Patents

Literature

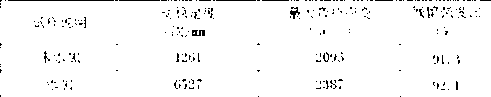

251 results about "Dodecylmercaptan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collecting agent and preparation method and application thereof

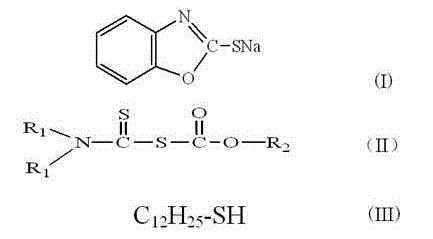

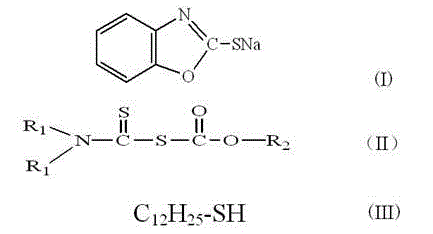

The invention discloses a collecting agent preparation and application method. The collecting agent is prepared from modified dithiocarbamic acid, sodium mercaptobenzothiazole, lauryl mercaptan and fatty alcohol. A molecular formula of the sodium mercaptobenzothiazole is shown as a formula I, a molecular formula of the modified dithiocarbamic acid is shown as a formula II, and a molecular formula of the lauryl mercaptan is shown as a formula III, wherein R1 refers to straight-chain alkyl groups with 1-4 carbon chains, and R2 refers to straight-chain alkyl groups with 2-4 carbon chains. The preparation method includes that the modified dithiocarbamic acid, the sodium mercaptobenzothiazole, the lauryl mercaptan and the fatty alcohol are mixed proportionally and mechanically stirred for 10-30min at the temperature of 15-35 DEG C to obtain reddish brown oily liquid which is the collecting agent. The collecting agent is applicable to associated precious metal sulfide flotation. Recovery rate of useful metals in associated precious metal sulfide ores can be increased by giving full play to synergistic effects of different collecting agents.

Owner:KUNMING METALLURGY INST

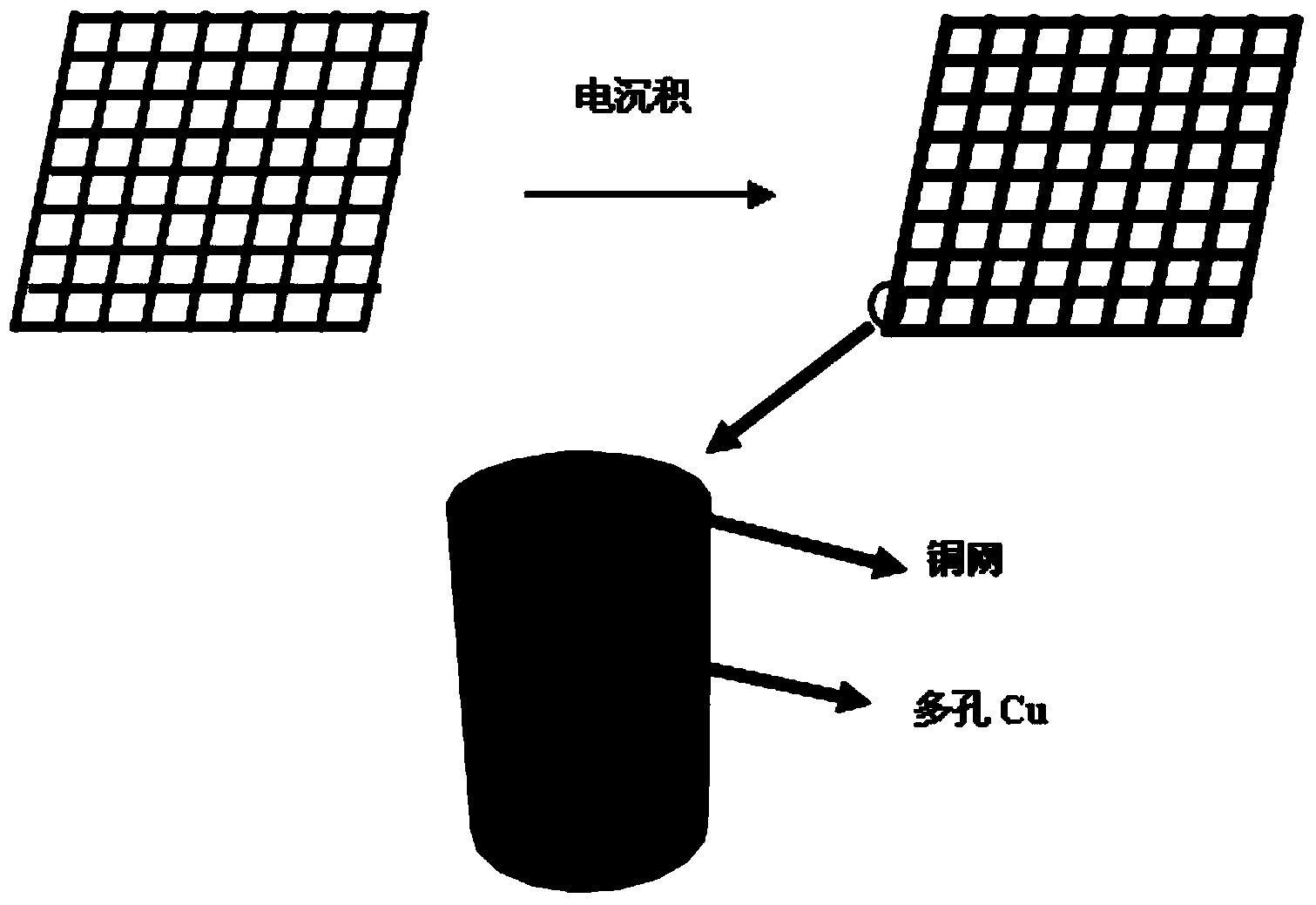

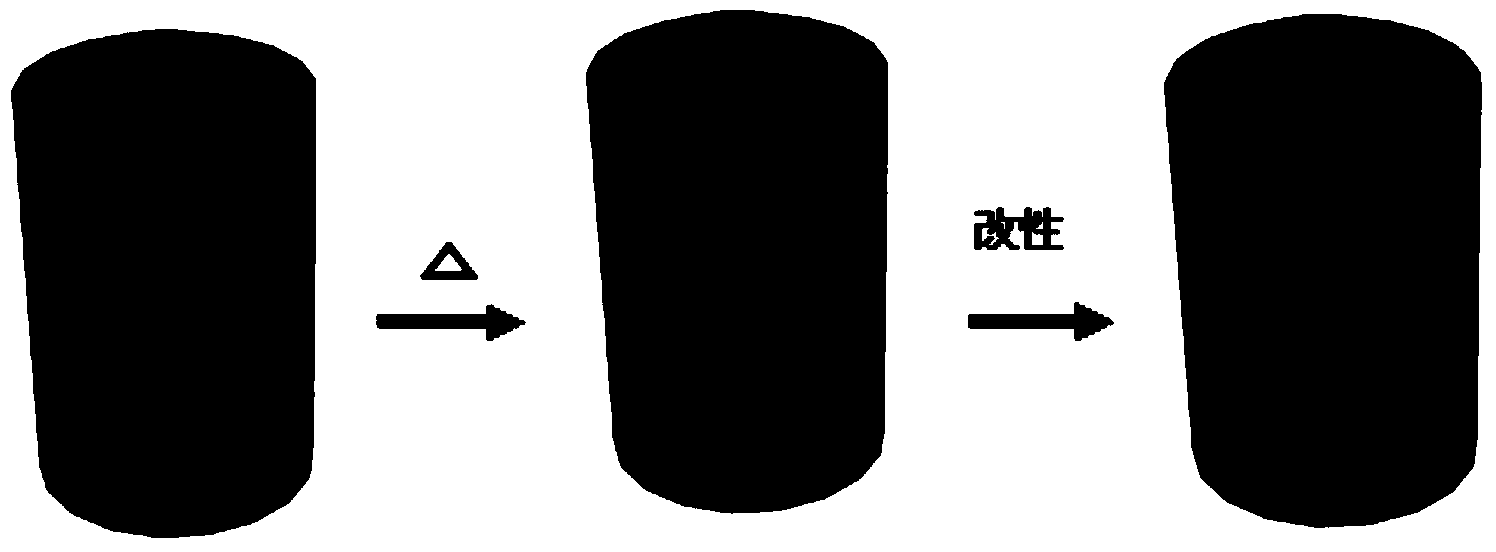

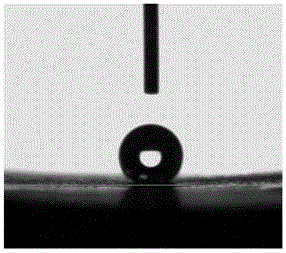

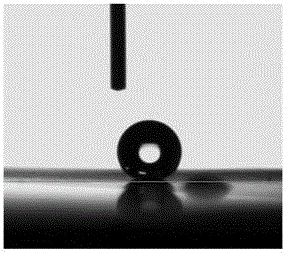

Preparation method of super-hydrophobic meshy material

ActiveCN103849910AEasy to operateExperimental parameters are controllableLiquid separationCopper wireControllability

The invention discloses a preparation method of a super-hydrophobic meshy material. The method comprises the following steps of (1) preparing a porous meshy Cu film by using a hydrogen bubble template method; (2) oxidizing the porous Cu film at a certain temperature to obtain Cu2O, and modifying the surface of the porous meshy Cu film by using dodecylthiol and tetradecanoic acid to obtain a super-hydrophobic porous meshy film. The hydrogen bubble template method for preparing a porous material has the advantages of simplicity, convenience, low cost and parameter controllability; a three-dimensional porous meshy film can be obtained through depositing on a copper wire mesh by using the method; the porous film is prepared by taking a dynamic hydrogen bubble as a template; compared with a hard template method, the method has the advantages that the template is not needed to be removed, the problems such as high cost, complexity in operation and serious film pollution in the traditional method are solved, and the industrial production is expected to be realized.

