Patents

Literature

259results about How to "Improve flotation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

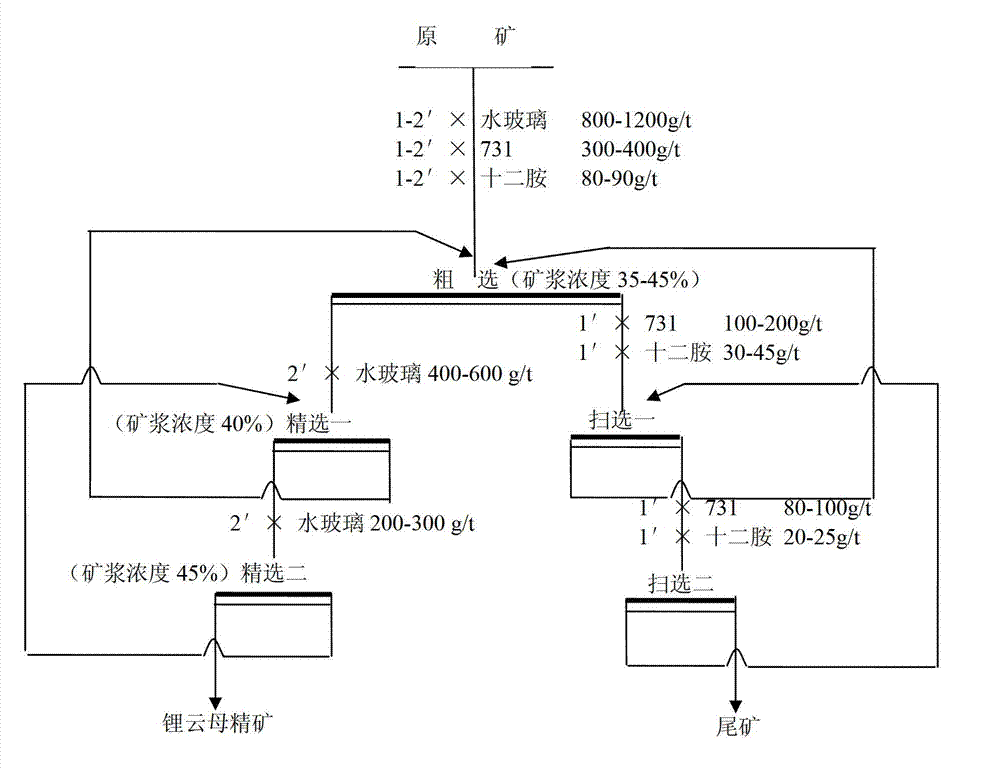

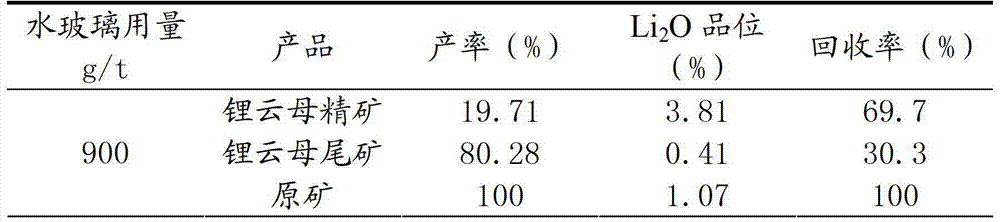

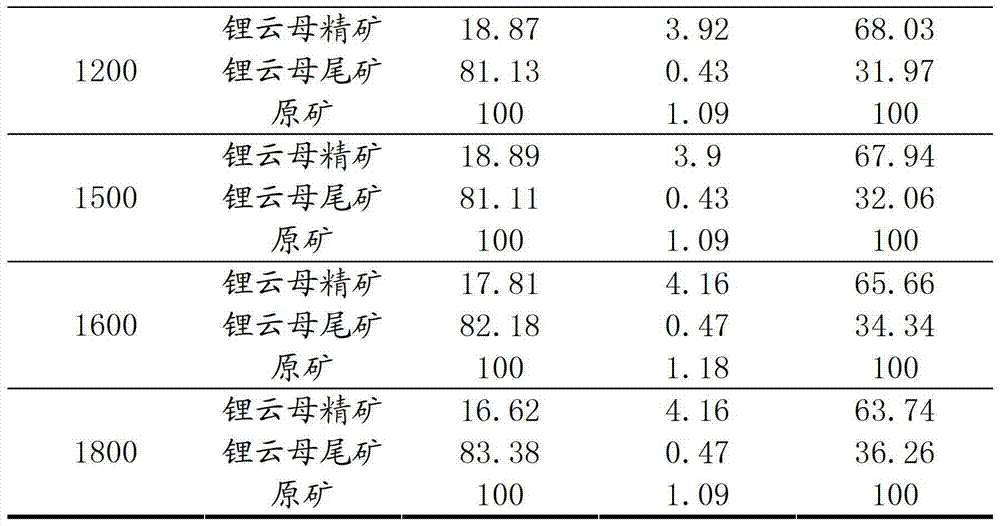

Novel lepidolite flotation method

InactiveCN103240185AEfficient separationLarge adsorption capacityFlotationCoconut oilCharge compensation

The invention discloses a novel lepidolite flotation method including primary rough selection, secondary fine selection and secondary scavenging. During the flotation, sodium silicate is added as an inhibitor with the amount ranging from 1400g / t to 1900g / t; an anionic collector is sodium oleate or oxyparaffin soap 731 with the amount ranging from 480g / t to 700g / t; and a cationic collector is dodecylamine or coconut oil amine with the amount ranging from 130g / t to 160g / t. The adding sequence of collectors is the anionic collector first and the cationic collector second, or the anionic collector and the cationic collector are added together. By the method, the lepidolite is selected through the combination of the anionic and the cationic, good flotation effect can be realized, flotation efficiency is high, and meanwhile, the synergistic effect is generated between the anionic collector and the cationic collector, and results from joint action of three mechanisms of coadsorption, charge compensation and function complementation.

Owner:JIANGXI UNIV OF SCI & TECH

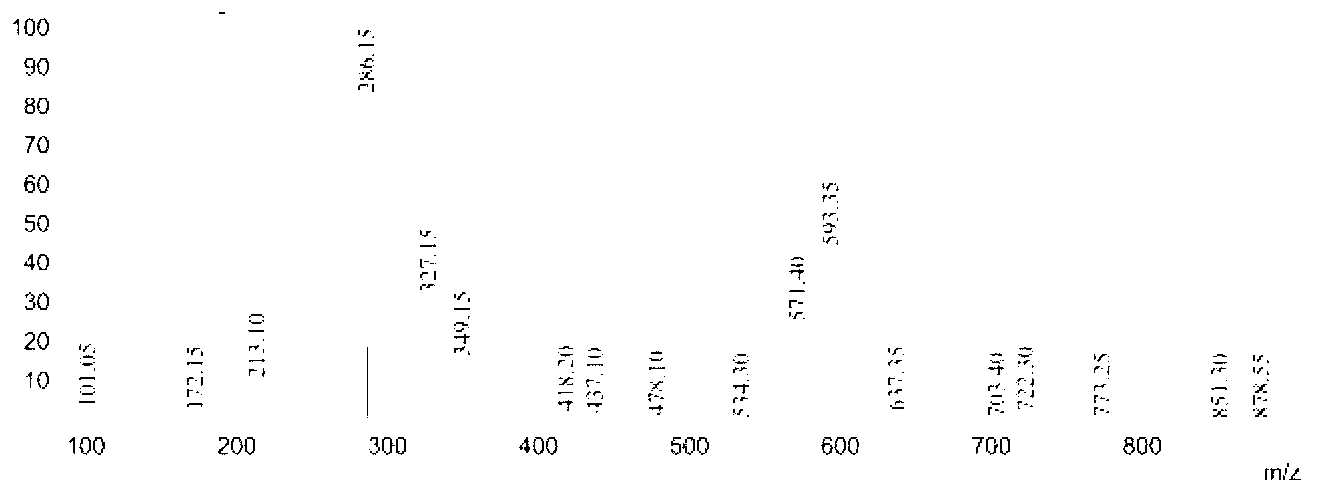

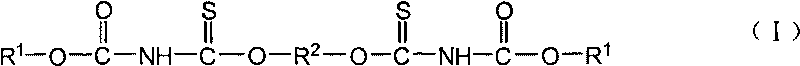

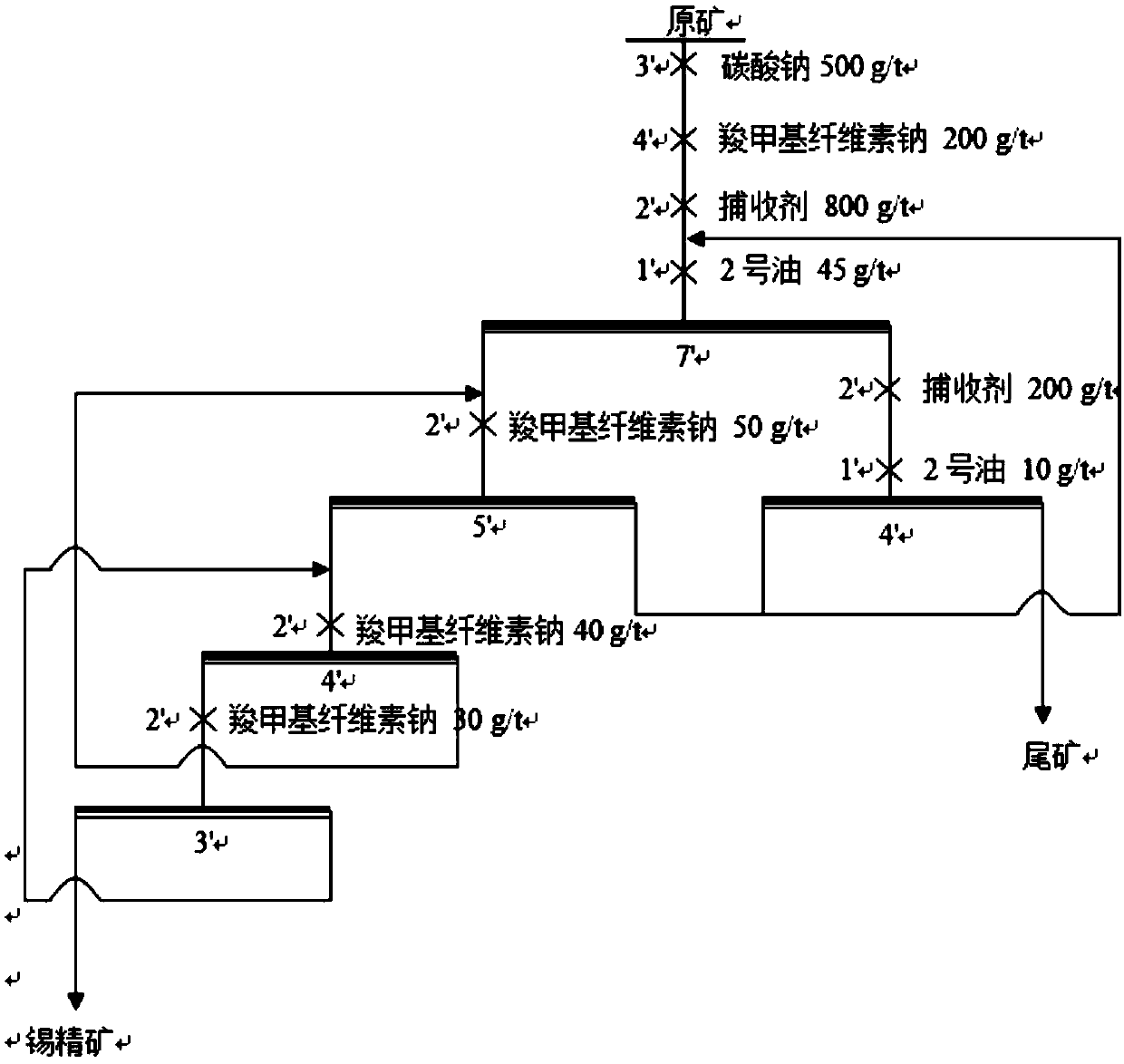

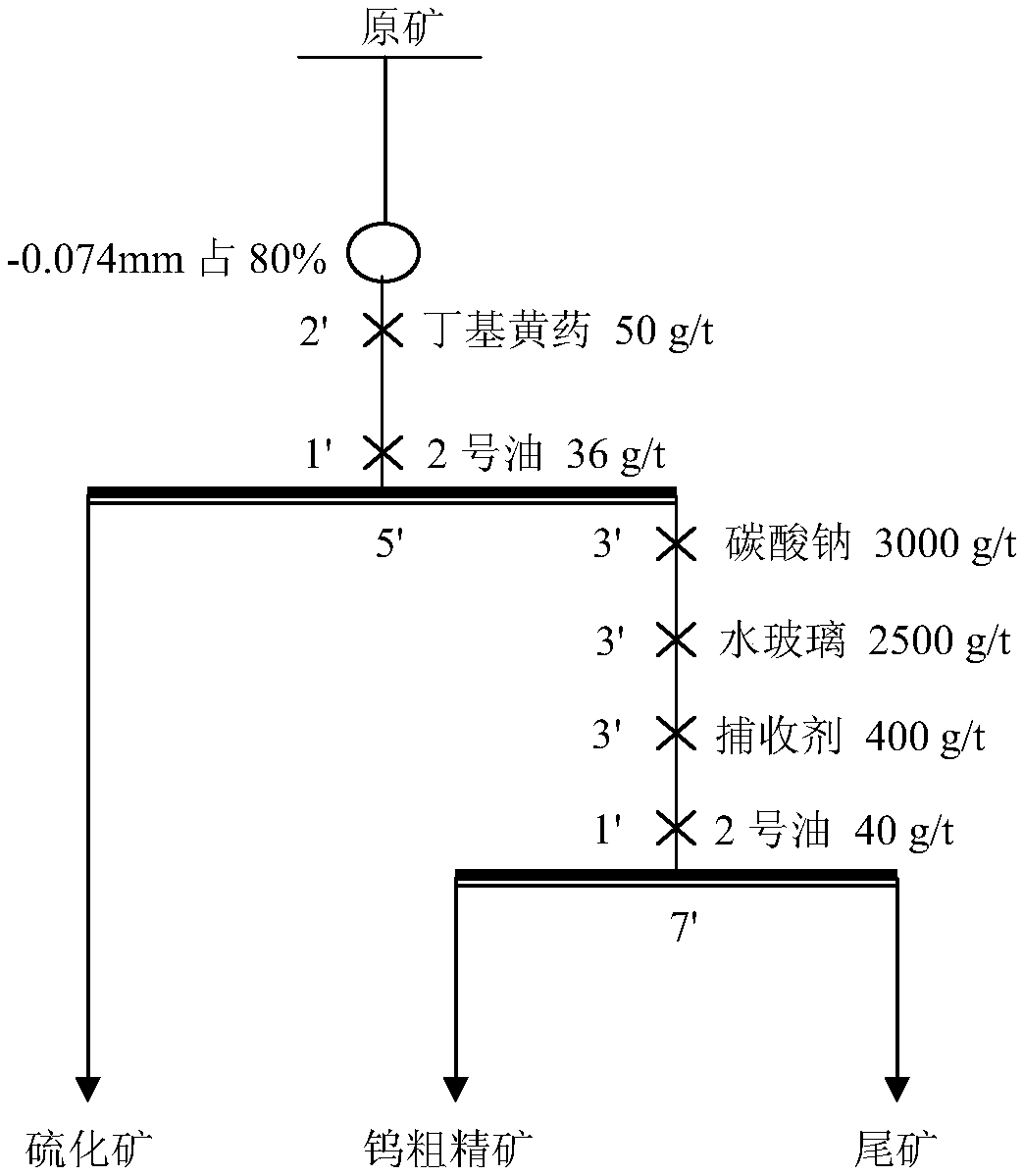

6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301952AImprove flotation recoveryAchieve high flotation separationFlotationReaction temperatureCarboxylic acid

A structural formula of a 6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent is represented by a formula (I), wherein R represents C2-C18 aliphatic hydrocarbon group. The preparation method comprises the steps as follows: caprolactam and hydroxylamine hydrochloride or hydroxylamine sulphate are taken as raw materials, methylbenzene is taken as a solvent, the reaction temperature ranges from 80 DEG C to 110 DEG C, the reaction lasts for 1-4 hours, and 6-amino hexyl hydroximic acid is generated; 6-amino hexyl hydroximic acid reacts with C2-C18 fat carboxylic acid at the reaction temperature ranging from 100 DEG C to 160 DEG C for 1-4 hours to generate 6-aliphatic hydrocarbon amido hexyl hydroximic acid, and the product yield can be higher than 91%; and 6-aliphatic hydrocarbon amido hexyl hydroximic acid used in flotation of scheelite, wolframite, tombarthite ore, tin ore, bauxite, titanic iron ore or fluorite ore is taken as the collecting agent, so that the flotation recovery rate can be increased by 3%-10%.

