Method for recovering specular stone from debris containing specular stone

A technology for mica tailings and mica, which is applied in solid separation, flotation and other directions, can solve the problems of high cost, harsh medium conditions and environment, low recovery rate, etc., and achieve the effects of low cost, high flotation efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

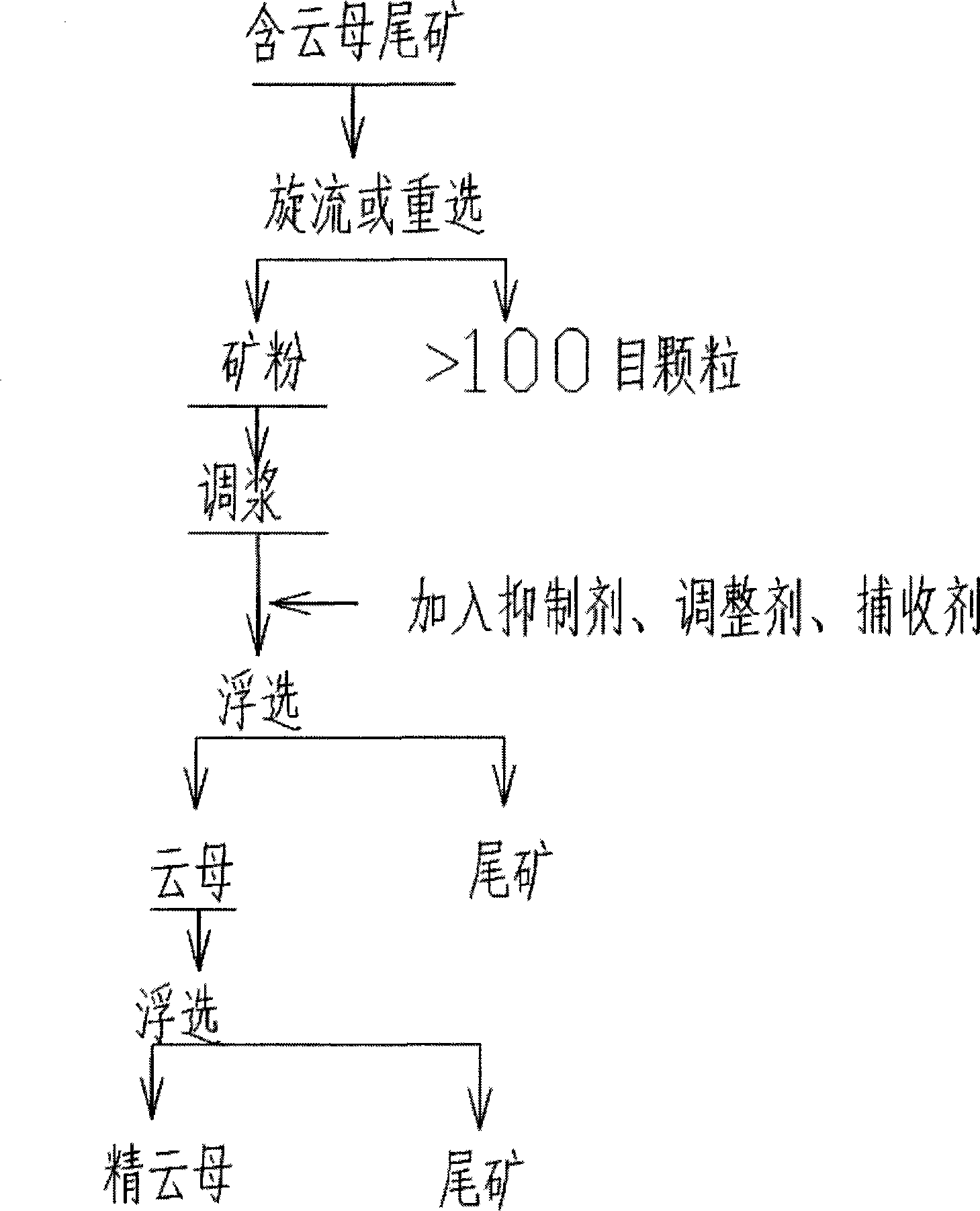

[0014] After the tailings powder containing mica is removed through a cyclone or chute to remove single minerals and cuttings above 100 mesh, it is prepared into a slurry with a concentration of 20-40%; then add inhibitors, regulators and collectors in sequence, After stirring evenly, pour it into the flotation tank for flotation.

[0015] Take 1000g of tailings from Shandong Jiaojia Metal Mine Concentration Plant, remove rock debris > 160 mesh particles and single minerals such as feldspar, quartz and hornblende through a cyclone, and add water to the remaining slurry to adjust its concentration to 30%, add 0.5g cornstarch successively, dissolve cornstarch in hot water above 70℃, and stir until transparent, lead sulfate 0.5g, sulfuric acid 0.002L, dodecylamine 0.05g, dodecylamine 0.05g Add after dissolving in 0.25L of 10% sulfuric acid, stir evenly and pour into flotation tank for flotation. After the first flotation, the mica grade is over 90%, and the second selected mica ...

Embodiment 2

[0017] After the tailings powder containing mica is removed through a cyclone or chute to remove single minerals and cuttings above 100 mesh, it is prepared into a slurry with a concentration of 20-40%; then add collectors, inhibitors and regulators in sequence, After stirring evenly, pour it into the flotation tank for flotation.

[0018] Take 1000g of tailings from Shandong Zhaoyuan Metal Mine Concentration Plant, remove rock debris > 160 mesh particles and single minerals such as feldspar, quartz and hornblende through a cyclone, and add water to the rest to adjust the concentration to 40%, add in sequence, cornstarch 0.4g / , dissolve cornstarch in hot water above 70°C, and stir until transparent, lead-containing nitrate 0.35g, add sulfuric acid 3L with a concentration of 90%, dodecylamine 0.08 g, 0.08g of dodecyl ammonium is dissolved in 0.4L of 7% sulfuric acid and added, stirred evenly and then poured into a flotation tank for flotation. After the first flotation, the gr...

Embodiment 3

[0020] After the tailings powder containing mica is removed through a cyclone or chute to remove single minerals and cuttings above 100 mesh, it is prepared into a slurry with a concentration of 20-40%; then add collectors, inhibitors and regulators in sequence, After stirring evenly, pour it into the flotation tank for flotation.

[0021] Take 1000g of tailings from Shandong Jincheng Metal Mine Concentration Plant, and remove rock debris > 160 mesh particles and single minerals such as feldspar, quartz and hornblende through a cyclone, and add water to the rest to adjust the concentration to 20 %, cornstarch 0.3g, cornstarch dissolved in hot water above 70°C, and stirred until transparent, lead hydrochloride 0.2g, hydrochloric acid with a concentration of 90% 0.002L, dodecylamine 0.1g, 0.1g dodecyl Ammonium is dissolved in 0.5L of 5% hydrochloric acid and added, stirred evenly and then poured into a flotation cell for flotation. After the first flotation, the mica grade is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com