Owner:HARBIN INST OF TECH

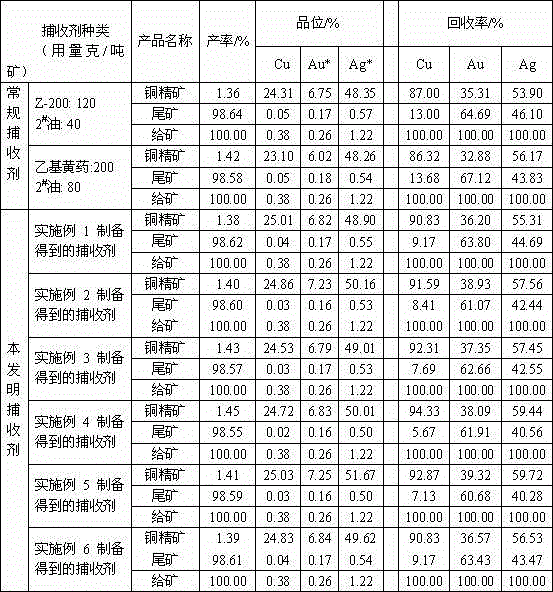

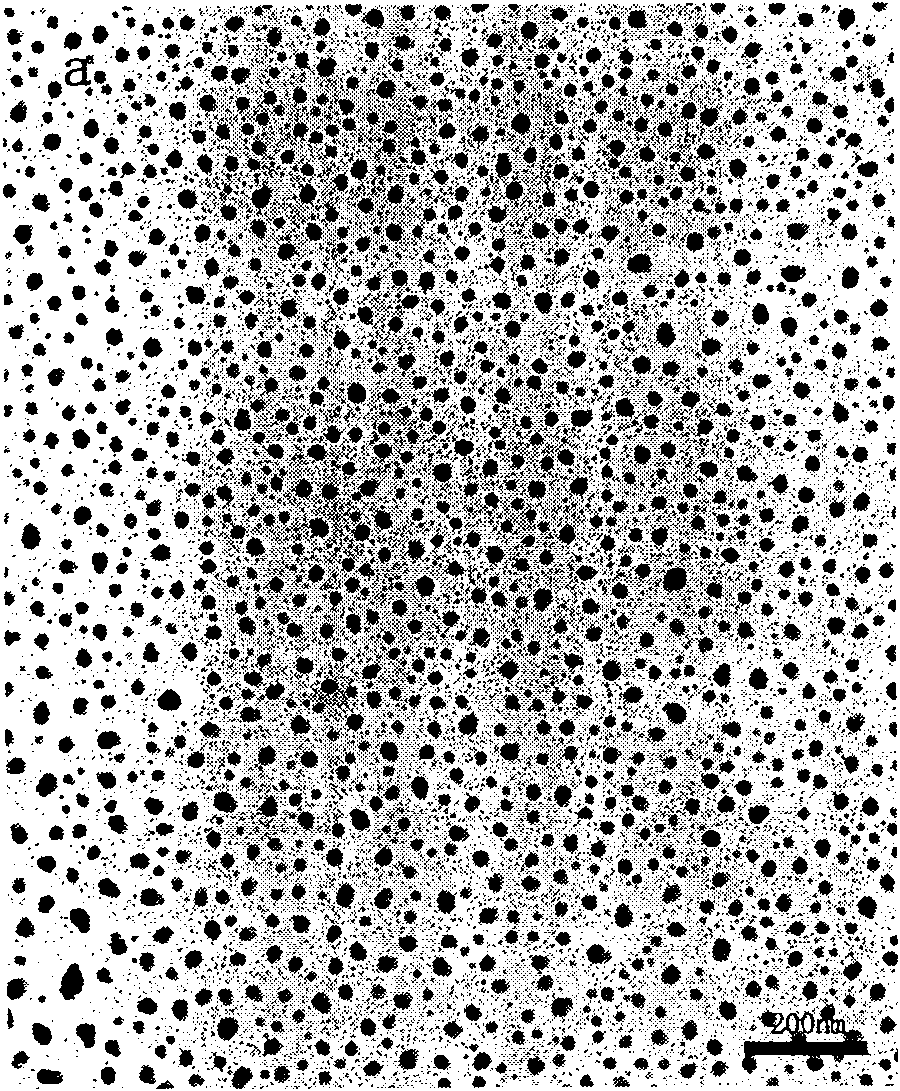

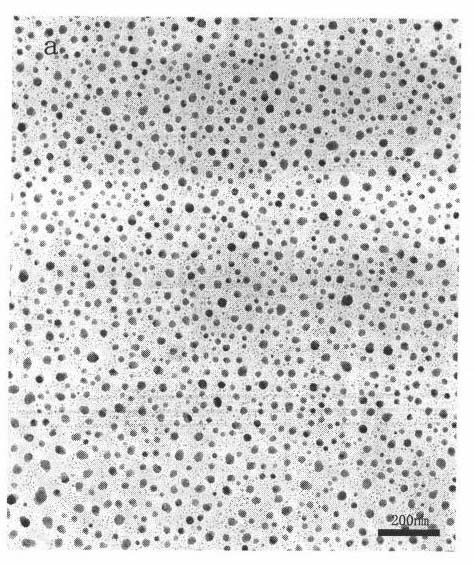

Method for preparing nano copper powder

The invention discloses a method for preparing nano copper powder, which comprises the following steps of: compounding copper sulfate, lauryl sodium sulfate and polyoxyethylene sorbitan monooleate in a molar ratio of 1:0.5-2:0.05-0.3, dissolving the mixture in water, blending the aqueous solution and lauryl mercaptan-containing benzene solution in a molar ratio of copper sulfate to lauryl mercaptan of 1:0.5-2, and uniformly stirring; pouring the emulsion fluid into an electrolytic bath, taking pure copper as an anode and stainless steel as a cathode, and regulating the pH value to between 0.5 and 4; supplying direct current to the anode and the cathode to ensure that the lauryl mercaptan dissolved in an electrolyte performs in-situ clad on precipitated copper atoms, the generated copper powder loosely attaches to the surface of the cathode, copper ions near the anode are continuously migrated to the place near the cathode under the action of diffusion and directional migration of electric charge at the same time, and the electrolytic time is 30 to 120 minutes; adding the cathode to which the copper powder is attached into absolute ethyl alcohol, and putting the cathode in an ultrasonic cleaner for desorption by using ultrasonic waves for 5 to 20 minutes to obtain dark purple copper solution; and filtering the solution, and drying the filtrate for 1 to 3 hours at the temperature of between 60 and 100 DEG C in a vacuum environment to obtain brown powder, namely a nano copper composite.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Heat-resistant and flame-retardant modified acrylic emulsion paint

InactiveCN105176287AImprove flame retardant performanceImprove the defect of low bond strengthFireproof paintsEpoxy resin coatingsEpoxyNano al2o3

The invention discloses a heat-resistant and flame-retardant modified acrylic emulsion paint. The paint comprises the following raw materials: acrylic emulsion, copolymer emulsion of vinyl acetate and ethylene, brominated epoxy resin, boron phenolic resin, zinc borate, nanometer magnesium hydroxide, hexamethylene tetramine, organic modified montmorillonite, sepiolite, nanometer silicon nitride, nanometer silicon carbide, aluminum tripolyphosphate, nanometer zinc oxide, nanometer aluminum oxide, ethanol, 2-ethyl-4-methylimidazole, polyvinylpyrrolidone, dodecyl mercaptan, 1,2-benzisothiazole-3-ketone, sodium carboxymethylcellulose, a defoaming agent and water. The heat-resistant and flame-retardant modified acrylic emulsion paint has the advantages of good heat resistance and water resistance, excellent weather resistance, good flame retardant effect, strong adhesive force with a substrate, and long service life.

Owner:TIANCHANG YINHU PAINT

Anti-oxidation metal surface treatment agent

InactiveCN104862680AHigh tensile strengthImprove thermal stabilityMetallic material coating processesPolyvinyl alcoholHeat stability

The invention discloses an anti-oxidation metal surface treatment agent. The anti-oxidation metal surface treatment agent consists of the following raw materials in parts by weight: 13-20 parts of polyvinyl alcohol, 0.4-1 part of tea saponin, 0.8-1 part of sodium citrate, 0.2-0.3 part of lauryl mercaptan, 0.1-0.3 part of 2-thiol group benzimidazole, 0.1-0.2 part of antioxidant BHT, 0.4-1 part of calcium lignosulphonate, 2-3 parts of amino tri(methylene phosphonic acid), 6-8 parts of sericin, 0.08-0.1 part of boric acid, 10-20 parts of methyl benzotriazole, and 180-200 parts of de-ionized water. The water soluble high-molecular polyvinyl alcohol is mixed with the sericin and is modified by the boric acid to improve the tensile strength and the heat stability of a blended membrane; corrosion inhibition alkali liquid using the methyl benzotriazole as a main material is added, so that the film attached on the metal surface is more uniform and stable to protect a metal material from being corroded by harmful media in atmosphere and water so as to achieve a better corrosion inhibition effect; and the added 2-thiol group benzimidazole and antioxidant BHT can improve the oxidation resistance of the metal surface treatment agent.

Owner:ANHUI HAODING METAL PROD LIMITED

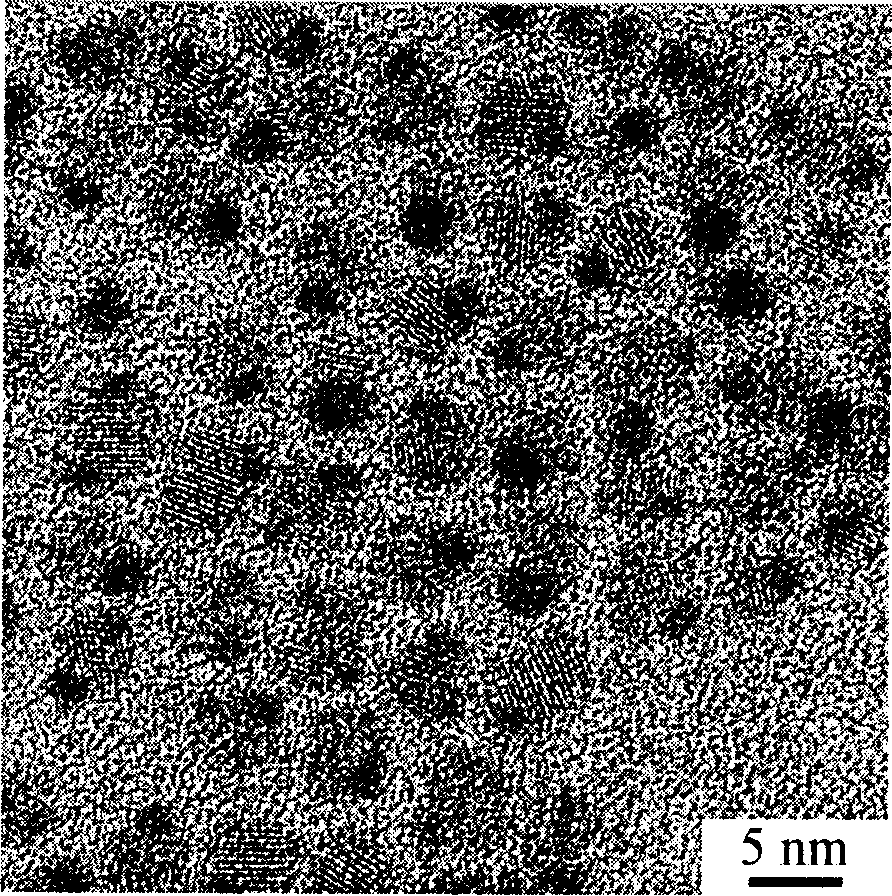

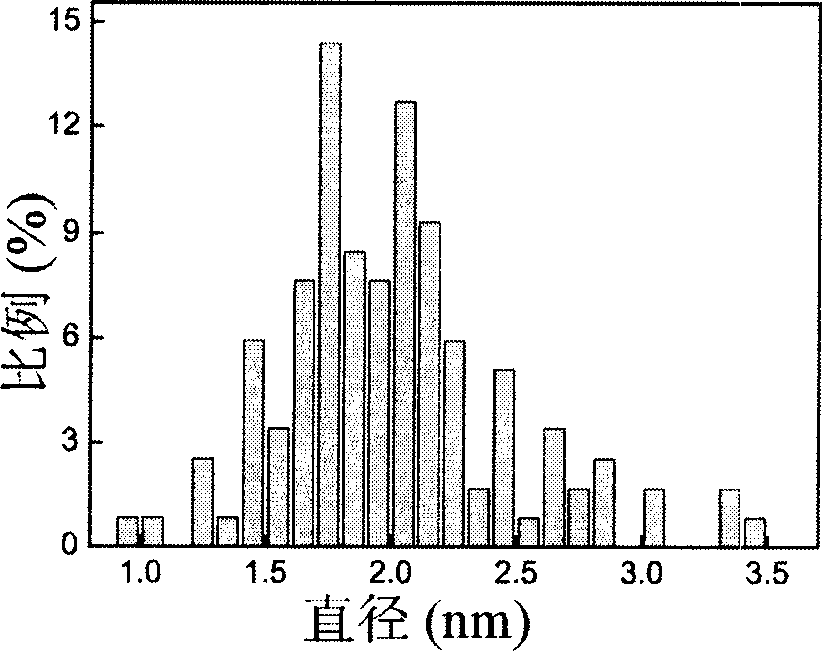

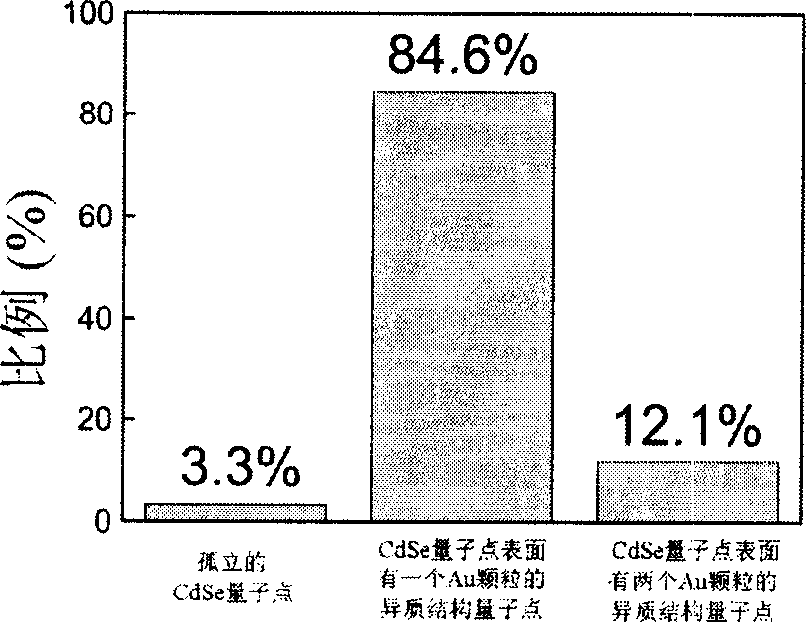

Au/CdSe heterostructure quantum point and its preparation method

The invention relates the Au / CdSe heterostructure quantum point and preparing method, comprising the following steps: extracting HAuCl4*4H2O solution with toluene solution, stewing, washing the toluene solution, adding them into dodecanethiol, stirring, and getting gold solution; mixing the toluene solution and gold solution, and stirring; purifying, and getting the product composed by Au particle whose grain size is 2.0nm and CdSe particle whose grain size is 3.4nm. The invention has the advantages of metal and semi-conductor light absorption feature and dissymmetrical structure. The product can be used in nanometer electron device, light sensor and solar battery.