Owner:CENT SOUTH UNIV

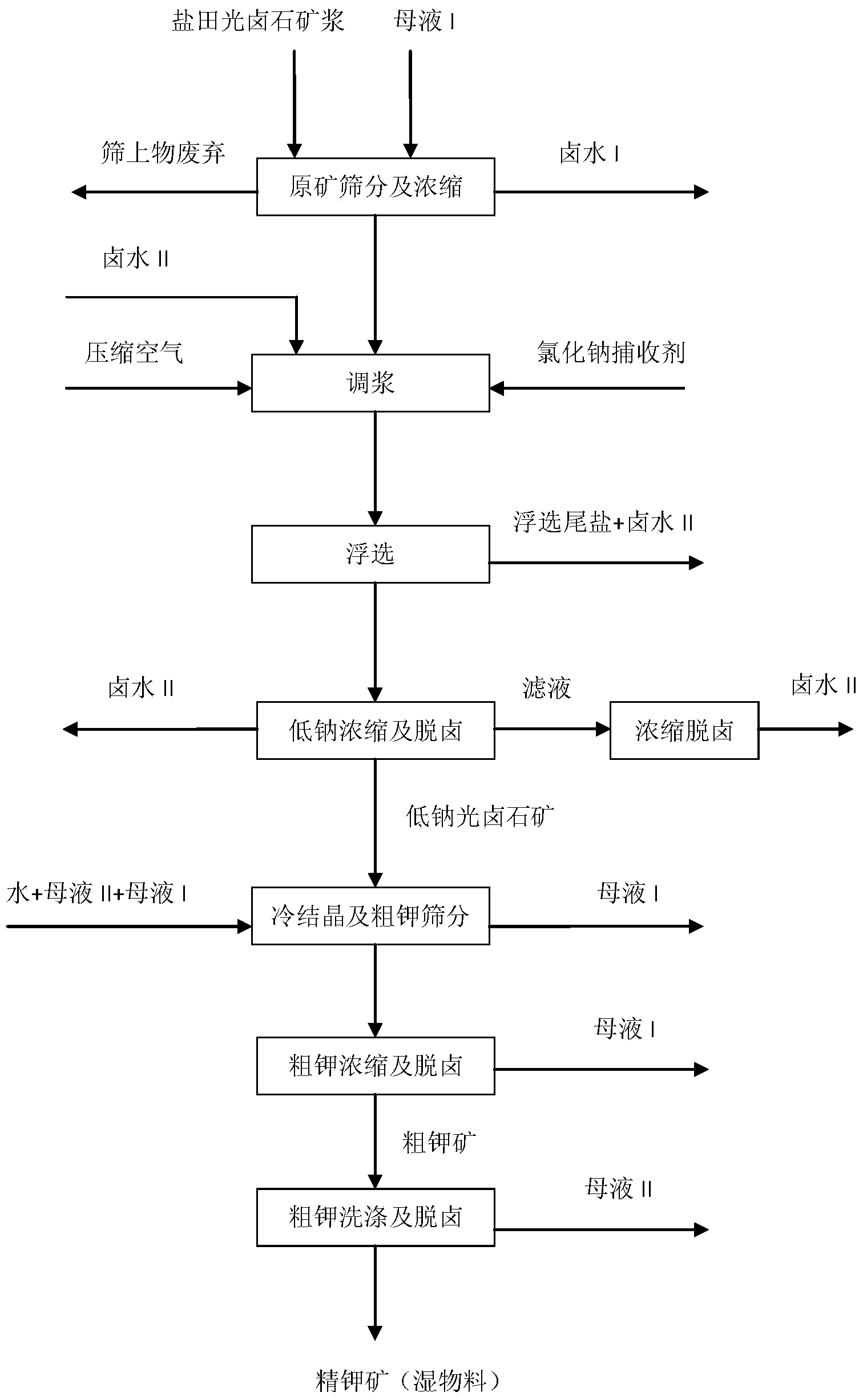

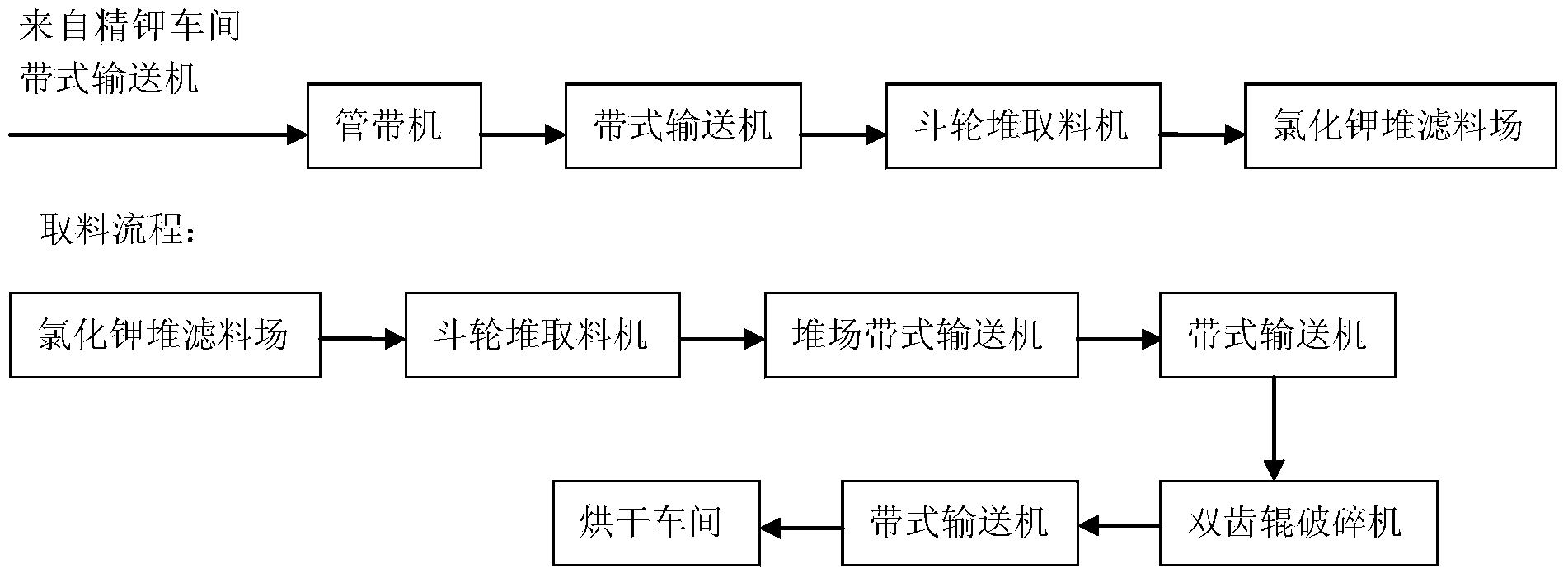

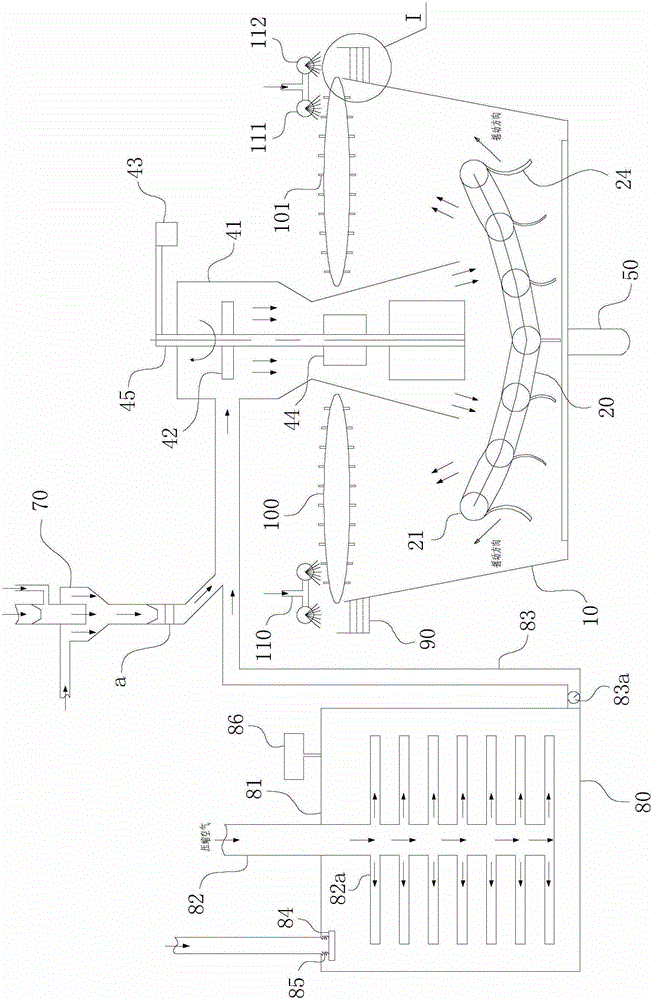

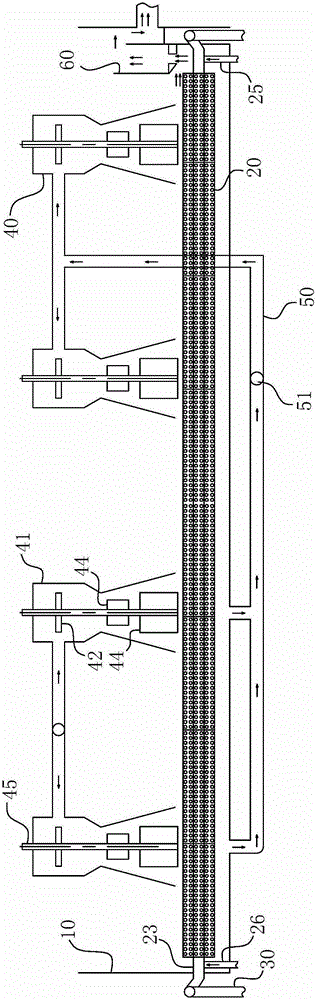

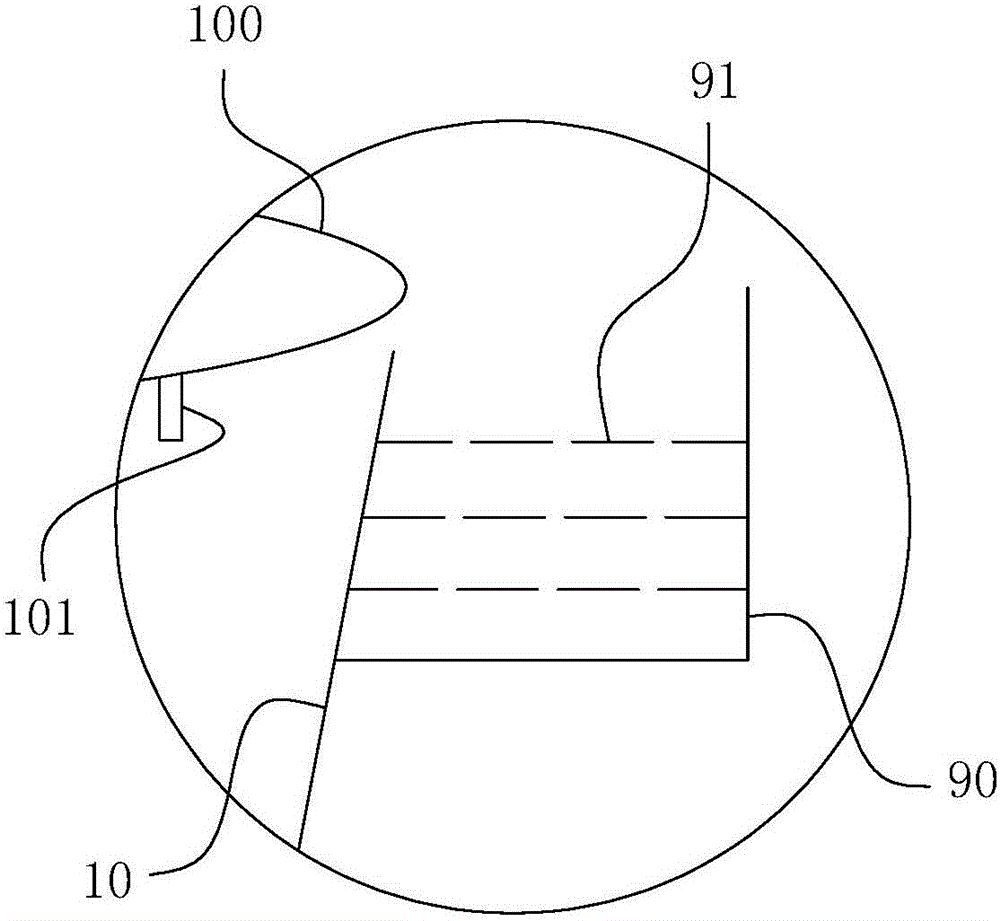

High-grade potassium chloride production system and method thereof

ActiveCN104058427ARaise the gradeReduce dosageAlkali metal chloridesAlkali metal halide purificationChemistryLow sodium

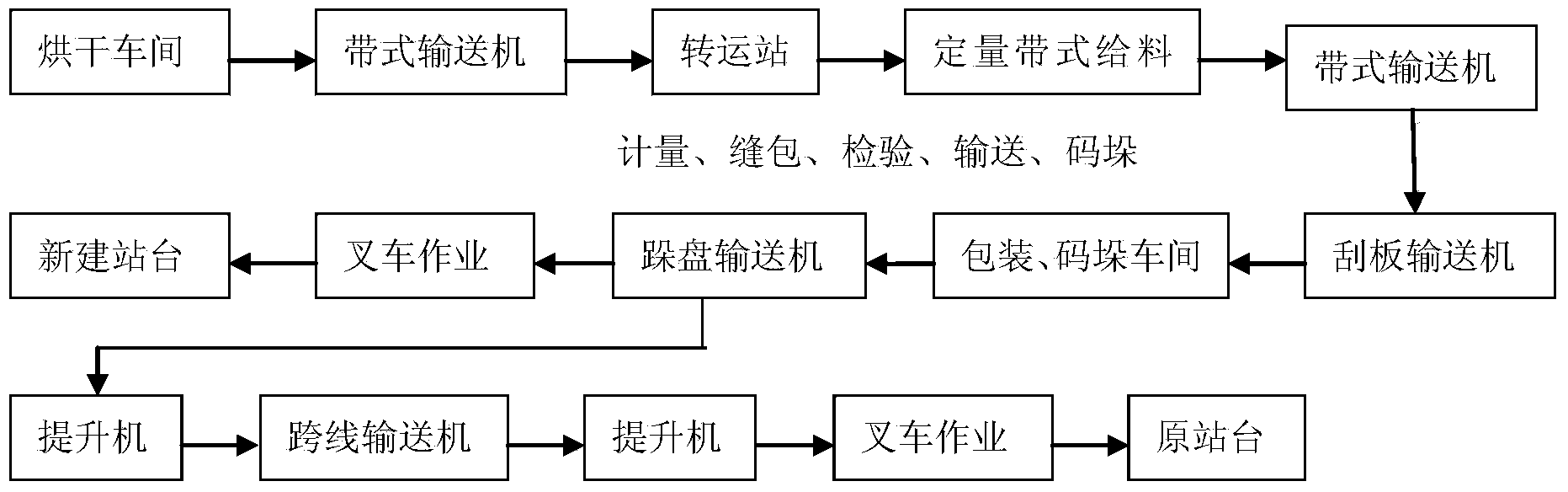

The invention discloses a high-grade potassium chloride production system and a method thereof. The system comprises a raw ore screening and concentrating system, a size mixing system, a floatation system, a low sodium concentration and dehalogenation system, a cold crystallization and thick potassium screening system, a thick potassium concentration and dehalogenation system, a refined potassium washing and dehalogenation system, a piling and filtering storage stock ground system, a breaking and conveying system and a drying cooling, packing, stacking and line crossing conveying system, and all the systems are sequentially connected and are arranged in a three-dimensional mode. Materials enter a next system in a self-flowing mode. An automatic dosing, automatic water adding and dehalogenation device is adopted, a spiral screen type centrifugal machine is used for replacing a horizontal belt type filter, and other technology improvements are adopted, so that the potassium chloride grade is improved to 98 percent from 95 percent, the piling and filtering technology is adopted in the system so that the natural gas using amount can be saved, production operation is convenient, and equipment operation is stable.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

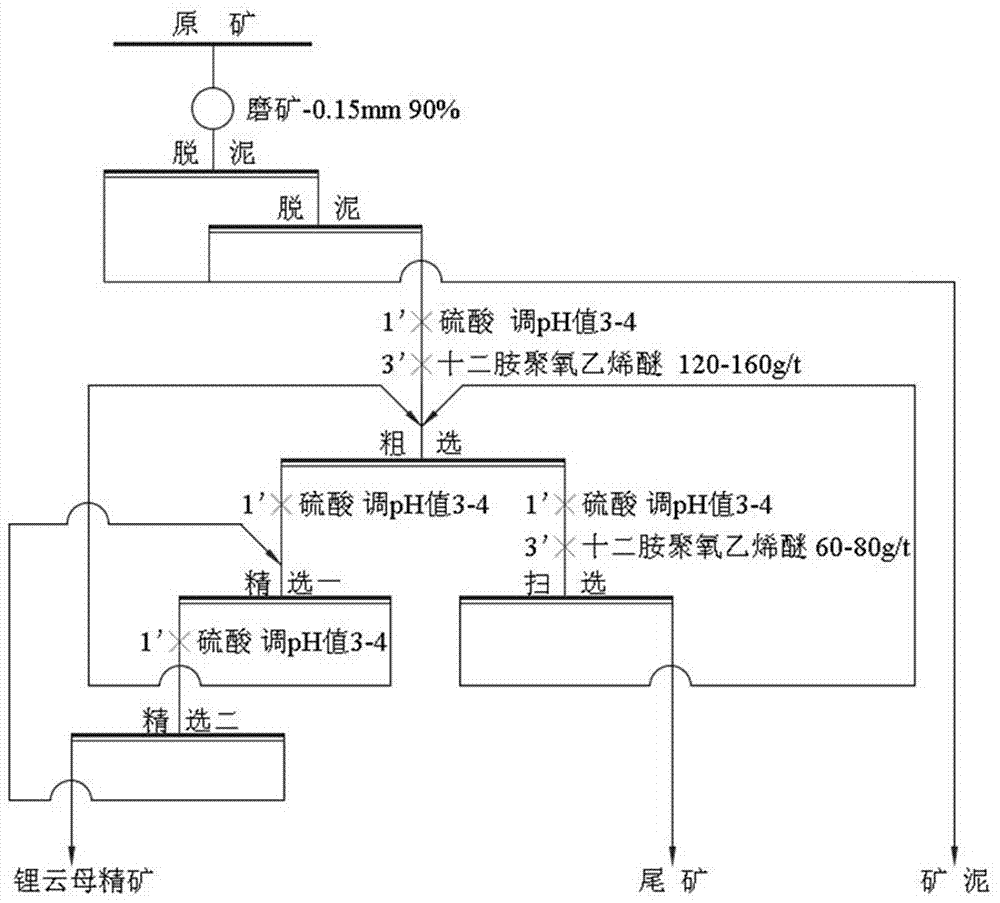

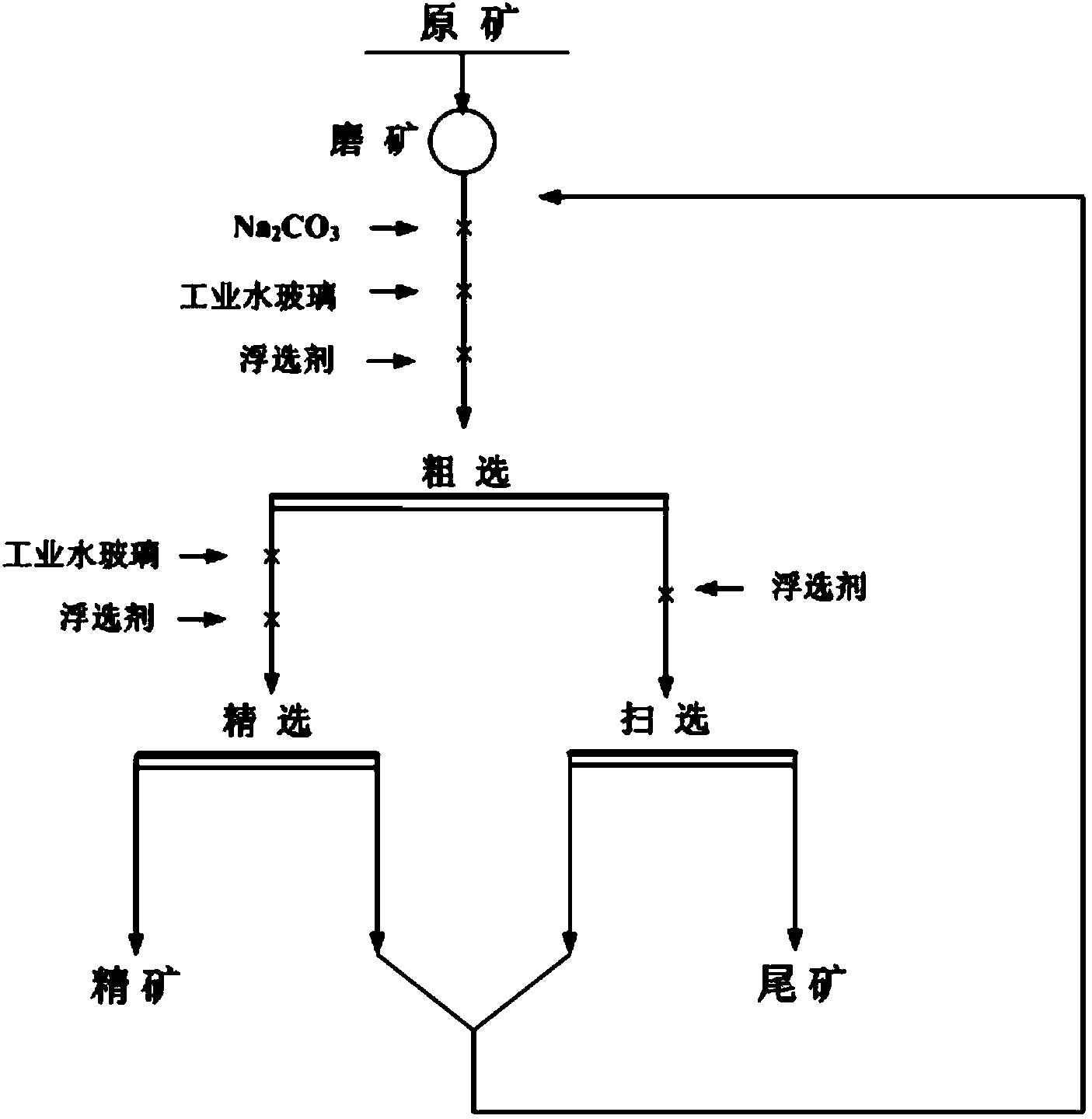

Lepidolite floatation method

ActiveCN107008567AImprove adaptabilityEasy to makeFlotationWet separationConcentration ratioLepidolite

The invention discloses a lepidolite floatation method. The lepidolite floatation method comprises the steps that raw ore is subjected to wet ball milling after being crushed to obtain ore pulp; and the ore pulp is subjected to floatation separation with a lauryl amine polyoxyethylene ether solution serving as a collecting agent and with sulfuric acid serving as a regulating agent to obtain high-quality lepidolite concentrate. The lepidolite floatation method has the characteristics of being simple in process, low in agent consumption and production cost and good in adaptability to slime, the recovery rate of the lepidolite concentrate reaches 66.38% relative to Li2O in the raw ore, the content of lepidolite concentrate grade Li2O reaches 3.17%, the concentration ratio reaches 4.80, comprehensive utilization value of lepidolite resources is remarkably improved, and the floatation method is environmentally friendly and has sustainable-development long-term and practical significance.

