Patents

Literature

39 results about "Chalcocite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chalcocite (UK: /ˈkælkəˌsaɪt/), copper(I) sulfide (Cu₂S), is an important copper ore mineral. It is opaque and dark-gray to black with a metallic luster. It has a hardness of 2 ¹⁄₂ - 3 on the Mohs scale. It is a sulfide with an orthorhombic crystal system.

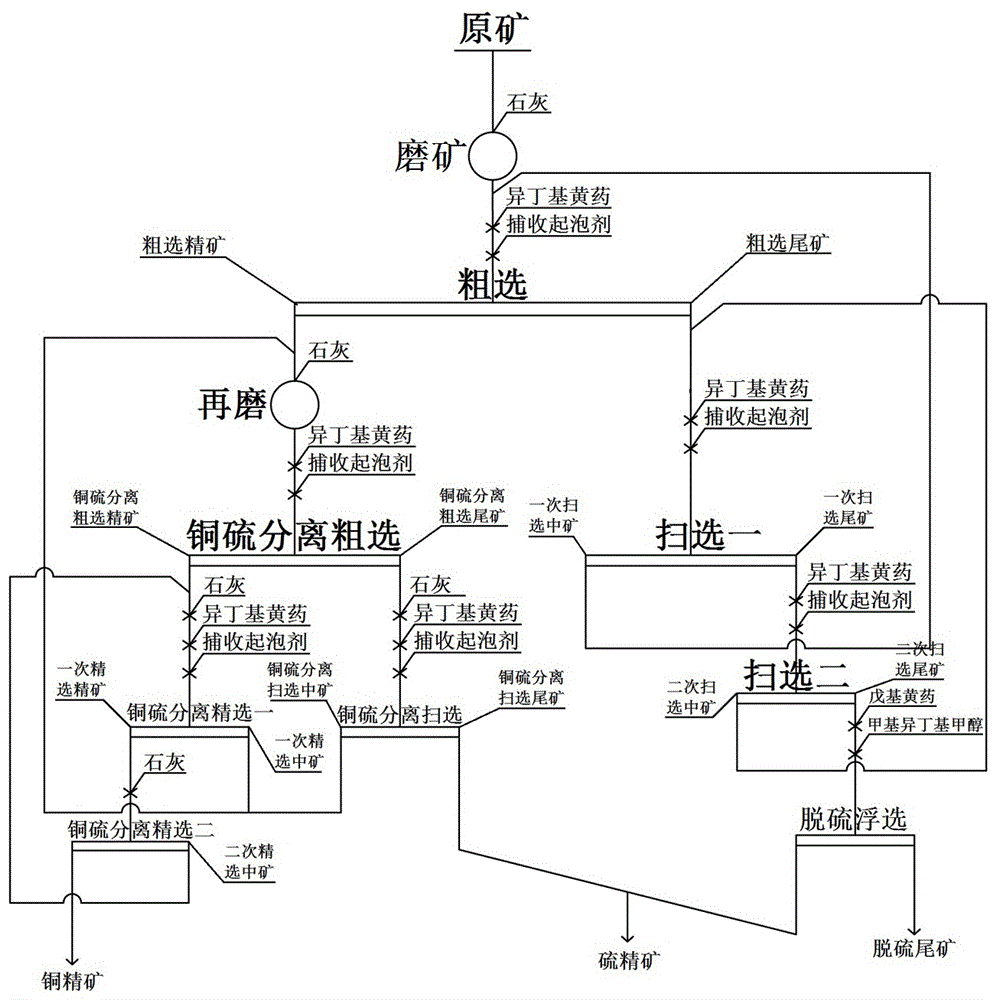

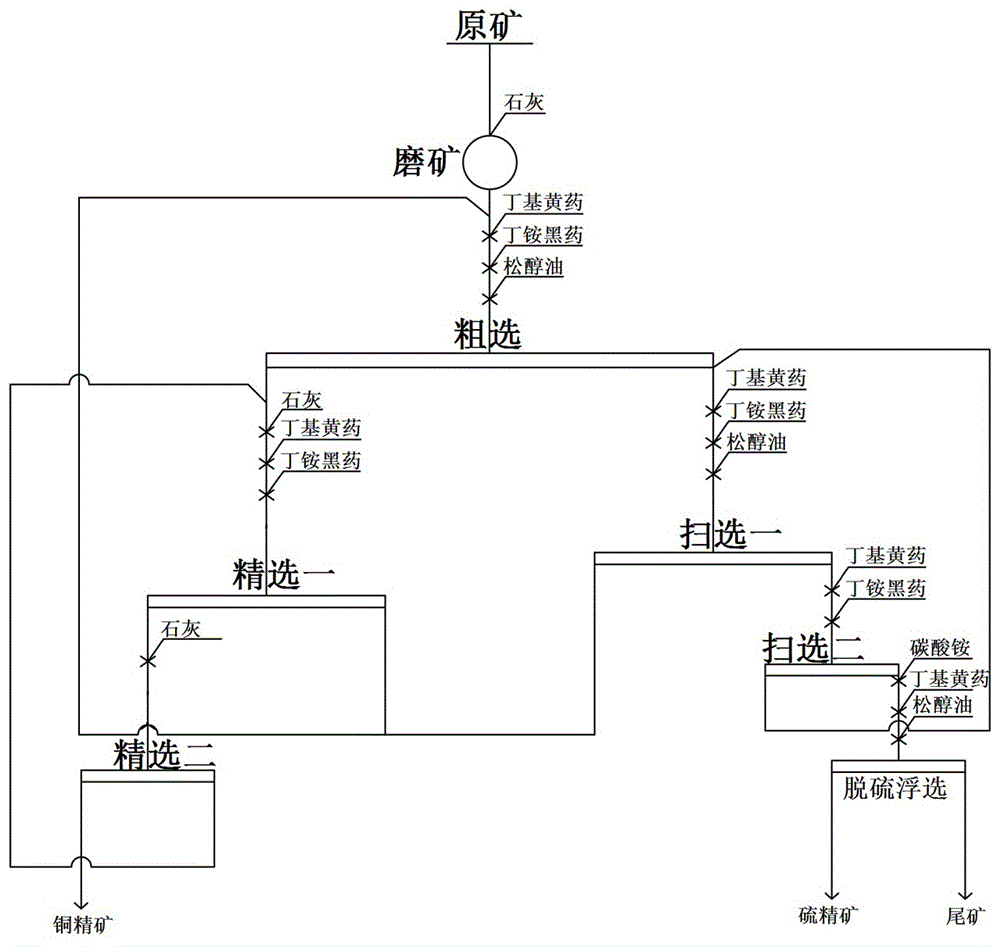

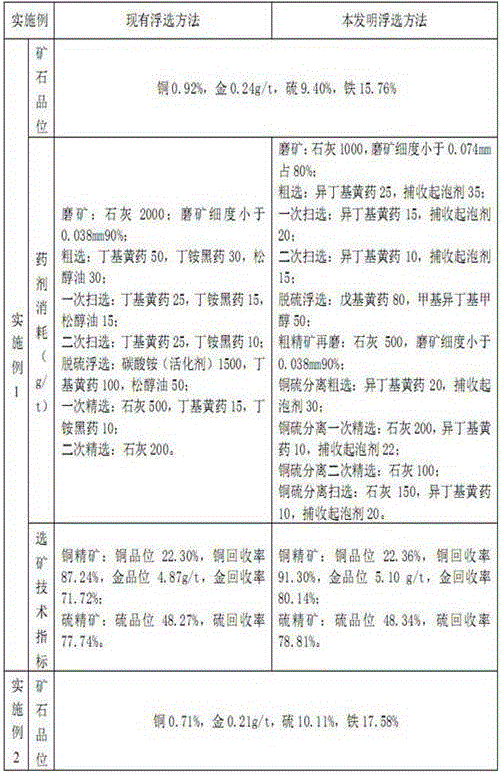

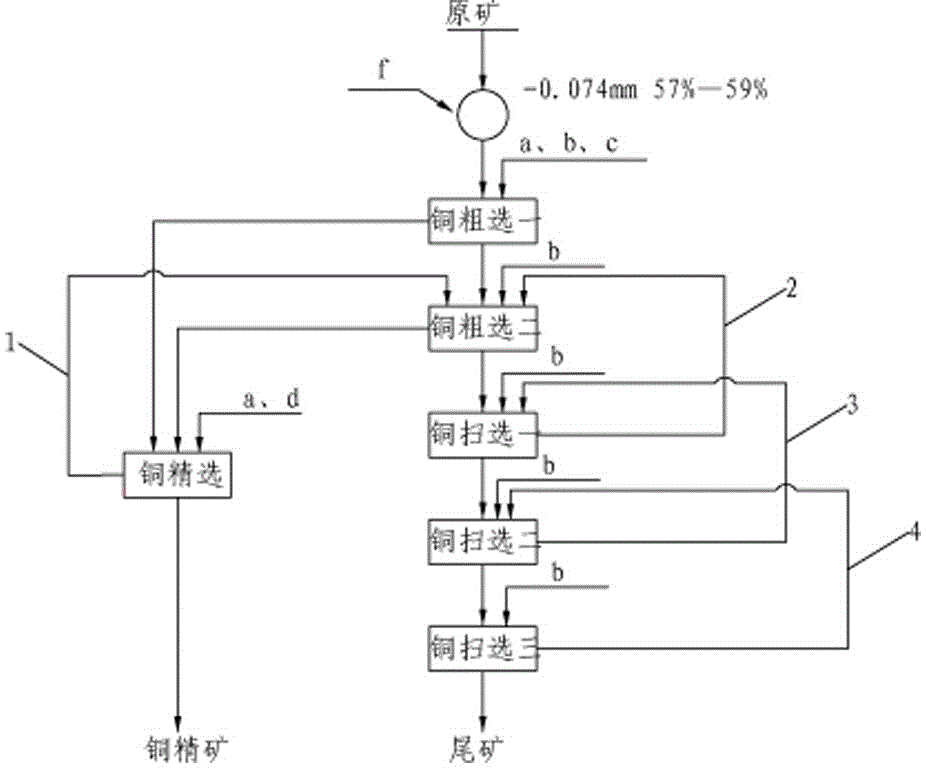

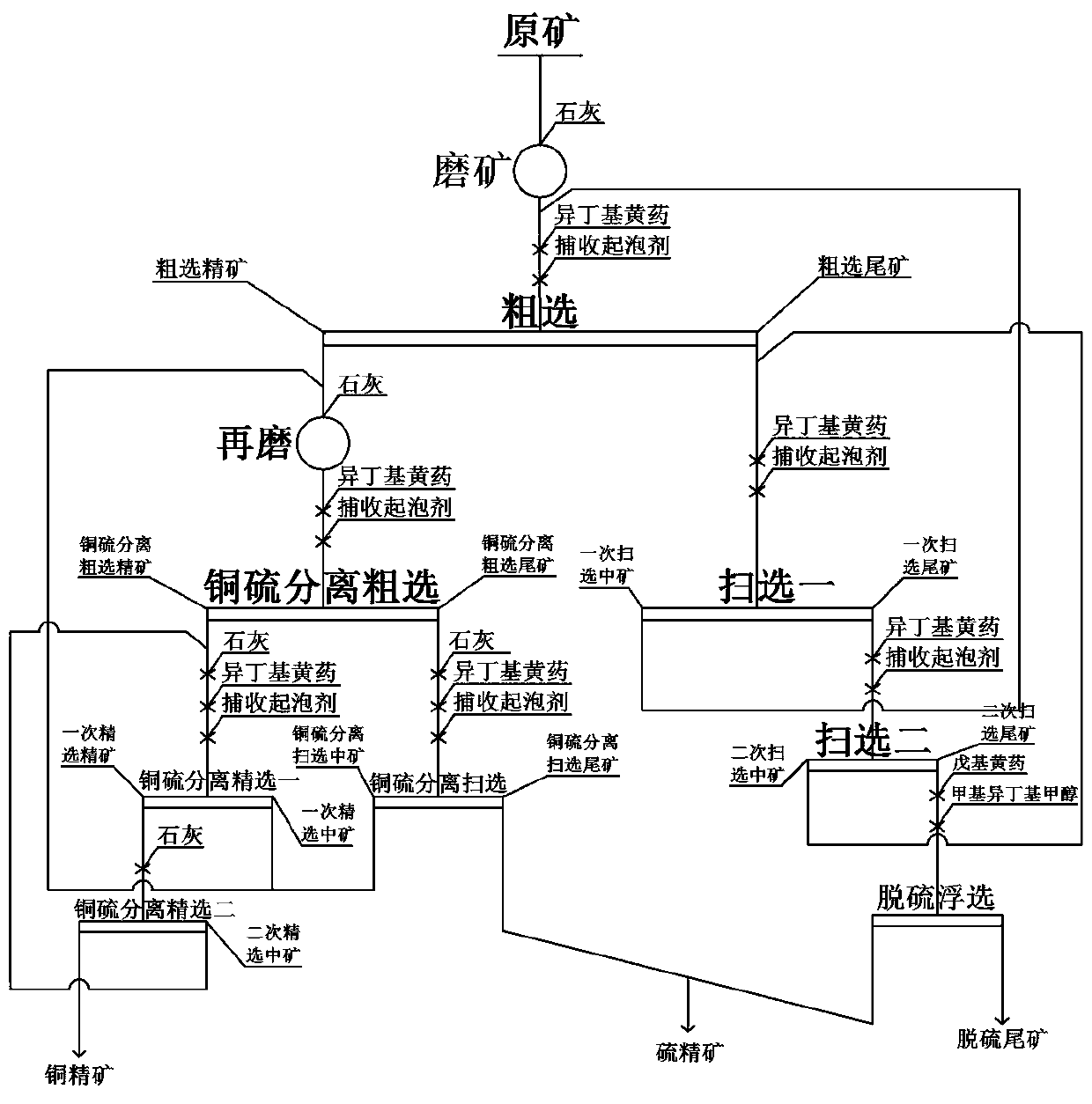

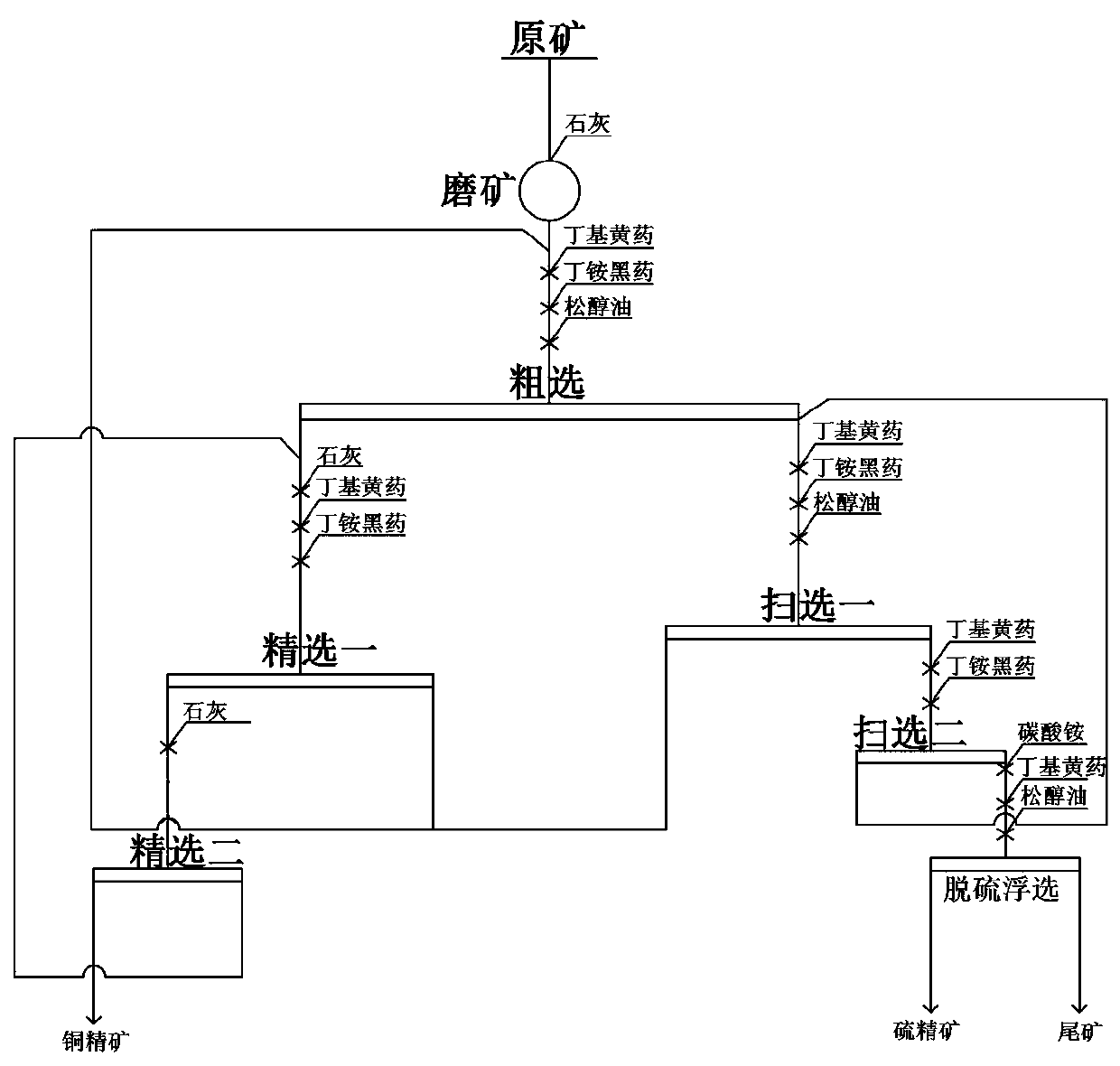

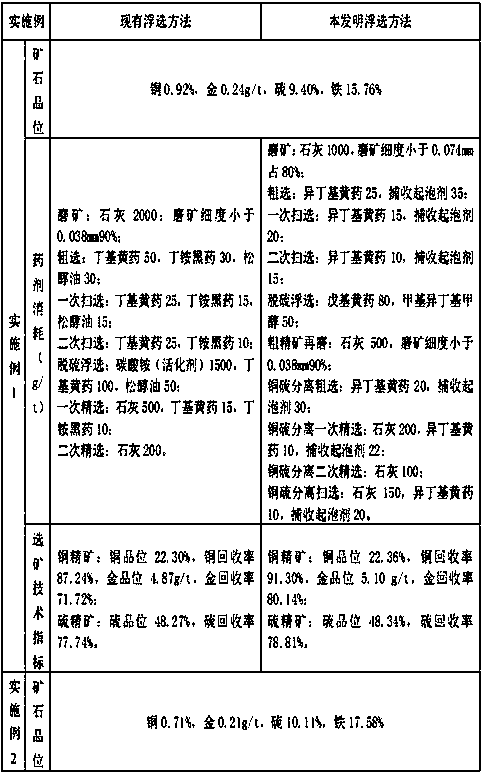

Floating method for finely disseminated copper sulfide ores

The invention discloses a floating method for finely disseminated copper sulfide ores. The floating method specifically comprises steps such as ore grinding, roughing, roughed concentrate re-grinding, roughed concentrate copper-sulfur separating and floating and roughened tailing scavenging, wherein multi-time concentrating and multi-time scavenging are performed on roughened concentrate and roughened tailings, cyclic ore dressing is performed on ores, and different ore dressing reagents are matched, so that the recovery rate of raw ores is increased. The floating method has the advantages that: by optimizing an ore grinding process and reasonably adding a collecting agent and a collecting-foaming agent, surface characteristics of ores are improved, selective adsorption, on copper sulfide ore particle surfaces such as fine-grained copper pyrite and chalcocite, of the collecting agent is strengthened, and hydrophobic agglomeration is formed, so that the recovery rate of copper concentrate is increased by 3-6% in comparison with that of an existing ore dressing method.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