Owner:UNIV OF SCI & TECH OF CHINA

Heat-resisting waterproof wallpaper and production method thereof

InactiveCN106703311AImprove waterproof performanceImprove heat resistanceCovering/liningsFibre treatmentMaterials scienceGlycerol Ethers

The invention discloses a heat-resisting waterproof wallpaper. The heat-resisting waterproof wallpaper comprises a base material layer, a waterproof layer and a heat-resisting layer, wherein the heat-resisting layer is made of waterborne silicon-acrylate resin, hydroxyl-polyacrylate emulsion, cellulose acetate butyrate solution, amino resin, iron oxide red, iron oxide yellow, pearl powder, lauryl mercaptan, dimethylethanolamine, thiethylamine, triethanolamine, 2-amino-2-methylpropanol, ammonium hydroxide, acrylic glycidyl ether, ethylene glycol monobutyl ether, waterborne aluminum powder, charcoal powder, talcum powder, sodium bicarbonate, glass fiber, vermiculite powder, perlite powder, EVA (ethylene-vinyl acetate copolymer) wax, polyethylene wax, nano titanium dioxide, waterborne polyisocyanate curing agent, wetting agent, magnesium stearate, polyoxypropylene glycerol ether, carboxymethyl cellulose and anti-setting agent. The invention also discloses a preparation method of the heat-resisting waterproof wallpaper. The prepared heat-resisting waterproof wallpaper is excellent in heat-resisting and waterproof performance.

Owner:安徽易有墙纸有限公司

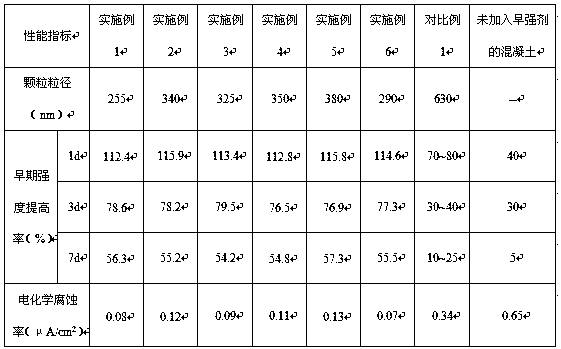

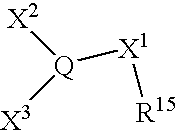

Nano C-S-H seed crystal early strength agent for building concrete and preparation method thereof

The invention relates to the field of concrete additives, and discloses a nano C-S-H seed crystal early strength agent for building concrete and a preparation method thereof. The preparation method comprises the following steps that (1) acrylic monomer, a silane coupling agent, modified polyoxyethylene ether are added into ammonium persulfate, vitamin C and dodecyl mercaptan to prepare a polymer solution; (2) sodium metasilicate is prepared into a solution A of which mass concentration is 45-50%, and calcium nitrate is prepared into a solution B of which mass concentration is 30-40%; (3) the solution A and the solution B are added into the polymer solution, and the uniform and stable nano C-S-H seed crystal early strength agent for the building concrete is prepared through reaction. Compared with an ordinary early strength agent, the nano C-S-H seed crystal early strength agent for the building concrete has the advantages that the grain size of the particles is small, the distributionis uniform, the reaction process of the cement hydration can be accelerated, the early strength is significantly improved, no electrochemical corrosion phenomenon exists, the production efficiency isgreatly improved, the late strength of concrete members is not affected, and the production and application can be promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Aqueous amphiphilic copolymer emulsions having controlled viscosity and methods for making the same

The present invention provides aqueous amphiphilic emulsion copolymer compositions comprising one or more aqueous phase copolymer, a residue of one or more hydrophilic chain transfer agent, and a residue of one or more hydrophobic chain transfer agent, as well as methods of making such copolymers in water or an aqueous liquid by copolymerizing a monomer component of from 20 to 80 wt. %, based on the weight of the monomer component, of a hydrophilic group-containing monomer and the remainder of a copolymerizable ethylenically unsaturated monomer or prepolymer in the presence of a mixed chain transfer agent component comprising a hydrophilic chain transfer agent, such as 3-mercaptopropionic acid, and a hydrophobic chain transfer agent, such as N-dodecyl mercaptan. The aqueous amphiphilic emulsion copolymers of the present invention are storage stable and exhibit excellent viscosity control even in high solids compositions, e.g. from 50 to 80 wt. % of the composition. The high solids compositions can be diluted at the point of use, thus reducing shipment costs.

Owner:ROHM & HAAS CO

Abrasive material

InactiveUS7001252B2Good polishing performanceReduce generationOther chemical processesAbrasion apparatusEmulsionItaconic acid

An object of the present invention is to provide a polishing body, wherein the abrasive in the polishing body are extremely dispersed well, which provides stable polishing performance in the polishing process, and which can effectively reduce the occurrence of scratches even in a case a large quantity of the abrasive are contained. A polishing part constituting the polishing body in the invention is produced obtained by loading predetermined amounts of butadiene, styrene, methyl methacrylate, itaconic acid, acrylic acid, α-methylstyrenedimer, and t-dodecylmercaptan in an autoclave, making the mixture react for 16 hours at 75° C. to obtain an emulsion wherein a copolymer is dispersed, adjusting this emulsion to pH8.5, incorporating cerium oxide powder with an average primary particle diameter of 0.3 μm and stirring to obtain an aqueous dispersion, drying this aqueous dispersion by spreading it thinly across a film, and mold pressing the dried product obtained. The above-mentioned polishing part may have a crosslinked structure. The polishing body in the invention can be used favorably in a polishing pad and the like, for polishing the surface of a semiconductor wafer or the like.

Owner:JSR CORPORATIOON

Preparation method of environment-friendly type emulsion for water-based ink

The invention relates to an environment-friendly type emulsion for water-based ink and a preparation method thereof. The emulsion provided by the invention is prepared by the following method: aqueous polymerization is carried out to produce a water-soluble resin with ethyl acrylate and methacrylic acid as comonomers, persulfate as an initiator and TDM as a chain transfer agent; then the emulsion polymerisation preparation technology is adopted, wherein styrene, acrylate, methacrylate, methacrylic acid, acrylic acid and a functional monomer are selected as comonomers, the water-soluble resin produced from the last step is used as a protective colloid, a small amount of an emulsifier is added and persulfate is used as an initiator. The emulsion obtained by the above method is mainly characterized by integrating respective advantages of the water-soluble resin and an acrylic acid emulsion. As a binder of the water-based ink, the product provided by the invention has good leveling property, low viscosity, high luster, fast drying speed, high adhesion, pollution resistance, viscosity resistance, salt resistance, water proofness, alkali resistance, alcohol dilution resistance and good wear resistance.

Owner:上海拜道化学有限公司

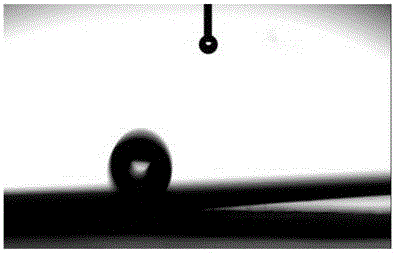

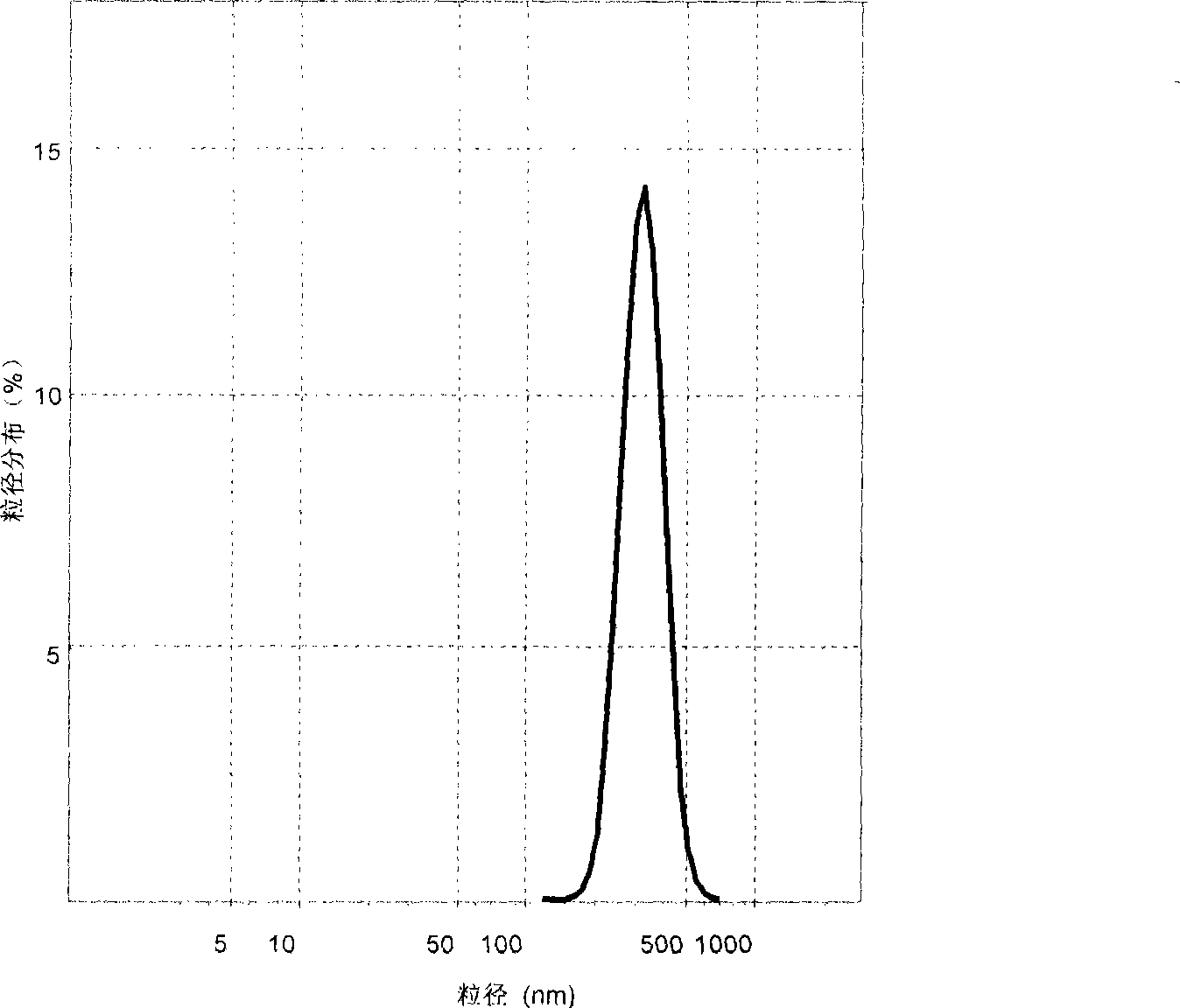

Method for preparing polybutadiene rubber latex with extra large particle size

ActiveCN102050889ASimple preparation processMild conditions for agglomerationSodium bicarbonatePolymer science

The invention relates to a method for preparing polybutadiene rubber latex with extra large particle size, comprising the following steps: adding deionized water, sodium bicarbonate, sodium lauryl sulphate, potassium peroxydisulfate, dodecyl hydrosulfide, butyl acrylate and styrene into a reactor, carrying out replacement with nitrogen after stirring and emulsifying are started, heating, controlling the temperature to be 50-70 DEG C, polymerizing for 0.5-1 hour, then dropwise adding mixed monomers of styrene, methacrylic acid, butyl acrylate and OP-10, reacting for 1-4 hours, heating until the temperature is 70-85 DEG C, then stirring for 0.5-2 hours until the reaction is finished, and cooling and filtering to obtain a high polymer agglomerant; adding the high polymer agglomerant into polybutadiene rubber latex while slowly stirring for 1-60 minutes, and standing for 4 hours, thus the polybutadiene rubber latex with extra large particle size of 400-1000nm is obtained. The preparation process is simple, the agglomeration condition is mild, the agglomeration process is controllable, and the impact strength of an ABS (acrylonitrile butadiene styrene) finished product is greatly improved.