Owner:CENT SOUTH UNIV

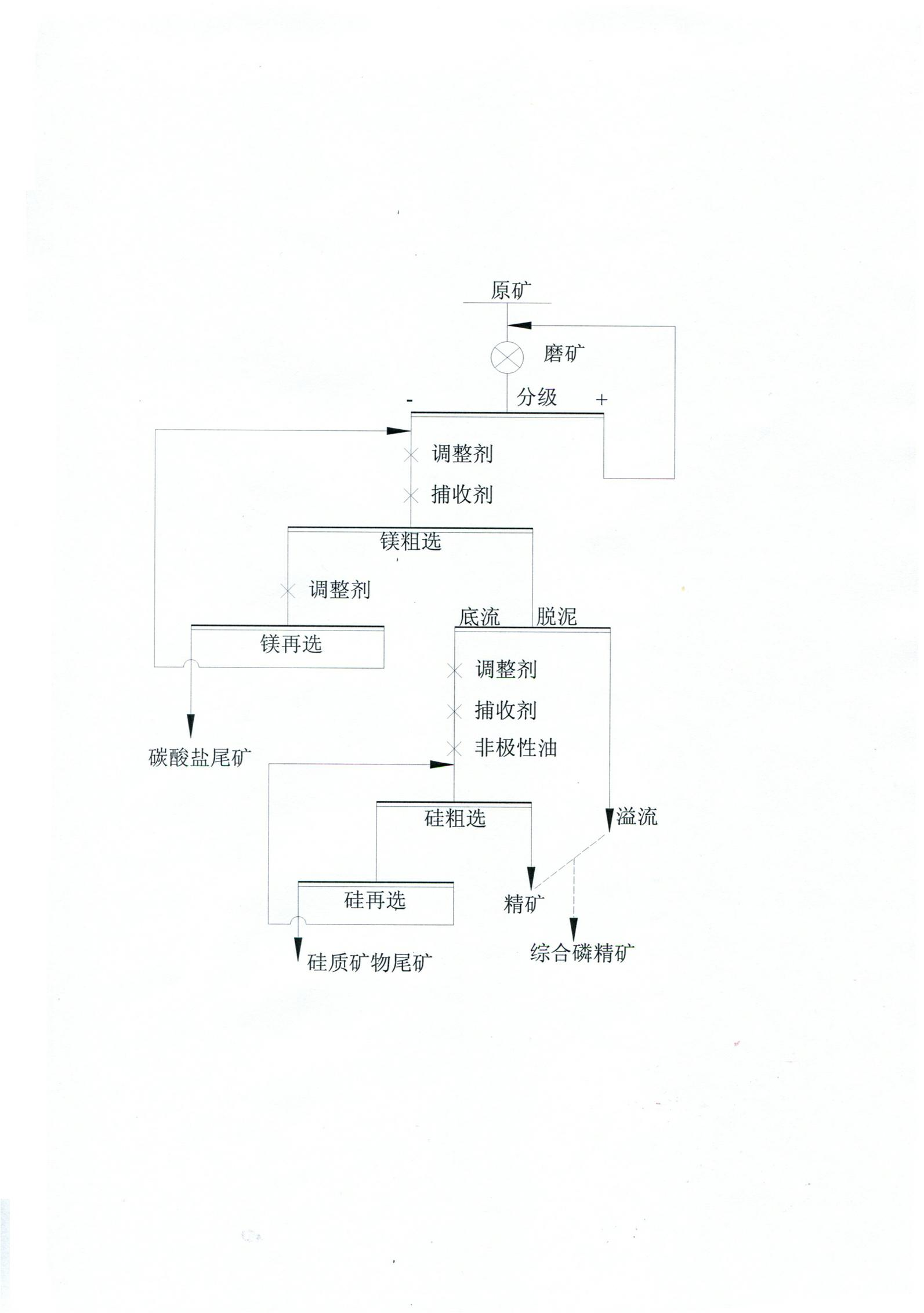

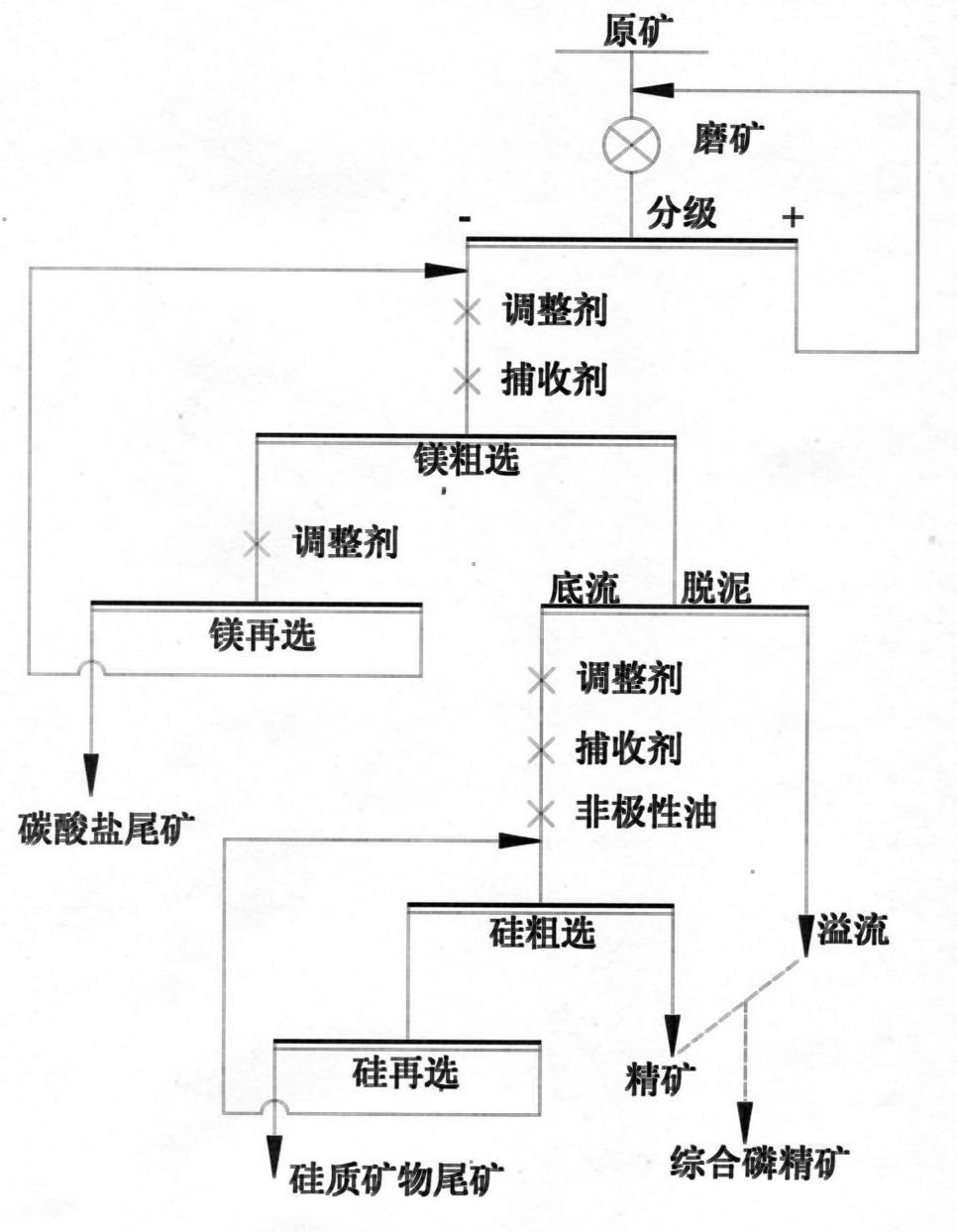

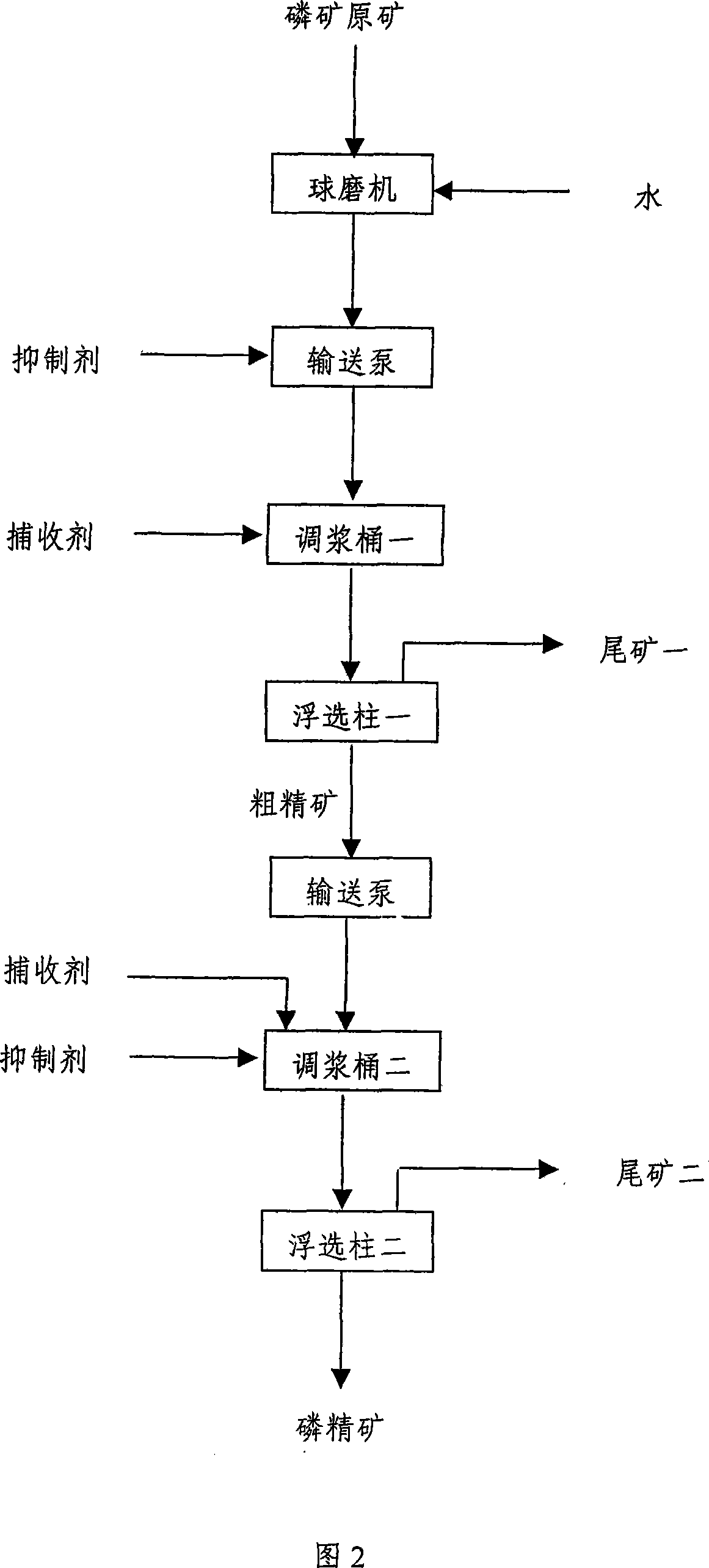

Phosphorite double-reverse flotation process

The invention relates to phosphorite double-reverse flotation process, which comprises reverse flotation de-magging, desliming and pulp mixing and reverse flotation desilicication. The phosphorite double-reverse flotation process is characterized in that ore pulp after reverse flotation de-magging realizes desliming, the concentration of a desliming bottom flow and the content of fine particles are controlled, and reverse flotation desilicication is realized after pulp mixing of the bottom flow. The phosphorite double-reverse flotation process can eliminate or mostly remove interference of slime to reverse flotation desilicication, increases flotation efficiency, more importantly, improves fluidity of flotation foam, and lead phosphorite double-reverse flotation to be engineered.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