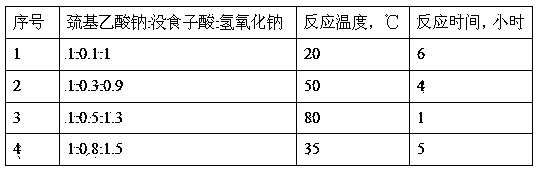

Floatation depressant and methods for preparing and using depressing agent

ActiveCN103949351AEfficient separationOvercoming a large amountFlotationGallic acid esterChemical reaction

The invention relates to a floatation depressant for obtaining molybdenum concentrate and copper concentrate by mineral separation, particularly by separation of copper-molybdenum mixed concentrate, and methods for preparing and using the floatation depressant. The floatation depressant is characterized by being an organic liquid agent obtained through chemical reaction by using mercaptoacetic acid, gallic acid and sodium hydroxide as raw materials. The floatation depressant is the organic liquid agent obtained through the chemical reaction of pyrogallic acid, the mercaptoacetic acid and the sodium hydroxide, and can be used for effectively depressing primary and secondary copper sulfide ores such as copper pyrite and chalcocite, and the copper-molybdenum mixed concentrate can be effectively separated. The defects of large usage of common sodium sulfide, severe operation environment and serious pollution are overcome, and the floatation depressant has the advantages of convenience in addition, safety in use and the like. An effective method which is small in agent usage, convenient to use and low in environmental pollution is provided for the separation of molybdenum copper sulfide mixed concentrate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

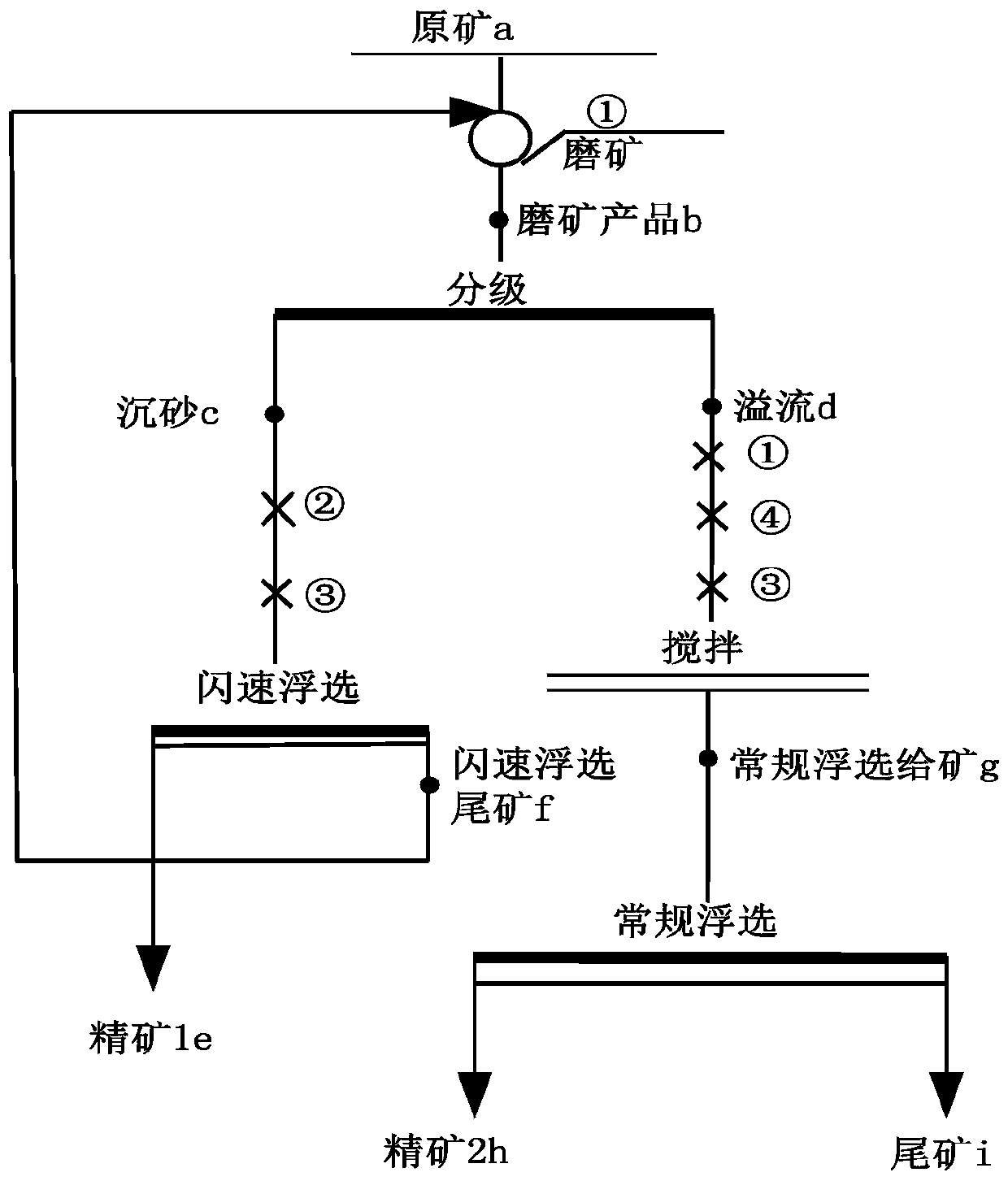

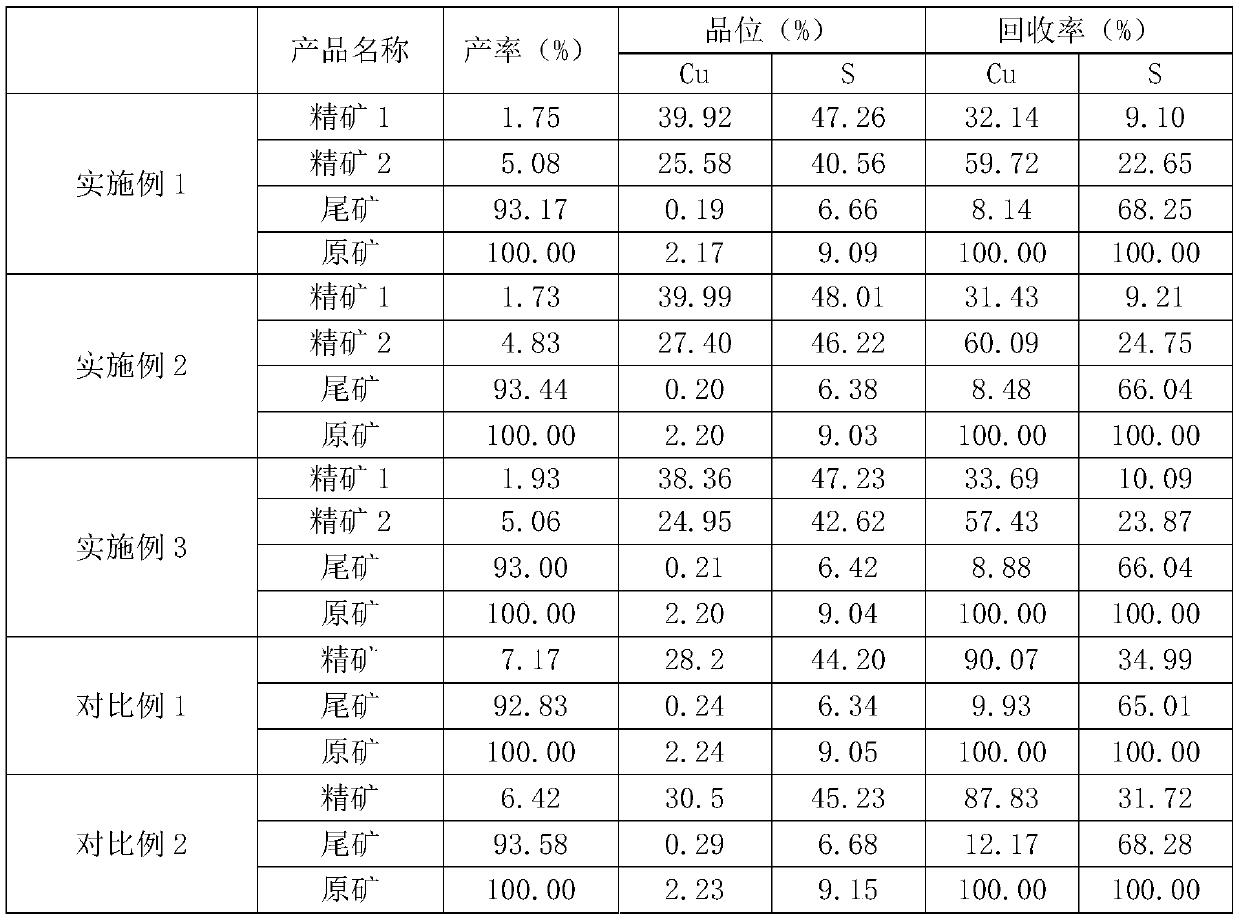

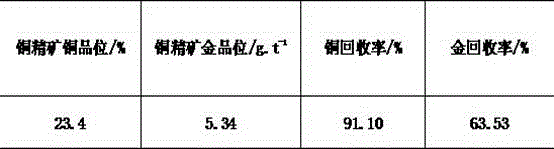

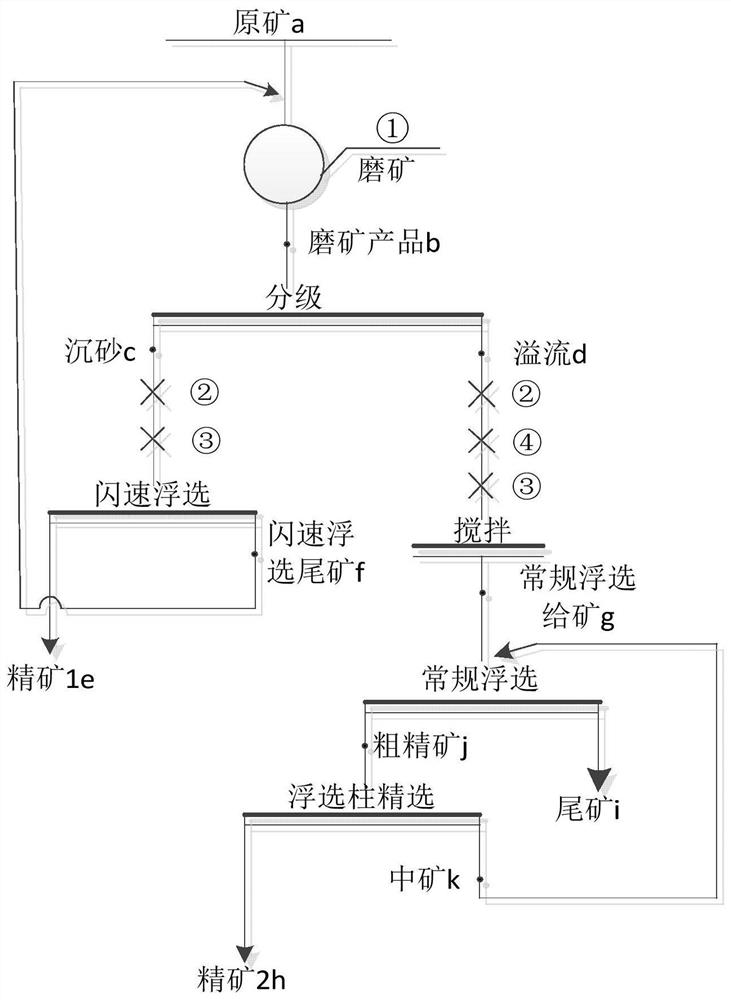

Chalcocite-contained coarse-grain disseminated copper sulfide ore step-by-step ore grinding flotation method

InactiveCN110292984AGuaranteed concentrate gradeGuaranteed RecoveryFlotationWet separationFoaming agentSulfide

The invention relates to a chalcocite-contained coarse-grain disseminated copper sulfide ore step-by-step ore grinding flotation method. According to the chalcocite-contained coarse-grain disseminatedcopper sulfide ore step-by-step ore grinding flotation method, raw ores are subjected to ore grinding and then are graded into two kinds of ore pulp, namely, overflow d and setting sand c to form twoloops to be subjected to flash flotation and conventional flotation correspondingly; during one loop of flash flotation, a high-selectivity collecting agent (2) and a foaming agent (3) are added to the setting sand c ore pulp fed into a single-tank flash flotation machine to be subjected to optimized flotation to obtain a copper concentrate product 1 and flash flotation tailings f; the concentrate grade and the recovery rate of the copper concentrate product 1 can be ensured, ore feeding fluctuation of conventional flotation can be reduced, the stability of the preparation process is improved, and valuable minerals in ores can be recovered as early as possible; during the other loop of conventional flotation, calcium oxide (1), a high-collectivity collecting agent (4) and the foaming agent (3) are added to the overflow d ore pulp to be subjected to stirring and conventional flotation to enable valuable metals such as gold, silver and copper in the overflow d to be enriched into copperconcentrate 2h and remove tailings 1. The chalcocite-contained coarse-grain disseminated copper sulfide ore step-by-step ore grinding flotation method has the advantages of being simple in operation,smooth in process, easy to apply industrially, high in recovery rate, low in production cost, good in comprehensive benefit and the like and is particularly suitable for mineral separation of chalcocite-contained coarse-grain disseminated copper sulfide ores.

Owner:ZIJIN MINING GROUP

Low-alkalinity flotation separation method for pyrite activated by Cu2+ and chalcocite

The invention discloses a low-alkalinity flotation separation method for pyrite activated by Cu2+ and chalcocite. The method comprises the steps that lime is firstly added in the ore grinding stage so as to keep low alkalinity, a composition of citric acid, sodium sulfite and pyrogallic acid is added as a composite inhibitor in the rougher flotation stage to inhibit the pyrite, copper rougher flotation is achieved under the condition of low alkalinity, then a dispersing agent is added for concentration, inhibition on gangue minerals is intensified, and copper concentrates are obtained. Compared with the traditional manner of inhibiting sulfur through lime, the inhibition effect of the composite inhibitor on the pyrite activated by Cu2+ is remarkable, wherein citric acid is used for removing the activation action of Cu2+ on the pyrite, so that natural floatability of the pyrite is restored, the inhibition effect on the pyrite is intensified through sodium sulfite and pyrogallic acid, meanwhile, the phenomenon of trough moving caused by foam viscosity is eliminated, and the index of the mineral processing technology is improved; and in addition, due to the fact that the flotation pH value is lowered, recycling of associated gold in ore is facilitated.

Owner:ZIJIN MINING GROUP

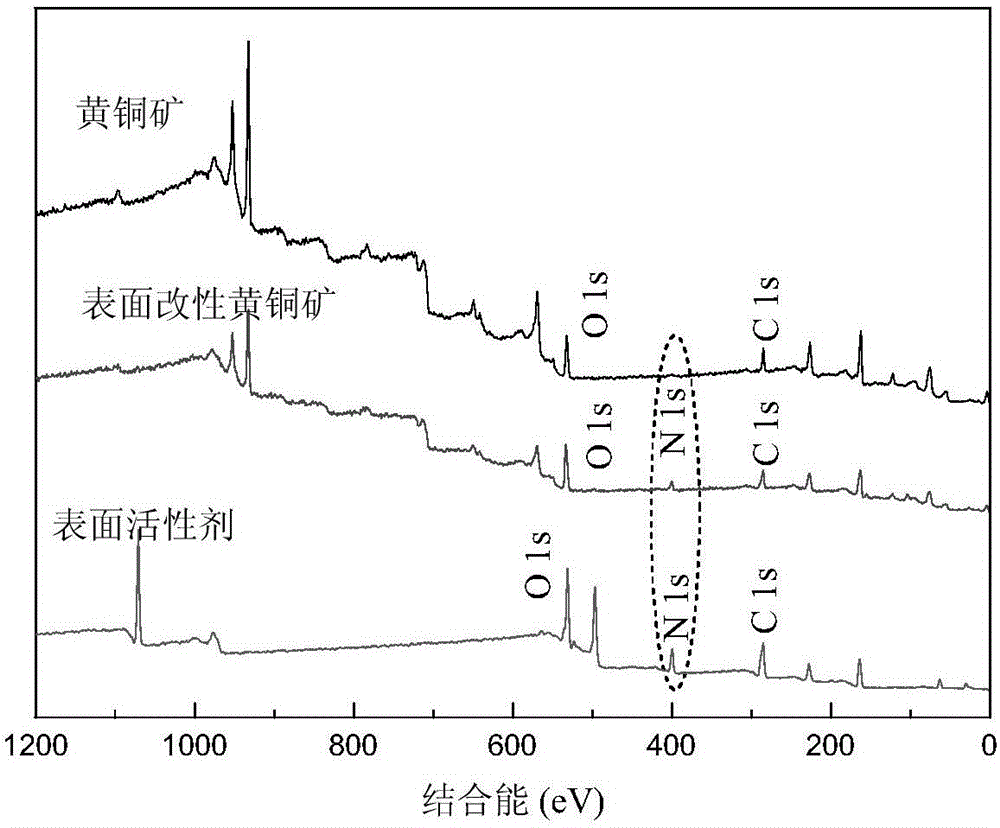

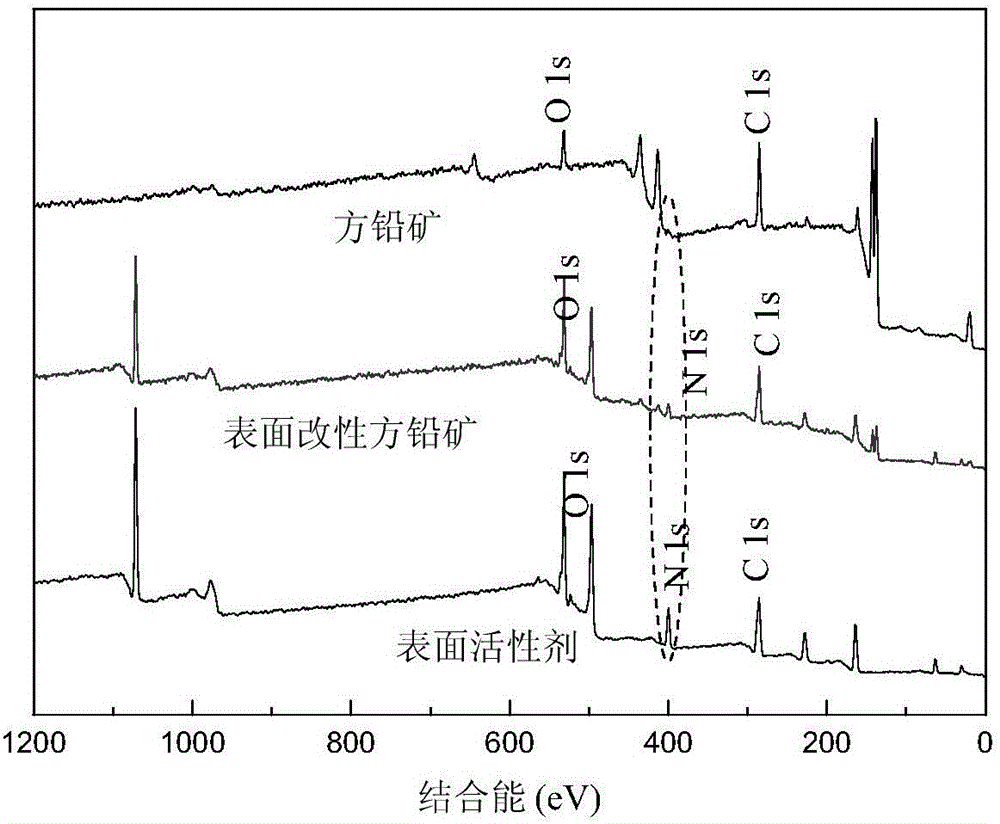

Application of aminotriazolethione compound serving as metal sulfide mineral surface modification agent

ActiveCN107029893ASpecial molecular structureSuppression of floatingFlotationBismuth sulfideChemical compound

The invention discloses application of an aminotriazolethione compound serving as a metal sulfide mineral surface modification agent. The aminotriazolethione compound comprises a hydrophilic modification perssad and an aminotriazolethione perssad at the same time. The aminotriazolethione compound mainly serves as the non-molybdenum sulfide mineral surface modification agent for flotation separation of the molybdenum sulfide mineral and the non-molybdenum sulfide mineral, the hydrophilia of the surfaces of the sulfide minerals with the natural hydrophobicity can be enhanced, especially, the hydrophilia of the surfaces of copper pyrites, chalcocite, galena, blende, brasses, the bismuth sulfide mineral and other non-molybdenum sulfide minerals can be effectively improved, and efficient flotation separation of the molybdenum sulfide mineral and the non-molybdenum sulfide mineral is achieved.

