcopper choiceness process are intensively returned to the copper roughing process, therefore, the influence of impurities on grades is prevented, and the purpose of enhancing the grades of the copperconcentrates is achieved; in the copper scavenging process, concentrates subjected to primary choiceness are reground, and ore charges are conveyed to the copper choiceness process to form selective milling after regrinding, thereby not only enhancing the dissociation degree of copper-lead ores but also preventing overgrinding, and enabling the copper concentrates to obtain higher recovery rate.

Owner:BAIYIN NONFERROUS GROUP +1

Method for improving recovery rate of valuable metals

ActiveCN113369019AHigh recovery rateReduce mutual inclusionFlotationProcess efficiency improvementSulfidationCopper

The invention discloses a method for improving the recovery rate of valuable metals. When copper-zinc sulphide ore or copper-lead-zinc sulphide ore is taken as raw ore for mineral separation, copper mineral recovery is carried out in the following two steps: step 1, the copper-zinc sulphide ore or copper-lead-zinc sulphide ore is taken as the raw ore for ore grinding to obtain raw ore pulp, then the raw ore pulp is subjected to flotation, most of copper minerals are recovered through flotation, most of micro-particle copper minerals are in an undissociated state and enter tailings, and the lead mineral content and the zinc mineral content of the tailings are allowed not to affect recovery of the copper minerals in the tailings, so the tailings containing the micro-particle copper minerals are obtained; and step 2, the copper minerals are recycled from the tailings containing the micro-particle copper minerals. According to the method, efficient separation of minerals can be achieved, mutual inclusion of the minerals can be effectively reduced, the purpose of effectively improving the recovery rate of valuable metal elements is achieved, the problems that fine particles are difficult to separate due to fine grinding of raw ores and that a lead recovery rate is reduced due to excessive grinding of lead are solved, and meanwhile, energy consumption of production is greatly reduced.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

A Flotation Separation Agent System of Copper-Molybdenum Mixed Concentrate and Its Application

ActiveCN110548600BReduce mutual inclusionExcellent separation indexFlotationPharmacySodium thioglycollate

The invention discloses a copper-molybdenum mixed concentrate flotation separation agent system and its application; the copper-molybdenum mixed concentrate flotation separation agent system includes a copper mineral inhibitor and a molybdenum mineral collector in the copper-molybdenum flotation separation process and foaming agents. Wherein, the copper mineral inhibitor includes by weight: 3-7 parts of sodium hydroxide, 3-6 parts of hydrogen peroxide, 15-25 parts of sodium thioglycolate, 2 parts of pentasodium diethylenetriaminepentaacetate -5 parts, an appropriate amount of water; the molybdenum mineral collector includes by weight parts: 20-30 parts of kerosene, 5-10 parts of tert-dodecylmercaptan; the foaming agent is 2-hexanol. The inhibitor and collector of the invention have strong selective adsorption capacity, excellent synergistic performance, strong foaming agent group activity, brittle and dense foam formed, and good mineralization effect. The copper-molybdenum flotation separation agent system of the present invention can greatly improve the difference in floatability between molybdenum minerals and copper minerals in complex and difficult-to-separate copper-molybdenum mixed concentrates, effectively reduce the mutual inclusion of copper and molybdenum, and the separation index is excellent. It is harmless and has little impact on the environment.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