Owner:PETROCHINA CO LTD

Method of preparing high molecular weight cationic polyacrylamide

This invention relates to a method to prepare cationic polyacrylamide with high molecular weight. Acrylamide and DAC are adopted as raw materials and aqueous copolymerization takes place in an oxygen-free initiating system with the existence of auxiliary reagents and nitrogen. The auxiliary reagents is one of urea, isopropanol, sodium formate, EDTA, dodecanethiol, OP-10 and polyether AD4074 and weighs 0.5~5% of monomers. The composite initiating system comprises oxidant, reductant, chain extender, and azo compounds, where the oxidant is persulphate weighing 0.001~0.15% of monomers, the reductant is organic amine weighing 0.01~0.20% of monomers, the chain extender weighs 0.01~0.20% of monomers and the azo compounds weigh 0.005~0.20% of monomers. In the end, instant product with high molecular weight and high cation proportion can be obtained.

Owner:大连广汇化学有限公司

Preparation method of high-speed coating/connecting line peeling transfer adhesive

ActiveCN104178065AHigh coating hardnessHigh strengthEster polymer adhesivesSodium bicarbonateWater based

The invention relates to a preparation method of a high-speed coating / connecting line peeling transfer adhesive, which comprises the following steps: (1) adding butyl acrylate, methyl methacrylate or styrene, acidic functional monomer and crosslinking monomer into an emulsifier solution to prepare a core preemulsion; (2) adding butyl acrylate, methyl methacrylate or styrene, acidic functional monomer and tert-dodecyl mercaptan into the emulsifier solution to obtain a shell preemulsion; (3) preparing an initiator solution; (4) adding deionized water, water-based acrylic resin, anionic emulsifier, sodium bicarbonate and part of the core preemulsion into a reaction vessel, and adding part of the initiator solution; dropwisely adding the rest of core preemulsion and the rest of initiator solution to obtain a core emulsion; and (5) dropwisely adding the shell preemulsion and the rest of initiator solution into the core emulsion, adding ammonia water, defoaming agent and wetting agent, and filtering to obtain the transfer adhesive. The transfer adhesive can adapt to high-speed coating and connecting line peeling transfer, and has the advantages of high peeling completeness and favorable adhesive force.

Owner:汕头市龙湖昌丰化工有限公司

Preparation method of high-strength wood-plastic composite material and high-strength wood-plastic composite material

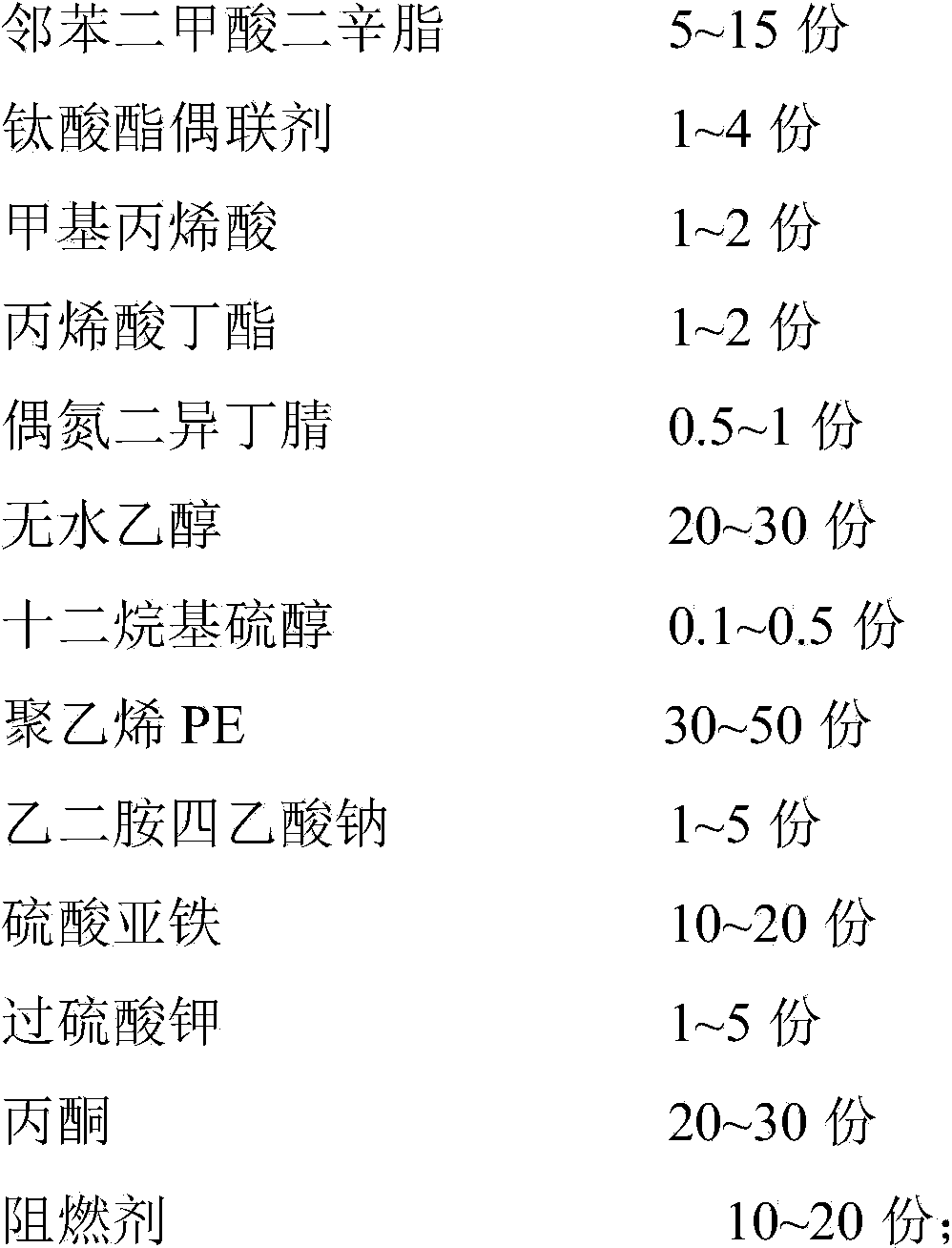

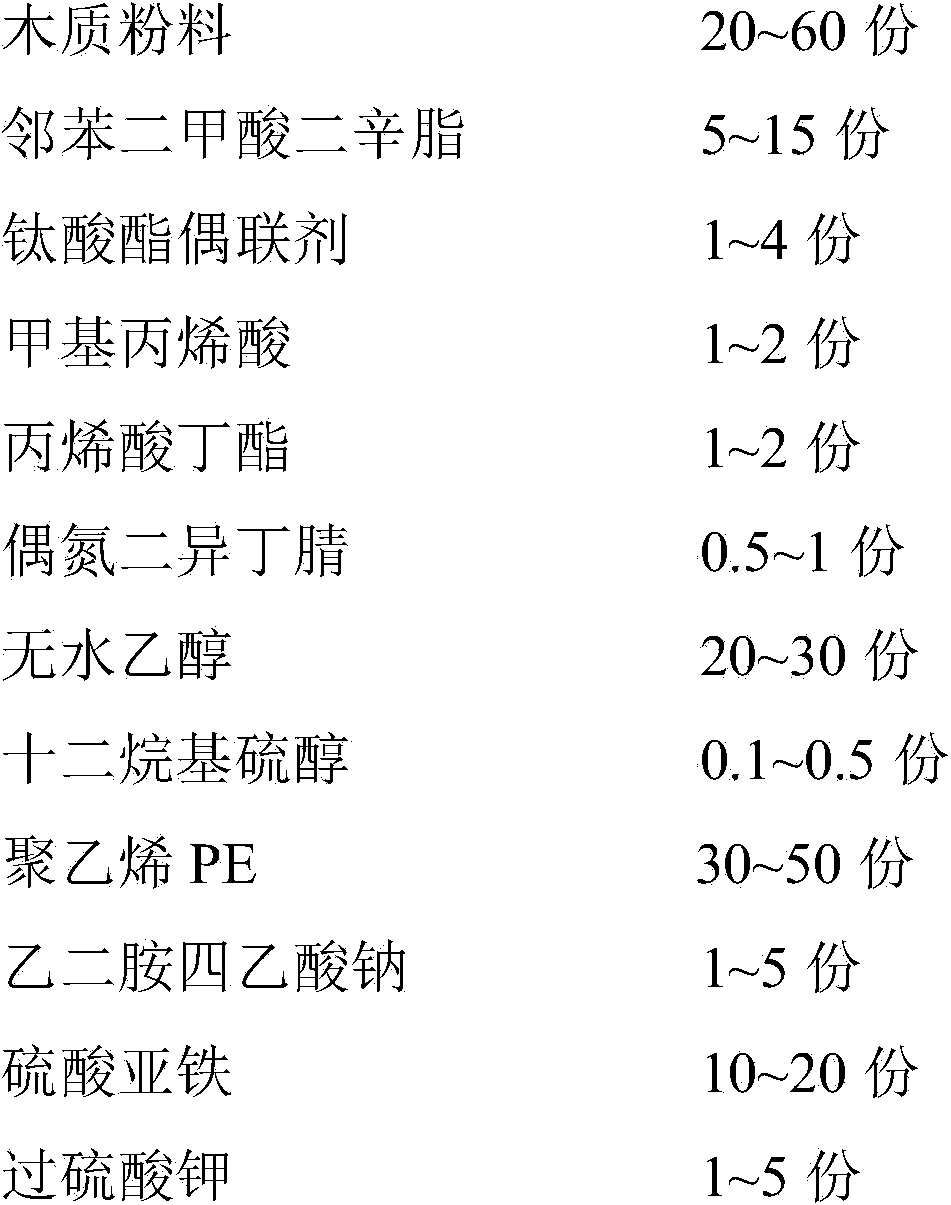

The invention relates to a preparation method of a high-strength wood-plastic composite material. The preparation method comprises the following steps of (1) preparing the following components in parts by weight: 20-60 parts of wood powder, 5-15 parts of dioctyl phthalate, 1-4 parts of titanate coupling agent, 1-2 parts of methacrylic acid, 1-2 parts of butyl acrylate, 0.5-1 part of azobisisobutyronitrile, 20-30 parts of absolute ethyl alcohol, 0.1-0.5 part of dodecylthiol, 30-50 parts of polyethylene (PE), 1-5 parts of ethylenediamine tetraacetic acid, 10-20 parts of ferrous sulfate, 1-5 parts of potassium peroxodisulfate, 20-30 parts of acetone and 10-20 parts of flame retardant; (2) drying the wood powder, and modifying; (3) copolymerizing methacrylic acid and butyl acrylate; (4) mixing; and (5) granulating and carrying out compression molding. The invention also discloses the high-strength wood-plastic composite material prepared by using the method.

Owner:GUANGDONG HONGYUN FURNITURE CO LTD +3

Resin for UV-cured strippable protection film, preparation method and applications thereof

The invention discloses a resin for UV-cured strippable protection film, a preparation method and applications thereof. The preparation method comprises the following steps: adding the following monomers: methyl methacrylate, butyl acrylate, acrylic acid, hydroxypropyl acrylate, isooctyl methacrylate, and azodiisobutyronitrile into an organic solvent, evenly mixing to obtain a mixed solution, introducing nitrogen gas into the mixed solution; adding part of the mixed solution into a four-mouth flask, carrying out reactions; dropwise adding the rest mixed solution and lauryl mercaptan, keeping on reactions; dissolving azodiisobutyronitrile by an organic solvent, then dropwise adding into the four-mouth flask, carrying out reactions; cooling the solution, dropwise adding diisocyanate, heating to carry out reactions; after cooling, dropwise adding a mixed solution of hydroxy acrylate and a polymerization inhibitor, heating; adding monohydric alcohol, cooling, and discharging the product. The provided resin can be easily peeled off from the surface of steel or glass. Furthermore, the UV curing system is more environment-friendly, the resin is nontoxic and harmless, the curing time is short, the resin can be cured within 10 seconds to form a film, and the production efficiency is largely improved.