Owner:CENT SOUTH UNIV

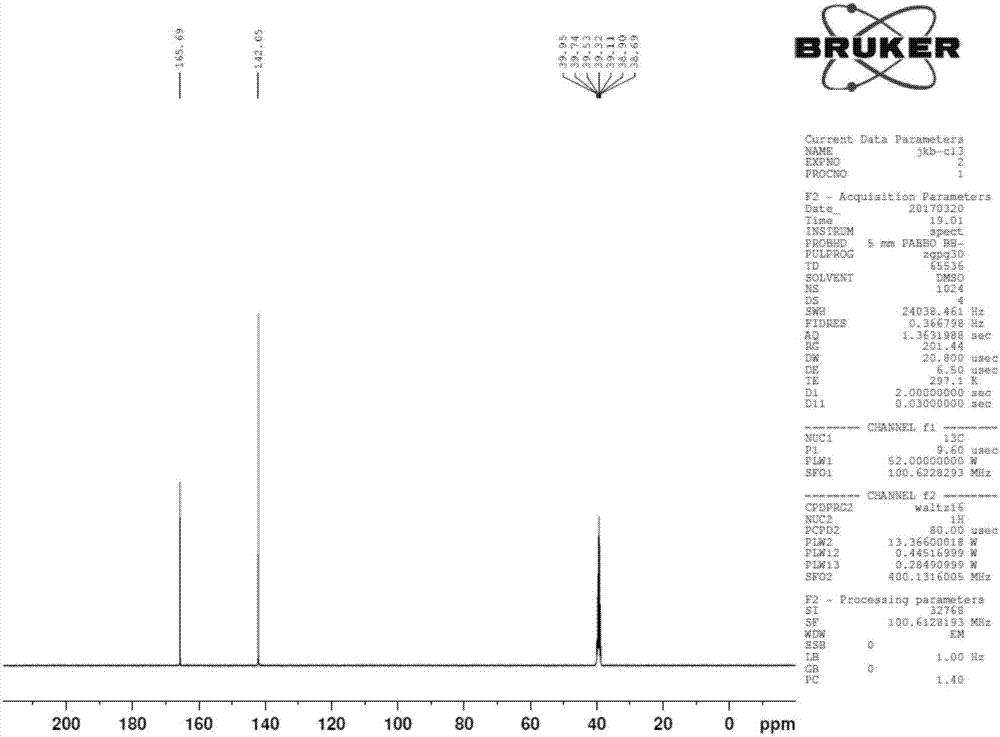

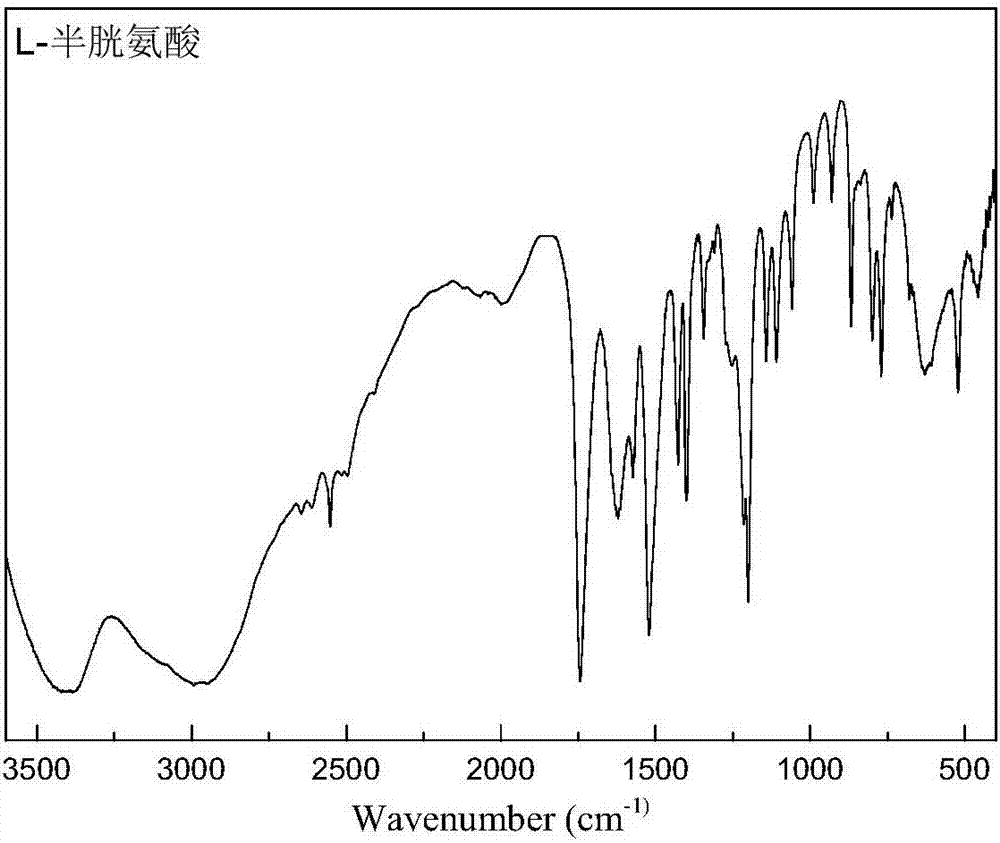

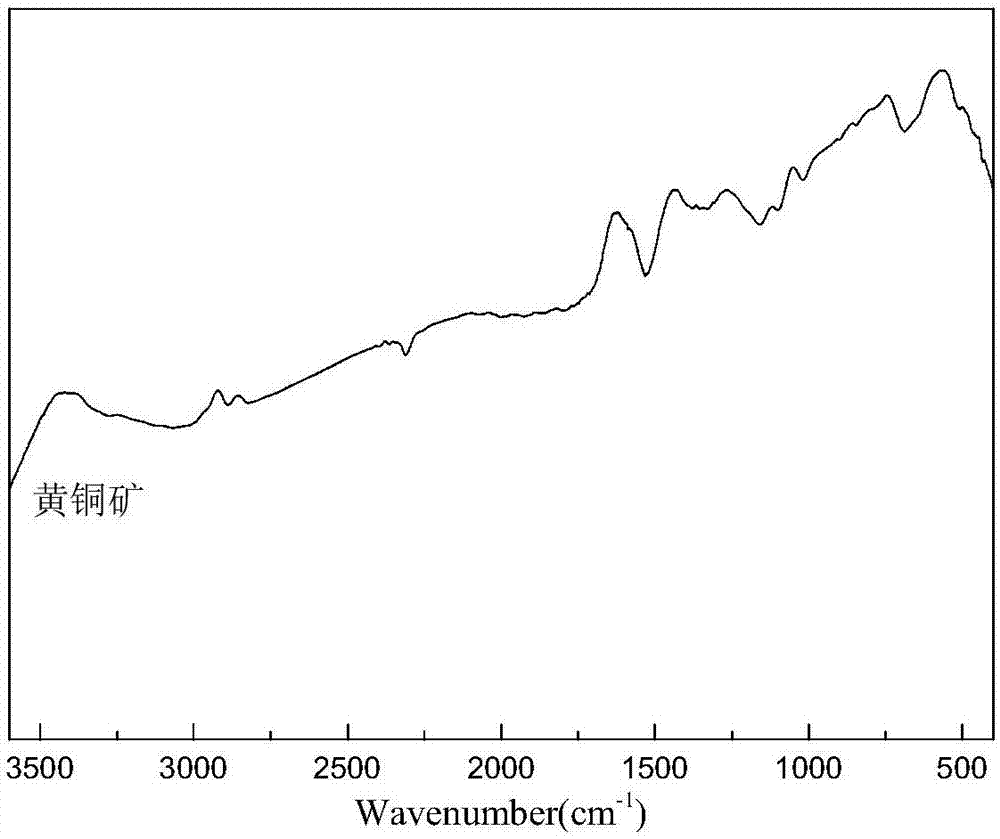

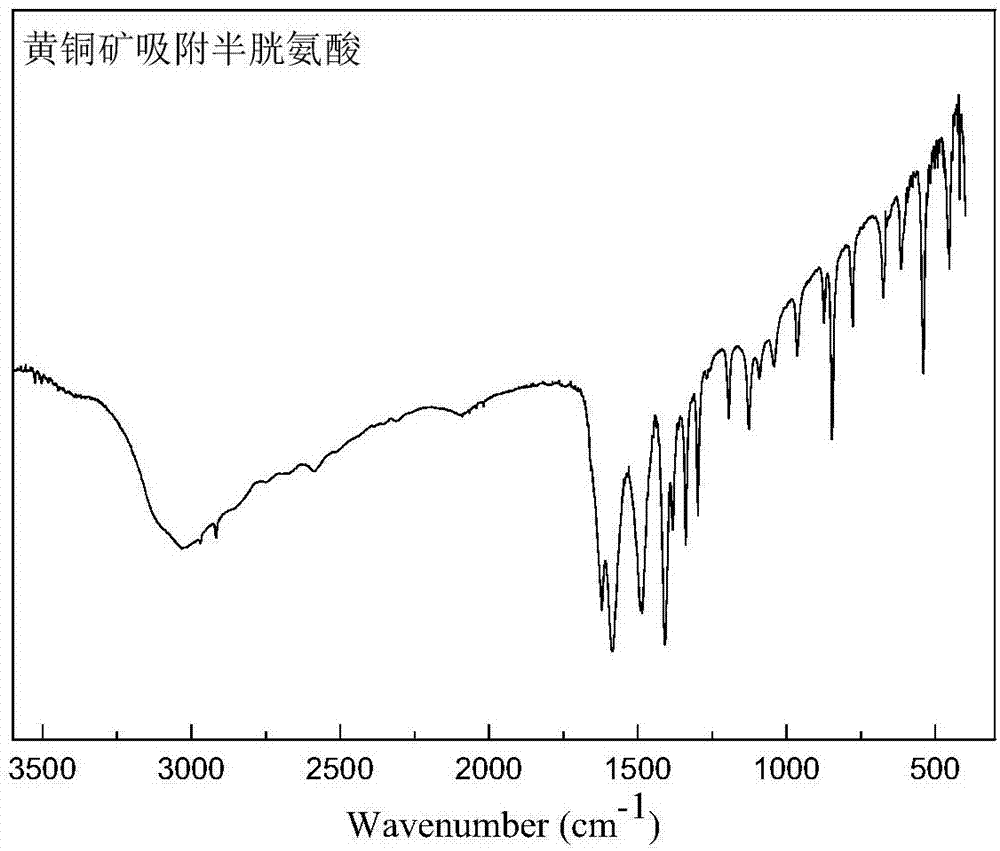

Application of L-cysteine and L-cysteine salt in metal sulfide mineral flotation separation

InactiveCN107138286AImprove surface hydrophilicityEfficient flotation separationFlotationBismuth sulfideCysteine thiolate

The invention discloses application of L-cysteine and L-cysteine salt in metal sulfide mineral flotation separation. L-cysteine and / or L-cysteine salt are / is used as non-molybdenum sulphide mineral inhibitors to be applied to flotation separation of sulphur molybdenum and non-molybdenum sulfide mineral; and the molecular structure of L-cysteine simultaneously contains three kinds of functional groups comprising sulfydryl, amidogen and carboxyl, wherein sulfydryl and amidogen are solid-philic groups and can be combined with metal ions to generate stable pentacyclic chelate, and carboxyl is a hydrophilic group mainly. The L-cysteine is mainly used as a non-molybdenum sulfide mineral surface modification activator, can enhance the hydrophilia of the surface of the sulfide mineral with the natural hydrophobicity, particularly can effectively enhance the hydrophilia of the surface of the non-molybdenum sulphide mineral such as copper pyrites, chalcocite, galena, blende, iron pyrite and bismuth sulfide ore, restrains upward flotation of the non-molybdenum sulphide mineral, and achieves efficient flotation separation of the sulphur molybdenum and the non-molybdenum sulfide mineral.

Owner:刘秀云

Friction material for preparing NAO brake pad

ActiveCN102180618AGood resistance to high temperature thermal recessionEffective absorptionFiberSpeed test