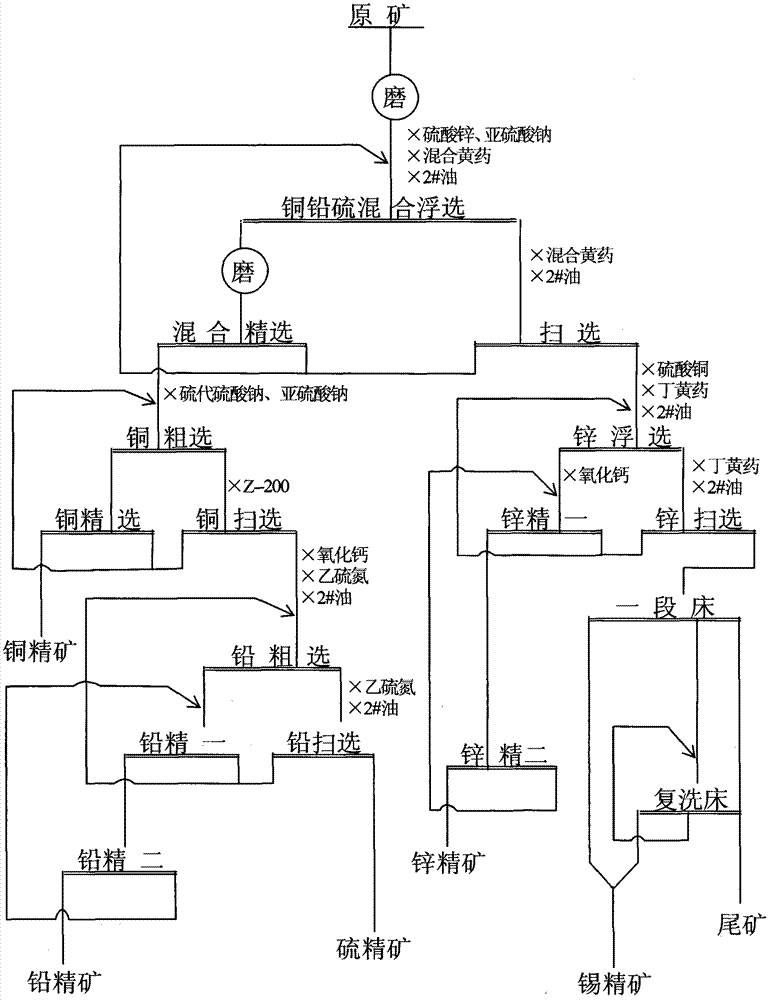

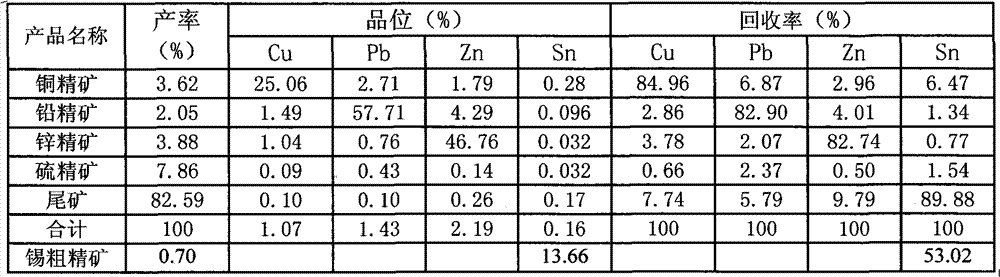

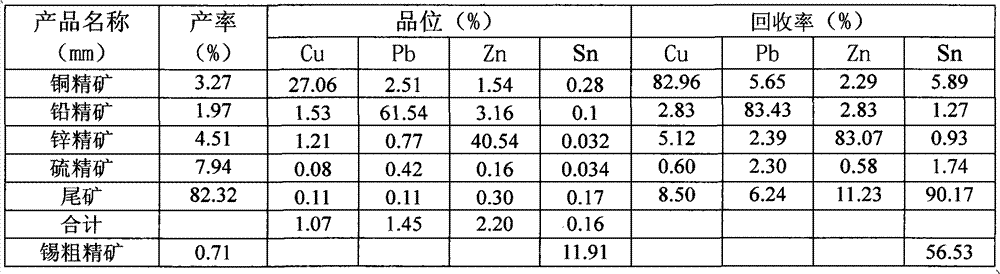

Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

Owner:云南锡业研究院有限公司研究设计院

Sequential priority flotation separation method of low-sulfur copper-lead-zinc polymetallic ore

ActiveCN110280395BInhibition of mutual inclusionReduce mutual inclusionFlotationMineral SourcesMining engineering

The invention discloses a method for separating low-sulfur type copper-lead-zinc polymetallic ores by sequential preferential flotation. The technical scheme is carried out in the order of first flotation of copper and then flotation of lead. In the copper priority flotation operation, the combined inhibitor T‑9 is used to realize the combination of valuable elements copper, lead, and Effective separation of zinc; in the lead priority flotation operation, the inhibitor F‑8 is used to effectively inhibit the flotation of zinc minerals. T-9 reduces the planktonic activity of lead and zinc minerals, effectively increases the difference in floatability between copper and lead and zinc minerals, and its components are non-toxic, harmless, green and non-polluting; inhibitor F-8 has a strong effect on sphalerite Good inhibitory effect, while galena and silver minerals have high activity, and galena has a certain collection effect, which is beneficial to reduce the mutual content of lead and zinc in the product. After the method is adopted, the target minerals copper, lead and zinc are effectively separated, and the purpose of comprehensive recovery and utilization of mineral resources is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com