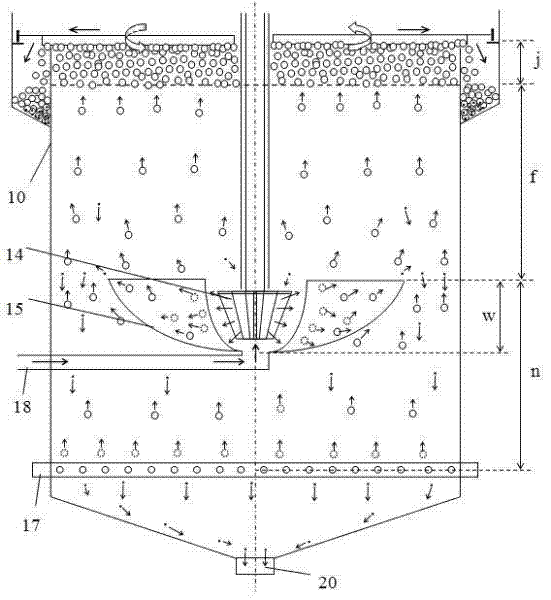

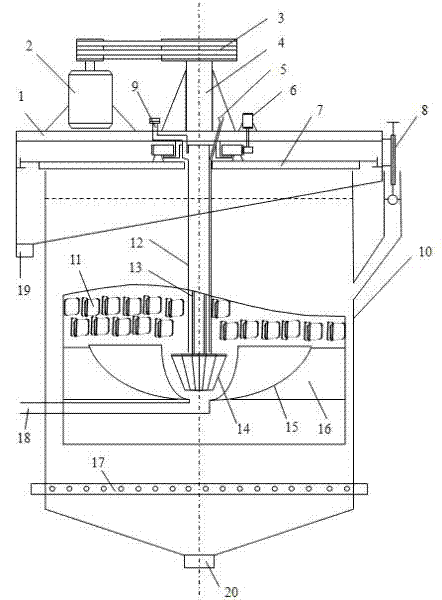

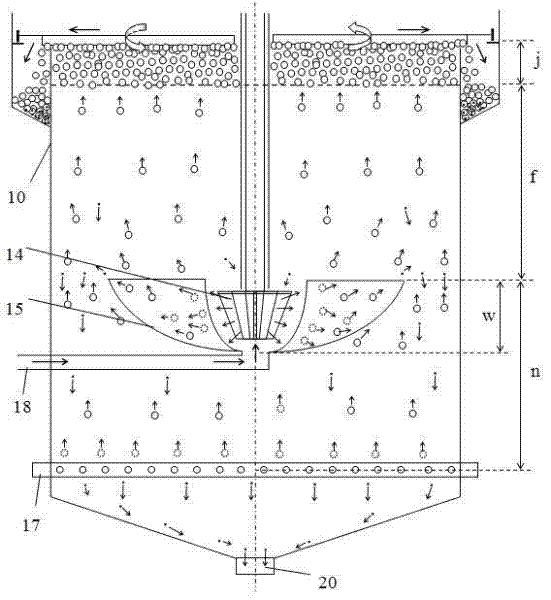

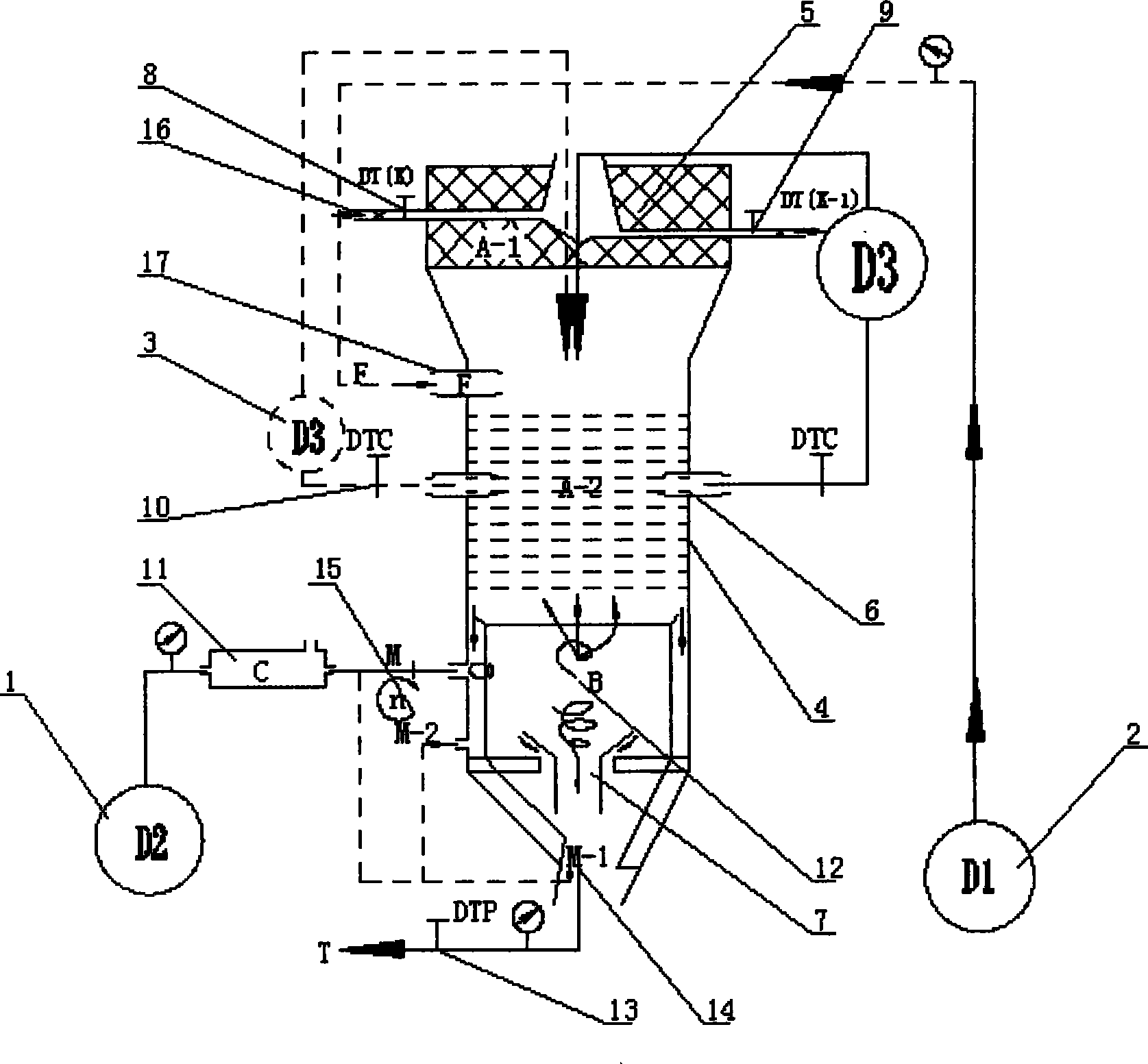

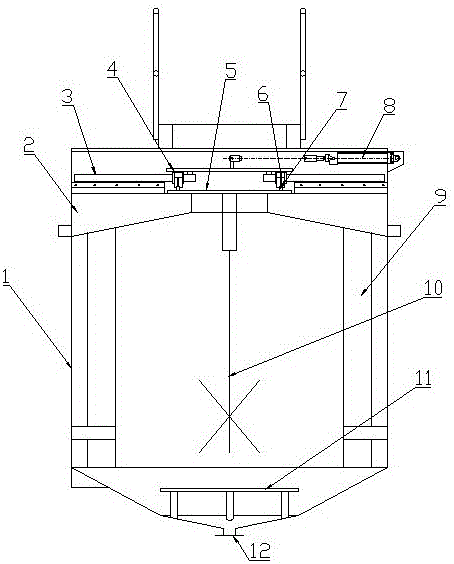

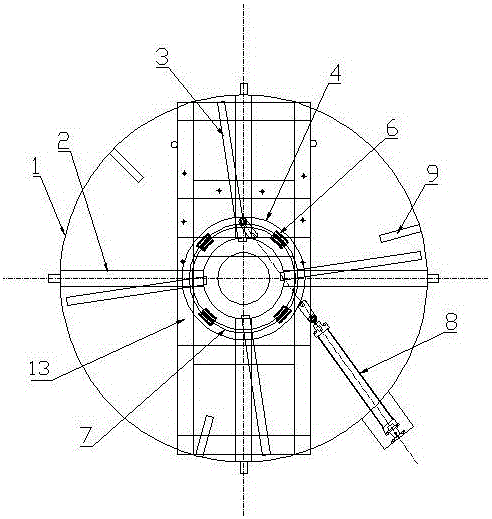

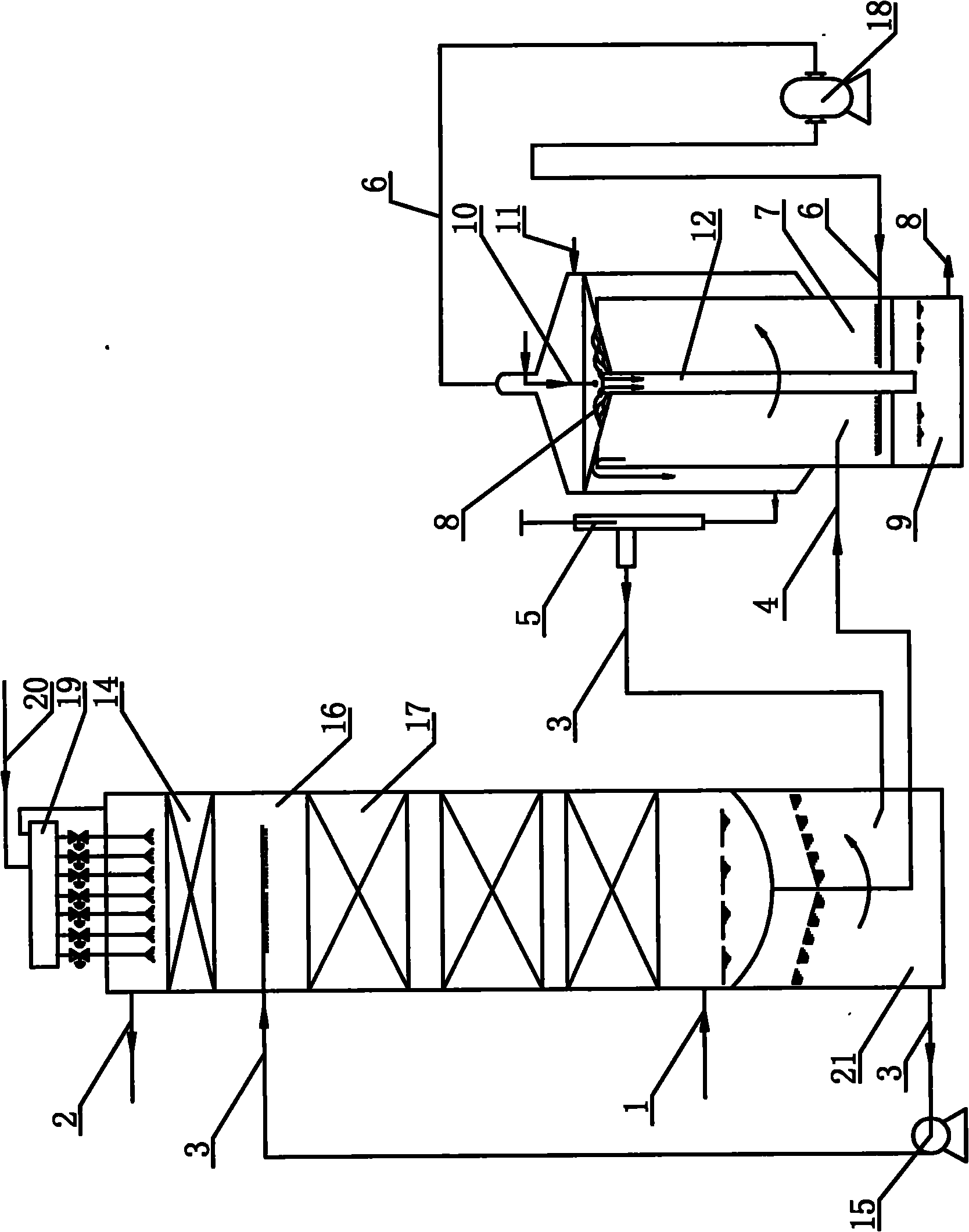

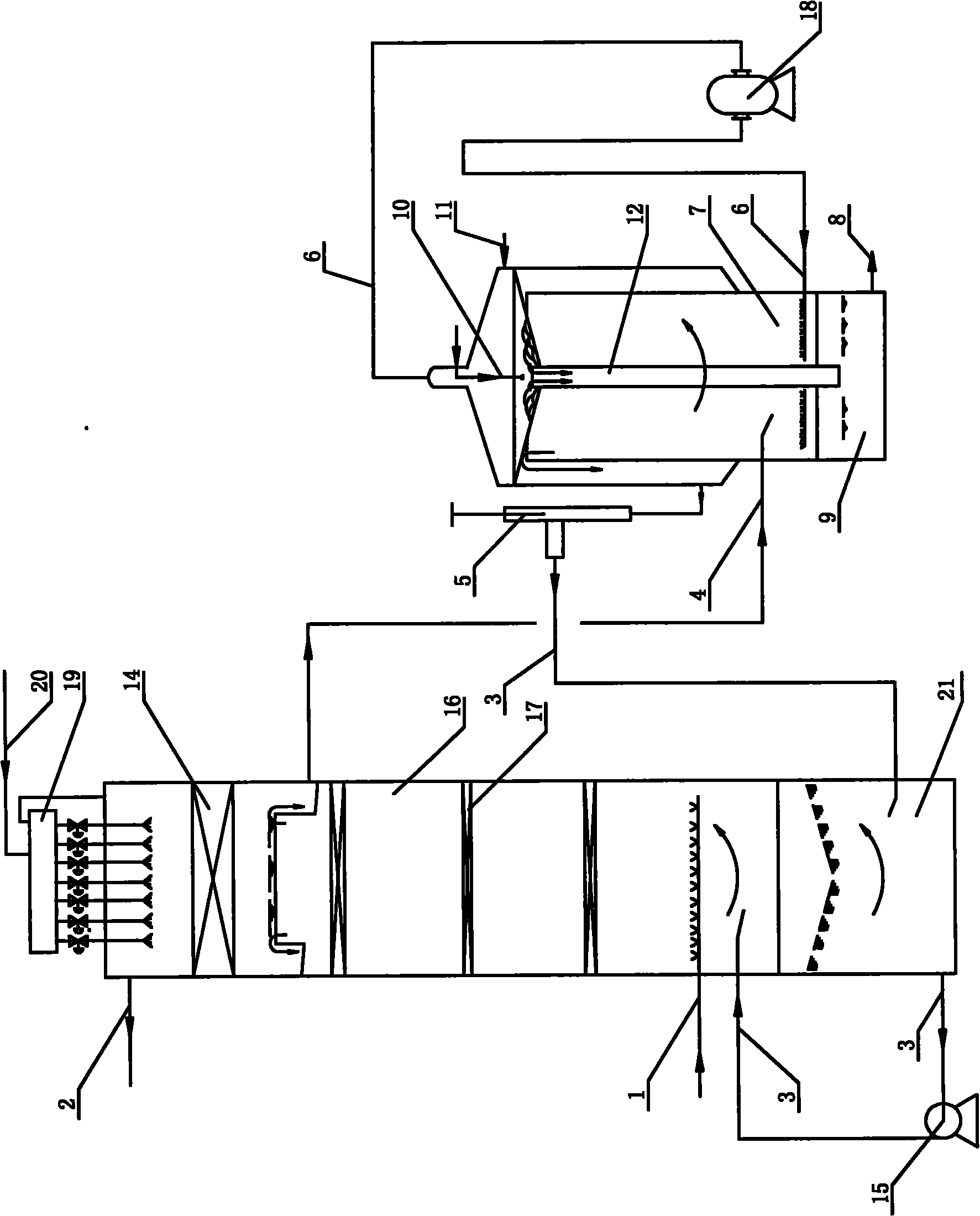

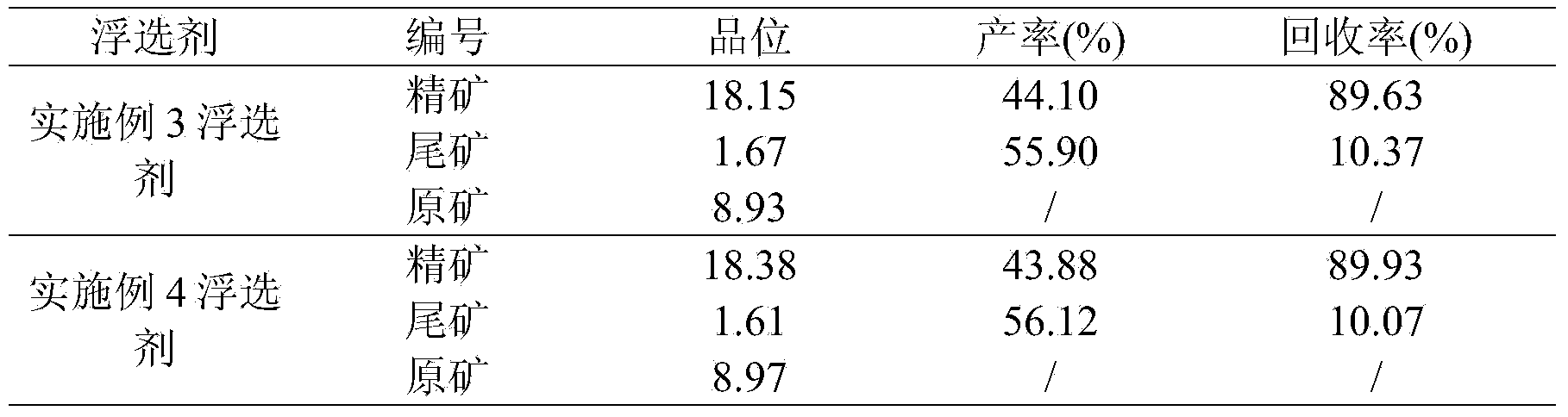

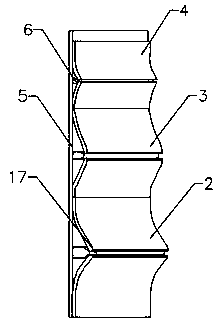

High-efficiency flotation method and its flotation equipment

ActiveCN102284371AAchieve weak turbulence separationImprove mineralization abilityFlotationImpellerEngineering

The invention discloses a column combined reinforced high-efficiency flotation method and flotation equipment thereof. The method comprises four processes, namely strong turbulence mineralization realized by a raw ore through mechanical stirring, static flotation realized by settled sands through counterflow mineralization, weak turbulence separation realized by bubbles through a rectification effect, as well as concentrate secondary enrichment and accurate scraping realization. In the flotation equipment, a bracket is arranged on the top of a cylinder body, a flat scraper is arranged on the lower side of the bracket; a feed pipe is arranged on a position in lower middle of the cylinder body; the outlet end of the feed pipe is connected with the lower end of a false bottom; the false bottom is connected with a rectification plate; an annular inflating pipe is arranged on the lower part of the cylinder body; a monomer rectification plate is connected to the inner wall of the cylinder body; a sleeve is sleeved outside a hollow shaft; and an impeller is connected with the lower end of the hollow shaft. By integrating the advantages of strong mineralization effect of a flotation machine and better separation environment of a flotation column, the defects of high turbulence degree of the traditional flotation machine and insufficient mineralization of the traditional flotation column can be overcome, reinforced high-efficiency flotation is realized, and adaptability to the flotation process is stronger. The column combined reinforced high-efficiency flotation method and the flotation equipment thereof can be applied to separation operation of coals, chemical minerals and the like.

Owner:云南贝凡科技有限公司

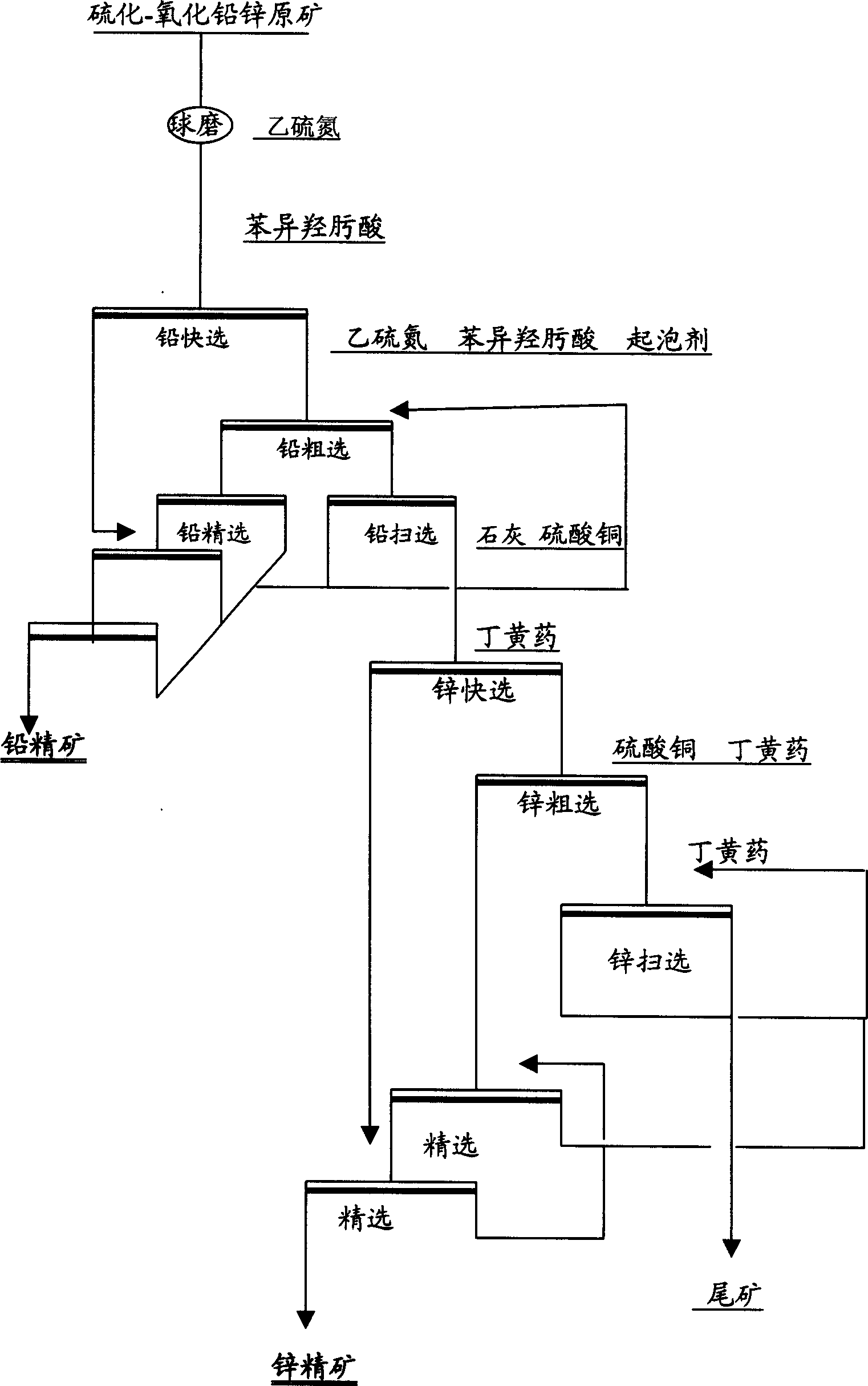

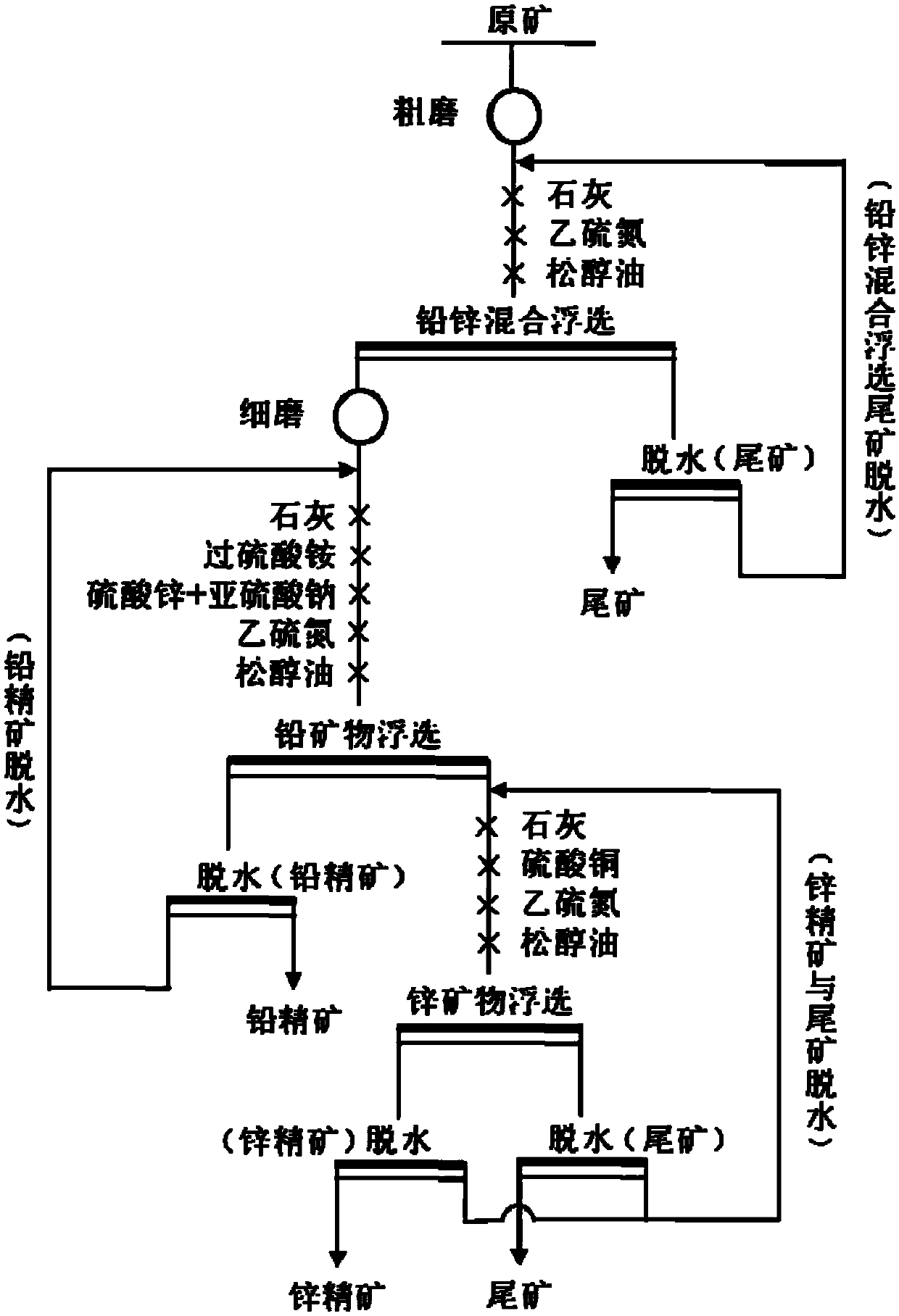

Flotation method for sulfidization-oxidization mixed lead-zinc ore

InactiveCN1704170AHigh recovery rateImprove concentrate qualityFlotationGrain treatmentsLead zincChemistry

The invention relates to a floating method of sulfide-oxide mixing Pb-Zn mine. The lead floating method adopts the flow process of one fast separation, one roughing separation, one sweeping separation and three classifications so that the mine grouting acidity of the full floating process can keep at pHú¥11. The zinc floating method adopts the flow process of one fast separation, one roughing separation, one sweeping separation and two classifications so that the mine grouting acidity of the full floating process can keep at pHú¥12. It can increase the recovery ratio of PbíóZn over 10% when Pb-Zn mine has oxide ratio over 30%.

Owner:黎东明

Flotation column for sorting mineral

The invention relates to a floatation column used for mineral separation, which is characterized in that: the floatation column comprises a column body, the interior of the column body is divided into a concentrated mineral collecting tank, a separation bucket and a tail discharge box in sequence from top to down; more than one concentrated mineral discharge ports are opened on the concentrated mineral collecting tank and provided with an electromagnetic valve used for regulating the liquid surface of the discharge of the concentrated mineral; the separation bucket comprises a middle static micro-bubble separation section and a lower cyclonic separation section, and is connected with an external inflator pump and internally provided with a cyclone in the column; the tail discharge port at the bottom of the tail discharge box is provided with an automatic discharge valve linked with the concentrated mineral discharge electromagnetic valve. The invention is a floatation column used for mineral separation which has the advantages of simple and compact structure, low cost, high efficiency and energy conservation, small land occupancy, long service life, rapid floatation speed and large processing capability.