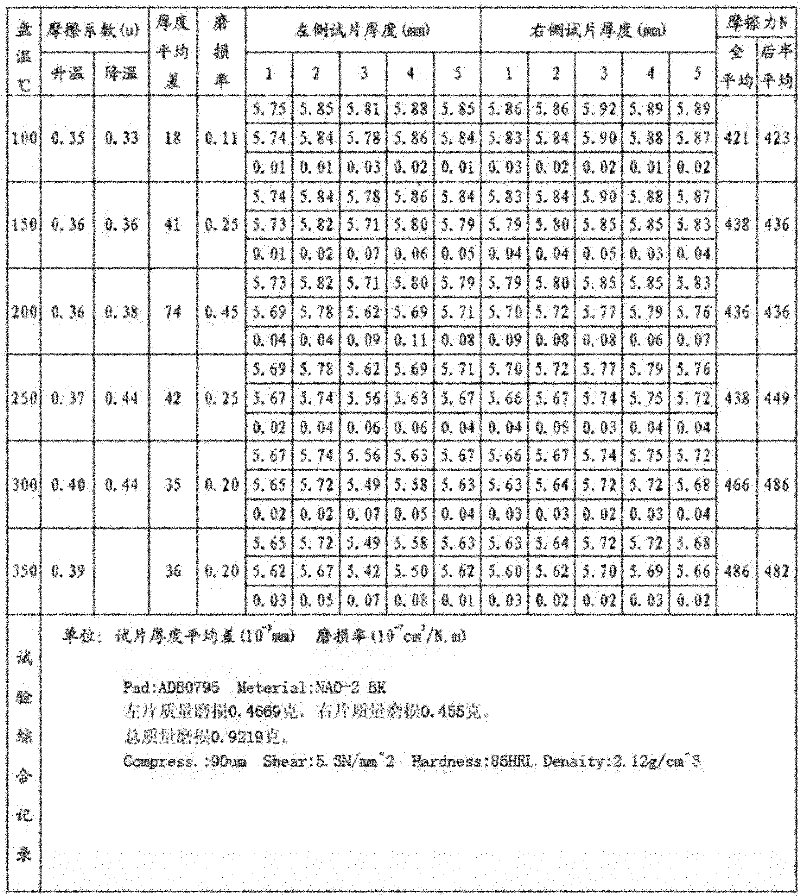

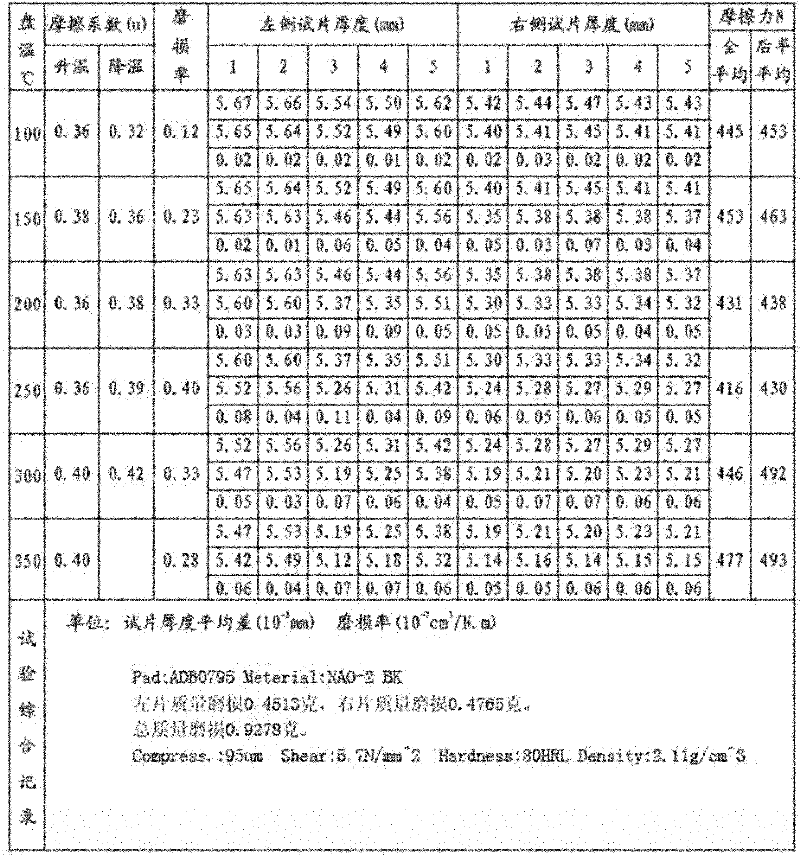

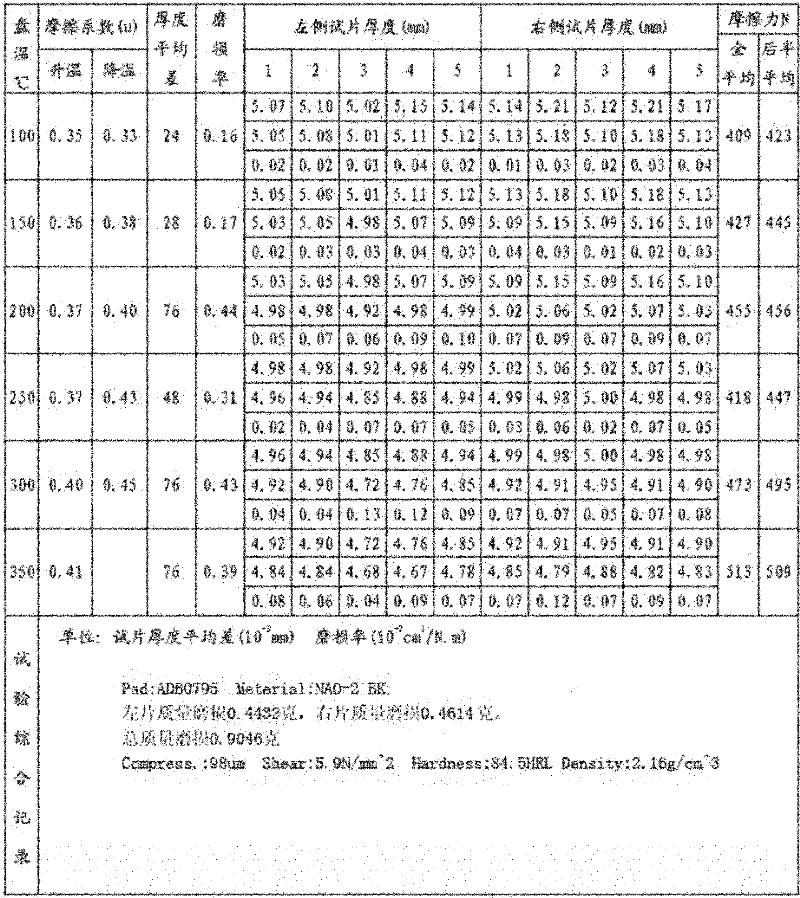

The invention discloses a friction material for preparing NAO brake pads, which is prepared with the following materials by weight through a conventional brake pad compacting method: 5-15% of ceramic fibers, 5-15% of mineral fibers, 5-10% of resin, 5-10% of chalcocite powder, 10-20% of graphite, 10-20% of barium sulfate, 3-15% of biologically calcified particles, 3-10% of coke, 10-20% of antifriction agents, 5-10% of performance modifying agents, and 10-20% of fillers. The friction material of the invention contains natural biologically calcified particles as fillers, and is used to prepare brake pads together with other raw materials through a conventional brake pad compacting method. According to GB5763-2008, the brake pad is tested as the fourth class on a fixed speed test machine; the friction coefficient is stable; during a temperature increasing period, the friction coefficient is 0.35-0.40, and during a temperature decreasing period, the friction coefficient is 0.33-0.44; the wear rate is low, is stabilized within 0.11-0.25*10-7 / N.m with a maximum of only 0.45*10-7 / N.m which occurs at 200 DEG C; and the national standard is completely reached. By widely used in Santana, Sonata and Jetta taxis, the brake pad has smooth braking and low braking noise, and the life of the friction material is up to above 35000 kilometers.

Owner:HANGZHOU UNITED FRICTION MATERIAL

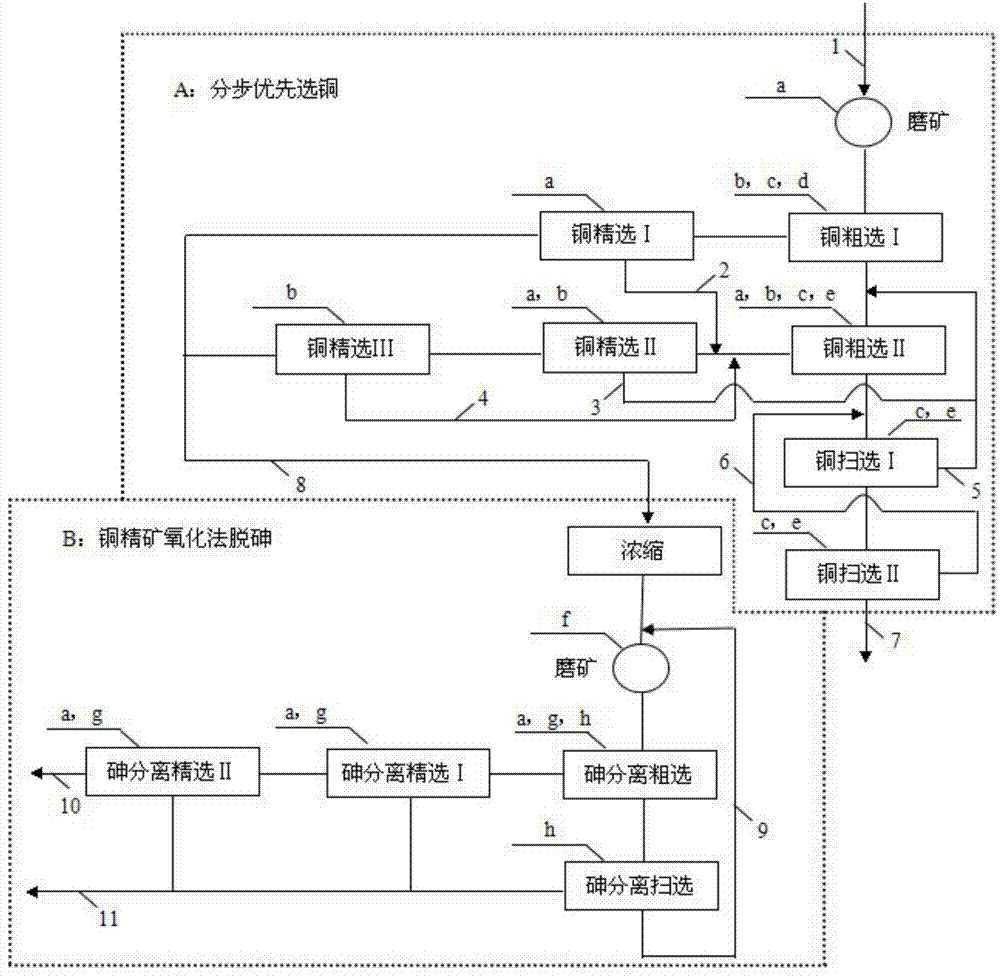

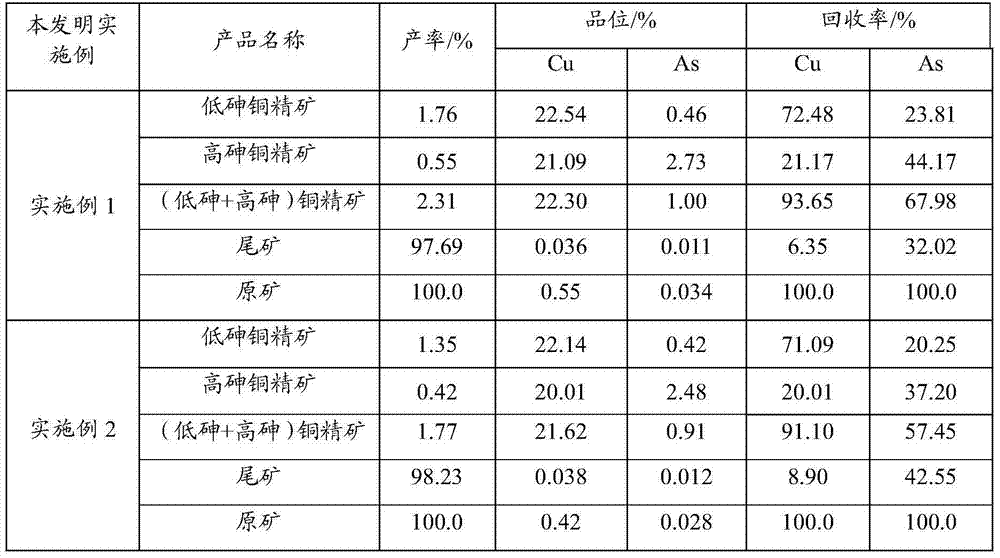

Method for selecting copper concentrate from copper ore with high sulfur and arsenic content

ActiveCN104117433AIncrease salesPromote smelting recyclingFlotationWet separationCalcium hypochloriteCovellite

The invention provides a method for selecting copper concentrate from copper ore with the high sulfur and arsenic content. The method includes the steps that firstly, pyrites are restrained, and differential flotation is conducted on the copper ore step by step; secondly, enargite is selectively removed from the copper concentrate. A regrinding reagent removing-oxidizing method is adopted in the process of removing the enargite from the copper concentrate, lime and calcium hypochlorite are used for size mixing, and the copper ore such as chalcocite, blue chalcocite and covellite which do not contain arsenic are preferentially oxidized under the strong oxidizing property of potassium permanganate, hydrophilic oxide films are formed on the surfaces of the ore such as the chalcocite, the blue chalcocite and the covellite so thatrestraining can be achieved, floatation separation with the sulfur and arsenic copper ore can be achieved, the product scheme of the copper concentrate is optimized, and copper concentrate marketing, smelting and recycling can be easily promoted.

Owner:ZIJIN MINING GROUP

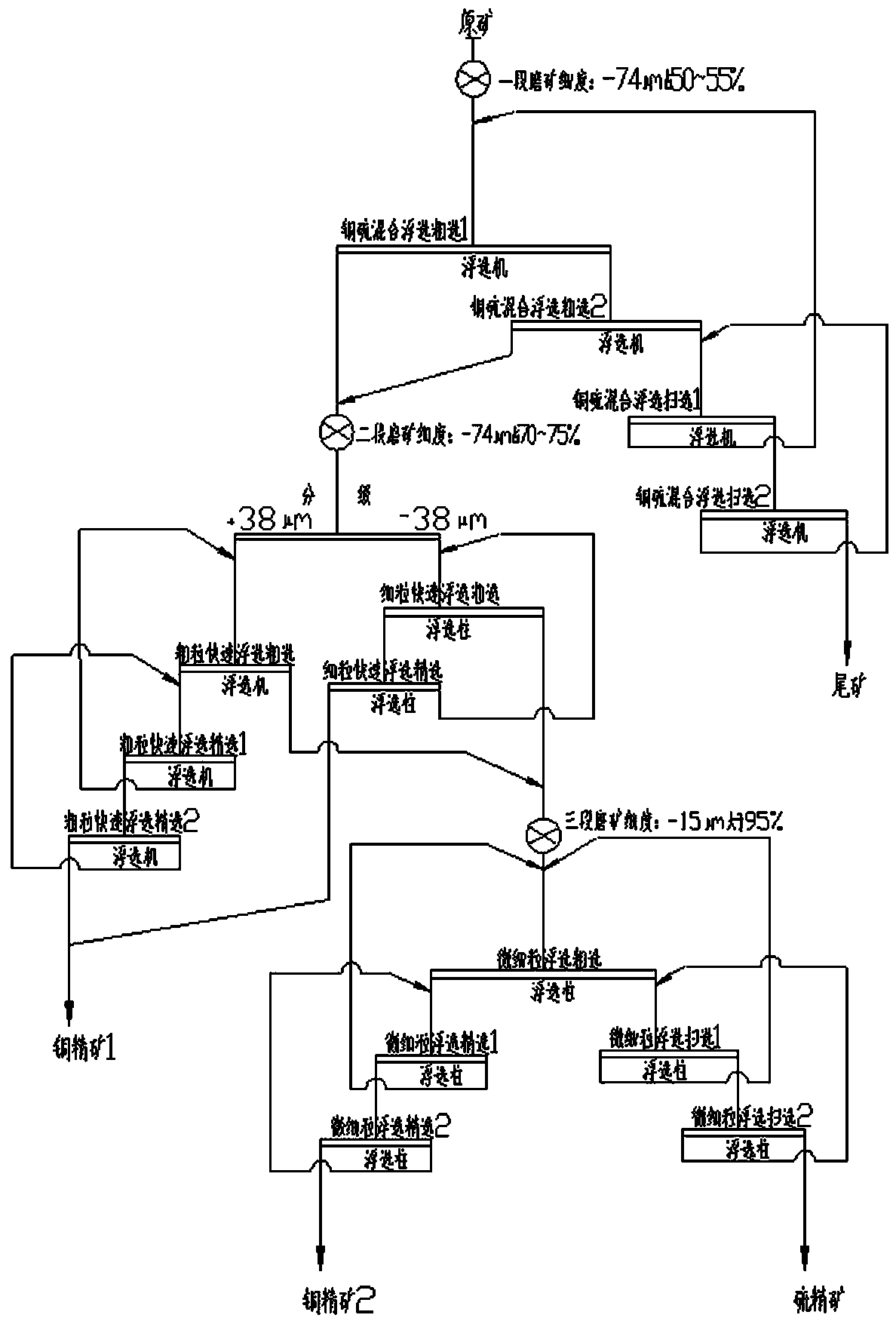

Process for recovering chalcocite and chalcopyrite with non-uniform disseminated grain size from high pyritized skarn copper ores

ActiveCN110841796AHigh recovery rateAvoid excessive muddying and deteriorating flotation processSolid separationPyriteCopper ore

The invention discloses a process for recovering chalcocite and chalcopyrite with the non-uniform disseminated grain size from high pyritized skarn copper ores. The process for recovering chalcocite and chalcopyrite with the non-uniform disseminated grain size from high-pyrite skarn copper ores is characterized by comprising the steps of first-stage grinding, copper-sulfur mixed flotation, second-stage grinding, rapid copper-sulfur flotation, third-stage grinding and copper-sulfur separation column flotation for recovering fine copper particles. The process adapts to the characteristics of thenon-uniform disseminated grain size and different floatability of chalcocite and chalcopyrite, realizes the recovery of ultra-fine grain disseminated chalcocite and chalcopyrite, avoids the adverse effect of a micro-fine grain ore pulp system on the flotation process, and realizes the efficient separation of refractory high-iron copper ores.

Owner:KUNMING METALLURGY INST

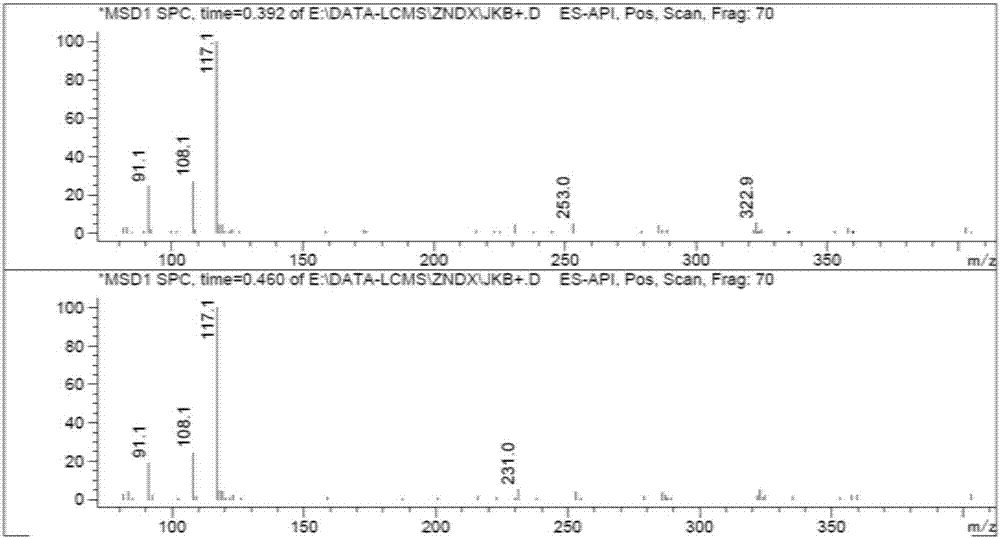

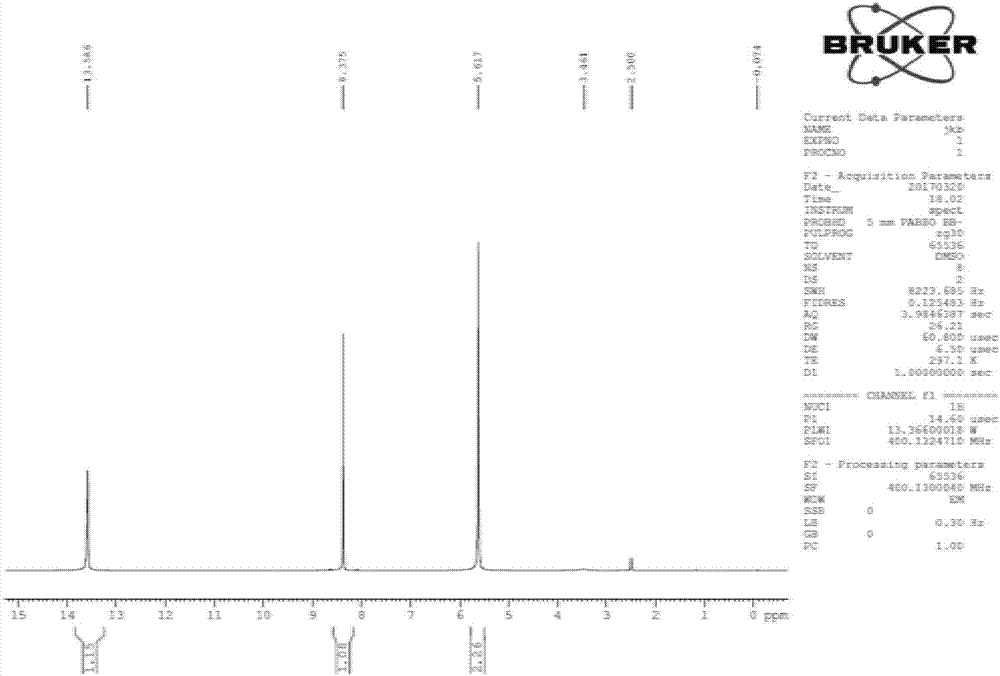

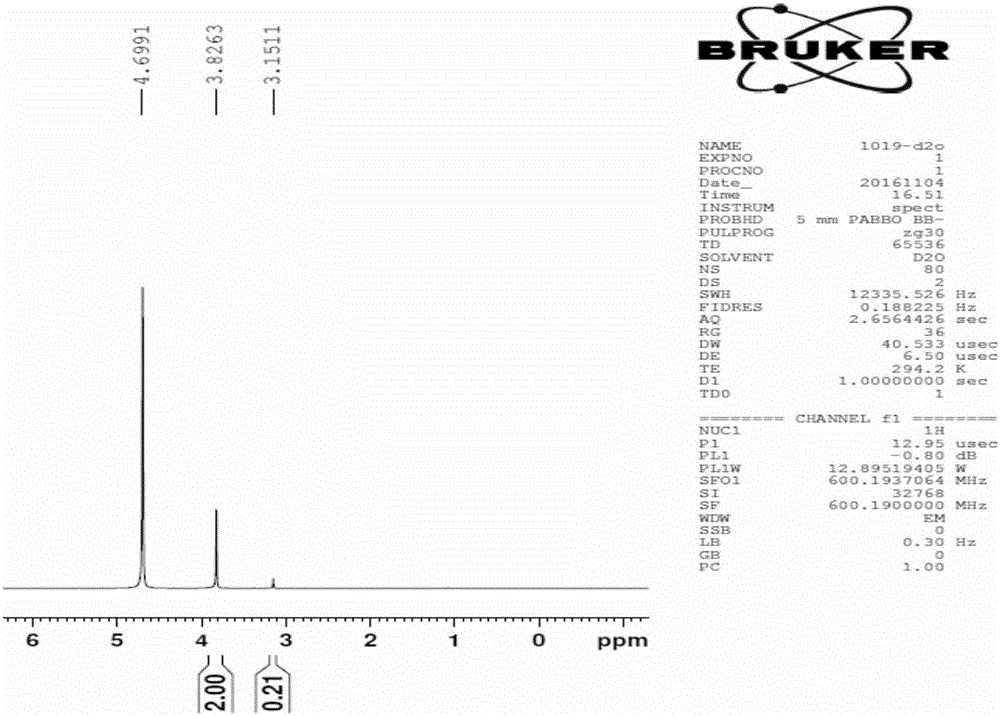

Hydrazine derivative, preparation method of hydrazine derivative and application of hydrazine derivative as sulphide ore surfactant

ActiveCN106748938ASpecial molecular structureHas surfactant propertiesOrganic chemistryFlotationTroiliteHydrazine compound

The invention provides a hydrazine derivative, and a preparation method and application of the hydrazine derivative. .The hydrazine derivative structurally contains sulphide ore surface solid-tropy groups of hydrazine, dithioacid and the like, and hydrophilic groups of carboxyl, sulfonic group, hydroxyl, amidogenand the like. According to the preparation method, the hydrazine and carbon disulfide take a reaction under the alkaline condition to obtain 1-diazanyl-dithio formate; the 1-diazanyl-dithio formate takes a reaction with one-molecule or two-molecule halogenated carboxylate to obtain the hydrazine derivative; the hydrazine derivative is used as the sulphide ore modified surfactant. The hydrophilicity of the sulphide ore with the natural hydrophobicity can be enhanced; particularly, the hydrophilicity of non-molybdenum sulphide ore such as chalcopyrite, chalcocite, galena, blende, troilite and bismuth sulphide ore can be effectively enhanced.

