Collecting agent and preparation method and application thereof

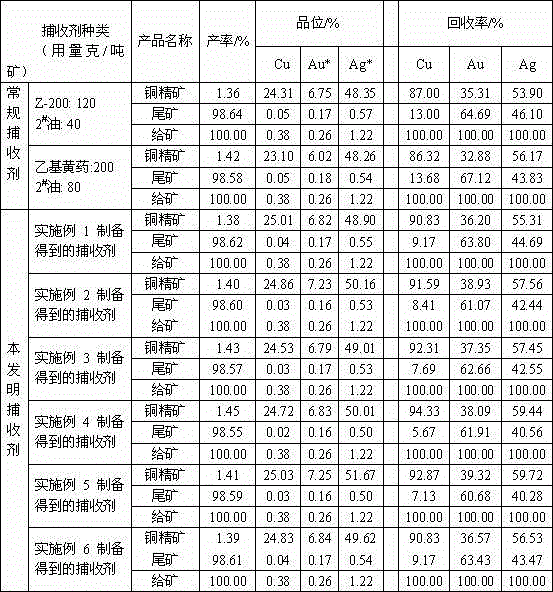

A technology of collector and dithiocarbamate, which is applied in the field of metallurgy, can solve the problems of low selectivity and unfavorable recovery of associated precious metals, and achieve the effects of strong collection ability, good solid affinity and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

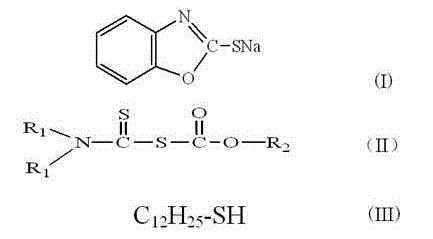

[0021] The preparation method of the collector described in the present invention is to mix the raw materials modified dithiocarbamate, sodium mercaptobenzothiazole, dodecyl mercaptan and fatty alcohol according to the formula ratio and then set the temperature at 15~35°C Under mechanical stirring for 10-30 minutes, a reddish-brown oily liquid was obtained, which was the target collector.

[0022] The application of the present invention is the application of the collector in the flotation of associated precious metal sulfide ore.

[0023] The associated precious metal sulfide ore is gold-bearing sulfide ore, copper-molybdenum sulfide ore or copper-lead-zinc sulfide ore.

[0024] The amount of the collector is 10-200 g / ton ore.

[0025] The collector is used under the condition of pulp temperature of 5-35°C.

[0026] Described collector is used for sulfide ore flotation and comprises the following specific steps:

[0027] A. Grinding the raw material sulfide ore until the p...

Embodiment 1

[0031] at 2m 3 Add 250 parts of ethoxycarbonyl diethyldithiocarbamate, 100 parts of sodium mercaptobenzothiazole 45% aqueous solution, 140 parts of dodecyl mercaptan, 50 parts of sec-butanol, 40 parts Pine alcohol oil, mechanically stirred at 15~35°C for 10~30min, the reddish-brown oily liquid obtained is a composite collector EMTA-1.

Embodiment 2

[0033] at 2m 3 Add 250 parts of butoxycarbonyl diethyldithiocarbamate, 100 parts of sodium mercaptobenzothiazole 45% aqueous solution, 140 parts of dodecyl mercaptan, 60 parts of methyl isobutyl carbinol respectively in the reaction kettle , 30 parts of terpineol oil, mechanically stirred at 15~35°C for 10~30min, and the reddish-brown oily liquid was obtained, which was another composite collector BMTA-1. (The time and temperature have a span and need to be accurate to specific values. The value of each example is a different value within the stated range)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com