Owner:湖南君毅科技发展有限公司

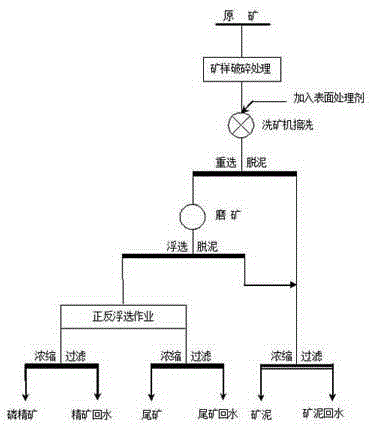

Floating technology for low-grade refractory weathering collophanite section desliming

InactiveCN104959239AAvoid secondary adsorptionImprove flotation efficiency andFlotationWet separationOre concentrateMining engineering

The invention provides a floating technology for low-grade refractory weathering collophanite section desliming. The technology comprises the steps that after coarse crushing and fine crushing are carried out on raw ore, a surface treating agent is added, and the raw ore is subjected to washing in an ore washer; washed pulp enters a shaking table to be subjected to a first-section desliming, coarse particle minerals are subjected to next desliming, and fine silt serves as slurry and is processed; the ore grinding treatment is carried out on the coarse particle minerals, ore grinding pulp is subjected to second-segment desliming, deslimed pulp is subjected to the positive and negative floating operation, and floating concentrate and floating tailings are obtained; after concentrating and filtering are carried out on the floating concentrate, a phosphorus concentrate product and concentrate backwater are obtained, the concentrating and the filtering are carried out on positive floating tailings and negative floating tailings, a tailings product and tailings backwater are obtained, deslimed two-section slurry is subjected to the concentrating and the filtering, and a slurry product and slurry backwater are obtained; according to needs, the concentrate backwater, the tailings backwater and the slurry backwater are back to the floating operation and backwater points of the ore washer to be subjected to recycling. The phosphorus concentrate quality can be improved, and the resource utilization of the low-grate collophanite is achieved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

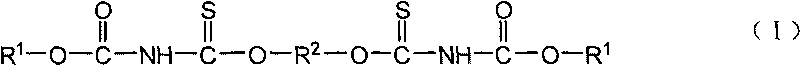

Sulfide flotation collector and preparation method

InactiveCN101698160AImprove flotation recoveryStrong harvesting abilityFlotationArylReaction temperature

A sulfide flotation collector is chemically named dialkyloxycarbonyl bisthionocarbamate and has a general molecular formula shown as formula (I). In the formula, R1 represents alkyl, aryl or aralkyl of C1-C8 and R2 represents alkylene of C2-C6 or ether-containing alkyl with the general formula being -R3-(OR4)n-, wherein R3 and R4 are respectively ethylidene or propylidene, and n is equal to 1-3. A preparation method of the sulfide flotation collector is characterized in that N-alkyloxycarbonyl isothiocyanates and a diol compound are subjected to addition reaction for 2-10h under reaction temperature of 20-80 DEG C. The synthetic method is simple and convenient. Being used as the sulfide collector, the compound with the structure of the formula (I) can efficiently recover valuable metal ores from the sulfide ores and the sulfide ores of associated precious metals and has the characteristics of high flotation efficiency and metal recovery, etc. The invention also relates to the preparation method of the collector.

Owner:CENT SOUTH UNIV

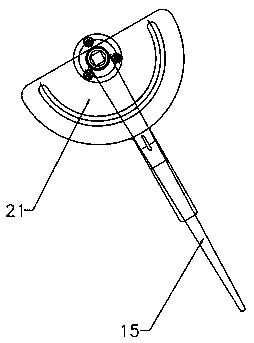

Flotation device and method for removing free carbon in silicon carbide powder

The invention relates to a flotation device and method for removing free carbon in silicon carbide powder. The device comprises a tank and a stirring device. The stirring device is connected with the tank through a fixed frame. A material inlet is arranged at the top of the tank, and a material outlet is arranged at the bottom of the tank. A foam scraping-away device is arranged at the position, between the inner wall of the tank and the stirring device, close to the material inlet, and comprises a foam collecting tank arranged in the radial direction of the tank and a rotary scraping plate matching the foam collecting tank. The outer end of the foam collecting tank is connected with the side wall of the tank, and a foam output opening is formed in the connecting position. The inner end of the foam collecting tank is connected with a fixed seat at the bottom of the fixed frame. A rotary seat is arranged on the fixed seat and provided with the rotary scraping plate. The foam collecting tank and the rotary scraping plate are arranged, so that foam with free carbon on a liquid face is removed smoothly in time, and flotation efficiency is improved. The foam output opening is arranged, so that automatic discharge is achieved. The rotary seat is arranged to avoid dead corner scraping. A power mechanism is arranged, so that the automation degree is high, good stability is achieved, and the flotation efficiency is improved.

Owner:连云港龙塔研磨材料有限公司

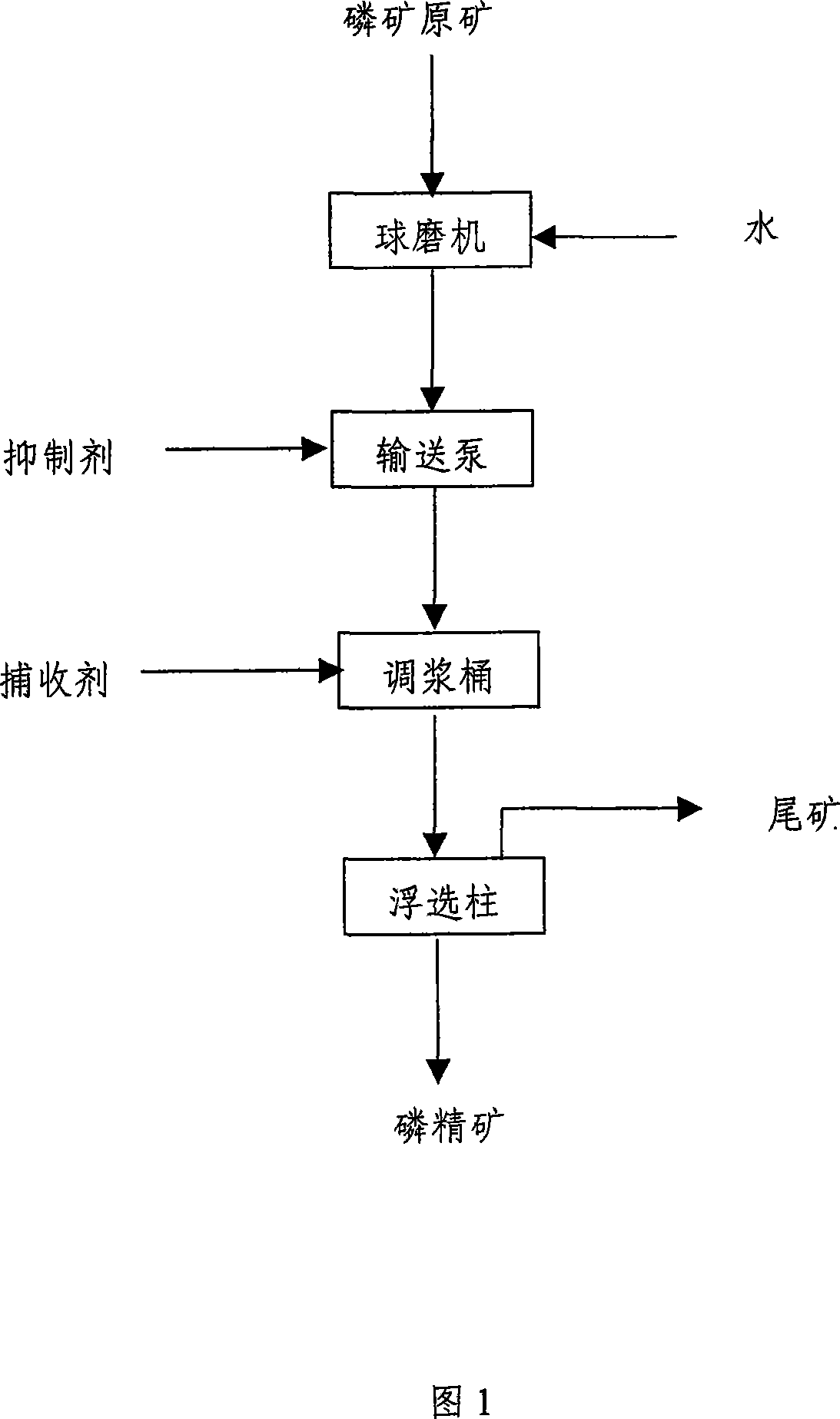

Method for demagging from phosphate ore

ActiveCN101049584ATo removeAchieve the effect of removing magnesium impurities in phosphate rockFlotationSludgePhosphoric acid

A process for removing Mg from phosphorus ore in order to prepare phosphoric acid by wet method features use of static microbubble floatation column, and includes such steps as breaking the crude phosphorus ore, grinding, classifying, mineralizing by mixing the reverse floatation chemical with ore sludge, and floatating in said static microbubble floatation column while conditioning the ore sludge to obtain the bubble-phase tailings and low-Mg phosphorus ore concentrate from the column bottom.

Owner:YUNNAN CHEM RES INST

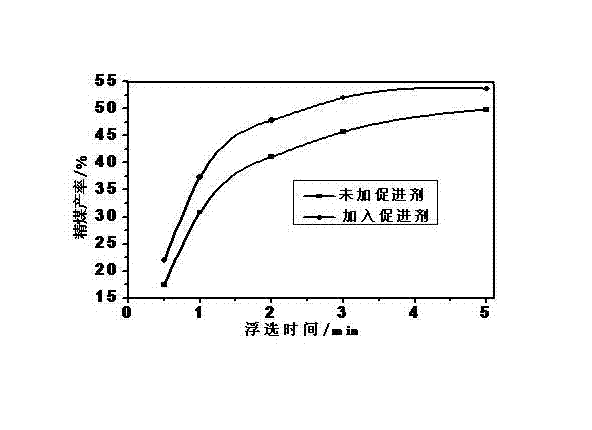

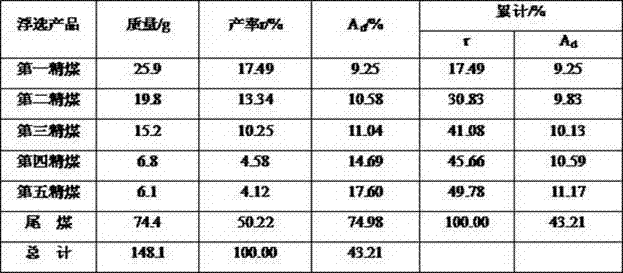

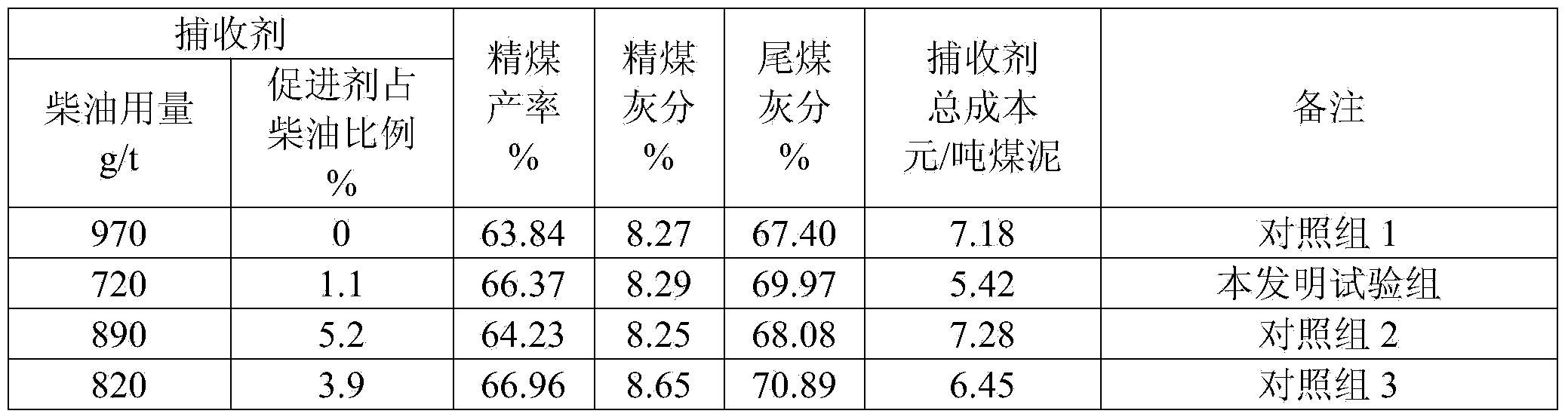

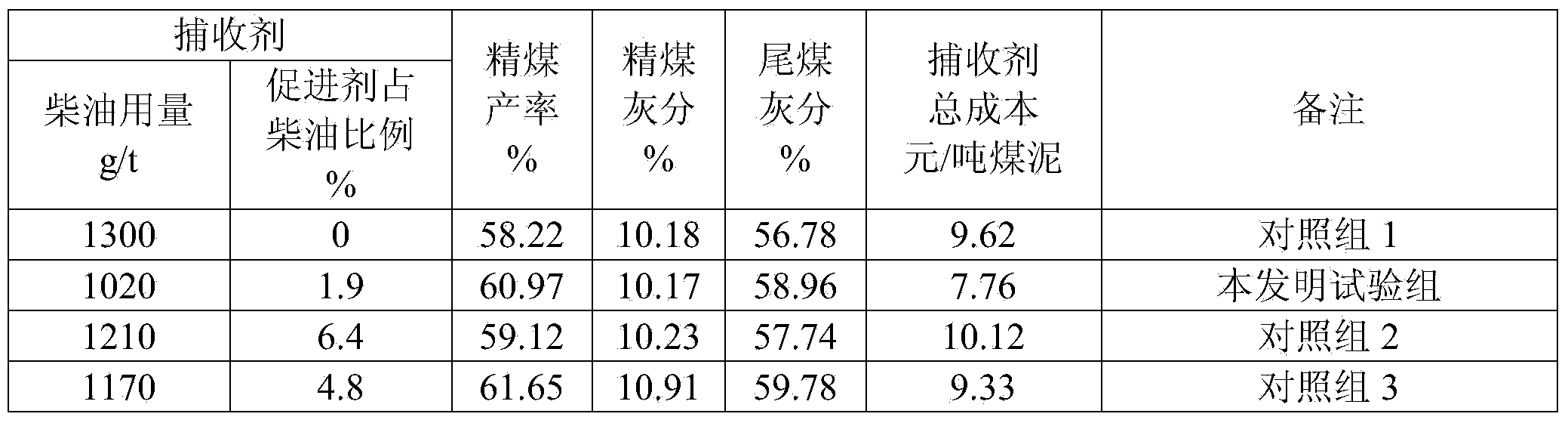

Flotation promoter of coal slime and method for preparing flotation reagent

The invention discloses a flotation promoter of coal slime. The flotation promoter comprises the following materials in percent by weight: 40%-70% of a gemini surfactant, 20%-40% of a polyoxyethylene ether surfactant and 0%-20% of an aliphatic ester surfactant. The invention also discloses a method for preparing a flotation reagent from the flotation promoter of the coal slime. The flotation promoter disclosed by the invention has the advantages that since a novel surfactant-bisamide diester group non-ionic gemini surfactant is mainly adopted as a main component, not only can the flotation effect be obviously improved, but also the used quantity of the flotation reagent can be reduced, the adaptability to different coal types and different flotation reagents is strong, the problem of poor cooperativity of the promoter to different flotation reagents in the prior art is solved, the emulsification is not needed, the defects in the prior art that the emulsification is required to be carried out in advance, even the original flotation process is changed and the operation is fussy are overcome, so that the purposes of reducing the reagent consumption and improving the flotation efficiency are achieved.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

Gas desulfurization and regeneration process and device by liquid phase iron oxide powder suspension method

InactiveCN101890287AImprove oxidation regeneration efficiencyImprove flotation efficiencyDispersed particle separationIron(II) oxideOxygen

The invention relates to a gas desulfurization and regeneration process by a liquid phase iron oxide powder suspension method, which is characterized in that: iron oxide powder or ferrous oxide powder suspension is adopted to remove hydrogen sulfide from gas; and the method comprises the following steps of: 1) mixing iron oxide powder or ferrous oxide powder with the granularity between 0.01 and 300 micrometers and water to form the suspension for desulfurization, and pumping the suspension into a desulfurization tower for circular spray by using a pump; 2) fully mixing sulfur-containing gas and the suspension for desulfurization in the desulfurization tower, discharging the desulfurized gas from the top of the desulfurization tower, and adding the suspension which has absorbed the sulfur into a regeneration tank; 3) in the regeneration tank, reacting oxygen-containing cyclic gas with the sulfur-containing suspension to generate iron oxide and sulfur element, and floating sulfur foam; and 4) flowing the regenerated iron oxide or ferrous oxide powder suspension out of the regeneration tank, and discharging into an intermediate tank on the bottom of the desulfurization tower for recycling. The process has the advantages that: the process has good desulfurization effect; the desulfurized suspension can be regenerated and recycled; and the equipment occupies a small area and runs safely.