Owner:CENT SOUTH UNIV

Chalcocite flotation agents and preparation method thereof

Chalcocite flotation agents are made of the following raw materials including, by weight, 15-18 parts of black powder, 20-24 parts of m-benzenedicarbonyl thiourea, 8-10 parts of drainage oil, 5-7 parts of ethyl alcohol, 2-4 parts of butyl acrylate, 5-7 parts of AEO, 2-4 parts of polyacrylamide, 1-2 parts of chitosan, 0.6-1.4 parts of nanometer titanium dioxide, 1-2 parts of sodium hydroxide, 1-2 parts of sodium hydrogen phosphate, 1-2 parts of boronic acid and 4-5 parts of activating agents. As the nanometer titanium dioxide is added, the chalcocite flotation agents are uniform and stable in dispersion, have stable foam and are good in flocculation effect, good in copper collecting performance, high in copper yield, good in selectivity, good in rejection capability and high in copper grade. The activating agents are stable in dispersion, good in permeability, good in activating performance, long in duration time of the flocculation effect and capable of improving the yield and grade of copper.

Owner:ANHUI AODE MINING MACHINERY & EQUIP LTD

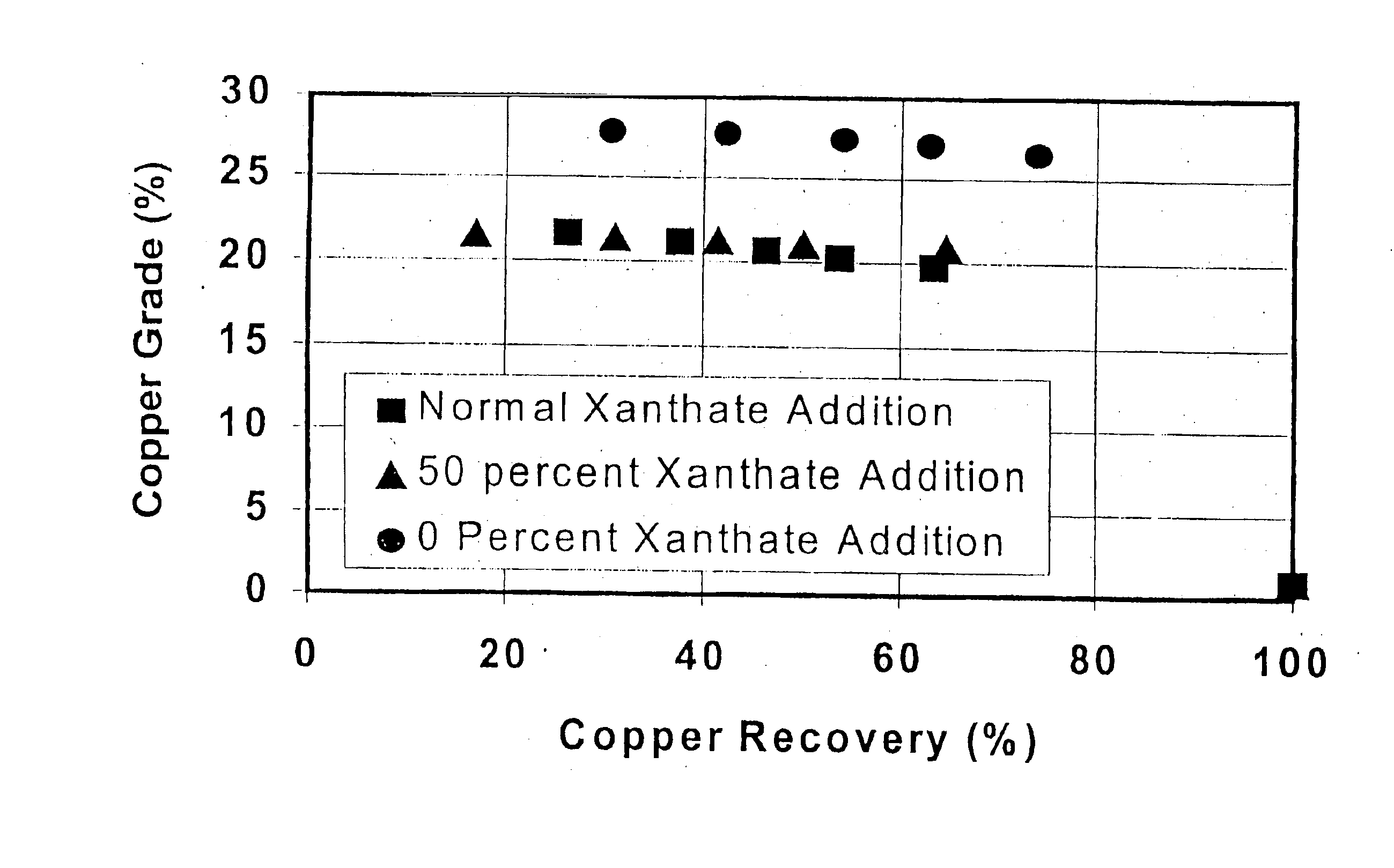

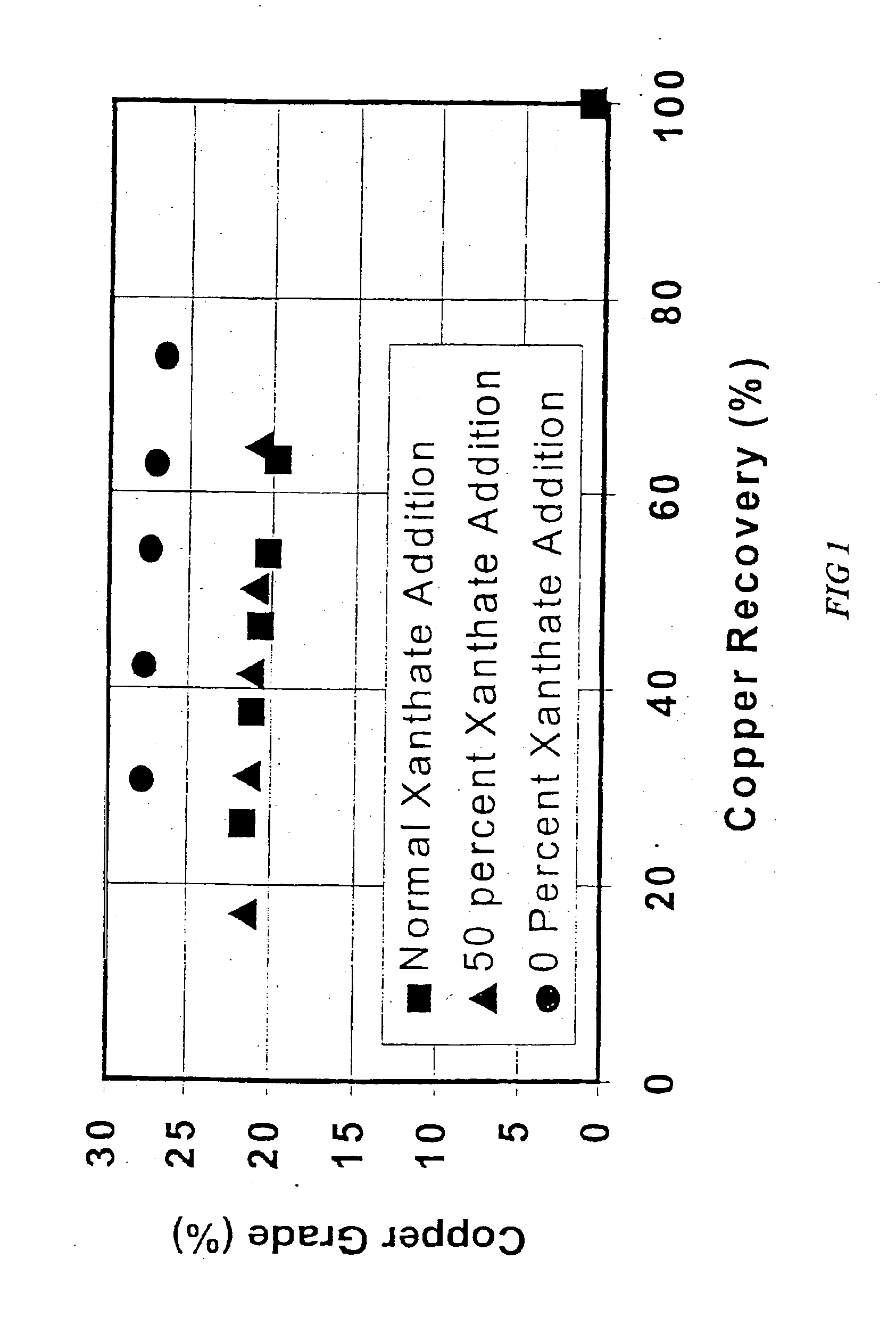

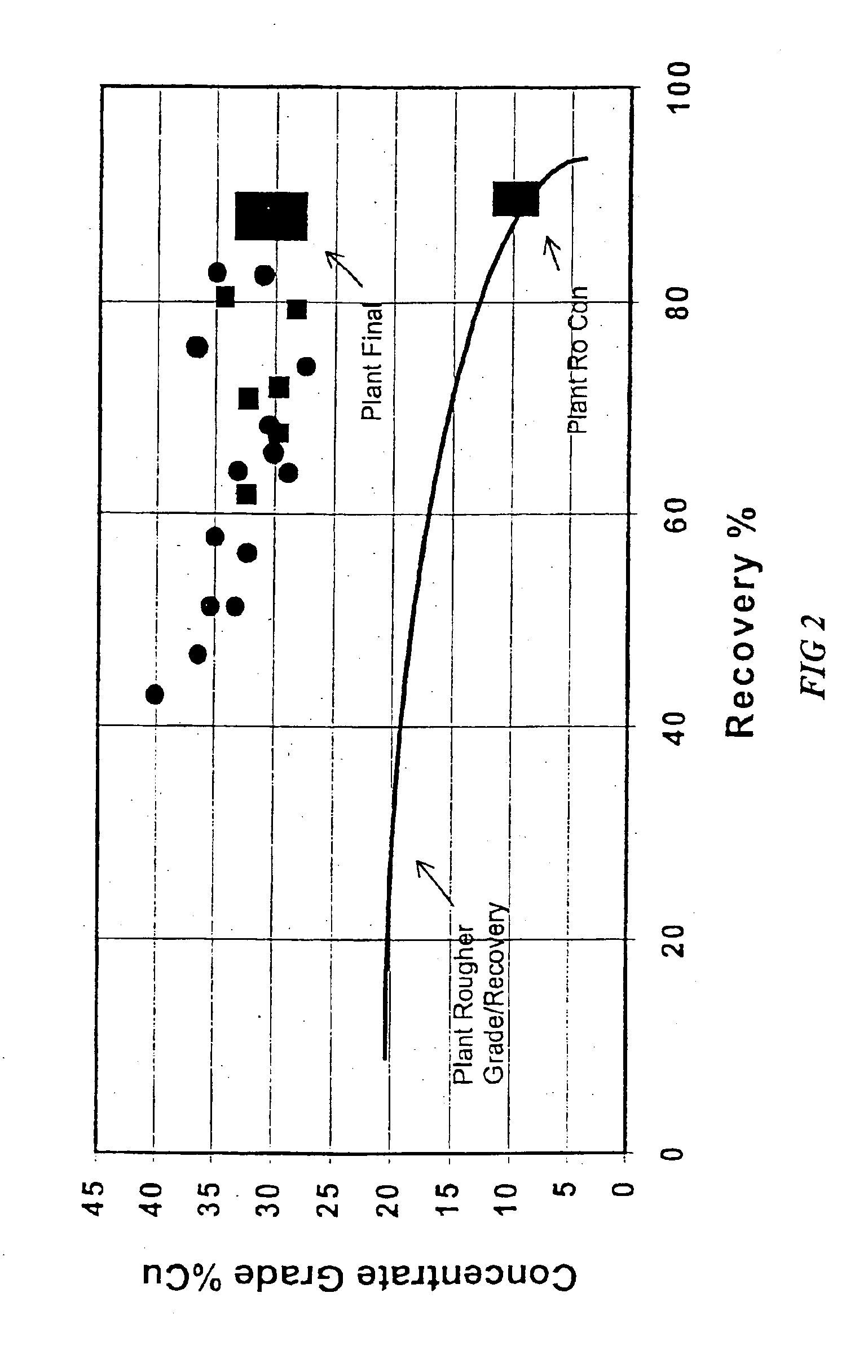

Collectorless flotation

Owner:MIM HOLDINGS LTD

Corrosion-resistant cement clinker warehouse top conveyor

The invention discloses a corrosion-resistant cement clinker warehouse top conveyor. A processing method for steel in the corrosion-resistant cement clinker warehouse top conveyor comprises the steps that (1) high-manganese steel, zinc oxide, chromic oxide, nickel sulfate, graphite, asbestos, chalcocite, stibnite and cassiterite are molten at the temperature of 1390-1450 DEG C so as to obtain molten mixture; and (2) silicon carbide, magnesium borate whiskers, graphene and the molten mixture are reheated at the temperature of 1550-1620 DEG C, and then water quenching is conducted at the temperature of 1240-1310 DEG C so as to obtain the steel in the corrosion-resistant cement clinker warehouse top conveyor. The corrosion-resistant cement clinker warehouse top conveyor has excellent mechanical strength and corrosion resistance.