Owner:SOUTH CHINA UNIV OF TECH

Two-dimensional CuCo2S4 nanosheet, preparation method thereof and application thereof as electrocatalyst during oxygen reduction reaction and oxygen evolution reaction

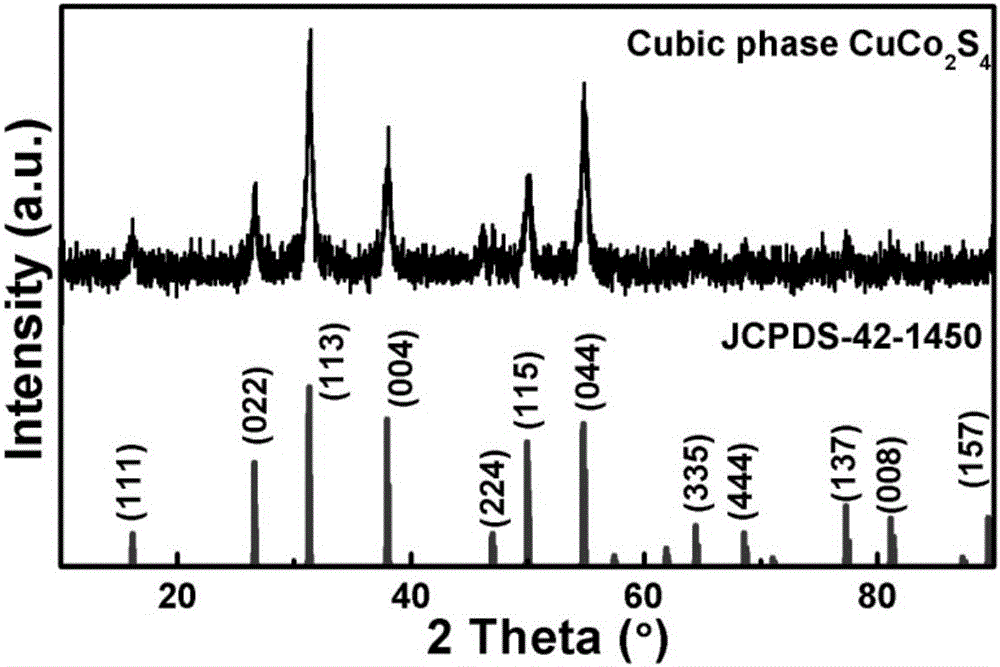

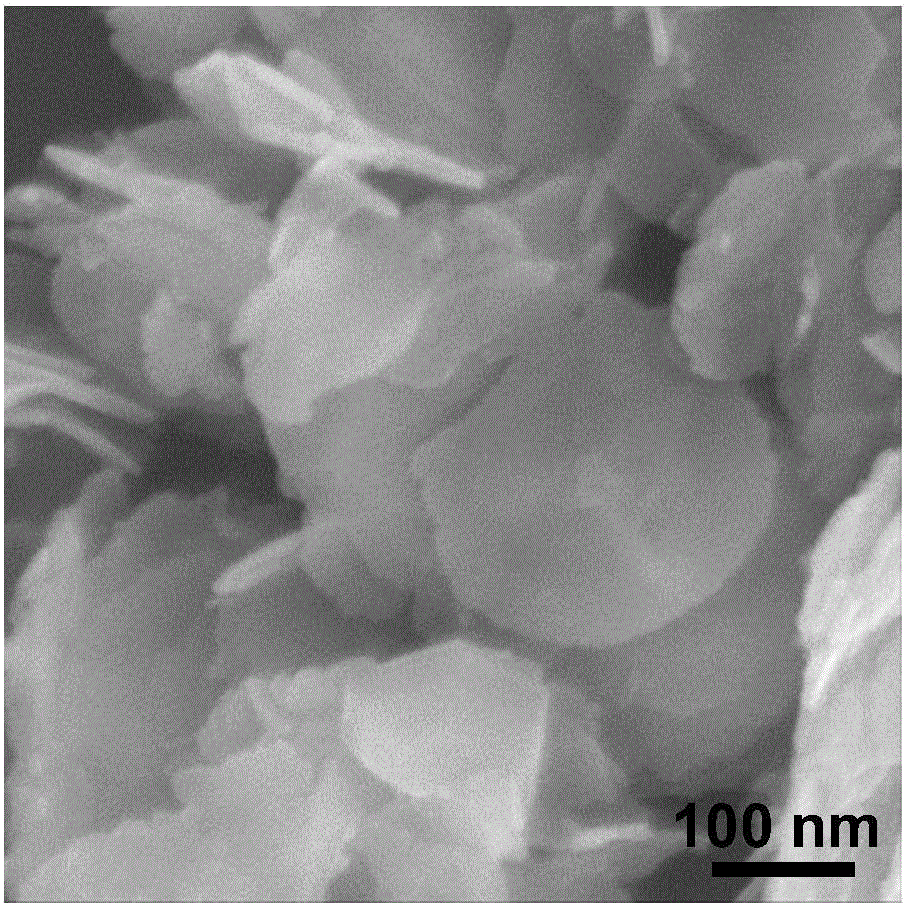

InactiveCN105948139ALow toxicityLow reaction temperatureMaterial nanotechnologyPhysical/chemical process catalystsChemical reactionSynthesis methods

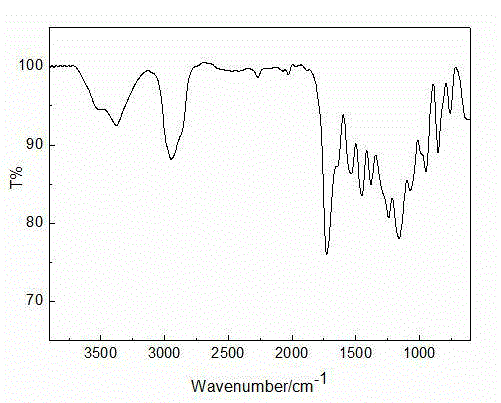

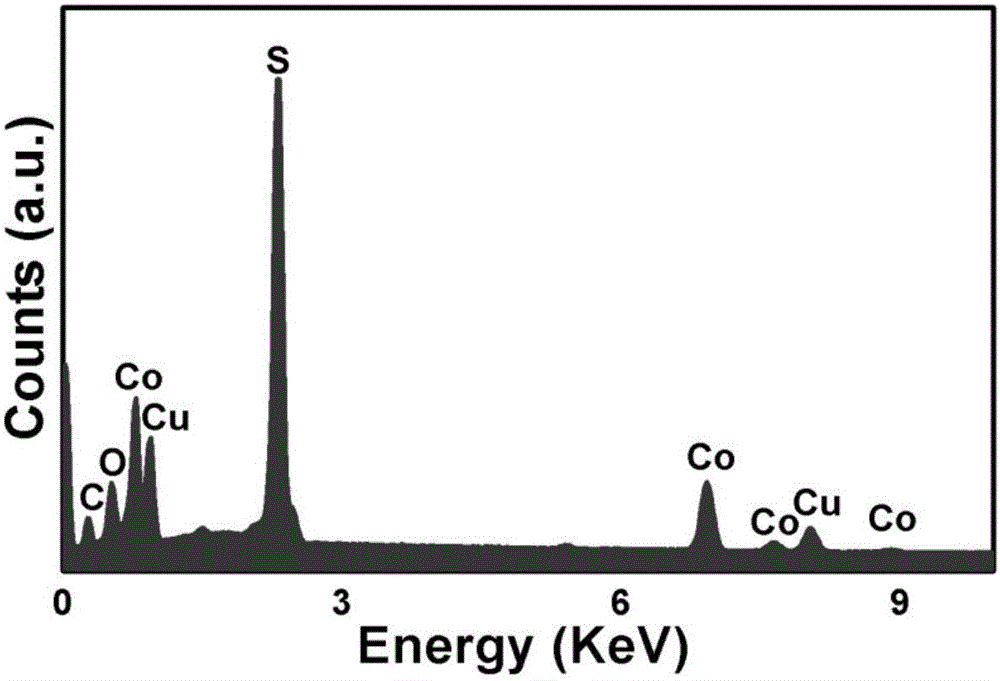

The invention discloses a two-dimensional CuCo2S4 nanosheet, a preparation method thereof and an application thereof as an electrocatalyst during the oxygen reduction reaction (ORR) and the oxygen evolution reaction (OER). The preparation method comprises the steps of adding copper acetylacetonate, cobalt acetylacetonate and dodecylamine into a reactor, heating the obtained mixture at a certain rate to 100-130 DEG C for further reaction, adding lauryl mercaptan into the above reactor, heating at a certain rate to 220-260 DEG C for further reaction, cooling the obtained reaction product to the room temperature, centrifugalizing, washing and drying to obtain the two-dimensional CuCo2S4 nanosheet. The solid-liquid phase chemical reaction is conducted according to the preparation method, and the two-dimensional CuCo2S4 nanosheet is synthesized at the normal pressure and at a relatively low temperature. Therefore, the method is simple in process, short in reaction time and high in repeatability, and is suitable for mass production. Currently, the synthesis method and the morphology of the two-dimensional CuCo2S4 nanosheet, and the application of the above two-dimensional CuCo2S4 nanosheet as the electrocatalyst during the ORR and the OER are not reported. Therefore, the two-dimensional CuCo2S4 nanosheet has a wide application prospect in the fields of low-cost alkaline fuel cells.

Owner:NANJING NORMAL UNIVERSITY

Water-resistant fireproof coating

The invention discloses a water-resistant fireproof coating. The coating comprises the following raw materials by weight: 20 to 50 parts of self-crosslinking elastic acrylic emulsion, 5 to 10 parts of copolymer emulsion of vinyl acetate and ethylene, 10 to 25 parts of a flame retardant, 10 to 25 parts of a pigment filler, 2 to 10 parts of propylene glycol, 0.2 to 1 part of 2-ethyl-4-methylimidazole, 0.5 to 1 part of polyvinylpyrrolidone, 0.2 to 1 part of sodium carboxymethylcellulose, 0.2 to 1.5 parts of 1,2-benzisothiazol-3-one, 0.3 to 1.2 parts of dodecyl mercaptan, 0.1 to 0.8 part of dodecyl dimethyl benzyl ammonium chloride, 0.5 to 1.5 parts of a defoaming agent, 0.5 to 2 parts of aluminium triphosphate and 25 to 40 parts of water. The water-resistant fireproof coating provided by the invention has the advantages of high strength, excellent fireproof property and water resistantce, strong adhesive force with a substrate, high bonding strength and long service life.

Owner:TIANCHANG YINHU PAINT

Rewetting repairable modified waterborne white latex and preparation method thereof

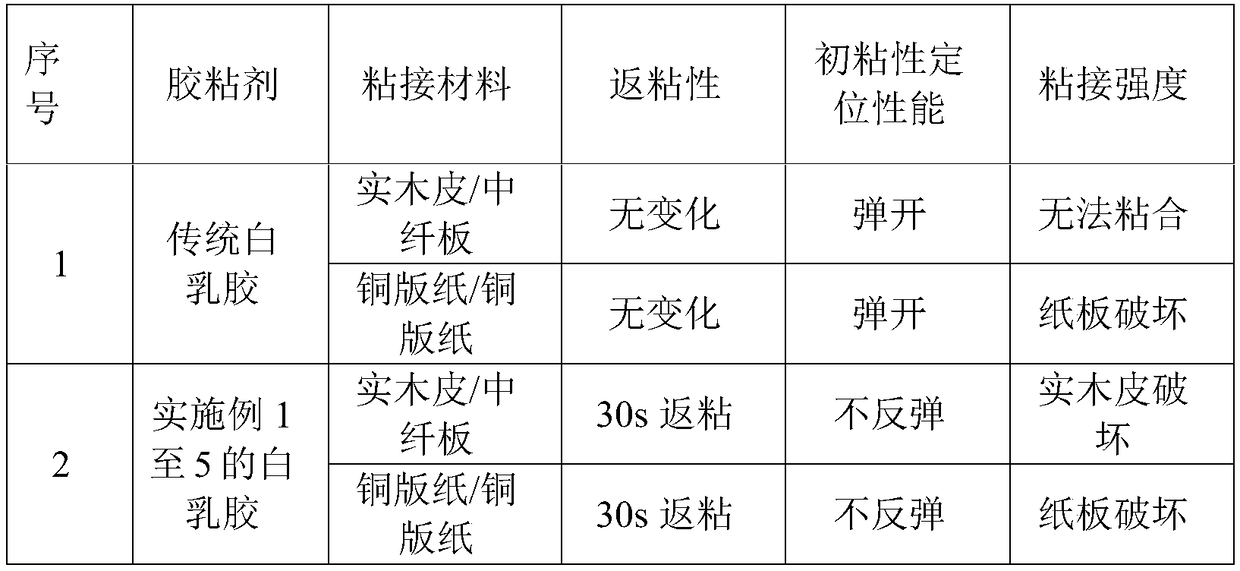

ActiveCN109306250ASolve irreparable technical problemsSensitive rehumidity responseMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPersulfateAdhesive

The invention relates to the technical field of waterborne adhesives and in particular relates to rewetting repairable modified waterborne white latex and a preparation method thereof. A formula comprises the following components: 35.0 to 50.0 parts of de-ionized water, 10.0 to 20.0 parts of protective colloid polyvinyl alcohol, 0.5 to 2.5 parts of a non-ionic emulsifier, 0.5 to 2.5 parts of a buffering agent, 0.5 to 1.5 parts of a persulfate initiator, 0.01 to 0.05 part of a chain transfer agent dodecyl mercaptan, 25.0 to 54.0 parts of vinyl acetate, 5.0 to 15.0 parts of butyl acrylate, 5.0 to 15.0 parts of a carboxyl-containing polymerizable monomer, a crosslinking agent and the like. Compared with the prior art, the white latex provided by the invention can be used for realizing secondary adhesion through the effect of water and the technical difficult in the prior art that the white latex cannot be repaired after the white latex is cured into a film is overcome; the wet-state adhesion performance of the white latex is greatly improved; the rewetting repairable modified waterborne white latex has the advantages of rapid rewetting viscosity response, good initial adhesion positioning and high bonding strength.