Owner:姜辉

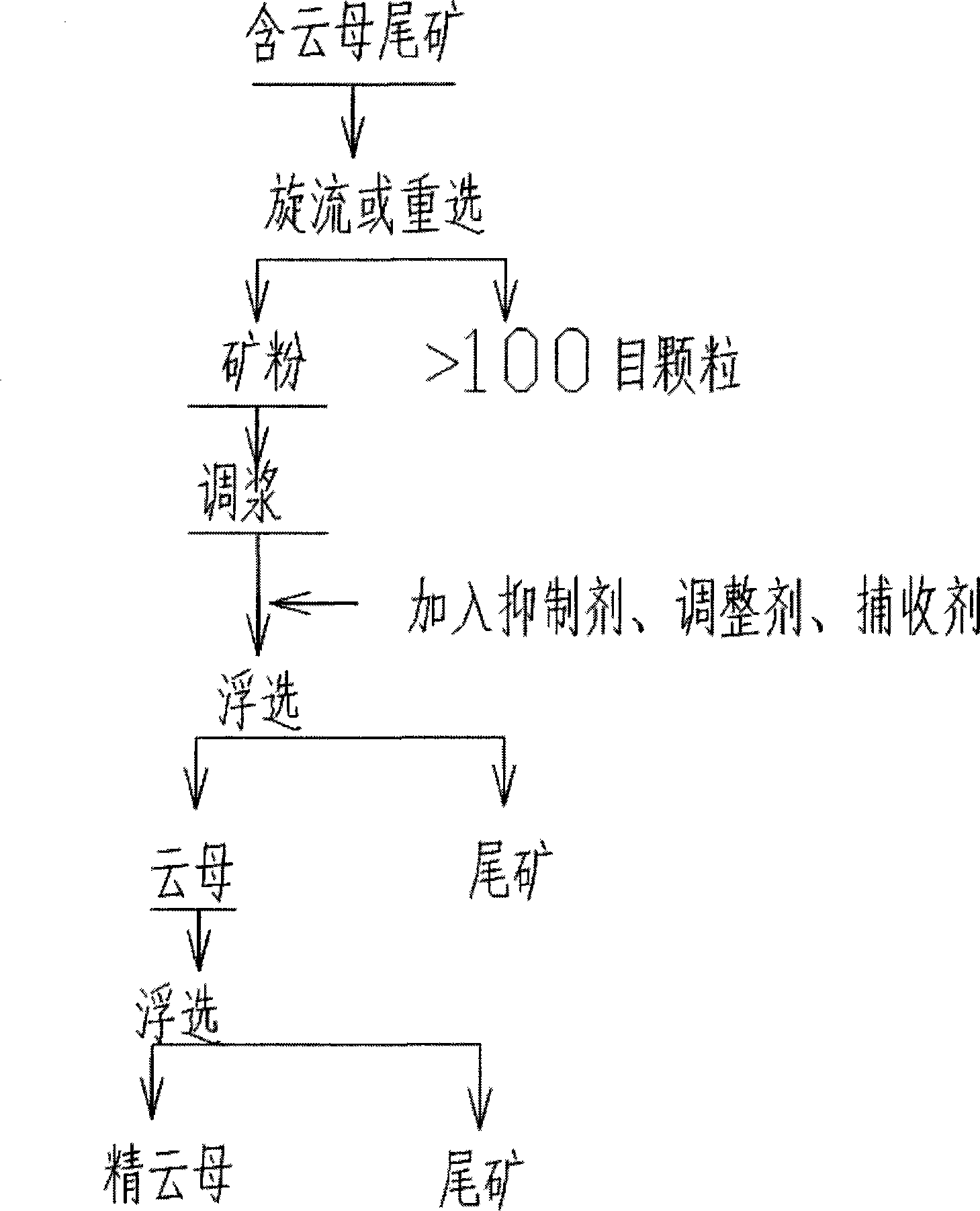

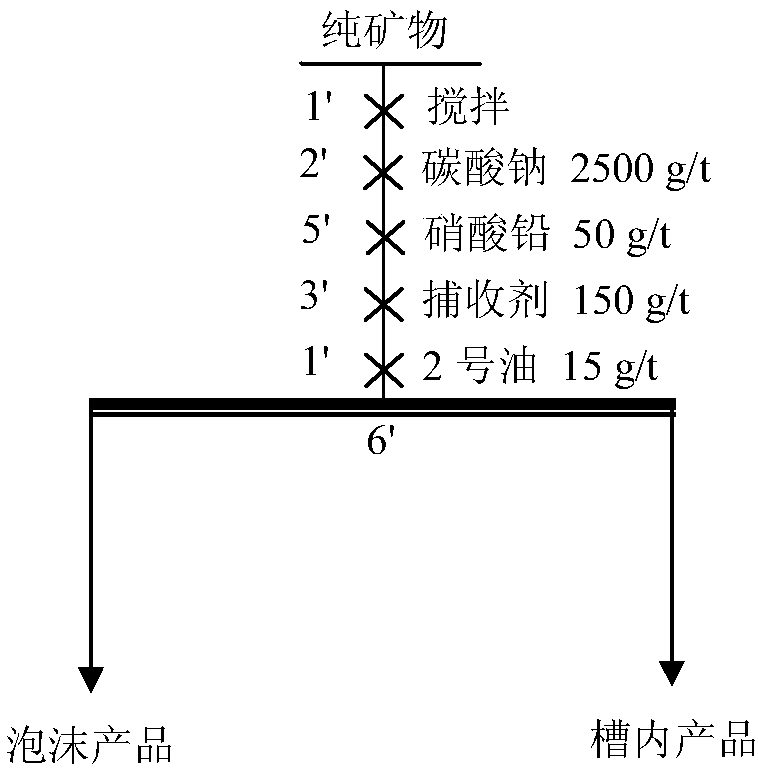

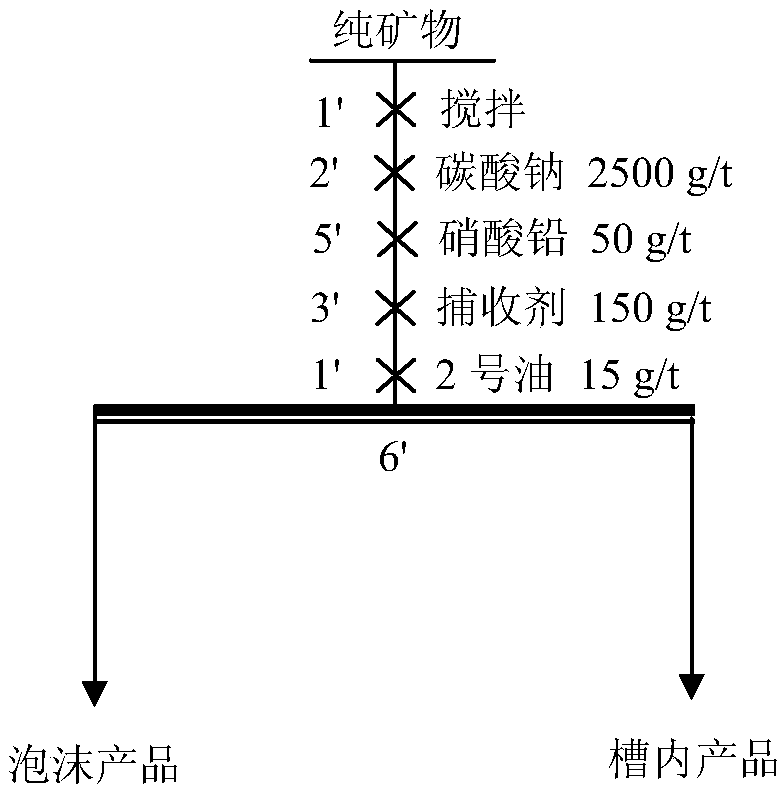

Method for recovering specular stone from debris containing specular stone

The invention relates to a separation process of non-metallic minerals, in particular to a method of recovering mica from tailings of clean mill in metal mines. After getting rid of single minerals and cuttings of over 100 meshes by a hydrocyclone or a chute, tailing powder that contains mica is mixed to slurry with the concentration of 20% to 40%, is added in sequence with inhibitor, regulator and collector, and is poured into a flotation cell for flotation after fully churning. The method needs no predesliming, mica of over 90% purity can be acquired by one separation, 99% purity can be acquired by twice separation, the flotation efficiency is high, the technique is simple and the cost is low.

Owner:JILIN UNIV

Method for preparing compounded collecting agent of vegetable fatty acid diethanolamide ester soap

The invention relates to a method for preparing a compounded collecting agent of vegetable fatty acid diethanolamide ester soap. The method comprises the following steps of: 1) performing amide esterification reaction on fatty acid with an iodine value of 85 to 135 and diethanolamine, performing saponification reaction on an obtained reaction product and 30 mass percent of sodium hydroxide solution, and thus obtaining fatty acid diethanolamine and a fatty acid soap mixture thereof; 2) performing the saponification reaction on raw materials such as the fatty acid with the iodine value of 120 to 135 and sodium hydroxide or sodium carbonate, and thus obtaining fatty acid soap; and 3) mixing the fatty acid diethanolamine and the fatty acid soap mixture thereof obtained in the step 1) with the fatty acid soap obtained in the step 2) to obtain fatty acid diethanolamide ester soap, compounding a surfactant into the fatty acid diethanolamide ester soap, and thus obtaining the compounded collecting agent of the vegetable fatty acid diethanolamide ester soap. By adoption of the method, phosphorus selectivity is obviously improved, flotation temperature is reduced, floatation efficiency is high, and the raw materials are easy to purchase and low in cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

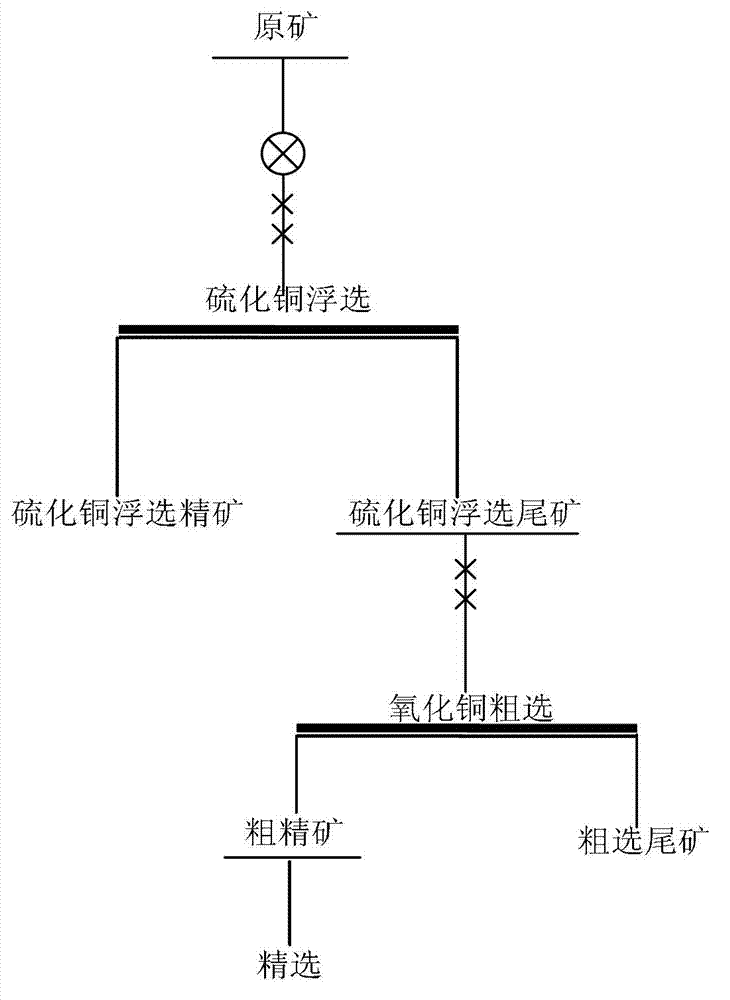

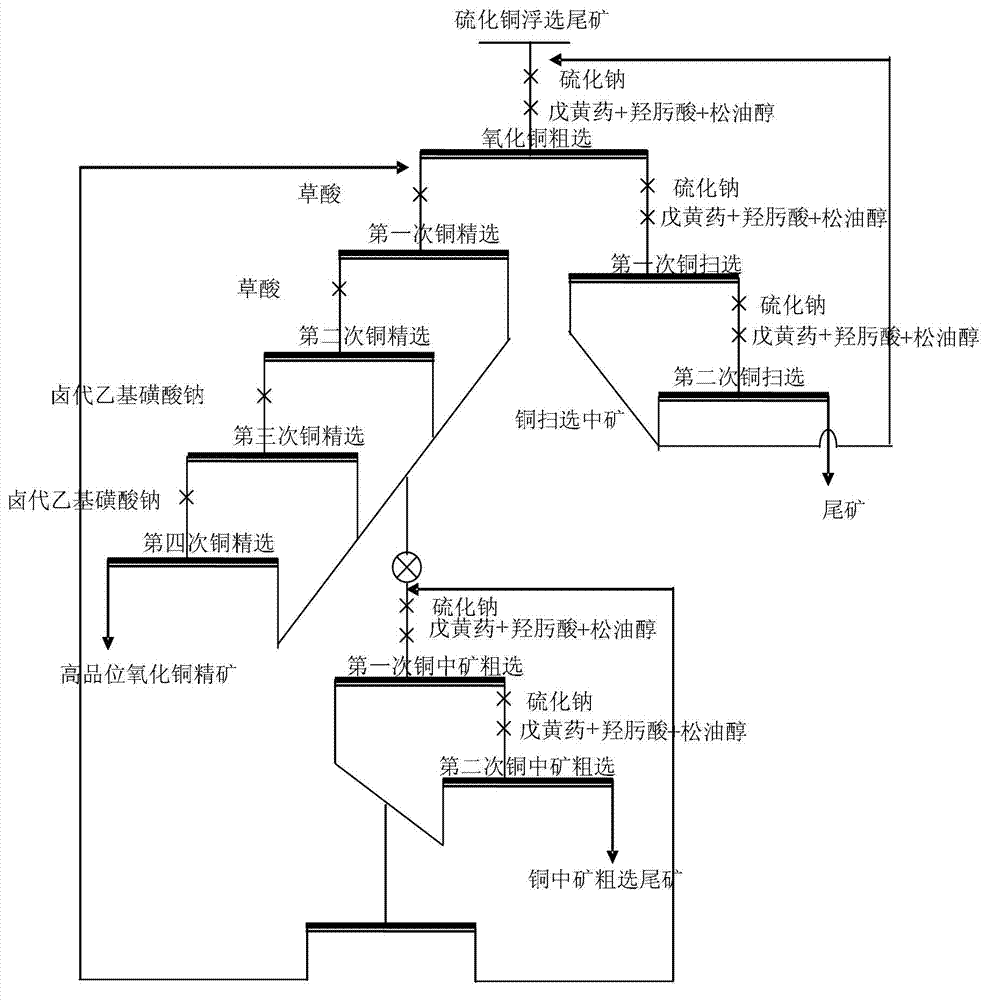

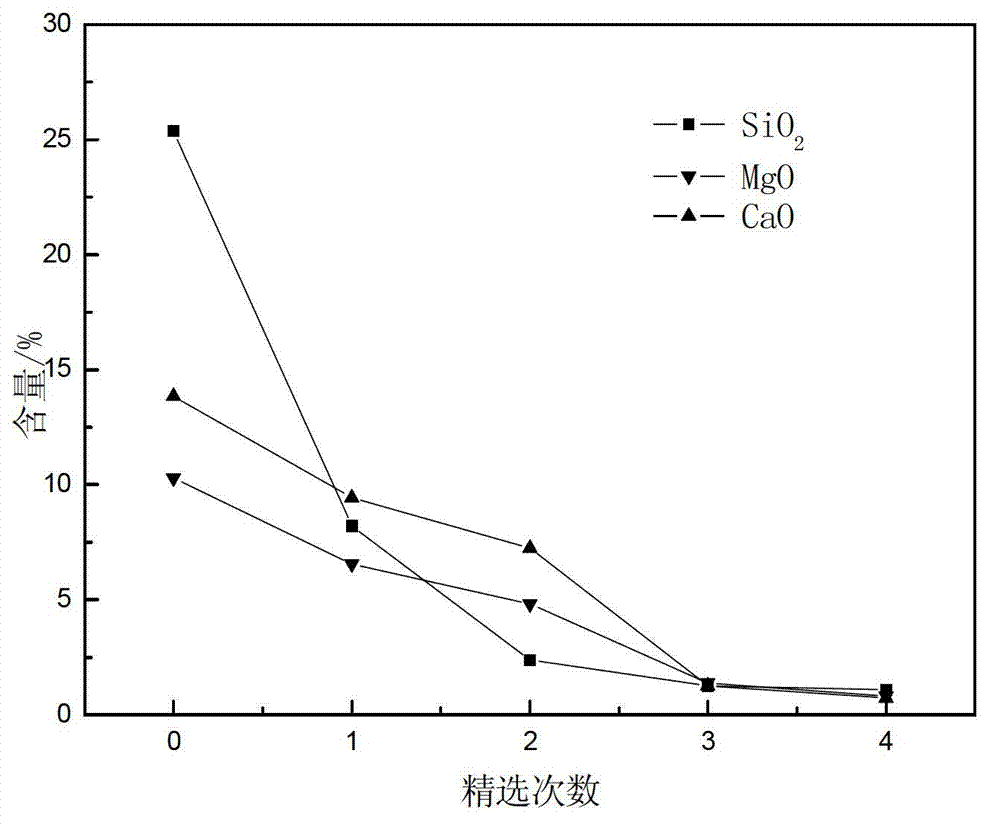

Preparation method of high grade copper oxide concentrate

The invention discloses a preparation method of high grade copper oxide concentrate. The preparation method sequentially comprises complex copper oxide crude ore grinding, copper sulphide flotation and copper oxide flotation. The copper oxide flotation comprises rough flotation and fine flotation, wherein the rough flotation includes that flotation reagents are added into tailings of copper sulphide flotation after the copper sulphide flotation, and rough concentrate and rougher tailings are obtained after mixing, stirring and separating. The fine flotation includes that gangue mineral depressants are added into the rough concentrate to be stirred, and the gangue mineral depressants are halogenate ethyl sodium sulfonate. According to the preparation method, in the fine flotation process, the halogenate ethyl sodium sulfonate is added to serve as the depressants, impurity gangue minerals are water loving, and therefore the separating effect of target minerals and the impurity gangue minerals is improved in the fine flotation process. The method drastically reduces contents of silica, calcium oxide, magnesium oxide and other impurity gangue minerals, and obtains the high grade copper oxide concentrate. The mineral processing process is low in cost, and simple and feasible in operation.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

Swinging-stirring flotation equipment with self-slurry-mixing function

ActiveCN105689157AAvoid "sand sinking" situationsTo promote floatingFlotationMicro bubbleEngineering

The invention relates to the field of coal slurry mixing and flotation treatment, and specifically relates to swinging-stirring flotation equipment with a self-slurry-mixing function. The swinging-stirring flotation equipment disclosed by the invention at least comprises a flotation cell, wherein a micro-bubble generation bed is arranged in the flotation cell; the micro-bubble generation bed comprises micro-bubble tubes; and a connection arm is arranged at each of the two ends of each micro-bubble tube to fix the co-end part of the micro-bubble tube. The equipment further comprises a gas pipeline, wherein the gas pipeline is communicated with the tube cavity of each micro-bubble tube through a prearranged gas channel in the corresponding connection arm; and micro-bubble generation holes used for ejecting a gas are densely distributed in the tube wall of each micro-bubble tube. The equipment further comprises power arms, wherein the two power arms are provided, and symmetrically arranged at the two sides of the micro-bubble generation bed; and a stirring baffle extends from the bottommost end of each micro-bubble tube, and the surface of each stirring baffle is vertical to the swinging direction of the micro-bubble generation bed. The equipment disclosed by the invention has the advantages of being great in micro-bubble flotation effect, easier in bubble mineralization, free from flotation 'dead areas' in the flotation cell, and more stable in foam layer; and the working efficiency and the flotation effect can both be effectively ensured.

Owner:内蒙古华星煤业有限公司

Flotation technology for separating apatite, dolomite and quartz in enriched phosphorite

The invention provides a flotation technology for separating apatite, dolomite and quartz in enriched phosphorite. The technology comprises the following specific steps that (1) raw phosphorite is ground; (2) phosphorite grinding products in the step (1) are subjected to active oil bubble direct flotation, and flotation forth I with apatite as the main ingredient and flotation underflow I are obtained; (3) a collecting agent is directly added into the flotation underflow I in the step (2), conventional bubble direct flotation is carried out, and flotation forth II with dolomite as the main ingredient and flotation underflow II with quartz as the main ingredient are obtained; and (4) the flotation forth I in the step (2) and the flotation forth II and the flotation underflow II in the step (3) are subjected to filtering and vacuum drying to obtain flotation products. According to the method, the flotation process of the phosphorite is simplified, the use level of the collecting agent is reduced, the flotation recovery rate and selectivity are increased, and efficient normal-temperature flotation of the phosphorite is achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

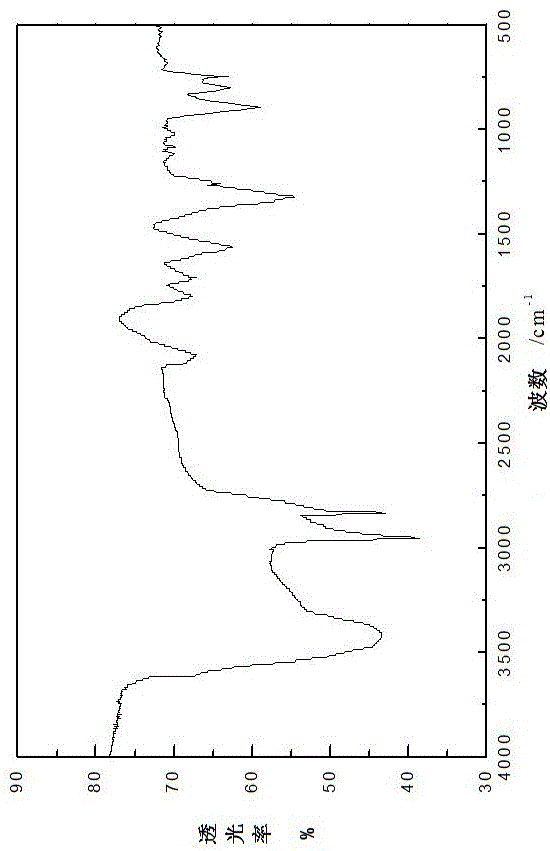

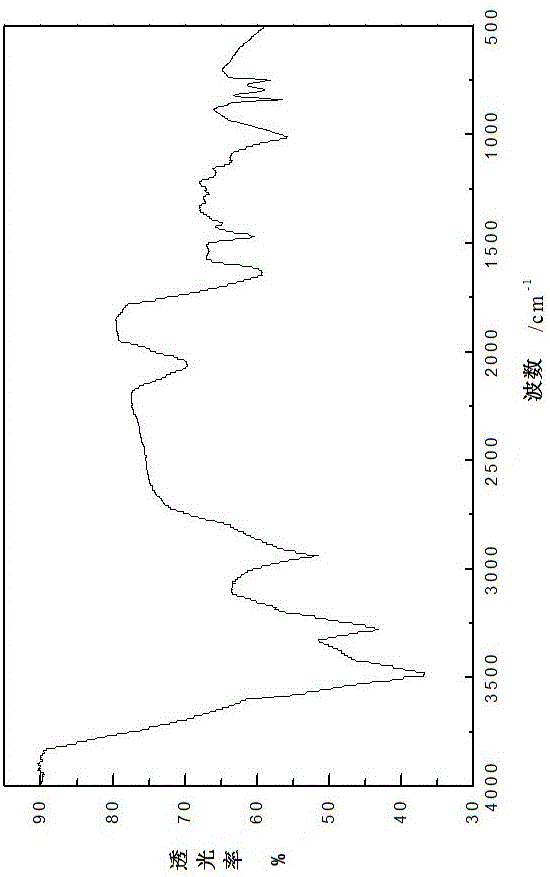

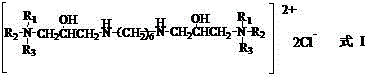

Collophane quaternary ammonium salt cationic collector, synthesis method and application of collophane quaternary ammonium salt cationic collector

The invention discloses a quaternary ammonium salt cationic collector and a synthesis method of the quaternary ammonium salt cationic collector. The prepared quaternary ammonium salt cationic collector is mainly used for collophane reverse floatation desilication. A preparation technology comprises the two steps of: synthesizing an intermediate containing chlorine and hydroxypropyl by taking C1-C4 tertiary amine, hydrochloric acid and epoxy chloropropane as raw materials, and allowing the synthesized intermediate to react with hexamethylenediamine under alkaline conditions to prepare the quaternary ammonium salt cationic collector. The synthetic route of the collector is simple, a raw material source is wide, the prepared collector is stable, has good water solubility, is convenient to use, and has the advantages of good selectivity, strong collecting force and the like in the collophane reverse floatation desilication.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Method for promoting sulfide floatation of copper oxide ores with amino acid

InactiveCN106824545AImprove flotation efficiencyImprove flotation recoveryFlotationCopper oxideXanthate

The invention discloses a method for promoting sulfide floatation of copper oxide ores with amino acid. The method comprises the following steps: adding an amino acid solution which serves as an activating agent into sulfurized copper oxide ore pulp and floating in a floatation machine with xanthate which serves as a collecting agent. In the method, according to the characteristics of sulfide floatation of the copper oxide ores, the amino acid is added in a floatation process, so that the floatation efficiency of the copper oxide ores is improved. According to the method, firstly, the copper oxide ores are crushed and sieved; then, the amino acid, a sulfide and relevant floatation agents are added into the floatation machine; and floatation is performed by controlling time. Compared with a conventional floatation process with no added amino acid, the method has the advantage that the floatation recovery rate of the copper oxide ores is improved by 10%. The amino acid has an obvious promoting effect in the sulfide floatation process of the copper oxide ores, so that a novel application way is provided for industrial floatation of the copper oxide ores.