Owner:WUHU ADER CONVEYOR MACHINERY

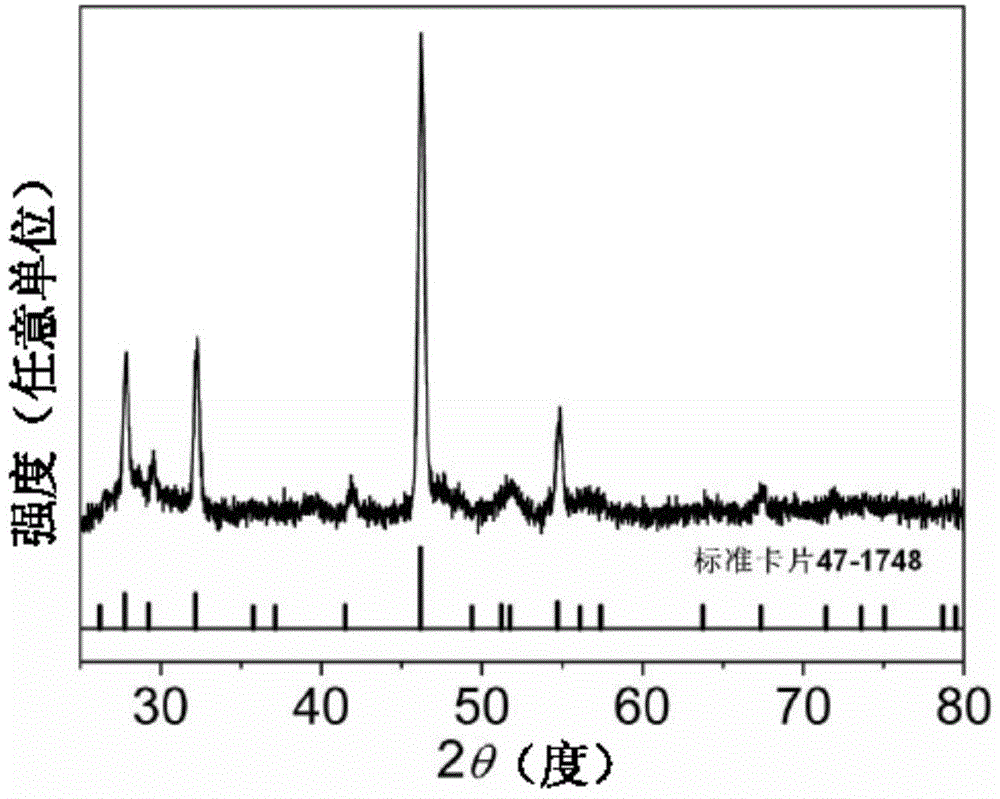

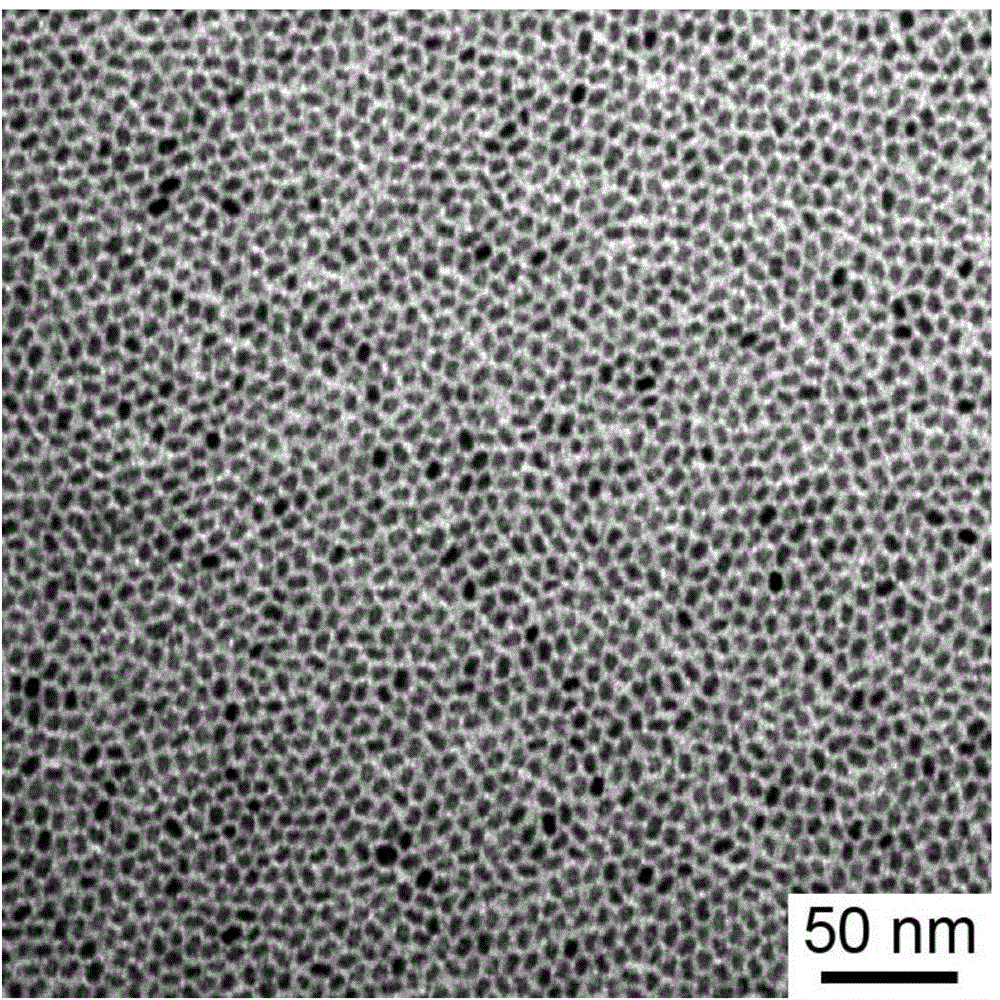

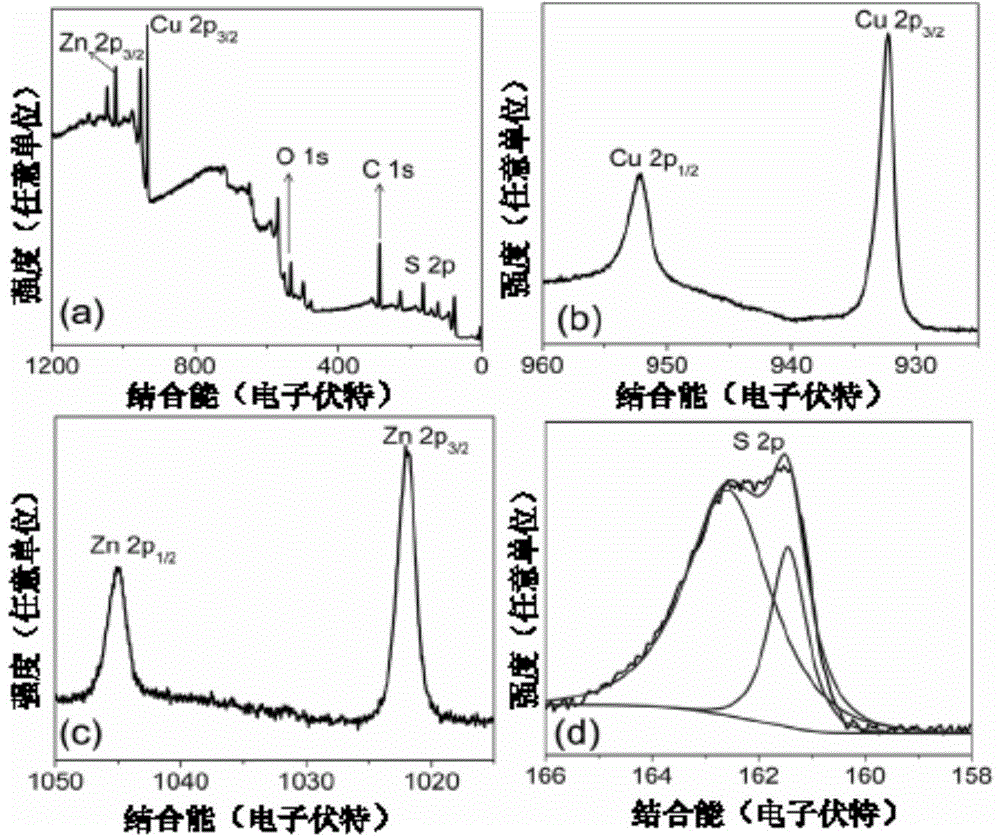

A kind of monodisperse blue chalcocite semiconductor nanocrystal and preparation method thereof

ActiveCN103922386BSimple and safe operationRaw materials are cheap and easy to getMaterial nanotechnologyCopper sulfidesSemiconductor nanocrystalsSolvent

The invention discloses a monodisperse Cu9S5 semiconductor nanocrystal and a preparation method thereof and belongs to the technique field of emiconductor nanocrystal synthesis. In the invention, copper salt is taken as a copper raw material, a small amount of other metal salt is doped, and aliphatic series mercaptan is taken as a sulphur raw material, and in a high-boiling-point solvent, a pyrolysis method is adopted to prepare a Cu9S5 semiconductor nanocrystal with good monodispersity. According to the invention, the raw materials are low in price and easily available, the experiment and process are simple, the operation is safe, simple and convenient and the repeatability is good. The Cu9S5 semiconductor nanocrystal prepared by the preparation method in the invention has a diameter less than 5 nanometers, the shape is spherical or rice-shaped, and the crystal form is a rhombohedral system or tetragonal system.

Owner:BEIJING JIAOTONG UNIV

Automobile front top lamp support being high in outer-wall hardness and tensile strength, and preparation method of automobile front top lamp support

InactiveCN106244896AHigh hardnessHigh tensile strengthProcess efficiency improvementMetal rolling arrangementsCinnabarEngineering

The invention discloses an automobile front top lamp support being high in outer-wall hardness and tensile strength. The automobile front top lamp support is characterized by comprising the following components in parts by weight: 500-550 parts of limonite, 30-40 parts of maghemite I, 400-480 parts of pyrite, 10-20 parts of cinnabar, 8-9 parts of malachite, 10-14 parts of maghemite II, 5-6 parts of sphalerite, 3-4 parts of azurite, 6-7 parts of chalcocite, 2-3 parts of cassiterite, 3-4 parts of tantalite-columbite, 1-2 parts of jamesonite, 2-3 parts of scheelite, 8-9 parts of ilmenite, 3-4 parts of tantalum rutile, 20-30 parts of niccolite and 200-260 parts of a nickel ore biological metallurgy catalyst. According to the automobile front top lamp support disclosed by the invention, the biological metallurgy technology is adopted and the nickel utilization ratio is improved; meanwhile, the mechanical properties of parts are improved by adopting a multi-channel machining process; and the machined automobile front top lamp support is high in outer-wall hardness and the tensile strength.

Owner:WUHU CHANGRUI AUTO PARTS

Rear door left hinge reinforcing plate with good-corrosion-resistance easy-to-weld welding zone and preparation method thereof

InactiveCN106319331ASimple processEasy to operateHingesProcess efficiency improvementEngineeringBack door

The invention discloses a rear door left hinge reinforcing plate with a good-corrosion-resistance easy-to-weld welding zone. The rear door left hinge reinforcing plate is characterized by comprising the following components in parts by weight: 500-550 parts of siderite, 400-480 parts of alferric minerals, 10-20 parts of chalcocite, 8-9 parts of malachite, 10-14 parts of maghemite, 5-6 parts of sphalerite, 2-3 parts of cassiterite, 1-2 parts of jamesonite, 2-3 parts of scheelite, 5-6 parts of bonamite, 3-4 parts of tantalorutile, 2-3 parts of ilmenite, 20-30 parts of pentlandite and 200-260 parts of a nickel ore biological metallurgical catalyst. The rear door left hinge reinforcing plate is good in wear resistance and is resistant to corrosion; and the easy-to-weld welding zone is good in corrosion resistance.

Owner:HEFEI CHANGQING MACHINERY

Short-process high-recycling-rate smelting method for chalcocite

InactiveCN111334671AHigh recovery rateReduce joinRotary drum furnacesCrucible furnacesCement factoryNonferrous metal

The invention belongs to the field of nonferrous metal smelting, and particularly relates to a short-process high-recycling-rate smelting method for chalcocite. The short-process high-recycling-rate smelting method comprises the following steps that chalcocite and copper sulfonium are fed into a converting furnace with the oxygen concentration capable of being adjusted within a certain range to beconverted; crude copper generated by converting is sent to an anode furnace for fire refining, and converting slag generated by converting serves as a return material to be mixed into a smelting furnace to generate copper matte and smelting slag; the smelting slag is sent to a beneficiation workshop to be subjected to grinding and floating, and slag concentrate with high copper content and tailings with low copper content are selected; and the slag concentrate serving as a raw material is added into the smelting furnace to recycle copper metal, and the tailings serve as a raw material of a cement plant for recycling. The method is short in process and free of a smelting process, and the processing cost is reduced; and due to the fact that addition of a slag former is reduced and no high-sulfur and high-iron materials exist, the converting slag type is FeO-SiO2 after converting is finished, good fluidity is achieved, the yield of the converting slag is greatly reduced, and the copper recycling rate is increased and can reach 99% or above.

Owner:HENAN YUGUANG GOLD & LEAD

Oil filler lining plate being lower in surface roughness, smaller in machining allowance and higher in strength, as well as preparation method thereof

InactiveCN106282749AHigh hardnessSimple processFurnace typesProcess efficiency improvementSurface roughnessNickel sulfide

The invention discloses an oil filler lining plate being lower in surface roughness, smaller in machining allowance and higher in strength. The oil filler lining plate is characterized by comprising the following components in parts by weight: 500-550 parts of limonite, 50-70 parts of siderite, 400-480 parts of pyrite, 10-20 parts of chalcopyrite, 5-6 parts of hydromica, 8-9 parts of malachite, 10-14 parts of maghemite, 5-6 parts of sphalerite, 2-3 parts of cassiterite, 1-2 parts of jamesonite, 5-6 parts of chalcocite, 6-7 parts of ilmenite, 2-3 parts of wolframite, 3-4 parts of tantalorutile, 20-30 parts of copper-nickel sulfide ore and 200-260 parts of a nickel ore biological metallurgy catalyst. According to the oil filler lining plate disclosed by the invention, the nickel utilization ratio is improved by adopting the biological metallurgy technology, and the mechanical properties of parts are improved by adopting a plurality of machining processes.

Owner:HEFEI CHANGQING MACHINERY

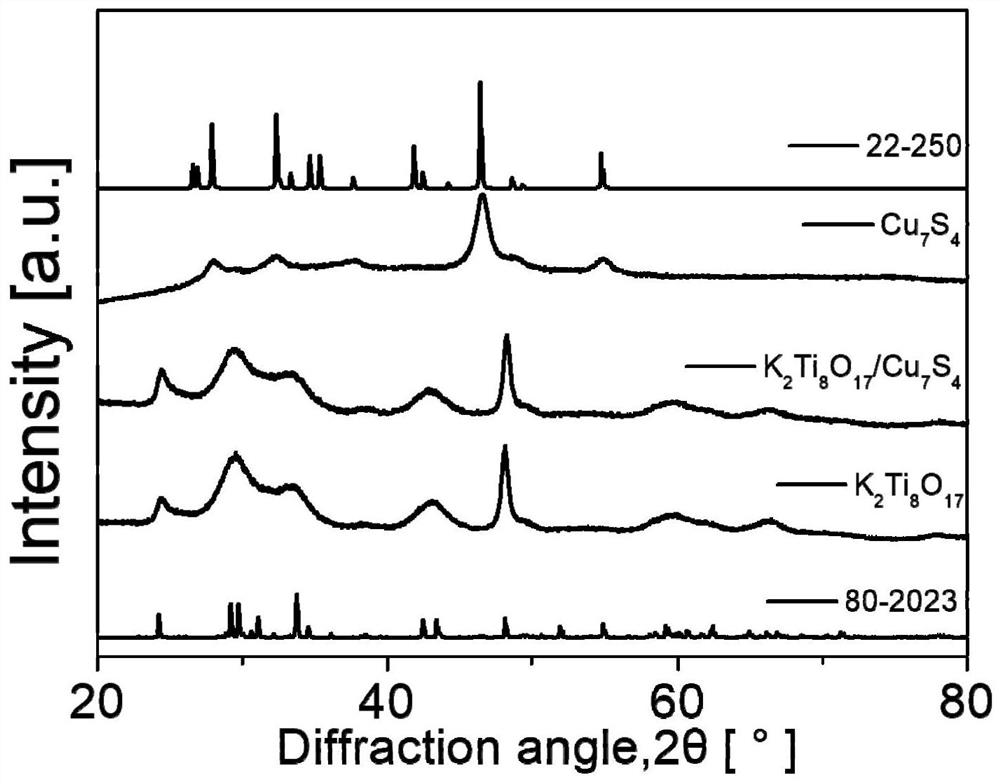

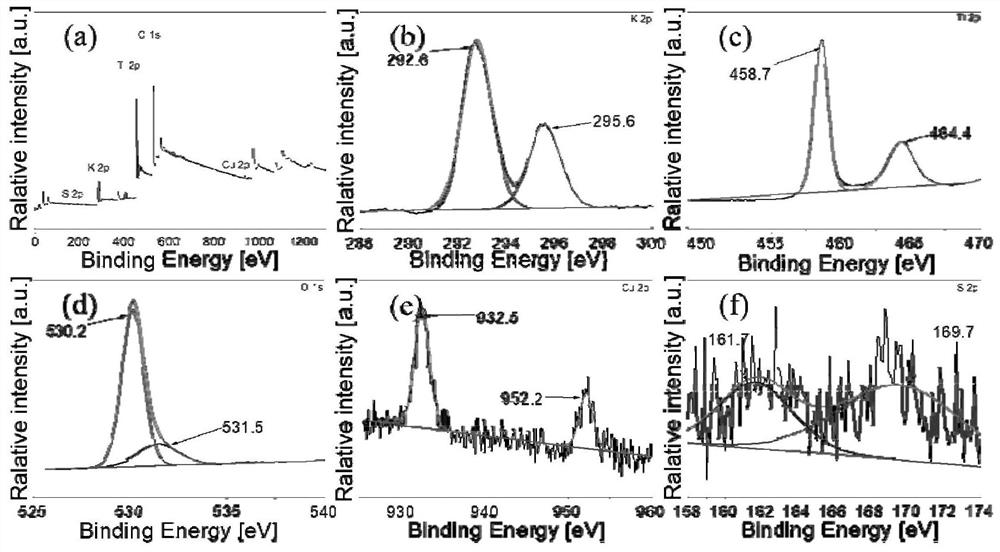

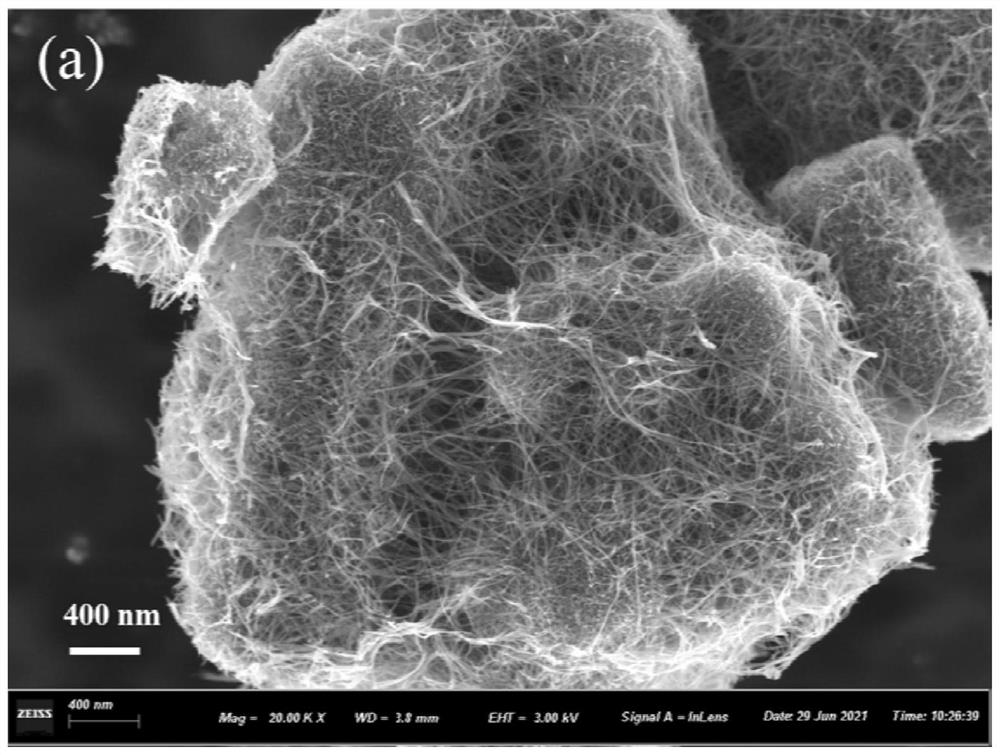

Potassium titanate-hepta-copper tetrasulfide composite material and preparation method and application thereof

ActiveCN113828331AEffective contactImprove photocatalytic activityHydrocarbon from carbon oxidesCatalyst activation/preparationHydration reactionNanowire

The invention discloses a potassium titanate-hepta-copper tetrasulfide composite material which is formed by loading orthorhombic blue chalcocite type hepta-copper tetrasulfide nanoparticles with the particle size of 10-30 nm on the surface of a potassium titanate nanowire. The preparation method comprises the following steps: adding a certain amount of titanium dioxide and a potassium hydroxide solution into water, uniformly mixing, carrying out a hydrothermal reaction, and carrying out centrifugal washing and drying after the hydrothermal reaction is ended, so as to obtain the potassium titanate nanowire; adding the obtained potassium titanate nanowire and a certain amount of cadmium acetate dihydrate into ethanol, adding thioacetamide under the condition of heating and stirring to react for a period of time, then adding cuprous chloride to react, and then carrying out centrifugal washing and drying to obtain a potassium titanate-hepta-copper tetrasulfide composite material. According to the invention, small-sized copper tetrasulfide particles are distributed on the potassium titanate nanowire, the load of the copper tetrasulfide is beneficial to effective separation of photo-induced electrons and holes, and the reduction performance of the photo-induced electrons is fully exerted to realize effective photo-reduction of carbon dioxide to generate methane and carbon monoxide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Preparation method of automobile transmission shaft for reducing structural stress and preventing inner cracks from being generated

The invention discloses an automobile transmission shaft for reducing structural stress and preventing inner cracks from being generated. The automobile transmission shaft is characterized by comprising, by weight, 500 to 550 parts of limonite, 10 to 25 parts of aluminum-iron ores, 300 to 310 parts of magnetite, 10 to 12 parts of chromite, 6 to 8 parts of asbestos ores, 8 to 9 parts of chalcocite, 5 to 7 parts of malachite, 8 to 10 parts of cinnabar, 1 to 2 parts of smithsonite, 7 to 8 parts of ilmenite, 30 to 40 parts of diaspore, 4 to 5 parts of columbite-tantalite, 3 to 4 parts of cerussite, 4 to 5 parts of galena, 3 to 4 parts of nontronite, 2 to 3 parts of wolframite and 10 to 11 parts of violarite. The ores are pretreated through a nickel metal independent refining and pressure leaching technology, the refining efficiency of trace metals in the low-grade ores is improved, the purity of the trace metals in an alloy material is improved, the structural stress is reduced, and the inner cracks are prevented from being generated.