Owner:DONGGUAN STAR COSM POLYMER

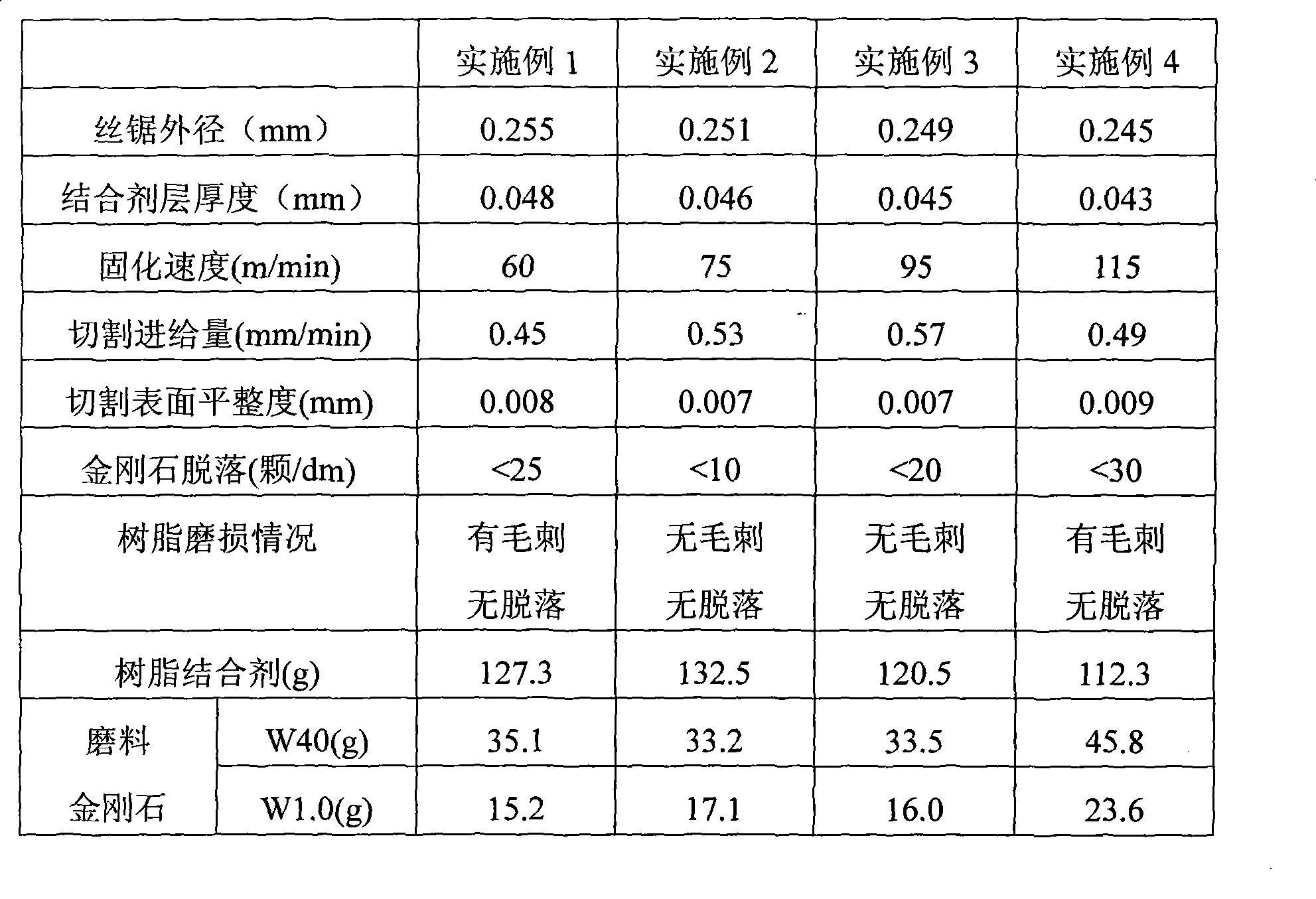

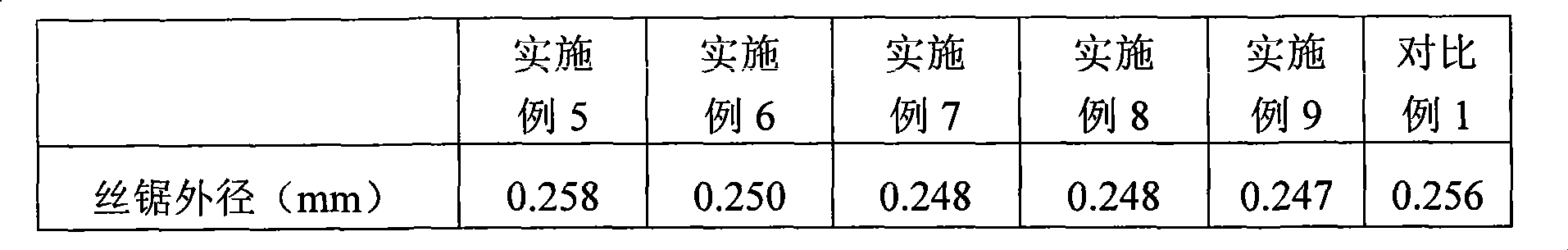

Resin binding agent for a diamond wire saw and preparation method thereof

InactiveCN101445587AReduce energy consumptionNo pollution in the processAbrasion apparatusVinyl etherPhosphate

The invention relates to a resin binding agent for a diamond wire saw and a preparation method thereof. The resin binding agent comprises the following components by the weight proportion: 30 to 90 portions of UV cured resin, 1 to 30 portions of solvents, 1 to 30 portions of inorganic fillers, 0.5 to 20 portions of mixed crystal whiskers, 0.5 to 10 portions of accelerating agents and 0.5 to 10 portions of coupling agents. The adopted resin is positive ion cured UV resin; a photoinitiator is selected from chloride diphenyl iodine salt or sulfur chloride triphenyl salt; and a prepolymer is selected from an activated epoxy compound or a polyalcohol mixture. The solvent is an activated monomer solvent; one or more of acrylic acid monomers or vinyl ethers with the simple function or the multifunction are adopted; the mixed crystal whisker is a silicon-contained crystal whisker and a polytetrafluoroethylene crystal whisker mixture; the accelerating agent is selected from a compound containing 1 to aziridine or ethylene phosphate, a vulcanization type chain transfer agent, and one or more of thiobarbituric acid ester different kwai or dodecyl mercaptan; and the coupling agent is a silane coupling agent. The invention has the advantages of low energy consumption, no pollution and high cutting efficiency.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing acrylonitrile butadiene-styrene (ABS) resin through double peak emulsion grafting

The invention relates to a method for preparing acrylonitrile butadiene-styrene (ABS) resin through double peak emulsion grafting, which comprises the following steps of: adding polybutadiene latex with big particle diameter, polybutadiene latex with ultra-large particle diameter, and partial emulsifier, styrene, acrylonitrile, tert-dodecylthiol and desalted water into a reactor, and controlling the temperature to be 30-80DEG C; when the temperature is raised to 35-50DEG C, adding partial activator and oxidant; reacting for 0.5 to 2 hours, and adding the rest emulsifier, styrene, acrylonitrile, tert-dodecylthiol and desalted water within 1 to 5 hours; and adding the rest activator and oxidant, curing for 0.5 to 2 hours, and finishing the reaction to obtain low-gloss ABS latex.

Owner:PETROCHINA CO LTD

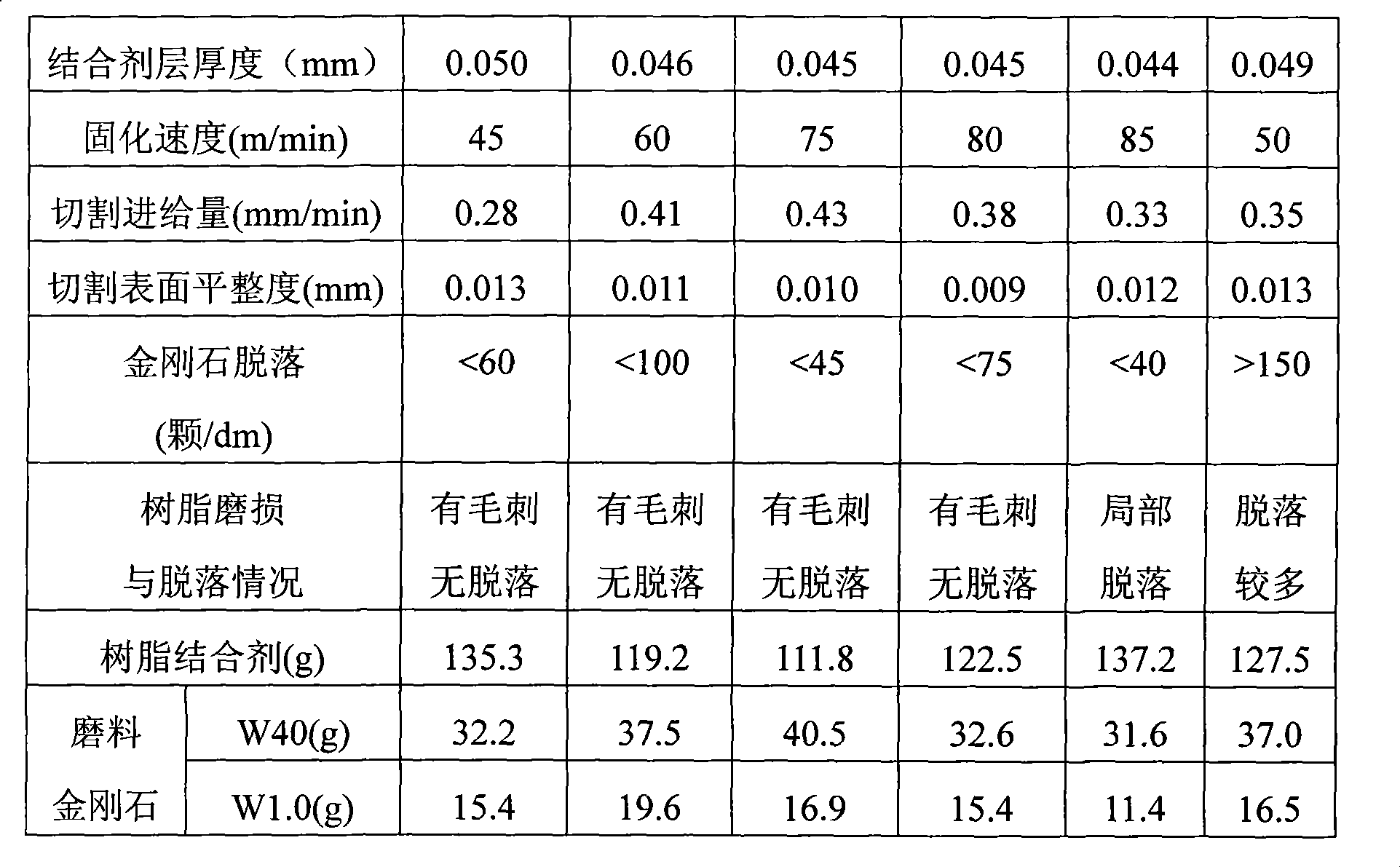

Method for preparing doublet acrylonitrile butadiene styrene (ABS) resin

The invention relates to a method for preparing doublet acrylonitrile butadiene styrene (ABS) resin. Styrene-butadiene latex with small diameter and butadiene latex with large diameter are fully stirred and mixed together and are added with part emulsifier, styrene, acrylonitrile, dodecyl mercaptan and desalted water at the temperature of 40-80 DEG C, when the temperature is heated to 42-50 DEG C, part activator and cumyl hydroperoxide are added to react for 0.5-2 hours, a continuous feeding mode is adopted to add the residual emulsifier, styrene, acrylonitrile, dodecyl mercaptan and desalted water in 1-3 hours, the activator and the cumyl hydroperoxide are added to cure for 0.3-1 hour, the obtained ABS latex is added into concentrated sulphuric acid at the temperature of 80-98 DEG C for 5-20 minutes, coagulating, filtering and drying are carried out so as to obtain dry powder, the dry powder is mixed with styrene-acrylonitrile copolymer (SAN), and an extruding machine is used to extrude and pelletize so as to obtain an ABS finished product. The impact strength, tensile strength and gloss of the resin are all improved.

