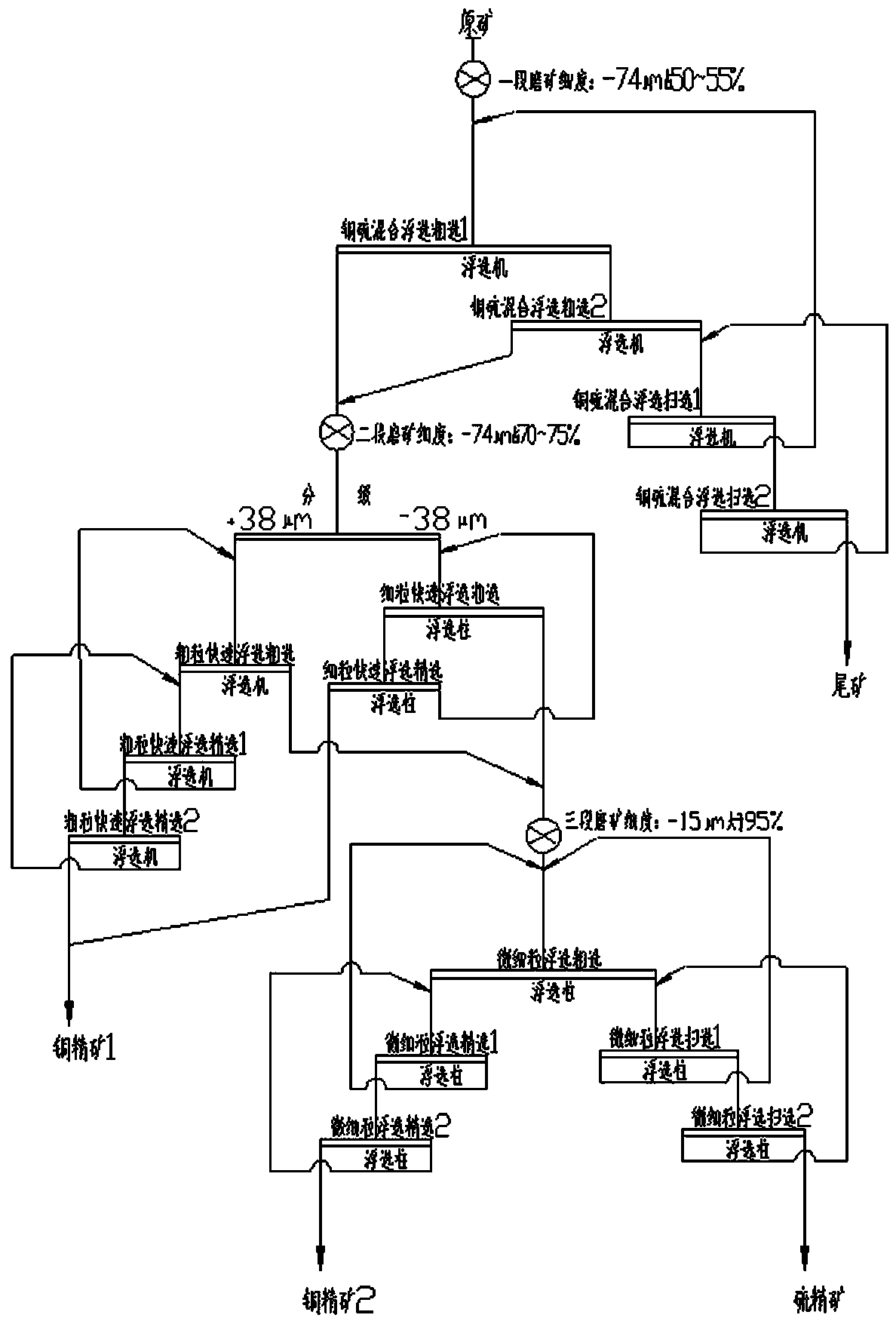

Process for recovering chalcocite and chalcopyrite with non-uniform disseminated grain size from high pyritized skarn copper ores

A technology of pyrite and skarn, which is applied in the field of mining engineering, can solve the problems of uneven particle size of copper mineral embedding, low grade of copper mineral concentrate, and low dispersion of flotation bubbles, and achieve fine bubbles. , improve the grade, and improve the flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A processing plant in Yuxi, Yunnan, contains 0.54% copper and 16.72% iron. The main metal minerals are sulfide minerals (chalcopyrite, chalcocite and pyrite). If the ore sample is large, the above-mentioned ore sample is processed by the following process steps:

[0061] A. One-stage grinding: The crushed copper ore is ground for one-stage grinding, and the grinding fineness is -74μm, accounting for 55%.

[0062] B. Copper-sulfur mixed flotation: the grinding products are subjected to copper-sulfur mixed flotation. The process conditions of copper-sulfur mixed flotation roughing 1 are adding activator 500 g / ton, stirring for 4 minutes, adding butyl xanthate 80 g / ton , 50 g / ton of pine alcohol oil, stirring for 3 minutes; the process conditions of copper-sulfur mixed flotation roughing 2 are adding 40 grams / ton of butyl xanthate, adding 20 grams / ton of pine alcohol oil, stirring for 3 minutes; copper-sulfur mixed flotation The process condition of flotation sweep 1 is t...

Embodiment 2

[0069] A concentrator in Longyan, Fujian, contains 0.60% copper and 17.57% iron. The main metal minerals are sulfide minerals (chalcopyrite, chalcocite and pyrite). If the ore sample is large, the above-mentioned ore sample is processed by the following process steps:

[0070]A. One-stage grinding: The crushed copper ore is ground for one-stage grinding, and the grinding fineness is -74μm, accounting for 50%.

[0071] B. Copper-sulfur mixed flotation: the grinding products are subjected to copper-sulfur mixed flotation. The process conditions of copper-sulfur mixed flotation roughing 1 are adding activator 300g / ton, stirring for 4 minutes, adding isopentyl xanthate 90g / ton, 24K 40 g / ton, stirring for 4 minutes; the process conditions of copper-sulfur mixed flotation roughing 2 are adding isopentyl xanthate 45 g / ton, adding 24K 20 g / ton, stirring for 3 minutes; copper-sulfur mixed The process condition of flotation sweep 1 is to add isopentyl xanthate 25g / ton, add 24K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com