Owner:安徽丰源车业有限公司

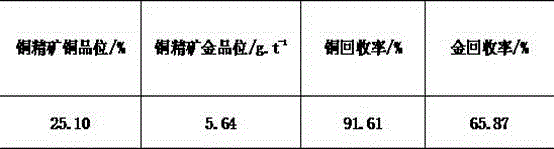

Simple beneficiation method for chalcocite-containing coarse-grain disseminated copper sulphide ore

ActiveCN114178045ARealize early collection and fast collectionShorten cycle timeSolid separationMining engineeringGraphite

The invention relates to a simple beneficiation method of chalcocite-containing coarse-grain disseminated copper sulphide ore, which is characterized in that graphite is used for replacing a copper selection collecting agent in flash flotation and graded overflow flotation stages to improve the selective adsorption capacity of coarse-grain minerals, a flotation machine for copper selection is changed into a flotation column, and the method comprises the following steps: ore grinding: adding calcium oxide into raw ore a added into a ball mill for ore grinding; grading: grading the ore grinding product b to obtain ore pulp overflow d and ore pulp settled sand c; flash flotation is carried out, specifically, the settled sand c is subjected to flash flotation, especially coarse-fraction ore is directly discharged from a tailing opening, the proper-fraction ore is subjected to flash flotation, graphite and 2 # oil are added, and product copper concentrate 1e and tailings f are obtained; conventional flotation is conducted, graphite, LY01 and 2 # oil are added into the overflow d, and copper rough concentrate j and tailings i are obtained; the rough concentrate j is subjected to flotation column concentration, and product copper concentrate 2 h and middling k are obtained. The method has the advantages that the problems of over-grinding smashing loss, large flotation recovery difficulty, insufficient flotation time and serious tailing running of useful minerals can be solved; and the selective adsorption capacity of coarse-grained minerals can be improved, the system flow is shortened, enrichment of coarse and fine-grained copper minerals is accelerated, and energy consumption is reduced.

Owner:ZIJIN MINING GROUP

Automotive rear axle driving bevel gear capable of preventing side edge longitudinal cracking and manufacture method thereof

InactiveCN106222524AIncrease profitIncreased purity of alloy contentProcess efficiency improvementMagnetiteAlloy

The invention discloses an automotive rear axle driving bevel gear capable of preventing side edge longitudinal cracking and a manufacture method thereof. The automotive rear axle driving bevel gear is characterized by comprising the following components in parts by weight: 500-550 parts of hematite, 300-310 parts of magnetite, 10-12 parts of chromite, 8-9 parts of chalcocite, 1-2 parts of blende, 7-8 parts of ilmenite, 5-7 parts of wolframite, 30-40 parts of bauxite, 4-5 parts of stannite, 3-4 parts of columbite-tantalite, 2-3 parts of hydromica and 10-11 parts of pentlandite. Chlorination segregation and a pressure leaching technique are adopted for pretreating ores; the refining efficiency of trace metal in low-grade ores is improved; the purity of trace alloys in alloy materials is improved; and quality of part materials is improved.

Owner:安徽丰源车业有限公司

Application of aminotriazolethione compounds as surface modifiers of metal sulfide minerals

ActiveCN107029893BSpecial molecular structureSuppression of floatingFlotationBismuth sulfideChemical compound

Owner:CENT SOUTH UNIV

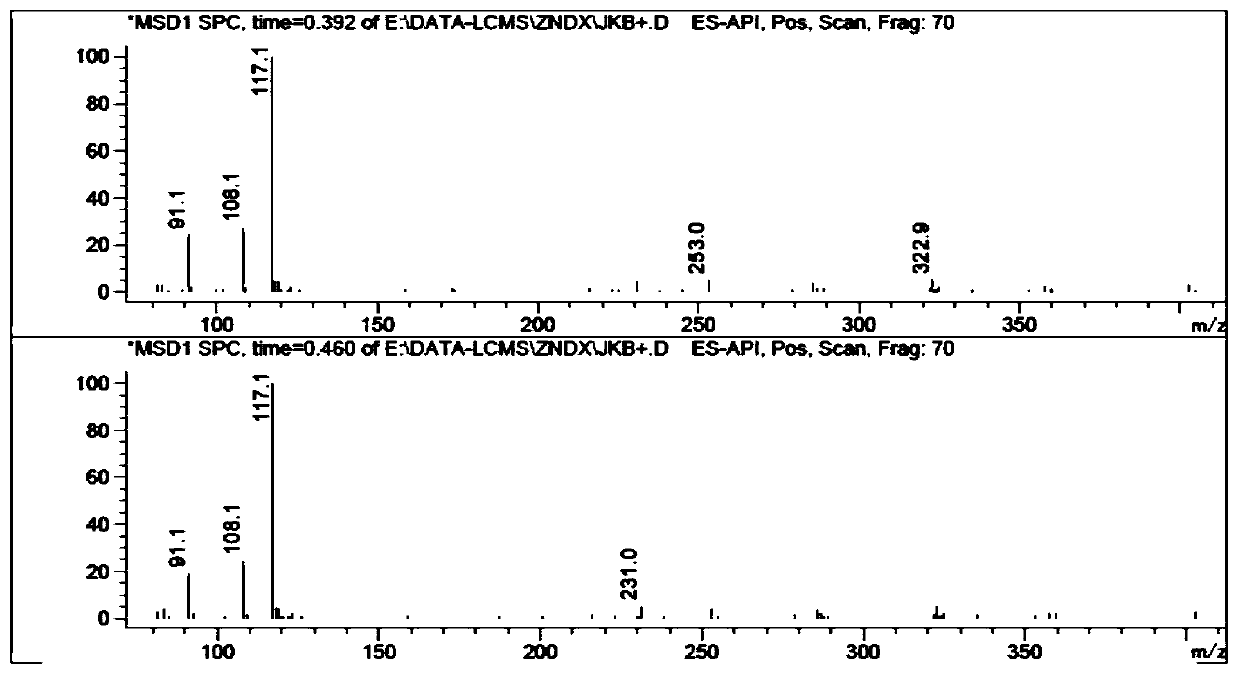

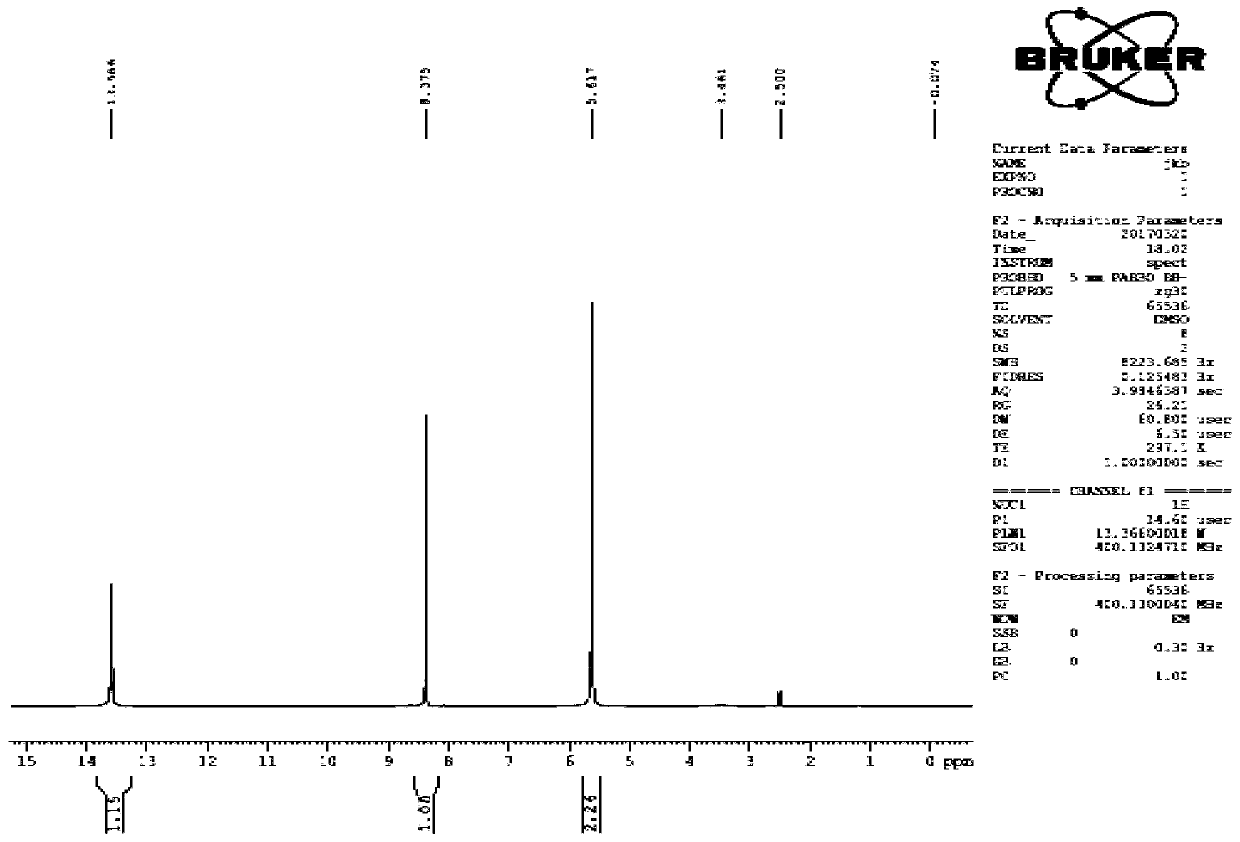

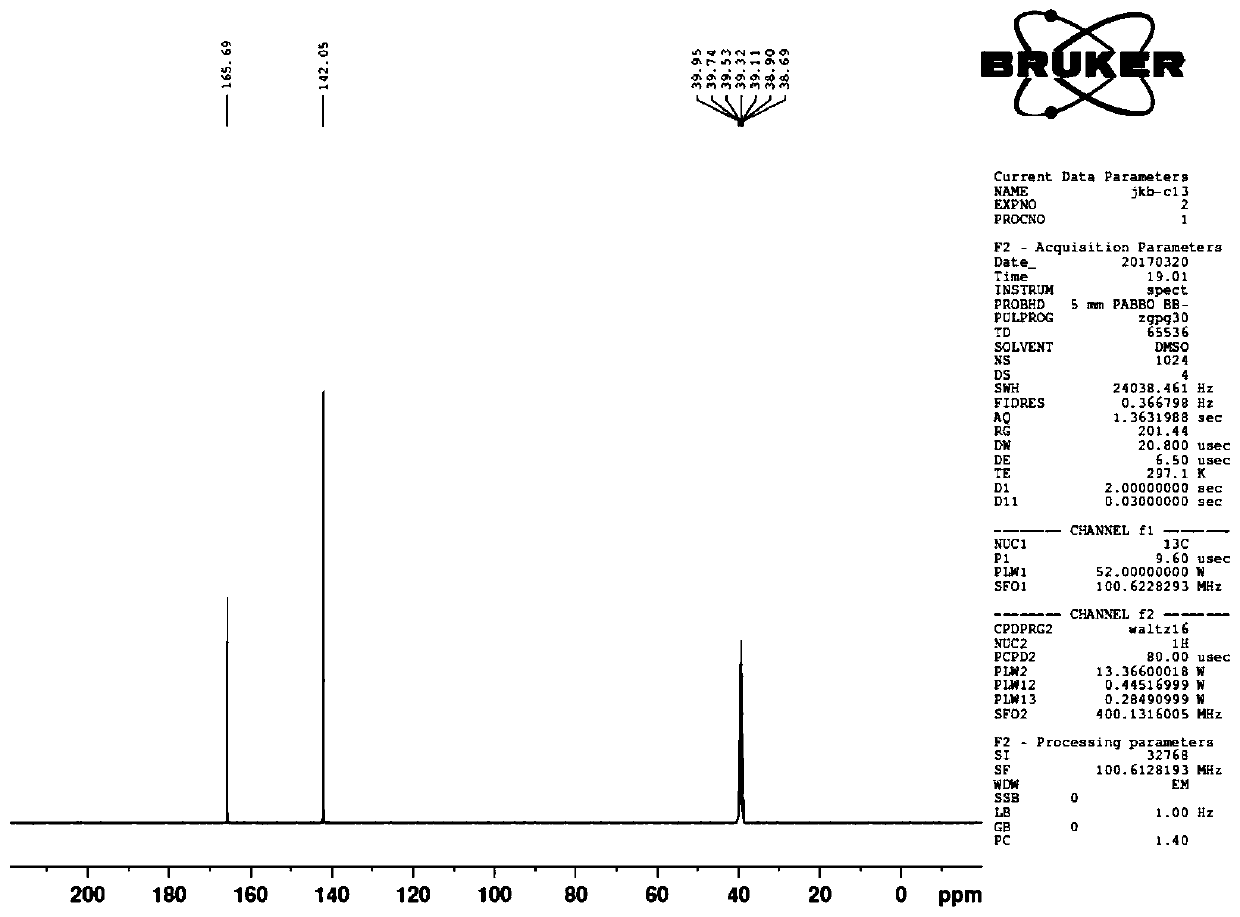

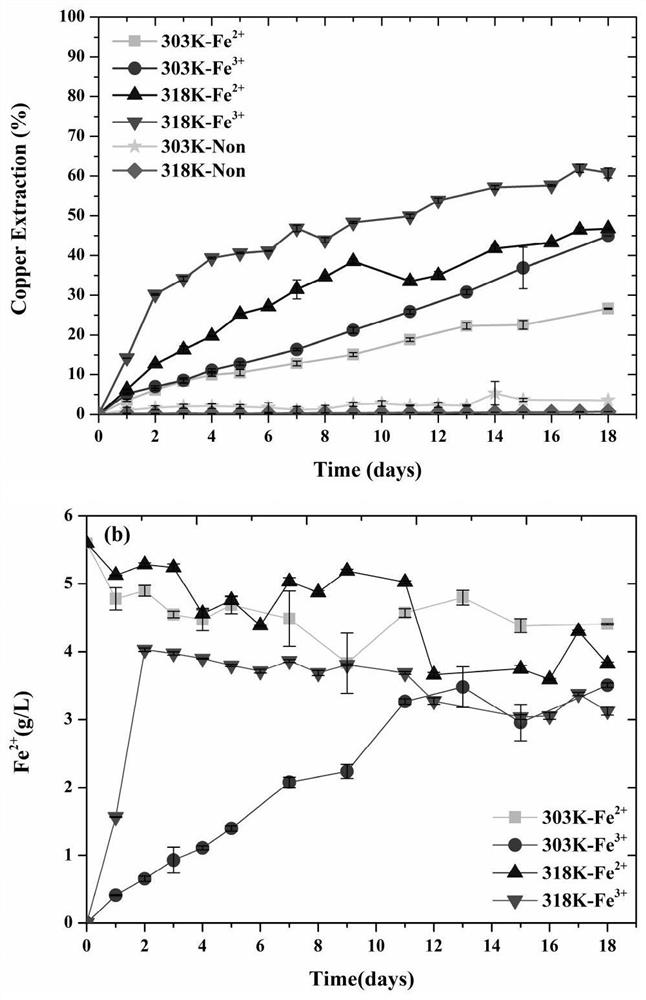

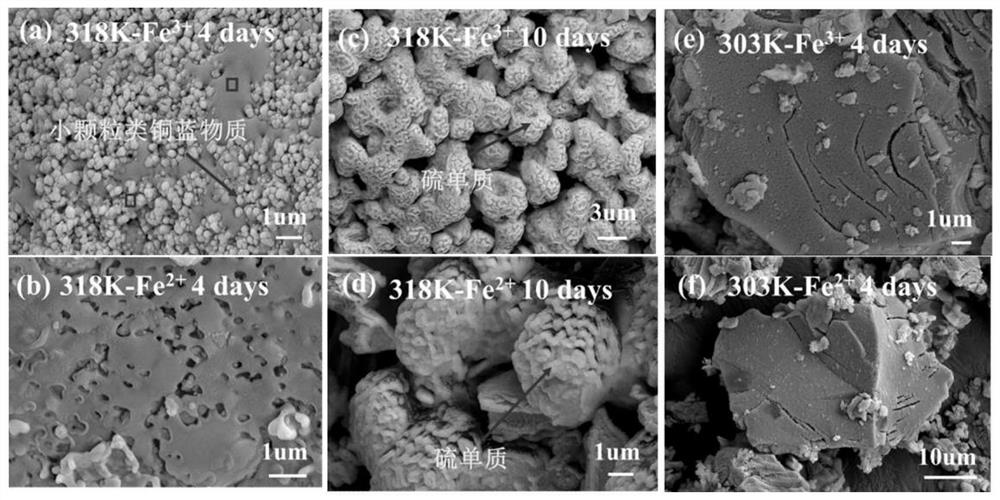

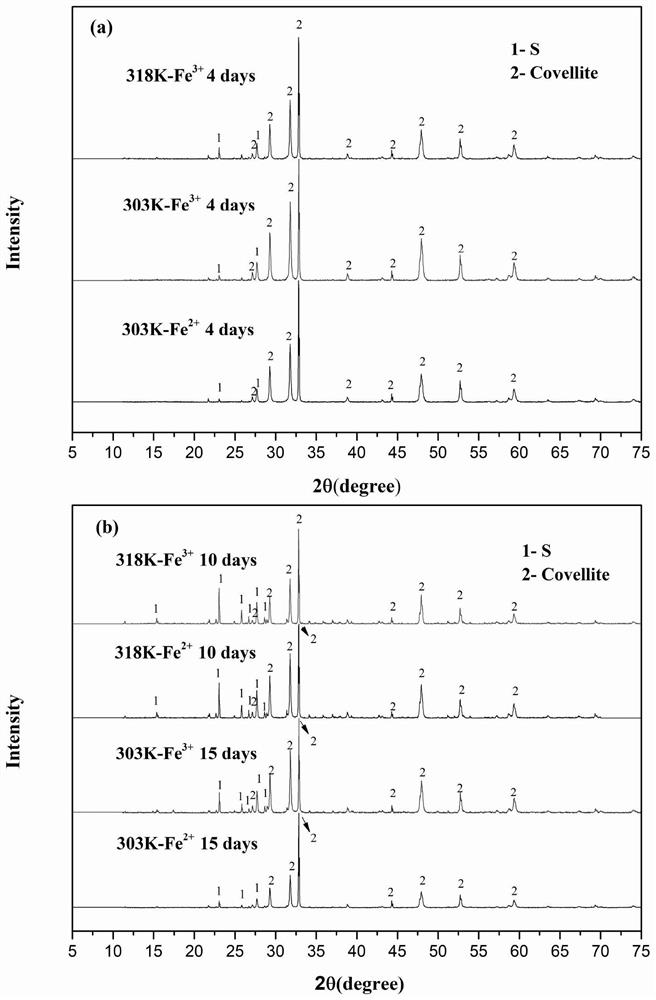

Method for strengthening copper blue bioleaching by comprehensively utilizing ferric ions and ferrous ions

ActiveCN112391527APromote growthImprove solubilityProcess efficiency improvementIron sulfateReaction rate

The invention belongs to the technical field of biological metallurgy, and particularly relates to a method for strengthening copper blue bioleaching by comprehensively utilizing ferric ions and ferrous ions. The method can be used for improving the ore leaching efficiency of low-grade copper sulfide ore. The method specifically comprises the steps that ferric sulfate and sulfur-containing oxidizing bacteria are adopted as a leaching agent for leaching copper blue; and then iron-oxidizing bacteria are added into a leaching system for achieving leaching. According to the method, efficient utilization of an iron source and bacteria is achieved, and the situation that due to addition of exogenous iron, passivated objects such as compact jarosite on the surface of the ore are generated too early, and the reaction rate is limited by a sulfur layer formed on the surface in the reaction process is avoided. The method has important significance in improving the bioleaching efficiency of chalcocite.