Owner:PETROCHINA CO LTD

Preparing method for fine copper hydrophobic surface with wetting anisotropy

The invention relates to a preparing method for a fine copper hydrophobic surface with wetting anisotropy. According to the method, copper sulfate serves as plating solution main salt, copper foil is pretreated so that surface oil dirt and grease can be removed; then the pretreated copper foil is etched through a physical etching method; then brush plating treatment is conducted; and finally, the copper foil is then put into an ethanol solution of dodecylthiol to be soaked, a super-hydrophobic film is generated on the coarse surface of fine copper in a self-assembling manner, then washing and drying are conducted, and the fine copper hydrophobic surface with a micron, sub-micron and nanometer three-grade graded structure is finally obtained. The prepared super-hydrophobic surface structure is very similar to a rice leaf surface structure and has the anisotropic wetting performance achieved on the surface of a rice leaf. The preparing method is relatively novel and simple in technology, the structure is relatively easy to control, the cost is relatively low, and a very wide application prospect is achieved.

Owner:JILIN UNIV

Blocked high-temperature resistant integrated solvent-free polyurethane resin for leather, and preparation method and application thereof

InactiveCN108570137AStrong production operabilityLow costPolyurea/polyurethane coatingsTextiles and paperPolyesterFoaming agent

Blocked high-temperature resistant integrated solvent-free polyurethane resin for leather, and a preparation method and application thereof are disclosed. The polyurethane resin comprises a resin component A and a resin component B. The resin component A comprises a polyether ester polyol-polyisocyanate prepolymer, polyester polyol, a small molecule alcohol chain extender, a foaming agent and a catalyst. The resin component B comprises diisocyanate, polyester polyol and a NCO blocking agent. The blocking agent is one or more selected from phenol, nitrophenol, 2-pyridinol, 3-hydroxyquinoline, triphenylmethanethiol, hexanethiol, dodecanethiol, 3,5-dimethylpyrazole, 1,2,4-triazole, 2-methyl imidazoline, 2-ethyl-4-methylimidazole, caprolactam, N-methylacetamide, phenylacetamide, bisulfate or amine. The polyurethane resin can be used for preparing high-temperature resistance solvent-free polyurethane synthetic leather. The production efficiency is high. Equipment specially used for solvent-free leather synthesis is not needed, operable time is long after product mixing and stability is high.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Method for synthesizing fluorine-containing anti-fingerprint agent

The invention relates to a method for preparing a fluorine-containing anti-fingerprint agent. The method comprises the following steps of by adopting perfluoroalkyl ethyl methacrylate, 3-(methacryloxy)propyl trimethoxysilane and methyl methacrylate as reaction substrates, dodecyl mercaptan as a chain transfer agent and diisopropyl peroxydicarbonate as an initiator and in the presence of a solvent, initiating polymerization reaction for a reaction time of 1-2 hours, controlling the reaction temperature at 30-40 DEG C to prepare a crude product; carrying out reduced pressure distillation to remove the solvent to obtain a perfluoroalkyl silane compound; and diluting the perfluoroalkyl silane compound into a 0.1% (by mass concentration) solution with hydrofluoroether to obtain the finished product, namely, fluorine-containing anti-fingerprint agent. The method has the advantages of mild reaction conditions, no need of precious metal catalyst, safe and easily available raw materials, simple process, good safety and low production costs and is conducive to industrial production.

Owner:锦州恒通氟化学有限公司

Semi-continuous process for preapring organofluorine polymer grafted polyether polyol

A process for semi-continuously preparing organofluorine polymer grafted polyether polyol includes such steps as adding mixed solvent, xylene and methylisobutyl methanone to reactor, adding the monomer mixture liquid including vinyl or acryl ester, unsaturated polyether polyol, AIBN, etc and the organofluorine monomer liquid to reactor, and copolymerizing reaction. The product can be used to prepare F-C paint which features high weatherability and resistance to acid, alkali, chemical corrosion and ultraviolet ray, and high adhesion.

Owner:QINGDAO CHEM COLLEGE

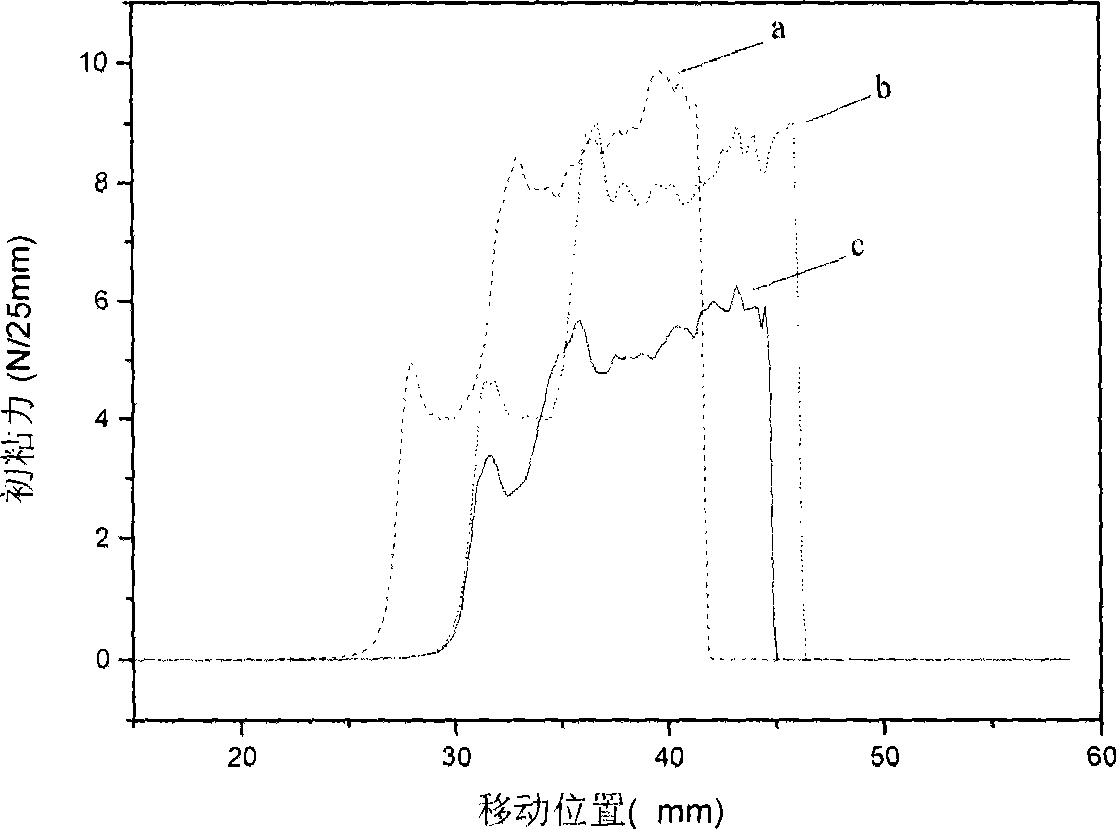

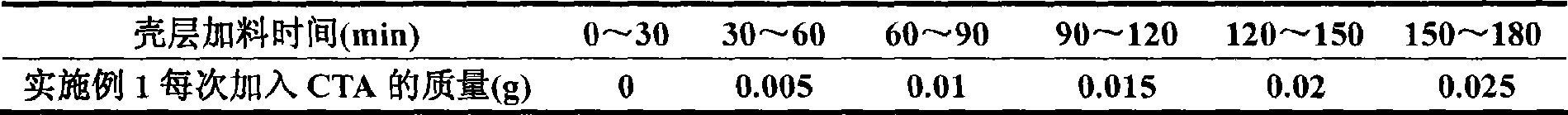

Preparation of acrylate polymer emulsion with gradient network structure for pressure-sensitive adhesive

ActiveCN101412782AImprove performanceImprove conversion rateEster polymer adhesivesPolymer scienceEmulsion

The invention relates to a method for preparing an acrylate polymer emulsion which is used for a pressure sensitive adhesive and is provided with a gradient network structure, which relates to an adhesive based on acrylate polymer. The method comprises the following steps: (1) preparation of a seed emulsion; (2) pre-emulsification of shell layer monomers; and (3) gradient feeding of a shell layer. The acrylate polymer emulsion is prepared through dipping a chain-transferring agent, namely tert dodecyl mercaptan (CTA) into the shell layer to make the concentration discontinuously changed in a phasic mode, wherein poly(butyl acrylate) is taken as a core and a copolymer of acrylic ester and acrylic monomers is taken as the shell layer; and the crosslinking density of the network structure of the shell layer shows gradient change. The acrylate polymer emulsion provided with the gradient network structure can be used as the pressure sensitive adhesive after drying and film forming. The method realizes optimization of the performance of the pressure sensitive adhesive, improves the initial adhesion and simultaneously maintains large peeling strength and continuous viscous force.