Owner:HUNAN RES INST FOR NONFERROUS METALS

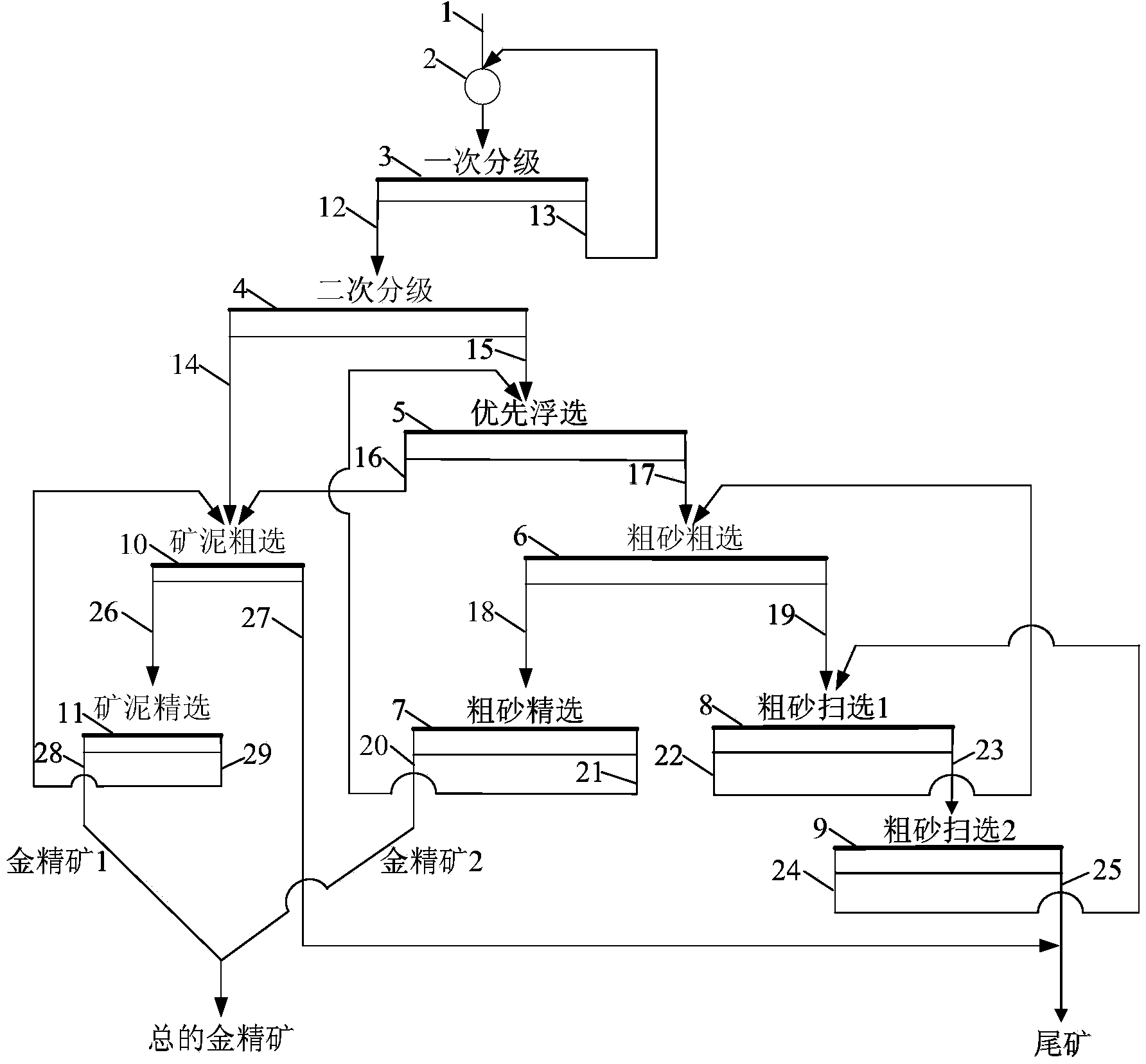

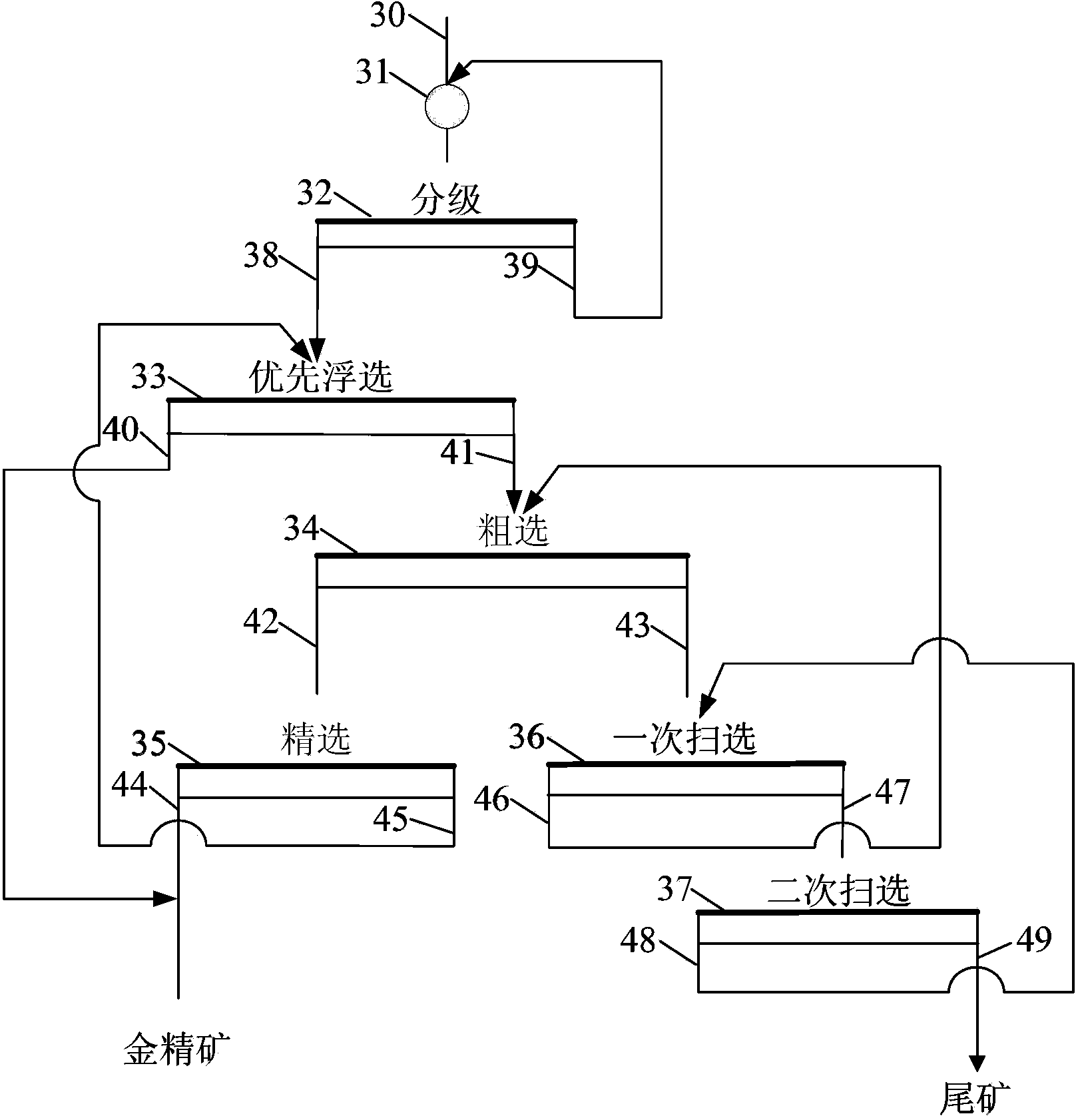

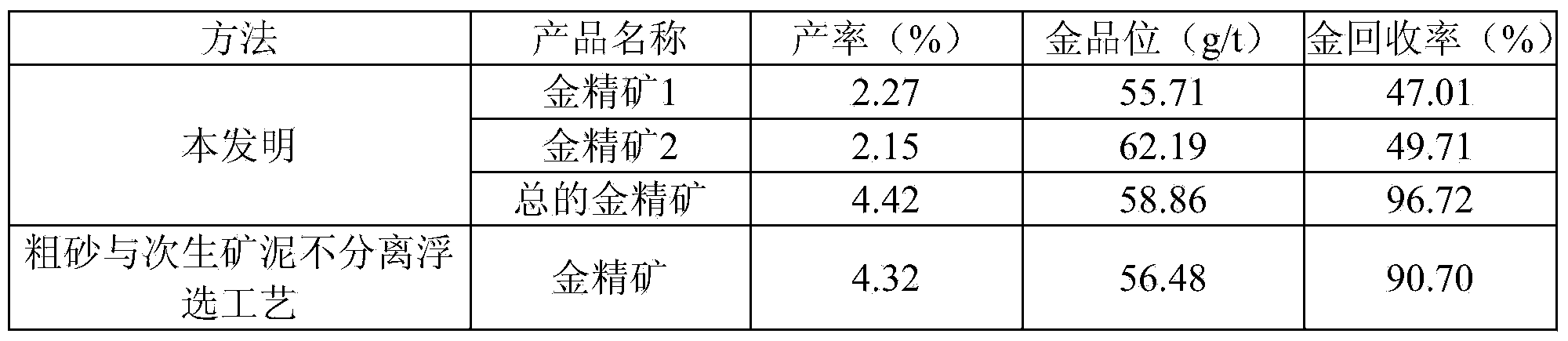

Separation-flotation technology of rough sand and secondary slime of vein gold ores

The invention relates to a separation-flotation technology of rough sand and secondary slime of vein gold ores. The separation-flotation technology is especially and mainly applied to ore dressing of the quartz vein type ores of gold-carrier ores, mainly iron pyrites. The separation-flotation technology includes the following steps of ore grinding grading operation, rough sand flotation operation, secondary slime flotation operation and combining forming operation of total gold ore concentrate. The recovery rate of gold of the obtained total gold ore concentrate is larger than or equal to 95.46%, the recovery rate of the gold is obviously improved, the use efficiency of resources is improved and the separation-flotation technology is small in use amount of medicaments and reduces environment pollution.