Owner:CENT SOUTH UNIV

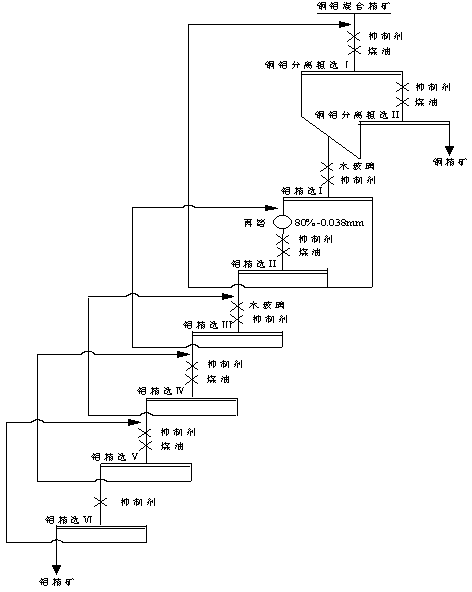

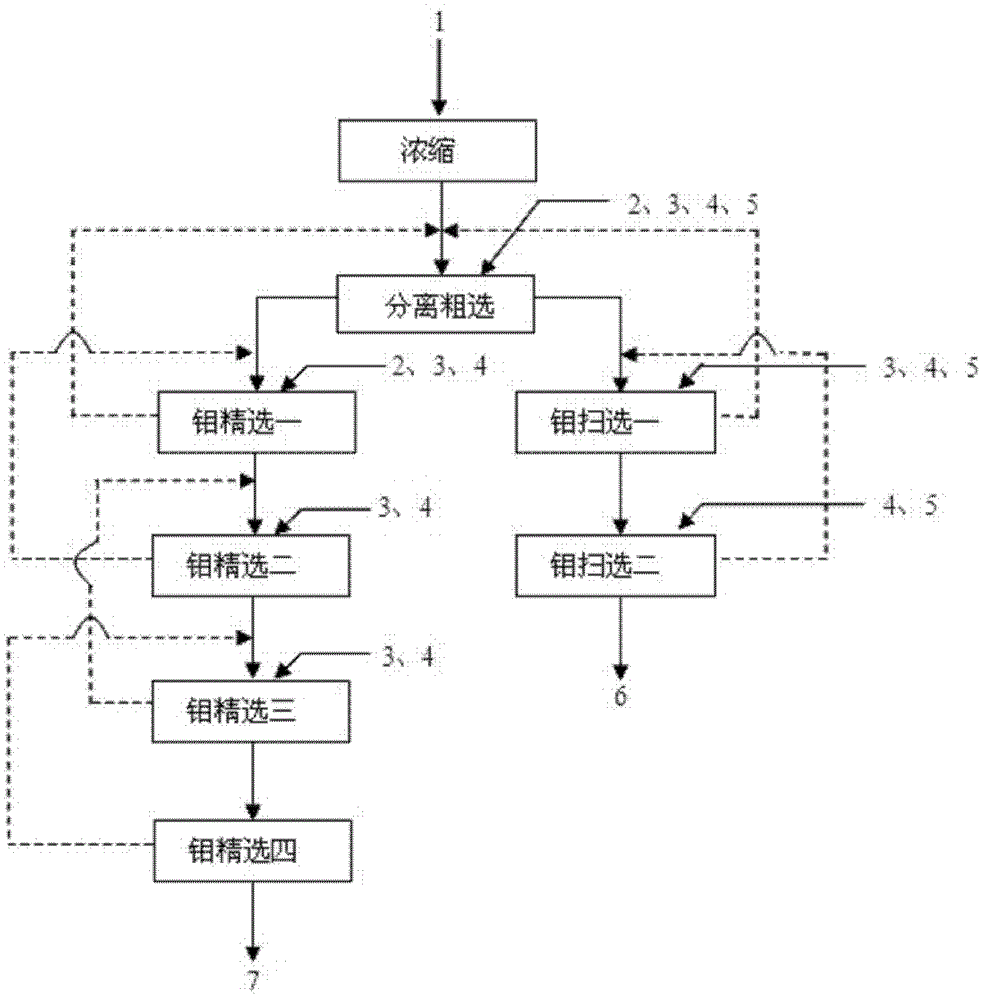

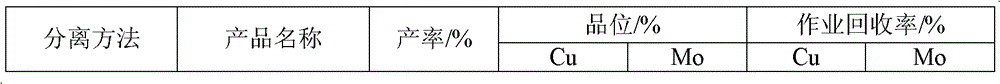

Beneficiation reagent and method for separating copper-molybdenum mixed concentrates

The invention provides a beneficiation reagent and method for separating copper-molybdenum mixed concentrates. According to the invention, the effective separation of copper-molybdenum mixed concentrates can be realized by using a concentrated reagent removal and an oxalic acid reduction method, and the oxalic acid reduction method has an effective restraining effect on primary and secondary copper-sulphide ores such as chalcopyrite and chalcocite and the like, the process is simple and reasonable, and the recovery rate of molybdenum is high. The method disclosed by the invention concurrentlyhas the characteristics of good stability, strong adaptability and less reagent consumption, and can greatly reduce the production cost.

Owner:ZIJIN MINING GROUP

A kind of flotation method of fine grain embedding copper sulfide ore

The invention discloses a floating method for finely disseminated copper sulfide ores. The floating method specifically comprises steps such as ore grinding, roughing, roughed concentrate re-grinding, roughed concentrate copper-sulfur separating and floating and roughened tailing scavenging, wherein multi-time concentrating and multi-time scavenging are performed on roughened concentrate and roughened tailings, cyclic ore dressing is performed on ores, and different ore dressing reagents are matched, so that the recovery rate of raw ores is increased. The floating method has the advantages that: by optimizing an ore grinding process and reasonably adding a collecting agent and a collecting-foaming agent, surface characteristics of ores are improved, selective adsorption, on copper sulfide ore particle surfaces such as fine-grained copper pyrite and chalcocite, of the collecting agent is strengthened, and hydrophobic agglomeration is formed, so that the recovery rate of copper concentrate is increased by 3-6% in comparison with that of an existing ore dressing method.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Preparation method of heat-conductive and flame-retardant material for lithium batteries

InactiveCN106147131AThe ratio is scientific and reasonableCompatibility is scientific and reasonableHeat-exchange elementsEpoxyMagnetite

The invention relates to a preparation method of a heat-conductive and flame-retardant material for lithium batteries. The method includes the following steps that 1, granite, magnetite, barium sulfate, coke, chalcocite powder, aluminum hydroxide, montmorillonite, titanium oxide, gypsum, potassium titanate and silver are ground into powder to form mixture filler, the mixture filler is hated to 880 DEG C at a uniform speed at the normal temperature and sintered for 4-8 h at the constant temperature, and the temperature is lowered to the normal temperature for cooling; 2, aluminum oxide, zircon sand and eucryptite are heated to 820 DEG C at a uniform speed and sintered for 4-6 h at the constant temperature to serve as ceramic filler; 3, the ground mixture filler and the ground ceramic filler are mixed evenly, the temperature is raised to 1160 DEG C for sintering, filler is obtained, and then the filler is ground to be 100-400 micrometers; 4, the filler is cooled, epoxy resin is added, and after even mixing, the heat-conductive and flame-retardant material for lithium batteries is obtained. The raw material cost is low, the proportion and compatibility are scientific and reasonable, the preparation method is fast to implement, and the working temperature of battery packs can be lowered by 10-20 DEG C with the obtained flame-retardant material.

Owner:NINGBO VEKEN BATTERY

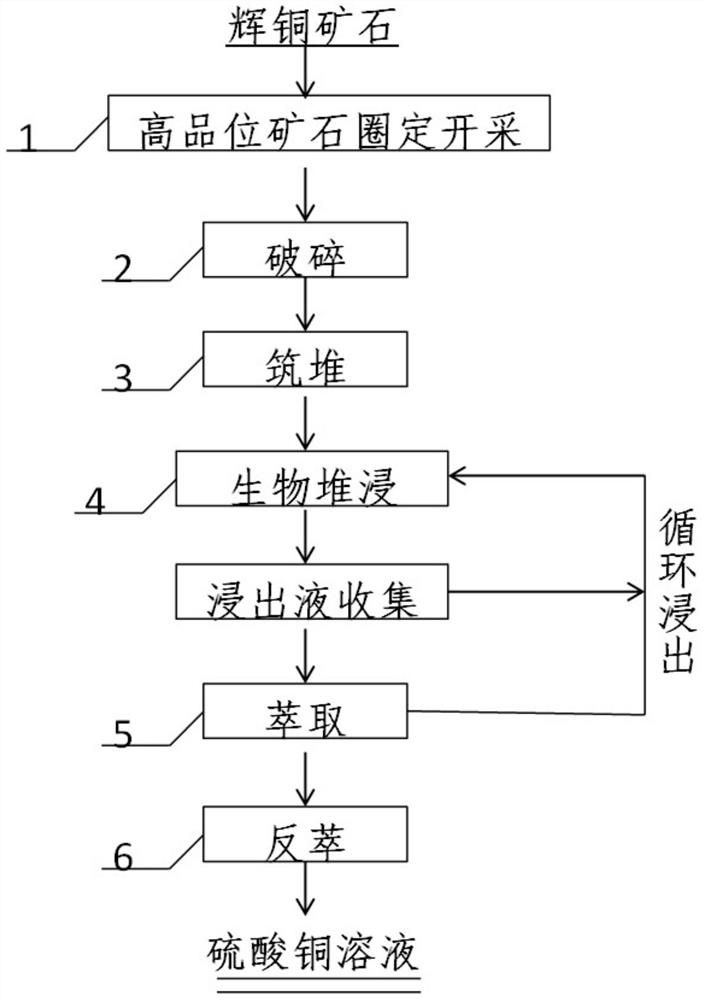

Method for intensively extracting copper in high-grade chalcocite

PendingCN112626336AFast leachingPromote leachingProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention relates to a method for intensively extracting copper in high-grade chalcocite, and belongs to the field of wet nonferrous metallurgy. According to the method, the high-grade chalcocite ore is crushed and heaped, after heaped, high-acid and high-iron bacterium-containing raffinate is adopted for cyclic leaching operation, leachate is sampled at regular intervals to analyze the copper concentration, when the copper concentration of the leachate is larger than 3.5 g / l, the leachate is extracted, and the extracted raffinate returns to continue to be leached. According to the method, a high-acid and high-iron leaching system is formed in a high-grade chalcocite dump leaching system in a manner of combining biological dump leaching circulating leaching and extraction acid returning, and rapid leaching of the chalcocite is enhanced and promoted, so that the leaching period is shortened, massive leaching of copper metal is realized, and the utilization rate of copper resources is increased.

Owner:WANBAO MINING

Full-glaze cinnabar red porcelain and preparation process thereof

The invention discloses full-glaze cinnabar red porcelain and a preparation process thereof. The cinnabar red porcelain comprises a green body and cinnabar red glaze coated on the green body, the cinnabar red glaze is prepared from the following raw materials: Dehua quartz, kaolin, chalcocite, hematite, lanthanum oxide, calcium oxide, sphalerite, magnesium oxide and frit; the surface of the porcelain prepared by the invention is a smooth vermilion glaze surface, and the porcelain is high in smoothness, good in glossiness and uniform in color distribution, so that the aesthetic property of the porcelain is greatly improved, and the market demand of people on red glazed porcelain can be met; wherein in the glaze composition, chalcocite, hematite, lanthanum oxide and calcium oxide are matched with one another to serve as a color developing agent, sphalerite and magnesium oxide are matched with the color developing agent, and meanwhile, a specific firing process is limited, so that the chromaticity, uniformity and integrity of the glaze surface of the prepared porcelain are guaranteed.

Owner:福建省德化县零度创意有限公司

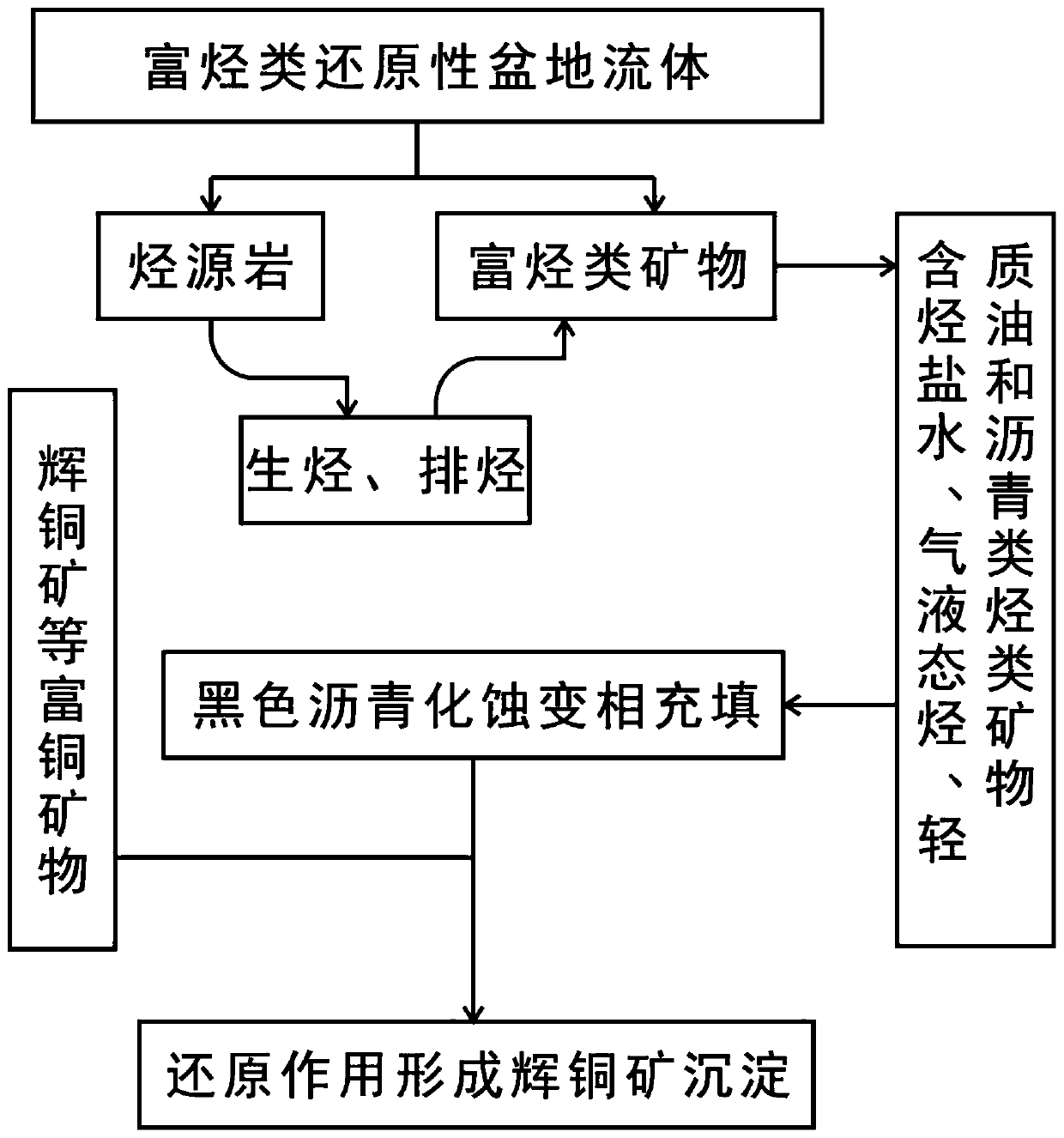

Hydrocarbon-rich reductive ore-forming fluid determination method

PendingCN109870744AResolve identifiabilitySolve delineationGeological measurementsCopperTotal organic carbon

The invention relates to a hydrocarbon-rich reductive ore-forming fluid determination method. The hydrocarbon-rich reductive ore-forming fluid determination method specifically comprises the followingsteps of (1) determining a main hydrocarbon source rock series according to petrography characteristics of sedimentary rock; (2) determining matter sources of hydrocarbon-rich reductive ore-forming fluid and a hydrocarbon source rock area by determining total organic carbon; and (3) massively reducing oxidized copper formed by an initial concentration effect in copper-containing amaranthine anagenite by using hydrocarbon-rich reductive ore-forming fluid as an important reduction agent to form chalcocite precipitates. The hydrocarbon-rich reductive ore-forming fluid determination method has the following advantages that the identification and delineation of the hydrocarbon-rich reductive ore-forming fluid can be solved, the gathering and positioning capacity of sedimentary ore-forming sandy conglomerate copper-lead-zinc mineral deposits can be effectively improved, and the characteristics of high recognition degree, rapidness and effectiveness can be realized.

Owner:有色金属矿产地质调查中心

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com