Owner:HEBEI UNIV OF TECH

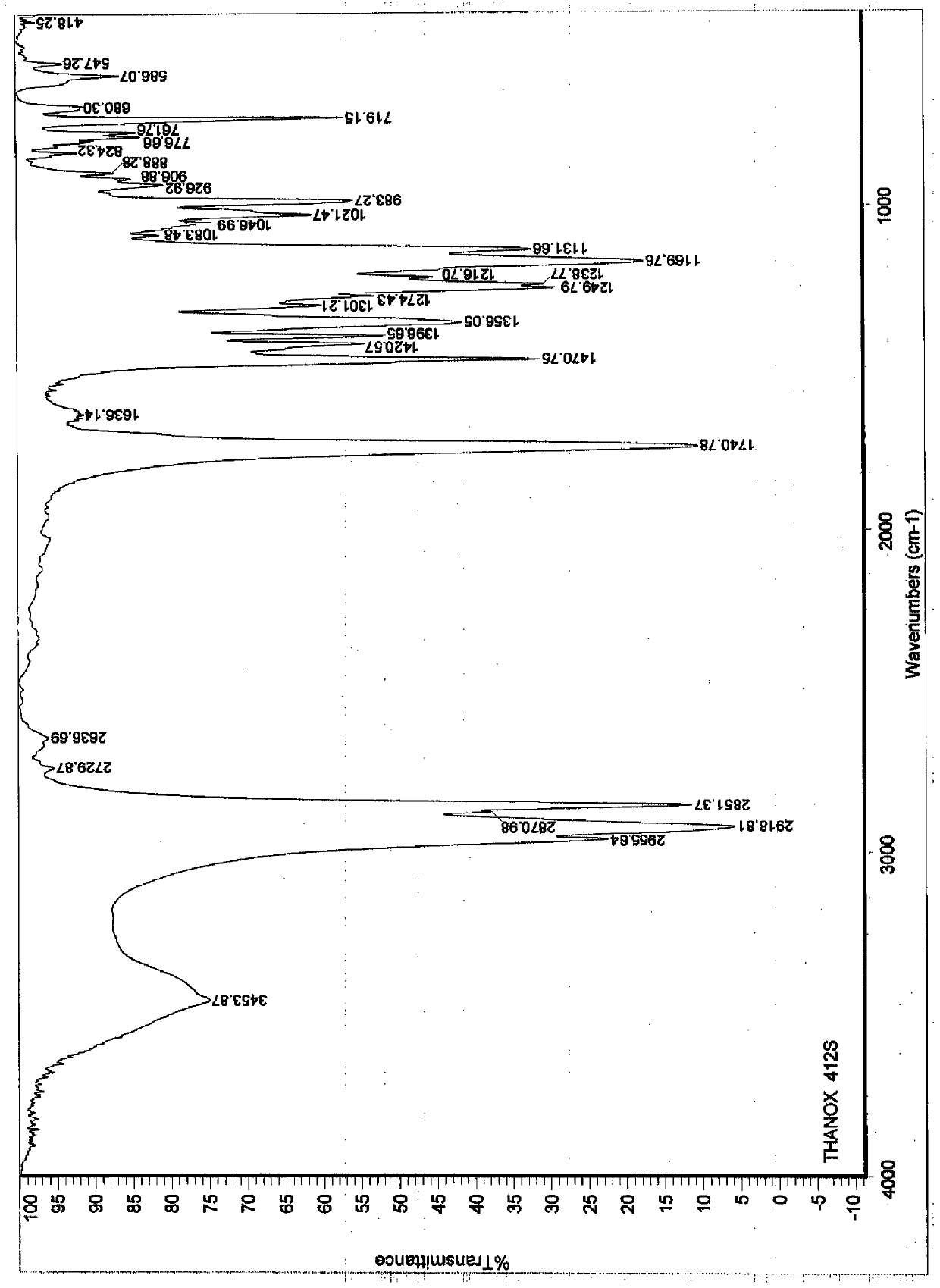

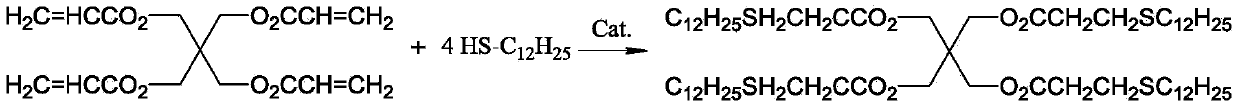

Preparation method of pentaerythritol tetra(3-n-dodecylthiopropionate)

The invention provides a preparation method of pentaerythritol tetra(3-n-dodecylthiopropionate), which initially provides a one-step synthesis method of pentaerythritol tetra(3-n-dodecylthiopropionate) from pentaerythritol tetraacrylate and 1-dodecyl mercaptan. The method comprises the following steps: adding 1-dodecyl mercaptan and a catalyst into a reactor, dropwisely adding pentaerythritol tetraacrylate at 40-60 DEG C to react, distilling out excessive 1-dodecyl mercaptan under reduced pressure, adding formic acid or glacial acetic acid to regulate the pH value to 6-7, adding a crystallization solvent to recrystallize, filtering, and drying to obtain the white crystalline powder product. Compared with the prior art, the novel method provided by the invention has the advantages of simple technique, low equipment and operation cost, energy saving, environmental protection, high product quality and high yield.

Owner:RIANLON

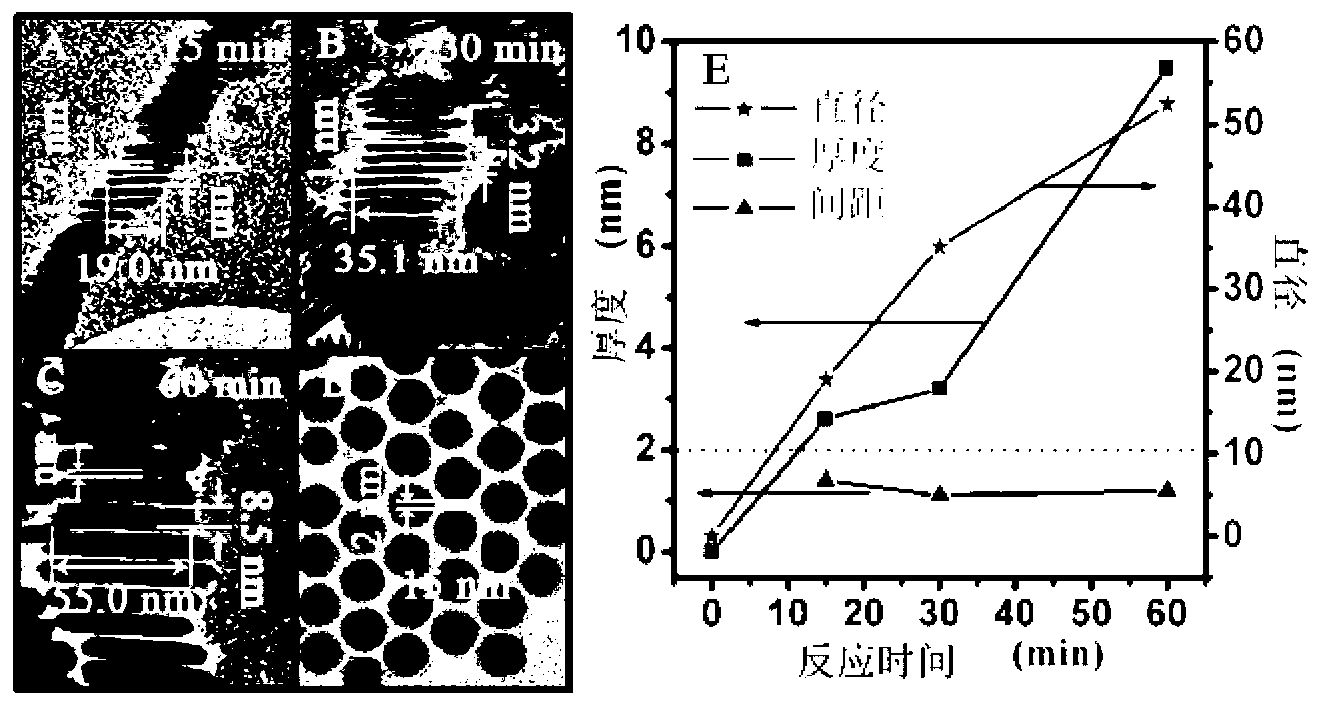

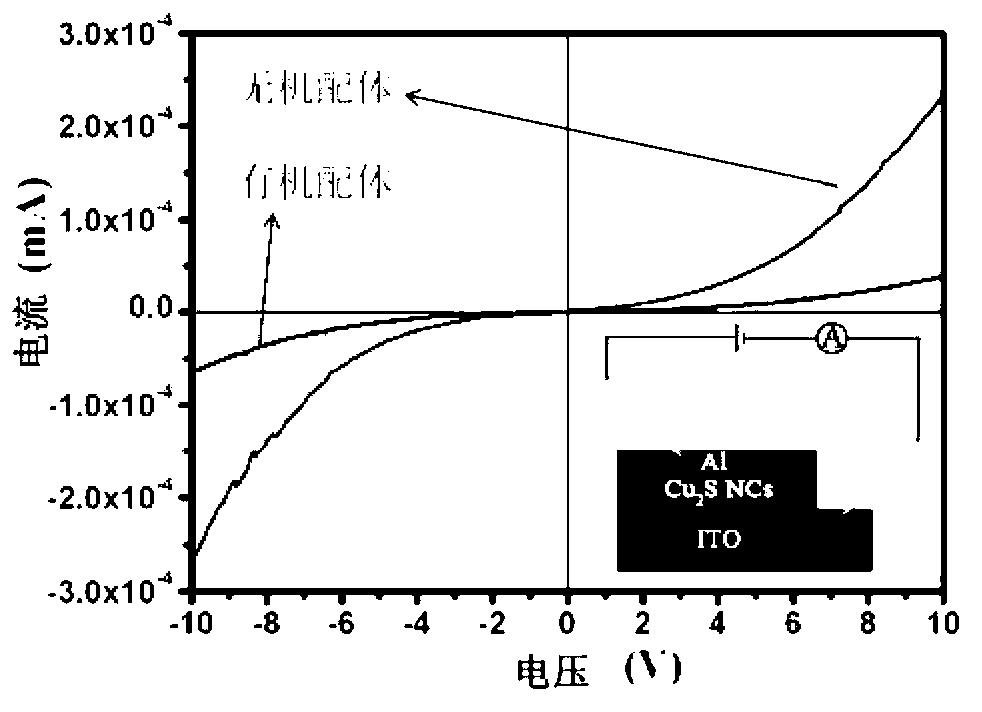

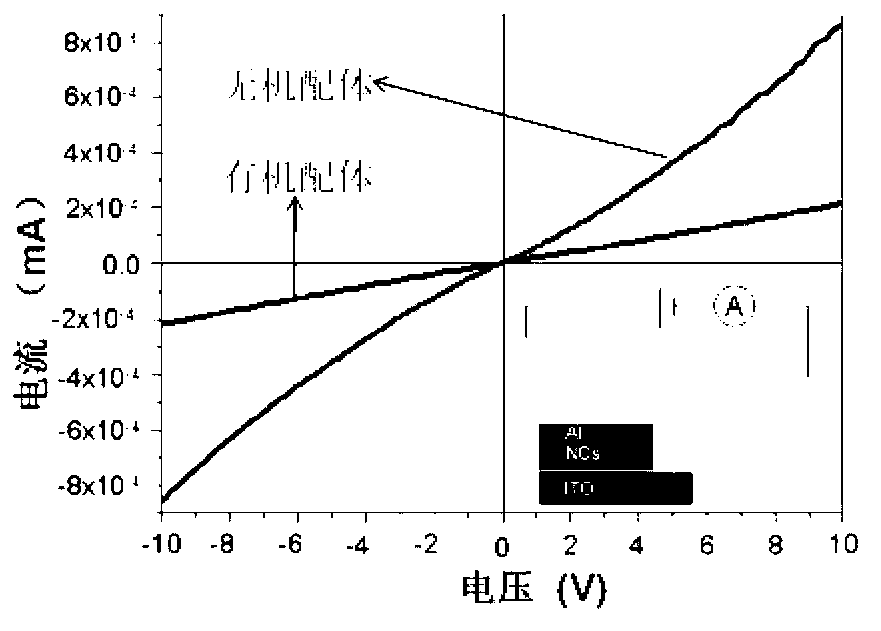

New method for induced synthesis of nano-crystals through using inorganic complex of Sn (IV)

InactiveCN102976288AEasy to synthesizeGood repeatabilityMaterial nanotechnologyCopper sulfidesInorganic compoundNanocrystal

The invention relates to a new method for the induced synthesis of nano-crystals with the morphology, the dimension and the assembling behavior being controllable through using an inorganic complex of Sn (IV). The method comprises the following steps: reacting an Sn (IV) salt which is a raw material with an excess pure dodecyl mercaptan or selenium solution to generate an Sn (IV) complex, and adopting the solution of the Sn (IV) complex as a reaction precursor to synthesize the nano-crystals with the morphology, the dimension and the assembling behavior being controllable. The method has the advantages of cheap and easily-available raw material, and simple experiment operation. For example, Cu2S and Cu2-xSe nano-crystals obtained through taking Cu2S and Cu2-xSe as raw materials are hexagonal sheets, and the hexagonal sheets can be assembled in a large area manner to form one-dimensional to three-dimensional cylindrical structures. The introduction of the inorganic complex enables the electrical conductivity of the synthesized semiconductor nano-crystals to be greatly improved. The method has very values in the laboratory research field or industrial application field based on the above characteristics.

Owner:HENAN UNIVERSITY

High-modulus bituminous concrete additive

The invention belongs to the technical field of bituminous road material and relates to a high-modulus bituminous concrete additive. The high-modulus bituminous concrete additive is composed of the following materials by mass: 60-90 parts of waste polyethylene, 10-30 parts of polypropylene, 5-10 parts of ethyl acetate and 0.5-1.5 parts of additive, wherein the additive is prepared by mixing a plasticizer and a modifier according to the mass ratio of 1:(2-4), wherein the plasticizer is dioctyl phthalate, diisobutyl phthalate or diethylene glycol dibenzoate, and the modifier is 19-tert-lauryl mercaptan, isooctyl 3-mercaptopropionate, ethanethio or dodecanethiol. The additive provided by the invention is convenient to use, low in cost and stable in performance, and the track prevention performance, the low temperature anti-cracking performance, the water stability and the anti-fatigue performance of the bituminous mixture are improved. Meanwhile, the waste plastic can be effectively recycled, the advantage of ecological environmental protection is achieved, the resource waste is directly reduced, the natural landscape and the ecological environment balance are greatly kept, and good social and environmental benefits are obtained.

Owner:辽宁省交通科学研究院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com