Owner:JIANGXI UNIV OF SCI & TECH

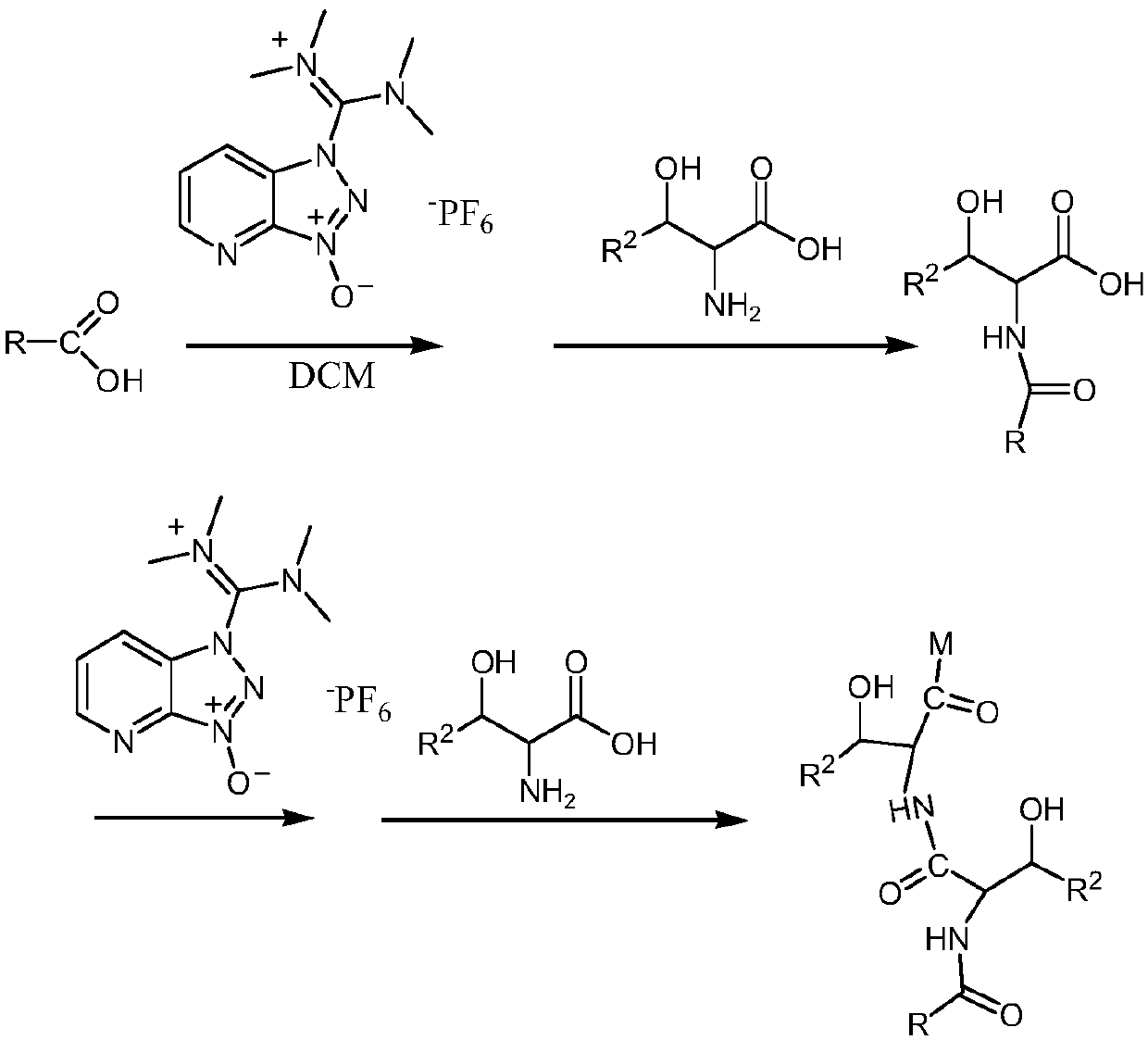

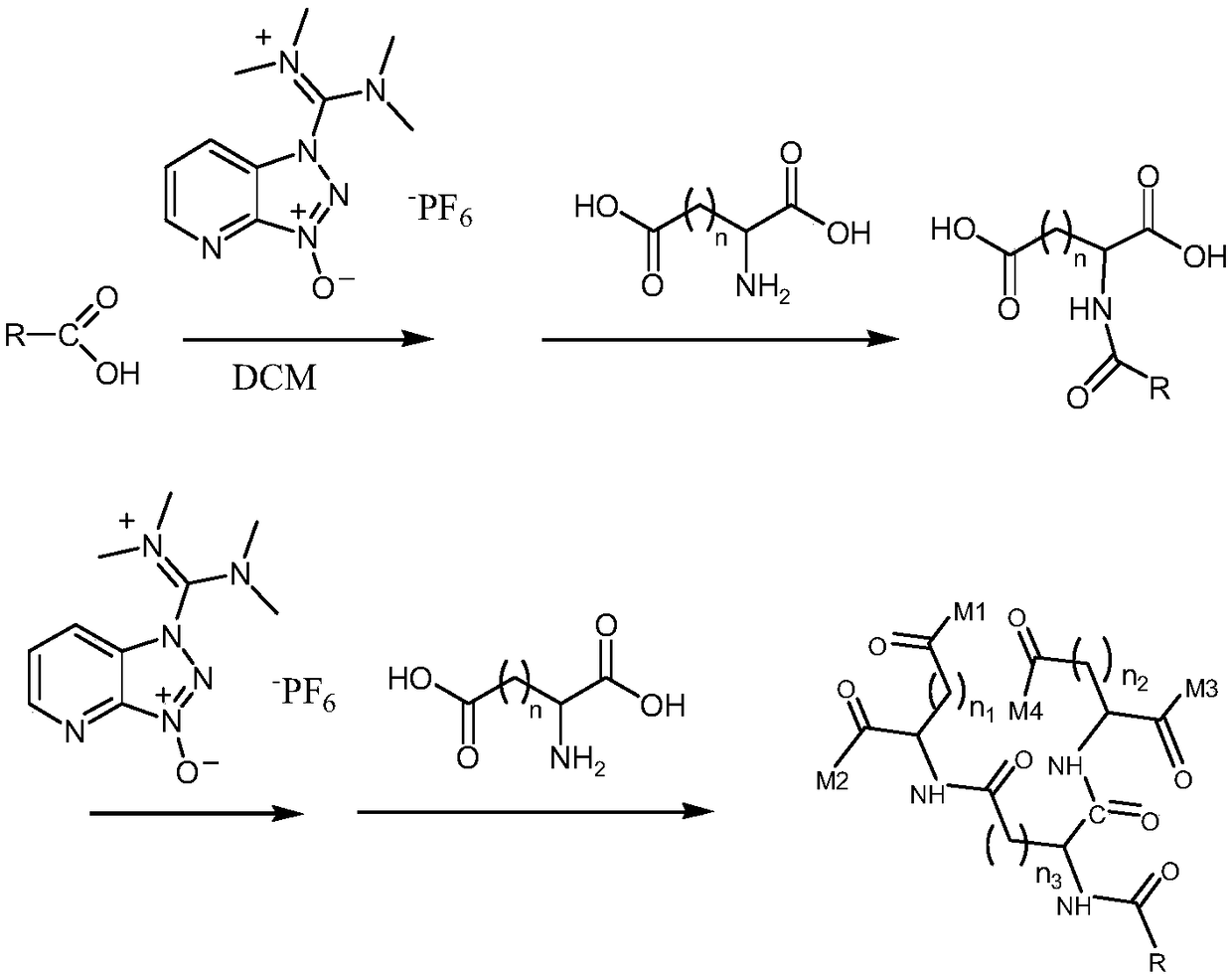

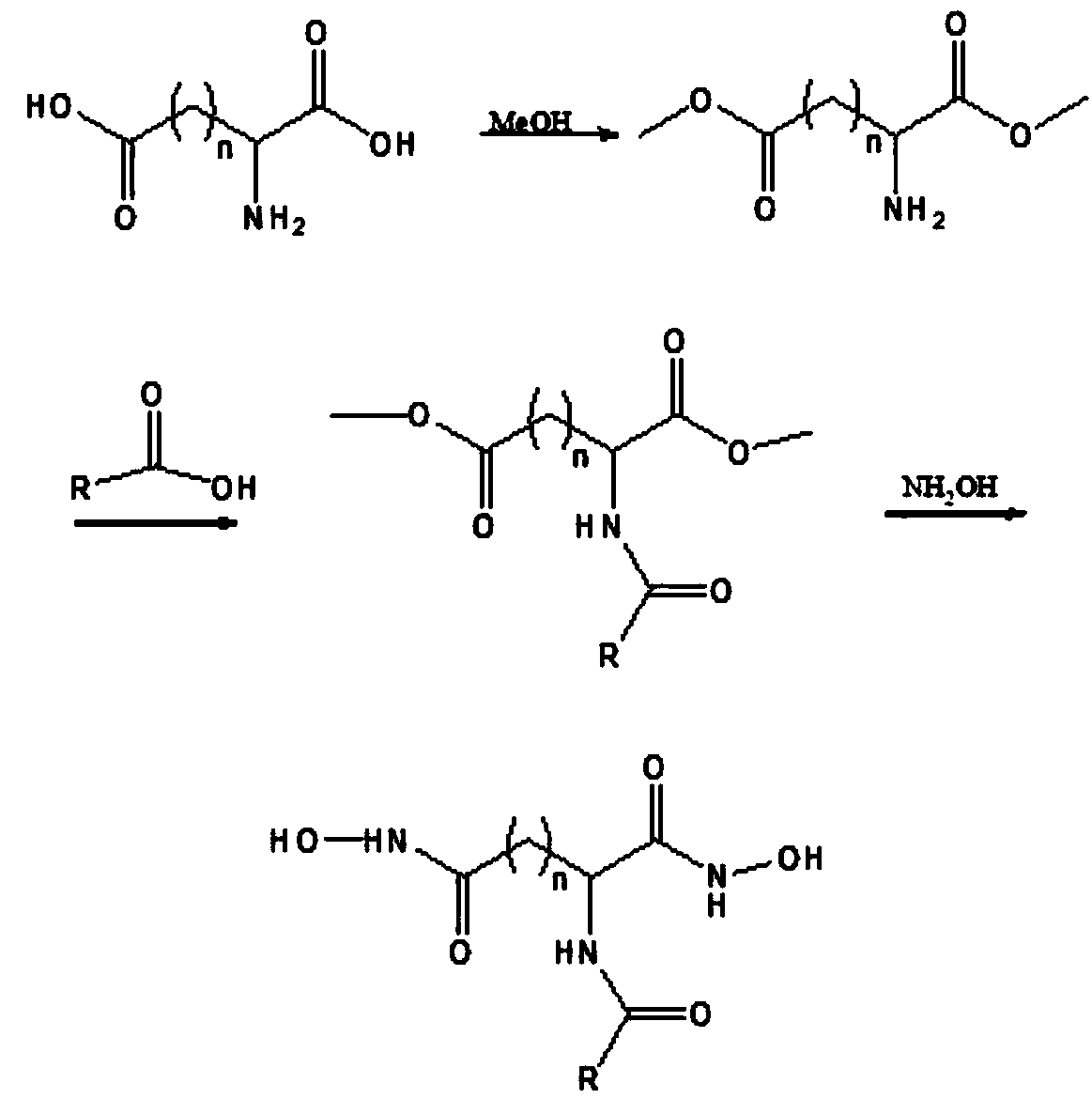

Amidohydroxycarboxylic acid/hydroximic acid compound and application thereof to ore flotation

ActiveCN109530094AImprove flotation recoveryHigh flotation separationFlotationRare earthMineral flotation

The invention provides an amidohydroxycarboxylic acid / hydroximic acid compound and application thereof to ore flotation. The compound has a structural formula shown as a formula (I) in the description, wherein in the formula (I), R1 represents C6-C18 aliphatic groups; R2 represents C1-C4 aliphatic groups; M represents -OH, -ONa, -OK, -NHOH, -NHONa or -NHOK. The amidohydroxycarboxylic acid / hydroximic acid compound provided by the invention is used as a collecting agent, and can reinforce the chelation and recognition effects of the collecting agent on metal oxidized ore; the ordered arrangementof the collecting agent on the surface of the ore is promoted; tungsten ore, rare earth ore, tin ore, lithium mineral, phosphorite, manganese oxide roe, copper oxide ore, fluorite or ilmenite can beeffectively recovered through floatation; the advantages of high collecting capability, high selectivity, low ton ore dosage and the like are realized; the compound is particularly suitable for beingused for treating refractory fine particle ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE +1

Application of acyl amino polycarboxylic acid/hydroximic acid like compound in mineral flotation

ActiveCN109499773AImprove flotation recoveryHigh flotation separationFlotationRare earthMineral flotation

The invention provides application of acyl amino polycarboxylic acid / hydroximic acid like compound in mineral flotation. A structural formula of the acyl amino polycarboxylic acid / hydroximic acid likecompound is shown as a formula (I); (shown in the description) wherein R in the formula (I) represents aliphatic hydrocarbyl of C<6>-C<18>, n=1-3, and M1, M2, M3 and M4 are separately selected from one or several of -OH, -ON, -OK, -NHOH, -NHON or -NHOK. And n<1>=1-3, n<2>=1-3, and n<3>=1-3. The acyl amino polycarboxylic acid / hydroximic acid like compound is used as a collecting agent to enhance the chelation and recognition action on metal oxidized ores, facilitate ordered arrangement of the collecting agent on the mineral surface, effective flotation recovery is carried out on tungstenores, rare earth ores, tin ores, lithium ores, phosphorus ores, manganese oxide ores, cooper oxide ores, fluorites or titanium iron ores, the acyl amino polycarboxylic acid / hydroximic acid collectingagent has the advantages of high collecting capacity, high selectivity, low ton ore use amounts and the like, and is especially suitable for processing difficultly selected fine grain ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE +1

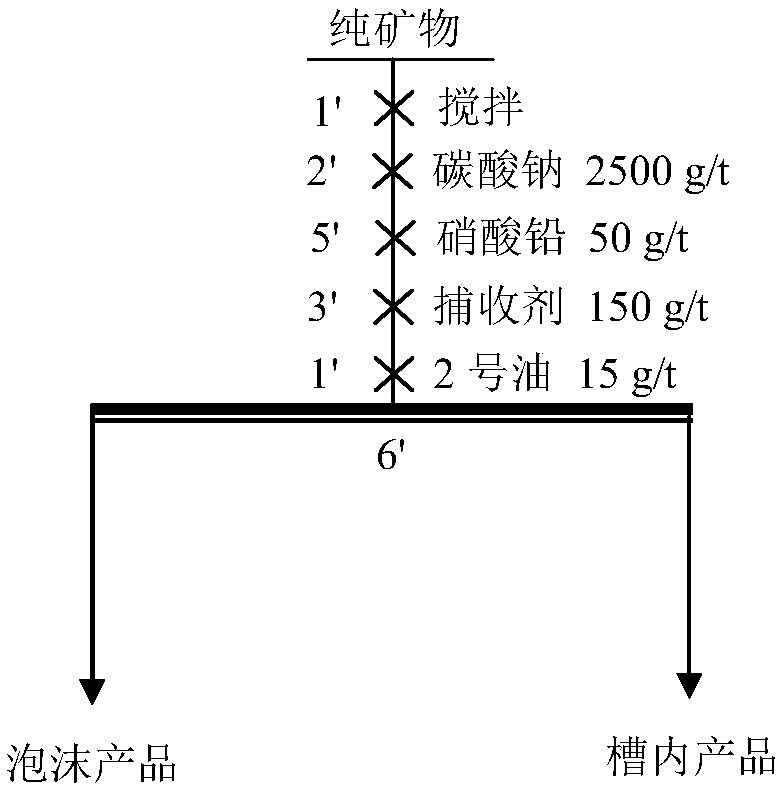

Hydrocarbon amide-bi-hydroxamic acid compound and application thereof in mineral flotation

ActiveCN108906331AStrong harvesting abilityImprove flotation recoveryFlotationHydroxamic acidRare earth

The invention provides a hydrocarbon amide-bi-hydroxamic acid compound and application thereof in mineral flotation. The structural formula of the hydrocarbon amide-bi-hydroxamic acid compound is as shown in the description, wherein R represents an aliphatic hydrocarbon group of C2 to C18, and n ranges from 1 to 10. The hydrocarbon amide-bi-hydroxamic acid compound serving as a collector can enhance the chelation and recognition to metal oxidized ores, promote the ordered arrangement of the collector on a mineral surface and effectively recover tungsten ores, rare earth ores, tin ores or ilmenite by flotation, has the advantages of strong collecting capacity, high selectivity, low consumption of tons of ores, etc., and is especially suitable for processing hard dressing fine grained ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE

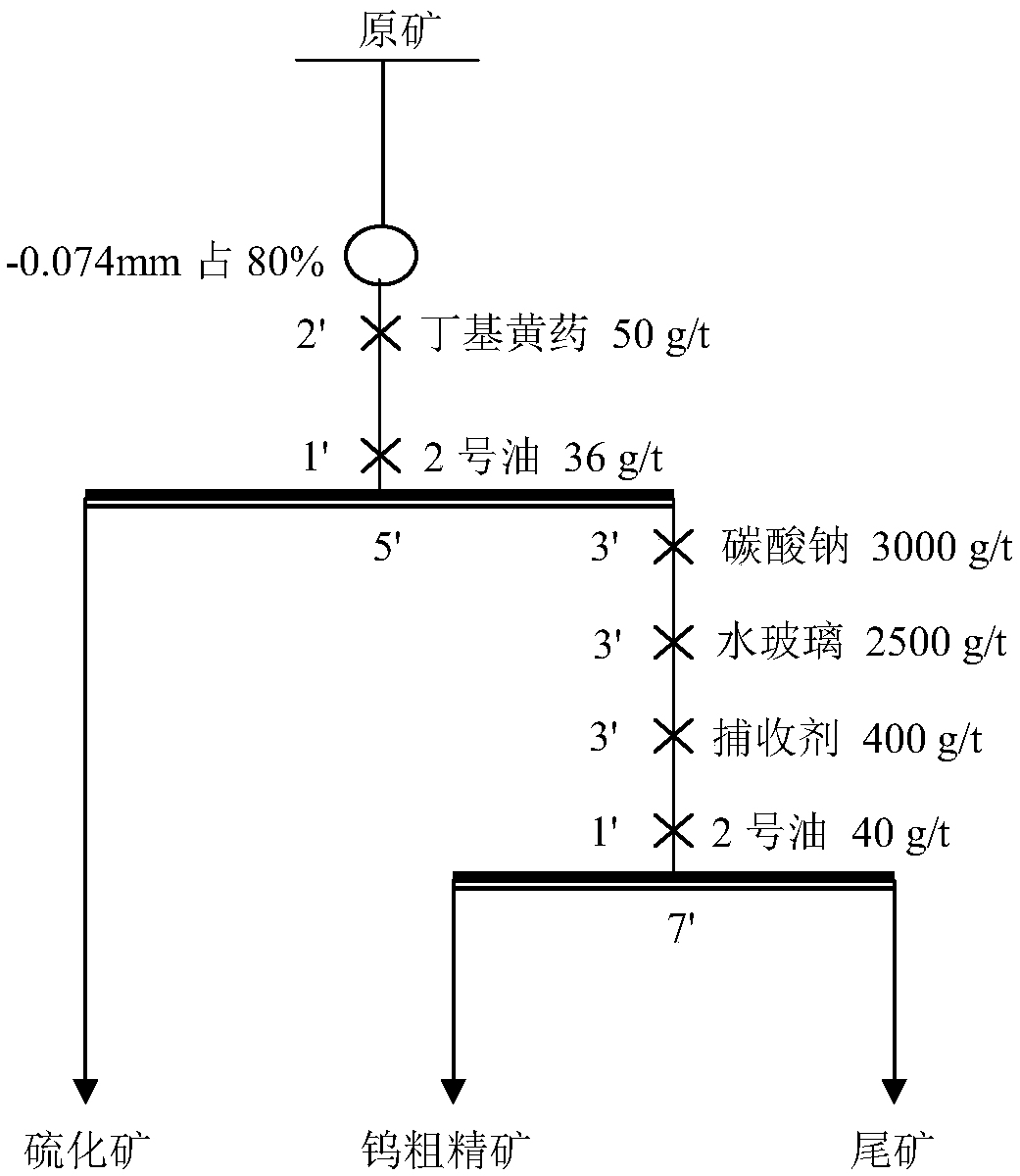

Floatation separation technology of refractory lead-zinc sulphide ores

ActiveCN107812616AImprove flotation efficiencyReduce flotation costsFlotationFoaming agentSeparation technology

The invention provides a floatation separation technology of refractory lead-zinc sulphide ores. The floatation separation technology comprises the steps that rough grinding is conducted on the lead-zinc sulphide ores, a pH regulator, a collector and a foaming agent are added, so that lead-zinc bulk floatation is conducted and lead-zinc bulk concentrates are obtained; and fine grinding is conducted on the lead-zinc bulk concentrates, a pH regulator, an electric potential regulator, an inhibitor and the like are added, so that lead ore floatation is conducted and lead concentrates are obtained,in the process, an electric potential of ore pulp is adjusted to be 210-350 mv by the electric potential regulator, and a pH value of the ore pulp is adjusted to be 9-11 by the pH regulator. A pH regulator, an activating agent and the like are added into lead ore floatation tailings, zinc ore floatation is conducted, and zinc concentrates and zinc ore floatation tailings are obtained. The lead-zinc floatation separation difficulty is reduced by adding the electric potential regulator, meanwhile waste water produced at various floatation stages is separated and independently recovered, the floatation separation technology is suitable for floatation separation of the lead concentrates and the zinc concentrates with high grades and recovery rates at low production cost from the refractory lead-zinc ores which are low in lead content and high in zinc content, and the application prospect is good.

Owner:SANMING UNIV

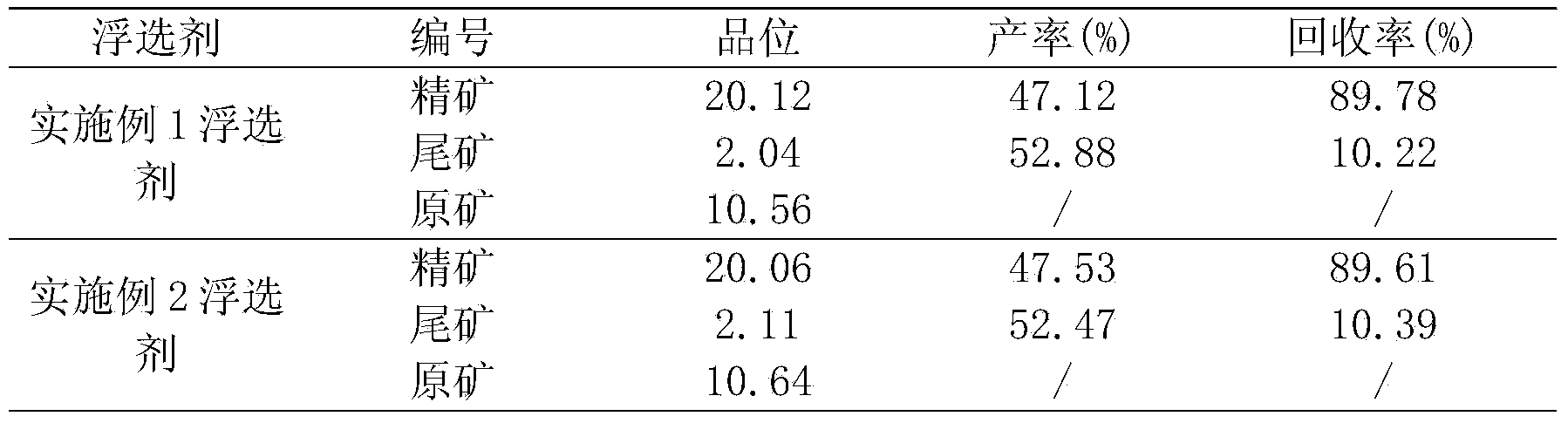

Manganese carbonate ore floatation agent and floatation method

The invention provides a manganese carbonate ore floatation agent and a flotation method. The floatation agent is prepared by taking soybean oil and hydroxylamine hydrochloride or hydroxylamine sulphate as raw materials and enabling the product obtained after the soybean oil is emulsified to react with the product obtained after the hydroxylamine hydrochloride or the hydroxylamine sulphate is neutralized through the alkali. The floatation method for recycling the manganese carbonate through the floatation agent comprises the step of raw ore processing and the step of closed loop floatation. The floatation agent has good electivity for the manganese carbonate, the grade of the flotation concentrate produced by processing the low-grade manganese carbonate ore with the raw ore grade ranging from 8% to 12% through the closed loop circulation floatation technology including the steps of coarse processing, rough processing and sweeping can be improved to be more than 20%, the manganese recycling rate is larger than 85%, no inhibitors need to be added during the floatation process, and the whole production cost is obviously reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparation of vegetable fatty acid and citric alkyl ester saponin compounded collecting agent

The invention relates to a compound collecting agent for flotation of phosphorus ores, in particular to a method for preparation of a vegetable fatty acid and citric alkyl ester saponin compounded collecting agent. The method includes the steps: 1) subjecting alkyl alcohol and citric acid to esterification reaction to obtain a reaction product which is a citric alkyl ester surfactant; 2) adding vegetable fatty acid with iodine value being 135 into the citric alkyl ester surfactant obtained at the step 1), heating and well mixing; 3) adding the mixture obtained at the step 2) to sodium hydroxide solution to realize saponification, and well mixing to obtain the vegetable fatty acid and citric alkyl ester saponin compounded collecting agent. The method has the advantages that by utilization of the vegetable fatty acid and citric alkyl ester saponin compounded collecting agent, phosphorus selectivity is evidently improved, flotation temperature is lowered, and flotation efficiency is improved; in addition, easiness in purchase of raw materials, low cost, simple production lines, safety in production process and avoidance of irritating odors are realized, ore dressing cost is reduced, and defects in the prior art are overcome.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Efficient winnowing material flotation equipment

InactiveCN110548679AIncrease throughputImprove flotation efficiencyTobacco treatmentGas current separationIndustrial engineeringWinnowing

The invention discloses efficient winnowing material flotation equipment which comprises a shell, a flotation chamber, an air supply device and a material throwing device; the shell is of a rectangular cavity structure and is internally provided with the flotation chamber; the flotation chamber is divided into three flotation cabins; each flotation cabin is provided with an air guide device; eachair guide device comprises a fixed plate, a second material throwing plate, a third material throwing plate and a fourth material throwing plate; the bottom of the shell is provided with an air inletpipeline; the joint of the air inlet pipeline is provided with an isolation net; the lower part of the isolation net is provided with the air supply device; the air supply device comprises an air supply guide plate and a handle connected with the air supply guide plate; the air supply guide plate is movably connected with the shell through the handle; the shell is provided with a feeding hole andthe material throwing device connected with the feeding hole; and the material throwing device comprises a second fan, a fixed shaft and an air adjusting guide plate. For the efficient winnowing material flotation equipment disclosed by the invention, efficient flotation is performed on materials for many times in a flexible environment through flexible material throwing for many times, so that the flotation efficiency is improved.

Owner:云南吉星德亿科技有限公司

Preparation method of coal slime flotation accelerant and coal slime flotation method

ActiveCN104028385AImprove conversion rateGood harvesting effectFlotationReaction temperatureAlkylphenol

The invention discloses a preparation method of coal slime flotation accelerant and a coal slime flotation method. The accelerant uses alkylphenol polyoxyethylene ether and sulfamic acid with the polymerization degree n=4-12 as raw materials, the mole ratio of the alkylphenol polyoxyethylene ether to the sulfamic acid is 1:0.5-1:0.6, reaction temperature is controlled at 70-90 DEG C, stirring is performed constantly during synchronization, reaction time is 30-40 minutes, and products are cooled to normal temperature after reaction to obtain the accelerant. When the accelerant is used for coal slime flotation, the amount of the accelerant accounts for 0.5-2wt% of that of collecting agent. Compared with methods independently using the hydrocarbon oil collecting agent, the coal slime flotation method using the accelerant has the advantages that under the situation of equivalent cleans ash, clean coal yield can be increased by 2-3wt%, oil saving rate can reach 20-30wt%, use amount of the hydrocarbon oil collecting agent is reduced favorably, separation index can be optimized, and overall economical benefits can be increased.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com